Page 1

RICOH GROUP COMPANIES

B121/B122/B123

SERVICE MANUAL

December 1st, 2003

Subject to change

Page 2

PRODUCT CODE

B121 DSM615 LD115 Aficio 2015 4015

B122 DSM618 LD118 Aficio 2018 4018

B123 DSM618D LD118D Aficio 2018D 4018D

LEGEND

GESTETNER LANIER RICOH SAVIN

Page 3

TABLE OF CONTENTS

1. INSTALLATION........................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS........................................................... 1-1

1.1.1 ENVIRONMENT .............................................................................. 1-1

1.1.2 MACHINE LEVEL ............................................................................ 1-2

1.1.3 MINIMUM SPACE REQUIREMENTS.............................................. 1-3

1.1.4 POWER REQUIREMENTS.............................................................. 1-3

1.2 COPIER INSTALLATION.......................................................................... 1-4

1.2.1 POWER SOCKETS FOR PERIPHERALS....................................... 1-4

1.2.2 ACCESSORY CHECK..................................................................... 1-4

1.2.3 INSTALLATION PROCEDURE........................................................ 1-5

1.3 PLATEN COVER INSTALLATION............................................................ 1-8

1.3.1 ACCESSORY CHECK..................................................................... 1-8

1.3.2 INSTALLATION PROCEDURE........................................................ 1-8

1.4 ARDF INSTALLATION.............................................................................. 1-9

1.4.1 ACCESSORY CHECK..................................................................... 1-9

1.4.2 INSTALLATION PROCEDURE........................................................ 1-9

1.5 ADF INSTALLATION .............................................................................. 1-12

1.5.1 ACCESSORY CHECK................................................................... 1-12

1.5.2 INSTALLATION PROCEDURE...................................................... 1-12

1.6 TWO-TRAY PAPER TRAY UNIT INSTALLATION ................................. 1-15

1.6.1 ACCESSORY CHECK................................................................... 1-15

1.6.2 INSTALLATION PROCEDURE...................................................... 1-15

1.7 ONE-TRAY PAPER TRAY UNIT INSTALLATION.................................. 1-19

1.7.1 ACCESSORY CHECK................................................................... 1-19

1.7.2 INSTALLATION PROCEDURE...................................................... 1-19

1.8 ONE-BIN TRAY INSTALLATION............................................................ 1-22

1.8.1 ACCESSORY CHECK................................................................... 1-22

1.8.2 INSTALLATION PROCEDURE...................................................... 1-22

1.9 ANTI-CONDENSATION HEATER INSTALLATION................................ 1-25

1.10 TRAY HEATERS .................................................................................. 1-26

1.10.1 UPPER TRAY HEATER............................................................... 1-26

1.10.2 LOWER TRAY HEATER (TWO-TRAY MODEL ONLY)............... 1-27

1.10.3 TRAY HEATERS FOR THE OPTIONAL PAPER FEED UNITS .. 1-28

1.11 KEY COUNTER INSTALLATION.......................................................... 1-31

1.12 MFP EXPANSION ................................................................................ 1-33

1.12.1 ACCESSORY CHECK................................................................. 1-34

1.12.2 INSTALLING EXPANSION COMPONENT.................................. 1-35

Step 1–Controller Box ........................................................................ 1-35

Step 2–Printer/Scanner...................................................................... 1-36

Step 3–PostScript .............................................................................. 1-36

Step 4–Fax......................................................................................... 1-37

Step 5–Reassembling........................................................................ 1-37

1.12.3 INSTALLING PANELS AND KEYS.............................................. 1-37

Step 6–Panel...................................................................................... 1-37

Step 7–Printer/Scanner Keys ............................................................. 1-38

i

Page 4

Step 8–Fax Keys................................................................................ 1-38

Step 9–Printer/Scanner and Fax Keys............................................... 1-39

1.12.4 SETTINGS................................................................................... 1-40

Step 10–MFP Settings and Time Settings ......................................... 1-40

Step 11–Fax Settings......................................................................... 1-40

1.13 IEEE1284/IEEE1394 INTERFACE ....................................................... 1-41

1.13.1 ACCESSORY CHECK................................................................. 1-42

1.13.2 INSTALLATION PROCEDURE.................................................... 1-42

UP Mode Settings for Wireless LAN .................................................. 1-44

