Page 1

Technical Bulletin No. RTB-001

SUBJECT: F400/F410 Fusing unit modification (manual corrections) DATE:SEP.15.’93

PAGE: 1 of 6

PREPARED BY: S.MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

FROM: Copier Technical Support Group

MODEL: F400/F410

Revision of service manual

Information only

Other

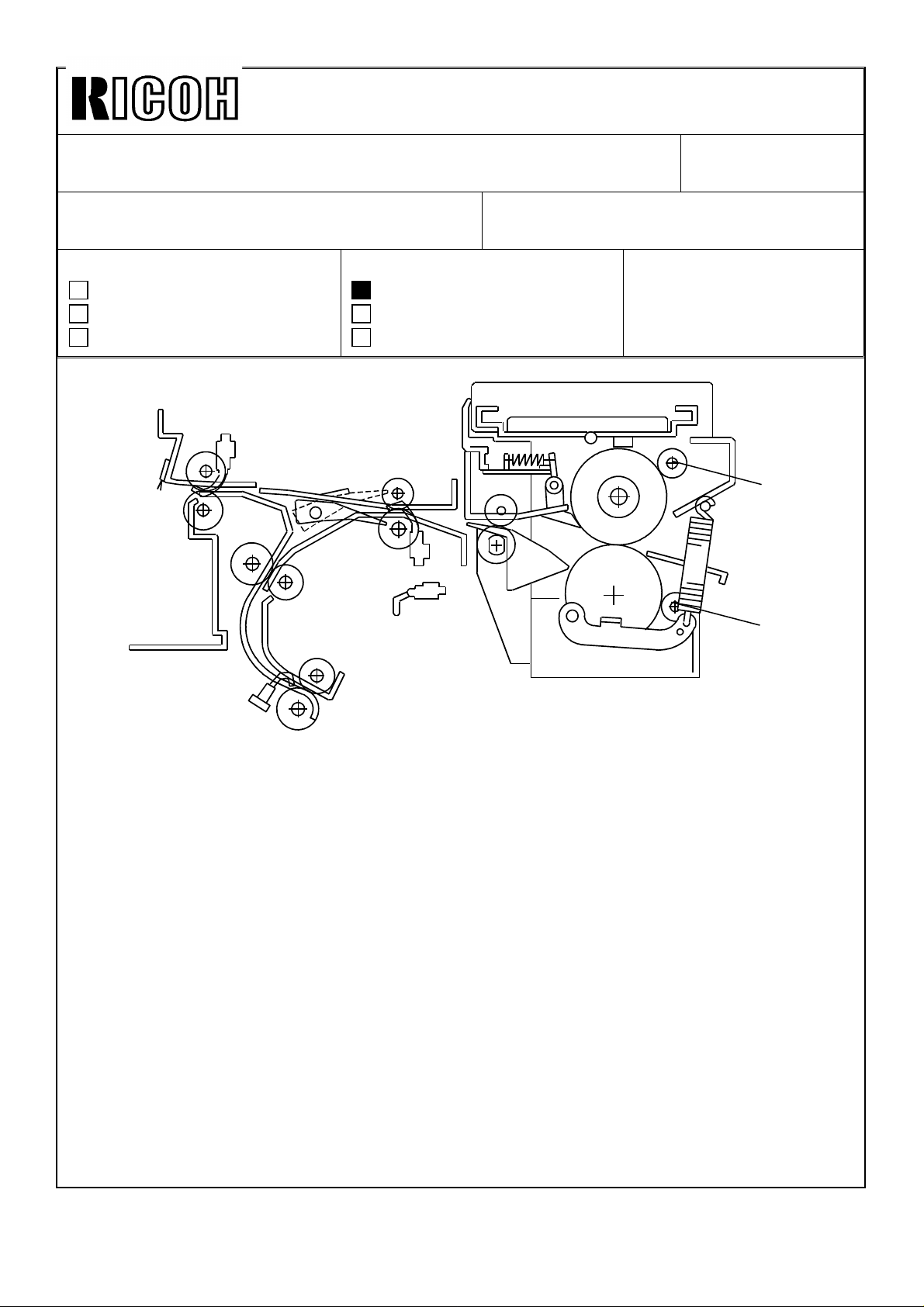

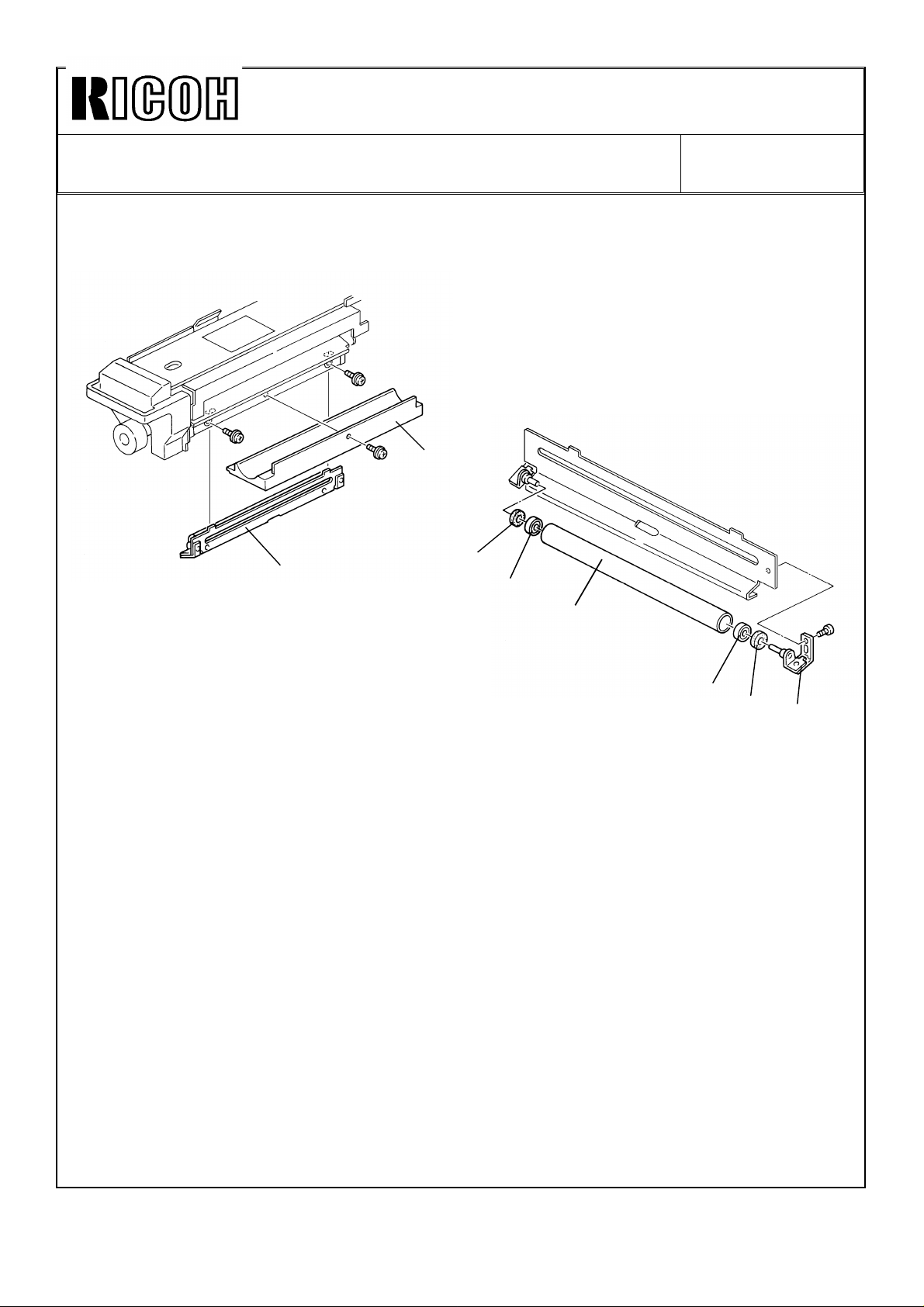

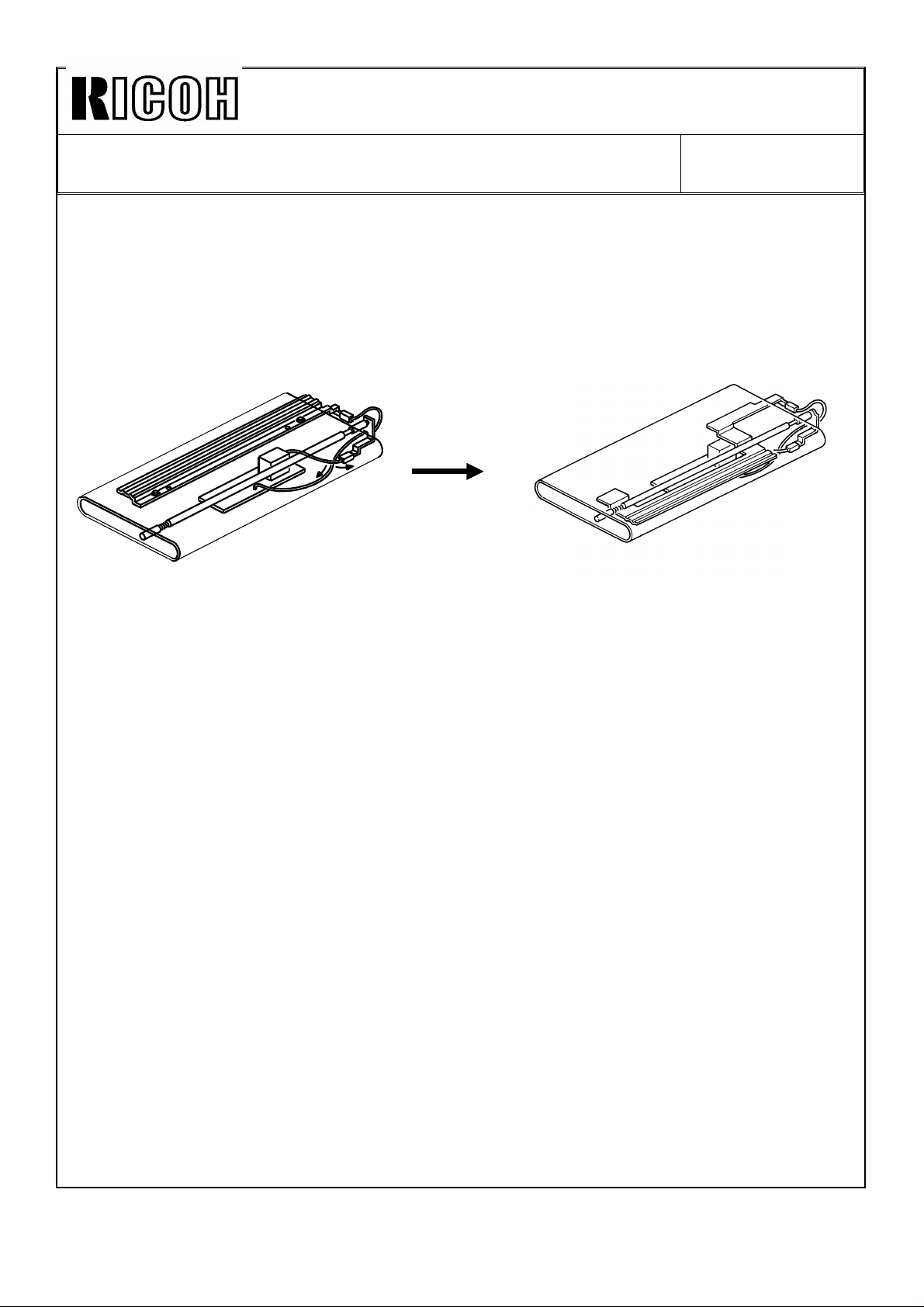

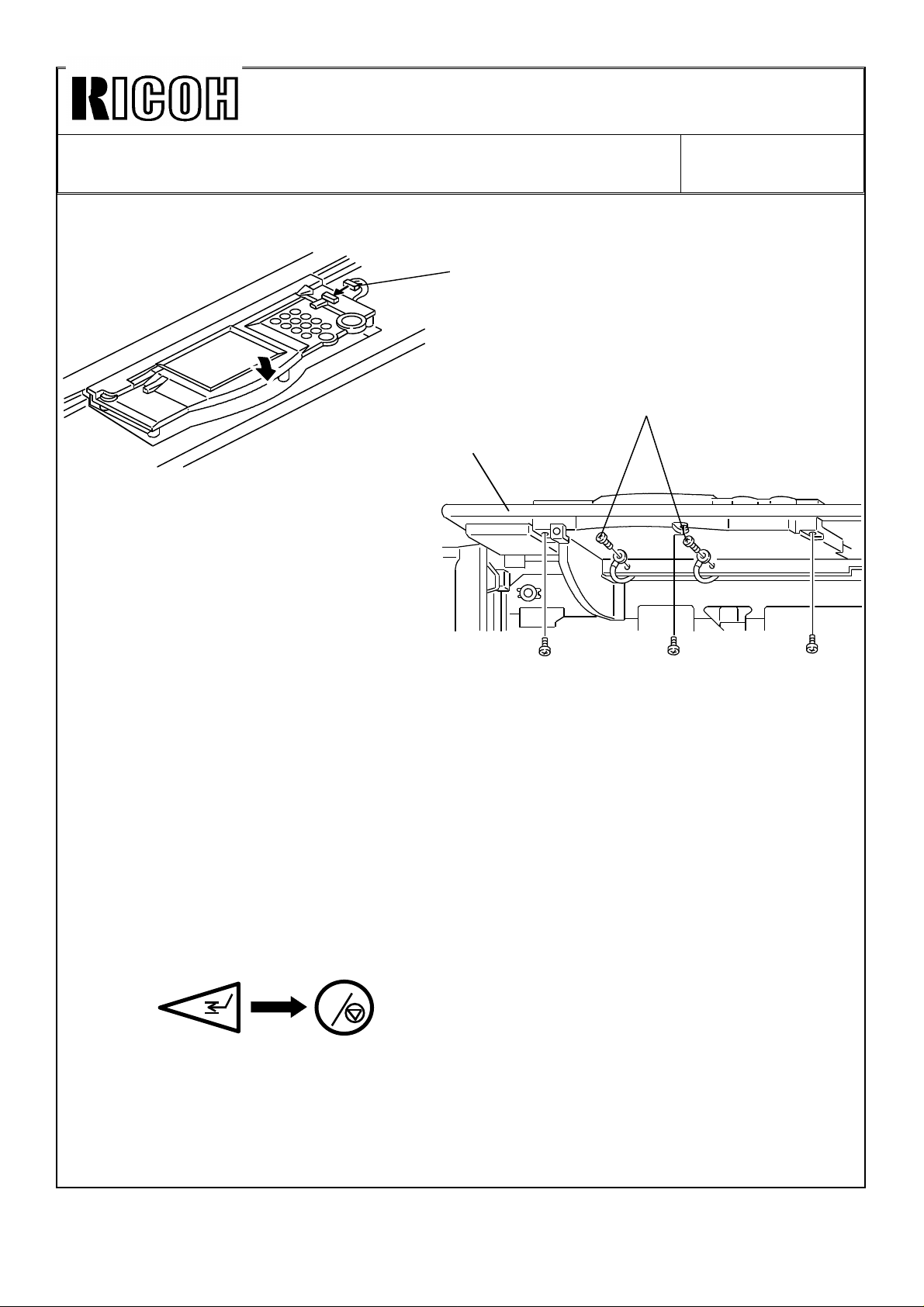

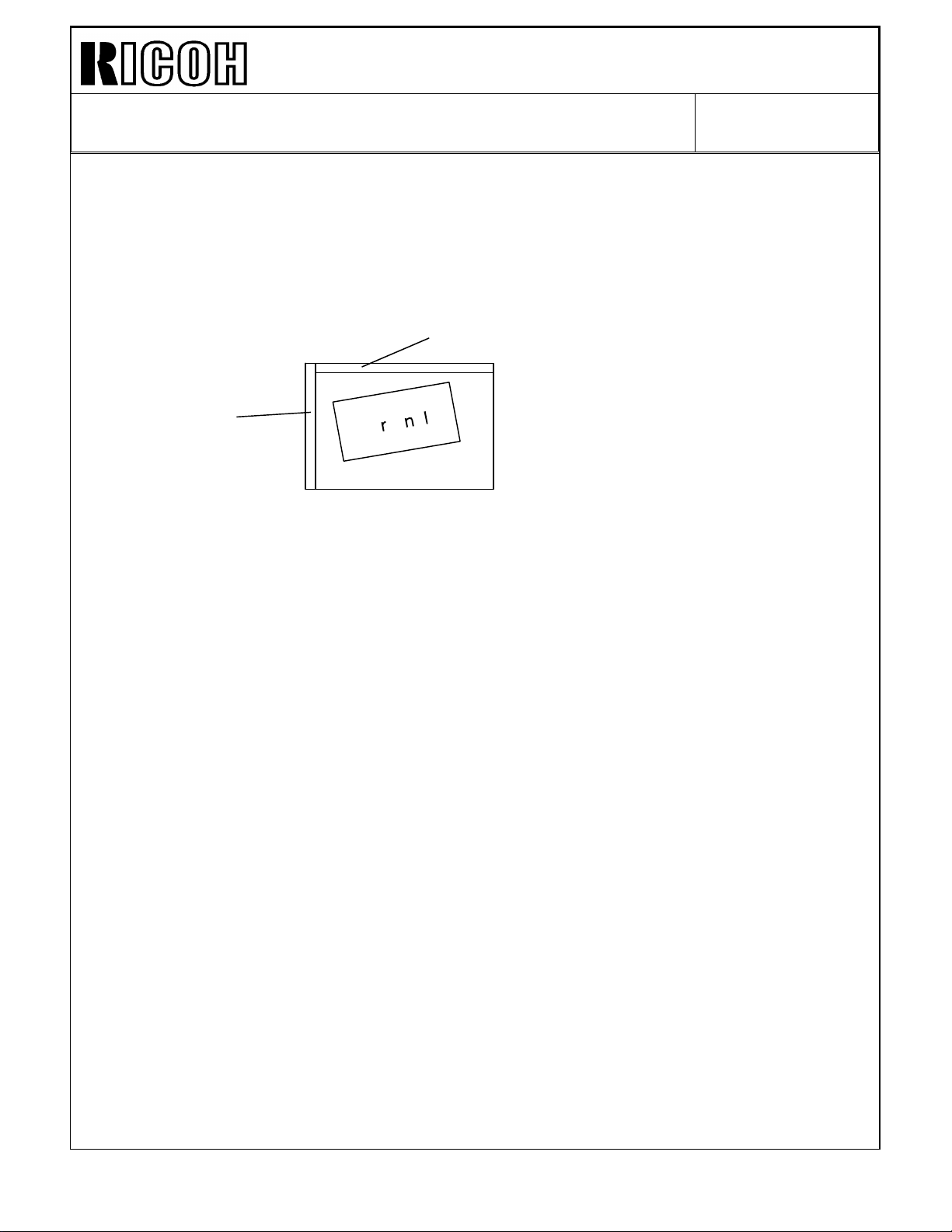

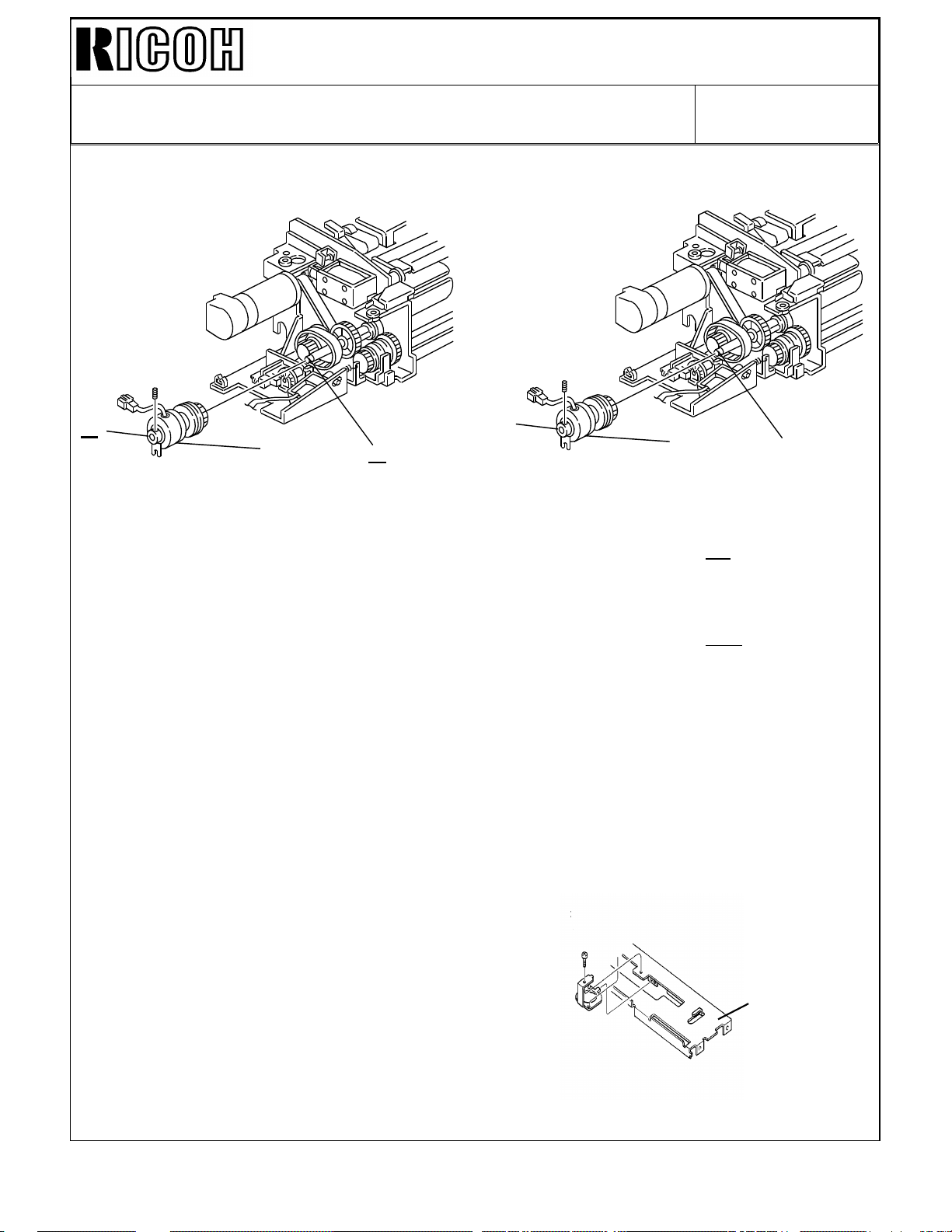

[A]

[B]

An oil supply roller [A] and a cleaning roller [B] are added in the fusing unit.

This modification is implemented from the first mass-production machine.

1. Oil supply roller

The oil supply roller touches the hot roller and applies a small amount of silicone oil to the

hot roller surface.

Purpose:

1) To prevent any foreign substance (ex. toner, paper powder) from adhering to the

hot roller surface.

2) To improve paper separation from the hot roller.

2. Cleaning roller

Purpose:

1. To clean the pressure roller surface.

Note: Both the oil supply roller and cleaning roller are PM parts. Please be sure to

replace them at every 120K copies.

Page 2

Technical Bulletin No. RTB-001

SUBJECT: F400/F410 Fusing unit modification (Manua corrections) DATE:SEP.15.’93

PAGE: 2 of 6

Manual corrections

Because of this modification, the following parts of the service manual should be corrected.

Section 2: DETAILED SECTION DESCRIPTIONS

P2-94: Please add two rollers to the overview illustration as shown by the illustration on

page 1 of this RTB.

Please delete the third paragraph "This model uses an oilless. . . . . ."

NEW Please add the attached "7.7 OIL SUPPLY" (attached - page 4 of this RTB)

Section 4: SERVICE TABLES

P4-5 Please add the following service remark as item No.4 of the 1.11 FUSING UNIT.

Level the oil supply roller while it is stored, otherwise the silicone oil in the oil supply roller

comes out from the lower part.

P4-58 Please change the Fusing Thermistor table as below.

EM 120K 240K 360K NOTE

Fusing

Thermistor

P4-59 Please add the following table to the PM table.

EM 120K 240K 360K NOTE

Oil Supply Roller R R R

Cleaning Roller R R R

CCC

Suitable solvent.

