Page 1

Model A-C3e/f

(Machine Code: B135/B138)

SERVICE MANUAL

Page 2

IIMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

manuals4u.commanuals4u.com

Page 3

1. SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

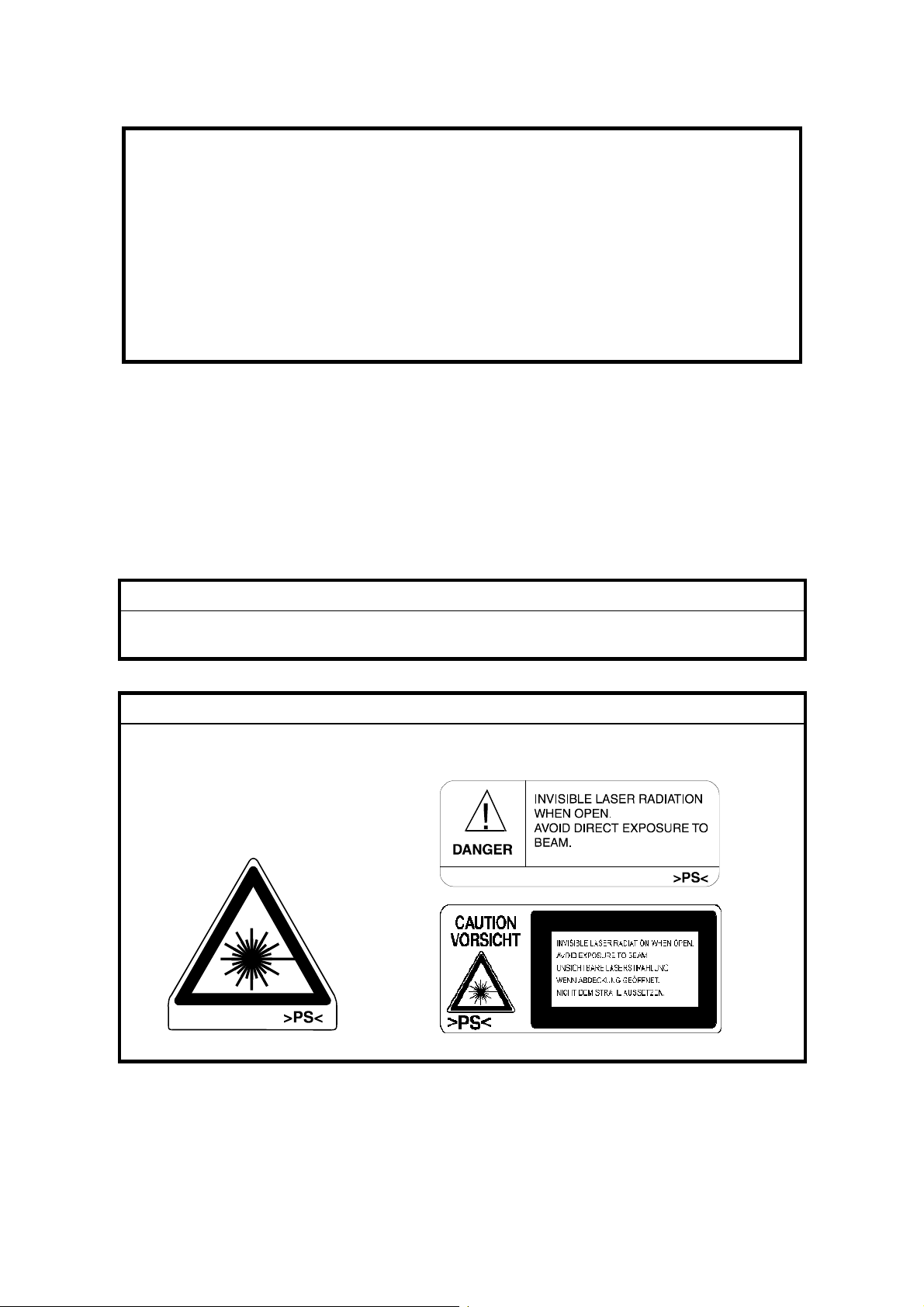

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can seriously damage

your eyes.

CAUTION MARKING:

Page 4

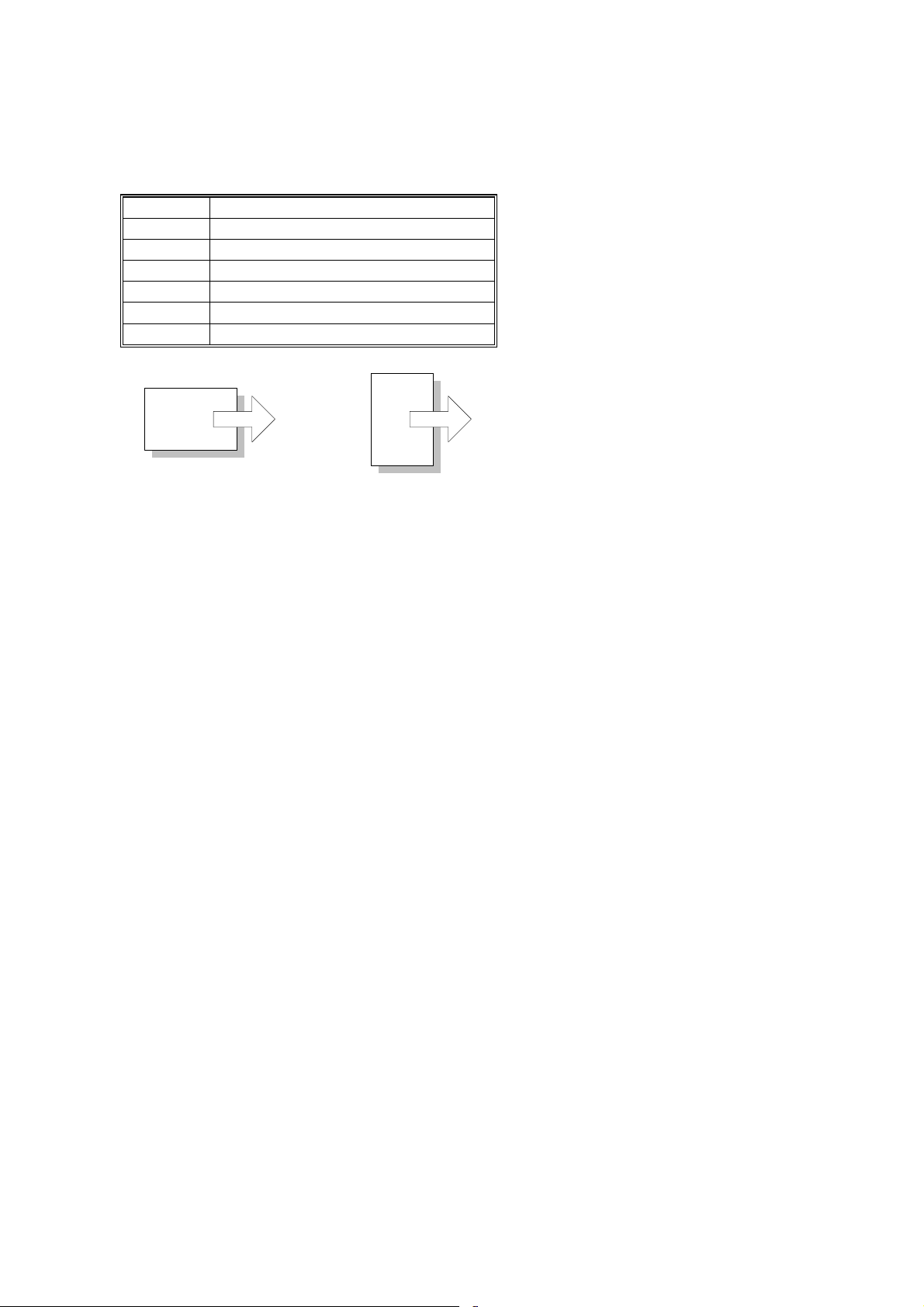

Conventions in this Manual

This manual uses several symbols.

Symbol What it means

☛

!

"

#

$

%

Refer to section number

See Core Tech Manual for details

Screw

Connector

E-ring

Clip ring

Long Edge Feed (LEF)Short Edge Feed (SEF)

manuals4u.commanuals4u.com

Page 5

TABLE OF CONTENTS

1. INSTALLATION PROCEDURE ................................................... 1-1

1.1 INSTALLATION REQUIREMENTS........................................................... 1-1

1.1.1 ENVIRONMENT .............................................................................. 1-2

1.1.2 MACHINE LEVEL ............................................................................ 1-2

1.1.3 MINIMUM SPACE REQUIREMENTS.............................................. 1-3

1.1.4 POWER REQUIREMENTS.............................................................. 1-5

1.2 INSTALLATION FLOW CHART................................................................ 1-6

1.3 MAIN MACHINE INSTALLATION............................................................. 1-7

1.3.1 ACCESSORY CHECK..................................................................... 1-7

1.3.2 INSTALLATION PROCEDURE........................................................ 1-8

Development Unit and PCU ................................................................. 1-9

Toner Bottle........................................................................................ 1-12

Paper Trays........................................................................................ 1-13

Initialize TD Sensor and Developer.................................................... 1-15

Set Paper Size for Paper Trays.......................................................... 1-16

Electrical Total Counter...................................................................... 1-17

HDD Caution Decal............................................................................ 1-17

Exposure Glass Cleaner .................................................................... 1-17

1.4 PAPER TRAY UNIT INSTALLATION (B542).......................................... 1-18

1.4.1 ACCESSORY CHECK................................................................... 1-18

1.4.2 PAPER TRAY UNIT INSTALLATION PROCEDURE..................... 1-19

1.5 1-BIN TRAY UNIT INSTALLATION (B544)............................................. 1-23

1.5.1 ACCESSORY CHECK................................................................... 1-23

1.5.2 1-BIN TRAY INSTALLATION PROCEDURE................................. 1-24

1.6 BRIDGE UNIT INSTALLATION (B538)................................................... 1-30

1.6.1 ACCESSORY CHECK................................................................... 1-30

1.6.2 BRIDGE UNIT INSTALLATION PROCEDURE.............................. 1-31

1.7 TWO-TRAY FINISHER INSTALLATION (B545)..................................... 1-33

1.7.1 ACCESSORY CHECK................................................................... 1-33

1.7.2 TWO-TRAY FINISHER INSTALLATION PROCEDURE................ 1-34

1.8 PUNCH UNIT INSTALLATION ............................................................... 1-37

1.8.1 ACCESSORY CHECK................................................................... 1-37

1.8.2 PUNCH UNIT INSTALLATION PROCEDURE............................... 1-38

1.9 ARDF INSTALLATION (B541)................................................................ 1-41

1.9.1 ACCESSORY CHECK................................................................... 1-41

1.9.2 ARDF INSTALLATION PROCEDURE........................................... 1-41

1.9.3 ARDF SKEW ADJUSTMENT......................................................... 1-44

1.10 LCT INSTALLATION (B543)................................................................. 1-45

1.10.1 ACCESSORY CHECK................................................................. 1-45

1.10.2 LCT INSTALLATION PROCEDURE............................................ 1-46

1.11 PLATEN COVER INSTALLATION (G329)............................................ 1-48

1.12 BOOKLET FINISHER INSTALLATION (B546) ..................................... 1-49

1.12.1 ACCESSORY CHECK................................................................. 1-49

1.12.2 BOOKLET FINISHER INSTALLATION PROCEDURE ................ 1-50

i

Page 6

1.13 1000 SHEET FINISHER (B408) ........................................................... 1-55

1.13.1 ACCESSORY CHECK................................................................. 1-55

1.13.2 1000 SHEET FINISHER INSTALLATION PROCEDURE ............ 1-56

1.14 FILE FORMAT CONVERTER B519-17 ................................................ 1-59

1.14.1 ACCESSORY CHECK................................................................. 1-59

1.14.2 INSTALLATION PROCEDURE.................................................... 1-59

1.14.3 CHECK ALL CONNECTIONS...................................................... 1-60

2. PREVENTIVE MAINTENANCE SCHEDULE............................... 2-1

2.1 PM TABLE................................................................................................ 2-1

3. REPLACEMENT AND ADJUSTMENT........................................ 3-1

3.1 SPECIAL TOOLS AND LUBRICANTS ............................................... 3-2

3.1.1 SPECIAL TOOLS............................................................................. 3-2

3.1.2 LUBRICANTS .................................................................................. 3-2

3.2 LASER UNIT............................................................................................. 3-3

3.2.1 CAUTION DECAL LOCATIONS ...................................................... 3-3

3.2.2 LASER UNIT.................................................................................... 3-4

3.3 PHOTOCONDUCTOR UNIT (PCU).......................................................... 3-6

3.3.1 PCU ................................................................................................. 3-6

3.3.2 DRUM .............................................................................................. 3-7

3.3.3 PICK-OFF PAWLS........................................................................... 3-9

Pick-off pawl position adjustment......................................................... 3-9

3.3.4 CHARGE ROLLER AND CLEANING ROLLER ............................. 3-10

3.3.5 DRUM CLEANING BLADE 2 ......................................................... 3-11

3.3.6 DRUM CLEANING BLADE 1 ......................................................... 3-12

3.4 FUSING UNIT......................................................................................... 3-13

3.4.1 FUSING UNIT REMOVAL.............................................................. 3-13

3.4.2 FUSING UNIT SIDE FAN............................................................... 3-14

3.4.3 FUSING UNIT CORNER FAN ....................................................... 3-16

3.5 PAPER FEED......................................................................................... 3-17

3.5.1 IDLE ROLLER DUST BLADE ........................................................ 3-17

3.5.2 REGISTRATION ROLLER DUST BLADE ..................................... 3-18

3.6 PRINTED CIRCUIT BOARDS ................................................................ 3-19

3.6.1 IOB................................................................................................. 3-19

IOB DIP Switch Settings (SW101) ..................................................... 3-20

3.7 HARD DISK, CONTROLLER BOARD .................................................... 3-21

4. TROUBLESHOOTING................................................................. 4-1

4.1 SERVICE CALL CONDITIONS................................................................. 4-1

4.1.1 SUMMARY....................................................................................... 4-1

4.1.2 SC CODE DESCRIPTIONS............................................................. 4-2

4.2 ELECTRICAL COMPONENT DEFECTS................................................ 4-10

4.2.1 SENSORS ..................................................................................... 4-10

4.2.2 SWITCHES.................................................................................... 4-11

4.3 BLOWN FUSE CONDITIONS................................................................. 4-11

4.4 LEDS ...................................................................................................... 4-12

4.5 TEST POINTS ........................................................................................ 4-12

ii

manuals4u.commanuals4u.com

Page 7

5. SERVICE TABLES...................................................................... 5-1

5.1 SERVICE PROGRAM MODE TABLES .................................................... 5-1

5.1.1 SERVICE TABLE KEY..................................................................... 5-1

5.1.2 SERVICE TABLES .......................................................................... 5-2

SP1-xxx: Feed...................................................................................... 5-2

SP2-xxx: Drum..................................................................................... 5-6

SP3-xxx: Process............................................................................... 5-16

SP4-xxx: Scanner .............................................................................. 5-17

SP5-xxx: Mode................................................................................... 5-26

SP6-xxx: Peripherals.......................................................................... 5-46

SP7-xxx: Data Log ............................................................................. 5-48

SP8-xxx: Data Log2 ........................................................................... 5-56

5.1.3 TEST PATTERN PRINTING: SP2-902 .......................................... 5-90

Test Pattern Table (SP2-902-2: IPU Test Print)................................. 5-90

Test Pattern Table: SP2-902-3 Printing Test Patterns ....................... 5-91

5.1.4 INPUT CHECK............................................................................... 5-92

Main Machine Input Check: SP5-803................................................. 5-92

ARDF Input Check: SP6-007 ............................................................. 5-96

5.1.5 OUTPUT CHECK........................................................................... 5-97

Main Machine Output Check: SP5-804 .............................................. 5-97

ARDF Output Check: SP6-008) ......................................................... 5-99

