G112/G113/G116/G094/G095/G091

SERVICE MANUAL

001705MIU

RICOH GROUP COMPANIES

SERVICE MANUAL

G112/G113/G116/G094/G095/G091

®

®

RICOH GROUP COMPANIES

G112/G113/G116/

G094/G095/G091

SERVICE MANUAL

001705MIU

f

r

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use o

any trade name, or web site is intended to convey endorsement or othe

affiliation with Ricoh products.

2005 RICOH Corporation. All rights reserved.

p

t

r

g

l

y

p

WARNING

The Service Manual contains information

regarding service techniques, procedures,

rocesses and spare parts of office equipmen

distributed by Ricoh Corporation. Users of this

manual should be either service trained o

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizin

information contained in this service manual to

repair or modify Ricoh equipment risk persona

injury, damage to property or loss of warrant

rotection.

Ricoh Corporation

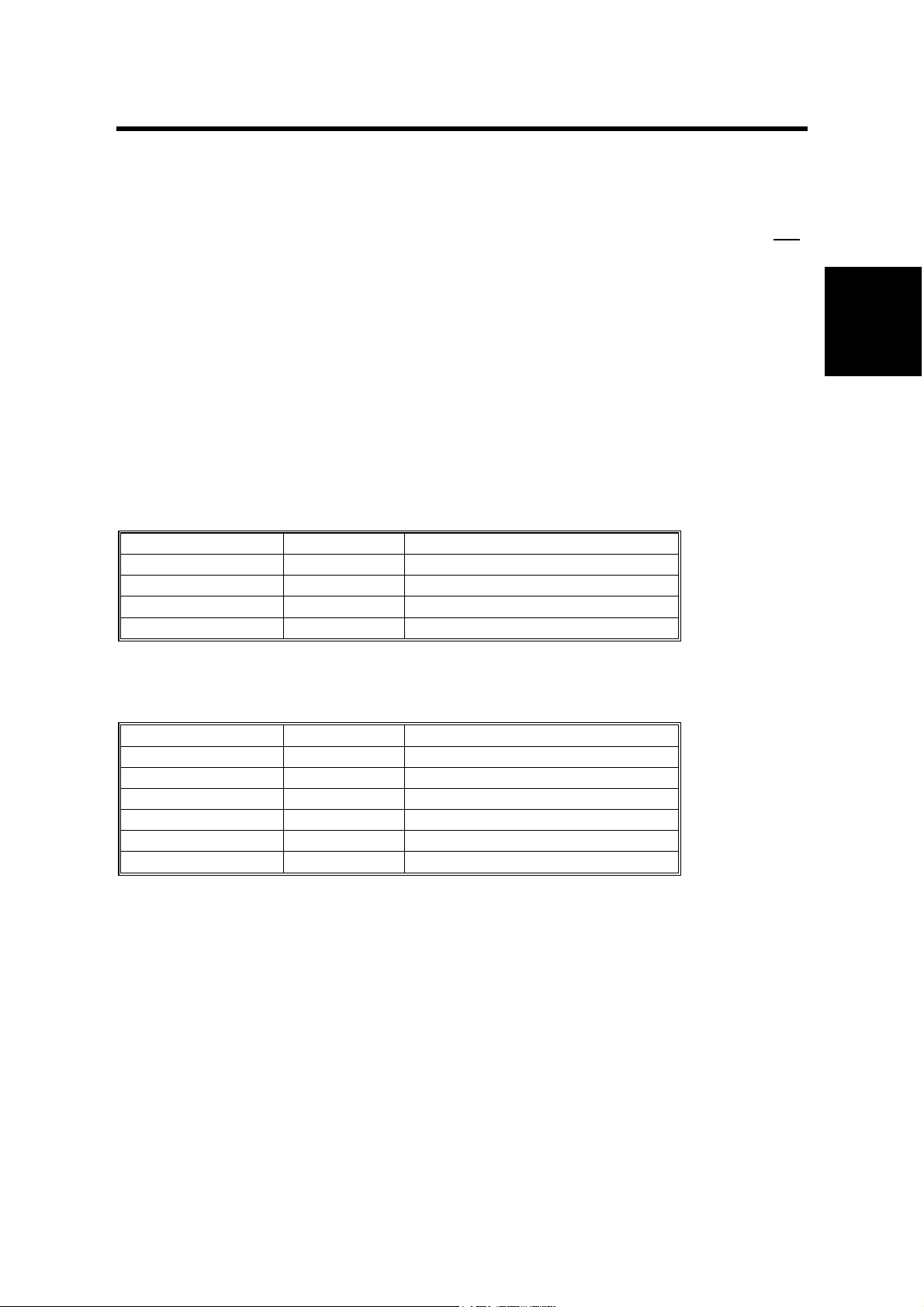

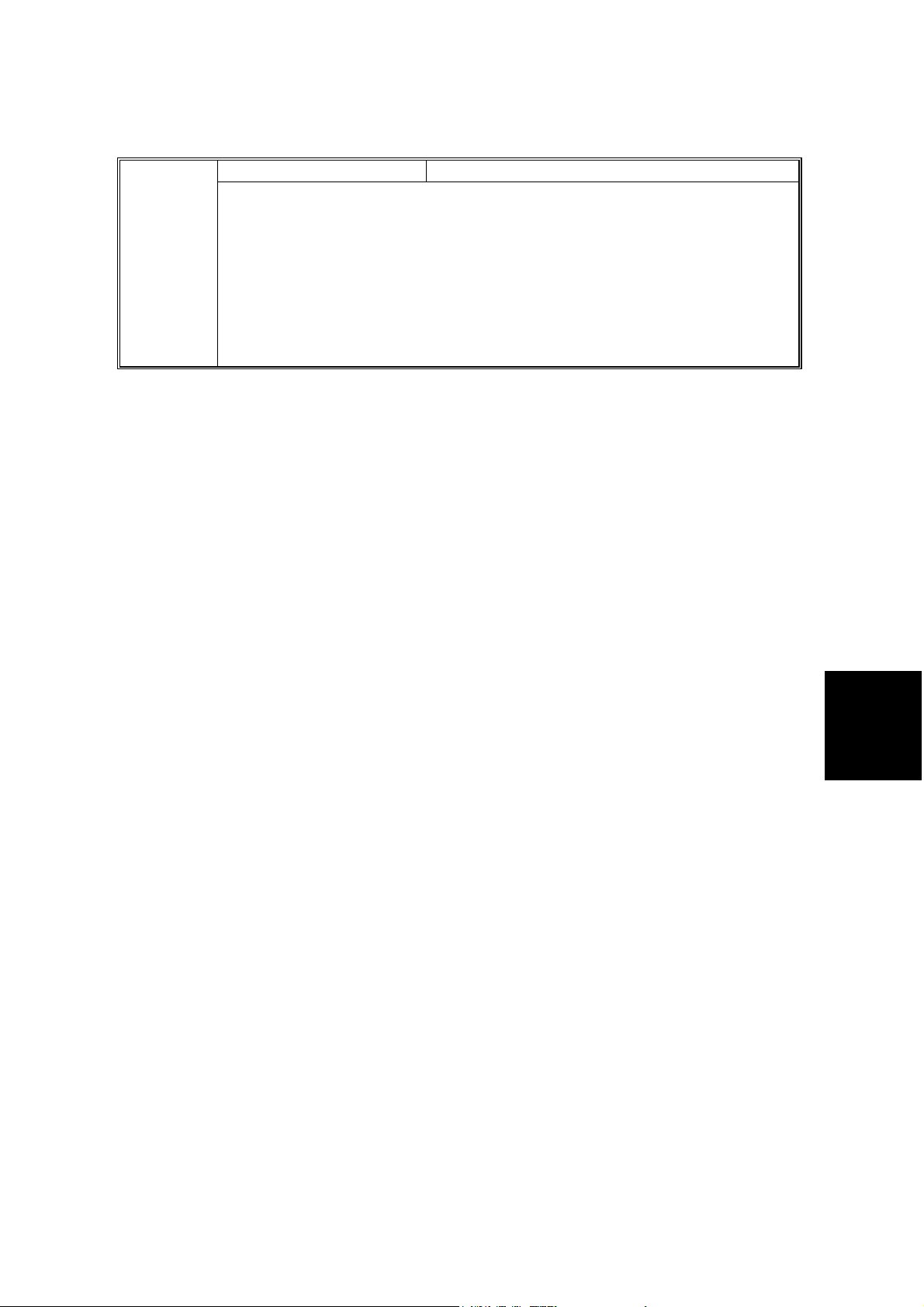

LEGEND

PRODUCT CODE COMPANY

G112 P7527 LP128 Aficio AP410 MLP28

G113 P7527n LP128n Aficio AP410N MLP28n

G116 P7535n LP135n Aficio AP610N MLP35n

G094 P7325 LP026 Aficio AP400 MLP25

G095 P7325n LP026n Aficio AP400N MLP25n

G091 P7132n LP032 Aficio AP600N MLP32

GESTETNER LANIER RICOH SAVIN

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

1 03/2005 G112/G113/G116 Addition

09/2003 Original Printing

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft

Corporation in the United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines

Corporation.

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved

with those marks.

NOTE: In this manual, “G112 Series” includes the G112, G113, G094, and G095

models.

“G116 Series” includes the G116 and G091 models.

G112/G113/G116/G094/G095/G091

TABLE OF CONTENTS

INSTALLATION

1. INSTALLATION............................................................................ 1-1

1.1 INSTALLATION REQUIREMENTS ...........................................................1-1

1.1.1 ENVIRONMENT [ALL MODELS]......................................................1-1

1.1.2 MACHINE LEVEL [ALL MODELS]....................................................1-1

1.1.3 MACHINE SPACE REQUIREMENT [ALL MODELS] .......................1-1

1.1.4 POWER SUPPLY [ALL MODELS]....................................................1-2

1.2 MACHINE INSTALLATION [ALL MODELS] ..............................................1-2

1.2.1 MAIN UNIT [ALL MODELS]..............................................................1-2

1.2.2 HARDWARE OPTIONS....................................................................1-2

1.2.3 MEMORY OPTIONS [ALL MODELS]............................................... 1-2

1.2.4 PRINTER INTERFACE OPTIONS [ALL MODELS] ..........................1-3

1.2.5 DRIVERS AND SOFTWARE [ALL MODELS] ..................................1-3

1.2.6 FIRMWARE UPGRADE [ALL MODELS] ..........................................1-3

1.3 SUPPLIES [ALL MODELS]........................................................................1-3

PREVENTIVE MAINTENANCE SCHEDULE

2. PREVENTIVE MAINTENANCE SCHEDULE............................... 2-1

2.1 USER MAINTENANCE .............................................................................2-1

2.1.1 G112 SERIES (G112/G113 AND G094/G095).................................2-1

2.1.2 G116 SERIES (G116 AND G091) ....................................................2-1

2.2 SERVICE MAINTENANCE........................................................................2-2

2.2.1 MAIN UNIT [ALL MODELS]..............................................................2-2

2.2.2 PAPER TRAY UNIT [ALL MODELS] ................................................2-2

2.2.3 ONE-BIN SHIFT TRAY [G091 ONLY] ...............................................2-3

2.2.4 FOUR-BIN MAILBOX [G091 ONLY] ..................................................2-3

REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT ........................................ 3-1

3.1 GENERAL .................................................................................................3-1

3.1.1 PRECAUTIONS ON DISASSEMBLY [ALL MODELS]......................3-1

3.1.2 RELEASING PLASTIC LATCHES [ALL MODELS] ..........................3-3

3.1.3 AFTER SERVICING THE MACHINE [ALL MODELS] ......................3-3

3.2 SPECIAL TOOLS [ALL MODELS].............................................................3-3

3.3 COVERS ...................................................................................................3-4

SM i G112/G113/G116/G094/G095/G091

3.3.1 FRONT COVER [ALL MODELS] ......................................................3-4

3.3.2 UPPER COVER [G112 SERIES]......................................................3-4

3.3.3 UPPER COVER [G116 SERIES]......................................................3-5

3.3.4 BY-PASS TRAY UNIT [ALL MODELS].............................................3-5

3.3.5 EXTERIOR COVERS [G112 SERIES] .............................................3-6

3.3.6 EXTERIOR COVERS [G116 MODELS] ...........................................3-6

3.4 LASER UNIT .............................................................................................3-7

3.4.1 CAUTION DECAL LOCATIONS [ALL MODELS] .............................3-7

3.4.2 POLYGON MIRROR MOTOR [ALL MODELS].................................3-8

3.4.3 LASER SYNCHRONIZATION DETECTOR [ALL MODELS] ............3-8

3.4.4 LASER UNIT ....................................................................................3-9

3.4.5 LASER UNIT [G116 SERIES]......................................................... 3-10

3.4.6 LASER DIODE UNIT [ALL MODELS].............................................3-12

3.4.7 LASER BEAM PITCH ADJUSTMENT [ALL MODELS]...................3-13

3.5 TRANSFER ROLLER [ALL MODELS] ....................................................3-14

3.6 TONER END SENSOR [ALL MODELS]..................................................3-14

3.7 FUSING................................................................................................... 3-15

3.7.1 FUSING UNIT [ALL MODELS] .......................................................3-15

3.7.2 HOT ROLLER AND FUSING LAMP [ALL MODELS]......................3-16

3.7.3 PRESSURE ROLLER [ALL MODELS] ...........................................3-18

3.7.4 THERMISTOR AND THERMOSTAT [ALL MODELS] ....................3-19

3.7.5 HOT ROLLER STRIPPERS [G112 SERIES]..................................3-20

3.7.6 HOT ROLLER STRIPPERS [G116 SERIES]..................................3-21

3.8 PAPER FEED..........................................................................................3-22

3.8.1 PAPER FEED ROLLER [ALL MODELS] ........................................3-22

3.8.2 FRICTION PAD [ALL MODELS].....................................................3-22

3.9 BY-PASS TRAY [G112/G113/G116] ....................................................... 3-23

3.9.1 BY-PASS TRAY UNIT AND BY-PASS FEED ROLLER

[ALL MODELS]............................................................................... 3-23

3.10 PRINTER CONTROLLER BOARD [ALL MODELS] .............................. 3-24

3.11 ENGINE BOARD [ALL MODELS]..........................................................3-25

3.12 MAIN MOTOR [ALL MODELS]..............................................................3-26

3.13 SOLENOIDS AND CLUTCHES [ALL MODELS] ...................................3-26

3.14 POWER SUPPLY BOARD AND HIGH VOLTAGE SUPPLY BOARD

[ALL MODELS] ......................................................................................3-27

3.15 COOLING FAN [ALL MODELS] ............................................................3-28

3.16 IMAGE ADJUSTMENT..........................................................................3-29

3.16.1 REGISTRATION ADJUSTMENT [ALL MODELS] ........................3-29

3.16.2 PARALELLOGRAM IMAGE ADJUSTMENT [ALL MODELS] .......3-29

TROUBLESHOOTING

4. TROUBLESHOOTING ................................................................. 4-1

4.1 SERVICE CALL CONDITIONS .................................................................4-1

4.1.1 SUMMARY ....................................................................................... 4-1

4.1.2 SC CODE DESCRIPTIONS .............................................................4-2

4.2 CONTROLLER ERROR ............................................................................4-5

4.3 ELECTRICAL COMPONENT DEFECTS [ALL MODELS] .........................4-7

G112/G113/G116/G094/G095/G091 ii SM

4.3.1 SENSORS ........................................................................................4-7

4.3.2 SWITCHES [ALL MODELS] ............................................................. 4-7

4.4 BLOWN FUSE CONDITIONS [ALL MODELS] ..........................................4-8

4.5 LEDS [ALL MODELS]................................................................................4-8

SERVICE TABLES

5. SERVICE TABLES....................................................................... 5-1

5.1 SERVICE PROGRAM MODE [ALL MODELS] ..........................................5-1

5.1.1 ENABLING AND DISABLING SERVICE PROGRAM MODE ...........5-1

Entering the Service Mode....................................................................5-1

Inputting a Value or Setting for a Service Program............................... 5-1

Exiting Service Mode ............................................................................5-2

5.2 PRINTER CONTROLLER SERVICE MODE [ALL MODELS]....................5-2

5.2.1 SERVICE MODE MENU (“1. SERVICE MENU”)..............................5-2

5.2.2 BIT SWITCH PROGRAMMING ........................................................5-2

5.3 PRINTER ENGINE SERVICE MODE [ALL MODELS] .............................. 5-3

5.3.1 SERVICE MODE TABLE..................................................................5-3

SP1-xxx: Feed ...................................................................................... 5-3

SP2-xxx: Drum......................................................................................5-5

SP3-xxx: Process..................................................................................5-6

SP5-xxx: Mode .....................................................................................5-8

SP7-xxx: Data Log.............................................................................. 5-20

SP8-xxx: Counters..............................................................................5-24

SP9-xxx: Counters..............................................................................5-28

5.4 UPDATING THE FIRMWARE .................................................................5-29

5.4.1 CONTROLLER FIRMWARE [G091/G094/G095] ...........................5-29

5.4.2 ENGINE FIRMWARE [G091/G094/G095] ......................................5-30

5.4.3 TYPE OF FIRMWARE [G112/G113/G116].....................................5-30

5.4.4 PRECAUTIONS [G112/G113/G116]...............................................5-30

5.4.5 MACHINE FIRMWARE [G112/G113/G116] ...................................5-31

5.5 ERROR RECOVERY [ALL MODELS] .....................................................5-32

Controller ............................................................................................ 5-32

Engine.................................................................................................5-32

5.6 REMOTE FIRMWARE UPDATE (RFU) [ALL MODELS] .........................5-33

5.7 LOOP-BACK TEST [ALL MODELS] ........................................................5-33

5.8 POWER-ON SELF TESTS [ALL MODELS].............................................5-33

5.9 USER PROGRAM MODES [ALL MODELS]............................................5-34

User Mode Tree.................................................................................. 5-34

5.10 DIP SWITCHES [ALL MODELS] ...........................................................5-35

Controller Board.................................................................................. 5-35

