Page 1

B173

SERVICE DOCUMENTATION

001954MIU

RICOH GROUP COMPANIES

Page 2

Page 3

B173

SERVICE DOCUMENTATION

RICOH GROUP COMPANIES

®

®

Page 4

Page 5

B173

SERVICE

DOCUMENTATION

001954MIU

Page 6

Page 7

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

A

ll product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use o

f

any trade name, or web site is intended to convey endorsement or othe

r

affiliation with Ricoh products.

2004 RICOH Corporation. All rights reserved.

Page 8

Page 9

The Service Manual contains information

regarding service techniques, procedures,

p

rocesses and spare parts of office equipmen

t

distributed by Ricoh Corporation. Users of this

manual should be either service trained o

r

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizin

g

information contained in this service manual to

repair or modify Ricoh equipment risk persona

l

injury, damage to property or loss of warrant

y

p

rotection.

Ricoh Corporation

WARNING

Page 10

Page 11

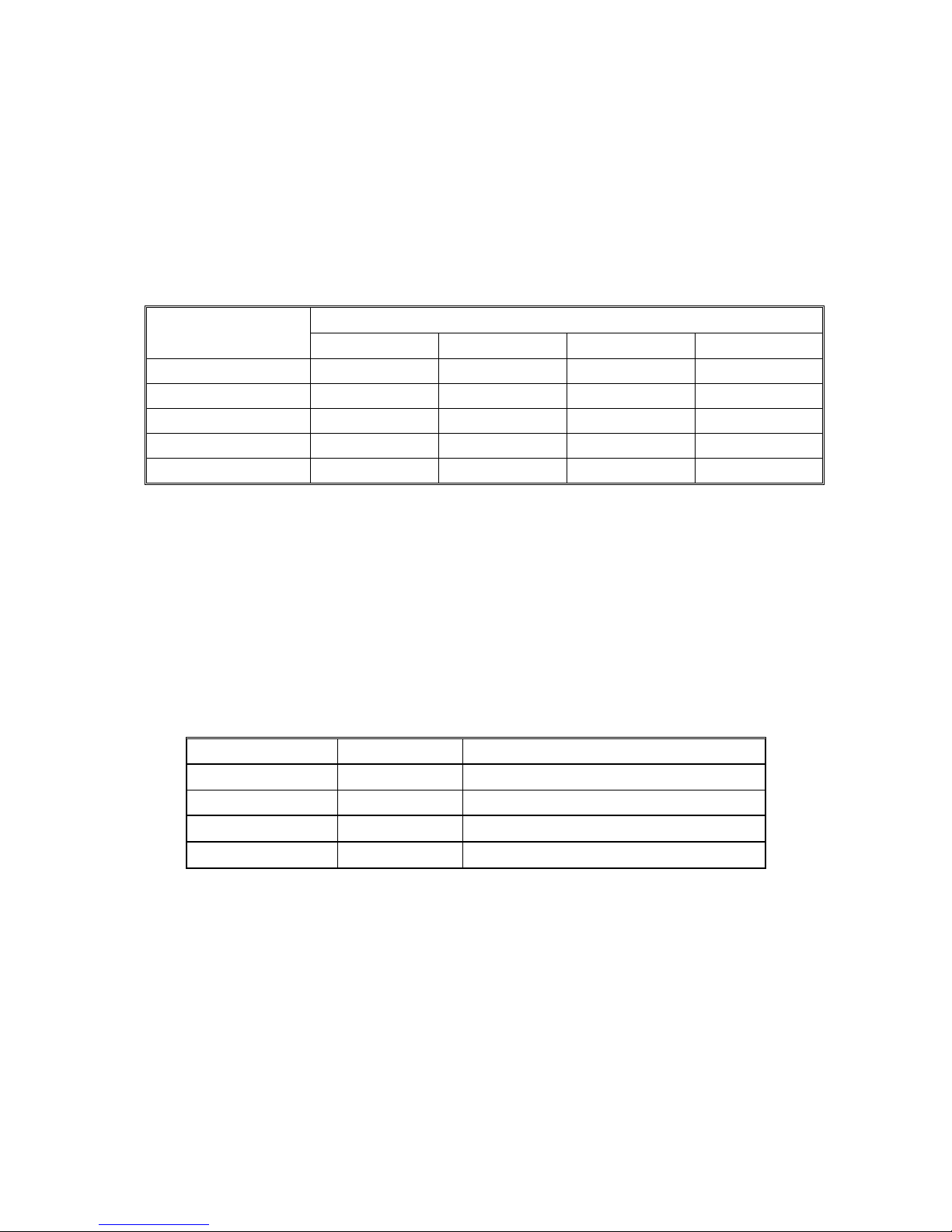

LEGEND

PRODUCT CODE COMPANY

GESTETNER LANIER RICOH SAVIN

B173 DSm516 AC017 AC104 AC104

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

6/2004 Original Printing

Page 12

Page 13

SM i B173

B173

TABLE OF CONTENTS

INSTALLATION

1. INSTALLAITON............................................................................ 1-1

PREVENTIVE MAINTENANCE

2. PREVENTIVE MAINTENANCE.................................................... 2-1

REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT ........................................ 3-1

3.1 GENERAL PRECAUTIONS ON DISASSEMBLY ......................................3-1

You must do these before you service the machine: ............................3-1

Releasing Plastic Latches.....................................................................3-1

3.2 REAR COVER...........................................................................................3-2

3.3 SIDE COVERS ..........................................................................................3-3

3.4 FRONT COVER ........................................................................................3-4

3.5 SCANNER ASS’Y......................................................................................3-5

3.6 ADF MOTOR ASS’Y................................................................................ 3-11

3.7 OPE UNIT (ALSO KNOWN AS OP-PORT).............................................3-13

3.8 MIDDLE COVER AND EXIT ROLLER ....................................................3-14

3.9 ENGINE SHIELD ASS’Y .........................................................................3-16

3.10 MAIN PBA (MAIN BOARD) ...................................................................3-17

3.11 SMPS (ALSO KNOWN AS POWER SUPPLY UNIT) ............................3-18

3.12 FUSER ASS'Y (ALSO KNOWN AS FUSING UNIT)..............................3-19

3.13 FAN ....................................................................................................... 3-20

3.14 LSU (LASER SCANNING UNIT) ...........................................................3-21

3.15 DRIVE ASS’Y ........................................................................................3-22

3.16 TRANSFER ASS’Y................................................................................3-23

3.17 FEED ASS’Y..........................................................................................3-24

3.18 PICK UP ASS’Y AND SOLENOID.........................................................3-26

TROUBLESHOOTING

4. TROUBLESHOOTING ................................................................. 4-1

4.1 PAPER PATH............................................................................................4-1

4.1.1 COPY & SCAN DOCUMENT PATH.................................................4-2

4.1.2 PRINTER PAPER PATH ..................................................................4-2

4.2 CLEARING JAMS......................................................................................4-3

4.2.1 CLEARING PAPER JAMS................................................................4-3

Page 14

B173 ii SM

JAM0 (In the Paper Feed Area) ............................................................4-4

JAM1 (In the Fuser Area of Around the Toner Cartridge Area).............4-5

JAM2 (In the Paper Exit Area) .............................................................. 4-6

BYPASS JAM (In the Bypass Tray) ......................................................4-7

Tips for Avoiding Paper Jams ...............................................................4-7

4.2.2 CLEARING DOCUMENT JAMS .......................................................4-8

Input Misfeed ........................................................................................4-8

Exit Misfeed ..........................................................................................4-8

Roller Misfeed.......................................................................................4-9

