Ricoh A 120, A 1013, A 1013F Service Manual

RICOH GROUP COMPANIES

B044/B045/B046

SERVICE MANUAL

001209MIU

SERVICE MANUAL

B044/B045/B046

RICOH GROUP COMPANIES

B044/B045/B046

SERVICE MANUAL

001209MIU

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use of

any trade name, or web site is intended to convey endorsement or other

affiliation with Ricoh products.

2001 RICOH Corporation. All rights reserved.

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Corporation. Users of this

manual should be either service trained or

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Corporation

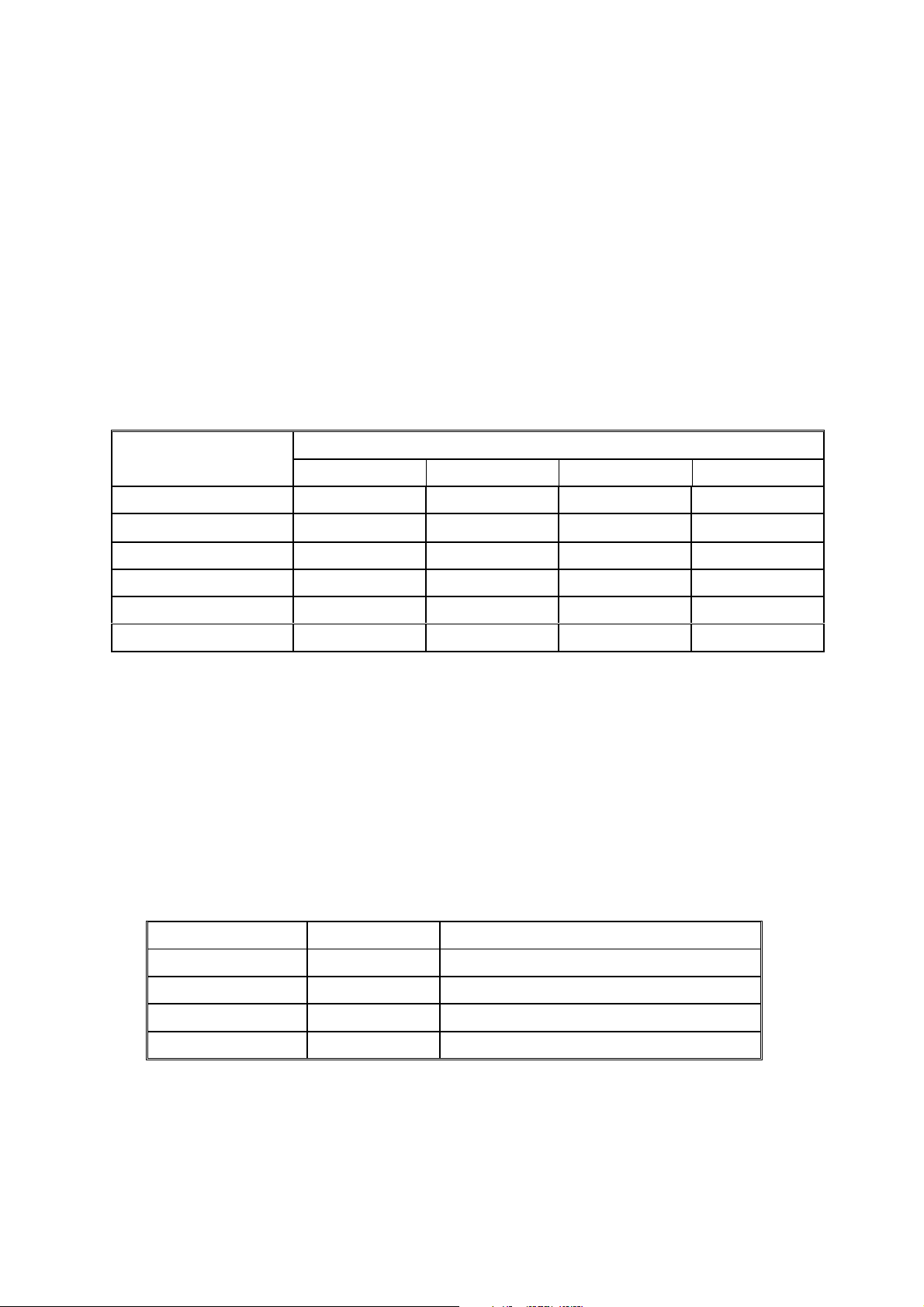

LEGEND

COMPANYPRODUCT CODE

GESTETNER LANIER RICOH SAVIN

B044 1302 5613 Aficio 1013 2513

B045

B046 1302f 5613F Aficio 1013f 2513f

−

Aficio 120

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

* 10/2001 Original Printing

−

B044/B045/B046

TABLE OF CONTENTS

INSTALLATION

1 INSTALLATION ........................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS ...........................................................1-1

