Page 1

Model-U

(Machine Code: G071)

SERVICE MANUAL

Page 2

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

4. The printer drives some of its components when it completes the warm-up

period. Be careful to keep hands away from the mechanical and electrical

components as the printer starts operation.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner and developer are non-toxic, but if you get either of them in your eyes by

accident, it may cause temporary eye discomfort. Try to remove with eye drops

or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be serviced by a customer service

representative who has completed the training course on those models.

2. The NVRAM module (option) installed on the controller has a lithium battery

which can explode if replaced incorrectly. Replace the NVRAM only with an

identical one. The manufacturer recommends replacing the entire NVRAM.

Do not recharge or burn this battery. Used NVRAM must be handled in

accordance with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the

organic photoconductor in accordance with local regulations. (These are

non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

When keepi ng used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

4. When keeping used lithiu m batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

Page 3

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!

WARNING

WARNING: Turn off the main switch before atte mpting any of the

procedures in the Laser Optics Housing Unit section. Laser

beams can seriously damage your eyes.

CAUTION MARKING:

Page 4

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft

Corporation in the United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines

Corporation.

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved

with those marks.

Page 5

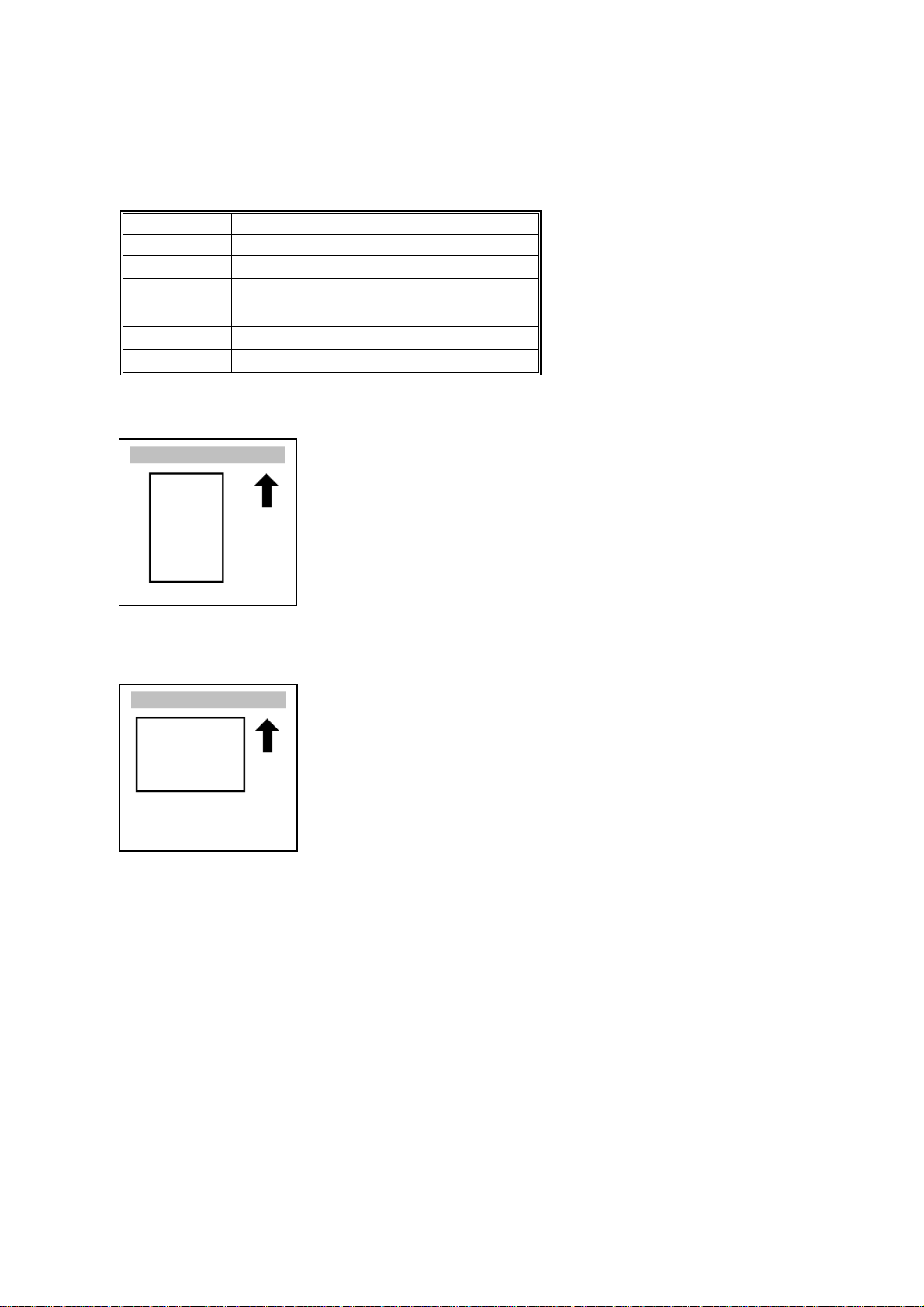

Conventions in this Manual

This manual uses several symbols.

Symbol What it means

☛

!

"

#

$

%

Refer to section number

See Core Tech Manual for details

Screw

Connector

Clip ring

E-ring

Lengthwise, SEF (Short Edge Feed)

Sideways, LEF (Long Edge Feed)

Page 6

TABLE OF CONTENTS

1 INSTALLATION ........................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS...........................................................1-1

1.1.1 ENVIRONMENT...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-1

1.1.3 SPACE REQUIREMENTS................................................................1-2

1.1.4 POWER REQUIREMENTS..............................................................1-2

1.2 MACHINE INSTALLATION .......................................................................1-3

1.3 OPTIONS..................................................................................................1-4

2 PREVENTIVE MAINTENANCE.................................................... 2-1

2.1 OVERVIEW...............................................................................................2-1

Users Do the User PM Procedures.......................................................2-1

All PM Done by Technicians.................................................................2-1

Counters...............................................................................................2-1

2.2 USER MAINTENANCE .............................................................................2-1

Main Unit...............................................................................................2-1

Optional Paper Tray Unit......................................................................2-2

2.3 SERVICE MAINTENANCE........................................................................2-2

Main Unit...............................................................................................2-2

Bypass Tray..........................................................................................2-2

Optional Units.......................................................................................2-3

Paper Tray Unit.....................................................................................2-3

Finisher.................................................................................................2-3

Mail Box................................................................................................2-3

Duplex Unit...........................................................................................2-3

Interchange Unit ...................................................................................2-3

3 REPLACEMENT AND ADJUSTMENT......................................... 3-1

3.1 SPECIAL TOOLS......................................................................................3-1

3.2 EXTERIOR COVERS................................................................................3-2

3.2.1 REAR COVER..................................................................................3-2

3.2.2 LOWER LEFT COVER.....................................................................3-3

3.2.3 UPPER COVER, OPERATION PANEL............................................3-3

3.3 ELECTRICAL COMPONENTS..................................................................3-4

3.3.1 PRINTER CONTROLLER ................................................................3-4

3.3.2 CONTROLLER BOX.........................................................................3-4

3.3.3 BCU BOARD....................................................................................3-4

3.3.4 I/O BOARD.......................................................................................3-5

3.3.5 PSU..................................................................................................3-5

3.3.6 HIGH VOLTAGE SUPPLY BOARD..................................................3-6

3.4 DRIVE UNITS............................................................................................3-7

3.4.1 DEVELOPMENT CLUTCHES..........................................................3-7

K/Y Development Units.........................................................................3-7

C/M Development Units........................................................................3-7

3.4.2 DEVELOPMENT MOTOR................................................................3-8

i

Page 7

3.4.3 MAIN MOTOR..................................................................................3-8

3.4.4 PCU GEAR BOX AND OPC BELT CLEANING CLUTCH ................3-9

3.4.5 FUSING UNIT MOTOR ....................................................................3-9

3.4.6 PAPER FEED MOTOR...................................................................3-10

3.4.7 PAPER FEED CLUTCH.................................................................3-10

3.4.8 REGISTRATION CLUTCH.............................................................3-10

3.5 LASER OPTICS SECTION .....................................................................3-11

3.5.1 CAUTION DECAL LOCATION.......................................................3-11

3.5.2 LASER OPTICS HOUSING UNIT ..................................................3-12

Adjusting for Image Skew...................................................................3-14

3.5.3 LD UNIT..........................................................................................3-14

3.5.4 POLYGONAL MIRROR MOTOR AND SYNC. DETECTION

BOARD...........................................................................................3-15

3.6 DEVELOPMENT UNIT............................................................................3-16

3.7 PHOTOCONDUCTOR UNIT (PCU)........................................................3-17

3.7.1 MAIN UNIT.....................................................................................3-17

3.7.2 WASTE TONER BOTTLES............................................................3-18

3.7.3 CHARGE CORONA WIRE.............................................................3-19

3.7.4 CHARGE CORONA WIRE CLEANER MOTOR.............................3-20

3.7.5 OPC BELT CLEANING UNIT.........................................................3-20

3.7.6 OPC BELT UNIT ............................................................................ 3-21

3.7.7 IMAGE TRANSFER BELT CLEANING UNIT .................................3-21

3.7.8 IMAGE TRANSFER BELT UNIT ....................................................3-22

Reassembling.....................................................................................3-22

3.8 PAPER TRANSFER UNIT.......................................................................3-23

3.8.1 VERTICAL TRANSPORT UNIT......................................................3-23

3.8.2 TRANSFER ROLLER.....................................................................3-23

3.9 FUSING/PAPER EXIT............................................................................. 3-24

3.9.1 FUSING UNIT.................................................................................3-24

3.9.2 OIL SUPPLY UNIT.........................................................................3-24

3.9.3 LAMPS ...........................................................................................3-25

3.9.4 FUSING INNER UNIT..................................................................... 3-26

3.9.5 PRESSURE ROLLER THERMOFUSE...........................................3-26

3.9.6 FUSING BELT UNIT AND PRESSURE ROLLER UNIT.................3-26

3.9.7 PRESSURE ROLLER THERMISTOR............................................3-27

3.9.8 PAPER EXIT UNIT AND PAPER EXIT/OVERFLOW SENSOR.....3-27

3.10 PAPER FEED AND TRANSPORT........................................................3-28

3.10.1 FEED ROLLER AND FRICTION PAD..........................................3-28

3.10.2 REGISTRATION SENSOR...........................................................3-29

3.10.3 PAPER FEED SENSOR...............................................................3-30

3.10.4 PAPER NEAR-END SENSOR......................................................3-30

3.10.5 PAPER END SENSOR.................................................................3-30

3.11 BYPASS TRAY......................................................................................3-31

3.11.1 PICKUP/FEED ROLLER..............................................................3-31

3.11.2 PAPER FEED CLUTCH...............................................................3-32

3.11.3 REVERSE ROLLER.....................................................................3-32

ii

Page 8

4 TROUBLESHOOTING ................................................................. 4-1

4.1 SERVICE CALL.........................................................................................4-1

4.1.1 SERVICE CALL CONDITIONS ........................................................4-1

4.1.2 SC TABLE........................................................................................4-2

4.2 CONTROLLER ERROR TABLE................................................................4-9

4.3 BLOWN FUSE CONDITIONS.................................................................4-12

4.4 CHECK POINTS FOR IMAGE PROBLEMS AT REGULAR

INTERVALS ............................................................................................4-12

5 SERVICE TABLES....................................................................... 5-1

5.1 SERVICE PROGRAM MODE....................................................................5-1

5.1.1 OPERATION PANEL KEYS.............................................................5-1

5.1.2 STARTING SERVICE PROGRAM MODE........................................5-2

Procedure 1..........................................................................................5-2

Procedure 2..........................................................................................5-2

5.1.3 MAIN MENU.....................................................................................5-2

5.1.4 SPECIFYING A VALUE OR SETTING.............................................5-3

5.1.5 LEAVING SERVICE MODE..............................................................5-3

5.2 SP MODE TABLES...................................................................................5-4

5.2.1 SERVICE (CONTROLLER SERVICE MODES) ...............................5-4

Bit Switch Settings................................................................................5-6

How to Change Bit Switch Settings ......................................................5-6

Bit Switch 1...........................................................................................5-7

Bit Switch 2...........................................................................................5-7

Bit Switch 3...........................................................................................5-7

Bit Switch 4...........................................................................................5-7

Gamma Adjustment..............................................................................5-8

Summary ..............................................................................................5-8

Adjustment Procedure ..........................................................................5-9

5.2.2 ENGINE SERVICE MODES...........................................................5-11

SP1-XXX: (Feed)................................................................................5-11

SP2-XXX: (Drum)................................................................................5-15

SP3-XXX: (Process) ...........................................................................5 -24

SP5-XXX: (Mode) ...............................................................................5-27

SP7-XXX: (Data Log)..........................................................................5-33

Input Check Table...............................................................................5-39

Table 1: Tray 1 Paper Size.................................................................5-42

Table 2: 1st/2nd Bank Paper Size ......................................................5-42

Table 3: 1st/2nd Bank Near End.........................................................5-42

Output Check Table............................................................................5-43

5.3 CONTROLLER SELF-DIAGNOSTICS....................................................5-45

5.3.1 OVERVIEW....................................................................................5-45

5.3.2 DETAILED SELF-DIAGNOSTICS..................................................5-46

5.4 USER PROGRAM MODE.......................................................................5-47

5.5 UPGRADING SOFTWARE .....................................................................5-48

5.5.1 OVERVIEW....................................................................................5-48

5.5.2 UPGRADING..................................................................................5-49

Procedure...........................................................................................5-49

iii

Page 9

Error Recovery....................................................................................5-50

Installation Error..................................................................................5-50

Power Failure......................................................................................5-50

5.6 DIP SWITCHES.......................................................................................5-51

Controller Board..................................................................................5-51

BCU Board..........................................................................................5-51

6 DETAILED SECTION DESCRIPTIONS ....................................... 6-1

6.1 OVERVIEW...............................................................................................6-1

6.1.1 MAJOR COMPONENTS ..................................................................6-1

6.1.2 PAPER PATH...................................................................................6-2

6.1.3 DRIVE COMPONENTS....................................................................6-3

6.1.4 ELECTRICAL COMPONENTS.........................................................6-4

Image Transfer .....................................................................................6-4

