Page 1

Technical Bulletin No. RTB-001

SUBJECT: Additional information to TD check DATE: 15 July, ’92

PAGE: 1 of 5

PREPARED BY: I. Kakegawa

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This is additional information to TD check. (Refer to page 5-5 to 5-10)

1. Step 3, data input in SPD106 (Page 5-5)

Whenever TD check is performed, always input the proper humidity data.

If it is not changed although the humidity has changed, the pointer will not able to shift

as required due to the pointer limit data. (Refer to page 2-7, #8)

2. In step 11, you must make a A3/11" x 17" copy using the C4 chart.

This is to confirm that all four colors are developed properly.

[Example] If the charge corona unit for cyan has not been set in position, a cyan solid

image without any white copy margin will be made over the other colors. In

this condition if the following steps are continued, cyan process data will be

abnormal.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

PDC-1E

3. Step 12, TD and TGRD Data Sheet (Page 5-7)

When filling in TGRD column based upon TGRD target data (SPD515 ~ 518), be sure

to write the correct range as shown in page 5-7 of the service manual.

If not, there is a possibility of making a mistake in plotting the data due to

misunderstanding of the range. A typical mistake that we have seen is shown on the

next page. Due to the TGRD column being filled in incorrectly, ∆TD was judged as "0"

(OK). (Correct ∆TD is "--1".) As a result, cyan toner is controlled low, showing "low

cyan image density."

Page 2

Technical Bulletin No. RTB-001

SUBJECT: Additional information to TD check DATE: 15 July, ’92

PAGE: 2 of 5

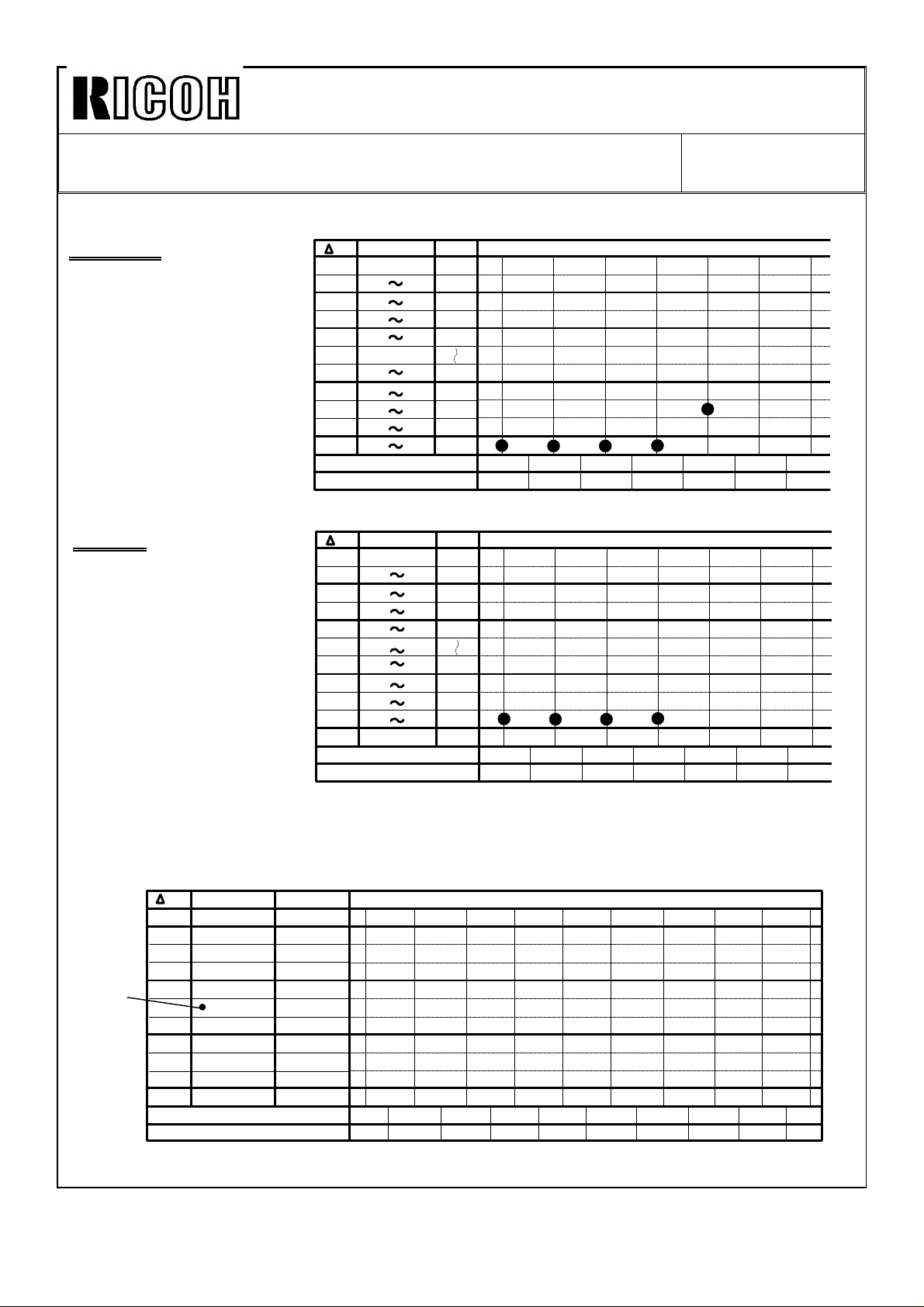

[CYAN]

CORRECT

Since 4th detected TGRD

data is out of OK range,

TD data is changed from 9

to 8. Then, a 5th time.

TD

+1

OK

OK

OK

OK

OK

OK

OK

OK

-1

TD

TGRD

109 118

104 108

101 103

89 100

88

83 87

78 82

73 77

68 72

48 67

(493)

(523)

±α

+30

+20

+15

+12

-5

-10

-15

-20

-40

9

50 61 64 66

2 3 4 5 6 71TGRD

8

73

[CYAN]

WRONG

Due to the TGRD column

being incorrectly filled in,

TGRD data from 1st to 4th

checks are plotted in the

wrong locations, resulting

in no TD change.

