Page 1

FRESA PS (G024)

SERVICE MANUAL

[Controller]

Page 2

IMPORTANT SAFETY NOTICES

ø

PHYSICAL INJURY PREVENTION

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some printer components are supplied with electrical voltage even

if the main switch is turned off.

4. If an adjustment or operation check must be made requiring the removal or

opening of the exterior covers while the main switch is on, keep hands away

from electrified or mechanically driven components.

5. The printer drives some of its components when it completes the warm-up

period. Keep hands away from mechanical and electrical components when

the printer starts operation.

6. The interior and metal parts for the fusing unit become extremely hot while

the printer is operating. Do NOT touch these components with bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the printer without ozone filters installed.

2. Always replace the ozone filters with the specified replacement at the

specified maintenance intervals.

3. Toner is non-toxic, but if it gets in your eyes by accident, it may cause

temporary eye discomfort. Remove it with eye drops or flush eyes with

water. If this is unsuccessful, get medical attention immediately.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do NOT incinerate toner cartridges, development toner magazine (DTM) or

used toner. Toner dust may ignite suddenly when exposed to an open

flame.

2. Dispose of used toner bottle and photoconductor unit (PCU) in accordance

with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

Page 3

Trademarks

Microsoft, Windows 95/98, and Windows NT 4.0 are registered trademarks of

Microsoft Corporation.

Macintosh and EtherTalk are registered trademarks of Apple Computer, Inc.

PostScript is a registered trademark of Adobe System Inc.

PCL is a registered trademark of Hewlett-Packard Company.

NetWare is a registered trademark of Novell, Inc.

Ethernet is a registered trademark of Xerox Corporation.

Token Ring is a registered trademark of IBM Corporation.

General Notice:

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights in those

marks.

Page 4

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION........................................1-1

1.1 SPECIFICATIONS.................................................................................... 1-1

1.2 LAYOUT ................................................................................................... 1-2

2. FUNCTIONAL OVERVIEW .........................................................2-1

2.1 BLOCK DIAGRAM AND FUNCTIONS...................................................... 2-1

CPU ..................................................................................................... 2-1

Memory................................................................................................ 2-1

DRAM .................................................................................................. 2-2

SRAM................................................................................................... 2-2

NVRAM Functionality........................................................................... 2-2

Fiery Rip Chips (EFI ASICs)................................................................. 2-3

Real Time Clock................................................................................... 2-3

2.2 PRINT DATA PROCESSING.................................................................... 2-4

2.3 BUILT-IN COLOR MANAGEMENT .......................................................... 2-5

3. INSTALLA T ION...........................................................................3-1

4. SERVICE TABLES AND PROCEDURES...................................4-1

4.1 DIAGNOSTICS MODE............................................................................. 4-1

4.1.1 OVERVIEW ..................................................................................... 4-1

Map of the Diagnostic Menu ................................................................ 4-1

4.1.2 RUNNING THE DIAGNOSTICS ...................................................... 4-2

Basic Procedure................................................................................... 4-2

Using the Custom Diagnostics Set....................................................... 4-3

Diagnostic Test Result Display............................................................. 4-4

Exit Custom Menu................................................................................ 4-4

4.1.3 CONTENTS OF INDIVIDUAL DIAGNOSTIC TESTS ...................... 4-5

IDE Diagnostic Test ............................................................................. 4-5

Ethernet Diagnostics............................................................................ 4-6

RAM Diagnostics.................................................................................. 4-7

Video Chip Diagnostics........................................................................ 4-8

Boot ROM Diagnostics......................................................................... 4-8

Firmware Diagnostics........................................................................... 4-8

I2CEEPROM diagnostics..................................................................... 4-8

4.2 BOOT ROM MENU................................................................................... 4-9

4.2.1 PURPOSE OF THE ROM MENU.................................................... 4-9

Entering the Boot ROM Menu.............................................................. 4-9

Contents of the Boot ROM Menu......................................................... 4-9

Exiting the Boot ROM Menu................................................................. 4-9

4.2.2 NAVIGATING THE MENU............................................................. 4-10

Boot ROM menu map ........................................................................ 4-10

Key Usage in the Main Menu............................................................. 4-11

Key Usage in each Menu Item........................................................... 4-11

1

Page 5

4.2.3 DISPLAYING VERSION INFORMATION...................................... 4-11

4.2.4 INSTALLING SOFTWARE UPGRADES........................................ 4-12

Preparation ........................................................................................ 4-12

Procedure .......................................................................................... 4-12

Recovery Mechanism......................................................................... 4-12

4.2.5 FORMATTING THE HARD DISK................................................... 4-13

Procedure .......................................................................................... 4-13

4.2.6 CHANGING THE ETHERNET MAC ADDRESS............................ 4-13

Preparation ........................................................................................ 4-13

Procedure .......................................................................................... 4-13

4.2.7 BRAND NAME SELECTION.......................................................... 4-14

Preparation ........................................................................................ 4-14

Procedure .......................................................................................... 4-14

4.2.8 CLEARING THE NVRAM PARAMETERS..................................... 4-14

Procedure .......................................................................................... 4-14

4.3 SERVICE MODE.................................................................................... 4-15

4.3.1 OVERVIEW ................................................................................... 4-15

Password........................................................................................... 4-15

Service Menu Map............................................................................. 4-15

Entering the Service Menu................................................................. 4-15

4.3.2 PRINT SERVICE INFORMATION LIST......................................... 4-16

4.3.3 PRINT COLOR CHART................................................................. 4-17

4.3.4 CLEAR FUSER CTR ..................................................................... 4-17

5. PERIODIC MAINTENANCE........................................................ 5-1

6. REPLACEMENT AND ADJUSTMENT........................................6-1

6.1 CONTROLLER BOARD REPLACEMENT................................................ 6-1

7. TROUBLESHOOTING.................................................................7-1

7.1 TYPES OF PROBLEMS........................................................................... 7-1

7.2 TROUBLESHOOTING PROCEDURE...................................................... 7-2

7.2.1 HARDWARE TESTS ....................................................................... 7-2

7.2.2 OPERATION-RELATED TESTS...................................................... 7-2

7.2.3 SOFTWARE-RELATED TESTS...................................................... 7-3

7.3 ERROR MESSAGES................................................................................ 7-4

7.3.1 OVERVIEW ..................................................................................... 7-4

7.3.2 CONTROLLER DIAGNOSTICS ERRORS ...................................... 7-5

7.3.3 ENGINE USER ERRORS (CAUTIONARY)..................................... 7-7

7.3.4 ENGINE SERVICE CODES............................................................. 7-7

2

Page 6

12 May, 1999 OVERALL MACHINE INFORMATION

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Page Description Language: Adobe PostScript 3

PCL 5e/5c compatible

Printer Driver Platform: Macintosh, Windows 95/98, Windows NT4.0

Resolution: 600 dpi

Gradation Mode: 2 bits/pixel

Interface: IEEE1284 Compatible, Nibble or ECP mode

Ethernet 10BaseT/100BaseTX, 10Base 5

Network Protocol: NetWare 3.10, 3.11, 4.X, IPX/SPX

EtherTalk System 7 and later

TCP/IP, SNMP, ARP, UDP

Frame Types: 802.2, 802.3, SNMP, Ethernet-II, Ether net SNMP

Printing Services: LPD (Line Printer Daemon)

Pserver (Print Server)

PAP (Printer Access Protocol)