5.1.6 SMC PRINT OUT LISTS: SP5-990................................................ 5-99

5.1.7 MEMORY CLEAR: SP5-801........................................................ 5-100

5.2 DIP SWITCHES.................................................................................... 5-102

5.3 USING THE DEBUG LOG.................................................................... 5-103

5.3.1 SWITCHING ON AND SETTING UP SAVE DEBUG LOG .......... 5-103

5.3.2 RETRIEVING THE DEBUG LOG FROM THE HDD ................... 5-107

5.3.3 RECORDING ERRORS MANUALLY .......................................... 5-107

6. DETAILED SECTIOIN DESCRIPTIONS...................................... 6-1

6.1 BOARD STRUCTURE.............................................................................. 6-2

6.1.1 BLOCK DIAGRAM........................................................................... 6-2

6.1.2 CONTROLLER ................................................................................ 6-4

6.2 IMAGE PROCESSING ............................................................................. 6-7

6.2.1 OVERVIEW...................................................................................... 6-7

6.2.2 SBU (SENSOR BOARD UNIT)........................................................ 6-8

6.2.3 AUTO IMAGE DENSITY (ADS) ....................................................... 6-9

6.2.4 IPU (IMAGE PROCESSING UNIT)................................................ 6-10

Overview ............................................................................................ 6-10

6.2.5 IMAGE PROCESSING MODES .................................................... 6-11

6.2.6 SUMMARY OF IMAGE PROCESSING FUNCTIONS ................... 6-13

6.2.7 IMAGE PROCESSING STEPS AND RELATED SP MODES........ 6-14

Text Mode .......................................................................................... 6-14

Text/Photo Mode................................................................................ 6-15

Photo Mode........................................................................................ 6-16

Pale (Low-Density Mode)................................................................... 6-17

Generation Copy Mode ...................................................................... 6-18

iii

Page 8

v

6.2.8 PRE-FILTERING............................................................................ 6-19

6.2.9 BACKGROUND ERASE ................................................................ 6-20

6.2.10 INDEPENDENT DOT ERASE...................................................... 6-21

6.2.11 LINE WIDTH CORRECTION ....................................................... 6-22

6.2.12 FILTERING .................................................................................. 6-23

Interactive SP Codes ......................................................................... 6-23

Text Mode MTF Filter......................................................................... 6-27

Text/Photo, Photo Mode Filter............................................................ 6-28

Pale, Generation Mode Filter ............................................................. 6-29

Photo Mode Smoothing for Dithering ................................................. 6-30

Photo Mode Grayscale....................................................................... 6-30

Photo Mode Image Quality................................................................. 6-31

6.2.13 OTHERS...................................................................................... 6-32

Vertical Black Line Correction ............................................................ 6-32

Density Settings ................................................................................. 6-32

ADS Level .......................................................................................... 6-33

6.2.14 PRACTICAL APPLICATION OF SP MODES .............................. 6-34

Solving Problems ............................................................................... 6-34

Recommended Settings for MTF Filters............................................. 6-35

6.3 PHOTOCONDUCTOR UNIT (PCU)........................................................ 6-37

6.3.1 OVERVIEW.................................................................................... 6-37

6.3.2 DRUM CLEANING......................................................................... 6-38

6.4 DRUM CHARGE..................................................................................... 6-39

6.4.1 CORRECTION FOR PAPER WIDTH AND THICKNESS............... 6-39

6.4.2 DEVELOPMENT BIAS................................................................... 6-40

Mechanism......................................................................................... 6-40

Correction for paper width and thickness (by-pass tray only)............. 6-40

6.5 PAPER FEED......................................................................................... 6-41

6.5.1 PAPER REGISTRATION............................................................... 6-41

6.6 IMAGE FUSING AND PAPER EXIT....................................................... 6-42

6.6.1 CLEANING MECHANISM.............................................................. 6-42

6.6.2 HOT ROLLER STRIPPER CLEANING.......................................... 6-43

6.6.3 FUSING TEMPERATURE CONTROL........................................... 6-45

Temperature Control.......................................................................... 6-46

Fusing Idling Temperature ................................................................. 6-47

6.6.4 CPM DOWN FOR THICK PAPER ................................................. 6-48

6.6.5 COOLING AND OVERHEAT PROTECTION................................. 6-49

6.6.6 TONER SCATTER PREVENTION ................................................ 6-50

i

manuals4u.commanuals4u.com

Page 9

v

PERIPHERALS

BOOKLET FINISHER (B546)

1. OVERALL MACHINE INFORMATION ..................................B546-1

1.1 MECHANICAL COMPONENT LAYOUT............................................. B546-1

2. DETAILED DESCRIPTIONS .................................................B546-2

2.1 JUNCTION GATE MECHANISM ........................................................ B546-2

2.1.1 SHIFT TRAY MODE .................................................................. B546-2

A4/LT sideways or shorter ............................................................. B546-2

Longer than A4 sideways............................................................... B546-2

2.1.2 PROOF TRAY MODE................................................................ B546-3

2.1.3 BOOKLET STITCH MODE ........................................................ B546-3

2.2 PRE-STACK MECHANISM ................................................................ B546-4

2.3 PAPER SHIFT MECHANISM ............................................................. B546-5

2.4 PAPER POSITIONING MECHANISM ................................................ B546-6

2.5 STAPLER UNIT MOVEMENT MECHANISM...................................... B546-7

2.5.1 DRIVE........................................................................................ B546-7

2.5.2 MOVEMENT .............................................................................. B546-7

Front and Rear Stapling................................................................. B546-7

Tow-position Stapling..................................................................... B546-7

2.6 STAPLER ........................................................................................... B546-8

2.7 SHIFT TRAY MECHANISM ................................................................ B546-9

2.8 BOOKLET UNIT GATE MECHANISM.............................................. B546-10

2.9 RELAY ROLLER AND POSITIONING PLATE MECHANISM........... B546-12

2.10 POSITIONING ROLLER MECHANISM .......................................... B546-13

2.11 BOOKLET UNIT JOGGER MOVEMENT MECHANISM................. B546-14

2.12 BOOKLET STAPLER UNIT ............................................................ B546-15

2.13 PAPER FOLDER MECHANISM ..................................................... B546-16

3. REPLACEMENT AND ADJUSTMENT................................B546-18

3.1 REMOVAL ........................................................................................ B546-18

3.1.1 UPPER DOOR......................................................................... B546-18

3.1.2 UPPER REAR COVER............................................................ B546-19

3.1.3 LOWER REAR COVER ........................................................... B546-19

3.1.4 TOP COVER............................................................................ B546-20

3.1.5 UPPER INNER COVER........................................................... B546-20

3.1.6 SHIFT TRAY UNIT................................................................... B546-21

3.1.7 UPPER SHIFT GUIDE............................................................. B546-22

3.1.8 LOWER SHIFT GUIDE ............................................................ B546-22

3.1.9 EXIT UNIT................................................................................ B546-23

3.1.10 BUFFER ROLLER UNIT........................................................ B546-24

3.1.11 STAPLER............................................................................... B546-25

3.1.12 FINISHER BOARD ...............................................................B546-26

3.1.13 BOOKLET UNIT..................................................................... B546-27

3.1.14 FOLDER ROLLERS............................................................... B546-29

Page 10

3.1.15 FOLDER PLATE.................................................................... B546-32

Removal....................................................................................... B546-32

Reinstalling................................................................................... B546-33

3.1.16 BOOKLET STAPLER UNIT ................................................... B546-34

Removal....................................................................................... B546-34

Adjustment ................................................................................... B546-35

3.1.17 BOOKLET BOARD ................................................................ B546-37

3.1.18 POSITIONING PLATE UNIT.................................................. B546-37

3.1.19 1ST AND 2ND BOOKLET UNIT GATES ............................... B546-38

3.2 ADJUSTMENT.................................................................................. B546-39

3.2.1 SHIFT TRAY HEIGHT ............................................................. B546-39

3.2.2 JOGGER FENCE POSITION................................................... B546-40

3.2.3 STAPLING POSITION............................................................. B546-41

3.2.4 BOOKLET STAPLING POSITION ........................................... B546-42

SPECIFICATIONS.................................................................... SPEC-1

1. GENERAL SPECIFICATIONS.............................................................SPEC-1

2. MACHINE CONFIGURATION .............................................................SPEC-3

3. OPTIONAL EQUIPMENT ...................................................................SPEC-5

vi

manuals4u.commanuals4u.com

Page 11

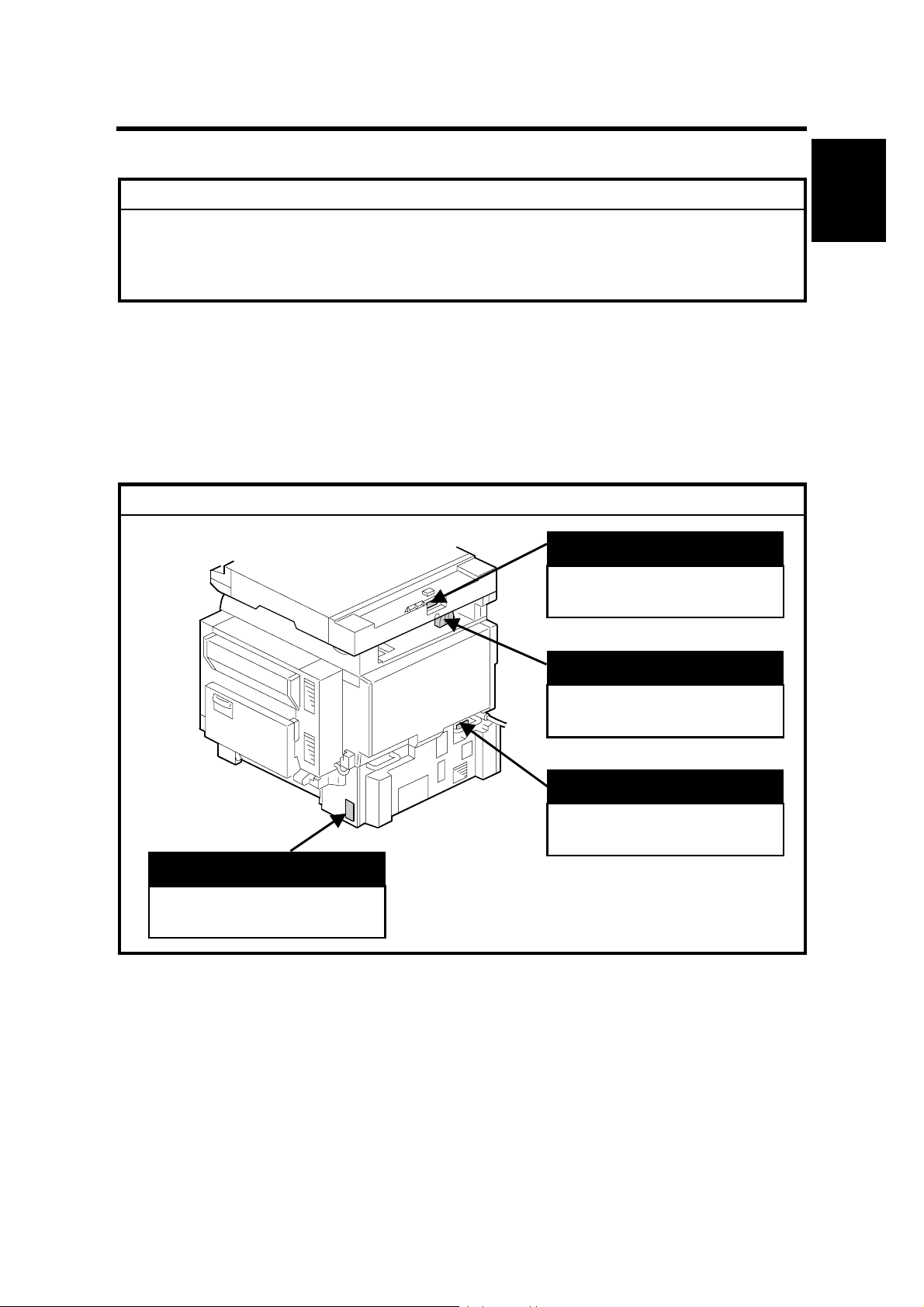

1 August, 2003 INSTALLATION REQUIREMENTS

1. INSTALLATION PROCEDURE

!CAUTION

Never turn off the main power switch when the power LED is lit or flashing.

To avoid damaging the hard disk or memory, press the operation power

switch to switch the power off, wait for the power LED to go off, and then

switch the main power switch off.

NOTE: The main power LED lights or flashes while the platen cover or ARDF is

open, while the main machine is communicating with a facsimile or the

network server, or while the machine is accessing the hard disk or memory

for reading or writing data.

1.1 INSTALLATION REQUIREMENTS

CAUTION

!

ARDF

Installation

B135I016.WMF

LCT

“Rating Voltage of Output

Connector, Max. DC24 V”

“Rating Voltage of Output

Connector, Max. DC24 V”

Scanner Unit

“Rating Voltage of Output

Connector, Max. DC24 V”

Finisher

“Rating Voltage of Output

Connector, Max. DC24 V”

1-1

Page 12

INSTALLATION REQUIREMENTS 1 August, 2003

1.1.1 ENVIRONMENT

1. Temperature Range:

2. Humidity Range:

3. Ambient Illumination:

10 °C to 32 °C (50 °F to 90 °F)

15% to 80% RH

Less than 1,500 lux (do not expose to direct

sunlight.)

4. Ventilation:

5. Ambient Dust:

Room air should turn over

at least 30 m

Less than 0.10 mg/m

3

/hr/person

3

(2.7 x 10/6 oz/yd3)

6. Avoid areas exposed to sudden temperature changes:

1) Areas directly exposed to cool air from an air conditioner.

2) Areas directly exposed to heat from a heater.

7. Do not place the machine where it will be exposed to corrosive gases.

8. Do not install the machine at any location over 2,000 m (6,500 ft.) above sea

level.

9. Place the main machine on a strong and level base. Inclination on any side

should be no more than 5 mm (0.2").

10. Do not place the machine where it may be subjected to strong vibrations.

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

1-2

manuals4u.commanuals4u.com

Page 13

1 August, 2003 INSTALLATION REQUIREMENTS

A

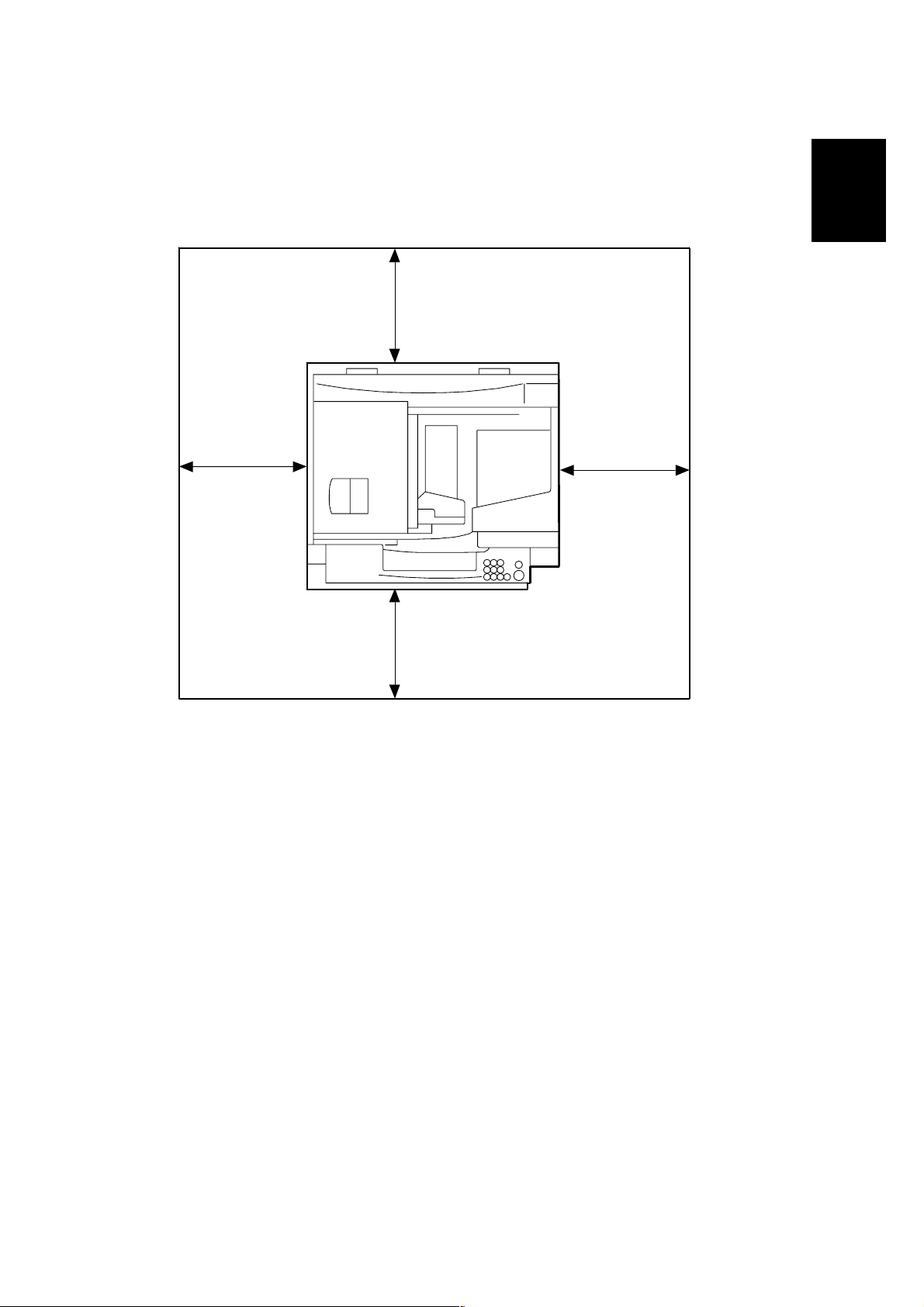

1.1.3 MINIMUM SPACE REQUIREMENTS

Place the main machine near the power source, providing clearance as shown:

Installation

C

B

D

A

B135I010.WMF

: Front: >75 cm (29.6")

B: Left: > 10 cm (4")

C: Rear: > 10 cm (4")

D: Right > 10 cm (4")

NOTE: The 75 cm (29.5") recommended for the space at the front is for pulling out

the paper tray only. If the operator stands at the front of the main machine,

more space is required.