1.1.1 ENVIRONMENT ...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-2

1.1.3 MINIMUM OPERATIONAL SPACE REQUIREMENTS ....................1-2

1.1.4 POWER REQUIREMENTS ..............................................................1-3

1.2 COPIER.....................................................................................................1-4

1.2.1 ACCESSORY CHECK......................................................................1-4

1.2.2 INSTALLATION PROCEDURE ........................................................1-4

Initial Programming: Faxless models (B044, B045).............................1-8

Initial Programming: Fax-equipped models (B046)..............................1-8

1.3 PAPER TRAY UNIT ................................................................................1-10

1.3.1 ACCESSORY CHECK....................................................................1-10

1.3.2 INSTALLATION PROCEDURE ......................................................1-10

1.4 PAPER TRAY UNIT HEATER.................................................................1-12

1.4.1 ACCESSORY CHECK....................................................................1-12

1.4.2 INSTALLATION PROCEDURE ......................................................1-12

1.5 DOCUMENT FEEDER ............................................................................1-17

1.5.1 ACCESSORY CHECK....................................................................1-17

1.5.2 INSTALLATION PROCEDURE ......................................................1-17

1.6 DIMM.......................................................................................................1-21

1.6.1 INSTALLATION PROCEDURE ......................................................1-21

PREVENTIVE MAINTENANCE

2 PREVENTIVE MAINTENANCE SCHEDULES............................. 2-1

2.1 PM TABLES ..............................................................................................2-1

2.2 HOW TO CLEAR THE PM COUNTER......................................................2-2

REPLACEMENT AND ADJUSTMENT

3 REPLACEMENT AND ADJUSTMENT......................................... 3-1

3.1 PRECAUTIONS.........................................................................................3-1

3.1.1 GENERAL ........................................................................................3-1

3.1.2 LITHIUM BATTERIES ......................................................................3-1

3.1.3 PCU (PHOTOCONDUCTOR UNIT) .................................................3-1

3.1.4 TRANSFER ROLLER.......................................................................3-1

3.1.5 SCANNER UNIT...............................................................................3-2

3.1.6 LASER UNIT ....................................................................................3-2

3.1.7 FUSING UNIT...................................................................................3-2

SM i B044/B045/B046

3.1.8 PAPER FEED...................................................................................3-2

3.1.9 IMPORTANT ....................................................................................3-3

3.2 SPECIAL TOOLS AND LUBRICANTS ......................................................3-3

3.3 EXTERIOR COVER AND OPERATION PANEL .......................................3-4

3.3.1 PLATEN COVER..............................................................................3-4

3.3.2 REAR COVER..................................................................................3-4

3.3.3 COPY TRAY.....................................................................................3-5

3.3.4 SCALE PLATE (B044 AND B045 ONLY) .........................................3-5

3.3.5 LEFT COVER ...................................................................................3-6

3.3.6 RIGHT COVER.................................................................................3-6

3.3.7 FRONT LEFT COVER AND OPERATION PANEL ..........................3-6

3.3.8 FRONT RIGHT COVER ...................................................................3-6

3.3.9 RIGHT DOOR...................................................................................3-7

3.3.10 BYPASS TRAY (B044 AND B046 ONLY) ......................................3-7

3.3.11 PLATEN COVER SENSOR............................................................3-8

3.4 SCANNER SECTION................................................................................3-9

3.4.1 EXPOSURE GLASS.........................................................................3-9

Non-DF machines.................................................................................3-9

DF-equipped machines.........................................................................3-9

3.4.2 LENS BLOCK .................................................................................3-10

3.4.3 EXPOSURE LAMP, LAMP STABILIZER BOARD ..........................3-10

3.4.4 SCANNER MOTOR........................................................................3-11

3.4.5 SCANNER HP SENSOR................................................................3-11

3.4.6 SCANNER ALIGNMENT ADJUSTMENT .......................................3-12

3.5 FUSING...................................................................................................3-13

3.5.1 FUSING UNIT.................................................................................3-13

3.5.2 EXIT SENSOR ...............................................................................3-13

3.5.3 HOT ROLLER STRIPPER PAWLS ................................................3-14

3.5.4 HOT ROLLER & FUSING LAMP ....................................................3-15

3.5.5 THERMOFUSE, THERMOSWITCH, AND THERMISTOR.............3-15

3.5.6 PRESSURE ROLLER.....................................................................3-16

3.6 PCU.........................................................................................................3-17

3.7 TONER SUPPLY CLUTCH .....................................................................3-18

3.8 PAPER FEED SECTION.........................................................................3-19

3.8.1 PAPER FEED ROLLER AND FRICTION PAD...............................3-19

3.8.2 PAPER END SENSOR...................................................................3-19

3.8.3 REGISTRATION SENSOR.............................................................3-20

3.8.4 BYPASS PAPER END SENSOR (B044 AND B046 ONLY) ...........3-20

3.8.5 BYPASS FEED ROLLER (B044 AND B046 ONLY) .......................3-21

3.8.6 BYPASS FEED CLUTCH (B044 AND B046 ONLY).......................3-22

3.8.7 BYPASS FRICTION PAD (B044 AND B046 ONLY).......................3-22

3.8.8 REGISTRATION CLUTCH .............................................................3-22

3.8.9 PAPER FEED CLUTCH .................................................................3-23

3.9 IMAGE TRANSFER.................................................................................3-24

3.9.1 IMAGE TRANSFER ROLLER ........................................................3-24

3.9.2 ID (IMAGE DENSITY) SENSOR ....................................................3-24

3.9.3 DISCHARGE PLATE......................................................................3-25

3.10 FUNCTION CONTROL UNIT (FCU) .....................................................3-25

3.11 LASER UNIT .........................................................................................3-27

B044/B045/B046 ii SM

3.11.1 LOCATION OF “CAUTION” DECAL ............................................3-27

3.11.2 PSU BRACKET ............................................................................3-28

3.11.3 LASER UNIT ................................................................................3-29

3.11.4 LD UNIT........................................................................................3-29

3.11.5 POLYGON MIRROR MOTOR ......................................................3-29

3.12 OTHER REPLACEMENTS....................................................................3-30

3.12.1 QUENCHING LAMP.....................................................................3-30

3.12.2 HIGH-VOLTAGE POWER SUPPLY BOARD ...............................3-30

3.12.3 PSU ..............................................................................................3-30

3.12.4 MAIN MOTOR ..............................................................................3-31

3.12.5 EXHAUST FAN ............................................................................3-31

3.13 COPY IMAGE ADJUSTMENTS: PRINTING/SCANNING .....................3-32

3.13.1 PRINTING ....................................................................................3-32

Registration - Leading Edge/Side-to-Side...........................................3-32

