Page 1

Technical Bulletin No. RTB-001

SUBJECT: Software Modification (No. 1) DATE: June 30, ’92

PAGE: 1 of 3

PREPARED BY: H. Kokubo

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

To enable the use of new functions, the ROMs on the operation ROM board, main board,

paper feed control board, and ADF main control board have been changed. This

modification has been applied from the March ’92 production machines. (The old type

ROMs were used only for the five machines of the February ’92 production.) To use each

new function, the new type ROMs are required as shown in table 2.

NOTE: 1. The ROMs on each PCB must be replaced as a set.

2. The part number of each PCB is not changed because the old and new PCBs

are interchangeable individually (interchangeability o/o). (Their suffixes, which are

described on each PCB, are changed as shown in table 1 for identification.) The

new ROMs are required only when the new functions are required.

3. The part numbers of each ROM are not changed, except for the ADF main

board ROM (see table 1). (Their suffixes, which are described on each ROM, are

changed as shown in table 1 for identification.)

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F5 (NRG 25101)

4. A sorter stapler will be produced for this model. To control this unit, the ROMs

for the operation ROM board and main board will be changed again. Because

those ROMs will completely cover all functions of the sorter version machine, the

ROMs for the sorter version machine will no longer be supplied as service parts.

We will inform you of details next month. (The ROMs for the sorter stapler version

machine are not available yet.)

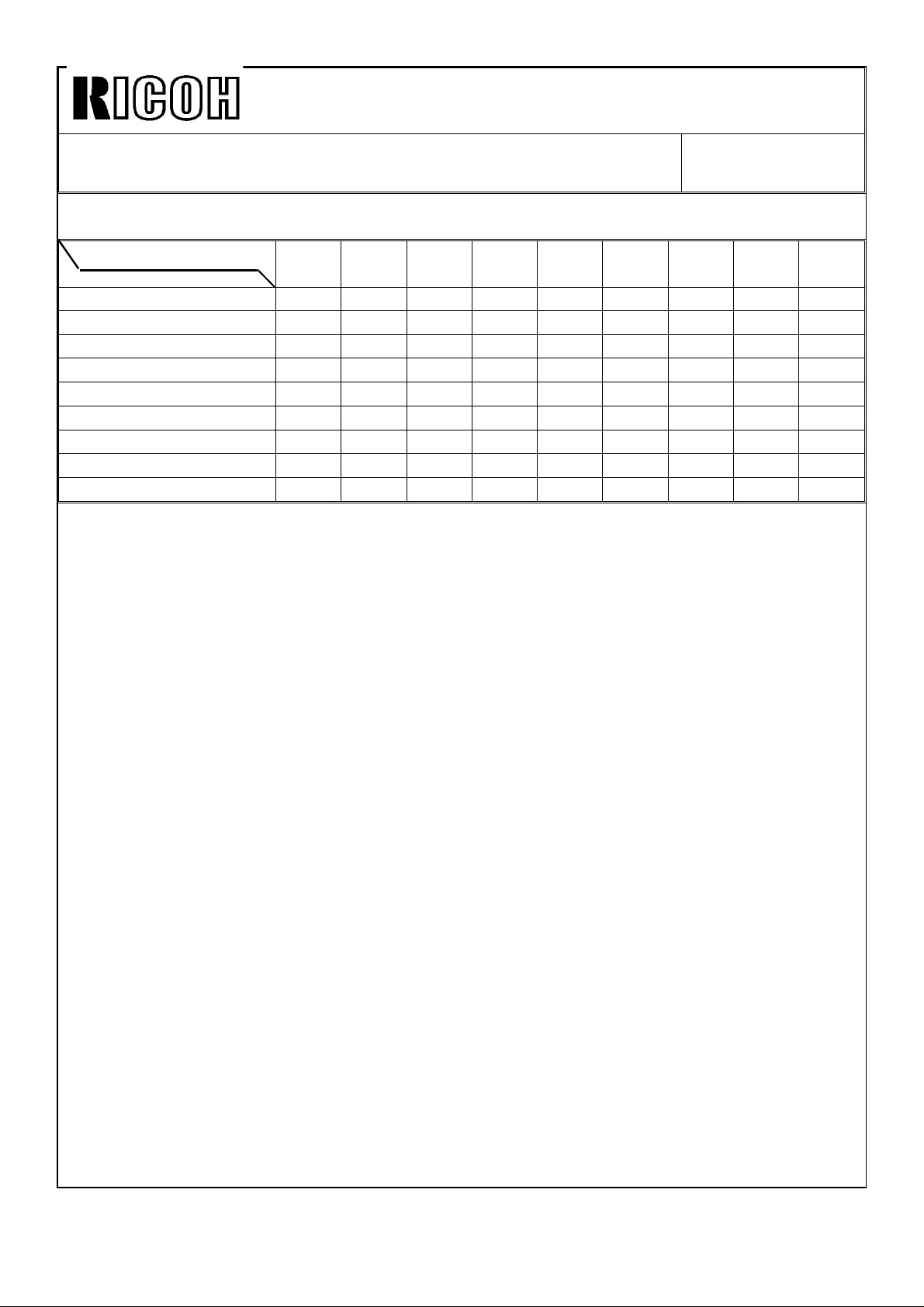

Table 1: Modified Items

Item No. Modified PCB (Old → New) Rom(s) for Modified PCB (Old → New)

Operation ROM Board

1

2

3

4

(A0285242 → A)

* The operation panel ass’y

(AG011286) also contains this PCB.

Main Board

(A0285091A → B)

Paper Feed Control Board

(A0285086 → A)

ADF Main Control Board

(A0285805 → A)

A0285290, 5291, 5292, 5293, 5294, 5295, 5296,

5297, 5298, 5299 (All have been changed to suffix

A)

A0285093, 5094, 5095, 5096, 5097, 5098 (All have

been changed to suffix A)

A0285087, 5088 (All have been changed to suffix A)

A0285851 → A0285855

Page 2

Technical Bulletin No. RTB-001

SUBJECT: Software Modification (No. 1) DATE: June 30, ’92

PAGE: 2 of 3

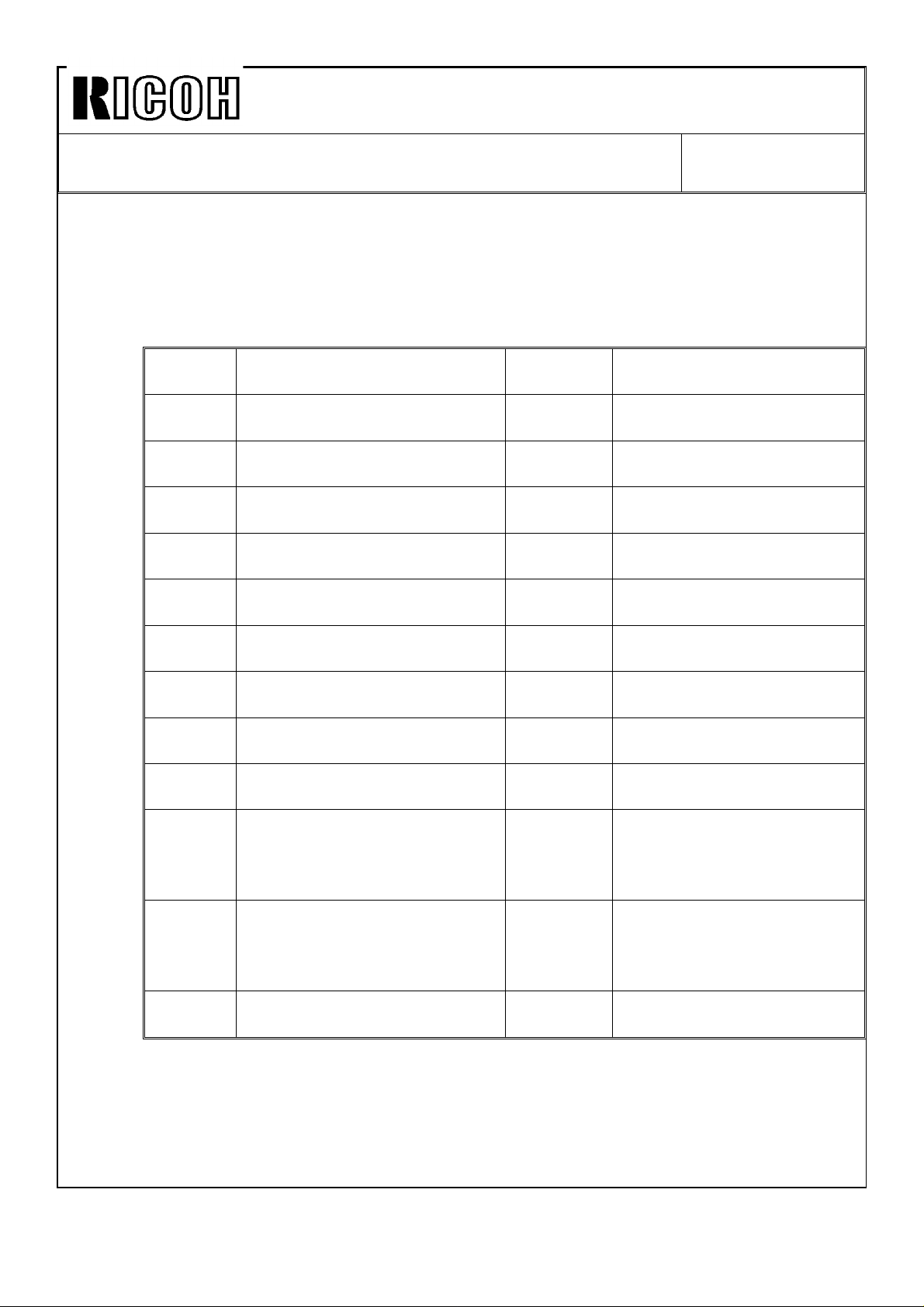

Table 2: Description of New Functions

Item of New

Functions

F4 Paper/Original

Size Detection

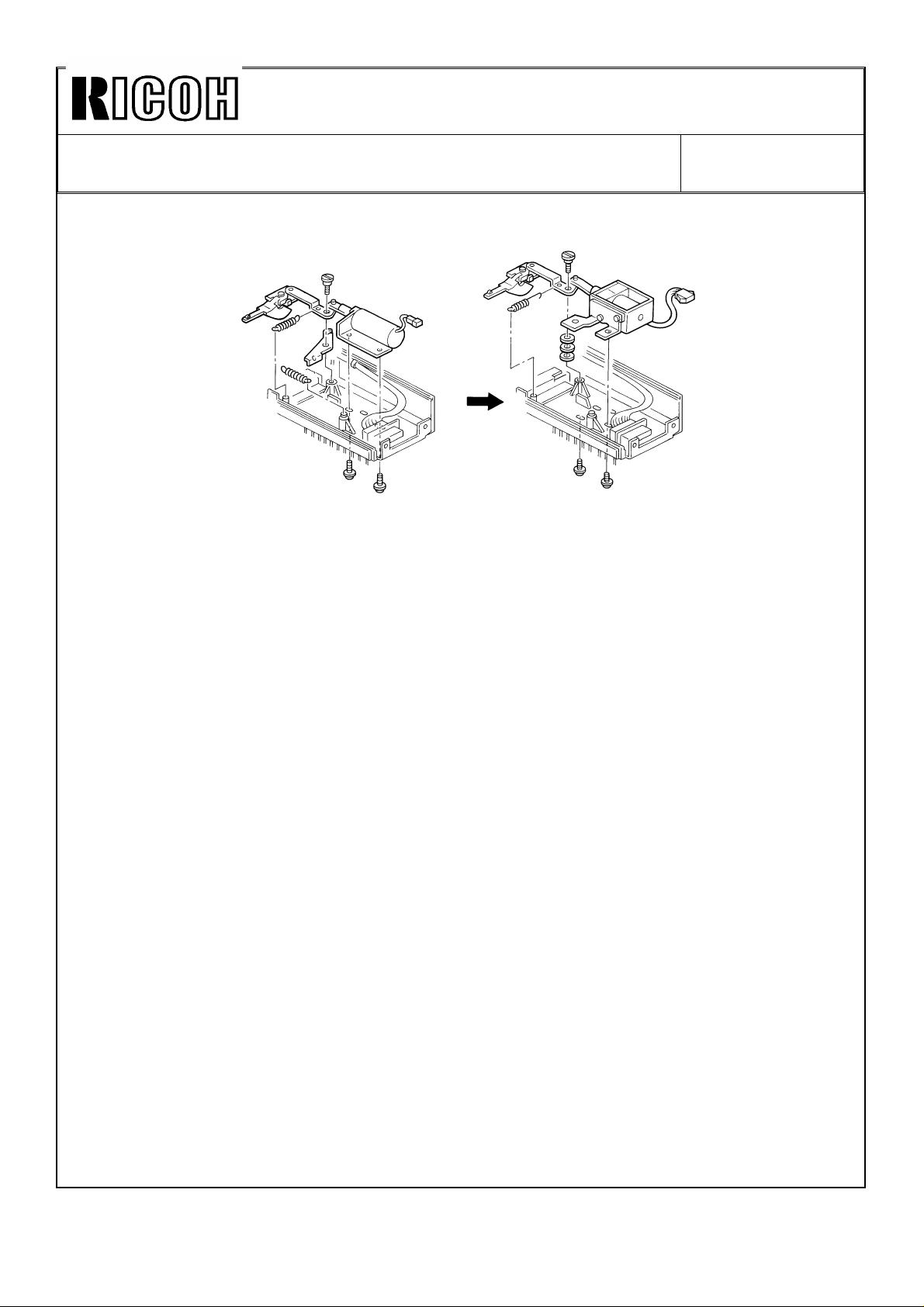

Gear:

A0287907

Description Necessary

Modification

The [81/2" x 13"] key

is displayed by

selecting user tool

no. 3 (copy/original

size selection) to use

81/2" x 13" (F4 size)

paper and originals.

* Paint this

surface white.

Item No. 1,

2, 3, and 4

in Table 1

(All items)

Note

1. A4 originals and paper cannot be

used when the [81/2" x 13"] key is

pressed, and 81/2" x 13" originals

and paper cannot be used when

the [A4] key is pressed.

2. When the [81/2" x 13"] key is

pressed, the [Tray 4] key in user

tool no. 7 (disable unit) is

automatically pressed and the LCT

cannot be used. (This is because

81/2" x 13" paper cannot be set in

the LCT.) When the [A4] key is

selected again, the [Tray 4] key

must be manually turned off to use

the LCT.

Fuser Oil End

Detection

The message display

indicates "Add

silicone oil" when no

fuser oil is detected.

Modified

Item No. 1

and 2 in

table 1

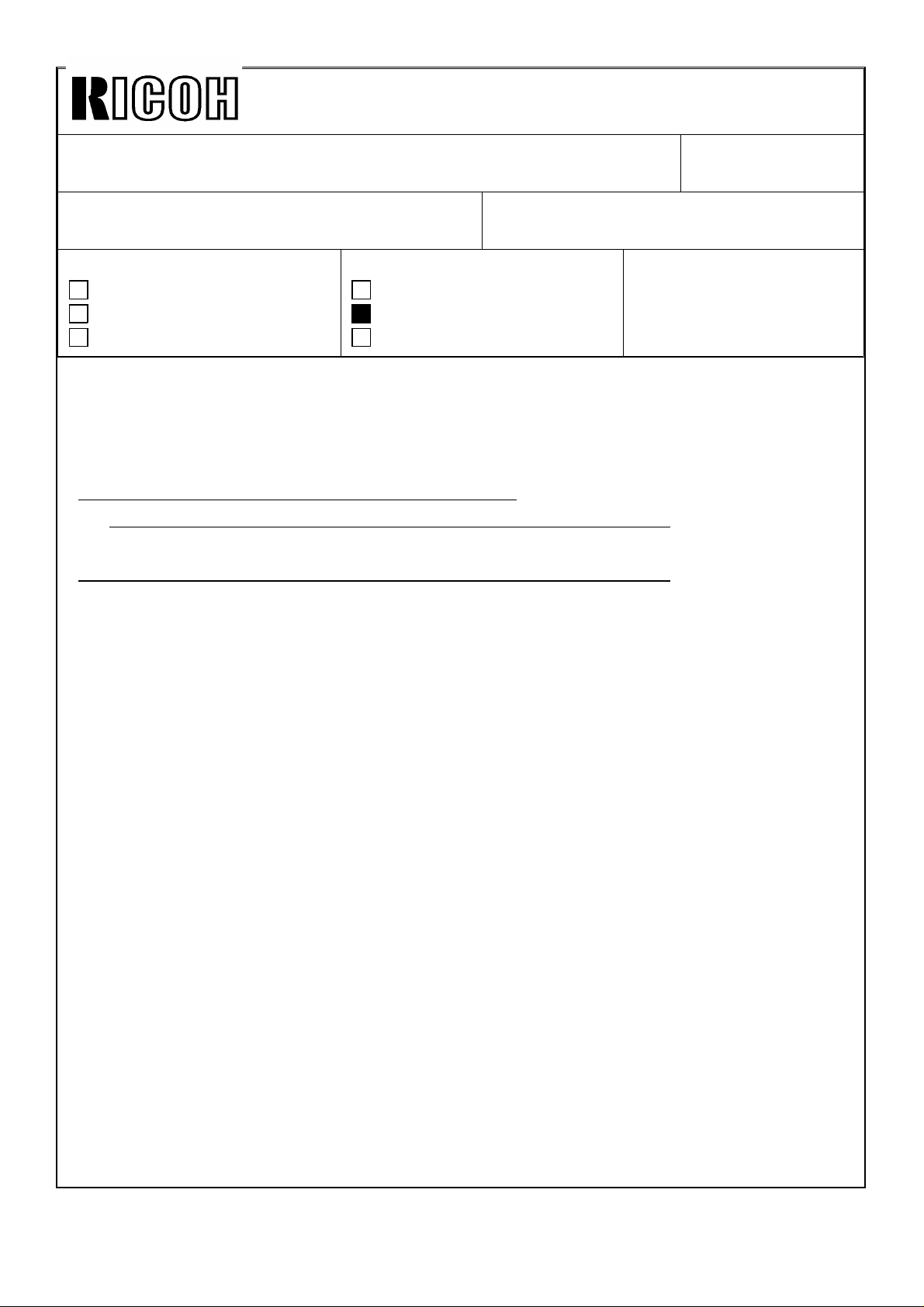

3. The machine detects an 81/2" x

13" original when the original length

sensor is activated by the gear on

the front of the original stopper

(A0287907). To ensure this, the side

of the gear, which is detected by

the sensor, must be painted white

(see illustration in the left). This has

been applied from the March ’92

production. Therefore, this

procedure is required for the 5

machines of the February ’92

production or when the gear is

replaced with a service part.

The silicone oil sensor

(P/N-52055258) and sensor bushing

(P/N-5446 4278) are required. (They

have been installed from the March

’92 production machines.)

Page 3

Technical Bulletin No. RTB-001

SUBJECT: Software Modification (No. 1) DATE: June 30, ’92

PAGE: 3 of 3

Item of New

Functions

Exit Tray Copy

Limit

Duplex Side

Fence Width

Adjustment

Description Necessary

Modification

The number of the

exit tray copy limit

can be selected from

300, 350, 400, or "no

limit" using service

tool 2-15 (initial

setting: 300).

The initial setting for

the duplex side fence

width (service tool

5-02) is changed

from 0 mm to -0.6

mm. This allows

adjustment of the

fence width not only

in the narrower

direction, but also in

the wider direction in

the field. (It can be

made 0.6 mm wider

from the production

setting.) The

adjustable range is

still the same (0 to

-1.8 mm in 0.6 mm

steps).

Modified

Item No. 1

and 2 in

Table 1

Modified

Item No. 3 in

Table1

Note

Even when "no limit" is selected,

"Remove copies from the copy tray"

is also displayed without stopping

the copy run.

NOTE: 1. If only the operation ROM board is replaced with the new type:

* The [A4] and [81/2" x 13"] keys will be displayed in user tool no. 3, but they

cannot be pressed.

* The [300], [350], [400], and [No] keys for the exit tray copy limit are displayed in

service tool 2-15, but only the [300] key can be pressed.

2. If only the ADF main control board is replaced with the new type, the machine

will stop the operation when an 81/2" x 13" original is used. To recover that

condition, the main switch must be turned off then on.

3. If only the ADF main control board is the old type, 81/2" x 13" originals cannot

be detected.

4. If only the paper feed control board is the old type, the duplex side fence width

for 81/2" x 13" paper cannot be adjusted by service tool 5-02.

Page 4

Technical Bulletin No. RTB-002

SUBJECT: Software Modification (No. 2) DATE: Sep. 15, ’92

PAGE: 1 of 7

PREPARED BY: H. Kokubo

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

To enable the use of the A372 sorter stapler, the ROMs on the operation ROM board and

main board have been changed as shown in table 1. This modification has been applied

from the July ’92 production machines. The differences between the sorter version

software (old ROMs) and sorter stapler version software (new ROMs) are listed in table 2.

NOTE: 1. The ROMs (10 pieces for the operation ROM board and 6 pieces for the main

board) must be replaced as a set.

2. The new ROMs completely cover all functions of the sorter version machine.

Therefore, the ROMs for the sorter version machine will no longer be supplied as

service parts. (NRG ITS had already received 2 sets of the master ROMs.)

3. The old and new operation ROM board and main board are interchangeable

with one another (interchangeability o/o) for the A458 sorter version machines.

(The old PCBs can still be used for the A458 sorter version machines.)

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F5 (NRG 25101)

Table 1: Modified Items

Modified

PCB

Operation

ROM Board

(Operation

Panel Ass’y)

Main Board A0285091 A0288802 IC210 A0285093 A0288850 83A9

Old Part

Number

A0285242

(AG011286)

New Part

Number

A0288803

(A0288800)

IC Number

(Printed on

the PCB)

IC201 A0285290 A0288900 5619

IC202 A0285291 A0288901 0BB7

IC205 A0285292 A0288902 F7C6

IC206 A0285293 A0288903 76BB

IC203 A0285294 A0288904 4FBC

IC204 A0285295 A0288905 1909

IC207 A0285296 A0288906 ECEF

IC208 A0285297 A0288907 644D

IC210 A0285298 A0288908 527D

IC211 A0285299 A0288909 6CC2

IC198 A0285094 A0288851 2A4E

IC205 A0285095 A0288852 D0E9

IC190 A0285096 A0288853 ED4D

IC123 A0285097 A0288854 52BF

IC124 A0285098 A0288855 D124

Old ROM

Part

Number

New ROM

Part

Number

Total

Check

Sum

Page 5

Technical Bulletin No. RTB-002

SUBJECT: Software Modification (No. 2) DATE: Sep. 15, ’92

PAGE: 2 of 7

Table 2: Description of New Functions

Item of New

Functions

Access to the

sorter stapler

Access to the

special features

User Tools See table 3 on page 5.

Service Tools See table 4 on page 5.

New Service Call

Status Codes

Beeper for SC82 The beeper sounds

Description Note

The A372 sorter

stapler is accessible.

The special features

(cover mode,

chaptering mode,

and paper designate

mode) can be used.

SC95 for the first

sorter, SC96 for the

second sorter, and

SC97 for the third

sorter are displayed

as a communication

error between the

copier and sorter

staplers.

when SC82

(operation unit

transmission error) is

displayed.

Both systems for the sorter and sorter stapler can

be used by changing the setting of utility 12-5-8

(default: sorter stapler system). For details, refer to

the accompanying table of "New Utility Modes."

For the details of the sorter stapler operation, refer

to page 53 and 108 through 111 of the operating

instructions.

The special features can be used only with the

sorter stapler system. For details, refer to page 64

of the operating instructions.

If SC82 is displayed, there is a possibility of CPU

malfunction and of the machine going out of

control. The beeper sound instructs the customer

to turn off the main switch or to call the service

representative.

SC82 can be displayed forcibly, by disconnecting

the optical fiber cable connector between the

operation unit and main board.

