Page 1

FRESA WIN+

(Machine Code: G047/G048)

SERVICE MANUAL

[Engine]

Page 2

IMPORTANT SAFETY NOTICES

PHYSICAL INJURY PREVENTION

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some printer components are supplied with electrical voltage even

if the main switch is turned off.

4. If an adjustment or operation check must be made requiring the removal or

opening of the exterior covers while the main switch is on, keep hands away

from electrified or mechanically driven components.

5. The printer drives some of its components when it completes the warm-up

period. Keep hands away from mechanical and electrical components when

the printer starts operation.

6. The interior and metal parts for the fusing unit become extremely hot while

the printer is operating. Do NOT touch these components with bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the printer without ozone filters installed.

2. Always replace the ozone filters with the specified replacement at the

specified maintenance intervals.

3. Toner is non-toxic, but if it gets in your eyes by accident, it may cause

temporary eye discomfort. Remove it with eye drops or flush eyes with

water. If this is unsuccessful, get medical attention immediately.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do NOT incinerate toner cartridges, development toner magazine (DTM) or

used toner. Toner dust may ignite suddenly when exposed to an open flame.

2. Dispose of used toner bottle and photoconductor unit (PCU) in accordance

with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

Page 3

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical unit can only be repaired in a

factory or at a location with the requisite equipment. The laser subsystem is only

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

field repairable. Customer engineers are therefore directed to return all chassis and

laser subsystems to the factory or service depot when the optical subsystem

requires replacement.

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

Page 4

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMAT ION........................................ 1-1

1.1 SPECIFICATIONS.....................................................................................1-1

1.2 MECHANICAL OVERVIEW.......................................................................1-3

1.3 MAIN UNIT LAYOUT.................................................................................1-3

1.4 SYSTEM BLOCK.......................................................................................1-5

1.4.1 BLOCK DIAGRAM............................................................................1-5

2. DETAILED SECTION DESCRIPTIONS ...................................... 2-1

2.1 DIFFERENT POINTS FROM BASE MODEL (G024)................................2-1

2.1.1 OVERVIEW......................................................................................2-1

2.1.2 FUSING UNIT...................................................................................2-2

2.1.3 OPTICAL UNIT.................................................................................2-2

2.1.4 PAPER FEEDING AND REGISTRATION........................................2-3

2.1.5 PROCESS CONTROL......................................................................2-3

2.1.6 ELECTRICAL COMPONENTS.........................................................2-3

2.2 DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY).............................2-4

2.2.1 OVERVIEW......................................................................................2-4

Layout...................................................................................................2-4

Electrical Components..........................................................................2-5

2.2.2 EXIT UNIT........................................................................................2-7

Driving Mechanism...............................................................................2-7

Junction Gate........................................................................................2-7

Exit Cover Open Detection...................................................................2-8

2.2.3 VERTICAL TRANSPORT UNIT........................................................2-9

Driving Mechanism...............................................................................2-9

Paper Feed Detection...........................................................................2-9

Vertical Transport Unit Cover Open Detection....................................2-10

2.2.4 DUPLEX UNIT................................................................................2-11

Driving Mechanism.............................................................................2-11

Reverse Mechanism...........................................................................2-11

Jogging Mechanism............................................................................ 2-12

Feed-out .............................................................................................2-12

Reverse Tray Detection......................................................................2-12

2.2.5 INTERLEAF....................................................................................2-13

Paper Path for Duplex Printing ...........................................................2-13

Print Order for Duplex Black & White Printing.....................................2-14

Print Order for Duplex Color Printing..................................................2-14

3. INSTALLATION PROCEDURE................................................... 3-1

i

Page 5

4. SP MODE.................................................................................... 4-1

4.1 OVERVIEW...............................................................................................4-1

4.2 ENGINE SP MODE...................................................................................4-1

4.2.1 OVERVIEW......................................................................................4-1

To enter and exit engine SP mode .......................................................4-1

Outline of the engine SP mode functions..............................................4-1

4.2.2 MENU OPERATION/DISPLAY.........................................................4-2

4.2.3 MARGIN (REGISTRATION ADJUSTMENT)....................................4-2

4.2.4 PARAMETER...................................................................................4-3

4.2.5 CLEAR MEMORY.............................................................................4-3

4.2.6 SENSOR CHECK.............................................................................4-4

4.2.7 NIP WIDTH.......................................................................................4-5

4.2.8 RESET SC........................................................................................4-5

4.2.9 PROCESS CTRL..............................................................................4-6

4.2.10 TEST PRINT...................................................................................4-6

4.2.11 ID SENSOR PWM (PULSE WIDTH MODULATION)......................4-6

4.2.12 IMAGE ADJUST.............................................................................4-6

4.2.13 OUTPUT CHECK...........................................................................4-7

4.2.14 HIGHLIGHT ADJUSTMENT...........................................................4-8

4.2.15 LUB_INTERVAL

(BELT LUBRICATION INTERVAL ADJUSTMENT)........................4-8

4.2.16 PRIMARY BIAS ADJUSTMENT.....................................................4-9

5. PREVENTIVE MAINTENANCE................................................... 5-1

5.1 PM TASKS ................................................................................................5-1

5.1.1 REPLACEMENT...............................................................................5-1

5.1.2 CLEANING.......................................................................................5-1

5.1.3 INSPECTION....................................................................................5-1

5.2 PM TABLE.................................................................................................5-2

5.2.1 MAIN UNIT.......................................................................................5-2

5.2.2 OPTIONAL PAPER FEED UNIT ......................................................5-2

6. REPLACEMENT AND ADJUSTMENT

(AUTO-DUPLEX MODEL)........................................................... 6-1

6.1 EXTERIOR................................................................................................6-1

6.1.1 TOP OVER.......................................................................................6-1

6.2 PAPER EXIT UNIT....................................................................................6-2

6.2.1 UPPER COVER ...............................................................................6-2

6.2.2 LOWER COVER...............................................................................6-2

6.2.3 PAPER EXIT UNIT...........................................................................6-3

6.2.4 JUNCTION GATE SOLENOID.........................................................6-4

6.3 VERTICAL TRANSPORT UNIT.................................................................6-5

6.3.1 VERTICAL TRANSPORT UNIT COVER..........................................6-5

6.3.2 UPPER, LEFT AND RIGHT SIDE COVER.......................................6-5

6.3.3 VERTICAL UNIT SENSOR...............................................................6-6

6.3.4 VERTICAL TRANSPORT MOTOR...................................................6-6

ii

Page 6

6.3.5 VERTICAL TRANSPORT UNIT........................................................6-7

6.4 DUPLEX UNIT...........................................................................................6-8

6.4.1 DUPLEX TRAY.................................................................................6-8

6.4.2 REVERSE ROLLER.........................................................................6-9

6.4.3 DUPLEX FEED MOTOR/REVERSE MOTOR................................6-10

6.4.4 DUPLEX FEED SENSOR...............................................................6-10

6.4.5 JOGER HOME POSITION SENSOR.............................................6-11

6.4.6 JOGGER MOTOR/REVERSE SOLENOID.....................................6-12

6.4.7 REVERSE SENSOR......................................................................6-13

6.4.8 TEMPERATURE/HUMIDITY SENSOR..........................................6-13

6.4.9 RELAY MOTOR/RELAY ROLLER..................................................6-14

6.5 FUSING SECTION..................................................................................6-15

6.5.1 FUSING UNIT.................................................................................6-15

6.6 LASER SECTION....................................................................................6-16

6.6.1 CAUTION DECAL LOCATIONS.....................................................6-16

6.6.2 OPTICAL HAUSING UNIT..............................................................6-17

6.7 ELECTRICAL COMPONENTS................................................................6-18

6.7.1 CONTROLLER BOARD.................................................................6-18

6.7.2 DUPLEX DC SUPPLY UNIT...........................................................6-19

6.7.3 POWER SUPPLY UNIT..................................................................6-20

6.7.4 HIGH VOLTAGE SUPPLY UNIT....................................................6-21

6.7.5 MCU ...............................................................................................6-22

6.7.6 DUPLEX DRIVER BOARD.............................................................6-22

7. TROUBLESHOOTING ................................................................ 7-1

7.1 SC TABLES...............................................................................................7-1

7.1.1 TYPES OF SERVICE CALL.............................................................7-1

Fusing Unit SC Errors...........................................................................7-1

7.1.2 SC ERROR LIST..............................................................................7-2

7.1.3 PROCESS CONTRL ERROR LIST..................................................7-6

7.2 USER ERROR LIST...................................................................................7-8

iii

Page 7

30 June 2000 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Configuration Desk top

Print Process Dry electrostatic transfer system

Resolution 600 dpi

Paper Size Standard tray

Short edge feed (SEF):

A3, 11" x 17", 8

8

" x 13", 8

1/4

Long edge feed (LEF):

A4, 8

5

1/2

1/2

" x 8

" x 11", 7

")

1/2

By-pass feed tray*

Short edge feed:

A3, A6, B4 JIS, B6 JIS, 12" x 18",11" x 17",

8

" x 14", 8" x 13", 8

1/2

Long edge feed:

A4, A5, B5 JIS, 8

Custom size paper (Length: 148 to 457.2 mm,

Width: 90 to 297 mm)

" x 14", Others* (B4 JIS, 8" x 13",

1/2

" x 13")

1/2

" x 10

1/4

1/2

1/2

" x 13", 8

1/4

" x 11", 5

", Others* (B5 JIS, A5,

" x 13"

1/2

1/2

" x 8

1/2

", 7

1/4

" x 10

1/2

Overall

Information

"

* Specify the paper size with the system menu (at the

operation panel by the user).

Paper Weight Standard and optional trays: 64 to 105 g/m2 (17 to 28 lbs.)

By-pass feed tray: 64 to 160 g/

Plain paper mode: 64 to 105 g/m

m2 (17 lbs to 43 lbs

2

)

Thick paper mode: 105 to 160 g/m2, adhesive labels

OHP transparency mode: OHP transparencies

First Printout Time Color: Less than 26 seconds (A4 A4/8

Monochrome: Less than 13 seconds (A4 A4/8

" x 11" LEF)

1/2

1/2

" x 11"

LEF)

Print Speed Simplex prints

Color: 6 ppm (A4/8

Monochrome: 24 ppm (A4/8

" x 11" LEF)

1/2

" x 11" LEF)

1/2

Duplex prints

Warm-up Time

Color: 5.5 ppm (A4/8

Monochrome: 21.7 ppm (A4/8

Less than 380 seconds (at 23°C/73°F)

" x 11" LEF)

1/2

" x 11" LEF)

1/2

Paper Capacity Standard tray: 250 sheets (80 g/m2, 20 lbs.)

By-pass feed tray: 50 sheets (80 g/m2, 20 lbs.)

Optional trays: 500 sheets (80 g/m2, 20 lbs.)

1-1

Page 8

SPECIFICATIONS 30 June 2000

Paper Output

Capacity

250 sheets (A4/8

" x 11" or less)

1/2

100 sheets (More than A4/8

" x 11")

1/2

Output Method Face down

Power Supply 120 V, 60 Hz, 10 A

220 to 240 V, 50/60 Hz, 5.2 A

Power Consumption Maximum: Less than 1,200 W

Average during printing: Less than 750 W

Stand-by mode: Less than 150 W

Energy saver mode: Less than 45 W

Noise Emission

(Sound Power Level)

Stand-by: Less than 43 dB

Operating: Less than 65 dB

Dimensions Simplex model (G047)

660 x 575 x 475 mm (26” x 22.6” x 18.7”)

(without paper tray)

Auto duplex model (G048)

660 x 652 x 610 mm (26” x 25.7” x 24”)

(without paper tray)

Weight Simplex model (G047)Approximately 62 kg (136.7 lbs.)

(including consumables)

Auto-Duplex model (G048)

Approximately 82 kg (180.8 lbs.)

(including consumables)

Option Paper Feed Unit Type 305 (Paper Tray Unit) – up to two of

these units can be installed

1-2

Page 9

30 June 2000 MECHANICAL OVERVIEW

1.2 MECHANICAL OVERVIEW

Same as base model (G024)

Refer to the Section 1-2 of base model manual.

