Page 1

Operating Instructions Maintenance Guide 2

Introduction ........................................................................................................................... 3

Trademarks............................................................................................................................ 4

ENERGY STAR Program.................................................................................................... 5

How to Read This Manual.................................................................................................... 7

1.Paper and Other Media

Paper and Other Media Supported by This Printer.......................................................... 9

Paper Types and Sizes....................................................................................................................... 9

Loading Paper...................................................................................................................... 21

Loading Paper in Tray 1.................................................................................................................. 21

Loading Paper in Tray 2 and the Optional Paper Feed Unit........................................................... 22

Loading paper in Paper Bank PS470 (2000-sheet Large Capacity Tray) ....................................... 25

If you load a paper size that is not selected automatically.............................................................. 26

Changing the paper type.................................................................................................................. 28

Load Paper in the Bypass Tray........................................................................................................ 30

1

Page 2

Operating Instructions Maintenance Guide 2

2.Troubleshooting

Error & Status Messages on the Operation Panel ........................................................... 37

Printer Does Not Print ........................................................................................................ 55

Other Printing Problems .................................................................................................... 58

Removing Misfed Paper...................................................................................................... 64

Detaching the 2 Tray Finisher......................................................................................................... 64

Opening and Closing the Duplex Reversal Unit............................................................................. 65

When "Remove Misfeed A: Internal Path" Appears....................................................................... 67

When "Remove Misfeed B: Fusing Unit" Appears......................................................................... 68

When "Remove Misfeed W: Mailbox" Appears............................................................................. 70

When "Remove Misfeed R: Finisher" Appears............................................................................... 71

When "Remove Misfeed Y: Paper Tray" Appears.......................................................................... 74

When "Remove Misfeed: Duplex Unit" Appears........................................................................... 75

Removing Jammed Staples................................................................................................. 77

Adding Staples..................................................................................................................... 79

Removing Punch-hole Chips .............................................................................................. 82

2

INDEX.................................................................................................................................. 83

Page 3

Operating Instructions Maintenance Guide 2

Introduction

To get maximum versatility from this machine all operators should carefully read and follow the instructions in this manual. Please keep this manual in a handy place near the machine.

Please read the Safety Information in the "Printer Reference" before using this machine. It contains important information related to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS.

3

Page 4

Operating Instructions Maintenance Guide 2

Trademarks

Microsoft, Windows and Wi ndows NT are reg istered trademark s of Micros oft Corpo ration i n the Unit ed States and/or other countries.

PostScript is a registered trademark of Adobe Systems Incorporated.

PCL is a registered trademark of Hewlett-Packard Company.

IPS-PRINT Printer Language Emula ti on Co pyri ght 19 99- 2000, XIONICS DOCUMENT TECHNOL-

OGIES, INC., All Rights Reserved.

Ethernet is a registered trademark of Xerox Corporation.

Other product names used here in are f or i dent if ic at ion purposes only and might be trad emar ks of thei r

respective companies. We disclaim any and all rights in those marks.

Notes:

Some illustrations might be s lightly different from your machine.

Certain options might not be available in some countries. For details, please contact your local dealer.

Note

The proper names of the Windows operating systems are as follows:

• Microsoft

• Microsoft

• Microsoft

• Microsoft

• Microsoft

• Microsoft

• Microsoft

®

Windows® 95 operating system

®

Windows® 98 operating system

®

Windows® Millennium Edition (Windows Me)

®

Windows ® 2000 Professional

®

Windows ® 2000 Server

®

Windows NT® Server operating system Version 4.0

®

Windows NT® Workstation operating system Version 4.0

4

Page 5

Operating Instructions Maintenance Guide 2

ENERGY STAR Program

As an ENERGY STAR Partner, we have determined that this machine

model meets the ENERGY STAR Guidelines for energy efficiency.

The ENERGY STAR Guidelines intend to establish an international energy-saving system for developing and introducing energy-efficient office equipment to deal with environmental issues, such as global warming.

When a product meets the ENERGY STAR Guidelines for energy efficiency, the Partner shall place the ENERGY

STAR logo onto the machine model.

This product was designed to reduce the environmental impact associated with office equipment by means of energysaving features, such as Low-power mode.

5

❖❖❖❖ Low-power Mode (Energy Saver mode)

This printer aut omatically lower s its power con sumption 60 minu tes after th e last operat ion has been

completed. To exit Low-power (En ergy Save r) mode, pr ess an y key o n the ope rati on panel . For details about how to configure Energy Saver mode, see “Making Printer Settings with the Operation

Panel” in Administrator Reference 2 as a PDF file on the CD-ROM.

Page 6

Operating Instructions Maintenance Guide 2

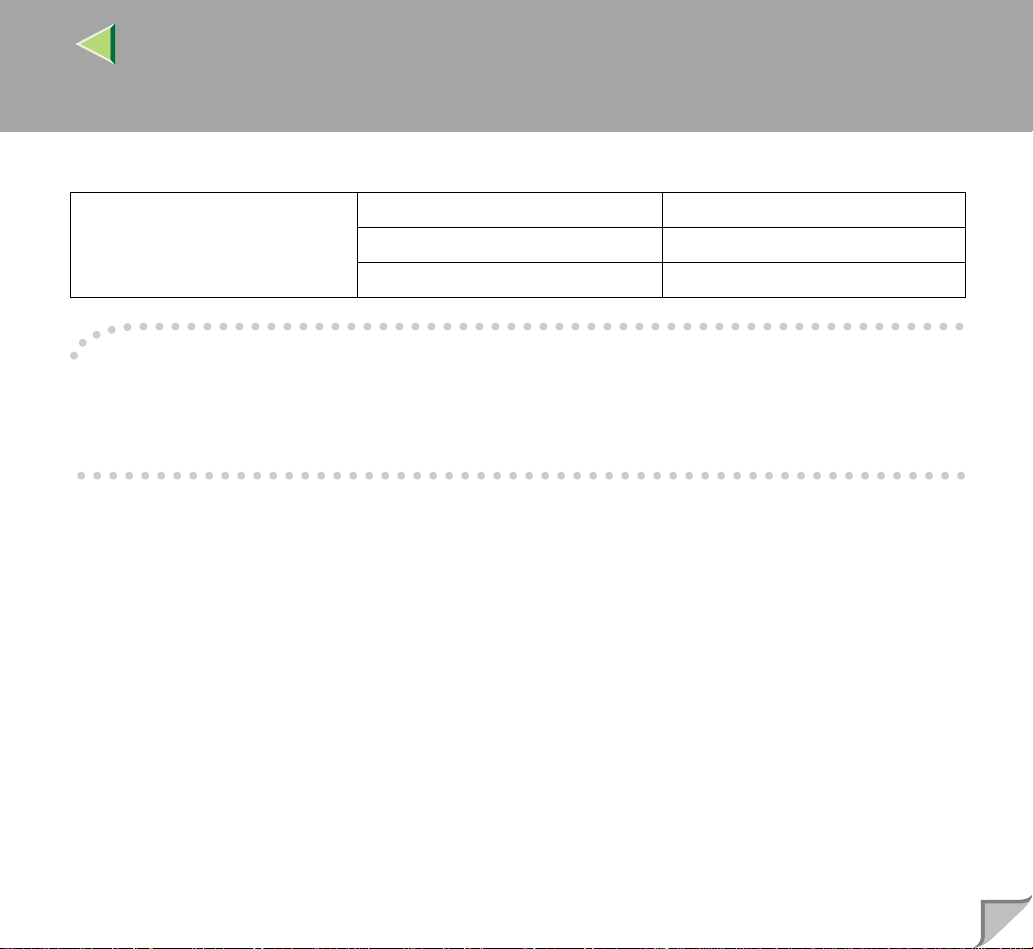

❖❖❖❖ Specifications

Energy Saver mo de Power Consum ption 45 W or less

Default Time 60 minutes

Recovery Time 120 seconds or less

----Recycled Paper

In accordance with the ENERGY STAR Program, we recommend use of recycled paper which is environment friendly. Please contact your sales or service representative for recommended paper.

6

Page 7

Operating Instructions Maintenance Guide 2

R

R

How to Read This Manual

Symbols

In this manual, the following symbols are used:

WARNING:

This symbol indicates a potentially hazardous situation which, if instructions are not followed, could

result in death or serious injury.

CAUTION:

This symbol indicates a potentially hazardous situation which, if instructions are not followed, may result in minor or moderate injury or damage to property.

* The statements above are notes for your safety.

Important

If this instruction is not foll owed, pape r might be misf ed, origin als might be d amaged, or d ata might be

lost. Be sure to read this.

7

Preparation

This symbol indicates the prior knowledge or preparations required before operating.

Note

This symbol indicates precautions for operation, or actions to take after misoperation.

Limitation

This symbol indicates numerical limits, functions that cannot be used together, or conditions in which

a particular function cannot be used.

Page 8

Operating Instructions Maintenance Guide 2

Reference

This symbol indicates a reference.

[]

Keys that appear on the machine's panel display.

Keys and buttons that appear on the computer's display.

{}

Keys built into the machine's operation panel.

Keys on the computer's keyboard.

8

Page 9

Operating Instructions Maintenance Guide 2

1. Paper and Other Media

Paper and Other Media Supp orted by This Printer

Paper Types and Sizes

This section describes the type, size, feed direction , and maximum amou nt of paper that can be loaded

into each paper tray in this printer.

Note

❒ The following symbols and terminology are used to represent the feed direction.

In this manual On the panel display Paper feed direction

L ← (Feed direction)

K ← (Feed direction)

❒ Be careful of the paper feed direction. The direction is determined for each paper size.

A4 (210 x 297)

8 1/2 x 11

A4 (297 x 210)

