Ricoh FW740 Service Manual j2ss 2

J2SS Mark II

(Machine Code: A251/A252)

Service Manual

Insert Version

The A251/A252 machines are based on the A163 copier.

Only the differences from the base copier are described in the following pages.

Therefore, this documentation should be treated as an insert version of the base

copiers service manual. It should always be utilized together with the base

copiers service manual.

INSERTION PROCEDURE OF SERVICE MANUAL

1. Replace the book spine tag with the new one.

2. Insert the A251/A252 service manual after the A163 manual.

I

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the peripherals are supplied

with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

6. The copier is not attached to the table. Pushing the copier too hard may

cause it to drop onto the floor. While moving the copier, push the table.

7. When the main switch is turned on, the machine will suddenly start turning to

perform the developer initialization. Keep hands away from any mechanical

and electrical components during this period.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

Caution:

2.

which can explode if replaced incorrectly. Replace the RAM pack only with

an identical one. The manufacturer recommends replacing the entire RAM

pack. Do not recharge or burn this battery. Used RAM packs must be

handled in accordance with local regulations.

The RAM pack on the main control board has a lithium battery

1

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may ignite

suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductors according to

local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used RAM packs in order to dispose of them later, do not put

more than 100 RAM packs per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

2

15 April 1998 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Configuration: Table top

Copy Process: Electrostatic transfer system

Original Feed: Sheet feed

Original Size: Maximum: 914 x 2,000 (36" x 80")mm

Minimum: A4 (8

Copy Size: Same as Original Size

Copying Speed: 3 cpm (A1/D sideways)

First Copy: 24 seconds (A1/D sideways): A251 copier

30 seconds (A1/D sideways): A252 copier

Warm-up Time:

Multi-Copy: 1 to 1 only (A251 copier), 1 to 10 (A252 copier)

Automatic Reset: 2 minutes after copying is finished (can be set to 1,

Photoconductor: Organic photoconductor drum

Drum Charge: Single-wire with grid plate (Negative Charge)

Within 5 minutes (Room temperature 23°C)

3, 4, or 5 minutes or to no auto reset)

1/2

" x 11") lengthwise

Overall

Information

Reproduction Ratio:

Exposure System: Slit exposure via fiber optic array

Exposure Lamp: Fluorescent lamp (26 W)

Development: Dual-component dry toner system

Toner Replenishment: Cartridge system (750 g toner/cartridge)

Toner Consumption: 1,860 A1 or D copies per cartridge (6% original)

Development Bias: Negative

Toner Density Control: Direct toner density detection by induction sensor

Image Density Adjustment: Development bias control + exposure control

Paper Separation: Dual wire ac corona and pick-off pawls

Cleaning: Cleaning blade

Paper Feeding: Manual feed (roll feeder optional)

Image Fusing: Heat and pressure type, teflon (upper) and silicone

Fusing Lamp: Nichrome wire lamp

1 : 1 (±0.5%)

rubber (lower) rollers

(115 V: 1,100 W, 230 V: 1,100 W)

Self-diagnostic Codes: 13 codes, displayed in copy counter

1-1

SPECIFICATIONS 15 April 1998

Power Source: 115 V/60 Hz..... 12 A

220 V/50 Hz..... 7 A

230 V/50 Hz..... 7 A

240 V/50 Hz..... 7 A

Power Consumption: Maximum: 1.4 kW

Warm-up: 1.2 kW

Ready: 0.04 to 1.2 kW

Copy cycle: 1.4 kW

Dimensions (W x D x H): A251: 1,080 x 570 x 490 mm

42.1" x 22.2" x 19.1"

A252: 1,080 x 623 x 480 mm

42.1" x 24.6" x 18.9"

Weight: A251: 79 kg, 174.0 lb

A252: 80 kg, 176.2 lb

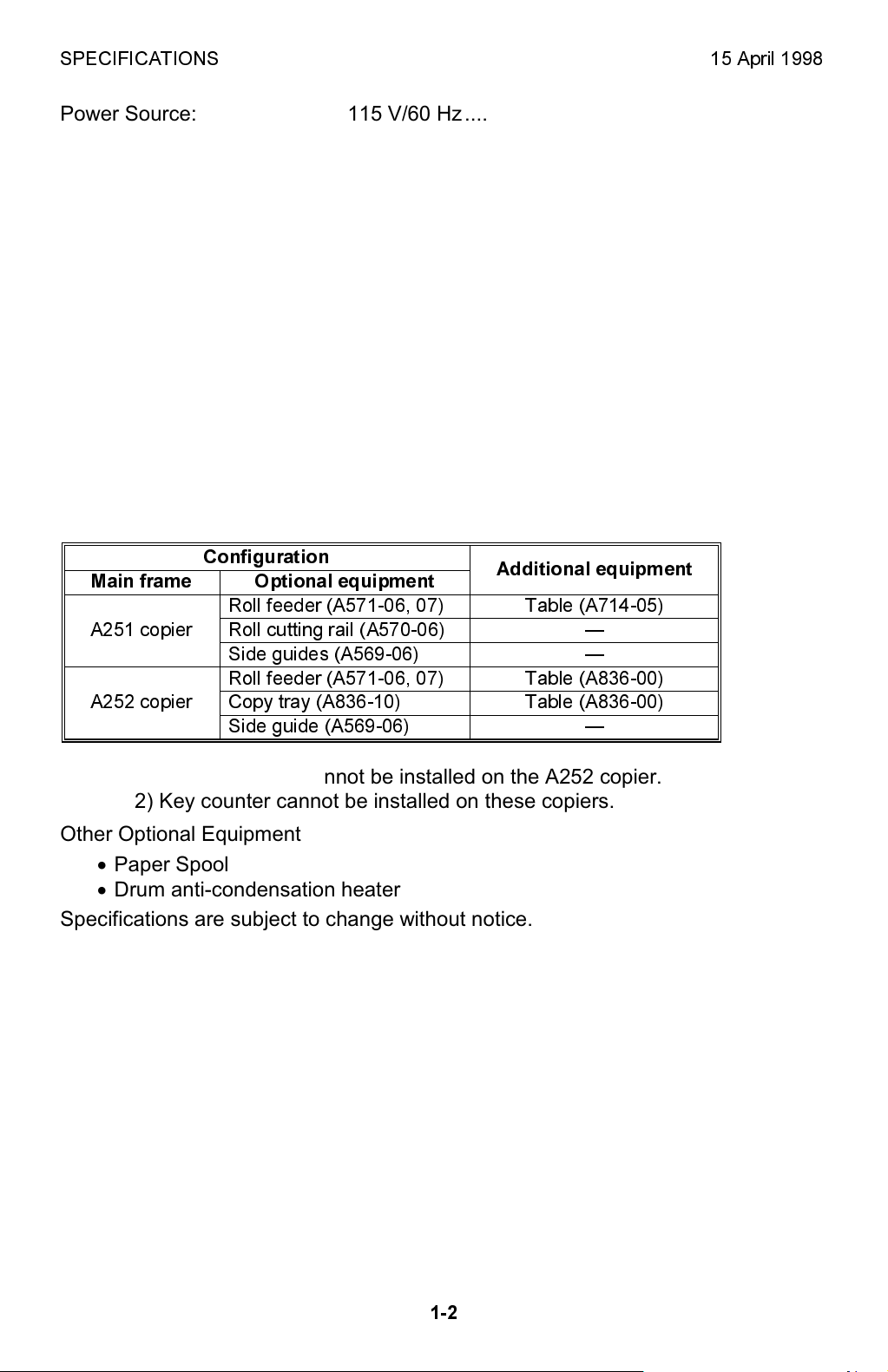

Optional Equipment and Machine Configuration

Configuration

Main frame Optional equipment

Roll feeder (A571-06, 07) Table (A714-05)

A251 copier

A252 copier

NOTE:

1) Roll cutting rail cannot be installed on the A252 copier.

