Page 1

DOCUMENT FEEDER

(Machine Code: A662)

Page 2

24 February 1997 SPECIFICATIONS

1. SPECIFICATIONS

Original Size: Maximum: A3 or 11" x 17"

Minimum: A5 Lengthwise or 51/2" x 81/2"

Original Weight: 52 to 105 g/m2 (14 to 28 lb)

Original Feed: Automatic Feed - ADF mode

Semi-automatic Feed - SADF mode

Original Tray Capacity: 30 sheets - 80 g/m2 (20 lb)

Original Set: Face up, first sheet on top

Original Separation: Feed roller and friction belt

Original Transport: One flat belt

Copying Speed: 15 copies/minute

(A4 lengthwise or 81/2" x 11" lengthwise)

Power Consumption: 45 W

Dimensions (W x D x H): 590 x 443 x 87.5 mm (23.3" x 17.5" x 3.4")

(Not including the original table)

Weight: Approximately 7 kg (15.5 lb)

• Specifications are subject to change without notice.

Option

A662-1

Page 3

COMPONENT LAYOUT 24 February 1997

2. COMPONENT LAYOUT

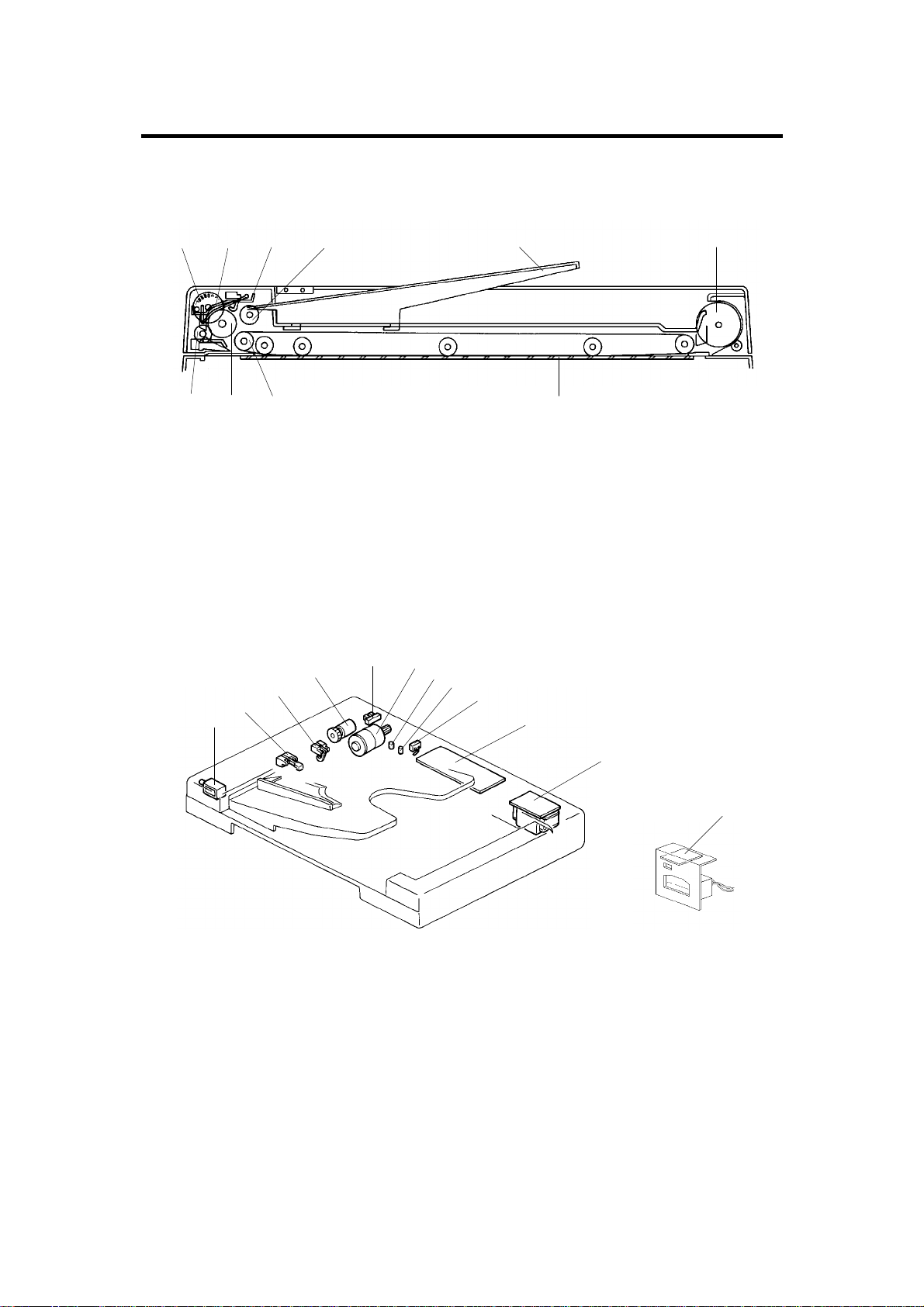

2.1 MECHANICAL COMPONENTS

1 2 3 4 65

1. Pulse Generator Disk

2. Friction Belt

3. Pick-up Lever

4. Pick-up Roller

5. Original Table

2.2 ELECTRICAL COMPONENTS

4

5

3

2

1

6

7

8

78910

6. Exit Roller

7. Transport Belt

8. Transport Belt Roller

9. Feed Roller

10. Relay Roller

9

10

11

A662V500.img

12

1. Pick-up Solenoid

2. Registration Sensor

3. Original Set Sensor

4. Feed Clutch

5. Pulse Generator Sensor

6. DF Motor

A662-2

A662V501.img

A662V502.img

7. Insert Original Indicator

8. SADF Indicator

9. Lift Switch

10. DF Main Board

11. DF Transformer

12. DF Interface Board

Page 4

24 February 1997 ELECTRICAL COMPONENT DESCRIPTIONS

3. ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

Motor

M1 DF Motor Drives all the document feeder components. 6

Solenoid

Pick-up Solenoid Energizes to press the pick-up lever against

SOL1

Clutch

CL1

Switch

SW1

Feed Clutch Turns on to transmit main motor rotation to

Lift Switch Informs the CPU when the DF is lifted and

the stack of originals in preparation for

original feed-in.

the feed roller.

also serves as the misfeed reset switch for

the DF.

1

4

9

Option

Sensors

S1

S2

S3

Printed Circuit Board

PCB1 DF Main Board Controls all DF functions. 10

PCB2

Transformer

TR1 DF Transformer Steps down the wall voltage to 25 volts ac. 11

LEDs

LED1

LED2

Pulse Generator

Sensor

Original Set Sensor Informs the copier CPU that originals have

Registration Sensor Sets original stop timing and checks for

