Ricoh AZALEA Service Manual

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assemb ling part s of th e cop ier an d peripherals,

make sure that the copier po wer cord is unplugg ed .

2. The wall outlet should be near the copie r and easily acce ssible .

3. Note that some comp on en ts of the copie r and the paper tra y unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or opera tio n che ck has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically drive n comp on en ts.

5. If the start key is pressed before the copier completes the warm-up period

(Start key starts blinking red an d gre en alte rna tively), keep hands away

from the mechanical and th e ele ctrica l compo ne nt s as the copie r st art s

making copies as soon as the warm-up period is completed.

6. The inside and the meta l parts of the fusing unit beco me ext reme ly hot

while the copier is operat ing . Be careful to avoid touching th ose

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate th e cop ier with ou t th e ozone filters installed .

2. Always replace the ozo ne filte rs wit h th e spe cifie d on es at the specif ied

intervals.

3. Toner and develope r are no n-t oxic, but if you ge t eit he r of them in your

eyes by accident, it may cause temp ora ry eye discomfort. Try to remove

with eye drops or flush with wat er as first aid. If unsucce ssful, get medical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be inst alle d and main ta ine d by a

customer service represen ta tive who has comple te d th e training course

on those models.

CAUTION

I

2. The RAM board on the system control board has a lithium battery

which can explode if replace d incor re ctl y. Repla ce the batter y only

with an identical one. The manufacturer recommends replacing the

entire RAM board. Do not recharge or burn this batte ry . Use d

batteries must be handled in accor danc e wi th local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the ton er bottle or the used toner. Toner dust may ignite

suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductor according

to local regulations. (These are non-to xic supp lies. )

3. Dispose of replaced part s in accord an ce with local reg ula tio ns.

4. When keeping use d lith ium ba tt eries in order to dispose of them later, do

not put more than 100 batteries per sealed box. Storin g larg er numbers or

not sealing them apart may lead to chemical rea ctions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair

of laser-based optical units in the field. The optical housin g unit can only be

repaired in a factory or a t a loca tio n with the requ isite equ ipme nt. The laser

subsystem is replaceable in th e fie ld by a qu alif ied Custo mer En gin ee r. The

laser chassis is not repairable in the fie ld. Customer engineers are th ere fo re

directed to return all chassis and laser subsystems to the factory or service

depot when replacemen t of the opt ical sub syste m is required.

DANGER

I

Use of controls, or adjustment, or perform anc e of proce dure s other

than those specified in this ma nual may result in hazardous radiation

exposure.

WARNING FOR LASER UNIT

I

DANGER: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams

can seriously damage your eyes.

CAUTION MARKING:

SECTION 1

OVERALL

MACHINE INFORMATION

A579

FP Table

10 May 1996 SPECIFICATIONS

1. SPECIFICATIONS

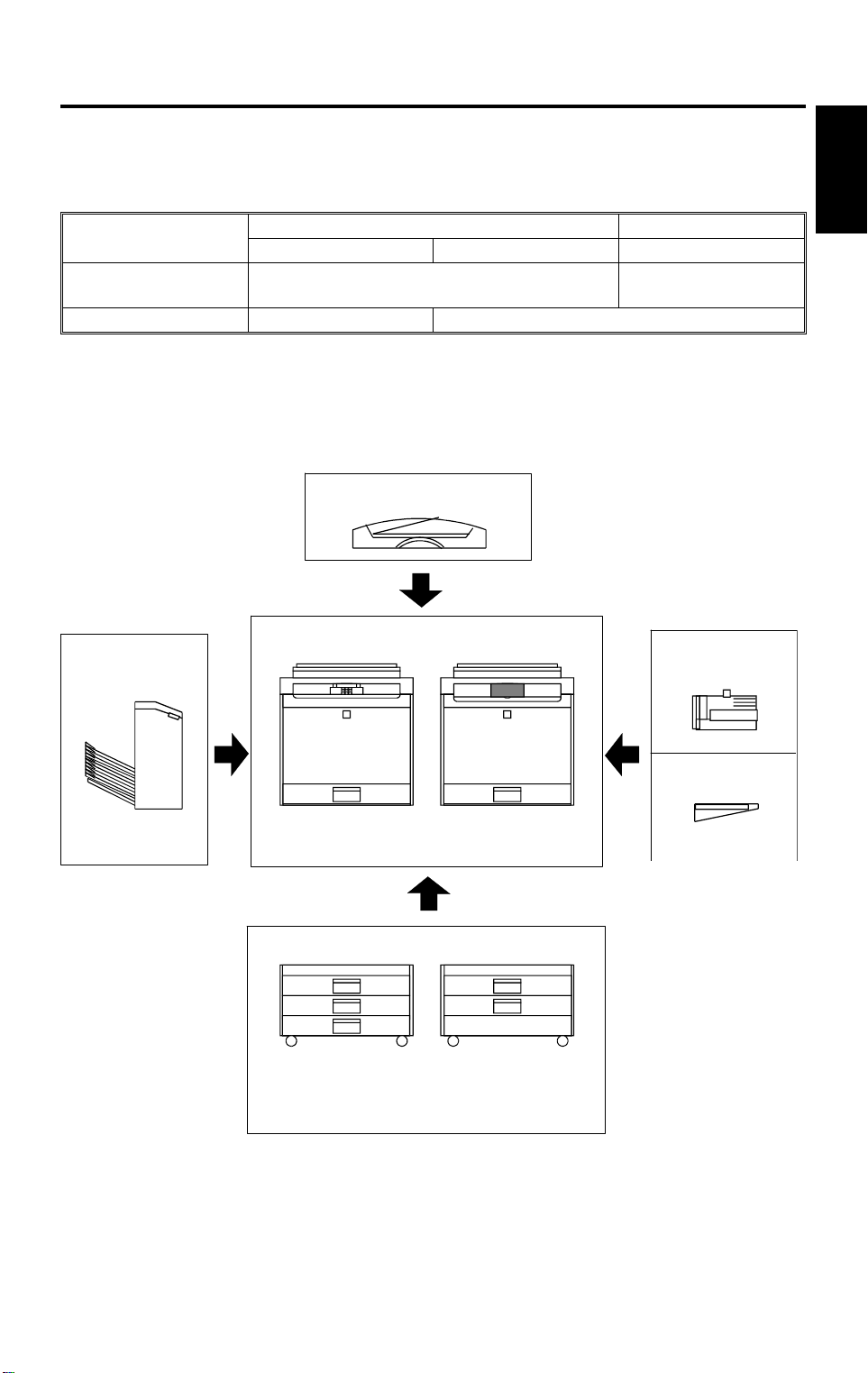

1.1 MACHINE CONFIGURATION

Basic Machine Edit Machine

A166 A187 A189

Operation Panel 20-digit 2-line LCD

Paper Tray Unit 250 Sheets Duplex

ARDF

A548

Copier

Sorter/Stapler

A166/A187 A189

A555

Overall

Information

144 mm x 192 mm

Touch Panel Display

FPU

A718

BASIC

250-sheet Paper

Tray / Duplex Tray

Paper Tray Unit

A549

500 sheets

x 3 Trays

EDIT

Duplex Tray

A550

500 sheets

x 2 Trays

A166V517.wmf

1-1

SPECIFICATIONS 10 May 1996

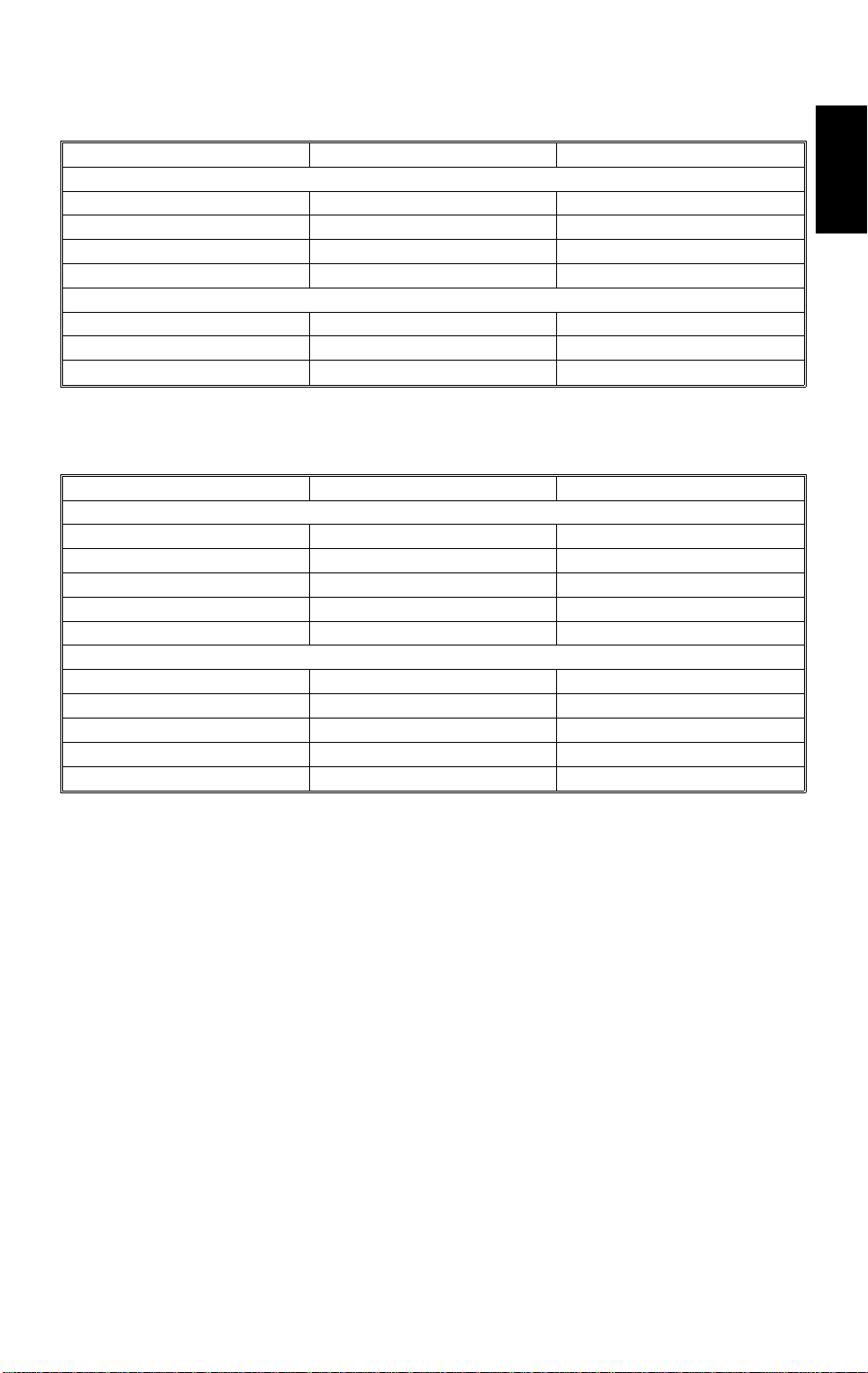

1.2 GENERAL SPECIFICATI ON S

Configuration: Desk Top

Copy Process: Dry Electrostatic Transfe r Syste m

Resolutions: 400 dpi

Gradations: 256 gradations

Originals: Sheet/Book/Object

Original Size: Maximum 11" x 17" /A3

Copy Paper Size:

Maximum Minimum

Paper Tray Feed 11" x 17" /A3 5

Bypass Feed 11" x 17" /A3 5

1/2 x 81/2 /A5(S)

1/2 x 81/2 /A5(L/S), A6(L)

Copy Paper Weight:

Paper Tray Feed 17 to 24 lbs 64 to 90 g/m

Bypass Feed 14 to 43 lbs 52 to 157 g/m

Auto Duplex

Tray

17 to 28 lbs 64 to 104 g/m

2

2

2

Reproduction Ratios:

81/2" x 11"/11" x 17" version A4/A3 version

Enlargement 121, 129, 155, 200, 400% 115, 122, 141, 200, 400%

Full size 100% 100%

Reduction 25, 50, 65, 74, 77, 85, 93% 25, 50, 65, 71, 75, 82, 93%

Programmable 2 user ratios 2 user ratios

Zoom: From 25% to 400 % in 1% steps.

1-2

10 May 1996 SPECIFICATIONS

Copying Speed:

81/2" x 11" (S) /A4 11" x 17"/A3

Normal Mode

Full Color (4 scans) 3 cpm 1.5 cpm

Single Color (C, M Y, K) 21 cpm 11 cpm

Single Color (R, B) 4 cpm 3 cpm

Single Color (G) 3 cpm 2.5 cpm

OHP/Thick Paper Mode

Full Color (4 scans) 1.5 cpm 1 cpm

Single Color (C, M Y, K) 2.5 cpm 1.5 cpm

Single Color (R, G, B) 2 cpm 1 cpm

First Copy Time:

81/2" x 11" (S) /A4 11" x 17" /A3

Normal Mode

Full Color (4 scans) 32 seconds 52 seconds

Single Color (K) 15 seconds 20 seconds

Single Color (C, M, Y) 20 seconds 20 seconds

Single Color (R, B) 25 seconds 35 seconds

Single Color (G) 30 seconds 40 seconds

OHP/Thick Paper Mode

Full Color (4 scans) 50 seconds 70 seconds

Single Color (K) 35 seconds 45 seconds

Single Color (C, M, Y) 35 seconds 45 seconds

Single Color (R, B) 40 seconds 55 seconds

Single color (G) 45 seconds 60 seconds

Overall

Information

Warm-up Time: Approx. 6 minutes (at 68°F / 20°C)

1-3

SPECIFICATIONS 10 May 1996

Duplexing:

Basic Manual Duplex

Model (A166):

Basic Auto Duplex

Model (A187):

Edit Auto Duplex Model

(A189):

Non-Reproductio n Are a:

Leading Edge:

Side:

Manual Duplexing in full color and Single

Color mode

Manual & Auto Duplexing in Full Color an d

Single Color mode

Manual & Auto Duplexing in Full Color an d

Single Color mode

Duplex can be done on 64-104 g/m2 paper.

