Ricoh FW870 SAFETY NOTICES

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

6.The copier is not attached to the table. Pushing the copier too heard may

cause it to drop onto the floor. While moving the copier, push the table.

7. When the main switch is tuned on, the machine will suddenly start turning

to perform the developer initialization. Keep hans away from any

mechanical and electrical components during this period.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get medical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

CAUTION

2. The RAM board on the main cont rol board has a lithium battery

which can explode if replaced incorrectly. Replace the RAM board

only with an identical one. The manufacturer recommends

replacing the entire RAM board. Do not recharge or burn this

battery. Used RAM board must be handled in accordance with

local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may

ignite suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductor according

to local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used RAM boards in order to dispose of them later, do not

put more than 100 RAM boards per sealed box. Storing larger numbers

or not sealing them apart may lead to chemical reactions and heat

build-up.

SECTION 1

OVERALL

MACHINE INFORMATION

25 July 1996 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Console

Copy Process: Electrostatic transfer system

Original Feed: Sheet feed

Original Size: Maximum: 914 x 3,600 (36" x 142")mm

Minimum: 182 x 257 (B5), 8

Copy Size: Same as "Original Size"

Copying Speed: 7.5 cpm (A1/D sideways)

First Copy: 18 seconds (A1/D sideways)

1/2

" x 11" lengthwise

Overall

Information

Warm-up Time: Within 6 minutes (Room temperature 23

o

C)

Multi-Copy: 1 to 10

Automatic Reset: 2 minutes after copying is finished (can be set

to 1, 3, 4, or 5 minutes or to no auto reset)

Photoconductor: Organic photoconductor drum

Drum Charge: Single-wire with grid plate (Negative Charge)

Reproduction Ratio: 1 : 1 (

0.5%)

±

Exposure System: Slit exposure via fiber optic array

Exposure Lamp: Fluorescent lamp (26 W)

Development: Dual-component dry toner system

Toner Replenishment: Cartridge system (750 g toner/cartridge)

Toner Consumption: 1,860 A1 or D copies per cartridge (6% original)

Development Bias: Negative

Toner Density Control: Direct toner density detection by induction

sensor

Image Density Adjustment: Development bias control + exposure control

Auto Image Density Control: Development bias control + exposure control

Paper Separation: Dual wire ac corona and pick-off pawls

Cleaning: Cleaning blade

1-1

SPECIFICATIONS 25 July 1996

Paper Feeding: Manual feed and 2 roll feeds

(3rd roll feeder optional)

Image Fusing: Heat and pressure type, teflon (upper) and

silicone rubber (lower) rollers

Fusing Lamp: Halogen lamp

(115 V: 1,100 W, 230 V: 1,100 W)

Self-diagnostic Codes: 18 codes, displayed in copy counter

Power Source: 115 V/60 Hz....12 A

220 V/50 Hz....7 A

230 V/50Hz.....7 A

240 V/50 Hz....7 A

Power Consumption: Maximum: 1.41 kW

Warm-up: 1.21 kW

Ready: 0.1 to 1.2 kW

Copy cycle: 1.36 kW

Dimensions (W x D x H): 1230 x 690 x 1065 mm

48.4" x 27.2" x 41.9"

Weight: 195 kg, 429 lb

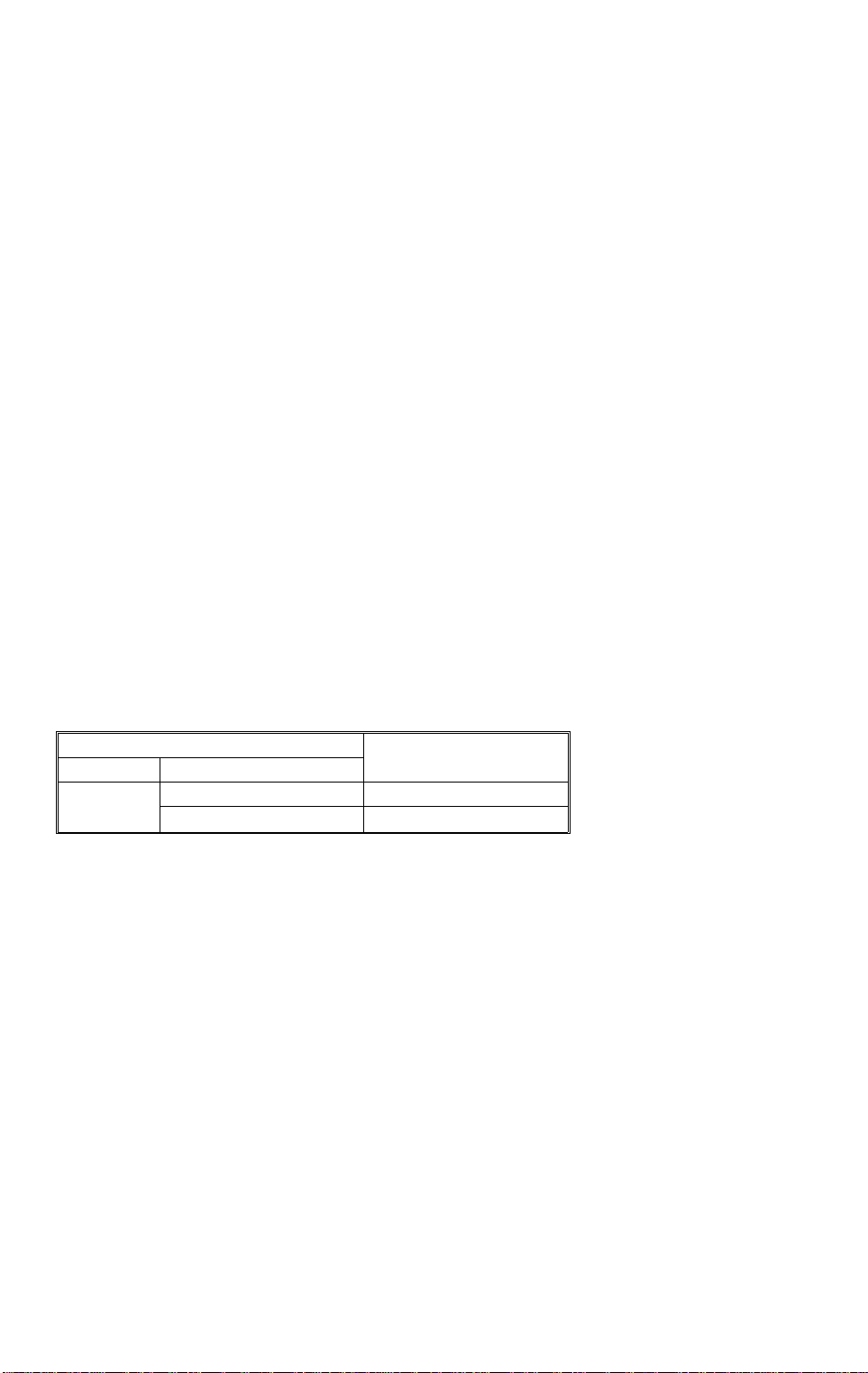

Optional Equipment and Machine Configuration

Configuration

Main frame Optional equi pm ent

A174

copier

3rd Roll feeder (A613) –

Side gui des (A569) –

Additional equi pm e nt

Other Optional Equipment

Paper Spool (Spare parts)

•

Key Counter Bracket Set (A902-15)

•

Key Counter (Procured locally)

•

Key Counter Holder (Procured locally)

•

Specifications are subject to change without notice.

1-2

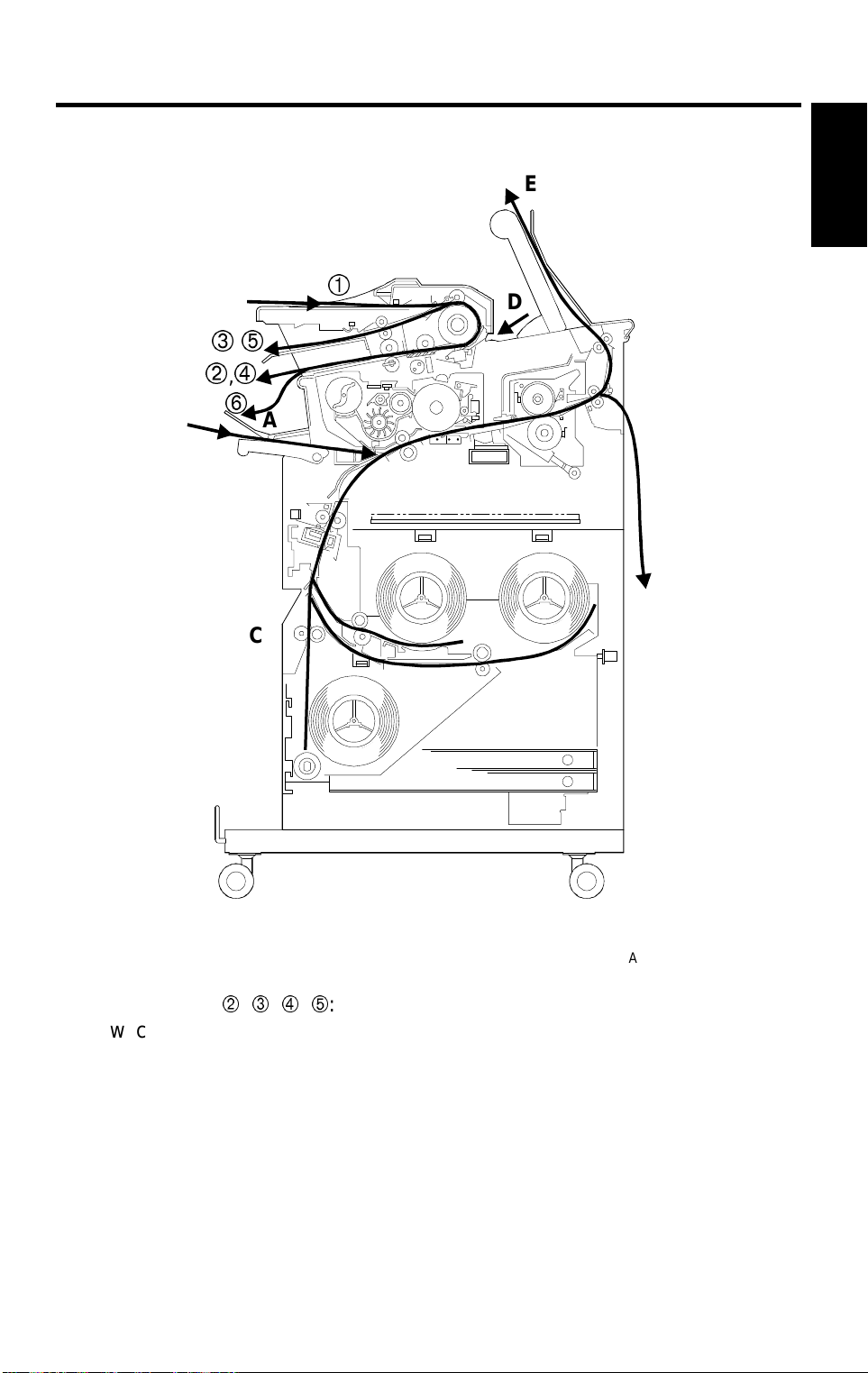

25 July 1996 PAPER PATH

2. PAPER PATH

E

Overall

Information

D

,

,

B

A

F

C

A: Original Path , , , :

