Page 1

RICOH M5

SERVICE MANUAL

Page 2

OPERATING

INSTRUCTIONS

Page 3

INTRODUCTION

May, 25, 1985

The Ricoh M5 is a desktop plain

carefully manufactured to exacting

formance.

a superior finish.

This manual contains detailed instructions on the opera-

tion and care of the M5.

from this copier, all

follow the instructions in this manual. Please

manual in the holder provided on the machine.

It consistently yields high contrast copies with

T

O get the maximum

operators should carefully

paper copier which is

standards of high per-

versatility

read and

keep this

MAJOR FEATURES

1

.

Copies everything from

1 l“) sized documents.

2

Easy-to-maintain cartridge design.

.

Black, blue, green and red color application.

3.

business cards to A4 (8-1/2” x

4

Lightweight design for easy transport.

.

“Clam-shell” design makes misfeeds easy to clear.

.

5

6

.

Simple and reliable operation.

7

Inner cassette makes the copier compact.

.

Page 4

CONTENTS

1. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1. Unpacking procedure . . . . . . . . . . . . . . . . . . . 1

1-2. Installation procedure . . . . . . . . . . . . . . . . . . . 2

1-3. Installation requirements . . . . . . . . . . . . . . . . 6

2. GUIDE TO COMPONENTS . . . . . . . . . . . . . 9

2-1. Overall machine layout . . . . . . . . . . . . . . . . . 9

2-2. operation panel . . . . . . . . . . . . . . . . . . . . . . ...10

2-3. Operator controls . . . . . . . . . . . . . . . . . . . . . ..ll

May, 25, 1985

3. COPYING

.

3-1

3-2

3-3

3-4

3-5

4

REPLENISHING SUPPLIES . . . . . . . . . . . . . . . . . . ...17

.

4-1. Loading paper...........*.. . . . . . . . . . . ...17

4-2. Adding toner . . . . . . . . . . . . . . . . . . . . . . . . ...19

.

5

6

.

7

Starting the copier . . . . . . . . . . . . . . . . . . . . . . 13

Normal copying . . . . . . . . . . . . . . . . . . . . . ...13

.

Manual feed copying . . . . . . . . . . . . . . . . . ...14

.

Two-sided copying . . . . . . . . . . . . . . . . . . ...15

.

Color copying . . . . . . . . . . . . . . . . . . . . . . . ...16

.

REPLACING THE MASTER UNIT . . . . . . . . . . . . . . .

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . ...23

6-1. Clearing misdeeds . . . . . . . . . . . . . . . . . . . . ...23

6-2. Troubleshooting guide . . . . . . . . . . . . . . . . . . 24

6-3. Service codes . . . . . . . . . . . . . . . . . . . . . . . ...27

’IAINTENANCE . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .. < . . . . ...13

0

. . . . . . . . . . . . . ...28

21

TRANSPORTING THE COPIER . . . . . . . . . . . . . . ...29

8

DO’S AND DON’TS . . . . . . . . . . . . . . .

9

10

.

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . ...30

. . . . . . . . ...29

Page 5

1. INSTALLATION

May, 25, 1985

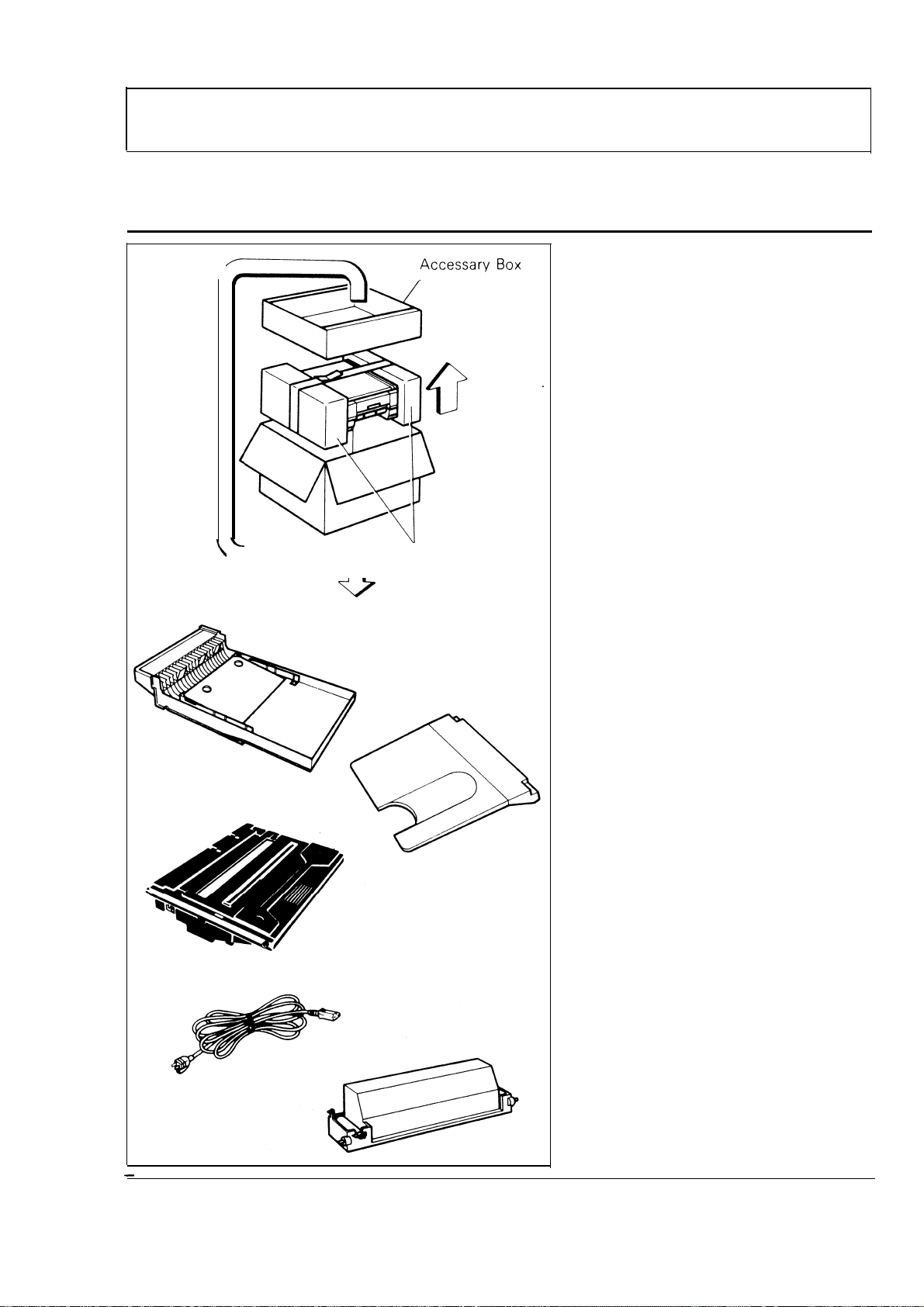

1-1.

UNPACKING PROCEDURE

1.

Take out the accessary box

and the machir

2

.

Remove the

blocks.

3,

Open the viny

out the machine.

4.

Check the quantity of the

accessories using the follow-

ing list.

1)

Cassette

e.

two

bag and take

cushion

1

pc

2)

Copy Tray

3)

Master Unit

(115V and 220V machines

only)

Note: Keep the master unit in

the box until installing it

in the copier.

4)

Power Supply Cord

Toner

5)

(115V and 220V machines

only)

1 cartridqe (Black)

1

pc

1 pc

1 pc

.

–1-

Page 6

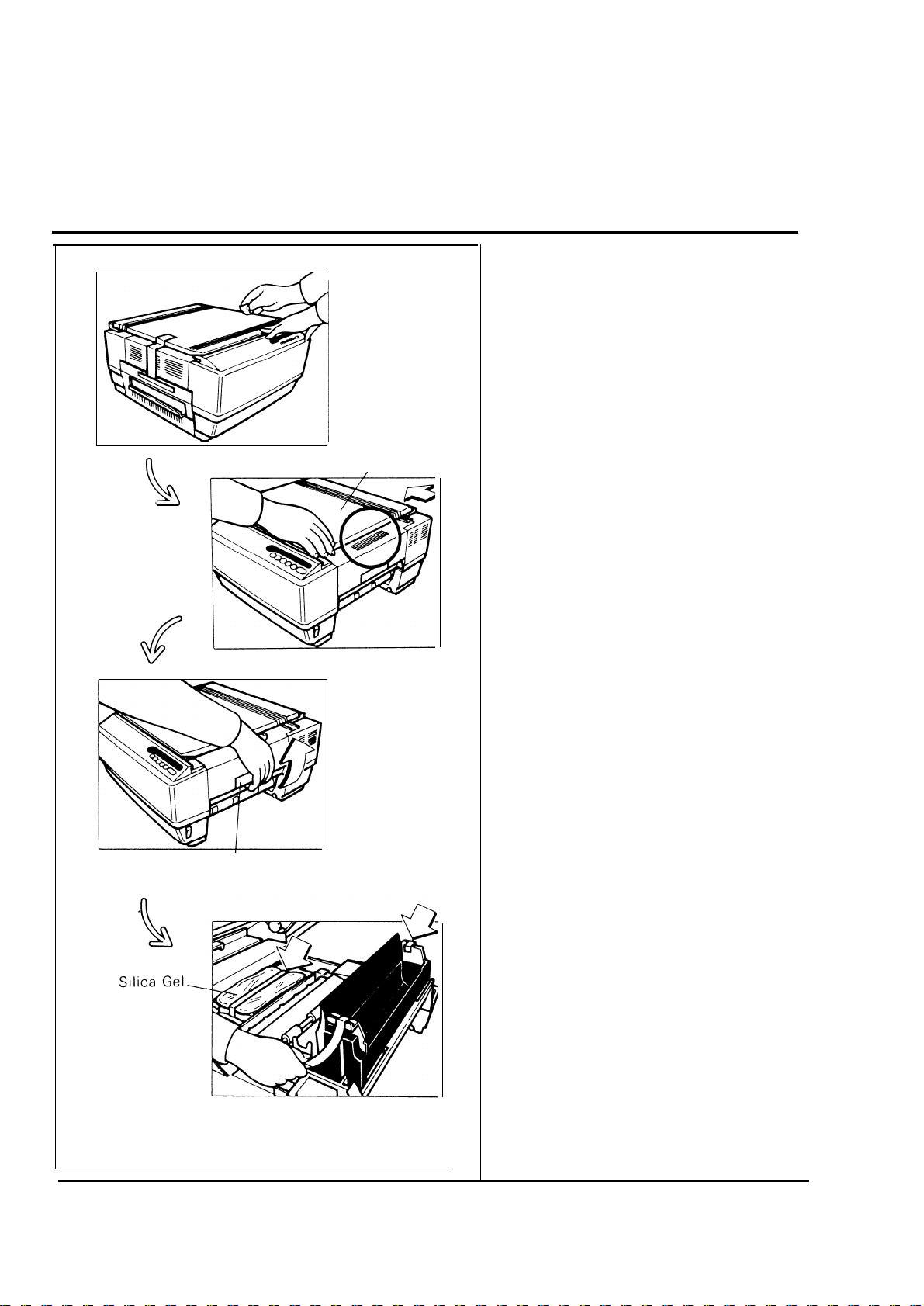

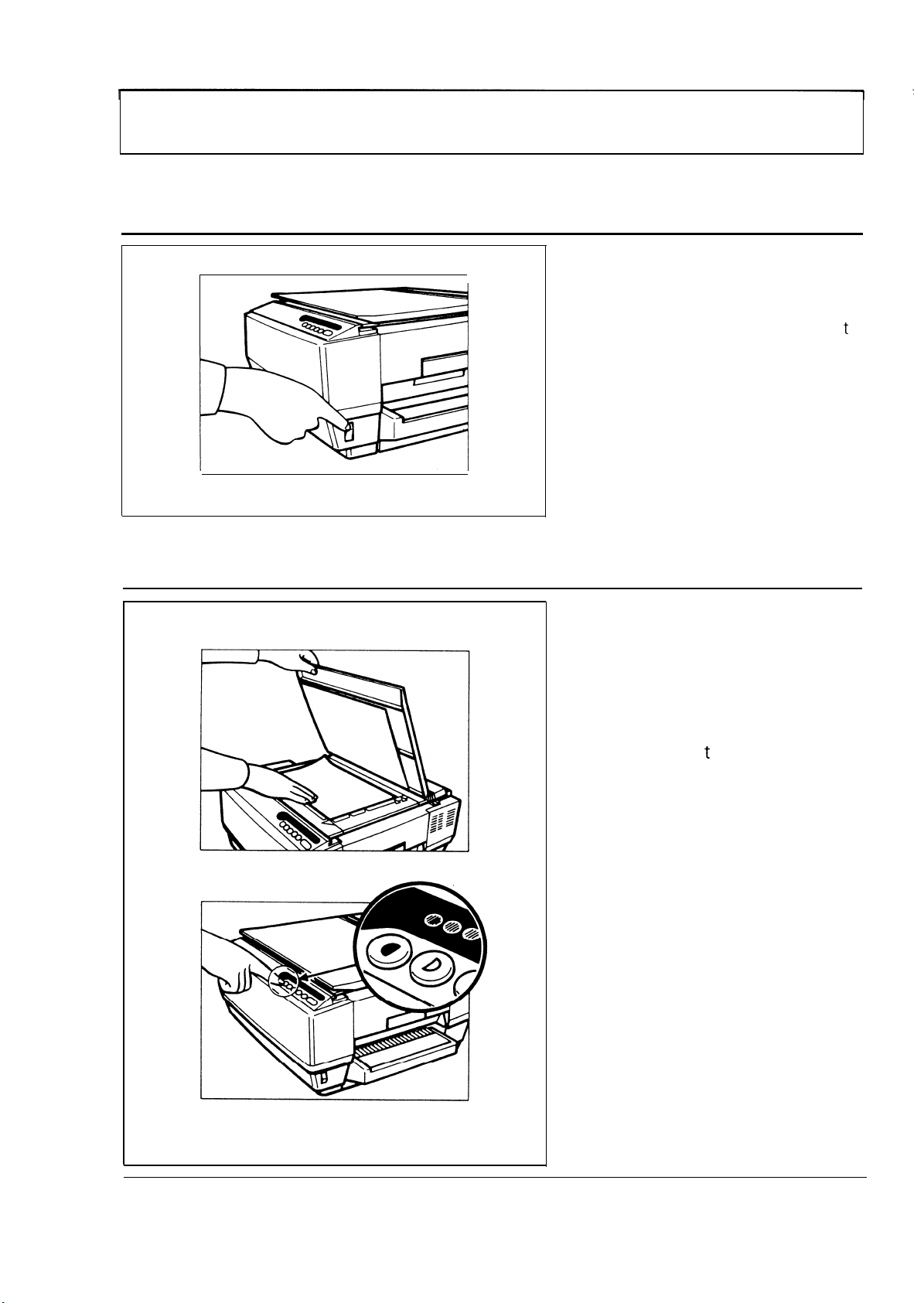

1-2. INSTALLATION PROCEDURE

Slider

May, 25, 1985

1

Remove the two strips of tape.

.

Z. Move the slider to the left until

the right edge of the copier is

exposed.

Release Latch

3. Squeeze the release latch and

open the top unit.

4. Remove the three strips of

tape and the silica gel.

—

Turn to the next page.

