Page 1

DOCUMENT FEEDER

Page 2

24 June 1994 SPECIFICATIONS

1. SPECIFICATIONS

Original Size: Maximum: A3 or 11" x 17"

Minimum: A5 Lengthwise or 51/2" x 81/2"

Original Weight: 53 to 105 g/m2 (14 to 28 lb)

Original Feed: Automatic Feed - ADF mode

Original Tray Capacity: 30 sheets - 80 g/m2 (20 lb)

Original Set: Face up - First sheet on top

Original Transport: One flat belt

Copying Speed: 13 copies/min ute

(A4 lengthwise or 81/2" x 11" lengthwise)

Power Consumption: 35 W

Dimensions (W x D x H): 590 x 443 x 100 mm (23.3" x 17.5" x 4.0")

Weight: Approximately 7 kg (15.5 lb)

• Specifications are subject to change without notice.

1

Page 3

COMPONENT LAYOUT 24 June 1994

2. COMPONENT LAYOUT

2.1 MECHANICAL COMPONENTS

1

234 65

8

910

7

1. Pulse Generator Disk

2. Friction Belt

3. Pick-up Lever

4. Pick-up Roller

5. Original Table

6. Exit Roller

7. Transport Belt

8. Transport Belt Roller

9. Feed Roller

10. Relay Roller

2.2 ELECTRICAL COMPONENTS

45

6

7

3

2

1

8

9

10

12

11

1. Pick-up Solenoid

2. Registration Sensor

3. Original Set Sensor

4. Feed Clutch

5. Pulse Generator Sensor

6. DF Motor

7. Insert Original Indicator

8. Original Misfeed Indica to r

9. Lift Switch

10. DF Main Board

11. DF Transformer

12. DF Interface Board

2

Page 4

24 June 1994 ELECTRICAL COMPONENT DESCRIPTIONS

3. ELECTRICAL COMPONENT DESCRIPTIONS

SYMBOL NAME FUNCTION LOCATION

Motor

M1 DF Drives all the document feeder components. 6

Solenoid

SOL1 Pick-up Solenoid Energizes to press the pick-up lever against

the stack of originals in preparation for

original feed-in.

Clutch

CL1 Feed Clutch Turns on to transmit main motor rotation to

the feed roller.

Switch

SW1 Lift Switch Informs the CPU when the DF is lifted and

also serves as the misfeed reset switch for

the DF.

Sensors

S1 Pulse Generator

Sensor

S2 Original Set

Sensor

S3 Registration

Sensor

Printed Circuit Board

PCB1 DF Main Board Controls all DF functions. 10

PCB2 DF Interface

Board

Transformer

TR1 DF Transformer Steps down the wall voltage to 25 volts ac. 11

LEDs

LED1 Original Misfeed

Indicator

LED2 Insert Original

Indicator

Supplies timing pulse to the DF main board. 5

Informs the copier CPU that originals have

been placed and causes the Insert Original

indicator to go out.

Sets original stop timing and checks for

original misfeeds.

Interfaces between the copier main board

and the DF.

Turns on when an original is misdeed. 8

Turns off when the originals are inserted into

the original table.

1

4

9

3

2

12

7

3

Page 5

POWER DISTRIBUTION 24 June 1994

4. POWER DISTRIBUTION

+24 V (VA)

Regulator

+5 V (VC)

Rectifier

AC Drive Board

(PCB2)

115 Vac

220–230 Vac

240 Vac

DF

Transformer

(TR1)

25 Vac

Smoothing

Rectifier

DF Main Board (PCB1)

The document feeder uses two dc powe r levels: +24 volts, and +5 volts.

When the main switch is turned on, th e DF t ran sfo rmer receives the wall

outlet ac power thro ugh the ac drive board and output s 2 5 volt s ac to th e DF

main board. Then, the dc power supply circuit on the DF main board con vert s

the 25 volts ac input to +24 volts and +5 volts.

+24 volts is used by the DF moto r, th e pick-up solenoid, and the feed clut ch.

+5 volts is used by other electrical components.

4

Page 6

24 June 1994 BASIC OPERATION

5. BASIC OPERATION

When the main switch is turned on, the DF CPU sends the "DF installed"

signal to the copier CPU. Receivin g th is sig nal, the copier CPU recognizes

that the document fee de r is inst alle d an d sen ds the "DF confirmed" signal to

the DF CPU.

