Page 1

RICOH Modification

Bulletin

PAGE: 1/2

Model:

Modified Article:

From:

Reason for

Modification:

Please make the following corrections to your Adonis-P parts catalog.

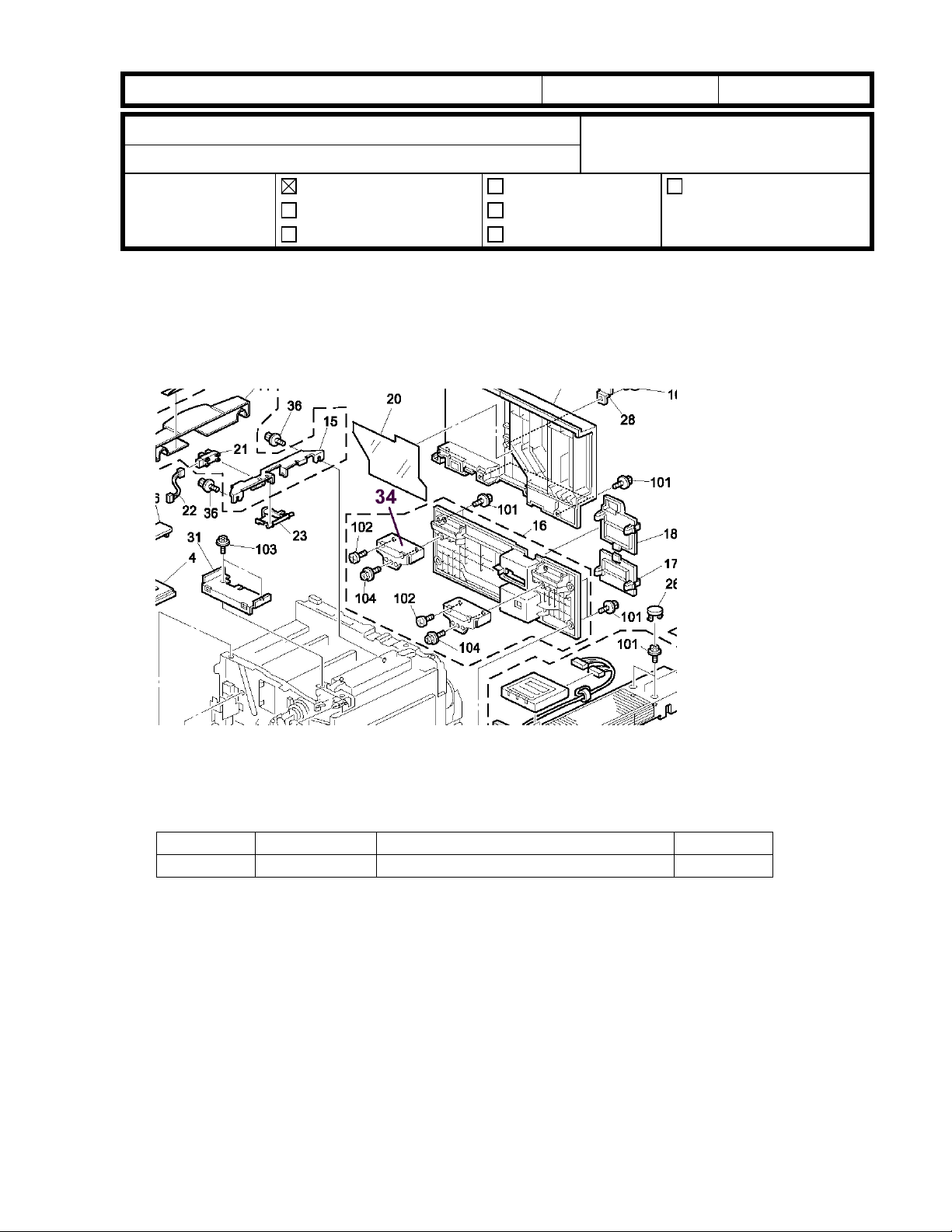

1. Adonis-P (G035): Page 10

Adonis-P

Parts Catalog Correction

Technical Service Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Add index number 34 as follows

Date:

Vendor change

To improve reliability

Other

31-Oct-99

Prepared by:

To meet standards

No.:

K. Takagi

( )

MG035001

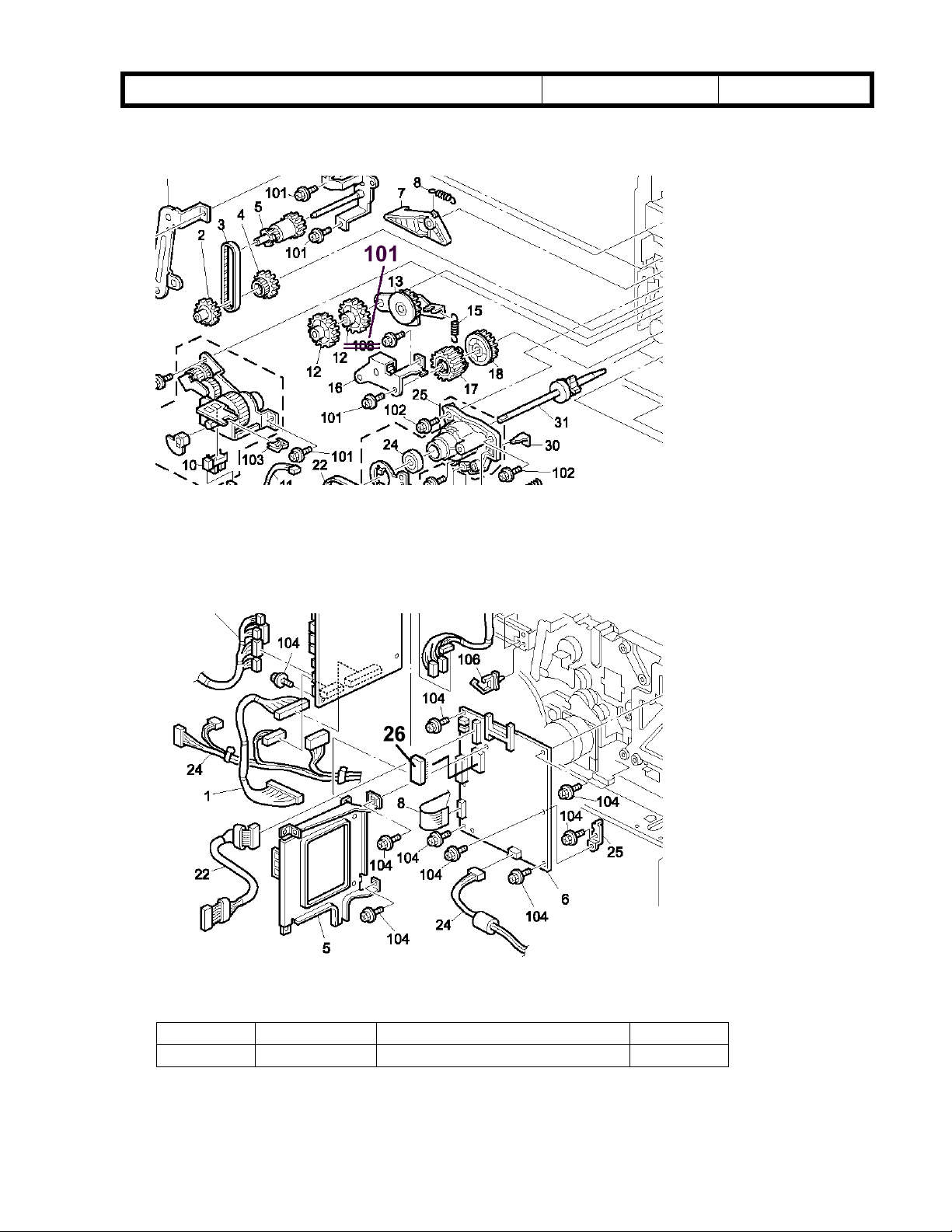

2. Adonis-P (G035): Page 25

Add the following part number for index number 1

Index No. Part No. Description Q'ty

1 A2327266 Toner Supply Unit – 115V (RIC) 1

Page 2

RICOH Modification

Bulletin

PAGE: 2/2

Model:

