Page 1

Russian Printer-2

SERVICE MANUAL

September 29, 2000

Subject to change

Page 2

I

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

Page 3

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

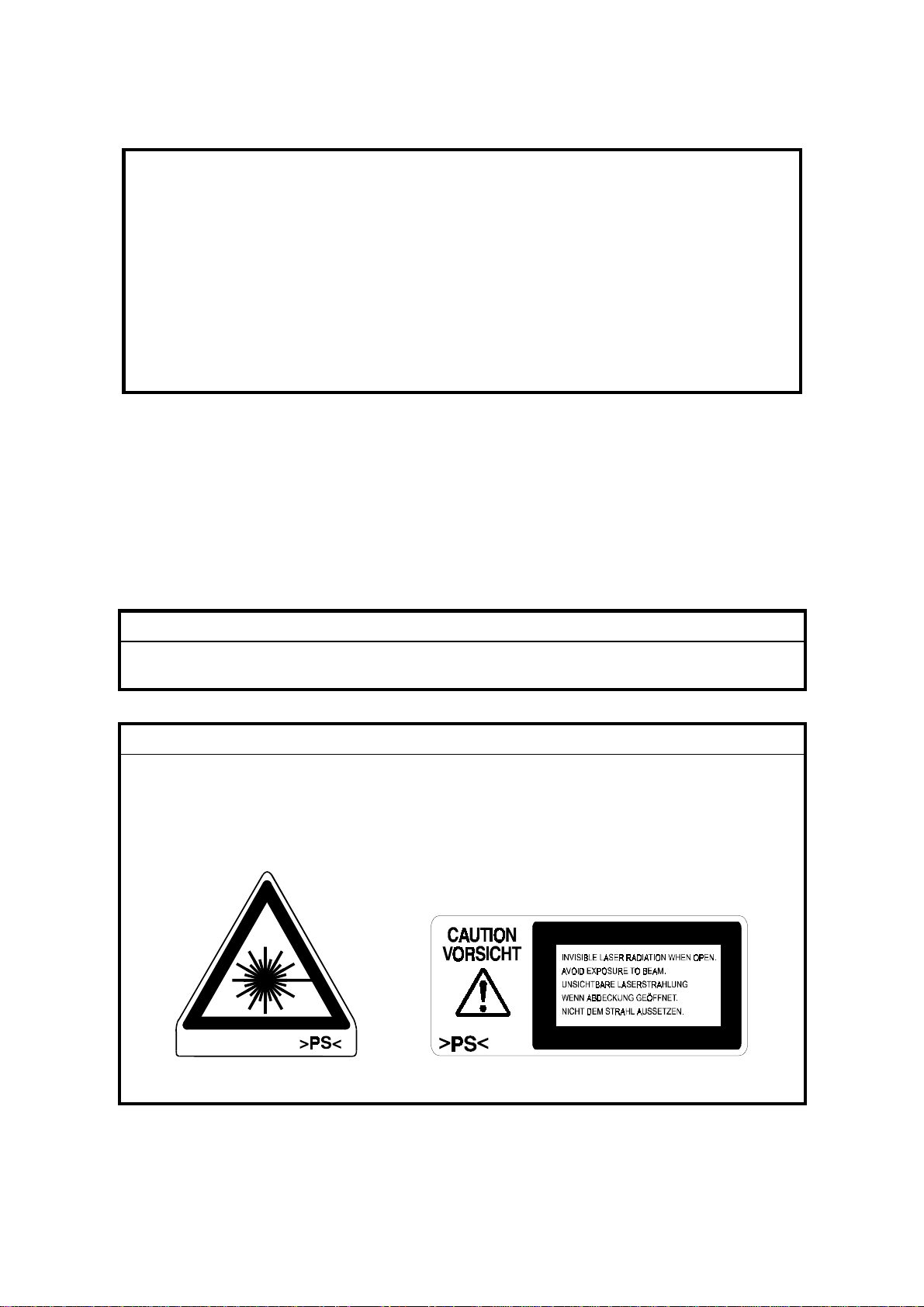

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!

WARNING

WARNING: Turn off the main switch before atte mpting any of the

procedures in the Laser Unit section. Laser beams can seriously damage

your eyes.

CAUTION MARKING:

Page 4

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft

Corporation in the United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines

Corporation.

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved

with those marks.

Page 5

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION....................................... 1-1

1.1 SPECIFICATIONS.....................................................................................1-1

1.1.1 GENERAL SPECIFICATIONS..........................................................1-1

1.1.2 SUPPORTED PAPER SIZES...........................................................1-2

1.2 SOFTWARE ACCESSORIES ...................................................................1-3

1.2.1 PRINTER DRIVERS.........................................................................1-3

1.2.2 UTILITY SOFTWARE.......................................................................1-3

1.2.3 SERVICE TOOLS.............................................................................1-3

1.3 MACHINE CONFIGURATION...................................................................1-4

1.3.1 SYSTEM COMPONENTS ................................................................1-4

1.4 ELECTRICAL COMPONENT DESCRIPTIONS ........................................1-6

1.5 BOARD STRUCTURE...............................................................................1-8

1.5.1 OVERVIEW ......................................................................................1-8

2. DETAILED SECTION DESCRIPTIONS ...................................... 2-1

2.1 DIFFERENT POINTS FROM BASE MODEL (G038) ................................2-1

2.1.1 OVERVIEW ......................................................................................2-1

2.1.2 PAPER FEED SECTION..................................................................2-2

2.1.3 LASER EXPOSURE SECTION........................................................2-2

2.1.4 DEVELOPMENT SECTION..............................................................2-2

2.1.5 ENGINE CONTROLLER BOARD.....................................................2-2

2.1.6 CONTROLLER BOARD ...................................................................2-3

3. INSTALLA TION .......................................................................... 3-1

3.1 INSTALLING THE MACHINE ....................................................................3-1

3.2 INSTALLING OPTIONAL UNITS...............................................................3-2

3.2.1 1,000-SHEET FINISHER..................................................................3-2

Installation Procedure ...........................................................................3-2

4. SERVICE TABLES...................................................................... 4-1

4.1 PRINTER CONTROLLER SERVICE MODE.............................................4-1

4.2 PRINTER ENGINE SERVICE MODE........................................................4-1

4.3 CONTROLLER FIRMWARE UPDATE......................................................4-2

4.3.1 FIRMWARE DOWNLOAD................................................................4-2

5. PREVENTIVE MAINTENANCE................................................... 5-1

6. REPLACEMENT AND ADJUSTMENT........................................ 6-1

6.1 LASER UNIT .............................................................................................6-1

6.1.1 CAUTION DECAL LOCATIONS.......................................................6-1

6.1.2 LASER UNIT ....................................................................................6-2

7. TROUBLESHOOTING................................................................ 7-1

i

Page 6

OPTIONS

500-SHEET FINISHER (G302)

1. REPLACEMENT AND ADJUSTMENT..................................G302-1

1.1 EXTERIOR ......................................................................................... G302-1

1.2 ENTRANCE UPPER GUIDE / PAPER EXIT UNIT............................. G302-4

1.3 ENTRANCE LOWER GUIDE .............................................................G302-5

1.4 PAPER EXIT UNIT GEAR / PADDLE ROLLER SOLENOID............. G302-5

1.5 STAPLER UNIT.................................................................................. G302-6

1.6 JOGGER TRAY UNIT ........................................................................ G302-6

1.7 PAPER EXIT SENSOR FEELER .......................................................G302-7

1.8 MAIN MOTOR .................................................................................... G302-7

1.9 JOGGER MOTOR.............................................................................. G302-8

1.10 CONTROL BOARD .......................................................................... G302-8

1.11 SHIFT TRAY UNIT ........................................................................... G302-9

2. DETAILED DESCRIPTIONS...............................................G302-10

2.1 OVERALL MACHINE INFORMATION ............................................. G302-10

2.1.1 COMPONENT LAYOUT.......................................................... G302-10

Mechanical component layout .....................................................G302-10