2–

Page 7

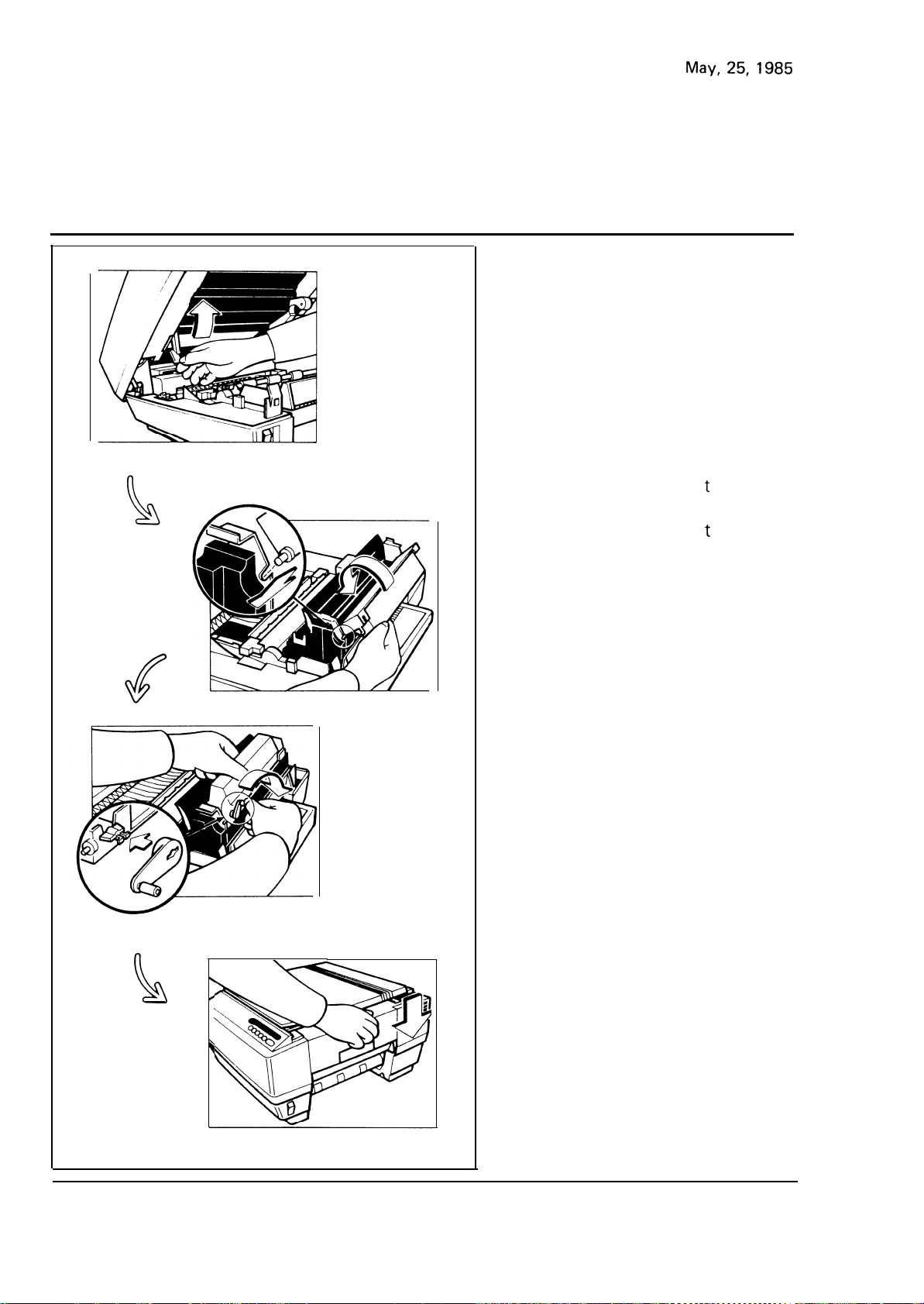

Master Release Lever

May, 25, 1985

5. Lower the master release lever.

6. Remove the three wedges

from the master unit.

Note: Do not touch the master

(purple material) and

avoid’ exposing

it to

light.

7. Insert the master unit into the

copier until it stops.

8. Peel the polyester cover off of

the master.

Page 8

Return the master release lever

9

.

to its original position.

10

.

Shake a cartridge of

11

.

Set the pins of

cartridge into the slots on the

development unit. Then, turn

the

clockwise.

cartridge counter-

oner well.

he toner

Install the cartridge crank on

12

.

the shaft. Then, turn the

cartridge crank clockwise to

strip off the cartridge seal.

Remove the cartridge crank.

Note:

13

.

Lower the top unit.

At installation, it is recommended to load

two cartridges of toner.

Turn to the next page.

—

—

4

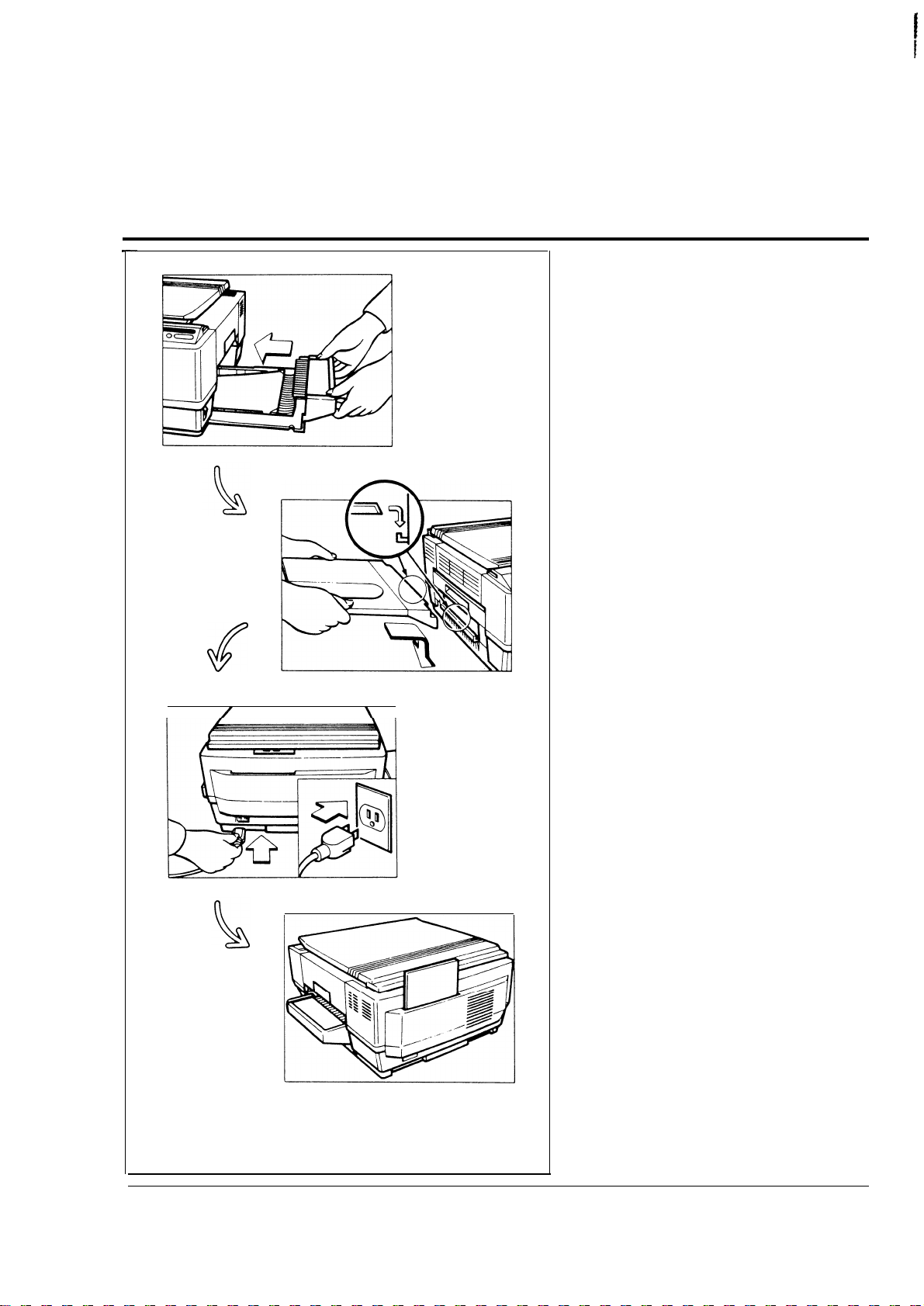

Page 9

May, 25, 1985

14. Load paper in the cassette as

shown on page 17, and insert

the loaded cassette until it

stops.

15. Install the copy tray on the left

side of the machine.

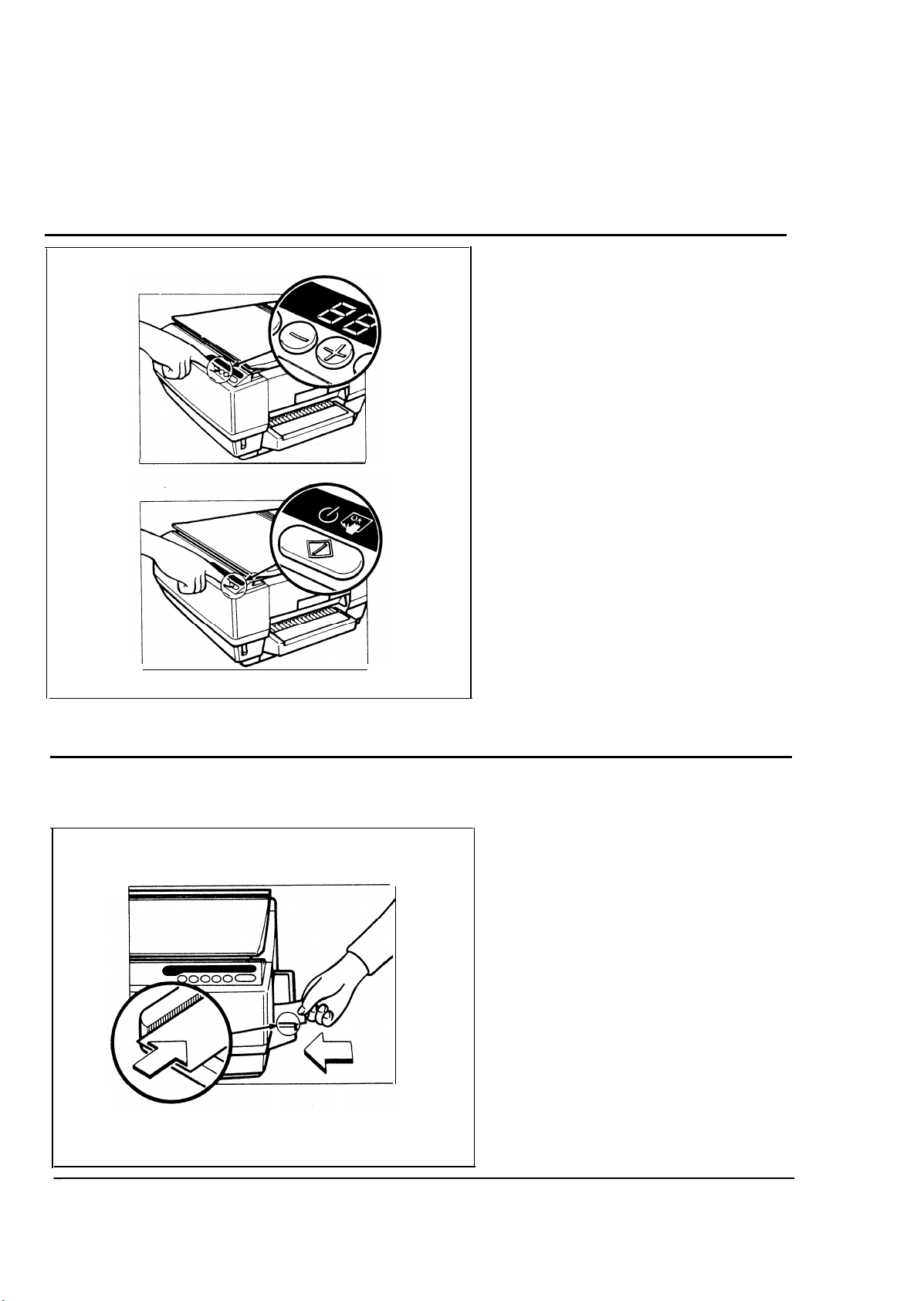

16. Connect the power

supply

cord.

17. When not using this

tion booklet, keep it

holder on the back

instruc-

in the

of the

copier.

This completes machine installation.

–5–

Page 10

May, 25, 1985

1-3. INSTALLATION REQUIREMENTS

The installation Iocatlon should be carefully chosen because environmental condi-

1l-ons greatly affect the performance of a copier

Optimum environmental conditions:

. Temperature . . . . . . . . 10–30° C

(50-86° F)

. Humidity . . . . . . . . .

. On a strong and level base (a

sturdy desk, etc. )

. The copier must be level within

5 mm (1 3/64”) both front to rear

and left to right

15–90% RH

. Well-ventilated and wide room

Minimum ventilation: air turnover

3 times/hour

—

Turn to the next page.

—

6

Page 11

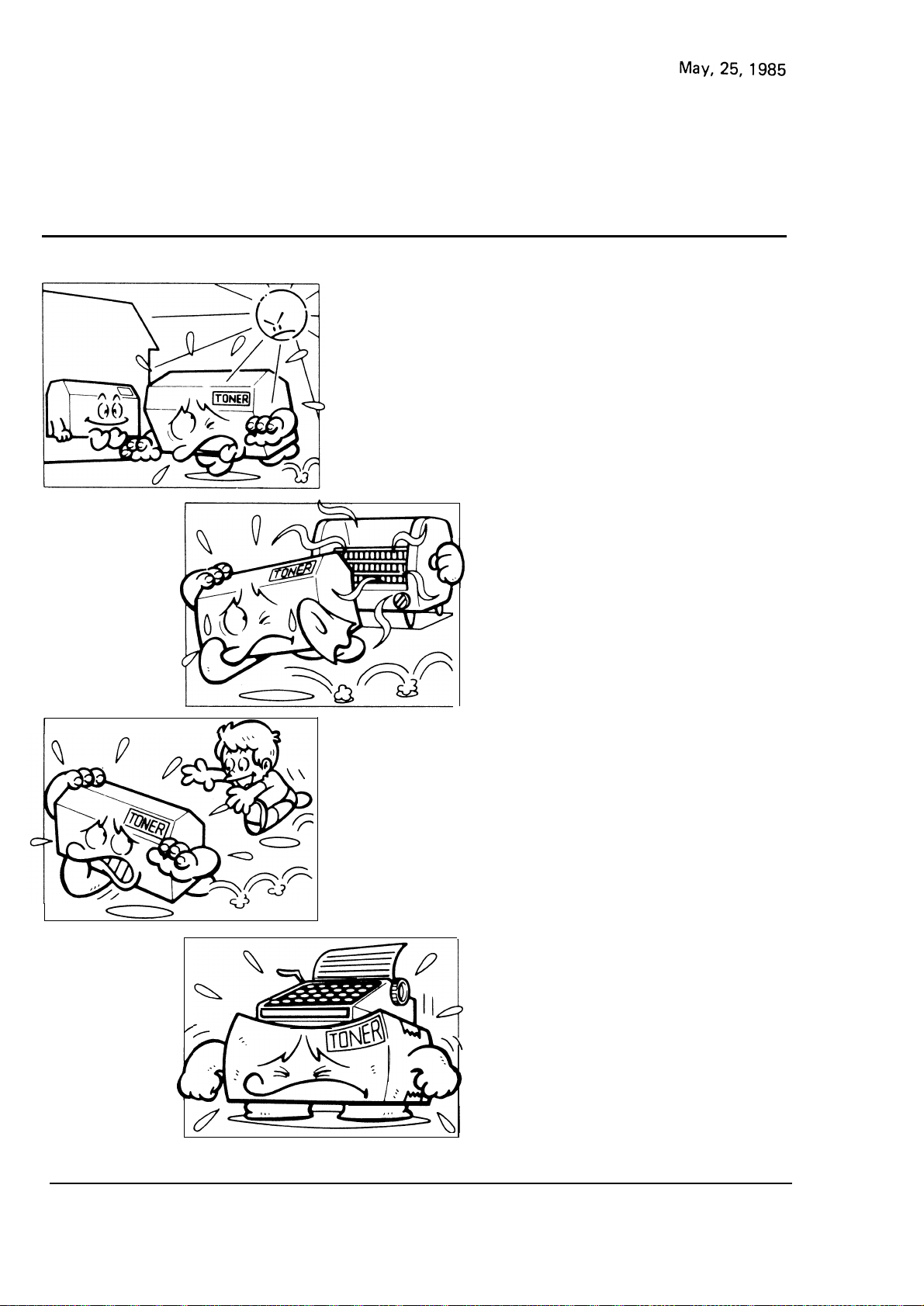

Environments to avoid:

May, 25, 1985

● Locations exposed to direct sun-

light or strong light (more than

1,500

Iux)

● Dusty areas ‘

● Areas higher than 2,000 m

(6,500 ft) above sea level

● Areas where the copier may be

subjected to frequent strong

vibration

● Locations directly exposed to the cool air from an aircondi -

tioner or to reflected heat from a space heater

(Sudden temperature changes from low to high or vice versa may cause condensation within the copier. )

—

–7

Page 12

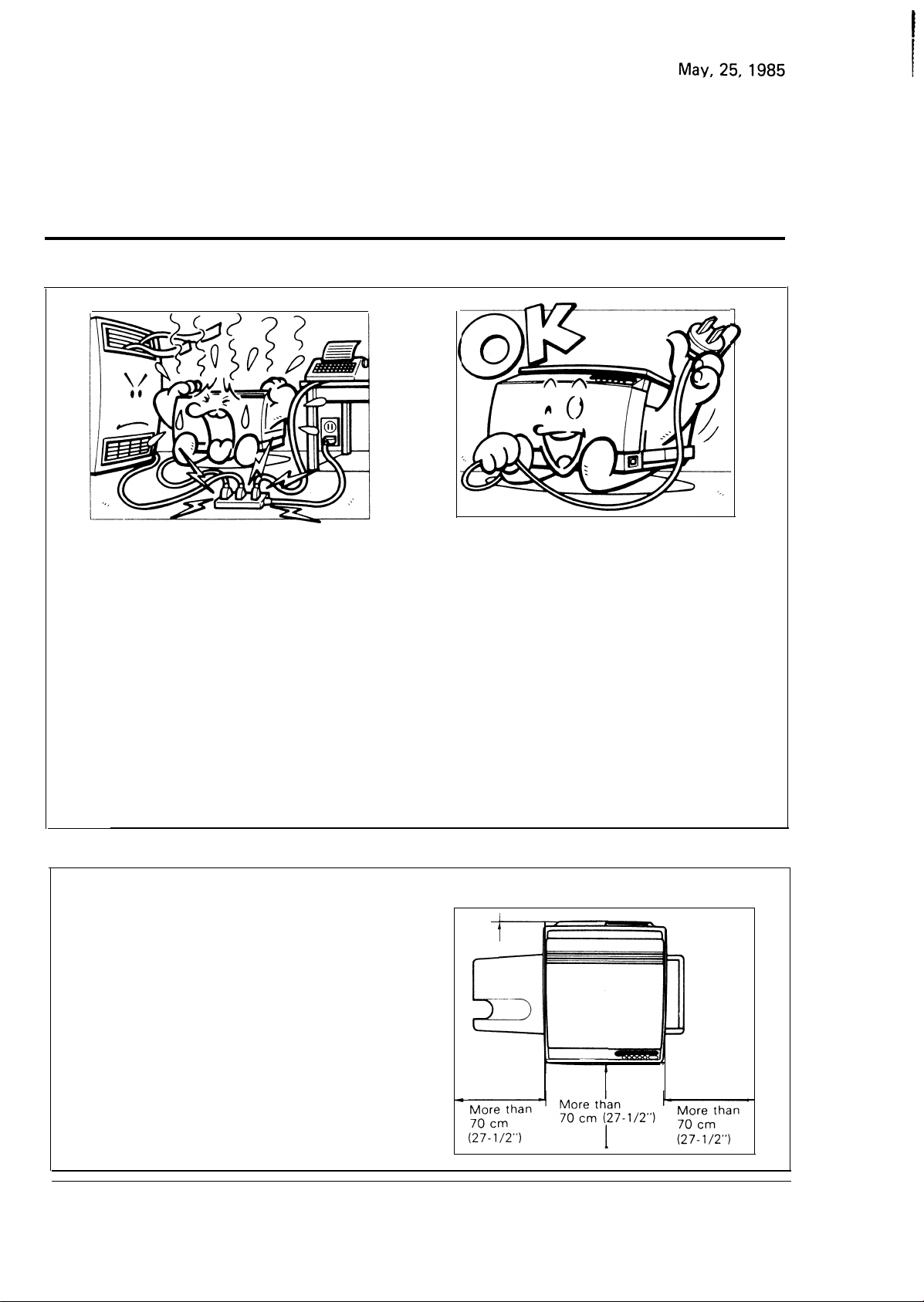

● POWER CONNECTION

●

Connect the power cord to a

power source as shown below

a) 115 V/60Hz : More than 12A

b) 220 V/50Hz : More than 6A

c) 240 V/50Hz : More than 6A

●

Voltage must not fluctuate more

than 10%.

●

Avoid multiwiring.

●

If an extension cord must be used, it must have a capacity of more than 300 V/30A

(300WZOA for 220/240V

machine) and be less than 5m (5.5 yds) long.

● ACCESS TO COPIER

Place the copier near a power source

●

providing clearance as shown.

.

●

Do not set anything on the

power cord.

●

Ground the copier properly to

prevent accidents.

Do not ground to a gas line.

●

Make sure the plug is firmly

inserted in the outlet.

More than 12 cm (4-3/4”)

—

—

8

Page 13

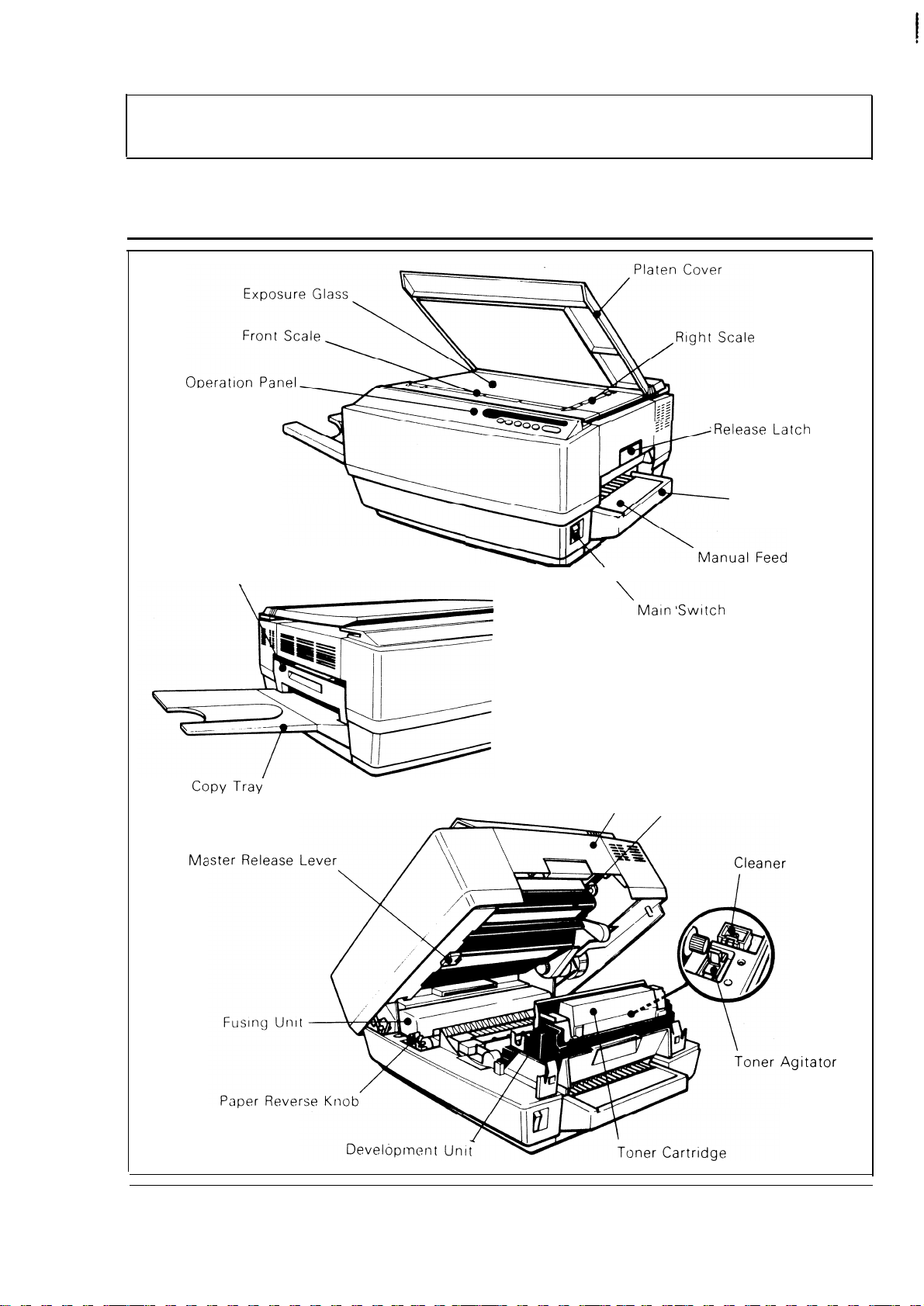

2. GUIDE TO COMPONENTS

May, 25, 1985

2-1.

Exit Cover

OVERALL MACHINE LAYOUT

—

Cassette

I

Guide

\

/

Top Unit

Master Unit

–9

—

Page 14

/

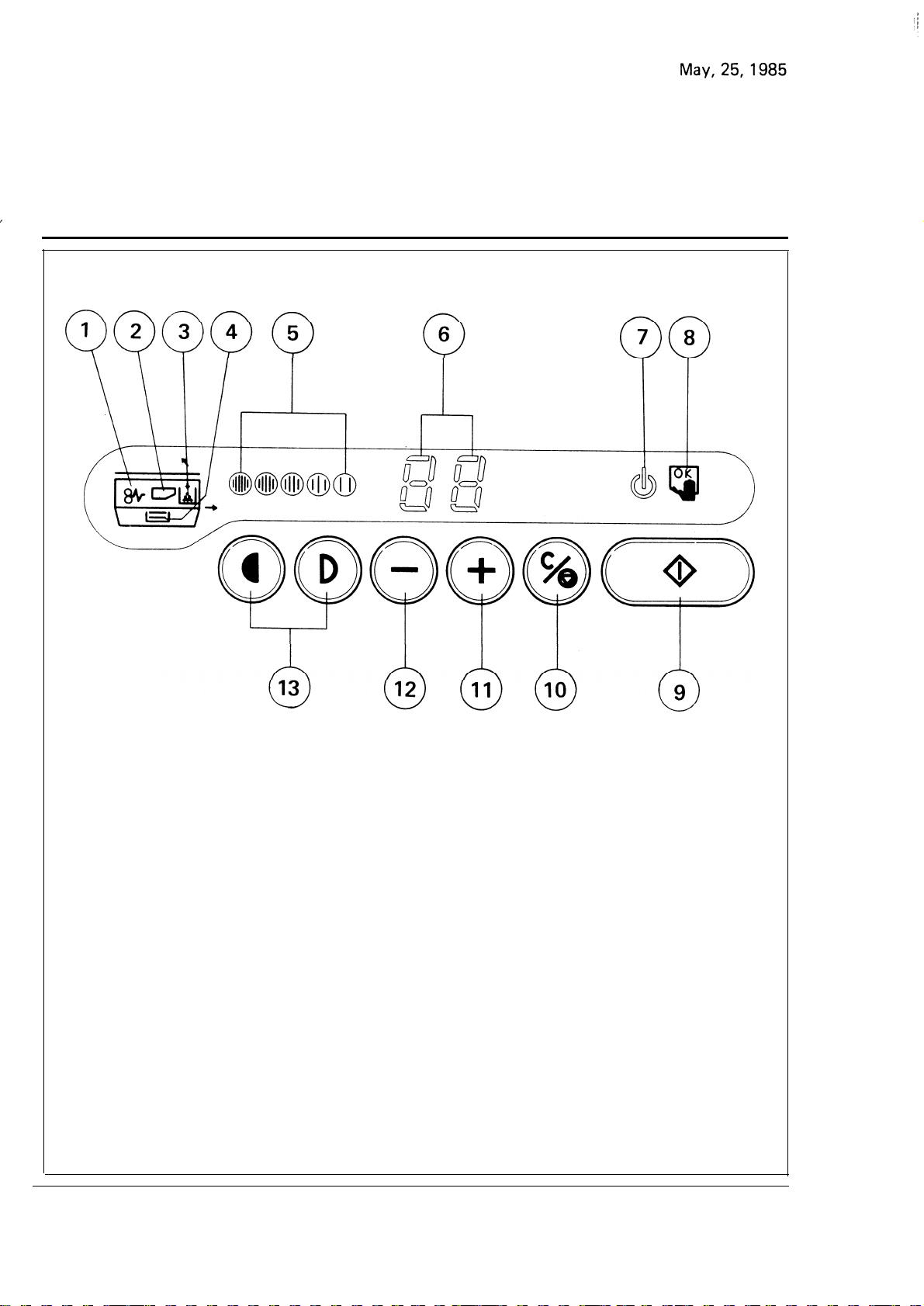

2-2. OPERATION PANEL

1.

Check Paper Path Indicator

2. Replace Master Unit

Indicator

3. Add Toner Indicator

4. Check Cassette Indicator

5.

Image Density Indicators

6. Copy Counter

7. Wait Indicator

—

10-

8. Manual Feed Indicator

9. Start Key

10, Clear/Stop

11.

Increase Quantity Key

12. Decrease Quantity Key

13. Image Density Keys

Key

Page 15

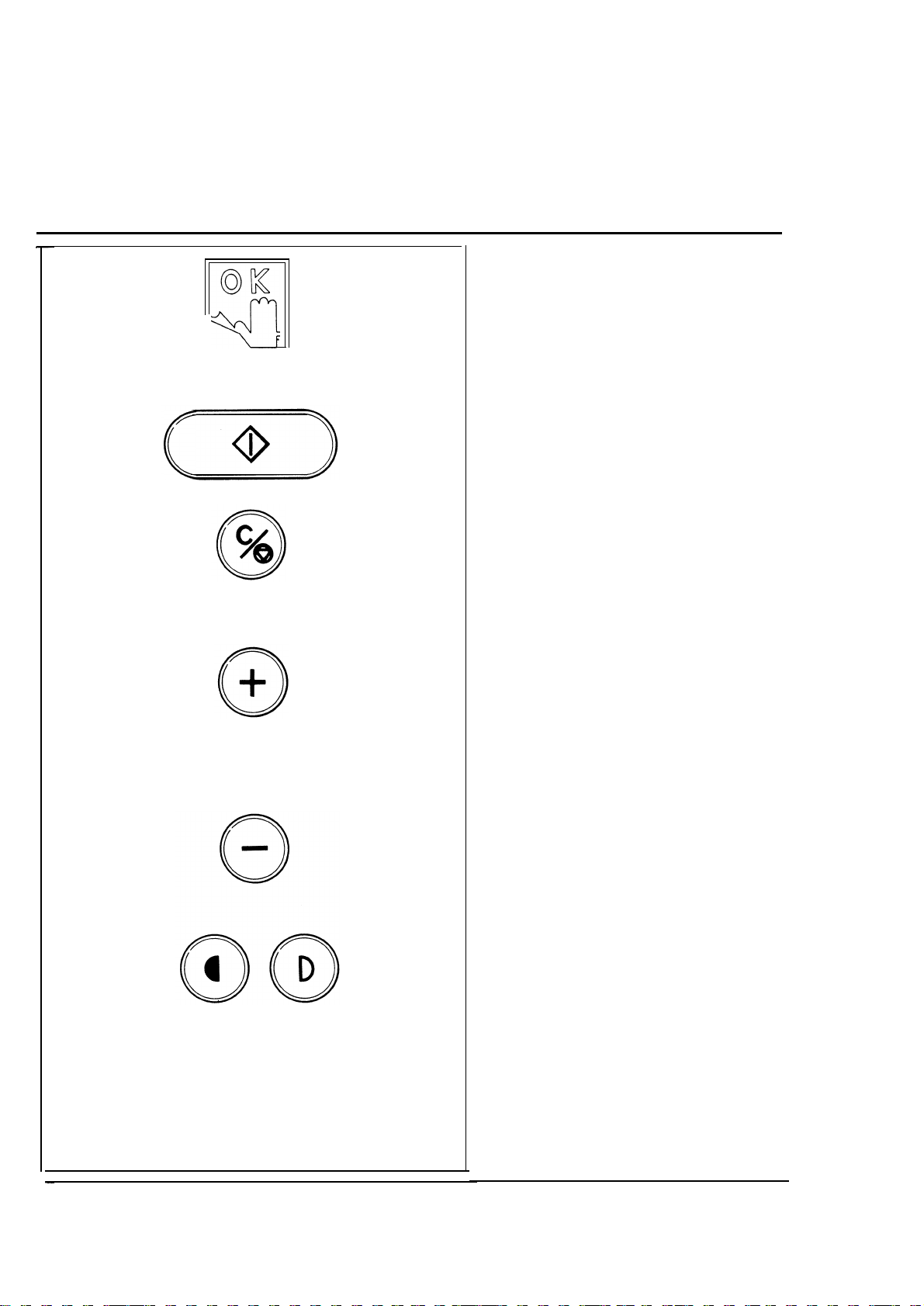

2-3. OPERATOR CONTROLS

May, 25,1985

Check Paper Path Indicator

Lights when there is a paper

misfeed within the copier.