Page 6

Technical Bulletin No. RTB-002

SUBJECT: Software Modification (No. 2) DATE: Sep. 15, ’92

PAGE: 3 of 7

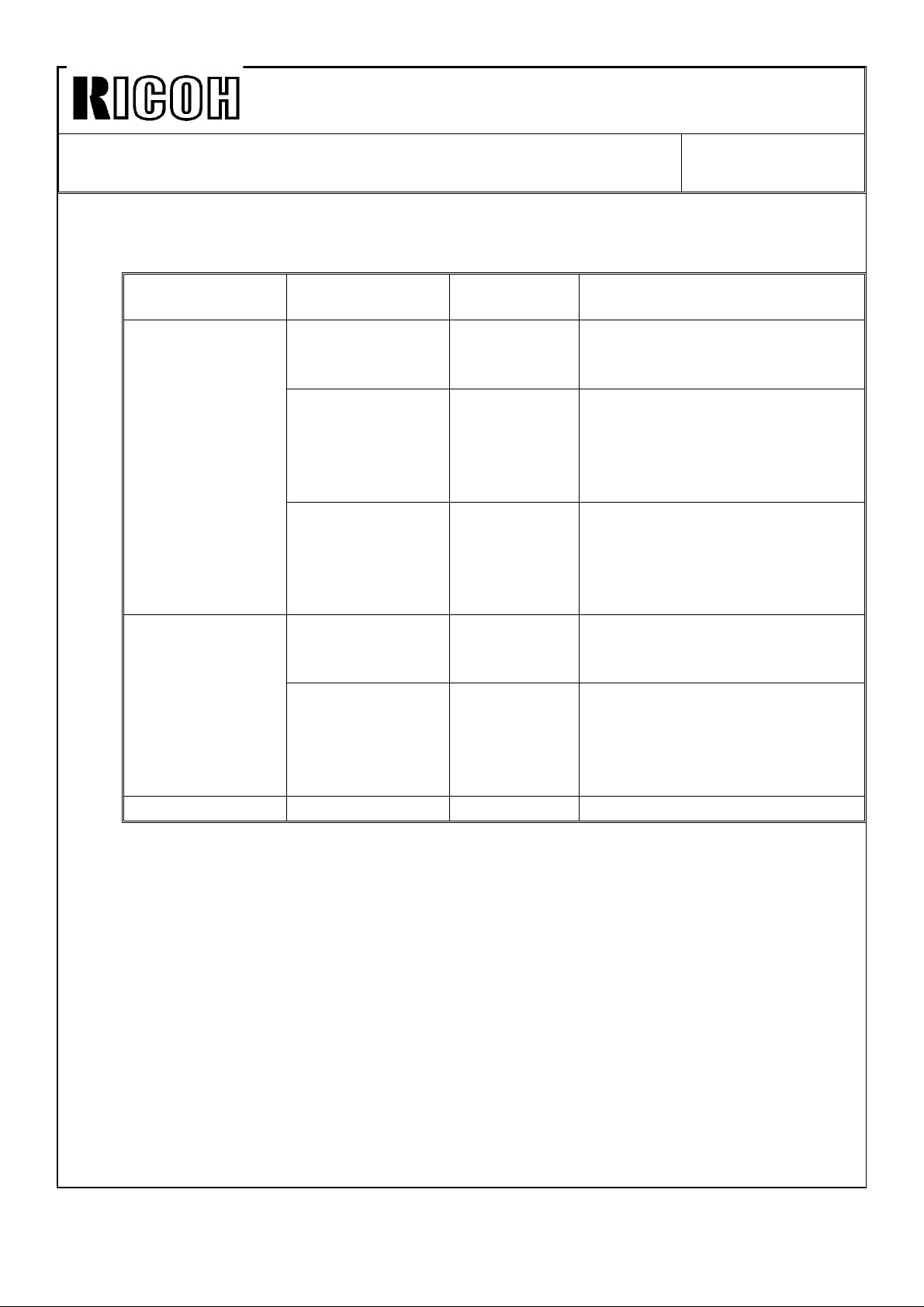

NOTE: 1. To ensure the paper is squared in the sorter stapler bins, the copying speed is

reduced to 80.8 cpm (only for B5, A4, 81/2"x11", 81/2x"13", and 81/2"x14" sizes

paper) when copies are continuously fed to the same bin. The copy modes in

which this happens are as follows:

Copy Modes that the Copy Speed is Reduced

Original

Set

ADF Sort and 1-sided original to

ADF Sort and 2-sided original to

Exposure

glass

Exposure

glass

Exposure

glass

Exposure

glass

SADF Stack and 1-sided original to

SADF Stack and 1-sided originals to

ADF Stack and 1-sided original to

ADF Stack and 1-sided originals to

ADF Stack and 2-sided original to

ADF Stack and 2-sided original to

Copy Mode Copy Set

1-sided copy mode

2-sided copy mode

Stack and 1-sided original to

1-sided copy mode

Stack and 1-sided originals to

2-sided copy mode

Stack and 2-sided original to

2-sided copy mode

Stack and 2-sided original to

1-sided copies mode

1-sided copy mode

2-sided copy mode

1-sided copy mode

2-sided copy mode

2-sided copy mode

1-sided copies mode

Note

Number

1

1

2 or more

2 or more The speed of front side

copying is 101 cpm.

2 or more The speed of front side

copying is 101 cpm.

2 or more

2 or more

2 or more The speed of front side

copying is 101 cpm.

1 or more

1 or more When the copy set number

is 4 or more, the speed of

front side copying is 101

cpm.

1 or more When the copy set number

is 4 or more, the speed of

front side copying is 101

cpm.

1 or more

Page 7

Technical Bulletin No. RTB-002

SUBJECT: Software Modification (No. 2) DATE: Sep. 15, ’92

PAGE: 4 of 7

2. Copying speed with the ADF mode varies depending on paper and original

sizes as shown below:

Paper Size Original Size Copying

Speed (cpm)

B5, A4, 81/2"x11",

81/2"x13",

81/2"x14"

B4 B5, A4, 81/2"x11",

A3, 11"x17" All sizes 61

B5, A4, 81/2"x11",

81/2"x13",

81/2"x14"

B4 81(101) The copying speed is 101 cpm

A3, 11"x17" 61(101) The copying speed is 101 cpm

81/2"x13",

81/2"x14", B4

A3, 11"x17" 61(81) The copying speed is 101 cpm

101

81

Note

when the copy set number is 4

or more. However, one copy is

skipped each time the original is

exchanged.

when the copy set number is 3

or more. However, one copy is

skipped each time the original is

exchanged.

when the copy set number is 4

or more. However, one copy is

skipped each time the original is

exchanged.

Page 8

Technical Bulletin No. RTB-002

SUBJECT: Software Modification (No. 2) DATE: Sep. 15, ’92

PAGE: 5 of 7

Table 3: User Tools with the Sorter Stapler

Item (Menu No.) Description

Disable Display (6) The Staple key has been added in this screen.

By pressing this key, when more than the maximum copy number for

stapling (default: 50) is made in the sort mode, and the copies reach that

number, the copying is paused and the Manual Staple key is displayed.

This allows the use of the stapling function with the sort mode for

operators even when they forget to set the staple mode first. (This means

that the priority is given to the staple mode, not the sort mode.)

As an initial setting, copying in the sort mode is not paused even when

more than the maximum copy number for stapling is made. (The priority

of the sort mode.)

Disable Unit (7) The screen is the same as before. In the sorter stapler system, the 1st,

2nd, and 3rd sorter staplers (including the staple function) are disabled by

pressing the "Sorter 1", Sorter 2", and "Sorter 3" keys.

Table 4: Service Tools with the Sorter Stapler

Item (Menu No.) Description

Sorter Bin Copy Limit

(2-07)

Dual Sort (2-08) This function is not effective for the sorter stapler system. (In the

Set Initial Display (2-16) In addition, the auto staple mode can be set as an initial display. (The

Supply Yield/Forming

(3-04)

Utility (4-05) See table 5 on page 6.

Copies per bin in the stack mode can be limited in a range from 35 to

50. The same number is effective for the staple mode. (Default: 50)

Copies per bin in the sort mode can be limited in a range from 55 to

100. (Default: 70)

sorter stapler system, more than two sets of a sort or stack job can

be made without removing copies from bins.)

cover/chaptering modes are not possible.)

The number of the used staple is displayed separately for the 1st,

2nd and 3rd sorter staplers.

Page 9

Technical Bulletin No. RTB-002

SUBJECT: Software Modification (No. 2) DATE: Sep. 15, ’92

PAGE: 6 of 7

Table 5: New Utility Modes

Mode No.

Set No. of Mode No. 5

0 to 7 6-5-0 7-5-0 11-5-0 13-5-0

8 6-5-8 7-5-8 10-5-8 11-5-8 12-5-8 14-5-8

9 6-5-9 7-5-9 8-5-9 9-5-9 10-5-9 12-5-9 13-5-9 14-5-9

10

11

12

13

14

15

NOTE: The bold numbers in the table shows new or modified functions. Their descriptions

are as follows:

6-5-0: Automatic Sort Selection

The default has been changed to ON (the Automatic Sort Selection is effective).

6-5-9: A3 Double Copy Count

The mechanical copy counter counts up 2 when an A3 or 11"x17" size copy is made.

(Default: OFF, Double Count) The old software was for A3 (or 11"x17") double count only.

7-5-8: Automatic APS Selection•

The default has been changed to ON (the Automatic APS Selection is effective).

6 7 8 9 10 11 12 13 14

7-5-9: Pause Stapling

During stapling of copies in the bins, stapling can be paused by pressing the Clear/Stop

key. (Default: ON, the pause is effective)

8-5-9: Duplex Tray Maximum Limit

The maximum number of copies stacked in the duplex tray can be changed. ON: 50 for

A3, B4, 11"x17", and 81/2"x14" and 100 for A4, B5, 81/2"x11", and 81/2"x13". OFF: 40/80.

(Default: OFF)

9-5-9: Automatic Staple Mode Selection

The auto staple mode is automatically selected when the sort key is pressed. (Default:

OFF, not effective)

10-5-9: Valid 81/2"x13" Key

The 81/2"x13" and A4 keys are displayed in user tools no. 3 to select original and copy

paper sizes. (Default: ON, effective)

11-5-8: Fusing Rush Current Prevention

Rush current from the wall outlet is absorbed to prevent the circuit breaker for the wall

outlet from being blown. This must be always ON. (Default: ON, effective) There was the

same function with the old software, but the default setting has been changed.

Page 10

Technical Bulletin No. RTB-002

SUBJECT: Software Modification (No. 2) DATE: Sep. 15, ’92

PAGE: 7 of 7

12-5-8: Sorter/Sorter Stapler System Switching

The sorter or sorter stapler systems can be selected. (Default: ON, sorter stapler system)

12-5-9: Disable Cover/Chaptering Modes

The special features (cover/chaptering modes) are disabled. (Default: OFF, the modes are

effective) The special features are available only with the sorter stapler system.

13-5-9: Stapling with Stack Mode

Stapling with the stack mode is available. (Default: OFF, not effective) Stapling with the

stack mode is not possible when the sorter stack face up mode is selected by user tool

no. 8. (The staple position will be wrong in this mode.)

14-5-8: Valid Pre-heat Key

By holding on the Clear Modes key for a while, all displays on the operation unit turn off.