Switching back

B: Paper from the manual feed

C: Paper from the roller feed

A174V502.wmf

D: Original Path from Rear Feeder

E: Upper Copy Exit

F: Lower Copy Exit

1-3

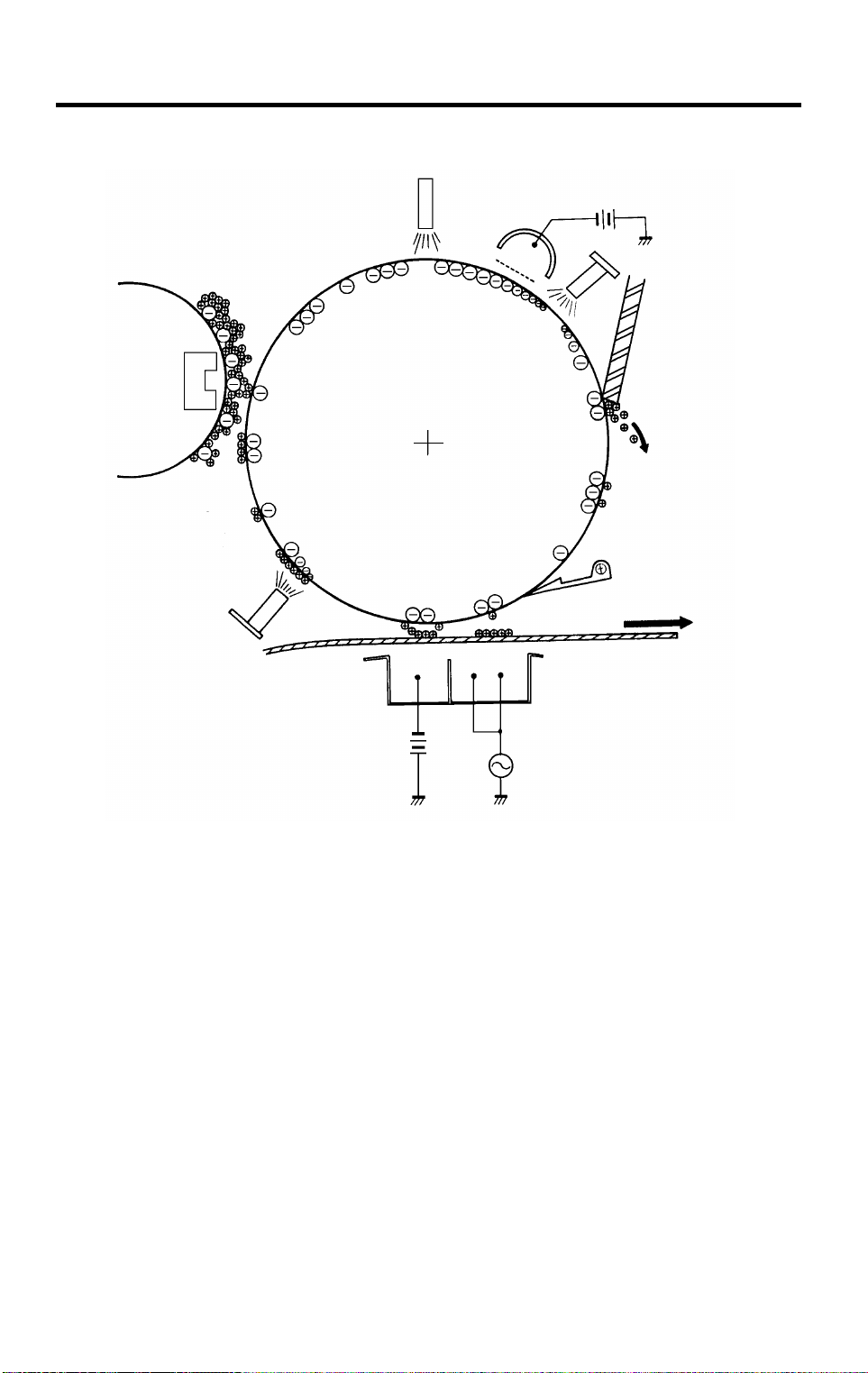

DRUM PROCESSES 25 July 1996

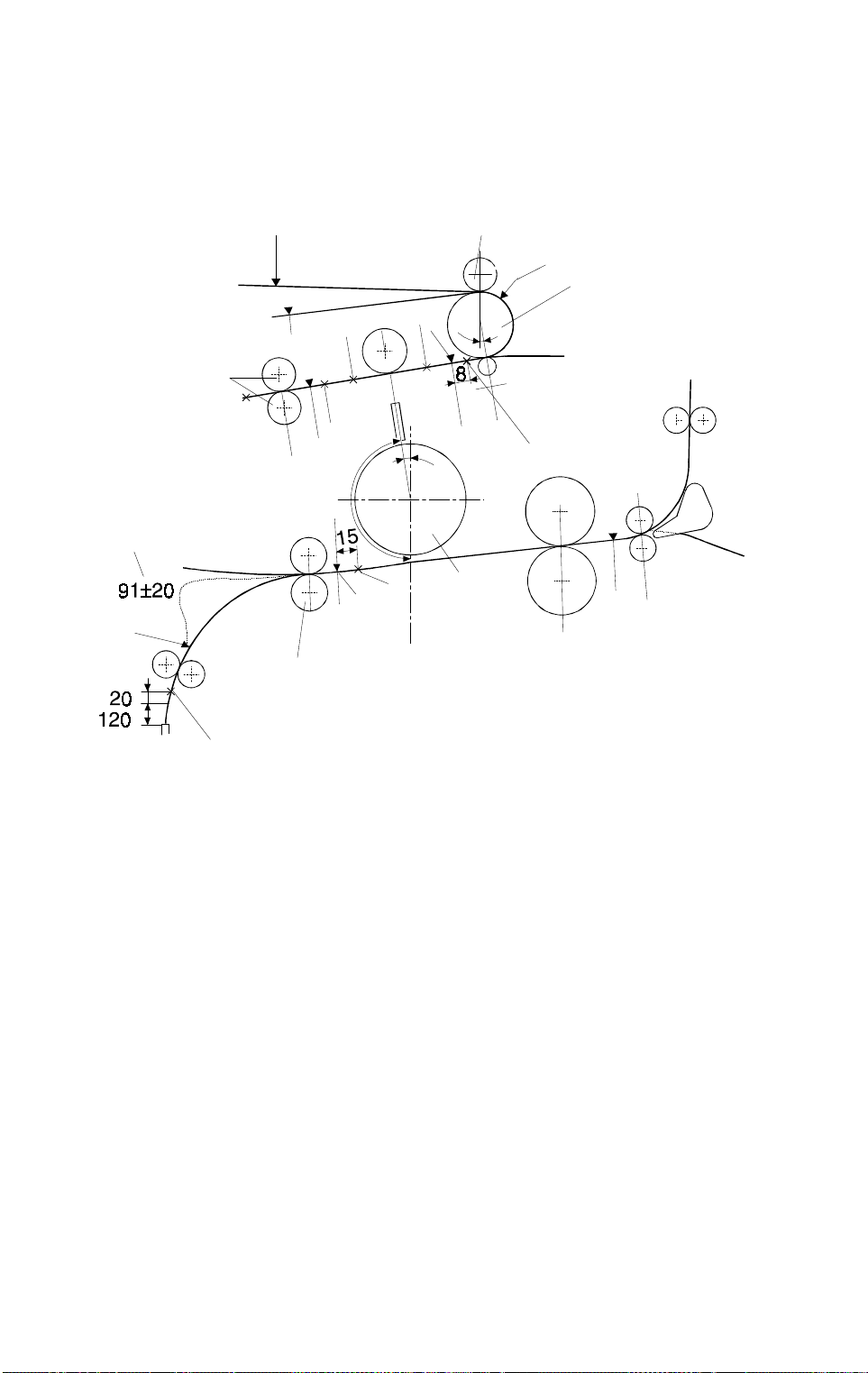

3. DRUM PROCESSES

2

1

8

7

3

4

5

6

A174V503.img

1. Charge

In the dark the charge corona unit applies a negative charge to the drum.

The grid plate ensures the charge is applied uniformly. The charge remains

on the surface of the drum because the photoconductive drum has a high

electrical resistance in the dark.

2. Exposure

High intensity light from a fluorescent lamp is reflected from the moving

original through the fiber optic array. The charge on the drum surface is

dissipated in direct proportion to the intensity of the reflected light, thus

producing an electric latent image on the drum surface.

1-4

25 July 1996 DRUM PROCESSES

3. Development

The magnetic developer brush on the development roller comes in contact

with the latent image on the drum surface. Toner particles are

electrostatically attracted to the negatively charged latent image areas.

4. Pre-Transfer Lamp

The pre-transfer lamp (PTL) illuminates the drum prior to image transfer. This

reduces the attraction between the toner and the drum, thus making image

transfer easier.

5. Image Transfer

Copy paper is fed to the drum surface, at the exact timing, to align the copy

paper and the developed image on the drum surface. Then a strong negative

charge is applied to the back side of the paper. The negative charge pulls

the toner particles from the drum surface onto the paper.

6. Paper Separation

A strong ac corona discharge is applied to the back side of the copy paper,

reducing the charge on the paper and breaking the electrostatic attraction

between the paper and the drum. Then, the stiffness of the copy paper

causes it to separate from the drum. The pick-off pawls help to separate

paper which has low stiffness.

Overall

Information

7. Cleaning

The cleaning blade, which is angled against drum rotation (counter blade

system), removes any toner remaining on the drum surface.

8. Quenching

The light from the quenching lamp electrically neutralizes the surface of the

drum.

