Ricoh M156, M176, M157, M177, M154 Service Training

...

1

Rm-MF1/Rm-P1 Training

Slide 1

M156/M157/M176/M177 (Rm-MF1)

M154/M155/M174/M175 (Rm-P1)

Service Training

Version 1.0

These models are similar to the Rn series of printers and copiers.

2

Rm-MF1/Rm-P1 Training

Slide 2

M156/M157/M176/M177 (Rm-MF1)

M154/M155/M174/M175 (Rm-P1)

Service Training

Product Overview

No additional notes

3

Rm-MF1/Rm-P1 Training

Slide 3

What Models are in this Series?

Rm-MF1a

Rm-MF1a

M156: SP 311SFN, No AIO refill

M176: SP 310SFN, AIO can be refilled

Rm-MF1aw

M157: SP 311SFNw, Wireless LAN, No AIO refill

M177: SP 310SFNw, Wireless LAN, AIO can be refilled

Type A and B models

M15x is also known as Type A; M17x is also known as

Type B

For Type B there are two sub-types, based on destination:

» For CHN: The AIO has hole through which the AIO can be

refilled with toner. Bags of toner for refilling are also sold.

» For EU/AA/NA: The AIO has no hole. The machine is

designed for refill, but bags of toner for refilling are not sold

No additional notes

4

Rm-MF1/Rm-P1 Training

Slide 4

What Models are in this Series?

Rm-P1a

Rm-P1a

M154: SP 311DN, No AIO refill

M174: SP 310DN, AIO can be refilled

Rm-P1aw

M155: SP 311DNw, Wireless LAN, No AIO refill

M175: SP 310DNw, Wireless LAN, AIO can be

refilled

The note about Type A and Type B models on the

previous slide also applies here.

