Ricoh Fx880, FAX880 MP, MV 74 Service Manual

IFO

RICOH FAX880 MP

MV 74

SERVICE MANUAL

November 28th, 1995

Subject to change

Printed in Japan

Lithium Batteries (Memory Back-up )

CAUTION

I

The danger of explosion exists if a battery of this type is incorr ec tly

replaced. Replace only with the same or an equiv alent type

recommended by the manufac ture r. Discard used batteries in

accordance with the manufacturer’s instructions.

Important:

Before servicing this machine, please read the following notes.

• Do not touch the nozzle sect ion in the ink cart ridge. This helps preven t

the nozzles from clogging.

• Do not touch the wiper blade on the purge unit. This a lso h elp s prevent

the nozzles from clogging. (Ple ase re fe r to sect ion 2.2 for details.)

• Do not touch the aluminum plat e on the ink ca rtrid ge . Th e a lumin um

plate heats up during prin ting. It becomes quite hot du ring co nt inuous

high duty printing.

• After repairs or maintena nce , excessive ink may remain on the contact

section of the cartridge, covers, and TIJ unit. Remove this ink with a dry

cloth. The ink is electrically conductive and it may sh ort an electrical

component.

• Always store an extra cartridge (if unp acke d) in th e cartridge box in-

cluded with the machine .

• Ensure that the TI J unit has completed its cleaning o per at ion before un-

plugging the machine.

• Ensure that the carriage is at the head capp ing posit ion (h ome posit ion )

before leaving the machine unplugged for long pe riod s.

Table of Contents

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . 1-1

1.2. FEATURES . . . . . . . . . . . . . . . . . . . . . 1-2

1.3. COMPONENT LAYOUT . . . . . . . . . . . . . . . . 1-5

1.3.1. Mechanical Comp on en ts . . . . . . . . . . . . . . 1-5

1.3.2. Electrical Compo ne nt s . . . . . . . . . . . . . . . 1-6

1. PCBs . . . . . . . . . . . . . . . . . . . . . . 1-6

2. Motors . . . . . . . . . . . . . . . . . . . . . . 1-7

3. Sensors . . . . . . . . . . . . . . . . . . . . . 1-7

1.4. OVERALL MACHINE CONTROL . . . . . . . . . . . . 1-8

1.5. VIDEO DATA PATH . . . . . . . . . . . . . . . . . . 1-10

1.5.1. Transmission . . . . . . . . . . . . . . . . . . . 1-10

1.5.2. Recept ion . . . . . . . . . . . . . . . . . . . . 1-11

1.5.3. Copying . . . . . . . . . . . . . . . . . . . . . 1-12

1.5.4. Printing fro m t he Centronics Interface . . . . . . . . . 1-13

1.6. POWER DISTRIBUTION . . . . . . . . . . . . . . . . 1-14

1.6.1. Distribution Diagram . . . . . . . . . . . . . . . . 1-14

1.6.2. Memory Back-up Circuit . . . . . . . . . . . . . . 1-15

2. DETAILED SECTION DESCRIPTIO N S

2.1. SCANNER . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1. Mechanisms . . . . . . . . . . . . . . . . . . . 2-1

1. Document Detect ion , Pick-up and Separation and

Drive Mechanism . . . . . . . . . . . . . . . . . 2-1

2.1.2. Image Scanning . . . . . . . . . . . . . . . . . 2-2

2.2. PRINTER . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.1. Printer Configuration . . . . . . . . . . . . . . . . 2-4

2.2.2. Ink Cartridge (Black an d Colo r ) . . . . . . . . . . . . 2-5

2.2.3. Printe r He ad . . . . . . . . . . . . . . . . . . . 2-6

1. Mechanism . . . . . . . . . . . . . . . . . . . . 2-6

2. Drive Circuitry . . . . . . . . . . . . . . . . . . . 2-7

3. Print Signals . . . . . . . . . . . . . . . . . . . 2-8

2.2.4. Purge Unit . . . . . . . . . . . . . . . . . . . . 2-9

1. Components . . . . . . . . . . . . . . . . . . . 2-9

2. Purge Unit Functions . . . . . . . . . . . . . . . . 2-10

2.2.5. Paper Feed . . . . . . . . . . . . . . . . . . . 2-11

1. Overview . . . . . . . . . . . . . . . . . . . . . 2-11

2. Drive Mechanism . . . . . . . . . . . . . . . . . 2-12

2.2.6. Ink End Detection . . . . . . . . . . . . . . . . . 2-13

2.2.7. Maximum Print Lengt hs . . . . . . . . . . . . . . 2-14

2.2.8. Data Red uction and Page Sepa rat ion . . . . . . . . . 2-15

2.3. PCBs . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.3.1. FCE . . . . . . . . . . . . . . . . . . . . . . 2-16