1-5

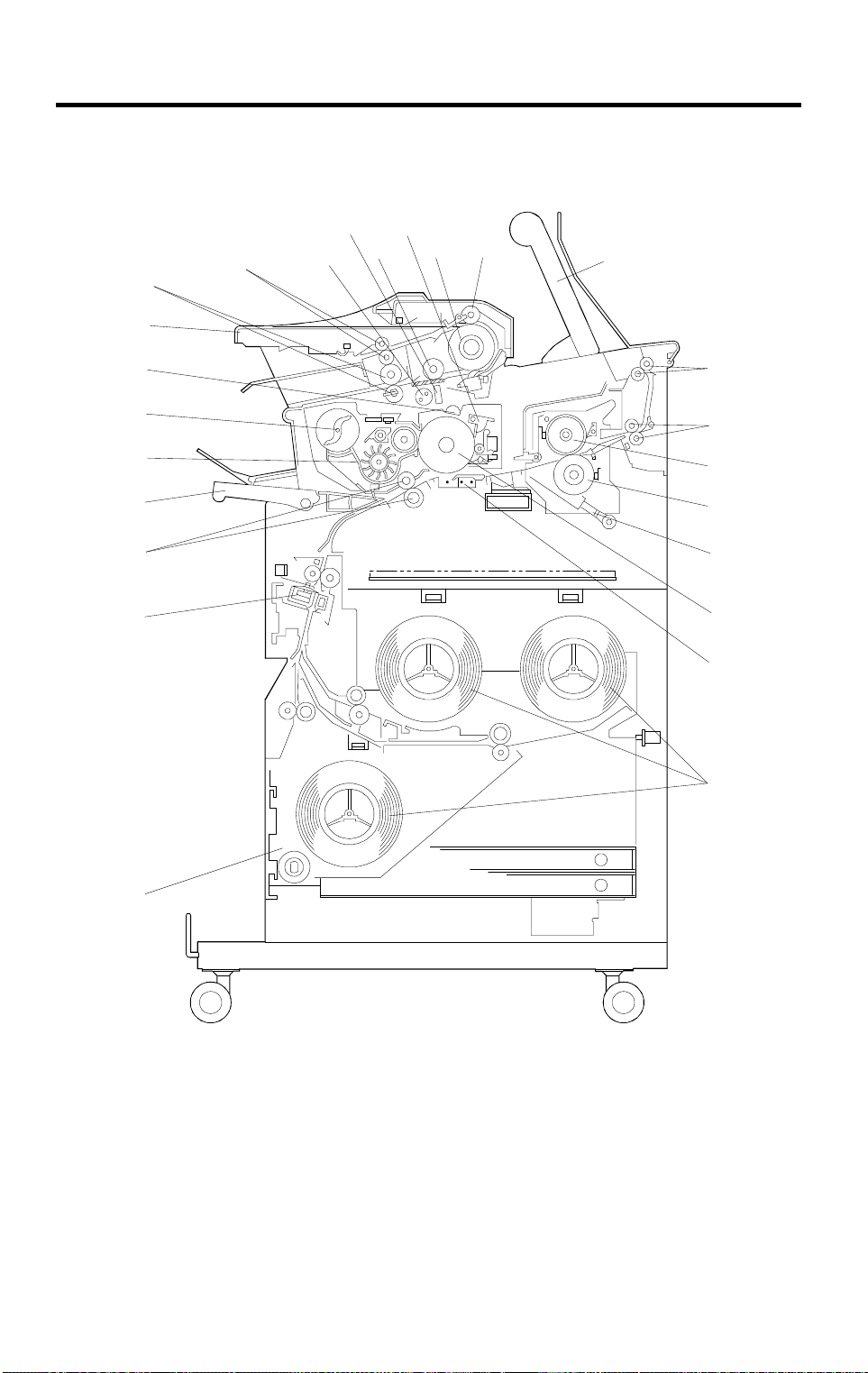

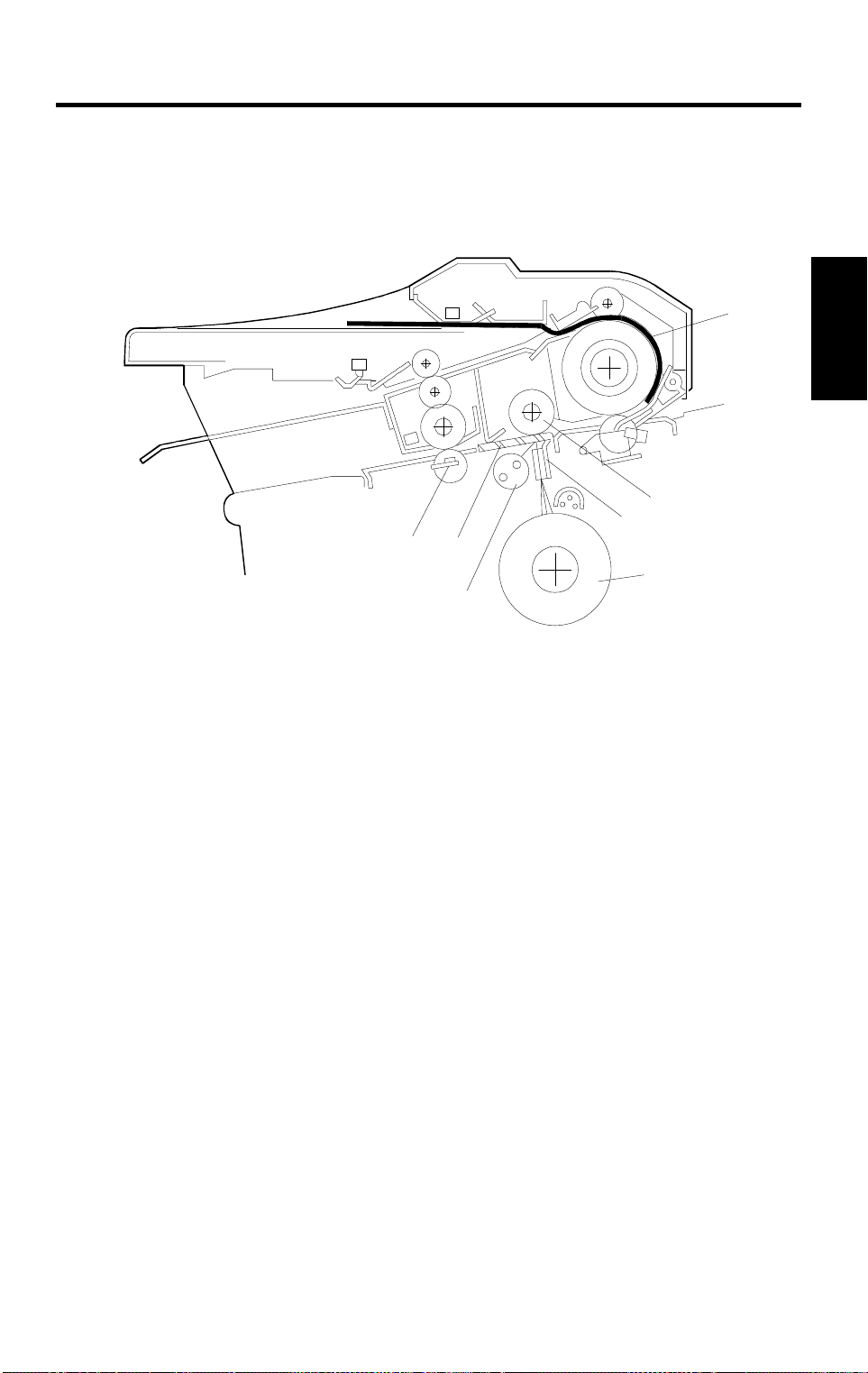

MECHANICAL COMPONENT LAYOUT 25 July 1996

4. MECHANICAL COMPONENT LAYOUT

20

19

18

17

16

15

14

13

21

22

23

24

25

1

2

3

4

5

6

7

8

9

10

12

11

A174V500.wmf

1-6

25 July 1996 MECHANICAL COMPONENT LAYOUT

1. Original Registration Roller

2. Original Feed Roller

3. Copy Tray

4. Exit Rollers

5. Fusing Exit Rollers

6. Hot Roller

7. Pressure Roller

8. Gas Spring

9. OPC Drum

10. T/S Corona Unit

11. Paper Spool

12. 3rd Roll Feeder

13. Cutter Unit

14. Paper Registration Rollers

15. Manual Feed Table

16. Development Unit

17. Toner Cartridge

18. Charge Corona Unit

19. Original Table

20. Origin al Ex it Rollers

21. Original Repeat Roller

22. Exposure Lamp

23. Fiber Optic Array

24. Platen Roller

25. Cleaning Blade

Overall

Information

1-7

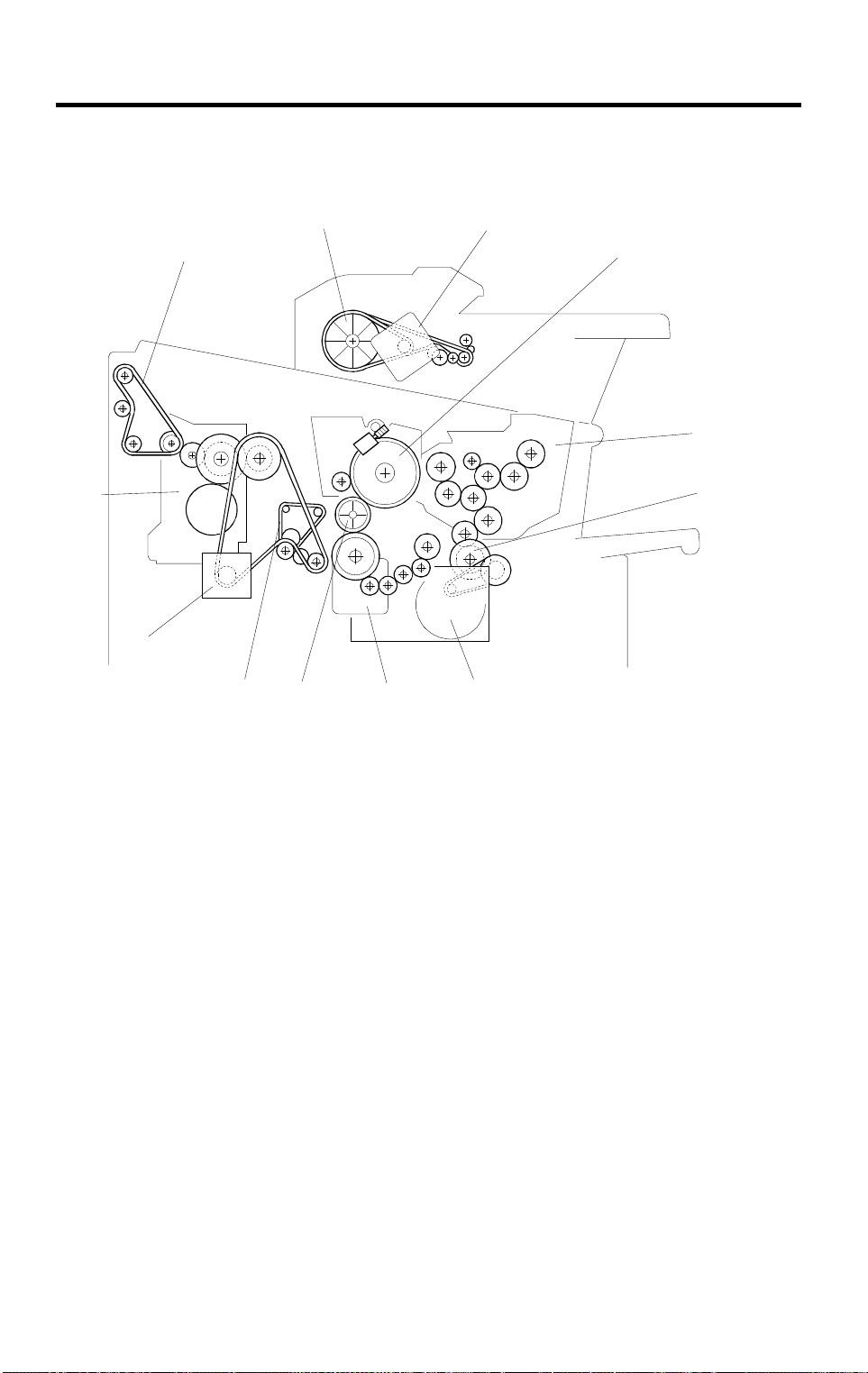

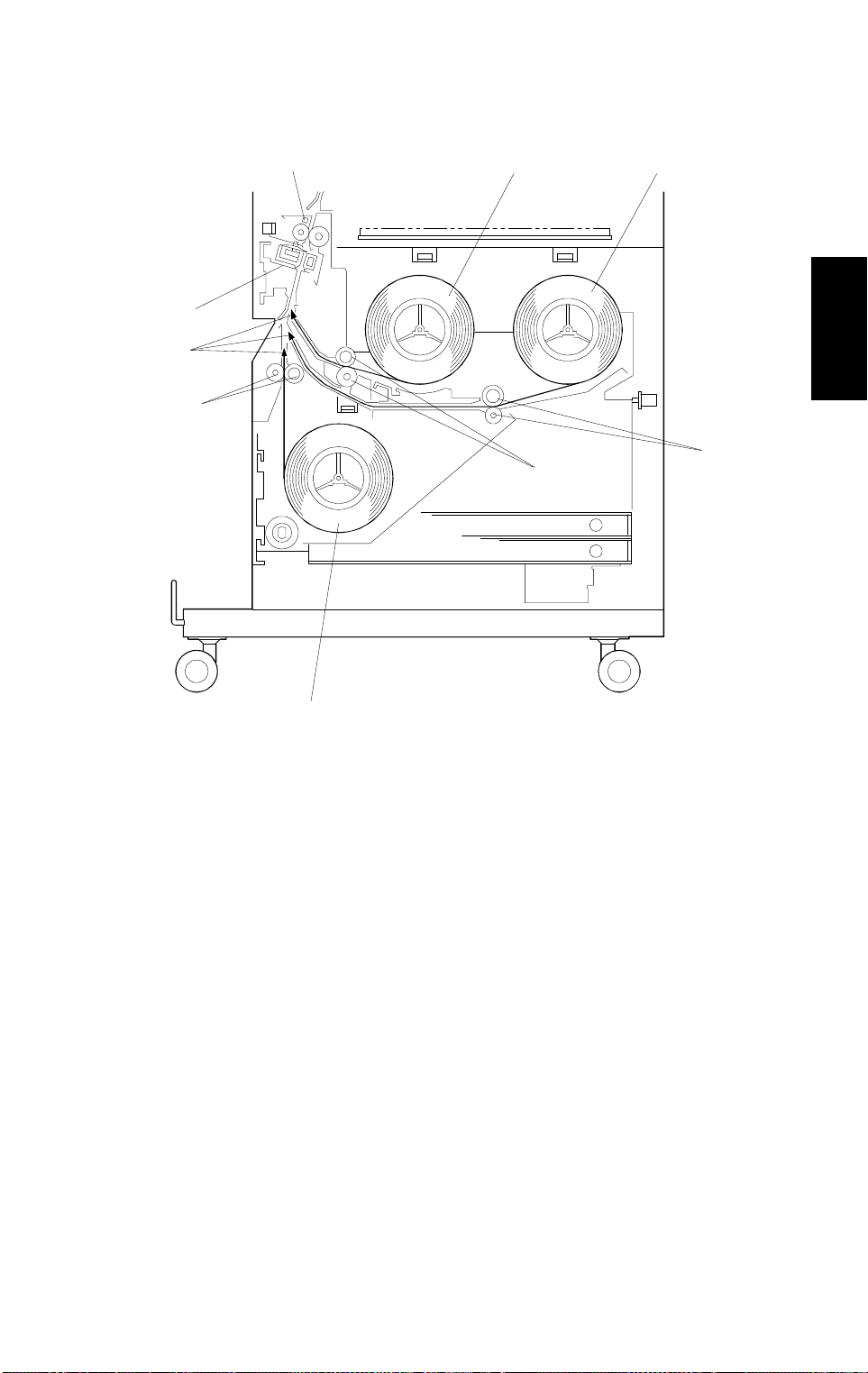

DRIVE LAYOUT 25 July 1996

5. DRIVE LAYOUT

10

12

11

1

2

3

4

9

8

7

6

5

A174V501.wmf

1. Original Feed Motor

2. Drum

3. Development Unit

4. Development Relay Gear

5. Development Motor

6. Main Motor

7. Drum Drive Relay Gear

8. Transport Unit Drive Belt

9. Fusing Drive Motor

10. Fusing Unit

11. Exit Unit D r iv e Be lt

12. Original Feed Drive Pulley

1-8

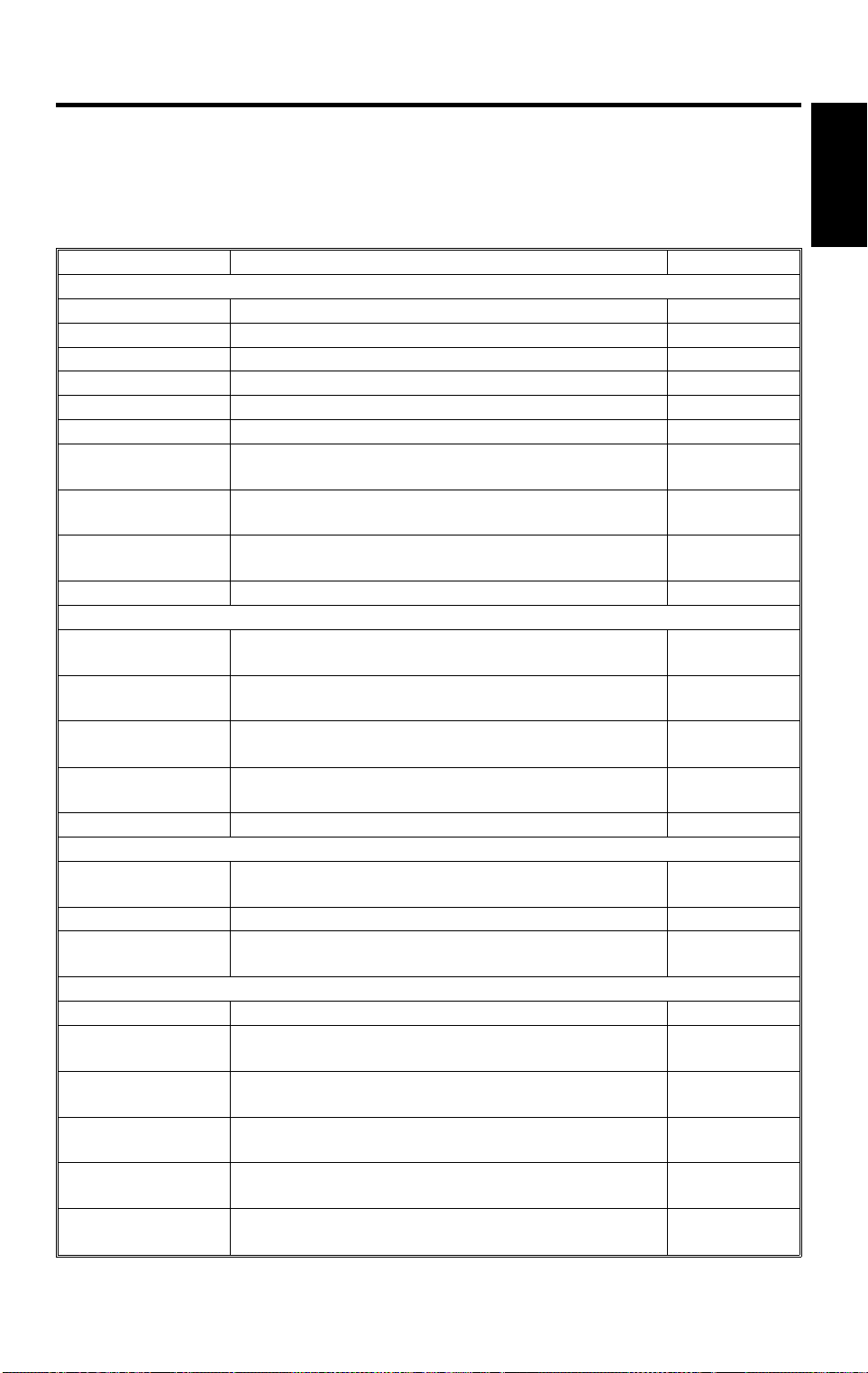

25 July 1996 ELECTRICAL COMPONENT DESCRIPTIONS

6. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout on the reverse side of the Point to

Point (Water proof paper) index numbers.