Roll cutting rail (A570-06)

Side guides (A569-06)

Roll feeder (A571-06, 07) Table (A836-00)

Copy tray (A836-10) Table (A836-00)

Side guide (A569-06)

Additional equipment

2) Key counter cannot be installed on these copiers.

Other Optional Equipment

· Paper Spool

· Drum anti-condensation heater

Specifications are subject to change without notice.

1-2

15 April 1998 PAPER PATH

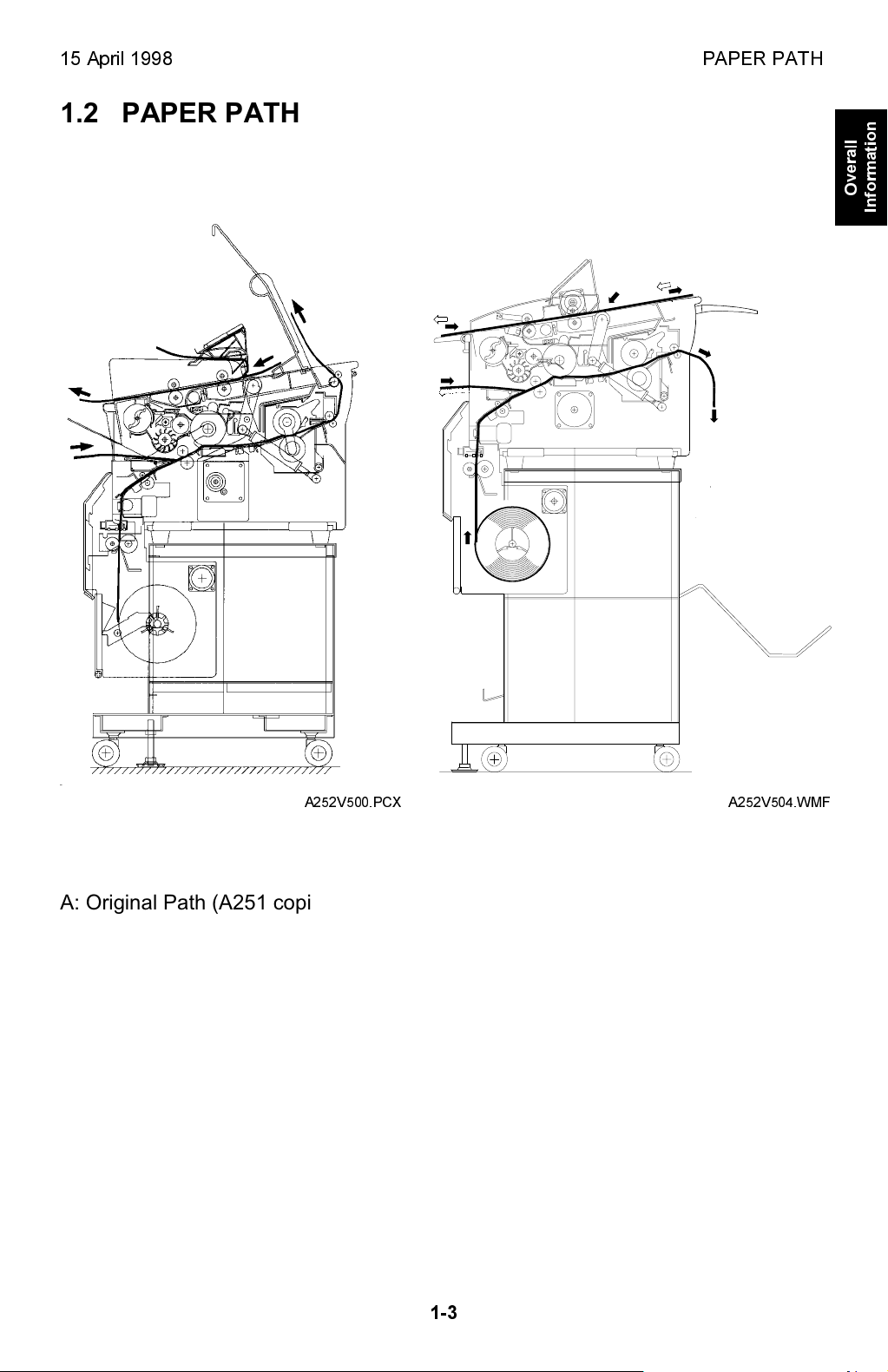

1.2 PAPER PATH

B

A

C

- A251 copier -

E

D

B

- A252 copier -

Overall

Information

E

F

D

C

A252V500.PCX

A: Original Path (A251 copier)