1-3

Page 14

INSTALLATION REQUIREMENTS 1 August, 2003

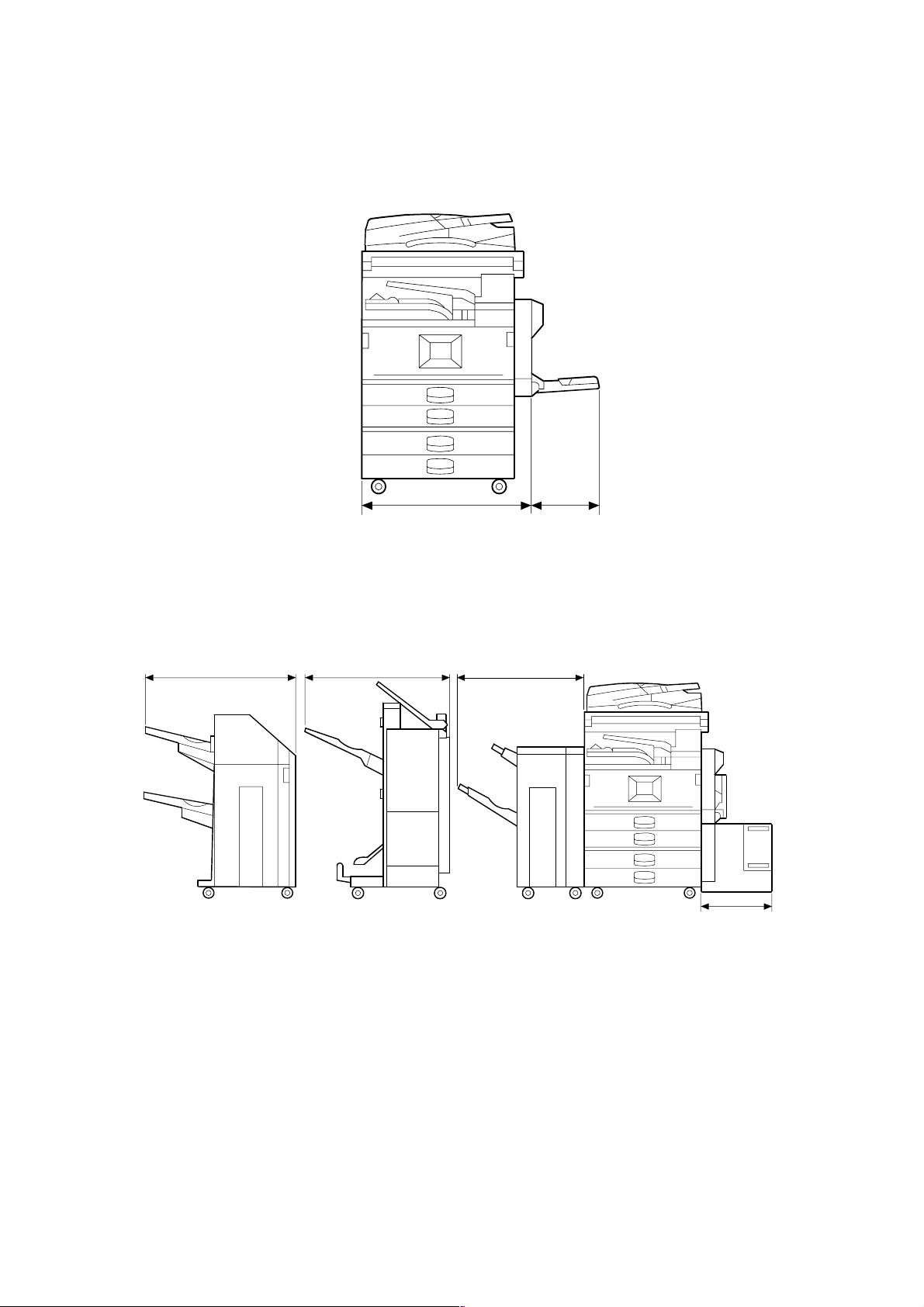

726 mm (28.6") 670 mm (23.4")

670 mm (26.4")

620 mm (24.4")

180 mm (7.1")

B135I012.WMF

B135I014.WMF

1-4

manuals4u.commanuals4u.com

Page 15

1 August, 2003 INSTALLATION REQUIREMENTS

1.1.4 POWER REQUIREMENTS

!CAUTION

1. Make sure that the wall outlet is near the main machine and easily

accessible. Make sure the plug is firmly inserted in the outlet.

2. Avoid multi-wiring.

3. Be sure to ground the machine.

1. Input voltage level:

North America 120 V, 60 Hz: More than 12.5 A

Europe/Asia 220 V ~ 240V, 50 Hz/60 Hz: more than 6.8 A

2. Permissible voltage fluctuation: ±10 %

3. Never set anything on the power cord.

Installation

1-5

Page 16

INSTALLATION FLOW CHART 1 August, 2003

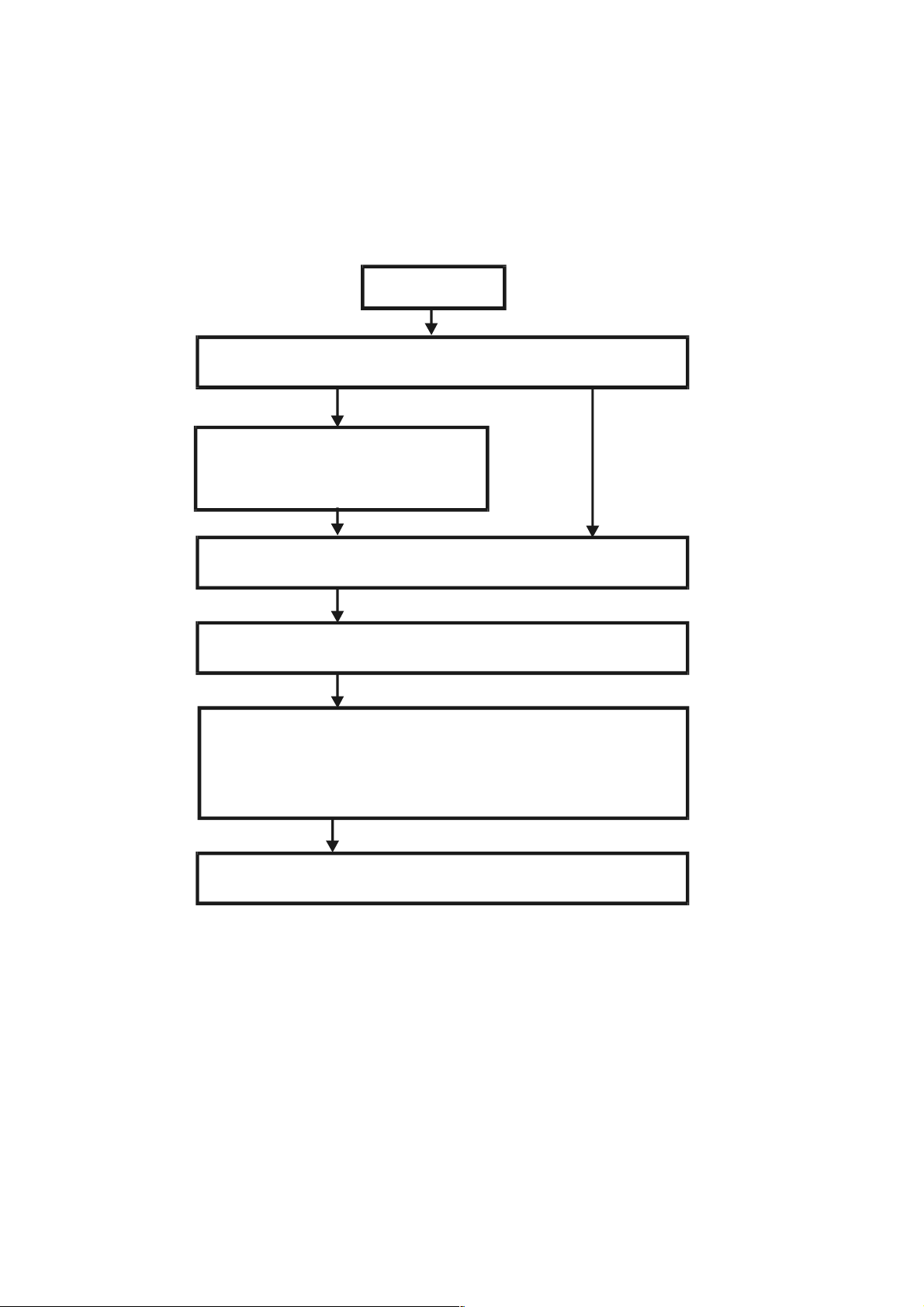

1.2 INSTALLATION FLOW CHART

The following flow chart shows how to install the optional units more efficiently.

Unpack Copier

Does the user require the Paper Tray Unit, LCT, or Finisher?

Yes No

Place Copier on the paper tray unit

Install the paper tray unit

Install the copier

Install the bridge unit (if required)

If the customer requires the 1-bin tray:

Remove the scanner unit

Install the 1-bin tray

Replace the scanner unit

Install the remaining options in any order

Bridge Unit: Needed for the finishers and external output tray.

Paper Tray Unit: Needed for LCT and finishers.

B135I510.WMF

Other requirements: See Overall Machine Information – Installation Option Table.

1-6

manuals4u.commanuals4u.com

Page 17

1 August, 2003 MAIN MACHINE INSTALLATION

1.3 MAIN MACHINE INSTALLATION

1.3.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Operation Instructions – System Setting............................... 1

2. Operation Instructions – Copy Reference ............................. 1

3. Exposure Glass Cleaner Holder............................................ 1

4. Exposure Glass Cleaner ....................................................... 1

5. Paper Size Decal .................................................................. 1

6. Middle Front Cover................................................................ 1

7. NECR – English (-17, -19, -21, -28, -29, -57 Machines)........ 1

8. NECR – Multi-Language (-26, -27, -66, -67 Machines)......... 1

9. HDD Caution Decals (-17, -29, -57 Machines)...................... 1

10. Model Name Decal (-17, -29, -57 Machines) ........................ 1

11. Stamp (-17 Machine)............................................................. 1

Installation

12. EU Safety Information (-26, -27, -66, -67 Machines)............. 1

13. Operation Panel Indicator Decals

(-26, -27, -66, -67 Machines)................................................. 1

14. Address Information Sheet – China (-21 Machine) ............... 1

15. Paper Caution Sheet – China (-21 Machine) ........................ 1

16. Energy Start Sticker (-26, -66 Machines) .............................. 1

1-7

Page 18

MAIN MACHINE INSTALLATION 1 August, 2003

1.3.2 INSTALLATION PROCEDURE

[A]

[B]

[D]

[C]

B135I100.WMF

B135I102.WMF

B135I103.WMF

[D]

[E]

B135I101.WMF

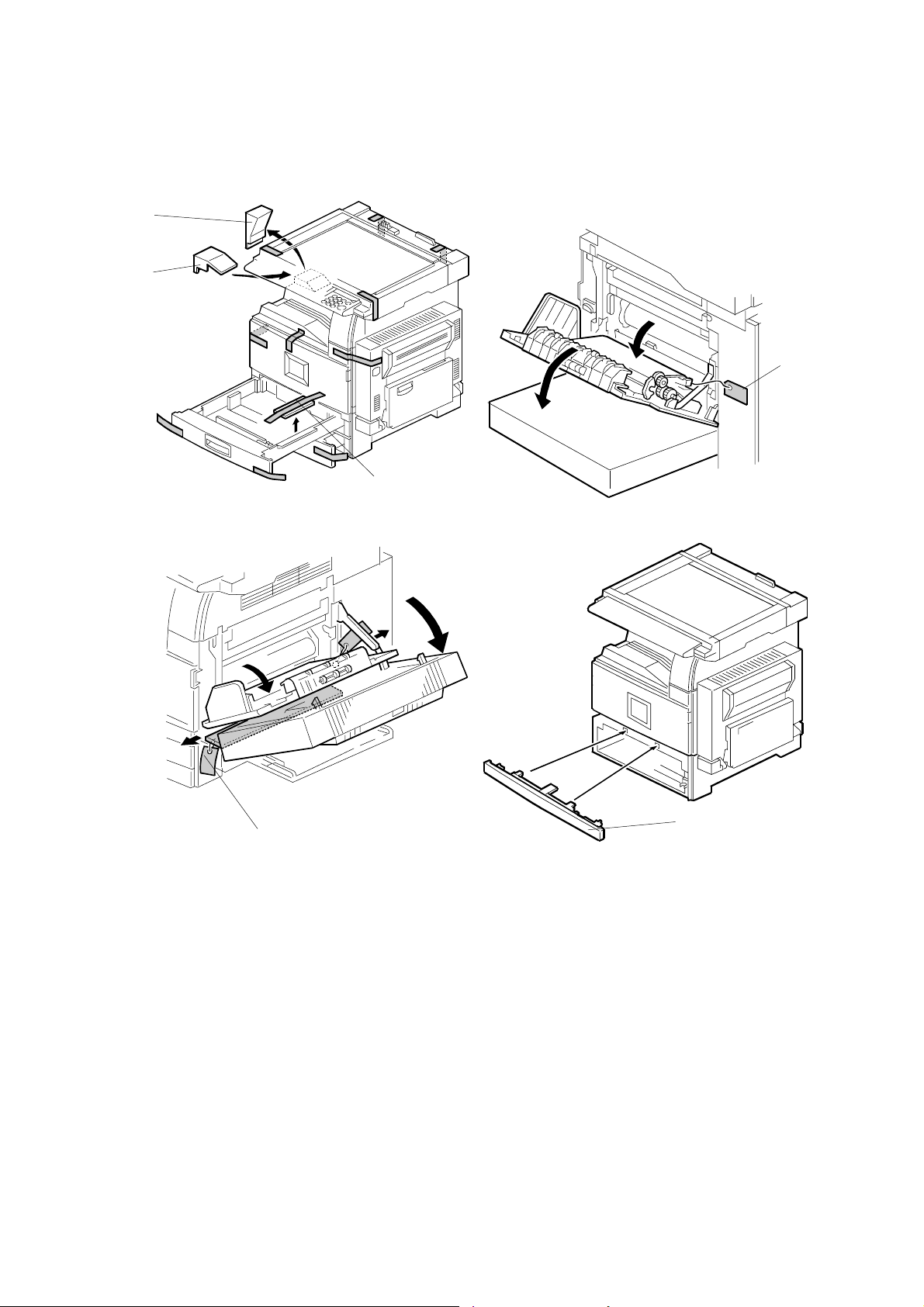

1. Remove the main machine from the box, and remove all shipping retainers and

tapes.