TD

+1

OK

OK

OK

OK

OK

OK

OK

OK

-1

TD

TGRD

109 118

104 108

101 103

89 100

84 88

79 83

74 78

69 73

49 68

Upto 48

(493)

(523)

±α

+30

+20

+15

+12

-5

-10

-15

-20

-40

9

50 61 64 66

2 3 4 5 6 71TGRD

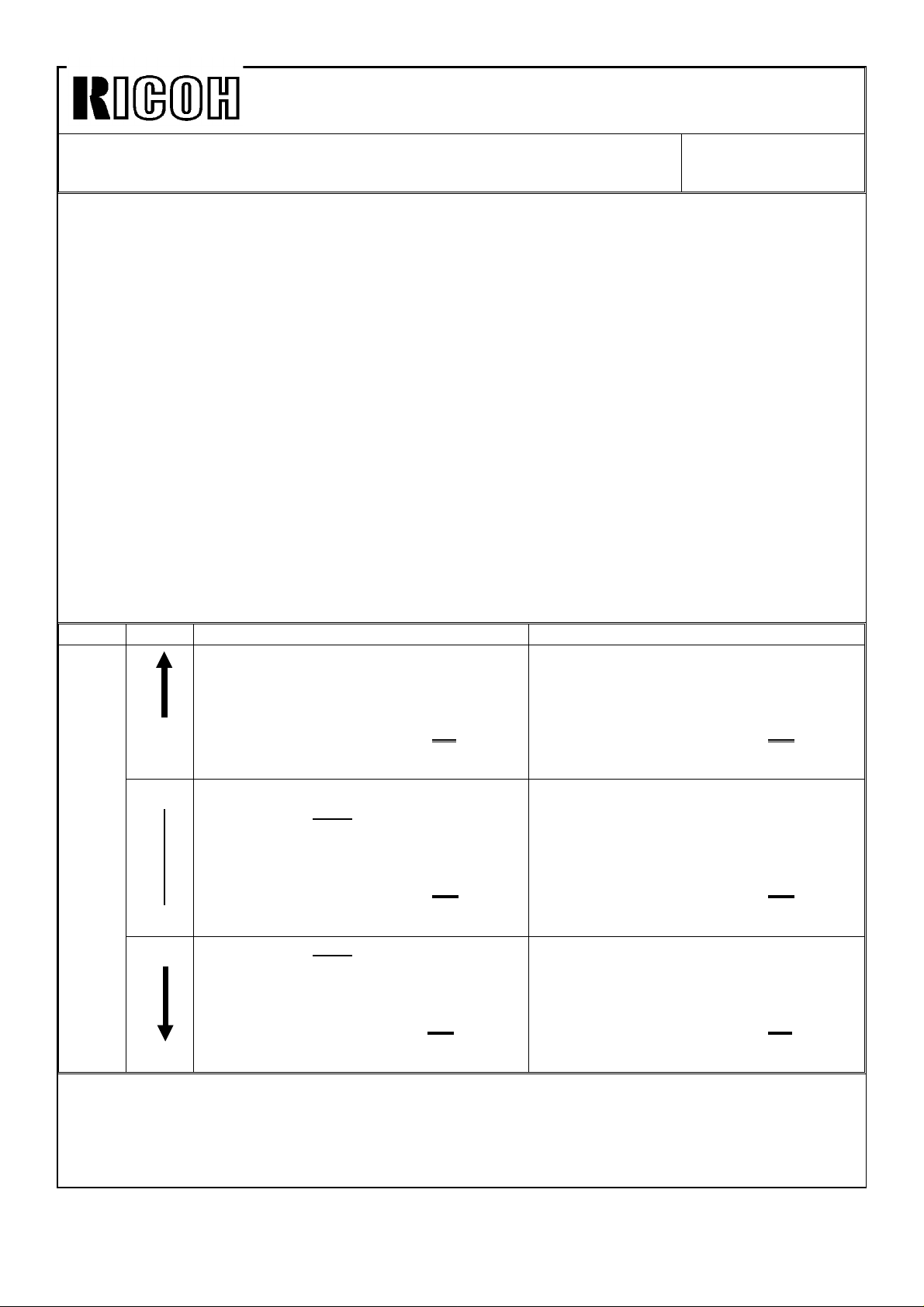

To prevent this mistake, this sheet has been changed as shown below.

This new sheet is attached to the last page of this RTB. Keep it in your service manual.

[Black]

SPD515

data

(TGRD

Target)

TD TGRD Range

+1

OK

OK

OK

OK

OK

OK

OK

OK

OK

-1

TD Data

TGRD Detected Data

± Range

+26 ~ +35

+21 ~ +25

+16 ~ +20

+11 ~ +15

+ 1 ~ +10

±0

-- 5 ~ -- 1

--10 ~ -- 6

--15 ~ --11

--20 ~ --16

--40 ~ --21

(490)

(520)

