Page 1

G056/G058/G073/G074

RICOH GROUP COMPANIES

SERVICE MANUAL

001048MIU

Page 2

Page 3

®

®

G056/G058/G073/G074

SERVICE MANUAL

RICOH GROUP COMPANIES

Page 4

Page 5

G056/G058/G073/G074

SERVICE MANUAL

001048MIU

Page 6

Page 7

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2002 RICOH Corporation. All rights reserved.

Page 8

Page 9

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Corporation. Users of this

manual should be either service trained or

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

RICOH CORPORATION

Page 10

Page 11

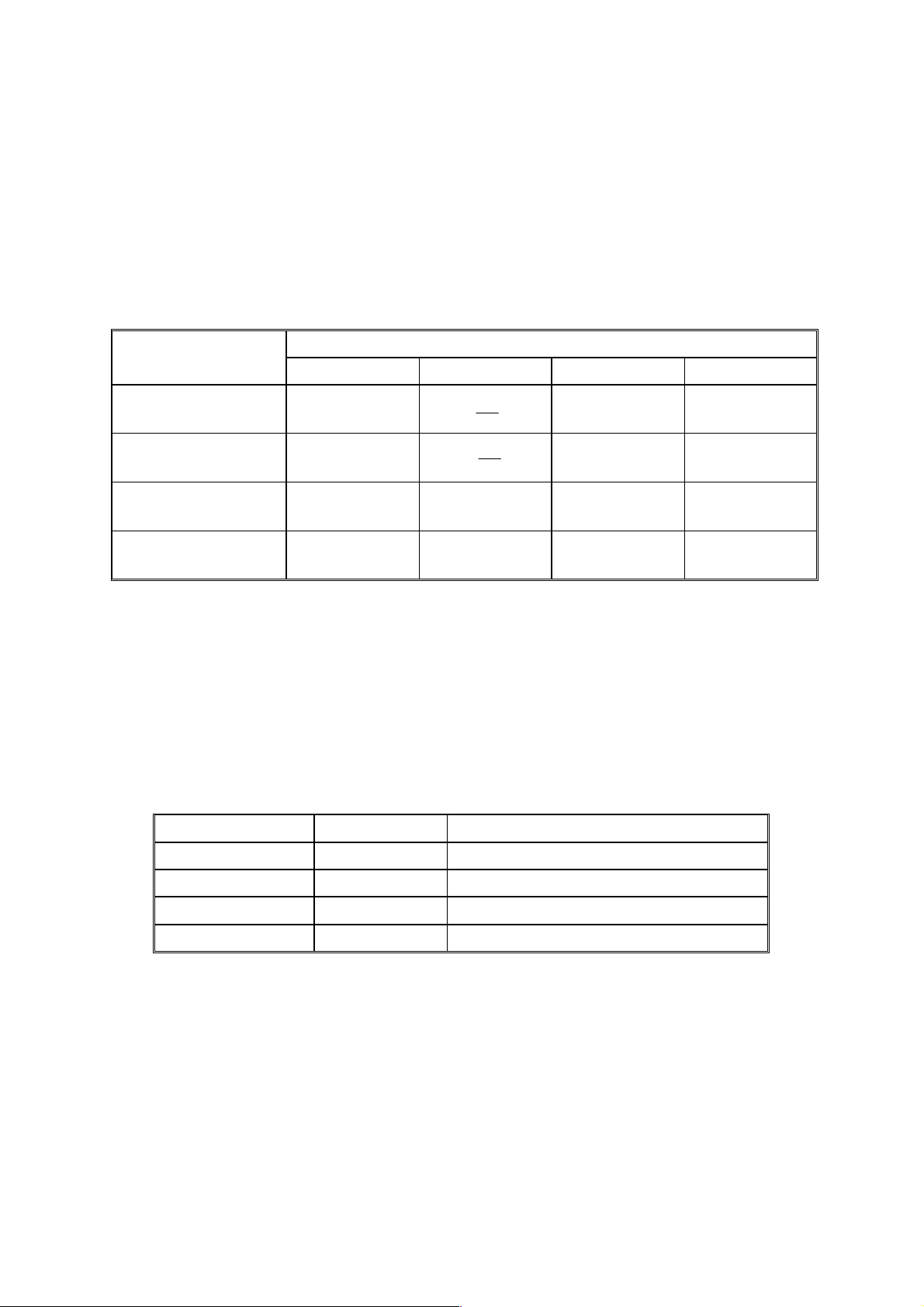

LEGEND

PRODUCT CODE

GESTETNER LANIER RICOH SAVIN

G056 P7026 Aficio

G058 P7026n Aficio

G073 P7126n Ricoh

AP2610N

G074 P7126 Ricoh

AP2610

COMPANY

AP2600

AP2600N

AP2610N MLP26n

AP2610 MLP26

DOCUMENTATION HISTORY

SLP26

SLP26n

REV. NO. DATE COMMENTS

* 12/2000 Original Printing

1 3/2002 G073/G074 Addition

Page 12

Page 13

IMPORTANT SAFETY NOTICES

I

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check needs to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner and developer are non-toxic, but if you get either of them in your eyes it

may cause temporary eye discomfort. Try to remove with eye drops or flush with

water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

The printer and its peripherals must be installed and maintained by a customer

service representative who has completed the training course on those models.

Page 14

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!

WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can seriously damage

your eyes.

CAUTION MARKING:

G058R500.WMF

Page 15

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft

Corporation in the United States and other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines

Corporation.

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved

with those marks.

Page 16

Page 17

G056/G058

TABLE OF CONTENTS

INSTALLATION

1. INSTALLATION .......................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS ...........................................................1-1

1.1.1 ENVIRONMENT ...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-1

1.1.3 MACHINE SPACE REQUIREMENT.................................................1-1

1.1.4 POWER REQUIREMENTS ..............................................................1-2

1.2 MACHINE INSTALLATION .......................................................................1-2

1.3 OPTIONAL UNIT INSTALLATION.............................................................1-2

PREVENTIVE MAINTENANCE

2. PREVENTIVE MAINTENANCE................................................... 2-1

2.1 USER MAINTENANCE .............................................................................2-1

2.2 SERVICE MAINTENANCE........................................................................2-2

REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT........................................ 3-1

3.1 SPECIAL TOOLS ......................................................................................3-1

3.2 EXTERIOR COVERS ................................................................................3-2

3.3 LASER UNIT .............................................................................................3-3

3.3.1 CAUTION DECAL LOCATIONS.......................................................3-3

3.3.2 POLYGON MIRROR MOTOR ..........................................................3-4

3.3.3 LASER SYNCHRONIZATION DETECTOR......................................3-4

3.3.4 LASER UNIT ....................................................................................3-5

3.3.5 LASER DIODE UNIT ........................................................................3-7

Laser beam pitch adjustment................................................................3-8

3.4 TRANSFER ROLLER................................................................................3-9

3.5 TONER END SENSOR .............................................................................3-9

3.6 FUSING...................................................................................................3-10

3.6.1 FUSING UNIT.................................................................................3-10

3.6.2 HOT ROLLER AND FUSING LAMP...............................................3-11

3.6.3 THERMISTOR AND THERMOSTAT..............................................3-13

3.7 PAPER FEED..........................................................................................3-14

3.7.1 FEED ROLLER...............................................................................3-14

3.7.2 FRICTION PAD ..............................................................................3-14

3.8 BY-PASS TRAY ......................................................................................3-15

3.8.1 BY-PASS TRAY UNIT AND BY-PASS FEED ROLLER .................3-15

3.9 PRINTER CONTROLLER BOARD..........................................................3-16

3.10 ENGINE BOARD...................................................................................3-16

SM i G056/G058/G073/G074

Page 18

3.11 MAIN MOTOR .......................................................................................3-17

3.12 SOLENOIDS AND CLUTCHES.............................................................3-17

3.13 POWER SUPPLY UNIT AND HIGH VOLTAGE SUPPLY BOARD .......3-18

3.14 IMAGE ADJUSTMENT..........................................................................3-19

3.14.1 REGISTRATION ADJUSTMENT..................................................3-19

3.14.2 PARALLELOGRAM IMAGE ADJUSTMENT ................................3-19

TROUBLESHOOTING

4. TROUBLESHOOTING ................................................................ 4-1

4.1 SERVICE CALL CONDITIONS .................................................................4-1

4.1.1 SUMMARY .......................................................................................4-1

4.1.2 SC CODE DESCRIPTIONS .............................................................4-2

4.2 CONTROLLER ERROR ............................................................................4-4

4.3 ELECTRICAL COMPONENT DEFECTS ..................................................4-6

4.3.1 SENSORS ........................................................................................4-6

4.3.2 SWITCHES.......................................................................................4-6

4.4 BLOWN FUSE CONDITIONS ...................................................................4-7

4.5 LEDS .........................................................................................................4-7

SERVICE TABLES

5. SERVICE TABLES...................................................................... 5-1

5.1 SERVICE PROGRAM MODE....................................................................5-1

5.1.1 ENABLING AND DISABLING SERVICE PROGRAM MODE...........5-1

Entering the Service Mode....................................................................5-1