SMB (Server Message Block) over TCP/IP

Overall

Information

Font: 136 PostScript fonts

35 Intelli fonts, 10 TrueType fonts, and 1 bitmap

line printer font for PCL5c

Memory: Standard 32MB

DIMM Slots: 2 (for optional memory)

EIDE Interface: 1 (for optional HDD)

Options: 32/64MB DIMM

2.5-inch 1.6-GB hard disk drive

1-1

Page 7

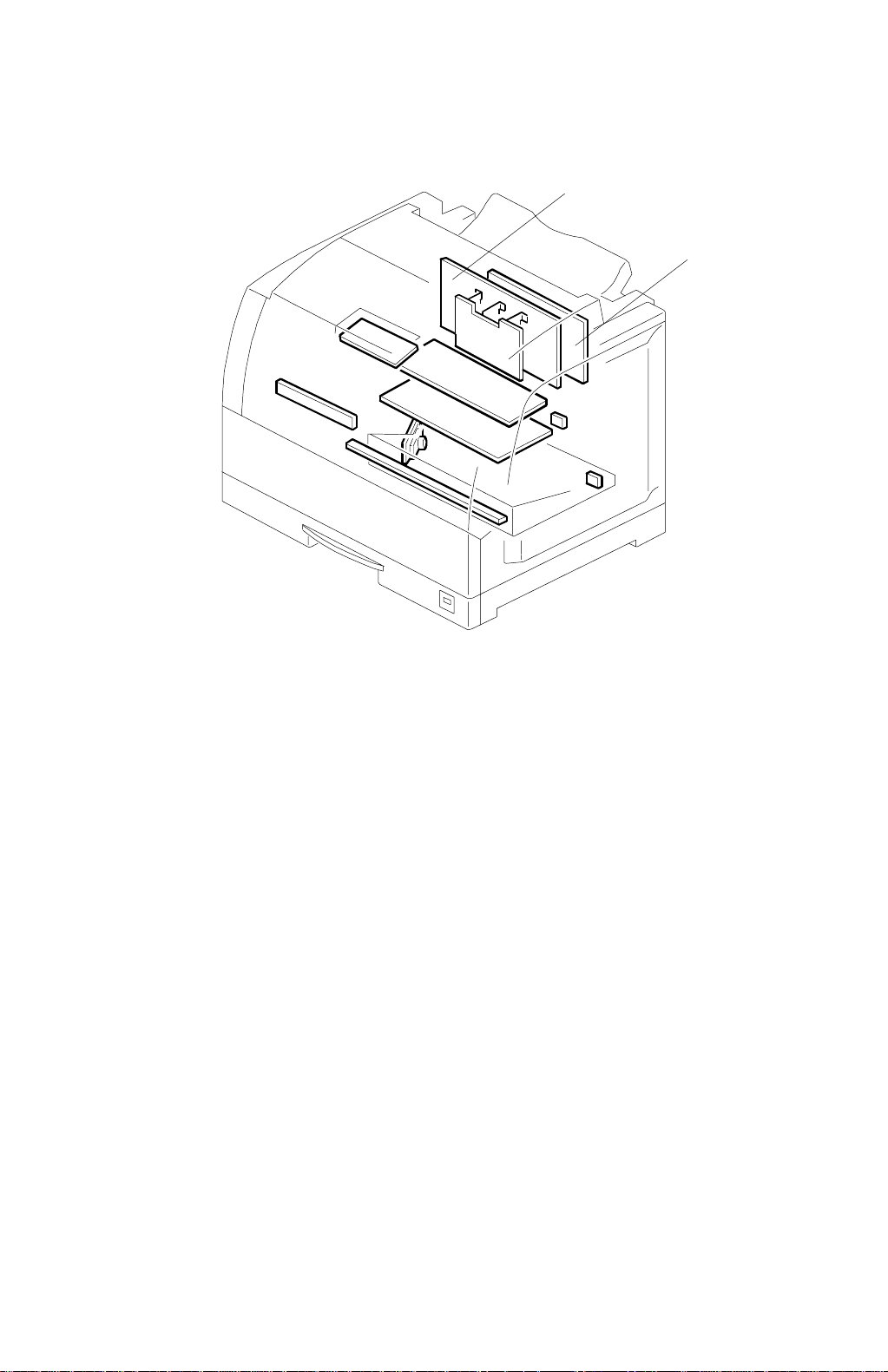

LAYOUT 12 May, 1999

1.2 LAYOUT

2

1

1. Controller

2. MCU

G024O011.WMF

1-2

Page 8

12 May, 1999 FUNCTIONAL OVERVIEW

2. FUNCTIONAL OVERVIEW

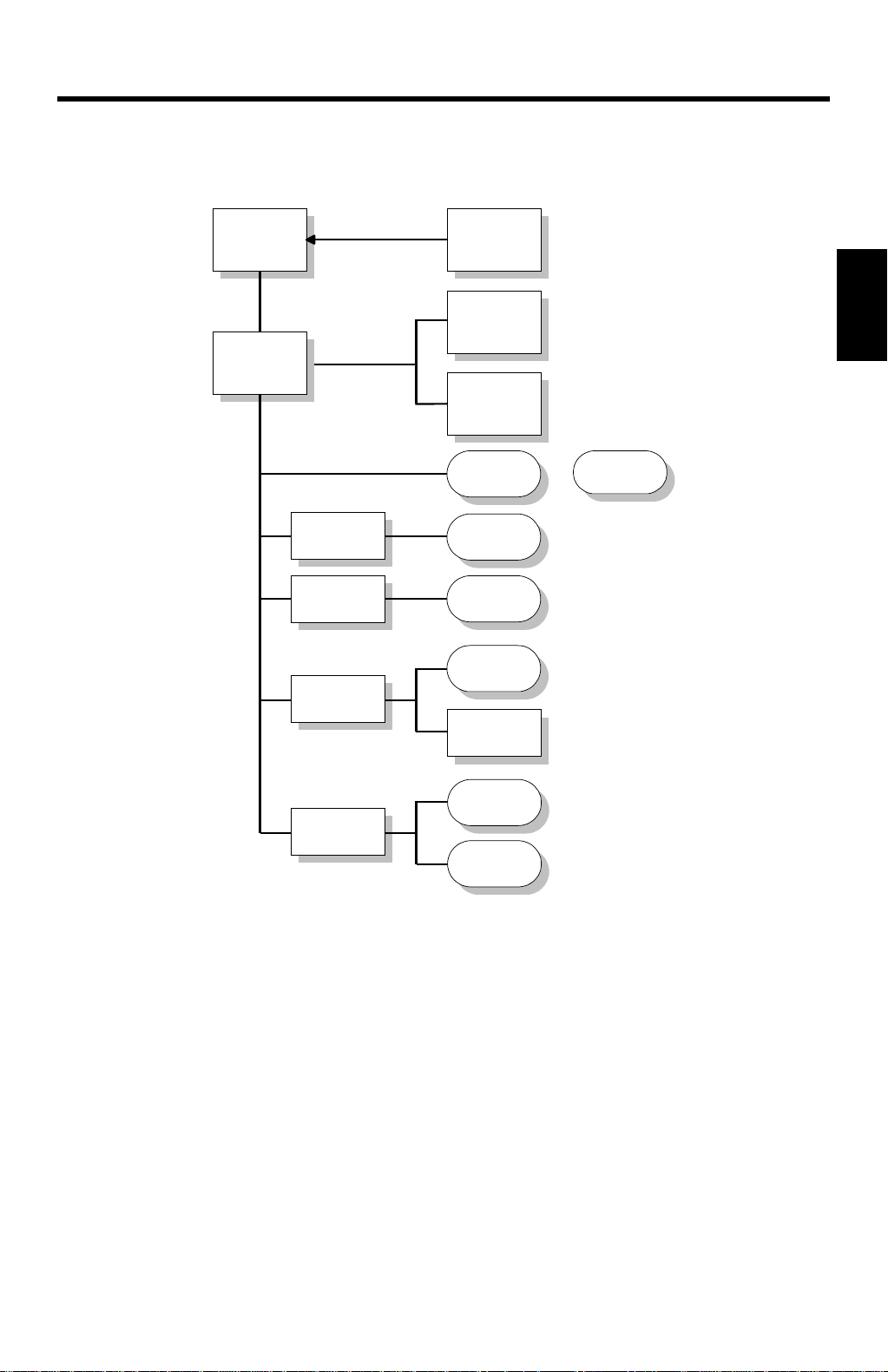

2.1 BLOCK DIAGRAM AND FUNCTIONS

CPU

MIPS R4700

Memory

Controller

ASIC (DX)