1. FCIP (Facsimile Contro ller an d Ima ge Proce ssor) . . . . . 2-16

2. ROM . . . . . . . . . . . . . . . . . . . . . . 2-16

3. DRAM . . . . . . . . . . . . . . . . . . . . . . 2-17

4. SRAM . . . . . . . . . . . . . . . . . . . . . . 2-17

5. Video SRAM . . . . . . . . . . . . . . . . . . . 2-17

6. Oscillators . . . . . . . . . . . . . . . . . . . . 2-17

7. Jumpers, Switche s, a nd Test P oints . . . . . . . . . . 2-17

2.3.2. FDU . . . . . . . . . . . . . . . . . . . . . . 2-18

1. Printer Head Drive Circuit . . . . . . . . . . . . . . 2-18

2. Drivers . . . . . . . . . . . . . . . . . . . . . . 2-18

3. Sensors . . . . . . . . . . . . . . . . . . . . . 2-18

4. DC/DC Converter . . . . . . . . . . . . . . . . . 2-19

5. Battery . . . . . . . . . . . . . . . . . . . . . . 2-19

6. Jumpers, Switche s, a nd Test P oints . . . . . . . . . . 2-19

2.3.3. IJC . . . . . . . . . . . . . . . . . . . . . . . 2-20

1. CPU (MPU) . . . . . . . . . . . . . . . . . . . . 2-20

2. Printer controller . . . . . . . . . . . . . . . . . . 2-20

3. ROM . . . . . . . . . . . . . . . . . . . . . . 2-20

4. DRAM . . . . . . . . . . . . . . . . . . . . . . 2-20

5. Oscillators . . . . . . . . . . . . . . . . . . . . 2-21

6. Raster Image Data Controlle r (RI DC2) . . . . . . . . . 2-21

7. SRAM . . . . . . . . . . . . . . . . . . . . . . 2-21

8. HIC (Hybrid IC) . . . . . . . . . . . . . . . . . . 2-21

9. EEPROM . . . . . . . . . . . . . . . . . . . . . 2-21

10. Centronics Interface . . . . . . . . . . . . . . . . 2-21

11. Jumpers, Switches, and Test Poin ts . . . . . . . . . . 2-21

2.3.4. PSU . . . . . . . . . . . . . . . . . . . . . . 2-22

2.3.5. NCU (USA) . . . . . . . . . . . . . . . . . . . 2-23

1. Jumpers . . . . . . . . . . . . . . . . . . . . . 2-23

2.3.6. NCU (Europe/Asia) . . . . . . . . . . . . . . . . 2-24

1. Control Signals and Jumpers . . . . . . . . . . . . . 2-24

3. INSTALLATION

3.1. INSTALLING THE MACHINE . . . . . . . . . . . . . . 3-1

3.2. INITIAL PRO GRAMMI NG . . . . . . . . . . . . . . . 3-1

4. SERVICE TABLES AND PROCEDURES

4.1. SERVICE LEVEL FUNCTIONS . . . . . . . . . . . . . 4-1

4.1.1. Bit Switch Programming (Function 01) . . . . . . . . . 4-1

4.1.2. System Parame te r L ist (Fun ction 02) . . . . . . . . . 4-2

4.1.3. Error Code Display (Function 03) . . . . . . . . . . . 4-2

4.1.4. Service Monitor Repo rt (Fun ctio n 04 ) . . . . . . . . . 4-2

4.1.5. Protocol Dump (Fu nct ion 05) . . . . . . . . . . . . 4-3

4.1.6. RAM Display/Rewrite (Fu nct ion 06) . . . . . . . . . . 4-3

4.1.7. RAM Dump (Function 06) . . . . . . . . . . . . . . 4-4

4.1.8. Counter Displa y/Rewrite (Function 07) . . . . . . . . . 4-4

4.1.9. NCU Parameters (Function 08) . . . . . . . . . . . . 4-5

4.1.10. Modem Test (Function 08) . . . . . . . . . . . . . 4-5

4.1.11. DTMF Tone Test (Function 08) . . . . . . . . . . . 4-6

4.1.12. Modem Detection Test (Function 08) . . . . . . . . . 4-7

4.1.13. Oper at ion Panel Test (Function 09) . . . . . . . . . 4-7

4.1.14. LED Arra y Test (Function 10) . . . . . . . . . . . . 4-8

4.1.15. ADF Test (Function 10) . . . . . . . . . . . . . . 4-8

4.1.16. Printer Test Patterns (Function 11) . . . . . . . . . . 4-9

4.1.17. Printing the EEPROM Information Sheet and Initializing

the EEPROM (Function 11) . . . . . . . . . . . . . 4-10

4.1.18. Printer Mechanism Test - Free Run (Function 11) . . . . 4-11

4.1.19. Ink End Sensor Init ialization (Function 11) . . . . . . . 4-12

4.1.20. RAM Tests (Function 12) . . . . . . . . . . . . . . 4-12

4.1.21. Softwa re Down load (Function 12) . . . . . . . . . . 4-13

4.1.22. Softwa re Uplo ad (Function 12) . . . . . . . . . . . 4-14

4.1.23. SRAM Data Down loa d (Fun ction 12) . . . . . . . . . 4-15

4.1.24. Serial Numbe r (Fu nct ion 14) . . . . . . . . . . . . 4-16

4.1.25. Service Sta tio n Fax Number (Function 13) . . . . . . . 4-16

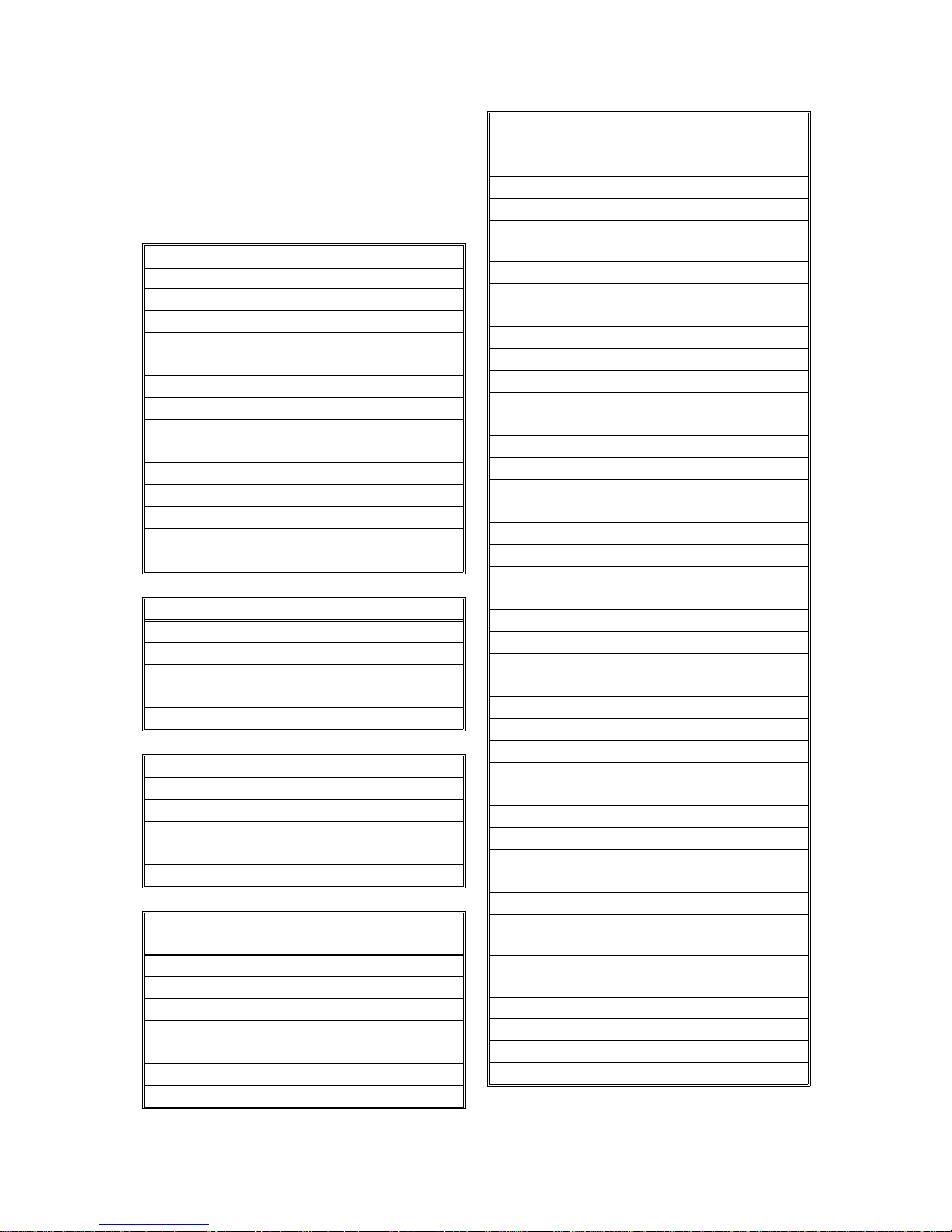

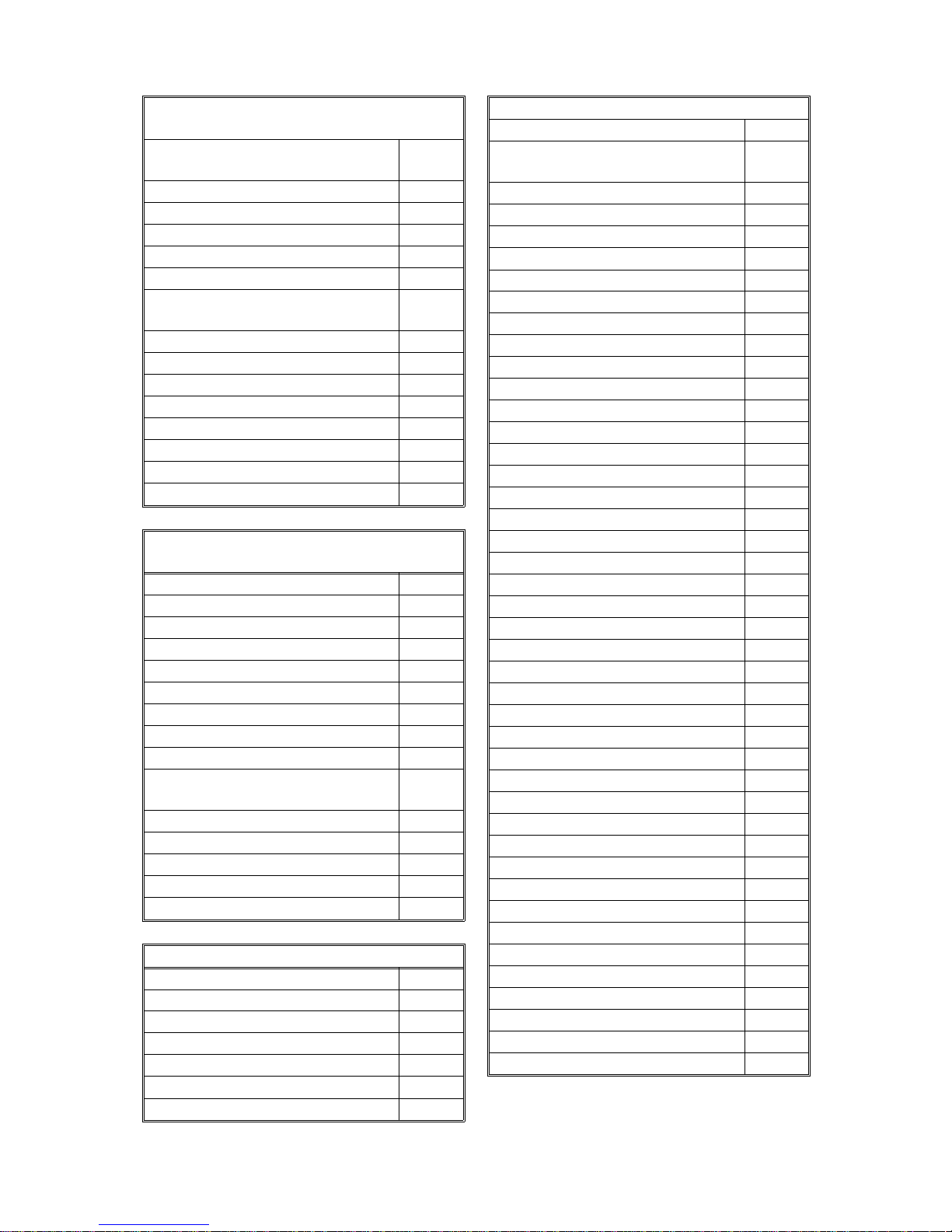

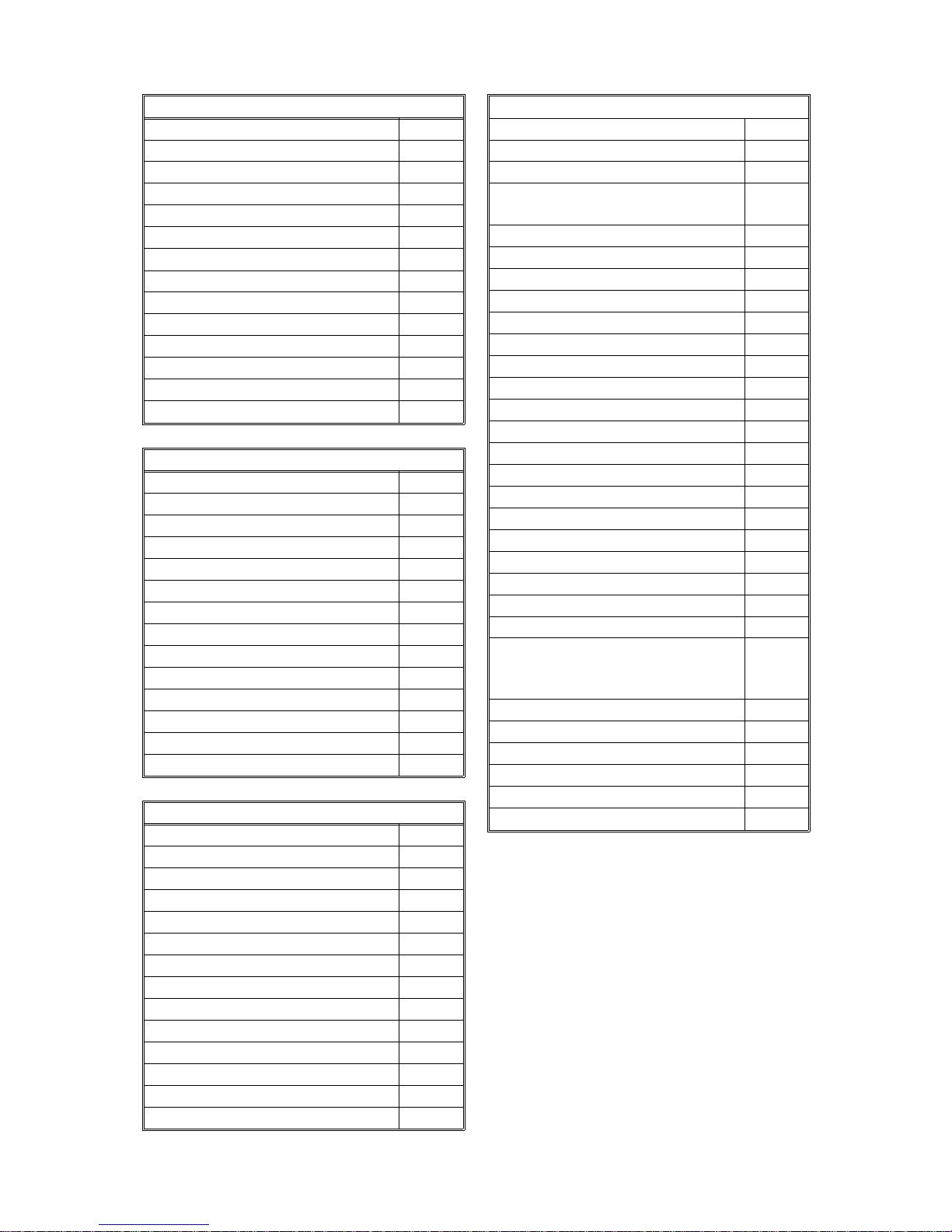

4.2. BIT SWITCHES . . . . . . . . . . . . . . . . . . . 4-17

4.2.1. System Switche s . . . . . . . . . . . . . . . . . 4-17

4.2.2. Scanner Switche s . . . . . . . . . . . . . . . . 4-25

4.2.3. Printer Switches . . . . . . . . . . . . . . . . . 4-27

4.2.4. Communicatio n Switches . . . . . . . . . . . . . . 4-28

4.2.5. G3 Switches . . . . . . . . . . . . . . . . . . . 4-34

4.3. NCU PARAMETERS . . . . . . . . . . . . . . . . . 4-39

4.4. DEDICATED TRANSMISSION PARAMETERS . . . . . . . 4-65

4.4.1. Programming Procedure . . . . . . . . . . . . . . 4-65

4.4.2. Parame te rs . . . . . . . . . . . . . . . . . . . 4-66

4.5. SERVICE RAM ADDRESSES . . . . . . . . . . . . . . 4-68

4.6. SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . 4-79

5. REMOVAL AND ADJUSTMENT

5.1. COVERS . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1. Operat ion P an el Assembly [A and B] . . . . . . . . . 5-1

5.1.2. Upper Cover [A] and IC Card Cover [B] . . . . . . . . 5-2

5.2. Paper Feed Uni t and Roller Assembl y . . . . . . . . . . 5-2

5.2.1. Paper Feed Unit [A] . . . . . . . . . . . . . . . . 5-2

5.2.2. Paper Feed Roller Assembly [A] . . . . . . . . . . . 5-3

5.3. PCBs . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3.1. PSU [A] . . . . . . . . . . . . . . . . . . . . . 5-3

5.3.2. IJC [A] . . . . . . . . . . . . . . . . . . . . . 5-4

5.3.3. FDU [A] . . . . . . . . . . . . . . . . . . . . . 5-5

5.3.4. NCU [A] . . . . . . . . . . . . . . . . . . . . . 5-5

5.4. SCANNER . . . . . . . . . . . . . . . . . . . . . 5-6

5.4.1. Conta ct Image Sensor [A] . . . . . . . . . . . . . . 5-6

5.4.2. Scanner Rolle rs [A, B, C] . . . . . . . . . . . . . . 5-6

5.5. PRINTER . . . . . . . . . . . . . . . . . . . . . . 5-7

5.5.1. Chassis [C] . . . . . . . . . . . . . . . . . . . 5-7

5.5.2. Thermal Ink Jet (TIJ) Unit [A] and Pape r Ou tp ut Gu ide [B] . 5-8

5.5.3. Purge Unit . . . . . . . . . . . . . . . . . . . . 5-8

5.5.4. Ink Absorbers . . . . . . . . . . . . . . . . . . 5-9

6. TROUBLESHOOTING

6.1. COPY QUALITY TROUBLESHOOTING . . . . . . . . . . 6-1

6.1.1. Blank Copies . . . . . . . . . . . . . . . . . . . 6-2

6.1.2. Black Copies . . . . . . . . . . . . . . . . . . . 6-3

6.1.3. Dirty Background . . . . . . . . . . . . . . . . . 6-3

6.1.4. Uneven Image Density . . . . . . . . . . . . . . . 6-3

6.1.5. Vertical Black Lines . . . . . . . . . . . . . . . . 6-4

6.1.6. Vertical White Lines . . . . . . . . . . . . . . . . 6-5

6.1.7. Horizontal White Lin es . . . . . . . . . . . . . . . 6-6

6.1.8. Faint Cop ies . . . . . . . . . . . . . . . . . . . 6-7

6.1.9. Misaligned Output (Da ta shift ed to the righ t or lef t) . . . . 6-8

6.1.10. Replace Cartridge Still Displayed

After Cartridge Replacement . . . . . . . . . . . . 6-8

6.2. MECHANICAL PROBLEMS . . . . . . . . . . . . . . 6-9

6.2.1. ADF/Scanner . . . . . . . . . . . . . . . . . . . 6-9

1. Non-feed . . . . . . . . . . . . . . . . . . . . . 6-9

2. Jam . . . . . . . . . . . . . . . . . . . . . . . 6-10

3. Skew . . . . . . . . . . . . . . . . . . . . . . 6-11

4. Multi-feed . . . . . . . . . . . . . . . . . . . . 6-11

6.2.2. Printe r . . . . . . . . . . . . . . . . . . . . . 6-12

1. Non-feed . . . . . . . . . . . . . . . . . . . . . 6-12

2. Paper Jam . . . . . . . . . . . . . . . . . . . . 6-12

3. Skew . . . . . . . . . . . . . . . . . . . . . . 6-13

4. Multi-feed . . . . . . . . . . . . . . . . . . . . 6-13

6.3. SERVICE CALL CONDITIONS . . . . . . . . . . . . . 6-14

6.4. ERROR CODES . . . . . . . . . . . . . . . . . . . 6-15

6.5. ELECTRICAL COMPONE NT DE FECTS . . . . . . . . . 6-21

6.5.1. Defe ctive Sensor Table . . . . . . . . . . . . . . . 6-21

6.5.2. Blown Fuse Table . . . . . . . . . . . . . . . . . 6-21

November 28th, 1995 OVERALL MACHINE INFORMATION

SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS

Type

Desktop type transceiver

Circuit

PSTN, PABX

Connection

Direct couple

Document Size

Length: 105 - 600 mm [4.1 - 23.6 ins]

Width: 148 - 220 mm [5.8 - 8.7 ins]

Thickness: 0.05 to 0.15 mm [2 to 6 mils]

(equivalent to 50 - 80 g/m

Document Feed

Automatic feed, face down

ADF Capacity

15 sheets (using 20 lb. or 80 g/m

Scanning Method

Contact image sensor

Maximum Scan Width

216 mm [8.5 ins]

2

)

2

paper)

Transmission Time

9 s at 9600 bps; Measured with G3 ECM using memory for a ITU-T #1 test document

(Slerexe letter) at standard resolution

Printing System

Ink jet printing

Paper Size

Europe/Asia: A4

USA: Letter, Legal

Paper Capacity

150 sheets

Maximum Printing Width

203 mm [8.0 ins]

Maximum Printer Resolutions

Main scan: 360 dpi

(720 dpi in the printer mode)

Sub scan: 360 dpi

Power Supply

Europe/Asia: 220 - 240 Vac, 50 ± 3 Hz

USA: 115 ± 20 Vac, 60 ± 3 Hz

Scan Resolutions

Main scan: 8 dots/mm [203 dpi]

Sub scan:

Standard - 3.85 lines/mm [98 lpi]

Detail - 7.7 lines/mm [196 lpi]

Fine - 15.4 lines/mm [391 lpi]

Memory Capacity

ECM: 64 kbytes (single buffer) for tx

SAF: 400 kbytes

(272 kbytes for tx)

Compression

MH, MR, EFC, MMR, SSC (MMR only with

ECM)

Protocol

Group 3 with ECM

Modulation

V.29 (QAM), V.27ter (PHM), V.21 (FM)

Data Rate (bps)

9600/7200/4800/2400, Automatic fallback

Power Consumption

Standby: 5 W Transmit: 12 W

Receive: 14 W Copying: 24 W

Printer: 19 W

Operating Environment

Temperature: 17 - 28 °C [63 - 82 °F]

Humidity: 40 - 70 %Rh

Dimensions (W x D x H)

370 x 280 x 235 mm [14.6 x 11.0 x 9.3 ins]

Excluding handset, trays, and tables

Weight

Approx. 7 kg [15 lbs]

1-1

OVERALL MACHINE INFORMATION November 28th, 1995

FEATURES

1.2. FEA TURES

KEY: O = Used, X = Not Used,

A = With optional memory only

B = With optional handset only

C = With color cartridge only

Equipment

ADF O

Book scan X

Built-in handset X

Bypass feed X

Optional cassette X

Cabinet X

Counter X

Cutter X

Handset (option) B

Hard disk X

Manual feed mechanism X

Marker (Stamp) X

Monitor speaker O

PC printer interface (IBM) O

Video Processing Features

Contrast X

Halftone (Basic & Error Diffusion) O

MTF O

Reduction X

Resolution O

Communication Features - Auto

Automatic fallback O

Automatic redialing O

Confidential reception A

Dual Access O

Substitute reception O

Communication Features -

User Selectable

Action as a transfer broadcaster X

AI Redial (last ten numbers) X

Answering machine interface O

Authorized Reception O

Auto-answer delay time X

Auto dialing (pulse or DTMF) O

Auto Document X

Communication Features -

User Selectable

Auto image density selection X

Auto paper size selection X

Automatic Voice Message X

Batch Transmis sion

(max 35 files)