Blank Margin.......................................................................................3-33

Main-Scan Magnification.....................................................................3-33

3.13.2 SCANNING...................................................................................3-34

Registration: Platen Mode...................................................................3-34

Magnification.......................................................................................3-34

Standard White Density Adjustment ...................................................3-35

3.13.3 DF IMAGE ADJUSTMENT ...........................................................3-36

Registration and Blank Margin............................................................3-36

Sub-scan Magnification.......................................................................3-36

TROUBLESHOOTING

4 TROUBLESHOOTING ................................................................. 4-1

4.1 SERVICE CALL CONDITIONS .................................................................4-1

4.1.1 SUMMARY .......................................................................................4-1

4.1.2 SC CODE DESCRIPTIONS .............................................................4-2

4.2 ELECTRICAL COMPONENT DEFECTS ..................................................4-7

4.2.1 SENSOR/SWITCH OPEN ERRORS................................................4-7

4.3 BLOWN FUSE CONDITIONS ...................................................................4-7

4.4 DUMPING THE FUSER TEMPERATURE LOG........................................4-8

SERVICE TABLES

5 SERVICE TABLES....................................................................... 5-1

5.1 USING SERVICE PROGRAM MODE .......................................................5-1

Accessing SP Mode..............................................................................5-1

Accessing Copy Mode from within SP Mode ........................................5-1

How to Select a Program Number ........................................................5-2

To Input a Value or Setting ...................................................................5-2

5.1.1 SP MODE TABLES ..........................................................................5-3

SP1-XXX (Feed) ...................................................................................5-3

SP2-XXX (Drum)...................................................................................5-4

SP4-XXX (Scanner) ..............................................................................5-9

SM iii B044/B045/B046

SP5-XXX (Mode) ................................................................................5-14

SP6-XXX (Peripherals) .......................................................................5-18

SP7-XXX (Data Log)...........................................................................5-19

5.1.2 TEST PATTERN PRINTING (SP5-902) .........................................5-23

5.1.3 INPUT CHECK (SP5-803)..............................................................5-24

Input Check Table...............................................................................5-24

5.1.4 OUTPUT CHECK (SP5-804)..........................................................5-25

Input Check Table...............................................................................5-25

5.1.5 SMC PRINTING (SP5-992) ............................................................5-26

5.1.6 MEMORY ALL CLEAR (SP5-801)..................................................5-27

5.1.7 FREE RUNS...................................................................................5-28

5.1.8 PROGRAM UPLOAD/DOWNLOAD ...............................................5-29

Program Download (SP5-827)............................................................5-29

Program Upload (SP5-826) ................................................................5-31

5.1.9 SRAM DATA UPLOAD/DOWNLOAD.............................................5-32

SRAM Data Upload (SP5-824) ...........................................................5-32

SRAM Data Download (SP5-825).......................................................5-33

5.1.10 SERIAL NUMBER INPUT (SP5-811) ...........................................5-33

5.1.11 ID SENSOR ERROR ANALYSIS (SP2-221) ................................5-34

5.1.12 MEMORY READ/WRITE..............................................................5-35

5.2 USER TOOLS .........................................................................................5-36

5.2.1 HOW TO ENTER AND EXIT USER TOOLS ..................................5-36

5.2.2 USER TOOLS TABLE ....................................................................5-36

System Settings Table........................................................................5-36

Copy Features Table ..........................................................................5-36

DETAILED SECTION DESCRIPTIONS

6 DETAILED SECTION DESCRIPTIONS ....................................... 6-1

6.1 OVERVIEW ...............................................................................................6-1

6.1.1 COMPONENT LAYOUT...................................................................6-1

6.2 PAPER PATH............................................................................................6-5

6.3 DRIVE LAYOUT ........................................................................................6-6

6.4 BLOCK DIAGRAM: PCBS AND COMPONENTS......................................6-7

6.5 MAIN PCBS...............................................................................................6-8

6.5.1 FCU (FUNCTION/FACSIMILE CONTROL UNIT).............................6-8

SPC2 ....................................................................................................6-9

VPL (Video Processing LSI) .................................................................6-9

CIOP (Communications and I/O Processing)........................................6-9

FROM (Flash ROM) – 2MB ..................................................................6-9

DRAM – 8MB.......................................................................................6-9

SRAM – 128K .......................................................................................6-9

3V/5V Converter ...................................................................................6-9

Energy-Save Switching.........................................................................6-9

Reset/Backup Circuit ..........................................................................6-10

SAF Backup........................................................................................6-10

Analog Processing Circuit...................................................................6-10

Modem................................................................................................6-10

B044/B045/B046 iv SM

Speaker Driver....................................................................................6-10

Heater Control ....................................................................................6-10

Video Processing Circuit.....................................................................6-10

Power Pack Control ............................................................................6-10

Scanner Driver....................................................................................6-10

Plotter Driver.......................................................................................6-10