When originals are placed on the origin al ta ble, the Insert Original ind icat or

turns off and the DF CPU sends the "original set" signal to the copier CPU to

inform that the orig ina ls h ave bee n set .

When the Start key is pressed, the copier CPU sends the "feed-in" signal to

the document feeder. On rece ipt of th is signa l, th e DF CPU e nergizes the DF

motor, the pick-up sole no id, and the fee d clut ch to fee d in th e bo ttom sheet of

the original stack onto the exposu re glass. The pick-up solenoid, and the

feed clutch remain energized until t he origin al’s leading edge reaches the

registration sensor. The DF motor tu rns off shortly after the original’s trailing

edge passes the registration sensor. Then, the DF mo to r pau ses an d

reverses for a moment to alig n th e ed ge of th e original with the scale.

The scanner starts, and the start timing does not depe nd on th e pro gress of

the original through the DF. When the scanner reaches the return position,

the copier CPU sends the "origina l chan ge" sign al to the DF CPU in order to

exchange the current origin al with the next origin al.

5

Page 7

Fiber Optics

Fiber Optics

INTERFACE CIRCUIT 24 June 1994

6. INTERFACE CIRCUIT

Copier Main Board (PCB1) DF Interface Board (PCB4)

CPU

TXD

RXD

+5V

CN120-2

CN120-5

CN120-4

CN120-1

CN2-1

CN2-4

CN1

CN2-2

CN2-3

DF Main Board (PCB1)

CN118

RXD

CPU

TXD

The copier CPU and the DF CPU communicate via the interface board usin g

fiber optics. The interfa ce bo ard chan ge s the opt ical sign als to electrical

signals (and vice versa).

6

Page 8

[A]

[D]

24 June 1994 ORIGINAL FEED

7. ORIGINAL FEED

7.1 ORIGINAL PICK-UP MECHANISM

[C]

[B]

After setting the origina ls on th e orig ina l tab le, the origin als con ta ct th e feeler

[A] of the original se t sen sor an d cau se the feeler to move out of th e sensor.

The DF CPU then sends the origina l set signal to the copier CPU to inform it

that the document fee de r will be used . When the Start key is pressed , th e

pick-up solenoid [B] is energized. The original stack is then pressed be twe en

the pick-up lever [C] and pick-up roller [D]. The rota tio n of the pick-up roller

advances the bottom original.

7

Page 9

[B]

[D]

ORIGINAL FEED 24 June 1994

7.2 ORIGINAL SEPARATION ME CHANI SM

[A]

[C]

[E]

[B]

[D] [C]

[A]

[E]

The feed roller [A] and the friction belt [B] are use d to feed in an d separate

the originals [C]. Only the bottom original is fed beca use the frictio n belt

prevents any other origin als fro m f eeding.

Original feed starts when the pick-up lever [D] presses the original stack and

the rotation of the pick-up roller [E] advances the bo tt om original of the stack.

The feed roller moves the original pa st th e friction belt because the driving

force of the feed roller is greater than the resistan ce of the friction belt. The

friction belt prevents multiple feeds becau se th e resist ance of the frictio n belt

is greater than the friction between original she et s.

8

Page 10

24 June 1994 ORIGINAL FEED

7.3 ORIGINAL FEED-IN MECHANIS M

[C]

[G]

[E]

[A]

[D]

[B]

[F]

The DF motor [A] drives the feed roller [B], the pick-up roller [C] , th e relay

rollers [D], and the transport belt roller [E] via timing belts and a gear train.

The feed roller and the pick-up roller are controlled by the feed clutch [F] , but

the relay rollers and the transport roller are dire ctly driven by the DF motor.

The idler rollers [G] on the feed roller shaf t are free from the shaft.

When the Start key is pressed, the DF mot or is energized and the relay

rollers and transport belt roller start tu rnin g. 100 millisecon ds af ter t he DF

motor starts turning, the pick-up solenoid an d th e feed clutch is energized.

The pick-up and feed rollers then start turning and carry the original be twe en

the relay rollers and the idler rollers. The pick-up solen oid and the fee d clutch

are de-energized when the origin al’s leading edge passes thro ugh the

registration sensor.

