Ricoh B282-69, B283-69 Service Training

B282-69/B283-69

Service Training

Draft start – 27 June 2011

Final released – 7 July 2011

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

1

Course Contents

1 Product Outline

2 Specifications

3 Installation

4 Machine Overview

5 PM

6 Scanner

7 Image Processing

8 Laser Exposure

9 PCU

10 Drum Charge

11 Development and Toner Supply

12 Transfer and Separation

13 Drum Cleaning

14 Paper Feed

15 Fusing

16 Duplex

17 ADF

18 ARDF

19 Paper Tray

20 Troubleshooting

21 Environmental Conservation

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

2

No additional notes.

B282-69/B283-69

Service Training

1. Product Overview

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

3

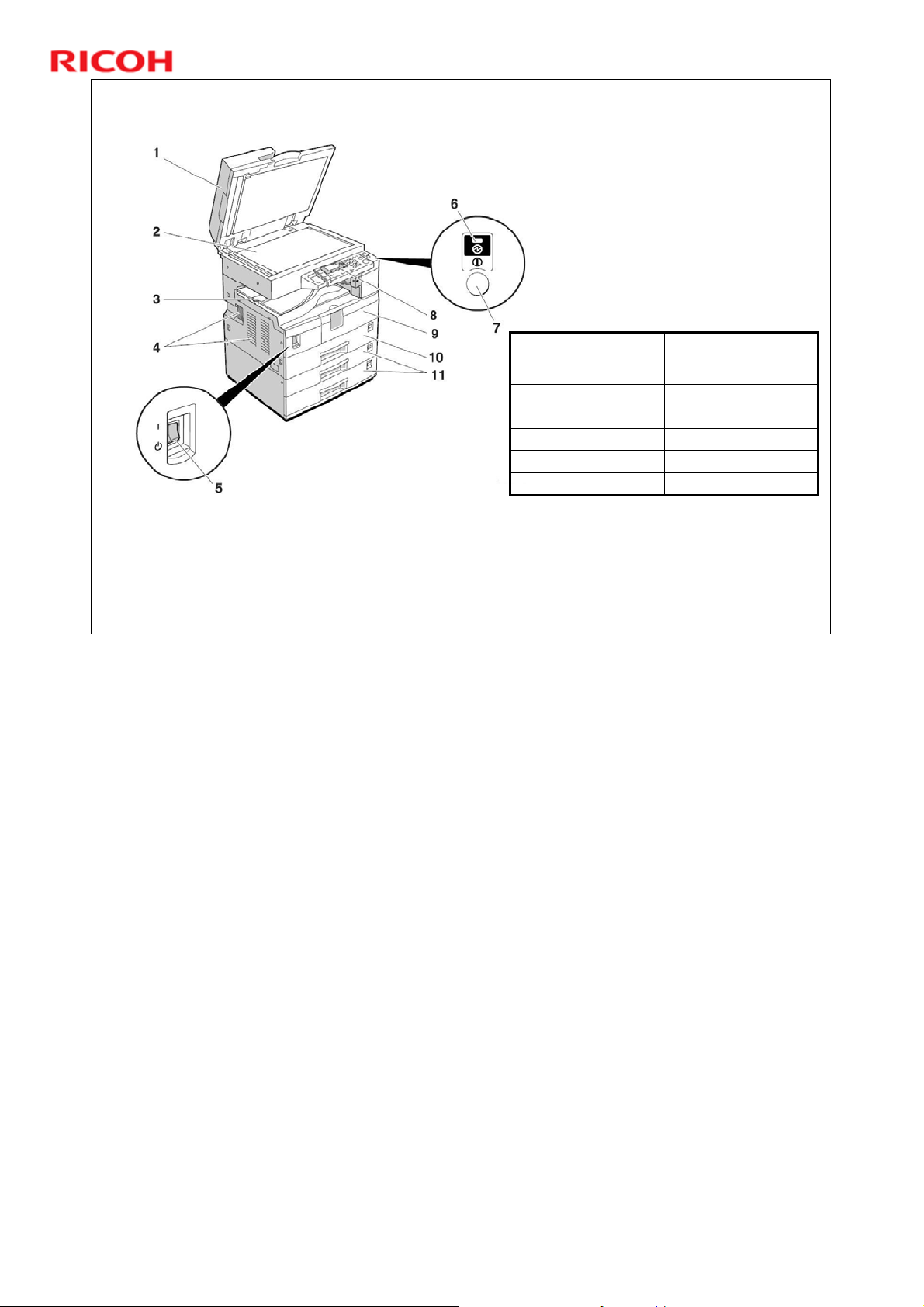

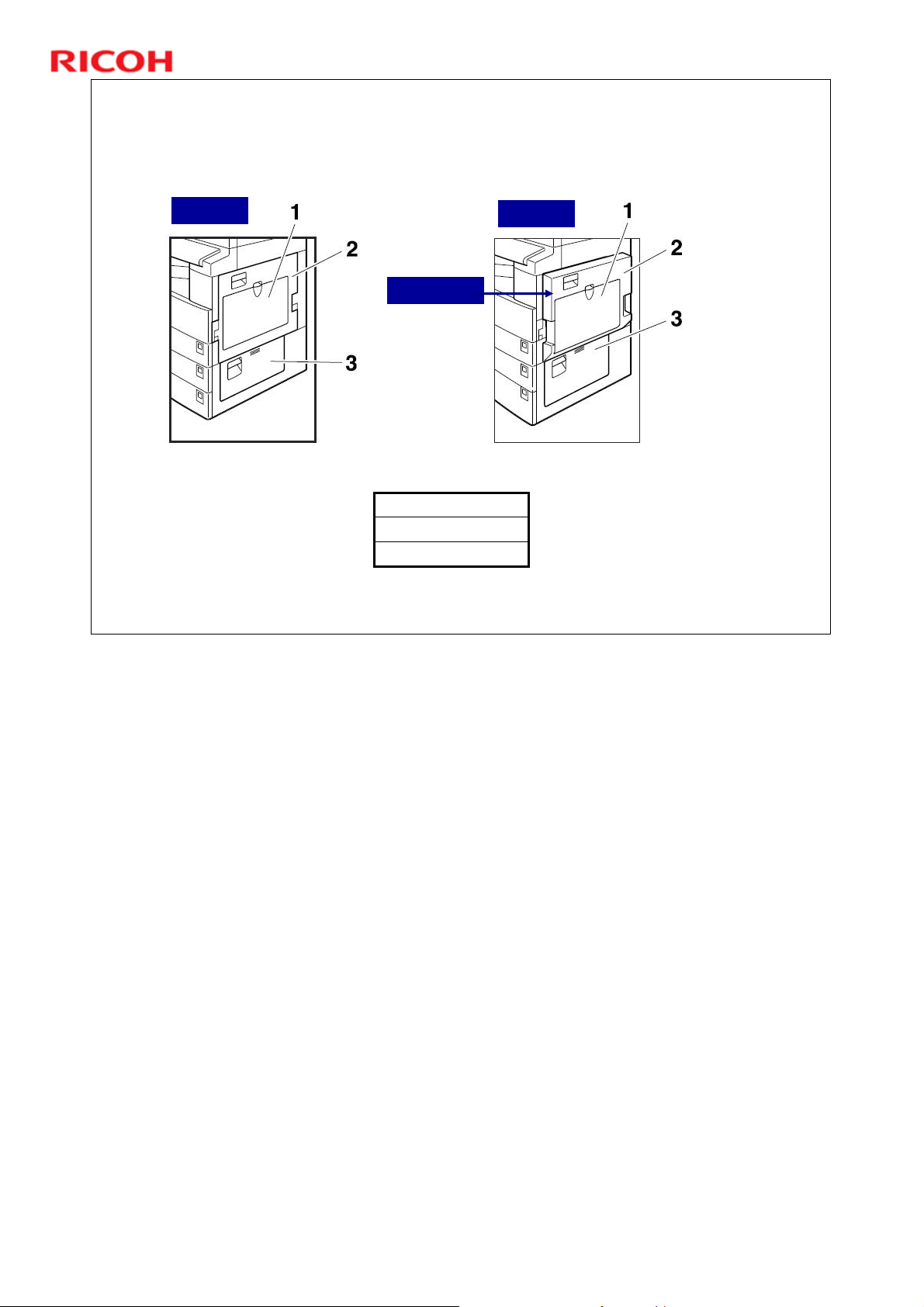

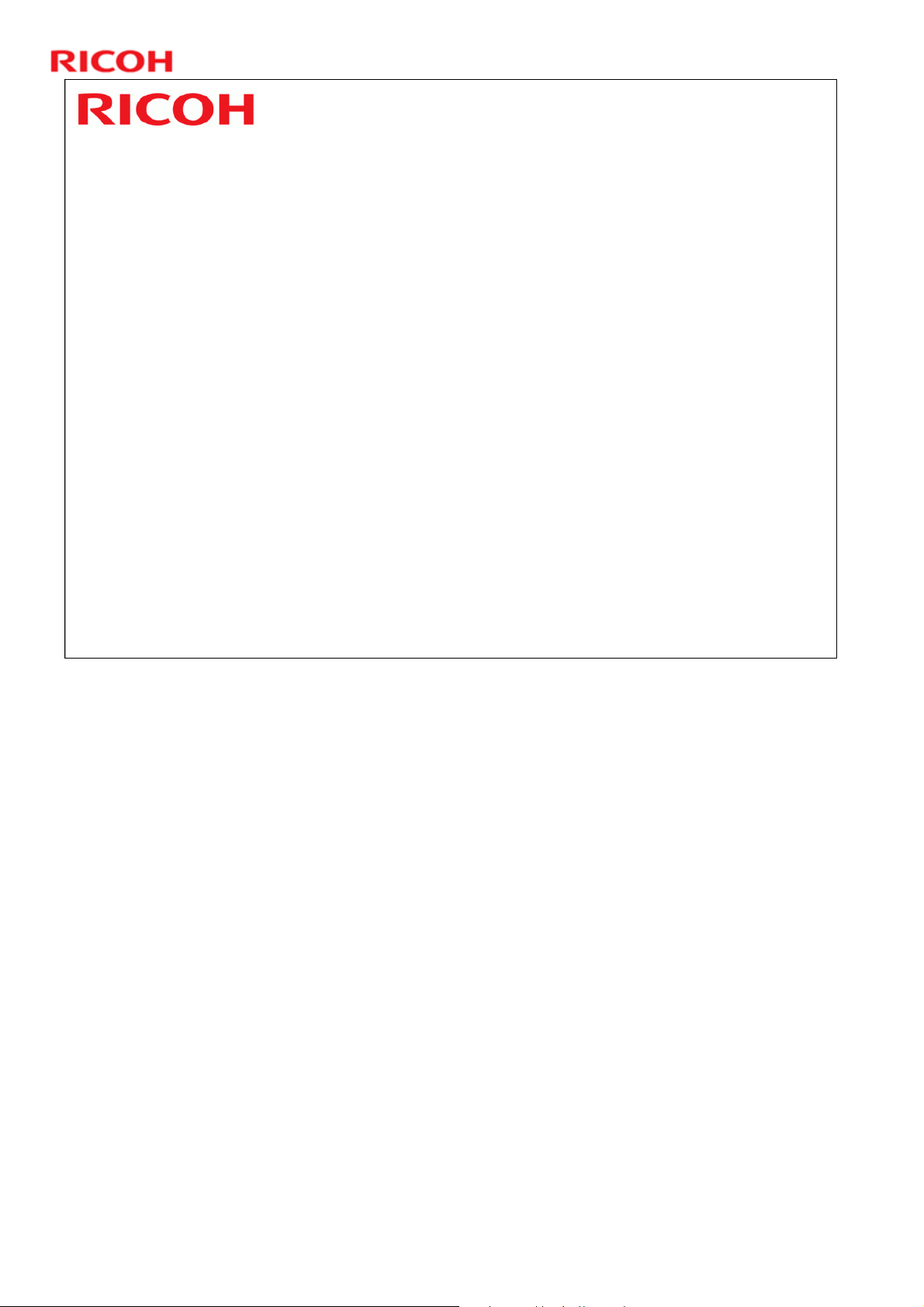

The Machine – Overall

Exposure glass cover

(options)

6. Main power indicator

7. Operation switch1. ARDF, ADF, or

8. Control panel2. Exposure glass

9. Front cover3. Internal tray

10. Paper tray4. Ventilation holes

11. Paper tray unit5. Main power switch

This the machine you will study in this training course.

The B384 Two-Paper Tray unit or the B385 One-Tray unit can attached

below the machine. (Maximum of three paper trays.)

Refer to the operating instructions for more details.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

4

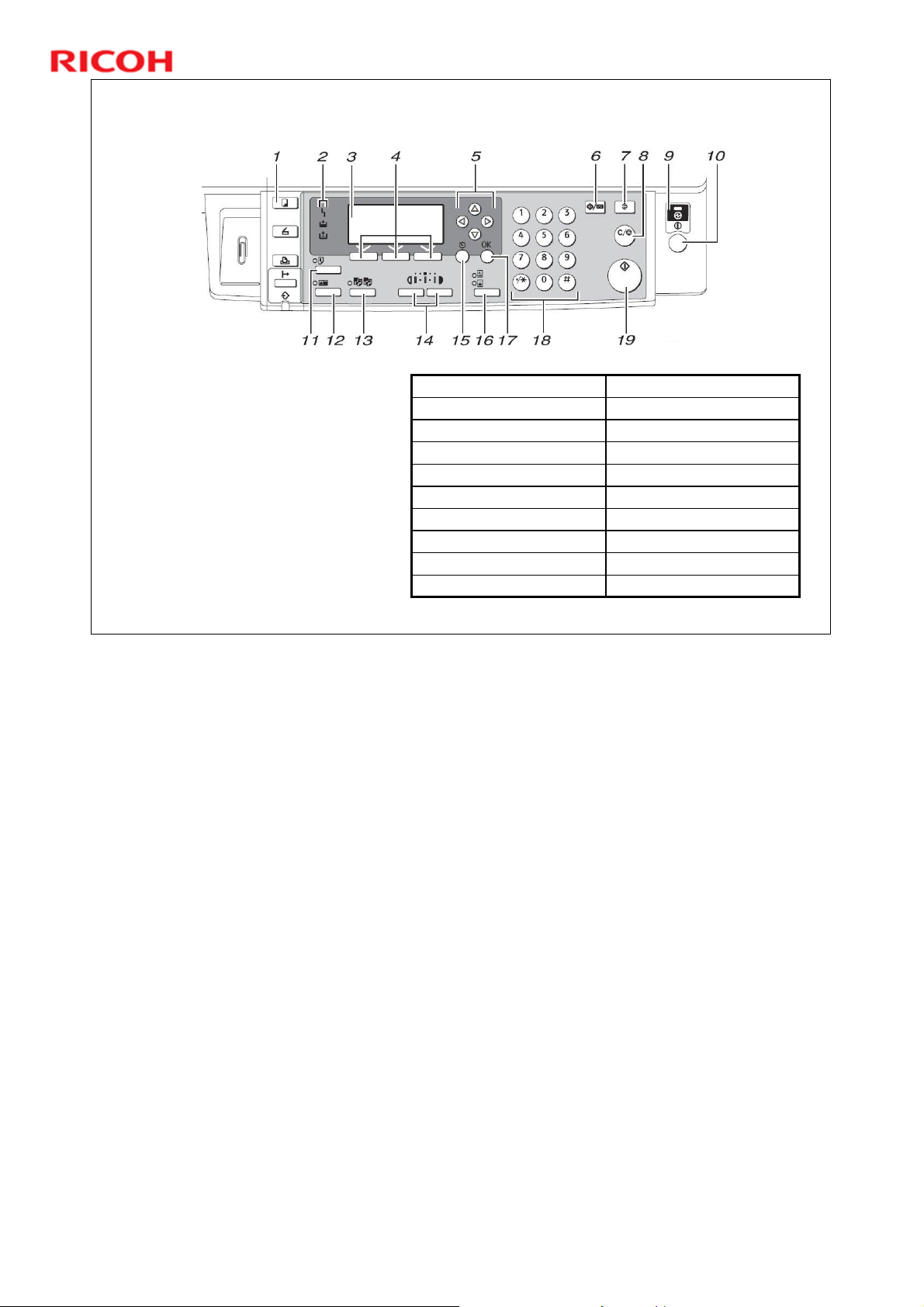

The Machine – Right Side

B283-69

No additional notes.

