Page 1

Technical Bulletin No. RTB-001

SUBJECT: Oil end sensor harness wiring DATE: April 30 ’94

PAGE: 1 of 2

PREPARED BY: S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

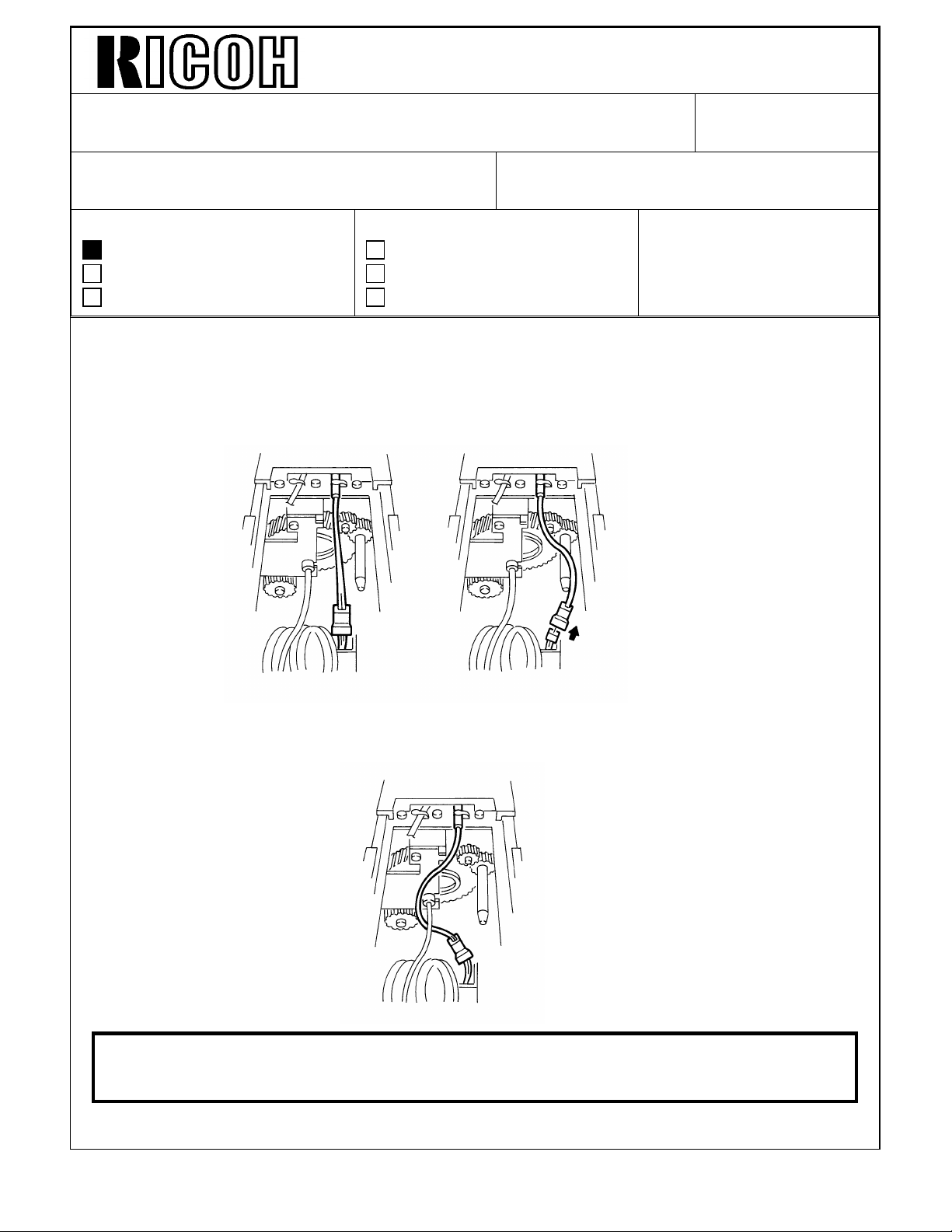

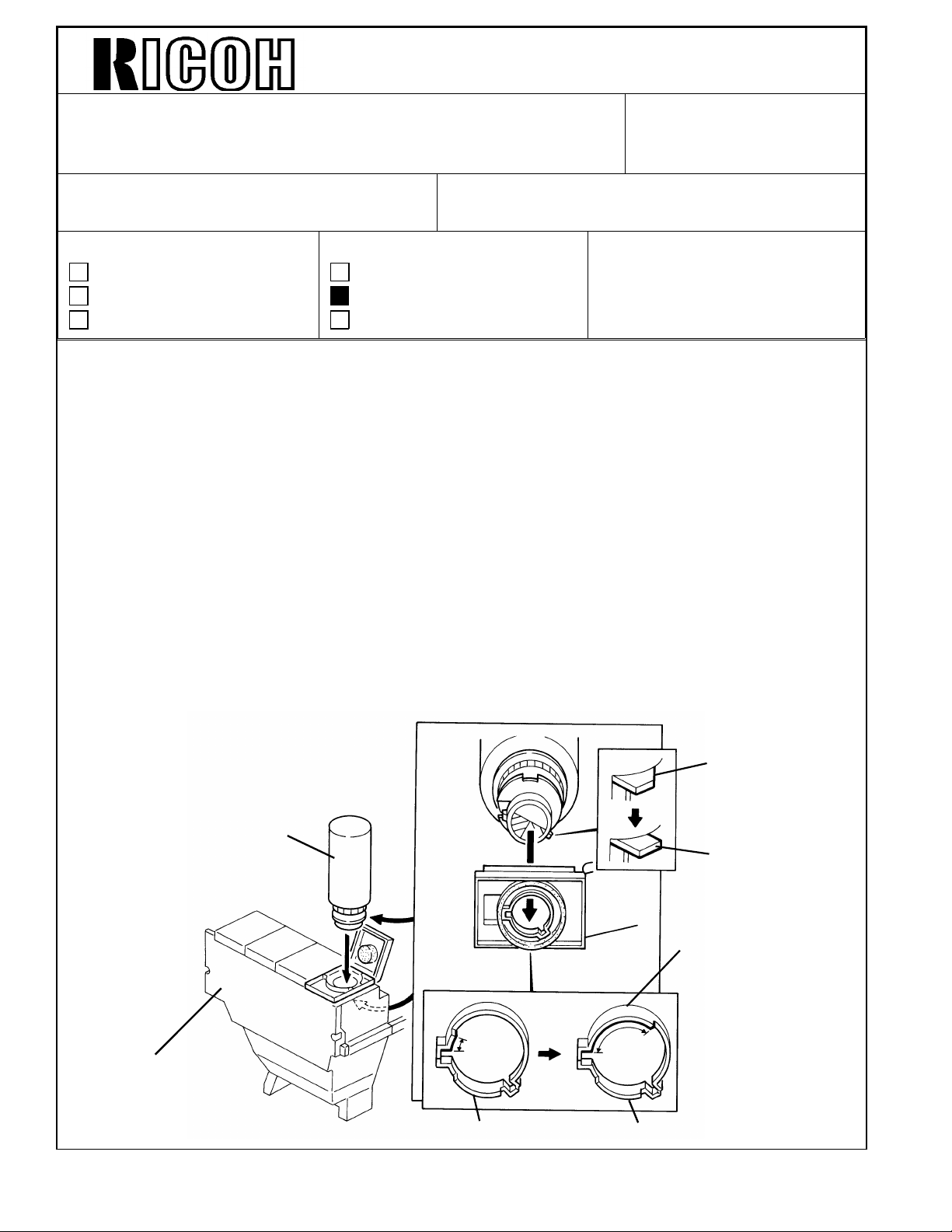

We have found the following problem in the factory.

The oil end sensor harness is caught by the positioning pin and it is disconnected after the

fusing unit is pulled out and pushed in several times. If this occurs, oil end is not detected.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: DFC-α

Normal condition When problem occur

To prevent this, the wiring route has been changed as shown below.

Caution: When reconnecting the hot roller’s fusing lamp after replacing hot roller

and/or pressure roller, be sure to route the oil end sensor harness as

shown above.

Page 2

Technical Bulletin No. RTB-001

SUBJECT: Oil end sensor harness wiring DATE: April 30, ’94

PAGE: 2 of 2

The oil end sensor harness wiring will be changed from the first May 1994 production

machine. (The cut-in serial number is as shown below.)

A109-17: A351405xxxx ~

A109-22: 67 940500 01 ~

A109-27: A351405xxxx ~

For the machines prior to the above serial number, we recommend changing the wiring at

the machine installation.

Page 3

Technical Bulletin No. RTB-002

SUBJECT: MANUAL CORRECTIONS DATE: MAY 15 ’94

PAGE: 1 of 2

PREPARED BY:S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Please correct your service manual as follows:

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

DFC - α

PAGE 4-21 Item "❷" Note

Incorrect :

standard data: (Standard data of the potential sensor calibration is blank)

Correct:

standard data: 230 ±20

PAGE 4-21 Item "❹"

Incorrect :

Indicates data (Vsg, Vsp, Vsg/Vsp) relate to ID sensor for each color and potential sensor

output while detecting the ID sensor pattern.

Correct:

Not used. (Actually this page 3 exists but all data indicated is " 0 ")

PAGE 4-24 Item "❶"

Incorrect :

Default setting must be selected.

Default:PID

Correct:

"PID" setting must be selected.

Default: Reset

Page 4

Technical Bulletin No. RTB-002

SUBJECT: MANUAL CORRECTIONS DATE: MAY 15 ’94

PAGE: 2 of 2

PAGE 4-26 Item "❼"

Incorrect :

Table of item ❼ is tinted

