Page 1

MODIFICATION BULLETIN NO. 1 Page 1 of 8 ISSUED ON: June 30, ’92

Model F5 (NRG 25101) Volt/Hz

Modified Article Parts Catalog A028 - 22

Reason for

Parts catalog correction

Modification

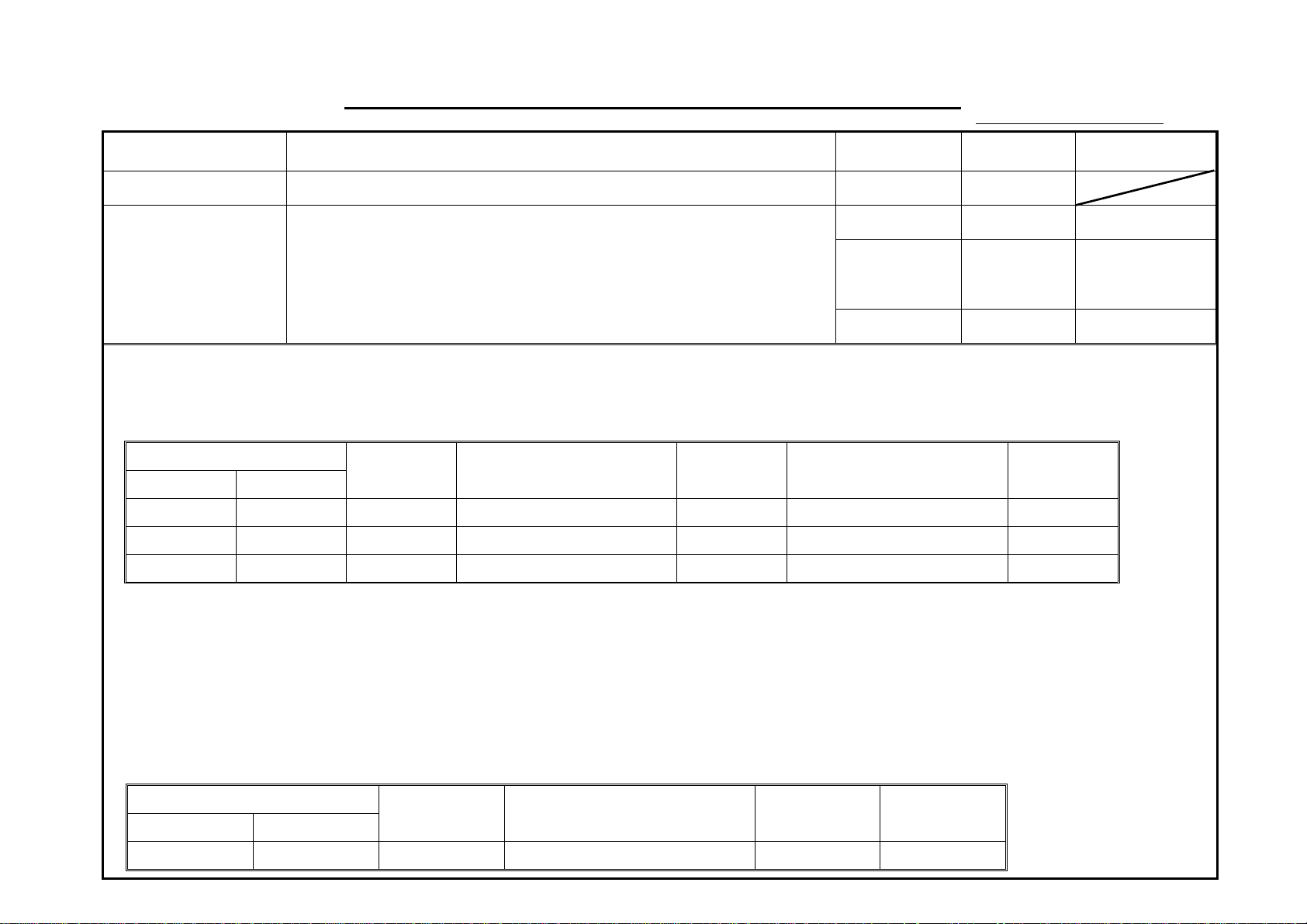

Correct your parts catalog as follows:

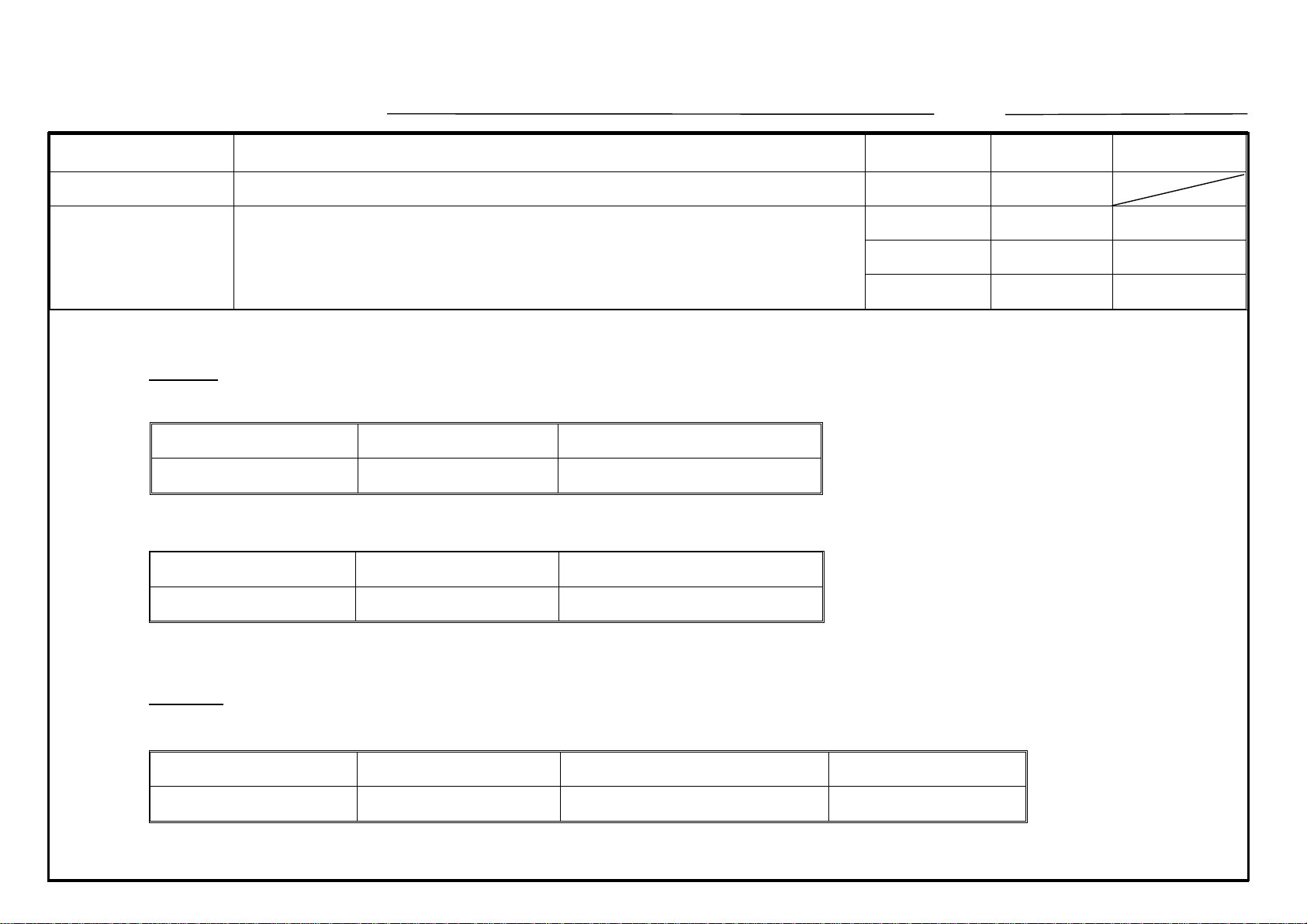

Page 17

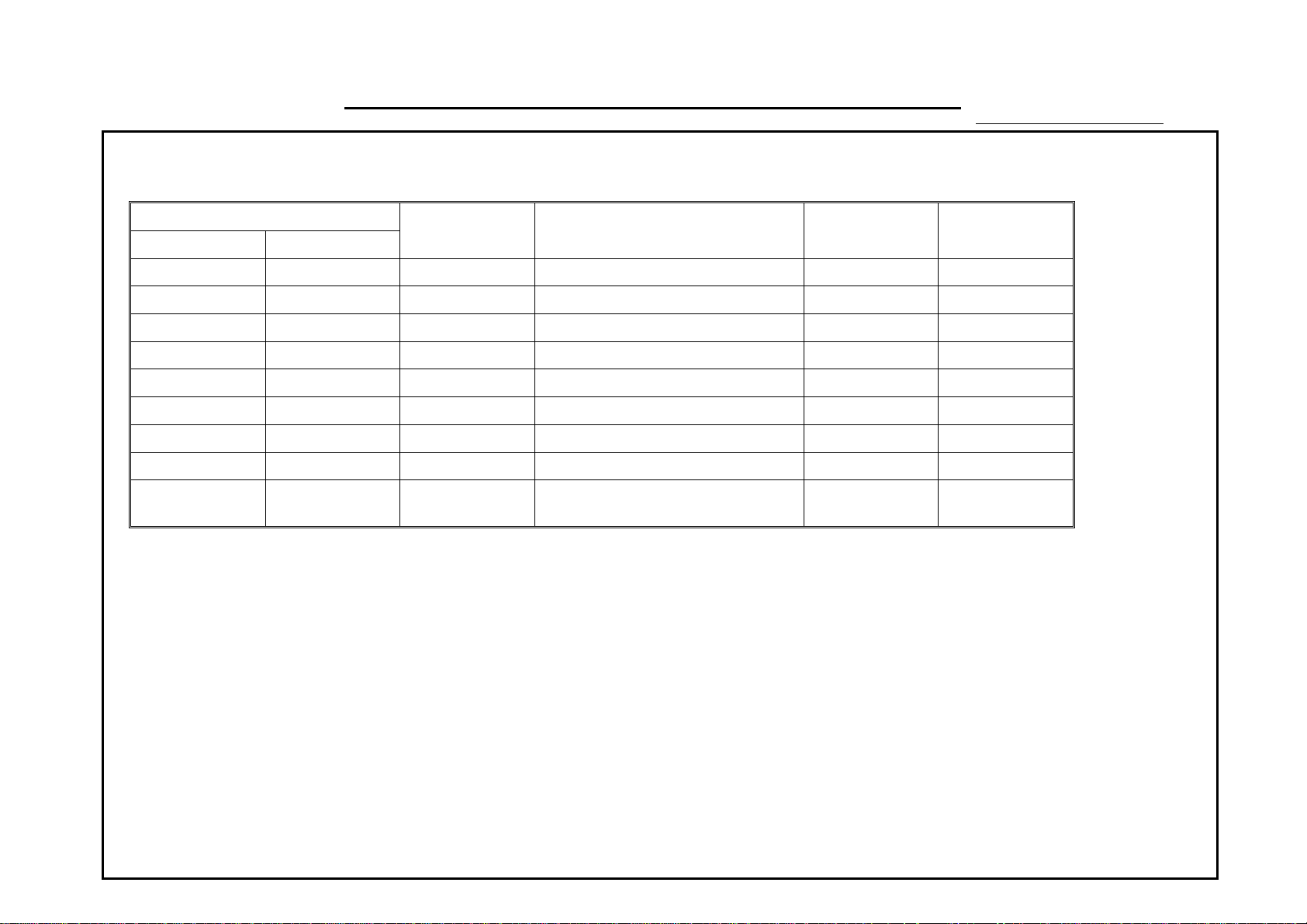

1. Delete the following from the parts list.

Index Part Number Description

7 54462686 Paper End Feeler

2. Add the following to the parts list.

Index Part Number Description

Date of

Modification

Serial Number

126 03130120W Philips Pan Head Screw - M3 x 12

3. Correct the illustration on page 16 as shown in Drawing No. 1.

Page 51

Add the following to the part list (see Drawing No. 2):

Index Part Number Description Q’ty

54 A0284384 Separation Sensor Ass’y 1

Page 2

DETAILS OF MODIFICATION

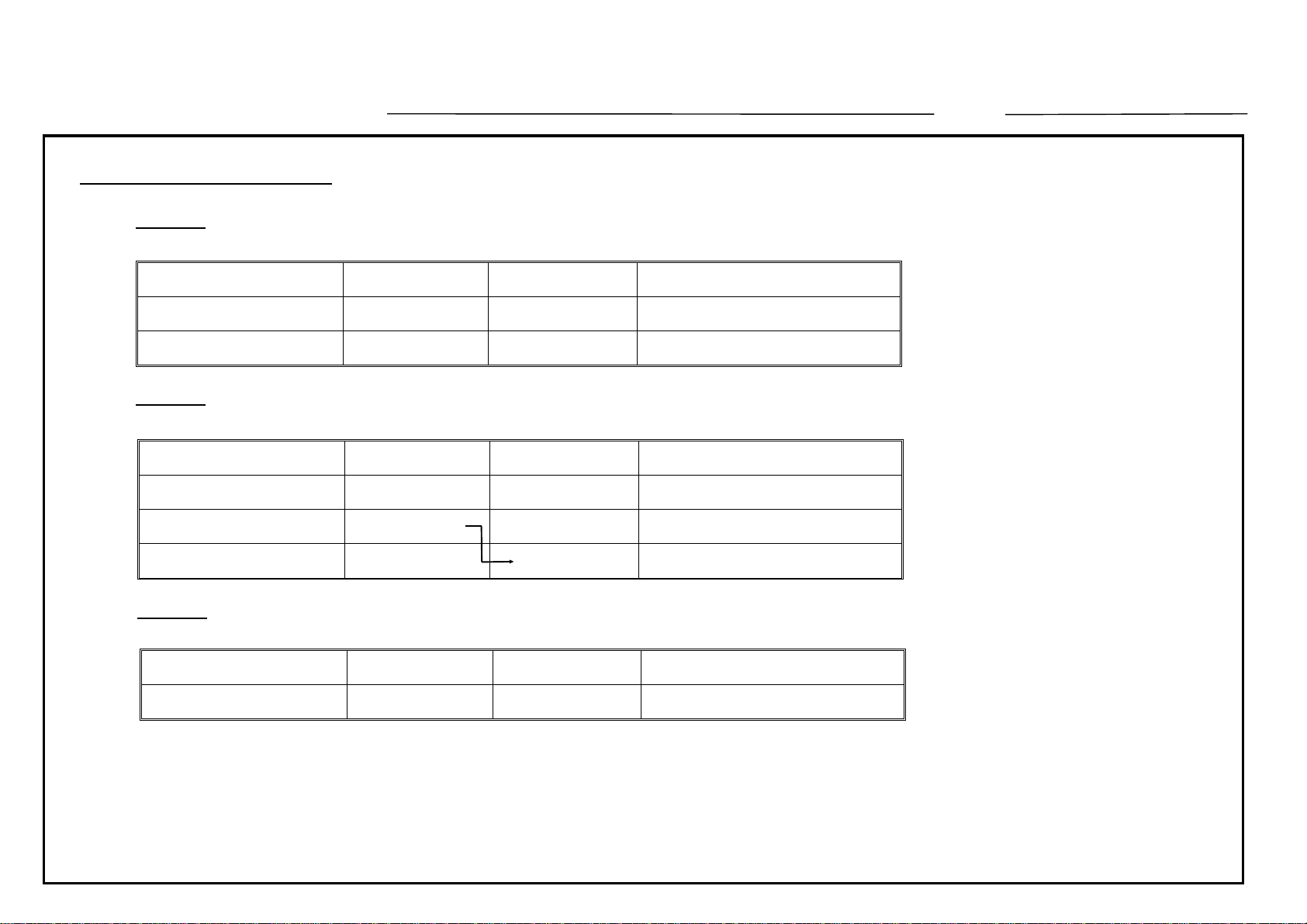

Page 53

Correct the part number as follows:

Index Incorrect P/N Correct P/N Description

* A0283909 A0283913 Cleaning Unit

51 A0285431 A0285432 Varistor Harness

Page 57

Correct the part numbers as follows:

Index Incorrect P/N Correct P/N Description

112 05850101W 05850100B Bolt - M5 x 10

119 03150120W Philips Pan Head Screw - M5 x 12

MODIFICATION BULLETIN NO. 1 Page 2 of 8 ISSUED ON: June 30, ’92

05850121B Bolt - M5 x 12

Page 75

1. Correct the part number as follows (see Drawing No. 3):

Index Incorrect P/N Correct P/N Description

32 A0285210 A0285310 Timer Control Board

NOTE : The timer control board: A0285210 can still be used. However, as a heat sink has

been added from the first massproduction machines as shown Drawing No. 3, the

assembly part number (A0285310) only is used for this part.

Page 3

DETAILS OF MODIFICATION

2. Add the following to the parts list on page 75 and illustration on page 74 (see Drawing No. 4) :

Index Part Number Description Q’ty

93 A0285382 Lightning Surge Absorber 2

Page 77

Correct the part number as follows:

Index Incorrect P/N Correct P/N Description

31 A0287777 A0287781 Rear Cover

Page 83

Correct the part number as follows:

MODIFICATION BULLETIN NO. 1 Page 3 of 8 ISSUED ON: June 30, ’92

Index Incorrect P/N Correct P/N Description

108 09513060W Screw - M3 x 6

09513006W Philips Screw With Flat Washer - M3 x 6

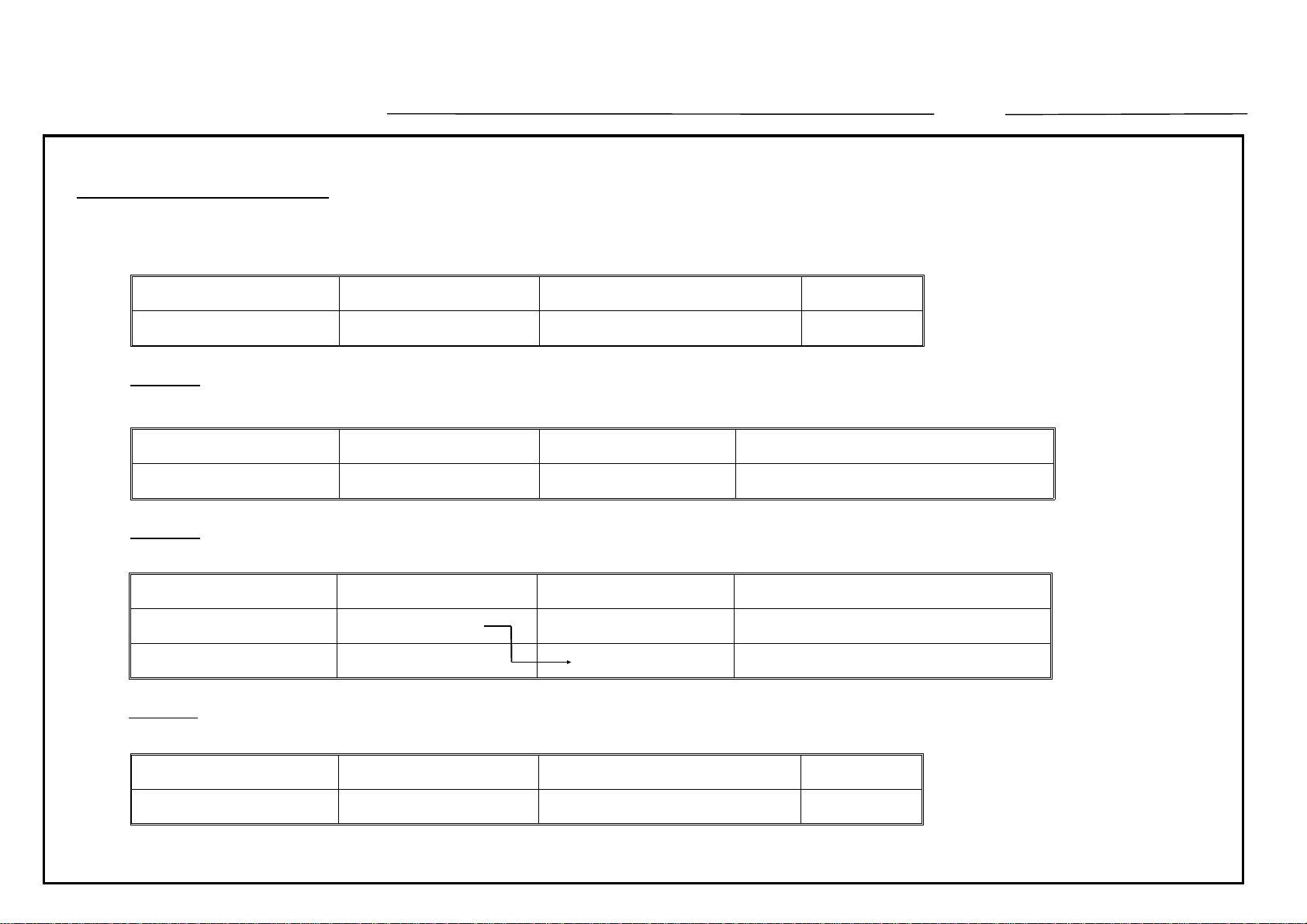

Page 85

Add the following to the parts list on page 85 and illustration on page 84 (see Drawing No.5):

Index Part Number Description Q’ty

60 A0287524 Inverter Guide Plate Ass’y 1

Page 4

DETAILS OF MODIFICATION

Page 109

Correct the part number as follows (the same correction as page 75):

Index Incorrect P/N Correct P/N Description

* A0285210 A0285310 Timer Control Board

Page 112

Delete CN99 and CN100 from the illustration (see Drawing No. 6).

