Page 1

G035

SERVICE MANUAL

RICOH GROUP COMPANIES

000872MIU

Page 2

Page 3

®

®

SERVICE MANUAL

G035

RICOH GROUP COMPANIES

Page 4

Page 5

G035

SERVICE MANUAL

MIU000872

Page 6

Page 7

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2000 RICOH Corporation. All rights reserved.

Page 8

Page 9

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Corporation. Users of this

manual should be either service trained or certified

by successfully completing a Ricoh Technical

Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Corporation

Page 10

Page 11

LEGEND

PRODUCT CODE COMPANY

GESTETNER RICOH SAVIN

G035 P7045 AP4500 SLP45

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

* 10/99 Original Printing

1 08/2000 A683, G909/G912, A688, A681,

A697 Addition

Page 12

Page 13

TABLE OF CONTENTS

OVERALL INFORMATION

1. OVERALL MACHINE INFORMATION ........................................1-1

1.1 SPECIFICATIONS .................................................................................... 1-1

1.1.1 PRINTER.......................................................................................... 1-1

1.1.2 NETWORK INTERFACE BOARD .................................................... 1-4

1.2 PAPER EXIT TRAY SELECTION .............................................................1-5

1.3 MACHINE CONFIGURATION................................................................... 1-6

1.3.1 SYSTEM COMPONENTS................................................................ 1-6

1.3.2 INSTALLABLE OPTION TABLE.......................................................1-7

1.4 MECHANICAL COMPONENT LAYOUT ...................................................1-8

1.5 PAPER PATH............................................................................................1-9

1.6 ELECTRICAL COMPONENT DESCRIPTIONS ...................................... 1-10

1.7 DRIVE LAYOUT...................................................................................... 1-13

1.8 PRINT PROCESS................................................................................... 1-15

1.8.1 OVERVIEW....................................................................................1-15

1.9 BOARD STRUCTURE ............................................................................1-17

1.9.1 BLOCK DIAGRAM..........................................................................1-17

1.9.2 DESCRIPTIONS ............................................................................1-18

DETAILED DESCRIPTIONS

2. DETAILED SECTION DESCRIPTIONS....................................... 2-1

2.1 PRINTER CONTROLLER ......................................................................... 2-1

2.1.1 HARDWARE OVERVIEW ................................................................2-1

2.1.2 IMAGE PRINTING............................................................................ 2-3

2.1.3 IMAGE DATA PROCESSING .......................................................... 2-4

2.1.4 FEATURES ......................................................................................2-5

2.1.5 HARD DISK...................................................................................... 2-8

2.1.6 PAPER OVERFLOW DETECTION .................................................. 2-9

2.2 LASER EXPOSURE................................................................................2-10

2.2.1 OVERVIEW....................................................................................2-10

2.2.2 OPTICAL PATH .............................................................................2-11

2.2.3 AUTO POWER CONTROL (APC).................................................. 2-12

2.2.4 DUAL BEAM WRITING .................................................................. 2-13

2.2.5 LASER BEAM PITCH CHANGE MECHANISM..............................2-14

2.2.6 LD SAFETY SWITCHES................................................................ 2-15

2.3 PHOTOCONDUCTOR UNIT (PCU) ........................................................ 2-16

2.3.1 OVERVIEW....................................................................................2-16

2.3.2 DRIVE MECHANISM......................................................................2-17

2.4 DRUM CHARGE .....................................................................................2-18

2.4.1 OVERVIEW....................................................................................2-18

2.4.2 CHARGE ROLLER VOLTAGE CORRECTION.............................. 2-19

2.4.3 ID SENSOR PATTERN PRODUCTION TIMING ...........................2-21

2.4.4 DRUM CHARGE ROLLER CLEANING.......................................... 2-21

SM i G035

Page 14

2.5 DEVELOPMENT ..................................................................................... 2-22

2.5.1 OVERVIEW....................................................................................2-22

2.5.2 DRIVE MECHANISM......................................................................2-23

2.5.3 DEVELOPER MIXING.................................................................... 2-24

2.5.4 DEVELOPMENT BIAS ................................................................... 2-25

2.5.5 TONER SUPPLY............................................................................ 2-26

2.5.6 TONER DENSITY CONTROL........................................................ 2-28

2.5.7 TONER NEAR END/END DETECTION ......................................... 2-31

2.5.8 TONER END RECOVERY ............................................................. 2-33

2.5.9 TONER SUPPLY IN ABNORMAL SENSOR CONDITIONS...........2-34

2.6 DRUM CLEANING AND TONER RECYCLING ......................................2-35

2.6.1 DRUM CLEANING .........................................................................2-35

2.6.2 TONER RECYCLING..................................................................... 2-36

2.7 PAPER FEED..........................................................................................2-37

2.7.1 OVERVIEW....................................................................................2-37

2.7.2 PAPER FEED DRIVE MECHANISM.............................................. 2-38

2.7.3 PICK-UP AND SEPARATION ROLLER RELEASE

MECHANISM .................................................................................2-39

2.7.4 PAPER LIFT MECHANISM............................................................ 2-40

2.7.5 PAPER END DETECTION............................................................. 2-42

2.7.6 PAPER HEIGHT DETECTION ....................................................... 2-43

2.7.7 PAPER REGISTRATION ...............................................................2-44

2.7.8 PAPER SIZE DETECTION.............................................................2-45

2.7.9 PAPER FEED AND JAM TIMING .................................................. 2-46

2.8 BY-PASS FEED ...................................................................................... 2-47

2.8.1 BASIC OPERATION.......................................................................2-47

2.9 IMAGE TRANSFER AND PAPER SEPARATION................................... 2-48

2.9.1 OVERVIEW....................................................................................2-48

2.9.2 BELT DRIVE MECHANISM............................................................2-49

2.9.3 IMAGE TRANSFER AND PAPER SEPARATION

MECHANISM .................................................................................2-49

2.9.4 TRANSFER BELT UNIT CONTACT MECHANISM........................ 2-51

2.9.5 TRANSFER BELT CHARGE.......................................................... 2-52

2.9.6 TRANSFER BELT CLEANING MECHANISM................................ 2-53

2.10 IMAGE FUSING AND PAPER EXIT......................................................2-54

2.10.1 OVERVIEW..................................................................................2-54

2.10.2 FUSING DRIVE AND RELEASE MECHANISM........................... 2-55

2.10.3 FUSING ENTRANCE GUIDE SHIFT MECHANISM..................... 2-56

2.10.4 PRESSURE ROLLER ..................................................................2-57

2.10.5 CLEANING MECHANISM ............................................................ 2-57

2.10.6 FUSING TEMPERATURE CONTROL .........................................2-58

2.10.7 OVERHEAT PROTECTION ......................................................... 2-59

2.11 DUPLEX................................................................................................ 2-60

2.11.1 BASIC OPERATION.....................................................................2-60

2.11.2 FEED IN AND EXIT MECHANISM............................................... 2-62

2.12 ENERGY SAVER MODE ......................................................................2-63

2.13 NEW UNIT DETECTION MECHANISM ................................................ 2-64

G035 ii SM

Page 15

Rev. 08/2000

INSTALLATION

3. INSTALLATION PROCEDURE ................................................... 3-1

3.1 INSTALLATION REQUIREMENTS........................................................... 3-1

3.1.1 ENVIRONMENT............................................................................... 3-1

3.1.2 MACHINE LEVEL............................................................................. 3-1

3.1.3 MINIMUM SPACE REQUIREMENTS ..............................................3-2

3.1.4 POWER REQUIREMENTS..............................................................3-3

3.2 PRINTER INSTALLATION ........................................................................ 3-4

3.2.1 CONNECTING THE INTERFACE CABLES..................................... 3-4

3.2.2 CHECKING THE CONNECTION .....................................................3-4

3.2.3 HARD DISK DRIVE INSTALLATION (A853).................................... 3-7

3.3 NETWORK INTERFACE BOARD (NIB) INSTALLATION ......................... 3-8

3.3.1 SERIAL NUMBER AND MAC ADDRESS ........................................3-8

3.3.2 STATUS SHEET ..............................................................................3-8

3.3.3 PROGRAMMING NETWORK/PROTOCOL PARAMETERS............3-9

3.3.4 SETUP FOR VARIOUS NETWORK TYPES.................................. 3-12

3.4 BRIDGE UNIT INSTALLATION (A688)................................................... 3-14

3.4.1 ACCESSORY CHECK ...................................................................3-14

3.4.2 INSTALLATION PROCEDURE ...................................................... 3-15

3.5 LCT INSTALLATION (A683) ................................................................... 3-18

3.5.1 ACCESSORY CHECK ...................................................................3-18

3.5.2 INSTALLATION PROCEDURE ...................................................... 3-19

3.6 1,000-SHEET FINISHER INSTALLATION (A681) .................................. 3-21

3.6.1 ACCESSORY CHEK...................................................................... 3-21

3.6.2 INSTALLATION PROCEDURE ...................................................... 3-22

3.7 3,000-SHEET FINISHER INSTALLATION (A697) ..................................3-25

3.7.1 ACCESSORY CHECK ...................................................................3-25

3.7.2 INSTALLATION PROCEDURE ...................................................... 3-26

3.8 MAILBOX INSTALLATION (G909).......................................................... 3-30

3.8.1 ACCESSORY CHECK ...................................................................3-30

3.8.2 REQUIREMENT OPTIONS FOR MAIN MACHINE........................ 3-30

3.8.3 INSTALLATION PROCEDURE ...................................................... 3-31

3.9 BRIDGE UNIT FOR MAILBOX INSTALLATION (G912) ......................... 3-34

3.9.1 ACCESSORY CHECK ...................................................................3-34

3.9.2 INSTALLATION PROCEDURE ...................................................... 3-35

3.10 PUNCH UNIT INSTALLATION.............................................................. 3-40

3.10.1 ACCESSORY CHECK .................................................................3-40

3.10.2 INSTALLATION PROCEDURE .................................................... 3-41

3.11 DRAM SIMM ......................................................................................... 3-44

3.11.1 .......................................................................................................3-44

3.11.2 .......................................................................................................3-44

