Page 1

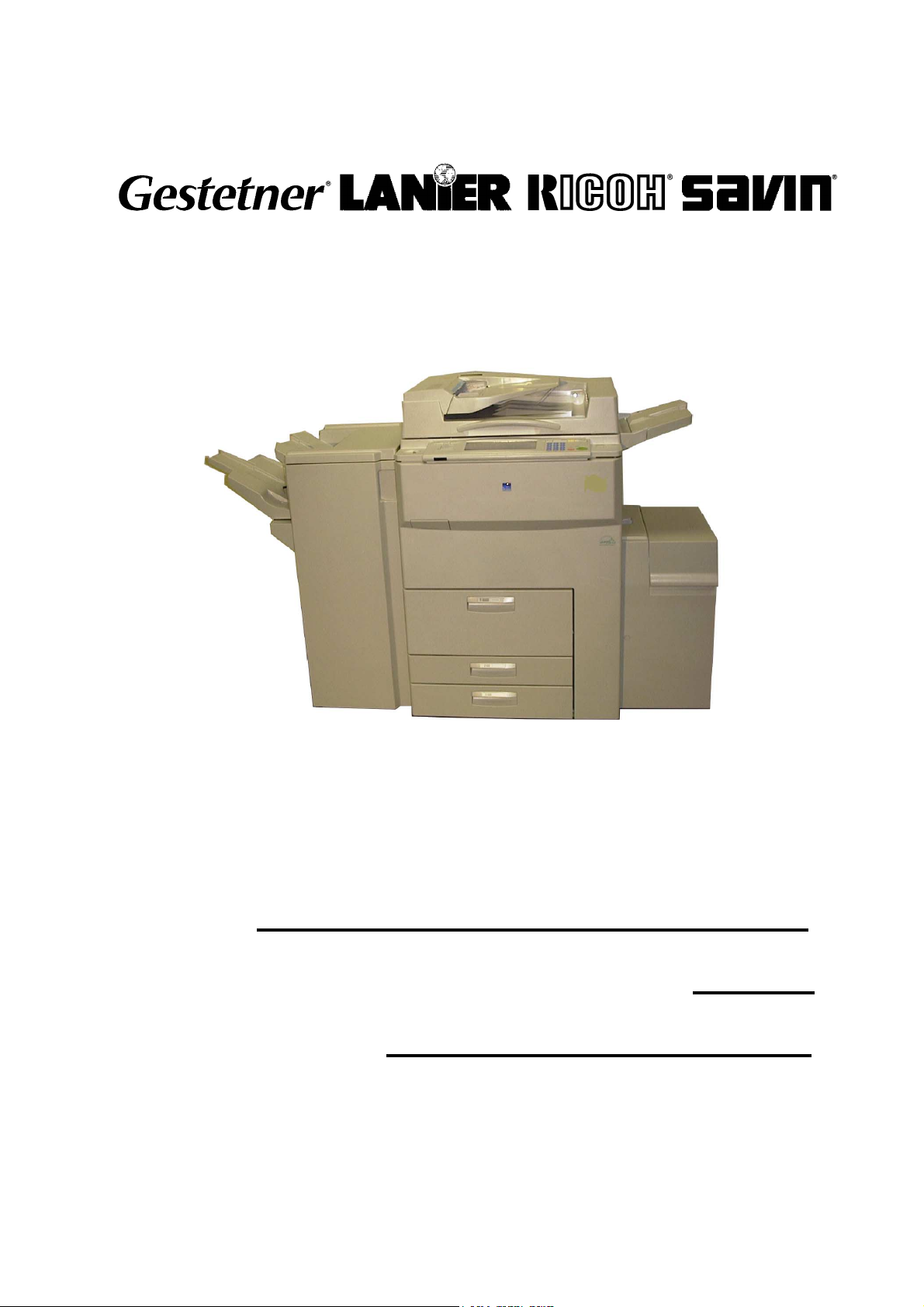

A292/A293/A292P/A293P

(To be used in conjunction with A229 Service Manual)

RICOH GROUP COMPANIES

B098

SERVICE MANUAL

000930MIU

Page 2

Page 3

®

®

A292/A293/A292P/A293P/B098

SERVICE MANUAL

RICOH GROUP COMPANIES

Page 4

Page 5

A292/A293/A292P/A293P

B098

SERVICE MANUAL

000930MIU

Page 6

Page 7

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2002 RICOH Corporation. All rights reserved.

Page 8

Page 9

p

t

r

g

l

y

p

WARNING

The Service Manual contains information

regarding service techniques, procedures,

rocesses and spare parts of office equipmen

distributed by Ricoh Corporation. Users of this

manual should be either service trained o

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizin

information contained in this service manual to

repair or modify Ricoh equipment risk persona

injury, damage to property or loss of warrant

rotection.