DF Interface Board Interfaces between the copier main board

SADF Indicator Informs the operator that the SADF mode is

Insert Original

Indicator

Supplies timing pulses to the DF main board.

been placed and causes the Insert Original

indicator to go out.

original misfeeds.

and the DF.

available.

Turns off when the originals are inserted into

the original table.

5

3

2

12

8

7

A662-3

Page 5

POWER DISTRIBUTION 24 February 1997

4. POWER DISTRIBUTION

A662D500.wmf

The document feeder uses two dc power levels: +24 volts, and +5 volts.

When the main switch is turned on, the DF transformer receives the wall

outlet ac power through the ac drive board and outputs 25 volts ac to the DF

main board. Then, the dc power supply circuit on the DF main board converts

the 25 volts ac input to +24 volts and +5 volts.

+24 volts is used by the DF motor, the pick-up solenoid, and the feed clutch.

+5 volts is used by other electrical components.

A662-4

Page 6

24 February 1997 BASIC OPERATION

5. BASIC OPERATION

When the main switch is turned on, the DF CPU sends the "DF installed"

signal to the copier CPU. Receiving this signal, the copier CPU recognizes

that the document feeder is installed and sends the "DF confirmed" signal to

the DF CPU.

When originals are placed on the original table, the Insert Original indicator

turns off and the DF CPU sends the "original set" signal to the copier CPU to

inform that the originals have been set.

When the key is pressed, the copier CPU sends the "feed-in" signal to

the document feeder. On receipt of this signal, the DF CPU energizes the DF

motor, then the pick-up solenoid and feed clutch to feed in the bottom sheet

of the original stack onto the exposure glass. The pick-up solenoid and the

feed clutch remain energized until the original’s leading edge reaches the

registration sensor. The DF motor turns off shortly after the original’s trailing

edge passes the registration sensor. Then, the DF motor pauses and

reverses for a moment to align the edge of the original with the scale.

Option

Then the scanner starts to move (scanner start timing does not depend on

the progress of the original through the DF; it starts at a fixed time after the

key is pressed). When the scanner reaches the return position, the

copier CPU sends the "original change" signal to the DF CPU in order to feed

out the current original and feed in the next original.