Video Control

ASIC (VX)

IDE

Controller

I/F Control

ASIC (IX)

Power

Supervisor

On Board

Flash ROM

(Boot Code)

SDRAM

Flash ROM

4 DIMM Slots

PCI

Connector

Engine I/F

Connector

IDE HDD

Connector

IEEE 1284

Connector

System I2C

EEPROM

Detailed

Descriptions

Token Ring

Card (Option)

Ethernet RJ45

Ethernet

Controller

Connector

Ethernet AUI

Connector

G024C503.WMF

CPU

This is a MIPS R4700 (133 MHz).

Memory

There is a proprietary memory ASIC that supports up to 8 DIMMs, up to 32 MB of

boot PROM or flash memory. The ASIC can support burst accesses for 8 or 64 bit

wide PROMs.

However, this controller only supports 4 DIMMs. Three of these are for optional

memory, and one is for the flash/mask ROM that holds internal fonts.

2-1

Page 9

BLOCK DIAGRAM AND FUNCTIONS 12 May, 1999

DRAM

The Memory ASIC supports industry standard synchronous DRAM DIMMs for

optional printer memory (see the previous page).

The R4700 bus is 64 bits wide. Architecturally, the system can support up to 256

bytes of DRAM and 8 DIMM slots (64 MB DIMMs will be supported when

commercially available).

SRAM

The SRAM is used for processing print data.

NVRAM Functionality

The NVRAM holds printer parameters that must be maintained across power

cycles. NVRAM space is in the order of 32KB.

The NVRAM consists of 1 MB of flash memory soldered to the motherboard.

2-2

Page 10

12 May, 1999 FUNCTIONAL OVERVIEW

Fiery Rip Chips (EFI ASICs)

The three ASICs (designed by EFI) are responsible for the high-speed and

performance of the controller. They are as follows:

Memory ASIC (DX3)

This provides high speed interfaces between the CPU, memory, and PCI bus. The

DX3 supports 64-MB DRAM DIMMs.

IO ASIC (IX)

This supports the internal and external I/O interfaces including:

•

PCI direct memory access

•

User interface (front panel)

•

IEEE 1284 compliant parallel port (Centronics, Nibble, ECP)

•

Generic synchronous serial interface

Video ASIC (VX)

The video ASIC is responsible for:

•

PCI direct memory access

•

Decompression

•

Video interface to the engine

All three ASICs interface to a high speed PCI bus (64 bits wide) and comply Rev

2.1 of the PCI specification.

Real Time Clock

The controller does not have a real time clock.

Detailed

Descriptions

2-3

Page 11

PRINT DATA PROCESSING 12 May, 1999

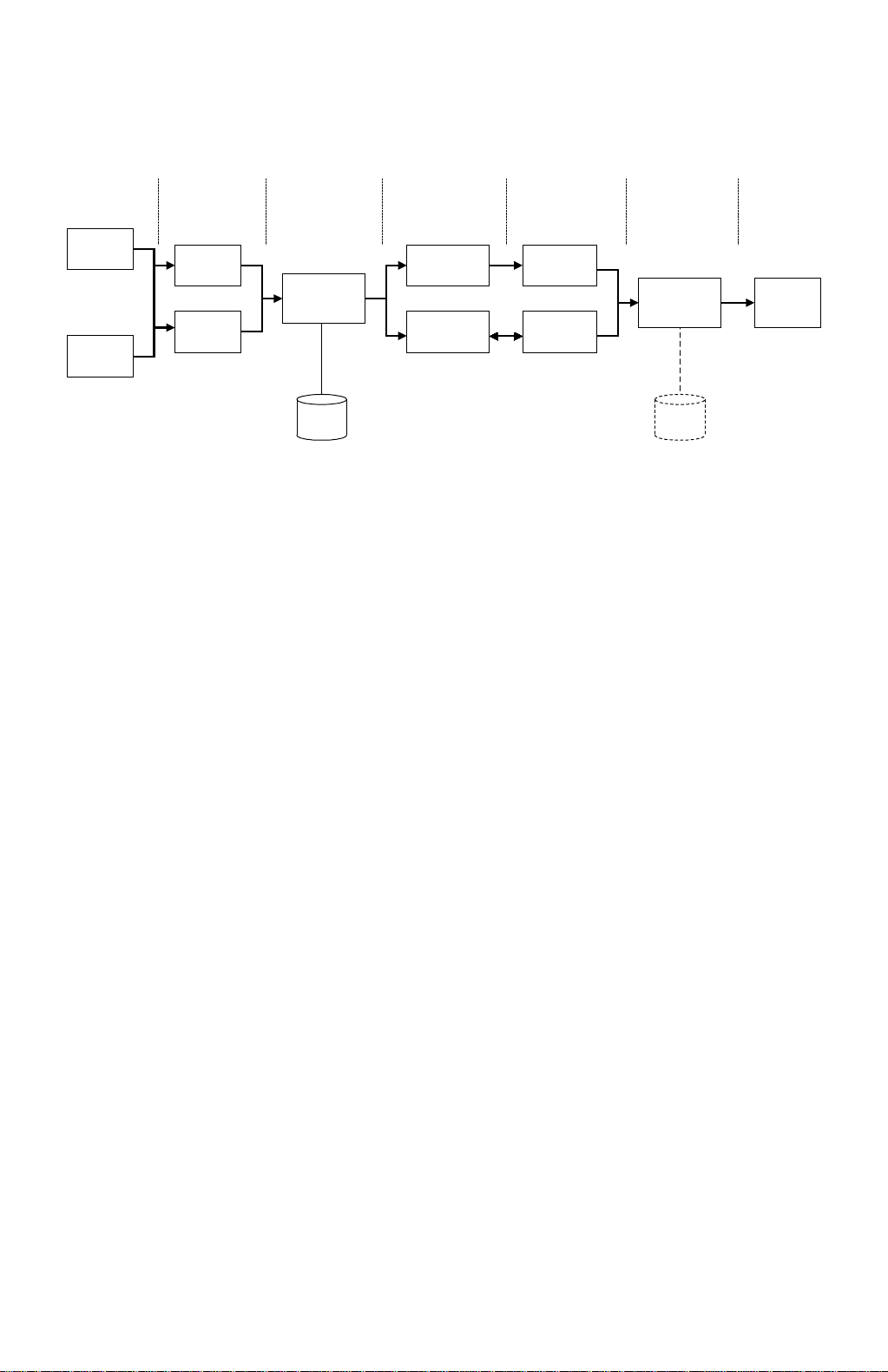

2.2 PRINT DATA PROCESSING

Drivers Connectivity

PostScript

generation

PCL

generation

Ethernet

Parallel

IO/Print/

Device Mgr

Spooling, PDL

switching

PDLs Compression Page Mgr

DSC

parsing

PostScript

PJL parsing

PCL 5e/5c

Page

Compression

Page

Compression

Engine loading

The key roles of each part of the print system are outlined below.