No additional notes

5

Rm-MF1/Rm-P1 Training

Slide 5

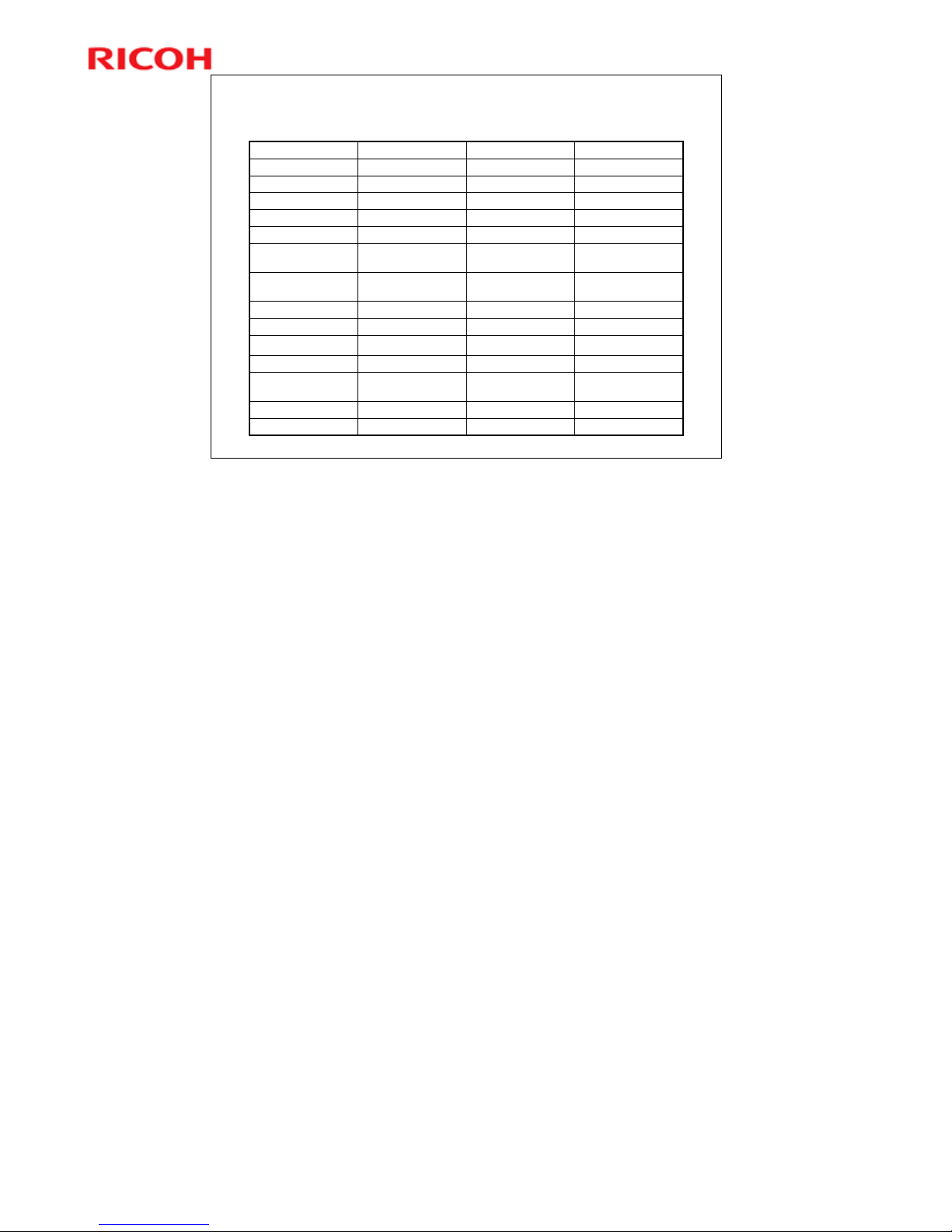

Differences from Previous Models

Rm-MF1 vs Rn-MF1/MF2

PCLPCL/PS3PCL/PS3PDL

NoYesYesOptional Tray

Some models (China

only)

NoNoAIO Refill

200k350k200kMachine Life

Some modelsNoNoWireless LAN

50 sheets125 sheets125 sheetsOutput Capacity

All modelsSome modelsSome models Duplex

2 boards1 board1 boardPSU and High

Voltage Power Pack

1 board2 boards2 boardsController and

Engine Boards

4 lines2 lines2 linesDisplay Panel

China onlyNoNoHandset

CISCCDCCDScanner

ADFADF/ARDFADFADF

282828PPM (A4)

Rm-MF1Rn-MF2Rn-MF1

No additional notes

6

Rm-MF1/Rm-P1 Training

Slide 6

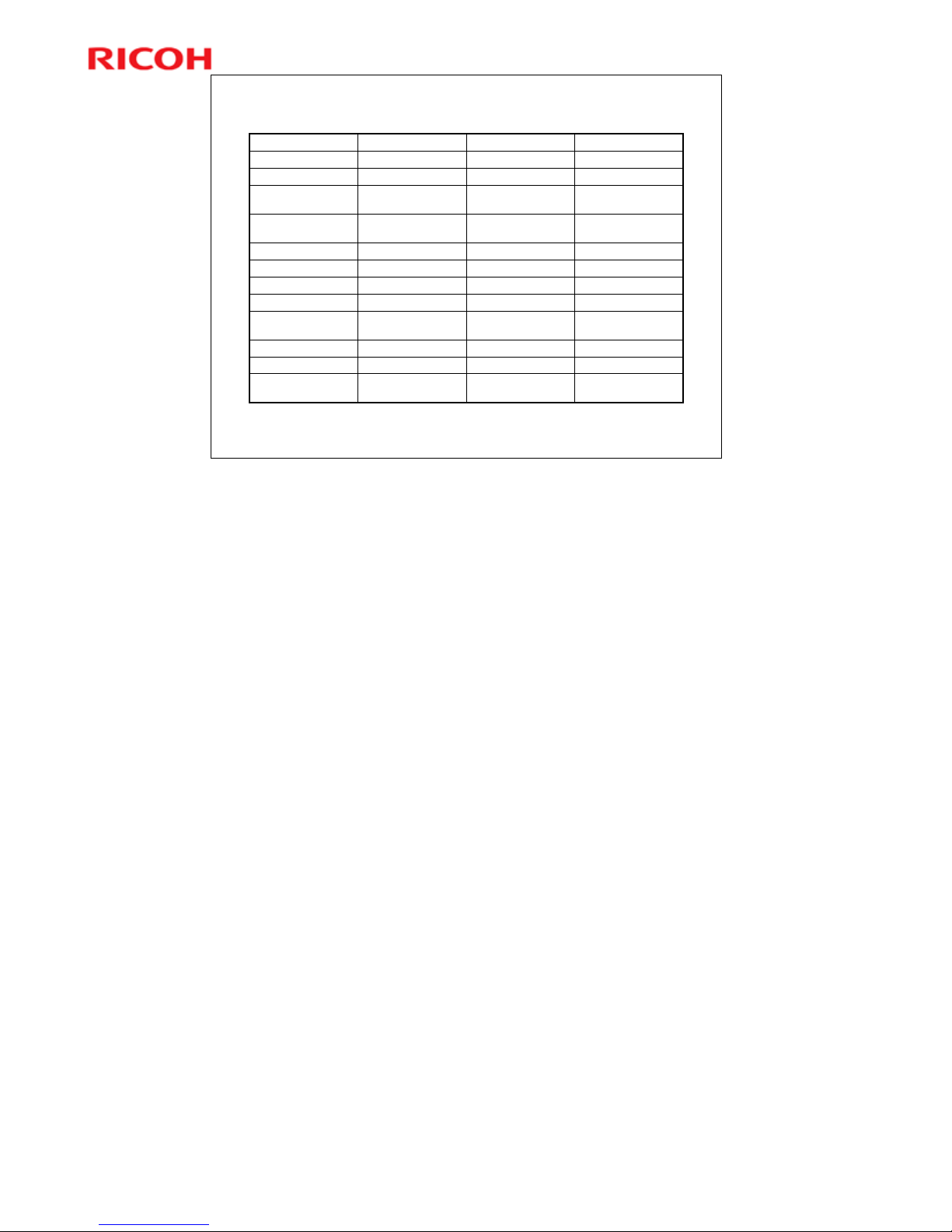

Differences from Previous Models

Rm-P1 vs Rn-P1/P2

YesNoYesSOM (Smart

Organizing Monitor)