Development Units ...............................................................................6-5

Paper Path............................................................................................6-6

Drive Components................................................................................6-7

Circuit Boards.......................................................................................6-8

6.2 PRINTING PROCESS OVERVIEW...........................................................6-9

6.3 PROCESS CONTROL ............................................................................6-11

6.3.1 OVERVIEW....................................................................................6-11

6.3.2 PROCESS CONTROL STEPS....................................................... 6-12

Six Steps.............................................................................................6-12

When is Process Control Done?.........................................................6-12

6.4 PHOTOCONDUCTOR UNIT (PCU)........................................................6-13

6.4.1 OVERVIEW....................................................................................6-13

6.4.2 NEW PHOTOCONDUCTOR UNIT DETECTION...........................6-14

New PCU Sensor................................................................................6-14

Mechanism .........................................................................................6-14

PCU Counter ......................................................................................6-14

6.4.3 CHARGE CORONA UNIT..............................................................6-15

Power Supply......................................................................................6-15

Wire Cleaning.....................................................................................6-15

Cleaning Interval .................................................................................6-15

Quenching ..........................................................................................6-16

6.4.4 OPC BELT DRIVE..........................................................................6-16

6.4.5 OPC BELT CLEANING UNIT.........................................................6-17

Toner Collection Augurs.....................................................................6-17

Counter Blade + Brush.......................................................................6-17

Waste Toner Bottle Sensors...............................................................6-17

Drive ...................................................................................................6-18

6.4.6 IMAGE TRANSFER BELT UNIT ....................................................6-19

Drive ...................................................................................................6-19

Belt Mark Sensor................................................................................6-19

Bias Roller ..........................................................................................6-20

6.4.7 TRANSFER BELT CLEANING UNIT..............................................6-21

Bias Brush ..........................................................................................6-21

Bias Roller and Cleaning Blade..........................................................6-21

Collecting Coil.....................................................................................6-21

iv

Page 10

Waste Toner Bottle Sensors...............................................................6-21

Contact Mechanism............................................................................6-22

Power Supply......................................................................................6-23

Drive ...................................................................................................6-23

6.5 LASER EXPOSURE................................................................................6-24

6.5.1 OVERVIEW....................................................................................6-24

Dust Shield Glass Cleaning................................................................6-25

LD Unit Adjustment.............................................................................6-25

Polygonal Mirror..................................................................................6-25

Laser Diode Power Control.................................................................6-25

Maintenance Adjustment....................................................................6-25

6.5.2 LD SAFETY SWITCH.....................................................................6-26

Operation Panel Message and Switch Mechanism.............................6-27

“Close Front Cover”........................................................................6-27

“Close Right Cover”........................................................................6-27

“Close Left Cover” ..........................................................................6-27

6.6 DEVELOPMENT.....................................................................................6-28

6.6.1 OVERVIEW....................................................................................6-28

6.6.2 DEVELOPMENT UNIT...................................................................6-29

Rollers and Agitators...........................................................................6-29

Replacing Units...................................................................................6-29

Memory Chip ......................................................................................6-29

6.6.3 TONER SUPPLY MECHANISM.....................................................6-30

Toner Cartridge Agitators....................................................................6-30

Drive Power Path................................................................................6-30

Development Unit Agitator..................................................................6-30

Toner Supply Roller and Doctor Roller...............................................6-30

Shutter................................................................................................6-30

6.6.4 TONER END DETECTION .............................................................6-31

Mechanism .........................................................................................6-31

Toner Near-end Detection ..................................................................6-31

Toner End Detection...........................................................................6-31

Toner End Recovery...........................................................................6-31

6.6.5 DEVELOPMENT UNIT CONTACT MECHANISM..........................6-32

Mechanism .........................................................................................6-32

Reverse Rotation................................................................................6-32

6.6.6 POWER SOURCE..........................................................................6-33

Development, Toner Supply, and Doctor Rollers................................6-33

Doctor Roller.......................................................................................6-33

6.7 PAPER FEED..........................................................................................6-34

6.7.1 OVERVIEW....................................................................................6-34

Transport Speed.................................................................................6-35

Friction Pad.........................................................................................6-35

6.7.2 STANDARD TRAY DRIVE .............................................................6-35

Feed and Vertical Transport Rollers...................................................6-35

Registration Roller..............................................................................6-35

6.7.3 STANDARD TRAY – BOTTOM PLATE LIFT .................................6-36

Lift Mechanism....................................................................................6-36

Paper Near End Detection..................................................................6-36

v

Page 11

Paper End Detection...........................................................................6-36

6.7.4 STANDARD TRAY - PAPER SIZE DETECTION ...........................6-37

Mechanism .........................................................................................6-37

Switch Pattern.....................................................................................6-37

6.7.5 BYPASS TRAY...............................................................................6-38

Paper Feed Mechanism......................................................................6-38

Bypass Tray Drive Power Path...........................................................6-38

Pick-up Solenoid.................................................................................6-38

Paper End Sensor ..............................................................................6-38

6.8 PAPER TRANSFER AND SEPARATION ...............................................6-39

6.8.1 OVERVIEW....................................................................................6-39

Jammed Paper Release.....................................................................6-39

Image Transfer and Paper Separati on................................................6-39

6.8.2 MECHANISM..................................................................................6-40

Contact/Separation.............................................................................6-40

Drive Power Path................................................................................6-40

6.8.3 POWER SUPPLY...........................................................................6-42

Electric Power Path ............................................................................ 6-42

Transfer Roller Bias............................................................................6-42

Discharge Plate .................................................................................. 6-42

Temperature/Humidity Control............................................................6-42

Roller Cleaning...................................................................................6-43

6.9 FUSING UNIT AND OIL SUPPLY UNIT..................................................6-44

6.9.1 OVERVIEW....................................................................................6-44

6.9.2 FUSING UNIT CONFIGURATION..................................................6-45

Fusing Belt..........................................................................................6-45

Oil Supply ...........................................................................................6-45

Heating Roller Lamp...........................................................................6-45

Pressure Roller Lamp......................................................................... 6-45

Pressure Roller Pawls.........................................................................6-45

Fusing Bias.........................................................................................6-46

Fusing Unit SCs..................................................................................6-46

6.9.3 TEMPERATURE CONTROL..........................................................6-47

6.9.4 OIL SUPPLY AND CLEANING.......................................................6-48

Oil Supply ...........................................................................................6-48

Oil Path...............................................................................................6-48

Oil Recycling.......................................................................................6-48

Belt Cleaning ......................................................................................6-48

Oil End Detection................................................................................6-49

Fusing unit switch...............................................................................6-49

6.9.5 DRIVE.............................................................................................6-49

Drive Power Path (Fusing Unit and Oil Supply Roller)........................6-49

Drive Power Path (Pressure Roller)....................................................6-49

6.9.6 ENERGY SAVER MODE................................................................6-50

Level 1 Energy Saver Mode (default: on)............................................6-50

Level 2 Energy Saver Mode................................................................6-50

Ready Mode .......................................................................................6-50

6.9.7 PAPER EXIT ..................................................................................6-51

Drive Power Path................................................................................6-51

vi

Page 12

Paper Jam Detection..........................................................................6-51

6.9.8 OVERFLOW DETECTION.............................................................6-51

6.10 PRINTED CIRCUIT BOARDS...............................................................6-52

6.10.1 PRINTER CONTROLLER ............................................................6-52

Function..............................................................................................6-52

Memory............................................................................................... 6-52

Interfaces............................................................................................6-52

Slots....................................................................................................6-53

Options ...............................................................................................6-53

DIP Switch..........................................................................................6-53

LED Indicators....................................................................................6-53

6.10.2 BASE ENGINE CONTROL UNIT (BCU).......................................6-54

Function..............................................................................................6-54

Upgrading...........................................................................................6-54

Nonvolatile Random Access Memory (NVRAM).................................6-54

DIP Switch..........................................................................................6-54

6.10.3 INPUT/OUTPUT (I/O) BOARD.....................................................6-55

6.10.4 POWER SUPPLY UNIT (PSU) .....................................................6-55

6.10.5 HIGH VOLTAGE SUPPLY............................................................6-55

6.11 CONTROLLER......................................................................................6-56

6.11.1 OVERVIEW..................................................................................6-56

6.11.2 BOARD LAYOUT..........................................................................6-58

6.11.3 PRINT DATA PROCESSING .......................................................6-59

RPCS Driver.......................................................................................6-59

PCL5c Driver ......................................................................................6-59

PS3 Driver ..........................................................................................6-60

CMS (Color Management System)..................................................... 6-60

Gray Correction ..................................................................................6-60

BG/UCR (Black Generation/Under Color Removal)............................6-60

Gamma Correction .............................................................................6-60

Toner Limitation..................................................................................6-61

Dither Processing and ROP/RIP.........................................................6-61

6.11.4 CONTROLLER FUNCTIONS.......................................................6-62

Sample Print.......................................................................................6-62

Locked Print........................................................................................6-62

Paper Source Selection......................................................................6-63

Tray Priority (Auto Tray Select)...........................................................6-63

Tray Lock............................................................................................6-63

Manual Tray Select.............................................................................6-63

Auto Continue.....................................................................................6-64

Overview.............................................................................................6-64

Auto Tray Select.................................................................................6-64

Manual Tray Select.............................................................................6-64

Paper Output Tray..............................................................................6-65

Output Tray Selected..........................................................................6-65

Sequential Stacking............................................................................6-65

Stapling...............................................................................................6-66

6.12 IEEE1394 INTERFACE.........................................................................6-67

6.12.1 SPECIFICATIONS........................................................................6-67

vii

Page 13

Hardware Specification.......................................................................6-67

System Requirements.........................................................................6-67

6.12.2 IEEE1394 .....................................................................................6-67

6.12.3 BLOCK DIAGRAM........................................................................6-68

6.12.4 PIN ASSIGNMENT.......................................................................6-68

6.12.5 REMARKS ABOUT THIS INTERFACE KIT..................................6-69

6.12.6 TROUBLESHOOTING NOTES....................................................6-69

PERIPHERALS

PAPER TRAY UNIT (Machine Code: G313)

1 REPLACEMENT AND ADJUSTMENT...................................G313-1

1.1 REAR COVER....................................................................................G313-1

1.2 PAPER FEED CLUTCH.....................................................................G313-1

1.3 LIFT MOTOR......................................................................................G313-2

1.4 PAPER FEED MOTOR ......................................................................G313-2

1.5 CONTROLLER BOARD.....................................................................G313-2

1.6 PICK-UP/FEED/SEPARATION ROLLERS.........................................G313-3

2 DETAILED DESCRIPTIONS..................................................G313-4

2.1 MECHANICAL COMPONENT LAYOUT ............................................G313-4

Feed and Reverse Roller (FRR)....................................................G313-4

Drive Path......................................................................................G313-4

Paper End Feeler Method..............................................................G313-4

2.2 ELECTRICAL COMPONENT LAYOUT..............................................G313-5

2.3 DRIVE LAYOUT.................................................................................G313-6

2.4 PAPER SIZE DETECTION.................................................................G313-7

2.5 PAPER LIFT.......................................................................................G313-8

2.6 PAPER HEIGHT AND END DETECTION..........................................G313-9

Paper Height Detection..................................................................G313-9

Paper End Detection......................................................................G313-9

INTERCHANGE UNIT (Machine Code: G305)

1. REPLACEMENT AND ADJUSTMENT..................................G305-1

1.1 EXTERIOR COVER AND PAPER EXIT SENSOR.............................G305-1

1.2 CONTROL BOARD............................................................................G305-1

2. DETAILED DESCRIPTIONS.................................................G305-2

2.1 ELECTRICAL COMPONENTS...........................................................G305-2

2.2 DRIVE ................................................................................................G305-2

2.3 MECHANISM......................................................................................G305-3

viii

Page 14

DUPLEX UNIT (Machine Code: G303)

1 REPLACEMENT AND ADJUSTMENT...................................G303-1

1.1 EXTERIOR COVER...........................................................................G303-1

1.2 ENTRANCE/EXIT SENSORS............................................................G303-1

Entrance Sensor............................................................................G303-1

Exit Sensor ....................................................................................G303-1

1.3 INVERTER MOTOR...........................................................................G303-2

1.4 CONTROLLER BOARD.....................................................................G303-2

1.5 TRANSPORT MOTOR.......................................................................G303-2

2 DETAILED DESCRIPTIONS..................................................G303-3

2.1 OVERVIEW........................................................................................G303-3

2.2 ELECTRICAL COMPONENT LAYOUT..............................................G303-4

2.3 DRIVE LAYOUT.................................................................................G303-5

2.4 DUPLEX PAPER FEED ORDER........................................................G303-6

2.4.1 LONGER THAN A4/LT LEF.......................................................G303-6

2.4.2 UP TO A4/LT LEF......................................................................G303-7

2.5 REVERSE MECHANISM ...................................................................G303-8

500-SHEET FINISHER (Machine Code: G314)

1 REPLACEMENT AND ADJUSTMENT...................................G314-1

1.1 EXTERIOR COVERS.........................................................................G314-1

Front Cover....................................................................................G314-1

Rear Cover ....................................................................................G314-1

Lower Guide ..................................................................................G314-2

Reassembly...................................................................................G314-2

Upper Cover ..................................................................................G314-3

Right Cover....................................................................................G314-3

1.2 ENTRANCE UPPER GUIDE AND PAPER EXIT UNIT......................G314-4

1.3 MOTORS............................................................................................G314-5

1.3.1 MAIN MOTOR...........................................................................G314-5

1.3.2 JOGGER MOTOR.....................................................................G314-5

1.4 STAPLER...........................................................................................G314-6

1.5 PADDLE ROLLER SOLENOID ..........................................................G314-6

1.6 MAIN CONTROL PCB........................................................................G314-7

1.7 OUTPUT TRAY UNIT.........................................................................G314-8

2 DETAILED DESCRIPTIONS................................................G314-10

2.1 OVERALL MACHINE INFORMATION .............................................G314-10

2.1.1 COMPONENT LAYOUT..........................................................G314-10

2.1.2 DRIVE LAYOUT......................................................................G314-11

2.1.3 ELECTRICAL COMPONENTS................................................G314-12

2.2 DETAILED SECTION DESCRIPTIONS...........................................G314-14

2.2.1 OUTPUT TRAY.......................................................................G314-14

ix

Page 15

Stack Height Detection................................................................G314-14