•

The

drivers

are responsible for generating the page description on the host

system and for transmitting data to the printer.

•

I/O manager

The

mediates the connection between the parallel port or

network interface and establishes a device or print manager connection.

•

print manager

The

is responsible for spooling the job (if appropriate) and for

feeding jobs to the correct PDL interpreter.

•

PDL interpreters

The

are responsible for turning page descriptions into

rendered pages and for parsing job management comments.

•

•

compression

The

page manager

The

subsystem manages compressed pages in memory.

coordinates pages for sending to the engine for the most

efficient printing, finishing, and accessory handling.

•

The

video

subsystem is responsible for decompressing pages and feeding

the engine with appropriate engine signals. The video subsystem also

handles certain print quality processing functions.

Finishing,

Video

Mgr

Decomp,

Video

G024C504.WMF

2-4

Page 12

12 May, 1999 FUNCTIONAL OVERVIEW

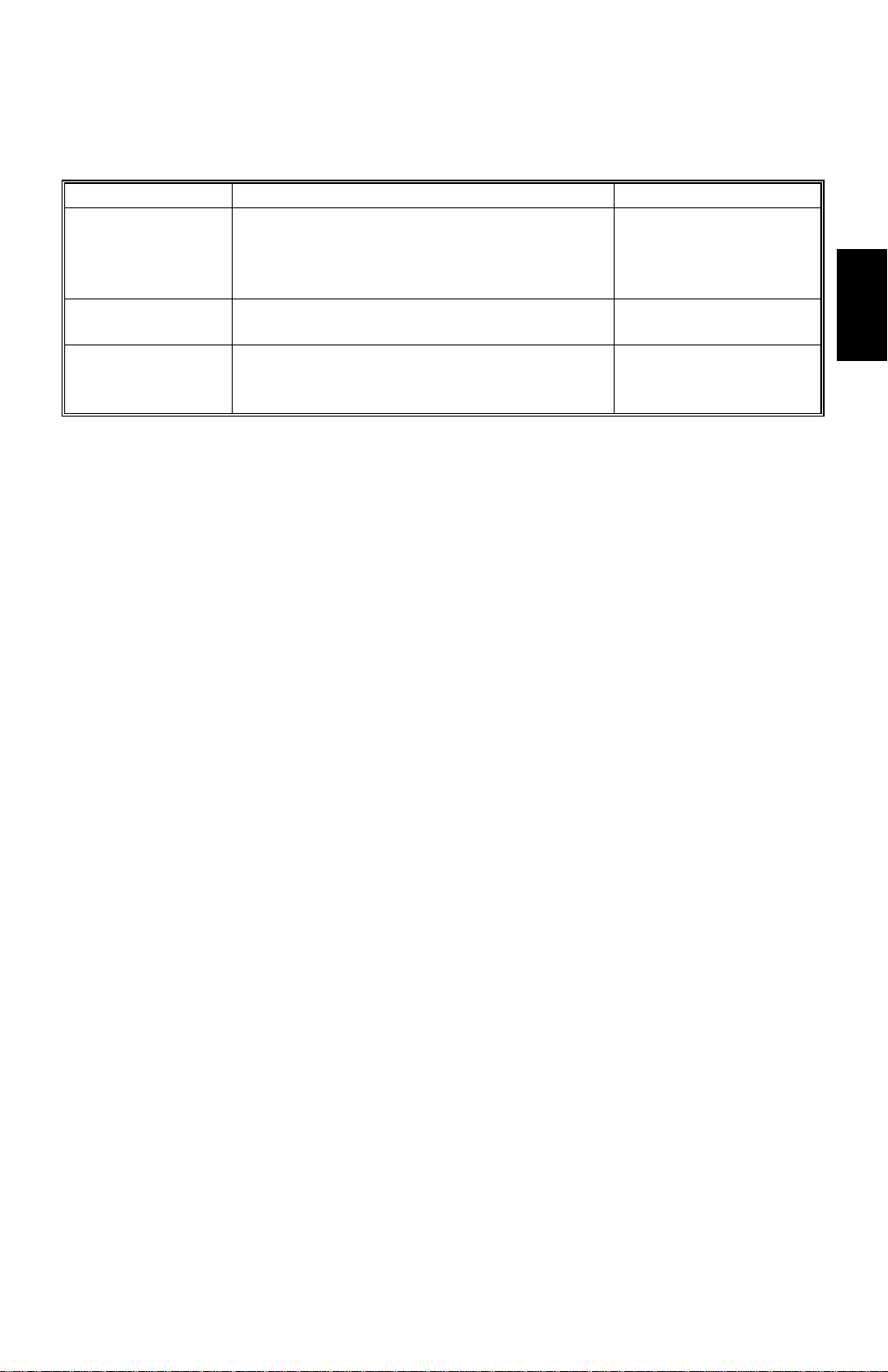

2.3 BUILT-IN COLOR MANAGEMENT

This controller has a full complement of built-in color management technologies.

Component Description Location/Platforms

PostScript color

rendering

dictionaries

(CRDs)

Press simulation

control

Device profiles

CRDs optimized for photos, graphics,

presentation objects;

plain paper/transparency media types

Lookup tables to simulate density

characteristics of offset printing processes

ColorSync 2/ICM profiles compatible with

Macintosh and Windows color

management systems

In controller

ROM/Flash memory

Controller SRAM

Macintosh/Windows

95 and 98

Detailed

Descriptions

2-5

Page 13

12 May, 1999 INSTALLATION

3. INSTALLATION

Refer to the following operation man ual s.

•

For the printer: Quick Installation Guide, Printer Reference, Getting Started

and User’s Guide.

•

For options: Printer Reference

Installation

3-1

Page 14

12 May, 1999 SERVICE TABLES AND PROCEDURES

4. SERVICE TABLES AND PROCEDURES

4.1 DIAGNOSTICS MODE

4.1.1 OVERVIEW

There are several sets of diagnostic tests. This section includes an outline of how

to select, run, and stop a custom diagnostic test set and a brief description of the

messages displayed on the front panel during and after the diagnostic test.

Map of the Diagnostic Menu

BEGIN

VVVV

]

[

[MENU]

[MENU]

[MENU]

WWWW

[

START SELF-TEST

VVVV

[

DIAGNOSTIC SETS

CUSTOM

WWWW

[

]

DIAGNOSTIC SETS

FUNCTION

WWWW

]

[

DIAGNOSTIC SETS

BURN-IN

WWWW

]

[

DIAGNOSTIC SETS

START-UP

]

[MENU]/[#ENTER]

RUN START-UP

TESTS

SCROLLS THROUGH

VVVV

WWWW

[

]/[

]

]

VVVV

]

[

VVVV

[

]

VVVV

]

[

TESTS & GROUPS

[#ENTER]

VVVV

[

]

[#ENTER]

[#ENTER]

DIAGNOSTIC TESTS

<TEST/GROUP NAME>

TOGGLES SELECTION

[#ENTER]

OF CURRENT TEST/GROUP

RUN BOARD TESTS

[CANCEL]

RUN BURN-IN

TESTS

[CANCEL]

VVVV

[

]/[

TESTS & GROUPS

[MENU]

RUN CUSTOM TESTS

EXIT CUSTOM?

