Ricoh FW740 Technical Bulletin

Technical Bulletin No. RTB-001

SUBJECT: Service Code E11 DATE:Dec. 15, ’94

PAGE: 1 of 1

PREPARED BY: S. Hizen

FROM: 2nd Technical Support Section

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL: J2SS

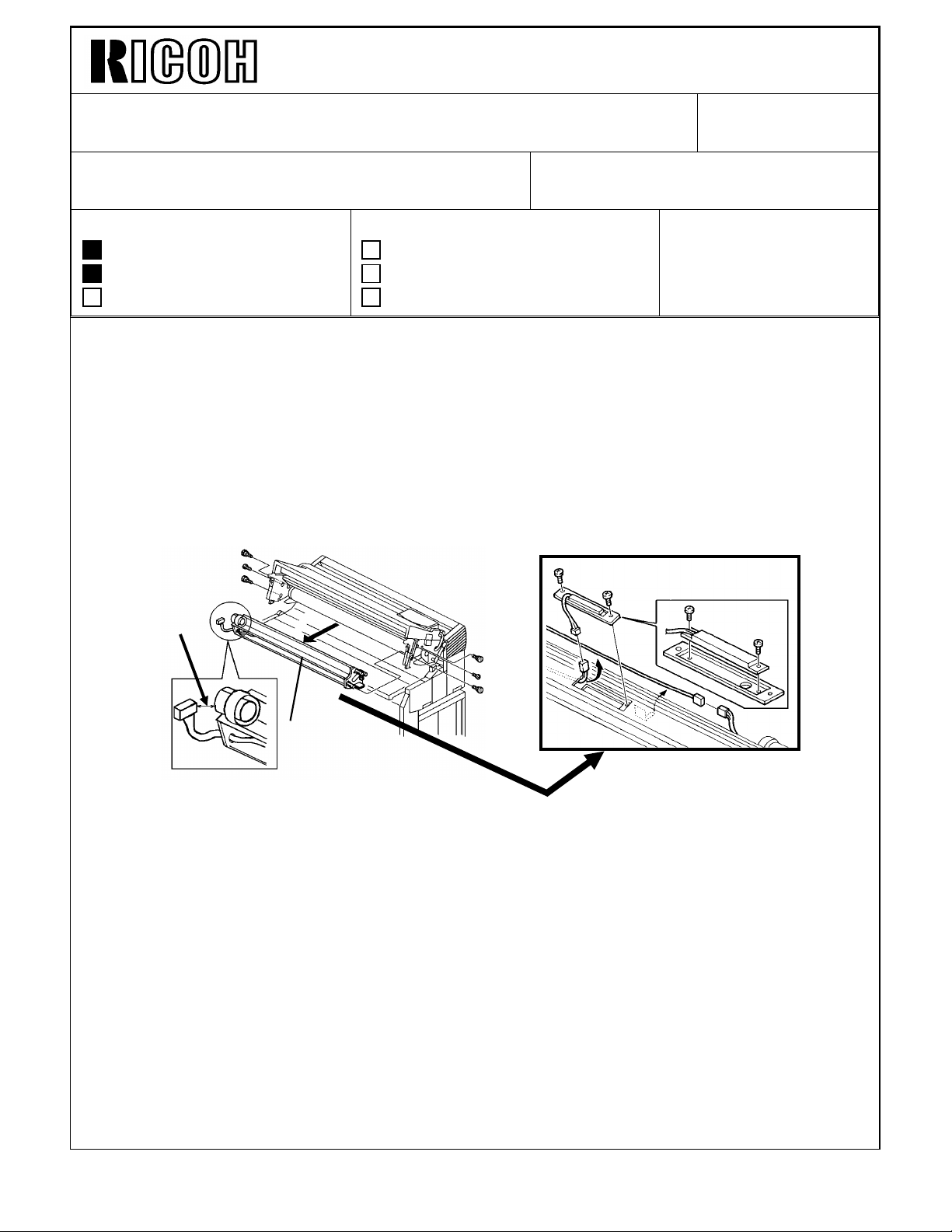

[Phenomenon]

Service Code E11 is displayed on the operation panel when the machine

is initialized either at installation or after developer replacement.