4.3 ABNORMAL IMAGE PRINTING AND DEFECTIVE ROLLER.................4-10

4.4 PAPER FEEDING PROBLEMS...............................................................4-11

4.4.1 WRONG PRINT POSITION............................................................4-11

4.4.2 JAM 0 .............................................................................................4-11

4.4.3 JAM 1 .............................................................................................4-12

4.4.4 JAM 2 .............................................................................................4-13

4.4.5 MULTI-FEEDING............................................................................4-14

4.4.6 PAPER STAYS ROLLED IN THE FUSER......................................4-14

4.4.7 PAPER ROLLED IN THE OPC.......................................................4-15

4.4.8 DEFECTIVE ADF ...........................................................................4-15

4.5 PRINTING PROBLEMS ..........................................................................4-16

4.5.1 DEFECTIV OPEPATION (LCD WINDOW) DISPLAY..................... 4-16

4.5.2 DEFECTIVE LCD OPERATION .....................................................4-16

4.5.3 NOT FUNCTIONING OF THE FUSER GEAR DUE TO

MELTING AWAY ........................................................................... 4-16

4.5.4 PAPER EMPTY ..............................................................................4-17

4.5.5 PAPER EMPTY WITHOUT INDICATION.......................................4-17

4.5.6 COVER OPEN................................................................................4-17

4.5.7 NO LAMP ON WHEN THE COVER IS OPEN................................4-18

4.5.8 DEFECTIVE MOTOR OPERATION ...............................................4-18

4.5.9 NO POWER....................................................................................4-18

4.5.10 VERTICAL LINE GETTING CURVED ..........................................4-19

4.6 PRINTING QUALITY PROBLEMS ..........................................................4-20

4.6.1 VERTICAL BLACK LINE AND BAND .............................................4-20

4.6.2 VERTICAL WHITE LINE.................................................................4-21

4.6.3 HORIZONTAL BLACK BAND.........................................................4-22

4.6.4 BLACK/WHITE SPOT.....................................................................4-23

4.6.5 LIGHT IMAGE ................................................................................4-24

4.6.6 DARK IMAGE OR A BLACK...........................................................4-25

4.6.7 UNEVEN DENSITY ........................................................................4-25

4.6.8 BACKGROUND..............................................................................4-26

4.6.9 GHOST (1) .....................................................................................4-27

4.6.10 GHOST (2) ...................................................................................4-28

4.6.11 GHOST (3) ...................................................................................4-28

4.6.12 GHOST (4) ...................................................................................4-29

4.6.13 STAINS ON THE FRONT OF THE PAGE....................................4-29

4.6.14 STAINS ON BACK OF THE PAGE...............................................4-30

4.6.15 BLANK PAGE PRINT OUT (1) ..................................................... 4-30

4.6.16 BLANK PAGE PRINT OUT (2) ..................................................... 4-31

4.7 FAX & PHONE PROBLEMS....................................................................4-32

Page 15

SM iii B173

4.7.1 NO DIAL TONE ..............................................................................4-32

4.7.2 DEFECTIVE TONE DIAL................................................................4-32

4.7.3 DEFECTIVE FAX FORWARD/RECEIVE .......................................4-33

4.7.4 DEFECTIVE FAX FORWARD ........................................................4-33

4.7.5 DEFECTIVE FAX RECEIVE (1) .....................................................4-33

4.7.6 DEFECTIVE FAX RECEIVE (2) .....................................................4-34

4.7.7 DEFECTIVE FAX RECEIVE (3) .....................................................4-34

4.7.8 DEFECTIVE FAX RECEIVE (4) .....................................................4-34

4.7.9 DEFECTIVE AUTOMATIC RECEIVING.........................................4-35

4.8 COPY PROBLEMS .................................................................................4-36

4.8.1 WHITE COPY.................................................................................4-36

4.8.2 BLACK COPY.................................................................................4-36

4.8.3 ABNORMAL NOISE .......................................................................4-36

4.8.4 DEFECTIVE IMAGE QUALITY.......................................................4-37

4.9 SCANNING PROBLEMS......................................................................... 4-38

4.9.1 DEFECTIVE PC SCAN...................................................................4-38

4.9.2 DEFECTIVE IMAGE QUALITY OF PC SCAN................................4-38

4.10 ERROR MESSAGES ............................................................................4-39

BYPASS JAM ..................................................................................... 4-39

COMM. ERROR..................................................................................4-39

DOCUMENT JAM...............................................................................4-39

DOOR OPEN......................................................................................4-39

GROUP NOT AVAILABLE..................................................................4-39

HEATING ERROR..............................................................................4-39

LINE BUSY ......................................................................................... 4-39

LINE ERROR......................................................................................4-40

LOAD DOCUMENT ............................................................................4-40

MEMORY FULL..................................................................................4-40

NO ANSWER...................................................................................... 4-40

NO CARTRIDGE ................................................................................4-40

NO. NOT ASSIGNED .........................................................................4-40

NO PAPER [ADD PAPER]..................................................................4-40

OPEN HEAT ERROR .........................................................................4-40

OVERHEAT ........................................................................................ 4-40

PAPER JAM 0 OPEN/CLOSE DOOR.................................................4-41

PAPER JAM 1/2 OPEN/CLOSE DOOR..............................................4-41

RETRY REDIAL?................................................................................4-41

TONER EMPTY..................................................................................4-41

TONER LOW ......................................................................................4-41

4.11 TONER CARTRIDGE (AIO) SERVICE.................................................. 4-42

4.11.1 PRECAUTIONS ON SAFE-KEEPING OF TONER CARTRIDGE ...4-42

4.11.2 SERVICE FOR THE LIFE OF TONER CARTRIDGE ...................4-42

Redistributing Toner............................................................................4-42

4.11.3 SIGNS AND MEASURES AT POOR TONER CARTRIDGE ........ 4-44

Page 16

B173 iv SM

SERVICE TABLES

5. SERVICE TABLES....................................................................... 5-1

5.1 USER MODE.............................................................................................5-1

5.2 TECH MODE .............................................................................................5-2

5.2.1 HOW TO GO INTO TECH MODE .................................................... 5-2

5.2.2 SETTING-UP SYSTEM IN TECH MODE .........................................5-3

5.2.3 DATA SET-UP..................................................................................5-4

SEND LEVEL........................................................................................5-4

DIALING MODE....................................................................................5-4

MODEM SPEED...................................................................................5-4

ERROR RATE ...................................................................................... 5-4

NOTIFY TONER ...................................................................................5-4

CLEAR ALL MEMORY .........................................................................5-5

CLEAR COUNT ....................................................................................5-5

FLASH UPGRADE................................................................................5-5

SILENCE TIME.....................................................................................5-5

5.2.4 MACHINE TEST...............................................................................5-6

SWITCH TEST .....................................................................................5-6

MODEM TEST......................................................................................5-6

DRAM TEST .........................................................................................5-6

ROM TEST ...........................................................................................5-6

PATTERN TEST...................................................................................5-6

SHADING TEST ...................................................................................5-7

5.2.5 REPORT...........................................................................................5-8

PROTOCOL LIST .................................................................................5-8

SYSTEM DATA ....................................................................................5-8

5.2.6 NEW CARTRIDGE ...........................................................................5-8

5.3 DATE OF SALE.........................................................................................5-8

5.4 FIRMWARE DOWNLOAD.........................................................................5-9

5.4.1 DOWNLOAD PROCEDURE.............................................................5-9

RCP (Remote Control Panel) mode......................................................5-9

To get the system data list .................................................................... 5-9

5.4.2 RECOVERY PROCEDURE............................................................5-10

5.4.3 REMOTE MACHINE UPDATE .......................................................5-10

How to update firmware by remote fax ...............................................5-10

5.5 ENGINE TEST MODE.............................................................................5-11

5.5.1 TO ENTER THE ENGINE TEST MODE.........................................5-11

5.5.2 DIAGNOSTIC ................................................................................. 5-11

5.5.3 STATUS PRINT...............................................................................5-13

DETAILED DESCRIPTIONS

6. DETAILED DESCRIPTIONS ........................................................ 6-1

6.1 PRINTER COMPONENTS ........................................................................6-1

6.1.1 FRONT VIEW ...................................................................................6-1

6.1.2 REAR VIEW .....................................................................................6-1

6.2 SYSTEM LAYOUT ....................................................................................6-2

Page 17

SM v B173

6.2.1 FEEDING SECTION......................................................................... 6-2

6.2.2 TRANSFER ASSEMBLY ..................................................................6-2

6.2.3 DRIVER ASSEMBLY........................................................................6-2

6.2.4 FUSING ............................................................................................6-3

Thermostat............................................................................................6-3

Thermistor.............................................................................................6-3

Heat Roller............................................................................................6-3

Pressure roller ......................................................................................6-3

Safety Features ....................................................................................6-3

6.2.5 SCANNER ........................................................................................ 6-4

Hardware: .............................................................................................6-4

Mechanical:...........................................................................................6-4

6.2.6 LSU (LASER SCANNER UNIT)........................................................ 6-4

6.3 CRU (ALSO KNOWN AS AIO) ..................................................................6-5

6.3.1 NEW CRU (AIO) DETECTION .........................................................6-6

6.3.2 TONER END DETECTION...............................................................6-6

6.4 MAIN BOARD............................................................................................6-7

6.4.1 ASIC (CHORUS2) ............................................................................6-7

Main function block ...............................................................................6-7

6.4.2 FLASH MEMORY.............................................................................6-8

6.4.3 SDRAM.............................................................................................6-8

6.4.4 SENSOR INPUT CIRCUIT ...............................................................6-8

Paper Empty Sensor:............................................................................6-8

MP Sensing: .........................................................................................6-8

Paper Feed and Toner Cartridge Sensor:.............................................6-8

Paper Exit Sensor:................................................................................6-8

Cover Open Sensor: .............................................................................6-9

DC FAN / SOLENOID Drive:.................................................................6-9

Motor Drive: ..........................................................................................6-9