Accessing the Required Program .........................................................5-1

Inputting a Value or Setting for a Service Program...............................5-2

Exiting Service Mode ............................................................................5-2

5.2 PRINTER CONTROLLER SERVICE MODE.............................................5-3

5.2.1 SERVICE MODE MENU (‘1. SERVICE MENU’)..............................5-3

5.2.2 BIT SWITCH PROGRAMMING ........................................................5-3

5.3 PRINTER ENGINE SERVICE MODE........................................................5-4

5.3.1 SERVICE MODE TABLE (‘2. ENGINE MAINTE’)............................5-4

Memory Clear .......................................................................................5-8

5.3.2 INPUT CHECK TABLE...................................................................5-10

Table 1: Paper Size Switch (Main Unit) ..............................................5-11

Table 2: Paper Size Switch (optional paper tray)................................5-12

Table 3: Paper Height Sensor (standard cassette).............................5-12

Table 4: Paper Height Sensor (optional paper tray)............................5-12

5.3.3 OUTPUT CHECK TABLE...............................................................5-13

5.4 FIRMWARE UPDATE PROCEDURE......................................................5-14

5.4.1 CONTROLLER/NIB/ENGINE FIRMWARE UPDATE......................5-14

5.4.2 ERROR RECOVERY......................................................................5-15

Controller ............................................................................................5-15

NIB/Engine Board ...............................................................................5-15

G056/G058/G073/G074 ii SM

Page 19

Rev. 12/2002

5.5 POWER-ON SELF TEST ........................................................................5-16

5.6 OTHER TESTS .......................................................................................5-16

5.7 USER PROGRAM MODE ....................................................................... 5-17

5.8 DIP SWITCHES.......................................................................................5-18

Controller Board.................................................................................. 5-18

Engine Board ......................................................................................5-18

5.9 FIRMWARE HISTORY ............................................................................5-19

5.9.1 G056/G058 ENGINE FIRMWARE MODIFICATION HISTORY ......5-19

5.9.2 G056/G058 NIB FIRMWARE MODIFICATION HISTORY..............5-20

5.9.3 G056/G058 CONTROLLER FIRMWARE HISTORY ......................5-23

DETAILED DESCRIPTIONS

6. DETAILED SECTION DESCRIPTIONS ....................................... 6-1

6.1 OVERVIEW ...............................................................................................6-1

6.1.1 MECHANICAL COMPONENT LAYOUT...........................................6-1

6.1.2 PAPER PATH...................................................................................6-2

6.2 BOARD STRUCTURE............................................................................... 6-3

6.2.1 OVERVIEW ......................................................................................6-3

6.2.2 DESCRIPTIONS............................................................................... 6-4

6.2.3 CONTROLLER BOARD ...................................................................6-5

6.3 PRINTING PROCESS...............................................................................6-6

6.3.1 OVERVIEW ......................................................................................6-6

6.3.2 LASER EXPOSURE .........................................................................6-7

Overview...............................................................................................6-7

Automatic Power Control (APC) ...........................................................6-8

LD Safety Mechanisms .........................................................................6-9

6.3.3 CARTRIDGE OVERVIEW .............................................................. 6-10

6.3.4 DRUM CHARGE.............................................................................6-10

6.3.5 DEVELOPMENT.............................................................................6-11

Overview.............................................................................................6-11

Toner Supply ......................................................................................6-11

Development Unit ...............................................................................6-11

Toner Density Control .........................................................................6-12

Development Bias...............................................................................6-12

Toner End Detection ...........................................................................6-13

6.3.6 IMAGE TRANSFER AND PAPER SEPARATION ..........................6-14

Overview.............................................................................................6-14

Transfer Roller Cleaning .....................................................................6-14

6.3.7 CLEANING ..................................................................................... 6-15

6.3.8 QUENCHING..................................................................................6-15

6.3.9 ID CHIP ..........................................................................................6-16

6.4 PAPER FEED..........................................................................................6-17

6.4.1 OVERVIEW .................................................................................... 6-17

Paper Tray ..........................................................................................6-17

By-pass Tray.......................................................................................6-17

6.4.2 PAPER TRAY.................................................................................6-18

Tray Extension....................................................................................6-18

SM iii G056/G058/G073/G074

Page 20

Paper Lift ............................................................................................6-18

Paper Feed and Registration..............................................................6-19

Paper Size Detection ..........................................................................6-20

Paper End/Paper Near-end Detection ................................................6-20

6.4.3 BY-PASS TRAY..............................................................................6-21

6.5 IMAGE FUSING AND PAPER EXIT........................................................6-22

6.5.1 OVERVIEW ....................................................................................6-22

6.5.2 FUSING DRIVE ..............................................................................6-22

6.5.3 FUSING ENTRANCE GUIDE SHIFT..............................................6-23

6.5.4 PRESSURE ROLLER.....................................................................6-23

6.5.5 NEW FUSING UNIT DETECTION..................................................6-24

6.5.6 FUSING TEMPERATURE CONTROL............................................6-25

6.5.7 PAPER EXIT ..................................................................................6-26

6.5.8 ENERGY SAVER MODE................................................................6-27

Entering Energy Saver Mode..............................................................6-27

Leaving Energy Saver Mode...............................................................6-27

6.6 CONTROLLER FUNCTIONS ..................................................................6-28

6.6.1 METER-CHARGE MODE...............................................................6-28

Meter-charge Counter Display ............................................................6-28

PM Warning Display ...........................................................................6-28

6.6.2 SAMPLE PRINT .............................................................................6-28

6.6.3 LOCKED PRINT .............................................................................6-29

6.6.4 PAPER SOURCE SELECTION......................................................6-29

Tray Priority (Auto Tray Select)...........................................................6-29

Tray Lock............................................................................................6-29

Manual Tray Select.............................................................................6-29

6.6.5 AUTO CONTINUE..........................................................................6-30

Auto Tray Select .................................................................................6-30

Manual Tray Select.............................................................................6-30

6.6.6 PAPER OUTPUT TRAY .................................................................6-31

Output Tray Selected..........................................................................6-31

Auto Tray Switching............................................................................6-31

6.7 NIB ..........................................................................................................6-32

6.7.1 BLOCK DIAGRAM..........................................................................6-32

6.7.2 LED INDICATORS..........................................................................6-32

6.8 IEEE1394 INTERFACE...........................................................................6-33

6.8.1 SPECIFICATIONS..........................................................................6-33

Hardware Specification.......................................................................6-33

System Requirements.........................................................................6-33

