Page 1

B230/B237

B230/B237

Course Reference Material

This presentation is the intellectual property of Ricoh University and may not be duplicate or distributed in any format.

Copyright © 2000-2005 Ricoh US Corporation. All Rights Reserved.

1

Page 2

B230/B230 TRAINING PROGRAM

2

2

Page 3

Introduction:

The B230/B237 is a mid-range network multi-functional color copier.

Based on the GW Architecture.

Provides:

Network Scanning (color originals can be scanned)

Local Storage (with the HDD)

Copying

Printing

3

Page 4

Objectives

The objectives of this training program is to:

• Understand installation, detailed descriptions, and routine

maintenance.

− Understand the PM table.

− Understan d the important SP codes.

• Understand troubleshooting and repair procedures of this

product as you would in the field.

4

ORIENTATION

Provide the trainees with information about the training course procedures,

facilities, objectives and rules.

Introduction of instructors

Introduce yourself to the class, and any other instructors who will be taking part.

Tell them who to talk to if they have any problems.

Introduction of trainees

Distribute a list of those attending the course.

Try to generate a friendly and relaxed atmosphere, and encourage the class to

get to know each other.

If it will help, have the trainees introduce themselves (name, company, work

experience).

Explanation of curriculum

Pass out copies of the training schedule

Impress the importance of getting to the class on time

Go over the course objectives (key points listed on the slide).

Explanation of training center rules

Explain the general rules of your training center (smoking, breaks, use of facilities,

etc.)

Explain the tools and equipment available at the facility.

Impress on the trainees that they should not touch the machines until the

instructor says so, and that they are responsible for replacing tools and keeping

the classroom in order.

4

Page 5

Course Overview

This presentation is the int e llectual property of Ricoh University and may not be duplicate or dist ributed in any format.

Copyright ©2000-2005 Ricoh US Corporation. All Rights Reserved.

The course is broken up into several modules. This section outlines these

modules.

The course covers the copier and the opt ional peripherals. Scanner, printer, fax,

and connectivity are not covered in this course.

5

Page 6

PRODUCT OUTLINE

The model will be introduced to the class.

The optional peripherals will be introduced to the class.

The product concept, sales points, and targets will be presented.

SPECIFICATIONS

The main specifications will be outlined. Significant items will be stressed.

Course Overview

Product Outline

Specifications

Installation

Machine Overview

Scanner

Image Processing

Laser Unit

PCU

Process Contr ol

6

MACHINE OVERVIEW

The components will be discussed.

The paper feed path and copying process will be outlined.

The machine's organization and overall PCB structure will also be covered.

SCANNER

The scanner mechanism will be discussed.

IMAGE PROCESSING

This section explains the image processing done inside this machine.

LASER UNIT

The laser diode circuits and laser optics will be described.

PCU

This section explains the components of the PCU.

All the image-creation processes around the drum, including development, are

covered in this section.

PROCESS CONTROL

This section explains the basic points about how the machine controls the copy

process to compensate for changes in operating conditions.

Toner supply control, and toner near-end/end detection are covered in this section.

6

Page 7

Toner Supply

Waste Toner Collection

Transfer and Separation

Paper Feed

Fusing

Paper Exit

Duplex

TONER SUPPLY

The toner supply mechanism will be described.

Toner supply control, and near-end/end detection are covered in the process

control section.

WASTE TONER COLLECTION

Waste toner collection will be discussed. There is no recycling.

TRANSFER & SEPARATION

Course Overview Continued

7

Image transfer, paper transfer, and paper separation will be described.

PAPER FEED

The paper feed mechanism for the main body will be described. The optional LCT

and tray units will be dealt with in later sections.

FUSING

Fusing will be described.

PAPER EXIT

The paper feed out mechanisms will be described.

DUPLEX

The duplex mechanisms will be described.

The duplex tray is a standard component of this model.

7

Page 8

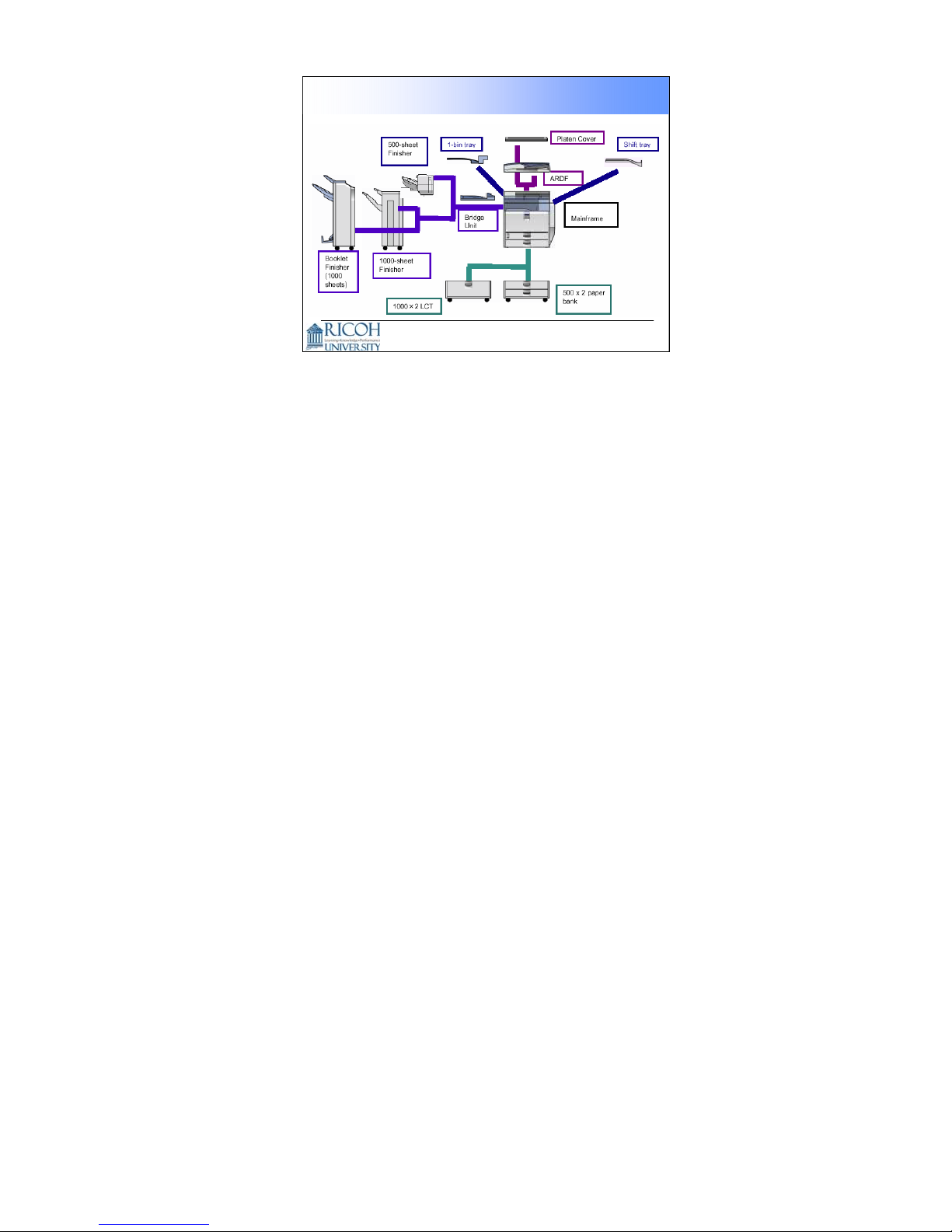

OPTIONS

The options listed above will be described in the indicated order.

The only new one is the booklet finisher, and that contains mechanisms from the

V-C1 booklet finisher.

MAINTENANCE

PM is described briefly.

Course Overview Continued

Options

• ARDF

• Paper Tray Unit

• LCT

• Shift Tray

• One-bin Tray

• Bridge Unit

• 500-sheet finisher

• 1000-sheet finisher

• Booklet finisher

Maintenance

Troubleshooting

8

TROUBLESHOOTING

Basic points concerning service codes, diagnostics, and other troubleshooting

tools will be covered.

8

Page 9

Product Overview

This presentation is the int e llectual property of Ricoh University and may not be duplicate or dist ributed in any format.