Drive layout.................................................................................. G302-11

2.1.2 ELECTRICAL COMPONENT DESCRIPTIONS ...................... G302-12

2.2 DETAILED SECTION DESCRIPTIONS ........................................... G302-14

2.2.1 SHIFT TRAY MECHANISM..................................................... G302-14

Stack height detection..................................................................G302-14

Shift tray up/down mechanism..................................................... G302-15

2.2.2 PAPER FEED.......................................................................... G302-16

Overview...................................................................................... G302-16

Straight feed out mode.................................................................G302-16

Shifting mode............................................................................... G302-17

Staple mode................................................................................. G302-19

2.2.3 JAM CONDITIONS.................................................................. G302-20

2.2.4 ERROR DETECTION.............................................................. G302-20

3. SPECIFICATIONS...............................................................G302-21

PAPER TRAY UNIT (A860): Common with Russian-P

1. OVERALL MACHINE INFORMAT ION..................................A860-1

1.1 SPECIFICATIONS.............................................................................. A860-1

1.2 MECHANICAL COMPONENT LAYOUT ............................................ A860-2

1.3 ELECTRICAL COMPONENT LAYOUT.............................................. A860-3

1.4 ELECTRICAL COMPONENT DESCRIPTION.................................... A860-4

1.5 DRIVE LAYOUT ................................................................................. A860-5

ii

Page 7

2. DETAILED DESCRIPTIONS.................................................A860-6

2.1 PAPER FEED AND SEPARATION MECHANISM ............................. A860-6

2.2 PAPER LIFT MECHANISM................................................................ A860-7

2.3 PAPER END DETECTION................................................................. A860-9

2.4 PAPER HEIGHT DETECTION ......................................................... A860-10

2.5 PAPER SIZE DETECTION............................................................... A860-12

2.6 SIDE AND END FENCES ................................................................ A860-13

Side Fences................................................................................. A860-13

End Fence ................................................................................... A860-13

3. REPLACEMENT AND ADJUSTMENT................................A860-14

3.1 FEED ROLLER REPLACEMENT..................................................... A860-14

3.2 TRAY MAIN BOARD REPLACEMENT ............................................ A860-15

3.3 TRAY MOTOR REPLACEMENT...................................................... A860-15

3.4 RELAY CLUTCH REPLACEMENT .................................................. A860-16

3.5 UPPER PAPER FEED CLUTCH REPLACEMENT .......................... A860-17

3.6 LOWER PAPER FEED CLUTCH REPLACEMENT ......................... A860-18

3.7 LIFT MOTOR REPLACEMENT........................................................ A860-19

3.8 PAPER END SENSOR REPLACEMENT......................................... A860-20

3.9 VERTICAL TRANSPORT SENSOR REPLACEMENT ..................... A860-20

3.10 PAPER SIZE SWITCH REPLACEMENT ....................................... A860-21

LCT (A862): Common with Russian-P

1. OVERALL MACHINE INFORMAT ION..................................A862-1

1.1 SPECIFICATIONS.............................................................................. A862-1

1.2 MECHANICAL COMPONENT LAYOUT ............................................ A862-2

1.3 ELECTRICAL COMPONENT LAYOUT.............................................. A862-3

1.4 ELECTRICAL COMPONENT DESCRIPTIONS ................................. A862-4

2. DETAILED SECTION DESCRIPTIONS ................................A862-5

2.1 PAPER FEED..................................................................................... A862-5

2.2 REVERSE ROLLER AND PICK-UP ROLLER RELEASE .................. A862-6

2.3 TRAY LIFT ......................................................................................... A862-7

2.4 NEAR END/END DETECTION........................................................... A862-8

2.5 RIGHT TRAY SIDE FENCE ............................................................... A862-9

2.6 LEFT TRAY REAR FENCE................................................................ A862-9

2.7 RIGHT TRAY PAPER END DETECTION ........................................ A862-10

3. REPLACEMENT AND ADJUSTMENT................................A862-11

3.1 DETACHING THE TRAY FROM THE MAINFRAME........................ A862-11

3.2 REAR FENCE HP SENSOR ............................................................ A862-11

3.3 CHANGING THE TRAY PAPER SIZE ............................................. A862-12

3.4 LEFT TRAY PAPER END SENSOR ................................................ A862-12

3.5 TRAY LIFT MOTOR ......................................................................... A862-13

3.6 TRAY MOTOR.................................................................................. A862-14

iii

Page 8

3.7 PAPER FEED CLUTCH AND RELAY CLUTCH............................... A862-15

3.8 PAPER FEED UNIT ......................................................................... A862-16

3.9 UPPER LIMIT, RIGHT TRAY PAPER END, AND

RELAY SENSORS ........................................................................... A862-17

3.10 REAR FENCE MOTOR .................................................................. A862-18

3.11 PICK-UP/PAPER FEED/REVERSE ROLLERS.............................. A862-19

BY-PASS UNIT (A899): Common with Russian-P

1 OVERALL MACHINE INFORMATION...................................A899-1

1.1 SPECIFICATIONS.............................................................................. A899-1

1.2 MECHANICAL COMPONENT LAYOUT ............................................ A899-1

1.3 ELECTRICAL COMPONENT LAYOUT.............................................. A899-2

1.4 ELECTRICAL COMPONENT DESCRIPTION.................................... A899-2

2 DETAILED DESCRIPTIONS..................................................A899-3

2.1 BASIC OPERATION........................................................................... A899-3

2.2 PAPER SIZE DETECTION................................................................. A899-4

3 REPLACEMENT AND ADJUSTMENT...................................A899-5

3.1 PAPER FEED ROLLER/FRICTION PAD/PAPER END SENSOR...... A899-5

3.2 PAPER SIZE SENSOR BOARD......................................................... A899-6

3.3 PAPER FEED CLUTCH ..................................................................... A899-7

INTERCHANGE UNIT (G531): Common with Russian-P

1. OVERALL MACHINE INFORMATION..................................G531-1

1.1 SPECIFICATIONS..............................................................................G531-1

1.2 MECHANICAL COMPONENT LAYOUT ............................................G531-2

1.3 DRIVE LAYOUT ................................................................................. G531-3

2. DETAILED DESCRIPTION ................................................... G531-4

2.1 JUNCTION GATE MECHANISM........................................................ G531-4

To the Exit Tray or Bridge Unit (for the Upper Tray on top of

the Bridge Unit, or the Finisher) ..................................................... G531-4

To the 1-bin Tray............................................................................G531-4

To the Duplex Unit ......................................................................... G531-4

3. REPLACEMENT AND ADJUSTMENT..................................G531-5

3.1 EXIT SENSOR REPLACEMENT........................................................G531-5

iv

Page 9

DUPLEX UNIT (G582) : The contents of manual are the same as

G529 manual.

1. OVERALL MACHINE INFORMATION..................................G529-1

1.1 SPECIFICATIONS..............................................................................G529-1

1.2 MECHANICAL COMPONENT LAYOUT ............................................G529-2

1.3 ELECTRICAL COMPONENT LAYOUT.............................................. G529-3

1.4 ELECTRICAL COMPONENT DESCRIPTION.................................... G529-4

1.5 DRIVE LAYOUT ................................................................................. G529-5

2. DETAILED DESCRIPTIONS.................................................G529-6

2.1 BASIC OPERATION...........................................................................G529-6

Larger than A4 lengthwise/LT Lengthwise..................................... G529-6

Up to A4 Lengthwise/LT lengthwise............................................... G529-7

2.2 FEED IN AND EXIT MECHANISM ..................................................... G529-8

When Paper is Fed Into Duplex Unit:............................................. G529-8

Inversion and Exit: ......................................................................... G529-8