SP Mode Settings for IEEE 802.11b Wireless LAN............................ 1-45

1.14 BLUETOOTH........................................................................................ 1-46

1.14.1 ACCESSORY CHECK................................................................. 1-46

1.14.2 INSTALLATION PROCEDURE.................................................... 1-46

2. PREVENTIVE MAINTENANCE ................................................... 2-1

2.1 PM TABLES.............................................................................................. 2-1

Optics................................................................................................... 2-1

Drum Area............................................................................................ 2-1

Paper Feed .......................................................................................... 2-1

Fusing Unit........................................................................................... 2-2

ADF/ARDF ........................................................................................... 2-2

Paper Tray Unit.................................................................................... 2-2

2.2 HOW TO RESET THE PM COUNTER..................................................... 2-3

3. REPLACEMENT AND ADJUSTMENT........................................ 3-1

3.1 GENERAL CAUTIONS ............................................................................. 3-1

3.1.1 PCU (PHOTOCONDUCTOR UNIT)................................................. 3-1

3.1.2 TRANSFER ROLLER ...................................................................... 3-1

3.1.3 SCANNER UNIT .............................................................................. 3-1

3.1.4 LASER UNIT.................................................................................... 3-2

3.1.5 FUSING UNIT.................................................................................. 3-2

3.1.6 PAPER FEED .................................................................................. 3-2

3.1.7 IMPORTANT.................................................................................... 3-2

3.2 SPECIAL TOOLS AND LUBRICANTS ..................................................... 3-3

3.3 EXTERIOR COVERS & OPERATION PANEL ......................................... 3-4

3.3.1 REAR COVER ................................................................................. 3-4

3.3.2 REAR LOWER COVER (TWO-TRAY MODELS ONLY).................. 3-4

3.3.3 COPY TRAY .................................................................................... 3-5

3.3.4 UPPER COVERS ............................................................................ 3-5

3.3.5 LEFT COVER .................................................................................. 3-6

3.3.6 FRONT COVER............................................................................... 3-6

3.3.7 FRONT RIGHT COVER................................................................... 3-7

3.3.8 RIGHT REAR COVER..................................................................... 3-7

3.3.9 RIGHT DOOR (B121/B122)/DUPLEX UNIT (B123)......................... 3-8

3.3.10 BY-PASS TRAY............................................................................. 3-9

3.3.11 LEFT LOWER COVER (TWO-TRAY MODELS ONLY) ............... 3-10

3.3.12 RIGHT LOWER COVER (TWO-TRAY MODELS ONLY)............. 3-10

3.3.13 PLATEN COVER SENSOR ......................................................... 3-10

ii

Page 5

3.4 SCANNER UNIT..................................................................................... 3-11

3.4.1 EXPOSURE GLASS/DF EXPOSURE GLASS............................... 3-11

Exposure Glass.................................................................................. 3-11

DF Exposure Glass............................................................................ 3-11

3.4.2 LENS BLOCK ................................................................................ 3-12

3.4.3 LAMP STABILIZER BOARD AND EXPOSURE LAMP.................. 3-12

3.4.4 ORIGINAL WIDTH/LENGTH SENSOR ......................................... 3-13

Sensor Positions ................................................................................ 3-13

Sensor Positions for China Model (8K/16K)....................................... 3-14

3.4.5 SCANNER MOTOR ....................................................................... 3-15

3.4.6 SCANNER HOME POSITION SENSOR ....................................... 3-15

3.4.7 ADJUSTING SCANNER POSITIONS............................................ 3-16

Overview ............................................................................................ 3-16

Adjusting the First Scanner Contact Points........................................ 3-17

Adjusting the Second Scanner Contact Points................................... 3-18

3.5 LASER UNIT........................................................................................... 3-19

3.5.1 LOCATION OF CAUTION DECAL................................................. 3-19

3.5.2 TONER SHIELD GLASS................................................................ 3-20

3.5.3 LASER UNIT.................................................................................. 3-20

3.5.4 LD UNIT......................................................................................... 3-21

3.5.5 POLYGONAL MIRROR MOTOR................................................... 3-21

3.5.6 LASER UNIT ALIGNMENT ADJUSTMENT................................... 3-22

3.6 PCU SECTION ....................................................................................... 3-23

3.6.1 PCU ............................................................................................... 3-23

3.6.2 PICK-OFF PAWLS AND TONER DENSITY SENSOR .................. 3-23

3.6.3 OPC DRUM ................................................................................... 3-24

3.6.4 CHARGE ROLLER AND CLEANING BRUSH............................... 3-25

3.6.5 CLEANING BLADE........................................................................ 3-25

3.6.6 DEVELOPER................................................................................. 3-26

3.6.7 AFTER REPLACEMENT OR ADJUSTMENT................................ 3-27

3.7 TONER SUPPLY MOTOR...................................................................... 3-28

3.8 PAPER FEED SECTION ........................................................................ 3-28

3.8.1 PAPER FEED ROLLER................................................................. 3-28

3.8.2 FRICTION PAD.............................................................................. 3-28

3.8.3 PAPER END SENSOR.................................................................. 3-29

3.8.4 EXIT SENSOR............................................................................... 3-29

Non-duplex Models ............................................................................ 3-29

