Page 1

®

RICOH GROUP COMPANIES

A166/A187/A189

SERVICE MANUAL

PN: RCSM2003

Page 2

®

®

®

SERVICE MANUAL

A166/A187/A189

RICOH GROUP COMPANIES

Page 3

Page 4

A166/A187/A189

SERVICE MANUAL

PN: RCSM2003

Page 5

Page 6

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2000 RICOH Corporation. All rights reserved.

Page 7

Page 8

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Corporation. Users of this

manual should be either service trained or certified

by successfully completing a Ricoh Technical

Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Corporation

Page 9

Page 10

LEGEND

PRODUCT CODE COMPANY

GESTETNER RICOH SAVIN

A166 2703 Aficio 2003 SDC103

A187 2703D Aficio 2103 SDC103A

A189 2703DE Aficio 2203 SDC103E

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

10/96 Original Prin ti n g

Page 11

Page 12

Table of Contents

OVERALL MACHINE INFORMATION

1. SPECIFICA TIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 MACHINE CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 GENERAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 DETECTABLE ORIGINAL SIZE BY PLATEN/ARDF . . . . . . . . . . . . . . . . . . . 1-6

1.4 COPY PAPER SIZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.5 PAPER SIZES AVAILABLE WITH APS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.6 NOISE EMISSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.7 POWER CONSUMPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.8 DISPLAY EDITOR SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2. MACHINE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

2.1 COPY PROCESSES AROUND THE DRUM AND BELT . . . . . . . . . . . . . . . 1-11

3. MAJOR UNIT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

4. PARTS LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

4.1 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

4.2 PCB (A166/A187 COPIERS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

4.3 PCB (A189 COPIER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

4.4 SOLENOIDS AND CLUTCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

4.5 SWITCHES AND HEATERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

4.6 SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

4.7 MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

4.8 DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

4.9 FANS AND AIR FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

4.10 COUNTERS (A166/A187 COPIERS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

4.11 COUNTER (A189 COPIER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

5. ELECTRICAL COMPONENT LIST . . . . . . . . . . . . . . . . . . . . . . . . 1-27

5.1 PRINTED CIRCUIT BOARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

5.2 SOLENOIDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

5.3 CLUTCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

SM i A166/A187/A189

Page 13

5.4 SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

5.5 LAMPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

5.6 HEATERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

5.7 THERMISTORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

5.8 THERMOFUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

5.9 THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

5.10 SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

5.11 MOTORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

5.12 FAN MOTORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

5.13 COUNTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

DETAILED DESCRIPTIONS

1. PROCESS CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 PROCESS CONTROL MEASUREMENT TIMING . . . . . . . . . . . . . . . . . . . . . 2-3

1.3 POTENTIAL CONTROL (LATENT IMAGE CONTROL) . . . . . . . . . . . . . . . . . 2-4

1.3.1 Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

1.3.2 Process Control Self Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

1.3.3 Process Control Self Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

1.3.4 Drum Potential Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

1.3.5 Vsg Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

1.3.6 Writing the Gradation Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

1.3.7 Gradation Pattern Potential Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

1.3.8 Gradation Pattern Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

1.3.9 Gradation Pattern Density Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

1.3.10 Development Potential Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

1.3.11 V

1.3.12 V

1.3.13 Confirmation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

, VB, VL Selection (Pointer Table) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

D

, VB, ILD Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

G

1.3.14 Potential Control in Abnormal Sensor Conditions . . . . . . . . . . . . . . . . 2-11

1.3.15 Abnormal Sensor Conditions (SC). . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

A166/A187/A189 ii SM

Page 14

1.4 TONER SUPPLY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

1.4.1 Toner Supply Control Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

1.4.2 Fuzzy Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

1.4.3 Fixed Supply Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

1.4.4 Toner Supply in Abnormal Sensor Conditions. . . . . . . . . . . . . . . . . . . . 2-17

1.4.5 Toner End Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

1.4.6 Developer Agitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2. DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.1.1 OPC Drum Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.2 MECHANISMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.2.1 Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.2.2 Drum Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.2.3 Drum Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.2.4 Quenching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

