Page 1

Model DI-C1L/C1

Machine Code:

D037/D038/D040/D041

Field Service Manual

October 2008

Subject to change

Page 2

Page 3

Important Safety Notices

Responsibilities of the Customer Engineer

Customer Engineer

Maintenance shall be done only by trained customer engineers who have completed service training for

the machine and all optional devices designed for use with the machine.

Reference Material for Maintenance

• Maintenance shall be done using the special tools and procedures prescribed for maintenance of the

machine described in the reference materials (service manuals, technical bulletins, operating

instructions, and safety guidelines for customer engineers).

• In regard to other safety issues not described in this document, all customer engineers shall strictly

obey procedures and recommendations described the "CE Safety Guide".

• Use only consumable supplies and replacement parts designed for use of the machine.

Before Installation, Maintenance

Shipping and Moving the Machine

• Work carefully when lifting or moving the machine. If the machine is heavy, two or more customer

engineers may be required to prevent injuries (muscle strains, spinal injuries, etc.) or damage to the

machine if it is dropped or tipped over.

• Personnel moving or working around the machine should always wear proper clothing and footwear.

Never wear loose fitting clothing or accessories (neckties, loose sweaters, bracelets, etc. ) or casual

footwear (slippers, sandals, etc.) when lifting or moving the machine.

• Always unplug the power cord from the power source before you move the product. Before you move

the product, arrange the power cord so it will not fall under the product.

1

Page 4

Power

• Always disconnect the power plug before doing any maintenance procedure. After switching off the

machine, power is still supplied to the main machine and other devices. To prevent electrical shock,

switch the machine off, wait for a few seconds, then unplug the machine from the power source.

• Before you do any checks or adjustments after turning the machine off, work carefully to avoid injury.

After removing covers or opening the machine to do checks or adjustments, never touch electrical

components or moving parts (gears, timing belts, etc.).

• After turning the machine on with any cover removed, keep your hands away from electrical

components and moving parts. Never touch the cover of the fusing unit, gears, timing belts, etc.

Installation, Disassembly, and Adjustments

• After installation, maintenance, or adjustment, always check the operation of the machine to make

sure that it is operating normally. This ensures that all shipping materials, protective materials, wires

and tags, metal brackets, etc., removed for installation, have been removed and that no tools remain

inside the machine. This also ensures that all release interlock switches have been restored to normal

operation.

• Never use your fingers to check moving parts causing spurious noise. Never use your fingers to

lubricate moving parts while the machine is operating.

Special Tools

• Use only standard tools approved for machine maintenance.

• For special adjustments, use only the special tools and lubricants described in the service manual.

Using tools incorrectly, or using tools that could damage parts, could damage the machine or cause

injuries.

During Maintenance

General

• Before you begin a maintenance procedure: 1) Switch the machine off, 2) Disconnect the power plug

from the power source, 3) Allow the machine to cool for at least 10 minutes.

2

Page 5

• Avoid touching the components inside the machine that are labeled as hot surfaces.

Safety Devices

• Never remove any safety device unless it requires replacement. Always replace safety devices

immediately.

• Never do any procedure that defeats the function of any safety device. Modification or removal of a

safety device (fuse, switch, etc.) could lead to a fire and personal injury. Always test the operation of

the machine to ensure that it is operating normally and safely after removal and replacement of any

safety device.

• For replacements use only the correct fuses or circuit breakers rated for use with the machine. Using

replacement devices not designed for use with the machine could lead to a fire and personal injuries.

Organic Cleaners

• During preventive maintenance, never use any organic cleaners (alcohol, etc.) other than those

described in the service manual.

• Make sure the room is well ventilated before using any organic cleaner. Use organic solvents in small

amounts to avoid breathing the fumes and becoming nauseous.

• Switch the machine off, unplug it, and allow it to cool before doing preventive maintenance. To avoid

fire or explosion, never use an organic cleaner near any part that generates heat.

• Wash your hands thoroughly after cleaning parts with an organic cleaner to contamination of food,

drinks, etc. which could cause illness.

• Clean the floor completely after accidental spillage of silicone oil or other materials to prevent slippery

surfaces that could cause accidents leading to hand or leg injuries. Use "My Ace" Silicone Oil Remover

(or dry rags) to soak up spills. For more details, please refer to Technical Bulletin "Silicone Oil

Removal" (A024-50).

Lithium Batteries

• Always replace a lithium battery on a PCB with the same type of battery prescribed for use on that

board. Replacing a lithium battery with any type other than the one prescribed for use on the board

could lead to an explosion or damage to the PCB.

• Never discard used batteries by mixing them with other trash. Remove them from the work site and

dispose of them in accordance with local laws and regulations regarding the disposal of such items.

3

Page 6

Ozone Filters

• Always replace ozone filters as soon as their service life expires (as described in the service manual).

• An excessive amount of ozone can build up around machines that use ozone filters if they are not

replaced at the prescribed time. Excessive ozone could cause personnel working around the machine

to feel unwell.

Power Plug and Power Cord

• Before serving the machine (especially when responding to a service call), always make sure that the

power plug has been inserted completely into the power source. A partially inserted plug could lead

to heat generation (due to a power surge caused by high resistance) and cause a fire or other

problems.

• Always check the power plug and make sure that it is free of dust and lint. Clean it if necessary. A

dirty plug can generate heat which could cause a fire.

• Inspect the length of the power cord for cuts or other damage. Replace the power cord if necessary.

A frayed or otherwise damaged power cord can cause a short circuit which could lead to a fire or

personal injury from electrical shock.

• Check the length of the power cord between the machine and power supply. Make sure the power

cord is not coiled or wrapped around any object such as a table leg. Coiling the power cord can

cause excessive heat to build up and could cause a fire.

• Make sure that the area around the power source is free of obstacles so the power cord can be

removed quickly in case of an emergency.

• Make sure that the power cord is grounded (earthed) at the power source with the ground wire on

the plug.

• Connect the power cord directly into the power source. Never use an extension cord.

• When you disconnect the power plug from the power source, always pull on the plug, not the cable.

After Installation, Servicing

Disposal of Used Items

• Never incinerate used toner or toner cartridges.

4

Page 7

• Toner or toner cartridges thrown into a fire can ignite or explode and cause serious injury. At the work

site always carefully wrap used toner and toner cartridges with plastic bags to avoid spillage before

disposal or removal.

• Always dispose of used items (developer, toner, toner cartridges, OPC drums, etc.) in accordance

with the local laws and regulations regarding the disposal of such items.

• To protect the environment, never dispose of this product or any kind of waste from consumables at

a household waste collection point. Dispose of these items at one of our dealers or at an authorized

collection site.

• Return used selenium drums to the service center for handling in accordance with company policy

regarding the recycling or disposal of such items.

Points to Confirm with Operators

At the end of installation or a service call, instruct the user about use of the machine. Emphasize the following

points.

• Show operators how to remove jammed paper and troubleshoot other minor problems by following

the procedures described in the operating instructions.

• Point out the parts inside the machine that they should never touch or attempt to remove.

• Confirm that operators know how to store and dispose of consumables.

• Make sure that all operators have access to an operating instruction manual for the machine.

• Confirm that operators have read and understand all the safety instructions described in the operating

instructions.

• Demonstrate how to turn off the power and disconnect the power plug (by pulling the plug, not the

cord) if any of the following events occur: 1) something has spilled into the product, 2) service or

repair of the product is necessary, 3) the product cover has been damaged.

• Caution operators about removing paper fasteners around the machine. They should never allow

paper clips, staples, or any other small metallic objects to fall into the machine.

Special Safety Instructions for Toner

Accidental Physical Exposure

• Work carefully when removing paper jams or replacing toner bottles or cartridges to avoid spilling

toner on clothing or the hands.

5

Page 8

• If toner is inhaled, immediately gargle with large amounts of cold water and move to a well ventilated

location. If there are signs of irritation or other problems, seek medical attention.

• If toner gets on the skin, wash immediately with soap and cold running water.

• If toner gets into the eyes, flush the eyes with cold running water or eye wash. If there are signs of

irritation or other problems, seek medical attention.

• If toner is swallowed, drink a large amount of cold water to dilute the ingested toner. If there are signs

of any problem, seek medical attention.

• If toner spills on clothing, wash the affected area immediately with soap and cold water. Never use

hot water! Hot water can cause toner to set and permanently stain fabric.

Handling and Storing Toner

• Toner, used toner, and developer are extremely flammable.

• Never store toner, developer, toner cartridges, or toner bottles (including empty toner bottles or

cartridges) in a location where they will be exposed to high temperature or an open flame.

• Always store toner and developer supplies such as toner and developer packages, cartridges, and

bottles (including used toner and empty bottles and cartridges) out of the reach of children.

• Always store fresh toner supplies or empty bottles or cartridges in a cool, dry location that is not

exposed to direct sunlight.

Toner Disposal

• Never attempt to incinerate toner, used toner, or empty toner containers (bottles or cartridges). Burning

toner can explode and scatter, causing serious burns.

• Always wrap used toner and empty toner bottles and cartridges in plastic bags to avoid spillage.

Follow the local laws and regulations regarding the disposal of such items.

• Dispose of used toner and toner cartridges at one of our dealers or at an authorized collection site.

Always dispose of used toner cartridges and toner bottles in accordance with the local laws and

regulations regarding the disposal of such items.

6

Page 9

Safety Instructions for this Machine

Prevention of Physical Injury

1. Before disassembling or assembling parts of the machine and peripherals, make sure that the machine

and peripheral power cords are unplugged.

2. The plug should be near the machine and easily accessible.

3. Note that some components of the machine and the paper tray unit are supplied with electrical voltage

even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off or open while the main

switch is turned on, keep hands away from electrified or mechanically driven components.

5. If the [Start] key is pressed before the machine completes the warm-up period (the [Start] key starts

blinking red and green ), keep hands away from the mechanical and the electrical components as

the machine starts making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while the machine is operating.

Be careful to avoid touching those components with your bare hands.

