Page 1

A220 (FT6350)

Service Manual

–

Insert Version

–

The A220 machine is based on the A175/A176/A177/A191/A192

Copier.

Only the differences from the base copier are described in the

following pages. Therefo r e, this documentation should be treated

as an insert version of th e ba se cop i er ’s serv ic e ma nu al. It should

always be utilized together with the base copier’s service manual.

Page 2

INSERTION PROCEDURE OF

SERVICE MANUAL

1. Replace the binder inserts with the new ones provided.

2. Insert the A220 service manual after the A175/A176/A177/A191/A192

manual.

Page 3

LEGEND

PRODUCT

CODE

A220 (FT6350) 2751

RICOH GESTETNER

COMPANY

DOCUMENTATION

HISTORY

REV. DATE DATE COMMENT

* 12/97

Original printing

Page 4

Table of Contents

This manual describes new items for the (A220).

Please refer to the F401/F411/F421 (A175/A176/A177/A191/A192) manual for

the descriptions marked with "*" in page column.

1. OVERALL MACHINE INFORMATION

1. SPECIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. MACHINE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2.1 COPIER OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2.2 SYSTEM OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3. COPY PROCESS AROUND THE DRUM. . . . . . . . . . . . . . . . . . . . . . . *

4. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 1-7

5. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

6. PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

6.1 STANDARD COPYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.2 MULTIPLE 2-SIDED COPYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7. ELECTRICAL COMPONENT DESCRIPTION . . . . . . . . . . . . . . . . . 1-7

2. DETAILED SECTION DESCRIPTIONS

1. PROCESS CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.1.1 Latent Image Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.1.2 Image Density Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.2 PROCESS CONTROL DATA INITIAL SETTING . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3 LATENT IMAGE CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3.1 Drum Potential Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3.2 Drum Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3.3 V

Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SG

1.3.4 V

1.3.5 V

SM i A220

Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

R

Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

D

Page 5

1.3.6 VL Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3.7 V

1.3.8 Initial Setting Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.4 IMAGE DENSITY CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.4.1 Toner Density Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.4.2 Image Density Sensor Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.4.3 Sensor Abnormal Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

R

2. DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.2 OPC DRUM CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.3 DRUM CHARGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.3.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.3.2 Air Flow Around the Drum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.3.3 Charge Wire Cleaning Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.4 ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.4.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.4.2 Lead Edge and Trail Edge Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.4.3 Side Erase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.5 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.5.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.5.2 Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.5.3 Cleaning Blade Pressure Mechanism and Side-to-Side Movement . . . . . . . *

2.5.4 Toner Collection Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.5.5 Pick-off mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.5.6 Toner Collection Bottle Set Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.6 QUENCHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.2 SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.3 VERTICAL LENS DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.4 HORIZONTAL LENS DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.5 HORIZONTAL LENS POSITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SM ii A220

Page 6

3.5.1 For Original Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.5.2 For Paper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.5.3 For Reproduction Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.6 3RD SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.7 OPTICS CONTROL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.8 AUTOMATIC IMAGE DENSITY CONTROL SYSTEM (ADS) . . . . . . . . . . . . . . . *

3.9 MANUAL IMAGE DENSITY CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.10 UNEVEN LIGHT INTENSITY CORRECTION . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.11 ORIGINAL SIZE DETECTION IN PLATEN MODE . . . . . . . . . . . . . . . . . . . . . . *

3.12 HALF TONE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4. DEVELOPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

4.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.3 CROSSMIXING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.4 DEVELOPMENT BIAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.4.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.4.2 Bias Control In Copy Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.4.3 Bias Control Out of Copy Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.4.4 ID Sensor Pattern Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.5 TONER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.5.1 Toner Supply Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.5.2 Toner End Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.5.3 Toner Supply Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.5.4 Bottle Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5. IMAGE TRANSFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5.1 PRE-TRANSFER LAMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5.2 IMAGE TRANSFER AND PAPER SEPARATION OVERVIEW . . . . . . . . . . . . . . *

5.3 IMAGE TRANSFER AND PAPER SEPARATION MECHANISM. . . . . . . . . . . . . *

5.4 TRANSFER BELT UNIT LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5.5 PAPER TRANSPORTATION AND BELT DRIVE MECHANISM . . . . . . . . . . . . . *

5.6 TRANSFER BELT CLEANING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5.7 TONER COLLECTION MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SM iii A220

Page 7

6. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

6.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

6.2 FRR FEED SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.2.1 Pick-up Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.2.2 Feed and Separation Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.3 SLIP CLUTCH MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.4 FRR FEED DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.5 SEPARATION ROLLER RELEASE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . *

6.6 PAPER RETURN MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.7 PAPER SKEW PREVENTION MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.8 PAPER LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

6.9 PAPER NEAR END/PAPER END DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . *

6.10 TANDEM FEED TRAY (A176/A177/A191/A192 Copiers Only) . . . . . . . . . . . . . *

6.10.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.10.2 Fences Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.10.3 Rear Fence Drive Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.10.4 Tray Lock Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.11 PAPER SIZE DETECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.12 VERTICAL TRANSPORT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.13 TRAY POSITIONING MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.14 BUILT IN LCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.14.1 Paper Tray Lift Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.14.2 Tray Lock Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.15 BY-PASS FEED TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.15.1 Feed Mechanism/Paper End Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.15.2 Table Open/Close Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.15.3 Paper Size Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.16 PAPER REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.17 REGISTRATION DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.18 GUIDE PLATE RELEASE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7. IMAGE FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SM iv A220

Page 8

7.2 FUSING ENTRANCE GUIDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.3 FUSING DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.4 FUSING LAMP CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.5 INVERTER AND PAPER EXIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.6 INVERTER AND EXIT DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8. DUPLEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.3 DUPLEX ENTRANCE TO DUPLEX TRAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.4 DUPLEX STACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.5 DUPLEX PICK-UP ROLLER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.6 DUPLEX PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

9. ENERGY STAR COMPLIANT MACHINES

(North American version only). . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

10. ENERGY SAVING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . *

10.1 About The Energy Saving Features of this Copier . . . . . . . . . . . . . . . . . . . . . . . *

10.1.1 Auto Off Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

10.1.2 Duplex Default Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INSTALLATION

1. INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.1 ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.2 MACHINE LEVEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3 MINIMUM SPACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.4 POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2. COPIER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2.2 COPIER INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2.3 GUIDANCE ROM, INSTALLATION

(OPTION: EUROPE VERSION ONLY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

*

2.4 PLATEN COVER (OPTION) INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SM v A220

Page 9

2.5 PAPER SIZE CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.5.1 550 Sheets Paper Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.5.2 1,500 Sheets Paper Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.6 KEY COUNTER HOLDER INSTALLATION (OPTION) . . . . . . . . . . . . . . . . . . . . *

2.7 IMAGE DENSITY ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3. DUAL JOB FEEDER (A610) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4. SORTER STAPLER (A606) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5. RECIRCULATING DOCUMENT HANDLER (A607) . . . . . . . . . . . . . . *

5.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6. FINISHER (A608) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7. LCT (A609) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.2.1 PAPER SIZE CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4. SERVICE TABLES