SERVICE TABLES

4. SERVICE TABLES ...................................................................... 4-1

4.1 GENERAL CAUTIONS.............................................................................. 4-1

4.1.1 DRUM............................................................................................... 4-1

4.1.2 TRANSFER BELT UNIT................................................................... 4-2

SM iii G035

Page 16

4.1.3 LASER UNIT ....................................................................................4-2

4.1.4 CHARGE ROLLER........................................................................... 4-2

4.1.5 DEVELOPMENT ..............................................................................4-2

4.1.6 FUSING UNIT ..................................................................................4-3

4.1.7 PAPER FEED................................................................................... 4-3

4.1.8 USED TONER.................................................................................. 4-3

4.2 SERVICE PROGRAM MODE ...................................................................4-4

4.2.1 SERVICE PROGRAM MODE OPERATION ....................................4-4

4.2.2 SERVICE PROGRAM MODE TABLES............................................ 4-6

4.2.3 TEST PATTERN PRINTING (SP2-12) ........................................... 4-14

4.2.4 INPUT CHECK ............................................................................... 4-15

4.2.5 OUTPUT CHECK ........................................................................... 4-18

4.2.6 SYSTEM PARAMETER AND DATA LISTS (SMC LISTS) ............. 4-19

4.2.7 MEMORY ALL CLEAR (SP2-18)....................................................4-19

4.2.8 SOFTWARE RESET ...................................................................... 4-20

4.2.9 PRINTER RESTART AND MENU RESET (USER MENU) ............ 4-20

4.3 DOWNLOADING NEW FIRMWARE....................................................... 4-21

4.3.1 FIRMWARE UPDATE USING A FLASH MEMORY CARD

(SP1-1-2 AND 1-2-2)...................................................................... 4-21

4.3.2 FIRMWARE UPDATE FROM PARALLEL PORT

(SP1-1-1 AND 1-2-1)...................................................................... 4-22

4.3.3 FORMATING THE HARD DISK (SP1-4)........................................ 4-22

4.3.4 PARALLEL LOOP BACK TEST (SP1-9) ........................................ 4-23

4.4 DOWNLOADING NEW SOFTWARE ...................................................... 4-24

4.5 NETWORK INTERFACE BOARD........................................................... 4-25

4.5.1 FACTORY RESET (NVRAM CLEAR) ............................................ 4-25

4.5.2 FLASH ROM UPDATE................................................................... 4-26

4.6 USER MENU........................................................................................... 4-33

4.6.1 HOW TO ENTER AND EXIT USER MENU....................................4-33

4.6.2 USER MENU TABLE......................................................................4-33

4.7 TEST POINTS/DIP SWITCHES/LEDS....................................................4-35

4.7.1 DIP SWITCHES .............................................................................4-35

4.7.2 JUMPER PINS ...............................................................................4-36

4.7.3 TEST POINTS................................................................................ 4-36

4.7.4 LEDS.............................................................................................. 4-37

4.8 SPECIAL TOOLS AND LUBRICANTS.................................................... 4-37

4.8.1 SPECIAL TOOLS ........................................................................... 4-37

4.8.2 LUBRICANTS................................................................................. 4-37

PREVENTIVE MAINTENANCE

5. PREVENTIVE MAINTENANCE SCHEDULE...............................5-1

5.1 PM TABLE ................................................................................................5-1

REPLACEMENT AND ADJUSTMENT

6. REPLACEMENT AND ADJUSTMENT ........................................ 6-1

6.1 LASER UNIT ............................................................................................. 6-1

6.1.1 CAUTION DECAL LOCATIONS....................................................... 6-1

G035 iv SM

Page 17

6.1.2 LASER UNIT ....................................................................................6-2

6.1.3 POLYGON MIRROR MOTOR.......................................................... 6-3

6.1.4 LASER SYNCHRONIZATION DETECTOR .....................................6-4

6.1.5 LD UNIT ...........................................................................................6-4

6.2 PHOTOCONDUCTOR UNIT (PCU) AND DEVELOPMENT UNIT ............6-6

6.3 PHOTOCONDUCTOR UNIT (PCU) .......................................................... 6-6

6.3.1 PCU.................................................................................................. 6-6

6.3.2 DRUM............................................................................................... 6-7

6.3.3 PICK-OFF PAWLS ........................................................................... 6-8

6.3.4 CHARGE ROLLER/CHARGE ROLLER CLEANING PAD................6-9

6.3.5 DRUM CLEANING BLADE............................................................. 6-10

6.3.6 ID SENSOR.................................................................................... 6-10

6.4 DEVELOPMENT ..................................................................................... 6-11

6.4.1 DEVELOPMENT UNIT................................................................... 6-11

6.4.2 DEVELOPMENT FILTER............................................................... 6-12

6.4.3 DEVELOPMENT ROLLER............................................................. 6-13

6.4.4 DEVELOPER .................................................................................6-14

6.4.5 TD SENSOR ..................................................................................6-15

6.5 DUPLEX.................................................................................................. 6-16

6.5.1 DUPLEX UNIT................................................................................ 6-16

6.5.2 DUPLEX UNIT COVER.................................................................. 6-17

6.5.3 ENTRANCE SENSOR....................................................................6-17

6.5.4 EXIT SENSOR ............................................................................... 6-18

6.6 TRANSFER UNIT.................................................................................... 6-19

6.6.1 TRANSFER BELT UNIT................................................................. 6-19

6.6.2 TRANSFER BELT .......................................................................... 6-20

6.6.3 TRANSFER BELT CLEANING BLADE/TONER OVERFLOW

SENSOR ........................................................................................ 6-21

6.6.4 RIGHT COVER ..............................................................................6-22

6.7 BY-PASS FEED ...................................................................................... 6-23

6.7.1 BY-PASS FEED UNIT.................................................................... 6-23

6.7.2 BY-PASS FEED UNIT COVERS.................................................... 6-24

6.7.3 PAPER FEED AND PICK-UP ROLLER .........................................6-25

6.7.4 SEPARETION ROLLER................................................................. 6-26

6.7.5 PAPER END SENSOR AND PICK-UP SELENOID .......................6-27

6.7.6 PAPER SIZE SENSOR BOARD ....................................................6-28

6.7.7 BY-PASS TABLE ........................................................................... 6-29

6.7.8 PAPER FEED CLUTCH ................................................................. 6-30

6.8 PAPER FEED..........................................................................................6-31

6.8.1 PICK-UP, SEPARATION, AND FEED ROLLERS.......................... 6-31

6.8.2 LOWER RIGHT COVER/LOWER REAR COVER..........................6-32

6.8.3 RELAY/UPPER PAPER FEED/LOWER PAPER FEED

CLUTCHES .................................................................................... 6-33

6.8.4 UPPER PAPER FEED UNIT.......................................................... 6-34

6.8.5 LOWER PAPER FEED UNIT ......................................................... 6-35

6.8.6 PAPER END/PAPER HEIGHT/RELAY SENSORS........................ 6-36

6.8.7 REGISTRATION SENSOR ............................................................6-37

6.9 FUSING................................................................................................... 6-39