Output Tray Up/Down Mechanism...............................................G314-15

Overview......................................................................................G314-15

Output Tray Downward Movement..............................................G314-15

Output Tray Upward Movement...................................................G314-15

2.2.2 PAPER FEED..........................................................................G314-16

Overview......................................................................................G314-16

Straight Feed-out Mode...............................................................G314-16

Shift Sorting Mode.......................................................................G314-17

Stapling Mode..............................................................................G314-19

2.2.3 JAM CONDITIONS..................................................................G314-20

2.2.4 ERROR DETECTION..............................................................G314-20

FOUR-BIN MAILBOX (Machine Code: G312)

1. REPLACEMENT AND ADJUSTMENT..................................G312-1

1.1 EXTERIOR COVER...........................................................................G312-1

1.2 MAIN MOTOR AND CONTROLLER BOARD.....................................G312-1

1.3 VERTICAL TRANSPORT AND PAPER OVERFLOW SENSORS.....G312-2

2. DETAILED DESCRIPTIONS.................................................G312-3

2.1 OVERVIEW........................................................................................G312-3

2.2 DRIVE ................................................................................................G312-4

Drive Path......................................................................................G312-4

2.3 ELECTRICAL COMPONENT LAYOUT..............................................G312-5

2.4 PAPER DISTRIBUTION.....................................................................G312-6

Mechanism ....................................................................................G312-6

Paper Overflow Sensor..................................................................G312-6

2.5 BASIC OPERATION...........................................................................G312-7

2.6 PAPER MISFEED DETECTION TIMING...........................................G312-7

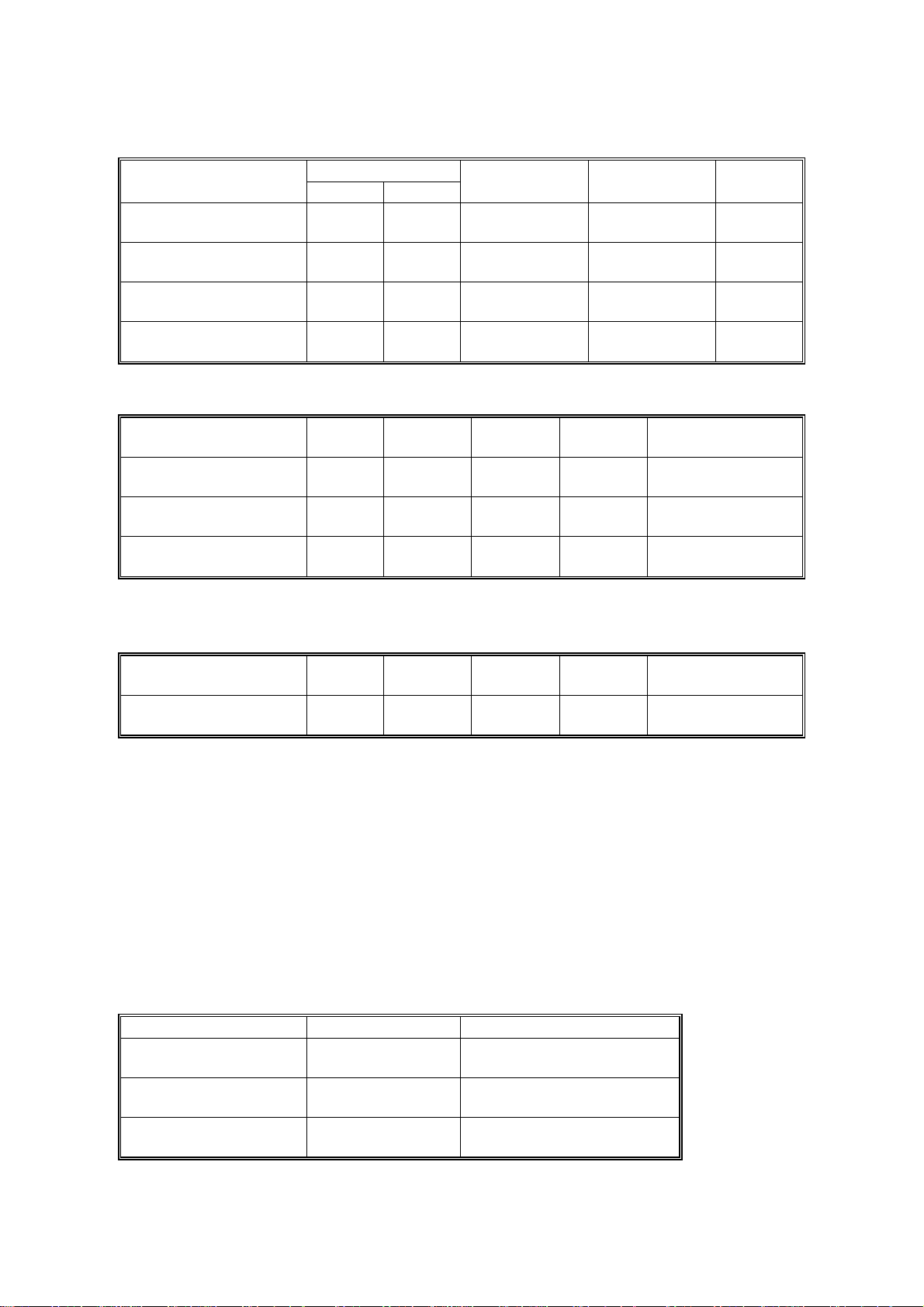

SPECIFICATIONS.....................................................................SPEC-1

1 GENERAL SPECIFICATIONS..............................................................SPEC-1

1.1 MAIN UNIT..................................................................................SPEC-1

1.2 SUPPORTED PAPER SIZES......................................................SPEC-4

1.2.1 MAIN TRAY, BYPASS TRAY, AND DUPLEX UNIT ...........SPEC-4

1.2.2 FINISHER, MAIL BOX, AND PAPER TRAY UNIT..............SPEC-5

2 SOFTWARE ACCESSORIES..............................................................SPEC-6

2.1 PRINTER DRIVERS....................................................................SPEC-6

2.2 UTILITY SOFTWARE..................................................................SPEC-6

3 MACHINE CONFIGURATION

3.1 SYSTEM COMPONENTS...........................................................SPEC-7

EXTERIOR ...................................................................................SPEC-7

INTERIOR.....................................................................................SPEC-8

x

Page 16

MAINTENANCE KITS...................................................................SPEC-8

3.2 OPTIONAL EQUIPMENT............................................................SPEC-9

PAPER TRAY UNIT......................................................................SPEC-9

FINISHER.....................................................................................SPEC-9

MAIL BOX...................................................................................SPEC-10

DUPLEX UNIT............................................................................SPEC-10

INTERCHANGE UNIT ................................................................SPEC-10

xi

Page 17

17 September, 2001 INSTALLATION REQUIREMENTS

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range:

2. Humidity Range: 20% to 80% RH

3. Ambient Illumination: Less than 2,000 lux (keep the machine out of direct

4. Ventilation: 3 times/hr/person or more

5. Avoid exposing the machine to sudden temperature changes, which include:

1) Direct cool air from an air conditioner

2) Direct heat from a heater

6. Avoid installing the machin e in areas that may be exposed to corrosive gas.

7. Install the machine at a location lower than 2,500 m (8,200 ft.) above sea level.

8. Install the machine on a strong, level base. (☛ 1.1.2)

9. Avoid installing the machine in areas that may be subjected to strong vibration.

10°C to 32°C (50°F to 89°F)

sunlight.)

Installation

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

1-1

Page 18

INSTALLATION REQUIREMENTS 17 September, 2001

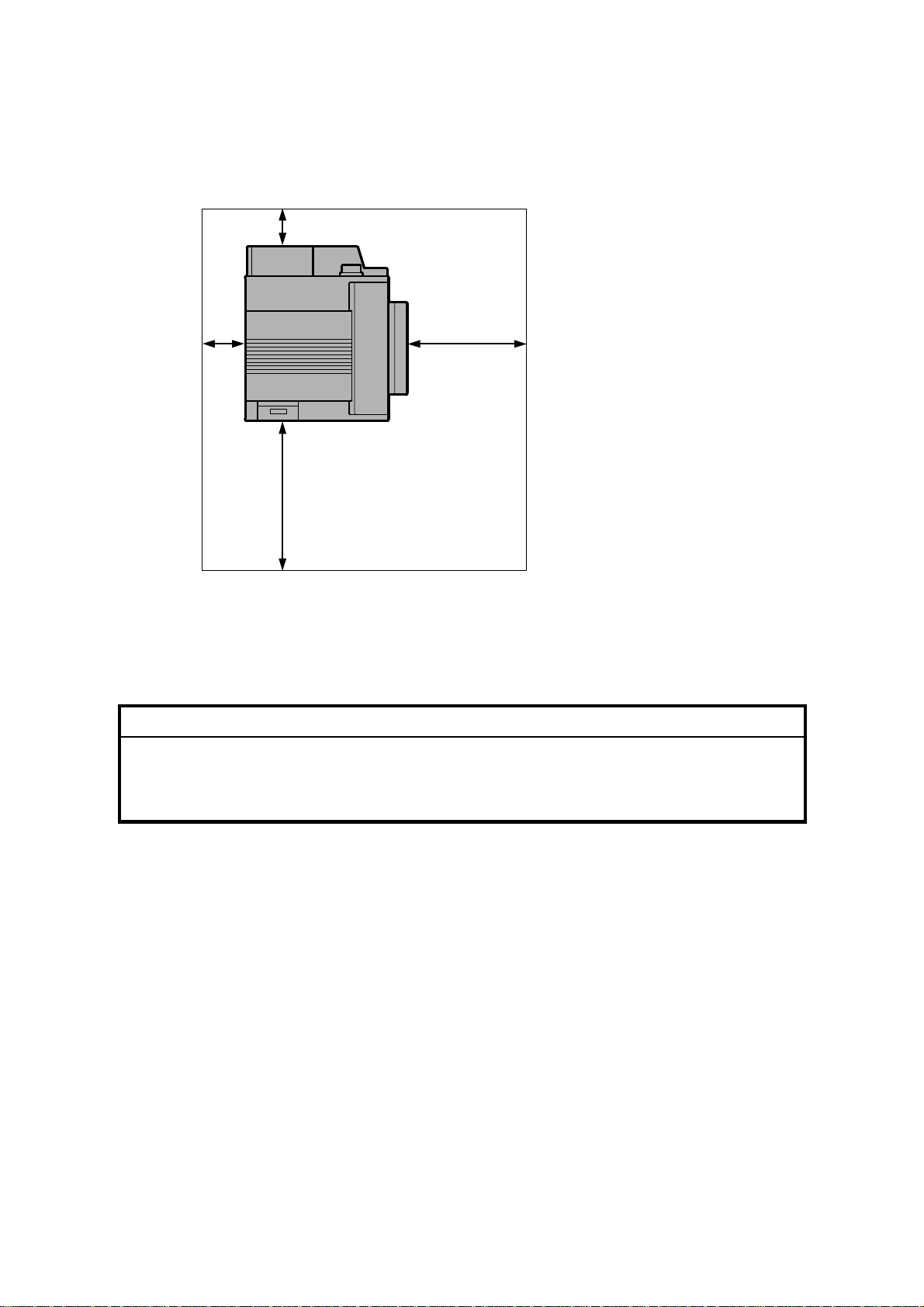

1.1.3 SPACE REQUIREMENTS

_

A: Over 100 mm (4")

B: Over 100 mm (4")

^

`

C:Over 550 mm (22")

D:Over 750 mm (30")

a

G070I001.WMF

1.1.4 POWER REQUIREMENTS

!

CAUTION

1. Insert the plug firmly in the outlet.

2. Avoid using an outlet extension plug or cord.

3. Ground the machine.

1. Input voltage level:

120 V, 60 Hz, More than 11 A

220 to 240 V, 50/60 Hz, More than 7 A

2. Permissible voltage fluctuation: ±10%

3. Do not put or place anything on the power cord.

1-2

Page 19

17 September, 2001 MACHINE INSTALLATION

1.2 MACHINE INSTALLATION

Refer to the Operating Instructions for details.

If the customer has a service contract, change the settings of the following SP

modes depending on the contract type.