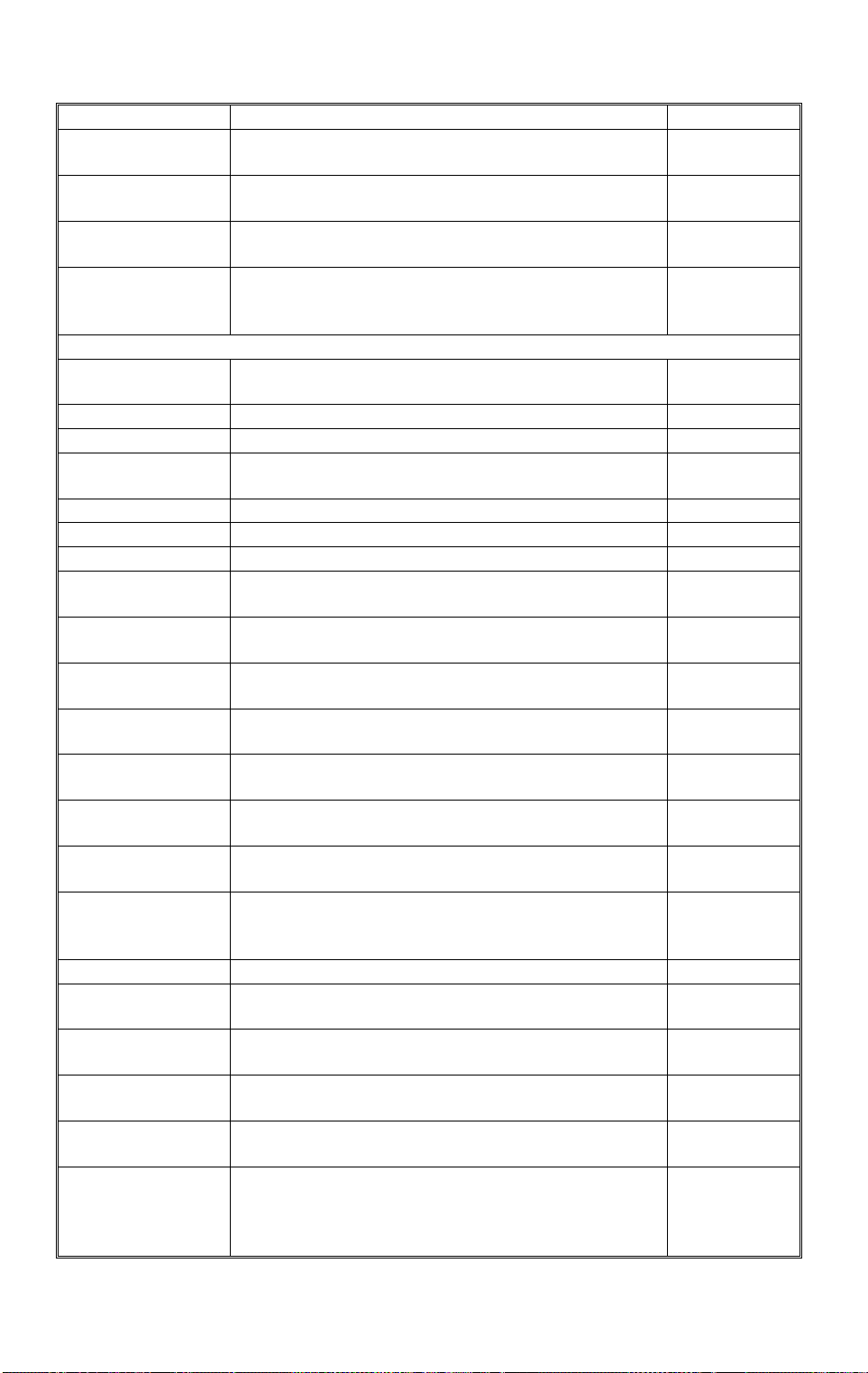

Name Function Index No.

Motor

Main Motor Drives the drum and the registrat i on r oll er . (dc mo tor) 20

Development Motor Drives the develo pm ent unit compon ent s. (d c m ot or ) 22

Fusing Driv e M ot or Drives the fusin g uni t com ponents. (dc mo to r) 2

Original Feed Motor Drives original feed rollers. (dc motor) 25

Roll Feed Moto r Drives the 1st, 2nd and 3r d r oll fe ed r oll er s. (d c m otor ) 52

Cutter Motor Drives the roll cutter. (dc motor) 56

Exhaust Fan Motor

Vacuum Motor 1

Vacuum Motor 2

Wire Cleaner Mo to r Drives the wire cleaner. 24

Magnetic Clutches

Roll Feed Clutch 1

Roll Feed Clutch 2

Roll Feed Clutch 3

Registrati on C lut ch

Toner Supply Clut ch Turns on to supply toner to the development unit . 21

Solenoids

Pick-off Pawl

Solenoid

Exit Gate Solenoid Moves the exit gate to change paper path . 12

Original Gate

Solenoid

Switches

Main Switch Supplies power to enable copy oper at ion. 37

Exit Cover Open

Switch

Left Cutter Switch

Right Cutter Switch

3rd Roll Feed Door

Open Switch

Upper Unit Safety

Switch

Removes the ozone bui lt up ar ound the drum sectio n

to the ozone filter. (dc motor)

Provides suction so paper is held firml y on t he

transport belt.

Provides suction so paper is held firml y on t he

transport belt.

Transmits the roll feed motor drive to the 1st roll feed

roller.

Transmits the roll f eed mo to r dri ve to the 2nd roll feed

roller.

Transmits the roll f eed mo to r dri ve to the 2nd roll feed

roller.

Transmits the main motor drive to the registration

roller.

Moves the pick-off pawls again st the drum. 66

Moves the origina l gat e to chan ge or i ginal path. 1

Detects whether the exit cover is open or not . 33

Detects whether the cutter unit is at the left home

position or not.

Detects whether the cutter unit is at the right home

position or not.

Detects whether the 3rd roll f eed door is open or not. 53

Cuts ac power when the upper unit is open. 38

7

19

10

55

58

54

23

57

50

Overall

Information

1-9

ELECTRICAL COMPONENT DESCRIPTIONS 25 July 1996

Name Function Index No.

Exit Cover Safety

Switch

Anti-humidify

Heater Switch

Roll Feed Unit

Safety Switch

Anti-humidify

Heater Safety

Switch

Cuts ac power when the ex i t co ver is open. 34

Supplies power to the anti-humidif y hea te r. 49

Cuts dc power when the r oll fe ed unit is open. 59

Cuts power to the anti- hum idify heater when the roll

feed unit is open.

48

Sensors

Upper Unit Open

Sensor

Detects whether the upper unit is open or not. 45

ADS Sensor Senses the background densi ty of the or i ginal. 61

Fusing Exit Senso r Detect paper jams after the registrati on sensor. 8

Roll Lead Edge

Sensor

Detects the leading edge and trailing edge of the

paper fed from the rol l fee der .

60

Roll End sensor 1 Detects the roll end cond i tio n of the 1st roll . 42

Roll End sensor 2 Detects the roll end cond i tio n of the 2nd r oll . 28

Roll End sensor 3 Detects the roll end cond i tio n of the 3rd roll. 54

Original Exit Sensor

1

Original Exit Sensor

2

Original Exit Sensor

3

Original Lea d Edge

Sensor

Original Switch

Back Sensor

Original Set Sensor

Original Feed Unit

Open Sensor

Original

Registration Sensor

Detects jams in the original exit section. 14

Detects jams in the original exit section. 3

Detects jams in the original exit section. 18

Detects the origin al l eading edge to determ i ne the

copy process tim i ng.

6

Detects original jam s i n the r epeat copy. 4

Detects when an ori gi nal is inserted from the front

side.

5

Detects whether th e original feed un it is ope n or not. 47

Detects the leading edge of the origin al to

synchronize the or igi nal leading ed ge wi t h the copy

62

paper.

Light Sensor Detects the intensit y of the expo sur e l am p output. 27

Rear Original Set

Sensor

Toner Density (TD)

Sensor

Paper Set Sensor

Registration Sensor

Detects when an ori gi nal is inserted from the rear

side.

9

detects the density of toner in the developer . 15

Detects when a she et of pa per i s set on t he by-pass

feed table.

Detects when cop y paper arrives at the registratio n

roller. Detects paper jams.

16

17

Detects whether the used toner bottle is full or not.

Toner Overflow

Sensor

36

1-10

25 July 1996 ELECTRICAL COMPONENT DESCRIPTIONS

Name Function Index No.

Printed Circuit Boards

Main Board

AC Drive Board Provides ac power to the lamp s, heat er s, and PSU. 39

PSU Converts the ac voltage to dc voltage. 43

Operation Pan el

Lamps

Exposure Lamp

Fusing Lamp Provides heat to th e hot ro ll er . 32

Pre-transfer Lamp

(PTL)

Quenching Lamp

(QL)

Power Packs

Charge/Bias/Grid

Power Pack

T & S Power Pack

Thermistors

Hot Roller

Thermistor

Pressure Roller

Thermistor

Heaters

Anti-humidit y H eater Removes humidi t y from t he r ol l paper. 63

Anti-condensa tio n

Heater

Others

Fusing Thermofuse Protects against fusi ng over heat. 31

Total Counter

Noise Filter Filters electrical noise on the ac po wer in put li nes. 35

FL Regulator

Controls all copier fu nct ions both directly and t hr oug h

other PCBs.

Informs the CPU of the selected modes, and displays

the situation on the panel.

Provides light to reflect the or igi n al ’ i m age ont o the

lamp. (fluorescent lamp)

Reduces the charge on th e dr um sur f ace prior to

image transfer.

Neutralizes any charge remaining on the drum

surface after cleaning.

Provides high voltage for the charge corona, grid and

development bias.

Provides high voltage for the transfer corona and

separation.

Monitors the hot roll er sur f ace temperature. 29

Monitors the pressur e r ol l er sur face temperature. 33

Prevents moisture from f or m i ng inside the copier. 64

Keeps track of the total length of copies made

(Europe) or total num ber of copi e s m ade (U.S.A.).

Stabilizes the power supplement to the exposure

lamp.

44

11

26

13

65

40

30

46

41

Overall

Information

1-11

SECTION 2

DETAILED SECTION

DESCRIPTIONS

25 July 1996 DRUM

1. DRUM

1.1 DRUM CHARACTERISTICS

The organic photoconductor (OPC) drum has the following characteristics:

It is able to accept a high negative electrical charge in the dark. (The

•

electrical resistance of the OPC drum is high in the absence of light.)

The electric charge on the drum surface dissipates when the drum is

•

exposed to light. (The conductivity of the OPC drum is greatly enhanced by

exposure to light.)

It dissipates an amount of charge that is in direct proportion to the intensity

•

of the light. That is, where stronger light is directed to the photoconductor

surface, a smaller voltage remains.

The OPC drum used in this model has high sensitivity, good color

reproduction, and good reproduction of low contrast originals (pencil

originals, etc.)