3. Adonis-P (G035): Page 46

4. Adonis-P (G035): Page 52 and 53

Adonis-P

Correct index number from 108 to 101

Add NV-RAM (index number 26) and part number as follows

Date:

31-Oct-99

No.:

MG035001

Page 52

Page 53

Index No. Part No. Description Q'ty

26 A2849001 NV-RAM - +1000 Counter 1

Page 3

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Hot Roller Stripper and Tension Spring

Parts catalog correction

To facilitate assembly

Part standardization

Date:

13-Aspr-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035002

K. Takagi

To meet standards

( )

Cause

Since a mixture of the toner and paper dust accumulates on the tip of the hot roller

stripper, a gap develops between the stripper and hot roller surface. Under this condition,

the copied paper is not separated by the hot roller stripper, leading to jams in the fusing

unit (the paper gets caught on the tip of the hot roller stripper).

Contents of Change

To reduce the amount of toner and paper dust attracted to the hot roller stripper, the

material of the stripper will be changed from PPS to PEK.

To increase the contact pressure between hot roller and stripper, the tension of the hot

roller stripper spring will be changed from 150 mN to 300 mN.

Old part

number

AE044022 AE044028 Hot Roller Stripper 5 O/O 37 6

AA060701 AA060837 Tension Spring 5 O/O 37 7

MODEL NAME V/Hz DESTINATION

SAVIN SLP45

Gestetner P7045

Ricoh Aficio AP4500 115/60 USA, Canada G035-17 P1800100021

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27 P1891200121

New part

number

Description Q’ty Int Page Index Note

JAPAN PRODUCTION

CODE SERIAL NUMBER

115/60 USA, Canada G035-15 P1891200023

220/50 Europe, etc. G035-22 P1891200106

Page 4

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Right Door Switch

Parts catalog correction

To facilitate assembly

Part standardization

Date:

13-Apr-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035003

K. Takagi

To meet standards

( )

Cause:

Jams in the fusing unit area (C-jams) are cleared by opening and closing either the front or

right door, even when the jammed paper has not been removed. This in turn causes jams

to reoccur when the next print job is done.

Countermeasure

The following will prevent C-jams from being cleared by opening and closing the front

door:

1. The front door push switch, switch bracket, and tapping screw have been deleted.

This switch was then added to the right door switch assembly, making a total of 4.

2. The length of the fastening screw for the right door microswitch has been increased.

3. The length of the front-upper DC harness has been increased and the harness has

been rerouted to the right door microswitch assembly.

Old part

number

A2325867 Angle Bracket-Push Switch 1-0 - 53 16

AW500022 Push Switch 1-0 - 53 17

04513006B Tapping Screw – M3x6 14-13 - 53 104

12042466 12042466 Micro Switch - V - 16506-1C25 3-4 - 53 101

AA143512 AA143519 Stepped Screw – M2.5 3-2 X/X 53 14

A2325402 A2845520 DC Harness – Front Upper 1-1 X/X 53 3

MODEL NAME V/Hz DESTINATION

SAVIN SLP45

Gestetner P7045

Ricoh Aficio AP4500 115/60 USA, Canada G035-17 P1890700011

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27 P1890800096

New part

number

Description Q’ty Int Page Index Note

JAPAN PRODUCTION

CODE SERIAL NUMBER

115/60 USA, Canada G035-15 P1890700001

220/50 Europe, etc. G035-22 P1890800086

Page 5

!"#$% M

odification Bulletin

PAGE: 1/2

Model:

Modified Article:

From:

Reason for

Modification:

Old part

number

AA120089 A2844460 Antistatic Brush 1-1 X/O 39 8

Adonis-P

Antistatic Brush and Grounding Plates

Technical Services Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

New part

Description Q’ty Int Page Index Note

number

A2844462 Grounding Plate – Exit Roller 0-1 - 39 *33

A2844463 Grounding Plate – Paper Feed Sensor 0-1 - 39 *34

Date:

13-Apr-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035004

K. Takagi

To meet standards

( )