The DF motor remains energized to deliver the original to the exposure glass

until a certain number of pulses (10 to 25 pulse s) aft er the original’s trailing

edge passes through the regist rat ion sensor. Then, the DF motor pauses and

reverses for 15 pulses to align the edge of the original wit h th e scale.

To feed the second original, the DF mot or sta rts rot at ing when the scanner

reaches the return position. (The copier CPU sends the original cha ng e

signal to the DF CPU.) At this time, the transport belt start s carrying the first

original on the exposure glass to the exit rolle r. The timing for when the

pick-up solenoid and the fee d clut ch are ene rgize d for the second original

depends on the length of the first origin al dete cte d by th e reg istra tio n sen sor.

9

Page 11

[D]

ORIGINAL FEED 24 June 1994

7.4 ORIGINAL FEED- OUT ME CHANI SM

[A] [B] [C]

The exit rollers are driven by the DF motor through a gear train , the tra nsp ort

belt roller, the transport be lt [A ], the transport belt idler roller [B ], and the exit

roller drive belt [C]. When the DF CPU receives the original change signal

from the copier CPU, the DF motor starts turning. Simult aneo usly, the

transport belt carries the original to the exit rolle rs [D] an d the exit ro llers take

over the original feed-out.

10

Page 12

+24 V (VA)

+5 V (VC)

R x D

CN117-1

CN117-2

Forward: +24 V

Reverse: 0 V

Forward: 0 V

Reverse: +24 V

24 June 1994 ORIGINAL FEED

7.5 DF MOTOR CIRCUIT

DF Main Board (PCB1)

Original

Change

Signal

CPU

Forward

Reverse

ON/OFF

GATE

IC

Forward

Reverse

DRIVER

IC

DF Motor

(M1)

Timing Pulse

A 24 volt dc motor is used as the DF moto r. When the CPU receives the feed

signal from the copier, the CPU out pu ts the ON signal and the Forward sign al

to the gate IC. On receipt of the forward signal from the gate IC, the driver IC

outputs 24 volts to CN117-1 and 0 volt s to CN11 7-2 . This cau ses the DF

motor to start turning in the forward direction .

Within 10 to 25 pulses after the original’s trailing edge passes throu gh the

registration senso r, the CPU stops sending the ON signal and the Forward

signal. The DF motor stops turnin g. Then the CPU outputs the ON signal an d

the reverse signal for 15 pulses. The n th e drive r I C out puts 0 volts to

CN117-1 and +24 volts to CN117-2 to reverse the DF motor.

Pulse

Generator

Sensor

(S1)

11

Page 13

DF Motor

ORIGINAL FEED 24 June 1994

7.6 ORIGINAL FEED AND MIS FEED DETECTION TIMING

Feed Signal (Start key) Original Change Signal

0 500 1000 0 500 1000

Timing (ms)

10 to 25 pulses

10 to 25 pulses

❋

15 pulses

J0

Pick-up Sol.

and

Feed Clutch

100 ms

15 pulses

J0

J0

Registration

Sensor

500 ms

500 ms

1,500 ms

❋: The timing depends on the length of the first original.

1,500 ms

The above chart shows the origina l fee d timin g for the origin al size of A4

lengthwise or 8.5" x 11" and the detection timing.

The registration sensor is used for a misfe ed det ect ion. If the DF CPU

detects that a misfeed exists, the DF CPU lights the Origina l Misfeed

indicator and sends the origin al misfe ed signa l to th e cop ier CPU. Then the

copier CPU lights the check paper p ath an d th e Misfe ed Loca tio n Number

(JO) on the operation panel. When the main switch is turn ed on, the DF CPU

checks the registration sensor output for initial original misfeed. During the

original feed-in, the DF CPU perfo rms two kind s of original misfeed detection:

1. Whether the registration senso r is actua ted with in 500 milliseco nds aft er

the pick-up solenoid and the feed clut ch turn on.

2. Whether the original has passed through the re gist ration sensor 1,500

milliseconds after the regist rat ion sensor has been actuated.

12

Page 14

[A]

24 June 1994 INSTALLATION PROCEDURE

8. INSTALLATION PROCEDURE

NOTE: This procedure is for the machin e code A152 copier.

[B]

[C]

[F] 230~240 V

[D] 220~230 V

[E]

CAUTION: When installing the DF, make sure that the copie r is

unplugged.

