Page 1

G160 Service Manual 23-Feb-06

Model G-P2

Machine Code: G160

SERVICE MANUAL

Copyright Ricoh Company, LTD©

Feb. 24th, 2006

Subject to change

Page 2

G160 Service Manual 23-Feb-06

ii

Read This First

Safety Notices

Important Safety Notices

Prevention of Physical Injury

1. Before disassembling or assembling parts of the printer and peripherals, make

sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or

open while the main switch is turned on, keep hands away from electrified or

mechanically driven components.

4. The printer drives some of its components when it completes the warm-up period.

Be careful to keep hands away from the mechanical and electrical components as

the printer starts operation.

5. The inside and the metal parts of the fusing unit become extremely hot while the

printer is operating. Be careful to avoid touching those components with your bare

hands.

Health Safety Conditions

Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it

may cause temporary eye discomfort. Immediately wash eyes with plenty of water. If

unsuccessful, get medical attention.

Observance of Electrical Safety Standards

The printer and its peripherals must be serviced by a customer service representative who

has completed the training course on those models.

Lithium Batteries

Incorrect replacement of lithium battery(s) on the EGB and controller board may pose risk of

explosion. Replace only with the same type or with an equivalent type recommended by the

manufacturer. Discard used batteries in accordance with the manufacturer’s instructions.

Page 3

G160 Service Manual 23-Feb-06

iii

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the

organic photoconductor in accordance with local regulations. (These are non-toxic

supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not put

more than 100 batteries per sealed box. Storing larger numbers or not sealing

them apart may lead to chemical reactions and heat build-up.

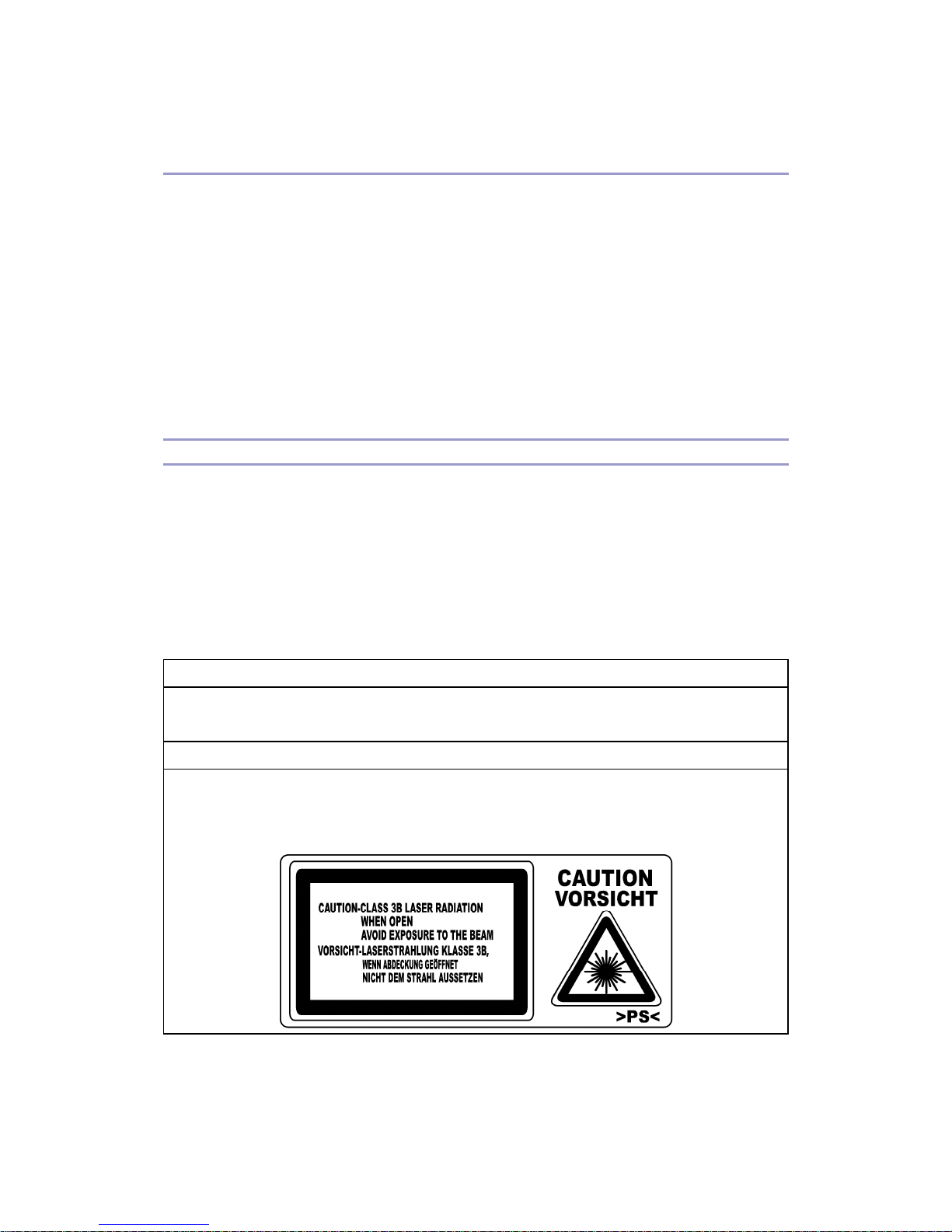

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based

optical units in the field. The optical housing unit can only be repaired in a factory or at a

location with the requisite equipment. The laser subsystem is replaceable in the field by a

qualified Customer Engineer. The laser chassis is not repairable in the field. Customer

engineers are therefore directed to return all chassis and laser subsystems to the factory or

service depot when replacement of the optical subsystem is required.

Use of controls, or adjustment, or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

Turn off the main switch before attempting any of the procedures in the Laser Optics Housing

Unit section. Laser beams can seriously damage your eyes.

CAUTION MARKING:

Page 4

G160 Service Manual 23-Feb-06

iv

Symbols, Abbreviations, and Trademarks

Symbols and Abbreviations

This manual uses the symbols and abbreviations shown below.

Symbol Meaning

Refer to section number

Clip ring

Screw

Connector

Clamp

SEF Short Edge Feed

LEF Long Edge Feed

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation

in the United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines Corporation.

Other product names used herein are for identification purposes only and may be trademarks

of their respective companies. We disclaim any and all rights involved with those marks.

Page 5

G160 Service Manual 23-Feb-06

v

Table of Contents

Read This First ..................................................................................................................... ii

Safety Notices................................................................................................................... ii

Important Safety Notices ...............................................................................................

ii

LASER SAFETY............................................................................................................

iii

Symbols, Abbreviations, and Trademarks ........................................................................

iv

Symbols and Abbreviations ..........................................................................................

iv

Trademarks...................................................................................................................

iv

Table of Contents..................................................................................................................

v

Installation Procedure ...........................................................................................................1

Installation Requirements..................................................................................................1

Optional Unit Installation ...................................................................................................

2

Preventive Maintenance .......................................................................................................

3

User Replaceable Items.................................................................................................... 3

Service Maintenance.........................................................................................................

4

Recommended Cleaning Procedure..............................................................................

4

Replacement And Adjustment...............................................................................................

5

Before You Start ................................................................................................................ 5

Laser Optics ......................................................................................................................

6

Caution Decal Locations................................................................................................

6

LD Unit...........................................................................................................................

7

Fusing .............................................................................................................................

10

Thermistor and Thermostat .........................................................................................

10

Electrical Components ....................................................................................................

13

Controller Board ..........................................................................................................

13

Installing the new NVRAM ...........................................................................................

14

Troubleshooting ..................................................................................................................

15

Process Control Results.................................................................................................. 15

Service Call Conditions ...................................................................................................

17

Summary .....................................................................................................................

17

SC Code Descriptions .................................................................................................

17

Troubleshooting Guide....................................................................................................

46

Blank Print ...................................................................................................................

46

All-black Print...............................................................................................................

46

Missing CMY Color......................................................................................................

46

Page 6

G160 Service Manual 23-Feb-06

vi

Light Print ....................................................................................................................47

Repeated Spots or Lines on Prints ..............................................................................

47

Dark Vertical Line on Prints .........................................................................................

48

White Horizontal Lines or Bands .................................................................................

48

Missing Parts of Images ..............................................................................................

49

Dirty Background .........................................................................................................

49

Partial CMY Color Dots................................................................................................

49

Dark Irregular Streaks on Prints...................................................................................

49

CMY Color Irregular Streaks........................................................................................

50

Ghosting ......................................................................................................................

50

Unfused or Partially Fused Prints ................................................................................

50

Image Skew.................................................................................................................

51

Background Stain ........................................................................................................

51

No Printing on Paper Edge..........................................................................................

51

Image not centered when it should be.........................................................................

52

Electrical Component Defects .........................................................................................

53

Sensors .......................................................................................................................

53

Blown Fuse Conditions ...................................................................................................

57

Power Supply Unit .......................................................................................................

57

IOB ..............................................................................................................................

57

LEDs ...............................................................................................................................

58

Controller .....................................................................................................................

58

Service Tables ....................................................................................................................

59

Service Program Mode ...................................................................................................59

Service Mode Operation..............................................................................................

59

Remarks ......................................................................................................................

60

Bit Switch Programming ..............................................................................................

62

Service Mode Table.........................................................................................................

64

Controller Service Mode ..............................................................................................

64

Engine Service Mode ..................................................................................................

68

Input Check Table......................................................................................................

216

Output Check Table ...................................................................................................

220

Firmware Update...........................................................................................................

223

Types of Firmware.....................................................................................................

223

Precautions................................................................................................................

223

SD Card Application Move ............................................................................................

224

Page 7

G160 Service Manual 23-Feb-06

vii

Overview....................................................................................................................224

Move Exec.................................................................................................................

224

Undo Exec .................................................................................................................

225

Keeping the SD Card.................................................................................................

226

Detailed Section Descriptions...........................................................................................

227

Beforehand.................................................................................................................... 227

Overview .......................................................................................................................

228

Component Layout ....................................................................................................

228

Board Structure..........................................................................................................

229

Process Control.............................................................................................................

232

Overview....................................................................................................................

232

Potential Control ........................................................................................................

232

Toner Supply Control .................................................................................................

235

Toner Near End/Toner End Detection ........................................................................

237

Developer Initialization...............................................................................................

238

Paper Feed ...................................................................................................................

239

By-pass Tray Feed and Size Detection......................................................................

239

Laser Exposure .............................................................................................................

240

LD Safety Switch .......................................................................................................

240

Automatic Line Position Adjustment ..........................................................................

241

Fusing ...........................................................................................................................

245

Overview....................................................................................................................

245

Fusing Temperature Control ......................................................................................

246

Drive ..........................................................................................................................

249

Controller.......................................................................................................................

250

Overview....................................................................................................................

250

Board Layout .............................................................................................................

252

Specifications....................................................................................................................

253

Specifications ................................................................................................................ 253

General Specifications...............................................................................................

253

Supported Paper Sizes..............................................................................................

256

Software Accessories ................................................................................................

257

Machine Configuration...............................................................................................

259

Page 8

G160 Service Manual 23-Feb-06

1

Installation Procedure

Installation Requirements

The installation procedure for G-P2 (G160/G161) is the same as G-P1 (G104/G105). For

details, refer to the Quick Installation Guide for G-P2 (G160/G161).

Page 9

G160 Service Manual 23-Feb-06

2

Optional Unit Installation

The following options are available for this machine. Refer to the Hardware Guide for how to

install these options:

Paper Tray Unit (G392)

HDD (G395)

IEEE802.11b Interface Unit (Wireless LAN: G813)

IEEE 1284 Interface Board (B679)

Bluetooth Interface Unit (B826)

Gigabit Ethernet Board (G874-01)

VM Card (G874-08)

USB Host Interface Unit (B825)

Data Overwrite Security Unit (G874-21)

PictBridge Interface (G874-19)

128 MB DIMM (B584)

256 MB DIMM (G818)

NVRAM (User account enhancement: G395)