A662-5

Page 7

INTERFACE CIRCUIT 24 February 1997

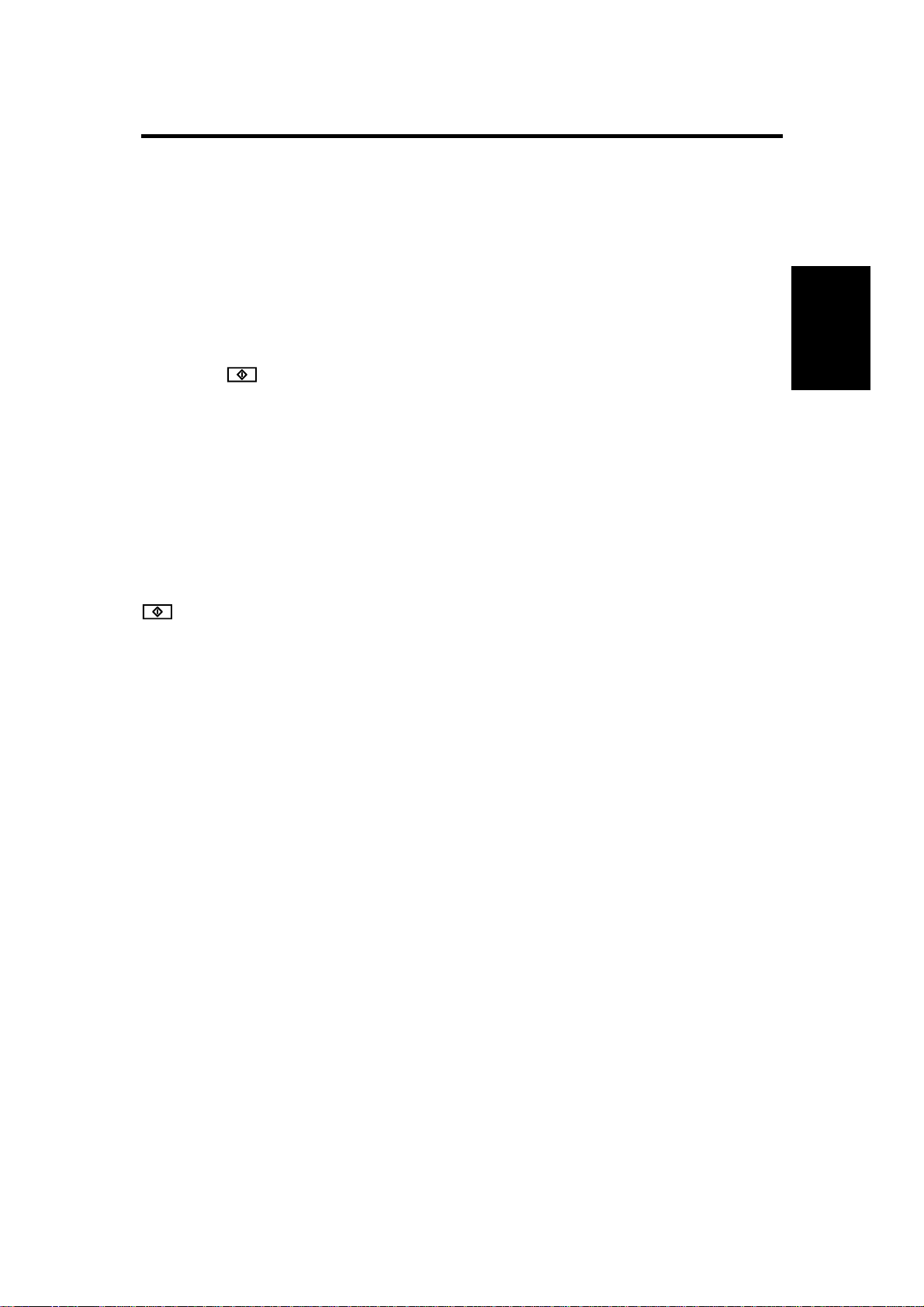

6. INTERFACE CIRCUIT

A662D509.wmf

The copier CPU and the DF CPU communicate via the interface board using

fiber optics. The interface board changes the optical signals to electrical

signals (and vice versa).