1. SERVICE REMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.1 HANDLING THE DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.2 DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3 CHARGE CORONA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.4 OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.5 ERASE LAMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.6 DEVELOPMENT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SM vi A220

Page 10

1.7 TRANSFER BELT UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.8 CLEANING SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.9 PRE-TRANSFER LAMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.10 PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.11 FUSING UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.12 OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. SERVICE PROGRAM MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2.1 SERVICE PROGRAM MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.1.1 Service Program Access Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.1.2 To Exit SP Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.1.3 To Return to the Index Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.1.4 Change the Menu Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.1.5 Access to "Copy in SP" Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.2 SERVICE PROGRAM MODE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2.3 SENSOR/SWITCH/SIGNAL DATA CHECK (INPUT MODE). . . . . . . . . . . . . . . . *

2.4 ELECTRICAL COMPONENT CHECK (OUTPUT MODE) . . . . . . . . . . . . . . . . . . *

2.5 USER TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.5.1 How To Access The User Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.6 TOUCH PANEL DISPLAY POSITION ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . *

3. PREVENTIVE MAINTENANCE SCHEDULE. . . . . . . . . . . . . . . . . . 4-7

3.1 PM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.2 EXPLANATION OF REGULAR PM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.3 REGULAR PM PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5. REPLACEMENT AND ADJUSTMENT

1. EXTERIOR AND INNER COVER REMOVAL . . . . . . . . . . . . . . . . . . . *

1.1 FRONT SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.1.1 Left Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.1.2 Right Front Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.2 REAR SIDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.2.1 Upper Rear Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SM vii A220

Page 11

1.2.2 Lower Rear Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.2.3 Left Inner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.2.4 Right Inner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.2.5 Shutter Inner Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3 RIGHT SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3.1 Feed Unit Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3.2 Upper Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3.3 Lower Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.4 LEFT SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.4.1 Upper Left Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.4.2 Lower Left Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.5 OPERATION PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.6 UPPER SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.6.1 Upper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.6.2 Rear Upper Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.1 EXPOSURE GLASS REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.2 EXPOSURE LAMP REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.3 OPTICS THERMOSWITCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.4 SCANNER HP SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.5 ADS SENSOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.6 SCANNER DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.7 SCANNER DRIVE WIRES REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.8 SCANNER CONTROL ADJUSTMENT (except for 70 CPM version). . . . . . . . . . *

2.9 THIRD SCANNER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.10 THIRD SCANNER DRIVE MOTOR/HP SENSOR REPLACEMENT . . . . . . . . . *

2.11 LENS HORIZONTAL DRIVE BELT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . *

2.12 LENS VERTICAL DRIVE BELT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.13 ORIGINAL SIZE SENSORS

(2 LENGTH SENSORS, 1 WIDTH SENSOR) . . . . . . . . . . . . . . . . . . . . . . . . . . *

3. DEVELOPMENT AND TONER SUPPLY. . . . . . . . . . . . . . . . . . . . . . . *

3.1 DEVELOPMENT UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SM viii A220

Page 12

3.2 DEVELOPER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.3 DEVELOPMENT ROLLERS REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.4 TONER DENSITY SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.5 TONER BOTTLE DRIVE MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . *

4. DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.1 DRUM UNIT REMOVAL AND OPC DRUM REPLACEMENT . . . . . . . . . . . . . . . *

4.2 QUENCHING LAMP REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.3 GRID PLATE/CHARGE WIRE/WIRE CLEANER REPLACEMENT. . . . . . . . . . . *

4.4 ERASE LAMP AND DRUM POTENTIAL SENSOR REPLACEMENT. . . . . . . . . *

4.5 CLEANING BLADE REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

4.6 CLEANING BRUSH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.7 PICK-OFF PAWL REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

4.8 TONER COLLECTION MOTOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . *

4.9 OZONE FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5. TRANSFER BELT UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5.1 TRANSFER BELT UNIT REMOVAL/INSTALLATION . . . . . . . . . . . . . . . . . . . . . *

5.2 TRANSFER BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5.3 CLEANING BLADE REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.1 PAPER TRAY UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.2 PAPER TRAY REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.3 PAPER FEED ROLLERS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.4 TANDEM REAR FENCE DRIVE BELT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . *

6.5 TANDEM SIDE FENCE MOTOR REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.6 PAPER FEED TIMING ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.7 PAPER FEED CLUTCH REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.8 BY-PASS FEED TABLE REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.9 BY-PASS FEED ROLLERS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.10 BY-PASS PAPER SIZE SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . *

6.11 BY-PASS FEED CLUTCH REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.12 REGISTRATION CLUTCH REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.13 PAPER DUST CLEANER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SM ix A220

Page 13

6.14 REGISTRATION SENSOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.15 COPIER FEED UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.16 TANDEM FEED TRAY PAPER SIZE CHANGE. . . . . . . . . . . . . . . . . . . . . . . . . *

6.17 UNIVERSAL TRAY PAPER SIZE CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.18 NOTE FOR THE PAPER FEED UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

7. FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.1 FUSING UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.2 FUSING THERMISTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

7.3 FUSING THERMOFUSE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.4 FUSING LAMP REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.5 HOT ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.6 PRESSURE AND BEARING ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . . *

7.7 FUSING STRIPPER PAWL REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.8 FUSING PRESSURE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

7.9 PAPER EXIT UNIT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7.10 OIL SUPPLY/CLEANING ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . *

7.11 PRESSURE ROLLER CLEANING ROLLER REPLACEMENT . . . . . . . . . . . . . *

8. DUPLEX UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.1 FEED ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.2 SEPARATION BELTS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.3 DUPLEX UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.4 SEPARATION CLUTCH/TRANSPORT CLUTCH REMOVAL . . . . . . . . . . . . . . . *

8.5 JOGGER MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

8.6 COPY QUALITY ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.6.1 SP Adjustment Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.6.2 Side-to-side Registration Adjustment

(except for copier with RDH and Finisher) . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.6.3 Side-to-side Registration Adjustment

(copier with RDH and Finisher). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.6.4 Uneven Exposure Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.6.5 Image Density Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8.6.6 Scanner Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SM x A220

Page 14

6. TROUBLESHOOTING

1. SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.1 SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.2 EXPOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.3 SCANNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.4 LENS MAGNIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.5 OPTICS THERMISTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.6 MAIN CHARGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.7 DEVELOPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.8 PROCESS SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.9 TRANSFER CURRENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.10 DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.11 PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.12 DUPLEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.13 FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.14 SYSTEM CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.15 DUAL JOB FEEDER/RECIRCULATING DOCUMENT HANDLER . . . . . . . . . . *

1.16 FINISHER/SORTER STAPLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

1.17 OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2. ELECTRICAL COMPONENT DEFECTS . . . . . . . . . . . . . . . . . . . . . . . *

2.1 SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.2 SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.3 FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2.3.1 DC Power Supply Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