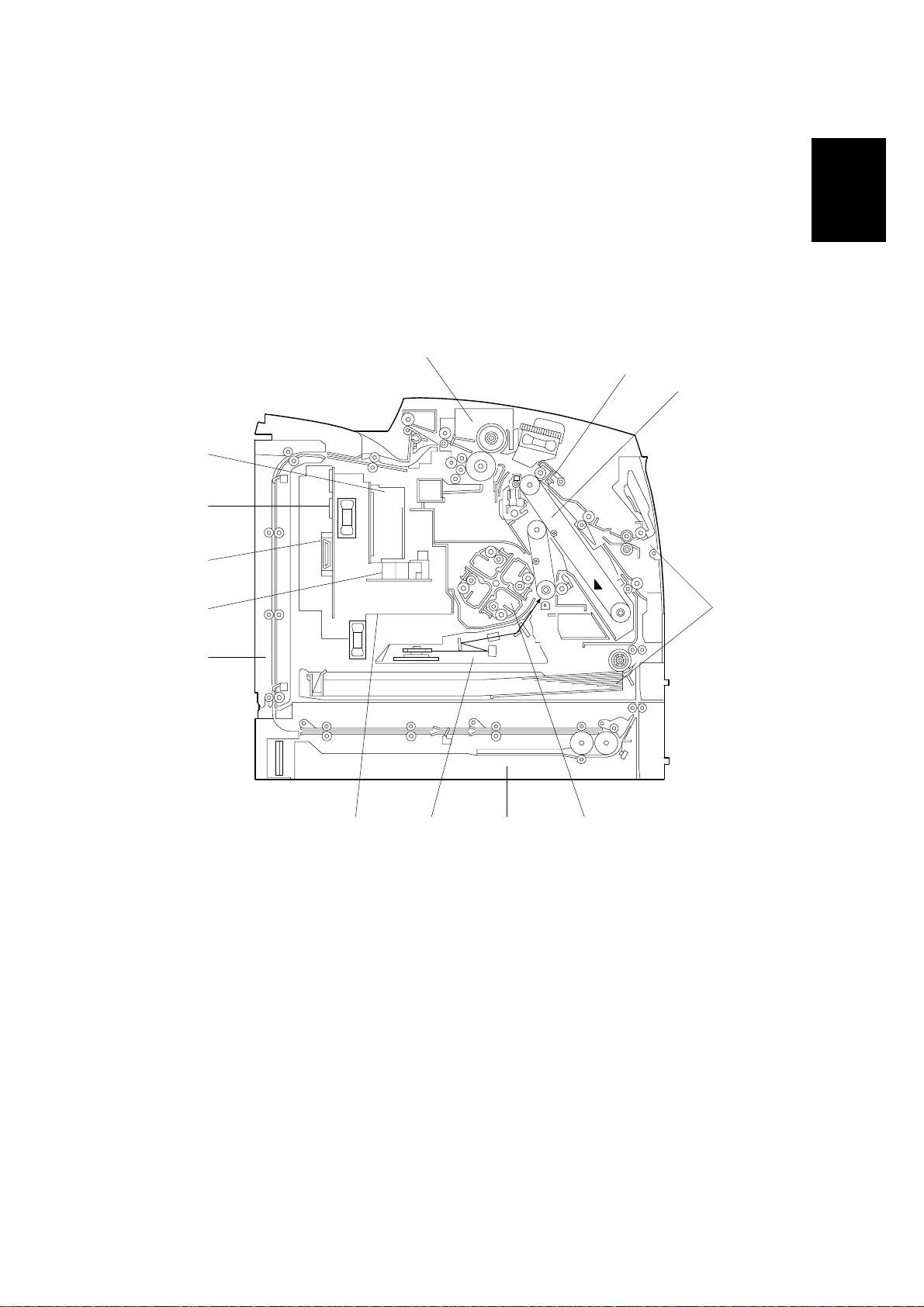

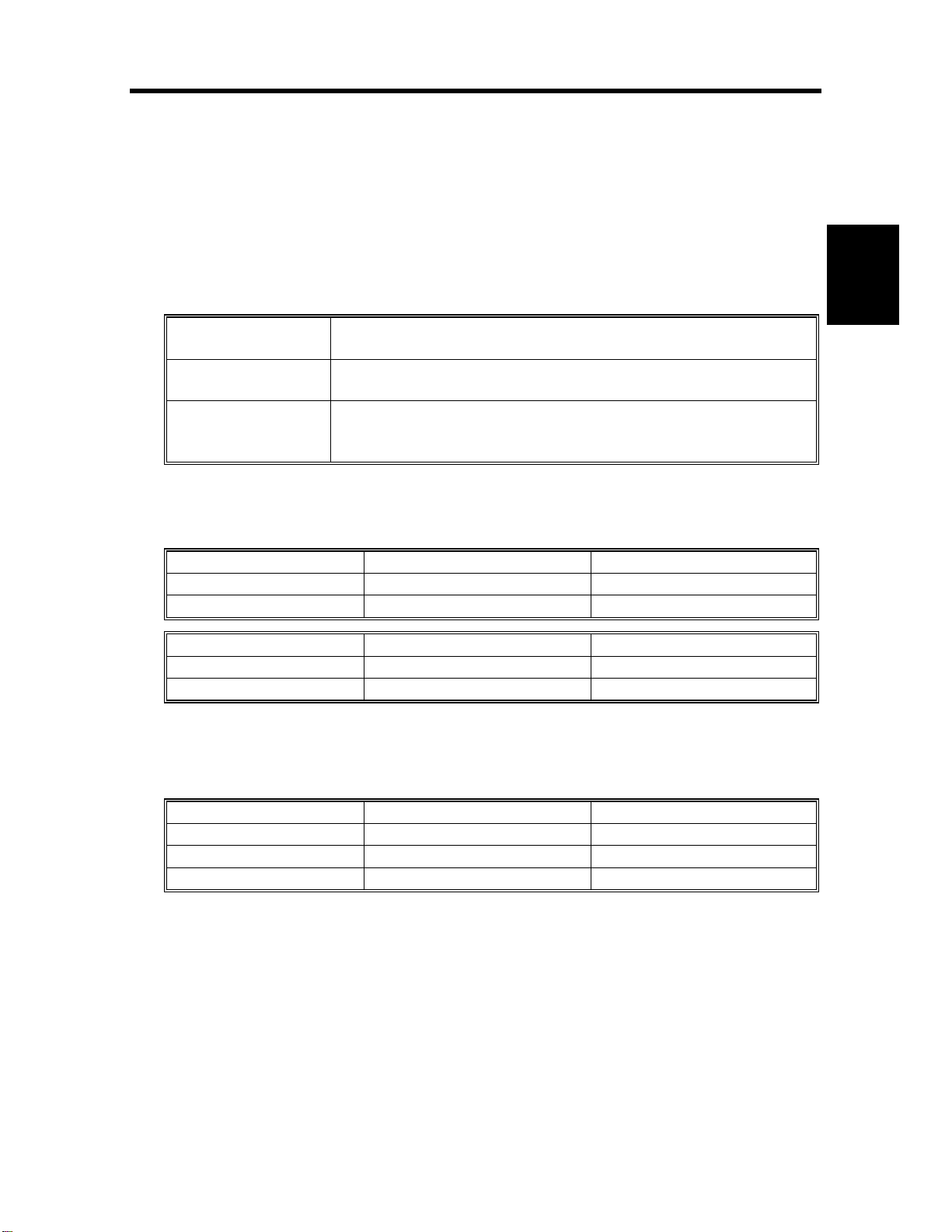

1.3 MAIN UNIT LAYOUT

13

1

2

12

11

Overall

Information

10

9

8

1. Paper Transfer Unit

2. Photoconductor Unit (PCU)

3. Paper Tray/Paper Feed Mechanism

4. Development Unit (DTM)

5. Duplex Unit

6. Optical Housing Unit

7. Main Control Unit (MCU)

5

467

G048V101.WMF

8. Vertical Transport Unit

9. High Voltage Supply Unit

10. DC Supply Unit

11. Controller Board

12. Power Supply Unit

13. Fusing Unit

3

1-3

Page 10

MAIN UNIT LAYOUT 30 June 2000

(1) Optical Housing Unit

• Optical system: 6-sided polygon mirror, F-theta mirror, BTL

• Resolution: 600 dpi

• Modulation method: PM+PWM

(2) MCU

• CPU: XC68334 GFC16

• Engine system control

• Process control

• Video interface

(3) Vertical Transport Unit (Auto-duplex Model Only)

• Paper feeding for duplex printing by rollers

(4) High Voltage Supply Unit

• Constant current: Paper transfer, charge corona wire

• Constant voltage: Charge corona grid, belt transfer, supply roller,

development blade

(5) DC Supply Unit (Auto-duplex Model Only)

• Outputs: +24 VDC supply for duplex unit

(6) Controller Board

• Host interface

• Video interface

• Image processing

• Operation panel control

(7) Power Supply Unit

• Outputs: +5 VDC, +24 VDC, 120/230 VAC

(8) Fusing Unit

• Fusing method: Hot roller method

• Oil application: Application roller method

• Cleaning: Cleaning roller method

• Temperature detection: Thermistor

• Safety precaution: Thermofuse

(9) Paper Transfer Unit

• Transfer: Transfer rol l er met hod

(10) PCU

A unit consisting of the OPC belt and the primary (belt) transfer section.

• OPC belt: 93-mm diameter

• Charging: Single scorotron charge corona wire

• Primary transfer: Transfer belt

• Cleaning: Counter blade

• Lubricant: Zinc stearate

1-4

Page 11

30 June 2000 SYSTEM BLOCK

(11) Tray/Transport

• Standard tray: Universal tray, friction pad separation

By-pass tray: FRR method

(12) Development Unit

• Development method: Monocomponent non-magnetic toner

• Development unit changeover: Revolver method

• Toner replenishment: DTM change

(13) Duplex Unit

• Stack-less

• Paper side edge jogging

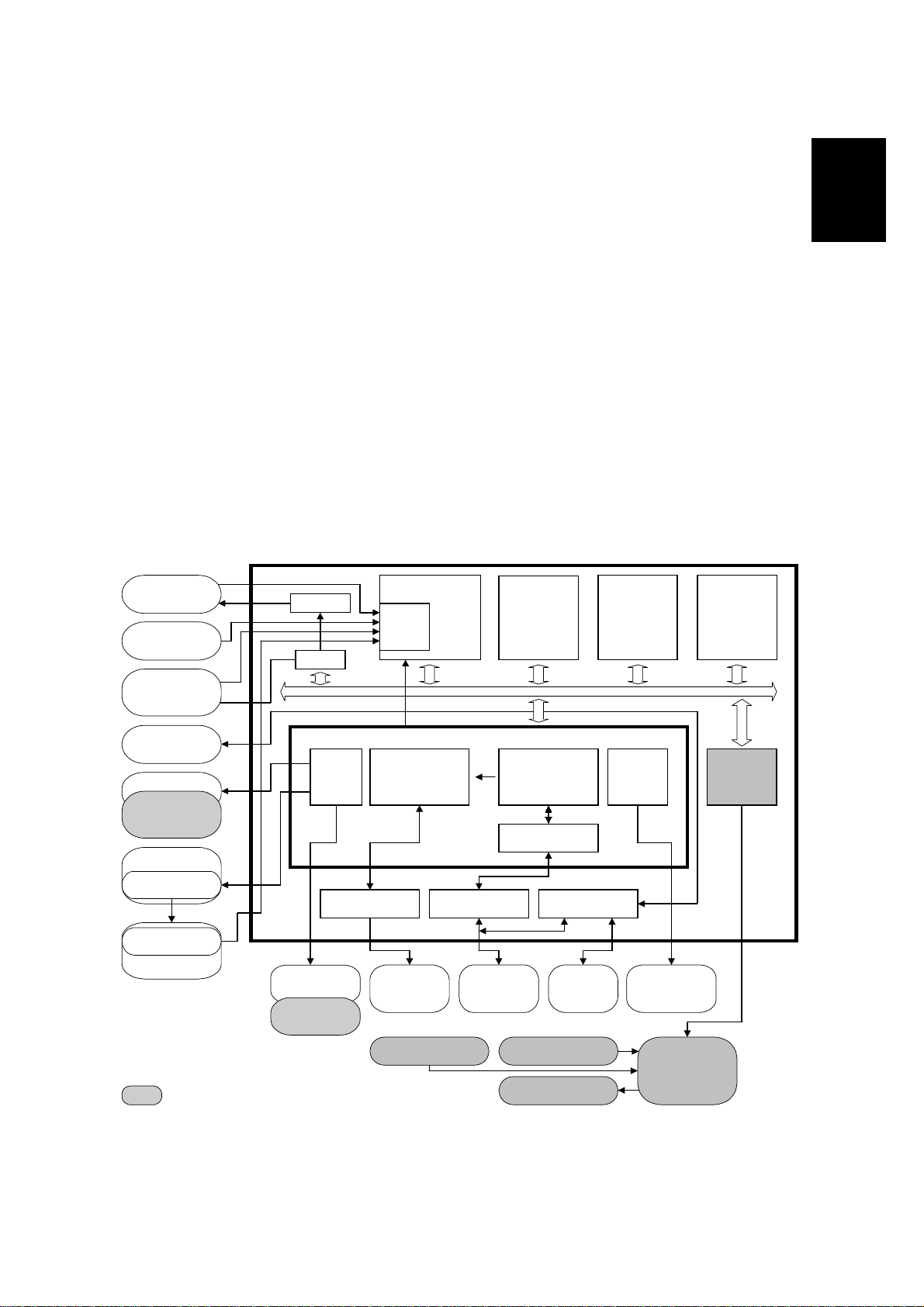

1.4 SYSTEM BLOCK

1.4.1 BLOCK DIAGRAM

ADC

CPU

ROM

ID Sensor

Humidity

Sensor

High Voltage

Supply Board

D/A

PWM

Overall

Information

NVRAM DRAM

IC Card

Sensors

Vertical

Transport

Sensor

PSU

Fusing

Control

I/O

AMDG

MCU

Thermistor

Fusing Unit

: Additional components on deplex model (G048)

Solenoids

Clutches

Interchange

Solenoids

LD

Modulation

Control

DC Supply Unit

ASIC

Video I/FGAVD/PLLC

Printer

Controller

Pattern

Generation

FIFO

Selector

Operation

Panel

Sensor

Motor Solenoids

Motor

Control

Revolver

Main Motor

PCU Motor

Expander

DDB

G048V554.WMF

1-5

Page 12

30 June 2000 DIFFERENT POINTS FROM BASE MODEL (G024)

2. DETAILED SECTION DESCRIPTIONS

2.1 DIFFERENT POINTS FROM BASE MODEL (G024)

2.1.1 OVERVIEW

The following points are different from the base model (G024).

