Page 1

RICOH GROUP COMPANIES

A265/A267

SERVICE MANUAL

000882MIU

Page 2

Page 3

SERVICE MANUAL

A265/A267

RICOH GROUP COMPANIES

Page 4

Page 5

A265/A267

SERVICE MANUAL

000882MIU

Page 6

Page 7

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2000 RICOH Corporation. All rights reserved.

Page 8

Page 9

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Corporation. Users of this

manual should be either service trained or

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Corporation

Page 10

Page 11

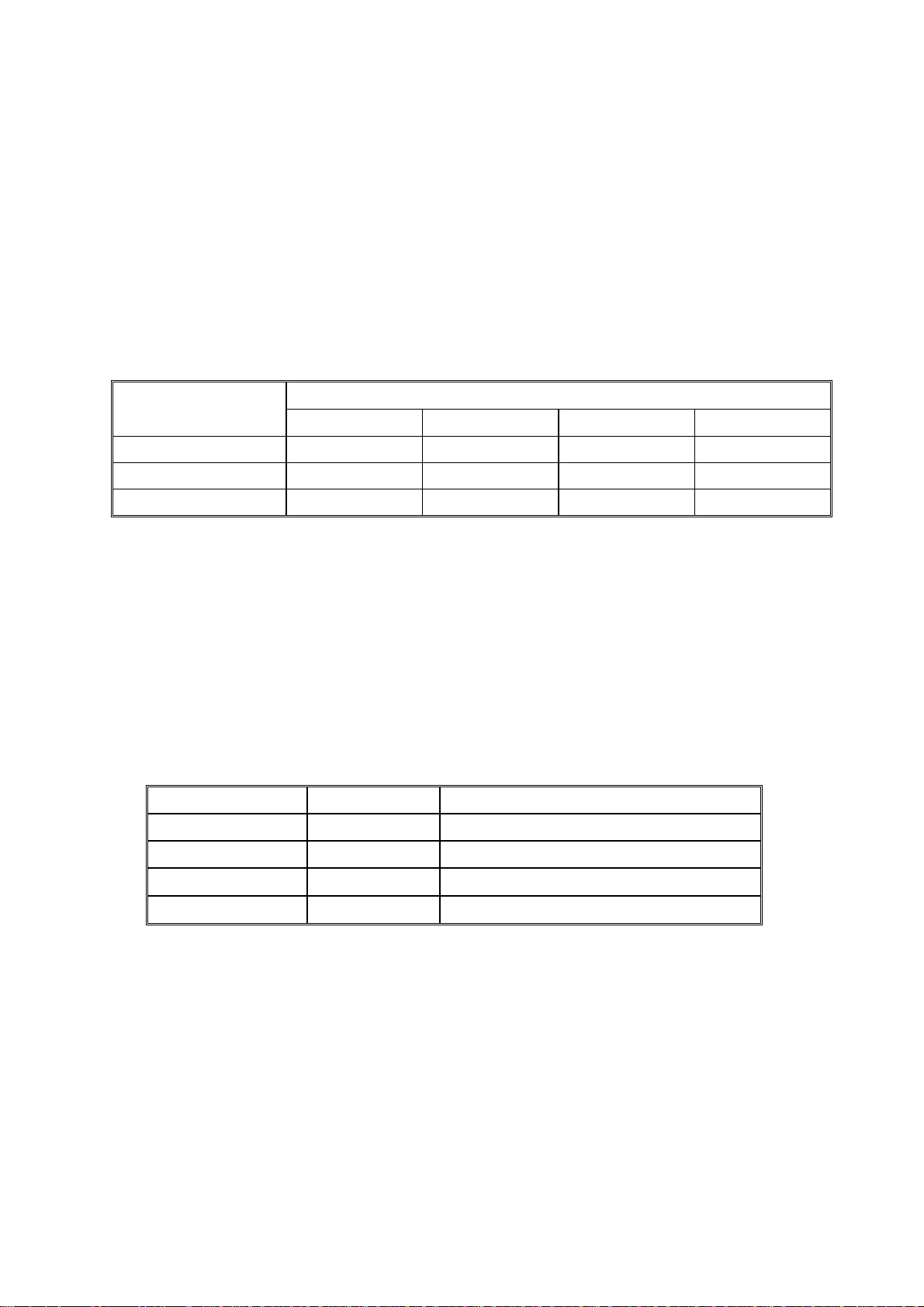

LEGEND

PRODUCT CODE COMPANY

GESTETNER LANIER RICOH SAVIN

A265 3222 5222 Aficio 220 9922DP

A267 3227 5227 Aficio 270 9927DP

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

12/99 Original Printing

Page 12

Page 13

TABLE OF CONTENTS

OVERALL INFORMATION

1. OVERALL MACHINE INFORMATION ........................................1-1

1.1 SPECIFICATIONS .................................................................................... 1-1

1.2 MACHINE CONFIGURATION................................................................... 1-5

1.2.1 SYSTEM COMPONENTS................................................................ 1-5

1.2.2 INSTALLABLE OPTION TABLE.......................................................1-7

Copier options ......................................................................................1-7

Fax and printer options......................................................................... 1-7

Scanner option .....................................................................................1-7

1.3 PAPER PATH............................................................................................1-8

1.4 MECHANICAL COMPONENT LAYOUT ...................................................1-9

1.5 ELECTRICAL COMPONENT DESCRIPTIONS ...................................... 1-11

1.6 DRIVE LAYOUT...................................................................................... 1-14

1.7 COPY PROCESS....................................................................................1-15

1.7.1 OVERVIEW....................................................................................1-15

1.8 BOARD STRUCTURE ............................................................................1-17

1.8.1 OVERVIEW....................................................................................1-17

1.8.2 DESCRIPTION............................................................................... 1-18

DETAILED DESCRIPTIONS

2. DETAILED SECTION DESCRIPTIONS....................................... 2-1

2.1 SCANNING ............................................................................................... 2-1

2.1.1 OVERVIEW......................................................................................2-1

2.1.2 SCANNER DRIVE............................................................................ 2-2

2.1.3 ORIGINAL SIZE DETECTION IN PLATEN MODE ..........................2-3

2.2 IMAGE PROCESSING.............................................................................. 2-5

2.2.1 OVERVIEW......................................................................................2-5

2.2.2 SBU (SENSOR BOARD UNIT) ........................................................2-6

2.2.3 AUTO IMAGE DENSITY .................................................................. 2-7

In the SBU ............................................................................................ 2-7

In the IPU..............................................................................................2-7

“Service Mode” Original Types ............................................................2-7

2.2.4 IPU (IMAGE PROCESSING UNIT) ..................................................2-8

Overview............................................................................................... 2-8

Image Processing Modes ..................................................................... 2-9

Image Processing Path.......................................................................2-11

SP Modes for Each Image Processing Step....................................... 2-12

Auto Shading......................................................................................2-18

White Line Erase Compensation ........................................................2-18

Black Line Erase Compensation......................................................... 2-18

Scanner Gamma (γ Correction ........................................................... 2-19

SM i A265/A267

Page 14

Main Scan Magnification/Reduction ...................................................2-20

Mirroring for ADF Mode ...................................................................... 2-20

Filtering............................................................................................... 2-21

ID Gamma (γ) Correction.................................................................... 2-25

Gradation Processing ......................................................................... 2-25

Line width correction........................................................................... 2-27

2.2.5 MEMORY CONTROLLER AND ENHANCED MEMORY

BOARD (EMB) .............................................................................. 2-28

2.2.6 VIDEO CONTROL UNIT (VCU) .....................................................2-29

Fine Character and Image (FCI)......................................................... 2-29

Printer Gamma Correction.................................................................. 2-29

2.3 LASER EXPOSURE................................................................................2-30

2.3.1 OVERVIEW....................................................................................2-30

2.3.2 AUTO POWER CONTROL (APC).................................................. 2-31

2.3.3 LD SAFETY SWITCH..................................................................... 2-32

2.4 PHOTOCONDUCTOR UNIT (PCU) ........................................................ 2-33

2.4.1 OVERVIEW....................................................................................2-33

2.4.2 DRIVE ............................................................................................ 2-34

2.4.3 NEW PCU DETECTION................................................................. 2-35

2.5 DRUM CHARGE ..................................................................................... 2-36

2.5.1 OVERVIEW....................................................................................2-36

2.5.1 CHARGE ROLLER VOLTAGE CORRECTION.............................. 2-37

Correction for Environmental Conditions ............................................2-37

2.5.2 ID SENSOR PATTERN PRODUCTION TIMING ...........................2-38

2.5.3 DRUM CHARGE ROLLER CLEANING.......................................... 2-39

2.6 DEVELOPMENT ..................................................................................... 2-40

2.6.1 OVERVIEW....................................................................................2-40

2.6.2 DRIVE ............................................................................................ 2-41

2.6.3 DEVELOPER MIXING.................................................................... 2-42

2.6.4 DEVELOPMENT BIAS ................................................................... 2-43

2.6.5 TONER SUPPLY............................................................................ 2-44

Toner bottle replenishment mechanism.............................................. 2-44