6.9.1 FUSING UNIT ................................................................................6-39

SM v G035

Page 18

Rev. 03/2000

6.9.2 HOT ROLLER STRIPPERS AND FUSING LAMP ......................... 6-40

6.9.3 THERMISTOR AND THERMOFUSE ............................................. 6-41

6.9.4 CLEANING ROLLER...................................................................... 6-42

6.9.5 HOT ROLLER AND PRESSURE ROLLER.................................... 6-43

6.10 DRIVE AREA.........................................................................................6-44

6.10.1 REGISTRATION CLUTCH AND TRANSFER BELT CLUTCH..... 6-44

6.10.2 MAIN MOTOR .............................................................................. 6-45

6.10.3 TONER BOTTLE MOTOR............................................................6-46

6.11 COVERS ............................................................................................... 6-47

6.12 PCBs ..................................................................................................... 6-49

6.12.1 POWER PACK ............................................................................. 6-49

6.12.2 PSU.............................................................................................. 6-49

6.12.3 PRINTER CONTROL BOARD AND NIB...................................... 6-50

6.12.4 HARD DISK.................................................................................. 6-51

6.12.5 I/O BOARD................................................................................... 6-52

6.12.6 BICU BOARD ............................................................................... 6-53

6.13 PRINT IMAGE ADJUSTMENTS............................................................6-54

TROUBLESHOOTING

7. TROUBLESHOOTING................................................................. 7-1

7.1 SERVICE CALL CONDITIONS ................................................................. 7-1

7.1.1 SUMMARY ....................................................................................... 7-1

7.1.2 SC CODE DESCRIPTIONS ............................................................. 7-1

7.1.3 PRINTER CONTROLLER .............................................................. 7-20

7.1.4 NETWORK INTERFACE BOARD .................................................. 7-22

7.2 ELECTRICAL COMPONENT DEFECTS ................................................ 7-24

7.2.1 SENSORS...................................................................................... 7-24

7.2.2 SWITCHES ....................................................................................7-25

7.3 BLOWN FUSE CONDITIONS ................................................................. 7-25

7.4 ROM HISTORY....................................................................................... 7-26

PAPER TRAY UNIT G520

1. OVERALL MACHINE INFORMATION ........................................8-1

1.1 SPECIFICATIONS .................................................................................... 8-1

1.2 MECHANICAL COMPONENT LAYOUT ...................................................8-2

1.3 ELECTRICAL COMPONENT LAYOUT.....................................................8-3

1.4 ELECTRICAL COMPONENT DESCRIPTION ..........................................8-4

1.5 DRIVE LAYOUT........................................................................................ 8-5

2. DETAILED DESCRIPTIONS........................................................8-6

2.1 PICK-UP AND SEPARATION ROLLER RELEASE MECHANISM............ 8-6

2.2 PAPER LIFT MECHANISM....................................................................... 8-7

2.3 PAPER END DETECTION........................................................................ 8-9

2.4 PAPER HEIGHT DETECTION................................................................ 8-10

2.5 PAPER SIZE DETECTION .....................................................................8-11

G035 vi SM

Page 19

3. SERVICE TABLES .................................................................... 8-12

3.1 DIP SWITCHES ...................................................................................... 8-12

3.2 TEST POINTS......................................................................................... 8-12

3.3 SWITCHES .............................................................................................8-12

3.4 FUSES ....................................................................................................8-12

4. REPLACEMENT AND ADJUSTMENT ...................................... 8-13

4.1 COVER REPLACEMENT........................................................................ 8-13

4.2 ROLLER REPLACEMENT ...................................................................... 8-14

4.2.1 PAPER FEED, SEPARATION, AND PICK-UP ROLLERS ............. 8-14

4.3 TRAY MOTOR REPLACEMENT.............................................................8-15

4.4 PAPER FEED AND RELAY CLUTCH REPLACEMENT......................... 8-16

4.5 PAPER FEED UNIT REPLACEMENT ....................................................8-17

4.6 PAPER END, TRAY LIFT, AND RELAY SENSOR

REPLACEMENT .....................................................................................8-19

SWAPBOX AND SWAPFTL INSTALLATION MANUAL

1. INTRODUCTION ......................................................................... 9-1

1.1 PRECAUTIONS ......................................................................................... 9-1

1.1.1 SWAPBOX AND SOFTWARE .........................................................9-1

1.1.2 SOFTWARE LICENSE AGREEMENT ............................................. 9-1

1.2 SYSTEM REQUIREMENTS ...................................................................... 9-1

1.3 ITEMS TO PREPARE BEFORE INSTALLATION ..................................... 9-1

1.4 WINDOWS 95 VERSION CONFIRMATION .............................................9-2

2. SWAPBOX INSTALLATION ........................................................ 9-4

2.2 DRIVER INSTALLATION ..........................................................................9-4

3. SOFTWARE (SWAPFTL) INSTALLATION .................................9-5

3.1 SWAPFTL SOFTWARE INSTALLATION .................................................. 9-5

3.2 VERIFICATION ......................................................................................... 9-5

3.2.1 SOFTWARE VERSION .................................................................... 9-5

3.2.2 FLASH MEMORY CARD AUTOMATIC DETECTION ...................... 9-6

4. TROUBLESHOOTING..................................................................9-7

4.1 SWAPBOX RESOURCE CONFLICT ........................................................ 9-7

4.11 IRQ AND I/O ADDRESS ...................................................................9-7

4.1.2 MEMORY ADDRESS........................................................................ 9-7

4.2 FAILED TO OPEN PCCARD ERRORS ..................................................... 9-8

4.2.1 TIMELAG TO LOADING DRIVER ..................................................... 9-8

4.2.3 RESOURCE CONFLICT ................................................................... 9-8

4.3 INVALID DYNAMIC LINK CALL FROM SWAPENUM ERROR.................9-9

4.4 SWAPFTL PROBLEM WITH NOTEBOOK COMPUTERS.........................9-9

4.4.1 WINDOWS AND PC CARD DRIVER VERSION ............................... 9-9

4.4.2 SYSTEM SUMMERY ........................................................................9-9

4.5 COMPLETE UNINSTALL......................................................................... 9-10

SM vii G035

Page 20

Rev. 08/2000

SWAPFTL BINARY UTILITY OPERATION MANUAL

1. OVERVIEW................................................................................. 10-1

2. OPERATION............................................................................... 10-2

2.1 PROGRAMMING A FLASH MEMORY CARD .........................................10-2

2.1.1 GETTING A SOURCE FILE ............................................................ 10-2

2.1.2 PROGRAMMING A CARD WITH THE SOURCE ...........................10-2

2.2 DOWNLOADING TO A MACHINE........................................................... 10-4

2.3 SAVING DATA TO A FILE ....................................................................... 10-4

3. FUNCTIONS ...............................................................................10-5

3.1 FILE MENU .............................................................................................. 10-5

3.1.1 FILE – OPEN................................................................................... 10-5

3.1.2 FILE – CLOSE................................................................................. 10-5

3.1.3 FILE – SAVE ................................................................................... 10-5

LARGE CAPACITY TRAY (A683)