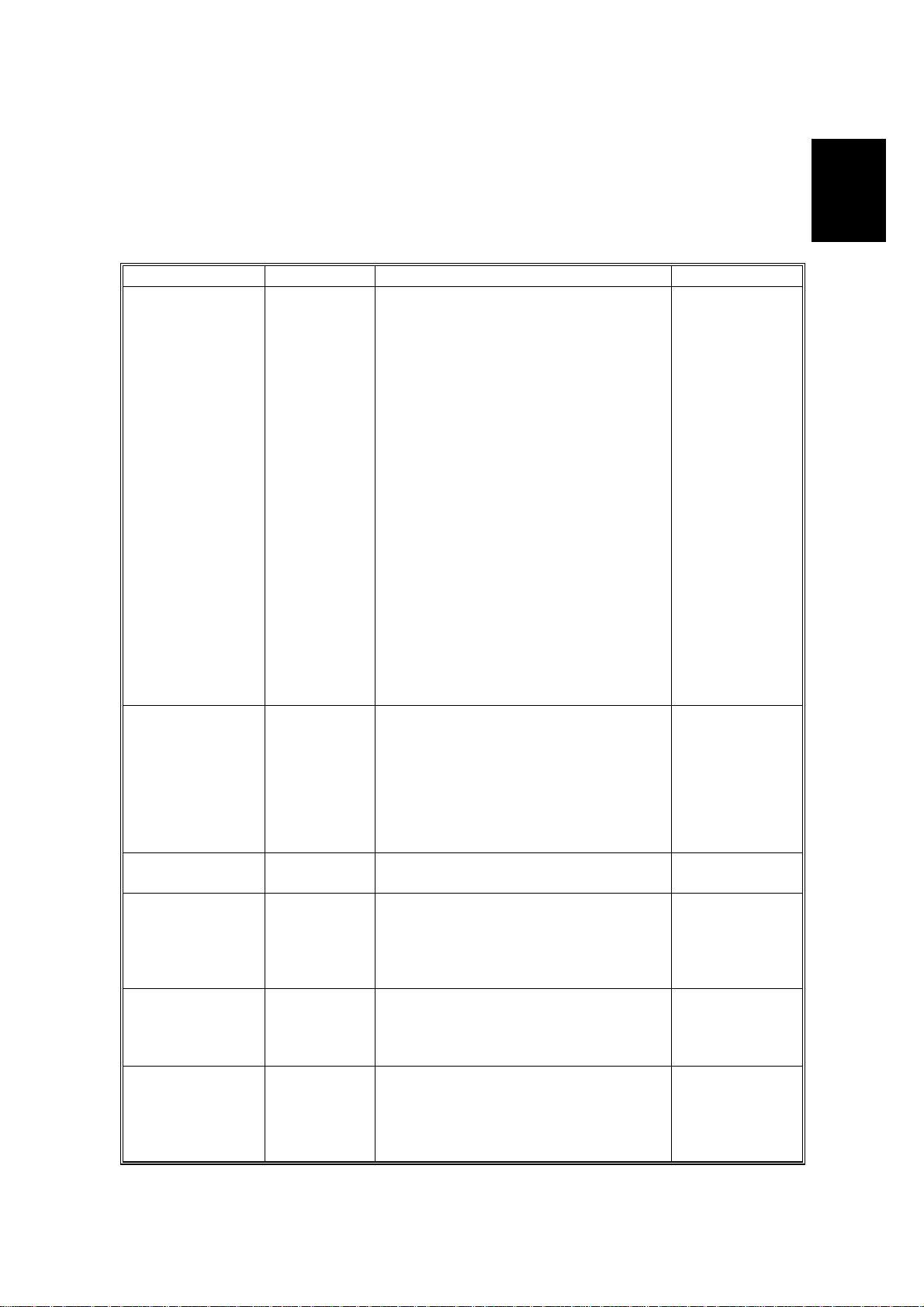

Item SP No. Function Default

Meter charge SP5-930-1 Specifies whether the meter charge

mode is enabled or disabled.

If the user is doing the user PM

procedures, set meter charge to ‘Off’.

If the technician is doing all the PM,

set meter charge to ‘On’.

Meter charge mode enabl ed:

• The Counter menu appears

immediately after the Menu key is

pressed.

• The counter type selected by the

counting method (SP5-045-1) can be

displayed with the Co unt er menu.

• The counter values can also be

printed with the Counter menu.

• The selected counter starts from a

negative number.

Meter charge mode disabled:

• The Counter menu is not displayed.

• The t otal counter starts from 0.

Counting method SP5-045-1 Specifies whether the counting

method used in meter charge mode is

based on developments or prints.

Off

Developments

Installation

A3/11" x 17"

double counting

PM warning

display 1

PM warning

display 2

PM warning

display 3

Important:

This SP can only be done before t he

negative counters are reset with S P7825-001

SP5-104-1 Specifies whether the counter is

doubled for A3/11" x 17" paper.

SP5-931-1

SP5-931-2 Specifies whether the PM warning f or

SP5-931-3 Specifies whether the PM warning f or

Specifies whether the PM warning f or

the charge corona unit is displayed

when the replacement time arriv es.

1: Displayed

0: Not displayed

the PCU is displayed.

1: Displayed

0: Not displayed

the feed rollers in the optional paper

feed unit is displayed.

1: Displayed

0: Not displayed

1-3

No: Single

counting

1

1

0

Page 20

OPTIONS 17 September, 2001

Item SP No. Function Default

Fax No. setting SP5-812-2 Programs the service station fax

number.

The number is printed on the counter

list when the meter charge mode is

selected, so that the user can fax t he

counter data to the service station.

Counter reset SP7-825-1 Resets the counters to 0.

Important: This must be done at

installation after all the a bove settings

have been finished. The ne gat ive

counters used in meter charge mode

will be reset to zero.

NOTE: 1) The def ault setting for this machine is meter-c harge mode off.

2) The meter-charge counter cannot be reset.

1.3 OPTIONS

Refer to the Option Setup Guide for details.

No. Optional Unit Alternative Requirements

500-sheet finisher

1

2 4-bin mailbox No. 1

3 Interchange unit

Duplex unit

4

5 Paper tray unit

6 Printer hard disk

DIMM memory (64, 128, or 256

7

MB modules available)

IEEE1394 interface unit

8

9 User account enhancement unit

No. 2

NOTE: 1) You cannot install the finisher and mailbox on the same machine.

2) You can install either 1 or 2 paper tray units.

• No. 3

• Hard disk or memory (extra 64

MB or more) for sort mode

• No. 3

• No. 3

• Extra 64 MB (or more) optional

SDRAM module

1-4

Page 21

17 September, 2001 OVERVIEW

2. PREVENTIVE MAINTENANCE

2.1 OVERVIEW

Users Do the User PM Procedures

The user does PM for the items in section 2.2. The technician does PM for the

items in section 2.3 . Meter-charge mode mu st be set to “off” (SP5-9 30, ☛ 5.2).

All PM Done by Technicians

The technician does PM for the items in sections 2.2 and 2.3. Meter-charge mode

must be set to “on” (SP5-930, ☛ 5.2).

Counters

When a maintenance counter for a unit has reached the limit, the corresponding

message is displayed on the operation panel. After completing the maintenance

procedure for that item, reset the counter (SP7-804, ☛ 5.2).

Preventive

Maintenance

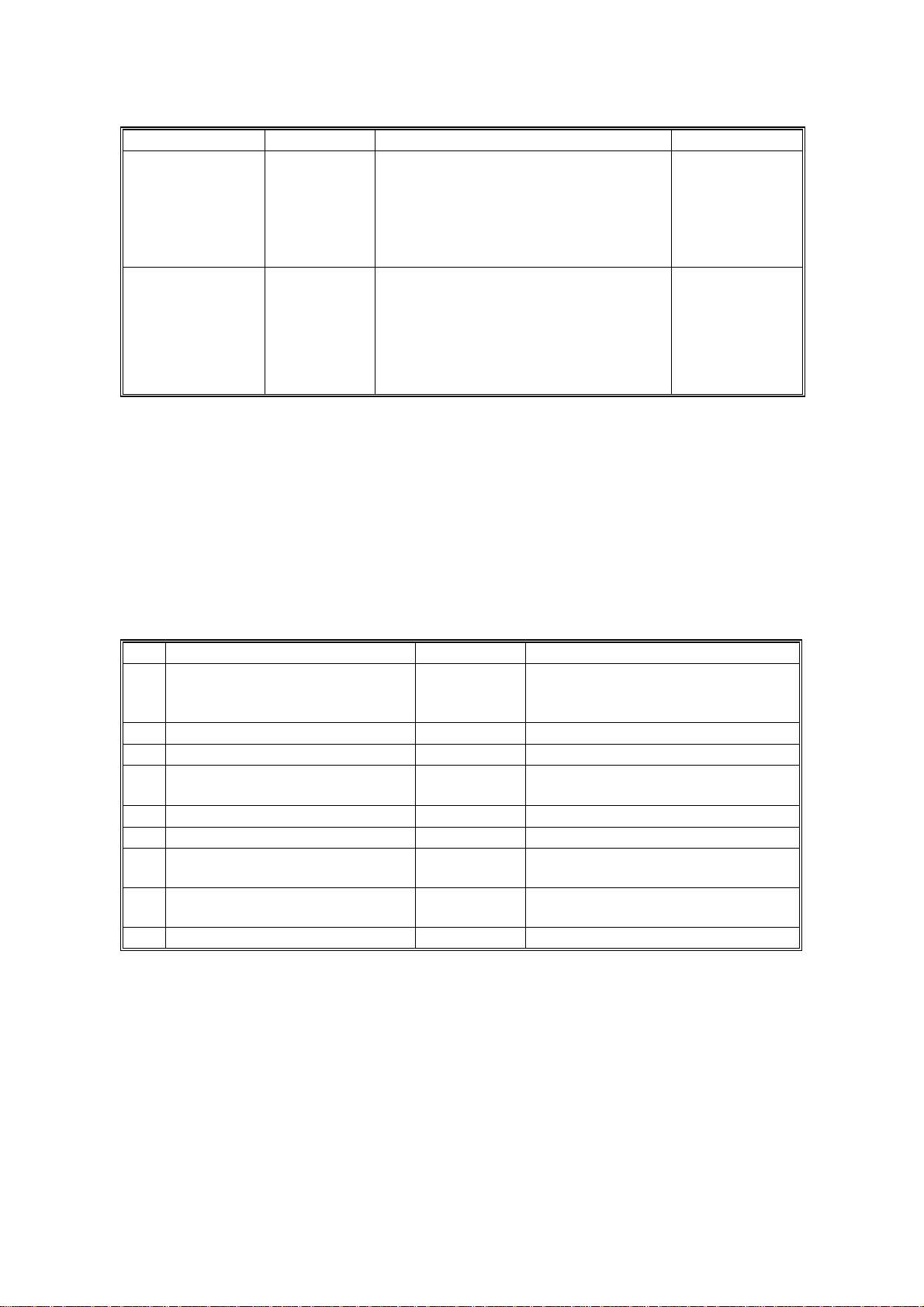

2.2 USER MAINTENANCE

Abbreviations:

C

lean

Main Unit

O/B and T/B waste

toner bottles

Oil supply unit

Fusing unit with paper

feed roller

* : Replacement period calculated for a 50% color rat io (the actual waste toner bottle conditi on

**: Standard replacement period (the actual oil amount is detected w it h t he sensor)

nspect

, I

Item

is detected with the sensors)

, L

ubricate

eplace

, R

30 120

R*

R**

, K

KP

iloPrints

R

iloDevelopments

, K

Detection Reset

Waste toner

sensors

Oil end sensor

Exit sheet

counter

, W

heneverNecessary

Auto-reset

(sensor)

Auto-reset

(sensor)

Manual reset

Machine

stops

Yes

Yes

Yes

2-1

Page 22

SERVICE MAINTENANCE 17 September, 2001

Item

Black development unit

Color development unit

Charge corona unit &

dust filters

PCU

*Displayed with SP7-906

Item WN Detection Reset

Registration roller

Dust shield glas s

(LD unit)

Bottom plate pad

KD

120 240

R

R

R

R

Detection Reset

Dev. Bk

counter*

Dev. color

counter*

Charge corona

counter*

PCU counter* Auto-reset (new

Machine

stops

C None None No

C None None No

C None None No

Auto-reset

(memory chip)

Auto-reset

(memory chip)

Manual reset

PCU sensor)

➀ damp cloth and

➁ dry cloth

Built-in cleaning

brush

➀ damp cloth and

➁ dry cloth

Machine

stops

Yes

Yes

No

No

Remarks

Optional Paper Tray Unit

Item 150KP Detection Reset

Feed, pick-up, and

separation rollers

R None None No

2.3 SERVICE MAINTENANCE

Abbreviations:

lean

C

Main Unit

Bypass Tray

Feed Roller

Pick-up Roller

Separation Roller

, I

nspect

, L

ubricate

, R

eplace

, K

iloPrints

, K

Item WN Remarks

C

C

C

Machine

iloDevelopments

➀ damp cloth and

➁ dry cloth

➀ damp cloth and

➁ dry cloth

➀ damp cloth and

➁ dry cloth

stops

heneverNecessary

, W

Remarks

➀ damp cloth and

➁ dry cloth

2-2

Page 23

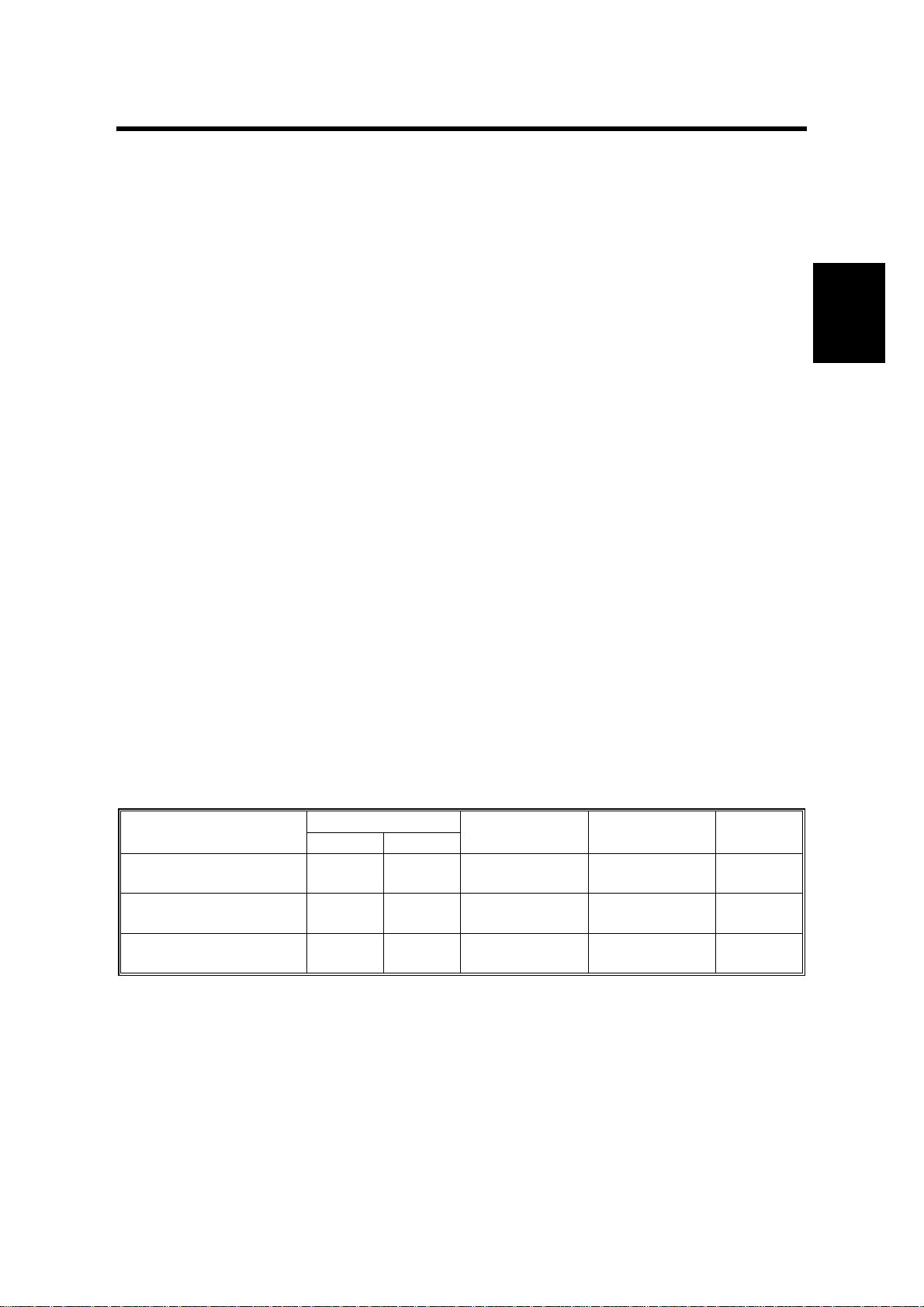

17 September, 2001 SERVICE MAINTENANCE

Optional Units

Paper Tray Unit

Item WN Remarks

Relay Roller

Bottom Plate Pad

C

C

➀ damp cloth and

➁ dry cloth

➀ damp cloth and

➁ dry cloth

Finisher

Item WN Remarks

Rollers

Sensors C Blower blush or dry cloth

Anti-Static Brush C Blower blush or dry cloth

Bushings

Stapler

C

L

R

➀ damp cloth and

➁ dry cloth

Launa oil when abnormal

noise occurs

Every 200K staples

(estimated replacement

period)