Page 117

Correct the part number as follows:

Index Incorrect P/N Correct P/N Description

* A0285811 A0285805 Main Control Board - ADF (See NOTE 1.)

MODIFICATION BULLETIN NO. 1 Page 4 of 8 ISSUED ON: June 30, ’92

1 A0285851 A0285855 ROM - ADF (See NOTE 2.)

112 11070391 Fuse - 5A, 125V

11070752 Fuse - 5A, 250V (See NOTE 1.)

NOTE 1. To meet the safety standard, the fuse on the board has been changed (11070391 → 11070752) from the first

production machines. As a result, the part number of the ADF main control board has also been changed. (The

difference between A0285811 and A0285805 is the fuse only.)

NOTE 2. To enable the use of F4 size paper (8

1/2 x 13"), the ROM’s on the main board, operation ROM board, and paper feed

control board have been changed. (Their part numbers have not been changed. For details, refer to RTB No. 1. ) To

enable the use of the same function on the ADF (original size detection), the ROM has been changed from the March ’92

production. (5 machines of the first production use the old type ROM : A0285851.) The part number of the board is still the

same (A0285805 → A).

Page 5

DETAILS OF MODIFICATION

MODIFICATION BULLETIN NO. 1 Page 5 of 8 ISSUED ON: June 30, ’92

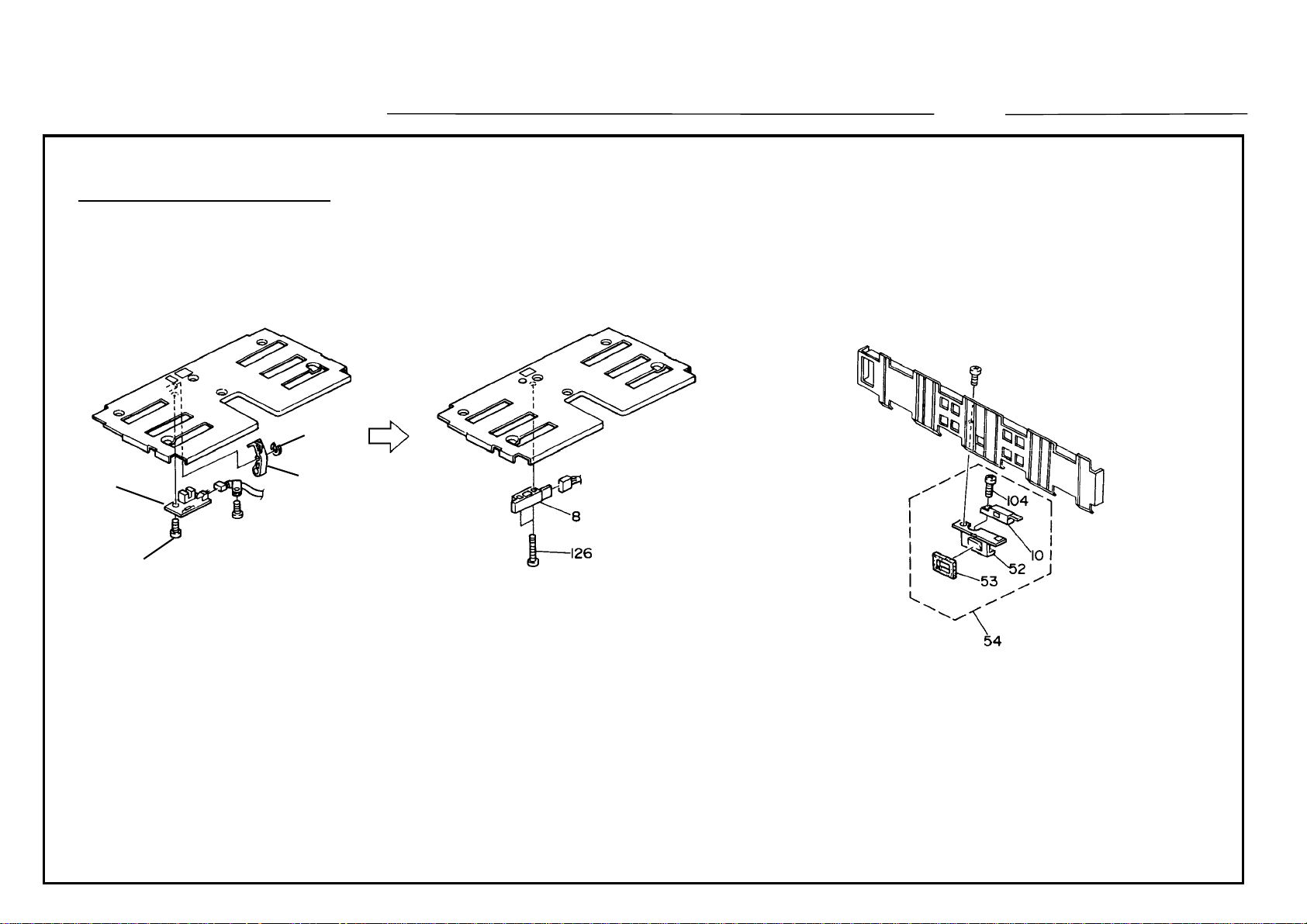

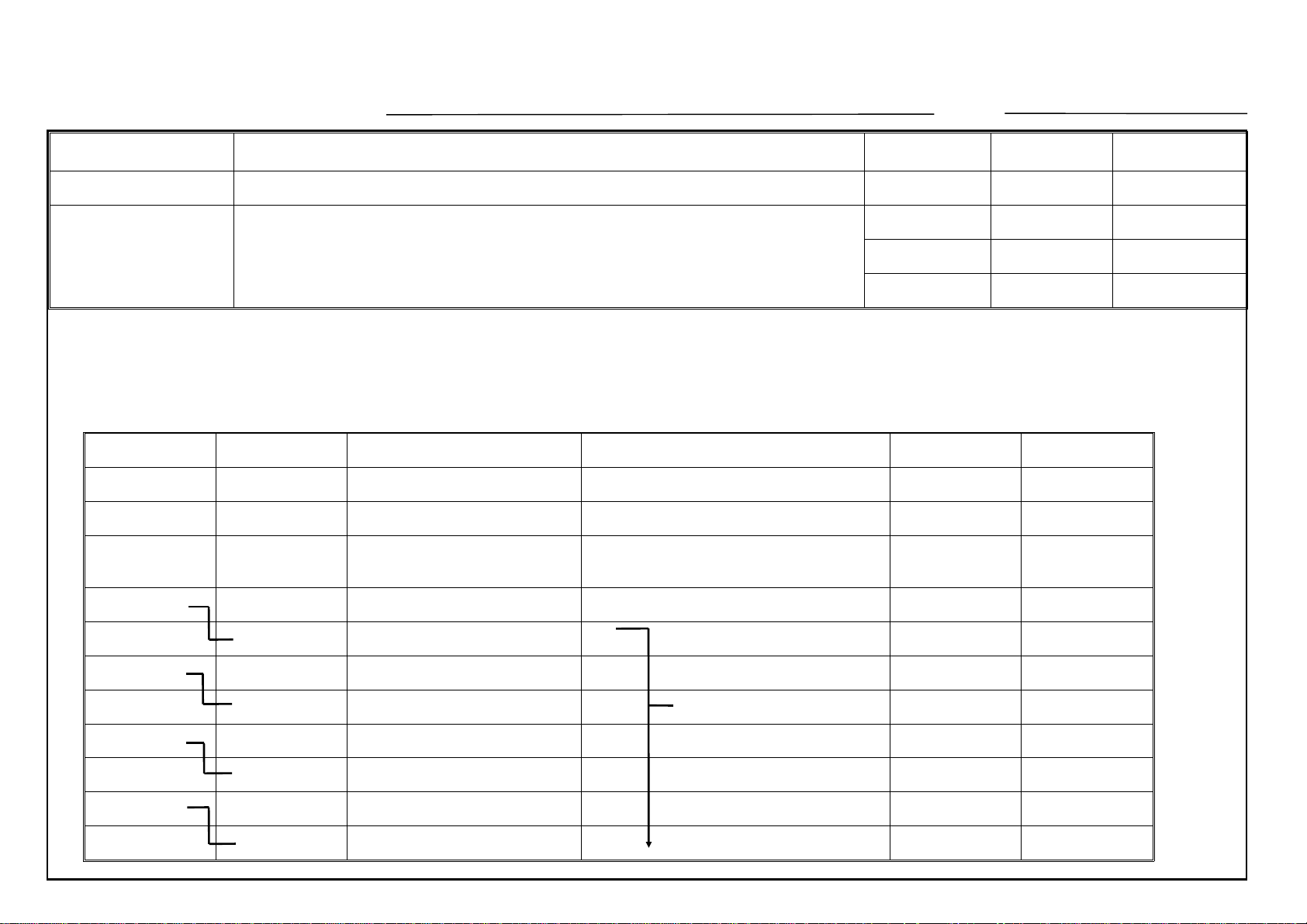

Drawing No. 1 (Page 16)

8

108

Drawing No. 2 (Page 50)

111

7

* New Index

Page 6

DETAILS OF MODIFICATION

MODIFICATION BULLETIN NO. 1 Page 6 of 8 ISSUED ON: June 30, ’92

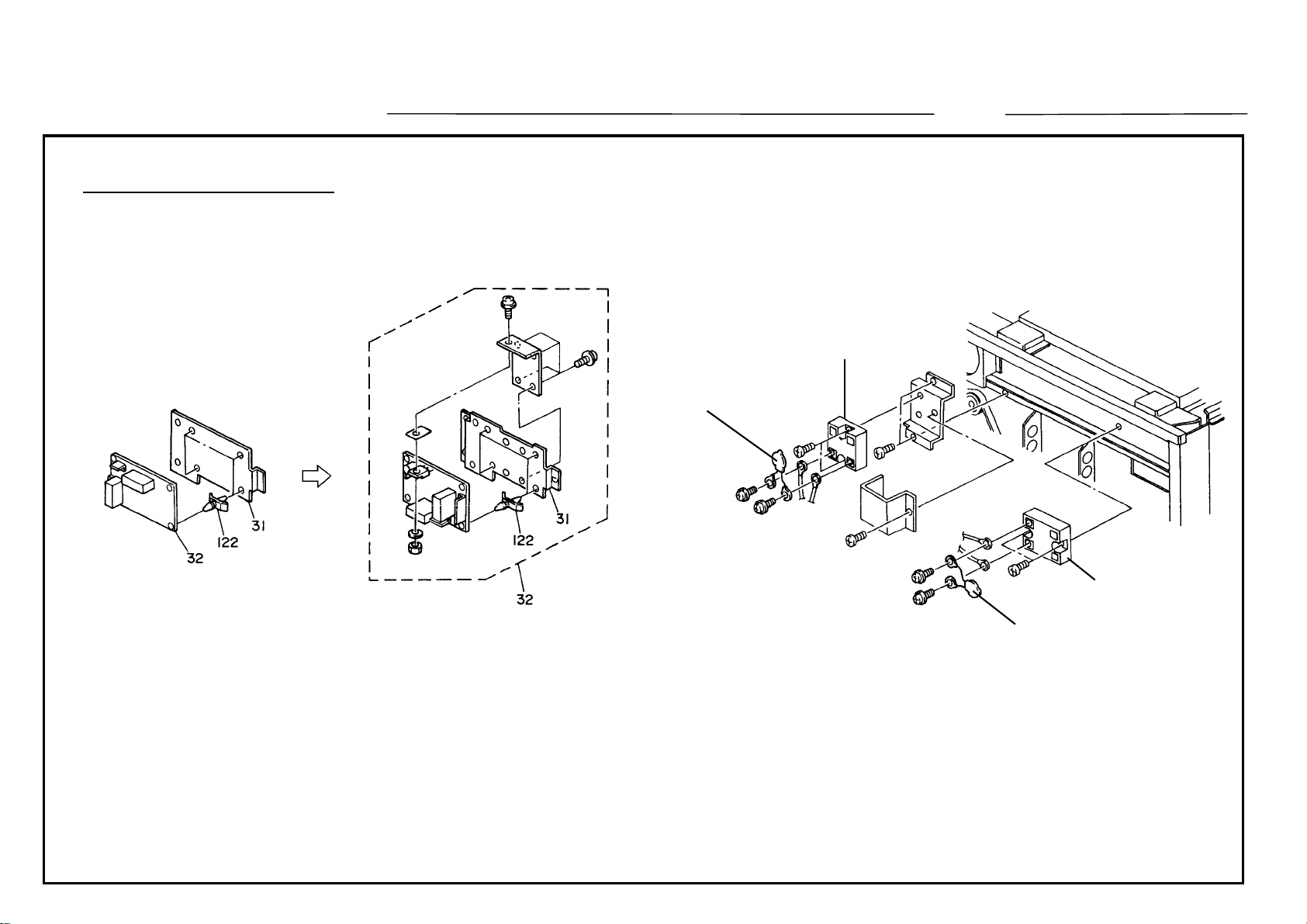

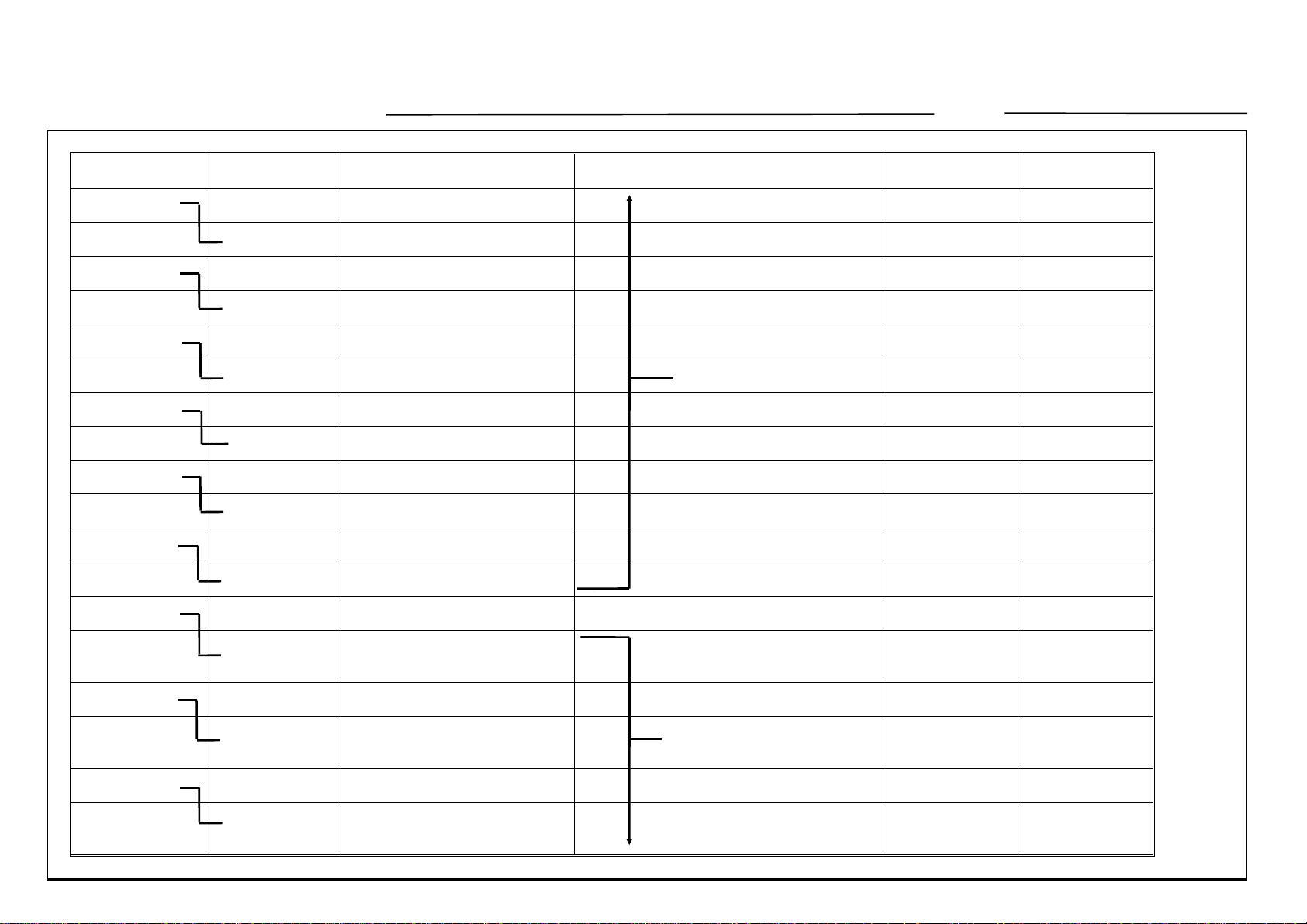

Drawing No. 3 (Page 74)

Drawing No. 4 (Page 74)