Page 10

G160 Service Manual 23-Feb-06

3

Preventive Maintenance

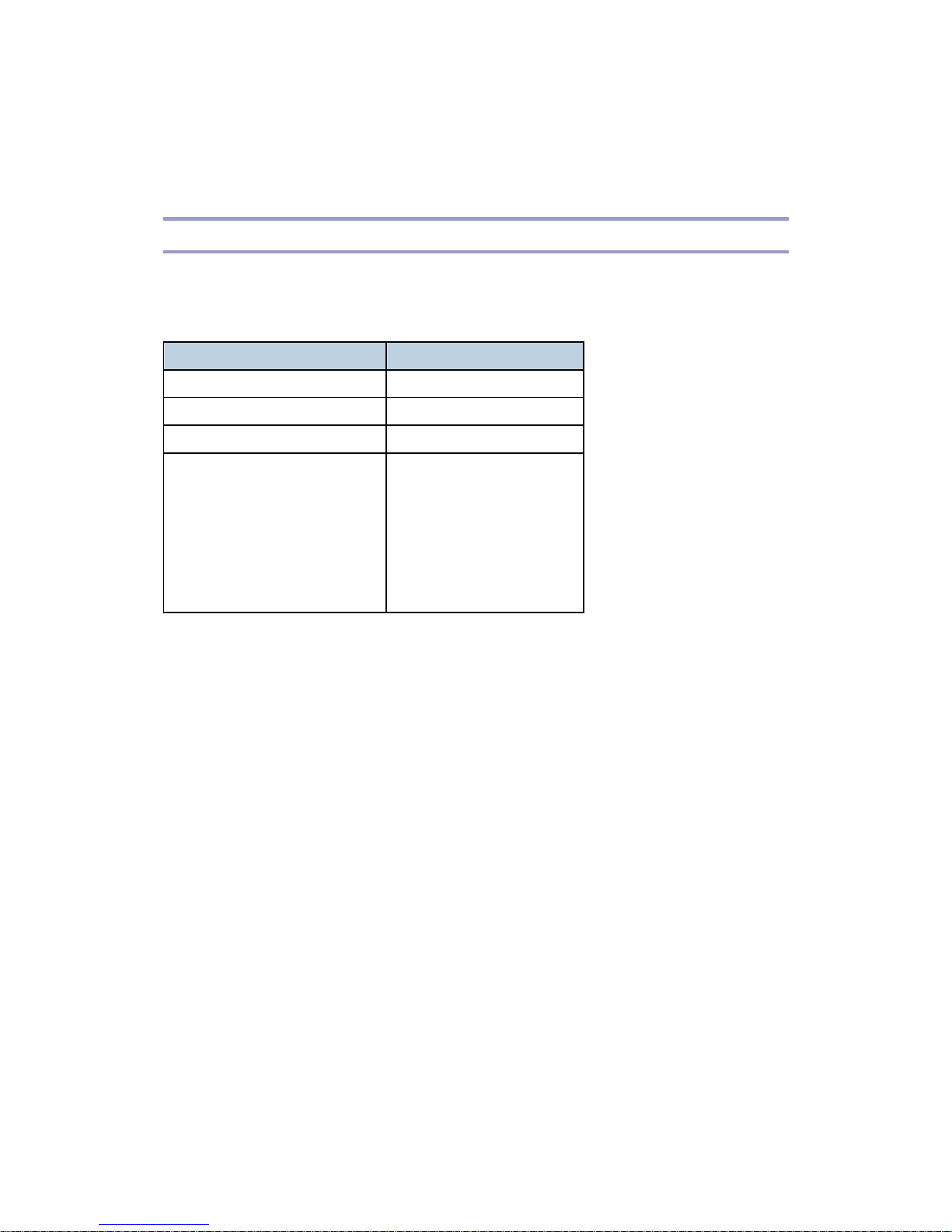

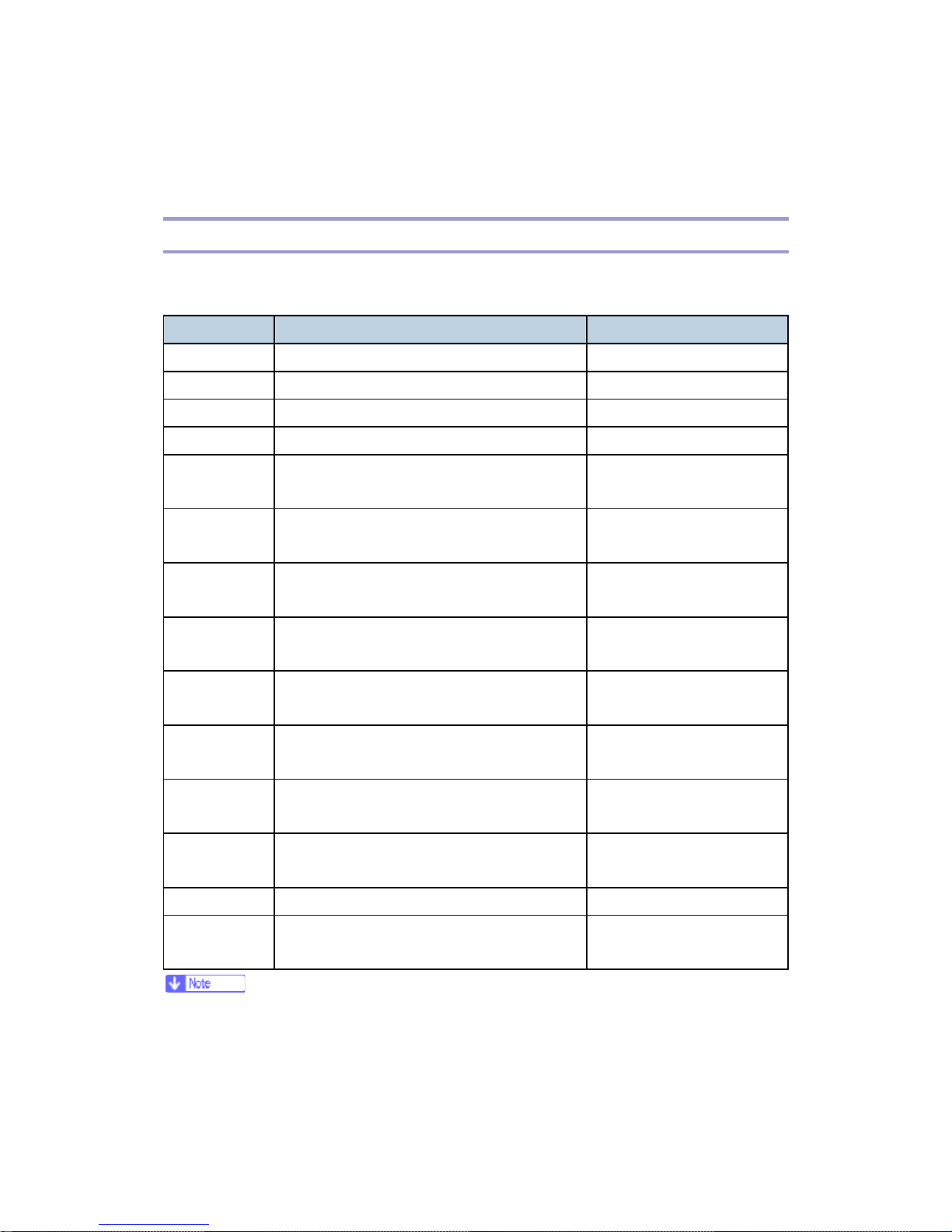

User Replaceable Items

The user replaces the following items if the service contract requires that the user does some

of the PM.

Item Remarks

PCU 50 KP (YMC, BK)

Transfer Belt Unit 100 KP

Waste Toner Bottle 50 KP

Maintenance Kit

Fusing Unit

Transfer Roller

Paper Feed Roller x 3

Friction Pad x 3

Dust Filter x 2

100 KP

Chart: A4 (LT), 5%

Mode: Continuously Printing

Environment: Recommended temperature and humidity

Yield changes depend on circumstances and print conditions

An error message shows when a maintenance counter gets to the value in the PM table when

the machine’s default settings are used.

It is not necessary to reset counters for each part if the technician does the PM. The machine

detects new components automatically and resets the necessary counters.

Page 11

G160 Service Manual 23-Feb-06

4

Service Maintenance

Recommended Cleaning Procedure

1. Turn off the main switch.

2. Remove the waste toner bottle.

3. Remove the PCUs.

4. Remove the transfer belt unit. Do not touch the transfer belt surface.

5. Remove the fusing unit.

6. Remove the standard paper tray.

7. Clean the paper path.

8. Clean all printer rollers with dry cloth only.

Do not clean the transfer roller.

9. Use a blower brush to clean the laser unit windows.

10. Vacuum the interior of the printer.

11. Carefully clean the area around the transfer roller.

Page 12

G160 Service Manual 23-Feb-06

5

Replacement And Adjustment

Before You Start

This section shows the differences between G-P1 (G104/G105) and G-P2 (G160/G161). For

other items procedures, refer to the service manual for G-P1 (G104/G105).

Turn off the main power switch and unplug the machine before you do the

procedures in this section.

Remove these before you do a removal procedure:

4 toner bottles (cyan, magenta, yellow, and black)

Waste toner bottle

Standard paper tray

Page 13

G160 Service Manual 23-Feb-06

6

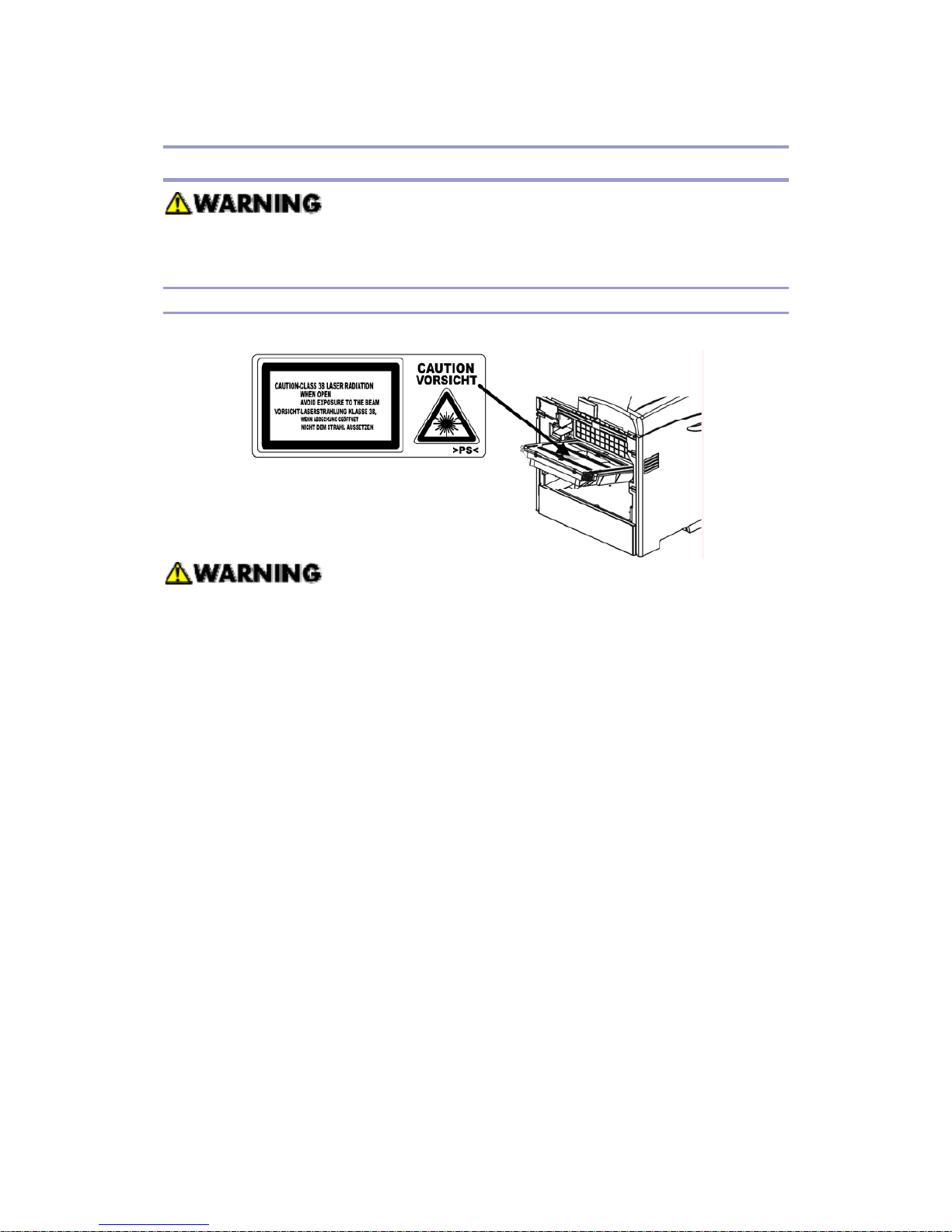

Laser Optics

Turn off the main power switch and unplug the printer before you do the procedures

in this section. Laser beams can cause serious eye injury.

Caution Decal Locations

The caution decal is attached as shown below

Make sure to turn off the main power switch and disconnect the power plug from the

power outlet before you do any disassembly or adjustment of the laser unit. This

printer uses a class 3B laser beam with a wavelength of 655 nm and an output of 7

mW. The laser can cause serious eye injury.