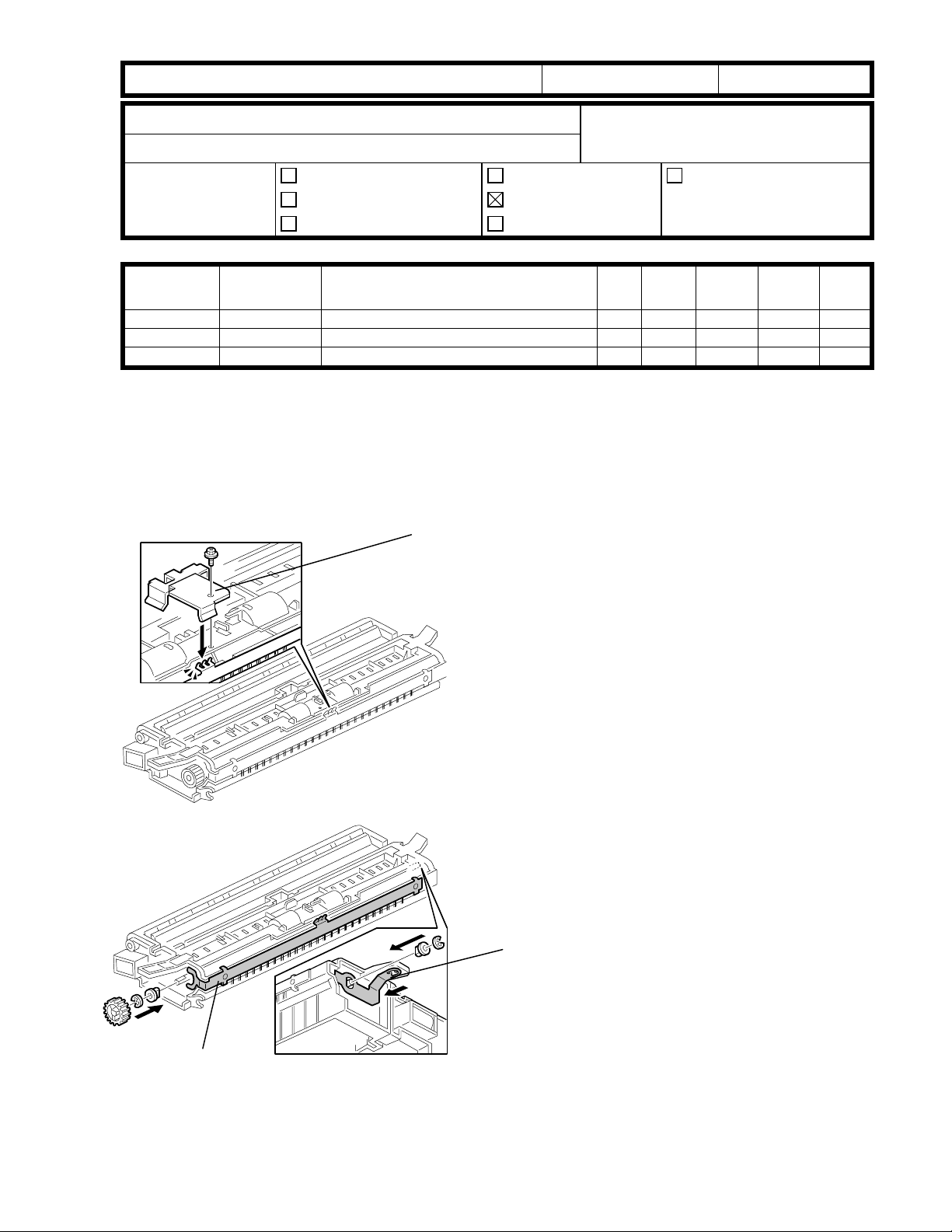

To ensure proper grounding, the shape of the anti-static brush has been changed and

grounding plates for the exit and paper feed rollers have been added. Please refer to the

illustration below. This modification reduces the occurrence of paper jams caused by

static electricity buildup.