Replace Master Unit Indicator

Lights when it is time to change

the master unit.

Add Toner Indicator

Lights when it is time to change

the toner cartridge.

Check Cassette Indicator

Lights when either no paper is

in the cassette or the cassette is

not properly positioned.

Image Density Indicators

Shows the image density level

selected.

(Five levels from darkest to

lightest)

Copy Counter

Shows the number of copies

entered.

counter shows the number of

copies made.

While copying, this

(Count up type.)

–11–

Wait Indicator

Lights when the copier is warming up.

made when this indicator is on.

Copies cannot

be

Page 16

May, 25, 1985

●

Manual Feed Indicator

Lights when copy paper has

been inserted.

Blinks when the next sheet of

copy paper should be inserted.

●

Start Key

Press to start copy operation.

●

Clear/Stop Key

Press to cancel the copy number entered.

While copying,

press to stop copy operation.

●

Increase Quantity Key

Press to increase the copy entry

number. (The maximum number of copies that can be

entered is 20.)

● Decrease Quantity Key

Press to reduce the copy entry

number.

● Image Density Keys

Use these keys to

make copies

lighter or darker.

–12–

Page 17

3. COPYING

.

May, 25, 1985

3-1. STARTING THE COPIER

3-2. NORMAL COPYING

Turn on the main switch.

The Wait indicator ( ~ ) will turn

on, which means the copier

warming up. When this

turns off, copies can be m

1

Raise the platen cover and

.

place the original face down

on the exposure glass.

indica or

ade.

,

is

Make sure the original is flush

with both

right scales

2. Adjust the image density to

match the type and quality of

the original by pressing the

Image Density keys.

he front and the

–

13

—

Page 18

May, 25, 1985

Enter the number of copies

3

.

required by pressing

Increase Quantity key.

(Use the Decrease Quantity

key if you enter too many

copies.)

* Up to 20 copies can be

entered at one time.

* Press the Clear/Stop key to

cancel the entry.

4

Press the Start Key.

the

The number of copies made

will be continuously shown by

the copy counter.

(To stop the machine during a

multicopy

Clear/Stop key.)

3-3. MANUAL FEED COPYING

Use the manual feed entrance to copy onto paper of unusual

1

Insert

.

feed

above

Manual Feed indicator lights.

Note: Make sure that the

Position the original on the

2●

exposure glass and press the

Start key.

run,

size or weight.

paper into the manual

entrance

the cassette) until the

paper is flush against

the front edge of the

manual feed guide as

shown.

press

(the space

the

–14–

If making multiple copies,

3.

insert the next sheet of paper

into the entrance when the

Manual Feed indicator starts to

blink.

Page 19

3-4. TWO-SIDED COPYING

May, 25, 1985

1. Copy the first side in the normal manner. Then, insert the

copy into the manual feed

entrance

Feed indicator lights.

Important:

The copy must be inserted

facedown, and flush against

the front edge of the manual

feed guide.

until the Manual

2. Set the second original, and

press the Start key.

1

–15–

Page 20

May, 25, 1985

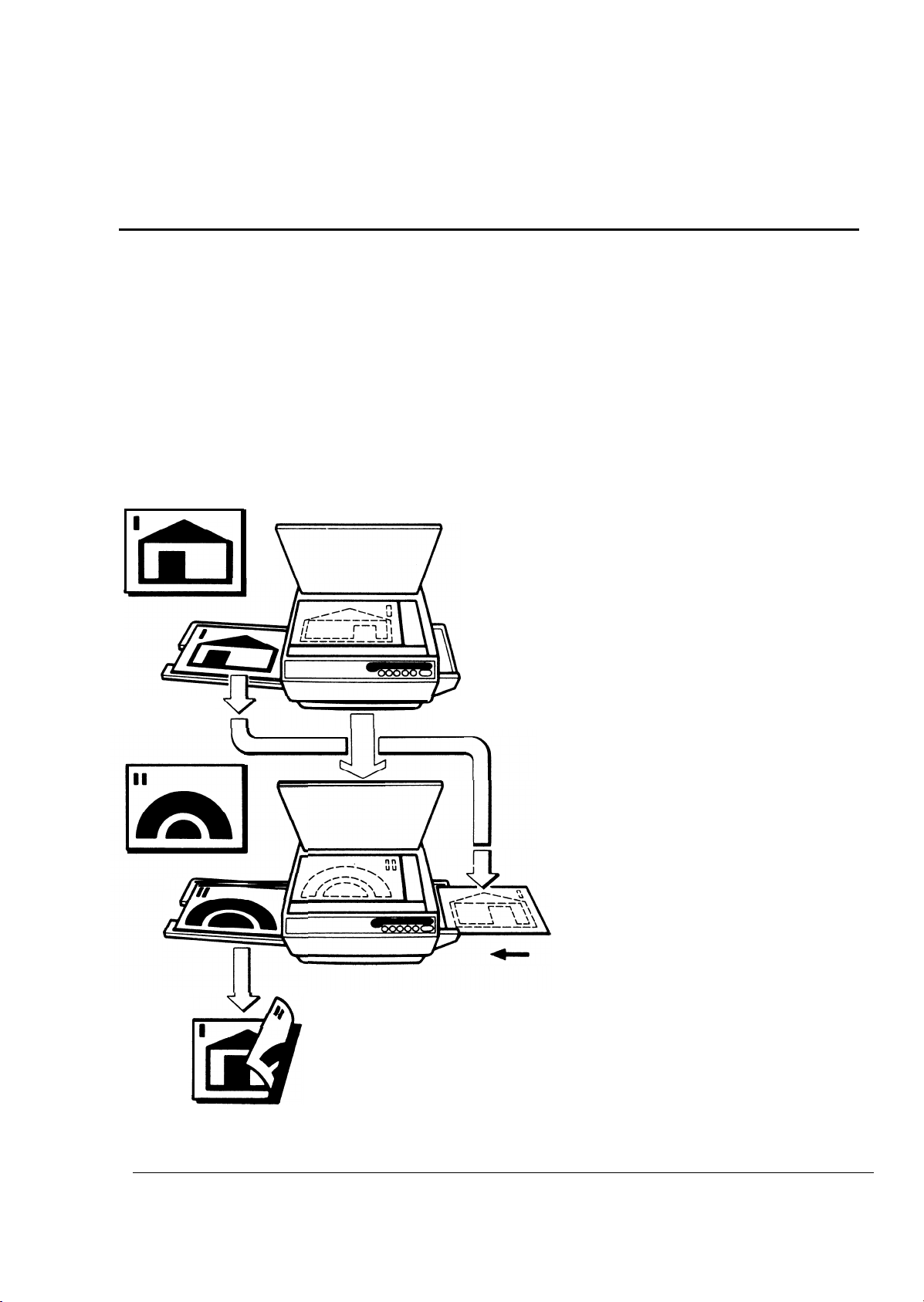

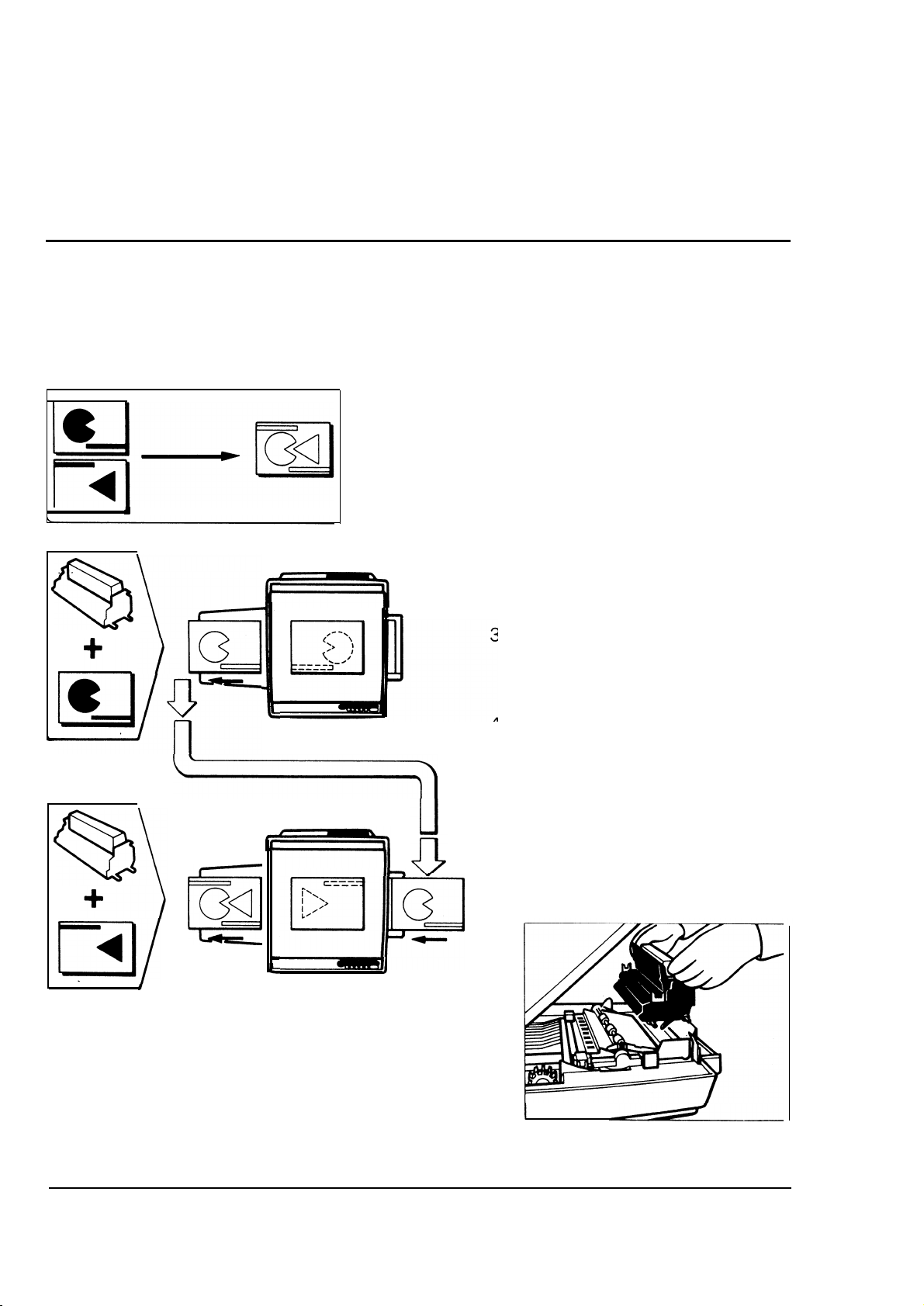

3-5. COLOR COPYING

Blue, green, and red development units and toner are available as options in addition

to standard black.

(You need a separate development unit for each color.)

Example: Making a green and blue

copy.

1

Install the green development

.

unit in the copier.

Place the black development

unit in the spare development

unit case.

2. Place the original to be copied

in green on the exposure glass,

and make the copy.

3. Insert the copy faceup into the

manual feed entrance.

4.

Exchange the green and blue

development units.

Place the original to be copied

.

5

in blue on the exposure glass

and press the Start key.

–16–

Page 21

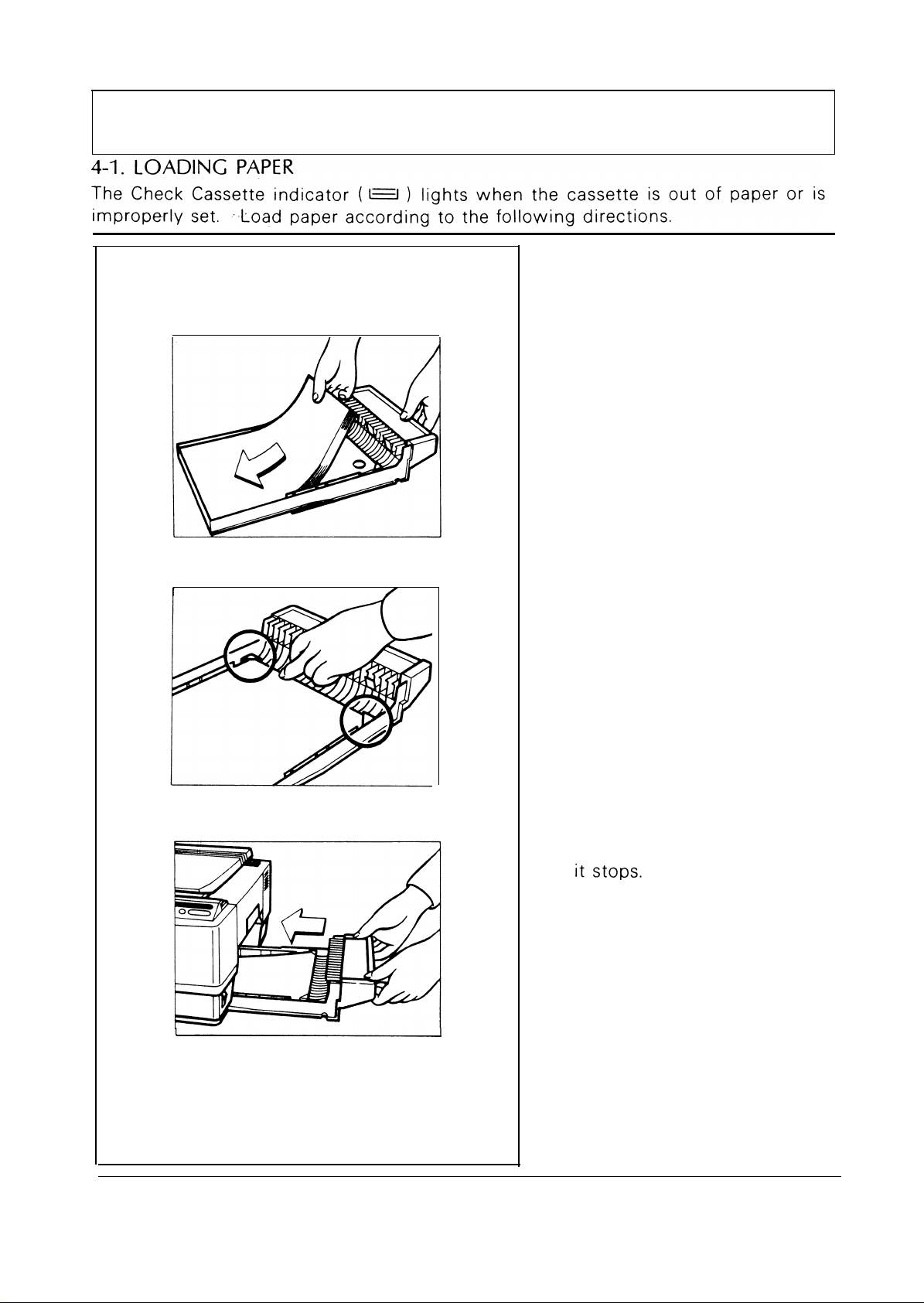

4. REPLENISHING SUPPLIES

1

.