Refer to NOTE 6

P4-64 Please delete "Then apply small amount of silicone oil there every 240K copies."

from item (1) of NOTE 6: Fusing Section. This is because the oil supply roller

applies small amount of silicone oil. Just clean the thermistor at every PM.

Page 3

Technical Bulletin No. RTB-001

SUBJECT: F400/F410 fusing unit modification (Manual corrections) DATE:SEP.15.’93

PAGE: 3 of 6

P4-70 Please remove "and apply silicone oil." from the item 8-2 of the preventive

maintenance (PM) schedule.

Please add the following PM procedure as item No.8-4 and 8-5 of the PM

schedule.

8-4. Replace the oil supply roller.

8-5. Replace the pressure roller cleaning roller.

Section 5: REPLACEMENTS AND ADJUSTMENTS

P5-100 Please correct step 4 of procedure "7.5 HOT ROLLER REPLACEMENT" as

follows.

•

Original expression:

4. Remove the upper entrance guide [D] (1 screw).

•

Corrected expression

4. Remove the oil supply roller unit.

(Refer to Oil Supply Roller Replacement.)

This is because:

1) Since the oil supply roller is installed to the upper entrance guide, the upper

entrance guide is renamed as "cleaning roller unit".

2) No screw is used to install the cleaning roller unit to the fusing unit. (The upper

entrance guide used to be installed with a screw.)

Please delete the screw fixing part [D] from the illustration.

New Please add procedure "7.10 OIL SUPPLY ROLLER REPLACEMENT" (attached -

page 6 of this RTB) and "7.11 CLEANING ROLLER REPLACEMENT" (attached -

page 7 of this RTB).

Section 6: TROUBLESHOOTING

P 6-15 Please add the following sentence as a possible cause for SC520. (To prevent this

from occurring, replace the cleaning roller at every PM.)

Cleaning roller is too dirty and applies a great load to the fusing/duplex drive motor.

Page 4

Technical Bulletin No. RTB-001

SUBJECT: F400/F410 fusing unit modification (Manual corrections) DATE:SEP.15.’93

PAGE: 4 of 6

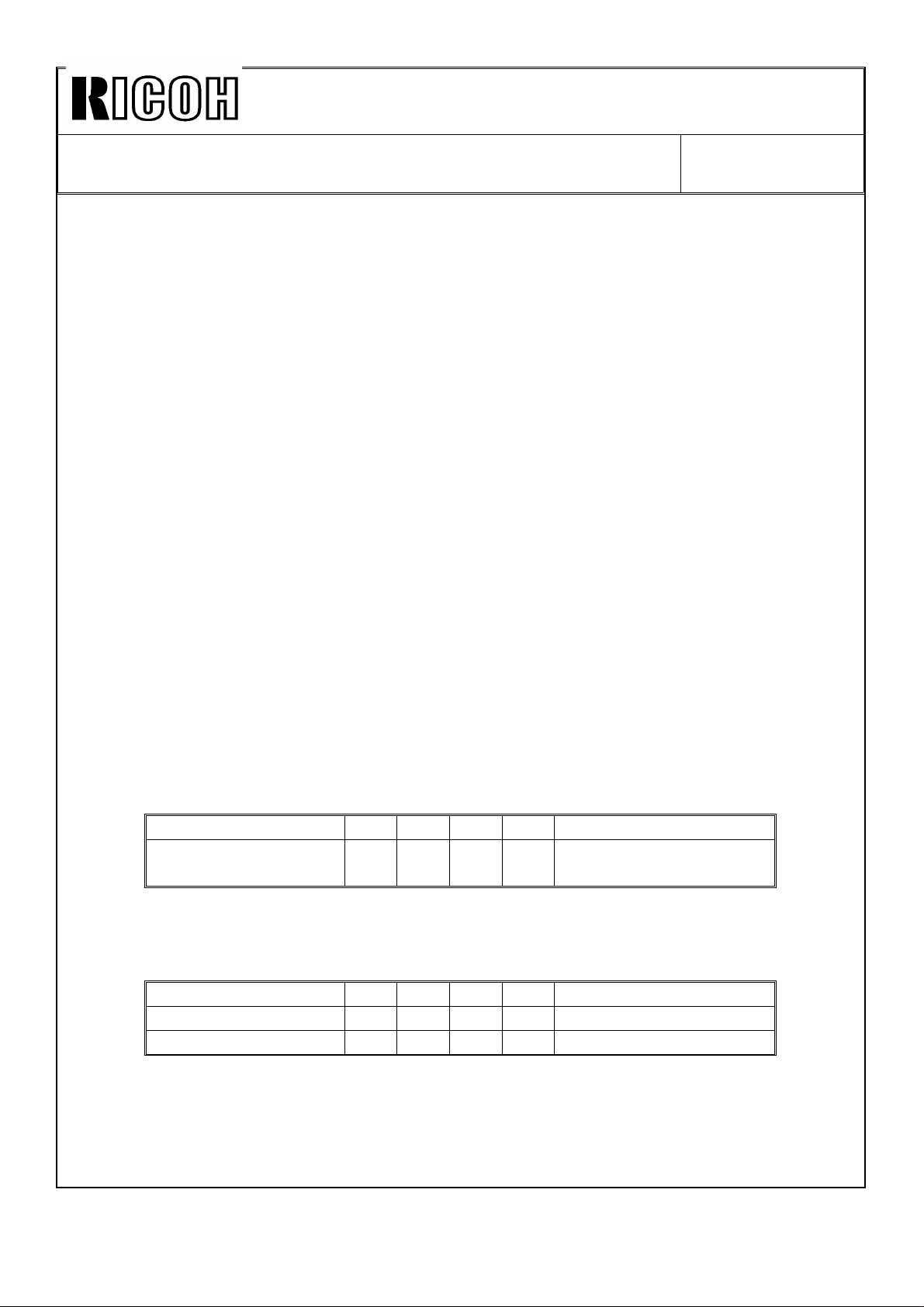

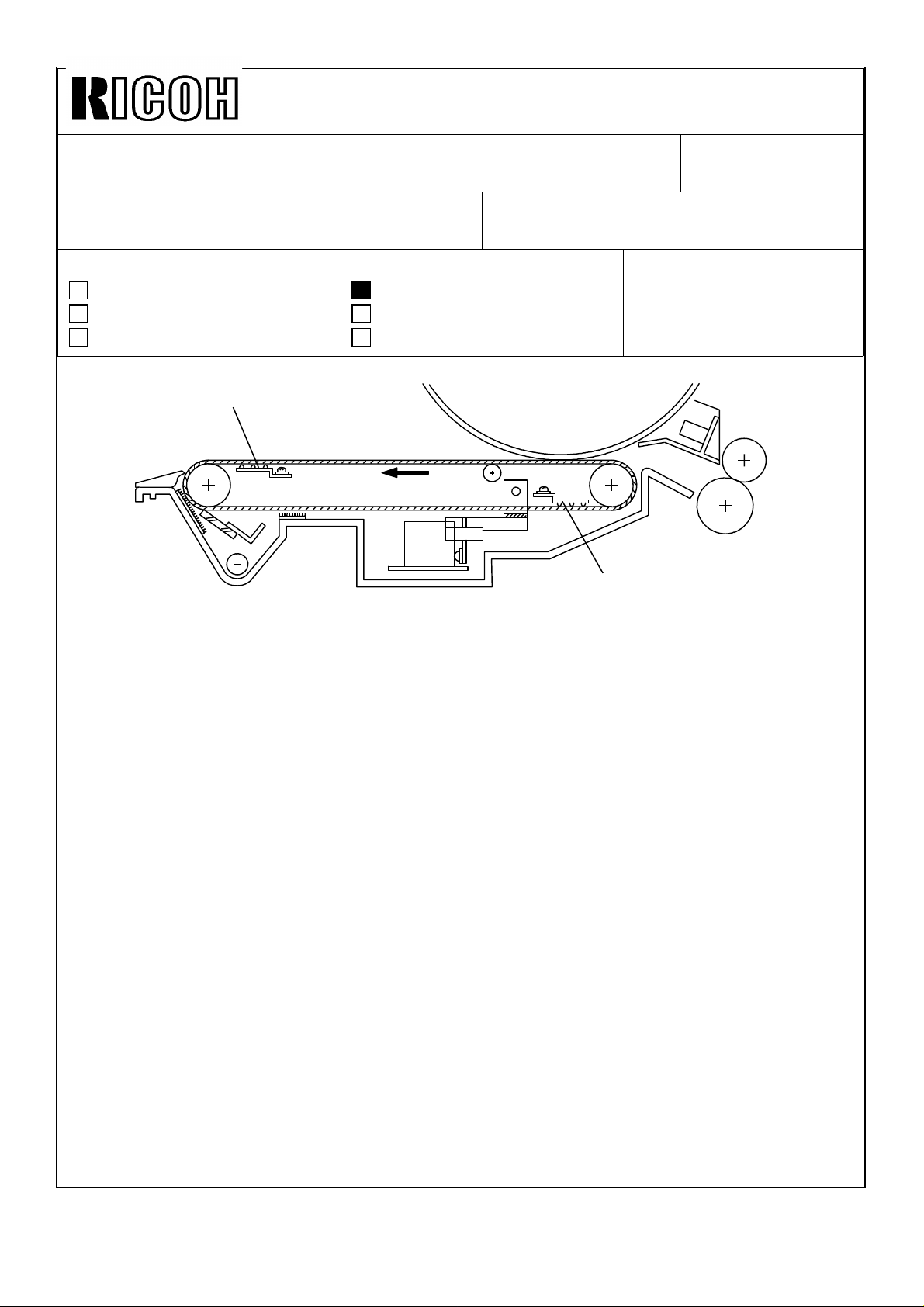

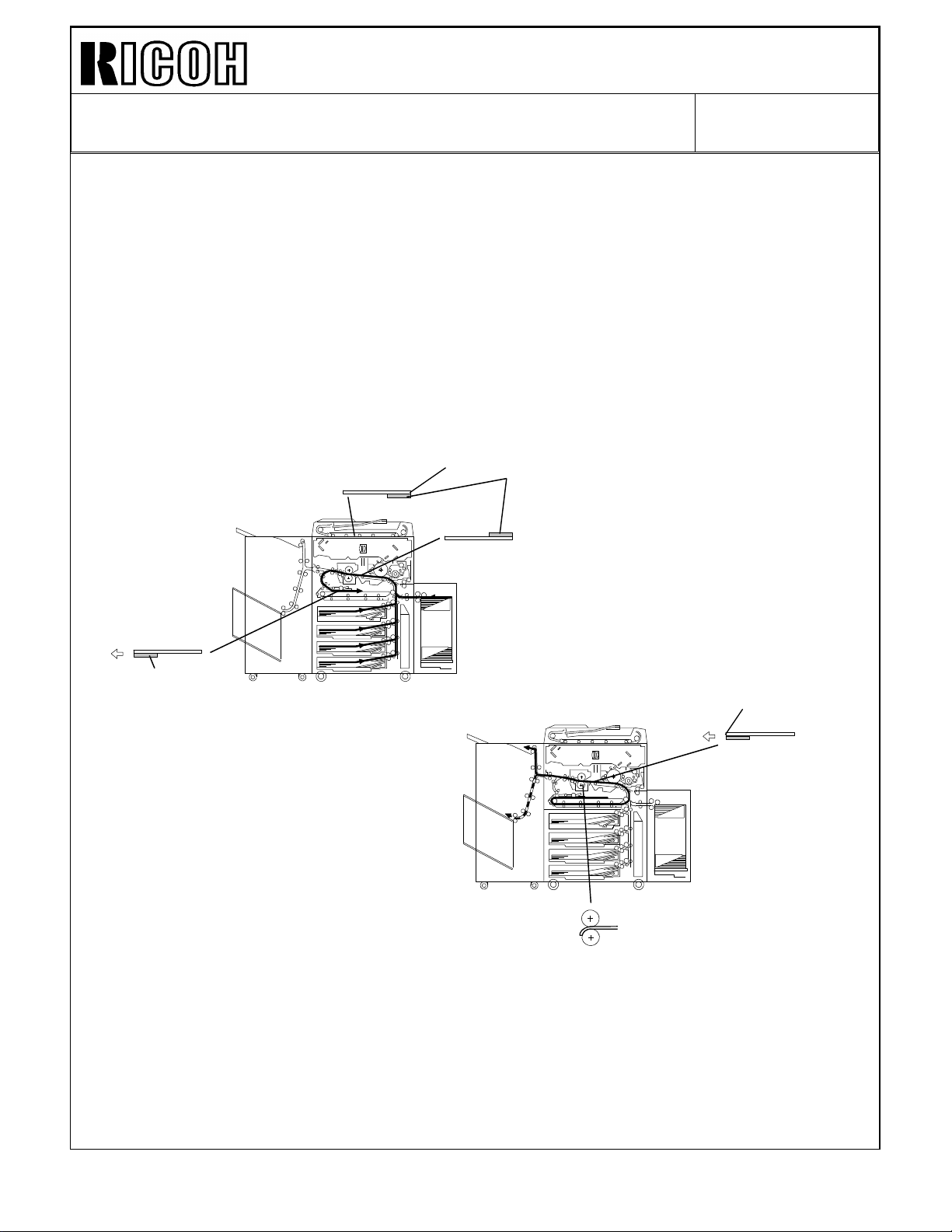

7.7 OIL SUPPLY AND CLEANING

[A]

[A]

[C]

The oil supply roller [A] is soaked with silicon oil [B]. The roller contacts the hot roller by a

spring. It turns with the hot roller and applies a light coat of silicon oil to the hot roller.

