IMPORTANT SAFETY NOTICES

PREVENTION OF PHYS ICAL INJURY

1. Before disassembling or asse mblin g pa rts of the copie r and perip herals,

make sure that the copier power cord is unplu gg ed.

2. The wall outlet should be near the copier an d easily accessible.

3. Note that some compo ne nt s of th e copier and the peripherals are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operat ion check ha s to be made with exterior covers

off or open while the main switch is turned on, kee p ha nds away from

electrified or mechanically drive n comp on ents.

5. The inside and the met al pa rts of the fusin g un it be come extremely hot

while the copier is operat ing . Be careful to avoid touching those

components with your bare hands.

HEALTH & SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specifie d

intervals.

3. Toner and developer are non-to xic, bu t if you get eith er of them in your

eyes by accident, it may cause temp ora ry e ye disco mfo rt. Try to remove

with eye drops or flush with wat er as first aid. If un succe ssfu l, ge t med ical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be insta lled and maintained by a

customer service represen tative who has completed the training course

on those models.

2. The RAM board on the main control board has a lithium battery which can

explode if replaced incorre ctly. Re pla ce th e ba tt ery on ly with an iden tica l

one. The manufacturer reco mmen ds replacing the entire RAM board. Do

not recharge or burn this ba tt ery. Used batteries must be handle d in

accordance with local regula tio ns.

SAFETY AND ECOLOGICAL NOTES FOR DISP OS AL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may

ignite suddenly when exposed to open flame.

2. Dispose of used tone r, developer, and organic photoconductors

according to local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in acco rda nce with local regulations.

4. When keeping used lithiu m bat teries in order to dispose of them later, do

not put more than 100 batteries per sealed box. Storin g larger nu mbe rs or

not sealing them apart may lead to che mical rea ctions and heat build-up.

SECTION 1

OVERALL MACHINE INFORMATION

31 December 1992 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Table top

Copy Process: Electrostatic transfer system

Original Feed: Sheet feed

Original Size: Maximum: 914 x 3,600 mm

Minimum: 182 x 257 mm (B5 lengthwise)

Copy Size: Same as "Original Size"

Copying Speed: Manual feed: 6 cpm (A1/D sideways)

Sheet & Roll feed: 7 cpm (A1/D sideways)

First Copy: 19 seconds (A1 sideways)

Warm-up Time: Within 6.5 minutes (Room temperature 20oC)

Multi-Copy: 1 to 10 (A1/D or smaller)

1 to 5 (A0/E)

Automatic Reset: 2 minutes after copyin g is finish ed (can be set

to 1, 3, 4, or 5 minutes or to no auto reset)

Photoconducto r: Organic photocond uctor drum

Drum Charge: Single-wire with grid plate (Negative Charge )

Reproduction Ratio: 1 : 1 (±0.5%)

Exposure System: Slit exposure via fiber optic arra y

Exposure Lamp: Fluorescent lamp (65 W)

Development: Dual-component dry toner system

Toner Replenishment: Cartridge system (750 g toner/ca rtridge)

Toner Consumption: 1,860 A1 or D copies per cartridge (6% origin al)

Development Bias: Negative

Toner Density Control: Pattern density detection by photosensor and

direct toner density detection by induction

sensor

Image Density Adjustmen t: Development bias contro l + exposu re control

Auto Image Density

Control:

Development bias control and exposure control

1-1

SPECIFICATIONS 31 December 1992

Image Transfer: Single wire dc corona (negative charge) with

pre-transfer lamp

Paper Separation: Dual wire ac corona and pick-off pawls

Cleaning: Cleaning blade

Quenching: Photo quenching by LEDs

Paper Feeding: Manual feed (sheet and roll feeder optional)

Image Fusing: Heat and pressure type, teflon (u pper) an d

silicone rubber (lower) rollers

Fusing Lamp: Halogen lamp (115 V: 1,100 W, 220/240 V:

1,100 W)

Self-diagnostic Codes: 14 codes, displayed in copy cou nt er

Power Source: 115 V/60 Hz....15 A

220 V/50 Hz....7 A

240 V/50 Hz....7 A

Power Consumption: Maximum: 1.47 kW

Warm-up: 1.25 kW

Ready: 0.1 to 1.2 kW

Copy cycle: 1.42 kW

Dimensions (W x D x H): 1,410 x 800 x 600 mm

55.51 x 31.50 x 23.62 in

Weight: 180 kg, 397 lb

Optional Equip ment: — Sheet feeder

— Roll feeder

— Roll feeder connector

— Paper spool

— Table

1-2

2

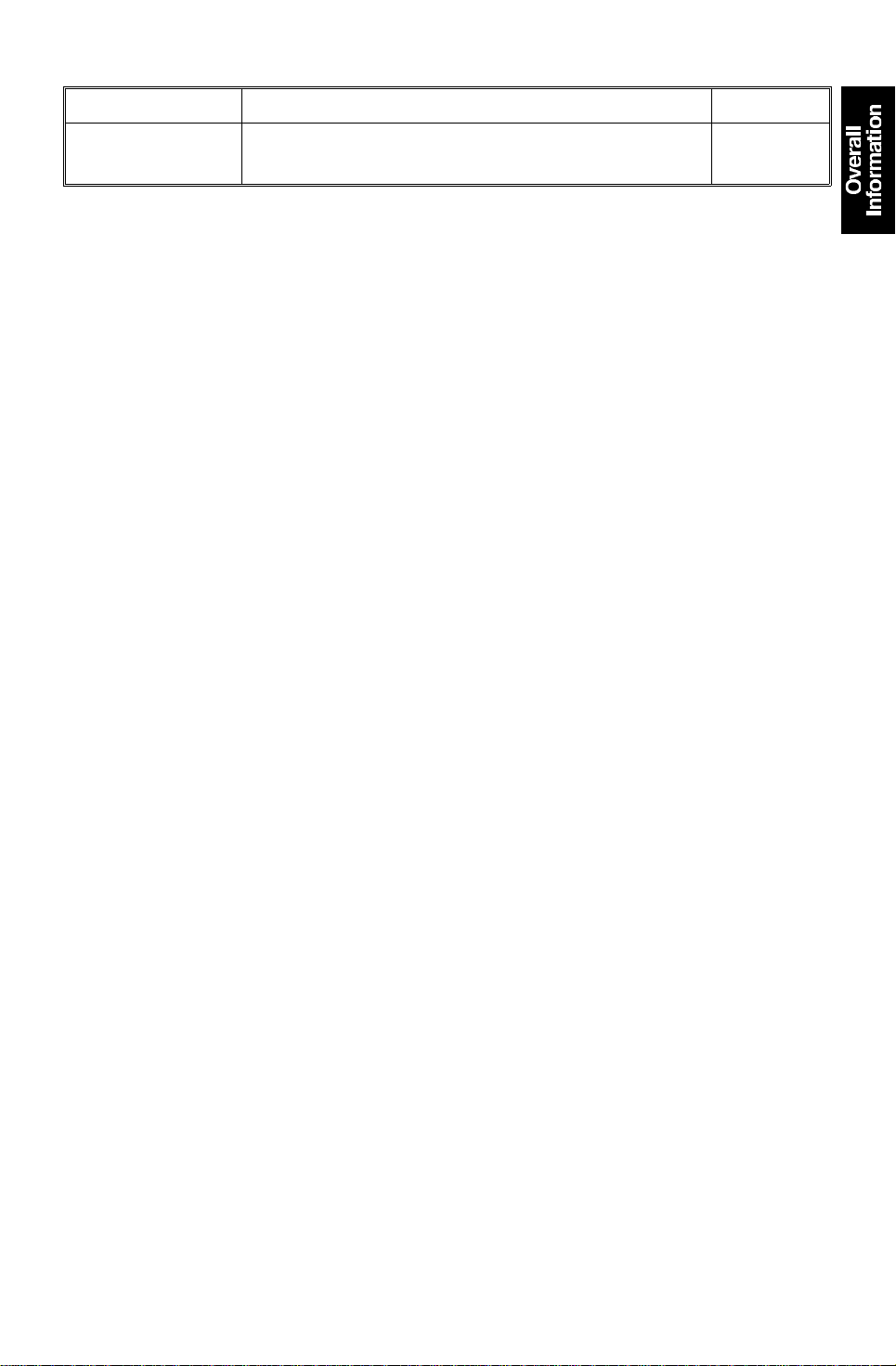

31 December 1992 MACHINE CONFIGURATION

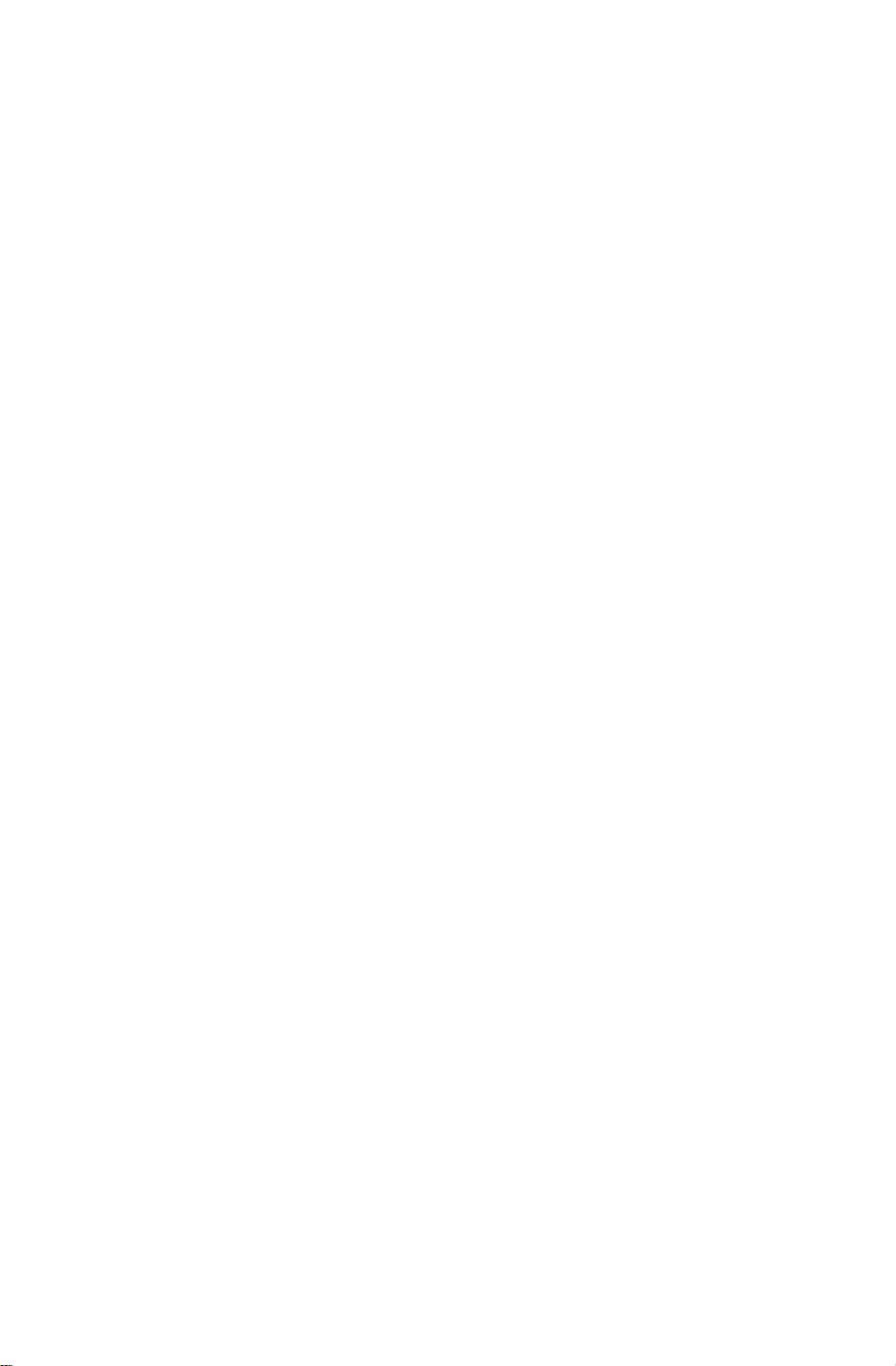

2. MACHINE CONFIGURATION

1

3

This copier can be equipped wit h op tio na l equ ipment as show above.