Duplex Models ................................................................................... 3-29

3.8.5 BY-PASS FEED ROLLER AND PAPER END SENSOR ............... 3-30

3.8.6 REGISTRATION ROLLER............................................................. 3-31

3.8.7 BY-PASS PAPER SIZE SWITCH .................................................. 3-32

3.8.8 REGISTRATION CLUTCH............................................................. 3-32

3.8.9 REGISTRATION SENSOR............................................................ 3-33

3.8.10 UPPER PAPER FEED CLUTCH AND BY-PASS FEED CLUTCH3-33

3.8.11 RELAY CLUTCH.......................................................................... 3-34

3.8.12 RELAY SENSOR......................................................................... 3-34

3.8.13 LOWER PAPER FEED CLUTCH (TWO-TRAY MODELS ONLY) 3-34

3.8.14 VERTICAL TRANSPORT SENSOR

(TWO-TRAY MODELS ONLY) .................................................... 3-35

iii

Page 6

v

3.8.15 PAPER SIZE SWITCH................................................................. 3-35

3.9 IMAGE TRANSFER................................................................................ 3-36

3.9.1 IMAGE TRANSFER ROLLER........................................................ 3-36

3.9.2 IMAGE DENSITY SENSOR........................................................... 3-36

3.10 FUSING ................................................................................................ 3-37

3.10.1 FUSING UNIT.............................................................................. 3-37

3.10.2 THERMISTOR ............................................................................. 3-37

3.10.3 FUSING LAMPS .......................................................................... 3-38

3.10.4 HOT ROLLER STRIPPER PAWLS.............................................. 3-38

3.10.5 HOT ROLLER.............................................................................. 3-39

3.10.6 THERMOSTAT ............................................................................ 3-39

3.10.7 PRESSURE ROLLER AND BUSHINGS...................................... 3-40

3.10.8 NIP BAND WIDTH ADJUSTMENT .............................................. 3-41

3.10.9 CLEANING ROLLER ................................................................... 3-42

3.11 DUPLEX UNIT (DUPLEX MODELS ONLY).......................................... 3-43

3.11.1 DUPLEX EXIT SENSOR.............................................................. 3-43

3.11.2 DUPLEX ENTRANCE SENSOR.................................................. 3-43

3.11.3 DUPLEX INVERTER SENSOR ................................................... 3-44

3.11.4 DUPLEX TRANSPORT MOTOR ................................................. 3-45

3.11.5 DUPLEX INVERTER MOTOR ..................................................... 3-45

3.11.6 DUPLEX CONTROL BOARD ...................................................... 3-45

3.12 OTHER REPLACEMENTS................................................................... 3-46

3.12.1 QUENCHING LAMP .................................................................... 3-46

3.12.2 HIGH-VOLTAGE POWER SUPPLY BOARD............................... 3-46

3.12.3 BICU (BASE-ENGINE IMAGE CONTROL UNIT) ........................ 3-47

3.12.4 MAIN MOTOR.............................................................................. 3-47

3.12.5 REAR EXHAUST FAN (B123 ONLY) .......................................... 3-48

3.12.6 LEFT EXHAUST FAN.................................................................. 3-48

3.12.7 PSU (POWER SUPPLY UNIT) .................................................... 3-48

3.12.8 GEARBOX ................................................................................... 3-49

Replacement Procedure .................................................................... 3-49

Gear Arrangement in the Gearbox..................................................... 3-51

3.13 COPY ADJUSTMENTS: PRINTING/SCANNING ................................. 3-52

3.13.1 PRINTING.................................................................................... 3-52

Registration - Leading Edge/Side-to-Side .......................................... 3-52

Blank Margin ...................................................................................... 3-53

Main Scan Magnification.................................................................... 3-53

3.13.2 SCANNING.................................................................................. 3-54

Registration: Platen Mode.................................................................. 3-54