B: Paper from the manual feed

C: Paper from the roller feed

D: Paper exit

E: Original Path from Rear Feeder

F: Original Path (A252 copier): Switching back

A252V504.WMF

1-3

MECHANICAL COMPONENT 15 April 1998

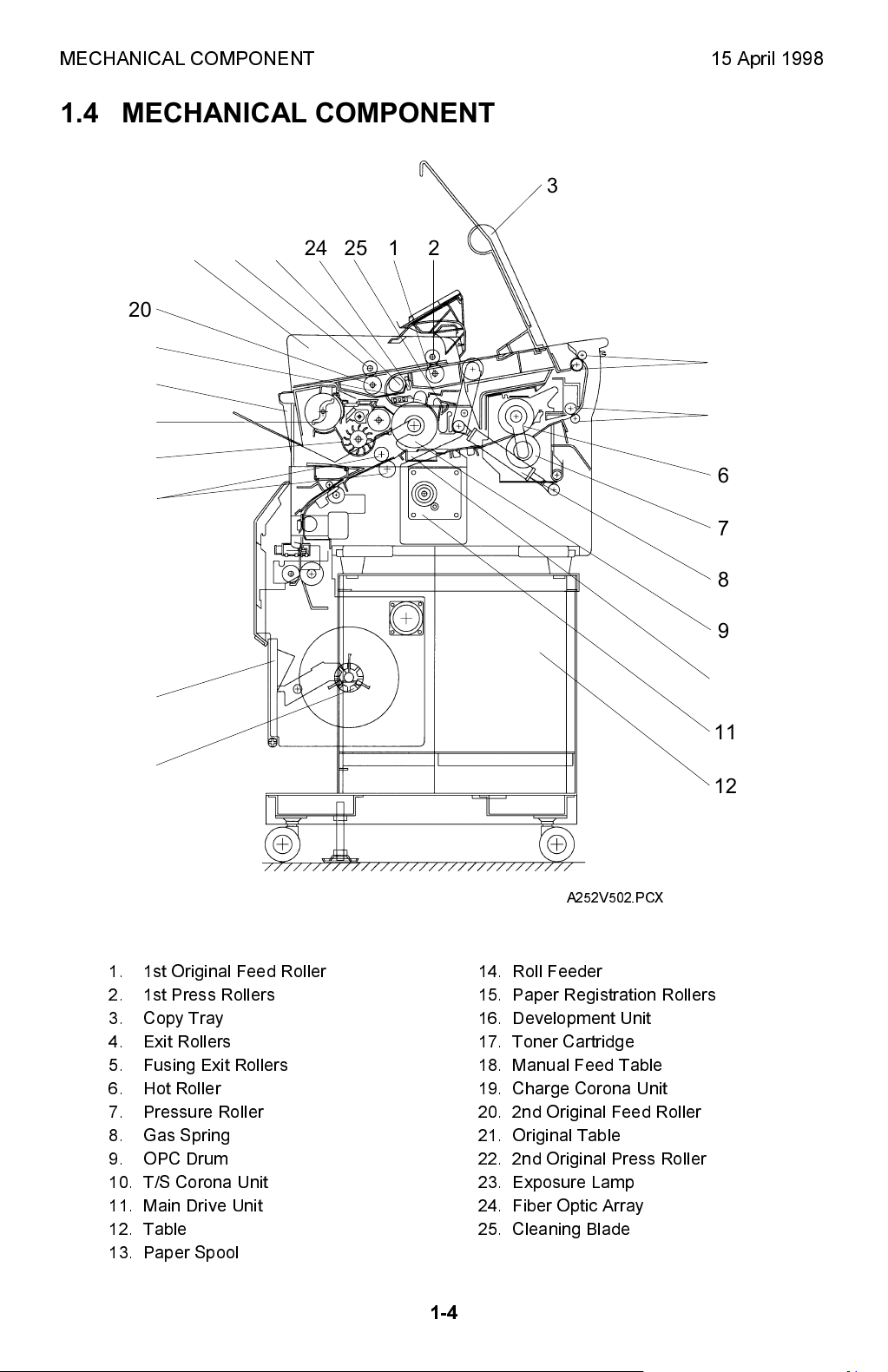

1.4 MECHANICAL COMPONENT

3

25 1 2

24232221

20

19

18

17

16

15

14

13

4

5

6

7

8

9

10

11

12

1. 1st Original Feed Roller

2. 1st Press Rollers

3. Cop y Tray

4. Exit Rollers

5. Fusing Exit Rollers

6. Hot Roller

7. Pressure Roller

8. Gas Spring

9. OPC Drum

10. T/S Corona Unit

11. Main Drive Unit

12. Table

13. Paper Spool

A252V502.PCX

14. Roll Feeder

15. Paper Registration Rollers

16. Development Unit

17. Toner Cartridge

18. Manual Feed Table

19. Charge Corona U nit

20. 2nd Original Feed Roll er

21. Original Table

22. 2nd Original Press Roller

23. Exposure Lamp

24. Fiber Optic Arra y

25. Cleaning Blade

1-4

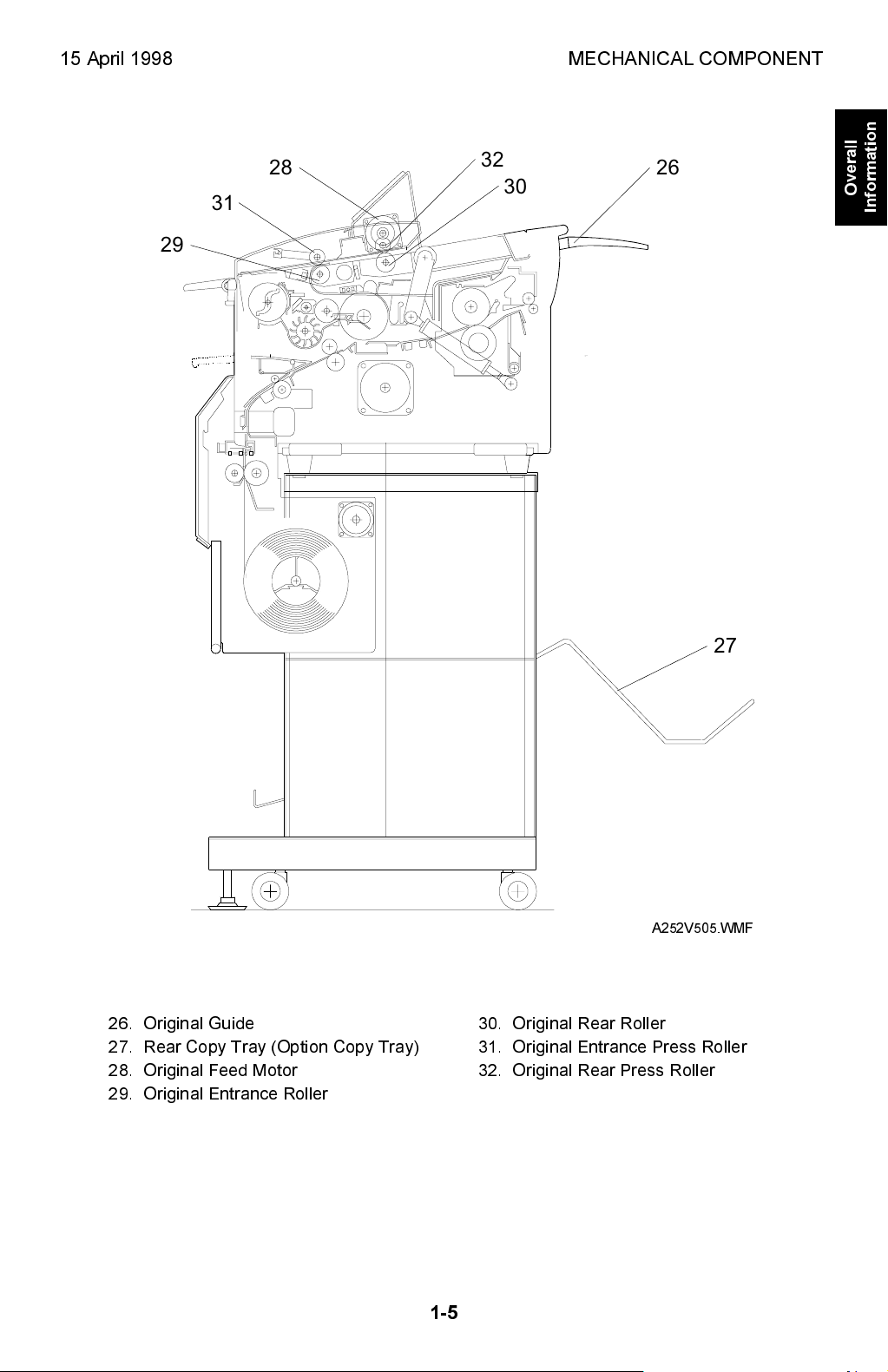

15 April 1998 MECHANICAL COMPONENT

29

31

28

32

30

26

Overall

Information

27

26. Original Guide

27. Rear Copy Tray (Option Copy Tray)

28. Original Feed Motor

29. Original Entrance Roller