Correct:

Table of item ❼ is not tinted. This means the data can be changed in the field.

Select " Display " when editor is installed.

PAGE 4-42 Step #1, #3, #6

Incorrect :

1. Confirm that the main switch is ON.

2. Turn the DIP-switch 501 No.4 of the main control board ON and OFF.

3. Turn the main switch OFF and ON.

6. Replace all developer. (See section 5, Developer section.)

Correct:

1. Confirm that the main switch is OFF.

2. Turn the DIP-switch 501 No.4 of the main control board ON.

3. Turn the main switch ON. Then turn OFF the DIP-switch 501 No.4.

6. Replace all developer. (See section 5, Developer section.)

NOTE: SP4-2, No.403 (Process Control Mode Selection) - change the setting to "PID".

PAGE 5-69 DEVELOPER INSTALLATION Step #10

Incorrect :

Shake 2 packs of developer [G] 20 times then pour them in.

Correct:

Shake a pack of black developer [G] 20 times then pour them in.

Page 5

Technical Bulletin No. RTB-003

SUBJECT: SP402 ADJUSTMENT DATE: MAY 15 ’94

PAGE: 1 of 2

PREPARED BY: S.MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

DFC - α

SYMPTOM

If paper becomes very dry under low humidity, the following symptoms are most visible.

1. Rough solid image surface and poor color reproduction in 4C mode.

2. Scattered toner around solid image areas in 1C mode.

The level of these symptoms depend on paper kinds such as smoothness and electrical

resistance, and how paper is dried.

POSSIBLE CAUSE

The transfer belt bias and transfer roller bias are adjusted for the machine under normal,

high, and low humidity conditions. The absolute humidity is detected by the humidity

sensor and the bias voltage changes accordingly. However, as the humidity sensor cannot

detect the moisture in the paper, those bias settings are for the paper just from the

package and not for too dried or too moistened paper.

Therefore, when we face the above symptoms, we can use the SP402 as a

troubleshooting but it might not solve them completely.

The best solution is to instruct the customer to keep the paper as fresh as possible and to

use a good pa per brand .

Page 6

Technical Bulletin No. RTB-003

SUBJECT: SP402 ADJUSTMENT DATE: MAY 15 ’94

PAGE: 2 of 2

COUNTERMEASURE

The following is how to use the SP as a troubleshooting.