Broadcasting O

Chain Dialing O

Communication Result Display X

Confidential ID Override O

Confidential Transmission O

Direct Fax Number Entry O

Economy Transmission X

Fax on demand X

Forwarding A

Free Polling O

Groups (3 groups) O

Group Transfer Station X

Hold X

ID Transmission O

Immediate Redialing O

Immediate transmission O

Keystroke Programs O

Memory transmission O

Multi-step Transfer X

Next Transfer Station X

OMR X

On Hook Dial O

Ordering Toner X

Page Count O

Personal Codes X

Personal Codes with Conf. ID X

Polling Reception O

Polling Transmission O

Polling tx file lifetime in the SAF O

Quick Dial (10 stations) O

Reception modes (Auto, Tel,

TAM)

Length Reduction (in Rx mode,

called Auto Reduction)

Remote control features X

Remote Transfer X

Restricted Access X

Secured Polling O

A

O

O

1-2

November 28th, 1995 OVERALL MACHINE INFORMATION

FEATURES

Communication Features -

User Selectable

Secured Polling with Stored ID

Override

O

Secure Transmiss ion X

Send Later O

Silent ringing detection X

Specified Image Area X

Speed Dial (50 stations) O

Super Fine Resolution

(16 x15.4 l/mm : 400 x 400 dpi)

X

Telephone Directory X

Tonal Signal Transmission O

Transfer Request X

Transmission Deadline (TRD) A

Turnaround Polling X

Two- step Transfer X

Two in one X

Voice Request (immed. tx only) X

Communication Features -

Service Selectable

AI Short Protocol O

Auto-reduction override option O

Busy tone detection O

Closed Network (tx and rx) O

Continuous Polling Reception X

Dedicated tx parameters O

ECM O

EFC O

Inch-mm conversion X

Page retransmission: no. of

times

O

Page separation mark O

Protection against wrong conn. O

Resol’n stepdown override option X

Short Preamble X

Well log X

Other User Features

Area code prefix X

Automatic service call X

Center mark X

Checkered mark X

Clearing a memory file O

Clearing a polling file O

Clock O

Other User Features

Confidential ID O

Copy editing (Erase Center/Mar-

gin)

Copy mode O

Copy Mode Restriction X

Counters O

Daylight Saving Time X

Destination Check X

Direct entry of names O

File Retention Time X

File Retransmission X

Function Programs X

ID Code O

Label Insertion ("From xxx") X

Language Selection O

LCD contrast control X

Memory Lock A

Memory Lock ID A

Modifying a memory file X

Multi Sort Document Reception A

Multicopy mode O

Own telephone number X

Power Saver X

Print density control X

Printing a memory file O

RDS on/off O

Reception Mode Switching Timer X

Reception time printing X

Reduction/Enlargement X

Remaining memory indicator O

Remote ID X

Reverse Order Printing A

RTI, TTI, CSI O

Secure ID X

Service Report Transmission X

Speaker volume control O

Specified Cassette Selection X

Substitute reception on/off O

Telephone line type O

Toner Saving Mode X

TTI on/off O

User Function Keys X

User Parameters O

Wild Cards O

X

1-3

OVERALL MACHINE INFORMATION November 28th, 1995

FEATURES

Reports - Automat ic

Charge Control Report X

Communication Failure Report O

Confidential File Report A

Error Report O

Memory Storage Report O

Mode Change Report X

Polling Clear Report X

Polling Reserve Report O

Polling Result Report O

Power Failure Report O

TCR (Journal) O

Toner Cassette Order Form X

Transfer Result Report X

Transmission Result Report O

Reports - User-initiated

Authorized Reception List O

Charge Control Report X

File List O

Forwarding List A

Group List O

Personal Code List X

Program List O

Quick Dial List O

Specified Cassette Selection List X

Speed Dial List O

TCR O

Transmission Status Report X

User Function List X

User Parameter List O

Service Mode Features

Auto Paper Select test X

Back-to-back test O

Bit switch programming O

Book mode test X

Buzzer test O

Cable equalizer O

Comm. parameter display O

Counter check O

Country code O

DTMF tone test O

Echo countermeasure O

Effective term of service calls X

Error code display O

Excessive jam alarm X

Service Mode Features

File Transfer O

LCD contrast adjustment X

Line error mark O

Memory file printout

(substitute reception only)

Modem test O

NCU parameters O

Operation panel test O

Periodic service call X

PM Call X

Printer mechanism test O

Printer test patterns O

Programmable attenuation X

Protocol dump list O

RAM display/rewrite O

RAM dump O

RAM test O

Ringer test X

Scanner lamp test O

Scanner mechanism test O

Sensor initialization X

Serial number O

Service monitor report O

Service station number O

Software upload/download

(Available only in machines with

the FLASH ROM.)

SRAM data download O

System parameter list O

Technical data on the TCR O

Thermal head parameters X

Transmission Status Report X

User data transfer O

Memory Files

Max. number of files: 100

Max. number of stations/ file: 100

O

O

1-4

November 28th, 1995 OVERALL MACHINE INFORMATION

COMPONENT LAYOUT

1.3. COMPONENT LAYOUT

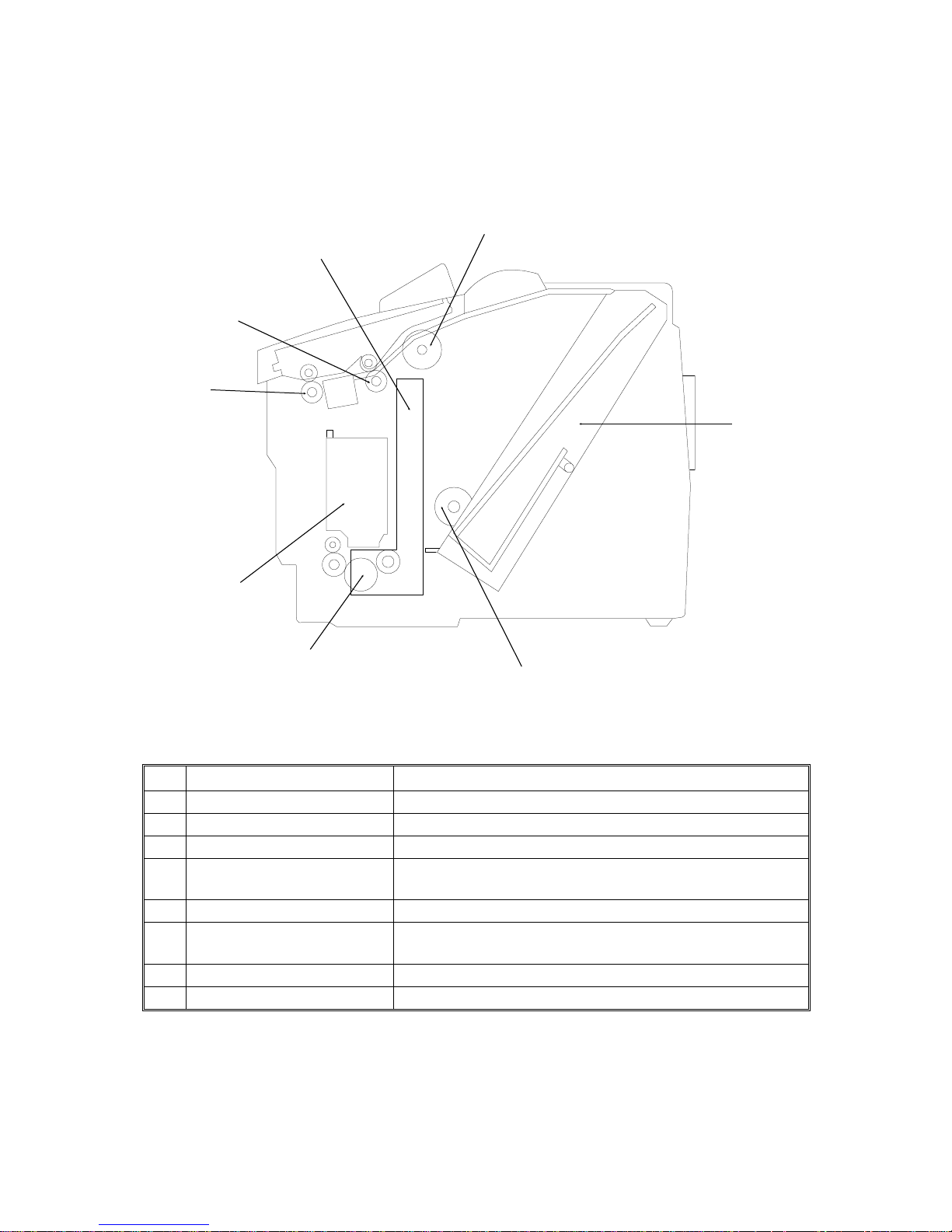

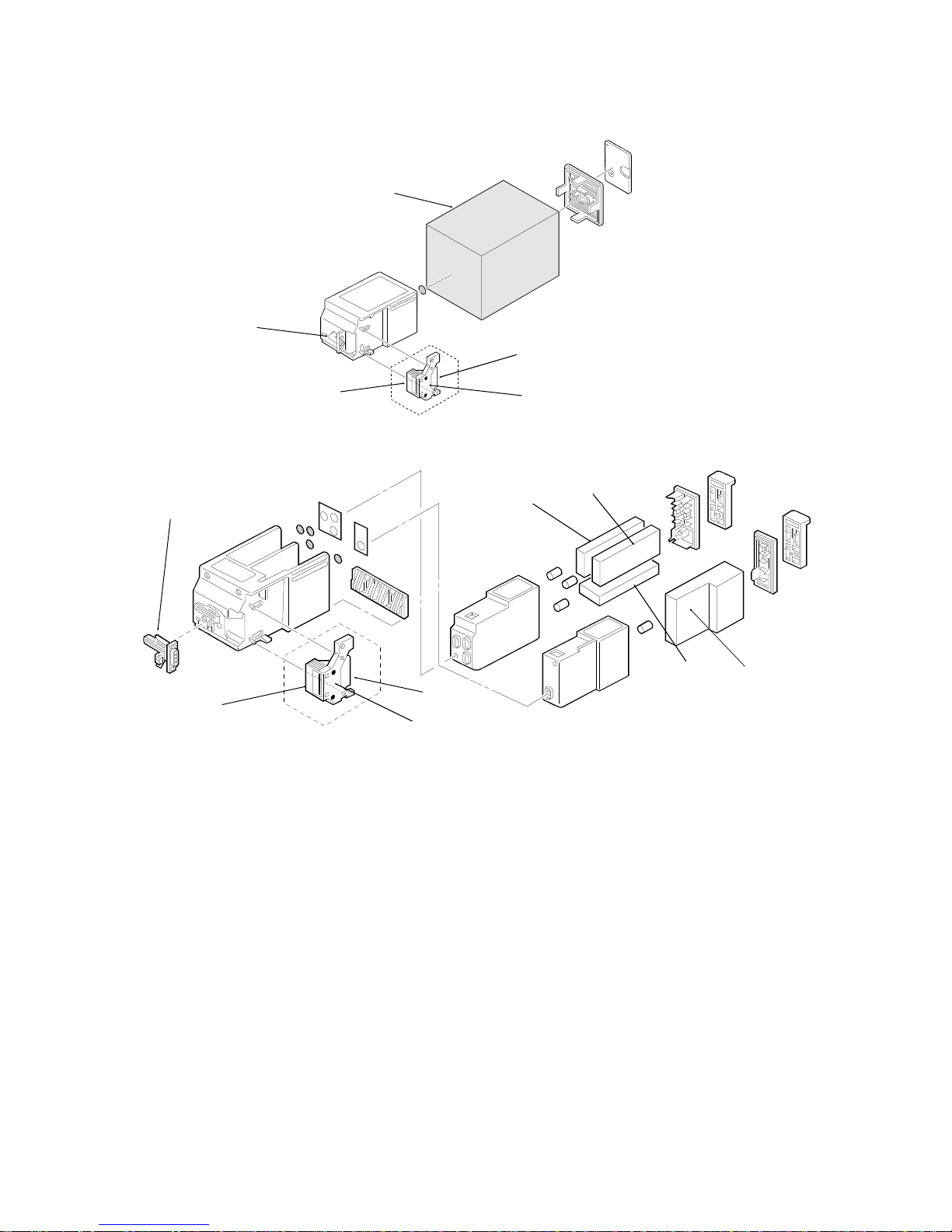

1.3.1. Mechanical Components

2

1

8

7

3

6

5

4

No. Name Descri ption

TIJ Thermal ink jet printer unit.

1

Document Feed Roller This roller feeds the document into the scanner.

2

Paper Feed Unit This unit can hold up to 150 sheets.

3

Paper Feed Roller This roller picks up the top sheet of paper, and feeds it

4

Registration Roller This roller carries out the registration process.

5

Carriage Unit / Ink

6

Cartridge

R2 Roller This roller feeds the document through the scanner.

7

R1 Roller This roller feeds the document through the scanner.

8

into the printer.

The carriage unit holds the ink cartridge. The cartridge

contains the ink jet printer head and the ink.

