Page 1

LARGE CAPACITY TRAY

LT4000

(C563)

Page 2

15 June 1995 OVERALL MACHINE INFORMATION

1. OVERALL MACHINE INFORMATION

1.1 S PECIFICATIONS

Paper Size: The following sizes can be placed in the large

capacity tray and the LCT cassette .

A3 M, B4 M, A4 LM, B5 LM, A5 M,

11" x 17" M, 81/2 x 14" M, 81/2" x 11"

In addition, the following size can be pla ced in

the LCT cassette.

A6 M.

Paper Capacity: LCT: 4,000 sheets (64 g/m2, 17 lb)

3,000 sheets (80 g/m2, 20 lb)

Cassette: 500 she ets (64 g/m2, 17 lb)

400 sheets (80 g/m2, 20 lb)

Copy Paper Weight 47.1 g/m2 to 209.3 g/m2, 12.5 lb to 55.6 lb

ML

Power Source: (DC) 24 V, 5 V

Power Consumption: Less than 100W

Weight: Less than 37 kg, 82 lb

Dimensions:

(W x D x H)

Image Shifting:

550 x 500 x 688 mm, 21.7" x 19.7" x 27.1"

±10 mm (±3 mm if the optional sorter is

installed)

1

Page 3

2

OVERALL MACHINE INFORMATION 15 June 1995

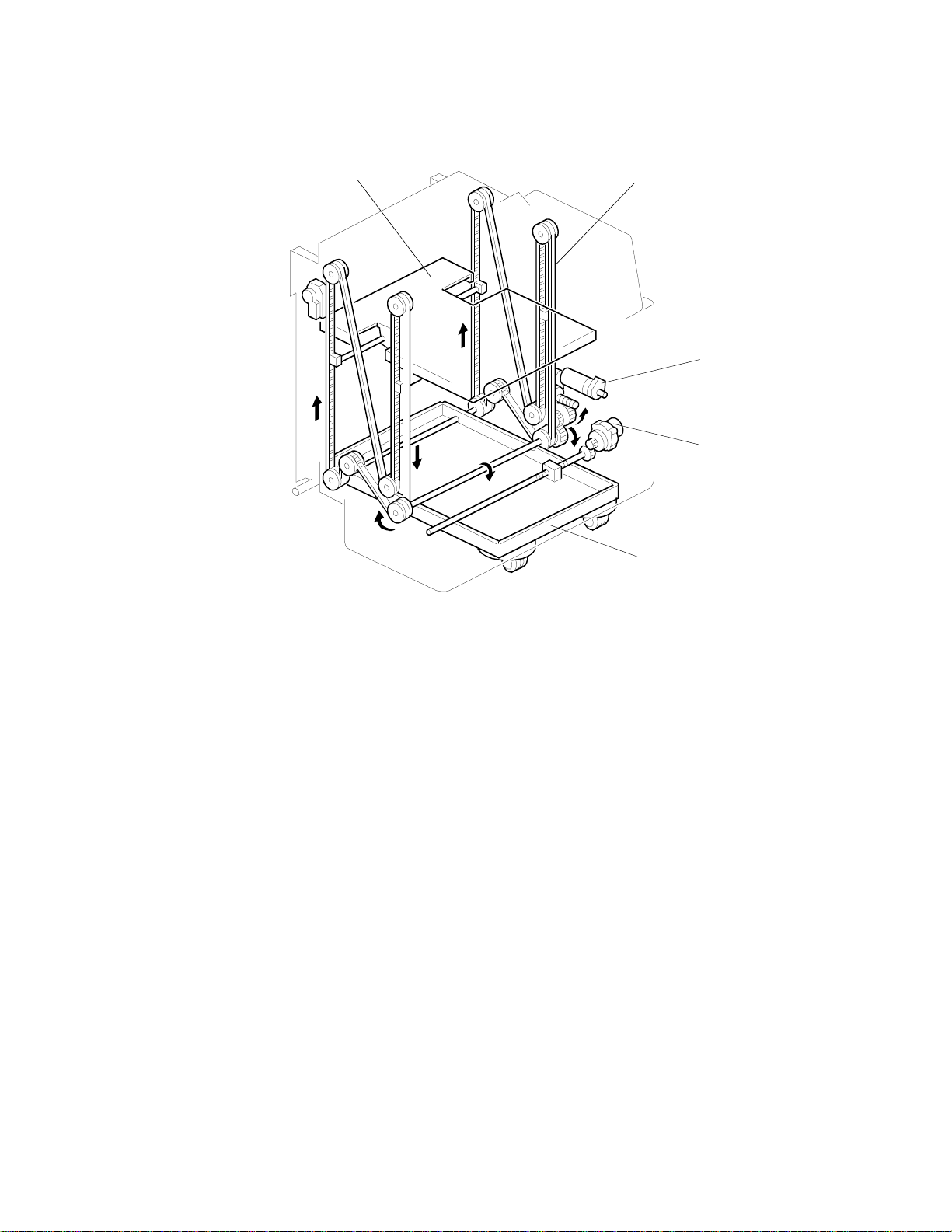

1.2 ME CHANI CAL COMP ONE NT LAYO UT

1

3

4

1. Bottom Plate

2. Tray Drive Belt

3. Tray Drive Motor

4. Tray Shift Motor

5. Feed Unit Base

5

C563V500.wmf

2

Page 4

15 June 1995 OVERALL MACHINE INFORMATION

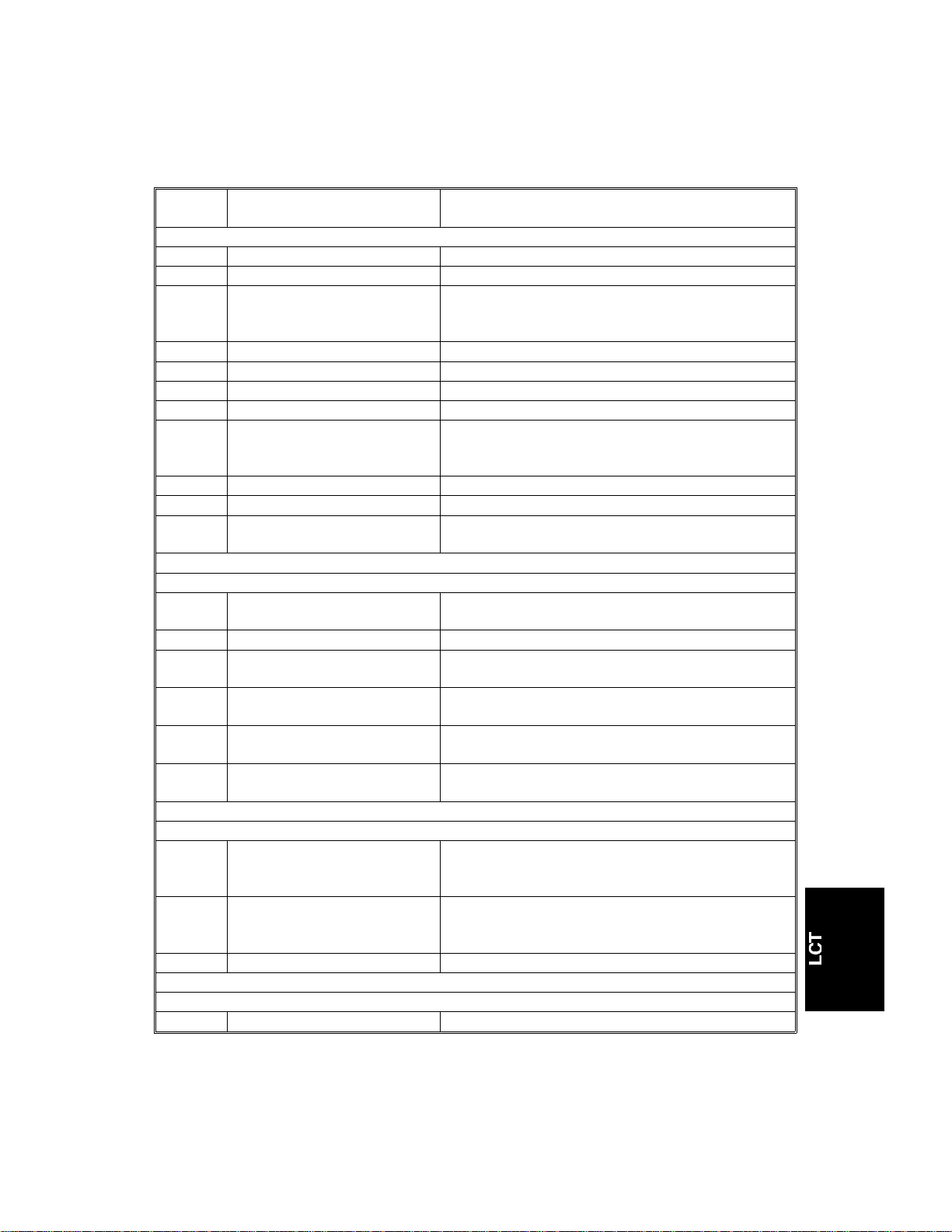

1.3 E LECTRI CAL CO MPO NENT DE SCRI P TI ON

Refer to the electrical compone nt layou t on the reverse side of the

point-to-point diagram (on the waterproof paper).

Index.

No.