B282-69

Duplex unit

1. By-pass tray

2. Right cover

3. Lower right cover

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

5

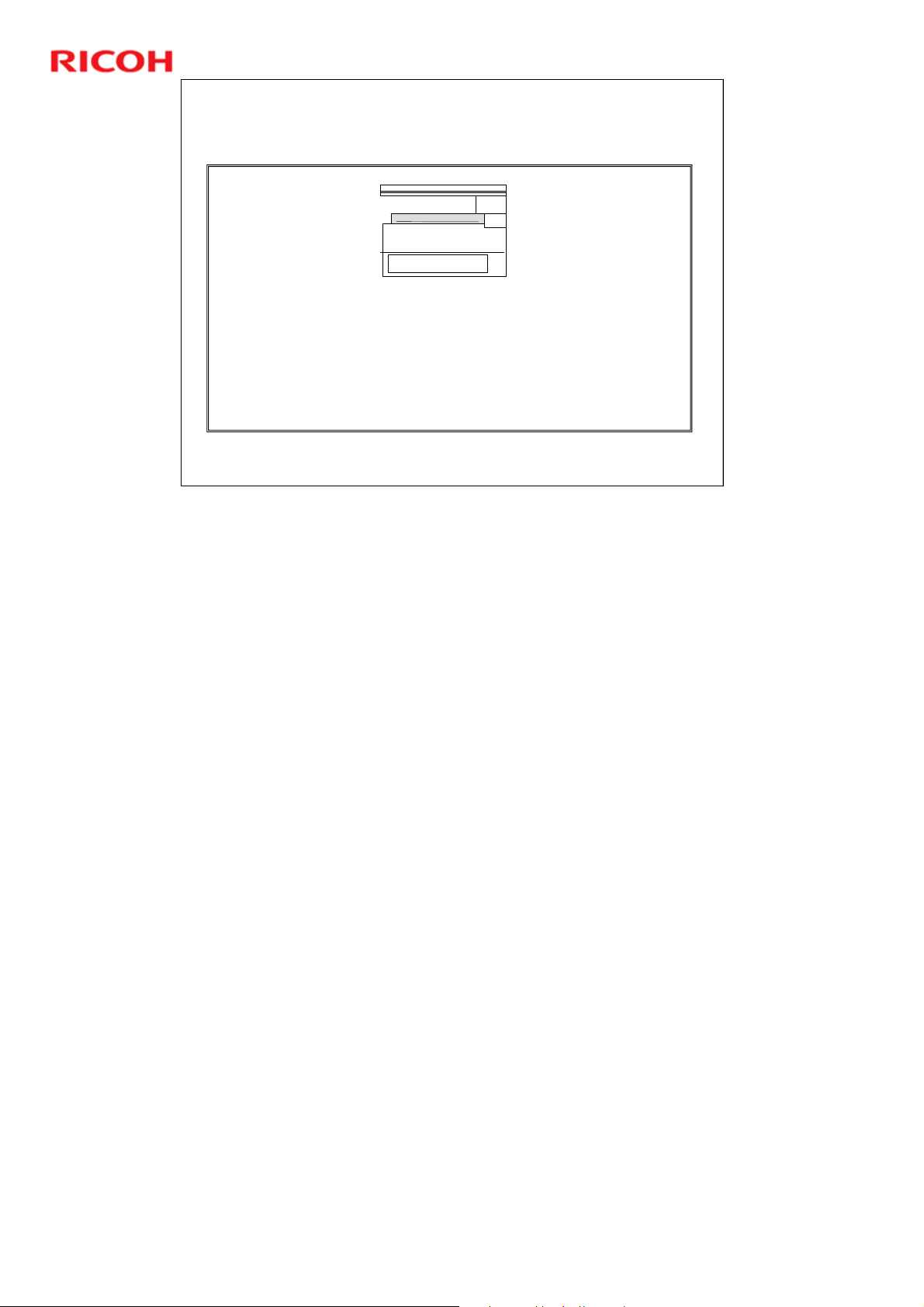

Operation Panel

Familiarize yourself with the

operation panel.

See the operating instructions

for detailed descriptions of

key and indicator function.

11. Duplex key1. Function keys

12. ID copy key2. Indicators

13. Sort key3. Display panel

14. Image density keys4. Selection keys

15. Escape key5. Scroll keys

16. Original key6. User tools/Counter key

17. OK key7. Clear modes key

18. Number keys8. Clear/Stop key

19. Start key9. Main power indicator

10. Operation switch

Round Start Key and bar in Clear/Stop Key make them easy to find and easy to press.

Color frequency adjusted 4-line LCD display ensures that users with color vision deficiency will be able to

easily distinguish between LED colors.

Panel Keys are easy to press and easy to find.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

6

B283-69 Mainframe B282-69 Mainframe

•Copy/Printer/Twain Scanner

•16MB Memory

•16MB+32MB memory (w/o NIC model)

•250-sheet x1 tray

•100-sheet bypass tray

•250-sheet output tray

•USB 2.0

Note: The GDI controller is standard with the B282/B283. There is no GW controller option.

No additional notes.

Standard Components

250

•Copy/Printer/Twain Scanner

•Duplex

•16MB Memory

•16MB+32MB memory (w/o NIC model)

•250-sheet x 1 tray

•100-sheet bypass tray

•250-sheet output tray

•USB 2.0

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

7

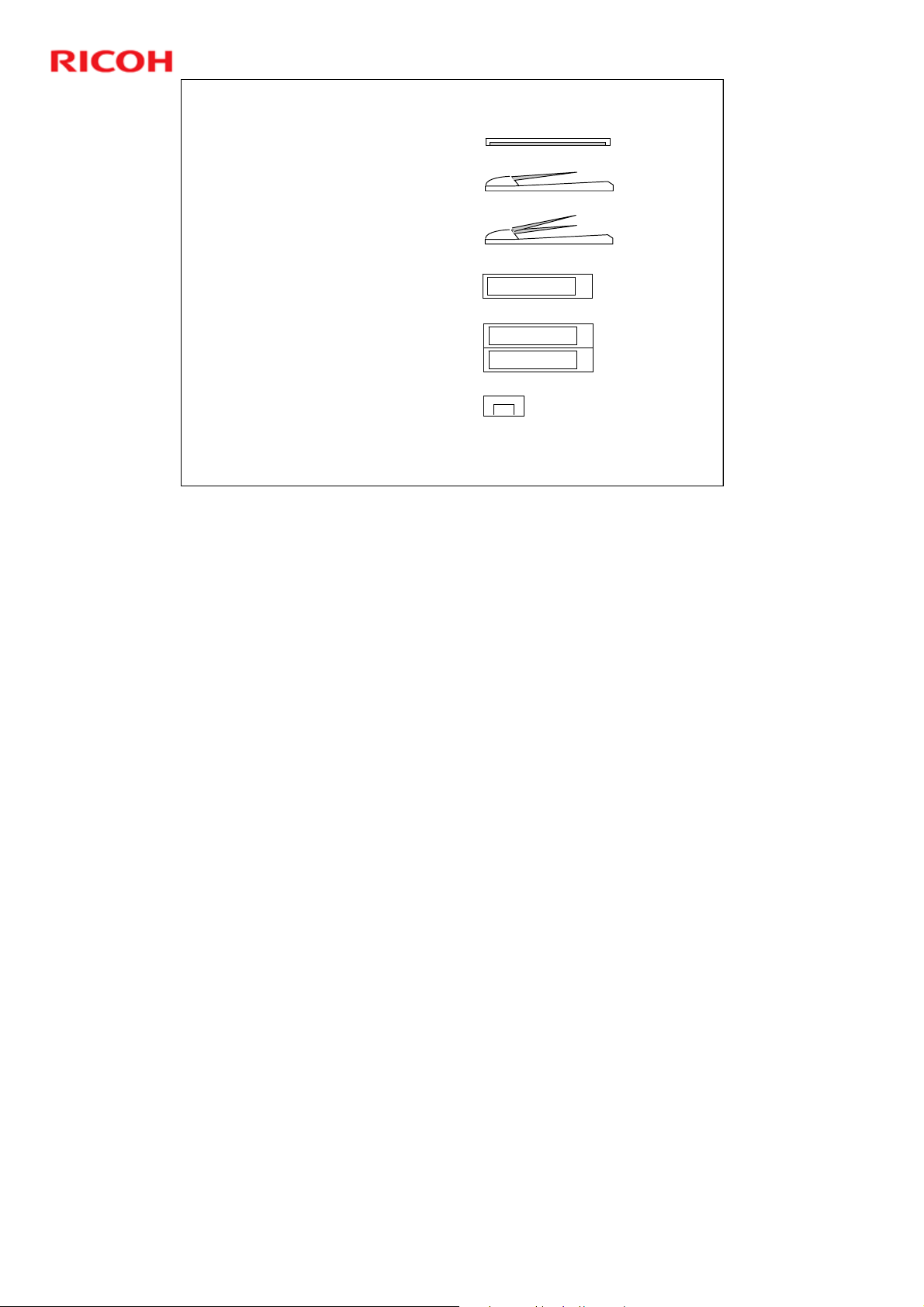

Optional Units

The external optional

units are shown to the

right.