Copyright ©2000-2005 Ricoh US Corporation. All Rights Reserved.

The course is broken up into several modules. This section outlines these

modules.

The course covers the B230/B237 and the optional peripherals. Scanner, printer,

and network software are not covered in this course.

9

Page 10

Appearance

Booklet

Finisher

ADF

Two-tray

Paper Tray Unit

10

Here is a view of the machine with three optional peripherals installed.

There are other options, as we will see later.

10

Page 11

B230:

• 25 cpm

B237:

• 30 cpm

Models in this line

11

11

Page 12

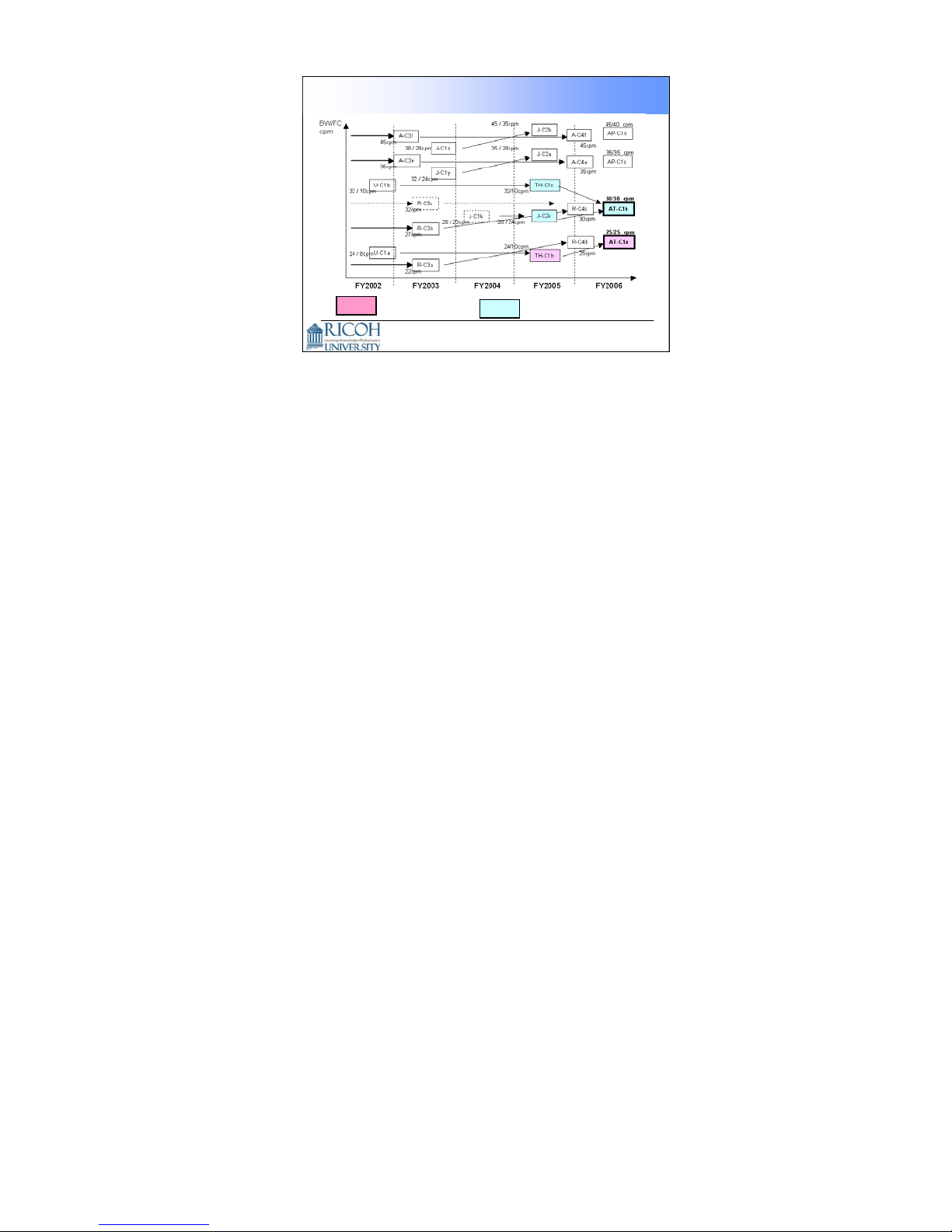

Product Positioning

= B230

AT-C1a

AT-C1b

= B237

12

This chart shows which machines the B230/B237- could be used as alternatives

or as replacements.

The faster machine could be seen as a replacement for the slower models of the

Jupiter-C1/C2 series. The B230/B237 uses a four-PCU tandem color copying

system, like the Jupiter, so it is quite fast.

12

Page 13

SALES POINTS

This presentation is the intellectual property of Ricoh University and may not be duplicate or distributed in any format.

Copyright © 2000-2005 Ricoh US Corporation. All Rights Reserved.

13

Page 14

Main Sales Points

High performance (near black-and-white model performance)

• Short Warm Up time: 45 sec.

• Shorter First Copy Output Time:

− Black-and-white 6.7 sec

− Full color: 9.7 sec

Productivity

• High speed color output

− B230: 25 cpm, B237: 30 cpm

• Booklet Finisher

• Large Paper Capacity: Max. 3,100 sheets

• LCT can be refilled during copying

• High Speed Scanning: 50 pages/minute (monochrome or color, LT

LEF, 600dpi)

• Thick paper (up to 216 g/m

2

) can be fed from the front tray

14

There are also a lot of connectivity features, which we will not explain in this class.

We will limit ourselves to the engine in this course.