1. OVERALL MACHINE INFORMATION ......................................11-1

1.1 SPECIFICATIONS .................................................................................. 11-1

1.2 MECHANICAL COMPONENT LAYOUT .................................................11-2

1.3 ELECTRICAL COMPONENT LAYOUT...................................................11-3

1.4 ELECTRICAL COMPONENT DESCRIPTION ........................................11-4

1.5 DRIVE LAYOUT...................................................................................... 11-5

2. DETAILED DESCRIPTIONS...................................................... 11-6

2.1 PAPER FEED MECHANISM................................................................... 11-6

2.2 TRAY LIFT AND PAPER HEIGHT DETECTION MECHANISM.............. 11-7

Tray lifting conditions.......................................................................... 11-7

Tray lowering conditions..................................................................... 11-7

2.3 TRAY UNIT SLIDE MECHANISM ........................................................... 11-8

3. SERVICE TABLES .................................................................... 11-9

3.1 DIP SWITCHES ...................................................................................... 11-9

3.2 TEST POINTS......................................................................................... 11-9

3.3 SWITCHES .............................................................................................11-9

3.4 FUSES ....................................................................................................11-9

4. REPLACEMENT AND ADJUSTMENT .................................... 11-10

4.1 COVER REPLACEMENT...................................................................... 11-10

Tray Cover........................................................................................ 11-10

Front Cover....................................................................................... 11-10

Rear Cover .......................................................................................11-10

Right Lower Cover............................................................................ 11-10

Upper Cover .....................................................................................11-10

4.2 ROLLER REPLACEMENT .................................................................... 11-11

G035 viii SM

Page 21

Rev. 08/2000

4.2.1 PAPER FEED, SEPARATION, AND PICK-UP ROLLERS ........... 11-11

Pick-up Roller ...................................................................................11-11

Paper Feed Roller ............................................................................11-11

Separation Roller.............................................................................. 11-11

4.3 TRAY LIFT AND PAPER END SENSOR REPLACEMENT ..................11-12

Tray Lift Sensor ................................................................................ 11-12

Paper End Sensor ............................................................................ 11-12

4.4 RELAY SENSOR REPLACEMENT.......................................................11-13

4.5 SIDE FENCE POSITION CHANGE ......................................................11-14

NINE-TRAY MAILBOX AND BRIDGE UNIT G909/G912

1. OVERALL MACHINE INFORMATION ......................................12-1

1.1 SPECIFICATIONS .................................................................................. 12-1

1.2 COMPONENT LAYOUT.......................................................................... 12-2

1.2.1 MECHANICAL COMPONENT LAYOUT ........................................12-2

1.2.2 DRIVE LAYOUT ............................................................................. 12-3

1.3 ELECTRICAL COMPONENT DESCRIPTIONS ...................................... 12-4

2. DETAILED DESCRIPTIONS...................................................... 12-6

2.1 BASIC OPERATION ...............................................................................12-6

Proof Tray........................................................................................... 12-6

Bridge Unit.......................................................................................... 12-6

Trays................................................................................................... 12-6

2.2 PROOF TRAY SENSORS ......................................................................12-7

2.2.1 PAPER SENSOR ........................................................................... 12-7

2.2.2 PAPER OVERFLOW SENSOR...................................................... 12-7

2.3 TRAY SENSORS .................................................................................... 12-8

2.3.1 PAPER SENSOR ........................................................................... 12-8

2.3.2 PAPER OVERFLOW SENSOR...................................................... 12-8

2.3.3 TRAY EXIT SENSOR..................................................................... 12-8

2.4 TIMING CHART AND MISFEED DETECTION .......................................12-9

3. INSTALLATION PROCEDURE ............................................... 12-11

3.1 MAILBOX (G909) .................................................................................. 12-11

3.1.1 ACCESSORY CHECK .................................................................12-11

3.1.2 REQUIREMENT OPTIONS FOR MAIN MACHINE...................... 12-11

3.1.3 INSTALLATION PROCEDURE .................................................... 12-12

1.2 BRIDGE UNIT FOR MAILBOX (G912)..................................................12-15

1.2.1 ACCESSORY CHECK .................................................................12-15

1.2.2 INSTALLATION PROCEDURE .................................................... 12-16

4. REPLACEMENT AND ADJUSTMENT .................................... 12-21

4.1 PROOF TRAY UNIT.............................................................................. 12-21

4.1.1 PROOF TRAY SENSOR AND PAPER

OVERFLOW SENSORS ............................................................... 12-21

4.1.2 PROOF TRANSPORT UNIT ........................................................ 12-21

SM ix G035

Page 22

Rev. 08/2000

4.2 TRAY UNIT ...........................................................................................12-22

4.2.1 TRAYS ......................................................................................... 12-22

4.2.2 PAPER SENSOR, PAPER OVERFLOW SENSOR,

AND TRAY EXIT SENSOR .......................................................... 12-23

Paper Overflow Sensor.....................................................................12-23

Paper Sensor....................................................................................12-23

Tray Exit Sensor (above the 1st tray, and in the 3rd, 6th,

and 9th trays).................................................................................... 12-23

4.2.3 MAIN CONTROL BOARD ............................................................ 12-24

4.2.4 TRAY EXIT SENSOR ADJUSTMENT.......................................... 12-25

5. SERVICE TABLES .................................................................. 12-27

5.1 DIP SWITCHES/VRIABLE RESISTORS/LEDS .................................... 12-27

5.1.1 DIP SWITCHES ...........................................................................12-27

5.1.2 VARIABLE RESISTORS .............................................................. 12-28

5.1.3 LEDS............................................................................................ 12-28

BRIDGE UNIT A688

1. OVERALL MACHINE INFORMATION ......................................13-1

1.1 SPECIFICATIONS .................................................................................. 13-1

1.2 MECHANICAL COMPONENT LAYOUT .................................................13-2

1.3 ELECTRICAL COMPONENT LAYOUT...................................................13-3

1.4 ELECTRICAL COMPONENT DESCRIPTION ........................................13-3

1.5 DRIVE LAYOUT...................................................................................... 13-4

2. DETAILED DESCRIPTION........................................................ 13-5

2.1 JUNCTION GATE MECHANISM.............................................................13-5

3. REPLACEMENT AND ADJUSTMENT ...................................... 13-6

3.1 EXIT SENSOR REPLACEMENT ............................................................13-6

1,000-SHEET FINISHER A681

1. OVERALL MACHINE INFORMATION ......................................14-1

1.1 SPECIFICATIONS .................................................................................. 14-1

1.2 MECHANICAL COMPONENT LAYOUT .................................................14-2

1.3 ELECTRICAL COMPONENT LAYOUT...................................................14-3

1.4 ELECTRICAL COMPONENT DESCRIPTIONS ...................................... 14-4

1.5 DRIVE LAYOUT...................................................................................... 14-6

2. DETAILED DESCRIPTIONS...................................................... 14-7

2.1 JUNCTION GATE MECHANISM.............................................................14-7

Staple mode .......................................................................................14-7

No staple mode ..................................................................................14-7