#8 Anti-static Brush

#34 Grounding Plate – Paper Feed Sensor

#33 Grounding Plate – Exit Roller

Page 6

!"#$% M

odification Bulletin

PAGE: 2/2

Model:

SAVIN SLP45

Gestetner P7045

Ricoh Aficio AP4500 115/60 USA, Canada G035-17 P1891000078

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27 P1891100159

Adonis-P

MODEL NAME V/Hz DESTINATION

115/60 USA, Canada G035-15 P1891000006

220/50 Europe, etc. G035-22 P1891000130

Date:

13-Apr-00

JAPAN PRODUCTION

CODE SERIAL NUMBER

No.:

MG035004

Page 7

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Quenching Lamp Magnet

Parts catalog correction

To facilitate assembly

Part standardization

Date:

13-Apr-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035005

K Takagi

To meet standards

( )

To standardize the part with other models, the quenching lamp magnet has been changed.

Old part

number

A2322373 A2673455 Magnet – Quenching Lamp 1-1 O/O 55 9

New part

number

Description Q’ty Int Page Index Note

Page 8

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Hard Disk Drive

Parts catalog correction

To facilitate assembly

Part standardization

Date:

13-Apr-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035006

K. Takagi

To meet standards

( )

The following is the P/N change history for the printer engine hard disk drive.

The hard disk for the printer engine has been changed as shown below because of

discontinuances in production.

Old part

number

A6915877 A6915878 Hard Disk Drive 1 O/O 59 14

A6915878 A6915879 Hard Disk Drive 1 O/O 59 14

A6915879 A6915860 Hard Disk Drive 1 O/O 59 14

New part

number

Description Q’ty Int Page Index Note

Page 9

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Seals : PSU

Parts catalog correction

To facilitate assembly

Part standardization

Date:

Vendor change

To improve reliability

Other

The following part has been registered as a service part.

Please add this to your parts catalog.

Old part

number

- A2322350 Seal - Entrance 2 - 27 33

- A2322348 Seal – Blade 12 x 7 x 3 2 - 27 35

New part

Description Q’ty Int Page Index Note

number

A2322399 Seal – Blade 13 x 9.5 x 3 2 - 27 34

08-May-00

Prepared by:

To meet standards

No.:

K. Takagi

( )

MG035007

Page 10

2 M

odification Bulletin

PAGE: 1/2

Model:

Modified Article:

From:

Reason for

Modification:

Symptom

The connection between the toner supply unit and toner bottle is loose, which causes the unit to

separate from the bottle when the unit is pulled out. Toner then spills out onto the toner supply unit

and sometimes onto the front cover as well.

Countermeasure

A seal has been added to the inside of the toner supply unit to minimize the freedom of movement

of the toner bottle. This will tighten the hold of the toner supply unit on the bottle, preventing any

separation of the bottle from the unit.

Adonis-P

Seal - Toner Bottle Cover

Technical Services Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

- AA153083 Seal – Toner Supply Unit Cover

- AA153084 Seal – Toner Supply Unit Cover

New part

number

Description Q’ty Int Page Index Note

(RIC NA)

(RIC EU and OEM)

Date:

17-Jul-00

Prepared by:

Vendor change

To improve reliability

Other

1 - 25 13

1 - 25 13

No.:

MG035008

K. Takagi

To meet standards

( )

Page 11

2 M

odification Bulletin

PAGE: 2/2

Model:

Adonis-P

Date:

17-Jul-00

No.:

RCL Production

MODEL NAME V/Hz DESTINATION CODE SERIAL NO.

SAVIN SLP45

Gestetner P7045

Ricoh Aficio AP4500 115/60 USA, Canada G035-17

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27

115/60 USA, Canada G035-15

220/50 Europe, etc. G035-22

P18006XXXX

P1800500001

P1800500081

P1800500101

MG035008

Page 12

1 M

odification Bulletin

PAGE: 1/1

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Laser Synch. Detector

Parts catalog correction

To facilitate assembly

Part standardization

Date:

17-Jul-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035009

K. Takagi

To meet standards

( )

Symptom

SC322/326 is generated at installation.

Cause

Most likely, the lasers in some machines tested at the factory had passed through the

lower end of the Laser Synch. Detector, very close to the edge. Then, during transport,

the LD unit housing was slightly deformed or shifted due to some form of shock or shaking.