H505V501.wmf

1-5

OVERALL MACHINE INFORMATION November 28th, 1995

COMPONENT LAYOUT

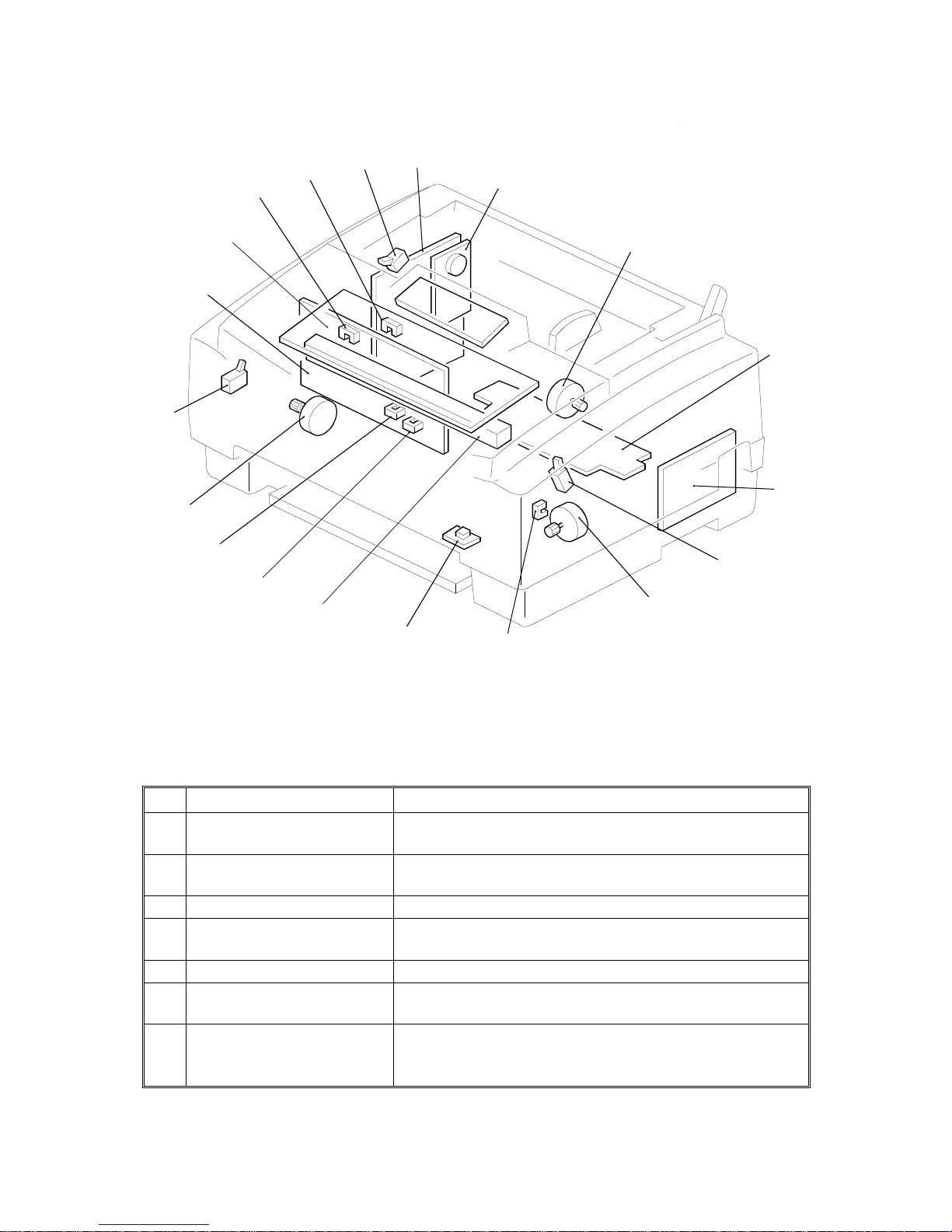

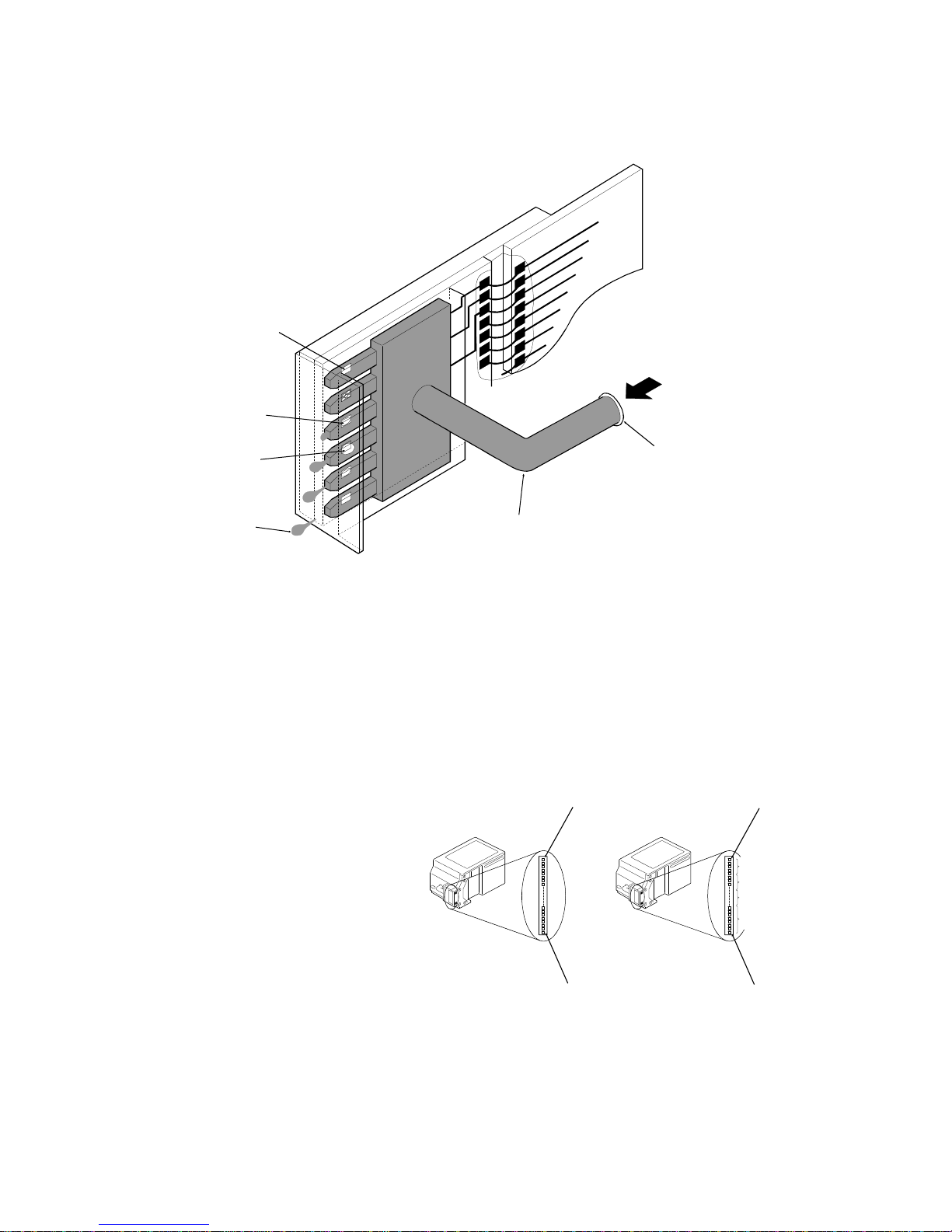

1.3.2. Electrical Components

19

18

1

17

4

5

3

2

6

7

8

9

10

11

16

15

14

13

12

1. PCBs

No. Name Description

FDU (Facsimile Driver

1

Unit)

OPU (Operation Panel

2

Unit)

IJC (Ink Jet Controller) This board controls the ink jet printer.

6

FCE (Facsimile Control

7

Engine)

PSU (Power Supply Unit) This board supplies power to the machine.

9

NCU (Network Control

10

Unit)

Contact Image Sensor

Assembly

15

This board contains drivers for the motors, a dc-dc

converter, and the DRAM backup circuit.

This board controls the operation panel.

This board controls the machine. It contains the main

cpu, ROM, system RAM, and other control components.

This board contains a relay and switches to interface

the machine to the network.

This sensor reads and converts the light reflected from

the document into an analog video signal. It uses an

RLA (Rod Lens Arr ay) sens or unit.

H505V502.wmf

1-6

November 28th, 1995 OVERALL MACHINE INFORMATION

COMPONENT LAYOUT

2. Motors

No. Name Description

Tx Motor This stepper motor drives the scanner rollers.

8

Carriage Motor This motor drives the printer’s carriage mechanism.

12

Paper Feed Motor This motor drives the paper feed roller and the

18

registration roller.

3. Sensors

No. Name Description

Scan Line Sensor This sensor detects when the document approaches

3

Document Sensor This sensor detects the presence of a document in the

4

Top Cover Sensor This sensor detects whether the top cover is opened or

5

Paper Release Lever

Sensor

11

Carriage Home Position

13

Sensor

Ink End Sensor This sensor detects when the ink in the cartridge has

14

Paper Feed Roller Sensor This sensor detects the initial rotation position of the

16

Paper End Sensor This sensor detects the presence of paper in the printer.

17

Front Cover Sensor This sensor detects whether the front cover is opened

19

the scanning position.

feeder.

closed.

This sensor detects when the paper release lever is

released. (The paper release lever is also known as the

paper feed lever.)

This sensor detects when the carriage is at the home

position.

run out.

paper feed roller.

or closed.