2 3 4 5 6 7 8 9 101

Page 3

Technical Bulletin No. RTB-001

SUBJECT: Additional information to TD check DATE: 15 July, ’92

PAGE: 3 of 5

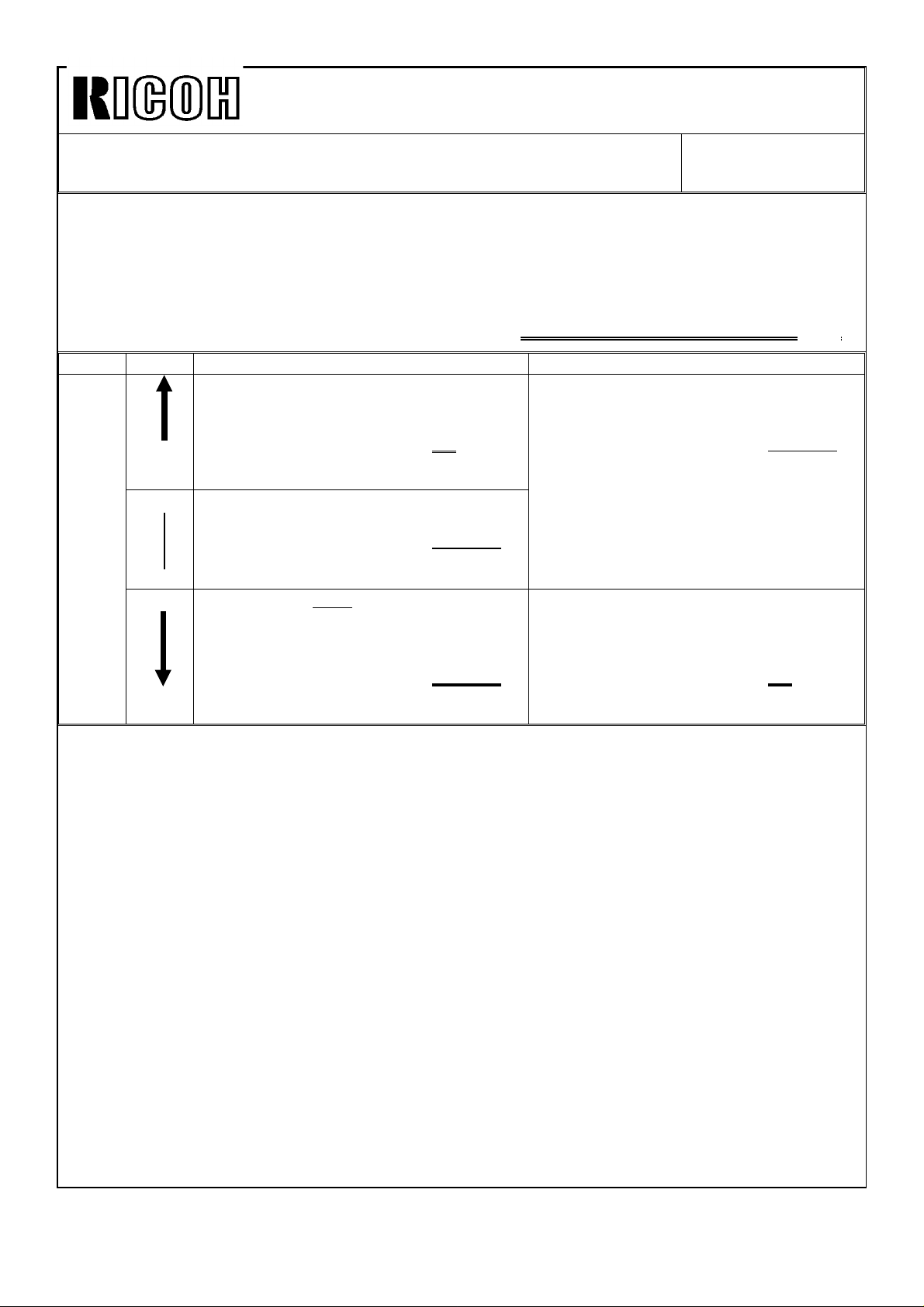

4. Step 21, image density for each color using color patch (SPD 82--H)

1) After getting TGRD detected data into "OK" area (SPD520 ~ 523), set SPD82 to "H"

to print 15 mm color patches using 7th LD power.

2) Make a test copy and check the following two points:

➀. Image density of color patches in BK, M, Y, and C. (See the one on the left side

which is 100% dots filling.)

➁. Toner scattering around those patches.

STANDARD: Compared with the standard color patch sample of the 7th LD power

enclosed in the manual, image density of each color on copy should

be equal to or higher than the standard sample, but there shouldn’t

be any toner scattering around those patches.

3) If a patch is lighter than standard, or if it is too dark with toner scattering, the next

steps should be done only for the abnormal color(s) depending upon the difference

of ±α.

±α=

[Last TGRD detected data (SPD 520 ~ 523)--TGRD target data (SPD 515 ~ 518)]

±α

Color patch is too dark. (ID is too high.) Color patch is too light. (ID is too low.)

1. ∆TD: +1 (Increase TD data by "1", using

SPD490 ~ 493.)

+16

+15

--10

--11 1. Lower TGRD target data

[(SPD520 ~ 523) - - - - (SPD515 ~ 518)]

Last TGRD detected data ---- TGRD target data

2. Repeat steps #13 through #17 two times,

and plot TGRD detected data on a new

check sheet.

1. ∆TD: +1 (SPD490 ~ 493.) 1. ∆TD: --1 (SPD490 ~ 493.)

2. Lower TGRD target data

by -15 for BK and M or

-20 for Y and C.

(SPD515 ~ 518)

3. Repeat steps #13 through #17 four times,

and plot TGRD detected data on a new

check sheet.

by -15 for BK and M or

-20 for Y and C.

(SPD515 ~ 518)

2. Repeat Step #13 through #17 four times,

and plot TGRD detected data on a new

check sheet.

1. Raise TGRD target data

by +15 for BK and M or

+20 for Y and C.

(SPD515 ~ 518)

2. Repeat steps #13 through #17 four times,

and plot TGRD detected data on a new

check sheet.

2. Raise TGRD target data

by +15 for BK and M

+20 for Y and C.

(SPD515 ~ 518)

3. Repeat steps #13 through #17 four times,

and plot TGRD detected data on a new

check sheet.

1. ∆TD: --1 (SPD490 ~ 493.)

2. Repeat steps #13 through #17 two times,

and plot TGRD detected data on a check

new sheet.

NOTE1: The TD setting can be between 0 and 30. If there are no more steps to shift,

change the ND setting by same value. (SPD495 ~ 498)

NOTE2: When TGRD target data is changed, the free run/self-check must be done

four times. (A new check sheet is required.)

Page 4

Technical Bulletin No. RTB-001

SUBJECT: Additional information to TD check DATE: 15 July, ’92

PAGE: 4 of 5

4) After repeating Step #13 through #17 two times (only when TD data is changed), or four

times (when TGRD target data is changed.), check the color patches (7th LD power) again.

If it is too light or too dark, the next steps should be done only for the abnormal color(s)

depending upon the difference of

[Last TGRD detected data (SPD520 ~ 523) -- TGRD new target data (SPD515 ~ 518)]

Color patch is too dark. (ID is too high.) Color patch is too light. (ID is too low.)

1. ∆TD: +1 (Increase TD data by "1", using

SPD490 ~ 493.)

2. Repeat steps #13 through #17 two times,

+16

+15

--10

--11 1. Lower TGRD target data

(SPD520 ~ 523) - - - - (SPD515 ~ 518)

Last TGRD detected data ---- TGRD target data

and plot TGRD detected data on a check

sheet.

1. Lower TGRD target data by --10.

(SPD515 ~ 518)

2. Repeat steps #13 through #17 four times,

and plot TGRD detected data on a check

sheet.

by -15 for BK and M,

-20 for Y and C from the present data.

(SPD515 ~ 518)

2. Repeat steps #13 through #17 four times,

and plot TGRD detected data on a new

check sheet.

1. Raise TGRD target data

by +10.

(SPD515 ~ 518)

2. Repeat steps #13 through #17 four times,

and plot TGRD detected data on a check

sheet.

1. ∆TD: --1 (SPD490 ~ 493.)

2. Repeat steps #13 through #17 two times,

and plot TGRD detected data on a check

sheet.

Page 5

Technical Bulletin No. RTB-002

SUBJECT: Exposure lamp position DATE: 15 July, ’92

PAGE: 1 of 1

PREPARED BY: I. Kakegawa

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This is additional troubleshooting information for the exposure lamp experienced in Europe.

1. Additional information to the service manual, page 5-28, #2

2. Set both lamp-heater assemblies in the scanner so that:

•

open parts face the center, and

•

two pins on the rear lamp terminal are fully inserted into the rear

New

lamp receptacle.

(There should be no gap between the rear receptacle and the

rear end of the lamp.)

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

PDC-1E

2. Troubleshooting

If the two pins on the rear lamp terminal are not fully inserted, the rear lamp terminal

connection may be poor. Then, the inner surface of the lamp tube turns black on the

rear side due to abnormal heat generation, resulting in low illumination on this area. In

this case, the following will be observed:

1) The exposure lamp is turned on and off during scanning, because the lamp is just

going to be open circuit.

2) Color tone on the rear side of the copy image is not the same as at other areas

because of the dark lamp area. Under this condition, replace the exposure lamps.