6.8.2 IEEE1394 .......................................................................................6-33

6.8.3 BLOCK DIAGRAM..........................................................................6-34

6.8.4 PIN ASSIGNMENT.........................................................................6-34

6.8.5 REMARKS ABOUT THIS INTERFACE KIT....................................6-35

6.8.6 TROUBLESHOOTING NOTES ......................................................6-35

G056/G058/G073/G074 iv SM

Page 21

SPECIFICATIONS

7. SPECIFICATIONS....................................................................... 7-1

7.1. GENERAL SPECIFICATIONS..................................................................7-1

7.1.1 SUPPORTED PAPER SIZES...........................................................7-3

7.2. SOFTWARE ACCESSORIES ..................................................................7-4

7.2.1 PRINTER DRIVERS.........................................................................7-4

7.2.2 UTILITY SOFTWARE.......................................................................7-4

7.3. MACHINE CONFIGURATION..................................................................7-5

7.3.1 SYSTEM COMPONENTS ................................................................7-5

7.4. OPTIONAL EQUIPMENT.........................................................................7-6

7.4.1 PAPER TRAY UNIT..........................................................................7-6

7.4.2 ENVELOPE FEEDER.......................................................................7-6

7.4.3 DUPLEX UNIT..................................................................................7-6

7.4.4 FOUR-BIN MAILBOX .......................................................................7-7

7.4.5 ONE-BIN SHIFT TRAY.....................................................................7-7

PAPER TRAY UNIT G555/ENVELOPE FEEDER G556

1. REPLACEMENT AND ADJUSTMENT........................................ 8-1

1.1 PAPER FEED UNIT ..................................................................................8-1

1.2 PAPER FEED ROLLER ............................................................................8-2

1.3 FRICTION PAD .........................................................................................8-2

2. DETAILED DESCRIPTIONS ....................................................... 8-3

2.1 OVERALL MACHINE INFORMATION ......................................................8-3

2.1.1 MECHANICAL COMPONENT LAYOUT...........................................8-3

2.1.2 ELECTRICAL COMPONENT LAYOUT............................................8-3

2.2 DETAILED SECTION DESCRIPTIONS ....................................................8-4

2.2.1 PAPER FEED AND SEPARATION ..................................................8-4

2.2.2 PAPER LIFT.....................................................................................8-5

2.2.3 PAPER END DETECTION ...............................................................8-5

2.2.4 PAPER HEIGHT DETECTION .........................................................8-6

2.2.5 PAPER SIZE DETECTION...............................................................8-7

3. ENVELOPE FEEDER.................................................................. 8-8

3.1 OVERALL MACHINE INFORMATION ......................................................8-8

3.1.1 MECHANICAL COMPONENT LAYOUT...........................................8-8

DUPLEX UNIT G552

1. REPLACEMENT AND ADJUSTMENT........................................ 9-1

1.1 EXTERIOR COVERS ................................................................................9-1

1.2 DUPLEX BOARD AND SENSORS ...........................................................9-2

SM v G056/G058/G073/G074

Page 22

2. DETAILED DESCRIPTION ......................................................... 9-3

2.1 OVERALL MACHINE INFORMATION ......................................................9-3

2.1.1 MECHANICAL COMPONENT LAYOUT...........................................9-3

2.1.2 DRIVE LAYOUT ...............................................................................9-4

2.1.3 ELECTRICAL COMPONENT LAYOUT............................................9-4

2.2 DETAILED SECTION DESCRIPTIONS ....................................................9-5

2.2.1 BASIC OPERATION.........................................................................9-5

Longer than A4 LEF/LT LEF.................................................................9-5

Length up to A4 LEF/LT LEF ................................................................9-6

2.2.2 FEED IN AND EXIT MECHANISM ...................................................9-7

Feeding paper into the duplex unit:.......................................................9-7

Inversion and exit:.................................................................................9-7

FOUR-BIN MAILBOX G553

1. REPLACEMENT AND ADJUSTMENT...................................... 10-1

1.1 EXTERIOR COVERS ..............................................................................10-1

1.2 OVERFLOW AND VERTICAL TRANSPORT SENSORS .......................10-2

1.3 MAIN MOTOR .........................................................................................10-3

2. DETAILED DESCRIPTIONS ..................................................... 10-5

2.1 OVERALL MACHINE INFORMATION ....................................................10-5

2.1.1 MECHANICAL COMPONENT LAYOUT.........................................10-5

2.1.2 DRIVE LAYOUT .............................................................................10-6

2.1.3 ELECTRICAL COMPONENT LAYOUT..........................................10-7

2.2 DETAILED SECTION DESCRIPTIONS ..................................................10-8

2.2.1 BASIC OPERATION.......................................................................10-8

ONE-BIN SHIFT TRAY G554

1. REPLACEMENT AND ADJUSTMENT...................................... 11-1

1.1 EXTERIOR COVERS ..............................................................................11-1

1.2 SHIFT TIMING AND TRAY PAPER SENSORS......................................11-2

1.3 COVER AND OVERFLOW SENSORS ...................................................11-2

1.4 MAIN MOTOR .........................................................................................11-3

2. DETAILED DESCRIPTIONS ..................................................... 11-5

2.1 OVERALL MACHINE INFORMATION ....................................................11-5

2.1.1 MECHANICAL COMPONENT LAYOUT.........................................11-5

2.1.2 DRIVE LAYOUT .............................................................................11-5

2.1.3 ELECTRICAL COMPONENT LAYOUT..........................................11-6

2.2 DETAILED SECTION DESCRIPTIONS ..................................................11-7

2.2.1 BASIC OPERATION.......................................................................11-7

2.2.2 SORT MODE OPERATION............................................................11-7

G056/G058/G073/G074 vi SM

Page 23

SWAPBOX

AND SWAPFTL

INSTALLATION MANUAL

1. INTRODUCTION ...................................................................... 12-1

1.1 PRECAUTIONS........................................................................................12-1

1.1.1 SWAPBOX AND SOFTWARE ........................................................12-1

1.1.2 SOFTWARE LICENSE AGREEMENT ...........................................12-1

1.2 SYSTEM REQUIREMENTS ....................................................................12-1

1.3 ITEMS TO PREPARE BEFORE INSTALLATION ...................................12-1

1.4 WINDOWS 95 VERSION CONFIRMATION ............................................12-2

2. SWAPBOX INSTALLATION ..................................................... 12-4

2.2 DRIVER INSTALLATION ........................................................................12-4

3. SOFTWARE (SWAPFTL) INSTALLATION ............................... 12-5

3.1 SWAPFTL SOFTWARE INSTALLATION ................................................12-5

3.2 VERIFICATION ...................................................................................... 12-5

3.2.1 SOFTWARE VERSION ..................................................................12-5

3.2.2 FLASH MEMORY CARD AUTOMATIC DETECTION ....................12-6

4. TROUBLESHOOTING ............................................................... 12-7

4.1 SWAPBOX RESOURCE CONFLICT ......................................................12-7

4.11 IRQ AND I/O ADDRESS ..................................................................12-7

4.1.2 MEMORY ADDRESS ......................................................................12-7

4.2 FAILED TO OPEN PCCARD ERRORS ...................................................12-8

4.2.1 TIMELAG TO LOADING DRIVER ...................................................12-8

4.2.3 RESOURCE CONFLICT .................................................................12-8

4.3 INVALID DYNAMIC LINK CALL FROM SWAPENUM ERROR...............12-9

4.4 SWAPFTL PROBLEM WITH NOTEBOOK COMPUTERS.......................12-9

4.4.1 WINDOWS AND PC CARD DRIVER VERSION .............................12-9

4.4.2 SYSTEM SUMMERY.......................................................................12-9

4.5 COMPLETE UNINSTALL .......................................................................12-10

SWAPFTL

BINARY UTILITY OPERATION MANUAL

1. OVERVIEW ................................................................................ 13-1

2. OPERATION .............................................................................. 13-2

2.1 PROGRAMMING A FLASH MEMORY CARD..........................................13-2

2.1.1 GETTING A SOURCE FILE ............................................................13-2

2.1.2 PROGRAMMING A CARD WITH THE SOURCE............................13-2

2.2 DOWNLOADING TO A MACHINE ...........................................................13-4

2.3 SAVING DATA TO A FILE .......................................................................13-4

3. FUNCTIONS............................................................................... 13-5

3.1 FILE MENU ..............................................................................................13-5

3.1.1 FILE – OPEN...................................................................................13-5

SM vii G056/G058/G073/G074

Page 24

3.1.2 FILE – CLOSE.................................................................................13-5

3.1.3 FILE – SAVE ...................................................................................13-5

3.14 FILE – SAVE AS...............................................................................13-6

3.2 VIEW MENU.............................................................................................13-6

3.2.1 VIEW – TOOLBAR ..........................................................................13-6

3.2.2 VIEW – STATUS BAR.....................................................................13-6

3.3 IMAGE MENU ..........................................................................................13-7

3.3.1 IMAGE – ERASE.............................................................................13-7

3.3.2 IMAGE – READ ...............................................................................13-8

3.3.3 IMAGE – WRITE .............................................................................13-9

3.3.4 IMAGE – VERIFICATION..............................................................13-10

3.4 HELP MUNU ..........................................................................................13-11

3.4.1 HELP – ABOUT SWAPUTI............................................................13-11

G056/G058/G073/G074 viii SM

Page 25

Rev. 12/2002

G073/G074

TABLE OF CONTENTS

INSTALLATION

1. INSTALLATION............................................................................ 1-1

1.1 OPTIONAL UNIT INSTALLATION.............................................................1-1

PREVENTIVE MAINTENANCE

2. PREVENTIVE MAINTENANCE.................................................... 2-1

2.1 USER/SERVICE MAINTENANCE.............................................................2-1

REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT ........................................ 3-1