A662-6

Page 8

24 February 1997 ORIGINAL FEED

7. ORIGINAL FEED

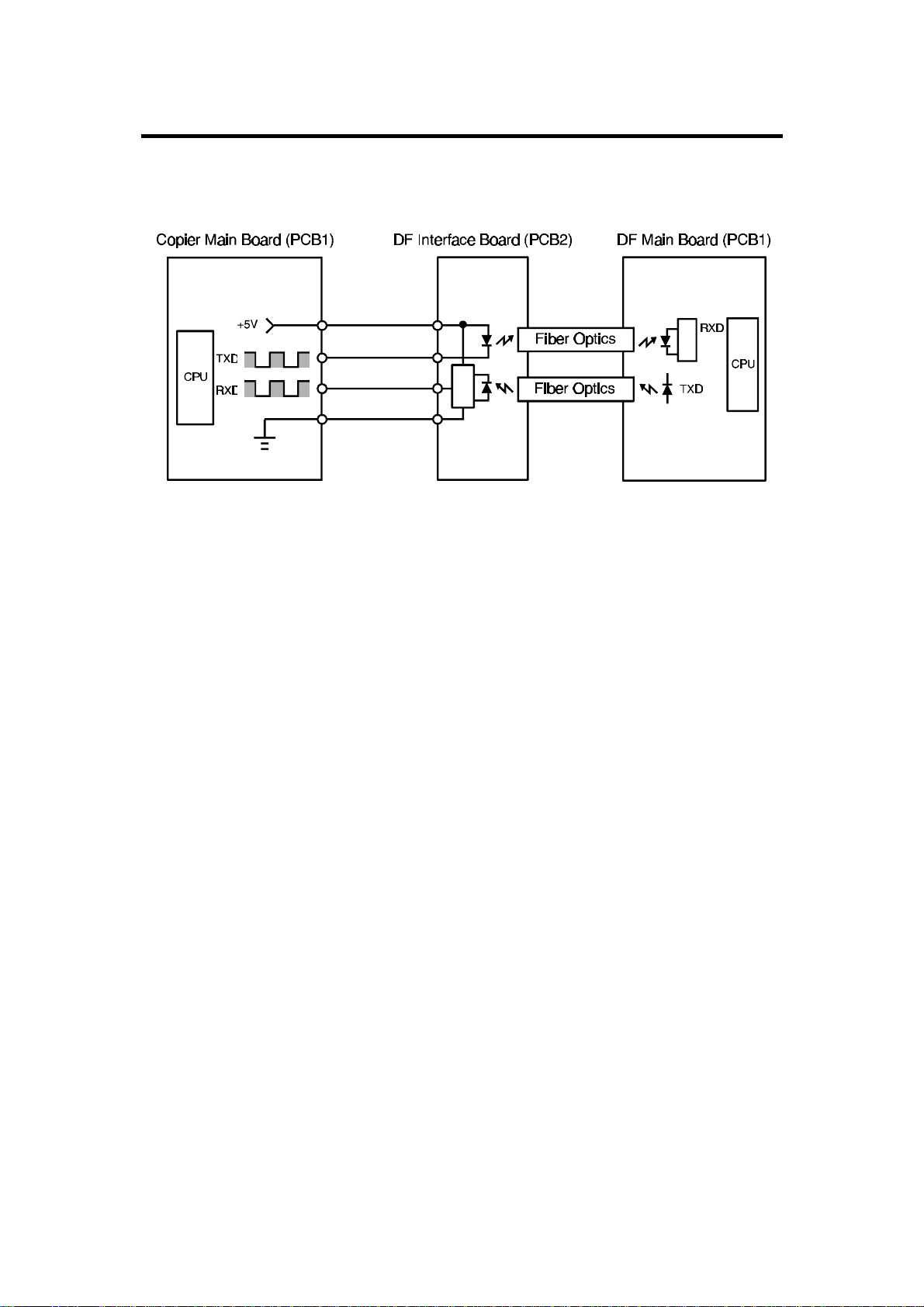

7.1 ORIGINAL PICK-UP MECHANISM

[B]

[C]

[A]

Option

[D]

A662D502.img

After setting the originals on the original table, the originals contact the feeler

[A] of the original set sensor and cause the feeler to move out of the sensor.

The DF CPU then sends the original set signal to the copier CPU to inform it

that the document feeder will be used. When the key is pressed, the

pick-up solenoid [B] is energized. The original stack is then pressed between

the pick-up lever [C] and pick-up roller [D]. The rotation of the pick-up roller

advances the bottom original.

A662-7

Page 9

ORIGINAL FEED 24 February 1997

7.2 ORIGINAL SEPARATION MECHANISM

[B]

[D]

[C]

[A]

[E]

[C][D][B]

A662D503.img

[E]

[A]

A662D504.img

The feed roller [A] and the friction belt [B] are used to feed in and separate

the originals [C]. Only the bottom original is fed because the friction belt

prevents any other originals from feeding.

Original feed starts when the pick-up lever [D] presses the original stack and

the pick-up roller [E] advances the bottom original of the stack. The feed

roller moves the original past the friction belt because the driving force of the

feed roller is greater than the resistance of the friction belt. The friction belt

prevents multiple feeds because the resistance of the friction belt is greater

than the friction between original sheets.

A662-8

Page 10

24 February 1997 ORIGINAL FEED

7.3 ORIGINAL FEED-IN MECHANISM

[C]

[E]

[G]

[A]

[D]

[B]

[F]

A662D505.img

The DF motor [A] drives the feed roller [B], the pick-up roller [C], the relay

rollers [D], and the transport belt roller [E] via timing belts and a gear train.

The feed roller and the pick-up roller are controlled by the feed clutch [F], but

the relay rollers and the transport roller are directly driven by the DF motor.

The idler rollers [G] on the feed roller shaft are free from the shaft.

Option

When the key is pressed, the DF motor is energized and the relay rollers

and transport belt roller start turning. 100 milliseconds after the DF motor

starts turning, the pick-up solenoid and the feed clutch are energized. The

pick-up and feed rollers then start turning and carry the original between the

relay rollers and the idler rollers. The pick-up solenoid and the feed clutch are

de-energized when the original’s leading edge passes through the

registration sensor.

The DF motor remains energized to deliver the original to the exposure glass

until a certain number of pulses (10 to 25 pulses) after the original’s trailing

edge passes through the registration sensor. Then, the DF motor pauses and

reverses for 15 pulses to align the edge of the original with the scale.

To feed the second original, the DF motor starts rotating when the scanner

reaches the return position. (The copier CPU sends the original change

signal to the DF CPU.) At this time, the transport belt starts carrying the first

original on the exposure glass to the exit roller. The timing for when the

pick-up solenoid and the feed clutch are energized for the second original

depends on the length of the first original detected by the registration sensor.