NOTE: Store all shipping retainers as you remove them. You will need them if

the machine is moved to another location in the future.

2. Remove scanner cushion [A], and install the end fence [B].

3. Pull out the paper trays and remove all tape and bottom plate stoppers [C].

4. On the right side of the machine, open the by-pass tray, duplex unit, and

transfer right cover, and then remove all the shipping retainers [D]

NOTE: If the paper tray unit is to be installed, do this now. (☛1.4)

5. If the paper tray unit is not to be installed, install the middle front cover [E]

(provided in the second paper tray).

1-8

manuals4u.commanuals4u.com

Page 19

1 August, 2003 MAIN MACHINE INSTALLATION

Development Unit and PCU

[C]

[A]

[B]

B135I104.WMF

B135I900.WMF

Installation

[G]

[E]

[F]

B135I511.WMF

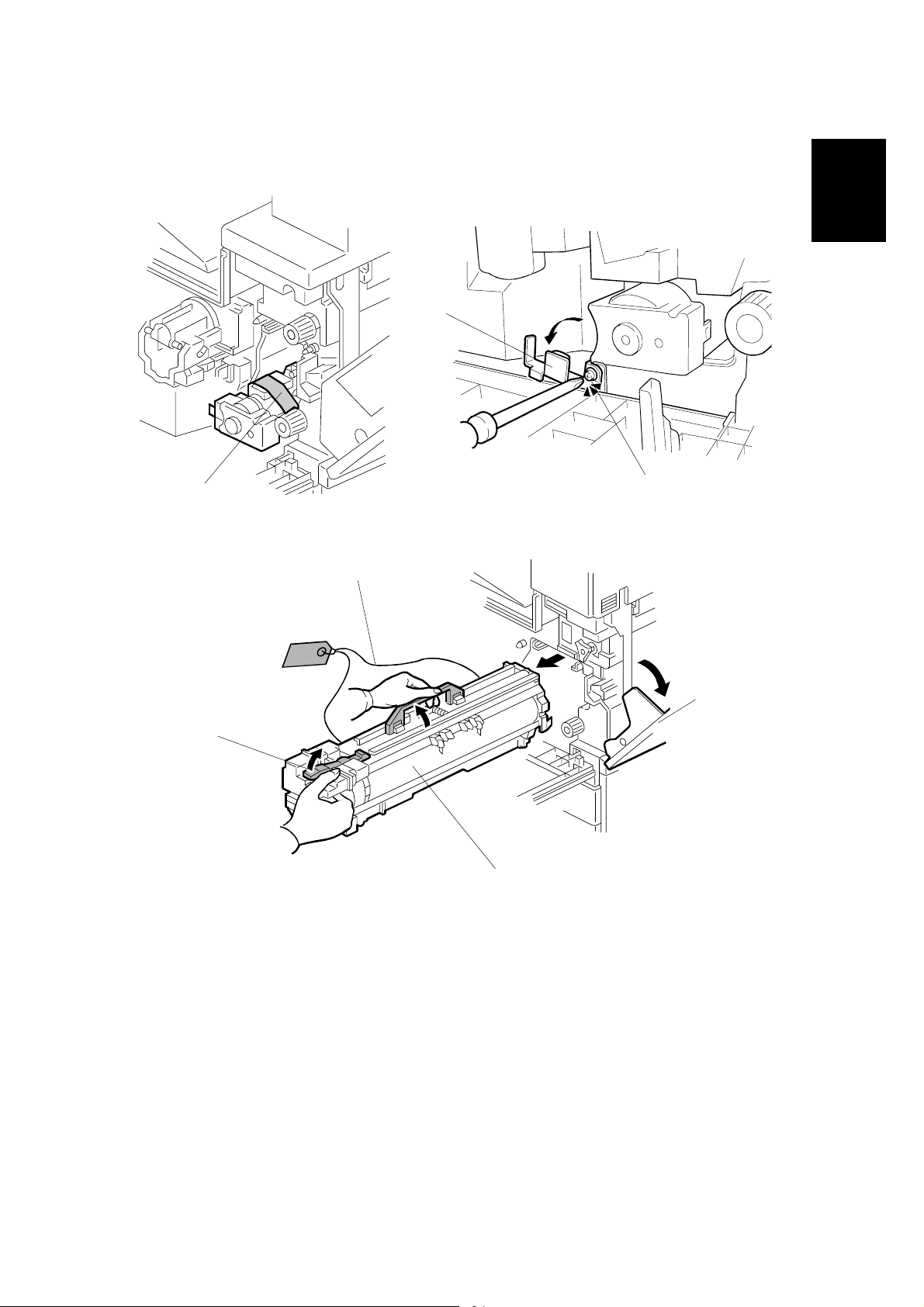

1. Open the front cover and remove the tape and retainers [A].

2. Loosen [B] (! x 1) and rotate the bracket [C].

3. Open the right cover [D].

4. Raise the lever [E]

[D]

5. Holding the PCU [F] as shown slide it out and place it on a clean flat surface.

6. Remove clamps and wire [G].

1-9

Page 20

MAIN MACHINE INSTALLATION 1 August, 2003

[A]

B135I512.WMF

[C]

[B]

B135I105.WMF

7. Spread a large piece of paper on a flat surface.

NOTE: Make sure the area is free of pins, paper clips, staples, etc. to avoid

attraction to the magnetic development roller.

8. Slide the development unit [A] out and place it on the paper.

9. Remove the tape and tag [B] from the development unit

10. Remove the entrance seal plate [C] (" x 2).

1-10

manuals4u.commanuals4u.com

Page 21

1 August, 2003 MAIN MACHINE INSTALLATION

[A]

[C]

[B]

B135I106.WMF

[D]

B135I513.WMF

Installation

B135I019.WMF

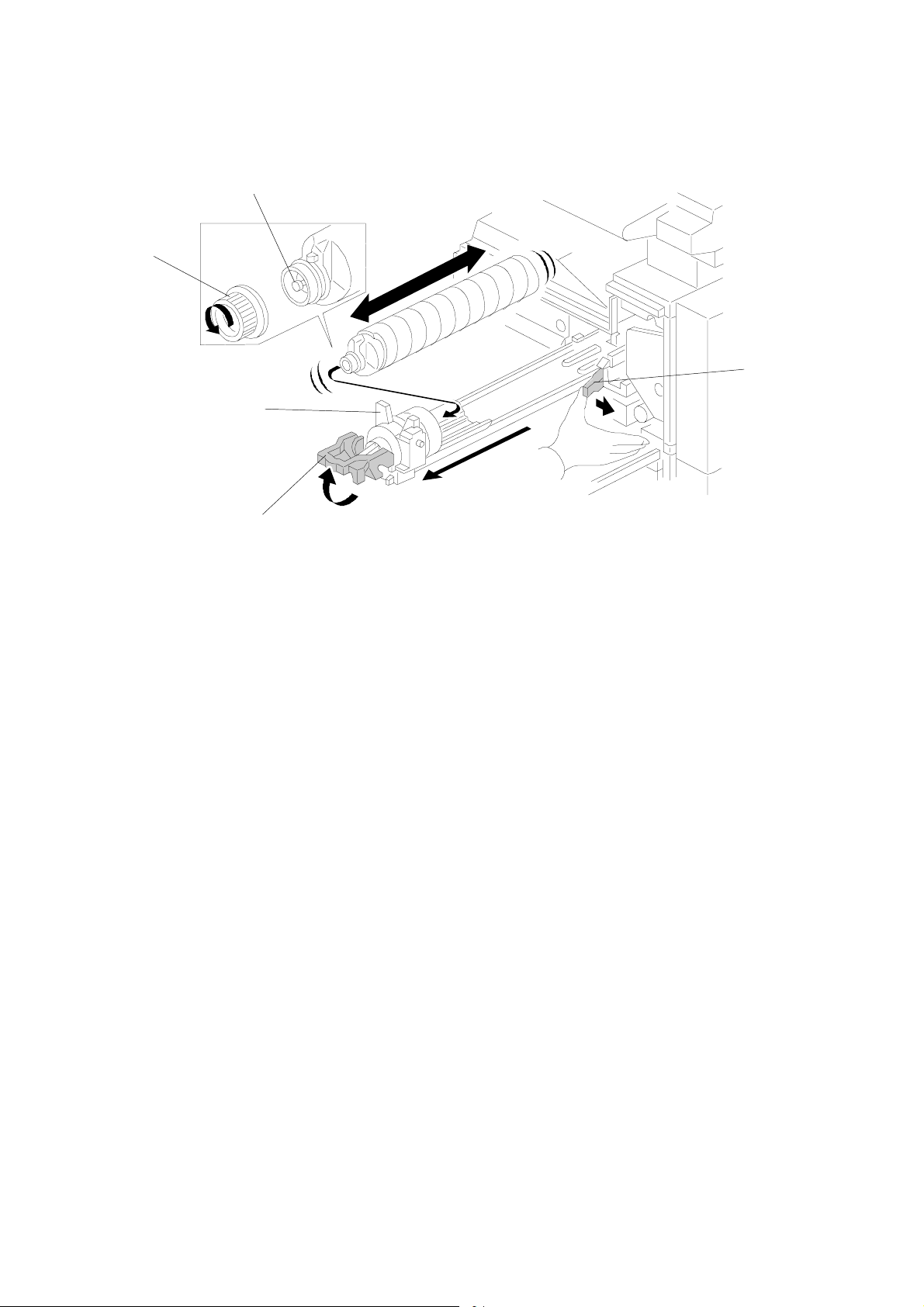

11. Remove the development roller unit [A], and set it on the paper.

12. Pour the developer [B] into the development unit.

NOTE: The developer lot number is embossed on the end of the developer

package. Do not discard the package until you have recorded the lot

number. (☛1-15)

1) Pour approximately 1/3 of the developer evenly along the length of the

development unit.

2) Rotate the drive gear [C] to work the developer into the unit.

3) Repeat until all the developer is in the development unit.

4) Continue to turn the drive gear until the developer is even with the top of the

unit.

13. Reassemble the development unit.

NOTE: Make sure that the earth plate [D] is positioned correctly.

14. Re-install the development unit and PCU.

1-11

Page 22

MAIN MACHINE INSTALLATION 1 August, 2003

[E]

[D]

[B]

[C]

[A]

B135I514.WMF

Toner Bottle

1. Raise the toner bottle holder lever [A], push the lever [B] to the side, and then

pull the toner bottle holder [C] out.

2. Shake the new toner bottle well.

NOTE: Do not remove the toner bottle cap [D] until after shaking.

3. Unscrew the bottle cap and set the bottle in the holder.

NOTE: Do not touch the inner bottle cap [E].

4. Push the toner bottle holder into the main machine until it locks in place, and

then lower the holder lever to secure the toner bottle.

NOTE: The holder lever cannot be lowered unless the toner bottle is installed.

1-12

manuals4u.commanuals4u.com

Page 23

1 August, 2003 MAIN MACHINE INSTALLATION

Paper Trays

B135I107.WMF

[A]

[C]

[B]

[D]

Installation

[E]

B135I109.WMF

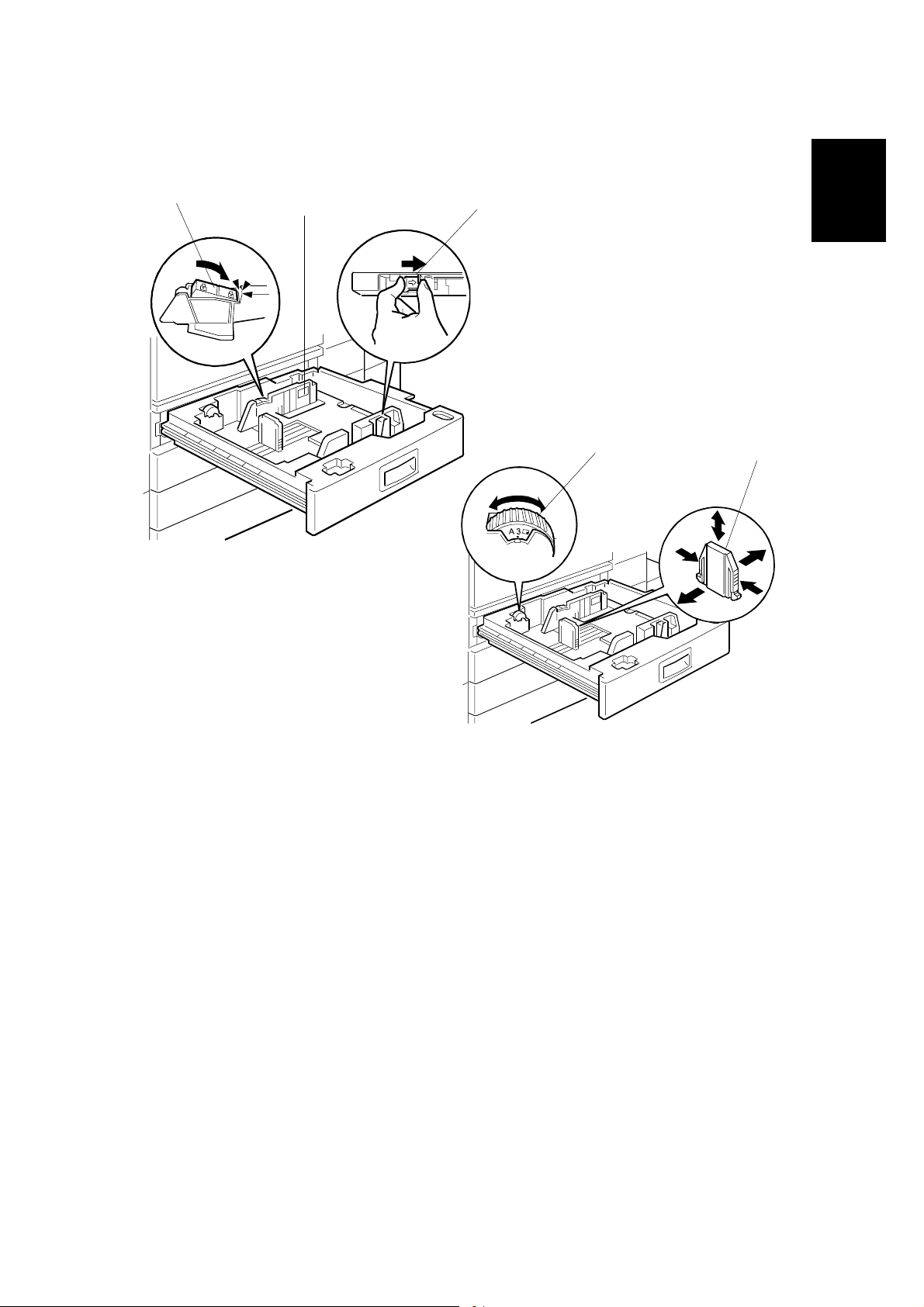

1. Open the 1st paper tray, and then press down on the right side of the lock [A]

switch to unlock the side fences.

2. Press in on the sides of the fence release [B], and slide the side fences [C] to

the appropriate mark for the paper size.

3. Turn the dial [D] to the correct setting for the paper size.

4. Pinch the sides of the bottom fence [E] and move it to the appropriate mark for

the paper size, then load the paper.

5. Check the position of the stack.

• Confirm that there is no gap between the stack and the side fences. If you

see a gap, adjust the position of the side fences.

• After loading the stack, confirm that the right side of the stack is not on top of

both cushions.

1-13

Page 24

MAIN MACHINE INSTALLATION 1 August, 2003

[A]

B135I108.WMF

B135I110.WMF

[B]

6. Press down the lock [A] to lock the side fences.

7. Attach the appropriate paper size decal [B] to the paper tray.

8. Paper size decals are also used for the optional paper tray unit. Keep any

remaining decals for use with the paper tray unit.