139

93 * New index

139

93 * New index

Page 7

DETAILS OF MODIFICATION

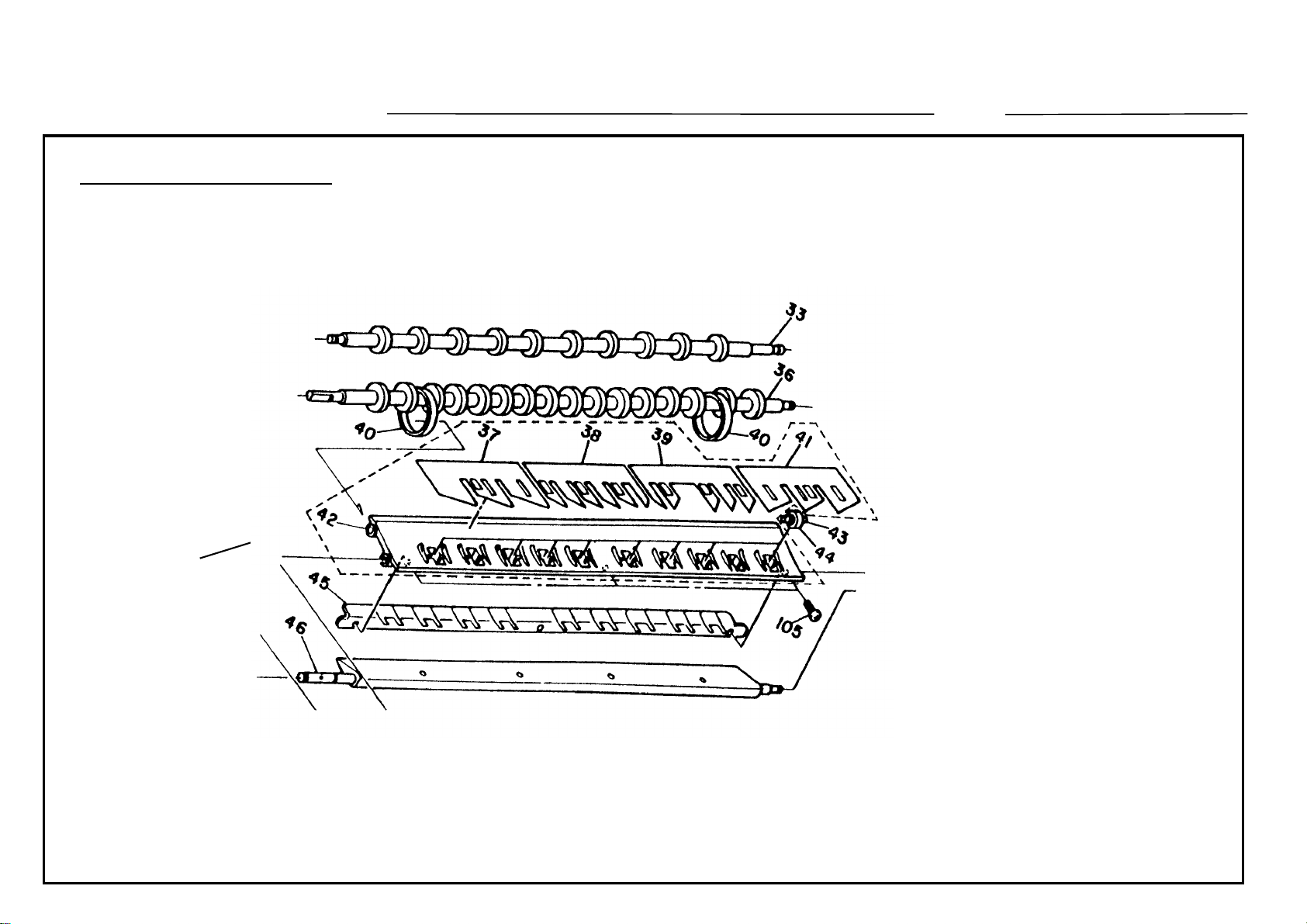

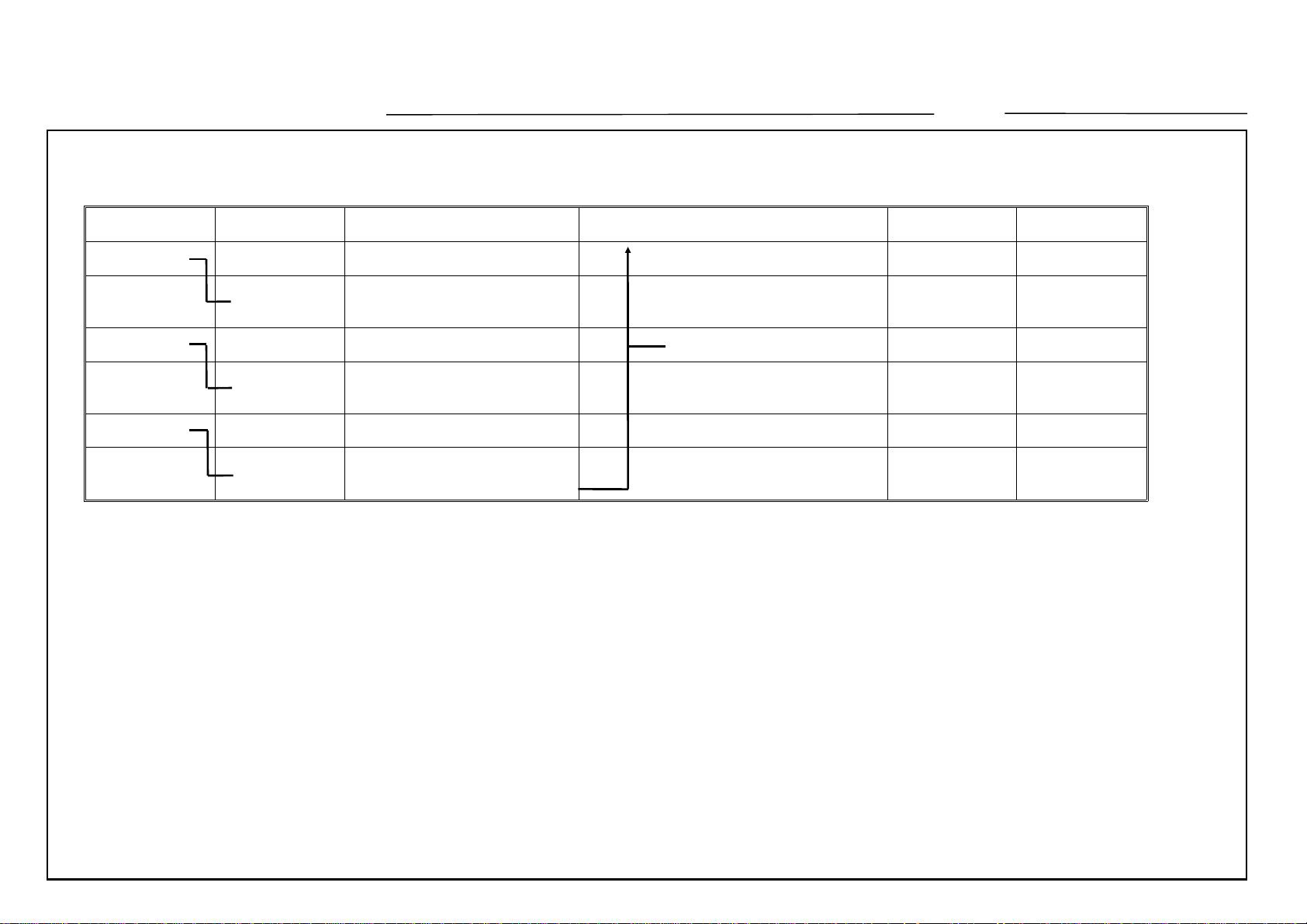

Drawing No. 5 (Page 84)

MODIFICATION BULLETIN NO. 1 Page 7 of 8 ISSUED ON: June 30, ’92

60

New Index

Page 8

DETAILS OF MODIFICATION

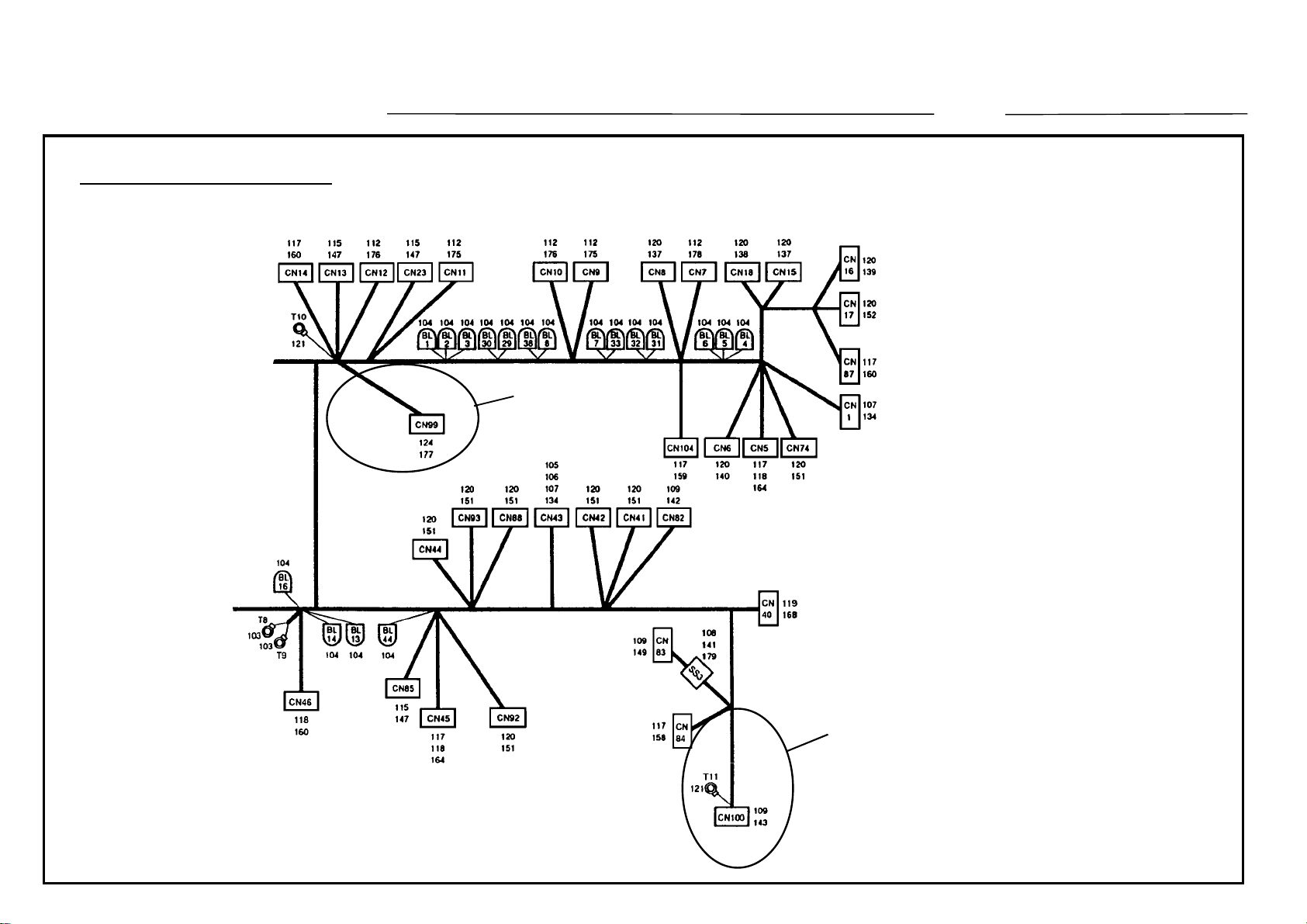

Drawing No.6 (Page 112)

MODIFICATION BULLETIN NO. 1 Page 8 of 8 ISSUED ON: June 30, ’92

Delete

Delete

T. Ito, Manager

Copier Technical Support

Page 9

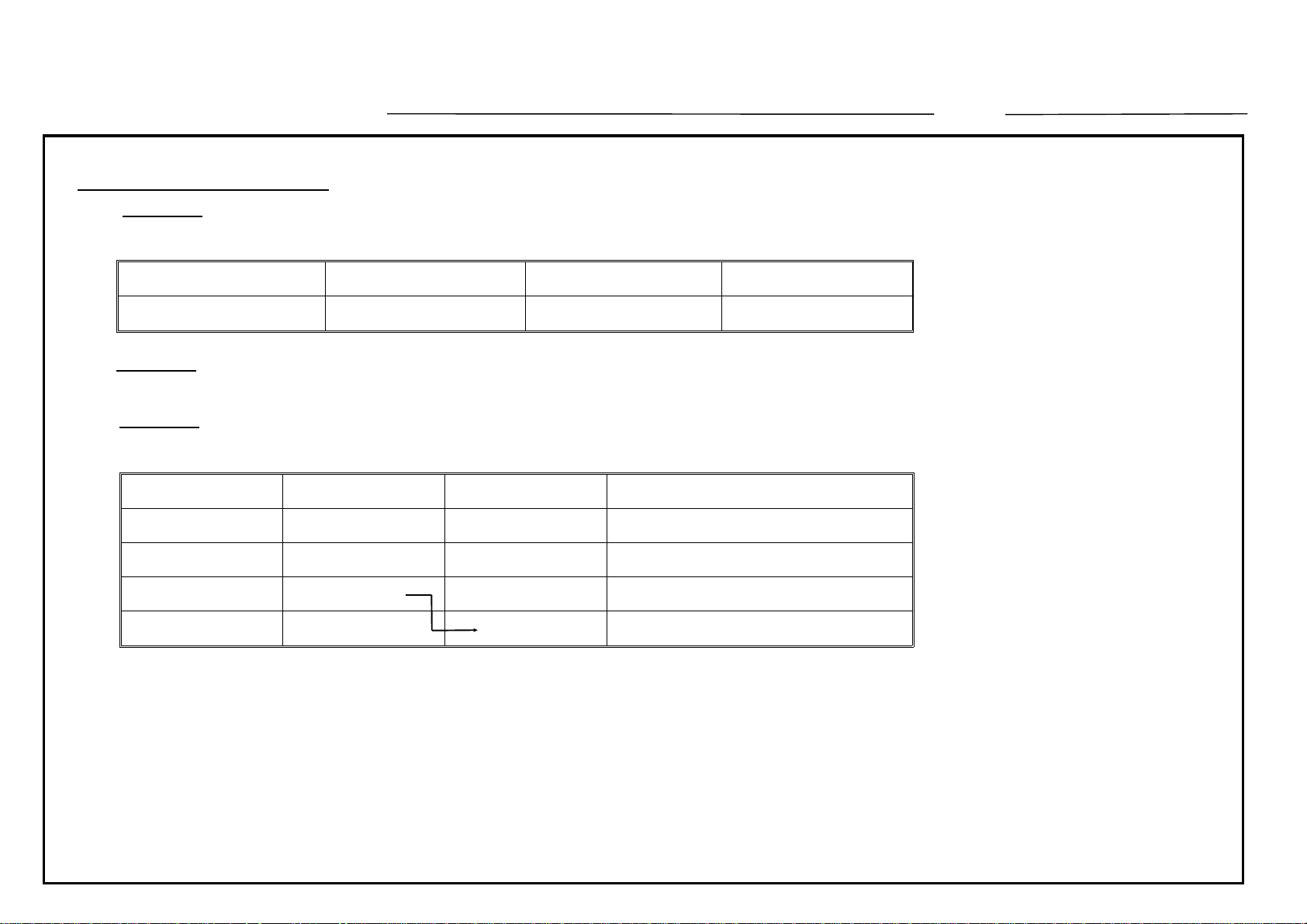

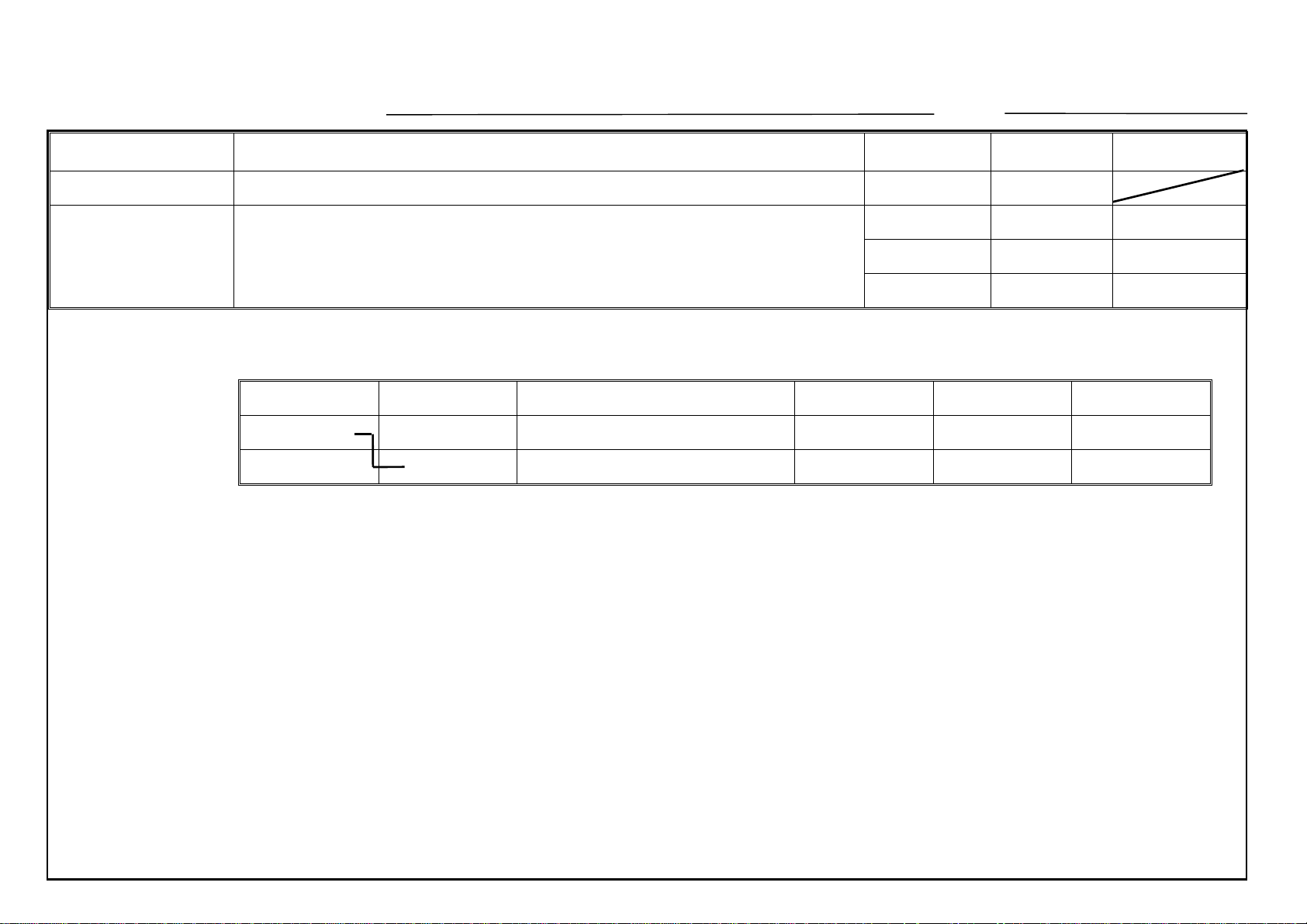

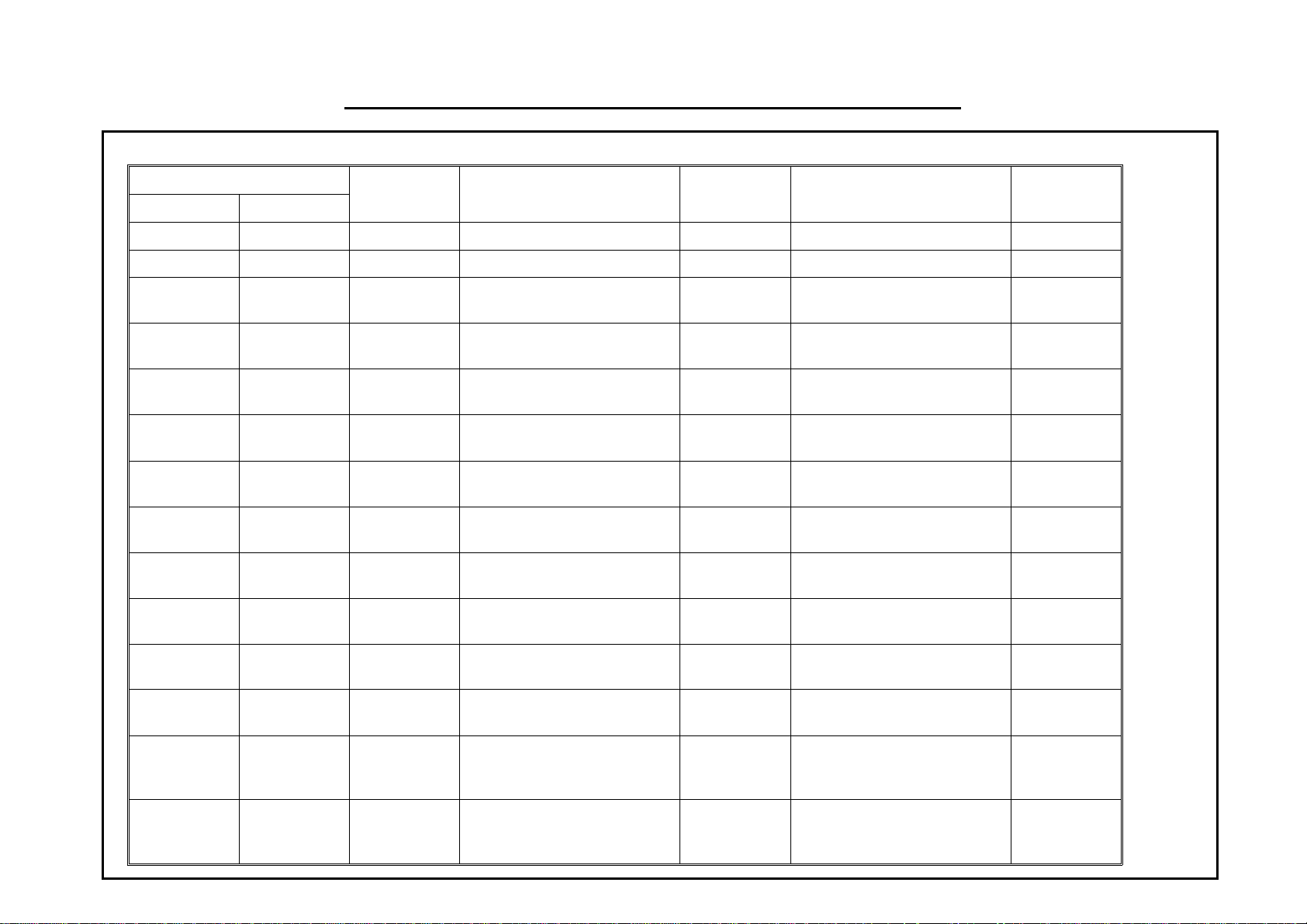

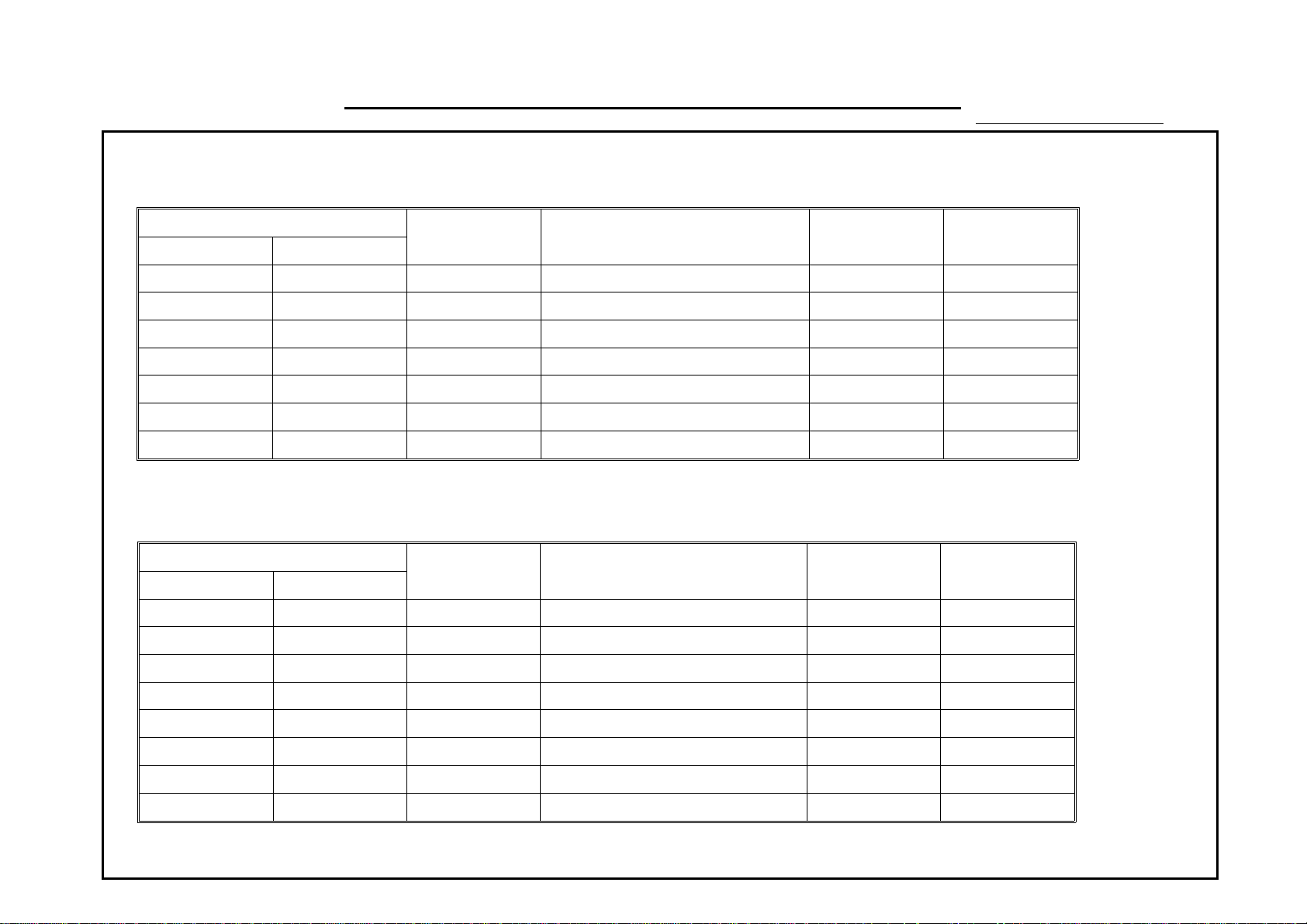

MODIFICATION BULLETIN NO. 2 Page 1 of 3 ISSUED ON: December 31, ’92

Model F5 (NRG25101) Volt/Hz

Modified Article ROMs A028-22 6202070001

Reason for

To enable the use of the sorter stapler

Modification

Date of

Modification

Serial Number

To enable the use of the sorter stapler, the ROMs on the operation ROM board and main con trol board have been changed. For

identification, the part numbe rs of the opera tion panel ass’y, Rom board, and main control board have also been changed. However,

the old ones can still be used for the sorte r version machines. (The interchangeability for the sorter version machine is O/ O. )

For details, please refer to RTB-002 issued on September 15.