11 x 8 1/2

Short-edge feed direction

Long-edge feed direction

9

Page 10

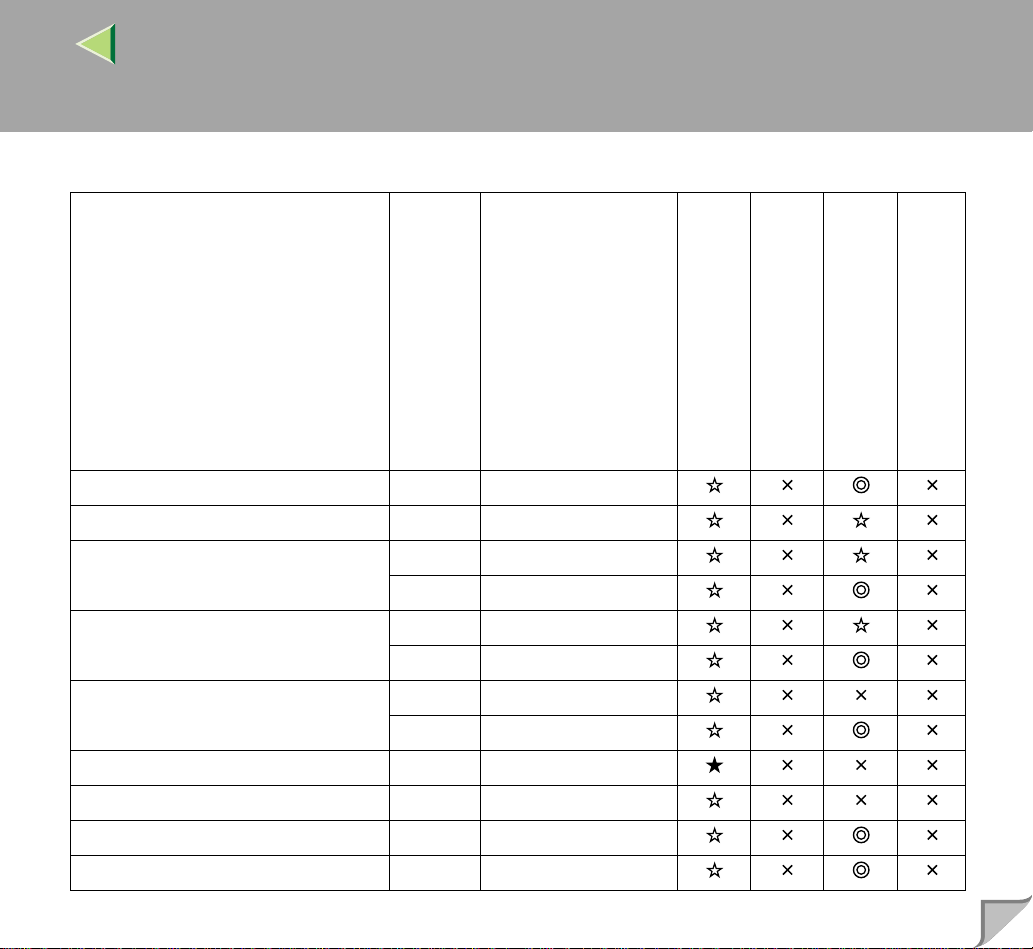

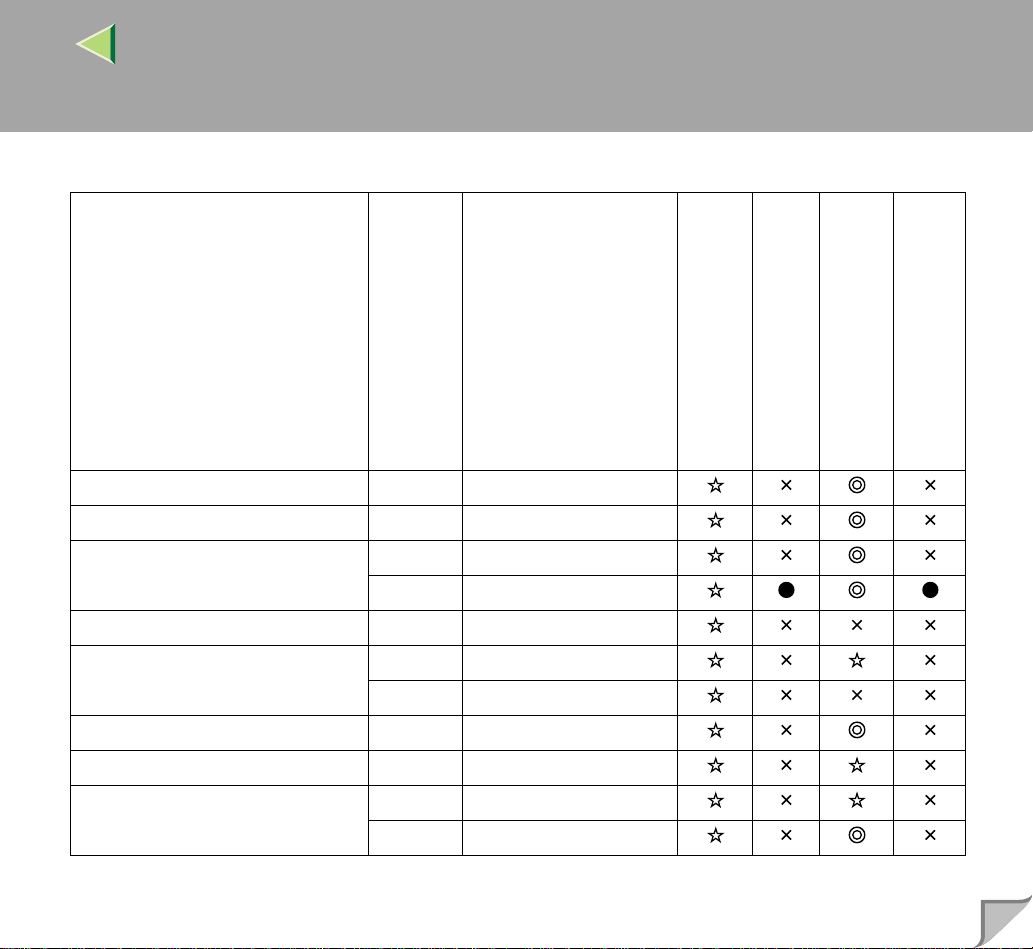

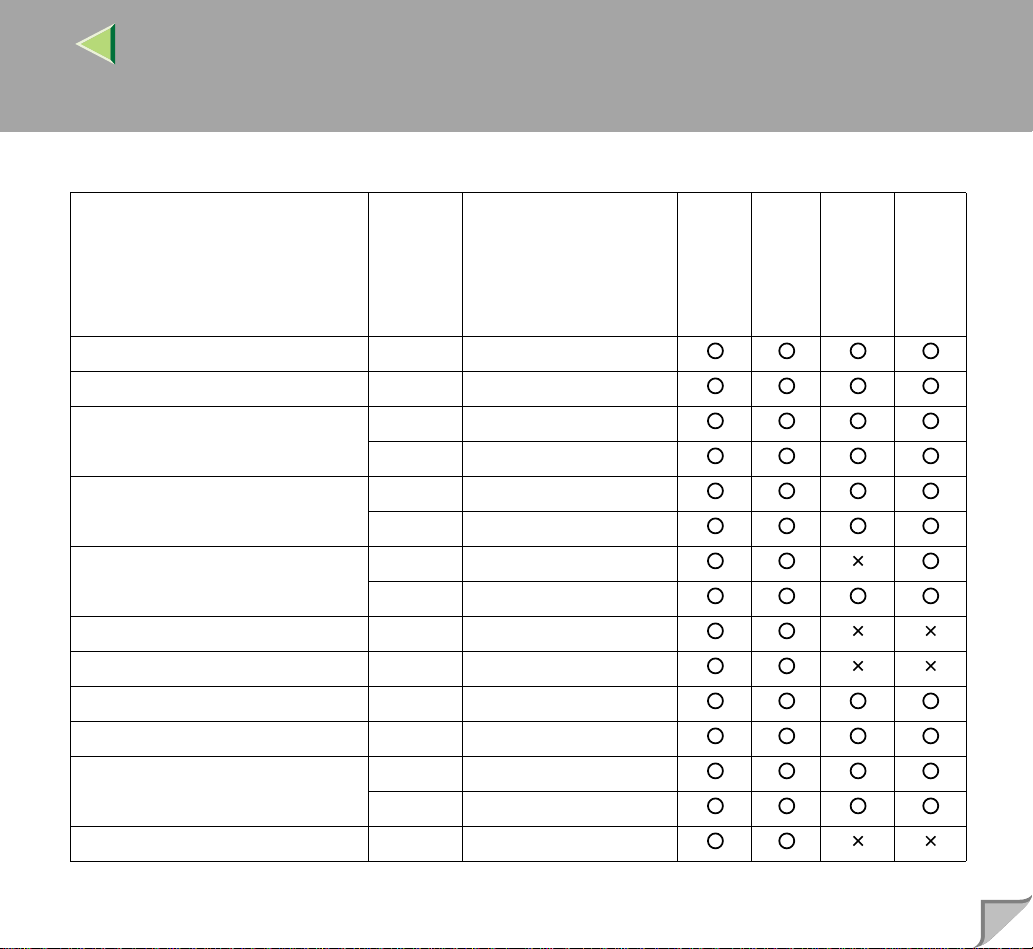

❖❖❖❖ Input Paper Sizes (Metric version)

Operating Instructions Maintenance Guide 2

10

Feed direction

A3 L 297 × 420

B4 JIS L 257 × 364

A4 L 210 × 297

K 297 × 210

B5 JIS L 182 × 257

K 257 × 182

A5 L 148 × 210

K 210 × 148

B6 JIS L 128 × 182

A6 L 105 × 148

Double Letter (DLT, 11" × 17") L 279 × 432

1

Legal (LG, 8

/2" × 14") L 216 × 356

Size (mm)

Bypass tray

Paper Tray (Tray 1)

Paper Feed Unit (Tray 2/3/4)

2000-sheet Large Capacity Tray

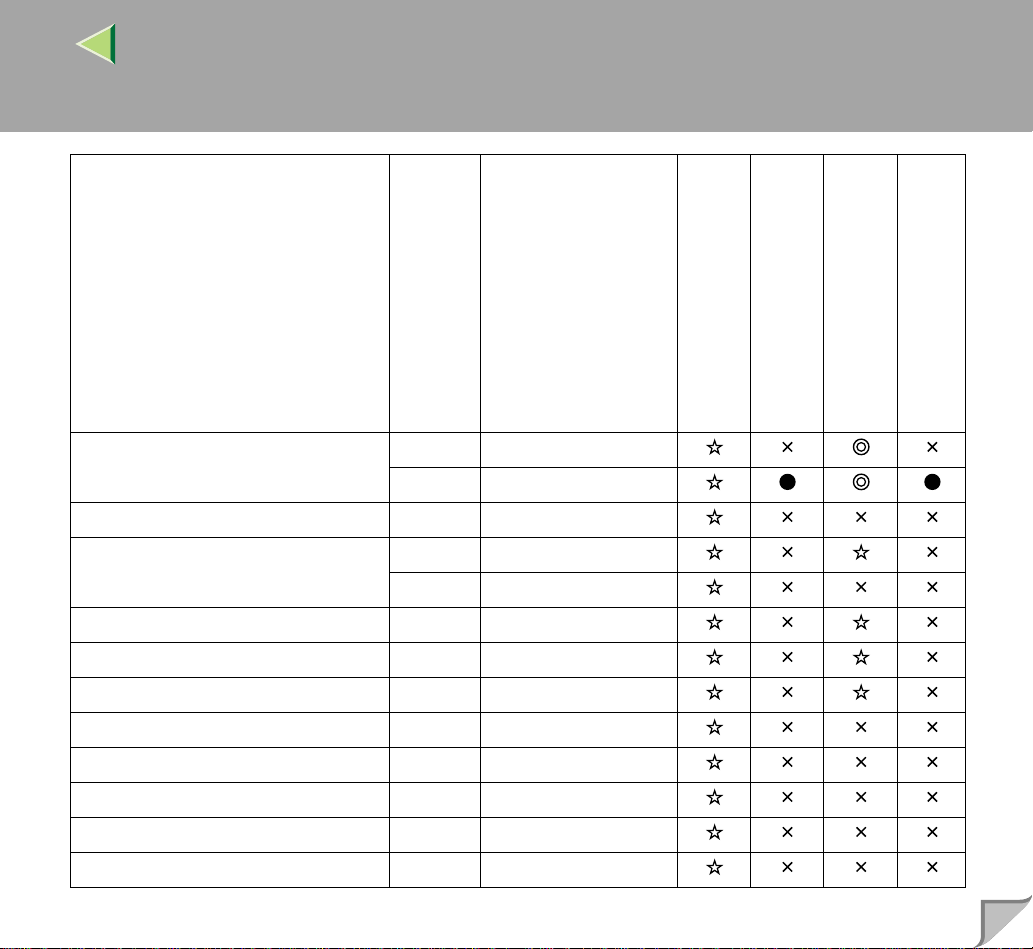

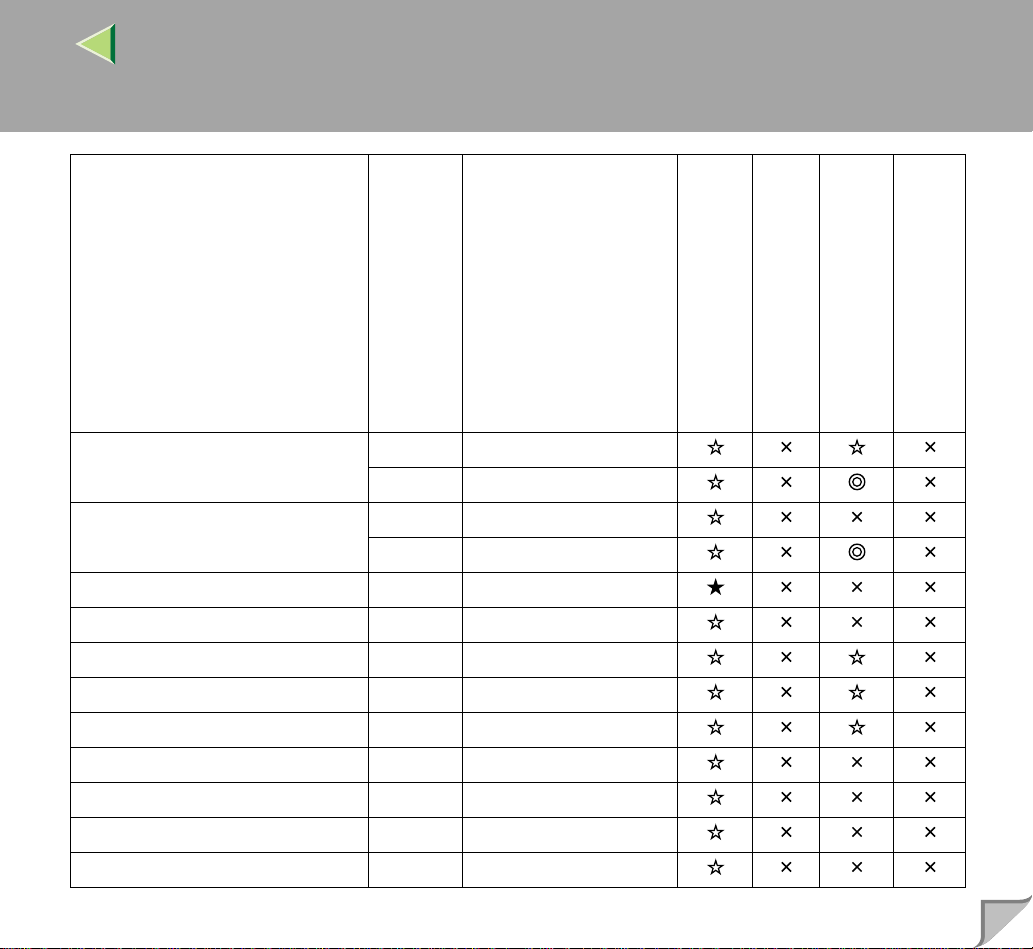

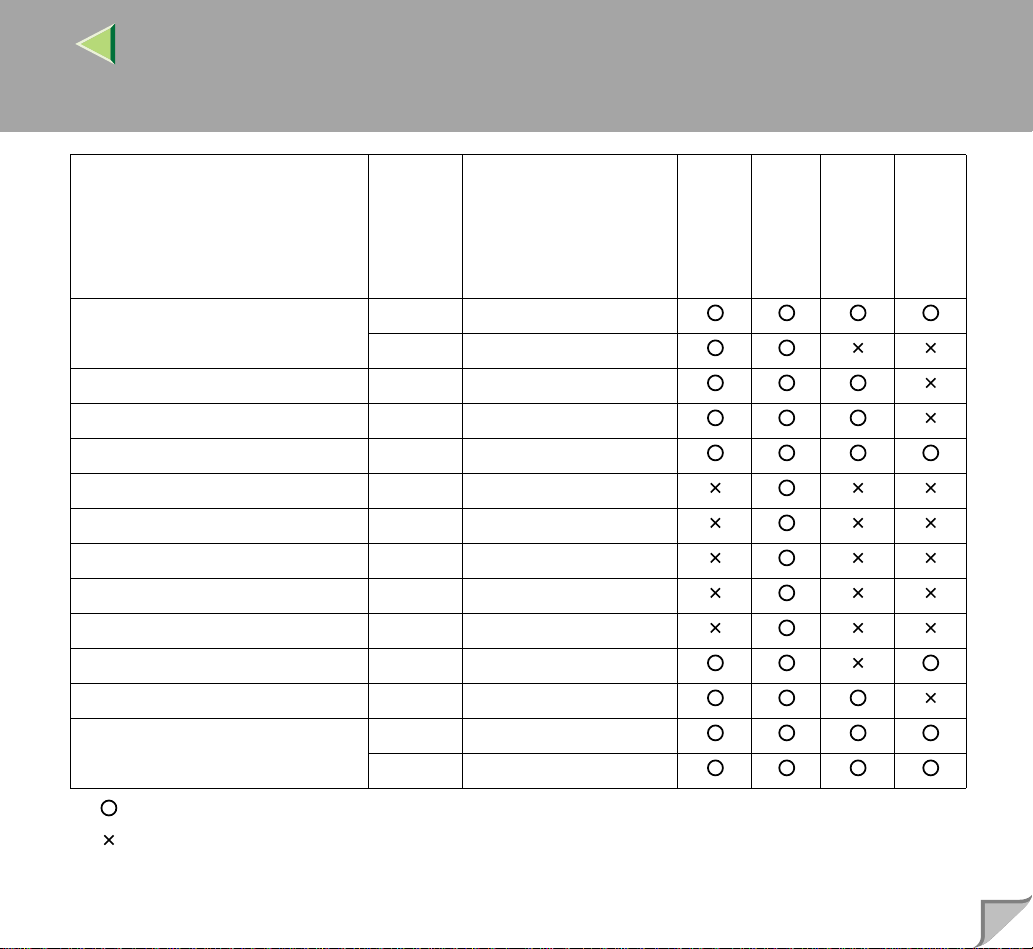

Page 11

Operating Instructions Maintenance Guide 2

11

Feed direction

Size (mm)