Magnification...................................................................................... 3-54

Standard White Density Adjustment................................................... 3-55

3.13.3 ADF IMAGE ADJUSTMENT ........................................................ 3-56

Registration and Blank Margin ........................................................... 3-56

Sub-scan Magnification...................................................................... 3-56

4. TROUBLESHOOTING................................................................. 4-1

4.1 SERVICE CALL CONDITIONS................................................................. 4-1

4.1.1 SUMMARY....................................................................................... 4-1

4.1.2 SC CODE DESCRIPTIONS............................................................. 4-2

i

Page 7

v

4.2 ELECTRICAL COMPONENT DEFECTS................................................ 4-12

4.2.1 SENSORS ..................................................................................... 4-12

4.2.2 SWITCHES.................................................................................... 4-14

4.3 BLOWN FUSE CONDITIONS................................................................. 4-14

4.4 LED DISPLAY......................................................................................... 4-15

4.4.1 BICU .............................................................................................. 4-15

5. SERVICE TABLES...................................................................... 5-1

5.1 SERVICE PROGRAM MODE................................................................... 5-1

5.1.1 USING SP MODE............................................................................ 5-1

Starting SP Mode................................................................................. 5-1

Starting SSP Mode............................................................................... 5-2

Selecting Programs.............................................................................. 5-2

Specifying Values................................................................................. 5-2

Activating Copy Mode .......................................................................... 5-2

Quitting Programs/Ending (S)SP Mode................................................ 5-2

5.1.2 SP MODE TABLES–BASIC............................................................. 5-3

SP1-XXX (Feed) .................................................................................. 5-3

SP2-XXX (Drum).................................................................................. 5-6

SP4-XXX (Scanner) ........................................................................... 5-11

SP5-XXX (Mode)................................................................................ 5-16

SP6-XXX (Peripherals) ...................................................................... 5-19

SP7-XXX (Data Log) .......................................................................... 5-20

SP8-XXX (History) ............................................................................. 5-24

5.1.3 SP MODE TABLES–MFP.............................................................. 5-27

SP1-XXX (Feed) ................................................................................ 5-27

SP2-XXX (Drum)................................................................................ 5-30

SP4-XXX (Scanner) ........................................................................... 5-34

SP5-XXX (Mode)................................................................................ 5-41

SP6-XXX (Peripherals) ...................................................................... 5-54

SP7-XXX (Data Log) .......................................................................... 5-55

SP8-XXX (History) ............................................................................. 5-60

SP9-XXX (Etc.) .................................................................................. 5-71

5.1.4 ADJUSTING REGISTRATION AND MAGNIFICATION................. 5-73

5.1.5 ID SENSOR ERROR ANALYSIS (SP2-221).................................. 5-74

5.1.6 DISPLAY APS DATA (SP4-301-1)................................................. 5-75

Sensor Positions ................................................................................ 5-75

Reading the Data ............................................................................... 5-75

5.1.7 MEMORY CLEAR.......................................................................... 5-76

Basic Machine and MFP Machine...................................................... 5-76

Exceptions.......................................................................................... 5-76

With Flash Memory Card (Basic Machine Only)................................. 5-77

Without Flash Memory Card............................................................... 5-77

5.1.8 INPUT CHECK (SP5-803) ............................................................. 5-78

Conducting an Input Check................................................................ 5-78

Input Check Table.............................................................................. 5-78

5.1.9 OUTPUT CHECK (SP5-804) ......................................................... 5-80

Conducting an Output Check ............................................................. 5-80

Output Check Table ........................................................................... 5-80

Page 8

5.1.10 SERIAL NUMBER INPUT (SP5-811)........................................... 5-81

Specifying Characters........................................................................ 5-81

Serial Number and NVRAM ............................................................... 5-81

5.1.11 NVRAM DATA UPLOAD/DOWNLOAD (SP5-824/825) ............... 5-82

Overview ............................................................................................ 5-82

NVRAM Upload (SP5-824-1) ............................................................. 5-82

NVRAM Download (SP5-825-1)......................................................... 5-83

5.1.12 FIRMWARE UPDATE PROCEDURE FOR BASIC MACHINES .. 5-84

5.1.13 TEST PATTERN PRINT (SP5-902-1).......................................... 5-85

Executing Test Pattern Printing.......................................................... 5-85

Test Patterns...................................................................................... 5-85