[NO]/[YES]

VVVV

WWWW

TOGGLES

[

]/[

]

SELECTION

WWWW

SCROLLS THROUGH

]

RUN UNTIL

DONE <OTHER>

[#ENTER]

[#ENTER]

Tables

Service

END

G024C505.WMF

Using the diagnostics menu, you can use the printer’s operation panel to select

one of several different diagnostic sets (Custom, Start-up, Burn-in, Function) and

various test options.

4-1

Page 15

DIAGNOSTICS MODE 12 May, 1999

4.1.2 RUNNING THE DIAGNOSTICS

Basic Procedure

1. To run a diagnostic test, switch the printer off and on again.

·

By default, the power-up diagnostic self-test is run when the system is turned

on. During the power-up diagnostics, optional components (such as hard disk

drives) that are not installed will be reported on the front panel.

2. To run a different set of diagnostics, hold down the

SELF-TEST appears on the front panel display.

3. Release the

diagnostic set can be selected from this menu.

4. Press the

·

These are Custom, Start-up, Functional, or Burn-in; see the notes at the end

of the procedure for more information.

5. Press the

menu.

·

Alternatively, the user may press the

(default) diagnostic set and exit this menu.

Custom:

specify which tests should be run. It also allows you to specify the conditions for

the tests to stop (e.g., stop if an error is detected, or do all tests until the end). If

any diagnostic set other than ‘Custom’ is selected, it will begin immedia t ely.

Start-Up:

the same set of tests that is done every time the system is powered up.

Functional:

test the functionality of all the components.

[s]

[#Enter]

If this set is selected, a series of menus appears that allows you to

If this set is selected, the default (power-up) diagnostic set is run. This is

If this set is selected, a more comprehensive set of tests is run. These

key when the DIAGNOSTIC SETS menu is displayed. A

[s]

or

buttons to scroll through the available diagnostic sets.

[t]

button to select the displayed diagnostic set and exit this

[MENU]

button to select the start-up

key when START

[s]

Burn-In:

board functions. External connections are unnecessary.

If this is selected, a set of tests is executed repeatedly to exercise all

4-2

Page 16

12 May, 1999 SERVICE TABLES AND PROCEDURES

Using the Custom Diagnostics Set

1. If CUSTOM was selected, you may select the individual diagnostic tests. You

can view all the available tests by pressing the

VVVV

[

or down.

•

The tests in the menu are organized into groups of related tests. When

scrolling through the menu, both groups and individual tests are displayed.

A group is identified by a colon (:) after the group name (for example, IDE:).

A test is identified by either a blank or “+” symbol before the test name (for

example, +IDE), and this follows the group name. (The “+” symbol indicates

that the test has been selected; see below.)

2. Initially, no group/test is selected. Select or deselect a group/test by pressing

the

[#Enter]

•

If a test is selected, the “+” symbol will be displayed before the test name.

•

If a test is deselected, the “+” symbol will disappear.

•

If a group is selected or deselected, all items in the group will be selected or

button when the group/test name is displayed.

deselected.

or

]

WWWW

buttons to scroll up

[

]

3. After selecting the tests to run, exit the Diagnostic Tests menu by pressing the

[MENU]

•

You are now presented with a menu that allows you to specify the condition

key.

which will cause the tests to terminate. This menu will display RUN UNTIL

followed by either DONE, TIME..., FAILURE, or INTERRUPTED.

4. Cycle through the choices with

VVVV

[

5. To select the currently displayed condition, press

•

If you select DONE or press the

WWWW

or

]

[

[MENU]

.

]

[#Enter]

.

button, each test that you selected

will be run once. Selecting DONE will exit the menu and begin the tests.

•

If you select FAILURE, the tests will repeat until a failure is detected. To stop

the test, press

•

If you select INTERRUPTED, the tests will run until you interrupt the tests by

pressing the

•

If you select TIME..., the tests will run for a preset duration.

NOTE:

Selecting FAILURE, INTERRUPTED or TIME... will exit the menu.

[CANCEL]

[CANCEL]

.

button.

Tables

Service

4-3

Page 17

DIAGNOSTICS MODE 12 May, 1999

Diagnostic Test Result Display

When execu ting each selected test, the message "TESTING:”, followed by the

name of the test will be displayed on the front panel. The green LED will be lit for

the duration of each test. If the test fails, the red LED will turn on.

At the end of the diagnostics, a summary error report is displayed in the event of

any error(s). This error report consists of the message

TESTS FAILED

UP/DOWN/CANCEL

After this report appears, view the names of the failed tests and the corresponding

VVVV

error code using the

individual tests and section 7 for descriptions of the error codes. Exit this process

at any time by pressing the

WWWW

[

buttons. Refer to section 4-1-3 for descriptions of the

]/[

]

[CANCEL]

key.

Exit Custom Menu

If CUSTOM was selected in the DIAGNOSTIC SETS selection menu, a menu is

presented after the tests have ended, asking the user if he wants to exit the custom

VVVV

tests. The user can toggle between the choices YES and NO using the

buttons, and accept the choice using the

Diagnostic Menu, while selecting NO presents the Custom Diagnostic Tests menu

again.

[#Enter]

button. Selecting YES exits the

WWWW

[

]/[

]

4-4

Page 18

12 May, 1999 SERVICE TABLES AND PROCEDURES

4.1.3 CONTENTS OF INDIVIDUAL DIAGNOSTIC TESTS

IDE Diagnostic Test

IDE CHIP

This is an IDE initialization and register test.

All CMD 64X controller chips are located on the controller board. For each IDE

controller chip, the following tests are performed:

1. The PCI configuration registers are initialized.

2. The programming interface of the CMD 64X chips is made ready.

3. The IDE controller (PCI I/O) bus mastering is disabled.

4. A base address is specified. Note that this address is recycled to prevent I/O

address space exhaustion. The normal value is 0x11F0.

5. PCI I/O is enabled.

IDE HD

If an optional hard disk drive is not present, the front panel will display a message

and these tests will be skipped.

For a count of 128 (0 <= I <= 127).

•

Set M to the last readable sector.

•

Set buffer 1, buffer 2, buffer 3, buffer 4 to all zeros.

•

Read sector 0+I into buffer 1.

•

Read sector MI into buffer 2.

•

Read sector 0+I into buffer 3.

•

Read sector MI into buffer 4.

•

Buffers 1 and 3 are compared. They should be equal, byte for by te, other wise

an error will result.

•

Buffers 2 and 4 are compared. They should be equal, byte for by te, other wise

an error will result.

•

Reading 128 alternating sectors from both ends of the disk will result in a 4-

second buzzer sounding as the heads go back and forth, giving an audible

indication that they are working.

Tables

Service

4-5

Page 19

DIAGNOSTICS MODE 12 May, 1999

Ethernet Diagnostics

ENET SLV REG (Slave register test)

This searches for the ethernet controller chip and performs an internal register test.

ENET INIT (Chip initialization test)

The ethernet chip is configured on the PCI bus. It can perform memory address

recognition and bus mastering. It has the base address set and is compared to

ensure the correct value was set.

A speed detection error may occur if the external loopback plug is not plugged in.

Internal loopback testing is not done because of hardware idiosyncrasies.

ENET READ (Packet read test)

256 packets on the network are captured at random.

