Page 1

FRESA WIN+

(Machine Code: G047/G048)

SERVICE MANUAL

[Controller]

Page 2

IMPORTANT SAFETY NOTICES

PHYSICAL INJURY PREVENTION

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some printer components are supplied with electrical voltage even

if the main switch is turned off.

4. If an adjustment or operation check must be made requiring the removal or

opening of the exterior covers while the main switch is on, keep hands away

from electrified or mechanically driven components.

5. The printer drives some of its components when it completes the warm-up

period. Keep hands away from mechanical and electrical components when

the printer starts operation.

6. The interior and metal parts for the fusing unit become extremely hot while

the printer is operating. Do NOT touch these components with bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the printer without ozone filters installed.

2. Always replace the ozone filters with the specified replacement at the

specified maintenance intervals.

3. Toner is non-toxic, but if it gets in your eyes by accident, it may cause

temporary eye discomfort. Remove it with eye drops or flush eyes with

water. If this is unsuccessful, get medical attention immediately.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do NOT incinerate toner cartridges, development toner magazine (DTM) or

used toner. Toner dust may ignite suddenly when exposed to an open flame.

2. Dispose of used toner bottle and photoconductor unit (PCU) in accordance

with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

Page 3

Trademarks

Microsoft, Windows 98/95/3.1x, and Windows NT 4.0 are registered trademarks of

Microsoft Corporation.

Macintosh and AppleTalk are registered trademarks of Apple Computer, Inc.

NetWare is a registered trademark of Novell, Inc.

Ethernet is a registered trademark of Xerox Corporation.

General Notice:

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights in those

marks.

Page 4

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION....................................... 1-1

1.1 BASIC SPECIFICATIONS.........................................................................1-1

2. DETAILED DESCRIPTIONS....................................................... 2-1

2.1 DIFFERENT POINT FROM BASE MODEL (G024)...................................2-1

2.1.1 SYSTEM SOFTWARE......................................................................2-1

2.1.2 HARDWARE.....................................................................................2-1

2.2 FUNCTIONAL OVERVIEW.......................................................................2-2

2.2.1 SYSTEM LAYOUT............................................................................2-2

2.2.2 CONTROLLER BOARD LAYOUT....................................................2-3

2.2.3 FUNCTION OF EACH DEVICE........................................................2-4

2.3 PRINT DATA PROCESSING....................................................................2-5

2.3.1 GRADATION & PRINTABLE DATA..................................................2-5

2.3.2 IMAGE DATA PROCESSING FLOW ...............................................2-6

IPDL-C (Intelligent Page Description Language for Color)....................2-7

CMS (Color Management System).......................................................2-8

Color Correction by the Driver ..............................................................2-8

BG/UCR (Black Generation/Under Color Removal)..............................2-8

Gamma Correction ...............................................................................2-8

Dither Processing .................................................................................2-9

Maximum Amount Toner Control..........................................................2-9

4 Bit Expansion.....................................................................................2-9

3. INSTALLA T ION.......................................................................... 3-1

4. SERVICE TABLES...................................................................... 4-1

4.1 CONTROLLER SP MODE ........................................................................4-1

4.1.1 ENTERING AND EXITING CONTROLLER SP MODE....................4-1

4.1.2 MENUS AND DISPLAY.................................................................... 4-2

4.1.3 SP MODE MENU HIERARCHY........................................................4-2

4.1.4 SP MODE DETAILS.........................................................................4-6

S1. Maintenance Sheet.........................................................................4-6

S2. Color Chart.....................................................................................4-7

S3. Maintenance Clear.........................................................................4-7

S4. Clear All Memory............................................................................4-7

S5. Gamma (γ) Calibration....................................................................4-7

S6. Printer ID........................................................................................4-7

S7. Toner Limiter..................................................................................4-8

S8. Brand (Default Setting: RICOH.EXP) .............................................4-8

S9. Meter Click .....................................................................................4-8

IPDL-C Menu........................................................................................4-9

Media Menu ([Media] key) ....................................................................4-9

i

Page 5

4.2 POWER-UP SELF-DIAGNOSTICS.........................................................4-10

4.3 POWER-UP SELF-DIAGNOSTICS FLOW CHART................................4-10

4.4 DETAILED SELF-DIAGNOSTICS MODE ...............................................4-11

4.5 DETAILED SELF-DIAGNOSTICS FLOW CHART...................................4-11

5. PERIODIC MAINTENANCE........................................................ 5-1

6. REPLACEMENT AND ADJUSTMENT........................................ 6-1

6.1 CONTROLLER BOARD REPLACEMENT ................................................6-1

6.2 IMAGE ADJUSTMENT..............................................................................6-1

6.3 SOFTWARE UPGRADE PROCEDURE....................................................6-1

7. TROUBLESHOOTING ................................................................ 7-1

7.1 TYPES OF PROBLEMS............................................................................7-1

7.2 TROUBLESHOOTING PROCEDURE.......................................................7-2

7.2.1 HARDWARE TESTS........................................................................7-2

7.2.2 OPERATION-RELATED TESTS......................................................7-2

7.2.3 SOFTWARE-RELATED TESTS.......................................................7-2

7.3 ERROR MESSAGES ................................................................................7-3

7.3.1 OVERVIEW......................................................................................7-3

7.3.2 CONTROLLER SELF-DIAGNOSTICS ERRORS.............................7-4

7.3.3 CONTROLLER USER ERRORS......................................................7-5

7.3.4 INTERNAL ERRORS........................................................................7-6

7.3.5 ENGINE USER ERRORS (CAUTIONARY)......................................7-7

7.3.6 ENGINE USER ERRORS.................................................................7-7

7.3.7 ENGINE SERVICE CODES .............................................................7-7

8. NETWORK INTERFACE BOARD (C4000 FERRET).................. 8-1

8.1 OVERVIEW...............................................................................................8-1

8.1.1 SPECIFICATIONS............................................................................8-1

8.1.2 BLOCK DIAGRAM............................................................................8-1

8.2 COMPONENT LAYOUT............................................................................8-2

8.2.1 NETWORK INTERFACE BOARD DIAGRAM...................................8-2

8.2.2 DEVICES..........................................................................................8-2

8.3 BASIC OPERATIONS...............................................................................8-3

8.3.1 OVERVIEW......................................................................................8-3

8.3.2 SWITCH FUNCTION........................................................................8-4

NVRAM Reset Procedure.....................................................................8-4

ii

Page 6

30 June 2000 OVERALL MACHINE INFORMATION

1. OVERALL MACHINE INFORMATION

1.1 BASIC SPECIFICATIONS

Page Description

Language:

Printer Driver:

Resolution: 600 dpi

Color Mode: Color, B&W

Gradation Mode 1 or 2 bits/pixel

Toner Saving: On/Off (printer driver setting) Default Setting: Disabled

Color Correction: On/Off (printer driver setting) Default setting: Enabled

Interface:

Fonts Ricoh-Script 2: 39 Roman fonts

Memory Standard: 32 MB (simplex model), 64 MB (duplex model),

• IPDL-C (Intelligent Page Description Language for Color)

• Ricoh-Script 2

• IPDL-C: Windows 95/98/2000/NT 4.0

• Ricoh-Script 2: Windows 95/98/2000/NT 4.0, Macintosh

(PPD for LaserWriter 8)

• Standard: Parallel port (IEEE1284: Compatible/Nibble/

ECP mode supported)

• Option: Parallel port (IEEE1284: only Compatible mode

supported), Ethernet (100 BASE-TX, 10 BASE-T)

(It can be replaced with optional memory.)

Overall

Information

Up to 256 MB (Replace the standard memory with optional

128-MB memory SDRAMS.)

SDRAM DIMM Slot 2 (for optional memory)

Option Bus Interface 2 (for optional network I/F board and optional parallel I/F)

Options

• 32 MB Memory

• 64 MB Memory

• 128 MB Memory

• Network Interface Board

• IEEE1284 Parallel Interface

1-1

Page 7

30 June 2000 DETAILED DESCRIPTIONS

2. DETAILED DESCRIPTIONS

2.1 DIFFERENT POINT FROM BASE MODEL (G024)

2.1.1 SYSTEM SOFTWARE

1. Automatic duplex printing is available for the duplex model.

2. Manual duplex printing (printing on the reverse side) is available for the simplex

model.

3. The appropriate electric counter can be selected depending on the type of

maintenance contract for meter click charge. A new User mode, “Show

Counter”, has been added to display the Color and B/W counter values.

4. If the printer driver has been installed, the printer keeps a record of the number

of pages printed out under each registered User Code (Up to 100).

5. This printer has a job log which shows the time, number of pages and current

status of each print job. Up to 64 User IDs (User Codes) can be set.