7. To prevent a fire or explosion, keep the machine away from flammable liquids, gases, and aerosols.

Health Safety Conditions

1. Never operate the machine without the ozone filters installed.

2. Always replace the ozone filters with the specified types at the proper intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may cause

temporary eye discomfort. Try to remove with eye drops or flush with water as first aid. If unsuccessful,

get medical attention.

Observance of Electrical Safety Standards

1. The machine and its peripherals must be installed and maintained by a customer service representative

who has completed the training course on those models.

2. The NVRAM on the system control board has a lithium battery which can explode if replaced

incorrectly. Replace the NVRAM only with an identical one. The manufacturer recommends replacing

the entire NVRAM. Do not recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an

open flame.

7

Page 10

2. Dispose of used toner, developer, and organic photoconductors in accordance with local regulations.

(These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not put more than 100

batteries per sealed box. Storing larger numbers or not sealing them apart may lead to chemical

reactions and heat build-up.

• The danger of explosion exists if a battery of this type is incorrectly replaced.

• Replace only with the same or an equivalent type recommended by the manufacturer. Discard used

batteries in accordance with the manufacturer's instructions.

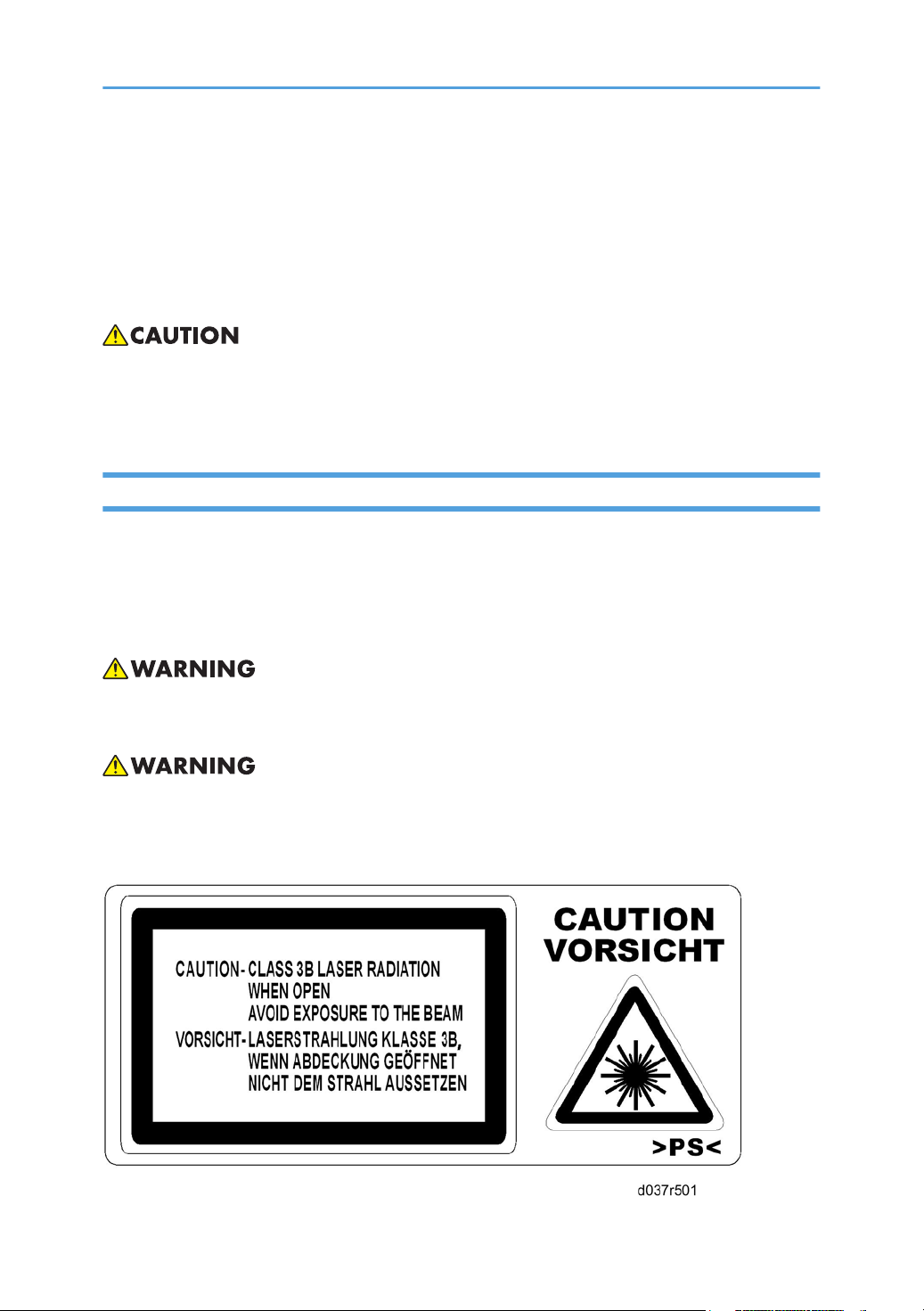

Laser Safety

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based optical units

in the field. The optical housing unit can only be repaired in a factory or at a location with the requisite

equipment. The laser subsystem is replaceable in the field by a qualified Customer Engineer. The laser

chassis is not repairable in the field. Customer engineers are therefore directed to return all chassis and

laser subsystems to the factory or service depot when replacement of the optical subsystem is required.

• Use of controls, or adjustment, or performance of procedures other than those specified in this manual

may result in hazardous radiation exposure.

• WARNING: Turn off the main switch before attempting any of the procedures in the Laser Optics

Housing Unit section. Laser beams can seriously damage your eyes.

• CAUTION MARKING:

8

Page 11

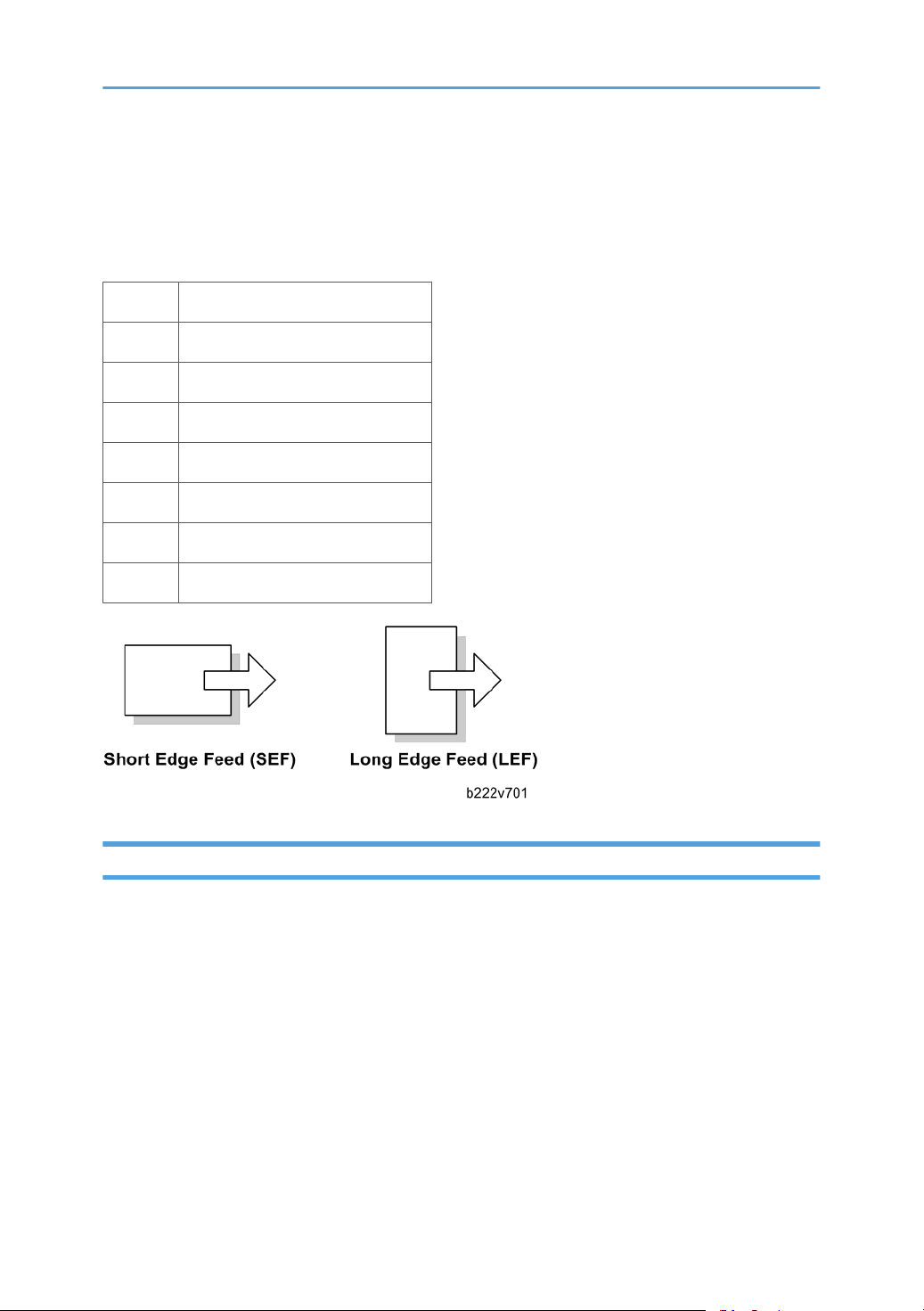

Symbols, Abbreviations and Trademarks

This manual uses several symbols and abbreviations. The meaning of those symbols and abbreviations are

as follows:

* See or Refer to

Clip ring

Screw

Connector

Clamp

E-ring

SEF Short Edge Feed

LEF Long Edge Feed

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation in the United

States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines Corporation.

Other product names used herein are for identification purposes only and may be trademarks of their

respective companies. We disclaim any and all rights involved with those marks.