When these packets have been read without a single error, the test ends

successfully.

For this test, the network must be clean, and there must be no collisions, runts

(incomplete packets), etc. It is important that all packets on the network must be

free of errors, as this test assumes that any kind of packet error will result in a test

failure.

ENET WRITE (Packet write test)

128 packets are transmitted. The packet type is set to 0xDEAD to ensure that other

systems ignore it.

When 128 packets transmit without a single error. The test passes successfully.

Each packet has a 1 millisecond gap between it and the next packet.

For this test, the network must be clean, and there must be no collisions, runts

(incomplete packets), etc. It is important that all packets on the network must be

free of errors, as this test assumes that any kind of packet error will result in a test

failure.

4-6

Page 20

12 May, 1999 SERVICE TABLES AND PROCEDURES

RAM Diagnostics

RAM diagnostics tests the DIMMs and the system paths to the DIMMs (I2 C and

memory bus).

These tests are running in memory without corrupting the diagnostics area. Before

the memory test executes, it displays the test region on the serial port.

All tests are performed in a cache (L2 where available).

MEM DIMM INFO

Determines whether the DIMM configuration can be detected via I2 C (serial

presence detect). It is presumed that the bus works; otherwise, diagnostics would

not be running in memory. However, transient conditions and any additional DIMMs

will be tested.

MEM PATTERN

This test writes various patterns to the entire untested memory area, then confirms

that they were written correctly.

MEM ADDRESS

This test writes the inverse of the address into the address. It then reads it back

and verifies.

MEM GND BOUNCE

This diagnostic tests the ground bounce in the memory.

Ground bounce occurs when there is excessive inductance on leads from the

memory chip. If ground bounce causes the ground level on the chip to float to the

logical 1 level, the chip will output a 1-level output when it should output a 0.

The stress test for this condition is to read all 1’s from the chip (maximizing the

current flow through the leads), then read all 0’s.

This test writes alternating 64-bit words of all 1’s and all 0’s (i.e., 64-bits of 1, then

64-bits of 0, etc.) When written from or read into the processor’s internal cache, the

chip will be stressed as described in the above paragraph.

MEM RANDOM

This diagnostic tests the memory by writing random data, reading it, and verifying.

Tables

Service

4-7

Page 21

DIAGNOSTICS MODE 12 May, 1999

Video Chip Diagnostics

VX CHIP (VX Internal Register)

This test locates the VX chip and tests its register.

Boot ROM Diagnostics

BOOTROM (General Boot ROM Diagnostics)

This tests the boot ROM to ensure that the checksum is valid, and that the

parameter blocks are writable.

BOOTROM WRITE (Boot ROM Write Diagnostics)

This test writes various patterns to the parameter blocks in the boot ROM. If these

parameter blocks are full, the test will not occur and a failure will be reported.

Firmware Diagnostics

EFIDIMM (System DIMM diagnostics)

This test searches for the system DIMM, and calculates and verifies the checksum

on the system DIMM.

I2CEEPROM diagnostics

This test reads the contents of the on-board I2C EEPROM at sequential and

random addresses to ensure that data is readable.

4-8

Page 22

12 May, 1999 SERVICE TABLES AND PROCEDURES

4.2 BOOT ROM MENU

4.2.1 PURPOSE OF THE BOOT ROM MENU

[A] [B]

On Line

Menu Cancel

ErrorPower Data in

#Enter

G024C500.WMF

[A] [B]

G024C501.WMF

Entering the Boot ROM Menu

During power-on, hold down the

[ONLINE]

until the LEDs turn off. The ROM menu will start after diagnostics.

[A] and

[B] keys on the front panel

[ ]

Tables

Service

Contents of the Boot ROM Menu

Currently there are 6 functions accessible from the front panel.

•

Displaying the version information

•

Installing software upgrades

•

Formatting the hard disk drive

•

Changing the Ethernet MAC address

•

Selecting the brand name

•

Clearing the NVRAM parameters

Exiting the Boot ROM Menu

Press the

[CANCEL]

key at the first level menu

4-9

.

Page 23

BOOT ROM MENU 12 May, 1999

4.2.2 NAVIGATING THE MENU

Boot ROM menu map

WWWW

[

]

WWWW

[

VERSION INFO

[MENU]

[#ENTER]

BOOTSTRAP

V1.3.26 02/04/98

[MENU]/[#ENTER]

]

SYSTEM CODE

MAR 23 1999

VVVV

[

]

WWWW

[

]

BOOTCODE

V1.3.26 02/04/98

[

]

VVVV

[MENU]/

[#ENTER]

INSTALL UPGRADES

[MENU]

FORMAT DISK

[MENU]

Note 2

CHANGE ENET MAC

ADDRESS

[MENU]

Note2

CHANGE DEFAULT

OEM

[MENU]

CLEAR NVRAM

PARAMETERS

Note 1:

J10 must be shorted.

Note 2:

Short J8 to access these menus.

[#ENTER]

Note 1

[#ENTER]

[#ENTER]

[#ENTER]

[#ENTER]

[MENU]

INSTALL:

BOOT ROM

[#Enter]

Installs upgrade and returns

[MENU]

FORMAT DISK:

NO

[MENU]

ENET MAC ADDRESS

1234:5678:90AB

[#Enter]

Saves the MAC address and returns

DEFAULT OEM:

RICOH *

[MENU]

CLEAR NVRAM:

NO

VVVV

]

[

[

]

WWWW

VVVV

]/[

[

VVVV

]/[

[

[

[MENU]

INSTALL:

SYSTEM CODE

WWWW

[

]

[#Enter]

Installs upgrade and returns

[MENU]

FORMAT DISK:

LOW LEVEL

VVVV

]

[

WWWW

]

DEFAULT OEM:

XXXX

WWWW

]

CLEAR NVRAM:

VVVV

YES

WWWW

]/[

]

[#Enter]

Formats hard disk drive and return

[#ENTER]

[MENU]

[#Enter]

Clears the NVRAM parameters and

returns

VVVV

]

[

]

[

WWWW

WWWW

[

]

VVVV

[

]

INSTALL:

FILE SYSTEM

FORMAT DISK:

HIGH LEVEL

[MENU]

[#Enter]

Installs upgrade

and returns

[#ENTER]

4-10

G024C506.WMF

Page 24

12 May, 1999 SERVICE TABLES AND PROCEDURES

Key Usage in the Main Menu

Key Description

[MENU]

[CANCEL]

[#Enter]

Cycle through the functions in the menu.

Exit the Boot ROM menu and continue system startup.

Enter a menu.

Key Usage in each Menu Item

Key Description

[MENU]

[CANCEL]

[#Enter]

[

]/[

WWWW

]

VVVV

[ ]/[ ]

Return to the main menu.

Exit the Boot ROM menu and continue system startup.

Select the current item in the menu or save the current value.

Scroll through the list of items available. or change the value of the

current item.

Position the cursor to select the character/number to change.

4.2.3 DISPLAYING VERSION INFORMATION

The version information for the bootstrap and the boot code can be displayed. The

version number and the release date is shown. The version can be different for the

bootstrap and the boot code.

For more information about bootstrap and boot code, see “Install Upgrades Menu”.

Tables

Service

4-11

Page 25

BOOT ROM MENU 12 May, 1999

4.2.4 INSTALLING SOFTWARE UPGRADES

The system software has three different parts: the boot ROM, the system code and

the file system. All of these can be upgraded through the parallel port.