SM xi A220

Page 15

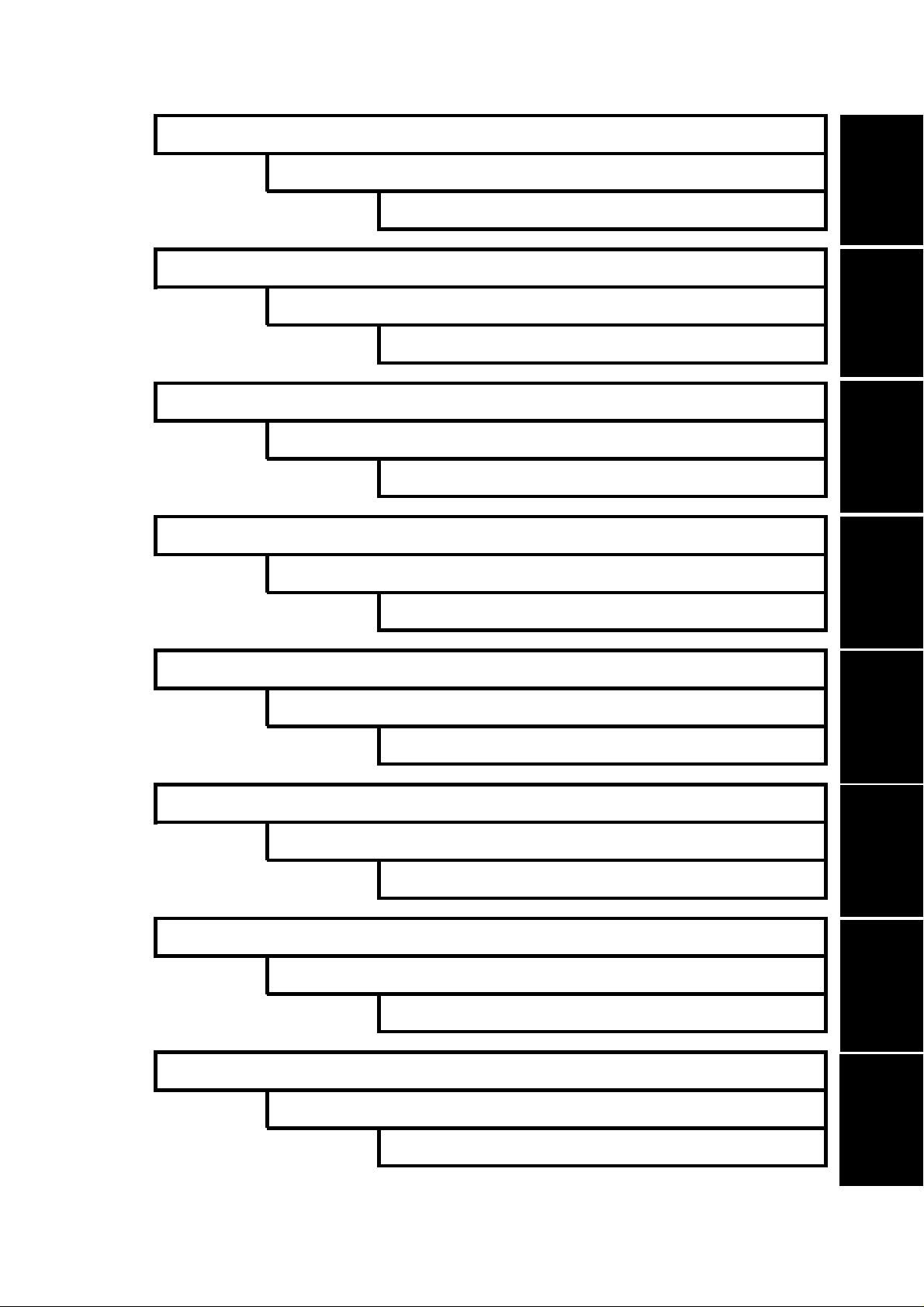

TAB INDEX FOR A220 (FT6350)

OVERALL MACHINE INFORMATION

DETAILED SECTION DESCRIPTION

INSTALLATION

TAB POSITION 1

TAB POSITION 2TAB POSITION 3TAB POSITION 4

SERVICE TABLES AND PROCEDURES

REPLACEMENT AND ADJUSTMENT

TAB POSITION 5TAB POSITION 6

TAB POSITION 8

TAB POSITION 7

Page 16

SECTION 1

OVERALL MACHINE

INFORMATION

Page 17

1. SPECIFICATION

Configuration: Console

Copy Process: Dry electrostatic transfer system

Toner Supply Control: Fuzzy Control

Photoconductor: OPC drum

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Original Alignment: Left rear corner

Copy Paper Size: Maximum A3/11" x 17"

Minimum A5/5

B5/8

A6/5

" x 8

1/2

" x 11" (1.5 k LCT)

1/2

" x 8

1/2

" (Tray)

1/2

" (By-pass)

1/2

SPECIFICATION

Overall

Machine

Information

Duplex Copying: Maximum A3/11" x 17"

Minimum A5/5

1/2

" x 8

" (sideways)

1/2

Copy Paper Weight: Paper tray: 52 ~ 128 g/m2, 14 ~ 34 lb

Bypass feed table: 52 ~ 157 g/m2, 14 ~ 42 lb

Duplex copying: 64 ~ 104 g/m2, 17 ~ 24 lb

Reproduction Ratios: 4 Enlargement and 6 Reduction

A4/A3 Version LT/LDG Version

200%

Enlargement

Full Size 100% 100%

Reduction

141%

122%

115%

93%

82%

75%

71%

65%

50%

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

SM 1-1 A220

Page 18

SPECIFICATION

Power Source: 115 V, 60 Hz, more than 20 A (for N.A)

220 ~ 240 V, 50 Hz/60 Hz, more than 10 A (for

Europe and Asia)

Power Consumption: A220 copier

Warm up 0.90 kVA 0.92 kVA

Stand-by*

Low Power mode*

Copying 1.20 kVA 1.20 kVA

Maximum 1.45 kVA 1.50 kVA

2

2

*1 Full System:

• Mainframe with dual job feeder, floor type

sorter stapler an d 3, 500-sheet large capaci t y

tray

• Mainframe with recirculating document

handler, finisher and 3,500-sheet large

capacity tray

*2 When the anti-condensation heaters are off.

Noise Emission: Sound Pressure Level:

The measurements are made according to

ISO7779

(average)

Copier only Full system*

0.22 kVA 0.24 kVA

0.19 kVA 0.21 kVA

1

A220 copier

Sound pressure level

Sound power level

A220 1-2 SM

(The measurements are made according to ISO 7779 at

the operator position.)

Stand-by less than 34 dB (A)

Copying less than 57 dB (A)

(The measurements are made according to ISO 7779.)