9. Repeat this procedure to load paper in the 2nd paper tray.

1-14

manuals4u.commanuals4u.com

Page 25

1 August, 2003 MAIN MACHINE INSTALLATION

Initialize TD Sensor and Developer

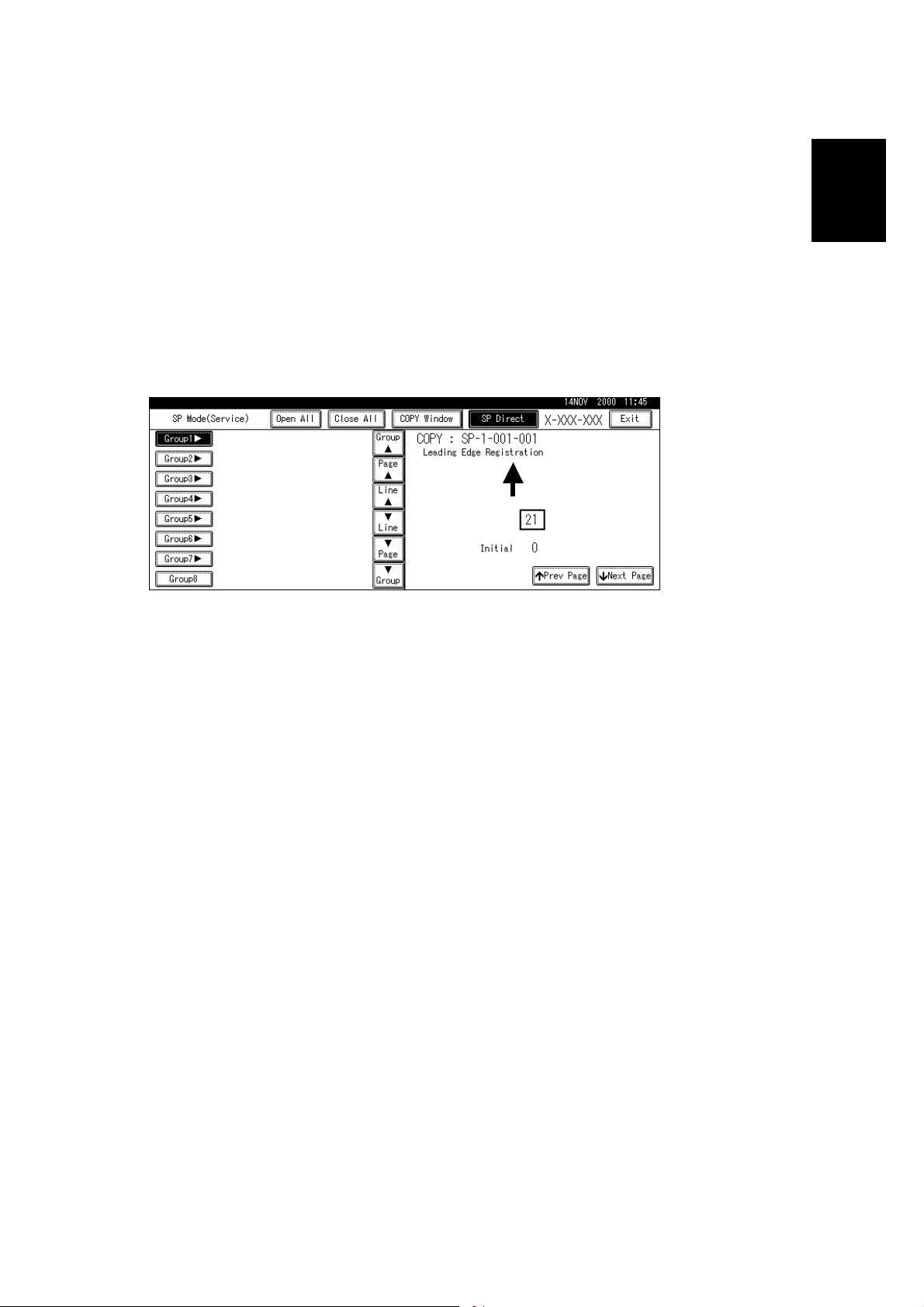

1. Connect the main machine to the power outlet, switch on the main machine,

and wait for the fusing unit to warm up.

2. On the operation panel, press Clear Mode

".

3. Use the number keys to enter 107.

4. Press and hold Clear/Stop # for three seconds.

5. On the touch-panel, press Copy SP.

6. Press SP Direct to highlight “SP Direct”, enter 2801, and then press $.

Installation

B135I500.WMF

7. When the message prompts you to enter the lot number of the developer, enter

the 7-digit lot number, press [Yes], and then press [Execute] on the touchpanel. This initializes the TD sensor.

NOTE: The lot number is printed on the end of the developer package.

Recording the lot number could help troubleshoot problems later. If the

lot number is unavailable, enter any seven-digit number.

8. Press SP Direct to highlight “SP Direct” and enter 2805, press $, and then

press Execute on the touch-panel. This initializes the developer.

9. Press Exit twice to return to the copy window.

1-15

Page 26

MAIN MACHINE INSTALLATION 1 August, 2003

Set Paper Size for Paper Trays

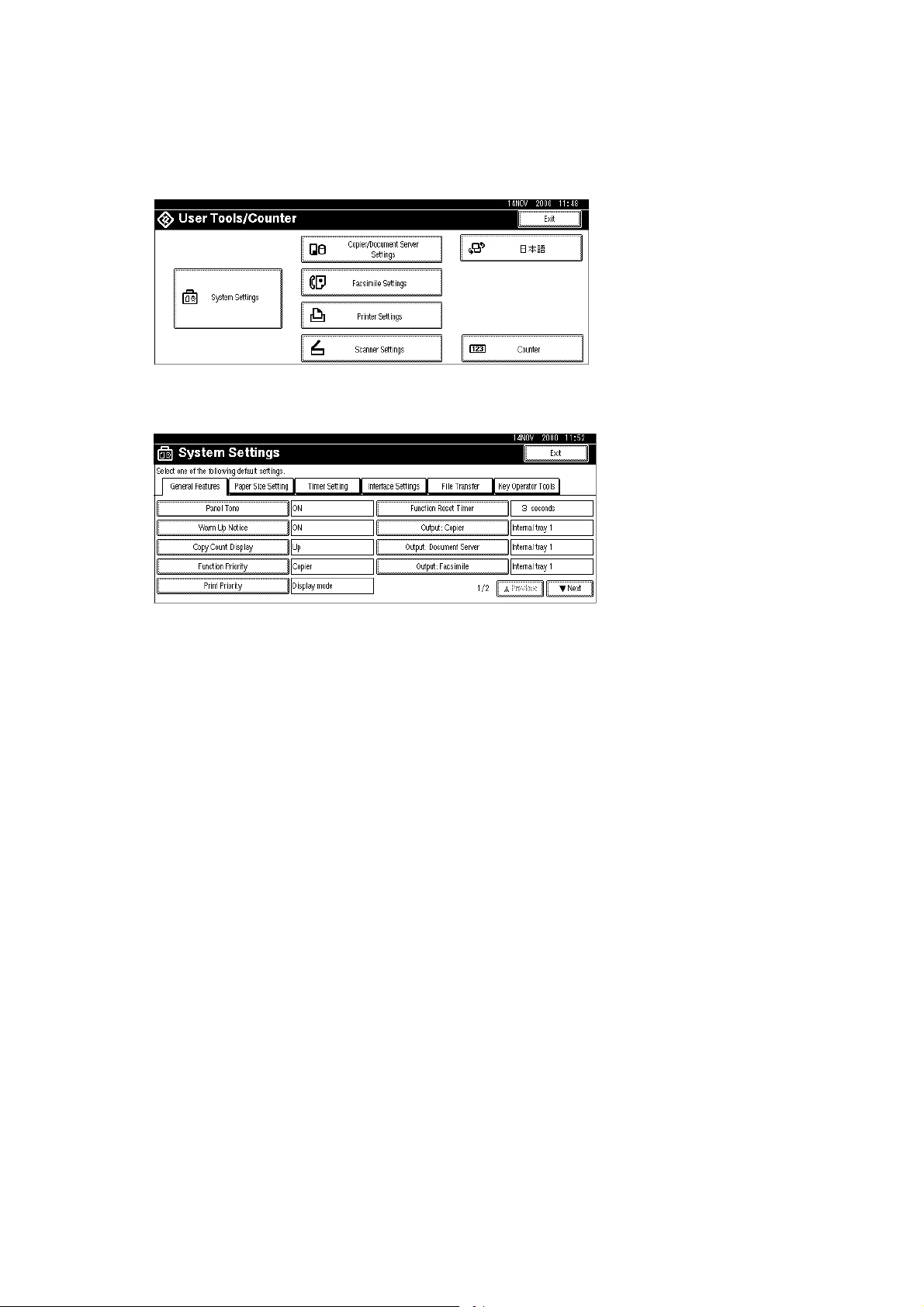

1. Press User Tools/Counter #.

B135I501.WMF

2. On the touch panel, press System Settings.

B135I502.WMF

3. Press the Paper Size Setting tab.

4. Press the button for the tray to change.

5. Change the setting and press the [OK] button.

6. Repeat for each tray installed.

7. Press Exit twice to return to the main display

• The 1st, 2nd, 3rd, and 4th paper trays are provided with paper size dial

selectors. The dial settings on the paper trays have priority over the UP

settings. However, if you select the asterisk (*) position on the paper size

dial, you can select the paper size with the UP setting.

8. Check the copy quality and machine operation.

NOTE: The test pattern print procedure is slightly different for this machine.

Use SP2-902 and select 2 for the IPU Test Print or 3 for the Print Test

Patterns. (☛ Chapter 5, 5.1.3 Test Pattern Printing)

1-16

manuals4u.commanuals4u.com

Page 27

1 August, 2003 MAIN MACHINE INSTALLATION

Electrical Total Counter

The electrical total counter no longer requires initialization. The new incrementing

counter is set to “0” at the factory.

NOTE: SP7825 (Total Counter Reset) remains in the Service but executing this SP

has no effect.

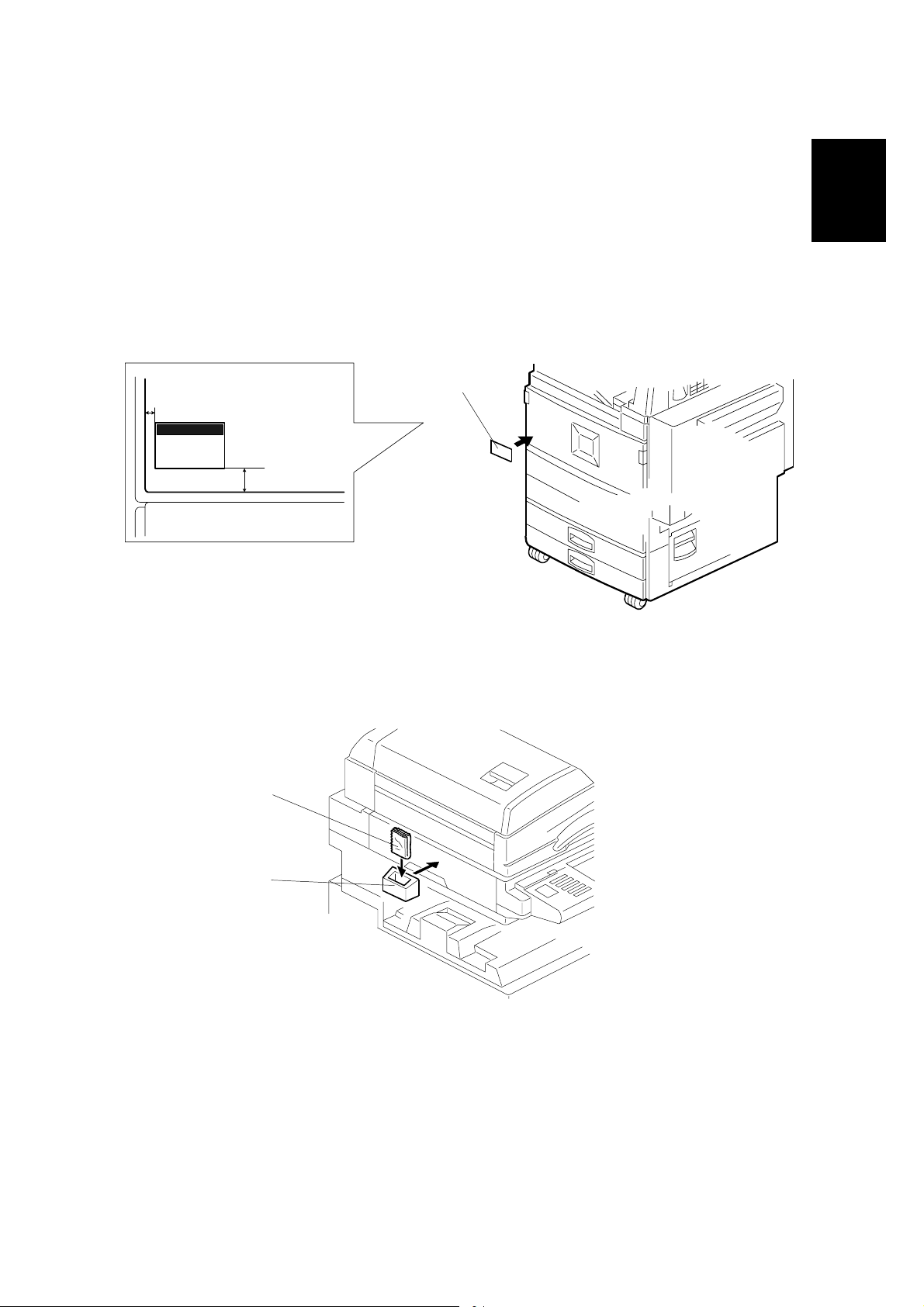

HDD Caution Decal

[A]

10 mm (0.4")

25 mm (1.0")

Installation

B135I017.WMF

1. Attach the HDD Caution decal [A] to the front cover.

Exposure Glass Cleaner

[C]

[B]

B135I111.WMF

B135I018.WMF

1. Attach the exposure glass cleaner holder [B] to the left side of the machine.

2. Place the exposure glass cleaner [C] inside the holder.

NOTE: The exposure glass cleaner is used to clean the ARDF exposure glass,

the glass strip to the left of the large exposure glass.