Old P/N New P/N Description Interchangeability Page Index No.

AG011286 A0288800 Operation Panel Board O/O (For the sorter stapler version, X/O) 71 9

A0285242 A0288803 ROM Board O/O (For the sorter stapler version, X/O) 71 10

A0285091 A0288802 Main Control Board O/O (For the sorter stapler version, X/O)

71

93

26

*

A0285290 IC - Operation Board 1

A0288900 IC201 - M5M27C101K - 2 X/X 71 58

A0285291 IC - Operation Board 2

A0288901 IC202 - M5M27C101K - 2 X/X X/O as a set 71 59

A0285292 IC - Operation Board 3

A0288902 IC205 - M5M27C101K - 2 X/X 71 60

A0285293 IC - Operation Board 4

A0288903 IC206 - M5M27C101K - 2 X/X (Next Page) 71 61

Page 10

MODIFICATION BULLETIN NO. 2 Page 2 of 3 ISSUED ON: December 31, ’92

Old P/N New P/N Description Interchangeability Page Index No.

A0285294 IC - Operation Board 5 (Preceding Page)

A02888904 IC203 - MBM27C512-20 X/X 71 62

A0285295 IC - Operation Board 6

A0288905 IC204 - MBM27C512-20 X/X 71 63

A0285296 IC - Operation Board 7

A0288906 IC207 - MBM27C512-20 X/X X/O as a set 71 64

A0285297 IC - Operation Board 8

A0288907 IC208 - MBM27C512-20 X/X 71 65

A0285298 IC - Operation Board 9

A0288908 IC210 - MBM27C512-20 X/X 71 66

A0285299 IC - Operation Board 10

A0288909 IC211 - MBM27C512-20 X/X 71 67

A0285093 IC - Main Control 1

A0288850 IC210 - MBM27C512-20 X/X

A0285094 IC - Main Control 2

A0288851 IC198 - MBM27C512-20 X/X X/O as a set

A0285095 IC - Main Control 3

A0288852 IC205 - MBM27C512-20 X/X (Next Page)

71

93

71

93

71

93

27

1

29

2

28

3

Page 11

T. Ito, Manager

Copier Technical Support

MODIFICATION BULLETIN NO. 2 Page 3 of 3 ISSUED ON: December 31, ’92

Old P/N New P/N Description Interchangeability Page Index No.

A0285096 IC - Main Control 4 (Preceding Page)

A0288853 IC190 - MBM27C512-20 X/X

A0285097 IC - Sequence Control 1 X/O as a set

A0288854 IC123 - MBM27C512-20 X/X

A0285298 IC - Sequence Control 2

A0288855 IC124 - MBM27C512-20 X/X

71

93

71

93

71

93

30

4

31

5

32

6

Page 12

T. Ito, Manager

Copier Technical Support

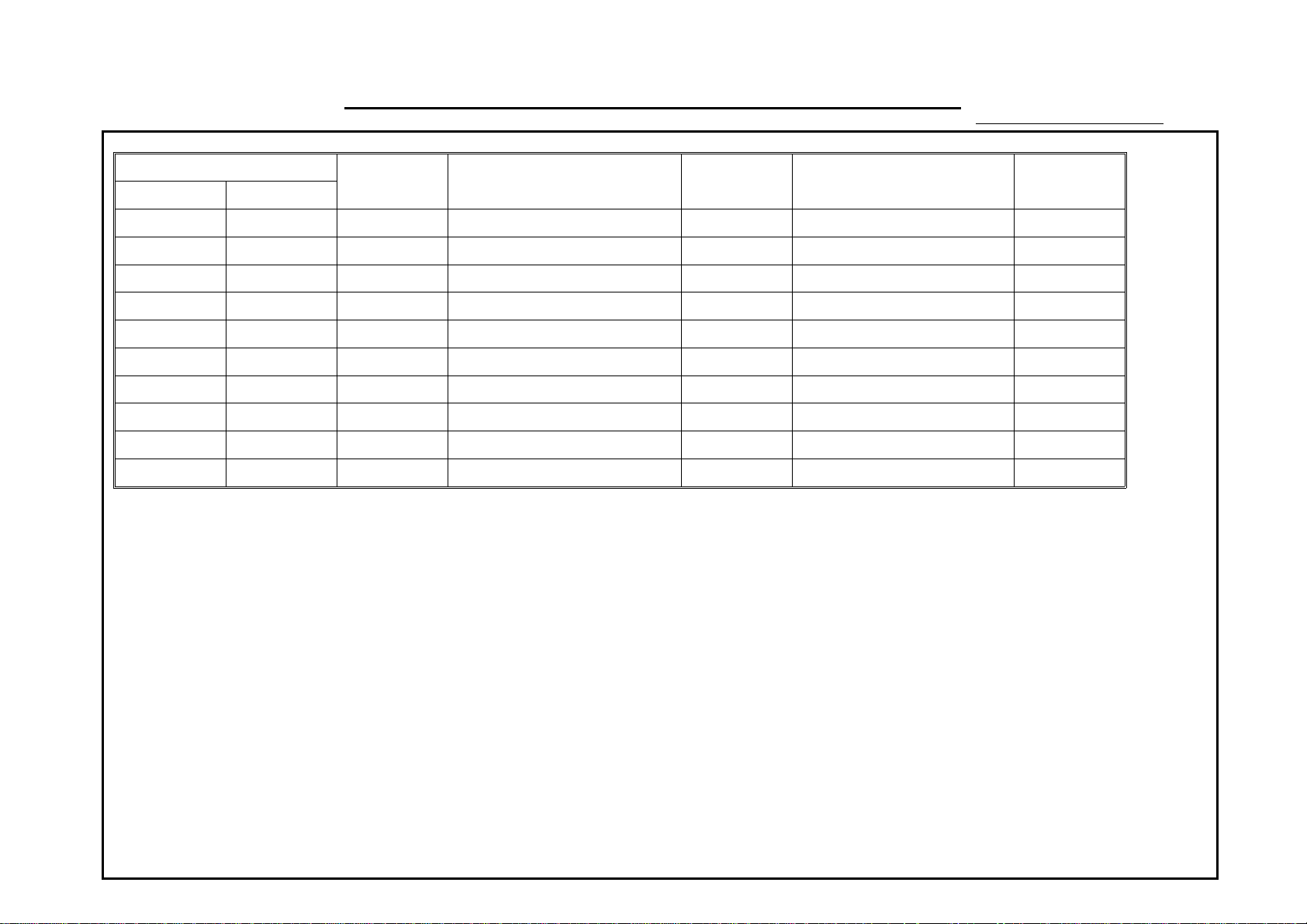

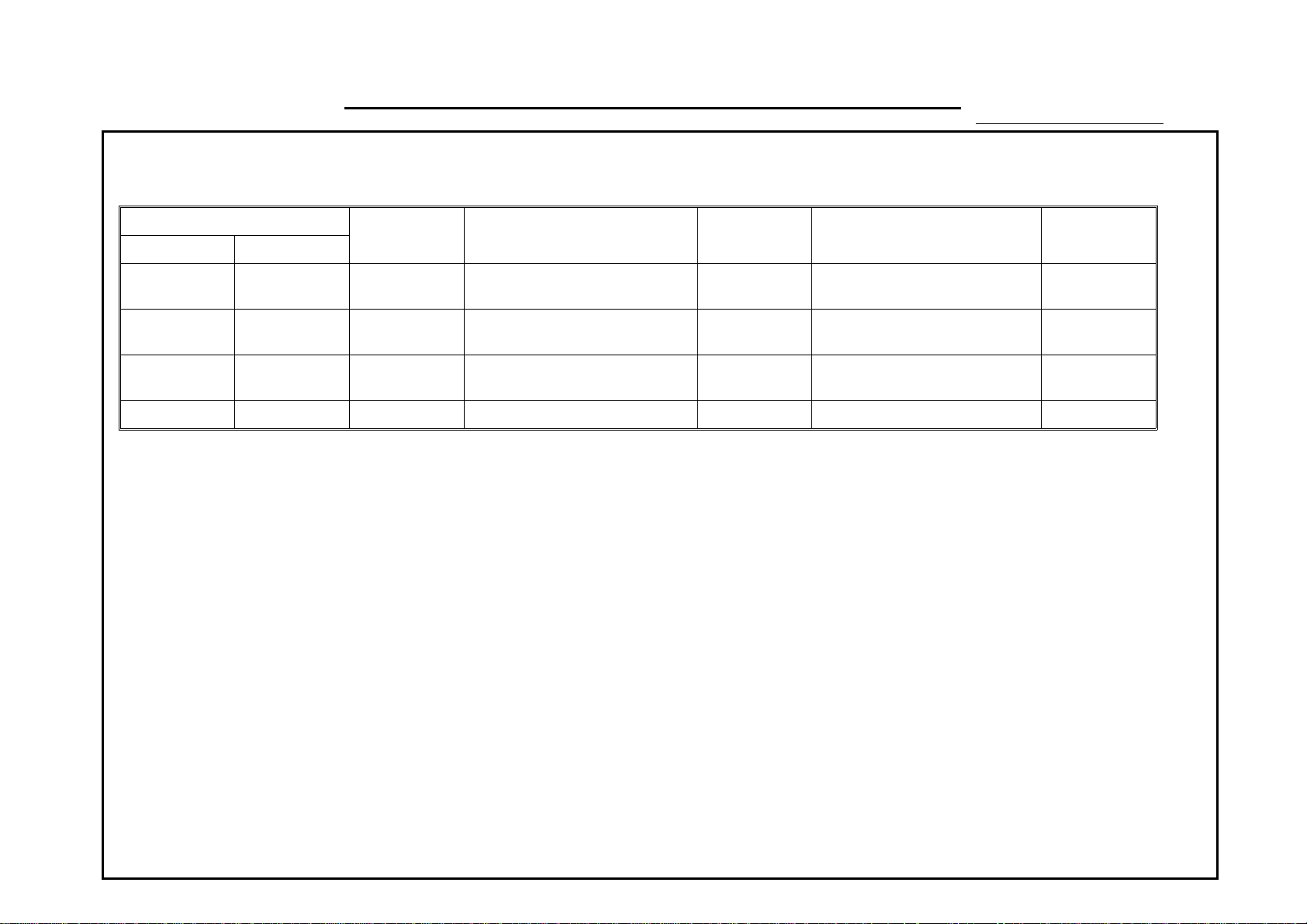

MODIFICATION BULLETIN NO. 3 Page 1 of 1 ISSUED ON: December 31, ’92

Model F5 (NRG25101) Volt/Hz

Modified Article Noise Filter A028-22

Reason for

Due to vendor change

Modification

Due to vendor change, the following parts has been changed.

Old P/N New P/N Description Interchangeability Page Index No.

16020946 Noise Filter - 220V/240V

16027075 Noise Filter - RG208F O/O 75 136

Date of

Modification

Serial Number

Page 13

NOTE

MODIFICATION BULLETIN NO. 4 PAGE 1 OF 27

ISSUED ON: July15, ’93

Model F5 (Gestetener 25101 / Nashuatec 53101) Volt/Hz

Modified Article Parts Catalog A028-22

Reason for

F5 Finisher Version (Nashuatec 53101) Information

Modification

A112-22

A new version machine for the F5 has bee n adde d (A1 12 -22 : F5 Finish er Ve rsion ).

1. Add the following parts unique to the finisher version to your parts cat alo g:

Parts Catalog

Part Number Description Q’ty Used

Page Index No.

11 2 A1121409 Left Door 1 A0281407 —

11 76 AA012055 Dust Filter 1 → 2 Fig.1

11 78 A0281637 Optics Filter Cover 1 → 2 Fig.1

A028-22 Unique Part (P/N)

(Description)

Date of

Modification

Fig. NO.

Serial Number

6203030001

(First

Mass-production)

1) The left door is different because of the model name logotype.

2) The dust filter is replaces with th e Air Filte r (Ind ec # 38 , Page 73, Part Numbe r AA0 12 017) to allow

the installation of the new cleaning roller cooling pump unit.

3) One set of the dust filter an d op tics filt er cover is used in the sorter version machine, but both sets

are used for the finishe r ve rsion ma chine.

2. Add the following part uniq ue to th e fin isher version machine. For the sorter versio n mach ine , two Rear Upper

Support Plates - ADF (Index # 20, Page 15, Pa rt Numb er A0 28 1193 ) are used, and the upper one is replaced with

# A1121193 on the finisher version mach ine , to allow th e installation of the new cleanin g rolle r cooling pump unit.

Parts Catalog

Part Number Description Q’ty Used Fig. No.

Page Index No.

15 * 49 A1121193 Left Side Support Plate 1 Fig 2

*

Page 14

MODIFICATION BULLETIN NO. 4 PAGE 2 OF 27

3. Add the following parts unique to the finisher version machine.

Parts Catalog

Page Index No.

39 * A1122510 OPC Unit 1 A0282500

41 35 A0285306 DC Motor - DC24V 1 A0285307

69

73

71 9 A1121450 Operation Panel Unit 1

71 10 A1125070 Operation ROM Board 1

71

93

71

93

71

93

71

93

71

93

16

41

26

*

27

1

28

3

29

2

30

4

Part Number Description Q’ty Used

A1124095 Pump Tube 1 A0284088

A1125041 Main Control Board 1 A0288802 FIg. 9

A1125102 IC210 - HN27C101AG-17 1

A1125104 IC205 - HN27C101AG-17 1

A1125103 IC198 - HN27C101AG-17 1

A1125105 IC190 - HN27C101AG-17 1

A028-22 Unique Part (P/N)

A0288800

(Operation Panel Board)

A0288803

(ROM Board)

A0288850

(IC210 - MBM27C512-20)

A0288852

(IC205 - MBM27C512-20)

A0288851

(IC198 - MBM27C512-20)

A0288853

(IC190 - MBM27C512-20)

(Description)

Fig. NO.

71

93

71

93

71

73

113

71

73

115

31

5

32

6

33

1

34

2

A1125108 IC123 - MBM27C512-20 1 A0288854

A1125109 IC124 - MBM27C512-20 1 A0288855

A1125400 DC Harness 1 A0285403 Fig. 10

*

A1125500 AC Harness 1 A0285503 Fig. 11

*

Page 15

MODIFICATION BULLETIN NO. 4 PAGE 3 OF 27

ISSUED ON: July15, ’93

Parts Catalog

Page Index No.

71 58 A1125205 IC201 - M5M27C101K-2 1 A0288900

71 59 A1125206 IC202 - M5M27C101K-2 1 A0288901

71 60 A1125207 IC205 - M5M27C101K-2 1 A0288902

71 61 A1125208 IC206 - M5M27C101K-2 1 A0288903

71 62 A1125209 IC203 - MBM27C512-20 1 A0288904

71 63 A1125210 IC204 - MBM27C512-20 1 A0288905

71 64 A1125211 IC207 - MBM27C512-20 1 A0288906

71 65 A1125212 IC208 - MBM27C512-20 1 A0288907

71 66 A1125213 IC210 - MBM27C512-20 1 A0288908

71 67 A1125214 IC211 - MBM27C512-20 1 A0288909

NOTE:

1) The OPC unit is different because th e OP C drive motor (DC Motor - DC24V, # A0285306), which sat isfie s the

Part Number Description Q’ty Used

German electromagnet ic field interference standards (VDE 24 3), is used in the finisher version.

2) The pump tube is different due to the new cleaning roller cooling pump unit. The pump unit has been changed

to meet VDE 243 standards (see fig. 4).

A028-22 Unique Part (P/N)

(Description)

Fig. No.

3) The operation panel unit is differen t du e to the new EPROM’s on the ope rat ion RO M board.

4) The main control board was newly designed to allo w the insta llation of the 4 one-megabyte EPROM’s.

5) The DC and AC main harness are different to allow the installa tio n of the optional key counter an d prin ter

connector unit, and to meet the new ac power dist ribution for approval by VDE 243. The thre e circuit brea kers

used for each phase of the ac 3-phase power distribution have been changed to three choke coils (see fig. 4

and 6).

Page 16

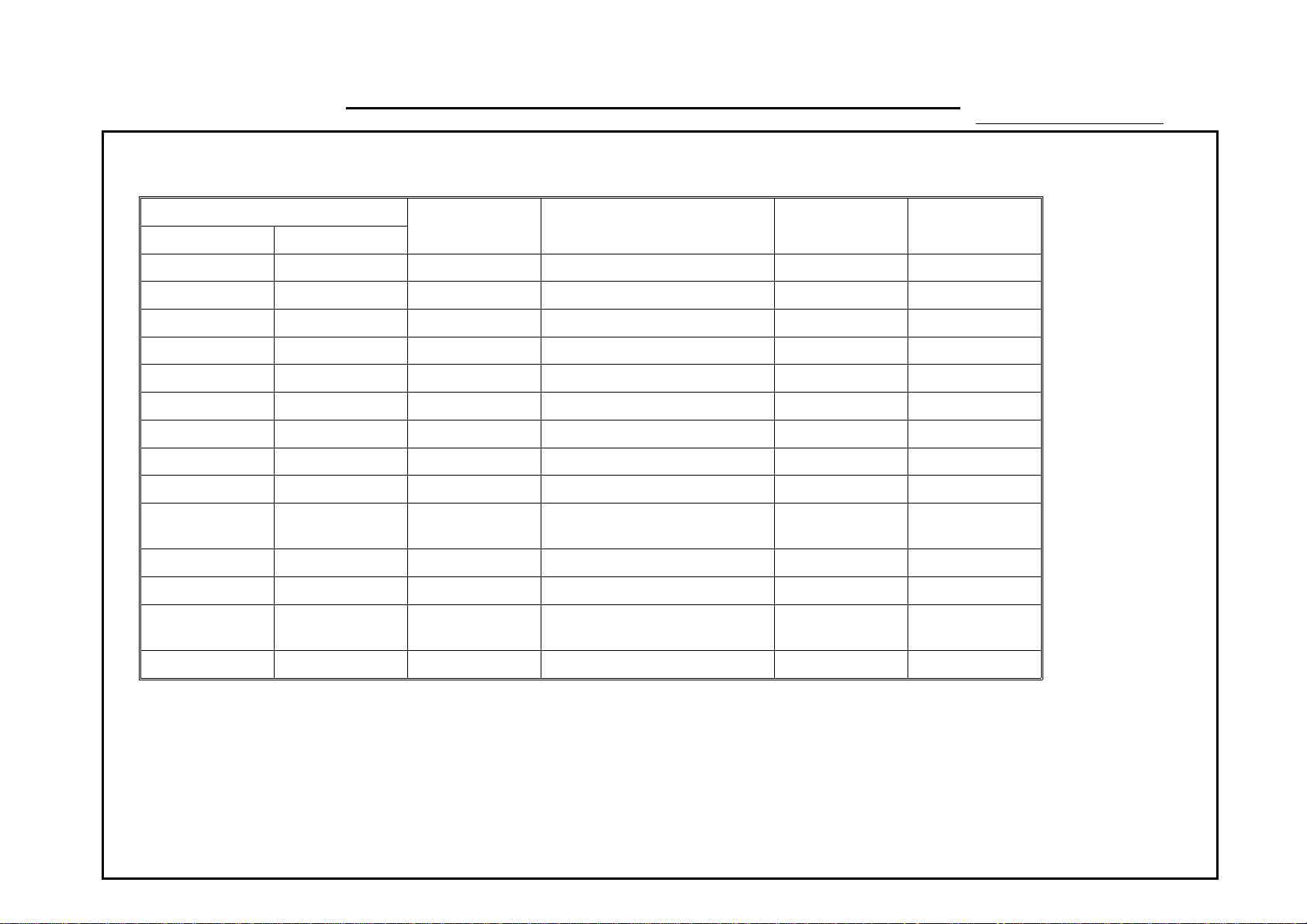

MODIFICATION BULLETIN NO. 4 PAGE 4 OF 27

4. Add the following pa rts un iqu e to the finisher version machine.

ISSUED ON: July15, ’93

Parts Catalog

Page Index No.