Letter (LT, 81/2" × 11") L 216 × 279

K 279 × 216

1

Half Letter (HLT, 5

Executive (Exec., 7

/2" × 81/2") L 140 × 216

1

/4" × 101/2") L 184 × 276

K 276 × 184

1

Folio (8

Foolscap (F4, 8

/4" × 13") L 210 × 330

1

/2" × 13") L 216 × 330

F/GL (8" × 13") L 203 × 330

Com#10 Env (4

1

/8" × 91/2") L 104.8 × 241.3

C5 Env (6.38" × 9.02") L 162 × 229

C6 Env (4.49" × 6.38") L 114 × 162

DL Env (4.33" × 8.66") L 110 × 220

Monarch Env (3

7

/8" × 71/2") L 98.4 × 190.5

Bypass tray

Paper Tray (Tray 1)

Paper Feed Unit (Tray 2/3/4)

2000-sheet Large Capacity Tray

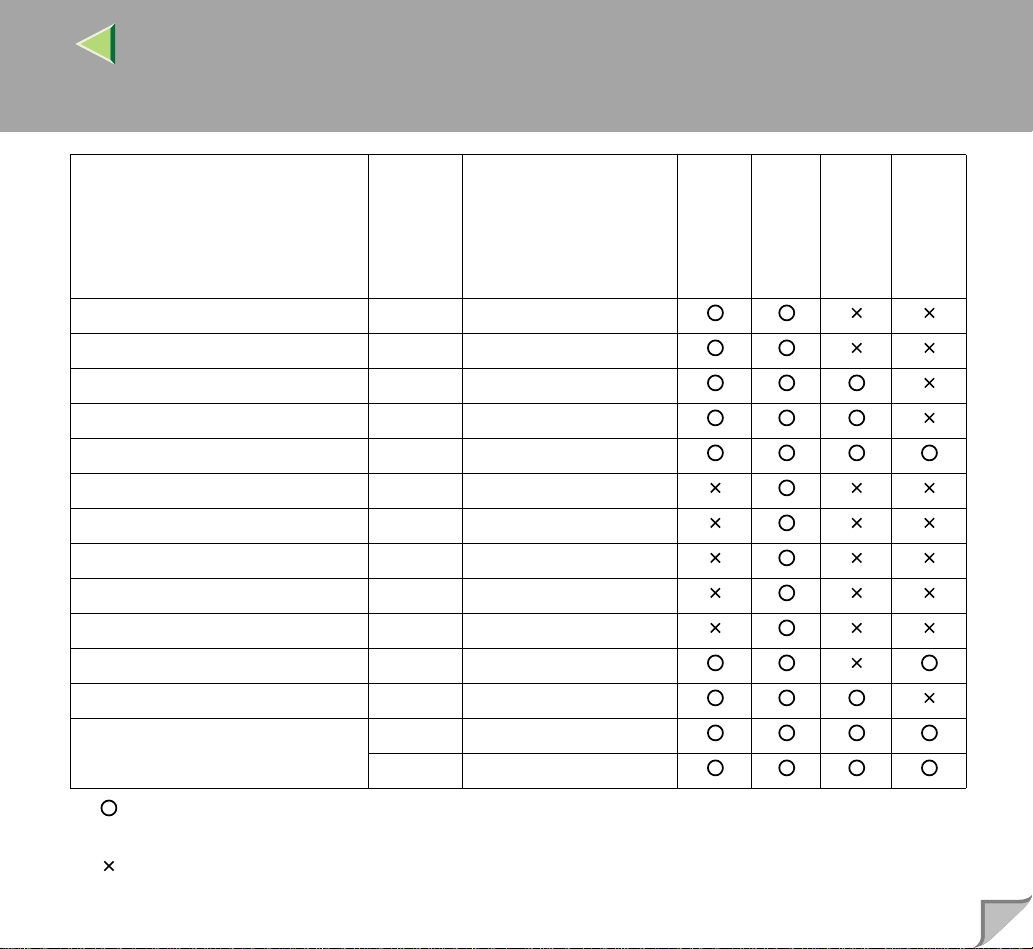

Page 12

Operating Instructions Maintenance Guide 2

12

Feed direction

Custom Size - 8K (101/2" × 15.35") L 267 × 390

16K (7.68" × 10

1

/2") L 195 × 267

K 267 × 195

Size (mm)

Bypass tray

Paper Tray (Tray 1)

*

Paper Feed Unit (Tray 2/3/4)

2000-sheet Large Capacity Tray

• means that the size is supported and printer select the paper size automatically.

• means that the size is supported but paper size should be selected with the operation panel.

• means that the size is support ed but paper siz e should be set with the operat ion panel as a cus tom

size.

*

•

means that the supported size is approximately 90 - 305 mm in width, and approximately 148 458 mm in length. The s upport ed size may di ffer de pendin g on the p rinter language y ou use. Set the

custom size setting with the operation panel.

• means that the size is not supported.

Page 13

❖❖❖❖ Input Paper Sizes (Inch version)

Operating Instructions Maintenance Guide 2

13

Feed direction

Size (inch)

Double Letter (DLT) L 11" × 17"

Legal (LG) L 8

Letter (LT) L 8

K 11" × 8

Half Letter (HLT) L 5

Executive (Exec.) L 7

K 10

1

/2" × 14"

1

/2" × 11"

1

/2"

1

/2" × 81/2"

1

/4" × 101/2"

1

/2" × 71/4"

A3 L 11.26" × 16.54"

B4 JIS L 10.12" × 14.33"

A4 L 8.26" × 5.83"

K 5.83" × 8.26"

Bypass Tray

Paper Tray (Tray 1)

Paper Feed Unit (Tray 2/3/4)

2000-sheet Large Capacity Tray

Page 14

Operating Instructions Maintenance Guide 2

14

Feed direction

B5 JIS L 7.17" × 10.12"

K 10.12" × 7.17"

A5 L 5.83" × 8.26"

K 8.26" × 5.83"

B6 JIS L 5.04" × 7.17"

A6 L 4.13" × 5.63"

Folio L 8

Foolscap F4 L 8

F/GL L 8" × 13"

Com#10 Env L 4

C5 Env L 6.38" × 9.02"

C6 Env L 4.49" × 6.38"

DL Env L 4.33" × 8.66"

Size (inch)

1

/4" × 13"

1

/2" × 13"

1

/8" × 91/2"

Bypass Tray

Paper Tray (Tray 1)

Paper Feed Unit (Tray 2/3/4)

2000-sheet Large Capacity Tray

Page 15

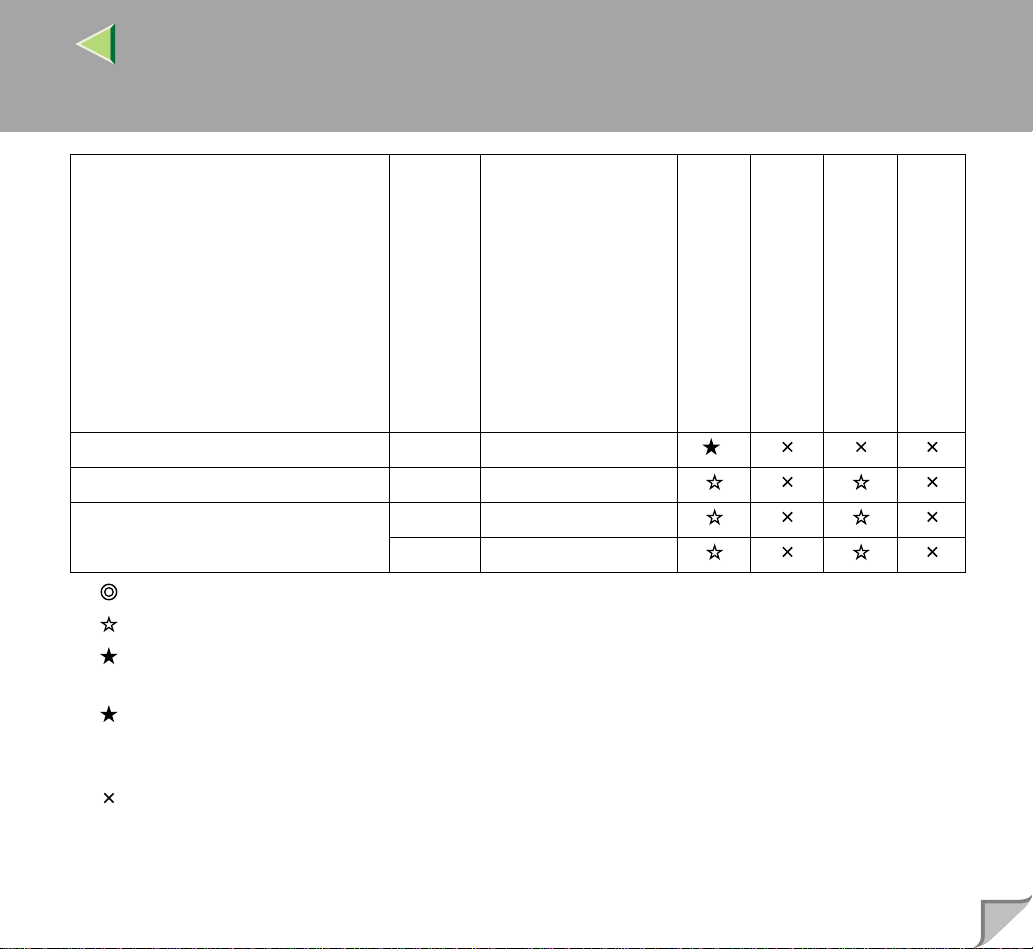

Operating Instructions Maintenance Guide 2

15

Feed direction

Monarch Env L 37/8" × 71/ 2"

Custom Size - 8K L 101/2" × 15.35"

16K L 7.68" × 10

K 10

Size (inch)

1

1

/2" × 7.68"

/2"

Bypass Tray

Paper Tray (Tray 1)

*

Paper Feed Unit (Tray 2/3/4)

2000-sheet Large Capacity Tray

• means that the size is supported and printer select the paper size automatically.

• means that the size is supported but the paper size should be selected with the operation panel.

• means that the size is supported but the paper size should be set with the operation panel as a

custom si ze.

*

•

means that the supported size is approximately 3.5 - 12 inch in width, and approximately 5.8 18 inch in length. The supported siz e may differ dependi ng on the printe r la nguage you use. Set the

custom size setting with the operation panel.

• means that the size is not supported.

Page 16

Operating Instructions Maintenance Guide 2

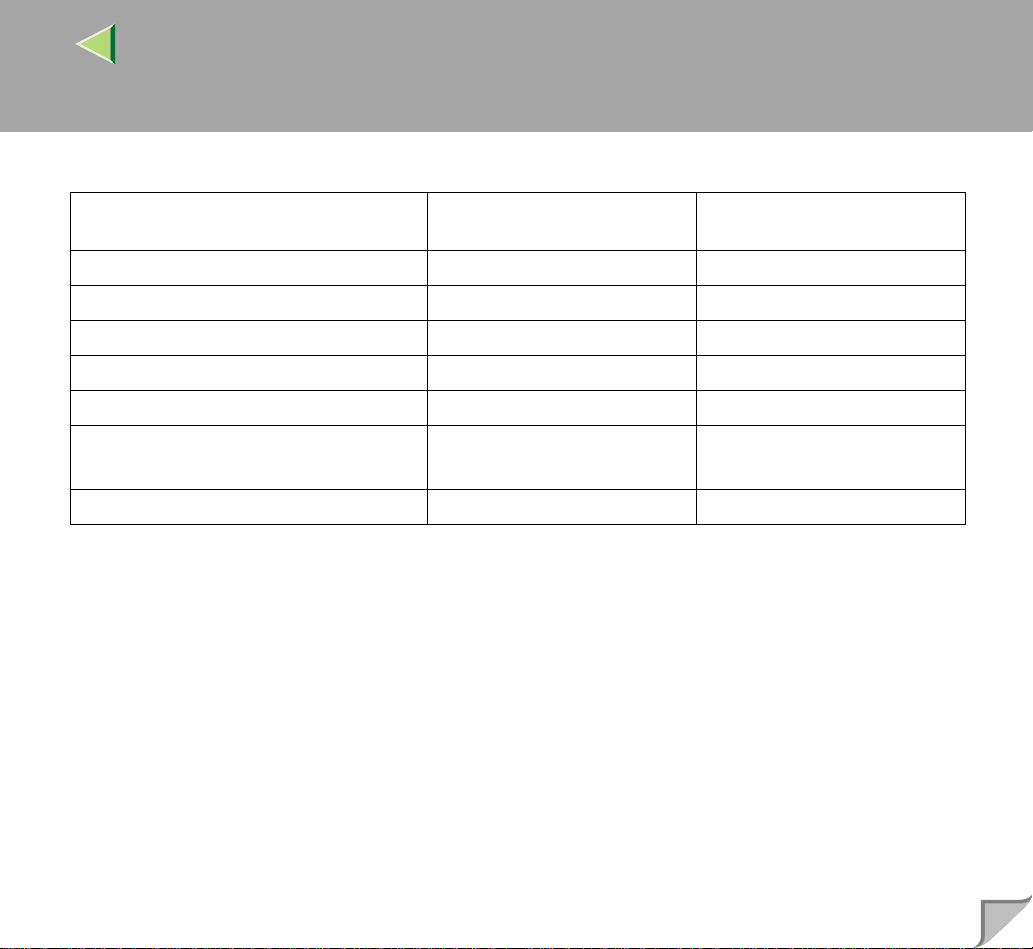

❖❖❖❖ Paper weight and number of sheets to be set

16

Supported paper weight

Maximum number of sheets

(plain paper)

*1

Tray 1 60 - 105 g/m2 (16 - 28 lb) 500 (80 g/m2, 20 lb)

Tray 2 60 - 105 g/m

Bypass Tray 52 - 162 g/m

PAPER FEED UNIT Type 3800C (500 × 1) 60 - 105 g/m

PAPER FEED UNIT Type 3800C (500 × 2) 60 - 105 g/m

Paper Bank PS470

60 - 105 g/m

2

(16 - 28 lb) 500 (80 g/m2, 20 lb)

2

(14 - 42 lb) 100 (80 g/m2, 20 lb)

2

(16 - 28 lb) 500 (80 g/m2, 20 lb)

2

(16 - 28 lb) 1000 (80 g/m2, 20 lb)

2

(16 - 28 lb) 2000 (80 g/m2, 20 lb)

(2000-sheet Large Capacity Tray)

2

SR770 (2 Tray Finisher) 60 - 105 g/m

*1

Confirm that the to p of the stack is not higher than the limit mark inside the tray.