A252V505.WMF

30. Original Rear Roller

31. Original Entrance Press Roller

32. Original Rear Press Roller

1-5

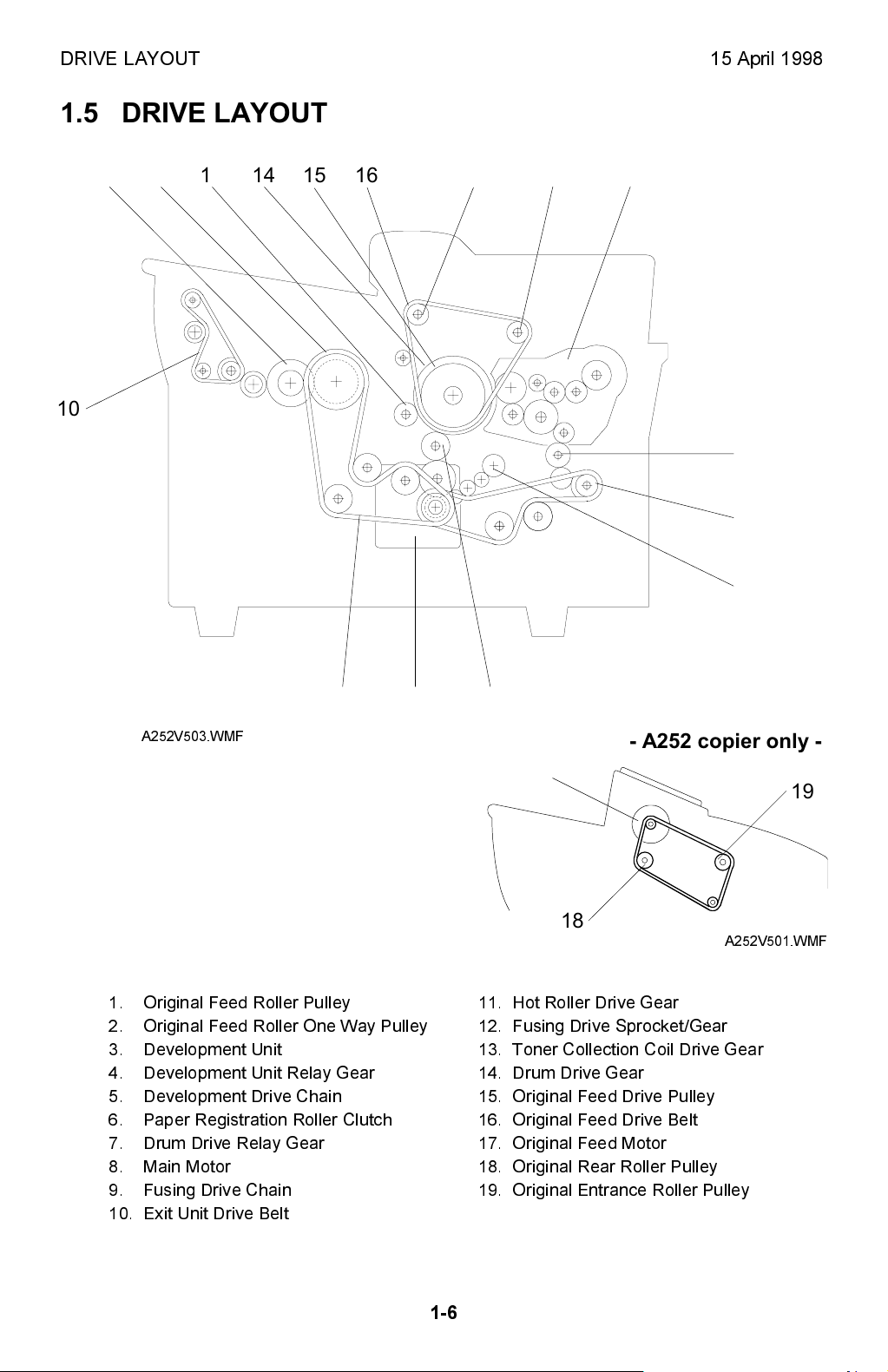

DRIVE LAYOUT 15 April 1998

A

1.5 DRIVE LAYOUT

16

1514131211 1 2 3

10

4

5

89 7

252V503.WMF

1. Original Feed Roller Pulley

2. Original Feed Roller One Way Pulley

3. Development Unit

4. Development Unit Relay Gear

5. Development Drive Chain

6. Paper Registration Roller Clutch

7. Drum Drive Relay Gear

8. Main Motor

9. Fusing Drive Chain

10. Exit Unit Drive Belt

6

- A252 copier only -

17

18

A252V501.WMF

11. Hot Roller Drive Gear

12. Fusing Drive Sprocket/Gear

13. Toner Collection Coil Drive Gear

14. Drum Drive Gear

15. Original Feed Drive Pulley

16. Original Feed Drive Belt

17. Original Feed Motor

18. Original Rear Roller Pulley

19. Original Entrance Roller Pulley

19

1-6

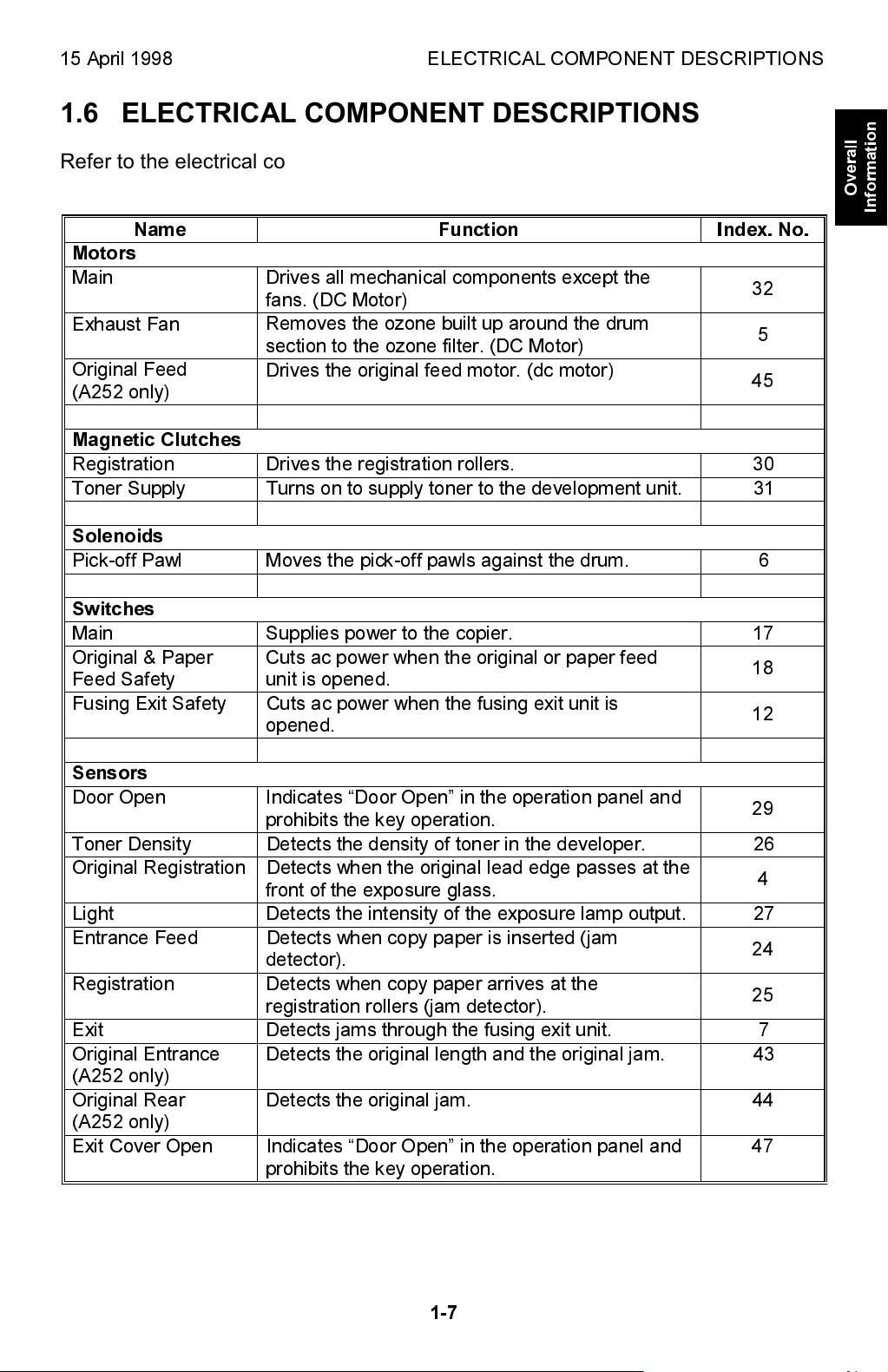

15 April 1998 ELECTRICAL COMPONENT DESCRIPTIONS

1.6 ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout on the reverse side of the Point to Point

(Water proof paper) index numbers.

Name Function Index. No.