3.1 DIFFERENCES FROM THE MODEL K-P1 ...............................................3-1

TROUBLESHOOTING

4. TROUBLESHOOTING ................................................................. 4-1

4.1 SERVICE CALL CONDITIONS .................................................................4-1

4.1.1 SUMMARY .......................................................................................4-1

4.1.2 CONTROLLER SC CODE DESCRIPTIONS ....................................4-2

4.2 JAM LOCATIONS......................................................................................4-6

4.3 FIRMWARE HISTORY ..............................................................................4-7

4.3.1 PRINTER ENGINE FIRMWARE HISTORY......................................4-7

4.3.2 PRINTER CONTROLLER FIRMWARE HISTORY ...........................4-8

SERVICE TABLES

5. SP MODE TABLES ...................................................................... 5-1

5.1 PRINTER CONTROLLER SERVICE MODE .............................................5-1

5.1.1 SERVICE MODE MENU (“1. SERVICE MENU”) .........................5-1

5.1.2 BIT SWITCH PROGRAMMING ........................................................5-2

5.2 PRINTER ENGINE SERVICE MODE........................................................5-3

5.2.1 SERVICE MODE TABLE (“2. ENGINE MAINTE”) .......................5-3

5.2.2 INPUT / OUTPUT CHECK TABLE ...................................................5-8

5.3 USER PROGRAM MODE .........................................................................5-9

SM i G056/G058/G073/G074

Page 26

DETAILED DESCRIPTIONS

6. DETAILED SECTION DESCRIPTIONS ...................................... 6-1

6.1 CONTROLLER BOARD ............................................................................6-1

6.2 USB ...........................................................................................................6-2

6.2.1 SPECIFICATIONS............................................................................6-2

6.2.2 USB 1.1/2.0 ......................................................................................6-2

6.2.3 USB CONNECTORS........................................................................6-3

6.2.4 PIN ASSIGNMENT...........................................................................6-3

6.2.5 REMARKS........................................................................................6-4

Related SP Mode..................................................................................6-4

6.3 IEEE802.11B (WIRELESS LAN) ...............................................................6-5

6.3.1 SPECIFICATIONS............................................................................6-5

6.3.2 BLOCK DIAGRAM............................................................................6-5

6.3.3 TRANSMISSION MODE...................................................................6-6

Ad hoc Mode.........................................................................................6-6

Infrastructure Mode...............................................................................6-6

6.3.4 SECURITY FEATURES ...................................................................6-7

Using the SSID in Ad hoc mode............................................................6-7

6.3.5 TROUBLESHOOTING NOTES ........................................................6-8

Communication Status..........................................................................6-8

Channel Settings...................................................................................6-8

Troubleshooting Steps..........................................................................6-9

6.4 NEW FEATURES ....................................................................................6-10

6.4.1 IP OVER 1394 ................................................................................6-10

6.4.2 JOB SPOOLING.............................................................................6-11

Description..........................................................................................6-11

Related SP Modes..............................................................................6-11

SPECIFICATIONS

7. SPECIFICATIONS

1. GENERAL SPECIFICATIONS.....................................................................7-1

1.1 SUPPORTED PAPER SIZES..............................................................7-3

2. SOFTWARE ACCESSORIES .....................................................................7-4

2.1 PRINTER DRIVERS ............................................................................7-4

2.2 UTILITY SOFTWARE..........................................................................7-4

3. MACHINE CONFIGURATION ......................................................................7-5

3.1 SYSTEM COMPONENTS ...................................................................7-5

3.2 INTERNAL OPTIONS..........................................................................7-6

4. OPTIONAL EQUIPMENT .............................................................................7-7

G056/G058/G073/G074 ii SM

Page 27

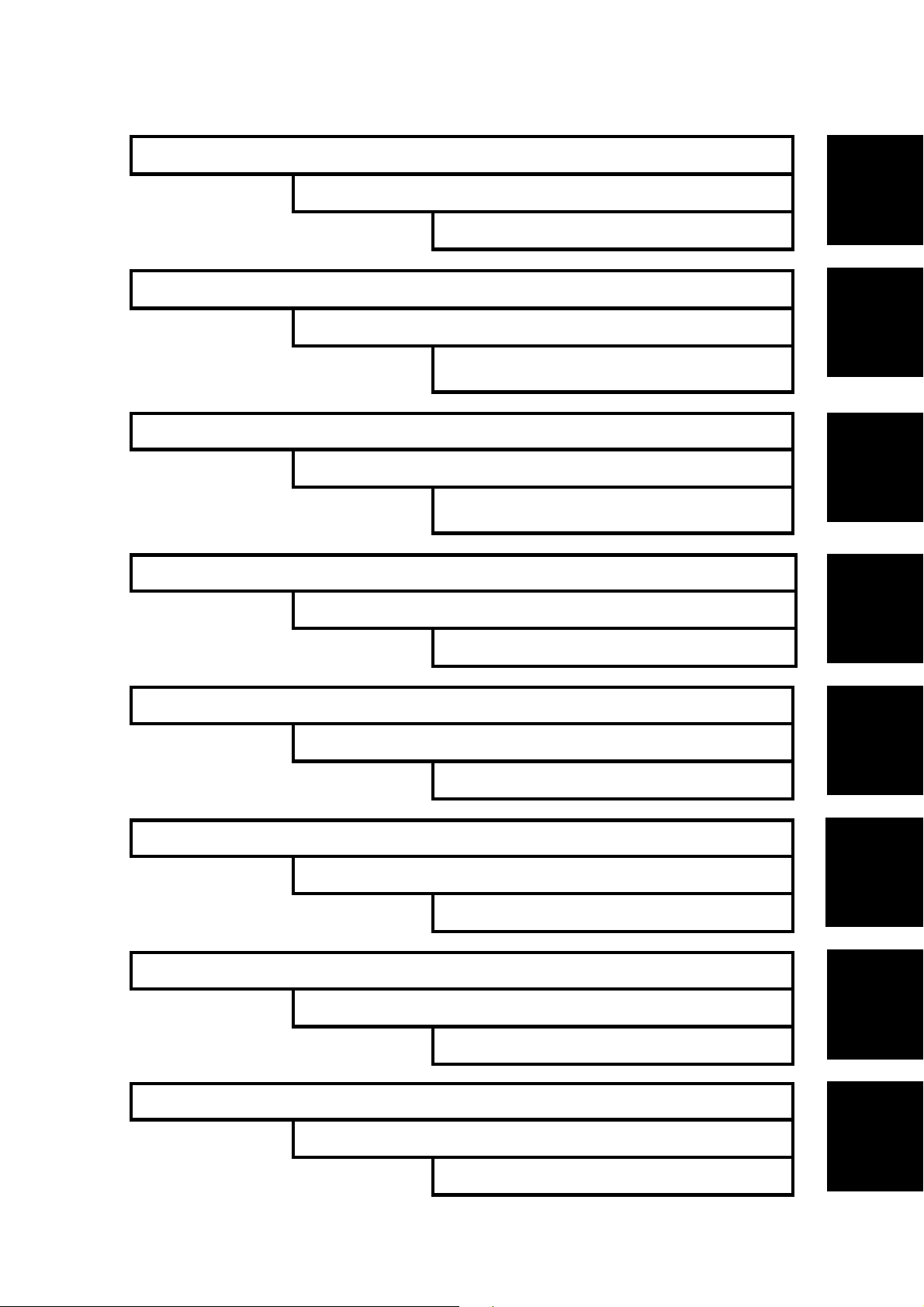

INSTALLATION B056/B058

DUPLEX UNIT G552

INSTALLATION G073/G074

PREVENTIVE MAINTENANCE B056/B058

FOUR-BIN MAILBOX G553

PREVENTIVE MAINTENANCE

G073/G074

REPLACEMENT AND ADJUSTMENT B056/B058

ONE-BIN SHIFT TRAY G554

REPLACEMENT AND ADJUSTMENT

G073/G074T

TROUBLESHOOTING B056/B058

SWAPBOX

TM

AND SWAPFTL

TROUBLESHOOTING G073/G074

TM

INSTALLATION MANUAL

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

SERVICE TABLES B056/B058

SWAPFTLTM BINARY UTILITY OPERATION MANUAL

SERVICE TABLES G073/G074

DETAILED DESCRIPTIONS B056/B058

DETAILED DESCRIPTIONS G073/G074

SPECIFICATIONS B056/B058

SPECIFICATIONS G073/G074

PAPER TRAY G555/ENVELOPE FEEDER G556

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 28

Page 29

INSTALLATION

Page 30

Page 31

INSTALLATION REQUIREMENTS

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range: 10 °C to 32 °C (50 °F to 89.6 °F)

2. Humidity Range: 15 % to 80 % RH

3. Ambient Illumination: Less than 2,000 lux (do not expose to direct sunlight).

4. Ventilation: 3 times/hr/person

5. Avoid areas which are exposed to sudden temperature changes. This includes:

1) Areas directly exposed to cool air from an air conditioner.