73 * A1124085 Cleaning Cooling Pump Ass’y 1 Fig.3

73 * 71 AZ020004 Coil - 750MH 15A 1 Fig. 3

73 * 72 AZ020005 Coil - 4MH 10A 1 Fig. 3

73 * 73 A1124087 Shielding Sheet 1 Fig. 3

73 * 74 A1124093 Pump Bracket 1 Fig. 3

73 * 75 A1124095 Pump Tube 1 Fig. 3

73 * 76 A1124098 Pump Tube Elbow 1 Fig. 3

73 * 77 A1124091 Coil Bracket 1 Fig. 3

73 * 78 A1124092 Shielding Sheet 1 Fig. 3

73 101 03140060W

73 111 11050196 Harness Clamp 1 Fig. 3

73 * 123 08000094 Philips Screw - M3 x 16 2 Fig. 3

73 * 124 09514006W

Part Number Description Q’ty Used Fig. No.

Philips Pan Head Screw - M4 x

6

Philips Screw With Flat Washer

- M4 x 6

9 Fig. 3

4 Fig. 3

73 * 125 11050011 Nylon Clip - 8N 1 Fig. 3

* : New Index No.

Page 17

MODIFICATION BULLETIN NO. 4 PAGE 5 OF 27

NOTE: The following are parts uniqu e to the sorter version machine. (Info rmat ion only)

ISSUED ON: July15, ’93

Parts Catalog

Page Index No.

73 36 AA151272 Seal - 6 x 81 x 84 1 Fig. 4

73 37 A0284076 Filter Holder 1 Fig. 4

73 38 AA012017 Air Filter 1 Fig. 4

73 39 A0284070 Pump Bracket 1 Fig. 4

73 41 A0284088 Pump Tube 1 Fig. 4

73 42 A0284080 Pump Duct 1 Fig. 4

73 101 03140060W Philips Pan Head Screw - M4 x 6 4 Fig. 4

73 104 03130300W Philips Pan Head Screw - M3 x 30 2 Fig. 4

73 114 09514010W

Part Number Description Q’ty Used Fig. No.

Philips Screw With Flat Washer

- M4 x 10

2 Fig. 4

Page 18

MODIFICATION BULLETIN NO. 4 PAGE 6 OF 27

5. Add the following pa rts un iqu e to the finisher version machine.

ISSUED ON: July15, ’93

Parts Catalog

Page Index No.

75 * 94 AZ020004 Coil - 750MH 15A 1 Fig. 5

75 * 95 A1125510 Power Supply Unit Harness - B 1 Fig. 5

75 * 96 A1125520 Power Supply Unit Harness - C 1 Fig. 5

75 * 97 A1125601 Power Supply Unit Bracket 1 Fig. 5

75 101 03140060W Philips Pan Head Screw - M4 x 6 6 Fig. 5

75 * 144 03140040W Philips Pan Head Screw - M4 x 4 6 Fig. 5

75 * 145 11070781 Circuit Bracket - 250V / 15A 1 Fig. 5

Part Number Description Q’ty Used Fig. No.

NOTE: The following are parts unique to the sorter version mach ine. (Information only)

Parts Catalog

Page Index No.

75 58 A0285628 Power Supply Unit Bracket 1 Fig. 6

75 87 A0285532 Power Supply Unit Harness-B 1 Fig. 6

75 88 A0285533 Power Supply Unit Harness-C 1 Fig. 6

Part Number Description Q’ty Used Fig. No.

75 127 03140120W Philips Pan Head Screw - M4 x 12 10 Fig. 6

75 129 11070264 Circuit Breaker - 8A 1 Fig. 6

75 130 11070468 Circuit Breaker - 2-5000 5A / 250V 1 Fig. 6

75 131 11070469 Circuit Breaker - 250V 10A 2 Fig. 6

75 132 11070470 Circuit Breaker - 15A / 250V 1 Fig. 6

Page 19

ISSUED ON: July15, ’93

MODIFICATION BULLETIN NO. 4 PAGE 7 OF 27

6. Add the following parts unique to the finisher version machine.

Parts Catalog

Page Index No.

79 4 A1125841 Connector Harness 1

79

117

83 5 59365501 Transport Drive Motor - DC 21W 3

117 1 A1125855 EPROM - MBM27C128-30 1 A0285855

NOTE:

1) The connector harness is different to allow the operation of the new recycle arm solen oid .

30

*

Part Number Description Q’ty Used

A1125805 Main Control Board - ADF 1

2) The ADF main control board is different due to the new EPROM on the board.

A028-22 Unique Part (P/N)

(Description)

A0285841

(Harness - Relay Board)

A0285805

(ADF Control Board)

AX060027

(Drive Motor - DC24V / 21W)

Fig. No.

Fig. 7

Page 20

MODIFICATION BULLETIN NO. 4 PAGE 8 OF 27

7. Add the following parts unique to the finisher version machine.

ISSUED ON: July15, ’93

Parts Catalog

Page Index No.

81 * 76 A1127881 Solenoid Bracket 1 Fig. 8

81 * 77 A1127885 Solenoid Spring 1 Fig. 8

81 * 78 A1127886 Recycle Arm Solenoid Ass’y 1 Fig. 8

81 * 79 A1127919 Nozzle Upper Casing 1 Fig. 8

81 * 119 07010060G Flat Washer - M6 1 Fig. 8

81 * 120 07010040G Flat Washer - M4 2 Fig. 8

Part Number Description Q’ty Used Fig. No.

* : New Index No.

NOTE: The following are parts uniqu e to the sorter version machine. (Information only)

Parts Catalog

Page Index No.

81 7 A0287919 Nozzle Upper Casing 1 Fig. 8

81 10 A0287883 Pressure Lever 1 Fig. 8

81 11 A0287885 Solenoid Spring 1 Fig. 8

Part Number Description Q’ty Used Fig. No.

81 14 A0287886 Recycle Arm Solenoid Ass’y 1 Fig. 8

81 15 A0287881 Solenoid Bracket 1 Fig. 8

81 17 A0287970 Spring - Separation Plate 1 Fig. 8

Page 21

MODIFICATION BULLETIN NO. 4 PAGE 9 OF 27

ISSUED ON: July15, ’93

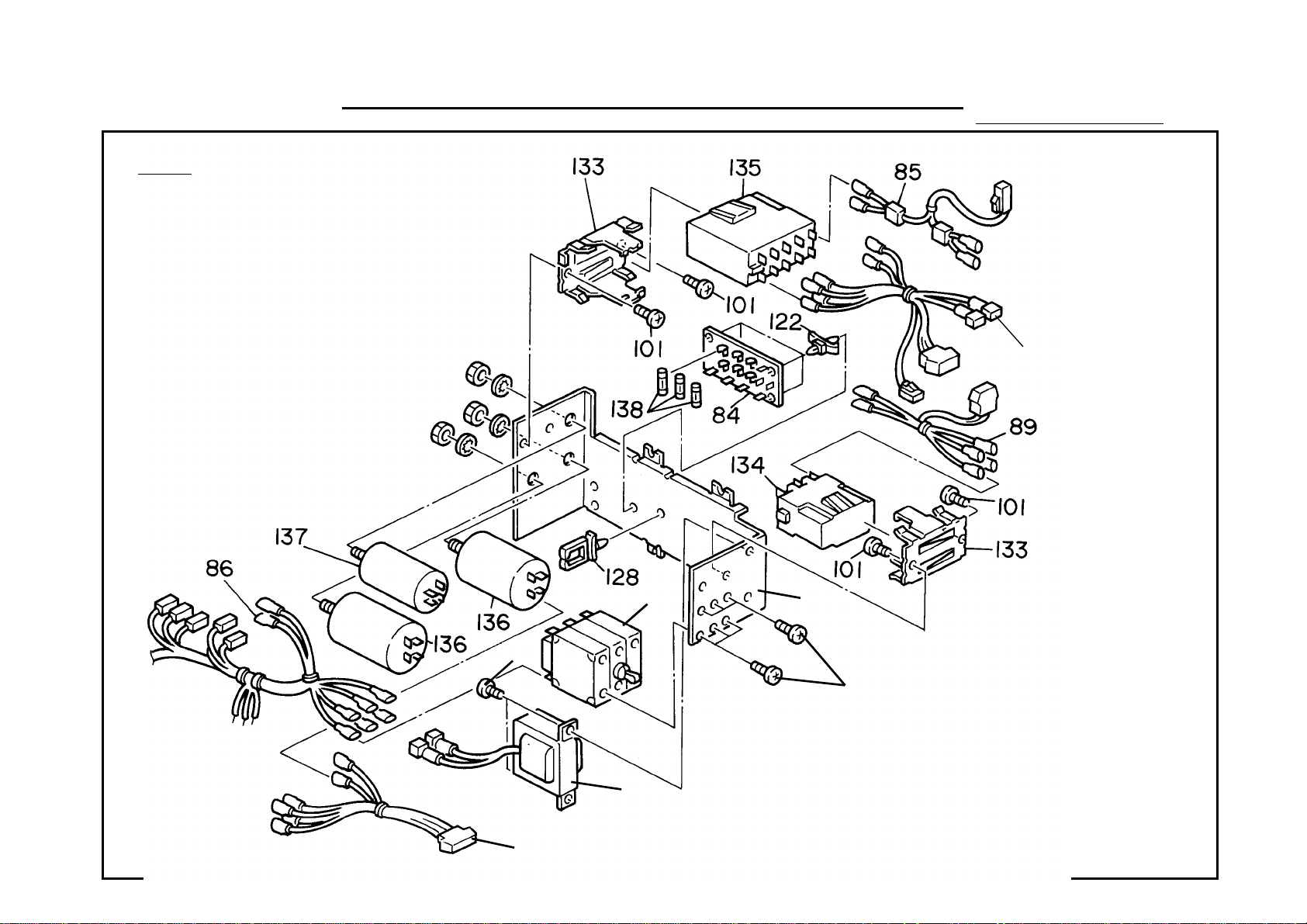

8. Add the following to page 93 "41. MA IN CONTRO L BO ARD" as parts unique to the finisher

version machine (see fig. 9 for th e referrence illustration).

Index P/N Description Q’ty Index P/N Description Q’ty

* A1125041 Main Control Board 1

1 A1125102 IC 210 - HN27C101AG-17 1

2 A1125103 IC 198 - HN27C101AG-17 1

3 A1125104 IC 205 - HN27C101AG-17 1

4 A1125105 IC 190 - HN27C101AG-17 1

5 A1125108 IC 123 - MBM27C512-20 1

6 A1125109 IC 124 - MBM27C512-20 1

101 11001093 Connector - 6P

102 11010328 Connector Pin Contact

103 11022484 Connector

104 11024053 Connector - 1P

105 11030428 Connector - 20P

106 11030648 Connector - 60P

107 11030649 Connector - 50P

108 11030653 Connector - 34P

109 11030655 Connector - 16P

110 11031022 Connector - 5P

111 11031889 Connector - 6P

112 11040588 DIP Socket - 28P

113 11040589 DIP Socket : 32P

114 11021436 Dip Switchi

115 12060046 Battery - BR-2/3AE

116 14000418 Capacitor - FA1

117 14000492 Transistor - 2SA1461-Y24

118 14000493 Transistor - 2SC3734-B24

119 14010835 Diode - 1SS190

120 14020593 Zener Diode - RD6.2P

121 14020643 Zener Diode - RD3.3M-B1

122 14020711 Zener Diode - RD4.7MB3

123 14020852 Zener Diode - RD15P 15V 1W

124 14030416 LED - Red

125 14030499 LED - Yellow

126 14030500 LED - Green

127 14071597 IC - SN74LS10NS

128 14071600 IC - SN74LS244NS

129 14071605 TTL - SN74LS157NS

130 14071740 IC - SN74LS27NS

131 14071741 TTLIC - SN74LS32NS

132 14071745 IC - SN74LS139NS

133 14071783 IC - SN74LS02NS

134 14071880 IC - SN74LS04NS

135 14071882 IC - SN74LS373NS

136 14071883 IC - TC4050BF

137 14071925 IC - SN15189ANS

138 14071926 IC - SN75188NS

139 14072051 IC - SN74LS00NS

140 14072052 IC - NS74LS74ANS

141 14072055 IC - TD62304F

142 14072077 IC - SN74LS138NS

143 14072081 IC - SN74LS08NS

144 14072187 IC - SN74LS07NS

145 14072253 IC - SN74LS393NS

146 14072468 IC - TC5565AFL-15L

147 14072767 IC - MB89254-PF

148 14072796 IC - TC4584BF

149 14072797 IC - TC5564AFL-15

Page 22

MODIFICATION BULLETIN NO. 4 PAGE 10 OF 27

ISSUED ON: July15, ’93

Index P/N Description Q’ty Index P/N Description Q’ty

150 14072798 SRAM - MB8421-90LF

151 14072799 IC - MBL8086-2

152 14072800 IC - MB89255A

153 14072801 LSI - MB89251A

154 14072803 IC - MB89284A

155 14072804 TTL - SN74LS122NS

156 14072805 IC - SN74LS03NS

157 14072807 IC - RTC-62421

158 14072825 IC - TD62384F

159 14072933 IC - MB89259A-PF

160 14080611 IC - MB3771PF

161 14080701 IC - TL331CPS

162 14080702 IC - TL431CPS

163 14080704 IC - ADC0808CCN

164 14080945 IC - LM324ANS

165 15030195 Oscillator - 24MHz

166 15030202 IC - JCK1100MC

167 16011871 Resistor - 220 Ohm 1/4W +-1%

168 16011872 Resistor - 240 Ohm 1/4W +-1%

169 16011873 Resistor - 270 Ohm 1/4W +-1%

170 16011874 Resistor - 360 Ohm 1/4W +-1%

171 16011875 Resistor - 820 Ohm 1/4W +-1%

172 16013928 Resistor - 26K Ohm 1/8W +-1%

173 16015188 Resistor - 100K Ohm 1/8W +-1%

174 16018476 Resistor - 2K Ohm 1/2W

175 16027007 Capacitor 0.001UF 12V

176 16041367 Capacitor - 100uF +-20% 25V

177 16042017 Capacitor - 10uF 10V +-20%

178 16042018 Capacitor - 4.7mF 10V +-20%

179 16042019 Capacitor - 0.68uF +-20%

180 16050211 Capacitor - 47000PF -20 +80%

181 16050359 Capacitor - 22pF 50V

182 16050362 Capacitor - GRM40B103J50

183 16050513 Capacitor - 2200pF 50V +80% -20%

184 16050517 Capacitor - 330pF +80 -20% 50V

185 16050636 Capasitor - 0.1MF

186 16100656 Resistor - 9.1K Ohm 1/8W +-5%

187 16100660 Resistor - 62K Ohm 1/8W +-5%

188 16100889 Resistor - 4.7K Ohm 1/16W +-5%

189 16100890 Resistor - 160 Ohm +-5% 1/8W

190 16100891 Resistor - 270 Ohm 1/8W +-5%

191 16100892 Resistor - 1K Ohm 1/8W +-5%

192 16100893 Resistor - 3.9K Ohm 1/8W +-5%

193 16100894 Resistor - 5.6K Ohm 1/8W +-5%

194 16100895 Resistor - 8.2K Ohm 1/8W +-5%

195 16100896 Resistor - 10K Ohm 1/8W +-5%

196 16100897 Resistor - 390K Ohm 1/8W +-5%

197 16100898 Resistor - 150 Ohm 1/8W +-5%

198 16100899 Resistor - 82 Ohm 1/8W +-5%

199 16100902 Resistor - 100K Ohm 1/8W +-5%

200 16100903 Resistor - 4.7K Ohm 1/8W +-5%

201 16114101 Resistor - 100 Ohm 1/4T +-5%

202 16114181 Resistor - 180 Ohm 1/4T +-5%

203 16114471 Resistor - 470 Ohm 1/4T +-5%

204 16221501 Resistor - 1.5k Ohm 1/4T +-1%

205 16224701 Resistor - 4.7k Ohm +-1% 1/4W

206 16302560 Resistor - 56 Ohm +5% 1/8W

Page 23

MODIFICATION BULLETIN NO. 4 PAGE 11 OF 27

ISSUED ON: July15, ’93

9. Add the following to page 113 " 50 DC MAIN HARNESS " as parts un iqu e to the finisher version machine (see fig . 10 for th e

referrence illustration).

Index P/N Description Q’ty Index P/N Description Q’ty

* A1125400 DC Harness 1

1 54085160 Short Connector 1

101 11000340 Connector - 1P

102 11000350 Closed Terminal

103 11000503 Socket - Mate-N-Lock

104 11000844 Socket - Mate-N-Lock

105 11000853 Closed Terminal

106 11001041 Pin - Mate-N-Lock

107 11001043 Pin - Mate-N-Lock

108 11001061 Pin - Mate-N-Lock

109 11001155 Contact

110 11001159 Socket - Mate-N-Lock

111 11001172 Fastening Recept acle

112 11001181 Socket - Mate-N-Lok

113 11001182 Socket - Mate-N-Lock

114 11001187 Pin - Mate-N-Lok

115 11001188 Pin - Mate-N-Lok

116 11001190 Socket - Mate-N-Lock

117 11001239 Pin - Mate-N-Lock

118 11001240 Socket - Mate-N-Lock

119 11001241 Socket - Mate-N-Lock

120 11001254 Socket - Mate-N-Lock

121 11001259 Socket - Mate-N-Lock

122 11001264 Wire Terminal

123 11001270 Fastening Recept acle

124 11001271 Fastening Recept acle

125 11001326 Socket - Mate-N-Lock

126 11001342 Terminal

127 11001345 Pin Contact

128 11001346 Pin Contact

129 11001396 Connector - 1P

130 11001402 Connector - 14-16P

131 11001499 Connector - 1P

132 11001505 Connector - 1P

133 11001506 Connector - 1P

134 11020185 Connector - 4P

135 11020984 Connector - 2P

136 11020989 Connector - 9P

137 11021089 Connector - 3P

138 11021090 Connector - 4P

139 11021091 Connector - 6P

140 11021093 Connector - 10P

141 11021094 Connector - 12P

142 11021178 Connector - 5P

143 11021286 Connector - 2P

144 11021306 Connector - 3P

145 11021322 Connector - 20P

146 11021323 Connector - 30P

147 11021344 Connector - QP - 16XS - C

148 11021375 Connector - 4P

149 11021376 Connector - 6P

150 11021397 Connector - 2P

151 11021398 Connector - 2P

152 11021412 Connector - 2P

153 11021418 Connector - 8P

154 11021419 Connector - 2P

Page 24

MODIFICATION BULLETIN NO. 4 PAGE 12 OF 27

Index P/N Description Q’ty

155 11021507 Connector - 2P

156 11021508 Connector - 3P

157 11021509 Connector - 4P

158 11021511 Connector - 9P

159 11021515 Connector - 2P

160 11021516 Connector - 3P

161 11021517 Connector - 4P

162 11021518 Connector - 6P

163 11021519 Connector - 9P

164 11021520 Connector - 12P

165 11021521 Connector - 15P

166 11021526 Connector - 4P

167 11021563 Connector - 12P

168 11021715 Connector - 26P

169 11021731 Connector - 20P

170 11021740 Connector - 7P

171 11021983 Connector - 3P

172 11022103 Connector - 1P

173 11023762 Connector - 4P

174 11024055 Connector - 24P

175 11024185 Connector - 26P

176 11030656 Connector - 16P

177 11030657 Connector - 50P

178 11030661 Connector

179 11030663 Connector - 16P

180 14020110 Diode - V06C

181 14020471 Zener Diode - Z1015

ISSUED ON: July15, ’93

Page 25

MODIFICATION BULLETIN NO. 4 PAGE 13 OF 27

ISSUED ON: July15, ’93

ISSUED ON: July15, ’93

10. Add the following to page 115 " 51 AC MAIN HARNES S" as part s uniq ue to th e fin isher version machine (see fig. 11 for the

referrence illustration).

