Page 1

Russian Printer

Aficio AP2700

SERVICE MANUAL

October 1st, 1999

Subject to change

Page 2

I

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

Page 3

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1.

Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in or der to dispos e of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

WARNING

ø

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING

ø

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can seriously damage

your eyes.

CAUTION MARKING:

Page 4

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft

Corporation in the United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines

Corporation.

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved

with those marks.

Page 5

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMAT ION........................................1-1

1.1 SPECIFICATIONS.................................................................................... 1-1

1.1.1 GENERAL SPECIFICATIONS......................................................... 1-1

1.1.2 SUPPORTED PAPER SIZES.......................................................... 1-3

1.2 SOFTWARE ACCESSORIES................................................................... 1-4

1.2.1 PRINTER DRIVERS........................................................................ 1-4

1.2.2 UTILITY SOFTWARE...................................................................... 1-4

1.2.3 SERVICE TOOLS............................................................................ 1-4

1.3 MACHINE CONFIGURATION.................................................................. 1-5

1.3.1 SYSTEM COMPONENTS ............................................................... 1-5

1.4 PAPER PATH........................................................................................... 1-7

1.5 MECHANICAL COMPONENT LAYOUT................................................... 1-8

1.6 ELECTRICAL COMPONENT DESCRIPTIONS........................................ 1-9

1.7 PRINTING PROCESS............................................................................ 1-11

1.8 BOARD STRUCTURE............................................................................ 1-13

1.8.1 OVERVIEW ................................................................................... 1-13

1.8.2 DESCRIPTIONS............................................................................ 1-14

2. DETAILED SECTION DESCRIPTIONS.......................................2-1

2.1 LASER EXPOSURE................................................................................. 2-1

2.1.1 OVERVIEW ..................................................................................... 2-1

2.1.2 AUTO POWER CONTROL (APC)................................................... 2-2

2.1.3 LD SAFETY SWITCH...................................................................... 2-3

2.2 PHOTOCONDUCTOR UNIT (PCU).......................................................... 2-4

2.2.1 OVERVIEW ..................................................................................... 2-4

2.2.2 DRIVE MECHANISM....................................................................... 2-5

2.2.3 NEW PCU DETECTION MECHANINSM......................................... 2-6

2.3 DRUM CHARGE....................................................................................... 2-7

2.3.1 OVERVIEW ..................................................................................... 2-7

2.3.2 CHARGE ROLLER VOLTAGE CORRECTION............................... 2-8

2.3.3 ID SENSOR PATTERN PRODUCTION TIMING............................. 2-9

2.3.4 DRUM CHARGE ROLLER CLEANING......................................... 2-10

2.4 DEVELOPMENT..................................................................................... 2-11

2.4.1 OVERVIEW ................................................................................... 2-11

2.4.2 DRIVE MECHANISM..................................................................... 2-12

2.4.3 DEVELOPER MIXING................................................................... 2-13

2.4.4 DEVELOPMENT BIAS................................................................... 2-14

2.4.5 TONER SUPPLY........................................................................... 2-15

2.4.6 TONER DENSITY CONTROL....................................................... 2-17

2.4.7 TONER NEAR END/END DETECTION AND RECOVERY........... 2-21

2.5 DRUM CLEANING AND TONER RECYCLING...................................... 2-22

2.5.1 DRUM CLEANING......................................................................... 2-22

2.5.2 TONER RECYCLING .................................................................... 2-23

i

Page 6

2.6 PAPER FEED.........................................................................................2-24

2.6.1 OVERVIEW ................................................................................... 2-24

2.6.2 PAPER FEED DRIVE MECHANISM ............................................. 2-25

2.6.3 PAPER FEED AND SEPARATION MECHANISM......................... 2-26

2.6.4 PAPER LIFT MECHANISM............................................................ 2-27

2.6.5 PAPER END DETECTION............................................................. 2-28

2.6.6 PAPER HEIGHT DETECTION....................................................... 2-29

2.6.7 PAPER SIZE DETECTION............................................................ 2-30

2.6.8 SPECIAL PAPER SETTING.......................................................... 2-31

2.6.9 SIDE AND END FENCES.............................................................. 2-32

2.6.10 PAPER REGISTRATION............................................................. 2-33

2.7 IMAGE TRANSFER AND PAPER SEPARATION.................................. 2-34

2.7.1 OVERVIEW ................................................................................... 2-34

2.7.2 IMAGE TRANSFER MECHANISM................................................ 2-35

2.7.3 TRANSFER ROLLER CLEANING................................................. 2-36

2.7.4 PAPER SEPARATION MECHANISM............................................ 2-36

2.8 IMAGE FUSING AND PAPER EXIT....................................................... 2-37

2.8.1 OVERVIEW ................................................................................... 2-37

2.8.2 FUSING DRIVE AND RELEASE MECHANISM............................. 2-38

2.8.3 FUSING ENTRANCE GUIDE SHIFT MECHANISM...................... 2-39

2.8.4 PRESSURE ROLLER.................................................................... 2-40

2.8.5 CLEANING MECHANISM.............................................................. 2-40

2.8.6 NEW FUSING UNIT DETECTION................................................. 2-41

2.8.7 FUSING TEMPERATURE CONTROL........................................... 2-42

2.8.8 OVERHEAT PROTECTION........................................................... 2-44

2.8.9 PAPER EXIT.................................................................................. 2-44

2.9 ENERGY SAVER MODES..................................................................... 2-45

2.10 CONTROLLER FUNCTIONS ............................................................... 2-46

2.10.1 PAPER SIZE/TYPE DETECTION AND SELECTION.................. 2-46

2.10.2 PAPER SOURCE SELECTION................................................... 2-46

2.10.3 OUTPUT TRAY SELECTION ......................................................2-48

2.10.4 COLLATION (SORT)................................................................... 2-49

2.10.5 DUPLEX PRINTING .................................................................... 2-50

2.10.6 STAPLING................................................................................... 2-50

2.10.7 PROOF PRINT ............................................................................ 2-51

2.10.8 RESET OPERATIONS ................................................................2-52

2.10.9 HDD (OPTIONAL)........................................................................ 2-52

3. INSTALLA T ION...........................................................................3-1

3.1 INSTALLING THE MACHINE................................................................... 3-1

3.2 INSTALLING OPTIONAL UNITS.............................................................. 3-2

3.2.1 BRIDGE UNIT.................................................................................. 3-2

3.2.2 1,000-SHEET FINISHER................................................................. 3-4

3.2.3 HARD DISK (HDD).......................................................................... 3-6