[Cause]

The transistor TR2 in the toner density sensor is broken by static electricity applied

through the pins of the development unit connector when the connector is disconnected.

[Action Required]

The following preventive actions are required when the development connector is

disconnected to protect the sensor from static electricity.

Toner Density Sensor

30mm

Development

Unit

Preventive Actions:

1: Keep the connector at least 30mm away from the development unit when the unit is

cleaned using a vacuum cleaner.

2: Do not touch the pins of the connector when the development unit is carried away from

the main frame or cleaned.

Once Code E11 is displayed, the toner density sensor must be replaced with a new one.

Toner Density Sensor Replacement Procedure :

Please refer to sections 3.1 DEVELOPMENT UNIT REMOVAL and 3.3 TONER DENSITY

SENSOR REPLACEMENT in Service Manual for the procedure.

Please handle the connector carefully to prevent static electricity damage after the sensor

is replaced.

Technical Bulletin No. RTB-002

SUBJECT: Service Manual Correction DATE: Dec. 15, ’94

PAGE: 1 of 1

PREPARED BY: S. Hizen

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

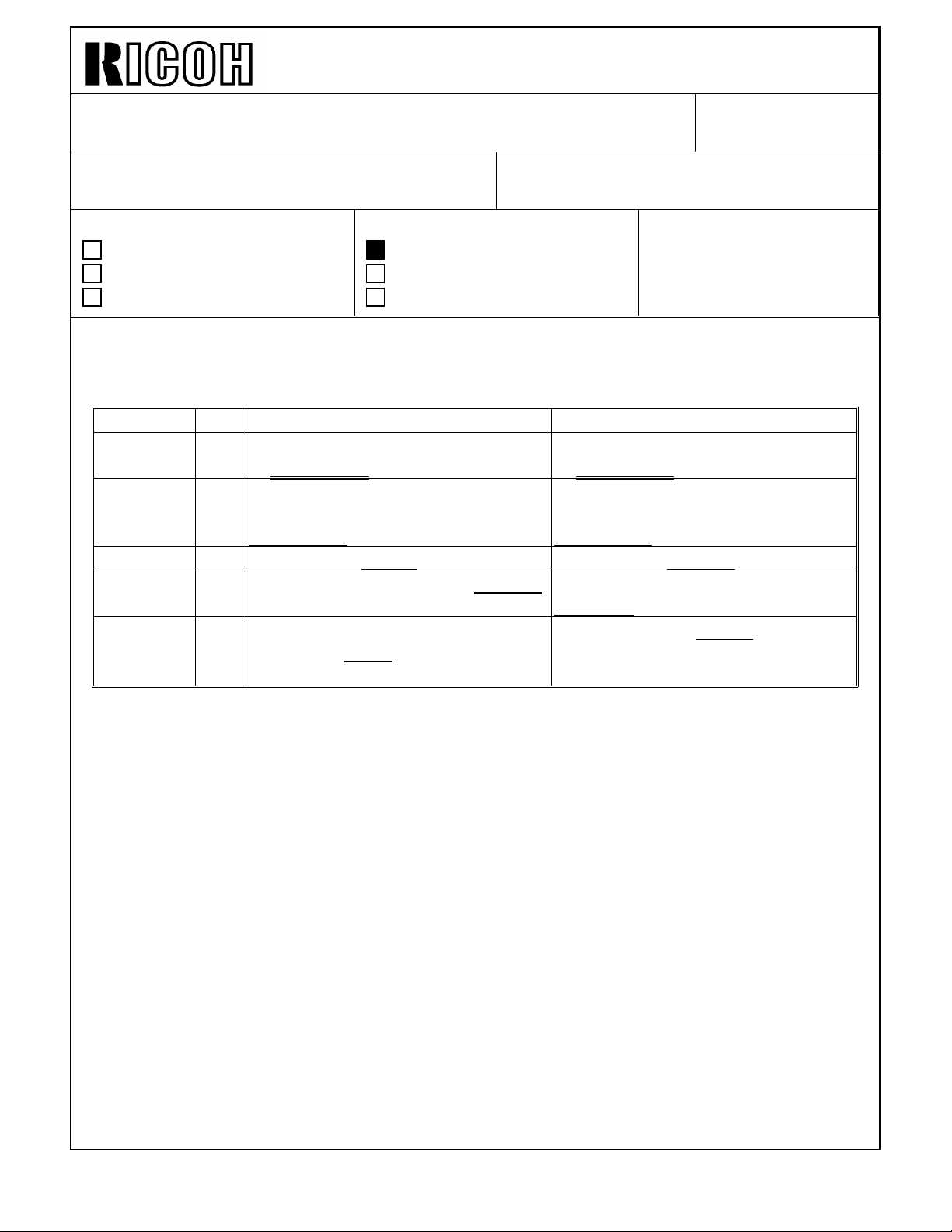

Please correct your service manual as follows:

Page Line Incorrect Correct

2-18 12 decreases and the voltage applied

to CN104-B20

2-18 14 carrier on the sensor coils

increases and the voltage at

CN104-B20

2-29 7 power drives PT201 and RA201 power drives PTC201 and RA201

2-29 9 activates the photocoupler (PT201)

