Page 1

Technical Bulletin No. RTB-001

SUBJECT: Service Manual Correction DATE: March 31. ’94

PAGE: 1 of 4

PREPARED BY: S. Orita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Please correct your service manual as follows:

1. Page 4-13

Incorrect

Mode No. Function Data

1 ADF

Destination

Revision of service manual

Information only

Other

Selects metric size or letter for Auto

Paper Select (APS) and Auto

Reduce/Enlarge (ARE) with ADF.

FROM: 2nd Technical Support Section

DF must be installed on the machine.

In APS and ARE functions with ADF,

the metric size and letter size do not

function together.

MODEL: KITE (A121)

0: Metric Size

1: Letter Size

Correct

1 ADF

Mode No. Function Data

Destination

Selects metric size or letter for Auto

Paper Select (APS) and Auto Reduce

Enlarge (ARE) with ADF.

1. DF must be installed on the

machine.

0: Metric Size

1 Letter Size

("1" is the default

for A121-12

machines.)

2. In APS and ARE functions with

ADF, the metric size and letter size

do not function together.

3. When "0" is selected, the data of

SP25 should be selected "0", "2",

"3", "4", or "5". When "1" is

selected, the data of SP25 should

be selected "1".

4. After changing the data from "0" to

"1" or from "1" to "0", the main

switch must be turned off and on.

Page 2

Technical Bulletin No. RTB-001

SUBJECT: Service Manual Correction DATE: March 31, ’93

PAGE: 2 of 4

2. Page 4-14

Incorrect

Mode No. Function Data

°16

Correct

Count Up/Down Selects count up or count down 0: Up

1: Down

Mode No. Function Data

°16

Count

Up/Down

Selects count up or count down 0: Up

1: Down

("1" is the default

for A121-12

machines)

Page 3

Technical Bulletin No. RTB-001

SUBJECT: Service Manual Correction DATE: March 31, ’93

PAGE: 3 of 4

3. Page 4-15

Incorrect

Mode No. Function Data

25 Original Size

Selection

(APS)

Selects the detectable original size in

APS or ARE modes without ADF.

0: A3, B4, A4, A4R

1: 11" x 17", 81/2" x 14", 11" x 81/2",

81/2" x 11"

2: A3, A4R, B5R, B5

3: A4R, 267 mm x 390 mm, 267 mm x

195 mm, 195 mm x 267 mm

4: B4, A4R, B5R, B5

5: A3, B4, A4, A4R, B5R, B5

Note

1. When "2", "3", or "4" is selected, the

positions of the original width and

length sensors should be changed.

2. When "5" is selected, the additional

original width sensor should be

added.

0 ~ 5

Correct

Mode No. Function Data

25 Original size

Selection (APS)

Selects the detectable original size in

APS or ARE modes without ADF.

0: A3, B4, A4, A 4R

1: 11" x 17", 8 1/2" x 14", 11" x 81/2",

81/2" x 11"

2: A3, A4R, B5R, B5

3: A4R, 267 mm x 390 mm, 267 mm x

195 mm, 195 mm x 267 mm

4: B4, A4R, B5R, B5

5: A3, B4, A4, A4R, B5R, B5

Note

1. When "2 , "3", or "4" is selected, the

positions of the original width and

length sensors should be changed.

2. When "5" is selected, the additional

original width sensor should be

added.

0 ~ 5

("1" is the default for

A121-12 machines.)

Page 4

Technical Bulletin No. RTB-001

[I]

SUBJECT: Service Manual Correction DATE: March 31, ’93

PAGE: 4 of 4

4. Page 5-10 (1.7 SCANNER MOTOR REPLACEMENT)

Incorrect

10. Install the new scanner motor and reassemble.

NOTE: a) When installing the scanner motor, make sure the 3p connector is

positioned on the left-hand side.

b) Make sure that the scanner motor is positioned at the point where the drive

belt is tightened by the tension spring.

11. Examine the scanner drive wire for proper installation.

Correct (From step 1 to 9 are not changed)

10. Remove the motor cushion [H], pulley [I], and fly wheel [J] from the scanner motor [K]

(2 screws and 2 hexagon headless screws)

11. Install the new scanner motor and reassemble.

NOTE: a) When reinstalling the fly wheel, adjust the gap between the fly wheel and

the scanner motor to 3.5 ± 0.5 mm as shown.

b) When installing the scanner motor, make sure the 3p connector is

positioned on the left-hand side.

c) Make sure that the scanner motor is positioned at the point where the drive

belt is tightened by the tension spring.