1. Copier (A098)

2. Sheet Feeder (A453)

3. Roll Feeder (A454) and Connector (A384)

4. Roll Feeder (A454) and Sheet Feeder (A453)

1-3

4

1

DRUM PROCESSES 31 December 1992

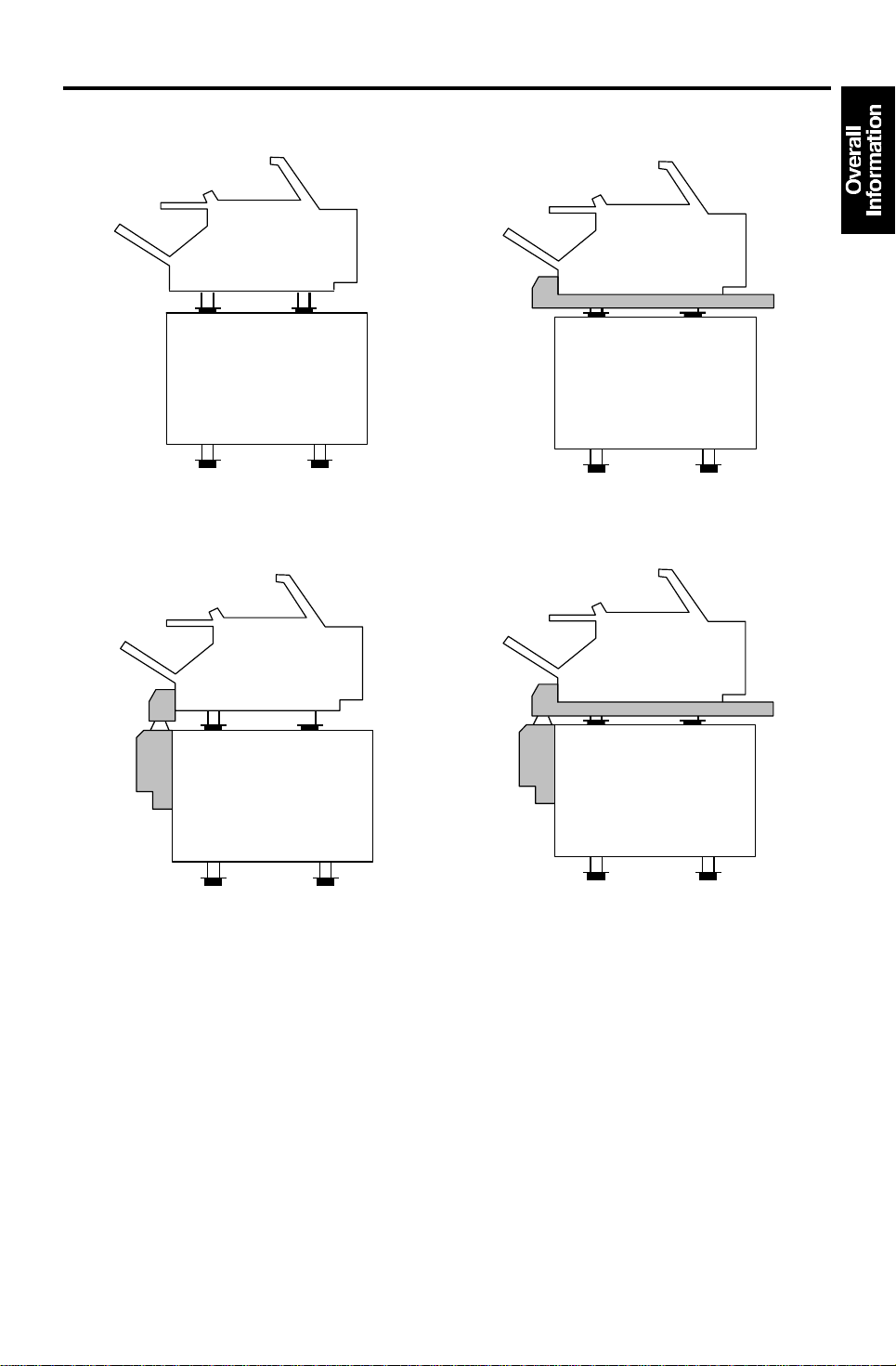

3. DRUM PROCESSES

2

8

3

7

4

5

6

1. Charge

In the dark the charge coro na unit app lies a ne gative charge to the drum.

The grid plate ensures the charg e is app lied unif ormly. The charge remains

on the surface of the drum because the photo con du ctive drum has a high

electrical resistance in the dark.

2. Exposure

High intensity light from a fluo rescent lamp is reflected from the mo ving

original through the fiber optic array. The cha rge on the drum surface is

dissipated in direct proportio n to the inte nsit y of th e ref lect ed light , th us

producing an electric latent image on the drum surfa ce.

1-4

31 December 1992 DRUM PROCESSES

3. Development

The magnetic developer brush on th e development roller comes in contact

with the latent image on the drum surface . Toner particles are

electrostatically attracted to the negatively charged latent imag e are as.

4. Pre-Transfer Lamp

The pre-transfer lamp illumina tes the drum prior t o image tra nsf er. This

reduces the attraction between the toner and th e drum, thus making image

transfer easier.

5. Image Transfer

Copy paper is fed to the drum surf ace , at the exact timing, to align the copy

paper and the develope d image on the drum surface. Then a stro ng negat ive

charge is applied to the back side of the paper. The negat ive charge pulls

the toner particles from the drum surface onto the paper.

6. Paper Separation

A strong ac corona discharge is applied to the back side of the copy pap er,

reducing the charge on the pap er an d breaking the electrosta tic at traction

between the paper a nd the drum. Then , th e stiffness of the copy paper

causes it to separate from the dru m. The pick-off pawls help to separate

paper which has low stiffness.

7. Cleaning

The cleaning blade re move s any toner remaining on the drum su rfa ce.

8. Quenching

The light from the quenching lamp electrically neutralizes the surface of the

drum.