6. The bypass tray can be used as a manual tray. If it is set to “Manual”, the paper

size selected by the printer driver takes priority over the size selected on the

operation panel.

Detailed

Descriptions

7. The printer can be set so that it will either stop or continue printing when toner

has run out.

8. 300-dpi mode is not supported.

9. It is possible to enter SP mode without turning the machine off and on.

10. The optional network interface board (C4000 Ferret) supports PortNavi.

2.1.2 HARDWARE

1. CPU

NEC VR4310-177

2. ASIC

Rocky-R, which is compatible with SDRAM. FCI2.5C was removed because

300-dpi mode is not supported. Therefore, toner saving mode is controlled by

firmware.

3. SDRAM

The type of SDRAM used has been changed from SIMM to DIMM.

4. NVRAM

The capacity of the NVRAM has been expanded to 8 KB to store the Job and

Print Logs.

5. DIP Switches

Dip switches do not require resetting when upgrading firmware.

2-1

Page 8

DETAILED DESCRIPTIONS 30 June 2000

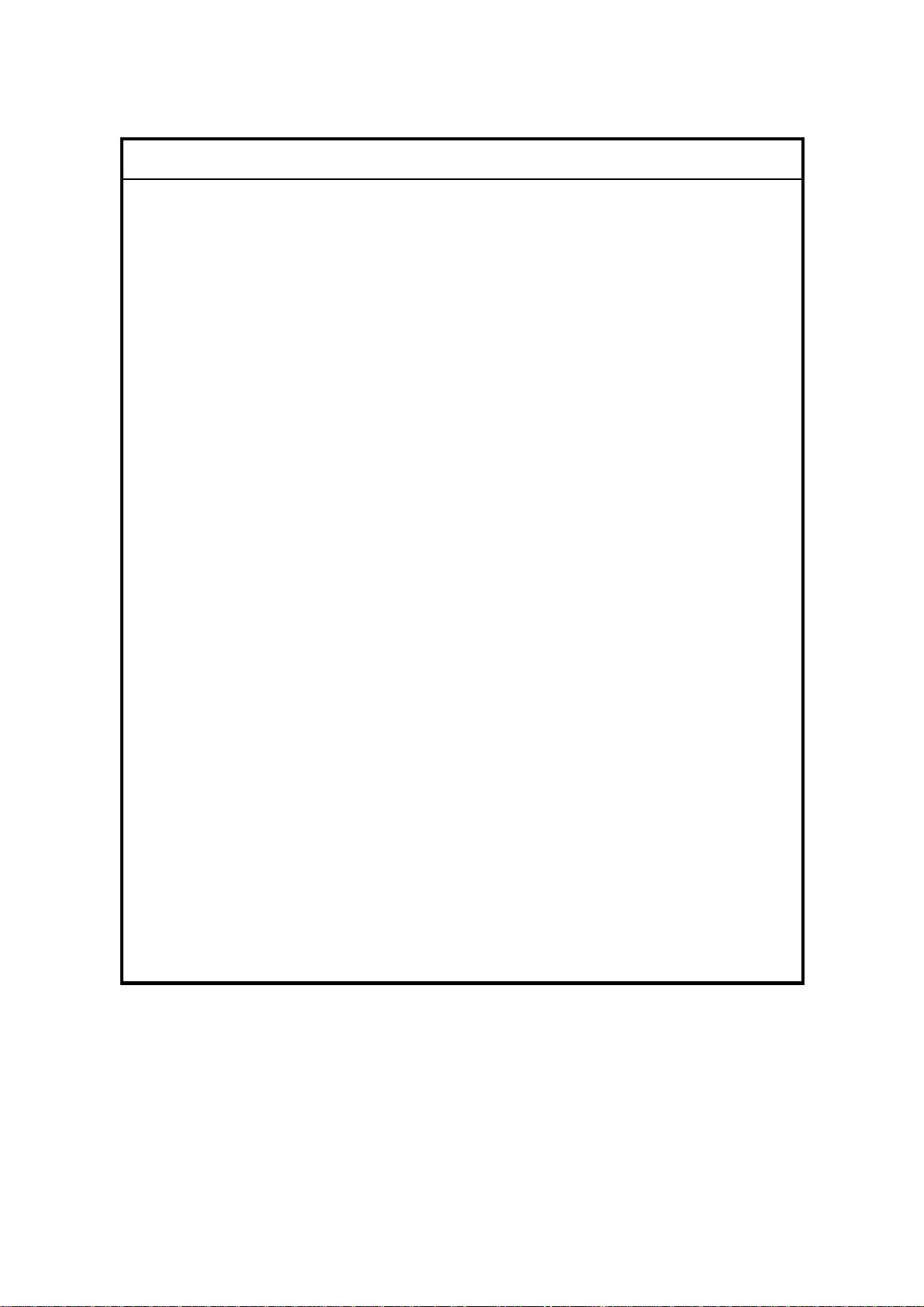

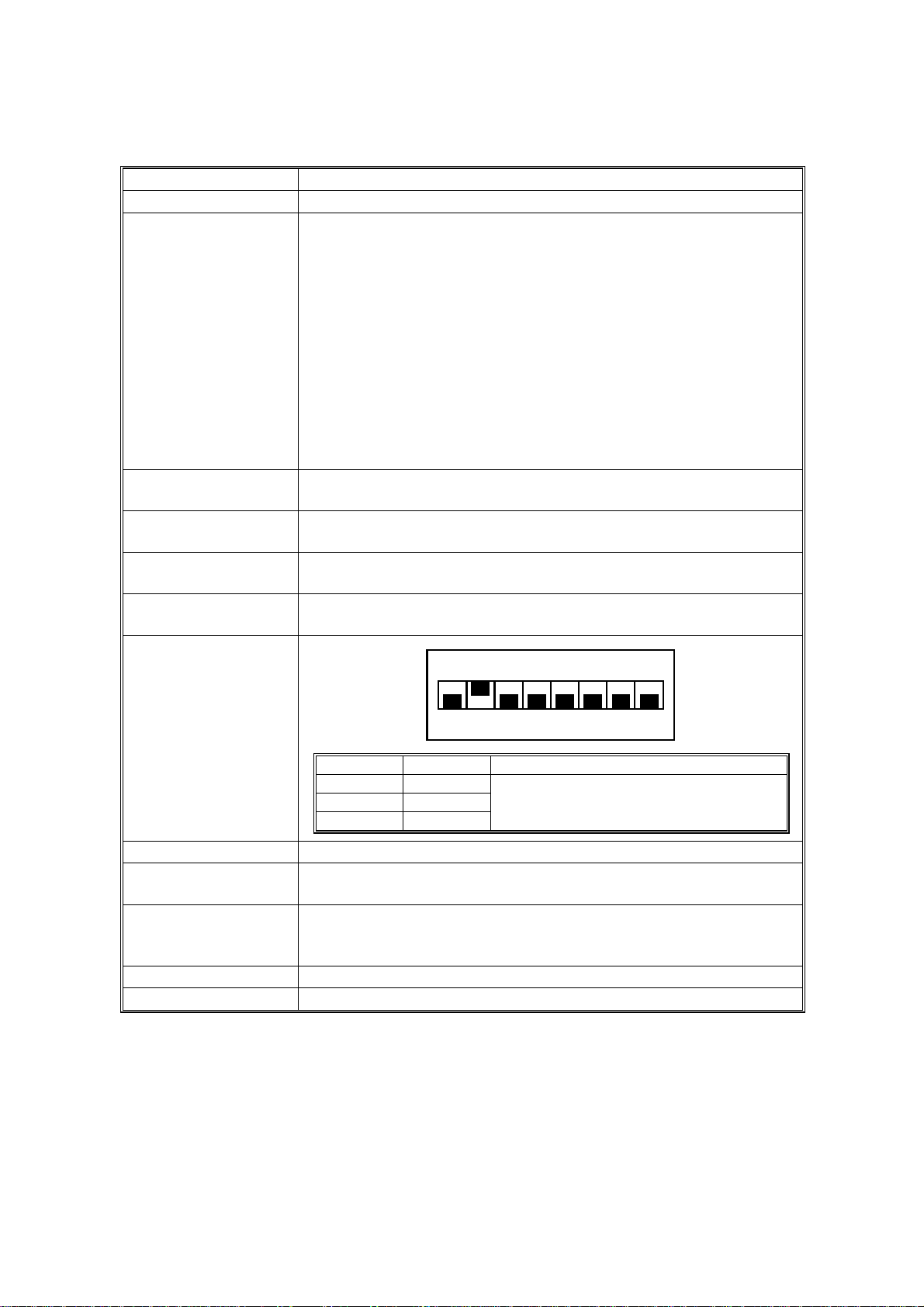

2.2 FUNCTIONAL OVERVIEW

2.2.1 SYSTEM LAYOUT

Controller Board

SDRAM

IC Card

RPS2

IC Card I/F

Program ROM I/F

Video I/F

SDRAM I/F

SDRAM

SDRAM I/F

IEEE1284 I/F

Host

Network I/F

Board

Option Bus I/F

2-2

Host

G048O701.WMF

Page 9

30 June 2000 DETAILED DESCRIPTIONS

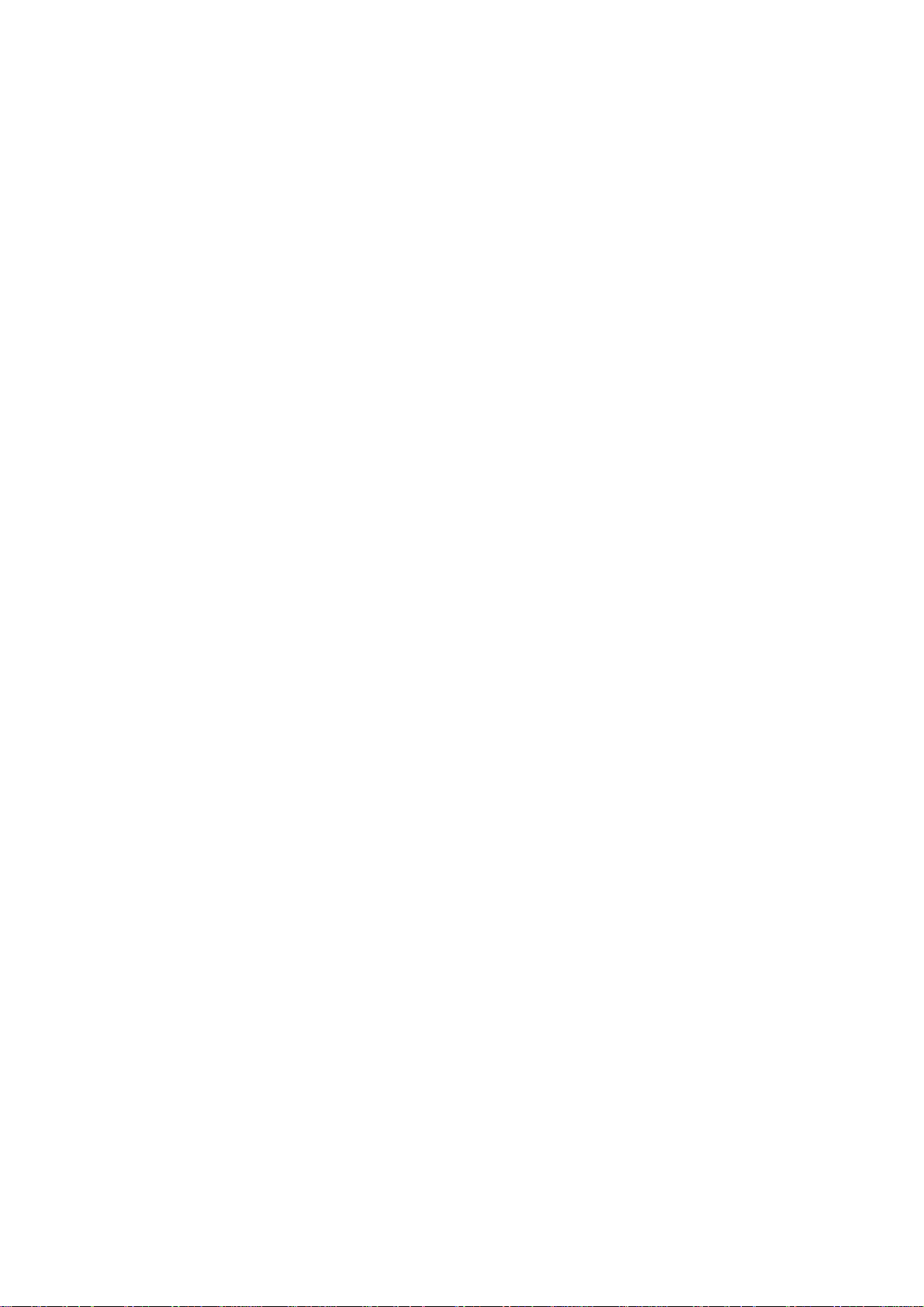

2.2.2 CONTROLLER BOARD LAYOUT

NVRAM

DIP SW

Option RAM I/F

IC Card I/F

Option RAM I/F

Detailed

Descriptions

ROM

Flash

Program ROM I/F

ROM

Flash

Font

ROM

Option Bus I/F Option Bus I/F

Video I/F

CPU

R4310

ASIC

ROCKY R

IEEE1284 I/F

G048O702.WMF

2-3

Page 10

DETAILED DESCRIPTIONS 30 June 2000

2.2.3 FUNCTION OF E ACH DEVICE