A662-9

Page 11

ORIGINAL FEED 24 February 1997

7.4 ORIGINAL FEED-OUT MECHANISM

[D]

[C]

[A]

[B]

A662D506.img

The exit rollers are driven by the DF motor through a gear train, the transport

belt roller, the transport belt [A], the transport belt roller [B], and the exit roller

drive belt [C]. When the DF CPU receives the original change signal from the

copier CPU, the DF motor starts turning. The transport belt carries the

original to the exit rollers [D] and the exit rollers take over the original

feed-out.

A662-10

Page 12

24 February 1997 ORIGINAL FEED

7.5 DF MOTOR CIRCUIT

Option

A662D507.wmf

The DF motor is a 24 volt dc motor. When the CPU receives the feed signal

from the copier, the CPU outputs the ON signal and the Forward signal to the

gate IC. On receipt of the forward signal from the gate IC, the driver IC

outputs 24 volts to CN117-1 and 0 volts to CN117-2. This causes the DF

motor to start turning in the forward direction.

Within 10 to 25 pulses after the original’s trailing edge passes through the

registration sensor, the CPU stops sending the ON signal and the Forward

signal. The DF motor stops turning. Then the CPU outputs the ON signal and

the reverse signal for 15 pulses. Then the driver IC outputs 0 volts to

CN117-1 and +24 volts to CN117-2 to reverse the DF motor.

A662-11

Page 13

ORIGINAL FEED 24 February 1997

7.6 ORIGINAL FEED AND MISFEED DETECTION TIMING

A662D508.wmf

The above chart shows the original feed timing for A4 lengthwise or 8.5" x

11" originals, and the misfeed detection timing.

The registration sensor is used for misfeed detection. If the DF CPU detects

a misfeed, the DF CPU lights the Original Misfeed indicator and sends the

original misfeed signal to the copier CPU. Then the copier CPU lights the

Check Paper Path and Misfeed Location (J0) indicators on the operation

panel.

When the main switch is turned on, the DF CPU checks the registration

sensor output for initial original misfeed.

During original feed-in, the DF CPU performs two types of original misfeed

detection:

1. Whether the registration sensor is actuated within 500 milliseconds after

the pick-up solenoid and the feed clutch turn on.

2. Whether the original has passed through the registration sensor 1,500

milliseconds after the registration sensor has been actuated.

A662-12

Page 14

24 February 1997 SERVICE TABLES

8. SERVICE TABLES

8.1 DIP SWITCHES

DPS 1

1 2 3 4

0 0 0 0 Normal Setting

1 0 0 1 Free Run

0 0 1 1 Solenoid Test

1 1 0 1 Motor Test

1 1 1 1 All Indicators On

Function

NOTE: All the functions are executed when the DF is closed.

8.2 VARIABLE RESISTORS

VR No. Function

VR1 Adjusts registration

8.3 FUSE

Fuse No. Rating Blown Fuse Condition

F1 F2 A/250 V The DF will not operate.

Option

A662-13

Page 15

REPLACEMENT AND ADJUSTMENT 24 February 1997

9. REPLACEMENT AND ADJUSTMENT

9.1 TRANSPORT BELT REPLACEMENT

[A]

[B]

A662R500.img

[E]

[I]

[F]

[G]

[D]

[H]

A662R501.img

1. Turn off the main switch.

2. Remove the original table [A].

3. Remove the DF [B] from the copier (2 knob screws, 1 power supply cord,

and 1 optics harness).

4. Remove the grip guide [C] (2 screws).

5. Remove the transformer cover [D] (3 screws), DF motor cover [E]

(4 screws) and main board cover [F] (2 screws).

[C]

6. Remove the transport belt assembly [G] (5 screws and 1 drive belt [H]).

NOTE: When installing the transport belt assembly, make sure that the

positioning pin [I] fits into the DF frame.

A662-14

Page 16

24 February 1997 REPLACEMENT AND ADJUSTMENT

[A]

[B]

A662R502.img

Option

7. Remove the transport roller holder [A] (1 screw, 1 snap ring and 1

bearing).

8. Pull out the transport belt [B].

NOTE: After reinstalling the transport belt, make sure that the bushings

of the transport rollers set correctly and the transport belt turns

smoothly.

A662-15

Page 17

REPLACEMENT AND ADJUSTMENT 24 February 1997

9.2 FEED-IN UNIT REMOVAL

[C]

[A]

[B]

A662R503.img

1. Turn off the main switch.

2. Remove the transport belt assembly. (See Transport Belt Replacement.)

3. Remove the left hinge bracket [A] (4 screws and 1 connector).

4. Disconnect five connectors from the main board [B] (CN111, CN113,

CN115, CN116 and CN117).

5. Remove the feed-in unit [C] (5 screws).

NOTE: When reinstalling the feed-in unit, the harness must be

positioned underneath the right hinge bracket.