(Default: OFF, not effective)

14-5-9: Sort Copies in Reverse Order

When the sorter stack face up mode is selected with user tool no. 8, not only in the stack

mode, but also in the sort mode, copies are delivered to the bins with the face (image

side) up. This sorts copies in the reverse page order. (Default: OFF, not effective)

Page 11

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 1 of 23

PREPARED BY: H. Kokubo

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F5

(Gestetner 25101/

Nashuatec 53101)

TABLE OF CONTENTS

1. UNIQUE FUNCTIONS OF THE FINISHER

VERSION MODEL 3

2. FUNCTIONAL DETAILS 3

2.1 COPY MODE 3

1. Simplex original to simplex copy mode ........................................ 4

2. Simplex originals to duplex copy mode ........................................ 4

3. Duplex original to duplex copy mode .......................................... 6

4. Duplex original to simplex copies mode ...................................... 6

2.2 ALTERNATE PAPER FEEDING TIMING CHART 7

2.3 ACCOUNTING MODES 10

1. How to e nter the c opy mod e .......... ........ .......... ........ ........ ........ ... 10

2. How to leave the copy mode in the accounting mode ................. 10

3. How to set the accounting modes ................................................. 10

4. How to enter the copy mode in the accounting mode

for servicing .................................................................................. 10

Page 12

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 2 of 23

TABLE OF CONTENTS

2.4 COVER SHEET AND CHAPTERING MODES 11

1. How the copies are collated into sets in the duplex

copy mode with the cover or chaptering mode ............................ 11

2. How the designated original is copied in the duplex

original to duplex copy mode ........................................................ 12

2.5 DIFFERENCES IN MECHANISM BETWEEN

THE ADF AND RDH 13

1. Recycle arm solenoid .................................................................... 13

2. Original transport drive motor ........................................................ 13

3. Instruction decal ............................................................................. 13

3. NEW SELF-DIAGNOSTICS FOR THE FINISHER 14

4. MAIN CONTROL BOARD DIP SWITCH SETTING 15

5. MEAN POWER CONSUMPTION DATA 16

6. USER TOOLS 17

1. User tools unique for the finisher version ..................................... 17

2. User utility table (user tool no. 10) ................................................ 18

7. SERVICE TOOLS 19

1. Service tools unique for the finisher version ................................. 19

2. Utility modes unique for the finisher version ................................. 21

3. Utility mode comparison table of the sorter,

sorter/stapler, and finisher ............................................................ 22

.

Page 13

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 3 of 23

1. UNIQUE FUNCTIONS OF THE FINISHER VERSION MODEL

The major differences between the sorter version and finisher version of the F5 are

as follows:

1. Permits the installation of the optional finisher (with the original recirculating

motion of the RDH).

2. Permits the installation of the optional key counter bracket and printer connector

unit.

3. New or modified user and service tools.

4. Advanced cover and chaptering modes.

5. Enables the use of the normal accounting mode and of the security accounting

mode.

6. Satisfies the German electromagnetic field interference standard (VDE 243).

2. FUNCTIONAL DETAILS

2.1 COPY MODES

There are two copy modes: sort and stack. In the stack mode copies of the same

page are grouped together. When this mode is selected with user tool number 10,

the originals set in the stack original feed table of the RDH are copied just like with

the sorter or sorter/stapler version machine. The originals are fed and returned to

the table just once (ADF mode).

On the other hand, in the sort mode the copies are assembled as sets in

sequential order. This mode is always selected when originals are set in the stack

feed table of the RDH, except when the stack mode is selected. In this mode, the

RDH performs the original recirculating motion (RDH mode).

The following explains the differences in original and copy paper motions when

simplex or duplex copies are made from the simplex or duplex originals in the sort

mode:

Page 14

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 4 of 23

1. Simplex original to simplex copy mode

One original feeding cycle makes one set of copies. To make more sets of copies,

originals recirculate in the RDH accordingly. (Copies are always collated into sets.)

When copy delivery to the finisher is selected, the copies are inverted in the

finisher in order to stack the copies with the image side down on the shift tray. The

copies are stacked in page order.

When one original is set in the stack original feed table, the original is recirculated

once, as usual. Then, the machine detects that only one original has been set.

The original is again fed from the table, then the machine enters the original

non-recirculating mode (ADF mode) to complete copying. The original stays on the

exposure glass until the copy run finishes.

2. Simplex originals to duplex copy mode

In case of the other RDH and finisher systems, usually two cycles of the simplex

original feeding makes one set of duplex copies. The first cycle of the original

feeding is to make copies of the odd pages of originals. The copies are stacked in

the duplex tray. Then, for the second original feeding, the even pages of originals

are copied onto the reverse sides of the copies from the duplex tray. This motion

is repeated until all the desired sets of copies are completed.

For this copier, the alternate paper feeding system is used to speed up the

simplex to duplex copy job. The first original feeding is just like the other RDH and

finisher systems. The odd pages of originals are copied and the copies are

stacked in the duplex tray. However, the second original feeding and the following

steps are different.

Unlike the other RDH and finisher systems, from the second original feeding, both

the odd and even pages of originals are copied in one original feeding cycle. (This

means that originals are copied in sequential order.) The alternate paper feeding

system allows this.

When the odd page of originals is copied, paper is fed from the normal paper tray.

The copy is stacked in the duplex tray. When the next original (the even page of

originals) is copied, the copy, which was made and stacked in the duplex tray

during the previous cycle of the original feeding, is fed from the duplex tray. The

original image is copied onto the reverse side of the copy then the copy is

delivered. The copier repeats feeding the paper from the normal paper tray and

from the duplex tray alternately. This is called the alternate paper feeding. For

more details, refer to the "Alternate Paper Feeding Timing Chart".

The copier repeats the above motion until the desired sets of copies are

completed. (During the final original feeding cycle, only the even pages of originals

are copied and all the copies in the duplex tray are fed out.) As a result, the copier

can complete the copy job in the same number of original feeding cycles as the

desired number of copies, plus one. On the other hand, in the other RDH and

finisher systems, the original feeding cycle is repeated twice the desired number of

copy sets.

Page 15

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 5 of 23

The duplex copies are automatically delivered to the finisher shift tray, not to the

copier copy tray. The copies are stacked in page order on the tray without the

inversion of copies unlike the simplex original to simplex copy mode.

NOTE: When the simplex originals to duplex copy mode is selected, if a margin of 15 mm

or more is entered in the margin adjustment mode, the copying speed is set at 61

cpm, whatever size of original or copy paper is used. Copies are made using the

OPC segment for A3 size copy. (The images of 3 originals are produced for one

rotation of the OPC belt.) If the difference in the selected margin between the front

and reverse side of the copy image is 15 mm or greater, e.g. 5 mm margin at the

left on the front side and 10 mm margin at the right on the reverse side, the

copying speed is also set at 61 cpm.

This is because the originals copied on the front and reverse side are alternately

copied due to the alternate paper feeding system. As the margin can be adjusted

by changing the original flash (exposing) timing, the original stop on the exposure

glass must correspond to the adjusted flash timing. (If a margin is created at the

left, the flash timing is advanced. If a margin is created at the right, it is delayed.)

When the margin is created on the front and rear of copies separately, two

different flash timings alternate with each other. If the difference in the flash timing

between two originals becomes greater, i.e. 15 mm or more in the margin, the

original transportation cannot correspond to the alternate two different flash timings

due to the limit of the original transportation speed.

For example, if a margin is created at the left on the front side of copies, after an

original for which no margin is created, the original which has the margin must be

transported to the exposure glass faster than usual in order to catch up with the

advanced flash timing. If the margin is 15 mm or greater, the original cannot catch

up with the advanced flash timing.

This copier has one more copying speed: 81 cpm. However, this is not used in

case of a slow down in the margin adjustment mode. To enable 81 cpm, the copy

mode for B4 size paper (B4 size copy mode), where the images of 4 originals are

produced for one rotation of the OPC belt, must be used. In the A4 size copy

mode three originals are fed into the RDH from the stack original feed tray before

the first original is flashed. For the B4 size copy mode, it is two originals. Due to

this, the original transport speed in the B4 size copy mode is almost the same as

that in the A4 size copy mode, even though the copying speed of the B4 size copy

mode is 81 cpm. Therefore, even if A4 size copies are made using the B4 size

copy mode, there is not enough margin in the original transportation speed.

Page 16

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 6 of 23

3. Duplex original to duplex copies mode

The front side of originals is copied during one cycle of original feeding. The

copies are stacked in the duplex tray. At the same time the originals are inverted

and returned onto the original table. Due to this, the reverse side of the originals is

copied during the next cycle of the original feeding. The images are copied on the

reverse side of the copies from the duplex tray and the duplex copies are

automatically delivered to the finisher shift tray, not to the copier copy tray. The

copies are stacked in page order on the tray without the inversion of copies as in

the simplex originals to duplex copy mode.

To make more sets of copies, the above motion is repeated. (Copies are always

collated into sets.) This means that the original feeding cycle is repeated twice the

desired number of copy sets.

4. Duplex original to simplex copies mode

One cycle of original feeding makes one set of copies. For each original feeding,

the front side image is copied and the copy is stacked in the duplex tray. Then the

original is inverted in the RDH and the reverse side image is copied onto the copy

from the duplex tray. After the images on both sides of the original are copied, the

original returns to the original table. To make more sets of copies, originals

recirculate in the RDH accordingly. (Copies are always collated into sets.)

When copy delivery to the finisher is selected, the copies are inverted in the

finisher in order to stack the copies with the image side down on the shift tray. The

copies are stacked in page order.

Page 17

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 7 of 23

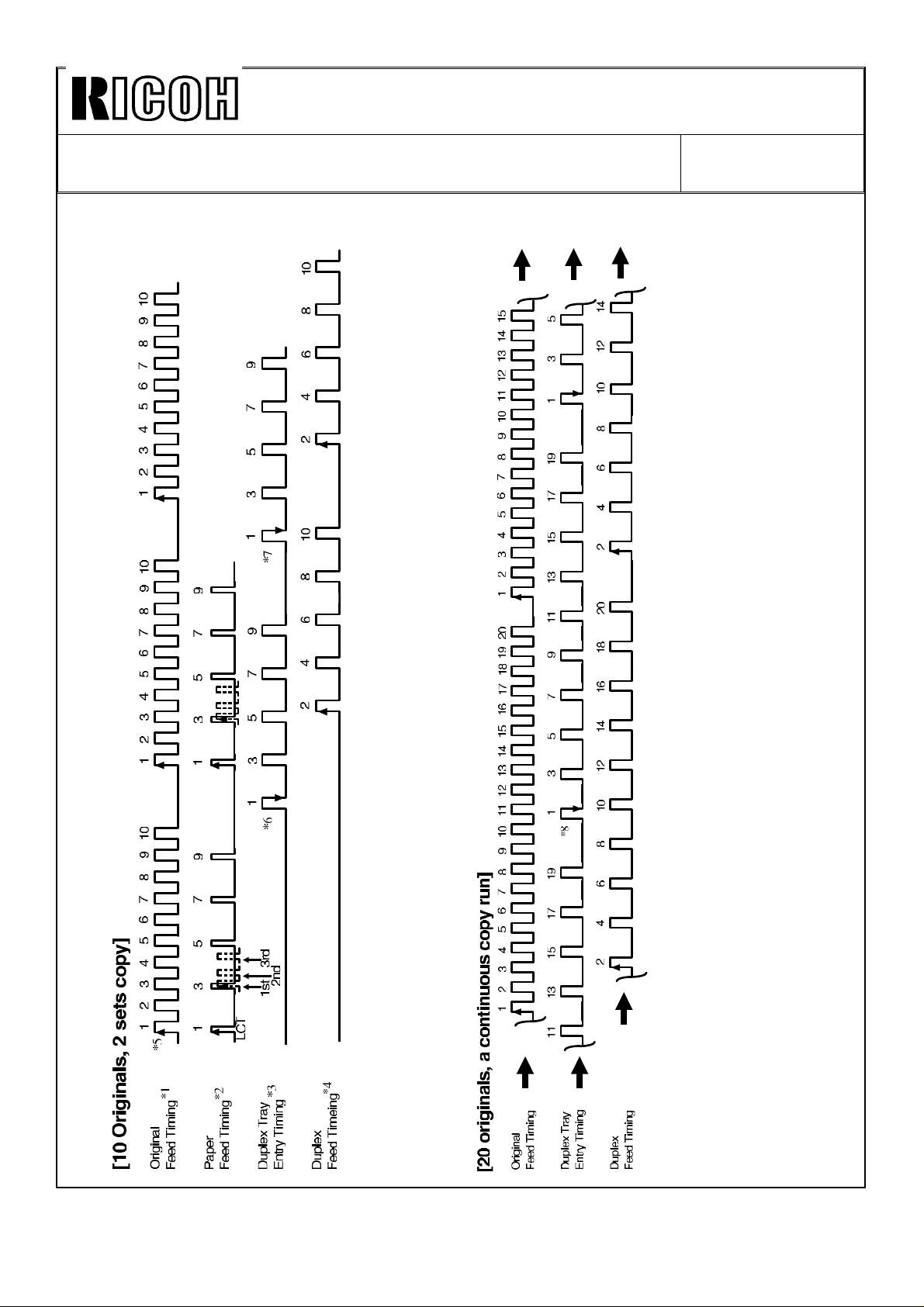

2.2 ALTERNATE PAPER FEEDING TIMING CHART

Page 18

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 8 of 23

*1 to *8 on the charts in the previous page show the key points for understanding

the alternate paper feeding. Refer to the explanation below for each key point. The

timing charts are based in the following copy mode conditions:

Upper One: Two sets of copies are made from 10 originals in the simplex original

to duplex copy mode.