(16 - 28 lb) 2000 (80 g/m2, 20 lb)

Page 17

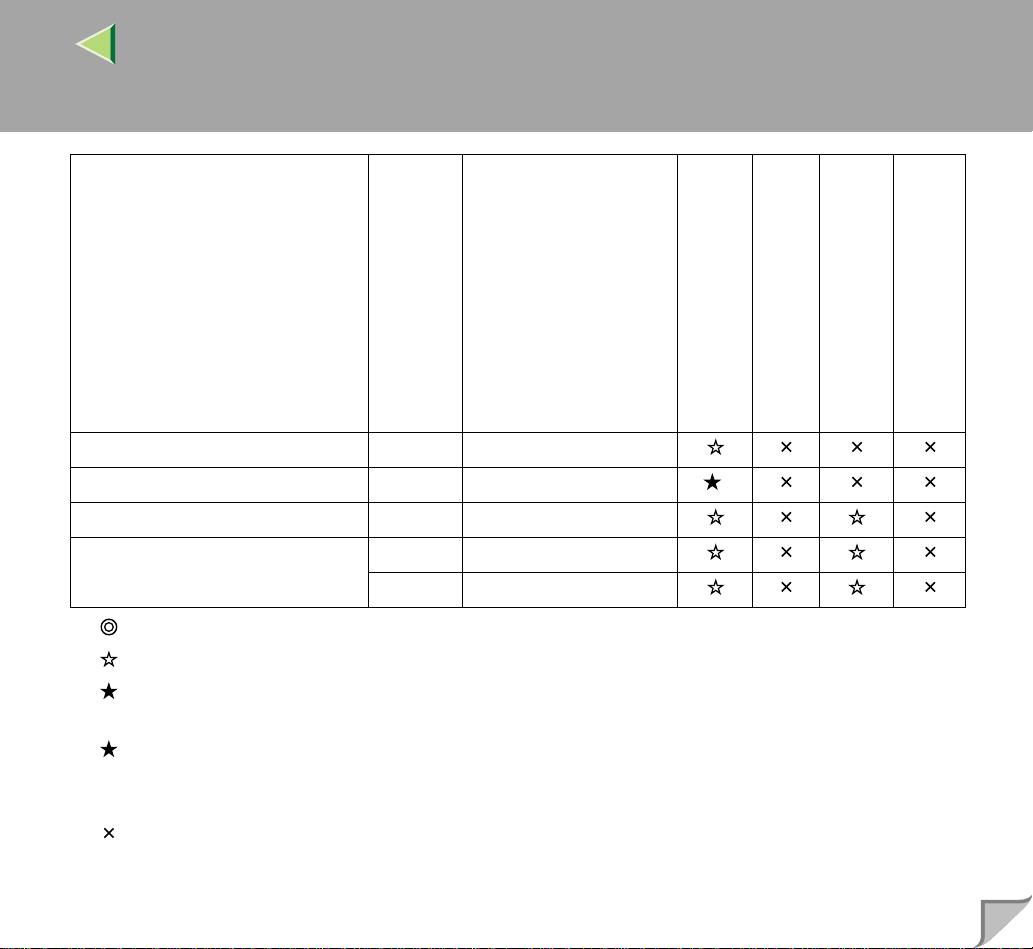

❖❖❖❖ Output Paper Sizes (Metric version)

Operating Instructions Maintenance Guide 2

17

Feed direction

A3 L 297 × 420

B4 JIS L 257 × 364

A4 L 210 × 297

K 297 × 210

B5 JIS L 182 × 257

K 257 × 182

A5 L 148 × 210

K 210 × 148

B6 JIS L 128 × 182

A6 L 105 × 148

Double Letter (DLT, 11" × 17") L 279 × 432

1

Legal (LG, 8

Letter (LT, 8

Half Letter (HLT, 5

/2" × 14") L 216 × 356

1

/2" × 11") L 216 × 279

K 279 × 216

1

/2" × 81/2") L 140 × 216

Size (mm)

Standard Tray

Output Tray

2 Tray Finisher

4-bin Mailbox

Page 18

Operating Instructions Maintenance Guide 2

18

Feed direction

Size (mm)

Executive (Exec., 71/4" × 101/2") L 184 × 276

K 276 × 184

1

Folio (8

Foolscap (F4, 8

/4" × 13") L 210 × 330

1

/2" × 13") L 216 × 330

F/GL (8" × 13") L 203 × 330

Com#10 Env (4

1

/8" × 91/2") L 104.8 × 241.3

CA Env (6.38" × 9.02" ) L 162 × 229

C6 Env (4.49" × 6.38") L 114 × 162

DL Env (4.33" × 8.66") L 110 × 220

Monarch Env (3

7

/8" × 71/2") L 98.4 × 190.5

Custom Size - -

1

8K (10

16K (7.68" × 10

/2" × 15.35") L 267 × 390

1

/2") L 195 × 267

K 267 × 195

• means that the size is supported.

• means that the size is not supported.

Standard Tray

Output Tray

2 Tray Finisher

4-bin Mailbox

Page 19

❖❖❖❖ Output Paper Sizes (Inch version)

Operating Instructions Maintenance Guide 2

19

Feed direction

Size (inch)

Double Letter (DLT) L 11" × 17"

Legal (LG) L 8

Letter (LT) L 8

K 11" × 8

Half Letter (HLT) L 5

Executive (Exec.) L 7

K 10

1

/2" × 14"

1

/2" × 11"

1

/2"

1

/2" × 81/2"

1

/4" × 101/2"

1

/2" × 71/4"

A3 L 11.26" × 16.54"

B4 JIS L 10.12" × 14.33"

A4 L 8.26" × 5.83"

K 5.83" × 8.26"

B5 JIS L 7.17" × 10.12"

K 10.12" × 7.17"

A5 L 5.83" × 8.26"

K 8.26" × 5.83"

Standard Tray

Output Tray

2 Tray Finisher

4-bin Mailbox

Page 20

Operating Instructions Maintenance Guide 2

20

Feed direction

Size (inch)

Standard Tray

Output Tray

2 Tray Finisher

4-bin Mailbox

B6 JIS L 5.04" × 7.17"

A6 L 4.13" × 5.63"

Folio L 8

Foolscap F4 L 8

1

/4" × 13"

1

/2" × 13"

F/GL L 8" × 13"

Com#10 Env L 4

1

/8" × 91/2"

C6 Env L 4. 49" 6.38"

C5 Env L 6.38" × 9.02"

DL Env L 4.33" × 8.66"

Monarch Env L 3

7

/8" × 71/2"

Custom Size - 8K L 10

16K L 7.68" × 10

K 10

1

/2" × 15.35"

1

1

/2" × 7.68"

/2"

• means that the size is supported and that the paper size should be set with the operation panel.

There is no dial in the tray.

• means that the size is not supported.

Page 21

Operating Instructions Maintenance Guide 2

Loading Paper

Load paper and change the paper size in Tray 1,

Tray 2 and the optional Paper Feed Unit by following the procedures below.

Important

❒ Tray 1 uses 11 × 8

Load only 11 × 8

❒

2000-sheet Large Capacity Tray uses 11 × 81/

K

paper exclusively. Load only 11 × 81/2 paper

at all times.

❒ If you want to load A4 K paper in Tray 1 and

optional 2000-sheet Lar ge Capacity Tray,

contact your sales or service representative.

Reference

❒ See P.9 “Paper Types and Sizes” concerning

paper to be loaded in the Paper Tra y an d optional Paper Feed Unit.

1

/2 K paper exclusively.

1

/2 paper at all times.

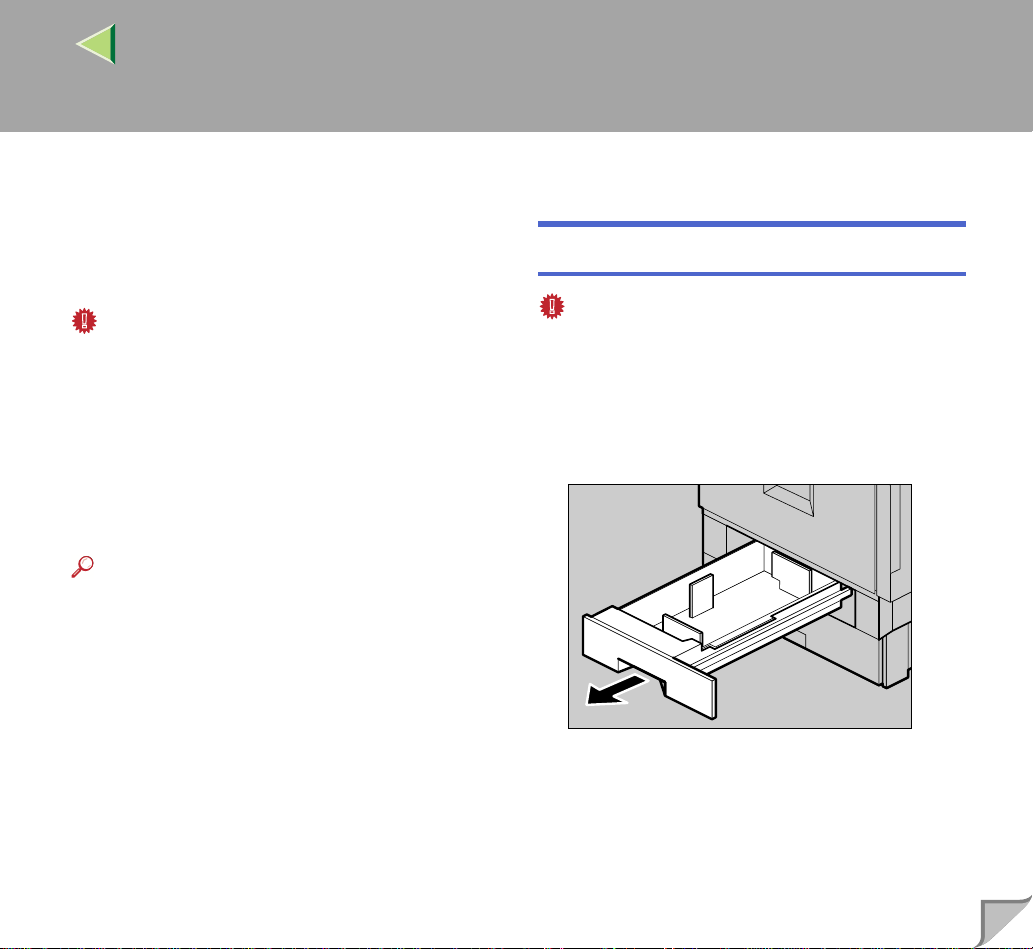

Loading Paper in Tray 1

Important

❒ Tray 1 uses 11 × 8

Load only 11 × 8

❒ If you want to load A4 K paper in Tray 1, con-

2

tact your sales or service representative.

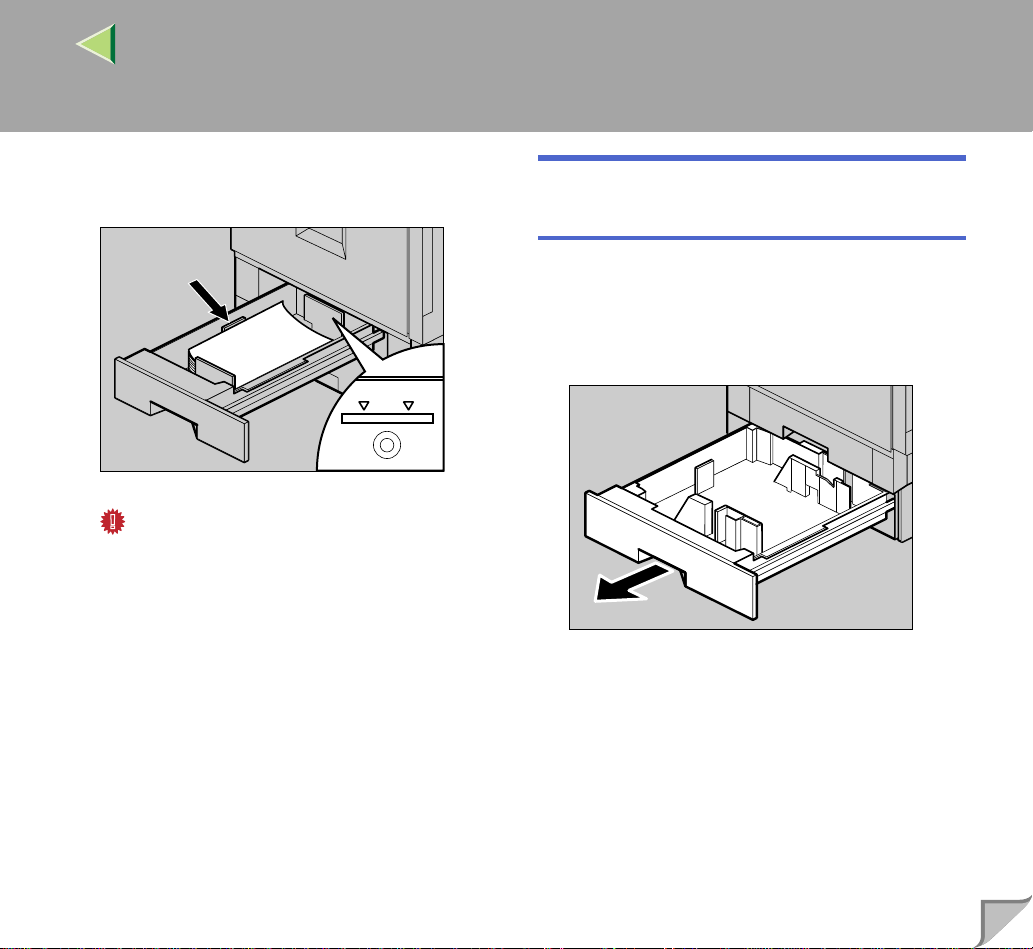

A

Pull out the paper tray slowly un til it stops.