Manual Duplexing can be done thro ug h th e

Bypass table only, and th e use r sh ould press

the Duplex Side 2 key before coying the reverse

side.

0.2" ± 0.08" (5 mm ± 2 mm)

0.08" ± 0.08" (2 mm ± 2 mm)/

Total less than 0.16" (4 mm)

Trailing Edge

Front side 2.5 mm ± 2.0 mm

Back side 6.0 ± 2.0 mm

(back side trailing edge is adjustab le by SP

mode from 0.5 to 10 mm)

Copy Number Input: Number keys, 1 to 99

Copy Number Input

(Auto Duplex):

Number keys

Single Color - 1 to 50: smaller than A3, 11" x 17"

1 to 30: A3, 11" x17"

Full Color 1 to 20: all sizes

Image Density: Auto/Manual (7 steps)

Automatic Reset: Yes (10 to 900 seconds or Off )

Paper Capacity: Tra y:

250 sheets x 1 tray

(Basic Manual Duplex Model: A166)

Bypass:

40 sheets Normal paper (80 g/m2)

20 sheets OHP

1 sheet Adhesive paper

1-4

10 May 1996 SPECIFICATIONS

Toner Replenishment: Black:

Toner Addition (300 g/ca rtid ge )

Color (Y, M, C):

Toner Addition (100 g/ca rtrid ge )

Copy Tray Capacity: 100 sheets (11" x 17"/A3 and smaller )

Power Source: 120 V/ 60Hz, 220-2 40 V/ 50,6 0 Hz

Overall

Informati o n

Maximum Power

1.5 kVA

Consumption:

Dimensions (with Platen Cover):

Width Depth Height

Basic Manual Duplex

(A166)

Basic Auto Duplex

(A187)

Edit Auto Duplex

(A189)

620 mm

24.4"

620 mm

24.4"

620 mm

24.4"

700 mm

27.5"

700 mm

27.5"

750 mm

29.5"

632 mm

24.9"

632 mm

24.9"

632 mm

24.9"

Weight: Manual Duplex: 105 kg (231.3 lb)

Auto Duplex: 109 kg (240.1 lb)

Optional Equipmen t: Automatic Document Feeder (ARDF): A548

Sorter Stapler: A555

Film Projector: A718

Holder for Film Projector Unit: A579

Paper Tray Unit (3 Trays & 2 Trays): A549/A550

Key Counter

1-5

SPECIFICATIONS 10 May 1996

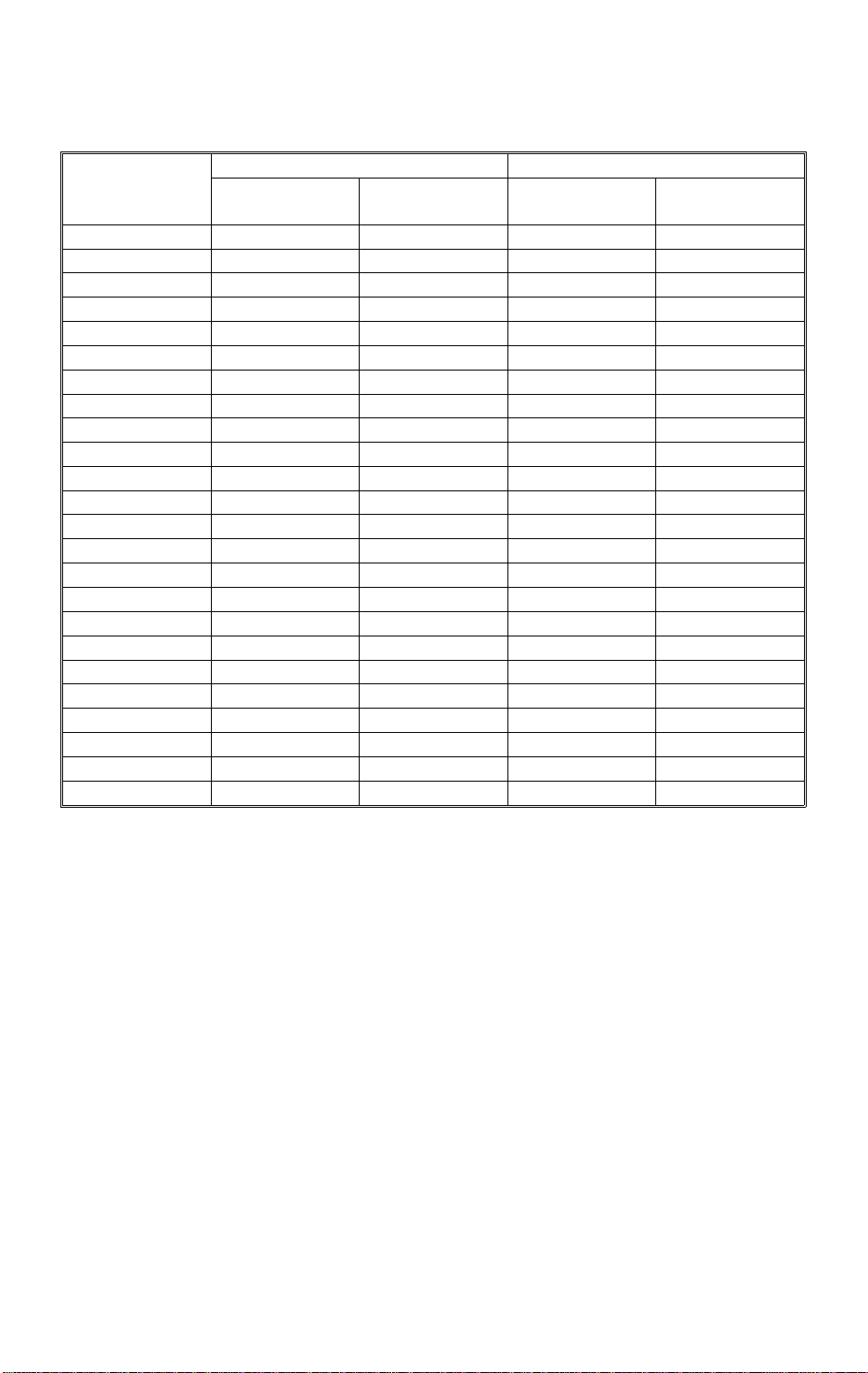

1.3 DETECTABLE ORIGINAL SIZE BY PLATEN/ARDF

Size

(width x length)

[mm]

A3 (297 x 420)L No Yes No Yes

B4 (257 x 364)L No Yes No Yes

A4 (210 x 297)L No Yes Yes Yes

A4 (297 x 210)S No Yes Yes Yes

B5 (182 x 257)L No Yes No Yes

B5 (257 x 182)S No Yes No Yes

A5 (148 x 210)L No No* No Yes

A5 (210 x 148)S No Yes No Yes

B6 (128 x 182)L No No No Yes

B6 (182 x 128)S No No No Yes

11" x 17" (DLT) Yes No Yes Yes

11" x 15" No No Yes No

10" x 14" Yes No Yes No

8.5" x 14" (LG) Yes No Yes No

8.5" x 13" (F4) No Yes No Yes

8.25" x 13" No No No No

8" x 13"(F) No No Yes No

8.5" x 11" (LT) Yes No Yes Yes

11" x 8.5" (LT) Yes No Yes Yes

8" x 10.5" No No No No

8" x 10" No No Yes No

5.5" x 8.5" (HLT) No* No Yes No

8.5" x 5.5" (HLT) Yes No Yes No

A6 (105 x 148)L No No No No

Inch version Metric version Inch version Metric version

Platen ARDF

* : For A5 lengthwise/HLT, SP4-303 can be used to select "Can no t de te ct

original size" or "A5 lengthwise/5.5 " x 8.5"(HLT)".

1-6

10 May 1996 SPECIFICATIONS

1.4 COPY PAPER SIZE

Size

(width x length)

[mm]

A3 (297 x 420)L No Yes Yes Yes Yes Yes

B4 (257 x 364)L No Yes Yes Yes Yes Yes

A4 (210 x 297)L Yes Yes Yes Yes Yes Yes

A4 (297 x 210)S Yes Yes Yes Yes Yes Yes

B5 (182 x 257)L No Yes No Yes Yes Yes

B5 (257 x 182)S No Yes No Yes Yes Yes

A5 (148 x 210)L No No No No Yes Yes (1)

A5 (210 x 148)S No Yes Yes Yes Yes Yes (2)

B6 (128 x 182)L No No No No Yes Yes (1)

B6 (182 x 128)S No No No No No No

11" x 17" (DLT) Yes Yes Yes Yes Yes Yes

11" x 15" Yes No Yes No Yes Yes

10" x 14" Yes No Yes No Yes Yes

8.5" x 14" (LG) Yes No Yes No Y es Yes

8.5" x 13" (F4) Yes Yes Yes Yes Yes Y e s

8.25" x 13" No No Yes Yes Yes Yes

8" x 13"(F) No No Yes Yes Yes Yes

8.5" x 11" (LT) Yes Yes Yes Yes Yes Y e s

11" x 8.5" (LT) Yes Yes Yes Ye s Y es Yes

8" x 10.5" No No Yes No Yes Ye s

8" x 10" Yes No Yes Yes Yes Yes

5.5" x 8.5" (HLT) No No No No Yes Yes (1)

8.5" x 5.5" (HLT) Yes No Yes Yes Yes Yes (2)

A6 (105 x 148)L No No No No Yes Yes (2)

Inch

version

Trays in the main body Bypass

Paper Tray Duplex Tray

Metric

version

Inch

version

Metric

version

All

versions

Optional

S.Stapler

Overall

Informati o n

Yes (1): Stapling is not allowed.

Yes (2): Using the Proof Tray only. Sort er bins cannot be used.