5.11 NVRAM DATA UPLOAD/DOWNLOAD [G112/G113/G116] ..................5-36

Uploading NVRAM Data .....................................................................5-36

Downloading NVRAM Data.................................................................5-37

5.12 SD CARD APPLI MOVE [G112/G113/G116].........................................5-37

5.12.1 OVERVIEW ..................................................................................5-37

5.12.2 MOVE EXEC ................................................................................5-38

5.12.3 UNDO EXEC ................................................................................5-39

SM iii G112/G113/G116/G094/G095/G091

DETAILED SECTION DESCRIPTIONS

6. DETAILED SECTION DESCRIPTIONS ....................................... 6-1

6.1 OVERVIEW ...............................................................................................6-1

6.1.1 MECHANICAL COMPONENT LAYOUT [ALL MODELS] .................6-1

6.1.2 PAPER PATH [G112 SERIES] .........................................................6-2

6.1.3 PAPER PATH [G116 SERIES] .........................................................6-3

6.2 BOARD STRUCTURE............................................................................... 6-4

6.2.1 BLOCK DIAGRAM [G112 SERIES].................................................. 6-4

6.2.2 BLOCK DIAGRAM [G116 SERIES].................................................. 6-5

6.2.3 DESCRIPTIONS [ALL MODELS] .....................................................6-6

6.2.4 CONTROLLER BOARD [G112 SERIES]..........................................6-8

6.2.5 CONTROLLER BOARD [G116 SERIES]..........................................6-9

6.3 PRINTING PROCESS............................................................................. 6-10

6.3.1 OVERVIEW [ALL MODELS]...........................................................6-10

6.3.2 LASER EXPOSURE [ALL MODELS]..............................................6-11

Overview.............................................................................................6-11

Automatic Process Control (APC) [ALL MODELS] ............................6-12

LD Safety Mechanisms [ALL MODELS]..............................................6-13

6.3.3 CARTRIDGE OVERVIEW [ALL MODELS].....................................6-14

6.3.4 DRUM CHARGE [ALL MODELS] ...................................................6-14

6.3.5 DEVELOPMENT [ALL MODELS] ...................................................6-15

Toner Supply ......................................................................................6-15

Development Unit ...............................................................................6-15

Toner Density Control .........................................................................6-16

Development Bias...............................................................................6-16

Toner End Detection ...........................................................................6-17

Toner near-end ...................................................................................6-17

Toner end ...........................................................................................6-17

6.3.6 IMAGE TRANSFER AND PAPER SEPARATION [ALL MODELS]. 6-18

Overview.............................................................................................6-18

Transfer Roller Cleaning .....................................................................6-19

6.3.7 CLEANING [ALL MODELS]............................................................6-19

6.3.8 QUENCHING [ALL MODELS] ........................................................ 6-20

6.3.9 ID CHIP AND INTERNAL THERMISTOR [ALL MODELS] .............6-20

6.4 PAPER FEED [ALL MODELS] ................................................................6-21

6.4.1 OVERVIEW .................................................................................... 6-21

Paper Tray ..........................................................................................6-21

By-pass Tray.......................................................................................6-21

6.4.2 PAPER TRAY [ALL MODELS] .......................................................6-22

Tray Extension....................................................................................6-22

Paper Sizes [G112 SERIES]...............................................................6-22

Paper Sizes [G116 SERIES]...............................................................6-22

Paper Lift ............................................................................................6-23

Paper Feed and Registration ..............................................................6-24

Paper Size Detection ..........................................................................6-25

Paper Size Detection [G112 SERIES] ................................................6-26

G112/G113/G116/G094/G095/G091 iv SM

Paper Size Detection [G116 SERIES] ................................................6-26

Paper End Detection...........................................................................6-27

Remaining Paper Detection ................................................................6-28

6.4.3 BY-PASS TRAY [G091/G094/G095] ..............................................6-29

6.4.4 BY-PASS TRAY [G112/G113/G116] ..............................................6-30

6.5 IMAGE FUSING AND PAPER EXIT [ALL MODELS] ..............................6-31

6.5.1 OVERVIEW .................................................................................... 6-31

6.5.2 FUSING DRIVE [ALL MODELS]..................................................... 6-32

6.5.3 FUSING ENTRANCE AND GUIDE SHAFT [ALL MODELS] ..........6-32

6.5.4 PRESSURE ROLLER [ALL MODELS] ...........................................6-33

6.5.5 NEW FUSING UNIT DETECTION [ALL MODELS] ........................6-34

6.5.6 FUSING TEMPERATURE CONTROL [ALL MODELS] ..................6-35

Overheat Protection............................................................................6-36

6.5.7 PAPER EXIT [ALL MODELS] .........................................................6-36

6.5.8 ENERGY SAVER MODE [ALL MODELS] ......................................6-37

Entering Energy Saver Mode..............................................................6-37

Exiting Energy Saver Mode ................................................................6-37

6.6 CONTROLLER FUNCTIONS [ALL MODELS].........................................6-38

6.6.1 METER CHARGE MODE ...............................................................6-38

Meter-charge Counter Display ............................................................6-38

PM Warning Display ...........................................................................6-38

SPECIFICATIONS

SPECIFICATIONS (G091)................................................................. 7-1

1. GENERAL SPECIFICATIONS.....................................................................7-1

2. PHYSICAL SPECIFICATIONS.................................................................... 7-2

3. CONTROLLER ............................................................................................7-3

4. SUPPORTED PAPER SIZES...................................................................... 7-4

5. OPERATION PANEL LED SPECIFICATIONS............................................ 7-5

6. EXTERNAL OPTIONS ................................................................................7-6

7. SOFTWARE ACCESSORIES .....................................................................7-7

7.1 PRINTER DRIVERS............................................................................7-7

7.2 CD-ROM CONTENTS .........................................................................7-8

7.2.1 NORTH AMERICAN VERSION........................................................7-8

7.2.2 EUROPEAN VERSION ....................................................................7-9

8. MACHINE CONFIGURATION................................................................... 7-10

8.1 SYSTEM COMPONENTS .................................................................7-10

8.2 INTERNAL OPTIONS........................................................................7-11

SPECIFICATIONS (G094/G095)..................................................... 7-12

1. GENERAL SPECIFICATIONS...................................................................7-12

2. PHYSICAL SPECIFICATIONS................................................................... 713

3. CONTROLLER ..........................................................................................7-14

4. SUPPORTED PAPER SIZES....................................................................7-15

5. OPERATION PANEL LED SPECIFICATIONS.......................................... 7-16

6. EXTERNAL OPTIONS ..............................................................................7-16

7. SOFTWARE ACCESSORIES ...................................................................7-17

SM v G112/G113/G116/G094/G095/G091

7.1 PRINTER DRIVERS .......................................................................... 7-17

7.2 CD-ROM CONTENTS ....................................................................... 7-18

7.2.1 NORTH AMERICAN VERSION...................................................... 7-18

7.2.2 EUROPEAN VERSION ..................................................................7-19

8. MACHINE CONFIGURATION ..................................................................7-20

8.1 SYSTEM COMPONENTS ................................................................. 7-20

8.2 INTERNAL OPTIONS........................................................................7-21

SPECIFICATIONS (G116)............................................................... 7-22

1. GENERAL SPECIFICATIONS...................................................................7-22

2. PHYSICAL SPECIFICATIONS ..................................................................7-23

3. CONTROLLER ..........................................................................................7-24

4. SUPPORTED PAPER SIZES....................................................................7-25

5. OPERATION PANEL LED SPECIFICATIONS .......................................... 7-26

6. EXTERNAL OPTIONS ..............................................................................7-27

7. SOFTWARE ACCESSORIES ...................................................................7-28

7.1 PRINTER DRIVERS .......................................................................... 7-28

7.2 OPERATING SYSTEMS/NETWORKS..............................................7-28

7.3 CD-ROM CONTENTS ....................................................................... 7-29

7.3.1 NORTH AMERICAN VERSION...................................................... 7-29

7.3.2 EUROPEAN VERSION ..................................................................7-30

8. MACHINE CONFIGURATION ................................................................... 7-31

8.1 SYSTEM COMPONENTS ................................................................. 7-31

8.2 INTERNAL OPTIONS......................................................................7-32

SPECIFICATIONS (G112/G113)..................................................... 7-33

1. GENERAL SPECIFICATIONS...................................................................7-33

2. PHYSICAL SPECIFICATIONS ..................................................................7-34

3. CONTROLLER ..........................................................................................7-35

4. SUPPORTED PAPER SIZES....................................................................7-36

5. OPERATION PANEL LED SPECIFICATIONS .......................................... 7-37

6. EXTERNAL OPTIONS ..............................................................................7-37

7. SOFTWARE ACCESSORIES ...................................................................7-38

7.1 PRINTER DRIVERS .......................................................................... 7-38

7.2 CD-ROM CONTENTS ....................................................................... 7-39

7.2.1 NORTH AMERICAN VERSION...................................................... 7-39

7.2.2 EUROPEAN VERSION ..................................................................7-40

8. MACHINE CONFIGURATION ................................................................... 7-41

8.1 SYSTEM COMPONENTS ................................................................. 7-41

8.2 INTERNAL OPTIONS........................................................................7-42

PAPER TRAY UNIT (G360)/ENVELOPE FEEDER (G362)

SEE SECTION G360/G362 FOR DETAILED TABLE OF CONTENTS

DUPLEX UNIT (G361)

SEE SECTION G361 FOR DETAILED TABLE OF CONTENTS

G112/G113/G116/G094/G095/G091 vi SM

DUPLEX UNIT (G552)

SEE SECTION G552 FOR DETAILED TABLE OF CONTENTS

FOUR-BIN MAILBOX (G553)

SEE SECTION G553 FOR DETAILED TABLE OF CONTENTS

ONE-BIN SHIFT TRAY (G554)

SEE SECTION G554 FOR DETAILED TABLE OF CONTENTS

PAPER TRAY UNIT (G555)/ENVELOPE FEEDER (G556)

SEE SECTION G555 FOR DETAILED TABLE OF CONTENTS

PAPER TRAY UNIT (G399)/ENVELOPE FEEDER (G807)

SEE SECTION G399/G807 FOR DETAILED TABLE OF CONTENTS

DUPLEX UNIT (G806)

SEE SECTION G806 FOR DETAILED SECTION DESCRIPTION

SM vii G112/G113/G116/G094/G095/G091

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner and developer are non-toxic, but if you get either of them in your eyes by

accident, it may cause temporary eye discomfort. Try to remove with eye drops

or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can seriously damage

your eyes.

Caution Labels

G065RLW.WMF

LASER-3.WMF

LASER-1.WMF

Lithium Batteries (Memory Back-up)

CAUTION

The danger of explosion exists if a battery of this type is incorrectly

replaced. Replace only with the same or an equivalent type recommended

by the manufacturer. Discard used batteries in accordance with the

manufacturer’s instructions.

Warning Concerning Copyright

Many documents are copyrighted. Such documents may not be reproduced by

copying or in any other form without the express permission of the copyright holder.

Conventions in this Manual

This manual uses several symbols and some simple abbreviations.

Symbol What it means

HP Home Position

T/S Transfer/Separation

The following notations are used in text to describe the direction of paper feed:

lengthwise and sideways. The annotations “SEF” and “LEF” denote “Short Edge

Feed” and “Long Edge Feed’. (The arrows indicate the direction of paper feed.)

Refer to section number

See Core Tech Manual for details

Screw

Connector

E-ring

C-ring

Lengthwise (SEF) Sideways (LEF)

INSTALLATION

PREVENTIVE MAINTENANCE

REPLACEMENT AND ADJUSTMENT

TROUBLESHOOTING

FOUR-BIN MAILBOX G553

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

SERVICE TABLES

DUPLEX UNIT G361

DUPLEX UNIT G552

DUPLEX UNIT G806

DETAILED DESCRIPTIONS

SPECIFICATIONS

PAPER TRAY UNIT G360/ENVELOPE FEEDER G362

PAPER TRAY UNIT G555/ENVELOPE FEEDER G556

PAPER TRAY UNIT G399/ENVELOPE FEEDER G807

ONE-BIN SHIFT TRAY G554

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

INSTALLATION

INSTALLATION REQUIREMENTS

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT [ALL MODELS]

1. Temperature Range: 10 °C to 32 °C (50 °F to 89.6 °F)

2. Humidity Range: 15 % to 89 % RH

3. Ambient Illumination: Less than 2,000 lux (do not expose to direct sunlight).

4. Ventilation: 3 times/hr/person

5. Avoid areas that are exposed to sudden temperature changes. This includes:

1) Areas directly exposed to cool air from an air conditioner.

2) Areas directly exposed to heat from a heater.

6. Do not install this machine in an area where it will be exposed to corrosive

gases.

7. Do not install the machine at locations over 2,500 m (8,125 ft.) above sea level.

8. Put the machine on a strong and level base. Inclination on any side should not

exceed 5 mm.

9. Do not put the machine where it may be subjected to strong vibrations.

1.1.2 MACHINE LEVEL [ALL MODELS]

Installation

Front to back: Within 5 mm. (0.2 inches) of level.

Right to left: Within 5 mm. (0.2 inches) of level.

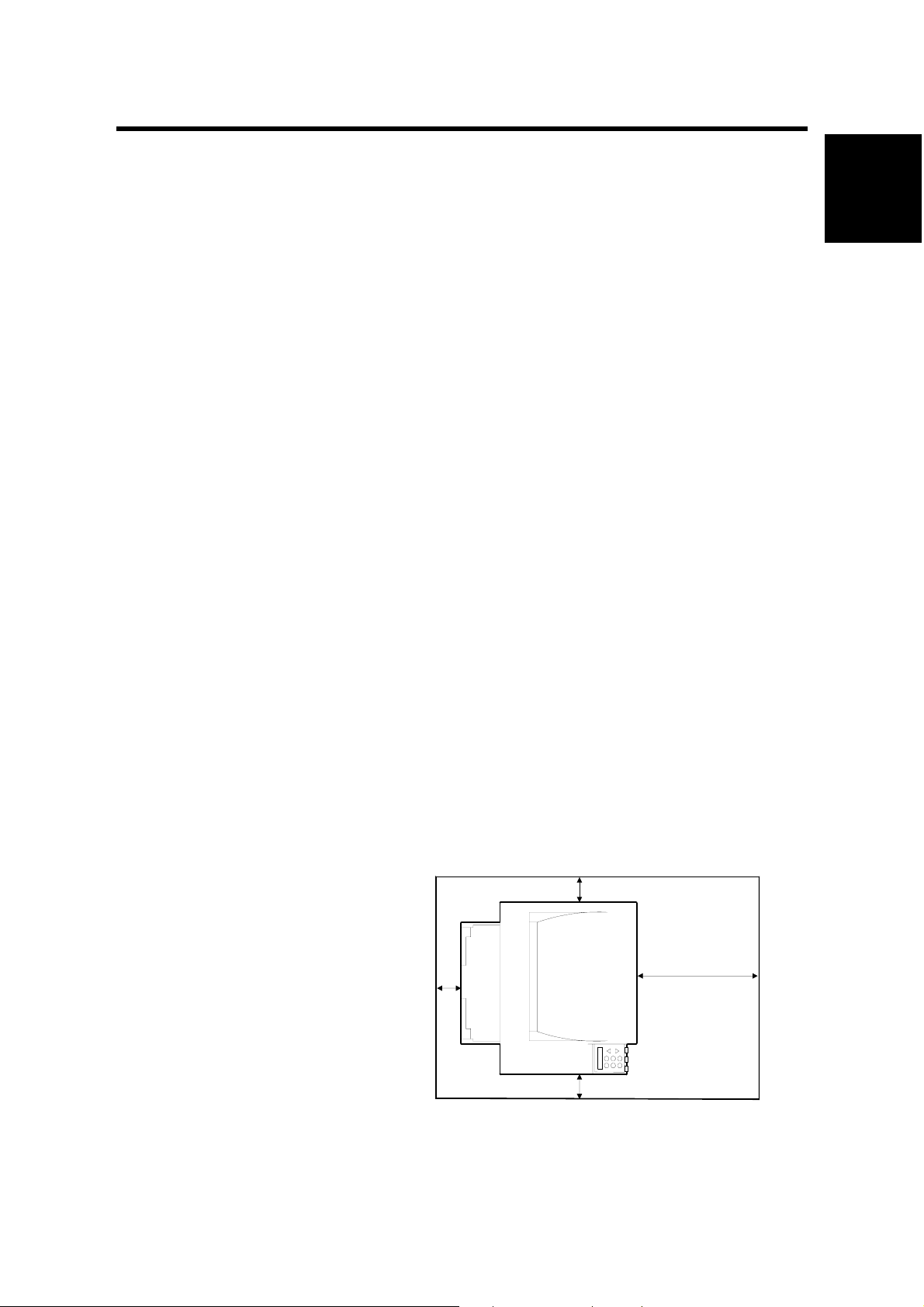

1.1.3 MACHINE SPACE REQUIREMENT [ALL MODELS]

Place the machine near the power source, providing the clearance as shown

below:

A: Over 10 cm (4 inches)

B: Over 10 cm (4 inches)

C: Over 100 cm (40 inches)

A

D: Over 10 cm (4 inches)

B

C

D

G094I500.WMF

SM 1-1 G112/G113/G116/G094/G095/G091

MACHINE INSTALLATION [ALL MODELS]

1.1.4 POWER SUPPLY [ALL MODELS]

CAUTION

1. Make sure the plug is firmly inserted in the outlet.

2. Avoid multi-wiring.

3. Be sure to ground the machine.

Input voltage level

Permissible voltage Fluctuation: ±10 %

Do not set anything on the power cord

120 volts, 60 Hz: More than 10 A

220-240 volts, 50 Hz/60Hz: More than 6 A

1.2 MACHINE INSTALLATION [ALL MODELS]

Refer to the following sections of the Operating Instructions for installation details

for all models.