Preventive

Maintenance

Mail Box

Item WN Remarks

Rollers

Tray Paper Sensors C Blower blush or dry cloth

C

➀ damp cloth and

➁ dry cloth

Duplex Unit

Item WN Remarks

Rollers

Feed/exit sensors C Blower blush or dry cloth

C

➀ damp cloth and

➁ dry cloth

Interchange Unit

Item WN Remarks

Paper Exit Sensor C Blower blush or dry cloth

2-3

Page 24

17 September, 2001 SPECIAL TOOLS

3. REPLACEMENT AND ADJUSTMENT

!

CAUTION

Turn off the main power switch and unplug the machine before beginning

any of the procedures in this section.

NOTE: This manual uses the following symbols.

☛ : See or Refer to ! : Screws " : Connector # : Clip ring

$ : E-ring

3.1 SPECIAL TOOLS

Part Number Part Name

N8036701 Flash Memory Card - 4MB

G0219350 Loop-back connector - Parallel

Adjustment

Replacement

3-1

Page 25

EXTERIOR COVERS 17 September, 2001

3.2 EXTERIOR COVERS

3.2.1 REAR COVER

1. Duct cover [A] (4 hooks)

2. Ozone filter [B]

3. Printer controller [C] (! x 2)

[A]

4. Rear cover [D] (! x 2)

[C]

[B]

G070R702.WMF

[D]

G070R703.WMF

3-2

Page 26

17 September, 2001 EXTERIOR COVERS

3.2.2 LOWER LEFT COVER

1. Lower left cover [A] (! x 3)

[A]

3.2.3 UPPER COVER, OPERATION PANEL

1. Open the right cover [A].

2. Upper right cover [B]

3. Paper exit cover [C] (! x 1)

4. Open the front cover [D].

5. Upper cover [E] (! x 4)

6. Operation panel [F] (4 hooks,

" x 2, ! x 1)

NOTE: Insert a screwdriver between

the upper cover and the main

unit and unhook the panel.

[F]

[D]

[E]

G070R704.WMF

G070R701.WMF

[C]

[B]

[A]

Adjustment

Replacement

3-3

Page 27

ELECTRICAL COMPONENTS 17 September, 2001

3.3 ELECTRICAL COMPONENTS

3.3.1 PRINTER CONTROLLER

☛ 3.2.1

NOTE: Remove the NVRAM from the old controller board, and install it on the new

one.

If the controller NVRAM is defective, reset the total counter to 0 after

changing the NVRAM, if meter charge mode is enabled.

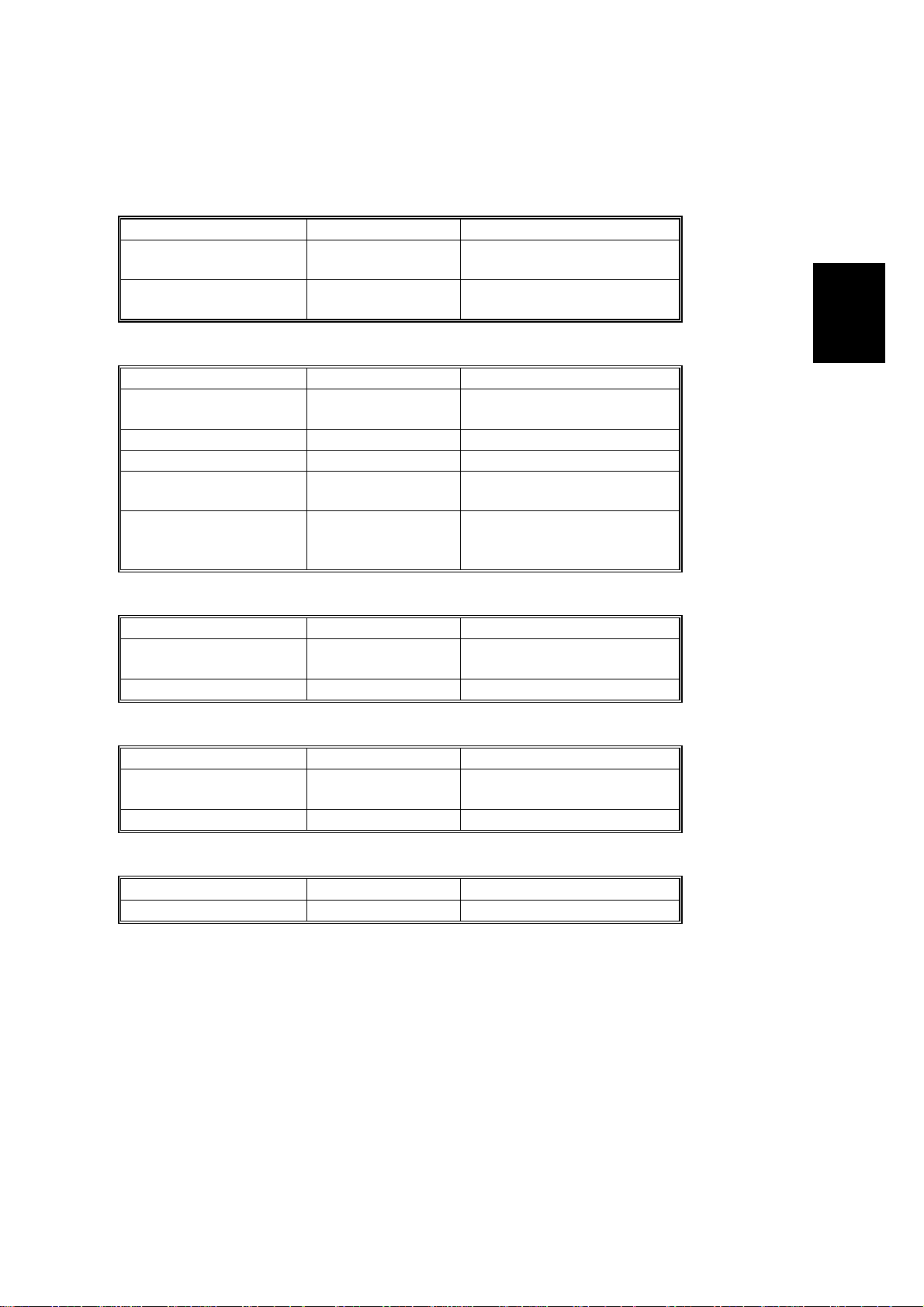

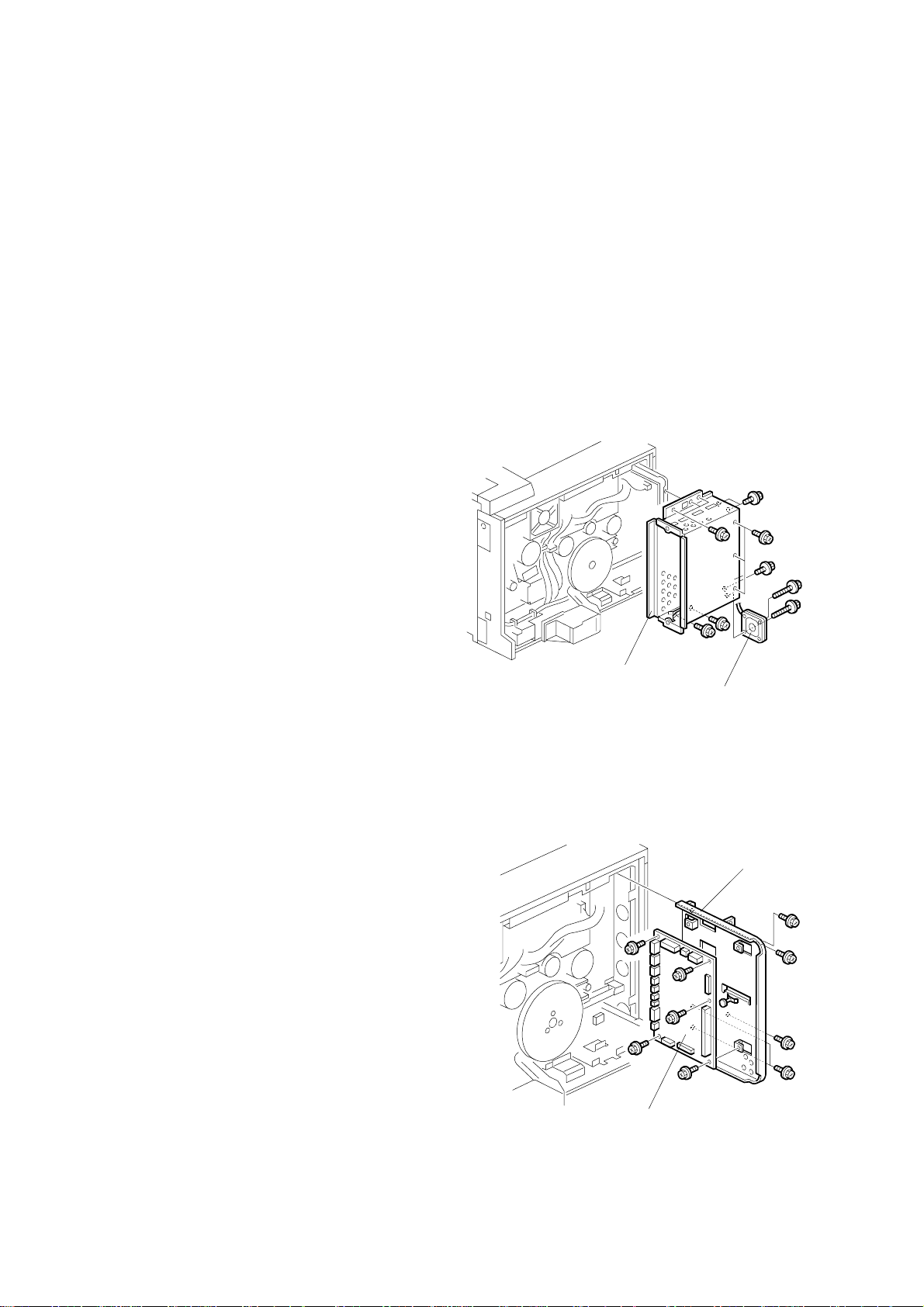

3.3.2 CONTROLLER BOX

1. Rear cover (☛ 3.2.1)

2. Cooling fan [A] (! x 2)

NOTE: When reassembling, inst all

the fan with the label

facing the inside.

3. Controller box [B] (! x 11)

NOTE: Do not remove the BCU

board base with the

controller box.

NOTE: When pu tting back the

controller box, take care

not to pinch the cable from

the I/O board.

3.3.3 BCU BOARD

1. Controller box (☛ 3.3.2)

2. All " (12)

3. 1 flat cable

4. BCU board base [A] (! x 5)

5. BCU board [B] (! x 5)

NOTE: Remove the NVRAM f rom the old

BCU board, and install it on the

new one.