1-7

OVERALL MACHINE INFORMATION November 28th, 1995

OVERALL MACHINE CONTROL

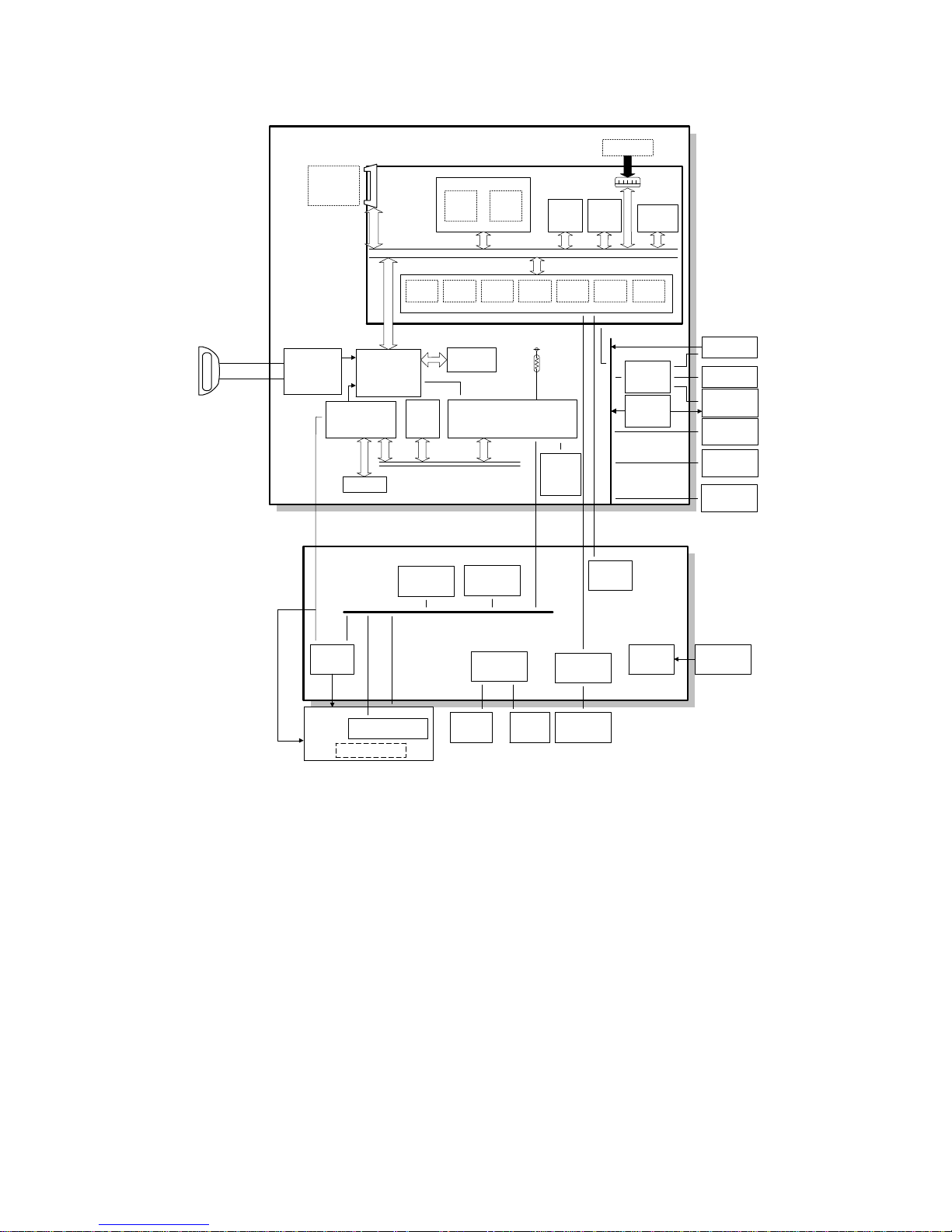

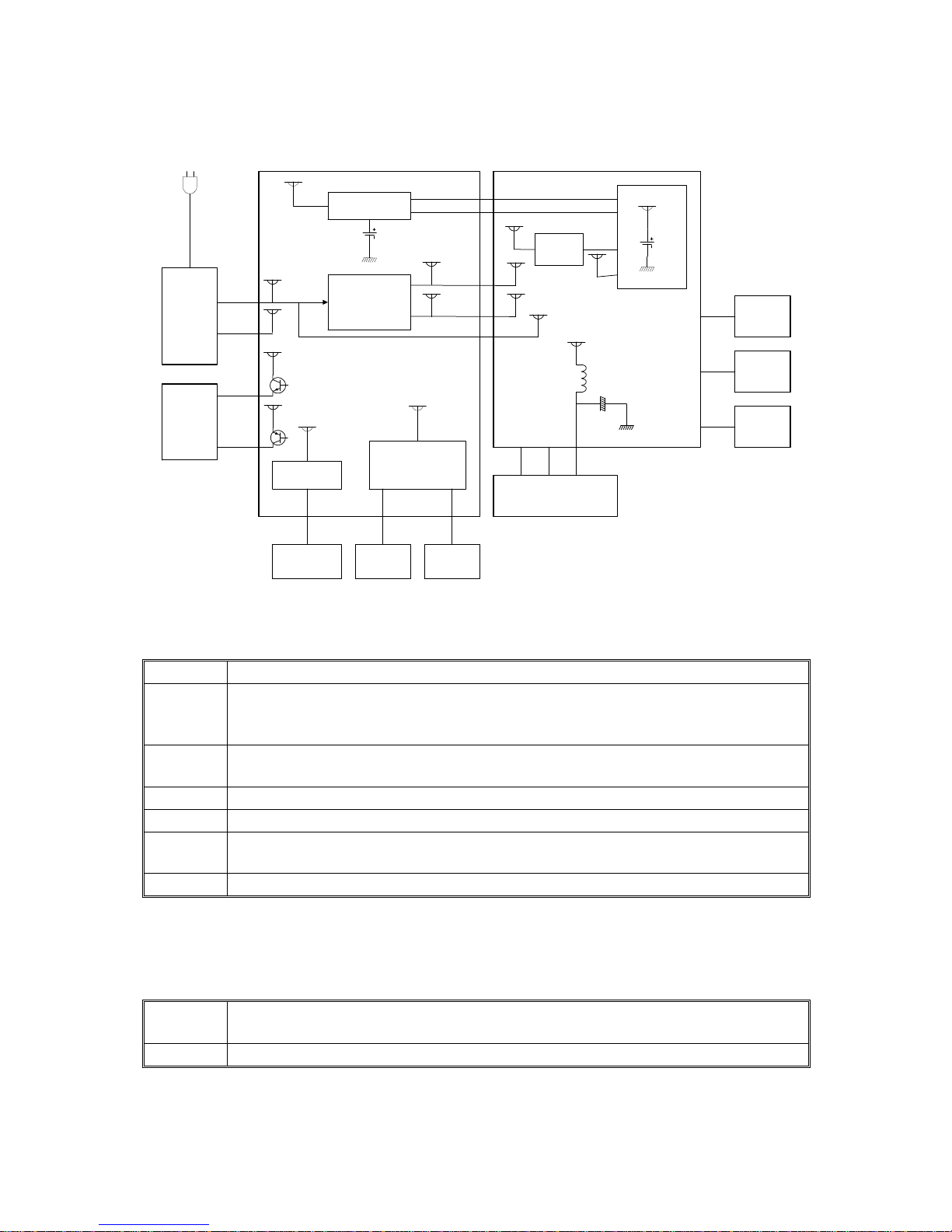

1.4. OVERALL MACHINE CONTROL

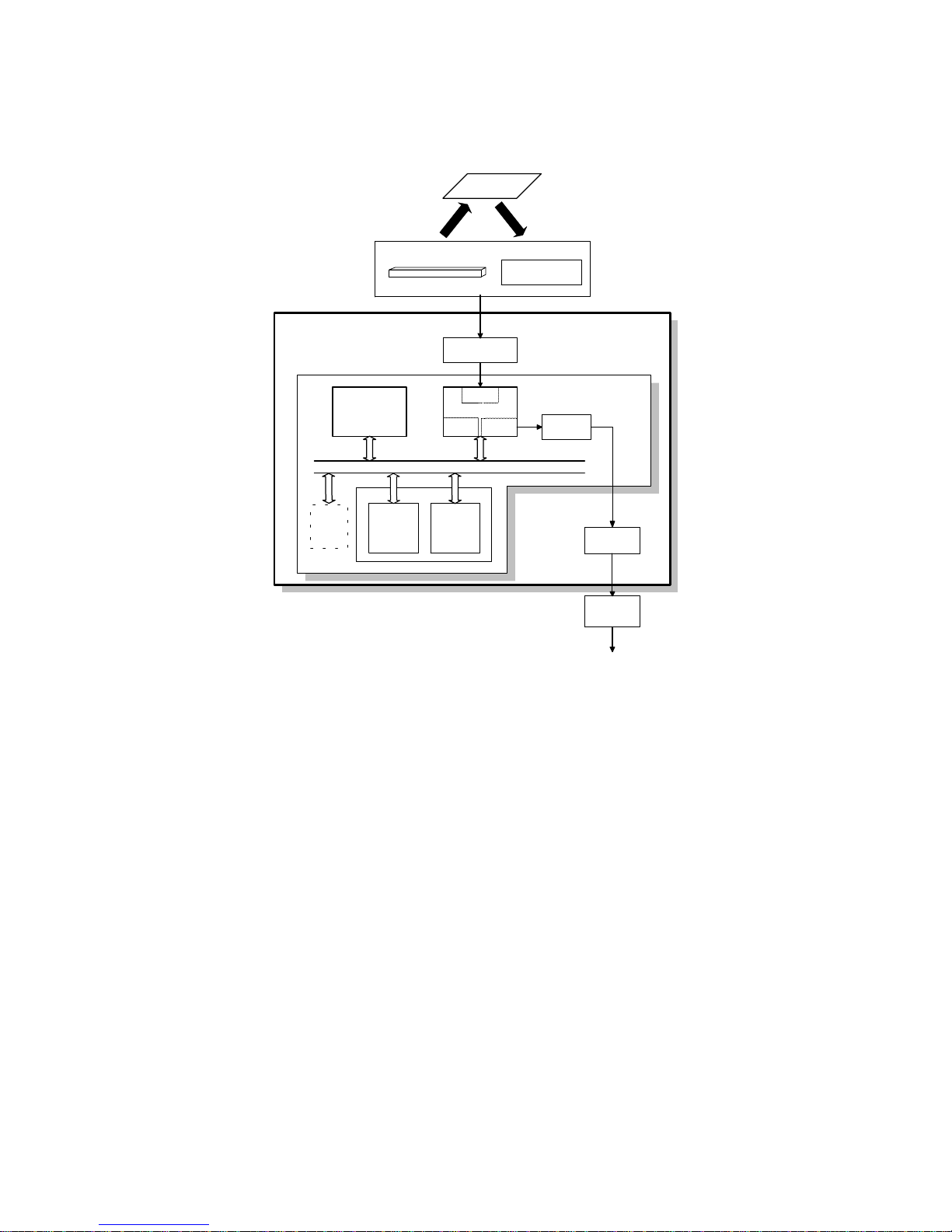

Optional

RS232C I/F

Centronics

Interface

Optional

IC Card

IJC

I/F

Controller

RIDC

Print

Controller

DRAM

FDU

FCE

MDM

FCIP

ROM

Paper Feed

Roller Sensor

DRAM

Working

ECM/

SAF

RAM

Memory

DATA/ADDRESS BUS

CPU

DMAC DCR DIP LIF

RU8

SRAM

CPU

Paper End

Sensor

System

ROM

Thermistor

EEPROM

System

RAM

(SRAM)

DRAM

Video

SRAM

PRIF

HIC

LED

Driver

NCU

Speaker

Contact Image

Sensor

Cover

Sensors

Ink End

Sensor

Operation

Panel

Heater

Drivers

Carriage

Printer Head

Cartridge

Detection

Home Position

Sensor

Type/

Color

Carriage

Motor

Drivers

Paper

Feed

Motor

Driver

Tx Motor

DC-DC

Converter

PSU

H505V504.wmf

The FCE (Facsimile Control Engine) contains th e FCIP (Facsimile Control

and Image Processor), DRAM, SRAM, Syste m ROM, an d vide o processing

memory. It controls the entire system through the IJC (Ink Jet Controller) and

the FDU (Facsimile Driver Unit).

There are two cpus in the mach ine: the main cpu (FCIP) on the FCE an d th e

ink jet control cpu on the IJC.

The FCIP consist s of th e following component blocks:

• MDM - Modem• RU8 CPU - Main CPU

• PRIF - Printer Interface• DMAC - DMA Controller

• DIP - Digital Imag e Processor

• DCR - Data Compression and Recon-

struction

1-8

November 28th, 1995 OVERALL MACHINE INFORMATION

OVERALL MACHINE CONTROL

The 512 KB DRAM contains the SAF memory, ECM buffer memory, and work

area. The SAF memory can be exte nd ed by 2 or 4 Mbytes with an IC card.

A 512 KB (4 Mbit) ROM is used for the system ROM.

For the USA and some Europe models, th e sof tware in this ROM can be rewritten from the IC card slot or by RDS (because a Flash ROM is used ).

The IJC consists of the following compo ne nt s:

• CPU - 16-bit CPU with 16-MHz external clock input

• Printer Controller - Gate Array

• RIDC - Raster Image Data Controller, interface between FCE and IJC

• ROM - The inkjet printer control prog ram an d the bitmap font data

• DRAM - Receive buffer, download buffer, and working area for printing

• I/F Controller - Centronics Interface Controller

• SRAM - Working area

• HIC - Hybrid IC, Tx/Rx Amplifie r

• Thermistor - Detects the temperature in the print er

• LED Driver - LED on/off control

• EEPROM - Contains the following data:

• Total amount of waste ink

• Total number of pages that have passed throu gh the printer

mechanism

1-9

OVERALL MACHINE INFORMATION November 28th, 1995

VIDEO DATA PATH

1.5. VIDEO DATA PATH

1.5.1. Transmission

Original

Contact Image Sensor Assembly

LED Array

Image Sensor

IJC

HIC

FCE

HIC

NCU

To the network

H505V505.wmf

SAF IC

Card

Video

Processing

Memory

DRAM

Memory

Line

Buffer/

FIFO

FCIP

DCR

DATA/ADDRESS BUS

ECM/SAF

Memory

DIP

MDM

Amplifier

Immediate Transmission:

Scanned data from the contact image sensor passes to the DIP blo ck in the

FCIP. After analog/digita l vide o p rocessing, the DCR block comp resse s t he

data for transmission . The compressed data then passes eit he r to the FIFO

memory or to the ECM memory, before it is sent to the telephone line through

the modem.

Memory Transmission:

First, the scanned data is stored in the SAF memory after compression in the

DCR block. At the time f or t ransmission, the DCR block decomp resse s t he

data from the SAF memory, then compresses it again after han dsh aking with

the other terminal is done. The compre ssed dat a th en pa sses e ith er t o t he

FIFO memory or to the ECM memory, before it is sent to the telephone line

through th e modem.

1-10

November 28th, 1995 OVERALL MACHINE INFORMATION

VIDEO DATA PATH

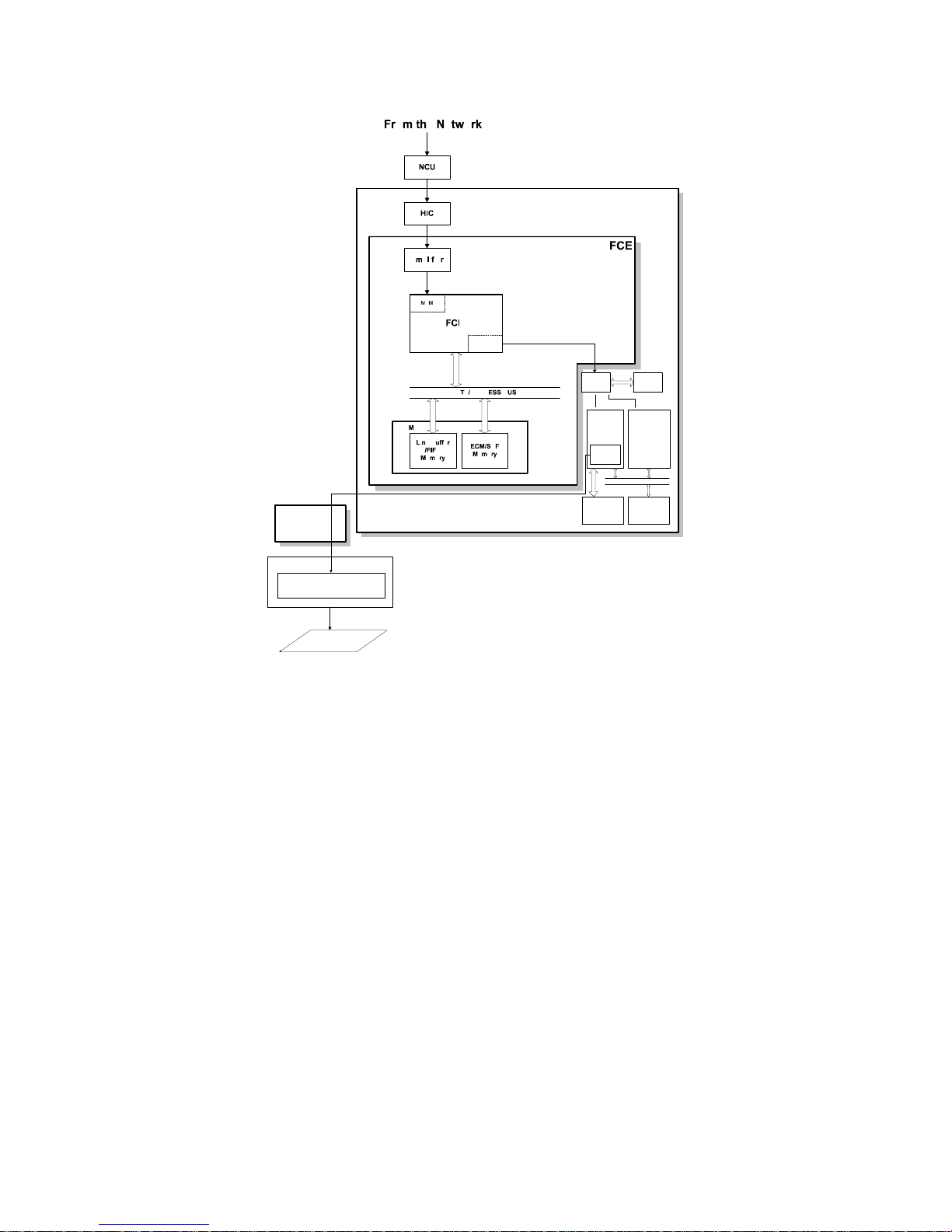

1.5.2. Reception

IJC

DCR

RIDC SRAM

Print

Controller

Print Head

Controller

CPU

FDU

Carriage

Printer Head

Copy Paper

DRAM ROM

H505V506.wmf

Data from the line p asse s to the modem throu gh th e NCU a nd hybrid IC. After the modem demodula tes the data, the data (which is compressed) passes

to the SAF memory. After the data has been stored in the SAF memory, it

passes through either t he FIFO or the ECM memory to the DCR block, where

the data is decompressed to rast er image data.

The image data is then passed to the Print Controlle r for printing, through th e

RIDC.

After the data has been stored in the DRAM (which acts as a print buf f er), the

data is sent to the printer head through the printer head cont rol blo ck.