ii

Page 7

4. SERVICE TABLES......................................................................4-1

4.1 GENERAL CAUTION................................................................................ 4-1

4.1.1 PCU................................................................................................. 4-1

4.1.2 TRANSFER ROLLER UNIT............................................................. 4-1

4.1.3 LASER UNIT.................................................................................... 4-1

4.1.4 FUSING UNIT.................................................................................. 4-2

4.1.5 PAPER FEED.................................................................................. 4-2

4.1.6 OTHERS.......................................................................................... 4-2

4.2 SERVICE PROGRAM MODE................................................................... 4-3

4.2.1 ENABLING AND DISABLING SERVICE PROGRAM MODE.......... 4-3

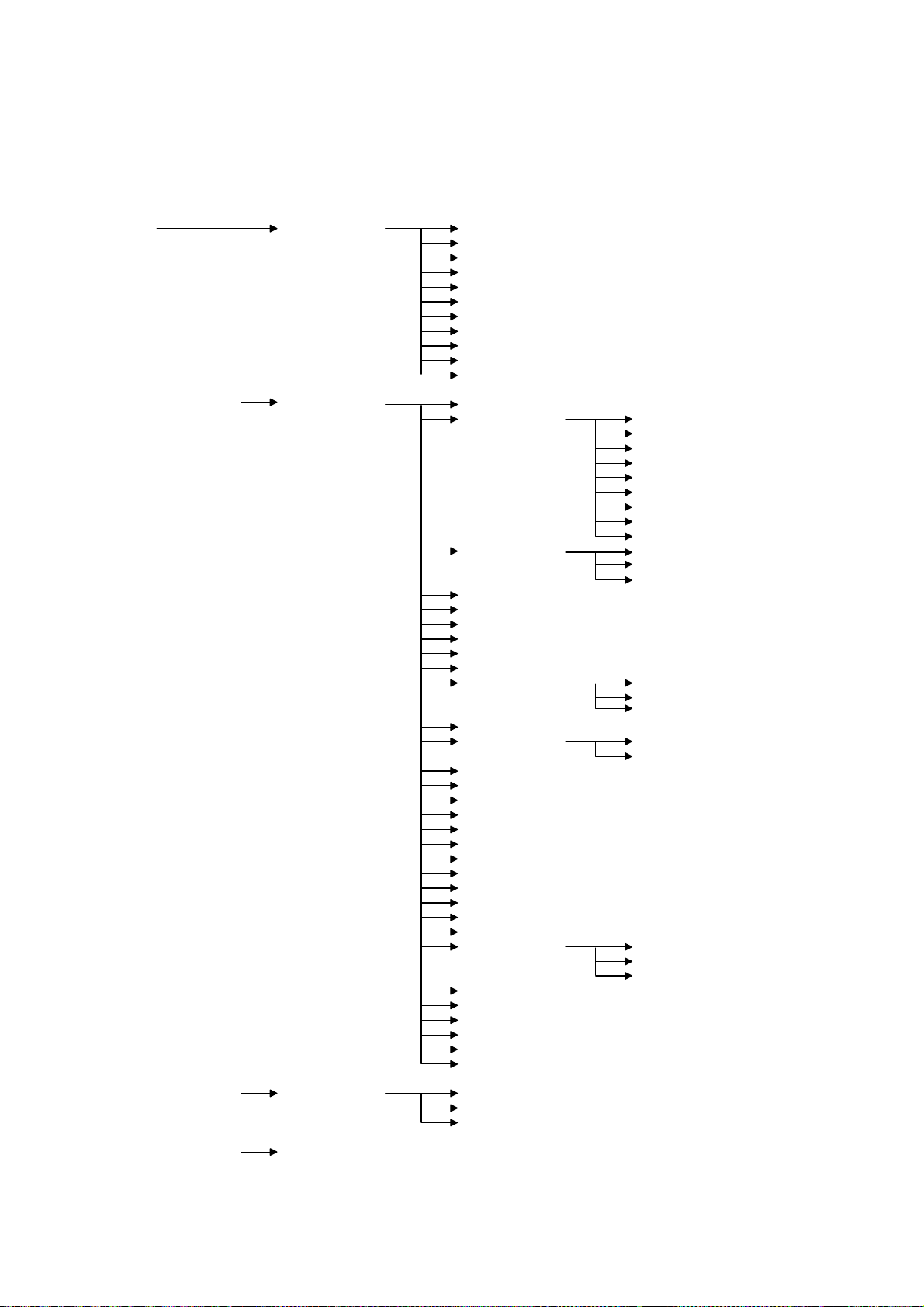

4.2.2 SERVICE PROGRAM MODE MENU TREE.................................... 4-4

4.3 PRINTER CONTROLLER SERVICE MODE............................................ 4-5

4.3.1 BIT SWITCH PROGRAMMING ....................................................... 4-5

4.3.2 NVRAM RESET............................................................................... 4-6

4.3.3 POWER-ON DIAGNOSTICS ERROR DISPLAY............................. 4-7

4.3.4 VENDER MAKER............................................................................ 4-7

4.3.5 SERVICE SUMMARY...................................................................... 4-7

4.4 PRINTER ENGINE SERVICE MODE....................................................... 4-9

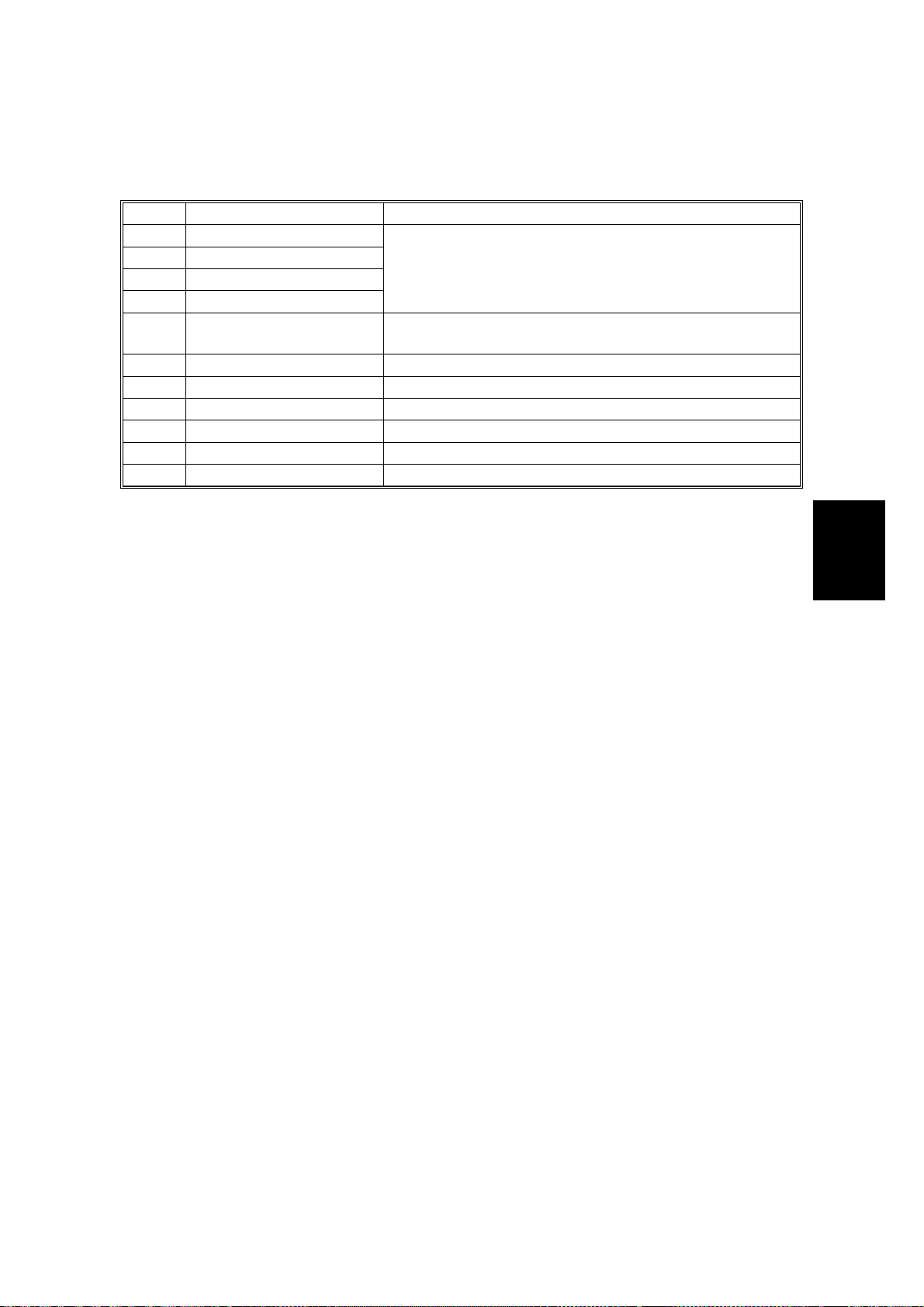

4.4.1 SERVICE MODE MENU.................................................................. 4-9

4.4.2 SERVICE MODE TABLES............................................................. 4-10

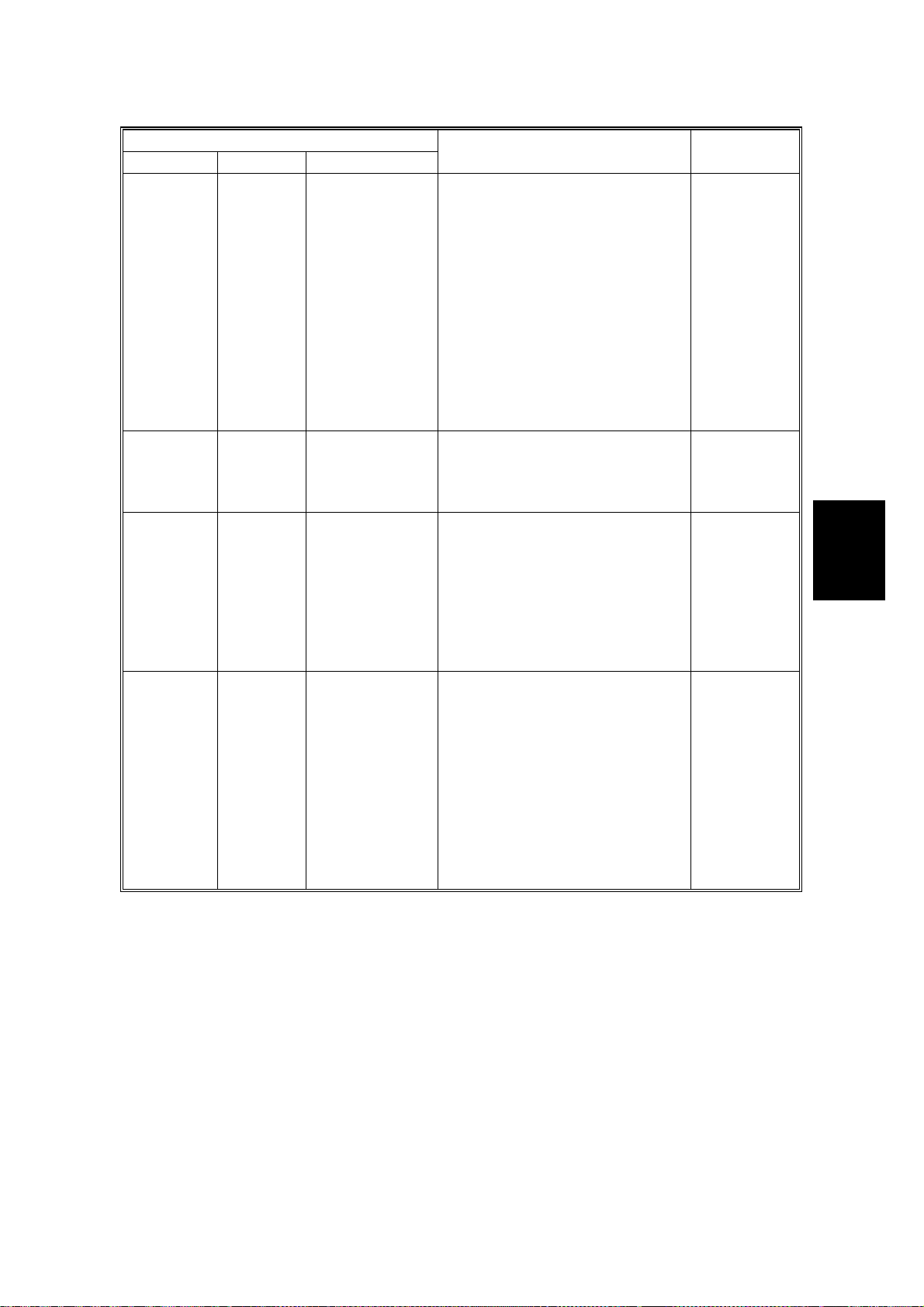

4.4.3 INPUT CHECK TABLE.................................................................. 4-16

4.4.4 OUTPUT CHECK TABLE.............................................................. 4-20

4.4.5 ENGINE BOARD PROGRAM DOWNLOAD.................................. 4-22

4.5 SERVICE TOOLS................................................................................... 4-23

4.5.1 SERVICE TOOL MENU................................................................. 4-23

4.5.2 HDD TEST..................................................................................... 4-23

4.5.3 HDD FORMAT...............................................................................4-24

4.5.4 NIB NVRAM BACKUP AND RESTORE ........................................ 4-24

4.6 CONTROLLER FIRMWARE UPDATE................................................... 4-26

4.6.1 FIRMWARE DOWNLOAD............................................................. 4-26

4.6.2 ERROR RECOVERY..................................................................... 4-27

4.7 POWER-ON SELF TEST........................................................................ 4-28

4.7.1 PARALLEL LOOP-BACK TEST..................................................... 4-28

4.7.2 OTHER TESTS.............................................................................. 4-28

5. PREVENTIVE MAINTENANCE...................................................5-1

5.1 USER MAINTENANCE............................................................................. 5-1

5.2 SERVICE MAINTENANCE....................................................................... 5-2

5.2.1 PM TABLE....................................................................................... 5-2

6. REPLACEMENT AND ADJUSTMENT........................................ 6-1

6.1 LASER UNIT............................................................................................. 6-1

6.1.1 CAUTION DECAL LOCATIONS...................................................... 6-1

6.1.2 LASER UNIT.................................................................................... 6-2

6.1.3 POLYGONAL MIRROR MOTOR..................................................... 6-4

6.1.4 LASER DIODE (LD) UNIT ............................................................... 6-4

6.1.5 LASER SYNCHRONIZATION DETECTOR..................................... 6-5

iii

Page 8

6.2 PHOTOCONDUCTOR UNIT (PCU)..........................................................6-6

6.2.1 PCU.................................................................................................6-6

6.3 TRANSFER UNIT.....................................................................................6-7

6.3.1 TRANSFER ROLLER UNIT.............................................................6-7

6.4 ID SENSOR..............................................................................................6-8

6.5 PAPER EXIT........................................................................................6-9

6.5.1 PAPER EXIT AND OVERFLOW SENSORS...................................6-9

6.6 PAPER FEED AND REGISTRATION.....................................................6-10

6.6.1 PAPER LIFT MOTORS..................................................................6-10

6.6.2 REGISTRATION CLUTCH.............................................................6-11

6.6.3 PAPER FEED CLUTCHES............................................................6-11

6.6.4 UPPER PAPER TRANSPORT CLUTCH.......................................6-12

6.6.5 LOWER PAPER TRANSPORT CLUTCH......................................6-12

6.6.6 REGISTRATION SENSOR............................................................6-13

6.6.7 UPPER RELAY SENSOR..............................................................6-14

6.6.8 LOWER RELAY SENSOR.............................................................6-15

6.6.9 UPPER PAPER SIZE SENSOR....................................................6-16

6.6.10 LOWER PAPER SIZE SENSOR/SPECIAL PAPER SENSOR....6-17

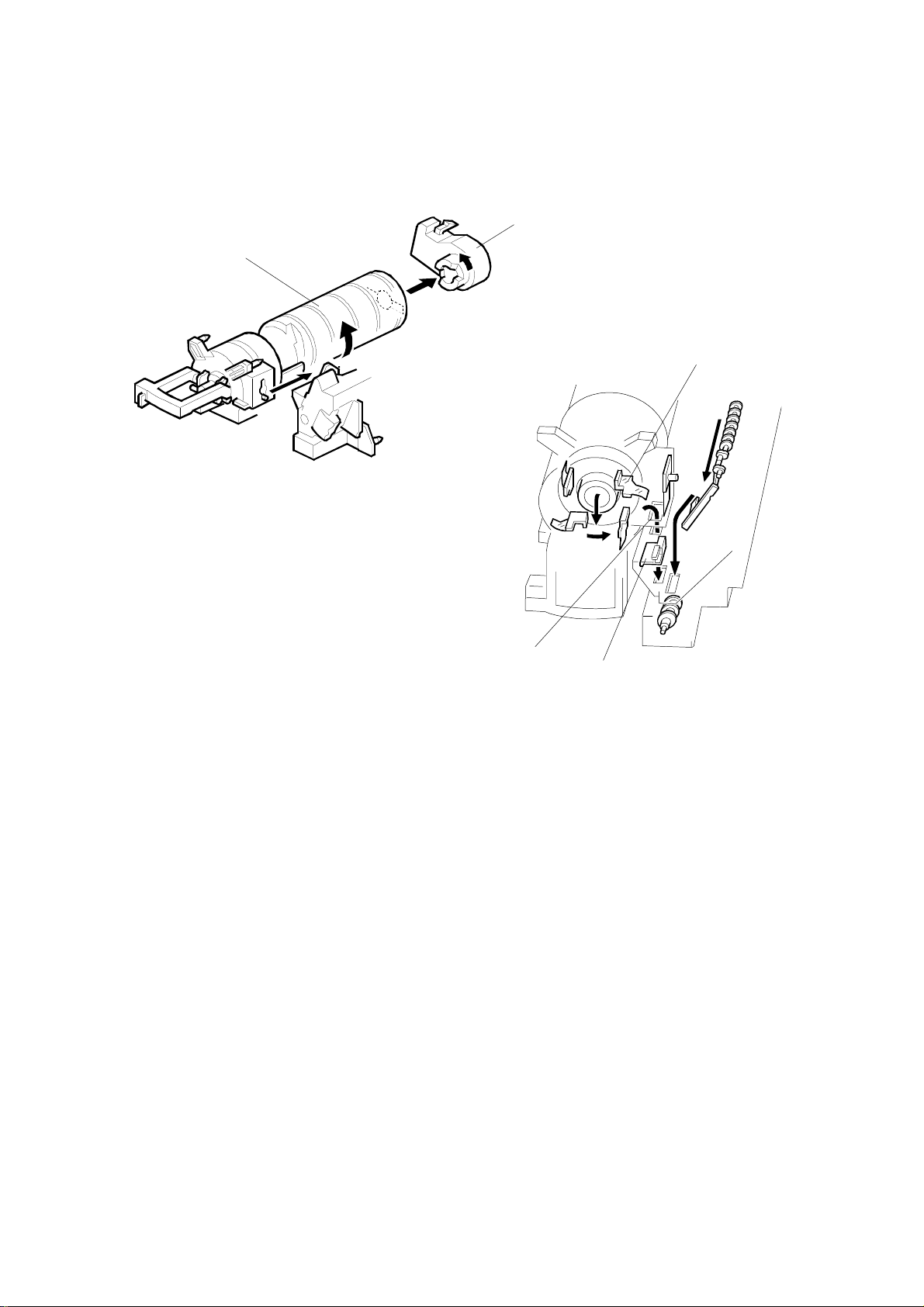

6.6.11 FEED ROLLERS..........................................................................6-18

6.6.12 PAPER END SENSOR (1ST AND 2ND PAPER FEED TRAYS).6-19

6.7 FUSING..................................................................................................6-20

6.7.1 FUSING UNIT................................................................................6-20

6.7.2 THERMISTOR...............................................................................6-20

6.7.3 THERMOFUSE..............................................................................6-21

6.7.4 HOT ROLLER AND FUSING LAMP..............................................6-22

6.7.5 PRESSURE ROLLER/CLEANING ROLLER.................................6-23

6.8 PCBS AND MOTORS.............................................................................6-24

6.8.1 PSU...............................................................................................6-24

6.8.2 ENGINE BOARD...........................................................................6-25

6.8.3 PRINTER CONTROLLER / NIB.....................................................6-26

6.8.4 HIGH VOLTAGE SUPPLY BOARD...............................................6-27

6.8.5 MAIN MOTOR................................................................................6-27

6.8.6 TONER BOTTLE MOTOR.............................................................6-28

7. TROUBLESHOOTING.................................................................7-1

7.1 SERVICE CALL CONDITIONS.................................................................7-1

7.1.1 PRINTER ENGINE SC CODES SUMMARY....................................7-1

7.1.2 PRINTER ENGINE SC CODES.......................................................7-2

7.2 PRINTER CONTROLLER ERROR.........................................................7-11

7.2.1 ERROR CODES............................................................................7-11

7.3 CONTROLLER LED DISPLAY...............................................................7-12

7.3.1 LOCATION.....................................................................................7-12

7.3.2 FATAL ERROR..............................................................................7-12

7.4 ELECTRICAL COMPONENT DEFECTS................................................7-15

7.4.1 SENSORS.....................................................................................7-15

7.4.2 SWITCHES....................................................................................7-17

7.5 BLOWN FUSE CONDITIONS.................................................................7-18

iv

Page 9

OPTIONS

PAPER TRAY UNIT (A860)