Lift up and pull out the

cassette.

Load paper into the cassette

2

.

so that it is flush with the front

and side fences.

May, 25, 1985

Note: The

approximately

sheets.

Press down the corners of the

3

.

paper stack so that they catch

underneath the corner separators.

Insert the loaded cassette until

4,

cassette

holds

100

–17–

Page 22

May, 25, 1985

Paper Storage

Paper should always be stored properly, because poor paper condition will result in

.poor image reproduction, creased copies, and paper jams.

Generally, to avoid absorption

of moisture and curling:

. Avoid storing paper in humid

areas.

. NEVER store paper where it will

be exposed to heat.

● Store on a FLAT SURFACE.

● Use OLDER STOCK first.

● Do not lay any heavy objects on

paper.

. Keep open reams of paper in the

PACKAGE, and store as you

would unopened paper.

–18–

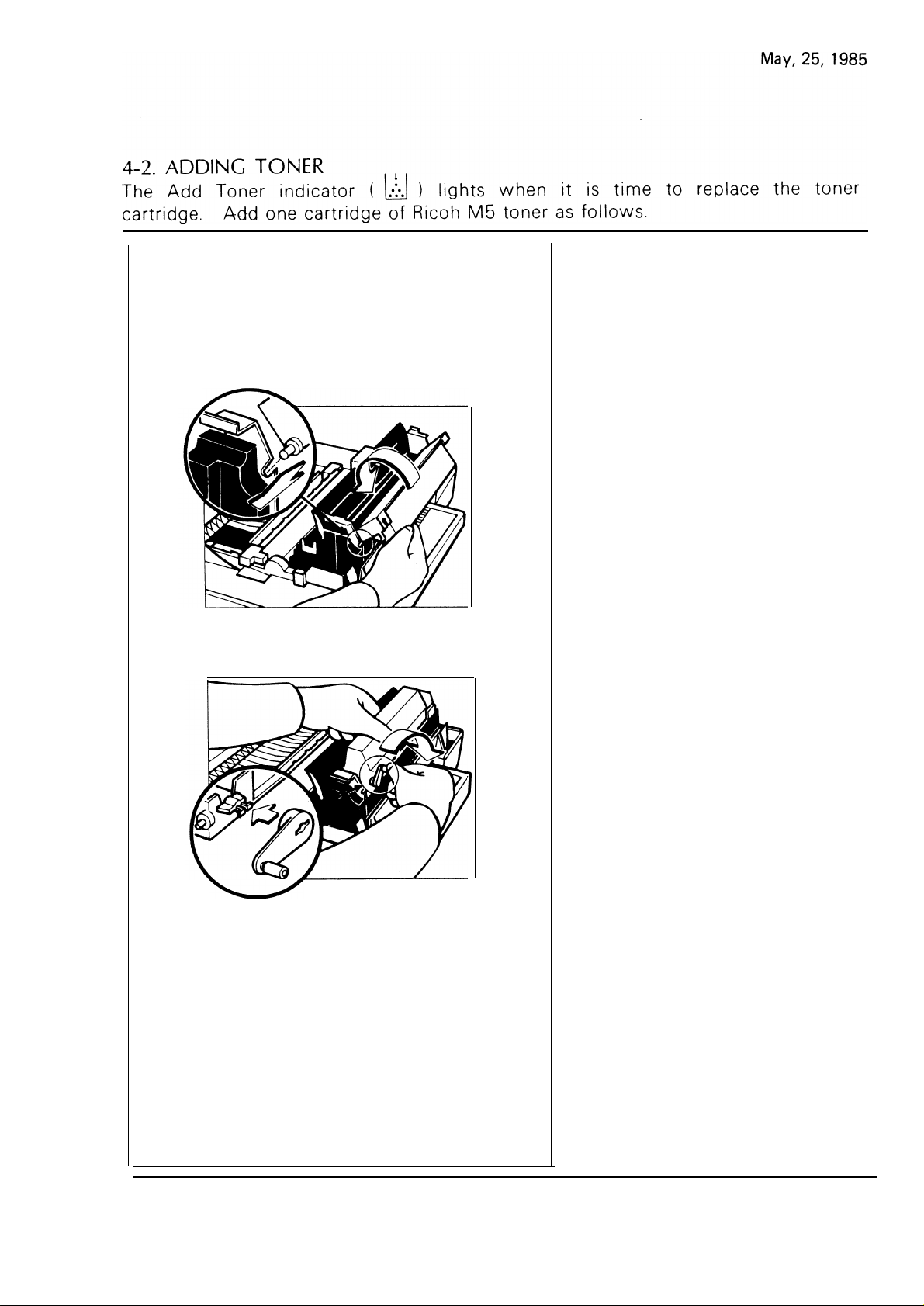

Page 23

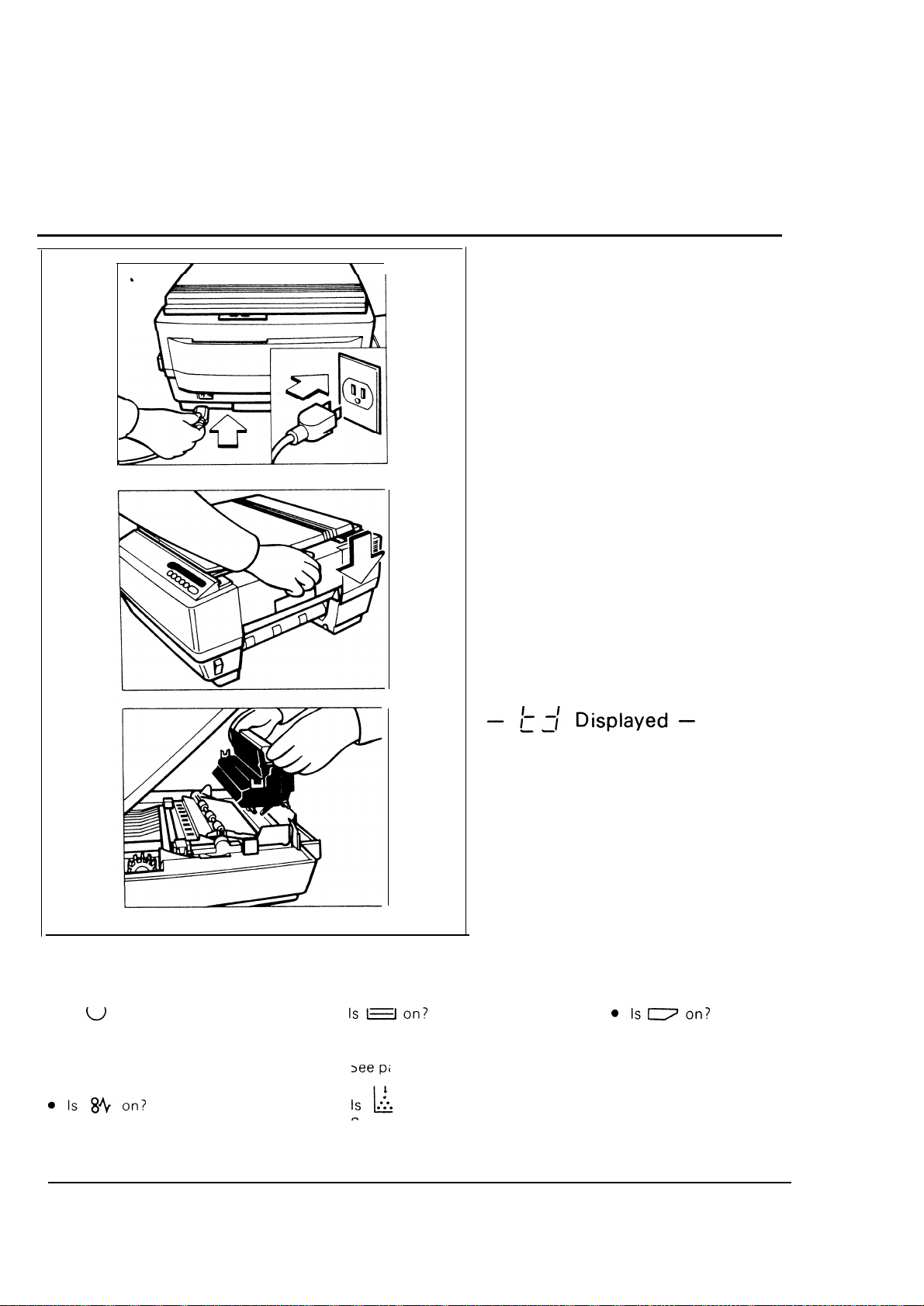

1.

Open the top unit.

2. Take out the toner cartidge.

3. Shake a new cartridge of toner

well

4. Set

the pins of the toner

cartridge into the slots on the

development unit. Then, turn

the

cartridge

counter-

clockwise.

5. Install the cartridge crank onto

the shaft and turn the cartridge

crank clockwise to strip off the

cartridge seal.

Then, remove the cartridge

crank and lower the top unit.

–

19

—

Page 24

Toner Storage

●

Store in a COOL, DARK place.

●

NEVER store toner where it will

be exposed to heat.

. Keep out of reach of children.

● Do not take internally.

●

Do not lay

anything heavy on

toner cartridges.

–

20

—

Page 25

May, 25, 1985

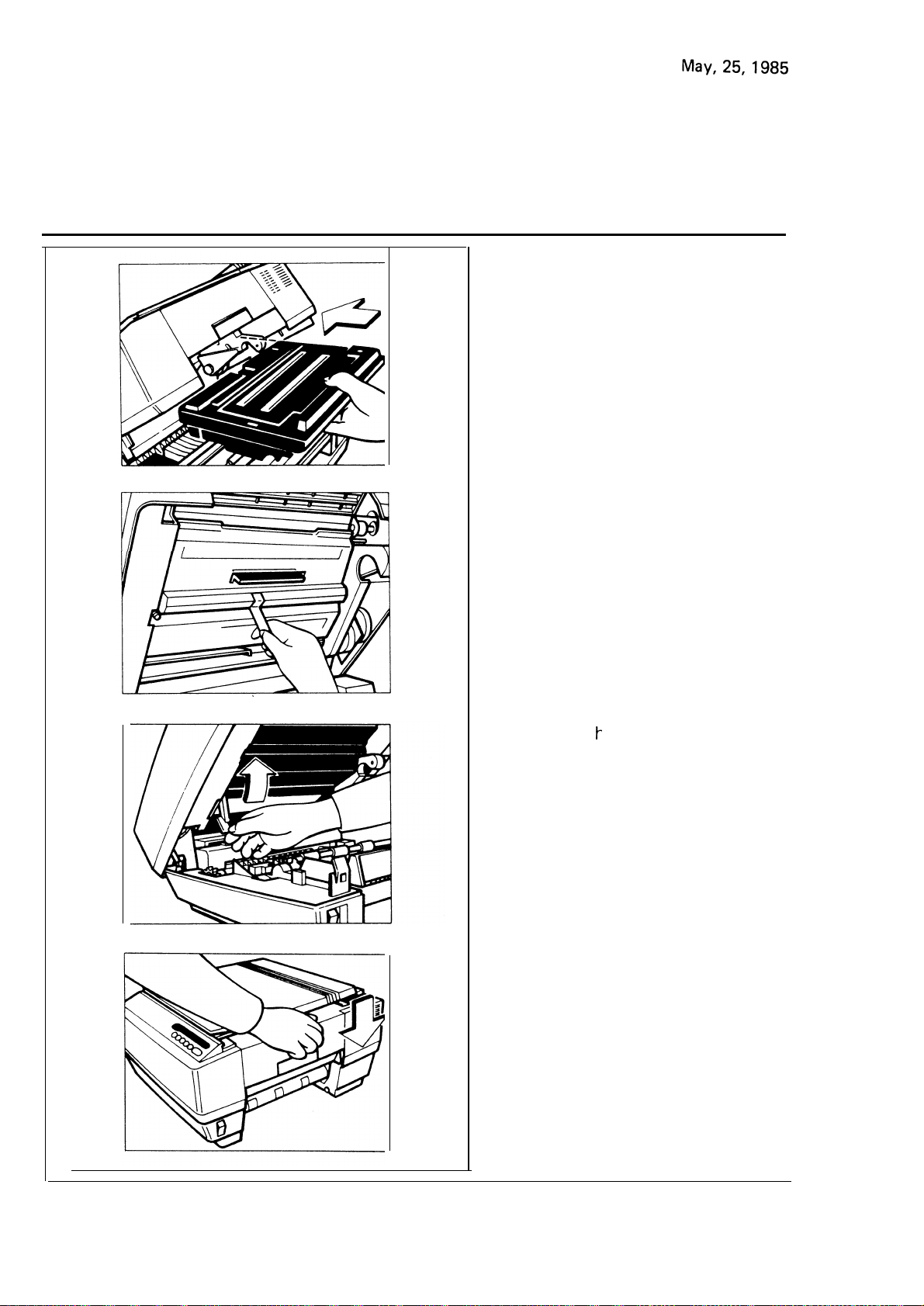

5.

REPLACING THE MASTER

1.

Squeeze the release latch and

open the top unit.

2

Lower the master release lever

.

and slide Out the used master

unit.

Dispose of the used unit using

the provided vinyl bag.

UNIT

Remove the three wedges

3

from the new master unit

Page 26

4. Insert the master unit into the

copier.

5. Peel off the polyester cover

that protects the master.

6. Returnth

e master release lever

to its original position.

7. Lower the top unit.

—

22

–

Page 27

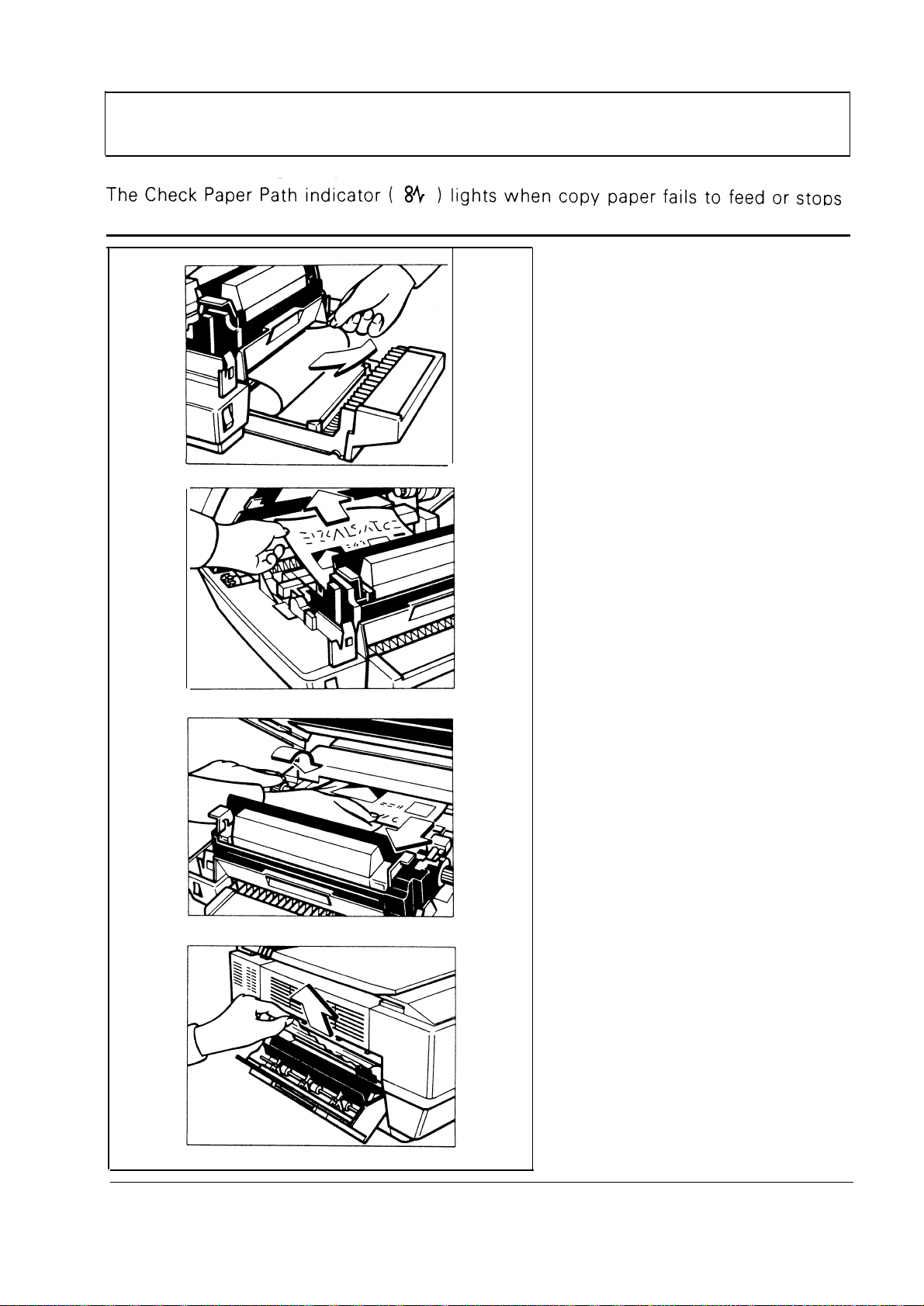

6. TROUBLESHOOTING

May, 25, 1985

6-1.

before exiting the copier.