Page 14

G160 Service Manual 23-Feb-06

7

LD Unit

Replacement

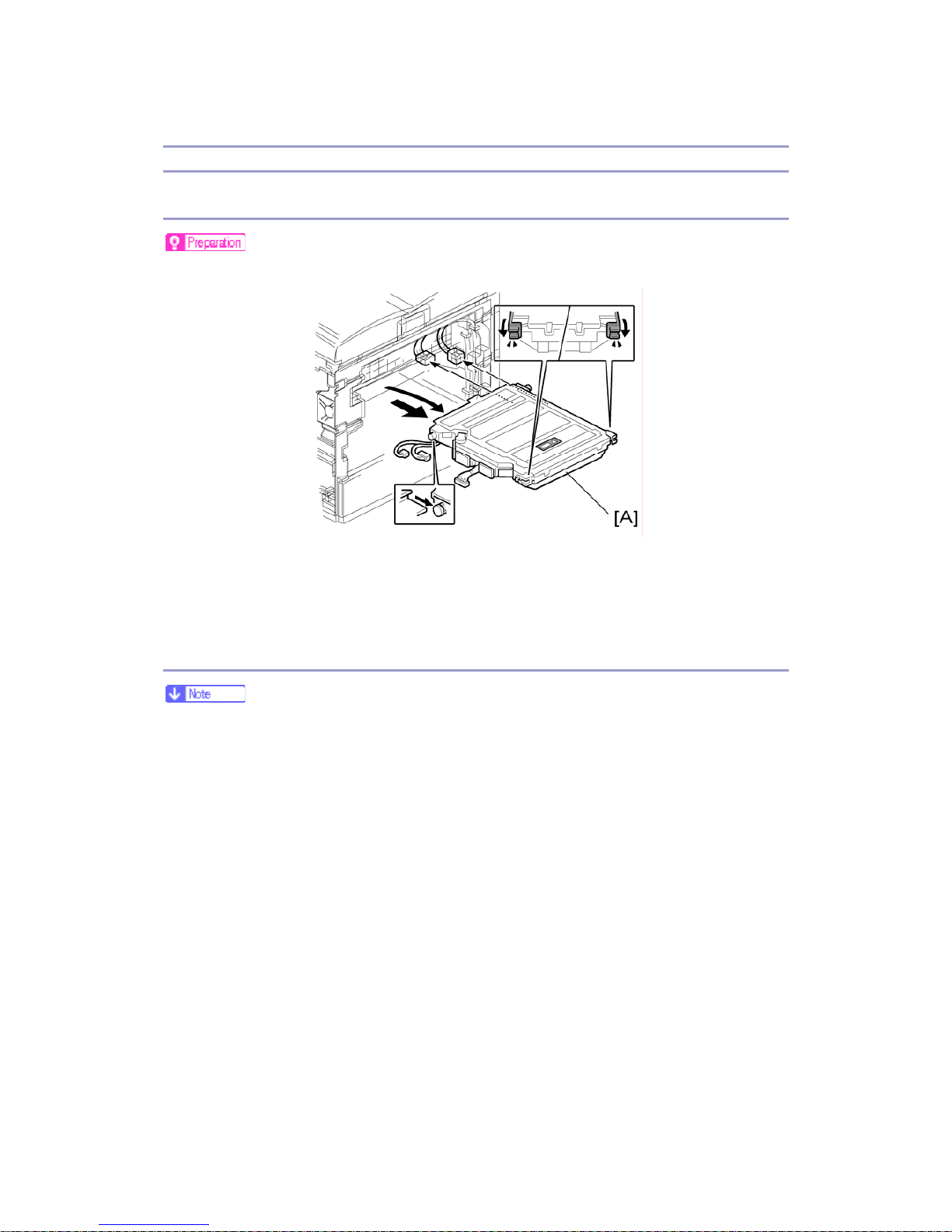

Print the SMC report with SP 5990 2 before you replace the LDU.

1. Electrical board unit (see the Service Manual for G-P1 (G104/G105): ‘Electrical

Components – Electrical Board Unit’)

2. LDU [A]

Color Registration Adjustment

You must manually do the color registration adjustment after you install the new

LDU.

When the polygon mirror motor or LDB unit is defective, only replace the defective

parts. At this time, if only the motor is changed it is not necessary to do this

adjustment procedure.

1. Print the SMC report with SP 5990 2 before you replace the LDU. Find the values

for SP 2181 1, SP 2181 11, 2181 21, and 2181 31.

2. Do SP 2111 2 (Pro. Position Adj > Execute) to roughly adjust the line position after

you install the new LDU. “Result = OK” shows on the LCD if this is done correctly .

If not, do it again until you get “OK”.

3. Do SP2111 3 (Skew Adjust. > Execute) to measure the skew values for each color.

“Result = OK” shows on the LCD if this is done correctly. If not, do it again until

you get “OK”.

4. Check the skew values with SP 2181: Then write down the values. (You can also

check these if you print the SMC report again with SP 5990 2. The values will

Page 15

G160 Service Manual 23-Feb-06

8

probably be different from the values on the report that you printed in step 1.)

SP 2181 1 for black skew

SP 2181 11 for magenta

SP 2181 21 for cyan

SP 2181 31 for yellow

5. Open the left cover

6. Adjust the skew adjustment cam [A] for each color with a screwdriver. You must

adjust the skew values for each color until they are all the same as the value for

magenta that you found in step 1, before you replaced the LDU.

For example: If the new value for K (after step 4) is –300 and the old value for

magenta (in step 1) is –250, you must adjust the skew for K until it is –250.

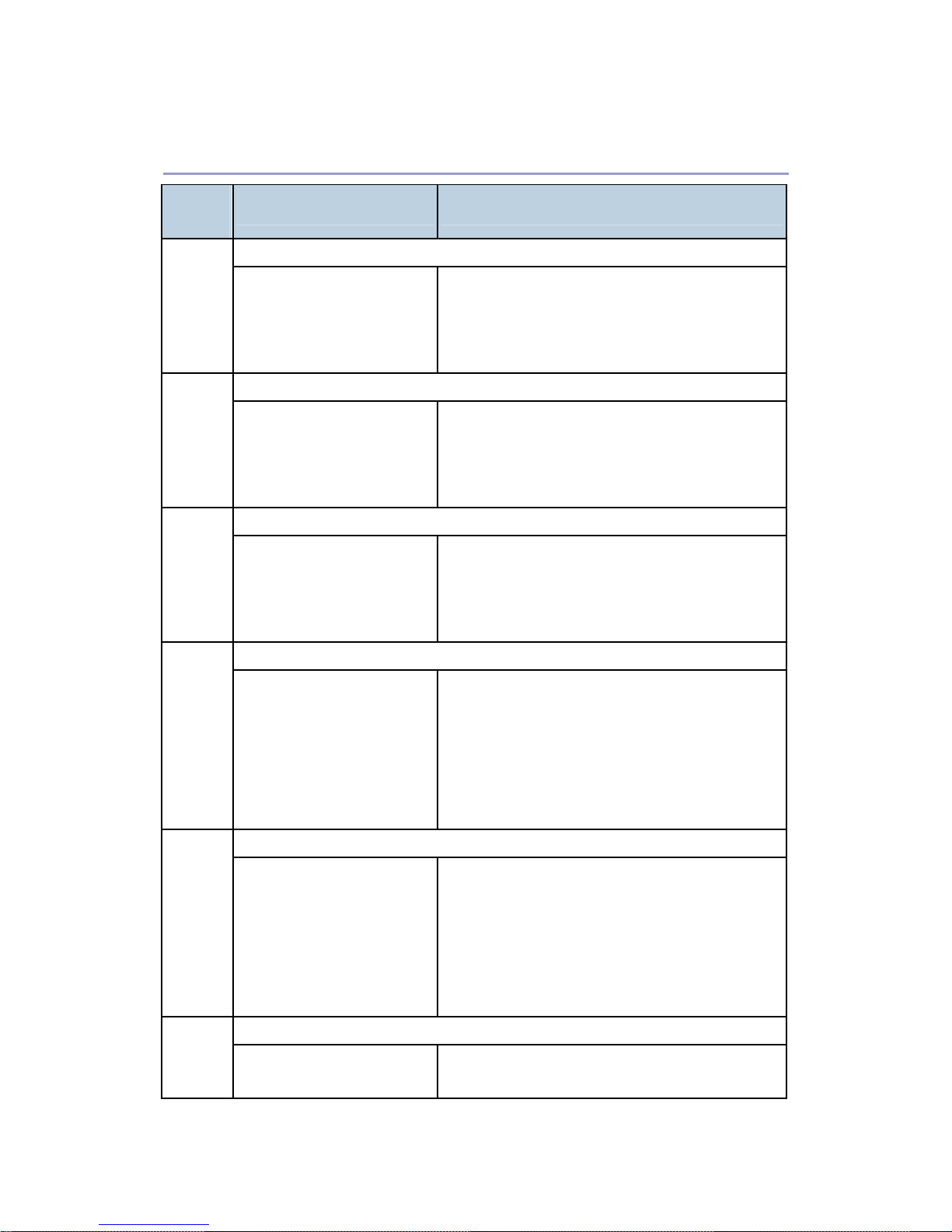

Turn the cam as shown in the “Cam Rotation Direction” column below to increase

the skew value.

Turn it in the opposite direction from this to decrease the skew value.

“Adjustment value” shows the change when you turn the cam one click.

Color

Cam Rotation

Direction

Adjustment

Value

Yellow CW 14 μm

Cyan CW 10 μm

Magenta CCW 10 μm

Black CCW 10 μm

The adjustment values in the table are not exact values. These are

approximate values.

Page 16

G160 Service Manual 23-Feb-06

9

CW: Clockwise, CCW: Counter-clockwise

The diagram shows the effect on line skew [B] when you turn the cam in a

counter clockwise direction.

7. Close the left cover. Then measure the skew values again with SP 2111 3. (To do

this, repeat step 3.)

If these are close to the value for magenta that you found in step 1 (within one click in

the above table), go to the next step. If not, do SP 2111 3 again until you get a good

result.

8. Do SP 2111 1 to finely adjust the line position for each color.

Try SP 2111 2 if “Result = OK” does not show.

9. When you get “Result = OK”, this adjustment is completed.

Page 17

G160 Service Manual 23-Feb-06

10

Fusing

Make sure that the fusing unit is cool before you touch it. The fusing unit can

be very hot.

Make sure to restore the insulators, shields, etc after you service the fusing

unit.

Thermistor and Thermostat

1. Front door

2. Fusing unit (see the Service Manual for G-P1 (G105/G16): ‘Fusing Unit’)

3. Fusing unit guide plate [A] (

x 4)

4. Release the connector [B] from the fusing lower cover [C] (hook x 1).

5. Fusing lower cover [C] (

x 2)

Page 18

G160 Service Manual 23-Feb-06

11

6. Thermistor with bracket [D] (

x 2, x 1)

Do not remove the thermistor from the bracket when removing it. The pressure

of the thermistor plate to the fusing belt is adjusted properly in the factory. If you

remove it, some image problem may occur.

7. Fusing upper cover [E] (

x 4)

Page 19

G160 Service Manual 23-Feb-06

12

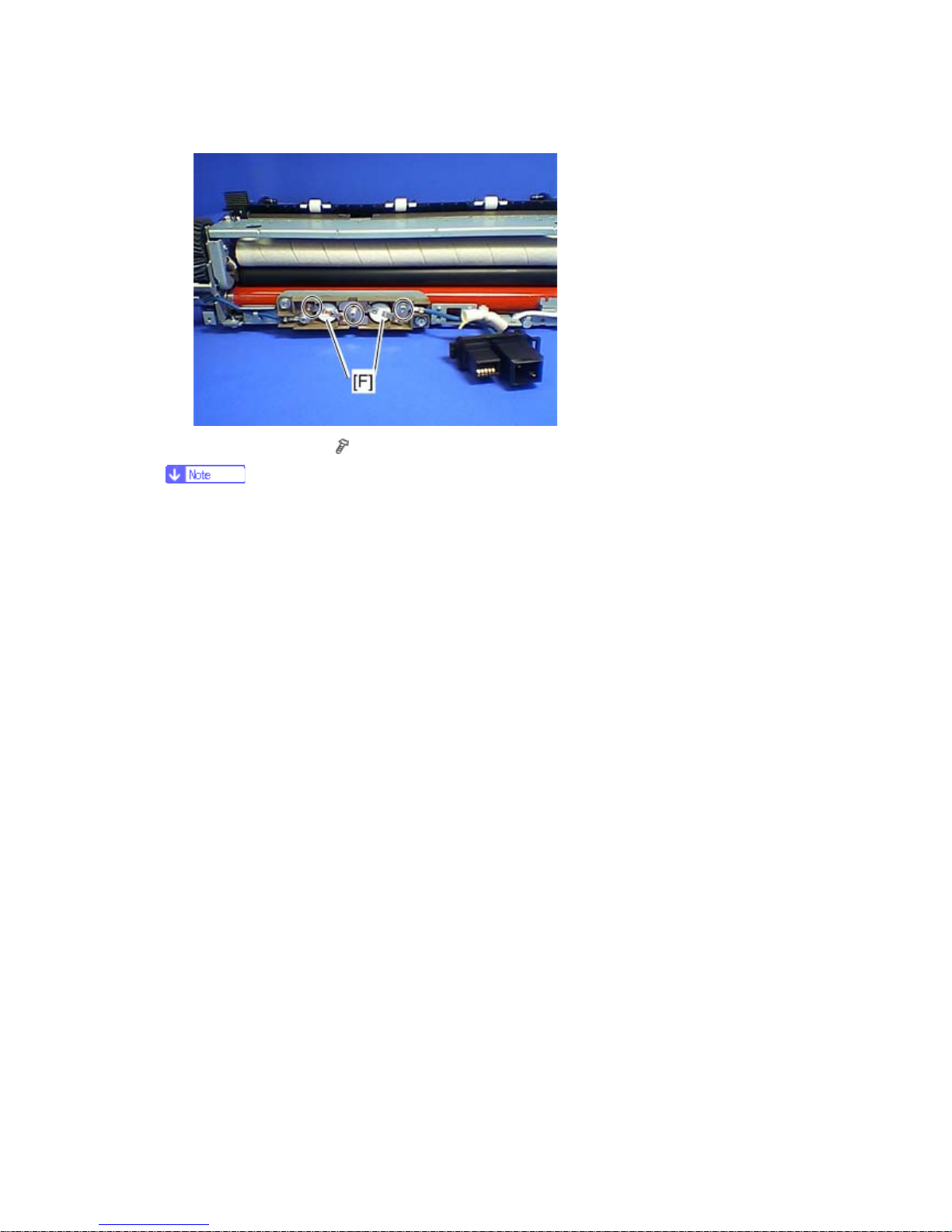

8. Thermostat [F] x 2 (

x 3)

Do not recycle a thermostat that is already opened. Safety is not guaranteed if you

do this.