14

Page 15

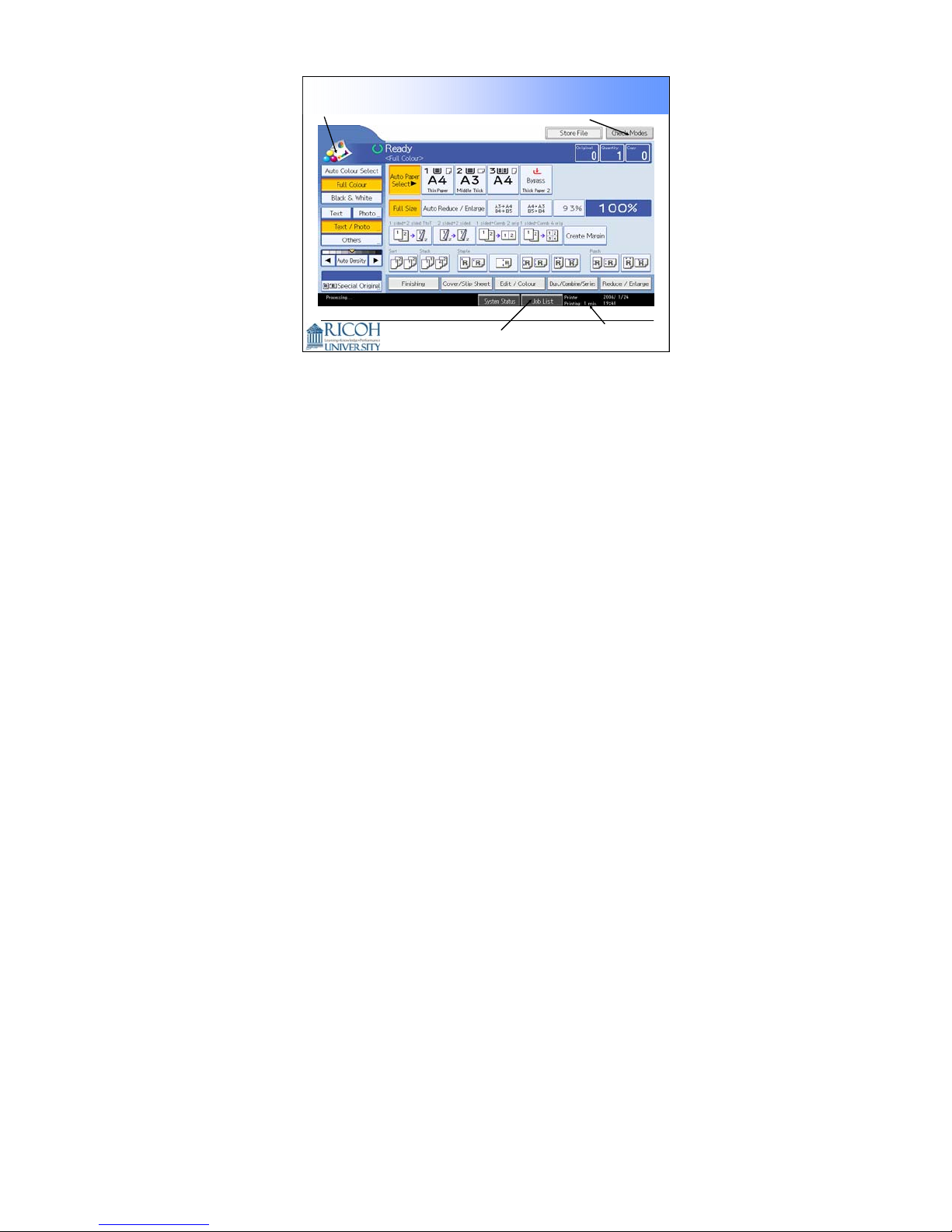

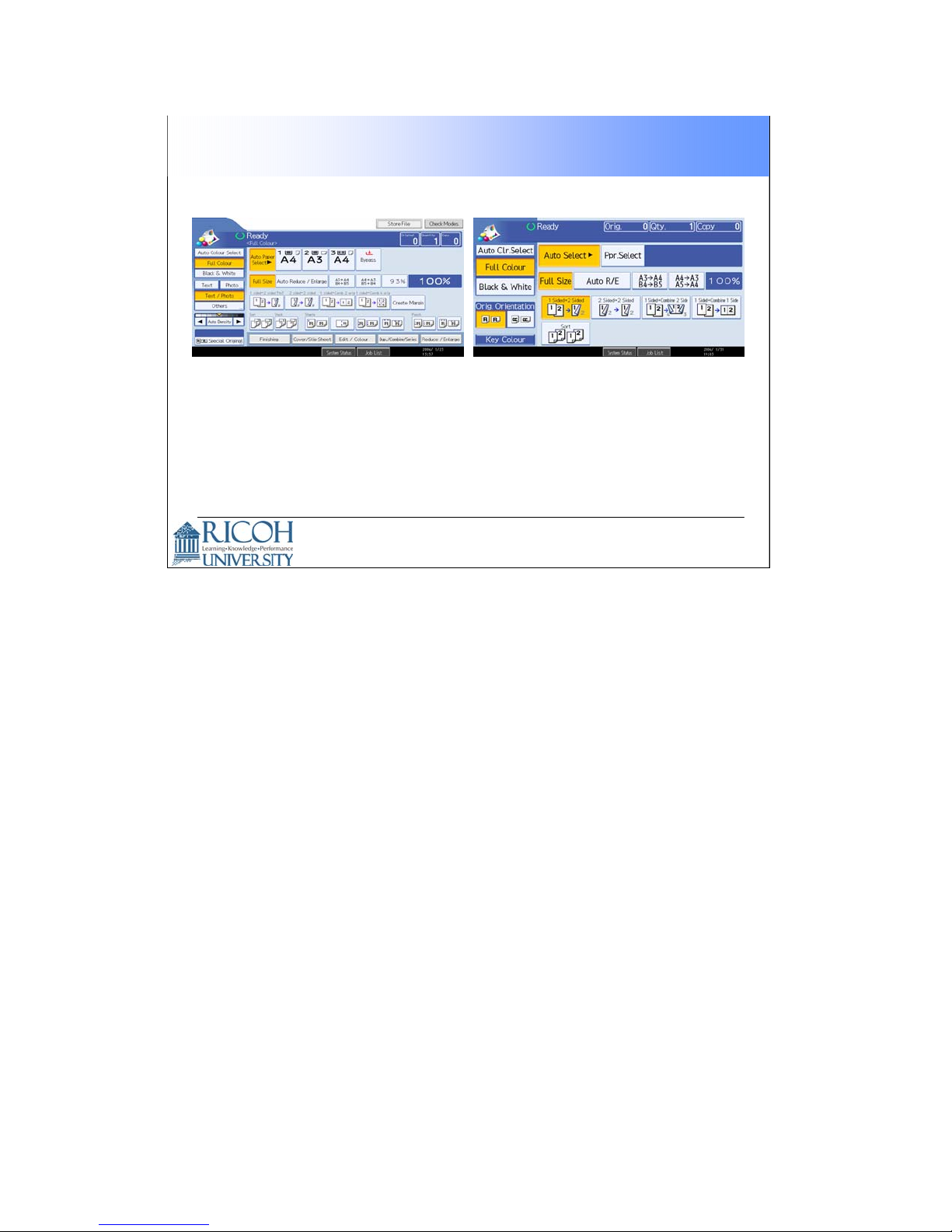

Color Mode

Icon

New Display Panel

Check Modes

Job List Remaining Job Time

15

The color mode icon changes when you select Auto color Select, Full color, or

Black and White. Ask the class to try it on the machine, if you have one set up

already.

Other modes, such as two-color mode, can also be shown as options on

the display by adjusting machine settings.

The Check Modes button is part of the LCD display.

The Job List button is a new feature.

You can also see an estimate of the remaining time for the job, at the bottom of

the screen. (Does not work for fax communication.)

15

Page 16

Animated Guidance Display

16

For some functions, such as removing jams and replacing toner, an animated

guidance appears on the screen.

16

Page 17

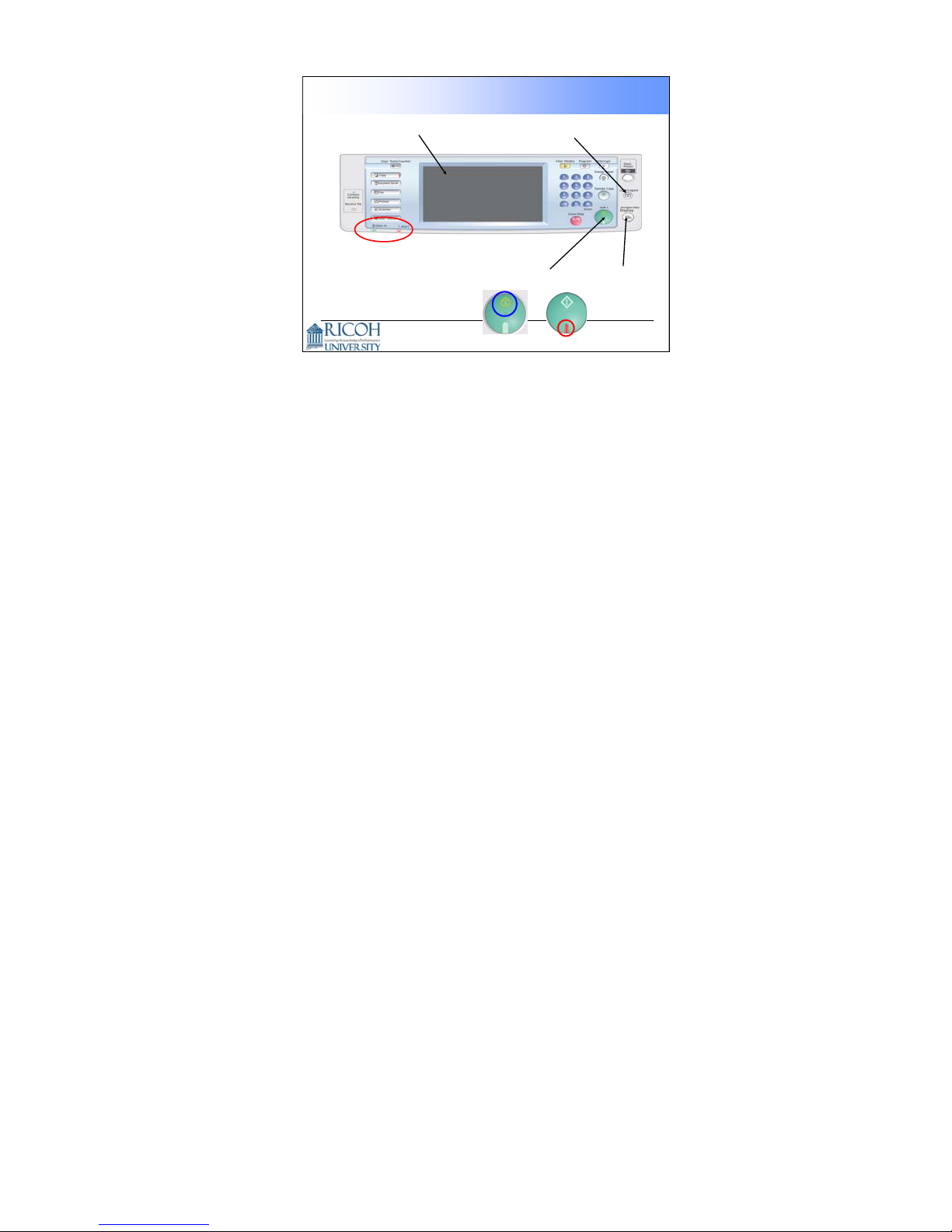

Improved Operation Panel Layout

Larger LCD

Login/Logout,

for Authentication

Status Lamps

Can be seen from a distance

Start Key

Simplifies

the Display

17

The login/logout button makes authentication a bit easier.