Index P/N Description Q’ty Index P/N Description Q’ty

* A1125500 AC Harness 1

101 11000051 Wire Terminal

102 11000270 Fastening Recepta cle

103 11000350 Closed Terminal

104 11000853 Closed Terminal

105 11000916 Connector - 2P

106 11001041 Pin - Mate-N-Lock

107 11001042 Socket - Mate-N-Lock

108 11001043 Pin - Mate-N-Lock

109 11001061 Pin - Mate-N-Lock

110 11001062 Socket - Mate-N-Lock

111 11001171 Fastening Recepta cle

112 11001181 Socket - Mate-N-Lok

113 11001190 Socket - Mate-N-Lock

114 11001238 Pin - Mate-N-Lock

115 11001239 Pin - Mate-N-Lock

116 11001240 Socket - Mate-N-Lock

117 11001241 Socket - Mate-N-Lock

118 11001249 Receptacle Terminal

119 11001259 Socket - Mate-N-Lock

120 11001264 Wire Terminal

121 11001327 Contact

122 11001341 Pin Contact

123 11001345 Pin Contact

124 11001491 Pin Contact - 1P

125 11020512 Connector - 3P

126 11020782 Connector - 4P

127 11020983 Connector - 2P

128 11020987 Connector - 6P

129 11020991 Connector - 12P

130 11020992 Connector - 12P

131 11021005 Connector - 1P

132 11021006 Pin Housing - 1P

133 11021089 Connector - 3P

134 11021323 Connector - 30P

135 11021373 Connector - 3P

136 11021377 Connector - 5265 - 7P

137 11021401 Receptacle Housing - 1P

138 11021402 Receptacle Housing - 1P

139 11021403 Receptacle Housing

140 11021404 Connector - 1P

141 11021506 Connector - 1P

142 11021507 Connector - 2P

143 11021508 Connector - 3P

144 11021510 Connector - 6P

145 11021511 Connector - 9P

146 11021515 Connector - 2P

147 11021516 Connector - 3P

148 11021518 Connector - 6P

149 11021519 Connector - 9P

150 11021520 Connector - 12P

151 11021521 Connector - 15P

152 11021715 Connector - 26P

153 11021918 Connector - 10P

154 11022101 Connector - 1P

Page 26

MODIFICATION BULLETIN NO. 4 PAGE 14 OF 27

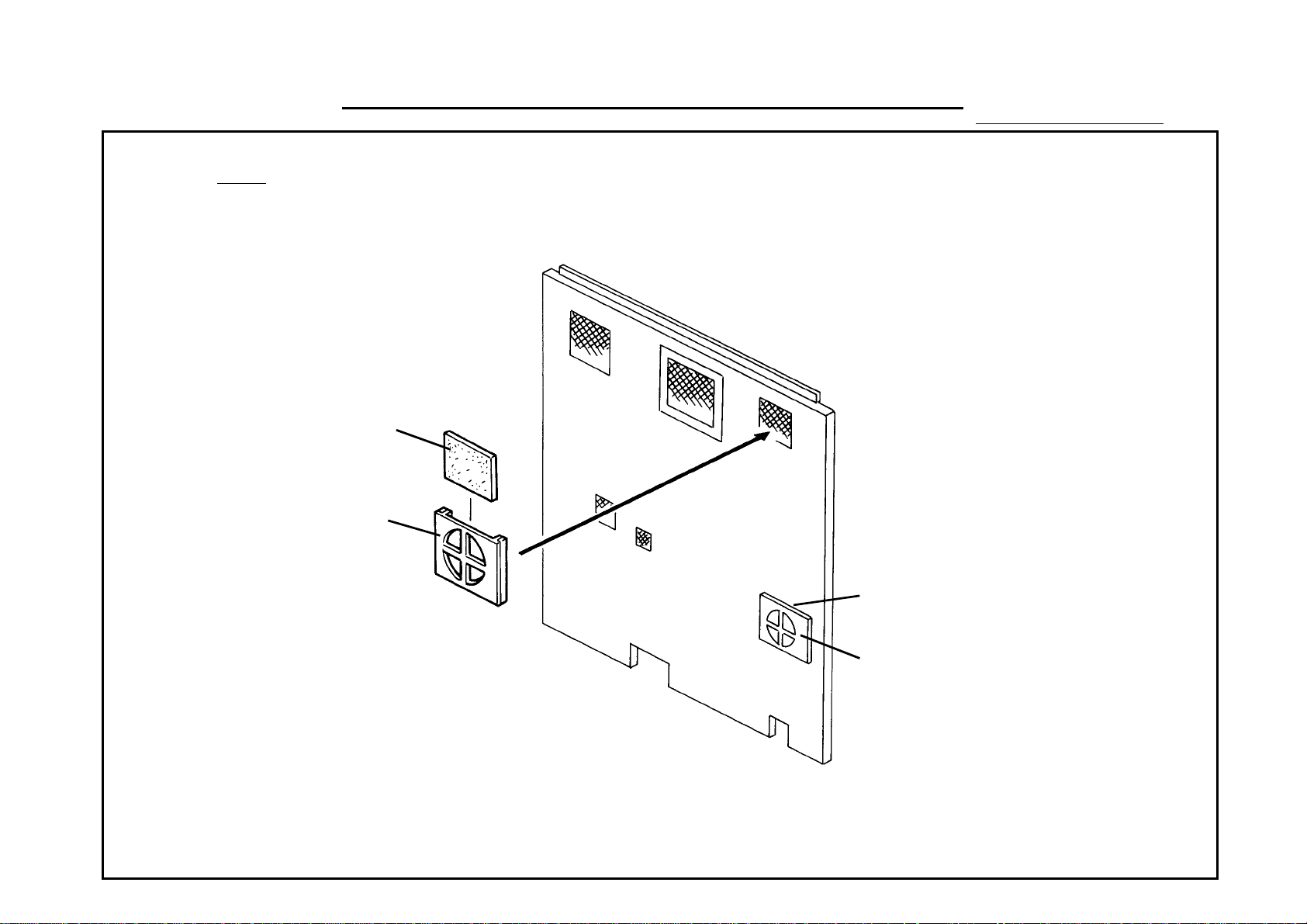

Fig. 1 1. EXTERIOR

* 76

* 78

ISSUED ON: July15, ’93

* : Part unique to the finisher version

76

78

Page 27

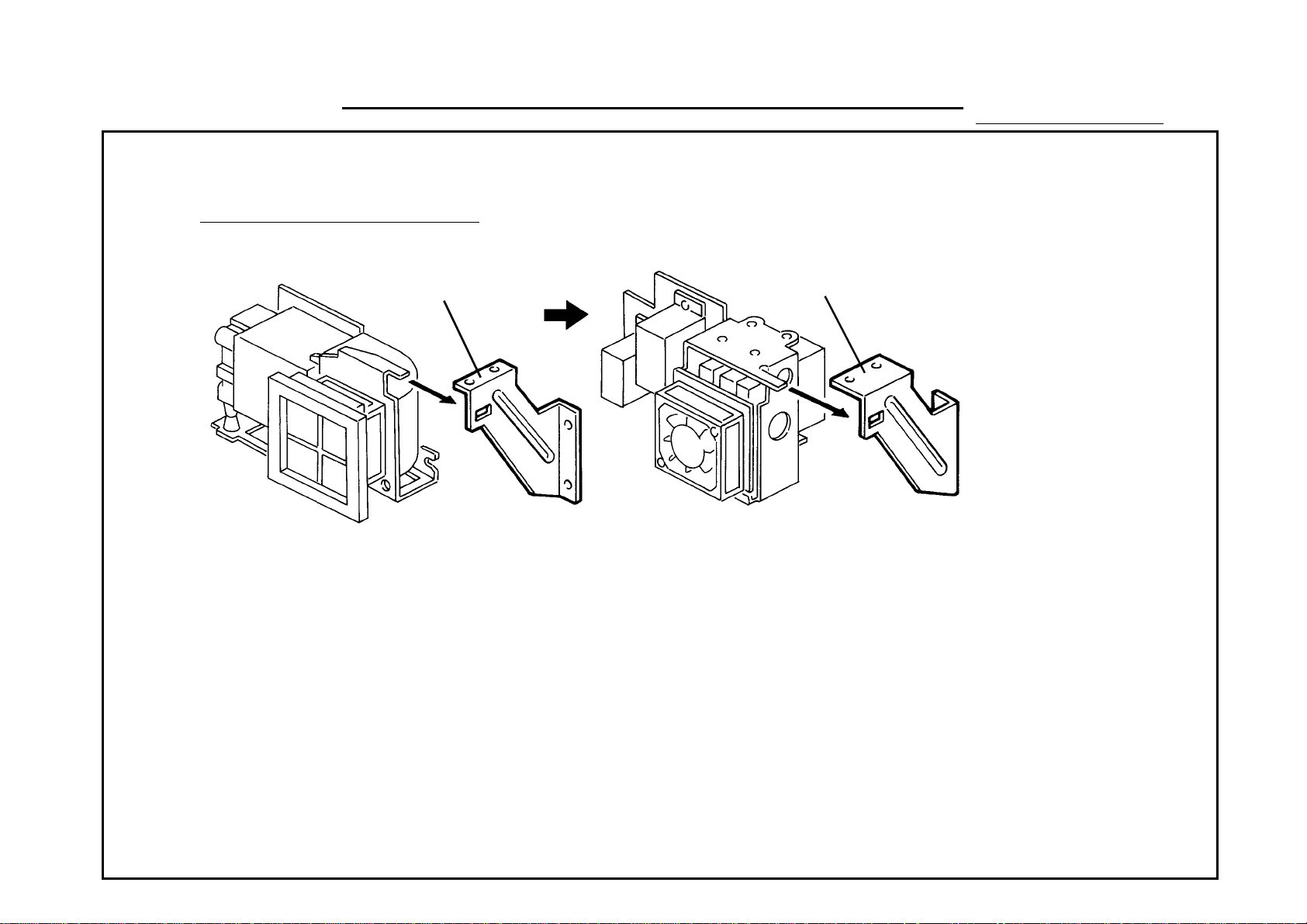

MODIFICATION BULLETIN NO. 4 PAGE 15 OF 27

* 49

Fig. 2 3. FRAME SECTION 2

# 20

ISSUED ON: July15, ’93

# : Part unique to the sorte r ve rsion

* : Part unique to the finishe r ve rsion

Page 28

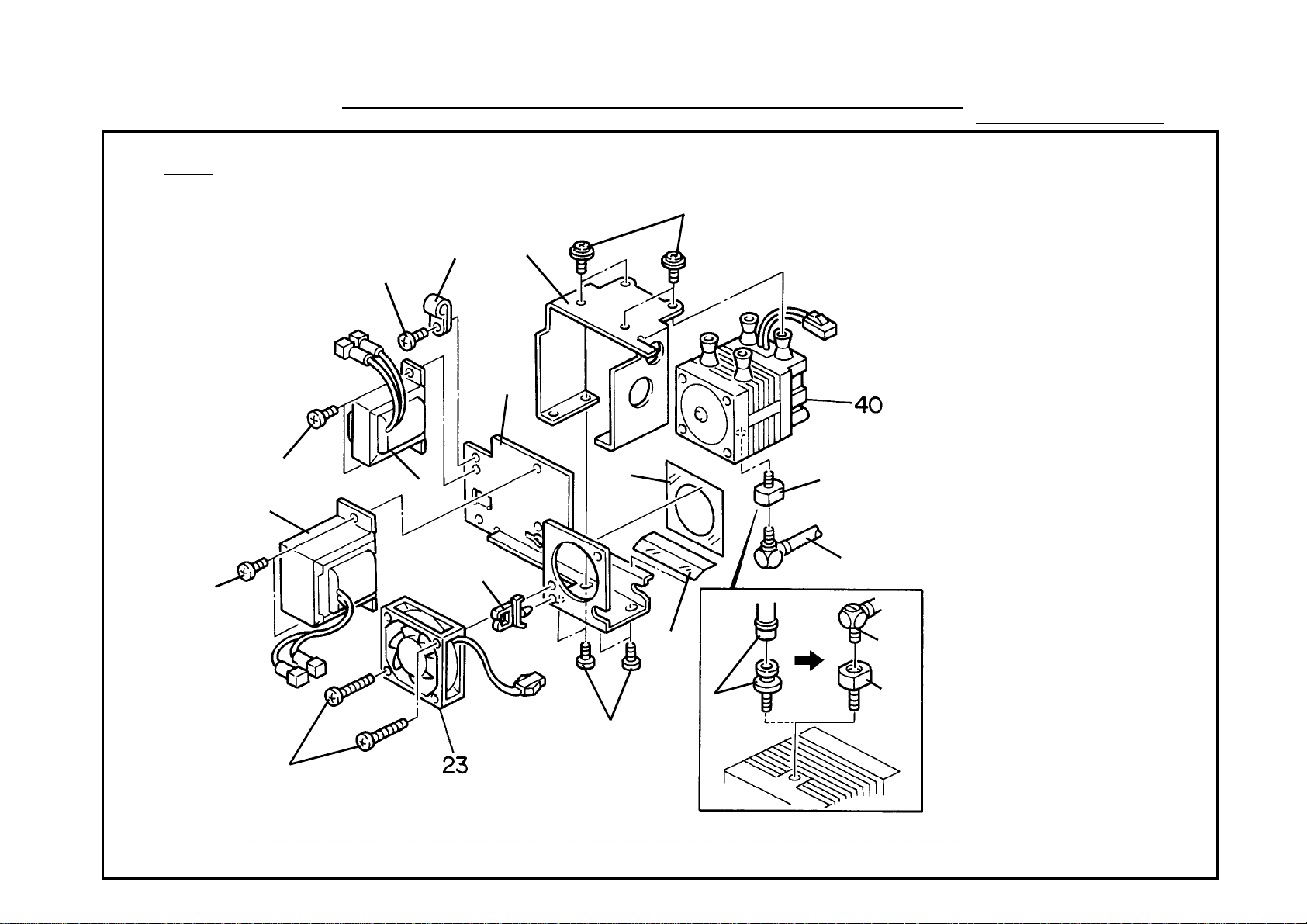

MODIFICATION BULLETIN NO. 4 PAGE 16 OF 27

# 101

Fig. 3 32. ELECTRICAL SECTION 2 (Finisher Version Unique Parts)

* 124

ISSUED ON: July15, ’93

# 101

* 72

# 101

* 71

* 125

# 111

* 74

* 77

* 73

* 78

Old

* 76

* 75

* 75

* 76

# 101

* 123

Page 29

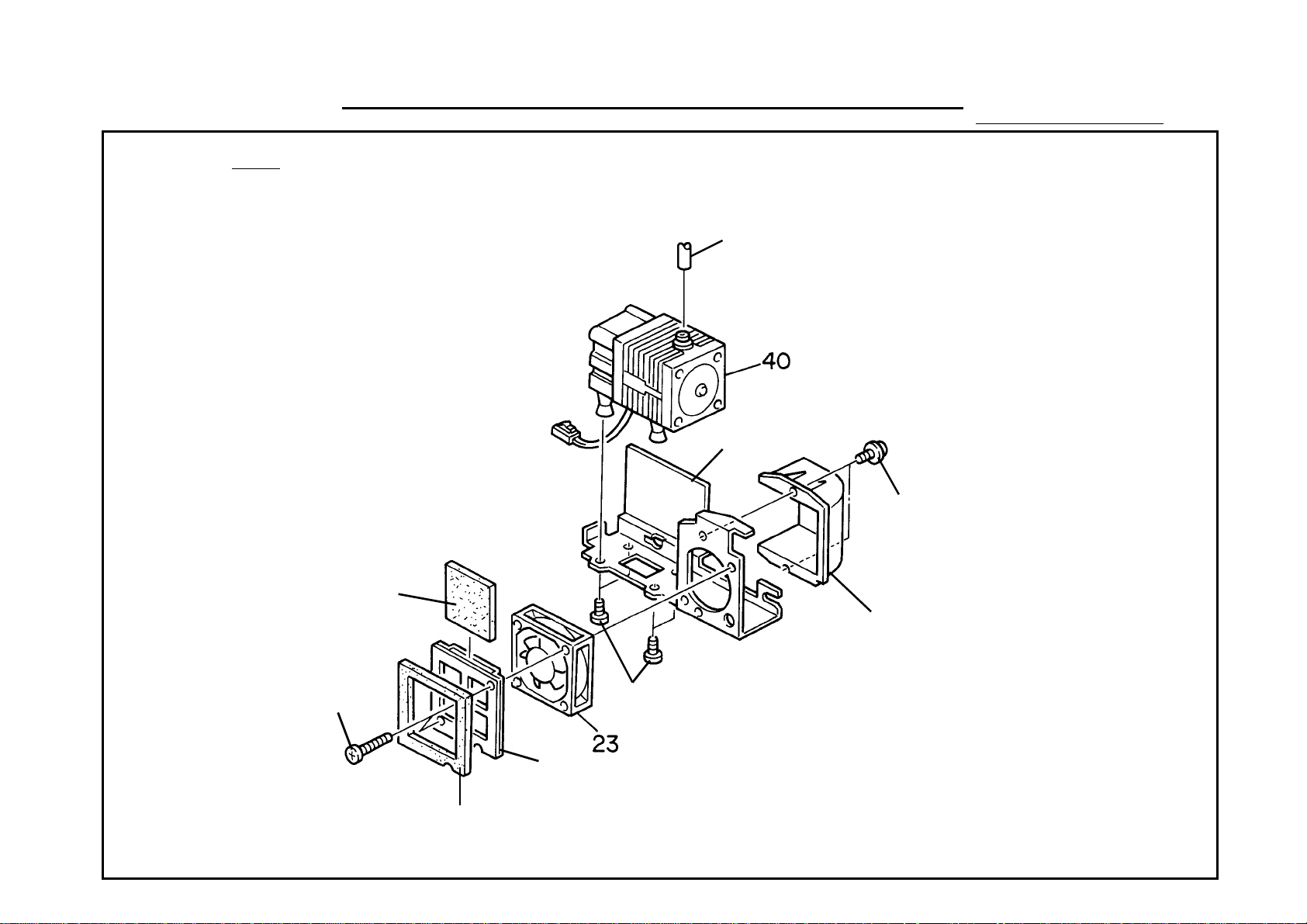

MODIFICATION BULLETIN NO. 4 PAGE 17 OF 27

Fig. 4 32. ELECTRICAL SECTION 2 (Sorter Version Unique Parts)

# 41

# 39

ISSUED ON: July15, ’93

# 114

# 104

# 38

# 36

# 42

# 101

# 37

# : Part unique to the sorte r ve rsion

Page 30

MODIFICATION BULLETIN NO. 4 PAGE 18 OF 27

* 95

Fig. 5 33. ELECTRICAL SECTION 3

(Finisher Version Unique Parts)

ISSUED ON: July15, ’93

# 101

* 96

* 145

* 94

* 97

* 144

# : Part unique to the finish er versio n

* : Part unique to the finishe r ve rsion , bu t

used elsewhere in the sort er versio n

Page 31

MODIFICATION BULLETIN NO. 4 PAGE 19 OF 27

Fig. 6 33. ELECTRICAL SECTION 3 (Sorter Version Unique Parts)

# 87

ISSUED ON: July15, ’93

# 88

# 132

# 131

# 130

# 129

# 131

# 58

# 127

# 127

Page 32

T. Ito, Manager

Copier Technical Support

MODIFICATION BULLETIN NO. 4 PAGE 20 OF 27

Fig. 7 35. ADF FRAME AND ELECTRICAL SECTION

ISSUED ON: July15, ’93

Sorter Version

Finisher Version

4 (Connector Harness)

Sorter Version

Finisher Version

Page 33

MODIFICATION BULLETIN NO. 4 PAGE 21 OF 27

* 78

Fig. 8 36. ADF FEED SECTION

( # 14)

# 14

ISSUED ON: July15, ’93

( * 78)