3. REPLACEMENT AND ADJUSTMENT..................................G529-9

3.1 COVER REMOVAL ............................................................................ G529-9

3.2 ENTRANCE SENSOR REPLACEMENT.......................................... G529-10

3.3 EXIT SENSOR REPLACEMENT...................................................... G529-11

BRIDGE UNIT (G583): The contents of manual are the same as

A897 manual

1. OVERALL MACHINE INFORMAT ION..................................A897-1

1.1 SPECIFICATIONS.............................................................................. A897-1

1.2 MECHANICAL COMPONENT LAYOUT ............................................ A897-2

1.3 ELECTRICAL COMPONENT LAYOUT.............................................. A897-3

1.4 ELECTRICAL COMPONENT DESCRIPTION.................................... A897-4

1.5 DRIVE LAYOUT ................................................................................. A897-5

2. DETAILED DESCRIPTION ...................................................A897-6

2.1 JUNCTION GATE MECHANISM........................................................ A897-6

3. REPLACEMENT AND ADJUSTMENT..................................A897-7

3.1 BRIDGE UNIT DRIVE MOTOR REPLACEMENT .............................. A897-7

3.2 TRAY EXIT SENSOR REPLACEMENT ............................................. A897-8

3.3 RELAY SENSOR REPLACEMENT.................................................... A897-8

v

Page 10

FINISHER (A681): Common with Russian-P

1. OVERALL MACHINE INFORMAT ION..................................A681-1

1.1 SPECIFICATIONS.............................................................................. A681-1

1.2 MECHANICAL COMPONENT LAYOUT ............................................ A681-2

1.3 ELECTRICAL COMPONENT LAYOUT.............................................. A681-3

1.4 ELECTRICAL COMPONENT DESCRIPTIONS ................................. A681-4

1.5 DRIVE LAYOUT ................................................................................. A681-6

2. DETAILED DESCRIPTIONS.................................................A681-7

2.1 JUNCTION GATE MECHANISM........................................................ A681-7

Staple Mode................................................................................... A681-7

No staple Mode.............................................................................. A681-7

2.2 JOGGER UNIT PAPER POSITIONING MECHANISM....................... A681-8

2.3 EXIT GUIDE PLATE OPEN/CLOSE MECHANISM............................ A681-9

2.4 STAPLER ......................................................................................... A681-10

2.5 FEED OUT MECHANISM ................................................................ A681-11

2.6 SHIFT TRAY UP/DOWN MECHANISM ........................................... A681-12

2.7 SHIFT TRAY SIDE-TO-SIDE MECHANISM..................................... A681-13

2.8 JAM CONDITIONS........................................................................... A681-14

2.9 TIMING CHARTS ............................................................................. A681-15

2.9.1 NO STAPLE MODE (A4 SIDEWAYS, 3 SHEETS/2SETS)...... A681-15

2.9.2 STAPLE MODE (A4 SIDEWAYS, 2 SHEETS/2 SETS)........... A681-16

3. SERVICE TABLE................................................................A681-17

3.1 DIP SWITCH TABLE........................................................................ A681-17

3.2 TEST POINTS.................................................................................. A681-17

3.3 FUSES ............................................................................................. A681-17

4. REPLACEMENT AND ADJUSTMENT................................A681-18

4.1 COVER REMOVAL .......................................................................... A681-18

Front Door.................................................................................... A681-18

Front Cover.................................................................................. A681-18

Rear Cover .................................................................................. A681-18

Upper Cover ................................................................................ A681-18

Lower Left Cover ......................................................................... A681-19

Front Shift Tray Cover.................................................................. A681-19

Rear Shift Tray Cover .................................................................. A681-19

Shift Tray ..................................................................................... A681-19

4.2 ENTRANCE SENSOR REPLACEMENT.......................................... A681-20

4.3 EXIT SENSOR REPLACEMENT...................................................... A681-21

4.4 STACK HEIGHT SENSOR REPLACEMENT ................................... A681-22

4.5 POSITIONING ROLLER REPLACEMENT....................................... A681-23

4.6 STAPLER REPLACEMENT ............................................................. A681-24

vi

Page 11

MAILBOX (G518): Common with Russian-P

1. OVERALL MACHINE INFORMATION..................................G518-1

1.1 SPECIFICATIONS..............................................................................G518-1

1.2 COMPONENT LAYOUT..................................................................... G518-2

1.2.1 MECHANICAL COMPONENT LAYOUT.................................... G518-2

1.2.2 DRIVE LAYOUT ........................................................................ G518-2

1.3 ELECTRICAL COMPONENT DESCRIPTIONS ................................. G518-3

2. DETAILED DESCRIPTIONS.................................................G518-5

2.1 BASIC OPERATION...........................................................................G518-5

2.2 PAPER OVERFLOW DETECTION .................................................... G518-6

2.2.1 OVERVIEW ............................................................................... G518-6

2.2.2 DETECTION TIMING ................................................................ G518-6

2.3 PAPER MISFEED DETECTION TIMING ........................................... G518-7

3. REPLACEMENT AND ADJUSTMENT..................................G518-9

3.1 EXTERIOR COVER REMOVAL ......................................................... G518-9

3.2 TRAY OVERFLOW AND VERTICAL TRANSPORT SENSOR

REPLACEMENT .............................................................................. G518-10

3.3 MAIN MOTOR REPLACEMENT ...................................................... G518-11

vii

Page 12

29 September, 2000 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

1.1.1 GENERAL SPECIFICATIONS

Printing Speed: Maximum 32 pages per minute (A4/LT LEF)

(25 pages: duplex printing)

Printer Language: PCL 6 / PCL 5e

PostScript 3

Resolution: Max. 600 dpi (PCL 6/PCL5e/PS3)

Resident Fonts: PCL:

35 Intellifonts

10 True Type fonts

1 Bitmap font

PS3:

136 fonts (24 Type 2 fonts, 112 Type 14 fonts)

Host Interface: Bi-directional IEEE1284 parallel x 1 (Standard)

Ethernet (100 Base-TX/10 Base-T for TCP/IP, IPX/SPX,

NetBEUI, Apple Talk)

Printing Paper Size: Maximum: A3/11" x 17"

Minimum:

1st paper Tray: A5 SEF

2nd paper Tray: A6 SEF

By-pass: A6/ 90 x 148 mm SEF

Overall

Information

(Refer to section 1.1.2, "Supported Paper Size".)

Printing Paper

Weight:

Print Paper

Capacity:

1st paper tray: 60 to 105 g/m

2nd paper tray: 60 to 157 g/m

By-pass Tray: 60 to 200 g/m

1st and 2nd paper tray: 500 sheets x 2

Optional paper tray unit:

2

(16 to 28 lb.)

2

(16 to 42 lb.)

2

(16 to 110 Index)

500 sheets x 2

Optional LCT

1000 sheets x 2

Optional by-pass tray:

100 sheets

Output Paper

Capacity:

Standard output tray: 500 sheets

Optional 1000-finisher: 1,000 sheets

Optional 500-finisher: 500 sheets

Optional 4-bin mailbox: 500 sheets total

First Print Speed: 5 seconds or less (A4/LT LEF, 1st tray)

Warm-up Time Less than 45 seconds

1-1

Page 13

SPECIFICATIONS 29 September, 2000

Memory:

Standard 32 MB, up to 160 MB with optional DIMM.

Power Source: 120 V, 60 Hz: More than 10 A (for North America)

220 V - 240 V, 50/60 Hz: More than 6.0 A (for Europe)

Power Consumption:

120V 230V

Maximum

(Full Option)

Printing 620W or less 620W or less

Energy Saver

(Mode 1)

980W or less 980W or less

25 W or less 25 W or less

Noise Emission:

Mainframe Only Full System

Sound Power Lev el

Printing 65 dB or less 71 dB or less

Stand-by 40 dB or less 40 dB or less

NOTE: The above measurements were made in accordance with ISO 9296 at

the operator position.

Dimensions (W x D x H): 550 x 548 x 516 mm

Weight:

Approximately 40 kg

1.1.2 SUPPORTED PAPER SIZES

No differences from base model (G038).

Refer to the Field Service Manual for G308.