1. ROUGH SOLID IMAGE SURFACE AND POOR COLOR REPRODUCTION IN

4C MODE

Increase the transfer roller bias for low humidity to improve this symptom.

Adjustment range: From 100% (1700V) to 150% (2550V)

If you have following side effect, decrease the setting to improve the side effect to an

acceptable level:

1) Incomplete toner transfer for low density areas (Too much transfer ability)

2) Feed roller mark in half toner image area in 1C mode

You should also check if the fresh paper can get reasonable copy image or not.

If not, decrease the setting.

2. SCATTERED TONER AROUND SOLID IMAGE AREAS IN 1C MODE

Increase the transfer belt bias for low humidity to improve this symptom.

Adjustment range: From 100% (2000V) to 140% (2800V)

If you have the following side effect, decrease the setting to improve the side effect to an

acceptable level:

1) The edge of letters become blurred with scattered toner (Toner scatters not all over

around the image but along the letter edges as thin lines.)

You should also check if the fresh paper can reasonable copy image or not. If not,

decrease the setting.

Page 7

Technical Bulletin No. RTB-004

SUBJECT:MAIN BOARD REPLACEMENT IN THE FIELD DATE: June 15 ’94

PAGE: 1 of 1

PREPARED BY: S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Just after the mass-production started, the software (Main ROMs on the main control

board) was modified. (We do not mention the detail in this RTB)

We replaced the ROMs on all the mass-produced machines before shipping. In other

words, all of your machines have updated ROMs. (Up to now, the latest version main

ROMs are A1095265E and A1095267E).

However, the main control boards shipped out as initial stock parts were shipped without

the modification.

The main ROMs on the initial stock parts are A1095265B and A1095267B or A1095265D

and A109 5267D.

Therefore, when replacing the main control board in the field, please check the part

number suffix of the main ROMs on the main control board. If the suffix is B or D (C does

not exist), remove the main ROMs on the old main control board and install them on the

new main control board.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: DFC - α

It is possible that the following symptoms occur if the ROMs are not updated when

replacing the main control board.

1. Toner scattering

2. Copy image leaning to some color (Bk,C,Y, mostly magenta).

3. Dirty background at the front or rear side of copies

4. Dirty background on entire copies

5. Toner spots on copies

6. Toner end misdetection

7. Toner end recovery error.

Page 8

Technical Bulletin No. RTB-005

SUBJECT: ORIGINAL DOUBLE FEEDING DATE:June 30, ’94

PAGE: 1 of 2

PREPARED BY: S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This is additional information of RTB-025 "DJF double feeding".

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:DUAL JOB

FEEDER FOR DFC-α

<PHENOMENON>

Original double feeding (two or more sheets of the originals are fed at a time)

<POSSIBLE CAUSE>

The separation belts become dirty with the toner, loosing the friction to separate the

originals.

This is especially true when the customer feeds lots of poorly fused originals such as laser

output or cotton paper.

Separation Belts

Page 9

Technical Bulletin No. RTB-005

SUBJECT: ORIGINAL DOUBLE FEEDING DATE: June 30, ’94

PAGE: 2 of 2

<FIELD COUNTERMEASURE>

Replace the separation belts with the new parts. The new part number is A3769502.

The material of the separation belts has been changed to the one which less toner

adheres to.

NOTE: Depending on the type of originals that the customer use, there is still a possibility

that the separation belts become dirty. For those cases, cleaning the belts at every

visits, which was introduced in the previous RTB, is recommended.

This modification is implemented from the following serial numbers.

A376-10: 537403xxxx

A376-15: 41 240300 01

A376-17: A33840 30001

A376-22: 53 240300 01

A376-26: 3D80340001

A376-27: A33840 30150

Page 10

Technical Bulletin No. RTB-006

[A]