1. Duplex printing

The following units were added to the Auto-duplex model (G048)

Paper Exit Unit Switching the paper path to the exit or to the duplex unit after

fusing.

Vertical Transport

Unit

Duplex Unit This unit is located at the bottom of the main-body. In this

Interleaf control is used for this model to increase the printing speed.

For duplex printing, feeding a sheet to duplex unit after fusing.

This unit is located behind the main-body.

unit, a sheet is turned, jogged and then fed to the main-body

again. Sheets are fed into this unit one-by-one.

Detailed

Descriptions

2. Printing Speed

Printing Speed G047/G048 Base Model (G024)

Black & White mode 24 ppm 17 ppm

Color mode 6 ppm 5 ppm

First Print G047/G048 Base Model (G024)

Black & White mode 13 sec. 14 sec.

Color mode 26 sec. 30 sec.

3. Image Quality Improvement

Increasing the line frequency in photograph and text mode improves the quality

of the image. A new laser optical unit is used to increase the line frequency.

Line Frequency G047/G048 Base Model (G024)

Photograph 180 lpi 106 lpi

Graphics 106 lpi 106 lpi

Text 268 lpi 211 lpi

2-1

Page 13

DIFFERENT POINTS FROM BASE MODEL (G024) 30 June 2000

2.1.2 FUSING UNIT

The followings differ from the base model (G024) in the Fusing unit.

1. Pressure Roller

For the duplex printing, The material used to make the pressure roller was

changed from Teflon to Silicon rubber to improve duplex printing performance.

2. Heat Isolation

To maintain the fusing roller temperature, heat isolation bushings are mounted

between the fusing roller bushing and drive gear.

3. Connector

All of the drawer connectors were replaced with harness connectors.

4. Exit Cover Switch (Auto-duplex model only)

The location of paper exit cover switch was moved to the main-body of the

machine from the fusing unit..

2.1.3 OPTICAL UNIT

The following optical unit ite ms differ from the previous model.

1. Polygonal Mirror Motor

The speed of the polygonal mirror motor was increased to increase the printing

speed.

G047/G048 Base Model (G024)

Paper feed speed 121.54 mm/sec 101.27 mm/sec.

Mirror motor revolution

speed

28,706 rpm 23,922 rpm

2. LD Unit

To improve the image quality, the diameter of the beam was decreased and the

power of the beam was increased.

G047/G048 Base Model (G024)

Diameter of Beam

LD Power 1.91 mW 1.58 mW

69 µm x 76 µm 76 µm x 76 µm

3. Dust Prevention

To prevent the polygonal mirror and polygon mirror motor from collecting dust,

two sponges were added to the optical housing. One is above the polygon

mirror motor and the other is on the side of the housing unit.

2-2

Page 14

30 June 2000 DIFFERENT POINTS FROM BASE MODEL (G024)

2.1.4 PAPER FEEDING AND REGISTRATION

1. Paper size detection of bypass tray

Paper width detection mechanism on the bypass tray is not available.

2. Pick-up roller

The material of pick-up roller is changed to Silicone rubber for duplex printing

from the bypass tray.

2.1.5 PROCESS CONTROL

1. K-DTM Initialization

The image density target level was lowered.

G047/G048 Base Model (G024)

ID on sheet 1.6 1.7

Volume of toner 0.56 mg/cm

2

0.60 mg/cm

2

Detailed

Descriptions

2. Color-DTMs Initialization

The image density target level was changed.

G047/G048 Base Model (G024)

ID on sheet 1.4 1.5

Volume of toner (C) 0.56 mg/cm

Volume of toner (Y) 0.54 mg/cm

Volume of toner (M) 0.62 mg/cm

2

2

2

0.55 mg/cm

0.55 mg/cm

0.60 mg/cm

3. Charge Grid Bias Compensation

Compensation control was changed because the number of lines in photo

mode was changed from 106 to 180.

2.1.6 ELECTRICAL COMPONENTS

1. Main Motor

The main motor was changed to increase the print speed.

The PCU motor was not changed but the clock rate was changed.

2. MCU

The MCU was changed to improve the efficiency of duplex printing by adding

new electrical components.

2

2

2

3. PSU

A different PCU was used to increase the current level.

A DC supply unit was added for Auto-duplex models only.