Device Function

CPU VR4310-177 (177 MHz)

ASIC ROCKY R This ASIC controls the following:

• Memory mapping

• Reset

• DRAM

• Data r eceived from the parallel

• Video DMA

• PvDMA

• Interrupt

• Serial communication with engine

• IEEE1284 interface

• Timer

•

I/O Port

FLASH ROM Stores program (2 MB) The flash ROM is programmable via an

IC card.

NVRAM

FONT ROM Stores internal printer fonts.

Program ROM Ricoh-Script 2 Emulation Module

DIP SW

Stores the initial settings and printer parameters.

(8 KB EEPROM)

(One 64-Mbit mask ROM)

The emulation module is programmable by IC card.

12345678

OFF

SW No. Setting Content

1OFF

2ON

3-8 OFF

Do not touch these switches in the field.

G048O708.WMF

Video I/F Interface the controller with the printer engine.

IEEE1284 I/F

Provides an interface that connects to a local host (IEEE1284

compliant).

Option Bus I/F Two slots; each can hold either an optional network interface or

a parallel interface board. You cannot install two boards of the

same type.

Option RAM I/F A slot for accommodating the memory.

IC Card Accommodates an IC card to upgrade firmware.

2-4

Page 11

30 June 2000 DETAILED DESCRIPTIONS

2.3 PRINT DATA PROCESSING

2.3.1 GRADATION & PRINTABLE DATA

The image can be printed with 1 bit or 2 bits (Default) in 600 dpi. However, a page

cannot be printed and the job is automatically canceled if the memory for image

processing overflows while converting the image data to bitmap format. This may

happen depending on the mode selected or the image data size.

If the memory overflows, gradation settings in the driver require changing by

printing the error message.

The printable size (combination of resolution, gradation and page size) is as

follows:

Detailed

Descriptions

2-5

Page 12

DETAILED DESCRIPTIONS 30 June 2000

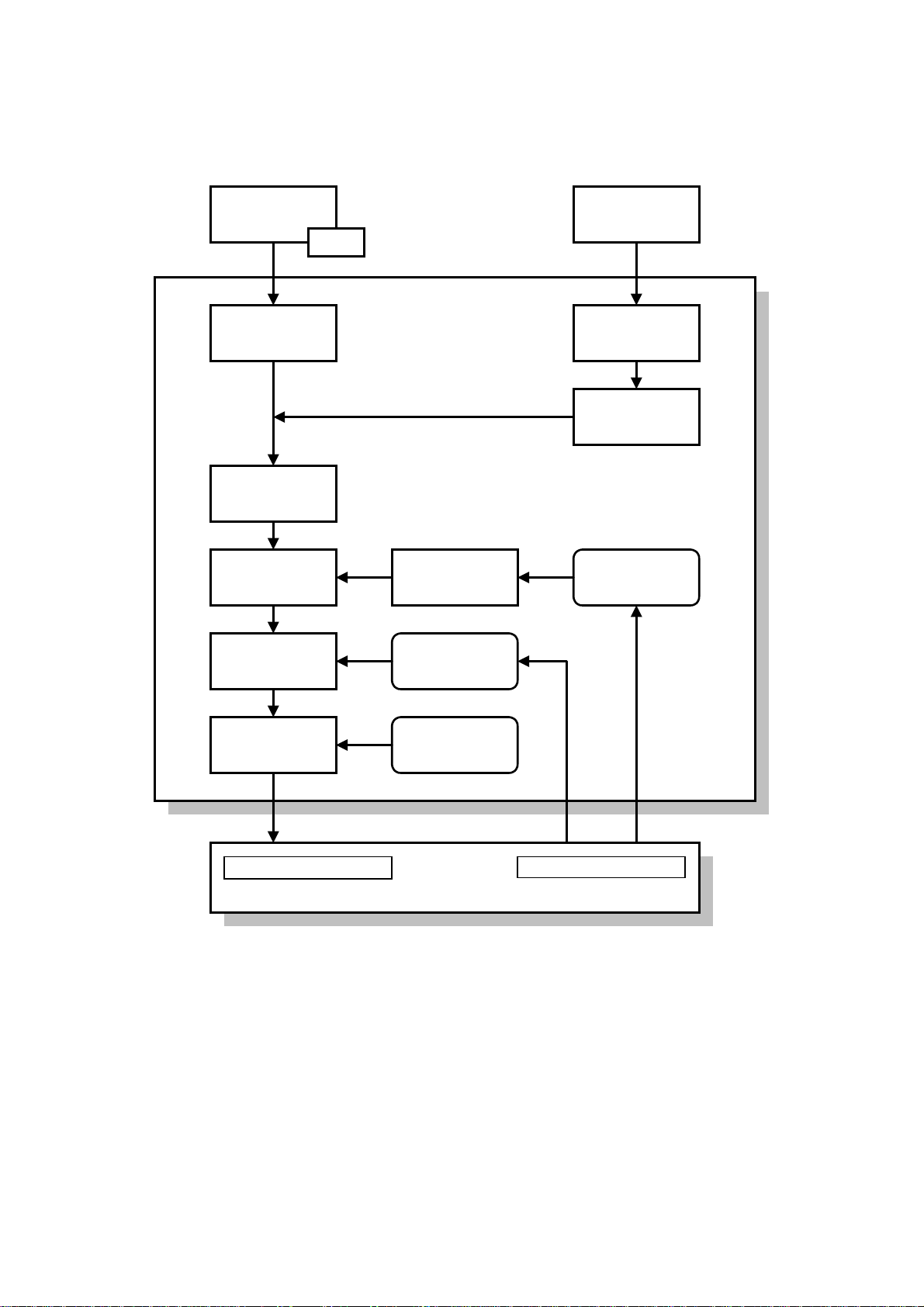

2.3.2 IMAGE DATA PROCESSING FLOW

IPDL-C Driver

BG/UCR

CMYK 8bit

Gamma

Correction

CMYK 8bit

Maximum

Amount

Toner Control

Dithering

CMS

Controller

CMYK 8bit

Gamma

Correction

Table

Maximum

Amount Value

(for service)

PS Driver

RGB 8bit CMYK 8bitRGB 8bit

RPS2 Module

(including CMS)

BG/UCR

Manual Gamma

Correction

CMYK 1/2bit

4bit Expansion

CMYK 4bit

MCU

1/2bit

Text/Photo

Dither

Operation Panel

Printer Engine

G048O706.WMF

2-6

Page 13

30 June 2000 DETAILED DESCRIPTIONS

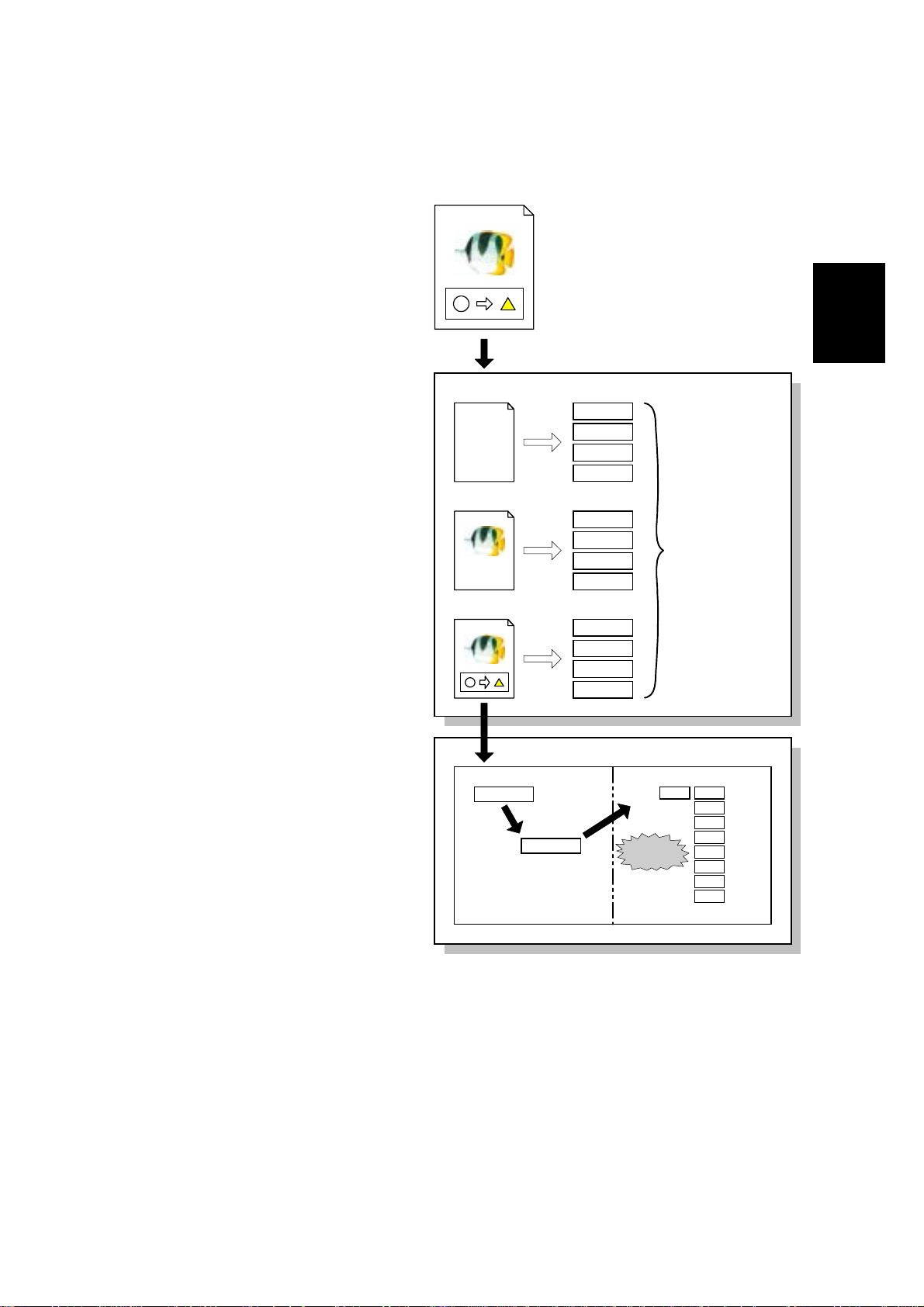

IPDL-C (Intelligent Page Description Language for Color)

The image data received from an

application is separated into three

elements: text, graphics, and

images. Then, the data for each

element is converted to IPDL-C.

The data converted is not done for

the whole page at once. Each

band (area specified) is

independently processed (banding

processing) for the data

conversion as shown in the figure.

The IPDL-C conversion from each

element is stored in free memory

and converted to bitmap data.

Bitmap data is compressed and

stored into the band pool memory ,

DRAM.

After data processing is complete,

the controller sends the

decompressed data to the printer

engine and the engine starts

printing.

APPLICATION

What is IPDL-C....

GDI

TEXT

What is IPDL-C....

IPDL-C

IMAGE

IPDL-C

GRAPHICS

IPDL-C

Detailed

Descriptions

DRIVER

Banding processing

(Converted to IPDL-C)

Free Memory

Converted from

IPDL-C to bitmap

format

CONTROLLER

Band pool memory

Compression

Compressed bitmap data

G048O707.WMF

2-7

Page 14

DETAILED DESCRIPTIONS 30 June 2000

CMS (Color Management System)

CMY realizes to optimize the color print quality by the color profile based on the

characteristics of the printer.

In Rcioh-Script2, CMS functions like the IPDL-C; but RGB conversion is done in

the controller.

CMS is used whenever the color profile setting in the printer driver is set to any

value other than “Off”.

Color Correction by the Driver

The driver adjusts the following parameters in accordance with the driver settings

made by the users: Brightness, Contrast, Saturation, and Color Balance

The driver does not perform RGB to CMYK conversion.

BG/UCR (Black Generation/Under Color Removal)

The RGB data sent to the controller is converted to CMYK data. During CMYK

conversion, some CMY data is replaced with K data by the BG/UCR algorithm.

Gamma Correction

The gamma curve can be adjusted in SP mode. For the adjustment procedure, see

“Section 6:Replacement and Adjustments” in the Controller Service Manual for the

base model (G024).

For CMYK, the density can be adjusted every 15 points from 0 to 100% (0,15, 30,

etc.). The corrected gamma data is stored in NVRAM memory.

The controller performs the gamma correction, RGB/CMYK conversion and

dithering.