Page 6

Technical Bulletin No. RTB-003

SUBJECT: Key counter mode copy DATE: 15 July, ’92

PAGE: 1 of 1

PREPARED BY: I. Kakegawa

FROM: Copier Technical Support Section

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL:

PDC-1E

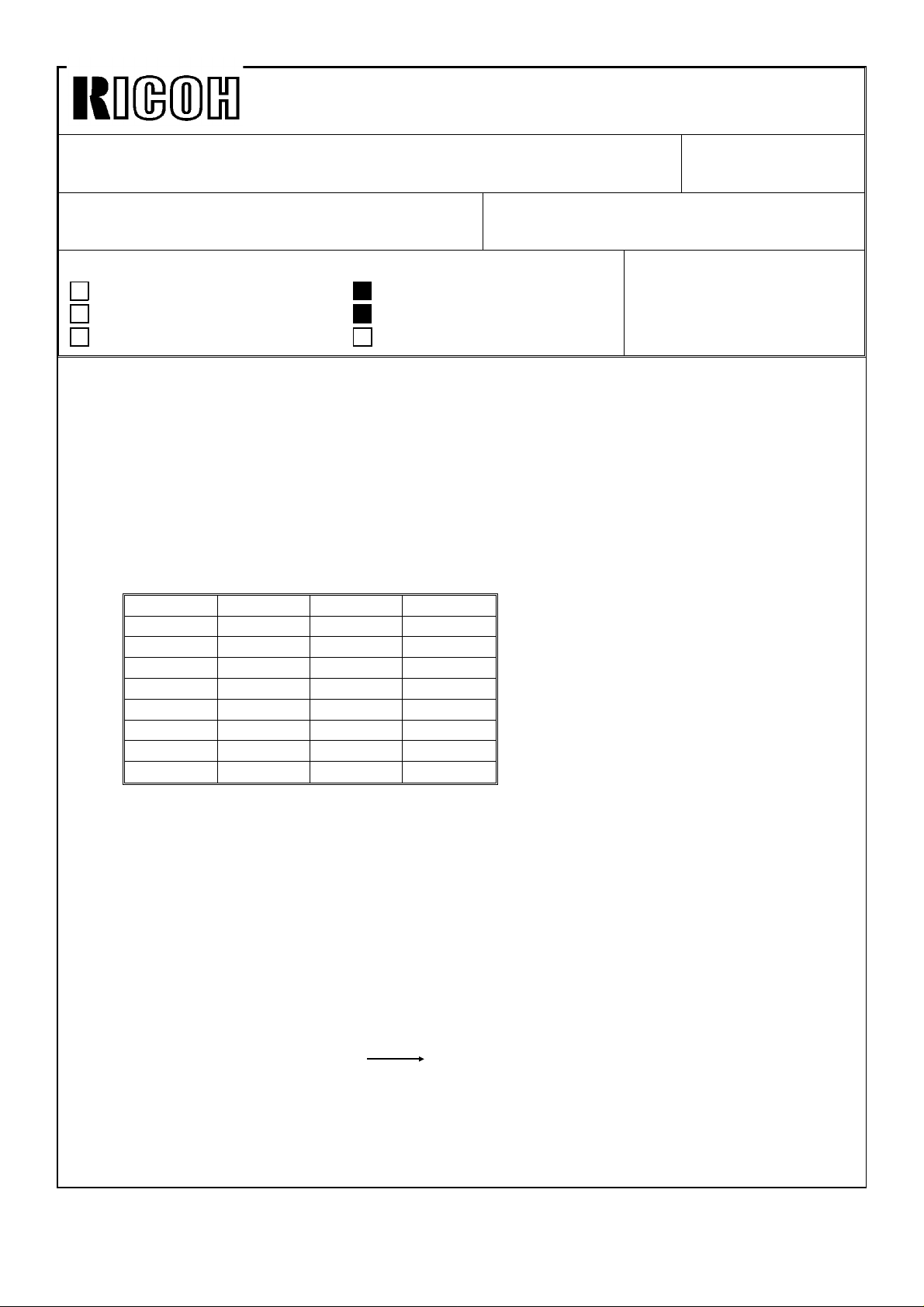

To enable copy operation with the key counter, do the following:

1. Install the key counter receptacle.

2. Turn off SW100 on the sequence control board (rear side) to select key counter mode.

3. Then, depending upon the customer’s request for key counter management, input the

appropriate data (from 0 to 7) in SPD12. (See page 4-24)

This is to decide in which color modes the key counter is incremented.

Data Full Color Single Color Black

0 0 0 x x x

0 0 1 o x x

0 0 2 x o x

0 0 3 o o x

0 0 4 x x o

0 0 5 o x o

0 0 6 x o o

0 0 7 o o o

o: Count up

x: No count up

[Example] SPD12-001: The key counter shows the number of full color copies made.

SPD12-007: The key counter shows the total number of copies made in

all three color modes.

NOTE: When key counter mode is selected by turning off SW100 on the sequence

control board, the key counter should be set for any copy operation

regardless of SPD12 data.

[Manual correction on page 4-24, SPD12]

o: Key counter required o: Count up

x: No key counter required x: No count up

Default: 0 0 7 Default: 0 0 0

Page 7

Technical Bulletin No. RTB-004

SUBJECT: Forced self check operation with new ROMs DATE: 15 July, ’92

PAGE: 1 of 3

PREPARED BY: I. Kakegawa

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

1. SPD-22, Forced self check operation

In order to perform the self check operation at a certain copy interval, the following two

ROMs has been changed to "C" version.

P/N A0925507B C (ROM on the sequence control board)

P/N A0925509B C (ROM on the process board)

This modification will be applied from July,’92 production onward. By replacing old ROMs

with these two new ROMs as a set, SPD-22 can be accessed.

SPD-22: Forced self check operation at a certain copy interval

0: No self check operation (Default)

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

PDC-1E

1: Yes, at every 200 copies

2: Yes, at every 400 copies

3: Yes, at every 600 copies

4: Yes, at every 800 copies

5: Yes, at every 1,000 copies

The default setting of SPD-22 is "0". If a data from 1 to 5 is selected, self check operation

automatically starts just after the last copy of that copy job is fed out when the total copies

made since the last self check becomes more than the set copy number.

The self check at around noon, set by SPD-21, is performed independently, regardless of

the number of copies made since the last check.

Page 8

Technical Bulletin No. RTB-004

SUBJECT: Forced self check operation with new ROMs DATE: 15 July, ’92

PAGE: 2 of 3

By both morning and noon self checks, the copy counter for the next self check is reset to

"0". However, it is not reset by just turning off and on the main switch.

[EXAMPLE] Conditions 1. SPD20-L: Noon self check on.

2. SPD21-120: 90 + 120 = 210 minutes, Noon check is

done 3.5 hours after the main switch is turned on.

3. SPD22-2: Self check at every 400 copies.

4. In the morning, 210 copies are made.

5. In the afternoon, 560 copies are made.

Turn on/Self check Self check Self check

9:00 12:30

1 job: 70 copies

Counter

Reset to 0

210 copies

381

0 0

(Start)

450 (Finish)

400

Turn off

110 copies

2. Purpose

Under the following conditions, there is a possibility of a toner concentration problem,

especially for magenta color.

1) Since the last self check, 800 to 1000 copies or more have been made.

2) The number of copies from one original (C/O), is rather high.

3) Low humidity.

