Ricoh M116, M117 Service Manual

M116/M117

SERVICE MANUAL

It is the reader' s resp onsibili ty when discuss ing th e info rmation c ontained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Americas Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH AMERICAS CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are us ed thr ou gh out this book in an i nf orm a ti on al o r editorial fas hi o n

only and for the benefit of such companies. No such use, or the use of

any trad e name, or web si te is int ended to convey e ndorsement or other

affiliation with Ricoh products.

2012 RICOH Americas Corporation. All rights reserved.

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Americas Corporation.

Users of this manual should be either service

trained or cer tified by successfull y completing a

Ricoh Technic al Trai ning Progr am .

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Americas Corporation

WARNING

LEGEND

PRODUCT

CODE

COMPANY

LANIER RICOH SAVIN

M116 SP 3500N Aficio SP 3500N SP 3500N

M117 SP 3510DN Aficio SP 3510DN SP 3510DN

DOCUMENTATION HI S TORY

REV. NO.

DATE

COMMENTS

*

05/2012

Original Printing

SM 1 M116/M117

M116/M117

TABLE OF CONTENTS

1. PRODUCT INFORMATION ........................................................... 1-1

1.1 SPECIFICATIONS ..................................................................................... 1-1

1.2 MACH INE OVERVIEW .............................................................................. 1-2

1.2.1 CO MPONENT LAYOUT ................................................................... 1-2

1.2.2 PAPER PAT H ................................................................................... 1-3

1.2.3 DRIVE LAYOUT ............................................................................... 1-3

1.3 MACHINE CONFIGURATION ................................................................... 1-4

2. INSTALLATION ............................................................................. 2-1

2.1 I NSTALLATION REQUIREMENTS ............................................................ 2-1

2.1.1 ENVIRONMENT ............................................................................... 2-1

2.1.2 MACHI NE LEVEL ............................................................................. 2-2

2.1.3 MACHI NE SPACE REQUIREMENT ................................................. 2-2

2.1.4 POWER REQUI REMENTS .............................................................. 2-3

2.1.5 IN STALLATION PROCEDURE ........................................................ 2-3

3. PREVENTIVE MAINTENANCE..................................................... 3-1

3.1 PM I NTERVALS ......................................................................................... 3-1

3.1.1 PM PARTS ....................................................................................... 3-1

3.1.2 YIELD COUNTER ............................................................................. 3-1

Counter Reset ...................................................................................... 3-2

4. REPLACEMENT AND ADJUSTMENT ......................................... 4-1

4.1 BEFORE YOU START ............................................................................... 4-1

4.2 SPECIAL TOOLS ....................................................................................... 4-1

4.3 EXTERIOR COVERS ................................................................................ 4-2

4.3.1 FRONT COVER ................................................................................ 4-2

4.3.2 LEFT COVER ................................................................................... 4-4

4.3.3 REAR COVER .................................................................................. 4-6

4.3.4 RIGHT COVER ................................................................................. 4-7

4.3.5 TOP COVER ..................................................................................... 4-8

When installing the top cover ............................................................... 4-8

4.3.6 OPER ATION PANEL ........................................................................ 4-9

M116/M117 2 SM

4.4 LASER UNIT ............................................................................................ 4-10

4.4.1 CAUTIO N DECAL L OCATIONS ..................................................... 4-10

4.4.2 LASER UNIT ................................................................................... 4-11

4.4.3 POLYGON MIRROR MOTOR ........................................................ 4-12

4.5 PAPER FEED AND E XIT ......................................................................... 4-13

4.5.1 PAPER FEED ROLLER .................................................................. 4-13

After installing a new paper feed roller ............................................... 4-13

4.5.2 FRICTION PAD .............................................................................. 4-14

4.5.3 PAPER END SENSOR ................................................................... 4-14

4.5.4 BY-PASS FEED ROLLER .............................................................. 4-15

4.5.5 BY-PASS FEED ROLLER FRICTIO N PAD .................................... 4-16

4.5.6 BY-PASS FEED SENSOR .............................................................. 4-17

4.5.7 PAPER FEED CLUTCH .................................................................. 4-17

4.5.8 RELAY CLUTCH ............................................................................ 4-18

4.5.9 REGISTRATION CLUTCH ............................................................. 4-19

4.5.10 TONER END SENSOR ............................................................ 4-19

4.5.11 PAPER EXIT SENSOR ............................................................ 4-20

4.5.12 RELAY SENSOR ..................................................................... 4-20

4.5.13 INVERTER SENSOR ............................................................... 4-20

4.5.14 REGISTRATION ROLLER AND SENSOR .............................. 4-21

4.6 PAPER TRANSFER ................................................................................ 4-24

4.6.1 TRANSFER ROLLER ..................................................................... 4-24

After installing a new transfer roller .................................................... 4-24

4.7 FUSING ................................................................................................... 4-25

4.7.1 FUSING UNIT ................................................................................. 4-25

Reinstallation ...................................................................................... 4-27

After installing a new fusing unit ......................................................... 4-27

4.7.2 THERMOSTAT ............................................................................... 4-28

4.7.3 THERMISTOR ................................................................................ 4-29

4.7.4 FUSING LAMP ............................................................................... 4-30

When reinstall the fusing lamp ........................................................... 4-31

4.7.5 HOT ROLLER ................................................................................. 4-32

4.7.6 PRESSURE ROLLER ..................................................................... 4-33

4.7.7 HO T ROLLER ST RIPPER PAWLS................................................. 4-33

4.8 MOTORS ................................................................................................. 4-34

4.8.1 MAIN MOTOR ................................................................................ 4-34

4.8.2 DUPLEX MOTOR (FOR M117) ...................................................... 4-34

4.9 ELECTRICAL CO MPONENTS ................................................................ 4-35

SM 3 M116/M117

4.9.1 LAYOUT OF PC BOAR DS ............................................................. 4-35

ECB (Engine Controller Board) .......................................................... 4-36