Sensors

1 Cassette Size Determines what size paper is in the cassette.

3 Paper Length Detects the paper length.

Maximum Paper Load Informs the printer CPU when the LCT bottom

5

10 Paper Size 0 Determines what paper size is in the tray.

11 Paper Size 1 Determines what paper size is in the tray.

12 Paper Size 2 Determines what paper size is in the tray.

13 Paper Size 3 Determines what paper size is in the tray.

Tray Lower limit Turns off the tray drive motor when the tray

9

20 LCT Paper End Detects the presence of paper in the LCT.

21 Cassette Paper End Detects the presence of paper in the cassette.

Tray Paper Position Detects the top of the LCT tray or the paper stack

17

Switches

Cassette Informs the printer CPU when the cassette is

2

4 Cover Open Detects if the LCT cover is open or not.

Rear Shift Limit Cuts the line to the tray shift motor when the feed

8

Front Shift limit Cuts the line to the tray shift motor when the feed

14

Tray Down The LCT bottom plate lowers when the user

16

Image Position The tray shift motor moves forward or in reverse

19

Description Note

plate is at the lowest position for loading paper,

and that no more can be loaded.

reaches the lowest possible position (for loading

the cassette).

when adding paper.

installed.

unit base reaches the rear end.

unit base reaches the front end.

presses this.

when the user presses this.

Motors

Tray Drive Lifts the LCT bottom plate to bring paper to the

6

Tray Shift Shifts the feed unit base from front to rear to shift

7

18 Cassette Bottom Plate Drive Lifts the cassette bottom plate.

PCBs

15 I/O Control Controls all the LCT operations.

feed position and and lowers it to allow paper to

be loaded.

the LCT bottom plate, in order to shift the image

position.

3

Page 5

OVERALL MACHINE INFORMATION 15 June 1995

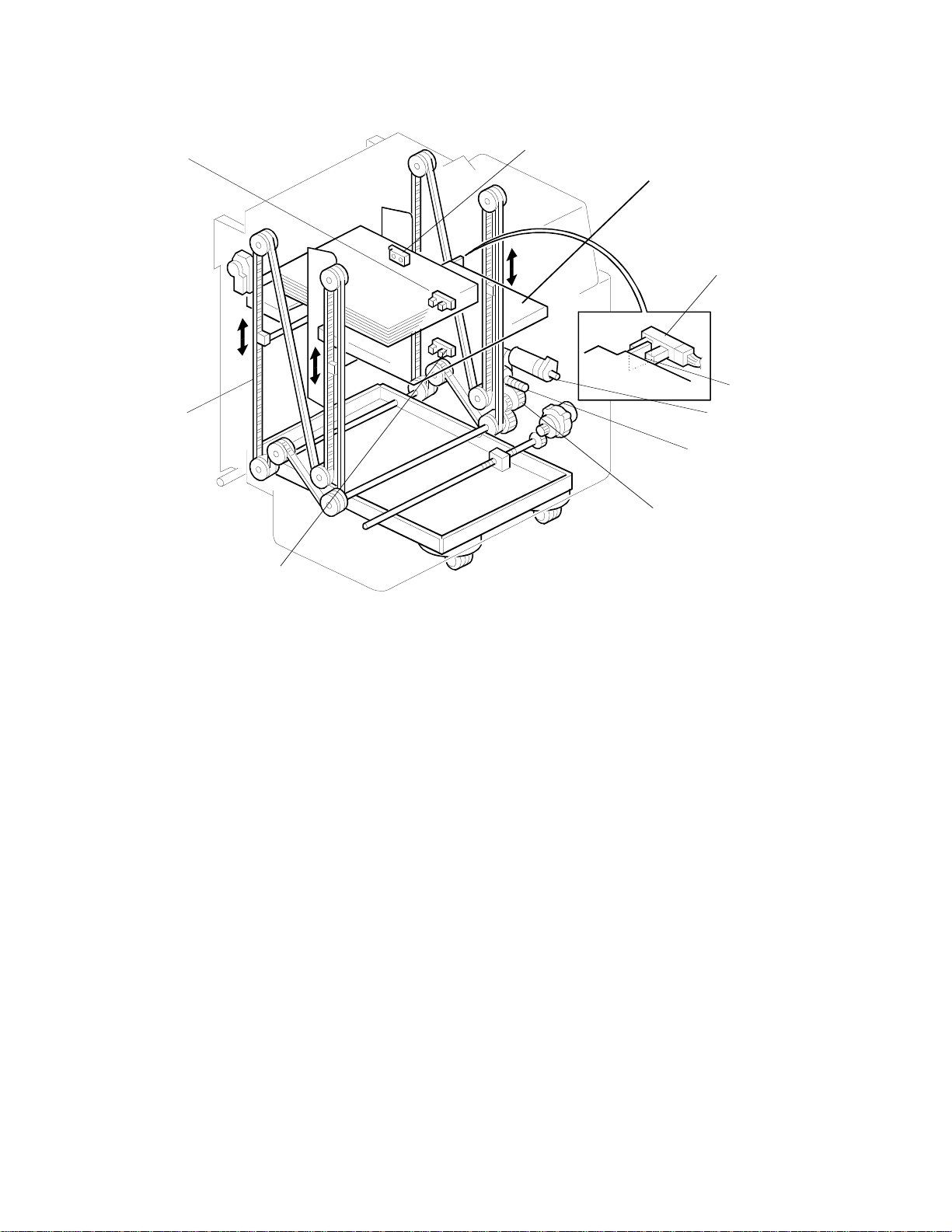

1.4 BAS IC OP ERATION

[F]