5.1.14 COUNTER–EACH PAPER JAM (SP7-504)................................. 5-86

5.1.15 SMC PRINT (SP5-990)................................................................ 5-87

5.1.16 ORIGINAL JAM HISTORY DISPLAY (SP7-508) ......................... 5-88

Viewing the Copy Jam History ........................................................... 5-88

Jam History Code............................................................................... 5-88

5.1.17 ADF APS SENSOR OUTPUT DISPLAY (SP6-901) .................... 5-89

Sensor Positions ................................................................................ 5-89

Reading Data ..................................................................................... 5-89

5.2 FIRMWARE UPDATE PROCEDURE FOR MFP MACHINES................ 5-90

5.2.1 BEFORE YOU BEGIN…................................................................ 5-90

5.2.2 FIRMWARE UPDATE PROCEDURE FOR MFP MACHINES ....... 5-91

5.2.3 NVRAM DATA UPLOAD/DOWNLOAD.......................................... 5-95

Uploading Content of NVRAM to an SD card..................................... 5-95

Downloading an SD Card to NVRAM................................................. 5-95

6. DETAILED SECTION DESCRIPTIONS....................................... 6-1

6.1 OVERVIEW .............................................................................................. 6-1

6.1.1 COMPONENT LAYOUT .................................................................. 6-1

6.1.2 PAPER PATH .................................................................................. 6-3

6.1.3 DRIVE LAYOUT............................................................................... 6-4

6.2 BOARD STRUCTURE.............................................................................. 6-5

6.2.1 BLOCK DIAGRAM........................................................................... 6-5

1. BICU (Base Engine and Image Control Unit) ..................................... 6-6

2. SBU (Sensor Board Unit)................................................................... 6-6

6.3 COPY PROCESS OVERVIEW ................................................................. 6-7

6.4 SCANNING............................................................................................... 6-9

6.4.1 OVERVIEW...................................................................................... 6-9

Lamp Stabilizer Fuse ........................................................................... 6-9

6.4.2 SCANNER DRIVE ......................................................................... 6-10

6.4.3 ORIGINAL SIZE DETECTION IN PLATEN MODE ........................ 6-11

6.5 IMAGE PROCESSING ........................................................................... 6-13

6.5.1 OVERVIEW.................................................................................... 6-13

6.5.2 SBU (SENSOR BOARD UNIT)...................................................... 6-14

6.5.3 IPU (IMAGE PROCESSING UNIT)................................................ 6-15

Overview ............................................................................................ 6-15

Image Processing Modes................................................................... 6-16

Image Processing Path ...................................................................... 6-17

Original Modes................................................................................... 6-18

vi

Page 9

SP Modes for Each Image Processing Step ...................................... 6-18

Auto Shading...................................................................................... 6-20

White Line Erase................................................................................ 6-21

Black Line Erase ................................................................................ 6-21

Auto image density (ADS).................................................................. 6-22

Scanner Gamma (γ) Correction.......................................................... 6-23

Main Scan Magnification.................................................................... 6-24

Mirroring for ADF Mode...................................................................... 6-24

Filtering .............................................................................................. 6-25

ID Gamma (γ) Correction ................................................................... 6-26

Gradation Processing......................................................................... 6-27

6.5.4 VIDEO CONTROL UNIT (VCU)..................................................... 6-28

Fine Character and Image (FCI) ........................................................ 6-28

Printer Gamma Correction ................................................................. 6-28

6.6 LASER EXPOSURE ............................................................................... 6-29

6.6.1 OVERVIEW.................................................................................... 6-29

6.6.2 AUTO POWER CONTROL (APC) ................................................. 6-30

6.6.3 LD SAFETY SWITCH .................................................................... 6-31

6.7 PHOTOCONDUCTOR UNIT (PCU)........................................................ 6-32

6.7.1 OVERVIEW.................................................................................... 6-32

6.7.2 DRIVE............................................................................................ 6-33

6.8 DRUM CHARGE..................................................................................... 6-34

6.8.1 OVERVIEW.................................................................................... 6-34

6.8.2 CHARGE ROLLER VOLTAGE CORRECTION ............................. 6-35

Correction for Environmental Conditions............................................ 6-35

6.8.3 ID SENSOR PATTERN PRODUCTION TIMING........................... 6-36

6.8.4 DRUM CHARGE ROLLER CLEANING ......................................... 6-37

6.9 DEVELOPMENT..................................................................................... 6-38

6.9.1 OVERVIEW.................................................................................... 6-38

6.9.2 DRIVE............................................................................................ 6-39

6.9.3 DEVELOPER MIXING ................................................................... 6-39

6.9.4 DEVELOPMENT BIAS................................................................... 6-40

6.9.5 TONER SUPPLY ........................................................................... 6-41

Toner Bottle Replenishment Mechanism ........................................... 6-41