Ricoh Corporation

Page 10

Page 11

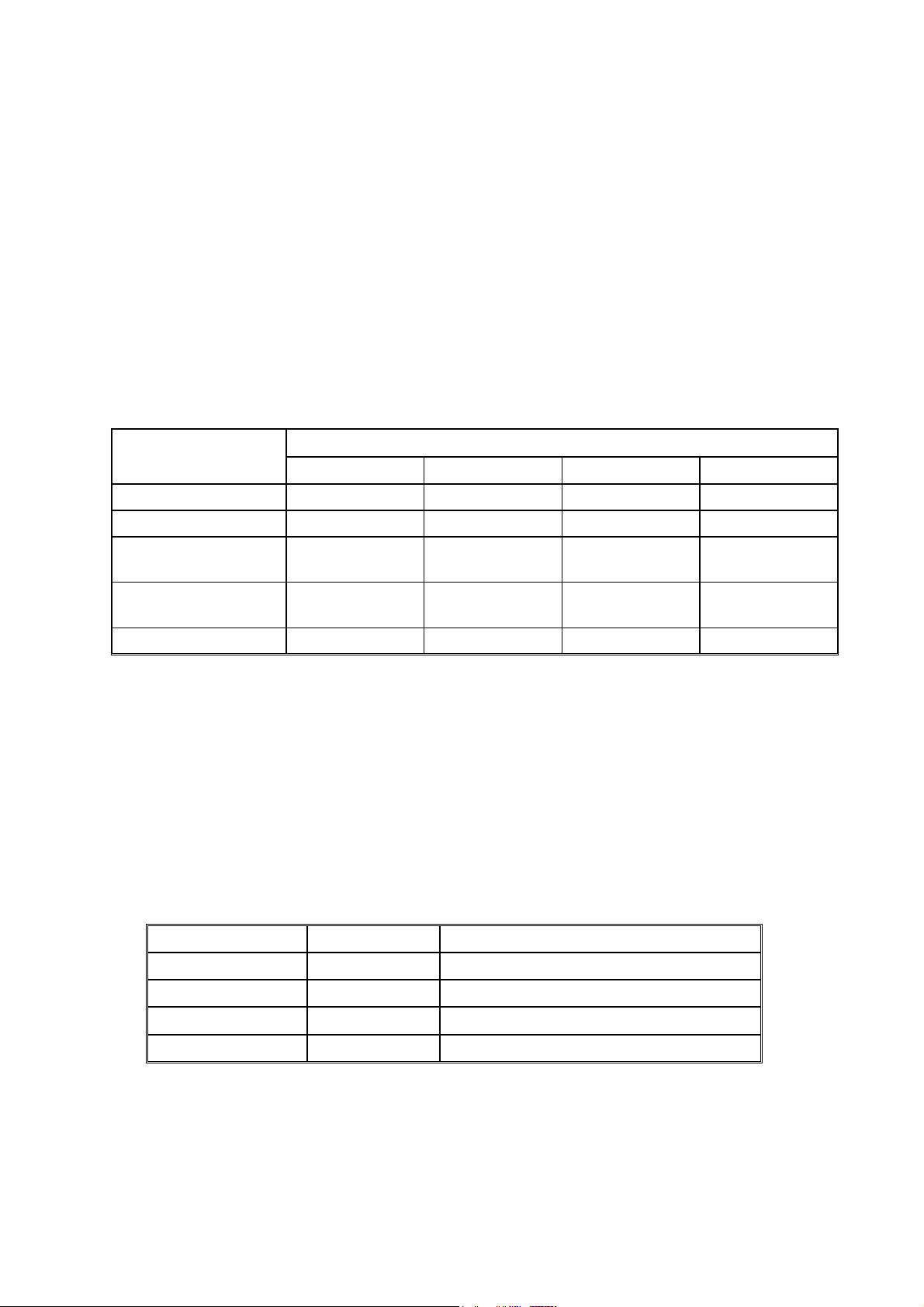

PRODUCT CODE

A292 3355 5455 Aficio 551 2055DP

A293 3370 5470 Aficio 700 2070DP

LEGEND

GESTETNER LANIER RICOH SAVIN

A292

w/G594 Controller

A293

w/G594 Controller

B098

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

* 5/2000 Original Printing

1 10/2002 B098 Addition

--

--

5502

LD055

Aficio 551P

Aficio 700P

Aficio 1055

--

--

2555

Page 12

Page 13

Rev. 10/2002

TABLE OF CONTENTS

COMPARISON BETWEEN A292/A293 AND A229

OVERALL INFORMATION

1. OVERALL MACHINE INFORMATION........................................ 1-1

1.1 SPECIFICATIONS.....................................................................................1-1

1.1.1 COPIER ENGINE .............................................................................1-1

1.1.2 ADF ..................................................................................................1-5

1.2 MACHINE CONFIGURATION...................................................................1-6

1.3 MECHANICAL COMPONENT LAYOUT ...................................................1-7

1.3.1 COPIER ENGINE .............................................................................1-7

1.3.2 ADF ..................................................................................................1-9

1.4 PAPER PATH..........................................................................................1-10

1.5 COPY PROCESS....................................................................................1-11

1.6 DRIVE LAYOUT ......................................................................................1-13

1.6.1 COPIER ENGINE ...........................................................................1-13

1.6.2 ADF ................................................................................................1-14

1.7 ELECTRICAL COMPONENT DESCRIPTION.........................................1-15

1.7.1 COPIER ENGINE ...........................................................................1-15

1.7.2 ADF ................................................................................................1-21

DETAILED DESCRITPIONS

2. DETAILED DESCRIPTIONS ....................................................... 2-1

2.1 DOCUMENT FEEDER ..............................................................................2-1

2.1.1 PICK-UP ROLLER RELEASE ..........................................................2-1

2.1.2 BOTTOM PLATE LIFT......................................................................2-2

2.1.3 PICK-UP AND SEPARATION ..........................................................2-3

2.1.4 ORIGINAL FEED..............................................................................2-4

2.1.5 ORIGINAL SIZE DETECTION..........................................................2-5

Original Length .....................................................................................2-5

Original Width .......................................................................................2-5

2.1.6 ORIGINAL TRANSPORT .................................................................2-6

2.1.7 ORIGINAL SKEW CORRECTION....................................................2-7

2.1.13 ORIGINAL INVERSION AND FEED-OUT......................................2-8

General Operation ................................................................................2-8

Original Inversion..................................................................................2-9

Original Exit (Single-Sided Original Mode)..........................................2-10

Original Exit (Double-Sided Original Mode) ........................................2-11

2.1.9 JAM CONDITIONS.........................................................................2-12

Feed-in................................................................................................2-12

Feed-out .............................................................................................2-12

Inversion .............................................................................................2-12

SM i A292/A293/B098

Page 14

Rev. 10/2002

2.2 SCANNING..............................................................................................2-13

2.2.1 OVERVIEW ....................................................................................2-13

2.2.2 SCANNER DRIVE ..........................................................................2-14

2.2.3 ORIGINAL SIZE DETECTION IN BOOK MODE ............................2-15

2.3 IMAGE PROCESSING ............................................................................2-16

2.3.1 OVERVIEW ....................................................................................2-16

2.3.2 SBU ................................................................................................2-17

2.3.3 AUTO IMAGE DENSITY (ADS) ......................................................2-18

2.3.4 IPU (IMAGE PROCESSING UNIT).................................................2-19

Overview.............................................................................................2-19

2.3.5 IMAGE PROCESSING STEPS AND RELATED SP MODES.........2-20

2.3.6 AUTO SHADING ............................................................................2-25

Black Level Correction........................................................................2-25

White Level Correction........................................................................2-25

2.3.7 BACKGROUND ERASE.................................................................2-26

Background Erase ..............................................................................2-26

2.3.13 INDEPENDENT DOT ERASE ......................................................2-27

2.3.9 FILTERING, MAIN SCAN MAGNIFICATION/REDUCTION ...........2-28

Overview.............................................................................................2-28

Filtering ...............................................................................................2-28

Main Scan Magnification/Reduction....................................................2-29

Sub Scan Magnification ......................................................................2-29

2.3.10 GAMMA (G) CORRECTION.........................................................2-30

2.3.11 GRADATION PROCESSING .......................................................2-30

Three-graduation Processing..............................................................2-30

Four-graduation Processing................................................................2-31

Error Diffusion and Dithering...............................................................2-31

2.3.12 LINE WIDTH CORRECTION........................................................2-31

2.4 LASER EXPOSURE................................................................................2-32

2.4.1 AUTO POWER CONTROL.............................................................2-32

2.4.2 DUAL BEAM WRITING ..................................................................2-33

2.4.3 LASER BEAM PITCH CHANGE MECHANISM

(FOR A292/A293 ONLY).................................................................2-34

2.4.4 LD SAFETY SWITCHES ................................................................2-35

2.5 DRUM UNIT ............................................................................................2-36

2.5.1 PROCESS CONTROL....................................................................2-36

Overview.............................................................................................2-36

Drum potential sensor calibration .......................................................2-37

VSG adjustment..................................................................................2-37

VG Adjustment....................................................................................2-38

LD power adjustment..........................................................................2-39

Toner Density Adjustment...................................................................2-39

VREF Update......................................................................................2-40

2.5.2 DRUM UNIT COMPONENTS.........................................................2-41

2.5.3 DRUM CHARGE.............................................................................2-42

Overview.............................................................................................2-42

Charge Corona Wire Cleaning Mechanism.........................................2-43

2.5.4 DRUM CLEANING AND TONER RECYCLING..............................2-44

Overview.............................................................................................2-44

A292/A293/B098 ii SM

Page 15

Rev. 10/2002

Drive Mechanism ................................................................................2-45

Cleaning Blade Pressure Mechanism and Side-to-Side Movement....2-46

2.5.5 OTHERS.........................................................................................2-47

Air Flow Around the Drum...................................................................2-47

Pick-off Mechanism ............................................................................2-48

2.6 DEVELOPMENT AND TONER SUPPLY ................................................2-49

2.6.1 OVERVIEW ....................................................................................2-49

2.6.2 DEVELOPMENT MECHANISM......................................................2-50

2.6.3 DEVELOPMENT BIAS ...................................................................2-51

2.6.4 TONER DENSITY CONTROL ........................................................2-52

Overview.............................................................................................2-52

Sensor control mode...........................................................................2-52

Image pixel count control ....................................................................2-53

2.6.5 TONER END DETECTION.............................................................2-54

Toner Near End ..................................................................................2-54

Toner End...........................................................................................2-54

2.6.6 TONER END RECOVERY .............................................................2-54

2.6.7 ABNORMAL TD AND ID SENSOR CONDITIONS .........................2-55

2.7 IMAGE TRANSFER AND PAPER SEPARATION ...................................2-56

2.7.1 IMAGE TRANSFER AND PAPER SEPARATION MECHANISM ...2-56

2.7.2 TRANSFER BELT UNIT LIFT MECHANISM..................................2-57

2.7.3 TRANSFER BELT CLEANING MECHANISM ................................2-58

2.13 PAPER FEED........................................................................................2-59

2.13.1 OVERVIEW ..................................................................................2-59

2.13.2 DRIVE MECHANISM....................................................................2-60

2.13.3 TANDEM LCT – TRAY 1 ..............................................................2-61

Overview.............................................................................................2-61

Connecting the Left and Right Sides of the Tray ................................2-62

Paper Lift/Remaining Paper Detection................................................2-63

Fence Drive ........................................................................................2-65

Rear Fence Drive................................................................................2-66

Tray Positioning ..................................................................................2-67

2.13.4 TRAY POSITIONING MECHANISM – TRAYS 1 TO 3 .................2-68

2.13.5 PAPER LIFT MECHANISM - TRAYS 2 AND 3.............................2-69

2.13.6 VERTICAL TRANSPORT MECHANISM ......................................2-70

2.13.7 PAPER REGISTRATION..............................................................2-71

Overview.............................................................................................2-71

2.13.13 PAPER SIZE DETECTION – TRAY 2 ........................................2-72

2.9 IMAGE FUSING ......................................................................................2-73

2.9.1 OVERVIEW ....................................................................................2-73

2.9.2 FUSING ENTRANCE GUIDE .........................................................2-74

2.9.3 FUSING DRIVE MECHANISM .......................................................2-75

2.10 PAPER EXIT/DUPLEX..........................................................................2-76

2.10.1 OVERVIEW ..................................................................................2-76

2.10.2 INVERTER ...................................................................................2-77

Feed-in and Jogging ...........................................................................2-77

Feed-out .............................................................................................2-78

2.10.3 DUPLEX TRAY FEED MECHANISM ...........................................2-79

2.10.4 BASIC DUPLEX FEED OPERATION...........................................2-80

SM iii A292/A293/B098

Page 16

Rev. 10/2002

Longer than A4 / Letter lengthwise .....................................................2-80

2.11 ENERGY SAVER MODES ....................................................................2-83

2.11.1 LOW POWER MODE ...................................................................2-83

Entering low power mode ...................................................................2-83

What happens in low power mode ......................................................2-83

Return to stand-by mode ....................................................................2-83