Toner supply mechanism....................................................................2-45

2.6.6 TONER DENSITY CONTROL........................................................ 2-46

Overview............................................................................................. 2-46

Toner density sensor initial setting ..................................................... 2-48

Toner density measurement............................................................... 2-48

Vsp/Vsg detection............................................................................... 2-48

Toner supply reference voltage (Vref) determination.......................... 2-48

Toner supply determination ................................................................ 2-48

Toner Supply Motor On Time Determinations ....................................2-49

2.6.7 TONER SUPPLY IN ABNORMAL SENSOR CONDITIONS...........2-50

ID sensor ............................................................................................ 2-50

TD Sensor ..........................................................................................2-50

2.6.8 TONER NEAR END/END DETECTION AND RECOVERY............ 2-50

Toner Near End Detection.................................................................. 2-50

Toner Near End Recovery.................................................................. 2-51

Toner End Detection........................................................................... 2-51

Toner End Recovery........................................................................... 2-51

A265/A267 ii SM

Page 15

2.7 DRUM CLEANING AND TONER RECYCLING ...................................... 2-52

2.7.1 DRUM CLEANING ......................................................................... 2-52

2.7.2 TONER RECYCLING..................................................................... 2-53

2.8 PAPER FEED..........................................................................................2-54

2.8.1 OVERVIEW....................................................................................2-54

2.8.2 PAPER FEED DRIVE MECHANISM.............................................. 2-55

2.8.3 PAPER FEED AND SEPARATION MECHANISM ......................... 2-56

2.8.4 PAPER LIFT MECHANISM............................................................ 2-57

2.8.5 PAPER END DETECTION............................................................. 2-58

2.8.6 PAPER HEIGHT DETECTION....................................................... 2-59

2.8.7 FEED PRESSURE ADJUSTMENT FOR PAPER SIZE..................2-60

Overview............................................................................................. 2-60

Paper Size Thresholds .......................................................................2-60

Feed Pressure Adjustment ................................................................. 2-61

Effect of the Amount of Remaining Paper...........................................2-61

2.8.8 PAPER SIZE DETECTION.............................................................2-63

2.8.9 SPECIAL PAPER SETTING...........................................................2-64

2.8.10 SIDE AND END FENCES ............................................................ 2-65

Side Fences........................................................................................ 2-65

End Fence .......................................................................................... 2-65

2.8.11 PAPER REGISTRATION ............................................................. 2-66

2.9 IMAGE TRANSFER AND PAPER SEPARATION................................... 2-67

2.9.1 OVERVIEW....................................................................................2-67

2.9.2 IMAGE TRANSFER CURRENT TIMING........................................2-68

2.9.3 TRANSFER ROLLER CLEANING .................................................2-69

2.9.4 PAPER SEPARATION MECHANISM ............................................ 2-69

2.10 IMAGE FUSING AND PAPER EXIT......................................................2-70

2.10.1 OVERVIEW..................................................................................2-70

2.10.2 FUSING DRIVE AND RELEASE MECHANISM........................... 2-71

2.10.3 FUSING ENTRANCE GUIDE SHIFT MECHANISM..................... 2-72

2.10.4 PRESSURE ROLLER .................................................................. 2-73

2.10.5 CLEANING MECHANISM ............................................................ 2-73

2.10.6 FUSING TEMPERATURE CONTROL ......................................... 2-74

Temperature Control...........................................................................2-74

Fusing Lamp Control .......................................................................... 2-75

2.10.7 OVERHEAT PROTECTION ......................................................... 2-76

2.10.8 PAPER EXIT ................................................................................ 2-76

2.11 ENERGY SAVER MODES.................................................................... 2-77

2.11.1 OVERVIEW..................................................................................2-77

2.11.2 ENERGY SAVER MODE ............................................................. 2-78

Entering the energy saver mode......................................................... 2-78

What happens in energy saver mode ................................................. 2-78

Return to stand-by mode .................................................................... 2-78

2.11.3 LOW POWER MODE................................................................... 2-79

Entering the low power mode ............................................................. 2-79

What happens in low power mode...................................................... 2-79

Return to stand-by mode .................................................................... 2-79

2.11.4 AUTO OFF MODE........................................................................2-80

Entering auto off mode .......................................................................2-80

SM iii A265/A267

Page 16

What happens in auto off mode.......................................................... 2-80

Returning to stand-by mode ...............................................................2-80

Disabling auto off mode...................................................................... 2-80

2.11.5 NIGHT MODE ..............................................................................2-81

Entering night stand-by and night modes ........................................... 2-81

What happens in night stand-by and night modes.............................. 2-81

Returning to stand-by mode ...............................................................2-82

INSTALLATION PROCEDURE

3. INSTALLATION PROCEDURE ................................................... 3-1

3.1 INSTALLATION REQUIREMENTS........................................................... 3-1

3.1.1 ENVIRONMENT............................................................................... 3-1

3.1.2 MACHINE LEVEL............................................................................. 3-1

3.1.3 MINIMUM SPACE REQUIREMENTS ..............................................3-2

3.1.4 POWER REQUIREMENTS..............................................................3-3

3.2 COPIER INSTALLATION..........................................................................3-4

3.2.1 POWER SOCKETS FOR PERIPHERALS ....................................... 3-4

3.2.2 INSTALLATION FLOW CHART ....................................................... 3-5

3.2.3 ACCESSORY CHECK ..................................................................... 3-6

3.2.4 INSTALLATION PROCEDURE ........................................................ 3-7

3.3 PAPER TRAY UNIT INSTALLATION...................................................... 3-11

3.3.1 ACCESSORY CHECK ................................................................... 3-11

3.4 LCT INSTALLATION............................................................................... 3-14

3.4.1 ACCESSORY CHECK ................................................................... 3-14

3.5 AUTO REVERSE DOCUMENT FEEDER INSTALLATION..................... 3-17

3.5.1 ACCESSORY CHECK ................................................................... 3-17

3.5.2 INSTALLATION PROCEDURE ...................................................... 3-17

3.6 INTERCHANGE UNIT INSTALLATION ..................................................3-20

3.6.1 COMPONENT CHECK...................................................................3-20

3.6.2 INSTALLATION PROCEDURE ...................................................... 3-21

3.7 1-BIN TRAY UNIT INSTALLATION......................................................... 3-23

3.7.1 COMPONENT CHECK...................................................................3-23

3.7.2 INSTALLATION PROCEDURE ...................................................... 3-23

3.8 SHIFT TRAY ........................................................................................... 3-26

3.8.1 COMPONENT CHECK...................................................................3-26

3.8.2 INSTALLATION PROCEDURE ...................................................... 3-26

3.9 BY-PASS FEED UNIT INSTALLATION .................................................. 3-28

3.9.1 COMPONENTS CHECK ................................................................ 3-28

3.9.2 INSTALLATION PROCEDURE ...................................................... 3-28

3.10 DUPLEX UNIT INSTALLATION ............................................................ 3-30

3.10.1 ACCESSORY CHECK ................................................................. 3-30

3.10.2 INSTALLATION PROCEDURE .................................................... 3-31

3.11 BRIDGE UNIT INSTALLATION............................................................. 3-33

3.11.1 ACCESSORY CHECK ................................................................. 3-33

3.11.2 INSTALLATION PROCEDURE .................................................... 3-33

3.12 1,000-SHEET FINISHER INSTALLATION............................................ 3-35

3.13 COPIER FEATURE EXPANDER INSTALLATION................................ 3-38

A265/A267 iv SM

Page 17

3.14 PLATEN COVER INSTALLATION ........................................................ 3-39

3.15 KEY COUNTER INSTALLATION.......................................................... 3-40

3.16 ANTI-CONDENSATION HEATER.........................................................3-42

3.17 TRAY HEATER ..................................................................................... 3-43

3.18 TRAY HEATER (OPTIONAL PAPER TRAY UNIT)............................... 3-45

3.19 TRAY HEATER (OPTIONAL LCT)........................................................ 3-48

SERVICE TABLES

4. SERVICE TABLES ...................................................................... 4-1

4.1 GENERAL CAUTION ................................................................................4-1

4.1.1 PCU (PHOTOCONDUCTOR UNIT) ................................................. 4-1

4.1.2 TRANSFER ROLLER UNIT .............................................................4-1

4.1.3 SCANNER UNIT ..............................................................................4-1

4.1.4 LASER UNIT .................................................................................... 4-2

4.1.5 FUSING UNIT ..................................................................................4-2

4.1.6 PAPER FEED................................................................................... 4-2

4.1.7 OTHERS .......................................................................................... 4-2

4.2 SERVICE PROGRAM MODE ................................................................... 4-3

4.2.1 SERVICE PROGRAM MODE OPERATION .................................... 4-3

Service Program Access Procedure..................................................... 4-3