1. Remove the platen cover [A] from the copier.

2. Replace the 2 screws with the 2 stud screws [B].

3. Remove the strips of tape from the DF.

CAUTION: This procedure (step 3) must be done only in 240 volt areas

4. Perform the conversion fro m 220∼230 V to 240 V as follows:

1) Remove the main board cover [C] (2 screws).

2) Disconnect the connector for 220∼230 V [D] (Black Wire ) from th e ac

harness connector [E] an d reco nn ect the connector for 240 V [F]

(White Wire) to the ac harness connecto r.

3) Reinstall the cover.

13

Page 15

INSTALLATION PROCEDURE 24 June 1994

[E]

[A]

[I]

[C]

[B]

[D]

[F]

[G]

[K]

[J]

[H]

5. Insert the DF [A] into the holes [B] in the copier upper cover.

6. Secure the DF to the copier (2 thumb screws [ C]).

7. Remove the upper rear cover [D] (2 screws).

[H]

8. Remove the ADF bracket [E ] (1 screw an d 1 clamp ).

9. Locate the 4P connector [F] and connect it to the ADF interface board

[G], then fix the ADF interface unit [H] to the copier (1 screw) while

securing the harnesses through the wire clamp.

NOTE: Use the screw that secured th e ADF bracket [I].

10. Plug in the connector [J] (3 P/ Bla ck) t o CN41 8 on the ac drive board [K].

14

Page 16

[B]

24 June 1994 INSTALLATION PROCEDURE

[D]

[A]

[C]

11. Reinstall the upper rear cove r.

12. Plug the optics fiber cable [A] into the DF and the copier.

13. Plug the power supply cord [B] of the DF into th e outle t in th e cop ier rea r

cover.

14. Attach the volta ge reference decal [C].

15. Install the origina l tab le [D] .

15

Page 17

INSTALLATION PROCEDURE 24 June 1994

[D]

[A]

[E]

[C]

[A]

[B]

16. Open the front cover.

17. Lift the upper unit.

18. Remove 2 screws [A].

19. Tighten the shorter stepped screw [B].

20. Install the upper u nit stan d [C]

(1 longer stepped screw [D]).

21. Attach th e magnet [E].

22. Attach th e decal [F].

23. Close the uppe r u nit and t he front cover.

24. Check the operatio n of the DF.

25. Instruct key operators ho w to use the uppe r unit stand.

[F]

16

Page 18

15 January 1992 INSTALLATION PROCEDURE

8. INSTALLATION PROCEDURE

NOTE: This procedure is for machine code A077/A078 copiers.

8.1 INSTALLATION

[A]

[B]

[D]

CAUTION: When installing the DF, make sure that the copie r is

unplugged.

1. Remove the platen cover [A] from the copier.

2. Remove the strips of tape from the DF.

CAUTION: This procedure (step 3) must be done only in 240 volts

areas.

[E] 230~240 V

[C] 220~230 V

3. Perform the conversion fro m 220 ~23 0 V to 240 V as follo ws:

1) Remove the main board cover [B ] (2 screws).

2) Disconnect the connector for 2 20~230 V [C] (Black Wire) from ac

harness connector [ D] and reconnect the connector for 240 V [E]

(White Wire) to the ac harness connect or.

3) Reinstall the cover.

13

Page 19

[E]

INSTALLATION PROCEDURE 15 January 1992

[G]

[A]

[C]

[B]

[D]

[F]

4. Insert the DF [A] into the hole s [B] of th e copier up pe r cover.

5. Secure the DF to the copier (2 thumb screws [ C]).

6. Remove the seal [D] from th e ou tle t of the copier.

7. Plug in the optics fiber cable [E] to the DF and the copier as shown.

8. Plug in the power supply cord [F] of the DF to the outlet of the copier rear

cover as shown.

9. Install the orig ina l t ab le [G ] as shown.

10. Check the operatio n of the DF.

14

Page 20

[D] 230~240 V

[B] 220~230 V

15 January 1992 INSTALLATION PROCEDURE

8.2 220 ~ 230 V/24 0 V CONV ERSION

[A]

[C]

1. Remove the main board cover [A] (2 screws).

2. Disconnect the connect or for 2 20~230 V [B] (Black Wire) from ac harness

connector [C] and reconne ct th e con nector for 240 V [D] (White Wire) to

the ac harness connector.