Detailed

Descriptions

2-1

DRUM 25 July 1996

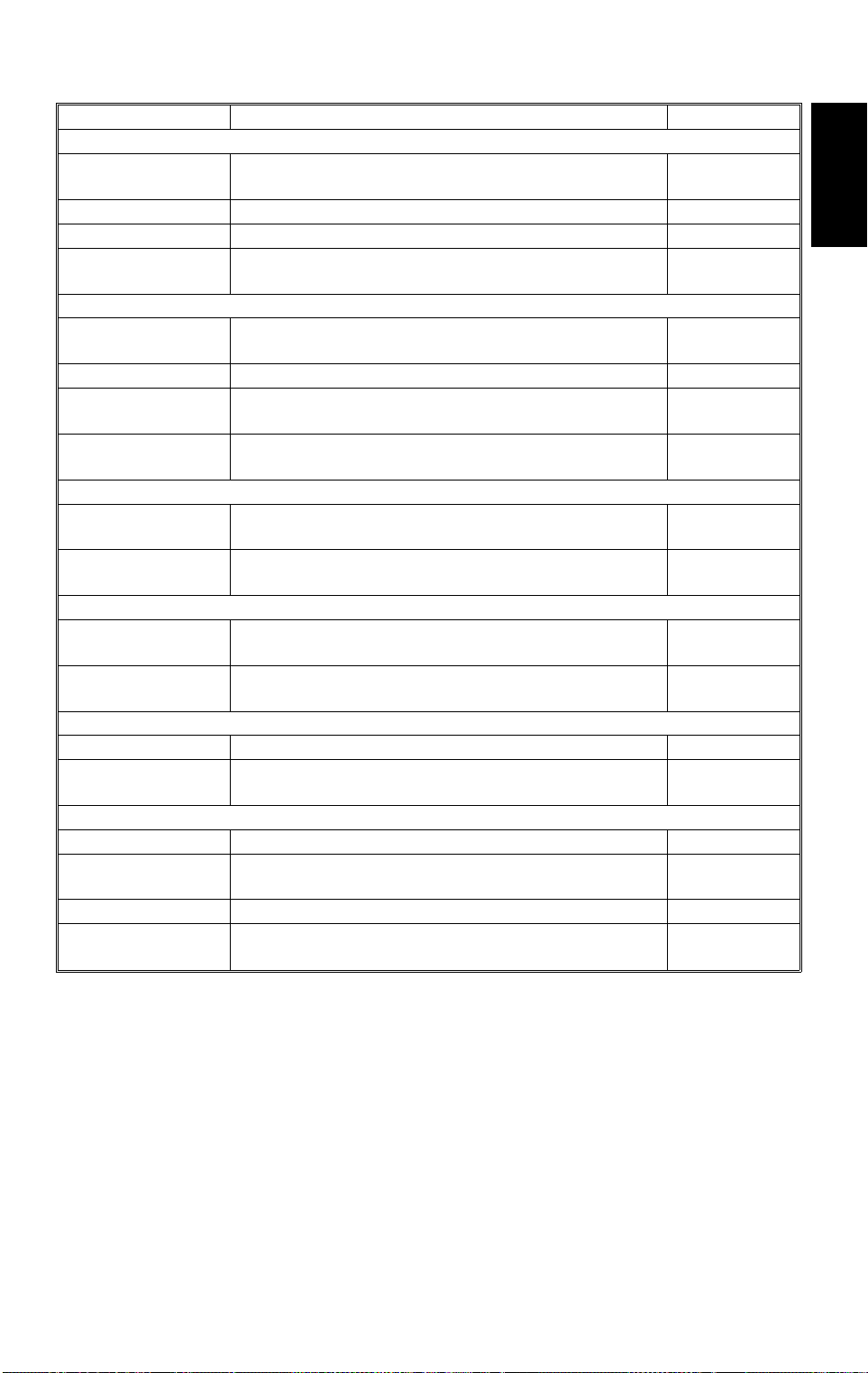

1.2 DRUM DRIVE

[D]

[C]

[E]

[F]

[A]

[B]

A174D517.wmf

The OPC drum [A] is 80 millimeters in diameter and 970 millimeters long. It

turns constantly when the main motor [B] is on.

When the main motor turns on, the drive is transmitted to the drum in the

following way:

main motor drive gear [C]

drum flange [F]

drum

⇒

idle gears [D] ⇒ drum drive gear [E] ⇒

⇒

When the drum knob is tightened, the right flange presses firmly against the

drum so that the drum is held tightly between the flanges. The drum and

flanges turn together when the main motor is on.

2-2

25 July 1996 CHARGE

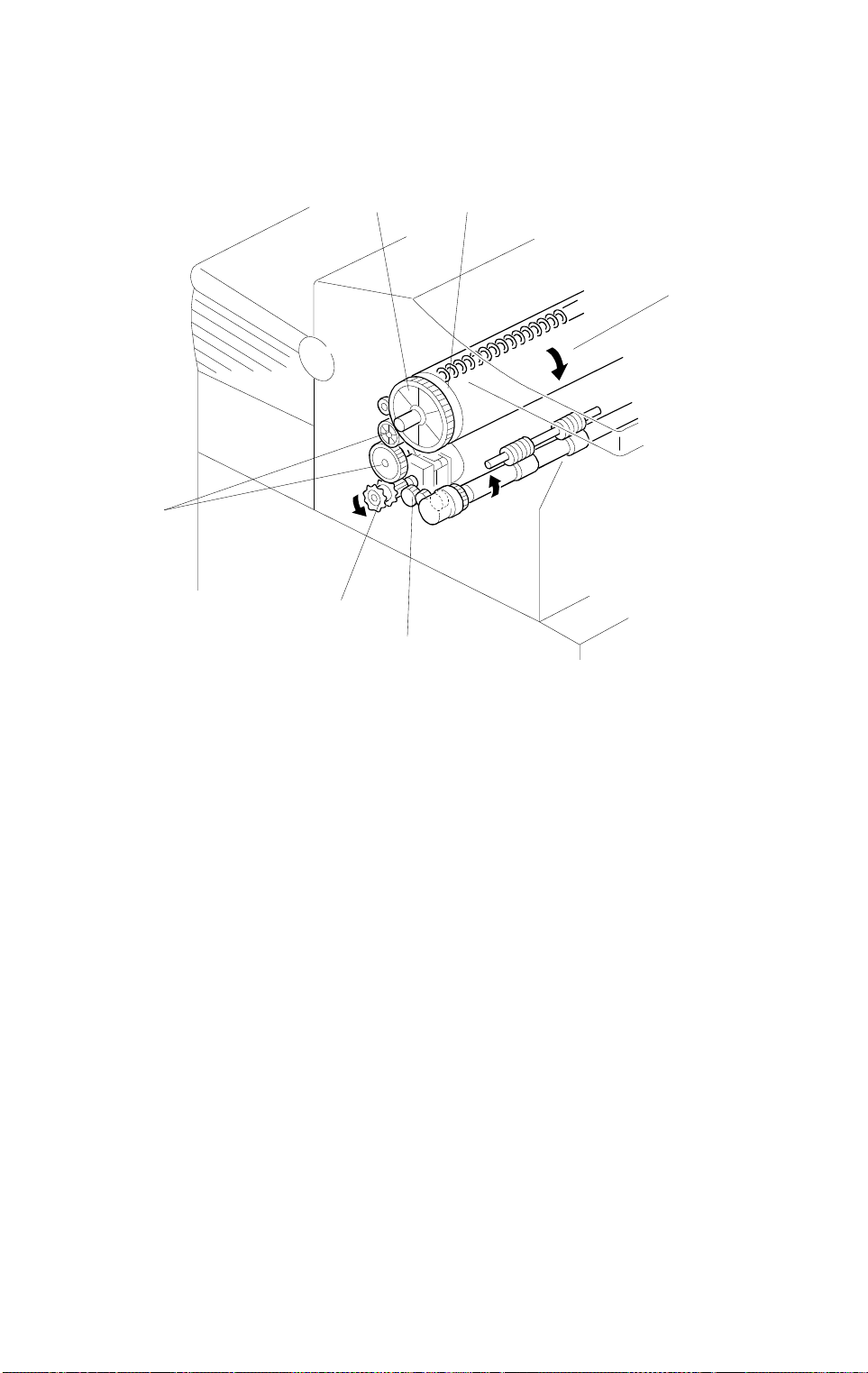

2. CHARGE

2.1 OVERVIEW

[A]

Detailed

Descriptions

[B]

A174D501.wmf

A174D502.wmf

This model uses a single wire corona unit [A] to charge the OPC (organic

photoconductor) drum [B]. The corona unit generates a corona of negative

ions when a high negative voltage is applied to it by the charge/grid power

pack.

To make the negative corona uniform, a grid consisting of 8 wires is installed

on the charge corona unit between the corona wire and the drum. This grid

drains off any charge in excess of –860 volts, thus preventing fluctuation of

the charge potential.