2-3

Page 15

DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY) 30 June 2000

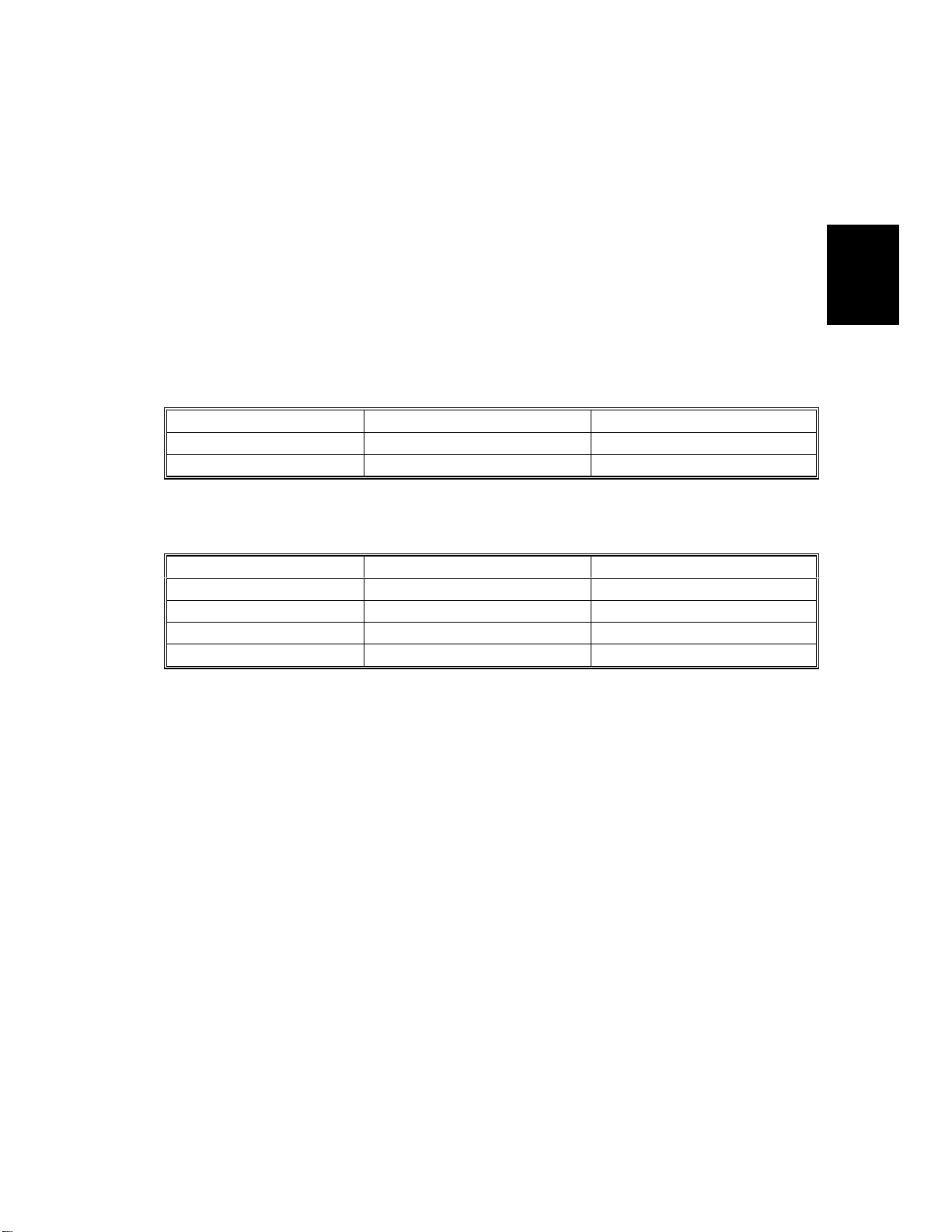

2.2 DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY)

2.2.1 OVERVIEW

Layout

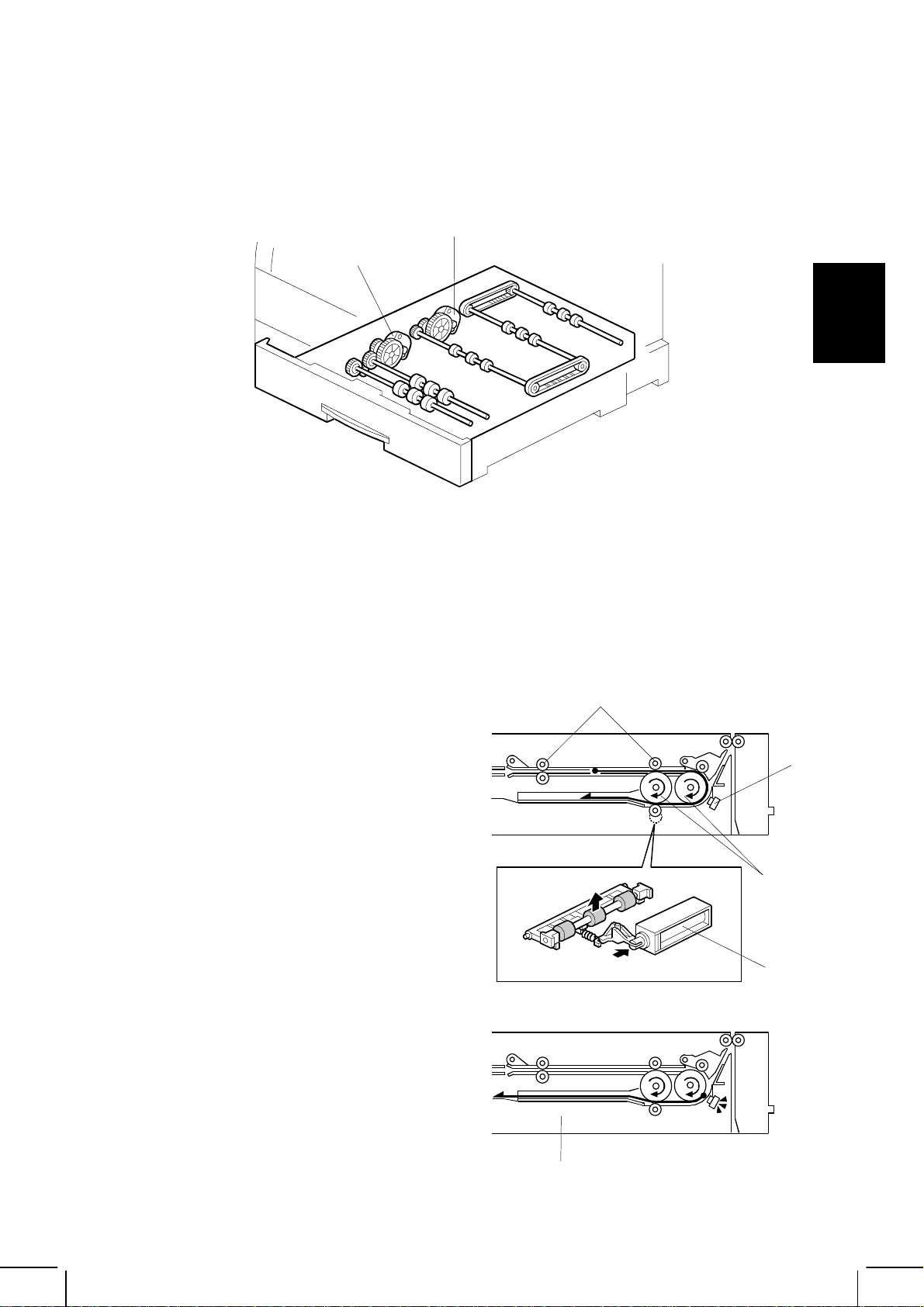

10

9

8

7

1

2

1. Junction Gate

2. Relay Roller

3. Duplex Roller

4. Duplex Pick-up Roller

5. Jogger Fence

56

G048D101.WMF

6. Duplex Feed Roller

7. Duplex Unit

8. Vertical Transport Roller

9. Vertical Transport Unit

10. Exit Unit

34

2-4

Page 16

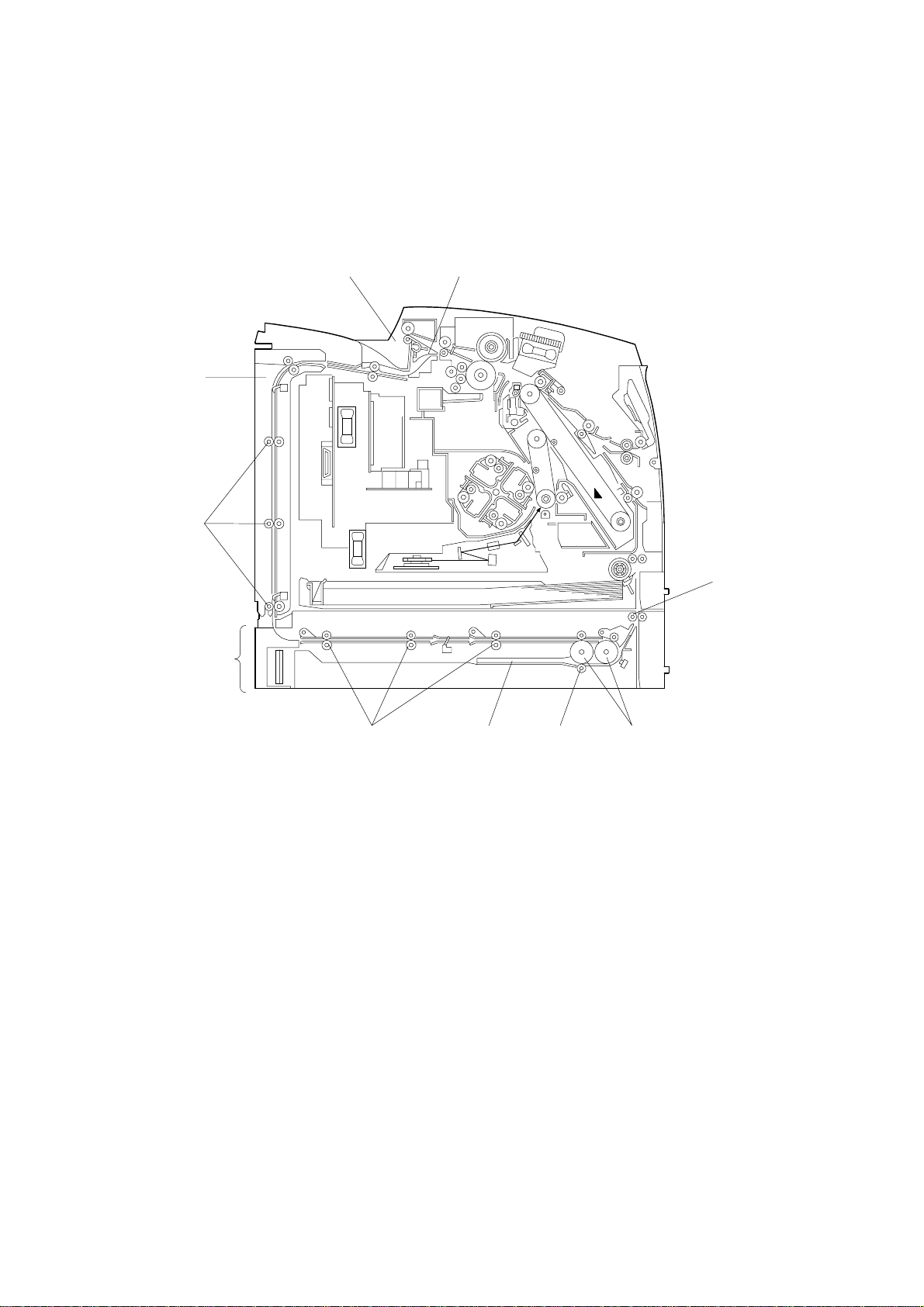

30 June 2000 DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY)

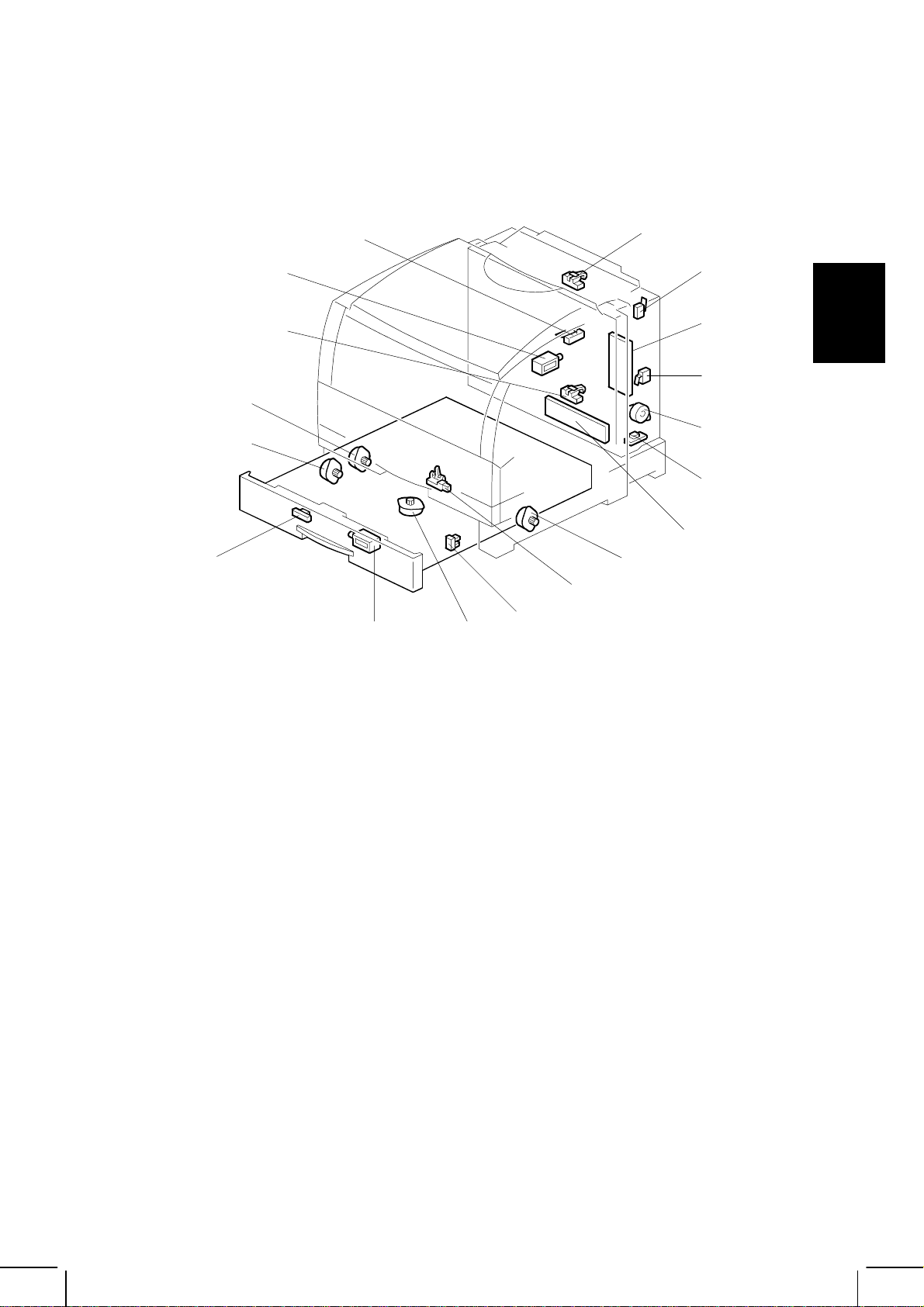

Electrical Components

13

15

14

17

16

18

12

11

10

1

8

9

G048D103.WMF

2

3

Detailed

Descriptions

4

5

6

7

1. Vertical Transport Entrance Sensor

2. Vertical Transport Cover Switch

3. Duplex DC Supply Unit

4. Vertical Transport Unit Switch

5. Vertical Transport Motor

6. Temp./Hum. Sensor

7. Duplex Driver Board

8. Relay Motor

9. Duplex Feed Sensor

10. Jogger HP Sensor

11. Jogger Motor

12. Reverse Solenoid

13. Reverse Sensor

14. Duplex Reverse Motor

15. Duplex Feed Motor

16. Vertical Transport Exit Sensor

17. Junction Gate Solenoid

18. Exit Cover Switch

Exit Unit

- A solenoid moves the junction gate.

- A micro-switch detects if the cover is open.

Vertical Transport Unit

- The vertical transport rollers driven by the vertical transport motor feed paper

to the duplex unit.

- Two sensors detect paper fed in the entrance and out the exit of the unit.

- Two micro-switches detect whether the vertical transport unit and cover are

open.

2-5

Page 17

DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY) 30 June 2000

Duplex Unit

- The duplex, duplex transport and duplex pick-up rollers reverse the paper in

the unit.

- The jogger fence prepares to feed paper into the main body after reversing it.

- The duplex, duplex pick-up, and relay rollers feed paper into the main body for

reverse side printing.

- The duplex feed sensor and reverse sensor detect paper.

2-6

Page 18

30 June 2000 DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY)

2.2.2 EXIT UNIT

Driving Mechanism

[D]

[E]

Detailed

Descriptions

[A]

[B]

[C]

G048D002.WMF

The fusing unit [A] and drive gears [B], powered by the main motor [C], drive the

feed and exit rollers [D and E].

Junction Gate

[A]

[B]

G048D001.WMF

The Junction gate [A] is located at the entrance of exit unit. Paper is fed to the exit

tray or to the vertical transport unit by this gate. This gate is driven by solenoid [B].

When this solenoid activates, the paper is fed into the vertical transport unit.

2-7

Page 19

DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY) 30 June 2000

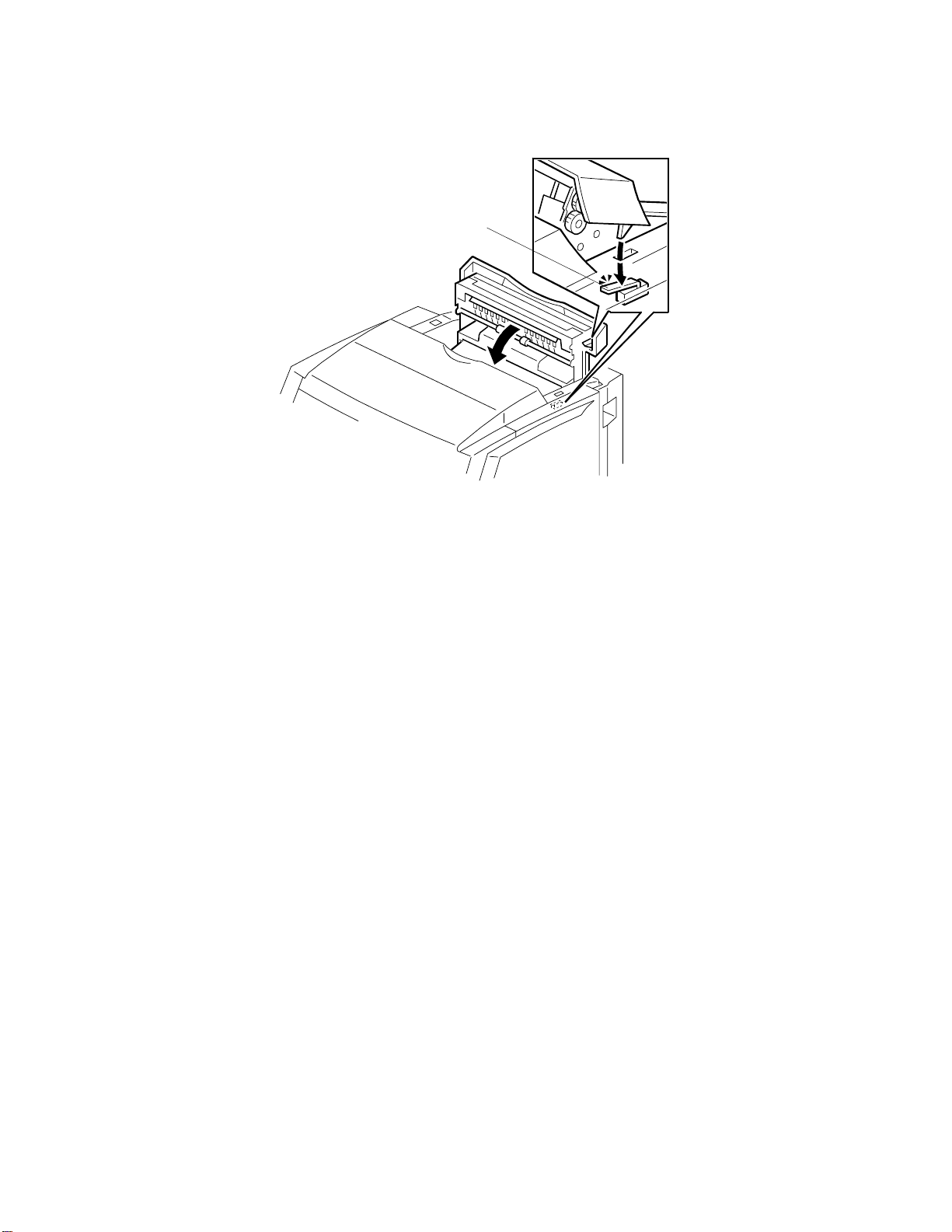

Exit Cover Open Detection

[A]

G048D003.WMF

The exit unit cover switch [A] is on the right side of the unit to detect whether the

cover is open. This switch interrupts the 24VDC line to the main control board

(PCB2).