INSTALLATION

3. INSTALLATION PROCEDURE................................................... 3-1

3.1 INSTALLATION REQUIREMENTS ...........................................................3-1

3.1.1 ENVIRONMENT ...............................................................................3-1

3.1.2 MACHINE LEVEL.............................................................................3-1

3.1.3 MINIMUM SPACE REQUIREMENTS...............................................3-2

3.1.4 POWER REQUIREMENTS ..............................................................3-2

3.2 COPIER (A292/A293/B0913) ....................................................................3-3

3.2.1 ACCESSORY CHECK......................................................................3-3

3.2.2 INSTALLATION PROCEDURE ........................................................3-4

3.3 LCT (11/B5137).......................................................................................3-14

3.3.1 ACCESSORY CHECK....................................................................3-14

3.3.2 INSTALLATION PROCEDURE ......................................................3-15

3.4 3,000-SHEET FINISHER (9/B5136)........................................................3-20

3.4.1 ACCESSORY CHECK....................................................................3-20

3.4.2 INSTALLATION PROCEDURE ......................................................3-21

3.5 PUNCH UNIT INSTALLATION (A1312) FOR 9/B5136 FINISHER..........3-24

3.5.1 ACCESSORY CHECK....................................................................3-24

3.5.2 PUNCH UNIT INSTALLATION .......................................................3-25

3.6 FINISHER (B302)....................................................................................3-28

3.6.1 INSTALLATION PROCEDURE ......................................................3-28

3.7 PUNCH UNIT INSTALLATION (A1312) FOR B302 FINISHER...............3-31

3.7.1 ACCESSORY CHECK....................................................................3-31

3.7.2 PUNCH UNIT INSTALLATION .......................................................3-32

3.13 KEY COUNTER INSTALLATION ..........................................................3-35

3.9 COPY CONNECTOR KIT INSTALLATION (10)......................................3-36

3.10 LG KIT (B375/B51313) ..........................................................................3-39

3.10.1 ACCESSORY CHECK..................................................................3-39

3.10.2 INSTALLATION PROCEDURE ....................................................3-40

SERVICE TABLES

4. SERVICE TABLES...................................................................... 4-1

4.1 GENERAL CAUTIONS..............................................................................4-1

4.1.1 DRUM...............................................................................................4-1

4.1.2 DRUM UNIT .....................................................................................4-1

4.1.3 TRANSFER BELT UNIT ...................................................................4-2

4.1.4 SCANNER UNIT...............................................................................4-2

4.1.5 LASER UNIT ....................................................................................4-2

4.1.6 CHARGE CORONA..........................................................................4-3

A292/A293/B098 iv SM

Page 17

Rev. 10/2002

4.1.7 DEVELOPMENT ..............................................................................4-3

4.1.13 CLEANING .....................................................................................4-4

4.1.9 FUSING UNIT...................................................................................4-4

4.1.10 PAPER FEED.................................................................................4-4

4.1.11 USED TONER ................................................................................4-4

4.2 SERVICE PROGRAM MODE....................................................................4-5

4.2.1 SERVICE PROGRAM MODE OPERATION.....................................4-5

Service Program Access Procedure .....................................................4-5

Accessing Copy Mode from within an SP Mode ...................................4-7

Selecting the Program Number.............................................................4-8

Inputting a Value or Setting for an SP Mode.........................................4-9

4.2.2 SERVICE PROGRAM MODE TABLES..........................................4-10

4.2.3 TEST PATTERN PRINTING (SP2-902) .........................................4-66

Test Pattern Table (SP2-902-2: Test Pattern Printing – IPU) .............4-66

Test Pattern Table (SP2-902-3: Test Pattern Printing – Printing) .......4-66

4.2.4 INPUT CHECK ...............................................................................4-67

Main Machine Input Check (SP5-1303)..............................................4-67

ADF Input Check (SP6-007) ...............................................................4-71

4.2.5 OUTPUT CHECK ...........................................................................4-72

Main Machine Output Check (SP5-1304) ...........................................4-72

ADF Output Check (SP6-0013) ..........................................................4-73

4.2.6 SYSTEM PARAMETER AND DATA LISTS (SMC LISTS) .............4-73

4.2.7 MEMORY ALL CLEAR (SP5-1301) ................................................4-74

4.2.13 SOFTWARE RESET ....................................................................4-75

4.2.9 SYSTEM SETTING AND COPY SETTING (UP MODE) RESET ...4-75

System Setting Reset .........................................................................4-75

Copy Features Reset..........................................................................4-75

4.3 PROGRAM AND DATA DOWNLOAD.....................................................4-76

4.3.1 OVERVIEW ....................................................................................4-76

4.3.2 DOWNLOAD THE BICU SOFTWARE FROM BICU TO FLASH

MEMORY CARD .............................................................................4-77

4.3.3 DOWNLOAD NVRAM DATA TO THE BICU ..................................4-78

4.3.4 DOWNLOAD NVRAM DATA FROM BICU TO FLASH MEMORY

CARD .............................................................................................4-79

4.3.5 DOWNLOAD STAMP DATA TO THE BICU ...................................4-80

4.4 USER PROGRAM MODE .......................................................................4-81

4.4.1 HOW TO ENTER AND EXIT UP MODE.........................................4-81

4.4.2 UP MODE TABLE ..........................................................................4-81

System Setting Table..........................................................................4-81

Copy Features Table ..........................................................................4-82

4.4.3 IMAGE QUALITY SETTING BY UP MODE....................................4-86

Text Mode...........................................................................................4-86

Text/Photo Mode ................................................................................4-90

Photo Mode ........................................................................................4-91

Pale Mode...........................................................................................4-92

Generation Mode ................................................................................4-92

4.5 TEST POINTS/DIP SWITCHES/LEDS....................................................4-93

4.5.1 DIP SWITCHES..............................................................................4-93

4.5.2 TEST POINTS ................................................................................4-93

SM v A292/A293/B098

Page 18

Rev. 10/2002

4.5.3 FUSES............................................................................................4-94

4.5.4 VARIABLE RESISTORS ................................................................4-95

4.5.5 LEDS ..............................................................................................4-95

4.6 SPECIAL TOOLS AND LUBRICANTS ....................................................4-95

4.6.1 SPECIAL TOOLS ...........................................................................4-95

4.6.2 LUBRICANTS.................................................................................4-95

4.7 FIRMWARE HISTORY .............................................................................4-96

PREVENTIVE MAINTENANCE

5. PREVENTIVE MAINTENANCE SCHEDULE .............................. 5-1

5.1 PM TABLE.................................................................................................5-1

REPLACEMENT AND ADJUSTMENT

6. REPLACEMENT AND ADJUSTMENT........................................ 6-1

6.1 EXTERIOR ................................................................................................6-1

6.1.1 FILTERS...........................................................................................6-1

Ozone Filter: Duct.................................................................................6-1

Filter Vacuum........................................................................................6-1

6.2 DOCUMENT FEEDER ..............................................................................6-2

6.2.1 COVER REMOVAL ..........................................................................6-2

6.2.2 FEED UNIT REMOVAL AND SEPARATION ROLLER

REPLACEMENT...............................................................................6-4

6.2.3 FEED BELT REPLACEMENT ..........................................................6-5

6.2.4 PICK-UP ROLLER REPLACEMENT ................................................6-6

6.2.5 SENSOR REPLACEMENT...............................................................6-7

Entrance and Registration Sensors ......................................................6-7

Width Sensor ........................................................................................6-8

Exit Sensor and Inverter Sensor ...........................................................6-9

6.2.6 TRANSPORT BELT REPLACEMENT............................................6-10

6.3 SCANNER UNIT......................................................................................6-11

6.3.1 EXPOSURE GLASS.......................................................................6-11

6.3.2 LENS BLOCK .................................................................................6-12

6.3.3 ORIGINAL SIZE SENSORS...........................................................6-13

6.3.4 EXPOSURE LAMP.........................................................................6-14

6.3.5 SCANNER MOTOR / MCU.............................................................6-15

Scanner Motor ....................................................................................6-15

MCU....................................................................................................6-15

6.3.6 SCANNER WIRES .........................................................................6-16

Rear Scanner Drive Wire....................................................................6-19

Front Scanner Drive Wire ...................................................................6-20

Reinstallation ......................................................................................6-21

6.4 LASER UNIT ...........................................................................................6-23

6.4.1 CAUTION DECAL LOCATIONS.....................................................6-23

6.4.2 LD UNIT REPLACEMENT..............................................................6-24

6.4.3 LASER BEAM PITCH ADJUSTMENT............................................6-25

6.4.4 POLYGON MIRROR MOTOR REPLACEMENT ............................6-29

A292/A293/B098 vi SM

Page 19

Rev. 10/2002

6.5 DRUM UNIT ............................................................................................6-30

6.5.1 DRUM POTENTIAL SENSOR REPLACEMENT............................6-30

6.5.2 DRUM MOTOR REPLACEMENT...................................................6-31

6.5.3 TONER OUTPUT AND RECYCLING PUMP UNIT

REPLACEMENT.............................................................................6-32

6.6 DEVELOPMENT AND TONER SUPPLY ................................................6-34

6.6.1 DEVELOPMENT AND AIR DUST FILTER REPLACEMENT .........6-34

6.6.2 DEVELOPER REPLACEMENT ......................................................6-35

6.6.3 TONER END SENSOR REPLACEMENT.......................................6-37

6.6.4 DEVELOPMENT MOTOR REPLACEMENT ..................................6-37

6.7 TRANSFER BELT UNIT..........................................................................6-38

6.7.1 TRANSFER BELT UNIT REMOVAL/INSTALLATION ....................6-38

- Removal - .........................................................................................6-38