[G]

[A]

[G, I]

[H]

[E]

[B]

[C]

[D]

[I]

C563V502.wmf

- Overview -

The LCT bottom plate [A] is lifted up and down by th e tra y drive mot or (a

reversible motor) [B]. Drive from the tra y drive mot or is tran smitted through

the worm gear [C], worm wheel, drive pulley [D] to the drive belts [E ]. The

drive belts connect the ends of the LCT botto m plate.

The bottom plate is con tro lled so that the top of the pap er sta ck is in one of

two basic positions: the paper feed position or the sta ndby position. The

paper feed position is used during print ing , an d at all oth er time s, th e sta nd by

position is used. When the top of the pa pe r stack is in the stan dby position,

there is enough room for the user to add about 1,000 sheets of paper.

- Power-up -

When the main switch is turned on, the tray drive motor lifts the LCT botto m

plate until the top of the paper stack is at the stan dby position. This is the

initialization procedure for the bottom plate position.

The bottom plate is lifted until the top sheet pu she s up th e feed roller and th e

paper table height sen sor in th e main body is de-actuated (this is th e pape r

feed position; refer to "Printing" below for more de tails). The n, the tray drive

motor lowers the bottom pla te until the top of the paper stack just passe s the

4

Page 6

15 June 1995 OVERALL MACHINE INFORMATION

tray paper position sensor [ F] (a phot oco up ler), wh ich turns of f at this time .

This is the standby position.

If there is no paper or only a small amount of paper on the bottom plate, the

tray paper position senso r t urn s o n th en off soon aft er (be cause the bottom

plate passes the sensor), before the top shee t pushes up the feed roller.

When this happens, the bottom plate stops rising immed iat ely and is lowere d

until the top of the pape r stack comes to the standby position (th e tray paper

position sensor turns on th en back of f again). This process allows

initialization to be completed more quickly.

- Printing -

When the Print Start key is pressed, the bot to m plat e starts rising from the

standby position. It stop s when the top shee t pushes the paper feed roller

and the paper table heig ht sensor in the main body is deactu at ed (t his is the

paper feed position ). The machine can now start to feed.

As pages are printed, the top sheet posit ion beco mes lower, and eventually

the main body’s paper table he igh t sensor is actuated. When th is hap pe ns,

the tray drive motor raises the bottom plate until the paper height sensor is

de-actuated again; this kee ps th e to p she et at th e paper f eed po sitio n.

When a printing job finishes or a paper misfeed occurs, the tray drive motor

slightly lowers the bottom plate (for 500 ms). If the tray paper posit ion sensor

turns off (this is possible whe n th ere is only a small a mou nt of pape r on th e

bottom plate an d the paper stack is in between th e sensor and the paper

feed roller), the bottom pla te moves do wn un til th e tra y pap er po sitio n sen sor

is just activated by the bottom plate. This is to allow the user to add pap er. It

is not possible to add paper by pressing the tray down switch if th e tra y pap er

position sensor remains off (refe r to the Addin g Pape r sectio n below).

Unlike after a normal printing job, after a pro of print ing job mad e with the

Proof Printing key fin ishe s (o ne sh eet is f ed each time th e Proof Printing key

is pressed), the bottom pla te is not lowe red. This is to save time for the top

sheet to reach the paper feed position when the next job starts.

If paper runs out during printing , th e pape r end cond itio n is det ect ed by the

LCT paper end sensor (a photoco upler). The bottom plate moves down until

the tray paper position sensor turns on then off (it stops in the standby

position). Then, the user can add some pa per.

5

Page 7

OVERALL MACHINE INFORMATION 15 June 1995

- Adding Paper -

The bottom plate can be lowered by pre ssing the tray down switch only when

the tray paper position senso r turn s on. This is becau se if the sensor stays

off, the top of the paper stack (or the bottom plate if there is no paper) is in

the standby position. The user can add paper without lowering the bottom

plate in this case.

When the top of the paper stack is above th e tray paper position sensor (the

sensor is On) and the tray down switch is pressed , the tray drive motor

lowers the bottom plate until the top sheet of the remain ing paper stack just

passes the tray paper position sensor (the sensor turns off). This gives

enough space for the user to add about 1,000 sheets of paper.