1-2

Page 14

29 September, 2000 SOFTWARE ACCESSORIES

1.2 SOFTWARE ACCESSORIES

The printer drivers and utility software are provided on one CD-ROM. An auto-run

installer allows you to select which components to install. The service tools are not

provided on the CD-ROM.

1.2.1 PRINTER DRIVERS

Printer Language Windows 95/98 Windows 2000 Windows NT4.0 Macintosh

PCL 6 Yes Yes Yes No

PCL 5e Yes Yes Yes No

PS3 Yes Yes Yes Yes

NOTE: 1) The printer drivers for Windows NT 4.0 are only for the Intel x86

platform. There is no Windows NT 4.0 printer driver for PowerPC, Alpha,

or MIPS platforms.

2) The PS3 drivers are all genuine AdobePS drivers. A PPD file for each

operating system is provided with the driver.

3) The PS3 drivers for Macintosh support Mac OS 7.1 or later versions.

Overall

Information

1.2.2 UTILITY SOFTWARE

Software Description

Agfa Font Manager

(Win 95/98, 2000, NT4)

Printer Manager for Admin

(Win 95/98, 2000, NT4)

Printer Manager for Client

(Win95/98, 2000, NT4)

Port Navi

(Win95/98, 2000, NT4)

Multi-Direct Print

(Win95/98, 2000, NT4)

Acrobat Reader Document reader for PDF format

A font management utility with screen fonts for the printer.

A printer management utility for network administrators. NIB

setup utilities are also available.

A printer management utility for client users.

A peer to peer print utility over a TCP/IP network. This provides

parallel printing and recovery printing function.

A utility for peer-to-peer printing over a NetBEUI or TCP/IP

network.

1.2.3 SERVICE TOOLS

Software Description

NBTFTP NIB firmware update utility for use on a NetBEUI network.

This utility is not on the Driver and Utilities CD-ROM; it is issued

separately as a service tool

1-3

Page 15

MACHINE CONFIGURATION 29 September, 2000

1.3 MACHINE CONFIGURATION

1.3.1 SYSTEM COMPONENTS

[H]

[G]

[I]

[J]

[A]

[B]

[C]

[D]

[F]

1-4

[E]

G062V502.WMF

Page 16

29 September, 2000 MACHINE CONFIGURATION

Item

Main Unit G062 I User

Option

Paper Tray Unit - 2

trays

LCT A862

By-pass Tray A899

Interchange Unit G531 B User Common with Russian-P

Duplex Unit G582 C User

4-bin Mailbox G518 A

Bridge Unit G583 J User New model

500-sheet Finisher G302 H User New model

1000-sheet

Finisher

Internal Option

HDD G690 User Common with Stinger-

Memory 32MB G578 User

Memory 64MB G579 User

Memory 128MB G580 User

Others

Maintenance Kit G719

Machine

Code

A860

A681 G Service

No.

F

E

D

Installable

by

User

(Note 1)

User

(Note 1)

User Common with Russian-

(Note 2, 3)

User

(Note 2)

(Note 4)

Common with Stinger-

C/Russian-C/P with

modified motor.

Common with Russian-

C/P with modified tray

motor.

C/P

New model

Common with Russian-P

with modified motor and

driver board.

Common with RussianC/P/NAD

C/Russian-C/P

Remarks

Overall

Information

NOTE: 1) Only one of these options can be installed on the machine.

2) Requires the installation of the Interchange unit.

3) Requires the installation of the memory option.

4) The Bridge unit must be installed together with the 1000 sheet Finisher.

Either the LCT or Paper Tray Unit (2 trays) must also be installed.

1-5

Page 17

ELECTRICAL COMPONENT DESCRIPTIONS 29 September, 2000

1.4 ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout on the reverse side of the point-to-point

diagram for component location.

A polygonal mirror motor fan (M7) was added.

Symbol Name Function

Motors

M1 Polygonal Mirror Turns the polygonal mirror.

M2 Main Motor Drives the main unit components.

M3 Exhaust Fan Removes heat from around the fusing unit.

M4 Upper Paper Lift Raises the bottom plate in the 1st paper tray.

M5 Lower Paper Lift Raises the bottom plate in the 2nd paper tray.

M6 Toner Supply

M7

Magnetic Clutches

MC1 Upper Paper Feed Starts paper feed from the 1st paper tray.

MC2 Lower Paper Feed Starts paper feed from the 2nd paper tray.

MC3 Upper Paper Transport Drives the upper transport rollers.

MC4 Lower Paper Transport Drives the lower transport rollers.

MC5 Registration Drives the registration rollers.

Switches

SW1 Main Switch

SW2 Right Upper Cover Detects whether right upper cover is open or not.

SW3 Right Cover

SW4 Right Lower Cover Detects whether right lower cover is open or not.

SW5 Upper Paper Size

SW6 Lower Paper Size

SW7 Special Paper

SW8 New PCU Detect Detects when a new PCU is installed.

SW9 Front Cover Safety

Sensors

S1 Toner Density (TD)

S2 1st Paper End

S3 1st Paper End

S4 Image Density (ID)

S5 Paper Overflow Detects paper overflow condition.

S6 Paper Exit Detects misfeeds.

S7 Upper Relay Detects misfeeds.

Polygonal Mirror Motor

Fan

Rotates the toner bottle to supply toner to the

development unit.

Removes heat from around the optical unit

Provides power to the machine. If this is off, there is

no power supplied to the machine.

Cuts the +5VLD and +24V dc power line and

detects whether the right cover is open or not.

Determines what size of paper is in the upper

paper tray.

Determines what size of paper is in the Lower

paper tray.

Determines the special paper is in the lower paper

tray.

Cuts the +5VLD and +24V dc power line and

detects whether the front cover is open or not.

Detects the amount of toner inside the

development unit.

Informs the CPU when the 1st paper tray runs out

of paper.

Informs the CPU when the 2nd paper tray runs out

of paper.

Detects the density of various patterns and the

reflectivity of the drum for process control.

1-6

Page 18

29 September, 2000 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function

S8 Lower Relay Detects misfeeds.

S9 Registration

S10 1st Paper Lift

S11 2nd Paper Lift

Detects misfeeds and controls registration clutch

off-on timing.

Detects when the paper in the 1st paper tray is at

the feed height.

Detects when the paper in the 2nd paper tray is at

the feed height.

S12 1st Paper Height - 1 Detects the amount of paper in the 1st paper tray.

S13 1st Paper Height - 2 Detects the amount of paper in the 1st paper tray.

S14 2nd Paper Height - 1 Detects the amount of paper in the 2nd paper tray.

S150 2nd Paper Height - 2 Detects the amount of paper in the 2nd paper tray.

PCBs

PCB1 Engine Board Controls all printer engine functions.

PCB2 Printer Controller Board Controls the printer functions

PCB3 Network Interface Board Network interface board

PCB4 PSU (Power Supply Unit)

Provides dc power to the system and ac power to

the fusing lamp and heaters.

PCB5 LDD (Laser Diode Driver) Controls the laser diode.

PCB6 Operation Panel Controls the operation panel.

PCB7 High Voltage Supply

Supplies high voltage to the drum charge roller,

development roller, and transfer roller.

PCB8 Memory (Option) Expands memory capacity.

Lamps

L1 Fusing Lamp Heats the hot roller.

L2 Quenching Lamp

Neutralizes any charge remaining on the drum

surface after cleaning.

Others

TF1 Fusing Thermofuse

Opens the fusing lamp circuit if the fusing unit

overheats.

TH1 Fusing Thermistor Detects the temperature of the hot roller.

LSD 1

Laser Synchronization

Detector

Detects the laser beam at the start of the main

scan.

Overall

Information

1-7

Page 19

BOARD STRUCTURE 29 September, 2000

1.5 BOARD STRUCTURE

1.5.1 OVERVIEW

The PS module is contained in the Printer Controller Board.

1-8

G062V501.WMF

Page 20

29 September, 2000 DIFFERENT POINTS FROM BASE MODEL (G038)

2. DETAILED SECTION DESCRIPTIONS

2.1 DIFFERENT POINTS FROM BASE MODEL (G038)

2.1.1 OVERVIEW

The following points are different from the base model (G038)

1. Printing Speed

G062 Base Model (G038)

Printing Speed

(25 ppm duplex printing)

To obtain the above higher printing speed, the following sections were changed

from the base model G038.