# 17

# 11

# 10

# 7

# 15

* 77

# 7

* 119

* 120

* 76

* 79

* 79

# : Part unique to the sorte r version

* : Part unique to the finishe r ve rsion

Page 34

MODIFICATION BULLETIN NO. 4 PAGE 22 OF 27

Fig. 9 41. MAIN COTROL BOARD (A112) 1/4

ISSUED ON: July15, ’93

Page 35

MODIFICATION BULLETIN NO. 4 PAGE 23 OF 27

Fig. 9 41. MAIN COTROL BOARD (A112) 2/4

ISSUED ON: July15, ’93

Page 36

MODIFICATION BULLETIN NO. 4 PAGE 24 OF 27

Fig. 9 41. MAIN COTROL BOARD (A112) 3/4

ISSUED ON: July15, ’93

Page 37

MODIFICATION BULLETIN NO. 4 PAGE 25 OF 27

Fig. 9 41. MAIN COTROL BOARD (A112) 4/4

ISSUED ON: July15, ’93

Page 38

MODIFICATION BULLETIN NO. 4 PAGE 26 OF 27

Fig. 10 50. DC MAIN HARNESS (A112)

ISSUED ON: July15, ’93

Page 39

MODIFICATION BULLETIN NO. 4 PAGE 27 OF 27

T. Ito, Manager

Copier Technical Support

Fig. 11 51. AC MAIN HARNESS (A112)

ISSUED ON: July15, ’93

Page 40

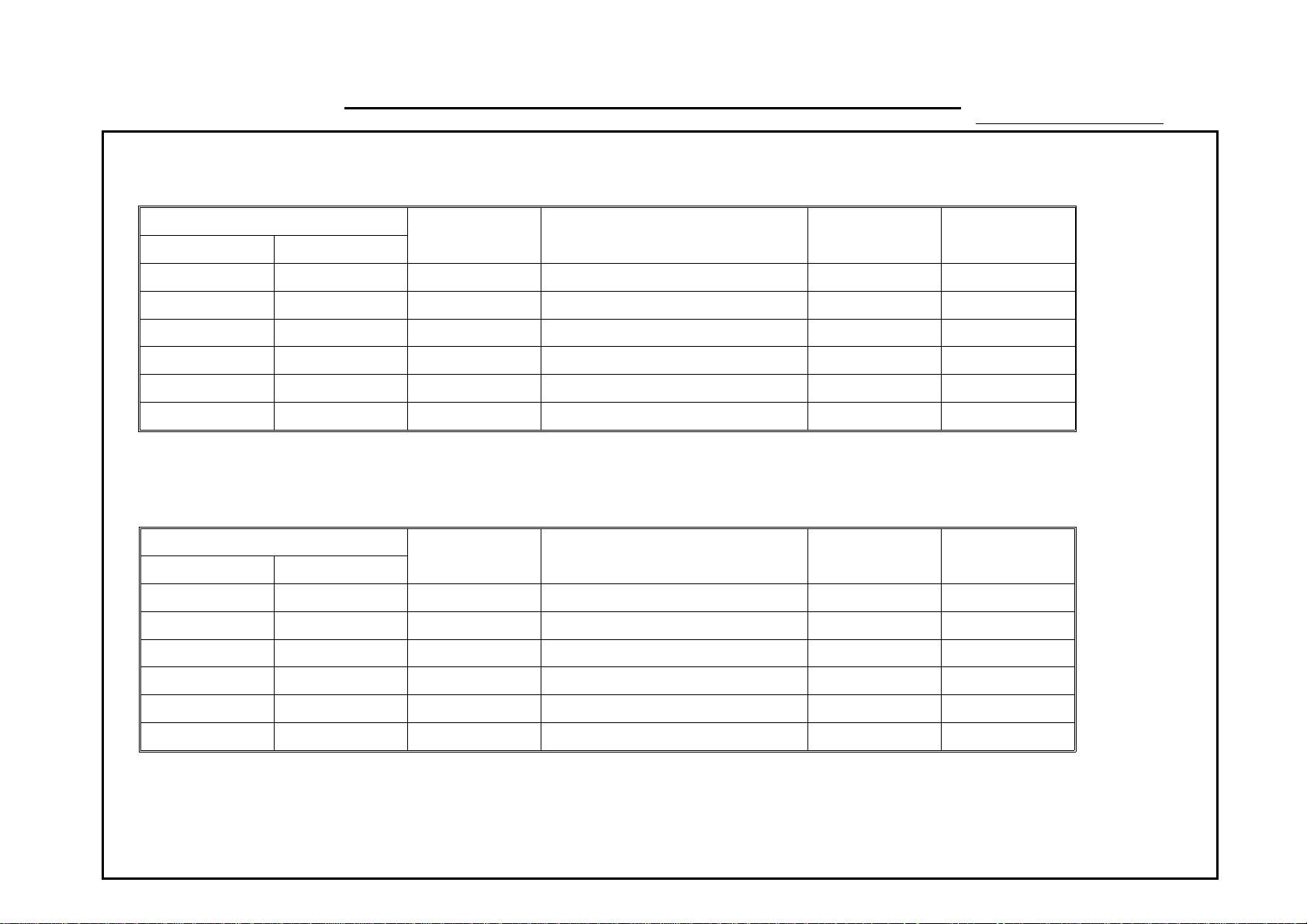

MODIFICATION BULLETIN NO. 5 PAGE 1 OF 3

ISSUED ON: July 15, ’93

Model F5 (Gestetner 25101 / Nashuatec 53101) Volt/Hz

Modified Article Printer Interface Board etc. A028-22

Draw

No.

Reason for

Modification

Old Parts

No.

To enable the use of the printer for servicing

(Nashuatec 53101 only)

New Parts

No.

A1125060 Printer Interface Board 0 → 1 * 11 125

A1127110 PCB Holder 0 → 1 * 12 125

A1127120

A5315420 Printer Harness 0 → 1 * 14 125

11024039 Connector Joint Stud 0 → 2 * 101 125

11050193 Nylon Stud 0 → 4 * 102 125

Description Rank

Printer Harness Main / Interface

Q’ty Used

Old→New

0 → 1 * 13 125

Inter-

change-

ability

Parts needed for replacement by new part

Part No. Description No. Page

Date of

Modification

A112-22 6203060001

Serial

Number

Parts

Catalog

* : New Index No.

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 41

CAUTION:

MODIFICATION BULLETIN NO. 5 PAGE 2 OF 3

ISSUED ON: July 15, ’93

MODIFICATION DETAILS

To facilitate servicing, the part s describ ed in the previo us page have been adde d as acce ssories. By using those parts,

service tool number 6 " Print Out " can be used, eve n whe n th e optio na l print er connector unit is not installed. The part s

can be set as follows:

1. Fully open the front door to access the main control board.

2. Disconnect CN101 on the main control board. Then, connect the two harne sses an d prin ter interface board

as shown in the illustration in the following page.

1. Never disconnect CN101 before turning off the main switch.

2. Bind the grounding wire [A] wit h vinyl tape to avoid po ssible dama ge to PCB ’s. The grou nd ing wire is

necessary when the harness is used with th e op tio na l print er connector.

3. The bottom of the PCB holder is a permanent magnet. Stick it on the copier left cover befo re tu rnin g on the

main switch to avoid possible damag e to PCB’s.

3. Connect the printer. (For the printer, refe r to RTB No. 5.)

4. Turn on the main switch and access service to ol nu mbe r 6 " Print Out ". Then, pre ss t he app rop r iat e key.

NOTE: The printer inte rfa ce bo ard (#A1 12 5060 ), prin ter harness (#A5315420), and two con ne cto r joint studs (2 x

#11024039) have been removed fro m the optional printer connector unit (fro m the first mass-p rod uction) then

included in the copier accessories. Those parts are used when th e op tional printer connector unit is installed.

Keep them for each machine for future use.

Page 42

T. Ito, Manager

Copier Technical Support

MODIFICATION BULLETIN NO. 5 PAGE 3 OF 3

102

[A]

ISSUED ON: July 15, ’93

13

14

11, 12,

102

101

11

102

12

Page 43

MODIFICATION BULLETIN NO. 6 PAGE 1 OF 2

ISSUED ON: February 15, ’94

Model F5 (Gestetner 25101 / nashuatec 53101) Volt/Hz

Modified Article Side Plate - First Tray A028-22

Reason for

To allow the use of thick paper in the first tray

Modification

Draw

No.

Old Parts

No.

A0282823 Side Fence

New Parts

No.

A0282848 Side Plate - First Tray

Description

Rank

Q’ty Used

Old→New

1 → 0

0 → 1

Inter-

change-

ability

X/O 4 17

Parts needed for replacement by new part

Part No. Description No. Page

Date of

Modification

A112-22 6203080001

Serial

Number

Service parts

only

Parts

Catalog

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 44

MODIFICATION BULLETIN NO. 6 PAGE 2 OF 2

ISSUED ON: February 15, ’94

DETAILS OF MODIFICATION

It was found that the paper leading edge hit s the side pla te and a paper misfe ed may occur whe n 170 g/ m m

2

paper is used in the first tray. Although 160 g/mm2 paper can be fed from the first tray without any problem (the

maximum paper weight specification is 163 g/mm2), the configuration of the side plate has been changed as

shown below to allow the use of thicker paper.

51.8mm

3.5mm

51mm

4.5mm

4

(Side Plate - First Tray)

S. Hamano, Assistant General Manager

Technical Support Department

Page 45

MODIFICATION BULLETIN NO. 7 PAGE 1 OF 2

ISSUED ON: February 15, ’94

Model F5 (Gestetner 25101 / nashuatec 53101) Volt/Hz

Modified Article Manual Feed Exit Roller A028-22

Reason for

To prevent the roller from generating sponge dust

Modification

Draw

No.

Old Parts

No.

A0287997 A1127997 Manual Feed Exit Roller

New Parts

No.

Description

Rank

Q’ty Used

Old→New

2 → 2

Inter-

change-

ability

O/O 50 85

Parts needed for replacement by new part

Part No. Description No. Page

Date of

Modification

A112-22 6203060001

Serial

Number

Service parts

only

Parts

Catalog

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 46

MODIFICATION BULLETIN NO. 7 PAGE 2 OF 2

ISSUED ON: February 15, ’94

DETAILS OF MODIFICATION

To prevent the manual fee d exit rollers (spo ng e like mat erial) from being rubbed against the exterior cover and

generating sponge dust (alth ou gh there is n o problem with roller faunction), the diameter of the roller has been

reduced by 1mm as shown below. This allows for a 0.5mm gap between the roller and exterior cover. Origina ls can

still be transported properly.

OLD

27mm

(Manual Feed Exit Roller)

NEW

26mm

0.5mm

50

S. Hamano, Assistant General Man ag er

Technical Support Department

Page 47

MODIFICATION BULLETIN NO. 8 PAGE 1 OF 1

ISSUED ON: February 15, ’94

Model F5 (Gestetner 25101 / nashuatec 53101) Volt/Hz

Modified Article DC Motor - DC24V (Tracking Motor) A028-22

Reason for

Due to part standardization (Sorter version: Gestetner 25101 only)

Modification

A112-22

Date of

Modification

To unify the tracking motor with that of the finish er versio n model (nashuatec 53101), it s part numb er ha s been

changed as follows:

Old P/N New P/N Description Q’ty Used

A0285307 A0285306 DC Motor - DC24V

1 → 1

Inter-

change-

ability

O/O 35 41

Parts Catalog

Index No. Page

Serial Number

Service Part

only

S. Hamano, Assistant General Manager

Technical Support Department

Page 48

MODIFICATION BULLETIN NO. 9 PAGE 1 OF 1

ISSUED ON: February 15, ’94

Model F5 (Gestetner 25101 / nashuatec 53101) Volt/Hz

Modified Article Decal - Front Scale, etc. A028-22 620309XXXX

Reason for

Due to part standardization

Modification

A112-22 6203090001

Date of

Modification

Serial Number

Due to part standardization , th e following parts have been obsoleted.

Part Number Description Q’ty Page Index No.

*1 AG070002 Door Catch

*1 A0282468 Plate Nut - Door Catch

AA002072 Decal - Front Scale

2 → 1

1 → 0

1 → 0

*2

11 11

11 12

31

121

5

13

*1 These two changes are for the sorter version machine (Gest etner 25101) only. The ozone filte r casing (P/N -

A0282450) fixing method has been chan ged from using the door catch (magnet) to usin g a screw (P/ N 03440080F). A screw hole has been added in the ozone filter casing and rear left cover (P/ N - A02816 52). (Their

part numbers remain the same.)

*2 One of the door catches which is used for the toner supply cover (P /N-A 02 8142 7) is still u sed .

S. Hamano, Assistant General Manager

Technical Support Department

Page 49

MODIFICATION BULLETIN NO. 10 PAGE 1 OF 2

ISSUED ON: February 15, ’94

Model F5 (Gestetner 25101/ nashuatec 53101) Volt/Hz

Modified Article Tightener Spring, etc. A028-22

Draw

No.

Reason for

Modification

Old Parts

No.

A0287741 Timing Belt - S3M 117X4

To increase durability of the original exit roller shaft

(Finisher version : nashuatec 53101 only)

New Parts

No.

A1127620 Tightener Spring

A1127616 Tightener Bracket

A1127614 Collar - Tightener

07010040W Flat Washer - M4

A1127615 Timing Belt - B40S3M354

Description

Rank Q’ty Used

OldNew

0 → 1

0 → 1

0 → 1

0 → 1

1 → 0

0 → 1

Inter-

change-

ability

X/X 58 85

Parts needed for replacement by new part

Part No. Description No. Page

Date of

Modification

A112-22 6203060001

X/O as a set *61 85

Serial

Number

Parts

Catalog

*62 85

*63 85

*118 85

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

* : New Index

Page 50

S. Hamano, Assistant General Man ag er

Technical Support Department

MODIFICATION BULLETIN NO. 10 PAGE 2 OF 2

ISSUED ON: February 15, ’94

DETAILS OF MODIFICATION

It was found that the bearing on the front side of the original exit roller (A0 28 7498) b rea ks or the roller sha ft wears out du e to

too high tension of the drive belt . This may occur after making 800,000 copies (in worst case) and cause original misfeeds at

the exit area.

To control the drive belt tension properly, a belt tightener has been added as shown below.

Due to this, the drive belt has been lengthe ne d. The pulle y (A 0287 635) an d E-rin g (07 2000 40 E) are still used in the

different locations as shown.

Note: As a temporary method in the production, the tigh tener spring which has stronger t ension than that of the prope r

tightener spring (A112 76 20 ) has be en used . The proper tightener spring ha s bee n use d from November 1993

production (S/N-620311 00 01).

*63

*118

108 (07200040E)

*61

*62

57 (A028 7635)

58

Page 51

MODIFICATION BULLETIN NO. 11 PAGE 1 OF 5

ISSUED ON: Febra uary 15, ’94

Model F5 (Gestetner 25101 / nashuatec 53101) Volt/Hz

Modified Article Exit Pinch Roller, etc. A028-22

Reason for

To ensure the paper feed for thick originals

Modification

Draw

No.

Old Parts

No.

<Finisher Version Only>

A0287498 A1127498 Exit Roller

New Parts

No.

A1127879 Air Knife Nozzle Ass’y *82 81

A1127805 Spring - Pinch Roller

A1127801 Exit Pinch Roller

Description Rank

Q’ty Used

Old → New

1 → 1

0 → 2

0 → 2

Inter-

change-

ability

X/X X/O as a set 32 85

Part needed for replacement by new

Part No. Description No. Page

Date of

Modification Serial Number

Service part

only

A112-22 6203070004

part

Parts Catalog

*80 81

*81 81

A0287983 A1127983 Exit Guide Mylar

A0287971 A1127971 Nozzle Lower Casing

A1127919 A1127920 Nozzle Upper Casing

07010040G Flat Washer - M4

Rank: A : Replace with new parts immediately.B : Replace with new parts at time of repair.C : Replace with new parts at time of overhaul.

I nterchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

1 → 1

1 → 1

1 → 1

2 → 0

X/X * : New Index 3 81

X/O 20 81

X/X 79 81

X/O as a set 120 81

Page 52

MODIFICATION BULLETIN NO. 11 PAGE 2 OF 5

ISSUED ON: February 15,’94

Draw

No.

Old Parts

No.

<Sorter Version Only>

A0287919

A0287971 A1127971 Nozzle Lower Casing

New Parts

No.

A1127920 Nozzle Upper Casing

Description Rank

Q’ty Used

Old → New

1 → 0

0 → 1

1 → 1

Inter-

change-

ability

O/X O/O as a set 79 81

O/O 20 81

Part needed for replacement by new part

Part No. Description No. Page

Parts

Catalog

781

Page 53

MODIFICATION BULLETIN NO. 11 PAGE 3 OF 5

ISSUED ON: February 15, ’94

DETAILS OF MODIFICATION

To increase the paper tran spo rt ab ility at the exit are a esp ecia lly for thick originals, the two exit pinch rollers and

springs have been added as shown be low. (This is fo r the finish er versio n machine only.)

The configuration of the exit guide myla r has be en chan ged an d two st rips of adh esive tap e have been added .

Also, two cutouts for the pinch rollers ha ve be en made in the nozzle upper casin g.

79 [Old]

3 [Old]

Adhesive Tape

3 [New]

* 81

* 81

* 80

79 [New]

Page 54

MODIFICATION BULLETIN NO. 11 PAGE 4 OF 5

Moved Rollers

ISSUED ON: February 15, ’94

DETAILS OF MODIFICATION

To correspond to the cutou ts of the new no zzle up pe r casing, the configuratio n of the nozzle lo wer casin g ha s bee n

changed as shown lower left.

Also, as the cutouts could not be made corresp on din g to the exit roller positions (there are ribs in those po sitio ns), the two

rubber rollers of the exit roller, which meet the new exit pinch rollers, have been moved as sho wn lowe r rig ht .

NOTE: As the rubber rollers are not fixed on the shaf t, they can be moved manually. Therefore, the old exit roller can be

used with the new air knife nozzle ass’y if you move the two rollers according to the exit pinch roller’s po sitio n.

Exit Roller (Index 32)

[Old]

[New]

[Old]

20 (Nozzle Lower Casing)

[New]

Page 55

MODIFICATION BULLETIN NO. 11 PAGE 5 OF 5

ISSUED ON: February 15, ’94

79

(Nozzle Upper Casing)

DETAILS OF MODIFICATION

The boss in the nozzle upper casing has been le ngthened as shown below. Due to this, the two washers

(07010040G) have been obsolet ed . The large washer (07010060G) is still used.

(119)

120

(119)

For the sorter version machine (G est etner 25101), due to part standardiza tion, the upper and lower nozzle

casings have been changed. Note that the old exit guide mylar (A0287983) and old exit rolle r (A02 87 498) are

still used for the sorter version ma chin e.

S. Hamano, Assistant General Man ag er

Technical Support Department

Page 56

MODIFICATION BULLETIN NO. 12 PAGE 1 OF 4

ISSUED ON: March 31, ’94

Model F5 (FT9101 / Gestetner 25101 / nashuatec 53101) Code Model Name Serial Number

Modified Article Right Turn Guide Plate, Entrance Turn Roller Pulley A028-22 25101

A112-22 53101 6203120010

A112-20 FT9101 A3543120001

part

X/O as a set 39 87

* : New Index *121 87

Draw

No.

Reason for

To minimize original smearing or jams

Modification

Old Parts

No.

A0287361 A1127350 Right Turn Guide Plate

[Finisher Version Only]

A0287638 A1127638 Pulley - 42Z

07200060E Retaining Ring - M6

New Parts

No.

05750080E

Description

Hexagon Headless Set

Screw - M5 x 8

Rank

Q’ty Used

Old→New

1 → 1

1 → 1

n → n-1

0 → 2

Inter-

change-

ability

X/O 12 87

Parts needed for replacement by new

Part No. Description No. Page

Service part

only

Parts Catalog

115 87

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 57

MODIFICATION BULLETIN NO. 12 PAGE 2 OF 4

ISSUED ON: March 31, ’94

First Transport

Sensor

Information for Ricoh model (Ricoh FT9101 ) star ts from thi s bull eti n. MB no. 1 to no. 11 are for the Ge ste tner

and nashuatec models only.

To minimize original smearing or jams in the RDH mode, the pulley, which drive s the entrance turn roller, and the right turn

guide plate have been changed . Deta ils of th e cha nges are as follows.

NOTE: This improvement is more effective with the new RDH ROM (refer to RTB-017).

1. In the RDH the original is stopped once at the ent ran ce of the inte rmediate transport section as soo n as the first tran spo rt

sensor detects it. At this time, while the first and secon d relay rollers stop immediately, the entrance turn roller still turns

because of a one-way clutch built-in the roller’s pulle y. As a result , the orig ina l rubs ag ain st th e first relay roller and this will

cause smearing on the reverse of orig ina ls after many original recirculations. This ma y also cau se orig inal jams if the

original stop position is too late.

Original

Entrance Turn

(Original Feed) Roller

First Relay Roller

Buckle of Original

Page 58

MODIFICATION BULLETIN NO. 12 PAGE 3 OF 4

ISSUED ON: March 31, ’94

To prevent this symptom, the one -way clut ch in th e en tra nce turn roller pulley has been removed, and th e pu lley is fixed on th e

roller shaft with two headle ss set screws. The one-way clutch was used to make it easier to pull out the jammed origina l

stopped between the rollers. Due to this mo dif ication, the removal of such a jam slightly becomes harder but it remains no

problem.