The ‘simplified display’ button reduces the amount of information on the LCD

panel. The next slide gives an example.

The red and green lamps on the Start key show clearly when the machine will or

will not start.

17

Page 18

Simplified Display

Normal Display Simplified Display

The simplified display appears when you push the

Simplified Display button.

18

18

Page 19

Easy Jam Removal

Simple paper path

All jams can be removed from the right side of the

machine.

If the finisher is installed, jams can occ ur in the finisher.

•

19

The photo on the left shows that the path through the machine is simple.

19

Page 20

LED indication on the One-bin Tray

One-bin

Tray

Standard

Output Tray

This LED lights when an output arrives on the one-bin tray.

The one-bin tray is an optional device.

•

If the one-bin tray is set up to receive fax messages, then

the LED tells the customer when a fax message has been

printed.

This LED lights

when the one-bin

tray has paper in

it

20

20

Page 21

Paper Tray Handle

The handle allows the paper tray to be pulled easily with an

‘overhand’ or ‘underhand’ grip.

21

21

Page 22

Replacing Toner is Easy

Toner cartridges can be changed with one hand, and with

one easy movement.

22

22

Page 23

ARDF Accessibility

To make the machine

accessible to people in

wheelchairs, the

components operated by a

users must be in the red

area as shown in the

diagram.

USA regulations

•

The ref ore, the lifting angle

of the ARDF must be

limited to within 40

degrees.

See the next slide for the next part of this story.

23

23

Page 24

ARDF Accessibility Continued

To limit the ADRF angle, these hinges will be available as

options or service parts.

24

24

Page 25

Mainframe with No Options

Duplex

Bypass tray

2x500-sheet trays

500-sheet output tray

8.5-inch W-VGA touch

panel

Printer/Scanner

1024MB Memory

40GB HDD

PCL5c/6, RPCS

10/100 BaseTX

USB2.0

This slide shows what you get with the base machine.

Note that the printer/scanner is standard.

25

25

Page 26

Paper Handling Options

26

You can install up the following:

The platen cover or the ARDF

Shift tray or one of the three finishers (a finisher requires the bridge unit)

One-bin tray

The two-tray paper feed unit (also called a ‘paper bank’) or the LCT

Except for the booklet finisher, all the above items are the same as those used

with the B156, but with a different color for the cover.

The booklet finisher is a new item. The booklet mechanism is the same as in the

Euphrates booklet finisher for the B200.

The platen cover is like the one that is used with J-P2+CFE, J-C1 , B202 series.

The platen cover, two-tray feed unit, LCT, and bridge unit will also be used with

the AP-C1.

26

Page 27

Fax Options

Fax Option: New Item

Optional G3 unit: New Item

SAF memory (32MB): Same as B202 series/B156

Handset: Same as B202 series/B156

Fax Stamp Ink: Same as B079/B082, B202 series

27

27

Page 28

Printer/Scanner Options

PostScript3 option: New Item

Required to use the PDF Direct Print Function

•

Wireless LAN (IEEE 802.11b): Same as B202 series, B156

IEEE 1284: Same as B202 series, B156

IEEE 1394: Same as B202 series, B156

Bluetooth: Same as K-C2.5, PG-C1, MT-C3, B-C3, AP-C1

USB Host: New, also used with PG-C1, MT-C3, B-C3

Required to attach IC card or PictBridge

•

Media Link Board: New, also used with PG-C1, MT-C3, B-

C3

Video Link Board : New, also used with MT-C3, B-C3

Required to connect the Fiery controller

•

PictBridge: New

Enables direct printing from a digital camera

•

28

28

Page 29

Security Options

HDD Data Overwrite Security Unit: Also used with

B202 series, B156

Copy Data Security Unit: Also used with

B079/B082, R-C4

29

29

Page 30

Other Options

Java VM Card: New Item, also used with MT-C3,

B-C3

Web Browser Option (SDK): New Item

Optional counter Interface: New Item

• This is a 20-pin interface. It is required when you attach a

key counter.

Key Counter Bracket: Also used with B202 series

30

30

Page 31

Reliability Targets

Unit life (2 prints per job): 1200K or 5 years

Average Copy Volume per month (copy + fax +

print):

• B230: 5K

• B237: 8K

Max Copy Volume per month: 20K (Target Color

Ratio: 30%)

PM cycle: 80K (Target Color Ratio: 30%)

31

31

Page 32

Yield Targets

Toner

• Cartridge Capacity

− Black: 450g /cartridge

− Cyan / Magenta / Yellow: 360g /cartridge

• Target Yield (LT, 5% coverage)

− Black: 20K outputs /cartridge

− Cyan / Magenta / Yellow: 15K outputs /cartridge

Staples

• 5,000 staples per cartridge (all finishers)

32

The toner bottles are not compatible with other products.

The staple refill cartridges are compatible with those used in the U-C1, B156, and

B202 series.

The set staple cartridges are also compatible for the above models, except for the

booklet finisher. The cartridge for that finisher is not compatible.

32

Page 33

Specifications

This presentation is the intellectual property of Ricoh University and may not be duplicate or distributed in any format.

Copyright ©2000-2005 Ricoh US Corporation. All Rights Reserved.

.

33

Page 34

Original scanning:

Development:

Copy/Print Resolution:

Mainframe

Desk Top Configuration:

One-dimensional solid scanning

through CCD

Dry electrostatic transfer system Copy process:

Dry two-component magnetic brush

development system

Belt pressure system Fusing:

Sheet / Book / Object Original Type:

Max: 11”x17”(DLT) / A3 Original Size:

Less than 30mm (Less than 5kg) Thickness of Original:

600dpi / 256gradations Scan Resolution:

Copy: 600dpi /4bit,

Print: 600dpi/4bit, 2bit, 1bit

12”x18” / 297x432mm Max Printable Area:

34

34

Page 35

Mainframe

Paper Weight:

Copy Speed B230

(ARDF 1to1)

B237

(Simplex to duplex)

st

(LT/A4 LEF/from 1

tray)

Standard Tray: 16-57lbs / 60-216 g/m

Bypass Tray: 16-57lbs / 60-216 g/m

Paper Bank: 16-67lbs / 60-253 g/m

Duplex Unit: 17 to 45lbs / 64 to 169 g/m

2

2

2

2

FC: 25cpm / BW: 25cpm (LT/A4 LEF)

OHP/Thick Paper(over105gsm): 16cpm (LT/A4 LEF,

FC/BW)

FC: 30cpm / BW: 30cpm (LT/A4 LEF)

OHP/Thick Paper(over105gsm): 16cpm (LT/A4 LEF,

FC/BW)

FC: 23cpm /BW: 23cpm(LT/A4 LEF) Copying Speed B230

FC: 28cpm /BW:28cpm(LT/A4 LEF) B237

FC:9.7sec. / BW: 6.7sec. 1stCopy Time :

Less than 45sec. Warm-up Time:

35

35

Page 36

Mainframe

US model: 120V 60Hz Power Source:

Max. Power Consumption:

Machine Dimensions:

(Width x Depth x Height)

Counter:

US model: 1,440W

EU/Asia model: 1,500W (Full Configuration)

650 x 654 x 740mm (Standard)

670 x 698 x 1,000mm (with 2-Tray Paper

Bank)

Less than 120kg (with ARDF) Machine Weight:

US model:

Electronic counter & optional mechanical

counter

Other models:

Electronic counter

36

36

Page 37

Thick Paper Productivity

Mode

Thin Paper

Plain Paper

Middle Thick

Paper

Thickness

2

(g/m

)

52-59

-81

-105

BK CPM

25

25

25

FC CPM Model

25B230

25

25

1616-169Thick Paper 1

1616-219Thick Paper 2

16 16 -253Thick Paper 3

303052-59Thin Paper B237

3030-81Plain Paper

3030-105Middle Thick

1616-169Thick Paper 1

1616-219Thick Paper 2

1616-253Thick Paper 3

37

37

Page 38

Resolution

Fonts

Host Interface

Std.