3. SCANNER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

3.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

3.2 SCANNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

3.3 SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

3.4 COLOR CCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

3.5 WHITE PLATE SCANNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

3.6 SCANNER IPU BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

3.7 ORIGINAL SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

3.8 OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

4. IMAGE PROCESSING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

4.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

4.2 SCANNER SECTION BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

4.3 SCANNER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

4.3.1 Photoelectric Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

4.3.2 Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

4.3.3 A/D Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

4.3.4 Shading Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

SM iii A166/A187/A189

Page 15

4.3.5 D/A Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

4.3.6 Scan Line Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

4.4 IPU SECTION BLOCK DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

4.5 IPU SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

4.5.1 Picture Element Correction and Scanner Gamma Correction . . . . . . . . 2-45

4.5.2 ACS (Auto Color Selection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

4.5.3 Auto Letter/Photo Separation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

4.5.4 Filtering and Color Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

4.5.5 Main Scan Magnification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

4.5.6 Gamma Correction (Printer Gamma) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

4.5.7 Gradation Treatment (Dither Processing) . . . . . . . . . . . . . . . . . . . . . . . 2-61

4.6 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

4.7 EXTENDED IPU (EDIT MACHINE ONLY) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

4.8 OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

4.8.1 Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

4.8.2 IPU Board Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

5. LASER EXPOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

5.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

5.2 OPTICAL PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

5.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

5.2.2 Cylindrical Lens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

5.2.3 Polygon Mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

5.2.4 F-theta Lenses and the BTL

5.2.5 Laser Synchronizing Detector Boards . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

5.3 GRADATION CONTROL (LASER POWER MODULATION) . . . . . . . . . . . 2-70

5.4 AUTO POWER CONTROL (APC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

5.5 LD SAFETY SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-72

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

6. DEVELOPMENT UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-73

6.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-73

6.2 MECHANISMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

6.2.1 Revolver Development Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

A166/A187/A189 iv SM

Page 16

6.2.2 Development Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

6.2.3 Toner Mixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

6.2.4 Developer Mixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

6.2.5 Development Roller Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-84

6.2.6 Development Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-85

6.2.7 Toner Cartridge Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

6.2.8 Color Toner Positioning Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-87

6.2.9 Revolver Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-88

7. TRANSFER BELT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -93

7.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-93

7.2 LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-94

7.3 BELT TRANSFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-95

7.3.1 Transfer Belt Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-95

7.3.2 Transfer Belt Release Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-101

7.3.3 Belt Transfer Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-102

7.3.4 Belt Mark Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-103

7.3.5 Transfer Belt Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-104

7.3.6 Toner Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-105

7.3.7 Belt Lubricant Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-106

7.3.8 PTL (Pre-transfer Lamp) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-107

7.4 PAPER TRANSFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-108

7.4.1 Paper Transfer Bias. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-108

7.4.2 Paper Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-110

7.4.3 Uniform Transfer Belt Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-110

8. PAPER FEED AND REGISTRATION . . . . . . . . . . . . . . . . . . . . 2-111

8.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-111

8.2 PAPER TRAY MECHANISM (A166 COPIER ONLY) . . . . . . . . . . . . . . . . 2-112

8.2.1 Paper Feed Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-112

8.2.2 Paper Lift Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-114

8.2.3 Paper End Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-115

8.2.4 Paper Size Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-116

8.2.5 Vertical Transport Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-117

SM v A166/A187/A189

Page 17

8.2.6 Side Fence Double-stopper Mechanism . . . . . . . . . . . . . . . . . . . . . . . 2-118

8.3 BY-PASS FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-119

8.3.1 By-pass Feed Table Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-119

8.3.2 Paper Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-120

8.3.3 Paper End Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-120

8.3.4 By-pass Feed Paper Width Detection . . . . . . . . . . . . . . . . . . . . . . . . 2-121

8.3.5 Pick-up Roller Pressure Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . 2-122

8.4 REGISTRATION DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-123

9. PAPER TRANSPORT AND IMAGE FUSING. . . . . . . . . . . . . . . 2-1 24

9.1 PAPER TRANSPORT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-124

9.1.1 Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-124

9.1.2 Transport Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-124

9.2 FUSING UNIT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-125

9.3 FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-126

9.3.1 Fusing Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-126

9.3.2 Fusing Pressure Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-127

9.3.3 Oil Supply Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-128

9.3.4 Cleaning Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-129

9.3.5 Fusing Drive Release Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-130

9.4 JUNCTION GATE AND PAPER EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-131

9.4.1 Paper Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-131

9.4.2 Junction Gate Mechanism (A187/A189 copiers only) . . . . . . . . . . . . 2-132

9.4.3 Paper Exit Door (A187/A189 copiers only) . . . . . . . . . . . . . . . . . . . . . 2-133

10. DUPLEX UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-134

10.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-134

10.2 DUPLEX UNIT MECHANISMS (A187/A189 copiers only) . . . . . . . . . . . . 2-135

10.2.1 Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-135

10.2.2 Duplex Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-136

10.2.3 Duplex Entrance To Duplex Tray . . . . . . . . . . . . . . . . . . . . . . . . . . 2-137

10.2.4 Jogger Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-138

10.2.5 Paper Feed from the Duplex Tray . . . . . . . . . . . . . . . . . . . . . . . . . . 2-139

10.2.6 Paper Feed System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-140

A166/A187/A189 vi SM

Page 18

11. SYSTEM CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . 2-141

11.1 BLOCK DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-141

11.2 COMMAND SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-142

11.2.1 Normal Copy Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-142

11.2.2 Edit Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-143

INSTALLATION

1. INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.2.1 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.2.2 Minimum Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

1.2.3 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

2. COPIER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

2.1 ACCESSORY CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

2.2 COPIER INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3. INSTALLATION PROCEDURE FLOWCHART . . . . . . . . . . . . . . 3-36

4. PAPER TRAY UNIT (A549/A550) INSTALLATION . . . . . . . . . . . 3-40

4.1 ACCESSORY CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

4.2 INSTALLATION PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

4.3 TRAY HEATER (OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

5. ARDF (A548) INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

5.1 ACCESSORY CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

5.2 INSTALLATION PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

6. 10-BIN SORTER (A555) INSTALLATION . . . . . . . . . . . . . . . . . . 3-46

6.1 ACCESSORY CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

INSTALLATION PROCEDURE

6.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

7. FILM PROJECTOR TABLE (A579) INSTALLATION. . . . . . . . . . 3-51

8. FILM PROJECTOR UNIT (A718) INSTALLATION . . . . . . . . . . . 3-53

8.1 ACCESSORY CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

SM vii A166/A187/A189

Page 19

8.2 INSTALLATION PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

9. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

9.1 KEY COUNTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

9.1.1 Key Counter Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

9.1.2 Setting up the SP Modes for the Key Counter. . . . . . . . . . . . . . . . . . . . 3-62

9.2 MOUNTING THE PACKING RETAINERS FOR MOVING THE COPIER . . 3-63

SERVICE TABLES

1. SERVICE PROGRAM MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1 SP TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.2 SERVICE PROGRAM MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.2.1 LCD Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.3 SP MODE ADDITIONAL NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.3.1 SP 3-973 Process Control Interval Self Check . . . . . . . . . . . . . . . . . . . . 4-2

1.3.2 SP4-301 APS Data Confirmation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.3.3 SP5-501 PM Counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.3.4 SP5-802-1 Printer Free Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.3.5 SP5-802-4 System Free Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.3.6 SP5-803 Input Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.3.7 SP5-804 Output Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

1.3.8 SP5-955 Printer Test Pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

1.3.9 SP5-974 Auto Memory Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

1.3.10 SP6-102 Sort/Stack Limitation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

1.3.11 SP6-107 Sorter Free Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

1.3.12 SP6-901 Optional Paper Bank Input Check. . . . . . . . . . . . . . . . . . . . . 4-10

1.3.13 SP6-902 Output Check for the Optional Paper Bank Unit . . . . . . . . . . 4-12

1.3.14 SP6-903 Sorter Input Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

1.3.15 SP6-904 Sorter Output Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

1.3.16 SP7-507-1 Paper Jam (Last 10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

1.3.17 SP7-507-2 Original Jam (Last 10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

2. USER PROGRAM MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

A166/A187/A189 viii SM

Page 20

2.1 USER PROGRAM MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

2.2 UP MODE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

3. TP/FUSE/LED/SW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

3.1 TEST POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

3.2 FUSE CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

3.3 LED CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

3.4 SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4. REGULAR PM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

5. SP MODES USED AFTER REPLACEMENT

AND CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

6. REGULAR PM PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

REPLACEMENT AND ADJUSTMENT

1. EXTERIOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1 PLATEN COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.2 FRONT COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.3 REAR COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.4 EXPOSURE GLASS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.5 UPPER COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