2-3

CHARGE 25 July 1996

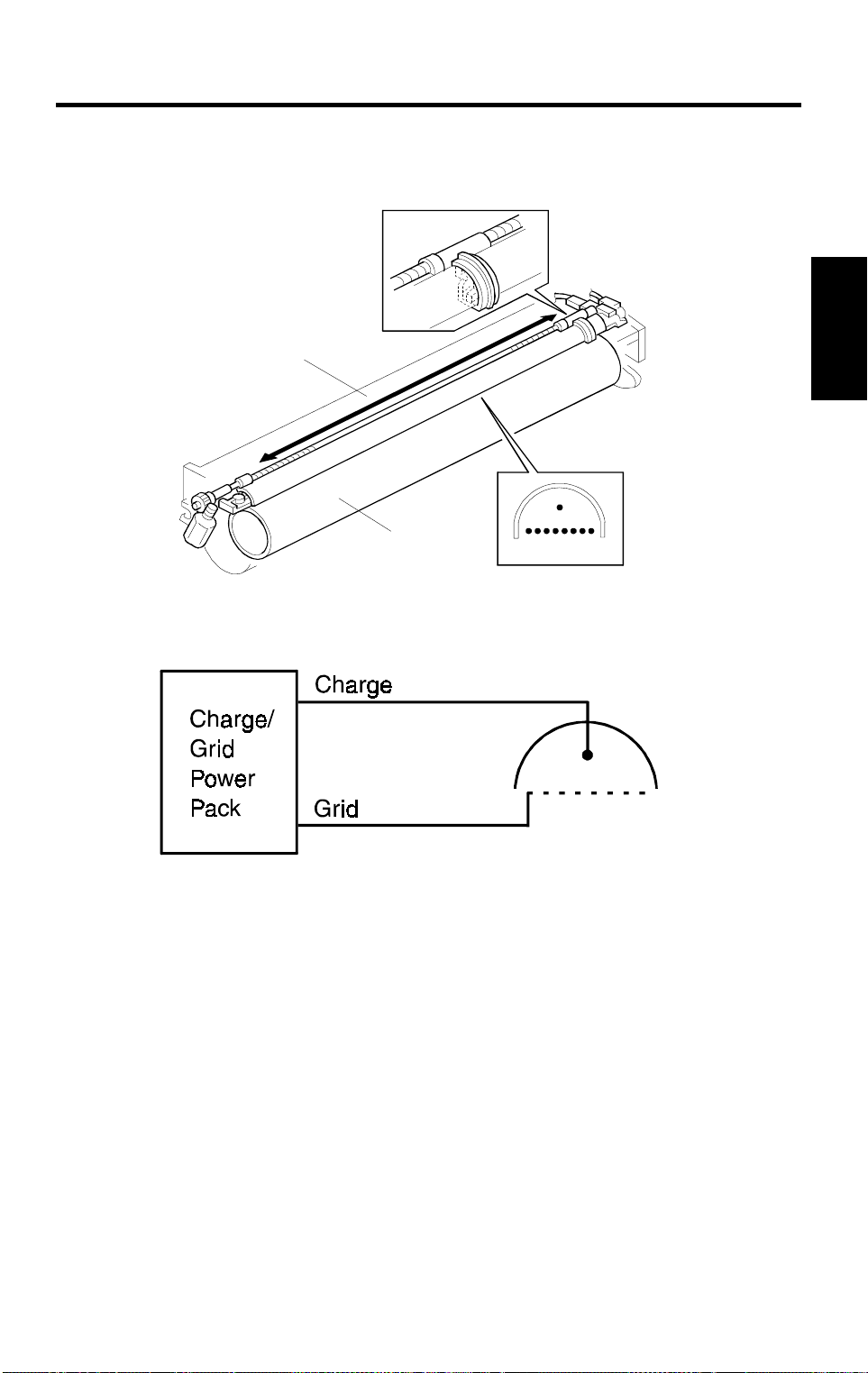

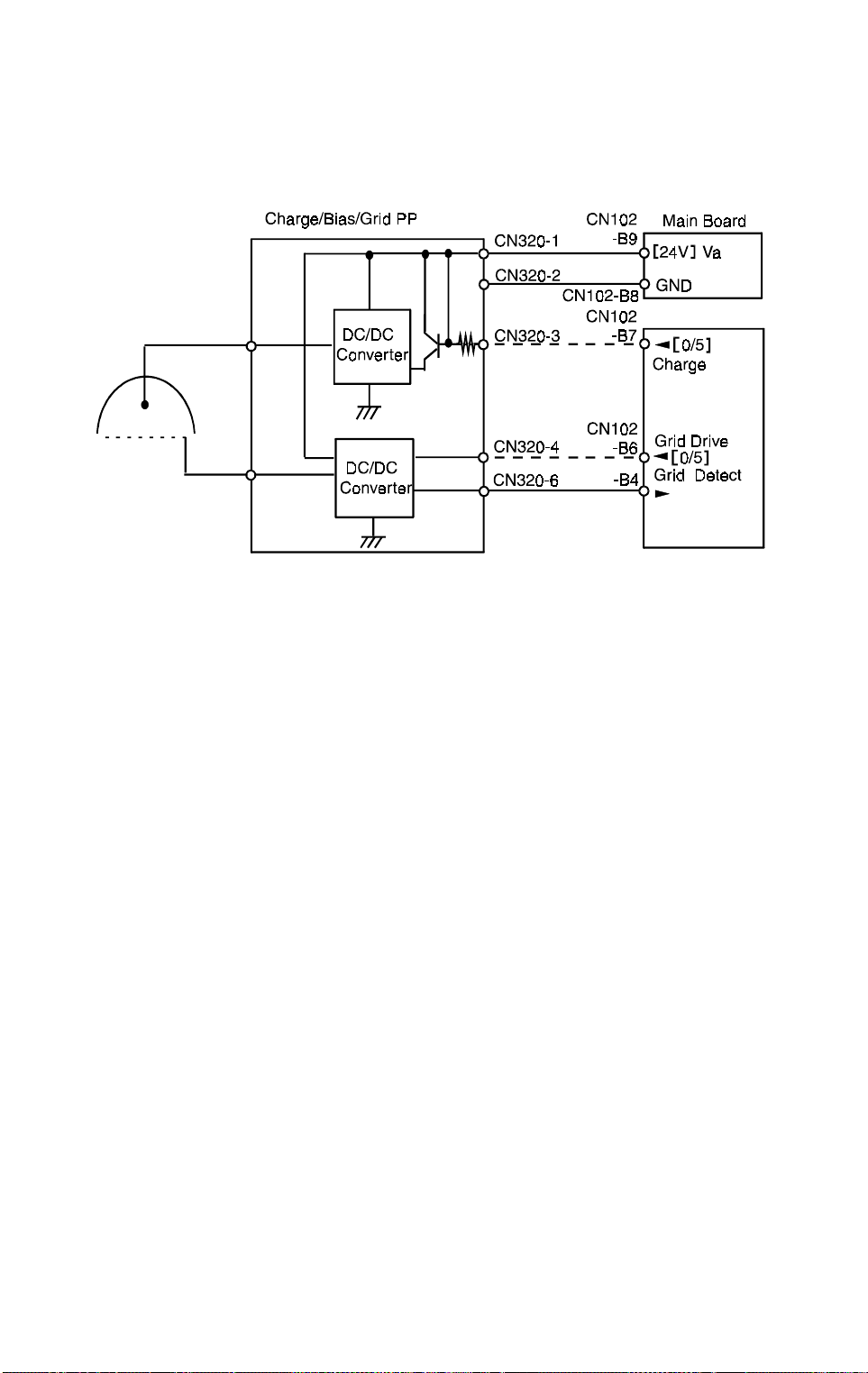

2.2 CHARGE CORONA CIRCUIT

A174D503.wmf

AA

The main board supplies +24 volts (V

) to the charge/bias/grid power pack

as the power supply source. Approximately 12 seconds after the copy

process starts, the CPU drops CN102-B7 from 5 volts to 0 volts. This

actuates the dc/dc converter within the power pack which applies a high

negative voltage of approximately –5.0 kV to the charge corona wire. The

corona wire then generates a negative corona charge.

The grid limits the maximum corona charge to –860 volts. This ensures that

the charge does not fluctuate and an even charge is applied to the drum

surface.

The copy grid voltage and charge voltage amounts can be adjusted using

SP# –14 and SP#–13 respectively.

The grid drive signal applied to CN320-4 is a pulse width modulated signal.

As the width of the pulses applied increases, the strength of the grid charge

also increases. The main board monitors the grid charge at CN102-B4 and

controls the width of the drive pulses based on this feedback.

2-4

25 July 1996 CHARGE

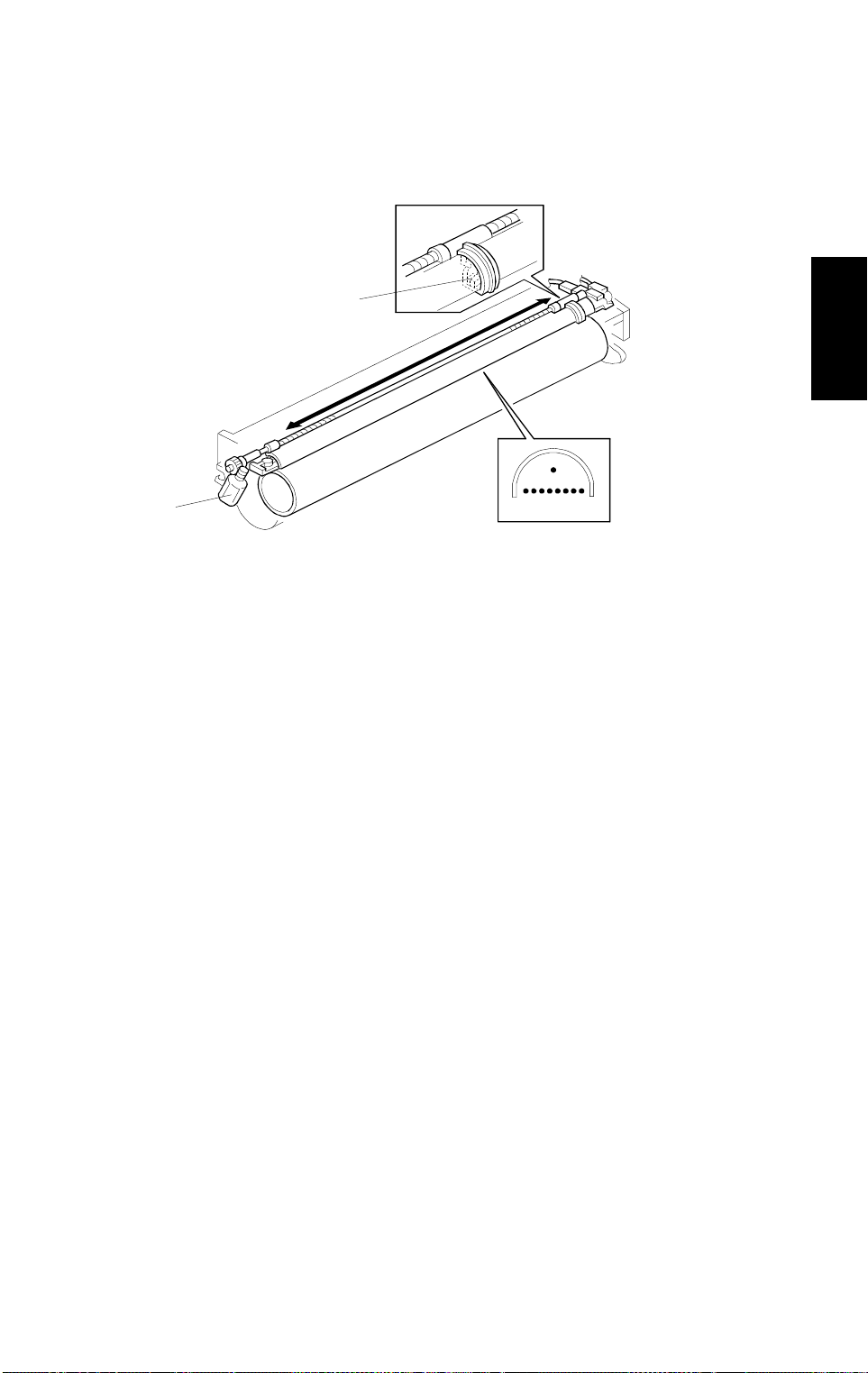

2.3 CHARGE WIRE CLEANING MECHANISM

[A]

[B]

A174D501-2.wmf

Detailed

Descriptions

The wire cleaner pads [A] automatically clean the wires every 297 m (500

copies/A1).

The wire cleaner is driven by a dc motor [B]. Normally the wire cleaner is

located at the front end position (home position). After 297 m (500 copies/A1)

or more copies are made and fusing temperature is less than 100°C after the

main switch is turned on, the wire cleaner motor turns on to bring the wire

cleaner to the rear end and then back to the home position.

When the wire cleaner moves from the rear to the home position, the wire

cleaner pads clean the wires.

There are no home position and return position sensors. The CPU monitors

the input voltage (5 V). When the wire cleaner reaches the end, it is stopped

and the motor is locked. At this time, input voltage slightly decreases (to

about 4 V) and the CPU judges to rotate the motor in reverse.

2-5

CHARGE 25 July 1996

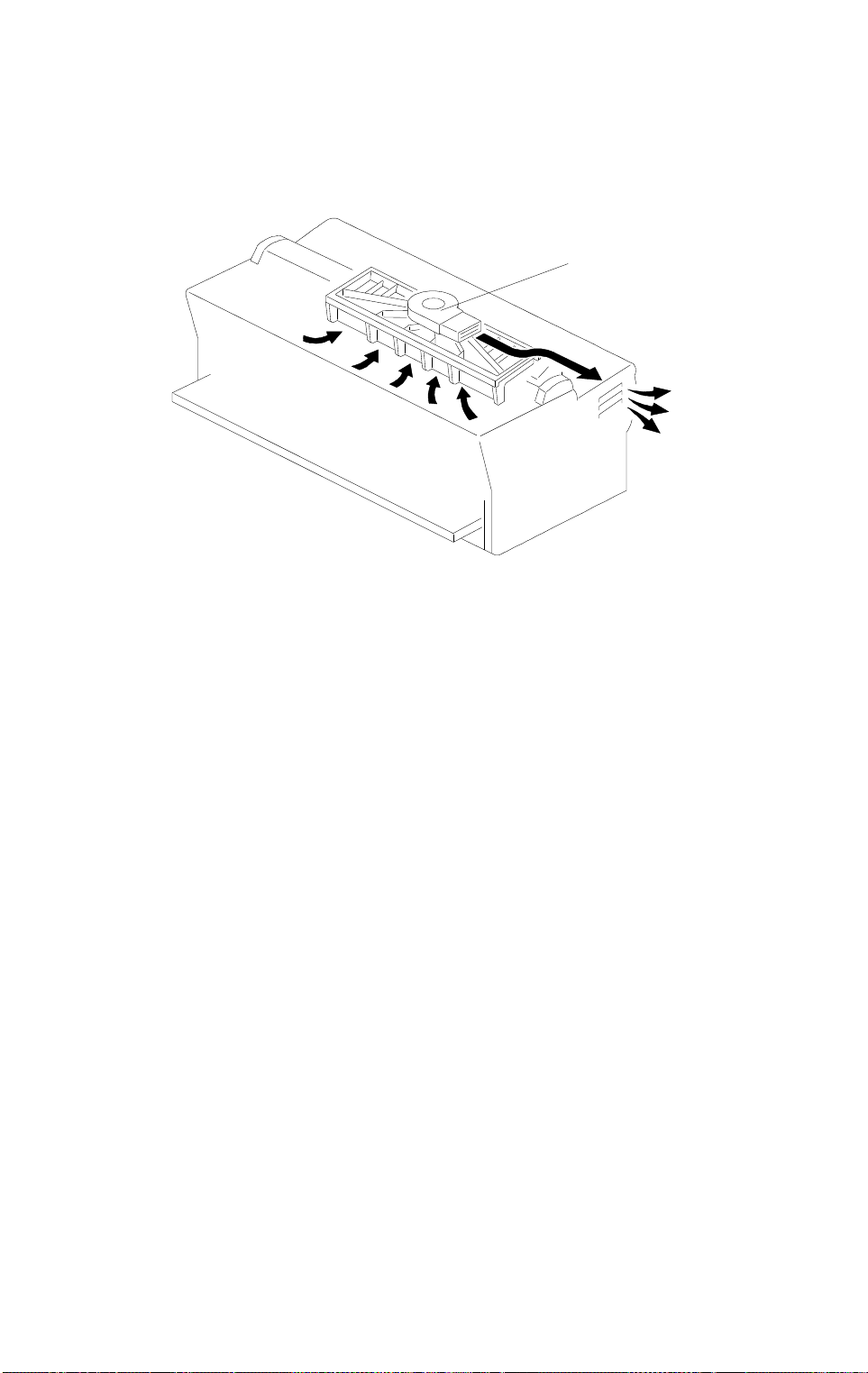

2.4 CORONA UNIT VENTILATION

[A]

A174D504.wmf

If ozone produced by the corona charge stays in the charge corona area, it

may cause uneven corona charging to the drum. To prevent this, ozone is

vacuumed out through the exhaust fan [A], and changed to oxygen by the

ozone filter before being blown out of the copier.

2-6

25 July 1996 EXPOSURE

3. EXPOSURE

3.1 OVERVIEW

[E]

[D]

[G]

[F]

[B]

[C]

Detailed

Descriptions

[A]

A174D505.wmf

Light from the exposure lamp [A] reflects off the original and through the fiber

optics [B] to the OPC drum [C]. During exposure, the original moves across

the exposure glass at the same speed as the drum’s peripheral velocity.

The platen roller [D] presses the original [E] flat against the exposure glass

[F] just above the fiber optic array. This ensures that the image is properly

focused. (The original must be within 0.2 mm of the exposure glass surface.)

The exposure lamp is a 125 V, 37 W exposure lamp.

The light sensor [G] monitors the intensity of the exposure lamp output.