Accessing Copy Mode from within an SP Mode ...................................4-4

How to Select the Program Number ..................................................... 4-4

To input a value or setting for an SP mode...........................................4-4

4.2.2 SERVICE PROGRAM MODE TABLES............................................ 4-5

4.2.3 TEST PATTERN PRINTING (SP4-417 AND SP5-902).................. 4-60

4.2.4 INPUT CHECK (SP5-803).............................................................. 4-61

Input Check Table ..............................................................................4-61

4.2.5 OUTPUT CHECK (SP5-804).......................................................... 4-66

Output Check Table............................................................................ 4-66

4.2.6 COPY JAM HISTORY DISPLAY (SP7-903)................................... 4-68

4.2.7 SMC DATA LISTS (SP5-992).........................................................4-69

4.2.8 ORIGINAL JAM HISTORY DISPLAY (SP7-905)............................ 4-70

4.2.9 MEMORY ALL CLEAR (SP5-801)..................................................4-71

Using a Flash Memory Card............................................................... 4-71

Without Using a Flash Memory Card.................................................. 4-71

4.2.10 PROGRAM UPLOAD/DOWNLOAD ............................................. 4-72

Program Download (SP5-827)............................................................ 4-72

Program Upload (SP5-826) ................................................................ 4-73

4.2.11 NVRAM DATA DOWNLOAD........................................................ 4-74

NVRAM Data Download (SP5-825).................................................... 4-74

NVRAM Data Upload (SP5-824) ........................................................4-75

4.2.12 APS AND PLATEN/DF COVER SENSOR OUTPUT DISPLAY

(SP4-301) ......................................................................................4-76

4.2.13 DF APS SENSOR OUTPUT DISPLAY (SP6-901) .......................4-77

4.2.14 NIP BAND WIDTH MEASUREMENT........................................... 4-78

4.2.15 DISPLAY LANGUAGE (SP5-808)................................................ 4-79

4.2.16 SERIAL NUMBER INPUT (SP5-811) ........................................... 4-79

SM v A265/A267

Page 18

Rev. 10/2001

4.2.17 ID SENSOR ERROR ANALYSIS (SP2-221)................................4-80

4.3 USER TOOLS.........................................................................................4-81

4.3.1 HOW TO ENTER AND EXIT USER TOOLS..................................4-81

4.3.2 USER TOOLS TABLE....................................................................4-81

System Setting Table..........................................................................4-81

Copy Setting Table.............................................................................4-82

4.4 LEDS.......................................................................................................4-83

BICU...................................................................................................4-83

IOB......................................................................................................4-83

4.5 SPECIAL TOOLS AND LUBRICANTS....................................................4-83

4.5.1 SPECIAL TOOLS...........................................................................4-83

4.5.2 LUBRICANTS.................................................................................4-83

4.6 FIRMWARE MODIFICATION HISTORY.................................................4-84

4.6.1 BICU FIRMWARE MODIFICATION HISTORY...............................4-84

4.6.2 ROM HISTORY – BICU (FOR CAPTURE BOX TYPE 270)...........4-87

PREVENTIVE MAINTENANCE

5. PREVENTIVE MAINTENANCE SCHEDULE............................... 5-1

5.1 PM TABLE.................................................................................................5-1

REPLACEMENT AND ADJUSTMENT

6. REPLACEMENT AND ADJUSTMENT........................................ 6-1

6.1 SCANNER UNIT........................................................................................6-1

6.1.1 EXPOSURE GLASS.........................................................................6-1

6.1.2 SCANNER EXTERIOR/OPERATION PANEL..................................6-2

6.1.3 LENS BLOCK ASSEMBLY...............................................................6-3

6.1.4 ORIGINAL SIZE SENSORS/LAMP STABILIZER.............................6-4

6.1.5 EXPOSURE LAMP...........................................................................6-5

6.1.6 SCANNER MOTOR..........................................................................6-6

6.1.7 SCANNER WIRES...........................................................................6-7

6.2 LASER UNIT...........................................................................................6-10

6.2.1 CAUTION DECAL LOCATIONS.....................................................6-10

6.2.2 LASER UNIT ..................................................................................6-11

6.2.3 POLYGON MIRROR MOTOR........................................................6-12

6.2.4 LD UNIT..........................................................................................6-12

6.2.5 LASER SYNCHRONIZATION DETECTOR....................................6-13

6.3 PHOTOCONDUCTOR UNIT (PCU)........................................................6-14

6.3.1 PCU................................................................................................6-14

6.4 TRANSFER UNIT ....................................................................................6-15

6.4.1 TRANSFER ROLLER UNIT............................................................6-15

6.4.2 IMAGE DENSITY SENSOR ...........................................................6-16

6.5 FUSING/EXIT..........................................................................................6-17

6.5.1 FUSING UNIT.................................................................................6-17

6.5.2 THERMISTOR................................................................................6-17

6.5.3 THERMOFUSE ..............................................................................6-18

A265/A267 vi SM

Page 19

Rev. 04/2000

6.5.4 HOT ROLLER AND FUSING LAMP.............................................. 6-19

6.5.5 PRESSURE ROLLER/CLEANING ROLLER ................................. 6-20

6.5.6 PAPER EXIT SENSOR/PAPER OVERFLOW SENSOR............... 6-21

6.6 PAPER FEED......................................................................................... 6-22

6.6.1 FEED ROLLERS............................................................................ 6-22

6.6.2 PAPER END SENSOR.................................................................. 6-23

6.6.3 PAPER TRAY LIFT MOTORS....................................................... 6-24

6.6.4 REGISTRATION CLUTCH............................................................. 6-25

6.6.5 PAPER FEED CLUTCHES............................................................ 6-26

Lower Paper Feed Clutch .................................................................. 6-26

Upper Paper Feed Clutch. ................................................................. 6-26

6.6.6 RELAY CLUTCHES....................................................................... 6-27

6.6.7 PAPER SIZE DETECTOR/SPECIAL PAPER SENSOR................ 6-28

6.6.8 REGISTRATION SENSOR............................................................ 6-29

6.6.9 RELAY SENSORS......................................................................... 6-30

Upper Relay Sensor........................................................................... 6-30

Lower Relay Sensor........................................................................... 6-30

6.7 PCBS AND OTHER ITEMS.................................................................... 6-31

6.7.1 BICU BOARD................................................................................. 6-31

6.7.2 I/O BOARD .................................................................................... 6-32

6.7.3 POWER PACK............................................................................... 6-32

6.7.4 MAIN MOTOR................................................................................ 6-33

6.7.5 PSU ............................................................................................... 6-34

6.8 COPY ADJUSTMENTS: PRINTING/SCANNING ................................... 6-35

6.8.1 PRINTING...................................................................................... 6-35

Registration - Leading Edge/Side-to-Side.......................................... 6-35

Blank Margin...................................................................................... 6-36

Main Scan Magnification.................................................................... 6-36

Parallelogram Image Adjustment....................................................... 6-37

6.8.2 SCANNING.................................................................................... 6-38

Registration: Platen Mode.................................................................. 6-38

Magnification...................................................................................... 6-38

Standard White Density Adjustment................................................... 6-39

6.8.3 ADF IMAGE ADJUSTMENT.......................................................... 6-40

Registration........................................................................................ 6-40

TROUBLESHOOTING

7. TROUBLESHOOTING.................................................................. 7-1

7.1 SERVICE CALL CONDITIONS................................................................. 7-1

7.1.1 SUMMARY....................................................................................... 7-1

7.1.2 SC CODE DESCRIPTIONS............................................................. 7-2

SC194: IPU White Level Detection Error ............................................. 7-4

SC546: Unstable fusing temperature................................................... 7-9

SC620: Communication error between IOB and ADF........................ 7-10

SC760: ADF gate abnormal............................................................... 7-14

SC900: Electrical total counter error .................................................. 7-14

SC901: Mechanical Total Counter ..................................................... 7-14

SM vii A265/A267

Page 20

Rev. 04/2000

SC921: EMB (Copier feature expander) hardware error.................... 7-15

SC980: Program loading error ........................................................... 7-15

SC990: Communication error between BICU and IOB....................... 7-15

SC999: Program version error ........................................................... 7-15

7.2 PAPER FEED TROUBLESHOOTING.................................................... 7-16

7.3 SKEWED IMAGE.................................................................................... 7-17

7.4 TONER DENSITY ................................................................................... 7-18

7.4.1 ADJUST THE TONER DENSITY CONTROL ................................ 7-18

If the toner density is too low.............................................................. 7-18

If the toner density is too high ............................................................ 7-18