6.5.2 SBU (SENSOR BOARD UNIT).......................................................6-11

Buffer ..................................................................................................6-11

CCD ....................................................................................................6-11

Amplifier..............................................................................................6-11

6.5.3 NCU (NETWORK CONTROL UNIT) ..............................................6-12

North America version ........................................................................6-12

Europe/Asia version............................................................................6-12

6.6 COPY PROCESS OVERVIEW ...............................................................6-13

6.7 SCANNING..............................................................................................6-15

6.7.1 OVERVIEW ....................................................................................6-15

6.7.2 SCANNER DRIVE ..........................................................................6-16

6.8 IMAGE PROCESSING ............................................................................6-17

6.8.1 OVERVIEW ....................................................................................6-17

6.8.2 IMAGE PROCESSING PATH.........................................................6-18

6.8.3 ORIGINAL MODES ........................................................................6-19

Original Modes: Copying....................................................................6-20

6.8.4 IMAGE PROCESSING STEPS FOR EACH MODE .......................6-21

6.8.5 MODE ADJUSTMENTS .................................................................6-22

To customize... ...................................................................................6-22

Default plotter customization settings for each mode... ......................6-23

6.9 LASER EXPOSURE................................................................................6-24

6.9.1 OVERVIEW ....................................................................................6-24

6.9.2 LD SAFETY SWITCHES ................................................................6-25

6.10 PHOTOCONDUCTOR UNIT (PCU) ......................................................6-26

6.10.1 OVERVIEW ..................................................................................6-26

6.10.2 DRUM DRIVE...............................................................................6-27

6.11 DRUM CHARGE ...................................................................................6-28

6.11.1 OVERVIEW ..................................................................................6-28

6.11.2 CHARGE ROLLER VOLTAGE CORRECTION............................6-29

Correction for Ambient Environment...................................................6-29

6.11.3 CHARGE ROLLER CLEANING....................................................6-30

6.11.4 DETECTION OF A NEW PCU......................................................6-31

At time of copier installation................................................................6-31

When a replacement PCU is installed.................................................6-31

6.12 DEVELOPMENT ...................................................................................6-32

6.12.1 OVERVIEW ..................................................................................6-32

6.12.2 DEVELOPMENT BIAS .................................................................6-33

6.12.3 TONER SUPPLY..........................................................................6-34

Toner-Bottle Models (B044 and B046)................................................6-34

Toner Hopper Magazine (B045) .........................................................6-35

6.12.4 TONER DENSITY CONTROL ......................................................6-36

Overview.............................................................................................6-36

Reference Voltage ..............................................................................6-36

SM v B044/B045/B046

Toner Density Sensor Initial Setting....................................................6-36

Toner Concentration Measurement ....................................................6-37

Vsp/Vsg Detection ..............................................................................6-37

Calculation of Vref ..............................................................................6-37

Toner Supply Determination ...............................................................6-37

Toner Clutch ON Time........................................................................6-37

6.12.5 TONER SUPPLY IF SENSOR READING IS ABNORMAL ...........6-38

ID Sensor............................................................................................6-38

TD Sensor...........................................................................................6-38

6.12.6 DETECTION OF TONER NEAR END AND TONER END ...........6-38

Toner Near End detected when either of the following occurs............6-38

Toner End detected when any of the following occurs........................6-38

6.13 DRUM CLEANING AND TONER RECYCLING.....................................6-39

6.14 PAPER FEED........................................................................................6-40

6.14.1 OVERVIEW ..................................................................................6-40

6.14.2 PAPER FEED DRIVE MECHANISM ............................................6-41

From Paper Tray.................................................................................6-41

From 100-Sheet Bypass Tray (B044, B046).......................................6-41

From 1-Sheet Bypass Tray (B045) .....................................................6-41

6.14.3 PAPER FEED AND SEPARATION ..............................................6-42

6.14.4 PAPER LIFT MECHANISM ..........................................................6-42

PAPER END DETECTION .................................................................6-43

Main Tray............................................................................................6-43

100-Sheet Bypass Tray (B044, B046) ................................................6-43

6.14.5 PAPER REGISTRATION..............................................................6-43

6.15 IMAGE TRANSFER AND PAPER SEPARATION .................................6-44

6.15.1 OVERVIEW ..................................................................................6-44

6.15.2 IMAGE TRANSFER CURRENT TIMING......................................6-45

6.15.3 TRANSFER ROLLER CLEANING................................................6-46

6.16 IMAGE FUSING AND PAPER EXIT......................................................6-47

6.16.1 OVERVIEW ..................................................................................6-47

6.16.2 FUSING DRIVE AND RELEASE MECHANISM ...........................6-47

6.16.3 PRESSURE ROLLER...................................................................6-48

6.16.4 PRESSURE RELEASE ................................................................6-48

Separation ..........................................................................................6-48

6.16.6 FUSING TEMPERATURE CONTROL..........................................6-49

Overview.............................................................................................6-49

Fusing Temperature Control for Thick Paper......................................6-49