1-7

SPECIFICATIONS 10 May 1996

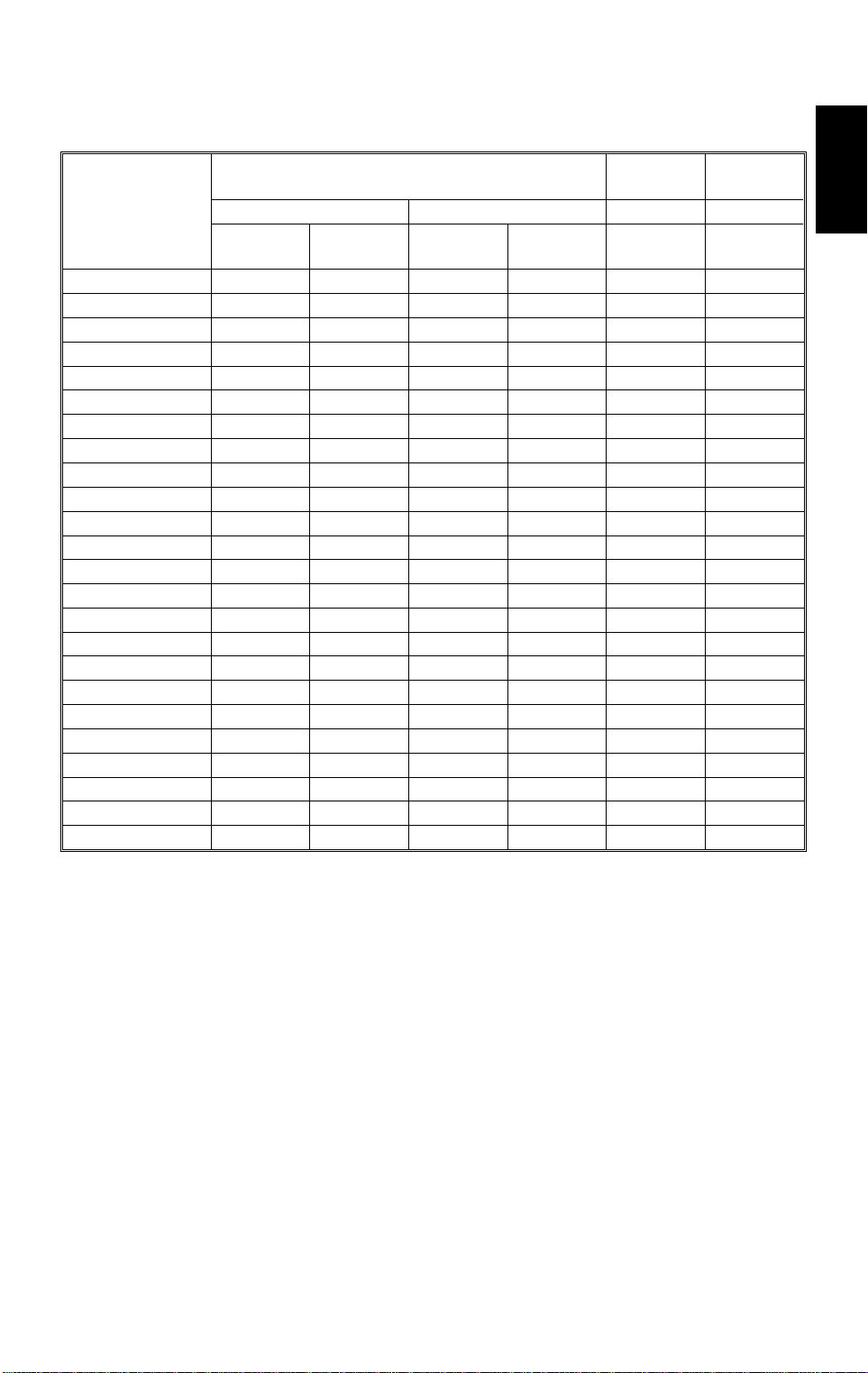

1.5 PAPER SIZES AVAILABLE WITH AP S

– For metric machines –

200

173

163

141

122

115

100

93

87

82

75

71

65

61

57

50

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

174

164

142

123

116

101

94

88

83

76

72

66

62

58

51

A3 – – – – – – A3 – B4 – – A4L 8.5

B4 –––––A3B4––A4L8.5

A4L – – – A3 B4 – A4L 8.5

B5L ––A3B4–A4LB5L––A5L––––––

A5L A3B4–A4LB5L–A5L–––––––––

A4S ––––––A4S–B5S––A5S––––

B5S –––––A4SB5S––A5S––––––

A5S –––A4SB5S–A5S–––––––––

8.5

x 11

x 8.5

8.5

x 13

x 15

––––––8.5

x11

11

––––––11x

8.5

––––A3–8.5

x 13

11

––––––11x15–––––––––

B5L – – A5L – – – –

x 13

–––––––––

–––––––––

––A4LB5L––––A5L

B5L – – A5L –

x 13

B5L – A5L

x 13

: Not allowed in platen cover mode. L: Len gt hwise S: Sidewa ys

– For inch machines –

200

176

155

129

121

100

93

85

77

74

65

~

~

~

~

~

~

~

~

~

~

~

177

156

130

122

101

94

86

78

75

66

51

11x17 – – – – – 11x17 11x17 11x15 8.5

x14

11x15 – – – – – 11x15 11x15 – 8.5

x14

8.5x14 ––––11

8.5x11 –– 11x17–8.5

5.5x8.5 11

x1711x15

8.5x5.5 –––11

11x8.5 –––––11

8x10 – – – 11x17 10x14 8x10 – – – – 5.5

10x14 – – – – – 10x14 – 8.5

8x13 – – – 11x17 – 8x13 – – – – 5.5

8.5

x14

8.5

x11

x8.5

8.5

x17

x14

x11

–5.5

x8.5

–8.5

x5.5

x8.5

––8.5

x11

––––5.5

––––––

––––––

––––8.5

8.5

x14

x11

–8.5

x11

8.5x11 – 5.5

––5.5

x8.5

x5.5

x8.5

––5.5

x8.5

50

~

5.5

x8.5

x8.5

x8.5

–

–

–

x14

–

: Not allowed in platen cover mode.

1-8

10 May 1996 SPECIFICATIONS

NOTE: 1) The tables show which copy paper size is select ed for each

original size for zoom ratios from 50 to 200 %.

2) When a zoom ratio is specified, APS automatically selects a

paper size that can guarantee the quality of the magnifie d cop y

image if there is a paper size available fo r the equivale nt standard

reproduction ratio.

3) If paper of the detect ed size has run out , th e mach ine displays

the message "Set xx M paper in tray" and stops the job (copyin g

is enabled ) .

4) For "–" in the above tables, the machin e disp lays the message

"Cannot detect orig inal size" and stops the job (copying is

enabled). The selected paper feed tray does not change.

5) When 49% or less or 201% or more is selected, APS works in

the same way as described in Note 4 ab ove .

6) APS also supports the by-pass feed table (excep t fo r

non-standard paper sizes). When a sele cte d pa per size can on ly

be fed from the by-pass fee d ta ble, the machine displays a

warning to instruct the user to use the by-pass fee d ta ble .

7) APS does not support A6 and B6 sizes.

Overall

Informati o n

1.6 NOISE EMISSION

Sound pressure level (The measurements are made in accordance with ISO

7779 at the operator positions.)

Copier only Full system*

Less than 61 dB (A) Less than 65 dB (A)

* Full system: Copier with documen t fe ed er, 500 shee ts x 3 trays unit, FPU,

and a sorter stapler.

Sound power level (The measurements are made in accordance with ISO

7779.)

Copier only Full system*

Stand-by Less than 54 dB (A) Less than 58 dB (A)

Copying

(This value is for the

black copy mode.)

* Full system: Copier with documen t fe ed er, 500 shee ts x 3 trays unit, FPU,

and a sorter stapler.

Less than 67 dB (A) Less than 71 dB (A)

1-9

SPECIFICATIONS 10 May 1996

1.7 POWER CONSUMPTION

(1) Maximum power consumption

1.5 kVA

(2) Average power consumption

A189 Copier

Standby 0.25 kW 0.5 kW

Warm-up 1.25 kW 1.25 kW

Copying 1.15 kW 1.15 kW

Energy Saver

Mode

Value for standby

minus 7 W

A189 Copier +

DJF + Sorter

Value for standby

minus 7 W

NOTE: 1) Copying was done in the 1C (A3) repea t mod e.

2) The power consumption in en erg y saver mod e was mea sure d with

the fusing lamp off.

1.8 DISPLAY EDITOR SPECI FI CATI O N

Scanned image • The copier’s scanner scans the image.

• Maximum A3/DLT (11" x 17"): Reduced image display

Displayed image • 144 x 192 mm, 16-gradation (4 bit/dot) monochrome

• 640 x 480 dots, 0.33 mm/dot

• Reduces the dpi of scanned images to approximately 33 dpi and

displays the entire image.

• Zoom display: 3 levels (50 dpi, 67 dpi, 100 dpi)

• Display processing time: 2 seconds or less

Area specification

procedure

• Move the arrow in the screen by using the cursor key and enter a

point by pressing the coordinate entry key.

1-10

10

10 May 1996 MACHINE CONFIGURATION

2. MACHINE CONFIGURATION

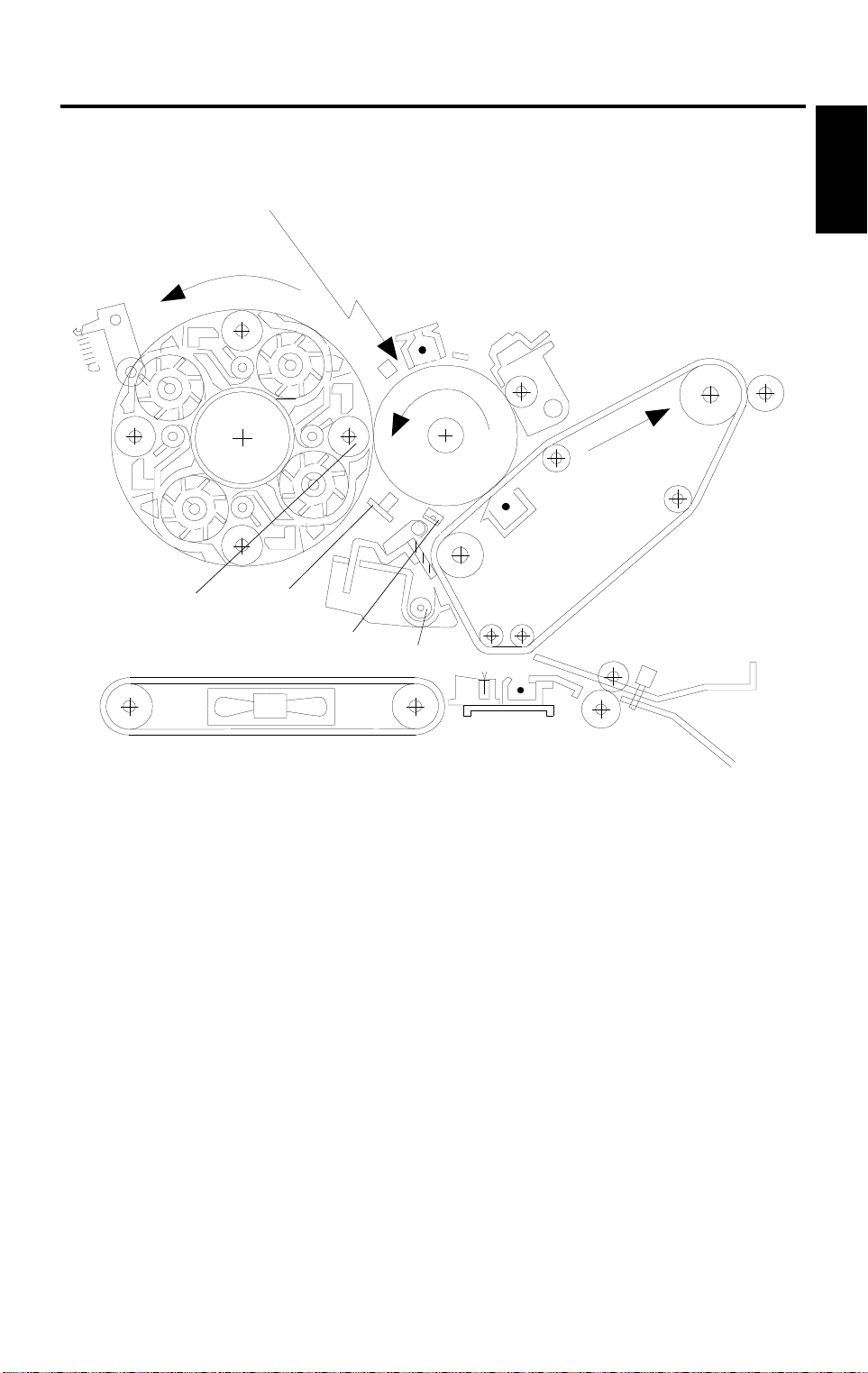

2.1 COPY PROCESSES AROUND THE DRUM AND BELT

2

1

11

3

7

4

5

6

9

13

Overall

Informati o n

8

12

1. Drum Charge

A166V516.wmf

In the dark, the charge coro na unit gives a nega tive charge to the organic

photoconductive (OP C) drum. The grid plate ensures that corona charg e

is applied uniformly. The charge remain s on the surf ace of the dru m

because the OPC layer has a high elect rical resist ance in th e dark. The

amount of negative charge on the dru m is proportional to the negative

voltage applied to the drum charge corona wire and casin g.

2. Laser Exposure

A laser beam is reflected onto the drum by the polygon and drum mirrors.

This forms an electrical latent image on the drum surface. The amo unt of

charge remaining as a late nt image on the drum depen ds on the laser

beam intensity.

3. Drum Potential Detection

The drum potential sensor detects the streng th of the ele ctric fie ld on the

charged drum. The senso r out pu t is one of th e sign als use d in process

control.

1-11

MACHINE CONFIGURATION 10 May 1996

4. Development

The negatively charged tone r is attra cte d to the latent image on the dru m

surface. Toner particles are electrostatically attracted to the area of the

drum surface where th e lase r redu ced the negat ive charge on the drum.

The development unit is a revolve r-typ e, cont ain ing sepa rat e

development sections for each color toner.

5. Image Density Detection

When the laser forms a sensor pa ttern on the drum surfa ce, the ID

sensor measures the image density of the se patterns. The output signal

is used in process control to regulate toner supply.

6. Pre-transfer Lamp

After development, the pre-transfer lamp reduces the potential of the

image background, right before the first belt tra nsf er (in 2C/ 3C/ 4C mod e).

This ensures that electrosta tic at tra ctio n be twe en belt and drum is about

the same for each color ton er tra nsfer, which ensures that th e colo r t on er

images are synchronized pro perly.

7. Belt Transfer

Toner on the drum is attracted to th e tra nsfer belt by the belt corona unit .

8. Belt Lubrication

The transfer belt lubricant brush applies a small amoun t of lubrica nt to the

surface of the transf er be lt. This aids the belt cleaning blade in re movin g

waste toner from the transfer belt.

9. Belt Cleaning

The cleaning blade removes an y toner on the belt aft er pape r tran sfer.

10. Drum Cleaning

The drum cleaning brush rolle r remove s remain ing ton er fro m the drum.

The cleaning brush also applies lubricant. This aids in drum cleaning.

11. Quenching

The light from the quenchin g lamp elect rically neutralizes the charge on

the drum surface. This prepares the drum for the next copy cycle.

12. Paper Transfer

When all toner has been transferred from the drum to the transfer belt,

the charged tone r on th e tra nsf er be lt is attracted to the paper by the

paper transfer unit . This cha rge is applie d to the underside of the pap er.