If these conditions are met, magenta toner concentration becomes high. Then, by VSG

detection, greater pointer data and ND data will be selected, lowering toner

concentration. Due to long copy runs without self check, toner control target (VTC) can

not be revised by TGRD detected data (ND and CD data). Then, low image density for

high tone areas may happen due to too low toner concentration. Due to high C/O, DIF

detection is not performed for long copy runs, resulting in no pointer shift even if

humidity condition have been changing. Because of this, toner concentration becomes

too high or too low against the latest humidity condition.

To avoid the toner concentration problem, perform the following action.

Page 9

Technical Bulletin No. RTB-004

SUBJECT: Forced self check operation with new ROMs DATE: 15 July, ’92

PAGE: 3 of 3

3. Action Taken

1) For machines from the July,’92 production with "C" version ROMs on both the

sequence control board (P/N A0925507C) and the process control board (P/N

A0925509C)

Set data "2" (400 copies) or "3" (600 copies) of SPD-22.

Then, explain the self check operation at set copy intervals to customers, and ask them to wait for one or two

minutes.

2) For machines upto the June,’92 with upto "B" version ROMs.

a) Manual self check

Set SPD30-H to perform a self check

whenever the main switch is turned on. Ask

the customer to turn off and on the main

switch at every 400 to 600 copies or at any

time the image density becomes too low or too

high.

b) Automatic self check by new ROMs

If it is difficult for the customer to turn off and on

the switch regularly, install the new ROMs as a

set, and set SPD22 to 2 or 3.

NOTE: These two ROMs are 512 K.

Page 10

Technical Bulletin No. RTB-005

SUBJECT: Important parts to be cleared regularly DATE: 15 July, ’92

PAGE: 1 of 1

PREPARED BY: I. Kakegawa

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

As explained in the PM table in the service manual (page 4-1 ~ 4-3), there are parts to be

cleaned at every EM. Among these parts, the most important parts are as follows;

1. Grid plate

If the grid plate becomes dirty, the copy image is not even, especially for low to middle

solid areas on originals. Then, vertical dark stripes are copied on such a solid area.

This is caused by a dirty grid plate. To prevent this, clean the grid plates at every EM visit.

Put them in water, wash them, and dry them.

NOTE: Do not fold them while washing.

Be sure that there is no fiber dust remaining on them.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

PDC-1E

2. Optical fiber array

If you have the impression that the copy image is less sharp or less crisp than at

installation, try to clean the optical fiber array with a soft cloth. (Black stains will be

removed.)

Clean the array at every EM with a soft cloth, and then discharge it by wiping with your

clean finger.

Page 11

Technical Bulletin No. RTB-006

SUBJECT: VLL/VLH pattern on the reverse side of copy DATE: 15 July,’92

PAGE: 1 of 1

PREPARED BY: I. Kakegawa

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

If VLL/VLH line pattern (10 mm x 10 mm, see page 2-17 of manual) is visible on the reverse

side of copy paper, set SPD-11-H.

These line patterns used for DIF detection are developed just after the last copy of that

copy job has been made. Then, they are checked by the ID sensor, and are transferred

on the transport belt. Normally, the belt stops turning just before the patterns on the belt

are cleaned. At the next copy job, they are cleaned.

However, if the machine is used less frequently due to low copy number, or is used under

high temperature conditions, these pattern made at last copy job may not be cleaned

completely. Then, they are put on the reverse side of the next copy paper.

SPD11 is to control belt cleaning time at the end of copy job.

If SPD11 data is changed to "H", the belt turns 2 seconds longer than usual to clean the

pattern before the belt stops.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

PDC-1E

NOTE: For the machines with low copy volume used under high temperature conditions,

set SP11 to "H". In this case, it takes 2 seconds longer for the machine to be

back to "Ready" condition.

Page 12

Technical Bulletin No. RTB-007

SUBJECT: Parameter setting for AC Power Pack (Discharge) DATE: July 15,1992

PAGE: 1 of 1

PREPARED BY: T. Okajima

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

1. Summary

The service manual describes that the data of SPD430 is "800" and SPD431 is "300"

(SPD430: Transfer belt discharge voltage, SPD431: Separation corona voltage).

However, these SPD’s were adjusted at the factory to other parameters for stabilizing

the output voltage of the power packs. So, to fix the parameter of these SPD, the power

packs have been modified.

AC Power Pack - Discharge : AZ310013 → AZ310013A → AZ310014

Two AC Discharge Power Packs are used in one machine. These parts are identical,

one is used for the transfer belt discharge, and the other is used for the separation

corona. When you replace the power pack with a new one, or when the parameter of

SPD430 or SPD431 is erased for some reason and some problems occur, refer to the

following section:

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: PDC-1E

2. Details

1) Possible problem

If the following parameter is bigger than the specified one;

SPD430 (Transfer belt discharge) - no problem but waste of power,

SPD431 (Separation corona voltage) - void image, toner scattering on the copy,

If the following parameter is lower than the specified one;

SPD430 - remained image, poor transfer of Bk image,

SPD431 - poor paper separation,

2) Parameter setting

If the problem above occurs, check the parameters of SPD430 and SPD431 refering to

the table.

According to our records, P/N AZ310013 and P/N AZ310013A do not exist as service

parts. When you replace the power pack with a new one (P/N AZ310014), set the

parameter for SPD430 at 780, and the parameter for SPD431 at 280 for any machine.

Note: If you have a P/N AZ310013(A), please inform us. We will send you the P/N

AZ310014 instead.

Serial number AC Power Pack A092 - 22 092 - 27 Discharge SPD 430 SPD 431

First production

~

No production A3012030001 ~ P/N AZ310013A 570 135

4302040001 ~ A3012030011 ~ P/N AZ310013A 570 050

4362040006 ~ A3012050001 ~ P/N AZ310014 780 280

First production ~ P/N AZ310013 800 300

Page 13

Technical Bulletin No. RTB-008

SUBJECT: Discolored spots on color background DATE:Sep. 15, ’92

PAGE:1 of 2

PREPARED BY: T. Okajima

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

To prevent discolored spots due to the carrier, install the following two ROM’s as a set:

• One new ROM on the sequence control board (512K): P/N A0925507D (Check sum:

E1E8)

• One new ROM on the process control board (256K): P/N A0925509C (Check sum:

DF8F)

Revision of service manual

Information only

Other

[Symptom]

• After the self check operation both in the morning and

around noon, discolored spots are obsorbed at the

leading and the trailing parts of the copy image for

about initial ten copies. After making ten copies, these

spots will gradually disappear.

FROM: Copier Technical Support Section

MODEL: PDC-1E

• When you touch these spots on the copy with your

fingers, you can feel the carrier. Due to carrier

particles, toner around the carrier particle can not be

transferred from the OPC drum to the copy paper,

resulting in discolored spots.

±5 mm

carrier

±10 mm

[Cause]

Due to a software error of the sequence control ROM, the "OFF" timing of development

bias was a little early compared to that of drum charge during the self check run. This

causes carrier to drop from the development unit onto the mylar of the cleaning unit.