Page 20

G160 Service Manual 23-Feb-06

13

Electrical Components

Before you replace the EGB (Engine Board), the controller, or the NVRAM, print

out the SMC reports (“SP Mode Data” and “Logging Data”).

After you replace the EGB (Engine Board) or the controller, remove the NVRAM

from the old board and install it on the new board. If the NVRAM on the old

board is defective, replace the NVRAM (see ‘NVRAM Replacement

Procedure’).

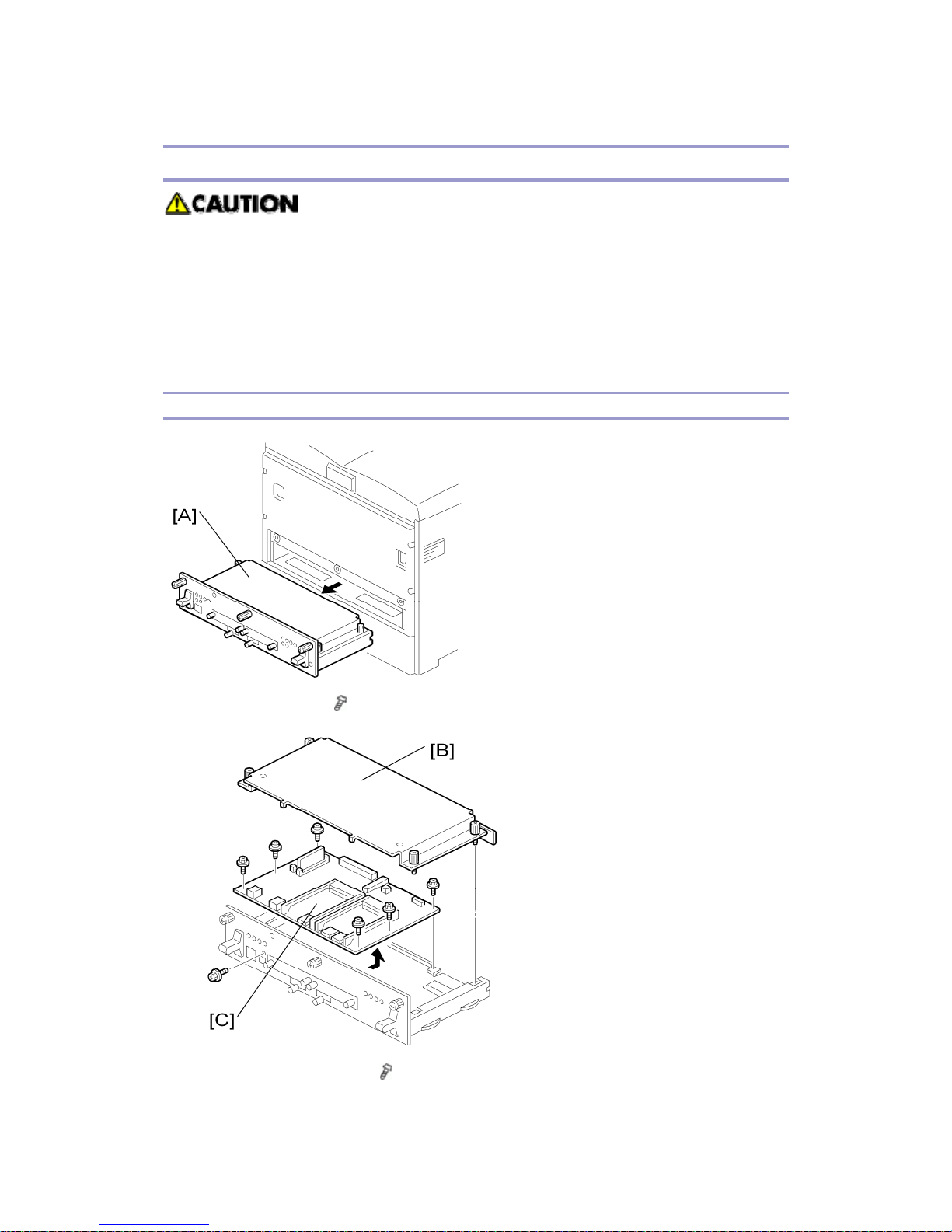

Controller Board

1. Controller unit [A] (

x 3)

2. Controller unit cover [B] (

x 4)

Page 21

G160 Service Manual 23-Feb-06

14

3. Controller board [C] (

x 7)

Remove the NVRAM from the old board. Then install it on the new board.

Keep NVRAMs away from objects that can cause static electricity. The data in

NVRAMs can be corrupted by static electricity.

Make sure the NVRAM is correctly installed on the board. A half-disk is

engraved on one side of the NVRAM, and a guide mark is on one side of the

NVRAM slot. When you install the NVRAM, the half-disk and the guide mark

must be on the same side.

Installing the new NVRAM

When the NVRAM on the controller board is detective, you must replace the detective

NVRAM to new NVRAM.

1. Controller board (see Controller Board)

2. Remove the defective NVRAM.

3. Install the new NVRAM on the controller board.

4. Reassemble the machine.

5. Plug in and turn on the main power

6. Set the date and time with the timer setting in the UP (Maintenance < Menu ) after

installing a new controller board.

If the date and time setting is not done, the WebImage Moniter can not be available.

Page 22

G160 Service Manual 23-Feb-06

15

Troubleshooting

Process Control Results

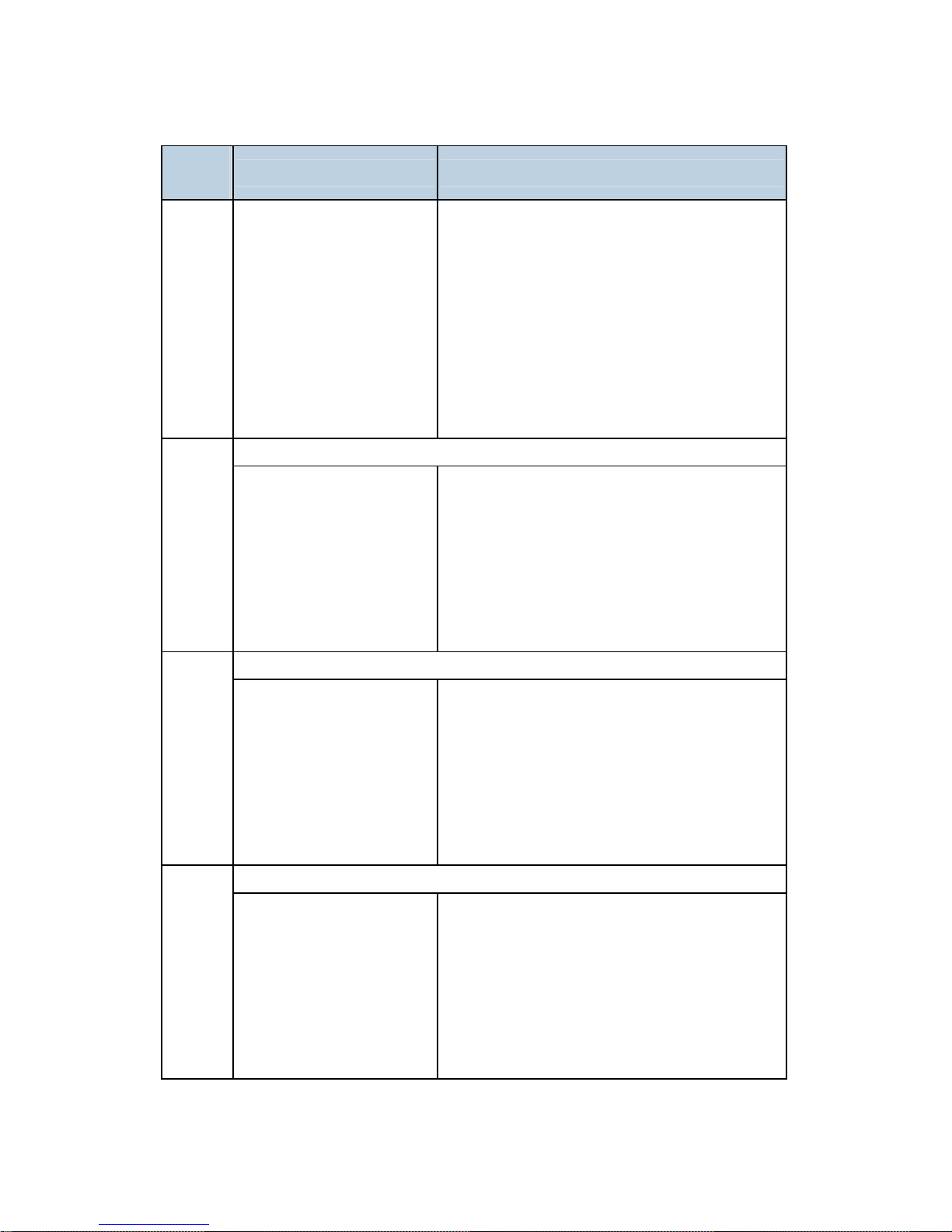

The table below lists the process control results shown in SP 3821.

Number Result Notes

10 Success No error

21 ID sensor correction error SC 400

22 ID sensor: LED adjustment error SC 418

31 Charge bias correction error SC 300 to 307

51 High Vmin (Bk), High K2 (Color) error

SP 3145 (see the note below

the table)

52 Low K2 (Color) error

SP 3146 (see the note below

the table)

53 High K5 error

SP 3147 (see the note below

the table)

54 Low K5 error

SP 3147 (see the note below

the table)

55 High development gamma

Gamma > 5.0 (see the note

below the table)

56 Low development gamma

Gamma < 0.5 (see the note

below the table)

57 Development bias adjustment error

Vk >150V (see the note

below the table)

58 Development bias adjustment error

Vk < -150V (see the note

below the table)

90 No process control -

99 Not successful

Interrupt during the process

control (e.g. Door open)

This error code does not usually occur. If no problem is observed with image density

and/or development gamma, nothing needs to be done. If an image problem such as

low image density is observed, check the following points: Transfer belt/PCU/ID

sensor/Toner bottle

Page 23

G160 Service Manual 23-Feb-06

16

The 8 numbers on the LCD in SP 3821 indicate the process control result for each color.

There are two numbers for each color. The numbers are shown from left to right on the

display as follows: Black, Magenta, Cyan, Yellow. For example, if process control for each

color is successful: 10 (Black), 10 (Magenta), 10 (Cyan), 10 (Yellow)

Page 24

G160 Service Manual 23-Feb-06

17

Service Call Conditions

Summary

1. All SCs are logged.

2. First disconnect then reconnect the connectors before you replace the PCBs if the

problem concerns electrical circuit boards.

3. First check the mechanical load before you replace motors or sensors if the

problem concerns a motor lock.

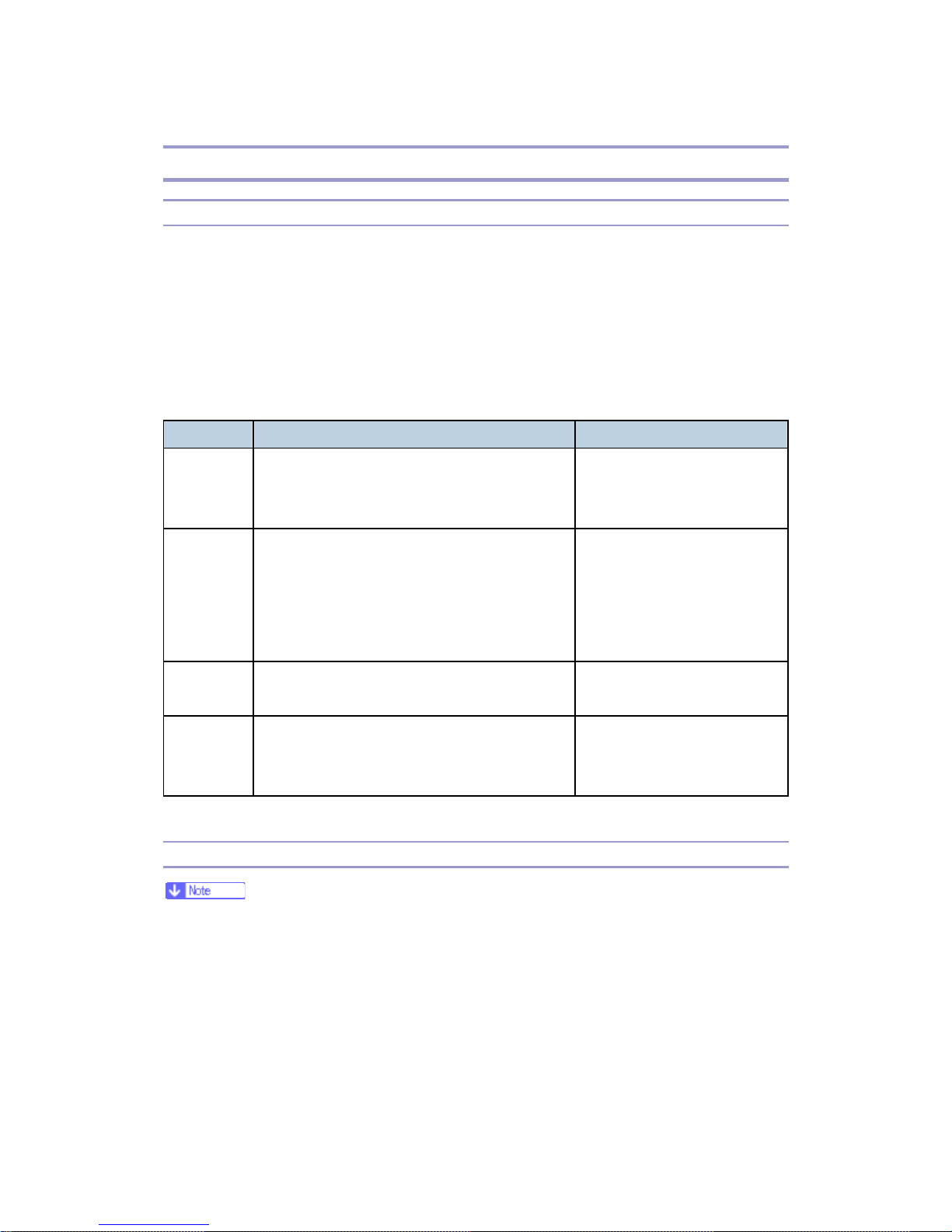

There are 4 levels of service call conditions.