The files used for upgrades are

for the boot ROM, system code and file system upgrades respectively. The file for

recovering from a bad boot code is

interchangeable.

bootrom.sys, system.sys

bootrom.rcy

. The file formats are not

filesys.sys

and

Preparation

If you are going to upgrade the boot ROM, turn off the printer, then short the

jumper pins together at J10 on the controller board. Then turn the printer back on

and enter the Boot ROM menu.

Procedure

1. Access the “Install Upgrades” menu, then press the

2. Use the

or file system). The options for the system code and the file system will not

appear if a flash DIMM is not installed.

3. Press the

4. Start downloading the appropriate file through the parallel port.

5. Downloading from a PC can be done by issuing the command

[s]/[t]

[#Enter]

copy /b <file name> lpt1

keys to select the item to upgrade (boot ROM, system code,

key to start the upgrade process.

[#Enter]

key.

·

The file size and the checksum automatically verify the file. The downloaded

file is processed and stored.

·

The front panel will display an error message if the upgrade fails. If an error

occurred, press any key to acknowledge.

6. If the boot ROM was upgraded, clear the NVRAM parameters. (See “Clearing

NVRAM parameters”)

Recovery Mechanism

The software in the boot ROM is divided into 2 sections: boot strap (in flash ROM)

and boot code (in DIMM).

The boot-strap is a small memory block where essential initialization code resides.

The system will continue to function properly even if the bootstrap is not upgraded.

The boot code is the section where the diagnostics and ROM menu function

resides. This is not locked and can always be updated when necessary. Since it is

possible to accidentally erase the boot code, a “disaster recovery” mechanism is

provided. This recovery mechanism can reload the boot ROM if the bootstrap is

valid. This should not be used as the procedure for upgrading the boot ROM.

1. Hold down any key on the front panel while booting.

2. After all LEDs turn off, start downloading the recovery file (bootrom.rcy) through

the parallel port.

4-12

Page 26

12 May, 1999 SERVICE TABLES AND PROCEDURES

·

The front panel will display the progress of the recovery. Only the special

recovery file will be loaded. If a recovery file is not detected, the system will

continue to boot.

4.2.5 FORMATTING THE HARD DISK

This function will perform a low-level or a h igh-level format of the hard disk drive,

creating a file system on the hard disk. This option will be available only if there is a

hard disk drive installed in the system.

Procedure

1. When in the appropriate menu (see section 4.2.2) , use the

[s]/[t]

keys to

select “LOW LEVEL” or “HIGH LEVEL” from the front panel.

2. Press the

·

To return to the main menu without formatting the disk, either select “NO”

with the

·

The front panel will report whether the disk drive formatted successfully. If it

[#Enter]

[s]/[t]

key to start formatting the hard disk drive.

keys and press

[#Enter]

, or press the

[MENU]

key.

was unsuccessful, press any key to continue.

4.2.6 CHANGING THE ETHERNET MAC ADDRESS

It is possible to change a Ethernet MAC address. This is necessary if the customer

wishes to use the same MAC address after the controller board has been replaced

(the network interface is built into the controller).

Preparation

Before entering the boot ROM menu, switch the machine off, then short the jumper

pins together at J8 on the controller board to make this item available.

Tables

Service

Procedure

1. When in the appropriate menu (see section 4.2.2) , use the

position the cursor at the digit to change, and the

[s]/[t]

[ ]/[ ]

keys to change the

digit at the cursor.

·

While changing the address, an asterisk (“*”) will be shown after the address

when the current address is displayed. This is a reference, in case you forget

the current MAC address during editing.

2. Press the

·

To return to the main menu without saving the MAC address, press the

[MENU]

[#Enter]

key.

key to save the Ethernet MAC address.

4-13

keys to

Page 27

BOOT ROM MENU 12 May, 1999

4.2.7 BRAND NAME SELECTION

It is possible to change the machine’s brand name.

Preparation

Before entering the boot ROM menu, switch the machine off, then short the jumper

pins together at J8 on the controller board to make this item available.

Procedure

1. Use the

2. Press the

[s]/[t]

[#Enter]

keys to select the required brand name.

key to save the Brand name.

4.2.8 CLEARING THE NVRAM PARAMETERS

User configurable settings are stored in the non-volatile memory within the boot

ROM. Use the following procedure to clear these parameters.

All data listed on the configuration sheet is erased, and these must be stored in the

NVRAM again after clearing.

Procedure

1. Use the

2. Press the

·

To return to the main menu without clearing the non-volatile RAM

parameters, either select “NO” with the

press the

·

The front panel will report if the procedure was successful. If it is

unsuccessful, press any key to continue.

[s]/[t]

[#Enter]

keys to select “YES” at the front panel.

key to clear the non-volatile RAM parameters.

[s]/[t]

[MENU]

key.

keys and press

[#Enter]

, or

4-14

Page 28

12 May, 1999 SERVICE TABLES AND PROCEDURES

4.3 SERVICE MODE

4.3.1 OVERVIEW

Password

A special key combination is required to enter this menu to prevent customers from

using this menu.

Serv ice Men u Map

SERVICE

[#Enter]

Incorrect

password

[#Enter]

Exits menu and

prints list

[#Enter]

Exits menu and

prints chart

[#Enter]

Clears fuser

counter and exits

menu

ENTER PASSWORD

Enter password

Correct password

PRINT SERVICE

INFORMATION LIST

[

] key

VVVV/WWWW

PRINT COLOR CHART

] key

[

VVVV/WWWW

CLEAR FUSE CTR

Tables

Service

Entering the Service Menu

While the LCD displays “ENTER PASSWORD”, press the

at the same time.

To exit this menu, turn off the machine.

4-15

G024C502.WMF

[ON LINE]

and

[ ]

keys

Page 29

SERVICE MODE 12 May, 1999

4.3.2 PRINT SERVICE INFORMATION LIST

The table below explains the contents of the engine maintenance list printout. The

controller obtains the data from the engine (MCU).

Item Description

MCU Firmware

version

Density Settings Customers can adjust the toner density via the maintenance menu.

Margin Settings Customers can adjust side-to-side registration from the optional tray

Total Indicates the total number of printouts. The counter is incremented

Color Print Counter value for printouts in color mode.

B/W color Counter value for printouts in monochrome mode.

PCU PCU replacement is indicated when this value reaches 60000. This

Fusing unit

Counters

Fusing Unit

Replacement

A3/DLT, A4/LT,

LG, B4 and etc.

Size counter

Feed Jam,

Transfer Jam

and Eject Jam

SC Number of SCs

SC Error History The most recent 3 SC codes.

Jam History The most recent 10 jam codes and the total counter value at the time.

Process-control error

History

ID sensor PWM

setting

The MCU board firmware version number.

Adjusted values are stored in the NVRAM on the MCU.

with the Maintenance Menu. In additi on, le ading edge registration can

be done with engine SP mode (1. Margin). These values are stored in

the NVRAM on the MCU.

when the paper exit sensor detects paper exit completion (regardless

of paper size, type, and mono/color mode).

value increases by 4 in color mode printing and by 1 in black mode

printing. When printing in A3/DLT, double counting occurs.

Fusing unit replacement is indicated when this value reaches to 60000.

This counter increases by 2 for A3/DLT size printing and by 1 for

printing in other sizes.

Number of fusing unit resets made with service mode.

Number of sheets of each size of paper that passed the exit sensor.

Number of paper jams in each section.

000: Paper cassette

001: Paper feed path

002: Paper exit

The most recent 3 errors during process control and the total counter

value at the time.

Not all of the errors are indicated as SC errors.