Since this mylar moves up and down while paper is passing through the image transfer

section, the carrier on the mylar will drop on the initial ten copies from the mylar.

This symptom will be worse when the pointer data (SPD110~113) is over 20. Because the

drum charge becomes so high that a greater amount of carrier will be dropped.

Page 14

Technical Bulletin No. RTB-008

SUBJECT: Discolored spots on color background DATE:Sep. 15, ’92

PAGE:2 of 2

[Action taken]

1. Clean the carrier dropped from the development units onto:

• The bracket located just under the black development unit.

• The mylar on the black, magenta, and yellow cleaning units.

• The black plastic parts located just under the rear half of each development unit.

2. Clean each cleaning unit.

3. Replace two ROM’s with the following new ones on both the sequence control board

and the process control board.

1) One new sequence control ROM (512K): P/N A0925507D (Check sum: E1E8)

2) One new process control ROM (256K): P/N A0925509C (Check sum: DF8F)

• For the July ’92 production and some of the June ’92 production, A0925509C has been

installed at the factory. (see below.) For these machines, install only A0925507D.

• Using the above ROM’s, SPD22 (forced self check operation at a certain copy interval)

can be operational as explained in RTB-004.

• P/N A0925509C was explained as 512K by mistake in RTB-004.

It was 256K.

[Cut-in serial number]

The above action is required for all machines up to the July ’92 production.

ROM’s Purpose

A0925507C

and

A0925509C

A0925507D

and

A0925509C

To enable SPD22

(explained by

RTB-004).

To prevent

discolored spots

(explained by this

RTB).

Ricoh

A092-17

No production.

From the first

production in

August ’92.

Gestetner

A092-22

Two June ’92

production

[#4302060001]

[#4302060002]

All July

production

[#4302070001~]

onward.

From August ’92

production.

Ricoh

A092-27

Four June

production

machines.

[#A3012060001

[#A3012060008

[#A3012060011

[#A3012060012

All July

production

[#A3012060001~]

onward.

From August ’92

production.

Page 15

Page 16

Technical Bulletin No. RTB-000

SUBJECT: DATE:

PAGE:

Page 17

Technical Bulletin No. RTB-010

SUBJECT: Blurred copy problem on editor board DATE: Dec.31,’93

PAGE: 1 of 3

PREPARED BY: T. Okajima

CHECKED BY:

CLASSIFICATION:

Action Required

Trouble shooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: Technical Support Group

MODEL:

PDC-1E (Editor Board)

1. Problem

When making copies with th e PDC-1E using the editor board, blurred images might appear

on copies.

2. Cause

This problem occurs due to the deformed pressure pads (mirror surface). The d eformed

pad cannot press an original completely and there is a gap betwee n the original and the

exposure glass. The focal depth of the scanner is only 0.25mm. If t his gap is 0.25mm or

wider, an image in that part will be blurred.

The present pressure pad is made of polypropylen, which starts to deform from about

79°C (174.2°F) or higher. We suppose th at the editor board suffers temperatures of 79°C

or higher during transportation.

The pressure pad of the platen cover for the PDC-1E is the same as that of th e editor

board. However, the pressure pad of the platen cover does not have the deformation

problem because during transportation, the pressure pad is on the exposure glass which is

flat. Even under high temperature (higher than 79°C) it will not be deformed by the

exposure glass.

3. Countermeasure

3-1. Material

We have changed the material of the pressure pad from polypropylen to p olycarbonate

which does not deform at temperatures under 130°C (266°F).

3-2. Part number for the new pre ssure pad

Old Part Number New Part Number Description

A0491576 A0921594

This part number will be available as a

service part in February 1994.

Original Pressure Pad

Page 18

Technical Bulletin No. RTB-010

SUBJECT: Blurred Copy Problem on Editor Board DATE: Dec.31,’93

PAGE: 2 of 3

3-3. Modification procedure for the field machine

[A]

[B]

W

W

W

W: 1 mm (0.04 inch)

1. Remove the pressure pad [A] from the editor b oard.

NOTE: As some adhesive tape or sponge might remain on the editor board, make sure

to check and remove everything.

2. Put the new pressure pad [B] as shown in the illustration.

Make a 1mm (0.04 inch) space between the front scale an d the front edge of the

pressure pad, and between the right scale and the right side of the pressure pad.

3. Peel off the cover from the two adhesive tapes, close the editor board and press the

editor board by hand. Especially, press the part directly above the tapes.

4. Confirm that there is no blurred image on the copy.

Page 19

Technical Bulletin No. RTB-010

SUBJECT: Blurred Copy Problem on Editor Board DATE: Dec.31,’93

PAGE: 3 of 3

3-4. Cut-in Serial Number

Machine Code Cut-in Serial Number

A988-17 From Oct. 1993 production run (#A3223100001–)

and #A3223080001, 06, 19, 20, #A3223090001, 03

A988-25 From Oct. 19 93 produc tion run (# 429310 0001–)

A988-27 From Oct. 1993 production run (#A3223100001–)

and #A3223070047, 50, 51, 52

4. Others

We do not recommend that you modify the editor board when it is not on the copier, it is

very difficult to adjust the position for setting the pressure pad. You might have matching

problems when the editor b oard is docked to the copier (e.g.. the pressure pad falls on the

scale or the space between the edge of the pressure pad and the scale is much larger).

Page 20

Technical Bulletin No. RTB-011

SUBJECT: 1st and 2nd synchronizing mirrors installation procedure DATE: Aug. 31, ’94

PAGE: 1 of 3

PREPARED BY: S. Orita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

During transportation, one or more of the 1st and 2nd synchronizing mirrors for black,

magenta, yellow, and cyan sometimes dislodges from the laser unit frame due to

insufficient adhesive.

As a result, the following service codes are displayed:

For black ……… SC640 and SC710

For magent a ……… SC640 and SC711

For yellow ……… SC640 and SC712

For cyan ……… SC640 and SC713

Previously, this could be corrected only by replacing the laser unit assembly, which is quite

expensive.

To reduce the service cost a nd meet the field requests, the 1st and 2nd synchronizing

mirrors have been registered as service parts as follows:

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

PDC-1E

1st synchronizing mirror (for black, magenta, cyan and yellow) ……P/N A0492128

2nd synchronizing mirror (for black, magenta, cyan and yellow)……P/N A0492130

The installation proced ure for the 1st and 2nd synchronizing mirrors are as follows:

[C]

1. Remove the laser unit from the copier

(See the service manual pages 5-39 and

5-40.)

2. Place the laser unit [A] on a flat table.

3. Remove the fiber optics cables [B] from the

clamps.

4. Remove the upper cover [C] with LD control

board [D] of the laser unit.

(6 screws and 5 connectors)

[B]

[D]

[A]

Page 21

Technical Bulletin No. RTB-011

2nd magenta mirror

1st yellow

mirror

1st

cyan

mirror

[E]

SUBJECT: 1st and 2nd synchronizing mirrors installation procedure DATE: Aug. 31, ’94

PAGE: 2 of 3

5. Reverse the laser unit and carefully place it on

the table.