7.4.2 DIRTY BACKGROUND ................................................................. 7-18

7.5 ELECTRICAL COMPONENT DEFECTS................................................ 7-19

7.5.1 SENSORS ..................................................................................... 7-19

7.5.2 SWITCHES.................................................................................... 7-21

7.6 BLOWN FUSE CONDITIONS................................................................. 7-22

AUTO RECIRCULATING DOCUMENT FEEDER A858

1. OVERALL MACHINE INFORMATION.........................................8-1

1.1 SPECIFICATIONS.................................................................................... 8-1

1.2 MECHANICAL COMPONENT LAYOUT................................................... 8-2

1.3 ELECTRICAL COMPONENT LAYOUT.................................................... 8-3

1.4 ELECTRICAL COMPONENT DESCRIPTION.......................................... 8-4

1.5 DRIVE LAYOUT ....................................................................................... 8-5

2. DETAILED SECTION DESCRIPTIONS .......................................8-6

2.1 ORIGINAL SIZE DETECTION.................................................................. 8-6

1.2 PICK-UP AND SEPARATION................................................................... 8-9

1.3 ORIGINAL TRANSPORT AND EXIT...................................................... 8-10

1.3.1 SINGLE-SIDED ORIGINALS......................................................... 8-10

1.3.2 DOUBLE-SIDED ORIGINALS........................................................ 8-11

1.3.3 ORIGINAL TRAILING EDGE SENSOR......................................... 8-12

1.4 STAMP ................................................................................................... 8-13

1.5 TIMING CHARTS.................................................................................... 8-14

1.5.1 LT SIDEWAYS (SINGLE-SIDED ORIGINAL MODE) .................... 8-14

1.5.2 LT SIDEWAYS STAMP MODE

(SINGLE-SIDED ORIGINAL MODE)......................................... 8-15

1.5.3 LT SIDEWAYS (DOUBLE-SIDED ORIGINAL MODE)................... 8-16

1.5.4 LT SIDEWAYS STAMP MODE

(DOUBLE-SIDED ORIGINAL MODE) ....................................... 8-17

1.6 CONDITION OF JAM DETECTION........................................................ 8-18

1.7 OVERALL ELECTRICAL CIRCUIT......................................................... 8-19

3. REPLACEMENT AND ADJUSTMENT.......................................8-20

3.1 DF EXIT TABLE AND COVER ............................................................... 8-20

3.2 ORIGINAL FEED UNIT........................................................................... 8-21

3.3 LEFT COVER......................................................................................... 8-22

A265/A267 viii SM

Page 21

Rev. 04/2000

3.4 PICK-UP ROLLER.................................................................................. 8-23

3.5 FEED BELT............................................................................................ 8-24

3.6 SEPARATION ROLLER ......................................................................... 8-25

3.7 ORIGINAL SET/ORIGINAL REVERSE SENSOR .................................. 8-26

3.8 ORIGINAL LENGTH, WIDTHSENSOR BOARD AND

TRAILING EDGE SENSOR.................................................................... 8-27

3.9 DF FEED CLUTCH/DF PICK-UP SOLENOID/ TRANSPORT/

DF FEED MOTORS................................................................................ 8-28

DF Feed Clutch.................................................................................. 8-28

Pick-up Solenoid................................................................................ 8-28

Transport Motor.................................................................................. 8-28

DF Feed Motor................................................................................... 8-28

3.10 REGISTRATION SENSOR................................................................... 8-29

3.11 STAMP SOLENOID AND ORIGINAL EXIT SENSOR .......................... 8-30

PAPER TRAY UNIT A860

1. OVERALL MACHINE INFORMATION.........................................9-1

1.1 SPECIFICATIONS.................................................................................... 9-1

1.2 MECHANICAL COMPONENT LAYOUT................................................... 9-2

1.3 ELECTRICAL COMPONENT LAYOUT.................................................... 9-3

1.4 ELECTRICAL COMPONENT DESCRIPTION.......................................... 9-4

1.5 DRIVE LAYOUT ....................................................................................... 9-5

2. DETAILED DESCRIPTIONS ........................................................ 9-6

2.1 PAPER FEED AND SEPARATION MECHANISM.................................... 9-6

2.2 PAPER LIFT MECHANISM ...................................................................... 9-7

2.3 PAPER END DETECTION ....................................................................... 9-9

2.4 PAPER HEIGHT DETECTION ............................................................... 9-10

1.5 PAPER SIZE DETECTION..................................................................... 9-12

1.6 SIDE AND END FENCES....................................................................... 9-13

Side Fences....................................................................................... 9-13

End Fence .......................................................................................... 9-13

3. REPLACEMENT AND ADJUSTMENT.......................................9-14

3.1 FEED ROLLER REPLACEMENT........................................................... 9-14

3.2 TRAY MAIN BOARD REPLACEMENT................................................... 9-15

3.3 TRAY MOTOR REPLACEMENT............................................................ 9-15

3.4 RELAY CLUTCH REPLACEMENT......................................................... 9-16

3.5 UPPER PAPER FEED CLUTCH REPLACEMENT................................. 9-17

3.6 LOWER PAPER FEED CLUTCH REPLACEMENT................................ 9-18

3.7 LIFT MOTOR REPLACEMENT .............................................................. 9-19

3.8 PAPER END SENSOR REPLACEMENT............................................... 9-20

3.9 VERTICAL TRANSPORT SENSOR REPLACEMENT ........................... 9-20

3.10 PAPER SIZE SWITCH REPLACEMENT.............................................. 9-21

SM ix A265/A267

Page 22

LARGE CAPACITY TRAY A862

1. OVERALL MACHINE INFORMATION ......................................10-1

1.1 SPECIFICATIONS .................................................................................. 10-1

1.2 MECHANICAL COMPONENT LAYOUT ................................................. 10-2

1.3 ELECTRICAL COMPONENT LAYOUT...................................................10-3

1.4 ELECTRICAL COMPONENT DESCRIPTIONS ...................................... 10-4

2. DETAILED SECTION DESCRIPTIONS..................................... 10-5

2.1 PAPER FEED..........................................................................................10-5

2.2 REVERSE ROLLER AND PICK-UP ROLLER RELEASE ....................... 10-6

2.3 TRAY LIFT ..............................................................................................10-7

2.4 NEAR END/END DETECTION................................................................10-8

2.5 RIGHT TRAY SIDE FENCE .................................................................... 10-9

2.6 LEFT TRAY REAR FENCE..................................................................... 10-9

2.7 RIGHT TRAY PAPER END DETECTION ............................................. 10-10

3. REPLACEMENT AND ADJUSTMENT .................................... 10-11

3.1 DETACHING THE TRAY FROM THE MAINFRAME ............................10-11

Rear Fence HP Sensor.....................................................................10-11

3.3 CHANGING THE TRAY PAPER SIZE .................................................. 10-12

3.4 LEFT TRAY PAPER END SENSOR ..................................................... 10-12

3.5 TRAY LIFT MOTOR.............................................................................. 10-13

3.6 TRAY MOTOR ...................................................................................... 10-14

3.7 PAPER FEED CLUTCH AND RELAY CLUTCH ...................................10-15

3.8 PAPER FEED UNIT .............................................................................. 10-16

3.9 UPPER LIMIT, RIGHT TRAY PAPER END, AND

RELAY SENSORS................................................................................ 10-17

3.10 REAR FENCE MOTOR....................................................................... 10-18

3.11 PICK-UP/PAPER FEED/REVERSE ROLLERS .................................. 10-19

BY-PASS UNIT A899

1 OVERALL MACHINE INFORMATION ....................................... 11-1

1.1 SPECIFICATIONS .................................................................................. 11-1

1.2 MECHANICAL COMPONENT LAYOUT ................................................. 11-1

1.3 ELECTRICAL COMPONENT LAYOUT...................................................11-2

1.4 ELECTRICAL COMPONENT DESCRIPTION ........................................11-2

2 DETAILED DESCRIPTIONs........................................................... 11-3

2.1 BASIC OPERATION ............................................................................... 11-3

2.2 PAPER SIZE DETECTION .....................................................................11-4

3 REPLACEMENT AND ADJUSTMENT ........................................... 11-5

3.1 PAPER FEED ROLLER/FRICTION PAD/PAPER END SENSOR ..........11-5

3.2 PAPER SIZE SENSOR BOARD .............................................................11-6

3.3 PAPER FEED CLUTCH..........................................................................11-7

A265/A267 x SM

Page 23

INTERCHANGE UNIT B300

1. OVERALL MACHINE INFORMATION ......................................12-1

1.1 SPECIFICATIONS .................................................................................. 12-1

1.2 MECHANICAL COMPONENT LAYOUT ................................................. 12-2

1.3 DRIVE LAYOUT...................................................................................... 12-3

2. DETAILED DESCRIPTION........................................................ 12-4

2.1 JUNCTION GATE MECHANISM.............................................................12-4

To the Exit Tray or Bridge Unit (for the Upper Tray on top of

the Bridge Unit, or the Finisher).......................................................... 12-4