Level Definition Reset Procedure

A

To prevent damage to the machine, the main

machine cannot be operated until a service

representative has reset the SC.

Do SP 5810, and then turn the

main power switch off and on.

B

SCs that disable only the features that use the

defective item. Although these SCs are not

shown to the user under normal conditions,

they are displayed on the operation panel only

when the defective feature is selected.

Turn the operation switch or

main switch off and on.

C

The SC history is updated. The machine can be

operated as usual.

The SC will not be displayed.

Only the SC history is updated.

D

Turning the main switch off then on resets SCs

displayed on the operation panel. These are

redisplayed if the error occurs again.

Turn the operation switch off

and on.

SC Code Descriptions

Remove the NVRAM from the old board and install it on the new one when you

replace the EGB or the controller board.

The SC level is indicated under SC number in the list below.

The numbers (1, etc.) in the “Possible Cause/Requirement Action” column indicate the

required actions.

Page 25

G160 Service Manual 23-Feb-06

18

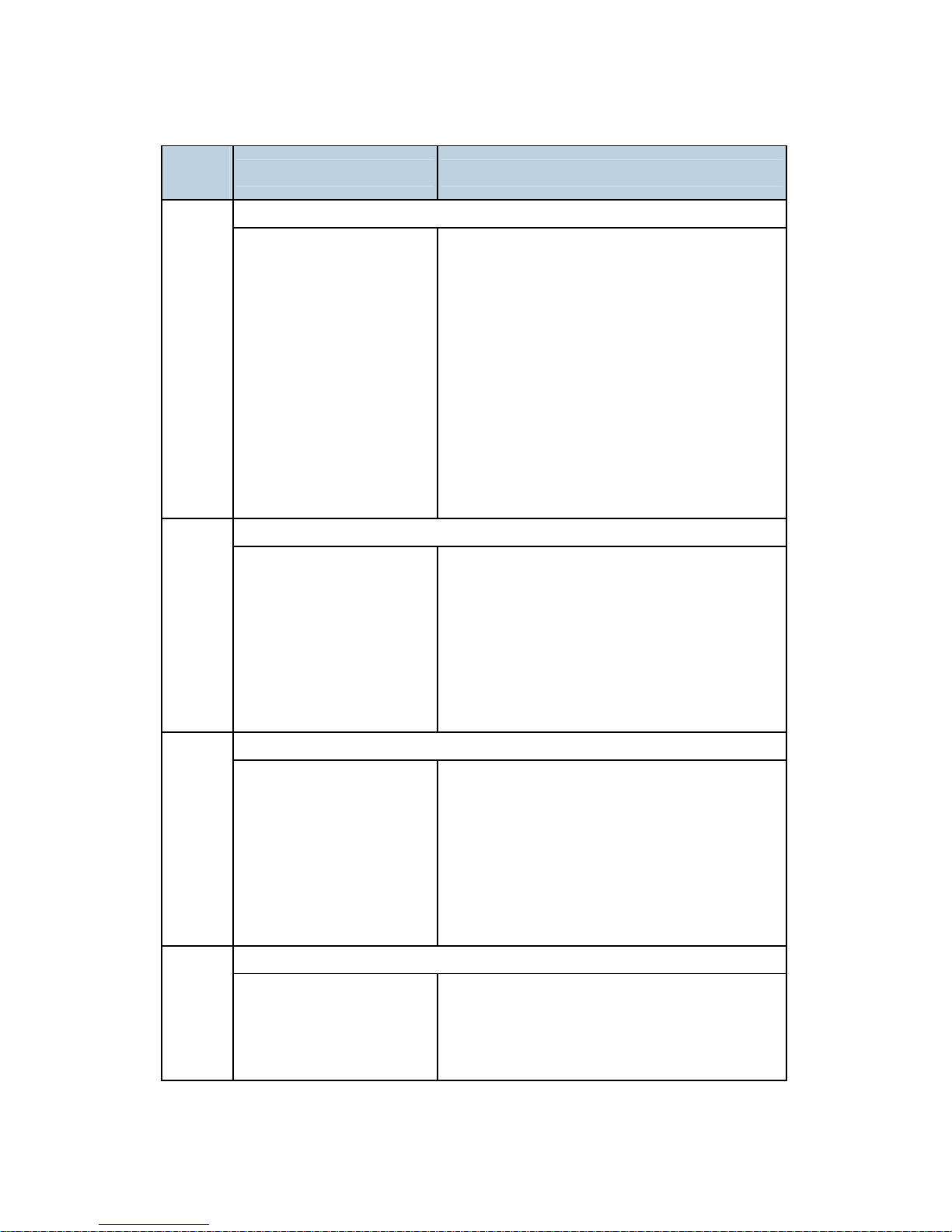

Engine SC

SC

[Level]

Symptom Possible Cause/Required Action

Incorrect serial number

195

[D]

When checking the

registered product number, it

does not match the printer’s

product number.

Registered product number does not match

the printer’s product number.

1. Ask your service key man.

Polygon motor error: Time out with the polygon motor activated

202

[D]

After the polygon motor turns

on or changes the speed,

SCRDY_N is not active

within 10 seconds.

Disconnected cable from the polygon motor

drive board or defective connection

Defective polygon motor or drive board

Polygon motor error: Time out with the polygon motor inactivated

203

[C]

After the polygon motor turns

off or changes the speed,

SCRDY_N is not inactive

within 10 seconds.

Disconnected cable from the polygon motor

drive board or defective connection

Defective polygon motor or drive board

Polygon motor error: XSCRDY signal error

204

[C]

PMRDY_N signal

consecutively detects that

the polygon motor is an

inactive state while LDB unit

scans.

Disconnected cable from the polygon motor

drive board or defective connection

Defective polygon motor or drive board

1. Check the connectors.

2. Replace the polygon motor.

3. Replace the polygon motor drive board.

Polygon motor error: XSCRDY signal not stable

205

[D]

PMRDY_N signal

consecutively detects that

the polygon motor is an

inactive state while the

polygon motor turns on or

changes the speed.

Disconnected cable from the polygon motor

drive board or defective connection

Defective polygon motor or drive board.

1. Check the connectors.

2. Replace the polygon motor.

3. Replace the polygon motor drive board.

Trailing edge laser detection error: [K]

210

[C]

The laser synchronizing

detection signal for LDB [K]

Disconnected cable from the laser

synchronizing detection unit or defective

Page 26

G160 Service Manual 23-Feb-06

19

SC

[Level]

Symptom Possible Cause/Required Action

of the trailing edge is not

detected for one second after

the LDB unit turned on when

detecting the main scan

magnification.

connection

Defective laser synchronizing detector

Defective LDB

Defective EGB

1. Check the connectors.

2. Replace the laser-synchronizing

detector.

3. Replace the LDB.

4. Replace the EGB.

Trailing edge laser detection error: [Y]

211

[C]

The laser synchronizing

detection signal for LDB [Y]

of the trailing edge is not

detected for one second after

the LDB unit turned on when

detecting the main scan

magnification.

Same as SC 210

Trailing edge laser detection error: [M]

212

[C]

The laser synchronizing

detection signal for LDB [M]

of the trailing edge is not

detected for one second after

the LDB unit turned on when

detecting the main scan

magnification.

Same as SC 210

Trailing edge laser detection error: [C]

213

[C]

The laser synchronizing

detection signal for LDB [C]

of the trailing edge is not

detected for one second after

the LDB unit turned on when

detecting the main scan

magnification.

Same as SC 210

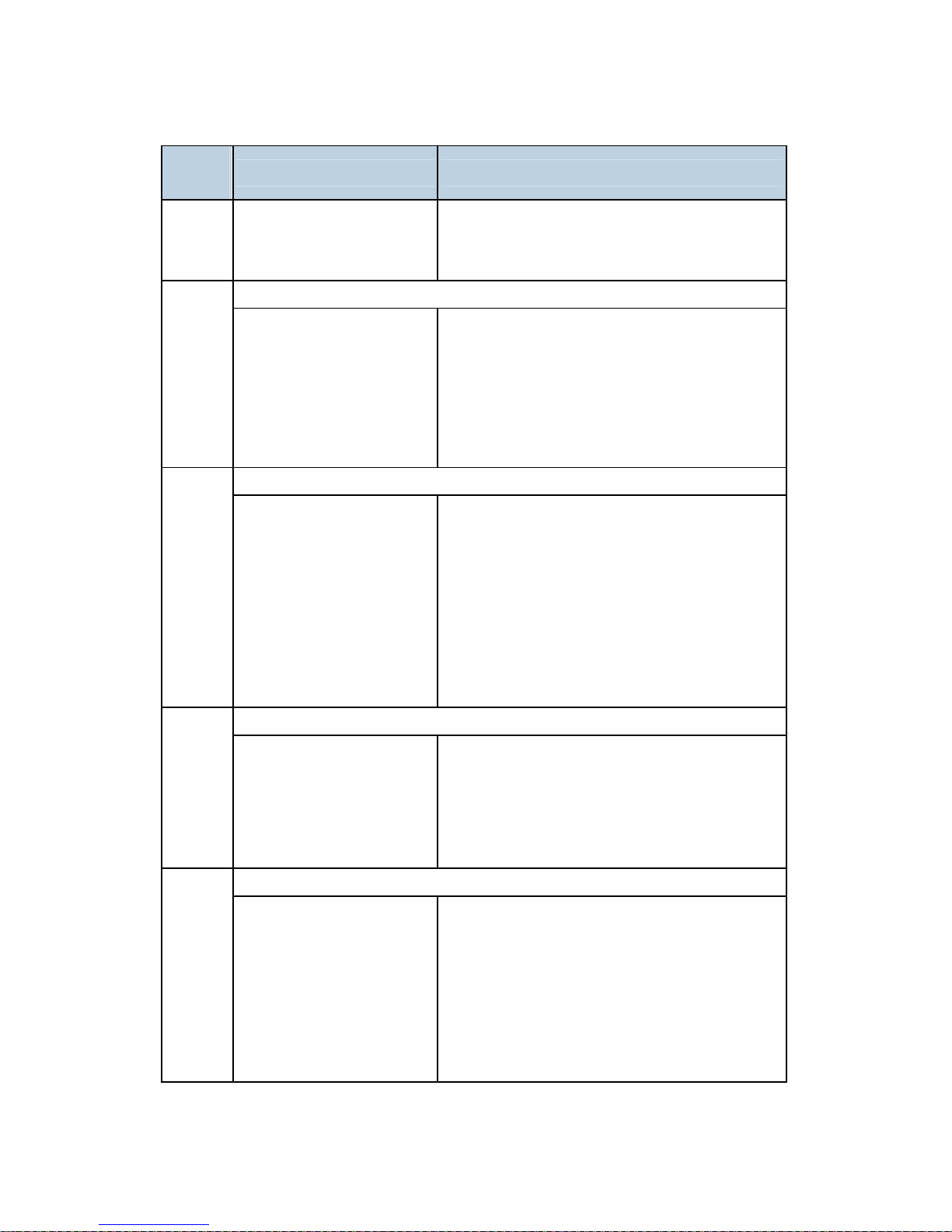

Page 27

G160 Service Manual 23-Feb-06

20

SC

[Level]

Symptom Possible Cause/Required Action

Laser Synchronizing Detection Error: LDB of the leading edge [K]

220

[D]

The laser synchronizing

detection signal for LDB [K]

of the leading edge is not

output for two seconds after

LDB unit turns on while the

polygon motor is rotating

normally.

Disconnected cable from the laser

synchronizing detection unit or defective

connection

Defective laser synchronizing detector

Defective LDB

Defective EGB

1. Check the connectors.

2. Replace the laser-synchronizing

detector.

3. Replace the LDB.

4. Replace the EGB.

Leading edge laser detection error: [Y]

222

[D]

The laser synchronizing

detection signal for LDB [Y]

of the leading edge is not

output for two seconds after

LDB unit turns on while the

polygon motor is rotating

normally.