CAUTION: As a special hard material is used for the roller’s shaft, be sure to tighten the set screws firmly t o prevent

the pulley from slipping on the shaft . The remo val of the pulle y is no prob lem eve n whe n th e set scre ws

are tightened strongly due to the hard mate rial of the shaf t.

Entrance Turn Roller Shaft

(A0287342)

121

39

121

Old Pulley

(with an E-ring)

Page 59

MODIFICATION BULLETIN NO. 12 PAGE 4 OF 4

Original

12

(Right Turn

Guide Plate)

ISSUED ON: March 31, ’94

2. When the original enters the right turn ro ller, the le ading edge tends to hit the driven rollers as shown below. If the

original is stopped there, th e second relay roller rubs the original beca use it still turns. This will make smearing on

the reverse of the original, an d it be come s visible after many original recirculatio ns.

To prevent this, the guid e strips have been added to the right turn guide plate, so th at the origin al leading edge

smoothly enters between the right turn rolle r and its driven roller.

NOTE: When you replace the right turn guide plate, be sure to remove the antistatic brush an d rein stall it.

21 (Antistatic Brush - Exit Lower)

Driven Roller

Right Turn Roller

Guide Strip

Guide Strip

S. Hamano, Assistant General Manager

Technical Support Department

Page 60

MODIFICATION BULLETIN NO. 13 PAGE 1 OF 3

ISSUED ON: March 31, ’94

Model F5 (FT9101 / Gestetner 25101 / nashuatec 53101) Code Model Name Serial Number

Modified Article Right Turn Pressure Roller A028-22 25101

A112-22 53101 6203120004

A112-20 FT9101 A3543120001

part

* : New Index

Draw

No.

Reason for

To minimize original jams

Modification

Old Parts

No.

A0287363 A1127363 Right Turn Guide Plate

New Parts

No.

07200050E Retaining Ring - M5

07403906 Ball Bearing - 6 x 15 x 5

Description

Rank

Q’ty Used

Old→New

1 → 1

0 → 8

0 → 4

Inter-

change-

ability

X/O 11 87

Parts needed for replacement by new

Part No. Description No. Page

Service part

only

Parts Catalog

* 122 87

* 123 87

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 61

MODIFICATION BULLETIN NO. 13 PAGE 2 OF 3

ISSUED ON: March 31, ’94

Angle for the

roller’s free

rotation

When an original stops in front the right turn rolle r, th e trailing edge of the previousely fed original is still caught with the

right turn roller as shown below. Due to a one-way clutch built-in th e righ t turn rolle r’s p ulle y, th e roller can still turn to feed

the original even after the original feed moto r stops.

As a side effect of the RDH ROM modification (refer to RTB-01 7), the trailin g edge of orig ina ls ten ds to be caugh t with the

right turn roller because th e orig inal feed motor stops earlier than old type. This might cause original jams, especially wh en

11" x 81/2" or 14" x 81/2" originals are used (their short edges are longer than that of A4 size). Also, as the original stop timing in the intermediate tran spo rt fo r t he last original is slightly earlier than usual in the simplex orig ina ls to du ple x copy

mode, the last original tends to be delayed to be transpo rted onto the exposure glass. Thus, creating an improper leadin g

edge registration for its co py. (This does not occu r with A4 origin als, but might occur with 11" x 81/2" or 14" x 81/2" origi-

nals.)

NOTE: These symptoms do no t occu r wh en the tran sport belt is replaced at the PM intervals. If the friction between

originals and the transport be lt be come s less, the problems will occur.

Right Turn Pressure

Roller

Originals

Page 62

MODIFICATION BULLETIN NO. 13 PAGE 3 OF 3

123

123

ISSUED ON: March 31, ’94

To allow the right turn roller to rotate free ly e ven aft er th e mot or sto ps, the frictio n of the right turn pressure

roller has been reduced by using 4 roller bearin gs as drive n rollers.

New Right Turn

Pressure Roller

(P/N - A1127363)

122

123

123

S. Hamano, Assistant General Manager

Technical Support Department

Page 63

MODIFICATION BULLETIN NO. 14 PAGE 1 OF 2

ISSUED ON: March 31, ’94

Model F5 (FT9101 / Gestetner 25101 / nashuatec 53101) Code Model Name Serial Number

Modified Article Right Turn Roller A028-22 25101

A112-22 53101 6204020001

A112-20 FT9101 A3544020004

part

* : New Index

Draw

No.

Reason for

To increase the tolerance for the modification of MB no. 13

Modification

Old Parts

No.

A0287362 A1127362 Right Turn Roller

New Parts

No.

A1127366 Flywheel

05740040

Description

Hexagon Headless Set

Screw - M4 x 4

Rank

Q’ty Used

Old→New

1 → 1

0 → 1

0 → 2

Inter-

change-

ability

O/O 14 87

Parts needed for replacement by new

Part No. Description No. Page

Service part

only

Parts Catalog

*56 87

* 124 87

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 64

MODIFICATION BULLETIN NO. 14 PAGE 2 OF 2

ISSUED ON: March 31, ’94

56

To increase the tolera nce for th e modification of MB no. 13 (the right tu rn pre ssure roller change), the right turn roller ha s

been changed as shown below.

The one of the rubber rollers (the non-op eration side) has been changed to a meta l f lywhe el. This allows the right turn

roller to rotate more smoothly after the origina l fee d mot o r sto ps. For the application to the field ma chin es, the change of

the right turn pressure roller is effective enough.

Old

New

(including the flywheel)

124

124

0 ± 0.5mm

S. Hamano, Assistant General Manager

Technical Support Department

Page 65

MODIFICATION BULLETIN NO. 15 PAGE 1 OF 3

ISSUED ON: March 31, ’94

Model F5 (FT9101 / Gestetner 25101 / nashuatec 53101) Code Model Name Serial Number

Modified Article Air Duct, etc. A028-22 25101

A112-22 53101 6204030001

A112-20 FT9101 A3544030002

part

Draw

No.

Reason for

To minimize original jams

Modification

Old Parts

No.

A0287579 A1127579 Air Duct

A0287597 A1127597 Shutter Spring Boss

A0287604

A0287589 Air Solenoid Link

New Parts

No.

07413504 Bushing - 4 x 8 x 3 mm

Description

Rank

Q’ty Used

Old→New

1 → 1

1 → 1

2 → 0

0 → 2

1 → 0

Inter-

change-

ability

X/X X/O as a set 74 81

X/O 65 81

X/X 67 81

Parts needed for replacement by new

Part No. Description No. Page

Service part

only

Parts Catalog

A1127589 Shutter Solenoid Ass’y

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

0 → 1

X/O 64 81

Page 66

MODIFICATION BULLETIN NO. 15 PAGE 2 OF 3

ISSUED ON: March 31, ’94

Air Duct

There is a possibility that the vacuum shutter might not be closed tightly an d orig inal feed jams occur after approximately 1,000,000 copies. Th e portio ns of the air duct which support the shutter’s shafts (via dry bearings), the

shaft of the shut te r spring boss, and the hole of the soleno id link tend to wear out.

Shutter Spring Boss

Solenoid Link

Page 67

MODIFICATION BULLETIN NO. 15 PAGE 3 OF 3

ISSUED ON: March 31, ’94

To increase the durability, the follo wing chan ge s have been mad e:

1) The dry bearings have been changed to ball bearings. Due to this, the portions of the air duct which sup po rt th e bearin gs ha ve

been enlarged. Also, to prevent th e shu tter spring boss from touching the new ball bearing, a groove has been made on the

boss. (Therefore, th e air duct, two ball bearings, and shutt er spring boss can be changed only as a set.)

2) To prevent the shaft of the shutter spring boss from wearing out, the material of the solenoid link has been chan ge d fro m me ta l

to plastic. The thickness has also been chan ged from 1 mm to 2.5 mm.

CAUTION : 1. Even after using the new pa rts, the shutter solenoid position mu st be ch ecke d every 2,000,000 copies to

prevent original feed jams. If necessary, adjust the position according to th e service manual.

2. When the solenoid is installed, fix it so tha t the link do es not interfere with the shutter spring bo ss as shown .

Air Duct

Shutter

Ball Bearing

Dry Bearing

Avoid this interference

Shutter Spring Boss

Groove

Shutter Solenoid

Solenoid Link

Ass’y

S. Hamano, Assistant General Manager

Technical Support Department

Page 68

MODIFICATION BULLETIN NO. 16 PAGE 1 OF 4

ISSUED ON: March 31, ’94

Model F5 (FT9101 / Gestetner 25101 / nashuatec 53101) Code Model Name Serial Number

Modified Article Recycle Arm Solenoid Ass’y A028-22 25101

Reason for

To increase the durability of the recycle arm (Finisher version only)

Modification

A112-22 53101 6203110001

A112-20 FT9101 A3543120001

There is a possibility that the recycle arm might break after the 200,000 time s of its opera tio n (ap pro ximat ely 1, 000, 000

copies). To increase the durab ility, the assembled recycle arm has been changed as follo ws:

Old P/N New P/N Description Q’ty Used

A1127886 A1127990 Recycle Arm Solenoid Ass’y

1 → 1

Inter-

change-

ability

X/O 78 81

Parts Catalog

Index No. Page

NOTE:

1. The air knife nozzle ass’y (P/N - A1127879) includ es th is p art , bu t its part nu mbe r remain s the same.

However, all service parts are the ne w type only.

2. The new part number is already mentio ne d on the Rico h versio n’s parts catalog.

Page 69

MODIFICATION BULLETIN NO. 16 PAGE 2 OF 4

Details of the charges are as follo ws:

ISSUED ON: March 31, ’94

1. The fence has been thickened by 0.5 mm to preve nt the pin

of the recycle arm from breaking. Also, the bot to m of th e

pin has been rounded as shown be low.

Fence

Pin

2. A rib has been added to guide the recycle arm smoother. A

mylar sheet has been added to cove r the metal plate on the

recycle arm. This reduces the attractio n force to the magnet

and prevents the recycle arm from bre akin g.

Mylar

Sheet

Recycle Arm

Rib

Page 70

MODIFICATION BULLETIN NO. 16 PAGE 3 OF 4

Link Stopper

Side View

ISSUED ON: March 31, ’94

3. A dry bearing has been added to preve nt the lin king

shaft from wearing out.

4. To prevent the recycle arm link stopper ( in the nozzle lower

casing) from wearing out, a flat face has been added to the

link.

Link Stopper

Flat Face

Worn Shaft

Dry Bearing

Link

Page 71

MODIFICATION BULLETIN NO. 16 PAGE 4 OF 4

ISSUED ON: March 31, ’94

5. To prevent the hole of the solenoid plunger link from

wearing out, the thickness of the link has bee n incre ase d

from 1mm to 1.5mm.

CAUTION: As a flat face has been added to the link

(modification number 4), ma ke sure that the flat

face is not caught with the harness when

assembling. Be sure that the recycle arm can move

smoothly by operating the solenoid plunger

manually.

Harness

Link

Worn Hole

S. Hamano, Assistant General Man ag er

Technical Support Departme nt

Page 72

MODIFICATION BULLETIN NO. 17 PAGE 1 OF 2

ISSUED ON: March 31, ’94

Model F5 (FT9101 / Gestetner 25101 / nashuatec 53101) Code Model Name Serial Number

Modified Article End Plate Stopper A028-22 25101 Service part only

Reason for

To prevent operators from setting the original end plate at the wrong position

Modification

A112-22 53101 6204010001

A112-20 FT9101 A3544020001

For the customers who use 11" x 81/2" o r 14" x 81/2" originals, a slot had to be made to sto p the original end plate at

the 81/2 inch position. (Refer to RTB-012 for the Gest et ner/nashuatec models or page 1-14 of the field service manual

for the Ricoh model.) If the slot is made, an opera to r may set th e orig ina l e nd plat e at the wrong posit ion (b eca use the

A4 and 81/2 inch positions are very close) and this will cause original feed jams.

To improve this, the end plate stopper has been changed as shown below.

Old P/N New P/N Description Q’ty Used

A0287903 A1127903 End Plate Stopper

1 → 1

Inter-

change-

ability

X/O 53 79

Parts Catalog

Index No. Page

Old End Plate Stopper

New Type

Page 73

MODIFICATION BULLETIN NO. 17 PAGE 2 OF 2

ISSUED ON: March 31, ’94

The new end plate stopper has different shapes at each end. One is for metric sized origin als and th e other is for inch

sized originals. Each end can be replaced as shown below, and you do no t ha ve to make the slot when the end for the

inch size is used.

CAUTION: When both inch size and metric sized origin als are used , the slot for the 8 1/2 inch position still has to be

made. (The end for the metric size is used in this case .)

New End Plate Stoppe r

S. Hamano, Assistant General Manager

Technical Support Department

Page 74

MODIFICATION BULLETIN NO. 18 PAGE 1 OF 3

ISSUED ON: April 15. ’ 94

Model F5 (FT9101 / Gestetner 25101 / nashuatec 53101) Code

Modified Article Inverter Entrance Roller, etc. A028-22 25101 Service part only

A112-22 53101 6203110001

A112-20 FT9101 A3543120001

new part

Draw

No.

Reason for

To increase the durability of the inverter entrance roller

Modification

Old Parts

No.

A0287540 A1127540 Inverter Entrance Roller

A0287538 Bushing Plate

03140060W Philips Pan Head Screw - M4 x 6

A0287878 Arm Spacer

New Parts

No.

07413506 Ball Bearing - 6 x 12 x 4 mm

A0287744 Exit Idler Collar

Description Rank

Q’ty Used

Old→New

1 → 1

n → n-1

n → n+1

n → n-1

n → n-1

n → n+1

Inter-

change-

ability

X/O 36 85

X/X X/O as a set 111 85

X/X 23 85

Parts needed for replacement by

Part No. Description No. Page

Model

Name

Serial Number

Parts Catalog

18 85

101 85

19 85

03140060W Philips Pan Head Screw - M4 x 6

09514006B

54101291 Return Lever Pin

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Philips Screw with Flat Washer M4 x 6

n → n-2

n → n+1

n → n+1

O/O 106 85

X/O 24 85

101 85

Page 75

MODIFICATION BULLETIN NO. 18 PAGE 2 OF 3

ISSUED ON: April 15, ’94

DETAILS OF MODIFICATION

It was found that the shaft of th e inve rte r e ntrance roller might wear out or that the rolle r’s bea ring s mig ht brea k

when the tension of its d rive belt is t oo string . Although the tension is determine d by a spring, too much tension is

applied when the screw in the lowe r right side (see illustration) is tighte ne d first .

To prevent this, the screw securing the lower side of the inverter idler pla te (P /N-A 02 8772 7) ha s been cha ng ed to a

stud (Return Lever Pin: P/N-5410129 1). The other screw has also be en change d to a golden (zinc plated) screw to

identify it as an adjusting point . The inverter idler plate is now fixed with only o ne scre w and the stud works as a

guide for the pla te.

Drive Belt

Inverter

Idler

Plate

Inverter Idler Plate

03140060W to 09514006B

Old

New

Inverter

Entrance Roller

Pulley

54101291

Page 76

MODIFICATION BULLETIN NO. 18 PAGE 3 OF 3

ISSUED ON: April 15, ’94

To increase the durability of the shaft of the inverte r ent rance roller, its material has been chan ge d to a harder metal. At the

same time, the end of the sha ft , to which the drive pulley is installed, has be en leng thened by 2mm. This makes the flat part

of the shaft visible so that the pulley can be prope rly positioned before tightenin g the two headless set screws.

CAUTION: With the old inverter ent ran ce roller, the pulley just meets the end of the rolle r’s sh af t, but with th e ne w one 2mm

from the end of the shaft must be seen when the pulley is installed as sho wn below.

To make the removal of the inverte r ent ran ce roller easier, the bushing plate (P/N-A0287538), which includes a ball

bearing, has been changed to a norma l ball be arin g (P/N-07413506). (The screw securing the bushing plate was hard to

access. ) Due to this, the spacer of 1mm thickness (P/N-A0287878) has be en ch ange d to another of 2mm thickness

(P/N-A0287744).

NOTE: At the same time with these mo dif icat ions (the same cut-in serial numbers), the proper tightener spring

(P/N-A1127620) for the origin al exit roller ha s been use d. Before this, a tightener spring which has stro ng er te nsion

had been used as a temporary method in the pro duction. (Even with the stronger tightene r spring, there was no

problem for the performance. But it has been changed to in crea se tolerance.)

Inverter Entrance Roller

A0287538

A0287878

Pulley

A0287744

07413506

2mm

Pulley

2mm

Old

New

S. Hamano, Assistant General Manager

Technical Support Department

Page 77

MODIFICATION BULLETIN NO. 19 PAGE 1 OF 2

ISSUED ON: April 15, ’94

Model F5 (FT9101 / Gestetner 25101 / nashuatec 53101) Code Model Name Serial Number

Modified Article Original Guide Mylar A028-22 25101 Service part only

Reason for

To minimize jams for thin originals

Modification

A112-22 53101 6204020002

A112-20 FT9101 A3544030001

To improve the original feed-out onto the original table, 4 of the 6 origin al gu ide mylars (P aper Fee d Cove r G uid e - C)

have been changed.

Old P/N New P/N Description Q’ty Used

A0287761 Paper Feed Cover Guide - C

A1127761 Original Guide Mylar

A1127763 Mylar - 31 x 15

6 → 2

0 → 4

0 → 4

Inter-

change-

ability

X/O

(as a set)

Index No. Page

Parts Catalog

77 24

77 * 38

77 * 39

* : New Index

NOTE: With the existing guide mylars, jams tend to occur at the exit area whe n a small number of thin (70 g/m2 or less)

A4, 11" x 81/2", or 14" x 81/2" originals is set in the RDH mode. The new guide mylars are effective in reducing

Page 78

MODIFICATION BULLETIN NO. 19 PAGE 2 OF 2

ISSUED ON: April 15, ’94

DETAILS OF MODIFICATION

For application to the fie ld units, remove the 4 old mylars and install the new ones as shown belo w. Before installing

them, clean with alcohol. (The mylar strip (P/ N-A1 12 7763) used in the original guide mylar is also available as a

service part separately.)

Old New

Original

A1127763

Original Table Cover

A1127761

New Original Guide Mylar

S. Hamano, Assistant General Manager

Technical Support Department

Page 79

MODIFICATION BULLETIN NO. 20 PAGE 1 OF 1

ISSUED ON: April 15, ’94

Model F5 (FT9101 / Gestetner 25101 / nashuatec 53101) Code Model Name Serial Number

Modified Article Parts Catalog A028-22 25101

Reason for

Parts Catalog Correction

Modification

Correct your parts catalog as follows:

Ricoh Version Catalog

Incorrect P/N Correct P/N Description

58055011 08055011 Caster - 250 KGF 15 45

Gestetner / nashuatec Vers ion Pa rts Catalog

Incorrect P/N Correct P/N Description

A0281198 08055011 Caster - 250 KGF 15 45

NOTE: A0281198 can also be used if you ha ve it in sto ck. Int erch an ge ability is O/O.

A112-22 53101

A112-20 FT9101

Parts Catalog

Index No. Page

Parts Catalog

Index No. Page

S. Hamano, Assistant General Manager

Technical Support Department

Page 80

MODIFICATION BULLETIN NO. 21 PAGE 1 OF 1

ISSUED ON: April 15, ’94

Model F5 (FT9101 only) Code Model Name Serial Number

Modified Article Main Control Board - ADF A028-22 25101

A112-22 53101

Reason for

To meet the safety standard

Modification

A112-20 FT9101

To meet the safety standard , the fu se in th e ADF main cont rol bo ard has be en chan ged.

Old P/N New P/N Description Q’ty

A1125805 A1125810 Main Control Board - ADF

11070752 Fuse - 5A, 250V

11070391 Fuse - 5A, 125V

1 → 1

1 → 0

0 → 1

Inter-

change-

ability

X/O

X/O

Index No. Page

Parts Catalog

30

*

114

112

79

117

79

117

NOTE: If the fuse is repla ced by the one approved by the UL (1107 03 91 ), th e old board can be used with no proble m.

From first

production

(September 1993)

S. Hamano, Assistant General Manager

Technical Support Department

Page 81

MODIFICATION BULLETIN NO. 22 PAGE 1 OF 2

ISSUED ON: November 15, ’94

Model F5 (FT9101 / Gestetner 25101 / nashuatec 53101) Code Model Name

Modified Article Resistor on Main Board A028 - 22 25101

A112 - 22 53101 See Page 2

A112 - 20 FT9101 See Page 2

* : New Index

Draw

No.

Reason for

To prevent abnormal leading edge registration

Modification

Old Parts

No.

16100890

[Gestetner 25101 (A028-22) Only]

New Parts

No.

16303120

Description Rank

Registor - 160Ω ±5% 1/8W n → n-1

Registor - 1KΩ ±5% 1/10W 0 → 1

Q’ty Used

Old→New

Inter-

change-

ability