6.5 SMPS & HVPS (ALSO KNOWN AS PSU AND POWER PACK).............6-10

6.5.1 HVPS (HIGH VOLTAGE POWER SUPPLY) ..................................6-10

6.5.2 SMPS (SWITCHING MODE POWER SUPPLY) ............................6-11

6.6 ENGINE F/W ...........................................................................................6-12

6.6.1 FEEDING........................................................................................6-12

Jam 0 ..................................................................................................6-12

Jam 1 ..................................................................................................6-12

Jam 2 ..................................................................................................6-12

6.6.2 DRIVE.............................................................................................6-12

6.6.3 TRANSFER .................................................................................... 6-12

6.6.4 FUSING .......................................................................................... 6-13

Error Type...........................................................................................6-13

6.6.5 LSU.................................................................................................6-13

Error Type...........................................................................................6-13

6.7 LIU BOARD .............................................................................................6-14

6.8 OPE BOARD ...........................................................................................6-14

Page 18

B173 vi SM

SPECIFICATIONS

SPECIFICATIONS

1. GENERAL SPECIFICATIONS.....................................................................7-1

2. PRINT SPECIFICATION ............................................................................. 7-2

3. SCAN SPECIFICATION .............................................................................. 7-2

4. COPY SPECIFICATION..............................................................................7-3

5. TELEPHONE SPECIFICAITON ..................................................................7-4

6. FAX SPECIFICATION ................................................................................. 7-5

7. PAPER HANDING.......................................................................................7-6

8. SOFTWARE ................................................................................................7-7

9. CONSUMABLES .........................................................................................7-7

APPENDIX

BLOCK DIAGRAM............................................................................................... 1

CONNECTION DIAGRAM................................................................................... 2

ACRONYMS AND ABBREVIATIONS .................................................................3

PARTS CATALOG

SEE PARTS CATALOG FOR DETAILED TABLE OF CONTENTS

Page 19

PRECAUTIONS

Please carefully read the cautions below to prevent accidents while servicing the

machine.

WARNING FOR SAFETY

1. Request the service by qualified service person.

The service for this machine must be performed by a qualified service person.

It is dangerous if an unqualified service person or user tries to repair the

machine.

2. Do not rebuild it discretionary.

Do not disassemble, fix, and rebuilt the machine. If you do, the machine may

not work and an electric shock or a fire can occur.

3. Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21

CFR, chapter 1 Subchapter J for Class 1(1) laser products, and elsewhere, it is

certified as a Class I laser product conforming to the requirements of IEC 825.

Class I laser products are not considered to be hazardous. The laser system

and printer are designed so there is never any human access to laser radiation

above a Class I level during normal operation, user maintenance, or prescribed

service condition.

WARNING

Never operate or service the printer with the protective cover removed from

Laser/Scanner assembly. The reflected beam, although invisible, can

damage your eyes. When using this product, these basic safety

precautions should always be followed to reduce risk of fire, electric shock,

and injury to persons.

CAUTION - INVISIBLE LASER RADIATION

WHEN THIS COVER OPEN.

DO NOT OPEN THIS COVER.

VORSICHT - UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GE…FFNET.

NICHT DEM STRAHL AUSSETZENz

ATTENTION - RAYONNEMENT LASER INVISIBLE EN CAS

DÕOUVERTURE. EXPOSITION DANGEREUSE

AU FAISCEAU.

ATTENZIONE - RADIAZIONE LASER INVISIBILE IN CASO DI

APERTURA. EVITARE LÕESPOSIZIONE AL

FASCIO.

PRECAUCION - RADIACION LASER IVISIBLE CUANDO SE ABRE.

EVITAR EXPONERSE AL RAYO.

ADVARSEL. - USYNLIG LASERSTR LNING VED BNING, N R

SIKKERHEDSBRYDERE ER UDE AF FUNKTION.

UNDG UDSAETTELSE FOR STR LNING.

ADVARSEL. - USYNLIG LASERSTR LNING N R DEKSEL

PNES. STIRR IKKE INN I STR LEN.

UNNG EKSPONERING FOR STR LEN.

VARNING - OSYNLIG LASERSTR LNING N R DENNA DEL

R PPNAD OCH SP RREN R URKOPPLAD.

BETRAKTA EJ STR LEN. STR LEN R FARLIG.

VARO! - AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTIINA N KYM TT M LLE LASERS TEILYLLE L KATSO S TEESEEN.

CAUTION.WMF

Page 20

CAUTION FOR SAFETY

PRECAUTION RELATED NOXIOUS MATERIAL

It is possible to be harmed from noxious material if you ignore the below

information.

1. Do not touch the damaged LCD. Noxious liquid to a human body exists in the

LCD. If it is got into the mouth, immediately see a doctor. If it gets into the eyes

or on the skin, immediately wash off with flowing water for 15 minutes and then

see a doctor.

2. The toner in a printer cartridge contains a chemical material, if swallowed,

might harm a human body.

Please keep the toner cartridge away from children.

PRECAUTION RELATED ELECTRIC SHOCK OR FIRE

It is possible to get an electric shock or burn by fire if you don't follow the

instructions of the manual.

1. Use the exact voltage and wall socket. If not, a fire or an electric leakage can

occur.

2. Use an authorized power cord. Use the power code supplied with machine. A

fire can occur when an over current condition flows in the power cord.

3. Do not insert many cords into an outlet. A fire can occur due to an over current

condition in the outlet.

4. Do not put water or other liquid, pin, clip, etc in the machine. It can cause a fire,

electric shock, or malfunction. If this occurs, immediately turn off the power off

and remove the power plug from outlet.

5. Do not touch the power plug with a wet hand. When servicing, remove the

power plug from the outlet.

6. Use caution when inserting or unplugging the power plug. The power plug has

to be inserted completely. If not, a fire can occur due to a poor contact. When

unplugging the power cord, grip the plug, not the wire.

7. Do not bend, twist, bind or place other materials on the power cord. Do not use

staples around machine. If the power cord becomes damaged, a fire or electric

shock can occur. A damaged power code must be replaced immediately. Do

not attempt to repair the damaged cord or reuse it. Repairing the cord with

plastic tape can cause a fire or electric shock. Do not spread chemicals or

insecticide on the power cord

8. Check whether the power outlet and the power plug are damaged, compressed

or cracked. When such inferiorities are found, replace it immediately. Do not roll

over the cord when moving the machine.

Page 21

9. Use caution during lightning storms. It may cause a fire or electric shock.

Unplug the power plug off under these conditions. Do not touch cable and

device during a lightning storm.

10. Avoid damp or dusty areas. Do not install the machine in dusty areas or around

humidifiers. A fire can occur. Clean the plug with dried fabric cloth to remove

dust.

11. Avoid direct sunlight. Do not install the machine near to a window where it is in

direct sunlight. If the machine operates in direct sunlight for a long periods, the

machine may not work correctly, because the increased inner temperature of

machine.

12. Turn off the machine and unplug the power cord when smoke, a strange smell,

or sound is detected from the machine. A fire can occur if the machine is used

under these conditions.

13. Do not insert steel or metal pieces inside/outside of the machine. Do not insert

metal pieces into the ventilator slots. An electric shock can occur.

PRECAUTION RELATED TO HANDLING THE MACHINE

If you ignore this information, you could get harm and machine could be damaged.

1. Do not install the machine on an uneven surface or slanted floor. Confirm that

the machine is correctly balanced after installation. The machine may fall over if

not balanced correctly.

2. Be careful not to insert a finger or hair in the rotating unit (motor, fan, paper

feeding part, etc) while the machine is operation.

3. Do not place any containers of water or chemical or small metals on top of the

machine. If these objects spill into the machine, a fire or electric shock can

occur.

4. Do not install the machine in areas where moisture or dust exists. For example,

do not install machine near open windows.

5. Do not place candles, burning cigarettes, etc. on the machine. Do not install it

near to a heater.

Page 22

PRECAUTIONS FOR WHEN ASSEMBLY/DISASSEMBLY

Replace parts very carefully. Remember the location of each cable before

removing parts, in order to reconnect it afterwards. Please perform the steps below

before replacing or disassembling any parts.

1. Check the contents stored in the memory. Either print a copy of stored data or

write down all of the needed information. All the stored information will be

erased when the main board is replaced.

2. Disconnect the power cord before servicing or replacing electrical parts.

3. Remove the printer cable.

4. Use formal parts and same standardized goods when replacing parts. Check

the product name, part code, rated voltage, rated current, operating

temperature, etc.

5. Do not use excessive force when loosening or tightening plastic components.

6. Be careful not to drop small parts or objects in the machine.

ESD PRECAUTIONS

Certain semiconductor devices can be easily damaged by static electricity. Such

components are commonly called “Electro statically Sensitive (ES) Devices”, or

ESD’s. Examples of typical ESD’s are: integrated circuits, some field effect

transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of

component damage caused by static electricity.

CAUTION

Be sure no power is applied to the chassis or circuit, and observe all other

safety precautions.