Same as SC 221

Leading edge laser detection error: [M]

224

[D]

The laser synchronizing

detection signal for LDB [M]

of the leading edge is not

output for two seconds after

LDB unit turns on while the

polygon motor is rotating

normally.

Same as SC 221

Leading edge laser detection error: [C]

226

[D]

The laser synchronizing

detection signal for LDB [C]

of the leading edge is not

output for two seconds after

Same as SC 221

Page 28

G160 Service Manual 23-Feb-06

21

SC

[Level]

Symptom Possible Cause/Required Action

LDB unit turns on while the

polygon motor is rotating

normally.

FGATE: On error [K]

230

[C]

The PFGATE ON signal does

not assert within 5 seconds

after processing the image in

normal job or MUSIC for [K]

starts.

Defective connection between the controller

board and EGB

Defective cable between the EGB and LDB

1. Check the connectors.

2. Replace the LDB.

3. Replace the EGB.

FGATE: Off error [K]

231

[C]

The PFGATE ON signal

still asserts within 5

seconds after processing

the image in normal job

or MUSIC for [K] ends.

The PFGATE ON signal

still asserts when the

next job starts.

Defective connection between the controller

board and EGB

Defective cable between the EGB and LDB

1. Check the connectors.

2. Replace the LDB.

3. Replace the EGB.

FGATE: On error [Y]

232

[C]

The PFGATE register of

GAVD does not assert within

5 seconds after processing

the image in normal job or

MUSIC for [Y] started.

Same as SC 230

FGATE: Off error [Y]

233

[C]

The PFGATE ON signal

still asserts within 5

seconds after processing

the image in normal job

or MUSIC for [K] ends.

The PFGATE ON signal

still asserts when the

Same as SC 231

Page 29

G160 Service Manual 23-Feb-06

22

SC

[Level]

Symptom Possible Cause/Required Action

next job starts.

FGATE: On error [M]

234

[C]

The PFGATE register of

GAVD does not assert within

5 seconds after processing

the image in normal job or

MUSIC for [M] started.

Same as SC 230

FGATE: Off error [M]

235

[C]

The PFGATE ON signal

still asserts within 5

seconds after processing

the image in normal job

or MUSIC for [M] ends.

The PFGATE ON signal

still asserts when the

next job starts.

Same as SC 231

FGATE: On error [C]

236

[C]

The PFGATE register of

GAVD does not assert within

5 seconds after processing

the image in normal job or

MUSIC for [C] started.

Same as SC 230

FGATE: Off error [C]

237

[C]

The PFGATE ON signal

still asserts within 5

seconds after processing

the image in normal job

or MUSIC for [C] ends.

The PFGATE ON signal

still asserts when the

next job starts.

Same as SC 231

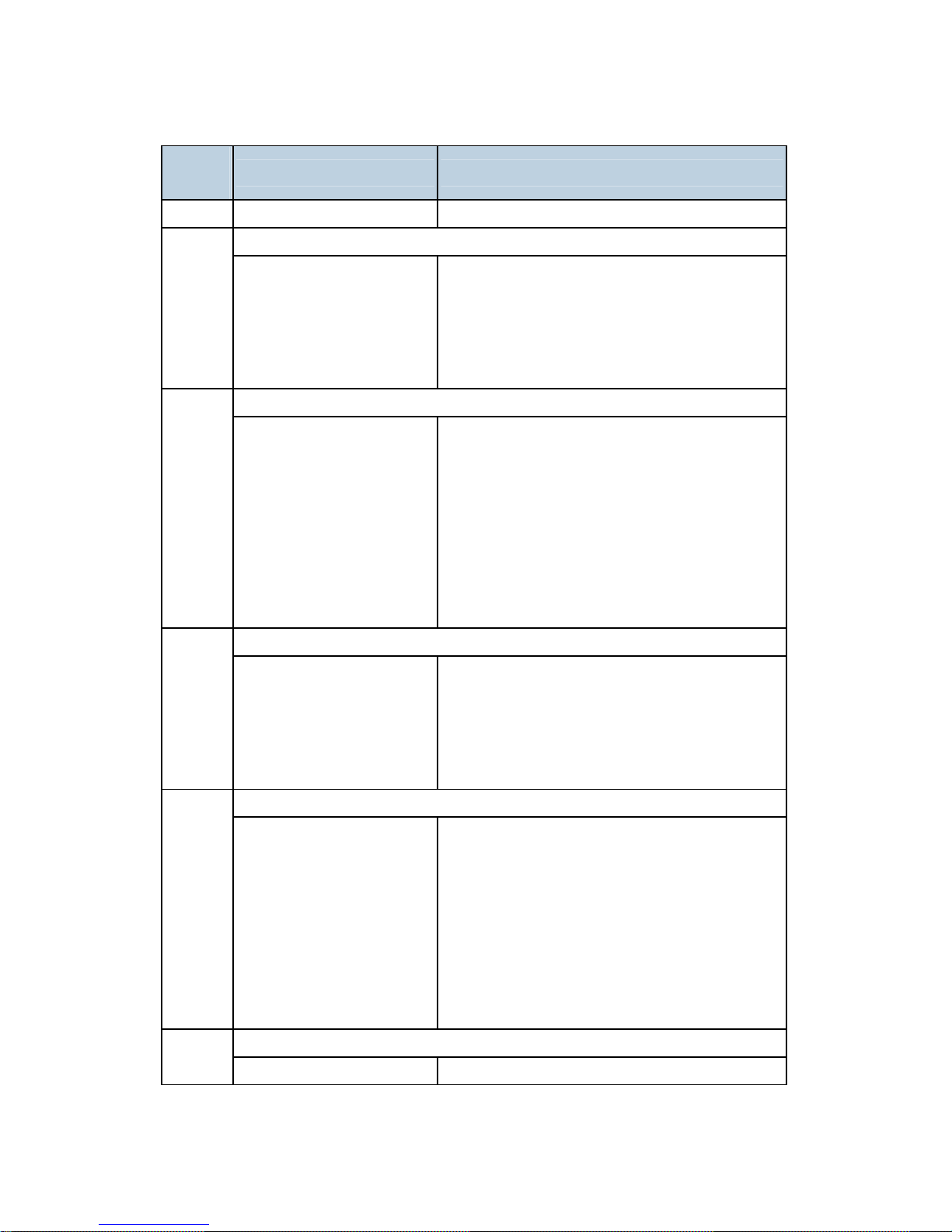

LDB error [K] 240

[D]

The EGB detects LDB error a Defective LDB

Page 30

G160 Service Manual 23-Feb-06

23

SC

[Level]

Symptom Possible Cause/Required Action

few times consecutively

when LDB unit turns on after

LDB initialization.

1. Replace the LDB.

LDB error [Y]

241

[D]

The EGB detects LDB error a

few times consecutively

when LDB unit turns on after

LDB initialization.

Same as SC240

LDB error [M]

242

[D]

The EGB detects LDB error a

few times consecutively

when LDB unit turns on after

LDB initialization.

Same as SC240

LDB error [C]

243

[D]

The EGB detects LDB error a

few times consecutively

when LDB unit turns on after

LDB initialization.

Same as SC240

LDU shutter error

270

[D]

Sensor output does not

change even if 1 second

passes after the LDU shutter

motor is on.

Sensor defective or LDU shutter motor

defective

1. Replace the LDU shutter sensor or

shutter motor.

High voltage power board: Charge voltage output error [K]

300

[D]

The measured voltage is not

proper when EGB measures

the charge output for each

color.

Defective charge roller

Defective connectors

Disconnected harness

Defective high voltage power 1

1. Check the connectors.

2. Replace the PCU for black.

3. Replace the drum positioning plate.

4. Replace the high voltage power 1.

301 High voltage power board: Charge voltage output error [M]

Page 31

G160 Service Manual 23-Feb-06

24

SC

[Level]

Symptom Possible Cause/Required Action

[D]

The measured voltage is not

proper when EGB measures

the charge output for each

color.

Defective charge roller

Defective connectors

Disconnected harness

Defective high voltage power 1

1. Check the connectors.

2. Replace the PCU for magenta.

3. Replace the drum positioning plate.

4. Replace the high voltage power 1.

High voltage power board: Charge voltage output error [C]

302

[D]

The measured voltage is not

proper when EGB measures

the charge output for each

color.

Defective charge roller

Defective connectors

Disconnected harness

Defective high voltage power 1

1. Check the connectors.

2. Replace the PCU for cyan.

3. Replace the drum positioning plate.

4. Replace the high voltage power 1.

High voltage power board: Charge voltage output error [Y]

303

[D]

The measured voltage is not

proper when EGB measures

the charge output for each

color.

Defective charge roller

Defective connectors

Disconnected harness

Defective high voltage power 1

1. Check the connectors.

2. Replace the PCU for yellow.

3. Replace the drum positioning plate.

4. Replace the high voltage power 1.

Charge AC bias error [K]

304

[D]

The charge current less than

200 µA is detected.

Defective charge roller

Defective connectors

Disconnected harness

Defective high voltage power 1

1. Check the connectors.

2. Replace the PCU for black.

3. Replace the drum positioning plate.

Page 32

G160 Service Manual 23-Feb-06

25

SC

[Level]

Symptom Possible Cause/Required Action

4. Replace the high voltage power 1.

Charge AC bias error [M]

305

[D]

The charge current less than

200 µA is detected.

Defective charge roller

Defective connectors

Disconnected harness

Defective high voltage power 1

1. Check the connectors.

2. Replace the PCU for magenta.

3. Replace the drum positioning plate.

4. Replace the high voltage power 1.

Charge AC bias error [C]

306

[D]

The charge current less than

200 µA is detected.

Defective charge roller

Defective connectors

Disconnected harness

Defective high voltage power 1

1. Check the connectors.

2. Replace the PCU for cyan.

3. Replace the drum positioning plate.

4. Replace the high voltage power 1.

Charge AC bias error [Y]

307

[D]

The charge current less than

200 µA is detected.

Defective charge roller

Defective connectors

Disconnected harness

Defective high voltage power 1

1. Check the connectors.

2. Replace the PCU for yellow.

3. Replace the drum positioning plate.

4. Replace the high voltage power 1.

Color development motor error

325

[D]

LOCK signal is not

detected for more than

two seconds while the

motor START signal is

Color development motor slip due to the

increase of the load torque

1. Adjust the load torque properly by

replacing or cleaning the development

Page 33

G160 Service Manual 23-Feb-06

26

SC

[Level]

Symptom Possible Cause/Required Action

on.

LOCK signal is not

cancelled within two

seconds after the motor

is off.

unit.

2. Replace or repair the development

motor if the load torque is normal.

TD sensor: Output maximum error [K]

360

[D]

Vt is more than the maximum

value (4.5) for three times

consecutively.

Defective connector connection

Increasing toner density

1. Replace the PCU.

TD sensor: Output maximum error [M] 361

[D]

Same as SC 360

TD sensor: Output maximum error [C] 362

[D]

Same as SC 360

TD sensor: Output maximum error [Y] 363

[D]

Same as SC 360

TD sensor: Output minimum error [K]

364

[D]

Vt is less than the minimum

value (0.5) for three times

consecutively.

Defective connector connection

Decreasing toner density

1. Replace the PCU.

TD sensor Output minimum error [M] 365

[D]

Same as SC 364

TD sensor: Output minimum error [C] 366

[D]

Same as SC 364

TD sensor: Output minimum error [Y] 367

[D]

Same as SC 364

TD sensor: Initial control voltage error [K]

368

[D]

Vt is less than 1 V even

though the control power

voltage is adjusted to the

maximum.

Vt is more than 1 V even

though the control power

voltage is adjusted to the

Defective connector connection

Defective TD sensor

The toner density in the developer is different

from the initial condition.

1. Replace the PCU.

Page 34

G160 Service Manual 23-Feb-06

27

SC

[Level]

Symptom Possible Cause/Required Action

minimum.

TD sensor: Initial control voltage error [M] 369

[D]

Same as SC 368

TD sensor: Initial control voltage error [C] 370

[D]

Same as SC 368

TD sensor: Initial control voltage error [Y] 371

[D]

Same as SC 368

TD sensor: Initial adjustment error [K]

372

[D]

Vt is not (A ±0.2) when initial

setting for TD sensor is

executed.

A = SP3011-001 for [K]

Defective connector connection

Defective TD sensor

The toner density in the developer is different

from the initial condition.

1. Replace the PCU.

TD sensor: Initial adjustment error [M]

373

[D]

Vt is not (A ±0.2) when initial

setting for TD sensor is

executed.

A = SP 3011 2 for [M]

Same as 372

TD sensor: Initial adjustment error [C]: same as 372

374

[D]

Vt is not (A ±0.2) when initial

setting for TD sensor is

executed.

A = SP 3011 3 for [C]

Same as 372

TD sensor: Initial adjustment error [Y]: same as 372

375

[D]

Vt is not (A ±0.2) when initial

setting for TD sensor is

executed.

A = SP 3011 4 for [Y]

Same as 372

Drum gear position sensor error

380

[C]

When receiving the input

signal of drum gear position

sensor is not correctly done,

SC380 is logged.

Dirty or defective drum gear position sensor

1. Clean the drum gear position sensor.

2. Replace the drive unit.

Page 35

G160 Service Manual 23-Feb-06

28

SC

[Level]

Symptom Possible Cause/Required Action

Drum motor error [K]

396

[D]

The LOCK signal is not

detected for 2 seconds more

while the start signal of the

drum motor for black PCU is

output.