The value set with engine SP mode, 9: ID Sensor PWM.

4-16

Page 30

12 May, 1999 SERVICE TABLES AND PROCEDURES

4.3.3 PRINT COLOR CHART

This prints a color test chart, so that the image quality can be tested for all colors at

various densities. This chart prints on A4/LTR or A3/DLT size paper or larger.

4.3.4 CLEAR FUSER CTR

This mode resets the fusing unit counter (this counter is in the NVRAM on the MCU

board). Use this mode after replacing the fusing unit.

Tables

Service

4-17

Page 31

12 May, 1999

5. PERIODIC MAINTENANCE

Refer to Section 5 (Periodic Maintenance) in the engine service manual.

Refer to Section 4 (Service Tables and Procedures – Service Mode – Clear Fuser

Ctr) for how to clear the fusing unit counter after fusing unit replacement.

Preventive

Maintenance

5-1

Page 32

12 May, 1999 REPLACEMENT AND ADJUSTMENT

6. REPLACEMENT AND ADJUSTMENT

6.1 CONTROLLER BOARD REPLACEMENT

[A]

G024R551.WMF

[C]

[D]

[E]

[B]

G024R552.WMF

[F]

G024R553.WMF

NOTE:

Print the “Configuration Sheet” (refer to the Operation Manual) prior to

removing the controller board, because the NVRAMs cannot be

exchanged. The user must restore this data manually.

1. Remove the controller cover [A] (6 screws).

2. Remove the tray cover [B] (2 screws).

3. Remove the temperature/humidity sensor cover (1 screw) and sensor [C], (1

screw, 1 connector [D]).

4. Remove the controller bracket [E] (5 screws).

5. Remove the controller board [F] (6 screws).

After replacing the controller board, make sure that the brand name (and MAC

address if required by the user) stored in the machine is correct. (See Section 4

“Service Tables and Procedures - Boot ROM Menu”.)

Adjustment

Replacement

6-1

Page 33

12 May, 1999 TYPES OF PROBLEMS

7. TROUBLESHOOTING

7.1 TYPES OF PROBLEMS

The problems can be classified as follows:

•

Printer-side Print Settings

Operation

Hardware

•

Printer-side Initial Settings

•

Host-side Application Settings

•

Faulty Engine

•

Faulty Controller

•

Hardware Limitations

•

Main Unit

•

Option

•

Consumables

•

Main Unit

•

Option

Software

Operating

conditions

•

Bug in Controller ROM

•

Bug in Emulation Module Software

•

Controller Limitations

•

Bug in Host-side Application

•

Host-side Application Limitations

•

Environment (power, temperature and humidity,

dust, noise, vibration)

•

Consumables

G024O014.WMF

Trouble-

shooting

7-1

Page 34

TROUBLESHOOTING PROCEDURE 12 May, 1999

7.2 TROUBLESHOOTING PROCEDURE

7.2.1 HARDWARE TESTS

1. Start-up diagnostics

Turn on the power and check whether the LCD displays an error code.

2. Custom diagnostic test

See “Section 4.1 Diagnostics Mode” in this manual for the procedure.

3. Checking the configuration page output.

Print out from the user menu.

4. Connectivity test

Make a test print from a computer.

•

Check that the correct cable is used (and connected properly).

•

Check the cable wire continuity

•

Check the cable length (Is it too long?).

•

Do not connect the printer to the computer through a printer selector switch

– connect the printer to the computer directly.

7.2.2 OPERATION-RELATED TESTS

Check the print conditions and initial settings.

Check the printer settings against the application settings. Check whether the

current settings match the settings on the configuration page that the customer

keeps.

Ask the customer to print a configuration page at some time when the controller is

working normally, and keep it for reference.

7-2

Page 35

12 May, 1999 TROUBLESHOOTING PROCEDURE

7.2.3 SOFTWARE-RELATED TESTS

Obtain information about the following:

•

PC model

•

OS type and version

•

Configuration page

•

Application software used, and the version

•

Data file being printed when the problem occurred (if obtainable)

•

Sample printouts when the error occurred and when the printer is normal

•

Detailed operating procedure

•

Controller version (bootstrap, system code and boot code)

•

Engine firmware version

•

Printer driver version

7-3

Trouble-

shooting

Page 36

ERROR MESSAGES 12 May, 1999

7.3 ERROR MESSAGES

7.3.1 OVERVIEW

The error messages for this unit are classified as follows:

1. Controller Diagno s tics Errors

Errors detected while the unit performs start-up diagnostics/custom diagnostics

on the controller hardware.

2. Engine User Errors (Cautionary)

Errors that do not require user intervention to continue printing (the printer can

still communicate with the PC over the interface). However, for the best printing

quality, the user should correct the problem as soon as possible.

3. Engine Service Codes (SCs)

Severe errors that cause the unit to stop printing, requiring a technician to fix

the problem before printing again.

7-4

Page 37

12 May, 1999 ERROR MESSAGES

7.3.2 CONTROLLER DIAGNOSTICS ERRORS

When a controller diagnostics error occurs, the first line of the operation panel LCD

displays the name of the test that detected the error.

The second line contains a 6-digit code following “TYPE ID” that gives error details

for designers to use when debugging.

IDE Test Error

Code Description Location

0x1001 IDE controller problems IDE chip

0x1002

0x1003 Unexpected return values of function calls Chip or HDD

Ethernet Test Error

Code Description Location

0x400 Cannot find Ethernet chip

0x401 Internal register test failed

0x2001 Internal error

0x2002 Chip error

0x2003 Receive error

0x2004 Transmit error

0x2005 No net activity

0x2006 Fatal summary

0x2007 Lost carrier

0x2008 Transmit flow error

0x2009 No chip

0x2010 Interrupt error

0x2011 Low receive

Hard disk problems or cable connection

problem

HDD or cable

Replace the controller.

MEM Test Error

Code Description Location

0x0300 Bad memory information

0x0301 Bad memory

0x0302 Ground bounce test failed

Replace the controller.

VX Test Error

Code Description Location

0x1801 Bad VX chip; registers cannot be

programmed correctly

7-5

Replace the controller.

Trouble-

shooting

Page 38

ERROR MESSAGES 12 May, 1999

Boot ROM Test Error

Code Description Location

0x1811 Internal error

0x1812 Unknown boot flash type

0x1813 Incorrect chip installed

0x1814 Successive reads return different values

0x1815 Checksum failed for boot ROM

0x1816 Erasing boot ROM not completed

successfully.

0x1817 Data written to the boot ROM cannot be

verified correctly.

0x1818

0x1819 Parameter blocks cannot be overwritten

Boot ROM write test not performed since

parameter blocks are not empty

Replace the controller.

EFIDIMM Test Error

Code Description Location

0x1820 System DIMM not found

0x1821 Cannot read from system DIMM properly,

or system DIMM located in an incorrect

slot

0x1823 Checksum for system code failed.

0x1824 Checksum for file system failed

0x1825

Checksum for system code and file

system failed.

Replace the controller.

I2CEEPROM Test Error

Code Description Location

0x1100 Read error at I2CEEPROM Replace the controller.

7-6

Page 39

12 May, 1999 ERROR MESSAGES

7.3.3 ENGINE USER ERRORS (CAUTIONARY)

Refer to the Troubleshooting section in the Operating Instructions.

7.3.4 ENGINE SERVICE CODES

Refer to the Troubleshooting section in the Engine Service Manual.

7-7

Trouble-

shooting

Loading...

Loading...