Std.

Std.

Option

Max.

Std.

Option

Std.

Option

Printer

General Specification

RM7035C-600MHz CPU

1024MB (DDR SDRAM-DIMM(PC-2100)) RAM

40GB Hard Disk Drive

RPCS, PCL5c, PCL6 PDL

Adobe PostScript3

600 x 600 dpi / 4bit

(= 2400 dpi equivalent x 600 dpi )

PCL: 46 fonts (Truetype: 10 fonts, Intell: 35

fonts, Bitmapped: 1 font) + International fonts:

13 Intellifonts

PS3 : 136 Roman fonts

Ethernet (RJ-45 network port : 10Base-

T/100Base-TX), USB2.0

USB Host I/F(PictBridge), IEEE1284/ECP,

IEEE1394,

Wireless LAN (IEEE802.11b, WPA support),

Bluetooth

38

38

Page 39

Printer

General Specification

Network Protocol

MIB support

Network/Operating

Systems

TCP/IP (IP v4, IP v6), IPX/SPX, SMB, Apple Talk

(Auto Switching)

Standard MIB (SMNP Printer MIB):

MIB-II(RFC1213), HostResource(RFC1514),

PrinterMib(RFC1759)

Private MIB: Ricoh Original

Windows 95/98SE/NT4.0/2000/Me/XP/Server 2003

Netware 3.12, 3.2, 4.1, 4.11, 5.0, 5.1, 6, 6.5

Unix; Sun Solaris, HP-UX, SCO OpenServer,

RedHat Linux, IBM AIX

Mac OS 8.6-9.2x, OS X 10.1 or later

SAP R/3, NDPS Gateway

IBM iSeries/ AS/400-using OS/400 Host Print

Transform

39

39

Page 40

Scanner

General Specification

Resolution:

Scan Speed:

Network Interface:

Protocol:

Compression

Method:

100 / 200 / 300 / 400 / 600/1200* dpi

Default = 200dpi *only BW TWAIN

BW: 50pages/minute (A4/LET LEF / 200dpi )

FC: 50pages/minute (A4/LET LEF / 200dpi)

Main Scan: 297mm, Sub Scan: 432mm Scan Area:

Option (With Optional File Format Converter) sRGB Support:

Ethernet 10/100BaseTX, IEEE 1394/IP over,

Wireless LAN(802.11b)

Network: TCP/IP

Sending E-mail: SMTP, POP3

Scan to Folder: SMB, FTP, NCP

BW: TIFF (MH, MR, MMR)

Grayscale, Full color: JPEG

40

40

Page 41

Scanner

General Specification

Scan Mode:

Image Density :

Standard:

BW Text, BW OCR, BW Text/Photo, BW Photo,

BW Grayscale, FC Photo, FC Text

Optional:

ACS (With Optional File Format Converter)

Auto Density Selection (Effective only in BW and

Grayscale scan mode)

Manual: 7 levels (Effective in BW/Grayscale and

FC scan mode)

YesImage Rotation:

Yes (Default = SADF)SADF / Batch Mode:

YesMixed Size Mode:

41

41

Page 42

Products Comparison

B230/B237 B156 B202/B178

Configuration Desk Top Desk Top Desk Top

Dimension

(W x D x H)

Weight 120kg 85kg 120kg

Scan Resolution 600x600dpi 600x600dpi 600dpi

Copy/Print Resolution

(dpi)

Max Print Paper Size 12”x18” 12”x18” 12”x18”

Paper Weight 52-253g/m

Paper

Feeding

Capacity

(80g/m

2

)

Std 1100sheets 500sheets 1,100sheets

Max. 3,100sheets 2,600sheets 3,100sheets

650 x 654x 740

mm

Copy:600x600

Print:600x600

(4bit)

2

550 x 682 x

781mm

Copy:600x600

Print:600x600

(2bit)

64-163g/m

17-43 lbs

2

670 x 698 x

859mm

Copy: 600x600

Print:1200x1200

600x600 (2bit)

60-163g/m

16-43 lbs

2

42

42

Page 43

Products Comparison

B230/b B156 B202/B178

Copy Speed

(A4/LT LEF)

1stCopy Speed BW 6.7sec.

Warm-up Time 45sec. 99sec. 99sec.

Multiple Copy 1-999 1 – 100 1 – 999

Duplex Standard Option *2 Standard

HDD Std. 40GB 40GB 80GB

Max. 40GB 40GB 80GB

Memory Std. 1,024MB 768MB 1,024MB

Max. 1,024MB 768MB 1,024MB

Booklet Finisher Yes No Yes

BW: 25/30cpm

FC: 25/30cpm

FC 9.7sec.

BW: 24/32cpm

FC: 10cpm

BW 7.8sec.

FC18.0sec.

BW: 28/35cpm

FC : 24/28cpm

BW 8.0sec.

FC10.0sec.

43

43

Page 44

Installation

This presentation is the intellectual property of Ricoh University and may not be duplicate or distributed in any format.

Copyright ©2000-2005 R icoh US Corporation. All Rights Reserved.

44

Page 45

Verify the following before installing the machine

and all its options:

Environment

Machine Level

Space Requirements

Power Requirements

Requirements:

Environment:

Installation Requirements

45

1. Temperature range: 10 degrees C to 32 degrees C (50 to 89.6F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 1500 lux

4. Ventilation: 3 times/hr/person or more

5. Do not install the machine in areas that are exposed to corrosive gas.

6. Install the machine at locations lower than 8,200 ft. above sea level

7. Install the machine on a strong, level base (no more than 5 mm inclination on

any side

Machine level:

Front to back: within 5mm or .2”

Right to left: within 5mm or .2”

Space Requirements (minimum):

Front: 30”

Back 3.9”

Left 3.9”

Right 20”

45

Page 46

Important Safety Notices

Observe all electrical safety standards

46

Power Requirements:

Input Voltage level: 120V, 60Hz. More than 12 Amps

Permissible voltage fluctuations:

+/-10%

46

Page 47

Optional Unit Combinations

Machine Options

47

47

Page 48

Optional Unit Combinations

Controller Options

48

48

Page 49

Installation Sequence

Be sure to follow the installation flowchart in the service manual.

49

49

Page 50

Accessory Check

Check the contents of all boxes thoroughly

Check the quantity and condition of the

accessory list

50

50

Page 51

Inside the Front Door

51

51

Page 52

Installation Steps

Remove the screw that locks the drum

positioning plate lever

Open the drum positioning plate

52

52

Page 53

Installation Steps

Installing and removing toner bottles

53

53

Page 54

Installation Steps

4 color PCUs/Dev Units

Installing and removing

PCUs/Dev Units

54

54

Page 55

After Installation

Plug in the power cord and turn on the main

switch

Obtain a color original and verify the operation of

the machine and all it’s options and accessories

Enter the User Tools mode and print a

Configuration page. Make sure all installed

options and accessories are listed in the ‘System

Reference” section of the Configuration Page

55

55

Page 56

Machine Overview

This presentation is the intellectual property of Ricoh University and may not be duplicate or distributed in any format.

Copyright © 2000-2005 Ricoh US Corporation. All Rights Reserved.