- Installation - ......................................................................................6-38

6.13 PAPER FEED........................................................................................6-40

6.13.1 PAPER TRAY REMOVAL ............................................................6-40

Tandem Tray Removal .......................................................................6-40

Universal trays (Customer adjust/Technician adjust) Removal...........6-42

6.13.2 REAR FENCE RETURN SENSOR REPLACEMENT...................6-43

6.13.3 REAR FENCE HP SENSOR REPLACEMENT.............................6-44

6.13.4 BOTTOM PAPER SENSOR REPLACEMENT .............................6-45

6.13.5 BOTTOM PLATE LIFT WIRE REPLACEMENT ...........................6-46

6.13.6 TANDEM LCT PAPER SIZE CHANGE ........................................6-48

6.13.7 BY-PASS PAPER SIZE BOARD REPLACEMENT.......................6-51

6.13.13 PAPER FEED CLUTCH/RELAY CLUTCH REMOVAL...............6-53

6.13.9 BY-PASS FEED MOTOR/CLUTCH REMOVAL ...........................6-56

6.13.10 REGISTRATION MOTOR REMOVAL........................................6-57

6.13.11 PAPER TRAY UNIT REMOVAL.................................................6-58

6.9 FUSING UNIT..........................................................................................6-59

6.9.1 FUSING UNIT REMOVAL ..............................................................6-59

6.9.2 FUSING THERMISTOR/THERMOFUSE/THERMOSTAT

REPLACEMENT.............................................................................6-60

Fusing Thermistor Replacement.........................................................6-60

Fusing Thermofuse Replacement (for A292/A293 only) .....................6-60

Fusing Thermostat Replacement (for B0913 only) .............................6-61

Fusing Thermostat Replacement (for B0913 only) .............................6-61

6.9.3 FUSING LAMP REPLACEMENT ...................................................6-62

6.9.4 HOT ROLLER REPLACEMENT.....................................................6-63

6.9.5 OIL SUPPLY/CLEANING ROLLER REPLACEMENT ....................6-65

6.9.6 PRESSURE ROLLER CLEANING ROLLER REPLACEMENT ......6-66

6.9.7 MAGNET POSITION ADJUSTMENT .............................................6-67

6.9.13 HOT ROLLER STRIPPER PAWL REPLACEMENT.....................6-68

6.10 PAPER EXIT/DUPLEX UNIT.................................................................6-70

6.10.1 1ST AND 2ND EXIT SENSOR .....................................................6-70

6.10.2 JOGGER MOTOR ........................................................................6-71

6.10.3 DUPLEX ENTRANCE SENSOR ..................................................6-71

6.10.4 DUPLEX TRANSPORT/DUPLEX FEED CLUTCHES ..................6-72

6.10.5 DUPLEX TRANSPORT SENSOR 1 .............................................6-72

6.10.6 DUPLEX TRANSPORT SENSORS 2 & 3 ....................................6-73

SM vii A292/A293/B098

Page 20

Rev. 10/2002

6.10.7 INVERTER EXIT CLUTCH...........................................................6-74

6.10.13 DUPLEX INVERTER SENSOR..................................................6-74

6.11 BOARDS AND OTHER ITEMS .............................................................6-75

6.11.1 BICU BOARD ...............................................................................6-75

6.11.2 I/O BOARD ...................................................................................6-76

6.11.3 PSU ..............................................................................................6-77

6.11.4 PAPER FEED CONTROL BOARD (PFC) ....................................6-77

6.12 COPY IMAGE ADJUSTMENTS: PRINTING/SCANNING .....................6-78

6.12.1 PRINTING ....................................................................................6-78

Registration - Leading Edge ...............................................................6-78

Registration – Side-to-Side.................................................................6-78

Tray 1..................................................................................................6-79

Tray 2..................................................................................................6-79

Tray 3..................................................................................................6-80

By-pass Tray.......................................................................................6-80

TROUBLESHOOTING

7. TROUBLESHOOTING ................................................................ 7-1

7.1 SERVICE CALL CONDITIONS .................................................................7-1

7.1.1 SUMMARY .......................................................................................7-1

7.1.2 SC CODE DESCRIPTIONS .............................................................7-2

7.2 ELECTRICAL COMPONENT DEFECTS ................................................7-46

7.2.1 SENSORS ......................................................................................7-46

7.2.2 SWITCHES.....................................................................................7-50

7.3 BLOWN FUSE CONDITIONS .................................................................7-51

FIRMWARE HISTORY

8. A292/A293 FIRMWARE MODIFICATION HISTORY .................. 8-1

3,000-SHEET FINISHER (B312/B586)

1. OVERALL MACHINE INFORMATION........................................ 9-1

1.1 SPECIFICATIONS.....................................................................................9-1

1.2 ELECTRICAL COMPONENT LAYOUT .....................................................9-4

1.3 ELECTRICAL COMPONENT DESCRIPTION...........................................9-6

1.4 MECHANICAL COMPONENT LAYOUT ...................................................9-8

1.5 DRIVE LAYOUT ........................................................................................9-9

2. DETAILED DESCRIPTIONS ..................................................... 9-10

2.1 TRAY AND STAPLER JUNCTION GATE MECHANISM ........................9-10

Upper tray mode.................................................................................9-10

Sort/stack mode..................................................................................9-10

Staple mode........................................................................................9-10

2.2 PRE-STACK MECHANISM .....................................................................9-11

2.3 JOGGER UNIT PAPER POSITIONING MECHANISM............................9-12

A292/A293/B098 viii SM

Page 21

Rev. 10/2002

Vertical Paper Alignment ....................................................................9-12

Horizontal Paper Alignment ................................................................9-12

2.4 STAPLER UNIT MOVEMENT MECHANISM ..........................................9-13

Side-to-side:........................................................................................9-13

Rotation: .............................................................................................9-13

2.5 STAPLER ................................................................................................9-14

2.6 FEED-OUT MECHANISM .......................................................................9-15

2.7 SHIFT TRAY UP/DOWN MECHANISM ..................................................9-16

2.13 SHIFT TRAY SIDE-TO-SIDE MECHANISM..........................................9-17

2.9 PUNCH UNIT DRIVE MECHANISM........................................................9-18

2.10 PUNCH WASTE COLLECTION MECHNISM........................................9-19

2.11 JAM CONDITIONS................................................................................9-20

3. SERVICE TABLES.................................................................... 9-21

3.1 DIP SWITCHES.......................................................................................9-21

3.2 TEST POINTS.........................................................................................9-21

3.3 FUSES ....................................................................................................9-21

4. REPLACEMENT AND ADJUSTMENT...................................... 9-22

4.1 COVER REPLACEMENT........................................................................9-22

Rear Cover .........................................................................................9-22

Upper Left Cover ................................................................................9-22

Upper Cover .......................................................................................9-22

Front Door...........................................................................................9-22

Left Front Cover..................................................................................9-22

Shift Tray ............................................................................................9-23

Lower Left Cover ................................................................................9-23

Right Cover.........................................................................................9-23

Front Shift Tray Cover.........................................................................9-23

Rear Shift Tray Cover .........................................................................9-23

4.2 POSITIONING ROLLER REPLACEMENT..............................................9-24

4.3 ALIGNMENT BRUSH ROLLER REPLACEMENT...................................9-25

4.4 SENSOR REPLACEMNT........................................................................9-26

4.4.1 STACK HEIGHT SENSOR 1 AND 2...............................................9-26

4.4.2 UPPER TRAY PAPER LIMIT AND EXIT SENSOR ........................9-27

Upper Tray Paper Limit Sensor ..........................................................9-27

Upper Tray Exit Sensor.......................................................................9-27

4.4.3 SHIFT TRAY EXIT SENSOR..........................................................9-28

4.4.4 ENTRANCE AND STAPLER TRAY ENTRANCE SENSOR...........9-29

Entrance Sensor .................................................................................9-29

Stapler Tray Entrance Sensor.............................................................9-29

4.4.5 STAPLER ROTATION HP SENSOR..............................................9-30

4.5 STAPLER REMOVAL..............................................................................9-31

4.6 PUNCH POSITION ADJUSTMENT.........................................................9-32

Right to left..........................................................................................9-32

Front to rear........................................................................................9-32

SM ix A292/A293/B098

Page 22

Rev. 10/2002

BOOKLET FINISHER A763

1. OVERALL MACHINE INFORMATION...................................... 10-1

1.1 SPECIFICATIONS...................................................................................10-1

1.2 ELECTRICAL COMPONENT DESCRIPTION.........................................10-3

1.3 MECHANICAL COMPONENT LAYOUT .................................................10-7

2. DETAILED DESCRIPTIONS ..................................................... 10-8

2.1 JUNCTION GATE MECHANISM.............................................................10-8

2.1.1 SHIFT TRAY MODE.......................................................................10-8

A4/LT sideways or shorter ..................................................................10-8