6. Remove the bottom cover [E] of the laser unit

(6 screws).

[F]

7. Confirm the location of each synchronizing mirror

and confirm which mirror should be removed.

8. Remove the fiber cable bracket [F]

corresponding to the position of the

mirror to be removed. (3 screws)

Bottom

1st black mirror

1st magenta

Upper

2nd cyan mirror

2nd

black

2nd yellow

mirror

Page 22

Technical Bulletin No. RTB-011

SUBJECT: 1st and 2nd synchronizing mirrors installation procedure DATE: Aug. 31, ’94

PAGE: 3 of 3

- 1st synchronizing mirror [G] -

9. Remove the 1st synchronizing

mirror. (1 screw)

10. Reassemble the machine.

- 2nd synchronizing mirror [H] -

9. Before removing the 2nd

synchronizing mirror, mark the

groove position [I] of the adjusting

cam [J].

10. Remove the 2nd synchronizing mirror.

(1 short screw [K], 2 washers [L],

1 long screw [M], and adjusting cam [J] )

11. When installing the 2nd synchronizing

mirror, at first, fix the mirror by th e short

screw and washers while holding the

mirror. Then, install the long screw and

adjusting cam.

Note: Make sure that the groove [I] of the adjusting cam matches the mark made in

step 9, and the dot [N] on the cam is on the opposite side from the short screw

hole [O].

[L]

[K]

[M]

[O]

[J]

[I]

[G]

[H]

[N]

12. Reassemble the machine.

13. Check the copy quality. If an SC code is displayed or a synchronizing problem occurs,

adjust the mirror position by turning the adjusting cam [J].

Page 23

Technical Bulletin No. RTB-012

SUBJECT: Hot Roller and Pressure Roller Chan ges DATE: Nov. 15, ’94

PAGE: 1 of 10

PREPARED BY: S. Orita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

To increase the expected life time of the hot roller, we have had a new hot roller and pressure

roller installed since the first product ion of the PDC-1 0E.

The PDC-1E is no longer produced, so, the se new hot roller an d pre ssure roller are available

as service parts.

Detailed information for these changes is as follo ws:

Old P/N New P/N Description Modified Point

AE010005 AE010008 Hot Roller The hardness of the rubb er ha s bee n

AE020018 AE020043 Pressure Roller The hardness of the rubber has been

Revision of service manual

Information only

Other

FROM: 2nd Technical S upport Section

MODEL:

PDC-1E

decreased.

The diameter has bee n changed from

44.7 mm to 44.5 mm.

increased.

When replacing the hot roller and/or pressure rolle r, th e followin g pro ced ure is required.

NOTE: We recommend replacing the hot roller and pressure roller at the same time in orde r t o

increase the expect ed life time of the hot roller.

Page 24

Technical Bulletin No. RTB-012

SUBJECT: Hot Roller and Pressure Roller Chan ges DATE: Nov. 15, ’94

PAGE: 2 of 10

Fusing Unit Adjustment Flow Chart

When replacing the

hot roller or pressure

roller separately.

When replacing the

hot roller and

pressure roller at the

same time.

Start from "Procedure 1"

Procedure 1

Fusing Pressure Adjustment Using Nip

Band Width

Procedure 2

Fusing Pressure Fine Adjustment by

Forcing "Mimizu" on Copy Image

Start from "Procedure 3"

Procedure 3

Fusing Unit Positioning Ad just men t by

Forcing "Mimizu" on Copy Image

Could you

finish "Procedure 3"

completely?

Procedure 4

Main Motor Speed Adjustmen t

Yes

No

Go back to

"Procedure

2"

Page 25

Technical Bulletin No. RTB-012

SUBJECT: Hot Roller and Pressure Roller Chan ges DATE: Nov. 15, ’94

PAGE: 3 of 10

1. Procedure 1

Fusing Pressure Adjustment Using Nip Band Width

Adjustment Standard:

• 7.6 ± 0.4 mm (center of nip band width; L)

• Less than 0.2 mm (d ifference between a and b)

a

L

[B]

[A]

b

1. Prepare Folex OHP she et Typ e 100.

2. Place a white paper (A3/11" x 17") on the exp osure grass and perform free run (SP1) for

3 minutes.

3. As soon as the print key be come s green, pull out the transfer belt unit and open the

fusing exit cover.

4. Insert an OHP shee t into the center of the fusing unit by turning the fusing knob manually

and wait 15 seconds to make the nip ba nd on th e OHP sheet.

5. Turn the fusing rolle r 90 degrees and then wait for 15 seconds. Repeat this step two

more times and exit the OHP sheet. You sho uld now have fo ur nip ban ds on the OHP

sheet.

6. Measure the width L, a, and b. Ave rag e ea ch pa rame ter and confirm that they are within

specification. If th ey are not , go to ste p 7. If OK, this adju stme nt is finished.

7. Remove the slotted-screws [A] (at both side) an d adjust the fusing pressure by turn ing

nuts [B].

• Turning the nut clockwise to reduce the fusin g pre ssure

• Turning the nut counterclockwise to increase the fusing pressure

Page 26

Technical Bulletin No. RTB-012

Fig. 1

–0.4

–0.6

–0.8

–1.0

SUBJECT: Hot Roller and Pressure Roller Chan ges DATE: Nov. 15, ’94

PAGE: 4 of 10

2. Procedure 2

Fusing Pressure Fine Adjustment by Forcing "Mimizu " on Copy Ima ge

1. Loosen the screws [A]

2. Turn the adjustment cam [B] which po int s to th e scale (±0) on the bracket [C] as shown

in figure 1.

±0

[B]

–0.2

[A]

(–)

±0

[A]

(+)

+0.6

+0.8

+1.0

[C]

+0.4

+0.2

±0

3. Force "Mimizu" on the copy image as follows:

• Set SPD#51 to 003 (1 horizontal line for every main sca ns)

• Set SPD#52 to 003 (Full length pattern of paper)

• Set SPD#720 to 007 (Main motor speed fine adju stment)

• Set 11" x 17"/A3 size paper in the cassette and make 5 copie s co nt inuously.

NOTE: If "Mimizu" pattern does not appear on the copy image, increase the main motor speed

by setting SPD#720 to 008 or higher.

When making copies, use the same pape r as the custom er uses .

Page 27

Technical Bulletin No. RTB-012

SUBJECT: Hot Roller and Pressure Roller Chan ges DATE: Nov. 15, ’94

PAGE: 5 of 10

Paper Feeding

Mimizu

Rear

Fusing

Unit

Go to "Case 1" in step 4

Front

Go to "Case 2" in step 4

Go to "Case 3 " in step 4

[C]

Figure 2

[B]

[A]

Figure 3

4. Confirm the locatio n an d size of the "Mimizu" patterns on the copy imag e. Then do the

appropriate procedu re (Case 1, Case 2, or Case 3). See Figu re 2.