OPC motor slip due to the excessive load

1. Clean the PCU.

2. Check the cable from the Black OPC/

Development motor. Replace it if

necessary.

3. Replace the EGB.

4. Replace the Black OPC/Development

motor.

Drum motor error [CMY]

397

[D]

The LOCK signal is not

detected for 2 seconds more

while the start signal of the

drum motor for color PCU is

output.

Same as SC 396

ID sensor correction error

400

[D]

Regular Vsp is not (4 ±0.5V)

when ID sensor correction is

executed.

Defective ID sensors

Dirty ID sensors or transfer belt

ID sensor life is over.

1. Replace the ID sensors.

ID sensor: LED adjustment error

418

[D]

LED PWM adjustment is not

[A] for three times

consecutively.

[A] = 50 < [A] < 400

Defective ID sensors

Dirty ID sensors or transfer belt

ID sensor life is over.

1. Replace the ID sensors.

Transfer belt contact error

442

[D]

The transfer belt contact

sensor does not detect the

movement of actuator at the

sensor while the polygon

motor rotates.

Dirty transfer belt contact sensor

Defective transfer belt contact motor

Disconnected connector of transfer belt

contact sensor or motor

Disconnected cable

1. Replace the transfer belt contact sensor.

2. Replace the transfer belt contact motor.

Page 36

G160 Service Manual 23-Feb-06

29

SC

[Level]

Symptom Possible Cause/Required Action

Transfer roller contact error

452

[D]

The transfer roller contact

sensor does not detect the

movement of actuator at the

sensor while the polygon

motor rotates.

Defective transfer roller contact sensor

Defective transfer roller contact motor

Defective IOB

1. Replace the transfer roller contact

sensor.

2. Replace the transfer roller contact

motor.

3. Replace the IOB.

High Voltage Power 1: High voltage output error

490

[D]

Error signal is detected for 10

times consecutively.

One of the DC bias outputs for each PCU is

shorted or one of the transfer belt bias outputs

for [Y], [M] and [C].

Power leaking

Defective connection

Disconnected cable

Defective PCU

Defective High Voltage Power 1

1. Replace the High Voltage Power 1.

2. Reset the cables and components.

3. Replace the PCU.

High Voltage Power 2: High voltage output error

491

[D]

Error signal is detected for 10

times consecutively.

One of the separation bias output,

development bias output and transfer belt

cleaning bias output is shorted or one of the

transfer belt bias output for [K] and transfer

roller bias output is shorted.

Power leaking

Defective connection

Defective PCU

Defective High Voltage Power 2

1. Replace the High Voltage Power 2.

2. Reset the cables and components.

3. Replace the PCU.

Page 37

G160 Service Manual 23-Feb-06

30

SC

[Level]

Symptom Possible Cause/Required Action

Paper feed / Fusing motor error

531

[D]

LOCK signal is not

detected for more than

two seconds while the

motor START signal is

on.

LOCK signal is not

cancelled within two

seconds after the motor

is off.

Defective paper feed/ fusing motor

1. Replace the paper feed/ fusing motor.

Fan motor error

532

[D]

The fan motor “On” signal is

not detected for the

components below after the

drum motor for black is set to

“On”.

PSU fan

Fusing unit fan

Polygon motor fan

Drive unit fan

Exit paper fan

Defective fan motor

1. If the error occurs again, one of the fans

is defective. Remove the covers, find the

defective fan and replace it.

Thermistor error

541

[A]

The thermistor output is less

than 0 °C for six seconds.

Disconnected thermistor

Defective connector connection

Print ready temperature error

542

[A]

The heating roller

temperature increase

that is less than 67

degrees for 9 seconds is

detected five times

consecutively.

The fusing temperature

does not reach the print

Defective thermistor

Thermistor coming off

Incorrect power supply input at the main power

socket

Defective fusing lamp

Page 38

G160 Service Manual 23-Feb-06

31

SC

[Level]

Symptom Possible Cause/Required Action

ready temperature within

15 seconds after the

fusing lamp was

controlled.

High temperature detection: Software

543

[A]

The thermistor detects 230°C

for 0.2 seconds.

Defective thermistor

Defective I/O board

Defective EGB

High temperature detection: Hard

544

[A]

The thermistor detects

250°C.

Defective thermistor

Defective I/O board

Defective EGB

Defective fusing unit, PSU, or EGB

1. Replace the fusing unit.

2. Replace the PSU.

Heating lamp error

545

[A]

The fusing lamp is

full-powered for 8 seconds

after the heating roller

reaches the print ready

temperature.

Deformed thermistor

Thermistor coming off

Defective fusing lamp

Zero cross error

547

[D]

The zero cross signal is

detected three times

even though the heater

relay is off when turning

on the main power.

The zero cross signal is

not detected for three

seconds even though the

heater relay is on after

turning on the main

power or closing the front

Defective fusing lamp relay

Defective fusing lamp relay circuit

Unstable power supply

1. Check the power supply source.

2. Replace the PSU.

Page 39

G160 Service Manual 23-Feb-06

32

SC

[Level]

Symptom Possible Cause/Required Action

door.

The detection error

occurs twice or more in

the ten zero cross signal

detections. This error is

defined when the

detected zero cross

signal is less than 17 for

200 ms.

Zero cross frequency error

557

[C]

The detection error occurs

ten times in a row in ten zero

cross signal detections. This

error is defined when the

detected zero cross signal is

more than 28 for 200 ms.

This SC is only logged. In this

case, the power frequency is

defined as 60 Hz.

Noise (high frequency)

1. Check the power supply source.

Continuous paper jam at Fusing unit

559

[A]

The paper jam occurs three

times consecutively at the

fusing unit only when the SP

1159 1 is set to "1 (ON)". If

not, this SP does not occur.

The jam counter is cleared

when a sheet of paper is fed

normally.

Defective fusing entrance sensor

Defective EGB

1. Replace the fusing entrance sensor.

2. Replace the EGB.

Controller board command error

687

[D]

A command from the

controller board is not

received.

Loose connection

Defective controller board

Defective EGB

1. Check the connection of the controller

board.

Page 40

G160 Service Manual 23-Feb-06

33

SC

[Level]

Symptom Possible Cause/Required Action

2. Replace the controller board.

3. Replace the EGB.

EGB data error

690

[D]

The data transfer in the EGB

is interrupted by some

incident (e.g. cover open

etc.) during the data transfer.

Defective EGB

1. Replace the EGB.

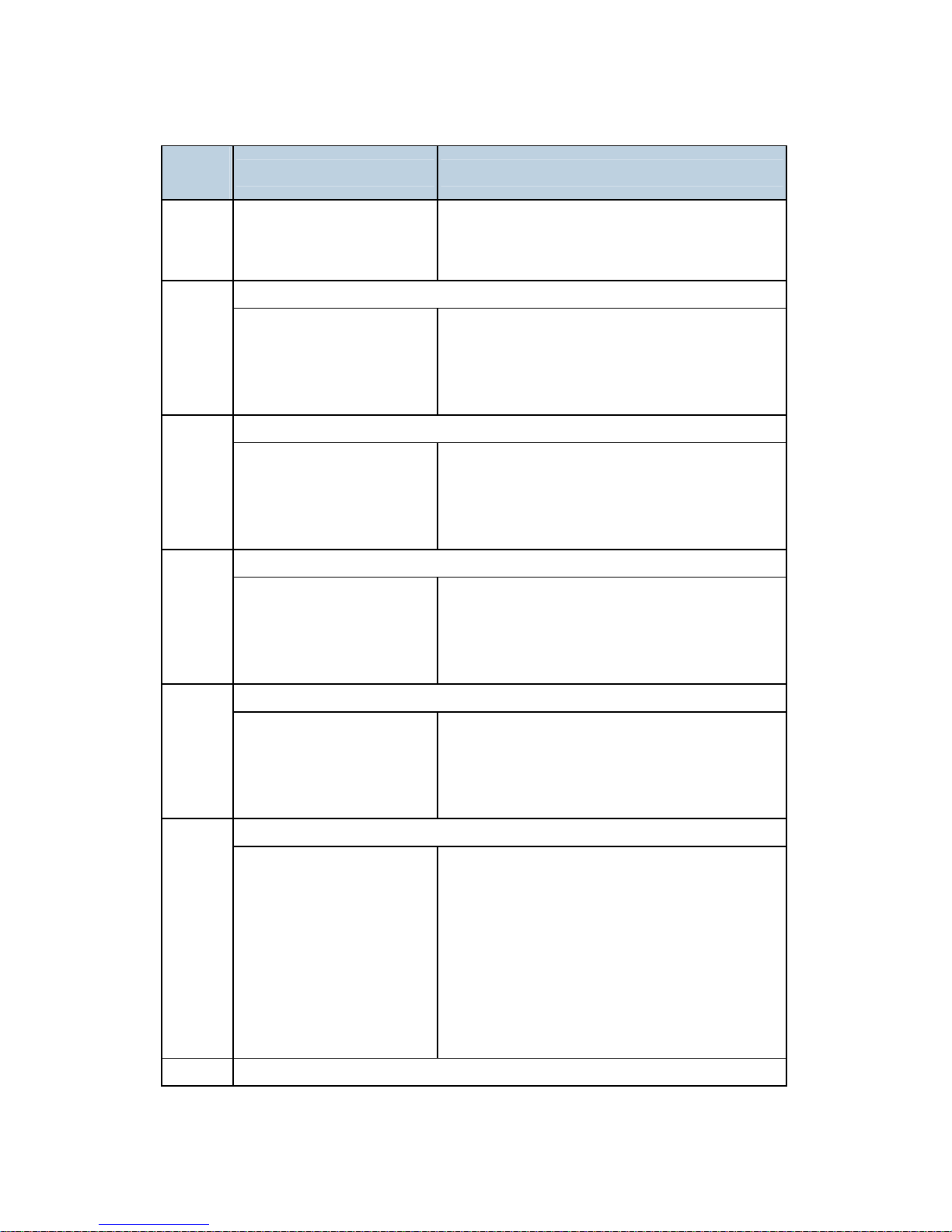

Controller Error

The following table shows the controller error codes. These codes show at these times if an

error occurs:

Power-on

After the power-on self diagnostic test

Always try turning the main switch off and on and check if the problem persists.

SC

[Level]

Symptom Possible Cause/Required Action

636 SD Card Error

Expanded authentication module error

-001

[B]

There is no expanded

authentication module in the

machine.

The SD card or the file of the

expanded authentication

module is broken.

There is no DESS module in

the machine.

No expanded authentication module

Defective SD card

No DESS module

1. Install the expanded authentication

module.

2. Install the SD card.

3. Install the DESS module.

Version error

-002

[B]

The version of the expanded

authentication module is not

correct.

Incorrect module version

1. Install the correct file of the expanded

authentication module.

Page 41

G160 Service Manual 23-Feb-06

34

SC

[Level]

Symptom Possible Cause/Required Action

Engine start-up error

670

[D]

A command from the

controller board is not

received.

Defective engine board.

1. Replace the engine board.

Watchdog error

818

[B]

While the system program is

running, no other programs

can run (due to a bus hold or

endless loop).

Defective system program

Defective controller board

1. Reinstall the system program.

2. Replace the controller board.

819 Kernel stop

Process error

[0696e]

[B]

System completely down

Defective RAM DIMM

Defective controller

Software error

1. Check and/or replace the RAM DIMM.

2. Replace the controller.

VM full error

[0766d]

[B]

Unexpected system memory

size

Defective RAM DIMM

Defective controller

Software error

1. Check and/or replace the RAM DIMM.

2. Replace the controller.

Cache error

[4361]

[B]

Cache error in the CPU

Defective CPU

1. Replace the controller board.

The others

[----]

[B]

Error in OS

Defective memory

Defective flash memory

Defective CPU

1. Replace the controller board.

820 Self-Diagnostic Error: CPU

[0001-0015] [000A-000D]: Detailed error code

[B]

During the boot monitor Defective CPU device

Page 42

G160 Service Manual 23-Feb-06

35

SC

[Level]

Symptom Possible Cause/Required Action

program and self-diagnostic,

any exception or cut-in are

not supposed to happen. If

these happen, it is defined as

SC.

Defective boot monitor program or

self-diagnostic program

1. Replace the controller board.

2. Reinstall the system firmware.

[00FF]: Detailed error code

[B]

Cache access error in the

CPU

Defective CPU

Defective local bus

1. Turn the main power switch off and on.

2. Reinstall the system program.

3. Replace the controller board.

[0601, 0602, 0605, 0606, 0607, 0609]: Detailed error code

[B]

Exceptional command does

not operate even though it is

executed on purpose.

Defective CPU devices

1. Replace the controller board.

[B] [060A-060E]: Detailed error code

Cut-in command does not

operate when it is executed.

Defective CPU devices

Defective ASIC devices

1. Replace the controller board.

[0610]: Detailed error code

[B]

Timer cut-in does not operate

even though it is set.

Defective CPU devices

1. Replace the controller board.

[0612]: Detailed error code

[B]

Cut-in in ASIC occurs.

Defective ASIC

Defective devices in which ASIC detects

cut-in.