2.2 JOGGER UNIT PAPER POSITIONING MECHANISM ...........................14-8

G035 x SM

Page 23

Rev. 08/2000

2.3 EXIT GUIDE PLATE OPEN/CLOSE MECHANISM.................................14-9

2.4 STAPLER.............................................................................................. 14-10

2.5 FEED OUT MECHANISM .....................................................................14-11

2.6 SHIFT TRAY UP/DOWN MECHANISM ................................................ 14-12

2.7 SHIFT TRAY SIDE-TO-SIDE MECHANISM ......................................... 14-13

2.8 JAM CONDITIONS................................................................................ 14-14

2.9 TIMING CHARTS..................................................................................14-15

2.9.1 NO STAPLE MODE (A4 SIDEWAYS, 3 SHEETS/2SETS) .......... 14-15

2.9.2 STAPLE MODE (A4 SIDEWAYS, 2 SHEETS/2 SETS)................ 14-16

3. SERVICE TABLE..................................................................... 14-17

3.1 DIP SWITCH TABLE............................................................................. 14-17

3.2 TEST POINTS....................................................................................... 14-17

3.3 FUSES ..................................................................................................14-17

4. REPLACEMENT AND ADJUSTMENT .................................... 14-18

4.1 COVER REMOVAL............................................................................... 14-18

Front Door ........................................................................................14-18

Front Cover....................................................................................... 14-18

Rear Cover .......................................................................................14-18

Upper Cover .....................................................................................14-18

Lower Left Cover ..............................................................................14-19

Front Shift Tray Cover ......................................................................14-19

Rear Shift Tray Cover....................................................................... 14-19

Shift Tray .......................................................................................... 14-19

4.2 ENTRANCE SENSOR REPLACEMENT............................................... 14-20

4.3 EXIT SENSOR REPLACEMENT ..........................................................14-21

4.4 STACK HEIGHT SENSOR REPLACEMENT........................................ 14-22

4.5 POSITIONING ROLLER REPLACEMENT............................................ 14-23

4.6 STAPLER REPLACEMENT .................................................................. 14-24

4.7 ROM HISTORY..................................................................................... 14-25

3,000-SHEET FINISHER A697

1. OVERALL MACHINE INFORMATION ......................................15-1

1.1 SPECIFICATIONS .................................................................................. 15-1

1.2 MECHANICAL COMPONENT LAYOUT .................................................15-3

1.3 ELECTRICAL COMPONENT LAYOUT...................................................15-4

1.4 ELECTRICAL COMPONENT DESCRIPTION ........................................15-5

1.5 DRIVE LAYOUT...................................................................................... 15-7

2. DETAILED DESCRIPTIONS...................................................... 15-8

2.1 TRAY AND STAPLER JUNCTION GATE MECHANISM ........................ 15-8

Normal mode ...................................................................................... 15-8

Sort/stack mode.................................................................................. 15-8

Staple mode .......................................................................................15-8

2.2 JOGGER UNIT PAPER POSITIONING MECHANISM ...........................15-9

SM xi G035

Page 24

Rev. 08/2000

Vertical Paper Alignment .................................................................... 15-9

Horizontal Paper Alignment................................................................ 15-9

2.3 STAPLER UNIT MOVEMENT MECHANISM ........................................ 15-10

Side-to-side: .....................................................................................15-10

Rotation: ........................................................................................... 15-10

2.4 STAPLER.............................................................................................. 15-11

2.5 FEED-OUT MECHANISM ..................................................................... 15-12

2.6 SHIFT TRAY UP/DOWN MECHANISM ................................................ 15-13

2.7 SHIFT TRAY SIDE-TO-SIDE MECHANISM ......................................... 15-14

2.8 PUNCH UNIT DRIVE MECHANISM .....................................................15-15

2.9 PUNCH WASTE COLLECTION MECHNISM........................................15-16

2.10 JAM CONDITIONS.............................................................................. 15-17

2.11 TIMING CHARTS................................................................................ 15-18

2.11.1 A4 SIDEWAYS (2 SHEETS): NORMAL AND

PUNCH MODE ...........................................................................15-18

2.11.2 A4 SIDEWAYS (2 SHEETS): SORT/STACK AND

PUNCH MODE ...........................................................................15-19

2.11.3 A4 SIDEWAYS (2 SHEETS): STAPLE AND

PUNCH MODE ...........................................................................15-20

3. SERVICE TABLES .................................................................. 15-21

3.1 DIP SWITCHES .................................................................................... 15-21

3.2 TEST POINTS....................................................................................... 15-21

3.3 LED .......................................................................................................15-21

3.4 VARIABLE RESISTORS....................................................................... 15-21

3.5 FUSES ..................................................................................................15-21

4. REPLACEMENT AND ADJUSTMENT .................................... 15-22

4.1 COVER REPLACEMENT...................................................................... 15-22

Rear Cover .......................................................................................15-22

Upper Left Cover ..............................................................................15-22

Upper Cover .....................................................................................15-22

Front Door ........................................................................................15-22

Left Front Cover................................................................................ 15-22

Shift Tray .......................................................................................... 15-23

Lower Left Cover ..............................................................................15-23

Right Cover....................................................................................... 15-23

Front Shift Tray Cover ......................................................................15-23

Rear Shift Tray Cover....................................................................... 15-23

4.2 POSITIONING ROLLER REPLACEMENT............................................ 15-24

4.3 ALIGNMENT BRUSH ROLLER REPLACEMENT................................. 15-25

4.4 SENSOR REPLACEMNT...................................................................... 15-26

4.4.1 STACK HEIGHT SENSOR 1 AND 2 ............................................15-26

4.4.2 UPPER TRAY PAPER LIMIT AND EXIT SENSOR...................... 15-27

Upper Tray Paper Limit Sensor ........................................................15-27

Upper Tray Exit Sensor ....................................................................15-27

4.4.3 SHIFT TRAY EXIT SENSOR .......................................................15-28

4.4.4 ENTRANCE AND STAPLER TRAY ENTRANCE SENSOR.........15-29

Entrance Sensor............................................................................... 15-29

G035 xii SM

Page 25

Rev. 08/2000

Stapler Tray Entrance Sensor ..........................................................15-29

4.4.5 STAPLER ROTATION HP SENSOR............................................15-30

4.5 STAPLER REMOVAL ...........................................................................15-31

4.6 PUNCH POSITION ADJUSTMENT ......................................................15-32

Right to left .......................................................................................15-32

Front to rear...................................................................................... 15-32

4.7 STACK FEED-OUT MOTOR SPEED ADJUSTMENT........................... 15-33

4.8 ROM HISTORY..................................................................................... 15-34

APPENDIX

APPENDIX 1.....................................................................APPENDIX-1

1.1 JAM HISTORY .......................................................................... APPENDIX-1

1.1.1 JAM CONDITION TABLE................................................. APPENDIX-1

SM xiii G035

Page 26

Page 27

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

4. If the print job process starts before the printer completes the warm-up

period, keep hands away from the mechanical and the electrical components

because the printer starts printing sheets as soon as the warm-up period is

complete.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer’s peripherals (except for paper tray unit) must be installed and

maintained by a customer service representative who has completed the

training course on those models.

2. The NVRAM on the controller board has a lithium battery which can explode

if replaced incorrectly. Replace the NVRAM only with an identical one. The

manufacturer recommends replacing the entire NVRAM. Do not recharge or

burn this battery. Used NVRAM must be handled in accordance with local

regulations.