1.2.1 MAIN UNIT [ALL MODELS]

1. Installing the Printer Unit: Quick Installation Guide.

2. Connecting the machine to a computer: Quick Installation Guide.

1.2.2 HARDWARE OPTIONS

1. Installing the Paper Feed Unit: Section two of the Set-up Guide. (Note: The

G116 Paper Tray is unique and is not compatible with the G091 model.)

2. Installing the Envelope Feeder: Section two of the Set-up Guide. (Note: The

G116 Envelope Feeder is unique, and is not compatible with the G091 model.)

3. Installing the Duplex Unit: Section two of the Set-up Guide. (Note: The G116

Duplex Unit is unique, and is not compatible with the G091 model.)

4. [G091 only] Installing the One-Bin Shift Tray. Section two of the Set-up Guide.

5. [G091 only] Installing the Four-Bin Mailbox. Section two of the Set-up Guide.

(NOTE: The Mailbox and One-Bin Shift Tray are not supported for the G116

model.)

1.2.3 MEMORY OPTIONS [ALL MODELS]

1. Installing the Memory Unit: Section two of the Set-up Guide.

2. Installing the Hard Disk: Section two of the Set-up Guide.

G112/G113/G116/G094/G095/G091 1-2 SM

SUPPLIES [ALL MODELS]

1.2.4 PRINTER INTERFACE OPTIONS

1. Ethernet (G112/G094 models only): Section two of the Set-up Guide.

2. IEEE1394: Section two of the Set-up Guide.

3. IEEE802.11b: Section two of the Set-up Guide.

4. Bluetooth: Section two of the Set-up Guide.

NOTE: The Ethernet is standard for the G113/G116 and G091/G116 models.

1.2.5 DRIVERS AND SOFTWARE [ALL MODELS]

Refer to section 4 of the Set-up Guide for installation procedures.

1.2.6 FIRMWARE UPGRADE [ALL MODELS]

Refer to section 5.4 of the Service Manual.

1.3 SUPPLIES [ALL MODELS]

Installation

• Maintenance kit (NOTE: The G094/G095 and G112/G113 Maintenance

Kits are not interchangeable. The same applies to the G094 versus the

G116 Maintenance Kits. Use the Maintenance Kit that is unique to each

model.)

• AIO (NOTE: The G094/G095 AIO can be used in the G112/G113 models,

and vice versa. The same interchangeability applies to the G091 and

G116 AIO cartridges.)

SM 1-3 G112/G113/G116/G094/G095/G091

PREVENTIVE MAINTENANCE

USER MAINTENANCE

2. PREVENTIVE MAINTENANCE SCHEDULE

2.1 USER MAINTENANCE

NOTE: The G091/G094/G095 and the G112/G113/G116 Maintenance Kits are not

interchangeable. Ensure you are using the correct kit for the model you are

servicing.

The customer can do all PM items with the Maintenance Kit.

Meter-charge mode must be set to “disabled” (Engine SP mode 5930).

Cross-reference: Section 5.3 Engine service mode

The Operation panel shows “Replace Maintenance Kit” when the PM counter gets

to 90K. After the user replaces the fusing unit in the maintenance kit, the machine

automatically resets the PM counter.

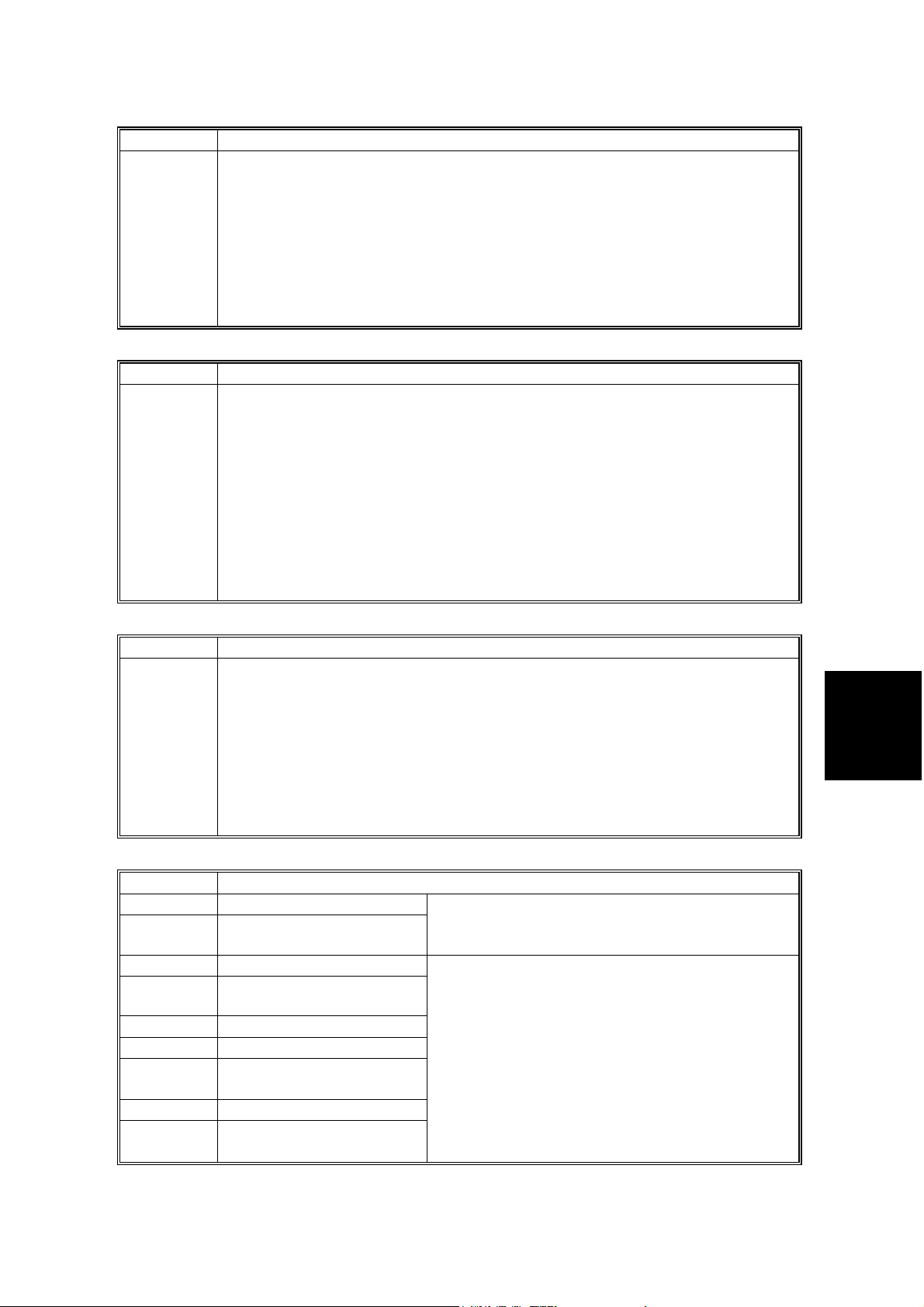

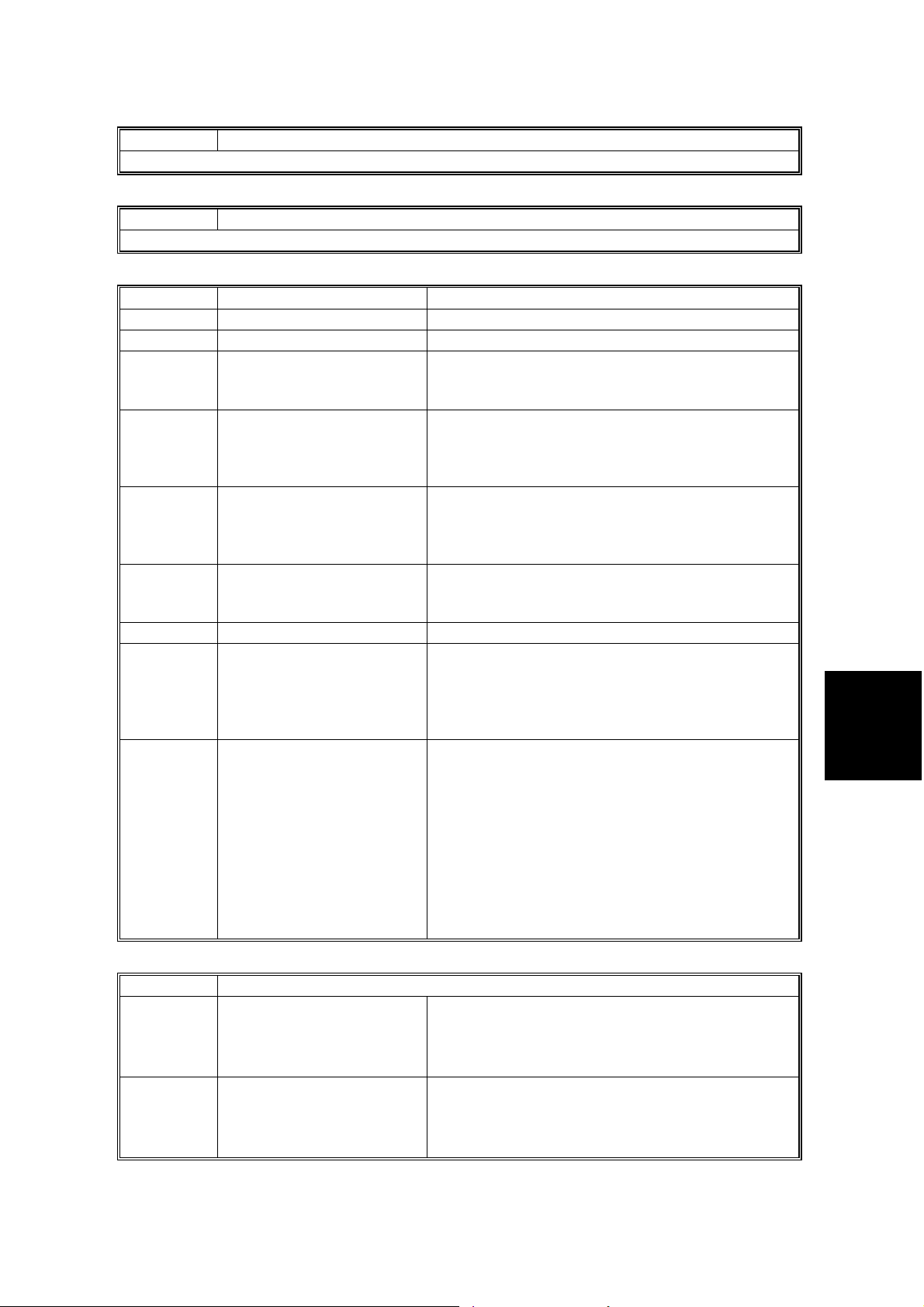

2.1.1 G112 SERIES (G112/G113 AND G094/G095)

Item Quantity Remarks

Fusing unit 1

Transfer roller 1

Paper feed roller 3 For standard and optional trays

Friction pad 3 For standard and optional trays

Preventive

Maintenance

2.1.2 G116 SERIES (G116 AND G091)

Item Quantity Remarks

Fusing unit 1

Transfer roller 1

Paper feed roller 1 For standard tray

Paper feed roller 2 For optional tray(s)

Friction pad 1 For standard tray

Friction pad 2 For optional tray(s)

SM 2-1 G112/G113/G116/G094/G095/G091

SERVICE MAINTENANCE

2.2 SERVICE MAINTENANCE

The table shows the PM items done by service.

NOTE:

1) To disable the user's PM warning, set meter-charge mode to “ON” in

Printer Engine Service Mode.

2) Make sure to reset the PM counters with engine SP mode 7-804 after

you complete PM.

• 7-804-1: Transfer roller

• 7-804-2: Paper feed roller

• 7-804-3: Fusing unit.

• (G116/G112/G113 only) SP 7804 255: Paper

Symbol key: C: Clean, R: Replace, L: Lubricate, I: Inspect

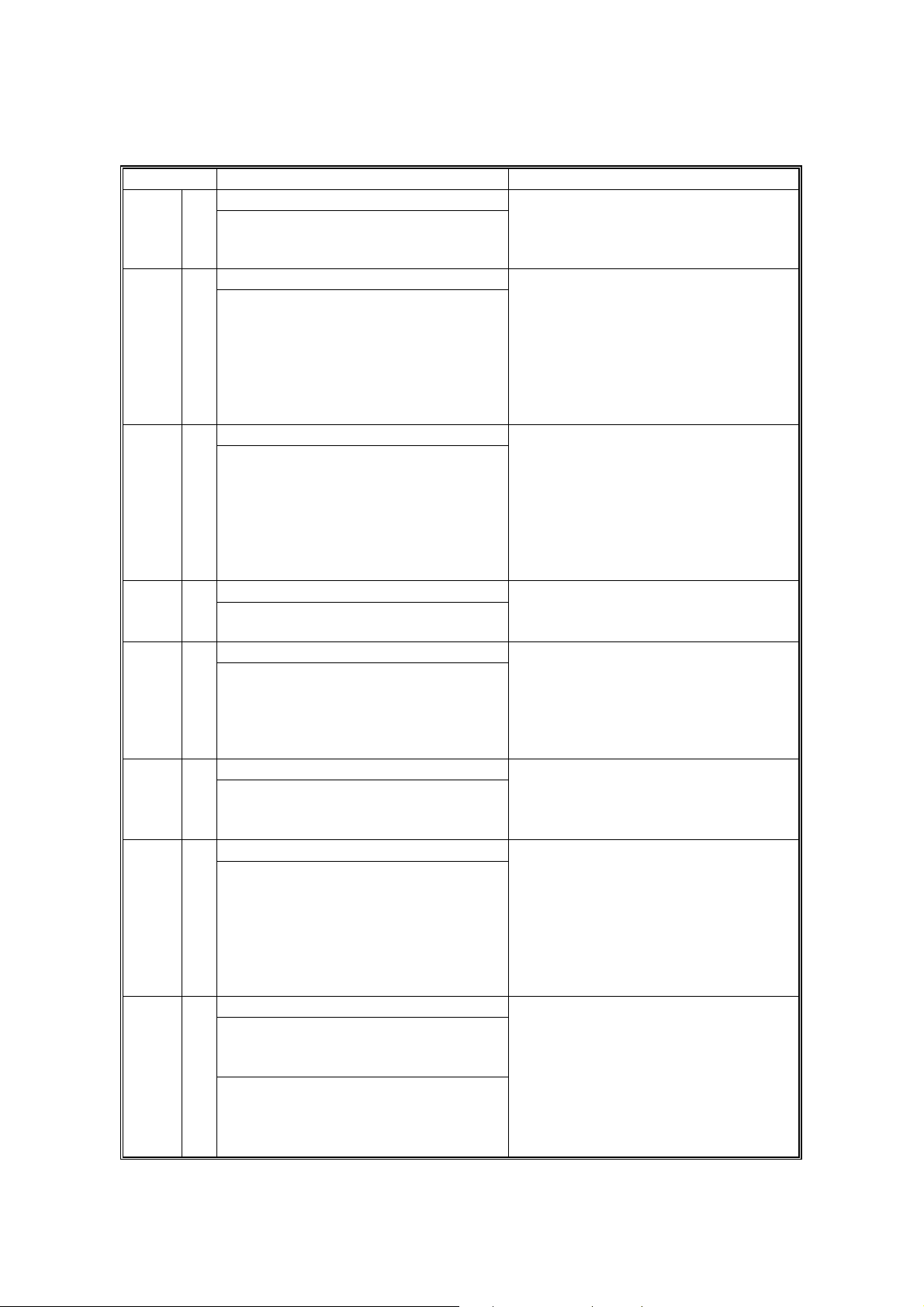

2.2.1 MAIN UNIT [ALL MODELS]

Item 90K EM Quantity Remarks

Paper Feed

Paper Feed Roller R C 1 Clean with water

Friction Pad R C 1 Clean with water

Registration Roller C C 1 Clean with water

Bottom Plate Pad C C 1 Clean with water

Around the Drum

Transfer Roller R 1

Fusing Unit and Paper Exit

Hot Roller R 1

Pressure Roller R 1

Hot Roller Strippers

R

Fusing Thermistor

Bushings - Hot Roller R 2

Bushings - Pressure Roller R 2

Fusing Entrance and Exit Guide

Plates

R C

C 1 each

G091/G116: 5

G094/G095/

G112/G113: 3

1

Clean with alcohol if

necessary.