13. Paper Separ ati on

The copy paper separates from the tran sfe r belt due to the belt’s

curvature. This curvature allows the paper to natu rally fall away from the

transfer belt. The discharg e bru sh aid s in the separation process by

discharging any remainin g ele ctric cha rge from th e pa per.

1-12

10 May 1996 MAJOR UNIT OVERVIEW

3. MAJOR UNIT OVERVIEW

1

10

Overall

Information

2

3

9

4

8

5, 6

7

A166V506.wmf

1-13

MAJOR UNIT OVERVIEW 10 May 1996

1. Copier

1. Dimensions (W x D x H):

Basic machine - 620 x 700 x 632 mm (with paper tray unit: 620 x 700 x

1010)

Edit machine - 620 x 750 x 632 mm (with paper tra y unit : 620 x 750 x

1010)

2. The printer unit, system con tro l unit , an d scan ner u nit are ind epen dent

modules connected with an interface.

2. Scanner Unit

1. 400 dpi (8 bits/dot) scan nin g in bo th main an d sub scan directions

2. 3-line CCD with reduction optics

3. Exposure lamp: Haloge n lamp

4. 5-phase stepper motor drive

3. Drum Unit

1. The drum unit contains the phot oco nd uct or dru m, cha rge coron a un it,

and cleaning unit

2. Charge corona unit: Sing le scorotron charge

3. Quenching Lamp: Red LEDs

4. Drive: Synchronized with th e transfer belt (dc brushless moto r +

flywheel); full speed = 105 mm/s

5. Potential sen sor and ID sensor included

4. Fusing and Paper Exit Section

1. Fusing: Silicone roller fusin g (bo th hot and pressu re rolle rs)

2. Oil application method: Double rolle r

3. Cleaning: Roller cleaning for the hot roller

Cleaning blade for the pressure roller

4. OHP/Thick paper mode: Half spe ed (52. 5 mm/s)

5. Development and Toner Supply

1. Development: Two-comp on en t mag netic bru sh de velo pme nt

2. Development switching : Revolver System

3. Image density control: ID sensor + Pot entia l senso r (Proce ss cont rol)

4. Toner supply

Black: Screw-in bottle (300 g)

Color: Sector cartridg e (100 g)

5. Toner supply unit: Front of develo pment unit (rotation typ e)

1-14

10 May 1996 MAJOR UNIT OVERVIEW

6. Toner and Developer

1. Color toner: Type E

2. Black toner: Type E

3. Developer: Type F

7. Paper Feed and Transport

1. Paper Tray Unit (A166 copier only)

• Corner Separation System

• Front loading tray (250 sheets) + By-pass table

2. Transport: Transport belt with fan

3. Duplex unit (A187, A189 copier only)

• Duplex unit + By-pass table

4. Paper Tray Unit (option): • 500 sheets x 3 trays (FRR Feed System)

• 500 sheets x 2 trays (FRR Feed System)

8. Transfer and Belt Driv e

1. Transfer belt: Full time cont act with th e dru m

2. Belt transfer: Sing le coro na charg e

3. Paper transfer: Single corona charge

4. Registration: Synchronization by the transfer belt H.P. sensor

5. Drive: Synchronized with th e drum (same motor)

6. Separation: Curva ture separation + discha rge brush

7. Transfer cycle: 1 belt rotation/A4

8. Belt cleaning: Coun te r blade

9. Lubrication: Brush roller with lubrica nt bar

Overall

Informati o n

9. Printer Unit

1. Optics: 6-sided polygon mirror + 2 fθ lenses + BTL

2. Polygon motor (16535 rpm), with ball bearing

3. Resolution: 400 dp i

4. Modulation: PM + PWM

10. System Control Unit (SCU)

1. Basic machine: The SCU is on th e ba ck side of the operation panel

(20-digit 2-line LCD)

2. Edit machine: The SCU is under t he sca nner un it an d con ne cte d to the

touch panel display (640 x 480 dots).