1.6 OPERATION PANEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

1.6.1 A166/A187 Copiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

1.6.2 A189 Copier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

1.7 RIGHT COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

1.8 LEFT COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

1.9 INNER COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

1.10 USED TONER TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

1.11 LIFTING THE SCANNER UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

2. DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

2.1 DRUM REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

2.2 CLEANING BLADE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

2.3 CLEANING BRUSH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

SM ix A166/A187/A189

Page 21

2.4 LUBRICANT BAR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

2.5 CHARGE GRID AND CORONA WIRE REPLACEMENT . . . . . . . . . . . . . . 5-13

3. SCANNER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

3.1 SCANNER UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

3.2 HALOGEN LAMP REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

3.3 SCANNER INNER COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

3.4 SBU REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

3.5 SCANNER IPU BOARD REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

3.6 SCANNER HOME POSITION SENSOR REPLACEMENT . . . . . . . . . . . . . 5-18

3.7 SCANNER WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

3.8 IDU (IMAGE DISCRIMINATE UNIT) REPLACEMENT . . . . . . . . . . . . . . . . 5-23

4. COPY IMAGE ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

4.1 PRINTER γ ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

4.1.1 Auto Color Calibration (ACC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

4.1.2 BkCMY Color Balance Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

4.2 MAIN SCAN POSITION DOT CORRECTION. . . . . . . . . . . . . . . . . . . . . . . . 5-28

5. LASER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

5.1 POLYGON MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

5.2 LASER SYNCHRONIZING DETECTOR BOARD REPLACEMENT. . . . . . . 5-34

5.3 LD UNIT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

6. DEVELOPMENT UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

6.1 DEVELOPER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

6.1.1 Developer Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

6.2 PROCESS CONTROL SELF-CHECK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

6.3 REVOLVER MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

6.4 DEVELOPMENT MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-50

7. TRANSFER BELT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

7.1 TRANSFER BELT SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

7.1.1 Transfer Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

7.2 CLEANING UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

7.2.1 Cleaning Blade Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

A166/A187/A189 x SM

Page 22

7.2.2 Belt Cleaning Solenoid Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

7.2.3 Entrance Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

7.3 BELT TRANSFER CORONA WIRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

7.4 LUBRICANT UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-57

7.4.1 Lubricant Brush and Bar Replacement . . . . . . . . . . . . . . . . . . . . . . . . 5-57

7.4.2 Lubricant Solenoid Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

7.5 PAPER TRANSFER CORONA WIRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

8. PAPER FEED AND REGISTRATION. . . . . . . . . . . . . . . . . . . . . . 5-60

8.1 BY-PASS FEED TABLE REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

8.2 BY-PASS FEED ROLLER, PICK-UP ROLLER, AND SEPARATION

ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

8.3 BY-PASS FEED UNIT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

8.4 BY-PASS FEED PICK-UP SOLENOIDS AND END

SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

8.5 BY-PASS FEED PAPER SIZE SENSOR REPLACEMENT . . . . . . . . . . . . . 5-64

8.6 REGISTRATION SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 5-65

8.7 PAPER FEED TRAY REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

8.8 PAPER FEED ROLLER (SEMICIRCULAR ROLLER) REPLACEMENT . . . 5-67

8.9 PAPER FEED CLUTCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

8.10 VERTICAL TRANSPORT SWITCH AND SENSOR

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

8.11 COPY IMAGE AREA ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

9. PAPER TRANSPORT AND FUSING . . . . . . . . . . . . . . . . . . . . . . 5-72

9.1 TRANSPORT UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

9.2 TRANSPORT BELT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

9.3 FUSING UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-74

9.4 OIL SUPPLY PAD REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

9.5 HOT ROLLER, PRESSURE ROLLER, AND FUSING

LAMP REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

9.6 HOT ROLLER THERMISTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 5-81

9.7 HOT ROLLER THERMOFUSE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 5-81

9.8 PRESSURE ROLLER THERMISTOR REPLACEMENT . . . . . . . . . . . . . . . 5-82

9.9 PRESSURE ROLLER THERMOFUSE REPLACEMENT . . . . . . . . . . . . . . 5-82

9.10 CLEANING ROLLER OIL PAN AND SCRAPER . . . . . . . . . . . . . . . . . . . . 5-83

SM xi A166/A187/A189

Page 23

9.11 OIL PAN PADS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-84

9.12 FUSING ENTRANCE GUIDE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 5-85

9.13 NIP BAND WIDTH ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-86

9.13.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-86

9.13.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-87

10. DUPLEX UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-88

10.1 DUPLEX UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-88

10.2 SEPARATION ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 5-88

10.3 FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-89

10.4 DUPLEX FEED MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-90

11. FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-92

11.1 OPTICS FAN FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-92

11.2 EXHAUST OZONE FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . 5-92

11.3 FUSING FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-93

11.4 CHARGE INLET FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-93

11.5 REAR OZONE FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 5-94

11.6 FRONT OZONE FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-94

11.7 PAPER IT OZONE FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . 5-95

11.8 POWER SUPPLY OZONE FILTER REPLACEMENT . . . . . . . . . . . . . . . . 5-95

12. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-96

12.1 SCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-96

12.1.1 SCU Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-96

12.2 RAM CLEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-98

12.2.1 RAM (Memory Board) Clear Procedure. . . . . . . . . . . . . . . . . . . . . . . . 5-98

12.3 MAIN COUNTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-98

12.3.1 Main Counter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-98

12.4 TOUCH PANEL CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-101

TROUBLESHOOTING

1. SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. HOW TO DETERMINE IF THE POTENTIAL

SENSOR OR ID SENSOR IS DEFECTIVE. . . . . . . . . . . . . . . . . . 6-34

A166/A187/A189 xii SM

Page 24

3. TROUBLESHOOTING FOR COUNTERS. . . . . . . . . . . . . . . . . . . 6-37

AUTO REVERSE DOCUMENT FEEDER A548

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.1 MECHANICAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.2 ELECTRICAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