Motors

Main Drives all mechanical components except the

fans. (DC Motor)

Exhaust Fan

Original Feed

(A252 only)

Magnetic Clutches

Registration Drives the registration rollers. 30

Toner Supply Turns on to supply toner to the development unit. 31

Solenoids

Pick-off Pawl Moves the pick-off pawls against the drum. 6

Removes the ozone built up around the drum

section to the ozone filter. (DC Motor)

Drives the original feed motor. (dc motor)

32

5

45

Overall

Information

Switches

Main Supplies power to the copier. 17

Original & Paper

Feed Safety

Fusing Exit Safety Cuts ac power when the fusing exit unit is

Sensors

Door Open Indicates Door Open in the operation panel and

Toner Density Detects the density of toner in the developer. 26

Original Registration Detects when the original lead edge passes at the

Light Detects the intensity of the exposure lamp output. 27

Entrance Feed Detects when copy paper is inserted (jam

Registration

Exit Detects jams through the fusing exit unit. 7

Original Entrance

(A252 only)

Original Rear

(A252 only)

Exit Cover Open Indicates Door Open in the operation panel and

Cuts ac power when the original or paper feed

unit is opened.

opened.

prohibits the key operation.

front of the exposure glass.

detector).

Detects when copy paper arrives at the

registration rollers (jam detector).

Detects the original length and the original jam. 43

Detects the original jam. 44

prohibits the key operation.

18

12

29

4

24

25

47

1-7

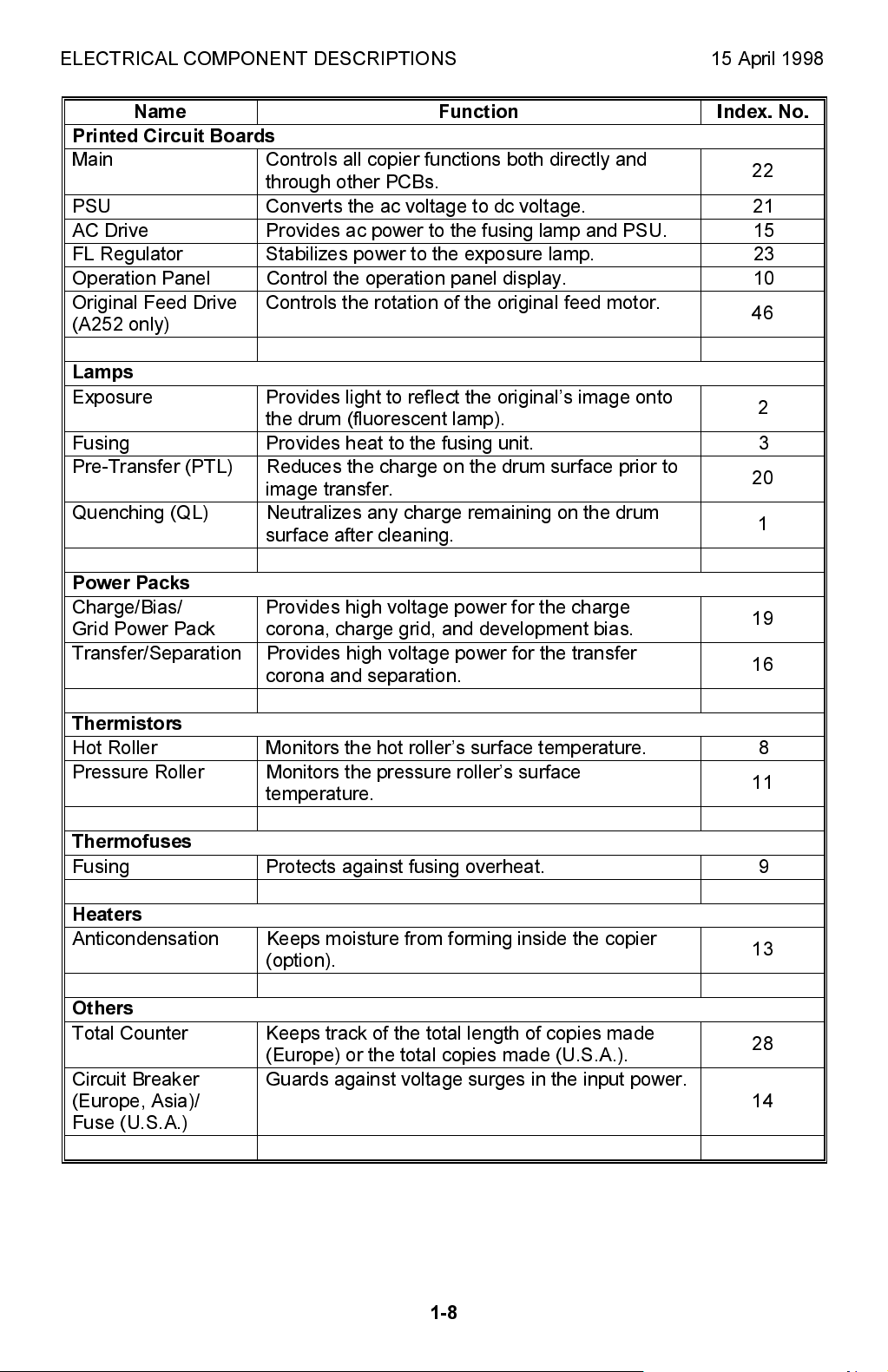

ELECTRICAL COMPONENT DESCRIPTIONS 15 April 1998

Name Function Index. No.

Printed Circuit Boards

Main Controls all copier functions both directly and

through other PCBs.

22

PSU Converts the ac voltage to dc voltage. 21

AC Drive Provides ac power to the fusing lamp and PSU. 15

FL Regulator Stabilizes power to the exposure lamp. 23

Operation Panel Control the operation panel display. 10

Original Feed Drive

(A252 only)

Controls the rotation of the original feed motor.

46

Lamps

Exposure Provides light to reflect the originals image onto

the drum (fluorescent lamp).

2

Fusing Provides heat to the fusing unit. 3

Pre-Transfer (PTL) Reduces the charge on the drum surface prior to

image transfer.

Quenching (QL) Neutralizes any charge remaining on the drum

surface after cleaning.

20

1

Power Packs

Charge/Bias/

Grid Power Pack

Transfer/Separation Provides high voltage power for the transfer

Provides high voltage power for the charge

corona, charge grid, and development bias.

corona and separation.

19

16

Thermistors

Hot Roller Monitors the hot rollers surface temperature. 8

Pressure Roller Monitors the pressure rollers surface

temperature.

11

Thermofuses

Fusing Protects against fusing overheat. 9

Heaters

Anticondensation Keeps moisture from forming inside the copier

(option).

13

Others

Total Counter Keeps track of the total length of copies made

(Europe) or the total copies made (U.S.A.).

Circuit Breaker

Guards against voltage surges in the input power.

(Europe, Asia)/

28

14

Fuse (U.S.A.)