The cleaning roller [C] collects any foreign substance (toner, paper dust) on the pressure

roller.

[B]

Page 5

Technical Bulletin No. RTB-001

SUBJECT: F400/F410 fusing unit modification (Manual corrections) DATE:SEP.15.’93

PAGE: 5 of 6

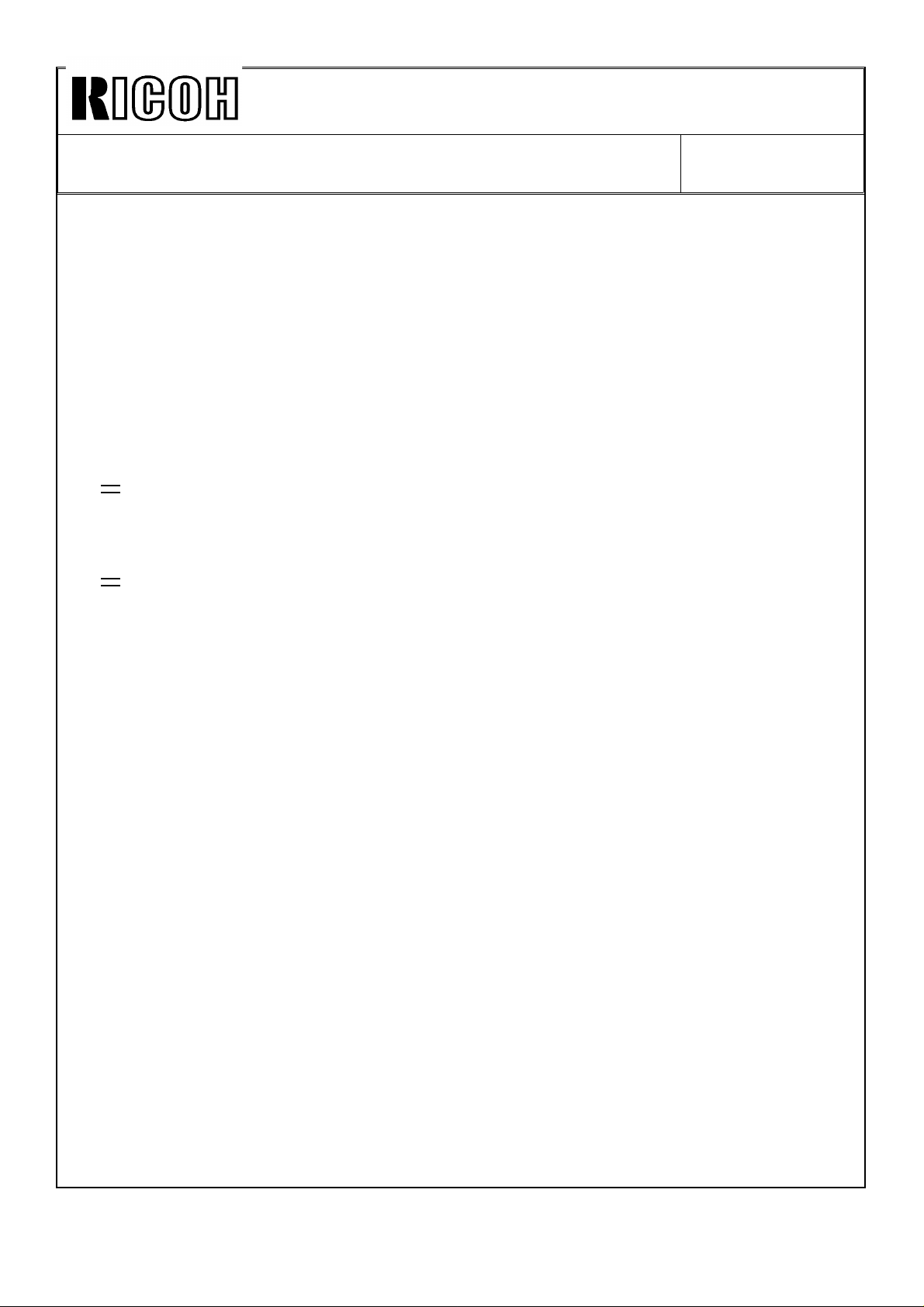

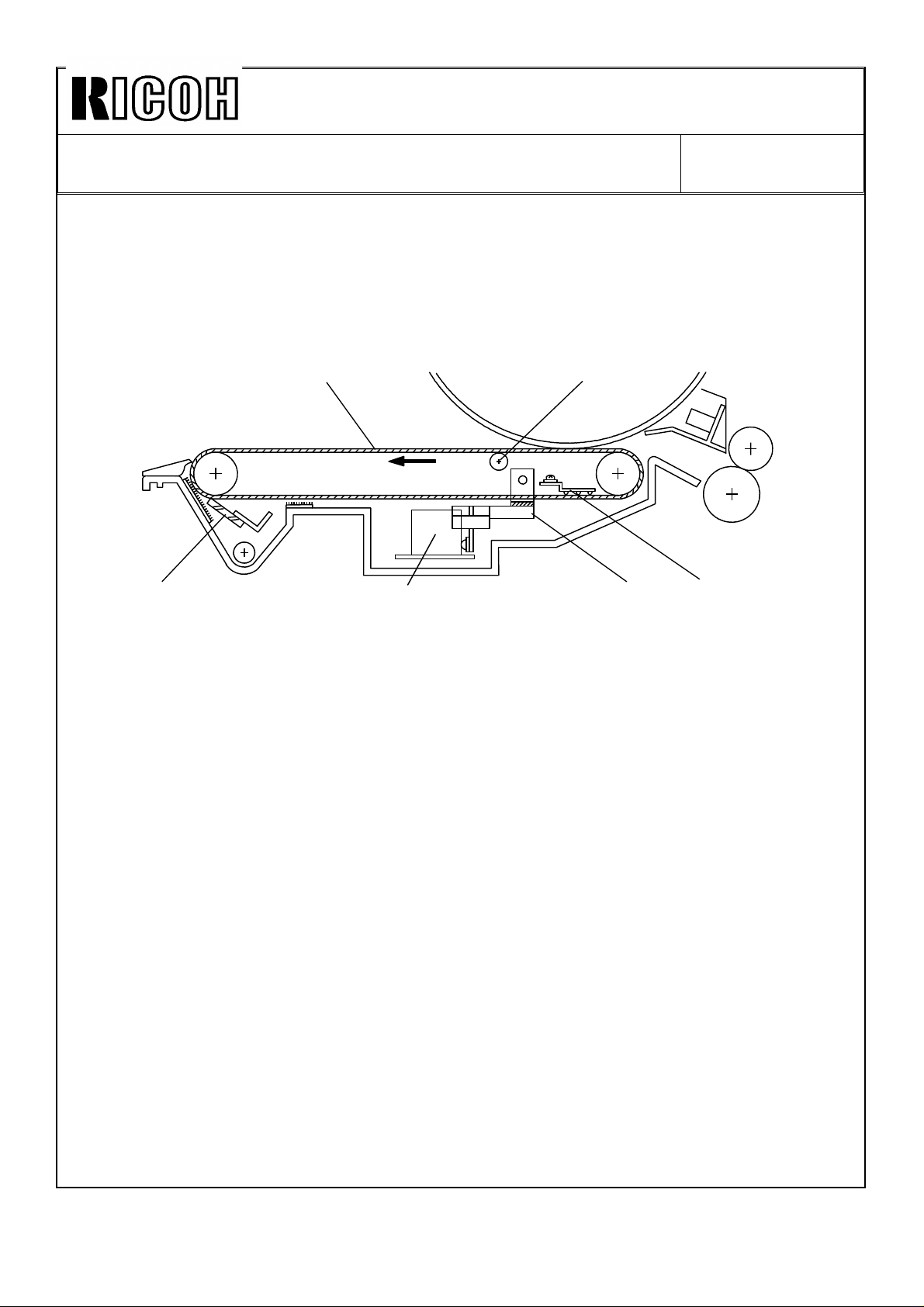

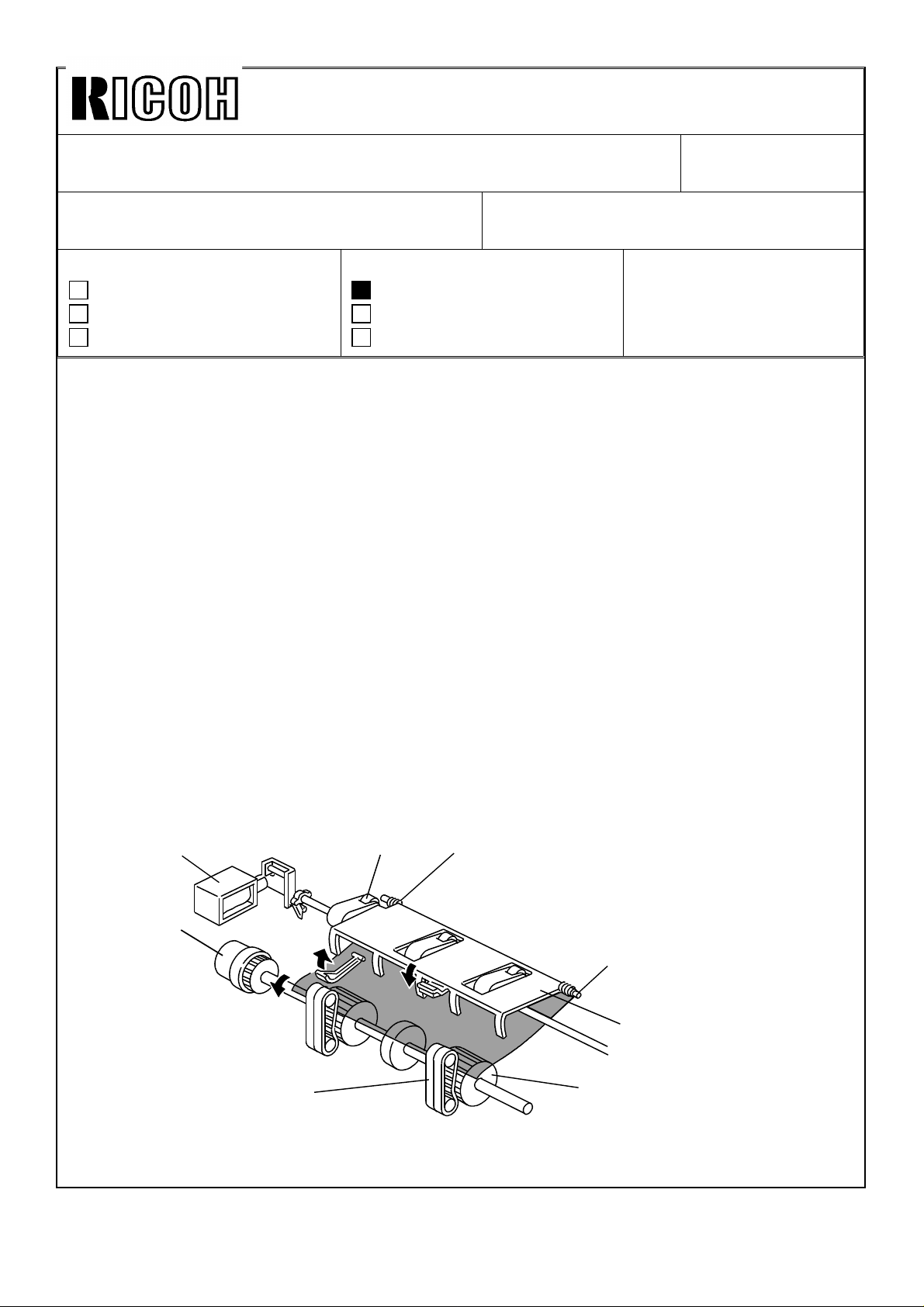

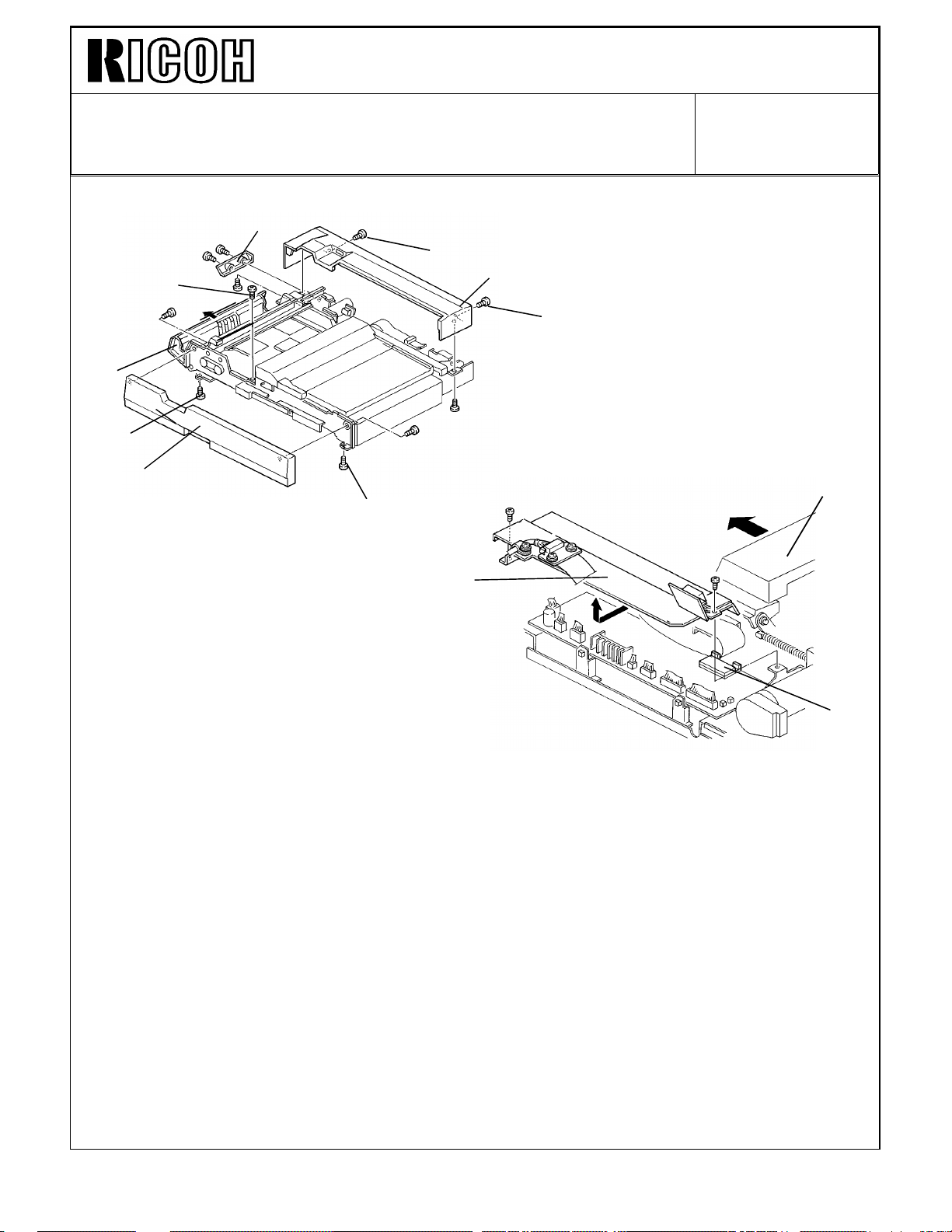

7.10 OIL SUPPLY ROLLER REPLACEMENT

[A]

[E]

[B]

[D]

[C]

1. Pull out the fusing unit.

2. Lower the lever [A].

3. Remove the oil supply unit [B].

4. Remove the spring [C].

5. Remove the bushing [D].

6. Replace the oil supply roller [E].

7. Reassemble the unit.

NOTE: While lowering the lever [A], install the oil supply unit.