1. OVERALL MACHINE INFORMATION..................................A860-1

1.1 SPECIFICATIONS..............................................................................A860-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................A860-2

1.3 ELECTRICAL COMPONENT LAYOUT..............................................A860-3

1.4 ELECTRICAL COMPONENT DESCRIPTION....................................A860-4

1.5 DRIVE LAYOUT.................................................................................A860-5

2. DETAILED DESCRIPTIONS.................................................A860-6

2.1 PAPER FEED AND SEPARATION MECHANISM..............................A860-6

2.2 PAPER LIFT MECHANISM................................................................A860-7

2.3 PAPER END DETECTION.................................................................A860-9

2.4 PAPER HEIGHT DETECTION.........................................................A860-10

2.5 PAPER SIZE DETECTION...............................................................A860-12

2.6 SIDE AND END FENCES.................................................................A860-13

Side Fences.................................................................................A860-13

End Fence....................................................................................A860-13

3. REPLACEMENT AND ADJUSTMENT................................A860-14

3.1 FEED ROLLER REPLACEMENT.....................................................A860-14

3.2 TRAY MAIN BOARD REPLACEMENT.............................................A860-15

3.3 TRAY MOTOR REPLACEMENT......................................................A860-15

3.4 RELAY CLUTCH REPLACEMENT...................................................A860-16

3.5 UPPER PAPER FEED CLUTCH REPLACEMENT..........................A860-17

3.6 LOWER PAPER FEED CLUTCH REPLACEMENT..........................A860-18

3.7 LIFT MOTOR REPLACEMENT........................................................A860-19

3.8 PAPER END SENSOR REPLACEMENT.........................................A860-20

3.9 VERTICAL TRANSPORT SENSOR REPLACEMENT.....................A860-20

3.10 PAPER SIZE SWITCH REPLACEMENT........................................A860-21

PAPER TRAY UNIT (A861)

1. OVERALL MACHINE INFORMATION...........................................1

1.1 SPECIFICATIONS........................................................................................1

1.2 MECHANICAL COMPONENT LAYOUT.......................................................2

1.3 ELECTRICAL COMPONENT LAYOUT........................................................3

1.4 ELECTRICAL COMPONENT DESCRIPTION..............................................4

1.5 DRIVE LAYOUT...........................................................................................5

2. DETAILED DESCRIPTIONS..........................................................6

2.1 PAPER FEED AND SEPARATION..............................................................6

2.2 PAPER LIFT MECHANISM..........................................................................7

2.3 PAPER END DETECTION...........................................................................9

v

Page 10

2.4 PAPER HEIGHT DETECTION ...................................................................10

2.5 PAPER SIZE DETECTION.........................................................................12

2.6 SIDE AND END FENCES...........................................................................13

3. REPLACEMENT AND ADJUSTMENT......................................... 14

3.1 FEED ROLLER REPLACEMENT...............................................................14

3.2 TRAY MAIN BOARD REPLACEMENT....................................................... 15

3.3 TRAY MOTOR REPLACEMENT................................................................15

3.4 TRAY MOTOR REPLACEMENT................................................................16

3.5 LIFT MOTOR REPLACEMENT..................................................................17

3.6 PAPER END SENSOR REPLACEMENT...................................................18

3.7 PAPER SIZE SWITCH REPLACEMENT....................................................18

LCT (A862)

1. OVERALL MACH INE INFORMATION..................................A862-1

1.1 SPECIFICATIONS..............................................................................A862-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................A862-2

1.3 ELECTRICAL COMPONENT LAYOUT..............................................A862-3

1.4 ELECTRICAL COMPONENT DESCRIPTIONS..................................A862-4

2. DETAILED SECTION DESCRIPTIONS.................................A862-5

2.1 PAPER FEED.....................................................................................A862-5

2.2 REVERSE ROLLER AND PICK-UP ROLLER RELEASE...................A862-6

2.3 TRAY LIFT..........................................................................................A862-7

2.4 NEAR END/END DETECTION...........................................................A862-8

2.5 RIGHT TRAY SIDE FENCE................................................................A862-9

2.6 LEFT TRAY REAR FENCE................................................................A862-9

2.7 RIGHT TRAY PAPER END DETECTION.........................................A862-10

3. REPLACEMENT AND ADJUSTMENT ................................A862-11

3.1 DETACHING THE TRAY FROM THE MAINFRAME........................A862-11

3.2 REAR FENCE HP SENSOR.............................................................A862-11

3.3 CHANGING THE TRAY PAPER SIZE..............................................A862-12

3.4 LEFT TRAY PAPER END SENSOR.................................................A862-12

3.5 TRAY LIFT MOTOR..........................................................................A862-13

3.6 TRAY MOTOR..................................................................................A862-14

3.7 PAPER FEED CLUTCH AND RELAY CLUTCH...............................A862-15

3.8 PAPER FEED UNIT..........................................................................A862-16

3.9 UPPER LIMIT, RIGHT TRAY PAPER END, AND

RELAY SENSORS...........................................................................A862-17

3.10 REAR FENCE MOTOR..................................................................A862-18

3.11 PICK-UP/PAPER FEED/REVERSE ROLLERS..............................A862-19

vi

Page 11

BY-PASS UNIT (A899)

1 OVERALL MACHINE INFORMATION...................................A899-1

1.1 SPECIFICATIONS..............................................................................A899-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................A899-1

1.3 ELECTRICAL COMPONENT LAYOUT..............................................A899-2

1.4 ELECTRICAL COMPONENT DESCRIPTION....................................A899-2

2 DETAILED DESCRIPTIONS..................................................A899-3

2.1 BASIC OPERATION...........................................................................A899-3

2.2 PAPER SIZE DETECTION.................................................................A899-4

3 REPLACEMENT AND ADJUSTMENT...................................A899-5

3.1 PAPER FEED ROLLER/FRICTION PAD/PAPER END SENSOR......A899-5

3.2 PAPER SIZE SENSOR BOARD.........................................................A899-6

3.3 PAPER FEED CLUTCH......................................................................A899-7

INTERCHANGE UNIT (G531)

1. OVERALL MACH INE INFORMATION................................. G531-1

1.1 SPECIFICATIONS..............................................................................G531-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................G531-2

1.3 DRIVE LAYOUT .................................................................................G531-3

2. DETAILED DESCRIPTION................................................... G531-4

2.1 JUNCTION GATE MECHANISM........................................................G531-4

To the Exit Tray or Bridge Unit (for the Upper Tray on top of

the Bridge Unit, or the Finisher).....................................................G531-4

To the 1-bin Tray............................................................................G531-4

To the Duplex Unit .........................................................................G531-4

3. REPLACEMENT AND ADJUSTMENT................................. G531-5

3.1 EXIT SENSOR REPLACEMENT........................................................G531-5

DUPLEX (G529)

1. OVERALL MACH INE INFORMATION................................. G529-1

1.1 SPECIFICATIONS..............................................................................G529-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................G529-2

1.3 ELECTRICAL COMPONENT LAYOUT..............................................G529-3

1.4 ELECTRICAL COMPONENT DESCRIPTION....................................G529-4

1.5 DRIVE LAYOUT .................................................................................G529-5

vii

Page 12

2. DETAILED DESCRIPTIONS ................................................ G529-6

2.1 BASIC OPERATION...........................................................................G529-6

Larger than A4 lengthwise/LT Lengthwise.....................................G529-6

Up to A4 Lengthwise/LT lengthwise...............................................G529-7

2.2 FEED IN AND EXIT MECHANISM.....................................................G529-8

When Paper is Fed Into Duplex Unit:.............................................G529-8

Inversion and Exit:..........................................................................G529-8

3. REPLACEMENT A N D ADJUSTMENT................................. G529-9

3.1 COVER REMOVAL ............................................................................G529-9

3.2 ENTRANCE SENSOR REPLACEMENT..........................................G529-10

3.3 EXIT SENSOR REPLACEMENT......................................................G529-11

BRIDGE UNIT (A897)

1. OVERALL MACH INE INFORMATION..................................A897-1

1.1 SPECIFICATIONS..............................................................................A897-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................A897-2

1.3 ELECTRICAL COMPONENT LAYOUT..............................................A897-3

1.4 ELECTRICAL COMPONENT DESCRIPTION....................................A897-4

1.5 DRIVE LAYOUT .................................................................................A897-5

2. DETAILED DESCRIPTION....................................................A897-6

2.1 JUNCTION GATE MECHANISM........................................................A897-6

3. REPLACEMENT AND ADJUSTMENT..................................A897-7

3.1 BRIDGE UNIT DRIVE MOTOR REPLACEMENT...............................A897-7

3.2 TRAY EXIT SENSOR REPLACEMENT .............................................A897-8

3.3 RELAY SENSOR REPLACEMENT....................................................A897-8

FINISHER (A681)

1. OVERALL MACH INE INFORMATION..................................A681-1

1.1 SPECIFICATIONS..............................................................................A681-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................A681-2

1.3 ELECTRICAL COMPONENT LAYOUT..............................................A681-3

1.4 ELECTRICAL COMPONENT DESCRIPTIONS..................................A681-4

1.5 DRIVE LAYOUT .................................................................................A681-6

viii

Page 13

2. DETAILED DESCRIPTIONS .................................................A681-7

2.1 JUNCTION GATE MECHANISM........................................................A681-7

Staple Mode...................................................................................A681-7

No staple Mode..............................................................................A681-7

2.2 JOGGER UNIT PAPER POSITIONING MECHANISM.......................A681-8

2.3 EXIT GUIDE PLATE OPEN/CLOSE MECHANISM............................A681-9

2.4 STAPLER .........................................................................................A681-10

2.5 FEED OUT MECHANISM.................................................................A681-11

2.6 SHIFT TRAY UP/DOWN MECHANISM............................................A681-12

2.7 SHIFT TRAY SIDE-TO-SIDE MECHANISM.....................................A681-13

2.8 JAM CONDITIONS...........................................................................A681-14

2.9 TIMING CHARTS .............................................................................A681-15

2.9.1 NO STAPLE MODE (A4 SIDEWAYS, 3 SHEETS/2SETS)...... A681-15

2.9.2 STAPLE MODE (A4 SIDEWAYS, 2 SHEETS/2 SETS)...........A681-16

3. SERVICE TABLE................................................................A681-17

3.1 DIP SWITCH TABLE........................................................................A681-17

3.2 TEST POINTS..................................................................................A681-17

3.3 FUSES.............................................................................................. A681-17

4. REPLACEMENT AND ADJUSTMENT ................................A681-18

4.1 COVER REMOVAL ..........................................................................A681-18

Front Door....................................................................................A681-18

Front Cover..................................................................................A681-18

Rear Cover...................................................................................A681-18

Upper Cover.................................................................................A681-18

Lower Left Cover..........................................................................A681-19

Front Shift Tray Cover..................................................................A681-19

Rear Shift Tray Cover ..................................................................A681-19

Shift Tray......................................................................................A681-19

4.2 ENTRANCE SENSOR REPLACEMENT..........................................A681-20

4.3 EXIT SENSOR REPLACEMENT......................................................A681-21

4.4 STACK HEIGHT SENSOR REPLACEMENT...................................A681-22

4.5 POSITIONING ROLLER REPLACEMENT.......................................A681-23

4.6 STAPLER REPLACEMENT..............................................................A681-24

ix

Page 14

MAILBOX (G518)

1. OVERALL MACH INE INFORMATION................................. G518-1

1.1 SPECIFICATIONS..............................................................................G518-1

1.2 COMPONENT LAYOUT.....................................................................G518-2

1.2.1 MECHANICAL COMPONENT LAYOUT ....................................G518-2

1.2.2 DRIVE LAYOUT.........................................................................G518-2

1.3 ELECTRICAL COMPONENT DESCRIPTIONS..................................G518-3

2. DETAILED DESCRIPTIONS ................................................ G518-5

2.1 BASIC OPERATION...........................................................................G518-5

2.2 PAPER OVERFLOW DETECTION ....................................................G518-6

2.2.1 OVERVIEW ...............................................................................G518-6

2.2.2 DETECTION TIMING.................................................................G518-6

2.3 PAPER MISFEED DETECTION TIMING............................................G518-7

3. REPLACEMENT AND ADJUSTMENT................................. G518-9

3.1 EXTERIOR COVER REMOVAL.........................................................G518-9

3.2 TRAY OVERFLOW AND VERTICAL TRANSPORT SENSOR

REPLACEMENT...............................................................................G518-10

3.3 MAIN MOTOR REPLACEMENT....................................................... G518-11

x

Page 15

1 October, 1999 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

1.1.1 GENERAL SPECIFICATIONS

Printing Speed: Maximum 27 pages per minute (A4/LT LEF)

(22 pages: duplex printing)

Printer Language: PCL6/PCL5e

PostScript Level 3

TIFF (rev 6.0 compatible)

Resolution: 600 dpi (PCL 6/PCL5e/PS3)

300 dpi (PCL 5e/PS3)

Resident Fonts: PCL:

35 Intellifonts

10 True Type fonts

1 Bitmap font

PS3:

136 fonts (24 Type 2 fonts, 112 Type 14 fonts)

Host Interface: Bi-directional IEEE1284 parallel x 1 (Standard)

Ethernet (100 Base-TX/10 Base-T for TCP/IP, IPX/SPX,

NetBEUI, Apple Talk)

Overall

Information

Printing Paper Size: Maximum: A3/11" x 17"

Minimum:

1st paper Tray: A5 SEF

2nd paper Tray: A6 SEF

By-pass: A6/ 90 x 148 mm SEF

(Refer to section 1.1.2, "Supported Paper Size".)