6.16.7 OVERHEAT PROTECTION .........................................................6-49

6.17 ENERGY SAVER MODES ....................................................................6-50

6.17.1 MODE TRANSITIONS..................................................................6-50

6.17.2 SYSTEM SETTINGS....................................................................6-51

6.17.3 LOW POWER MODE LEVELS.....................................................6-51

6.17.4 AUTO-OFF LEVEL .......................................................................6-51

6.17.5 TRANSITION OPERATION..........................................................6-51

B044/B045/B046 vi SM

SPECIFICATIONS

1 GENERAL SPECIFICATIONS..................................................................... 7-1

2 MACHINE CONFIGURATION ..................................................................... 7-5

3 OPTIONAL EQUIPMENT ............................................................................ 7-6

ADF .......................................................................................................... 7-6

PAPER TRAY UNIT................................................................................... 7-6

DOCUMENT FEEDER B444

SEE SECTION B444 FOR A DETAILED TABLE OF CONTENTS

PAPER TRAY UNIT B421

SEE SECTION B421 FOR A DETAILED TABLE OF CONTENTS

FAX UNIT B465

SEE SECTION B465 FOR A DETAILED TABLE OF CONTENTS

PRINTER CONTROLLER UNIT B441

SEE SECTION B411 FOR A DETAILED TABLE OF CONTENTS

SM vii B044/B045/B046

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Be sure that the power cord is unplugged before disassembling or

assembling parts of the copier or peripherals.

2. The wall outlet should be near the copier and easily accessible.

3. Note that electrical voltage is supplied to some components of the copier

and the paper tray unit even while the main power switch is off.

4. If you start a job before the copier completes the warm-up or initializing

period, keep hands away from the mechanical and electrical components

until job execution has started. The copier will start making copies as soon

as warm-up or initialization is finished.

5. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner and developer are nontoxic, but getting either of these into your eyes may

cause temporary eye discomfort. Try to remove with eye drops or flush with

water. If material remains in eye or if discomfort continues, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

The copier and its peripherals must be installed and maintained by a customer

service representative who has completed the training course on those relevant

models.

LITHIUM BATTERIES

Incorrect replacement of lithium battery(s) on the FCU may pose risk of

explosion. Replace only with the same type or with an equivalent type

recommended by the manufacturer. Discard used batteries in accordance with

the manufacturer’s instructions.

SAFE AND ECOLOGICAL DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

if exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are nontoxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls not specified in this manual, or performance of

adjustments or procedures not specified in this manual, may result in

hazardous radiation exposure.

!

WARNING FOR LASER UNIT

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can cause

serious damage to eyes.

CAUTION MARKING:

Symbols and Abbreviations

This manual uses the symbols and abbreviations shown below.

Symbol Meaning

☛

!

"

#

SEF Short Edge Feed

LEF Long Edge Feed

$

"See," "Refer to"