3. ELECTRICAL COMPONENT DESCRIPTION . . . . . . . . . . . . . . . . 7-4

4. DETAILED DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

4.1 ORIGINAL PICK-UP MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

4.2 SEPARATION AND PAPER FEED MECHANISM . . . . . . . . . . . . . . . . . . . . . 7-6

4.3 FRICTION BELT DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

4.4 ORIGINAL SIZE DETECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

4.5 PAPER TRANSPORT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

4.6 THICK/THIN ORIGINAL MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

4.7 ORIGINAL FEED-OUT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

4.8 TWO-SIDED ORIGINAL FEED MECHANISM . . . . . . . . . . . . . . . . . . . . . . . 7-12

5. TIMING CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

5.1 A4 SIDEWAYS: 1 SIDED ORIGINAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

5.2 COMBINE 2 ORIGINAL MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

5.3 A4 SIDEWAYS: DUPLEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

6. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

6.1 DIP SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

6.2 VARIABLE RESISTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

6.3 LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

6.4 FUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 7-18

7.1 TRANSPORT BELT REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

7.2 FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

7.3 FRICTION BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

7.4 ORIGINAL SET AND ORIGINAL WIDTH SENSOR REPLACEMENT . . . . . 7-21

SM xiii A166/A187/A189

Page 25

7.5 VERTICAL REGISTRATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . 7-22

7.5.1 One Sided Thin Original Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

7.5.2 Two Sided Original Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.6 SIDE-TO-SIDE REGISTRATION (DF POSITIONING) ADJUSTMENT . . . . 7-24

PAPER TRAY UNIT A549/A550

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.1 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.2 DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

2.3 ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . 8-4

3. OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

4. DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

5. PAPER FEED AND MISFEED DETECTION TIMING. . . . . . . . . . . 8-7

6. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

6.1 DIP SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

6.2 TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

7. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 8-10

7.1 EXTERIOR COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

7.2 PAPER FEED CLUTCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

7.3 PAPER FEED UNIT REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

7.4 FEED ROLLER, PICK-UP ROLLER, AND REVERSE

ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

7.5 RELAY SENSOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

10-BIN SORTER STAPLER A555

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

2.1 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

2.2 DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

2.3 ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . 9-5

A166/A187/A189 xiv SM

Page 26

3. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

3.1 NORMAL MODE AND SORT/STACK MODE . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

3.2 STAPLE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

3.3 BIN DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

3.4 BIN HOME POSITION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

3.5 JOGGER MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

3.6 GRIP ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

3.7 STAPLER UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

3.8 STAPLER SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

3.9 PAPER FEED AND MISFEED DETECTION TIMING. . . . . . . . . . . . . . . . . . 9-16

3.10 JAM DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

4. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

4.1 DIP SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

4.2 TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

4.3 LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

4.4 VARIABLE RESISTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

5. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 9-21

5.1 EXTERIOR COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

5.2 STAPLE UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

5.3 GRIP ARM REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

5.4 BIN REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

5.5 TRANSPORT MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

5.6 BIN JAM SENSOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

FILM PROJECTOR UNIT A718

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. ELECTRICAL COMPONENT LAYOUT AND DESCRIPTIONS. . 10-2

3. SECTIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

3.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

3.2 SHADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

3.3 MIRROR UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

SM xv A166/A187/A189

Page 27

APPENDIX

1. TIMING CHART

Timing Chart 1 Normal speed/Bk/A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Timing Chart 2 Normal speed/Bk/A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Timing Chart 3 Normal speed/Red/A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Timing Chart 4 Normal speed/Red/A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Timing Chart 5 Normal speed/Green/A4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

Timing Chart 6 Normal speed/Green/A3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

Timing Chart 7 Normal speed/Full Color/A4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

Timing Chart 8 Normal speed/Full Color/A3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

Timing Chart 9 Half-speed/Bk/A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Timing Chart 10 Half-speed/Bk/A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

Timing Chart 11 Half-speed/Red/A4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

Timing Chart 12 Half-speed/Red/A3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Timing Chart 13 Half-speed/Green/A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

Timing Chart 14 Half-speed/Green/’A3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

Timing Chart 15 Half-speed/Full Color/A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

Timing Chart 16 Half-speed/Full Color/A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

Timing Chart 17 Cartridge check sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-17

Timing Chart 18 Sequence for the Revolver H.P. Process. . . . . . . . . . . . . . . . . 11-18

Timing Chart 19 Sequence for Lubrication (Forced Belt Cleaning) . . . . . . . . . . 11-19

2. SP MODE TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-20

BULLETINS

A166/A187/A189 xvi SM

Page 28

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

5. If the start key is pressed before the copier completes the warm-up period

(Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bar e hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get medical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

CAUTION

2. The RAM board on the system control board has a lithium battery

which can explode if replaced incorrectly. Replace the battery only

with an identical one. The manufacturer recommends replacing the

entire RAM board. Do not recharge or burn this battery. Used

batteries must be handled in accordance with local regulations.

SM a A166

Page 29

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner bottle or the used toner. Toner dust may ignite

suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductor according

to local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do

not put more than 100 batteries per sealed box. Storing larger numbers or

not sealing them apart may lead to chemical reactions and heat build-up.