1. Immediately before handling a semiconductor component or semiconductorequipped assembly, drain off any electrostatic charge on your body by touching

a known earth ground. Alternatively, use a commercially available wrist strap

device, which should be removed for your personal safety reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD’s, place the

assembly on a conductive surface, such as aluminum or copper foil, or

conductive foam, to prevent electrostatic charge buildup in the vicinity of the

assembly.

3. Use only a grounded tip soldering iron to solder an ESD’s.

Page 23

4. Only use an “anti-static” solder removal device. Some solder removal devices

not classified as “anti-static” and can generate an electrical charge sufficient to

damage ESD’s.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate

electrical charges sufficient to damage ESD’s.

6. Do not remove a replacement ESD from its protective packaging until

immediately before installing it. Most replacement ESD’s are packaged with all

leads shorted together by conductive foam, aluminum foil, or a comparable

conductive material.

7. Immediately before removing the protective shorting material from the leads of

a replacement ESD, touch the protective material to the chassis or circuit

assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into

which it will be installed, until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESD’s.

Normal motions, actions such as brushing together of clothing fabric or lifting

one’s foot from a carpeted floor, can generate static electricity sufficient to

damage an ESD.

Page 24

Page 25

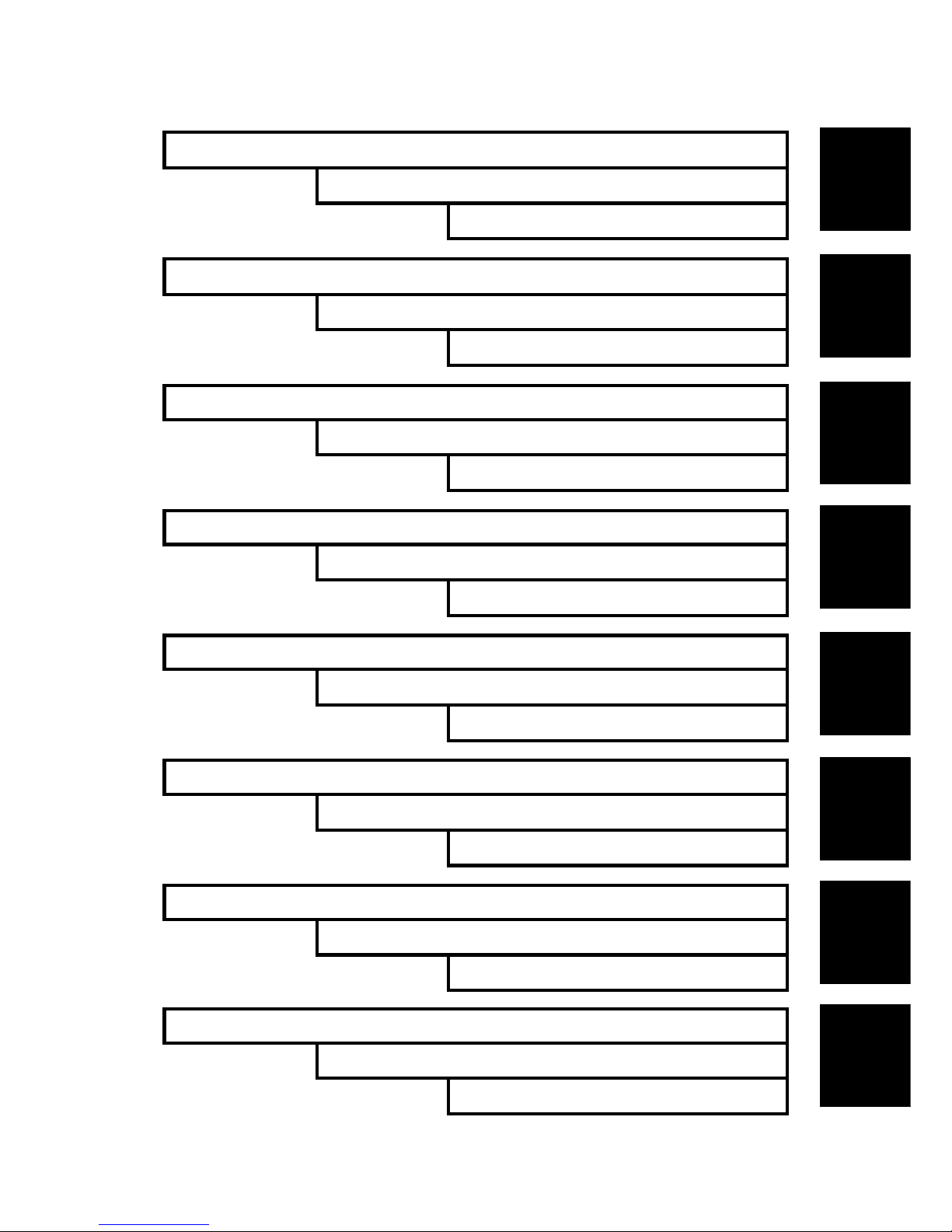

INSTALLATION

PREVENTIVE MAINTENANCE

REPLACEMENT AND ADJUSTMENT

TROUBLESHOOTING

SERVICE TABLES

DETAILED DESCRIPTIONS

SPECIFICATIONS

APPENDIX

TAB

POSITION 2

TAB

POSITION 1

TAB

POSITION 3

TAB

POSITION 4

TAB

POSITION 6

TAB

POSITION 5

TAB

POSITION 8

TAB

POSITION 7

Page 26

Page 27

INSTALLATION

Page 28

Page 29

INSTALLAITON

SM 1-1 B173

Installation

1. INSTALLAITON

Refer to the operating instructions for details.

Page 30

Page 31

PREVENTIVE MAINTENANCE

Page 32

Page 33

PREVENTIVE MAINTENANCE

SM 2-1 B173

Preventive

Maintenance

2. PREVENTIVE MAINTENANCE

The cycle period shown below is for maintenance.

Environmental conditions and use will change.

The cycle period shown is for reference only.

Component Replacement Cycle Done by

ADF Rubber 20,000 Pages Service

Scanner

ADF Pick-up Ass’y 60,000 Pages Service

Friction Pad 60,000 pages Service

Paper Feed Roller 60,000 Pages Service

Transfer Roller 60,000 Pages Service

Printer

Fuser 60,000 Pages Service

Page 34

Page 35

REPLACEMENT AND ADJUSTMENT

Page 36

Page 37

GENERAL PRECAUTIONS ON DISASSEMBLY

SM 3-1 B173

Replacement

and Adjustment

3. REPLACEMENT AND ADJUSTMENT

3.1 GENERAL PRECAUTIONS ON DISASSEMBLY

Use caution when you disassemble and reassemble components. Make sure that

you put all cables in the correct position, after you replace a part.

You must do these before you service the machine:

1. Make sure that no documents are in the memory.

2. Disconnect the power cord.

3. Remove the toner and drum cartridges before you disassemble parts.

4. Use a flat and clean surface.

5. Replace only with necessary components.

6. Do not use high force when you push plastic-material components.

7. Make sure that all components are in their correct position.

Releasing Plastic Latches

Many parts set in their positions with plastic latches. The latches break easily.

Release them carefully. Push the hook end of the latch away from the part to which

it is latched to remove these parts.

B173R967.WMF

Page 38

REAR COVER

B173 3-2 SM

3.2 REAR COVER

1. Remove the four screws from the rear

cover.

2. Remove the rear cover [A] from the

frame assembly and scanner assembly.

3. Release the cover - face up [B] that

attaches the rear cover. Then lift the

cover - face up out.

B173R900.WMF

B173R901.WMF

B173R902.WMF

[A]

[B]

Page 39

SIDE COVERS

SM 3-3 B173

Replacement

and Adjustment

3.3 SIDE COVERS

1. You must remove the rear cover (! 3.2) before you remove the side covers.

2. Disconnect the speaker [A].

3. Lift the Left cover [B] and Right cover

[C] in the direction of arrow.

B173R903.WMF

B173R904.WMF

[B]

[C]

[A]

Page 40

FRONT COVER

B173 3-4 SM

3.4 FRONT COVER

1. Remove the cassette [A].

2. Open the front cover[B].

3. Remove the front cover that attaches the

frame assembly. Then remove the front

cover.

B173R905.WMF

B173R906.WMF

B173R907.WMF

[A]

[B]

Page 41

SCANNER ASS’Y

SM 3-5 B173

Replacement

and Adjustment

3.5 SCANNER ASS’Y

1. You must remove these before you remove the scanner ass’y:

• Rear cover (! 3.2)

• Side covers (! 3.3)

2. Remove the two screws from the

scanner ass’y [A].

3. Disconnect the 6 connectors from the

connector PBA [B].

B173R908.WMF

B173R909.WMF

[B]

[A]

Page 42

SCANNER ASS’Y

B173 3-6 SM

4. Pull up the scanner ass’y [A].

5. Pull the platen cover [B] up. Then

remove it.