1-5

11

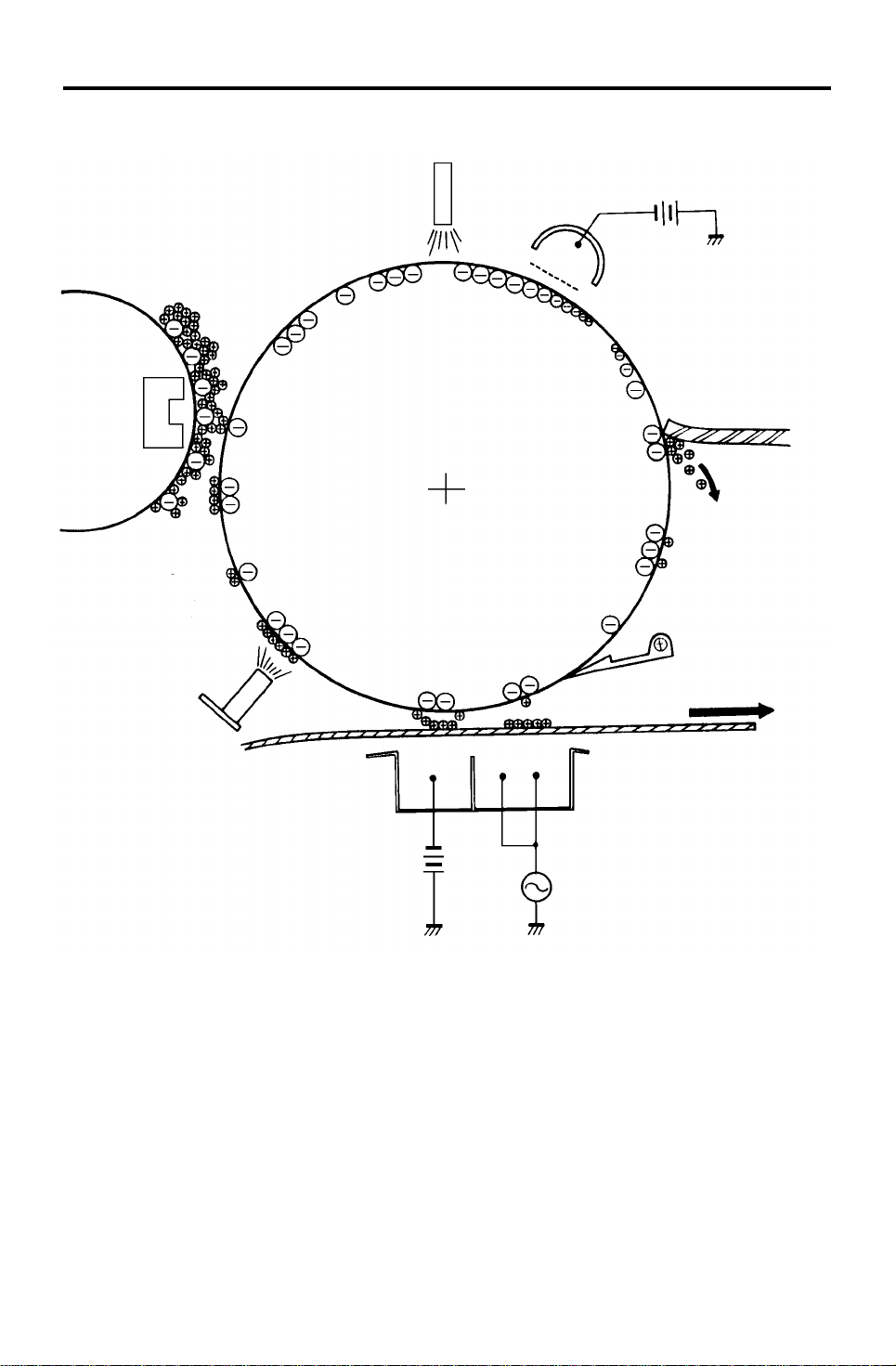

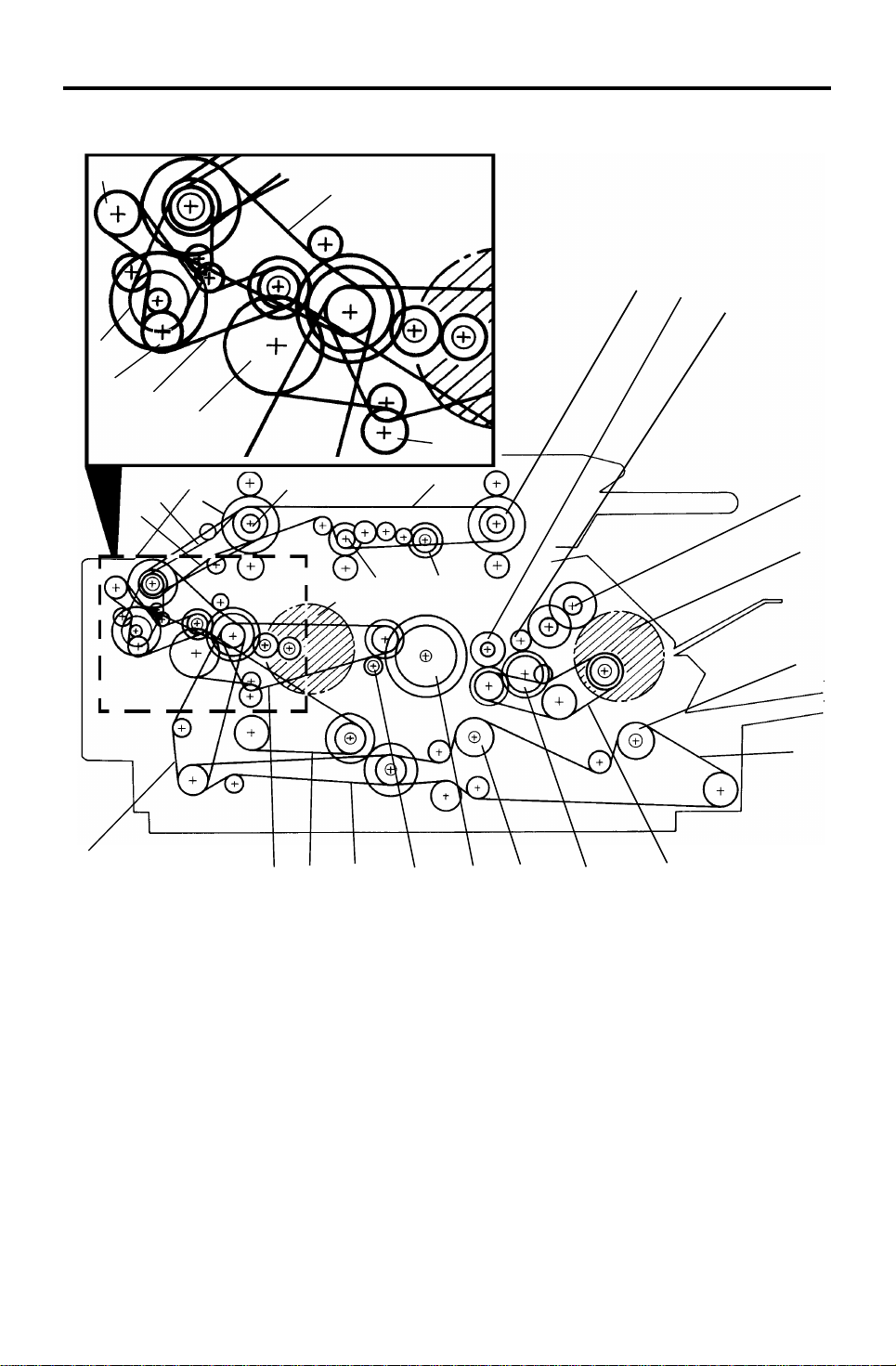

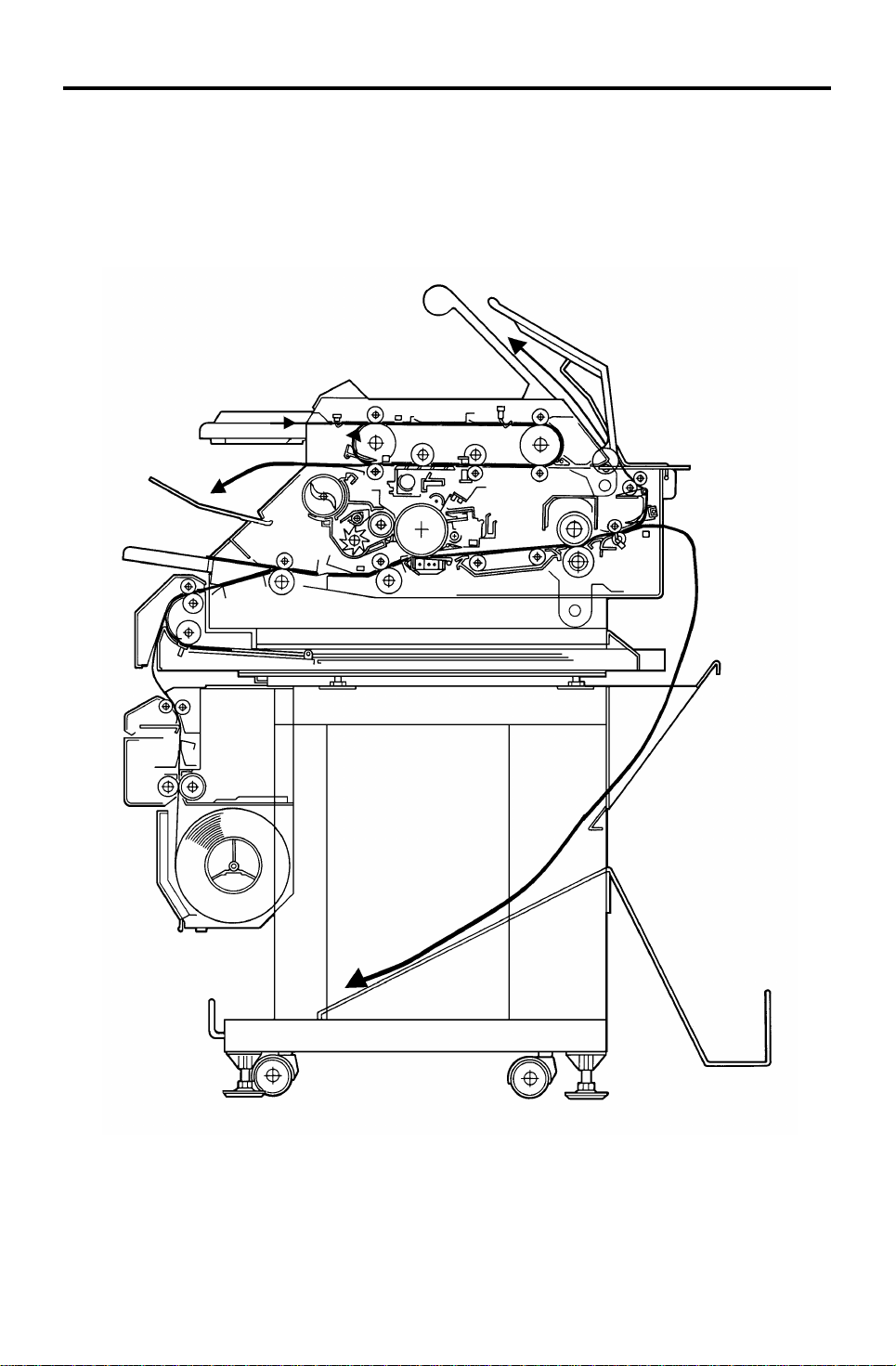

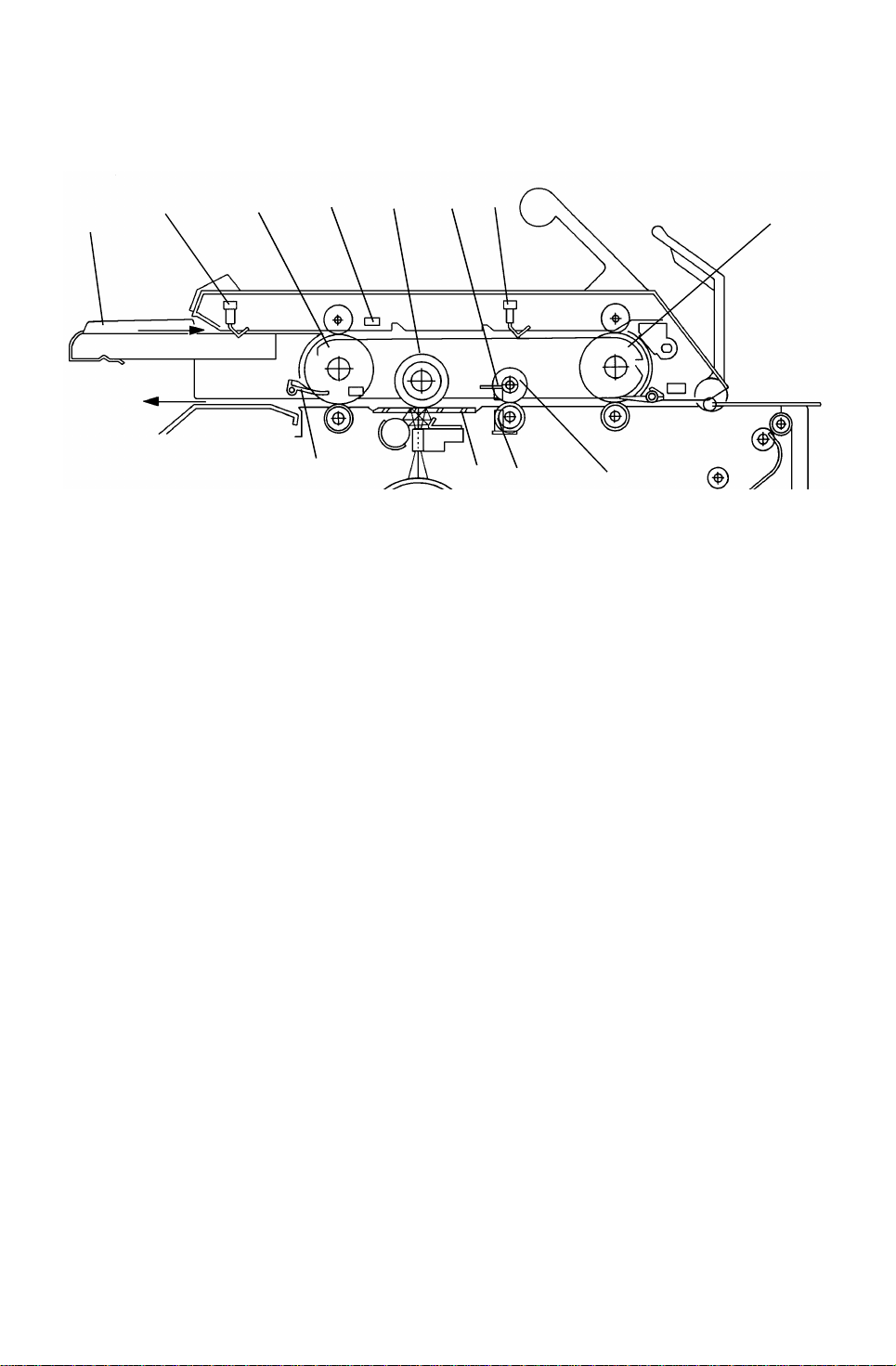

MECHANICAL COMPONENT LAYOUT 31 December 1992

4. MECHANICAL COMPONENT LAYOUT

4

8

10

12

13

14

15

9

34

32

33

35

36

2

1

5

3

7

6

30

29

28

27

26

31

16

17

18

19

20

21

22

23

24

25

1-6

31 December 1992 MECHANICAL COMPONENT LAYOUT

1. Front Original Feed Roller

2. Exposure Lamp

3. 1st Press Rollers

4. Fiber Optic Array

5. Platen Roller

6. Charge Corona Unit

7. Cleaning Blade

8. Original Registration

Rollers

9. 4th Press Rollers

10. Rear Table Lever

11. 2nd Press Rollers

12. Rear Original Feed Roller

13. 3rd Press Roller

14. Switch Back Gate

15. Hot Roller

16. Upper Exit Rollers

17. Exit Gate

18. Exit Rollers

19. Pressure Roller

20. Transport Belt

21. Pick-off Pawls

22. T/S Corona Unit

23. Paper Registration Rollers

24. Lower Copy Guide

25. Table

26. Roll Feeder

27. Manual Feed Rollers

28. Sheet Feeder

29. Manual Feed Table

30. Original Guides

31. Development Roller

32. Toner Cartridge

33. OPC Drum

34. Original Table

35. 5th Press Roller

36. Original Recycle Gate

1-7

9

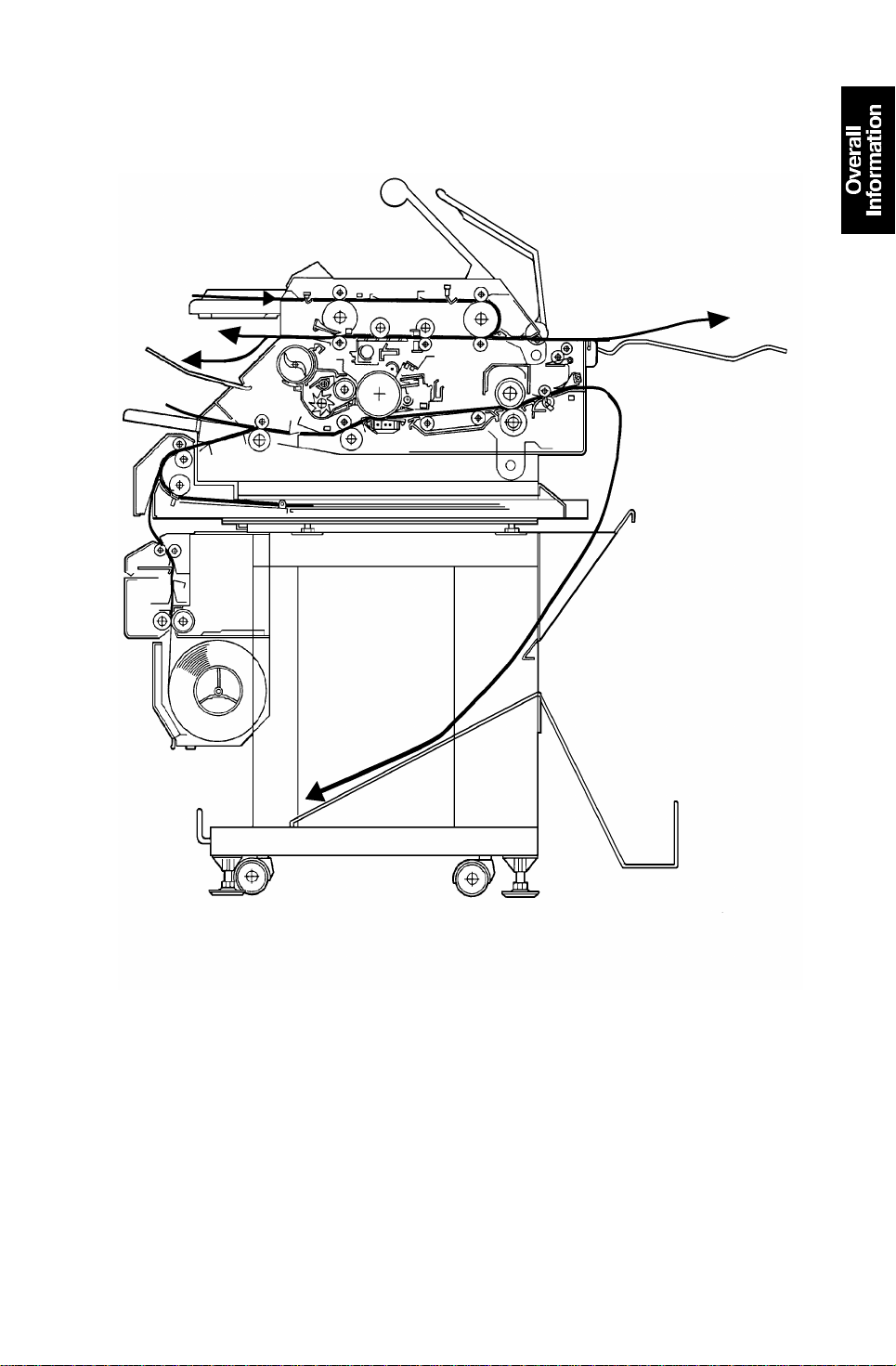

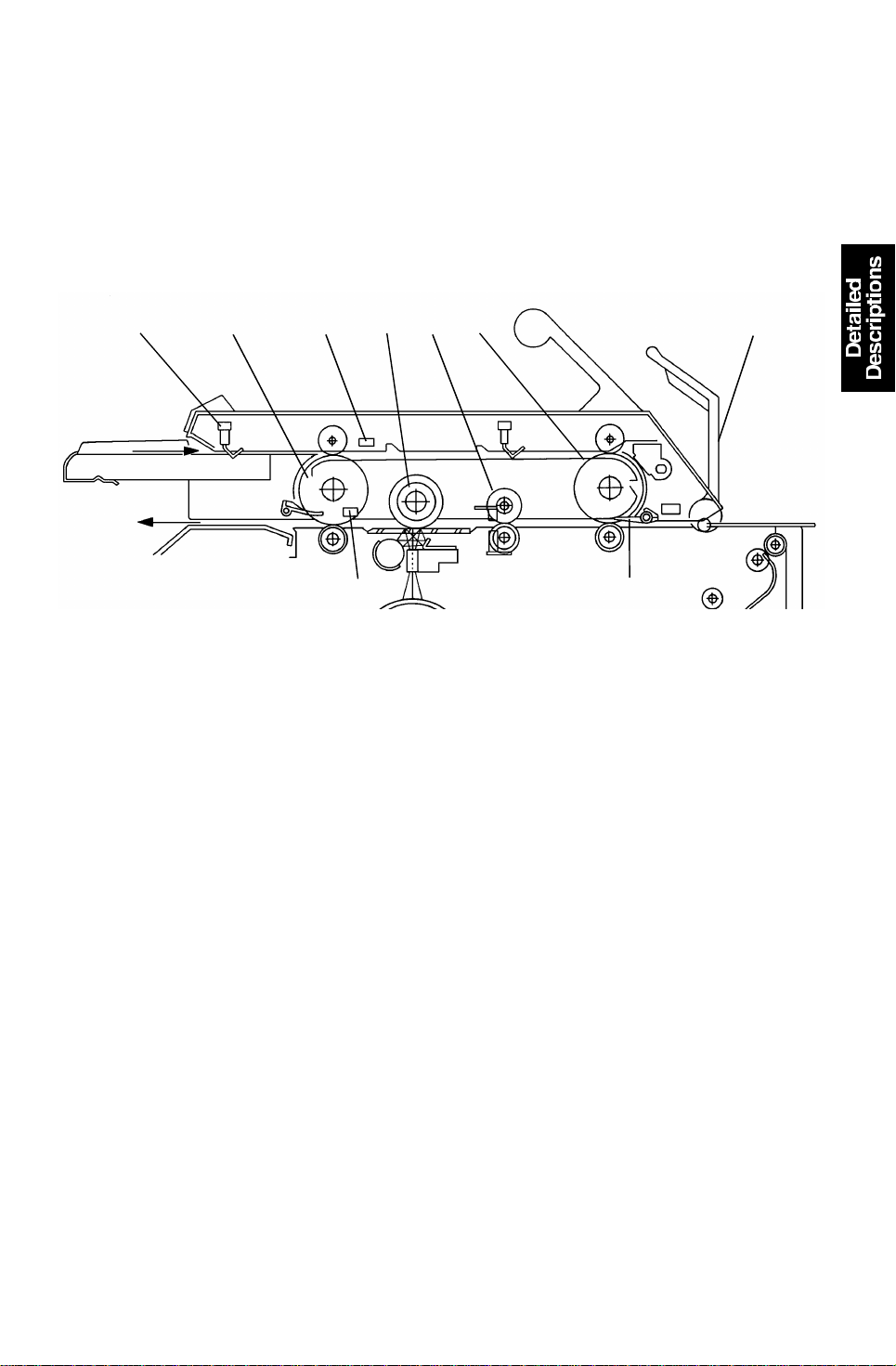

DRIVE LAYOUT 31 December 1992

5. DRIVE LAYOUT

29

28

27

31

8

10

26

25

24

30

2

3

6

11

1

12

5

4

7

13

23

21

22

1. Original Drive Belt 2

2. Rear Original Feed Rollers

3. Original Drive Clutch

4. Main Drive Motor

5. Original Registration

Rollers

6. Original Drive Belt 3

7. Platen Roller

8. Front Original Feed Rollers