New style stopper

SUBJECT: Overtoning / Undertoning Countermeasures Reissued on: Nov. 30, ’94

DATE: OCT. 15 ,’94

PAGE: 1 of 2

PREPARED BY: S. Hizen

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

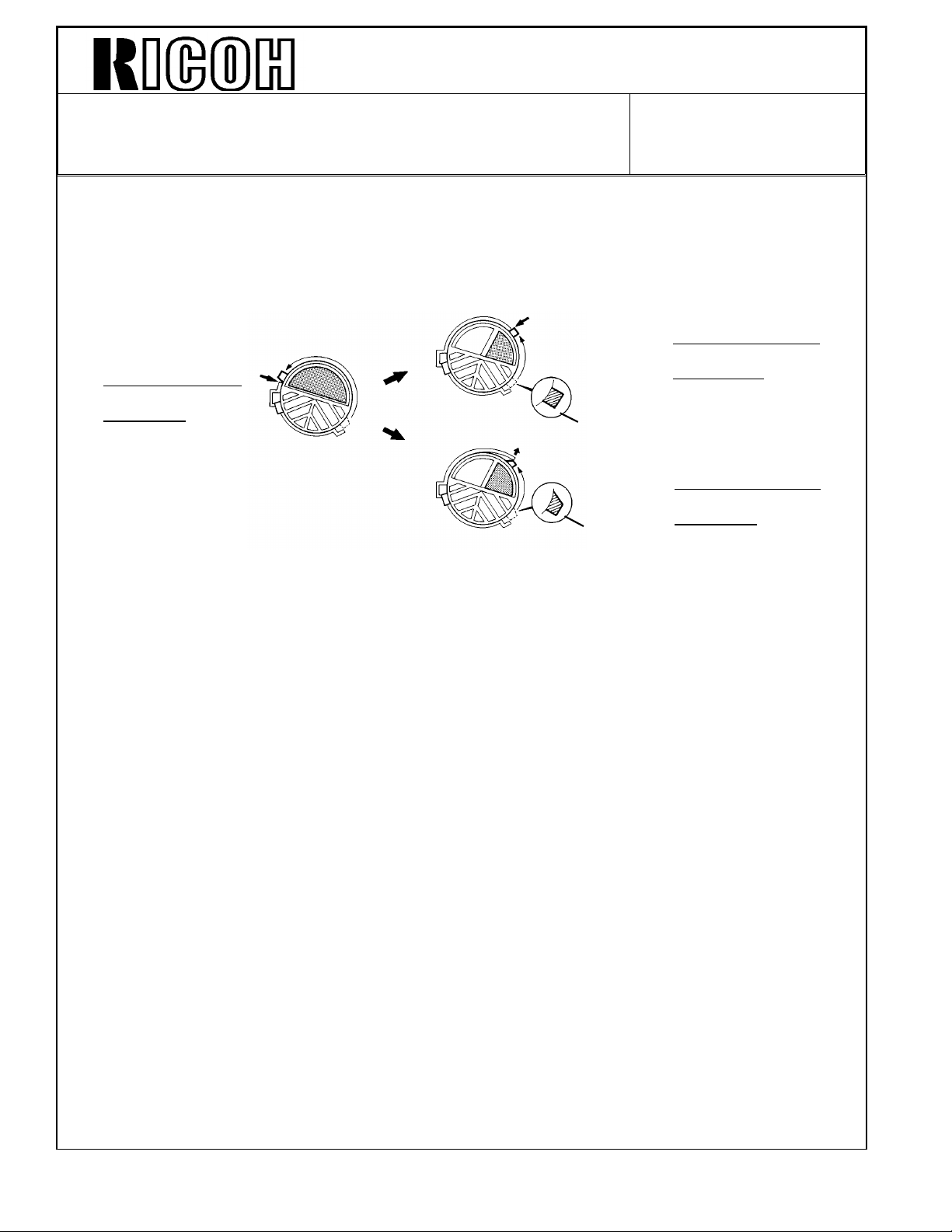

SYMPTOM 2: Overtoning

Overtoning in the development unit just after installing a new toner bottle at toner end

CAUSE:

The toner fluidity increases when the toner bottle is shaken because the toner holds a lot

of air. This results in excessive toner being supplied into the development unit when a

new toner bottle is set by a customer.

COUNTERMEASURE:

The open angle of the toner bottle shutter has been changed from 180 degrees to 70

degrees to make the toner supply time longer. This is to reduce the amount of air held by

toner at toner bottle installation. The following two modifications have been implemented

to change the shutter open angle.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: DFC-alpha

Toner Bottle Guide Modification:

The toner bottle guide rib has been changed as shown in the illustration [A] from the first

production to stop the bottle rotation at 70 degrees.

Old style stopper

[B]

Toner

Bottle

Toner bottle guide rib

Toner Tank

Old toner guide New toner guide

Page 11

Technical Bulletin No. RTB-006

SUBJECT: Overtoning / Undertoning Countermeasure Reissued on: Nov. 30, ’94

DATE: OCT. 15, ’94

PAGE: 2 of 2

Toner Bottle Modification:

The shape of the stopper has been changed as shown in the illustration [B] (on the

previous page) from the following lots in each color toner. This is to prevent the stopper

from going inside the guide rib as shown below [C] when the toner bottle is turned strongly.

Open angle of toner bottle.

180°

Old Bottle Guide

with

Old Bottle

[C]

Start Lot # for the new style shape stopper bottle.

Black: Lot #4416001

Cyan: Lot #4416001

Magenta Lot #4416001

Yellow Lot #4416001

SYMPTOM 2: Undertoning when making many copies with a high image ratio.

70°

70°

New

style

stopper

Old

style

stopper

New Bottle Guide

with

New Bottle

New Bottle Guide

with

Old Bottle

The Toner End indicator is on even if there is toner still in the bottle.

CAUSE:

The toner supply amount from the toner hopper to the development unit is not enough

when making many copies with a high image ratio at the same time. This is due to the

development ability limitation.

COUNTERMEASURE:

Instruct a customer to make copies using lengthwise paper feed rather than sideways

paper feed. lengthwise feed takes longer than sideways feed. This allows enough toner

be supplied to the development unit to develop copies with a high image ratio.

Note: Continuous copy runs using lengthwise paper cause the undertone problem on

both sides of copy. (Please refer to RTB - 007 for details.)

Side-way paper feeding is recommended when more than 30 continuous copies

are made.