Longer than A4 sideways....................................................................10-8

2.1.2 PROOF TRAY MODE.....................................................................10-9

2.1.3 BOOKLET STITCH MODE.............................................................10-9

2.2 PRE-STACK MECHANISM ...................................................................10-10

2.3 PAPER SHIFT MECHANISM ................................................................10-11

2.4 PAPER POSITIONING MECHANISM...................................................10-12

2.5 STAPLER UNIT MOVEMENT MECHANISM ........................................10-13

2.5.1 DRIVE...........................................................................................10-13

2.5.2 MOVEMENT.................................................................................10-13

Front and Rear Stapling....................................................................10-13

Tow-position Stapling........................................................................10-13

2.6 STAPLER ..............................................................................................10-14

2.7 SHIFT TRAY MECHANISM...................................................................10-15

2.13 BOOKLET UNIT GATE MECHANISM.................................................10-16

2.9 RELAY ROLLER AND POSITIONING PLATE MECHANISM ...............10-18

2.10 POSITIONING ROLLER MECHANISM...............................................10-19

2.11 BOOKLET UNIT JOGGER MOVEMENT MECHANISM......................10-20

2.12 BOOKLET STAPLER UNIT.................................................................10-21

2.13 PAPER FOLDER MECHANISM..........................................................10-22

3. INSTALLATION ...................................................................... 10-24

3.1 ACCESSORY CHECK ..........................................................................10-24

3.2 INSTALLATION PROCEDURE .............................................................10-25

4. REPLACEMENT AND ADJUSTMENT.................................... 10-30

4.1 REMOVAL.............................................................................................10-30

4.1.1 UPPER DOOR .............................................................................10-30

4.1.2 UPPER REAR COVER.................................................................10-31

4.1.3 LOWER REAR COVER................................................................10-31

4.1.4 TOP COVER ................................................................................10-32

4.1.5 UPPER INNER COVER ...............................................................10-32

4.1.6 SHIFT TRAY UNIT .......................................................................10-33

4.1.7 UPPER SHIFT GUIDE..................................................................10-34

4.1.13 LOWER SHIFT GUIDE...............................................................10-34

4.1.9 EXIT UNIT ....................................................................................10-35

4.1.10 BUFFER ROLLER UNIT.............................................................10-36

4.1.11 STAPLER ...................................................................................10-37

A292/A293/B098 x SM

Page 23

Rev. 10/2002

4.1.12 FINISHER BOARD ....................................................................10-38

4.1.13 BOOKLET UNIT .........................................................................10-39

4.1.14 FOLDER ROLLERS ...................................................................10-41

4.1.15 FOLDER PLATE.........................................................................10-44

Removal............................................................................................10-44

Reinstalling .......................................................................................10-45

4.1.16 BOOKLET STAPLER UNIT........................................................10-46

Removal............................................................................................10-46

Adjustment........................................................................................10-47

4.1.17 BOOKLET BOARD.....................................................................10-49

4.1.113 POSITIONING PLATE UNIT ....................................................10-49

4.1.19 1ST AND 2ND BOOKLET UNIT GATES ....................................10-50

4.2 ADJUSTMENT ......................................................................................10-51

4.2.1 SHIFT TRAY HEIGHT ..................................................................10-51

4.2.2 JOGGER FENCE POSITION .......................................................10-52

4.2.3 STAPLING POSITOIN..................................................................10-53

4.2.4 BOOKLET STAPLING POSITION.................................................10-54

COPIER CONNECTION KIT B322

1. SPECIFICATIONS..................................................................... 11-1

2. DETAILED DESCRIPTIONS ..................................................... 11-2

2.1 OVERVIEW .............................................................................................11-2

2.2 BASIC OPERATION................................................................................11-3

2.2.1 NO SORT AND NO STAPLE MODE..............................................11-3

2.2.2 SORT, STAPLE MODE ..................................................................11-4

2.2.3 OPERATION IN IRREGULAR CONDITIONS.................................11-5

Paper end during copying ...................................................................11-5

Copy tray full.......................................................................................11-5

Paper jam ...........................................................................................11-5

LCT A698/B587

1. OVERALL MACHINE INFORMATION...................................... 12-1

1.1 SPECIFICATIONS...................................................................................12-1

1.2 MECHANICAL COMPONENT LAYOUT .................................................12-2

1.3 ELECTRICAL COMPONENT LAYOUT ...................................................12-3

1.4 ELECTRICAL COMPONENT DESCRIPTIONS ......................................12-4

1.5 DRIVE LAYOUT ......................................................................................12-5

2. DETAILED DESCRIPTIONS ..................................................... 12-6

2.1 PAPER FEED MECHANISM...................................................................12-6

2.2 TRAY LIFT MECHANISM........................................................................12-7

Tray lifting conditions ..........................................................................12-7

Tray lowering conditions .....................................................................12-7

2.3 PAPER STACK HEIGHT DETECTION ...................................................12-9

SM xi A292/A293/B098

Page 24

Rev. 10/2002

3. SERVICE TABLES.................................................................. 12-10

3.1 TEST POINTS.......................................................................................12-10

4. REPLACEMENT AND ADJUSTMENT.................................... 12-11

4.1 COVER REMOVAL ...............................................................................12-11

Tray Cover ........................................................................................12-11

Right Cover......................................................................................12-11

Front Cover.......................................................................................12-11

Upper Rear Cover.............................................................................12-11

Lower Rear Cover.............................................................................12-12

Feed Unit Cover................................................................................12-12

4.2 ROLLER REPLACEMENT ....................................................................12-13

4.2.1 PAPER FEED, SEPARATION, AND PICK-UP ROLLERS ...........12-13

Pick-up Roller ...................................................................................12-13

Paper Feed Roller.............................................................................12-13

Separation Roller..............................................................................12-13

4.3 PAPER END SENSOR REPLACEMENT..............................................12-14

4.4 PAPER FEED SENSOR REPLACEMENT............................................12-15

4.5 PAPER POSITION SENSOR REPLACEMENT ....................................12-16

4.6 PICK-UP SOLENOID REPLACEMENT.................................................12-17

4.7 LIFT MOTOR REPLACEMENT.............................................................12-18

4.13 SIDE FENCE POSITION CHANGE.....................................................12-19

3,000-SHEET FINISHER B302

1. OVERALL MACHINE INFORMATION...................................... 13-1

1.1 SPECIFICATIONS...................................................................................13-1

1.2 MECHANICAL COMPONENT LAYOUT .................................................13-3

1.3 ELECTRICAL COMPONENT DESCRIPTION.........................................13-4

1.4 DRIVE LAYOUT ......................................................................................13-6

2. DETAILED DESCRIPTIONS ..................................................... 13-7

2.1 TRAY AND STAPLER JUNCTION GATE ...............................................13-7

Upper Tray Mode................................................................................13-7

Sort/Stack Mode .................................................................................13-7

Staple Mode........................................................................................13-7

2.2 PAPER PRE-STACKING ........................................................................13-8

2.3 JOGGER UNIT PAPER POSITIONING ..................................................13-9

Vertical Paper Alignment ....................................................................13-9

Horizontal Paper Alignment ................................................................13-9

Paper Stack Correction.......................................................................13-9

2.4 STAPLER UNIT MOVEMENT ...............................................................13-10

Side-to-Side ......................................................................................13-10

Rotation (1) .......................................................................................13-11

Rotation (2) .......................................................................................13-11

2.5 STAPLER ..............................................................................................13-12

2.6 FEED-OUT ............................................................................................13-14

2.7 SHIFT TRAY UP/DOWN MOVEMENT..................................................13-15

A292/A293/B098 xii SM

Page 25

Rev. 10/2002

2.13 SHIFT TRAY SIDE-TO-SIDE MOVEMENT .........................................13-16

2.9 PUNCH UNIT DRIVE ............................................................................13-17

2.10 PUNCH WASTE COLLECTION ..........................................................13-18

2.11 JAM CONDITIONS..............................................................................13-19

3. SERVICE TABLES.................................................................. 13-20

3.1 DIP SWITCHES.....................................................................................13-20

3.2 TEST POINTS.......................................................................................13-20

3.3 FUSES ..................................................................................................13-20

4. REPLACEMENT AND ADJUSTMENT.................................... 13-21

4.1 COVER REPLACEMENT......................................................................13-21

Front Door.........................................................................................13-21

Left Inner Cover ................................................................................13-21

Inner Cover.......................................................................................13-21

Table.................................................................................................13-22

Upper Tray........................................................................................13-22

Left Upper Cover ..............................................................................13-22

Left Lower Cover...............................................................................13-22

Upper Cover .....................................................................................13-22

Rear Cover .......................................................................................13-22

Shift Tray ..........................................................................................13-23

Front Shift Tray Cover.......................................................................13-23

Rear Shift Tray Cover .......................................................................13-23