1-8

15 April 1998 DRUM

A

2. DETAILED SECTION DESCRIPTIONS

2.1 DRUM

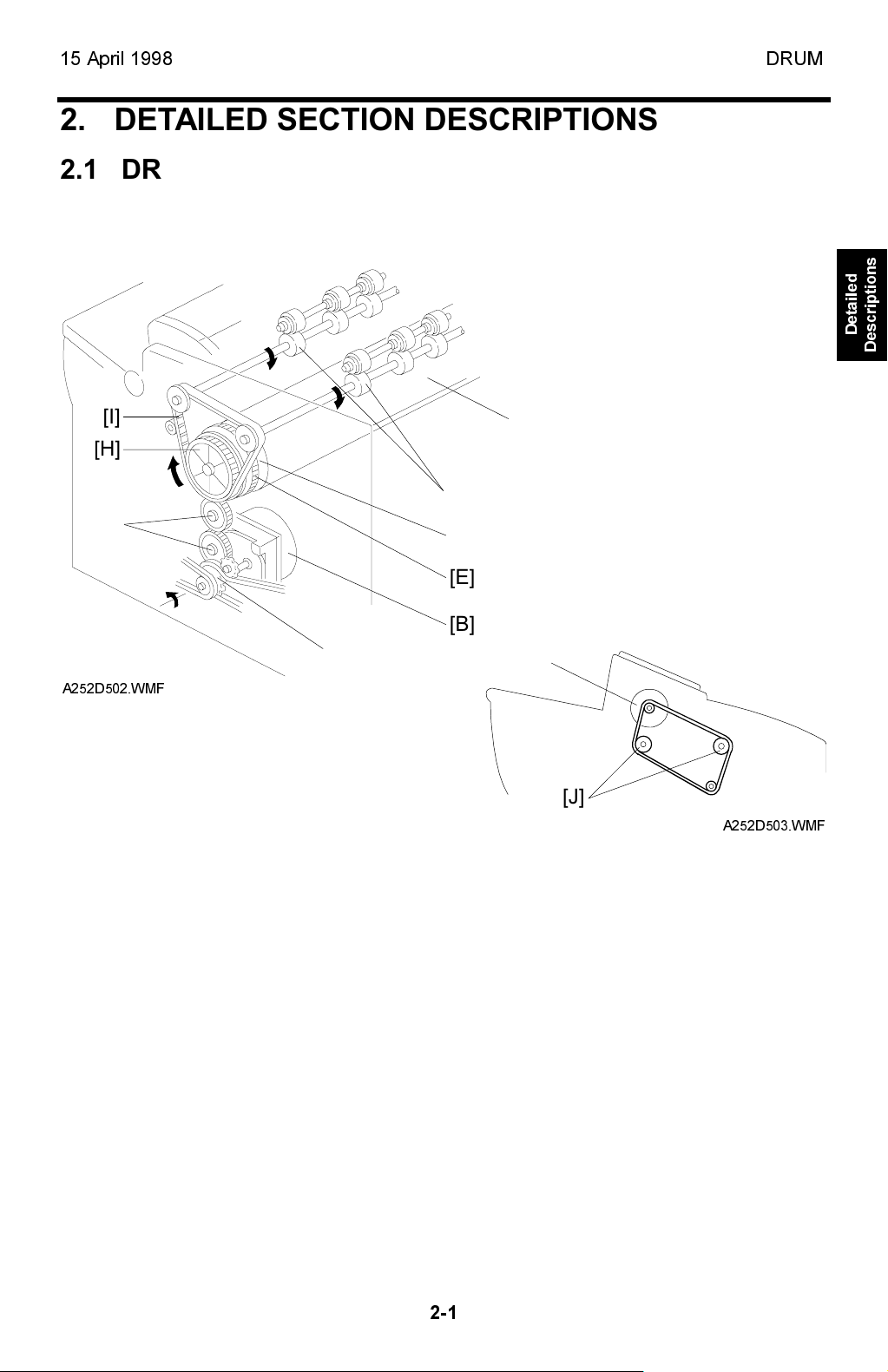

2.1.2 DRUM DRIVE

Detailed

Descriptions

[I]

[A]

[H]

[G]

[D]

[F]

[E]

[B]

- A252 copier only -

[C]

[K]

252D502.WMF

[J]

A252D503.WMF

The OPC drum [A] is 80 millimeters in diameter and 970 millimeters long. It turns

constantly when the main motor [B] is on.

When the main motor turns on, the drive is transmitted to the drum as follows:

main motor drive gear [C] Þ idle gears [D] Þ drum drive gear [E] Þ

drum flange [F] Þ drum

When the drum knob is tightened, the right flange presses firmly against the drum

so that the drum is held tightly between the flanges. The drum and flanges turn

together when the main motor is on. At this time, the drive is also transmitted to the

original feed rollers [G] through the original feed drive pulley [H] and belt [I] (A251

copier).

The original feed rollers [J] (original entrance and rear rollers) for the A252 copier

are driven by the original feed motor [K].

2-1

EXPOSURE 15 April 1998

A

2.3 EXPOSURE

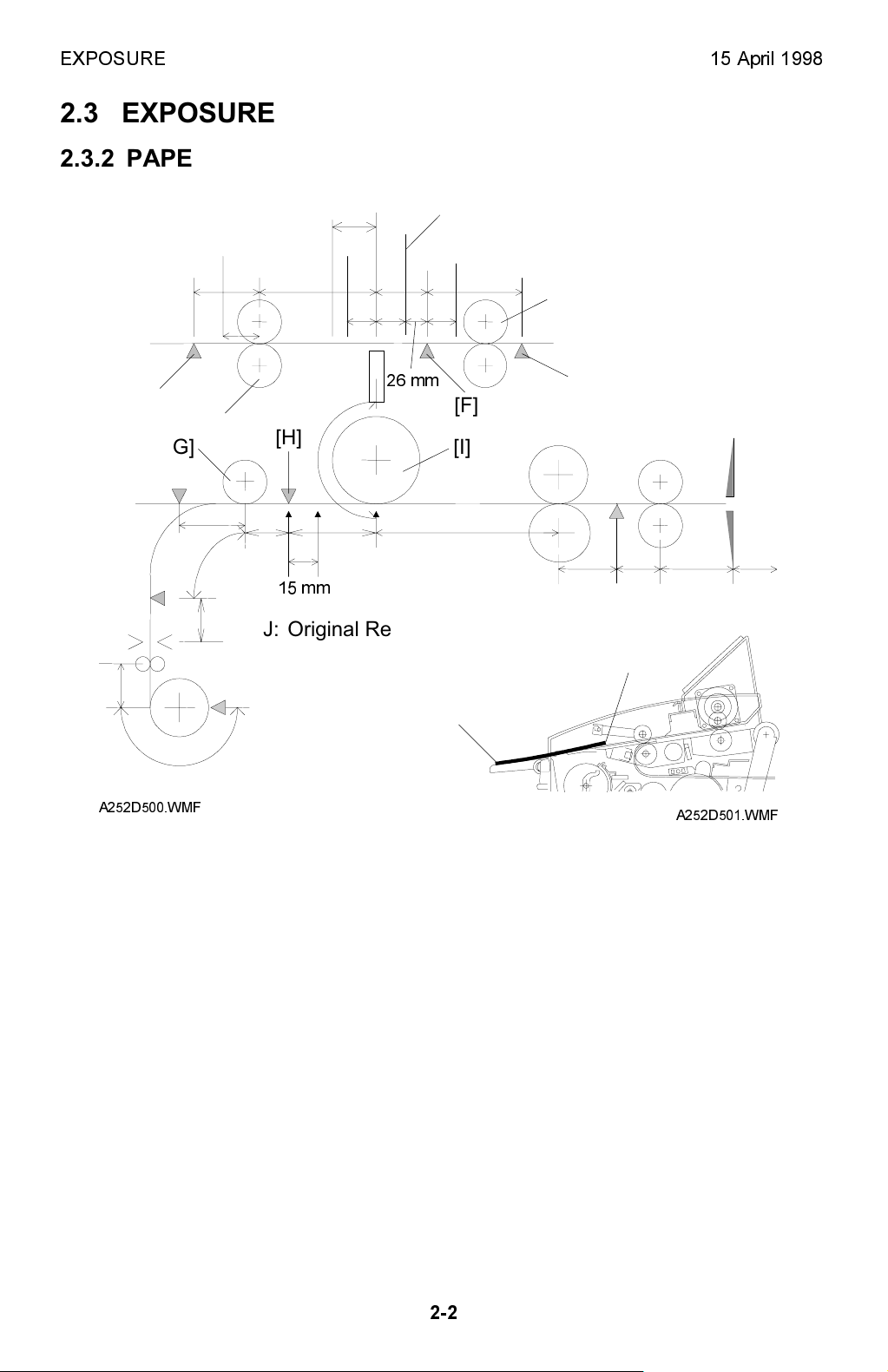

2.3.2 PAPER AND ORIGINAL FEED (A252 ONLY)

[D]

[J]

[B]

[G]

[C]

[H]

15 mm

26 mm

[F]

[I]

[K]

J: Original Rear Roller

K: Original Rear Sensor

[A]

[E]

252D500.WMF

A252D501.WMF

In this machine (A252 copier), first, the leading edge [A] of the original is inserted

into the original table and the original is delivered to the appropriate start position.