→

4bit Expansion

Printer Engine

Process ControlBG/UCR Dithering

Image Density

Adjustment in

Solid Areas

Image Density

Adjustment in

Highlight Area

Printer

Driver

8bit

1/2bit

Controller

Gamma

Correction

Manual

Gamma

Correction

2-8

G048O709.WMF

Page 15

30 June 2000 DETAILED DESCRIPTIONS

Dither Processing

The dither pattern is prepared for the photo, text, graphic and thin lines

independently for 1- and 2-bit modes. These dither patterns creates the illusion of

256 gradations for high quality prints.

The optimum dither pattern is automatically selected based on the Text,

Photographic, and Image elements on the pages.

Maximum Amount Toner Control

The maximum toner amount is controlled in order to prevent toner from being

scattered around texts or lines printed.

The maximum amount values are prepared independently for text and photo. They

can be adjusted by the SP mode

• Default: 300%

• Adjustable range: 100% to 400% (step: 10%)

4 Bit Expansion

When the controller sends the data to the printer engine, the co ntroller expands the

data to 4 bits to meet the image-processing algorithm of the printer engine. When

expanding 1/2 bit to 4 bit, add some of the same data to the original data as shown

in the figure. Even when the data is expanded, dithering remains the same.

1bit

b0

2bit

b1 b0

Detailed

Descriptions

4bit

Expansion

b0 b0 b0 b0'

2-9

4bit

Expansion

b1 b0 b1' b0'

G048O710.WMF

Page 16

30 June 2000 INSTALLATION

3. INSTALLATION

Refer to Section 3 INSTALLATION in the engine service manual.

Installation

3-1

Page 17

30 June 2000 SERVICE TABLES

4. SERVICE TABLES

4.1 CONTROLLER SP MODE

When accessing SP mode, the SP mode menu is add ed to the “Job Timeout”,

“Maintenance” and “Media” menu.

4.1.1 ENTERING AND EXITING CONTROLLER SP MODE

[B][A]

G048O015.WMF

[B][A]

G048O016.WMF

To enter controller SP mode: There are two ways to enter SP mode.

• Turn on the printer while holding down the [On Line] [A] and [Reset] [B] keys on

the operation panel. Hold the keys down until all of the LEDs and the LCD turn

off.

• When on-line, first press [Reset] [B], [On Line] [A], and then press [Enter] [C]

sequentially (don’t take more than a few seconds to press each key).

To exit controller SP mode: There are two ways to enter SP mode.

• Turn the main switch off and on. Be sure to exit from SP mode when you are

finished.

• Follow the procedure for entering SP mode.

Tables

Service

NOTE: When accessing SP mode, “SP” is displayed on the dis play. Do not forget

to exit SP mode after servicing, because users may change the settings or

clear all the settings by accident.

4-1

Page 18

SERVICE TABLES 30 June 2000

4.1.2 MENUS AND DISPLAY

Same as the base model (G024)

4.1.3 SP MODE MENU HIERARCHY

The table below shows the controller SP menu hierarchy. The items in the table

can be accessed in the controller SP mode. When in SP mode, S1 to S9 are added

to the Maintenance menu.

Layer 1 Layer 2 Layer 3 Layer 4

Show Counter Color: xxxxxxx

Black: xxxxxxx

IPDL-C Menu

(displayed if IPDL-C

is selected.)

RPS2 Menu

(displayed if RPS2 is

selected.)

1. Job Timeout Off

2. I/O Timeout 0 – 999 seconds

3. MinLineWidth 1 – 4 dots

4. Toner Usage

1. Color Level 1 bit

2. Color Mode Color

3. Color Set Off

4. ColorProfile Photograph

5. TonerSaving Off

6. Dithering Auto

7. Paper Type Plain Paper

8. Auto Tray SW

9. Duplex Print

A: Duplex Bind Long Edge

B: Job Timeout Off

C. I/O Timeout 0 – 999 seconds

0 – 999 seconds

Off

On

2 bit

Black & White

Vivid

Super Vivid

Fine

Super Fine

Presentation

Solid Color

On

Photographic

Text

OHP

Thick Paper

Plain (Duplex Backside)

Thick (Duplex Backside)

On

Off

Off

On

Short Edge

0 – 999 seconds

It can be accessed if the

meter click mode is

selected.

It can also be accessed

in SP mode.

Same as above

4-2

Page 19

30 June 2000 SERVICE TABLES

Layer 1 Layer 2 Layer 3 Layer 4

RPS2 Menu

(displayed if RPS2 is

selected.)

System Menu

D: Feed Timeout 60 seconds

0 – 999 seconds

E: Print Errors

F: Ktalk Mode Not available

G: Parallel IF1 System Default

H: Parallel IF2 System Default

1. Paper Tray Tray 1

2. Tray Size [*] 8.5 x 13

3. Bypass Use Manual

4. I/O Buffer 16 KB

5. Energy Saver

6. Energy Level Level 1

7. PDL Sensing Auto

8. Transfer Hi-speed

9. Parallel 1

10. Parallel 2

11. Bi-direction

12. OHP Slip

13. Printer Language IPDL-C

Off

On

ACK Inside

ACK Outside

ACK Inside

ACK Outside

By-pass

Tray 2

Tray 3

A5

B4 JIS

B5 JIS

8.5 x 5.5

8 x 13

8.25 x 15

Auto Tray

32 KB

64 KB

128 KB

256 KB

512 KB

Off

5 minutes

15 minutes

30 minutes

45 minutes

60 minutes

Level 2

Manual

Normal

ACK inside

ACK outside

STB down

ACK inside

ACK outside

STB down

Original Mode

Standard

On

Off

RPS

Displayed if an optional

parallel interface board

is installed.

“Tray 2 and 3” are

displayed if an optional

paper feed unit is

installed.

Tables

Service

4-3

Page 20

SERVICE TABLES 30 June 2000

Layer 1 Layer 2 Layer 3 Layer 4

System Menu

Maintenance

14. Language English

French

German

Italian

Dutch

Spanish

Japanese

32. IP ADDRESS to

39. Active PTL.

1. Reinstall Charger

2. Toner Select Cyan

Magenta

Yellow

Black

3. Toner level

4. Registration Byps.: Vert.

Bypass/Thick: V

Tray: Vert.

Dup.: Vert.

Tray1: Horiz.

Tray2: Horiz.

Tray3: Horiz.

5. Toner Empty Continue

Stop

6. Menu Reset

7. Menu Protect Off

On

8. Log Protect Off

On

9. Log Clear If “Menu Protect” is

10. Ethernet Auto

10 Mbps

100 Mbps

S1. Maint. Page

S2. Color Chart

S3. Maint. Clear Fusing Unit

S4. Clear All Mem.

Displayed if an optional

network interface board

is installed.

“Tray 2 and 3” are

displayed if an optional

paper feed unit is

installed.

It can also be accessed

if the [Enter], [Escape],

and [Menu] keys are

pressed in sequence

when the printer is on

line. It is always

displayed in SP mode.

Same as above

selected, it is not

displayed.

It can also be accessed

if the [Enter], [Escape],

and [Menu] keys are

pressed in sequence if

the printer is on line,

and if an optional

network interface board

is installed. It is always

displayed in SP mode.

4-4

Page 21

30 June 2000 SERVICE TABLES

Layer 1 Layer 2 Layer 3 Layer 4

Maintenance

List Print

S5. Gamma Calib.

S6. Printer ID Not used

S7. Toner Limiter Text

S8. Brand RICOH.EXP

S9. Meter Click Off

1. Config. Page

2. Color Sample

3. Job Log

4. Statistics

IPDL-CSelect PDL

OPTION#1 RPS2

Load Setting Default

Setting-Old

Setting-Current

Mode Select 1 bit/photo, 2 bit/photo

1 bit/Text, 2 bit/text

Print Sheet

Gamma Select Black

Cyan

Magenta

Yellow

Save Settings

Photo

It can be accessed only

SAVIN

NRG

Infotec

Gestetner

LANIER

RICOH.JPN

Print/Japan

Develop. Count

Print Count

Print/Japan: D

Dev.Count: D

Print Count: D

if [W], [V], and [Menu]

keys are pressed in

sequence.

Tables

Service

4-5

Page 22

SERVICE TABLES 30 June 2000

4.1.4 SP MODE DETAILS

S1. Maintenance Sheet

The table below explains the contents of the engine maintenance list printout. The

controller obtains the data from the engine (MCU).

Item Description

MCU version The MCU board firmware version number.

Toner density Toner density can be adjusted via the Maintenance. Menu by customers.

Adjusted values are stored in NVRAM on the MCU.

Registration Side registrations from Optional tray can be adjusted with Maint. Menu by

customers. And leading edge registration can be done with engine SP mode

(1. Margin). These values are stored in NVRAM on the MCU.