EEPROM ............................................................................................ 4-37

Controller Board ................................................................................. 4-38

4.9.2 PSU ................................................................................................ 4-38

4.9.3 CHARGE TERMINAL CASE ........................................................... 4-42

4.10 OTHERS ............................................................................................ 4-43

4.10.1 COOLING FAN ........................................................................ 4-43

4.10.2 QUENCHING LAMP ................................................................ 4-43

4.11 IMAGE ADJUSTMENT ....................................................................... 4-45

4.11.1 REGISTRAT ION ADJUSTMENT ............................................. 4-45

User Adjustment ................................................................................. 4-45

Service Adjustment ............................................................................ 4-45

5. SYSTEM MAINTENANCE REFERENCE ..................................... 5-1

5.1 SERVICE PROGRAM MODE .................................................................... 5-1

5.1.1 OVERVIEW ...................................................................................... 5-1

5.1.2 ENTERING ENGINE MAINTENANCE MODE .................................. 5-1

5.1.3 SERVI CE MODE MENU ................................................................... 5-1

Selecting an Item.................................................................................. 5-1

Going into the Next Level/ Returning to the Previous Level ................. 5-1

Exiting the Service Mode Menu ............................................................ 5-1

Menu List .............................................................................................. 5-2

5.2 CO NFIGURATION AND MAINTENANCE PAGE .................................... 5-12

5.2.1 OVERVIEW .................................................................................... 5-12

To Print the Configuration Page/ Maintenance Page ......................... 5-12

Other Types of Reports ...................................................................... 5-12

Total Counter ..................................................................................... 5-13

5.3 FIRMWARE UPDATING .......................................................................... 5-14

5.3.1 CHECKING THE M ACHINE FIRMWARE VERSION ...................... 5-14

5.3.2 UPDATING THE CONTROLLER FIRMWARE ............................... 5-14

Procedure ........................................................................................... 5-14

5.3.3 UPDATING THE ENGINE FIRMWARE .......................................... 5-16

Procedure ........................................................................................... 5-16

5.3.4 UPDATING THE BOOT LOADER FIRMWARE .............................. 5-17

5.3.5 UPDATING FAILURE ..................................................................... 5-17

5.3.6 FW UPDATE TOOL MESSAGES ................................................... 5-18

FW Update Tool Messages: Information ............................................ 5-18

FW Update Tool Messages: Error ...................................................... 5-21

M116/M117 4 SM

6. TROUBLESHOOTING................................................................... 6-1

6.1 SERVICE CALL CONDITIONS .................................................................. 6-1

6.1.1 SUMMARY ....................................................................................... 6-1

Fusing related SCs ............................................................................... 6-1

6.1.2 ENG INE SC ...................................................................................... 6-2

SC 2xx (Laser Optics Error) ................................................................. 6-2

SC 4xx (Image Transfer and Transfer Error) ........................................ 6-3

SC 5xx (Motor and Fusing Error).......................................................... 6-4

SC 6xx (Communication and Other Error) ............................................ 6-8

6.2 IMAGE PROBLEMS .................................................................................. 6-9

6.2.1 OVERVIEW ...................................................................................... 6-9

6.2.2 TEST PAGE PRINTI NG .................................................................. 6-10

Test Page Print Procedure ................................................................. 6-10

6.2.3 TEST PATTERN PRINTING ........................................................... 6-10

Test Pattern Print Procedure .............................................................. 6-10

6.2.4 DARK LINES IN HALFTONE AREAS AT 75MM INTERVALS ....... 6-11

6.3 JAM .......................................................................................................... 6-12

6.3.1 JAM SENSOR LAYOUT ................................................................. 6-12

Paper Jam .......................................................................................... 6-12

6.3.2 JAM MESSAGE LIST ..................................................................... 6-13

Paper Jam .......................................................................................... 6-13

7. ENERGY SAVER ........................................................................... 7-1

7.1 ENERGY SAVER MODES......................................................................... 7-1

7.1.1 TIMER SETTINGS ............................................................................ 7-1

7.1.2 RETURN TO STAND-BY MODE ...................................................... 7-2

7.1.3 RECOMMENDATION ....................................................................... 7-2

7.2 PAPER SAV E ............................................................................................ 7-3

7.2.1 EFFECTIVENESS OF DUPLEX/COMBINE FUNCTION .................. 7-3

1. Duplex: ............................................................................................. 7-3

2. Combine mode: ................................................................................ 7-3

3. Duplex + Combine: ........................................................................... 7-3

Total counter ........................................................................................ 7-4

READ THIS FIRST

Safety Notices

Important Safety Notices

Prevention of Physical Injury

1. Before disassembling or assembling parts of the machine and peripherals, make sure that the

machine power cord is unplugged.

2. The wall outlet should be near the machine and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or open while the

main switch is turned on, keep hands away from electrified or mechanically driven

components.

4. The machine drives some of its components when it completes the warm-up period. Be

careful to keep hands away from the mechanical and electrical components as the machine

starts operation.

5. The inside and the metal parts of the fusing unit become extremely hot while the machine is

operating. Be careful to avoid touching those components with your bare hands.

Health Safety Conditions

Toner is non-toxic, but if you get either of them in your eyes by accident, it may cause temporary

eye discomfort. Try to remove with eye drops or flush with water as first aid. If unsuccessful, get

medical attention.

Observance of Electrical Safety Standards

The machine and its peripherals must be serviced by a customer service representative who has

completed the training course on those models.