Case 1 The "Mimizu" pattern toward the front of th e fu sing unit is almost same size as that

toward the rear of the fusing unit.

• Go to "Procedure 3"

Case 2 The "Mimizu" pattern toward the front of th e fu sing unit is bigger than th at toward

the rear.

1) Remove the slotted - screw [A] an d th e nu t [B] at the front of the fusing unit.

2) Turn the nut [C] at the front of the fusing unit 90 degrees clockwise.

3) Make 5 copies continuously.

Page 28

Technical Bulletin No. RTB-012

SUBJECT: Hot Roller and Pressure Roller Chan ges DATE: Nov. 15, ’94

PAGE: 6 of 10

4) Confirm the location and size of the "Mimizu" pattern s. Is th e "Mimizu" patt ern

toward the front the same size as that toward the rear?

• Yes: Go to procedure 3.

• If not, do the appropriate procedure as follows until the "Mimizu" pattern toward

the front is the same size as tha t toward the rear:

• No, the "Mimizu" pattern towards the front of the fusin g unit is b igg er th an that

toward the rear:

Turn "the nut [C] at the front of the fusing unit"

45 degrees ∼ 90 degrees clockwise.

• No, the "Mimizu" pattern towards the front of the fusing un it is smaller than that

toward the rear:

Turn "the nut [C] at the front of the fusing unit"

45 degrees ∼ 90 degrees counterclockwise.

• Go to procedure 3.

Case 3 The "Mimizu" pattern towards the rear of the fusing unit is bigger than that of the

front.

1) Remove the slotted screw [A] and the nut [B] at the rear of the fusing unit. See

Figure 3 in the previous page.

2) Turn the nut [C] at the rear of the fusing unit 90 de gre es clockwise.

3) Make 5 copies continuously.

4) Confirm the location and size of the "Mimizu" pattern s on the copy image .

Is the "Mimizu" pattern toward the rear the same size as that toward the front?

• Yes: Go to procedure 3.

• If not, do the appropriate procedure as follows until the "Mimizu" pattern toward

the front is the same size as tha t toward rear:

• No, the "Mimizu" pattern toward the rear is bigger than that toward the front:

Turn the nut [C] at the rear 45 degrees ∼ 90 degrees

clockwise.

• No, the "Mimizu" pattern toward the rear is smaller t han that toward the front:

Turn the nut [C] at the rear 45 degrees ∼ 90 degrees

counterclockwise.

• Go to procedure 3.

Page 29

Technical Bulletin No. RTB-012

SUBJECT: Hot Roller and Pressure Roller Chan ges DATE: Nov. 15, ’94

PAGE: 7 of 10

3. Procedure 3

Fusing Unit Positioning Adju stme nt by Forcing "Mimizu" on the Cop y Imag e

Paper Feeding

Mimizu

Rear

Fusing

Unit

Go to Case 1 in procedure 3

Front

Go to Case 2 in procedure 3

Go to Case 3 in procedure 3

Figure 1

1. Force the "Mimizu" pattern on the copy image as follows:

• Set SPD#51 to 003 (1 horizontal line for every main scans)

• Set SPD#52 to 003 (Full length pattern of paper)

• Set SPD#720 to 007 (Main motor speed fine adju stment)

• Set 11" x 17"/A3 size paper in the cassette and make 5 copie s co nt inuously.

NOTE: If the "Mimizu" pattern does not appear on the copy image, increase the main mot or

speed by setting SPD#720 to 008 or higher. When making copies, use the same pap er

as the customer uses.

2. Confirm location and size of the "Mimizu" pat te rns on the copy imag e. Refer to figure 1,

and choose the necessary proced ure from th e following:

Page 30

Technical Bulletin No. RTB-012

SUBJECT: Hot Roller and Pressure Roller Chan ges DATE: Nov. 15, ’94

PAGE: 8 of 10

[A]

[A] [B]

Paper Feed

Rear

Counterclockwise

Case 2

Fusing

Unit

Front

Clockwise

Case 3

[B]

Case 1 The "Mimizu" pattern toward the front of the fusing unit is almost same size as tha t

toward the rear.

1) Decrease the data of SP D#7 20 (Ma in mot or speed) by 1.

2) Make 5 copies continuously.

3) Repeat step 1 un til the "Mimizu" pattern on the copy image just disappears.

Case 2 Th e "Mimizu " pa tt ern toward the fro nt of th e fu sing unit is bigger than th e "Mimizu"

pattern toward the rear.

1) Loosen the screws [A].

2) Turn the adjustment cam [B] counterclo ckwise to equalize the "Mimizu" patte rns

toward the front and the rear.

[B]

3) Decrease the data of SP D#7 20 (Ma in Mot or Speed) by 1.

4) Make 5 copies continuously.

5) Repeat step 3 un til the "Mimizu" pattern on the copy image just disappears.

Page 31

Technical Bulletin No. RTB-012

SUBJECT: Hot Roller and Pressure Roller Chan ges DATE: Nov. 15, ’94

PAGE: 9 of 10

Case 3 The "Mimizu" pattern toward the rear of the fusing unit is bigger than the "Mimizu "

pattern toward the front.

1) Loosen the screws [A].

2) Turn the adjustment cam [B] clockwise to equalize the "Mimizu " patterns toward

the front and the rear.

3) Decrease the data of SP D#7 20 (Ma in Mot or Speed) by 1.

4) Make 5 copies continuously.

5) Repeat step 3 un til the "Mimizu" patterns on the copy image just disappears.

Page 32

Technical Bulletin No. RTB-012

Fig. 1

Fig. 2

Fig. 3

SUBJECT: Hot Roller and Pressure Roller Chan ges DATE: Nov. 15, ’94

PAGE: 10 of 10

Procedure 4

Main Motor Speed Adjustment

Necessary tool: flash light

1. Read the data of SPD#720 (Main motor speed)

2. Set SPD#720 (Main motor speed) to the new data according to the following:

a) When replacing the hot roller or pressure roller se parat ely:

Decrease the data of SPD# 72 0 by one.

Example) Current data 006 New data 005

Good

Too fast

Too slow

b) When replacing the hot rolle r and pressu re rolle r at the same time:

Decrease the data of SPD# 72 0 by two .

Example) Current data 006 New data 004

NOTE: Make sure that the data of SP D # 720 is th ree or higher before decreasing the

data. If the data is less than thre e, go back to procedure 2.

3. Observe the paper con dition when the paper is pulled by the fusing rollers. If th e pa pe r is

pulled strongly by the fusing rollers (figure 2), lower the speed of the fusing rollers by

choosing a lower setting for SP D#7 20 . If the paper bu ckles (fig ure 3), incre ase the speed

of the fusing rollers by choo sing a high er setting for SPD#720.

NOTE: In the case of figure 3, th e copy image is scraped by the uppe r pape r g uid e.

4. Set SPD#51 and #52 as follows:

SPD#51 to 007

SPD#52 to 000.

Loading...

Loading...