2-7

EXPOSURE 25 July 1996

3.2 PAPER AND ORIGINAL FEED

3.2.1 Normal Original Feed

[B]

[D]

[C]

[Q]

[A]

[E]

[O]

[P]

[F]

[N]

[J]

[K]

[I]

[H]

[L]

[G]

P: Original Exit Sensor

Q: Original Switch Back Sensor

[M]

A174D506.wmf

When an original is placed on the original table, it activates the original set

sensor [A]. The main motor and development motor start rotating and the

exposure lamp turns on. 2.5 seconds later, the original feed motor starts

rotating to turning the original feed roller [B] and the original registration roller

[C]. An original feed starts. The 2.5 second delay allows time for the operator

to align the lead edge of the original against the first set of rollers to prevent

skew.

2-8

25 July 1996 EXPOSURE

When the original lead edge sensor [D]detects the leading edge of the

original, the roll feed motor and the roll feed clutch turn on, and paper feed

starts. The original is fed to the original registration sensor [E] and stops at 33

mm [F] ahead of the original registration sensor to wait for the copy paper.

The registration clutch is activated at the appropriate time after paper feed

begins. The copy paper is fed to the registration roller [G] and the registration

clutch turns off when the copy paper reaches 15 mm [H] ahead of the

registration sensor [I]. The speed of the roll feed motor is increased from 90

mm/s to 162 mm/s to form a paper buckle [J]. Then, the speed of the roll feed

motor returns to 90 mm/s and the registration clutch turns on again. The

paper feed resumes and the copy paper is transported to the drum [K].

At the appropriate time, the original feed motor rotates again and the original

is delivered to the exposure glass.

To measure the original length for synchro-cutting, the copier CPU counts the

time after the original lead edge sensor [D] detects the leading edge of the

original until the original set sensor [A] detects the trailing edge of the

original. The copy paper length is measured by counting the number of steps

as the roll feed motor (stepper motor) turns. The roll feed motor stops at the

appropriate time and the cutter motor rotates to cut the copy paper.

Repeat copies

Detailed

Descriptions

When making repeat copies, to increase the CPM, the roll feed motor starts

rotating 0.22 s after the roll lead edge sensor [L] is de-activated and advance

the copy paper 20 mm [M] (140 mm ahead of the paper feed start position).

After the 1st copy job, at the appropriate time after the trailing edge of the

original passes the original registration sensor [E], the original feed motor

rotates reverse 3.6 times as fast as the normal speed. The original is

returned to the position [N] where the leading edge of the original is 8 mm

before the original registration sensor.

When the leading edge of the original passes the original registration sensor,

the original feed motor rotates forwards again and the original is delivered to

the exposure glass and the copy job is repeated at the trigger timing. After

all the repeat copies have been made, the original is fed out.

After original scanning, the original can be stopped and caught by the original

exit rollers [O] or it can be fed out without being caught in the original exit

rollers. This is determined by SP No.24 (Original Hold mode). If the original

hold mode is selected, the original is fed out when the Clear/Stop key is

pressed or the next original is inserted.

2-9

EXPOSURE 25 July 1996

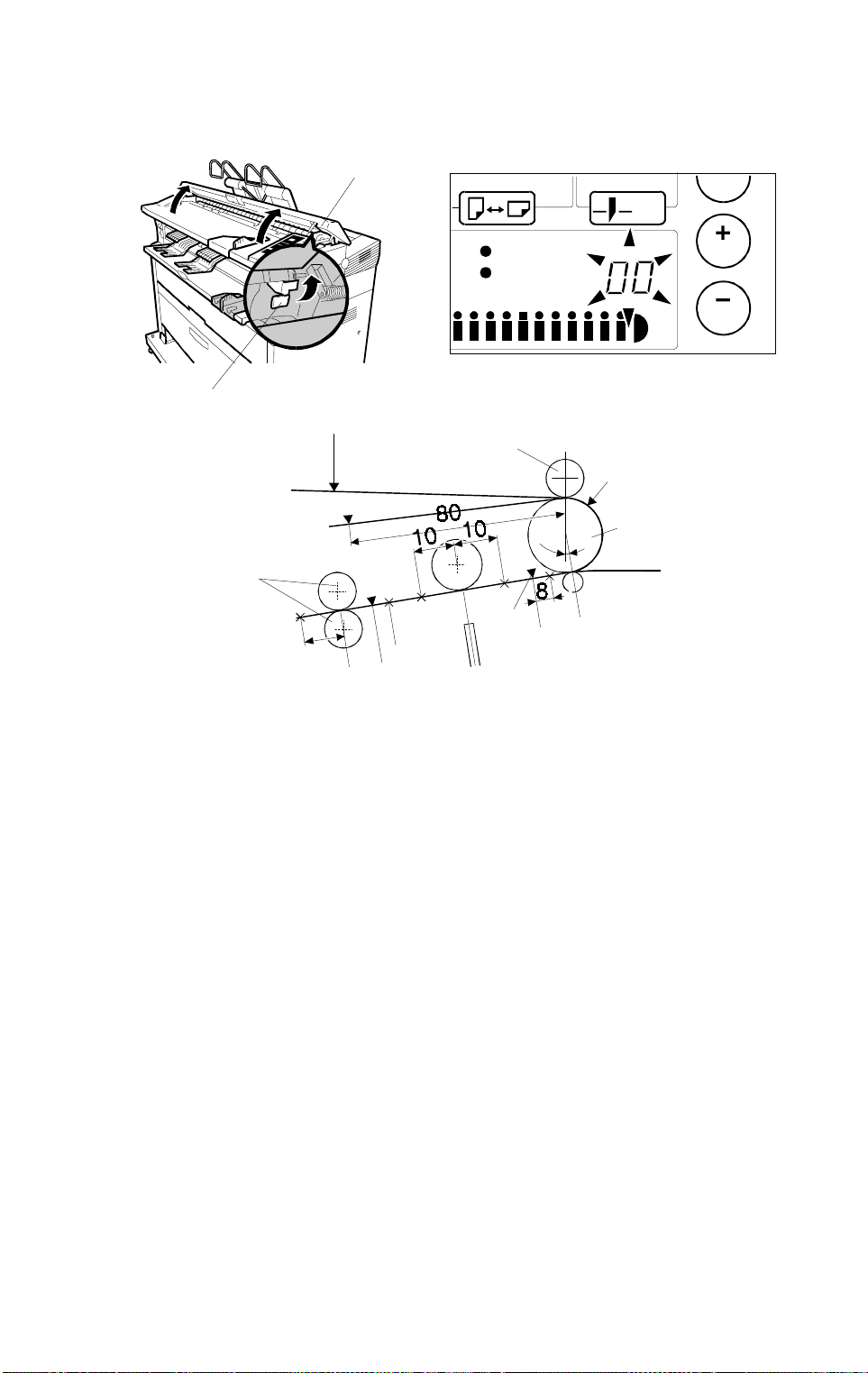

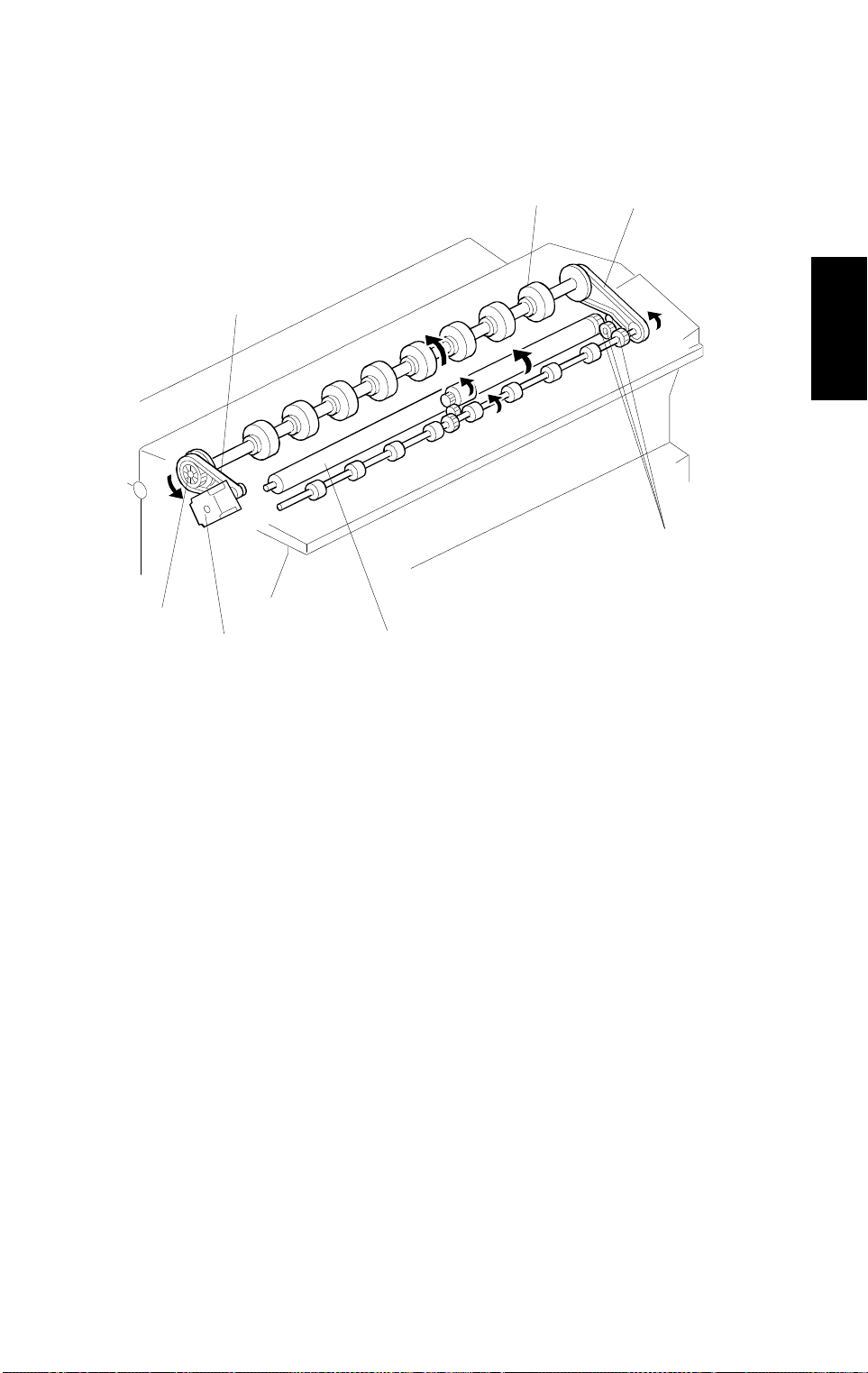

3.2.2 CHANGING MODE TO LONG NARROW ORIGINALS

[A]

A174D535.wmf

A174D536.wmf

[B]

[C]

[E]

[O]

[Q]

[P]

[D]

[F]

A174D537.wmf

If the original width is less than 515 mm (18’’) and it is longer than the

standard paper size (A0/E size), the original may be skewed by the middle

four of the 8 original feed rollers. The copy image may be warped. For such

originals, the "long narrow original" feed mode can be selected. In this mode,

the middle four original feed rollers are released while inserting the original.

When the original feed cover [A] is opened and the green lever at the right [B]

is pulled front, the middle four original feed rollers [C] are released from the

original registration roller [D]. This release condition of the middle four original

feed rollers is detected by the original mode change sensor in the rear feed

table assembly.

When the original cover is closed, "00" is blinking on the copy counter to

distinguish this mode from the normal original feed mode.

In this mode the detection of the original leading edge by the original lead

edge sensor [E] is used as a starting trigger of the main motor, development

motor, and exposure lamp. 3 seconds later, the original registration roller

delivers the original to the exposure glass. To measure the original length for

synchro-cutting, the copier CPU counts the time after the original registration

sensor [F] detects the leading edge of the original until the original lead edge

sensor detects the trailing edge of the original.

The repeat copy function cannot be used in this mode.

2-10

25 July 1996 EXPOSURE

3.3 ROLL FEED

[E]

[A]

[B]

[D]

[F]

Detailed

Descriptions

[H]

[H]

[H]

[C]

A174D507.wmf

This machine has two standard roll feed units (1st [A] and 2nd [B]), one

manual feed unit, and one optional roll feed unit (3rd [C]). The cutter unit [D]

uses a sliding rotary cutting blade.

When turning on the main switch or when roll paper is replenished, the roll

feed motor rotates and the leading edge of the roll paper is fed until the roll

lead edge sensor [E] is activated. Then, the leading edge of the roll paper is

returned to the paper feed start position (120 mm before the cutter unit) [F].

2-11

EXPOSURE 25 July 1996

3.3.1 Roll End Detection

[A]

A174D508.wmf

The roll paper end sensor [A] is located above each roll. When the roll paper

runs out and the roll paper end sensor detects the black core of the roll, roll

end is indicated on the operation panel. If the paper is not caught by the

pull-out rollers [H] (previous page), paper feed fails. In this case, roll end is

indicated instead of a paper misfeed indication.