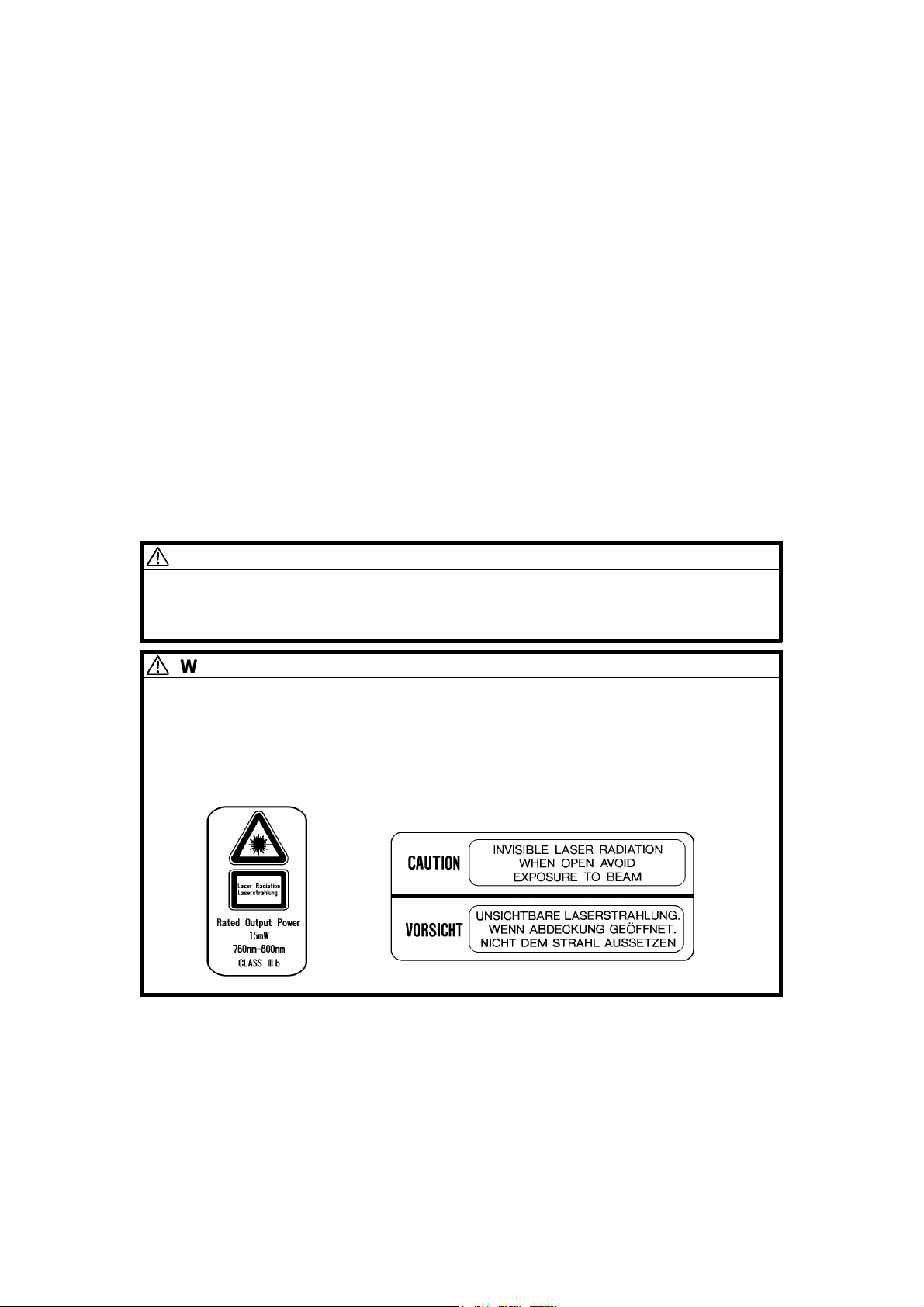

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair

of laser-based optical units in the field. The optical housing unit can only be

repaired in a factory or at a location with the requisite equipment. The laser

subsystem is replaceable in the field by a qualified Customer Engineer. The

laser chassis is not repairable in the field. Customer engineers are therefore

directed to return all chassis and laser subsystems to the factory or service

depot when replacement of the optical subsystem is required.

DANGER

Use of controls, or adjustment, or performance of procedures other

than those specified in this manual may result in hazardous radiation

exposure.

WARNING FOR LASER UNIT

DANGER: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser be ams

can seriously damage your eyes.

CAUTION MARKING:

A166 b SM

Page 30

TAB INDEX

OVERALL MACHINE INFORMATION

10-BIN SORTER STAPLER A555

DETAILED SECTION DESCRIPTIONS

FILM PROJECTOR UNIT A718

INSTALLATION PROCEDURE

APPENDIX - TIMING CHARTS / SP TABLES

SERVICE TABLES

REPLACEMENT AND ADJUSTMENT

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

TROUBLESHOOTI NG

AUTO REVERSE DOCUMENT FEEDER A548

PAPER TRAY UNIT A550/A549

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 31

Page 32

OVERALL

MACHINE INFORMATION

Page 33

Page 34

Rev. 11/96

1.

SPECIFICATIONS

SPECIFICATIONS

1.1 MACHINE CONFIGURATION

Aficio color (Basic Machine) Edit Machine

2003 (A166) 2103 (A187) 2203 (A189)

Operation Panel

Paper Tray Unit

Sorter/Stapler

ST10

(A555)

250 Sheets Duplex

Copier

Aficio Color

(A166/A187)

20-digit 2-line LCD

ARDF

(DF61)

(A548)

Aficio Color

)

(A189

144 mm x 192 mm

Touch Panel Display

FPU

SPU 3

(A718)

Overall

Machine

Information

BASIC

250-sheet Paper

Tray / Duplex Tray

Paper Tray Unit

PS290

(A549)

500 sheets

x 3 Trays

EDIT

Duplex Tray

PS280

(A550)

500 sheets

x 2 Trays

Type B

(A579)

FP Table

SM 1-1 A166/A187/A189

Page 35

SPECIFICATIONS

1.2 GENERAL SPECIFICATIONS

Configuration: Desk Top

Copy Process: Dry Electrostatic Transfer System

Resolutions: 400 dpi

Gradations: 256 gradations

Originals: Sheet/Book/Object

Original Size: Maximum 11" x 17" /A3

Copy Paper Size:

Maximum Minimum

1/2

Paper Tray Feed

Bypass Feed

11" x 17" /A3 5

1/2

11" x 17" /A3 5

x 8

1/2

x 8

/A5(S)

1/2

/A5(L/S), A6(L)

Copy Paper Weight:

Paper Tray Feed

Bypass Feed

Auto Duplex

Tray

17 to 24 lbs 64 to 90 g/m

14 to 43 lbs 52 to 157 g/m

17 to 28 lbs 64 to 104 g/m

2

2

2

Reproduction Ratios:

1/2

8

" x 11"/11" x 17" version A4/A3 version

Enlargement

Full size

Reduction

Programmable

121, 129, 155, 200, 400% 115, 122, 141, 200, 400%

100% 100%

25, 50, 65, 74, 77, 85, 93% 25, 50, 65, 71, 75, 82, 93%

2 user ratios 2 user ratios

Zoom: From 25% to 400 % in 1% steps.