If the tray down switch is the n pre ssed again after adding pap er (th e tra y

paper position sensor comes on), the botto m plate moves down and again

stops once the top sheet just passes the tray paper position sensor. This

operation can be repeated until the maximum paper load sensor [G] is

actuated by the actuator [H] on the bottom plate. Then, the bottom plate

cannot be lowered any more and no more paper can be added.

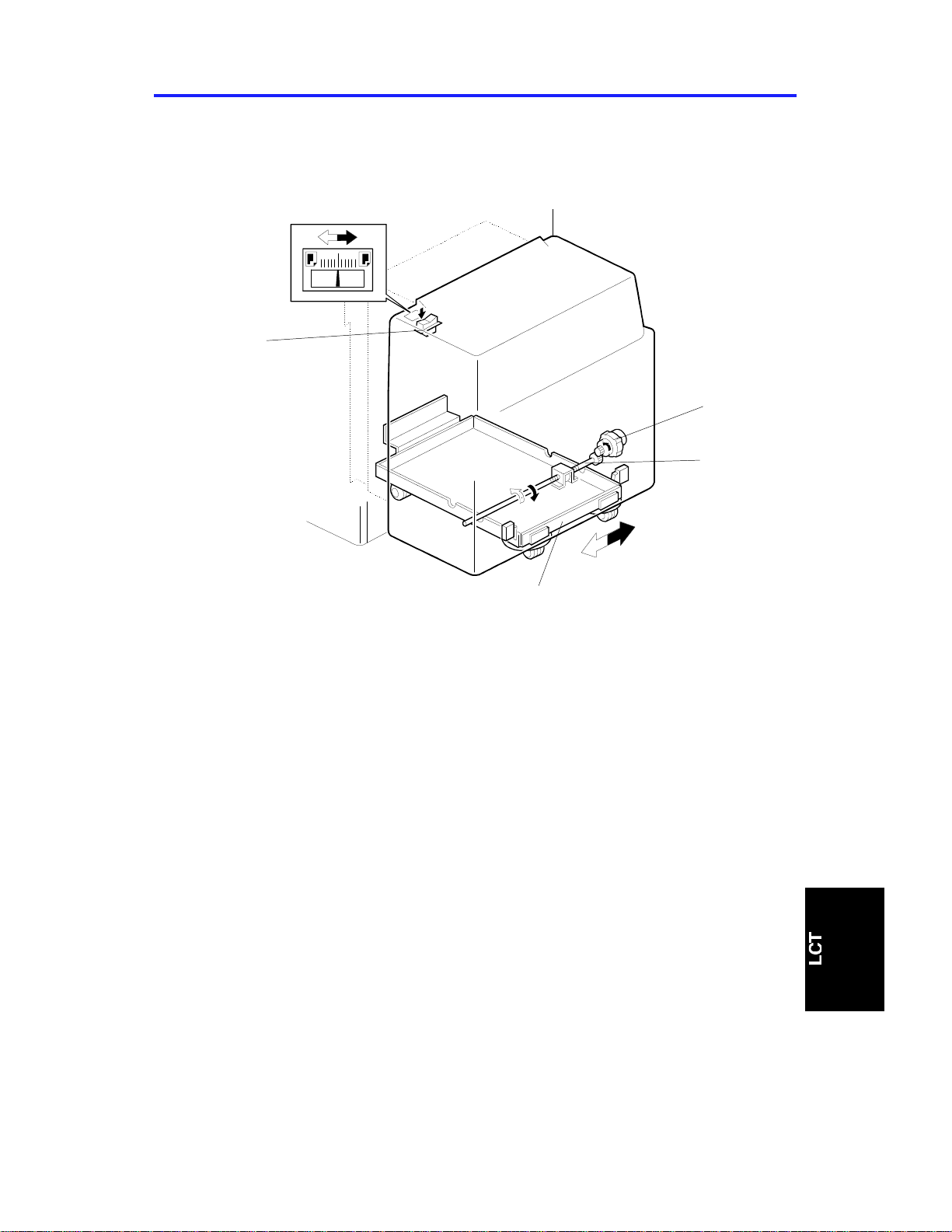

- Installing the Cassette -

When the tray down switch is pressed for aro und 2 seco nd s (when the user

wants to load the cassett e), the bottom plate lowers until the tray lowe r limit

sensor [I] detects the actuator on bottom plate.

6

Page 8

15 June 1995 DETAILED SECTION DESCRIPTIONS

2. DETAILED SECTION DESCRIPTIONS

2.1 TRAY SHI FT MECHANISM

[A]

[B]

[C]

c563d500.wmf

[D]

Image shifting is carried out by shift ing the LCT unit to the fro nt or to th e rea r.

When the image position switch [A ] is mo ved to the fro nt , th e tray sh ift moto r

(a reversible motor) [B] rot ates counterclockwise to rotate the shift shaf t [C]

clockwise. The shaft moves the feed unit base [D] of the LCT unit to the rear.