B173R910.WMF

B173R911.WMF

[A]

[B]

Page 43

SCANNER ASS’Y

SM 3-7 B173

Replacement

and Adjustment

6. Remove three screws from the scan

lower assembly.

7. Remove the OPE unit [A]. Then

disconnect the two connectors from

the OPE unit. Then remove it.

8. Remove the four screws from the

window cover.

B173R912.WMF

B173R913.WMF

B173R914.WMF

[A]

Page 44

SCANNER ASS’Y

B173 3-8 SM

9. Release the window cover [A] from the

scan lower assembly. Then pull the

window cover up. Then remove it.

10. Remove the CCD Cable [B].

11. Push the belt holder. Then remove the

Belt [C].

B173R915.WMF

B173R916.WMF

B173R917.WMF

[A]

[B]

[C]

Page 45

SCANNER ASS’Y

SM 3-9 B173

Replacement

and Adjustment

12. Pull up the CCD shaft [A]. Then remove

the scanner module [B].

13. Remove the reduction gear [C] and

idle gear [D].

14. Remove the two screws. Then remove

the motor bracket [E].

B173R918.WMF

B173R919.WMF

B173R920.WMF

[B]

[A]

[C]

[D]

[E]

Page 46

SCANNER ASS’Y

B173 3-10 SM

15. Disconnect the connector [A] from the

open sensor assembly [B].

16. Release the open sensor [C]. Then

remove it.

B173R921.WMF

B173R922.WMF

[C]

[B]

[A]

Page 47

ADF MOTOR ASS’Y

SM 3-11 B173

Replacement

and Adjustment

3.6 ADF MOTOR ASS’Y

1. Before you remove the ADF Motor Ass’y, you must remove these:

• Rear Cover (! 3.2)

• Side Covers (! 3.3)

• Scanner Ass’y (! 3.5)

2. Remove the two screws from the ADF

ass’y [A]. Then remove it.

3. Remove the open cover [B].

B173R923.WMF

B173R924.WMF

[A]

[B]

Page 48

ADF MOTOR ASS’Y

B173 3-12 SM

4. Pull the white bush [A]. Then turn it until

it gets to the slot. Then remove the pickup ass’y [B].

5. Remove the two screws from the upper

cover [C]. Then remove it.

6. Disconnect the connector. Then remove

four screws from the ADF motor ass’y

[D]. Then remove it.

B173R925.WMF

B173R926.WMF

B173R927.WMF

[B]

[A]

[C]

[D]

Page 49

OPE UNIT (ALSO KNOWN AS OP-PORT)

SM 3-13 B173

Replacement

and Adjustment

3.7 OPE UNIT (ALSO KNOWN AS OP-PORT)

1. Before you remove the OPE Unit, you must remove these:

• Rear Cover (! 3.2)

• Side Covers (! 3.3)

• Scanner Ass’y (! 3.5)

2. Remove the six screws from the OPE

PBA [A] and OPE cover [B].

3. Remove the contact rubber [C] and the

key pad [D] from the OPE cover.

B173R928.WMF

B173R929.WMF

B173R930.WMF

[D]

[C]

[A]

[B]

Page 50

MIDDLE COVER AND EXIT ROLLER

B173 3-14 SM

3.8 MIDDLE COVER AND EXIT ROLLER

1. Before you remove the Exit Roller, you must remove these:

• Rear Cover (! 3.2)

• Front Cover Ass’y (! 3.4)

• Side Covers (! 3.3)

• Scanner Ass’y (! 3.5)

2. Remove the six screws from the top

cover [A].

3. Release the top cover from the frame

assembly [B]. Then remove the top

cover.

B173R931.WMF

B173R932.WMF

[B]

[A]

Page 51

MIDDLE COVER AND EXIT ROLLER

SM 3-15 B173

Replacement

and Adjustment

4. Remove the two screws from the rear

upper cover [A].

5. Remove the exit gear [B] and bearing

[C] from exit roller [D].

B173R933.WMF

1

2

B173R934.WMF

[B]

[C]

[A]

[D]

Page 52

ENGINE SHIELD ASS’Y

B173 3-16 SM

3.9 ENGINE SHIELD ASS’Y

1. Before you remove the engine shield ass’y, you must remove these:

• Rear Cover (! 3.2)

• Side Covers (! 3.3)

• Scanner Ass’y (! 3.5)

2. Remove the two screws. Then

disconnect the FPC cable from the

main PBA. Then remove the LIU PBA

[A].

3. Disconnect two connectors [B].

B173R935.WMF

B173R936.WMF

[A]

[B]

Page 53

MAIN PBA (MAIN BOARD)

SM 3-17 B173

Replacement

and Adjustment

4. Remove the ten screws from the

engine shield ass’y [A]. Then remove

it. Then disconnect all connectors

from the main PBA and SMPS.

3.10 MAIN PBA (MAIN BOARD)

NOTE: 1) Print out the system data list in Tech mode to keep programmed data

before you do the replacement procedure.

2) Do the “Clear All Memory” in Tech mode (! 5.1.3) after you finish the

replacement procedure.

1. Before you remove the main PBA, you must remove these:

• Rear cover (! 3.2)

• Side covers (! 3.3)

• Scanner Ass’y (! 3.5)

• Engine shield ass’y (! 3.9)

2. Disconnect one connector. Then

remove the five screws from the main

PBA. Then remove the main PBA [A].

B173R937.WMF

B173R938.WMF

[A]

[A]

Page 54

SMPS (ALSO KNOWN AS POWER SUPPLY UNIT)

B173 3-18 SM

3.11 SMPS (ALSO KNOWN AS POWER SUPPLY UNIT)

1. Before you remove the SMPS, you must remove these:

• Rear cover (! 3.2)

• Side covers (! 3.3)

• Scanner Ass’y (! 3.5)

• Engine shield ass’y (! 3.9)

2. Remove the three screws from the inlet

bracket [A]. Then remove it

3. Disconnect one connector. Then

remove the one screw from the engine

shield.

4. Remove the three screws from the

SMPS [B]. Then remove the SMPS.

B173R939.WMF

B173R940.WMF

B173R941.WMF

[A]

[B]

Page 55

FUSER ASS'Y (ALSO KNOWN AS FUSING UNIT)

SM 3-19 B173

Replacement

and Adjustment

3.12 FUSER ASS'Y (ALSO KNOWN AS FUSING UNIT)

CAUTION

The fusing unit has tapping screws. Assembly/disassembly should be kept to a

minimum. Adjustments again and again can cause failure. To avoid hazardous

situations, do not replace any components inside the fusing unit such as

thermistor, hot roller, stripper pawls, fusing lamp, etc..

1. Before you remove the fuser ass’y, you must remove these:

• Rear cover (! 3.2)

• Side covers (! 3.3)

• Scanner Ass’y (! 3.5)

• Engine shield ass’y (! 3.9)

2. Disconnect the two connectors from the main PBA and SMPS. Then remove

the four screws from the fusing unit [A]. Then remove it.

B173R942.WMF

[A]

Page 56

FAN

B173 3-20 SM

3.13 FAN

1. Before you remove the fan, you must remove these:

• Rear cover (! 3.2)

• Side covers (! 3.3)

2. Disconnect the connector from the

SMPS. Then remove the one screw.

Then remove the fan [A].

B173R949.WMF

[A]

CAUTION: Make sure to set the fan in the correct position.

The label on the fan must face outward.

Page 57

LSU (LASER SCANNING UNIT)

SM 3-21 B173

Replacement

and Adjustment

3.14 LSU (LASER SCANNING UNIT)

1. Before you remove the LSU, you must remove these:

• Rear cover (! 3.2)

• Side covers (! 3.3)

• Scanner Ass’y (! 3.5)

• Front cover (! 3.4)

• Middle cover (! 3.8)

2. Disconnect the two connectors.

3. Remove the four screws from the LSU

[A]. Then remove it.

B173R950.WMF

B173R951.WMF

[A]

Page 58

DRIVE ASS’Y

B173 3-22 SM

3.15 DRIVE ASS’Y

1. Before you remove the drive ass’y, you must remove these:

• Rear cover (! 3.2)

• Side covers (! 3.3)

2. Remove the six screws from the drive

ass’y [A].

3. Remove the drive ass’y. Then

disconnect the connector from the

main PBA.

B173R952.WMF

B173R953.WMF

[A]

Page 59

TRANSFER ASS’Y

SM 3-23 B173

Replacement

and Adjustment

3.16 TRANSFER ASS’Y

1. Before you remove the transfer ass’y, you must remove these:

• Rear cover (! 3.2)

• Side covers (! 3.3)

• Scanner Ass’y (! 3.5)

• Front cover (! 3.4)

• Middle cover (!3.8)

• LSU (!3.14)

2. Remove the three screws from the

transfer ass’y [A]. Then remove it.