Page 28

SAFETY AND ECOLOGICAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

NOTES

FOR DISPOSAL

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

Page 29

OVERALL MACHINE INFORMATION G035

SWAPBOX

TM

AND SWAPFTL

TM

MANUAL

DETAILED SECTION DESCRIPTIONS G035

SWAPFTL

TM

BINARY UTILITY OPERATION MANUAL

INSTALLATION PROCEDURE G035

LARGE CAPACITY TRAY (A683)

SERVICE TABLES G035

NINE-TRAY MAILBOX AND BRIDGE UNIT (G909/G912)

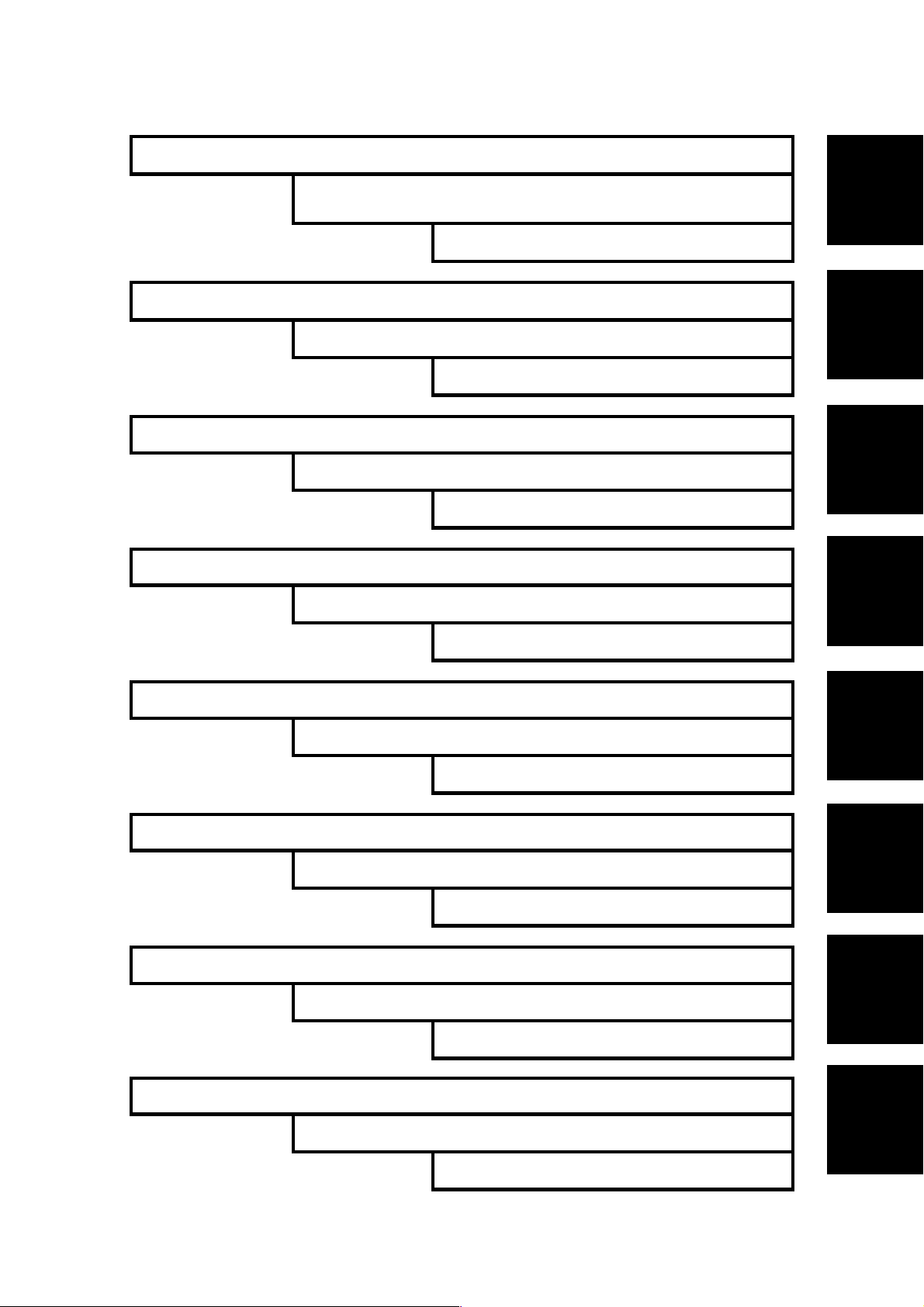

INSTALLATION

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

PREVENTIVE MAINTENANCE G035

BRIDGE UNIT (A688)

REPLACEMENT AND ADJUSTMENT G035

1000 SHEET FINISHER (A681)

TROUBLESHOOTING G035

3000 SHEET FINISHER (A697)

PAPER TRAY UNIT G520

APPENDIX

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 30

Page 31

OVERALL MACHINE

INFORMATION

Page 32

Page 33

Rev. 12/99

1. OVERALL MACHINE INFORMATION

SPECIFICATIONS

⇒

1.1 SPECIFICATIONS

1.1.1 PRINTER

Configuration: Desktop

Printing Process: Dry electrostatic transfer system

Resolution: 600 x 600 dpi (PCL5e, PCL6, PS)

400 x 400 dpi (PS)

300 x 300 dpi (PCL5e, simulated by doubling pixel

width and height at 600 dpi resolution)

Gray Scale: Not applicable to AP4500

Printing Speed (Maximum) 45 ppm (A4/11" x 8.5" sideways, simplex)

36 ppm (A4/11" x 8.5" sideways, duplex)

Printing Emulation: PCL5e and PCL6

PostScript 3

Printer Font: PCL5e/PCL6:

45 scaleable typefaces in 14 typeface families

(35 Intellifont and 10 TrueType format fonts)

6 bitmapped typefaces in the Line Printer typeface

family

PS:

136 Adobe Type1 fonts

Overall

Machine

Information

Printer Interface: Bi-directional Parallel x 1

Network Interface x 1

Ethernet (100 base-TX/10 base-T for TCP/IP,

IPX/SPX, EtherTalk)

DRAM Capacity: 8 MB (Standard)

2 DRAM SIMM slots (up to 64 MB)

Maximum Total: Up to 72 MB

Printer Driver: PCL5e Printer Driver for Windows 3.1/95/98/NT

PCL6 Printer Driver for Windows 3.1/95/98/NT

PS3 Printer Driver for Windows 3.1/95/98/NT and

Macintosh

SM 1-1 G035

Page 34

SPECIFICATIONS

Paper Size: Maximum

A3/11" x 17"

Minimum

A5/5.5" x 8.5" lengthwise (Paper tray/Duplex)

A6/5.5" x 8.5" lengthwise (By-pass)

Duplex:

Standard sizes

A5 lengthwise to A3

HLT to DLT

Non-standard sizes

Width: 100 to 305 mm

Length: 148 to 432 mm

By-pass:

Standard sizes

A6 lengthwise to A3

HLT lengthwise to DLT

Non-standard sizes

Width: 100 to 300 mm

Length: 148 to 432 mm

Rev. 12/99

⇒

Paper Weight: Paper Tray/Duplex:

64 ~ 105 g/m2, 20 ~ 28 lb

By-pass:

52 ~ 157 g/m2, 16 ~ 42 lb

Warm-up Time:

First Print Time (1st Tray): Less than 6.0 seconds

Auto Power Off (Energy

Saver Mode):

Paper Capacity: Paper Tray: 500 sheets (up to 56 mm, 2.2") x 2

Tray Capacity: A4/11" x 8.5": 500 sheets

Toner Replenishment: Cartridge exchange (700 g/cartridge)

Toner Yield: 30 k sheets printed

Less than 100 s (23°C, 73°F)

A4/11" x 8.5" sideways

30 minutes is the default setting; it can be changed

using the user menu.

By-pass Feed: 50 sheets (up to 5.5 mm, 0.2")

LCT: 1,500 sheets

A3/B4/8.5" x 14"/11" x 17": 250 sheets

Standard tray

(A4 sideways, 5% full black)

G035 1-2 SM

Page 35

Rev. 12/99

Power Source: North America

120 V, 60 Hz, More than 10 A

Europe/Asia

220 ~ 240 V, 50/60 Hz, More than 6 A

SPECIFICATIONS

Overall

Machine

Information

⇒

⇒

⇒

Dimensions (W x D x H): 665 x 640 x 570 mm (26.2" x 25.2" x 22.4")

Without options

Weight: 62 kg (136.7 lb)

Power Consumption: Mainframe only:

- 115 V/230 V machine -

Maximum Less than 1.2 kW

Warm-up Less than 1.0 kW

Energy Saver Mode Less than 45 W/h

Noise Emission:

NOTE:

The above measurements were made in accordance with ISO 7779.