4.2 POSITIONING ROLLER REPLACEMENT............................................13-24

4.3 ALIGNMENT BRUSH ROLLER REPLACEMENT.................................13-25

4.4 SENSOR REPLACEMENT ...................................................................13-26

4.4.1 STACK HEIGHT 1, 2 AND EXIT GUIDE OPEN SENSOR ...........13-26

Stack Height Sensors 1 and 2 ..........................................................13-26

Exit Guide Open Sensor ...................................................................13-26

4.4.2 UPPER TRAY PAPER LIMIT AND EXIT SENSOR ......................13-27

Upper Tray Paper Limit Sensor ........................................................13-27

Upper Tray Exit Sensor.....................................................................13-27

4.4.3 SHIFT TRAY EXIT SENSOR........................................................13-28

4.4.4 ENTRANCE AND STAPLER TRAY ENTRANCE SENSORS ......13-29

Entrance Sensor ...............................................................................13-29

Stapler Tray Entrance Sensor...........................................................13-29

4.4.5 PRE-STACK STOPPER SENSOR...............................................13-30

4.4.6 STAPLE WASTE HOPPER SENSOR ..........................................13-31

4.4.7 STAPLER ROTATION HP AND STAPLER RETURN SENSORS 13-32

Stapler Rotation HP Sensor..............................................................13-32

Stapler Return Sensor ......................................................................13-32

4.5 STAPLER REMOVAL............................................................................13-33

4.6 PUNCH POSITION ADJUSTMENT.......................................................13-34

Right to Left ......................................................................................13-34

Front to Rear.....................................................................................13-34

SM xiii A292/A293/B098

Page 26

Page 27

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

1

Page 28

1. SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!

WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can seriously damage

your eyes.

CAUTION MARKING:

2

Page 29

OVERALL INFORMATION A292/A293/B098

Rev. 10/2002

3,000 SHEET FINISHER B312/B586

DETAILED DESCRIPTIONS A292/A293/B098

BOOKLET FINISHER A763

INSTALLATION A292/A293/B098

COPIER CONNECTION KIT B322

SERVICE TABLES A292/A293/B098

LCT A698/B587

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

PREVENTIVE MAINTENANCE A292/A293/B098

3,000 SHEET FINISHER B302

REPLACEMENT AND ADJUSTMENT A292/A293/B098

TROUBLESHOOTING A292/A293/B098

FIRMWARE HISTORY A292/A293/B098

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 30

Page 31

COMPARISON BETWEEN

A292/A293 AND A229

Page 32

Page 33

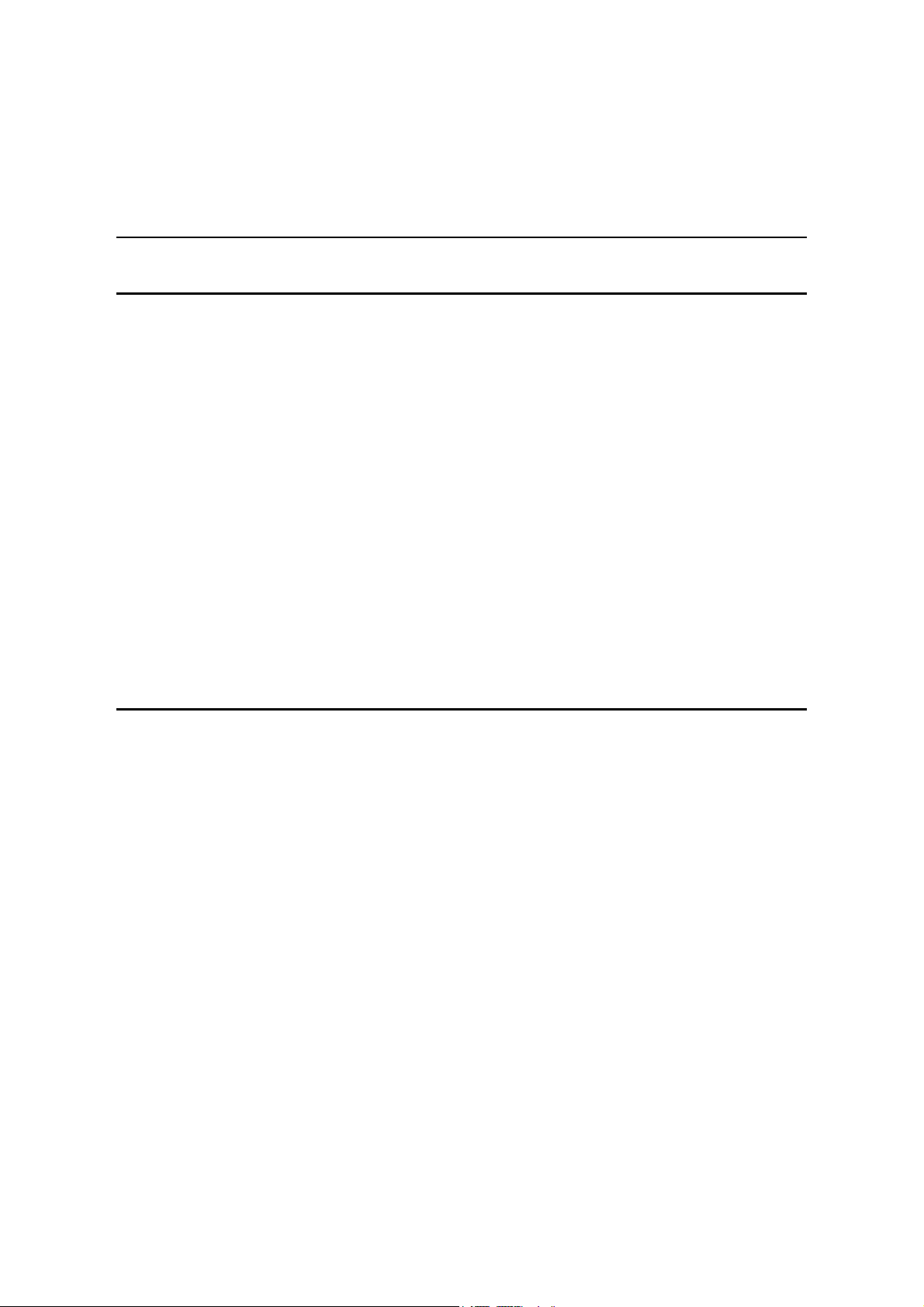

DIFFERENT POINTS

SECTION 1: OVERALL INFORMATION

Section Item Description Page

Specifications

Copy Size Minimum: A5/5

1/2

Zoom Minimum: 25% (A229: 32%) 1-2

Copying Speed 70/55 cpm (A229: 65/55 cpm) 1-2

1 to 1 Copying

Speed with ADF

70 cpm (A229: 50 cpm)

ARDF: New A294

Resolution Scanning: 600 dpi (A229: 400 dpi)

Printing: 600 dpi (A229: 400 dpi)

First Copy Time Face Up: 3.5 seconds, Face Down: 5.3 seconds

(A229: Face Up: 3.7 seconds, Face Down: 5.5

seconds)

Copy Paper

Capacity

Tray 1: 3,100 sheets (A229: 1,000 sheets)

Tray 3: 550 sheets (A229: 1,500 sheets)

Memory Capacity RAM: 48 MB (A229: 12 MB)

HDD: 4.3 GB (A229: 1.7 GB)

Power

(Refer to service manual) 1-3

Consumption

Additional Feature Document Server function is available as a

standard function.

Additional Feature User Stamp, etc. N/A

Peripherals Finisher (B312): Pre-stack function

Finisher (A763):

Folds paper in half with 2 staples

Finisher (B302):

Pre-stack function, 100 sheets for staple

Punch Unit (for B312 B302, A812):

2 holes (80 mm / 6.5 mm) (Same as A229)

3 holes (108-108 mm / 8 mm) (Same as A229)

4 holes (21-70-21 mm / 6.5 mm) (New)

4 holes (80-80-80 mm / 6.5 mm) (New)

2 holes (70 mm / 8 mm) (New)

LCT (A698): Upgraded version

Copy Connector Unit (B322)

Output Tray (B333)

Tab Sheet Holder (B373)

8

" x 14" Size Kit (B375)

1/2

Consumable

New Toner (NA: Type 5105D, EU/Asia: Type

5205D)

New Developer (Type 15)

Toner Particle: 9.5 µm (A229: 7.5 µm)