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed

to an open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the organic

photoconductor in accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

To prevent a fire or explosion, keep the machine away from flammable liquids, gases,

and aerosols. A fire or an explosion might occur.

M116/M117 6 SM

Handling Toner

Work carefully when removing paper jams or replacing toner bottles or cartridges to avoid

spilling toner on clothing or the hands.

If toner is inhaled, immediately gargle with large amounts of cold water and move to a well

ventilated location. If there are signs of irritation or other problems, seek medical attention.

If toner gets on the skin, wash immediately with soap and cold running water.

If toner gets into the eyes, flush the eyes with cold running water or eye wash. If there are

signs of irritation or other problems, seek medical attention.

If toner is swallowed, drink a large amount of cold water to dilute the ingested toner. If there

are signs of any problem, seek medical attention.

If toner spills on clothing, wash the affected area immediately with soap and cold water. Never

use hot water! Hot water can cause toner to set and permanently stain fabric.

Always store toner and developer supplies such as toner and developer packages, cartridges,

and bottles (including used toner and empty bottles and cartridges) out of the reach of

children.

Always store fresh toner supplies or empty bottles or cartridges in a cool, dry location that is

not exposed to direct sunlight.

Do not use the cleaner to suck spilled toner (including used toner). Sucked toner may

cause firing or explosion due to electrical contact flickering inside the cleaner. However, it

is possible to use the cleaner designed for dust explosion-proof purpose. If toner is

spilled over the floor, sweep up spilled toner slowly and clean remainder with wet cloth.

Laser Safety

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based optical

units in the field. The optical housing unit can only be repaired in a factory or at a location with the

requisite equipment. The laser subsystem is replaceable in the field by a qualified Customer

Engineer. The laser chassis is not repairable in the field. Customer engineers are therefore

directed to return all chassis and laser subsystems to the factory or service depot when

replacement of the optical subsystem is required.

Use of controls, or adjustment, or performance of procedures other than those specified

in this manual may result in hazardous radiation exposure.

Turn off the main switch before attempting any of the procedures in the Laser Optics

Housing Unit section. Laser beams can seriously damage your eyes.

CAUTION MARKING:

M116/M117 8 SM

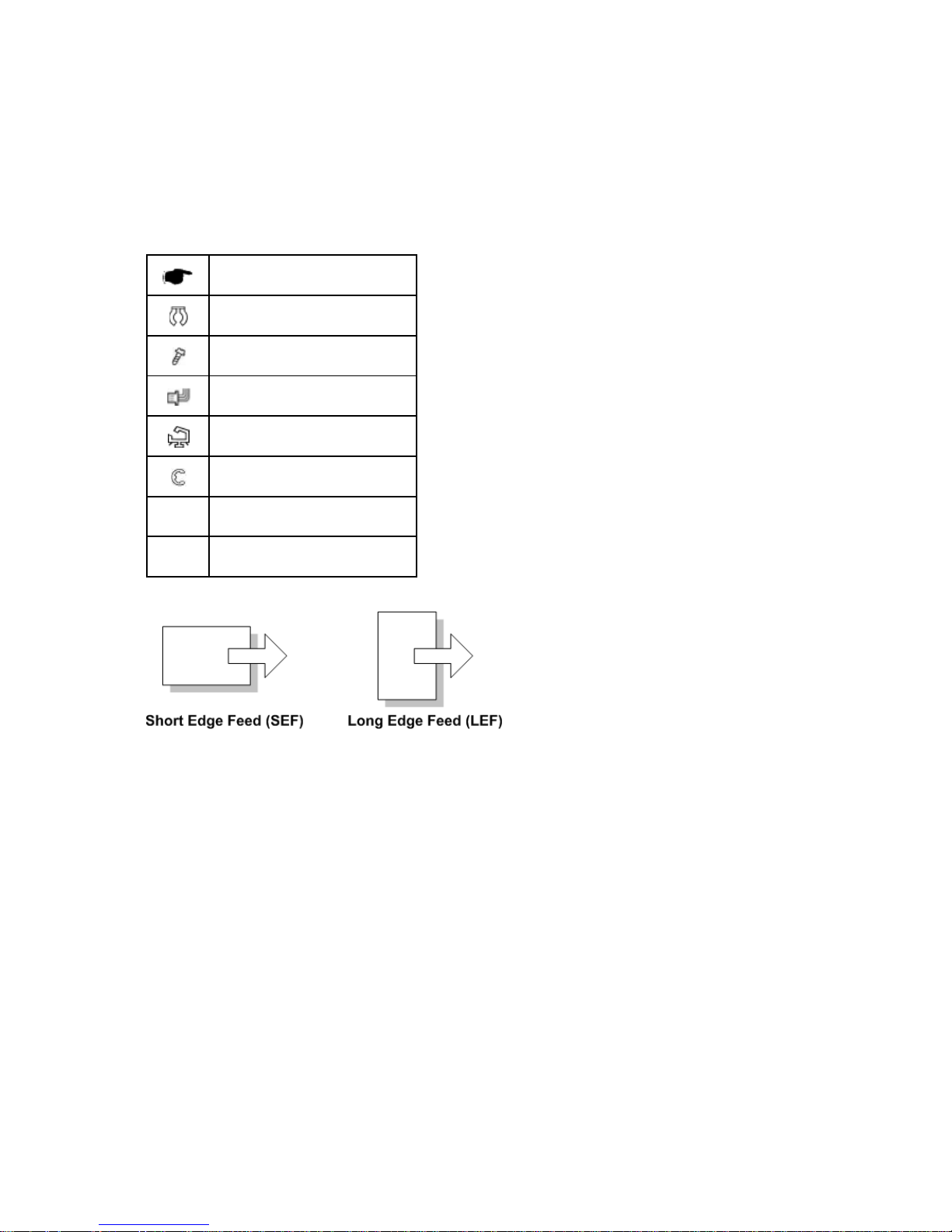

Symbols, Abbreviations and Trademarks

This manual uses several symbols and abbreviations. The meaning of those symbols and

abbreviations are as follows:

See or Refer to

Clip ring

Screw

Connector

Clamp

E-ring

SEF Short Edge Feed

LEF Long Edge Feed

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation in the

United States and /or other countries.