[B]

[A]

G070R705.WMF

[A]

3-4

[B]

G070R706.WMF

Page 28

17 September, 2001 ELECTRICAL COMPONENTS

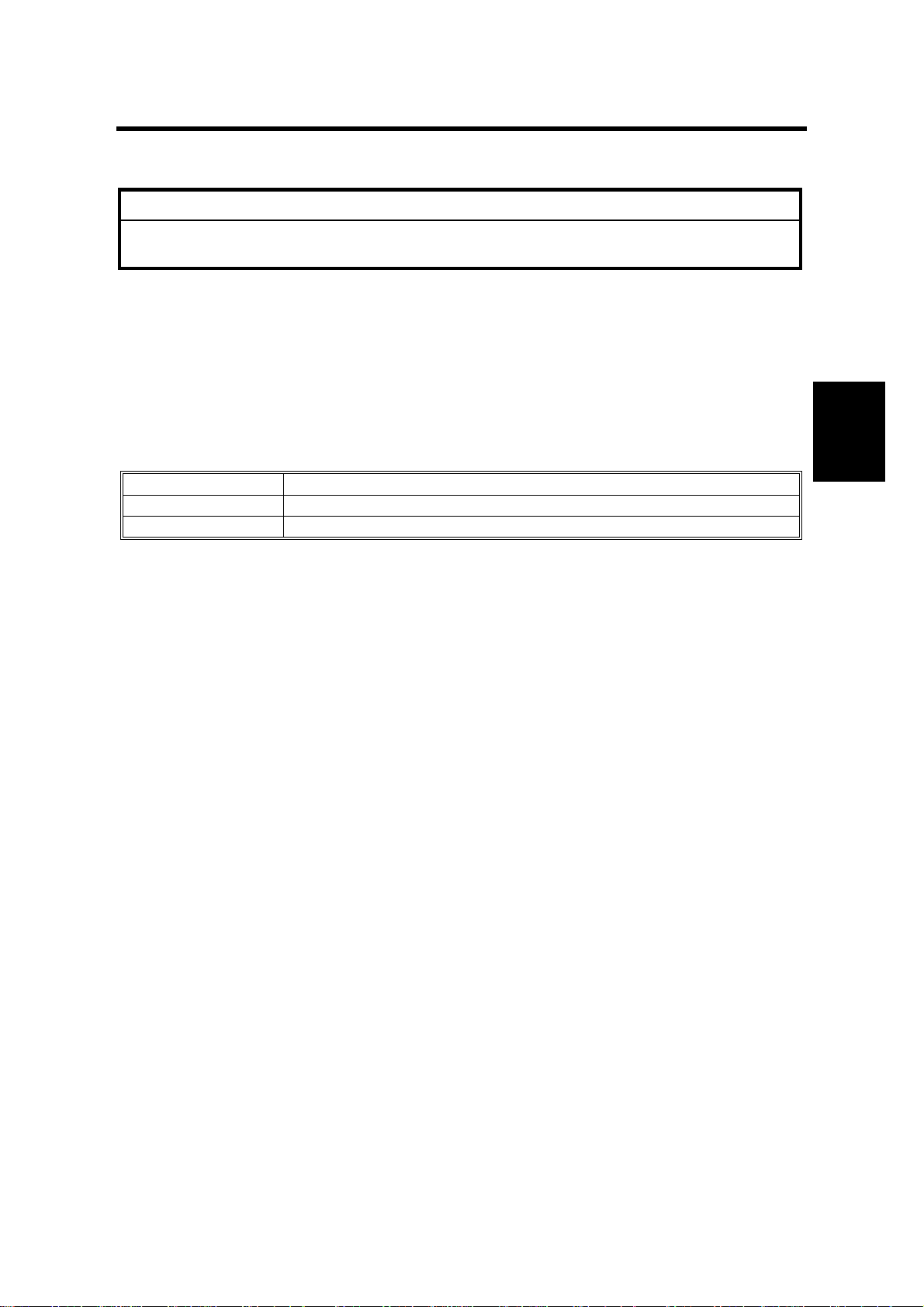

3.3.4 I/O BOARD

1. Controller box (☛ 3.3.2)

2. All " (33)

3. I/O board [A] (! x 4)

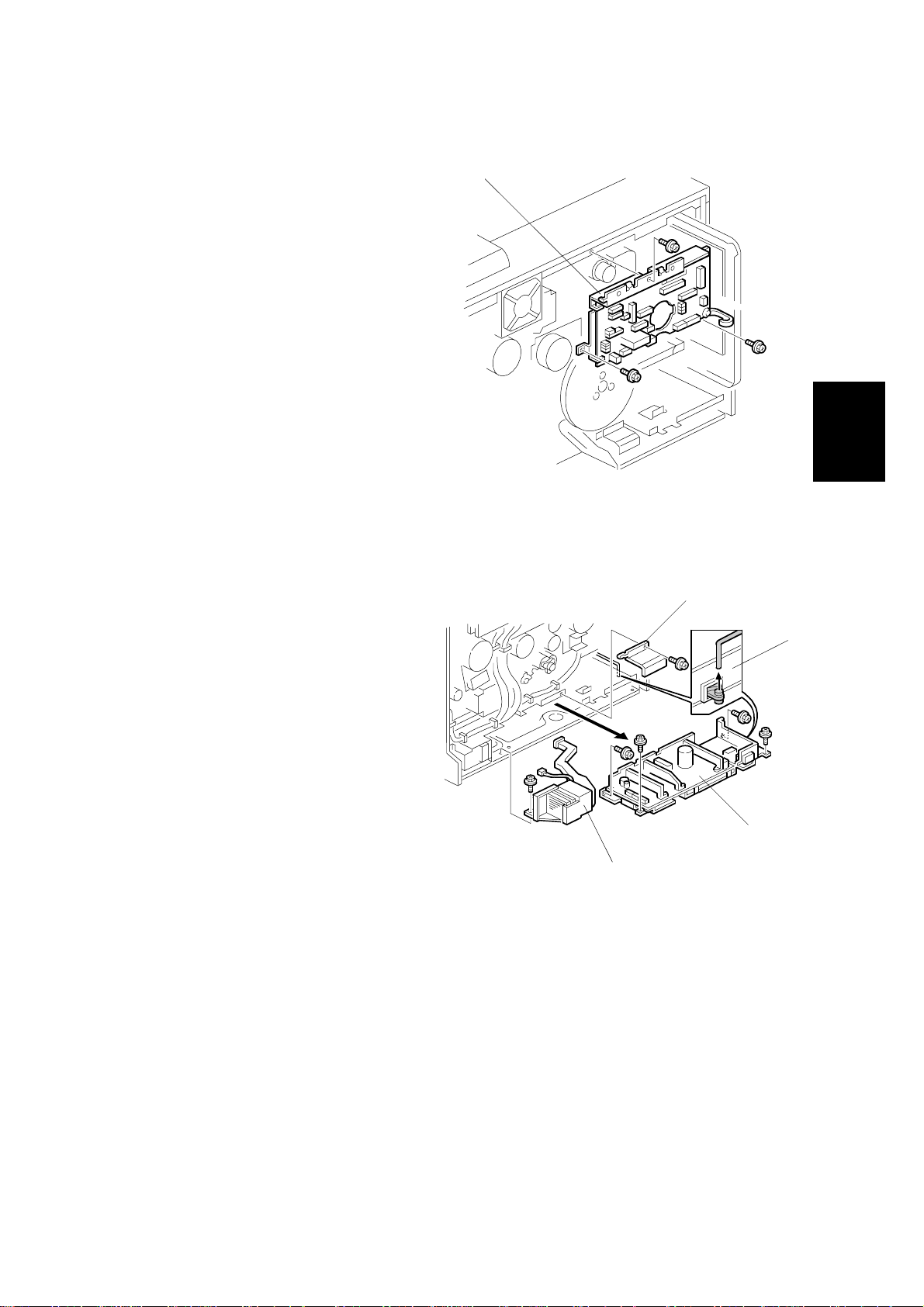

3.3.5 PSU

1. Controller box (☛ 3.3.2)

2. Flywheel (! x 3) (☛ 3.4.1)

[A]

G070R707.WMF

[B]

[C]

Adjustment

Replacement

3. Duct [A] (" x 1, ! x 1)

NOTE: When removing and

reassembling t he fan,

install it with the label

facing the outside.

4. PSU protector [B] (! x 1)

5. Unlink the main switch [C].

6. PSU base (" x 8, ! x 4)

NOTE: 1) Remove the PSU [D]

with the PSU base.

2) When reas semb lin g,

check that the main

switch is linked to the

PSU.

[A]

[D]

G070R717.WMF

3-5

Page 29

ELECTRICAL COMPONENTS 17 September, 2001

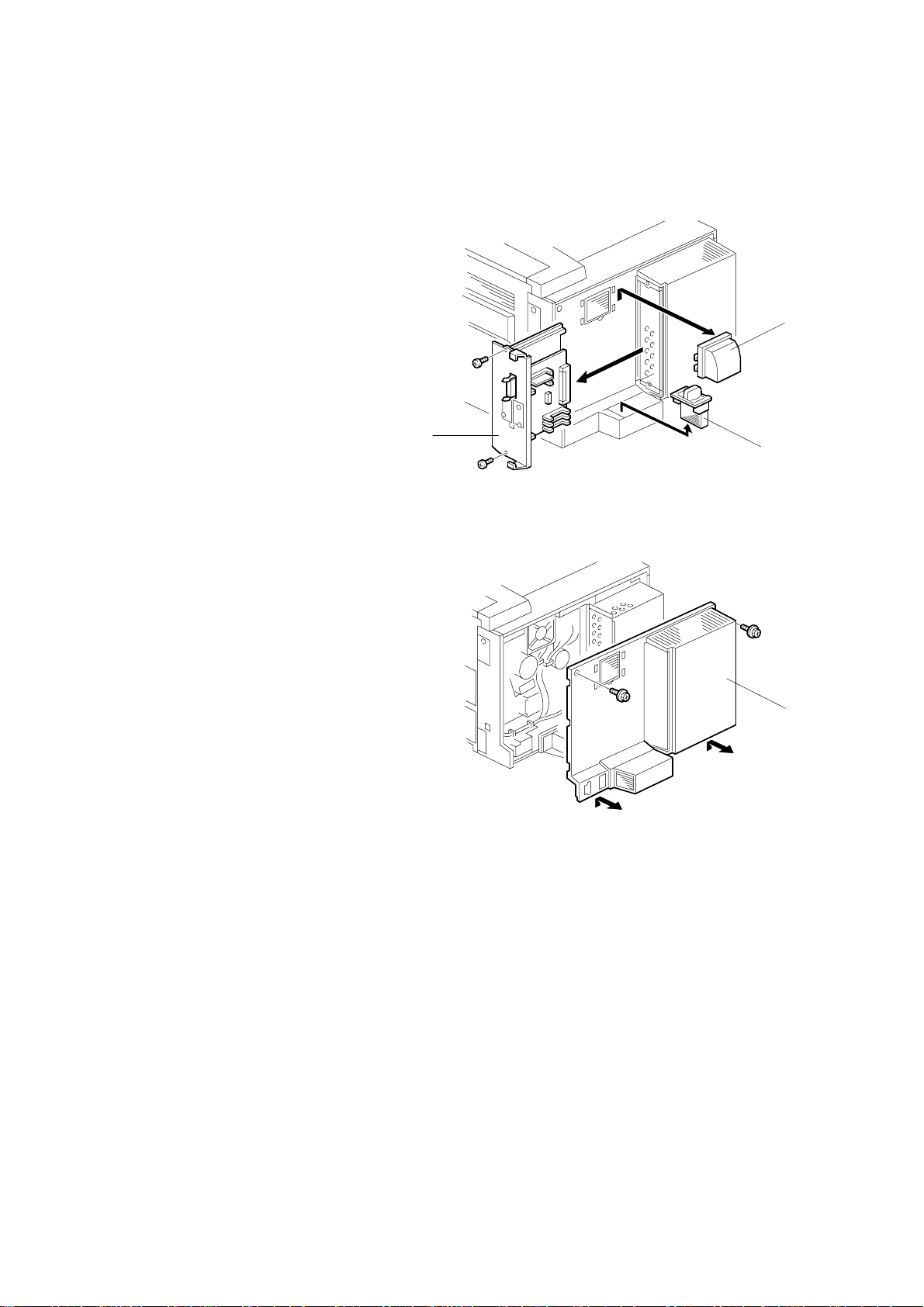

3.3.6 HIGH VOLTAGE SUPPLY BOARD

1. Photoconductor unit (☛ 3.7)

2. Right inner cover (☛ 3.10.2)

3. Photoconductor unit rail [A] (! x 2)

4. " [B] x 1

5. Bushing [C] x 1

[A]

G070R719.WMF

[C]

[B]

6. High voltage supply board [D] (" x 17,

! x 6)

[D]

G070R720.WMF

3-6

Page 30

17 September, 2001 DRIVE UNITS

3.4 DRIVE UNITS

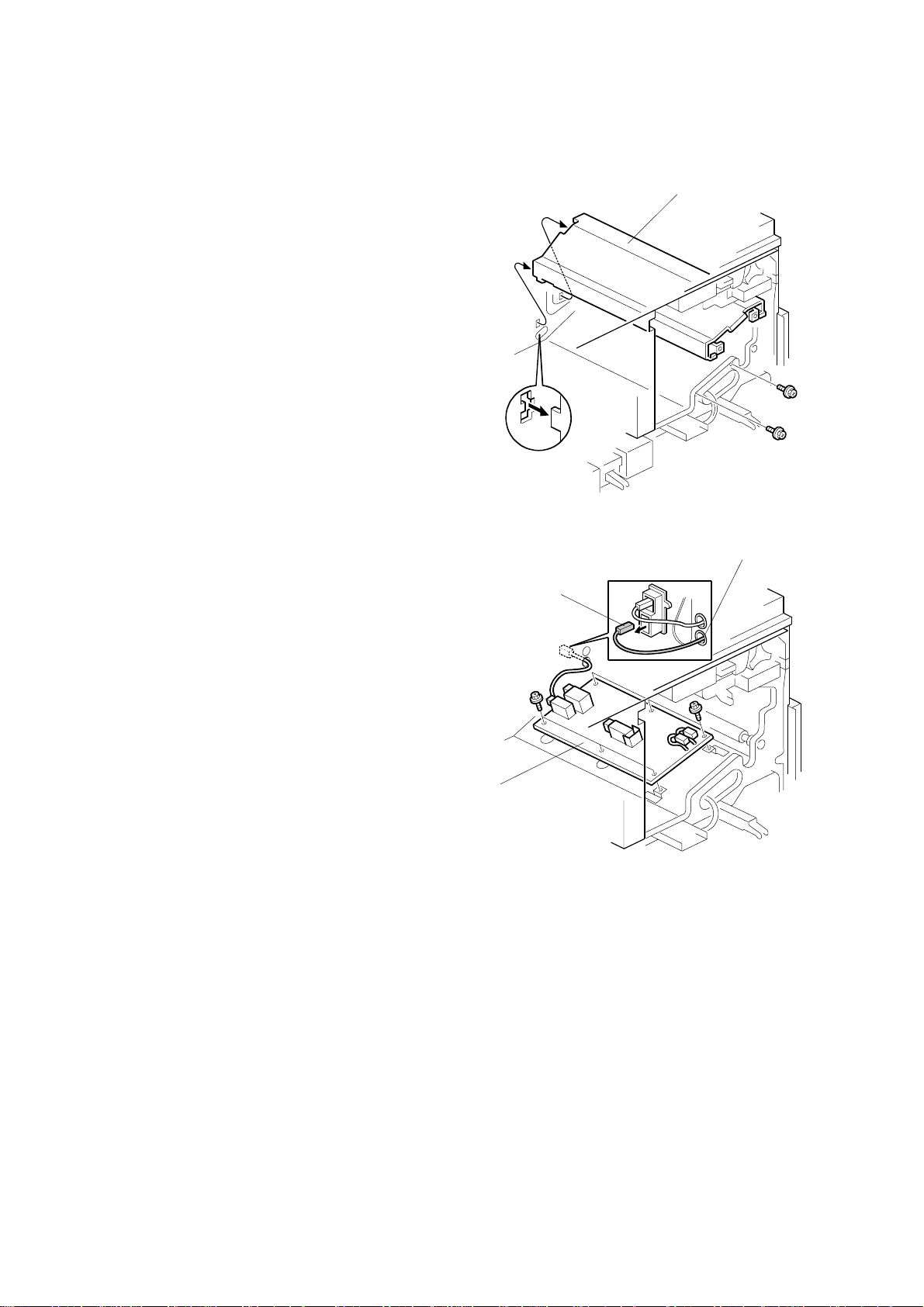

3.4.1 DEVELOPMENT CLUTCHES

1. Controller box (☛ 3.3.2)

K/Y Development Units

1. Unhook the lock [A] and pull out

the clutch [B] (" x 1).