To the 1-bin Tray ................................................................................ 12-4

To the Duplex Unit.............................................................................. 12-4

3. REPLACEMENT AND ADJUSTMENT ...................................... 12-5

3.1 EXIT SENSOR REPLACEMENT ............................................................ 12-5

DUPLEX A896

1. OVERALL MACHINE INFORMATION ......................................13-1

1.1 SPECIFICATIONS .................................................................................. 13-1

1.2 MECHANICAL COMPONENT LAYOUT ................................................. 13-2

1.3 ELECTRICAL COMPONENT LAYOUT...................................................13-3

1.4 ELECTRICAL COMPONENT DESCRIPTION ........................................13-4

1.5 DRIVE LAYOUT...................................................................................... 13-5

2. DETAILED DESCRIPTIONS...................................................... 13-6

2.1 BASIC OPERATION ............................................................................... 13-6

Larger than A4 lengthwise/LT Lengthwise.......................................... 13-6

Up to A4 Lengthwise/LT lengthwise ...................................................13-7

2.2 FEED IN AND EXIT MECHANISM.......................................................... 13-8

When Paper is Fed Into Duplex Unit: .................................................13-8

Inversion and Exit: .............................................................................. 13-8

3. REPLACEMENT AND ADJUSTMENT ...................................... 13-9

3.1 COVER REMOVAL................................................................................. 13-9

3.2 ENTRANCE SENSOR REPLACEMENT............................................... 13-10

3.3 EXIT SENSOR REPLACEMENT .......................................................... 13-11

1 BIN TRAY UNIT A898

1. OVERALL INFORMATION........................................................ 14-1

1.1 SPECIFICATIONS .................................................................................. 14-1

1.2 MECHANICAL COMPONENT LAYOUT ................................................. 14-2

1.3 ELECTRICAL COMPONENT LAYOUT...................................................14-3

SM xi A265/A267

Page 24

1.4 ELECTRICAL COMPONENT DESCRIPTION ........................................14-3

2. DETAILED SECTION DESCRIPTIONS..................................... 14-4

2.1 BASIC OPERATION ............................................................................... 14-4

3. REPLACEMENT AND ADJUSTMENT ...................................... 14-5

3.1 PAPER SENSOR REMOVAL .................................................................14-5

BRIDGE UNIT A897

1. OVERALL MACHINE INFORMATION ......................................15-1

1.1 SPECIFICATIONS .................................................................................. 15-1

1.2 MECHANICAL COMPONENT LAYOUT ................................................. 15-2

1.3 ELECTRICAL COMPONENT LAYOUT...................................................15-3

1.4 ELECTRICAL COMPONENT DESCRIPTION ........................................15-4

1.5 DRIVE LAYOUT...................................................................................... 15-5

2. DETAILED DESCRIPTION........................................................ 15-6

2.1 JUNCTION GATE MECHANISM.............................................................15-6

3. REPLACEMENT AND ADJUSTMENT ...................................... 15-7

3.1 BRIDGE UNIT DRIVE MOTOR REPLACEMENT ................................... 15-7

3.2 TRAY EXIT SENSOR REPLACEMENT.................................................. 15-8

3.3 RELAY SENSOR REPLACEMENT.........................................................15-8

SHIFT TRAY UNIT B313

1 OVERALL MACHINE INFORMATION ....................................... 16-1

1.1 SPECIFICATIONS .................................................................................. 16-1

1.2 COMPONENT LAYOUT.......................................................................... 16-2

2. DETAILED SECTION DESCRIPTIONS..................................... 16-3

2.1 BASIC OPERATION ............................................................................... 16-3

2.2 PRIMARY MECHANISMS....................................................................... 16-4

2.2.1 TRAY SHIFT ..................................................................................16-4

2.2.2 HALF TURN DETECTION..............................................................16-5

3. REPLACEMENT AND ADJUSTMENT ...................................... 16-6

3.1 TRAY COVER REPLACEMENT ............................................................. 16-6

3.1.1 TRAY COVER REMOVAL..............................................................16-6

3.1.2 TRAY COVER ATTACHMENT....................................................... 16-6

3.2 TRAY MOTOR AND HALF TURN SENSOR REPLACEMENT............... 16-7

3.2.1 REPLACING THE TRAY MOTOR.................................................. 16-7

3.2.2 REPLACING THE HALF TURN SENSOR: .................................... 16-7

A265/A267 xii SM

Page 25

Rev. 03/2000

FINISHER A681

1. OVERALL MACHINE INFORMATION.......................................17-1

1.1 SPECIFICATIONS.................................................................................. 17-1

1.2 MECHANICAL COMPONENT LAYOUT................................................. 17-2

1.3 ELECTRICAL COMPONENT LAYOUT.................................................. 17-3

1.4 ELECTRICAL COMPONENT DESCRIPTIONS...................................... 17-4

1.5 DRIVE LAYOUT ..................................................................................... 17-6

2. DETAILED DESCRIPTIONS ...................................................... 17-7

2.1 JUNCTION GATE MECHANISM............................................................ 17-7

Staple Mode....................................................................................... 17-7

No staple Mode.................................................................................. 17-7

2.2 JOGGER UNIT PAPER POSITIONING MECHANISM........................... 17-8

2.3 EXIT GUIDE PLATE OPEN/CLOSE MECHANISM................................ 17-9

2.4 STAPLER ..............................................................................................17-10

2.5 FEED OUT MECHANISM......................................................................17-11

2.6 SHIFT TRAY UP/DOWN MECHANISM.................................................17-12

2.7 SHIFT TRAY SIDE-TO-SIDE MECHANISM..........................................17-13

2.8 JAM CONDITIONS................................................................................17-14

2.9 TIMING CHARTS...................................................................................17-15

2.9.1 NO STAPLE MODE (A4 SIDEWAYS, 3 SHEETS/2SETS)...........17-15

2.9.2 STAPLE MODE (A4 SIDEWAYS, 2 SHEETS/2 SETS) ................17-16

3. SERVICE TABLE .....................................................................17-17

3.1 DIP SWITCH TABLE .............................................................................17-17

3.2 TEST POINTS.......................................................................................17-17

3.3 FUSES...................................................................................................17-17

4. REPLACEMENT AND ADJUSTMENT.....................................17-18

4.1 COVER REMOVAL................................................................................17-18

Front Door.........................................................................................17-18

Front Cover.......................................................................................17-18

Rear Cover........................................................................................17-18

Upper Cover......................................................................................17-18

Lower Left Cover...............................................................................17-19

Front Shift Tray Cover.......................................................................17-19

Rear Shift Tray Cover .......................................................................17-19

Shift Tray...........................................................................................17-19

4.2 ENTRANCE SENSOR REPLACEMENT...............................................17-20

4.3 EXIT SENSOR REPLACEMENT...........................................................17-21

4.4 STACK HEIGHT SENSOR REPLACEMENT ........................................17-22

4.5 POSITIONING ROLLER REPLACEMENT............................................17-23

4.6 STAPLER REPLACEMENT...................................................................17-24

4.7 ROM HISTORY .....................................................................................17-25

SM xiii A265/A267

Page 26

Rev. 05/2000

SCANNER KIT A844

1. OVERALL MACHINE INFORMATION ....................................... 18-1

1.1 SPECIFICATIONS................................................................................... 18-1

1.1.1 SCANNER CONTROL BOARD ...................................................... 18-1

1.1.2 DRAM SIMM................................................................................... 18-1

1.2 SOFTWARE ............................................................................................ 18-2

1.2.1 SCANNER DRIVERS ..................................................................... 18-2

1.2.2 SCANNER UTILITIES..................................................................... 18-2

2. DETAILED SECTION DESCRIPTIONS...................................... 18-3

2.1 HARDWARE OVERVIEW ....................................................................... 18-3

2.2 SCANNER FUNCTIONS ......................................................................... 18-5

2.2.1 SELF DIAGNOSTICS ..................................................................... 18-5

2.2.2. IMAGE PROCESSING IN THE SCANNER CONTROLLER................ 18-5

3. INSTALLATION PROCEDURE .................................................. 18-6

4. SERVICE TABLE ....................................................................... 18-9

4.1 SERVICE PROGRAM MODE.................................................................. 18-9

4.1.1 SERVICE PROGRAM ACCESS PROCEDURE ............................. 18-9

4.1.2 SERVICE PROGRAM MODE TABLES .......................................... 18-9

4.2 DOWNLOADING NEW SOFTWARE..................................................... 18-11

4.2.1 SOFTWARE DOWNLOAD PROCEDURE.................................... 18-11

4.2.2 ERROR MESSAGES DURING THE SOFTWARE DOWNLOAD . 18-12

5. REPLACEMENT AND ADJUSTMENT..................................... 18-12

5.1 NOTE FOR REPLACING THE SCANNER CONTROLLER BOARD..... 18-13

6. TROUBLESHOOTING.............................................................. 18-14

6.1 SERVICE CALL CONDITION................................................................ 18-14

6.1.1 SC CODE DESCRIPTIONS.......................................................... 18-14

6.2 LEDS ..................................................................................................... 18-15

6.3 FIRMWARE HISTORY .......................................................................... 18-16

6.3.4 A844 FIRMWARE MODIFICATION HISTORY ............................. 18-16

A265/A267 xiv SM

Page 27

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

4. If a job has started before the copier completes the warm-up or initializing

period, keep hands away from the mechanical and electrical components

because the starts making copies as soon as the warm-up period is

completed.

5. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner is non-toxic, but if you get it in your eyes by accident, it may cause

temporary eye discomfort. Try to remove with eye drops or flush with water as

first aid. If unsuccessful, get medical attention.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cassettes. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of toner cassettes in accordance with local regulations. (This is a

non-toxic unit.)

3. Dispose of replaced parts in accordance with local regulations.

i

Page 28

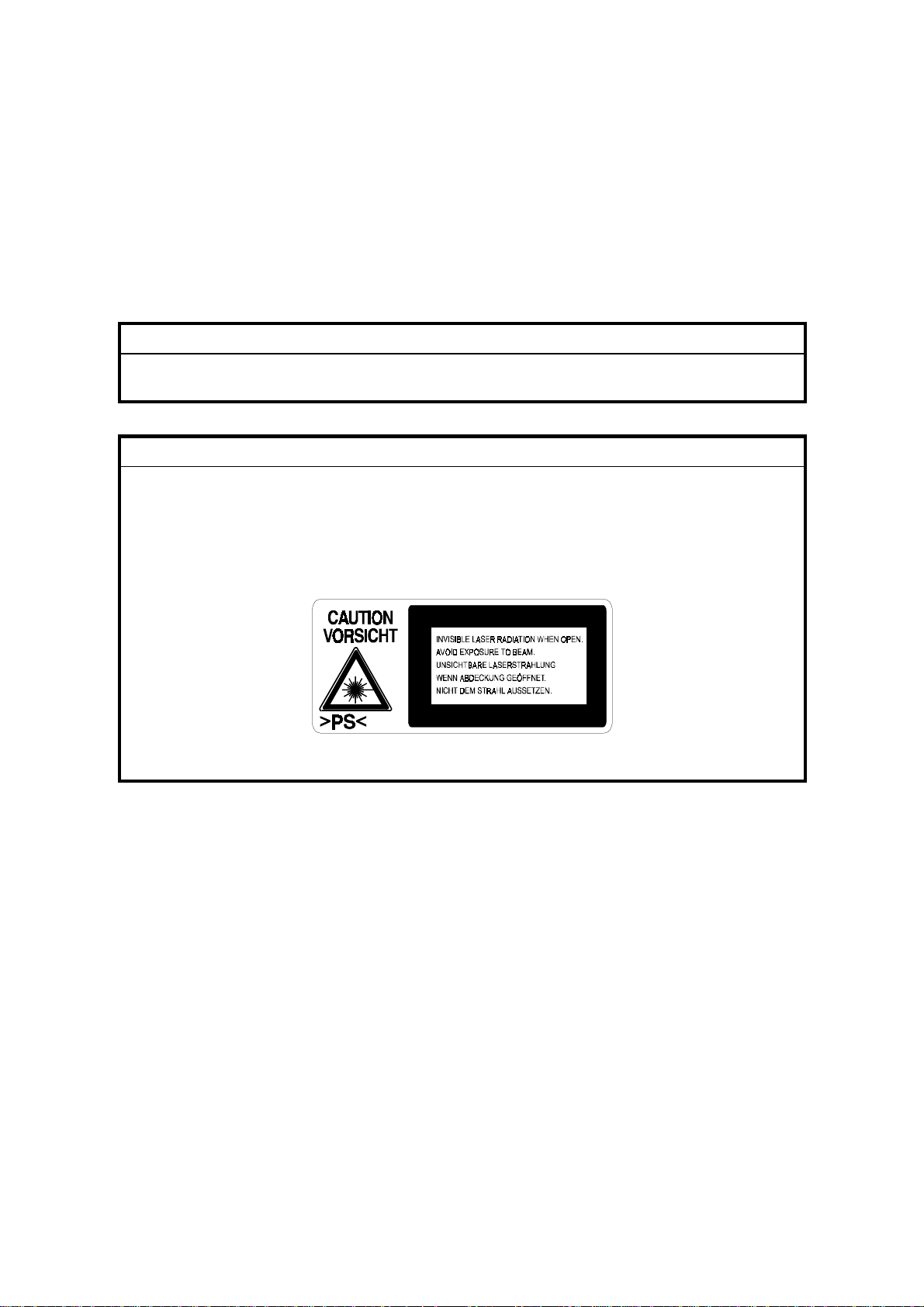

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!

WARNING FOR LASER UNIT

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

laser-4.WMF

ii

Page 29

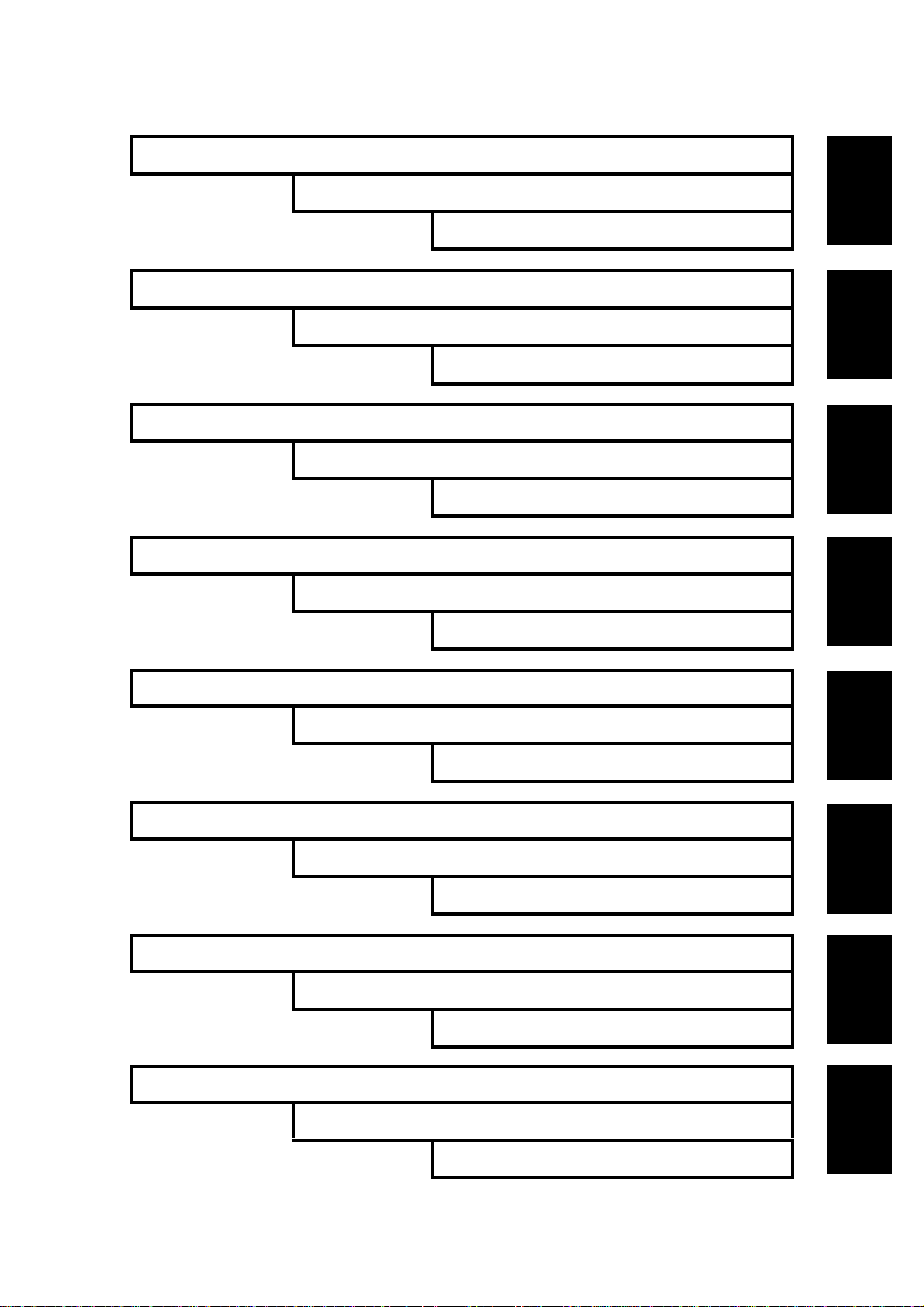

OVERALL INFORMATION

PAPER TRAY UNIT A860

DETAILED DESCRIPTIONS

LARGE CAPACITY TRAY A862

INSTALLATION

BY-PASS UNIT A899

SERVICE TABLES

INTERCHANGE UNIT B300

FINISHER A681

SCANNER KIT A844

FAX UNIT A895

ISDN UNIT A895

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

PREVENTIVE MAINTENANCE

DUPLEX A896

PRINTER CONTROLLER B306

REPLACEMENT AND ADJUSTMENT

1 BIN TRAY UNIT A898

NETWORK INTERFACE BOARD B307

TROUBLESHOOTING

BRIDGE UNIT A897

AUTO RECIRCULATING DOCUMENT FEEDER A858

SHIFT TRAY UNIT B313

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 30

Page 31

OVERALL MACHINE INFORMATION

Page 32

Page 33

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Copy Paper Size: Maximum

A3/11" x 17"