PostScript

®

is a registered trademark of Adobe Systems, Incorporated.

PCL

®

is a registered trademark of Hewlett-Packard Company.

Ethernet

®

is a registered trademark of Xerox Corporation.

PowerPC

®

is a registered trademark of International Business Machines Corporation.

Other product names used herein are for identification purposes only and may be trademarks of

their respective companies. We disclaim any and all rights involved with those marks.

PRODUCT INFORMATION

REVISION HISTORY

Page Date Added/Updated/New

None

Specifications

SM 1-1 M116/M117

Product

Information

1. PRODUCT INFORMATION

1.1 SPECIFICATIONS

See "Appendices" for the following information:

"General Specifications"

"Printer"

"Supported Paper Sizes"

Machine Overview

M116/M117 1-2 SM

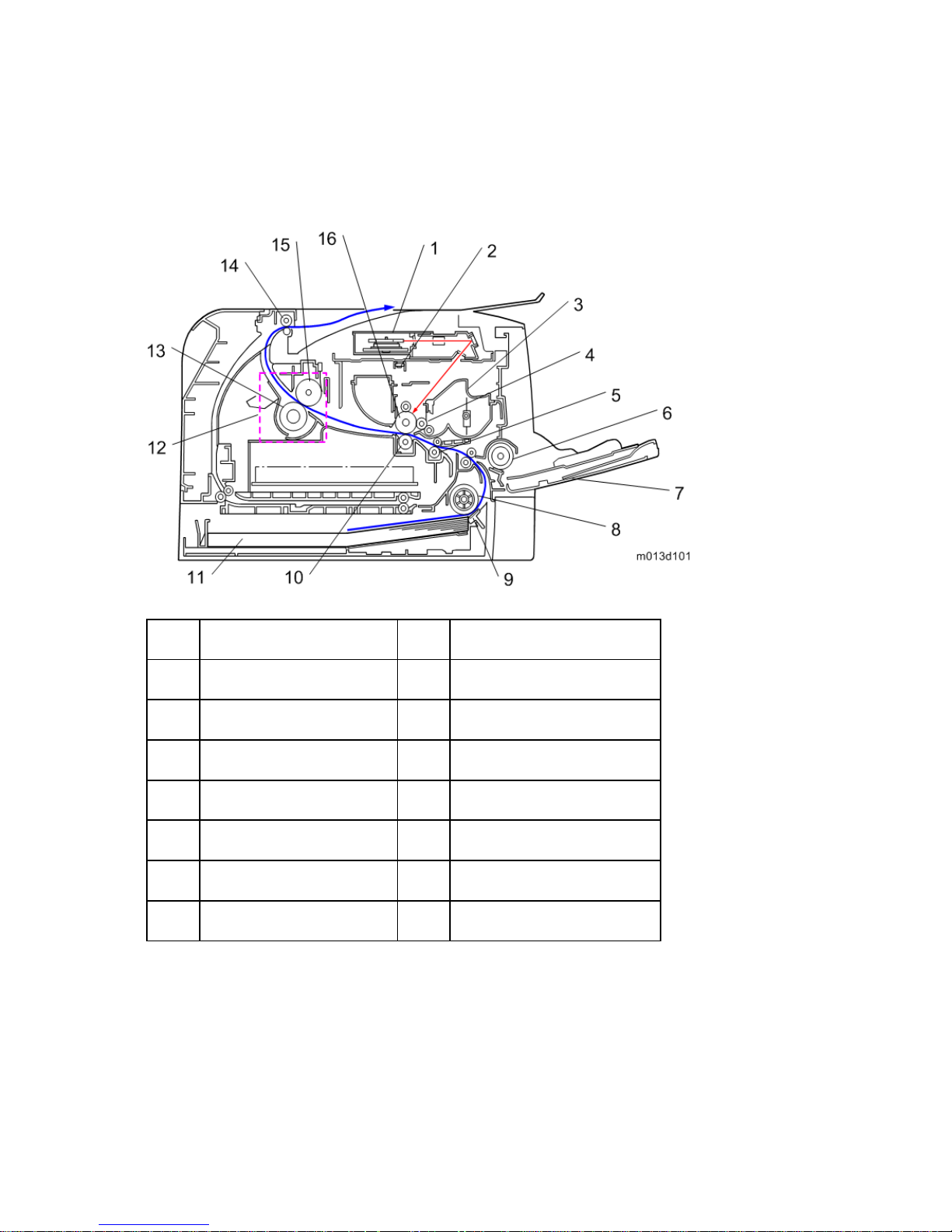

1.2 MACHI N E OVERVI EW

1.2.1 COMPONENT LAYOUT

1. Laser unit 9. Friction pad

2. Quenching lamp 10. Transfer roller

3. Cartridge (AIO-type) 11. Paper Tray

4. Development roller 12. Fusing Unit

5. Registration roller 13. Pressure Roller

6. By-pass feed roller 14. Paper exit roller

7. By-pass feed tray 15. Hot Roller

8. Paper feed roller 16. Drum

Machine Overview

SM 1-3 M116/M117

Product

Information

1.2.2 PAPER PATH

[A] Duplex section (For M117)