Lower One: A large number of copy sets are made from 20 originals in the

simplex original to duplex copy mode. The timing chart shows only part of the copy

run.

*1: "Original Feeding Timing" shows when each original feed starts from the stack

original feed table. The numbers 1 to 10 identify the originals. The chart means

that the 10 originals are recirculated three times.

*2: "Paper Feed Timing" shows the timing when each paper is fed from the LCT. The

numbers correspond to the number of the original which will be copied on the front

side of the paper.

The chart shows only odd number because the even numbered originals are

copied on the reverse side of the paper.

The paper feed start timing is different when paper is fed from the LCT, 1st tray,

2nd tray, and 3rd tray. This is because paper transportation takes more time

depending on where the paper feed starts and where images are transferred to the

paper. The time for the LCT is the longest and that for the 3rd tray is the shortest.

If the paper is fed from a station other than the LCT, the paper for the first original

starts being fed as shown in the dotted lines. The following paper feed intervals

are the same as that for the LCT.

*3: "Duplex Tray Entry Timing" shows when the paper activates the duplex entrance

junction sensor and is delivered to the duplex tray. The number on top of each

entry timing corresponds to the number of the original which has been copied on

the front side of the paper.

*4: "Duplex Feed Timing" shows when the paper for each original is fed from the

duplex tray. The number on top of each duplex feed timing correspond to the

number of the original which will be copied on the reverse side of the paper.

As the timing chart shows, during the first original feed cycle only the odd

numbered originals are copied onto the paper fed from the paper tray. During the

2nd cycle the odd numbered originals are copied as in the first cycle, and also

even numbered originals are copied onto the paper fed from the duplex tray.

Copying for the front and reverse sides is done alternately in this period. (This is

the alternate paper feeding.) For the 3rd original feed cycle (i.e. the last original

feed cycle) only the even numbered originals are copied onto the paper from the

duplex tray, completing the copy run (two sets of five duplex copies are completed).

Page 19

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 9 of 23

*5: When the LCT is used the original to be copied starts being fed from the stack

original feed table and the paper for it starts being fed from the LCT right away.

During the first original feeding cycle, the 2nd original (and also the following even

numbered originals) is just fed and returned without being copied. During the 2nd

cycle, all originals are copied. Finally during the last original feed cycle, only the

even numbered originals are copied.

*6: The copy of the first original enters the duplex tray just after the 10th (last) original

starts being fed and before the first original starts being fed for the 2nd feed cycle.

This duplex tray entry timing for the first copy does not depend on the paper being

fed from the LCT, first tray, 2nd tray, or 3rd tray. This is because the time for the

paper to enter the duplex tray after images are transferred to the paper is constant

no matter where paper is fed from.

Just after the 3rd paper has entered the duplex tray, the paper which first entered

in the duplex tray starts being fed from the duplex tray in order to match with the

copying for the 2nd original during the 2nd feeding cycle.

*7:‘ The 2nd copy of the first original enters the duplex tray just before the first original

starts being fed for the last original feed cycle. When this happens, the last copy in

the duplex tray just starts being fed. This means that

a) when the first copy made during the next original feed cycle enters

the duplex tray and

b) if the number of originals is 10 or less (as in this case) then

c) the duplex tray is empty even in the alternate paper feeding motion.

*8: The lower timing chart shows simplex original to duplex copying using 20 originals.

There are copies remaining in the duplex tray (approximately 6 copies in this case)

when the first copy made during the next original feed cycle enters the duplex tray.

This chart also shows that the copy of the first original enters the duplex tray just

after the 10th original starts being fed, as in the upper timing chart.

Page 20

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 10 of 23

2.3 ACCOUNTING MODES

There are two types of accounting mode: security accounting mode and (normal)

accounting mode. In the normal accounting mode, all of the operators can use the

user access code mode in user tool number 9. In the security accounting mode,

only key operators whose user access codes are registered by their service

representative can use all the user access code mode. (For the user access code

mode, refer to the operating instructions.)

1. How to enter the copy mode in the accounting mode

Enter one of user access codes by pressing the Number keys.

2. How to leave the copy mode in the accounting mode

Press the Clear/Stop key while pressing the Clear Modes key.

3. How to set the accounting modes

1. Normal Accounting Mode

Press the "Access Code" key in service tool 2-08. Then enter appropriate user

access codes with user tool number 9.

2. Security Accounting Mode

(1) Be sure that the "Free Use" key is selected with service tool 2-08. Then enter

an appropriate user access code with user tool number 9. The user access codes

entered in this condition will be the codes for the key operator.

(2) Press the "Access Code/Super User Mode" key with service tool 2-08. Then

return to the normal screen.

(3) Enter appropriate user access codes with user tool number 9. This will be the

codes for normal operator.

4. How to enter the copy mode in the accounting mode for servicing

The accounting mode is canceled when DIP switch 101- 2 on the main control

board is ON. Note that DIP switch 101-2 is commonly used to enable accessing

the service tool password "999900." DIP switch 101, 102, and 103 on the main

control board must be kept at the initial setting, except 101-1 and 101-2 which

have the same functions as the sorter and sorter stapler versions.

CAUTION: When the main control board is replaced with a new one, all data in

user tool number 9 must be cleared in order to reset RAM on the main control

board and start up the use of the user access code mode. (This is the same as

the data in service tools 3-01 to 3-07. All data must be cleared when the main

control board is replaced.)

Page 21

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 11 of 23

2.4 COVER SHEET AND CHAPTERING MODES

The following are different from the cover sheet and chaptering modes of the

sorter stapler version model. They are features unique to the finisher version

model.

1. With user tool number 8 " Select Special Tray," the 1st paper tray can be

designated as only for the cover sheet, and one of the 1st, 2nd and 3rd paper tray

can be designated as only for the slip sheet for the chaptering mode. Two paper

trays can be designated separately for the cover and slip sheets at the same time.

When no paper tray is designated, the paper in the 1st paper tray is automatically

used for the cover and slip sheets, just like in the sorter stapler version model.

2. In the chaptering mode with the simplex originals to duplex copies mode, the

original designated as the first page of each chapter is automatically copied onto

the front side of the copy. For example, when the 4th original is designated, the

reverse side of the 2nd copy will be blank and the 4th original is copied onto the

front side of the 3rd copy.

In this mode, users can select to have the designated original copied onto special

paper (slip sheet) or normal paper.

3. When the back cover is selected in the cover mode, it can be selected with user

tool number 10 "User Utility/Reverse Back Cover Sheet." In this case, the setting

decides if the image of the back cover faces inside of the copy set (normal) or

outside.

4. In the chaptering mode, up to 15 originals can be designated by pressing the

"Next" key, although for the sorter stapler version model, up to 10 can be.

5. Even in the duplex copy mode, the copy for the original which is designated as

the cover and slip sheets does not enter the duplex tray. This is to enable the use

of copy paper up to 163 g/m2 of paper weight. It is usually up to 120 g/m2 for

duplex copies. Therefore, the cover and slip sheets have images only on one side.

Refer to the following explanation for understanding how this is done. (In the

chaptering mode with the simplex originals to duplex copies mode, if the copy for

the designated original to normal paper is selected, the copy will enter the duplex

tray and have images on both sides as usual.)

1. How the copies are collated into sets in the duplex copy mode with the

cover or chaptering mode

In the simplex originals to duplex copy mode, the original next to the designated

one is copied on the front of the copy next to the cover or slip sheet, resulting in

having the reverse side of the cover and slip sheets blank. In the duplex original to

duplex copy mode, the reverse side of the designated original is not copied,

resulting in having the reverse side of the cover and slip sheets blank. (Therefore,

the reverse side of the designated original should be blank.)

Page 22

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 12 of 23

In the simplex or duplex original to duplex copy mode, the duplex copies are

automatically delivered to the finisher shift tray, not to the copier copy tray. The

copies are stacked in page order on the shift tray without being inverted. However,

as the copy image on the cover and slip sheets is made while the reverse side

copies are made, in order not to enter the cover and slip sheets into the duplex

tray, only the cover and slip sheets are inverted in the finisher to stack all copies in

page order.

2. How the designated original is copied in the duplex original to duplex

copy mode

In the duplex original to duplex copy mode, although the original designated with

the cover or chaptering mode is always copied on the front side of the cover or slip

sheet, it is copied during the second original feeding cycle, not during the first one.

This is because the cover or slip sheet must enter the duplex tray if the designated

original is copied during the first original feeding cycle. To allow this, the original

recirculating motion in this mode is different from that in the duplex original to

duplex copy mode without the cover or chaptering mode, as follows:

1. During the 1st Original Feeding Cycle: The front side of the originals set in the

RDH is copied as usual. However, the designated original is not copied during this

cycle. Before the designated original feeds out to the stack feed table, it is not

inverted. As a result, the front side (image side) of the designated original only

faces the direction of the reverse side of the other originals and stacked in the

stack feed table.

2. During the 2nd and the Following Original Feeding Cycle: During the 2nd cycle,

the reverse side of the originals is copied. The designated original is copied during

this cycle. The completed duplex copies are delivered to the shift tray. As the copy

image on the cover or slip sheet is made while the reverse side of the other

originals is copied, only the cover or slip sheet is inverted in the finisher to stack all

copies in page order.

For the following cycles, both sides of the originals, including the designated

original, are copied as usual in the duplex original to duplex copy mode until all the

desired copy sets complete. Even during this period, only the cover or slip sheet is

inverted in the finisher to stack all copies in page order.

3. During the Last Original Feeding Cycle: After completing the copy run, one more

original feeding is done. This is to return the designated original, which had been

made side down during the first original feeding cycle, into the original setting.

(The designated original is inverted before it feeds out to the stack feed tray, and

the other originals are not.)

As a result, the original feeding is twice the desired number of copy sets plus, one.

Page 23

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 13 of 23

2.5 DIFFERENCES IN MECHANISM BETWEEN THE ADF AND RDH

[ADF Type]

1. Recycle Arm Solenoid

The ADF feeds originals just once for each copy job. On the other hand, the RDH

recirculates originals according to the desired copy set number. Due to this, in the

RDH, the recycle arm is repeatedly placed on the original stack and repeatedly

returned for each copy set. If the existing type of the solenoid is used, it will

malfunction due to heat generated by the repeated on and off operation.

To cope with this, a new solenoid has been used to operate the recycle arm. It is a

two-way solenoid, which is the same as the one used for the finisher junction gate,

and once the position of the solenoid plunger is changed according to the signal

from the CPU, this solenoid keeps its position until a different signal is generated.

This works using a permanent magnet installed in the solenoid.

2. Original Transport Drive Motor

[RDH Type]

There are three dc motors (#AX060027) to drive the original transport rollers. In

the RDH, the motors have been changed to more durable ones. There is a groove

for an E-ring in the shaft of the existing motor, but the motor for the RDH

(#59365501) does not have such a groove.

3. Instruction Decal

There is a decal (#AA000114), which instructs how originals are set, in the stack

original feed table. There is no problem with the ADF system, but it has been

found that electrostatic charges are generated in the decal due to the recirculating

motion of originals. As a result, the bottom original stacked in the original table

tends to stick to the decal and misfeed.

To cope with this situation, the decal has been moved to the right end of the

original table cover.