A662-16

Page 18

24 February 1997 REPLACEMENT AND ADJUSTMENT

9.3 PICK-UP ROLLER REPLACEMENT

[D]

[C]

Option

[A]

[B]

A662R504.img

1. Turn off the main switch.

2. Remove the feed-in unit. (See Feed-in Unit Removal.)

3. Remove the DF motor [A] (2 screws and 1 timing belt [B]).

4. Remove the pick-up roller [C] (2 E-rings and 1 bushing) from the shaft [D].

A662-17

Page 19

REPLACEMENT AND ADJUSTMENT 24 February 1997

9.4 FEED ROLLER REPLACEMENT

[H]

[E]

[I]

[G]

[B]

[F]

[C]

[A]

[D]

A662R505.img

1. Turn off the main switch.

2. Remove the feed-in unit. (See Feed-in Unit Removal.)

3. Remove the feed roller timing belt [A], feed roller gear [B] (1 E-ring and 1

spring pin [C]) and 1 bushing [D].

NOTE: Be careful not to lose the spring pin.

4. Slide the feed roller shaft [E] towards the front and remove the feed clutch

[F] (1 E-ring and 1 connector).

5. Take out the feed roller shaft (1 spacer and 1 bushing ----- from the rear

side).

6. Remove the feed roller [G] from the shaft (3 idler rollers [H], 7 E-rings and

1 spring pin [I]).

NOTE: Be careful not to lose the spring pin.

A662-18

Page 20

24 February 1997 REPLACEMENT AND ADJUSTMENT

9.5 FRICTION BELT REPLACEMENT

[A]

Option

A662R507.img

1. Turn off the main switch.

[B]

[C]

A662R506.img

2. Remove the friction belt assembly [A] (1 screw).

3. Remove the friction belt [B] (2 springs, 1 pin).

NOTE: When installing the friction belt assembly, make sure the feed

roller [C] is set in the correct position. (See the illustration.)

A662-19

Page 21

REPLACEMENT AND ADJUSTMENT 24 February 1997

9.6 PICK-UP SOLENOID ADJUSTMENT

[F]

[E]

[B]

[C]

[A]

[D]

A662R508.img

1. Turn off the main switch.

2. Remove the feed-in unit. (See Feed-in Unit Removal.)

3. Loosen two screws [A] securing the pick-up solenoid [B].

4. Place a 1.2 mm thickness gauge [C] between the plunger and the

solenoid.

5. Turn the solenoid lever [D] clockwise until the plunger touches the

thickness gauge. Just at this point, tighten two screws.

6. Make sure that the pick-up lever [E] is touching the pick-up roller [F] when

the plunger is pushed. If not, repeat steps 3 to 5.

7. Reassemble the DF.

8. Turn on the main switch and check the original feed-in operation.

A662-20

Page 22

DOCUMENT FEEDER (A 662) 20 December 1996

3. DOCUMENT FEEDER (A662)

3.1 ACCESSORY CHECK

Check the accessories against the following list:

Description Q’ty

1. Voltage Reference Decal.................................................. 1

2. Thumb Screw M4 x 12...................................................... 2

3. Stud Screw (M3)............................................................... 2

4. Installation Procedure - English........................................ 1

5. NECR - Multi-language..................................................... 1

6. Interface Unit for A219 copier .......................................... 1

7. Accessory Kit for A203 copier .......................................... 1

Interface Unit Bracket.................................................. 1

•

Stud Screw (M4).......................................................... 2

•

Harness Clamp ........................................................... 1

•

Upper Unit Stand......... ................................................ 1

•

Stepped Screw (Short)................................................ 1

•

Stepped Screw (Long)................................................. 1

•

Magnet......................................................................... 1

•

Operation Decal .......................................................... 1

•

Screw Driver................................................................ 1

•

3-8

Page 23

20 December 1996 DOCUMENT FEEDER (A662)

3.2 INSTALLATION PROCEDURE

[B]

[A]

[F] 230 ~ 240 V

[C]

[D] 220 ~ 230 V

[E]

A662I500.wmf

Installation

CAUTION

When installing the DF, make sure the copier is unplugged.

1. Remove the platen cover [A] from the copier.

2. Replace the 2 screws with the 2 stud screws [B].

Use the M3 stud screws for A219.

•

Use the M4 stud screws for A203.

•

3. Remove the strips of tape from the DF.

CAUTION

The next step (step 4) must be done only in 240 volt areas.

4. Perform the conversion from 220 ∼ 230 V to 240 V as follows:

1) Remove the main board cover [C] (2 screws).

2) Disconnect the connector for 220 ∼ 230 V [D] (Black Wire) from the ac

harness connector [E] and connect the connector for 240 V [F] (White

Wire) to the ac harness connector.

A662I501.img

3) Reinstall the cover.

3-9

Page 24

DOCUMENT FEEDER (A 662) 20 December 1996

[A]

[C]

[B]

A662I502.img

[F]

[E]

A662I503.wmf

[G]

[J]

[H]

[I]

A662I504.wmf

5. Insert the DF [A] into the holes [B] in the copier upper cover.

6. Secure the DF to the copier (2 thumb screws [C]).

7. Remove the rear cover [D] (2 screws) and cut away the portion [E] with

cutting pliers as shown.