PCLPCL/PS3PCL/PS3PDL

NoYesYesOptional Tray

Some models (China

only)

NoNoAIO Refill

200k350k200kMachine Life

Some modelsNoNoWireless LAN

125 sheets125 sheets125 sheetsOutput Capacity

All modelsSome modelsSome models Duplex

2 boards1 board1 boardPSU and High

Voltage Power Pack

1 board2 boards2 boardsController and

Engine Boards

No2 linesNoDisplay Panel

282828PPM (A4)

Rm-P1Rn-P2Rn-P1

No additional notes

7

Rm-MF1/Rm-P1 Training

Slide 7

Other Points

Rm-MF1/P1 do not have a USB host or the scan

to USB feature.

No additional notes

8

Rm-MF1/Rm-P1 Training

Slide 8

M156/M157/M176/M177 (Rm-MF1)

M154/M155/M174/M175 (Rm-P1)

Service Training

Specifications

No additional notes

9

Rm-MF1/Rm-P1 Training

Slide 9

General Specifications (1)

Printing Speed, A4(LT): 28 ppm (LT: 30 ppm)

First Print Speed: Less than 8 sec (A4, LT SEF)

Duplex Printing: Auto (Standard, approx 50% productivity)

Memory: 128 MB (no optional memory)

Resolution: 1200 x 600 / 600 x 600 dpi

Interfaces

MF1a/P1a: USB2.0, 10BASE-T/100BASE-TX Ethernet

MF1aw/P1aw: USB2.0, 10BASE-T/100BASE-TX Ethernet,

IEEE802.11b/g/n

PDL: PCL5e, PCL6

Network Protocols: TCP/IP, IPP

No additional notes

10

Rm-MF1/Rm-P1 Training

Slide 10

General Specifications (2)

Input capacity

Standard Tray: 250 sheets (80 g/m2)

Bypass tray: 50 sheets (80 g/m2)

Output capacity (Standard Tray, Face down)

MF1: Up to 50 sheets

P1: Up to 125 sheets (A4/LT or 80 g/m2, 20lb)

Input Paper Size

Standard Tray: A4,B5,A5,B6,A6,Legal,Letter,HLT,Exective,F,Foolscap,Folio,16K

» Custom size: Min. 100mm x 148mm (3.9" x 5.92"), Max. 216mm x 356mm (8.64" x 14.24")

Bypass Tray: A4,B5,A5,B6,A6,Legal,Letter,HLT,Exective,16K,Envelope:

#10,Monarch,C5,C6,DL

» Custom size: Min. 90mm x 140mm (3.6" x 5.92"), Max. 216mm x 356mm (8.64" x 14.24")

Media Type

Standard Tray: Plain Paper, Recycled Paper, Thick Paper, Thin Paper

Bypass Tray: Plain Paper, Recycled Paper, Thick Paper, Thin Paper

Paper Weight

Standard Tray: 52-162g/m2 (14-43lb)

Bypass tray: 52-162g/m2 (14-43lb)

Duplex: 60-105g/m2 (16-28lb)

ADF

Capacity: 35 sheets

Original size

» Min: 139.7mm x 139.7mm (5.5'' x 5.5''), Max: 215.9mm x 355.6mm (8.5'' x 14'')

Original weight: 52-105g/m2 (14-28lb)

No additional notes

11

Rm-MF1/Rm-P1 Training

Slide 11

General Specifications (3)

Power Consumption

US version

» Max.: 800W

» Energy Saver

– Normal mode (Energy saver 2): 5W

– Quick mode (Energy saver 1) : 70W

EU /CHN versions

» Max.: 890W

» Energy Saver

– Normal mode (Energy saver 2): 5W

– Quick mode (Energy saver 1): 70W

Warm-up Time:

MF1: Less than 30 sec

P1: Less than 26 sec

Energy Save Mode (MF1, P1)

» Normal (Energy Save Mode 2): Less than 20 sec.

» Quick (Energy Save Mode 1): Less than 10 sec.

No additional notes

12

Rm-MF1/Rm-P1 Training

Slide 12

Options

There are no optional units for these models.

The Rn series has an optional paper tray. The Rm series does not.