Page 6

Technical Bulletin No. RTB-001

SUBJECT: F400/F410 fusing unit modification (Manual corrections) DATE:SEP.15.’93

PAGE: 6 of 6

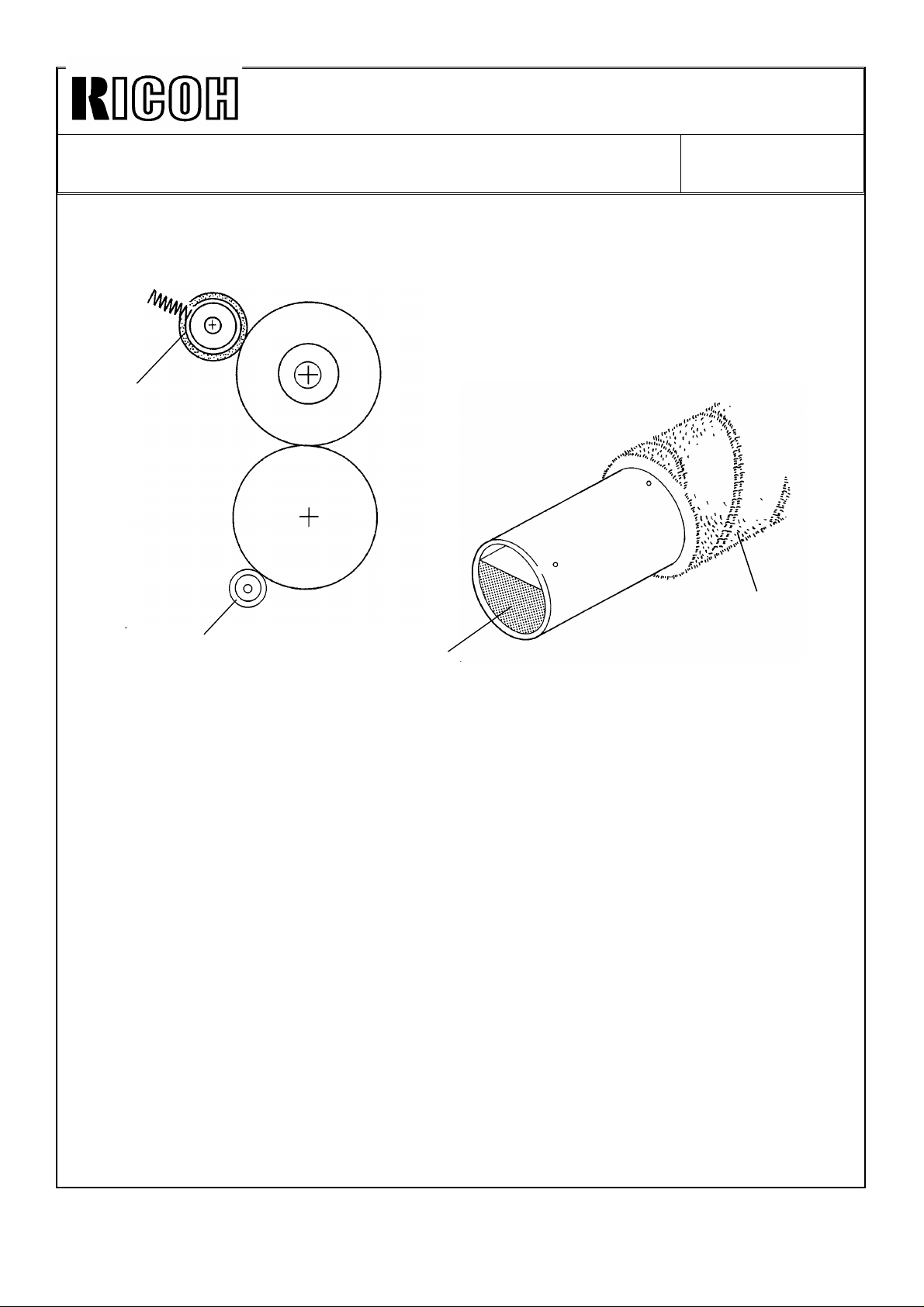

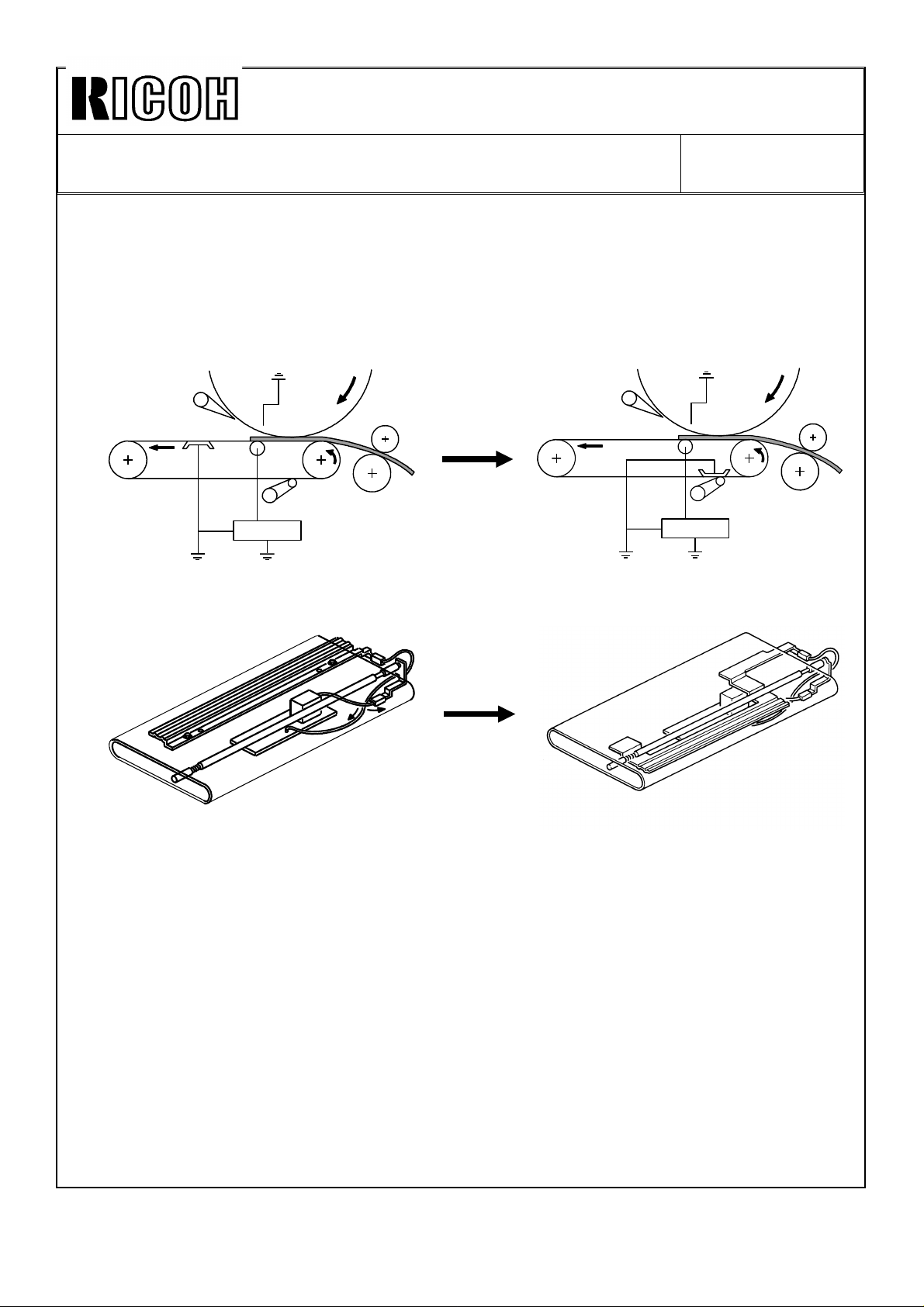

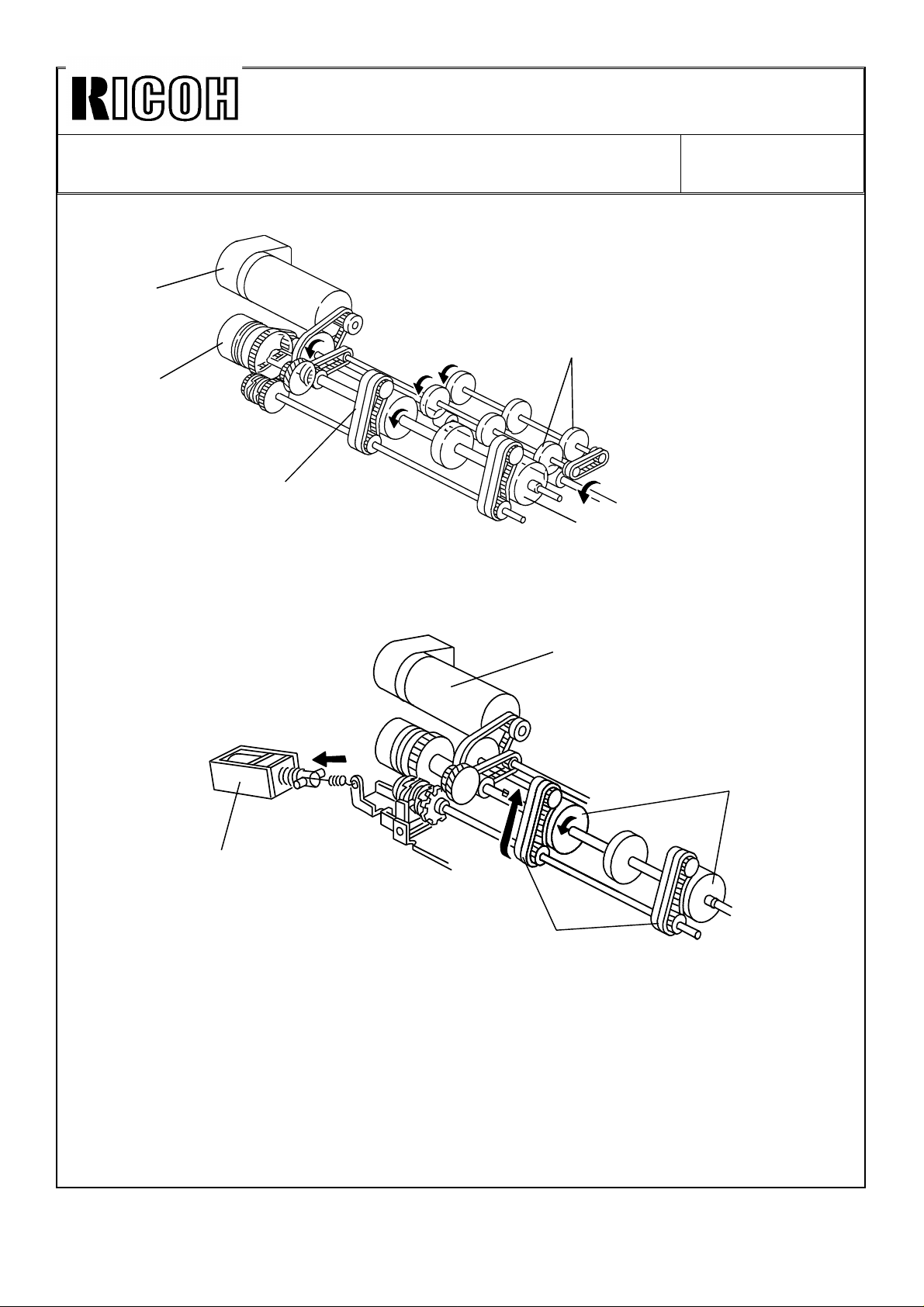

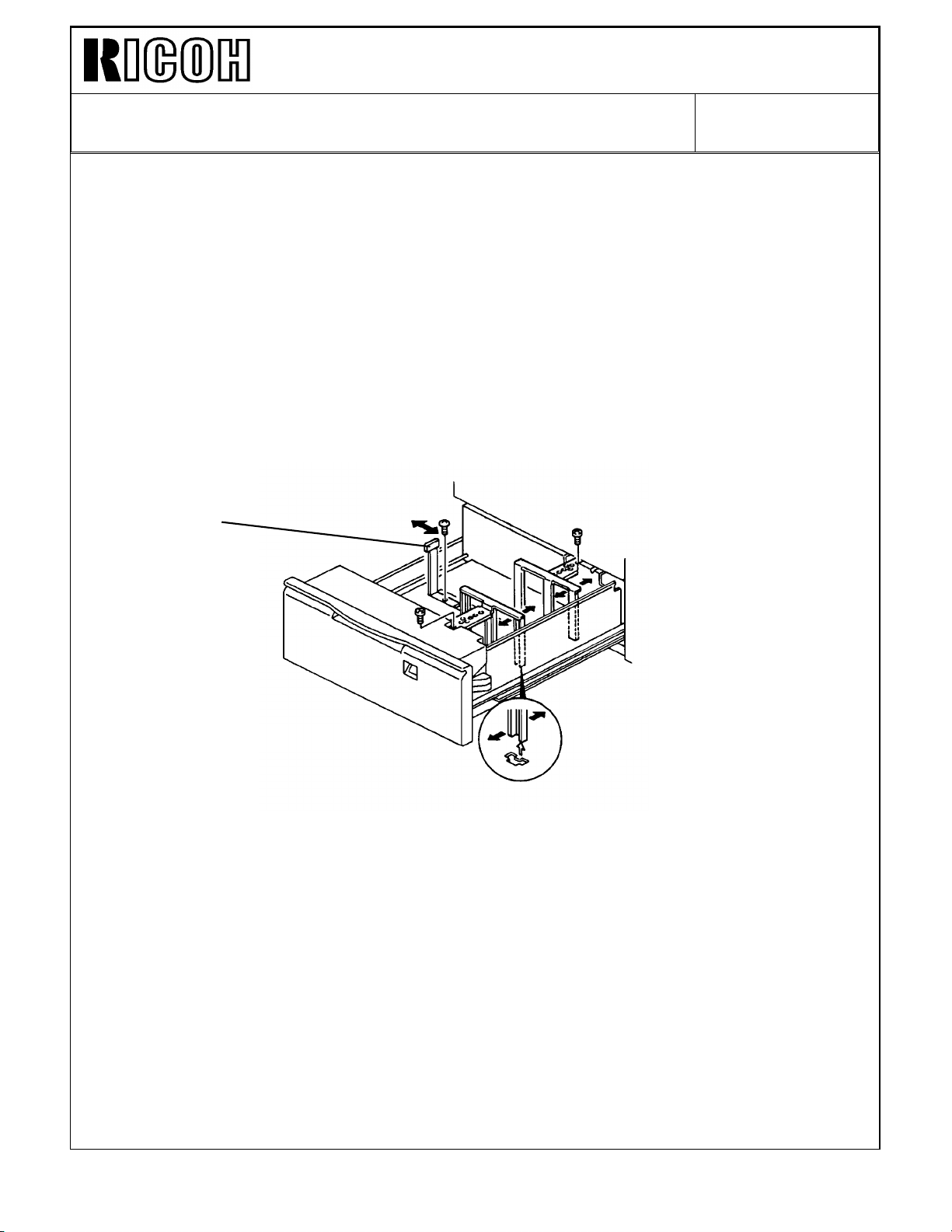

7.11 CLEANING ROLLER REPLACEMENT

[A]

[B]

1. Pull out the fusing unit.

2. Remove the bottom plate [A] (1 screw).

3. Remove the cleaning roller unit [B] (2 screws).

4. Remove the bracket [C] (1 screw).

5. Remove the cleaning roller [D].

6. Remove the seals [E] and bushings [F] from both sides of the cleaning

roller, then install them to the new cleaning roller.

7. Reassemble the unit.

[E]

[F]

[D]

[F]

[E]

[C]

Page 7

Technical Bulletin No. RTB-002

SUBJECT: F400/F410 transfer belt unit modification

(manual corrections)

PREPARED BY: S.MANO

FROM: Copier Technical Support Group

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

[A]

DATE:SEP.15.’93

PAGE: 1 of 4

MODEL: F400/F410

[B]

To improve copy quality, the following modification is implemented from the first

mass-production machine.

1. The discharge plate position is changed from [A] to [B].

2. The transfer current default data is changed from 40 µA to 50 µA.

Details:

Small gray dots appear under the following conditions:

• Low humidity

• Reverse side of the duplex copy

• Halftone image area

Under the above condition, the paper loses too much of its moisture when it passes the

fusing unit after the first side copy cycle. When the paper is separated from the transfer

belt during second side copying, the remaining electricity on the paper (because of the

high electrical resistance) is suddenly discharged and toner is spread around, creating the

gray dots.

To reduce the occurrence of the above image as much as possible, the position of the

discharge plate is changed and the transfer current is changed.

Page 8

Technical Bulletin No. RTB-002

[B]

SUBJECT: F400/F410 transfer belt unit modification

(manual corrections)

DATE:SEP.15.’93

PAGE: 2 of 4

Manual corrections:

Because of this modification, the following parts of the service manual should be corrected.

Section 2: DETAILED SECTION DESCRIPTIONS

P2-59 Change the discharge plate [F] position as shown in the illustration.

[A]

[E]

[D]

[C]

[F]

Correct the explanation concerning the discharge plate [F] as below:

Incorrect:

Helps paper separation from the transfer belt by discharging the remaining negative

charge on the transfer belt.

Correct:

Discharges the remaining negative charge on the transfer belt and feeds it back to the

transfer power pack to control the transfer current and keep it constant.

Note: Paper is separated from the transfer belt by its stiffness.

Page 9

Technical Bulletin No. RTB-002

SUBJECT: F400/F410 transfer belt unit modification

(manual corrections)

P2-61 Delete "Before separating the paper from the transfer belt," from the first

paragraph. Instead of this, write "After separating the paper from the transfer

belt,"

Also correct the illustrations as below

DATE:SEP.15.’93

PAGE: 3 of 4

Section 4: SERVICE TABLES

P4-13

Default transfer current value is changed from 40µA to 50µA.

Standard data is also changed from 40µA to 50µA.

Page 10

Technical Bulletin No. RTB-002

SUBJECT: F400/F410 Fusing unit modification

(manual corrections)

Section 5: REPLACEMENTS AND ADJUSTMENTS

P5-64 Correct the third (from the top) illustration, the discharge plate position is

changed as shown below.

DATE:SEP.15.’93

PAGE: 4 of 4

Page 11

Technical Bulletin No. RTB-003

SUBJECT: F410 RDH Finisher system duplex method change

(manual corrections)

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

For the F410, the alternate paper feed system is disabled.

The following is the new method the F410 uses for copying 1 sided originals to 2 sided

copies.