Clip ring

Screw

Connector

Core Technology manual

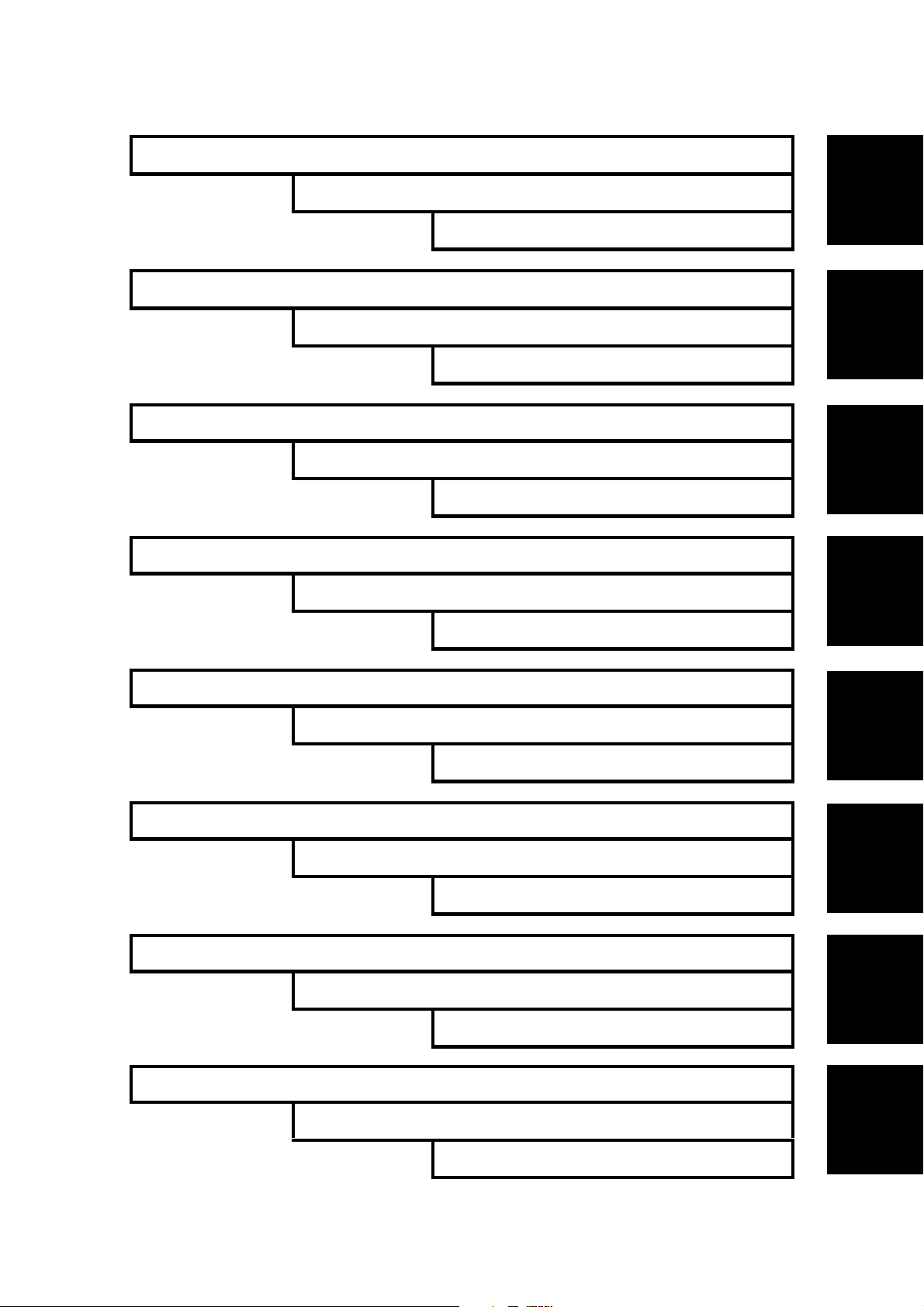

INSTALLATION B044/B045/B046

DOCUMENT FEEDER B444

PREVENTIVE MAINTENANCE B044/B045/B046

PAPER TRAY UNIT B421

REPLACEMENT AND ADJUSTMENT B044/B045/B046

FAX UNIT B465

TROUBLESHOOTING B044/B045/B046

PRINTER B441

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

SERVICE TABLES B044/B045/B046

DETAILED DESCRIPTIONS B044/B045/B046

SPECIFICATIONS B044/B045/B046

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

INSTALLATION

INSTALLATION REQUIREMENTS

1. INSTALLATION

!!!!

CAUTION

Before installing options, please do the following:

1. If there is a fax unit on the machine, print out all messages stored in the

memory, all user-programmed items, and a system parameter list.

2. If there is a printer option on the machine, print out all data in the

printer buffer.

3. Turn off the main switch and disconnect the power cord, the telephone

line, and the network cable.

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

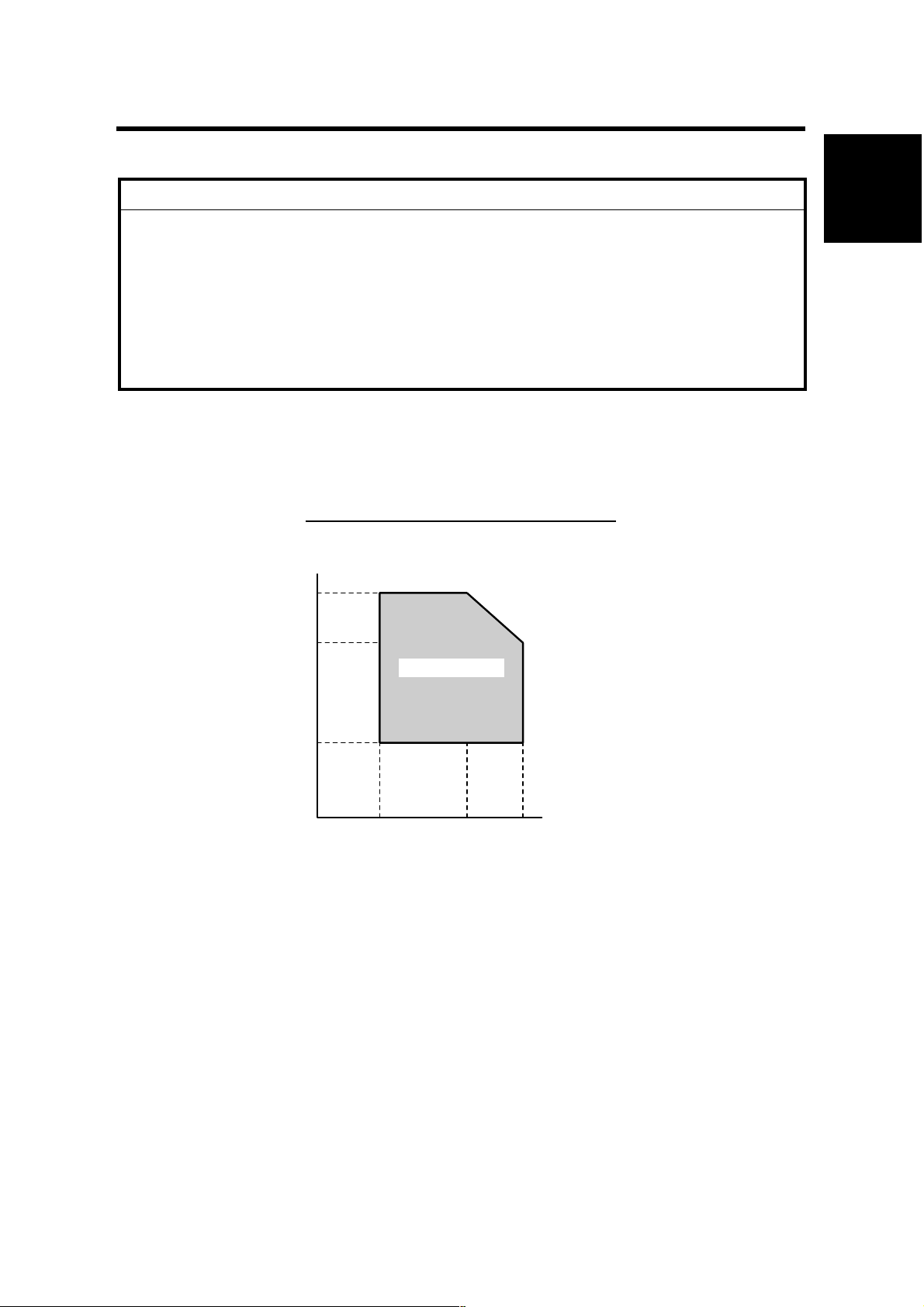

–Temperature and Humidity Chart–

Installation

Humidity

80%

54%

Operation range

15%

10°C

(50°F)

27°C

(80.6°F)

(89.6°F)

32°C

Temperature

B046I512.WMF

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 1,500 lux (Do not expose to direct sunlight.)