Thus, the image is shifted to the front.

7

Page 9

[D]

DETAILED SECTION DESCRIPTIONS 15 June 1995

2.2 PAPER SIZE DETECTION

[A]

[B]

[E]

[C]

C563D502.wmf

[G]

[F]

The rear side fence [A] and front side fence [B] can be slid to chan ge the

paper size. This is accomplished by loosening a knob screw and sliding the

rear end fence to anot he r pap er size. The rear side fence has an actu at or

plate [C] mounted on its undersid e. There are fo ur sen sors

(photo-interrupters: pap er size sen sor 0 [D] , 1 [E ], 2 [F], and 3 [G] ) on th e

bottom shaft for d et ect ing paper width and one sensor (a ref lect ive

photosensor, the paper len gt h sen sor) on the botto m plate for detecting the

paper length. The printer CPU determin es the paper size by reading the

combination of signals fro m t he sensors.

8

Page 10

15 June 1995 DETAILED SECTION DESCRIPTIONS

2.3 CAS SE TTE LOADING MECHANISM

2.3.1 BOTTOM PLATE DOWN

[C]

[A]

[C]

[B]

[D]

C563d501.wmf

When the tray down switch is held down for longer th an 2 secon ds, the

bottom plate [A] lowers unt il t he tray lowe r limit senso r det ects the actuator

on the bottom plate (re fe r t o "Basic Operation"). When the bo ttom plate

passes the position of th e maximum paper load sensor [B], the side fences

[C] are lowered together with the bottom plat e until th e tray lo wer limit sen sor

detects the bottom p lat e. The openings [D] in the side fen ces allow the

bottom plate to be lowered to the maximum paper load sen sor positio n and

allow the side fences to be lowe red tog et he r with the bottom plate.

9

Page 11

DETAILED SECTION DESCRIPTIONS 15 June 1995

2.3.2 CASSETTE LOADING

[A]

[F]

[B]

[D]

C563d503.wmf

[E]

[C]

C563d504.wmf

The printer cpu dete cts th at the cassette is loaded in th e prin ter when the

cassette switch [A] is pressed. When the cassette is loade d an d th e LCT

cover [B] is closed, the cassette bottom plate drive motor [C] raises the

bottom plate [D] by lifting th e bott om plate lever [E] until the top sheet push es

up the feed roller and the main body’s paper table heig ht senso r is

de-actuated. The n, the cassette bottom plate drive motor stops.

When the LCT cover is opened, the cassette bottom plate drive motor rotates

in reverse for 5 seconds to lower the bot to m plat e. The cassette size sensor

(composed of 5 photointerrupters) [F] dete cts the cassette tray paper size.

The cassette size sensor is actu ated by a plate on one corner of th e

cassette. Each pape r size has its own unique combination of no tch es in the

actuator plate . The CPU re ad s which ph ot ointerrupters have bee n

deactivated by the actuator plate to determin e which paper size has been

loaded in the cassette.

10

Page 12

15 June 1995 INSTALLATION PROCEDURE

3. INSTALLATION PROCEDURE

If the sorter will be installed on the same visit as the LCT installatio n, insta ll

the LCT first.

NOTE: The optional table (unit code C5 64) is necessa ry t o install this LCT.

3.1 ACCESSORY CHECK

Check the accessories in the box against the following list.

1. Installation Procedure...................................................1

2. Decal Sheet..................................................................1

3. Paper Change Decal ...................................................1

4. Right Paper Guide Plate.............. .. ............ .. .. ............ .. .1

5. Left Paper Guide Plate .................................................1

6. Paper Feed Small Cover..................... ............ ............ .1

7. Positioning Bracket.......................................................1

8. Short Connector.................. .......... .. .............................1

9. Knob Screw..................................................................2

10. Nylon Clamp.................................. .. .............................1

11. Flange Head Screw - M4 x 8............. .. ............ ............ .1

12. Philips Screw with Flat Washer - M4 x 6................... .. .3

13. Cassette .......................................................................1

11

Page 13

INSTALLATION PROCEDURE 15 June 1995

3.2 INSTALLATION PROCEDURE

CAUTION

I

Unplug the power cord of the printer before starting the foll owi ng

procedure.

[A]

[A]

C563I500.wmf

[B]

C563I501.wmf

[C]

1. Remove the strips of tape [A].

2. Put the printer [B] on the table (C564) [C] . Pu t th e she lf in if req uire d by

the user.

3. Remove the following covers from the print er: rig ht fron t cover, left upper

cover, right cover, and rear cover.