Printing Paper

Weight:

1st paper tray: 60 to 105 g/m

2nd paper tray: 60 to 157 g/m

By-pass Tray: 60 to 200 g/m

Print Paper

Capacity:

1st and 2nd paper tray: 500 sheets x 2

Optional paper tray unit:

500 sheets x 1/2

Optional LCT

1000 sheets x 2

Optional by-pass tray:

100 sheets

Output Paper

Capacity:

Standard output tray: 500 sheets

Optional finisher: 1,000 sheets

Optional 4-bin mailbox: 500 sheets total

2

(16 to 28 lb.)

2

(16 to 42 lb.)

2

(16 to 110 Index)

First Print Speed: 5 s or less (A4/LT LEF, 1st tray)

Warm-up Time Less than 45 seconds

1-1

Page 16

SPECIFICATIONS 1 October, 1999

Memory:

Standard 16 MB, up to 80 MB with optional DIMM.

Power Source: 120 V, 60 Hz: More than 10 A (for North America)

220 V - 240 V, 50/60 Hz: More than 6.0 A (for Europe)

Power Consumption:

120V

Maximum 900W or less 900W or less

Printing 550W or less 550W or less

Energy Saver 25 W or less 25 W or less

230V

Noise Emission:

Mainframe Only Full System

Sound Power Level

Printing 51 dB or less 58 dB or less

Stand-by 23 dB or less 23 dB or less

NOTE:

The above measurements were made in accordance with ISO 9296 at

the operator position.

Dimensions (W x D x H): 550 x 520 x 516 mm

Weight: Less than 46 kg

1-2

Page 17

1 October, 1999 SPECIFICATIONS

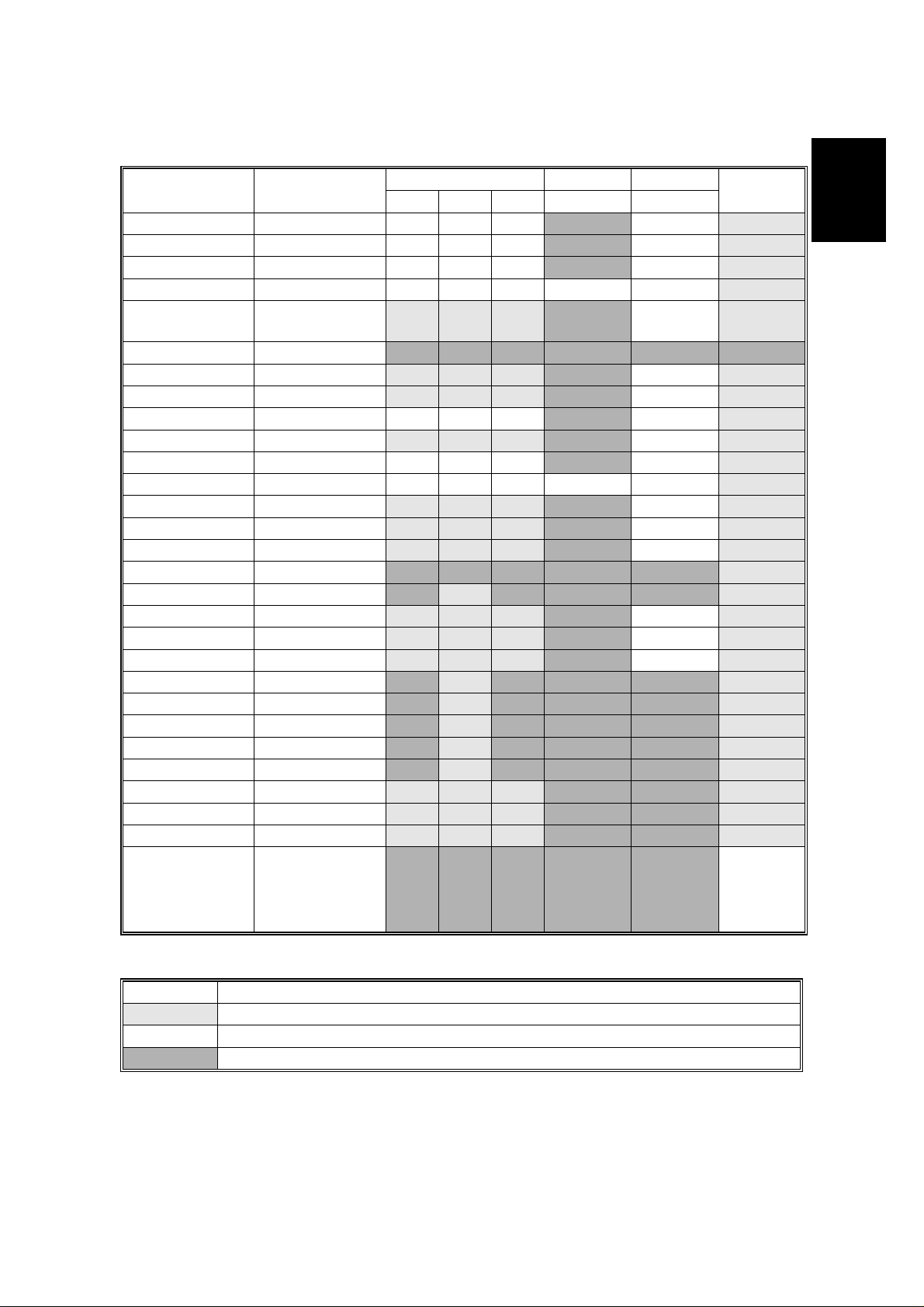

1.1.2 SUPPORTED PAPER SIZES

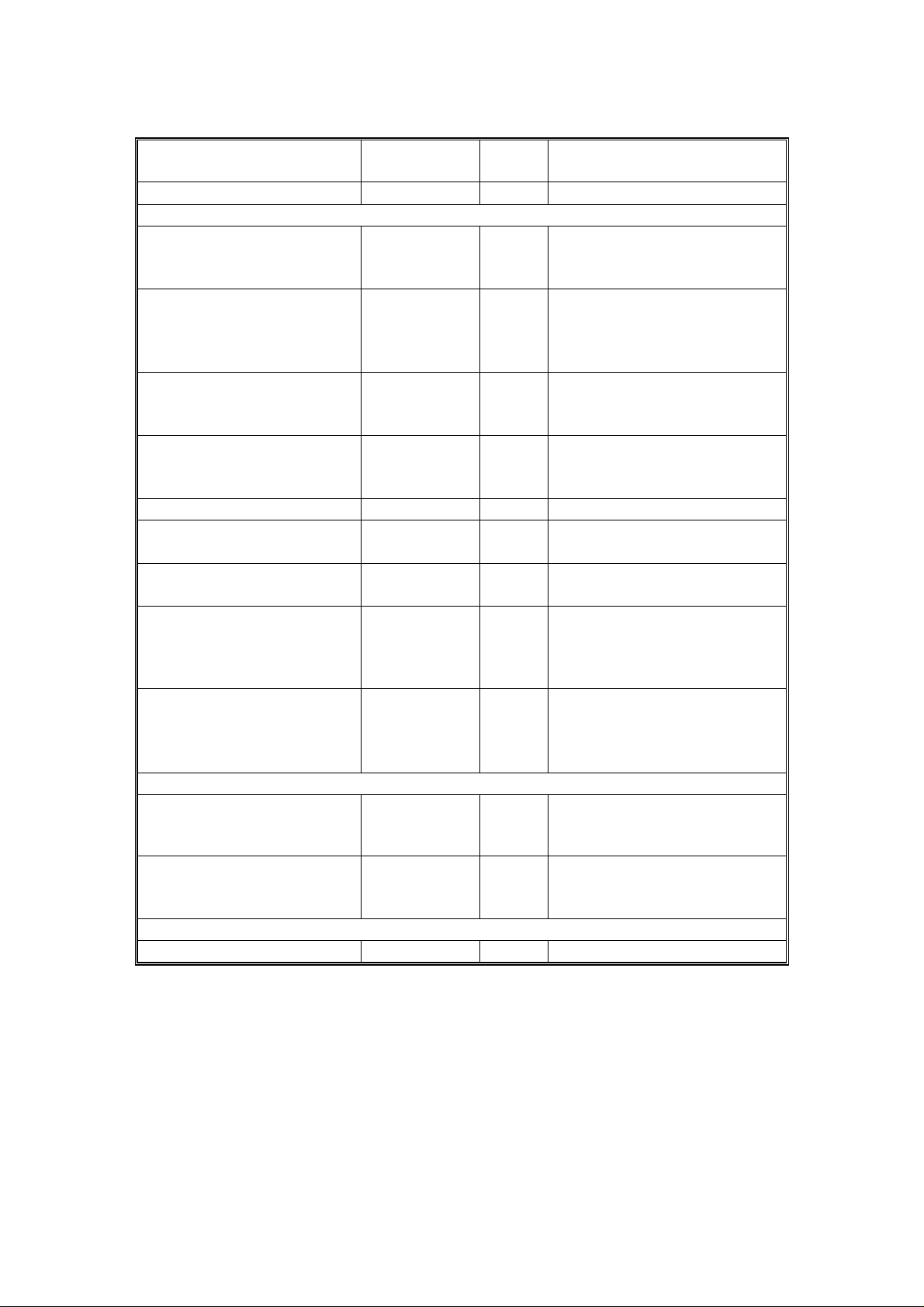

Paper Size (W x L)

Trays LCT Duplex

1st 2nd OP

By-pass/

Tray 2

Ledger 11 x 17” Y Y Y NYY

Legal 8.5 x 14“ Y Y Y NYY

Letter SEF 8.5 x 11” Y Y Y NYY

Letter LEF 11 x 8.5” Y Y Y Y Y Y

Half Letter

SEF

5.5 x 8.5”

#

Y

#

Y

#

Y

N N Y

Half Letter LEF 8.5 x 5.5” N N N N N N

Executive SEF 7.25 x 10.5” Y

Executive LEF 10.5 x 7.25” Y

#

#

#

Y

#

Y

#

Y

#

Y

NYY

N Y Y

A3 297 x 420 mm Y YY N Y Y

B4 257 x 364 mm Y

#

#

Y

#

Y

N Y Y

A4 SEF 210 x 297 mm Y Y Y NYY

A4 LEF 297 x 210 mm Y Y Y Y Y Y

B5 SEF 182 x 257 mm Y

B5 LEF 257 x 182 mm Y

A5 SEF 148 x 210 mm Y

#

#

#

#

Y

#

Y

#

Y

#

Y

#

Y

#

Y

NYY

NYY

NYY

A5 LEF 210 x 148 mm N N N N N Y

A6 SEF 105 x 148 mm N Y

Folio 8.25 x 13” Y

Foolscap 8.5 x 13” Y

F8 x 13”Y

#

#

#

Com10 Env. 4.125 x 9.5” N Y

Monarch Env. 3.875 x 7.5” N Y

C6 Env. 114 x 162 mm N Y

C5 Env. 162 x 229 mm N Y

DL Env. 110 x 220 mm N Y

8K 267 x 390 mm Y

16K SEF 195 x 267 mm Y

16K LEF 267 x 195 mm Y

#

#

#

#

N N N Y

#

Y

#

Y

#

Y

#

#

#

#

#

#

Y

#

Y

#

Y

#

Y

#

Y

#

Y

NYY

N Y Y

N Y Y

N N N Y

N N N Y

N N N Y

N N N Y

N N N Y

#

Y

#

Y

#

Y

N N Y

N N Y

N N Y

Custom [Minimum]

90 x 148 mm

[Maximum]

N N N N N Y

297 x 432 mm

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

C

Overall

Information

Remarks:

Y Supported. The paper size sensor detects the paper size.