Minimum

A5/8

Custom sizes

2nd paper tray

Width: 100 ~ 297 mm (3.9" ~ 11.5")

Length: 148 ~ 432 mm (5.8" ~ 17.0")

By-pass tray (Option):

Width: 90 ~ 305 mm (3.5" ~ 12.0")

Length: 148 ~ 1,260 mm (5.8" ~ 49.6")

1/2

" x 5

" lengthwise

1/2

SPECIFICATIONS

Overall

Information

Copy Paper Weight: Paper Tray:

60 ~ 105 g/m2, 16 ~ 28 lb (1st paper tray)

60 ~ 157 g/m2, 16 ~ 43 lb (2nd paper tray)

By-pass (Option):

60 ~ 157 g/m2, 16 ~ 42 lb

Reproduction Ratios: 5 Enlargement and 7 Reduction

A4/A3 Version LT/DLT Version

400%

200%

Enlargement

Full Size 100% 100%

Reduction

141%

122%

115%

93%

87%

82%

71%

65%

50%

25%

400%

200%

155%

129%

121%

93%

85%

78%

73%

65%

50%

25%

SM 1-1 A265/A267

Page 34

SPECIFICATIONS

Zoom: 25% to 400% in 1% steps (Platen mode)

50% to 200% in 1% steps (ADF mode)

Power Source: 120 V, 60 Hz:

More than 12 A (for North America)

220 ~ 240 V, 50/60 Hz

More than 6 A (for Europe/Asia)

110 V, 50/60 Hz

More than 13 A (for Taiwan)

Power Consumption:

Mainframe Only Full System

120 V 220 ~ 240 V 120 V 220 ~ 240 V

Maximum

Copying

Warm-up

Stand-by

Low Power Level 1 Approx. 80 Wh Approx. 85 Wh Approx. 80 Wh Approx. 85 Wh

Low Power Level 2 Approx. 50 Wh Approx. 50 Wh Approx. 50 Wh Approx. 50 Wh

Auto Off 10 W -- 10 W --

Less than

1.44 kW

Approx.

500 Wh

Approx.

1.0 kW

Approx.

120 Wh

Less than

1.44 kW

Approx.

500 Wh

Approx.

1.0 kW

Approx.

120 Wh

Less than

1.44 kW

Approx.

500 Wh

Approx.

1.0 kW

Approx.

130 Wh

Less than

1.44 kW

Approx.

500 Wh

Approx.

1.0 kW

Approx.

130 Wh

NOTE:

1) Full system: Mainframe + ADF + 1-bin Sorter + Paper Tray Unit +

Duplex Unit + Bridge Unit + Finisher

2) Without the optional heaters, fax unit, and printer controller

Noise Emission (Sound Power Level):

Stand-by (Mainframe only): US/Asia Model: 40 dB(A)

Europe Model: 40 dB(A)

Operating (Mainframe only): US/Asia Model: 64 dB(A)

Europe Model: 64 dB(A)

Operating (Full System): 67.5 dB(A)

NOTE:

1) The above measurements were made in accordance with ISO 7779.

2) Full System: Mainframe + ADF + 1-bin Sorter + Paper Tray Unit +

Duplex Unit + Bridge Unit + Finisher

A265/A267 1-2 SM

Page 35

SPECIFICATIONS

Dimensions (W x D x H): 550 x 580 x 709 mm (21.7" x 22.8" x 28.0")

NOTE:

Measurement Conditions

1) With the paper tray unit or LCT

2) Without the ADF

Weight: Less than 62 kg (136.7 lb)

Copying Speed (copies/minute):

Overall

Information

Russian-C1A

Non-memory copy mode 22 12

Memory copy mode 22 13

Russian-C1B

Non-memory copy mode 22 12

Memory copy mode 27 15

NOTE:

Measurement Conditions

A4 sideways/

11" x 8

A4 sideways/

11" x 8

1/2

1/2

"

"

A3/11" x 17"

A3/11" x 17"

1) Not APS mode

2) A4/LT copying

3) Full size

Warm-up Time: Less than 45 seconds (20°C, 68°F)

First Copy Time: Less than 4.9 s (A4), less than 5.0 s (LT)

NOTE:

Measurement Conditions

1) When the polygonal mirror motor is spinning.

2) From the 1st paper tray

3) Not APS mode

4) Full size

Copy Number Input: Ten-key pad, 1 to 99 (count up or count down)

Manual Image Density: 7 steps

SM 1-3 A265/A267

Page 36

SPECIFICATIONS

Paper Tray Capacity: Paper Tray:

500 sheets x 2

(Special paper in the 2nd paper tray: 50 sheets)

Paper Tray Unit (Option):

500 sheets x 2

LCT (Option):

1000 sheets x 2

By-pass Tray (Option):

100 sheets (A4, B5, A5, B6, 8

10 sheets (A3, B4, 11" x 17", 8

" x 11", 5

1/2

" x 13")

1/2

1/2

" x 8

1/2

")

1 sheet (non-standard sizes)

NOTE:

Copy paper weight: 80g/m2 (20 lb)

Toner Replenishment: Cartridge exchange (360 g/cartridge)

Toner Yield: 10 k copies (A4 sideways, 6% full black, 1 to 1 copying,

ADS mode)

Copy Tray Capacity: Copy Tray: 500 sheets (without 1-bin tray)

250 sheets (with 1-bin tray)

Memory Capacity: Standard 20 MB, Optional memory 48 MB

A265/A267 1-4 SM

Page 37

1.2 MACHINE CONFIGURATION

1.2.1 SYSTEM COMPONENTS

2

1

12

MACHINE CONFIGURATION

3

4

Overall

Information

11

10

5

6

7

A265V501.WMF

89

SM 1-5 A265/A267

Page 38

MACHINE CONFIGURATION

Version Item Machine Code No.

Copier

Copier A265 1

Copier A267 1

ARDF (Optional) A858 3

Platen Cover (Optional) A893 2

Paper Tray Unit - 2 tray (Optional)

LCT (Optional) A862 8

1-bin Tray (Optional) A898 4

Shift Tray (Optional) B313 12

Duplex Unit (Optional) A896 6

By-pass Tray (Optional) A899 7

Interchange Unit (Optional) B300 5

Bridge Unit (Optional) A897 11

1000-sheet Finisher (Optional) A681 10

Copier Feature Expander - Memory

48 MB (Optional)

Key Counter Bracket

Fax

Fax Controller (Optional)

G3 Interface Unit (Optional) A895-11, -12

Handset (Optional) H160

ISDN (Optional) A895-21, -22

PC Fax Expander (Optional) A894

Fax Function Expander (Optional) A892

Printer

Printer Controller (Optional) B306

PostScript Kit (Optional) B308

HDD (Optional) G690

NIB (Optional) B307

Memory 32 or 64 MB (Optional) G688

Scanner Scanner Controller (Optional) A844

A860-11, -21,

-56

A887

A895-01, -02,

-03

9

A265/A267 1-6 SM

Page 39

Rev. 03/2000

1.2.2 INSTALLABLE OPTION TABLE

Copier options

MACHINE CONFIGURATION

No. Option A265/A267 Note

1 ARDF (Optional)

2 Platen Cover (Optional)

3 Paper Tray Unit - 2 tray (Optional)

4 LCT (Optional)

5 1-bin Tray (Optional)

6 Shift Tray (Optional)

7 Duplex Unit (Optional)

8 By-pass Tray (Optional)

9 Interchange Unit (Optional)

10 Bridge Unit (Optional)

⇒

11 1000-sheet Finisher (Optional)

12 Memory 48 MB (Optional)

13 Key Counter Bracket

= Available

!

Fax and printer options

∆

= Requires another option

!

!

!

!

∆

!

∆

!

!

∆

∆

!

!

Overall

Information

Install either no. 1 or 2

Install either no. 1 or 2

Install either no. 3 or 4

Install either no. 3 or 4

Requires no.9

Install either no. 6 or 10

Requires no.9

No. 10 requires no.11

Install either no. 6 or 10

Requires no.10 and

either no.3 or 4

All options for the fax and printer units are available when these units have been

installed.