" x 8

1/2

" Lengthwise in 2nd Tray 1-1

N/A

1-2

1-2

1-2

N/A

N/A

1-4

2-49

SM 1 A292/A293

Page 34

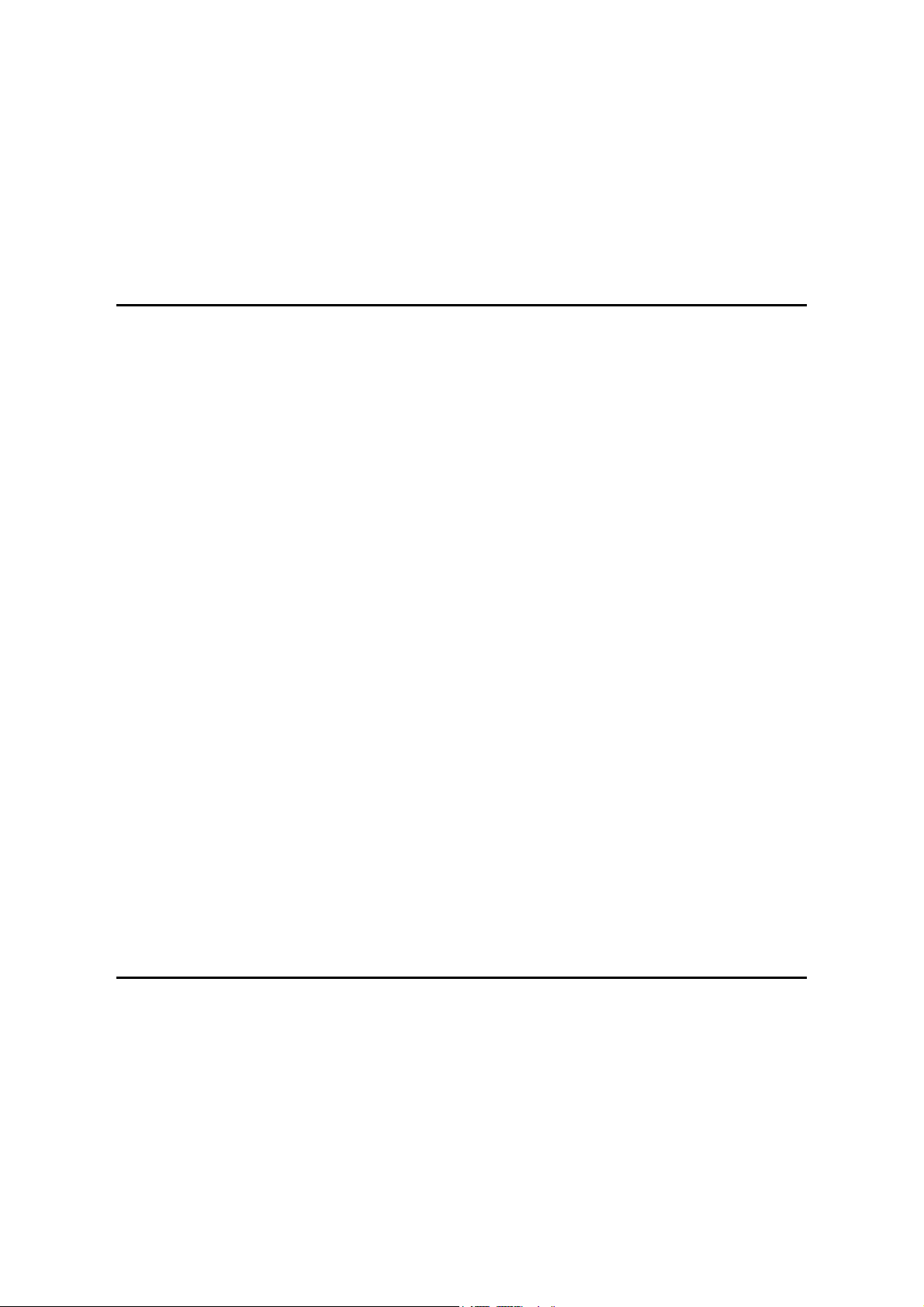

DIFFERENT POINTS

SECTION 2: DETAILED DESCRIPTIONS

Section Item Description Page

Scanning Overview

Laser

Exposure

Process

Control

Overview

Image Density

Control

• The number of exposure lamp is one. (A229: 2

lamps)

• The CCD is changed to 4-channel type because

of a higher processing speed. (A229: 2 channels)

• A reflector is added to 1st scanner.

• The Scanner Motor has been changed to a DC

Servo type because of a higher processing

speed.

• The location of Lamp Regulator moves onto the

1st scanner.

• The LD unit and Polygon Motor have been

changed because of a higher processing speed.

• The method controlling the LD has been changed

because the standard resolution has been

changed from 400 dpi to 600 dpi.

The toner amount in the development unit is

updated using Vsp/Vsg data in addition to the Vref

update.

2-13

N/A

2-36

Drum Unit Drum Flange The holes for airflow have been added to Drum

Flange to make cooling power up because of higher

processing speed.

Rotation Speed 362 mm/s (A229: 330 mm/s)

This is because a higher copying speed.

Development

Corona Wire

Cleaner

Cleaning Brush

Cleaning Blade

Side-to-Side

Movement

Toner Supply

Control

ID Sensor Pattern The pattern has become darker to increase

One of the conditions making the cleaner start

moving “only if the fusing temperature is lower than

100°C” has not been used any more because the

other condition “only when 5000 or more copies

have been made since the last movement” is

effective enough to function.

• The turning direction of the brush has been

changed to the counter direction to increase the

cleaning ability.

• The brush has been changed from a rope type to

a straight type. A rope type scrapes off the drum

surface too much because of the change of the

turning direction.

The location of the cam gear is changed onto the

main frame to increase reliability.

TBA N/A

reliability of toner supply control.

2-47

N/ADrum Unit

2-43

2-44Cleaning

2-46

N/A

Lower

Development

Roller

A292/A293 2 SM

The shaft of the roller does not turn.

It is not necessary to lubricate conductive grease on

the shaft.

N/A

Page 35

Rev. 08/2000

DIFFERENT POINTS

Section Item Description Page

Transfer

Paper

Feed

Toner

Recycling

Fusing

Paper

Exit/Duplex

Ozone

Filter

Transfer Belt The surface treatment has been changed to

increase cleaning ability.

Cleaning Bias

Roller

Bushing A bearing has been added to the bushing to make

Gear The gear has been changed to a diagonal type with

Transfer Current 1st Copy (Front): 65µA (A229: 60µA)

Torque Limitter The type of the Torque Limitter has been changed

Paper size setting

in 2nd tray

By-pass Tray

Switch

Paper Feed Mode

Condition of “Full

Toner Collection

Bottle”

Inner Cover The grip and the jam removal decal have been

Fusing Sensor The Fusing Sensor has been added to detect a

Inverter Exit

Clutch

Duplex Inverter

Sensor

Jogger Start

Timing

The nylon tube has been added as the surface of

the cleaning bias roller to increase the cleaning

ability.

This allows to increasing the maximum charging

voltage up to 1000 V (A229: 330 V).

the movement smoother.

the color of black to decrease a jitter level.

2nd Copy (Front): 65µA (A229: 60µA)

By-pass Tray (Front): 75µA (A229: 70µA)

Post Card (Front): 165µA (A229: 150µA)

This is because of a higher drum rotation speed.

from a non-contact magnet type to a metal powder

type to increase reliability.

The paper size setting can be done at the front side

of the tray for easier operation.

The By-pass Tray Switch has been deleted. The bypass tray indicator is always on the operation panel

and turns on when paper is placed in the tray.

The thick paper mode is used for any paper type in

all paper feed stations to increase paper

transportation ability.

The number of copies, which can be made after the

toner overflow switch is activated and the “full toner

collection bottle” indication lights, becomes only “up

to 100 copies”. The other one “the copy job is

allowed to end” is not effective any more.

changed.

The procedure of jammed paper removal has also

been changed.

jammed paper with an accordion shape.

The Inverter Exit Clutch has been added to stop a

paper coming into the duplex unit for a while.

This is to keep the maximum productivity of printing

even when it takes a longer time for image

processing for a paper coming out of the duplex

unit.

When the clutch is ON, paper stops.

The Inverter Exit Sensor has been added to control

the ON/OFF timing of the Inverter Exit Clutch.

The Jogger Fences start moving 83 ms after the

trailing edge of paper passes the Duplex Entrance

Sensor. (A229: 100 ms)

An inlet is added to change the airflow direction of

the exhaust fan to downward. This is to increase the

cooling ability and decrease the ozone smell level.

The shape of the rear cover has been changed.

N/A

N/A

N/A

2-58

SP

2-301

N/A

2-72

N/A

N/A

N/A

N/A

2-73

N/A

2-79

N/A

N/A

SM 3 A292/A293

Page 36

DIFFERENT POINTS

Section Item Description Page

Electrical

Components

BICU Board

I/O Board

• Scanner control circuit has been independent

from SBICU as MCU (Motor Control Unit) and

Scanner Motor Drive Board is deleted.

The name of SBICU is changed to BICU.

This is because the Scanner Motor has been

changed from a stepper motor to a servomotor to

enable the copying speed in the ADF 1 to 1 mode

to be 70 cpm.

• The exposure lamp, APS sensor and scanner HP

sensor are also connected to the MCU.

The RDS function has been independent from

the I/O board as RDS Board and has been

controlled by the BICU board because of the

following reasons:

1. The I/O board can completely turn off in the

weekly timer off mode.

2. It has been possible that only the RDS board is

replaced.

PSU A 38V output has been added for the scanner motor

that is changed from a stepper motor to a servomotor.

CNB

(Connector

Board)

This is a new name of the Interface Board

which the functions for the registration motor,

by-pass motor and development motor are

deleted from.

Those functions are on the DRB (Driver Board) as a

new board.

This is to reduce the harnesses used.