#

Y

C

Y

N Not supported.

Supported. The user has to select the correct paper size for the tray.

Supported. The user has to enter the width and length of the paper.

1-3

Page 18

SOFTWARE ACCESSORIES 1 October, 1999

1.2 SOFTWARE ACCESSORIES

The printer drivers and utility software are provided on one CD-ROM. An auto-run

installer allows you to select which components to install. The service tools are not

provided on the CD-ROM.

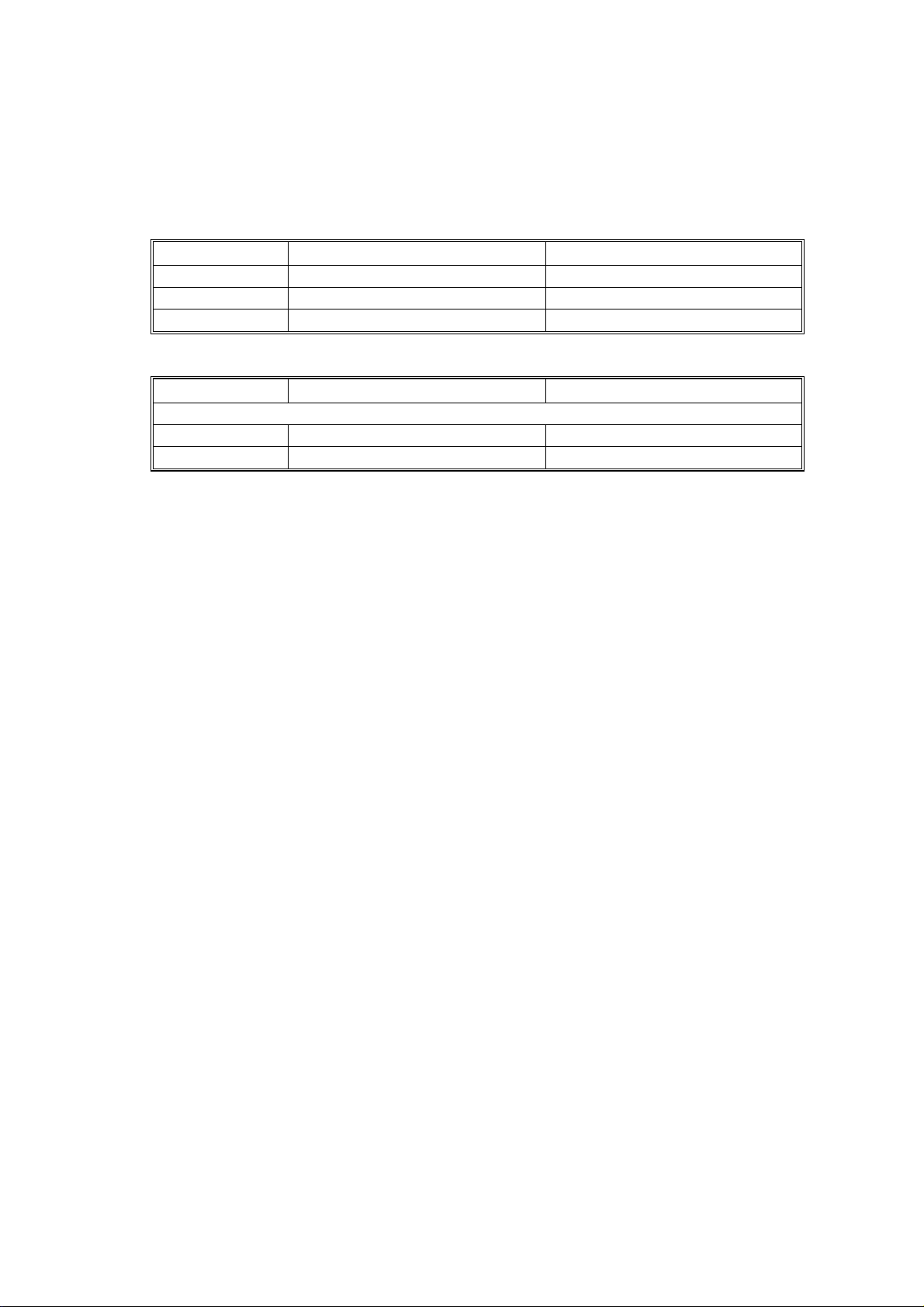

1.2.1 PRINTER DRIVERS

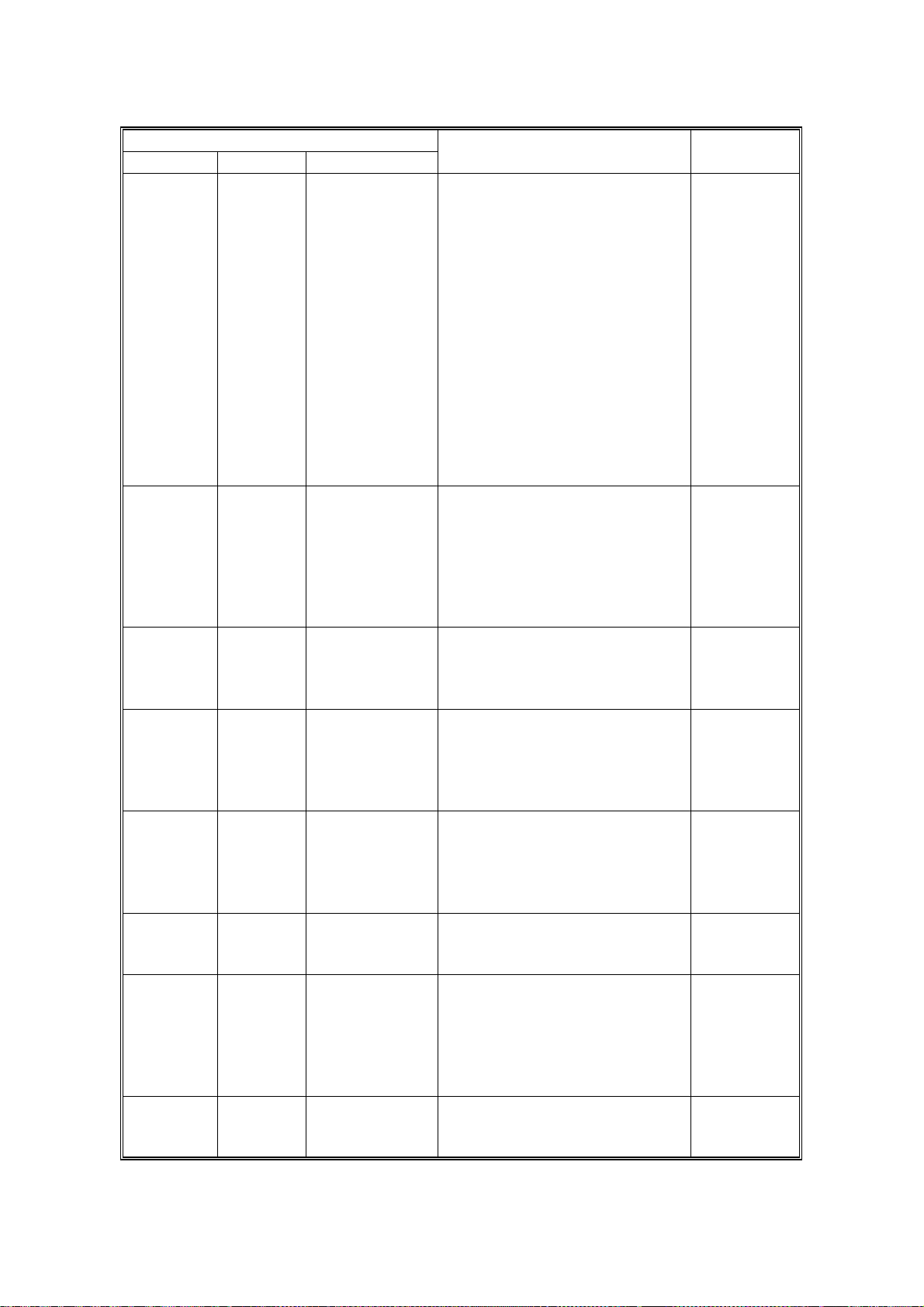

Printer Language Windows 3.1x Windows 95/98 Windows NT4.0 Macintosh

PCL 6 Yes Yes Yes No

PCL 5e Yes Yes Yes No

PS3 Yes Yes Yes Yes

NOTE:

1) The printer drivers for Windows NT 4.0 are only for the Intel x86

platform. There is no Windows NT 4.0 printer driver for PowerPC, Alpha,

or MIPS platforms.

2) The PS3 drivers are all genuine AdobePS drivers. A PPD file for each

operating system is provided with the driver.

3) The PS3 drivers for Macintosh support Mac OS 7.1 or later versions.

4) The PS3 drivers for Windows 3.1x and Windows NT4.0 do not support

the “Proof Print” function.

1.2.2 UTILITY SOFTWARE

Software Description

Agfa Font Manager

(Win3.1x, 95/98, NT4)

Aficio Manager for Admin

(Win 95/98, NT4)

Aficio Manager for Client

(Win95/98, NT4)

Multi-Direct Print

(Win95/98, NT4)

Port Navi

(Win95/98, NT4)

A font management utility with screen fonts for the printer.

A printer management utility for network administrators. NI B

setup utilities are also available.

A printer management utility for client users.

A utility for peer-to-peer printing over a NetBEUI or TCP/IP

network.

A peer to peer print utility over a TCP/IP network. This

provides parallel printing and recovery printing function.

1.2.3 SERVICE TOOLS

Software Description

NBTFTP NIB firmware update utility for use on a NetBEUI network.

This utility is not on the Driver and Utilities CD-ROM; it is

issued separately as a service tool

1-4

Page 19

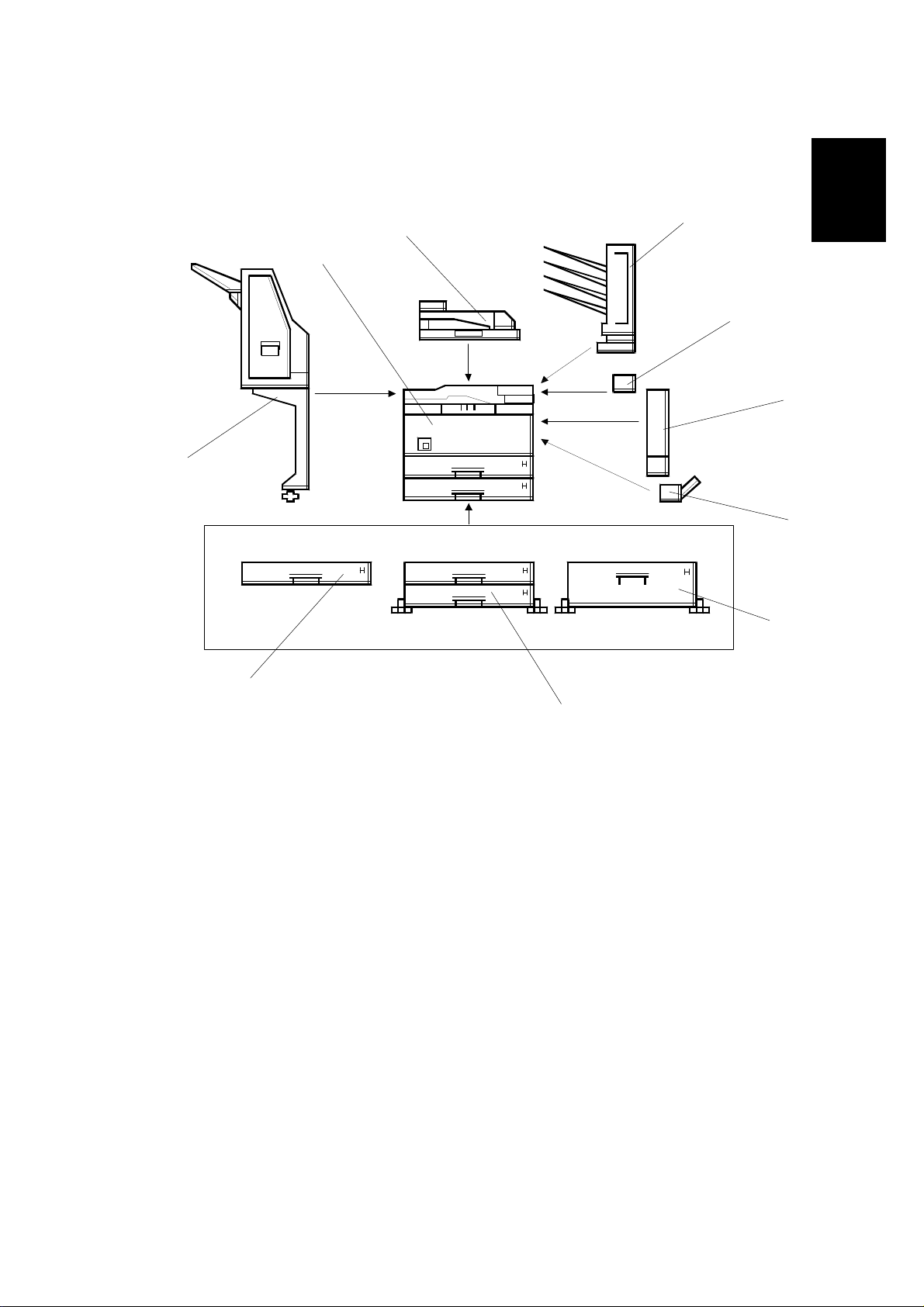

1 October, 1999 MACHINE CONFIGURATION

1.3 MACHINE CONFIGURATION

1.3.1 SYSTEM COMPONENTS

[A]

[J]

[I]

[B]

[C]

[H]

Overall

Information

[D]

[G]

[E]

G038V502.WMF

[F]

1-5

Page 20

MACHINE CONFIGURATION 1 October, 1999

Item

Main Unit G038 I

Option

Paper Tray Unit - 1 tray A861

Paper Tray Unit - 2 trays A860

LCT A862

By-pass Tray A899

Interchange Unit G531 B

Duplex Unit G529 C (See note 2, 3)

4-bin Mailbox G518 A (See note 2)

Bridge Unit A897 I

1000-sheet Finisher A681 H Used in common with

Internal Option

HDD G690

Memory 32or 64 MB G688 Used in common with

Others

Maintenance Kit G719

Machine

Code

No. Remarks

User installable

Used in common with

G

F

E

D

Stinger-C (See note 1)

User installable

Used in common with

Stinger-C/Russian-C

(See note 1)

User installable

Used in common with

Russian-C (See note 1)

User installable

Used in common with

Russian-C

User installable

User installable

User installable

User installable

Used in common with

Russian-C

(See note 4)

Service installation

Russian-C/NAD

(See note 4)

Service installation

Used in common with

Stinger-C/Russian-C

Service installation

Stinger-C/Russian-C

User installable

NOTE:

1) Only one of these options can be installed on the machine.