Stand-by less than 48 dB (A)

Copying less than 71 dB (A)

Copier only

Copier only

Page 19

SPECIFICATION

Dimensions:

Width Depth Height

Copier only 690 mm

27.2"

Copier with dual job feeder, sorter stapler, and

3,500-sheet large capacity tray

Copier with dual job feeder, sorter stapler with

punch, and 3,500-sheet large capacity tray

Copier with recirculating document handler,

finisher, and 3,500-sheet large capacity tray

1,659 mm

65.4"

1,659 mm

65.4"

1,764 mm

65.9"

690 mm

27.2"

690 mm

27.2 mm"

690 mm

27.2"

690 mm

27.2"

980 mm

38.6"

1,116 mm

43.9"

1,113 mm

43.9

1,112 mm

43.8"

Weight: Copier only:(Without the optional platen cover

= Approximately 2 kg)

Two-Tray version copier: Approximately 152 kg

Three-Tray version copiers: Approx imately 162 kg

Zoom: From 50% to 200% in 1% steps

Overall

Machine

Information

Copying Speed:

A220 copier

A4/LT (sideways) A3/DLT B4/LG

51 (A4)

50 (LT)

26 32

Warm-up Time: Less than 5 minutes (20°C)

First Copy Time:

3.1 seconds

(A4/81/2: x 11" sideways

from the 1st feed station)

Copy Number Input: Number keys, 1 to 999 (count up or count down)

Manual Image Density

7 steps

Selection:

Automatic Reset: 1 minute standard setti n g; can al so be set from 1

second to 999 seconds or no auto reset .

Copy Paper Capacity:

•

By-pass feed table: approximately 50 sh eets

•

Paper tray: approximately 550 sheets

•

Large capacity tray: approximately 1500

sheets

Toner Replenis hm e nt: 1,100 g/cartr i dg e

SM 1-3 A220

Page 20

SPECIFICATION

Optional Equipment: • Platen cover (A528-04)

• Dual job feeder (A610)

• Recirculating document handler (A607)

• 20 bin sorter stapler (Floor type) (A606-17:

Ricoh, -22: NRG, -15: Savin)

• Finisher (A608)

• 3500-sheet Larg e cap aci t y tr ay ( A6 09 )

• Receiving Tray (A446-05)

• Key Counter Bracket D (A509-03)

• 20 bin sorter stapler (Floor type) with punch

(A606-57, -67: Ricoh, -52, -62: NRG , -55:

Savin)

• Editing sheet (spare part)

A220 1-4 SM

Page 21

MACHINE CONFIGURATION

2. MACHINE CONFIGURATION

2.1 COPIER OVERVIEW

There are two types of ma i nf r ame.

A220 - (10, 17, 20, 29:) copiers

Three 550-sheet paper trays

Optional 3,50 0- sh ee t l arg e capacity

tray

550

(3,500)

550

Overall

Machine

Information

550

A220V500.img

A220 - (22: china) copier

Two 550-sheet paper trays

storage tray

Optional 3,50 0- sh ee t l arg e capacity

tray

550

550

(3,500)

storage

A220V501.img

SM 1-5 A220

Page 22

MACHINE CONFIGURATION

2.2 SYSTEM OVERVIEW

DJF version

(Mainframe type with dual job feeder and floor type sorter stapler. The

mainframe in the illustration below is the two-tray version.)

Floor type sorter

stapler (A60617,

22, 15) or Floor

type sorter stapler

with punch (A60 657,

67, 52, 62, 55)

Dual job feeder

(A610)

3,500-sheets

large capacity

tray (A609)

A220V502.img

RDH version

(The mainframe wit h r eci rc u l at i ng docum en t ha ndler and finisher.

The mainframe in the illustration below is the two-tray version.)

Finisher (A608)

Recirculating document handler (A607)

3,500-sheets

large capacity

tray (A609)

A220V503.img

A220 1-6 SM

Page 23

MECHANICAL COMPONENT LAYOUT

DRIVE LAYOUT

PAPER PATH

ELECTRICAL COMPONENT DESCRIPTION

MACHINE CONFIGURATION

4. MECHANICAL COMPONENT LAYOUT

5. DRIVE LAYOUT

6. PAPER PATH

As indicated in the machine configuration section, there are neither

1,500-sheet LCT or 4th feed station versions. Refer to the

A175/A176/A177/A191/A192 service manual by ignoring these feed stations.

7. ELECTRICAL COMPONENT DESCRIPTION

There are no 1,500-sheet LCT, 4th tray, tandem tray, 60 CPM, or 70 CPM

versions. Refer to the A175/A176/A177/A191/A192 service manual. You can

find those components, which are not used for the A220 copier bec ause the

notes for the various ver si o ns ar e indi ca te d i n th e com p on en t na m e colu m n.

The versions except for the A220-22 machine also have the following

components.