Page 24

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 14 of 23

3. NEW SELF-DIAGNOSTICS FOR THE FINISHER

The following Error reset status codes have been added for the finisher

self-diagnostics:

NOTE: There are two types of self-diagnostics: one is "Service call" and the other is "Error

reset." A Service call occurs when a problem that may cause serious damage to

the machine is detected.

Classification

Finisher SC93 Wait/busy

Status

Code

SC94 Signal

SC95 Motor drive

SC96 Motor drive

SC97 Motor drive

Item Symptom Possible Cause Remarks

signal error

transmission

error from

the finisher

error 1

error 2

error 3

A wait or busy

signal from the

finisher stays

generated for more

than 25 seconds.

After the copier CPU

sends a status

request signal to the

finisher, there is no

response signal

from the finisher for

more than 10

seconds.

A status that the

finisher cannot

make copies in both

shift tray and staple

modes due to a

defective motor is

detected.

A status that the

finisher cannot

make copies in shift

tray mode due to a

defective shift motor

is detected.

A status that the

finisher cannot

make copies in

staple mode due to

a defective motor is

detected.

Defective finisher or

inverter control board.

Optics fiber cable

disconnected, or

defective copier main,

finisher, or inverter

control board.

Defective inverter or

finisher transport

motor, shift tray lift

motor, exit drive

motor, stopper drive

motor, or their related

sensor.

Defective shift motor

or shift tray half turn

sensor.

Defective jogger,

stapler drive, staple,

stack feed-out, or

inverter stopper drive

motor, or their related

sensor.

Service call

indication

appears in

the

operation

display

when these

symptoms

are

detected.

Page 25

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 15 of 23

4. MAIN CONTROL BOARD DIP SWITCH SETTING

As the main control board has been changed, the new one has three dipswitches.

Each function is as follows:

Dipswitch No. Function at ON Function at OFF

Allows the use of the service

DPS101-1

DPS101-2

DPS101-3 Not used. Not used. OFF

DPS102-1

DPS102-2 Not used. Not used. OFF

DPS102-3 Not used. Not used. OFF

DPS103-1

DPS103-2

DPS103-3 Not used. Not used. OFF

tool access code which is

entered with service tool "1-02."

1) Allows the use of the initial

service tool access code: 99900.

2) Allows the operation of the

copier without entering any user

codes, even in the normal and

security accounting modes.

Japanese version (destination

identification).

Production use only. (Must be

ON.)

Production use only. (Must be

OFF)

Disables the service tool access

code which is entered with service

tool "1-02. "

1) Disables the initial service tool

access code: 99900.

2) Allows the selection of the

normal and security accounting

modes with service tool "2-08."

Overseas version. ON

Production use only. (Must be ON.) ON

Production use only. (Must be

OFF)

Default

Setting

OFF

OFF

OFF

Page 26

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 16 of 23

5. MEAN POWER CONSUMPTION DATA

Mean Power Consumption

Copier only Copier + LCT Copier + LCT + Finisher

During copying

During warm-up

During stand-by

(Fusing Lamp OFF)

Main switch OFF

(During first 30min.)

Main switch OFF

(After 30 min.)

3.10 kW (380 V)

3.27 kW (400 V)

3.43 kW (415 V)

2.32 kW (380 V)

2.46 kW (400 V)

2.61 kW (415 V)

0.25 kW (380 V)

0.25 kW (400 V)

0.25 kW (415 V)

0.11 kW (380 V)

0.12 kW (400 V)

0.13 kW (415 V)

0.07 kW (380 V)

0.07 kW (400 V)

0.07 kW (415 V)

3.12 kW (380 V)

3.28 kW (400 V)

3.44 kW (415 V)

2.33 kW (380 V)

2.48 kW (400 V)

2.62 kW (415 V)

0.26 kW (380 V)

0.26 kW (400 V)

0.26 kW (415 V)

0.11 kW (380 V)

0.12 kW (400 V)

0.13 kW (415 V)

0.07 kW (380 V)

0.07 kW (400 V)

0.07 kW (415 V)

3.45 kW (380 V)

3.60 kW (400 V)

3.70 kW (415 V)

2.40 kW (380 V)

2.55 kW (400 V)

2.69 kW (415 V)

0.32 kW (380 V)

0.32 kW (400 V)

0.32 kW (415 V)

0.11 kW (380 V)

0.12 kW (400 V)

0.13 kW (415 V)

0.07 kW (380 V)

0.07 kW (400 V)

0.07 kW (415 V)

NOTE: The mean power consumption data for the "Copier only" and "Copier +

LCT" are the same as those of the sorter version machine.

Page 27

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 17 of 23

6. USER TOOLS

The following are the new user tools for the finisher version model:

1. User Tools Unique for the Finisher Version

Item

(Menu No.)

Disable

Display

(6)

Disable Unit

(7)

Select

Special

Tray

(8)

User

Access

Code

(9)

Description

1) The option installation (system setup) function has been moved to service tool

1-08.

2) The "Staple" key used for the sorter stapler version model has been removed.

3) The other functions are the same.

A "Finisher" key for disabling the finisher has been added instead of the "Sorter

1 to 3" keys.

The 1st paper tray can be designated as only for cover sheets. One of the 1st,

2nd, and 3rd paper trays can be separately designated as only for slip sheets.

The designated paper tray will also have the same features as the special tray

that is set with service tool 2-12.

Menu number 8 "Sorter Stack Face Up/Down" used in the sorter stapler version

has been removed. (The "Select face up/down in stack mode" has been added

to user tool number 10 "User Utility" instead.)

When the accounting mode (the "access code" key) or security accounting mode

(the "Access Code/Super User Mode" key) is selected with service tool 2-08, the

following are available with this function:

1) Up to 500 user codes can be registered.

2) The registered user codes can be changed or deleted.

3) The number of copies made using each user code can be displayed. The data

can also be printed if the optional printer and printer connector unit are installed.

NOTE: The DIP switch setting (the printer side) is different from that for the

F200. The data bit length for the F200 is 7-bit, and that for the F5 is 8-bit.

4) When the security accounting mode is selected, selected only key operators

can use the above features. Other operators can only check the number of

copies made using their own user codes.

User Utility

(10)

For understanding how to use this mode, refer to the operating instructions.

Some functions in the service tools have become available in the user tools. In

addition, some new functions have been added. For details, refer to the "User

Utility Table" below.

Page 28

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 18 of 23

2. User Utility Table (User Tool No. 10)

Item Description

Select the finisher mode The sort or stack mode can be selected. (Default: Sort)

Staple in stack mode Stapling with the stack mode is available. (Default: No, not

effective) This function is the same as service tool utility (4-05)

13-5-9.

Auto tray switching This function is the same as service tool 2-10. The title has been

changed from "Limitless Paper Feed." (Default: Yes, the default has

been changed from that for the sorter stapler version.)

3-side full image copy A new key, beside the Check modes key, to select the 3-side full

image copy mode can be used. This function is the same as

service tool utility (4-05) 7-5-0. The title has been changed from

"No Erase Copy." (Default: No)

The 3-side full image mode is selected at power on when "Yes" is

selected with service tool 2-09 "3-side Full Image"

Select count up or down

mode

Display the number of

originals

Exit originals to tray A new key, beside the Check modes key, to select the original tray

Select face up/down in

stack mode

Reverse back cover sheet This is a new function. When the back cover is selected in the

Copy onto slip sheets This is a new function. When copies are made in the chaptering

NOTE: For functions which can be set with both the user utility and service tools, if the

data is changed with one, the data in the other will be changed automatically.

Adding each copy or subtracting each copy for the copy number

counter can be selected. This function is the same as service tool

2-01. (Default: Up)

The number of originals copied in the stack original feed mode is

displayed in the message area after copying. This function is the

same as service tool 2-11 "Original Count Display." (Default: No)

exit mode can be used. This function is the same as service tool

utility (4-05) 4-1. (Default: No)

Copies made in the stack mode can be delivered face up (image

side up) to the shift tray. This function is the same as user tool

number 8 "Sorter Stack Face Up/Down" used in the sorter stapler

version. (Default: No)

cover mode, users can select to have the image of the back cover

face inside of the copy set or outside. (Default: Yes, It faces

outside.)

mode, users can be select to have the image of the designated

original copied on the slip sheet or not. (Default: Yes)

Page 29

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 19 of 23

7. SERVICE TOOLS

The following are the new service tools for the finisher version model:

1. Service Tools Unique for the Finisher Version

Item

(Menu No.)

1 System Set-up

Option

Installation

(1-08)

2 User Functions

Maximum

Copy Number

(2-06)

Staple Copy

Limit

(2-07)

Free/User

Access Code

Operation

(2-08)

3 Data Logging

Duplex/

Finishing

Copies (3-02)

Supply

Yield/Forming

(3-04)

RDH/Finisher

Misfeeds

(3-06)

The option installation (system setup) function, which is in user tool number 6

"Disable display" for the sorter stapler version, has been moved.

To install the LCT, finisher, and key counter, this function must be used.

The maximum copy set number can be changed within a range of 1 to 9999.

(Default: 9999)

The selection of the maximum copy set number for the sort mode has been

removed because this is only for the ADF and sorter system.

The maximum staple capacity in the staple mode can be changed within a

range of 40 to 50 sheets. (Default: 50)

The "sorter bin copy limit" function used in this position of the sorter and sorter

stapler versions has been removed.

This is a new function. The accounting mode and security accounting mode can

be set. Press the "Access Code" key for the accounting mode and the "Access

Code/Super User Mode" key for the security accounting mode. Press "Free

Use" key to cancel these mode. (Default: Free Use) For the accounting and

security accounting modes, refer to the "2.2 ACCOUNTING MODES."

The "dual sort" function used in this position of the sorter and sorter stapler

versions has been removed.

The number of sheets entered into the finisher is displayed by paper size,

instead of that for the sorter. The number of the sheet entered into the duplex

tray is also displayed as in the sorter and sorter stapler versions.

In addition, the number of used staple is displayed. (In sorter stapler version, it

was displayed separately for the 1st, 2nd, and 3rd sorters.)

Paper misfeeds in the finisher is accumulated and displayed by location and

type: Inverter On Check, Inverter Off Check, and Finisher On check, instead of

that for the sorter. Original misfeeds in the RDH is also accumulated and

displayed as in the sorter and sorter stapler versions.

Description

Page 30

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 20 of 23

Item

(Menu No.)

4 Process Control

Utility

(4-05)

5 System Test

Set Staple

Position

(5-07)

6 Print Out

(6)

Description

Some new functions have been added. For details, refer to the "Utility Modes

Unique for the Finisher Version" below.

This is a new function. The staple positions on the copy paper can be

adjusted by following the instructions on the screen.

This is a new function. The following data can be printed If the optional

printer and printer connector unit are installed.

NOTE:

(1) A printer with a standard RS232C interface is required. Use the printer

with functions as follows:

Mode: Asynchronous

Data format: Start/Stop/Data bit: 1 bit each

Data bit length: 8 bits

Parity permission: With

Parity setting: Even parity

Baud rate setting: 1,200 bps

Connector: 25 pins, D-connector

(2) If a Seiko printer DPU-411 is used, the dip switch settings are as follows

(note that the setting of DIP02 SW1 is different from that for the F200. The

data bit length for the F200 is 7 bits, and that for the F5 is 8 bits):

SW1 to 8 of DIP01: OFF/OFF/OFF/ON/ON/OFF/ON/ON

SW1 to 6 of DIP02: ON/OFF/OFF/OFF/ON/ON

(3) This function can be used without the optional printer connector unit if the

interface board (P/N A112 5060), harness between the interface board and

printer (P/N A531 5420), harness between the main control board and

interface board (P/N A112 7120), and 2 connector joint studs (P/N 1102

4139) are available, so that the printer can be connected to CN101 on the

main control board. The parts will be included in the copier from the June ’93

production. (For details, refer to MB no. 5.)

Process Control: Data for service tool 4-01 to 4-03.

Copies: Data for service tool 3-01 to 3-04.

Misfeeds: Data for service tool 3-05 and 3-06.

Service Ca lls: Data for service tool 3-07.

Operation Time: Data for service tool 3-08.

System Setup: Data for user tool no. 2, 3, 4, 6, 7, 8, 10, service tool 1-01 to

1-08, 2-01 t o 2-16, 4-04 , 4-05, 5- 02, 5-03 , 5-07.