56

Page 57

1. Scanner HP sensor

2. ADF exposure glass

nd

3. 2

scanner (2ndcarriage)

Component Layout

Refer to Section 6.1.1 SM

57

4. Exposure glass

5. Original width sensor

6. Scanner Lamp

7. 1stscanner (1stcarriage)

8. Original length sensor

9. Lens Block

10.Sensor board unit (SBU)

11.Scanner motor

12.Fusing unit

13.Duplex unit

14.Paper transfer unit

15.Registration roller

16.By-pass feed table

17.Tray 2

18.Tray 1

19.Toner collection bottle

20.Laser optics housing unit

21.PCU (4 colors)

22.Image transfer Belt Cleaning Unit

23.Image Transfer Belt Unit

24.Toner bottles (4 colors)

25.Toner ID sensor

57

Page 58

Machine Details

Laser optics unit

• There are four lasers, and four sets of optics. One for

each color toner (KYCM). Each polygon mirror reflects

light from two LD units.

PCU

• There are four PCU units, one for each color toner. It

includes the drum unit and development unit.

Toner cartridges

• Toner is supplied from the cartridges to the development

units by a toner supply pump.

58

58

Page 59

Machine Details continued

Image transfer unit

• Bias rollers located opposite the OPC drums transfer

toner from the drums to the transfer belt. Four toner

images are super-imposed onto the belt.

Paper transfer roller unit

• The ITB drive roller pushes the toner from the transfer

belt to the paper (the transfer roller is an idle roller).

Fusing unit

• This is a belt-type fusing unit. A heating roller, not in the

paper feed path, heats a belt. Then the belt in turn, heats

the hot roller. This type of unit warms up the rollers faster

than a conventional two-roller system.

59

59

Page 60

1. Original tray

Paper Path

2. Original exit tray

3. Duplex inverter

4. Duplex feed

5. By-pass tray feed

6. Tray 1 feed

7. Tray 2 feed

8. Tray 3: Optional paper feed unit/LCT

9. Tray 4: Optional paper feed unit

10. Finisher stapler (Optional)

11. Finisher punch (Optional)

12. Finisher lower tray (Optional)

13. Finisher proof tray (Optional)

14. Inner Tray

Refer to Section 6.1.2 SM

60

60

Page 61

Drive Layout

Rear View

Refer to Section 6.1.3 SM

61

1. Scanner motor: Drives the scanner unit.

2. Drum drive motor-CMY: Drives the drums for magenta, cyan, and yellow.

3. ITB (Image Transfer Belt) contact motor:

Moves the ITB into contact and away from the color PCUs.

4. Toner transport motor: Drives the toner attraction pumps and the toner collection coils

from the PCUs, from the transfer belt unit, and inside the toner collection bottle. Also

rotates the toner bottles.

5. Development drive motor-CMY:

Drives the color development units (magenta/cyan/yellow).

6. Development clutch-K Turns on/off the drive power to the development unit-K.

7. Paper feed clutch Switches the drive power between the tray 1 and tray 2.

8. Paper feed motor: Drives the paper feed mechanisms (tray 1/tray 2/by-pass tray).

9. Drum/Development drive motor-K:

Drives the black drum and development unit.

10. Registration motor: Drives the registration roller.

11. Paper transfer contact motor Moves the paper transfer roller in contact with the transfer

belt.

12. ITB drive motor: Drives the transfer belt unit.

13. Fusing/paper exit motor: Drives the fusing unit and paper exit section.

61

Page 62

Board Structure

BICU (Base Engine Control Unit):

62

The BICU controls all the mechanical components. The BICU has six CPUs. The

CPUs control the following functions:

• Engine sequence

• Engine operation

• Polygon motor control

• Image processing

Controller:

The controller connects to the BICU through a PCI bus. The controller handles the

following functions:

• Machine-to-host interface

• Operation panel interface

• Network interface

• Interfacing and control of the optional IEEE1284, Bluetooth, IEEE1394,

IEEE802.11b (wireless LAN), USB Host, HDD, and DRAM DIMM

LD Drive Board:

This is the laser diode drive circuit board.

SBU:

The Sensor Board Unit has a CCD (cha rge-coupled device) and an analog-to digital

conversion circuit.

Operation Panel Board:

Controls the display panel, the LED and the keypad.

Scanner I/O Board (SIO):

The scanner I/O board is a circuit board that transmits control signals, image data,

and electricity.

I/O Board (IOB)

Contains drivers for motors and other mechanical components.

Motherboard:

Connects the FCU board to the BICU. This board i s supplied with the optional fax

unit.

FCU:

The FCU (fax controller unit) controls the fax programs and communicates with the

controller to share copier resources.

62

Page 63

Transfer

Belt

OPC

Drum

Printing Process

ITB Drive roller

Laser Optics Housing Unit

Transfer roller

63

1. A latent image is written to each OPC drum by the laser unit. There are 4 separate laser

beams, one for each color drum.

2. Each drum is charged with a negative charge using a charge roller.

3. When the laser beam hits the drum, it neutralizes the charge in the area where the beam

strikes the drum, creating a latent image.

4. Negatively charged toner (one color for each drum) is attracted to the discharged areas of

the drum (latent image) and develops a toner image on each drum.

5. The developed toner image (on each drum) is then transferred to the Image Transfer Belt

(ITB) to create a full color image on the surface of the ITB.

6. The full color image is again transferred from the surface of the ITB to a passing sheet of

paper. The image on the sheet of paper is then sent to the fusing unit to fuse the image

permanently to the paper.

63

Page 64

SCANNER

This presentation is the intellectual property of Ricoh University and may not be duplicate or distributed in any format.

Copyright ©2000-2005 Ricoh US Corporation. All Rights Reserved.

In this section, the mechanical components of the scanner will be described.

The optional ADF is described in a separate section.

64

Page 65

Optical Path

ADF Exposure

Glass

One exposure lamp

600 dpi color CCD

Anti-condensation heater is optional

No adjustments required in the field for the CCD and lens

block

Main Exposure

Glass

Exposure

Lamp

CCD

65

Outline the optical path.

In platen mode, the original is fed to the main exposure glass, and the scanner moves

down the original during scanning.

In ADF mode, the scanner stays at the home position, and the original is fed past the

ADF exposure glass.

The optics anti-condensation heater is an option. It prevents condensation on the

mirrors, which will cause image problems.

65

Page 66

Scanner Drive

Scanner Motor

Motor and wire drive mechanism

The same motor drives the first and second scanners.

The first scanner contains the exposure lamp, reflectors, the 1st mirror, and the

lamp regulator. The second scanner contains the 2nd and 3rd mirrors.

The regulator is mounted on the scanner to reduce the wiring between the lamp

and the regulator.

66

The second scanner moves at half the speed of the first scanner. This is to

maintain the focal distance between lens and original.

In this machine, wires are used instead of timing belts. These are more difficult to

replace, but copy quality is better (less jitter).

Note that the operation in ADF mode is different from platen mode (as shown on the

previous page).

The service manual explains how the motor speed and image processing control the

magnification.

66

Page 67

APS sensors.

There are two width sensors and three length sensors. The service manual

shows where these sensors are located.

The CPU checks the sensors when the platen cover sensor detects that the

cover is being closed.

Original Size Detection

Platen Cover

Sensor

Reflective photosensors detect the size.

67

If the cover stays open during copying, the CPU checks the sensors when the

Start key is pressed.

Make sure that you are familiar with the table of sensor output vs original size.

Make sure that you understand what happens when all sensors are off (such as when

A5 sideways is set - too small for the sensors to detect).

Use SP 4-303 this to select the machine’s behaviour if the sensors cannot

detect the size.

Use SP 5126 to control the size that is detected for the ‘F’ sizes, which are very similar

(8½ x" 13", 8¼" x 13", 8" x 13").

67

Page 68

Image Processing

This presentation is the intellectual property of Ricoh University and may not be duplicate or distributed in any format.

Copyright © 2000-2005 Ricoh US Corporation. All Rights Reserved.

68

Page 69

How the Image is Processed

The CCD (Charged Coupled Device) generates

three analog video signals.

The SBU (Sensor Board Unit) converts the

three analog signals to 10-bit digital signals. It

then sends these signals to the IPU (Image

Processing Unit).

The IPU processes the image. Then the image

data (4 bits/pixel) is sent to the controller.