2) Requires the Interchange unit to be installed.

3) Requires the memory option to be installed.

4) The Bridge unit must be installed together with the 1000 sheet Finisher.

Either the LCT or Paper Tray Unit (2 trays) must also be installed.

1-6

Page 21

1 October, 1999 PAPER PATH

1.4 PAPER PATH

[F]

[A]

[B]

[E]

[C]

Overall

Information

[A]: Optional interchange unit

[B]: Optional duplex unit

[C]: Optional by-pass tray

[D]: Optional paper tray unit (2 trays)

[E]: Optional 1000-sheet finisher

[F]: Optional bridge unit

[D]

G038V101.WMF

1-7

Page 22

MECHANICAL COMPONENT LAYOUT 1 October, 1999

1.5 MECHANICAL COMPONENT LAYOUT

17

16

15

18

1

2

3

4

5

6

7

8

9

10

11

12

1. Exit roller

2. Hot roller

3. Fusing pressure roller

4. Cleaning unit

5. Drum

6. Transfer roller

7. Development roller

8. ID sensor

9. Registration roller

13

G038V503.WMF

14

10. Friction pad

11. Paper feed roller

12. Paper size sensor

13. Special paper sensor

14. Bottom plate

15. Polygon mirror motor

16. Laser unit

17. Toner supply bottle holder

18. Charge roller

1-8

Page 23

1 October, 1999 ELECTRICAL COMPONENT DESCRIPTIONS

1.6 ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout on the reverse side of the point-to-point

diagram for the location of the components.

Symbol Name Function

Motors

M1 Polygonal Mirror Turns the polygonal mirror.

M2 Main Motor Drives the main unit components.

M3 Exhaust Fan Removes heat from around the fusing unit.

M4 Upper Paper Lift Raises the bottom plate in the 1st paper tray.

M5 Lower Paper Lift Raises t he bottom plate in the 2nd paper tray.

M6 Toner Supply

Magnetic Clutches

MC1 Upper Paper Feed Starts paper feed from the 1st paper tray.

MC2 Lower Paper Feed Starts paper feed from the 2nd paper tray.

MC3 Upper Paper Transport Drives the upper transport rollers.

MC4 Lower Paper Transport Drives the lower transport rollers.

MC5 Registration Drives the registration rollers.

Switches

SW1 M ain Switc h

SW2 Right Upper Cover Detects whether right upper cover is open or not.

SW3 Right Cover

SW4 Right Lower Cover Det ect s whether right lower cover is open or not.

SW5 Upper Paper Size

SW6 Lower Paper Size

SW7 Special Paper

SW8 New PCU Detect Det e ct s when a new PCU is installed.

SW9 Front Cover Safety

Sensors

S1 Toner Density (TD)

S2 1st Paper End

S3 1st Paper End

S4 Image Density (ID)

S5 Paper Overflow Detects paper overflow condition.

S6 Paper Exit Detects misfeeds.

S7 Upper Relay Detects misfeeds.

Rotates the toner bottle to supply toner to the

development unit.

Provides power to the machine. If this is off,

there is no power supplied to the machine.

Cuts the +5VLD and +24V dc power line and

detects whether the right cover is open or not.

Determines what size of paper is in the upper

paper tray.

Determines what size of paper is in the Lower

paper tray.

Determines the special paper is in the lower

paper tray.

Cuts the +5VLD and +24V dc power line and

detects whether the front cover is open or not.

Detects the amount of toner inside the

development unit.

Informs the CPU when the 1st paper tray runs

out of paper.

Informs the CPU when the 2nd paper tray runs

out of paper.

Detects the density of various patterns and the

reflectivity of the drum for process control.

Overall

Information

1-9

Page 24

ELECTRICAL COMPONENT DESCRIPTIONS 1 October, 1999

Symbol Name Function

S8 Lower Relay Detects misfeeds.

S9 Registration

S10 1st Paper Lift

S11 2nd Paper Lift

S12 1st Paper Height - 1

S13 1st Paper Height - 2

S14 2nd Paper Height - 1

S150 2nd Paper Height - 2

Detects misfeeds and controls registration clutch

off-on timin g.

Detects when the paper in the 1st paper tray is at

the feed height.

Detects when the paper in the 2nd paper tray is

at the feed height.

Detects the amount of paper in the 1st paper

tray.

Detects the amount of paper in the 1st paper

tray.

Detects the amount of paper in the 2nd paper

tray.

Detects the amount of paper in the 2nd paper

tray.

PCBs

PCB1 Engine Board Controls all printer engine functions.

PCB2 Printer Controller Board Controls the printer functions

PCB3 Network Interface Board Net work interface board

PCB4 PSU (Power Supply Unit)

Provides dc power to the system and ac power to

the fusing lamp and heaters.

PCB5 LDD (Laser Diode Driver) Controls the laser diode.

PCB6 Operation Panel Controls the operation panel.

PCB7 High Voltage Supply

Supplies high voltage to the drum charge roller,

development roller, and transfer roller.

PCB8 Memory (Option) Expands memory capacity.

Lamps

L1 Fusing Lamp Heats the hot roller.

L2 Quenching Lamp

Neutralizes any charge remaining on the drum

surface after cleaning.

Others

TF1 Fusing Thermofu s e

Opens the fusing lamp circuit if the fusing unit

overheats.

TH1 Fusing Thermistor Det ects the temperature of the hot roller.

LSD 1

Laser Synchronization

Detector

Detects the laser beam at the start of the main

scan.

1-10

Page 25

1 October, 1999 PRINTING PROCESS

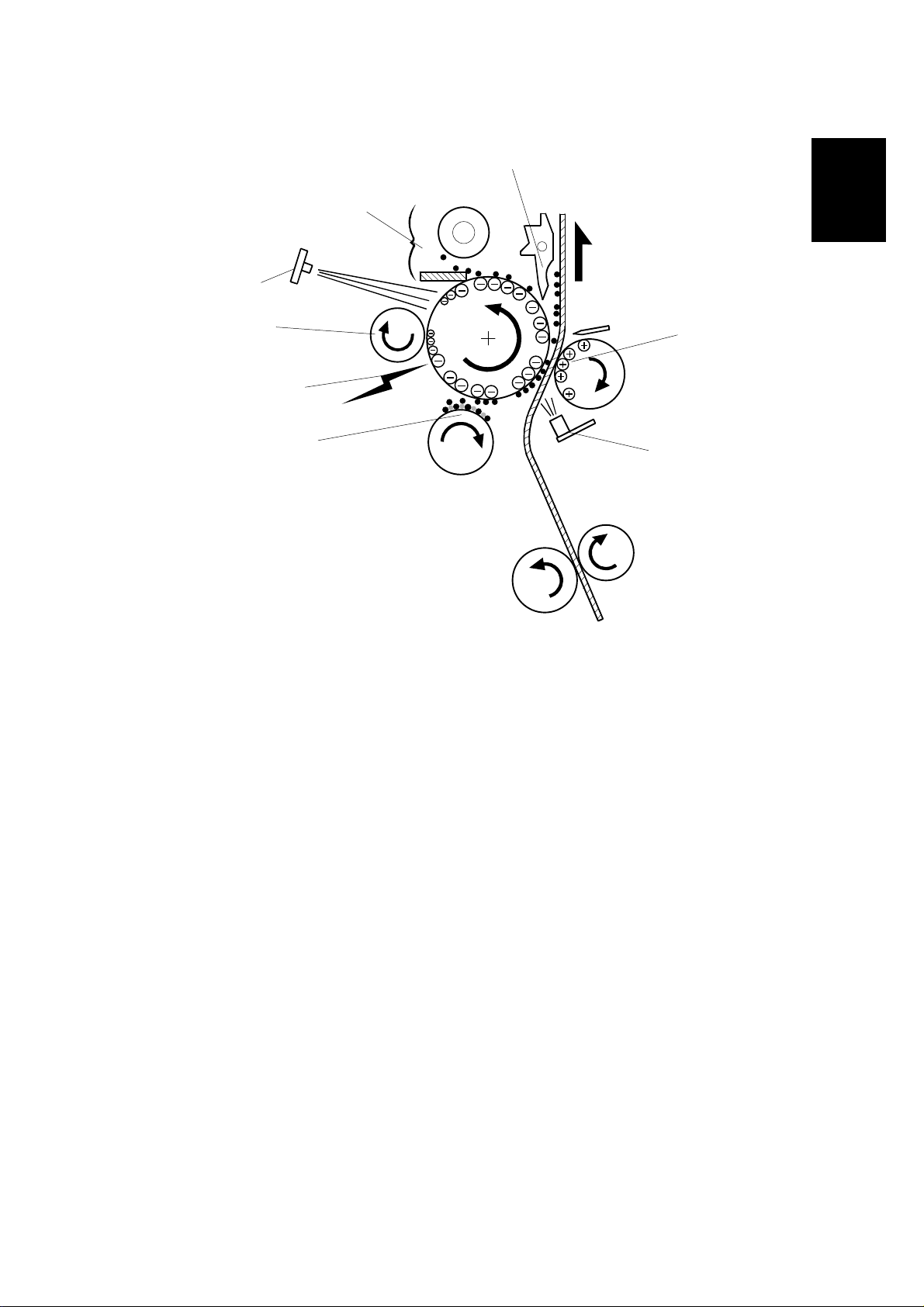

1.7 PRINTING PROCESS

[6]

Overview

[7]

[8]

Overall

Information

[1]

[5]

[2]

[3]

G038V504.WMF

[4]

1. DRUM CHARGE

The charge roller gives a negative charge to the organic photoconductive

(OPC) drum. The charge remains on the surface of the drum because the OPC

layer has a high electrical resistance in the dark.

2. LASER EXPOSURE

Processed data from the computer/network is retrieved from the memory and

transferred to the drum by a laser beam, which forms an electrical latent image

on the drum surface. The amount of charge remaining as a latent image on the

drum depends on the laser beam intensity, which is controlled by the engine

board.

3. DEVELOPMENT

The magnetic developer brush on the developm e nt rol ler s comes in contact

with the latent image on the drum surface. Toner particles are electrostatically

attached to the areas of the drum surface where the laser reduced the negative

charge on the drum.

4. ID SENSOR

The laser forms a sensor pattern on the drum surface. The ID sensor measures

the reflectivity of the pattern. The output signal is one of the factors used for

toner supply control. Also, the ID sensor measures the reflectivity of the drum

surface. The output signal is used for charge roller voltage control.

1-11

Page 26

PRINTING PROCESS 1 October, 1999

5. IMAGE TRANSFER

Paper is fed to the area between the drum surface and the transfer roller at the

proper time for aligning the print paper and the developed image on the drum

surface. Then, the transfer roller applies a high positive charge to the reverse

side of the paper. This positive charge pulls the toner particles from the drum

surface onto the paper. At the same time, the paper is electrostatically attracted

to the transfer roller.

6. PAPER SEPARATION

Paper separates from the drum as a result of the electrostatic attraction

between the paper and the transfer roller. The discharge plate helps separate

the paper from the drum.

7. CLEANING

The cleaning blade removes any toner remaining on the drum surface after the

image transfers to the paper.

8. QUENCHING

The light from the quenching lamp electrically neutralizes the charge on the

drum surface.