Page 12

Technical Bulletin No. RTB-007

SUBJECT: Light image along both sides of the copy DATE: OCT.15 ’94

PAGE: 1 of 2

PREPARED BY: S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:DFC-alpha

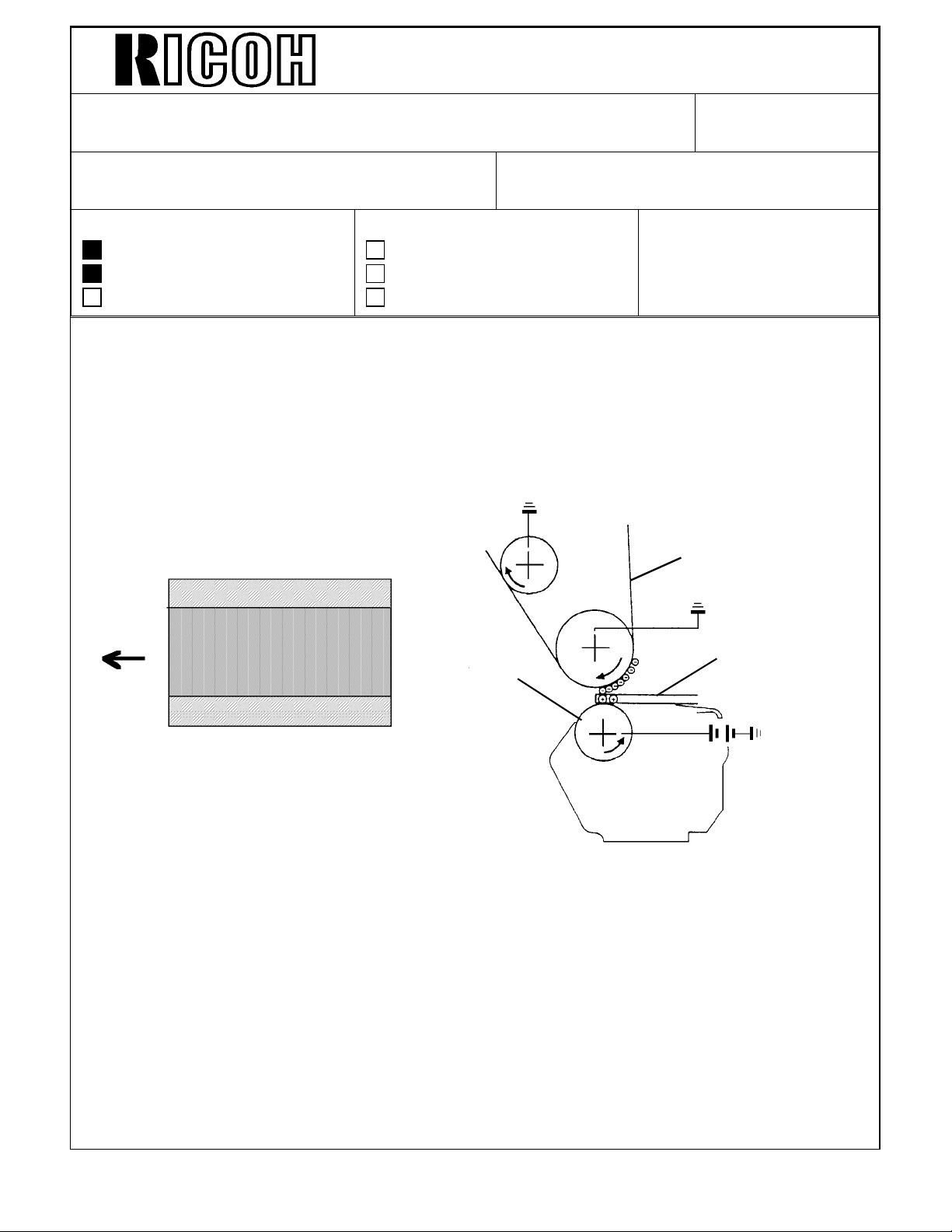

<SYMPTOM>

If the customer feeds small size paper (A4 or less/8 1/2 x 11 or less) mostly lengthwise, it

is possible that the image density of half tone areas image on both sides will become

lighter than the center area. (This symptom will be visible only when copying a half tone

original and using wide size copy paper.)

To prevent this, when feeding small size paper (A4 or less/8 1/2 x 11 or less), feed the

paper in sideways.

[B]

[A]

[C]

<REASON>

At the paper transfer area, the paper [A] affects the electrical resistance between the

transfer belt [B] and the transfer roller [C]. When the paper exists, less paper transfer bias

is applied from the transfer roller to the transfer belt.

If small size paper is continuously used, the front and rear areas of the transfer belt

continuously receive a stronger paper transfer bias than the center area of the transfer

belt. This is because the paper exists only at the center.

This gradually reduces the electrical resistance of the transfer belt ion the side. Especially

when many OHP transparency sheets are fed, the possibility to cause this symptom will be

higher due to higher paper transfer bias for OHP mode.

Page 13

Technical Bulletin No. RTB-007

SUBJECT: Light image along both sides of the copy DATE: OCT. 15 ’94

PAGE: 2 of 2

<COUNTERMEASURE>

If this symptom is weak, after feeding several (about 50 sheets) of wide paper, the transfer

belt’s electrical resistance will become even, and the symptom will disappear. (So, if the

customer feeds both narrow and wide paper alternately, the symptom does not appear.)

However, if this has no affect, you must replace the transfer belt. After replacing the

transfer belt, please instruct the customer to feed the paper in sideways as frequently as

possible.

Page 14

Technical Bulletin No. RTB-008

SUBJECT: Dirty background spots (377mm pitch) DATE: OCT. 15 ’94

PAGE: 1 of 2

PREPARED BY: S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: DFC-alpha

<SYMPTOM>

Slight dirty background areas appear. The distance between the background spots is

377mm. (diameter of the OPC drum is 120mm.)

377 mm

<POSSIBLE CAUSE>

Some of the adhesive from the tape [A] fixing the drum protective sheet is on the OPC

drum surface.

[A]

Page 15

Technical Bulletin No. RTB-008

SUBJECT: Dirty background spots (377mm pitch) DATE: OCT. 15’94

PAGE: 2 of 2

<INSTRUCTIONS>

Be sure not to contact the protective sheet tape with the OPC drum surface (Removing the

adhesive from the drum surface is difficult).

The surface of the OPC drum used in this model is easily dissolved by alcohol. So, for

normal maintenance, do not use alcohol.

However, you cannot remove the adhesive and all you can do is replace the OPC drum,

try to use alcohol with risk as a final solution. In this case, after wiping off the adhesive,

immediately remove the remaining alcohol on the OPC drum. Use the alcohol (isopropyl

alcohol is better than ethyl alcohol or methyl alcohol) after mixing it with water because

pure alcohol is too strong.

Page 16

REVISED ON JULY 31, ’95

Technical Bulletin No. RTB-009

SUBJECT: Add Toner Indication without Color Indication DATE: July 15, ’95

PAGE: 1 of 3

PREPARED BY: N. Kaiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: DFC - α

Problem

Add toner Indication is lit without any color indication.

This problem happens when all of the following conditions occur.

1. Add toner condition is indicated for any of the color toners. The indication is normal at

this point.

2. Black and white copy is selected. The add toner indication turns off and the print key

turns green.

3. Editing, user program, color balance adjustment, user tool or any other mode which

changes the display from standard screen is selected.

4. The front door is opened and closed. At this point, the add toner condition is cleared.

5. When the display returns to the standard screen, the add toner indicator is lit without

any color indication.

Cause

Except for when the operation panel display is showing the standard display, the add toner

condition is not cleared within the operation panel display software, even when toner

replenishment is done. When the display returns to the standard screen, the add toner

indication remains on the display without color indication.