Clean with water or

alcohol

2.2.2 PAPER TRAY UNIT [ALL MODELS]

90K EM Quantity NOTE

Paper Feed Roller R C 1 Clean with water

Friction Pad R C 1 Dry cloth

Bottom Plate Pad C C 1 Clean with water

G112/G113/G116/G094/G095/G091 2-2 SM

SERVICE MAINTENANCE

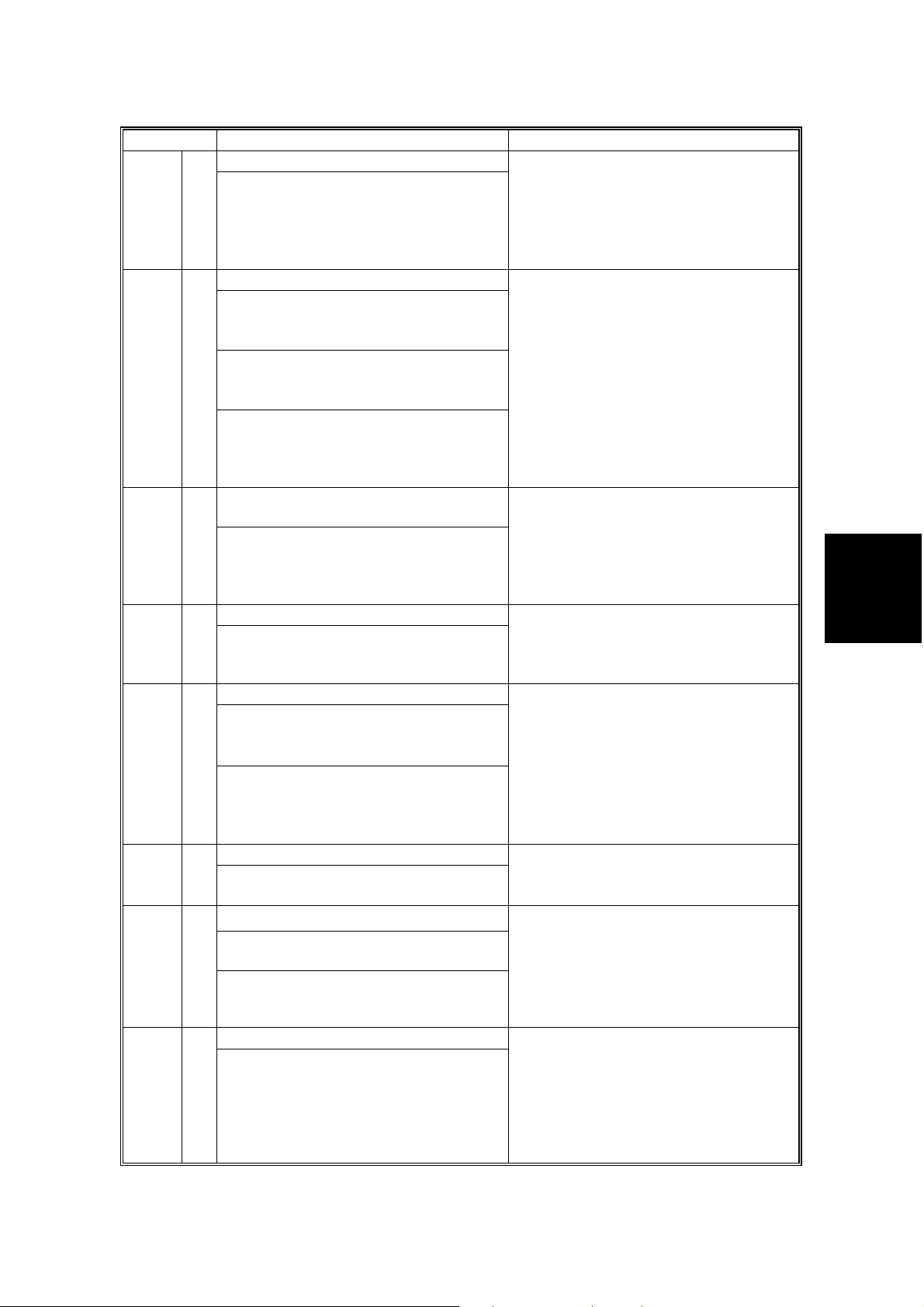

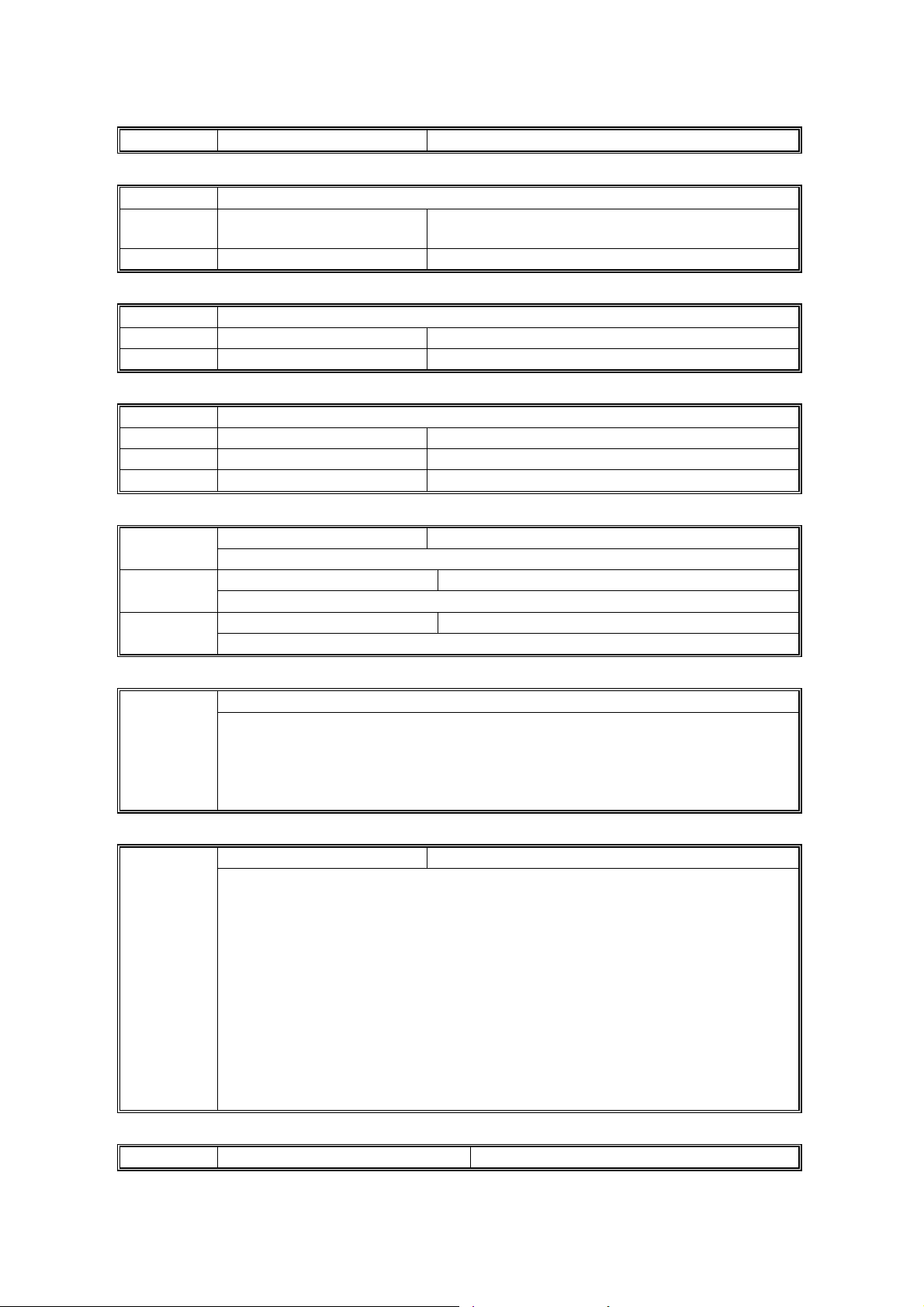

2.2.3 ONE-BIN SHIFT TRAY [G091 ONLY]

90K EM Quantity NOTE

Exit Rollers

Driven Rollers

Transport Rollers

Paper Tray

Tray Paper Sensor

C

C

C

C

C

Clean with water

Clean with water

Clean with water

Clean with water

Clean with water

2.2.4 FOUR-BIN MAILBOX [G091 ONLY]

90K EM Quantity NOTE

Exit Rollers

Driven Rollers

Trays

C

C

C

NOTE: The optional One-Bin Shift Tray and the Four Bin Mailbox units are for the

G091 machine only. [These two options are not supported for the

successor G116 model.]

Clean with water

Clean with water

Clean with water

Preventive

Maintenance

SM 2-3 G112/G113/G116/G094/G095/G091

REPLACEMENT AND ADJUSTMENT

GENERAL

3. REPLACEMENT AND ADJUSTMENT

CAUTION

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section.

The Replacement and Adjustment procedures in this section are for all models,

unless otherwise specified. Differences are shown with the machine code.

NOTE: This manual uses these symbols.

: See or Refer to : Screws : Connector

3.1 GENERAL

3.1.1 PRECAUTIONS ON DISASSEMBLY [ALL MODELS]

Use extreme caution when removing and replacing components. The cables in the

machine are located very close to moving parts. Proper cable routing is a must.

Before removing any component from the machine, note any cable routings that

may be affected. After components have been removed, any cables that have been

displaced during the procedure must be rerouted as closely as possible to their

original positions.

Before servicing the machine:

1. Verify that documents are not stored in memory.

2. Remove the toner cartridge before you remove parts.

3. Unplug the power cord.

4. Work on a flat and clean surface.

5. Replace with authorized components only.

6. Do not force plastic material components.

Ensure that all components are returned to their original positions, when you have

completed service activity.

Adjustment

Replacement

SM 3-1 G112/G113/G116/G094/G095/G091

GENERAL

Laser unit

1. Do not loosen or adjust the screws securing the LD drive board on the LD unit.

Doing so will throw the LD unit out of adjustment.

2. Do not adjust the variable resistors on the LD unit, as these are permanently

adjusted at the factory. If replacement of the LD drive board is necessary,

replace the entire LD unit.

3. Keep the polygon mirror and toroidal lens free of dust. Laser performance is

very sensitive to dust on these components.

4. Do not touch the shield glass or the surface of the polygon mirror with bare

hands.

5. Do not adjust the Laser Synchronization detector on the LD unit, as these are

permanently adjusted at the factory. If the position of the Laser Synchronization

detector has changed from the factory set position, SC 322 will be shown.

Transfer Roller

1. Never touch the surface of the transfer roller with bare hands.

2. Be careful not to scratch the transfer roller, as the surface is easily damaged.

Fusing

1. After installing the fusing thermistor, make sure that it is in contact with the hot

roller and that the roller can rotate freely.

2. Be careful to avoid damage to the hot roller stripper pawls and their tension

springs.

3. Do not touch the fusing lamp and rollers with bare hands.

4. Make sure that the fusing lamp is positioned correctly and that it does not touch

the inner surface of the hot roller.

Paper Feed

1. Do not touch the surface of paper feed rollers.

2. To avoid misfeeds, the side and end fences in each paper tray must be

positioned correctly so as to align with loaded paper size.

G112/G113/G116/G094/G095/G091 3-2 SM

SPECIAL TOOLS

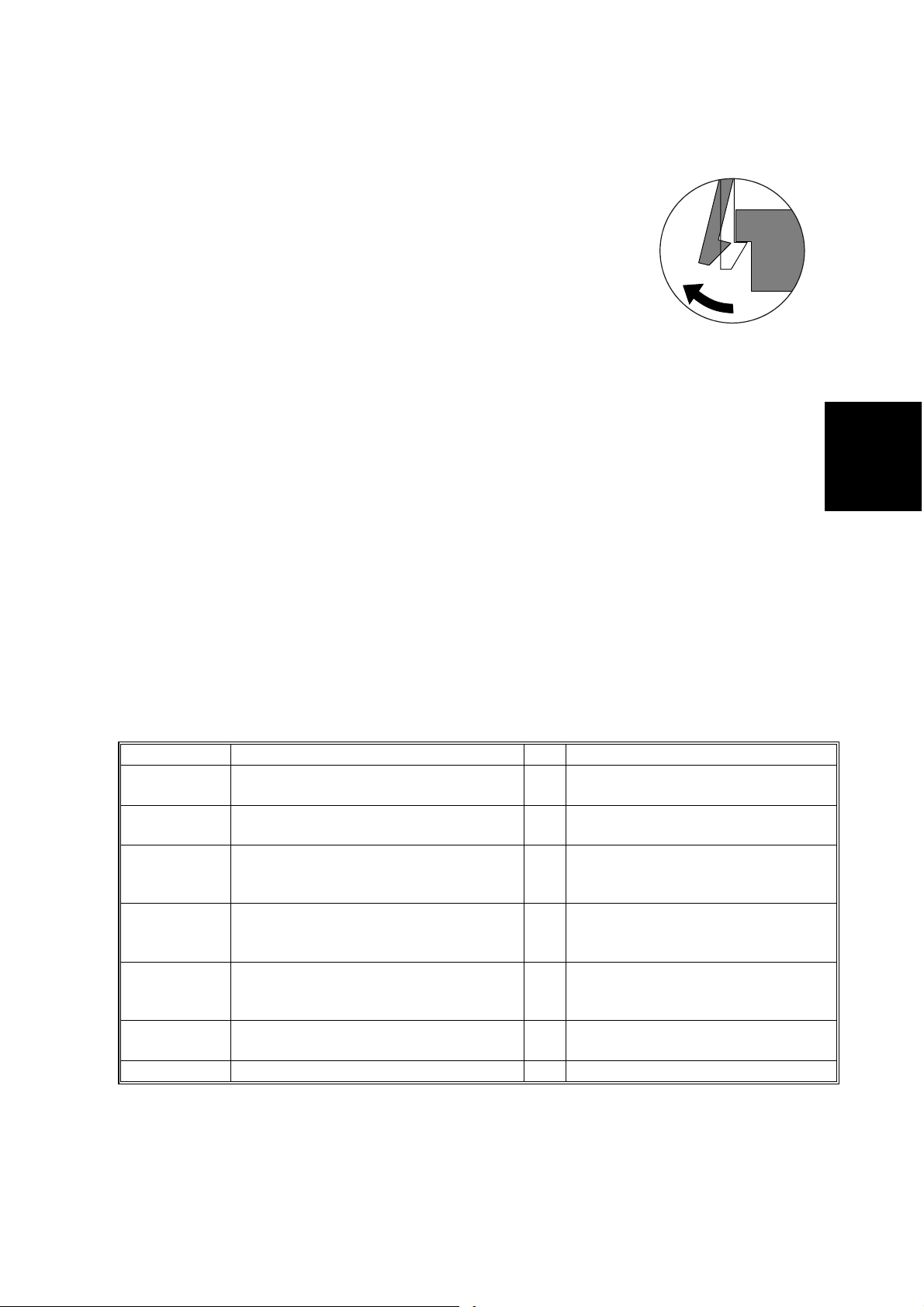

3.1.2 RELEASING PLASTIC LATCHES [ALL MODELS]

Many of the parts are held in place with plastic latches. The

latches break easily, so release them carefully.

To remove such parts, press the hook end of the latch away from

the part to which it is latched.

G094R513.WMF

3.1.3 AFTER SERVICING THE MACHINE [ALL MODELS]

1. Make sure all parts that require grounding are properly grounded.

2. Make sure the interlock switch is functioning.

3. Do not leave unused parts inside the machine.

4. Do not leave any tools inside the machine.

5. Make sure all wires are properly connected and routed.

6. Make sure wires are not jammed between parts of the machine.

7. Print a configuration sheet to verify machine operation. (See Printer Reference

Guide for procedure.)

3.2 SPECIAL TOOLS

Part Number Description Q’ty Remarks

N8036701 Flash Memory (PCMCIA) Card - 4MB 1

N8031000 Flash Memory (PCMCIA) Card Case 1

B6456700 PCMCIA Card Adapter 1

A0069104 Scanner Positioning Pin (4 pieces/set) 1

B6455010 SD Card Kit (64MB) 1

B6456800 USB Reader/Writer 1

G0219350 Loop Back Connector 1 Used in common with other printers.

Used in common with other printers.

(Use with G094/G095/G091)

Used in common with other printers.

(Use with G094/G095/G091)

Used to allow SD card download/

upload via a PCMCIA card slot.

(Use with G112/G113/G116)

Used for LD Unit positioning. Used

in common with the G073 series

and other models.

Used for service activities (firmware

update, etc.). (Use with G112/G113/

G116)

For use with SD Card Kit (Use with

G112/G113/G116)

Adjustment

Replacement

SM 3-3 G112/G113/G116/G094/G095/G091

COVERS

3.3 COVERS

3.3.1 FRONT COVER [ALL MODELS]

To open the front cover, gently push the

cover inward (2 hooks).

3.3.2 UPPER COVER [G112 SERIES]

NOTE: Remove the exit guide plate

after you have removed the

upper cover.

[A]

G094R514.WMF

[B]

[C]

Open the front cover and rear cover

(3 clamps, 2 harnesses). Then

remove the AIO.

[A]: Operation panel (2 hooks)

[B]: Open the exit guide plate

[C]: Upper cover ( x 4)

NOTE: Remove the exit guide plate

after you have removed the

upper cover.

G094R201.WMF

G112/G113/G116/G094/G095/G091 3-4 SM

COVERS

3.3.3 UPPER COVER [G116 SERIES]

Open the front cover and rear cover

(3 clamps, 2 harnesses). Then

[A]

remove the AIO.

[A]: Operation panel (2 hooks)

[B]: Upper exit cover

[C]: Open the exit guide plate.

[D]: Upper cover ( x4)

3.3.4 BY-PASS TRAY UNIT [ALL MODELS]

[D]

[B]

[C]

G091R201.WMF

Adjustment

Replacement

NOTE: Remove the by-pass tray unit before removing the exterior covers.

[A]: By-pass tray unit (2 hooks)

[A]

G094R006.WMF

SM 3-5 G112/G113/G116/G094/G095/G091

COVERS

3.3.5 EXTERIOR COVERS [G112 SERIES]

NOTE: Pull out the standard paper tray before removing the front cover.

To remove the left or right cover, separate the machine from the optional paper tray

unit first.

[B]

[A]

G094R515.WMF

[A]: Left cover ( x 2)

[B]: Front cover (3 clamps, x 2)

G094R001.WMF

[C]: Right cover (3 hooks, 1 fan cover)

3.3.6 EXTERIOR COVERS [G116 SERIES]

NOTE: Pull out the standard paper tray before removing the front cover.

[A]

G091R702.WMF

To remove the left or right cover, separate the machine from the optional paper

tray unit first.

[B]

G091R703.WMF

[C]

[C]

Open the front cover.

[A]: Left cover ( x 2)

[B]: Front Cover (3 clamps, x 2)

[C]: Right cover (3 hooks)

G112/G113/G116/G094/G095/G091 3-6 SM

LASER UNIT

3.4 LASER UNIT

WARNING

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section. Laser beams can cause serious eye

damage.

3.4.1 CAUTION DECAL LOCATIONS [ALL MODELS]

G094R516.WMF

Adjustment

Replacement

G094R517.WMF

SM 3-7 G112/G113/G116/G094/G095/G091

LASER UNIT

3.4.2 POLYGON MIRROR MOTOR [ALL MODELS]

WARNING

Turn off the main switch and unplug the machine before attempting any of

the procedures in this section. Laser beams can seriously damage your

eyes.

NOTE: Do not touch the surface of the mirror with bare hands.