9. Development Roller Gear

10. Auger Gear

20

11. Toner Supply Clutch

12. Development Motor

13. Paper Feed Clutch

14. Paper Feed Drive Chain

15. Development Drive Belt

16. Paddle Roller Gear

17. Registration Roller Clutch

18. Drum Drive Gear

19. Toner Collection Coil Gear

20. Feed/Fusing Drive Belt 2

21. Fusing Drive Chain

19

14

161718

22. Drum Drive Belt

23. Feed/Fusing Drive Belt 1

24. Transport Roller Sprocket

25. Hot Roller Sprocket

26. Exit Roller Drive Chain

27. Lower Exit Roller Sprocket

28. Original Reverse Drive

Belt 1

29. Upper Exit Roller Sprocket

30. Original Reverse Drive

Belt 2

31. Original Drive Belt 1

15

1-8

31 December 1992 ELECTRICAL COMPONENT DESCRIPTIONS

6. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical compone nt layou t on the reverse side of the Poin t to

Point (Water proof paper) ind ex nu mbe rs.

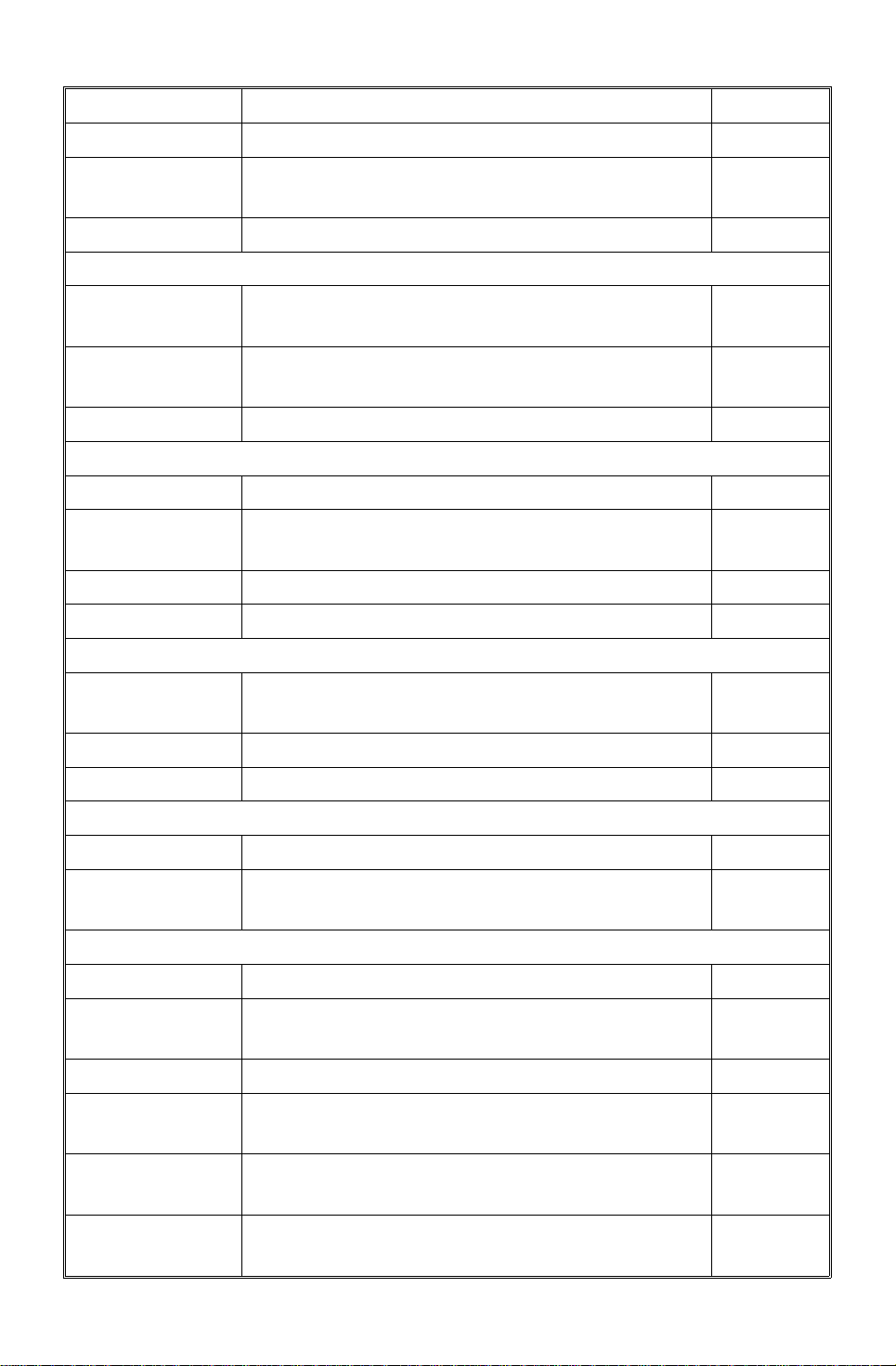

Name Function Index. No.

Motors

Main Drives all mechanical components except the

development un it and the fans. (100 Vac)

Development Drives the development unit. (100 Vac) 1

Exhaust Fan Removes heat from arou nd the fusin g un it.

(100 Vac)

Cooling Fan Provides air flow to the optics cavity. (100 Vac) 6

Vacuum Fan Provides suction so tha t pape r is held firmly

on the transport belts and rollers. (100 Vac)

Magnetic Clutches

Original

Forward Feed

Registration Drives the registration rollers. 50

Original Re-

verse Feed

Solenoids

Drives the original forward feed mechanism. 52

Drives the original reverse feed mechanism. 8

5

25

68

Toner Supply Turns on to supply toner to th e de velo pment

unit.