CLEARING MISFEEDS

1

Raise the top unit and remove

the jammed paper.

Note: Do not touch the master

(purple material).

If the paper is caught inside

2

the cassette,

cassette and remove the jammed paper.

3

If the paper is caught under

the development unit, remove

the jammed paper by pulling

on the leading edge.

This prevents the rollers from

getting dirty.

pull out the

Note: The copy image is not

fused at this time; be

careful not to get hands

or clothing dirty.

If the paper is caught in the

4

fusing unit, rotate the paper

reverse knob counterclockwise

to release it.

WARNING: The fusing unit is

hot. Avoid

touching it.

If the jammed paper can not be

5

removed by rotating the paper

reverse knob, close the top

unit and remove the copy

tray. Then,

cover and remove the jammed

paper.

open the exit

—

WARNING: Avoid touching

the INNER parts

of the machine.

23 –

Page 28

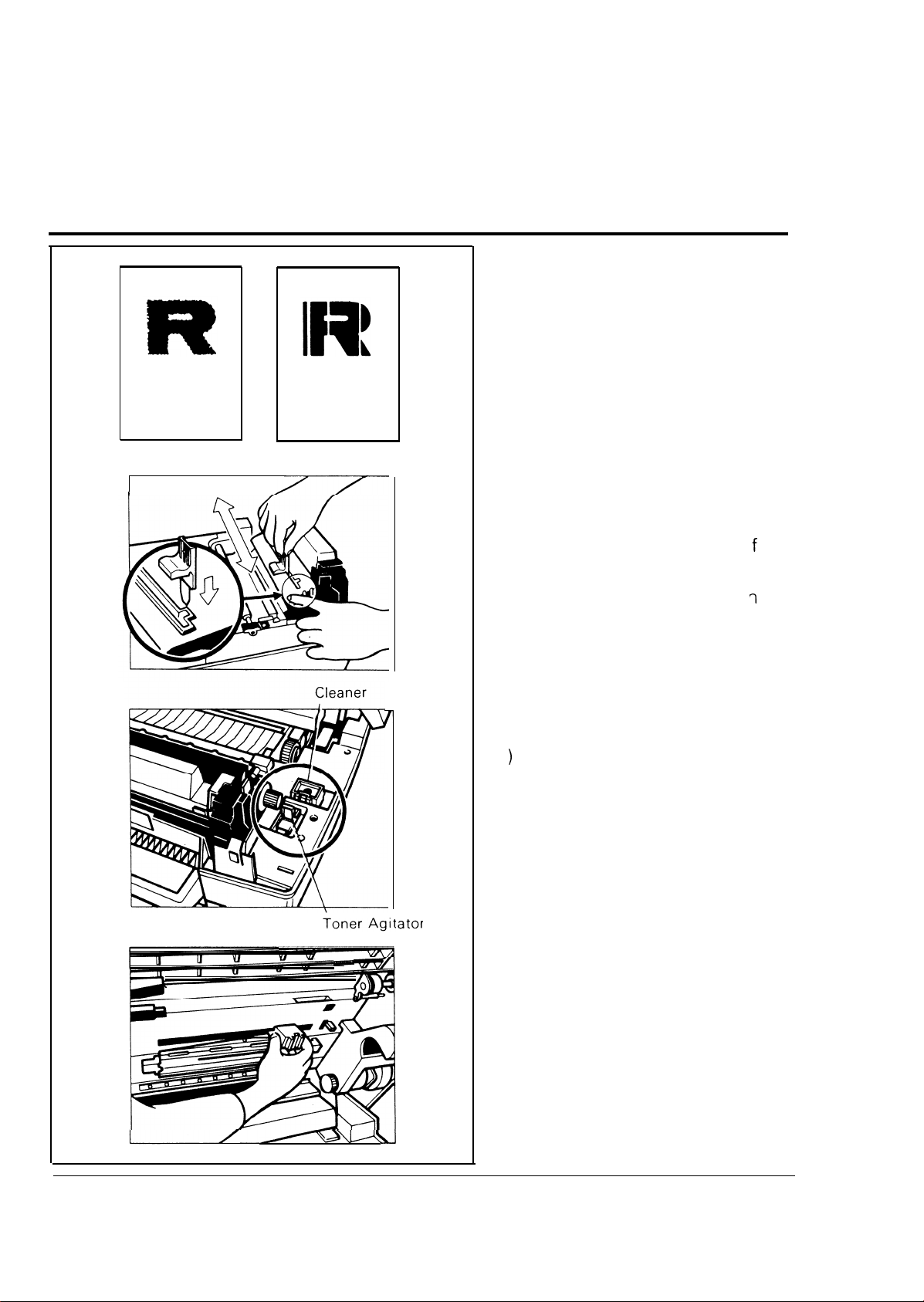

6-2. TROUBLESHOOTNG GUIDE

I

May, 25, 1985

1. Faint Copies or White

Stripes on Copies

● Agitate the toner.

(1) Open the top unit and insert

the narrow tab of the toner

agitator into the slot in

development unit cover.

Slide the toner agitator

end to end several times.

the

from

(2) Keep the toner agitator or

I

holder inside the copier.

If the problem still exists after the

above, do the following:

●

Clean the fiber optics and corona wire.

(1

Open the top unit and take out

the master unit. Set it on a

clean sheet of paper.

Caution: Do not touch the

master (purple material), and avoid exposing it to light.

Insert the long pad of the

(2)

cleaner in the fiber optics slot,

and slide it end to end.

the

–24–

Turn to the next page.

Page 29

May, 25, 1985

(3) Clean the corona wire with the

short pad of the cleaner.

Gently rub the cleaner along

the wire.

(4) Keep the cleaner on the holder

inside the copier.

#

2. Copies have Dark stripes

or Heavy Background

First, try pressing the Lighter key to

adjust the image density.

If that does not help, do the following:

● Clean the exposure glass and

platen cover. (See page 28.)

● Clean the fiber optics.

(1) Open the top unit and take out

the master unit. Set it on a

clean sheet of paper.

(2) Insert the long pad of the

cleaner in the fiber optics slot,

and slide it from end to end.

Page 30

May, 25, 1985

”

3. Nothing Happens When

the Main switch is Turn-

ed On

– No Indicators On –

● IS the power cord plugged in?

Has

it been firmly inserted into

the copier?

. I

S the top unit

ed?

completely clos-

4. Copies cannot be Made

I

● Is

Wait for the copier to warm up.

See page 23.

on?

. Is the development unit in the

machine?

●

Check that the cassette is loaded

and properly set.

See page 17.

u

on?

●

See page 19.

See page 21.

● Is a service code

displayed?

See page 27.

– 26

—

Page 31

6-3. SERVICE CODES

May, 25, 1985

The copier’s microcomputer constantly monitors mechanical and

electrical functions. If a malfunc-

will turn on and a service code will

be displayed in the copy counter. If this happens, turn off the

main switch, wait a few seconds,

and then turn it on again.

Then, try operating the copier. If

the service code is displayed again,

call your dealer and tell him which

code is on.

(The service code tells the service

representative which tools and

parts to bring.)

–27–

Page 32

May, 25, 1985

7.

MAINTENANCE

To maintain a high copy quality, clean the exposure glass and platen cover regularly.

● Exposure Glass

Clean the

soft cloth

cleaner.

. Platen Cover

Clean the platen cover with a damp

cloth.

use a weak cleaning solution.

Note: If the waterproof paper

exposure glass with a

and commercial glass

If stains do not come off,

covering the platen cover

pad becomes badly stained,

you can obtain a new one

from your dealer.

–28–

Page 33

May, 25, 1985

8. TRANSPORTING THE COPIER

Before moving the copier from its

place of installation, remove the

copy tray and secure the slider

with strips of tape.

may be badly damaged if it is

moved when the slider is not pro-

perly secured.

safety, use the grips diagonally

opposite each other to handle the

copier.

Leave the master unit and development unit in the machine.

The copier

For MAXIMUM

\

r

9. DO’S AND DON’TS

Operating

Cautions

1.

While copying:

Do not turn off the main switch. Do not hold the slider.

Do not lift the platen cover.

2

.

Do not overload the cassette. (The MAXIMUM

3

.

Do not let the copy tray become overloaded (The MAXIMUM capacity is 20

4

.

Do not lay anything weighing more than 3 kg on the exposure glass.

.

Do not lay tools or other hard objects on the exposure glass.

5

6.

Keep corrosive liquids, such as acid, off the machine.

7.

Do not touch the copy paper if your fingers are wet or oily; fingerprints may appear

on the copy.

8.

Do not allow paper clips, staples, or other small metallic objects to fall inside the

machine.

9.

To avoid misfeeds, copy transparencies without a backing sheet. (Use recommended transparencies.)

Do not unplug the power cord.

I

.

capacity is 100 sheets.)

copies.)

10.

Do not touch the master (purple material) and avoid exposing

General Cautions

1,

Since some parts of the copier are supplied with high voltage,

switch is off before working on the copier.

2.

Do not modify or replace any parts other than the ones mentioned in this manual.

3.

When not using the copier for a long period, disconnect the power supply plug.

4,

Never store the master unit where it will be exposed to heat,

it to light.

make sure the main

–29–

Page 34

May, 25, 1985

10. SPECIFICATIONS

Configuration

Copy Process

Originals

Copy Size

Multiple Copying

Warm-Up Time

Automatic Reset

First Copy Time : 10 seconds

: Desktop (moving platen)

: Dry process (mono-component toner)

: Sheet/Book

: Maximum –

Minimum –

:

up to 20

: Approximately 15 seconds

: After 60 seconds

,

A4 (8-1/2”

Business card size (84 x 49

mm) (3-1/2” x 2“)

X 11“)

Copying Speed

Reproduction Ratio

Paper Feed

Toner Supply

Copy Paper

Copy Paper Weight

Power Source

Power Consumption

Dimensions

Weight

Note: To obtain the best copies, use Ricoh FT paper or a similar bond paper,

Ask your sales or service representative to recommend a brand of paper

that is suitable for use with the M5.

: 8 copies/minute

:1:1

: Single cassette (100 sheets) and Manual

Feed

: Cartridge (black, blue, red, and green)

: Bond paper/colored paper/mailing labels

OHP transparencies/translucent paper

mimeographic paper

: 52 to 157 g/m

: 1 15V/601+z/l 2A

220 V/50 Hz/6A, 240 V/50 Hz/6A

: 1.2 WA (1 15V), 1.4 WA (220/240V)

.

.

w

404 mm x 485 mm x 225 mm

(16“

X 19“ x 8-7/8”)

: Approximately

2

(14to 42 lb) (Manual Feed)

D

H

20 kg (44 lb)

Specifications are subject to change without notice.

–30–

Page 35

SERVICE MANUAL

Page 36

Contents

Specifications . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . ...* . . ...*

●

.-.’

Overall Machine Information

Functional Operation . . . . . . .

1

.

Copy processes . . . . . . . . . . .

2.

Mechanical Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.

Electrical Component Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.

Drive Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

5

Power Distribution

6.

- Ac Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Dc Power Supply . .

-Power-On Reset . . .

Sectional Descriptions

Master Unit

1. Introduction . . . . . . . . .

2. Master Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Master Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..**.

●

1-1

2-1

2-2

2-4

2-6

2-8

2-10

2-11

2-12

3-1

3-2

3-3

Charge

I. Charge Corona . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Charge Corona Circuit.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Replacement of Parts

Charge Corona Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charge Corona Power Pack.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exposure

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

.

2.

Slider Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

.

Clutch Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

.

Slider Lock Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.

Slider Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.

Exposure Lamp Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

.

Lamp Heater Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

Replacement of Parts

.

Exposure Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fiber Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exposure Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exposure Lamp Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exposure Lamp Stabilizer.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Slider Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Slider Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Home Position Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4

3-5

3-6

3-7

3-8

3-10

3-13

3-15

3-16

3-17

3-19

3-20

3-21

3-22

3-23

3-24

3-25

3-27

3-28

Page 37

9. Cleaning of Parts

Fiber Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-29

10. Lubrication of Parts

Fiber Optics Holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-30

Development

Black Development

1 .

2.

Color Development

Bias Application . . .

.

3

4

Drive Mechanism . .

.

Toner End Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-37

5.

Development Cover Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-38

6.

Bias Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

7.

Toner End Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-40

8.

Replacement of Parts

9.

Toner Metering Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-41

Image Transfer and Separation

I. Image Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-42

2. paper Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-42

3. Transfer Corona Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-43

4. Replacement of Parts

Transfer Corona Nylon Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-44

Transfer Corona Wire..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-45

Transfer/Bias PowerPack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

May, 25, 1985

3-31

3-33

3-35

3-36

Cleaning

l. introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-47

2. Toner Overflow Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..3~48

3. Toner Overflow Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-49

Quenching

l. introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-50

2. Quenching Lamp Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-51

3. Replacement of Parts

Quenching Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-52

Paper Feed and Registration

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-53

1

.

2.

Manual Paper Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-53

Paper Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-54

3.

4

.

Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-55

.

Paper Feed Solenoid Circuits and Timing . . . . . . . . . . . . . . . . . . . . . . . ...3-57

5

Page 38

.

Replacement of Parts

6

Paper Feed Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Registration Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Feed Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

.

Adjustment of Parts

Leading Edge Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

,

Lubrication of Parts

Paper Feed Spring Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

May, 25,1985

3-58

3-59

3-60

3-61

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Fusing

1

.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

.

Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

.

Fusing Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

.

Fusing Lamp Control Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

.

Replacement of Parts

Fusing Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hot Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hot Roller Strippers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fusing Thermoswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Mechanical and Electrical Components

1

.

Safety Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

.

Pulse Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

.

Jam Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

.

Indicator Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

.

Replacement of Parts

Exterior Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standing up Clamshell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ozone Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dc Power Supply Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mylar and Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-63

3-64

3-65

3-66

3-68

3-70

3-71

3-72

3-73

3-74

3-75

3-76

3-77

3-78

3-79

3-80

3-81

3-82

3-83

3-84

3-85

3-86

Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

Page 39

Service Tables

I. Maintenance Guidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Lubrication Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...................

4. DIP Switch Table . . . . .

5. Service Call Conditions

6. Special Tools . . . . . . . .

.- .

5-1

5-2

5-3

5-4

5-5

5-6

Troubleshooting . . . . . . . . . .