Platen Cover (B406)

ADF (B813)

Internal option:

NIB (Network

interface board)

ARDF (B814): Only for B282-69

500

1-Tray paper bank (B385)

500

500

2-Tray paper bank (B384)

Accessibility handles for standard and

optional trays (B272 and B274)

The following service options are also available.

¾ Tray heaters

¾ Anti-condensation heater (for optics)

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

8

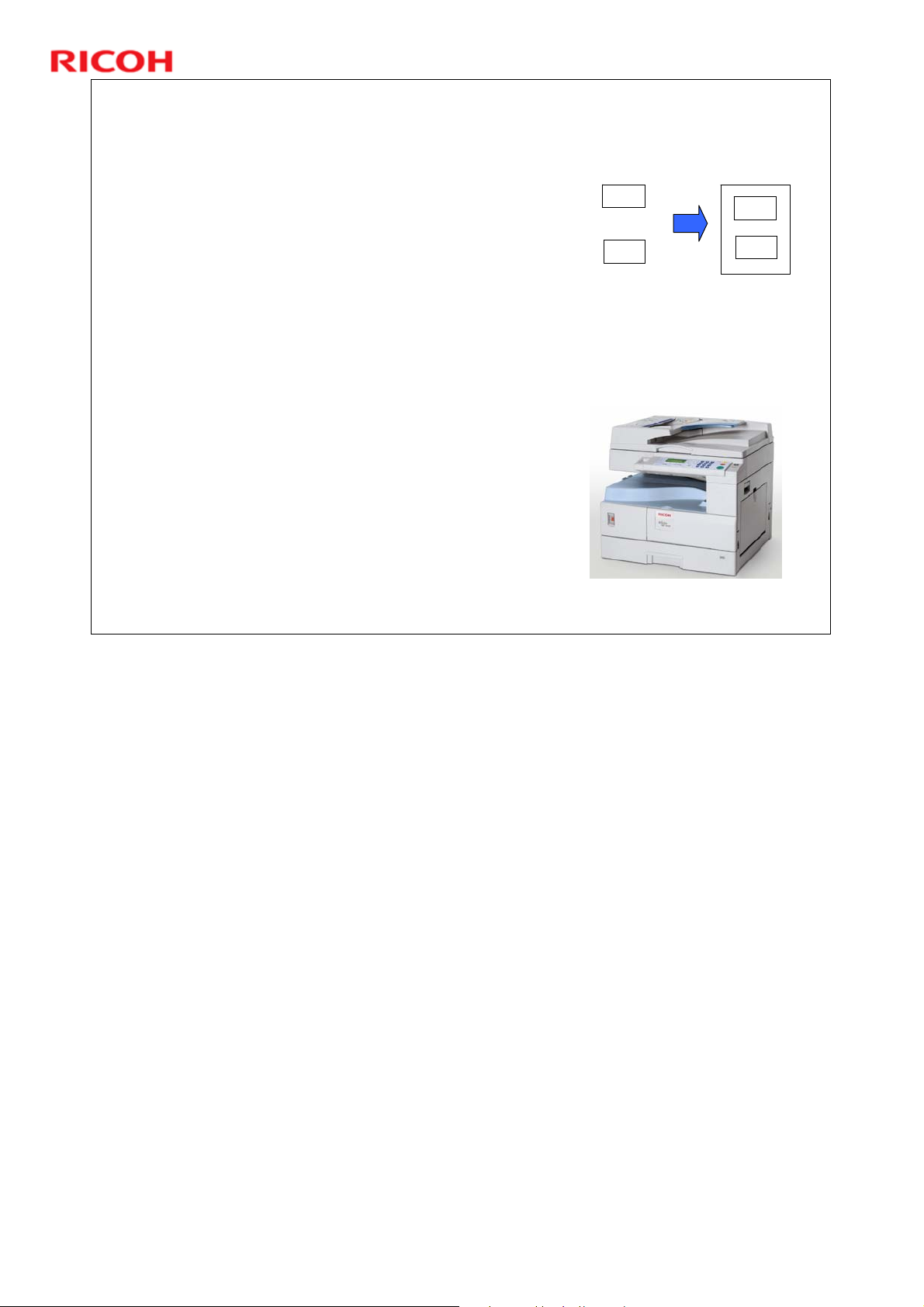

Major Differences from the B283-65 and B282-65

ID Copy Function

Allows copying of both sides of an ID card

(or other small document) onto one sheet.

No alignment problems. Don't have to feed

the paper back into the machine.

Increased Copy Speed

Multicopy rate has been increased for the

B282-69. (18 cpm ⇒ 20 cpm)

ADF 1 to 1 speed is still 18 cpm.

B283-69 multicopy rate is unchanged. (18

cpm)

Design Change

Internal tray is blue.

NIB

Front

Back

Front

Back

The ID Copy function is a requirement of the Chinese market. The Chinese ID

was changed in 2007 and now has important information on the reverse side.

Financial institutions and government offices especially need to easily copy both

sides.

ID Copy is different from Combine Copy function in that the output size is the

same as the original.

Users can identify output documents more easily with the blue internal tray.

The network interface board (NIB) is a new internal option.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

9

No additional notes.

B282-69/B283-69

Service Training

2. Specifications

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

10

Specifications - 1

Copy Process

Dry electrostatic transfer system

Maximum Original Size:

A3/11” x 17”

Maximum Copy Paper Size:

A3/11” x 17”

Reproduction Ratios:

3 enlargement and 4 reduction

Zoom

50% to 200%, in 1% steps

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

11

Specifications - 2

Power Source

220-240V, 50/60 Hz, 7A

Noise Emission

Standby (Mainframe/Full System)

» Not above 40 db

Operating (Mainframe only)

» Not above 62.7 db

Oper ating (Full System)

» Not above 66.7 db

Dimensions (W x D x H)

B283-69: 550 x 568 x 420 mm

B282-69: 587 x 568 x 460 mm

» With ADF height is 510 mm. With ARDF height is 615 mm.

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

12

Specifications - 3

Weight

B283 - 35 kg

B282 - 40 kg

Warm-up Time

Less than 25 seconds (at 20 C)

First Copy Time

Less than 6.5 seconds

Toner Yield

6,000 copies (A4 LEF, 6% full black)

Copy-Tray Capacity

250 sheets

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

13

Specifications - 4

Optional Equipment

Platen Cover

Auto-document feeder

Auto-reverse document feeder (B282-69 only)

Paper tray unit (1 tray)

Paper tray unit (2 trays)

Tray heater

Optics anti-condensation heater

Copy Paper Weight

60 - 90 g/m

2

(16 - 24 lb)

For more details regarding the machine’s

specifications, see the Field Service Manual and also

the User Guides.

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

14

No additional notes.

