Page 1

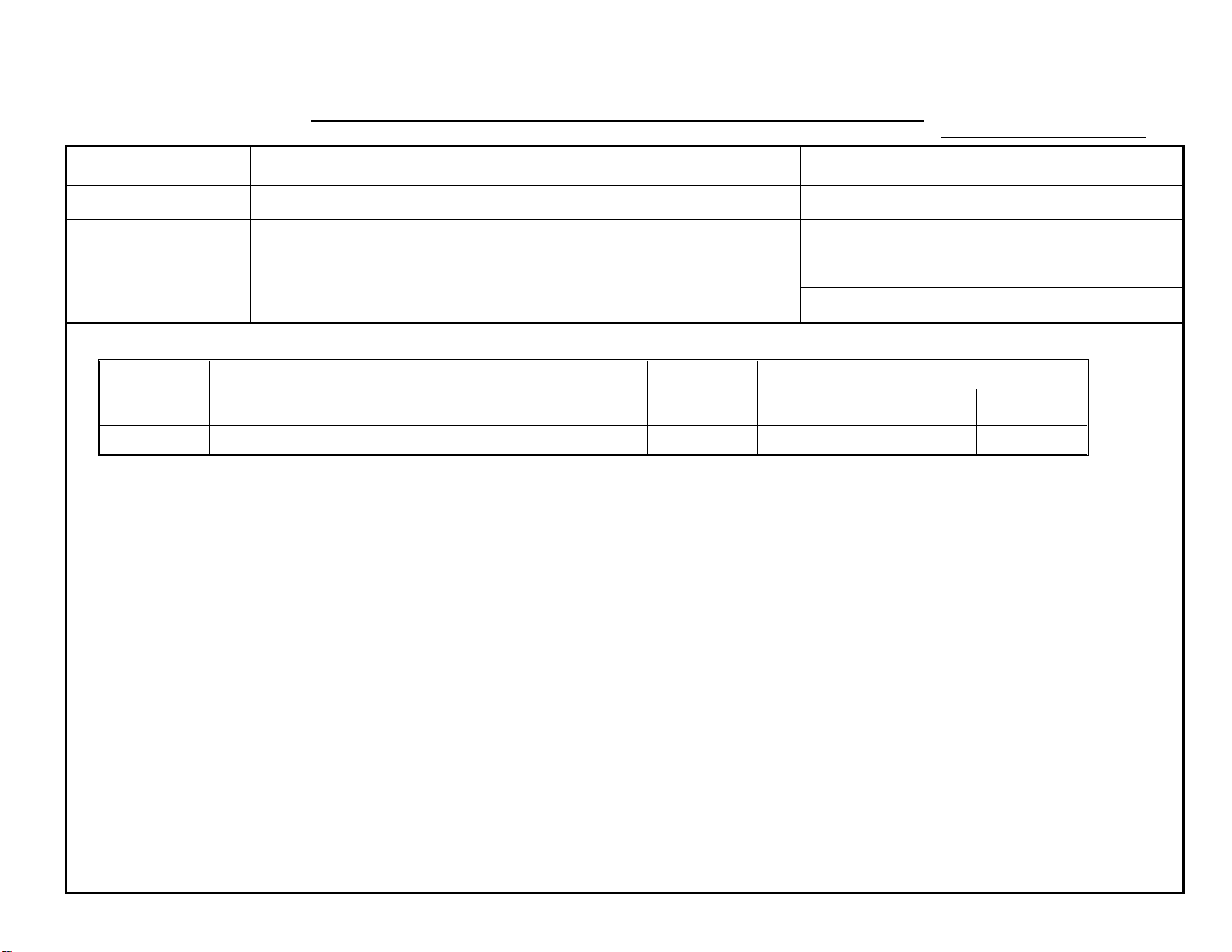

MODIFICATION BULLETIN NO. 1 Page 1 of 1 ISSUED ON: November 15, ’92

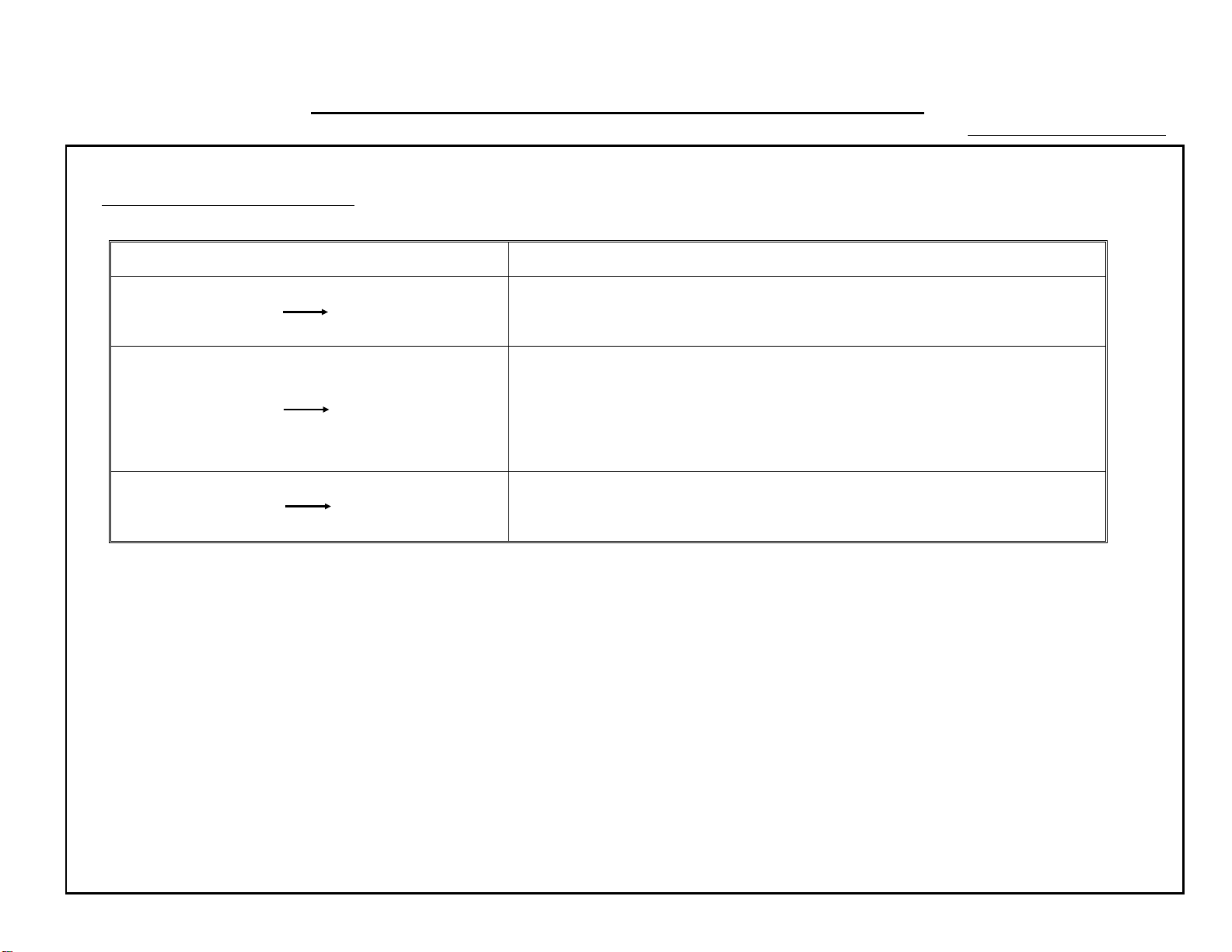

Model SP40 Volt/Hz

Modified Article Fusing Unit

Reason for

Part catalog corrections

Modification

Please correct your parts catalo g as follows:

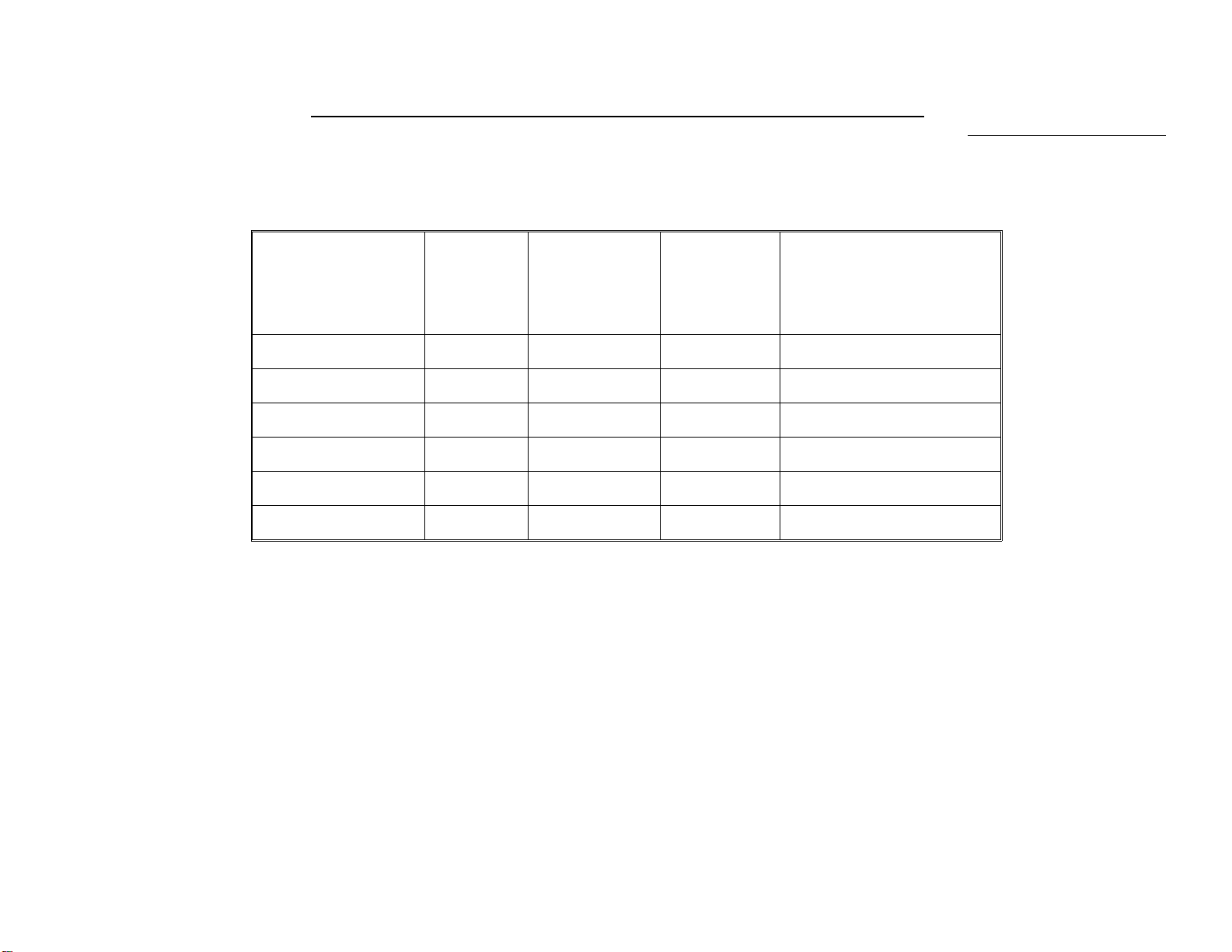

Incorrect P/N Correct P/N Description Index No. Page

AA060404 AA060493 Spring 37 37

52064390 AB013739 Gear - 20T 81 35

Date of

Modification

Serial Number

T. Ito, Manager

Copier Technical Support

Page 2

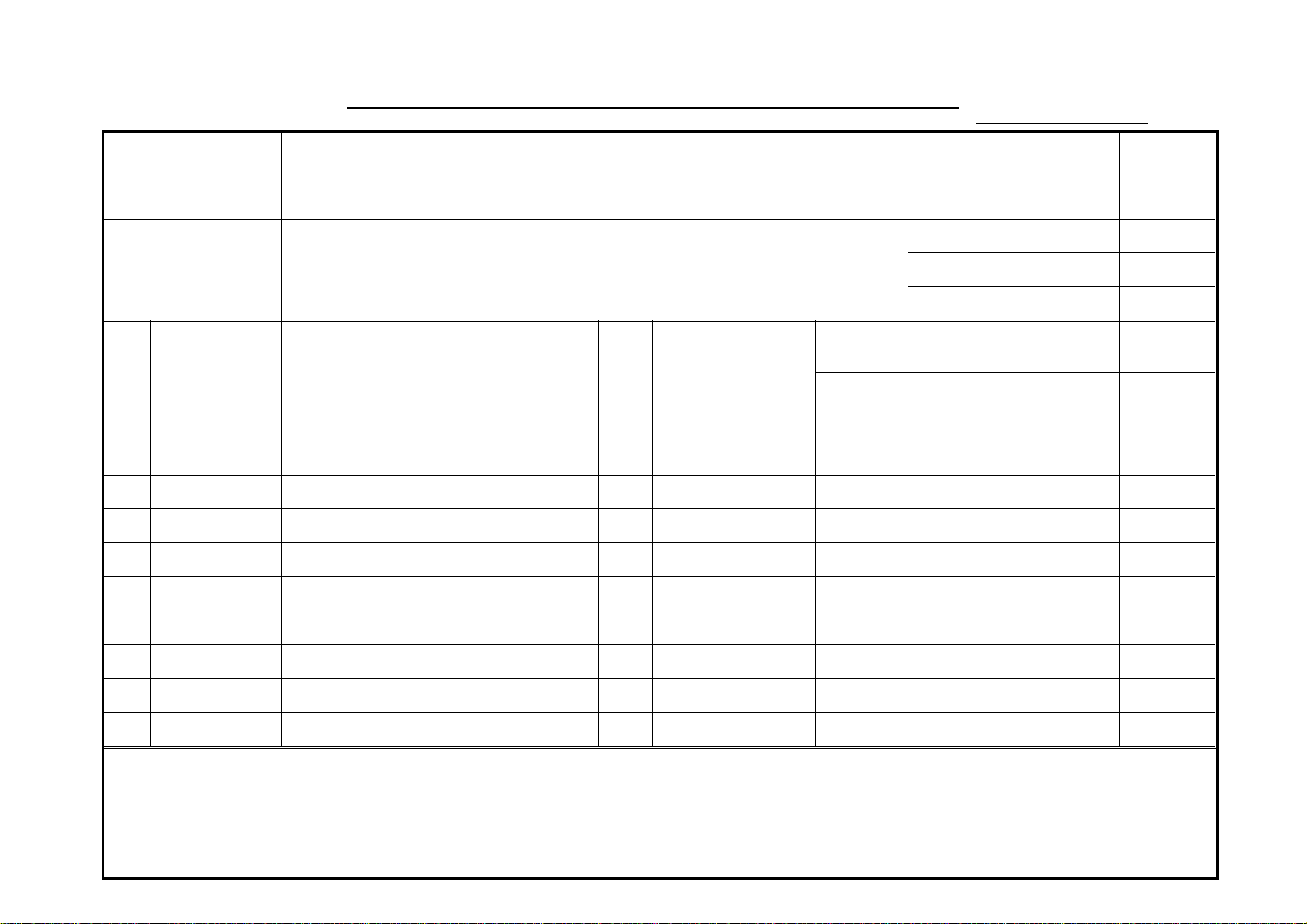

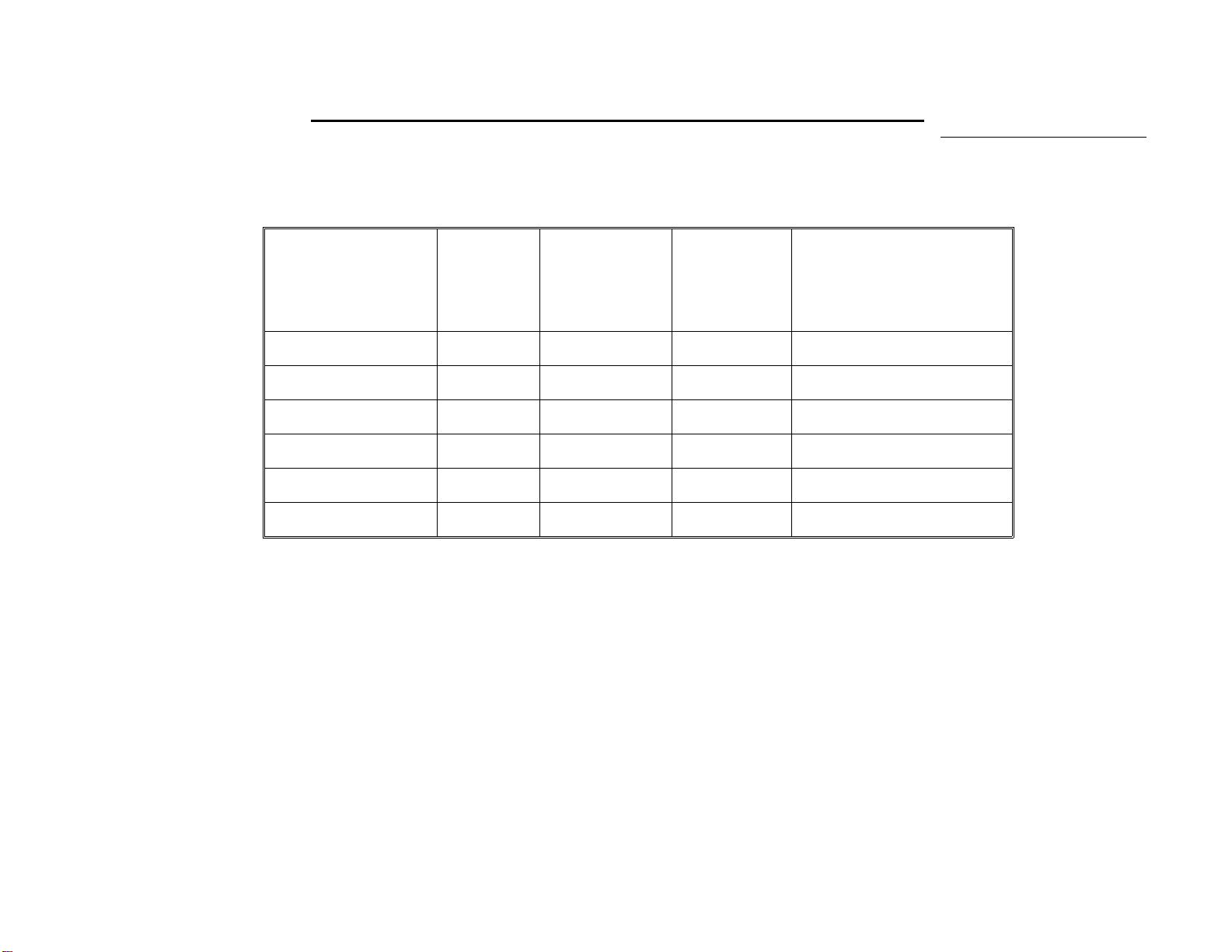

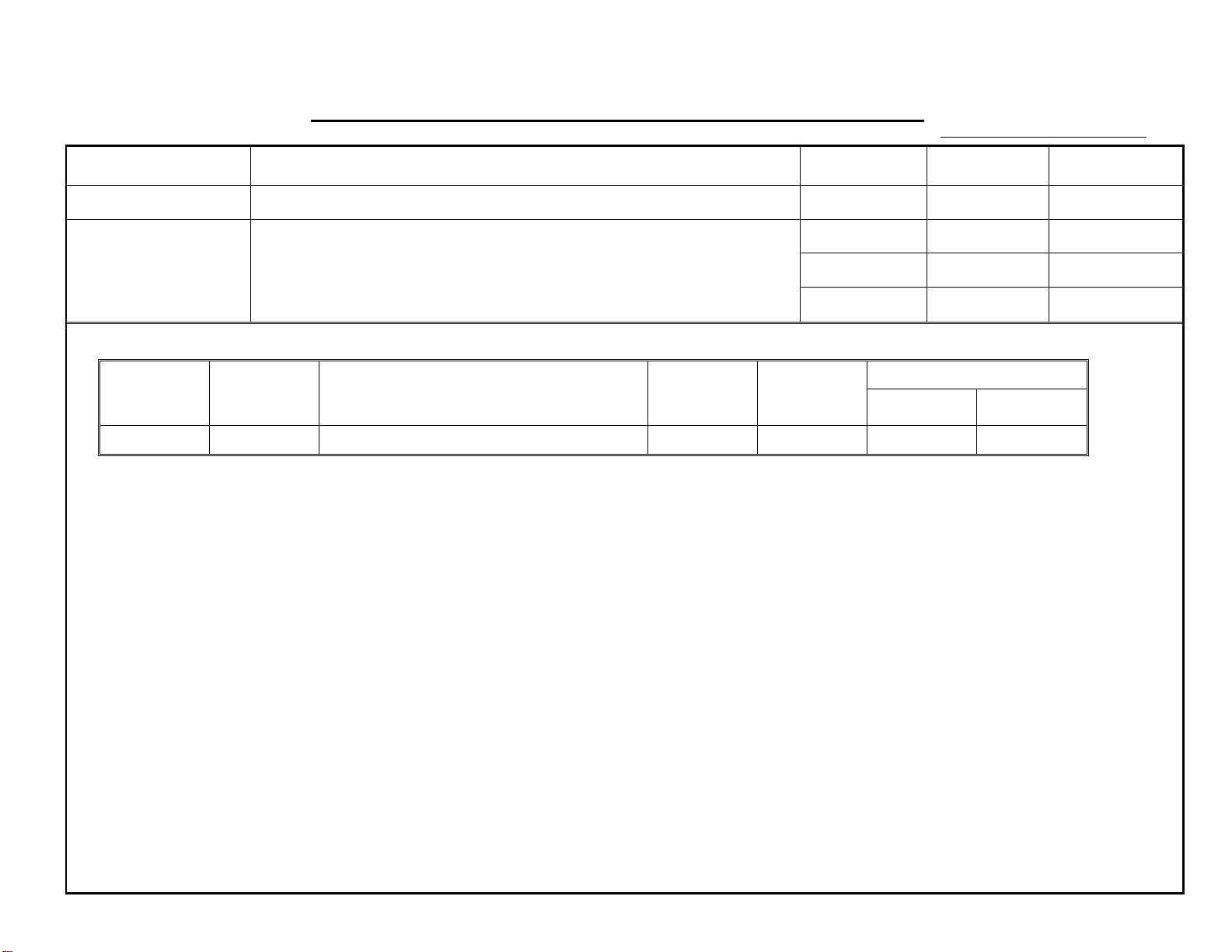

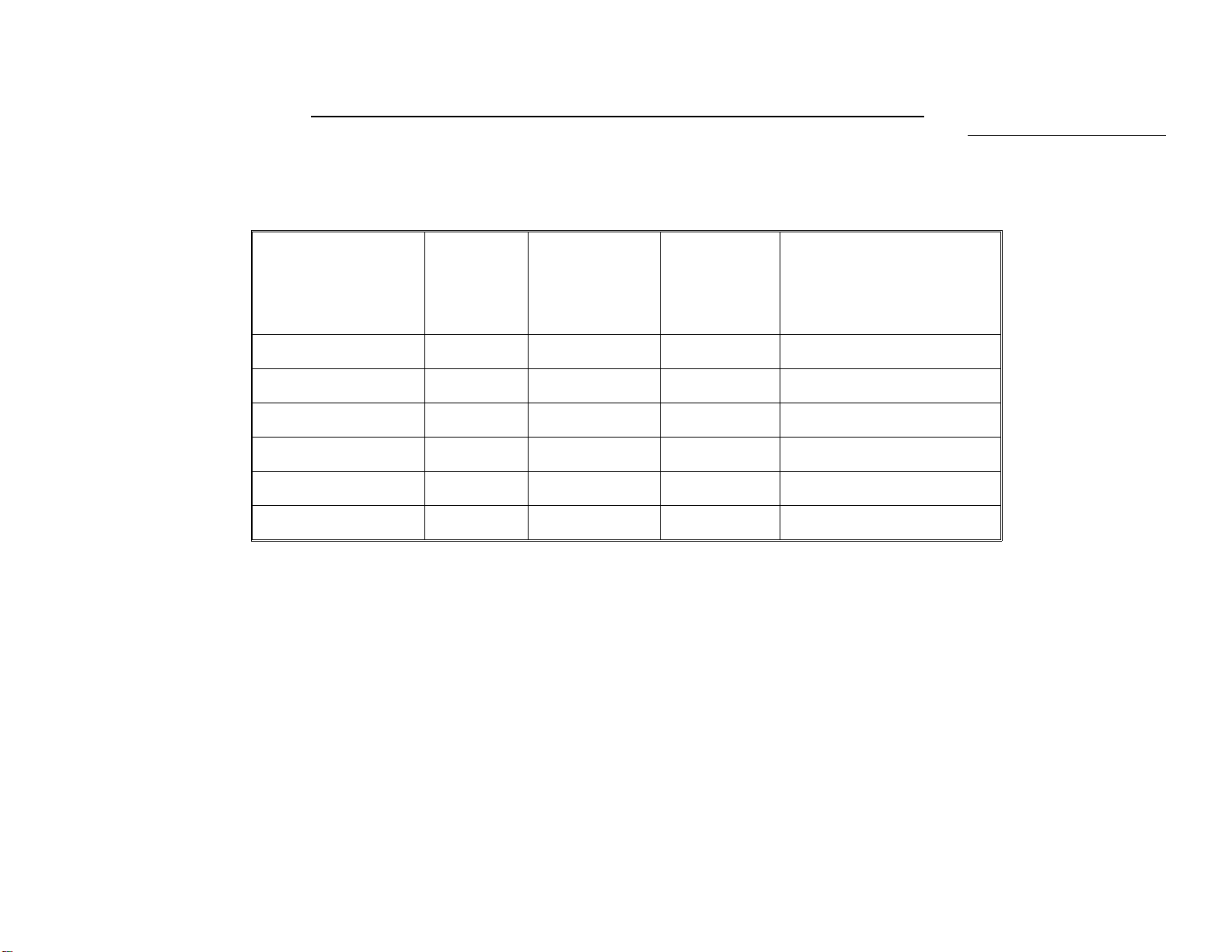