Toner Supply Mechanism................................................................... 6-42

6.9.6 TONER DENSITY CONTROL ....................................................... 6-43

Overview ............................................................................................ 6-43

Toner Density Sensor Initial Setting................................................... 6-45

Toner Concentration Measurement.................................................... 6-45

Vsp/Vsg Detection.............................................................................. 6-45

Toner Supply Reference Voltage (Vref) Determination ...................... 6-45

Toner Supply Determination............................................................... 6-45

Toner Supply Motor On Time Determinations.................................... 6-46

6.9.7 TONER SUPPLY IN ABNORMAL SENSOR CONDITIONS .......... 6-47

ID Sensor ........................................................................................... 6-47

TD Sensor.......................................................................................... 6-47

vii

Page 10

6.9.8 TONER NEAR END/END DETECTION AND RECOVERY ........... 6-48

Toner Near End Detection.................................................................. 6-48

Toner Near End Recovery ................................................................. 6-48

Toner End Detection .......................................................................... 6-48

Toner End Recovery .......................................................................... 6-48

6.10 DRUM CLEANING AND TONER RECYCLING.................................... 6-49

6.10.1 DRUM CLEANING....................................................................... 6-49

6.10.2 TONER RECYCLING .................................................................. 6-49

6.11 PAPER FEED ....................................................................................... 6-50

6.11.1 OVERVIEW.................................................................................. 6-50

6.11.2 PAPER FEED DRIVE MECHANISM ........................................... 6-51

6.11.3 PAPER FEED AND SEPARATION MECHANISM....................... 6-51

6.11.4 PAPER LIFT MECHANISM.......................................................... 6-52

6.11.5 PAPER END DETECTION........................................................... 6-52

6.11.6 PAPER SIZE DETECTION.......................................................... 6-53

Paper Tray ......................................................................................... 6-53

By-pass Tray...................................................................................... 6-54

6.11.7 SIDE FENCES............................................................................. 6-55

6.11.8 PAPER REGISTRATION............................................................. 6-55

6.12 IMAGE TRANSFER AND PAPER SEPARATION ................................ 6-56

6.12.1 OVERVIEW.................................................................................. 6-56

6.12.2 IMAGE TRANSFER CURRENT TIMING ..................................... 6-57

6.12.3 TRANSFER ROLLER CLEANING............................................... 6-58

6.12.4 PAPER SEPARATION MECHANISM.......................................... 6-58

6.13 IMAGE FUSING AND PAPER EXIT..................................................... 6-59

6.13.1 OVERVIEW.................................................................................. 6-59

6.13.2 FUSING UNIT DRIVE AND RELEASE MECHANISM ................. 6-60

Fusing Unit Drive................................................................................ 6-60

Drive Release Mechanism ................................................................. 6-60

Contact/Release Control.................................................................... 6-60

Drive Release Solenoid...................................................................... 6-61

6.13.3 FUSING ENTRANCE GUIDE SHIFT........................................... 6-62

6.13.4 PRESSURE ROLLER.................................................................. 6-62

6.13.5 FUSING TEMPERATURE CONTROL......................................... 6-63

Overview ............................................................................................ 6-63

Temperature Control.......................................................................... 6-64

6.13.6 OVERHEAT PROTECTION......................................................... 6-66

6.14 DUPLEX UNIT ...................................................................................... 6-67

6.14.1 OVERALL .................................................................................... 6-67

6.14.2 DRIVE MECHANISM ................................................................... 6-68

6.14.3 BASIC OPERATION .................................................................... 6-69

Larger than A4 Short-edge/LT Short-edge......................................... 6-69

Up to A4 Short-edge/LT Short-edge................................................... 6-70

6.14.4 FEED IN AND EXIT MECHANISM .............................................. 6-71

6.15 ENERGY SAVER MODES OF BASIC MACHINES .............................. 6-72

Overview ............................................................................................ 6-72

AOF.................................................................................................... 6-72

Timers ................................................................................................ 6-73

Recovery............................................................................................ 6-73

viii

Page 11

6.16 ENERGY SAVER MODES OF MFP MACHINES ................................. 6-74

Overview ............................................................................................ 6-74

AOF.................................................................................................... 6-74

Timers ................................................................................................ 6-75