12V Power

Supply Board

DRB

(Driver Board)

The DC/DC converter has been deleted and its

function has moved to the PSU.

This is an interface board for the signal lines of

the registration motor, by-pass motor and

development motor.

The power line for each motor is connected to the

CNB.

Copy Connect

Board

Printer Controller

The connection between the BICU and Copy

Connect Board has been changed from via the FCC

cable to via the interface board.

This is to make installation easier.

The connection between the BICU and Printer

Controller has been changed from only via the

FCC cable to via the interface board and the

FCC cable.

This is to make installation easier.

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

A292/A293 4 SM

Page 37

DIFFERENT POINTS

SECTION 3: INSTALLATION

Section Item Description Page

Installation

Procedure

Installation

Procedure

Finisher

(B302, B312)

Output Tray

• The caps on the upper left cover of the copier

have not been equipped, so that it is not

necessary to remove them when a finisher is

installed.

• New type of grounding bracket.

• A cavity has been made in each Paper Exit Roller

and a plug is prepared beside each roller on the

shaft. The plugs are necessary to be inserted into

the cavities.

• The caps on the upper left cover have become

accessories of the Output Tray and are

necessary to be installed.

• The stack height sensors at the paper exit area

have become accessories of the Output Tray and

are necessary to be installed.

3-22

3-29

SM 5 A292/A293

Page 38

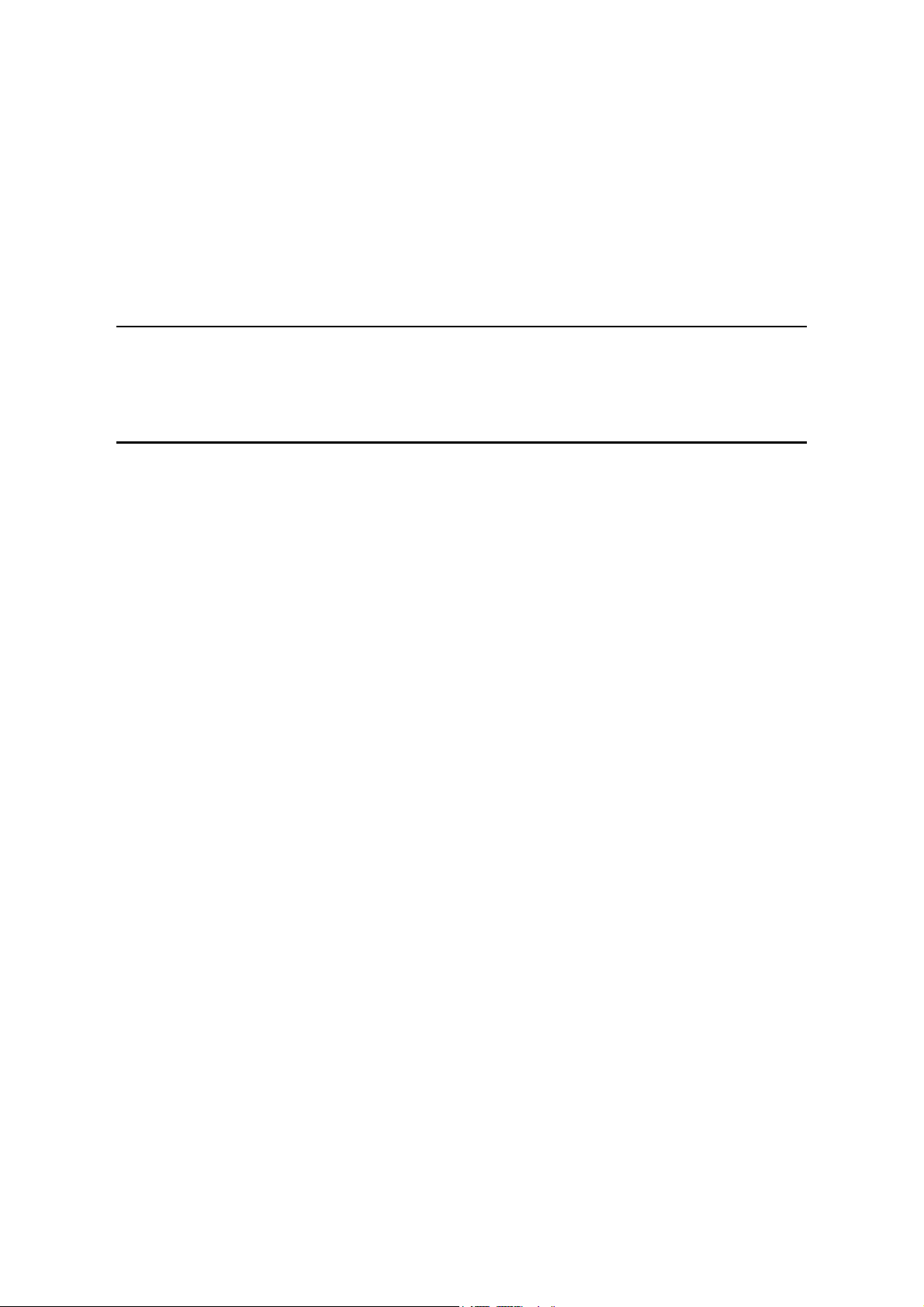

DIFFERENT POINTS

SECTION 4.2.2.: SERVICE PROGRAM MODE TABLE

Mode

No.

1-901 CPM change for thick

paper

2-001-3 Charge Corona Bias

Adjustment

2-201-2 ID Sensor Pattern Factory setting: -400 V (A229: -440 V) 4-14

2-201-3 OHP Sheet Factory setting: -300 V (A229: -550 V) 4-15

2-201-4

2-210 ID Sensor Interval Factory setting: 10 copies (A229: 50 copies) 4-15

2-220 V

2-301-1

2-301-2 Transfer Current

2-301-3 Transfer Current

2-301-4 Transfer Current

2-301-6

2-801 TD Sensor Initial Setting

2-902-4

2-902-5

2-906-2 Vcont Manual Setting This function is new. 4-18

2-962 Auto Process Control

2-963 Toner Supply From

2-966 Periodical Auto Process

2-967 Auto Image Density

2-970 Transfer Belt Resistance

2-971 Output Value Measured

3-001-2 ID Sensor PWM Setting

3-902-7

4-015 Scanner Speed

4-902 SBU Setting All the functions in SP4-901-X are shifted to

Development

Performance

REF

Transfer Current

Adjustment

Adjustment

Adjustment

Adjustment

Transfer Current

Adjustment

Printing Test Pattern These functions are new. 4-17

Toner Bottle

Control

Adjustment

Value Display

Between Copies

Process Control Data

Display

Adjustment

Mode Description Page

The setting range is changed from 0 to 2 to 0

to 3 as follows:

0: None

1: 55 cpm at 165°C (A229: 50 cpm)

2: 45 cpm at 165°C (A229: 45 cpm)

3: 35 cpm (newly added)

Factory setting: -1300 µA (A229: -1200 µA)

This is because the copy speed is increased.

Factory setting: -280 V (A229: -320 V) 4-15

Manual Setting Factory setting: 3.0 V or 2.5 V (A229:2.5 V) 4-15

Factory setting: 65 µA (A229: 60 µA)

This is because the copy speed is increased.

Factory setting: 65 µA (A229: 60 µA)

This is because the copy speed is increased.

Factory setting: 75 µA (A229: 70 µA)

This is because the copy speed is increased.

Factory setting: 165 µA (A229: 150 µA)

This is because the copy speed is increased.

This function is new. 4-16

This function can also be performed in the Wait

condition.

This function can also be performed in the Wait

condition.

This function can also be performed in the Wait

condition.

This function is new. 4-20

This function is new. 4-20

This function is new. 4-20

This function is new. 4-20

This function can also be performed in the Wait

condition.

This function is new. 4-21

This function is new. 4-22

SP4-902-X.

4-12

4-12

4-16

4-16

4-16

4-16

4-17

4-19

4-19

4-20

4-23

to 4-27

A292/A293 6 SM

Page 39

DIFFERENT POINTS

Mode

No.

5-824 Upload NVRAM Data This function is new. 4-50

5-825 Download NVRAM Data This function is new. 4-50

5-826 Program Upload This function is new. 4-50

5-829 Stamp Data Download This function is new. 4-50

5-921 Stamp Data Download This function is new. 4-51

5-922 Counter Operation

Setting

5-923 Edge Erase Standard This function is new. 4-51

5-954 Copy Server password

Display

5-965

6-116 Thick Paper Count This function is new. 4-53

6-801 Copy Connect I/F Test This function is new. 4-53

6-901 Original Exchange Time

6-902

7-304-24

7-304-25

7-304-26

7-330 Connect Copy Job This function is new. 4-58

7-331 Connect Copy: Copy This function is new. 4-58

7-332

7-333

7-504-35

to

7-504-40

7-808 Counters Reset The counters which are reset: SP7-003, SP7-

7-830 Copy Counter by Paper

All Copy Server File

Delete

Adjustment

Saddle Stitch

Adjustment

Total Copies By Copy

Mode

Connect Copy: Copy