Please delete pages 14, 15, and 16 of the RDH section and insert the following

explanation.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Group

MODEL: F410

DATE: SEP. 15. ’93

PAGE: 1 of 2

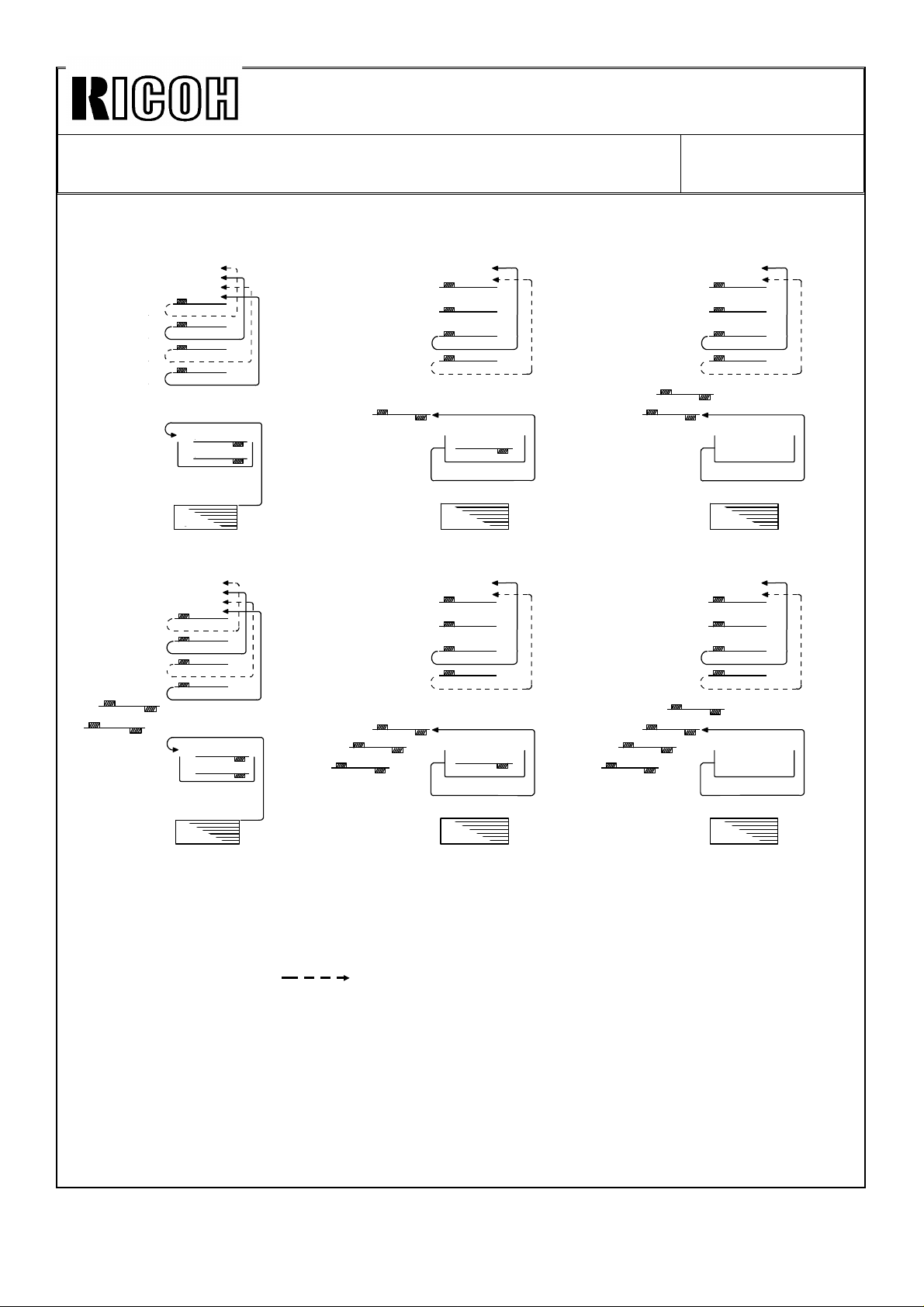

1 SIDED ORIGINAL TO 2 SIDED COPY MODE

When making two-sided copies, first of all, the even pages of the originals placed on the

RDH are copied to the paper from the paper tray. They are stored in the duplex tray. Then

the originals are recirculated, and the odd pages of the originals are copied to the sheets

stored in the duplex tray.

When making two or more sets of copies, the following copy sets are made in the same

way as the first set copy.

Therefore, the original recirculates twice for each copy set.

-Operation- (For example)

Two sets of two-sided copies are made from four one-sided originals.

1) When the start key is pressed, the 4th and 2nd originals are scanned then these

copies are stacked in the duplex tray. The 3rd and 1st originals have only

passed over the exposure glass [Fig. 1].

2) Soon after the 1st recirculation is completed, the second recirculation starts. The

4th originals just passes the exposure glass then the 3rd original is scanned.

This image is copied onto the copy which has been fed from the duplex tray and

is then fed out onto the finisher [Fig. 2].

3) The 2nd original just passes the exposure glass and then the 1st original is

scanned. The copy from the duplex tray is fed for copying the 1st original and

then fed out onto the finisher. At this moment, the duplex tray becomes empty

[Fig. 3].

4) The following steps repeat steps 1) to 3). [Fig. 4] to [Fig. 6].

Page 12

Technical Bulletin No. RTB-003

2 43’

4’3’1’

2’

②

③

SUBJECT: F410 RDH Finisher system duplex method change

(manual corrections)

<RDH>

1

2

3

4

<Duplex>

2

4

<Paper tray>

Fig 1

3’

4’

1’

2’

2’

3’

4

2

Fig 2

❶

①

❷

DATE: SEP. 15. ’93

PAGE: 2 of 2

1’

Fig 3

❸

❹

❸

④

1’

3’

2

4

②

1’

3’

④

❹

❸

④

2

4

②

1’

3’

❸

❶

❷

❶

②

④

2

4

Fig 4 Fig 5 Fig 6

1 2 3 4: 1st recirculated

1’ 2’ 3’ 4’: 2nd recirculated

① ② ③ ④: 3rd recirculated

❶ ❷ ❸ ❹: 4th recirculated

: Without exposing

(for RDH)

Page 13

Technical Bulletin No. RTB-004

SUBJECT: F400/F410 guidance ROMs installation procedure

(manual correction)

PREPARED BY: S.MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

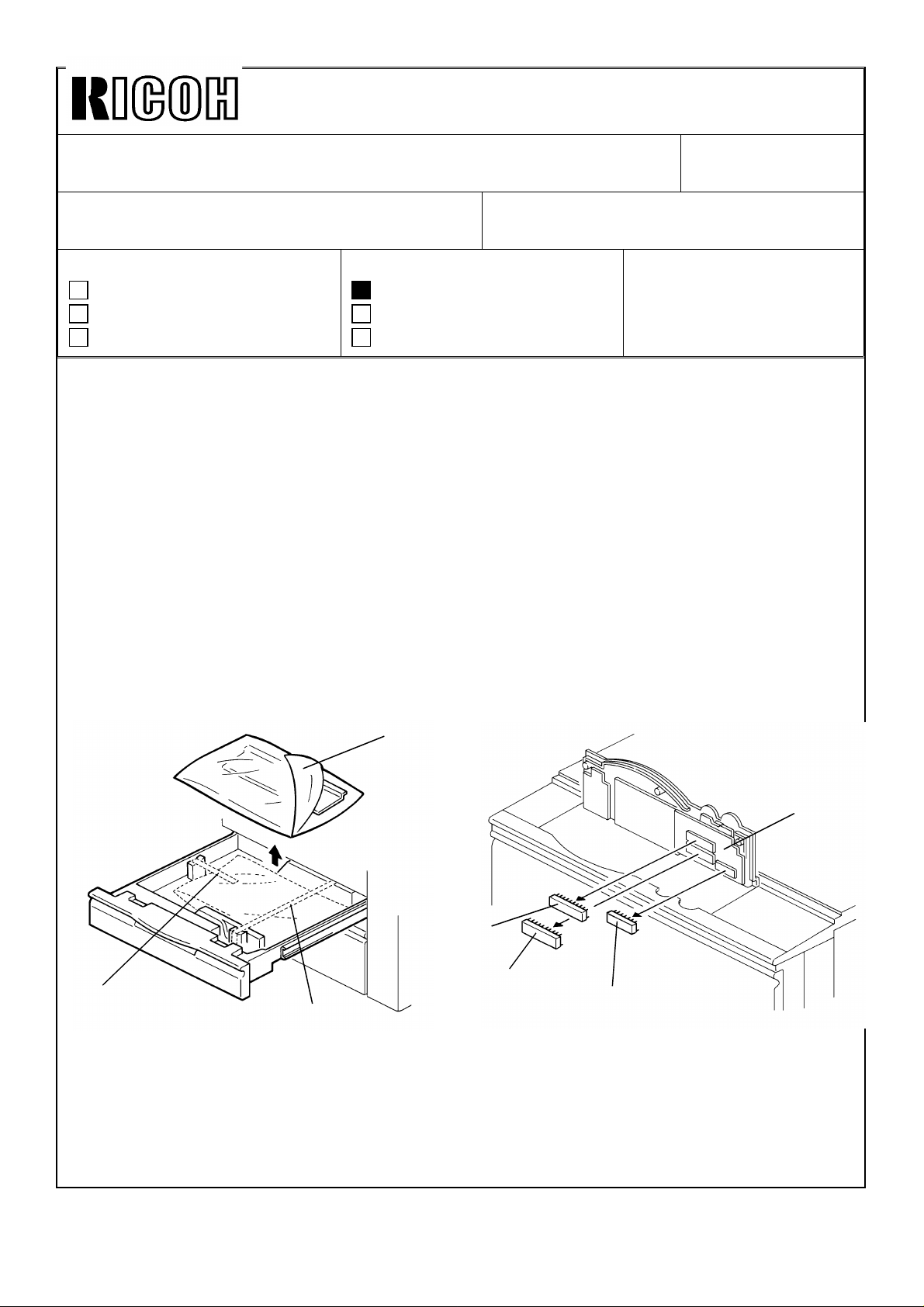

This information is only for Infotec version (A095/A096-26) machines and Ricoh Europe

version (A095/A096-27) machines.

Because it is necessary to install the guidance ROMs at machine installation, to facilitate

the installation procedure, the operation panel is separated from the copier and attached

as an accessory.

The operation panel, the three fixing screws and the two grounding screws are wrapped in

air packing (cushion) and stored in the second feed tray (universal tray).

Because of this, pages 3-12 and 3-13 of the service manual should be corrected as

follows:

Revision of service manual

Information only

Other

FROM: Copier Technical Support Group

MODEL: F400/F410

DATE:SEP.15.’93

PAGE: 1 of 2

2.3 GUIDANCE ROM, INSTALLATION

[B]

[C]

[A]

[A]

1. Open the 2nd tray then remove the tapes [A] securing the operation panel.

2. Unpack the air packing cushion [B].

3. Install the guidance ROMs (IC111 [C], IC112 [D], IC113 [E]) on the operation panel

board [F].

[E]

[D]

[F]

Page 14

Technical Bulletin No. RTB-004

SUBJECT: F400/F410 guidance ROMs installation procedure

(Manual correction)

[A]

[C]

DATE:SEP.15.’93

PAGE: 2 of 2

[B]

4. Connect the connector [A] to the operation panel.

5. Secure the two protective earth wires with screws [B].

6. Install the operation panel [C] to the copier (3 screws).

7. After installing the new guidance ROMs, plug in the power cord and turn on the main

switch then perform the "touch panel display position adjustment" as follows.

1) Press the interrupt key then press the clear/stop key more than three seconds.

C

2) Follow the guidance on the LCD.

Page 15

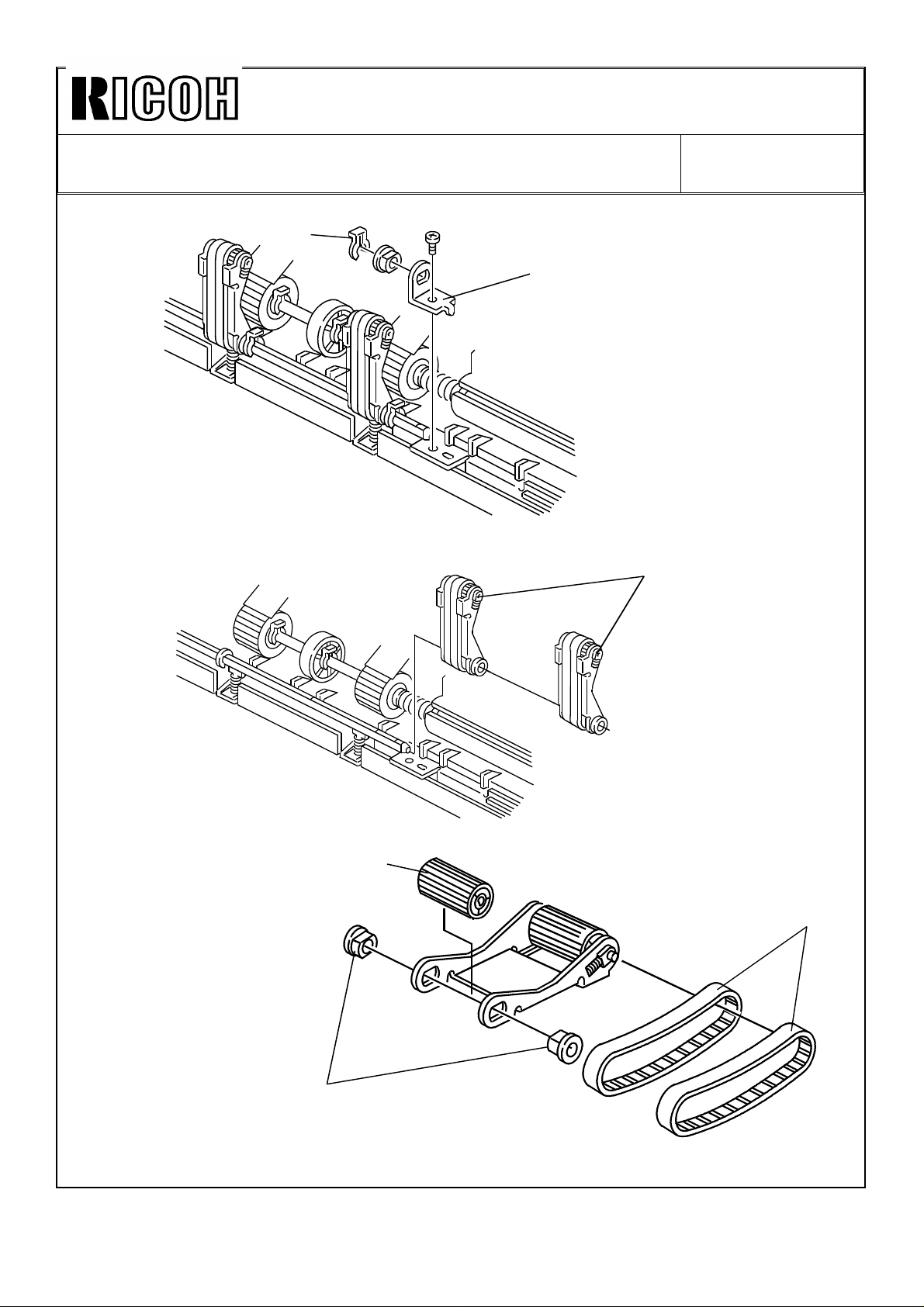

Technical Bulletin No. RTB-005

[B]

SUBJECT: F400/F410 Dual Job Feeder separation belts

(manual correction)

PREPARED BY: S.MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The quantity of the separation belt have been changed from two to four.

Reason of the modification:

On the original printed by the laser printer, the toner may not be fused sufficiently and the

image may smeared by the separation belts.

To prevent this, two more separation belts are added to widen the contacting area

between the separation belts and the original so that the separation pressure is not

concentrated to the narrow area.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Group

MODEL: F400/F410

DATE:SEP.15.’93

PAGE: 1 of 3

After this modification, these separation belts are still PM parts and the replacement

interval is 1PM (120k copies) as same as before this modification.

Because of this modification, the illustrations in page 7, 14, 15, 34 and 35 should be

changed. The quantity of the separation belts should be doubled. There is no correction

except illustrations.

Manual corrections:

Page 7 - upper illustration

[C]

[A]

[E]

[D]

[F]

Page 16

Technical Bulletin No. RTB-005

[B]

[C]

SUBJECT: F400/F410 Dual Job Feeder separation belts

(manual correction)

Page 14 lower illustration

[A]

[D]

[E]

Page 15 illustration

DATE:SEP.15.’93

PAGE: 2 of 3

[B]

[C]

[A]

[D]

Page 17

Technical Bulletin No. RTB-005

SUBJECT: F400/F410 Dual Job Feeder separation belts

(manual correction)

Page 34 lower illustration

[E]

[D]

Page 35 illustrations

DATE:SEP.15.’93

PAGE: 3 of 3

[A]

[B]

[C]

[D]

Page 18

Technical Bulletin No. RTB-006

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 1 of 10

PREPARED BY: S.MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: Copier Technical Support Group

MODEL: F400/F410

TROUBLESHOOTING

The following problems and solutions are based on our experience in the Japanese

market. We think the following countermeasures and customer instructions will help your

service activity in your field.

1. Dark copy/Dirty background

< Phenomenon>

If the machine is moved from a cold place to a warm place and the main switch is turned

on immediately, it is possible that a dark copy appears, or a dirty background copy,

followed by several light copies.

< Possible cause>

If condensation accumulates on the optics or drum because of a sudden temperature

change, less light reaches the drum during the process control data initial setting. The

machine controls for a lighter image density.

If condensation accumulates on the optics, a dark copy appears. If condensation

accumulates on the drum, a dirty background copy appears.

After some time, when the condensation on the optics evaporates or the condensation on

the drum is removed by copy paper going through the copier, the machine will return to

the normal condition and light copies appear.

< Countermeasure>

Wipe off the condensed water on the optics and drum, then perform the process control

data initial setting.

Page 19

Technical Bulletin No. RTB-006

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 2 of 10

2. Fusing jam

< Phenomenon>

If there is solid image at the trailing edge on the front side of an original [A] for the front

side copying, this solid image comes to the back side of the leading edge [B] during the

front side copying (front side copying is done after back side copying).

In this case, a fusing jam might occur. (Thinner paper has higher jam possibility.)

< Possible cause>

The solid image at the leading edge on the back side of the paper might stick to the

pressure roller and it will not separate, resulting in a fusing jam.

a. Front

Solid image

Original

b. Rear Side

[A]

Copy

Solid image

[B]

< Countermeasure>

Instruct the customer to select the edge erase mode.

Page 20

Technical Bulletin No. RTB-006

Normal condition

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 3 of 10

3. False toner end detection at installation

< Phenomenon>

It is possible that the toner end condition appears on the LCD just after installing a new

machine with a new toner bottle.

< Possible cause>

This is because there is some distance between the toner bottle and the toner supply roller

and it takes time to completely fill the toner hopper with toner. Therefore it is possible for

the toner end condition to occur. In particular, this tends to occur when continuous copies

are made from a high image density original just after installation (developer initial setting).