Overall

Machine

Information

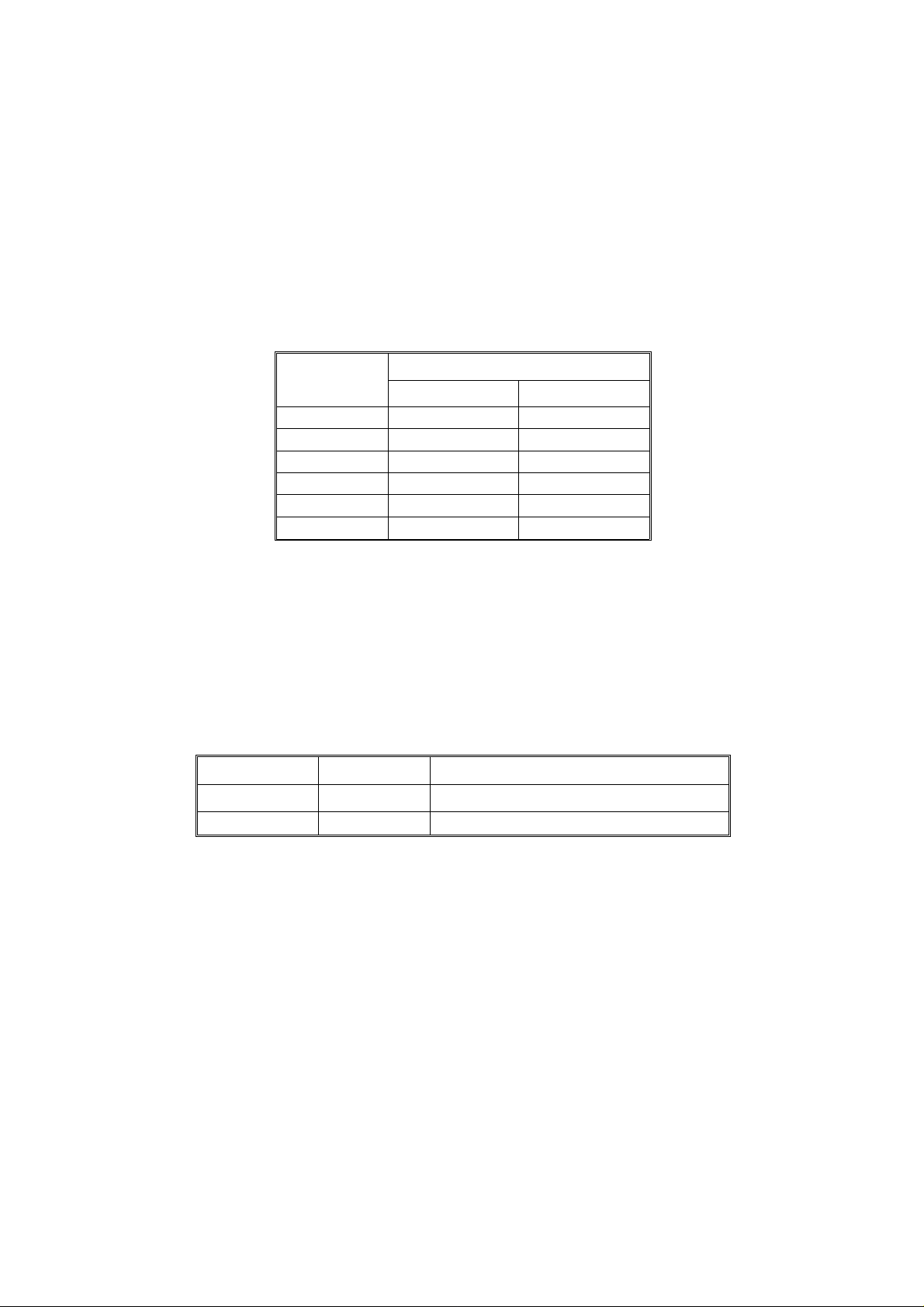

Symbol Name Function Index No.

M18

SW8 3rd Tray Set Detects if the 3rd tray is set or not. 84

S38

3rd Lift Raises the bottom plate in the 3rd

paper tray.

3rd Paper Near End Informs the CPU when the 3rd

cassette is in near end condition.

94

79

SM 1-7 A220

Page 24

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 25

DEVELOPMENT UNIT

4. DEVELOPMENT UNIT

Illustration Correction for the Paddle Roller (service manual page 2-46 and

2-48 of the A175/A176/A177/A191/A192 copiers)

The illustration for the paddle roller on page 2-46 and 2-48 is incorrect.

Please correct your service manuals, as shown below. This correction has

been already issued for the A175/A176/A177/A191/A192 copiers.

Incorrect

A220D502.wmf A220D503.wmf

Detailed

Descriptions

Correct

A220D504.wmf

A220D505.wmf A220D506.wmf

A220D507.wmf

SM 2-1 A220

Page 26

PAPER FEED

6. PAPER FEED

6.1 OVERVIEW

[B]

[A]

[B]

[A]

[C]

A220D500.wmf

This model has two or th ree dr aw e r t ray pa per feed stations.

The following table shows the configuration of each feed stations of the

copiers.

Feed station

1st 550 sheets tray 550 sheets tray

2nd 550 sheets universal tray 550 sheets universal tray

3rd 550 sheets tray storage tray

A220 - 10, 17, 20, 29

three tray copiers

A220 - 22

two tray copiers

Paper can also be fed using the by-pass feed table which has an

independent feed mechanism. The by-pass feed table can hold 50 sheets of

paper.

All feed stations use an FRR feed system. Rotation of the pick-up roller [A]

drives the top sheets of paper from each tray to the feed [B] and the

separation [C] rollers. The feed and separation rollers then take over paper

drive. If more than one sheet is fed by the pick-up roller, the separation rollers

rotates in the opposite direction and prevents all but the top sheet from

passing through to the registration rollers.

A220 2-2 SM

Page 27

6.8 PAPER LIFT MECHANISM

[F]

[D]

[E]

[B]

PAPER FEED

[A]

[C]

Detailed

Descriptions

A220D501.wmf

When the tray is set in the machine, the machine detects this condition by

using several detection m et ho ds as sho wn i n the ta bl e :

Feed station

1st Tray set switch

2nd Paper size switch

3rd Tray set switch (not used for storage tray version)

When the machine detects tha t th e pa pe r tray i s set in th e m achi ne , th e li ft

motor [A] rotat es an d th e cou pli n g ge ar [B ] on the tr ay l ift motor engages the

pin [C] of the lift arm shaft [D], then turns the tray lift arm [E] to lift the tray

bottom plate [F].

SM 2-3 A220

Page 28

ENERGY STAR COMPLIANT MACHINES (North American version only)

9. ENERGY STAR COMPLIANT MACHINES

(North American version only)

The lower power timer and the auto off periods have been revis ed.

Lower power timer: The copier enters Low Power mode automatically at the

selected time after your job is finished.

The maximum limit of the selectable time has been changed from 120

minutes to 240 minutes.

Auto off timer: To conserve energy, this copier automatically turns off at the

selected time after the last copying job has been comp let ed.

The maximum limit of the selectable time has been changed from 120

minutes to 240 minutes.

Refer to the A175/A176/A177/A191/A192 service manual for the other things.

A220 2-4 SM

Page 29

SECTION 3

INSTALLATION

Page 30

COPIER INSTALLATION

2. COPIER INSTALLATION

2.1 ACCESSORY CHECK

Check the quantity and condition of the access ories in the box according to

the following list:

Description Q’ty

1. Sensor Cover ................................................................... 1

2. Flat Head Screw 4 x 6...................................................... 1

3. Leveling Shoes................................................................. 2

Installation

SM 3-1 A220

Page 31

COPIER INSTALLATION

2.2 COPIER INSTALLATION PROCEDURE

NOTE:

Since the installation procedure is not packed with the copier as

an accessory, always bring this manual with you.

A220I500.wmf

Note: There are two types of

bottom plate. One has

two leveling feet [B]

installed. The other has

four leveling feet.

[B]

[A]

A220I501.wmf

CAUTION

When installing the copier, make sure that the copier is unplugged.

NOTE: Insert the leveling shoes [A] under the leveling feet [B] for the front

side, and level the machine before starting the installation. (The

leveling feet [B] can be screwed up or down.) Extra leveling shoes

(AH013008) and leveling feet (AH011004) are available as spare

parts.

1. Remove the tape strips.

NOTE: There are neither 1,500-sheet LCT or 4th feed station versions.

Refer to the A175/A176/A177/A191/A192 service manual for

installation.

A220 3-2 SM

Page 32

SECTION 4

SERVICE TABLES

Page 33

SERVICE REMARKS

1. SERVICE REMARKS

1.11 FUSING UNIT

The following remark is not written in the A175/A176/A177/A191/A192

service manual.

However, this remark has been added as a A175/A176/A177/A191/A192

copiers service remark by RTB.

5. Silicon oil may slightly soak into the surface of the hot roller during

machine storage. The silicon oil may stick to the surface of the pressure

roller when the hot roller was in contact with the pressure roller at

installation. The pressure roller may slip due to the oil because the hot

and pressure rollers are new. Therefore, the smeared image may appear

on the leading edge at about 10 mm on the 1st copy. This is because the

hot roller is rubbing the leading edge of the copy on the pressure roller.

This symptom occurs only at the 1st copy after installation. Make sample

copies and make sure that the symptom does not recu r aft er several

copies.

1.12 OTHERS

1. This machine has re-manufactured parts, which are selected from

dis-assembled machines in the Japanese do mest ic field . Not e that there

are old and new parts in the machine.

Tables

Service

SM 4-1 A220

Page 34

SERVICE PROGRAM MODE

2. SERVICE PROGRAM MODE

For service program mode operation, refer to the A175/A176/A177/A191/

A192 service manual.