1

/2 K paper exclusively.

1

/2 paper at all times.

21

ZDJH003J

Page 22

Operating Instructions Maintenance Guide 2

B

Load paper into the tr ay with the prin t side

down.

ZDJY001J

Important

❒ Confirm that the top of the stack is not

higher than the limit mark inside the tray.

C

Carefully slide the paper tray into the

printer until it stops.

Loading Paper in Tray 2 and the Optional Paper Feed Unit

This section descr ibes loading pape r which is different from default size in Tray 2.

A

Pull out the Paper Tray slowly until it

stops.

ZDJH005J

22

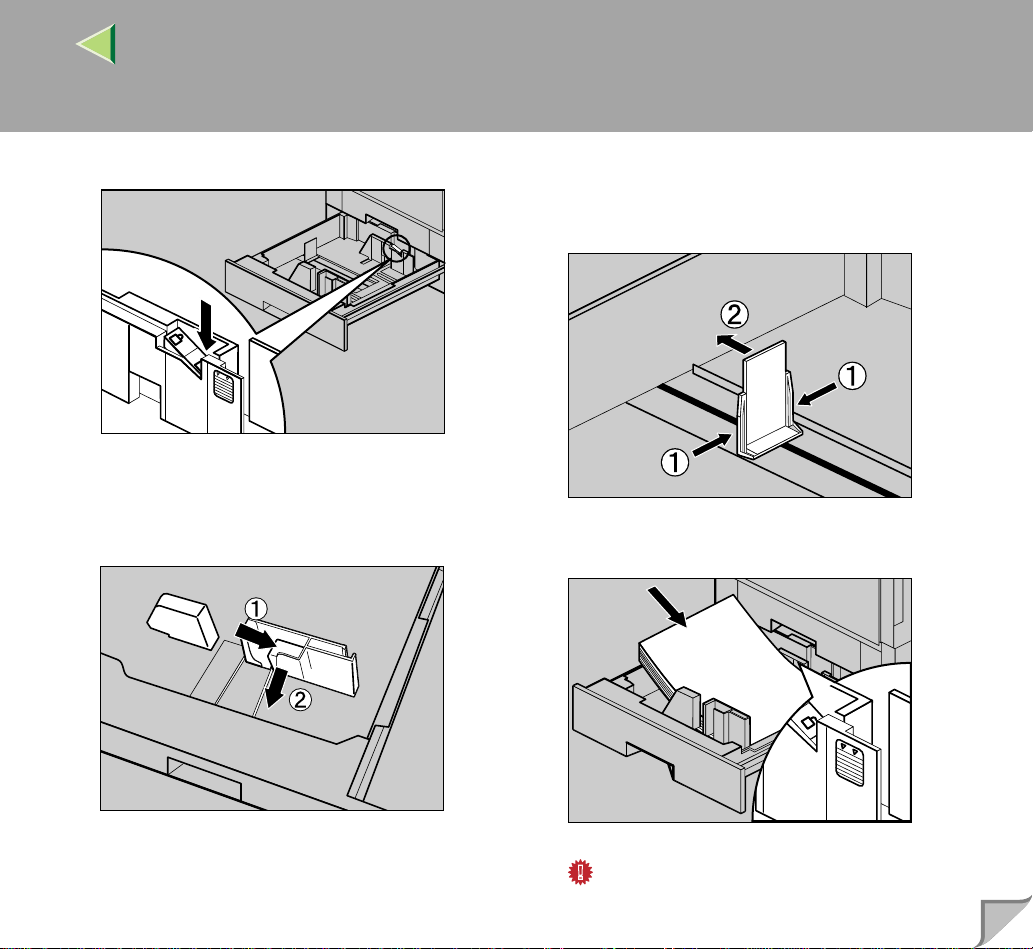

B

Set the paper guide lock to the "unlocked"

Page 23

Operating Instructions Maintenance Guide 2

23

position.

ZDJY003J

C

Pushing the green lever of the side guide

(AAAA), move the side guide tow ard you to

open it (BBBB).

D

Pinching both sides of the end guide (AAAA),

move the end guide in the direction of the

arrow to open it.

ZDJY801J

E

Load paper in the same direction.

ZDJY802J

ZDJY002J

Important

❒ Confirm that the top of the stack is not

higher than the limit mark inside the tray.

Page 24

Operating Instructions Maintenance Guide 2

24

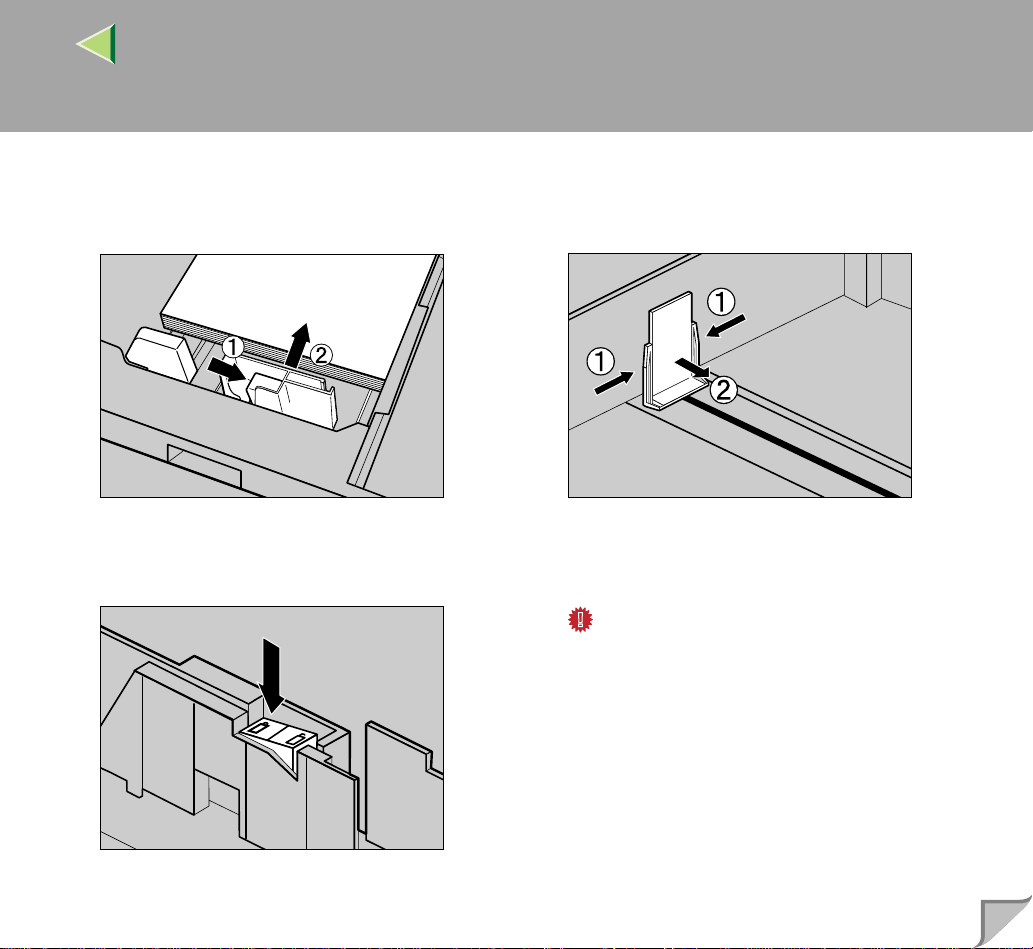

F

Pushing the green lever of the side guide

(AAAA), move the side guide tow ard the paper

stack until it stops (BBBB).

ZDJY006J

G

Make sure the paper is fixed in place, and

then lock the side guide.

H

Pinching both sides of the end guide (AAAA),

move the end guide towar d the pa per st ack

until it stops (BBBB).

ZDJY005J

I

Carefully slide the paper tray into the

printer until it stops.

Important

❒ Do not slide the pap er tr ay i n wi th forc e. If

you do, the front and side guides might

move.

ZDJY007J

Page 25

Operating Instructions Maintenance Guide 2

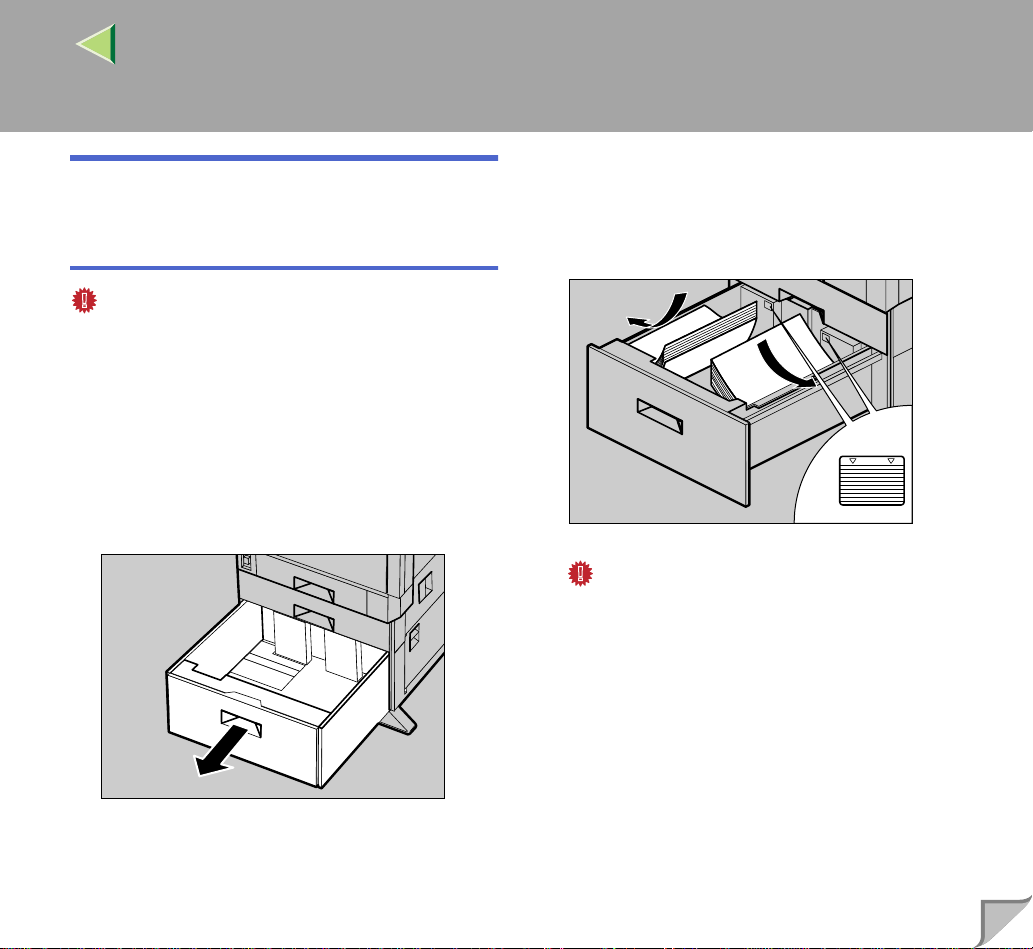

Loading paper in Paper Bank PS470 (2000-sheet Large Capacity Tray)

Important

❒

2000-sheet Large Capacity Tray uses 11 × 81/

K

paper exclusively. Load only 11 × 81/2 paper

at all times.

❒ If you want to load A4 K paper in the 2000-

sheet Large Capacity Tray, contact your sales

or service representa tiv e.

A

Pull out the Paper Tray slowly until it

stops.

25

B

With the print side down, align all four

sides of two paper stacks, and then load

them next to each other in the tray. Each

side has a limit of 1,000 sheets.

2

ZDJY009J

Important

❒ Align the paper and lo ad th em a gai ns t the

left and right walls, or a paper misfeed

might occur.

❒ Confirm that the top of the stack is not

higher than the limit mark inside the tray.

ZDJY008J

C

Push in the Paper Tray s lowly until it st ops.

Page 26

Operating Instructions Maintenance Guide 2

If you load a paper size that is not selected automatically

A

Press {{{{Menu}}}}.

26

Note

❒ Paper sizes that are not selected automatical-

ly are B4 L, A4K, B5L, 7

1

13L, 8

/2 × 13L, 81/4 × 13L, 8K (101/2 ×

15.35)L, 16K (7.68 × 10

7.68)K.

1

/4 × 101/

1

/2)L, 16K (101/2 ×

L, 8 ×

2

Reference

❒ See P.22 “Loading Paper in Tray 2 and the

Optional Paper Feed Unit” for deta ils about

how to load the paper.