B282-69/B283-69

Service Training

3. Installation

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

15

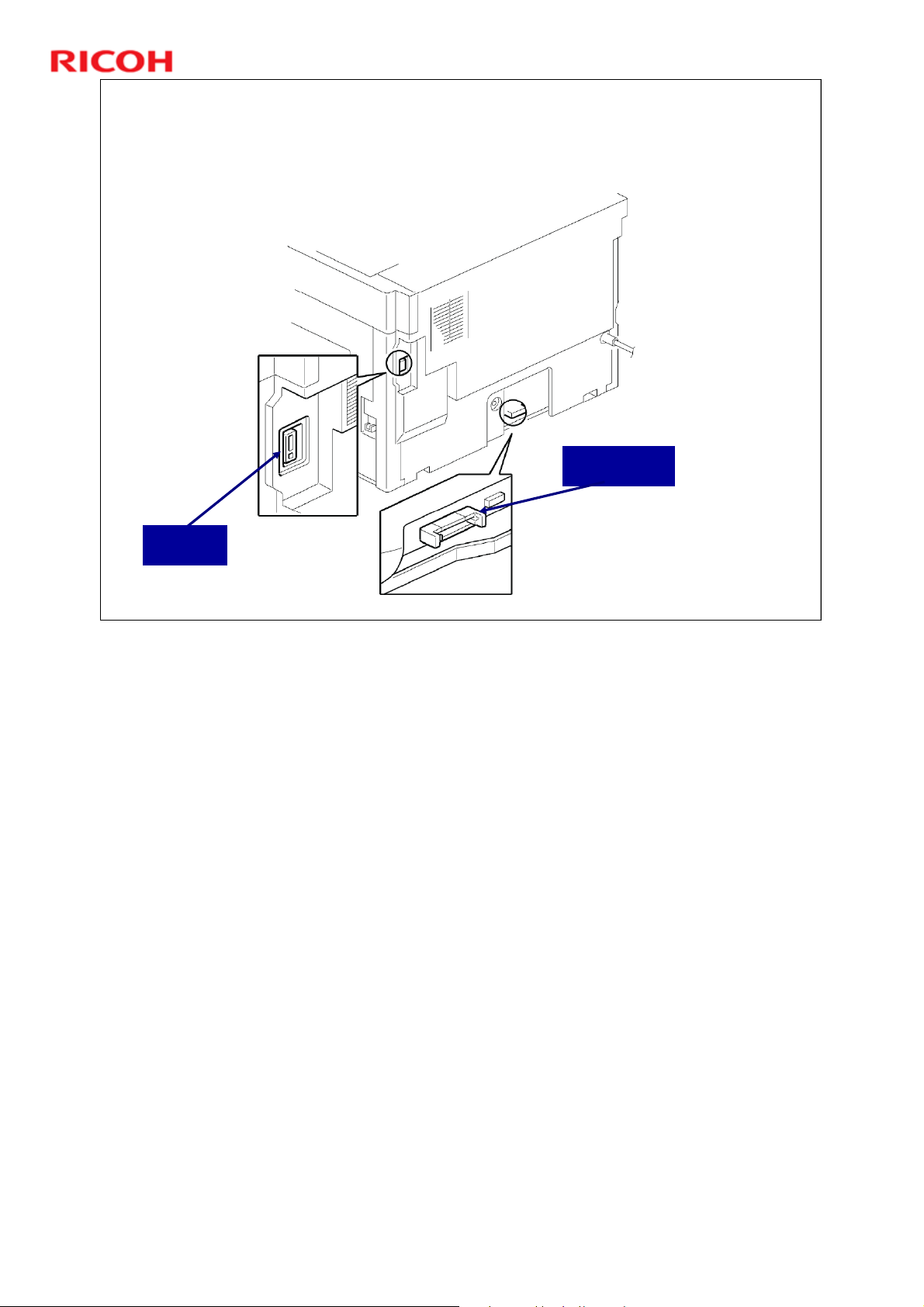

Installation Procedures - 1

In the Field Service Manual, see Copier Installation.

Socket for

Paper Tray Unit

Socket for

ADF/ARDF

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

16

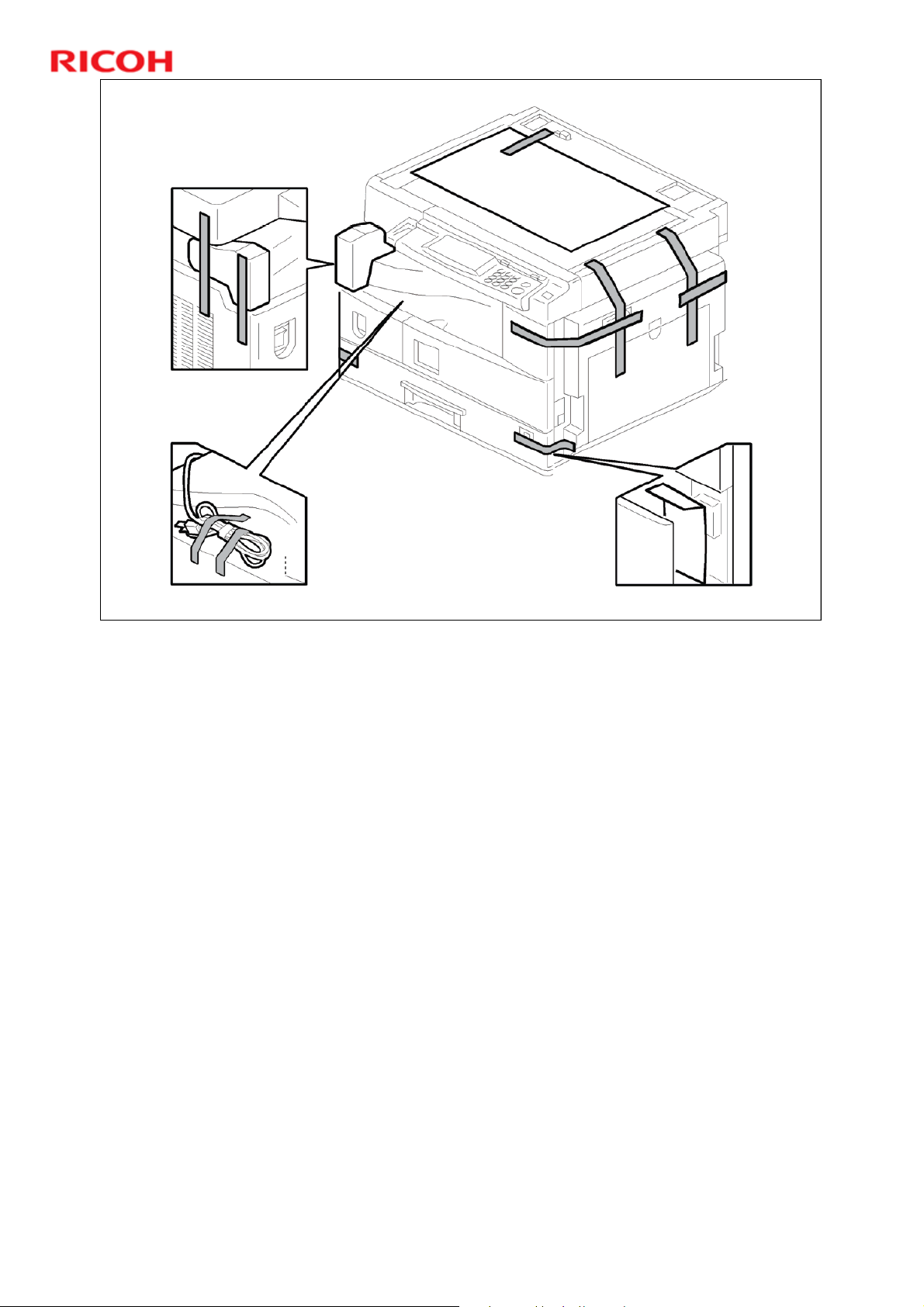

Installation

Procedures - 2

Remove all tape and padding from the machine.