9

Page 12

TABLE OF CONTENTS

Important Safety Notices...................................................................................................................................1

Responsibilities of the Customer Engineer....................................................................................................1

Before Installation, Maintenance..................................................................................................................1

During Maintenance......................................................................................................................................2

After Installation, Servicing............................................................................................................................4

Special Safety Instructions for Toner.............................................................................................................5

Safety Instructions for this Machine...............................................................................................................7

Laser Safety.....................................................................................................................................................8

Symbols, Abbreviations and Trademarks.........................................................................................................9

Trademarks.....................................................................................................................................................9

1. Product Information

Specifications....................................................................................................................................................19

Machine Configuration....................................................................................................................................20

H-Model.......................................................................................................................................................20

L-Model........................................................................................................................................................23

Overview..........................................................................................................................................................25

2. Installation

Installation Requirements.................................................................................................................................27

Environment..................................................................................................................................................27

Machine Level..............................................................................................................................................28

Machine Space Requirements....................................................................................................................28

Power Requirements....................................................................................................................................28

Optional Unit Combinations............................................................................................................................30

Machine Options.........................................................................................................................................30

Controller Options.......................................................................................................................................30

Copier Installation............................................................................................................................................32

Power Sockets for Peripherals....................................................................................................................32

Installation Flow Chart.................................................................................................................................32

Accessory Check..........................................................................................................................................33

Installation Procedure..................................................................................................................................36

Moving the Machine...................................................................................................................................46

Transporting the Machine...........................................................................................................................47

Paper Feed Unit (D331)..................................................................................................................................48

10

Page 13

Accessory Check..........................................................................................................................................48

Installation Procedure..................................................................................................................................48

Paper Feed Unit (D425)..................................................................................................................................51

Component Check.......................................................................................................................................51

Installation Procedure..................................................................................................................................51

Caster Table (D488)........................................................................................................................................54

Component Check.......................................................................................................................................54

Installation Procedure..................................................................................................................................54

ARDF (D366)....................................................................................................................................................57

Component Check.......................................................................................................................................57

Installation Procedure..................................................................................................................................57

Platen Cover Installation (G329)....................................................................................................................61

Side Tray (D427).............................................................................................................................................62

Component Check.......................................................................................................................................62

Installation Procedure..................................................................................................................................63

1-Bin Tray Unit (D426)....................................................................................................................................66

Component Check.......................................................................................................................................66

Installation Procedure..................................................................................................................................66

Shift Tray Unit (D428)......................................................................................................................................70

Component Check.......................................................................................................................................70

Installation Procedure..................................................................................................................................70

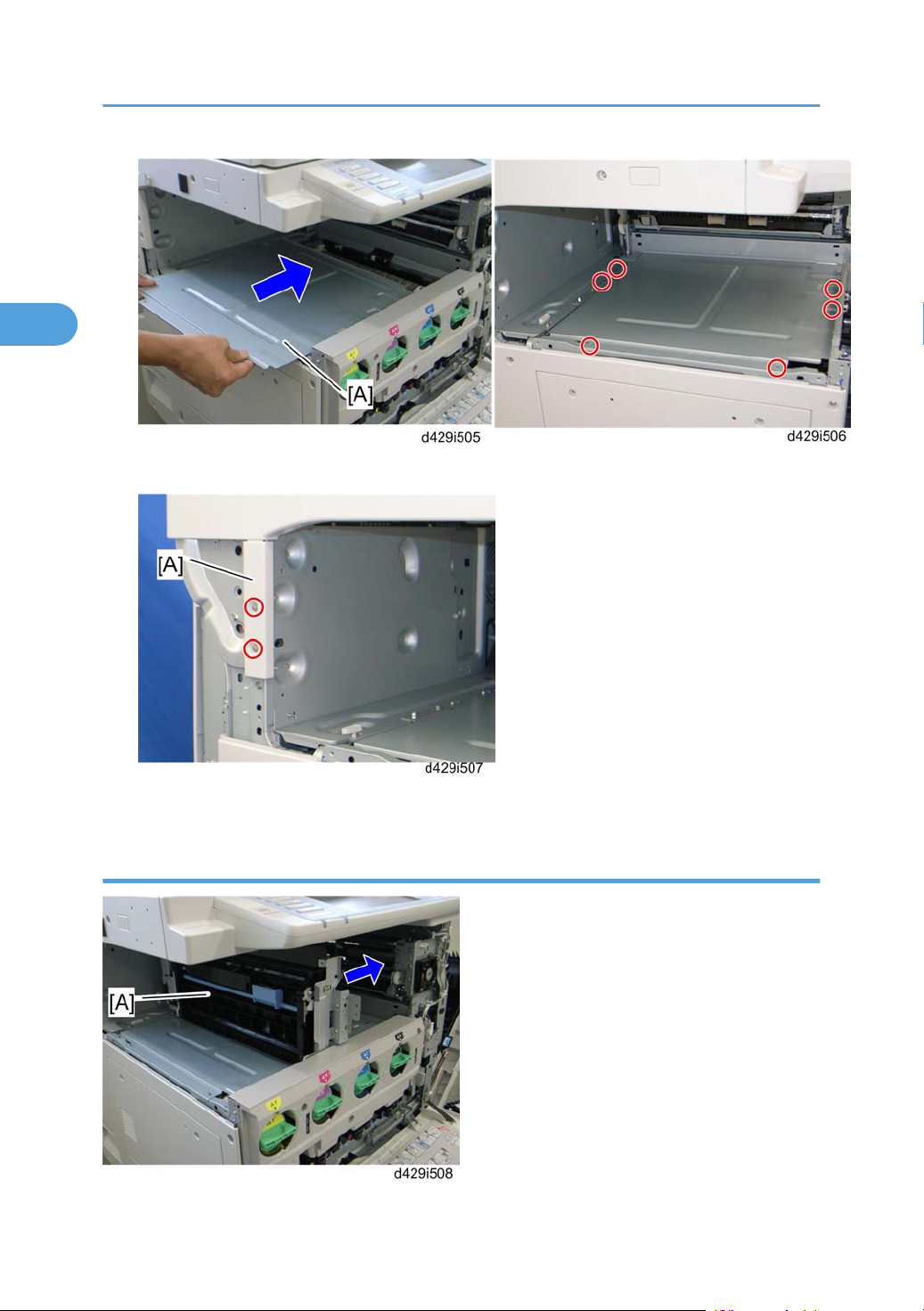

Internal Finisher (D429)...................................................................................................................................73

Component Check.......................................................................................................................................73

Installation Procedure..................................................................................................................................74

Punch Unit (D390)...........................................................................................................................................80

Component Check.......................................................................................................................................80

Installation Procedure..................................................................................................................................81

USB2.0/SD Slot Type A..................................................................................................................................93

Accessory Check..........................................................................................................................................93

Installation Procedure..................................................................................................................................93

Testing the SD Card/USB Slot....................................................................................................................96

Mechanical Counter (NA Only).....................................................................................................................98

Installation Procedure..................................................................................................................................98

11

Page 14

Key Counter Bracket......................................................................................................................................100

Installation Procedure................................................................................................................................100

Key Counter Interface Unit............................................................................................................................103

Installation Procedure................................................................................................................................103

Copy Data Security Unit Type F (B829)......................................................................................................105

Installation..................................................................................................................................................105

Anti-Condensation Heater............................................................................................................................107

Installation Procedure................................................................................................................................107

Tray Heater (Mainframe)..............................................................................................................................111

Installation Procedure................................................................................................................................111

Tray Heaters (Optional Unit)........................................................................................................................113

Installation Procedure................................................................................................................................113

Controller Options.........................................................................................................................................123

Overview....................................................................................................................................................123

SD Card Appli Move................................................................................................................................124

PostScript 3 (D038/D041 only).............................................................................................................127

File Format Converter (D038/D041 only).............................................................................................128

IEEE1284 (D038/D041 only)................................................................................................................129

IEEE 802.11 a/g, g (Wireless LAN: D038/D041 only).....................................................................130

Bluetooth (D038/D041 only).................................................................................................................134

DataOverwriteSecurity Unit Type I (D362: D038/D041 only)...........................................................135

HDD Encryption Unit (D038/D041 only)..............................................................................................138

PictBridge (D038/D041 only)................................................................................................................142

VM Card Type I (D038/D041 only)......................................................................................................143

Browser Unit Type E (D038/D041 only)...............................................................................................145

Gigabit Ethernet (D038/D041 only)......................................................................................................148

Memory Unit Type I 512MB (D038/D041 only).................................................................................149

Check All Connections..............................................................................................................................149

3. Preventive Maintenance

Maintenance Tables......................................................................................................................................151

PM Parts Settings............................................................................................................................................152

Before Removing the Old PM Parts.........................................................................................................152

After Installing the New PM parts............................................................................................................153

12

Page 15

Preparation before Operation Check......................................................................................................153

Operation Check.......................................................................................................................................154

4. Replacement and Adjustment

Beforehand.....................................................................................................................................................155

Special Tools..................................................................................................................................................156

Image Adjustment..........................................................................................................................................157

Scanning....................................................................................................................................................157

ARDF...........................................................................................................................................................158

Registration................................................................................................................................................160

Erase Margin Adjustment..........................................................................................................................161

Color Registration......................................................................................................................................162

Printer Gamma Correction........................................................................................................................163

Exterior Covers...............................................................................................................................................169

PCDU Toner Collection Bottle..................................................................................................................169

Front Door..................................................................................................................................................169

ITB Cleaning Unit Cover...........................................................................................................................170

Left Cover...................................................................................................................................................171

Rear Cover.................................................................................................................................................172

Rear Lower Cover......................................................................................................................................172

Dust Filter....................................................................................................................................................173

Right Rear Cover.......................................................................................................................................173

Operation Panel........................................................................................................................................174

Touch Panel Position Adjustment (D038/D041)...................................................................................175

Inner Right Cover.......................................................................................................................................176

Inner Cover................................................................................................................................................177

Front Right Cover.......................................................................................................................................177

Right Upper Cover ...................................................................................................................................178

Left Frame and Left Frame Rear Cover....................................................................................................178