Then the original is switched back while it is being scanned. Therefore, the original

is scanned from the trailing edge to the leading edge.

When an original is placed on the original table, it activates the original entrance

sensor [B]. The main motor starts rotating and the quenching lamp, development

bias, and PTL begin. Then, the exposure lamp turns on. To ensure correct original

feeding (especially for a thin original), the original is returned toward the operator

side (300 ms) before the original feed. Thus the original will be fed evenly by each

roller on the original entrance roller [C].

4 seconds after the original entrance sensor is activated, the original feed motor

starts rotating 200 mm/s to turn the original entrance rollers [C]. The original is

delivered to the original feed start position [D]. The 4 second delay allows time for

the operator to align the trailing edge (non-operator side) against the first set of the

rollers (to prevent skewing).

2-2

15 April 1998 EXPOSURE

When the original entrance sensor is turn off by the trailing edge [E] of the original,

the roll paper feed motor turns on and paper feeding starts.

When the trailing edge of the original reaches the original feed start position (26

mm ahead of the original registration sensor [F]), the original feed motor stops to

wait for the copy paper.

The registration clutch is activated after paper feed begins. The copy paper is fed

to the registration roller [G] and the registration clutch turns off when the copy

paper reaches 15 mm ahead of the registration sensor [H]. The voltage is applied

to the charge corona.

At the appropriate time the original feed motor rotates 50 mm/s in opposite

direction and the original is delivered to the exposure glass. The registration clutch

and roll paper feed motor turn on again after the trailing edge of the original passes

the original entrance sensor. The paper feed resumes and the copy paper is

transported to the drum [I].

To measure the original length for synchro-cutting, the copier CPU measures the

time from when the original registration sensor detects the leading edge of the

original until the original entrance sensor detects the trailing edge of the original

(delivering the original to appropriate start position). The copy paper length is

measured by counting the number of steps as the roll paper feed motor (stepper

motor) turns. Just before the cut length of the copy paper is fed, the speed of the

roll paper feed motor is doubled. A paper buckle forms at the trailing edge of the

copy paper. When the copy paper is fed out to the appropriate length, the roll

paper feed motor stops and the cutter unit cuts the paper.

When making duplicate copies, at the appropriate time after the trailing edge of the

original passes at the original registration sensor, the rotation of the original feed

motor changes in the opposite direction and the speed of the original feed motor

changes to 200 mm/s. The roll paper feed motor starts again. The original is

delivered to the original feed start position and roll paper feed starts again. The

above process is repeated. After all the duplicates have been made, the original is

stopped and caught by the original entrance roller (original hold mode: SP16). If

the original hold mode is canceled by SP16, the original is fed out without being

caught in the original entrance roller.

When the original hold mode is selected, the original is fed out when the C key is

pressed.

Detailed

Descriptions

2-3

DEVELOPMENT 15 April 1998

2.4 DEVELOPMENT

2.4.2 TONER DENSITY CONTROL

Recovery from Toner End Condition

After replacing the toner cartridge (opening and closing the original feed unit), the

main motor rotates the development unit for 60 seconds. During this period, toner

is supplied at 100% of the supply amount until TS level reaches 3. Then, the main

motor rotates the development unit for another 30 seconds. Then copies can be

made.

If the TS level does not reach 3 after rotation of the development unit, the CPU

stops the machine and displays the toner end condition. This prevents the operator

from resetting the toner end condition by simply opening and closing original feed

unit.

2-4

15 April 1998 FUSING AND PAPER EXIT

2.8 FUSING AND PAPER EXIT

2.8.1 OVERVIEW (A252 COPIER)

The copy paper is delivered to the lower paper exit.

The location of the fusing exit sensor is different from the A163 and A251 copier.

Except for this difference, the A252 copier is identical to the with A251 and A163

copiers. Please refer to A163 copier service manual for details.

Detailed

Descriptions

2-5

15 April 1998 INSTALLATION REQUIREMENTS

3. INSTALLATION

3.1 INSTALLATION REQUIREMENTS

3.1.1 ENVIRONMENT

1. Temperature Range:

2. Humidity Range: 20% to 80% RH

3. Ambient Illumination: Less than 1,500 lux (do not expose to direct

4. Ventilation: Minimum space 20 m

5. Ambient Dust: Less than 0.15 mg/m3 (4 x 10-3 oz/yd3)

6. If the installation place is air-conditioned or heated, place the machine as

follows:

a) Where it will not be subjected to sudden temperature changes from low to

high, or vice versa.

b) Where it will not be directly exposed to cool air from an air conditioner in

the summer.

c) Where it will be directly exposed to reflected heat from a space heater in

the winter.

7. Avoid placing the machine in an area filled with corrosive gases.

8. Avoid any area higher than 2,000 m (6,500 ft) above sea level.

9. Place the machine on a strong and level base.

15°C to 30°C (59°F to 86°F)

sunlight).

3

Room air should turn over at least 30 m3/hr/person.

Installation

10. Avoid any area where the machine may be subjected to frequent strong

vibration.