3. Disconnect the PTL holder connector.

Then remove the PTL holder [B] and

PTL Lens [C].

4. Release the bushing [D]. Then remove

it. Then remove transfer roller [E].

B173R954.WMF

B173R955.WMF

B173R956.WMF

[B]

[C]

[D]

[E]

[A]

Page 60

FEED ASS’Y

B173 3-24 SM

3.17 FEED ASS’Y

1. Before you remove the feed ass’y, you must remove these:

• Rear cover (! 3.2)

• Side covers (! 3.3)

• Scanner Ass’y (! 3.5)

• Front cover (! 3.4)

• Middle cover (!3.8)

• Drive ass’y (! 3.15)

2. Remove the two screws from the

paper guide [A]. Then remove it.

3. Pull up the feed idle bushing [B]. Then

pull up the feed idle shaft [C].

4. Remove the three screws from the

feed bracket [D]. Then remove it.

B173R957.WMF

B173R958.WMF

B173R959.WMF

[A]

[B]

[C]

[D]

Page 61

FEED ASS’Y

SM 3-25 B173

Replacement

and Adjustment

5. Remove the idle gear [A] and feed

gear 2 [B].

6. Remove feed gear 1 assembly [C] .

7. Pull up the feed roller [D] and feed roller

1 [E].

B173R960.WMF

B173R961.WMF

B173R962.WMF

[A]

[B]

[C]

[E]

[D]

Page 62

PICK UP ASS’Y AND SOLENOID

B173 3-26 SM

3.18 PICK UP ASS’Y AND SOLENOID

1. Before you remove the pick up ass’y, you must remove these:

• Rear cover (! 3.2)

• Side covers (! 3.3)

• Front cover (! 3.4)

• Scanner Ass’y (! 3.5)

• Middle cover (!3.8)

• Engine shield Ass’y (! 3.9)

• Drive Ass’y (! 3.15)

2. Remove the three screws from the

feed bracket [A]. Then remove it.

3. Remove the pick up gear assembly

[B].

B173R959.WMF

B173R964.WMF

[A]

[B]

Page 63

PICK UP ASS’Y AND SOLENOID

SM 3-27 B173

Replacement

and Adjustment

4. Remove the pick-up ass’y [A].

5. Remove the two screws from the

manual solenoid [B] and pick-up

solenoid [C]. Then remove the manual

solenoid and pick-up solenoid.

1

2

B173R965.WMF

B173R966.WMF

[A]

[B]

[C]

Page 64

Page 65

TROUBLESHOOTING

Page 66

Page 67

PAPER PATH

SM 4-1 B173

Trouble-

shooting

4. TROUBLESHOOTING

4.1 PAPER PATH

Scanner Part

PTL

PR

CR

DR

SR

TR FR

OPC

L S U

Fuser

Toner Cartridge

1

2

3

4

5

6

8

7

Sensor-Doc

ADF-Roller

Pickup-Roller

Exit-Roller

Doc-Paper(30Sheets)

ADF-Idle Roller

Feed-Roller

CCD-Module

White-Sheet

Sensor-Regi

Sensor-Scan

Engine Part

B173T936.WMF

Page 68

PAPER PATH

B173 4-2 SM

4.1.1 COPY & SCAN DOCUMENT PATH

4.1.2 PRINTER PAPER PATH

1. After receiving print job, the printer feeds the printing paper from the cassette or

manual feeder.

2. The fed paper passes the paper feeding sensor. (Jam 0 occurs if the sensor is

not operated after certain time passes)

3. The paper passed the paper feeding sensor moves to the paper exit sensor via

printing process. (Jam 1 occurs if the sensor is not operated after certain time

passes)

4. The paper passed the paper exit sensor moves out from the set. (Jam 2 occurs

sometime after if the tailing edge of the paper has not exited out from the set

after the leading edge of paper passes the paper exit sensor.)

Scanner Part

CCD-Module

White-Sheet

1

2

3

4

8

5

6

7

B173T937.WMF

Engine Part

PTL

PR

CR

DR

SR

TR FR

OPC

L S U

Fuser

Toner Cartridge

1

2

3

4

5

6

7

B173T938.WMF

!

Doc. Paper (30 Sheets)

"

Pickup Roller

#

ADF Roller

$

Sensor - Doc.

%

Sensor - Regi

&

Sensor - Scan

'

Feed Roller

(

Exit Roller

!

Paper Input (Cassette)

"

Paper Input (Manual Feeder)

#

Paper Out (Face Down)

$

Paper Empty Sensor (Manual)

%

Paper Empty Sensor (Cassette)

&

Paper Feeding Sensor

'

Paper Exit Sensor

Page 69

CLEARING JAMS

SM 4-3 B173

Trouble-

shooting

4.2 CLEARING JAMS

Occasionally, paper can be jammed during a print job. Some of the causes include:

• The tray is loaded improperly or overfilled.

• The tray has been pulled out during a print job.

• The front cover has been opened during a print job.

• Paper was used that does not meet paper specifications.

• Paper that is outside of the supported size range was used.

If a paper jam occurs, the On Line/Error LED on the control panel lights red. Find

and remove the jammed paper. If you don’t see the paper, open the covers.

Do not use a pinset or a sharp metal tool when removing a jam.

4.2.1 CLEARING PAPER JAMS

If paper jams occur, “ PAPER JAM ” appears on the display. Refer to the table

below to locate and clear the paper jam.

PAPER JAM 0: In the paper feed area

PAPER JAM 1: In the paper exit area

PAPER JAM 2: In the fuser area or around the toner cartridge

BYPASS JAM: In the Bypass tray

Follow the steps below to clear a jam. To avoid tearing the paper, pull the jammed

paper out gently and slowly.

B173T939A.WMF

B173T939B.WMF

B173T939C.WMF

MP Sensor

B173T939D.WMF

Paper Jam 2

Bypass Jam

Paper Jam 0

Paper Jam 1

Page 70

CLEARING JAMS

B173 4-4 SM

JAM 0 (In the Paper Feed Area)

1. Open and close the front cover. The jammed paper automatically exits the

machine. If the paper does not exit, continue to Step 2.

2. Pull the paper cassette open.

3. Remove the jammed paper by

gently pulling it straight out.

NOTE: If there is any resistance

when you pull the paper

or the paper is not seen

in this area, skip to the

fuser area around the

toner cartridge

4. Insert the paper tray into the machine

until it snaps into place.

5. Open and close the front cover to

resume printing.

B173T944.WMF

B173T945.WMF

B173T946.WMF

Page 71

CLEARING JAMS

SM 4-5 B173

Trouble-

shooting

JAM 1 (In the Fuser Area of Around the Toner Cartridge Area)

NOTE: The fuser area is hot. Be careful when removing paper from the machine.

1. Open the front cover and remove the

toner cartridge.

2. Remove the jammed paper by gently

pulling it straight out.

3. Replace the toner cartridge and close

the front cover. Printing automatically

resumes.

B173T950.WMF

B173T951.WMF

B173T952.WMF

Page 72

CLEARING JAMS

B173 4-6 SM

JAM 2 (In the Paper Exit Area)

1. Open and close the front cover. The jammed paper automatically exits the

machine. If the paper does not exit, continue to Step 2.

2. Gently pull the paper out of the front

output tray.

3. If there is any resistance when you pull

the paper or the paper is not seen in the

front output tray, open the rear cover.

4. Remove the jammed paper by gently

pulling it straight out.

5. Close the rear cover.

6. Open and close the front cover to

resume printing.

B173T947.WMF

B173T948.WMF

B173T949.WMF

Page 73

CLEARING JAMS

SM 4-7 B173

Trouble-

shooting

BYPASS JAM (In the Bypass Tray)

“BYPASS JAM ” appears on the display when the machine does not detect paper

in the Bypass tray due to no paper or improper paper loading when you try to print

using the Bypass tray.

“BYPASS JAM ” also may occur when the paper is not properly fed into the

machine through the Bypass tray. In that case, pull the paper out of the machine.

Tips for Avoiding Paper Jams

By selecting the correct paper types, most paper jams can be avoided. If a paper

jam occurs, follow the steps outlined in “Clearing Paper Jams ”

• Follow the procedures in “Loading Paper”. Ensure that the adjustable guides

are positioned correctly.

• Do not overload the paper tray. Ensure that the paper is below the paper

capacity mark on the inside wall of the paper tray.

• Do not remove the paper from the tray while printing.

• Flex, fan and straighten the paper before loading.

• Do not use creased, damp or highly curled paper.

• Do not mix paper types in the paper tray.

• Use only recommended print materials. See “Paper Specifications ”

• Ensure that the recommended print side is facing down when loading paper

in the paper tray and facing up in the Bypass tray.

B173T953.WMF

Page 74

CLEARING JAMS

B173 4-8 SM

4.2.2 CLEARING DOCUMENT JAMS

If a document jams while it is feeding through the ADF (Automatic Document

Feeder),“DOCUMENT JAM ” appears on the display.