69

69

Page 70

Overview

Operation Panel

LCD

8.5inch

SBU

CCD

Xenon

Lamp

INV

SIO

APS

AKS

CPU

RM7035

DDR

Securit y Unit

LVDS

CPU Path

SDR AM

Controller

ASIC

FM

Taurus

ASIC

Orion

CPU

eSOC

CPU

FLOC

ASIC

GASBU

AFE

Copy Dat a

BiCU

Scanner

STM

IOB

STM

STM

Driver

Opt iona

l Units

ARDF

HP Sens or

SOL&CL

Driver

Driver

Finisher

BANK/LCT

Shift Tray

Bridge Unit

ASIC

Trumpet

LOCAL P CI

ASIC

Shaker

RAPI6 4

ASIC

ASIC

Lupus

Strix

ASIC

GAVD

Type-W

FROM

SRAM

4MByte

512kByte

ASIC

ASIC

TRIO2

TRIO2

MT

CL&

Sensor

H.V. P. P

SOL

HDD

RiO3

Option

M ax.:3 Slot s

RAPI6 4

+5V, + 5VE, +12V, +24V

・to BiCU

AC Drive

Heater

FU sing

TH&Th.Pile

M o th e r B o ard

LDB

ASIC

PMAC- A

MT

PSU

・to IOB

・to SIO

G3

CCUIF

FCUIF

FCU

Expansion

S ynchronizing

Detection

MLB

Image

Data

CPU

Path

PCI

Path

70

70

Page 71

Signal processing

A/D conversion

White level correction

Black level correction

Others

More about the SBU

You need to adjust the following after you replace the SBU:

SP 4008. Scanner sub-scan magnification

How the SBU Processes the Signal

Signal Amplification

•

• Signal Composition

•

The SBU controller exchanges the R and B signals if the original

is scanned with the ARDF.

• The properties of the scanner unit, (necessary for controlling the

scanner VPU (video processing unit)), are stored in the NVRAM

on the controller.

• SBU test mode

71

SP 4010. Scanner leading edge registration

SP 4011. Scanner side-to-side registration

Output the VPU test pattern with SP 4907 to make sure the scanner VPU control

functions correctly. Look in the troubleshooting section if you need more details.

71

Page 72

What happens in the IPU?

Shading correction

Picture element (Dot Position) correction

Scan line correction

Image separation

Auto color select

Scanner gamma correction

Filtering

Auto Image Density Selection

Color conversion

Main scan magnification

Printer gamma correction

IPU test mode

72

72

Page 73

Printer Gamma Correction

K

The gamma curves for C, M, Y, and K are not equal.

If this causes copy quality problems, the user can do the ACC

procedure.

73

A gamma curve describes the relation between the image density of the original

and that of the copy. The relationship is not linear: doubling the ID of an original

does not double the ID of the copy.

The printer characteristics are much more variable than the scanner. Therefore,

the printer gamma needs recalibration and adjustment from time to time. This is

done using the ACC procedure.

Each color has separate gamma curves for photo mode and letter mode, and for

copier mode and printer mode.

The gamma curves for C, M, Y, and Bk toner should be identical, but they are not.

ACC (Auto color Calibration) can be used to correct for this if copy quality is

drifting too far. This is done by the customer.

If this does not work, you can do the printer gamma adjustment.

73

Page 74

Printer Gamma Correction

After ACC, you can adjust the gamma curve for

each color with SP 4909 to SP 4918. The

following four modes are available

•

ID Max, Shadow (high ID), Middle (middle ID),

Highlight (low ID).

74

A gamma curve describes the relation between the image density of the original

and that of the copy. The relationship is not linear: doubling the ID of an original

does not double the ID of the copy.

The printer characteristics are much more variable than the scanner. Therefore,

the printer gamma needs recalibration and adjustment from time to time. This is

done using the ACC procedure.

Each color has separate gamma curves for photo mode and letter mode, and for

copier mode and printer mode.

The gamma curves for C, M, Y, and Bk toner should be identical, but they are not.

ACC (Auto color Calibration) can be used to correct for this if copy quality is

drifting too far. This is done by the customer.

If this does not work, you can do the printer gamma adjustment.

74

Page 75

LASER EXPOSURE

This presentation is the intellectual property of Ricoh University and may not be duplicate or distributed in any format.

Copyright © 2000-2005 Ricoh US Corporation. All Rights Reserved.

75

Page 76

Overview

Polygon

There is one laser b eam for each color.

Maximum resolution is 600 dpi

•

Two polygon mirrors are attached to t h e same motor.

•

The upper mirror reflects

yellow and black.

yellow

• The lower mirror reflects magenta and cyan.

Mirrors

76

The optical components should be familiar to those who have worked on recent

models.

This diagram does not show the LD units . A more complete diagram of the optics is on

the next slide.

76

Page 77

LD Units:

Y, C, K, M

Synch:

Y/C (End)

Optic Components

Synch:

K/M (Start)

Synch:

Y/C

(Start)

Four LD units, one for each color.

Four laser synchronization detector boards:

Two for each color (one at the front, one at the rear)

•

• Each board is used by 2 colors

Synch:

K/M (End)

77

The LD units (shown in the red circle) are Y, C, K, M from left to right in the diagram.

The lasers go immediately to the polygon mirrors.

Laser exposure for black and magenta starts from the rear side of the drum. But

for yellow and cyan it starts from the front side of the drum. This is because the

LD units for black and magenta are on the other side of the polygon mirror from

the units for yellow and cyan.

The four laser synch detector boards (shown in blue circles) will be explained in more

detail on the next slide.

77

Page 78

Laser Synchronization Detectors

Synch:

Y/C (End)

Synch:

Y/C

(Start)

Scanning start and end detection for each color.

Each board handles two colors.

•

To determine which color beam hits the board, the machine checks the

timing.

Synch:

K/M (Start)

Synch:

K/M (End)

78

For magenta and black, the LSD at the rear detects the start of the main scan.

For yellow and cyan, the LSD at the front detects the start of the main scan.

With a detector at the start and at the end, it is possible to make sure that the number

of pulses for each color is the same. This reduces color registration errors in the main

scan direction.

To do this, the machine measures the number of clock pulses between start and end

detection.

If the number is not correct, the LD clock frequency is adjusted automatically.

If the board at the end position is defective, you must disable the detection

feature with SP2-186-1.

78

Page 79

LD Safety Switches

IN T E R L O C K S W

Front D oor SW

and

Right Door SW

CN921-2

CN921-1

CN921-4

CN921-3

+5V

+24V

24VS2

IO B

Polygon

Moter

RELAY

24VS1

PSU

CN920

-10

CN920

-1

CN920

-5

SCRDY_N

+24V

GND

PMON

PMCLK

+5VS

+24V

GND

+5V

CN530-10

CN530-1

CN530-5

CN520-1

REG

REG

1.8V

3.3V

1.8V_PLL

BiCU

GAVD

Type-W

CN521-14

CN521-7

CN522-7

CN522-14

LD5V

GND

VIDEO DATA

APCEN_N

LDOFF

LDLVL

LDERR_N

LD5V

GND

VIDEO DATA

APCEN_N

LDOFF

LDLVL

LDERR_N

LD5V

GND

VIDEO DATA

APCEN_N

LDOFF

LDLVL

LDERR_N

LD5V

GND

VIDEO DATA

APCEN_N

LDOFF

LDLVL

LDERR_N

CN 2 -1 (K)

CN 2 -1 (M )

CN 2 -1 (C )

CN 2 -1 (Y)

+5V

P-MACA

+5V

P-MACA

+5V

P-MACA

+5V

P-MACA

LDB(K)

LDB(M)

LDB(Y)

LDB(D)

Make sure you understands how the cover switches cut the laser power.

L

P

D

D

L

P

D

D

L

P

D

D

L

P

D

D

79

The switches used are the front and right front door.

Have the class follow the circuit on the diagram.

79

Page 80

Automatic Line Position Adjustment

CenterFront Rear

C

K

KK

Y

YY

M

MM

KC

CC

KY

KM

CC

KK

YY

MM

KC

KY

KM

KK

YY

MM

KC

CC

KY

KM

C

K

Y

M

During automatic line position adjustment, the line patterns above

are created eight times on the transfer belt.