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

7-1

4

Page 40

SECTION 1

SPECIFICATIONS

Page 41

May, 25, 1985

Configuration:

Copy Process:

Originals:

.-. ”

Maximum Original Size:

Copy Paper Size:

Copy Paper Weight:

Acceptable Original Weight:

Reproduction Ratio:

Copying Speed:

First Copy:

Warm-upTime:

Desktop (Moving platen)

Mono-component dry toner process

Book/sheet

A4 (210 x 297 mm)

Letter (8-1 /2” x 11”)

Maximum: A4 (210 x 297 mm)

Letter (8-1/2” x 11“)

Minimum: Business card size

(49 x 84 mm, 2“ x 3-1/2”)

(Lengthwise feed only)

Cassette Feed: 60 to 80 g/m

Manual Feed: 52 to 157 g/m

2

(16 to 21 lb)

2

(14 to 42 lb)

Maximum: 3 Kg

11

8 copies per minute (All sizes)

10 seconds

Approximately 15 seconds

(Room temperature 20°C)

Operation Control:

Start Switch:

Copy Counter:

Clear/Stop:

Image Density:

Automatic Reset:

Indicators:

Photoconductor:

Microcomputer

Profile key

1 to 20 copies (Count-up)

Profile key

Exposure intensity control (Fixed bias)

After 60 seconds (Copy counter only)

“check paper Path” indicator

1

.

2. “Replace Master Unit” indicator

3. “Check Cassette” indicator

4. “Add Toner” indicator

“Image Density” indicator

5

.

“Ready” indicator

6

●

“Manual Feed” indicator

7

.

Organic photoconductor (Master)

1-1

Page 42

May, 25, 1985

Master Charge:

Exposure System:

Exposure Lamp:

Exposure LampHeater:

Optics:

Development:

Toner Replenishment:

Toner Consumption:

Development Bias:

Image Transfer:

Cleaning:

Quenching:

Paper Feeding:

Single-wire with grid plate (Scorotron)

Slit exposure, moving platen

Fluorescent lamp 14 W

5 W (When plugged in)

Fiber optics

Floating electrode roller system

(mono-component dry toner)

Cartridge (70 g/black toner)

(50 g/color toner)

1700 copies

Negative fixed bias

Single wire dc corotron

(Negative charge)

Cleaning blade

LED Lamps

Cassette (100 sheet capacity) and manual

feed

Paper Feed System:

Image Fusing:

Fusing Lamp:

Copy Tray Capacity:

Self-diagnostic Codes:

Power Source:

Power Consumption:

Pick-up, feed roller and corner separators

Heat roll type, Teflon and silicone

rubber rollers

1,050 w

20 sheets

El : Exposure

E2: Slider

E3: Development

E5: Fusing

E6: Functional Drive

E7: Master Unit

1 15V/60Hz 12 A

220 V, 240 V/50Hz 6 A

Maximum: 1.2 kW (115 V)

Maximum: 1.4 kW (220/240 V)

1-2

Page 43

●

May, 25, 1985

Dimensions:

Weight:

Optional Equipment:

(W x D x H)

Without Cassette and Copy Tray

404mm x 485 mm x 225 mm

(16“

X 19“ X 8-7/8”)

With Cassette and Copy Tray

610 mm x 485 mm x 225mm

(24”

X 19“ X 8-7/8”)

Approximately 20 kg (44 lb)

- Cassettes (LT and A4 sizes)

- Development Units (Color toner)

1-3

Page 44

SECTION 2

OVERALL MACHINE

INFORMATION

I. Functional Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-1

2. Copy processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-2

3. Mechanical Component Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-4

4. Electrical Component Layout.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-6

5. Drive Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-8

6. Power Distribution

-AC Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-10

-DC Power Suppiy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-11

-Power-On Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 2-12

Page 45

2-1

1. Functional Operation

/

I

Page 46

2-2

2

8

Copy Process

Page 47

2-3

Page 48

3. Mechanical Component Layout

2-4

May, 25, 1985

Page 49

2-5

A

May, 25, 1985

Page 50

2-6

4. Electrical Component Layout

May, 25, 1985

‘1

Page 51

2-7

May, 25, 1985

Page 52

5. Drive Layout

Page 53

2-9

Page 54

6. Power Distribution

— AC Power Distribution —

-.”

May, 25, 1985

When the main switch is turned on, ac input voltage is supplied to the dc power supply board, ac drive

board, and the triac.

After the main board becomes active, it activates the triac, which then supplies ac power to the fusing

lamp. The ac drive board applies ac voltage to the exposure lamp heater when the machine is plugged in.

At the same time, the cooling fan motor (M2) starts rotating at low speed. When the Start key is

pressed, the CPU energizes RA501 to turn on the main motor (Ml), and the cooling fan motor starts

rotating at high speed.

2-10

Page 55

– DC Power Supply –

May, 25, 1985

This copier uses two dc power levels: +5 volts and +22 volts.

The 29.5 Vac input from the transformer is rectified by DBA20B.

smoothes the output and amplifies the potential to +22 volts.

components that have a relatively large current requirement, such as the power packs and solenoids.

The 9 Vac input from the transformer is rectified by a diode bridge (D 1 to D4). A voltage regulator

(IC2) smoothes the output and reduces the potential to +5 volts. This +5 volt output powers the

CPU, thermistor, and sensors.

The chopper-stabilized amplifier

This +22 volt output drives the dc

2-11

Page 56

– Power-On Reset –

May,

25, 1985

The reset circuit outputs a one-shot LOW pulse which resets the CPU.

When the main switch is turnedon, +3.9 volts is applied to pin 6 of ICI 02, and the output becomes

LOW. The output of IC102 stays LOW until Cl 05 charges

ins).

It then becomes HIGH and stays HIGH until the machine is turned off.

up to +3.9 volts (which takes about 35

2-12

Page 57

SECTION 3

SECTIONAL

DESCRIPTIONS

Master Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

image Transfer and Separation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quenching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Feed and Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Mechanical and Electrical Components . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

3-4

3-8

3-31

3-42

3-47

3-50

3-53

3-63

3-64

3-75

Page 58

MASTER UNIT

Introduction

1.

May, 25, 1985

lade

Overflow Sensor

caning Section

The master unit consists of the master belt, the grid plate, and the cleaning section.

The master is an organic-photoconductor belt. It makes two rotations per copy. The master has

the characteristics of high electrical resistance in the dark, low electrical resistance when exposed to

light, and flexibility.

The master has a seam on its surface where the ends of the belt were joined together. The seam

section is not used for image reproduction.

The cleaning section removes used toner from the master surface.

3-1

Page 59

2. Master Sensor

May, 25, 1985

Master Sensor

Master Sensor

The master sensor detects a reflective plate (called the sensor plate) on the edge of the master belt

once each master rotation.

timing.

The master starts turning when the Start key is pressed.

start until the master sensor detects the sensor plate.

This tells the CPU the location of the master bond seam and sets start

However, the copy cycle does not actually

3-2

Page 60

3. Master Sensor Circuit

Main Board

May, 25, 1985

The main board applies +5 volts from CN1 02-12 to CN709-1 of the master sensor. AS long as the

sensor is off, +5 volts is present at CN102-13.

passes under the sensor, the phototransistor turns on and CN102-13 drops to O volts.

– Service Call Condition –

The CPU also uses the master sensor to detect master malfunctions.

If the phototransistor does not turn on within 7.5 seconds after the Start key is pressed, the CPU

stops the copier and lights self-diagnostic code E7.

the master unit is not in the copier.

However, when the sensor plate on the master belt

The same service call condition occurs when

3-3

Page 61

CHARGE

1. Charge Corona

May, 25, 1985

This model uses a single wire corona unit to charge the master (organic photoconductor belt).

The corona wire generates a corona of negative ions when a high negative voltage is applied to it by

the charge power pack.

installed on the master unit.

applied to the master belt.

replaced along with the master unit.

The corona unit casing has three ventilation louvers to allow ozone to escape. The ozone is then

drawn through an ozone filter by the cooling fan.

To make the negative corona uniform, a thin stainless steel grid plate is

A varistor between the grid and ground ensures that an even charge is

This grid plate requires no maintenance other than cleaning, because it is

This is to prevent deterioration of the master belt

due to ozone buildup.

3-4

Page 62

2. Charge Corona Circuit

-.

Main Board

May, 25, 1985

I

Power Pack-Charge

I

The dc power supply board supplies +22 volts through the interface board and the main board to

CN706-I as the power input of the charge power pack. CN706-3 is the trigger input.

pulse after the sensor plate on the master is detected, the CPU drops CN102-4 from +22 volts to O

volt. This falling edge trigger actuates a hybrid IC within the power pack, which applies about -5600

volts to the charge corona wire.

When the grid reaches about

charge. Therefore, the potential does not fluctuate and an even charge is applied to the master sur-

face.

NOTE: The variable resistor (VR1 ) is set at the factory and should not be adjusted in the field.

-820 volts, the varistor begins draining off any excess

On the 24th

3-5

Page 63

3. Replacement of Parts

Charge Corona Wire –

—

.-. .

May, 25, 1985

Front Cover

1

.

Open the upper clamshell and

(Do not place the master unit where it will be exposed to strong light.)

Unplug the high voltage cable from the power pack.

2

.

Remove the charge corona unit (1 stud screw).

3 .

4

Remove the front cover gently using a small screwdriver as shown in the above figure.

.

Remove the rear cover gently, then remove the corona wire.

5.

Replace the charge corona wire as shown in the above figure.

6.

Hook the large eyelet of the wire to the stud screw.

Hook the small eyelet

stretch the spring or break the wire.)

Check that the wire is in the “V” slot of both endblocks.

- Install the front cover.

remove the master unit.

of the wire to the front cover spring; install the rear cover. (Do not

Rear Endblock

NOTE: Confirm that the cable is behind the quenching lamp.

3-6

Page 64

– Charge Corona Power Pack –

Ground Wire

May, 25, 1985

1. Remove the front cover.

2. Disconnect the 3P connector from the power pack.

3. Remove the ground wire from the frame (1 screw).

4. Remove the charge power pack (1 screw).

5. Unplug the high voltage cable from the power pack.

NOTE: The ground wire must securely contact the frame.

(See page 3-79.)

3-7

Page 65

EXPOSURE

1. Introduction

May, 25, 1985

-.

Exposure

Light

While the slider moves forward (in the arrow direction), a fluorescent lamp illuminates the surface of

the original on the exposure glass.

An image of the original is reflected through the fiber optics onto the master surface.

Where the light strikes the master surface, the electrical resistance of the master surface decreases

and the charge on the master surface is dissipated.

electrical resistance and surface charge remain high.

light; however, dark areas absorb light.

light is less, and only part of the charge leaks off.

In halftone or colored areas the strength of the reflected

Where no light strikes the master surface, the

White areas of the original reflect most of the

/

A reflector is used to maximize the light output from the exposure lamp. On the front side, a side

erase reflector eliminates the shadow created by the edge of the original.

3-8

Page 66

May, 25, 1985

Exposure Glass

Original

I

I

Slider

I

Copy Paper

The master’s rotation speed is the same as the forward speed of the slider. So, after exposure, the

charge pattern remaining on the master surface is an exact mirror replica of the original image as

shown above.

This charge pattern is called the latent image.

This model uses a photos ensor to monitor the intensity of the light output from the exposure

lamp.

If the intensity of the light decreases (such as when the lamp surface is dirty), the sensor

detects the’ change and the CPU increases the voltage to the exposure lamp.

A 5-watt heater is used to warm up the exposure lamp.

This decreases the time required to bring the

lamp’s light intensity within the compensation range of the photosensor. The warm up time

depends on the intensity of the exposure lamp output.

If the exposure intensity sensor detects that

the light intensity is too low for the selected Image Density level, the exposure lamp turns on and the

selected Image Density indicator blinks.

At this time the slider waits

in the home position until the

correct light intensity for the selected image density level is reached.

3-9

Page 67

2. Slider Drive

May, 25, 1985

Reverse Clutch

Slider

\ /

Cam

C (Forward)

When the main motor turns on, drive is transferred to the input gear as shown above. Drive then

passes through the clutch unit to the slider drive gear (pinion).

The slider drive gear is engaged with

the rack underneath the slider, and moves the slider as discussed in the following sections.

3-10

Page 68

Rest Position (1.8)

Home Position

Home Position SW

Return Position (4)

Cam B

Cam A

(2.6)

Forward (3.7)

Reverse (5)

3-11

Page 69

May, 25,

Rest Position

1.

When the Start key is pressed, the main motor turns on and the slider solenoid stays off. Since the

slider solenoid is off, the reverse pawl engages the ratchet ring of the reverse clutch. The reverse

clutch then engages and the slider moves from the rest position towards home position.

985

2. Home Position

Upon reaching the home position, cam C on the underside of the slider disengages the reverse pawl,

and the slider stops.

CPU is continua Ily monitoring the home

position.

At the same time,

the home position switch is actuated by cam A. Since the

position switch, it determines that the slider is now in home

3. Forward

The CPU energizes the slider solenoid which

of the forward clutch. The forward clutch

causes the forward pawl to engage with the ratchet ring

then engages and starts driving the slider forward.

4. Return Position

As the slider reaches the return position, cam B disengages the forward pawl.

5. Reverse

Soon after that, the solenoid turns off.

reverse clutch.

The reverse clutch engages and the slider moves in the reverse direction.

The reverse pawl, then engages with the ratchet ring of the

6. Home Position

As the slider reaches the home position again, cam C disengages the reverse pawl

and cam A actuates the home position switch.

7. Forward

The CPU energizes the slider solenoid which engages the forward pawl with the forward

clutch. This causes the slider to move forward.

8. Rest Position

AS the slider reaches the rest position, the CPU first turns off the main motor. After 0.3 second,

the CPU then turns off the slider solenoid.

3-12

Page 70

3. Clutch Operation

May, 25, 1985

(Figure A)

Solenoid OFF . Solenoid ON

Loosen

.- .

(Figure B)

Tighten

Input Gear

Clutch Sleeve

/

/ / Ratchet Ring

c

Slider

Slider Drive Gear

/

Slider Drive’ Gear

Gear B

— Forward –

Before the slider solenoid turns on, the clutch sleeve turns freely.

This allows the clutch spring to be loose (figure A). Since the clutch spring is loose, it does not touch

the hub of input gear.

The CPU energizes the slider solenoid to engage slider forward drive.

on, it pulls the forward pawl to engage with the ratchet ring.

So, there is no forward drive.

When the slider solenoid turns

The clutch sleeve stops turning, caus-

ing the clutch spring to tighten around the hub of the input gear (figure B).

The input gear then starts turning gear C, which rotates the slider drive gear.

Very soon after the clutch spring tightens, the torque on the forward clutch sleeve becomes greater

than the friction between it and the ratchet ring.

ratchet ring.

After it starts turning, friction resistance keeps the spring tight.

The clutch sleeve then starts turning within the

During forward movement, power is provided to the slider as follows:

Gears A and B rotate freely while the slider is moving forward.

3-13

Page 71

Input Gear

\

Slider Drive Gear

/

Input Gear

/

I

May, 25, 1985

Slider Drive Gear

Slider

rB

Gear

— Reverse –

When the slider solenoid turns off, the spring on the reverse pawl rotates the pawls counterclockwise.

(page 3- 11 figure 5) The reverse pawl engages with the reverse ratchet ring. The clutch then

engages as discussed previously under “-

Forward –.”

During reverse movement, power is provided to the slider as follows:

Gear C, which is in contact with the slider gear, rotates freely.

A rubber damper within gear B prevents the shock of slider reversal from affecting the image (pre-

vents image jitter).

3-14

Page 72

4. Slider Lock Mechanism

May, 25, 1985

Slider

Gear B

I

Slider

Lock Ratchet

/

When the clamshell is opened, a spring forces the slider stopper to engage with the slider lock ratchet

on gear B. The stopper prevents gear B from turning counterclockwise, so the slider drive gear can-

not turn clockwise.

When the upper clamshell is closed, the stopper pin pushes up the slider stopper and disengages it

from the ratchet.

This prevents the slider from moving to the left (as viewed from the front).

3-15

Page 73

5. Slider Control Circuit

May, 25, 1985

Slider Solenoid

I

When the slider home position is confirmed, the CPU drops CN103-12 from +22 volts to O volt

which energizes the slider solenoid.