4. Ventilation: Room air should turn over at least 3 times/hr/person

5. Ambient Dust Less than 0.1 mg/m

3

6. Do not install the machine where it will be exposed to direct sunlight or to direct

airflow (from a fan, air conditioner, air cleaner, etc.).

7. Do not install the machine where it will be exposed to corrosive gas.

8. Place the machine on a firm and level base.

9. Do not install the machine where it may be subjected to strong vibration.

SM 1-1 B044/B045/B046

INSTALLATION REQUIREMENTS

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

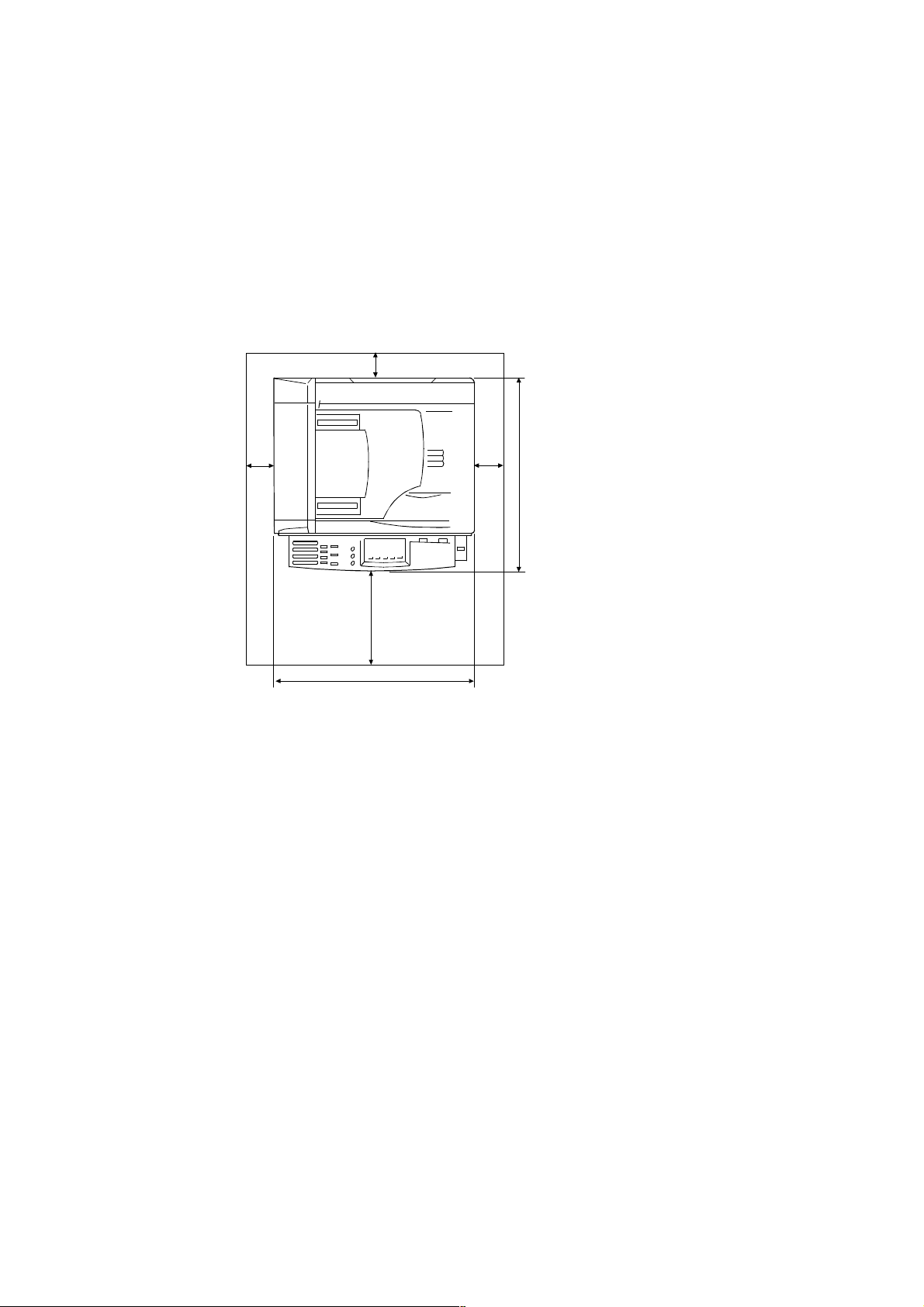

1.1.3 MINIMUM OPERATIONAL SPACE REQUIREMENTS

Place the machine near the power source, providing clearance as shown.

[C]

[D]

[B]

450 mm (17.7")

A: Front > 750 mm (29.6")

[A]

B: Left > 100 mm (3.9")

C: Rear > 105 mm (4.1")

D: Right > 230 mm (9.0")

468 mm (18.4")

B046I130.WMF

NOTE: 1) The 750-mm front space indicated above is sufficient to allow the paper

tray to be pulled out. Additional space is required to allow an operator to

stand at the front of the machine.

2) Actual minimum space requirement for left, rear, and right sides is

10mm (0.4") each, but note that this will not allow room for opening of

the bypass tray, right door, platen cover, or ADF unit.