1-15

PARTS LAYOUT 10 May 1996

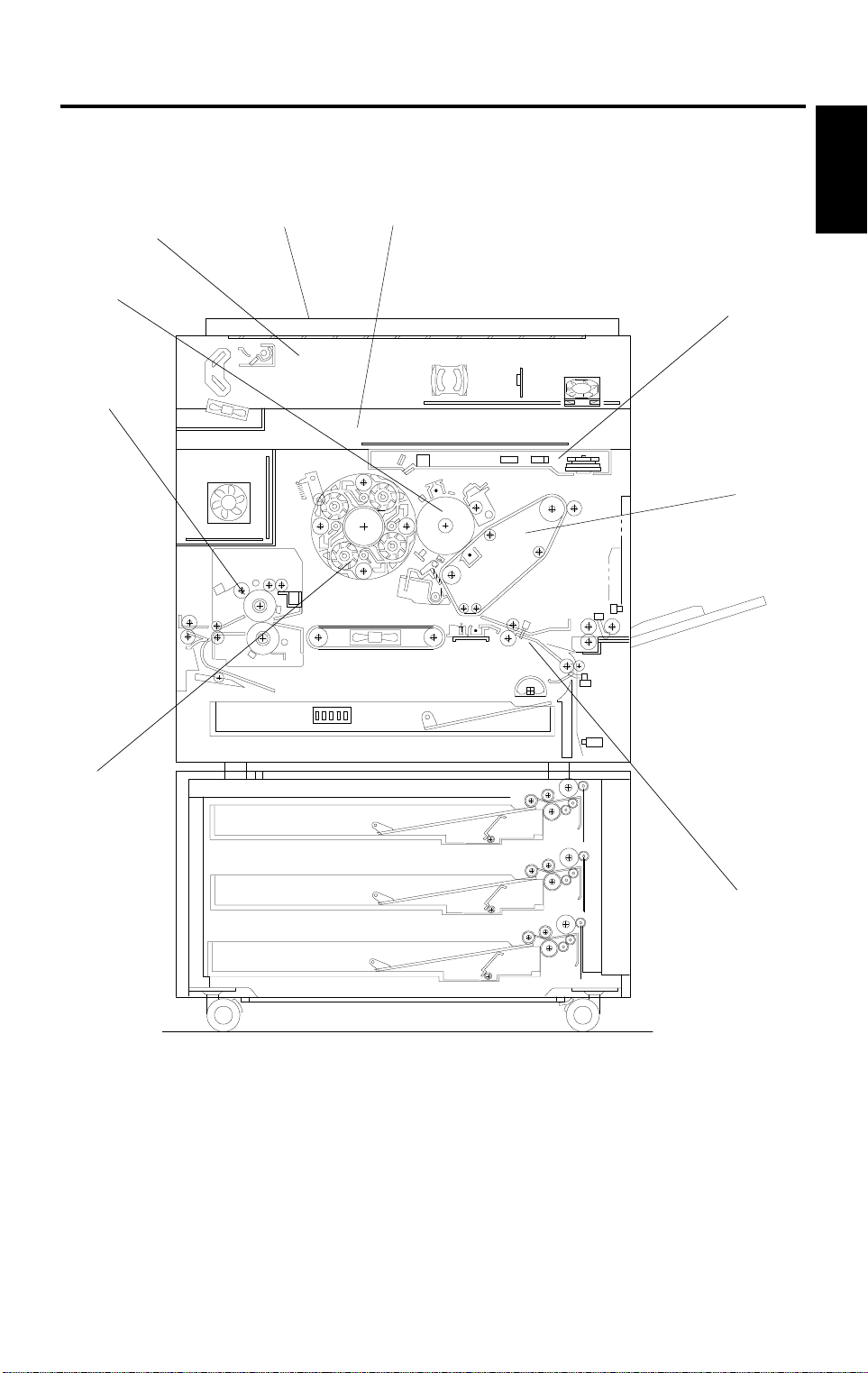

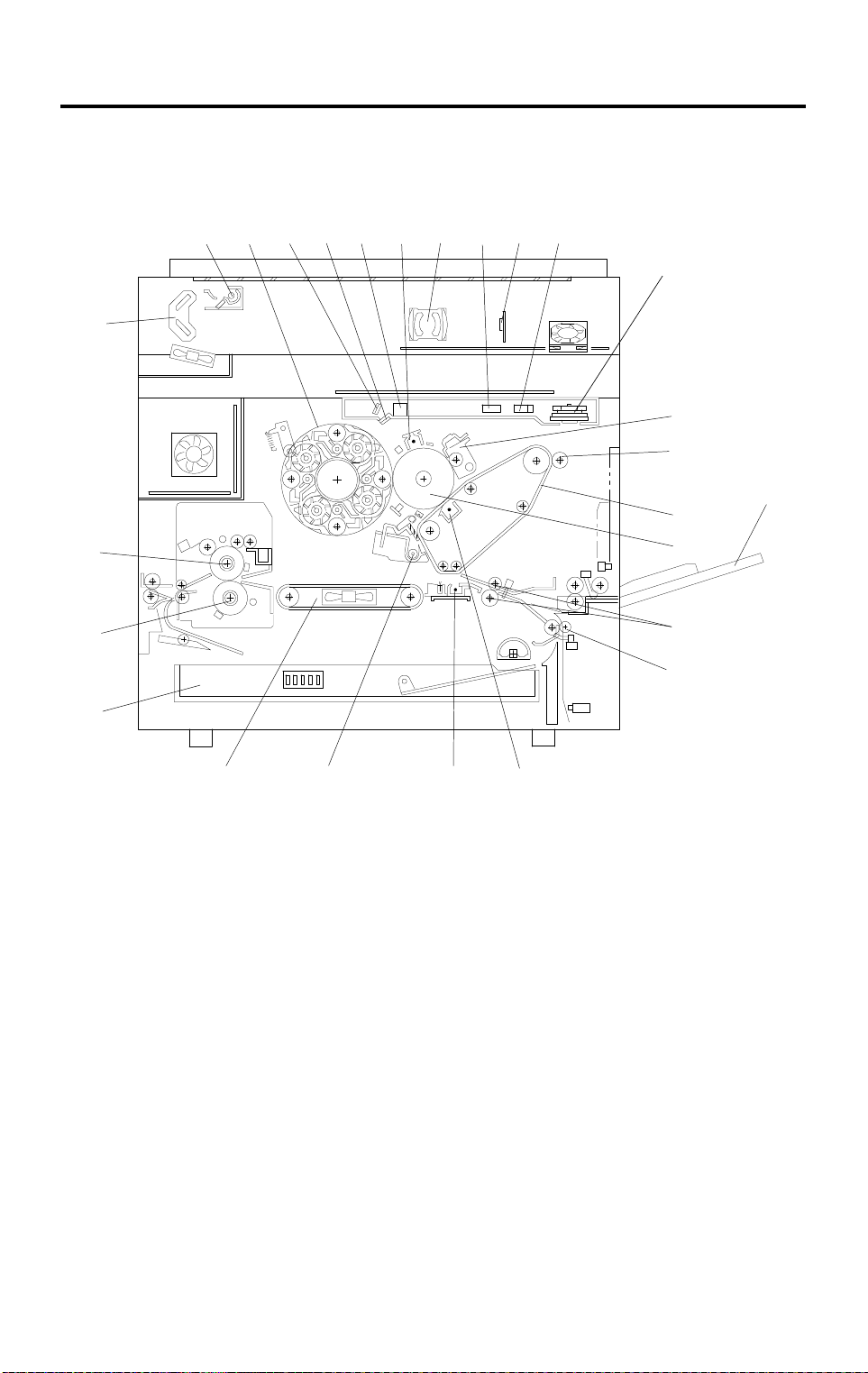

4. PARTS LAYOUT

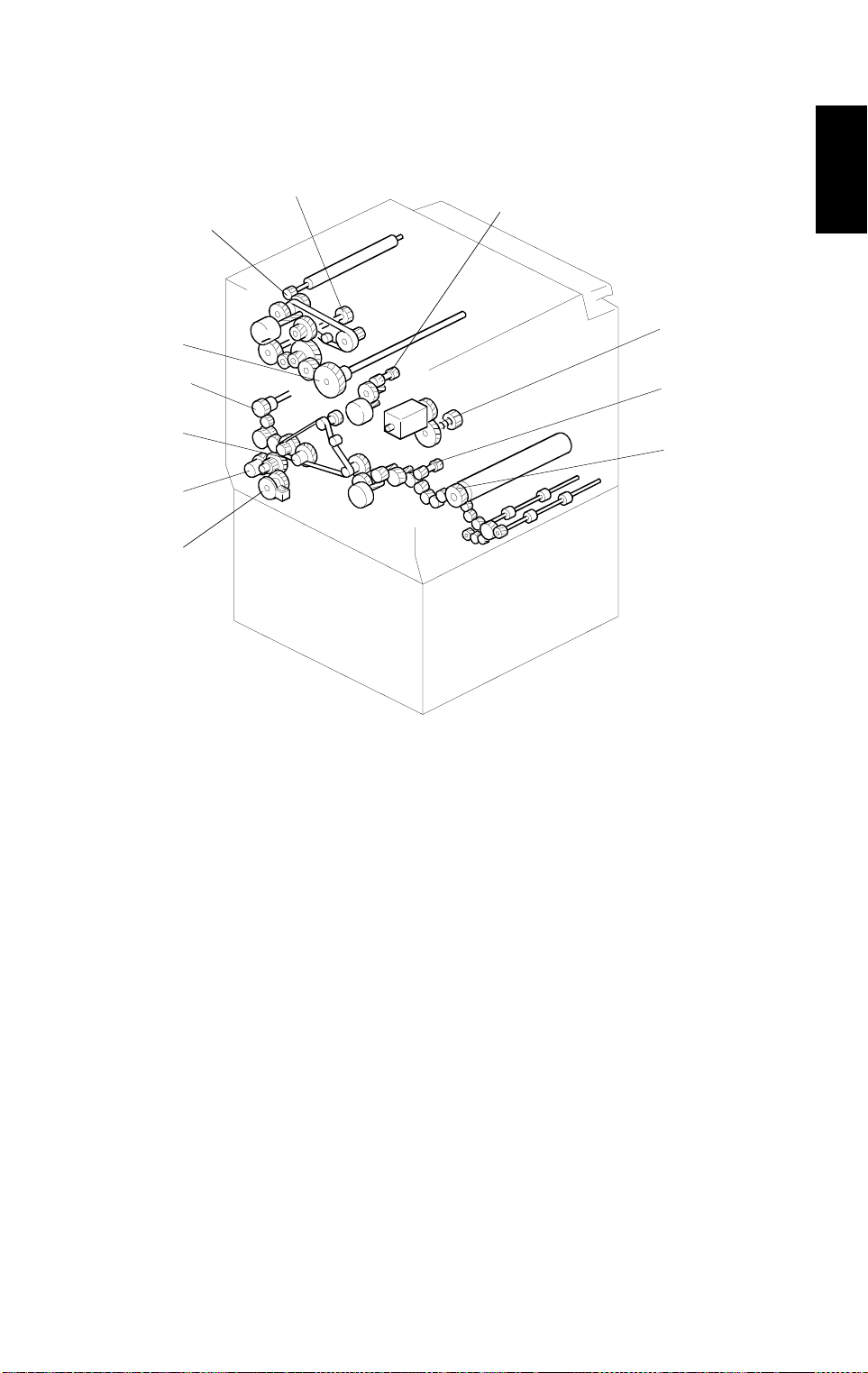

4.1 MECHANICAL COMPONENT LAYOUT

5 6

4

3

2

1

7

1098

11

1312

14

15

16

17

19

20

21

22

18

26

1. Paper Tray (A166)

Duplex Tray

(A187/189)

2. Pressure Roller

3. Hot Roller

4. 2nd Scann er

5. 1st Scanner

6. Development Unit

7. Drum Mirror

8. Toner Shield Glass

9. BTL

25

10. Charge Corona Unit

11. Lens

12. 2nd fθ Le ns

13. CCD Board

14. 1st fθ Lens

15. Polygon Mirror

16. Drum Cleaning Unit

17. Lubricant Brush

18. By-pass Feed Table

19. Transfer Belt

24

23

A166V500.wmf

20. OPC Drum

21. Registration Rollers

22. Relay Roller

23. Belt Transfer

Charge Unit

24. Paper Transfer

Charge Unit

25. Belt Cleaning Unit

26. Transport Belt

1-16

15

10 May 1996 PARTS LAYOUT

4.2 PCB (A166/A187 COPIERS)

4

3

2

1

18

6

7

5

8

Overall

Information

9

10

11

12

13

14

16

17

A166V507.wmf

1. RAM Board

2 . SCU Board

3. AC Drive/DC Power

Supply Board

4. Operation Panel

5. Scanner Motor Drive

Board

6. Scanner IPU Board

7. CCD Board

8. Lamp Regulator

9. IDU Board

10. Main Control Board

11. I/O Control Board 2

12. By-pass Paper Width

Detection Board

13. I/O Control Board 1

14. High Voltage Supply

Board

15. Laser Synchronizing

Detector Board 2

16. Laser Synchronizing

Detector Board 1

17. LD Drive Board

18. Duplex Control Board

(Except A166)

1-17

PARTS LAYOUT 10 May 1996

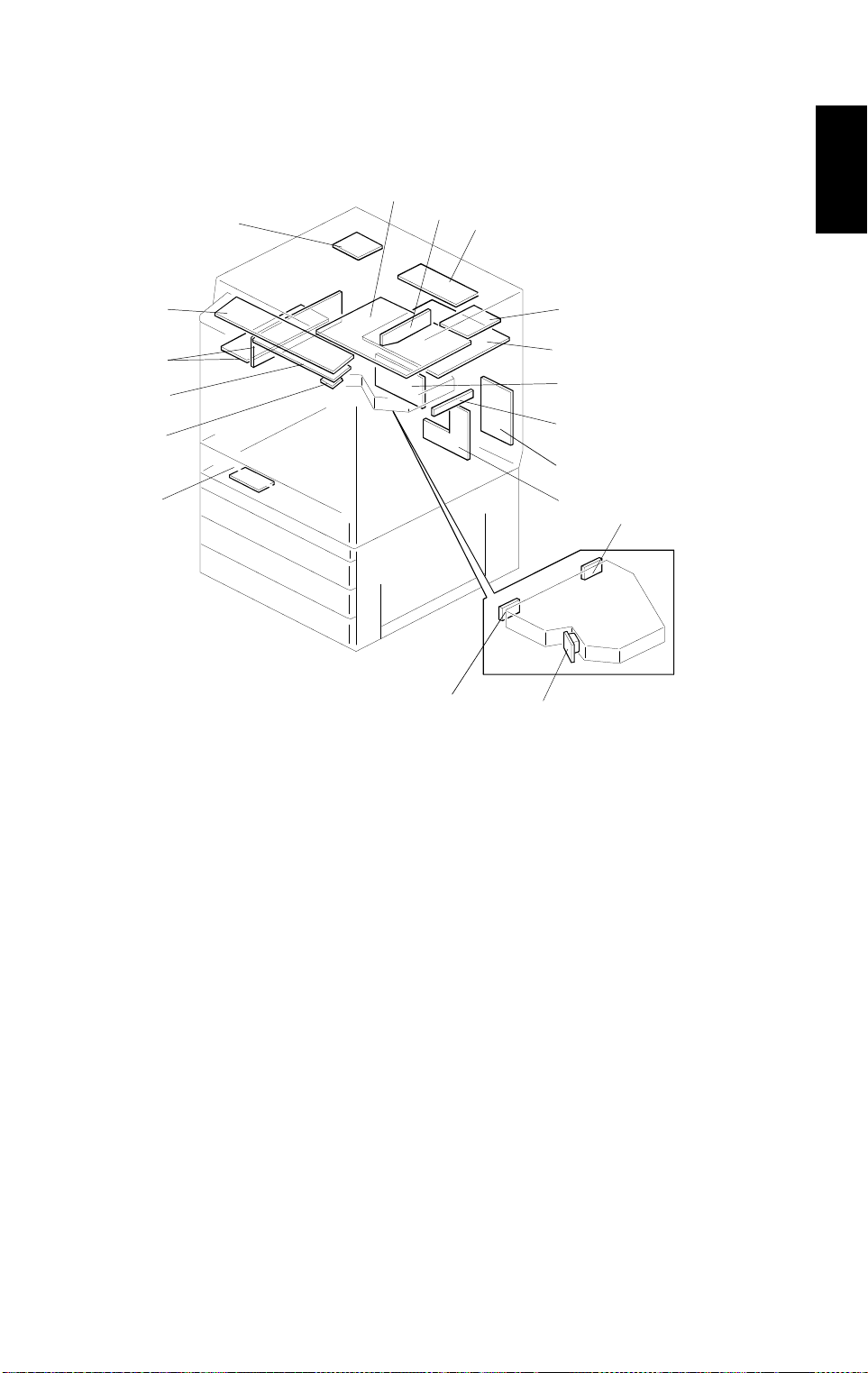

4.3 PCB (A189 COPIER)

20

19

21

23

22

19. SCU Board

20. Operation Panel

21. Extended IPU Board

22. Duplex Control Board

23. RAM Board

A166V508.wmf

1-18

9

765

10 May 1996 PARTS LAYOUT

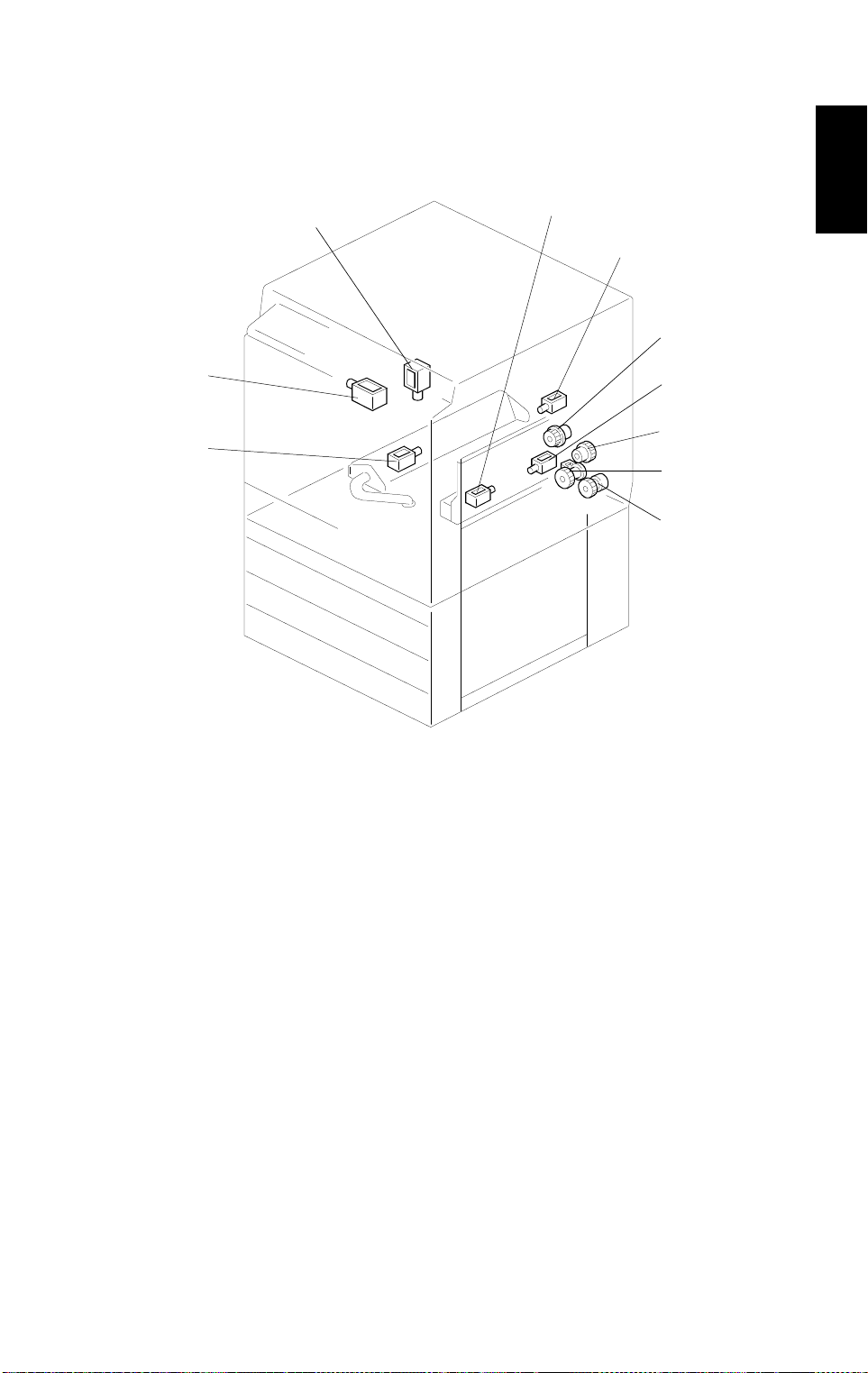

4.4 SOLENOIDS AND CLUTCHES

3

4

Overall

Informati o n

2

8

1

10

1. Transfer Belt Cleaning SOL

2. Toner Supply Release SOL

3. Junction Gate SOL

(A187/A189 only)