Pattern Shutter On ID check cycles, this solenoid turns on to

move the pattern plate into the light path .

Exit Gate Controls the position of the exit gate. (When

ON, the paper exits downward; when OFF,

the paper exits upward.)

Pick-off Pawl Moves the pick-off pawls again st th e dru m. 34

Paper Stopper Moves the paper stoppe r down to pre vent

paper from being inse rte d.

Manual Feed Turns ON to engage the man ua l fee d clut ch. 48

Recycle Gate Cont rols the positio n of the recycle ga te.

(ON = recycle gate in down position,

OFF = recycle gate in up position.)

1-9

46

19

24

40

26

ELECTRICAL COMPONENT DESCRIPTIONS 31 December 1992

Name Function Index. No.

Switch Back

Lifts the switch back gate to the up position. 9

Gate

Original Stopper Moves the original stopper down to prevent an

43

original from being inserted.

Switches

Main Supplies power to the copier. 65

Upper Safety Cuts ac 100 volt power when the upper unit is

27

opened.

Lower Safety Cuts ac 100 volt power when the middle unit

67

is opened.

Rear Safety Cuts ac 100 volt power when the paper exit

22

unit is opened.

Toner Cover Cuts power to the toner sup ply sole no id whe n

45

the toner cartridge cover is opened .

Sheet Feede r

Set

Prevents main motor op era tion when the

sheet feeder is n ot set.

64

Rear Feeder Detects when the rear feeder table is o pe ned. 21

Sensors

Image Density Detects the image density of the test pattern

33

on the drum.

Toner Density Detects the density of toner in the deve loper. 36

Toner Overflow Detects when the used toner tank is full. 28

Pulse Generator Supplies timing pulses to the main board

23

(photointerruptor).

Original Set Detects when an original is inserted. 41

1st Original

Monitors movement of the origin al. 11

Transport

2nd Original

Monitors movement of the origin al. 14

Transport

Original Registration

Light Detects the intensity of the exposure lamp

Detects when the orig inal lead edge passes

the original registration rollers.

12

4

output.

Original En-

trance

Detects when an original is inserted from the

rear feeder.

13

1-10

31 December 1992 ELECTRICAL COMPONENT DESCRIPTIONS

Name Function Index. No.

Switch Back

Gate

Detects if the switch back gate moves to the

up position during the original switch back.

10

Original Exit Detects jams in the original exit section. 39

Recycle Gate De te cts whe ther the recycle gate is in the up

30

or down position.

1st Feed Detects when copy paper is in sert ed . 38

2nd Feed Detects jams between the manual feed rollers

37

and the registration rollers.

Registration Detects when copy paper arrives at the

35

registration rollers.

Transport Monitors paper movement between the

71

transfer/separation section and the fusing unit.

Fusing Exit Detects jams through the exit unit. 17

Upper Exit Detects jams through the upper exit guid es. 16

Lower Exit Detects jams through the lower exit guides. 18

Printed Circuit Boards

Main Controls all copier functions both dire ctly and

63

through other PCBs.

DC Power

Supply

Provides dc power for all components of the

machine.

55

AC Controller 1 Provides ac power to the fusing lamp and triac. 57

Lamp Regulator Provides ac power to the fusing lamp. 51

AC Controller 2 Provides ac power to the main motor and

60

development mot or.

Indicator Panel Contains the paper and original insertion

42

indicators and the original feed stop key.

Operation Panel Control the operatio n panel d ispla y. 32

Auto Image

Density

Measures the reflectivity from the origin al’s

background.

15

Lamps

Exposure Provides light to reflect the original’s image

29

onto the drum.

Quenching Neutralizes any charge remaining on the drum

20

surface after cleaning.

1-11

ELECTRICAL COMPONENT DESCRIPTIONS 31 December 1992

Name Function Index. No.

Fusing Provides heat to the fusing unit. 53

Pre-Transfer

(PTL)

Reduces the charge on th e drum surface prior

to image transfer.

31

Power Packs

Charge/Bias/Grid

Power Pack

Transfer/

Separation

Provides high voltage power for the charg e

corona, charge grid, an d de velopment bias.

Provides high voltage power for the tran sfe r

corona and separa tion.

49

54

Thermistors

Hot Roller Monitors the hot roller’s surfa ce tempe rature. 56

Pressure Roller Mo nit ors th e pressure roller’s surface

58

temperature.

Exposure Lamp Monitors the fluorescent lamp’s temperature. 44

Thermofuses

Fusing Protects against fusing overheat. (Two

59

thermofuses in parallel.)

Exposure Lamp Protects against expo sure lamp overheat. 44

Heaters

Exposure Lamp Warms the scanning lamp. 44

Anticondensa-

Keeps moisture from forming inside the copie r. 47

tion

Others

Total Counter Keeps track of the total length of cop ies mad e. 66

Noise Filter Filters electrical noise on the ac power input

62

lines.

Transformer Steps down the line voltage to 100 Vac. 69

Development

Motor start capacitor. 2

Motor Capacitor

Main Motor Ca-

Motor start capacitor. 3

pacitor

Circuit Breaker Guards against voltage surg es in th e inp ut

61

power.

1-12

31 December 1992 ELECTRICAL COMPONENT DESCRIPTIONS

Name Function Index. No.

Vacuum Fan

Motor Capacitor

Motor start capacitor. 70

1-13

ORIGINAL AND PAPER PATH 31 December 1992

7. ORIGINAL AND PAPER PATH

Repeating Copy Exce pt for A0 /E, A1/D Lengthwise

➀

➁

➂

A

B

A: Upper Copy Exit

B: Lower Copy Exit

1-14

31 December 1992 ORIGINAL AND PAPER PATH

A0/E, A1/D Lengthwise Switching Back

➀

➂ ➄

➁ ④

⑥

② ③ ④ ⑤ : Switching Back

1-15

SECTION 2

DETAILED SECTION DESCRIPTIONS

31 December 1992 DRUM

1. DRUM

1.1 DRUM CHARACTERISTICS

The organic photoconductor (OPC) dru m has th e followin g cha ract erist ics:

• I t is able to accept a high negative electrical charge in the dark. (The

electrical resistance of the OP C drum is high in the abse nce of ligh t. )

• The electric charge on the drum surface dissip at es whe n th e drum is

exposed to light. (The conduct ivity of the OPC dru m is great ly enh an ced

by exposure to light.)

• Dissipating an amount of charge in direct pro po rtio n to the inte nsit y of th e

light. That is, where stronger light is directed to the photoconductor

surface, a smaller voltage remain s.

The OPC drum used in this model has high sen sitivit y, go od color

reproduction, and good rep rod uction of low contrast originals (pen cil

originals, etc.)

2-1

[F]

DRUM 31 December 1992

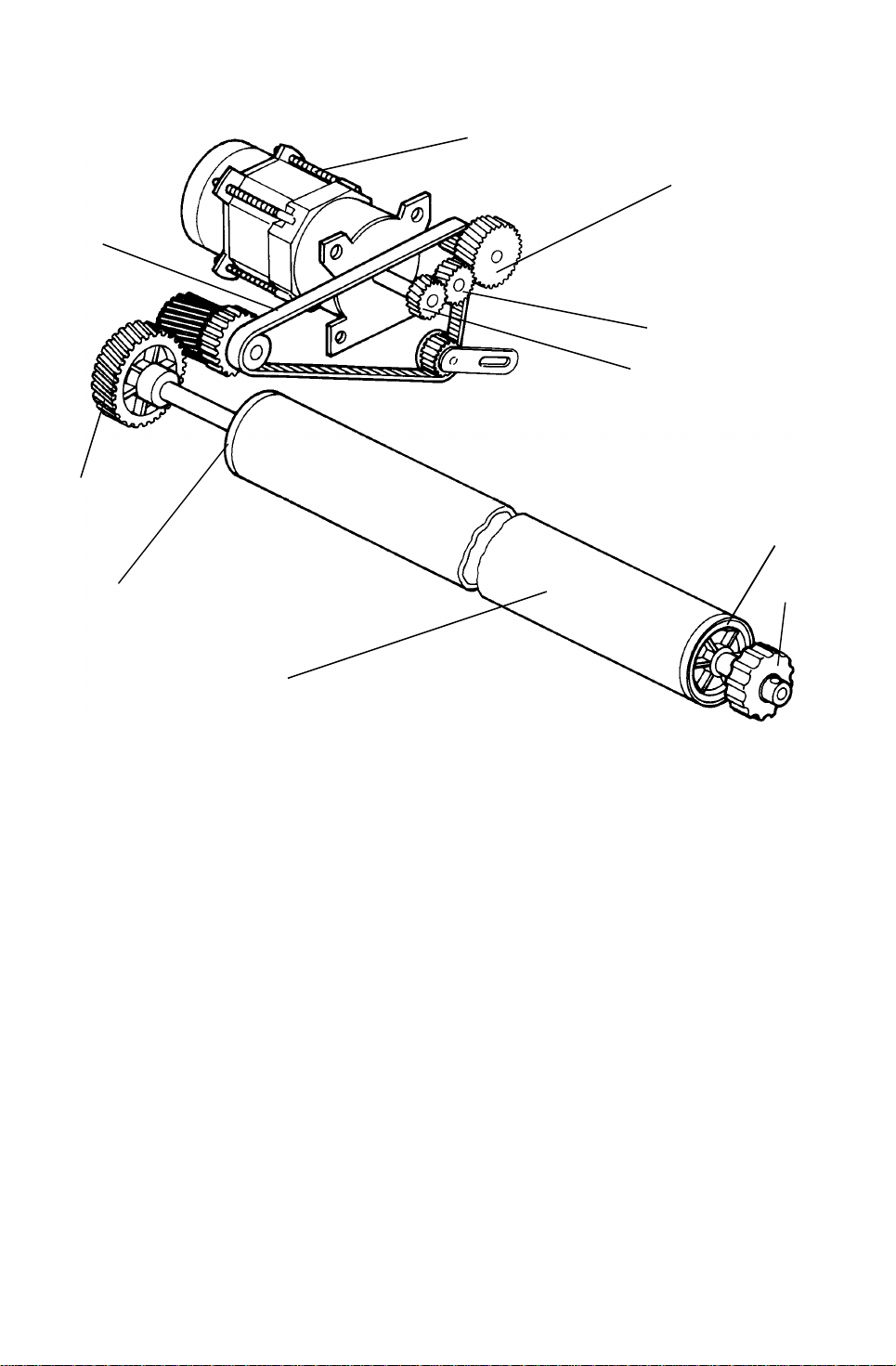

1.2 DRUM DRIVE

[B]

[E]

[D]

[C]

[G]

[J]

[H]

[I]

[A]

The OPC drum [A] is 80 millimeters in diameter and 970 millimet ers lon g. It

turns constantly whe n th e main motor [B] is on.

When the main motor turns on, drive is transmitte d to the drum as follows:

main motor drive gear [C] ⇒ idle gear [D] ⇒ main drive pulley gear [E ] ⇒

drum drive belt [F] ⇒ drum drive gear [G] ⇒ drum flange [H] ⇒ drum

When the drum knob [I] is tightene d, the rig ht flan ge [J] pre sses firmly against

the drum so that the drum is held tightly between the flanges. The drum and

flanges turn together when the main motor is on.