3. Reinstall the cove r.

15

Page 21

[B]

24 June 1994 REPLACEMENT AND ADJUSTMENT

9. REPLACEMENT AND ADJUSTMENT

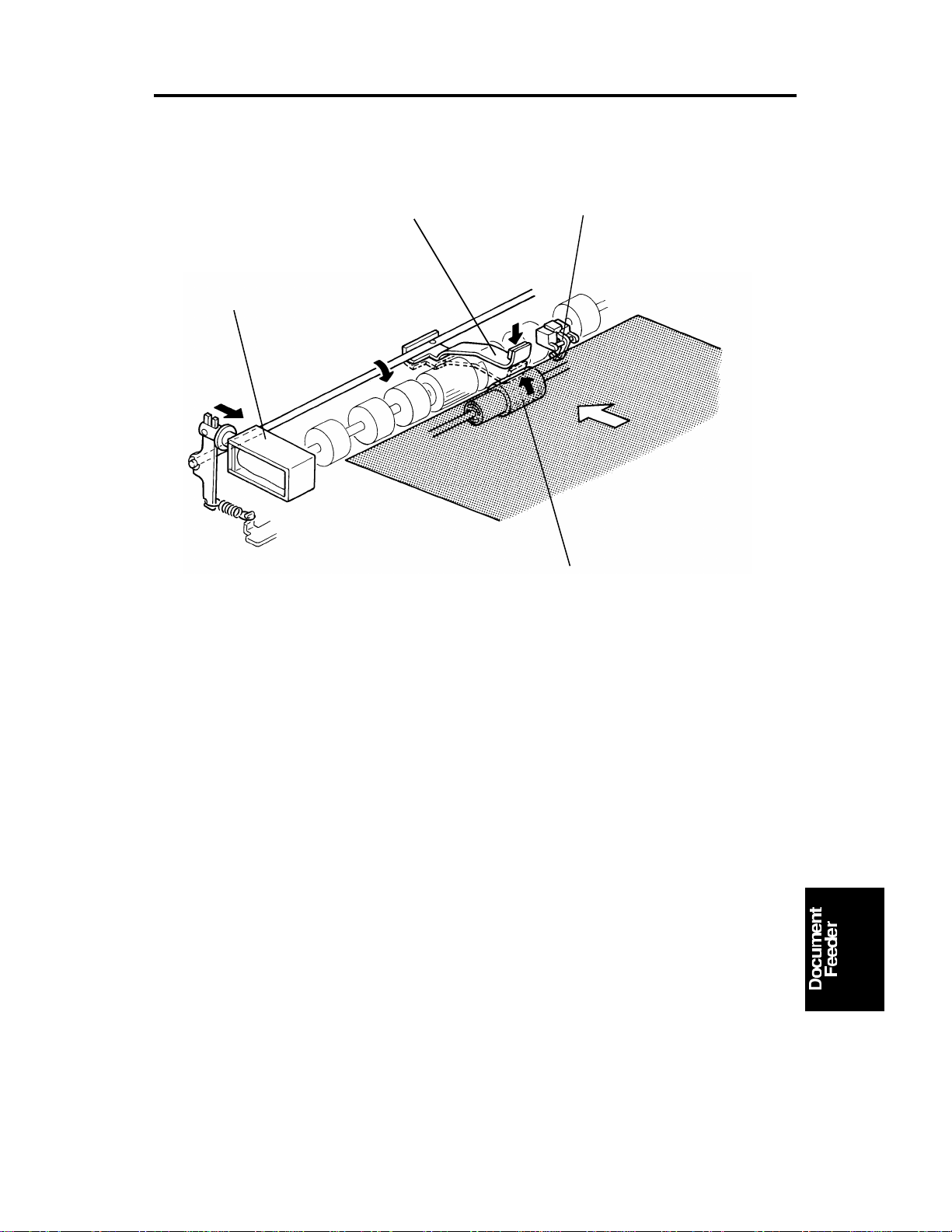

9.1 TRANSPORT BELT REPLACEMENT

[A]

[E]

[F]

[I]

[D]

[G]

[H]

[C]

1. Turn off the main switch.

2. Remove the original table [A].

3. Remove the DF [B] from t he copier (2 knob screws, 1 power supply cord

and 1 optics harness).