4. Sub By-pass Feed Pick-up

SOL

5. Transfer Belt Lubricant SOL

A166V509.wmf

6. Registration CL

7. Main By-pass Feed Pick-up

SOL

8. By-pass Feed CL

9. Paper Feed CL (A166 only)

10. Vertical Transport CL

1-19

13

PARTS LAYOUT 10 May 1996

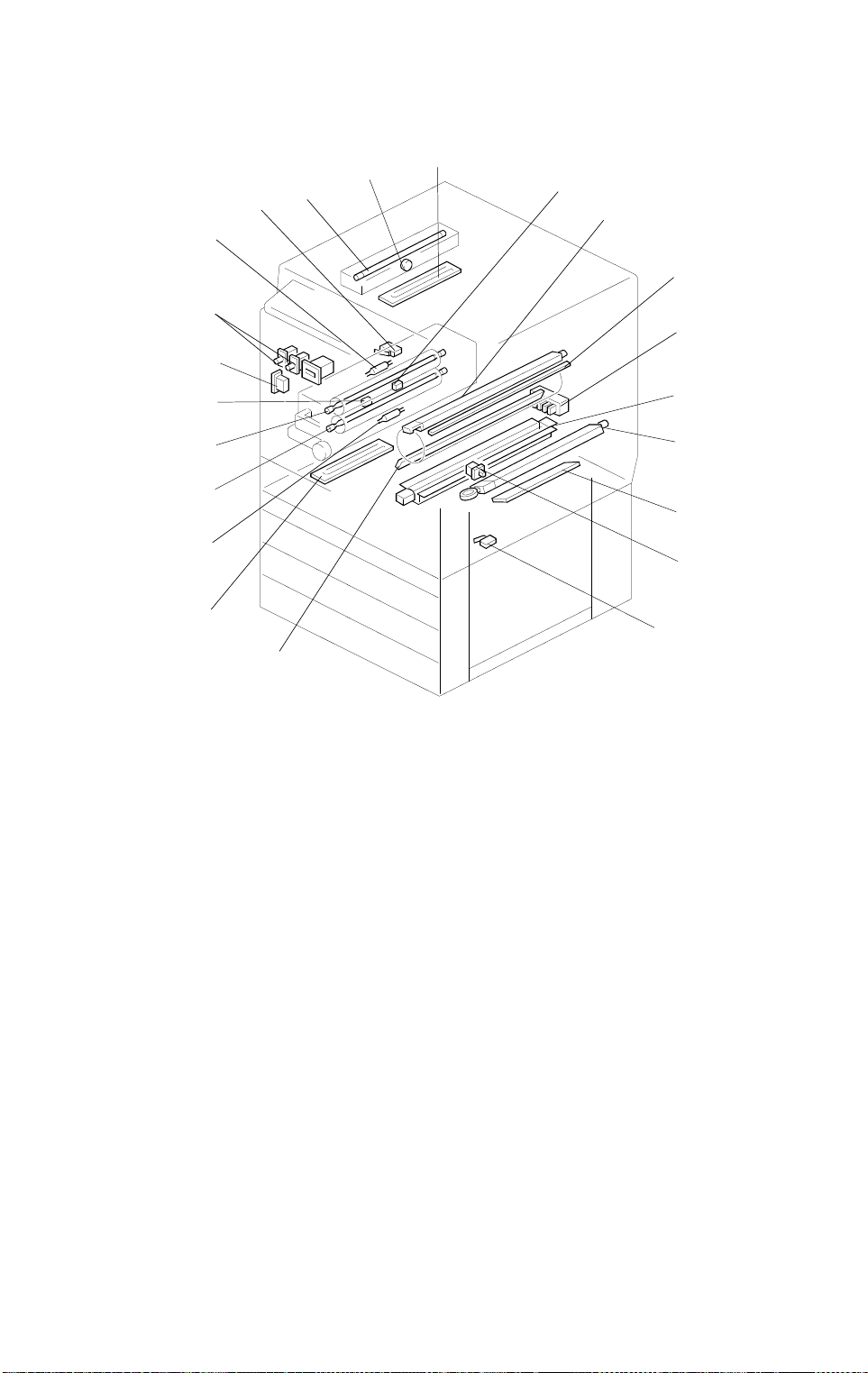

4.5 SWITCHES AND HEATERS

11

10

9

8

7

6

12

14

15

16

5

4

3

2

1

22

1. Lower Tray Heater

2. Pressure Roller Thermofuse

3. Pressure Roller Lamp

4. Fusing Lamp

5. Pressure Roller Thermistor

6. Main Switch

17

18

19

20

21

A166V510.wmf

12. Optics Anticondensat ion

Heater

13. Fusing Thermistor

14. Charge Corona Unit

15. Quenching La mp

16. Tray Paper Size SW

(A166 only)

7. Front Door Switch

8. Fusing Thermofuse

9. Paper Exit Door Switch

(A187/A189 only)

10. Exposure La mp

11. Thermostat

17. Paper Transfer Charge Unit

18. Belt Transfer Charge Unit

19. Drum Heater

20. By-pass Feed Table SW

21. Vertical Transport SW

22. Pre-transfer Lamp

1-20

11

19

10 May 1996 PARTS LAYOUT

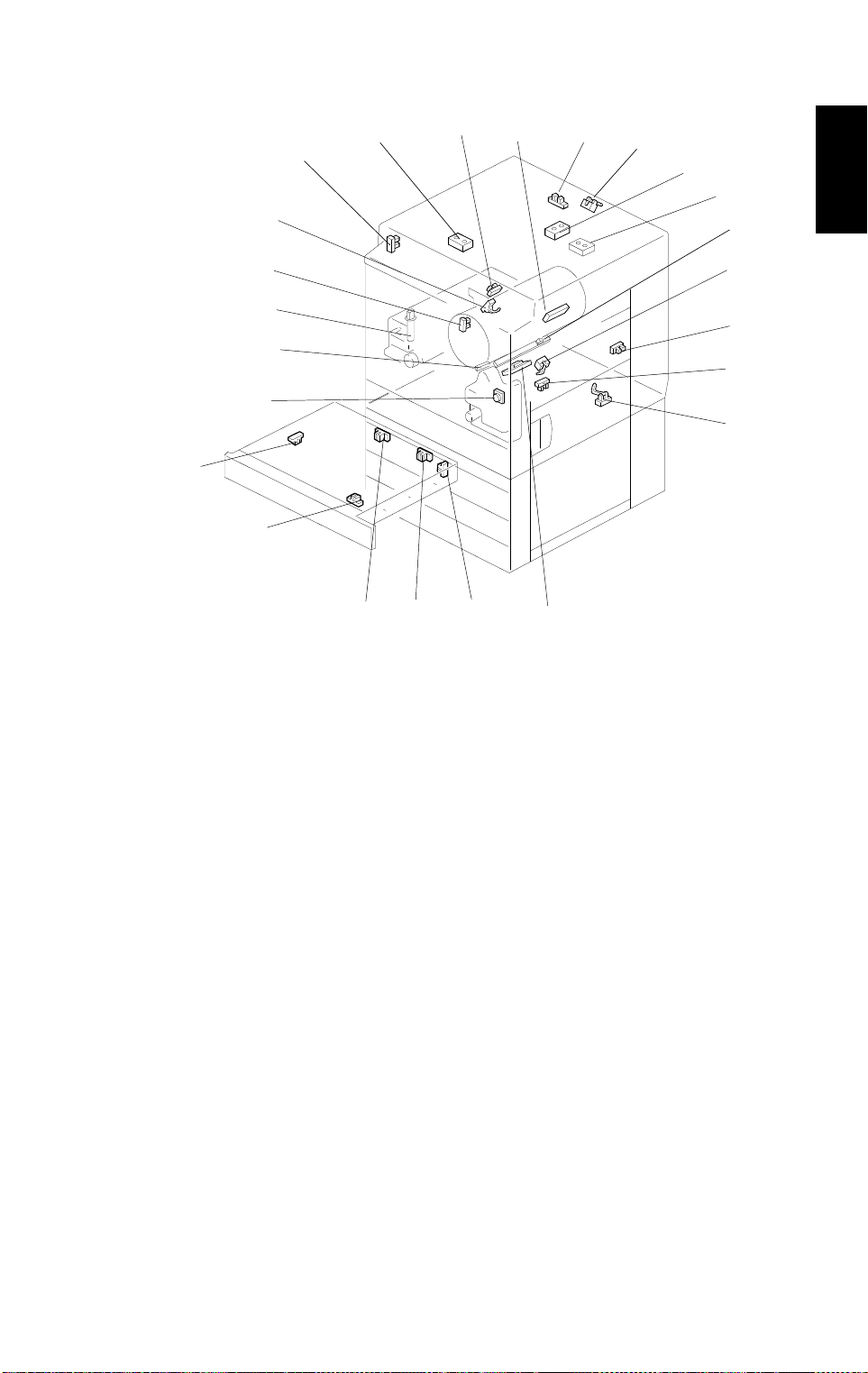

4.6 SENSORS

24

1. Used Toner Sensor

23

7

8

6

5

4

9

10

12

13

14

Overall

Information

15

3

16

2

17

1

18

A166V504.wmf

22

21

20

15. Registration Sensor

2. Color Toner Cartridge

Sensor

3 . Oil End Sensor

4. Revolver H.P. Sensor

5. Bk Toner Cartridge Sensor

6. Scanner H.P. Sensor

7. Original Width Sensor

8. Paper Exit Sensor

9. Drum Potential Sensor

10. Platen Cover Position

Sensor

11. Scanner Unit Lift Sensor

12. Original Length Sensor 1

13. Original Length Sensor 2

16. Tray Paper End Sensor

(A166 only)

17. By-pass Feed Paper End

Sensor

18. Vertical Transport Se nso r

19. Transfer Belt H.P. Sensor

20. Duplex Paper En d Sensor

(A187/A189 only)

21. Duplex Turn Sensor

(A187/A189 only)

22. Duplex Entrance Sensor

(A187/A189 only)

23. Side Fence Jogger HP

Sensor (A187/A189 only)

24. End Fence Jogger HP

Sensor (A187/A189 only)

14. ID Sensor

1-21

7

6

PARTS LAYOUT 10 May 1996

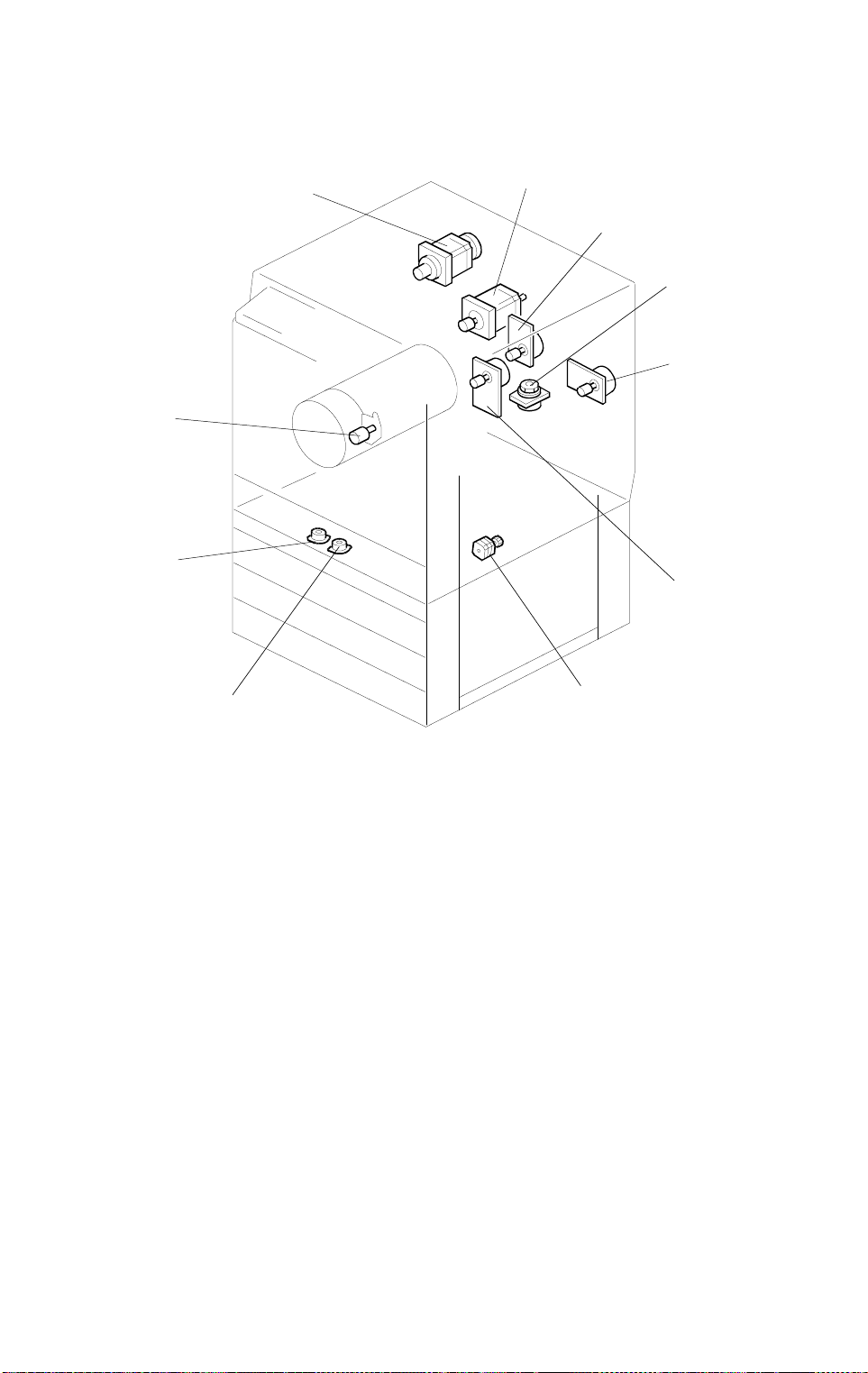

4.7 MOTORS

10

2

3

4

5

1

9

1. Toner Supply Motor

2. Scanner Motor

3. Revolver Drive Motor

4. Development Drive Motor

5. Polygon Motor

6. Drum Motor

8

A166V511.wmf

7. Main Motor

8. Duplex Feed Motor

(A187/A189 only)

9. Side Fence Jogger Motor

(A187/A189 only)

10. End Fence Jogger Motor

(A187/A189 only)