3-1

INSTALLATION REQUIREMENTS 15 April 1998

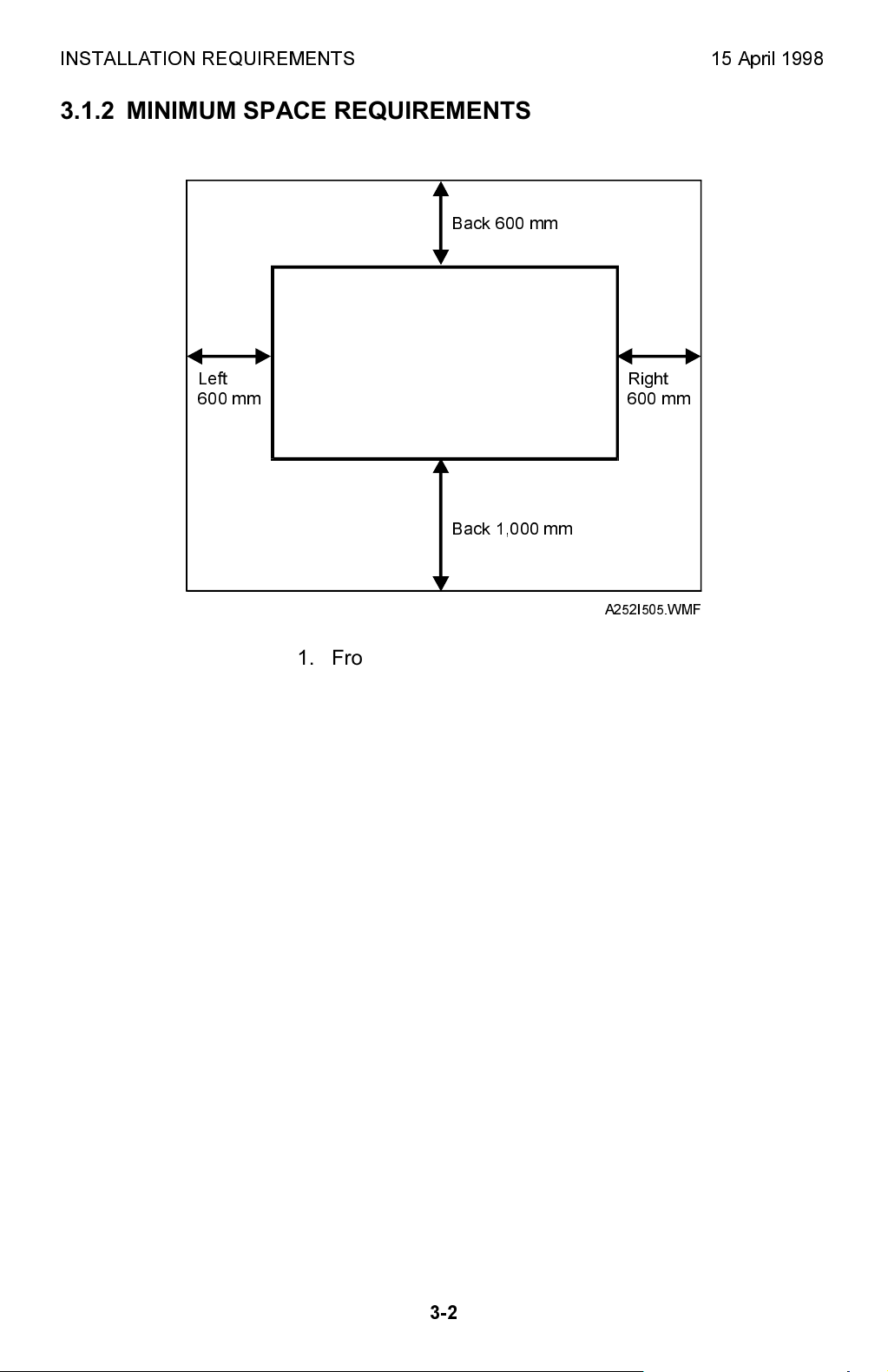

3.1.2 MINIMUM SPACE REQUIREMENTS

Back 600 mm

Left

600 mm

1. Front: 1,000 mm (39 in)

2. Back: 600 mm (24 in)

3. Right: 600 mm (24 in)

4. Left: 600 mm (24 in)

3.1.3 MACHINE LEVEL

Right

600 mm

Back 1,000 mm

A252I505.WMF

1. Front to back: Within 5 mm (0.2") of level

2. Right to left: Within 5 mm (0.2") of level

Make sure that the machine is level using a carpenters level.

3-2

15 April 1998 INSTALLATION REQUIREMENTS

3.1.4 POWER SOURCE

1. Input Voltage Level: 120 V, 60 Hz

More than 12 A (for U.S.A. version)

220 ~ 240 V, 50/60 Hz

More than 7 A (for European version)

2. Permissible Voltage

±10%

Fluctuation:

3. Do not set anything on the power cord.

NOTE:

1) Make sure the plug is firmly inserted in the outlet.

2) Avoid multi-wiring.

Installation

3-3

INSTALLATION PROCEDURE 15 April 1998

3.2 INSTALLATION PROCEDURE

3.2.1 COPIER

Accessory Check

Check the accessories and their quantities according to the following list:

- A252 copier -

Original Guide......................................................................... 6 pcs

Operating Instruction Holder................................................... 1 pc

- A251 copier -

Guide Wire.............................................................................. 2 pcs

Copy Tray ............................................................................... 1 pc

Copy Guide............................................................................. 1 pc

Operating Instruction Holder................................................... 1 pc

3-4

15 April 1998 INSTALLATION PROCEDURE

[D]

[E]

[B]

[E]

[C]

[A]

A252I500.WMF

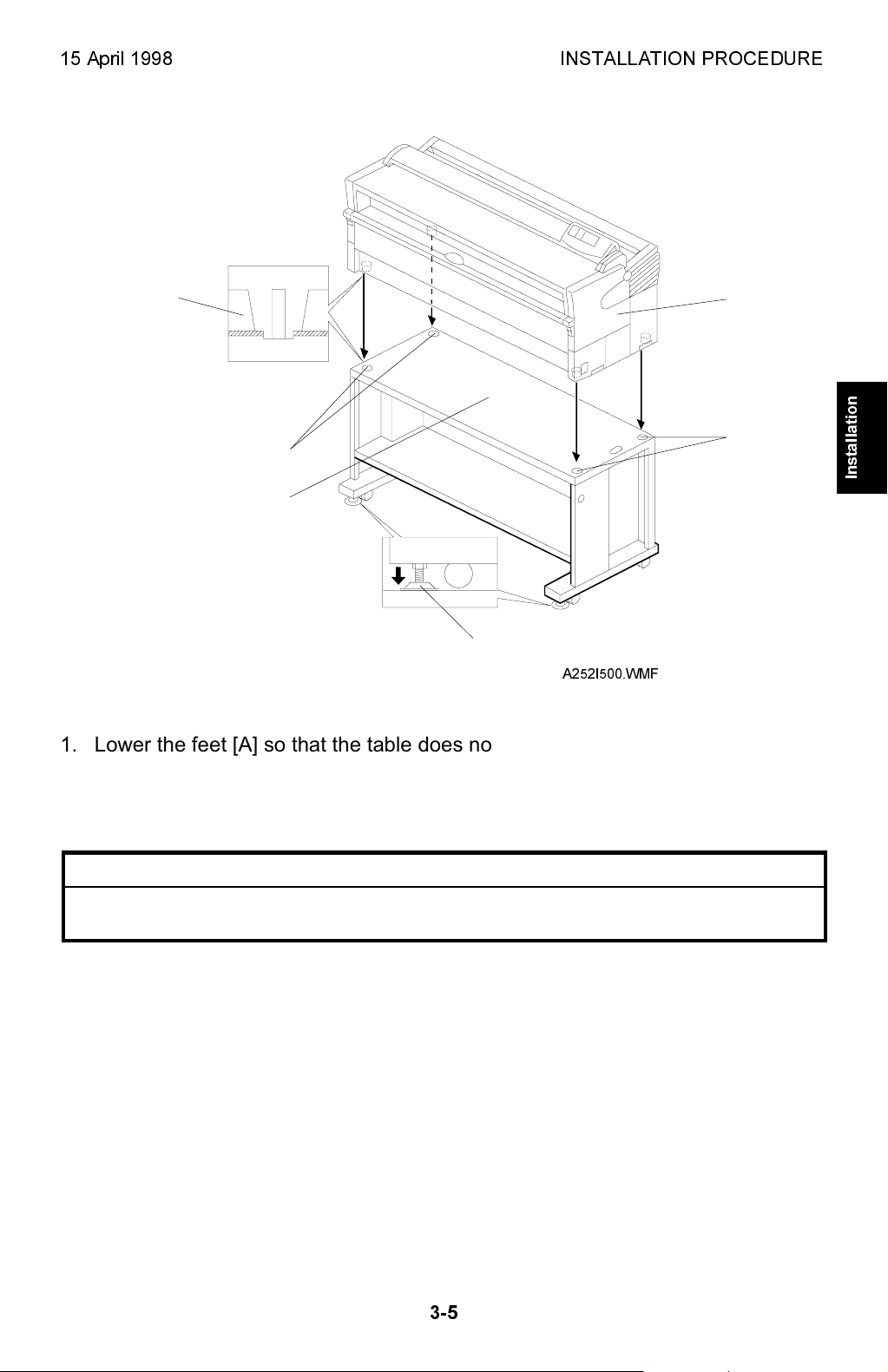

1. Lower the feet [A] so that the table does not move while the copier is being

installed on the table.

Installation

2. Place the copier [B] on the table [C] (Place the copier feet [D] into the table

holes [E]).

WARNING

I

The copier is not attached to the table. Pushing the copier too hard may

cause it to drop onto the floor. While moving the copier, push the table.

3-5

Loading...

Loading...