[B]

[A]

A175M500.img

The A220-22 copier do es no t ha ve th e 3r d and 4th tr ays. The other A220

copiers do not have 4th tr ay. In the SP mode there are 3rd and 4th tray

settings [A,B] because the software is the same as for the A175/A176/

A177/A191/A192 copiers. Note that changing the unused tray settings in the

SP mode does not affect the machine.

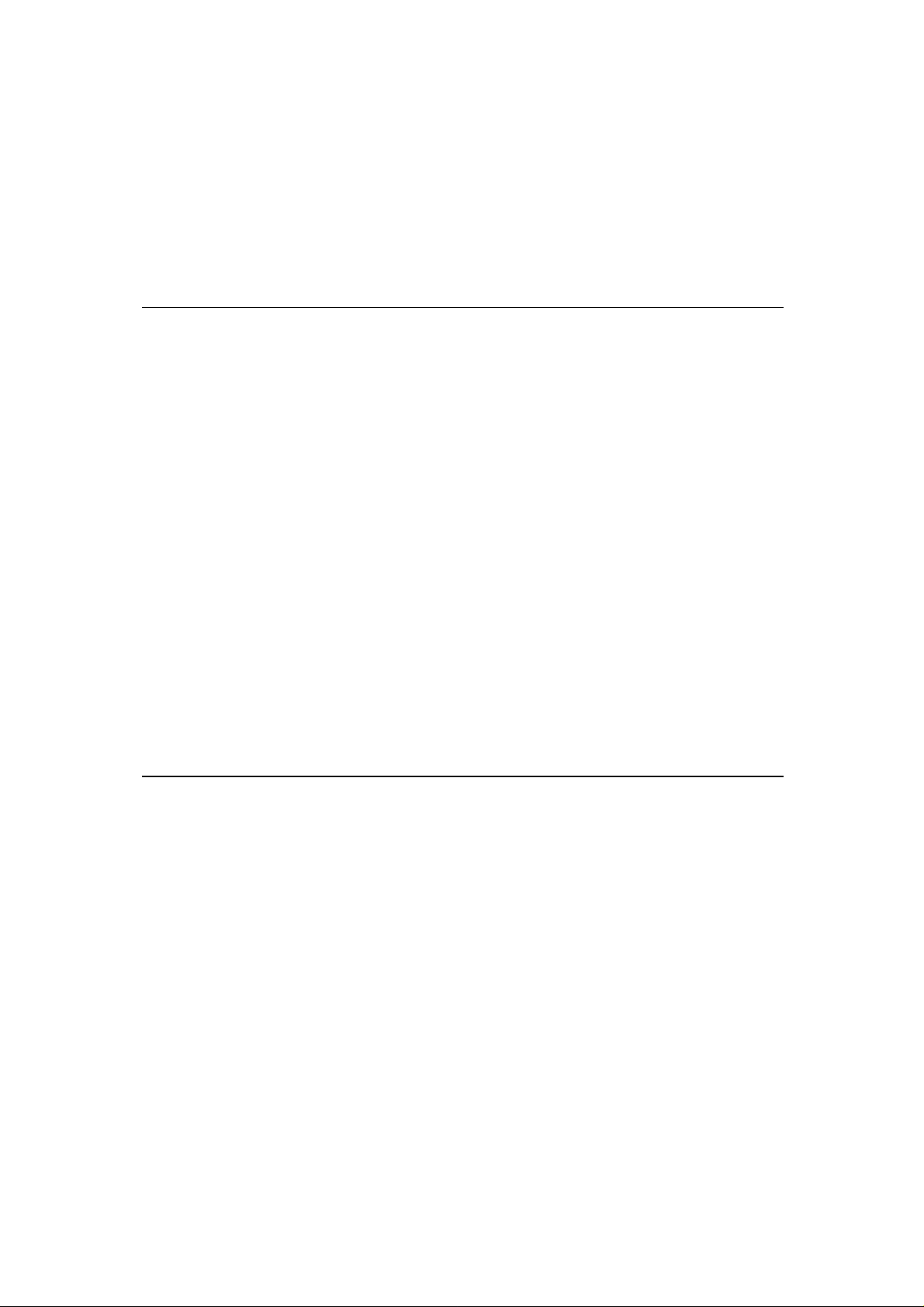

2.2 SERVICE PROGRAM MODE TABLE

Basically, the servi ce pr o gr a m mode table is the same as A175/A176/A177/

A191/A192 copier s.

The difference and corrected points from the A175/A176/A177/A191/A192

copiers are described as follows:

A220 4-2 SM

Page 35

1

SERVICE PROGRAM MODE

SP ADJUSTMENT

PAGE 7

û

A220M501.img

Item Function Note

❶

NOTE:

Changes the toner supply level in auto

and detect toner supply mode.

Default:

Toner Supply level L N H

Toner Supply Coeffcient x 0.3 x 0.5 x 1.0

Max. Toner Supply Ratio 30% 60% 90%

This item has been applied to the A175/A176/A177/A191/A192

Select "N" in the field.

copiers.

Tables

Service

SM 4-3 A220

Page 36

SERVICE PROGRAM MODE

1

SP ADJUSTMENT

PAGE 9

û

ù

ÿ

A220M502.img

Item Function Note

❶

❷

❸

NOTE:

Inputs the exposure lamp voltage when

auto process control is disabled or RAM

is cleared (0.5 V/step).

Default:

Adjusts the transfer current for the 1st

side (1 µA/step).

Default:

Adjusts the transfer current for the 2nd

side (1 µA/step).

Default:

65.0 V

40 µA (A175, A220)

50 µA (others)

50 µA (A175, A220)

55 µA (others)

7 has been added for all the versions (A175/A176/A177/A191/

❶

Enter the setting using the number keys,

then touch and 7.

Standard Data:

40 µA (A175, A220), 45 µA (others)

Enter the setting using the number keys,

then touch .

Standard Data:

50 µA (A175, A220), 55 µA (others)

Enter the data by using the number keys,

then touch .

A192/A220).

A220 information has been added.