1-22

11109

10 May 1996 PARTS LAYOUT

4.8 DRIVE LAYOUT

7

8

6

Overall

Informati o n

5

4

3

2

1

1. Paper Feed Clutch

2. Vertical Transport Clutch

3. Registration Clutch

4. By-pass Feed Clutch

5. Drum Drive Gear

6. Transfer Belt Lubricant

Gear

A166V512.wmf

7. Transfer Belt Drive Gear

8. Development Drive Gear

9. Revolver Drive Gear

10. Transport Unit Drive Gear

11. Fusing Unit Drive Gear

1-23

15

PARTS LAYOUT 10 May 1996

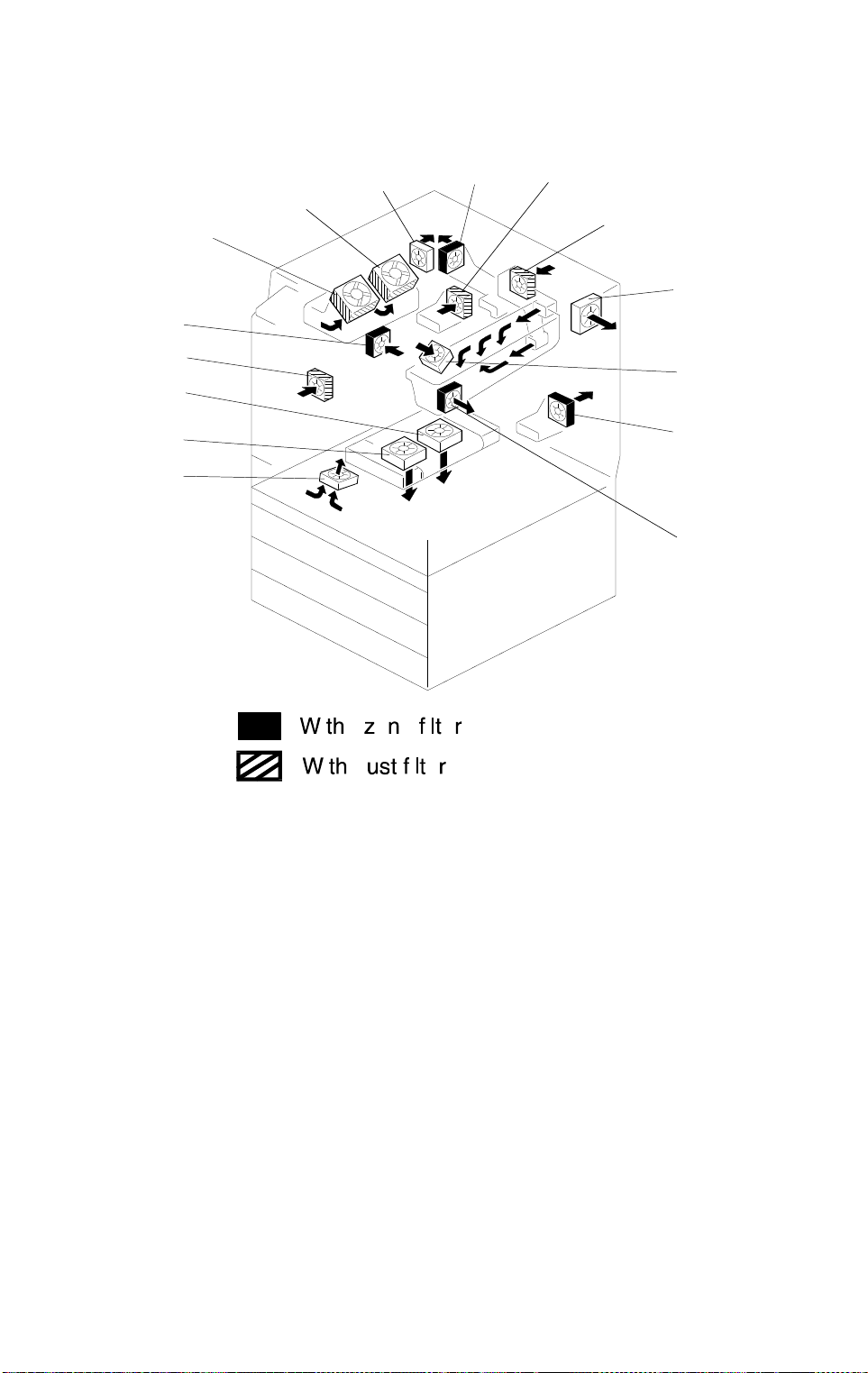

4.9 FANS AND AIR FLOW

8

9

10

7

11

6

12

5

4

13

3

2

14

1

1. Development Inlet Fan

2. Transport Fan 1

3. Transport Fan 2

4. Front Power Supply

Board Fan

5. Paper Exit Fan

6. Optics Cooling Fan 1

7. Optics Cooling Fan 2

8. Rear Power Supply Board

Fan

A166V513.wmf

9. Exhaust Fan

10. Fusing Fan

11. Charge Inlet Fan

12. Optics Exhaust Fan

13. Scanner Board Cooling

Fan

14. Rear Transfer Fan

15. Front Transfer Fan

1-24

10 May 1996 PARTS LAYOUT

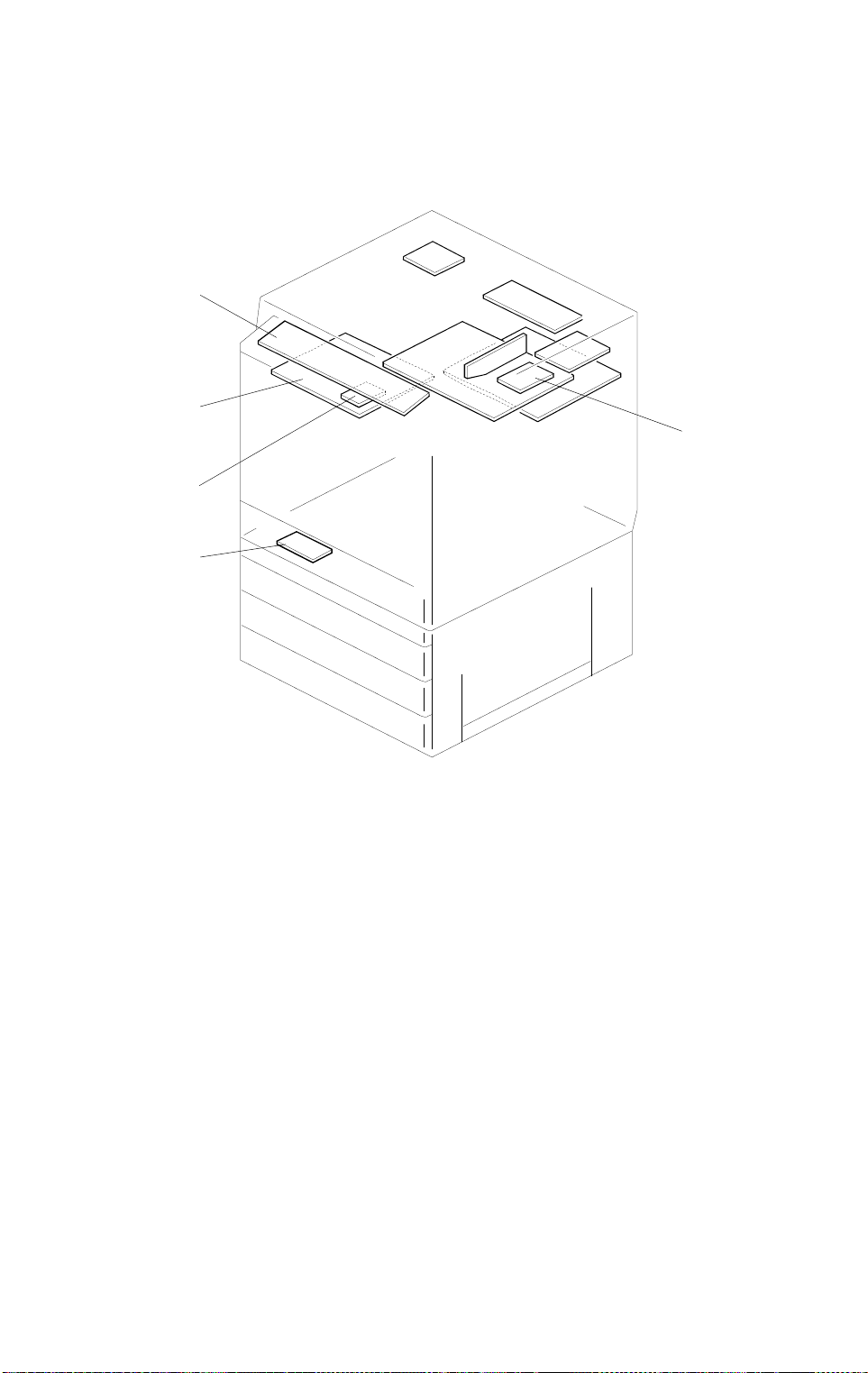

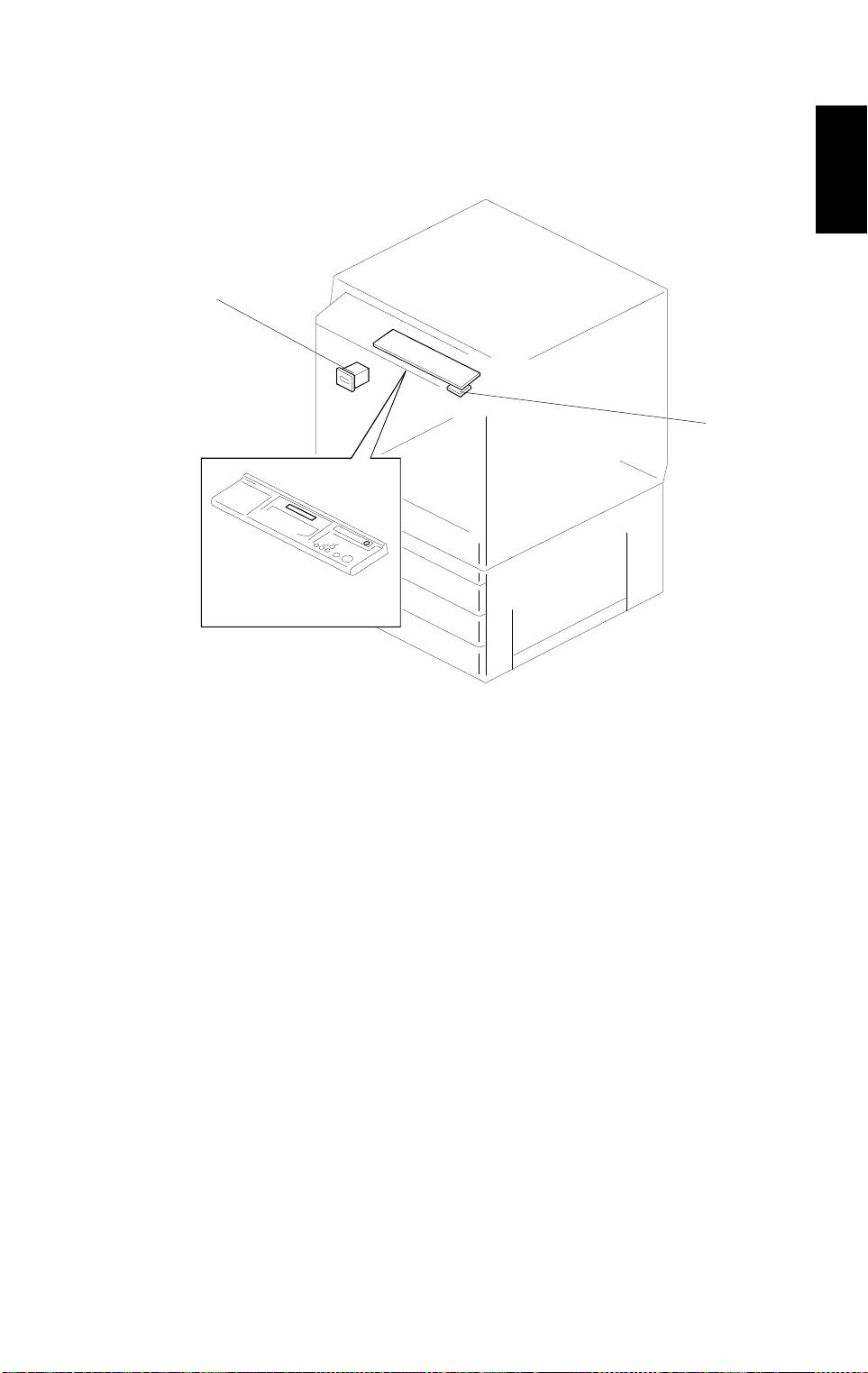

4.10 COUNTERS (A166/A187 COP IERS )

1

2

Overall

Informati o n

A166V515.wmf

1. Main Counter

2. Back-up Counter (stored in the RAM board on the SCU board )

1-25

PARTS LAYOUT 10 May 1996

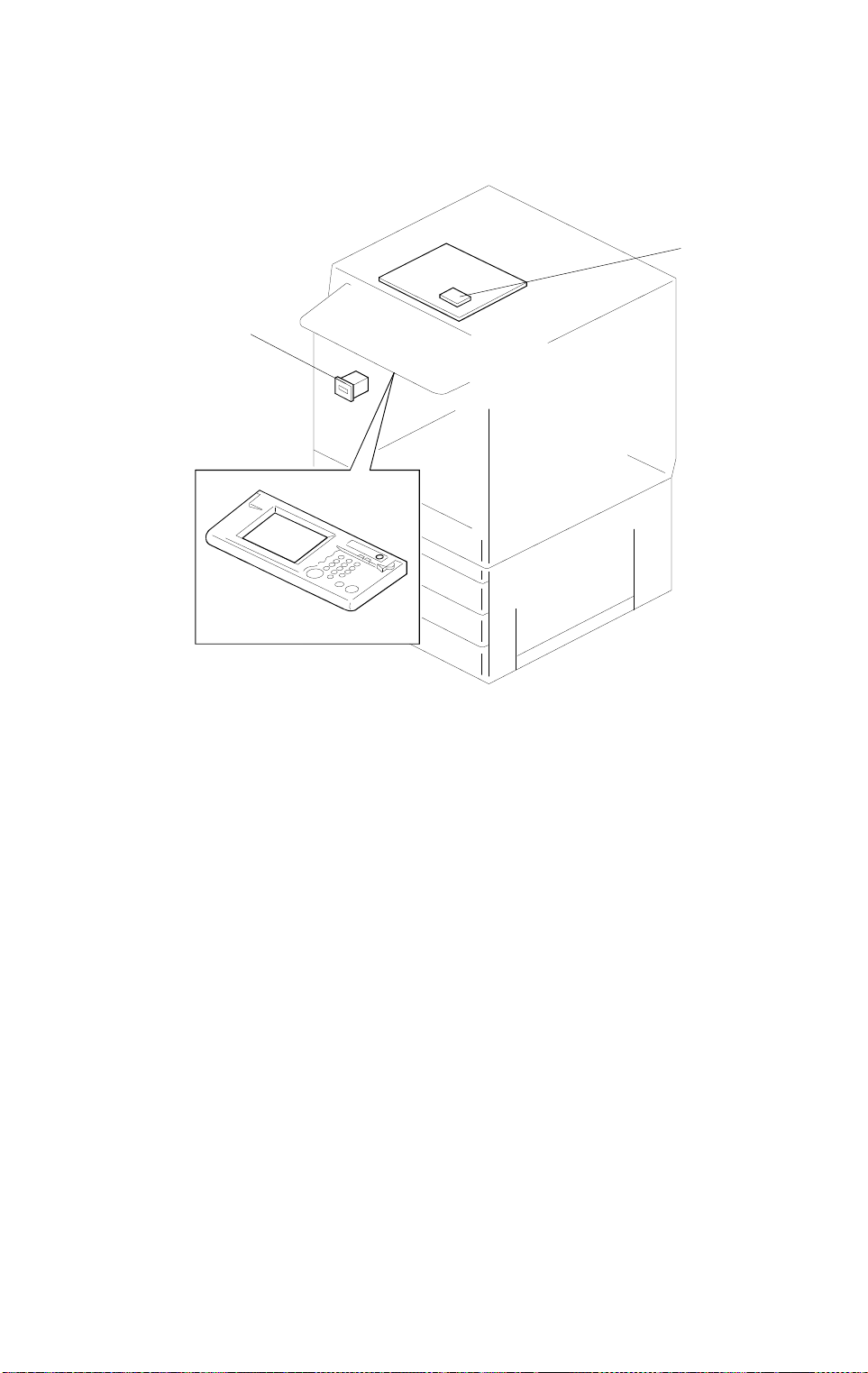

4.11 COUNTER (A189 COPIER)

2

1

A166V514.wmf

1. Main Counter

2. Back-up Counter (stored in the RAM board on the SCU board )

1-26

10 May 1996 ELECTRICAL COMPONENT LIST

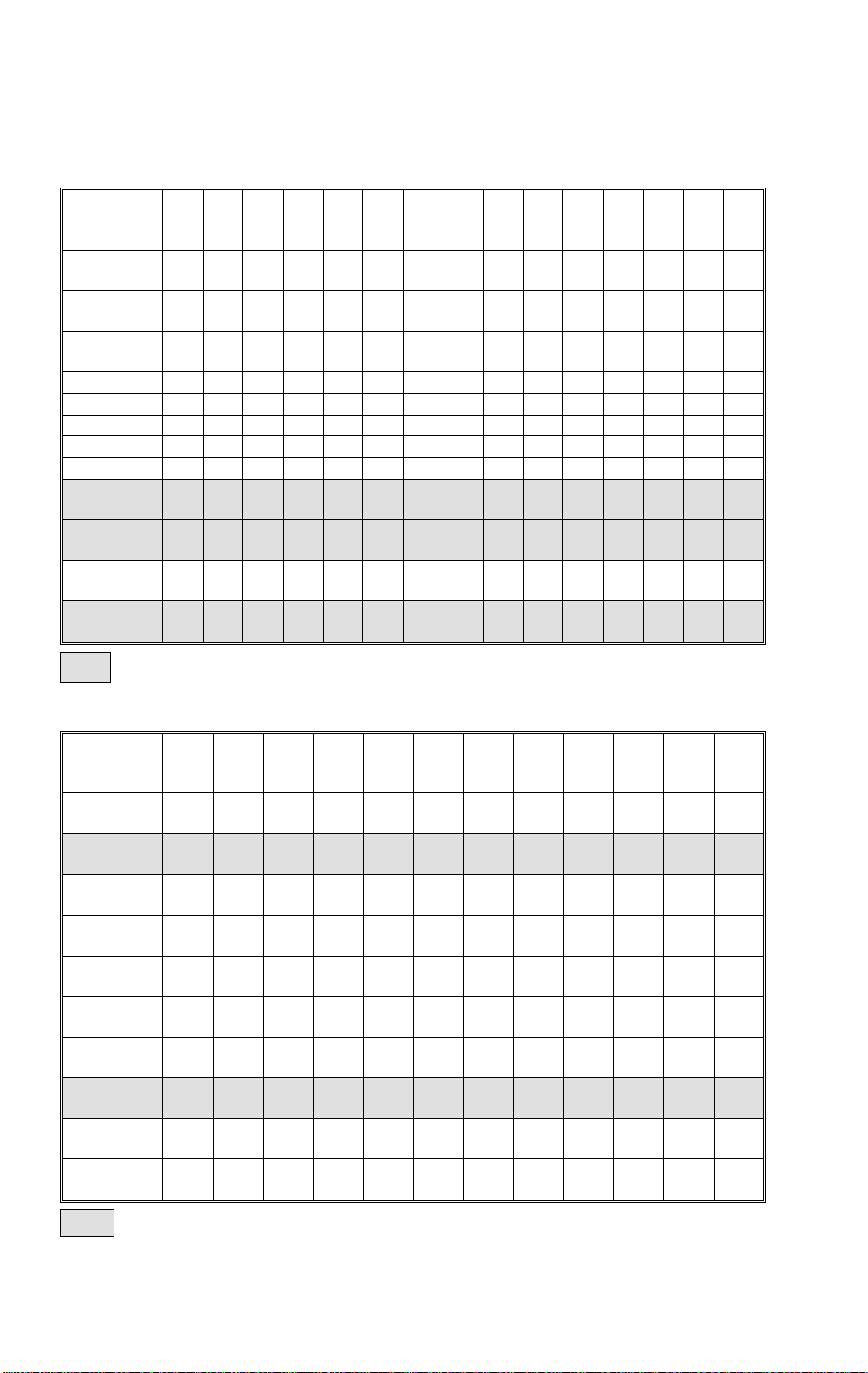

5. ELECTRICAL COMPONENT LIST

5.1 PRINTED CIRCUIT BOARDS

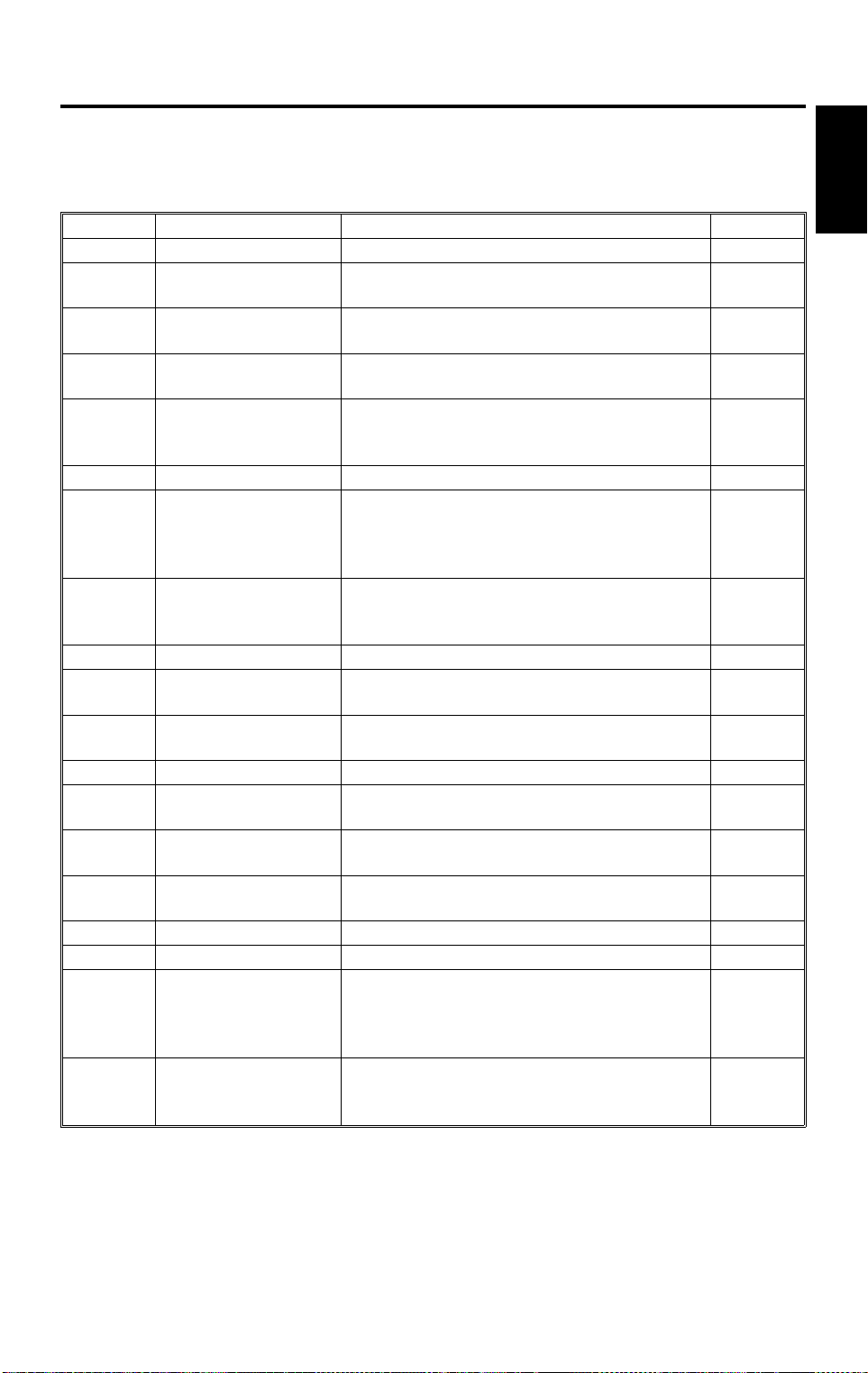

Symbol Name Function Remarks

PCB1 Lamp regulator Supplies dc power for the exposure lamp.

PCB2

PCB3

PCB4