1-11

OVERALL MACHINE INFORMATION November 28th, 1995

VIDEO DATA PATH

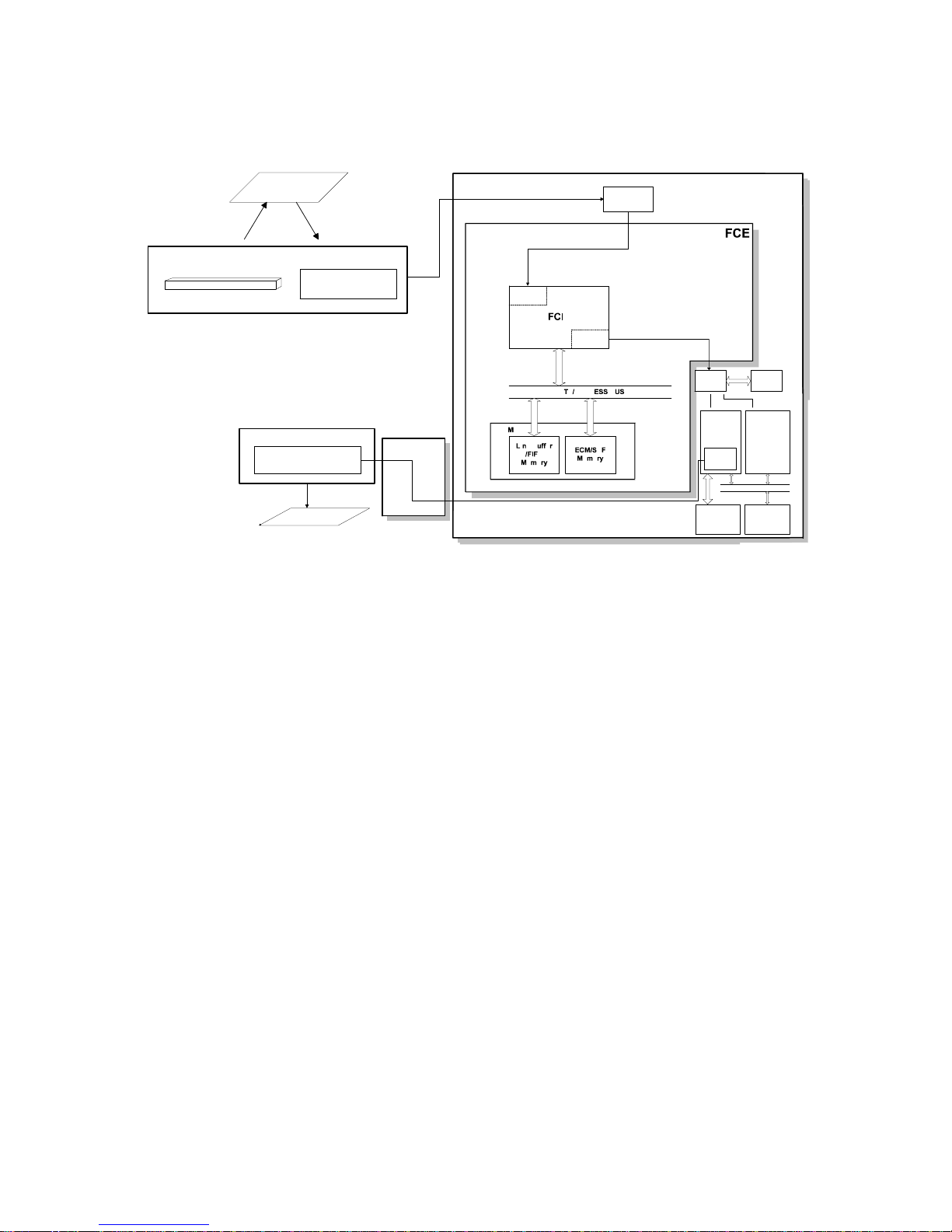

1.5.3. Copying

Original

Contact Image Sensor Assembly

Image Sensor

LED Array

Carriage

Printer Head

Copy Paper

FDU

HIC

DIP

DCR

IJC

RIDC SRAM

Print

Controller

Print Head

Controller

DRAM ROM

CPU

H505V507.wmf

Single copy

The scanned data is processed in the DIP block. After the da ta has been

stored in the DRAM for printing through the RIDC, the data is sent to the

printer head through the Print Controller.

Multi-page copy

The scanned data passe s t o th e SA F me mory af ter video processing (DIP)

and compression (DCR). After a pa ge of da ta has been stored in the SAF

memory, the data passes to the DCR block again for de compression, then it

passes to the print con tro ller for printing through th e RIDC.

1-12

November 28th, 1995 OVERALL MACHINE INFORMATION

VIDEO DATA PATH

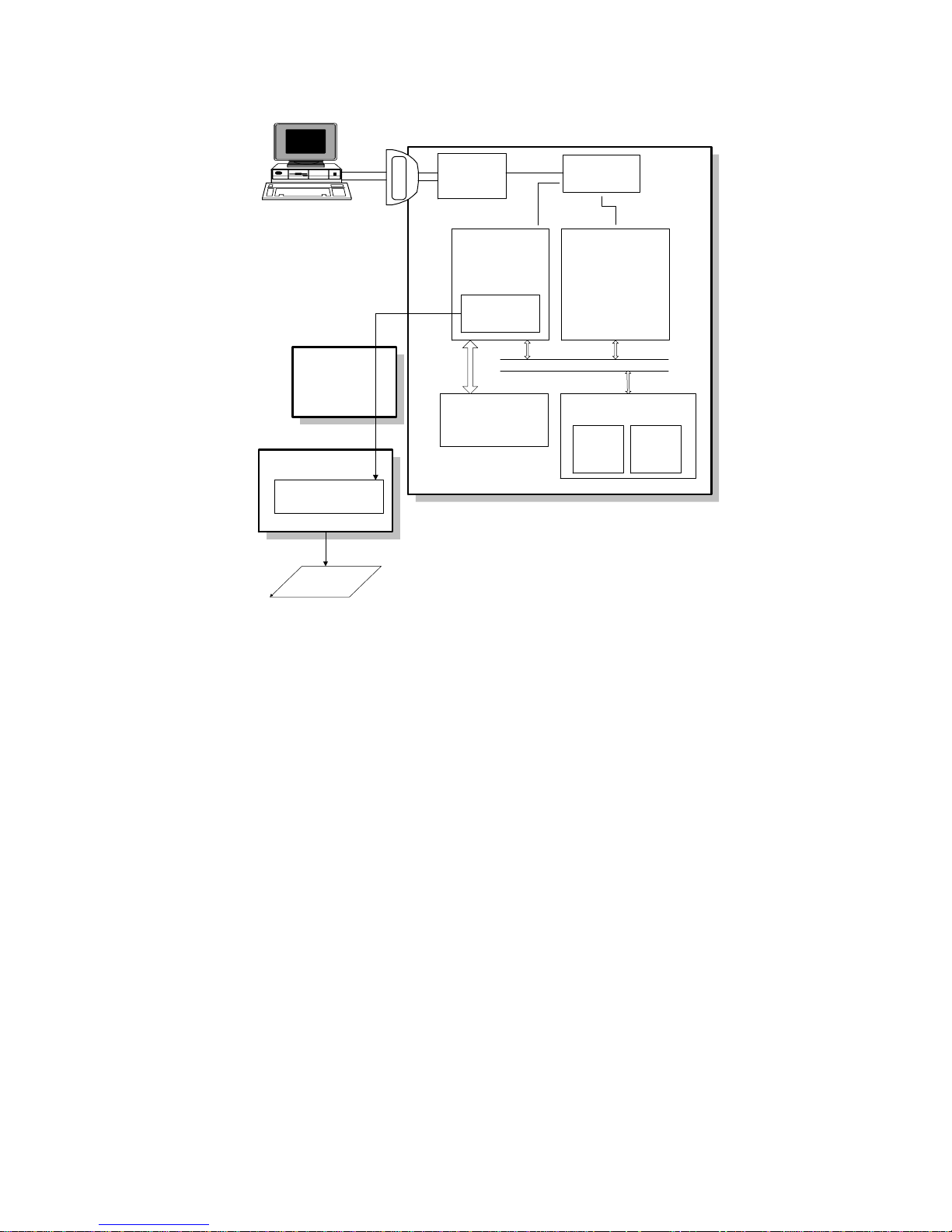

1.5.4. Printing from the Centronics Interface

Centronics

I/F

I/F

Controller

Print Controller

Printer Head

Controller

RIDC

CPU

FDU

Printer Control

Program

ROM

Bit Map Font

Data

DRAM

Carriage

Printer Head

Copy Paper

H505V508.wmf

The print data passes f rom th e Centronics interface to th e print controller

through the I/F controller and the RIDC.

The print data is stored in th e DRA M, which acts as a print buffer . At the

same time, font data from the ROM is stored in the DRAM, which also acts as

a downloaded font buffer if necessary.

After the print data has been stored with the font data in the print buffer, the

print data passes through the print er head cont rol block to the print controller

for printing.

1-13

OVERALL MACHINE INFORMATION November 28th, 1995

POWER DISTRIBUTION

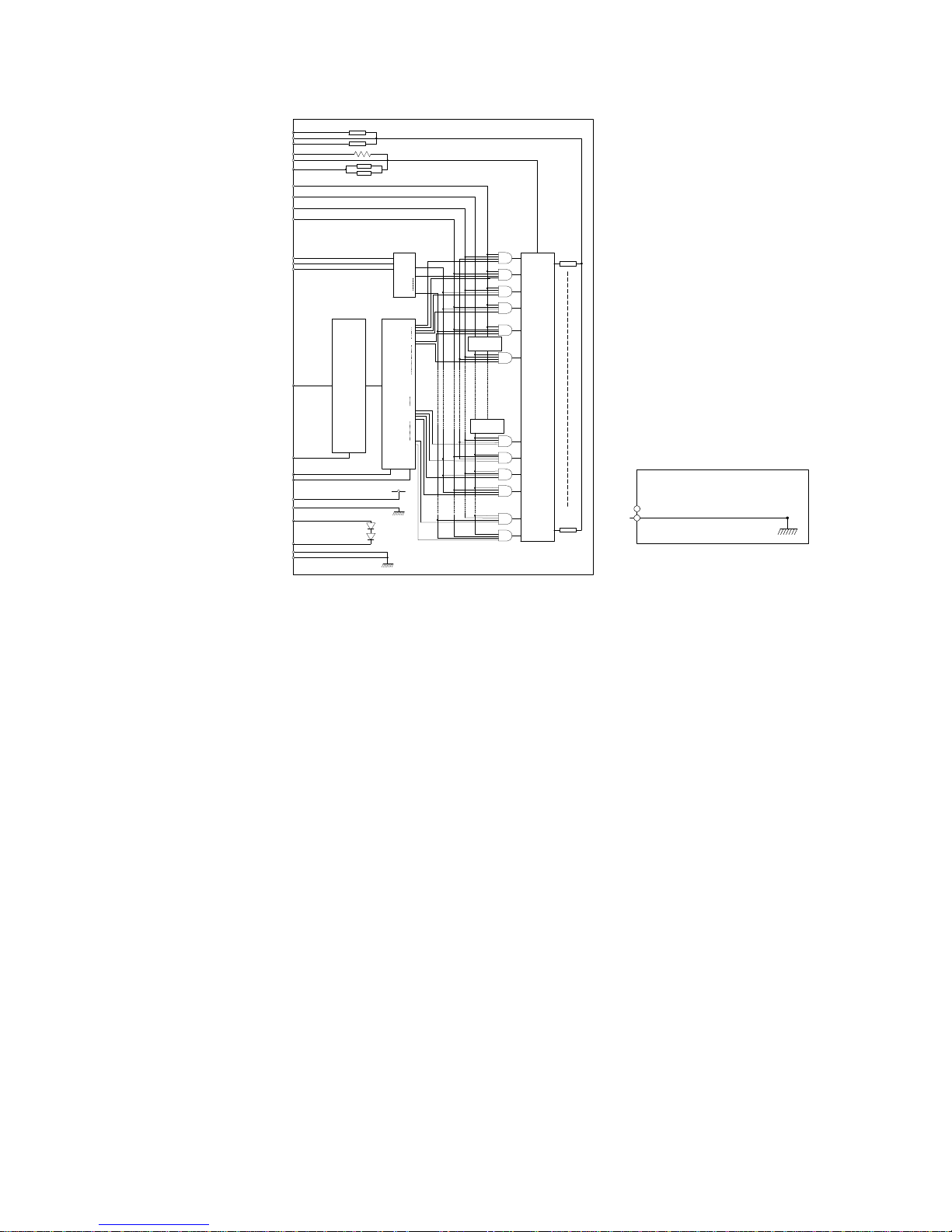

1.6. POWER DISTRIBUTION

1.6.1. Distribution Diagram

PSU

Carriage

HVH

HVDD

+24VH

FDU

+24VM

+24VM

+24VH

+5V

Tx Motor

+5V

Driver

+24VM

DRAM Backup

Circuit

BAT

DC-DC

Converter

(for Stepping Motors)

Carriage

Motor

Drivers

+5V

-5V

+24VM

Paper Feed

Motor

+24VM

+5V

-5V

+24VM

Contact Image

DC-DC

Comverter

+24VM

-5V

Sensor

+5V

+5VBAT

+12VP

+5V

+5VCIS

+5V

FCE

+5VBAT

IJC

+5V

+5V

+24VM

Ink End

Sensor

Operation

Panel

NCU

H505V509.wmf

The PSU supplies +24V dc power to the FDU. The FDU co nve rts the +24V

dc power supply to the following supplie s.

+5V

This is normally on when the main power is supplied.

This supplies the DRAM and the optional IC card on the FCE to back up the

+5VD

stored data for one hour. A rechargeable battery on the FDU is used to

generate +5VD.

+5VBAT

+24VM

-5V

+24VH/

This supplies the system RAM on the FCE to back up the programmed data. A

lithium battery is used to generate +5VBAT.

This is normally on when the power code is plugged in.

This is used for the image sensor.

This is supplied to the temperature control heater on the printer head.

HVH

HVDD

This is supplied to the drive circuit on the printer head.

The FDU supplies + 24V and ±5V dc power to the IJC. The IJC converts the

+24V and +5V dc power supplies to the fo llowin g sup plie s.

+5VCIS

+12VP

This is a more stable power supply than +5V. It is used for the Contact Image

Sensor.

This is supplied to the Flash ROMs on the FCE and the optional IC card.