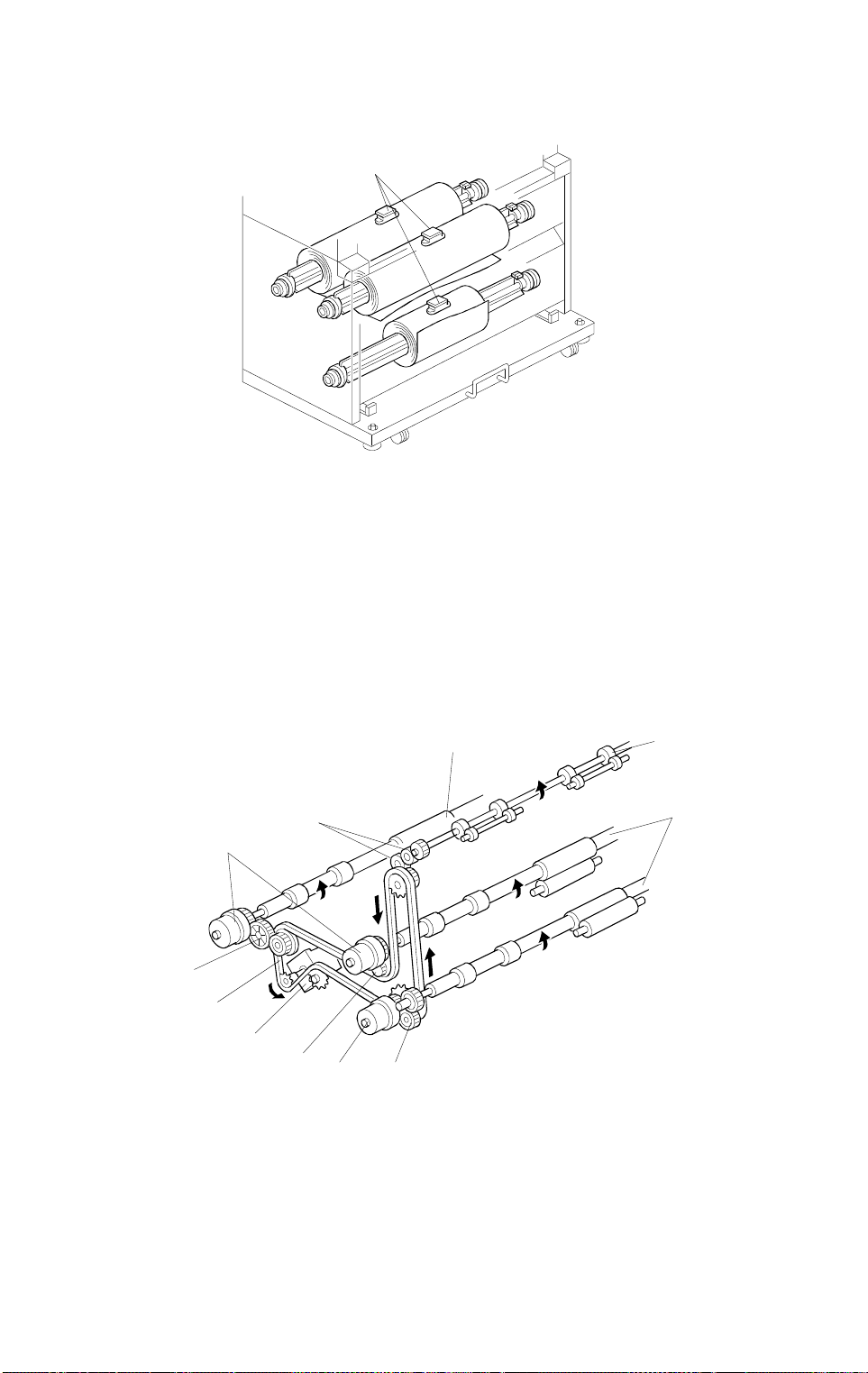

3.3.2 Drive Mechanism

[F]

[E]

[B]

[F]

[H]

[G]

[D]

[C]

[G]

[H]

[G]

A174D509.wmf

The roll feed roller [B] is driven by the roll feed motor [C] through the chain

[D] and gears [E]. The pull-out roller [F] of each roll feed unit is driven by the

roll feed motor through the chain and each gear [G] and each roll feed clutch

[H].

2-12

25 July 1996 EXPOSURE

3.3.3 Drive Mechanism

[B]

[D]

[C]

[E]

[A]

[G]

Detailed

Descriptions

[F]

A174D510.wmf

The original feed roller [A] is driven through the original feed drive pulley [B]

and belt [C] by the original feed motor [D].

The platen roller [E] is rotated by the original feed motor [D] through the

gears [F] and belt [G].

2-13

EXPOSURE 25 July 1996

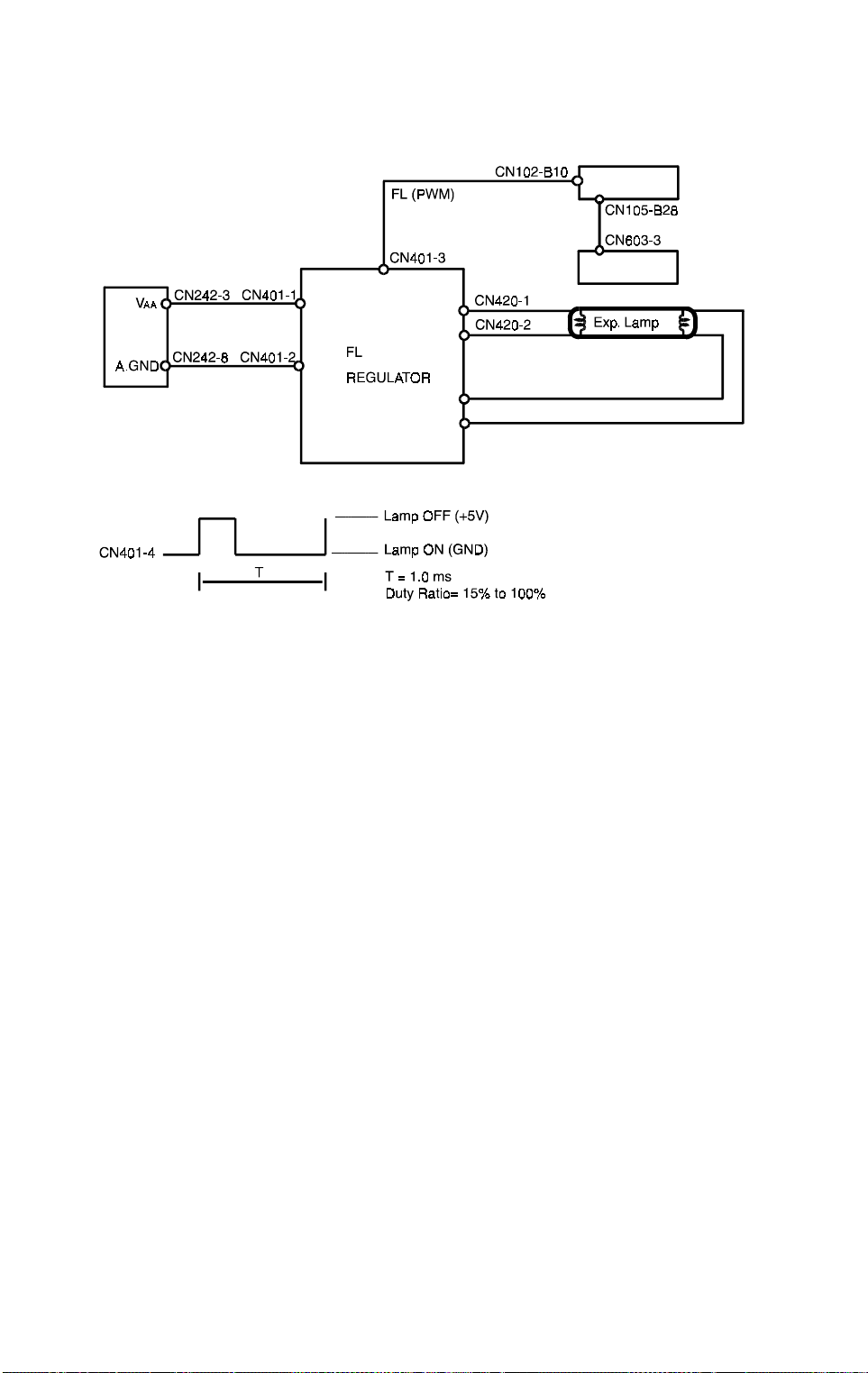

3.4 FL REGULATOR CONTROL

[D]

[C]

[A]

A174D511.wmf

The FL regulator [A] receives 24 volts dc at CN401-1 from the main board

[B]. The control signal, which is a pulse width modulated (PWM) signal, is

received at CN401-3. The PWM signal has a period (T) of 1 millisecond and

a duty ratio of 15% to 100%.

The basic light intensity level is determined either by the image density

selected at the operation panel (manual ID control) or by the original’s

background level as sensed by the ADS. The CPU uses the light sensor to

monitor the actual light intensity. The light sensor [C] directly detects the

lamp’s light output and feeds a light intensity signal back to CN105-B28 of the

main board [D]. This feedback allows the CPU to compensate for variations

in light intensity due to the lamp’s age or temperature.

2-14

25 July 1996 EXPOSURE

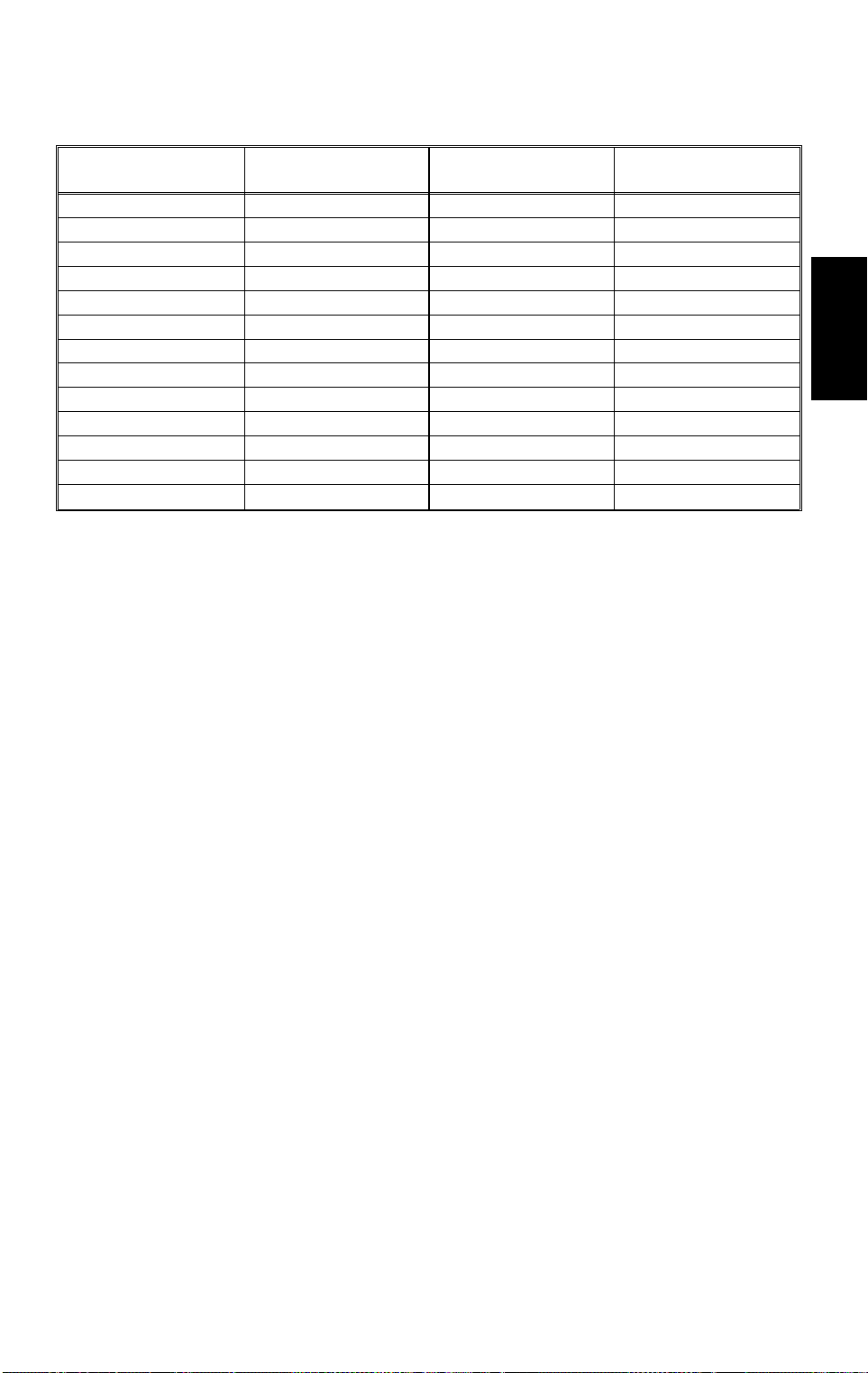

3.5 MANUAL ID CONTROL VS ADS

Manual ID Level

1 1.275 14 1.882

2 1.275 15 1.922

3 1.275 16 2.020

4 1.294 17 2.118

5 1.294 18 2.216

6 1.314 19 2.314

7 1.333 20 2.412

8 1.373 21 2.529

9 1.412 22 2.627

10 1.510 23 2.725

11 1.627 24 2.824

12 1.745 25 2.922

13 1.843 26 3.118

Light S e nsor

Output [V]

Manual ID Level

Light S e nsor

Output [V]

3.5.1 Manual ID Control

When in manual image density mode, the user can select one of 26 manual

ID levels. For each level, the intensity of the light output by the exposure

lamp (as measured by the light sensor) is fixed. This is shown in the above

table. The development roller bias also varies. (See the section on

development bias.)

Detailed

Descriptions

2-15

Loading...

Loading...