8. Locate the 4P connector [F] and connect it to the ADF interface board

[G], then secure the DF interface unit [H] to the copier (1 screw).

[D]

9. Plug the connector [I] (3P) in to CN202 on the ac drive dc power supply

board [J].

3-10

Page 25

20 December 1996 DOCUMENT FEEDER (A662)

[C]

[A]

[B]

A662I505.wmf

[E]

[F]

[D]

A662I514.img

Installation

[F]

A662I515.img

10. Reinstall the rear cover.

11. Plug the optics fiber cable [A] into the DF and the copier.

12. Plug the power supply cord [B] of the DF into the outlet in the copier rear

cover.

13. Attatch the voltage reference decal [C].

14. Check that the rubber pad [D] is in contact with the top of the operation

panel cover. If it is not, remove the DF grip [E] (2 screws), then adjust the

position of the magnet catch [F] so that the rubber pad is in contact with

the top of the operation panel cover.

15. Turn on the main switch and check the operation of the DF.

3-11

Page 26

INSTALLATION 24 February 1997

14.3 DOCUMENT FEEDER (A662) ACCESSORY CHECK

Check the accessories against the following list:

Description Q’ty

1. Voltage Reference Decal.................................................. 1

2. Thumb Screw M4 x 12...................................................... 2

3. Stud Screw (M3)............................................................... 2

4. Installation Procedure - English........................................ 1

5. NECR - Multi-language..................................................... 1

6. Interface Unit for A219 copier .......................................... 1

7. Accessory Kit for A203 copier .......................................... 1

• Interface Unit Bracket.................................................. 1

• Stud Screw (M4) ......................................................... 2

• Harness Clamp ........................................................... 1

• Upper Unit Stand......................................................... 1

• Stepped Screw (Short)................................................ 1

• Stepped Screw (Long)................................................ 1

• Magnet........................................................................ 1

• Operation Decal.......................................................... 1

• Screw Driver................................................................ 1

28

Page 27

24 February 1997 INSTALLATION

14.4 DOCUMENT FEEDER (A662) INSTALLATION

PROCEDURE

[B]

Copier

A202/A203

[A]

[F] 230 ~ 240 V

[C]

[D] 220 ~ 230 V

[E]

A662I517.wmf

A662I501.img

CAUTION

When installing the DF, make sure that the copier is unplugged.

1. Remove the platen cover [A] from the copier.

2. Replace the 2 screws with the 2 stud screws [B].

• Use the M4 stud screws.

3. Remove the strips of tape from the DF.

CAUTION

The next step (step 4) must be done only in 240 volt areas.

4. Perform the conversion from 220 ∼ 230 V to 240 V as follows:

1) Remove the main board cover [C] (2 screws).

2) Disconnect the connector for 220 ∼ 230 V [D] (Black Wire) from the ac

harness connector [E] and connect the connector for 240 V [F] (White

Wire) to the ac harness connector.

3) Reinstall the cover.

29

Page 28

INSTALLATION 24 February 1997

[A]

[C]

[E]

[B]

A662I506.img

[F]

[G]

[D]

A662I507.img

[H]

[I]

A662I513.wmf

5. Insert the DF [A] into the slots [B] in the copier upper cover.

6. Secure the DF to the copier (2 thumb screws [C]).

7. Remove the upper rear cover [D] (2 screws).

8. Remove the ADF bracket [E] (1 screw and 1 clamp).

9. Remove the interface harness [F] (3 screws) and the interface board with

2 locking supports [G] from the A219 interface unit bracket [H].

10. Attach the interface board and the interface harness to the A203 interface

unit bracket [I] (3 screws).

30

Page 29

24 February 1997 INSTALLATION

[A]

[C]

[B]

[D]

A662I508.img

[E]

Copier

A202/A203

[F]

[G]

A662I509.img

11. Locate the 4P connector [A] and connect it to the ADF interface board [B],

then attach the ADF interface unit [C] to the copier (1 screw) while

securing the harnesses through the wire clamp.

NOTE: Use the screw that secured the ADF bracket. (See the previous

page.)

12. Plug the connector [D] (3P/Black) into CN418 on the ac drive board [E] as

shown.

13. Reinstall the upper rear cover.

14. Plug the optics fiber cable [F] into the DF and the copier as shown.

15. Plug the DF power supply cord [G] into the outlet in the rear of the copier

as shown.

16. Open the front cover.

17. Lift up the upper unit.

31

Page 30

INSTALLATION 24 February 1997

[D]

[A]

[C]

[A]

[B]

18. Remove 2 screws [A].

A662I510.img

[E]

A662I511.img

[F]

A662I512.img

19. Tighten the shorter stepped screw [B].

20. Install the upper unit stand [C] (1 longer stepped screw [D]).

21. Attach the magnet [E] as shown.

22. Attach the decal [F] as shown.

23. Close the upper unit and the front cover.

24. Instruct key operators how to use the upper unit stand.

32

Page 31

24 February 1997 INSTALLATION

[C]

A662I514.img

[E]

Copier

A202/A203

[D]

[E]

A662I515.img

25. Check that the rubber pad [C] is in contact with the top of the operation

panel cover. If it is not, remove the DF grip [D] (2 screws), then adjust the

position of the magnet catch [E] so that the rubber pad is in contact with

the top of the operation panel cover.