12. Examine the scanner drive wire for proper installation.

[H]

3.5 ± 0.5 mm

[K]

[J]

Page 5

Technical Bulletin No. RTB-002

SUBJECT: Clear Counter Problem (SP98) DATE: March 31. ’94

PAGE: 1 of 2

PREPARED BY: S. Orita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

[Phenomenon]

When SP98 (Clear Counters) is performed, the copy counters for SP90 (for toner overflow

detection) and SP92 (for oil end detection) are cleared.

NOTE: SP98 normally clears the following counters:

• SP100 (1st Feed Station Copies)

• SP101 (2nd Feed Station Copies)

• SP102 (3rd Feed Station Copies)

• SP103 (DF Originals)

• SP120 (Total Service Calls)

• SP121 (Optics Section Service Calls)

• SP122 (Exposure Lamp Service Calls)

• SP123 (Drum Thermistor Service Calls)

• SP124 (Fusing Section Service Calls)

• SP130 (Total Misfeeds)

• SP131 (Number of Misfeeds by Location)

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: KITE (A121)

[Cause]

Software problem

[Solution]

To prevent SP90 and SP92 from being cleared by SP98, the ROM has been changed

from P/N A1215343B to P/N A1215343C.

NOTE: P/N A12153 43B was installed from the start of mass-production.

The cut-in serial numbers for the new ROM (R/N A1215343C) are as follows:

Machine Code Cut-in Serial Number

A121-10 155403X XXX

A121-11 004403X XXX

A121-12 1544020 001

A121-19 A3574020001

A121-20 1534020 001

A121-29 A3574020037

Page 6

Technical Bulletin No. RTB-002

SUBJECT: Clear counter Problem (SP98) DATE: March 31, ’94

PAGE: 2 of 2

[Required Action]

The following procedure is required when the SP98 is performed with machines which

have the old ROM (P/N A1215343B).

1. Fill the oil tank with silicone oil until the "max" line.

2. Empty the toner collection bottle.

3. Turn the main switch off and on.

4. Select SP83 and enter "1" to clear the memory counters for the toner overflow detection.

NOTE: Although SP98 is performed with the old ROM (P/N A1215343B), SP91 (toner end

counter for toner over flow detection) does not clear. Therefore, it is necessary to

perform SP83 after disposing of the toner in the used toner tank.

Page 7

Technical Bulletin No. RTB-003

SUBJECT: Add Toner Indicator does not turn off DATE: May 31, ’95

PAGE: 1 of 3

PREPARED BY: N. Kaiya

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Problem

The Add Toner indicator does not turn off even after replenishing the toner cartridge.

Estimated Cause

So far, we do not have sufficient field information to identify the real cause of the problem.

However, we have reviewed the control software of the machine and found the following

estimated cause;

In order to prevent the customer from resetting the toner end condition by simply opening

and closing the front door, the CPU checks Vsg/Vsp after it detects that the front door

haws been opened and closed. If Vsg is around 2.5V, the CPU may detect Vsg as Vsp,

and the toner end condition is not recovered.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

KITE (A121)

Countermeasure

The toner end recovery procedure in the software has been modified. Vsp checking after

toner replenishment is no longer performed. However, Vsg is still checked, and if it is less

than 2.5V, the CPU determines that the detected data is abnormal. It then changes from

detect supply mode to fixed supply mode. The amount of toner added is determined by

the data in SP Mode No. 32.

Please note that if Vsg is around 2.5V, most probably the ID sensor is dirty and needs

cleaning. In addition, it is necessary to find out and remove the reason for the ID sensor

getting dirty.

Action in the field

This problem may happen only if Vsg is around 2.5V. Therefore it is necessary to check

for the following to make sure that Vsg will be maintained in a good range.

1. Check for high toner density or toner scattering. If necessary, follow the troubleshooting

procedures in the service manual.

2. If the meter reading is reaching the PM cycle, perform PM.

3. Clean the ID sensor and adjust Vsg to 4.0 ± 0.2V.

4. Replace the Main Board ROM (P/N A1215343) to suffix G.

Page 8

Technical Bulletin No. RTB-003

SUBJECT: Add Toner Indicator does not turn off DATE: May 31, ’95

PAGE: 2 of 3

Production Machines

New ROMs are used from the following serial numbers.

S/N

NOTE: In order for us to further investigate this problem, please fill in the attached

questionnaire and return to us in case you meet this problem in the field.

CODE SERIAL NUMBER

A121-10 155502XXXX

A121-11 004502XXXX

A121-12 1545010001

A121-19 A3575030001

A121-20 1535010001

A121-29 A3574120623

A121-50 8395030001

Page 9

Technical Bulletin No. RTB-003

SUBJECT: Add Toner Indicator does not turn off DATE: May 31, ’95

PAGE: 3 of 3

FT4495

QUESTIONNAIRE OF ADD TONER INDICATION STAYS ON.