1-17

Page 28

PAPER TRAY UNIT INSTALLATION (B542) 1 August, 2003

1.4 PAPER TRAY UNIT INSTALLATION (B542)

1.4.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Knob Screw – M3.................................................................. 1

2. Knob Screw – M4.................................................................. 1

3. Joint Bracket ......................................................................... 1

4. Front Stand ........................................................................... 1

5. Rear Stand............................................................................ 1

6. Stand Bracket ....................................................................... 1

7. NECR.................................................................................... 1

8. Installation Procedure ........................................................... 1

1-18

manuals4u.commanuals4u.com

Page 29

1 August, 2003 PAPER TRAY UNIT INSTALLATION (B542)

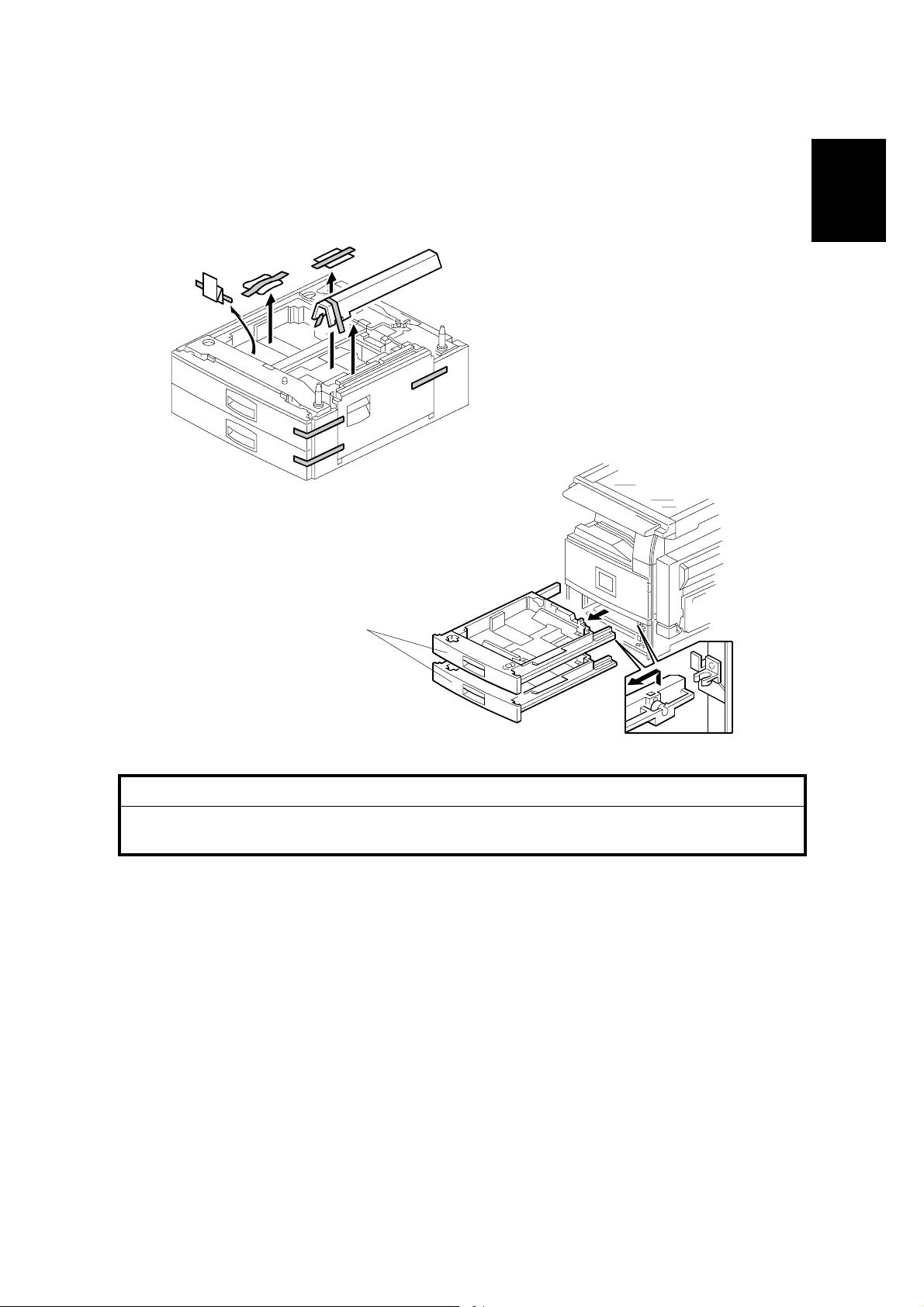

1.4.2 PAPER TRAY UNIT INSTALLATION PROCEDURE

B542I557.WMF

Installation

[A]

B542I112.W MF

!CAUTION

Unplug the main machine power cord before starting the following

procedure.

1. Unpack the paper tray unit.

2. Remove all tape and shipping materials.

3. Remove the paper trays [A].

1-19

Page 30

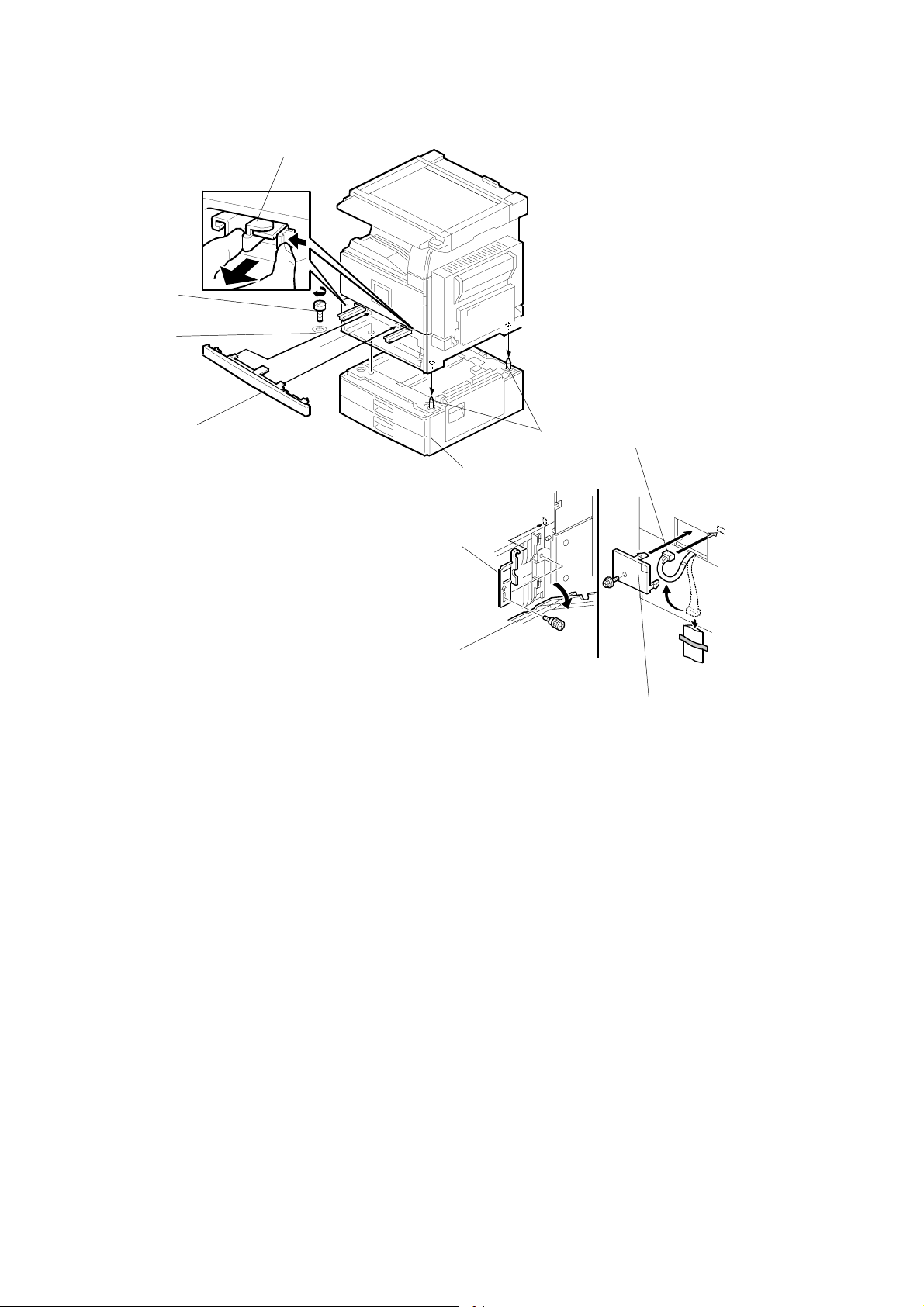

PAPER TRAY UNIT INSTALLATION (B542) 1 August, 2003

[B]

[F]

[E]

[A]

[D]

[J]

[C]

B542I113.W MF

[H]

[G]

B542I517.WMF

[I]

4. Remove the middle front cover [A] and pull out the front handles [B].

5. Using the front handles and rear handles, lift the machine and hold it over the

paper tray unit [C].

6. Slowly lower the machine onto the paper tray unit with the pegs [D] aligned with

the peg holes on the bottom of the machine.

NOTE: Do not hold the scanner unit.

7. Re-install the middle front cover [A].

8. Attach the spring washer [E] to the short knob screw [F]. Then, secure the

paper tray unit.

9. Open the right cover of the paper tray unit [G].

10. Secure the joint bracket [H] (1 long knob screw).

11. Remove the connector cover [I] of the main machine (! x 1).

12. Connect the paper tray unit harness [J] to the main machine and reinstall the

connector cover.

1-20

manuals4u.commanuals4u.com

Page 31

1 August, 2003 PAPER TRAY UNIT INSTALLATION (B542)

[A]

[A]

B542I118.W MF

Installation

[B]

B542I119.W MF

13. Install the front and rear stands [A] as shown above.

14. Install the stand bracket [B].

1-21

Page 32

PAPER TRAY UNIT INSTALLATION (B542) 1 August, 2003

[A]

[A]

B542I500.WMF

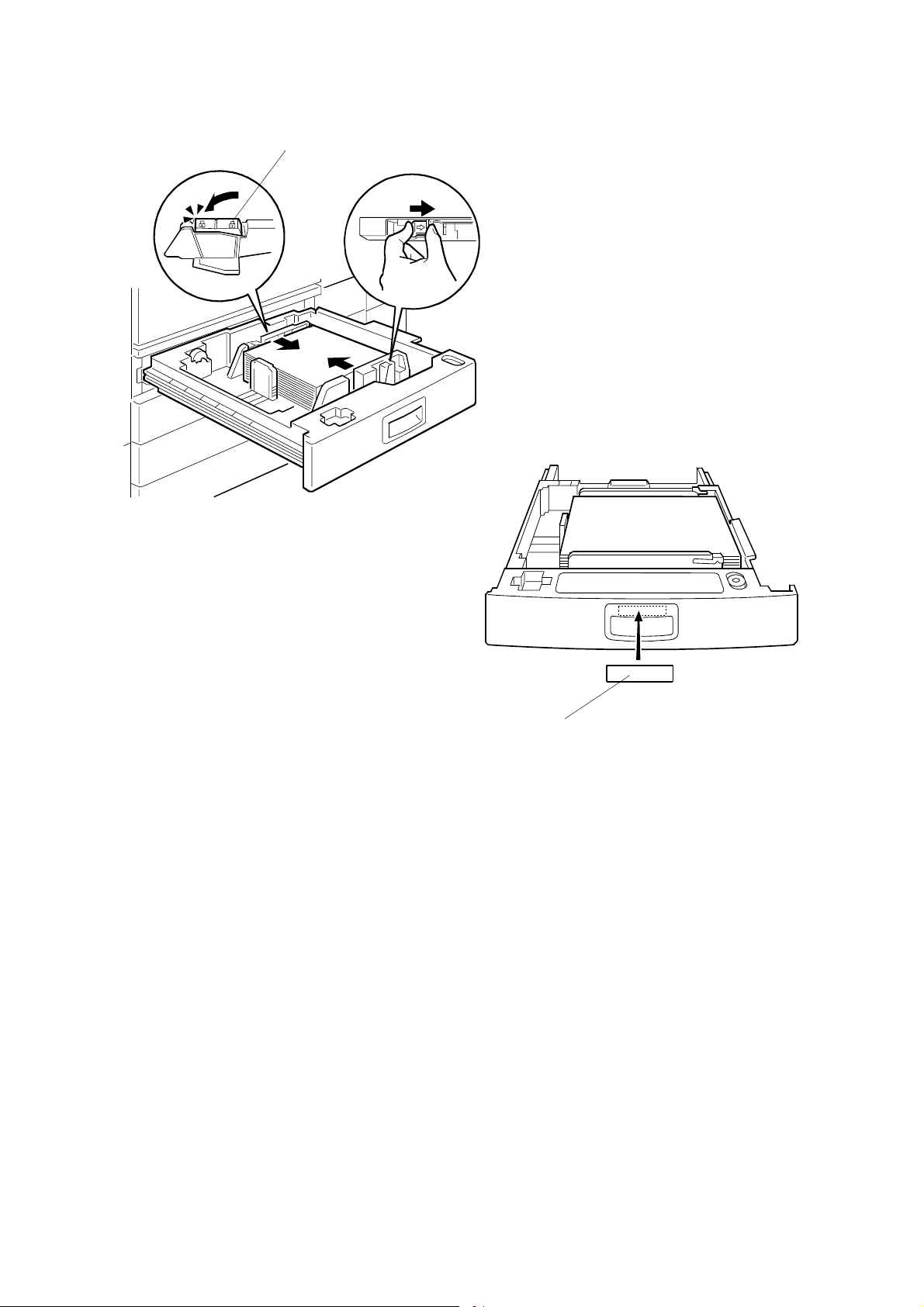

15. Load paper into the paper tray and install the paper trays.

16. Attach the appropriate tray decals [A] which are included in the accessory box

for the main machine.

17. Turn on the ac switch.

18. Turn the paper size dial to the correct setting for the paper size.

19. Check the machine’s operation and copy quality.

1-22

manuals4u.commanuals4u.com

Page 33

1 August, 2003 1-BIN TRAY UNIT INSTALLATION (B544)

1.5 1-BIN TRAY UNIT INSTALLATION (B544)

1.5.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Ground Bracket..................................................................... 1

2. Connector Cover................................................................... 1

3. Base Cover ........................................................................... 1

4. Arm Cover............................................................................. 1

5. Copy Tray ............................................................................. 1

6. Mylar Strip............................................................................. 2

7. Stepped Screw – M3 x 8....................................................... 5

8. Screw –M3 x 8 ...................................................................... 2

9. Screw – M4 x 7 ..................................................................... 1

10. Tapping Screw – M3 x 6 ....................................................... 2

11. Tapping Screw – M3 x 14 ..................................................... 1

Installation

12. Tapping Screw – M3 x 8 ....................................................... 1

13. Installation Procedure ........................................................... 1

1-23

Page 34

1-BIN TRAY UNIT INSTALLATION (B544) 1 August, 2003

1.5.2 1-BIN TRAY INSTALLATION PROCEDURE

[A]

[B]

B544I113.WMF

!CAUTION

Unplug the main machine power cord before starting the following

procedure.

1. Remove Scanner Unit

NOTE: If the ARDF is installed, remove the ARDF before removing the

scanner unit.

1) Remove the connector cover [A].

2) Disconnect the scanner cable [B].

3) Remove the scanner unit [C] (! x 3).

[C]

B544I114.WMF

1-24

manuals4u.commanuals4u.com

Page 35

1 August, 2003 1-BIN TRAY UNIT INSTALLATION (B544)

[B]

[C]

[A]

Installation

[F]

[E]

B544I201.WMF

[D]

B544I102.WMF

2. Unpack the 1-bin tray unit and remove the tapes.

3. Remove the front bracket [A] (! x 1) and rear bracket [B] (! x 1) from the top

of the paper exit cover [C].

4. Remove the paper exit cover [C] (! x 4).

5. Cut away two covers [D] from the base cover [E].

6. Trim the edges so they are smooth.

7. Install the base cover [E] (! x 3: stepped screw).

8. Set the 1-bin tray unit [F] on the base cover and slide onto the heads of the

stepped screws.

1-25

Page 36

1-BIN TRAY UNIT INSTALLATION (B544) 1 August, 2003

[A]

[E]

[D]

[G]

[C]

[B]

B544I492.WMF

[F]

B544I103.WMF

9. Secure the 1-bin tray unit [A] (! x 1 M3 x14).

10. Remove the cover [B].

11. Install the grounding bracket [C] (! x 2 M3 x 6).

12. Connect the harness [D].

13. Install the connector cover [E] (! x 1 M3 x 8)

14. Re-install the front bracket [F] (! x 2 M4 x 7, M4 x 10) and the rear bracket [G]

(! x 1 M4 x 10).

1-26

manuals4u.commanuals4u.com

Page 37

1 August, 2003 1-BIN TRAY UNIT INSTALLATION (B544)

[A]

[B]

[E]

B544I493.WMF

Installation

[D]

15. Attach the copy tray

Bridge Unit (B538) has not been installed:

1) Secure [A] (stepped ! x 2) into the side of the 1-bin tray housing.

2) Attach the copy tray [B] to the stepped screws.

Bridge Unit (B538) has been installed

1) Open the cover of the bridge unit [C].

2) First, remove the copy tray bracket [D] (" x 1).

3) Install the copy tray bracket (! x 1: tapping screw).

4) Re-install the copy tray [E] (" x 1).

[C]

B544I501.WMF

1-27

Page 38

1-BIN TRAY UNIT INSTALLATION (B544) 1 August, 2003

[C]

[A]

[B]

B544I104.WMF

[D]

B544I500.WMF

16. Remove the scanner stand cover [A] (! x 2).

17. To adjust the height of the scanner stand, first remove [B] (! x 2) to release the

scanner stand [C].

18. Raise the scanner stand until the next set of screw holes in the main frame can

be seen through the screw holes in the scanner stand.