1) Paper feed

2) Laser exposure

3) Development (Quenching)

32 ppm

27 ppm

(22 ppm duplex printing)

Detailed

Descriptions

4) Engine controller

5) Printer controller

2. Controller features

The following features were added.

1) Locked print

2) Sequential stack

2-1

Page 21

DIFFERENT POINTS FROM BASE MODEL (G038) 29 September, 2000

2.1.2 PAPER FEED SECTION

The followings differ from the base model (G038) in the paper feed section to get

higher printing speed.

1. Registration roller

The diameter of the gears were changed.

2. Registration pressure roller and pressure springs

The diameter of the roller and pressure force of springs were changed.

3. Relay rollers

Diameter of upper and lower relay roller is changed.

4. The number of flywheels was changed from 3 to 2 in order to stabilize the

rotation of the main motor.

2.1.3 LASER EXPOSURE SECTION

The following optical unit items differ from the base model(G038).

1. Polygonal Mirror Motor

An increase in the speed of the polygonal mirror motor enables an increase in

the printing speed.

G062 Base Model (G038)

Mirror motor revolution

speed

38,000 rpm 31,000 rpm

2. Polygonal Mirror Motor Fan

A polygonal mirror motor fan was added to remove heat from around the

Optical unit.

2.1.4 DEVELOPMENT SECTION

The quenching lamp was changed to increase the amount of light.

2.1.5 ENGINE CONTROLLER BOARD

1. The fusing temperature in energy saver mode was changed.

Energy saver mode G062 Base Model (G038)

Level 1

Level 2 Off Off

140 °C 60 °C

2. The hardware and firmware were changed to increase the printing speed.

2-2

Page 22

29 September, 2000 DIFFERENT POINTS FROM BASE MODEL (G038)

2.1.6 CONTROLLER BOARD

The following items differ from the base model:

1. A PS DIMM was included in the printer controller board.

2. CPU and standard memory size were changed for higher performance.

G062 Base Model (G038)

CPU

Standard Memory

RM5261 250MHz Vr.4310 167MHz

32 MB 16 MB

3. New controller features

Locked print

This function protects users' confidentiality for printouts using a shared printer

when anyone wishes to print confidential documents. With this function,

documents will not print out unless the user enters a valid password, which

was entered in the Printer Driver when sending the print job(s), at the printer

controller panel. This function is only applicable when the optional HDD is

attached.

Capacity

Max. Storing pages

Max. Job storing

Max. Overflow job record

Max. Storing capacity (HDD)

2000 pages*

30 jobs*

20 jobs

2GBMB

Detailed

Descriptions

*: These figures are for both the sample and locked print functions.

Sequential stack

This function, with optional mailbox, enables the user to continue printing by

automatically changing output trays when the current output tray becomes full.

To enable this function, select "Sequential Stack" mode from the operation

panel.

The output tray will automatically be chosen as follows.

(Case 1: Finisher is attached)

Finisher Tray -> Mailbox Tray 1 -> Mailbox Tray 2 -> Mailbox Tray 3 ->

Mailbox Tray 4

* Standard Tray (on the bridge unit) will not be used as output tray.

(Case 2: Finisher is not attached)

Standard Tray -> Mailbox Tray 1 -> Mailbox Tray 2 -> Mailbox Tray 3 ->

Mailbox Tray 4

2-3

Page 23

DIFFERENT POINTS FROM BASE MODEL (G038) 29 September, 2000

Other conditions and remarks are as follows.

1) The tray will automatically change after the full stack detection sensor is

activated for each tray.

2) When Mailbox Tray 4 is full, the "Remove Paper All Tray" message appears

on the LCD.

3) When all of the paper is removed from all of the trays (cancelled full stack

detection), printing will restart from the Finisher Tray (Case 1) or the

Standard Tray (Case 2).

4) When "Collation" is selected, SHIFT/SORT will be enabled on the Finisher

Tray, but rotate collation will be disabled for the Mailbox Trays. (Case 1)

5) When "Collation" is selected, rotate collation will be enabled. (Case 2)

6) When "Staple" is selected, it will be enabled on the Finisher Tray.

7) When “Sequential Stack” is selected during continuous multiple print jobs,

the tray will not be change between 2 different jobs. It will continue to output

paper to the current tray until the tray becomes full. Then, it will switch to

another tray.

8) If any tray is out of order, that particular tray will be skipped and if there are

no trays to change to, the machine will indicate "Remove Paper All Tray", as

in step 2.

2-4

Page 24

29 September, 2000 INSTALLING THE MACHINE

3. INSTALLATION

3.1 INSTALLING THE MACHINE

Refer to the Setup Guide for information about the installation environment and

instructions on how to install and set up this machine. Installation procedures for

the following items are described.

• Paper Tray (2 trays)

• LCT

• By-pass Tray Unit

• Interchange Unit

• Duplex Unit

• 4-bin Mailbox Unit

• Bridge Unit

• 500-Sheet Finisher

• Memory (SDRAM DIMM)

• HDD Unit

InstallationInstallation

If the customer has a service contract with a meter click system and counter

indication is required, set up the counter with an SP mode as follows:

1. Enter the Service mode.

2. Set 1 at the bit1 of “C. BitSw #3 set” in Service Menu1.

3. Exit Service mode

4. Confirm the counter is indicated on operation panel by pressing [Menu] and

[Enter] keys.

3-1

Page 25

INSTALLING OPTIONAL UNITS 29 September, 2000

3.2 INSTALLING OPTIONAL UNITS

!

CAUTION

Before installing this option, do the following:

1. Print out all data in the printer buffer.

2. Turn off the switch and disconnect the power cord.

3.2.1 1,000-SHEET FINISHER

NOTE: The following options must be installed before installing this finisher:

• Bridge Unit (G583)

• Paper Tray Unit (G532) or LCT (G539)

Installation Procedure

1. Unpack the finisher and remove the tapes.

A681I503.WMF

2. Install screw [A] loosely.

3. Hang the front stand [B] on the screw

that was installed in step 2.

4. Secure the front stand (3 screws,

including screw [A]).

5. Install the rear stand [C] (2 screws).

A681I504.WMF

[A]

[C]

[B]

A681I101.WMF

3-2

Page 26

29 September, 2000 INSTALLING OPTIONAL UNITS

6. Pull out the stapler unit [D].

7. Draw out the locking lever [E] (1 screw).

8. Align the finisher on the stands, and lock it in

place by pushing the locking lever.

9. Secure the locking lever (1 screw) and push

the stapler unit into the finisher.

10. Secure the finisher (1 screw from

step 2).

11. Adjust the securing knobs [F] under

the front and rear stand until the

finisher is perpendicular to the floor.

[G]

12. Install the shift tray [G] (1 snap ring).

NOTE: Make sure that the three pegs

[H] fit into the slots [I]

properly.

[H]

13. Connect the finisher cable [J] to the

optional bridge unit.

14. Turn on the main switch and check

[I]

the finisher operation.

[D]

[E]

A681I502.WMF

[J]

InstallationInstallation

A681I103.WMF

[F]

End of procedure

3-3

Page 27

29 September, 2000 PRINTER CONTROLLER SERVICE MODE

4. SERVICE TABLES

4.1 PRINTER CONTROLLER SERVICE MODE

The following Bit Switches were added to the base model G038.

Title Description Function / Note

C BitSw #3 Set

Bit 1 : Counter indication

0: Disable (default)

1: Enable

Bit 2 : Job uniting

0: Disable (default)

1: Enable

Bit 3 : HP GL/2 Emulation

0: Normal (default)

1: Enhancing thin lines

Bit 4 : DAZEL compatibility

0: Enable (default)

1: Disable

Bit 5 : Not used

Bit 6 : Not used

Bit 7 : Not used

Bit 8 : Border pattern printing

0: Disable (default)

1: Enable

The customer can view the

Charge Counter on the LCD

panel using the “Menu”

function.