Important

❒ Tray 1 uses 11 × 8

Load only 11 × 8

❒ Paper Bank PS 470 uses 11 × 8

exclusively. Load only 11 × 8

times.

❒ If you want to load A4 K paper in Tray 1 and

optional Paper Bank PS470, contact your

sales or service representative.

1

/2 K paper exclusively.

1

/2 paper at all times.

1

/2 K paper

1

/2 paper at all

This section uses Letter A4 L as an example.

On Line

Job Reset

Menu

Form Feed

Power Error Data In

Escape

#

Enter

ZDJS001N

"Menu" appears on the panel display.

B

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Paper Input", and then press {{{{Enter}}}}.

Menu:

Paper Input

The paper selection menu is displayed.

C

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Tray Paper

Size", and then press {{{{Enter}}}}.

Paper Input:

Tray Paper Size

The paper tray selection menu is displayed.

Page 27

Operating Instructions Maintenance Guide 2

27

D

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display the target paper tray, and then press {{{{Enter}}}}.

Tray Paper Size:

Tray 2

The paper size selection menu is displayed.

E

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display the loaded paper size, and then press {{{{Enter}}}}.

Tray2:

A4 (210 x 297)

After about two seconds, the display is r eturned to the menu.

F

Press {{{{On Line}}}}.

"Ready " appears on the panel display.

Ready

Important

❒ After printing on a paper size that is not se-

lected automatically, if you want to print on

paper that is selected automatically agai n,

reload the p aper, proceed t o step

return the setting to "Auto".

G

Press {{{{Menu}}}}.

On Line

Menu

Job Reset

Form Feed

Power Error Data In

"Menu" appears on the panel display.

H

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Paper Input", and then press {{{{Enter}}}}.

Escape

#

Enter

ZDJS001N

, and

G

This completes the change in setting.

Menu:

Paper Input

The paper selection menu is displayed.

Page 28

Operating Instructions Maintenance Guide 2

28

I

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Tray Paper

Size", and then press {{{{Enter}}}}.

Paper Input:

Tray Paper Size

The paper tray selection menu is displayed.

J

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display the target paper tray, and then press {{{{Enter}}}}.

Tray Paper Size:

Tray 2

The paper size selection menu is displayed.

K

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "ppppAuto",

and then press {{{{Enter}}}}.

Tray 2

*Auto

After about two seconds, the display is r eturned to the menu.

L

Press {{{{On Line}}}}.

"Ready " appears on the panel display.

Ready

Changing the paper type

By selecting the paper typ e you want to load, the

printer can execute better printing. You can select from the following paper types.

• Plain Paper, Recycled Paper, Special Paper,

Color Paper, Letterhead Paper, Preprinted Paper, Prepunched Paper, Bond Paper, Card Stock

A

Press {{{{Menu}}}}.

On Line

Job Reset

Menu

Form Feed

Power Error Data In

Escape

#

Enter

ZDJS001N

"Menu" appears on the panel display.

Page 29

Operating Instructions Maintenance Guide 2

29

B

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Paper Input", and then press {{{{Enter}}}}.

Menu:

Paper Input

The paper selection menu is displayed.

C

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Paper Type",

and then press {{{{Enter}}}}.

Paper Input:

Paper Type

The paper tray selection menu is displayed.

D

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display the target paper tray, and then press {{{{Enter}}}}.

Paper Type:

Tray 2

The paper type selection menu is displayed.

E

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display the loaded paper type, and then press {{{{Enter}}}}.

Tray 2

Recycled Paper

After about two seconds, the display is returned to the menu.

F

Press {{{{On Line}}}}.

"Ready " appears on the panel display.

Ready

Page 30

Operating Instructions Maintenance Guide 2

Load Paper in the Bypass Tray

Besides regular paper, you can load thick paper,

envelopes, OHP transpa ren ci es, and paper that is

longer than A3L onto the Bypass Tra y, which

cannot be loaded in the Paper Trays or Paper

Feed Unit.

Note

❒ Paper sizes supported by the Bypass Tray

are 3.5 - 12 inch in width, and 5.8 - 18 inch in

length.

❒ If you load custom size pape r or special pa-

per, select the paper size with the operation

panel. The RPCS printer driver can select the

paper size with the printer driver properties.

The paper size selected with the printer driver

overrides the one s ele ct ed with the operation

panel. See P.33 “Specifying a custom paper

size for the Bypass Tray”.

❒ If you load thic k paper, OHP t ransparencies,

or envelopes, make the settings for thick paper or OHP transparencies with the operation

panel or printer dri ver. See P.34 “Specifying

a paper type for the Bypass Tray”.

❒ The number of pages that can be loaded in

the Bypass Tray differ s de pen din g on the paper type. Confirm that the top of the stack is

not higher than the limit mark inside the tray.

Limitation

❒ You cannot use the follow ing functions when

printing on paper that is loaded in the Bypass

Tray.

• Duplex Print

• Collate, Job Separation

• Staple/Punch

• Limitless Paper Feed

A

Open the bypass tray.

ZDJH202J

30

Page 31

Operating Instructions Maintenance Guide 2

31

Note

❒ If you load A4 or larger size paper, pull out

the bypass tray extension, an d then flip it

open.

ZDJH203J

B

Slide the side guides outward(AAAA), and then

load paper until it stops with the print side

up (BBBB).

C

Adjust the side guides to the paper width.

ZDJH205J

Important

❒ Confirm that the top of the stack is not

higher than the limit mark inside the tray.

❒ Shuffle the paper befo re lo adi ng t he s tac k

onto the tray so multiple sheets are not fed

in at one time.

ZDJH204J

Page 32

Operating Instructions Maintenance Guide 2

32

D

Set the paper size u sing the operation panel

as follows:

A Press {{{{Menu}}}}.

On Line

Job Reset

Menu

Form Feed

Power Error Data In

Escape

#

Enter

ZDJS001N

"Menu" appears on the panel display

B Press {{{{UUUU}}}} or {{{{TTTT}}}} to "Paper Input"

menu, and then press {{{{Enter}}}}.

The following message appears on the

panel display.

Menu:

Paper Input

C Confirm that "Bypass Size" is dis-

played, and then press {{{{Enter}}}}.

The following message appears on the

panel display.

Paper Input:

Bypass Size

D Press {{{{UUUU}}}} or {{{{TTTT}}}} to display the size and

direction of the paper in th e bypass tray.

Bypass Size

*11 x 17

After about two seconds, the display is returned to the menu.

E Press {{{{On Line}}}}.

"Ready " appears on the panel display.

Ready

Page 33

Operating Instructions Maintenance Guide 2

Specifying a custom paper size for the Bypass Tray

Important

❒ The paper size selected with the printer driver

overrides the one s ele ct ed with the operation

panel. You do not have to make settings with

the operation panel if you already made them

with the printer driver. Howe ver, when pr inting with a printer drive r other than the R PCS

printer driver, you must make the settings using the operation panel. For more information

about the printer driver, see the Help Files.

❒ The printer cannot print from applications that

do not supports custom paper size.

A

Press {{{{Menu}}}}.

On Line

Job Reset

Menu

Form Feed

Power Error Data In

Escape

#

Enter

B

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Paper Input", and then press {{{{Enter}}}}.

The following message appears on the panel

display.

Menu:

Paper Input

C

Confirm that "Bypass Size" is displayed,

and then press {{{{Enter}}}}.

The following message appears on the panel

display.

Paper Input:

Bypass Size

D

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Custom

Size", and then press {{{{Enter}}}}.

The following message appears on the panel

display.

Bypass Size:

Custom Size

33

ZDJS001N

"Menu" appears on the panel display.

Page 34

Operating Instructions Maintenance Guide 2

E

Press {{{{UUUU}}}} or {{{{TTTT}}}} to set the horizontal value, and then press {{{{Enter}}}}.

The following message appears on the panel

display.

Custom Size:

Vert. 0 "

F

Press {{{{UUUU}}}} or {{{{TTTT}}}} to set the vertical value,

and then press {{{{Enter}}}}.

Custom Size:

Horiz. 0 "

After about two seconds, the display is r eturned to the menu.

G

Press {{{{On Line}}}}.

The following message appears on the panel

display.

Ready

34

Specifying a paper type for the Bypass Tray

By selecting the paper typ e you want to load, the

printer can execute better printing. You can select from the following paper types.

• Plain Paper, Recycled Paper, Special Paper,

Color Paper, Letterhead, Preprinted, Prepunched, Labels, Bond Paper, Card Stock,

OHP Transparencies, Thick Paper, Plain Paper (Duplex), Thick Paper (Duplex)

Important

❒ Be sure to select the paper type when you

load labels, thick paper, or OHP transparencies in the Bypass Tray.

Limitation

❒ You cannot use the follow ing functions when

printing on paper loaded in the Bypass Tray.

• Duplex Print

• Collate, Job Separation

• Staple, Punch

• Limitless Paper Feed

Page 35

Operating Instructions Maintenance Guide 2

35

A

Press {{{{Menu}}}}.

On Line

Menu

Job Reset

Form Feed

Power Error Data In

"Menu" appears on the panel display.

B

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Paper Input", and then press {{{{Enter}}}}.

The following message appears on the panel

display.

Escape

#

Enter

ZDJS001N

Menu:

Paper Input

C

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Paper Type",

and then press {{{{Enter}}}}.

The following message appears on the panel

display.

Paper Input:

Paper Type

D

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display "Bypass

Tray", and then press {{{{Enter}}}}.

The following message appears on the panel

display.

Paper Type:

Bypass Tray

E

Press {{{{UUUU}}}} or {{{{TTTT}}}} to display th e tar get paper type, and then press {{{{Enter}}}}.

Bypass Tray:

*Thick Paper

After about two seconds, the display is returned to the menu.

Page 36

Operating Instructions Maintenance Guide 2

F

Press {{{{On Line}}}}.

The following message appears on the panel

display.

Ready

36

Page 37

Operating Instructions Maintenance Guide 2

2. Troubleshooting

Error & Status Messages on the Operation Panel

❖❖❖❖ Status Messages

Messages/Second messages Description Solution

Calibrating... The printer is calibrating the color. Wait for a while.

Energy Save Mode In Energy Save Mode Level 2. No action requ ired.

Hex Dump Mode In Hex Dump Mode. No action required.

Loading Toner... The printer is loading the toner. Wait for a while.

Offline The printer is offline and cannot print

data.

Initializing... Please Wait The printer is initializing the develop-

ment unit.

Printing... The printer is doing print job. Wait for a while.

Processing... Print data is being processed. Wait for a while.

Ready The default ready messag e . The

printer is ready to use.

Press {

Wait for a while.

No action required.

On Line

}.

37

Resetting Job... Job is being reset. Wait for a while.

Waiting... The printer is waiting for the next

data to print.

Warming Up... The printer is warming up and not

ready.

Wait for a while.

Wait until the printer signals Ready.

Page 38

Operating Instructions Maintenance Guide 2

❖❖❖❖ Alert Messages

Messages/Second messages Description Solution

38

Add Staples The stapler is out of staples. Job is not

stapled.

Add Toner/Yellow/Magenta/Cyan/

Black

Add Toner Black The printer is out of toner (K). Replace a new toner cartridge (K).

Add Toner Cyan The printer is out of toner (C). Replace a new toner cartridge (C).

Add Toner Magenta The printer is out of toner (M). Replace a new toner cartridge (M).

Add Toner Yellow The printer is out of toner (Y). Replace a new toner cartridge (Y).

The printer is out of the indicated ton-

er(s).

Replace new staples.

See P.79 “Adding Staples”.

Replace a new toner cartridge of the

indicated color(s).

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

Page 39

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

39

Call Service: EC Power Off On

/If Error Reoccur Call Service

Change Setting Tray #

/Paper Size: Paper Type:

Close Duplex Unit Cover The cover for the duplex unit is open. Close the cover for the duplex unit.

Close Finisher Front Cover

Close Right Cover The upper right cover (the cover for

Close Finisher Upper Cover The finisher upper cover is open. Close the upper cover for the finisher.

Close Finisher Upper Cover The paper entrance cover for the fin-

Close Front Cover Th e front cover is open. Close the front cover for the printer.

Close Lower Right Cover The right cover for the paper feed ta-

A communication error sent from the

engine to the controller.

The paper size and type setting in the

tray differs from that of actual paper

size and type in the tray.

The front cover for the finisher is open.

the toner cartridge) is open.

isher is open.

ble/large capacity tray is open.

Turn the power switch off and then

on. If the message appears again,

contact your sales or service representative.

Load {paper size and type} pa per with

the selec t ed fe ed direction into the

tray, and then change the paper size

and type with the operat ion pa ne l.

Or press {

the tray with the operational panel.

Or press {

print job.

Close the front cover for finisher.

Close the upper right cover.

Close the upper entrance cover for

the finisher.

Close the right cover for the paper

feed table/large capacity tray.

Form Feed

Job Reset

}, and then select

} to cancel the

Close Mailbox Cover The cover for 4-bin Mailbox is open. Close the cover for the 4-bin Mailbox

tray.

Page 40

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

Close Right Cover The right cover is open. Close the right cover.

40

Close Upper Left Cover The upper left cover (the c over for the

fusing unit) is open.

Driver Setting Error (Memory) The printer identified a download er-

ror.This error may occur when the in-

stalled memory amount is less than

the driver setting.

Duplex Cancelled The setting of Duplex Print has been

cancelled.

Error:Tray 1 Reset The Job

/Then Power OffOn

Error:Tray 1 Form Feed

/Or Job Reset Then Power OffOn

Exceeded Max. Pages (Collate) The printer identified a collation page

Exceeded Max. Stored Files The maximum number of stored file s

There is a problem with the current

specified tray. The job can not be

processed.

The printer identified the failure of

the indicated paper tray. The job is

not printed.

overflow error.

has been exceeded during Sample

Print of Lacked Print.

Close the upper left cover.

Verify that the paper memory size is

specified with tha driver setting.

(a) To print the image correctly, add

memory to the printer. (b) Be sure to

use the correct paper.

Reset the job then turn the printer

Off, and then back On.