Recovery............................................................................................ 6-75

PERIPHERALS

ONE-BIN TRAY (B621)

1. REPLACEMENT AND ADJUSTMENT..................................B621-1

1.1 TRAY OPEN SWITCH........................................................................ B621-1

1.2 PAPER SENSOR ...............................................................................B621-3

1.3 EXIT SENSOR.................................................................................... B621-3

2. DETAILED DESCRIPTION....................................................B621-4

2.1 COMPONENTS .................................................................................. B621-4

2.2 SETTINGS.......................................................................................... B621-5

Settings .......................................................................................... B621-5

Limitation........................................................................................ B621-5

2.3 PAPER TRANSPORT......................................................................... B621-6

2.3.1 PAPER HANDLING ................................................................... B621-6

2.3.2 JUNCTION GATE ...................................................................... B621-6

2.3.3 PAPER-SIZE LIMITATION......................................................... B621-6

2.4 EXIT TRAY LED ................................................................................. B621-7

2.5 TRAY OPEN SWITCH........................................................................ B621-8

3. TROUBLESHOOTING...........................................................B621-9

3.1 PAPER JAM .......................................................................................B621-9

3.2 PAPER-JAM HANDLING.................................................................. B621-10

3.2.1 RESETTING THE COPIER...................................................... B621-10

3.2.2 COMPONENT-RELATED PAPER JAM................................... B621-11

Motor-Related Paper Jam............................................................ B621-11

Solenoid-Related Paper Jam ....................................................... B621-11

ADF (B616) AND ARDF (B617)

ADF (B616) AND ARDF (B617) .................................................B616-1

ix

Page 12

SPECIFICATIONS.................................................................... SPEC-1

1. GENERAL SPECIFICATIONS.............................................................SPEC-1

Duplex Unit (B123 only) ................................................................SPEC-5

2. SUPPORTED PAPER SIZES..............................................................SPEC-6

2.1 ORIGINAL SIZE DETECTION .....................................................SPEC-6

North America, Europe, Asia, Taiwan ...........................................SPEC-6

China, Korea .................................................................................SPEC-7

2.2 PAPER FEED AND EXIT.............................................................SPEC-8

Main Frame, Duplex......................................................................SPEC-8

Optional Paper Tray, One-Bin Tray, By-pass Tray......................SPEC-10

3. MACHINE CONFIGURATION ...........................................................SPEC-12

4. OPTIONAL EQUIPMENT ..................................................................SPEC-15

ARDF ..........................................................................................SPEC-15

ADF.............................................................................................SPEC-16

ONE-TRAY PAPER TRAY UNIT.................................................SPEC-17

TWO-TRAY PAPER TRAY UNIT................................................SPEC-18

One-Bin Tray...............................................................................SPEC-18