2-8

Page 20

30 June 2000 DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY)

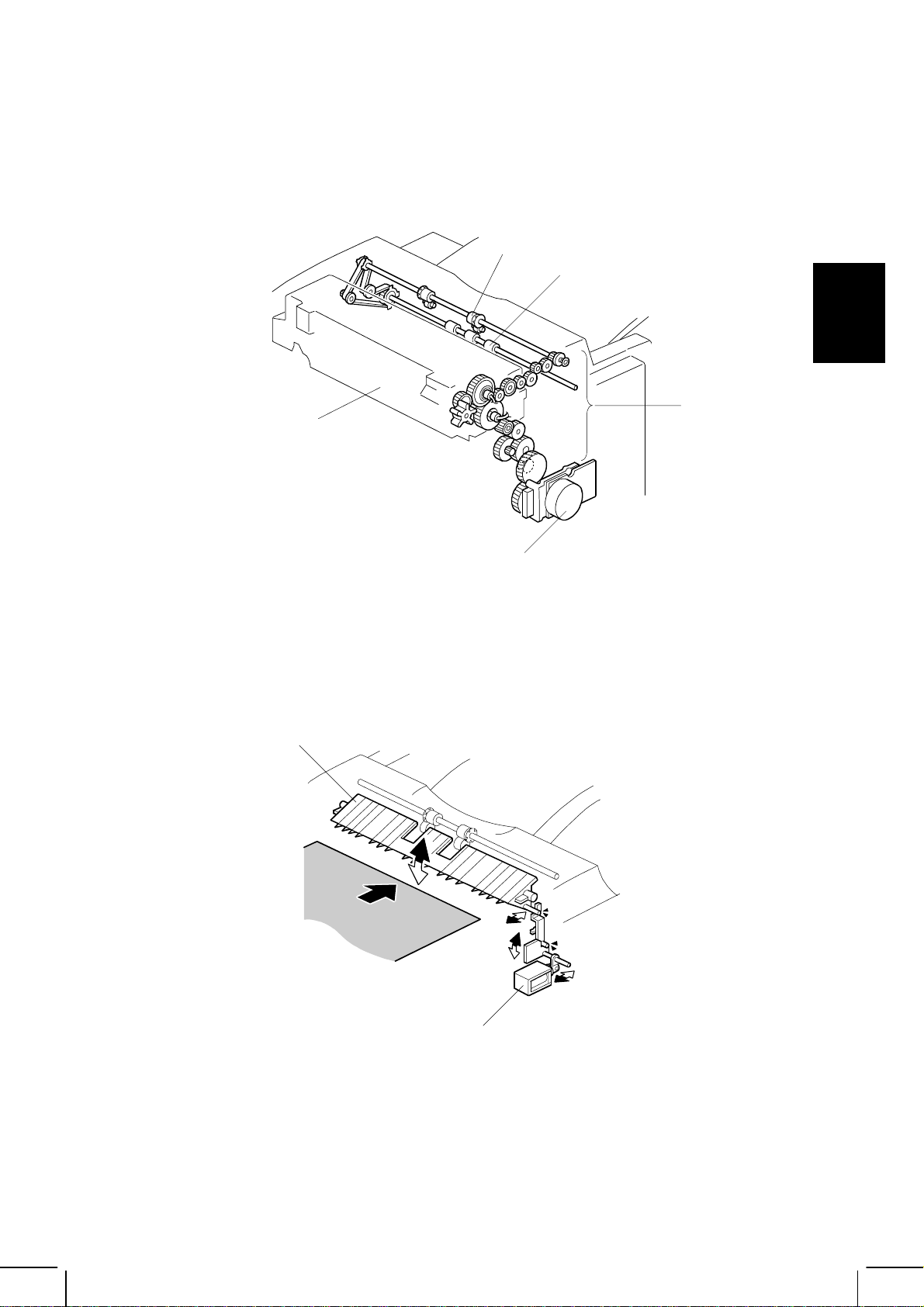

2.2.3 VERTICAL TRANSPORT UNIT

Driving Mechanism

[B]

[D]

[D]

[A]

[C]

G048D501.WMF

The vertical transport motor [A] drives the vertical transport rollers [B] using gears

[C] and timing-belts [D].

Paper Feed Detection

[A]

Detailed

Descriptions

[B]

G048D010.WMF

Two sensors (photo interrupters) detect paper: One is the entrance sensor [A] and

the other is the exit sensor [B].

2-9

Page 21

DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY) 30 June 2000

Vertical Transport Unit Cover Open Detection

[A]

G048D008.WMF

G048D007.WMF

The interruption of the current for the vertical transport switches [A and B]

determines whether the vertical transport unit or cover is open.

[B]

2-10

Page 22

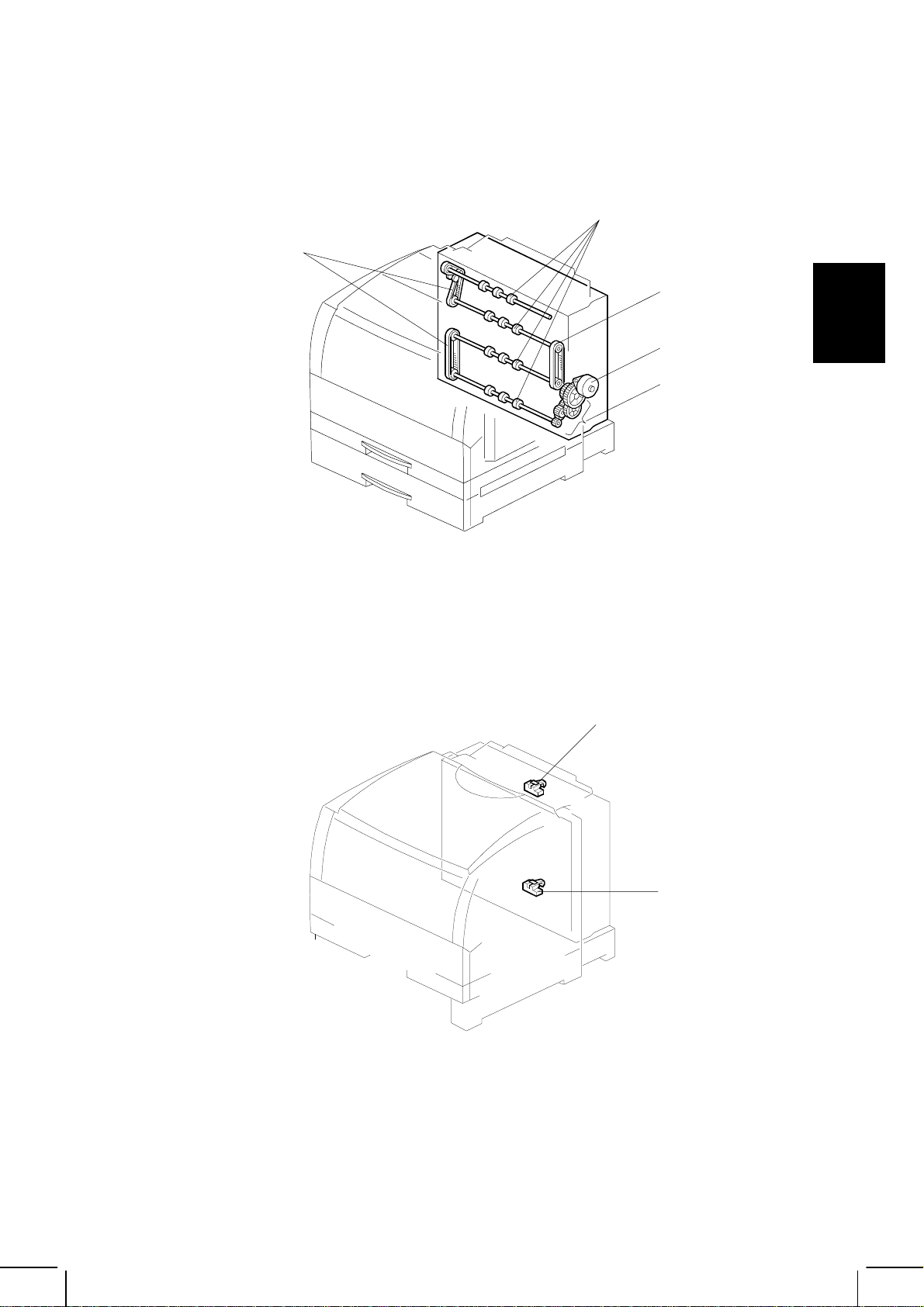

30 June 2000 DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY)

2.2.4 DUPLEX UNIT

Driving Mechanism

[A]

[B]

G048D502.WMF

Detailed

Descriptions

The duplex feed motor [A] feeds paper from the vertical transport unit up to the

reverse tray. Then the duplex reverse motor [B] feeds the paper from the reverse

tray to the relay rollers.

Reverse Mechanism

[A]

First, paper is fed by the duplex feed

rollers [A] and then by the duplex rollers

[B]. When the reverse sensor [C] detects

the leading edge of paper, the reverse

solenoid [D] activates and paper is fed

into the duplex tray [E].

When the reverse sensor detects the

trailing edge of paper, the reverse

solenoid deactivates.

[B]

[D]

[C]

2-11

[E]

G048D015.WMF

Page 23

DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY) 30 June 2000

Jogging Mechanism

The standby position distance

between jogger fences [A] is 10mm

wider than the printed paper width

while printing.

After the duplex roller stops, the

jogger motor [B] slides the jogger

fences so that they are 1mm

narrower than the printed paper

width.

After finishing all print job s , the

fences return to the home position,

until the home position sensor [C]

activates.

Feed-out

After jogging the paper, the duplex

roller turns counter-clock wise and the

reverse solenoid activates. This fee ds

paper to the relay roller [A], which is

driven by the relay motor [B].

[A]

[B]

[C]

G048D006.WMF

Reverse Tray Detection

The tray is connected to the duplex

driver board [A] through drawer

connectors [B] when the tray is

pushed into the machine. This

connection is monitored by a loop

back signal to make sure that the tray

is positioned properly in the machine.

[B]

[A]

G048D009.WMF

[A]

[B]

2-12

G048D153.WMF

Page 24

30 June 2000 DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY)

2.2.5 INTERLEAF

An interleaf mechanism was added to increase duplex printing performance in

black & white print mode. Also, this model only prints face down.

E

D/J

K

C/I

B/H

Detailed

Descriptions

A-1

G

F

A-2

G048D211.WMF

Paper Path for Duplex Printing

A: Paper feed for back-side print ( -1: Standard tray -2: Optional tray)

B: Secondary transfer for back-side print

C: Fusing back-side print

D: Junction

E: Vertical transport

F: Reverse

G: Paper fee d for front-s ide print

H: Secondary transfer for front-side print

I: Fusing for front-side print

J: Junction

K: Paper exit

2-13

Page 25

DUPLEX PRINTING (AUTO-DUPLEX MODEL ONLY) 30 June 2000

Print Order for Duplex Black & White Printing

The following example shows what happens when printing 8 sheets of A4/LTR size

in duplex black & white mode. 4 sheets of A4/LTR size paper can be kept inside

the machine during this print mode.

2

➀➁➂➃

135

➀➄➁➅➂➆

10

4 6 8

12 14

➃➇

7

16

1513119

➇➆➅➄

G048D212.WMF

Print Order for Duplex Color Printing

The following example shows what happens when printing 8 sheets of A4/LTR size

in duplex color mode.

2 sheets print 2 sheets print 2 sheets print

2 4 6 81357

➁➂➃➀➃➂➁➀

G048D214.WMF

2-14

Page 26

30 June 2000 INSTALLATION PROCEDURE

3. INSTALLATION PROCEDURE

Refer to the following materials.

• For the printer: Quick Installation Guide

• For options: Operating Instructions

If the customer has a service contract with a meter click system, set up the counter

with an SP mode as follows:

1. Enter Controller SP mode (se e 4.1.1 ENTERING AND EXITING

CONTROLLER SP MODE in Service manual for controller).

2. Set “Meter Click” from the maintenance menu to the proper mode depending

on the contract type (see 4.1.4 SP MODE DETAILS in Service manual for

controller).

3. Exit SP mode, and then confirm that display of both “Color” and “Black” is 0 by

executing “ Show Counter”

Installation

3-1

Page 27

30 June 2000 OVERVIEW

4. SP MODE

4.1 OVERVIEW

This printer has two SP modes:

1) Engine SP mode

2) Controller SP mode

The controller SP modes are described in the service manual for the controller.

These two modes contain different functions.

4.2 ENGINE SP MODE

4.2.1 OVERVIEW

To enter and exit engine SP mode

Same as the base model (G024)

Outline of the engine SP mode functions

The following table shows differences from the base model (G024)

Menu Item Difference from the base model (G024)

1: Margin Duplex printing menu and two adjustable items were added.