B044/B045/B046 1-2 SM

1.1.4 POWER REQUIREMENTS

!

CAUTION

INSTALLATION REQUIREMENTS

1. Make sure that the wall outlet is near the machine and easily accessible.

After completing installation, make sure the plug fits firmly into the

outlet.

2. Avoid multi-wiring.

3. Be sure to ground the machine.

Input voltage:

North America: 110 – 120 V, 50/60 Hz, 10 A

Europe: 220 – 240 V, 50/60 Hz, 5 A

Image quality guaranteed at rated voltage ± 10%.

Operation guaranteed at rated voltage ± 15%.

Installation

SM 1-3 B044/B045/B046

COPIER

1.2 COPIER

1.2.1 ACCESSORY CHECK

Check that you have the accessories indicated below. Note that accessories vary

according to model and location.

No. Description Q’ty

1 Copier Operating Instructions (-17, -26, -29) 1

2 EU safety sheet (-22, -24, -26, -27) 1

3 NECR (-17, -27, -29) 1

4 Paper-size decals 1 set

5 Energy Star seal (-26) 1

6 Branding plaques (-22) 1 set

7 Brand decals 1 set

8 Handset bracket (B046) 1

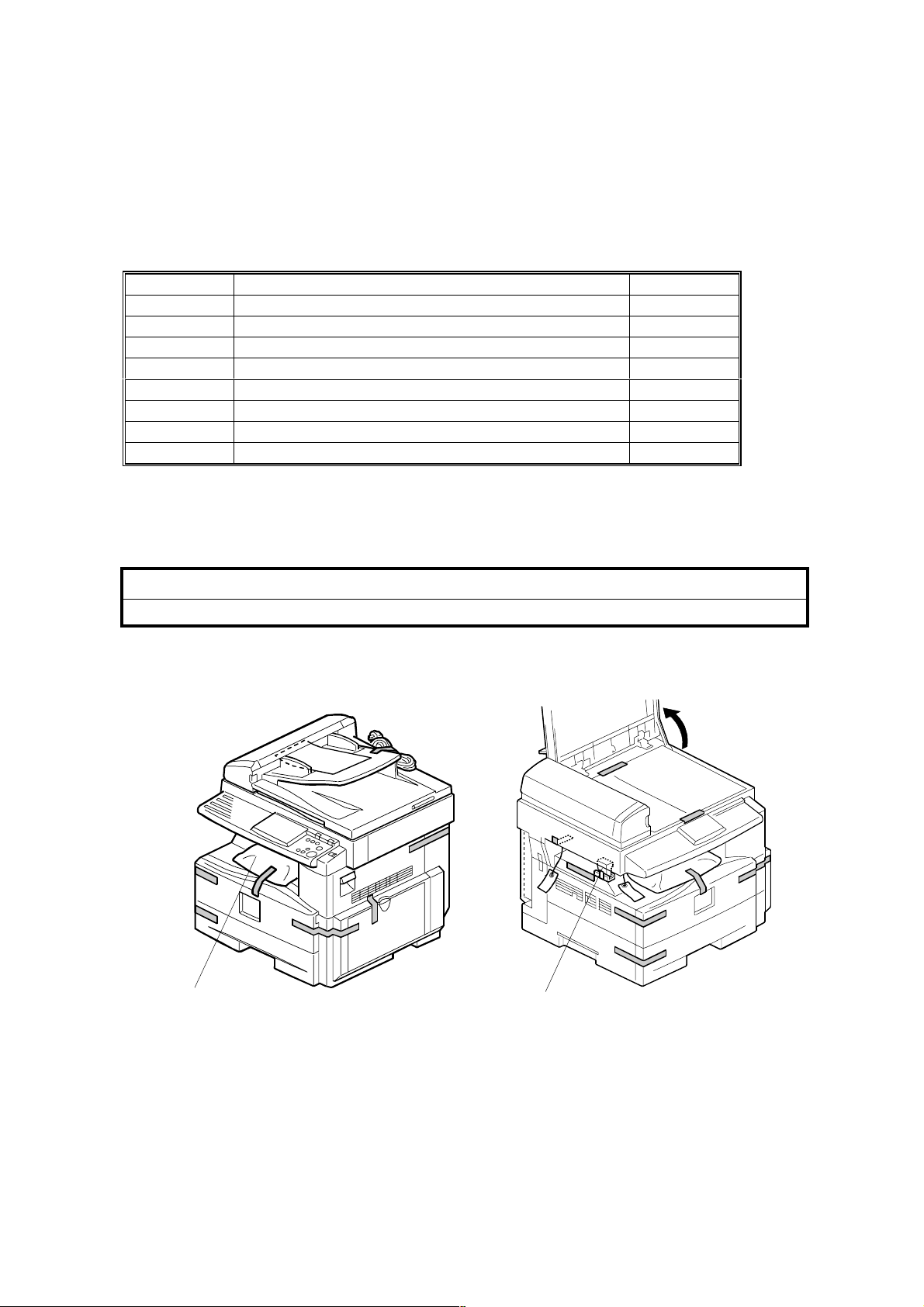

1.2.2 INSTALLATION PROCEDURE

!

CAUTION

Make sure that the copier remains unplugged during installation.

[A]

B046I101.WMF

[B]

B046I124.WMF

1. Remove the strips of tape.

2. Remove the bag [A] holding the included accessories.

3. Remove the spacing wedge [B].

B044/B045/B046 1-4 SM

Loading...

Loading...