DISTRIBUTOR’S NAME: COUNTRY:

REPORTED BY: CUSTOMER’S NAME:

MACHINE SERIAL No.: METER READ:

REPORT DATE: OCCURRENCE DATE:

MAIN BOARD ROM No.:

1. During the toner recovery, did the main motor and toner supply clutch turn on?

YES NO

2. What are the Vsp/Vsg values while the toner end indication is on? (Check with SP55)

Vsp: (not pressing the "0" key in SP55)

Vsg: (pressing the "0" key in SP55)

3. Did you have a charge leakage problem before?

YES NO

Please check the answers to the following questions with your customers.

6. Whether the toner cartridge still has toner or not when the toner indication is on?

Yes, it has toner. No, it has not.

7. Did you install a new toner cartridge for toner end recovery?

YES NO

8. Did the customer add toner at the "toner near end" or "toner end" condition?

"Toner near end" "Toner end"

9. Is the toner a Ricoh product? (The toner used in the machine which has a problem.)

YES NO

(Ricoh Lot No. ) (Name of the o ther manu facturer : )

Page 10

Technical Bulletin No. RTB-004

SUBJECT: Improper Used Toner Collection DATE: May 31, ’95

PAGE: 1 of 2

PREPARED BY: N. Kaiya

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Problem

Used toner builds up in the front side of the toner collection bottle. Used toner is tightly

packed in the neck of the toner collection bottle. This may result in damage to the toner

collection coil. The problem appears before the PM cycle when the technician has to

empty the used toner collection bottle.

Cause

Vibration of the toner collection bottle is not sufficient. When the toner collection bottle is

moved from front to rear by the vibration mechanism, the rear side of the bottle is pushed

against the cushion (P/N A1211077) which is provided to absorb the vibration noise. The

amount of bottle vibration is slightly different from machine to machine depending on the

position of the cushion and its condition. In the worst case, the amount of collection bottle

vibration is not sufficient to keep the used toner in the bottle level.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

KITE (A121)

Action in the Field

Attach a newly prepared 2 mm thick spacer (P/N A1213670) to the rear of the toner

collection bottle. By adding this seal, the bottle will be pushed more strongly against the

spring (P/N AA063119), and the amount of bottle vibration will be increased.

Procedures

1. Remove the toner collection bottle.

2. Remove the used toner inside the toner collection bottle.

3. Clean the rear side of the toner collection bottle.

4. Attach the seal to the rear side of the toner collection bottle as shown in the diagram.

5. Reinstall the toner collection bottle.

6. Hold the neck of the bottle and shake it back and forth several times to loosen the

movement of the toner collection bottle.

Page 11

Technical Bulletin No. RTB-004

SUBJECT: Improper Used Toner Collection DATE: May 31, ’95

PAGE: 2 of 2

Spacer - Collection Bottle

(P/N A1213670)

For the cut-in serial number, please refer to MB No. 13.

Page 12

Technical Bulletin No. RTB-005

SUBJECT: Toner Overflow Sensor DATE: May 31, ’96

PAGE: 1 of 2

PREPARED BY: N. Kaiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This RTB explains how to install the add toner overflow sensor to detect the toner

collection bottle full condition.

Necessary Parts

Part

Number

52153818 Toner Overflow Sensor Assembly 1

11050120 Wire Clip 1

11050196 Harness Clamp 3

A0096001 Harness - Toner Overflow Sensor 1

Description Quantity

Revision of service manual

Information only

Other

FROM: 1st Field Information Dept. QAC

MODEL:

Kite

A121

Procedure

1. Remove the Toner Collection Bottle Cap from the Toner Collection Bottle and

attach the Toner Overflow Sensor to the Toner Collection Bottle.

2. Install the Wire Clip and Three Harness Clamps as shown in the figure.

3. Route the Harness - Toner Overflow Sensor as shown in the figure.

4. Set SP Mode no.81 to 1

Note : SP Mode NO.81 changes the method of detecting the toner collection bottle

full condition. When the setting is "0", the toner collection bottle full condition

is detected by copy quantity and number of toner end conditions. When the

setting is "1", the toner collection bottle full condition is detected by the toner

overflow sensor.