2) Areas directly exposed to heat from a heater.

6. Do not place the machine in an area where it will be exposed to corrosive

gases.

7. Do not install the machine at any location over 2,500 m (8,125 ft.) above sea

level.

8. Place the machine on a strong and level base. (Inclination on any side should

be no more than 5 mm.)

9. Do not place the machine where it may be subjected to strong vibrations.

Installation

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2”) of level

Right to left: Within 5 mm (0.2”) of level

1.1.3 MACHINE SPACE REQUIREMENT

Place the machine near the power source, providing clearance as shown.

A: Over 10 cm (4”)

B: Over 10 cm (4”)

C: Over 100 cm (40”)

D: Over 10 cm (4”)

A

B

D

C

G056I500.WMF

SM 1-1 G056/G058

Page 32

MACHINE INSTALLATION

1.1.4 POWER REQUIREMENTS

!

CAUTION

1. Make sure the plug is firmly inserted in the outlet.

2. Avoid multi-wiring.

3. Be sure to ground the machine.

1. Input voltage level: 120 V, 60 Hz: More than 10 A

220 V ~ 240 V, 50 Hz/60 Hz: More than 6 A

2. Permissible voltage fluctuation: ±10 %

3. Do not set anything on the power cord.

1.2 MACHINE INSTALLATION

Refer to the Operating Instructions for details.

1.3 OPTIONAL UNIT INSTALLATION

The following options are available for this machine. Refer to the Operating

Instructions for how to install these options.

• Paper Tray Unit

• 4-bin Mailbox

• 1-bin Shift Tray

• Duplex Unit

• Envelope Feeder

• NIB (G056 only) - the NIB is a standard component for the G058

• Hard disk

• IEEE1394 (G056/G058 - to install in the G058, the NIB must be removed first)

• 64-MB DIMM

G056/G058 1-2 SM

Page 33

PREVENTIVE MAINTENANCE

Page 34

Page 35

USER MAINTENANCE

2. PREVENTIVE MAINTENANCE

2.1 USER MAINTENANCE

All PM items can be done by the customer, using the maintenance kit. The

maintenance kit contains the items listed below.

Meter-charge mode must be set to 'disabled' (controller service mode).

Cross-reference: Section 5.3 Engine service mode

When the PM counter reaches 90K, "Replace Maintenance Kit" is displayed. After

the user replaces the fusing unit in the maintenance kit, the machine automatically

resets the PM counter.

Item Quantity Remarks

Fusing unit 1

Transfer roller 1

Paper feed roller for the standard tray 1

Paper feed rollers for the optional

PFU

Friction pad - standard tray 1

Friction pads - optional trays 2 Optional paper tray unit

2

Optional paper tray unit

Preventive

Maintenance

SM 2-1 G056/G058

Page 36

SERVICE MAINTENANCE

2.2 SERVICE MAINTENANCE

The following tables list the PM items when the PM is done by service.

NOTE: 1) You must switch on meter-charge mode in printer engine service mode

to disable the user's PM warning.

2) After replacing the fusing unit, make sure to reset the PM counter using

the printer engine service mode “PM Counter Reset”.

Symbol key: C: Clean, R: Replace, L: Lubricate, I: Inspect

Main unit

Item 90K EM Remarks

Paper Feed

Paper Feed Roller R C Clean with water

Friction Pad R C Clean with water

Registration Mylar C C Clean with water

Around the Drum

Transfer Roller R

Fusing Unit and Paper Exit

Hot Roller R

Pressure Roller R

Hot Roller Strippers R

Fusing Thermistor R C Clean with alcohol if necessary.

Bushing - Fusing Roller R

Bushing - Fusing Pressure R

Fusing Entrance and Exit Guide

Plates

C

Clean with water or alcohol

Paper Tray Unit

90K EM NOTE

Paper Feed Roller R C Clean with water

Friction Pad R C Dry cloth

Bottom Plate Pad C C Clean with water

Four-bin Mailbox

90K EM NOTE

Exit Rollers C Clean with water

Driven Rollers C Clean with water

Trays C Clean with water

One-bin Shift Tray

90K EM NOTE

Exit Rollers C Clean with water

Driven Rollers C Clean with water

Transport Rollers C Clean with water

Paper Tray C Clean with water

Tray Paper Sensor C Clean with water

G056/G058 2-2 SM

Page 37

REPLACEMENT AND ADJUSTMENT

Page 38

Page 39

SPECIAL TOOLS

3. REPLACEMENT AND ADJUSTMENT

!

CAUTION

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section.

NOTE: This manual uses the following symbols.

☛ : See or Refer to ! : Screws " : Connector

3.1 SPECIAL TOOLS

Part Number Description

A0069104 Scanner Positioning Pin (4 pcs/set) 3.3 1

A2309352 Flash Memory Card - 4MB 5.4 1

G0219350 Loop-back connector - parallel 5.5 1

Described

Section

Q’ty

Replacement

and

Adjustment

SM 3-1 G056/G058

Page 40

EXTERIOR COVERS

3.2 EXTERIOR COVERS

[A]

[D]

[B]

[C]

[E]

G058R701.WMF

G058R201.WMF

[H]

[F]

[G]

G058R703.WMF

G058R702.WMF

To remove the left or right cover, separate the machine from the optional paper

tray unit first.

Open the front cover.

[A]: Remove paper tray

[B]: Operation panel (2 hooks, " x1)

[C]: Upper exit cover

[D]: Open the exit guide plate.

[E]: Upper cover (! x4)

[F]: By-pass tray unit (2 hooks)

[G]: Front cover (3 hooks, " x1)

[H]: Left cover (! x2)

[I]: Right cover (3 hooks)

G056/G058 3-2 SM

Page 41

LASER UNIT

3.3 LASER UNIT

!

WARNING

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section. Laser beams can seriously damage

your eyes.

3.3.1 CAUTION DECAL LOCATIONS

The caution decal is located in the laser section as shown below.

Replacement

and

Adjustment

G058R500.WMF

G058R202.WMF

SM 3-3 G056/G058

Page 42

LASER UNIT

3.3.2 POLYGON MIRROR MOTOR

!

WARNING

Turn off the main switch and unplug the machine before attempting any of

the procedures in this section. Laser beams can seriously damage your

eyes.

Operation panel (☛ 3.2 Exterior

Covers)

[A]

Upper cover (☛ 3.2 Exterior Covers)

[A]: Polygon mirror cover (! x2)

[B]: Polygon mirror motor

(! x4, " x1)

NOTE: Do not touch the surface of the

mirror with bare hands.

3.3.3 LASER SYNCHRONIZATION DETECTOR

Operation panel (☛ 3.2 Exterior Covers)

[B]

G058R204.WMF

Upper cover (☛ 3.2 Exterior Covers)

[A]: Laser synchronization detector (" x1)

[A]

G058R206.WMF

G056/G058 3-4 SM

Page 43

3.3.4 LASER UNIT

[A]

G058R730.WMF

LASER UNIT

[D]

Replacement

and

Adjustment

[C]

Operation panel (☛ 3.2 Exterior Covers)

Upper cover (☛ 3.2 Exterior Covers)

Left cover (☛ 3.2 Exterior Covers)

[A]: 230V machine only: Sheet (! x1)

[B]: Thermistor (! x1)

[C]: Clip

[D]: Laser unit (! x4, 1 flat cable, " x2)

[B]

G058R203.WMF

SM 3-5 G056/G058

Page 44

LASER UNIT

When reinstalling the laser unit

Use the scanner positioning pin (P/N: A0069104) to reinstall the unit.

[E]

G058R208.WMF

[E]: Set the positioning pins as shown above. Then secure the laser unit.