Start-up

Too much toner is spent

immediately

< Countermeasure>

Make 50 ∼ 100 copies to fully supply the toner into the toner hopper. Stop the copying at

every 10 copies to allow the machine creating the ID sensor pattern to maintain precise

toner density control.

Note: This countermeasure is the same as that for the next item "4. Uneven image

density just after the installation" .

We recommend to perform the above procedure anytime the machine is installed.

Page 21

Technical Bulletin No. RTB-006

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 4 of 10

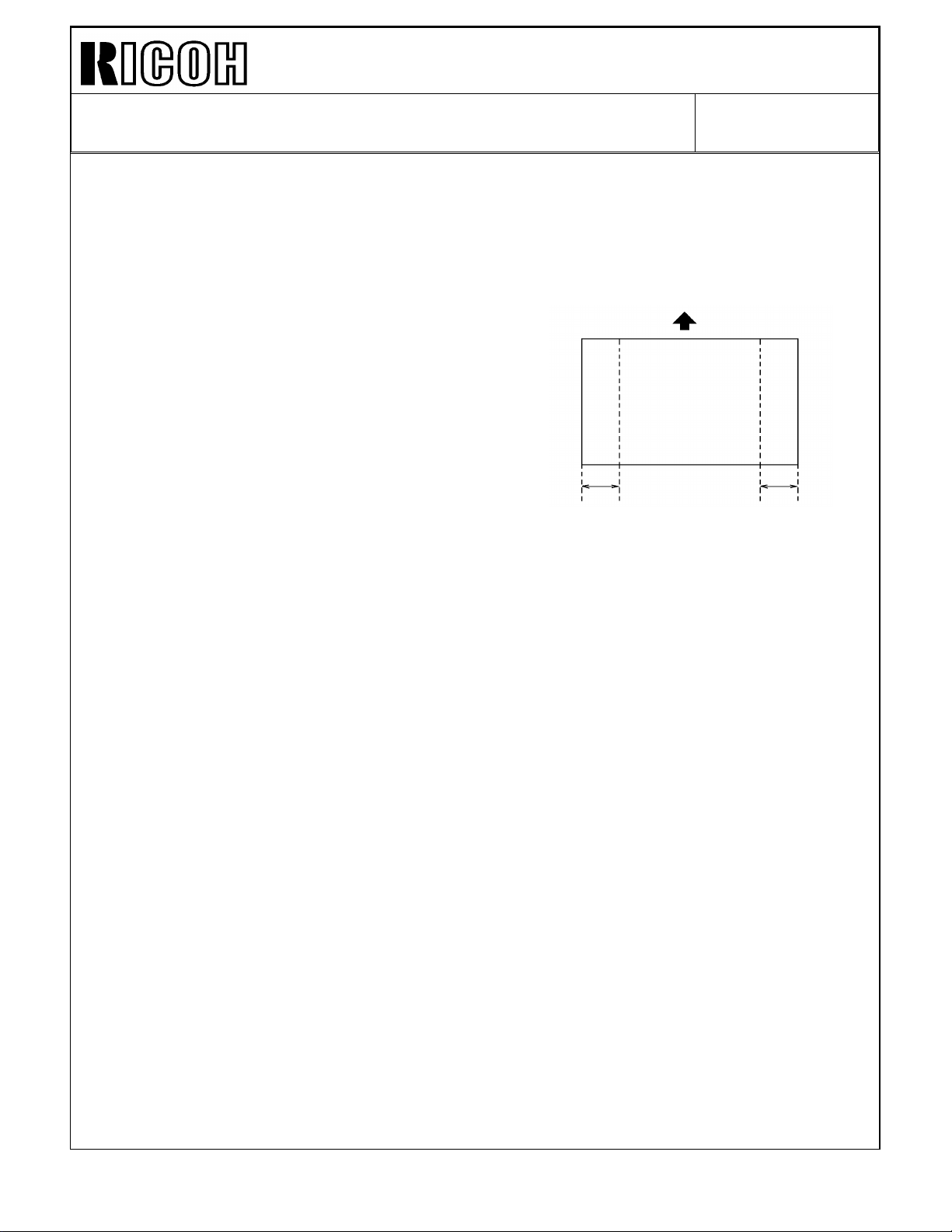

4. Uneven image density just after the installation

< Phenomenon>

Just after installation (up to 50 ∼ 100 copies), the image density (solid image) at the front

and the rear is lighter than the image density at the center.

Lighter Lighter

< Possible cause>

As shown in the illustration in the previous page, in the new toner hopper, the toner is

filled from the front to the rear. It takes time to completely fill the toner hopper. Therefore

it takes about 50 to 100 copies to evenly supply toner to the toner supply roller.

Also, the toner supply roller width is 210mm, which is narrower than wide size paper such

as A4 sideways (297mm) and letter sideways (279mm). Therefore, image density tends to

be lighter especially at the sides.

< Countermeasure>

The countermeasure is the same as that for "3. False toner end detection at

installation"

Make 50 ∼ 100 copies to fully supply the toner into the toner hopper. Stop the copying at

every 10 copies to allow the machine creating the ID sensor pattern to maintain precise

toner density control.

Page 22

Technical Bulletin No. RTB-006

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 5 of 10

5.DJF Original jam (F400 only)

When an original generates a lot of static electricity, it tends to stick to the exposure glass

and cause an original jam.

< Countermeasure>

If this occurs, apply a small amount of silicone oil on the exposure glass.

If this problem occurs frequently because of the kind of originals that the customer uses,

install the F410 type exposure glass which has an anti-static coating as a special

countermeasure.

6. Dirty background

< Phenomenon>

If the customer does not turn off the machine at all, a dirty background might appear.

< Possible cause>

The process control data initial setting does not work because it works when the machine

is turned on.

< Countermeasure>

Instruct the customer to turn off the main switch at the end of the day (Turn off the

machine at least 30 minutes; fusing temperature should be lower than 100 degrees ).

Caution: We will modify the software so that the process control data initial setting

functions when the weekly timer turns on the machine. This new software will be

implemented from December production machines. We will let you know the details,

such as cut-in serial number, in a later RTB.

Page 23

Technical Bulletin No. RTB-006

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 6 of 10

7. Distorted vertical lines

< Phenomenon>

Vertical lines are sometimes distorted because the original is wavy and is not completely

pressed against the exposure glass by the platen cover or DJF/RDH.

Note: This is the same situation as previous models (F30 series, F40)

< Countermeasure>

Instruct the customer to press the original against the exposure glass by using a weight,

such as a paper package.

8. Sorter stapler installation environment

< Phenomenon>

When direct sunlight strikes the bin jam sensor (a photo transistor), it causes a sensor

malfunction, and the machine does not staple even if staple mode is selected.

< Countermeasure>

1) Avoid installing the machine under direct sunlight

2) Install a piece of mylar around the bin-jam sensor (photo-transistor) to protect from

direct sunlight.

Page 24

Technical Bulletin No. RTB-006

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 7 of 10

9. DJF Original Skew

< Phenomenon>

If original skews occur as illustrated even if the DJF height is correctly adjusted, perform

the following adjustment.

Rear

Left scale

< Possible cause>

This skew is caused because the transport belt is faster than the feed-in motor speed,

even if both motor speeds are within the specification.

< Countermeasure>

1. Feed-in motor speed adjustment

Adjust the feed-in motor speed so that the motor speed becomes higher (within

specification).

1–1 Turn DIP SW 101-1, 2, 4 to "ON".

1–2 Turn DIP SW 102-1 to "ON".

1–3 Turn VR 103 towards "H" to turn LED 101 (Red) on.

1–4 Turn VR 103 towards "L" to turn LED 102 (Green) on.

2. Transport belt motor speed adjustment

Adjust the transport belt motor speed so that the motor speed becomes lower (within

specification).

1–1 Turn DIP SW 101-1, 2, 4 to "ON".

1–2 Turn DIP SW 102-2 to "ON".

1–3 Turn VR 104 towards "L" to turn LED 103 (Red) on.

1–4 Turn VR 104 towards "H" to turn LED 102 (Green) on.

Page 25

Technical Bulletin No. RTB-006

No good

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 8 of 10

10. Sorter Stapler Entrance jam

< Phenomenon>

If the mylar is set incorrectly, paper jams frequently occur around the sorter stapler

entrance.

Good

< Countermeasure>

Set the mylar in the correct position without buckling, curling or waving.

Page 26

Technical Bulletin No. RTB-006

No good

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 9 of 10

11. Abnormal LCD panel indication

< Phenomenon>

The copy counter indicates "8" even if another key (for example, the clear modes key) is

pressed. For instance, if the clear modes key is touched three times, the copy counter

indicates 888.

< Possible cause>

The grounding wire terminal is touching the operation panel board circuit pattern.

When the operation panel is opened while the grounding screws are left secured to the

machine frame, if the grounding wire is pulled strongly (this is especially possible when the

guidance ROM is pushed in the socket) the terminal may be rotated and bent. If the bent

terminal is pressed against the insulating sheet, it cuts part of insulating sheet and touches

the legs of electrical elements behind the insulating sheet, resulting in a short-circuit.

Good

< Countermeasure>

Correct the bent terminal and repair the insulating sheet with insulating tape such as teflon

tape.

Especially, be careful when you install the guidance ROMs at installation.

Page 27

Technical Bulletin No. RTB-006

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 10 of 10

12. PCBs or Power packs damage

< Possible causes>

When units such as drum unit or transfer belt unit are removed while the main switch is

turned on, electrical noise or surge current might occur, resulting in PCB damage.

< Countermeasure>

Replace the damaged PCB or power pack.

CAUTION: Turn off the main switch before disconnecting the connector

or removing the unit.

13. SC548 (Additional information for page 6-17 in the service manual)

< Countermeasure>

If this occurs, before replacing the optics PCB and main control board, check the

connection between the main harness and the relay harness (drawer connector terminals)

and the connection between the relay harness and the thermistor (2P connector).

Page 28

Technical Bulletin No. RTB-007

SUBJECT: SC502, 508, 510, 511 DATE:Nov.30, ’93

PAGE: 1 of 3

PREPARED BY: S.MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

< Phenomenon >

SC502, 508, 510, 511

< Possible causes >

When the tandem tray is closed roughly, it bounces slightly to the front. This breaks the

connection of the drawer connectors at the right or left tandem tray.

< Countermeasure >

1. Field countermeasure

Revision of service manual

Information only

Other

FROM: Copier Technical Support Group

MODEL: F400/F410

Instruct the customer to gently push in the tandem tray until it stops.

Also instruct the customer to do the following operation if the problem occur:

After drawing-out then pushing in the tandem tray, turn the main switch off and on.

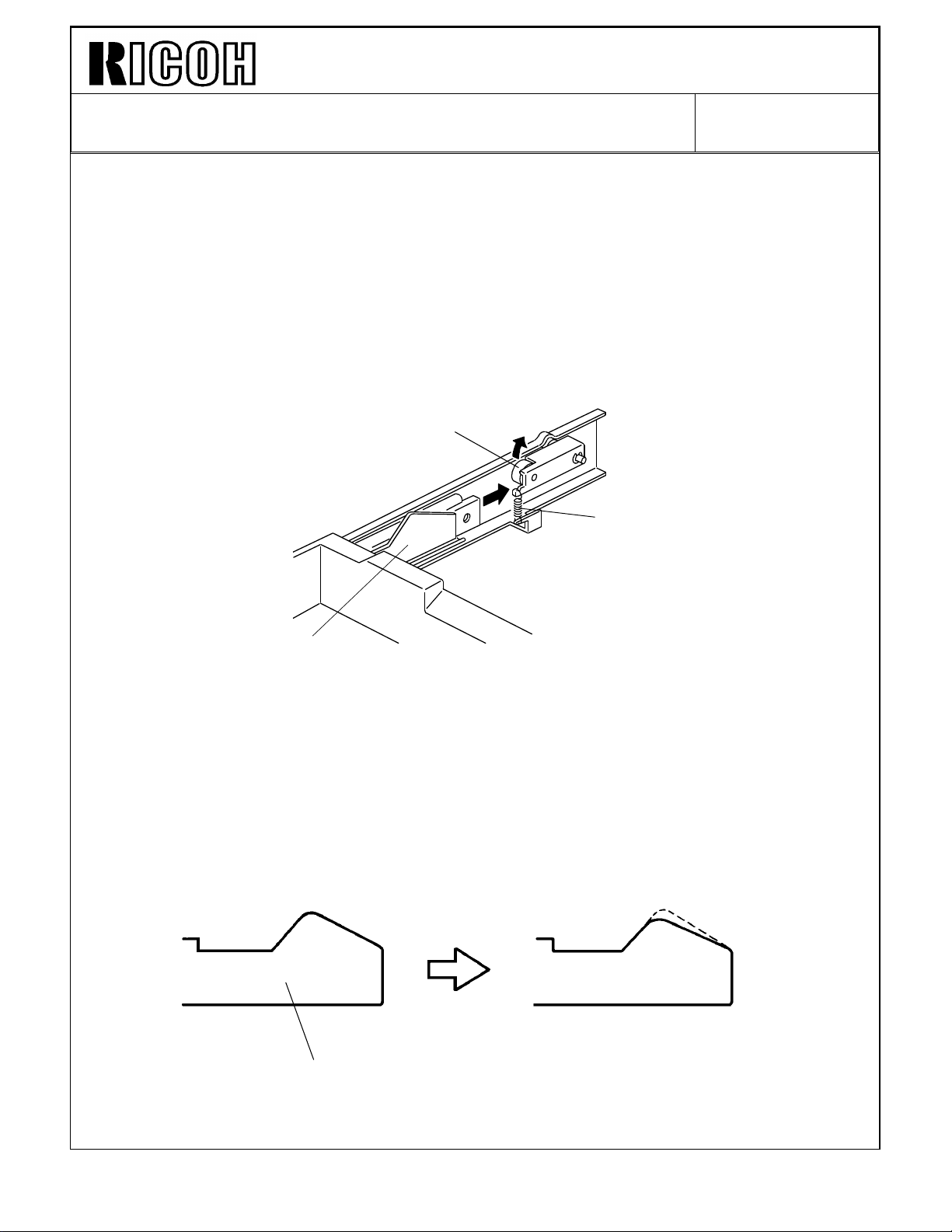

Apply grease (silicone grease G-501) to the following points (see the illustrations in the

following pages). This reduces the friction between the tandem tray and the guide rail to

make the drawing operation of the tandem tray smoother. This helps the lock lever to

position the tandem tray at the correct position. In other word, if the tandem tray bounces

slightly to the front, the lock lever pushes the lock plate to move the tray back to the

correct position.

Page 29

Technical Bulletin No. RTB-007

SUBJECT: SC502, 508, 510, 511 DATE:Nov.30, ’93

PAGE: 2 of 3

Point # 2

Point # 1

Lock Lever

Lock Plate

Point # 1 : The upper edge of the lock plate

Point # 2 : The surface of the lock lever roller where touching the lock plate

Point # 3

Point #4

Point #5

Point # 3 : Positioning Pin

Point # 4 & # 5 : Guide Rails

Page 30

Technical Bulletin No. RTB-007

SUBJECT: SC502, 508, 510, 511 DATE:Nov.30, ’93

PAGE: 3 of 3

2. Production machine countermeasure

To improve the accuracy of the tandem tray lock position, the following improvement will

be implemented in the mass-production machines. (Please refer to Modification Bulletin for

cut-in serial numbers. An MB will be issued as soon as the modification is implemented.)

1. Grease is applied at the factory as described in the previous page.

2. Also to make the tray movement smoother, the roller [A] on the lock lever is changed

from a resin roller to metal roller with ball bearings.

[A]

[B]

[C]

3. The spring [B] tension applied to the tray lock lever is increased from 1.5kgf to 3.0kgf

(spring is changed).

Because the spring tension is increased, to keep the tandem tray drawing force constant,

the lock plate [C] shape is flatter.

[C]

Page 31

Technical Bulletin No. RTB-008

SUBJECT: DJF Multiple feeding DATE:Nov.30, ’93

PAGE: 1 of 2

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

< Phenomenon >

Original multiple feeding occurs when there is high friction between the originals. This

tends to occur especially when the originals have staple holes, or computer forms with

rough edg es.

< Possible cause >

[C]

Revision of service manual

Information only

Other

FROM: Copier Technical Support Group

MODEL: F400/F410

[D]

[A]

[B]

When the originals [A] comes between the feed rollers [B] and the separation belts [C],

they meet the mylar [D] between them and the separation belts. This guide mylar

transports the originals smoothly to the gap between the feed rollers and the separation

belts. The mylar length determines the original separation force. If the mylar is longer, the

area where the originals touch the separation belt becomes narrower, therefore the

separation force become weaker. If the mylar is shorter, the separation force becomes

stronger. (If it is too short, too much separation force stops original feed)

As a result of our investigation, we found that making the mylar 2mm shorter is the best

condition (higher separation ability without feeding error).

Page 32

Technical Bulletin No. RTB-008

SUBJECT: DJF Multiple feeding DATE:Nov.30, ’93

PAGE: 2 of 2

< Countermeasure >

Replace the original guide mylars (2 mylars per machine). New part is the assembled part

of the mylar and the bracket. New part number is A3761254.

For the cut-in serial number, please refer to the modification bulletin which will be issued

soon.

Guide mylar ass’y : Part number A3761254

Page 33

Technical Bulletin No. RTB-009

SUBJECT: Installation procedure DATE:Nov.30, ’93

PAGE: 1 of 3

PREPARED BY: S.MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

1. Additional shipping tape on the fusing exit unit. (F400/F410 service manual - installation

procedur e, page 3-6 )

From the first mass-production machine, a retaining tape [A] is added to prevent the fusing

exit guide from opening during a transportation. Please be sure to remove the tape at

installation.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Group

MODEL: F400/F410

DJF

LCT

[A]

2. USA 20A plug socket

The shape of the socket for 20A [B] differs from that for 15A [C]. The two are not

interchangeable. If there is no 20 A socket at the customer location, the electrical line

must be changed as well as the socket. Contact the local electric company for more

information.

[B] [C]

Page 34

Technical Bulletin No. RTB-009

SUBJECT: Installation procedure DATE:Nov.30, ’93

PAGE: 2 of 3

3. Caution for DJF shipping tape removal (dual job feeder service manual - installation

procedure page, 24)

When removing the tape [B] fixing the original press roller shaft [C], be careful to confirm

that the shaft is correctly in the holder [D]. It is possible that the shipping tape adheres

strongly to the shaft. The shaft migit be pulled out from the holder when the tape is

removed.