26. Turn on the main switch and check the operation of the DF.

33

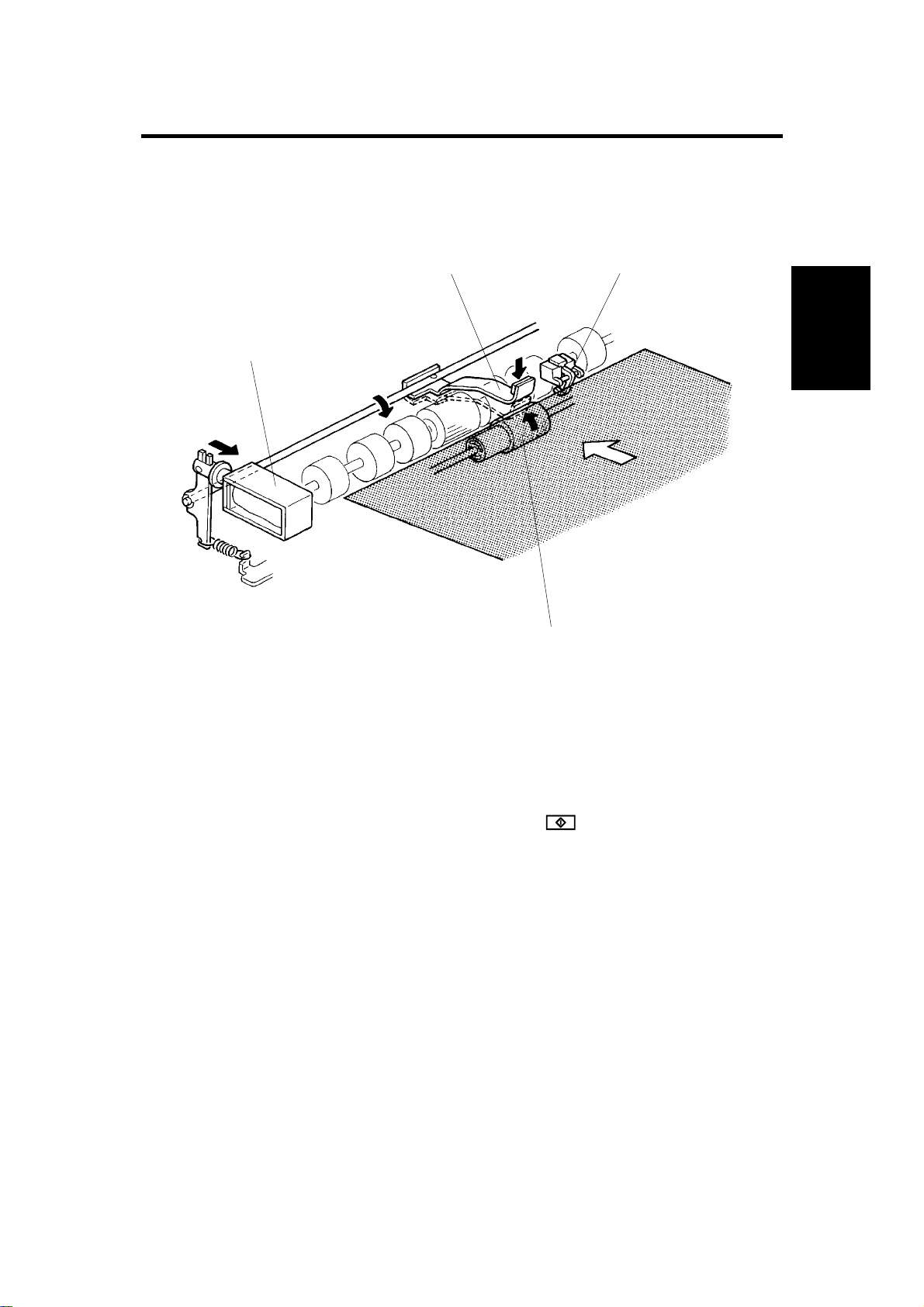

Page 32

DF (A662) ELECTRICAL COMPONENT LAYOUT

5

4

3

2

6

7

8

9

1

10

11

12

A662S500.img

A662S501.img

Description Index No. P to P Location

Pick-up Solenoid (SOL1) 1 A7

Registrati on Sensor (S3) 2 C7

Original Set Sensor (S2) 3 C7

Feed Clutch (CL1) 4 A7

Pulse Generator Sensor (S1) 5 A8

DF Motor (M1) 6 A7

Insert Original Indicator (LED2) 7 A8

SADF Indicator (LED1) 8 A8

Lift Switch (SW1) 9 C6

DF Main Board (P CB 1) 10 B8

DF Transformer (TR1) 11 B6

DF Interface Boar d (PC B2) 12 C8

Loading...

Loading...