which in turn energizes

3 in Roll

Feeder

section

22 Humidity sensor’ function: if the

humidity is lower than 45%

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: J2 SS

decreases and the voltage applied

to CN104-A10

carrier on the sensor coils

increases and the voltage at

CN104-A10

activates the photocoupler

(PTC201) which in turn energizes

if the humidity is higher than 45%

REVISED ON: DECEMBER 15, ’95 : Revised

Relay 12081392

*

Technical Bulletin No. RTB-003

SUBJECT: Energy Star DATE:October 31,

’95

PAGE: 1 of 4

PREPARED BY: S. Hizen

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

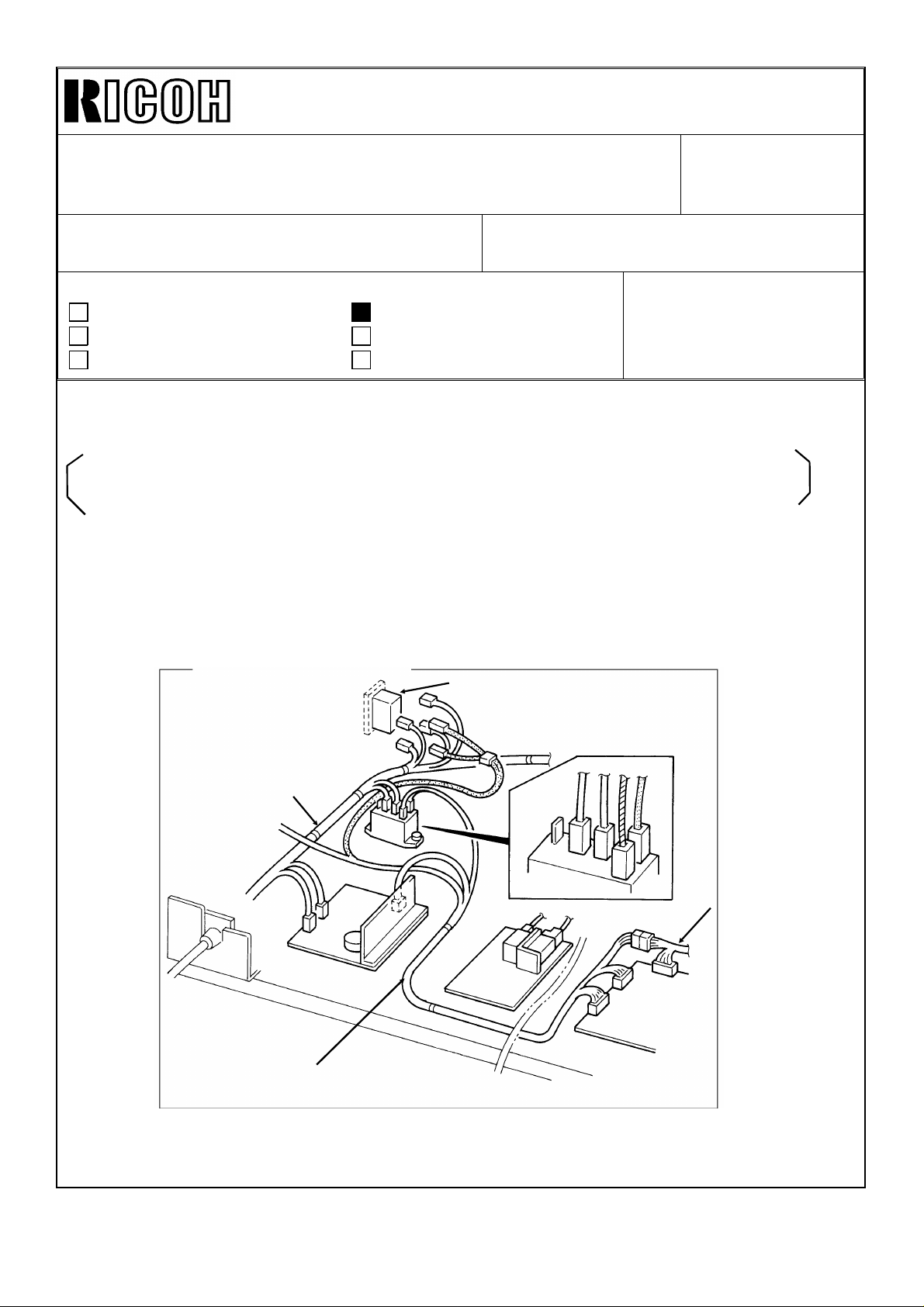

This RTB explains the modifications made to meet the Energy Star requirements.

With this modification, to conserve energy, the copier automatically turns off 30 minutes

after the last copying job has been completed.

The details of the machine operation can be found on pages 2, 3, and 4 of this RTB.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

J2SS

-12, -17 only

Auto Off Mode

To automatically turn off the copier, a new type of main switch with an incorporated coil is

used. The connector layout is shown below.

Harness Locations

Main Switch

12042421

*

AC Harness

A1635702

Lower DC Harness

A1635704

Upper

DC

Harness

A1635706

REVISED ON: DECEMBER 15, ’95 : Revised

*

Technical Bulletin No. RTB-003

SUBJECT: Energy Star DATE:October 31,

’95

PAGE: 2 of 4

SP Mode