Uniting jobs if PC sends the

next job before printer

completes the current job.

(see note)

If thin lines can not be

reproduced with CAD

application, set this bit “1”.

If malfunction occurs on the

printer because of job

command, disabling this

switch.

The border pattern is printed

on the Configuration sheet for

leading edge/side-to-side

registration adjustment.

Tables

Service

NOTE: When enabling this function, the “Jog log” does not show the actual job,

and job canceling is applied to whole combined jobs.

4.2 PRINTER ENGINE SERVICE MODE

Only the title of the following service menu differs from the base model G038.

Menu Level

Level 1 Level 2 Description

3:

Notify PM

Alarm

Maintenance

replacement

warning and

Select enabling / disabling PM

alert and printing stop after 5K

printing from the alert.

4-1

Function Settings

0.Alert only

1.Stop printing

2.No message

Page 28

CONTROLLER FIRMWARE UPDATE 29 September, 2000

4.3 CONTROLLER FIRMWARE UPDATE

4.3.1 FIRMWARE DOWNLOAD

The PS module is contained in the controller. The following two types of firmware

can be individually downloaded through the IC card connector on the controller.

- Controller firmware including PS module

- NIB firmware

The procedure is the same as base model G038.

4-2

Page 29

29 September, 2000

5. PREVENTIVE MAINTENANCE

No differences from the base model G038.

Refer to the Field Service Manual for G038.

Preventive

Maintenance

5-1

Page 30

29 September, 2000 LASER UNIT

6. REPL ACEMENT AND ADJUSTMENT

6.1 LASER UNIT

!

WARNING

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section. Laser beams can seriously damage

your eyes.

6.1.1 CAUTION DECAL LOCATIONS

The CAUTION decal is located in the laser section as shown below.

G062R500.WMF

G062R501.WMF

Adjustment

Replacement

6-1

Page 31

LASER UNIT 29 September, 2000

6.1.2 LASER UNIT

[B]

[C]

[A]

G062R161.WMF

[D]

[F]

[E]

G062R162.WMF

G062R508.WMF

!

WARNING

Turn off the main switch and unplug the machine before attempting any of

the procedures in this section. Laser beams can seriously damage your

eyes.

1. Remove the optional finisher and/or bridge unit, if these units have been

installed.

2. Remove the front cover [A] (2 pins).

3. Remove the right front cover [B] (1 screw).

4. Swing up the toner bottle lever. Then, remove the inner cover [C] (5 screws).

5. Remove the paper exit tray [D] (1 hook [E]).

6. Remove the polygon mirror motor fan together with holder [F]. (1 connector, 2

screws)

6-2

Page 32

29 September, 2000

7. TROUBLESHOOTING

No differences from the base model G038.

Refer to the Field Service Manual for G038.

7-1

Trouble-

shooting

Page 33

Polygonal Mirror

M7

-2

CN131-1

24 V

CN105

Paper Tray

Paper

Lift

Sensor

Lift Motor

High

Voltage

-3

-4

Feed Back-B [Analog]

-5

-6

s

PWM-C [ 5]

Feed Back-C [Analog]

s

PWM-T-I [ 5]

-7

Supply

PCB 7

-8

s

PWM-T-V [ 5]

Feed Back-T-I [Analog]

-9

-10

Feed Back-T-V [Analog]

-11

s

PWM-D [ 5]

-12

-13

+24V

Feed Back-D [Analog]

+5V

-14

GND

Paper

Exit Sensor

S6

-2

-1

CN2-3

-2

-3

CN324-1

t

GND

Paper Exit [ 5]

CN3-3

-4

+5V

Paper

-2

-5

GND

Overflow Sensor

S5

-1

-6

t

Paper Overflow [ 5]

CN4-2

-7

+5V

Right Upper

Cover Sensor

SW2

-1

-8

s

GND

Cover Open [ 5]

CN304-A1

t

Note 1

4th Feed Clutch [ 24]

M2

-4

CN105-5

s

s

Motor Up [ 24]

Motor Down [ 24]

-A2

-A3

-A4

t

t

Relay Clutch [ 24]

3rd Feed Clutch [ 24]

S1

-2

CN105-3

+5V

s

Paper Lift [ 5]

-A5

-A6

s

s

s

Paper Height-B [ 5]

Paper Height-A [ 5]

Paper Tray Unit Set [ 5]

-1

CN101-1

GND

-A7

-A8

s

Bank-Hight [ 5]

[24/0] A

t

4th Paper Size [ 5]

Motor Fan

RSVFAN

1st Paper

Lift Sensor

S10

-6

-7

CN309-5

s

GND

1st Paper Lift Sensor [ 5]

+5V

-1

1st Paper

M4

s

Motor-up [ 24]

Lift Motor

-2

2nd Paper

2n Paper

Lift Sensor

Lift Motor

S11

M5

-8

-9

-3

-4

-10

+5V

s

GND

s

s

Motor-up [ 24]

Motor-down [ 24]

2nd Paper Lift Sensor [ 5]

-2

CN1-1

-2

CN221-1

s

s

Set [ 5]

Motor-down [ 24]

TD Sensor

S1

-3

-3

GND

TD Sensor [Analog]

-4

-4

CN203-2

+5V

GND

New PCU

Detect SW

SW8

-1

Exhaust Fan

M3

-2

CN130-1

t

s

+24V

Fan Lock [ 5]

New PCU [ 5]

-3

CN205-1

t

Exhaust Fan [ 24]

Toner Supply

Motor

M6

t

Supply Motor [ 24]

-2

-3

+24 V

Quenching

Lamp

L2

-4

CN306-1

t

+24 V

Quenching Lamp [ 24]

1st Paper

End Sensor

S2

-2

s

GND

1st Paper End [ 5]

1st Paper

Feed Clutch

Upper Relay

Clutch

2nd Paper

End Sensor

Lower

-2

CN307-1

GND

t

Upper Relay Clutch [ 24]

Relay Sensor

Right Lower

Cover SW

2nd Paper

Feed Clutch

Lower

1st Paper

Relay Clutch

1st Paper

Height-1 Sensor

S3

S8

SW4

MC2

-3

-4

-5

-6

-7

-8

-10

GND

+24

+5V

s

s

GND

Door Open [ 5]

Lower Relay [ 5]

+5V

s

2nd Paper End [ 5]

S12

MC4

-2

-3

-4

-13

t

Lower Relay Clutch [ 24]

CN308-1

s

GND

1st Paper Height-1 [ 5]

+5V

-5

GND

-11

-12

+24V

t

2nd Paper Feed [ 24]

Height-2 Sensor

S13

-6

+5V

s

1st Paper Height-2 [ 5]

-7

2nd Paper

-8

GND

Height-1 Sensor

S14

-9

+5V

s

2nd Paper Height-1 [ 5]

-10

2nd Paper

GND

Height-2 Sensor

S15

-11

s

2nd Paper Height-2 [ 5]

1st Paper

Size SW

2nd Paper

Size SW

Special

Registration

Paper SW

Sensor

Registration Clutch

SW5

SW6

-2

-3

-4

-5

-6

-7

-8

-9

-12

CN305-1

+5V

t

t

t

GND

1st Paper Size SW 4 [ 5]

1st Paper Size SW 3 [ 5]

1st Paper Size SW 2 [ 5]

-11

-10

t

t

t

t

t

GND

1st Paper Size SW 1 [ 5]

2nd paper Size SW 2 [ 5]

2nd paper Size SW 1 [ 5]

2nd Paper Size SW 4 [ 5]

2nd Paper Size SW 3 [ 5]

SW7

-12

GND

CN216-8

s

+24 V

Special Paper [ 5]

MC5

S9

-9

-5

-6

-7

+5V

t

GND

t

Registration [ 5]

Registratioin Clutch [ 24]