G056/G058 3-6 SM

Page 45

Rev. 08/2001

3.3.5 LASER DIODE UNIT

⇒

[F]

[D]

[C]

[A]

[B]

LASER UNIT

Replacement

and

Adjustment

[E]

G058R209.WMF

Laser Unit (☛ 3.3.4 Laser Unit)

[A]: Spring

[B]: LD unit holders

[C]: Loosen the screw

[D]: Nut

[E]: LD Unit

NOTE: 1) Do not remove the screws that secure the LD board.

2) Do not touch any variable resistors on the LD board.

When installing the LD Unit:

Tighten the screw [C] until the unpainted portion of the screw [F] is not visible.

After installing the LD unit, check the test pattern for the final adjustment (see

Laser beam pitch adjustment the following procedure).

SM 3-7 G056/G058

Page 46

LASER UNIT

Laser beam pitch adjustment

1. Print out the following test patterns – cross-stitch pattern and grid pattern.

2. Check these test patterns. If the laser beam pitch is not correct, the images are

as follows.

• Cross-stitch pattern: Vertical black strips seem to appear.

• Grid pattern: The density of the diagonal lines is light or the lines have

disappeared.

3. Adjust the LD unit holder position: Tighten or loosen the screw [C] (see the

previous page) until the printout appears as follows.

• Cross-stitch pattern: The thin lines are of uniform thickness (no striping

effect should appear on the printout).

• Grid pattern: The diagonal lines appear clearly and are of normal density.

Feed direction

G056R502.WMF

Adjustment not complete Adjustment complete

G056/G058 3-8 SM

Page 47

3.4 TRANSFER ROLLER

Cartridge

[A]: Transfer roller

NOTE: Do not touch the transfer

roller surface.

TRANSFER ROLLER

3.5 TONER END SENSOR

Cartridge

[A]: Toner end sensor (4 hooks, " x1)

[A]

G058R401.WMF

Replacement

and

Adjustment

[A]

SM 3-9 G056/G058

G058R301.WMF

Page 48

FUSING

3.6 FUSING

3.6.1 FUSING UNIT

!

CAUTION

Allow time for the unit to cool before doing the following procedure.

[A]

[A]: Exit cover

[B]: Fusing unit (lift hooks [C])

G058R501.WMF

[C]

[C]

[B]

G058R502.WMF

G056/G058 3-10 SM

Page 49

3.6.2 HOT ROLLER AND FUSING LAMP

[A]

[B]

FUSING

[D]

Fusing unit (☛ 3.6.1 Fusing Unit)

[A]: Right cover (! x2)

[B]: Upper fusing unit assembly (! x4)

[C]: Left cover (! x1)

[D]: Lamp holders (! x1 each)

G058R508.WMF

[D]

[C]

G058R507.WMF

Replacement

and

Adjustment

SM 3-11 G056/G058

Page 50

FUSING

[E]

G058R506.WMF

[H]

[G]

G058R505.WMF

[E]: Fusing lamp (! x2)

NOTE: The shorter cable must be at the hot roller gear side.

[F]: Guide plate (3 hooks)

[G]: Hot roller strippers (1 spring each)

[H]: Hot roller (2 C-rings, 1 gear, 2 bushings).

NOTE: Before installing the new hot roller, peel off 3 cm (1 inch) from both

ends of the protective sheet on the new roller.

Remove protective sheet.

[F]

G058R510.WMF

G056/G058 3-12 SM

Page 51

3.6.3 THERMISTOR AND THERMOSTAT

[A]

[B]

[E]

[C]

[D]

G058R503.WMF

FUSING

Replacement

and

Adjustment

Hot roller (☛ 3.6.2 Hot Roller and Fusing Lamp)

[A]: Wire cover (! x1)

[B]: Grounding plate (! x1, 1 wire)

[C]: Fusing unit connector (! x3, " x1))

[D]: Thermistor (! x1)

[E]: Thermostat (! x1)

SM 3-13 G056/G058

Page 52

PAPER FEED

3.7 PAPER FEED

3.7.1 FEED ROLLER

Paper Tray

[A]: Paper feed roller

3.7.2 FRICTION PAD

Paper Tray

[A]: Friction pad (2 hooks, 1 spring)

[A]

[A]

G058R107.WMF

G058R404.WMF

G056/G058 3-14 SM

Page 53

BY-PASS TRAY

3.8 BY-PASS TRAY

3.8.1 BY-PASS TRAY UNIT AND BY-PASS FEED ROLLER

[A]

[B]

G058R102.WMF

[C]

By-pass tray unit (☛ 3.2 Exterior Covers)

Front cover (☛ 3.2 Exterior Covers)

Cartridge

[A]: Paper guide (! x2)

[B]: Actuator

[C]: Gear (1 hook)

[D]: By-pass feed roller

When reinstalling the paper guide:

1) Set the paper guide on the bushing.

2) Install the left part of the actuator in the machine.

3) Install the right part of the actuator on the paper guide.

4) Install the paper guide.

5) Make sure that the actuator moves smoothly.

[D]

G058R103.WMF

Replacement

and

Adjustment

SM 3-15 G056/G058

Page 54

PRINTER CONTROLLER BOARD

3.9 PRINTER CONTROLLER BOARD

[A]: Printer controller board (! x2)

NOTE: Remove the NVRAM [B] from the old

printer controller board and put it on

the new board.

[A]

3.10 ENGINE BOARD

[B]

[C]

[A]

[D]

G058R710.WMF

G058R712.WMF

[B]

Left cover (☛ 3.2 Exterior Covers)

Printer controller board (☛ 3.9 Printer Controller Board)

[A]: Bracket (! x6, 1 grounding wire)

NOTE: The sheet is used for 230V machine only.

[B]: Clip

[C]: Engine board (! x5, all connectors)

NOTE: Remove the NVRAM [D] from the old engine board and put it on the

new board.

G056/G058 3-16 SM

Page 55

3.11 MAIN MOTOR

Left cover (☛ 3.2 Exterior Covers)

[A]: Main motor (! x4, " x1)

3.12 SOLENOIDS AND CLUTCHES

[A]

MAIN MOTOR

G058R711.WMF

Replacement

and

Adjustment

[F]

[C]

[D]

[E]

[A]

Left cover (☛ 3.2 Exterior Covers)

[A]: By-pass feed solenoid (! x1, " x1)

[B]: Gear (1 hook)

[C]: Stopper (! x1)

[D]: Relay clutch (1 hook, " x1)

[E]: Paper feed clutch (1 hook, " x1)

Main motor (☛ 3.11 Main Motor)

[F]: Registration clutch (# x1, " x1)

[B]

G058R714.WMF

SM 3-17 G056/G058

Page 56

POWER SUPPLY UNIT AND HIGH VOLTAGE SUPPLY BOARD

3.13 POWER SUPPLY UNIT AND HIGH VOLTAGE SUPPLY

BOARD

[A]

G058R707.WMF

[D]

[C]

[E]

G058R709.WMF

Left cover (☛ 3.2 Exterior Covers)

Fusing unit (☛ 3.6.1 Fusing Unit)

[A]: PSU cover (! x2)

[B]: PSU assembly (! x9, all connectors)

[C]: High voltage supply board (! x4)

[D]: 230V machine only: Choke coil (! x2, " x1)

[E]: Power supply unit (! x5)

[B]

G058R708.WMF

G056/G058 3-18 SM

Page 57

IMAGE ADJUSTMENT

3.14 IMAGE ADJUSTMENT

3.14.1 REGISTRATION ADJUSTMENT

The registration is adjusted using the user mode; “Maintenance-RegistrationAdjustment”

3.14.2 PARALLELOGRAM IMAGE ADJUSTMENT

NOTE: Use the scanner positioning pin (P/N: A0069104) for the adjustment.

Do the following procedure if a parallelogram is printed while adjusting the printing

registration using a trimming pattern.

Replacement

and

Adjustment

(a) (b)

G058R210.WMF

G056R500.WMF

1. Remove the upper cover (☛ 3.2 Exterior Covers)

2. Set a positioning pin to one of the hole (The above illustration explains when

the image (a) is printed out).

3. Loosen four screws and move the laser unit.

4. Tighten the laser unit.

5. Print the trimming area pattern to check the image. If it is still the same, repeat

step 3 to 5.

SM 3-19 G056/G058

Page 58

Page 59

TROUBLESHOOTING

Page 60

Page 61

SERVICE CALL CONDITIONS

4. TROUBLESHOOTING

4.1 SERVICE CALL CONDITIONS

4.1.1 SUMMARY

There are 2 levels of service call conditions.

Level Definition Reset Procedure

To prevent the machine from being

A

B

damaged, the SC can only be reset by a

service representative.