Operation panel ( 3.3.2)

Upper cover ([G094/G095] 3.3.2,

[G091] 3.3.3)

[A]: Polygon mirror cover ( x 2)

[B]: Polygon mirror motor ( x 4,

x 1)

[A]

[B]

G094R518.WMF

3.4.3 LASER SYNCHRONIZATION DETECTOR [ALL MODELS]

Operation panel ( 3.3.2)

Upper cover ([G094/G095] 3.3.2,

[G091] 3.3.3)

By-pass tray unit ( 3.3.4)

Exterior covers ([G094/G095] 3.3.5,

[G091] 3.3.6)

[A]: Laser synchronization detector

( x 1)

[A]

G094R519.WMF

G112/G113/G116/G094/G095/G091 3-8 SM

LASER UNIT

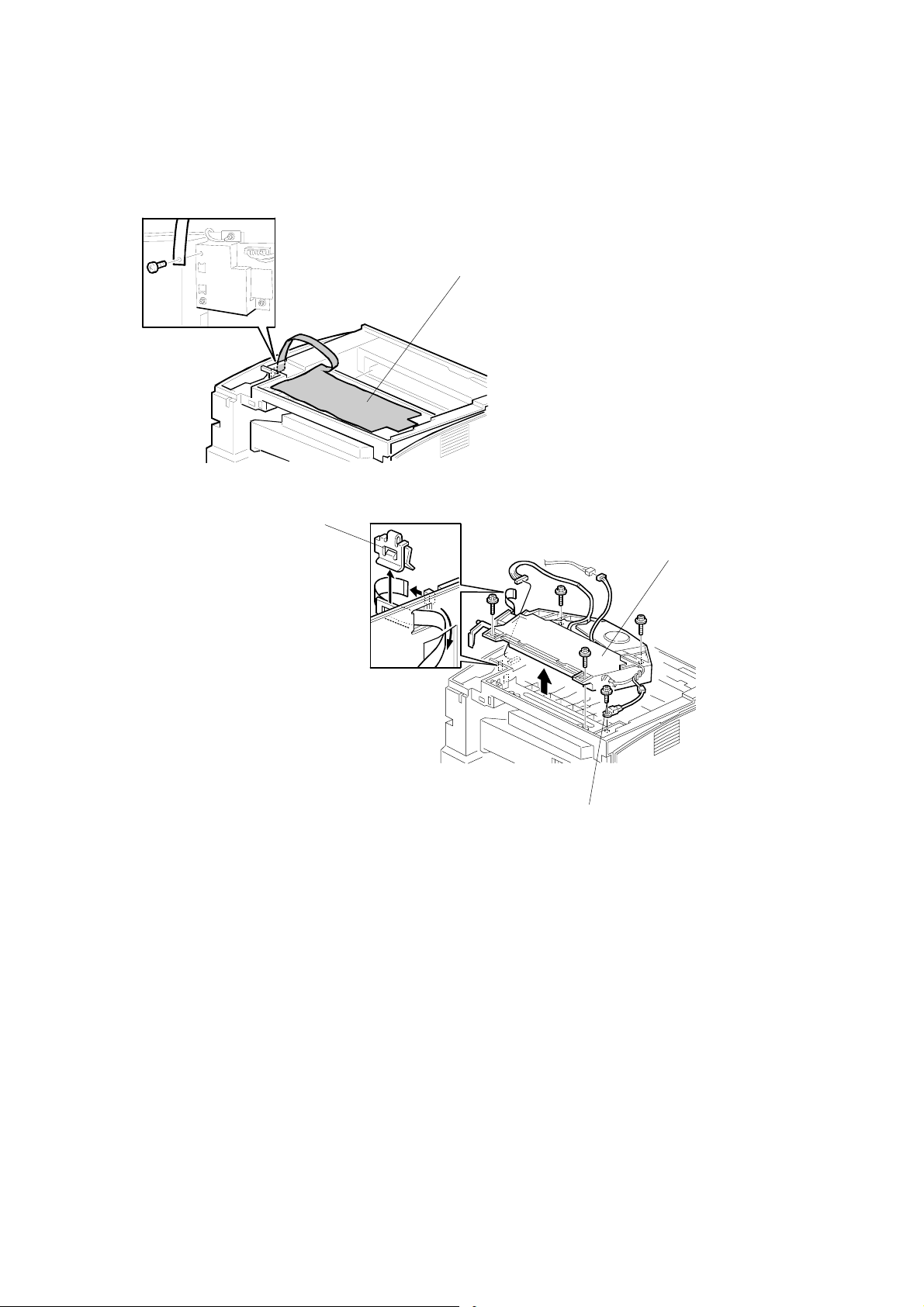

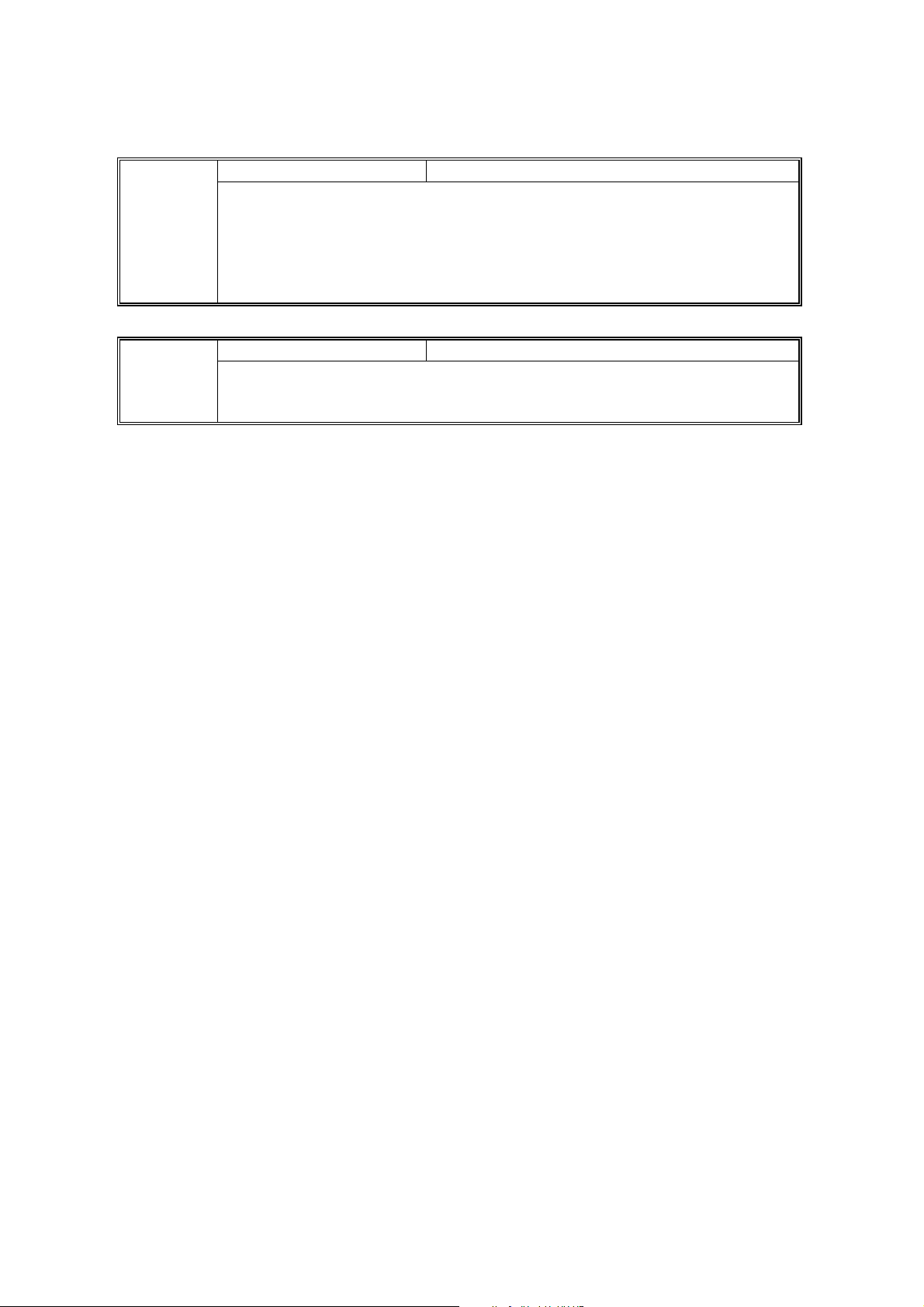

3.4.4 LASER UNIT [G112 SERIES]

Upper cover ([G112 Series] 3.3.2, [G116 Series] 3.3.3)

Exterior covers ([G112 Series] 3.3.5, [G116 Series] 3.3.6)

[A]: Clip

[B]: Laser unit ( x 4, 1 flat cable, x

2)

When reinstalling the laser unit.

Use the scanner positioning pins

(P/N: A0069104) to reinstall the

unit.

[C]: Set the positioning pins as

shown above. Then secure the

laser unit.

[A]

[C]

[B]

Adjustment

Replacement

SM 3-9 G112/G113/G116/G094/G095/G091

G094R521.WMF

LASER UNIT

3.4.5 LASER UNIT [G116 SERIES]

[A]

G091R730.WMF

[C]

Operation panel ( 3.2 Exterior Covers)

Upper cover ( 3.2 Exterior Covers)

Left cover ( 3.2 Exterior Covers)

[A]: 230V machine only: Sheet ( x 1)

[B]: Thermistor ( x 1)

[C]: Clip

[D]: Laser unit ( x 4, 1 flat cable, x 2)

[D]

[B]

G091R203.WMF

G112/G113/G116/G094/G095/G091 3-10 SM

LASER UNIT

When reinstalling the laser unit

Use the scanner positioning pin (P/N: A0069104) to reinstall the unit.

[E]

G091R208.WMF

[E]: Set the positioning pins as shown above. Then secure the laser unit.

Adjustment

Replacement

SM 3-11 G112/G113/G116/G094/G095/G091

LASER UNIT

3.4.6 LASER DIODE UNIT [ALL MODELS]

[C]

[a]

[D]

G094R522.WMF

Laser Unit ( 3.4.4)

[A]: Spring

[B]: LD unit holders (x 2)

[C]: Loosen the screw ( NOTE 1 below)

[D]: Nut

[E]: LD unit

NOTE:

1) Do not remove the screws that secure the LD board.

2) Do not touch any variable resistors on the LD board.

[A]

[B]

[E]

When re-installing the LD unit:

Tighten the screw [C] until the unpainted portion of the screw [a] is not visible.

After installing the LD unit, perform the Laser Beam Pitch Adjustment ( 3.4.7).