A166/A187/A189 1-2 SM

Page 36

SPECIFICATIONS

Copying Speed:

1/2

8

" x 11" (S) /A4 11" x 17"/A3

Normal Mode

Full Color (4 scans) 3 cpm 1.5 cpm

Single Color (C, M Y, K) 21 cpm 11 cpm

Single Color (R, B) 4 c pm 3 cpm

Single Color (G) 3 cpm 2.5 cpm

OHP/Thick Paper Mode

Full Color (4 scans) 1.5 cpm 1 cpm

Single Color (C, M Y, K) 2.5 cpm 1.5 cpm

Single Color (R, G, B) 2 cpm 1 cpm

First Copy Time:

1/2

8

" x 11" (S) /A4 11" x 17" /A3

Normal Mode

Full Color (4 scans) 32 seconds 52 seconds

Single Color (K) 15 seconds 20 seconds

Single Color (C, M, Y) 20 seconds 20 seconds

Single Color (R, B) 25 seconds 35 seconds

Single Color (G) 30 seconds 40 seconds

OHP/Thick Paper Mode

Full Color (4 scans) 50 seconds 70 seconds

Single Color (K) 35 seconds 45 seconds

Single Color (C, M, Y) 35 seconds 45 seconds

Single Color (R, B) 40 seconds 55 seconds

Single color (G) 45 seconds 60 seconds

Overall

Machine

Information

Warm-up Time: Approx. 6 minutes (at 68°F / 20°C)

SM 1-3 A166/A187/A189

Page 37

SPECIFICATIONS

Duplexing:

Basic Manual Duplex

Model (A166):

Basic Auto Duplex

Model (A187):

Edit Auto Duplex Model

(A189):

Non-Reprodu ction Ar ea:

Leading Edge:

Side:

Manual Duplexin g in full color and Sin gle

Color mode

Manual & Auto Duplexing in Full Color and

Single Color mode

Manual & Auto Duplexing in Full Color and

Single Color mode

Duplex can be done on 64-104 g/m2 (17-28lb

bond) paper.

Manual Duplexing can be done through the

By-pass table only, and the user should press

the Duplex Side 2 key before copying the

reverse side.

0.2" ± 0.08" (5 mm ± 2 mm)

0.08" ± 0.08" (2 mm ± 2 mm)/

Total less than 0.16" (4 mm)

Trailing Edge

Front side 2.5 mm ± 2.0 mm

Back side 6.0 ± 2.0 mm

(back side trailing edge is adjustable by SP

mode from 0.5 to 10 mm)

Copy Number Input: Number keys, 1 to 99

Copy Number Input

(Auto Duplex):

Number keys

Single Color - 1 to 50: smaller than A3, 11" x 17"

1 to 30: A3, 11" x17"

Full Color 1 to 20: all sizes

Image Density: Auto/Manual (7 steps)

Automatic Reset: Yes (10 to 900 seconds or Off)

Paper Capacity: Tray:

250 sheets x 1 tray

(Basic Manual Dupl ex Mod el: A16 6)

By-pass:

40 sheets Normal paper (80 g/m2)

20 sheets OHP

1 sheet Adhesive paper

A166/A187/A189 1-4 SM

Page 38

Toner Replenishment: Black:

Toner Addition (300 g/cartridge)

Color (Y, M, C):

Toner Addition (100 g/cartridge)

Toner Type E for C, M, Y; Ex for BK

Cyan - EDP# 889766

Magenta - EDP# 889765

Yellow - EDP# 889764

Black - EDP# 889763

Developer Type: F all colors

Cyan - EDP# 889762

Magenta - EDP# 889761

Yellow - EDP# 889760

Black - EDP# 889759

SPECIFICATIONS

Overall

Machine

Information

Copy Tray Capacity: 100 sheets (11" x 17"/A3 and smaller)

Power Source: 120V/60Hz, 220-240V/50,60 Hz

Maximum Power

1.5 kVA

Consumption:

Dimensions (with Platen Cover):

Width Depth Height

Basic Manual Duplex

(A166)

Basic Auto Duplex

(A187)

Edit Auto Duplex

(A189)

620 mm

24.4"

620 mm

24.4"

620 mm

24.4"

700 mm

27.5"

700 mm

27.5"

750 mm

29.5"

632 mm

24.9"

632 mm

24.9"

632 mm

24.9"

Weight: Manual Duplex: 105 kg (231.3 lb)

Auto Duplex: 109 kg (240.1 lb)

Optional Equipm ent: Automatic D ocum ent Fee der : ARDF (A548 )

Sorter Stapler: ST10 (A555)

Film Projector: SPU 3 (A718)

Holder for Film Projector Unit: Type B (A579)

Paper Tray Unit (3 Trays & 2 Trays):

PS290/PS280 (A549/A550)

Key Counter (Procure locally)

SM 1-5 A166/A187/A189

Page 39

SPECIFICATIONS

1.3 DETECTABLE ORIGINAL SIZE BY PLATEN/ARDF

Size

(width x length )

[mm]

A3 (297 x 420)L No Yes No Yes

B4 (257 x 364)L No Yes No Yes

A4 (210 x 297)L No Yes Yes Yes

A4 (297 x 210)S No Yes Yes Y es

B5 (182 x 257)L No Yes No Yes

B5 (257 x 182)S No Yes No Yes

A5 (148 x 210)L No No* No Yes

A5 (210 x 148)S No Yes No Yes

B6 (128 x 182)L No No No Yes

B6 (182 x 128)S No No No Yes

11" x 17" (DLT) Yes No Yes Yes

11" x 15" No No Yes No

10" x 14" Yes No Yes No

8.5" x 14" (LG) Yes No Yes No

8.5" x 13" (F4) No Yes No Yes

8.25" x 13" No No No No

8" x 13"(F) No No Yes No

8.5" x 11" (LT) Yes No Yes Yes

11" x 8.5" (LT) Yes No Yes Yes

8" x 10.5" No No No No

8" x 10" No No Yes No

5.5" x 8.5" (HLT) No* No Yes No

8.5" x 5.5" (HLT) Yes No Yes No

A6 (105 x 148)L No No No No

Inch version Metric version Inch version Metric version

Platen ARDF

* : For A5 lengthwise/HLT, SP4-303 can be used to select "Cannot detect

original size" or "A5 lengthwise/5.5" x 8.5"(HLT)".