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

17

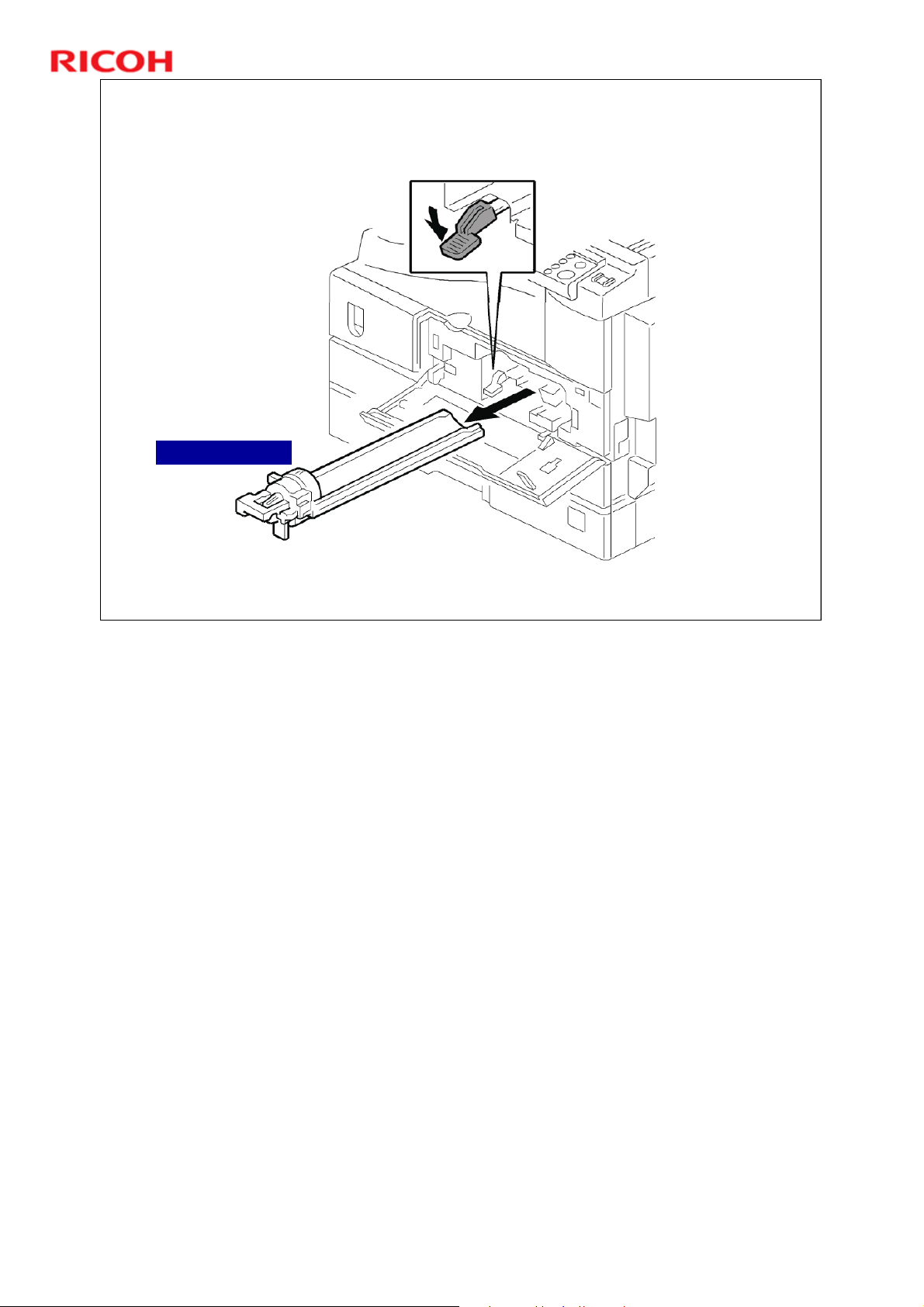

Installation Procedures - 3

Toner Bottle Holder

Open the front door and remove the toner bottle holder.

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

18

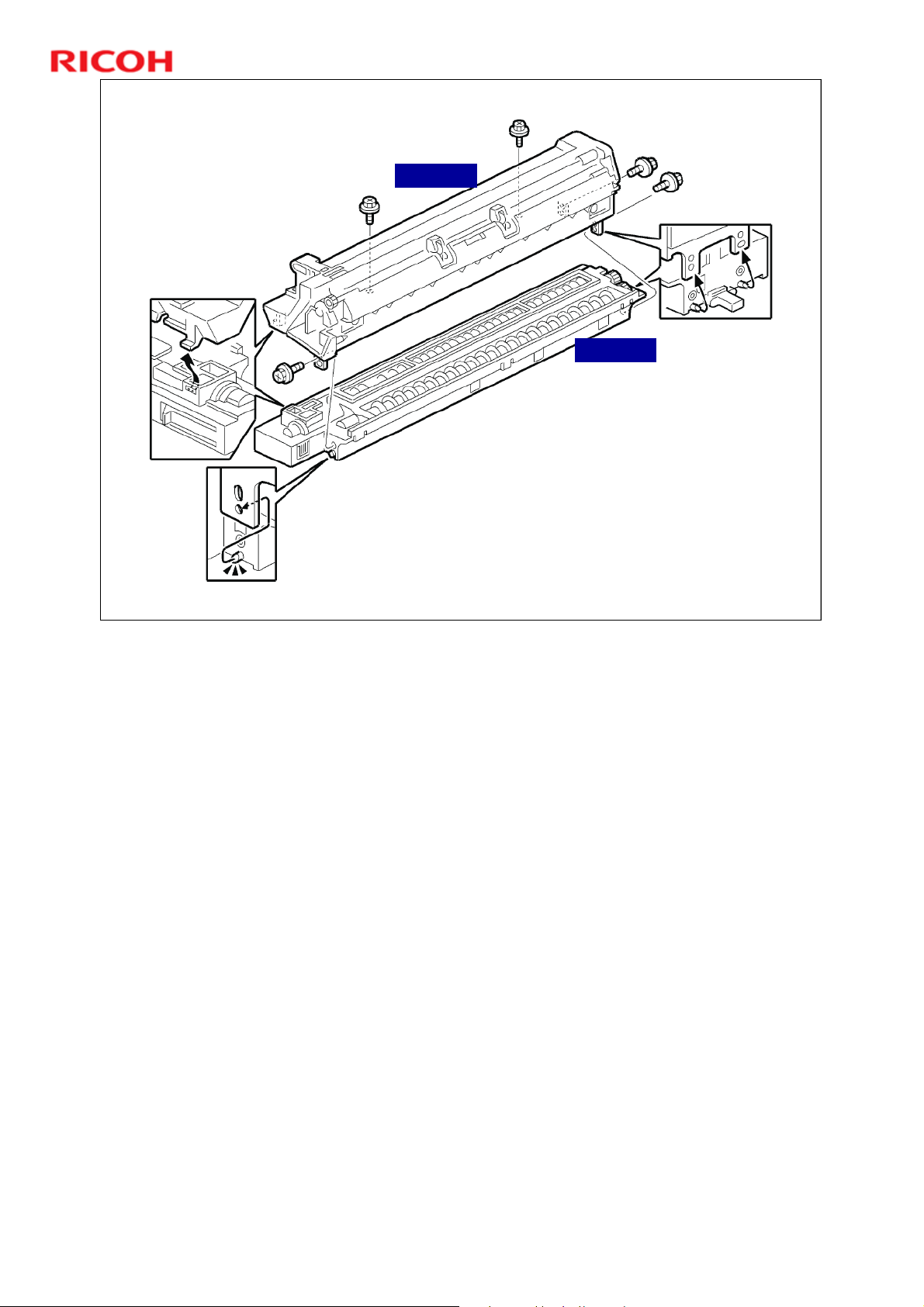

Installation Procedures - 4

Right Door

PCU (Photoconductor Unit)

Open the Right Door and remove the PCU (Photoconductor Unit)

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

19

Installation Procedures - 5

Upper Part

Separate the PCU into the

Upper Part and the Lower Part.

Put a sheet of paper on a level

surface and place the Upper

Part on it.

This is to prevent foreign

material from getting onto

the sleeve rollers.