Page 17

REVISED ON JULY 31, ’95

Technical Bulletin No. RTB-009

SUBJECT: Add Toner Indication without Color Indication DATE: July 15, ’95

PAGE: 2 of 3

Countermeasure

Software modification is made. Two ROMs on the Main Board and two out of four ROMs

on the Operation Panel Board are modified.

Main Board ROM A109 5265F G

A109 5267F G

Operation Panel ROM: for -10, -17 machines

A109 5547C D

A109 5548D E

for -22 machine

A109 5647C D

A109 5648D E

Language ROM Kit English IC101 A544 51 02C D (not service parts)

IC102 A544 51 03C D (not service parts)

German IC101 A544 5112B C (not service parts)

IC102 A544 51 13B C (not service parts)

French IC101 A544 5122B C (not service parts)

IC102 A544 51 23B C (not service parts)

ItalianI IC101 A544 5132A B (not service parts)

IC102 A544 5133A B (not service parts)

Spanish IC101 A544 5142A B (not service parts)

IC102 A544 5143A B (not service parts)

Page 18

REVISED ON JULY 31, ’95

Technical Bulletin No. RTB-009

SUBJECT: Add Toner Indication without Color Indication DATE: July 15, ’95

PAGE: 3 of 3

CUT IN SERIAL NUMBER

A109-10 678502XX XX

A109-22 67950100 01

A109-27 A3515010 121

A109-17 A3515010 001

A109-26 3E501500 01

A109-29 A351502X XXX

Language ROM Kit : from Jan. ’95 production

Note: For the moment, only English, German, French, Italian and spanish will be

modified.

In case this problem is experienced in your field, please inform us. We will provide you

with the master ROMs.

Page 19

Technical Bulletin No. RTB-010

SUBJECT: Improvement of Copy Quality DATE:August 31, ’95

PAGE: 1 of 4

PREPARED BY: N. Kaiya

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This RTB explains the modification made to the DFC alpha to improve its copy quality.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

DFC - α

Modified Parts

1. IPU Board

2. IPU ROM

3. Main Board ROM

4. Operation Panel Board ROM

5. An explanation sheet has been added to the Operating Instructions booklet.

(Page 4/4 of this RTB)

Please refer to MB No. 31 for part numbers, interchangeability, and the cut in serial

number.

Contents of the Modification

1. Improvement of the copy quality of photograph images

The copy quality of the photographic image varies depending on the type of original used.

With the new machine, the type of original to be copied can be specified from the following

three selections by User Tool 4. Sensitivity Adjustment, Photo Mode Setting

Printed Photo

Glossy Photo

Copied Photo

Based on the selection made, the copier will make adjustments to obtain the best copy

quality. This is achieved as follows.

The IPU converts the RGB video signal received from the Scanner Control Board into a

YMCBk video signal and outputs it to the LD unit. When doing this conversion, a color

correction is made to compensate for the difference between the ideal and actual

characteristics of each color toner. (Please refer to page 2-41 of the Service Manual for

details). With this modification, three different sets of color correction coefficient are

prepared to compensate for the differences in color reproduction resulting from differences

in characteristics of the photographic original used. The adjustment made for each type of

original is as follows.

Page 20

Technical Bulletin No. RTB-010

SUBJECT: Improvement of Copy Quality DATE:August 31, ’95

PAGE: 2 of 4

Printed Photo

When Printed Photo is selected, the copy quality is basically the same as in the old

machine.

Glossy Photo

Glossy photo should be selected when making copies from normal color photographs on

photographic paper. With this type of original;

- green may be copied brighter (or lighter)

- gray may become bluish.

To compensate for these,

- green is converted with less cyan

- the high ID part of cyan is made lighter.

Also, the amount of UCR is reduced to improve the reproduction of dark areas of the

original.

Copied Photo

Copied Photo should be selected when copying a copy. When doing this,

- a low ID area may not be reproduced well

- the copy may become reddish (strong magenta and less yellow).

To compensate for this:

- the low ID part of the original is reproduced darker

- yellow is reproduced darker and magenta is reproduced lighter.

General

For all three types of originals, The following improvements have been made.

The edge of black areas (for example, the girl’s hair on the C4 test chart) may be too

distinct (too black). To compensate for this, cyan, magenta, and yellow toner is added in

such areas.

Page 21

Technical Bulletin No. RTB-010

SUBJECT: Improvement of Copy Quality DATE:August 31,’95

PAGE: 3 of 4

2. Improvement of Auto Letter / Photo Separation

The letter/photo separation process is basically the same as before. A new algorithm is

used in the final evaluation process of the letter/photo separation to reduce separation

errors.

When installing Fiery Controller

When connecting a Fiery Controller to a modified machine, it is no longer necessary to

replace the ROMs on the main board and the IPU board. Please refer to the following

table for the necessary ROMs for each version of the IPU.

IPU Board P/ N A1095510 A109551 5 A1095519

IPU

Main

Board

Action

Replace the ROM

chips with the

following ROM chips.

IC303 V1.72 A109551 7 IC309 V1.72 A109551 8 IC509 A3996782 A3996782 IC522 A3996783 A3996783 -

Replace the ROM

chips with the

following ROM chips.

Do not replace the

ROMs.

Language ROM kit

Language ROM kit, necessary for some versions of the machines, are also modified but

the EDP code remains unchanged.

A round blue 9 mm sticker on the label indicates the new version of the ROM kit.

English ROM Type J

EDP CODE 208823

MODEL NO. A544-00

Blue sticker

Page 22

Technical Bulletin No. RTB-010

SUBJECT: Improvement of Copy Quality DATE:August 31, ’95

PAGE: 4 of 4

Supplemental Information (English) (A1098650)

Page 23

Technical Bulletin No. RTB-011

[B]

SUBJECT: Sorter Installation DATE: September 15, ’95

PAGE: 1 of 2

PREPARED BY: N. Kaiya

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

To comply with the CE mark, it is necessary to attach five ferrite cores when installing a

sorter on DFC - α. The ferrite cores have been enclosed in the screw bag of the DFC - α

from September production. Please refer to the following for the installation procedure of

the ferrite cores.