A166/A187/A189 1-6 SM

Page 40

1.4 COPY PAPER SIZE

SPECIFICATIONS

Size

(width x length)

[mm]

A3 (297 x 420)L No Yes Yes Yes Yes Yes

B4 (257 x 364)L No Yes Yes Yes Yes Yes

A4 (210 x 297)L Yes Yes Yes Yes Yes Yes

A4 (297 x 210)S Yes Yes Yes Yes Yes Yes

B5 (182 x 257)L No Yes No Yes Yes Yes

B5 (257 x 182)S No Yes No Yes Yes Yes

A5 (148 x 210)L No No No No Yes Yes (1)

A5 (210 x 148)S No Yes Yes Yes Yes Yes (2)

B6 (128 x 182)L No No No No Yes Yes (1)

B6 (182 x 128)S No No No No No No

11" x 17" (DLT) Yes Yes Yes Yes Yes Yes

11" x 15" Yes No Yes No Yes Yes

10" x 14" Yes No Yes No Yes Yes

8.5" x 14" (LG) Y es No Yes No Yes Yes

8.5" x 13" (F4) Yes Yes Yes Yes Yes Yes

8.25" x 13" No No Yes Yes Yes Yes

8" x 13"(F) No No Yes Yes Yes Yes

8.5" x 11" (LT) Yes Yes Yes Yes Yes Yes

11" x 8.5" (LT) Yes Yes Yes Yes Yes Yes

8" x 10.5" No No Y es No Yes Yes

8" x 10" Yes No Yes Yes Yes Yes

5.5" x 8.5" (HLT) No No No No Yes Yes (1)

8.5" x 5.5" (HLT) Yes No Yes Yes Yes Yes (2)

A6 (105 x 148)L No No No No Yes Yes (2)

Inch

version

Trays in the main body Bypass

Paper Tray Duplex Tray

Metric

version

Inch

version

Metric

version

All

versions

Optional

S.Stapler

Overall

Machine

Information

Yes (1): Stapling is not allowed.

Yes (2): Using the Proof Tray only. Sorter bins cannot be used.

SM 1-7 A166/A187/A189

Page 41

SPECIFICATIONS

1.5 PAPER SIZES AVAILABLE WITH APS

– For metric machines –

200

173

163

141

122

115

100

93

87

82

75

~

~

~

~

~

~

~

~

~

~

~

174

164

142

123

116

101

94

88

83

76

72

A3

B4

A4L

B5L

A5L

A4S

B5S

A5S

8.5

x 11

x 8.5

8.5

x 13

x 15

––––––A3–B4––A4L8.5

–––––A3B4––A4L8.5

x 13

– – – A3 B4 – A4L 8.5

––A3B4–A4LB5L––A5L––––––

A3 B4 – A4 L B5L – A5L – – – – – – – – –

––––––A4S–B5S––A5S––––

–––––A4SB5S––A5S––––––

–––A4SB5S–A5S–––––––––

––––––8.5

x11

11

––––––11x

8.5

––––A3–8.5

x 13

11

––––––11x15–––––––––

B5L– –A5L– – – –

x 13

–––––––––

–––––––––

––A4LB5L––––A5L

71

65

61

57

50

~

~

~

~

~

66

62

58

51

B5L – A5L

x 13

B5L– –A5L–

: Not allowed in platen cover mode. L: Lengthwise S: Sideways

– For inch machines –

200

176

~

~

177

156

11x17

11x15

8.5x14

8.5x11

5.5x8.5

8.5x5.5

11x8.5

8x10

10x14

8x13

– – – – – 11x17 11x17 11x15 8.5

– – – – – 11x15 11x15 – 8.5

––––11

– – 11 x17 – 8.5

11

x1711x15

–––11

–––––11

– – – 11x17 10x14 8x10 – – – – 5.5

–––––10x14–8.5

–––11x17–8x13––––5.5

155

~

130

8.5

x14

129

~

122

8.5

x11

x8.5

121

100

~

~

101

94

8.5

x17

x14

x11

–5.5

x8.5

–8.5

x5.5

x8.5

93

85

77

74

65

~

~

~

~

~

86

78

75

66

51

–8.5

x14

8.5x11 – 5.5

x14

––8.5

x11

––––5.5

––––––

––––––

––––8.5

8.5

x14

x11

x11

––5.5

x8.5

x5.5

x8.5

––5.5

x8.5

50

~

5.5

x8.5

x8.5

x8.5

–

–

–

x14

–

: Not allowed in platen cover mode.

A166/A187/A189 1-8 SM

Page 42

SPECIFICATI ONS

NOTE:

1) The tables show which copy paper size is selected for each

original size for zoom ratios from 50 to 200 %.

2) When a zoom ratio is specified, APS automatically selects a

paper size that can guarantee the quality of the magnified copy

image if there is a paper size available for the equivalent

standard rep rod uction rati o.

3) If paper of the detected size has run out, the machine displays the

message "Set xx $ paper in tray" and stops the job (copying is

enabled).

4) For "–" in the above tables, the machine displays the message

"Cannot detect original size" and stops the job (copying is

enabled). The selected paper feed tray does not change.

5) When 49% or less or 201% or more is selected, APS works in the

same way as described in Note 4 above.

6) APS also supports the by-pass feed table (except for

non-standard paper sizes). When a selected paper size can only

be fed from the by-pass feed table, the machine displays a

warning to instruct the user to use the by-pass feed table.

7) APS does not support A6 and B6 sizes.

Overall

Machine

Information

1.6 NOISE EMISSION

Sound pressure level (The measurements are made in accordance with ISO

7779 at the operator positions.)

Copier only Full system*

Less than 61 dB (A) Less than 65 dB (A)

* Full system: Copier with document feeder, 500 sheets x 3 trays unit, F PU,

and a sorter stapler.

Sound power level (The measurements are made in accordance with ISO

7779.)

Copier only Full system*

Stand-by Less than 54 dB (A) Less than 58 dB (A)

Copying

(This value is for the

black copy mode.)

* Full system: Copier with document feeder, 500 sheets x 3 trays unit, F PU,

and a sorter stapler.

Less than 67 dB (A) Less than 71 dB (A)

SM 1-9 A166/A187/A189

Page 43

SPECIFICATIONS

1.7 POWER CONSUMPTION

(1) Maximum power consumption

1.5 kVA

(2) Average power consumption

A189 Copier +

DJF + Sorter

Value for standby

minus 7 W

NOTE:

A189 Copier

Standby

Warm-up

Copying

Energy Saver

Mode

0.25 kW 0.5 kW

1.25 kW 1.25 kW

1.15 kW 1.15 kW

Value for standby

minus 7 W

1) Copying was done in the 1C (A3) repeat mode.

2) The power consumption in energy saver mode was measured

with the fusing lamp off.

1.8 DISPLAY EDITOR SPECIFICATION

Scanned image

Displayed image

Area specification

procedure

The copier’s scanner scans the image.

•

Maximum A3/DLT (11" x 17"): Reduced image display

•

144 x 192 mm, 16-gradation (4 bit/pixel) monochrome

•

640 x 480 dots, 0.33 mm/pixel

•

Reduces the dpi of scanned images to approximately 33 dpi and

•

displays the entire image.