2: Parameter The secondary transfer bias can be adjusted individually for

printing on the front side and for the other side of paper.

3: Clear Memory Same as the base model (G024)

4: Sensor Check

5: Nip Width Same as the base model (G024)

6: Reset SC Same as the base model (G024)

7: Process Ctrl Same as the base model (G024)

8: Test Print Three menus were added for auto-duplex printing.

9: ID Sensor PWM Same as the base model (G024)

10: Image Adjust Same as the base model (G024)

11: Output Check 10 more components were added to the vertical transport and

12: Hi-light Same as the base model (G024)

13: Lub_Interval Same as the base model (G024)

14: BLT-TR BIAS Additional function to adjust the primary transfer bias.

Eight more sensors were added to the vertical transport and

duplex units.

duplex units.

Tables

Service

4-1

Page 28

ENGINE SP MODE 30 June 2000

4.2.2 MENU OPERATION/DISPLAY

Same as the base model (G024)

4.2.3 MARGIN (REGISTRATION ADJUSTMENT)

NOTE: Items in bold are additional ones for this model.

Layer 1 Layer 2 Layer 3 Layer 4

Maintenance

1: Margin

Margin

Pattern Print

Margin

Adjust

Margin: Print

Std. Paper

Margin: Print

Thick Paper

Margin: Print

Transparency

Marg in: Adjust

Tray1: Left

Marg in: Adjust

Tray1: Top: 1st

Marg in: Adjust

Trans: Top : 1st

(For OHPs)

Margin: Adjust

Back: Left

Margin: Adjust

Back: Top

Print: Std

Tray 1

Tray 2

Tray 3

(D) Tray 1

(D) Tray 2

(D) Tray 3

By-pass Tray

(D) shows duplex

printing.

Print: Thick

By-pass Tray

Print: Trans

By-pass Tray

Tray1: Left

X.X

Tray1: Top: 1st

X.X

It can be adjusted

for tray 2, tray 3,

and the by-pass

tray in the same

way as for tray1.

Trans: Top : 1st

X.X

Back: Left

X. X

Back: Top

X. X

4-2

Page 29

30 June 2000 ENGINE SP MODE

4.2.4 PARAMETER

NOTE: Items in bold are additional ones for this model.

Layer 1 Layer 2 Layer 3 Layer 4

Maintenance

2: Parameter

Parameter

Std. Paper

Parameter

Thick Paper

Parameter

Transparency

Std. Paper

Transfer Bias

Std. Paper

(D) Transfer Bias

Std. Paper

Fusing Temp.

Same as Std. Paper Same as Std. Paper

Same as Std. Paper Same as Std. Paper

Bias

XXX%

(D) Bias

XXX%

Temp.

Low

Temp.

Normal

Temp.

High

4.2.5 CLEAR MEMORY

Same as the base model (G024)

NOTE: Counter values used for meter click are not cleared.

Tables

Service

4-3

Page 30

ENGINE SP MODE 30 June 2000

4.2.6 SENSOR CHECK

NOTE: Bolded items are additions to this model.

Sensor Name Sensor Status

Name Display 0 1

Paper End Sensor

(Tray 1)

Paper End Sensor

(By-pass Tray)

Paper End Sensor

(Tray 2)

Paper End Sensor

(Tray 3)

Registration Sensor Registration Paper not detected Paper detected

Exit Sensor Exit Paper detected Paper not detected

Paper Size Switch

(Tray 1)

Paper Size Switch

(Tray 2)

Paper Size Switch

(Tray 3)

By-pass Paper Width

Detection Board

PCU Set Switch PCU Set Detected Not detec te d

DTM Set Sensor CTC Set Detected Not detected

Toner End Sensor CTC Toner End Not end End

Door Safety Switch Cvr Opn-F Closed Open

Exit Cover Switch Cvr Opn-EX Closed Open

Oil End Sensor Oil End End Not end

(Fusing Unit) Fusing Set Detected Not detected

Used Toner Sensor Used Toner Not full Full

(Tray 2) Tray Set-2nd Not detected Detected

(Tray 3) Tray Set-3rd Not detected Detected

PCU Reset Sensor PCU Reset Old New

Revolver H.P. Sensor Revolver H.P. Home position Not home position

Transfer Roller

Position Sensor

Pull-out Sensor

(Tray 2)

Pull-out Sensor

(Tray 3)

ID Sensor ID *3 *3

Sensor

DTM Cover Switch Cvr Opn-S Open Closed

Pull-out Sensor (Main

Body)

Charger Corona Set

Switch

Vertical transport

unit/cover switch

Reverse sensor Reverse Sensor Paper detected Paper not detected

P End-1st Paper detected Paper not detected

P End-By-pass Paper detected Paper not detected

P End-2nd Paper detected Paper not detected

P End-3rd Paper detected Paper not detected

P Size-1st *1 *1

P Size-2nd *1 *1

P Size-3rd *1 *1

P Size-By-pass

Tfr Position Release Touch

P Feed-2nd Paper not detected Paper detected

P Feed-3rd Paper not detected Paper detected

Humidity *4 *4Temperature/Humidity

Temp *5 *5

Pick-up Paper detected Paper not detected

Main Charger Detected Not detected

Cvr Open-Duplex Open

*2 *2

Closed

*6

*6

4-4

Page 31

30 June 2000 ENGINE SP MODE

Sensor Name Sensor Status

Name Display 0 1

Duplex Feed sensor P Feed-Duplex Paper not detected Paper detected

Jogger HP sensor Jogger H. P Home position Not home position

Duplex unit

connection signal

Duplex tray

connection signal

Vertical transport

entrance sensor

Vertival transport

exit sensor

Duplex-Unit Set Not detected

*7

Duplex Tray Set Not detected

*8

V feed P1 Paper detected Paper not detected

V Feed P2 Paper detected Paper not detected

Detected

*7

Detected

*8

*1: “Paper size detection” in Section 2 explains the status of the paper size

switches for paper size detection. (0: Pressed, 1: Not pressed)

*2: The indicated value is always “1f” as there is no paper size detection

mechanism on this model.

*3: The displayed value indicates the K sensor output when the LED in the ID

sensor is turned on. The specified output value (reference for normal

operation) is 2.7 ± 0.8 V.

*4: The detection results are shown in the XXX YYY format. XXX indicates

absolute humidity, and YYY indicates relative humidity. (Reference for normal

operation: YYY should be between 5 and 95.)

Tables

Service

*5: The displayed value indicates the detected temperature. (Reference for normal

operation: Between 8 and 42)

*6: If either the vertical transport unit or vertical transport cover is open, “0”

(open) is indicated.

*7: The connection signal in between the MCU and the duplex driver board is

checked. (10th pin of the CN254 on the MCU)

*8: Loop back signal for the duplex driver board is checked. (13th pin of the

CN896 on the Duplex driver board)

4.2.7 NIP WIDTH

Same as the base model (G024)

4.2.8 RESET SC

Same as the base model (G024)

4-5

Page 32

ENGINE SP MODE 30 June 2000

4.2.9 PROCESS CTRL

Same as the base model (G024)

4.2.10 TEST PRINT

NOTE: Bolded items are additions to this model.

Layer 1 Layer 2 Layer 3 Layer 4

Maintenance

8: Test Print

Test Print

Pattern 1

Test Print

Pattern 2

Test Print

Pattern 3

Test Print

Pattern 1(D)

Test Print

Pattern 2(D)

Test Print

Pattern 3(D)

Pattern 1

Tray X

Same as Pattern 1 Same as Pattern 1

Same as Pattern 1 Same as Pattern 1

Same as Pattern 1 Same as Pattern 1

Same as Pattern 1 Same as Pattern 1

Same as Pattern 1 Same as Pattern 1

Printing

Tray X

4.2.11 ID SENSOR PWM (PULSE WIDTH MODULATION)

Same as the base model (G024)

4.2.12 IMAGE ADJUST

Same as the base model (G024)

4-6

Page 33

30 June 2000 ENGINE SP MODE

4.2.13 OUTPUT CHECK

NOTE: Bolded items are additions to this model.

Name Display Operation

By-pass Feed Clutch Bypass Feed Cl. O perating for a certain time

Pull-out Clutch Pick-up Cl. Operating until instructed to

turn OFF

Paper Feed Clutch Feed Cl. Operating for a certain time

Relay Roller Clutch Transport Cl. Operating until instructed to

turn OFF

Registration Clutch Regist. Cl.

Transfer Roller Clutch Tr. Roller Cl. Oper ating f or a certain time

Development Drive Solenoid Development Sol. Operating until instructed to

By-pass Feed Solenoid Bypass Sol. Operating for a certain time

Transfer Belt Cleaning Solenoid Cleaning Sol. Operating until instructed to

Quenching Lamp Quenching LED Operating until instructed to

PCU Motor

Main Mo tor

Polygon Mirror Motor Scanner Motor

Revolver Motor Revolver Motor Operating until instructed to

Tray Main Motor (for tray 2) OT1 Motor Operating until instructed to

Paper Feed Clutch (for tray 2) OT1 Feed Clutch Operating for a certain time

Tray Main Motor (for tray 3) OT2 Motor

Paper Feed Clutch (for tray 3) OT2 Feed Clutch Operating for a certain time

Vertical Transport Motor V Feed motor

Duplex Feed Motor Duplex Tray Mtr Operating until instructed

Duplex Reverse Motor

()

PCU Motor-slow

PCU Motor-normal Operating unt il instructed to

PCU Motor-fast Operating until instructed to

PCU Motor-reverse

Main Mtr-normal Operating until instructed to

Main Mtr-slow Operating until instructed to

Rvrs Mtr Operating until instructed

Operating until instructed to

turn OFF

turn OFF

turn OFF

turn OFF

Operating until instructed to

turn OFF

turn OFF

turn OFF

Operating until instructed to

turn OFF

turn OFF

turn OFF

Operating until instructed to

turn OFF

turn OFF

turn OFF

Operating until instructed to

turn OFF

Operating until instructed

to turn OFF

to turn OFF

to turn OFF

Tables

Service

4-7

Page 34

ENGINE SP MODE 30 June 2000

Name Display Operation

Duplex Reverse Motor

()

Reverse Solenoid Press Roller Sol Operating until instructed

Jogger

(for H.P.)

Jogger

(for

Jogger

(for

Relay Motor Pull Out Motor Operating until instructed

Junction Gate Solenoid Divergence Sol.

Rvrs Mtr-rvrs

Jogger HP Operating for a certain time

Jogger Operating for a certain time

Jogger reverse Operating for a certain time

Operating until instructed

to turn OFF

to turn OFF

to turn OFF

Operating until instructed

to turn OFF

4.2.14 HIGHLIGHT ADJUSTMENT

Same as the base model (G024)

4.2.15 LUB_INTERVAL (BELT LUBRICATION INTERVAL ADJUSTMENT)

Same as the base model (G024)

4-8

Page 35

30 June 2000 ENGINE SP MODE

4.2.16 PRIMARY BIAS ADJUSTMENT

Use this menu to adjust the primary bias (belt transfer bias).

The adjustment can be done in 100V steps between 800 V and 1,500 V.

The default value is 1,200 V.

Layer 1Layer 2Layer 3

Maintenance

14: BLT-TR BIAS

BLT-TR B IAS

Cyan

BLT-TR B IAS

Magenta

BLT-TR B IAS

Yellow

BLT-TR B IAS

Black

Cyan

XXX

Magenta

XXX

Yellow

XXX

Black

XXX

Tables

Service

4-9

Page 36

30 June 2000 PM TASKSPM TASKSPM TASKS

5. PREVENTIVE MAINTENANCE

5.1 PM TASKS

5.1.1 REPLACEMENT

Replace the PM parts every 100 K printouts as shown in the PM table on the next

page.

The fusing unit replacement interval is not determined in the same manner as the

base machine. For details, see the note after the PM table.

• For the replacement procedures, refer to Chapter 6 “Replacement and

Adjustment” in this manual and Chapter 3, “Replacement and Adjustment” in the

manual for the optional 500-sheet paper tray.

CAUTION

When replacing components, be aware that the fusing unit may be hot.

Handle it with care.

5.1.2 CLEANING

Clean the printer components when visiting the customer site.

• See the PM table for the correct way to wipe components.

NOTE: Make sure that the charge corona unit cleaner is in the home position.

5.1.3 INSPECTION

Inspect the printer components when visiting the customer’s site.

• Visually inspect the components, and replace them if there is any damage.

CAUTION

A high voltage is applied to bias electrodes. To inspect a bias electrode,

ensure that the power switch is turned off.

Preventive

Maintenance

5-1

Page 37

PM TABLE 30 June 2000

5.2 PM TABLE

5.2.1 MAIN UNIT

C: Clean R: Replace I: Inspect

Item EM 60K 100K Note

Paper Feed Roller C R Alcohol or water

Registration Roller C Alcohol or water

Frict ion Pad C R Water

Bottom Plate Pad C Water

By-pass Feed Roller C Alcohol or water

By-pass Pick up Roller C Alcohol or water

By-pass Separation Roller C Alcohol or water

Charge Corona Unit C*

Quenching Lamp I Blower brush (if dirty)

ID Sensor C Dry cloth

Dust Shield Glass C*

Fusing Unit R*

Exit roller-Exit Unit C Auto-duplex model only

Feed roller-Exit Unit C Auto-duplex model only

Feed rollers-Duplex Unit C Auto-duplex model only

Vertical Transport Rollers C Auto-duplex model only

Duplex Rollers C Auto-duplex model only

Relay Roller C Auto-duplex model only

1

1

2

Cleaner in the PCU

Cleaner brush (P/N: G0241533)

*1: This is a common item with user maintenance.