Paper Exit Cover........................................................................................................................................179

Inverter Tray...............................................................................................................................................179

Inner Tray...................................................................................................................................................180

Inner Rear Cover.......................................................................................................................................180

Scanner Unit...................................................................................................................................................181

13

Page 16

Exposure Glass..........................................................................................................................................181

Original Length Sensors............................................................................................................................183

Exposure Lamp..........................................................................................................................................184

Scanner Motor...........................................................................................................................................187

Sensor Board Unit (SBU)..........................................................................................................................187

Exposure Lamp Stabilizer.........................................................................................................................189

Scanner HP Sensor....................................................................................................................................189

Platen Cover Sensor..................................................................................................................................190

Front Scanner Wire...................................................................................................................................190

Rear Scanner Wire....................................................................................................................................196

Laser Optics....................................................................................................................................................199

Caution Decal Location............................................................................................................................199

Laser Unit....................................................................................................................................................199

Polygon Mirror Motor...............................................................................................................................204

Image Creation..............................................................................................................................................206

PCDU (Photo Conductor and Development Unit)...................................................................................206

Drum Unit and Development Unit............................................................................................................207

Toner Hopper Unit.....................................................................................................................................210

Toner Supply Motor..................................................................................................................................213

Toner Collection Motor.............................................................................................................................215

PCDU Toner Collection Bottle Full Sensor...............................................................................................217

PCDU Toner Collection Bottle Set Switch................................................................................................217

RFID Board.................................................................................................................................................218

Image Transfer...............................................................................................................................................220

ITB Cleaning Unit.......................................................................................................................................220

ITB Toner Collection Bottle Full Sensor....................................................................................................221

ITB (Image Transfer Belt) Unit...................................................................................................................221

ITB Unit Motor............................................................................................................................................222

Image Transfer Belt....................................................................................................................................223

ITB Contact Motor.....................................................................................................................................227

ITB Contact Sensor....................................................................................................................................229

Paper Transfer................................................................................................................................................230

PTR (Paper Transfer Roller) Unit...............................................................................................................230

14

Page 17

Opening the Paper Transfer Unit.............................................................................................................231

ID Sensor Board........................................................................................................................................231

PTR Contact Motor....................................................................................................................................234

PTR Contact Sensor...................................................................................................................................235

Temperature and Humidity Sensor..........................................................................................................236

Drive Unit........................................................................................................................................................237

Gear Unit...................................................................................................................................................237

Registration Motor.....................................................................................................................................239

Paper Feed Motor: T1...............................................................................................................................240

Paper Feed Motor: T2...............................................................................................................................241

Drum Motor: CMY....................................................................................................................................241

Development Motor: CMY.......................................................................................................................242

Drum/Development Motor: K..................................................................................................................242

Development Clutch: K.............................................................................................................................243

Fusing/Paper Exit Motor..........................................................................................................................243

Fusing..............................................................................................................................................................246

PM Parts.....................................................................................................................................................246

Fusing Unit..................................................................................................................................................246

Entrance Guide Plate................................................................................................................................247

Stripper Plate.............................................................................................................................................248

Exit Guide Plate Cleaning Procedure......................................................................................................250

Pressure Roller Fusing Lamp.....................................................................................................................251

Heating Roller Fusing Lamp......................................................................................................................253

Fusing Belt..................................................................................................................................................254

Heating, Fusing and Tension Roller.........................................................................................................258

Pressure Roller ..........................................................................................................................................259

Heating Roller Thermostats.......................................................................................................................261

Heating Roller Thermistor..........................................................................................................................262

Pressure Roller Thermistor ........................................................................................................................263

Pressure Roller Thermostat........................................................................................................................264

Thermopile.................................................................................................................................................265

Cleaning Unit (Option) Installation Procedure........................................................................................266

Paper Feed.....................................................................................................................................................269

15

Page 18

Paper Tray..................................................................................................................................................269

Feed Roller.................................................................................................................................................269

Friction Pad................................................................................................................................................270

Paper Size Switch......................................................................................................................................271

Paper End Sensor......................................................................................................................................272

Registration Sensor....................................................................................................................................273

Vertical Transport Sensor .........................................................................................................................275

Paper Exit........................................................................................................................................................279

Junction Gate Solenoid Fan.....................................................................................................................279

Paper Exit Unit...........................................................................................................................................279

Fusing Exit .................................................................................................................................................281

Paper Exit Sensor.......................................................................................................................................282

Inverter Sensor...........................................................................................................................................283

Inverter Motor............................................................................................................................................284

Fusing Front Fan.........................................................................................................................................285

Duplex Unit.....................................................................................................................................................287

Duplex Unit................................................................................................................................................287

Duplex Entrance Sensor............................................................................................................................288

Duplex Exit Sensor....................................................................................................................................290

Duplex Entrance Motor.............................................................................................................................291

Duplex Exit Motor.....................................................................................................................................292

By-pass Motor...........................................................................................................................................292

By-pass Tray Unit.......................................................................................................................................293

By-pass Paper Length Sensor ..................................................................................................................294

By-Pass Paper Size Sensor.......................................................................................................................295

By-pass Paper End Sensor........................................................................................................................297

By-pass Feed Roller...................................................................................................................................297

By-pass Tray HP Sensor............................................................................................................................298

Electrical Components...................................................................................................................................299

Boards........................................................................................................................................................299

Controller Box Cover ...............................................................................................................................300

Controller Box............................................................................................................................................301

BCU............................................................................................................................................................302

16

Page 19

HDD (Only for D038/D041)..................................................................................................................303

Controller Box Fan....................................................................................................................................304

Fusing Rear Fan.........................................................................................................................................304

PSU.............................................................................................................................................................305

HVPS: TTS Board.......................................................................................................................................306

HVPS: CB Board........................................................................................................................................307

i-Controller Board.....................................................................................................................................308

NVRAM Replacement Procedure............................................................................................................312

Machine Boot-Up .........................................................................................................................................314

5. System Maintenance Reference

Service Program Mode.................................................................................................................................315

SP Tables....................................................................................................................................................315

Types of SP Modes for DI-C1 H-model (D038/D041)........................................................................315

Types of SP Modes for DI-C1 L-model (D037/D040).........................................................................319

Remarks......................................................................................................................................................320

Firmware Update...........................................................................................................................................323

Type of Firmware.......................................................................................................................................323

Before You Begin.......................................................................................................................................325

Updating Firmware ..................................................................................................................................325

Updating the LCDC for the Operation Panel..........................................................................................328

Handling Firmware Update Errors...........................................................................................................328

Installing Another Language.........................................................................................................................330

Reboot/System Setting Reset.......................................................................................................................333

Software Reset...........................................................................................................................................333

System Settings and Copy Setting Reset..................................................................................................333

Controller Self-Diagnostics...........................................................................................................................335

Overview....................................................................................................................................................335

SD Card Appli Move....................................................................................................................................337

Overview....................................................................................................................................................337

Move Exec.................................................................................................................................................338

Undo Exec..................................................................................................................................................339

Downloading Stamp Data............................................................................................................................340

NVRAM Data Upload/Download..............................................................................................................341

17

Page 20

Uploading Content of NVRAM to an SD card.......................................................................................341

Downloading an SD Card to NVRAM....................................................................................................341

Address Book Upload/Download..............................................................................................................343

Information List...........................................................................................................................................343

Download..................................................................................................................................................343

Upload.......................................................................................................................................................344

Using the Debug Log.....................................................................................................................................345

Overview....................................................................................................................................................345

Switching ON and Setting UP Save Debug Log.....................................................................................345

Retrieving the Debug Log from the HDD.................................................................................................349

Recording Errors Manually.......................................................................................................................349

Card Save Function.......................................................................................................................................350

Overview....................................................................................................................................................350

Procedure...................................................................................................................................................350

Error Messages..........................................................................................................................................356

6. Troubleshooting

Service Call Conditions.................................................................................................................................357

Process Control Error Conditions..................................................................................................................358

Troubleshooting Guide..................................................................................................................................359

Sub-scan Magnification Error..................................................................................................................359

Trapezoid Image Adjustment...................................................................................................................362

Jam Detection.................................................................................................................................................366

Electrical Component Defects.......................................................................................................................367

Scanner Test Mode........................................................................................................................................368

SBU Test Mode..........................................................................................................................................368

IPU Test Mode...........................................................................................................................................368

INDEX...........................................................................................................................................................371

18

Page 21

1. Product Information

1

Specifications

See "Appendices" for the following information:

• Mainframe Specifications

• Printer Specifications

• Scanner Specifications

• Supported Paper Sizes

• Software Accessories

• Optional Equipment

19

Page 22

1. Product Information

1

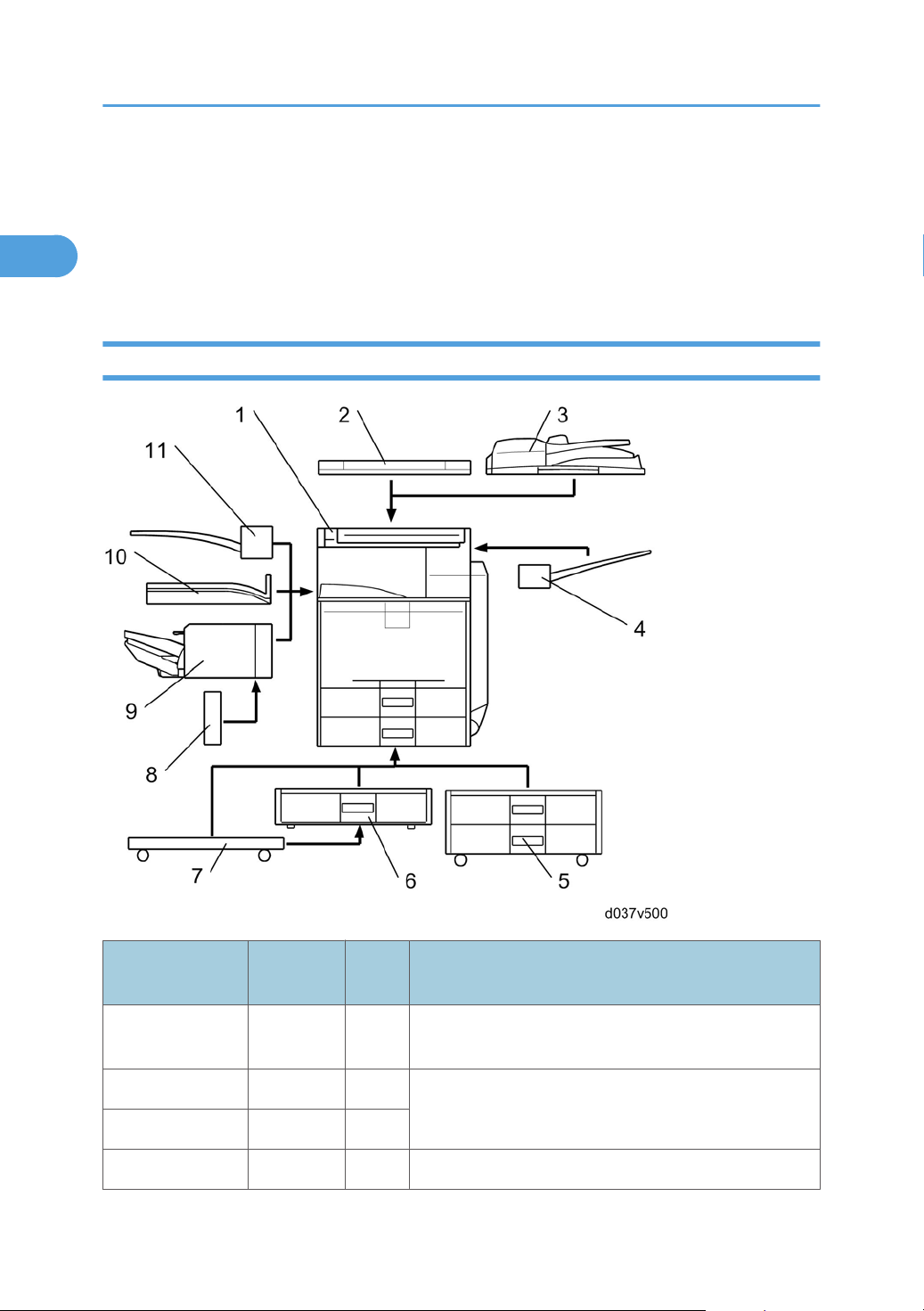

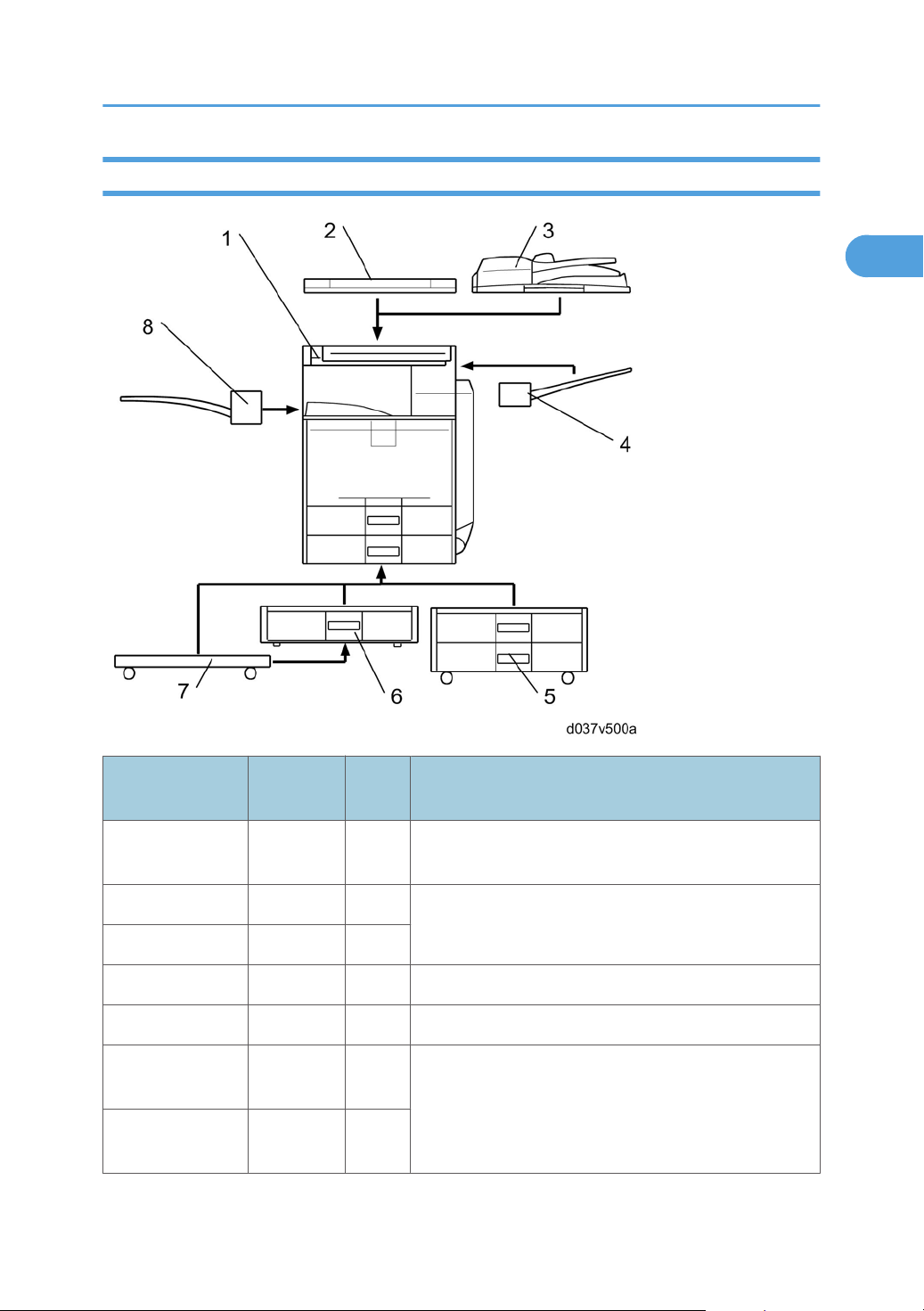

Machine Configuration

There are two grades for this machine.

• L-Model: This is a light model. Expansion functions and options are limited.

• H-Model: This is a high grade model. Various expansion functions and options can be used.

H-Model

20

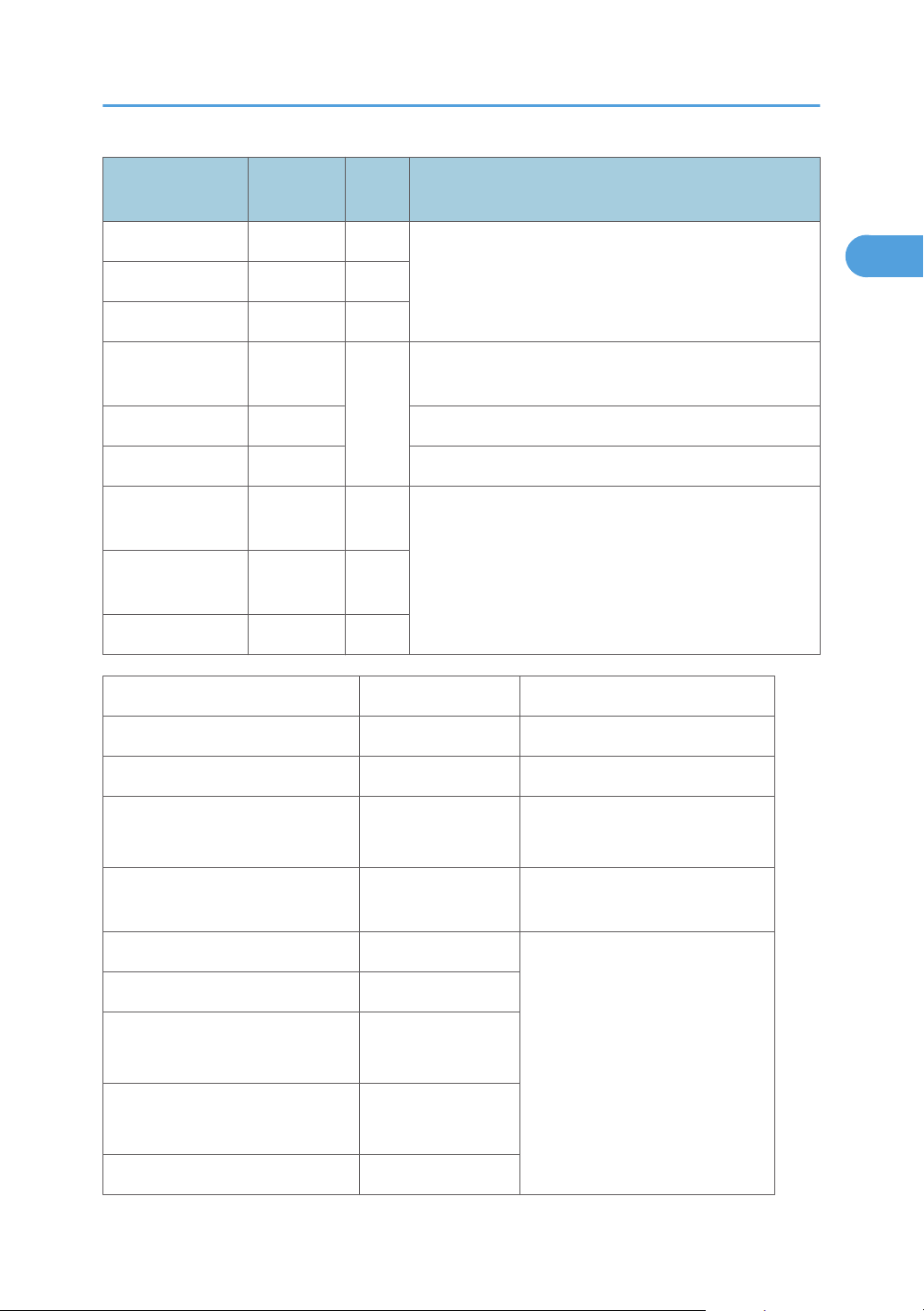

Item

Mainframe

Platen cover G329 [2]

ARDF D366 [3]

Side tray D427 [4] -

Machine

Code

D038/

D041

Call

out

[1] D038: C1a, D041: C1c

Remarks

One from the two;

[3] is standard.