x

Page 13

1 December, 2003 SERVICE CALL CONDITIONS

4. TROUBLESHOOTING

4.1 SERVICE CALL CONDITIONS

4.1.1 SUMMARY

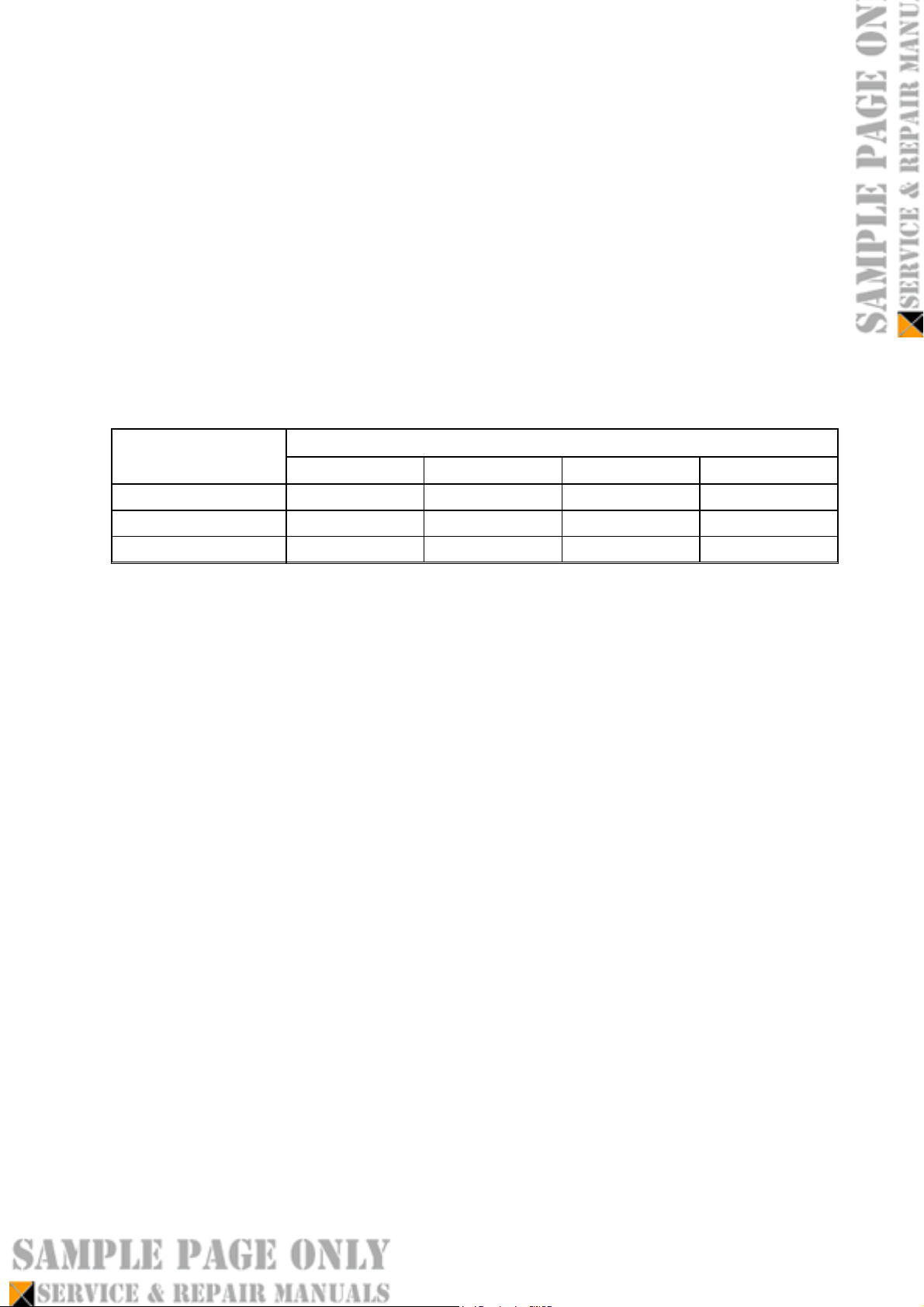

There are four levels of service call conditions.

Level Definition Reset Procedure

A

B

C

D

To prevent damage to the machine, the main

machine cannot be operated until the SC has

been reset by a service representative (see the

note below).

If the SC was caused by incorrect sensor

detection, the SC can be reset by turning the

main power switch off and on.

The main machine can be operated as usual,

excluding the unit related to the service call.

The SC history is updated. The machine can be

operated as usual.

Enter SP mode, and then turn

the main power switch off and

on.

Turn the main power switch off

and on.

Turn the main power switch off

and on.

The SC will not be displayed.

Only the SC history is updated.

NOTE: 1) If the problem concerns electrical circuit boards, first disconnect then

reconnect the connectors before replacing the PCBs.

2) If the problem concerns a motor lock, first check the mechanical load

before replacing motors or sensors.

Trouble-

shooting

4-1

Page 14

1 December, 2003 SPECIFICATIONS

SPECIFICATIONS

1. GENERAL SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book/Object

Original Size: Maximum A3/11" x 17"

Copy Paper Size: Maximum

A3/11" x 17"

Minimum

A5 LEF/8

A6 SEF/5

Custom sizes in the bypass tray:

Width: 90 – 297 mm (3.55" – 11.69")

Length: 148 – 600 mm (5.83" – 23.62")

NOTE: Physically, the by-pass tray can handle the following size

(but this size is not recognized by the application software):

Copy Paper Weight: Paper Tray:

60 – 90 g/m

Bypass:

52 – 162 g/m2, 14 – 43 lb.

1/2" x 51/2" (Paper tray)

1/2" x 81/2" (Bypass)

Width: 305 mm

Length: 1,260 mm

2

, 16 – 24 lb.

Reproduction Ratios: 3 enlargement and 4 reduction

A4/A3 Version LT/DLT Version

200%

Enlargement

Full Size 100% 100%

Reduction

141%

122%

93%

82%

71%

50%

Zoom: 50% to 200%, in 1% steps

155%

129%

121%

93%

78%

65%

50%

Spec.Spec.

SPEC-1

Loading...

Loading...