Total counter Indicates the total number of printouts. The counter is incremented when the

paper exit sensor detects paper exit completion (regardless of paper size,

type, and mono/color mode).

Color Counter value printed in color mode.

Mono color Counter value printed in black mode.

PCU counter PCU replacement is indicated when this value reaches 72000. This value is

incremented by 4 in color mode printing and by 1 in Black mode printing

except A3/DLT. When printing with A3/DLT, double counting occurs.

Fusing unit Fusing unit replacement is indicated when this value reaches to 60000. This

counter is incremented by 2 for A3/DLT size printing and by 1 for other size

printing.

Fusing

unit/Counter

reset time

Charger

Counter

Charger Reset

Counter

A3/DLT, A4/LT,

LG, B4 and

Other Size

counter

Feed Jam,

Transfer Jam

and Exit Jam

counter

Feed Jam,

Transfer Jam

and Exit Jam

counter (Duplex)

SC counter Number of SCs

Meter Click Type of counting method for meter click mode

Count by

developments

Count by prints Number of prints. This counter increases by 1 for any size printing.

Count by

developments

(A3/DLT double)

Count by prints

(A3/DTL double)

Number of Fusing unit resets with controller SP mode (S3).

Charger replacement is indicated when this value reaches to 24000.

Number of Charger resets with controller UP mode.

Number of each size paper that passed the exit sensor.

Number of paper jams in each section.

Number of paper jams in each section for duplex printing.

Number of developments. This counter increases by 1 when a print of any

size is made.

Number of developments. This counter increases by 2 for A3/DLT size

printing and by 1 for all other sizes.

Number of prints. This counter increases by 2 for A3/DLT size printing and by

1 for all other sizes.

4-6

Page 23

30 June 2000 SERVICE TABLES

Item Description

Count by prints

(Japan)

Count by prints

(Japan:A3/DTL

double)

SC Logging The most recent 3 SC codes.

Jam Logging The most recent 10 jamming codes and the total counter value at the time.

Process-Control

Error Logging

ID sensor PWM The value set with engine SP mode, 9: ID Sensor PWM.

Not used.

Not used.

000: At paper cassette

001: At paper pass

002: At paper exit

The most recent 3 errors while process control and the total counter value at

the time.

Not all of the errors are indicated as SC errors.

S2. Color Chart

Same as the base model (G024)

S3. Maintenance Clear

Same as the base model (G024)

S4. Clear All Memory

Executing this function resets the following user settings, stored in the NVRAM on

the controller, to their default values:

• System Menu

• Printer ID

• Printer name on the network

• Gamma (γ) calibration

• Brand

γγγγ)

S5. Gamma (

)

Calibration

) )

Same as the base model (G024)

S6. Printer ID

Tables

Service

Not used for this model.

NOTE: This is used for controller identification when installing fonts for Ricoh-

Script 2 onto the hard disk. However, since it is not possible to install the

hard disk in this model, it is not necessary to set the printer ID.

4-7

Page 24

SERVICE TABLES 30 June 2000

S7. Toner Limiter

The maximum toner values can be adjusted from 100 to 400% for both Text and

Photo Modes. The default value for both is 300%.

If this value is set high, the printed image appears more true to the original data.

However, since a greater amount of toner is used, it is easy to scatter the toner

around lines and text areas. If the value is set low, the color balance of low-density

areas varies, however toner does not scatter as easily.

NOTE: The values for the maximum toner amount are fixed for the base model

(G024), but adjustable for the G047/48.

S8. Brand (Default Setting: RICOH.EXP)

Use this mode to specify the brand. The machine will then display the correct

model name on the LCD and in the configuration page header.

NOTE: This must be done before delivering the printer to the customer site.

S9. Meter Click

In this mode, the counting method can be selected depending on the type of

Service Contract.

When the mode is activated:

1. A new user mode, “Show Counter” displays the counter values.

2. The printer will stop printing when toner has run out. In addition, “Toner Empty”

disappears from the Maintenance menu.

3. The configuration sheet includes the value for the counting method selected in

Meter Click mode, not the total counter value. Both counter values are included

in the engine maintenance sheet.

4. After selecting meter clock mode, the counter value for the selected counting

method is automatically set to 0. However, it cannot be reset to 0 after the

machine begins counting.

5. All developments/prints are counted at paper exit.

4-8

Page 25

30 June 2000 SERVICE TABLES

6. Counting method:

1) By developments

Black 1C 2C 3C Full col or

Full color +1 +2 +3 +3

Black and white +1 +1

NOTE: If the meter click mode is set to “Dev. Count: D”, it is incremented by 2

for A3/DLT size.

2) By prints

Black 1C 2C 3C Full col or

Full color +1 +1 +1 +1

Black and white +1

If the meter click mode is set to “Print Count: D”, it is incremented by 2 for

A3/DLT size.

7. The following are not counted:

1) A sheet of paper that is placed between printed transparencies in OHP Slip

Mode.

2) The final page when printing an odd number of pages in duplex mode.

3) The engine maintenance sheet, color chart and gamma calibration sheets in

controller SP mode.

4) All sheets printed out in engine SP mode.

5) The Low-Memory Error Sheet.

6) A list of settings (B/W) if a non-fatal error is detected during Self-Diagnostics.

Tables

Service

8. “Change Fuser”, “Change PCU”, and “Need Charger” are not displayed.

IPDL-C Menu

Item Description

3. MinLineWidth Adjust s the minimum line width within 1 to 4 dots.

4. Toner Usage

Displays the toner usage independently for each color when printing

the page. (Number of dots on the page/ maximum number of dots)

Media Menu ([Media] key)

Controller SP mode adds special menu items to the user menu accessed from the

[Media] (access by pressing the [Media] key, then scroll through the menu on the

display) menu.

Menu Item Function/Use

Displays the currently installed versions of the controller system,

3. Summary

emulation modules, and engine (MCU) firmware, and the amount of

memory installed in the controller.

4-9

Page 26

SERVICE TABLES 30 June 2000

4.2 POWER-UP SELF-DIAGNOSTICS

Same as the base model (G024)

4.3 POWER-UP SELF-DIAGNOSTICS FLOW CHART

Turn on power

Diagnostic

Code ROM sum check

Test Code ROM

Fatal Error Detected

Read/write test

Frequency check

Test of timer functions

of Rocky R

Operation Test

Font ROM sum check

DIMM (RPS2) sum check

Test Standard RAM

Test CPU

Test Timer

Test FPU

Test Font ROM

Test DIMM

Start System

Non-fatal Error

(user error)

No

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Display Error on LCD

Yes

Print List of Settings

(Black/white)

Standby Condition

4-10

G048O711.WMF

Page 27

30 June 2000 SERVICE TABLES

4.4 DETAILED SELF-DIAGNOSTICS MODE

Same as the base model (G024)

4.5 DETAILED SELF-DIAGNOSTICS FLOW CHART

Turn on power

Diagnostic

Code ROM sum check

Test Code ROM

Fatal Error Detected

Read/write test

Frequency check

Test of timer functions

of Rocky R

Read/write test

Operation test

Loop back test on the

standard parallel interface

Read/write test

Font ROM sum check

DIMM (RPS2) sum check

Test Standard RAM

Test CPU

Test Timer

Test Optional RAM

Test FPU

Test Parallel Interface

Test NVRAM

Test Font ROM

Test DIMM

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Display Error on LCD

Tables

Service

Start System

Non-fatal Error

No

Print List of Settings

(Color)

Standby Condition

4-11

Yes

Print List of Settings

(Black/white)

G048O712.WMF

Page 28

30 June 2000 PERIODIC MAINTENANCE

5. PERIODIC MAINTENANCE

Refer to Section 5 Periodic Maintenance in the engine service manual.

Periodic

Maintenance

5-1

Page 29

30 June 2000 REPLACEMENT AND ADJUSTMENT

6. REPLACEMENT AND ADJUSTMENT

6.1 CONTROLLER BOARD REPLACEMENT

Refer to section 6.7.1 Controller Board of the Engine Service manual for the

replacement.

6.2 IMAGE ADJUSTMENT

Same as the base model (G024)

6.3 SOFTWARE UPGRADE PROCEDURE

The controller, Ricoh-Script 2, and network interface boards have a flash ROM for

storing control software. This allows version upgrades using an IC card.

The engine firmware cannot be upgraded using this procedure. See the engine

service manual for details on how to upgrade the engine firmware.

NOTE: Before starting an upgrade procedure, make sure that the software in the

IC card is newer than the software in the controller, Ricoh-Script 2, or

network interface board.

To check, do one of the following:

• Print out a configuration page (user mode).

• Enter controller SP mode and execute “3. Summary” with the [Media]

key. The software version is shown on the operation panel LCD.