4. Remove the grip guide [C] (2 screws).

5. Remove the transfo rmer cove r [D] (3 screws), DF motor cover [E]

(4 screws) and main board cover [F] (2 screws).

6. Remove the transpo rt belt assembly [G] (5 screws and 1 drive belt [H]).

NOTE: When installing the tra nsport belt assembly, make sure th at the

positioning pin [I] fits into the DF frame.

17

Page 22

REPLACEMENT AND ADJUSTMENT 24 June 1994

[A]

[B]

7. Remove the transpo rt rolle r holder [A] (1 screw, 1 snap ring and 1

bushing).

8. Pull out the transport belt [B].

NOTE: After reinstalling the transport belt, make sure that the bushings

of the transport rollers set correctly an d the tra nsport belt turns

smoothly.

18

Page 23

[C]

24 June 1994 REPLACEMENT AND ADJUSTMENT

9.2 FEED-IN UNIT REMOVAL

[A]

[B]

1. Turn off the main switch.

2. Remove the transport belt assembly. (See Transport Belt Replacement.)

3. Remove the left hinge bracket [A] (4 screws and 1 connector).

4. Disconnect five connectors from th e main board [B ] (CN111, CN113,

CN115, CN116 and CN117).

5. Remove the feed-in unit [C] (5 screws).

NOTE: When reinstalling the feed-in unit , th e harne ss mu st be

positioned underneath the right hinge bracket.

19

Page 24

[C]

REPLACEMENT AND ADJUSTMENT 24 June 1994

9.3 PICK-UP ROLLER REPLACEMENT

[D]

[B]

[A]

1. Turn off the main switch.

2. Remove the feed-in unit . (Se e Feed-in Unit Removal.)

3. Remove the DF motor [A] (2 screws an d 1 timin g be lt [B ]).

4. Remove the pick-up roller [C] (2 E-rings and 1 bushing) from the shaft [D].

20

Page 25

24 June 1994 REPLACEMENT AND ADJUSTMENT

9.4 FEED ROLLER REPLACEMENT

[E]

[H]

[G]

[I]

[F]

[B]

[C]

[A]

[D]

1. Turn off the main switch.

2. Remove the feed-in unit . (Se e Feed-in Unit Removal.)

3. Remove the feed roller timing belt [A] , fe ed roller ge ar [B ] (1 E-rin g an d 1

spring pin [C]) and 1 bushing [D].

NOTE: Be careful not to lose the spring pin.

4. Slide the feed roller shaft [E ] to ward s t he fron t an d remo ve th e feed clutch

[F] (1 E-ring and 1 connector).

5. Take out the feed roller shaft (1 spacer and 1 bushing ----- from the rear

side).

6. Remove the feed roller [G] from th e shaft (3 idler rollers [H], 7 E-rings and

1 spring pin [I]).

NOTE: Be careful not to lose the spring pin.

21

Page 26

REPLACEMENT AND ADJUSTMENT 24 June 1994

9.5 FRICTION BELT REPLACEMENT

[C]

[A]

[B]

1. Turn off the main switch.

2. Remove the friction belt asse mbly [A] (1 screw).

3. Remove the friction belt [B ] (2 springs, 1 pin).

NOTE: When installing the frict ion belt assembly, make sure the fe ed

roller [C] is set in the correct position. (See the illustra tio n. )

22

Page 27

[D]

24 June 1994 REPLACEMENT AND ADJUSTMENT

9.6 PICK-UP SOLENOID ADJUSTMENT

[F]

[E]

[B]

[C]

[A]

1. Turn off the main switch.

2. Remove the feed-in unit. (See Feed-in Unit Removal.)

3. Loosen two screws [A] secu ring the pick-up solenoid [B] .

4. Place a 1.2 mm thickness gauge [C] between the plunger and the

solenoid.

5. Turn the solenoid leve r [D] clockwise until the plunger touches the

thickness gauge. Just at this po int , tig hten two screws.

6. Make sure that the pick-u p leve r [E] is to uch ing the pick-up roller [F] when

the plunger is pushed. If not, repeat steps 3 to 5.

7. Reassemble the DF.

8. Turn on the main switch and check th e orig ina l f eed-in operation.

23

Loading...

Loading...