Additional procedure for sorter installation

Ferrite core P/N 16070418 4 pcs.

Ferrite core P/N 16070721 1 pc.

1. Turn off the main switch and unplug

the machine.

2. Remove the sorter top cover

(3 screws).

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

DFC - α

[A]

3. Remove the sorter rear cover

(4 screws).

[D]

4. Attach the ferrite core ( [A] P/N

16070721 ) to the DC harness as

shown.

5. Remove the harnesses for second

bin solenoid (CN100) and third bin

solenoid (CN101). Pass the both

harnesses through the ferrite core

( [B] P/N 16070418 ) and reconnect

them to the sorter main board.

6. Remove the harnesses for the fourth bin solenoid (CN102) and the fifth bin solenoid

(CN103). Pass the both harnesses through the ferrite core ( [C] P/N 16070418 ) and

reconnect them to the sorter main board.

7. Remove the harnesses for the encoder (CN150) and the entry sensor LED (CN170).

Pass the both harnesses through the ferrite core ( [D] P/N 16070418 ) and reconnect

them to the sorter main board.

8. Remove the harnesses for the entry sensor Phototransistor (CN160) and the inlet

sensor (CN165). Pass the both harnesses through the ferrite core ( [E] P/N 16070418)

and reconnect them to the sorter main board.

[E]

[C]

9. Reassemble the unit.

Page 24

Technical Bulletin No. RTB-011

P/N 16070721

P/N 160706 38

P/N 16070623

SUBJECT: Sorter Installation DATE: September 15, ’95

PAGE: 2 of 2

Ferrite Cores Packed with DFC - α

For Sorter Installation

For DJF installation

P/N 160704 18

Page 25

Technical Bulletin No. RTB-012

SUBJECT: OPC Drum DATE:October 15, ’95

PAGE: 1 of 1

PREPARED BY: N. Kaiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The OPC drum for DFC - α has been changed from P/N A1099510 to P/N A1729510 as

informed by MB No.33.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: DFC - α

Reason for the change

To extend the expected yield of the OPC drum, the OPC material has been improved. The

yield for the old drum was expected to be 40k scans based on our laboratory test results.

The OPC material was deteriorated by ozone or NOx gas generated mainly by corona

discharge, resulting in dirty background after around 50k scans. The new OPC material is

stronger against such gases. According to our laboratory tests, the level of background

remains unchanged until after 80k scans.

Expected Yield

The expected yield will be changed from 40k scans to 80k scans.

Interchangeability

The old and new OPC drums are completely interchangeable.

Page 26

Technical Bulletin No. RTB-013

SUBJECT: Anticondensation Heater DATE: November

15, ’95

PAGE: 1 of 1

PREPARED BY: N. Kaiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The following problem has been found on the production line. Please check this point

at machine installation.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

DFC - α

Problem

The second scanner contacts the anti-condensation heater lead wire. As a result, jitter

image may appear.

Anti-condensation Heater

Cause

A part of the anti-condensation heater lead wire has bent above the scanner unit base

plate.

Action

At installation, please check the routing of the anti-condensation heater lead wire. If it is

bent away from the scanner unit base plate, please flatten the lead wire so it is within 5

mm away from the base plate.

Note: This problem has been found with some earlier September production machines,

after new workers were assigned to assembling the scanner unit. The routing of

the lead wire has been strictly checked on the production line since the problem

was discovered, so we presume that this problem may happen only with a limited

number of September production machines.

Page 27

Technical Bulletin No. RTB-014

SUBJECT: Interface Kit Type A CE Mark Compliance DATE: December

31, ’95

PAGE: 1 of 9

PREPARED BY: N. Kaiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

To comply with the CE mark standards, the following modifications have been made

to the Interface Kit Type A.

<Ferite Core>

Two ferrite cores are packed with the kit. Please refer to the attached installation

procedure of the interface kit for where to use these ferrite cores.

<Main Board ROMs>

The mainboard ROMs packed with the interface kit have been standardized with the

main board ROM on the copier main board.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

Interface Kit Type A

for DFC - α

A3996782 --> A1095104

A3996783 --> A1095106

At the same time, the ROMs have been updated from suffix L to suffix M.

A1095104L --> A1095104M

A1095106L --> A1095106M

The purpose of this update is to cut the signal from the scanner unit to the IPU when

using the copier in scanner mode. This will reduce the amount of electromagnetic

emission from the copier.

<CE Mark>

The CE mark is printed on the carton box. Please check this CE mark to distinguish

new kits from old kits, since there is no serial number for this kit.

Page 28

Technical Bulletin No. RTB-014

SUBJECT: Interface Kit Type A CE Mark Compliance DATE: December

31, ’95

PAGE: 2 of 9

Page 29

Technical Bulletin No. RTB-014

SUBJECT: Interface Kit Type A CE Mark Compliance DATE: December

31, ’95

PAGE: 3 of 9

Page 30

Technical Bulletin No. RTB-014

SUBJECT: Interface Kit Type A CE Mark Compliance DATE: December

31, ’95

PAGE: 4 of 9

Page 31

Technical Bulletin No. RTB-014

SUBJECT: Interface Kit Type A CE Mark Compliance DATE: December

31, ’95

PAGE: 5 of 9

Page 32

Technical Bulletin No. RTB-014

SUBJECT: Interface Kit Type A CE Mark Compliance DATE: December

31, ’95

PAGE: 6 of 9

Page 33

Technical Bulletin No. RTB-014

SUBJECT: Interface Kit Type A CE Mark Compliance DATE: December

31, ’95

PAGE: 7 of 9

Page 34

Technical Bulletin No. RTB-014

SUBJECT: Interface Kit Type A CE Mark Compliance DATE: December

31, ’95

PAGE: 8 of 9

Page 35

Technical Bulletin No. RTB-014

SUBJECT: Interface Kit Type A CE Mark Compliance DATE: December

31, ’95

PAGE: 9 of 9

Page 36

REVISED ON: MARCH 31, ’96

Technical Bulletin No. RTB-015

SUBJECT: New Type OPC Drum DATE: January 31, ’96

PAGE: 1 of 1

PREPARED BY: N. Kaiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The following is some additional information about the new type OPC drum used for DFC-α.