Follow the procedure shown below to upgrade the software:

1. Turn off the machine, and then unplug all cables from the parallel interface

boards and network interface board, if connected.

2. For the duplex model only: Open the vertical transport unit.

3. Remove the controller board cover.

4. Remove the controller board and then install the upgrade IC card in the card

slot.

5. Turn on the machine. The machine automatically copies the software from the

IC card to the appropriate IC (controller, Ricoh-Script 2, or network interface

board).

Adjustment

Replacement

CAUTION: Do NOT turn off the machine while the software is being updated.

Otherwise, the controller, NIB, or Ricoh-Script 2 module may be

damaged.

6-1

Page 30

REPLACEMENT AND ADJUSTMENT 30 June 2000

For the controller or Ricoh-Script 2:

The LCD display on the operation panel changes as shown below as the

rewrite procedure proceeds. (‘MELT’ is displayed during the software upgrade

for Ricoh-Script 2 since it involves a decompression process.)

(MELT ->) ERASE -> WRITE -> VERIFY -> OK!!OK!!

The appearance of the message “OK!!OK!!” indicates that the controller has

received the data from the IC card. However, note that it takes about 30

seconds to rewrite the data in the controller or Ricoh-Script 2 after this message

is displayed.

The message NG!!NG!!” is displayed if an error occurs during the rewrite

process. If this condition occurs, reinstall the IC card and turn the power off and

on again.

For the network interface board:

The appearance of the message “DOWNLOAD OK.” indicates that the

controller has received the data from the IC card. However, note that it takes

about 30 seconds to rewrite the data in the network interface board after this

message is displayed.

DOWNLOAD -> ############ -> DOWNLOAD OK.

The message “DOWNLOAD NG.” is displayed if an error occurs during the

rewrite process. If this condition occurs, reinstall the IC card and turn the power

off and on again.

1. When the rewrite ends, turn off the main unit, and remove the IC card.

2. Close the controller board cover.

3. For the duplex model only: Close the vertical transport unit.

4. Turn the power on again and print the user mode configuration page.

5. Check the new software version listed on the configuration page and make

sure that it matches the version on the IC card.

6-2

Page 31

30 June 2000 TROUBLESHOOTING

7. TROUBLESHOOTING

7.1 TYPES OF PROBLEMS

The problems can be classified as follows:

Printer-side Print Settings

•

Operation

Hardware

Printer-side Initial Settings

•

Host-side Application Settings

•

•

Faulty Engine

•

Faulty Controller

•

•

•

•

•

Main Unit

Option

Consumables

Main Unit

Option

Software

Operating

conditions

•

Hardware Limitations

Bug in Controller ROM

•

Bug in Emulation Module Software

•

•

Controller Limitations

Bug in Host-side Application

•

Host-side Application Limitations

•

Environment (power, temperature and humidity,

•

dust, noise, vibration)

•

Consumables

G048O014.WMF

Trouble-

shooting

7-1

Page 32

TROUBLESHOOTING 30 June 2000

7.2 TROUBLESHOOTING PROCEDURE

7.2.1 HARDWARE TESTS

Same as the base model (G024)

7.2.2 OPERATION-RELATED TESTS

Same as the base model (G024)

7.2.3 SOFTWARE-RELATED TESTS

Same as the base model (G024)

7-2

Page 33

30 June 2000 TROUBLESHOOTING

7.3 ERROR MESSAGES

7.3.1 OVERVIEW

The error messages for this unit are classified as follow s :

1. Controller Self -diagnostic Errors

Errors detected while the unit performs power-up self-diagnostics/detailed selfdiagnostics on the controller hardware.

2. Controller User Erro rs

Errors caused because the controller software cannot process the job because

of, for example, insufficient memory.

3. Internal Errors

Errors caused because the controller’s control function fails to function

normally.

4. Engine User Errors (Cautionary)

Errors that do not require user intervention to continue printing (the printer can

still communicate with the PC over the interface). However, for the best printing

quality, the user should correct the problem as soon as possible.

5. Engine User Errors

Severe errors that cause the unit to stop printing, requiring the user to fix the

problem before printing again.

6. Engine Service Codes (SCs)

Severe errors that cause the unit to stop printing, requiring a technician to fix

the problem before printing again.

Only one error message can be displayed at a time. There is an order of priority for

displaying errors. This is as follows, starting with the highest priority: Internal

Errors, Controller Self-d iagnostics Errors, Engine Service Codes (SCs), Engine

User Errors, Engine User Errors (Cautionary), and Controller User Errors.

Trouble-

shooting

7-3

Page 34

TROUBLESHOOTING 30 June 2000

7.3.2 CONTROLLER SELF-DI AGNOSTICS ERRORS

When a contro ller self-diagnostics error occurs, the error code is displayed on t he

first line of the operation panel LCD.

The second line contains an 8-digit code that gives details of the error for

designers to debug. For a memory error, the second line of the LCD indicates the

address where the error occurred. For errors other than memory errors, the second

line always reads “FFFFFFFF”.

Code Description Location

00XX Exception processing error Controller

0101 Code ROM sum check error Controller

0201 Standard memory read/write error Controller

0301/0401

060X CPU exception self-diagnostics error Controller

0D0X ASIC timer error Controller

0EXX AISIC operation panel interface error Controller

110X

1401 NVRAM error (Read/W rit e) Controller

160X Font ROM error (Sum) Controller

1B0X Optional Interface 1 Error Contr o ller

1C0X Optional Interface 2 Error Controller

1D0X

250X

400X FPU er r or Controller

Optional memory read/write error

Non-fatal error (printed as B0 in the error log.)

ASIC Centronics interface error

Non-fatal error (printed as B1 in the error log.)

Optional parallel interface board error

Non-fatal error (printed as B6 in the error log.)

DIMM (emulation module) error

Non-fatal error (printed as B5 in the error log.)

Optional memo ry

Controller

Optional parallel

interface board

Emulation

module/Controller

7-4

Page 35

30 June 2000 TROUBLESHOOTING

7.3.3 CONTROLLER USER ERRORS

Display Description Location/action

85: Error

86: Error

91: Error

94: Error

A3: Error

Graphics environment initialization

error

Invalid control code parameter I ncorrect pr inter driver or incorrect

Font/image environment

initialization error

Download data error

Receive buffer overflow Increase the I/O buffer size using

A6: Error Overflow during compression Install additional memory.

Error during drawing processing Use a smaller font size or a less

A7: Error

Error during library drawing Switch the machine off/on. If that

A8: Error

AB: Error Print overrun Install additional memory.

B0: Error Optional memory error Reinstall/replace optional memory.

B1: Error Standard parallel interface error Interface cable/controller

Invalid initial set-up setting Reset the printer settings using

B3: Error

B4: Error IC card slot error Controller/IC card

B5: Error Optional emulation module error Reset/replace emulation module.

B6: Error

B7: Error

Optional parallel interface board

error

Optional network interface board

error

Optional memory/Controller

cable installed

Install additional memory.

Incorrect ‘total memory size’ setting

in the driver

the system menu (user mode)

complex font, or replace the

controller

does not work, replace the

controller.

‘Menu reset’ in the Maintenance

menu (user mode).

Reset/replace optional parallel

interface board

Reinstall/replace network interface

board

7-5

Trouble-

shooting

Page 36

TROUBLESHOOTING 30 June 2000

7.3.4 INTERNAL ERRORS

When an internal error occurs, the mes sage “Power Off/On” is displayed on the

first line of the operation panel LCD. The internal error code is on the second line in

the format “Error XXYY-ZZZZZZZZ” (“XX” denotes a classification code; “YY”

denotes a process number, and “ZZZZZZZZ” indicates the program address where

the error occurred).

The classification code portions (XX) and their descriptions are shown below. The

“YY” and “ZZZZZZZZ” portions are for designer use only (for debugging).

Code (XX) Description

00 Error in the TLB user area.

01 CPU TLB update exception

02 CPU mismatch exception (load or fetch)

03 CPU mismatch exception (store)

04 CPU address error exception (load or fetch)

05

06 CPU bus error exception (load or fetch)

07 CPU bus error exception (store)

08 CPU system call exception

09 CPU break point exception

10 CPU reserved instruction exception

11 CPU coprocessor disabled exception

12 CPU operation overflow exception

13 CPU trap exception

14 Coherency (instruction) error

15 CPU floating-point operation exception

16 CPU timer interrupt

17 ROCKY level 4 interrupt (ART or Tim)

18 ROCKY level 3 interrupt (CP)

19 ROCKY level 2 interrupt (XINT1 or XINT0)

20 ROCKY level 1 interrupt (CBE, DBE, Dt c0, Verr , Fin, Vdtc, Fout)

21 ROCKY level 0 interrupt (Debug)

22 Software interrupt

23 Software interrupt

24 Other CPU exceptions

25 Memory allocation error

26 Overflow error

27 Frame allocation error

28 Card eject error

29 Printer engine error

30 Option board error

31 Session-to-network interface board communications error

CPU address error exception (store)

7-6

Page 37

30 June 2000 TROUBLESHOOTING

7.3.5 ENGINE USER ERRORS (CAUTIONARY)

The unit can continue printing even when one of the messages listed below is

encountered.