12

Page 14

15 June 1995 INSTALLATION PROCEDURE

[A]

[B]

C563I502.wmf

[C]

[F]

[E]

[D]

[C]

[G]

C563I503.wmf

4. Remove the main board [A] (8 screws).

5. Remove the actuator bracket [B] for th e pa per t able lower limit sensor (1

screw). (This actuator is not necessary after installing the LCT.)

6. Remove the three screws [C] that hold th e pape r tab le drive motor [D]

bracket. Disengage the motor gear from the table drive ge ar [E ] to enable

free movement of the pap er table [F].

7. Raise the paper table and disco nn ect the two connectors [G] at th e front.

13

Page 15

INSTALLATION PROCEDURE 15 June 1995

[A]

[C]

[E]

[D]

[B]

[D]

[C]

[H]

[A]

C563I504.wmf

[G]

[I]

[F]

C563I505.wmf

8. Remove the two screws that hold the grounding wires [A]. (Keep one of

the two screws for installing the grounding wire in step 22).

9. Remove the paper table holder [B ] (1 screw). (This is not necessary after

installing the LCT.)

10. Remove the four rack shafts [C] and rollers [D] . (These are not necessary

after installing the LCT.)

11. Remove the paper table [E] . (This ta ble is not necessary after installing

the LCT.)

12. Remove the paper feed botto m plate [F] (4 screws). (This is not

necessary after installing th e LCT. )

13. Disconnect the connector [G ] of the paper ta ble safety switch and install

the short connector [ H] pa cked wit h th e LCT.

14. Put back the three screws (re move d in step 6) to secure the paper table

drive motor bracket [I]. Reinstall the main board.

14

Page 16

[E]

15 June 1995 INSTALLATION PROCEDURE

[H]

[A]

[C]

[B]

C563I506.wmf

[F]

[G]

C563I508.wmf

[D]

C563I507.wmf

15. Install the positionin g bracket [A] from the LCT accessories (2 Philip s

screws with flat washers from the LCT acce ssorie s). Se cure the bracke t

to the copier first, then slide it into position until the two spring pins click

into the holes in the cab inet.

16. Position the main bo dy so th at the two pins [B] on the bracket fit into the

two openings in the ta ble. Then fix the main body to th e table with the two

knob screws [C] (packed with the table).

17. Remove the support bracket/safety switch assembly [D] (4 screws). (This

is not needed after installing the LCT.)

18. Remove the two screws [E] installe d on the st ay at the back side of th e

LCT.

19. Attach the left and right guide plates [F and G] to the LCT (from th e LCT

accessories), and secure them with the 2 screws [E] .

20. Reinstall the main body’s right cover [H].

15

Page 17

[H]

[J]

INSTALLATION PROCEDURE 15 June 1995

[E]

[C]

[F]

[A]

C563I509.wmf

[N]

[I]

[K]

[L]

[M]

C563I510.wmf

[B]

[D]

[G]

C563I511.wmf

NOTE: When the sorter is already installed, or will be installed immediately

after LCT installation, carry ou t ste p 21.

NOTE: Take care not to damage the connector of the harness where the

front upper cover [N] is conn ect ed.

21. a) Remove the upper [I], fron t lowe r [ J], rear up per [ K] , rea r lower [L],

right [M], and front upper [N] covers of the LCT.

b) Move both switch brackets [A] fully inward and tighten the screws.

c) Put back all the LCT covers except for the fron t up per co ver [N] .

22. Pass the LCT connecto r harness [B] through the bracke t cutout as

shown. Connect the 6-pin conn ect or [C] from th e LCT to the harn ess

connector from the printer. Con ne ct th e 22-pin conn ect or [D] to the main

board [E]. Attach the grounding wire [F] as shown (1 screw re move d in

step 8).

23. Secure the LCT harne ss with the harness clamper [G] and flan ge hea d

screw - M4 x 8 (both from the LCT accessories).

24. Push the LCT against the printer to connect them. Turn the LCT legs [H]

until each leg just contacts the floor.

16

Page 18

[D]

15 June 1995 INSTALLATION PROCEDURE

[C]

[E]

[A]

C563I512.wmf

[B]

[F]

[G]

[H]

C563I513-1.wmf

25. Attach the LCT position indica tor arm [A] to the inside of the printer side

plate (Philips screw with flat wash er M4 x 6 [B] , pa cked with the LCT).

NOTE: If the screw cannot be secured, readjust the LCT leg height .

Make sure that the indica to r a rm and the edg e [C] of th e prin ter

side plate are parallel.

26. Secure the LCT to the table with the two knob screws [D] (from th e LCT

accessories).

NOTE: Make sure that the position ing pin pro jects from the opening [E]

between the two knob screws.

27. Remove the magnet [F] (2 screws). Then install the paper feed small

cover [G] in its place with two Philip s screws wit h fla t washer M4 x 6 [H]

(all LCT accessories).

NOTE: Push the paper feed small cover to th e up permost position, then

secure it.