G112/G113/G116/G094/G095/G091 3-12 SM

LASER UNIT

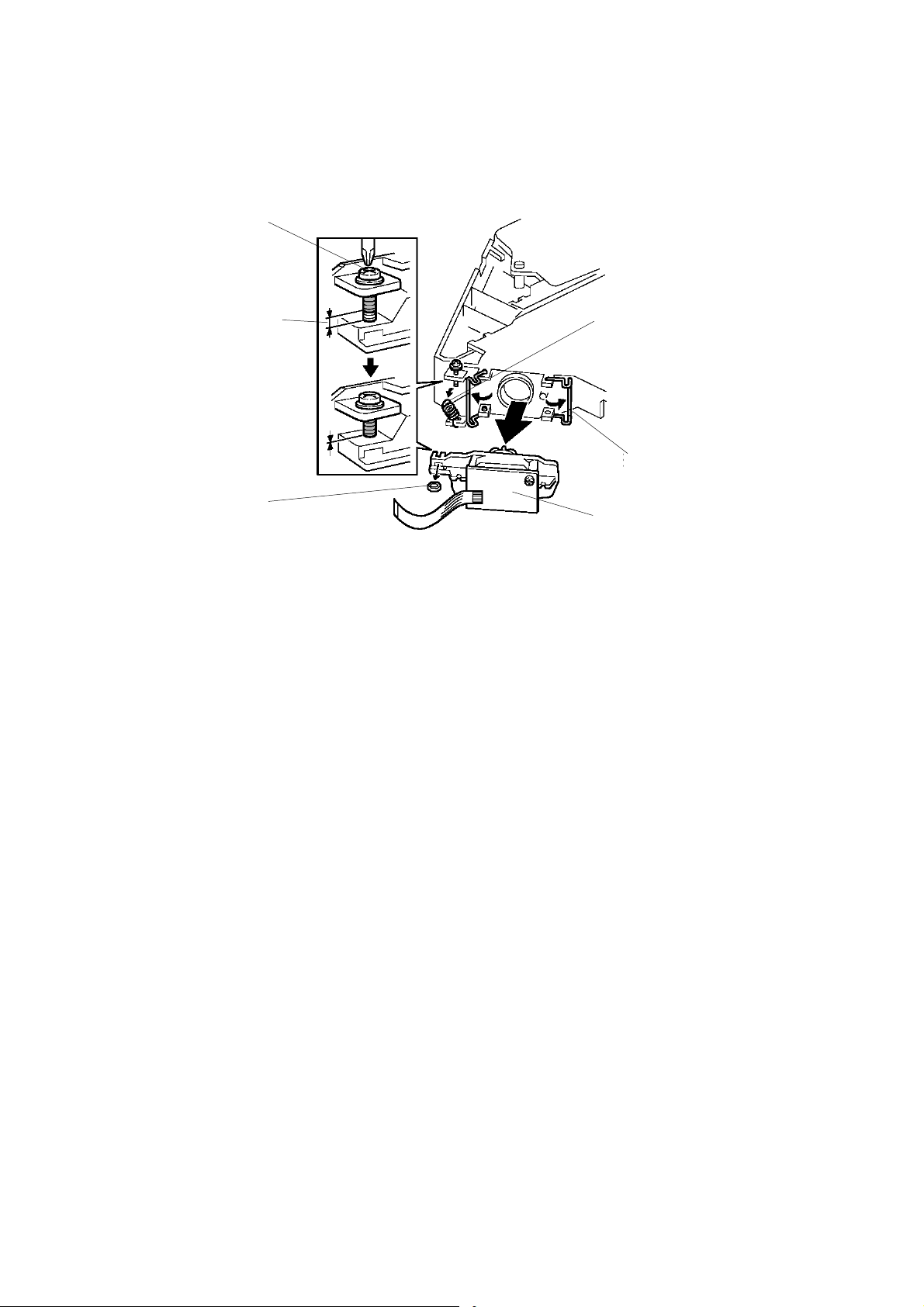

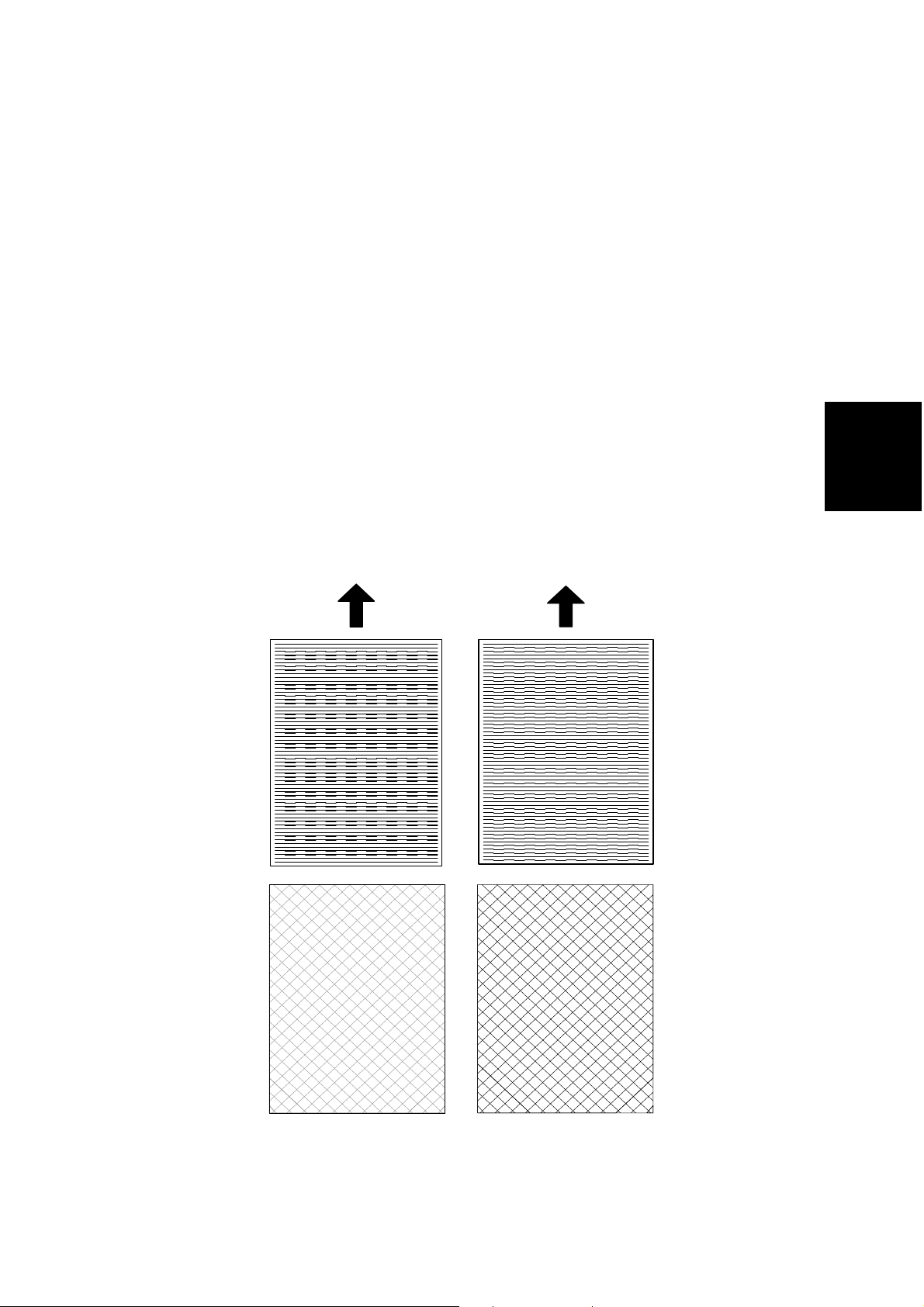

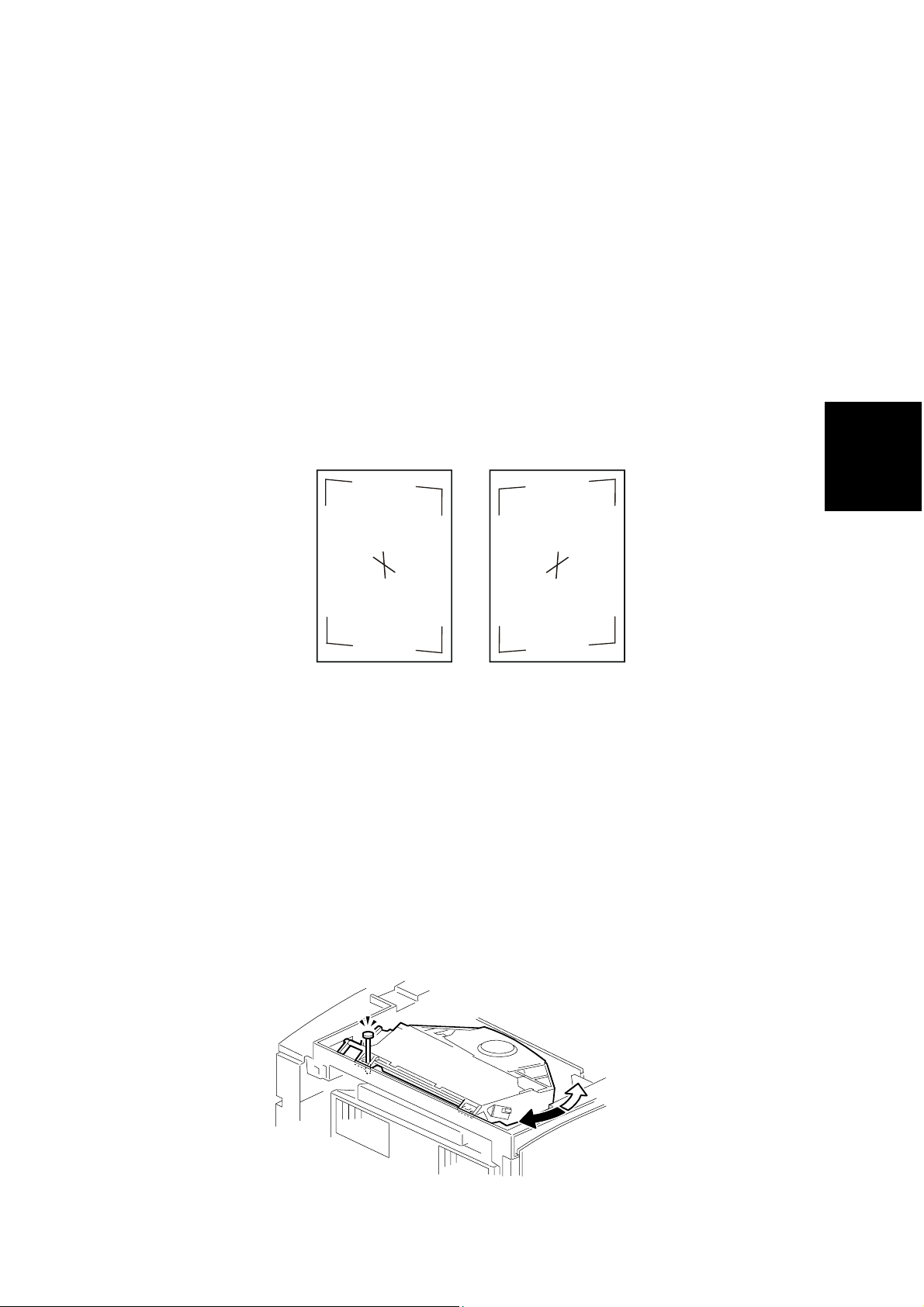

3.4.7 LASER BEAM PITCH ADJUSTMENT [ALL MODELS]

1. Print out the following test patterns – cross-stitch pattern and two-dot argyle

pattern.

• Select the test pattern with SP 2902.

• After selecting a pattern, the display automatically goes to SP 5902. Use SP

5902-1 to print one test pattern.

• After completing the adjustment, reset SP 2902 to ‘no specified’.

2. Check these test patterns. If the laser beam pitch is not correct, the images are

as follows.

• Cross-stitch pattern: Vertical black strips seem to appear.

• Argyle pattern: The density of the diagonal lines is light or the lines have

disappeared.

3. Adjust the LD unit holder position: Tighten or loosen the screw [C] (see the

previous page) until the printout appears as follows.

• Cross-stitch pattern: The thin lines are of uniform thickness (no striping effect

should appear on the printout).

• Grid pattern: The diagonal lines appear clearly and are of normal density.

Adjustment

Replacement

G094R523.WMF

SM 3-13 G112/G113/G116/G094/G095/G091

Adjustment not complete

Adjustment complete

TRANSFER ROLLER [ALL MODELS]

3.5 TRANSFER ROLLER [ALL MODELS]

NOTE: Do not touch the transfer roller surface.

Remove the AIO cartridge before removing the transfer roller

[A]: Transfer roller

[A]

3.6 TONER END SENSOR [ALL MODELS]

Remove the AIO cartridge before removing the transfer roller

[A]: Toner end sensor (4 hooks,

x 1)

[A]

G094R524.WMF

G094R525.WMF

G112/G113/G116/G094/G095/G091 3-14 SM

FUSING

3.7 FUSING

CAUTION

Allow time for the unit to cool before doing the following procedure.

3.7.1 FUSING UNIT [ALL MODELS]

NOTE: Lift both hooks before attempting to remove the fusing unit from the

machine.

[A]: Rear cover

[B]: Fusing unit (2 hooks [C])

[B]

[C]

[A]

Adjustment

Replacement

G094R007.WMF

SM 3-15 G112/G113/G116/G094/G095/G091

FUSING

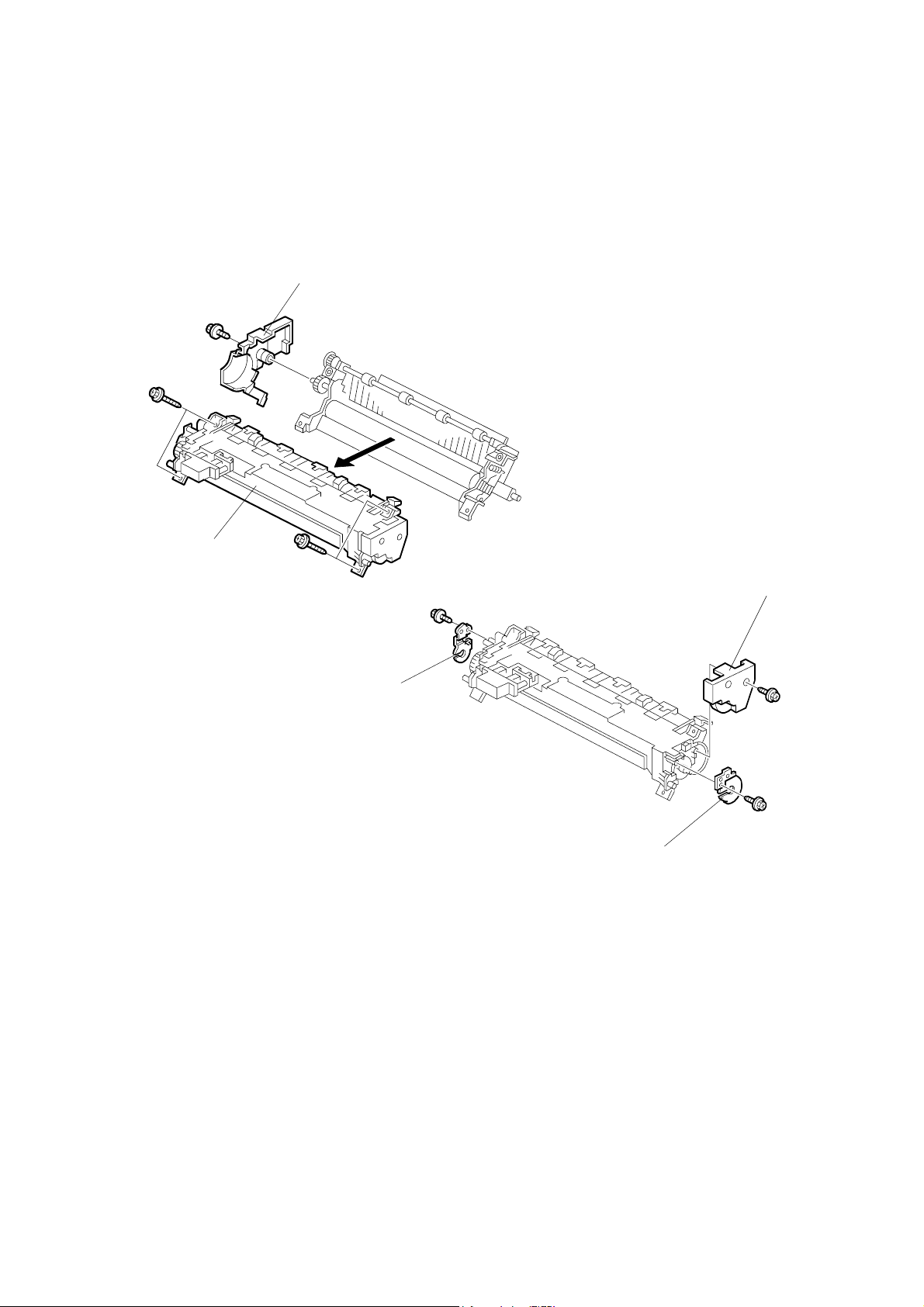

3.7.2 HOT ROLLER AND FUSING LAMP [ALL MODELS]

NOTE:

1) Remove both springs before taking apart the fusing unit assembly. This

will relieve pressure on the unit.

2) When reinstalling the fusing unit assembly, install both springs last. This

will reset the springs back to their default position.

[A]

[B]

G094R008.WMF

[C]

[D]

Fusing Unit ( 3.7.1)

[A]: Left cover ( x 1)

[B]: Upper fusing unit assembly ( x 4, 2 springs)

[C]: Right cover ( x 1)

[D]: Lamp holders ( x 1 each)

(Procedure continued on next page)

G094R009.WMF

[D]

G112/G113/G116/G094/G095/G091 3-16 SM

FUSING

3.7.2 Hot Roller and Fusing Lamp continued

NOTE:

1) Take the gear and the pin off first, before removing the hot roller

from the unit.

2) Use a small screwdriver to separate the guide plate from the unit.

3) Before installing the new hot roller, peel off 3 cm (1 inch) from both

ends of the protective sheet on the new hot roller. Make sure to

remove the rest of the paper before starting the machine.

Adjustment

Replacement

[E]

G094R526.WMF

[E]: Fusing Lamp ( x 2)

NOTE: The colored cable must be at the hot roller gear side.

[F]: Guide plate (3 hooks)

[G]: Hot roller strippers (1 spring each)

[H]: Hot roller (2 C-rings, 1 gear, 2 bushings)

[H]

[F]

[G]

G094R003.WMF

SM 3-17 G112/G113/G116/G094/G095/G091

FUSING

3.7.3 PRESSURE ROLLER [ALL MODELS]

[D]

[C]

[B]

[A]

Fusing Unit ( 3.7.1)

Hot roller and fusing lamp ( 3.7.2)

[A]: Pressure roller

[B]: Bushing

[C]: Pressure roller lever

[D]: Spring

[D]

[C]

G094R012.WMF

[B]

G112/G113/G116/G094/G095/G091 3-18 SM

FUSING

3.7.4 THERMISTOR AND THERMOSTAT [ALL MODELS]

[E]

[C]

[D]

[B]

[A]

Adjustment

Replacement

G094R011.WMF

Hot roller and fusing lamp ( 3.7.2)

[A]: Wire cover ( x 1)

[B]: Grounding plate ( x 2, 1 wire)

[C]: Fusing unit connector ( x 6, x 1, 2 hooks)

[D]: Thermistor ( x 1, 1 harness)

[E]: Thermostat ( x 1)

NOTE:

1) When removing the thermistor, remove the entire unit first and then

separate it into two parts.

2) Do not touch the thermostat with your hands.

SM 3-19 G112/G113/G116/G094/G095/G091

FUSING

3.7.5 HOT ROLLER STRIPPERS [G112 SERIES]

[A]

G094R003.WMF

Hot roller and fusing lamp ( 3.7.2)

NOTE: Extra Hot Roller Strippers

1) Two extra hot roller strippers [A] are available for this machine. These

are used to provide a better grip for narrower paper. This helps prevent

paper from curling around the hot roller.

2) When installing the 2 extra hot roller strippers, insert them in the two

slots using a small pair of pliers until they snap into place.

G112/G113/G116/G094/G095/G091 3-20 SM

FUSING

3.7.6 HOT ROLLER STRIPPERS [G116 SERIES]

[A]

[B]

G091R510.WMF

Adjustment

Replacement

[C]

G091R505.WMF

[A]: Guide plate (3 hooks)

[B]: Hot roller strippers (1 spring each)

[C]: Hot roller (2 C-rings, 1 gear, 2 bushings).

NOTE: Before installing the new hot roller, peel off 3 cm (1 inch) from both ends of

the protective sheet on the new roller. Also, remove the rest of the paper

before starting the machine.

SM 3-21 G112/G113/G116/G094/G095/G091

PAPER FEED

3.8 PAPER FEED

3.8.1 PAPER FEED ROLLER [ALL MODELS]

NOTE: Pull out the paper tray before removing the paper feed roller.

[A]: Paper feed roller

3.8.2 FRICTION PAD [ALL MODELS]

[A]

G094R002.WMF

NOTE: Remove the paper tray unit from the machine before removing the friction

pad.

[A]: Friction pad (2 hooks, 1 spring)

[A]

When reinstalling the friction pad

follow this order

1. Replace the spring.

2. Insert the right side of the friction

pad first followed by the left side.

3. Gently push the friction pad

down into the slot and then pull

forward very slightly.

G094R010.WMF

G112/G113/G116/G094/G095/G091 3-22 SM

BY-PASS TRAY

3.9 BY-PASS TRAY

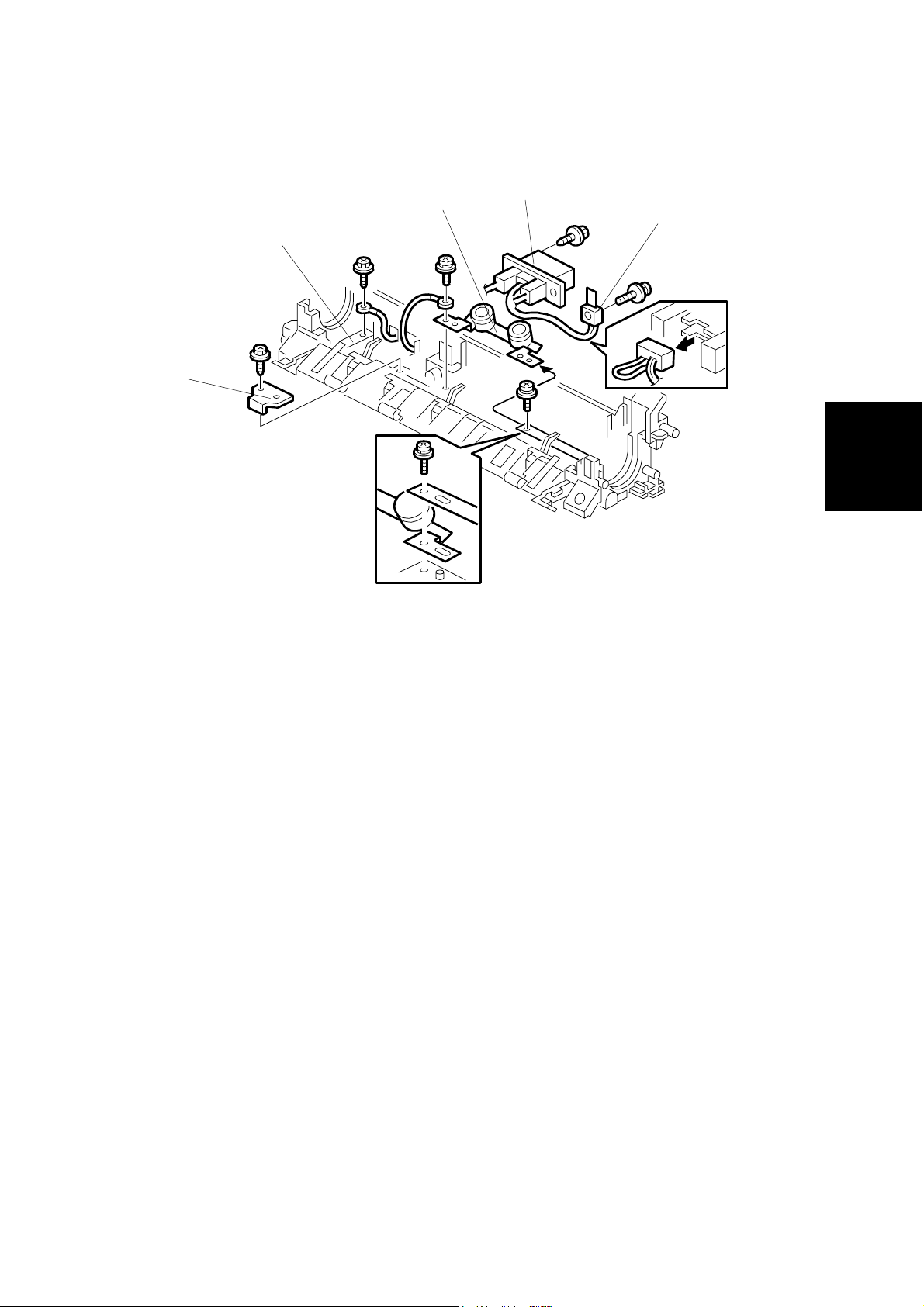

3.9.1 BY-PASS TRAY UNIT AND BY-PASS FEED ROLLER

[ALL MODELS]

[A]

[B]

[C]

G094R527.WMF

[E]

Left cover ([G112 Series] 3.3.5, [G116 Series] 3.3.6)

Front cover ([G112 Series] 3.3.5, [G116 Series] 3.3.6)

Remove the AIO

[A]: Paper guide ( x 2)

[B]: Actuator

[C]: Solenoid ( x 1)

[D]: By-pass feed roller

[E]: Gear (1 hook)

When reinstalling the paper guide.