The machine cannot be operated at all.

The SC can be reset by turning the

operation switch off and on, if the SC was

caused by a sensor error.

NOTE: 1) If the problem concerns electrical circuit boards, first disconnect then

reconnect the connectors before replacing the PCBs.

2) If the problem concerns a motor lock, first check the mechanical load

before replacing motors or sensors.

Enter engine service mode

(Fusing Error Clear) and press

“#”.

Turn the main power switch off

and on.

Trouble-

shooting

SM 4-1 G056/G058

Page 62

SERVICE CALL CONDITIONS

4.1.2 SC CODE DESCRIPTIONS

Code No. Symptom Possible Cause

Charge roller current leak302 B

A charge roller current leak signal is

detected.

Polygon motor error320 B

The polygon motor does not reach its

operating speed within 10 seconds

after the polygon motor on signal, or

the lock signal is not detected for

more than a certain time during

operation.

• Cartridge (charge roller) defective

• High voltage supply board

defective

• Poor cartridge connection

• Polygon motor

• Polygon motor cable

1st laser synchronization error322 B

The laser synchronization detector

cannot detect the laser

synchronization signal for more than

5 consecutive 100 ms intervals.

LD drive current exceeded323 B

The LD driver detects this error for

more than 500 ms.

2nd laser synchronization error326 B

st

The 1

LD1 is already on, but the

laser synchronization detector cannot

detect the laser synchronization

signal from the 2

nd

LD for more than 5

consecutive 100 ms intervals.

Development bias leak391 B

A development bias leak signal is

detected.

Main motor lock500 B

A main motor lock signal is not

detected for more than 700 ms after

the main motor starts to rotate, or the

lock signal is not detected for more

than a certain time during rotation

after the last signal.

• Laser synchronization detector

board out of position

• Laser synchronization detector

board or cable defective

• Laser synchronization mirror out of

position

• LD unit defective

• Engine board defective

• LD unit defective

• Laser synchronization detector

board out of position

• LD unit defective

• Engine board defective

• High voltage supply board

defective

• Poor cartridge connection

• Main motor defective

• Too much load on the drive

mechanism

541 A

Unstable fusing temperature

During warm-up, the fusing

temperature rises by less than 20 °C

during 11 seconds.

The fusing temperature detected by

• Thermistor defective

• Fusing lamp open

• Fusing thermostat open

• Power supply board defective

• Poor connection of the fusing unit

the thermistor was 0 °C 5 seconds

after the fusing relay was turned on.

G056/G058 4-2 SM

Page 63

SERVICE CALL CONDITIONS

Code No. Symptom Possible Cause

Fusing temperature warm-up error542 A

The fusing temperature does not

reach more than 80 °C 17.5 seconds

after the main switch is turned on.

• Thermistor defective

• Fusing lamp open

• Fusing thermostat open

• Power supply board defective

• Poor connection of the fusing unit

543 A

Fusing overheat error

A fusing temperature of over 245 °C

• Fusing thermistor defective

• Power supply board defective

is detected for 1 second by the fusing

thermistor.

A fusing temperature of over 235 °C

is detected for 1 second after the

fusing lamp has been turned off.

Fusing lamp stays on545 A

The fusing lamp stays on more than

12 seconds after the main motor has

• Fusing thermistor defective

• Power supply board defective

• Poor connection of the fusing unit

been turned off.

546 A

Unstable fusing temperature

During standby, within 500 ms, the

fusing temperature goes below 60 °C

• Fusing thermistor defective

• Power supply board defective

• Poor connection of the fusing unit

twice or over 60 °C three times.

Within 1 minute, a 60 °C increase or

decrease in fusing temperature is

detected during five different onesecond intervals.

Zero cross signal malfunction547 B

Zero cross signals are not detected

• Power supply board defective

• Poor mains power supply condition

within 5 seconds.

Communication error - duplex unit610 B

The engine board cannot

communicate with the duplex unit.

• Poor connection between engine

board and duplex unit

• Engine board defective

• Duplex control board defective

Communication error - GAVD650 B

• The engine board detects an

unknown device on the I

2

C I/F

• Engine board defective

bus (internal bus on the engine

control board).

• The engine board detects an I

2

C

I/F bus error.

Communication error - FCI651 B

• The engine board detects an

unknown device on the I

2

C I/F

• Engine board defective

bus (internal bus on the engine

control board).

• The engine board detects an I

2

C

I/F bus error.

Shift tray motor error726 B

Tray shift did not finish within a

certain time after the shift motor

• Shift motor defective

• Shift tray: Left shift sensor or right

shift sensor defective

turned on.

Trouble-

shooting

SM 4-3 G056/G058

Page 64

CONTROLLER ERROR

4.2 CONTROLLER ERROR

The following table describes the controller error codes. These codes are displayed

at power-on, or after the power-on self-test, if an error occurs.

Please refer to section 5.3 for details of the power-on self-test.

Code Description Required Action

640 Engine to controller communication

error.

641 Engine to controller communication

error (no answer).

800 Video data error

820 Controller CPU error

821 CPU and ASIC timer error

822 HDD timeout error

823 NIB self test error

824 NVRAM error

827 SDRAM error

828 Flash ROM error

829 Optional RAM error

835 Parallel interface error

836 Font ROM error

837 Optional font ROM error

838 Clock generator error

850 NIB interface error

851 IEEE1394 interface error

• Check the connection between the

controller and the engine board.

• Replace the engine board if the error is

consistent.

• Replace the controller if the error is

consistent.

• Check the connection between the

controller and the engine board.

• Replace the engine board if the error is

consistent.

• Check the connection between the

controller and the engine board.

• Replace the engine board if the error is

consistent.

• Replace the controller if the error is

consistent.

• Turn off the machine and turn it back on.

• Replace the controller if the error is

consistent.

• Check the connection between the HDD

and the controller

• Replace the HDD if the error is consistent.

• Turn off the machine and turn it back on.

• Check the connection between the NIB

and the controller.

• Replace the NIB if the error is frequent.

• Replace the NVRAM if the error is

consistent.

• Replace the controller if the error is

consistent.

• Replace the controller if the error is

consistent.

• Check the connection of the optional

memory.

• Replace the optional memory if the error

is consistent.

• Replace the controller if the error is

consistent.

• Not used for this model.

• Not used for this model.

• Replace the controller if the error is

consistent.

• Replace the controller if the error is

consistent.

• Replace the controller if the error is

consistent.

G056/G058 4-4 SM

Page 65

CONTROLLER ERROR

Code Description Required Action

860 HDD start-up error

• Turn off the machine and turn it back on.

• Check the connection between the HDD

and the controller.

• Replace the HDD if the error is consistent.

862 HDD damaged cluster error

• Replace the HDD if the error is consistent.

863 HDD data unable to read

864 HDD data access error

865 HDD access error

900 Controller counter error

• Replace the NVRAM if the error is

consistent.

999 Software update error

• Try downloading the controller software

again.

Trouble-

shooting

SM 4-5 G056/G058

Page 66

ELECTRICAL COMPONENT DEFECTS

4.3 ELECTRICAL COMPONENT DEFECTS

4.3.1 SENSORS

Component CN Condition Symptom

Open

Paper Exit 6-B2

Shorted

Paper Overflow 6-B5

Registration 16-A2

1st Paper End 16-A5

1st Paper Height 16-A8

Toner End 16-A12

Open

Shorted The paper overflow message is displayed.

Open

Shorted

Open

Shorted

Open

Shorted

High Toner near-end (toner end) is not detected.

Low The add toner message is displayed.

NOTE: The CN numbers describe the connector number on the engine board.

The Paper Jam indicator will light whenever

a print is made.

The Paper Jam indicator lights even if there

is no paper.

The paper overflow message is not

displayed even when a paper overflow

condition exists.

The Paper Jam indicator will light whenever

a print is made.

The Paper Jam indicator lights even if there

is no paper.

The Paper End indicator lights even if paper

is placed in the 1st paper tray.

The Paper End indicator does not light even

if there is no paper in the 1st paper tray.

Misfeed is indicated when paper supply

runs out.

The machine cannot determine the paper

near-end condition properly.

4.3.2 SWITCHES

Component CN Condition Symptom

272-1,3

Main

Front Cover

Safety

Rear Cover

Safety

(PSU 120V)

270-1,2

(PSU 230V)

9-1

9-3

5-3

NOTE: The CN numbers describe the connector number on the engine board

(except for the main switch).