2-2

31 December 1992 CHARGE

2. CHARGE

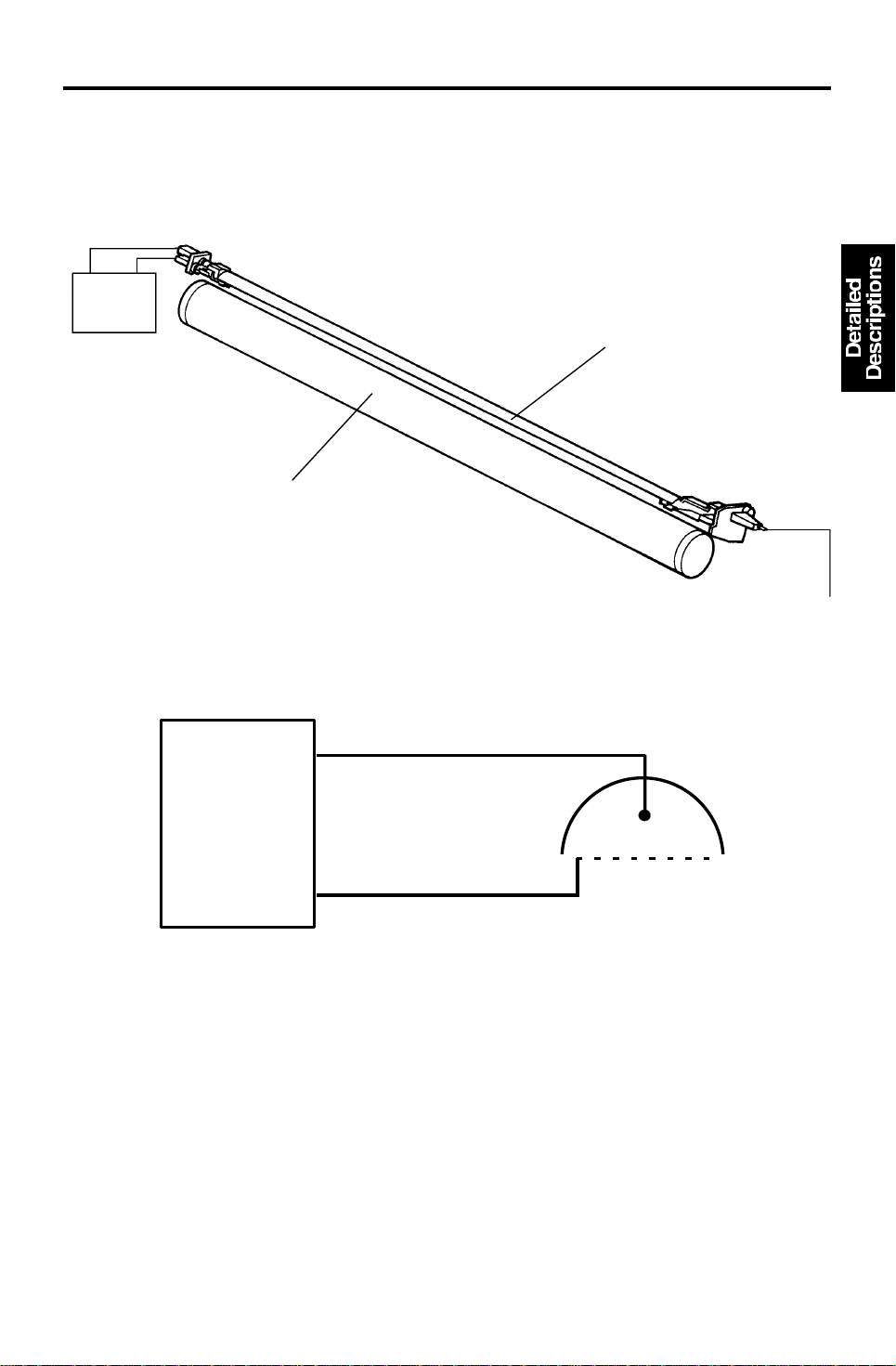

2.1 OVERVIEW

P1

[A]

[B]

Charge

P1

Grid

This model uses a single wire corona unit [A] to cha rge the OPC (org an ic

photoconductor) drum [B ]. The corona wire generates a corona of negative

ions when a high negative voltage is applied to it by the charge/ grid power

pack [P1].

To make the negative corona unifo rm, a grid consist ing of 8 wires is installed

on the charge corona unit betwe en the coron a wire and th e drum. This grid

drains off any charge in excess of –940 volts, thus preventing flu ctu ation of

the charge potential.

2-3

CHARGE 31 December 1992

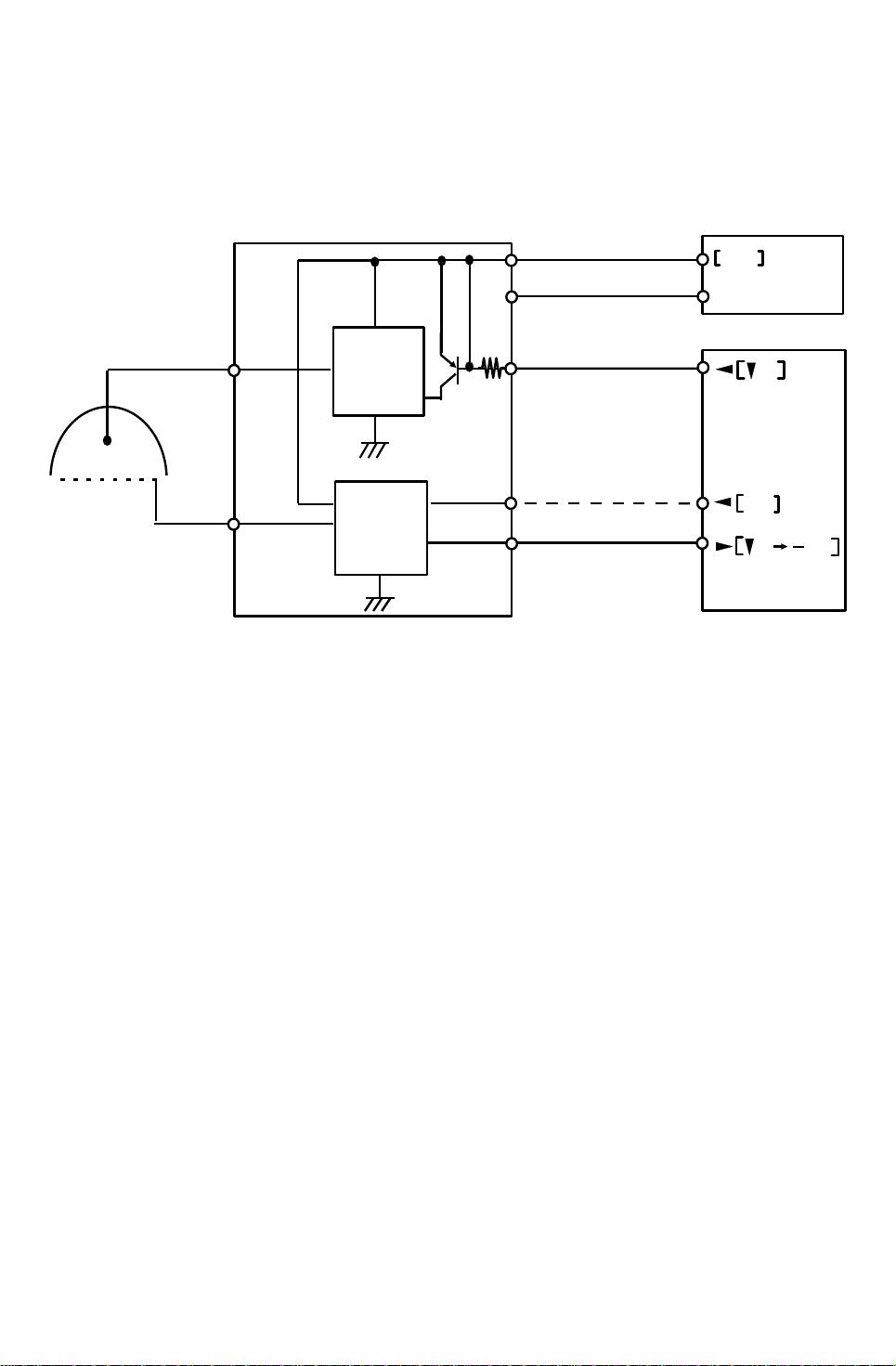

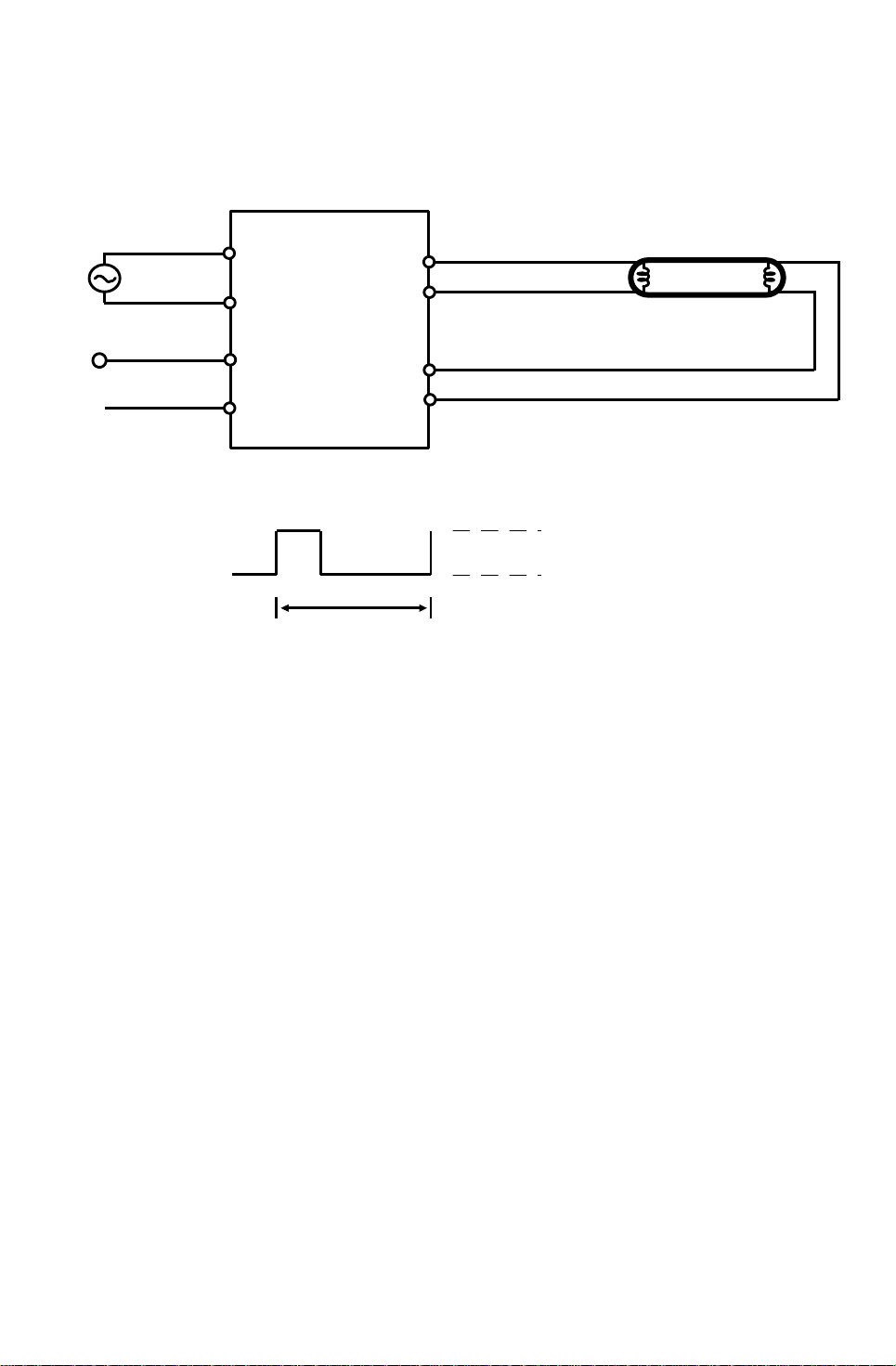

2.2 CHARGE CORONA CIRCUIT

Charge / Bias Grid PP

Charge/Bias/Grid PP

DC/DC

Converter

DC/DC

Converter

CN1-1

CN1-2

CN1-3

CN1-6

CN1-10

CN2

-6

CN107

-B14

CN110

-1

-8

DC Power

24V Va

GND

Main Board

24

Charge

Grid Drive

0/5

Grid monitor

0

2.5

The DC power supply board supplies +24 volts (Va) to the charge/bias/grid

power pack as the power supply source. About 8 seconds afte r t he copy

process starts, the CPU drops CN107-B14 from +24 volts to 0 volt. This

actuates the dc/dc convert er within the power pack which applies a high

negative voltage of approxima te ly – 5.3 kV to the charg e coro na wire. The

corona wire then genera te s a neg at ive corona charge.