Input Misfeed

1. Open the ADF top cover.

2. Pull the document gently to the right and

out of the ADF.

3. Close the ADF top cover. Then load the

documents back into the ADF.

NOTE: To prevent document jams, use the document glass for the thick, thin or

mixed documents.

Exit Misfeed

1. Open the document cover and turn the release knob to remove the misfed

documents from the exit area.

2. Close the document cover. Then load the documents back into the ADF.

B173T940.WMF

B173T941.WMF

Page 75

CLEARING JAMS

SM 4-9 B173

Trouble-

shooting

Roller Misfeed

1. Open the document cover.

2. Turn the release knob so that you can

easily remove the misfed document,

and remove the document from the

ADF or the feed area by carefully

pulling it towards the right by using both

hands.

3. Close the document cover. Then load the documents back into the ADF.

B173T942.WMF

B173T943.WMF

Page 76

ABNORMAL IMAGE PRINTING AND DEFECTIVE ROLLER

B173 4-10 SM

4.3 ABNORMAL IMAGE PRINTING AND DEFECTIVE

ROLLER

If abnormal image prints periodically, check the parts shown below.

No Roller Abnormal image period Kind of abnormal image

No Roller Abnormal Image Period Kind of Abnormal Image

1 OPC Drum 75.5 mm White spot, Block spot

2 Charge Roller 37.7 mm Black spot

3 Supply Roller 37.0 mm Horizontal density band

4 Develop Roller 35.2 mm Horizontal density band

5 Transfer Roller 45.3 mm Black side contamination/transfer fault

6 Hot Roller 66.3 mm Black spot and fuser ghost

7 Pressure Roller 75.5 mm Black side contamination

PTL

PR

CR

DR

SR

TR FR

OPC

L S U

Fuser

Ton er Cartridge

MP Sensor

B173T954.WMF

1 2 34

5

6

7

Page 77

PAPER FEEDING PROBLEMS

SM 4-11 B173

Trouble-

shooting

4.4 PAPER FEEDING PROBLEMS

4.4.1 WRONG PRINT POSITION

Description

Printing begins when the paper is in the wrong position.

Check and Cause Solution

A defective feed sensor actuator can

cause incorrect timing.

Replace the defective actuator.

4.4.2 JAM 0

Description

1. Paper has not exited from the cassette.

2. Jam-0 occurs if the paper feeds into the

printer.

Check and Cause Solution

Check the solenoid by using Engine

Test Mode: Diagnostic Mode 0.

Replace the solenoid.

Check if the pad is loose due to bad

sealing of the side-pad.

Replace the side-pad or assembly L

or R if necessary.

Check the surface of the roller-pick-up

for foreign matter.

Clean with a soft cloth dampened with

IPA (Isopropyl Alcohol) or water.

If continuous clusters occur, check

whether the assembly slot between

shaft-pickup and housing-pickup

become open or is broken away.

If the paper feeds into the printer and

Jam 0 occurs, perform Engine Test

Mode to check feed-sensor of the

engine board.

Replace the house pick-up unit and/or

shaft pick-up.

B173T910.WMF

Page 78

PAPER FEEDING PROBLEMS

B173 4-12 SM

4.4.3 JAM 1

Description

1. Recording paper is jammed in front of or

inside the toner cartridge.

2. Recording paper is stuck in the transfer roller

and in the fuser just after passing through the

Actuator-Feed.

Check and Cause Solution

If the recording paper is jammed in front

of or inside the toner cartridge.

Replace the SMPS. (Power supply)

The actuator may be defective if the

recording paper stays in the transfer

roller and the fuser after it passes

through the actuator-feed.

Reassemble the Actuator-Feed and

Spring-Actuator if the return is bad.

B173T911.WMF

Page 79

PAPER FEEDING PROBLEMS

SM 4-13 B173

Trouble-

shooting

4.4.4 JAM 2

Description

1. Recording paper is jammed in front of or

inside the fuser.

2. Recording paper is stuck in the transfer

roller and in the fuser just after passing

through the Actuator-Feed.

Check and Cause Solution

Exit sensor is defective if the paper is

completely fed out of the printer, but

Jam 2 occurs.

• After the paper is completely discharged,

actuator exit should return to the original

position to shut off the photo-sensor.

Sometimes it takes longer than it should

and does not return.

Check if the exit sensor actuator is

defective.

• Check if the actuator exit is deformed

(Check if the lever part is deformed in

shape).

• Check if burrs occur in the assembly part

of the actuator. Check if the actuator is

smoothly operated.

• Check if unwanted matters and wire got

caught in the actuator exit’s operation.

If the paper is rolled in the fuser roller:

• This occurs when a guide claw breaks away

or becomes deformed.

• It occurs when the guide spring breaks

away or becomes deformed.

• It occurs when the heat-roller or pressureroller gets too much toner powder.

If the paper is stuck in the fuser,

disassemble the fuser and remove the

jammed paper. Then clean the

surface of the pressure roller with dry

gauze.

Paper is accordion and jams in fuser.

Remove the jammed paper after you

disassemble the fuser: Clean the

surface of the pressure roller with dry

gauze.

• Remove the toner particles stained on

the rib.

• Check the assembly and the

performance of the exit.

B173T912.WMF

Page 80

PAPER FEEDING PROBLEMS

B173 4-14 SM

4.4.5 MULTI-FEEDING

Description

Multiple sheets of paper are fed at once.

Check and Cause Solution

Solenoid malfunction (the solenoid is not

working properly): Perform Engine Test

Mode: Diagnostic Mode code 0.

Replace the solenoid if necessary.

Friction-Pad is contaminated with

foreign matter (oil).

Clean the friction-pad with soft cloth

dampened with IPA (Isopropyl

Alcohol).

The front and back side of the paper is

mixed.

Use smooth paper.

4.4.6 PAPER STAYS ROLLED IN THE FUSER

Description

If contaminated at intervals of 57 mm on the back of a paper.

Check and Cause Solution

Disassemble the fuser, clean the area

between the Heat-roller and

Thermistor and remove the foreign

matter off of the pressure roller.

NOTE: As explained in page 3-19,

assembly/disassembly of the

fuser unit should be kept to a

minimum, in order to avoid

hazardous situations.

Contamination of the pressure roller.

(Background, Hot off set)

If background appears refer to the

Solutions for background. () 4.6.8)

Page 81

PAPER FEEDING PROBLEMS

SM 4-15 B173

Trouble-

shooting

4.4.7 PAPER ROLLED IN THE OPC

Description

Paper stays in the OPC.

Check and Cause Solution

Paper is too thin.

Recommend to use normal paper

thickness.

The face of paper is curled.

How to remove the rolled paper in the

OPC.

• Remove the paper while turning the OPC

against the ongoing direction.

• Clean fingerprints on the OPC softly with

soft cloth dampened with IPA (Isopropyl

Alcohol) and a tissue.

4.4.8 DEFECTIVE ADF

Description

ADF does not operate correctly.

Check and Cause Solution

Check if ADF rubber and holder rubber

are damaged.

Check if the document sensors of

OPE assembly (2 paper sensors) are

normal.

Check if the document sensors of ADF

Ass’y (3 sensors) are normal.

If you cannot visually confirm the

damaged part, try to replace the ADF

Ass’y.

Page 82

PRINTING PROBLEMS

B173 4-16 SM

4.5 PRINTING PROBLEMS

4.5.1 DEFECTIVE OPERATION (LCD WINDOW) DISPLAY

Description

Strange characters are displayed on the OPE Panel or buttons do not operated.

Check and Cause Solution

Clear the memory. () 5.2.3)

Then try again after clearing the

memory.

Check if OPE harness is connected to

the Connection Board correctly.

Confirm that the OPE HARNESS is

connected to the Main Board correctly

though the connector board. If it is so,

then replace the OPE assembly,

Connector Board and Main Board in

sequence.

4.5.2 DEFECTIVE LCD OPERATION

Description

Defective LCD Operation

Check and Cause Solution

Clear the memory. () 5.2.3)

The key is defective or incorrectly

assembled

Confirm to catch a click sound, while a

key on the OPE panel is pressed on.

Even after the key has been replaced,

if it still fails, try to replace the OPE

Ass’y and the Main Board in

sequence.

4.5.3 FUSER FAILURE DUE TO MELTED GEAR

Description

The motor breaks away from its place due to gear melting away.

Check and Cause Solution

Replace the Fuser.

Replace the Main Board.

Check the Fusing Lamp.

Replace the SMPS. (Power supply)

Page 83

PRINTING PROBLEMS

SM 4-17 B173

Trouble-

shooting

4.5.4 PAPER EMPTY

Description

The paper lamp on the operator panel is on even when paper is loaded in the

cassette.

Check and Cause Solution

Bending or deformation of the actuator

of the paper sensor.