Please refer to RTB No.12 and MB No.33 for this change.

1.Cut-in Serial Numbers

The new type drum has been used in production from the following serial numbers.

A109-17 A3515110158

A109-22 6795110001

A109-26 3E1150001

A109-27 A3515110261

A109-57 S115115001

A109-67 from next production

2.Lot Number

You can distinguish the new type drum by the lot number printed on the flange of the drum.

If the second digit of the lot number is C, then the drum is a new type. If it is D, then the

drum is an old type.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

DFC - α

Example

1D52921234 - Old Type

1C50101234 - New Type

3.Remarks

When installing a new type drum, do not forget to apply setting powder and to rotate the

drum counterclockwise 3 times, as explained on page 5-57 of the Service Manual.

Page 37

Technical Bulletin No. RTB-016

SUBJECT: Standardization of Toner and Developer DATE: Sept. 30, ’96

PAGE: 1 of 2

PREPARED BY: N. Kaiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The toner and the developer for DFC-α have been standardized with those developed for

the new product, Lily.

The new toner and the new developer are compatible with the current toner and current

developer. A mixture of new and current toner, or mixtures of new toner and current

developer or current toner and new developer have no effect on the performance or copy

quality.

For the product names of the new toner and developer, please refer to the tables below.

Ricoh

toner black RICOH COLOR TONER TYPE F BLACK

yellow RICOH COLOR TONER TYPE F YELLOW

magenta RICOH COLOR TONER TYPE F MAGENTA

cyan RICOH COLOR TONER TYPE F CYAN

developer black RICOH COLOR DEVELOPER TYPE F BLACK

yellow RICOH COLOR DEVELOPER TYPE F YELLOW

magenta RICOH COLOR DEVELOPER TYPE F MAGENTA

cyan RICOH COLOR DEVELOPER TYPE F CYAN

Revision of service manual

Information only

Other

FROM: 1st Field Information Dept. QAC

MODEL:

DFC - α

Savin

toner black SAVIN COLOR TONER BLACK FOR SAVIN SDC206

yellow SAVIN COLOR TONER YELLOW FOR SAVIN SDC206

magenta SAVIN COLOR TONER MAGENTA FOR SAVIN SDC206

cyan SAVIN COLOR TONER CYAN FOR SAVIN SDC206

developer black SAVIN COLOR DEVELOPER BLACK FOR SAVIN SDC103/206

yellow SAVIN COLOR DEVELOPER YELLOW FOR SAVIN SDC103/206

magenta SAVIN COLOR DEVELOPER MAGENTA FOR SAVIN

SDC103/206

cyan SAVIN COLOR DEVELOPER CYAN FOR SAVIN SDC103/206

Page 38

Technical Bulletin No. RTB-016

SUBJECT: Standardization of Toner and Developer DATE: Sept. 30, ’96

PAGE: 2 of 2

Infotec

toner black TONER BLACK TYPE XX/1

yellow TONER YELLOW TYPE XX/1

magenta TONER MAGENTA TYPE XX/1

cyan TONER CYAN TYPE XX/1

developer black DEVELOPER BLACK TYPE XX

yellow DEVELOPER YELLOW TYPE XX

magenta DEVELOPER MAGENTA TYPE XX

cyan DEVELOPER CYAN TYPE XX

NRG

toner black CT107BLK

yellow CT107YLW

magenta CT107MGT

cyan CT107CYN

developer black CD107BLK

yellow CD107YLW

magenta CD107MGT

cyan CD107CYN

Page 39

Technical Bulletin No. RTB-017

SUBJECT: Grease for Transfer Belt Unit and Transfer Roller Unit DATE:Oct. 31, ’96

PAGE: 1 of 1

PREPARED BY: N. Kaiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Please use the KS660 grease (P/N G0049668) for lubricating the end of the bias roller

shaft and the end of the transfer roller shaft. The KS660 grease is more conductive than

the 40M grease currently recommended.

Revision of service manual

Information only

Other

Transfer

Roller Shaft

FROM: 1st Field Information Dept. QAC

MODEL: DFC - α

Belt Bias Roller

Shaft

P/N G004 9668

Grease KS660

Page 40

RICOH Technical Bulletin

Model: DFC-α

Subject: Transfer Belt Tension Release Wedge Prepared by: N. Kaiya

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

In order to release the tension of the transfer belt during transportation, the Transfer Belt

Release Wedges are installed on the front and rear belt tension roller bearing holders.

Please do not forget to remove the wedges at machine installation.

To remove the wedge, push the wedge toward the bearing holder and slide it inside

slightly.

Troubleshooting

Mechanical

Paper path

Other ( )

Date: 31-Mar-97

Part information

Electrical

Transmit/receive

No: 18

Action required

Service manual revision

Retrofit information

1/2

Page 41

RICOH Technical Bulletin

Model: DFC-α

MODEL NAME V/ Hz DESTINATION CODE SERIAL NUMBER

Savin SC106 115V / 60Hz USA, CANADA A109- 15 50701xxxx

Ricoh NC5006 115V / 60Hz USA, CANADA A109- 17 A3517010001

Ges 2706 / NSA

C406 / REX

CC8406

Infotec 7306 230V / 50Hz EUROPE etc. A109- 26 3E5701xxxx

Ricoh NC 5006 230V / 50Hz EUROPE etc. A109- 27 A351701xxxx

Sharp AR- C860 115V / 60Hz USA, CANADA A109- 57 S11701xxxx

Sharp AR- C860 230V/ 50Hz EUROPE A109- 67 S11701xxxx

230V / 50Hz EUROPE etc. A109- 22 6797020001

Date: 31-Mar-97 No: 18 2/2

Loading...

Loading...