1. Set the paper guide on the bushing.

2. Install the right side of the actuator on the paper guide.

3. Install the left side of the actuator in the machine.

[D]

G094R528.WMF

Adjustment

Replacement

4. Install the paper guide.

5. Check that the actuator moves smoothly and swings freely.

SM 3-23 G112/G113/G116/G094/G095/G091

PRINTER CONTROLLER BOARD [ALL MODELS]

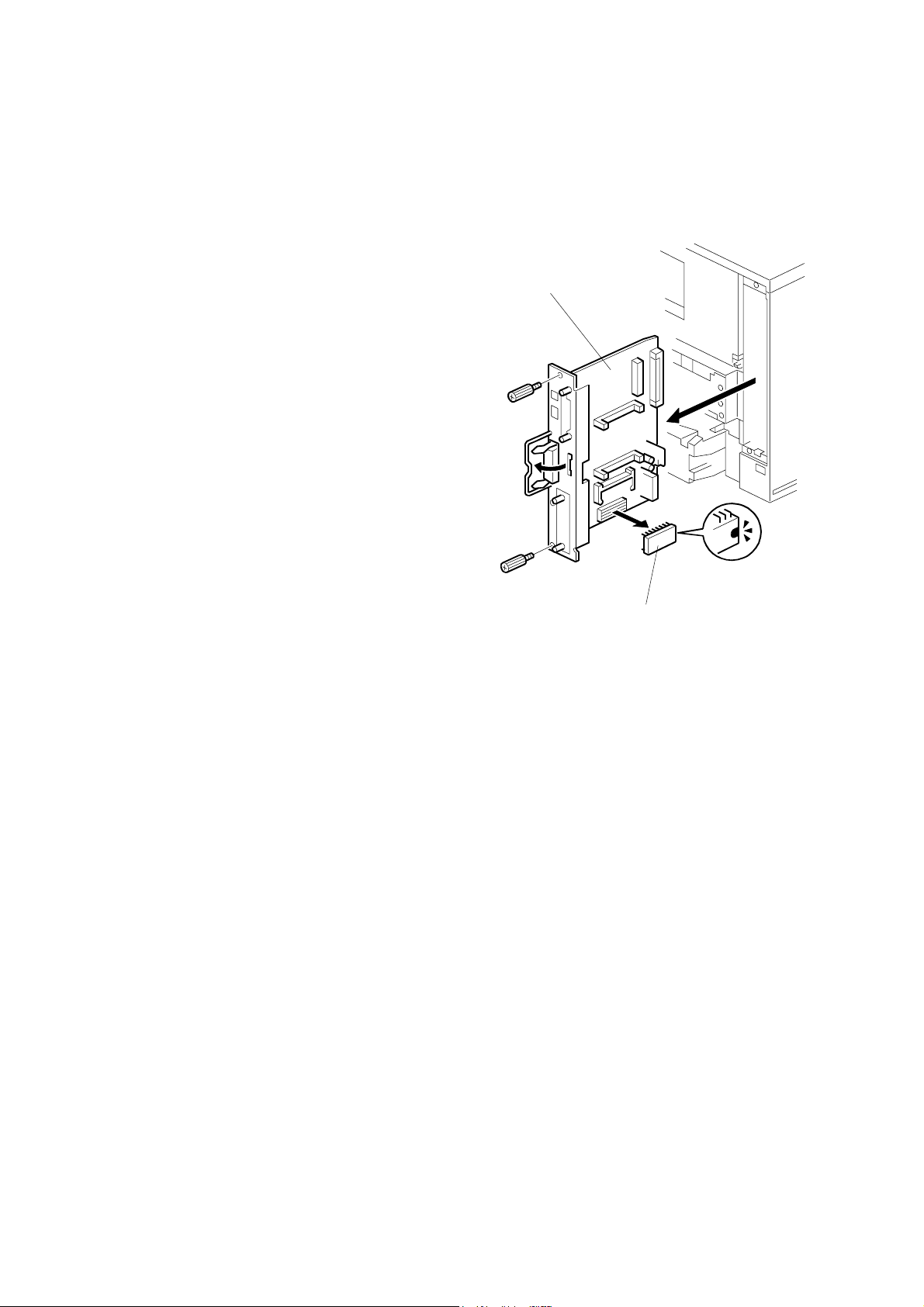

3.10 PRINTER CONTROLLER BOARD [ALL MODELS]

The board for the G112/G094 is different from the board for the G113/G095. Make

sure to install the correct board.

NOTE:

1) Remove the Duplex Unit before

you remove the controller

board. [G116/G091 machine

only]

2) The screws on the printer

controller board are hand

screws. Gently turn these

screws when removing the

printer control board.

3) Pull on the handle to remove

the printer controller board from

the machine.

[A]: Printer controller board ( x 2)

[B]: NVRAM

NOTE: Remove the NVRAM from the

old printer controller board

and insert it on the new board.

[A]

G094R005.WMF

[B]

G112/G113/G116/G094/G095/G091 3-24 SM

ENGINE BOARD [ALL MODELS]

3.11 ENGINE BOARD [ALL MODELS]

[B]

[C]

Adjustment

[A]

Replacement

G094R529.WMF

[D]

Left cover ([G112 Series] 3.3.5, [G116 Series] 3.3.6)

Printer controller board ( 3.10)

[A]: Bracket ( x 7, 1 grounding wire)

NOTE: Be careful not to damage the flat cable.

[B]: Clip

[C]: Engine board ( x 4, all connectors)

NOTE: Remove the NVRAM [D] from the old engine board and insert it on the

new board.

SM 3-25 G112/G113/G116/G094/G095/G091

MAIN MOTOR [ALL MODELS]

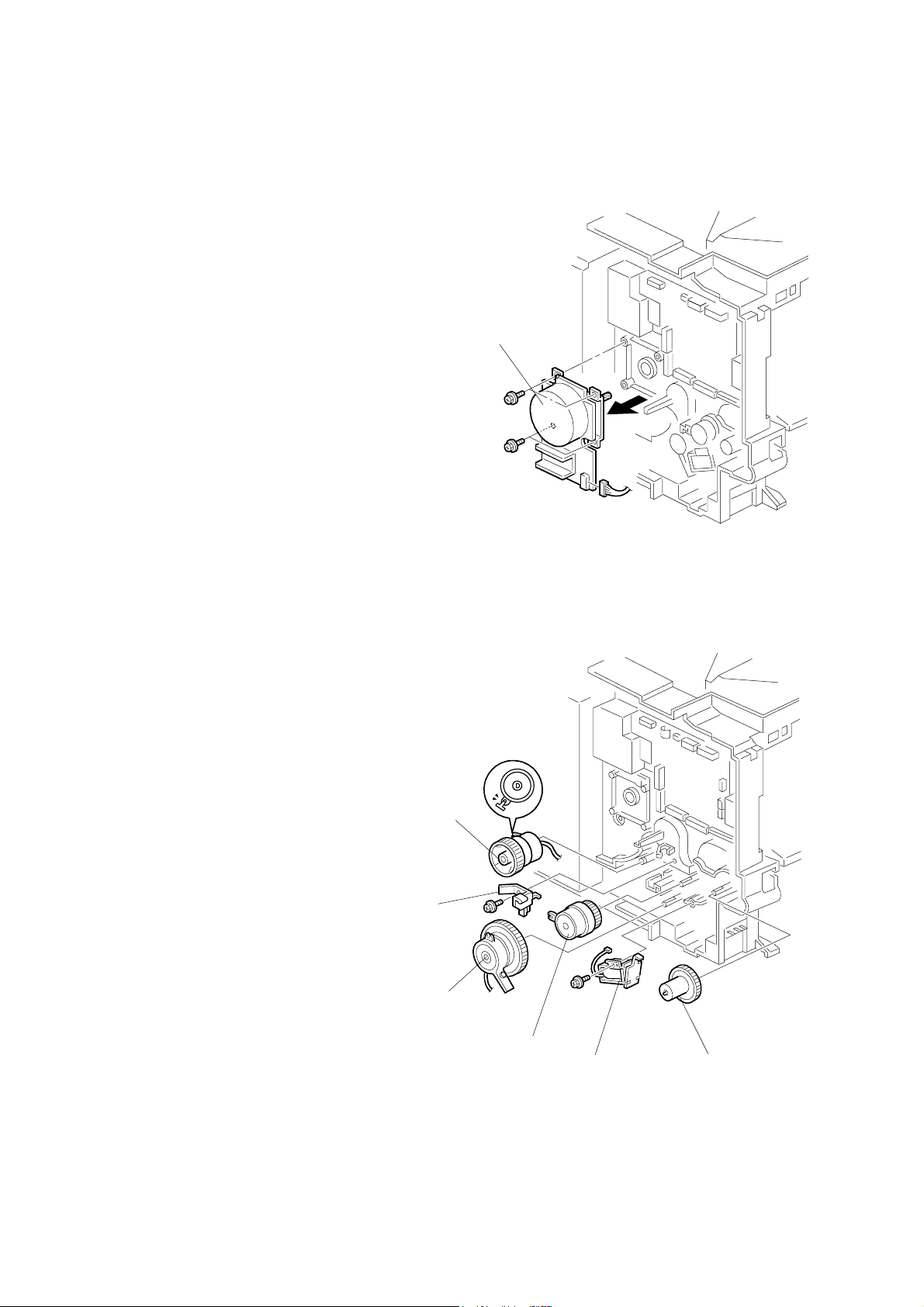

3.12 MAIN MOTOR [ALL MODELS]

Left cover ([G112 Series] 3.3.5, [G116

Series] 3.3.6)

[A]: Main motor ( x 4, x 1)

[A]

G094R530.WMF

3.13 SOLENOIDS AND CLUTCHES [ALL MODELS]

Left cover ([G094/G095] 3.3.5, [G091]

3.3.6)

[A]: By-pass feed solenoid

( x 1, x 1)

[B]: Gear (1 hook)

[C]: Stopper ( x 1)

[D]: Relay clutch ( x 1 x 1)

[E]: Paper feed clutch ( x 1)

Main motor ( 3.12)

[F]: Registration clutch

( x 1 x 1)

[F]

[C]

[E]

G094R531.WMF

[D]

[A]

G112/G113/G116/G094/G095/G091 3-26 SM

[B]

POWER SUPPLY BOARD AND HIGH VOLTAGE SUPPLY BOARD

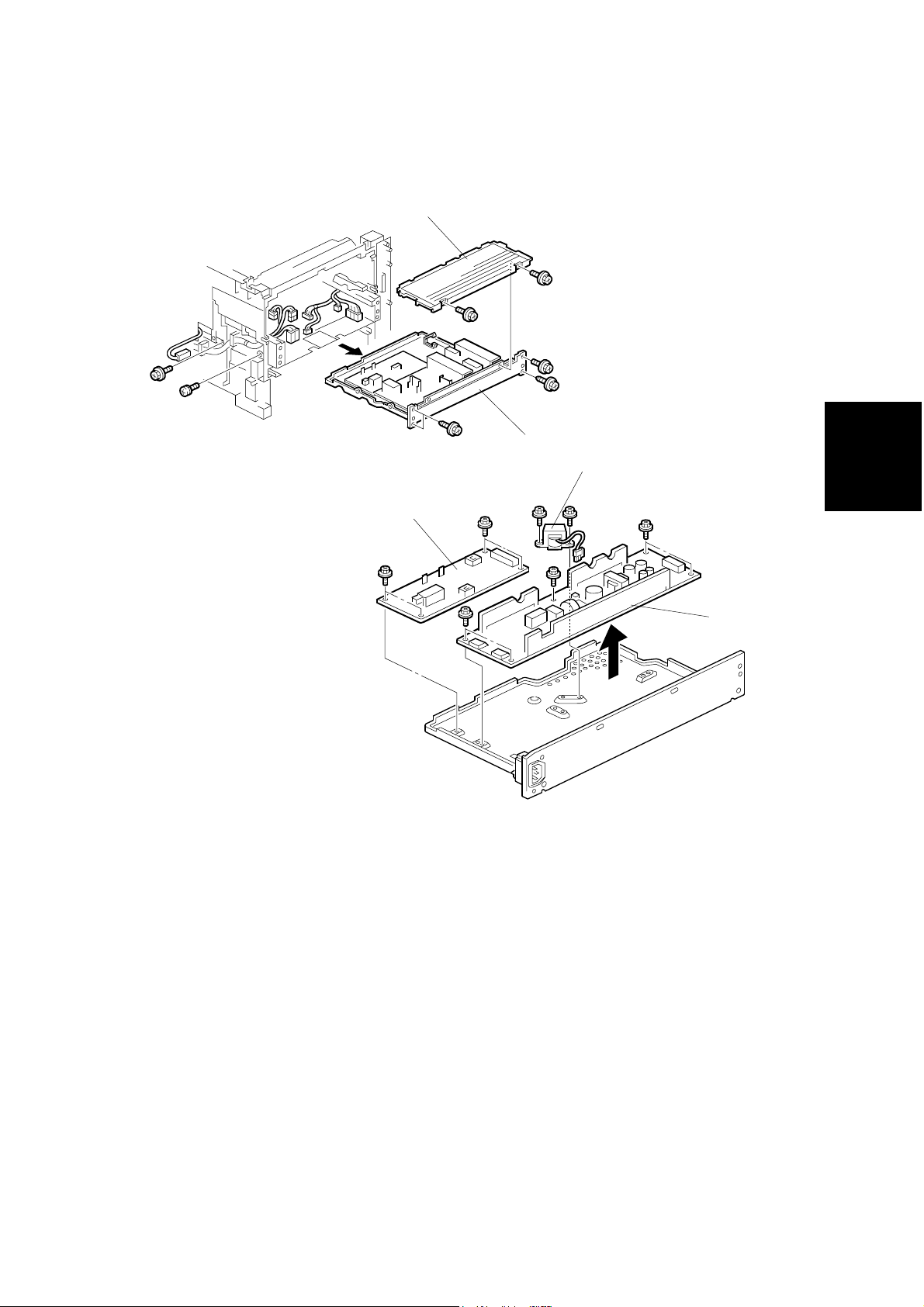

3.14 POWER SUPPLY BOARD AND HIGH VOLTAGE

SUPPLY BOARD

[ALL MODELS]

[A]

[B]

G094R004.WMF

[D]

Adjustment

Replacement

[C]

[E]

G094R532.WMF

Left cover ([G112 Series] 3.3.5, [G116 Series] 3.3.6)

Fusing unit ( 3.7.1)

[A]: PSU cover ( x 2)

[B]: PSU assembly ( x 7, all connectors)

[C]: High voltage supply board ( x 4)

[D]: 230-volt machine only: Choke coil ( x 2 x 1)

[E]: PSU ( x 5)

SM 3-27 G112/G113/G116/G094/G095/G091

COOLING FAN [ALL MODELS]

3.15 COOLING FAN [ALL MODELS]

NOTE: The cooling fan must be reinstalled to the original position. Do not reinstall

the cooling fan opposite to the original position.

Right cover ([G112 Series] 3.3.5, [G116 Series] 3.3.6)

[A]

[A]: Cooling fan ( x 1, x1)

G094R501.WMF

G112/G113/G116/G094/G095/G091 3-28 SM

IMAGE ADJUSTMENT

3.16 IMAGE ADJUSTMENT

3.16.1 REGISTRATION ADJUSTMENT [ALL MODELS]

The image registration is adjusted using the User Program Mode menu

“Maintenance-Registration”. See the Printer Reference guide, “Making Printer

Settings with the Control Panel-Maintenance Menu” for more details.

3.16.2 PARALELLOGRAM IMAGE ADJUSTMENT

[ALL MODELS]

If a parallelogram image (see example below) is printed while adjusting printing

registration, use the following procedure.

Examples of parallelogram images

Adjustment

Replacement

(a)

(b)

NOTE: Use the scanner positioning pin (P/N: A0069104) for the adjustment.

1. Remove the upper cover ([G112 Series] 3.3.2, [G116 Series] 3.3.3)

2. Put the positioning pin into one of the two positioning holes on the laser unit,

depending upon the image adjustment required.

3. Loosen the four screws and move the laser unit.

4. Tighten the laser unit.

5. Print the trimming area pattern to check the image alignment. If a parallelogram

still exists, repeat steps 3 to 5 until image squareness is achieved. (If you

cannot achieve image squareness using one positioning hole, try repeating this

procedure using the other positioning hole.)

G094R533.WMF

SM 3-29 G112/G113/G116/G094/G095/G091

TROUBLESHOOTING

SERVICE CALL CONDITIONS

4. TROUBLESHOOTING

4.1 SERVICE CALL CONDITIONS

NOTE: SC codes that are not the same for all models are shown in the left side

margin. If no model-specific identifier is present in the left side margin,

assume that code applies to all models.