The grid limits the maximum corona charg e to –94 0 volts. This en sure s t hat

the charge does not flu ctu ate and an even charge is applied to th e drum

surface. When developing the test pattern for the image density sensor, the

grid charge is –460 volts.

The copy grid voltage, and ID senso r grid volt ag e amo unts can be adjusted

using service program modes #23 and #22, respectively.

The grid drive signal applied to CN1-6 is a pulse width modulated signal. As

the width of the pulses applied increases, the streng th of th e grid charge also

increases. The main board mon ito rs t he grid cha rge at CN110-8 and controls

the width of the drive pulse s b ase d on this fe ed ba ck.

2-4

[G]

31 December 1992 EXPOSURE

3. EXPOSURE

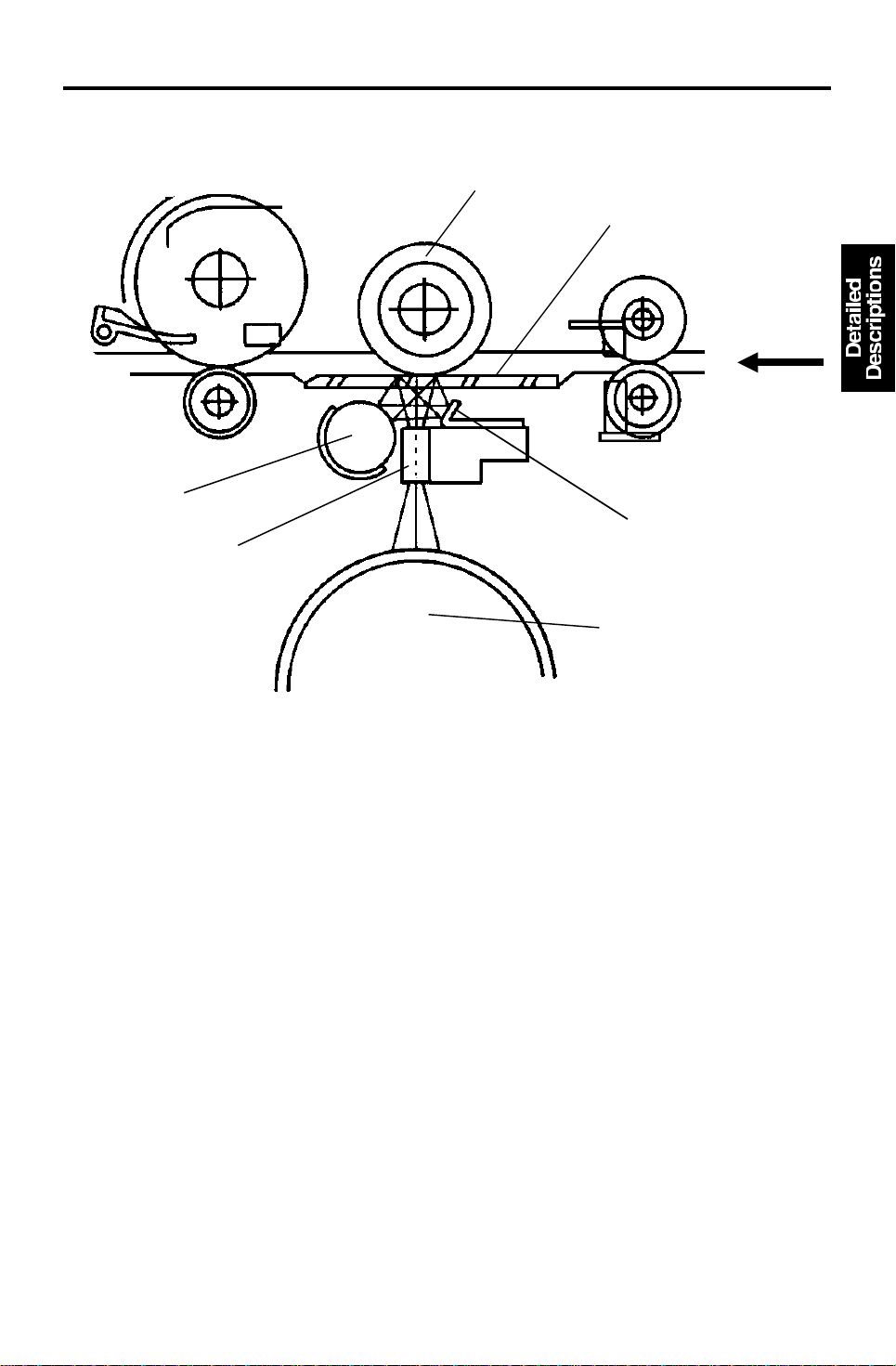

3.1 OVERVIEW

[A]

[B]

[E]

[F]

[D]

[C]

Light from the expo sure lamp [A] reflects off the original an d through the fiber

optics [B] to the OPC drum [C]. The reflector plate [D] aides the exposure

lamp intensity for high original moving speed. During exposure, the origin al

moves across the exposure glass at the same speed as the drum’s

peripheral velocity.

The platen roller [E] presses the original [F] flat against the exposure glass

[G] just above the fiber optic array. This ensures that the image is properly

focused. (The original must be with in 0. 2 mm of the exp osu re glass surface.)

The exposure lamp is a 100 V, 65 W fluo rescent lamp. This lamp has a

heater which prevents a reduction in light outpu t due to low temperatures.

The heater maintains the lamp’s temperature at 40oC

2-5

EXPOSURE 31 December 1992

3.2 ORIGINAL FEED

3.2.1 Basic Operation

[A]

[B]

[C]

[F]

[L]

[I]

[H]

[J]

[G]

[K]

[D]

[E]

When the original is inserted on the original table [A ], it activa te s the origin al

set sensor [B]. The main moto r t hen tu rns on . Two seco nd s late r t he origin al

feed clutch turns on to start turning the front origin al feed rollers [C] , rea r

original feed rollers [D], and original registration rollers [E]. The two secon d

delay allows time for the operator to alig n the lea d edge of the orig ina l

against the first set of rollers to prevent skew.

The original is fed past the 1st and 2nd original transport sensor [F,G] and

around the rear original feed rollers to the original registration rollers. The

original feed clutch turns off 0.2 second afte r the origin al’s lea din g edge

activates the original registratio n sen sor [H] . The origin al rema ins at this

position until a sheet of copy pa pe r is fe d.

Just before the copy p aper reaches the registration sensor, the original feed

clutch turns on again and original feed resumes. The original passes

between the platen roller [I] and the exposure glass [J] and from th ere to the

front original feed rolle rs. The origin al’s imag e de nsit y is mea sure d by th e

ADS [K] at this time. The original’s image is reflected through the fiber opt i c

array to the drum as it passes between the platen roller and the exposure

glass.

If making a single copy, the orig inal then exits the machine. However, if

making repeat copie s, th e recycle gate [L] directs the original around the front

original rollers to the upper part of th e orig inal transport mechanism. The

original transport cycle the n rep eats.

The maximum original lengt h fo r repe at copying is 610 millimeters. If the

operator attempt s repe at copyin g with an original longer than 610 millimeters,

it will automatically feed out aft er makin g a sing le copy.

2-6

31 December 1992 EXPOSURE

The main CPU determines th e original length for synchro cut tin g by counting

the generated pulses after the 1st original tran spo rt sensor detects the

leading edge of the original until the original set sen sor de tects th e tra iling

edge of the original.

Switching-back

[A]

[E]

[D]

[F]

[B]

[G]

[H]

[C]

[I]

The inserted origina l activates both the original se t [A ] an d original exit [B]

sensors when the lever [C] is lifted and the entered number of copies is two

or more. The copier CPU then detects that the switching -ba ck mode has

been entered.

In the switching back mode, the origin al is e xpo sured by passing between the

platen roller and exposure glass. At the approp riat e timin g afte r the trailin g

edge of the original passes through the 1st orig ina l t ran spo rt sensor [D], the

front original feed [E ], plat en [F], origin al reg istration [G], and rear original

feed [H] rollers turn backwards and the switch back gate [I] is lifte d to the up

position. The original is t ran sported to the machines rear side. At the

appropriate timing af ter the trailing edge of the orig ina l p asse s th ro ug h th e

registration sensor, th e fro nt origin al fe ed , pla te n, origin al reg istra tion, and

rear original feed rollers begin turnin g forward again. The orig ina l is exposed

in the exposure section. The copier repeats the switch ing -back operation until

the entered numbe r of th e copies have been made.

After all the copies are made, the original exits the machine.

The copies exit from the lower co py exit way in the switching-back mode

because the rear feeder table is opened.

If the operator attemp ts inserting an original longer than 610 mm witho ut

lifting up the rear feeder table lever, the origin al will aut oma tica lly fee d out

after being scanned once only.

2-7

[D]

[C]

EXPOSURE 31 December 1992

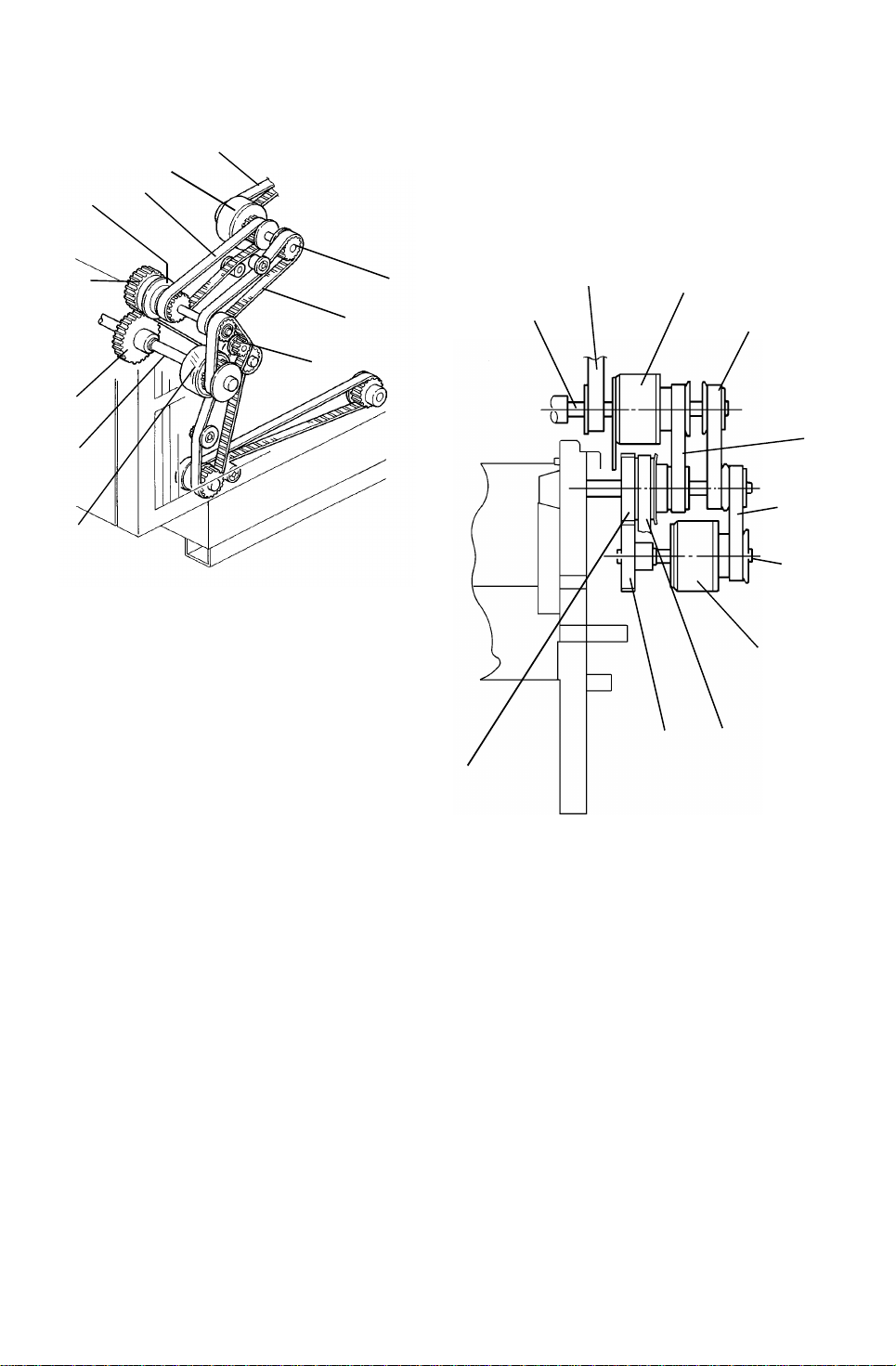

3.2.2 Drive Mechanism

[D]

[B]

[E]

[A]

[G]

[H]

[I]

[F]

[J]

[K]

[C]

[G]

[H]

[B]

[K]

[E]

[J]

[I]

[F]

[A]

Drive power from the main motor is transmitted to the relay pulley [A]. When

the original forward feed clutch [B] is energize d, the rear orig inal feed roller

shaft [C] starts turning the original drive belt 3 [D] forward throug h the orig ina l

drive belt 2[E]. The front origina l fee d rollers, th e rea r origin al feed rollers,

and the original registration rollers rotate in the origin al forward direct ion .