1-12

Page 27

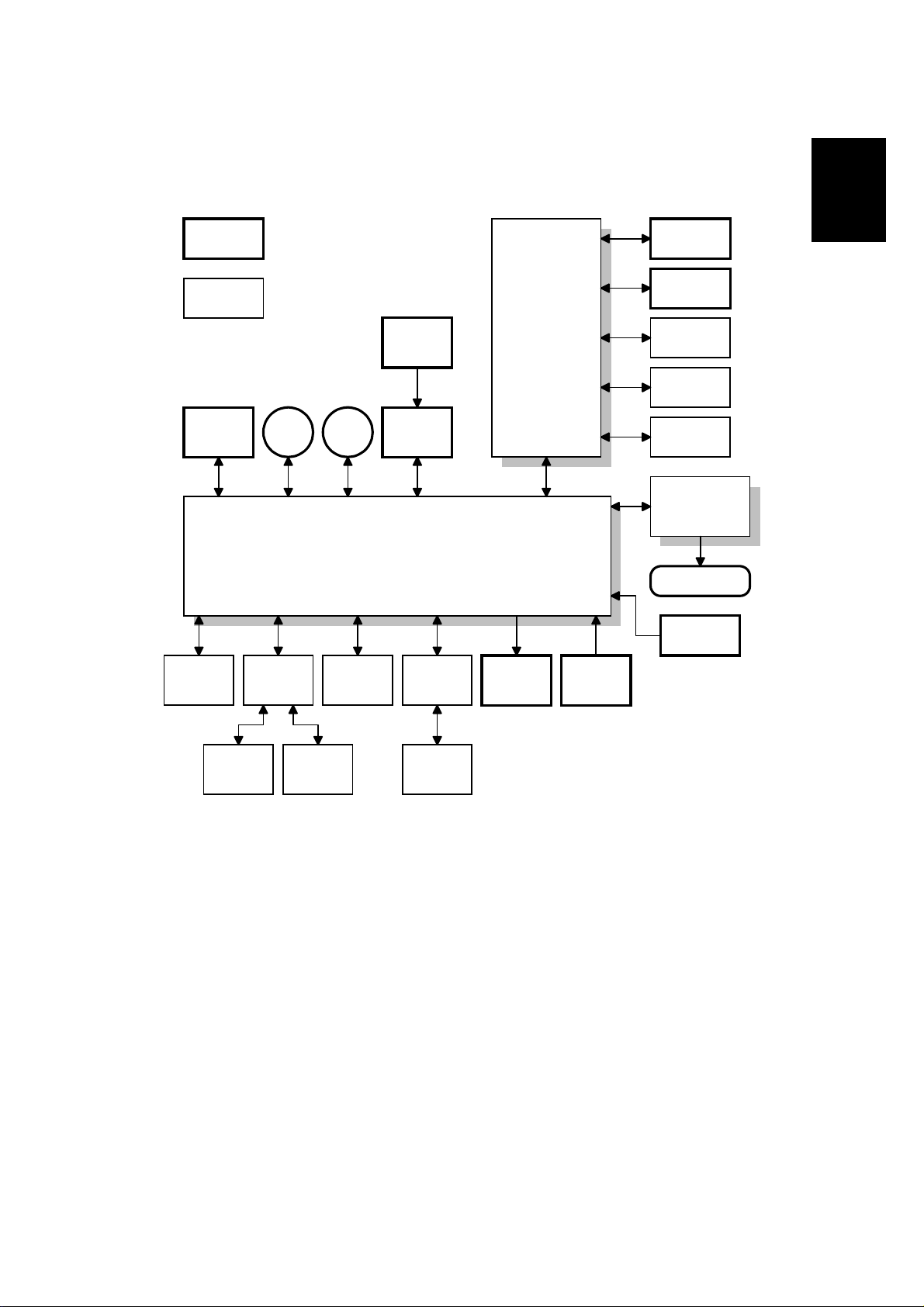

1 October, 1999 BOARD STRUCTURE

1.8 BOARD STRUCTURE

1.8.1 OVERVIEW

Standard

components

Operation

Panel

Overall

Information

Optional

components

Power

Pack

By-pass

Tray

Motors

Interchange

Unit

Polygon

Motor

Engine Board

Paper Tray

or

LCT

Laser

Synch.

LDDR

Bridge

Unit

Printer

Controller

Board

Clutches

Network

Interface

PS DIMM

DRAM DIMM

HDD

PSU

Fusing Lamp

Thermistor

Sensors

Duplex

Unit

4-bin

Mailbox

Finisher

G038V501.WMF

The engine control firmware controls the components connected to the engine

board. The printer control board controls the connected components.

1-13

Page 28

BOARD STRUCTURE 1 October, 1999

1.8.2 DESCRIPTIONS

1. Engine Board

The engine board controls the following functions:

•

Engine sequence

•

Machine control, printer engine control

•

Timing control for peripherals

•

Video control

•

Drive control for the sensors, motors, solenoids, and high voltage supply

board

2. Printer Control Board

The printer control board handles the following functions:

•

Interface of the connected components to the engine board

•

Printer host interface

•

Edge smoothing and toner saving

•

Operation panel interface

•

Interface and control of NIB and the other additional options (HDD, PS

DIMM, and DRAM DIMM)

3. LD Drive Board

This is the laser diode drive circuit board.

4. Network Interface Board (NIB)

The network interface board allows the printer to be used on a network

5. HDD Unit (Option)

The HDD unit stores the data to perform the following functions.

•

Additional soft fonts

•

Collation

•

Proof-print

•

Downloading forms for form overlay

6. PS DIMM

This is to add the PostScript feature.

7. DRAM DIMM (Option)

This is used for an additional printer processing memory area and for soft fonts.

8. Control Panel Board

Controls the display panel, the LED, and the touch keypad.

1-14

Page 29

1 October, 1999 LASER EXPOSURE

2. DETAILED SECTION DESCRIPTIONS

2.1 LASER EXPOSURE

2.1.1 OVERVIEW

[H]

[A]

[I]

[C]

[D]

[B]

[F]

[G]

The LD unit [A] outputs a laser beam to the polygon mirror [B] through the

cylindrical lens [C]. The shield glass [D] prevents dust from reaching the polygon

mirror.

[E]

G038D523.WMF

Detailed

Descriptions

Each surface of the polygon mirror reflects one full main scan line. The laser beam

goes to the F-theta mirror [E], mirror [F], and BTL (barrel toroidal lens) [G]. Then

the laser beam goes to the drum through the toner shield glass [H].

The laser synchronizing detector [I] determines the starting position for the main

scan.

The speed of the polygon mirror motor is 28,818.9 rpm for 600 dpi.

2-1

Page 30

LASER EXPOSURE 1 October, 1999

2.1.2 AUTO POWER CONTROL (APC)

LD LEVEL

LD ON

LD OFF

LD OFF

VIDEO

LD

Controller

LD Drive Board

VIDEO

LD Driver

LD

VREF

Reference

Circuit

+5V

PD LD

Monitor

G038D510.WMF

The LD driver IC drives the laser diode. To prevent the intensity of the laser beam

from changing because of the temperature, the machine monitors the current

passing through the laser diode (LD). The machine adjusts the current to the laser

diode by comparing it with the reference level from the reference circuit.

This auto power control is done just after the machine is turned on and during

printing while the laser diode is active.

The laser diode power is adjusted on the production line.

NOTE:

Do not touch the variable resistors on the LD unit in the field.

2-2

Page 31

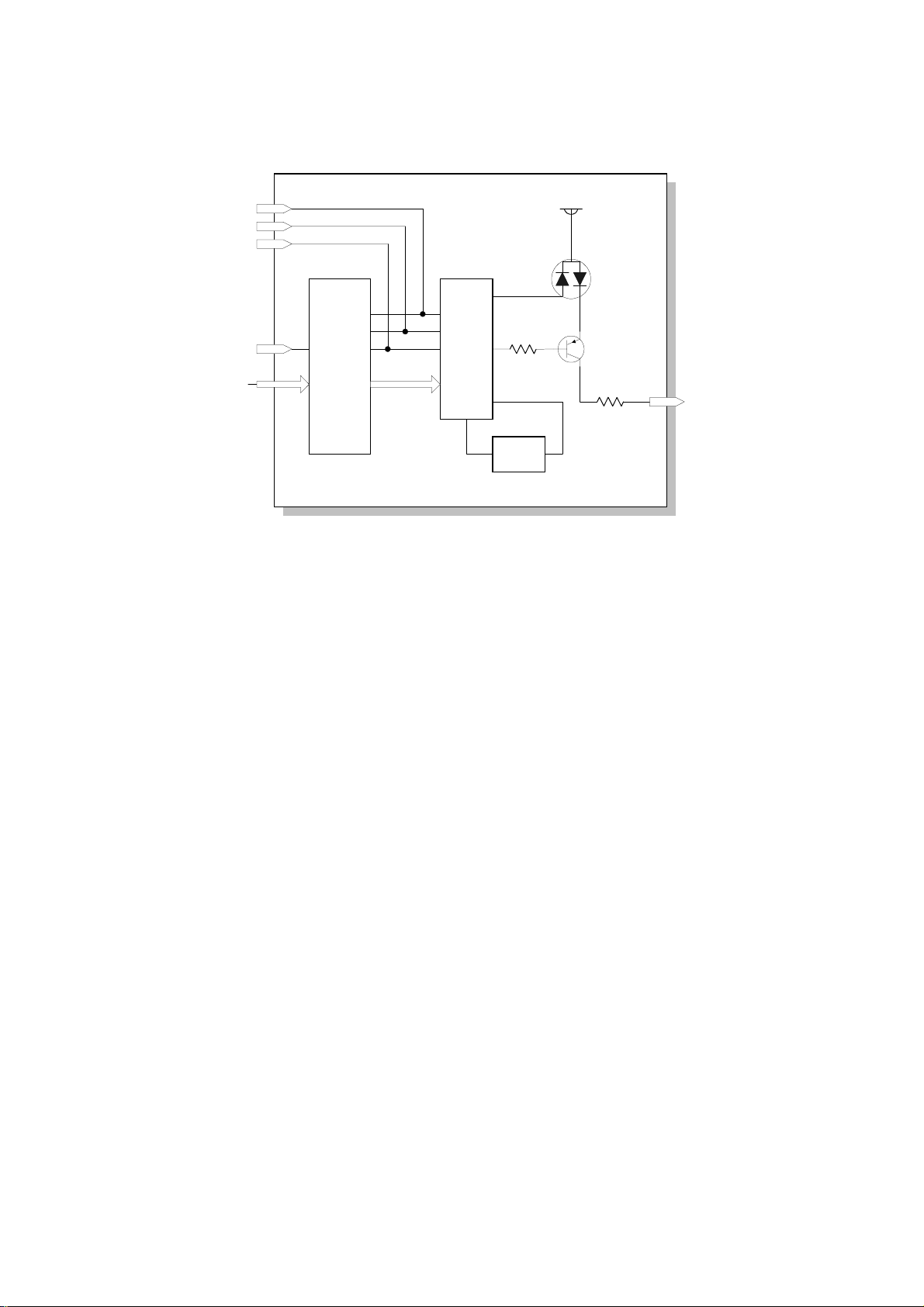

1 October, 1999 LASER EXPOSURE

2.1.3 LD SAFETY SWITCH

Interlock

SW

LD Drive Board

PSU

+5VLD +5VLD

Engine

Board

To ensure technician and user safety and to prevent the laser beam from

inadvertently switching on during servicing, safety switches are located at the front

cover and right cover. The switches are installed on the +5VLD line coming from

the power supply unit through the Engine control board.

LDD:

VCC

LD Control IC

PD

LD

Laser

Beam

Optical Path

OPC

Drum

G038D501.WMF

Detailed

Descriptions

When the front cover or the right cover is opened, the power supply to the laser

diode is interrupted.

2-3

Page 32

PHOTOCONDUCTOR UNIT (PCU) 1 October, 1999

2.2 PHOTOCONDUCTOR UNIT (PCU)

2.2.1 OVERVIEW

10

9

8

1

7

6

2

G038D201.WMF

3

4

11

5

The PCU consists of the components shown in the above illustration. An organic

photoconductor (OPC) drum (diameter: 30 mm) is used in this machine.

1. Cleaning Blade

2. Toner Collection Coil

3. Pick-off Pawl

4. OPC Drum

5. ID Sensor (see note)

NOTE:

The machine informs the user when the PCU life has finished. However, the user

can continue to make copies.

This warning message can be disabled by the printer engine service mode (Service

Menu 2: Change PM Mes).

These parts are not included in the PCU.

6. Development Roller

7. Development Unit

8. Charge Roller

9. Charge Roller Cleaning Pad

10. Quenching Lamp (see note)

11. Transfer Roller (see note)

2-4

Page 33

1 October, 1999 PHOTOCONDUCTOR UNIT (PCU)

2.2.2 DRIVE MECHANISM

[A]

[E]

[B]

[C]

[D]

G038D202.WMF

The main motor [A] drives the drum [B] through a series of gears, a timing belt [C],

and the drum drive shaft [D]. The main motor assembly includes a drive controller,

which outputs a motor lock signal when the rotation speed is out of the specified

range.

Detailed

Descriptions

The fly-wheel [E] on the end of the drum drive shaft stabilizes the rotation speed

(this prevents banding and jitter from appearing on printouts).

2-5

Page 34

PHOTOCONDUCTOR UNIT (PCU) 1 October, 1999

2.2.3 NEW PCU DETECTION MECHANINSM

[A]

G038D206.WMF

[B]

[C]

When the PCU counter reaches 60K, the “Replace PCU” message is displayed.