Zoom display: 3 levels (50 dpi, 67 dpi, 100 dpi)

•

Display processing time: 2 seconds or less

•

Move the arrow in the screen by using the cursor key and enter a

•

point by pressing the coordinate entry key.

A166/A187/A189 1-10 SM

Page 44

2.

MACHINE CONFIGURATION

MACHINE CONFIGURATION

2.1 COPY PROCESSES AROUND THE DRUM AND BELT

2

1

11

3

4

5

6

9

13

10

7

Overall

Machine

Information

8

12

1. Drum Charge

In the dark, the charge corona unit gives a negative charge to the

organic photoconductive (OPC) drum. The grid plate ensures that corona

charge is applied uniformly. The charge remains on the surface of the

drum because the OPC layer has a high electrical resistance in the dark.

The amount of negative charge on the drum is proportional to the

negative voltage applied to the drum charge corona wire and casing.

2. Laser Exposure

A laser beam is reflected onto the drum by the polygon and drum

mirrors. This forms an electrical latent image on the drum surface. The

amount of charge remaining as a latent image on the drum depends on

the laser beam intensity.

3. Drum Potential Detection

The drum potential sensor detects the strength of the electric field on the

charged drum. The sensor output is one of the signals used in process

control.

SM 1-11 A166/A187/A189

Page 45

MACHINE CONFIGURATION

4. Development

The negatively charged toner is attracted to the latent image on the drum

surface. Toner particles are electrostatically attracted to the area of the

drum surface where the laser reduced the negative charge on the drum.

The development unit is a revolver-type, containing separate

development sections for each color toner.

5. Image Density Detection

When the laser forms a sensor pattern on the drum surface, the ID

sensor measures the image density of these patterns. The output signal

is used in process control to regulate toner supply.

6. Pre-transfer Lamp

After development, the pre-transfer lamp reduces the potential of the

image background, right before the first belt transfer (in 2C/3C/4C mode).

This ensures that electrostatic attraction between belt and drum is about

the same for each color toner transfer, which ensures that the color toner

images are synchronized properly.

7. Belt Transfer

Toner on the drum is attracted to the transfer belt by the belt corona unit.

8. Belt Lubrication

The transfer belt lubricant brush applies a small amount of lubricant to

the surface of the transfer belt. This aids the belt cleaning blade in

removing waste toner from the transfer belt.

9. Belt Cleaning

The cleaning blade removes any toner on the belt after paper transfer.

10. Drum Cleaning

The drum cleaning brush roller removes remaining toner from the drum.

The cleaning brush also applies lubricant. This aids in drum cleaning.

11. Quenching

The light from the quenching lamp electrically neutralizes the charge on

the drum surface. This prepares the drum for the next copy cycle.

12. Paper Transfer

When all toner has been transferred from the drum to the transfer belt,

the charged toner on the transfer belt is attracted to the paper by the

paper transfer unit. This charge is applied to the underside of the paper.

13. Paper Separation

The copy paper separates from the transfer belt due to the belt’s

curvature. This curvature allows the paper to naturally fall away from the

transfer belt. The discharge brush aids in the separation process by

discharging any remaining electric charge from the paper.

A166/A187/A189 1-12 SM

Page 46

3.

MAJOR UNIT OVERVIEW

MAJOR UNIT OVER VI EW

1

2

3

4

10

9

8

Overall

Machine

Information

5, 6

7

SM 1-13 A166/A187/A189

Page 47

MAJOR UNIT OVERVIEW

1. Copier

1. Dimensions (W x D x H):

Basic machine - 620 x 700 x 632 mm [24.4"x27.6"x25.2"] (with paper

tray unit: 620 x 700 x 1010) [24.4"x27.6"x40.1"]

Edit machine - 620 x 750 x 632 mm [24.4"x29.8"x25.2"] (with paper tray

unit: 620 x 750 x 1010) [24.4"x29.8"x40.1"]

2. The printer unit, system control unit, and scanner unit are independent

modules connected wi th an interf ace.

2. Scanner Unit

1. 400 dpi (8 bits/dot) scanning in both main and sub scan directions

2. 3-line CCD with reduction optics

3. Exposure lamp: Halogen lamp

4. 5-phase stepper mot or drive

3. Drum Unit

1. The drum unit contains the photoco nduct or dru m, char ge coron a unit,

and cleaning unit

2. Charge corona unit: Single scorotron charge

3. Quenching Lamp: Red LEDs

4. Drive: Synchronized with the transfer belt (dc brushless motor and

flywheel); full speed = 105 mm/s

5. Potential sensor and ID sensor incl ude d

4. Fusing and Paper Ex it Se cti on

1. Fusing: Silicone roller fusing (both hot and pressure rollers)

2. Oil application method: Double roller

3. Cleaning: Roller cleaning for the hot roller

Cleaning blade for the pressure roller

4. OHP/Thick paper mode: Half speed (52.5 mm/s)

5. Development and Toner Supply

1. Development: Two-component magnetic brush development

2. Development switching: Revolver System

3. Image density control: ID sensor and Po tent ial sens or (Pro cess contro l )

4. Toner supply

Black: Screw-in bottle (300 g)

Color: Sector cartridge (100 g)

5. Toner supply unit: Front of development unit (rotation type)

A166/A187/A189 1-14 SM

Page 48

MAJOR UNIT OVER VI EW

6. Toner and Developer

1. Color toner: Type E

2. Black toner : Type EX

3. Developer: Type F

7. Paper Feed and Transport

1. Paper Tray Unit (A166 copier only)

Corner Separation System

•

Front loading tray (250 sheets) and By-pass table

•

2. Transport: Transp ort belt with fan

3. Duplex unit (A187, A189 copier only)

Duplex unit and By-pass table

•

4. Paper Tray Unit (option): • 500 sheets x 3 trays (FRR Feed System)

• 500 sheets x 2 trays (FRR Feed System)

8. Transfer and Belt Drive

1. Transfer belt: Full time contact with the drum

2. Belt transfer: Single corona charge

3. Paper transfer: Single corona charge

4. Registration: Synchronization by the transfer belt H.P. sensor

5. Drive: Synchronized with the drum (same motor)

6. Separation: Curvature separation + discharge brush

7. Transfer cycle: 1 belt rotation/A4

8. Belt cleaning: Counter blade

9. Lubrication: Brush roller with lubricant bar

Overall

Machine

Information

9. Printer Unit

1. Optics: 6-sided polygon mirror + 2 fθ lenses and BTL