Page 23

Machine Configuration

1

Item

1-bin tray D426 [11]

Shift tray D428 [10]

Internal finisher D429 [9]

Punch unit: 2/3

holes

Punch unit: 2 holes D390-27 Requires [9].

Punch unit: 4 holes D390-31 Requires [9].

Two-tray paper

feed unit

One-tray paper

feed unit

Caster Table D448 [7]

Machine

Code

D390-17

D331 [5]

D425 [6]

Call

out

One of the following 4 choices: [9] only, [10] only, [11]

only, or [10]+[11]

Requires [9].

[8]

One from [5], [6], and [7];

The one-tray PFU [6] requires [7].

If neither [5] nor [6] is installed, install [7] if required by the

customer.

Remarks

Item Machine code Remark

USB2.0/SD Slot D422 -

Fax Option D432

Memory Unit Type B G578

Hand Set B433

Gigabit Ethernet G874

IEEE 1284 B679

Wireless LAN

D377-01, 02

(IEEE 802.11a/g)

Wireless LAN

D377-19

(IEEE 802.11g)

Bluetooth B826

SAF memory:

Requires the Fax Option.

For NA model only: Requires the

Fax Option.

You can only install one of these at

a time.

21

Page 24

1. Product Information

1

File Format Converter D377-04

Copy Data Security Unit B829 -

Optional Counter Interface Unit B870 -

Key Counter Bracket A674 -

Memory Unit Type I D435-01 (For printer function)

Printer Enhanced Option D435-03, -04, -05

PostScript 3 D435-09, -10, -11

Data Overwrite Security Unit D362

PictBridge M344

VM Card D430-01, 02, 03

HDD Encryption Unit D377-16

You can only install one of these in

SD slot 1 at a time

In SD card slot 2Browser Unit D430-05, 06, 07

22

Page 25

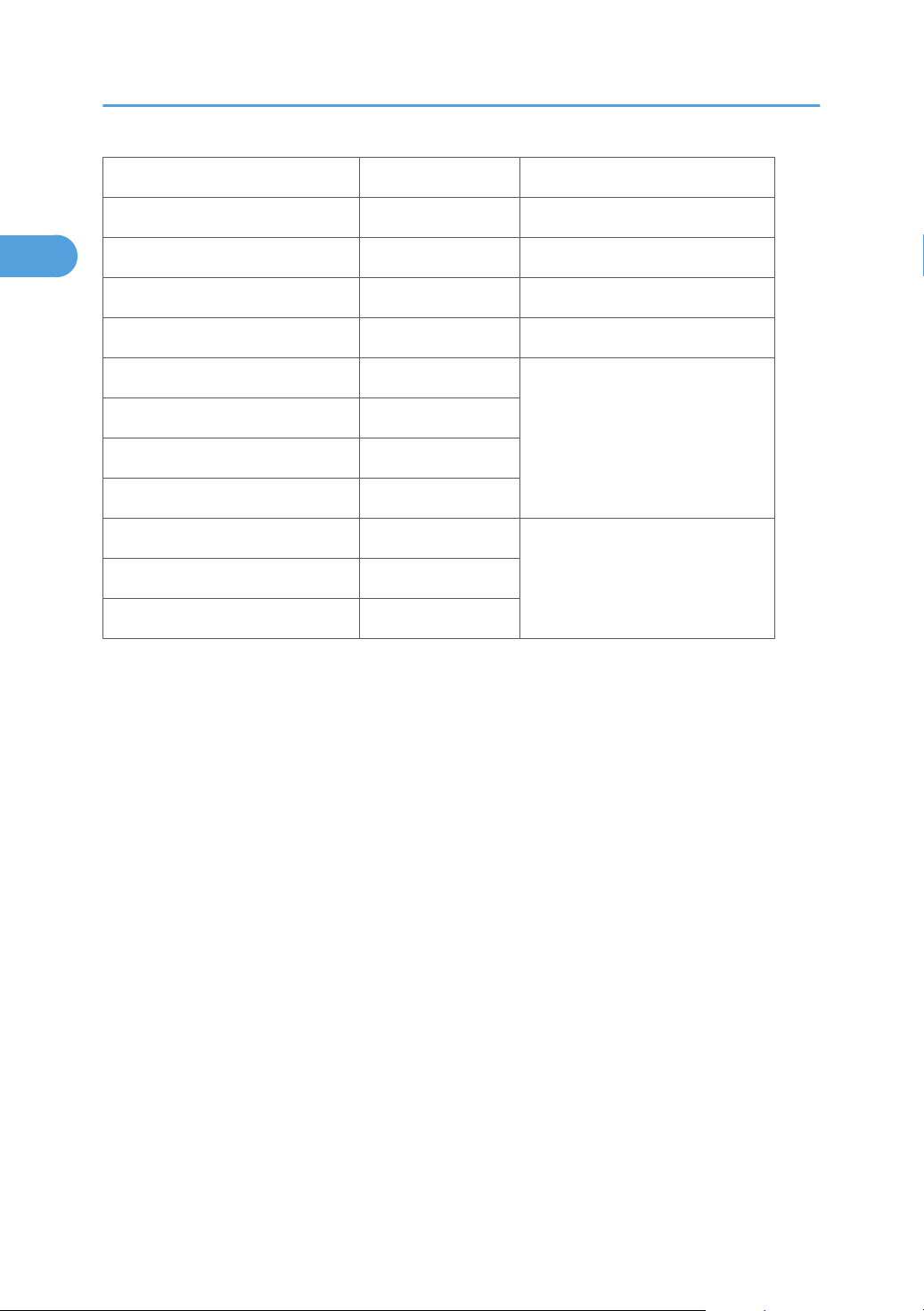

L-Model

1

Machine Configuration

Item

Mainframe

Platen cover G329 [2]

ARDF D366 [3]

Side tray D427 [4] -

1-bin tray D426 [8] -

Two-tray paper

feed unit

One-tray paper

feed unit

Machine

Code

D037/

D040

D331 [5]

D425 [6]

Call

out

[1] D037: C1La, D040: C1Lc

Remarks

One from the two;

[3] is standard for NA and EU

One from [5], [6], and [7];

The one-tray PFU [6] requires [7].

If neither [5] nor [6] is installed, install [7] if required by the

customer.

23

Page 26

1. Product Information

1

Item

Caster Table D448 [7]

Fax Option D433

Hand Set B433

Copy Data Security Unit B829 -

Optional Counter Interface Unit B870 -

Printer Enhanced Option D435-03, -04, -05

PictBridge M344

Machine

Code

Item Machine code Remark

Call

out

Remarks

For NA model only: Requires the

Fax Option.

You can only install one of these in

SD slot 1 at a time

24

Page 27

Overview

1

For "Overview" information, see "Appendices".

Overview

25

Page 28

1. Product Information

1

26

Page 29

2. Installation

2

Installation Requirements

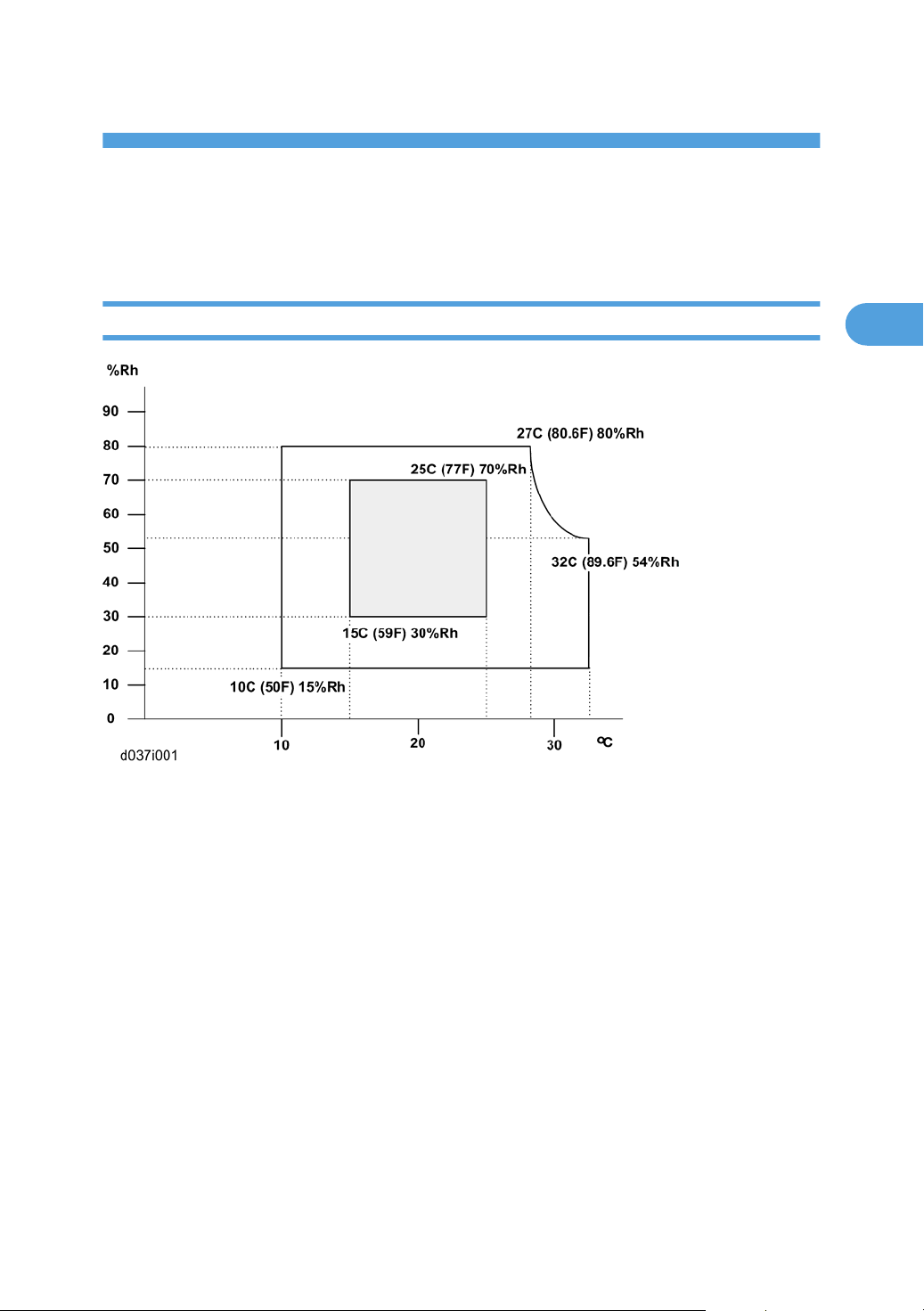

Environment

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 1500 lux (do not expose to direct sunlight)