The new PCU detect switch [A] detects when a new PCU is installed. Each PCU

has an actuator [B]. When a new PCU is installed in the machine, the actuator [B]

pushes the new PCU detect switch. The actuator is a sector gear, and this gear

engages with the drum gear [C]. When the drum rotates, the actuator is released

from the drum gear. The actuator drops away from the new PCU detect switch and

remains in this "down" position for the duration of the PCU's life.

The machine can recognize when a new PCU has been installed in the machine

because the actuator of the new PCU comes in contact with the new PCU detect

switch. Then, the machine automatically resets the PCU counter.

After the front cover and right cover are closed, the machine then performs the TD

sensor initial setting procedure automatically (for about 45 seconds). During this

time, the drum rotates and the actuator drops away from the sensor.

While the machine performs the TD sensor initial setting, the machine makes an ID

sensor pattern on the drum. This checks whether the developer has fallen into the

development unit (in other words, it checks whether the user or technician

remembered to remove the developer seal from the PCU at machine installation). If

the machine does not detect the ID sensor pattern, SC 392 is generated.

NOTE:

The PCU counter can be cleared by the printer engine service mode

(Service Menu 2: PCU Count clr).

2-6

Page 35

1 October, 1999 DRUM CHARGE

2.3 DRUM CHARGE

2.3.1 OVERVIEW

[D]

[C]

[A]

[B]

G038D203.WMF

This machine uses a drum charge roller to charge the drum. The drum charge

roller [A] always contacts the surface of the drum [B] to give it a negative charge of

-900V.

Detailed

Descriptions

The high voltage supply board gives a negative dc voltage to the drum charge

roller through the spring [C] and terminal plate [D].

2-7

Page 36

DRUM CHARGE 1 October, 1999

2.3.1 CHARGE ROLLER VOLTAGE CORRECTION

Correction for Environmental Conditions

[A]

28.9 cm

+

2 cm

[B]

ID Sensor Pattern

Charge Voltage

Laser Diode

Drum Potential

Development Bias

ID Sensor Output

On

Off

2 cm

Sub Scan Direction

-1650 V

-1450 V

-900 V

-700 V

-600 V

-400 V

-150 V

V sg (4.00 V)

V sdp (3.70 V)

V sp (0.50 V)

t

G038D516.WMF

With a drum charge roller system, the voltage transferred from roller to drum varies

with the temperature and humidity around the drum charge roller. The lower the

temperature or humidity is, the higher the applied voltage required.

To compensate, the machine uses the ID sensor to measure the effects of current

environmental conditions. For this measurement, the process control parameters

are balanced so that any small change in drum potential caused by environmental

effects is reflected in a change in the amount of toner transferred to the drum.

This measurement is made immediately after the ID sensor pattern for toner

density control. Immediately after making ID sensor pattern [A], the charge roller

voltage stays on, but the development bias goes up to -600V; as a result the drum

potential is reduced to -700V. The laser diode is not switched on, and the drum

potential is now slightly higher than the development bias, so only a very small

amount of toner transfers to the drum. The ID sensor measures the density of this

pattern [B], and the output voltage is known as Vsdp. This voltage is compared with

Vsg (read from the bare drum at the same time).

2-8

Page 37

1 October, 1999 DRUM CHARGE

If the humidity drops, the drum potential goes up (to a higher –ve voltage) even if

the charge roller voltage supply stays the same (efficiency of voltage transfer is

higher with lower humidity). As a result, less toner is transferred to ID sensor

pattern [B]. If the sensor output reaches a certain point, the drum charge voltage

will be reduced.

To determine whether to change the drum charge roller voltage, the machine

compares Vsdp with Vsg.

•

Vsdp / Vsg > 0.95 = Reduce the magnitude of the drum charge voltage by 50 V

•

Vsdp / Vsg < 0.90 = Increase the magnitude of the drum charge voltage by 50 V

2.3.2 ID SENSOR PATTERN PRODUCTION TIMING

An ID sensor pattern is made in the following conditions.

•

During warming up at power on

•

If the machine starts warming up after entering the energy saver mode

Detailed

Descriptions

2-9

Page 38

DRUM CHARGE 1 October, 1999

2.3.3 DRUM CHARGE ROLLER CLEANING

[C]

[D]

[B]

[A]

G038D205.WMF

Because the drum charge roller [A] always contacts the drum, it gets dirty easily.

So, the cleaning pad [B] also contacts the drum charge roller all the time to clean

the surface of the drum charge roller.

The pin [C] at the rear of the cleaning pad holder touches the cam gear [D], and

this gear moves the cleaning pad from side to side. This movement improves the

cleaning.

2-10

Page 39

1 October, 1999 DEVELOPMENT

2.4 DEVELOPMENT

2.4.1 OVERVIEW

5

4

G038D301.WMF

3

2

The development unit consists of the following parts.

1. Development roller

2. Mixing auger 2

4. Mixing auger 1

5. Doctor blade

3. TD sensor

Detailed

Descriptions

1

This machine uses a single-roller development system. Two mixing augers mix the

developer. The toner density (TD) sensor and image density (ID) sensor (see the

illustration in the PCU section) are used to control toner density.

2-11

Page 40

DEVELOPMENT 1 October, 1999

2.4.2 DRIVE MECHANISM

[A]

[B]

[D]

[C]

G038D304.WMF

The main motor [A] drives the development roller [B] and mixing augers [C] through

a train of gears and the development drive shaft [D]. When the PCU is pushed in,

the development drive shaft engages the development roller gear.

The development drive gears (except for the gears in the development unit) are

helical gears. These gears are quieter than normal gears.

2-12

Page 41

1 October, 1999 DEVELOPMENT

2.4.3 DEVELOPER MIXING

[D]

[C]

[A]

[B]

[B]

[A]

G038D302.WMF

This machine uses 2 mixing augers, [A] and [B], to keep the developer evenly

mixed. Mixing auger 2 [A] transports excess developer, scraped off the

development roller [C] by the doctor blade [D], towards the front of the machine.

Mixing auger 1 [B] returns the excess developer, along with new toner, to the rear

of the mixing assembly. Here the developer is reapplied to the development roller.

Detailed

Descriptions

2-13

Page 42

DEVELOPMENT 1 October, 1999

2.4.4 DEVELOPMENT BIAS

[B]

[A]

G038D303.WMF

This machine uses a negative-positive development system, in which black areas

of the latent image are at a low negative charge (about -150 ± 50 V) and white

areas are at a high negative charge (about -900 V).

To attract negatively charged toner to the black areas of the latent image on the

drum, the high voltage supply board applies a bias of -600 volts to the development

rollers throughout the image development process. The bias is applied to the

development roller shaft [A] through the drive shaft [B].

The development bias voltage (-600 V) can be adjusted with the printer service

mode (Service Menu 2: Developer bias).

2-14

Page 43

1 October, 1999 DEVELOPMENT

2.4.5 TONER SUPPLY

Toner bottle replenishment mechanism

[E]

[G]

[A]

[F]

Detailed

Descriptions

[H]

[D]

[C]

G038D507.WMF

[B]

When a toner bottle is placed in the bottle holder unit [A] and the unit is pushed in

completely, pin [B] moves against the side [C] of the PCU, and the toner shutter [D]

is pulled out to open the bottle. When the toner bottle holder lever [E] is put back in

the original position, the cap [F] on the toner bottle is pulled away and kept in place

by the chuck [G].

The toner supply mechanism transports toner from the bottle to the development

unit. The toner bottle has a spiral groove [H] that helps move toner to the

development unit.

When the bottle holder unit is pulled out to add a new toner bottle, the following

happens automatically to prevent toner from scattering.

•

The chuck releases the toner bottle cap into its proper position.

•

The toner shutter shuts to block the opening as a result of pressure from a

spring.

2-15

Page 44

DEVELOPMENT 1 October, 1999

Toner supply mechanism

[A]

[B]

[C]

G038D508.WMF

[D]

[E]

G038D306.WMF

The toner supply motor [A] drives the toner bottle [B] and the mylar blades [C].

First, the toner falls down into the toner bottle holder. The toner supply mylar

blades transfer the toner to the slit [D]. When the PCU is installed in the machine,

the shutter [E] above the PCU is opened by the machine frame. Then the toner

falls down into the development unit through the slit and the shutter.

2-16

Page 45

1 October, 1999 DEVELOPMENT

2.4.6 TONER DENSITY CONTROL

Overview

There are four modes for controlling toner supply as shown in the following tables.

The mode can be changed with by the printer service mode (Service Menu 2:

Toner supply). The factory setting is P+T control mode.

Basically, toner density is controlled using the standard TD sensor voltage (Vts),

toner supply reference voltage (Vref), actual TD sensor output voltage (Vt), and ID

sensor output data (Vsp/Vsg).

Cross-reference:

Section 4.2 Service Program Mode

Toner Supply Clutch On Time

Calculation

TD Sensor Output

(Vt)

Detailed

Descriptions

Vt Reference

Voltage (Vref)

New Vref

Vt Reference

Voltage Update

Vref Update

ID Sensor Output

(Vsp/Vsg)

TD Sensor Initial

Setting (Vts)

G038D517.WMF

2-17

Page 46

DEVELOPMENT 1 October, 1999

There are four toner density control modes:

Mode P+T Control (Normally use this setting only)

Toner supply decision Compare Vt with a reference voltage (Vts or Vref)

Toner control process

Toner is supplied to the development unit when Vt is higher

than the reference voltage (Vts or Vref). This mode keeps the

Vref value for use the next toner density control.

Vts is used for the first toner density control after a new PCU

has been installed, until it has been corrected with the ID

sensor output.

Vref is used after Vts has been corrected with the ID sensor

output voltage (corrected during the first toner density control

for a new PCU).

2-18

Page 47

1 October, 1999 DEVELOPMENT

Toner density sensor initial setting

The TD sensor initial setting procedure is performed automatically when the new

PCU is installed in the machine. During TD sensor initial setting, the TD sensor is

set to the TD sensor output to the value programmed in the printer service mode

(T sensor set: default: 2.3V). This value will be u s ed as the standard reference

voltage (Vts) of the TD sensor.

Toner density measurement

Toner density in the developer is detected once every print cycle. The sensor

output voltage (Vt) during the detection cycle is compare with the standard

reference voltage (Vts) or the toner reference voltage (Vref).

Vsp/Vsg detection

The ID sensor detects the following voltages.

•

Vsg: The ID sensor output when checking the drum surface

•

Vsp: The ID sensor output when checking the ID sensor pattern

In this way, the reflectivity of both the drum surface and the pattern on the drum are

checked. This compensates for any variations in the reflectivity of the pattern on

the drum or the reflectivity of the drum surface.

The ID sensor pattern is made on the drum by charge roller and laser diode.

Vsg/Vsp is not detected every page or job; it is detected at the following times to

decide Vref.

•

During warming up at power on

•

If the machine starts warming up after a certain time has passed since

entering the energy saver mode.

Detailed

Descriptions

Toner supply reference voltage (Vref) determination

The toner supply reference voltage (Vref) is the threshold voltage for the toner

supply determination. Vref is determined using the following data,

•

ID sensor output (Vsp/Vsg)

•

(Vts or the current Vref) - Vt

Toner supply determination

The reference voltage (Vts or Vref) is the threshold voltage for determining whether

or not to supply toner. If Vt becomes greater than the reference voltage, the

machine supplies additional toner.

2-19

Page 48

DEVELOPMENT 1 October, 1999

Toner Supply Motor On Time Determinations

For sensor control modes 1 and 2, the toner supply motor on time is decided by the

following factors.

•

Vt

•

Vref

•

TD sensor sensitivity (coefficient: S, value is 0.4)

There are seven levels for toner supply motor on time as shown below.

Level Decision M ot or On Time (seconds)

1

2

3

4

5

6

7

Vref < Vt ≤ S/16

Vref < Vt ≤ S/8

Vref < Vt ≤ S/4

Vref < Vt ≤ S/2

Vref < Vt ≤ 4S/5

Vt ≥ 4S/16

Vt ≥ Vref+S

(30); see note 3

(30); see note 3

0.6

1.2

2.4

4.8

9.6

NOTE:

1) (30) means that toner is supplied intermittently in a 1/3 duty cycle (1 s

on, 2 s off) for 30 seconds

2-20

Page 49

1 October, 1999 DEVELOPMENT

2.4.7 TONER NEAR END/END DETECTION AND RECOVERY

The toner near end and end conditions are detected using the Vt and Vref values,

in a similar way to toner density control.

This is done in all toner supply modes except for fixed quantity 2, when toner end is

not detected.

Toner Near End Detection

If Vt is at level 6 (see the table on the previous page) five times consecutively, the

machine enters the toner near end condition and the toner end indicator starts

blinking. Then the machine supplies toner for a certain time in accordance with the

table explained in the previous section.

Toner Near End Recovery

If the machine detects “Vt < (Vref or Vts) + 4S/5” twice consecutively when in one

of the following situations, the machine leaves the toner near end condition.

•

While in the toner recovery cycle (supplying toner on and off for 30 s - see

the previous page) after the machine has detected a toner near end

condition.

•

During printing in the toner near end condition.

•

If the front cover is opened and closed for more than 10 seconds while a

toner near end condition exists.

Detailed

Descriptions

Toner End Detection

There are two situations for entering the toner end condition.

•

When Vt is level 7 th ree times consecutively, the machine enters the toner

end condition.

•