[B]

Adjustment

Replacement

C/M Development Units

1. Flywheel [A] (! x 3)

2. Unhook the lock [B] and pull out

the clutch [C] (" x 1).

[C]

[A]

[A]

G070R708.WMF

[B]

G070R709.WMF

3-7

Page 31

DRIVE UNITS 17 September, 2001

3.4.2 DEVELOPMENT MOTOR

1. Controller box (☛ 3.3.2)

2. Development motor [A] (" x 1,

! x 3)

[A]

G070R710.WMF

3.4.3 MAIN MOTOR

1. Controller box (☛ 3.3.2)

2. Flywheel [A] (! x 3)

3. Main motor [B ] (" x 1, ! x 3)

[B]

[A]

G070R711.WMF

3-8

Page 32

17 September, 2001 DRIVE UNITS

3.4.4 PCU GEAR BOX AND OPC BELT CLEANING CLUTCH

1. I/O board (☛3.3.4 )

2. Main motor (☛ 3.4.3)

3. C/M development unit clutch

(☛ 3.4.1)

4. Bracket [A] (! x 2)

5. Tension spring [B]

6. " x 1 [C]

7. Gear box and clutch assembly

[D] (! x 5)

3.4.5 FUSING UNIT MOTOR

[A]

[C]

[B]

G070R712.WMF

[D]

Adjustment

Replacement

1. Rear cover (☛ 3.2.1)

2. Fusing unit motor (" x 1, ! x 3)

[A]

[A]

G070R713.WMF

3-9

Page 33

DRIVE UNITS 17 September, 2001

3.4.6 PAPER FEED MOTOR

1. Rear cover (☛ 3.2.1)

2. Pull out the handle [A].

3. Paper feed motor [B] (" x 1,

! x 3)

[A]

[B]

G070R714.WMF

3.4.7 PAPER FEED CLUTCH

1. Rear cover (☛ 3.2.1)

2. Pull out the handle [A].

3. Connector bracket [B] (" x 6,

! x 2)

4. Paper feed clutch [C] (" x 1,

[A]

! x 2)

3.4.8 REGISTRATION CLUTCH

1. Rear cover (☛ 3.2.1)

2. Unhook the lock [A] and pull the

clutch out [B] (" x 1).

[B]

[C]

G070R716.WMF

3-10

[B]

[A]

G070R715.WMF

Page 34

17 September, 2001 LASER OPTICS SECTION

3.5 LASER OPTICS SECTION

!

WARNING

Turn off the main switch and unplug the machine before beginning any of

the procedures in this section. Laser beams can cause serious eye injury.

3.5.1 CAUTION DECAL LOCATION

Adjustment

Replacement

LD_CAUTION.TIF

G070R208.WMF

!

DANGER

Turn off the main switch and disconnect the power plug from the power

outlet before beginning any disassembly or adjustment of the laser unit.

This printer uses a class-1 laser beam with a wavelength of 650 nm and an

output of 7 mW. The laser can cause serious eye injury.

3-11

Page 35

LASER OPTICS SECTION 17 September, 2001

3.5.2 LASER OPTICS HOUSING UNIT

1. Open the left cover [A].

2. ID chip connectors [B] (" x 4)

3. Development units [C] x 4

4. Rear cover (☛ 3.2.1)

5. Left cover [D]

6. Lower left cover [E] (! x 3)

[C]

[B]

[A]

G070R301.WMF

[E]

7. Controller box (☛ 3.3.2)

8. Flat cable [F]

NOTE: When reassembling,

connect the flat cable with

the blue side up.

9. " x 4 [G]

10. Harness clamps [H]

[D]

G070R201.WMF

[G]

[F]

[H]

G070R202.WMF

3-12

Page 36

17 September, 2001 LASER OPTICS SECTION

11. Open the front cover.

12. Remove the dust shield glass

cleaner lever [A] from the dust

shield glass cleaner.

NOTE: The dust shield glass

cleaner lever is the blue

lever at the right side of the

main switch.

13. LD cover [B] (! x 2)

14. Laser optics housing unit [C]

(! x 4)

[A]

[B]

G070R209.WMF

Adjustment

Replacement

[C]

G070R203.WMF

3-13

Page 37

LASER OPTICS SECTION 17 September, 2001

Adjusting for Image Skew

1. Positioning pin [A] (! x 1)

2. Loosen ! (x 4) [B].

3. Adjust the position of the laser

optics housing unit [☛ NOTE].

4. Fasten ! (x 4) [B].

NOTE: After changing the position

of the laser optics housing

unit, do not reinstall the

positioning pin. Keep the

pin in a safe place.

NOTE: When th e image skews as

shown, move the unit 1 mm

in the direction of the black

arrow as shown in the upper

diagram.

[B]

[A]

[☛ NOTE]

G070R207.WMF

3.5.3 LD UNIT

1. Laser optics housing unit (☛ 3.5.2)

2. Flat cable [A]

NOTE: When reassembling, co nnect

the flat cable with the blue

side down.

3. Harness [B]

4. LD unit [C] (! x 3)

NOTE: Do not move the screw [D].

Do not break the paint lock.

[A]

1mm

[D]

Paper feed

(A3 SEF)

G070R001.WMF

[B]

[C]

G070R206.WMF

3-14

Page 38

17 September, 2001 LASER OPTICS SECTION

3.5.4 POLYGONAL MIRROR MOTOR AND SYNC. DETECTION

BOARD

!

WARNING

Do not touch any edges of the polygon mirror, spring, or bracket. These

edges can cause serious injury.

1. Development units, LD cover (☛ 3.5.2)

2. Cover [A] (! x 1)

NOTE: Before removing th e cover, clean

up spilled toner around the laser

optics housing unit. Prevent the

toner from entering into the unit.

3. Polygonal mirror motor [B] (" x 1,

! x 4)

4. Sync. detection board [C] (" x 1,

! x 1)

[C]

[B]

[A]

G070R204.WMF

Adjustment

Replacement

3-15

G070R205.WMF

Page 39

DEVELOPMENT UNIT 17 September, 2001

3.6 DEVELOPMENT UNIT

!

CAUTION

Do not touch the development unit sleeves or ID chip terminals.

[B]

[C]

[A]

G070R301.WMF

1. Open the left cover [A].

2. ID chip connector [B]

3. Push the left end of the development unit [C] to the right, lift the unit, and pull

the unit out of the machine.

NOTE: 1) Remove the units in the order K, Y, C, and M. For example, before

removing the M unit, remove the K, Y, and C units first.

2) When reassembling, m ake sure each development unit is installed

correctly. Otherwise, a white line or band may appear on one half of the

paper.

3-16

Page 40

17 September, 2001 PHOTOCONDUCTOR UNIT (PCU)

3.7 PHOTOCONDUCTOR UNIT (PCU)

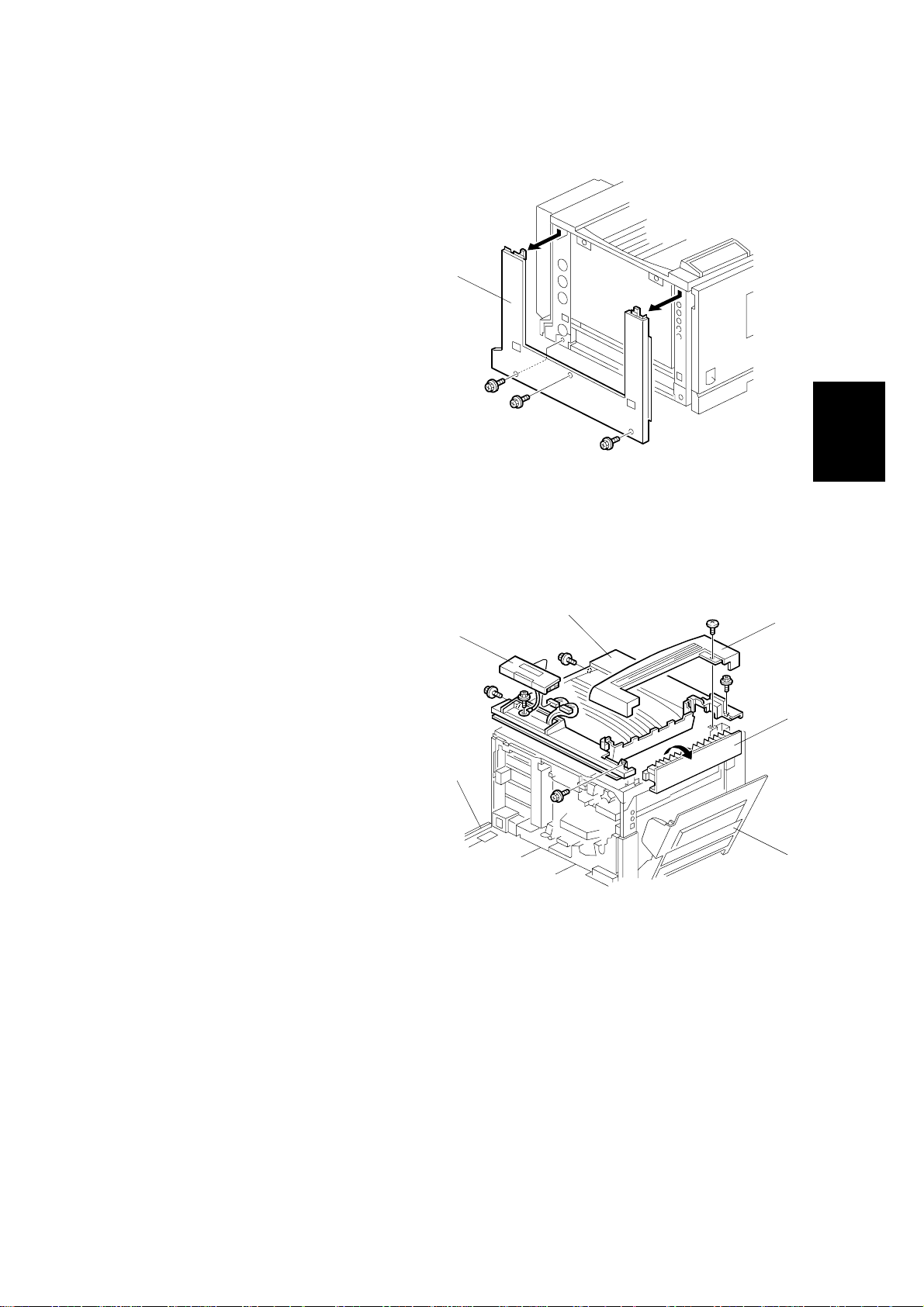

3.7.1 MAIN UNIT

NOTE: 1) Before replacing any of the parts or consumables in this section, cover

the floor with cloth or some sheets of paper.

2) Never tilt the unit. The toner may come out of the unit.

3) When handling the unit, grasp the brown (front) and green (top) grips.

Never touch the OPC (left) or transfer (right) belts.

4) After removing the photoconductor unit, cover it with a light-proof sheet.

Keep it in a dark place.