As a result, the position of the laser was shifted outside the detection range.

Countermeasure

1. The detection width of the Laser Synch. Detector has been increased from 2.3 to 3.0

mm.

Old part

number

A2325310 A2935310 Laser Sync. Detector 1-1 X/O 13 25

New part

number

Description Q’ty Int Page Index

RCL Production

MODEL NAME V/Hz DESTINATION CODE SERIAL NO.

SAVIN SLP45

Gestetner P7045

Ricoh Aficio AP4500 115/60 USA, Canada G035-17

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27

115/60 USA, Canada G035-15

220/50 Europe, etc. G035-22

P1890900001

P1890900041

P1890900091

P1890900156

Page 13

odification Bulletin

M

PAGE: 1/2

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Development Unit

Parts catalog correction

To facilitate assembly

Part standardization

Date:

26-Jul-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035010

K. Takagi

To meet standards

( )

Due to the reasons listed below, the A2327460 Development Unit (NAD) will be used for

the Adonis-P in place of the G0353050 Development Unit.

Old part

number

G0353050 Development Unit - - 35 1 -

• The original Development Unit (G0353050) is filled with developer before it is

New part

Description Q’ty Int Page Index Note

number

A2327460 Development Unit 1 -

shipped from the factory. The developer has a tendency to spill out during transport.

However, the factory will not supply this unit without the developer.

• The Development Unit for the NAD (A2327460) can also be used with the Adonis-P if

the three components listed below are installed.

NOTE:

When installing these three components in the A2327460 unit, you can either use the

components from the original development unit (G0353050) or newly purchased

components.

Additional components needed:

1. G0342450 (Index No. 32): Bracket – PCU and Development Unit

2. G0342451 (Index No. 31): Bracket – Development Stay

3. 04503010B (Index No. 106): Tapping Screw – M3x10

Page 14

odification Bulletin

M

PAGE: 2/2

Model:

Adonis-P

Date:

26-Jul-00

No.:

MG035010

Page 15

1 M

odification Bulletin

PAGE: 1/1

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Driven Roller and Guide Plate

Parts catalog correction

To facilitate assembly

Part standardization

Date:

08-Aug-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035011

K. Takagi

To meet standards

( )

To prevent deformation caused by heat, the material of the driven roller and the guide

plate has been changed.

Old part

number

AF040559 AF040575 Driven Roller – M9 2-2 X/O 33 16

A2324491 A2844491 Guide Plate – Fusing Unit 1-1 X/O 33 18

New part

number

Description Q’ty Int Page Index Note

RCL Production

MODEL NAME V/Hz DESTINATION CODE SERIAL NO.

SAVIN SLP45

Gestetner P7045

Ricoh Aficio AP4500 115/60 USA, Canada G035-17

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27

115/60 USA, Canada G035-15

220/50 Europe, etc. G035-22

P18008XXXX

P1800800001

P18008XXXX

P1800700376

Page 16

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Idler Gear - 27Z for the Transfer Unit

Parts catalog correction

To facilitate assembly

Part standardization

Date:

11-Aug-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035012

K. Takagi

To meet standards

( )

Symptom:

Bands of low image density appear at approximately 5mm intervals.

This is especially noticeable with half-tone areas.

Cause:

The supporting tension supplied by the ribs of the idler gear was slightly high, causing the

gear diameter to become slightly warped.

Countermeasure:

To ensure that the idler gear diameter is uniform, the gear ribs will be removed.

Old part

number

AB017429 AB014189 Gear – 27Z 1 X/O 31 12

New part

number

Description Q’ty Int Page Index Note

RCL (Japan) Production

MODEL NAME V/Hz DESTINATION CODE SERIAL NUMBER

SAVIN SLP45

Gestetner P7045

Ricoh Aficio AP4500 115/60 USA, Canada G035-17 P1800800001

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27 P1800700376

115/60 USA, Canada G035-15 P18008XXXX

220/50 Europe, etc. G035-22 P18008XXXX

Page 17

odification Bulletin

M

PAGE: 1/2

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

PFB Board

Parts catalog correction

To facilitate assembly

Part standardization

Date:

11-Aug-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035013

K. Takagi

To meet standards

( )

A counter electromotive force flows through the clutch drive circuits and causes the offtiming of the clutch to be delayed. This can result in a paper jam.