Replace the defective actuator.

The function of the Main Control board

is defective Perform Engine Test Mode:

diagnostic code 2.

Replace the Main Board.

4.5.5 PAPER EMPTY WITHOUT INDICATION

Description

The paper lamp on the operator panel does not come on when the paper cassette

is empty.

Check and Cause Solution

Bending or deformation of the actuator

of the paper sensor.

Replace the defective actuator.

The function of the Main Control board

is defective Perform Engine Test Mode:

diagnostic code 2.

Replace the Main Board.

4.5.6 COVER OPEN

Description

The ERROR lamp is on even when the front door is closed.

Check and Cause Solution

The hook lever in the Front Cover may

be defective.

Replace the hook lever, if defective.

Check the insertion of the Cover Open

S/W Connecter.

Check the connector (CN1) and circuit

of the cover switch department in the

Main Board.

Replace the Main Board or Cover

Open S/W.

Page 84

PRINTING PROBLEMS

B173 4-18 SM

4.5.7 NO LAMP ON WHEN THE COVER IS OPEN

Description

The ERROR lamp does not come on even when the front door is open

Check and Cause Solution

Check the insertion of the Cover Open

S/W Connecter.

Check the connector (CN1) and circuit

of the cover switch department in the

Main Board.

Replace the Main Board or Cover

Open S/W.

4.5.8 DEFECTIVE MOTOR OPERATION

Description

Main motor is not driving when printing, and paper does not feed into the printer,

resulting “Jam 0”.

Check and Cause Solution

Motor harness or Main Board may be

defective.

Check the motor harness, if defective,

replace.

Perform Engine Test Mode diagnostic

code 0 and Check the Motor operation.

Replace the SMPS, if necessary.

4.5.9 NO POWER

Description

When system power is turned on, all lamps on the operator panel do not come on.

Check and Cause Solution

Check if the power input and SMPS

output are normal.

Replace the power supply cord or

SMPS.

Check for defective of LED-Panel on the

OPE if the LED of panel does not

appear after normal warming-up.

Replace the OPE ass’y.

Page 85

PRINTING PROBLEMS

SM 4-19 B173

Trouble-

shooting

4.5.10 VERTICAL LINES CURVED

Description

When printing, vertical lines curve.

Check and Cause Solution

Replace LSU.

If the supply of +24v is unstable in the

Main Board linking with LSU, check

drive by Engine Test Mode: Diagnostic

Code Check -1- LSU Motor on.

Replace the Main Board.

Page 86

PRINTING QUALITY PROBLEMS

B173 4-20 SM

4.6 PRINTING QUALITY PROBLEMS

4.6.1 VERTICAL BLACK LINE AND BAND

Description

1. Straight thin black vertical line(s) occurs in the printing

2. Dark black vertical band(s) occur in the printing.

Check and Cause Solution

1. Damaged develop roller in the

Developer. Deformed Doctor-blade or

cleaning-blade.

If causes 1 and 2 occur in the

developer cartridge, replace the AIO

and try to print again.

2. Scratched surface of the discharge

roller in the developer.

3. Partial depression or deformation on

the surface of the transfer roller.

Replace the transfer roller if occurred

as No. 3.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B173T913.WMF

Page 87

PRINTING QUALITY PROBLEMS

SM 4-21 B173

Trouble-

shooting

4.6.2 VERTICAL WHITE LINE

Description

White vertical voids in the image.

Check and Cause Solution

Foreign matter stuck onto the window

of internal lenses of LSU mirror.

Clean the LSU window with

recommended cleaner(IPA) and a

clean cotton swab.

Foreign matter or toner particles

between the developer roller and blade.

(In case the life of the developer has

been expired, white lines or light image

occur in front of the image.)

Open the cover of LSU and clean with

a cotton swab on the surface of the

reflex mirror with a clean cotton swab.

It may occur when a Burr and foreign

substances are on the window of the

developer frame.

Remove the foreign matter and burr of

the exposure window. (Developer

cartridge)

Open the front cover and check if the

ribs correspond to the position of the

voids. Remove if found.

If the fuser is defective, voids occur

periodically at the top of a black image.

If the problems are not solved, replace

the AIO.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B173T914.WMF

Page 88

PRINTING QUALITY PROBLEMS

B173 4-22 SM

4.6.3 HORIZONTAL BLACK BAND

Description

Dark or blurry horizontal stripes occur in the printing periodically.

(They may not occur on each print.)

Check and Cause Solution

Bad contacts of the voltage terminals to

developer.

Clean each voltage terminal of the

Charge, Supply, Develop and Transfer

roller. (remove the toner particles and

paper particles)

The rollers of developer may be

stained.

Charge roller = 37.7 mm

Supply roller = 37 mm

Develop roller = 35.3 mm

Transfer roller = 45.3 mm

Clean the right Gear that has a

relatively small gap of the teeth in the

OPC.

If the malfunction persists, replace the

AIO.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B173T915.WMF

Page 89

PRINTING QUALITY PROBLEMS

SM 4-23 B173

Trouble-

shooting

4.6.4 BLACK/WHITE SPOT

Description

1. Dark or blurry black spots occur periodically in the printing.

2. White spots occur periodically in the printing.

Check and Cause Solution

If dark or blurry black spots occur

periodically, the rollers in the Developer

may be contaminated with foreign

matter or paper particles.

(Charge roller : 37.7 mm interval

OPC drum : 75.5 mm interval)

Run OPC cleaning Mode Print and run

the Self-test 2 or 3 times.

If faded areas or voids occur in a black

image at intervals of 75.5 mm, or black

spots occur elsewhere, the OPC drum

surface is damaged.

In case of 75.5 mm interval, clean

foreign substances stuck on the OPC

location equivalent to the black spots

and white spots with a dry duster.

The transfer roller is guaranteed for

60,000 sheets. If the roller’s life is

expired, replace it.

If a black image is partially broken, the

transfer voltage is abnormal or the

transfer roller’s life has expired.

In case of 37.7 mm interval, take

measures as to replace the AIO and

try to print again.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B173T916.WMF

Page 90

PRINTING QUALITY PROBLEMS

B173 4-24 SM

4.6.5 LIGHT IMAGE

Description

The printed image is light, with no ghost.

Check and Cause Solution

Check if the Toner Save mode is

selected.

Develop roller is stained when the toner

of developer cartridge is almost

consumed.

Replace the AIO and try to print again.

Ambient temperature is below than

10°C.

Wait 30 minutes after the machine is

powered on before you start printing.

Bad contact caused by the toner stains

between the high voltage terminal in the

HVPS and the terminal in the AIO.

Clean up the contaminated area by

the toner.

Abnormal output from the HVPS. (Run

self-test and check the solution)

Replace the HVPS (SMPS) if the

problems are not solved by the above

solutions.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B173T917.WMF

Page 91

PRINTING QUALITY PROBLEMS

SM 4-25 B173

Trouble-

shooting

4.6.6 DARK IMAGE OR A BLACK

Description

The printed image is dark.

Check and Cause

No charge voltage in the Main Board.

(Perform Engine Test Mode diagnostic

code 4 HVPS check.)

Clean the high voltage charge

terminal.

Charge voltage is not turned on due to

the bad contacts between power supply

in the side of the Developer and charge

terminal of HVPS.

Check the state of the connector,

which connects the Main Board and

HVPS.

If steps 1 and 2 above did not correct

the problem, replace the HVPS

(SMPS).

4.6.7 UNEVEN DENSITY

Description

Print density is uneven between left and right.

Check and Cause Solution

The pressure force on the left and right

springs of the transfer roller is not even,

the springs are damaged, the transfer

roller is improperly installed, or the

transfer roller bushing or holder is

damaged.

Replace both the left and right Spring

Holder.

The life of the Developer has expired.

The toner level is not even on the

developer roller due to the bad blade.

Problem with the toner cartridge,

replace the AIO and try to print again.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B173T919.WMF

B173T920.WMF

Page 92

PRINTING QUALITY PROBLEMS

B173 4-26 SM

4.6.8 BACKGROUND

Description

Light dark background appears in whole area of the printing.

Check and Cause Solution

Recycled recording paper has been

used.

Quality is not guaranteed when using

recycled paper.

The life of the Developer has expired. Replace the AIO.

The up-to-down movement of the

transfer roller is swift?

Clean the bushings on the transfer

roller.

The HVPS is normal?

(Perform Engine Test Mode diagnostic

code 4)

Replace the HVPS (SMPS).

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B173T921.WMF

Page 93

PRINTING QUALITY PROBLEMS

SM 4-27 B173

Trouble-

shooting

4.6.9 GHOST (1)

Description

Ghost occurs at 75.5 mm intervals of the OPC drum in the

whole printing.

Check and Cause Solution

Bad contacts caused by contamination

from toner particles between the high

voltage terminal in the main body and

the electrode of the developer.