Apply Form Feed from other tray or

cancel the job, and then switch your

printer Off then back On. If the error

continues,contact your sales or service representative.

Increase the RAM capacity.

Install the optional hard disk drive.

Delete the stored files.

Page 41

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

41

Exceeded Max. Stored Pages The maximum number of pages has

been exceeded during Sample Print

of Lacked Print

Hardware Problem DIMM The printer identified a DIMM sum

value error.

Hardware Proble m Ethernet The printer identified an ethernet error. Turn the power s witch off and then

Hardware Problem Finisher There is a problem with the finisher. Tu rn the power switch off and then

Hardware Problem HDD The printer identified a HDD Board

error.

Reduce the number of pages to print.

Remove and re-install the DIMM

correctly.

Remove any dust under the DIMM.

If the message appears again, contact

your sales or service representative.

See "Setting Up" in the Setup Guide.

on. If the message appears again,

contact your sales or service representative.

on. If the message appears again,

contact your sales or service representative.

Remove and re-install the HDD

Board correctly.

If the message appears again, contact

your sales or service representative.

See "Setting Up" in the Setup Guide.

Page 42

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

42

Hardware Problem IEEE1394 The printer identified an IEEE1394

Board error.

Remove and re-install the IEEE1394

Board correctly.

Confirm that the IEEE 1394 In-

A

terface Unit Type1045 is attached

to the computer correctly.

Confirm that the IEEE 1394 inter-

B

face cable is connected securely.

Restart the computer.

C

If the message appears again even

after executing above operation,

proceed to the following steps.

Unplug the IEEE 1394 interface

D

cable which is connected to the

printer.

Execute the utility tool for IEEE

E

1394 Interface Unit Type1045

which is stored in the following

path in the CD-ROM labeled

"Printer Drivers and Utilities".

UTILITY\1394

Important

❒ For details about using

the utility tool for IEEE

1394, see the README

file in the same directry in

the CD-ROM.

Page 43

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

43

Hardware Problem IEEE1394 The printer identified an IEEE1394

Board error.

Hardware Problem NV-RAM The printer identified a Memory

Switch(User Account Enhance Unit)

error.

Hardware Problem Option RAM The printer identified an optional

RAM error.

Hardware Problem Parallel I/F There is a problem with the parallel

interface.

Hardware Problem Staple Unit Th ere is misfeed in the finisher or

there is a problem with the staple unit

failure.

If the message appears again, contact

your sales or service representative.

See "Setting Up" in the Setup Guide.

Replace the User Account Enhance

Unit.

Remove and re-install the optional

RAM.

If the message appears again, contact

your sales or service representative.

If you use the parallel I/F, replace the

interface cable that caused the error.

If the message apperars again, contact your sales or service representative.

Remove the misfeed. If the message

appears again, contact your sales or

service representative.

See P.71 “When "Remove Misfeed R:

Finisher" Appears”

See P.77 “Removing Jammed Sta-

ples”

Hardware Problem Tray 1 There is a problem with the paper lift

motor of the Tray 1.

Turn the power switch off and then

on. If the message appears again,

contact your sales or service representative.

Page 44

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

44

Hardware Problem Tray 2 There is a problem with the paper lift

motor of the Tray 2.

Hardware Problem Tray 3 There is a problem with the paper lift

motor of the paper tray 3.

Hardware Problem Tray 4 There is a problem with the paper lift

motor of the paper tray 4.

HDD Full The maximum HDD area size for

form/font has been exceeded.

An HDD overflow error occurred

during Sample Print or Lacked Print.

HDD Not Installed The user tries to print the Lacked

Print data without HDD installed.

I/O Buffer Overflow The max i mum size of the I/O buffer

has been exceeded.

Turn the power switch off and then

on. If the message appears again,

contact your sales or service representative.

Turn the power switch off and then

on. If the message appears again,

contact your sales or service representative.

Turn the power switch off and then

on. If the message appears again,

contact your sales or service representative.

Delete the disused form /font types.

Delete the stored files or reduce the

size of the Sample Print file or

Lacked Print file.

If you use the Locked Print feature,

make sure to install HDD. If the error

continues, contact your sales or service representative.

Increase the size of the I/O buffer

through the I/F Setup.

Invalid Password Try Again The entered password with th e opera-

tion panel is not correct.

Enter the correct password with the

operation panel.

Page 45

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

45

Load Correct Size Paper

/Press # To Continue

Load Paper Tray # The indicated tray is out of paper. #:

Load Paper

/Paper Size: Paper Type:

Menu Protected Cannot Change The menu is protected and the setting

No Files Exist There are no files available for Sam-

The paper size setting in the tray dif-

fers from that of actual paper size in

the tray.

tray number

1:The printer received a request for a

paper type, or paper size not available

in the printer, and Tray Locking is not

applicable.

2:The paper type and size loaded in

the tray which the printer serched us-

ing Tray Locking is Invalid for Du-

plex Print.

cannot be changed.

ple Print job or Locked Print job.

Load {paper size} paper with the selected feed direction into the tray, and

then change the paper size with the

operation panel.

Or press {

tray with the operational panel.

Or press {

print job.

Load paper into the indicated paper

tray.

Change the setting of the indicated

paper input tray, or press {

set

here.

Wait for two seconds until the previous display appears.

Wait for two seconds until the previous display appears.

Form Feed

Job Reset

}. Form Feed is not applicable

}, and select the

} to cancel the

Job Re-

P=07 I=9Fc01234 Power Off On

/If Error Reoccur Call Service

A controller error. The SC number in-

dicates the problem.

Turn the power switch off and then

on. If the message appears again,

contact your sales or service representative.

Page 46

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

46

Paper Inval i d for Duplex:T ra y #

/Change Setting or Form Feed

Punch-hole Chips are Full The Punch Chips is full of punch

Remove MisfeedA:Internal Path

/See Instructions in Front Cover

Remove MisfeedB: Fusing Unit

/See Instructions in Front Cover

Remove MisfeedR: Finisher

/Open Front Cover

The printer detected the setting of the

indicated tray is invalid for Duplex

Tray. #: tray number

chips.

There is a misfeed in the printer. Remove the misfed paper following

There is a misfeed in the fusing unit. Remove the misfed paper following

There is a misfeed in the finisher. Open the finisher cover and remove

Change the setting of the indicated

paper input tray or apply Form Feed

using another t r a y, or press {

}.

set

Remove the punch chips from the

Punch Chips.

See P.82 “Removing Punc h- h ol e

Chips”

the instructions inside the front cover.

For more information, see P.67

“When "Remove Misfeed A: Internal

Path" Appears”.

the instructions inside the front cover.

For more information, see P.68

“When "Remove Misfeed B: Fusing

Unit" Appear s”.

misfeed.

For more information, see P.71

“When "Remove Misfeed R: Finisher" Appears”.

Job Re-

Page 47

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

47

Remove Misfee dW: Mailbox

/Open Mailbox Cover

Remove MisfeedY: Paper Tray

/See Instructions in Front Cover

Remove Misfeed: Duplex Unit

/See Instructions in Front Cover

Remove Misfeed: Dup.Feed Unit

/See Instructions in Front Cover

Remove Paper All Output Trays All output trays are full. Remove paper from all output trays.

Remove Paper Finisher Tray # The indicated finisher shift tray is

There is a misfeed in the output 4-bin

tray.

There is a misfeed in the specified in-

put tray, or the printer is not feeding

paper.

There is a misfeed in the duplex unit. Remove th e misfed paper following

There is a misfeed in the duplex feed

unit.

full. #:finisher shift tray number

Open the mailbox cover and remove

misfeed.

For more information, see P.70

“When "Remove Misfeed W: Mailbox" Appears”.

Remove the misfe d paper following

the instructions inside the front cover.

For more information, see P.74

“When "Remove Misfeed Y: Paper

Tray" Appears”.

the instructions inside the front cover.

For more information, see P.75

“When "Remove Misfeed: Duplex

Unit" Appear s”.

Remove the misfed paper.

See "Removing Misfed Paper in the

Duplex Feed Unit" in Maintenance

Guide 1.

Remove the pa per from the i ndicate d

finisher shift tray.

Remove Paper From Upper Tray The upper tray (output 1-bin tray)is

full.

Remove paper from the upper tray.

Page 48

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

Remove Paper Inside Finisher There is still paper in the finisher. Open the cover for the finisher and

remove paper.

See P.71 “When "Remove Misfeed R:

Finisher" Appears”

48

Remove Paper Inside Finisher A communication error is sen t from

the system unit to the duplex unit.

Remove Paper Mailbox Tray # The output tray # of the optional 4-

bin Mailbox is full. #:mailbox tray

number

Remove Paper St andard Tray The standard output tray is full Remove paper from sta ndard output

Replace Black Dev. Unit(TypeD) It is time to replace the black devel-

opment unit.

Remove and re-install the duplex

unit. If the problem continues, contact your sales or service representative.

Remove paper from the indicated 4bin Mailbox tray.

trays.

Replace a new black development

unit.

Depending on your service contract ,

contact your sales or service representative.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

Page 49

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

Replace Black PCU (Type F) It is time to replace the black PCU. Replace a new black PCU.

Depending on your service contract ,

contact your sales or service representative.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

49

Replace Color Dev. Unit(TypeB) It is time to replace the color develop-

ment unit.

Replace Color PCU (Type A) It is time to replace the color PCU. Replace a new color PCU.

Replace a new color development

unit.

Depending on your service contract ,

contact your sales or service representative.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

Depending on your service contract ,

contact your sales or service representative.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

Page 50

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

Replace Fuser Oil Unit (TypeG) It is time to replace the fuser oil unit. Replace a new fuser oil unit.

Depending on your service contract ,

contact your sales or service representative.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

Replace Fusing Unit (Type C) It is time to replace the fusing unit. Peplace a new fusing unit.

Depending on your service contract ,

contact your sales or service representative.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

Replace Waste Toner (Type E) It is time to replace the waste toner. Replace a new fusing unit.

Depending on your service contract ,

contact your sales or service representative.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

50

Reset Cyan Toner Correctly The toner cartridge (C) is not set cor-

rectly or is not set, and the color print-

ing is non-applicable.

Set the toner cartridge (C) correctly.

See "Setting Up" in the Setup Guide.

Page 51

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

51

Reset Develop. Unit Correctly

/Yellow/Magenta Cyan/Black

Reset Duplex Unit Correctly The duplex paper feed unit is not set

Reset Finisher Correctly Finisher is not set correctly, or is not

Reset Fuser Oil Unit Correctly The fuser oil unit is not set correctly,

Reset Fusing Unit Correctly There is no fusing unit, or the fusing

Reset Magenta Toner Correctly The toner cartridge (M) is not set cor-

The indicated development unit(s) is/

are not set correctly, or is not set.

correctly or is not set.

set.

or is not set.

unit is not installed correctly.

rectly or is not set, and the color print-

ing is non-applicable.

Set the indicated development unit(s)

correctly. See "Replacing Consuma-

bles and Maintenance Kit" in Maintenance Guide 1.

Remove and re-install the duplex paper feed unit. If the error continues,

contact your sales or service representative.

See "Setting Up" in the Setup Guide.

Set the finisher correctly.

See "Setting Up" in the Setup Guide.

Set the fuse oil unit correctly.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

Set the fusing unit correctly.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

Set the toner cartridge (M) correctly.

See "Setting Up" in the Setup Guide.

Page 52

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

52

Reset PCU Correctly

/Yellow/Magenta Cyan/Black

Reset Toner Black The indicated toner cartridge is not

Reset Toner Cyan The indicated toner cartridge is not

Reset Toner Magenta The indicated toner cartridge is not

Reset Toner Yellow The indicated toner cartridge is not

Reset Transfer Unit Correctly The transfer unit is not set correctly,

Reset Tray 1 Correctly The indicated paper input tray is not

The indicated Phot oc o ndu c t or

Unit(s) is/are not set correctly, or is

not set.

set correctly.

set correctly.

set correctly.

set correctly.

or is not set.

set correctly, or is not set.

Set the indicated Photoconductor

Unit(s) correctly.

See "Replacing Consumables and

Maintenance Kit" in Maintenance

Guide 1.

Set the indicated toner cartridge(s)

correctly.

See "Setting Up" in the Setup Guide.

Set the indicated toner cartridge(s)

correctly.

See "Setting Up" in the Setup Guide.

Set the indicated toner cartridge(s)

correctly.

See "Setting Up" in the Setup Guide.

Set the indicated toner cartridge(s)

correctly.

See "Setting Up" in the Setup Guide.

Contact your sales or service representative.

Set the indicated paper input tray correctly.

Reset Tray Correctly The printer detected, when process-

ing a job through Auto Tray Select,

that any of paper input tray is not set

correctly, or is not set.

Set the indicated paper input tray correctly.

Page 53

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

53

Reset Waste Toner Correctly The waste toner bottle is not set cor-

rectly, or is not set.

Reset Yellow Toner Correctly The toner cartridge (Y) is not set cor-

rectly or is not set, and the color print-

ing is non-applicable.

RPCS Graphic Error

RPCS Graphic Error The printer memory is not initialized

RPCS Syntax Error The printer identified a syntax error.

SC XXX-X Power Off On

/If Error Reoccur Call Service

Staple Cancelled

The graphic is not initialize d becaus e

the graphic memory was not reserved.

because the CDC memory was not re-

served via the system call.

This error results from; data trans-

mogrification caused by the transmis-

sion path problem, data interruption,

data transmission from other drivers,

etc.

The Service Code or SC numb er indi-

cates the problem.

The Staple feature has been cancelled.

Set the waste toner bottle correctly.

Set the toner cartridge (Y) correctly.

See "Setting Up" in the Setup Guide.

Replace the installed memory.

Replace the installed memory.

Be sure to use the correct driver.

Turn the power switch off and then

on. If the message appears again,

contact your sales or service representative.

Verify that the paper orientation and

layout is proper ty se t, and make sure

whether your desired settings for the

finisher is selected.

Toner is Almost Empty: Black The printer is almost out of toner (K). Prepare a new toner cartridge (K).