1. Replace the controller board.

[06FF]: Detailed error code

[B]

The pipeline clock frequency

rate is different from the

prescribed value.

Defective CPU devices

Mode bit data error, which is used for

initializing CPU.

1. Replace the controller board.

[B] [0702]: Detailed error code

Page 43

G160 Service Manual 23-Feb-06

36

SC

[Level]

Symptom Possible Cause/Required Action

The result when the program

is executed in the command

cache is different from

desirable value.

Insufficient CPU cache

Insufficient memory process speed

1. Replace the controller board.

2. Replace the RAM DIMM.

[0709, 070A]: Detailed error code

[B]

Even you write the data in the

only cache of memory, the

data is actually written in

another area (not cache) of

memory.

Defective CPU devices

Incorrect SPD

Boot mode setting error

1. Replace the controller board.

2. Replace the RAM DIMM.

[0801, 0804, 0807, 0808, 0809, 80A]: Detailed error code

[B]

An error occurs when

checking the TLB.

Defective CPU devices

1. Replace the controller board.

[4002-4005]: Detailed error code

[B]

The calculation error in the

CPU occurs.

Defective CPU

1. Replace the CPU.

821 Self-Diagnostic Error: ASIC

ASIC error

[0B00]

[B]

The write-&-verify check error

has occurred in the ASIC.

Defective controller board

1. Replace the controller.

ASIC not detected

[0B06]

[B]

The ASIC of the I/O is not

detected.

ASIC (controller board defective)

Poor connection between North Bridge and

PCI I/F.

1. Replace controller board.

SHM register check error

[0B10]

[B]

Failed to initialize or could not

read connection bus. Data in

SHM register incorrect.

Defective bus connection

Defective SHM

1. Replace controller board

Timer error between ASIC and CPU

[0D05]

[B]

The CPU checks if the ASIC

timer works properly

compared with the CPU timer.

System firmware problem

Defective RAM-DIMM

Defective controller

Page 44

G160 Service Manual 23-Feb-06

37

SC

[Level]

Symptom Possible Cause/Required Action

If the ASIC timer does not

function in the specified

range, this SC code is

displayed.

Reinstall the controller system firmware.

1. Replace the RAM-DIMM.

2. Replace the controller board.

822 Self-Diagnostic Error: HDD

Timeout error/ [3004]: Command error

[3003]

[B]

When the main switch is

turned on or starting the

self-diagnostic, the HDD

stays busy for the specified

time or more.

Loose connection

Defective HDD

Defective controller

1. Check that the HDD is correctly

connected to the controller.

2. Replace the HDD.

3. Replace the controller.

823 Self-diagnostic Error: NIB

MAC address check sum error

[6101]

[B]

The result of the MAC

address check sum does not

match the check sum stored

in ROM.

Defective controller

1. Replace the controller.

PHY IC error

[6104]

[B]

The PHY IC on the controller

cannot be correctly

recognized.

Same as SC823-[6101]

PHY IC loop-back error

[6105]

[B]

An error occurred during the

loop-back test for the PHY IC

on the controller.

Same as SC823-[6101]

Self-diagnostic Error: NVRAM

824

[B]

The controller cannot

recognize the standard

NVRAM installed or detects

that the NVRAM is defective.

NVRAM damaged or abnormal

Backup battery has discharged

NVRAM socket damaged

1. Replace the NVRAM.

826 Self-diagnostic Error: RTC/Optional NVRAM

Page 45

G160 Service Manual 23-Feb-06

38

SC

[Level]

Symptom Possible Cause/Required Action

Clock error

[1501]

[B]

An RTC device is

recognized, and the

difference between the

RTC device and the CPU

exceeds the defined limit.

No RTC device is

recognized.

RTC defective

NVRAM without RTC installed

Backup battery discharged

1. Replace the NVRAM with another

NVRAM with an RTC device.

RTC not detected

[15FF]

[B]

The RTC device is not

detected.

NVRAM without RTC installed

Backup battery discharged

1. Replace the NVRAM with another

NVRAM with an RTC device.

827 Self-diagnostic Error: RAM

Verification error

[0201]

[B]

Error is detected during a

write/verify check for the

standard RAM (SDRAM

DIMM).

Loose connection

Defective SDRAM DIMM

Defective controller

1. Replace the SDRAM DIMM.

2. Replace the controller.

Resident memory error

[0202]

[B]

The SPD values in all RAM

DIMM are incorrect or

unreadable.

Defective RAM DIMM

Defective SPD ROM on RAM DIMM

Defective 12C bus

1. Replace the RAM DIMM.

828 Self-diagnostic Error: ROM

Boost lap code error

[0101]

[B]

The boot monitor and OS

program stored in the ROM

DIMM is checked. If the check

sum of the program is

incorrect, this SC code is

displayed.

Defective ROM DIMM

Defective controller

1. Replace the ROM DIMM.

2. Replace the controller.

Page 46

G160 Service Manual 23-Feb-06

39

SC

[Level]

Symptom Possible Cause/Required Action

ROMFS error

[0104]

[B]

All areas of the ROM DIMM

are checked. If the check sum

of all programs stored in the

ROM DIMM is incorrect, this

SC code is displayed.

Defective ROM DIMM

1. Replace the ROM DIMM.

829 Self-diagnostic Error: Optional RAM

Verification error (Slot 1)

[0401]

[B]

The data stored in the RAM in

Slot 1 does not match the

data when reading.

Not specified RAM DIMM installed

Defective RAM DIMM

1. Replace the RAM DIMM.

2. Replace the controller board.

Composition error (Slot 1)

[0402]

The result of checking the

composition data of the RAM

in Slot 1 on the controller is

incorrect.

Not specified RAM DIMM installed

Defective RAM DIMM

1. Replace the RAM DIMM.

2. Replace the controller board.

IEEE1394 interface error

851

[B]

The 1394 interface is

unusable.

Defective IEEE1394

Defective controller.

1. Replace the IEEE1394 interface board.

2. Replace the controller.

Wireless LAN or Bluetooth card not detected at starting communication

853

[B]

The wireless LAN or

Bluetooth card is not detected

before communication is

established, though the

wireless LAN or Bluetooth

board is detected.

Loose connection

1. Check the connection.

2. Insert the wireless LAN or Bluetooth

card to its board.

Wireless LAN or Bluetooth card not detected during operation

854

[B]

The wireless LAN or

Bluetooth card is not detected

after communication is

Loose connection

1. Check the connection.

2. Insert the wireless LAN or Bluetooth

Page 47

G160 Service Manual 23-Feb-06

40

SC

[Level]

Symptom Possible Cause/Required Action

established, though the

wireless LAN or Bluetooth

board is detected.

card to its board.

Wireless LAN or Bluetooth card error

855

[B]

An error is detected in the

wireless LAN or Bluetooth

card.

Loose connection

Defective wireless LAN or Bluetooth card

1. Check the connection.

2. Replace the wireless LAN or Bluetooth

card.

Wireless LAN or Bluetooth board error

856

[B]

An error is detected in the

wireless LAN or Bluetooth

board.

Defective wireless LAN or Bluetooth board

Loose connection

1. Check the connection.

2. Replace the wireless LAN or Bluetooth

board.

USB interface error

857

[B]

The USB interface cannot be

used due to a driver error.

Defective USB driver

Loose connection

1. Check the connection.

2. Replace the controller.

HDD: Initialization error

860

[B]

The controller detects that the

hard disk fails.

HDD not initialized

Defective HDD

1. Reformat the HDD (SP5832).

2. Replace the HDD.

HDD: Reboot error

861

[D]

The HDD does not become

ready within 30 seconds after

the power is supplied to the

HDD.

Loose connection

Defective cables

Defective HDD

Defective controller

1. Check the connection between the HDD

and controller.

2. Check and replace the cables.

Page 48

G160 Service Manual 23-Feb-06

41

SC

[Level]

Symptom Possible Cause/Required Action

3. Replace the HDD.

4. Replace the controller.

HDD: Read error

863

[D]

The data stored in the HDD

cannot be read correctly.

Defective HDD

Defective controller

1. Replace the HDD.

2. Replace the controller.

HDD: CRC error

864

[D]

While reading data from the

HDD or storing data in the

HDD, data transmission fails.

Defective HDD

1. Replace the HDD.

HDD: Access error

865

[D]

An error other than SC863

and SC864 is detected while

operating the HDD.

Defective HDD

1. Replace the HDD.

SD card authentication error

866

[B]

A correct license is not found

in the SD card.

SD-card data is corrupted.

1. Store correct data in the SD card.

SD card error

867

[D]

The SD card for an

application is ejected from the

slot.

The SD card for an application is ejected from

the slot.

1. Install the SD card.

SD card access error [File system error, Device error]

868

[D]

SD card error occurs when

SD card is activated.

Defective SD card

Defective SD card controller

1. For a file system error, format the SD

card on your PC.

2. For a device error, turn the mains switch

off and on.

3. Replace the SD card.

4. Replace the controller.

Address data error 870

[B]

An error is detected in the Defective software program

Page 49

G160 Service Manual 23-Feb-06

42

SC

[Level]

Symptom Possible Cause/Required Action

data copied to the address

book over a network.

Defective HDD

Incorrect path to the sever

1. Initialize the address book data

(SP5846-50).

2. Initialize the user information (format the

hard disk with SP5832).

3. Replace the HDD.

HDD mail data error

872

[B]

An error is detected in the

mail receiving data area of

the HDD at machine

initialization.

Defective HDD

Power failure during an access to the HDD

1. Initialize the HDD (SP5-832-001).

2. Replace the HDD.

HDD mail transfer error

873

[B]

An error is detected in the

mail transmitting data area of

the HDD at machine

initialization.

Defective HDD

Power failure during an access to the HDD

1. Initialize the HDD (SP5-832-001).

2. Replace the HDD.

Delete All error 1: HDD

874

[D]

An error is detected while the

all data of the HDD or

NVRAM are formatted

physically by the Data

Overwrite Security Unit

(B735).

Not installed Data Overwrite Security Unit (SD

card)

Defective HDD

1. Install the Data Overwrite Security Unit

(B735).

2. Replace the HDD.

Delete All error 2: Data area

875

[D]

An error is detected while the

all data of the HDD or

NVRAM are formatted

logically by the Data

Overwrite Security Unit

(B735).

The logical format for HDD fails.

1. Turn the main switch off/on and try the

operation again.

876 Log Data Error

001 Log Data Error 1

Page 50

G160 Service Manual 23-Feb-06

43

SC

[Level]

Symptom Possible Cause/Required Action

[D] An error was detected in the handling of the log data at power on or during

machine operation. This can be caused by switching the machine off while it is

operating.

1. Initialize the HDD with SP5832-004.

Log Data Error 2

002

[D]

The DESS module is not installed when the DESS module is set to ON.

1. Replace the DESS module.

2. Turn off the DESS module function.

Log Data Error 3

003

[D]

Invalid encryption key log due to defective NVRAM data

1. Initialize the HDD with SP5832-004.

2. Disable the log encryption setting.

Log Data Error 4

004

[D]

Unusual encryption function log due to the defective NVRAM data

1. Initialize the HDD with SP5832-004.

Log Data Error 5

005

[D]

NVRAM or HDD, which is used in other machine, is installed.

1. Reinstall the previous NVRAM or HDD.

2. Initialize the HDD with SP5832-004.

Log Data Error 99

099

[D]

Other than above causes

1. Ask your supervisor.

HDD Data Overwrite Security SD card error

877

[B]

The all delete cannot be

executed even though the

Data Overwrite Security Unit

(B735) is installed and

activated.

Defective SD card (B735)

Not installed SD card (B735)

1. Replace the NVRAM and then install the

new SD card (B735).

2. Check and reinstall the SD card (B735).

Electric counter error

900

[D]

Abnormal data is stored in the

counters.

Defective NVRAM

Defective controller

1. Turn the main switch off and on.

2. Check the connection between the

Page 51

G160 Service Manual 23-Feb-06

44

SC

[Level]

Symptom Possible Cause/Required Action

NVRAM and controller.

3. Replace the NVRAM.

4. Replace the controller.

Printer function error

920

[B]

The error that causes the

malfunction in the software

application is detected.

Turn the main switch off/on, or install Printer

Application firmware

Unexpected hardware structure (insufficient

memory or hard disk space.)

Printer font error

921

[B]

No font is detected in the

machines that have the font in

the SD card when the printer

application is run.

Install the System, Printer Application, NIB,

and Web System firmware.

Software performance error 1

990

[D]

The software makes an

unexpected operation.

Defective software

Defective controller

Software error

1. Reinstall the controller and/or engine

main firmware.

2. See the Note at the end of the SC table.

Software performance error 2

991

[C]

Unexpected software error

detected, which does not

affect operation of the

machine

The machine does not stop and the SC code is not

displayed. The machine automatically recovers.

However, the SC code is logged in the engine

summary sheet (SMC).

SC not defined

992

[D]

SC that is not controlled in the

system occurs.

Defective system software

Application start error

998

[D]

No applications start within 60

seconds after the power is

turned on.

Loose connection of RAM, DIMM and SD card

in slot 1

Defective controller

Software problem

Page 52

G160 Service Manual 23-Feb-06

45

SC

[Level]

Symptom Possible Cause/Required Action

1. Check if the RAM, DIMM and SD card in

slot 1 are properly connected.

2. Reinstall the controller system firmware.

3. Replace the controller.