All Items: All data for the above items.

Page 31

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 21 of 23

2. Utility Modes Unique for the Finisher Version

Mode No.

Set No. of

Mode No. 5

0 to 7

8

9

10 6-5-10 7-5-10 8-5-10 9-5-10 11-5-10

11

12

13

14

15

NOTE: (1) "6-5-10" means that mode number 6, which can be turned ON or OFF, is ON

when mode number 5, which can be set at 0 to 15, is set at 10.

6 7 8 9 10 11 12 13 14

(2) The utility modes common with the sorter and sorter stapler versions are not

listed.

(3) Utility 2-10 "Duplex Speed-up Mode" is still valid when the stack mode, not sort

mode, is selected.

(4) Utility 1-8, 1-9, 2-8, 2-9, 7-5-9, and14-5-9 are not valid for the finisher version.

6-5-10: Automatic Staple Mode Selection

Users can select to have the auto staple mode (1 upper staple) or shift tray ON

mode selected when the Finishing key in the free operator screen is selected.

(Default: OFF, The shift tray ON mode is selected.)

7-5-10: Reverse Back Cover Sheet

This mode is the same as that in the user tool number 10 "User Utility."

8-5-10: Copy onto Slip Sheet

This mode is the same as that in the user tool number 10 "User Utility."

9-5-10: Manual Staple Mode

Enables the use of the manual staple mode when originals are set in the single

original feed mode or on the exposure glass. For understanding how to use the

manual staple mode, refer to the operating instructions. (Default: OFF, The manual

staple is not effective.)

11-5-10: Automatic Paper Feed Out in Manual Staple Mode

While copies are made in the manual staple mode, when this mode is selected

and the number of the copies stacked in the staple tray of the finisher exceeds the

stack capacity set with service tool 2-07, the copies are automatically fed out from

the jogger tray. (Default: OFF, This mode is not effective and the copies are

stacked in the jogger tray until the "#" key is pressed.)

Page 32

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 22 of 23

3. Utility Mode Comparison Table of the Sorter, Sorter/Stapler, and Finisher Versions

Mode

No.

1

2

3 8 Paper Size Erase Mode 0 0 0

4 1 Original Tray Exit Mode 0 0 0

5

Set No. Mode Name

8 Original Count Indication

9

10

12

8 Continues Duplex Copying

9

10

0 SADF 50 cpm

1 SADF 34 cpm

2 SADF 25 cpm

3 SADF 20 cpm

Combination of "1-8" and

"1-10"

Disables Paper Near-end

Indication

Clears All Stored User

Programs

Combination of "2-8" and

"2-10"

Duplex Speed-up Mode

Default Setting for Each Mode No.

Sorter Sorter/Stapler Finisher

00

10 10

000

NOTE: "1-8"

and "1-9" are

not effective.

1) "2-8" and

"2-9" are not

effective in the

stack mode

0

10

NOTE:

effective.

2) "2-10" is

only.

Mode

No. (6

to 14)

6

7 No Erase Copy Mode OFF OFF OFF

8 Not used Must be OFF Must be OFF Must be OFF

9 Not used Must be OFF Must be OFF Must be OFF

10 Not used Must be OFF Must be OFF Must be OFF

11 Automatic Dual Sort Mode OFF Not valid Not valid

12 Not used Must be OFF Must be OFF Must be OFF

13

14 Not used Must be OFF Must be OFF Must be OFF

Setting

of

Mode

No. 5

0 to 7

Mode Name

Automatic Sort Selection ON ON OFF

Margin Adjustment Present

Memory

Default Setting for Each Mode No.

Sorter Sorter/Stapler Finisher

OFF OFF OFF

Page 33

Technical Bulletin No. RTB-005

SUBJECT: Finisher Version Information DATE: July 15, ’93

PAGE: 23 of 23

Mode

No. (6

to 14)

6

7 Automatic APS Selection ON ON ON

8 Not used Must be OFF Must be OFF Must be OFF

9 Not used Must be OFF Must be OFF Must be OFF

10 Disable Flash Life Notice OFF OFF OFF

11

12

13 Not used Must be OFF Must be OFF Must be OFF

14 Valid Pre-heat Key OFF OFF OFF

6

7 Pause Stapling Not valid ON Not valid

8

9

10 Valid 81/2"x13" key ON ON ON

11 Not used Must be OFF Must be OFF Must be OFF

12

13 Stapling with Stack mode Not valid OFF OFF

14

6

7 Reverse Back Cover Sheet Not valid Not valid ON

8 Copy onto Slip Sheet Not valid Not valid ON

9 Manual Staple Mode Not valid Not valid OFF

10 Not used Must be OFF Must be OFF Must be OFF

11

12 Not used Must be OFF Must be OFF Must be OFF

13 Not used Must be OFF Must be OFF Must be OFF

14 Not used Must be OFF Must be OFF Must be OFF

Setting

of

Mode

No. 5

8

9

10

Mode Name

Fusing Jam Indication OFF OFF OFF

Fusing Rush Current

Prevention

Sorter/Sorter-stapler System

Switching

A3 Double Copy Count OFF: Double

Duplex Tray Maximum Limit OFF: 40 (A3)/

Automatic Staple Mode

Selection

Disable Cover/Chaptering

Modes

Sort Copies in Reverse

Order

Automatic Staple Mode

Selection

Automatic Paper Feed Out

in Manual Staple Mode

ON ON ON

ON (Must be

OFF to use

the sorter)

Count Mode

80(A4)

Not valid OFF Not valid

Not valid OFF OFF

Not valid OFF Not valid

Not valid Not valid OFF

Not valid Not valid OFF

Default Setting for Each Mode No.

Sorter Sorter/Stapler Finisher

ON Not valid

OFF: Double

Count Mode

OFF: 40 (A3)/

80(A4)

OFF:Double

Count Mode

OFF: 40 (A3)/

80(A4)

Page 34

Technical Bulletin No. RTB-006

SUBJECT: Installation Procedure for Key Counter/Printer Connector

Bracket and Printer Connector Unit (Finisher Version Only)

PREPARED BY: H. Kokubo

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F5

(Gestetner 25101/

Nashuatec 53101)

DATE: July 15, ’93

PAGE: 1 of 5

1. ACCESSORY CHECK

Check the quantity and condition of the accessories in the box according to the following

list.

Key Counter Bracket Accessory Check

1. Snap Bushing....................................................1

2. Wire Clamp .......................................................2

3. Philips Sunken Head Screw - M3 x 8 .............2

4. Philips Pan Head Screw - M4 x 8 ...................4

5. Philips Plated Screw - M4 x 8 .........................4

6. Grounding Screw with Star Washer ................2

7. Philips Plated Screw - M3 x 6 .........................2

8. Key Counter Hole Blind Cover ........................1

9. Key Counter Fixing Plate .................................1

10. Printer Connector Hole Blind Cover ................1

Printer Connector Unit Accessory Check

1. Grounding Screw with Star Washer ..................2

2. Philips Plated Screw - M4 x 8 ...........................1

3. Wire Clamp .........................................................1

CAUTION: The printer interface board (P/N A112 5060), printer harness (P/N

A531 5420), 2 connector joint studs (2 x P/N 1102 4039), and 4

nylon studs (4 x P/N 1105 0193), which are the copier’s

accessories, are required for the printer connector unit

installation.

Page 35

Technical Bulletin No. RTB-006

SUBJECT: Installation Procedure for Key Counter/Printer Connector

Bracket and Printer Connector Unit (Finisher Version Only)

2. INSTALLATION PROCEDURE

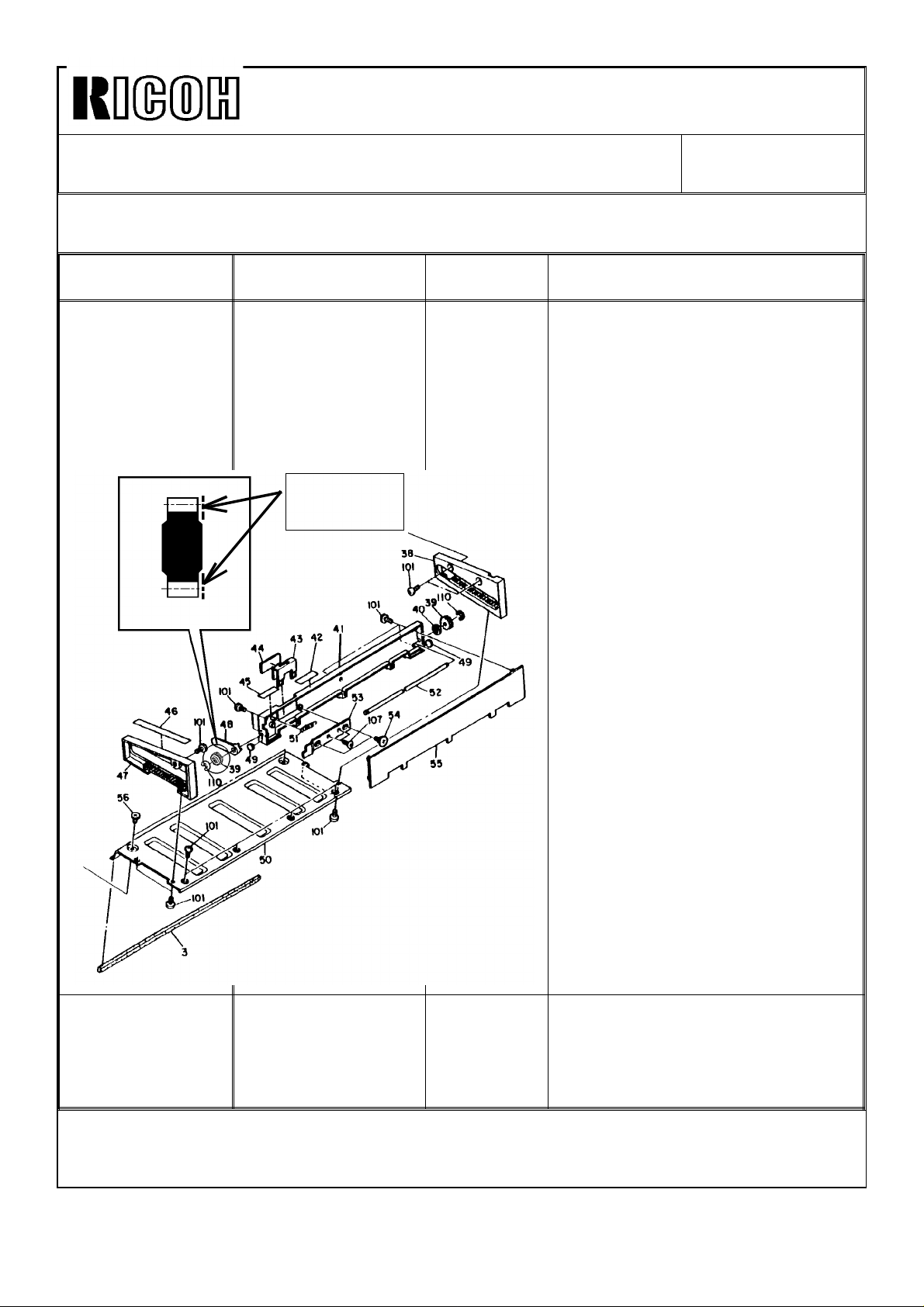

[A]

[D]

[B]

[C]

[D]

DATE: July 15, ’93

PAGE: 2 of 5

1. Remove the exterior cover [A] in the rear of the copy tray (3 screws). Then, remove

the two cover brackets [D] (2 screws each).

2. Install the key counter/printer connector bracket [C] with four M4x8 philips pan head

screws and one grounding screw [B] (accessories).

[A]

3. Install the snap bushing [A] (accessory) as shown.

4. Remove the copier rear right cover (2 screws).

5. Take the two connectors which are clamped behind the key counter/printer connector

bracket, then feed them through the hole in the bottom of the bracket as shown.