1-14

November 28th, 1995 OVERALL MACHINE INFORMATION

POWER DISTRIBUTION

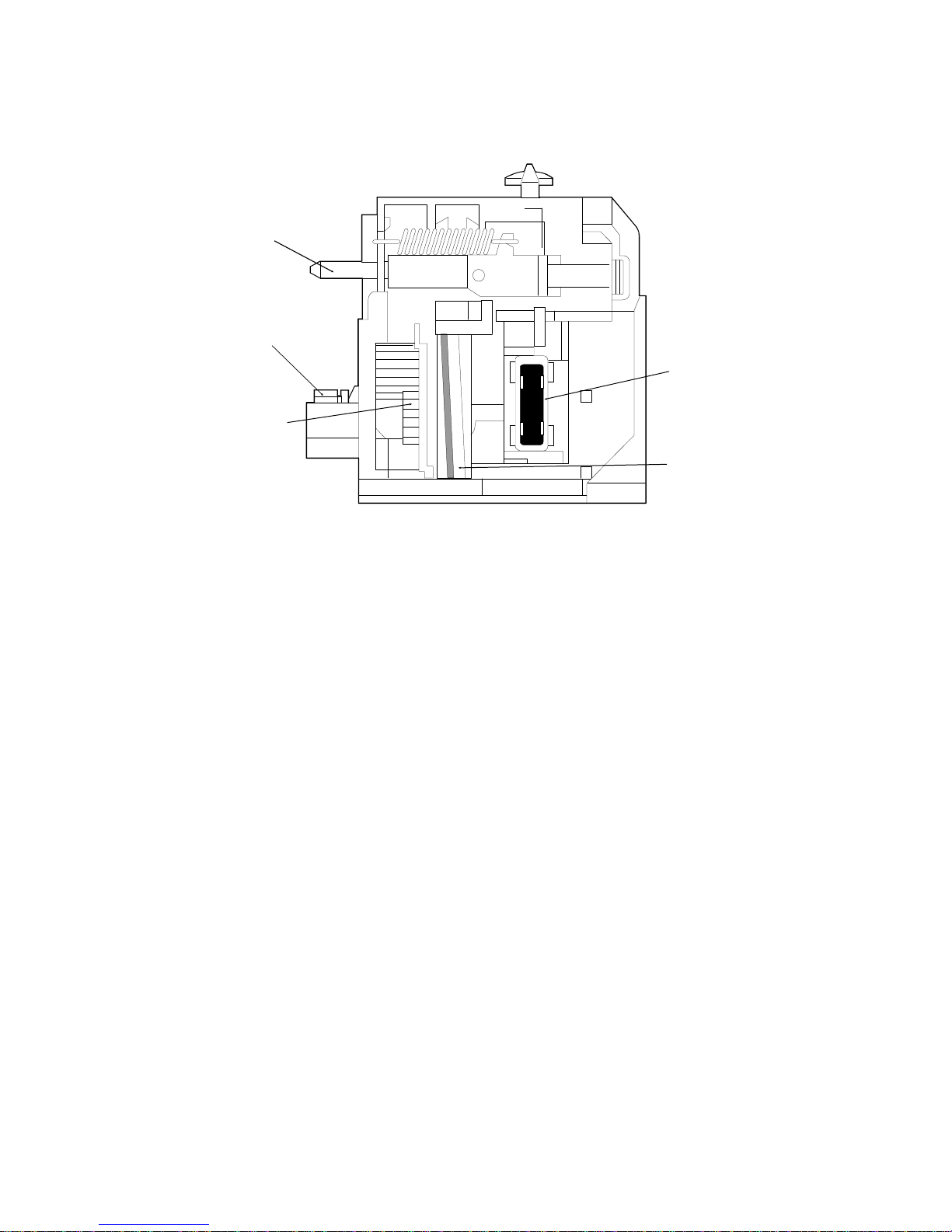

1.6.2. Memory Back-up Circuit

IJC

[A]

[B]

FDU

H505V510.wmf

The +5VBAT supply from the lithium bat te ry [A] backs up the system RAM

which contains system para met ers an d pro grammed telephone numbers,

and the real time clock in the main cpu. The 5R TCCS sig na l tells th e main

cpu whether the back-up powe r (+5 VB AT) is coming from the battery or from

the +5V power supply.

A rechargeable lithium batt ery [B] and the dc/dc converter on the FDU back

up the DRAM (SAF memory) for one hour. While the main power is on, the

+5V supply recharges th e ba ttery. The battery recharges in one or two days.

The battery [B] generat es abou t 3 volt s (max. 3. 2 vo lts). The dc/dc converter

(IC12) lifts this voltage to 5 volts so it can be used as the +5VD sup ply for

SAF backup. The CPU monit ors the voltage of the +5VD supply with the

1VDET signal. Whe n th e ba tt ery ha s run do wn, and the volta ge is lower t han

4.4 volts, the CPU stops the dc/dc converter by dropping 1SAFFG to low and

the machine stops backing up the memory.

There is no battery switch for the battery [B].

1-15

[D]

November 28th, 1995 DETAILED SECTION DESCRIPTIONS

SCANNER

2. DETAILED SECTION DESCRIPTIONS

2.1. SCANNER

2.1.1. Mechanisms

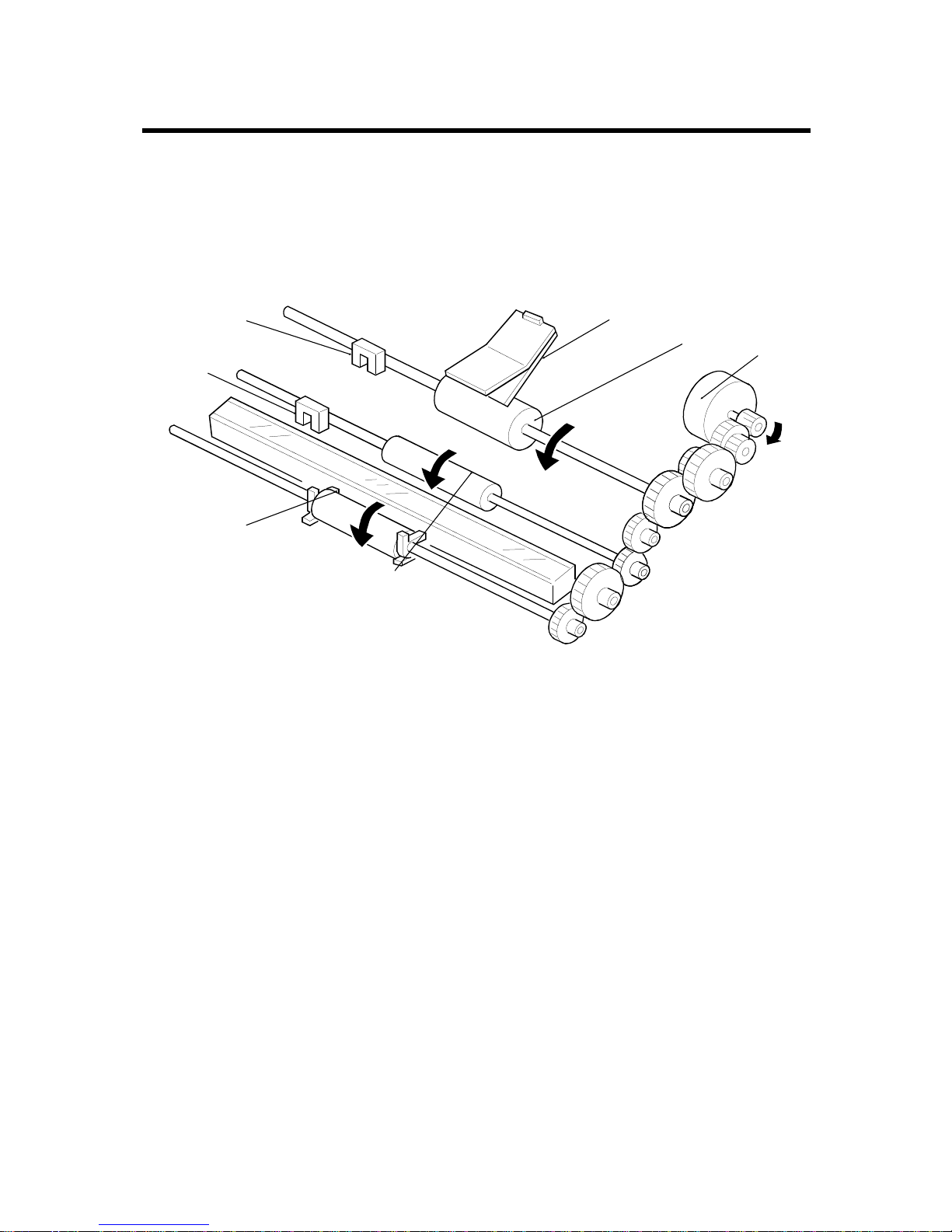

1. Document Detection, Pick-up and Separation and Dri ve Mecha nis m

[A]

[B]

[G]

A: Document Sensor

B: Scan Line Sensor

C: Separation Rubber Plate

E: Tx Motor

[C]

[E]

[F]

H505D501.wmf

The document se nso r [A] detects when a do cument is placed in the ADF. The

tx motor [E] then sta rts to prefeed the document unt il t he scan line se nso r [ B]

detects it. The separation rubb er pla te [C] pre vents the feed roller [D] from

feeding more than one sheet at a time.

To feed the document throught the scanne r, the Tx motor [E] dr ives t he feed

roller , the R1 roller [F], and the R2 roller [G].

2-1

[A]

[E]

DETAILED SECTION DESCRIPTIONS November 28th, 1995

SCANNER

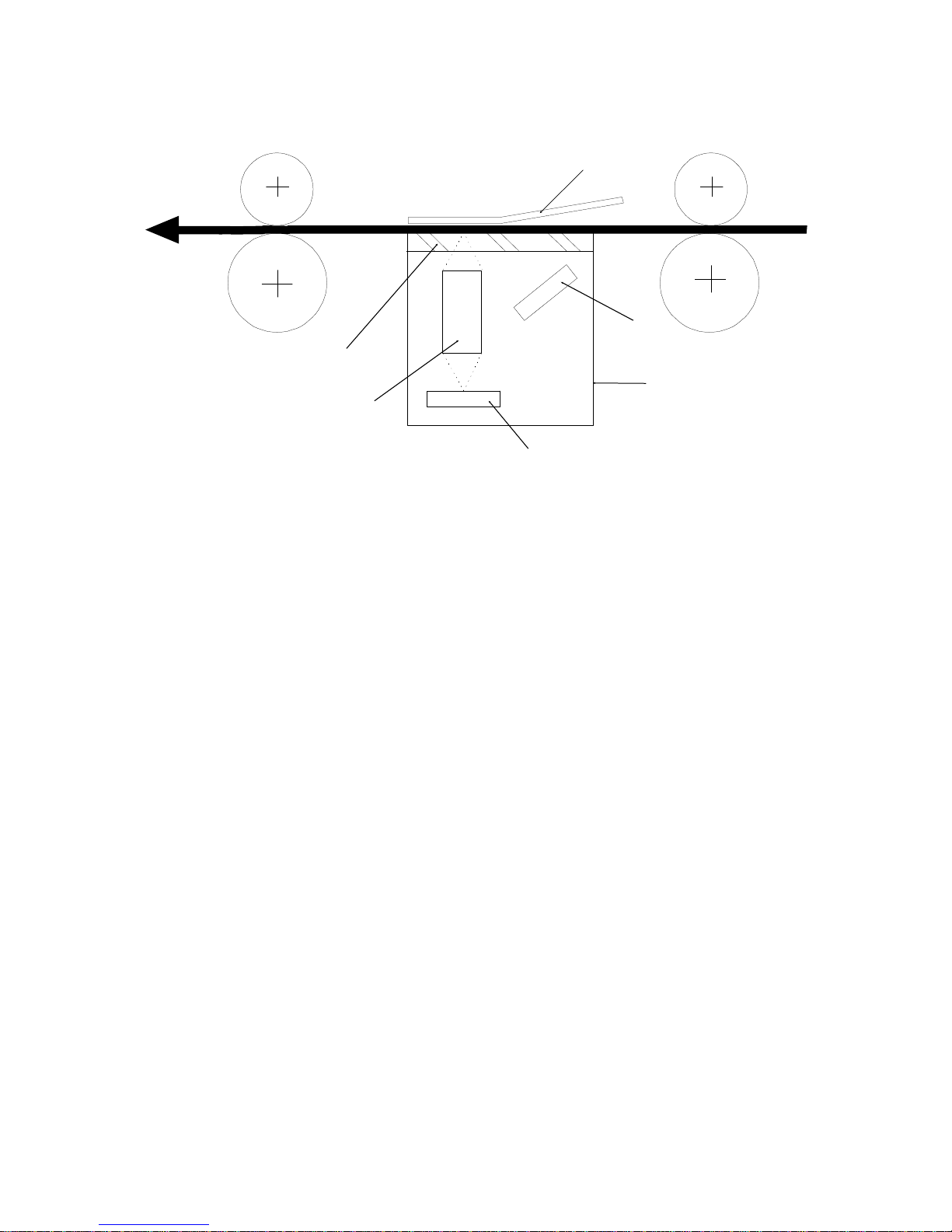

2.1.2. Image Scanning

[F]

[C]

[B]

[D]

H505D522.wmf

The scanner consists of a sha ding plate [A] and a contact image sensor

(CIS) assembly [B]. Insid e the CIS are an exposure glass [C], a rod lens array [D], an image sensor [E], and an LED array [F] .

The image sensor consists of a row of 1728 photo sensitive elements. Light

from the LED array is reflecte d from the document and focused onto the image sensor by the rod len s array. Because of the short optical path inside the

CIS, the focal depth is much short er than for a CCD type scanner. Because

of this, the shadin g plate pushes the document so that the document surface

always touches the exp osu re glass at the scan line.

The image sensor assembly is not adjusted at the factory, so it does not need

any adjustment at replacement in the field.

The image sensor scans the origin al on e line at a time, and outputs an analog signal for each line. The voltage from each element depends on the

intensity of the light reflected from the original onto the elemen t.

The machine feeds the document throug h the scanner using one of th e following step widths: th e scanned lines are transmitte d without any OR

processing.

3.85 lines/mm in Standard resolution

7.7 lines/mm in Detail resolut ion

15.4 lines/mm in Fine resolution

2-2

November 28th, 1995 DETAILED SECTION DESCRIPTIONS

SCANNER

Auto Contrast Thresholding

This machine determines the cont rast thresholds automatically whe n text

mode is used. The machine compares the video data ele men t with the surrounding elemen ts an d automatically calculates the threshold level.

When this mode is enabled, the contrast thresho ld set ting of scanner bit

switch 02 is ignored.

This function can be disable d with scann er bit swit ch 00.

Jam Conditions

The machine detect s a docu ment jam if one of the following cond itions occurs.

Jam Condition Description Error Code

The scan line sensor does not switch on within

Non-feed

Incorrect sensor

condition

3.0 s of the tx motor starting to prefeed the

document.

The scan line sensor does not turn off after the

maximum document length has been fed

since it turned on.