If the shaft is out of position, the original will not feed.

[B]

[C]

[D]

Page 35

Technical Bulletin No. RTB-009

[A]

SUBJECT: Installation procedure DATE:Nov.30, ’93

PAGE: 3 of 3

4. Caution when installing the LCT (large capacity tray service manual - installation

procedure, page 12)

When installing the tray unit [A] to the LCT connector [B], be careful not to pinch the

harness between the feed unit bracket [C] and the tray unit bracket [D], as shown.

[D]

[C]

[B]

To prevent this, fix the harness with a tape as shown before installing the tray unit.

Tape

Page 36

Technical Bulletin No. RTB-010

SUBJECT: DJF feed roller assembly replacement DATE:Nov.30, ’93

PAGE: 1 of 3

PREPARED BY: S.MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

1. Manual correction

In the feed roller replacement procedure (page 32 to 33), there are steps asking to remove

the original table and original guide. Actually, this procedure is not necessary. Please skip

steps 2, 3, 4, and 5. You can directly access the feed roller.

2. Procedure change due to modification.

In the domestic market, we have experienced that the customer took off the feed roller

assembly [A] when removing a jammed original. When the jammed original is pulled to the

front, the feed rollers are pulled to the front and the joint part [B] comes out from the drive

shaft. To prevent this, The middle roller [C] position has been changed (to the rear) as

shown below.

Revision of service manual

Information only

Other

[C]

FROM: Copier Technical Support Group

MODEL: F400/F410

[B]

Front

[A]

Guide Plate

[B]

Old

[C]

New

Page 37

Technical Bulletin No. RTB-010

SUBJECT: DJF feed roller assembly replacement DATE:Nov.30, ’93

PAGE: 2 of 3

Before the modification, the middle roller could be shifted to the front when the feed roller

was pulled to the front. After the modification, when the feed roller is pulled to the front,

the middle roller hits the guide plate and it cannot be moved to the front. This prevents the

joint part from being separated by mistake.

To replace the feed roller assembly, the following procedure is necessary before

performing step 6 (slide the feed roller assembly to the front, then remove it).

* Remove the guide mylars

* Remove the snap ring.

* Hold the feed roller.

After the modification, procedure "14.2 feed roller replacement" is changed as shown in

next page.

Page 38

Technical Bulletin No. RTB-010

SUBJECT: DJF feed roller assembly replacement DATE:Nov.30, ’93

PAGE: 3 of 3

[B]

[A]

Rear

[E]

[F]

[C]

1. Turn off the main switch then open the feed cover [A].

2. Remove the guide mylars [B] ( 1 screw each ).

3. Remove the snap ring [C].

4. Slide the roller [D] to the rear.

[D]

Front

5. Hold the feed roller [E] then slide the shaft to the front, then remove the feed roller

assembly as shown.

6. Remove the four snap rings [F], then remove the feed rollers.

7. Install the new feed rollers, then re-assemble the machine.

Page 39

Technical Bulletin No.RTB-011

SUBJECT: Software modification DATE:Dec.15, ’93

PAGE: 1 of 5

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

We learned of the following problems and have modified the software (ROMs on the main

control board) to solve them.

IC NUMBER OLD PART NUMBER NEW PART NUMBER

IC120 (4M Bite)

IC133 (1M Bite)

Revision of service manual

Information only

Other

A0965121K

A0965123K

FROM: Copier Technical Support Group

MODEL: F400/F410

A0965151

A0965153

1. Registration Jam for perforated paper (4 holes)

Continuous paper runs produce jams when perforated paper is fed in. This occur when the

holes match the location of the registration sensor.

At the paper leading edge, the registration sensor goes from OFF to ON. Just after the

registration sensor turns on, the chattering check is done. When the hole at the leading

edge of the paper passes above the registration sensor, the sensor output fluctuates,

resulting in a paper jam.

2. Process control data initial setting does not functions when the

machine is turned on by the weekly timer.

Process control data initial setting does not function when the machine is turned on by the

weekly timer. For customers who never turn off the main switch, the auto process control

does not work and after about 150k or more copies, maybe resulting in darker copies

followed by dirty backgrounds.

3. ADS does not functions with RDH last original

Only for the copy image of the last original fed by the RDH, the auto image density

selection does not function. Instead, the 4th ID level is selected.

If multiple sets of copies are made, this appears only for the last copy of the first set.

Page 40

Technical Bulletin No.RTB-011

SUBJECT: Software modification DATE:Dec.15, ’93

PAGE: 2 of 5

4. SC742

This occurs only for the RDH and Finisher system.

When the following conditions are met, the positioning roller [A] interrupts the paper feed

out pawl [B], resulting in an SC742 condition.

• The previous customer selected the staple mode and this mode is not

cleared. (The staple mode remains selected).

• Only one original to be copied.

• More than three copies are mode. (The problem occurs after feed-

ing 4 or more copies).

Note: After the modification, when the above conditions are met, the interval between the

copies becomes longer to prevent the interruption between the positioning roller [A]

and the paper feed out pawl [B]. Only in this case, the CPU reduces from 55CPM

to 22.5CPM (A4/Letter sideways).

If the above three conditions are not met, the copy speed is 55CPM.

[A]

[B]

[A]

Page 41

Technical Bulletin No.RTB-011

SUBJECT: Software modification DATE:Dec.15, ’93

PAGE: 3 of 5

5. Two roller marks on halftone image areas

When the following conditions are met, lighter lines appear at the latter half of the image.

• Last paper fed from the duplex tray.

• There is halftone image area at the latter half of the front side copy.

A3

This is caused by the duplex transport clutch turning off when the paper is still being

transported by the duplex transport rollers [A]. Under this condition, the leading edge of

the paper is transported by the vertical transport rollers [B], so the paper is rubbed by the

duplex transport rollers [A].

Especially for halftone images, there is little toner on the paper, and the toner particles are

not bound to each other. Therefore, half tone images are easier to smear than solid or line

images, resulting in lighter lines appearing.

[B]

[A]

Page 42

Technical Bulletin No.RTB-011

[A]

SUBJECT: Software modification DATE:Dec.15, ’93

PAGE: 4 of 5

6. Modes clear when the key counter is disconnected

When the key counter is disconnected from the copier, normally, the selected modes are

automatically cleared (mode clear function). At the field’s request, we have enabled

holding of the previous mode even after the key counter is disconnected. The default

setting is still the same as before (mode clear function).

When the customer connects the key card to the key counter connector, if this new mode

is selected, the input modes are still held even when the card’s credit is expired.

• How to access this mode

1. Enter SP adjustment mode.

2. Touch the "Prev." key (access page 16 - extra page).

3. Touch the "Set" key [A] of the 4th item.

4. Input "1".

5. Press the enter key of the numeral keys.

00000

00001

Page 43

Technical Bulletin No.RTB-011

SUBJECT: Software modification DATE:Dec.15, ’93

PAGE: 5 of 5

The cut-in serial number is as follows.

Japan production : From December ’93 Production

Code Serial number

A095 - 10 -----------A095 - 15 -----------A095 - 17 -----------A095 - 22

A095 - 26

A095 - 27

A095 - 29

A096 - 10 -----------A096 - 15 -----------A096 - 17 -----------A096 - 22

A096 - 26

A096 - 27

A096 - 29

5233120001 ∼

3D51230001 ∼

A3353120001 ∼

A335312XXXX ∼

52731200 01 ∼

3D61230001 ∼

A3363120001 ∼

A336312XXXX ∼

REI Production : From 1st Production

Code Serial number

A095 - 10

A095 - 15

A095 - 17

A096 - 10

A096 - 15

A096 - 17

5203520001 ∼

2635100001 ∼

A3353520001 ∼

5243520001 ∼

28351000 01 ∼

A3363520001 ∼

Page 44

Technical Bulletin No. RTB-012

SUBJECT: Electrical malfunctions due to improper grounding DATE:Jan. 31, ’93

PAGE: 1 of 6

PREPARED BY: S. Mano

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

If grounding is incomplete (the detailed locations are explained in the following pages),

electrical noise (created by the static charge arching) affects the 5V line. In this case, it is

possible that the following electrical malfunction may occur. Especially under low humidity

conditions, the malfunction occurrence will be higher due to higher static electricity

generation. When assembling the machine during servicing, be sure that the grounding is

complate.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F400/F410

Typical phenomenon

1. Scanner overruns the home position and hits the optic frame.

2. Exposure lamp turns off suddenly and the scanner stops during copying, causing the

copy paper to stop in the fusing unit. On the copy paper, a partially black solid image

will appear because the exposure lamp turns off during the copy process.

3. When the the paper is removed from the fusing unit after above mentioned (item #2)

paper jam occurs, the selected copy modes are cleared.

4. Erase lamp turns on at the wrong timing and wrong position. Therefore, the copy

image becomes partially void.

Page 45

Technical Bulletin No. RTB-012

SUBJECT: Electrical malfunctions due to improper grounding DATE:Jan. 31, ’93

PAGE: 2 of 6

POSSIBLE CAUSES

If the following grounding connection is incomplete, the electrical malfunctions may occur.

1. By-pass size sensor bracket

If the grounding wire [A] is not fixed to the by-pass paper size sensor [B] (variable resistor)

correctly, the paper tends to generate high static charge (especially when using the tracing

paper). The static electricity on the paper may leak to the by-pass size sensor bracket.

[A]

[B]

2. Development unit grounding spring

If the grounding spring [C] at the rear side of the development unit does not properly

contact the grounding plate [D], excessive static charge generated by the developer may

arc from the development unit to the registration guide plate.

From the December 1993 first production machines, the grounding spring inner diameter

has been reduced so that it is properly secured and positioned by the stepped screw.

[D]

[C]

Page 46

Technical Bulletin No. RTB-012

SUBJECT: Electrical malfunctions due to improper grounding DATE:Jan. 31, ’93

PAGE: 3 of 6

3. Development unit grounding spring plate

If the grounding spring plate [A] on the development unit guide rail contacts the

development unit incorrectly, the excessive static charge generated by the developer may

arc to the development unit guide rail.

[A]

4. ID sensor board bracket

If the grounding wire [B] is not fixed to the ID sensor board bracket correctly, when copy

paper with a high static charge touches the ID sensor board bracket, the static electricity

on the paper may arc to the ID sensor board bracket.

[B]

Page 47

Technical Bulletin No. RTB-012

SUBJECT: Electrical malfunctions due to improper grounding DATE:Jan. 31, ’93

PAGE: 4 of 6

5. Pick-off pawl shaft

When copy paper with a high static charge touches the pick-off pawl shaft [A], the static

electricity on the paper arcs to the pick- off pawl shaft.

To prevent this malfunction, the pick-off pawl tension spring [B] is electrically connected to

the ID sensor board bracket. This modification was implemented from the December 1993

first production machines.

[A]

[C]

[B]

Spring replacement procedure

1) Remove the ID sensor bracket [C] (2 screws).

2) Remove the old tension spring (1 E-ring).

3) Install the new tension spring (1 E-ring).

4) Re-install the ID sensor board bracket. Secure the hook [D] at the end of the spring

to the screw fixing the ID sensor board bracket.

[D]

Page 48

Technical Bulletin No. RTB-012

SUBJECT: Electrical malfunctions due to improper grounding DATE:Jan. 31, ’93

PAGE: 5 of 6

6. Main charge corona unit

If the main charge corona is not set correctly, poor electrical contact at the rear terminal

may result in high voltage line leakage. Be sure to secure the fixing screw and secure the

main charge corona unit to the drum stay with a screw.

7. Fusing roller anti-static brush

If the anti-static brush [A] does not touch the edge of the fusing roller, its possible for static

electricity to accumulate on the fusing roller. It may arc to nearby metal parts.

[A]

8. Drum shaft grounding terminal

If the drum shaft grounding terminal [B] is not set (does not contact the drum shaft)

correctly or it has too much wear (this part should be replaced at every 360k copies),

incomplete grounding may occur resulting in electrical malfunction.

[B]

Page 49

Technical Bulletin No. RTB-012

SUBJECT: Electrical malfunctions due to improper grounding DATE:Jan. 31, ’93

PAGE: 6 of 6

9. Cleaning brush roller grounding wire

If the grounding wire is not installed correctly, static charge on the cleaning brush may arc

to nearby metal parts resulting in electrical malfunction.

[A]

Concerning item 2 (Development unit grounding spring) and item 5 (Pick-off pawl shaft),

the countermeasure parts will improve the grounding condition, part number of the

countermeasure parts kit is A0969900.

Page 50

Technical Bulletin No. RTB-013

SUBJECT: SORTER STAPLER (A377) ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 1 of 6

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

It has been reported that several sorter stapler (A377) entrance guides became deformed.

This occurs when the sorter stapler (A377) is taken out of the carton or during

transportation.

Because the entrance guide plate sticks out from the machine, it is held and bend by the

transportor or it is hit during transportation.

To prevent the deformation of the sorter stapler entrance guide plate, the entrance guide

plate [A] is separated from the sorter stapler and attached on the front door.

This is implemented from the first February 1994 production machines.

Whenever transporting the sorter stapler after taking out of the carton box, separate the

guide plate from the sorter stapler. Reset it just before you dock the sorter stapler to the

copier.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F400/F4 10

SORTER STAPLER

(A377)

The installation procedure (accessory) is modified too. Please refer to the following pages.

Step #11 has been adde d. The othe r steps ar e the same as before.

[A]

Page 51

Technical Bulletin No. RTB-013

SUBJECT: SORTER STAPLER (A377) ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 2 of 6

INSTALLATION PROCEDURE

[B]

[A]

[B]

[A]

[B]

[A]

[B]

[A]

[A]

[E]

[C]

CAUTION: Unplug the copier power cord before starting the following

procedure.

[D]

1. Remove the strips of tape [A] and the cushions [B].

2. Open the front door and remove the inner cover [C] (3 screws).

3. Remove a strip of tape [D] securing the gripper unit and remove a

cushion [E]. Then re-install the inner cover [C].

Page 52

Technical Bulletin No. RTB-013

[C]

SUBJECT: SORTER STAPLER (A377) ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 3 of 6

[A]

[A]

[D]

[B]

[E]

4. Remove five plastic caps [A] on the copier’s left cover.

5. Install the front connecting bracket [B] (2 screws - M4 x 12) and the rear connecting

bracket [C] (2 screws - M4 x 12) on the copier.

6. Stick the entrance guide mylar [D] on the copier exit area as shown.

NOTE: Align the edge [E] of the cover and mylar.

Page 53

Technical Bulletin No. RTB-013

SUBJECT: SORTER STAPLER (A377) ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 4 of 6

[C]

[D]

[H]

[A]

[B]

[G]

[E]

[F]

7. Secure the protective earth wire [A]* (1 screw with spring washer) and the wire [B] (1

screw with spring washer).

NOTE*: For all models other than those intended for North America, the green wire is

intended as a functional ground and should be connected as shown.

8. Connect the 4P connector [C] and the fiber optic connector [D].

9. Open the front door of the sorter stapler and remove the screw [E] fixing the locking

lever [F], then lower the locking lever.

10. Stick the cushion [G] on the proof tray.

11. Install the entrance guide plate [H] (2 screws -M4 x 6) which is in the bag on the front

door.

12. Align and press the sorter stapler against the copier and fix them by raising the locking

lever [F].

[H]

Page 54

Technical Bulletin No. RTB-013

SUBJECT: SORTER STAPLER (A377) ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 5 of 6

[B]

[A]

[C]

13. Secure the locking lever [A] (1 screw).

14. Install the proof tray [B].

15. If the gap between the top of the sorter stapler and the copier is too great, adjust by

placing caster stoppers [C].

[C]

Page 55

Technical Bulletin No. RTB-013

SUBJECT: SORTER STAPLER (A377) ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 6 of 6

[A]

16. Remove the green plastic clip [A] from the staple cartridge, and install the cartridge in

the stapler.

NOTE: When installing the staple cartridge, make sure that all the staple sheets [B]

are in the initial position.

[B]

17. Plug in the copier.

18. Turn on the main switch of the copier and test the operation of the sorter stapler.

NOTE: The copier automatically recognizes that the sorter stapler has been installed.

The stapler will not staple for the first 10 or so copies until the first staple

moves to the proper position from the cartridge.

Page 56

Technical Bulletin No. RTB-014

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 1 of 6

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

It has been reported that several sorter stapler (A377) entrance guide become deformed.

(This is introduced in F400/F410 RTB No.13, please refer to it for details)

Since the F400 finisher has the same type of guide plate, the entrance guide plate [A] is

separated from the finisher and kept in the accessory bag.

This is implemented from the first February 1994 production machine.

Whenever transporting the sorter stapler after taking out of the carton box, separate the

guide plate from the finisher. Reset it just before you dock the finisher to the copier.

The installation procedure (accessory) has also been modified. Please refer to the

following pages. Step #13 has been added. The other steps are the same as before.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F410 FINISHER

[A]

Page 57

Technical Bulletin No. RTB-014

[F]

[D]

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 2 of 6

INSTALLATION PROCEDURE

[B]

[A]

[C]

[D]

[A]

[E]

[C]

[G]

CAUTION: Unplug the copier power cord before starting the following

procedure.

1. Remove the strips of tape [A] and the cushion [B].

2. Open the front door and remove the strips of tape [C] and cushions [D].

3. Remove a clamp [E] (1 screw).

4. Slide out the staple unit [F].

5. Remove a strip of tape [G].

Page 58

Technical Bulletin No. RTB-014

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 3 of 6

[C]

[B]

[A]

[D]

[E]

[D]

6. Remove five plastic caps [A] on the copier’s left cover.

7. Install the front connecting bracket [B] (2 screws– M4 x 12) and the rear connecting

bracket [C] (2 screws– M4 x 12) on the copier.

8. Stick the entrance guide mylar [D] on the copier exit area as shown.

NOTE: Align the edge [E] of the cover and the mylar.

Page 59

Technical Bulletin No. RTB-014

[F]

[K]

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 4 of 6

[C]

[I]

[A]

[J]

[G]

[L]

[D]

[B]

[H]

[E]

9. Secure the protective earth wire [A]* (1 screw with spring washer) and the wire [B] (1

screw with spring washer).