Right Cover

ID Sensor

S4

SW3

Fusing Unit

X1

X3

X5

X4

-4

-10

GND

Feed-back ID [Analog]

-11

s

Right Cover SW [ 5]

X2

-2

-3

CN228-1

t

GND

Fusing Set [5]

Thermistor [Analog]

-4

GND

-5

t

New Fusing Detect [ 5]

-1

-2

-3

+5V

s

GND

PWM-ID [ 5]

-2

-3

CN201-1

s

t

MM-ST [ 5]

MM-DR [ 5]

Main

Motor

M2

-4

-5

-6

-7

-8

-9

-2

-10

CN223-1

+5V

s

t

MM-BK [ 5]

MM-RDY [ 5]

GND

GND

GND

+24V

+24V

t

s

Trigger [ 5]

PWM-B [ 5]

Upper Relay

Sensor

S7

MC1

MC3

-3

-4

-5

-6

-7

-8

-9

-10

+5V

+5V

s

GND

+24V

t

+24V

Upper Relay [ 5]

1st Paper Feed Clutch [ 24]

Engine Baord (PCB 1)

t

+24V

GND

-3

-5

CN242-1

[5]ON

-6

t

[ 5] Ready

t

GND

+24V

+5V

-2

CN134-1

+24V

+5V

-2

-3

CN209-1

+5V LD

+24V

-4

CN226-1

[ 5] Clock

-7

+24V

-2

-3

GND

GND

-4

-5

+5V

s

t

[ 5] Zero Cross

[ 24] Lamp Trigger

-2

CN225-1

t

[ 24] Relay Trigger

GND

-4

-5

CN225-3

+24V

t

t

[ 5]Width3

[ 5]Width4

-2

-3

CN236-1

GND

-4

t

[ 5]Width1

t

t

t

-8

+24V

-9

[ 24] Feed Clutch

GND

-10

t

[ 5] Set

-11

CN101 (30P)

CN233

CN234

[ 5]Width2

GND

[ 5] Paper End

-5

-6

-7

-2

-A9

GND

t

3rd Paper Size [ 5]

Paper

-3

[24/0] A

-A10

t

4th Relay Sensor [ 5]

M1

-4

-A11

Feed

[24/0] B

t

3rd Relay Sensor [ 5]

Motor

-5

GND

-A12

s

4th Paper Lift Sensor [ 5]

-6

CN102-9

[24/0] B

-A13

-A14

s

3rd Paper Lift Senso [ 5]r

Paper

End

-8

+5V

s

Paper End [ 5]

-A15

s

s

4th Paper End Sensor [ 5]

3rd Paper End Sensor [ 5]

Paper

Sensor

S2

-7

-6

-5

+5V

GND

-B2

-B3

CN304-B1

GND

GND

Height-1

Sensor

S3

-4

-3

s

GND

Paper Height 1 [ 5]

-B4

-B5

GND

+24V

Paper

-2

+5V

-B6

+24V

Height-2

S4

s

Paper Height 2 [ 5]

+24V

Paper

Sensor

-2

-3

-1

CN103-1

s

s

GND

Size 1 [ 5]

Size 2 [ 5]

-B7

-B8

-B9

-B10

+5V

s

GND

Bank-MLD [ 5]

CN231 CN232

Size

SW2

GND

+5V

Switch

-4

s

Size 3 [ 5]

-B11

t

Bank-MON [ 5]

-5

-B12

Unit (A861)

Install

Detect

SW1

-6

-7

+5V

s

t

Size 4 [ 5]

Unit Set [ 5]

-B13

-B14

-B15

s

s

s

s

4th Lift Motor-Up [ 5]

3rd Lift Motor-Up [ 5]

4th Lift Motor-Down [ 5]

3rd Lift Motor-Down [ 5]

Thermofuse (TF1)

Fusing Lamp (L1)

TH1

Thermistor

AC SW

Main

Switch

(SW1)

(230V Machine only)

AC

LDDR

Coil

s

t

[]

CN220

(PCB 5)

Detector

Synchronization

CN282-1

CN281-4

CN289-1

Signal Table

AC Line

DC Line

Pulse

Signal Direction

Active High

Active Low

Voltage

T280

T281

X2

X4

t

Detect [ 5]

Analog

-2

-3

CN221-1

LSD1

-2

X1

X3

X5

-3

-2

-1

-2

GND

M1

Motor

Polygon

CN287-1

PSU

(PCB 4)

+24V

+24V

GND

GND

+5V

Zero Cross [ 5]

t

Lamp ON [ 24]

t

Relay Trigger [ 24]

GND

GND

-2

CN288-1

P

W

+24V

-3

Q

+24V

-4

R

t

GND

+24V

EEPROM

Clutch

Name

+5V

+5V

+5V

ARKD0

AKRD2

ARKD4

ARKD6

ARFGT

ARLGT

WRSYNC

TXD2

GND

GND

GND

GND

Name

/OE

/OPRES

/WEB3

/ACK

/OPCS

/XINT

LDIR

RSV

D31

D30

D29

D28

D27

D26

D25

D24

D23

D22

D21

D20

Name

GND

D0

D1

D2

D3

D4

D5

D6

D7

+5V

RSV

A2

A3

A4

A5

A6

A7

A8

A12

A14

D8

D9

D10

D11

Optional

By-pass Tray

Pin No.

Name

16

+5V

17

+5V

18

+5V

19

ARKD1

20

ARKD3

21

ARKD5

22

ARKD7

23

ARLSNC

24

ARCLK

25

FSYNC

26

RXD2

27

GND

28

GND

29

GND

30

GND

Pin No.

Name

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Name

Pin No.

D12

25

D13

26

D14

27

DA9

28

A13

29

+5V

30

A10

31

A11

32

A15

33

/ROCS1

34

D15

35

A16

36

D16

37

D17

38

GND

39

A20

40

A22

41

A23

42

A21

43

/ROCS2

44

A17

45

A18

46

/WEB3

47

A19

48

D19

D18

D17

D16

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

(CN509)

Pin No.

Pin No.

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

Pin No.

41

42

43

44

45

46

47

38

39

40

41

42

43

44

45

46

47

48

49

50

Pin No.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

Name

/CTSTB-CT

CNTRD1

CNTRD2

CNTRD3

CNTRD4

CNTRD5

CNTRD6

CNTRD7

CNTRD8

/CTACK-CT

CTBUSY-CT

PE-CT

SELECT-CT

/AFD-CT

NC

GND

GND

PLH-CT

Name

A17

NC

A16

NC

A15

NC

A14

NC

A13

+5V

A12

+5V

A11

+5V

A10

+5V

A9

RSV

A8

GND

Name

D18

D19

D20

D21

D22

D23

/OE

D24

D25

D26

D28

D27

+5V

D29

D30

D31

RSV

RSV

RSV

RSV

RSV

RSV

RSV

GND

CN504

Pin No.

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Pin No.

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Name

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

/INIT-CT

/FAULT-CT

GND

NC

NC

/SLCIN-CT

Name

A7

GND

A6

GND

A5

GND

A4

GND

A3

GND

A2

GND

/BE3

GND

/BE2

GND

NC

GND

NC

GND

(CN105)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Name

5V

5V

GND

GND

BD

REFCLK

LDDCLK

LDDDI

LDDDO

/DEVRST2

LDDAXD

LDDWXR

LDOFF

./LDERR

PSO

/PDO0

Optional

Bridge

Unit

(See A897

point to point

diagram.)

-2

-3

CN712-1

Q

W

R

P

Pin No.

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

-4

/PDO1

/PDO2

/PLGATE

/PLSYNC

/PCLK

/PFGATE

/LDSYNC

/PDE0

/PDE1

/PDE2

DATATHRU

Name

GND

PSE

GND

GND

5VS

MC1

S1

S2

Feed

Paper

End

Width

Paper

Paper

+5V

E

CN510-1

Sensor

Controller Board (PCB 2)

(CN504)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

(CN506, 507)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

(CN502)

Pin No.