Page 54

Operating Instructions Maintenance Guide 2

Messages/Second messages Description Solution

Toner is Almost Empty: Cyan The printer is almost out of toner (C). Prepare a new toner cartridge (C).

Toner is Almost Empty: Magenta The printer is almost out of toner (M). Prepare a new toner cartridge (M).

Toner is Almost Empty: Yellow The printer is almost out of toner (Y). Prepare a new toner cartridge (Y).

54

Waste Toner is Almost Full (E) The waste toner bottle is almost full

of toner dust.

Prepare a new waste toner bottle or

contact your sales or service representative.

See "Appendix" in the Setup Guide.

Page 55

Operating Instructions Maintenance Guide 2

Printer Does Not Print

Possible Cause Solutions

Is the power on? Confirm that the cable is securely plugged into the power outlet and the printer.

Turn on the power switch.

55

Does the

Does the

Is paper loaded? Load paper into the paper tray or on the bypass tray.

Can you print a configuration

page?

Is the interface cable connecting

the printer to the computer connected securely?

Are you using the correct interface cable?

indicator stay on?

Online

indicator stay red?

Error

Press {

Check the error message on the panel display and take the required action.

See P.9 “Paper and Other Media Supported by This Printer”.

If you cannot print a configuration page, it probably indicates a printer malfunc-

tion. You should contact your sales or service representative.

See "Printing a Configuration Page" in Administrat o r Re fe r e nc e 2.

Connect the interface cable properly. If there are any connectors or screws, confirm that they are fastened securely.

The type of interface cable you should use depends on the computer. Be sure to

use the correct one.

If the cable is damaged or worn, replace it with a new one.

See "Appendix" in Administrator Reference 2.

} so the indicator lights.

On Line

Page 56

Operating Instructions Maintenance Guide 2

Possible Cause Solutions

56

Is the Data In indicator blinking

or lit after starting the print job?

If not blinking or lit, the data is not being sent to the printer.

❖❖❖❖ If the printer is connected to the computer using the interface

cable

Make sure the printer port settings are correct. For a parallel port connection,

port LPT1 or LPT2 should be set.

• Windows 95/98/Me

Click [

A

Click to select the icon of the printer. Next, on the [

B

[

Properties

Click the [

C

Check the [

D

port is selected.

• Windows 2000

Click [

A

Click to select the icon of the printer. Next, on the [

B

[

Properties

Click the [

C

Check the [

D

port is selected.

• Windows NT 4.0

Click [

A

Click to select the icon of the printer. Next, on the [

B

[

Properties

Click the [

C

Check the [

D

port is selected.

], point to [

Start

].

Details

Print to the following port

], point to [

Start

].

] tab.

Port

Print to the following port

], point to [

Start

].

] tab.

Port

Print to the following port

Settings

] tab.

Settings

Settings

], and then click [

] box to confirm that the correct

], and then click [

] box to confirm that the correct

], and then click [

] box to confirm that the correct

Printers

File

Printers

File

Printers

File

] menu, click

] menu, click

] menu, click

].

].

].

Page 57

Operating Instructions Maintenance Guide 2

Possible Cause Solutions

57

Is the Data In indicator blinking

or lit after starting the print job?

When you use IEEE 1394 Interface Unit Type1045

❖❖❖❖ Network Connection

Contact your network ad ministrator.

Confirm that the IEEE 1394 Interface Unit Type1045 is attached to the com-

A

puter correctly.

Confirm that the IEEE 1394 interface cable is connected securely.

B

Restart the computer.

C

If the error occures even after executing above operation, proceed to the following steps.

Unplug the IEEE 1394 interface cable which is connected to the printer.

D

Execute the utility tool for IEEE 1394 Interface Unit Type1045 which is

E

stored in the following path in the CD-ROM labeled "Printer Drivers and Utilities".

UTILITY\1394

Important

❒ For details about using the utility tool for IEEE 1394, see the RE-

ADME file in the same directry in the CD-ROM.

Page 58

Operating Instructions Maintenance Guide 2

Other Printing Problems

Status Possible Causes, Descriptions, and Solutions

Black gradation is not natural. • PCL 5c/PostScript

Select "CMY+K" for Gray Reproduction in the printer driver's [

] dialog box under the [

vanced

• RPCS

Select "CMY+ K " fo r Gr a y Re pr od uc t i o n un d er th e [

] tab in the printer driver's [

ments

Print Quality

Change Use Setting

] tab.

58

Ad-

Image Adjust-

] dialog box.

Color documents are printed in black

and white.

Fine dot pattern does not print. • PCL 5c/PostScript

The printer driver is not set up for color printing.

• PCL 5c/PostScript

Select "Color" for the Color/Black and White under the printer driver's

[

] tab.

Setup

• RPCS

Select "Color" for the Color/Black and White under the printer driver's

[

Print Settings

For more information, see the printer driver's Help file.

Some applications normally print color text as black and white.

Change [

driver's [

• RPCS

Change [

[

Change User Settings

printer driver's dialog box.

For more information, see the printer driver's Help file.

] tab.

Dithering

Print Quality

Dithering

] setting in the Advanced dialog box under the printer

] tab.

] setting under the [

] dialog box under the [

Image Adjustments

Print Quality

] tab in the

] tab in the

Page 59

Operating Instructions Maintenance Guide 2

Status Possible Causes, Descriptions, and Solutions

59

Images are cut off, or excess pages are

printed.

It takes too much time to complete the

print job.

You might be printing on paper smaller than the paper size selected in the

application. Use paper the same size as that selected in the application. If

you cannot load paper of the correct size, use the reduction function to reduce the image, and then print.

See the printer driver's Help file.

Photographs and other data intensive pages take a long time for the printer

to process, so simply wait when printing such data.

Changing the following settings may help to speed up printing.

• PCL 5c

Select "600×600 dpi" for R esolut ion und er the [

printer driver's dialog box.

• PostScript

Select "1200×600 dpi" or "600×600 dpi" for Re solution under the [

] tab in the printer driver's dialog box.

Quality

Select "Post Script(optimize for speed)" for PostScript output format

under the [

• RPCS

Select "1200×600 dpi" or "600×600 dpi" for Resolution under the [

age Adjustments

printer dialog box.

Select "Speed" for Print priority under [

driver's dialog box.

For more information, see the printer driver's Help file.

PostScript

] tab in the printer driver's dialog box.

] tab in the Change Use Settings dialog box in the

Print Quality

Print Quality

] tab in the

Print

Im-

] tab in the printer

The data is so large or complex that it takes time to process it. If the Data

In indicator is blinking, the data processing is being done. Just wait until it

resumes.

If "Warming Up... " appears on the panel display, the printer is now warming up. Wait for a while.

Page 60

Operating Instructions Maintenance Guide 2

Status Possible Causes, Descriptions, and Solutions

60

It takes too much time to resume printing.

Multiple pages are fed through the

printer at once.

Output are not delivered to the selected

tray you require.

Paper misfeeds occur frequently. Check that the side guide of the Paper Tray is locked.

The data is so large or complex that it takes time to process it. If the Data

In indicator is blinking, the data processing is being done. Just wait until it

resumes.

The printer might be set to the Energy Saver mode. In the Energy Saver

mode, the printer has to warm up, and this takes time until printing starts.

To cancel the Energy Saver mode, select "Off" for "Energy Saver 1" in the

System Settings menu.

Paper misfeeds easily when the Paper Feed Roller is dirty. Contact your

sales or service representative to replace the Paper Feed Roller.

When using the bypass tray, the size selected on the display panel might be

different from actual paper size. Select the correct paper size.

See P.9 “Paper and Other Media Supported by This Printer”.

When you are using a Windows operating system, the printer driver set-

tings override those set using the operation panel. Set the desired output

tray using the printer driver.

See the printer driver's Help file.

See P.9 “Paper and Other Media Supported by This Printer”.

The paper size and feed direction of the paper in the Bypass Tray might not

be the same as those you selected with the operation panel. Check the settings on the operation panel, and load paper of the correct paper size and

feed direction.

See P.9 “Paper and Other Media Supported by This Printer”.

Check that the paper guide of the Paper Tray is attached properly.

Page 61

Operating Instructions Maintenance Guide 2

Status Possible Causes, Descriptions, and Solutions

61

Solid areas, lines or text are shiny or

glossy when created as a mixture of cyan, magenta, yellow.

Solid lines are printed as broken lines. • PCL 5c/PostScript

Some parts of the print image are not

clear.

The color of the printout is different from

the color on the computer's display.

• PCL 5c/PostScript

Select "K(Black)" for Gray Reproduction in the printer driver's [

] dialog box under the [

vanced

• RPCS

Select "K(Black)" for Gray Repr oduction under the [

] tab in the printer driver's [

ments

Change the [

printer driver's [

• RPCS

Change the [

[

Change User Settings

printer driver's dialog box.

For more information, see the printer driver's Help file.

Make the image density darker.

To adjust the image density, press {

lect Image Density from the Maintenance menu.

The toner based color settings with the printer driver causes a drastic

change in printout color.

Changing the color settings with the printer driver causes a drastic change

in printout color.

See the printer driver's Help file.

Dithering

Print Quality

Dithering

Ad-

Print Quality

Change Use Setting

] setting in the Advanced dialog box under the

] tab.

] setting under the [

] dialog box, under the [

Menu

] tab.

Image Adjust-

] dialog box.

Image Adjustments

Print Quality

} on the operation panel, and se-

] tab in the

] tab in the

The image is printed in the wrong orientation.

The feed direction you selected and the feed direction selected in Option

Setup of the printer driver might not be the same. Make the proper settings.

Page 62

Operating Instructions Maintenance Guide 2

Status Possible Causes, Descriptions, and Solutions

62

The operation panel error message stays

on after removing the misfed paper.

The print image is not clear. Due to a sudden change in temperature, condensation might appear inside

The print side of the page is a hazy gray. Adjust the image density.

The printed image is different from the

image on the computer.

Open the front cover of the printer, and then close it.

the printer, reducing print quality. If this occurs, when you move the printer

from a cold room to a warmer room, do not use the printer until it acclimatizes to the temperature.

To adjust the image density, press {

the Maintenance menu.

See "Cleaning and Adjusting the Printer" in Maintenance Guide 1.

If paper is curled, correct it.

Curled or folded paper might cause a hazy gray print. Curling often occurs

on postcards, so be sure to correct it before printing.

When you use some functions, such as enlargement and reduction, the layout of the image might be different from that displayed in the computer display.

You might have selected to replace True Type fonts with printer fonts in

the printing process.

To print an image similar to the image on the computer, make the settings

to print out True Type fonts as an image.

See the printer driver's Help file.

}, and select Image Density from

Menu

The printer does not print at 1200dpi,

even if 1200dpi resolution is selected.

Printing at 1200dpi uses much memory. Therefore, depending on the memory capacity, you may not be able to print at 1200dpi. Either add memory

to the printer, or reduce the size of data to be printed.

See "Memory Capacity and Paper Size" in Administrator Reference 2.

Page 63

Operating Instructions Maintenance Guide 2

Status Possible Causes, Descriptions, and Solutions

63

There are color differences in the color

documents.

Press {

See "Cleaning and Adjusting the Printer" in Maintenance Guide 1.

}, and select "Color Regist." from the "Maintenance" menu.

Menu

Note

❒ If the problem cannot be solved, contact your sales or service representative.

Page 64

Operating Instructions Maintenance Guide 2

Removing Misfed Paper

64

If a paper misfeed occurs, an error message appears indicating the location of the misfed paper

on the panel display. This printer has the auto-recovery function, by which misfe d paper is sent to

the Standard Tray or Right Cover. Usually, you

can remove the misfed paper easily with this

function.

Detaching the 2 Tray Finisher

There are times when you might have to detach

the 2 Tray Finisher from the printer to remove

misfed paper. This section describes how to detach the 2 Tray Finisher.

A

Hold the handle at the top of the 2 Tray

Finisher firmly with one hand, pull the 2

Tray Finisher straight out , and let g o when

it stops.

ZDJP201J

The 2 Tray Finisher is detached from the

printer.

Page 65

Operating Instructions Maintenance Guide 2

B

Use both hands to push it straight back in,

and let go when it clicks into place.

ZDJP202J

The 2 Tray Finisher is reattached to the print er.

Important

❒ Attach the 2 Tray Finisher to the printer af-

ter closing the Duplex Reversal Unit.

Opening and Closing the Duplex Reversal Unit

There are times when you might have to detach

the Duplex Reversal Unit to remove misfed paper. This section d escribes how to deta ch the Duplex Reversal Unit.

A

Push up the lock release butto n and keep it

in place.

65

ZDJP203J

Page 66

Operating Instructions Maintenance Guide 2

66

B

Lower the Duplex Reversal Unit slowly until it stops.

ZDJP204J

Important

❒ Open the Duplex Reversal Unit after de-

taching the 2 Tray Finisher from the printer.

Note

❒ You do not have t o rem o ve th e ou t u pt t ra y

even if the 2 Tray Finisher is attached.

The Duplex Reversal Unit is opened.

C

Raise the Duplex Reversal Uni t slowly wi th

both hands, and push it in until it clicks

into place.

ZDJP205J

The Duplex Reversal Unit is closed.

Important

❒ Attach the Duplex Reversal Unit after clos-

ing the upper left cover for the printer.

Page 67

Operating Instructions Maintenance Guide 2

When "Remove Misfeed A: Internal Path" Appears

A

Open the right cover.

B

Move the blue lever up and down to feed

the misfed paper, and then pull out the paper slowly.

ZDJY205J

67

ZDJH206J

C

Close the right cover by pushing the area

labeled "PUSH".

ZDJP708J

Page 68

Operating Instructions Maintenance Guide 2

R

When "Remove Misfeed B: Fusing Unit" Appears

CAUTION:

• The inside of the machine becomes very

hot. Do not touch the parts with a label indicating a "hot surface". Touching a "hot surface" could result in a burn.

A

If the 2 Tray Finisher is installed, detach it

from the printer.

C