*2: Regardless of the meter-click setting, the number of pages that the counter

counts depends on the paper size:

• A3 or larger: 2 counts

• Smaller than A3: 1 count

• When the fusing unit counter reaches 60 K a message is displayed on the

LCD only if “No meter-click mode” is selected. However, printing can still

continue.

NOTE: The following indication will NOT be shown on the display when one of

the meter-click mode is selected even if the counter reaches the PM

interval.

“Change Fusing Unit”

“Change PCU”

“Need Charger Unit”

The Charger unit and Fusing unit counter need to be manually cleared

by “Maintenance” menu and controller SP mode (S4).

5.2.2 OPTIONAL PAPER FEED UNIT

See the manual for base model (G024)

5-2

Page 38

30 June 2000 EXTERIOR

6. REPLACEMENT AND ADJUSTMENT (AUTO-DUPLEX MODEL)

6.1 EXTERIOR

6.1.1 TOP OVER

[D]

[B]

[A]

1. Open the front cover [A] and paper exit unit [B].

2. Open the vertical transport unit [C] (2 screws).

3. Remove the top cover [D] (2 screws).

G048R810.WMF

[C]

Adjustment

Replacement

6-1

Page 39

PAPER EXIT UNIT 30 June 2000

6.2 PAPER EXIT UNIT

6.2.1 UPPER COVER

[A]

[B]

G048R829.WMF

1. Open the paper exit unit [A].

2. Remove upper cover [B] (2 screws)

6.2.2 LOWER COVER

[B]

[A]

G048R830.WMF

1. Remove the upper cover. (Refer to section 6.2.1.)

2. Open the vertical transport unit.

3. Remove the paper exit tray [A] (2 screws).

4. Remove the lower cover [B] (2 screws).

6-2

Page 40

30 June 2000 PAPER EXIT UNIT

6.2.3 PAPER EXIT UNIT

[A]

[B]

[D]

[C]

G048R824.WMF

1. Remove the top cover. (Refer to section 6.1.1.)

2. Remove the stopper plate [A] (1 screw).

NOTE: Removing the stopper plate will allow this unit to tip fully back, so be

careful.

3. Remove the lower cover. (Refer to section 6.2.2.)

4. Remove clips [B], springs [C] and the unit [D].

Adjustment

Replacement

6-3

Page 41

PAPER EXIT UNIT 30 June 2000

6.2.4 JUNCTION GATE SOLENOID

[A]

[C]

G048R827.WMF

[E]

G048R825.WMF

1. Remove the fusing unit. (Refer to section 6.5.1.)

2. Remove the paper exit unit. (Refer to section 6.2.3.)

[D]

[B]

G048R840.WMF

3. Remove the guide plate [A] (4 screws).

4. Remove the clip [B] and the locking bar [C] while releasing the spring [D].

5. Remove the solenoid [E] together with the bracket.

6. Remove the solenoid from the bracket.

NOTE: Be sure to note the locations of the screws securing the solenoid to the

bracket.

6-4

Page 42

30 June 2000 VERTICAL TRANSPORT UNIT

6.3 VERTICAL TRANSPORT UNIT

6.3.1 VERTICAL TRANSPORT UNIT COVER

[A]

[B]

G048R802.WMF

1. Open the vertical unit cover [A].

2. Remove a screw [B] at the joint arm and then remove the cover.

6.3.2 UPPER, LEFT AND RIGHT SIDE COVER

[A]

[C]

[B]

Adjustment

Replacement

G048R803.WMF

1. Open the vertical transport unit (2 screws).

2. Remove the upper cover [A] (3 screws).

3. If present, open the vertical transport unit cover.

4. Remove the left side cover [B] (2 screws) and right side cover [C] (2 screws).

6-5

Page 43

VERTICAL TRANSPORT UNIT 30 June 2000

6.3.3 VERTICAL UNIT SENSORS

[B]

[A]

G048R801.WMF

1. Open the vertical transport unit

2. Remove the brackets [A] (1 screw each).

3. Remove the cables from the connectors, then remove the sensor [B].

6.3.4 VERTICAL TRANSPORT MOTOR

[A]

G048R804.WMF

1. Remove the vertical transport cover. (Refer to section 6.3.1.)

2. Remove the upper and left side cover. (Refer to section 6.3.2.)

3. Remove the motor [A] (2 screws and 1 connector).

6-6

Page 44

30 June 2000 VERTICAL TRANSPORT UNIT

6.3.5 VERTICAL TRANSPORT UNIT

[C]

[B]

[A]

G048R823.WMF

1. Remove the vertical transport cover. (Refer to section 6.3.1.)

2. Remove the upper, left side, right side covers. (Refer to section 6.3.2.)

3. Remove connectors.

4. Remove the brackets on the left [A] and right side [B] (1 screw each).

NOTE: The brackets on the left and right side differ from each other. The left

side bracket has a longer pin than the other.

5. Remove the clip [C] at the joint.

NOTE: Be sure that the harness for the vertical transport motor is removed

beforehand so the harness is not damaged.

Adjustment

Replacement

6-7

Page 45

DUPLEX UNIT 30 June 2000

6.4 DUPLEX UNIT

6.4.1 DUPLEX TRAY

[B]

[A]

G048R828.WMF

1. Pull the tray [A] out about halfway.

2. Loosen the screw that holds the stopper plate [B].

3. Move the stopper plate up and pull out the tray.

6-8

Page 46

30 June 2000 DUPLEX UNIT

6.4.2 REVERSE ROLLER

[C]

[A]

G048R811.WMF

[F]

G048R819.WMF

[G]

[B]

[D]

[E]

G048R813.WMF

Adjustment

Replacement

1. Pull the duplex tray out. (Refer to section 6.4.1.)

2. Remove the left [A] and right side covers [B] (4 screws each).

3. Open the upper and lower guide plate [C].

4. Remove the upper reverse plate [D] (2 clips).

5. Remove the lower reverse plate [E] (2 screws).

NOTE: Be sure not to damage the Myler sheet on the lower plate while

removing the plate.

6. Remove the reverse roller gears [F] and roller [G] (4 clips and 4 bushings).

6-9

Page 47

DUPLEX UNIT 30 June 2000

6.4.3 DUPLEX FEED MOTOR/REVERSE MOTOR

[A]

[B]

G048R815.WMF

1. Remove the duplex tray. (Refer to section 6.4.1.)

2. Remove the left and right side covers. (Refer to section 6.4.2.)

3. Remove the duplex feed motor [A] and duplex reverse motor [B] together with

the brackets (3 screws).

4. Remove motors from brackets (2 screws and 1 connector each).

6.4.4 DUPLEX FEED SENSOR

[A]

[B]

G048R817.WMF

1. Remove the duplex tray. (Refer to section 6.4.1.)

2. Remove the left and right side covers. (Refer to section 6.4.2.)

3. Remove the center plate [A] (2 screws).

4. Remove the duplex feed sensor [B] (1 connector).

NOTE: Be sure not to damage the Myler sheet while removing the plate and

sensor.

6-10

Page 48

30 June 2000 DUPLEX UNIT

6.4.5 JOGER HOME POSITION SENSOR

[B]

[C]

[E]

[A]

[F]

[D]

G048R812.WMF

1. Remove the duplex tray. (Refer to section 6.4.1.)

2. Remove the left and right side covers. (Refer to section 6.4.2.)

3. Remove the center plate and duplex feed sensor connector [A]. (Refer to

section 6.4.4.)

4. Remove the feed [B] and reverse motor [C] connectors.

5. Open the upper and lower guide plates and slide the jogger fences [D] to the

inside.

6. Remove the upper unit [E] (8 screws).

7. Remove the jogger H.P. sensor [F] (1 connector).

Adjustment

Replacement

6-11

Page 49

DUPLEX UNIT 30 June 2000

6.4.6 JOGGER MOTOR/REVERSE SOLENOID

[A]

[B]

G048R814.WMF

[C]

G048R816.WMF

1. Remove the duplex tray. (Refer to section 6.4.1.)

2. Reverse the tray and remove the bottom cover [A] (6 screws).

3. Remove the jogger motor [B] together with bracket (3 screws).

4. Remove the motor from the bracket (2 screws and 1 connector).

5. Remove the reverse solenoid [C] (3 screws, 1 connector and 1 spring).

6-12

Page 50

30 June 2000 DUPLEX UNIT

6.4.7 REVERSE SENSOR

[A]

G048R818.WMF

1. Remove the duplex tray. (Refer to section 6.4.1.)

2. Remove the bottom cover. (Refer to section 6.4.6.)

3. Remove the reverse sensor [A] together with bracket (1 screw).

4. Remove the sensor from the bracket (1 screw and 1 connector).

6.4.8 TEMPERATURE/HUMIDITY SENSOR

[A]

Adjustment

Replacement

G048R808.WMF

1. Open the vertical transport unit.

2. Remove the temperature/humidity sensor [A] (1 screw and 1 connector).

6-13

Page 51

DUPLEX UNIT 30 June 2000

6.4.9 RELAY MOTOR/RELAY ROLLER

[C]

[E]

G048R836.WMF

[F]

[D]

[A]

[B]

G048R835.WMF

[G]

[J]

[H]

G048R834.WMF

[I]

G048R839.WMF

1. Remove the left and right side mainframe covers.

2. Remove the vertical transport unit. (Refer to section 6.3.5.)

3. Remove the connector [A] and the grounding plate [B].

4. Remove the 4 screws [C] that join the mainframe and the duplex unit, then

separate them.

5. Remove the duplex tray. (Refer to section 6.4.1.)

6. Remove the temperature/humidity sensor. (Refer to section 6.4.8.)

7. Reverse the duplex unit and remove the unit frame [D] (8 screws).

8. Remove the gear [E] and motor bracket [F] (1 screw).

9. Remove the relay motor [G] (2 screws).

10. Remove the grounding plate [H] (1 screw).

11. Remove the relay roller drive gear [I] (1 clip)

12. Remove the relay roller [J] (2 clips and 2 bushings).

6-14

Page 52

30 June 2000 FUSING SECTION

6.5 FUSING SECTION

6.5.1 FUSING UNIT

CAUTION

1. The fusing unit is hot. Handle it with care.

2. Be careful not to spill silicone oil.

3. In the event of a fusing-related SC, replace the applicable components

and execute “6: Reset SC” from the engine SP menu to remove the SC.

4. When the fusing unit has been replaced, execute “S3 Maintenance

Clear” from the controller SP menu to reset the fusing counter.

[C]

[A]

[E]

[B]

G048R831.WMF

1. Remove the top cover of mainframe. (Refer to section 6.1.1.)

2. Open the front cover and paper exit unit.

3. Open the oil bottle cover [A] and remove the bottle [B].

4. Remove the harness cover [C] and all connectors.

[D]

G048R832.WMF

Adjustment

Replacement

5. Remove the grounding wire [D] (1 screw).

6. Remove the fusing unit [E] (3 dial screws).

6-15

Page 53

LASER SECTION 30 June 2000

6.6 LASER SECTION

WARNING

Turn off the main switch and unplug the machine before attempting any of

the procedures in this section. Laser beams can seriously damage your

eyes.

6.6.1 CAUTION DECAL LOCATIONS

Two caution decals are located in the laser section as shown below.

LASER_PS2.WMF

G048R504A.WMF

LASER_PS1.WMF

6-16

Page 54

30 June 2000 LASER SECTION

6.6.2 OPTICAL HAUSING UNIT

[A]

G048R827.WMF

[C]

[D]

G048R826.WMF

The procedure for removing the screws on the front side is the same as the base

model (G024). The following section explains how to remove the screws on the

back side.

1. Remove the top cover. (Refer to section 6.1.1.)

2. Remove the paper exit unit. (Refer to section 6.2.3.)

[B]

Adjustment

Replacement

3. Remove the guide plate [A] (4 screws).

4. Remove the clip [B] and the locking bar [C] with releasing the spring.

5. Remove the duct [D] (1 screw).

6. Remove 2 screws fixing the unit at backside.

6-17

Page 55

ELECTRICAL COMPONENTS 30 June 2000

6.7 ELECTRICAL COMPONENTS

6.7.1 CONTROLLER BOARD

NOTE: Before replacing the controller, print the list of settings whenever possible.

In the event of NV-RAM damage, it is necessary to configure all settings

according to this list.

[A]

G048R805.WMF

[C]

[D]

[B]

G048R806.WMF

1. Remove the top, left and right side covers.

2. Remove the vertical transport unit. (Refer to section 6.3.5.)

3. Remove the controller board cover [A] (14 screws).

4. Remove the RPS module [B] and RAM module [C].

5. Remove the controller board [D] (6 screws and 1 connector).

NOTE: 1) If the customer has added optional expansion memory or a NIC, remove

it before replacing the controller. Remember to install the memory or

NIC on the new controller board.