G056/G058 4-6 SM

Open The machine does not turn on.

The machine does not turn off.

Shorted

Open

Shorted

Open

Shorted

The Front Cover Open message is not

displayed even if the front cover is opened.

The Front Cover Open message is

displayed even if the front cover is closed.

The Rear Cover Open message is not

displayed even if the rear cover or paper

exit cover is opened.

The Rear Cover Open message is

displayed even if the rear cover or paper

exit cover is closed.

Page 67

4.4 BLOWN FUSE CONDITIONS

BLOWN FUSE CONDITIONS

Fuse

Power Supply Board

FU1 15 A/125 V ---- No power

FU2 6.3 A/250 V 3.15 A/250 V No power

FU3 5 A/125 V 5 A/250V No power

FU4 5 A/125 V 5 A/250V

115 V 220 - 240 V

Rating

Symptom when turning on the main

switch

No power

(LEDs flash once)

4.5 LEDS

No LEDs are used for this model (except for the NIB - refer to section 6.7).

Trouble-

shooting

SM 4-7 G056/G058

Page 68

FIRMWARE HISTORY

4.6 FIRMWARE HISTORY

4.6.1 G056/G058 FIRMWARE MODIFICATION HISTORY

G056/G058 FIRMWARE MODIFICATION HISTORY

DESCRIPTION OF MODIFICATION

• First Mass Production of Machine

• Firmware modified to make corrections for

the German language.

• Does not exist in the field

• Does not exist in the field

1. Firmware modified to improve print quality

when image data is printed using the PCL6

driver.

NOTE: This occurs only in the following

condition.

• When printing image data

• When using the PCL6 driver

2. New feature added in the user mode.

“Curl Prevention” mode is added in the user

mode. (Curl Prevention: User mode/

Maintenance). Please note that the function

of this mode is the same as the “Curl Control”

in the printer engine service mode. It lowers

the fusing temperature to prevent paper from

curling. Advise customer to use this mode

when paper jam occurs during duplex rear

side printing.

NOTE: When this mode is switched on, the

“Curl Control” in the service mode is

also switched on.

PART

NUMBER

G0565920 B

G0565920 C

G0565920 D

G0565920 E

G0565920 F

SERIAL

NUMBER

st Mass

1

Production

November 2000

production

N/A 1.03

N/A 1.04

December 2000

production

Rev. 05/2000

FIRMWARE

VERSION

1.01

1.02

1.05

Symptom:

In PCL printing, if data exists over the bottom

edge of the printable area, the machine

freezes, displaying "Processing" and

operation will no longer be possible.

Condition:

Printer driver is not being used

Print data exists on the bottom edge of the

printable area (at 4.2mm)

Action:

Update the controller firmware.

G056/G058 4-8 SM

Page 69

Rev. 08/2001

G056/G058 FIRMWARE MODIFICATION HISTORY

DESCRIPTION OF MODIFICATION

Corrects the following:

⇒

• In rare cases with graphic images, a dark

band(s) appears or part of the image

becomes black on prints.

Corrects the following:

• Modified so the machine can be used

with Axis print servers.

• Modified to correct Polish and

Portuguese langauage errors.

PART

NUMBER

G0565920 G

G0565920 J

FIRMWARE HISTORY

SERIAL

NUMBER

Does not exist in

the field

February 2001

production

FIRMWARE

VERSION

1.06

1.08

Trouble-

shooting

SM 4-9 G056/G058

Page 70

Page 71

SERVICE TABLES

Page 72

Page 73

SERVICE PROGRAM MODE

5. SERVICE TABLES

5.1 SERVICE PROGRAM MODE

!

CAUTION

Before accessing the service menu, do the following:

Confirm that there is no print data in the printer buffer (the Data In LED

must not be lit or blinking).

If there is some data in the buffer, wait until all data has been printed.

5.1.1 ENABLING AND DISABLING SERVICE PROGRAM MODE

Entering the Service Mode

There are two ways to enter the service mode.

Method 1:

Turn the machine on while pressing the “On

Line” key and “Escape” key together until “1. Service

Menu1” appears on the display.

On Line

Menu

NOTE: If you switch the machine off, any jobs stored

on the hard disk using the sample print and

Job Reset

Escape

protected print features will be deleted.

Check first with the user tools to see if there are

Form Feed

#

Enter

any jobs stored with these features

(Menu key - Sample Print, or Protected Print).

Method 2:

Press the “Up/Down arrow” keys together for

about 5 seconds, then press the “Enter” key.

“1. Service Menu1” appears on the display.

Power Error Data In

G058D520.WMF

NOTE: The machine automatically goes off line when you enter the service mode.

Accessing the Required Program

Use the “Up/Down arrow” keys to scroll through the menu listing.

1. Service Menu: Controller service modes

2. Engine Mainte: Engine service modes

3: End: Exit service mode

Tables

Service

To select an item, press the “Enter” key. Then the sub-menu will appear.

Scroll through the sub menu items using the “Up/Down arrow” keys.

To go back to a higher level, press the “Escape” key.

SM 5-1 G056/G058

Page 74

SERVICE PROGRAM MODE

Inputting a Value or Setting for a Service Program

Enter the required program mode as explained above. The setting appearing on

the display is the current setting.

Select the required setting using the “Up/Down arrow” keys, then press the “Enter”

key. The previous value remains if the “Enter” key is not pressed.

Exiting Service Mode

Select “3. End” from the service mode main menu, then press the “Enter” key.

NOTE: To make the settings effective, turn the main switch off and on after exiting

service mode.

G056/G058 5-2 SM

Page 75

PRINTER CONTROLLER SERVICE MODE

Rev. 04/2003

5.2 PRINTER CONTROLLER SERVICE MODE

5.9.1 SERVICE MODE MENU (‘1. SERVICE MENU’)

Service

Mode

BitSw#1 Set Bit switch

Clear Setting Initializes the

Service Print Controller

Disp Version Display

Description Function

Adjusts bit switch settings.

settings

system settings

summary print

controller

Note: Currently the bit switches are not being used.

Initializes settings in the “System” menu of the user mode.

Prints the service summary sheet (a summary of all the

controller settings).

Displays the version of the controller firmware.

5.9.2 BIT SWITCH PROGRAMMING

NOTE: Currently, the bit switches are not being used.

1. Enter the SP mode, select “Service Menu”, then press

[Enter] twice.

2. Select #1, #2, #3, or #4 for the desired bit switch, then

press [Enter].

• [V] [W]: Move to the next switch.

Service Menu

BitSW

BitSW

<BitSW#1>

3. Adjust the bit switch using the following keys.

• [V] [W]: Move to the next bit.

• [Escape]: Exit without saving changes.

• [Enter]: Exit and save changes.

NOTE: The left digit on the display is bit 7 and the right digit is bit 0.

4. Press [Enter] to save changes and exit.

⇒

Bit Switch 01 - Not used (do not change any of these settings)

Bit Switch 02

No Description Function

Not used Do not change the setting.

0-3

Treatment of the last page

when printing a job with an

odd number of pages using

the duplex unit

4

0: (default): Last page not

fed through the duplex unit

1: Last page fed through the

duplex unit

Not used Do not change the setting.

5-7

Bit Switch 03 - Not used (do not change any of these settings)

Bit Switch 04 - Not used (do not change any of these settings)

0: The last page is not fed through the duplex unit, so the

last page faces the opposite way from other pages in the

job.

1: The last page is fed through the duplex unit, so the last

page faces the same way as other pages of the job.

Set this switch to “1” when the customer wishes the last

page to be facing the same way as the other pages.

Sw#1 00000000

Bit0 _

Tables

Service

SM 5-3 G056/G058

Page 76

PRINTER ENGINE SERVICE MODE

5.3 PRINTER ENGINE SERVICE MODE

5.3.1 SERVICE MODE TABLE (‘2. ENGINE MAINTE’)

Service

Mode

Regist sag Paper feed

Fusing

Control

Fusing

Temp

Fusing

T Dis

OHP

Clutch Rt

Fusing

Start

Curl

Control

Charge

Rol Bias

Mainscan

mag

Subscan

mag

Developer

Bias

Toner End

Count

Description Function Setting

timing

Fusing power

control

Fusing

temperature

adjustment

Fusing

temperature

display

Bypass paper

feed roller

rotation for

transparencies

Initial fusing

setting

Low temperature

fusing

Charge roller

voltage

adjustment

Main scan

magnification

adjustment

Sub scan

magnification

adjustment