17

Page 19

[A]

[B]

INSTALLATION PROCEDURE 15 June 1995

[E]

[F]

C563I514.wmf

[C]

[D]

C563I513-2.wmf

C563I515.wmf

28. Stick the paper change deca l [ A] from th e accessories on top of the lower

paper table decal [B] (th e fu nct ion of the button has changed ).

29. Attach the operation decal [C] just below the decal already attached to

the small cover. (Operation de cals fo r 5 langua ge s are inclu de d on the

decal sheet in the accessories; select the appropriate one.)

30. Open the LCT cover [D] an d at tach the lever position deca ls [ E] as

shown. These decals are included on the decal sheet in the accessories.

31. Put back the printe r’s left and right front covers.

32. Reinstall the front upper cover [F] of the LCT and the rear cover of the

printer.

32. Check the LCT’s operatio n.

18

Page 20

15 June 1995 SERVICE TABLES

4. SERVICE TABLES

4.1 SERVICE REMARKS

1. When the printer and LCT are moved to anot he r place to comp ly wit h a

customer request, remove the LCT from the printer first.

2. If any adjustment or operation check ha s to be made with exterior covers

off or open, note that th e LCT bo ttom plate may move down and up while

the main switch is turned on. Keep hand s away fro m mechanically driven

components, especially unde r t he LCT bot to m p lat e an d th e space

between the right cover an d LCT bo tt om plate.

3. Do not raise the LCT bottom pla te while the LCT is removed from the

printer and the LCT harness is connect ed to the printer. Otherwise, the

bottom plate cont inu es to be lifted up and mechanical damage may occur.

4.2 PM TABLE (Every 6 months)

I: Inspect L: Lubricate C: Clean

Section 6 Months Notes

All Sensors &

Switches

bottom Plate C Clean with a dry cloth and blower brush.

Tray Drive Worm

Gear, Wheel

Tray Shift Shaft I, L

Bushings L Oil: Lubricate after cleaning.

Gears L

I,C

I, L

Clean with a blower brush.

Grease (Shell Albania No. 2): Lubricate after

cleaning.

Make sure that the bottom plate is lifted up and down

smoothly without abnormal noise.

Oil: Lubricate after cleaning.

Make sure that the LCT is shifted front to rear

smoothly without abnormal noise.

Grease (Shell Albania No. 2): Lubricate after

cleaning.

19

Page 21

REPLACEMENT AND ADJUSTMENT 15 June 1995

5. REPLACEMENT AND ADJUSTMENT

5.1 TRAY DRIVE BELT TENSION ADJUSTMENT

[A]

[C]

[B]

C563R500.wmf

1. Remove the LCT from the printer.

2. Loosen the tension plate screws [A].

3. Push the tension plat e up , so that the tension shaft [B] contacts the

bottom of the opening [C] and secure the screws.

20

Page 22

[A]

within 1.5mm

15 June 1995 REPLACEMENT AND ADJUSTMENT

5.2 HORIZONTAL ADJUSTMENT OF THE BOTTOM PLATE

[B]

[C]

C563R501.wmf

[A]

within 1.5mm

C563R502.wmf

1. Remove the paper from the LCT bottom plate.

2. Raise the bottom plate unt il the tray pa pe r position sensor detects the

bottom plate, then turn off the print er main switch.

3. Remove the LCT from the printer.

4. Confirm that the heights [A] at the thre e ind icated positions are within 1.5

mm.

5. If they are not, loosen the scre ws [B] on th e joints [C] and adjust the joint

positions so that the heights [A] at the three positions are within 1.5 mm.

21

Page 23

REPLACEMENT AND ADJUSTMENT 15 June 1995

5.3 IMAGE POSITION INDICATOR ADJUSTMENT

[B]

[C]

[A]

C563R503.wmf

NOTE: Take care not to damage the harn ess in ste p 1.

1. Using the Image Position switch [A], posit ion the paper tray at the center.

(The paper tray is at the center when the distance between the base and

the front shift limit switch equals the dista nce between the base and the

rear shift limit switch.)

2. Remove the indicator cover (2 screws and 1 con ne cto r).

3. Loosen the screw [B].

4. Adjust the indicator [C] to th e center.

5. Re-tighten the screw.

6. Reassemble the machine.

7. Carry out the image center adjustment in th e pla te n mod e (SP 9-2 ) and

image center adjustment in the ADF mode (SP9-52).

22

Page 24

[C]

[B]

15 June 1995 REPLACEMENT AND ADJUSTMENT

5.4 COVER OPEN SWITCH BRACKET POSITION

ADJUSTMENT

[A]

C563R504.wmf

1. Lift up the LCT cover [A] 20 mm as shown. Check wh et he r the cover

open switch has turned off.

2. If it has not, move the bracket [B ] by loo sening the screw [C].

23

Loading...

Loading...