2) To replace the controller boards, remove the NVRAM chip (IC23) on the

old board, install it on the new board, then install the new board. The

NVRAM chip stores user settings and service records. These settings

will be lost if the NVRAM chip is not transferred.

6-18

Page 56

30 June 2000 ELECTRICAL COMPONENTS

6.7.2 DUPLEX DC SUPPLY UNIT

WARNING

To avoid an electric shock, unplug the power cable before replacing the

power supply unit.

[A]

[B]

G048R807.WMF

1. Remove the controller board cover. (Refer to section 6.7.1.)

2. Remove the duplex dc supply unit [A] together with the bracket [B] (2 screws

and 2 connectors).

3. Remove the dc supply unit from the bracket (4 screws).

Adjustment

Replacement

6-19

Page 57

ELECTRICAL COMPONENTS 30 June 2000

6.7.3 POWER SUPPLY UNIT

WARNING

To avoid an electric shock, unplug the power cable before replacing the

power supply unit.

[A]

[B]

G048R820.WMF

1. Remove the controller board. (Refer to section 6.7.1.)

2. Remove the duplex dc supply unit. (Refer to section 6.7.2.)

3. Remove the stay for the paper exit tray [A] (2 screws).

[C]

G048R821.WMF

4. Remove the 6 screws holding the electrical wiring box [B], unplug 4 connectors,

and release 2 hooks. Lift the left side of the electrical wiring box [B] upwards

➀

to swing it out ➁.

5. Remove the power supply unit [C] (6 screws, 6 connectors and 2 hooks).

6-20

Page 58

30 June 2000 ELECTRICAL COMPONENTS

6.7.4 HIGH VOLTAGE SUPPLY UNIT

[A]

[B]

G048R255.WMF

1. Swing the electrical wiring box [A] out. (Refer to section 6.7.3.)

2. Remove the high voltage supply unit [B] (4 screws, 8 connectors and 2 hooks).

WARNING

Carefully connect the high-voltage wires as shown in the diagram below.

Blue connector:

Supply roller

CN190

White connector:

Belt transfer bias roller

White connector:

Development roller

Yellow connector:

Charge corona unit wire

White connector:

Transfer roller

Adjustment

Replacement

Yellow connector:

Development blade

Blue connector:

Charge corona unit grid

G048R512.WMF

6-21

Page 59

ELECTRICAL COMPONENTS 30 June 2000

6.7.5 MCU

[A]

G048R822.WMF

1. Swing the electrical wiring box out. (Refer to section 6.7.3.)

2. Remove the MCU [A] (2 screws and all connectors).

NOTE: When replacing an MCU, remove the NVRAM chip (IC106) from the old

board, install it on the new board, and then install the new board.

In the event of NVRAM damage, install a new NVRAM chip, and contact

your supervisor for additional steps. A forced process control will also be

necessary (Engine SP mode 7: Process Control – Initialize).

6.7.6 DUPLEX DRIVE BOARD

[B]

[A]

G048R833.WMF

1. Remove the duplex backside cover [A] (4 screws).

2. Remove all connectors from the board.

3. Remove the duplex drive board [B] (6 screws, 1 ground wire).

6-22

Page 60

30 June 2000 SC TABLES

7. TROUBLESHOOTING

7.1 SC TABLES

7.1.1 TYPES OF SERVICE CALL

For this printer engine, service calls and process control errors are classified into

three types:

Service Call Type Results

TYPE 1:

Safety warning and immediate

shutdown (Fusing unit errors)

TYPE 2:

Immediate shutdown

TYPE 3:

Log only (Process control errors)

NOTE: In this section, additional or different codes from the base model (G024)

are marked with an asterisk

The printer stops immediately and the LCD displays

an SC error message. The error is logged.

The printer stops immediately and the LCD displays

an SC error message. The error is logged.

The printer does not stop. No SC error message is

displayed. The error is only logged.

.

“*”

Fusing Unit SC Errors

Fusing unit SC errors (Type 1 errors) can be released by executing the Reset SC

item in the engine SP mode menu. They cannot be released by turning the main

power switch off and on.

Trouble-

shooting

7-1

Page 61

SC TABLES 30 June 2000

7.1.2 SC ERROR LIST

NOTE: The errors marked with an asterisk “*” are additional or changed codes for

this model.

SC

No.

20

21

22

23

24

25

26

* 27

Type Name Occurre nce conditi ons Detection conditions Cause

Type 2 Optional tray

Type 1 Pressure

Type 1 High

Type 1 Low

Type 1 Hot roller

Type 1 High hot

Type 1

Type 2

unit error

roller

thermistor

error

pressure

roller

temperature

pressure

roller

temperature

thermistor

error

roller

temperature

Low hot

roller

temperature

Zero-cross

cycle

detection

error

The detection signal for

the 500-sheet paper tray

unit is abnormal.

The roller temperature

has been at 0°C for five

seconds.

The roller temperature

has been at 190°C or

higher for three seconds.

Reheating has been done

and the motor is not

running, or 60 seconds

have passed after the

main motor halted. Then,

the roller temperature has

been below 130°C for 60

seconds

The roller temperature

has been 0°C for five

seconds.

The roller temperature

has been 190°C or higher

for three seconds.

Reheat has been done

and the motor is not

running, or 60 seconds

have passed after main

motor halt. Then, the

roller temperature has

been below 130°C for 60

seconds

50 Hz AC

The number of zero-cross

is detected less than 89

times or more than 111

times in one second for

continuous 5 seconds.

60 Hz AC

The number of zero-cross

is detected less than 109

times or more than 131

times in one second for

continuous 5 seconds.

Always monitored The optional tray

unit connector has a

bad connection.

No detection in the

event of a jam/door

open, SC, unit

absence, energysaving mode, or lack

of fusing unit

No detection in the

event of SC or lack of

fusing unit

No detection in the

event of a jam/door

open, SC, unit

absence, energysaving mode, or lack

of fusing unit

No detection in the

event of a jam/door

open, SC, unit

absence, energysaving mode, or lack

of fusing unit

No detection in the

event of SC or fusing

unit absence

No detection in the

event of a jam/door

open, SC, unit

absence, energysaving mode, or

fusing unit absence

No detection in the

event of a jam/door

open, SC, unit

absence, energysaving mode, or

fusing unit absence

Pressure roller

thermistor, MCU

Pressure roller

thermistor, MCU

Pressure roller

thermistor, MCU,

pressure roller lamp

connector

Hot roller thermistor,

MCU

Hot roller thermistor,

MCU

Hot roller thermistor,

MCU, hot roller

lamp connector

Frequency of the

commercial AC

power

7-2

Page 62

30 June 2000 SC TABLES

SC

No.

28

29

31

32

33

34

35

36

Type Name Occurre nce conditi ons Detection conditions Cause

Type 2

Type 2 Primary

Type 2 Supply bias

Type 2

Type 2 Charge

Type 2 Charge

Type 2 Main motor

Type 2 PCU motor

Paper

transfer

positive bias

release error

transfer bias

open

error

Blade bias

error

corona unit

bias open

corona unit

grid bias

error

error

error

The PWM duty has been

50% or higher for 240

ms. Or, the paper transfer

roller clutch does not

operate.

The PWM duty has been

50% or higher for 240

ms.

The voltage has been

higher than the

appropriate control

voltage for the target

voltage for 240 ms.

However, detection is

disabled when the

calculated control voltage

is 5 V or higher.

The voltage has been

higher than the

appropriate control

voltage for the target

voltage for 240 ms.

However, detection is

disabled when the

calculated control voltage

is 5 V or higher.

The PWM duty has been

50% or higher for 240

ms.

The voltage has been

higher than the

appropriate control

voltage for the target

voltage for 240 ms.

However, detection is

disabled when the

calculated control voltage

is 5 V or higher.

Continuous unlock for

two seconds

Continuous unlock for

two seconds

Detection starts 60

ms after control starts

for this component.

Detection starts 60

ms after control starts

for this component.

Detection starts 60

ms after control starts

for this component.

Detection starts 60

ms after control starts

for this component.

Detection starts 60

ms after control starts

for this component.

Detection starts 60

ms after control starts

for this component.

There is a

disconnection in the

paper transfer bias

supply circuit.

(Deformation of

terminals or springs,

dirty bearings)

When the

contact/separation

lever is normal: Bad

transfer roller

position sensor,

harness, or MCU

When the

contact/separation

lever is faulty: Bad

transfer roller clutch

or MCU

There is a

disconnection in the

primary transfer bias

supply circuit. (Dirty

or deformed

electrodes)

There is a short

circuit in the supply

bias supply circuit

(due to deformed

terminals or

electrodes or

conductive foreign

matter)

There is a short

circuit in the blade

bias supply circuit.

There is

disconnection in the

charge corona unit

bias supply circuit.

(Dirty or deformed

electrodes)

There is a short

circuit in the charge

corona unit grid bias

supply circuit (due

to deformed

terminals or

electrodes or

conductive foreign

matters).

Main motor, MCU

PCU motor, MCU

Trouble-

shooting

7-3

Page 63

SC TABLES 30 June 2000

SC

No.

38

39

40

41

42

43

45

46

47

48

49

Type Name Occurre nce conditi ons Detection conditions Cause

Type 2

Type 2

Type 2

Type 2 Transfer belt

Type 2

Type 2

Type 2 Charge bias

Type 2 Paper

Type 2

Type 2

Type 1 Pressure

Revolver

motor error

Polygon

mirror motor

error

ID sensor

error

H.P. sensor

error

Laser diode

error

Synchronizat

ion detection

error

short

transfer

positive

current error

Paper

transfer

negative bias

open

Paper

transfer

negative

current error

roller reheat

timeout

Movement to the home

position took four or more

seconds. For black,

movement to the home

position took one second

or longer.

Continuous unlock for

two seconds

The ID sensor output

voltage is not between

0.1 V and 1.1 V while the

ID sensor LED is off.

No mark has been

detected for 500 ms

during PCU motor

operation.

LD error (abnormal laser

power output)

Synchronization detection

error of the optical unit

A/D converted voltage

has been 4.8 V or more

for 240 ms.

A/D converted voltage

has been 0.2 V or less for

240 ms.

The PWM duty has been

50% or greater for 240

ms.

A/D converted voltage

has been 4.8 V or more

for 240 ms.

When reheating, the

roller temperature does

not reach the reheat start

temperature (target

temperature –20°C)

within five minutes.

Revolver motor,

MCU, or incorrect

installation of color

development unit

Polygon mirror

motor, MCU

ID sensor calibration ID sensor

Transfer belt H.P.

sensor, MCU

LD, LD control

board

During polygon mirror

motor revolution

Detection starts 60

ms after control starts

for this component.

Detection starts 60

ms after control starts

for this component.

Detection starts 60

ms after control starts

for this component.

Detection starts 60

ms after control starts

for this component.

During re-heating Pressure roller

Synchronization

detection board, LD

control board

There is a short

circuit in the charge

bias supply circuit

(due to deformed

terminals or

electrodes or

conductive foreign

matter)

There is a short

circuit in the paper

transfer bias supply

circuit (due to

deformed terminals

or electrodes or

conductive foreign

matter)

There is

disconnection in the

paper transfer bias

supply circuit. (Dirty

or deformed

electrodes)

There is a short

circuit in the paper

transfer bias supply

circuit (due to

deformed terminals

or electrodes or

conductive foreign

matter)

thermistor, pressure

roller lamp

connector, MCU

7-4

Page 64

30 June 2000 SC TABLES

SC

No.

50

51

52

57

59

60

*61

*62

*63

Type Name Occurre nce conditi ons Detection conditions Cause

Type 1

Type 1 Pressure

Type 1 Hot roller

Type 2 Print

Type 2

Type 2 Humidity

Type 2 Paper

Type 2 Auto-Duplex

Type 2 Jogger

Hot roller

reheat

timeout

roller lamp

full-power

operation

error

lamp fullpower

operation

error

command

error

Temperature

sensor error

sensor error

Transfer

roller error

unit detection

error.

movement

error

When reheating, the

roller temperature does

not reach the reheat start

temperature (target

temperature –10°C)

within five minutes.

When full-power

operation occurs during

reheating, the main motor

is not running and the

difference between the

current temperature and

that of 60 seconds ago is

18°C or less.

When full-power

operation occurs during

reheating, the main motor

is not running and the

difference between the

current temperature and

that of 60 seconds ago is

18°C or less.

When an abnormal

combination of print

commands is received.

5 V (4.75 V) or more has

continuously been

detected for five seconds.

5 V (4.75 V) or more has

continuously been

detected for five seconds.

Paper transfer position

sensor does not detect

the movement of roller.

Auto-duplex unit is

detected on the manualduplex model.

Jogger home position

sensor does not turn on.

During reheating

No detection in the

event of a jam/door

open, SC, unit

absence, energysaving mode, or

fusing unit absence.

No detection in the

event of a jam/door

open, SC, unit

absence, energysaving mode, or

fusing unit absence.

When the power is

on, or the AC