[B] Standard paper tray unit

[C] Optional paper tray unit

1.2.3 DRIVE LAYOUT

1. Duplex Motor

2. Main Motor

3. Registration Clutch

4. Relay Clutch

5. Paper Feed Clutch

Machine Configuration

M116/M117 1-4 SM

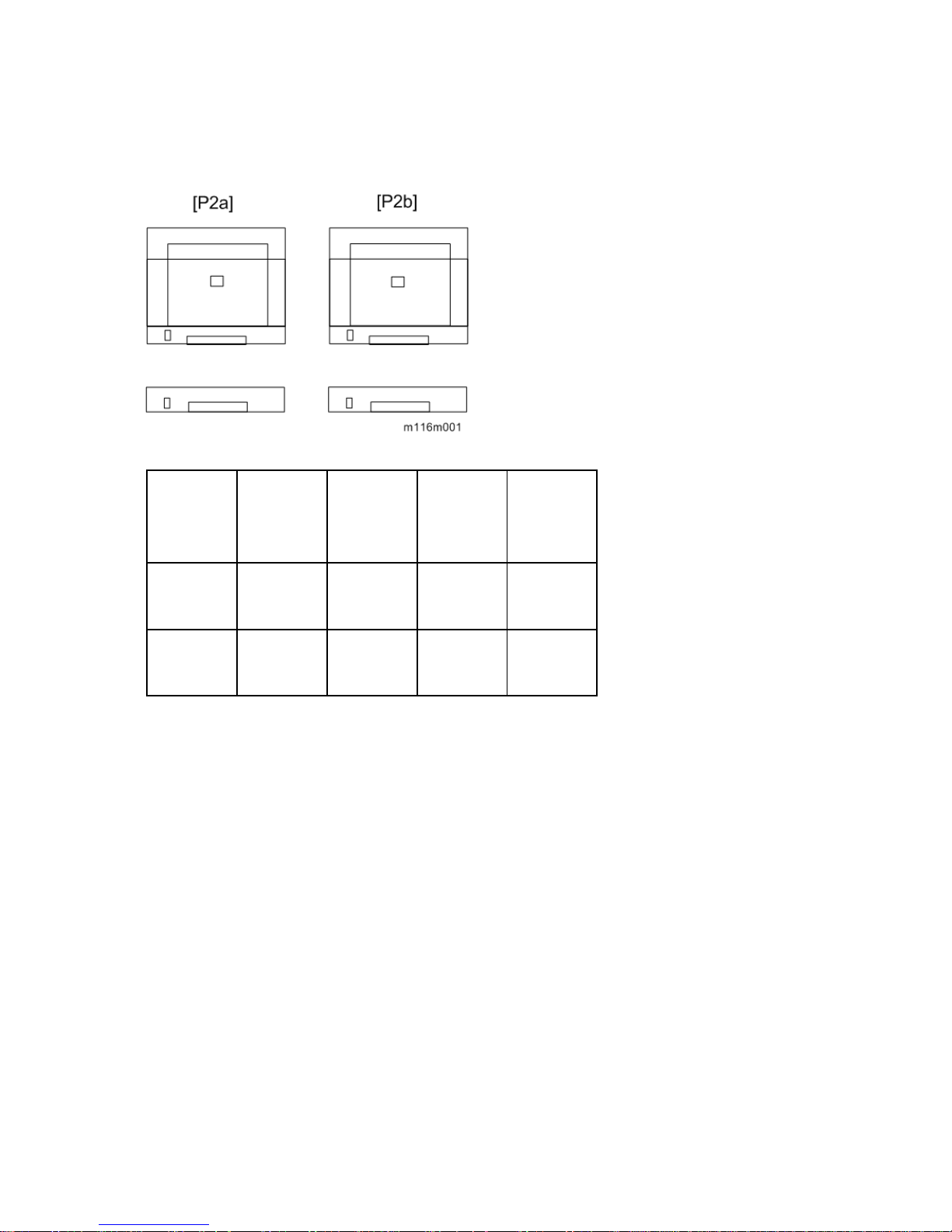

1.3 MACHINE CONFIGURATION

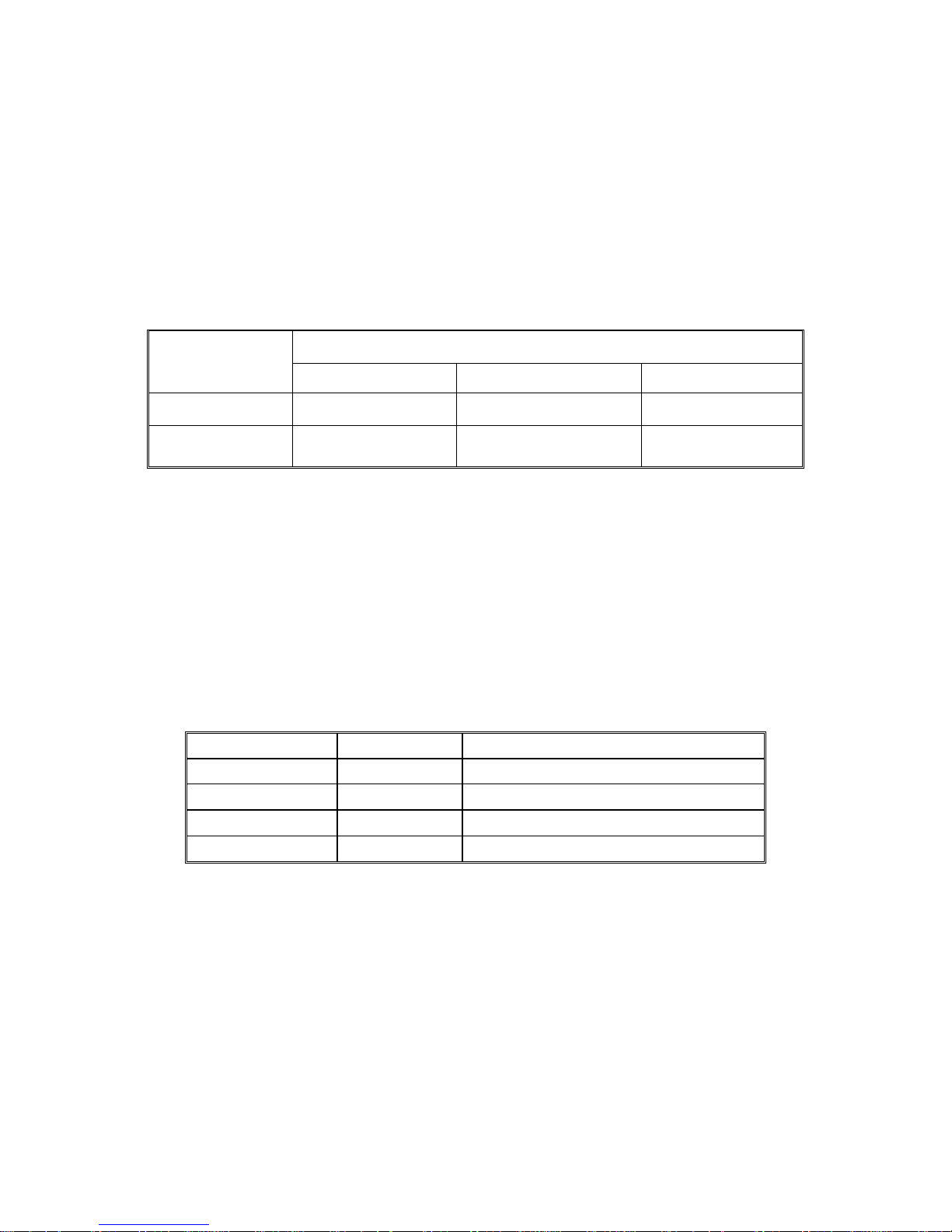

Models

Duplex

Unit

Optional

Memory

Optional

Tray

(M355)

PCL PS

RN-P2a

(M116)

NA NA 250x1 Yes

RN-P2b

(M117)

Auto NA 250x1 Yes

NA: Not Availab le

INSTALLATION

REVISION HISTORY

Page Date Added/Updated/New

None

Installation Requirements

SM 2-1 M116/M117

Installation

2. INSTALLATION

2.1 INSTALLATION REQUIREMENTS

2.1.1 ENVIRONMENT

This machine, which uses high voltage power sources, can generate ozone gas. High

ozone density is harmful to human health. Therefore, the machine must be installed in a

well-ventilated room.

1. Temperature Rage: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 2,000 lux (do not expose to direct sunlight)

4. Ventilation: 3 times/hr/person

5. Do not put the machine in areas with sudden temperature changes. This includes:

Areas directly exposed to cool air from air conditioning

Areas directly exposed to heat from a heating system.

6. Do not put the machine in areas exposed to corrosive gas.

7. Do not install the machine at locations over 2,000 m (6,562 ft.) above sea level.

8. Put the machine on a strong, level base. (Tilting towards any side must be no more than 3

mm.)