Display Description

Change Fuser

Change PCU Photoconductor unit

Need Charger Charger replacement time

Low on: XXX Toner near end

Add Fusing Oil Fusing oil near end 100

Waste T Full Waste toner bottle is nearly full. 20

Fusing unit replacement time

arrived.

replacement time arrived

arrived.

XXX denotes the color name

(CMYK or their combination).

Number of sheets until

warning state

Information only

Information only

Information only

100

NOTE: “Change Fuser”, “Change PCU”, and “Need Charger” are not displayed if

meter click mode is selected by SP mode.

7.3.6 ENGINE USER ERRORS

The unit can no longer continue printing when this error message is displayed.

Refer to the Troubleshooting section in Setup Guide of Operating Instructions.

7.3.7 ENGINE SERVICE CODES

Refer to the Troubleshooting sectio n in Engi ne Ser vice manual.

7-7

Trouble-

shooting

Page 38

30 June 2000 OVERVIEW

8. NETWORK INTERFACE BOARD (C4000 FERRET)

8.1 OVERVIEW

8.1.1 SPECIFICATIONS

Configuration: Embedded

LAN Interface: 100BASE-TX/10BASE-T

Frame Type: Ethernet II, IEEE802.3, IEEE802.2, SNAP

Protocol: TCP/IP, AppleTalk, NetWare, NetBEUI

SNAP: MIB-II, PrinterMIB, HostResourceMIB, RicohPrivateMIB

8.1.2 BLOCK DIAGRAM

Controller

Board

Option Bus I/F

Network

Environment

CPU

ASIC

Ethernet

Controller

Filter Module

LAN I/F

Flash ROM

1MB

SDRAM

8MB (64Mb)

EEPROM

1Kb

Options

8-1

G048O713.WMF

Page 39

COMPONENT LAYOUT 30 June 2000

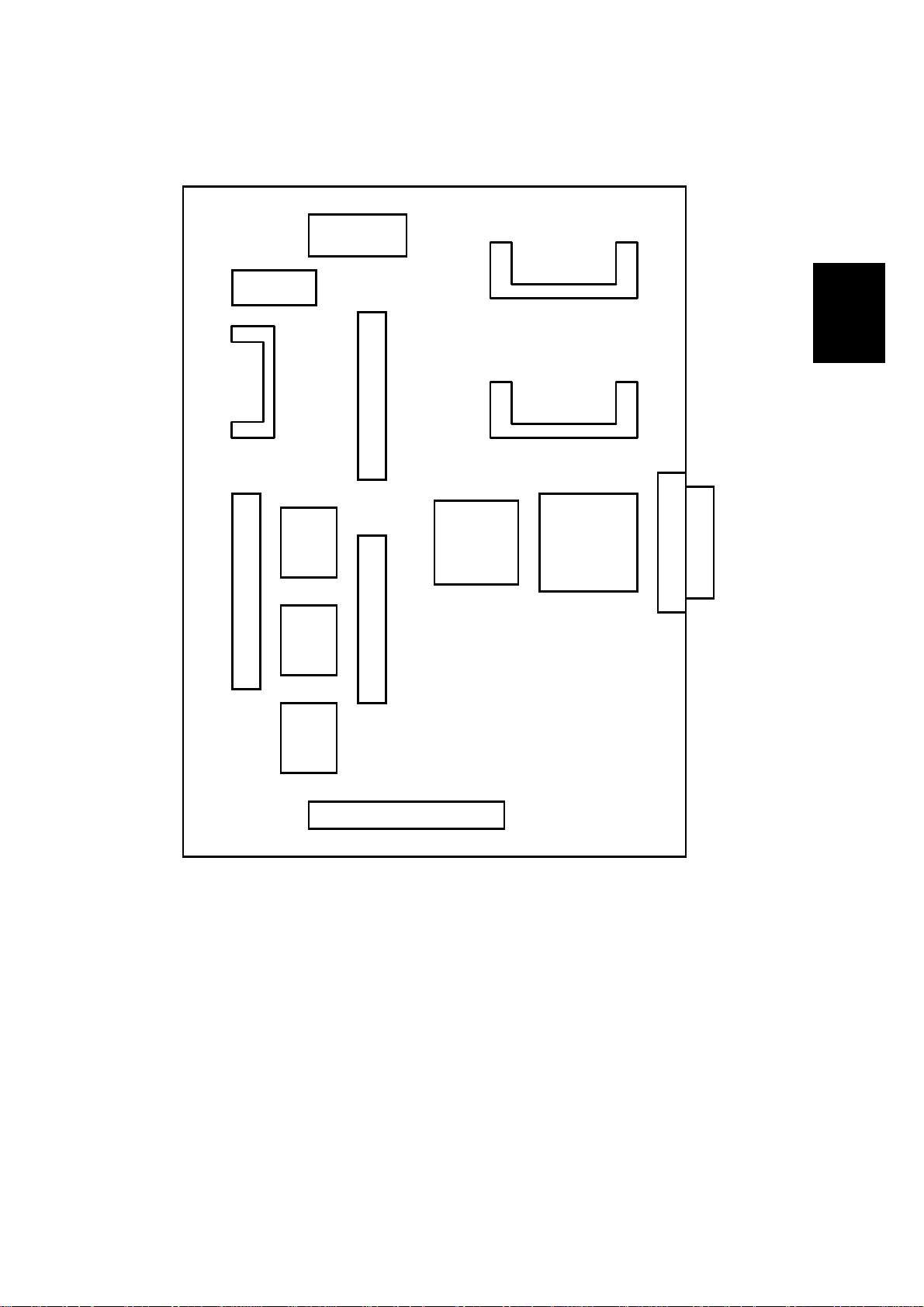

8.2 COMPONENT LAYOUT

8.2.1 NETWORK INTERF ACE BOARD DIAGRAM

Flash

ROM

MB87L1231

8.2.2 DEVICES

ASIC

SDRAM

CPU

HD6417612

Ethernet

Controller

AM79C973

RJ-45

LED4(G)

LED3(G)

EEPROM

LED1(Y)

SW2

G048O705.WMF

Device Description

CPU HD6417612RF

ASIC MB87L1231

Flash ROM MBM29LV800BA-70PFTN (8 Mbit)

SDRAM 64Mbit: 100MHz

EEPROM M93C46-WMN6 (1kbit)

Ethernet Controller AM79C973KC/W

8-2

Page 40

30 June 2000 BASIC OPERATIONS

8.3 BASIC OPERATIONS

8.3.1 OVERVIEW

This network board can manage both 100BASE-TX and 10BASE-T. It has a

maximum data transfer speed of 100Mbps.

The auto-negotiation function automatically switches the communication speed.

The controller board supplies the power source (+5V) and provides the reset

signal. The controller board communicates with the network interface board

through the option I/F connector.

The function of LED and SW is as follows;

Functions

LED1

LED2 Not used

LED3

LED4

SW1

Displays the operating status.

ON: Ready, OFF: Busy

Displays the LAN Type.

ON: 100 BASE-TX, OFF: 10 BASE-T

Displays the link status.

ON: Link safe, OFF: Link failure or Link disable

Resets the NVRAM on the network interface board.

NOTE:This board has the hardware to execute a “Summary Printout”.

However, it does not function on this printer due to the controller

specifications.

8-3

Options

Page 41

BASIC OPERATIONS 30 June 2000

8.3.2 SWITCH FUNCTION

SW1 resets the NVRAM on the network interface board.

NOTE: This board has the hardware to execute a "Summary Printout". However, it

does not function on this printer due to controller specifications.

NVRAM Reset Procedure

This procedure resets all the network settings to the defaults.

• IP address, Subnet Mask, Default Gateway Address, Access Control Mask,

Network Boot, Frame Type (NetWare), Active Protocol, and so on

1. Turn on the main switch while pressing SW1. Keep pressing SW1 for 15

seconds.

2. Release SW1 for 3 seconds, press it again for 3 seconds, and then release it.

3. Turn the main switch off/on to complete the NVRAM reset procedure.

NOTE: There is a margin of less than 1 second for error. Use a watch to

measure the time periods as accurately as possible.

4. Print out the configuration page, and then check the settings. If the procedure

failed, the previous settings remain. Repeat the above procedure until the old

settings have been cleared.

8-4

Loading...

Loading...