Lower Part

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

20

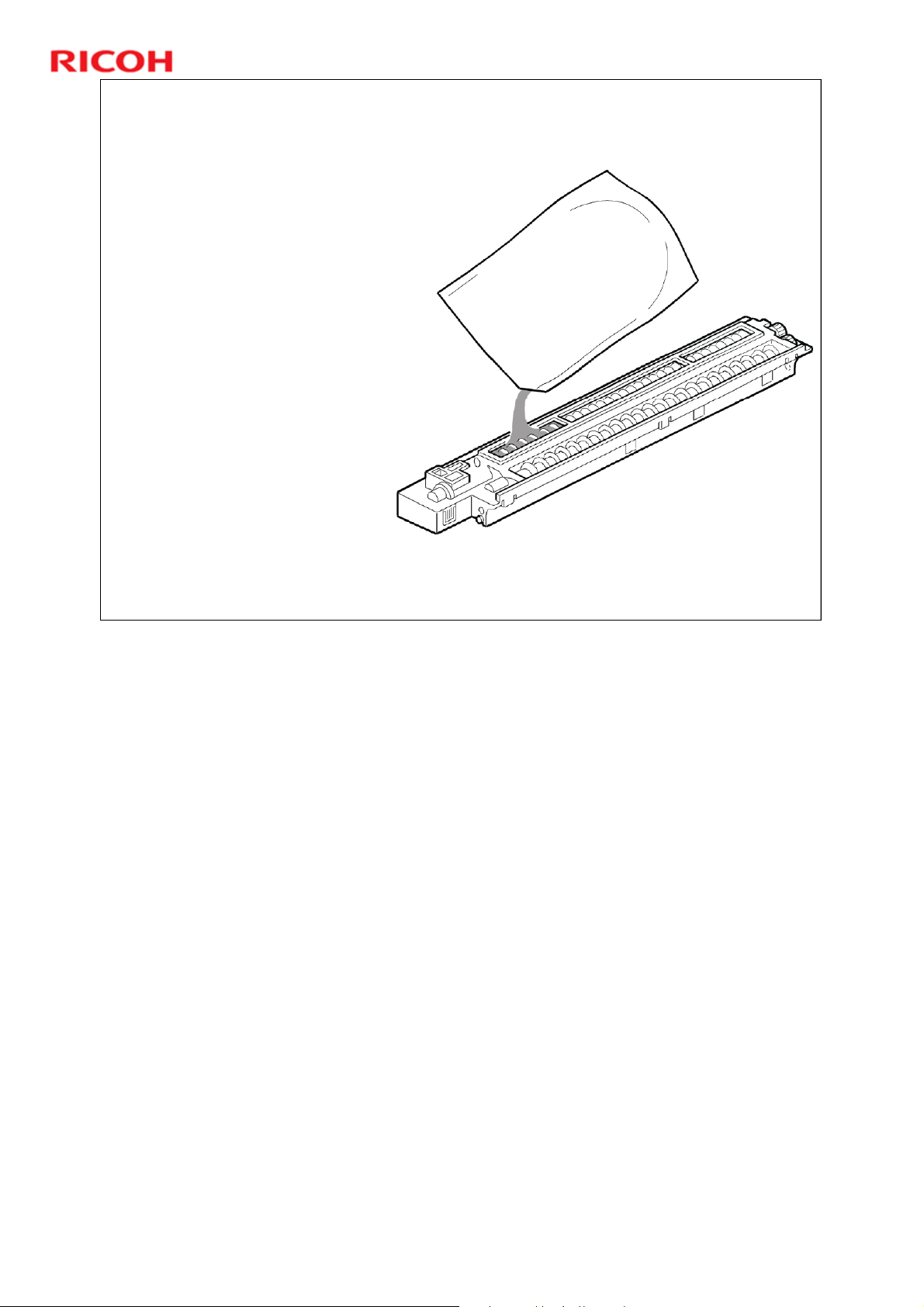

Installation Procedures - 6

Distribute a pack of

developer to all openings

equally.

Make only a small cut in

the top corner of the bag

for better control when

pouring.

Make sure not to spill

developer on the gears.

If you have to turn the gear

to distribute the developer

evenly, make sure to do so

very slowly and as little as

possible. Otherwise the

developer may spill.

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

21

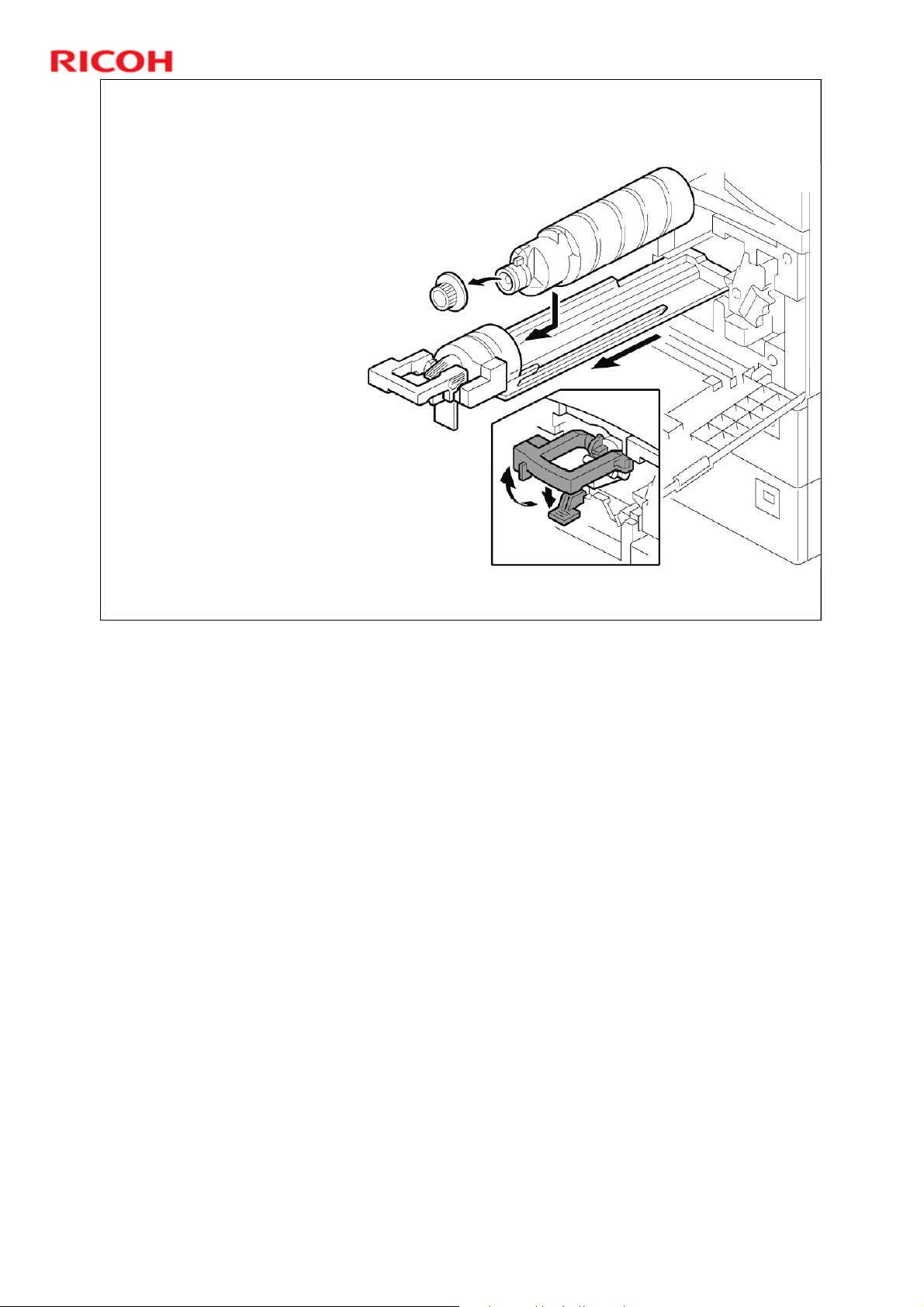

Installation Procedures - 7

Reassemble the PCU

and reinstall it.

Shake the toner bottle

(with the cap still on).

Remove the bottle

cap and install the

bottle on the holder

(do not touch the

inner cap).

Set the holder (with

the toner bottle) in the

machine.

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

22

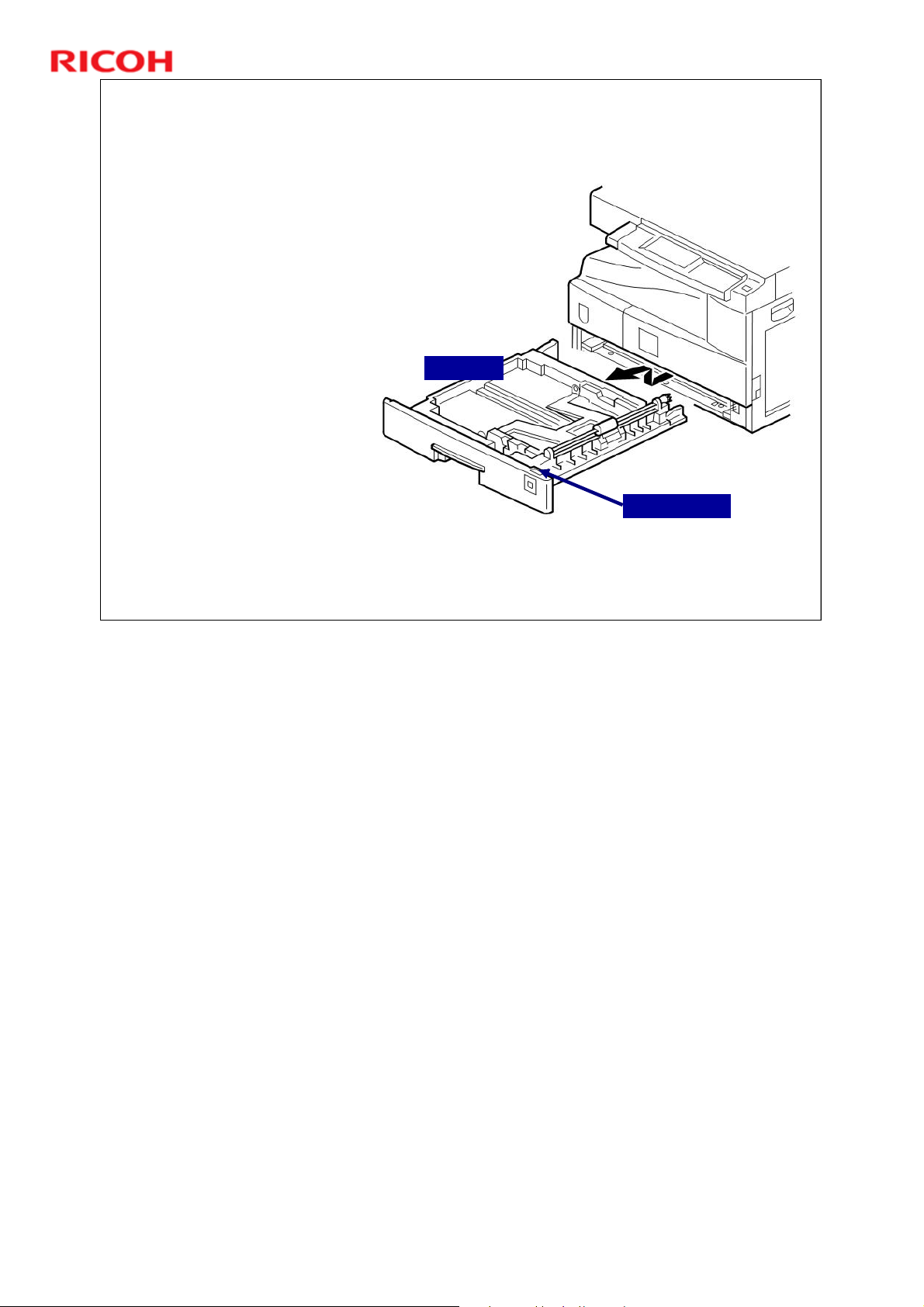

Installation Procedures - 8

Pull out the

paper tray.