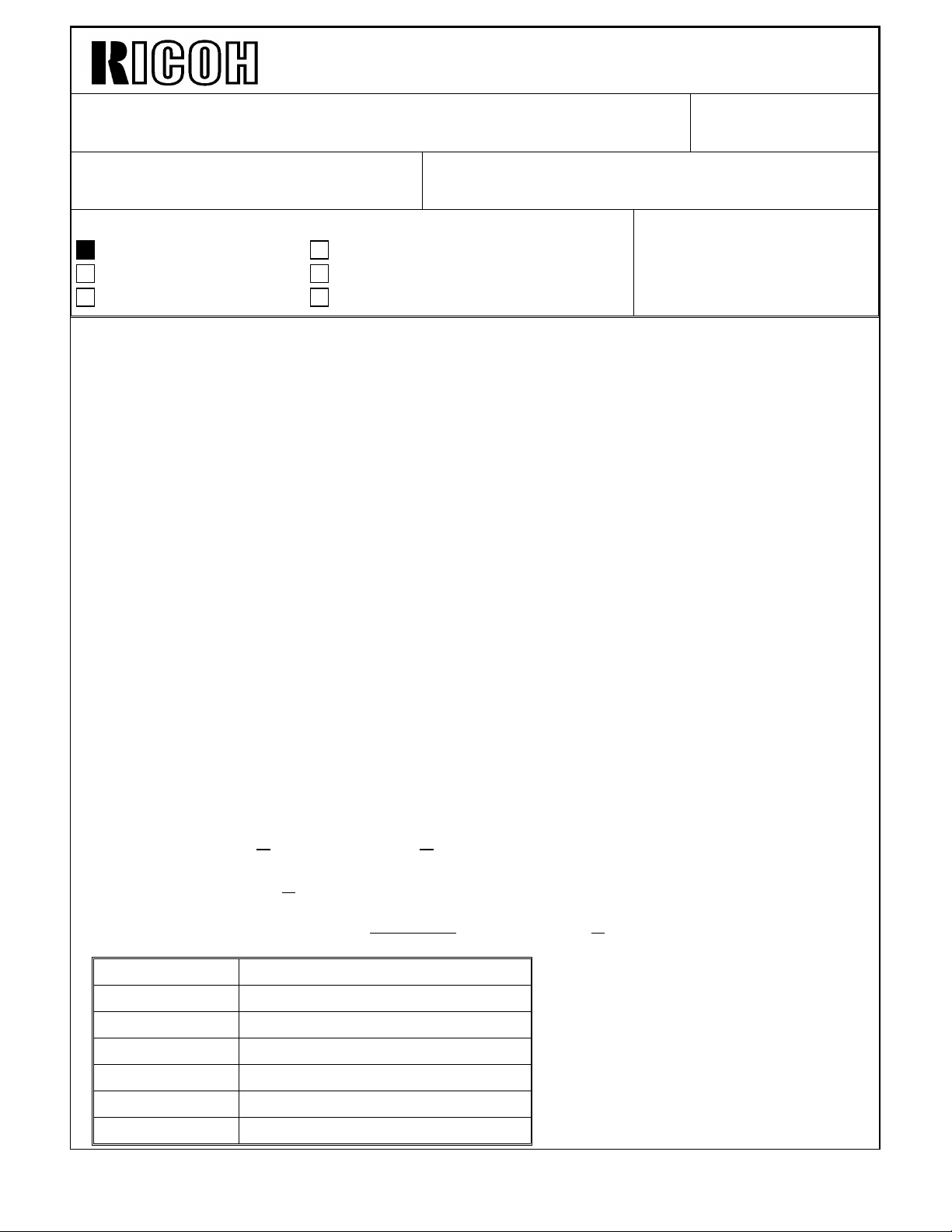

Page 13

Technical Bulletin No. RTB-005

Toner Overflow

Sensor Ass’y

(P/N 52153818)

SUBJECT: Toner Overflow Sensor DATE: May 31, ’96

PAGE: 2 of 2

Wire Clip

(P/N 110501 20)

Harness Clamp

(P/N 11050196)

Harness - Toner

Overflow Sensor

(P/N A0096001)

Page 14

Technical Bulletin No. RTB-006

SUBJECT: Oil End Sensor DATE: May 31, ’96

PAGE: 1 of 1

PREPARED BY: N. Kaiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This RTB explains how to install the oil end sensor to detect the oil end condition.

Necessary Parts

Part Number Description Quantity

52095320 Oil End Sensor 1

52154411 Spring Plate 1

04340080W Tapping Screw - M4x8 1

Procedure

1. Install the oil end sensor on the silicone oil bottle as shown in the figure.

2. Place the spring plate on the oil end sensor and fix it with the tapping screw M4 - 8.

Revision of service manual

Information only

Other

FROM: 1st Field Information Dept. QAC

MODEL:

Kite

A121

3. Connect the oil end sensor connector.

4. Set SP mode no.82 to 1.

Note : SP Mode NO.82 changes the method of detecting oil end conditions. When

the setting is "0", the oil end condition is detected by copy quantity. When the

setting is "1", the oil end condition is detected by the oil end sensor. After

installing the oil end sensor, if the SP mode is not changed to 1, oil end

detection will not be performed.

Tapping Screw

(P/N 043400 80W)

Spring Plate

(P/N 521544 11)

Oil End Sensor

(P/N 52095320)

Loading...

Loading...