-2

1

-3

2

-4

3

-5

4

-6

5

-7

6

-8

7

-9

8

-10

9

-11

10

-12

11

-13

12

-14

13

-15

14

-16

15

-17

16

-18

17

-19

18

-20

19

20

21

22

23

24

SW9

Right/Front

Cover Safety SW

-2

CN285

-1

-2

-3

-4

-5

CN284-5

-4

-3

-2

-1

NVRAM

LED 4

LED 3

LED 2

LED 1

Key 1

Key 2

Key 3

Key 4

Key 5

Key 6

Key 7

Key 8

DB 7

DB 6

DB 5

DB 4

Operation Panel (PCB 6)

RESET

GND

Optional Duplex Unit (G529) Optional Interchange Unit (G531)

CN8-12

s

GND

[ 5] Cover Open

-2

-3

CN150-1

SW1

Transport

Cover SW

+5V

-4

-11

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

s

GND

[ 5] Tray 4 Overflow

-5

S9

Sensor

Tray 4 Overflow

[ 5]IN1

t

GND

GND

+24V

+24V

Not Used

[ 5] Regist Sensor

t

[5]Set

t

[0-5] RXD

[0-5] TXD

GND

+5V

s

+5V

GND

[ 5] Tray 4 Paper

+5V

-6

-7

-8

-9

-10

S1

Sensor

Tray 4 Paper

s

GND

[ 5] Tray 3 Overflow

-11

-12

S8

Sensor

Tray 3 Overflow

+5V

GND

CN160-1

Tray 3 Paper

s

[ 5] Tray 3 paper

+5V

-2

-3

S2

Sensor

CN6-1

s

[ 5] Tray 2 Overflow

GND

-4

-5

-6

S7

Sensor

Tray 2Overflow

+5V

GND

-2

S1

Exit

+5V

GND

CN170-1

Tray 2 Paper

[ 5] Exit Sensort

-3

Sensor

s

[ 5] Tray 2 Paper

-2

S4

Sensor

Transport

Motor

Inverter

Motor

Inverter

Gate

Solenoid

(CN233)

Pin No.

10

11

(CN231)

Pin No.

10

11

12

M2

M1

SOL1

Optional

Finisher

(See A681

point to point

diagram.)

/ST_SET

1

/RYU_MRK

2

RYU_SOL

3

/RYU_M

4

RYU_FAN

5

/RYU_SET

6

RYU_ROP

7

RYU_MOP

8

/RYU_FULL

9

/RYU_RLYS

/RYU_EXTTS

Name

1

CLOCK

2

LATCH

3

OUTDATA

4

INDATA

5

SLOAD

6

SEN31

7

SEN32

8

ON31

9

ON32

Name

SET

GND

5V

CN503-1

CN504-1

CN505-1

(CN234)

Pin No.

-2

-3

-4

-5

-6

-2

-3

-4

-5

-6

-2

1

2

3

4

5

6

7

8

(CN232)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

GND

[24/0] A1

[24/0] /A1

GND

[24/0] B1

[24/0] /B1

GND

[24/0] A2

[24/0] /A2

GND

[24/0] B2

[24/0] /B2

GND

Entrance [ 5]

[24]

s

Gate

Clutch

Open [ 5]

Name

FIN_TXD

FIN_RXD

+5V

+5V

GND

GND

/RY_TRG

+24V

Name

GND

RXD

TXD

DPXSET

REG SNS

JCT ON22

JCT ON21

24V

24V

GND

GND

(PCB1)

GND

t

+5V

GND

Exit [ 5]

t

+5V

GND

s

5V

Main Board

CN501-12

CN502-1

-11

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

-2

Entrance

S1

-3

Sensor

-6

Exit

-7

S2

Sensor

-8

-4

Unit Open

SW1

-5

Sw

G062 Point to Point Circuit Diagram

CN1 CN1

t

t

[ 24] Exit Solenoid

+24V

-2

CN3-1

Duplex

Solenoid

s

GND

[ 5] Transport

-7

-8

-9

S3

Sensor

Vertical Transport

[ 24] Duplex Solenoid

-2

SOL1

Junction

Solenoid

+5V

GND

-11

-10

Tray 1 Paper

t

GND

s

[ 5] Tray 1 Paper

+5V

-12

S5

Sensor

[ 5] Unit Set

+24V

-1

CN140-2

SOL1

Turn Gate

Solenoid 1

t

[ 24] Sol 1

+24V

CN130-2

SOL2

Turn Gate

SLOAD

INDATA

OUTDATA

-2

-3

CN7-1

-9

-8

CN100-10

t

[ 24] Sol 2

+24V

-1

CN120-2

SOL3

Turn Gate

Solenoid 2

-4

-7

Latch

t

[ 24] Sol 3

-1

Solenoid 3

-5

-6

Optional 4-bin Mailbox (G518)

Clock

-6

-5

Set

GND

-7

-8

-4

-3

+24V

-5

CN110-6

+24V

CN4-1

SOL2

Exit

Junction

s

+5V

GND

[ 5] Tray 1 Overflow

+5V

-3

-4

-5

-6

S6

Sensor

Tray 1 Overflow

Note1

The signal names of CN304 on the engine baord

are for the optional tray unit.

The signal names for the optional LCT are

described in the LCT point to point diagram.

+24V

-9

-2

[24/0] B

GND

-4

+5V

-10

-1

[24/0] B

[24/0] A

[24/0] A

+24V

-3

-2

-1

M1

Mian Motor

Page 34

PRINTER (G062) ELECTRICAL COMPONENT LAYOUT

40

37

36

35

34 33

48

47

46

45

44

1

22

21

20

19

18

17

23

2

16

3

4

5

6

39

38

7

8

9

10

11

12

13

15

14

49

Symbol Name Index No. P to P

Motors

M1 Polygonal Mirror 1 B3

M2 Main Motor 25 G2

M3 Exhaust Fan 43 B1

M4 1st Paper Lift 37 B1

24

25

26

27

28

29

30

31

32

41

+

42

+

43

M5 2nd Paper Lift 35 B1

M6 Toner Supply 24 B1

M7 Polygonal Mirror Motor Fan 49 A1

Magnetic Clutches

MC1 1st Paper Feed 28 C1

MC2 2nd Paper Feed 31 D1

MC3 Upper Relay 29 C1

MC4 Lower Relay 30 D1

MC5 Registration 27 E1

Switches

SW1 Main Switch 39 A5

SW2 Right Upper Cover 21 H1

SW3 Right Cover 10 F1

SW4 Right Lower Cover 12 D1

SW5 1st Paper Size 18 E1

SW6 2nd Paper Size 17 E1

SW7 Special Paper 16 E1

SW8 New PCU Detect 8 B1

SW9 Front Cover Safety 40 B3

Sensors

S1 Toner Density (TD) 7 B1

S2 1st Paper End 19 C1

S3 2nd Paper End 15 C1

S4 Image Density (ID) 9 S4

S5 Paper Overflow 23 H1

S6 Paper Exit 22 H1

S7 Upper Relay 13 C1

S8 Lower Relay 14 C1

S9 Registration 11 E1

S10 1st Paper Lift 38 A1

S11 2nd Paper Lift 36 B1

S12 1st Paper Height - 1 26 D1

S13 1st Paper Height - 2 34 D1

S14 2nd Paper Height - 1 32 D1

S15 2nd Paper Height - 2 33 D1

PCBs

PCB1 Engine Board 47 F2

PCB2 Printer Controller Board 46 D4

PCB3 Network Interface Board 44 --PCB4 PSU (Power Supply Unit) 42 B5

PCB5 LDD (Laser Diode Driver) 3 A3

PCB6 Operation Panel 41 C7

PCB7 High Voltage Supply 48 G1

PCB8 Memory (Option) 45 ---

Lamps

L1 Fusing Lamp 6 A5

L2 Quenching Lamp 20 C1

Others

TF1 Fusing Thermofuse 5 A5

TH1 Fusing Thermistor 4 A5

LSD 1

Laser Synchronization

Detector

2A4

Loading...

Loading...