13

Rm-MF1/Rm-P1 Training

Slide 13

AIO Cartridges

There are 4 types:

Starter AIO: About 1k per cartridge

Low yield AIO: About 2k per cartridge

» Two types: Refill, or no refill, depending on the model

High yield AIO:

» Type A: 3.5k, no refill

» Type B: 5k, refill is possible

No additional notes

14

Rm-MF1/Rm-P1 Training

Slide 14

Targets

Monthly Print Volume

Average: 0.7K

Maximum: 5.8K

Estimated Unit Life: 5 years or 200K prints

whichever comes first

No additional notes

15

Rm-MF1/Rm-P1 Training

Slide 15

M156/M157/M176/M177 (Rm-MF1)

M154/M155/M174/M175 (Rm-P1)

Service Training

Maintenance

No additional notes

16

Rm-MF1/Rm-P1 Training

Slide 16

PM Intervals

There are no PM parts.

There are three "yield parts", but given the ACV

(Average Copy Volume) for this machine, these

"yield parts" are expected to outlast the life of

the machine.

Yield Parts

Paper Feed Roller (120 K)

Transfer Roller (120 K)

Fusing Unit (120 K)

The counters for each yield part can be

monitored using either of the following methods:

Web Image Monitor

Configuration Page in the “List/Test Print” menu

No additional notes

17

Rm-MF1/Rm-P1 Training

Slide 17

Note to Service Personnel

Yield parts are rated to last for 120 K, which

should be longer than the machine's rated

lifespan of five years.

For customers who are very heavy users, it may

be necessary to change yield parts during the life

of the machine.

After installing new yield parts, the counters must

be reset.

The counter reset procedure is not a user

function and must be done by a trained

technician.

See the replacement procedures in the FSM

(Field Service Manual) for the reset procedures

for each yield part.

No additional notes

18

Rm-MF1/Rm-P1 Training

Slide 18

Access to Service Functions

For MF models: To access Maintenance Mode, do

the following:

1. Type the following keys, in sequence:

[Clear/Stop] .. [1] .. [0] .. [7]

2. Hold down the [Start] key until the Maintenance

Mode screen is displayed.

» Note: This should take about 3 seconds.

For P models

To access the SP mode of Smart Organizing

Monitor, open the Printer Configuration screen

by inputting the field technician access code:

“Admin074”