Page 36

Technical Bulletin No. RTB-006

SUBJECT: Installation Procedure for Key Counter/Printer Connector

Bracket and Printer Connector Unit (Finisher Version Only)

[A]

[E]

[C]

[D]

[B]

DATE: July 15, ’93

PAGE: 3 of 5

6. If an optional key counter is installed, install the key counter receptacle [A] with the

two M3x8 philips sunken head screws and key counter fixing plate [B] (accessories).

NOTE: The key counter must be one of the following:

- Hengstler

- Hecon

- Veeder Ro ot

7. Remove the shorting connector [E], then connect the connectors from the key counter

and copier.

8. Install the two wire clamps [D] (accessories) and clamp the harness as shown.

9. If the optional printer connector unit is not installed, install the printer connector

hole blind cover [C] with the two M3x6 philips plated screws (all are accessories).

Page 37

Technical Bulletin No. RTB-006

SUBJECT: Installation Procedure for Key Counter/Printer Connector

Bracket and Printer Connector Unit (Finisher Version Only)

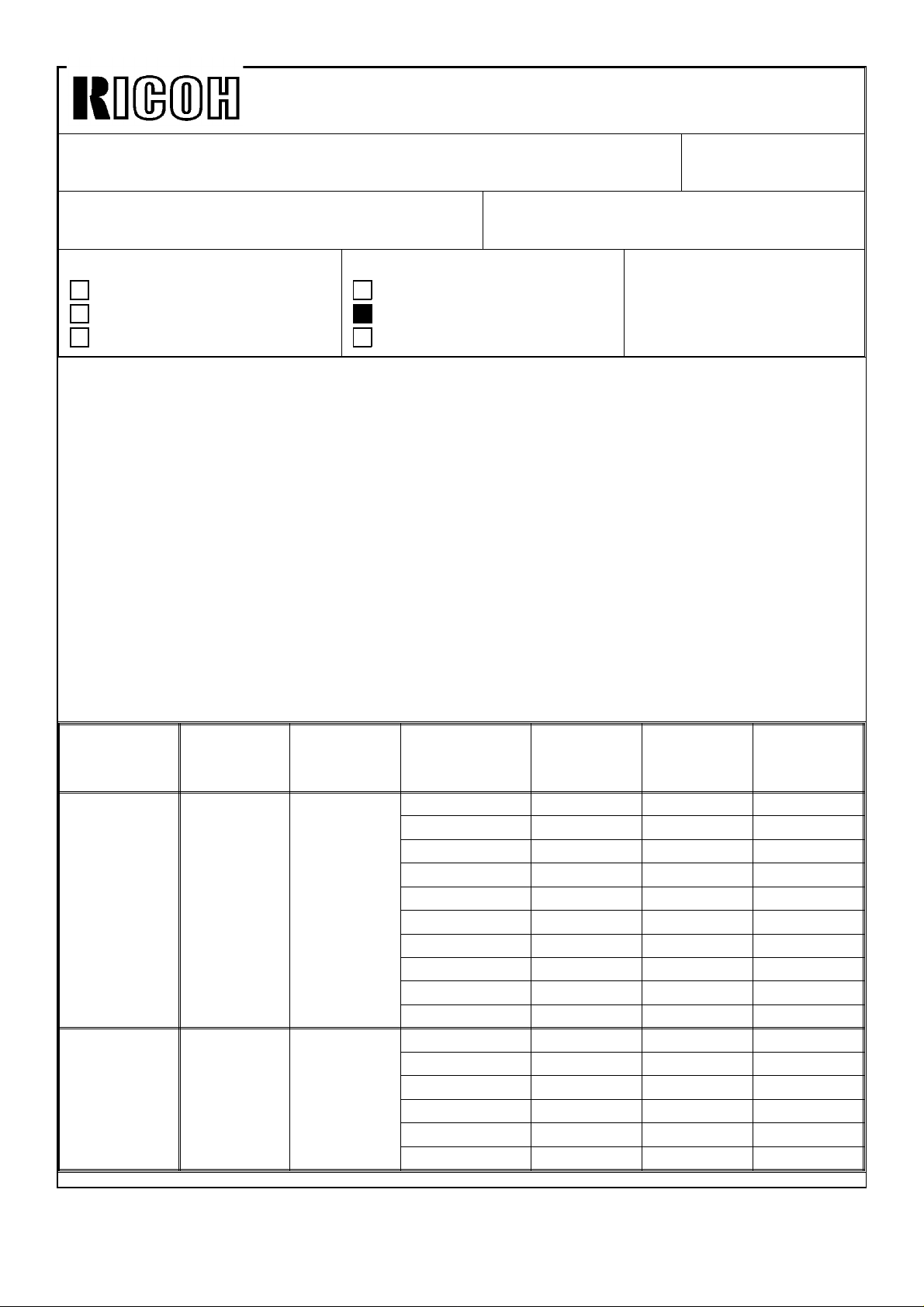

[B]

[A]

[C]

[D]

[E]

[L]

[H]

[I]

[K]

[J]

DATE: July 15, ’93

PAGE: 4 of 5

[F]

[G]

10. If the optional printer connector unit [A] is installed, install it with the grounding

screw [K] and M4x8 philips plated screw (accessories).

11. Connect the connector [J] of the harness form the copier to the PCB on the printer

connector unit.

12. Install the 4 nylon studs [E], then the printer interface board [D]. Connect the connector

of the harness from the printer connector unit to the interface board.

13. Install the printer harness [G] with the two connector joint studs [L].

NOTE: The printer interface board (P/N A112 5060), printer harness (P/N A531 5420),

2 connector joint studs (2 x P/N 1102 4039), and 4 nylon studs (4 x P/N 1105

0193), which are copier accessories, are required for the printer connector unit

installation.

14. Connect the other end of the printer harness to the connector on the printer interface

board.

15. Fix the grounding wire with the grounding screw [D] (accessory). Then, install the wire

clamp [F] (accessory) then clamp the printer harness with the clamp as shown.

16. If an optional key counter is not installed, install the key counter hole blind cover

[H] with the two M3x8 philips sunken head screws and key counter fixing plate [I]

(accessories).

Page 38

Technical Bulletin No. RTB-006

SUBJECT: Installation Procedure for Key Counter/Printer Connector

Bracket and Printer Connector Unit (Finisher Version Only)

[A]

[B]

17. Install the key counter/printer connector bracket cover [A] with the grounding screw [B]

and the 4 M4x8 philips plated screws (accessories).

DATE: July 15, ’93

PAGE: 5 of 5

NOTE: If the optional printer connector is installed, a printer with a standard RS232C

interface is required. Use a printer with the following functions:

Mode: Asynchronous

Data format: Start/Stop/Data: 1 bit each

Data bit length: 8 bits

Parity permission: With

Parity setting: Even parity

Baud rate setting: 1,200 bps

Connector: 25 pins, D-connector

Page 39

Technical Bulletin No. RTB-007

SUBJECT: Sorter Stapler Installation with Finisher Version Copier DATE: Sep. 30, ’93

PAGE: 1 of 4

PREPARED BY: H. Kokubo

CHECKED BY: T. Ito

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This bulletin is to inform you of how to modify the copier when the sorter stapler or sorter

(F5 sorter version copier’s options) is installed with the F5 finisher version copier.

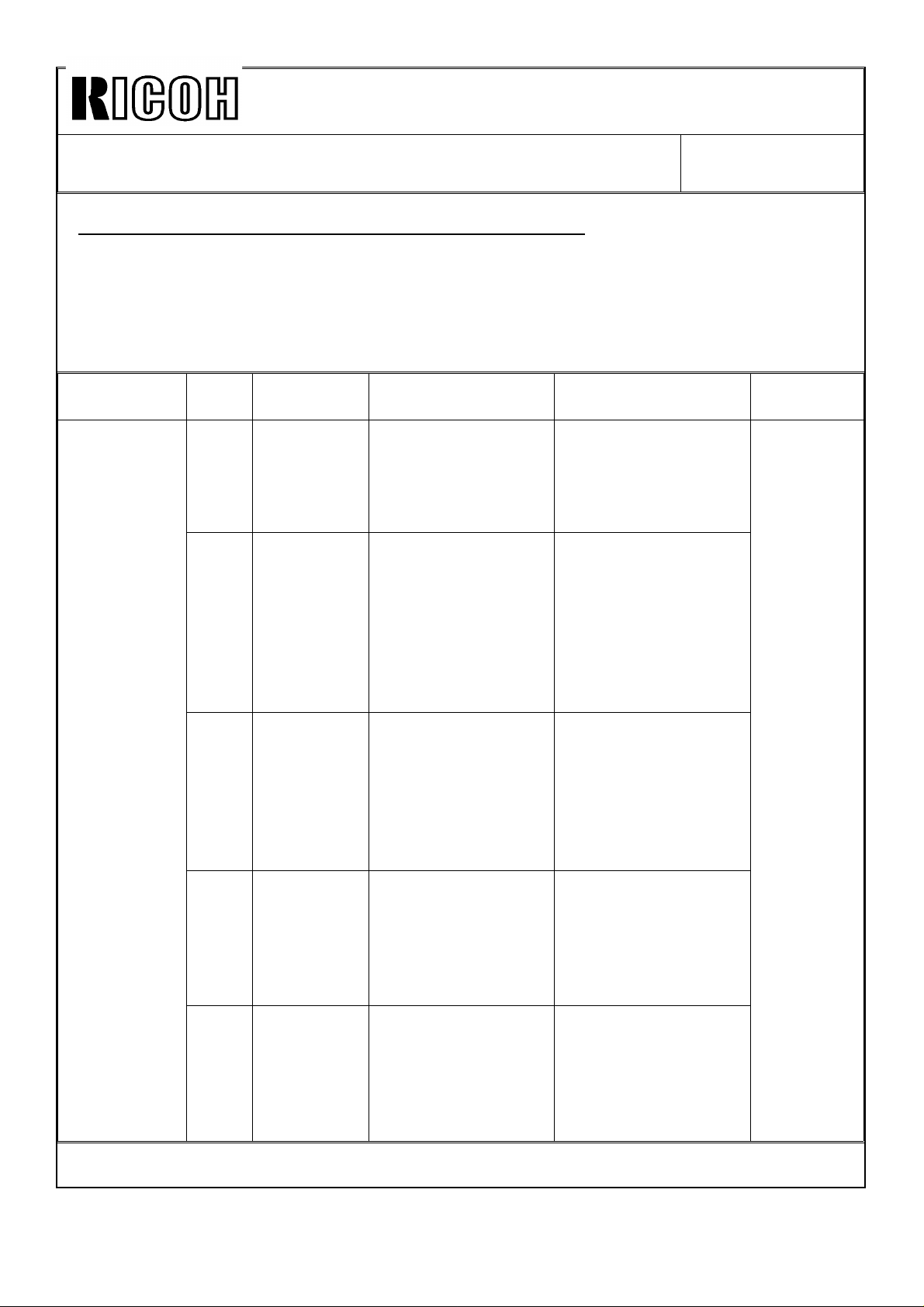

The table below shows all items to be modified:

Item To Be Modified Necessary Part Modification Procedure

All EPROMs on the operation

control board

All EPROMs on the main

board

DIP switch setting of the main

board

Short connector position on

the main board

10 ROMs. Refer to "ROM

Conversion Table" for details.

6 ROMs. Refer to "ROM

Conversion Table" for details.

None Turn OFF

None Disconnect the two short

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F5

Finisher Version Only

(nashuatec 53101)

Refer to Fig. 1 for the location

of each ROM.

Refer to Fig. 2 for the location

of each ROM. Fig.3 shows

necessary cautions when

replacing the ROMs.

DPS103-1

DPS103-2

connectors for

JP103

position. Then, set them to the

"512 KB" positions (see Fig.

5). This allows the use of the

512 k-byte ROMs, instead of 1

M-byte ROMs.

(see Fig. 4).

JP102

from the "1 MB"

and ON

and

Page 40

Technical Bulletin No. RTB-007

M3

M1

M2

M0

S1 S0

IC124 IC123

IC190

IC198

IC205

IC210

SUBJECT: Sorter Stapler Installation with Finisher Version Copier DATE: Sep. 30, ’93

PAGE: 2 of 4

ROM Conversion Table

ROM Location

Operation ROM

Board

Main Board

ROM Name