Adjustment

Replacement

1. Open the front cover.

2. Open the right cover.

3. ! x 4

4. Pull the unit out of the machine.

5. Grasp the brown and green grips.

6. Lift the unit and remove it.

G070R308.WMF

3-17

Page 41

PHOTOCONDUCTOR UNIT (PCU) 17 September, 2001

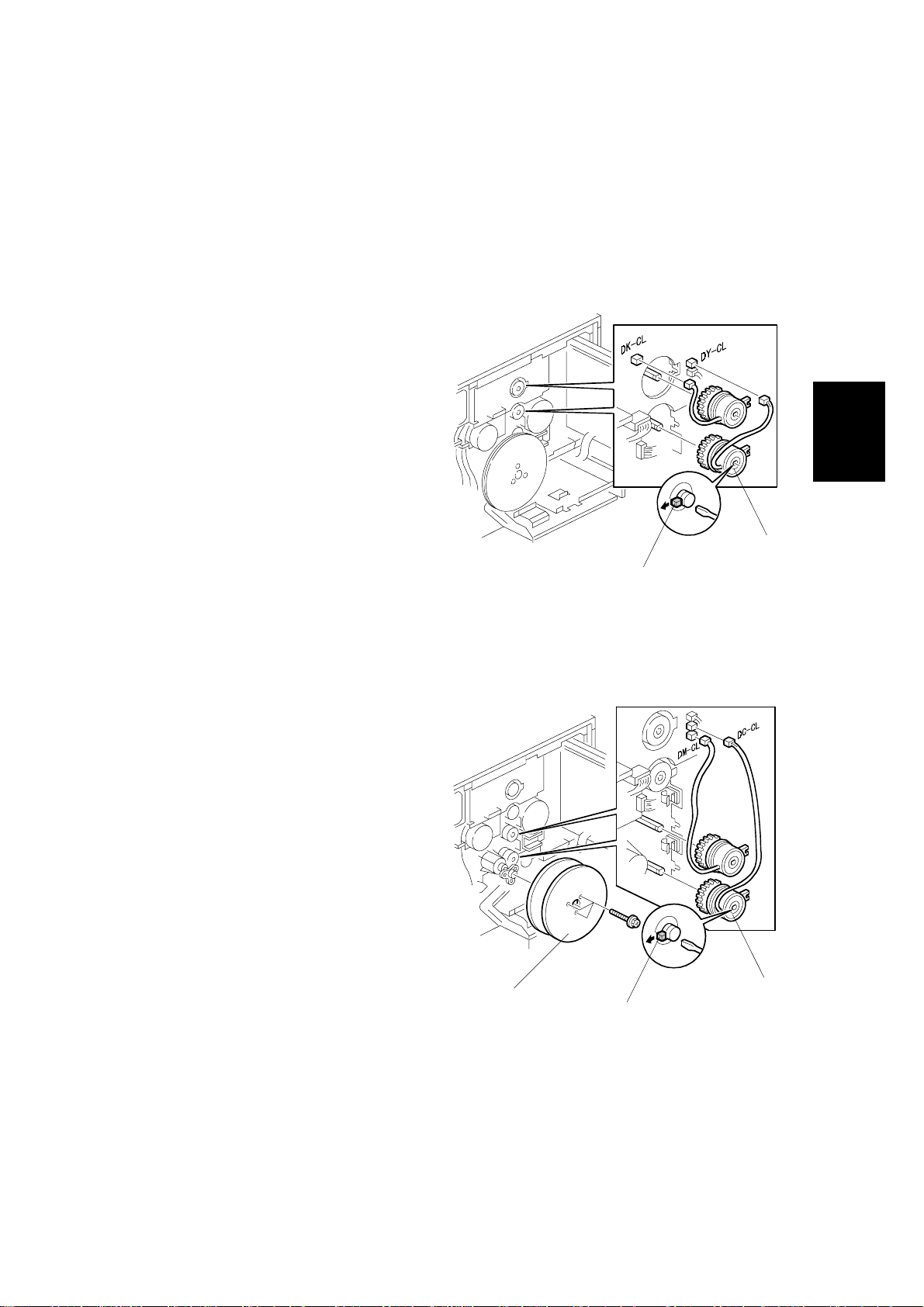

3.7.2 WASTE TONER BOTTLES

1. O/B waste toner bottle [A]

[A]

G070R302.WMF

2. T/B waste toner bottle [B]

[B]

G070R303.WMF

3-18

Page 42

17 September, 2001 PHOTOCONDUCTOR UNIT (PCU)

3.7.3 CHARGE CORONA WIRE

1. Modular cable [A]

2. Loosen ! (x 1) [B]

3. Charge corona unit [C]

[A]

[B]

4. Front bracket (! x 1) [D]

5. Grid [E]

6. Rear bracket [F]

7. Front wire cover [G]

8. Rear wire cover [H]

9. Unhook the charge wire [I].

[D]

[G]

[E]

[C]

[H]

[I]

G070R304.WMF

G070R305.WMF

[F]

Adjustment

Replacement

10. Wire cleaner [J] (# x 1)

[J]

G070R307.WMF

3-19

Page 43

PHOTOCONDUCTOR UNIT (PCU) 17 September, 2001

3.7.4 CHARGE CORONA WIRE CLEANER MOTOR

1. Charge corona unit (☛ 3.7.3)

2. Front motor cover [A] (! x 3)

3. Motor [B]

[A]

[B]

G070R306.WMF

3.7.5 OPC BELT CLEANING UNIT

1. Photoconductor unit (☛ 3.7.1)

2. Charge corona unit (☛ 3.7.3)

3. Drive gear [A] (! x 1)

4. Rear brace [B] (! x 1)

5. Front brace [C] (! x 1)

6. OPC belt cleaning unit [D]

(! x 2)

NOTE: Hold up the

photoconductor unit

while removing the

OPC belt cleaning unit.

[A]

[B]

[C]

G070R315.WMF

3-20

Page 44

17 September, 2001 PHOTOCONDUCTOR UNIT (PCU)

3.7.6 OPC BELT UNIT

1. Photoconductor unit (☛ 3.7.1)

2. OPC belt cleaning unit (☛ 3.7.5)

3. OPC belt unit [A] (! x 4)

NOTE: After installing a new

OPC belt, do SP 2-940

(OPC lubrication mode)

then SP 3-001 (forced

process control).

[A]

3.7.7 IMAGE TRANSFER BELT CLEANING UNIT

1. Photoconductor unit (☛ 3.7.1)

2. Bracket [A] (! x 2)

3. Image transfer belt cleaning unit

[B]

[B]

G070R316.WMF

[A]

Adjustment

Replacement

3-21

G070R309.WMF

Page 45

PHOTOCONDUCTOR UNIT (PCU) 17 September, 2001

3.7.8 IMAGE TRANSFER BELT UNIT

!

CAUTION

1. Never touch the surface of the OPC or image transfer belt with bare

hands.

2. Do not damage the OPC or image transfer belt.

1. Photoconductor unit (☛ 3.7.1)

2. T/B waste toner bottle (☛ 3.7.2)

3. Image transfer belt cleaning unit

(☛ 3.7.7)

4. Image transfer belt unit [A] (! x 6)

NOTE: 1) Do not damage the connectors.

2) Remove the 2 screws [B] to

lower the entrance guide [C].

Otherwise, the belt will be

caught by the entrance guide

when putting back the image

transfer belt unit.

Reassembling

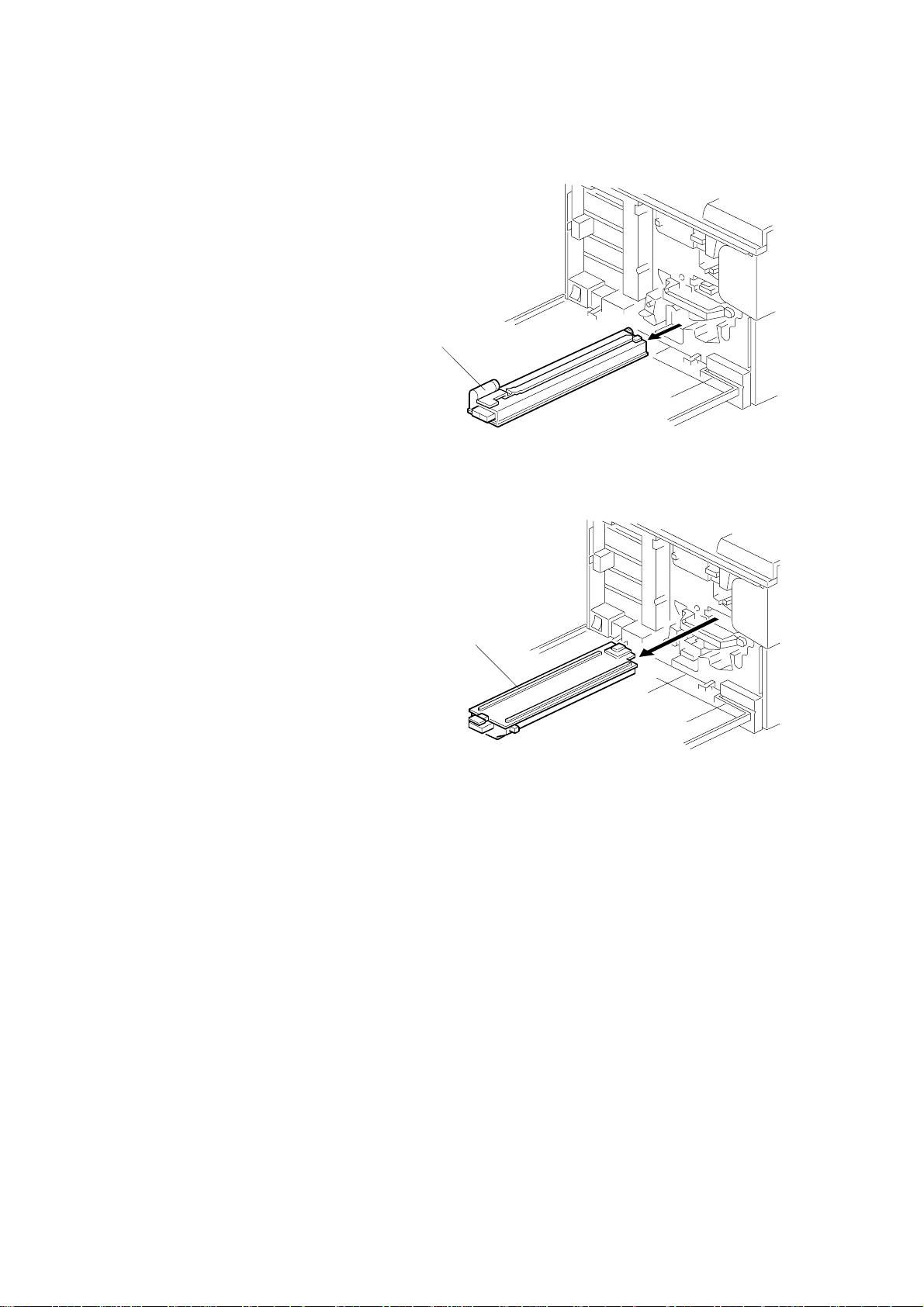

1. Put the guide [A] on the rail [B].

[A]

[C]

[B]

G070R311.WMF

2. Slide the unit in.

[A]

[B]

G070R314.WMF

3-22

Page 46

17 September, 2001 PAPER TRANSFER UNIT

3.8 PAPER TRANSFER UNIT

3.8.1 VERTICAL TRANSPORT UNIT

[A]: Right cover (pivot-screw x 1)

[A]

3.8.2 TRANSFER ROLLER

1. Brace [A] (! x 1)

2. Turn the roller unit on its pivot.

3. Bracket [B] (! x 3)

[A]

G070R401.WMF

G070R402.WMF

[B]

Adjustment

Replacement

4. Guide [C] (! x 4)

[C]

G070R403.WMF

3-23

Page 47

FUSING/PAPER EXIT 17 September, 2001

3.9 FUSING/PAPER EXIT

!

CAUTION

Turn off the main switch and wait until the fusing unit cools down before

beginning any of the procedures in this section. The fusing unit can cause

serious burns.

3.9.1 FUSING UNIT

[C]

1. Loosen the knob screw [A].

2. Pull the unit out of the machine.

3. Unhook the bottom stopper [B].

4. Grasp the rear end (marked with a

green label) [C].

5. Release the unit [D] from the base

plate [E].

[D]

[A]

3.9.2 OIL SUPPLY UNIT

NOTE: When removing eithe r of the

lamps (☛ 3.9.3), remove the

knob screw (☛ 3.9.1) before

removing the oil supply unit.

1. Fusing unit (☛ 3.9.1)

2. Put the fusing unit on a level place.

3. Oil supply unit [A]

NOTE: Do not touch the oiling felt.

[B]

[E]

G070R501.WMF

[A]

G070R502.WMF

3-24

Page 48

17 September, 2001 FUSING/PAPER EXIT

3.9.3 LAMPS

1. Oil supply unit (☛ 3.9.2)

2. Gear bracket [A] (! x 2)

3. Upper cover [B] (! x 2, shoulder

screw x 1)

4. Terminals [C] [D] (! x 5)

NOTE: [C]: Pressure roller lamp

terminals

[D]: Heating roller lamp

terminals

[D]

[B]

[C]

G070R503.WMF

[A]

[D]

Adjustment

Replacement

5. Pull out the lamp (350W) [E].

6. Pull out the lamp (770W) [F].

NOTE: “350W” and “770W” are etched

on the respective terminals.

G070R504.WMF

[H]

[E]

770W

[F]

350W

G070R510.WMF

3-25

Page 49

FUSING/PAPER EXIT 17 September, 2001

3.9.4 FUSING INNER UNIT

1. Lamps (☛ 3.9.3)

2. Drive gear [A]

3. Knob screw [B] ($ x 1)

4. Heating roller lamp harness terminal

[C] (! x 1)

5. Fusing inner unit [D] (! x 2,

" x 3)

[B]

3.9.5 PRESSURE ROLLER THERMOFUSE

1. Fusing inner unit (☛ 3.9.4)

2. Pressure roller th ermofuse [A] (! x 2)

[D]

[C]

[A]

G070R506.WMF

[A]

G070R508.WMF

3.9.6 FUSING BELT UNIT AND PRESSURE ROLLER UNIT

1. Fusing inner unit (☛ 3.9.4)

[C]

2. Springs [A] [B]

3. Separate the fusing belt unit [C] and

pressure roller unit [D].

[D]

[A]

3-26

[B]

G070R507.WMF

Page 50

17 September, 2001 FUSING/PAPER EXIT

3.9.7 PRESSURE ROLLER THERMISTOR

1. Pressure roller unit (☛ 3.9.6)

2. Pressure roller lower stay [A]

(! x 2)

3. Pressure roller thermistor

holder [B] (! x 1)

4. Pressure roller thermistor [C]

[C]

[B]

[A]

G070R509.WMF

Adjustment

Replacement

3.9.8 PAPER EXIT UNIT AND PAPER EXIT/OVERFLOW SENSOR

!

CAUTION

Turn off the main switch and wait until the paper exit unit cools down

before beginning any of the procedures in this section. The paper exit unit

can cause serious burns.

1. Paper exit cover (☛ 3.2.3)

2. Paper exit unit [A] (" x 3,

! x 1)

NOTE: Remove 2 connectors

before removing the unit.

To remove the last

connector, remove the

unit and turn it. The

connector is on the

bottom side.

3. Paper exit sensor [B]

4. Paper overflow sensor [C]

[C]

[A]

[B]

3-27

G070R601.WMF

Page 51

PAPER FEED AND TRANSPORT 17 September, 2001

3.10 PAPER FEED AND TRANSPORT

3.10.1 FEED ROLLER AND FRICTION PAD

1. Paper tray [A]

[A]

G070R101.WMF

2. # x 1 [B]

3. Slide the shaft [C].

4. Feed roller [D] (1 hook)

5. Friction pad [E]

[C]

[D]

[E]

[B]

G070R102.WMF

3-28

Page 52