❷ ❸

A220 4-4 SM

Page 37

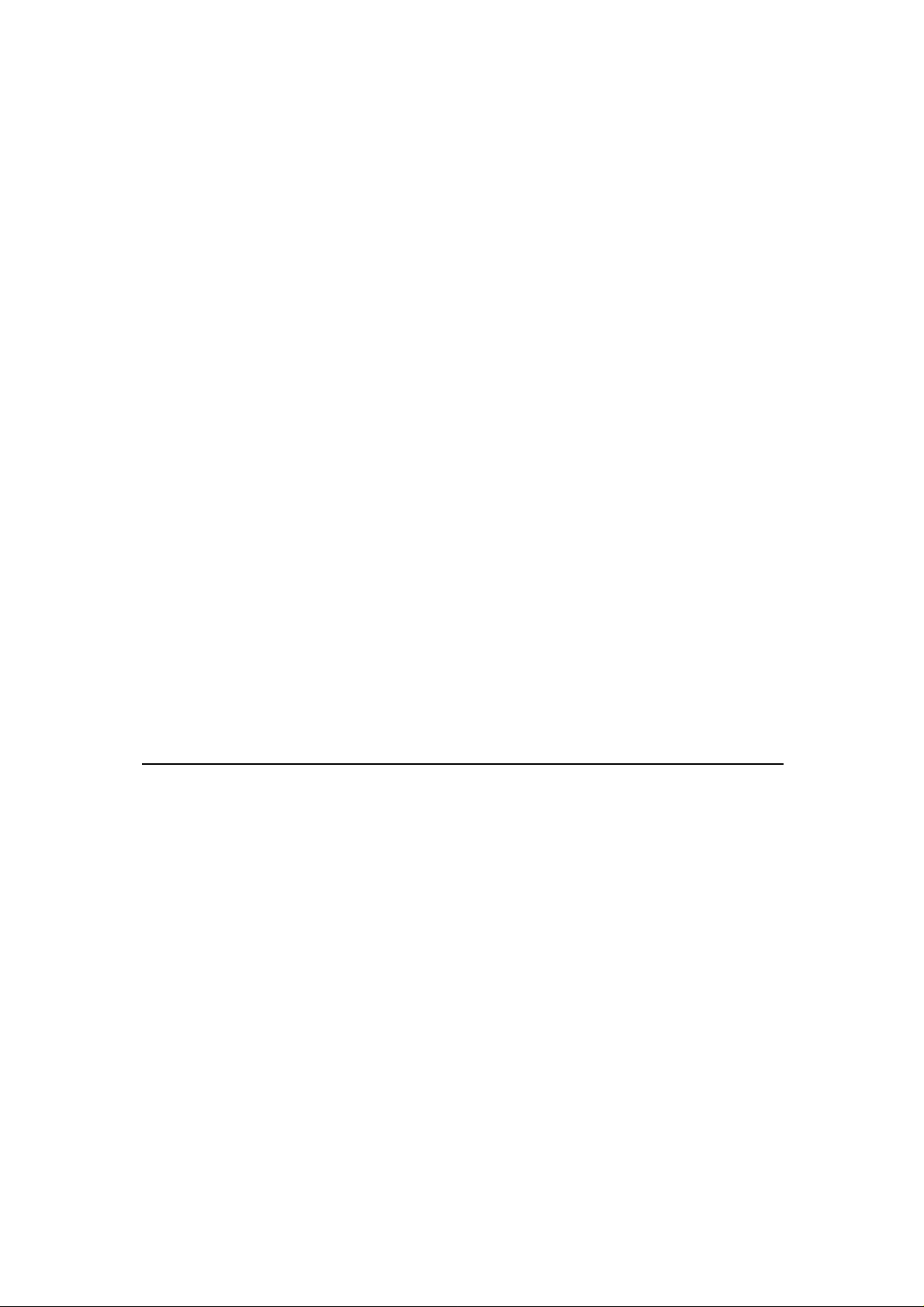

4

SERVICE PROGRAM MODE

SP SPECIAL FEATURES

PAGE 1

û

A220M503.img

Item Function Setting Default

Selects copy count up or down.

Count Up

❶

Count Down

NOTE:

The Default has been corrected for all the versions (A175/A176/A177/

A191/A192/A220).

Tables

Service

SM 4-5 A220

Page 38

SERVICE PROGRAM MODE

4

SP SPECIAL FEATURES

PAGE 3

û

ù

A220M504.img

Item Function Setting Default

❶

❷

NOTE:

Enables automatic sort mode selection

when 2 or more is entered in the copy

counter and an original is set on the DJF

feed tray.

Enables automatic feed-out of the last

copy on the duplex tray without copying

when an odd number of originals is set

on the DJF feed tray.

The Default has been correct ed for al l th e ver si o ns (A1 75 /

❶, ❷

Enable

Disable

Enable

Disable

A176/A177/A191/A192/A220).

A220 4-6 SM

Page 39

PREVENTIVE MAINTENANCE SCHEDULE

3. PREVENTIVE MAINTENANCE SCHEDULE

3.1 PM TABLE

Basically, PM items are the same with A175/A176/A177/A191/A192 copiers.

The following is the additional items and revised items from A175/A176/A177/

A191/A192 copier s.

NOTE:

The numbers mentioned for PM intervals indicate the number of

copies.

Symbol key: C: Clean R: Replace L: Lubricate I: Inspect

EM 120 k 240 k 360 k NOTE

OPTICS

Scanner Timing Belt Pulley

Shaft

DUPLEX

Duplex Drive Belt Tension I

Duplex Drive Belt Idle

Shaft and Gears

Duplex Paper End Sensor C C C *

FUSING/PAPER EXIT UNIT

Incorrect

Fusing Thermistor

Correct

Fusing Thermistor I I I Replace if necessary.

CCC

Lubricate with G501 (52039501) if

noise is excessive.

Lubricate with G501 (52039501) if

noise is excessive.

*Suitable solvent. Refer to NOTE

6.

The hot roller thermist or PM action has been revised. Please see th e

following table.

Tables

Service

*: These items have been revised for all the versions (A175/A176/A191/A192/

A220).

NOTE 6: Fusing Section

1. Do not apply silicone oil on the hot roller thermistor.

[A]

A220M505.wmf

SM 4-7 A220

Page 40

SECTION 5

REPLACEMENTS

AND ADJUSTMENTS

Page 41

4.5 CLEANING BLADE REPLACEMENT

[A]

DRUM UNIT

[G]

[C]

[D]

[H]

[B]

[E]

[C]

*NOTE:

A220R516.wmf

[F]

The callouts ([E] and [F]) have been added to the illustration for all

A220R517.wmf

the versions (A175/A176/A177/A191/A192/A220).

1. Remove the OPC drum. (Refer to Drum Unit Removal and OPC Drum

Replacement.)

2. Remove the cleaning blade [A] (2 screws).

3. Clean the entrance seal [B ], side sea l s [C] an d cl ea nin g bru s h [D] .

NOTE:

When a vacuum cleaner is used, to protect the electrical parts

from static electri city, disconnect the connector on the char g e

power pack and remove the ID sen s or as fo l low s:

1) Disconnect the 12P connector on the charge power pack [E] .

[F]

[I]

Replacement

and

Adjustments

2) Remove the screw [F] and separate the upper and the lower

drum units.

3) Remove the spur bracket [G] and pick-off pawl bracket [H] (2

screws).

4) Disconnect the connector [I].

5) While turning the bracket counterclockwise (front view), slide

the pick-off pawl bracket to the rear.

4. Install the new cleaning blade.

NOTE:

Do not clean the edge of the cleaning blade with cloth, otherwise

it damages the edge and caus es bla ck lin es on copy im ag es.

Do not touch the edge of the new cleaning blade, if some setting

powder or toner on the blade edge is removed, apply toner there.

When installing the cleaning blade, do not pinch the side seals.

SM 5-1 A220

Page 42

DRUM UNIT

4.7 PICK-OFF PAWL REPLACEMENT

[D]

[C]

[A]

[B]

A220R518.wmf

*NOTE:

Step1 has been added for all the versions (A175/A176/A177/A191/

A192/A220).