NOTE*: For all models other than those intended for North America, the green wire is

intended as a functional earth and should be connected as shown.

10. Connect the 4P connector [C] and the fiber optic connector [D].

11. Open the front door of the finisher and remove the screw [E] fixing the locking lever [F],

then lower the locking lever.

12. Stick the cushions [G] (middle) [H] (short) [I] (long) as shown.

NOTE: Stick the cushion [G] on the metal stay (not on the cover).

Align the upper edge of the cushion [H] with the edge of the stay [J].

Align the lower edge of the cushion [I] with the edge of the stay [K].

13. Install the entrance guide plate [L] (2 screws -M4 x 6).

Page 60

Technical Bulletin No. RTB-014

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 5 of 6

[D]

[E]

[G]

[C]

[B]

[A]

[F]

14. Align and press the finisher against the copier and fix them by raising the locking lever

[A].

NOTE: At this time, confirm that the myler [B] locates between the guides [C].

15. Secure the locking lever [A] (1 screw).

16. Install the shift tray [D] with 4 screws – M4 x 8.

(Remove tape [E].)

17. Adjust the height of the copier by using the leveling feet [F] so that the difference in

level [G] between the copier and the finisher will be 30 ± 1 mm.

Page 61

Technical Bulletin No. RTB-014

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 6 of 6

[B]

[A]

18. Remove the green plastic clip [A] from the staple cartridge, and install the cartridge in

the stapler.

NOTE: When installing the staple cartridge. Make sure that all the staple sheets [B]

are in the initial position.

19. Plug in the copier.

20. Turn on the main switch of the copier and test the operation of the finisher.

NOTE: The copier recognizes automatically that the finisher is installed.

The stapler will not staple for the first 10 or so copies until the first staple

comes to the proper position.

Page 62

Technical Bulletin No. RTB-015

SUBJECT: SHIPPING RETAINERS DATE:Jan. 31, ’93

PAGE: 1 of 1

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

During our survey in the field, we have observed many cases where the customer has

transported the machine after it has been installed in the workplace.

During transportation please be sure to set at least the following shipping retainers (with

red tags) to prevent scanner and drum damage.

Scanner cramp [A]

Transfer belt unit cramp [B]

Revision of service manual

Information only

Other

[A]

FROM: Copier Technical Support Section

MODEL:

F400/F4 10

[B]

Page 63

Technical Bulletin No. RTB-016

SUBJECT: DJF VERTICAL REGISTRATION ADJUSTMENT FOR TWO

SIDED ORIGINAL MODE

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Dual job feeders with the following serial numbers have the possibility that the vertical

registration for two sided original mode is improper due to insufficiant inspection during

production.

Machine Code From To

A376-15 first production 4123110190

A376-17 A3383100001 A338310674

A376-22 5323100001 5323110149

A376-26 3D81030001 3D81130040

A376-27 A3383100921 A3383111103

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F400/F4 10

DUAL JOB FEEDER

A376-10 No machine

DATE:Jan. 31, ’93

PAGE: 1 of 3

If necessary, please adjust the vertical registration (refer to page 46 of DJF service

manual).

If the vertical registration adjustment cannot be carried out using the procedure on page 46

of the DJF service manual (by using SP adjustment mode), return the SP adjustment data

to "00".

Then adjust the vertical registration by turning VR102 on the DJF main board. The VR102

adjustment has a wider adjustable range than SP adjustment mode (adjustable range by

SP adjustment: -7.5 mm ∼ +7.5 mm, 0.5mm/step).

Page 64

Technical Bulletin No. RTB-016

[B]

VR102

SUBJECT: DJF VERTICAL REGISTRATION ADJUSTMENT FOR TWO

SIDED ORIGINAL MODE

Two Sided Original Mode

[A]

10 ± 2

[C]

DATE:Jan. 31, ’93

PAGE: 2 of 3

1. Remove the copier’s left scale [A] (2 screws).

2. Remove the small cover at the rear side on the upper DJF cover then turn on DIP SW

101-2, 101- 4, and 102- 1.

3. Set a sheet of A4 / 8 1/2" x 11" (53 ∼ 80 g/m2 / 14 ∼ 22 lb) paper sideways on the

original table.

4. Push SW 101 [B].

5. After the original stops on the exposure glass, gently raise the DJF (so that the original

does not move).

6. Confirm that the gap between the trailing edge of the paper and the left edge [C] of the

original rear scale is 10 ± 2 mm.

7. If the gap is not within specification, adjust the registration by using the copier SP mode

1

( SP Adjustment - PAGE 6).

NOTE: 1. Before setting the original on the original table again, open and close the

feed unit cover [C].

2. After completing the adjustment, return the DIP switches to their original

condition.

Page 65

Technical Bulletin No. RTB-016

SUBJECT: DJF VERTICAL REGISTRATION ADJUSTMENT FOR TWO

SIDED ORIGINAL MODE

8. If the registration cannot be adjusted even though the SP data is changed to the

maximum value, return the data to "00".

9. Adjust the vertical adjustment by turning VR102 on the DJF main board.

DATE:Jan. 31, ’93

PAGE: 3 of 3

Page 66

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 1 of 13

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

Manual corrections

Please correct your service manual as follows.

Page 1-2 Power consumption

• Incorrect:

Copier only Full system

Stand-by 0.25 kVA 0.25 kVA

• Correct:

Copier only Full system

Stand-by 0.22 kVA 0.24 kVA

FROM: Copier Technical Support Section

MODEL:

F400/F4 10

Page 1-2 Noise emission

• Incorrect:

Copier only Full system

Copying 55 dB (A) 61 dB (A)

• Correct:

Copier only

Copying 55 dB (A) 62 dB(A) 61 dB(A)

Page 2-2 12th line

• Incorrect:

Dirty charge corona wire and grid plate

• Correct:

Dirty charge corona casing and grid plate

RDH/Finisher

system

DJF/ S/S

system

Page 67

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 2 of 13

Page 2-6 Illustration

• Incorrect

VO

V

D

New Drum

Used Drum

• Correct

VO

D

V

New Drum

Used Drum

Drum

Potential

VL

VR

Dark LightOriginal Density

Drum

Potential

VL

Dark LightOriginal Density

Page 2-17 c. Drum Potential Sensor abnormal

• Incorrect

Whenever V100 is over 1.6V or V100 falls under 0.1V or whenever V800 rises over 5.0V

or V800 falls under 2.7V, . . . .

• Correct

Whenever V100 is over 0.7V or V100 falls under 0.1V or whenever V800 rises over 4.2V

or V800 falls under 2.7V, . . . .

Page 2-17 Table

• Incorrect

VR

• Correct

Code Condition

357

Abnormal Vsp/Vsg Detection (Vsp/Vsg ≥ 0.25V)

358 Abnormal Vsp/Vsg Detection (Vsp/Vsg < 0.25V)

Code Condition

357

Abnormal Vsp/Vsg Detection (Vsp/Vsg ≥ 0.25)

358 Abnormal Vsp/Vsg Detection (Vsp/Vsg < 0.025)

Page 68

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 3 of 13

Page 2-20 2nd line in the 2nd paragraph

• Incorrect

wires (1100uA) and bias voltage.......

• Correct

wires (-1100uA) and bias voltage.......

Page 2-55 Fuzzy Control 1

• Incorrect

According to data of the ID sensor and TD sensor, . . . .

• Correct

According to data of the TD sensor, . . . .

Page 2-56 Last 2 lines in "Detect Mode" explanation

• Incorrect

In ID sensor abnormal condition or Drum Potential sensor abnormal condition, the machine automatically enter this mode.

• Correct

In ID sensor abnormal condition, the machine automatically enters this mode.

Page 2-56 Last 2 lines in "Fixed Mode" explanation

• Incorrect

In TD sensor abnormal condition ,the machine automatically enters this mode.

• Correct

In TD sensor abnormal condition or Drum Potential sensor abnormal condition, the machine automatically enters this mode.

Page 69

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 4 of 13

Page 2-57 last line

• Incorrect

on twice continually.

• Correct

on five times continuously.

Page 3-7 Step #12

• Incorrect

12. Remove the drum stay knob [J].

• Correct

12. Remove the drum stay knob [J], then take out the drum stay.

Page 3-11 3rd and 4th lines in NOTE of step #31

• Incorrect

..... then r epeat s teps 29 to 33 again. If the result is the same, see the troubleshooting

sectio "SC352" (Page 6-).

• Correct

.... then repeat steps 27 to 31 again. If the result is the same, see "SC352" the trou-

bleshooting section (Page 6-9).

Page 4-10 Note of item 6

• Incorrect

Refer to 8.9 . . . .

• Correct

Refer to 8.6.2 . . . .

Page 70

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 5 of 13

Page 4-11 Note for item 6 and 7

• Incorrect

6. Refer to page 43 of the DJF manual

7. Refer to page 44 of the DJF manual

• Correct

6. Refer to page 45 of the DJF manual

7. Refer to page 46 of the DJF manual

Page 4-12 SP PAGE7 illustration 3rd item

• Incorrect

Toner Supply Ratio (Detect Mode)

• Correct

Toner Supply Ratio (Fixed Mode)

Page 4-23 Step #1

• Incorrect

1. Register the user code by using user tool No.6.

• Correct

1. Register the user code by using user tool No.8.

Page 71

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 6 of 13

Page 4-24 Item #3 and #4

Item #3 (Stapler Limit) and #4 (Sort/Stack Limit) are not used in this machine and you

cannot access these items in the SP mode. Please delete these explanations from the

manual.

Page 4-25 Table

• Incorrect

Default of Item #2 is Reset.Default of Item #3 is Reset

• Correct

Default of Item #2 is Set.Default of Item #3 is 0000

Also please just delete the Setting for item #3 (Corrected table is as follows).

Item Function Setting Default

Enables automatic access to

û

the border/center erase mode

in platen cover mode.

Enables automatic selection

ù

of a right margin (5 mm, 0.2")

for the duplex back side when

making 2 sided copies from 1

sided originals.

Limits user access to User

ÿ

Tools No. 10 and 11 to only

those who know the access

code.

Procedure:

1. Touch the Key.

2. Input the access code

with the number keys.

3. Touch the enter key

*See the caution below.

0000

á

Set

Reset

Set

Reset

.

Enable

Disable

Enable

Disable

Reset

Set

0000

Page 72

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 7 of 13

Page 4-44 Item 20, 21, 24, 25

• Incorrect

20 Paper Feed Motor - Lo w Speed

21 Paper Feed Motor - High Speed

24 By-pass Feed Motor - Low

25 By-pass Feed Motor - High (First Copy)

• Correct

20 By-pass Feed Motor - Low Speed

21

By-pass Feed Motor - High Speed (First Copy from 1st

feed tray)

24 Paper Feed Motor - Lo w Speed

25

Paper Feed M otor - High Speed (First Copy from 1st

feed tray)

Page 4-45 to 4-46 Item 101 to 113 (Finisher only)

Output

No.

101 Not U sed (Finisher) Transport Drive Motor (Finisher)

102 T ransport Drive Motor (Finisher) Not Used (Finisher)

103 Not U sed (Finisher) Exit Drive Motor (Finisher)

104 E xit Drive Motor (Finisher) Junction Gate Solenoid (Finisher)

105 Junction Gate Solenoid (Finisher) Positioning Roller Solenoid (Finisher)

106 P ositioning Roller Solenoid (Finisher) Jogger Motor (Finisher)

107 Jogger Motor (Finisher) Shift Motor (Finisher)

108 S ift Motor (Finisher) Stack Feed-out Motor (Finisher)

109 S tack Feed-out Motor (Finisher) Shift Tray Lift Motor (Finisher)

110 S hift Tray Lift Motor (Finisher) Not Used (Finisher)

111 Not U sed (Finisher) Staple Drive Motor (Finisher)

112 S taple Drive Motor (Finisher) Staple Motor (Finisher)

113 S taple Motor (Finisher) Not used (Finisher)

Incorrect Correct

Page 73

Technical Bulletin No. RTB-017

[D]

[E]

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 8 of 13

Page 5-10 2nd line of NOTE

• Incorrect

(white: A095 copier/red: A096 copier)

• Correct

(white: A096 copier/red: A095 copier)

Page 5-77 Illustration

In the left lower illustration, the direction of the screwdriver rotation should be

counter-clockwise.

• Incorrect

• Correct

[E]

Page 5-78 step 13 and 14

• Incorrect

13. Remove the tray feed unit.

14. Disconnect the connectors [C].

• Correct

13. Disconnect the connectors [C].

14. Remove the tray feed unit.

Page 6-6 SC145

[C]

[D]

[C]

• Incorrect

SC145-3rd scanner home position sensor abnormal – stay off

• Correct

SC145-3rd scanner home position sensor abnormal – stay on

Page 74

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 9 of 13

Page 6-19 1.15

• Incorrect

1.15 DUAL JOB FEEDER

Definition: [Level:B]

Encoder pulse is not detected by the DJF main board......

Possible causes

DJF feed motor defective

DJF transport motor defective

DJF feed out motor defective

DJF inverter motor defective

• Correct

1.15 DUAL JOB FEEDER/RECIRCULATING DOCUMENT HANDLER

Definition: [Level:B]

Encoder pulse is not detected by the DJF/RDH main board......

Possible causes

DJF/RDH feed motor defective

DJF/RDH transport motor defective

DJF/RDH feed out motor defective

RDH inverter motor defective

Page 11 of DJF Illustration

• Incorrect

In Fig.2, the left paper is expressed by a dotted line and the right paper is expressed by

solid line.

• Correct

In Fig.2, the left paper position is shown

by a solid line and the right paper position

is shown by a dotted line as shown.

Page 75

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 10 of 13

Page 12 of DJF 3rd line of [Figure 3] explanation

• Incorrect

A few pulses (0 ∼ 14 pulses: depends on the SP mode adjustment) ....

• Correct

A few pulses (0 ∼ 14 pulses: depends on the DIP switch adjustment) ....

Page 27 of DJF 3rd line of upper NOTE and Illustration

• Incorrect

..... loosen four truss head screws [D], and tighten.

[D]

• Correct

..... remove the cover [D] (4 screws), and loosen then tighten 4 screws [E].

[D]

[E]

Page 76

Technical Bulletin No. RTB-017

[C]

51/2

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE:11 of 13

Page 43 of DJF Illustration

• Incorrect

• Correct

[D]

[C]

Page 46 of DJF Step 6

• Incorrect

6. Confirm that the gap between the trailing edge of the paper and the left edge [C] of

the original rear scale is 10 ± 2mm.

• Correct

6. Confirm that the gap between the trailing edge of the paper and the right edge of the

original rear scale is 10 ± 2mm.

Page 1 of A377 Sorter Stapler Table (Minimum paper size, Sort mode)

• Incorrect:

A5 51/2" x 81/2" lengthwise

• Correct:

lengthwise: A5 51/2" x 81/2"

Sideways: A5 81/2" x 11"

[E]

[E]

[D]

A5 sideways is long enough for transport

rollers’s distance. It is small difference

but 51/2 inch is not long enough for transport

roller’s distance. Therefore the minimum side

of inch size paper (side ways) is 81/2" x 11".

81/2

A5

Sideways

Page 77

Technical Bulletin No. RTB-017

[A]

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 12 of 13

Page 2 of A377 Sorter Stapler Power Consumption and Weight

• Incorrect

Power Consumption Average less than 80W

Maximum:

in sort/stack mode: less than 100W

in staple mode: less than 300W

Weight: Approximately 52 kg

• Correct

Power Consumption Average less than 55W

Maximum:

in sort/stack mode: less than 55W

in staple mode: less than 42W

Weight: Approximately 47 kg

Page 35 of RDH step #2

Since there is no LED cover, delete the cover [A] from the illustration and correct the

following sentence.

• Incorrect

Close the RDH and remove the LED cover [A] (1 screw).

• Correct

Close the RDH.

Page 1 of Finisher

• Incorrect

Paper size Minimum: 5 1/2" x 8 1/2" / A5 sideways

Weight: 34.2 kg (75.4lb )

• Correct

Paper size Minimum: 5 1/2" x 8 1/2" / A6 lengthwise

Weight: 35 kg (77.2lb)

Page 78

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 13 of 13

Page 2 of Finisher Staple position (2 staple)

• Incorrect

b=5.20" ± 0.12" (13.2 ± 3 mm)

• Correct

b=5.20" ± 0.8" (132 ± 2 mm)

Page 25 of Finisher Step #6

• Incorrect

6. Remove the rear cover [G] (5 screws).

• Correct

6. Remove the rear cover [G] (6 screws).

Page 29 of Finisher Illustration

• Incorrect

Page 29 of Finisher Standard of item #1

[C]

[D]

• Correct

[C]

• Incorrect

Standard: 6mm deflection at 50 ± 20g pressure

• Correct

Standard: 6mm deflection at 180 ± 100g pressure

Page 79

Technical Bulletin No. RTB-018

SUBJECT: PICK-OFF PAWL DATE: Feb.15,’94

PAGE: 1 of 2

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F400/F4 10

1. Manual correction

It is possible for the customer to touch the pick-off pawls and move them out of position

while removing jammed paper around the drum. If this occurs, the pick-off pawls may

touch the transfer belt and damaged it.

To prevent this, the pick-off pawl replacement method has been changed from the first

mass-production machine.

The pick-off pawls cannot be removed by just sliding them to the rear and turning

clockwise as described on page 5-55 of the service manual.

The new procedure is on the next page.

2. Pick-off pawl modification

Toner accumulated on the pick-off pawls sometimes drops to on the copy paper. To

prevent this, the pick-off pawls have been modified (Please refer to Modification Bulletin

No. 7 for cut-in serial number). The head of the pick-off pawl has been changed from

metal to resin. The part number of new part is AD025018.

Since the new pick-off pawl is made of resin, after long usage, the point that touches the

drum becomes worn and the contacting area with the drum is increased. This may cause

drum filming resulting in vertical gray lines on the copy image.

To prevent this, replace the pick-off pawls at every 240K copies.

EM 1 20k 240k 360k NOTE

Pick-off Pawl C C R C

Page 80

Technical Bulletin No. RTB-018

SUBJECT: PICK-OFF PAWL DATE:Feb. 15,’94

PAGE: 2 of 2

PICK-OFF PAWL REPLACEMENT

[E]

[C]

[G]

[D]

[A]

[F]

1. Remove the ID sensor board bracket [A] (2 screws).