4. Ventilation: 3 times/hr/person or more

5. Do not let the machine get exposed to the following:

1) Cool air from an air conditioner

2) Heat from a heater

6. Do not install the machine in areas that are exposed to corrosive gas.

7. Install the machine at locations lower than 2,500 m (8,200 ft.) above sea level.

8. Install the machine on a strong, level base. (Inclination on any side must be no more than 5 mm.)

9. Do not install the machine in areas that get strong vibrations.

27

Page 30

2. Installation

2

Machine Level

Front to back: Within 5 mm (0.2")

Right to left: Within 5 mm (0.2")

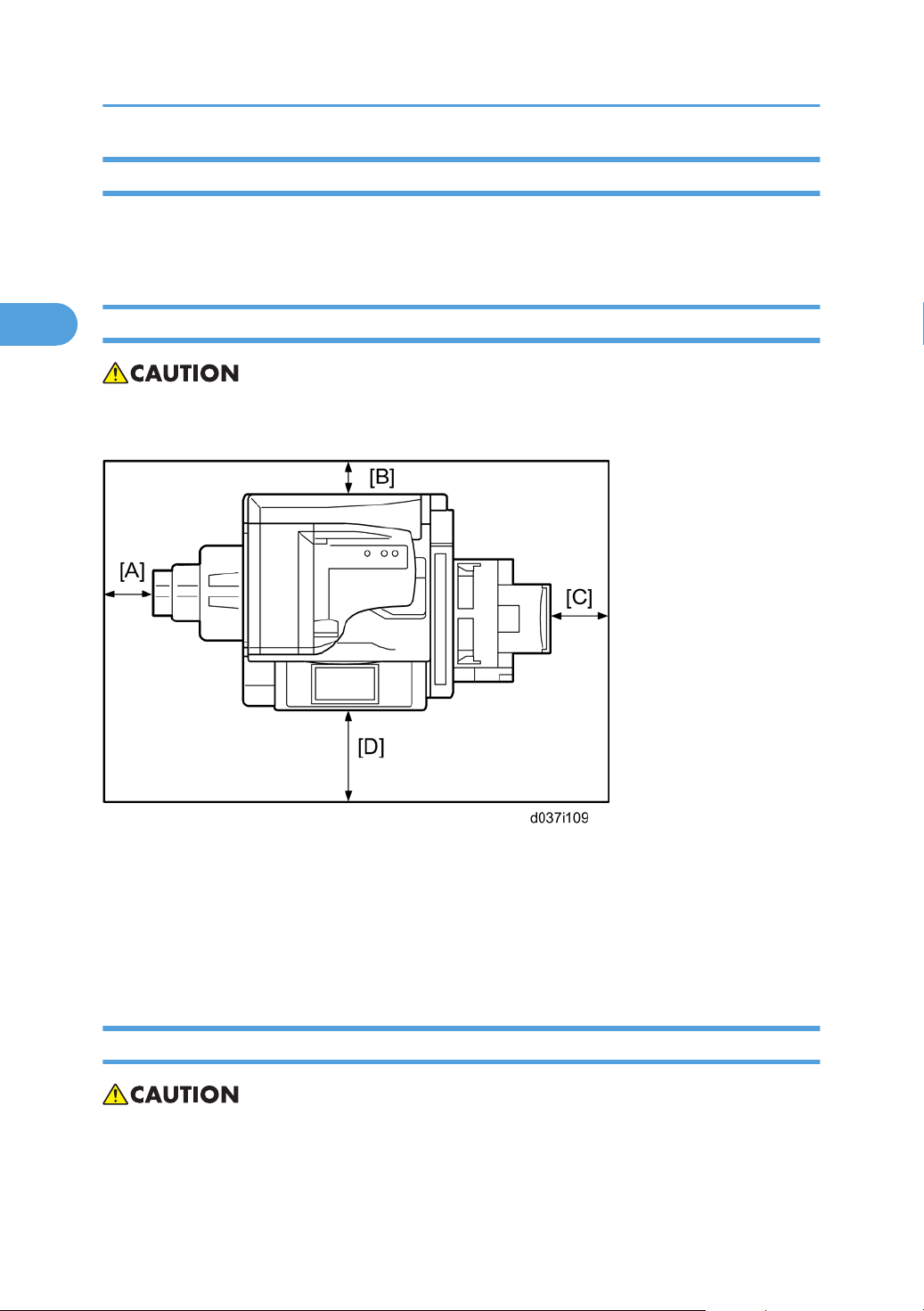

Machine Space Requirements

• This machine, which uses high voltage power sources, can generate ozone gas. High ozone density

is harmful to human health. Therefore, the machine must be installed in a well-ventilated room.

A: Over 100 mm (3.9")

B: Over 100 mm (3.9")

C: Over 100 mm (3.9")

D: Over 100 mm (3.9")

Put the machine near the power source with the clearance shown above.

Power Requirements

• Insert the plug firmly in the outlet.

• Do not use an outlet extension plug or cord.

28

Page 31

• Ground the machine.

2

1. Input voltage level:

• 120 V, 60 Hz: More than 12 A

• 220 V to 240 V, 50 Hz/60 Hz: More than 8 A

2. Permissible voltage fluctuation: ±10 %

3. Do not put things on the power cord.

Installation Requirements

29

Page 32

2. Installation

2

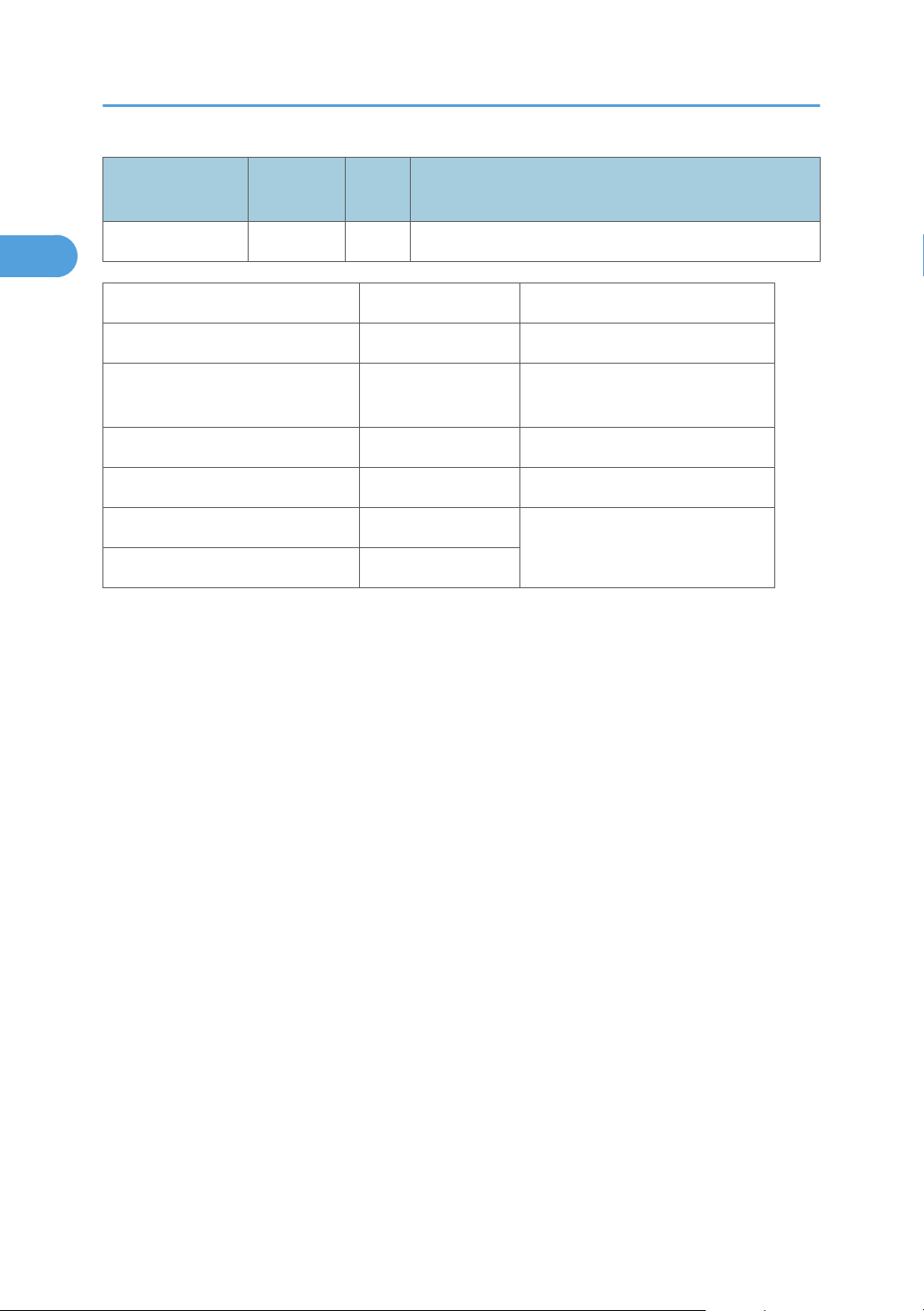

Optional Unit Combinations

Machine Options

Options

No.