1. Remove the pick-o ff paw l br a cket. (Refer to Clean ing Bl ad e

Replacement.)

2. Remove the bushin g [A ] ( 1 scr ew and retaining ring) .

3. While pulling the shaft [B] to the rear, turn the pick-off pawl about 45

degree clockwise (front v iew) and move up the pick-off pawl.

4. Replace the pick-off pawl [C].

NOTE:

Do not forget to ho ok th e te nsi o n spr in g [D ] .

After replacement, check the smooth movement of the pick-off

pawl.

A220 5-2 SM

Page 43

6. PAPER FEED

6.18 NOTE for the PAPER FEED UNIT

PAPER FEED

-OLDBlue circle

A220R519.wmf

-OLD-

12.5 mm

-NEW-

7.5 mm

A220R520.wmf

There are two types of the paper feed unit. One type has a blue circle on its

rear side plate (A220 only).

Replacement

and

Adjustments

SM 5-3 A220

Page 44

FUSING UNIT

7.2 FUSING THERMISTOR REPLACEMENT

[B]

[C]

[A]

A220R521.wmf

[E]

1. Remove the fusing unit. (Refer to Fusing Unit Removal.)

2. Remove the knob [A] (1 screw).

3. Remove the two screws fixing the fusing front cover [B].

[D]

A220R522.wmf

4. Pull the lever [C] then lower the cover [B] to unhook the fusing unit.

5. Remove the fusing unit upper cover [D] (1 screw).

6. Replace the thermistor [E] (1 screw, 1 connector).

NOTE:

When re-assembling the fusing unit, secure the harness in the

clamps correctly.

Do not apply silicon oil on the hot roller thermister.

A220 5-4 SM

Page 45

7.8 FUSING PRESSURE ADJUSTMENT

FUSING UNIT

Rear

[A]

Front

A220R523.wmf

[B]

A220R524.wmf

NIP BAND WIDTH ADJUSTMENT STANDARD: 8.1 ± 0.8 mm (A175, A220),

10.0 ± 0.5 (others)

1. Make a black copy (sky shot, A3/Double Letter paper).

2. As soon as the paper star t s to exit, open the left door to sto p th e pa pe r in

the fusing unit.

3. Wait about 20 seconds, then turn the fusing knob quickly to deliver the

paper.

4. Measure the nip band width [A] at the center.

5. If the nip band width is not within 8.1 ± 0.8 mm, cha ng e th e spri n g ho ok

position [B ].

Replacement

and

Adjustments

SM 5-5 A220

Page 46

DUPLEX UNIT

8.5 JOGGER MOTOR REPLACEMENT

[E]

[G]

[B]

[C]

[D]

[A]

A220R503.wmf

[F]

A220R504.wmf

– A220 only –

1. Take out the duplex unit. (Refer to the duplex unit removal.)

2. Remove the duplex front cover (3 screws).

3. Slide the lever [A] to the rear then open the separation belt unit [B].

4. Remove the lower sepa rat i on guid e pla te [C ] (2 scr ews) .

5. Remove the pressure arm [D] (1 snap-ring).

6. Remove the harness cover [E] (1 screw).

7. Remove the two connectors [F].

8. Remove the upper stay [G ] ( 4 screw s, 1 conn ect or) .

A220 5-6 SM

Page 47

DUPLEX UNIT

[D]

[C]

[B]

[E]

[A]

A220R505.wmf

[G]

[F]

[G]

A220R506.wmf

9. Remove the positioning roller drive gear [A] (1 E-ring).

10. Remove the bushing [B] (1 E-ring).

11. Remove the positioning roller assembly [C].

12. Remove the front jogger fence [D] and the rear jogger fence [E] (1 screw

each).

Replacement

and

Adjustments

13. Remove the duplex tray [F] (3 screws and a connector).

NOTE: To release the hooks [G], slide the duplex tray to the upper left as

shown.

SM 5-7 A220

Page 48

DUPLEX UNIT

-NEW-

[C]

[A]

[A]

[B]

A220R507.wmf

[C]

-OLD[A]

[B]

[A]

A220R500.wmf

[H]

[F]

[G]

[I]

[J]

[H]

[E]

A220R508.wmf

14. Remove the drive wir e stop pe rs [A] .

NOTE: There are two types of the drive wire stoppers [A].

15. Unhook the tension spring [B] and remove the drive wire [C].

16. Remove the E-ring [D] and slide the shaft [E] to the left.

17. Remove the jogger motor bracket [F] (1 screw).

18. Remove the pressure arm solenoid [G] (1 screw).

19. Replace the jogger m ot or [H] (2 screws).

NOTE: When installing the drive pulley [I] to the jogger motor shaft, align

the shaft head [J] with the pulley head [H].

[D]

A220R509.wmf

20. Re-assemble the duplex unit.

A220 5-8 SM

Page 49

-NEW-

[D]

[A]

[C]

-OLD-

DUPLEX UNIT

[D]

[A]

[B]

[G]

-NEW-

[B]

A220R510.wmf

[I]

A220R511.wmf

A220R501.wmf

[E]

-OLD-

[I]

[C]

Replacement

and

Adjustments

[F]

[H]

A220R512.wmf

A220R502.wmf

- Jogger Drive Wire Installation -

1) Set the bead [A] which is closer to the red colored hook [B] in the hole

[C] and install the sto pp er [D] (1 screw).

2) Round the drive wire twice around the drive motor pulley [E] as shown.

3) Move the rear jogger fence bra cket [F] to the rear end position (until

the bracket [F] touches the screw [G]) and keep this condition.

4) Under the above condition, place the fron t jogger fence bracket [H] to

the front end positio n ( unti l th e br a cket [H ] to uch es the fr o nt screw ) .

5) Install the stopper [I] to fix th e fr o nt jogg er fe nce bracke t wi th the wire .

SM 5-9 A220

Page 50

DUPLEX UNIT

[D]

[E]

[H]

[F]

[G]

A220R513.wmf

[A]

[I]

[C]

[B]

A220R514.wmf

A220R515.wmf

NOTE: 1) Adjust the position of the stopper [A] so that the jogger fences [B]

and side plate [C] are parrallel.

2) When installing the jogger fences, confirm if the two positioning

pins [D] are correctly set in the two holes on the side fences after

the screw is set.

3) When installing the positioning roller assembly, insert the plate [E]

in the hole [F] on the rear frame , th en set the pla te on th e leve r [G] .

4) When installing the rear paper press mylar, set the hook [H] to the

rear jogger fence [I] as shown so that the mylar moves together

with the jogger fence [I].

5) After installing the jogger fences, manually move the jogger fences

[I] to confirm that they move smoothly.

6) After re-assembling the duplex unit, manually pull the plungers of

the positioning roller solenoid and the pressure arm solenoid to

confirm that the posit ion i ng ro ll er asse m bly an d th e pr e ssure ar m

move up and down correctly.

7) After re-assembling the duplex unit, adjust the jogger fence width

so that the distance between both side fences become 1 mm wider

than the paper size, when paper is set on the duplex tray.

(

SP Adjustment - PAGE 10.)

.

A220 5-10 SM

Loading...

Loading...