1-00

1-01

2-3

DETAILED SECTION DESCRIPTIONS November 28th, 1995

PRINTER

2.2. PRINTER

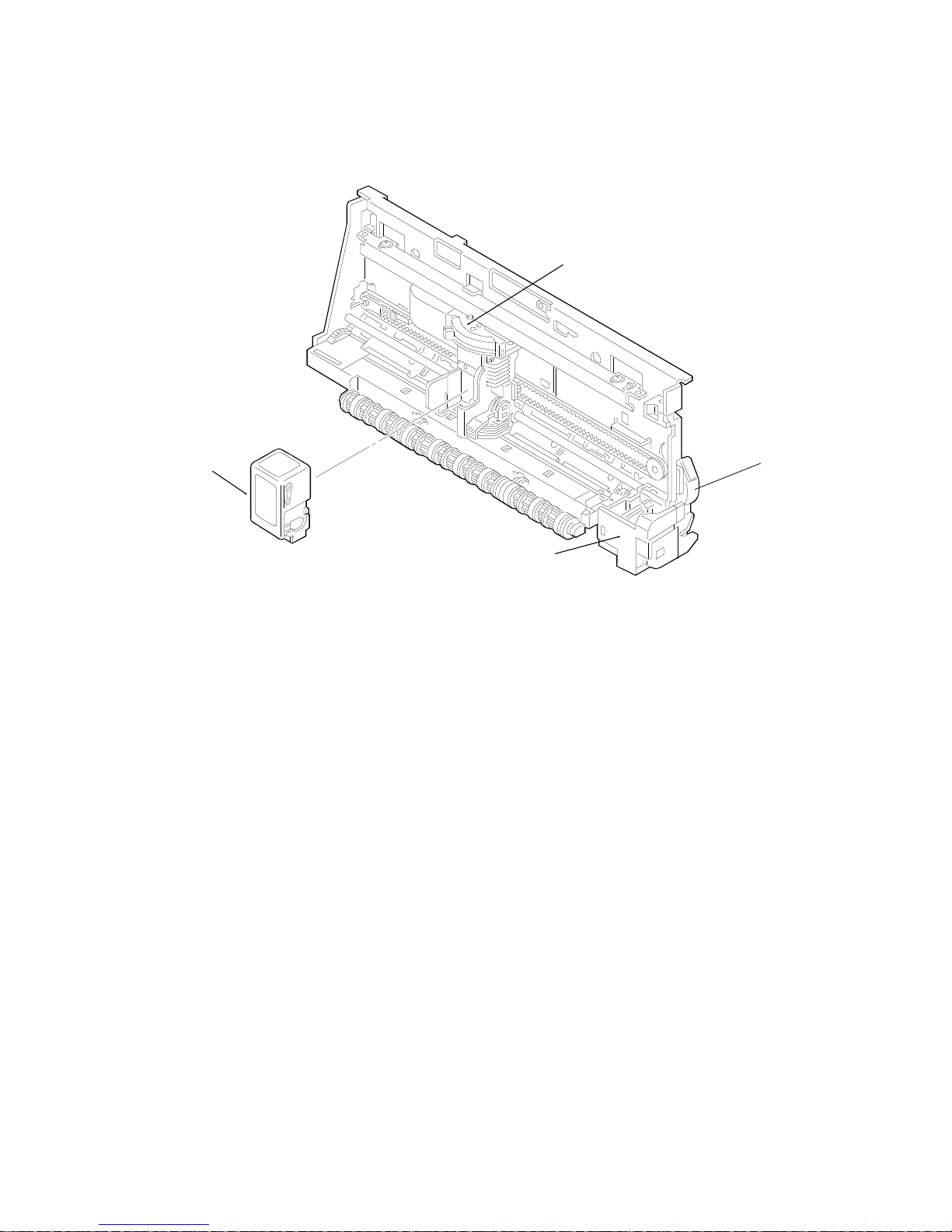

2.2.1. Printer Configuration

[C]

[A]

[D]

[B]

H505D512.wmf

Ink Cartridge [A]: The ink cartridge is ma de up of the printer head and the

cartridge body. The machine can use both black and color ink ca rtrid ge s.

The black ink cartridge is a single unit, but the color ink cartridge has separate ink refills (black and color) which can be replaced.

Purge Unit [B]: To sustain a high quality printing level, th e purge unit maintains the ink nozzles wit h a cap and wiper. The purge unit p rotects the

nozzles with the cap when the print er is not in use.

Carriage [C]: The carriage unit, driven by the carriage motor [D], moves horizontally across the print paper. The print signals are transmitte d t o t he ink

cartridge by the carriage ribbon cable. Whe n the carria ge unit is at home position, paper feed mot or drive can be transferred to the purge unit or the pap er

feed roller (see "Paper Feed - Drive Mechanism" for details).

2-4

[E]

November 28th, 1995 DETAILED SECTION DESCRIPTIONS

PRINTER

2.2.2. Ink Cartridge (Black and Color)

[A]

[H]

[I]

[F]

[D]

[J]

Black Ink Cartridge

H505D506.wmf

[C]

[H]

[B]

[I]

[G]

[J]

Color Ink Cartridge

H505D507.wmf

The black ink cartridge cont ains only the black ink sponge [A] while the color

cartridge contains ink sponge s for black [B], yellow [C], magenta [D], an d

cyan [E].

The black printer head face plat e [F] cont ain s a row o f 128 nozzles an d the

color printer head fa ce pla te [G] contains 136 nozzle s. In k passes to these

nozzles through an ink duct section [H]. Printing signals are sent to the printe r

head from the signal connection point [I].

2-5

Nozzle 136

DETAILED SECTION DESCRIPTIONS November 28th, 1995

PRINTER

2.2.3. Printer Head

1. Mechanism

[C]

[D]

[E]

[F]

[B]

[A]

H505D508.wmf

Ink from the sponge is filtered at [A] to remove dust, and then passes to the nozzles throug h pip e [B ]. W hen th e he ad dr ive cur re nt f low s thr ough a n ozzle ’s

heater plat e [C], th e ink at the plat e boil s. The bubb les for med [ D] even tuall y joi n

into one large bub ble [E] . The bubbl e forces a dro p of ink [F ] out of the nozzl e.

Head drive current stops before the bubble is fully formed. The remaining

heat of the heat plate complete s the bubble . The pla te cools b y th e t ime t he

ink drop is ejected, and fresh ink ent ers th e no zzle fro m t he spon ge .

The nozzles are arranged in a

straight line at intervals of 1/360

Nozzle 1

Nozzle 1

inch.

There are 128 nozzles in the

black ink cartridge.

The color ink cartridge has a

total of 136 nozzles: 24 yellow

Yellow 1~24

Magenta 25~48

Cyan 49~72

Black 73~136

nozzles, 24 magenta no zzles, 24

cyan nozzles, and 64 black nozzles.

Nozzle 128

Black Ink Cartridge Color Ink Cartridge

H505D509.wmf

2-6

ID0

ID1

November 28th, 1995 DETAILED SECTION DESCRIPTIONS

PRINTER

2. Drive Circuitry

Temperature Control Heater x 2

Rank Resistor

Sub-heater x 2

H ENB

Odd ENB

Even ENB

RANK

WH-T

HTO

HVH

HTI

VHG

<0>

<1>

128/136

Bit Tr.

Array

Heater 1

Heater

128/136

*

B ENB

HDATA

HCLOCK

HLATCH

DIODE A

DIODE K

HRES

HVdd

HVss

<0>

<1>

<2>

Decoder

128/136

Bit Shift

Register

ID0

ID1

3→8

128/

136

/

Temperature

128/136

Bit Latch

Head

Sensor

1

2

8

1

16

113

114

128/

136

Delay

Delay

H505D504.wmf

128/136 Bit Shift Register: This register store s the print data (HDAT A) sent

from the FCE with the HCLOCK timing signal.

128/136 Bit Latch: This latch sto res th e prin t data (HDATA) sen t from the

128/136 bit shift registe r with th e HLATCH timing signal.

3→8 Converter: This converts the three BENB (block enable) signals (<0>,

<1>, and <2>) into the 8-division timing signals for all heat ers.

Heaters 1-128/1-136: These heaters heat the nozzles. They are turned on

by a combination of OddENB or Eve nENB, HENB (heat enable), the timing

signals from the 3→8 converter, and the data signal (HDAT A ) from the latch.

Sub-heater: This heater keeps the ink in the nozzles warm.

Temperature Control Heater: This heater stabilizes the amo un t of in k in-

jected.

Heat Temperature Sensor: This sensor use s a diode to detect the t empera-

ture variation caused by th e flo w of ink at the nozzle s.

Cartridge ID: The cart ridg e typ e (color or black) is det ect ed with the I D0 a nd

ID1 signals.

*These ID signals identify a color cartridge.

The main illustration’s ID signals identify a black cartridge.

2-7

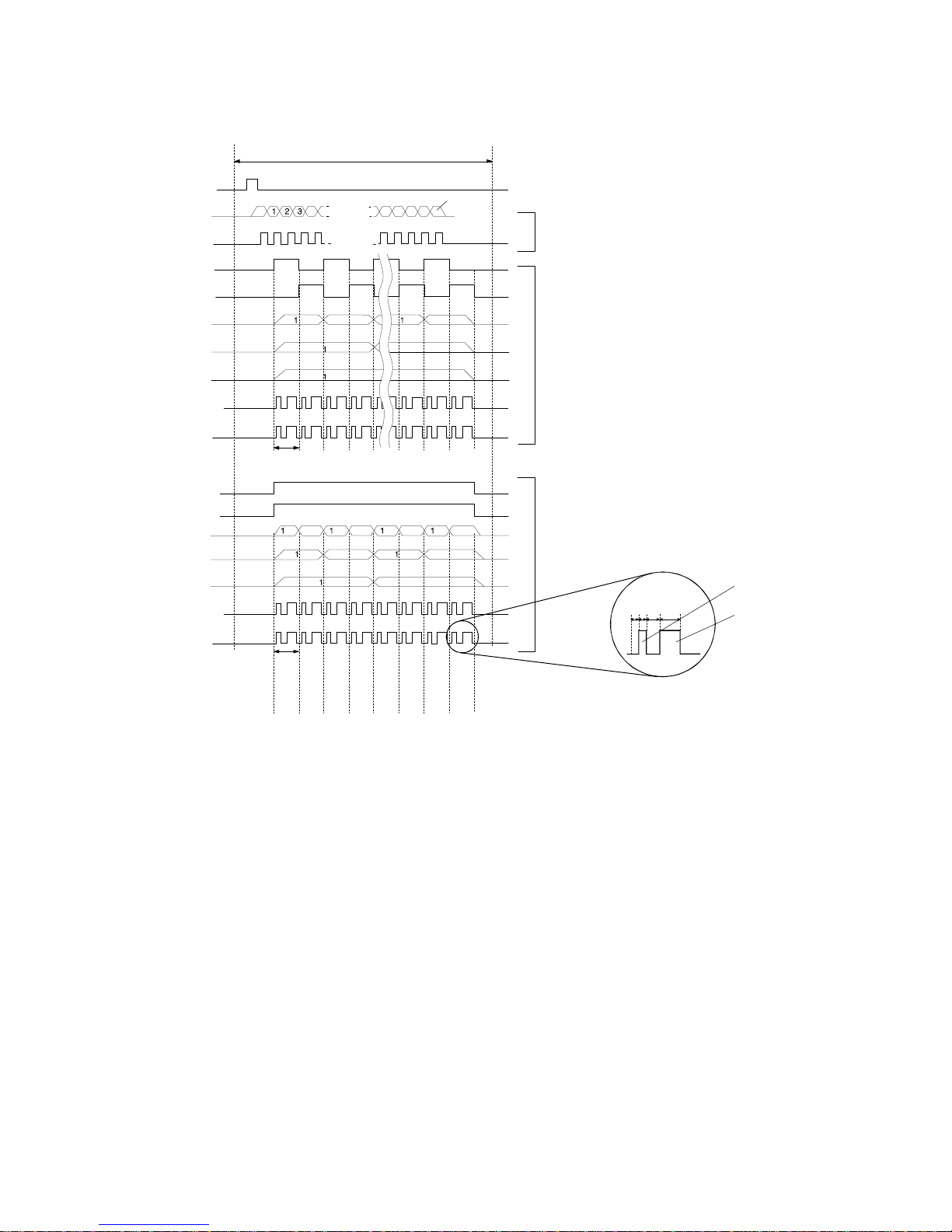

DETAILED SECTION DESCRIPTIONS November 28th, 1995

PRINTER

3. Print Signals

HQ 160s (6.25kHz)

Smoothing 128s (7.81kHz)

HS 112s (8.93kHz)

HLATCH

HDATA

HCLOCK

Odd ENB

Even ENB

B ENB 0

B ENB1

B ENB 2

H ENB 0,1,2

H ENB 3

Odd ENB

Even ENB

B ENB 0

B ENB 1

B ENB 2

H ENB 0,1,2

1 BLOCK

128 OR 136

Data transmission to shift

Head Driving in HQ Mode

Head Driving in HS Mode

register

(Divided into 16)

(Divided into 8)

Variable

Pulse Width

Pre-Pulse

Main Pulse

H ENB 3

1 BLOCK

H505D510.wmf

The 3→8 convert er changes the three signa ls, BENB 0, 1, and 2, into 8 signals, dividing the nozzles into 8 blocks. For HQ print mode, these blocks are

then further divided with the OddENB and EvenENB signals into 16 nozzle

groups.

The HENB signals make up the pre-pulse s (wh ich raise the temp era tu re of

the printer head to a suitable te mpe rat ure), and the main pulses (which cause

the ink to be ejected). These signals are input with the print data signals for

each nozzle into th e A ND circuits (see the diagram on the pre vious page).

The resulting signal drive s the hea te rs.

2-8

[C]

November 28th, 1995 DETAILED SECTION DESCRIPTIONS

PRINTER

2.2.4. Purge Unit

1. Components

[E]

[A]

[D]

[B]

H505D51 1.wm f

Purge Unit Drive Gear [A]: The paper feed motor drives this gear during

cleaning. The gear functions as a cam to control the ink p ump inside the

purge unit.

Wiper Unit [B]: The wip er unit wipes the ink from the ink cartridge face plate

during cleaning.

Cap Unit [C]: The cap unit caps t he print head fa ce plat e (n ozzle s) when the

nozzles move to the capping posit ion (this is when the carriage is at home position). The cap unit is also connect ed to th e ink pump. It extracts ink from

the ink cartridge during clea nin g op era tions. The waste ink is drained do wn

into the waste ink absorbers in the bottom of the unit.

Maintenance Jet Receiving Section [D]: This section receive s ink e ject ed

from the nozzles into the pu rge unit to prevent cloggin g. The g ea r fe ed s the

waste ink to the waste ink ab sorb ers in the bottom of the unit.

Slide Pin [E]: The slide pin causes the cap unit [C] to cap the nozzles when

the cartridge moves into the capping position. This unlo cks th e d rive transfer

mechanism inside the purge unit, allo wing the paper feed moto r drive to be

transferred eith er to the purge unit drive gear [A] or to the pa pe r f ee d unit

(see section 2-2-5).

2-9

Loading...

Loading...