19. Secure the stand (! x 2: ➀, ➁) and install the arm cover [D] (! x 1).

1-28

manuals4u.commanuals4u.com

Page 39

1 August, 2003 1-BIN TRAY UNIT INSTALLATION (B544)

[B]

Installation

[A]

B544I106.WMF

20. Attach two mylar strips [A] to the scanner stand [B].

21. Reinstall the scanner stand cover.

22. Reinstall the scanner unit.

23. Turn on the main switch and check the 1-bin tray unit operation.

1-29

Page 40

BRIDGE UNIT INSTALLATION (B538) 1 August, 2003

1.6 BRIDGE UNIT INSTALLATION (B538)

1.6.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Stepped Screw...................................................................... 2

2. Connector Cover ................................................................... 1

3. Exit Mylar .............................................................................. 2

4. Installation Procedure ........................................................... 1

1-30

manuals4u.commanuals4u.com

Page 41

1 August, 2003 BRIDGE UNIT INSTALLATION (B538)

1.6.2 BRIDGE UNIT INSTALLATION PROCEDURE

[A]

[D]

B538I401.WMF

Installation

[B]

B538I407.WMF

[C]

B538I500.WMF

!CAUTION

Unplug the main machine power cord before starting the following

procedure.

1. Unpack the bridge unit and remove all tapes shipping retainers.

2. Remove the inner tray [A].

3. On the side of the machine, remove the three small covers [B].

If the optional external output tray (A825) will be installed (instead of a

finisher), do Step 4.

[E]

4. Remove the two small covers [C].

5. Remove the cover [D] (! x 1).

6. Remove the cap [E].

1-31

Page 42

BRIDGE UNIT INSTALLATION (B538) 1 August, 2003

[A]

[E]

[D]

[B]

B538I402.WMF

[C]

B538I404.WMF

7. If an optional finisher is to be installed, attach two mylars [A] to the bridge unit.

8. Remove the cover [B].

9. Install the bridge unit [C] (! x 2).

10. Connect the bridge unit I/F harnesses [D] ($ x 2).

11. Install the connector cover [E].

12. Turn on the main switch and check the bridge unit operation (make sure that

there are no paper jams).

1-32

manuals4u.commanuals4u.com

Page 43

1 August, 2003 TWO-TRAY FINISHER INSTALLATION (B545)

1.7 TWO-TRAY FINISHER INSTALLATION (B545)

1.7.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Front Joint Bracket................................................................ 1

2. Rear Joint Bracket ................................................................ 1

3. Shift Tray............................................................................... 2

4. Screw – M4 x 8 ..................................................................... 2

5. Screw – M4 x 12 ................................................................... 5

6. Ground Plate......................................................................... 1

7. Installation Procedure ........................................................... 1

Installation

1-33

Page 44

TWO-TRAY FINISHER INSTALLATION (B545) 1 August, 2003

1.7.2 TWO-TRAY FINISHER INSTALLATION PROCEDURE

[A]

B545I101.WMF

[C]

[B]

B545I107.WMF

!CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE: The bridge unit (B538) and paper tray unit (B542) must be installed before

installing this finisher.

1. Unpack the finisher and remove all tapes and shipping retainers from outside

the unit [A].

2. Open the front door [B] and remove all tapes and shipping materials from inside

the finisher unit.

3. Save the retainer [C] and other shipping material.

NOTE: The retainer [C] must be re-installed in the finisher before moving or

shipping the finisher to another location.

1-34

manuals4u.commanuals4u.com

Page 45

1 August, 2003 TWO-TRAY FINISHER INSTALLATION (B545)

[A]

[B]

Installation

[C]

B545I104.WMF

[D]

B545I105.WMF

4. Install the left joint bracket [A] (! x 2 M4 x 12) and right joint bracket [B] (! x 2

M4 x 12).

5. Attach the ground plate [C] (! x 1 M4 x 12) to the center of the paper tray unit

as shown.

6. Open the front door of the finisher, and pull out the locking lever [D] (! x 1).

7. Push the finisher to the side of the machine with the holes in the finisher

aligned with the joint brackets, and then dock the finisher against the machine.

8. Push in the locking lever and secure it (! x 1), then close the front door.

1-35

Page 46

TWO-TRAY FINISHER INSTALLATION (B545) 1 August, 2003

[A]

B545I103.WMF

[B]

B545I106.WMF

9. Install two trays [A] (! x 1 each).

10. Connect the finisher cable [B] to the main machine below the right, rear handle.

11. Turn on the main switch and check the finisher operation.

1-36

manuals4u.commanuals4u.com

Page 47

1 August, 2003 PUNCH UNIT INSTALLATION

1.8 PUNCH UNIT INSTALLATION

1.8.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Punch unit ............................................................................. 1

2. Sensor arm ........................................................................... 1

3. Hopper .................................................................................. 1

4. Step screw ............................................................................ 1

5. Spring.................................................................................... 1

6. Spacer (2 mm) ...................................................................... 1

7. Spacer (1 mm) ...................................................................... 1

8. Tapping screw....................................................................... 1

9. Tapping screw....................................................................... 2

Installation

1-37

Page 48

PUNCH UNIT INSTALLATION 1 August, 2003

1.8.2 PUNCH UNIT INSTALLATION PROCEDURE

[A]

B377I102.WMF

[C]

B377I103.WMF

!CAUTION

Switch off the main machine and unplug its power cord. If the Two-Tray

Finisher is installed, disconnect it and pull it away from the machine.

(☛1.7)

1. Unpack the punch unit and remove all tapes and shipping retainers.

[B]

2. Open the front door and remove the rear cover [A] (! x4).

3. Remove the bracket [B] (! x2) and paper guide [C] (! x 1).

1-38

manuals4u.commanuals4u.com

Page 49

1 August, 2003 PUNCH UNIT INSTALLATION

[B]

[A]

[C]

B377I101.WMF

[E]

Installation

4. Remove the hopper cover [A] (! x 2).

5. Install the sensor bracket [B] (stepped ! x 1).

6. Install the spring [C].

7. Install the 2 mm spacer [D].

8. Install the punch unit [E] (! x 2, stepped ! x 1)

1-39

B377I104.WMF

[D]

Page 50

PUNCH UNIT INSTALLATION 1 August, 2003

[A]

B377I105.WMF

[B]

B377I106.WMF

9. Connect the harnesses [A] and clamp them as shown.

NOTE: No special DIP switch settings are required for this punch unit. The

punch unit sends an identification signal to the machine board so it

knows what type of punch unit has been installed.

10. Slide the hopper [B] into the machine.

11. Fasten the two 1 mm spacers [C] to the rear frame for future adjustment.

NOTE: The spacers are used to adjust the horizontal positioning of the holes.

[C]

12. Reassemble the finisher and check the punch operation.

1-40

manuals4u.commanuals4u.com

Page 51

1 August, 2003 ARDF INSTALLATION (B541)

1.9 ARDF INSTALLATION (B541)

1.9.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Stepped Screw...................................................................... 2

2. Screw – M4 x 10 ................................................................... 2

3. Attention Decal - Scanner ..................................................... 1

4. Attention Decal – Top Cover ................................................. 1

5. Installation Procedure ........................................................... 1

1.9.2 ARDF INSTALLATION PROCEDURE

Installation

B541I904.WMF

!CAUTION

Unplug the main machine power cord before starting the following

procedure.

1. Unpack the ARDF and remove all tapes and shipping retainers.

1-41

Page 52

ARDF INSTALLATION (B541) 1 August, 2003

[B]

[C]

[A]

B541I905.WMF

[D]

B541I124.WMF

2. Attach and tighten [A] (! x 2 stud).

3. Mount the ARDF by aligning the screw keyholes [B] of the ARDF support plate

over the stud screws, and slide the ARDF toward the front of the machine.

NOTE: To avoid damaging the ARDF, hold it as shown in the illustration.

4. Secure the ARDF [C] (! x 2).

5. Connect the I/F cable [D] ($ x 1) to the main machine.

1-42

manuals4u.commanuals4u.com

Page 53

1 August, 2003 ARDF INSTALLATION (B541)

[B]

Installation

[A]

B541I901.WMF

B541I902.WMF

[C]

[E]

B541I906.WMF

B541I903.WMF

6. Peel off the platen sheet [A] and place it on the exposure glass.

7. Line up the rear left corner of the platen sheet flush against corner [B] on the

exposure glass.

[D]

8. Close the ARDF.

9. Attach the decal [C] to the top cover as shown, choosing the language most

suitable for the machine installed.

10. Attach the decal [D] to the cover so that the arrow on the decal lines up with the

groove [E] of the left scale as shown. As with step 9, choose the language most

suitable for the machine installed.

11. Turn on the main switch.

12. Check the ARDF operation and copy quality. Be sure to check and adjust the

registration for the ARDF with the SP modes

1-43

Page 54

ARDF INSTALLATION (B541) 1 August, 2003

1.9.3 ARDF SKEW ADJUSTMENT

[B]

[C]

[A]

B541I907.WMF

1. Remove the tape [A] covering the elliptical hole.

2. Remove right screw [B] and install it into the elliptical hole [C].

3. Move the right side of the ARDF forward or back to adjust the position then

tighten the screw.

1-44

manuals4u.commanuals4u.com

Page 55

1 August, 2003 LCT INSTALLATION (B543)

1.10 LCT INSTALLATION (B543)

1.10.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Joint Pin ................................................................................ 2

2. Stepped Screw M3 x 18........................................................ 4

3. Magnet Cover ....................................................................... 1

4. NECR (-17, -27 machines).................................................... 1

5. Installation Procedure ........................................................... 1

Installation

1-45

Page 56

LCT INSTALLATION (B543) 1 August, 2003

1.10.2 LCT INSTALLATION PROCEDURE

[C]

[B]

[A]

B543I504.WMF

!CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE: The Paper Tray Unit (B542) must be installed before installing the LCT.

1. Unpack the LCT and remove the tapes.

2. Open the right cover of the paper tray unit [A].

3. Open the lower right cover [B] and cut the holding band [C].

NOTE: When cutting the holding band, the upper part of the band should be

cut as shown. Otherwise, paper jams may occur.

4. Remove the lower right cover.

1-46

manuals4u.commanuals4u.com

Page 57

1 August, 2003 LCT INSTALLATION (B543)

[A]

[E]

Installation

[B]

[D]

[C]

B543I503.WMF

6. Install the joint pins [A].

7. Push the release lever [B] and slide the LCT to the right (front view).

8. Hang the LCT [C] on the joint pins, then secure the brackets [D] (! x 4).

9. Return the LCT to the previous position and connect the LCT cable [E].

10. Open the LCT cover and load the paper.

11. Turn on the ac switch and check the LCT operation.

1-47

Page 58

PLATEN COVER INSTALLATION (G329) 1 August, 2003

1.11 PLATEN COVER INSTALLATION (G329)

[C]

[B]

[A]

[A]

B135I904.WMF

1. Install [A] (! x 2) on the top cover as shown.

2. Position the platen cover bracket [B] on the heads of the stud screws and slide

the platen cover [C] to the left.

1-48

manuals4u.commanuals4u.com

Page 59

1 August, 2003 BOOKLET FINISHER INSTALLATION (B546)

1.12 BOOKLET FINISHER INSTALLATION (B546)

1.12.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list.

7

5

4

2

9

1

10

6

3

8

B546I101.WMF

Installation

Description Q’ty

1. Upper Tray.......................................................................... 1

2. Shift Tray............................................................................. 1

3. Tapping Screw - M4 x 6...................................................... 2

4. Rail Ass’y ............................................................................ 1

5. Joint Bracket ....................................................................... 1

6. Tapping Screw - M4 x 16 .................................................... 8

7. Rail Bracket......................................................................... 1

8. Tapping Screw - M4 x 6...................................................... 1

9. Harness Cover.................................................................... 1

10. Sensor Feeler ................................................................... 1

1-49

Page 60

BOOKLET FINISHER INSTALLATION (B546) 1 August, 2003

1.12.2 BOOKLET FINISHER INSTALLATION PROCEDURE

B546I102.WMF

B546I104.WMF

!CAUTION

Keep the power cord unplugged when starting the following procedure.

1. Unpack the finisher and remove the tapes and shipping retainers.

1-50

manuals4u.commanuals4u.com

Page 61

1 August, 2003 BOOKLET FINISHER INSTALLATION (B546)

[A]

[B]

B546I105.WMF

[E]

Installation

[D]

2. Open the front under door and pull out the staple unit [A].

3. Remove the stapler unit lock plate [B] (! x 1).

4. Push in the stapler unit and shut the front lower door.

5. Remove the right lower cover [C] (! x 4).

6. Remove the front pressure release bracket [D] (! x 1).

7. Remove the rear pressure release bracket [E] (! x 1).

8. Reattach the cover [C].

[C]

B546I103.WMF

1-51

Page 62

BOOKLET FINISHER INSTALLATION (B546) 1 August, 2003

[A]

[B]

[C]

B546I106.WMF

[D]

B546I107.WMF

9. Set the hooks [A] of the shift tray [B] in the notches in the shift tray bracket, and

secure the tray with two M4 x 6 screws.

10. Connect the shift tray sensor harness [C].

11. Install the harness cover [D] (2 hooks).

1-52

manuals4u.commanuals4u.com

Page 63

1 August, 2003 BOOKLET FINISHER INSTALLATION (B546)

[A]

Installation

[C]

B546I108.WMF

[B]

B546I801.WMF

[E]

[D]

[F]

B546I921.WMF

12. Install the upper tray [A] (2 pins).

13. Attach the sensor feeler [B] (2 pins).

14. Remove the stand bracket [C].

15. Attach the rail [D] to the rail bracket [E] as shown.

16. Install the rail bracket [F] on the left lower cover of the copier (! x 4).

1-53

Page 64

BOOKLET FINISHER INSTALLATION (B546) 1 August, 2003

[A]

[C]

[D]

B546I920.WMF

[B]

B5 46I 111. WMF

17. Install the joint bracket [A] on the left side of the copier (! x 4).

18. Secure the rail [B] to the booklet finisher with 1 M4 screw.

19. Align the finisher on the joint bracket and lock the 2 hooks [C] of the finisher on

the joint bracket.

20. Connect the finisher cable [D] to the copier.

21. Turn on the main switch and check the finisher operation.

1-54

manuals4u.commanuals4u.com

Page 65

1 August, 2003 1000 SHEET FINISHER (B408)

1.13 1000 SHEET FINISHER (B408)

1.13.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

6

2

1

7

8

5

4

3

10

9

B408I502.WMF

Description Q’ty

1 Front Joint Bracket............................................................... 1

*1

2 Rear Joint Bracket

............................................................ 1

Installation

3 Rear Joint Bracket ............................................................... 1

4 Grounding Plate................................................................... 1

5 Copy Tray ............................................................................ 1

6 Staple Position Decal........................................................... 1

7 Screw - M4 x 14................................................................... 4

8 Knob Screw - M4 x 10.......................................................... 1

9 Screw - M3 x 8..................................................................... 1

10 Knob Screw - M3 x 8.......................................................... 1

*1

: Rear joint bracket is not required for these models.

1-55

Page 66

1000 SHEET FINISHER (B408) 1 August, 2003

1.13.2 1000 SHEET FINISHER INSTALLATION PROCEDURE

[A]

B408I102.WMF

!CAUTION

Unplug the main machine power cord before starting the following

procedure.

1. The following options must be installed before installing this finisher.

- Bridge Unit (B538)

- Paper Tray Unit (B542)

2. Unpack the finisher and remove the tapes.

NOTE: Be sure to keep screw [A]. It will be needed to secure the grounding

plate in Step 3.

B408I103.WMF

1-56

manuals4u.commanuals4u.com

Page 67

1 August, 2003 1000 SHEET FINISHER (B408)

[B]

[G]

Installation

[A]

[F]

[E]

B408I503.WMF

[C]

[D]

B408I201.WMF

B408I504.WMF

2. Install the front joint bracket [A] (2 screws - M4 x 14) and rear joint bracket [B]

(! x 2 M4 x 14).

3. Install the grounding plate [C] to the finisher (! x 2 M3 x 8).

NOTE: Use the screw removed in step 1 and the screw from the accessory

box.

4. Open the front door [D] then pull the locking lever [E].

5. Align the finisher on the joint brackets, and lock it in place by pushing the

locking lever.