This occurs 63 pulses after the sensor plate on the master is

detected.

The trigger signal goes back to +22 volts, turning off the slider solenoid, 356 pulses after the slider

moves away from the home position switch (after CN103-9 goes HIGH).

o

I

,63

— Service Call Condition –

The CPU also uses the home position switch to detect slider malfunctions. If the home position

switch does not turn on within 7 seconds after the Start key is pressed, the CPU stops the copier and

lights self-diagnostic code E2.

A service call condition is also detected in the home position switch

stays on for longer than 1.6 seconds.

3-16

Page 74

6. Exposure Lamp Control Circuit

May, 25, 1985

Exposure Sensor

f

1

I

Main Boar-cl

The control circuit shown above maintains a stable exposure lamp light output. The major compo-

nents are the main board, the exposure lamp stabilizer, and the exposure sensor.

– Image Density Level –

The Image Density keys are used to select five different levels of exposure light intensity. The key

input is sent to the CPU which then sends the lamp stabilizer a control signal consisting of a constant

1 millisecond pulse train (T).

power to the exposure lamp.

The LOW (Tl) of each pulse commands the lamp stabilizer to supply

The length of the LOW varies according to the selected image density

level.

— Exposure Lamp Stabilizer —

The exposure lamp stabilizer supplies drive power to the exposure lamp. The exposure lamp

stabilizer

receives +22 volts at CIW02-2. An internal switching circuit converts the +22 volts to a

48 kHz, 250-volt ac signal which is used to drive the exposure lamp. The exposure lamp stabilizer

turns on the exposure lamp only when the control signal to CN 702-1 is LOW.

3-17

Page 75

May, 25, 1985

— Exposure Sensor —

The exposure sensor measures the intensity of the light output by the exposure lamp and provides a

feedback signal to the main board.

in response to the light intensity of the exposure lamp. The amplifier circuit (IC1 ) converts the variations in photodiode current to voltage changes and applies it as a feedback signal at CN104-2 on the

main board.

— Compensation Processing –

Compensation processing consists of modifying the control signal in response to the feed-back signal. This processing is carried out by the CPU .

If the exposure light intensity is too LOW, the CPU increases the ratio T1 /T. (The width of T1 is

increased.) If the light is too strong, T1 /T is decreased. (T1 can vary from 0.2 ms to 0.95 ms and T

is fixed at 1ms.) Since power is provided to the lamp during T1, the lamp brightness changes

accordingly.

The sensing element is a photodiode (PD). It regulates current

The feedback circuit keeps the exposure lamp output very stable.

almost at the same time offset by a change in T1 width.

tant. Feedback compensates for fluctuations in the ac power supply, variations in lamp output due

to lamp temperature, and for the slow

Image

Density

Indicators

T1

Feedback Signal 13

– Service Call Condition –

The CPU monitors the exposure lamp control signal to detect exposure malfunctions. If the ratio of

T1 /T becomes greater than 0.95 ms or less than 0.15 ms, the CPU stops the copier and lights selfdiagnostic code El.

1

0.20 0.27 0.33 0.4 0.5 ms

.

decay in exposure lamp light output over the lamp’s lifetime.

2 3 4

16

. 20. 2.4 3.0 V

The voltage observed at CN104-2 is cons-

5

Any change in light intensity is

3-18

Page 76

7. Lamp Heater Circuit

May,

25, 1985

A heater is installed next to

Heating the lamp

exposure compensation.

decreases

the surface of the exposure lamp.

the time required to bring the lamp’s

light intensity within the range of

This lamp warm-up time depends on the selected image density level and atmospheric tem-

perature. A

the warm-up time (within 15 seconds).

S long as the copier is continuously plugged in, however, the heater is on and decreases

3-19

Page 77

8. Replacement of Parts

— Exposure Glass –

.-. .

May, 25, 1985

1. Hold the front side of the platen cover and push it towards the rear to disengage the fasteners.

CAUTION: The fasteners break off under strong force.

2. Remove the platen cover.

3. Remove the slider cover (2 screws).

4. Remove the exposure glass assembly (2screws).

NOTE: After installing the exposure glass, the front scale must be in the groove of the front

cover.

3-20

Handle the platen cover carefully.

Page 78

— Fiber Optics —

Reflector

May, 25, 1985

Leaf Spring

/

1. Remove the

2. Remove the

3. Remove the

4. Remove the

5. Remove the

6. Remove the

7. Pull out the

NOTE: 1. Do not touch the upper and lower surfaces of the fiber optics.

2. Fiber optics must contact the holders.

3. For installation of the seal, see page 3-86.

3-21

Page 79

– Exposure Lamp –

.-. ”

Front E

Term

May, 25, 1985

Exposure Lamp

Aperture Surface

1. Remove the front and rear covers. (See page 3-79.)

2. Remove the slider. (See page 3-79.)

3. Remove the exposure cover (1 screw).

4. Remove the reflector (2 screws). Do not get the reflector dirty.

5. Remove the front exposure lamp terminal (1 small screw).

6. Pull the exposure lamp out from the copier.

NOTE: 1. Do not touch the aperture of the new exposure lamp.

2. Make sure the aperture is facing up.

sure Lamp

3-22

Page 80

May, 25, 1985

Slider Drive Gear

Slider Clutch Bracket

Pulse Generator

Bracket

2P Connector

/

1

Follow steps 1 through 6 of Exposure Lamp Replacement.

.

Remove the accuride rail (3 screws).

2

.

Remove the pulse generator bracket (1screw).

3 .

4

Take off the slider clutch bracket (3 screws) and unhook the slider stopper spring from the

.

bracket. (Do not break the slider stopper pin.

Remove slider drive gear.

5.

Take off the rear exposure lamp terminal (1 small screw).

6.

7

.

Disconnect the 2P connector on the ac drive board.

Remove exposure lamp heater.

8.

(See page 3-22.)

NOTE: 1. When installing the new exposure lamp heater, use the old spring.

2. After reassembling, make sure the slider stopper spring and pin are securely

mounted.

3-23

Page 81

— Exposure Lamp Stabilizer –

-.’

May, 25, 1985

Exposure Lamp Stabilizer

1. Remove the front cover.

2. Disconnect the 5P and 3P connectors from the stabilizer.

3. Remove the exposure lamp stabilizer (2 screws).

(See page 3-79.)

3-24

Page 82

– Slider Clutch –

May, 25, 1985

1

.

Remove the slider and rear cover (See page 3-79.)

2.

Disconnect the two 2P and two 3P connectors.

.

Remove the pulse generator bracket (1 screw).

3

4

Remove the wire harness from the wire clamp.

.

Remove the slider clutch bracket (3 screws) and

5.

bracket.

6.

Remove the slider drive gear,

7

.

Remove gear

Remove the reverse clutch and/or forward clutch.

8.

(Do not break the slider stopper pin.)

gear B pulse generator disk, and bushings

C (1 E-ring and 1 spacer).

3-25

Page 83

May, 25, 1985

Reverse Clutch

I I I

Forward Clutch

9.

Install new clutch springs in the clutches.

NOTE: The forward and reverse clutch springs are similar, but they coil in different direc-

tions.

Be careful not to mix them up.

(See the figure.)

10. Install the clutches.

NOTE: The directions of the teeth of the clutches (forward and reverse) are different. Be careful

not to mix them up.

(See thefigure.)

11. Reassemble.

NOTE: Check that the slider stopper spring and pin are mounted correctly and that the slider

operates smoothly.

Do not damage the nylon gears

in the slider drive unit.

(Damaged teeth will cause jitter.)

3-26

Page 84

– Slider Solenoid –

Slider

2P

May, 25, 1985

Female Connector

1

Remove the slider and rear cover.

.

2

.

Disconnect two 2P and 3P connectors.

3.

Remove the pulse generator bracket (1 screw).

3.

Remove the slider clutch bracket (3 screws), and unhook the slider stopper spring. (Do not

(See page 3-79.)

break the slider stopper pin.)

4

.

Remove the solenoid 2P female connector from the slider clutch bracket.

5.

Remove the slider drive gear.

6.

Remove the slider solenoid (1 E-ring and 2 screws).

NOTE: Check that the slider stopper spring and pin are correctly mounted.

3-27

Page 85

– Home Position Switch –

May, 25, 1985

Bracket

Shaft

1. Remove the slider and the rear cover.

(See page 3-79.)

2. Remove the home position switch together with the plastic bracket using needle-nose pliers.

3. Remove the 2P female connector from the slider clutch bracket.

NOTE: After installing a new switch, make sure

it turns ON and OFF.

3-28

Page 86

May, 25, 1985

9. Cleaning of

Fiber Optics —

—

Parts

Slider

Fiber Optics

— Upper Side of Fiber Optics –

1. Move the slider to the right.

2. Remove the stud screw from

3. Move the slider to the left until the fiber optics are visible.

4. Clean the fiber optics with the fiber optics/charger cleaner or a silicone cloth.

5. Clean the reflectors with a silicone cloth.

— Lower Side of Fiber Optics –

1. Open the upper clamshell.

2. Remove the master unit.

3. Clean the lower side of the fiber optics with the “fiber optics/charger cleaner. (See Operating

Instructions.)

the accuride rail.

(Do not place it where it may be exposed to direct light.)

3-29

Page 87

10. Lubrication of Parts

– Fiber Optics Holder –

-.

May, 25, 1985

1. Move the slider to the right.

Remove the stud screw from the accuride rail.

2.

3. Move the slider to the left until the fiber optics holders are visible.

4. Apply “Grease

501” to the top of the fiber optics holders.

3-30

Page 88

DEVELOPMENT

1. Black Development

Master Belt

Brush

Bias

May, 25, 1985

Mixing

Development Roller

/

— Introduction —

The development unit transforms the electric latent image on the master surface into a visible toner

image.

The toner supply bar carries toner from the toner tank to the development roller. The development

roller rotates in the same direction as the master belt.

because the roller has a magnetic rubber layer.

ing blade, only a thin coating of positively charged toner particles stays adhered.

Then, the roller turns past the master belt.

face attracts toner from the development roller, making the image visible.

— Black Ferrite Toner —

This model uses monocomponent toner, which is composed of resin and ferrite. Attraction between

the ferrite and the magnetic rubber layer causes the toner to adhere to the development roller. This

toner also has a high electrical resistance, which gives it good development and image transfer

characteristics, even under high humidity conditions.

Toner Supply Bar \

S the development roller turns past the toner meter-

A

The negatively charged latent image on the master sur-

Toner Metering Blade

Toner adheres to the development roler

Plate

3-31

Page 89

– Development Roller –

Floating Electrode

Magnetic

May,

25, 1985

Insulating Layer

The development roller used in this copier is unique.

ly 300 rpm. Its surface has a floating electrode layer which insulates the surface charge from the

conductor.

These “floating electrodes”, which are imbedded in the layer are made of copper and create a strong

electric field.

straight. This results in a good, sharp image.

– Toner Metering Blade –

The toner metering blade is made of an iron based material.

roller by the magnetic field of the magnetic rubber layer.

because of the rapid changes in the magnetic field as the roller turns. The vibration allows toner to

pass by.

Toner particles receive a positive triboelectric charge as they move past the toner metering

blade.

metering blade.

This charge is created by the rubbing action among the development roller, toner, and toner

Since the electrodes contact the master surface directly, the lines of electric flux are

The development roller rotates at approximate-

It is attracted against the development

The toner metering blade vibrates

3-32

Page 90

2.

Color Development

Bias Brush

May, 25, 1985

Toner Cartridge

Toner

Mixing

– Color Toner –

The major difference between color development and black ferrite development is that color toner

contains no ferrite material.

electricity rather than magnetic attraction.

– Color Development –

The toner supply roller is made of foam rubber.

development roller.

charges the toner positively.

become negative, which is the primary triboelectric charge of the development roller. At this point,

the level of static electricity is still insufficient to fully develop the latent image with the color

toner.

For this reason a special color toner development roller is necessary (See the following page.)

Since these two rollers rotate in opposite directions, the friction between them

Color toner adheres to the development roller because of static

It carries colored toner from the toner tank to the

This makes the “floating electrodes” on the development roller

Plate

3-33

Page 91

– Color Development Roller –

May, 25,

Blade

1985

The difference between the ferrite-type

development roller

material of the floating electrodes.

The color development roller has carbon floating electrodes imbedded in it instead of cop-

per. Carbon has a high co-efficient of friction and a low electrical resistance, which helps in creating

static electricity.

Color toner has a tendency to adhere to itself.

So, a plastic film is installed on the toner metering

blade to make sure only a thin coating of color toner particles adhere to the development roller. This

film rubs against the development roller creating the secondary triboelectric charge. This charge

raises the level of static electricity to the point where color toner can fully develop the latent image on

the master belt.

3-34

Page 92

3. Bias Application

Black Toner Develo

Development

May, 25, 1985

as Plate

erminal

Color Toner Development

Develop

T

Bias Brush

Toner Metering Blade

Bias Plate

Bias Terminal

NOTE: (The color toner development)

In this copier, the development bias is applied to the toner metering blade, the bias brush, and the

core of the development roller.

attracts the positively charged toner to the roller surface.

voltage as the toner metering blade. It keeps the development roller voltage stable by bleeding off any

excess charge.

As the development roller turns past the blade, the bias charge

The bias brush is charged to the same

This model has a fixed development bias of -225 volts.

changes in the image density setting selected by the operator. (The exposure lamp’s light intensity

controls image density.)

3-35

The bias voltage does not change with

Page 93

3. Bias Application

Black Toner Develo

Development

May, 25, 1985

as Plate

erminal

Color Toner Development

Develop

T

Bias Brush

Toner Metering Blade

Bias Plate

Bias Terminal

NOTE: (The color toner development)

In this copier, the development bias is applied to the toner metering blade, the bias brush, and the

core of the development roller.

attracts the positively charged toner to the roller surface.

voltage as the toner metering blade. It keeps the development roller voltage stable by bleeding off any

excess charge.

As the development roller turns past the blade, the bias charge

The bias brush is charged to the same

This model has a fixed development bias of -225 volts.

changes in the image density setting selected by the operator. (The exposure lamp’s light intensity

controls image density.)

3-35

The bias voltage does not change with

Page 94

4. Drive Mechanism

May, 25, 1985

Black Toner Development

.-

85

6431

Color Toner Development

85

643

Drive of black toner development:

1 Timing Belt

2 Timing Belt Pulley

3 Idler Gear A

4

Development Roller Gear A

5 Development Roller

6 Idler Gear B

Toner Supply Gear A

7

8 Toner Supply Bar

9 Idler Gear C

10 Idler Gear D

11 Toner Mixing Gear

12 Toner Mixing Plate

Toner supply bar and roller both rotate in the same direction (clockwise), but the gear ratio is different.

This makes the toner supply roller gear rotate quickly so that the triboelectric charge can be pro-

duced.

Drive of color toner development:

1 Timing

2 Timing Belt Pulley

3 Idler Gear A

Belt

4 Development Roller Gear B

5 Development Roller

6 Idler Gear B

Toner Supply Gear A

7

8 Toner Supply Roller

9 Idler Gear D

10 Toner Mixing Gear

11 Toner Mixing Plate

3-36

Page 95

5. Toner End Mechanism

May, 25, 1985

Sufficient Condition

Toner

Drive Spring

Insufficient Condition

Toner End Sensor

Ill

The toner end detection mechanism uses an actuator and a photointerruptor. When the toner tank is

full, the actuator stays in the photointerruptor.

grams of toner, the actuator leaves the photo interrupter one time for every revolution of the toner

mixing gear.

If there is sufficient toner in the toner tank, the toner resists the movement of the toner mixing plate

and the drive spring stretches.

do not align and the actuator roller stays on the surface of the toner mixing gear.

The figures on the right above show the toner end condition. In this case, the amount of toner in the

tank is insufficient to resist the movement of the toner mixing plate. The drive spring pulls the mixing drive cam and aligns it with the toner mixing gear.

the spring pulls the roller

moment. As soon as the detent in the toner mixing gear moves, the actuator renters the toner end

sensor.