Turn the paper

size dial to the

appropriate size.

Adjust the

positions of the

end and side

guides.

Paper tray

Paper size dial

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

23

Installation Procedures - 9

ARDF or ADF Platen cover

Install the optional ARDF, ADF, or platen cover.

Follow the appropriate procedure in the field service manual.

Plug in the main power cord and turn on the main switch.

Activate the SP mode and execute "Developer Initialize" (SP 2214 -1).

It takes about 45 seconds. "Completed" will be displayed when finished.

Load paper and make some copies to check side-to-side and leading

edge registrations.

After completing installation, you may need to change the display language. Do

this with the User Tools. (Refer to "Changing the Language" in the operator's

manual.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

24

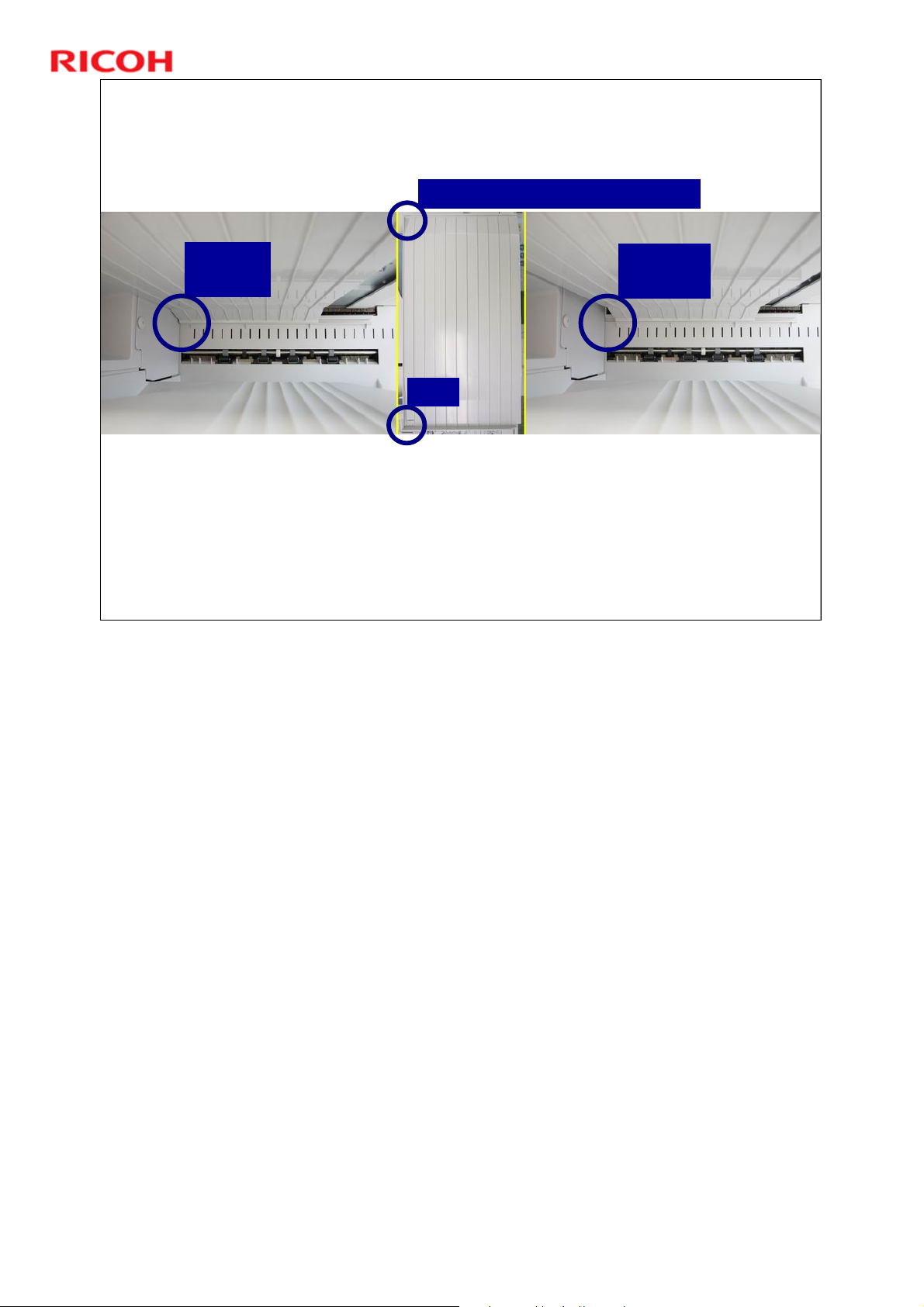

Inverter Tray - 1

(Duplex Model B282-69 only)

Back corner edge

of Inverter Tray

Check that the back corner edge of the Inverter tray is fully against the

back of the slot (see following slides for details).

Note: This is only applicable to when making duplex copies/prints. For single-

sided output, the paper doesn’t come out of the slot just above the Inverter Tray.

For this reason, if the Inverter Tray is out-of-position, single sided

printing/copying will proceed smoothly, with no jamming or errors, while duplex

printing/copying can produce a jam.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

25

Inverter Tray - 2

(Duplex Model B282-69 only)

Back corner edge of Inverter Tray

Correct

Position

Lock

Incorrect

Position

Insure that the back corner edge of the Inverter Tray is fully against

the back of the slot. If the back corner edge is away from the back

(see right photo above), then duplex printing will jam (see next slide),

due to paper hitting the corner edge (see previous slide).

Note: The Lock is easily released by pulling on the tray to remove it from its

slots.

Note: This is only applicable to when making duplex copies/prints. For single-

sided output, the paper doesn’t come out of the slot just above the Inverter Tray.

For this reason, if the Inverter Tray is out-of-position, single sided

printing/copying will proceed smoothly, with no jamming or errors, while duplex

printing/copying can produce a jam.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

26

Inverter Tray

Inverter Tray - 3

(Duplex Model B282-69 only)

Paper jam

Paper jam caused by protruding back corner edge of Inverter Tray

Note: This is only applicable to when making duplex copies/prints. For single-

sided output, the paper doesn’t come out of the slot just above the Inverter Tray.

For this reason, if the Inverter Tray is out-of-position, single sided

printing/copying will proceed smoothly, with no jamming or errors, while duplex

printing/copying can produce a jam.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

27

Options

See the Field Service Manual for installation

procedures for the following optional items:

Platen cover, ADF, or ARDF

» Only one of these may be installed.

Network interface board (NIB)

Two-tray paper tray (B384)

One-tray paper tray (B385)

Tray heaters*

Anti-condensation heater (for optics)*

Paper tray grip handles

» *Service options (available if required)

There are tray heaters for the main frame and the optional paper tray units

The paper tray grip handles are accessibility options. Install them if needed.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

28

Set SP Modes

Input the product serial number and service contact

numbers.

SP 5811: Serial number

SP 5812: Service telephone

No additional notes.

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

29

In previous models of this series all firmware

updates were done by flash memory card.

B282-69/B283-69 memory updating is done by:

Flash memory card for BICU firmware update.

SD card for GDI controller update.

Refer to the FSM for update procedure details.

FSM Æ Service Tables Æ Firmware Update

FSM Æ Service Tables Æ Firmware Update

No additional notes.

Firmware Update

Procedure Æ Engine (BICU) Firmware Update

Procedure

Procedure Æ GDI (Printer Scanner) Update

Procedure

R

/

.

t

d

.

h

i

c

t

t

h

w

/

w

/

:

p

L

o

C

o

w

o

i

r

c

.

m

o

h

.

c

30

Loading...

Loading...