9. Do not put the machine in areas with strong vibrations.

Installation Requirements

M116/M117 2-2 SM

2.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

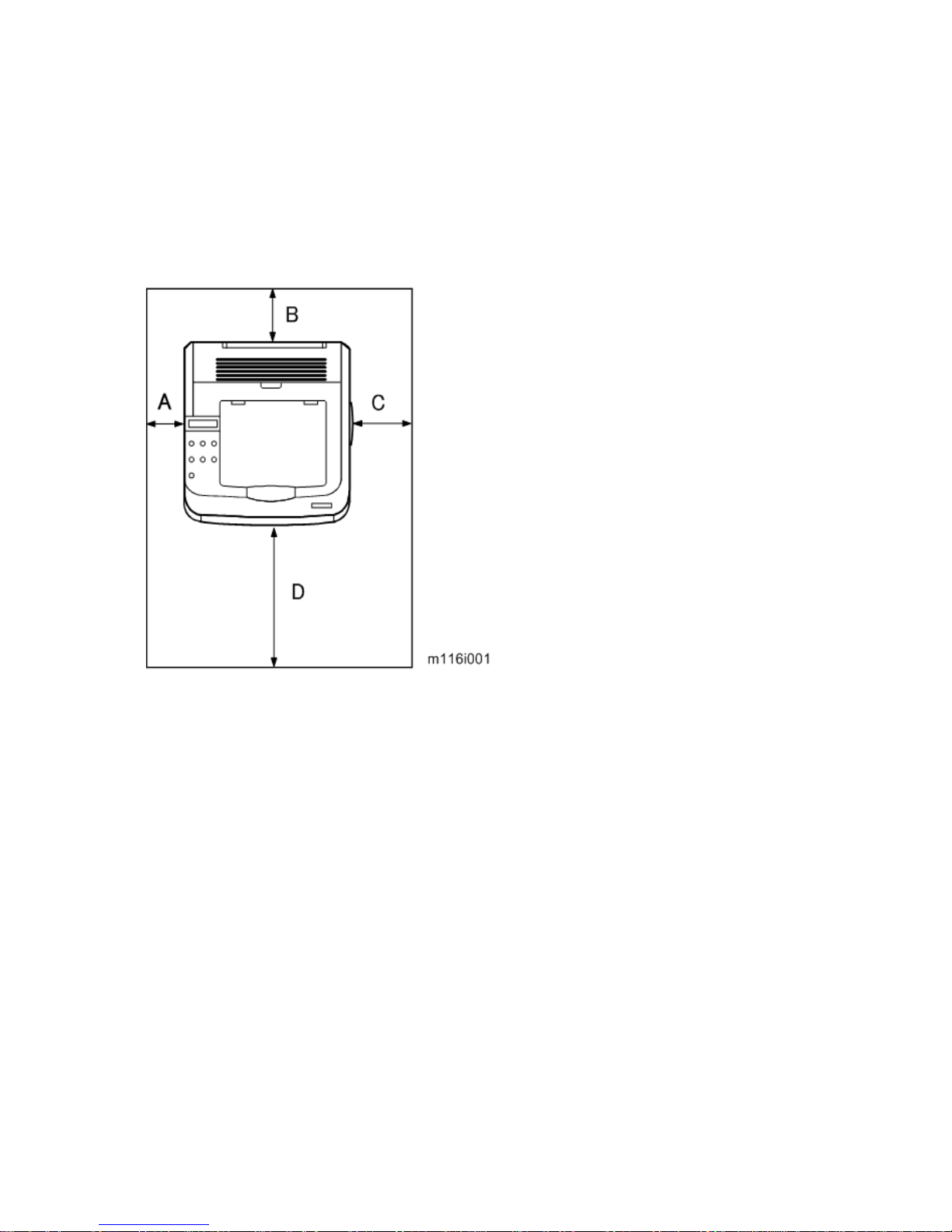

2.1.3 MACHINE SPACE REQUIREMENT

Put the machine near a power source with these clearances:

A: Over 10 cm (4")

B: Over 20 cm (7.9")

C: Over 20 cm (7.9")

D: Over 70 cm (27.6")

Installation Requirements

SM 2-3 M116/M117

Installation

2.1.4 POWER REQUIREMENTS

Make sure that the plug is tightly in the outlet.

Avoid multi-wiring.

Make sure that you ground the machine.

Input voltage level

NA: 120 V, TW: 110 V, 60 Hz: Less than 10 A

EU/ Asia/ CHN: 220 V to 240 V, 50 Hz/60 Hz: Less than 5 A

Permitted voltage fluctuation: 10%

Do not set anything on the power cord.

2.1.5 INSTALLATION PROCEDURE

Refer to the "Hardware Guide".

PREVENTIVE MAINTENANCE

REVISION HISTORY

Page Date Added/Updated/New

None

PM Intervals

SM 3-1 M116/M117

Preventive

Maintenance

3. PREVENTIVE MAINTENANCE

3.1 PM INTERVALS

3.1.1 PM PARTS

There are no PM parts in this machine.

Other than the three Yield Parts listed below, there are essentially no PM parts required

for this product.

These three items will need to be replaced in cases where their yield is near, however,

given the APV (Average Printer Volume) for this product, these "yield parts*

1

" are

expected to outlast the working life of the machine.

*

1

"Yield Parts": Parts whose expected yield is longer than the machine lifetime when taking into

consideration the machine's APV.