80

The spaces between the lines (YY, KK, CC, MM, KY, KC, KM) are measured by the

front, center, and rear ID sensors. The controller takes the average of the spaces.

Then it adjusts the following positions and magnification.

Sub scan line position for YCM

Main scan line position for KYCM

Magnification ratio for KYCM

Skew for YCM

The transfer belt-cleaning unit cleans the transfer belt after the patterns are

measured. SC 285 shows if an error is detected three times consecutively.

This will be covered in greater detail in the Troubleshooting training module.

What does K11, K12 etc mean on the diagram?

Don’t worry about this because you won’t see it again, but here are some examples

if you are interested.

K11: The distance between the straight line and the slanted line for K, in the

first pattern, at the front of the belt.

Y12: The distance between the straight line and the slanted line for Y, in the

first pattern, at the rear of the belt.

KY11: The distance between the straight line for K and the straight line for Y,

in the first pattern, at the front of the belt.

KC12: The distance between the straight line for K and the straight line for C,

in the first pattern, at the rear of the belt.

The last two numbers of each code are:

The first number refers to the pattern number (1 to 8)

The second number stands either for the front of the belt (1) or the rear (2)

80

Page 81

More about the Adjustments

Sub scan line position for YCM

•

The adjustment of the sub-scan line position for YCM is based on

the line position for K (color registration).

− The machine measures the gaps between the lines of each color in the pattern

on the transfer belt.

− If the gaps for a color are not correct, the machine moves the image of the

color up or down the sub scan axis.

− To do this, it changes the laser write timing for that color.

Main scan line position for KYCM

•

If the machine detects that the image is out of position in the main

scan direction, it changes the laser write start timing for each scan

line.

Magnification adjustment for KYCM

• If the machine detects that magnification adjustment is necessary, it

changes the LD clock frequency for the required color.

Skew for YCM

• The adjustment of the skew for YCM is based on the line positionfor K.

81

81

Page 82

Adjustment Conditions

Line position adjustment timing depends on

several SP mode settings.

• The setting of SP2-193 determines the timing.

• MUSIC counter: SP3-510-005 and –006.

82

82

Page 83

Main Scan Skew Correction

Y

The WTLs for C, M, and Y each have a motor.

The angle of each WTL can be adjusted by these motors.

The angle of the WTL for black is not changed.

CM

WTL

WTL

Positioning

Motor

83

The WTL positioning motors for magenta, cyan, and yellow adjust the angle of the

WTLs for these three colors, based on the WTL position for black.

83

Page 84

Shutter

Shutter

ClosedShutter

Open

The shutter stops dust and toner from entering the laser optics unit.

The shutter opens when the polygon motor starts, and closes after

the polygon motor stops.

The motor moves the shutter through a cam.

Two sensors detect when the shutter is open and closed.

Cam

Shutter

Motor

84

This mechanism makes sure that the shutter is only open when the laser is writing. At

all other times, the shutter is closed, to stop dust and toner getting in.

84

Page 85

Service Remarks

SWITCH THE POWER OFF AND UNPLUG THE

POWER CORD BEFORE STARTING WORK ON

THE LASER UNIT

Do not loosen the LD board securing screws.

Do not adjust any of the VRs.

Do not open the optical housing unit except

servicing.

Do not touch the faces of the polygon mirrors.

To avoid damage to the polygon motor, switch the

machine off and wait 3 minutes to allow the motor

to stop rotating before removing it.

85

85

Page 86

PCU

This presentation is the intellectual property of Ricoh University and may not be duplicate or distributed in any format.

Copyright © 2000-2005 Ricoh US Corporation. All Rights Reserved.

86

Page 87

Overview

Drum

Image Transfer

Roller

Cleaning

Blade

Cleaning

Brush

Development

Roller

Lubricant

Application

Blade

Charge Roller

One PCU for each color (Magenta, Cyan, Yellow and Black).

Each PCU has the same components, but they are not interchangeable

•

(you cannot use a PCU for yellow in the cyan position, for example).

Four colors are developed at the same time.

87

This shows the most important components of the PCU.

The image transfer roller pulls the toner off the PCU and onto the transfer belt.

87

Page 88

Drum Drive - K

Drum Gear Position

Sensor - K

Drum/Development

Drive Motor - K

The Drum Drive motor K also drives the development unit for K.

The drum gear position sensor detects when the motor is not

working.

It also ensures that the drum gear is at the correct position when printing

•

starts.

• This prevents variations in print quality.

88

88

Page 89

Drum Drive - CMY

Drum Drive

Motor - CMY

Drum Gear Position

Sensor - CMY

This motor drives three PCUs.

It does not drive the development units.

•

The drum gear position sensor detects when the motor is not

working.

•

It also makes sure that the drum gear is at the correct angle when printing

starts.

89

The function of the gear position sensor is similar to the sensor for black.

The motor drives all three color drums. This reduces color alignment errors.

The two gear position sensors (K, CMY) work together. Both gears must be at home

position at the start of the job. If there is an error, the position of the black gear is

corrected to match the position of the CMY gear.

The mechanism is initialized after every 30 jobs.

89

Page 90

Charge Roller

Drum

Charge

Roller

Charge Roller

Cleaning Roller

The roller does not contact t h e drum (Non-contact type).

There is a very small gap between roller and drum.

The cleaning roller is always in contacts the charge roller.

90

90

Page 91

Charge Roller Voltage

The charge roller charges the drum surface a negative charge.

An ac voltage is also applied to the charge roller, at a constant

current.

• The ac voltage helps to ensure that the charge given to the drum is as

uniform as possible.

The high voltage supply board - C.B, at the rear of the machine,

supplies the ac and dc to the charge roller.

The machine automatically controls the charge roller voltage if

automatic process control is enabled (this occurs if SP3-041-1 is

set to "CONTROL").

However, if process control is switched off, (SP3-041-1 set to

"FIXED"), the dc voltage is the value stored in SP2-001-1 to -12

(do not adjust in the field unless advised to do so).

91

91

Page 92

Quenching

The laser exposes all areas of the drum at the end

of each job.

This removes any charges remaining on the

drum.

92

92

Page 93

Drum Cleaning

Lubricant

Application

Cleaning

Blade

Blade

Cleaning

Roller

The cleaning blade removes any remaining toner from the drum.

This toner falls onto a collection coil, and is discarded.

•

The cleaning roller applies lubricant to the drum.

The lubricant application blade makes sure that the lubricant is

applied evenly.

The toner collection mechanism from the PCU is on the next slide.

93

93

Page 94

Waste Toner Transport from PCU

Gears

Auger

To the Waste Toner

Collection Bottle

The gears at the end of the drum drives the to ner collection

auger.

94

The waste toner collection bottle and collection mechanism is described in a later

section.

94

Page 95

Development

Mixing

Augers

Development

Roller

Filter

TD Sensor

Dual component developer

TD sensor in each

development unit

•

The TD sensor has a chip that

contains information about the

development unit.

95

The filter makes sure that pressure does not build up inside the development unit.

95

Page 96

Development Drive - K

Development

Clutch

Drum/Development

Drive Motor - K

The drum/development drive motor drives the K development

unit.

•

This motor also drives the K drum, so a clutch is necessary.

96

96

Page 97

Development Drive - CMY

Development

Drive Motor - CMY

This motor drives the C, M, and Y development units.

97

97

Page 98

Developer Agitation

Mixing

Augers

Two augers circulate the toner in the development unit.

Development

Roller

98

This diagram shows how the augers move the toner around inside the development

unit.

98

Page 99

New Unit Detection

The TD sensor has an ID chip. This chip tells the

machine if the PCU is new or not.

When the machine detects a new PCU, the

machine automatically does the following:

• PM counter clear for items related to the PCU

• Developer initialization

• Charge roller voltage control

• Process control

• Line position adjustment

If the PM counter is not reset automatically, you

must reset these SPs:

• 3-902-1 to -12

99

99

Page 100

Process Control

This presentation is the intellectual property of Ricoh University and may not be duplicate or distributed in any format.

Copyright ©2000-2005 Ricoh US Corporation. All Rights Reserved.

100

Loading...

Loading...