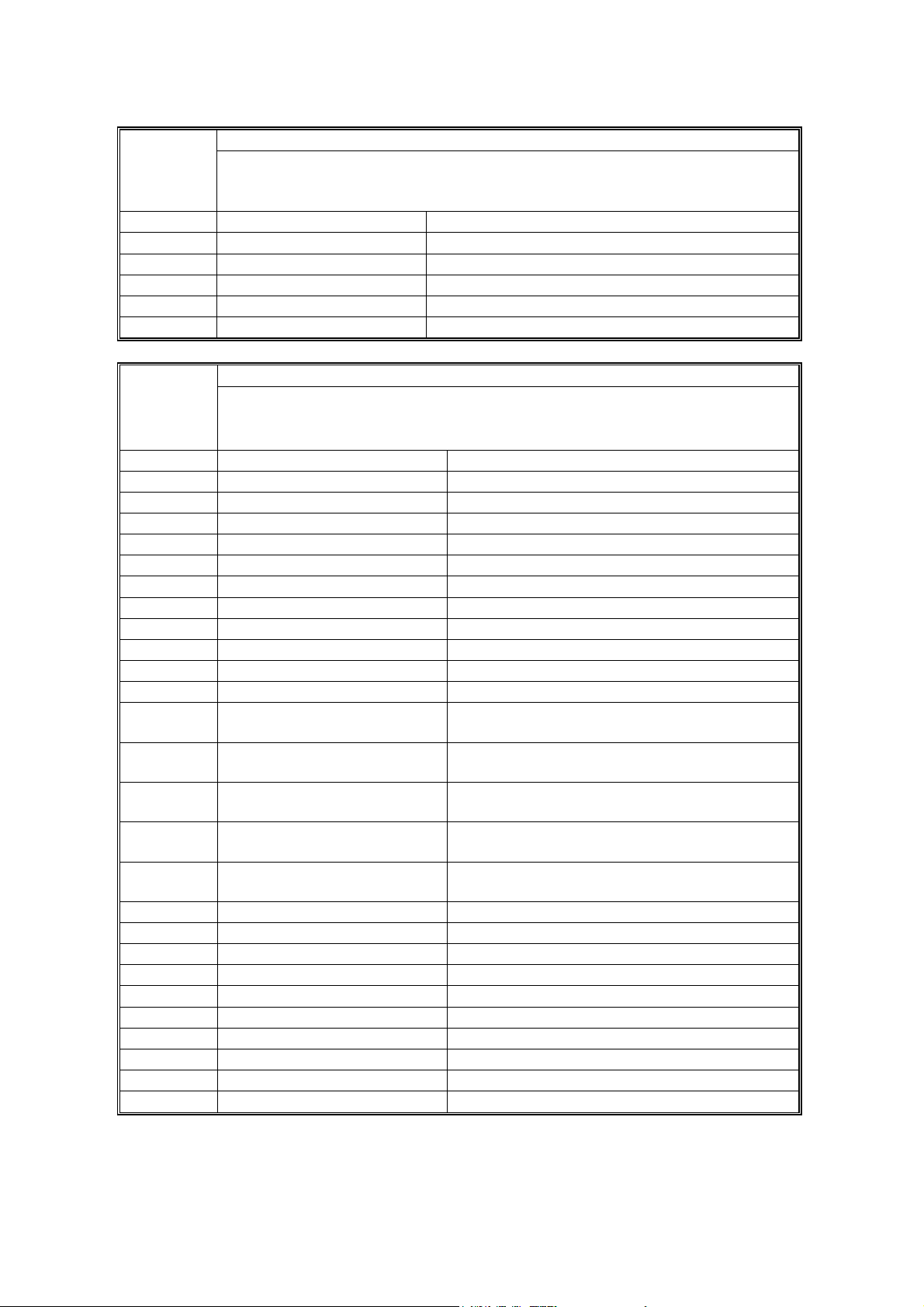

4.1.1 SUMMARY

There are 2 levels of service call conditions.

Level Definition Reset Procedure

A

B

Only a service representative can reset

this SC. This will prevent damage to the

machine.

The machine cannot be used.

The SC can be reset by turning the

operation switch off and on (if the SC was

caused by a sensor error).

Enter engine SP mode 5810

and press “#”. When ‘execute’

is displayed, press “#” again.

Then press ‘Escape’. Then

turn the main power off/on.

Switch the main power off and

on.

NOTE:

1) If the problem is with electrical circuit boards,disconnect the connectors

first. Then reconnect the connectors before you replace the PCBs.

2) If the problem is with a motor lock, first examine the mechanical load.

Then replace motors or sensors.

Trouble-

shooting

SM 4-1 G112/G113/G116/G094/G095/G091

SERVICE CALL CONDITIONS

4.1.2 SC CODE DESCRIPTIONS

Code No. Symptom Possible Cause

541 A

Charge roller current leak 302 B

A charge roller current leak signal is

detected.

Polygon motor error 320 B

The polygon motor does not reach its

operating speed within 10 seconds

after the polygon motor on signal, or

the lock signal is not detected for

more than a certain time during

operation.

1st laser synchronization error 322 B

The laser synchronization detector

cannot detect the laser

synchronization signal for more than

5 consecutive 100 ms intervals.

LD drive current exceeded 323 B

The LD driver detects this error for

more than 500 ms.

2nd laser synchronization error 326 B

st

The 1

LD1 is already on, but the

laser synchronization detector cannot

detect the laser synchronization

signal from the 2

nd

LD for more than 5

consecutive 100 ms intervals.

Development bias leak 391 B

A development bias leak signal is

detected.

Main motor lock 500 B

A main motor lock signal is not

detected for more than 700 ms after

the main motor starts to rotate, or the

lock signal is not detected for more

than a certain time during rotation

after the last signal.

Unstable fusing temperature

During warm-up, the fusing

temperature rises by less than 20 °C

during 11 seconds.

The fusing temperature detected by

the thermistor was 0 °C 5 seconds

after the fusing relay was turned on.

• Cartridge (charge roller) defective

• High voltage supply board

defective

• Defective cartridge connection

• Polygon motor

• Polygon motor cable

• Laser synchronization detector

board out of position

• Laser synchronization detector

board or cable defective

• Laser synchronization mirror out of

position

• LD unit defective

• Engine board defective

• LD unit defective

• Laser synchronization detector

board out of position

• LD unit defective

• Engine board defective

• High voltage supply board

defective

• Defective cartridge connection

• Main motor defective

• Too much load on the drive

mechanism

• Thermistor defective

• Fusing lamp open

• Fusing thermostat open

• Power supply board defective

• Defective connection of the fusing

unit

G112/G113/G116/G094/G095/G091 4-2 SM

SERVICE CALL CONDITIONS

Code No. Symptom Possible Cause

Fusing temperature warm-up error 542 A

The fusing temperature does not

reach more than 80 °C 17.5 seconds

after the main switch is turned on.

• Thermistor defective

• Fusing lamp open

• Fusing thermostat open

• Power supply board Defective

• Defective connection of the fusing

unit

543 A

Fusing overheat error

A fusing temperature of over 245 °C

is detected for 1 second by the fusing

• Fusing thermistor defective

• Power supply board defective

thermistor.

A fusing temperature of over 235 °C

is detected for 1 second after the

fusing lamp has been turned off.

The dual monitoring circuitry of the

BICU detects extremely high

temperature and tripped the relay

circuit off.

544

G091

Only

A

Fusing overheat error (hardware

circuit detection)

The dual monitoring circuitry of the

BICU detects extremely high

• Power supply unit defective

• I/O board (IOB) defective

• BICU defective

• Fusing thermistor defective

temperature and tripped the relay

circuit off.

546 A

Fusing lamp stays on 545 A

The fusing lamp stays on more than

12 seconds after the main motor has

been turned off.

Unstable fusing temperature

During standby, within 500 ms, the

fusing temperature goes below 60 °C

twice or over 60 °C three times.

Within 1 minute, a 60 °C increase or

• Fusing thermistor defective

• Power supply board defective

• Defective connection of the fusing

unit

• Fusing thermistor defective

• Power supply board defective

• Defective connection of the fusing

unit

decrease in fusing temperature is

detected during five different onesecond intervals.

590

G112

G113

G094

G095

Zero cross signal malfunction 547 B

Zero cross signals are not detected

within 5 seconds.

B

Fusing fan motor error

The CPU detects an exhaust fan lock

signal for more than 3.5 seconds.

The engine board cannot

communicate with the duplex unit.

• Power supply board defective

• Defective mains power supply

condition

• Poor connection of the exhaust fan

motor

• Too much load on the motor drive

Only

Communication error - duplex unit 610 B

The engine board cannot

communicate with the duplex unit.

• Defective connection between

engine board and duplex unit

• Engine board defective

• Duplex control board defective

Trouble-

shooting

SM 4-3 G112/G113/G116/G094/G095/G091

SERVICE CALL CONDITIONS

Code No. Symptom Possible Cause

Communication error - GAVD 650 B

• The engine board detects an

unknown device on the I

2

C I/F

• Engine board defective

bus (internal bus on the engine

control board).

2

• The engine board detects an I

C

I/F bus error.

651 B

Communication error - FCI

• Engine board defective

• The engine board detects an

unknown device on the IC I/F bus

(internal bus on the engine control

board).

• The engine board detects an IC I/F

bus error.

Tray shift did not finish within a

certain time after the shift motor

turned on.

The IPU does not respond with the

settings required to start memory

image processing.

Shift tray motor error 726

G091

only

B

Tray shift did not finish within a

certain time after the shift motor

• Shift motor defective

• Shift tray: Left shift sensor or right

shift sensor defective

turned on.

G112/G113/G116/G094/G095/G091 4-4 SM

CONTROLLER ERROR

4.2 CONTROLLER ERROR

The following table describes the controller error codes. These codes are displayed

at power-on, or after the power-on self test, if an error occurs.

Code Description Required Action

640

641

670 Engine response error

671

800 Video data error

818 System timeout error

819 Kernal end error

820 Controller CPU error

821 CPU and ASIC timer error

822 HDD timeout error

823 NIB self test error

824 NVRAM error

827 SDRAM error

828 Flash ROM error

829 Optional RAM error

835 Parallel interface error

836 Font ROM error

837 Optional font ROM error

838 Clock generator error

Engine to controller

communication error.

Engine to controller

communication error (no

answer).

Controller-to-operation panel

communication error at startup

• Examine the connection between the

controller and the engine board.

• Replace the engine board if the error is

frequent.

• Replace the controller if the error is frequent.

• Examine the connection between the

controller and the engine board.

• Replace the engine board if the error is

frequent.

• Engine board installed incorrectly

• Engine board defective

• Controller board defective

• Controller stalled

• Controller board installed incorrectly

• Controller board defective

• Operation panel connector loose or defective

• Examine the connection between the

controller and the engine board.

• Replace the engine board if the error is

frequent.

• Defective controller

• Replace the controller if it occurs frequently.

• HDD error

• Software application error

• RAM shortage

• Replace the controller if the error is frequent.

• Turn off the machine and turn it back on.

• Replace the controller if the error is frequent.

• Examine the connection between the HDD

and the controller

• Replace the HDD if the error is frequent.

• Turn off the machine and turn it back on.

• Examine the connection between the NIB

and the controller.

• Replace the NIB if the error is frequent.

• Replace the NVRAM if the error is frequent.

• Replace the controller if the error is frequent.

• Replace the controller if the error is frequent.

• Examine the connection of the optional

memory.

• Replace the optional memory if the error is

frequent.

• Replace the controller if the error is frequent.

• Not used for this model.

• Not used for this model.

• Replace the controller if the error is frequent.

Trouble-

shooting

SM 4-5 G112/G113/G116/G094/G095/G091

CONTROLLER ERROR

Code Description Required Action

850 NIB interface error

851 IEEE1394 interface error

853

Wireless LAN Error: Card Error 1

• Replace the controller if the error is frequent.

• Replace the controller if the error is frequent.

• Wireless LAN card not inserted into the

wireless LAN board

854

855

Wireless LAN Error: Card Error 2

Wireless LAN Error: Card Error 3

• Wireless LAN card has been removed

• Wireless LAN card defective

• Wireless card connection not tight

856

Wireless LAN Error 4: Board

• Wireless LAN card board defective

• PCI connector loose

857 USB I/F Error

• The USB driver can generate three types of

errors: RX, CRC, and STALL errors. Only the

STALL error can generate this SC code.

• Defective controller board

860

G116

G091

Only

862 HDD damaged cluster error

HDD start-up error

• Turn off the machine and turn it back on.

• Examine the connection between the HDD

and the controller.

• Replace the HDD if the error is frequent.

• Replace the HDD if the error is frequent.

863 HDD data unable to read

864 HDD data access error

865 HDD access error

900 Controller counter error

FGATE error 955

The IPU does not respond with

the settings required to start

• Replace the NVRAM if the error is frequent.

• Software bug; reboot the machine

• Internal parameter incorrect

• Insufficient working memory

memory image processing.

990 Software performance error

• Software defective; reboot the machine

• Internal parameter incorrect

• Insufficient working memory

• When this SC occurs, the file name, address,

and data will be stored in NVRAM.

Note the above data and the situation in which

this SC occurs. Then report the data and

conditions to your technical control center.

991 Software continuity error

• Software bug; reboot the machine

• Internal parameter incorrect

• Insufficient working memory

998 Application start error

• Software defective; change the firmware for

the application that failed

• An option required by the application (RAM,

DIMM, board) is not installed

999 Software update error

• Try downloading the controller software

again.

G112/G113/G116/G094/G095/G091 4-6 SM

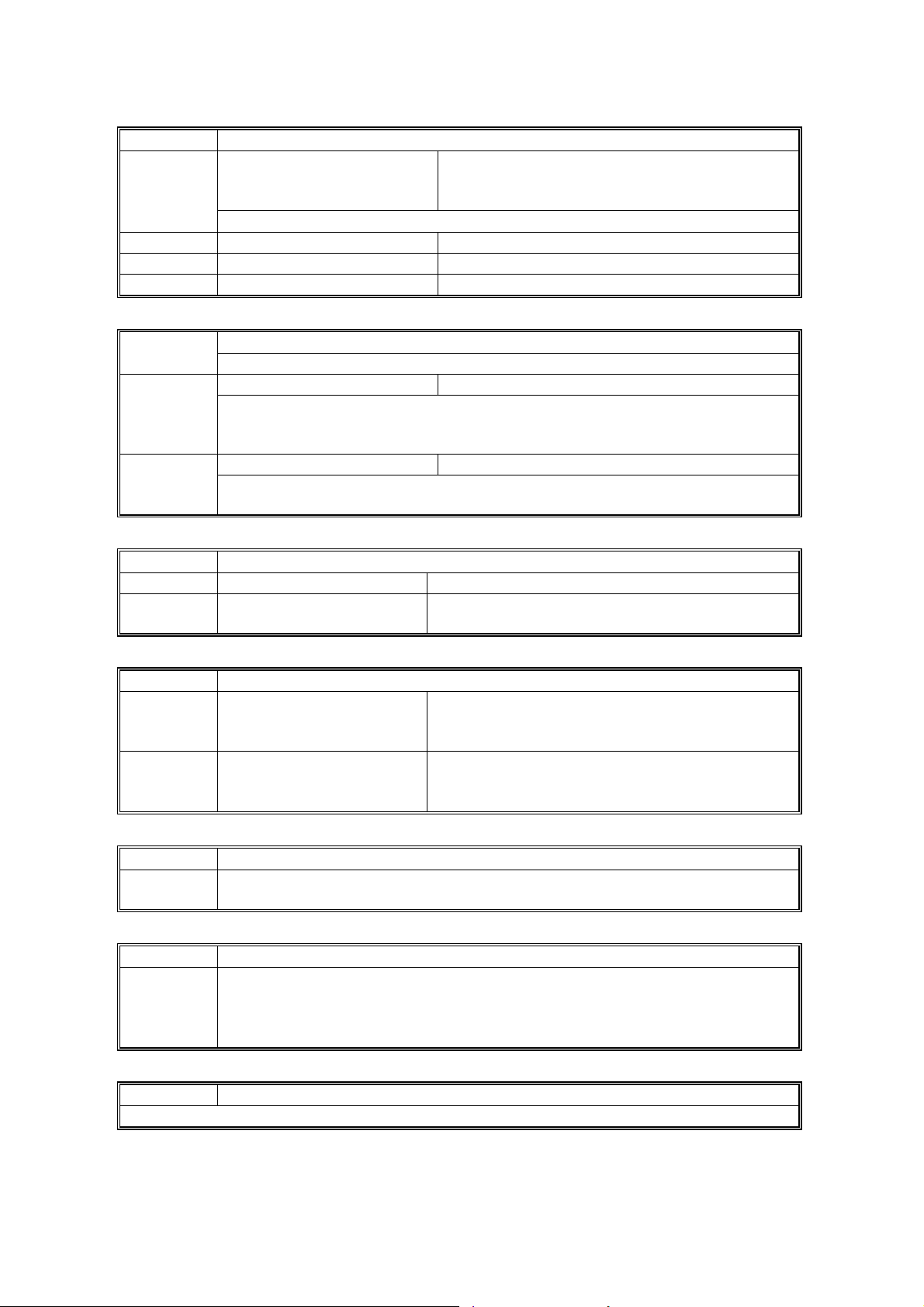

ELECTRICAL COMPONENT DEFECTS [ALL MODELS]

4.3 ELECTRICAL COMPONENT DEFECTS [ALL

MODELS]

4.3.1 SENSORS

Component CN Condition Symptom

Open

Paper Exit 6-B2

Shorted

Paper Overflow 6-B5

Registration 16-A2

Remaining paper

sensor 1

Remaining paper

sensor 2

Toner End 16-A12

16-A5

16-A8

Open

Shorted The paper overflow message is displayed.

Open

Shorted

Open

Shorted

Open

Shorted

High Toner near-end (toner end) is not detected.

Low The add toner message is displayed.

NOTE: The CN numbers describe the connector number on the engine board.

The Paper Jam indicator will light whenever

a print is made.

The Paper Jam indicator lights even if there

is no paper.

The paper overflow message is not

displayed even when a paper overflow

condition exists.

The Paper Jam indicator will light whenever

a print is made.

The Paper Jam indicator lights even if there

is no paper.

The Paper End indicator lights even if paper

is placed in the 1st paper tray.

The Paper End indicator does not light even

if there is no paper in the 1st paper tray.

The machine cannot determine the paper

near-end condition properly.

Trouble-

shooting

4.3.2 SWITCHES [ALL MODELS]

Component CN Condition Symptom

272-1,3

Main

Front Cover

Safety

Rear Cover

Safety

(PSU 120 V)

270-1,2

(PSU 230 V)

9-1

9-3

5-3

NOTE: The CN numbers describe the connector number on the engine board

(except for the main switch).

Open The machine does not turn on.

The machine does not turn off.

Shorted

Open

Shorted

Open

Shorted