The following two modes have been newly provided (ROM : A163-5208).

Mode No. Function Settings

15

The auto off time can also be selected by the customer.

Please refer to pages 3 and 4 of this RTB for the procedure.

The Auto off mode is prohibited in the following conditions.

* The roll feeder is operating.

* A sheet of paper is set on the feed table.

* A Jam or SC indicator in on.

* Toner end indicator is on or Used Toner bottle is full.

Auto off time can be selected 1 ~ 120 minute (1 minute per step)

Default : 30 minutes

*

Instruction Sheet

An additional explanation sheet has been added to the operating instructions booklet.

Please refer to pages 3 and 4 of this RTB for the contents of this sheet. The Energy

Saver Mode described on the second page of this instruction sheet is the Auto Energy

Saver Mode originally available with this copier.

Note: 1. When you use the new main board (main board modified for Energy Star) in a

non-Energy Star machine, please replace the ROM with the ROM

(A163-9506).

2. When you replace the RAM board, please clear all memories with SP mode -1

-21 and input the factory data refering to the service manual. (Memory clear

mode section)

*

REVISED ON: DECEMBER 15, ’95 : Revised

*

Technical Bulletin No. RTB-003

SUBJECT: Energy Star (J2SS O/I) DATE:October 31,

’95

PAGE: 3 of 4

REVISED ON: DECEMBER 15, ’95 : Revised

*

Technical Bulletin No. RTB-003

SUBJECT: Energy Star (J2SS O/I) DATE:October 31,

’95

PAGE: 4 of 4

Loading...

Loading...