When the original reverse feed clu tch [F] is ene rgize d, the rear original feed

roller shaft starts turning the original drive belt 3 backwards from the relay

pulley through the int erme dia te gear [G], reverse gear [H], origina l re verse

feed clutch shaft [I], and th e orig ina l reverse drive belt 1 and 2 [J, K]. The

front original feed rollers, the rea r origin al fe ed rollers, and the origin al

registration rollers rotate in the orig ina l re verse direct ion .

2-8

31 December 1992 EXPOSURE

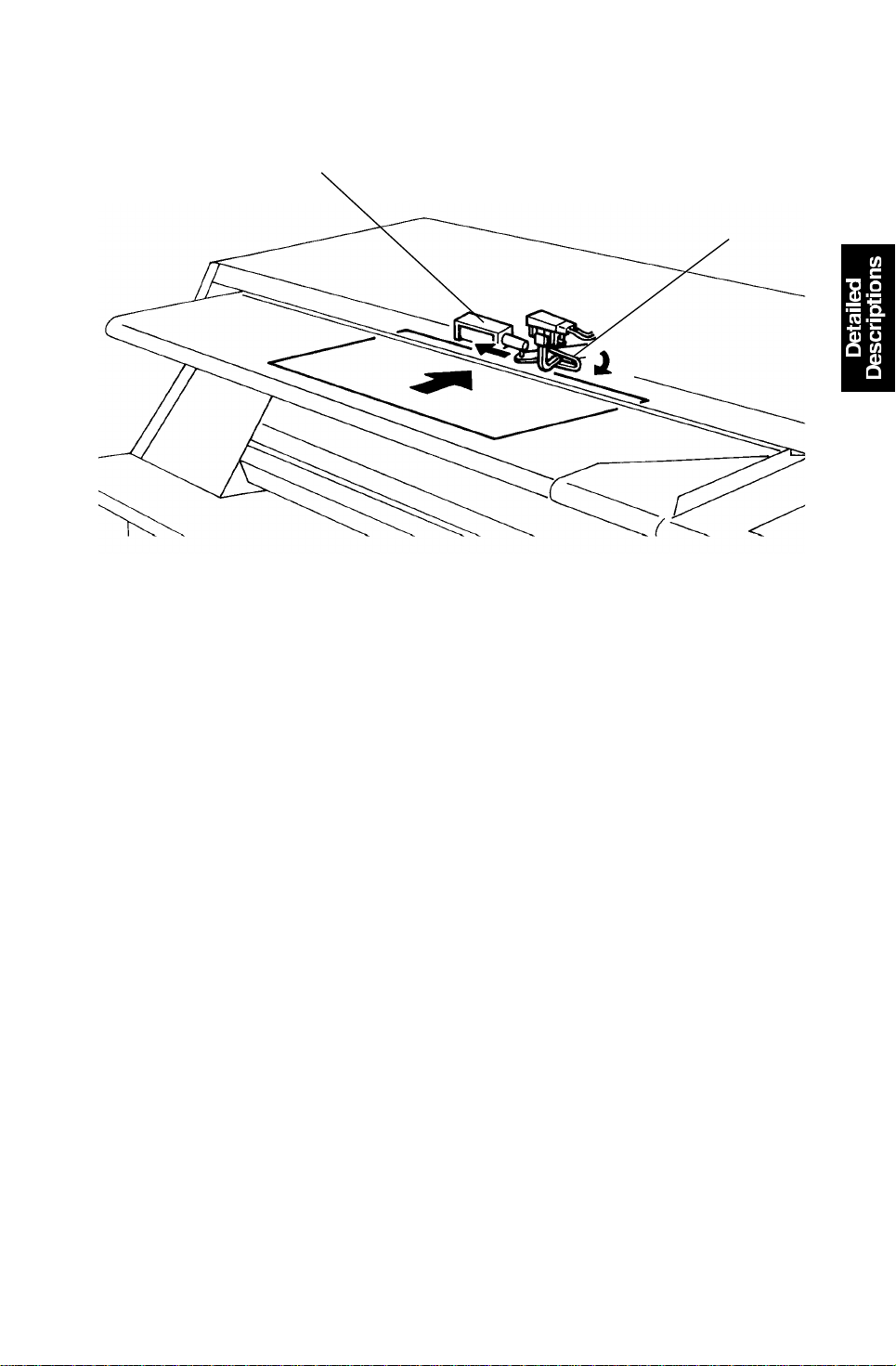

3.3 ORIGINAL STOPPER MECHANISM

[A]

[B]

Originals should not be inserted during a copy cycle. To prevent originals

from being inserted, the machine locks the feeler of the original set det ect or

in the down position while copying. This is accomplished by the origina l

stopper solenoid [A].

When the original stopper soleno id tu rns on , th e stopper arm [B] rotates

against the feeler of the original set sensor. This locks the feeler in the down

position so that originals can on ly be inse rted as far as the original set sensor.

2-9

EXPOSURE 31 December 1992

3.4 EXPOSURE LAMP CONTROL

[PCB4]

+5V

PWM

CN1-1

CN1-2

CN2-1

CN2-2

CN2-2

LAMP

REGULATOR

T

CN3-1

CN3-2

CN3-4

CN3-5

Lamp OFF (+5V)

Lamp ON (GND)

T = 1.0 ms

Duty = 15% to 100%

[L1]

Exp. Lamp

The lamp regulator receives 100 volts ac at CN1-1 and CN1-2. It also

receives +5 volts, which is used in the lamp regula to r’s cont rol circuit , fro m

the main board at CN2-1. The cont rol sign al, which is a pulse width

modulated (PWM) signal, is received at CN2-2. The PWM sign al ha s a period

(T) of 1 millisecond and a duty of 15% to 100%.

The basic light intensity level is determined eith er by the imag e densit y

selected from the operation panel (manual ID con tro l) o r by the origin al’s

background level as sensed by the ADS. The CPU uses the light senso r t o

monitor the actual light inte nsit y. The light sensor directly senses the lamp’s

light output and fe eds a light in te nsity signal back to the main board. This

feedback allows the CPU to compensate for variations in light intensity due to

the lamp’s age or temperature .

2-10

31 December 1992 EXPOSURE

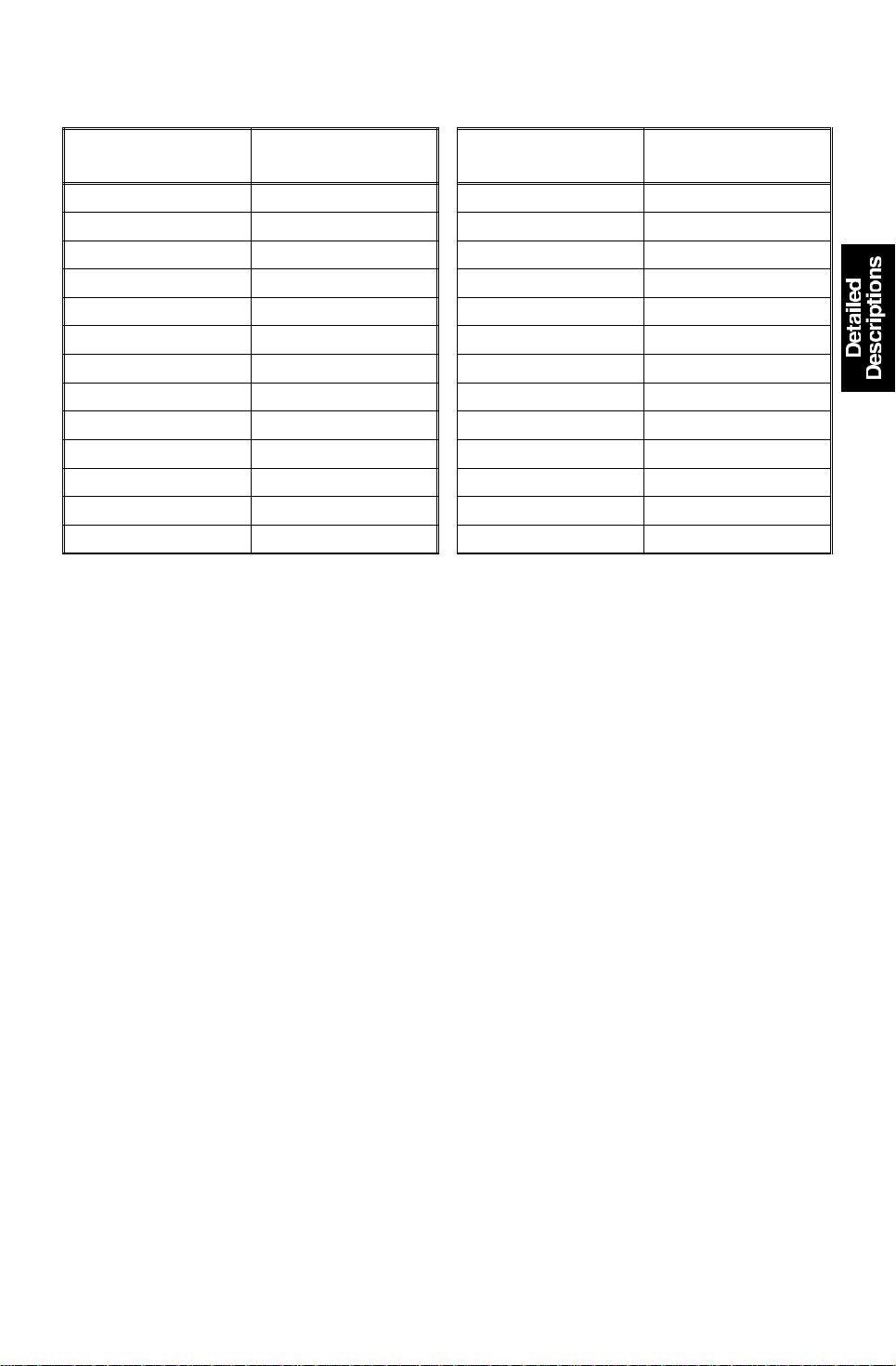

3.5 MANUAL ID CONTROL VS ADS

Manual ID Level

Light Sensor

Output [V]

Manual ID Level

Light Sensor

Output [V]

1 0.74 14 1.21

2 0.80 15 1.25

3 0.81 16 1.29

4 0.82 17 1.33

5 0.84 18 1.37

6 0.86 19 1.41

7 0.90 20 1.45

8 0.94 21 1.50

9 0.99 22 1.54

10 1.05 23 1.59

11 1.10 24 1.64

12 1.15 25 1.69

13 1.18 26 1.74

3.5.1 Manual ID Control

When in manual image densit y mo de , th e user can select one of 26 manual

ID levels. For each level, the intensity of the light output by the exposure

lamp (as measured by the light sensor) is fixed. This is shown in the above

table. For manual ID levels 2 thro ugh 12 , th e de velo pment roller bias also

varies. (See the section on development bias.)

2-11

Loading...

Loading...