D037/D040 D038/D041

1 2-tray paper feed unit 2-tray paper feed unit

2 1-tray paper feed unit 1-tray paper feed unit

3 Caster table Caster table

4 Platen cover Platen cover

5 ARDF ARDF (Standard)

6 1-bin tray unit 1-bin tray unit

Remarks

One from No.1 or No.2 (No.

2 requires No. 3)

One from No.4 or No.5

7 - Shift tray

8 Side Tray Side Tray

9 - Internal finisher

10 - *Punch kit (4 types)

11 Fax unit Fax unit -

12 - Memory Unit (32M)* Fax unit required

*: Child options (Child options require a parent option.)

If No 9 is installed, then No 6

and/or No 7 cannot be

installed.

No. 9 required; One of the

types

Controller Options

Options

No.

D037/D040 D038/D041

1 - IEEE 802.11a/g

2 - IEEE 1284

One from six items (I/F Slot)

Remarks

30

Page 33

3 - Bluetooth

2

4 - File Format Converter

5 - Gigabit Ethernet

6 - PostScript 3

7 Printer Enhanced Option -

8 PictBridge PictBridge

9 - DataOverwriteSecurity Unit

Optional Unit Combinations

One of these (SD card slot 1)

10 - HDD Encryption Unit

11 - Browser Unit

12 - VM Card SD card slot 2

13 Copy Data Security Unit Copy Data Security Unit -

14 - Memory Unit (512M) For SDK applications

SD card slot 2 (during

installation only)

SD card slot 2 (during

installation only)

31

Page 34

2. Installation

2

Copier Installation

Power Sockets for Peripherals

CAUTION

Rating voltage for peripherals.

Make sure to plug the cables into the correct sockets.

[1] ARDF: Rating voltage output connector for accessory Max. DC24V

[2] Finisher: Rating voltage output connector for accessory Max. DC24V

Installation Flow Chart

This flow chart shows the best procedure for installation.

32

Page 35

Copier Installation

2

*1: The shift tray should be installed first if you want to install the shift tray with the 1-bin tray at the same

time.

Accessory Check

Check the quantity and condition of these accessories.

For D037/D040

No. Description Q’ty Destination

1. Stamp 1 -17, -67

2. EU Safety Sheet 1

-67

3. WEEE 1

33

Page 36

2. Installation

2

No. Description Q’ty Destination

4. Certification 1

-21

5. Warranty Sheet (Chinese) 1

6. Operating Instruction – About this machine 1

7. Operating Instruction – Troubleshooting 1

8. Operating Instruction – Quick Reference Copy Guide 1

9. Operating Instruction – Quick Reference Fax Guide 1

10. Operating Instruction – Quick Reference Printer Guide 1

11. Operating Instruction – Quick Reference Scanner Guide 1

12. Operating Instruction – Quick Reference Printer & Scanner Guide

13. Operating Instruction – Manual for This Machine 1

14. Operating Instruction – Safety Information 1

15. CD-ROM Instruction – About this machine 1

16. CD-ROM Instruction – Troubleshooting 1

17. CD-ROM Instruction –Copy/Document Server Reference 1

18. CD-ROM Instruction –Facsimile Reference 1

19. CD-ROM Instruction –Printer Reference 1

20. CD-ROM Instruction –Scanner Reference 1

-17, -29, -21,

-19

-17, -67, -29,

-21, -19

-67, -29, -21,

-19

1 -17, -67, -29,

-21, -19, -28

-67

-17, -67, -29,

-21, -19

21. CD-ROM Instruction – Printer & Scanner Reference 1

22. CD-ROM Instruction – Network & General Setting Guide 1

23. CD-ROM Instruction – Security Reference 1

24. Printer Driver CD-ROM 1 -29, 28

25. Scanner Driver & Utility CD-ROM 1

-17, -67, -29

26. Clear Cover 1

34

Page 37

Copier Installation

2

For D038/D041

No. Description Q’ty Destination

1. Stamp 1 -57, -67

2. EU Safety Sheet 1

-67

3. WEEE 1

4. Certification 1

-21

5. Warranty Sheet (Chinese) 1

6. Operating Instruction – About this machine 1

7. Operating Instruction – Troubleshooting 1

8. Operating Instruction – Quick Reference Copy Guide

9. Operating Instruction – Quick Reference Printer Guide 1

10. Operating Instruction – Quick Reference Scanner Guide 1

11. Operating Instruction – Manual for This Machine 1

12. Operating Instruction – Safety Information 1

13. CD-ROM Instruction – About this machine 1

14. CD-ROM Instruction – Troubleshooting 1

15. CD-ROM Instruction –Copy/Document Server Reference 1

16. CD-ROM Instruction –Facsimile Reference 1

17. CD-ROM Instruction –Printer Reference 1

18. CD-ROM Instruction –Scanner Reference 1

-57, -29, -21,

-19

1 -67, -29, -21,

-19

-57, -67, -29,

-21, -19

-67

-57, -67, -29,

-21, -19

19. CD-ROM Instruction – Network & General Setting Guide 1

20. CD-ROM Instruction – Security Reference 1

21. PostScript 3 Supplement

22. Printer Driver CD-ROM 1 -29, 28

23. Scanner Driver & Utility CD-ROM 1

-67, -29, -21,

-19, -28

-57, -67, -29

35

Page 38

2. Installation

2

No. Description Q’ty Destination

24. Clear Cover 1

Installation Procedure

• Remove the tapes from the development units before you turn the main switch on. The development

units can be severely damaged if you do not remove the tapes.

Put the machine on the paper tray unit first if you install an optional paper tray unit at the same time. Then

install the machine and other options.

• Keep the shipping retainers after you install the machine. You may need them in the future if you

transport the machine to another location.

Tapes and Retainers

1. Remove all the tapes and retainers on the machine.

2. Remove all the tapes and retainers in trays 1 and 2.

36

Page 39

Copier Installation

2

3. Remove the scanner unit stay [A].

4. Keep the scanner unit stay in the cutout in the inner tray.

• For the EU models, the scanner unit stay cannot be inserted in the cutout on the inner tray. You

must bring this stay back to your depot.

5. Install the inverter tray [A] (hooks).

37

Page 40

2. Installation

2

6. Open the duplex unit [A].

7. Remove the sheet of paper [B].

8. Open the paper transfer unit [A].

9. Remove the front and rear stoppers [B] with a red tag.

10. Close the duplex unit.

38

Page 41

Copier Installation

2

11. Attach the handle cover [A] to the front side of the duplex unit.

Developer and Toner Bottles

1. Open the front door [A] and remove the PCDU toner collection bottle [B].

2. Remove all tapes except the tape [C] from the four development units and from the toner hopper units.

• Do not remove the tape [C] at this moment. You will find how to remove this tape later.

• The toner hopper cover [D] is removed with tape [E].

• Make sure that the all toner hopper covers are removed, when removing all tapes.

3. Check if the toner hopper shutter [A] is fully closed.

• If the toner hopper shutter is not fully closed and the inlet [B] of the toner hopper unit is visible,

the toner bottle cannot be installed properly.

39

Page 42

2. Installation

2

4. Press the ITB lock lever [A] and turn it up as shown above.

5. Remove the black PCDU [B] ( x 2).

6. Remove the cover sheet [A] from the black PCDU.

7. Reinstall the black PCDU into the mainframe ( x 2).

8. Reinstall the PCDU toner collection bottle.

9. Shake each toner bottle five or six times.

10. Slide the toner bottles in toner bottle cartridges, then turn each one to the right (clockwise).

11. Close the front door.

40

Page 43

Copier Installation

2

Paper Trays

1. Pull each paper tray [A] out. Then adjust the side guides and end guide to match the paper size.

• To move the side guides, first pull out the tray fully. Then push down the green lock at the rear

inside the tray.

Emblem and Decals

1. Attach the correct emblem [A] and the cover [B] to the front door [C] of the machine, if the emblem

is not attached.

• If you want to change the emblem that has been already attached, remove the panel with an

object (not a sharp object) as shown [D], and then install the correct emblem.

41

Page 44

2. Installation

2

2. Attach the correct paper tray number and size decals to the paper trays [E].

• Paper tray number and size decals are also used for the optional paper tray or the optional LCT.

Keep these decals for use with these optional units.

Fax Settings for D037-17

The D037-17 model has a fax unit as a standard function. Because of this, the fax settings are required at

machine installation. Refer to steps 7 to 9 and 14 to 16 in the "Fax Option (D432) Installation Procedure"

in the “Field Service Manual” of the fax option manual.

Initialize the Developer

1. Make sure that the platen or ARDF is closed and the main power is turned off.

2. Plug in the machine.

3. Turn the main power switch on. The machine automatically starts the initialization procedure. The Start

button LED () turns green when this procedure has finished.

4. Make copies of image samples (text, photo, and text/photo modes).

5. Do the Automatic Color Calibration process (ACC) for each mode (Copy mode, Printer 600 x 600

dpi, Printer 1800 x 600 dpi, and Printer 1200 x 1200 dpi) as follows ((Printer 1200 x 1200 dpi is

for D038/D041 only):

• 1) Print the ACC test pattern (User tools > Maintenance > ACC > Start).

• 2) Put the printout on the exposure glass.

• 3) Put 10 sheets of white paper on top of the test chart.

• 4) Close the ARDF or the platen cover.

• 5) Press “Start Scanning” on the LCD panel. The machine starts the ACC.

6. Check that the sample image has been copied normally.

7. Open the front cover.

42

Page 45