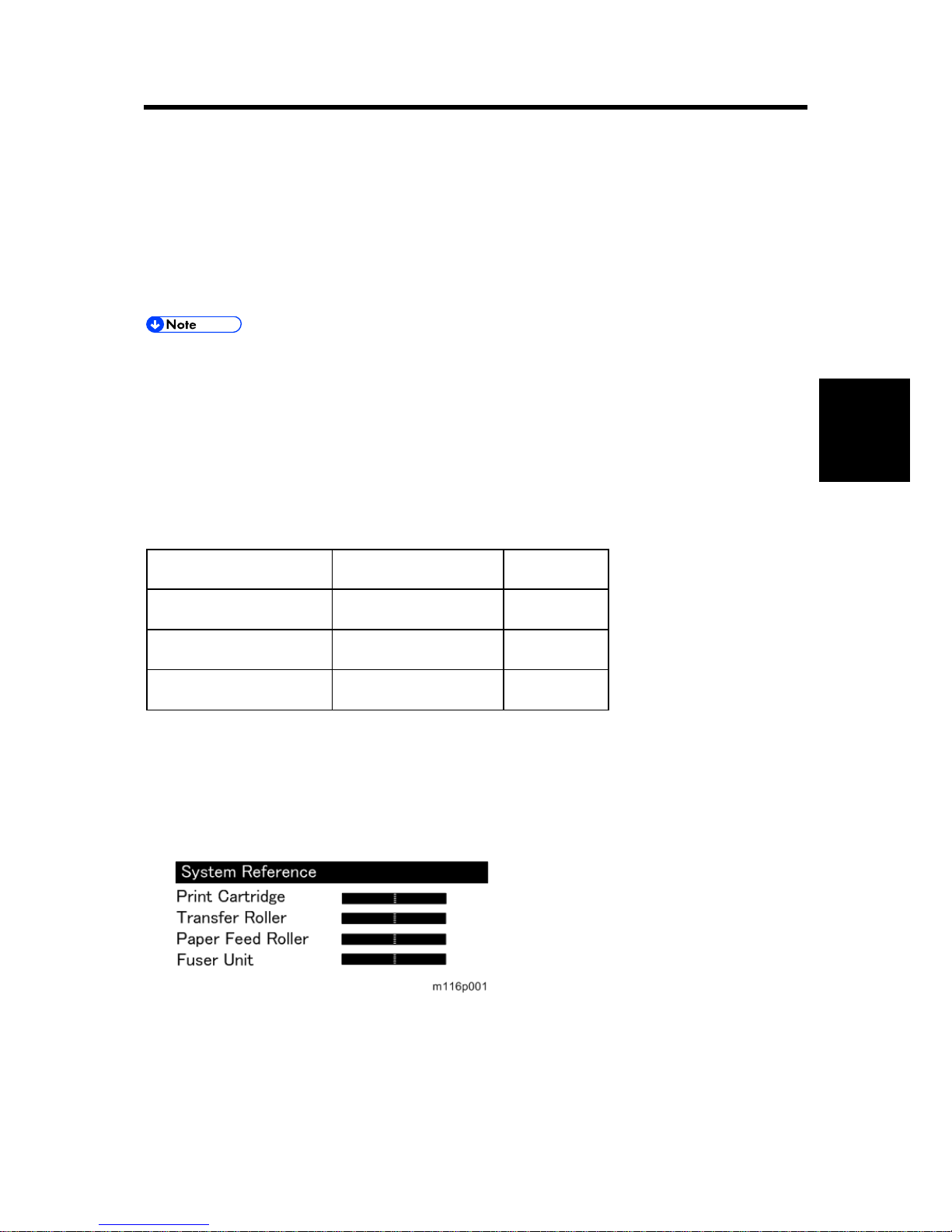

Description Expected Yield Q'ty/unit

Paper Feed Roller 120 K prints 1

Transfer Roller 120 K prints 1

Fusing Unit 120 K prints 1

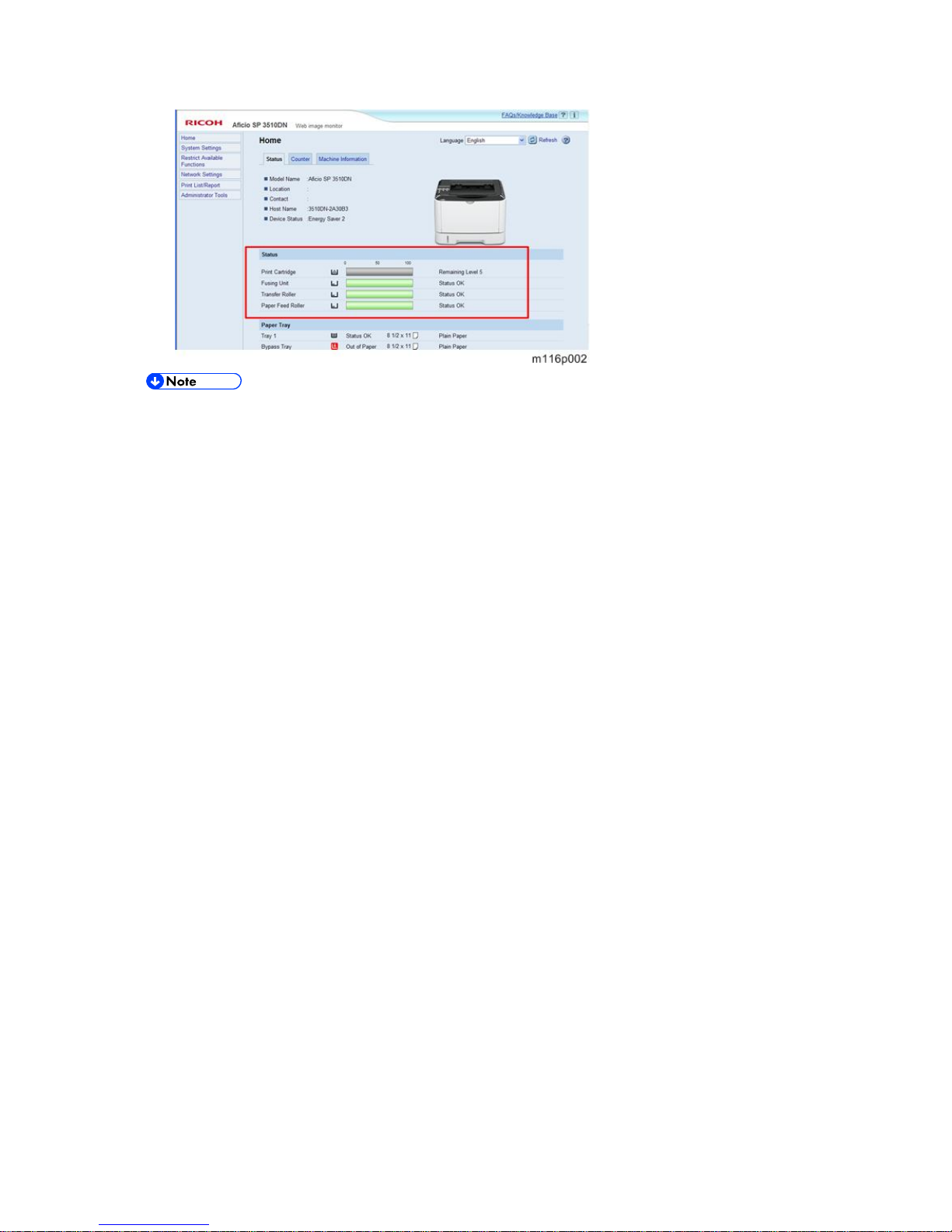

3.1.2 YIELD COUNTER

Yield counters for each yield part can be checked by the following methods.

Configuration Pa ge in the “List/Test Print” menu

Web Image Monitor

PM Intervals

M116/M117 3-2 SM

The machine displays "Fuser life end notice", "Transfer roller life end notice" or "Life End

of Paper Feed Roller Unit" when one of these counters reaches each yield.

Counter Reset

The process below shows how to reset the yield counters.

1. Enter the "Service Mode".

2. Select "Eng Maintenance", and then press "OK" key.

3. Select "Reset FuserUnit", "Reset Trans Rol" or "Reset Feed " and then press "OK" key.

4. Select “Execute” and the press “OK” key.

5. Exit the Service Mode".

REPLACEMENT AND ADJUSTMENT

REVISION HISTORY

Page Date Added/Updated/New

None

Loading...

Loading...