6. Secure the locking lever (! x 1 knob screw M3 x 8).

7. Close the front door.

8. Install the copy tray [F] (! x 1 knob screw M4 x 10).

9. Connect the finisher cable [G] to the main machine below the right rear handle.

1-57

Page 68

1000 SHEET FINISHER (B408) 1 August, 2003

[A]

B408I501.WMF

10. Attach the staple position decal [A] to the ARDF as shown.

11. Turn on the main power switch and check the finisher operation.

1-58

manuals4u.commanuals4u.com

Page 69

1 August, 2003 FILE FORMAT CONVERTER B519-17

1.14 FILE FORMAT CONVERTER B519-17

1.14.1 ACCESSORY CHECK

1. File Format Converter Board ......................................... 1

1.14.2 INSTALLATION PROCEDURE

!CAUTION

Switch the machine off and unplug the main machine power cord before

starting the following procedure.

[D]

[A]

Installation

[C]

B519I501.WMF

1. Remove the left corner cover (! x 2).

[B]

2. Remove the rear upper cover (! x 2).

3. Remove the rear lower cover (! x 4).

4. Remove the controller box [A] (! x 2).

5. Remove the two screws [B] from the controller board.

6. Use the screws removed in the previous step to attach the File Format

Converter board [C] to the controller board [D] (! x 2)

7. Reattach the controller box and covers.

B519I502.WMF

1-59

Page 70

FILE FORMAT CONVERTER B519-17 1 August, 2003

1.14.3 CHECK ALL CONNECTIONS

1. Plug in the power cord and turn on the main switch.

2. Enter the printer user mode and print the configuration page.

User Tools> Printer Settings> List Test Print> Config. Page

NOTE: The same data can also be printed by executing SP1-004 – Print

Summary. All installed options are listed in the “System Reference”

column.

1-60

manuals4u.commanuals4u.com

Page 71

1 August, 2003 PM TABLE

2. PREVENTIVE MAINTENANCE SCHEDULE

2.1 PM TABLE

NOTE: Amounts mentioned as the PM interval indicate the number of prints.

Symbol key: C: Clean, R: Replace, L: Lubricate, I: Inspect

B135/B138 EM 150K 300K 450K NOTE

SCANNER/OPTICS

Reflector C C C Optics cloth

1st Mirror C C C Optics cloth

2nd Mirror C C C Optics cloth

3rd Mirror C C C Optics cloth

Scanner Guide Rails

Platen Sheet Cover

Exposure Glass C C C Dry cloth or alcohol

Toner Shield Glass C C C Optics cloth

APS Sensor C C C Dry cloth or alcohol

Exposure Glass (Sheet

through)

DRUM (OPC) AREA

Charge Roller R R R

Charge Roller Cleaning

Roller

Drum Cleaning Blade 1 R R R

Drum Cleaning Blade 2 R R R

Quenching Lamp C Dry cloth

Pick-off Pawls R R R

Spurs C C C Dry cloth or alcohol

ID Sensor

Cleaning Entrance Seal

Side Seal I I I

I I I

C I I I

C C C

R R R

C C C

C C C

Do not use alcohol. Lubricate

if necessary.

Dry cloth or alcohol. Replace

platen sheet if required.

Dry cloth or alcohol

Perform SP3-001-2 after

blower brush cleaning.

Blower brush. Replace if

required.

Preventive

Maintenance

2-1

Page 72

PM TABLE 1 August, 2003

B003/B004B006/B007 EM 150K 300K 450K NOTE

DEVELOPMENT UNIT

Development Drive

Gears

I I I

Development Filter R R R

Developer I R I

Entrance Seal I I I

Side Seal I I I

Development Roller C C C Dry cloth

PAPER FEED

Registration Roller C C C C Water or alcohol.

Idle Roller Dust Blade

C C C

Detach and tap gently on flat

surface to empty. Blower

brush.

Registration Roller Dust

Blade

C R C

Paper Feed Roller I R R R

Separation Roller I R R R

Pick-up Roller I R R R

Paper Feed Roller (By-

pass feed table)

Separation Roller (By-

pass feed table)

Pick-up Roller

(By-pass feed table)

I R R R

I R R R

I R R R

Blower brush.

Check counter value for

each (SP7-204). If ≥ 150 K,

replace roller. After replacing

the roller, do SP7-816 to

reset counter.

Paper Feed Guides C C C Water or alcohol.

Relay Rollers C C C Water or alcohol.

Bottom Plate Pad C C C Water or alcohol.

Bottom Plate Pad (By-

pass feed)

C C C

Water or alcohol.

Registration Sensor C C C Blower brush

Paper Feed Roller Gear

L L L

Silicone Grease G-501. See

note below.*

1

Upper Relay Sensor C C C Blower Brush

DUPLEX UNIT

Upper Transport Roller C C C Water or alcohol.

Lower Transport Roller C C C Water or alcohol.

TRANSFER BELT UNIT

Transfer Belt C R R R Dry cloth

Transfer Belt Cleaning

Blade

R R R

Transfer Belt Rollers C C C Dry cloth

Entrance Seal C C C Dry cloth

Transfer Entrance

Guide

C C C C

Dry cloth

Used Toner Tank I C C C Empty the tank.

2-2

manuals4u.commanuals4u.com

Page 73

1 August, 2003 PM TABLE

B135/B138 EM 150K 300K 450K NOTE

FUSING UNIT AND PAPER EXIT

Fusing Entrance and

Exit Guide Plates

C C C

Water or alcohol.

Hot Roller R R R

Pressure Roller R R R

Fusing Thermistors R R R

Cleaning Roller R R R

Cleaning Roller

Bushings

L L L

Grease: Barrierta JFE 55/2

Hot Roller Strippers C R C Water or alcohol.

Paper Exit Guide Ribs

C C C

Water or alcohol. (See

illustration below.)

Exit Sensor C C C Blower brush

DRIVE

Drive Belts I Replace if necessary

Clean here.

Preventive

Maintenance

B135P901.WMF

B541 EM 80K 160K 240K NOTE

ARDF (for originals)

Pick-up Roller C R R R Belt cleaner

Feed Belt C R R R Belt cleaner

Separation Roller C R R R Dry or damp cloth

Sensors C C C Blower brush

Drive Gears L L L Grease, G501

B542 EM 150K 300K 450K NOTE

PAPER TRAY UNIT

Paper Feed Rollers R R R

Pick-up Rollers R R R

Separation Rollers

R R R

Check counter with SP7-204. If

≥ 150 K, replace roller. After

replacing the roller, do SP7-816

to reset counter.

Relay Rollers C C C Dry or damp cloth

Bottom Plate Pad C C C Dry or damp cloth

2-3

Page 74

PM TABLE 1 August, 2003

B543 EM 150K 300K 450K NOTE

LCT

Paper Feed Roller

R R R

Check counter with SP7-204. If

≥ 150 K, replace roller. After

replacing the roller, do SP7-816

to reset counter.

Pick-up Roller R R R

Separation Roller R R R

Bottom Plate Pad C C C Dry or damp cloth

B408/B545 EM 150K 300K 450K NOTE

1000-SHEET/TWO-TRAY FINISHER

Rollers C Water or alcohol.

Brush Roller

(A681 only)

I I I I

Replace if required.

Discharge Brush C C C C Dry cloth

Sensors C Blower brush

Jogger Fences I I I I Replace if required.

Punch Waste Hopper* I I I I Empty hopper.

*: Only for B545

B546 EM 150K 300K 450K NOTE

BOOKLET FINISHER

Transport Belt C C C

Stapler Paddles C C C

B544 EM 150K 300K 450K NOTE

1-BIN TRAY UNIT

Rollers C Dry or damp cloth

Copy Tray C Dry or damp cloth

Sensors C Blower brush

*1

: Lubricate the paper feed clutch gear [A]

with Silicone Grease G501 every P.M.

[A]

2-4

manuals4u.commanuals4u.com

B135P900.WMF

Page 75

1 August, 2003 SPECIAL TOOLS AND LUBRICANTS

3. REPLACEMENT AND ADJUSTMENT

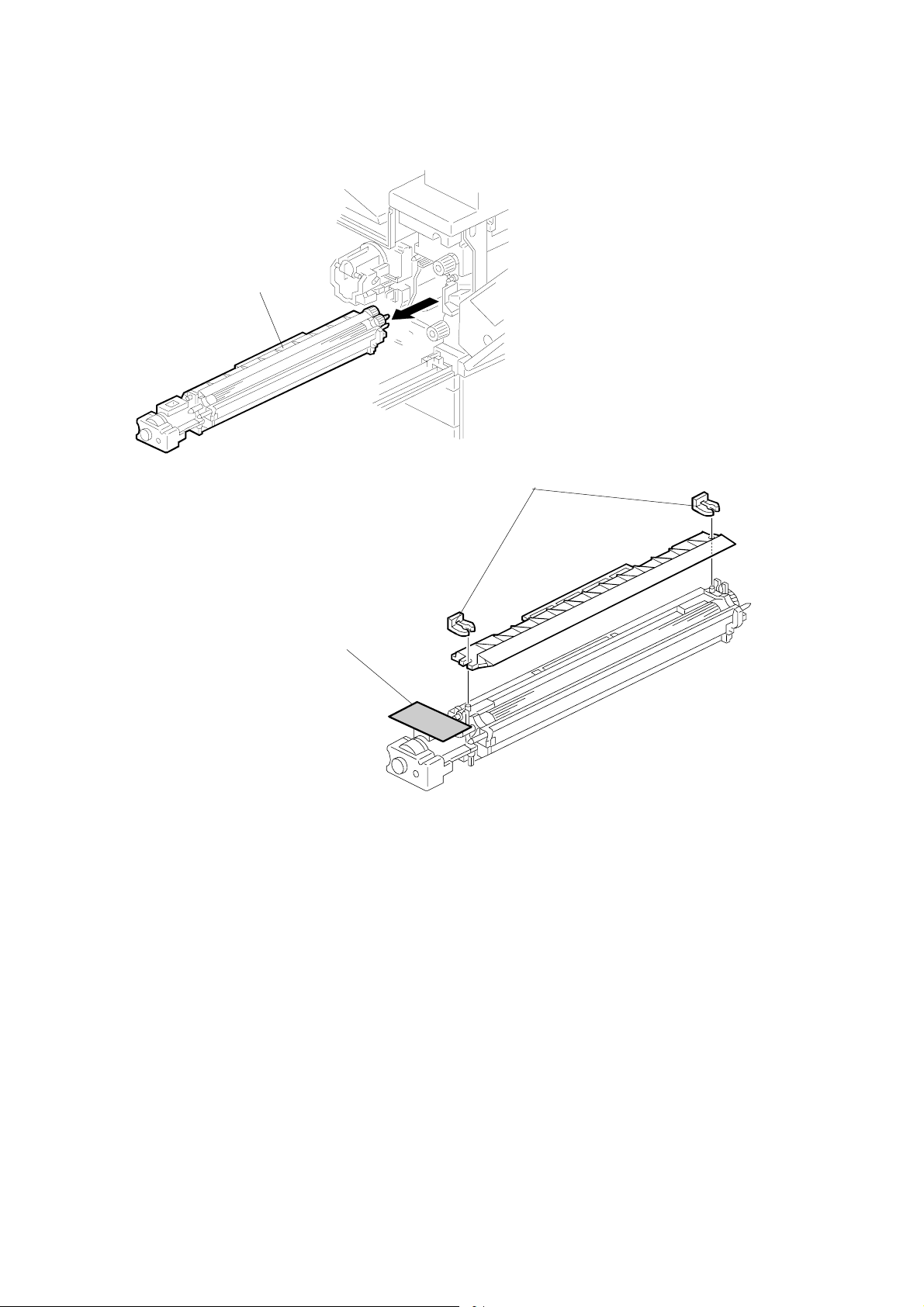

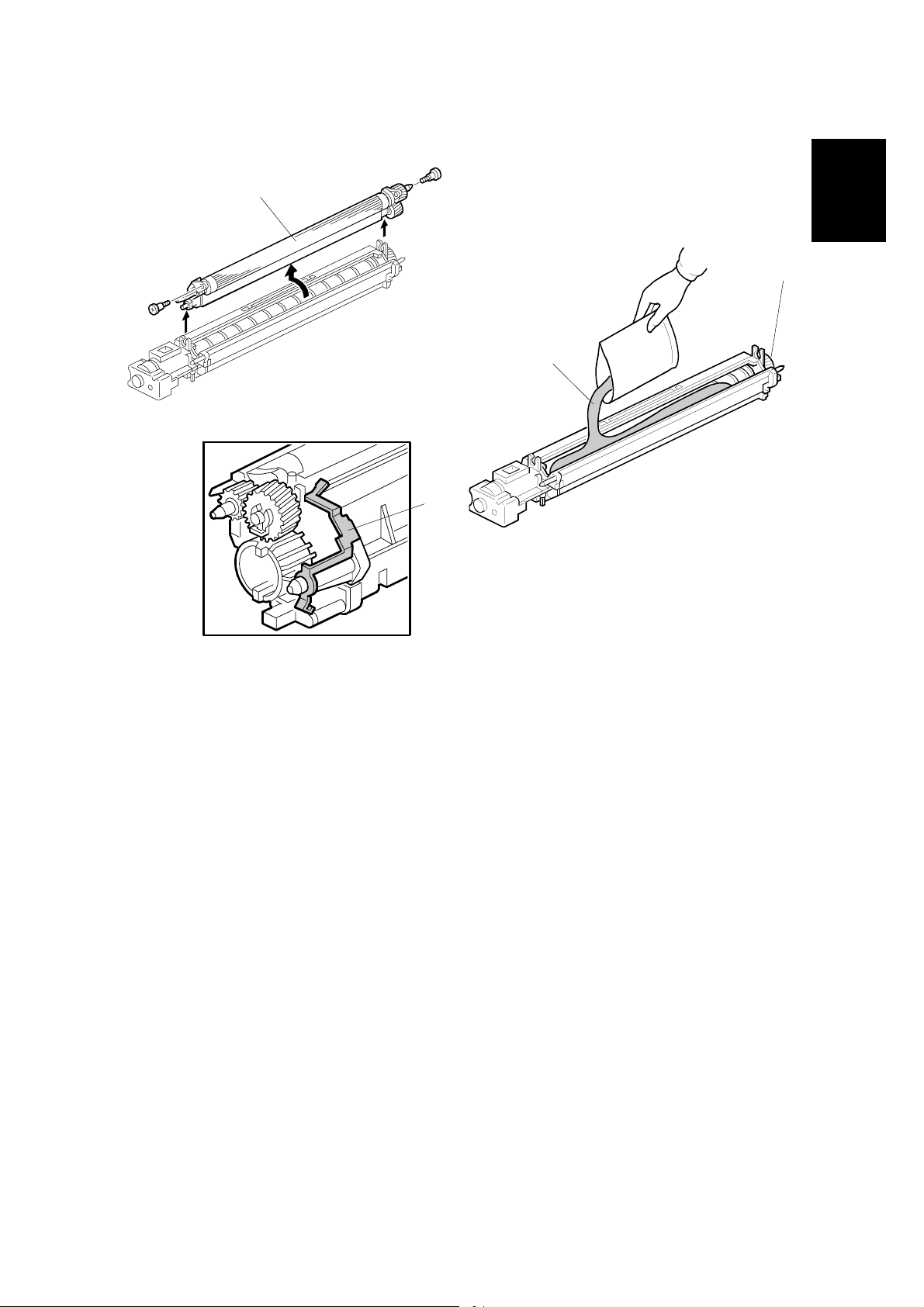

New design changes have been implemented in order to accommodate the new

PxP (Polyester Polymerization) toner, which is of smaller particle size and allows

lower fusing temperatures. This section describes some of these design changes

and how they affect replacement and adjustment procedures.

PCU

• New cleaning blade: The PCU (Photoconductor Unit) must handle finer toner,

so in addition to the stationary drum cleaning blade, a spring-loaded blade has

been added for drum cleaning. The additional cleaning blade is required for the

finer toner, and a new procedure for removal has been added. (☛ Drum

Cleaning Blade)

• Charge roller replacement: The standard voltages for SP2001 1 have changed

and must be checked after charge roller replacement.

Fusing Unit

The fusing unit can be operated at a lower temperature for the finer toner because