No additional notes

19

Rm-MF1/Rm-P1 Training

Slide 19

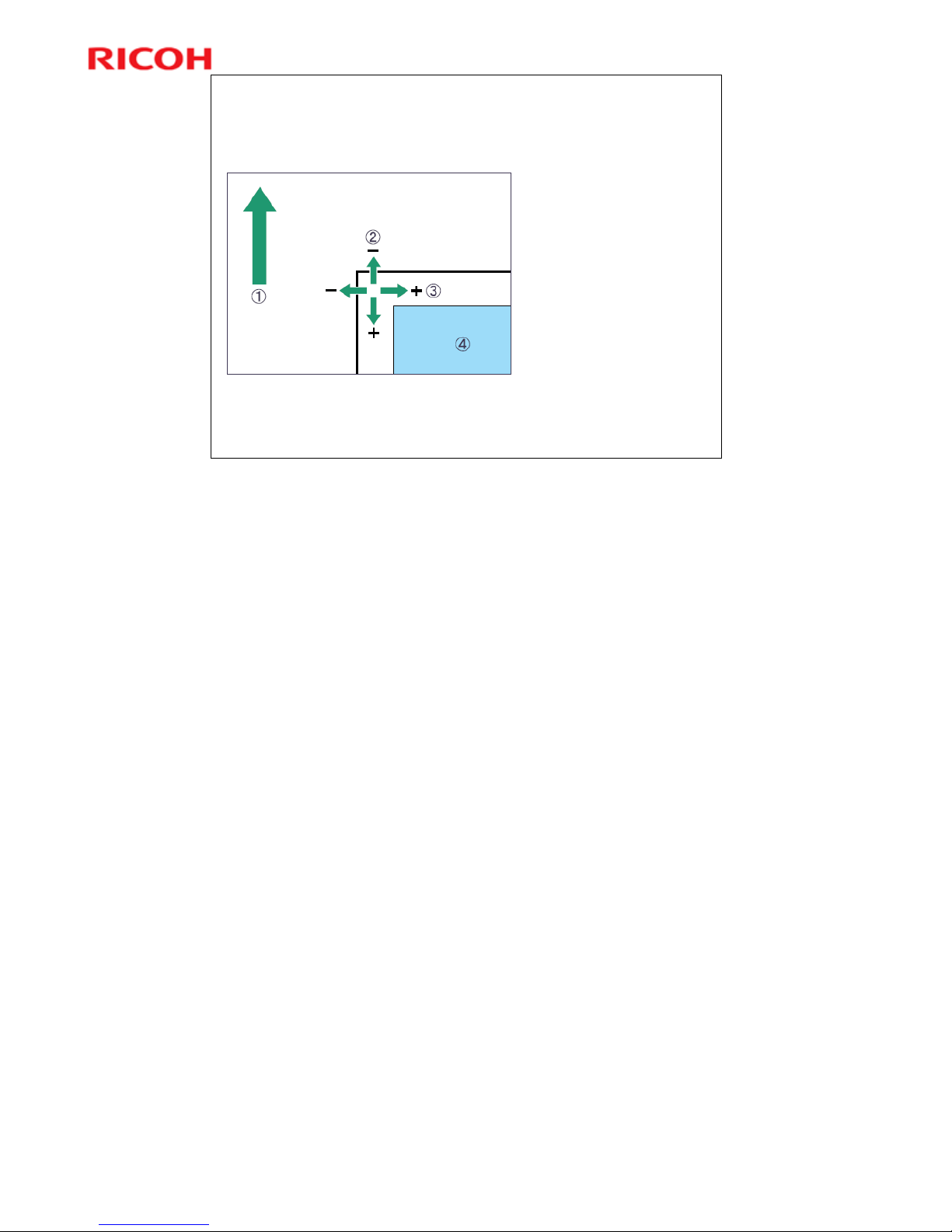

Image Adjustment

This adjustment can be

done by both technicians

and users.

Technicians:

Maintenance Mode

(MF1)

SOM (P1)

Users:

User Mode

See FSMs (Field Service

Manuals) for procedures.

No additional notes

20

Rm-MF1/Rm-P1 Training

Slide 20

Firmware Updating

A computer is necessary for updating the

firmware.

Use the correct procedures (see the service

manual for details) to update the firmware.

No additional notes

21

Rm-MF1/Rm-P1 Training

Slide 21

M156/M157/M176/M177 (Rm-MF1)

M154/M155/M174/M175 (Rm-P1)