Sound Power Level

Printing 70 dB(A) 74 dB(A)

Stand-by 42 dB(A) —

Mainframe Only System

SM 1-3 G035

Page 36

SPECIFICATIONS

1.1.2 NETWORK INTERFACE BOARD

Type: Internal Network Interface Board

Network Topology: Ethernet (10 base-T) and Fast Ethernet (100 base-TX)

Network Interface: RJ45 x 1

Protocols: IPX, TCP/IP, EtherTalk

SNMP Support:

•

IP and IPX SNMP support of MIB-2 and proprietary

NIC MIB.

•

SNMP support of standard MIB and proprietary

printer MIBs on compatible printers.

Required Cable: STP (Shielded Twisted-Pair) cable

Category/Type 5 or better

Utility Software:

Other:

NOTE:

•

MAP (Management Access Protocol)

•

IPX peer-to-peer printing

•

IP peer-to-peer printing

•

BOOTP (16-bit and 32-bit)

•

NetWare setup utility

•

Built-in web server

•

Built-in Telnet server

•

Firmware update over an IPX or IP network

A cable is not enclosed with this option.

G035 1-4 SM

Page 37

1.2 PAPER EXIT TRAY SELECTION

" x 13" [C]

1/2

PAPER EXIT TRAY SELECTION

[A] A4, LT[B] Longer than B4, 8

Overall

Machine

Information

G035V508.WMF

The machine allows selection between the paper tray exit trays: Internal Tray [A]

(standard output tray), External Tray [B] (finisher) and [C] (mail box). If the subscan length is more than 330 mm, the exit tray is as shown below, if the relevant

options have been installed.

Installed options Exit tray for paper longer than 330 mm

Bridge unit & Finisher (1,000-sheet) Internal Tray [A]

Bridge unit & Finisher (3,000-sheet) External Tray [B]: The finisher upper tray

Bridge unit and Mailbox [C]: The mail box tray

Bridge unit and Mailbox and Finisher 3000 [C] : The mail box tray

SM 1-5 G035

Page 38

MACHINE CONFIGURATION

1.3 MACHINE CONFIGURATION

1.3.1 SYSTEM COMPONENTS

8

4

7

9

10

6

1

5

Version Item Machine Code No.

Printer G035 1

LCT (Option) A683 2

RAM SIMM (Option) — 3

Hard Disk (Option) A853 4

Paper Tray Unit (Option) G520 5

Printer

3,000-sheet Finisher (Option) A697 6

1,000-sheet Finisher (Option) A681 7

Bridge Unit (Option) A688 8

Mailbox Bridge Unit (Option) G912 9

Mailbox (Option) G909 10

Punch Unit (Option for 3000-sheet Finisher)

A812-17 (3 holes)

A812-27 (2 holes)

2

G035V502.WMF

3

G035 1-6 SM

Page 39

1.3.2 INSTALLABLE OPTION TABLE

Printer Options

MACHINE CONFIGURATION

Option Note

Paper Tray Unit

LCT

By-pass Feed Unit

Duplex Unit

Bridge Unit

1,000-sheet Finisher

3,000-sheet Finisher

Punch Unit

Mailbox

Mailbox Bridge Unit

!

= Standard " = Available # = Requires another option

"

#

Requires the paper tray unit.

!

!

"

#

Requires the paper tray unit and bridge unit.

#

Requires the paper tray unit and bridge unit.

#

Requires the 3000-sheet finisher.

#

Requires the bridge unit and the paper tray unit

#

Requires the Mailbox

Overall

Machine

Information

SM 1-7 G035

Page 40

MECHANICAL COMPONENT LAYOUT

1.4 MECHANICAL COMPONENT LAYOUT

54321 6 7 8

32

31

30

29

9

10

11

12

13

14

15

16

17

1. Hot roller

2. Exit roller

3. Paper exit sensor

4. Exit junction gate

5. Pressure roller

6. Entrance sensor

7. Inverter gate

8. Inverter roller

9. Transfer belt cleaning blade

10. Upper transport roller

11. OPC drum

12. Transfer belt

13. Registration roller

14. Lower transport roller

15. Exit sensor

16. Paper end sensor

19

20

21

2425262728

2223

G035V504.WMF

17. Pick-up roller

18. By-pass tray

19. Paper feed roller

20. Separation roller

21. Upper relay rollers

22. Feed roller

23. Separation roller

24. Pick-up roller

25. Bottom plate

26. Development unit

27. Charge roller

28. Fθ mirror

29. Polygonal mirror m otor

30. Laser unit

31. Barrel toroidal lens (BTL)

32. Toner supply bottle holder

18

G035 1-8 SM

Page 41

1.5 PAPER PATH

PAPER PATH

8 1 2

Overall

Machine

Information

3

7 6 5 4

1. Bridge unit

2. Duplex unit

3. By-pass feed unit

4. LCT

5. Paper tray unit

6. Mailbox

7. 3,000-sheet finisher

8. Mailbox bridge unit

G035V500.WMF

SM 1-9 G035

Page 42

ELECTRICAL COMPONENT DESCRIPTIONS

1.6 ELECTRI CAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the

waterproof paper in the pocket for the locations of these components.

Symbol Description Note Index No.

Printed Circuit Boards

Printer Controller Controls the PC interface, print image

PCB1

PCB2 Mother Connects the controller to the BICU board. 2

PCB3

PCB4

PCB5

PCB6

PCB7

PCB8

PCB9

PCB10 Main (Duplex) Controls the duplex unit. 60

NIB (Network

Interface Board)

BICU (Base Engine &

Image Control Unit)

IOB

(Input/Output Board)

PFB (Paper Feed

Control)

High Voltage Supply

PSU

(Power Supply Unit)

LDDR

(Laser Diode Driver)

processing, operation panel, and other

controller options.

Interfaces printer to the network.

Controls all printer engine functions both

directly and through other control boards.

Controls the mechanical parts of the printer

(excluding the paper feed section), and the

fusing lamp power.

Controls the mechanical parts of all paper

feed sections.

Supplies high voltage to the drum charge

roller, development roller, and transfer belt.

Provides DC power to the system and AC

power to the fusing.

Controls the laser diode.

1

3

6

10

9

11

7

17

Motors

M1 Main Drives the main body components. 25

M2 Tray Lift Raises the bottom plate in the paper tray. 37

M3 Polygonal Mirror Turns the polygonal mirror. 20

M4

M5 Cooling Fan Removes heat from the main PCBs. 26

M6 Exhaust Fan Removes heat from around the fusing unit. 28

M7

M8 PSU Cooling Fan Removes heat from the PSU. 8

M9 Inverter (Duplex) Drives the inverter roller. 59

M10 Transport (Duplex) Drives the upper and lower transport rollers. 61

Sensors

S1

S2

S3 Paper Exit Detects misfeeds. 46

LD Positioning Rotates the LD unit to adjust the LD beam

pitch when a different resolution is selected.

Toner Supply Rotates the toner bottle to supply toner to

the development unit.

LD Unit Home

Position

Toner Density (TD) Detects the amount of toner inside the

Informs the CPU when the LD unit is at the

home position.

development unit.

19

24

18

15

G035 1-10 SM

Page 43

ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Description Note Index No.

Registration

S4

Detects the leading edge of the paper to

determine the stop timing of the paper feed

49

clutch, and detects misfeeds.

Image Density (ID) Detects the density of various patterns and

S5

the reflectivity of the drum for process

48

control.

S6

S7

S8

S9

Upper Paper Lift Detects when the paper in the upper paper

tray is at the feed height.

Lower Paper Lift Detects when the paper in the lower paper

tray is at the feed height.

Upper Paper End

Informs the CPU when the upper paper tray

runs out of paper.

Lower Paper End Informs the CPU when the lower paper tray

runs out of paper.