PCB5

PCB6 Main control board Controls the printer sequence.

PCB7

PCB8

PCB9 LD drive board Controls the LD output.

PCB10

PCB11

PCB12 IDU board Discriminates image for anti-counterfeiting

PCB13

PCB14

PCB15

PCB16 RAM board Stores the copy process data and counters.

PCB17 Operation panel Used to operate the copier.

PCB18

PCB19

Scanner motor drive

board

CCD board Converts the light reflected from the original

AC drive/

DC power suppy

Scanner IPU board Converts the RGB image signal from the

I/O control board 1 Interfaces the sensors, clutches, solenoids

I/O control board 2 Interfaces the sensors, clutches, solenoids

Laser synchronizing

detector board 1

Laser synchronizing

detector board 2

By-pass paper width

detection board

High voltage supply

board

System control unit

(SCU) board

Extended IPU board Converts scanned image data and sends it

Duplex control board Controls the duplex unit. A187/A189

Supplies dc power for the scanner motor.

into signals.

Supplies ac and dc power.

CCD to a KCMY signal and sends it to the

printer and SCU.

and motors in the printer module with the

main control board. Includes temperature

and humidity sensors.

and motors in the printer module with the

main control board.

Detects laser main scan synchronization

while writing the latent image to the drum.

Detects laser main scan synchronization

while writing the latent image to the drum.

Detects the paper width in the by-pass feed

table.

Supplies power to the corona units.

Controls the system.

to SCU for the display. Performs image

processing on an area specified in the

display.

A189

copier

only

copiers

only

Overall

Information

1-27

Loading...

Loading...