Service Training

Machine Overview

No additional notes

22

Rm-MF1/Rm-P1 Training

Slide 22

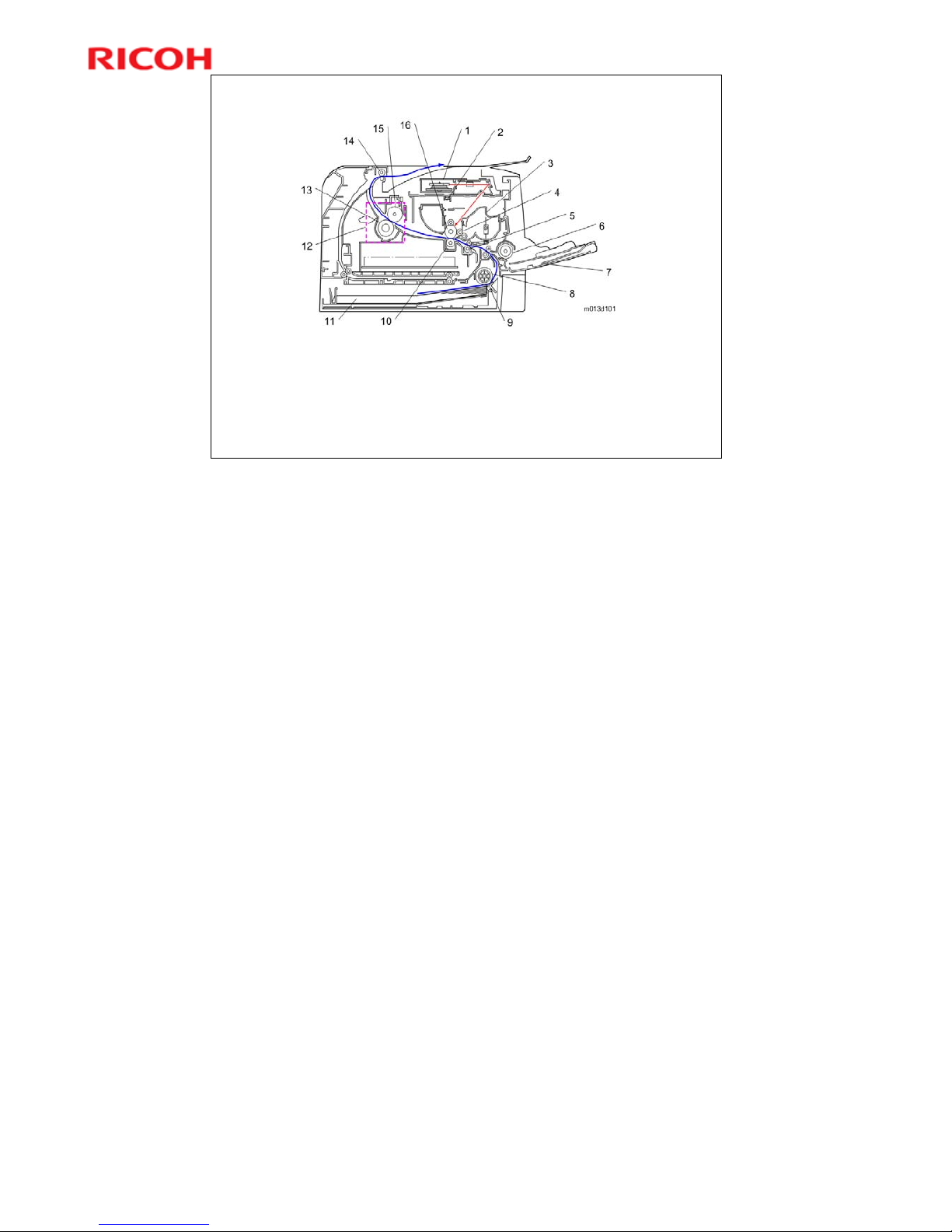

Component Layout – Rm-P1

1. Laser unit

2. Quenching lamp

3. Cartridge (AIO-type)

4. Development roller

5. Registration roller

6. By-pass feed roller

7. By-pass feed tray

8. Paper feed roller

9. Friction pad

10. Transfer roller

11. Paper Tray

12. Fusing Unit

13. Pressure Roller

14. Paper exit roller

15. Hot Roller

16. Drum

No additional notes

23

Rm-MF1/Rm-P1 Training

Slide 23

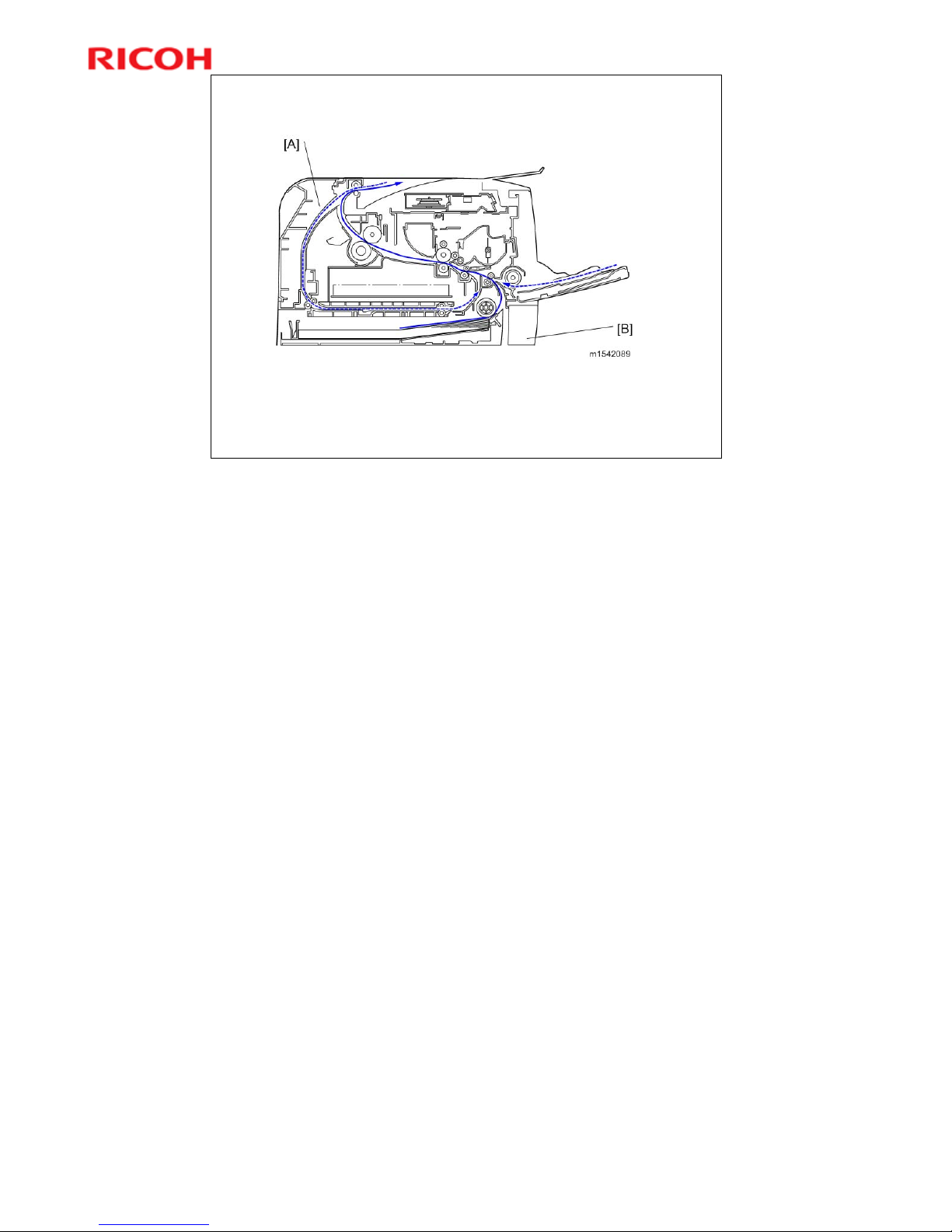

Paper Path – Rm-P1

[A]: Duplex section

[B]: Paper tray

No additional notes

24

Rm-MF1/Rm-P1 Training

Slide 24

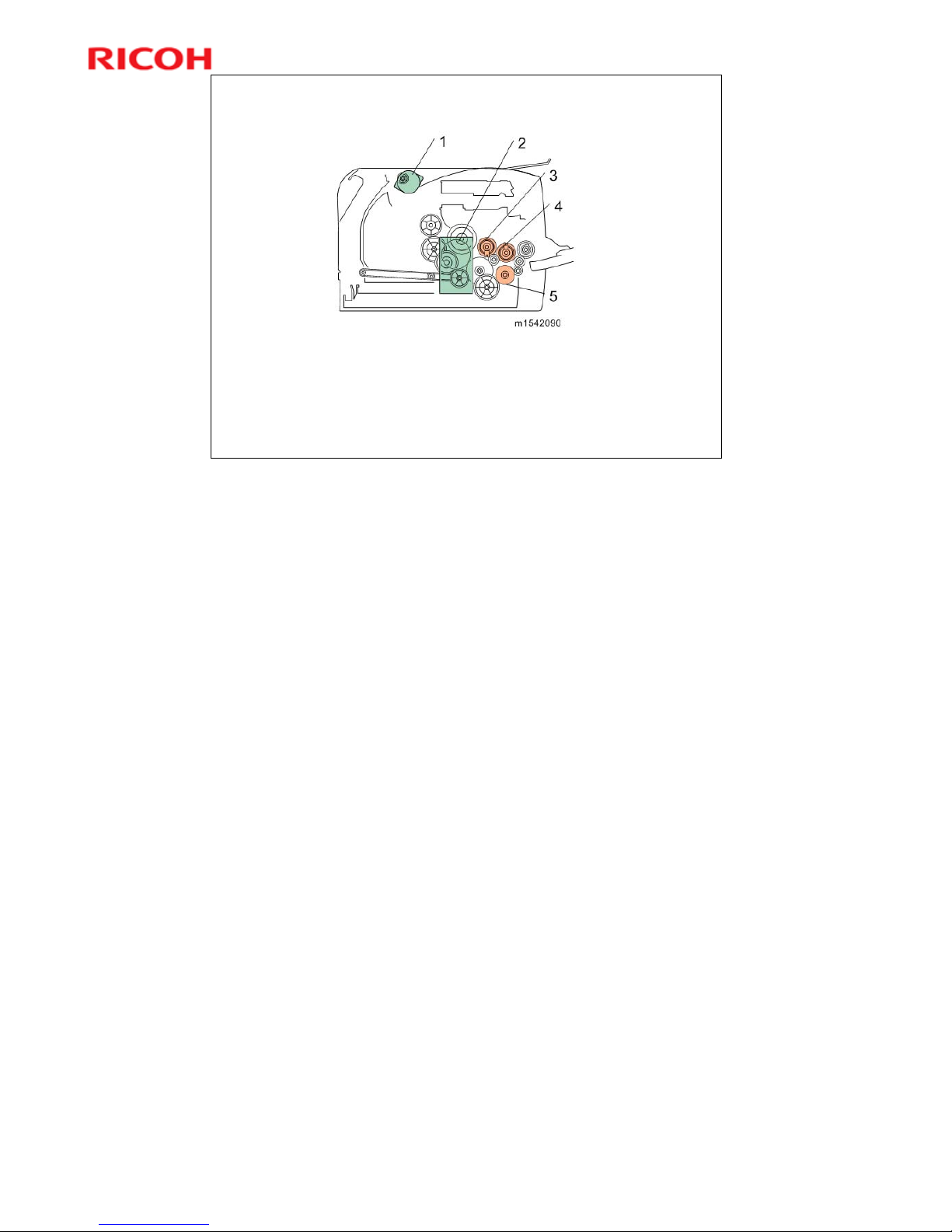

Drive Layout – Rm-P1

1. Duplex Motor

2. Main Motor

3. Registration Clutch

4. Relay Clutch

5. Paper Feed Clutch

No additional notes

25

Rm-MF1/Rm-P1 Training

Slide 25

M156/M157/M176/M177 (Rm-MF1)

M154/M155/M174/M175 (Rm-P1)

Service Training

Cover Removal & Part Replacement

No additional notes

26

Rm-MF1/Rm-P1 Training

Slide 26

General Precautions

Before starting to work on the machine:

If there are printer jobs in the machine, print out

all jobs in the printer buffer.

Turn off the main power switch and unplug the

machine.

The slides in this presentation only cover a few

important points. For full details of all

procedures, see the field service manual.

Follow the notes and cautions in all procedures.

No additional notes

27

Rm-MF1/Rm-P1 Training

Slide 27

General Precautions

Many of the parts are held

in place with plastic

latches which can break

easily.

Release them carefully,

pushing the hook end of

the latch away from the

part to which it is latched.