Scanner option

When the scanner option is installed, the printer option must be installed.

SM 1-7 A265/A267

Page 40

PAPER PATH

1.3 PAPER PATH

8

1

2

3

4

7

5

6

1. Optional ADF

2. Optional 1-bin Tray

3. Optional Interchange Unit

4. Optional Duplex Unit

5. Optional By-pass Feed Tray

6. Optional Paper Tray Unit

7. Optional 1000-sheet Finisher

8. Optional Bridge Unit

A267V102.WMF

A265/A267 1-8 SM

Page 41

MECHANICAL COMPONENT LAYOUT

1.4 MECHANICAL COMPONENT LAYOUT

1 2 3 4 5 6 7

29

28

Overall

Information

8

9

27

26

25

24

10

11

12

13

14

15

16

17

18

19

20

21

A265V100.WMF

2223

SM 1-9 A265/A267

Page 42

MECHANICAL COMPONENT LAYOUT

1. 2nd scanner

2. Original width sensor

3. Exposure lamp

4. 1st scanner

5. Original length sensor

6. Lens

7. Scanner motor

8. SBU board

9. Exit roller

10. Fusing hot roller

11. Fusing pressure roller

12. Cleaning unit

13. OPC drum

14. Transfer roller

15. Development roller

16. ID sensor

17. Registration roller

18. Friction pad

19. Paper feed roller

20. Paper size sensor

21. Special paper sensor

22. Bottom plate

23. Tray heater

24. Polygon mirror motor

25. Laser unit

26. Toner supply bottle holder

27. Drum charge roller

28. Anti-condensation heater

29. Scanner home position sensor

A265/A267 1-10 SM

Page 43

ELECTRICAL COMPONENT DESCRIPTIONS

1.5 ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout on the reverse side of the point-to-point

diagram for the location of the components.

Symbol Name Function

Motors

M1 Scanner Drives the 1st and 2nd scanners.

M2 Polygonal Mirror Turns the polygonal mirror.

M3 Main Drives the main unit components.

M4 Exhaust Fan Removes heat from around the fusing unit.

M5 Upper Paper Lift Raises the bottom plate in the 1st paper tray.

M6 Lower Paper Lift Raises the bottom plate in the 2nd paper tray.

M7

Magnetic Clutches

MC1 Upper Paper Feed Starts paper feed from the 1st paper tray.

MC2 Lower Paper Feed Starts paper feed from the 2nd paper tray.

MC3 Upper Relay Drives the upper relay rollers.

MC4 Lower Relay Drives the lower relay rollers.

MC4 Registration Drives the registration rollers.

Toner Supply Rotates the toner bottle to supply toner to the

development unit.

Overall

Information

Switches

SW1 Main

SW2 Right Upper Cover

SW3 Right Cover

SW4 Right Lower Cover

SW5 Upper Paper Size

SW6 Lower Paper Size

SW7 Special Paper

SW8 New PCU Detect Detects when a new PCU is installed.

SW9 Front Cover Safety

SW10 Operation

Provides power to the machine. If this is off, there

is no power supplied to the machine.

Detects whether the right upper cover is open or

not.

Cuts the +5VLD and +24V dc power line and

detects whether the right cover is open or not.

Detects whether the right lower cover is open or

not.

Determines what size of paper is in the upper

paper tray.

Determines what size of paper is in the lower

paper tray.

Determines whether there is special paper in the

lower paper tray.

Cuts the +5VLD and +24V dc power line and

detects whether the front cover is open or not.

Provides power for machine operation. The

machine still has power if this switch is off.

SM 1-11 A265/A267

Page 44

ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function

Sensors

S1 Scanner HP

Informs the CPU when the 1st and 2nd scanners

are at home position.

Informs the CPU that the platen cover is in the up

S2 Platen Cover

or down position (related to the APS/ARE

functions).

S2 Original Width

S4 Original Length 1

S5 Original Length 2

S6 Toner Density (TD)

S7 1st Paper End

S8 2nd Paper End

S9 Image Density (ID)

Detects original width. This is one of the APS

(Auto Paper Select) sensors.

Detects original length. This is one of the APS

(Auto Paper Select) sensors.

Detects original length. This is one of the APS

(Auto Paper Select) sensors.

Detects the amount of toner inside the

development unit.

Informs the CPU when the 1st paper tray runs out

of paper.

Informs the CPU when the 2nd paper tray runs out

of paper.

Detects the density of various patterns and the

reflectivity of the drum for process control.

S10 Paper Overflow Detects paper overflow in the built-in copy tray.

S11 Paper Exit Detects misfeeds.

S12 Upper Relay Detects misfeeds.

S13 Lower Relay Detects misfeeds.

S14 Registration

S15 1st Paper Lift

S16 2nd Paper Lift

Detects misfeeds and controls registration clutch

off-on timing.

Detects when the paper in the 1st paper tray is at

the feed height.

Detects when the paper in the 2nd paper tray is at

the feed height.

S17 1st Paper Height – 1 Detects the amount of paper in the 1st paper tray.

S18 1st Paper Height – 2 Detects the amount of paper in the 1st paper tray.

S19 2nd Paper Height – 1 Detects the amount of paper in the 2nd paper tray.

S20 2nd Paper Height – 2 Detects the amount of paper in the 2nd paper tray.

PCBs

PCB1

BICU (Base Engine and

Image Control Unit)

PCB2 PSU (Power Supply Unit)

PCB3 IOB (Input/Output Board)

PCB4 SBU (Sensor Board Unit)

Controls all base engine functions both directly

and through other control boards.

Provides dc power to the system and ac power to

the fusing lamp and heaters.

Controls the fusing lamp and the mechanical parts

of the machine.

Contains the CCD, and outputs a video signal to

the BICU board.

PCB5 Lamp Stabilizer Stabilizes the power to the exposure lamp.

PCB6 LDD (Laser Diode Driver) Controls the laser diode.

PCB7 Operation Panel Controls the operation panel.

A265/A267 1-12 SM

Page 45

ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function

PCB8 High Voltage Supply

PCB9 Memory (Option)

Supplies high voltage to the drum charge roller,

development roller, and transfer roller.

Expands the memory capacity for the copier

features.

Lamps

L1 Exposure Lamp

Applies high intensity light to the original for

exposure.

L2 Fusing Lamp Heats the hot roller.

L3

Quenching Lamp Neutralizes any charge remaining on the drum

surface after cleaning.

Heaters

H1

Anti-condensation

(Option)

Turns on when the main power switch is off to

prevent moisture from forming on the optics.

Turns on when the main power switch is off to

H2 Tray (Option)

prevent moisture from forming around the paper

trays.

Overall

Information

Others

TF1 Fusing Thermofuse

Opens the fusing lamp circuit if the fusing unit

overheats.

TH1 Fusing Thermistor Detects the temperature of the hot roller.

LSD 1

Laser Synchronization

Detector

Detects the laser beam at the start of the main

scan.

CO1 Mechanical Counter Keeps track of the total number of prints made.

Used for control of authorized use. If this feature is

CO2 Key Counter (Option)

enabled for copying, copying will be impossible

until it is installed.

SM 1-13 A265/A267

Page 46

DRIVE LAYOUT

1.6 DRIVE LAYOUT

Scanner

2

1

A267V301.WMF

Fusing

3

4

5

PCU/Transfer Drive

1. Scanner Drive Motor

2. Main Motor

3. Registration Clutch

4. Upper Paper Feed Clutch

5. Upper Transport Clutch

6. Lower Paper Feed Clutch

7. Lower Transport Clutch

6

7

A267V302.WMF

A265/A267 1-14 SM

Page 47

1.7 COPY PROCESS

1.7.1 OVERVIEW

9

2

COPY PROCESS

Overall

Information

1

A267V401.WMF

7

8

6

3

5

4

A267V101.WMF

1. EXPOSURE

A xenon lamp exposes the original. Light reflected from the original passes to

the CCD, where it is converted into an analog data signal. This data is

converted to a digital signal, processed and stored in the memory. At the time

of printing, the data is retrieved and sent to the laser diode. For multi-copy runs,

the original is scanned once only and stored to the memory.

2. DRUM CHARGE

In the dark, the charge roller gives a negative charge to the organic photoconductive (OPC) drum. The charge remains on the surface of the drum

because the OPC layer has a high electrical resistance in the dark.

SM 1-15 A265/A267

Page 48

COPY PROCESS

3. LASER EXPOSURE

The processed data scanned from the original is retrieved from the memory

and transferred to the drum by a laser beam, which forms an electrical latent

image on the drum surface. The amount of charge remaining as a latent image

on the drum depends on the laser beam intensity, which is controlled by the

BICU board.

4. DEVELOPMENT