A zener diode has been added to the drive circuits of the PFB board for the following

clutches, preventing any counter electromotive force from flowing through the circuits:

1. Relay Clutch

2. Upper Paper Feed Clutch

3. Lower Paper Feed Clutch

4. By-pass Tray Feed Clutch

The new part number for the PFB board is as follows:

Old part

number

A2325130 A2325135 PFB Board 1-1 X/O 49 20

New part

number

Zener Diode

Description Q’ty Int Page Index

Relay Clutch

Upper Paper Feed Clutch

Lower Paper Feed Clutch

Zener Diode

Zener Diode

Bypass Tray Clutch

Page 18

odification Bulletin

M

PAGE: 2/2

Model:

Adonis-P

Date:

11-Aug-00

No.:

RCL Production

MODEL NAME V/Hz DESTINATION CODE SERIAL NO.

SAVIN SLP45

Gestetner P7045

Ricoh Aficio AP4500 115/60 USA, Canada G035-17

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27

115/60 USA, Canada G035-15

220/50 Europe, etc. G035-22

MG035013

P18008XXXX

P1800800001

P18008XXXX

P1800800201

Page 19

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Modified Article:

From:

Reason for

Modification:

To prevent toner from adhering to the spur, the material of the spur has been changed.

Adonis-P

Spur

Technical Services Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

A2322374 B0042310 Spur 8 O/O 21 2

New part

number

Description Q’ty Int Page Index Note

Date:

26-Sep-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035014

K. Takagi

To meet standards

( )

RCL (Japan) Production

MODEL NAME V/Hz DESTINATION CODE SERIAL NUMBER

SAVIN SLP45

Gestetner P7045

115/60 USA, Canada G035-15 P18010XXXX

Ricoh Aficio AP4500 115/60 USA, Canada G035-17 P18010XXXX

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27 P1800900001

220/50 Europe, etc. G035-22 P18010XXXX

Page 20

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Copy Tray Guide

Parts catalog correction

To facilitate assembly

Part standardization

Date:

26-Sep-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MG035015

K. Takagi

To meet standards

( )

The edge of the copy tray guide has been rounded to ensure that scratches or other minor

injuries do not occur.

Old part

number

A2324498 A2844498 Copy Tray Guide 1 X/O 11 2

New part

number

Description Q’ty Int Page Index Note

RCL Production

MODEL NAME V/Hz DESTINATION CODE SERIAL NO.

SAVIN SLP45

Gestetner P7045

Ricoh Aficio AP4500 115/60 USA, Canada G035-17

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27

115/60 USA, Canada G035-15

220/50 Europe, etc. G035-22

P18010XXXX

P18010XXXX

P18010XXXX

P1800900001

Page 21

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Adonis-P

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

End Fence

Parts catalog correction

To facilitate assembly

Part standardization

Date:

21-Dec-00

Prepared by: K. Takagi

Vendor change

To improve reliability

Other

No.:

MG035016

To meet standards

( )

1. The shape of the end fence edge has been changed so that the user will pinch the

hooks in the correct place, allowing the fence to be properly removed. This will ensure

that the hook portions do not get caught and break when the user is trying to remove the

end fence.

2. The material of the end fence has been changed to a stronger one.

Old part

number

AF017020 AF017026 End Fence 1 X/O 23 6

New part

number

Description Q’ty Int Page Index Note

RCL Production

MODEL NAME V/Hz DESTINATION CODE SERIAL NO.

SAVIN SLP45

Gestetner P7045

Ricoh Aficio AP4500 115/60 USA, Canada G035-17

Gestetner P7045

Nashuatec P7045

Rex-Rotary P7045

Ricoh Aficio AP4500 220/50 Europe, etc. G035-27

115/60 USA, Canada G035-15

220/50 Europe, etc. G035-22

P18012XXXX

P1810100001

P18012XXXX

P1810100003

Loading...

Loading...