No additional notes

28

Rm-MF1/Rm-P1 Training

Slide 28

Removing Covers

The covers have a lot of hooks and tabs.

Disconnect these carefully, as explained on the

previous slide.

See the procedures in the service manual for the

locations of the hooks and tabs, and follow the

instructions carefully to remove the covers

properly.

No additional notes

29

Rm-MF1/Rm-P1 Training

Slide 29

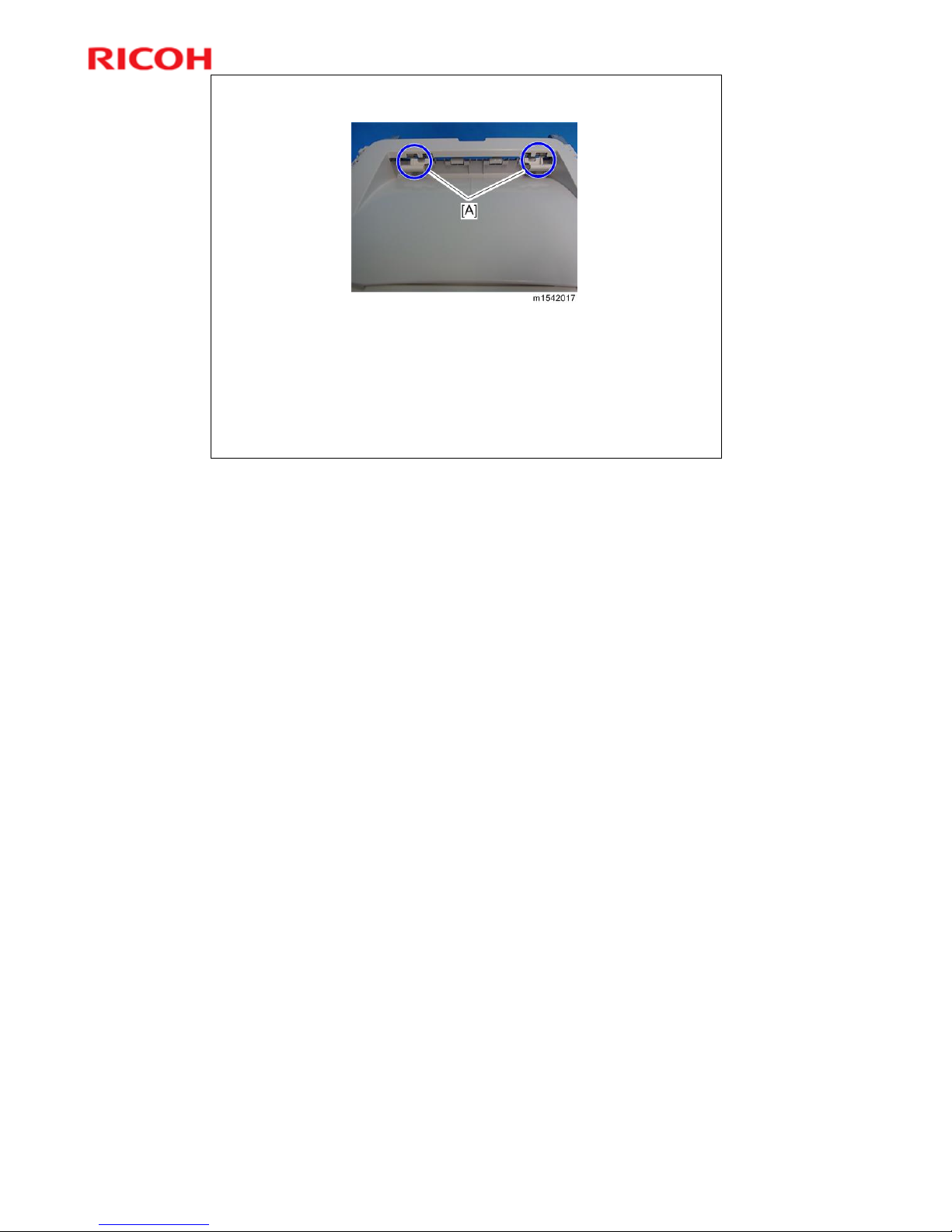

Re-installing the Top Cover

When re-installing the top cover, alway s verify that the two

paperweights [A] are lifted. If they are not lifted to fit into

the paper slot, the paperweights could be damaged.

Make sure that these paperweights can be move d smoothly

(up and down) after installing the top cover. If these

paperweights do not move smoothly, install the top cover

again.

No additional notes

30

Rm-MF1/Rm-P1 Training

Slide 30

Replacing the Main Board

Do not connect any connectors to JRS1 and JRS2 when

reinstalling the main board [A]. These are only used at the

factory.

Do not adjust the dip switch. The dip switch is only for

factory use.

Remove the EEPROM from the old board (see below), and

install it on the new one.

No additional notes

Loading...

Loading...