50

52

51

53

S10 Upper Relay Detects misfeeds. 55

S11 Lower Relay Detects misfeeds. 54

S12

S13

S14

Transfer Belt Position Informs the CPU of the current position of

the transfer belt unit.

Toner Overflow Detects toner overflow in the toner

collection tank.

Upper Paper Height 1

Detects the amount of paper in the upper

tray in combination with upper paper height

29

16

41

sensor 2.

Upper Paper Height 2 Detects the amount of paper in the upper

S15

tray in combination with upper paper height

40

sensor 1.

Lower Paper Height 1 Detects the amount of paper in the lower

S16

tray by the in combination with lower paper

39

height sensor 2.

Lower Paper Height 2 Detects the amount of paper in the lower

S17

tray by the in combination with lower paper

38

height sensor 1.

S18

New Unit Detection

Detects the new photoconductor and

development unit.

31

Entrance (Duplex) Detects the trailing edge of the paper to turn

S19

on the inverter gate solenoid and turn on

the inverter motor in reverse. Checks for

56

misfeeds.

S20 Exit (By-pass) Checks for misfeeds. 62

S21 Cover Guide Detects whether the cover guide is opened. 63

S22

S23

Paper End (By-pass) Informs the copier when the by-pass tray

runs out of paper.

Paper Size Sensor

Detects the paper width.

Board (By-pass)

64

67

Overall

Machine

Information

Switches

SW1

SM 1-11 G035

Right Lower Cover Detects whether the right lower cover is

open or closed.

35

Page 44

ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Description Note Index No.

Right Upper Cover

SW2

Cut the +5VLD and +24 V DC power line

and detects whether the right upper cover is

22

open or closed.

SW3

SW4

SW5

SW6

Main Power Supplies power to the printer. If this is off,

there is no power supplied to the printer.

Front Cover Safety

Cuts the +5VLD and +24 V DC power line

and detects whether the front cover is open.

Upper Paper Size Determine the size of paper in the paper

tray, based on the dial setting.

Lower Paper Size Determine the size of paper in the paper

tray, based on the dial setting.

44

45

43

42

SW7 Duplex Unit Open Detects whether the duplex unit is opened. 57

Solenoids

SOL1 Inverter Gate Controls the inverter gate. 58

SOL2

Pick-up Moves the pick-up roller to contact the

paper.

66

SOL3 Duplex Junction Gate Controls the duplex junction gate. 23

SOL4 Exit Junction Gate Controls the exit junction gate. 27

Magnetic Clutches

CL1

Transfer Belt Controls the touch and release movement

of the transfer belt unit.

CL2 Registration Drives the registration rollers. 32

CL3 Relay Drives the relay rollers. 34

CL4 Upper Paper Feed Starts paper feed from the upper paper tray. 33

CL5 Lower Paper Feed Starts paper feed from the lower paper tray. 36

CL6 Paper Feed (By-pass) Starts paper feed from the by-pass tray. 65

Lamps

L1 Fusing Provides heat to the hot roller. 14

L2

Quenching

Neutralizes any charge remaining on the

drum surface after cleaning.

Thermistor

TH1

Fusing Monitors the temperature at the central area

of the hot roller.

Thermofuse

TF1

Fusing Pr ovides back up overheat protection in the

fusing unit.

30

47

12

13

Other

LSD

Laser

Synchronization

Detects the laser beam at the start of the

main scan. 21

Detector

G035 1-12 SM

Page 45

1.7 DRIVE LAYOUT

PCU Drive

6

DRIVE LAYOUT

Overall

Machine

Information

1

Fusing

2

Development

1. Transfer belt clutch

2. Registration clutch

3. Upper paper feed clutch

3

Transfer

5

4

G035V108.WMF

4. Lower paper feed clutch

5. Relay clutch

6. Main motor

SM 1-13 G035

Page 46

DRIVE LAYOUT

Duplex

2

1

3

4

1. Inverter roller

2. Inverter motor

3. Upper transport roller

5

G035V002.WMF

4. Transport motor

5. Lower transport roller

G035 1-14 SM

Page 47

1.8 PRINT PROCESS

1.8.1 OVERVIEW

8

1

PRINT PROCESS

Overall

Machine

Information

7

5

6

4

2

3

G035V101.WMF

SM 1-15 G035

Page 48

PRINT PROCESS

1. DRUM CHARGE

In the dark, the charge roller gives a negative charge to the organic photoconductive (OPC) drum. The charge remains on the surface of the drum

because the OPC layer has a high electrical resistance in the dark.

2. LASER EXPOSURE

The processed data from the scanned original is retrieved from the memory

and transferred to the drum by two laser beams, which form an electrostatic

latent image on the drum surface. The amount of charge remaining as a latent

image on the drum depends on the laser beam intensity, which is controlled by

the BICU board.

3. DEVELOPMENT

The magnetic developer brush on the development roller comes in contac t w i th

the latent image on the drum surface. Toner particles are electrostatically

attracted to the areas of the drum surface where the laser reduced the negative

charge on the drum.

4. IMAGE TRANSFER

Paper is fed to the area between the drum surface and the transfer belt at the

proper time to align the copy paper and the developed image on the drum

surface. Then, the transfer bias roller applies a high positive charge to the

reverse side of the paper through the transfer belt. This positive charge pulls

the toner particles from the drum surface on to the paper. At the same time, the

paper is electrically attracted to the transfer belt.

5. PAPER SEPARATION

Paper separates from the drum as a result of the electrical attraction between

the paper and the transfer belt. The pick-off pawls help separate the paper from

the drum.

6. ID SENSOR

The laser forms a sensor pattern on the drum surface. The ID sensor measures

the reflectivity of the pattern. The output signal is one of the factors used for

toner supply control. Also, the ID sensor measures the reflectivity of the drum

surface. The output signal is used for charge roller voltage control.

7. CLEANING

The drum cleaning blade removes any toner remaining on the drum surface

after the image is transferred to the paper.

8. QUENCHING

The light from the quenching lamp electrically neutralizes the charge on the

drum surface.

G035 1-16 SM

Page 49

1.9 BOARD STRUCTURE

1.9.1 BLOCK DIAGRAM

BOARD STRUCTURE

Overall

Machine

Information

NIB

HDD

Bridge Unit

Printer Controller

Mother

Board

Operation

Panel

BICU

HDD

Polygon

Mirror

Motor

High

Voltage

Supply

LDDR

PSU

LD Posi-

tioning

Motor

LSD

LD H.P

Sensor

Duplex

Finisher/

Mailbox

Main

Motor

Fans

IOB

Sensors

Clutches

Controller

Paper

Tray Unit

: Standard

: Option

Paper

Feed

(PFB)

Sensors

Clutches

LCT

G035V501.WMF

SM 1-17 G035

Page 50

BOARD STRUCTURE

1.9.2 DESCRIPTIONS

1. Printer Controller

The printer controller handles the following functions:

•

Printer host interface

•

Printing functions

•

Operation panel control

•

Interface and control of the network interface board

•

Interface and control of additional controller options (HDD and DRAM SIMM)

2. Hard Disk (Option)

⇒

This HDD stores the additional soft fonts (both PCL and PS fonts).

3. Network Interface Board

The network interface board is a printer interface to allow the printer to be used

on a network.

4. DRAM SIMM (Option)

There are two DRAM SIMM slots. This is used for an additional printer

processing memory area. 8, 16, or 32 Mbytes standard SIMM modules can be

installed. As a result, up to 72 Mbytes of RAM are installable (8 Mbytes on

board plus 64 Mbytes of optional SIMM).

Rev. 03/2000

5. MB (Mother Board)

This connects the controller to the BICU board in the machine.

6. BICU (Base Engine and Image Control Unit)

This is the main board. It controls the following functions.

•

Engine sequence

•

Timing control for peripherals

7. IOB (Input/Output Board)

The IOB handles the following functions.

•

Drive control for the sensors, motors, and solenoids of the printer

•