MODIFICATION BULLETIN NO. 2 PAGE 1 OF 4

ISSUED ON: June 30, ’93

Model SP40 / 50 Volt/Hz

Modified Article Parts Catalog for the SP50

Reason for

SP50 Unique Parts

Modification

Draw

No.

Old Parts

No.

New Parts

No.

A1081311 Upper Cover 0 → 1137

A1081276 Rear Cover 0 → 1177

A1085120 Main Board 0 → 1347

A0011897 Front Cover - Terminal 0 → 11811

AX530013 Exposure Lamp 0 → 11911

A1081667 Wire Fixing Plate 0 → 12211

Description Rank

Q’ty Used

Old → New

Inter-

change-

ability

Date of

Modification

Part needed for replacement by new part

Part No. Description No. Page

Serial

Number

Parts

Catalog

A1081650 First Scanner 0 → 12511

AW110013 Thermostat 0 → 12811

A1085396 Halogen Lamp Harness 0 → 12911

Not used Optics Fan Cover 1 → 05411

Rank: A : Replace with new parts immediately.B : Replace with new parts at time of repair.C : Replace with new parts at time of overhaul.

I nterchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 3

MODIFICATION BULLETIN NO. 2 PAGE 2 OF 4

ISSUED ON: June 30, ’93

Draw

No.

Old Parts

No.

New Parts

No.

AX020024 Cooling Blower 0 → 15511

A0015465 Interface Harness 0 → 1 * 69 11

A1085395 Halogen Lamp Harness 0 → 15811

A1081112 Pulley 0 → 13421

AB013799 Gear - 33Z 0 → 13721

AX500045 Erase Lamp 0 → 1729

A1082002 Charge & Quenching Unit 0 → 14529

AA060531 Spring 0 → 22437

A1084111 Pressure Lever 0 → 22537

AX030005 Main Motor 0 → 11739

AB013813 Gear - 25Z 0 → 21839

Description Rank

Q’ty Used

Old → New

Inter-

change-

ability

Part needed for replacement by new part

Part No. Description No. Page

Parts

Catalog

07413808 Ball Bearing - 8 x 16 x 5 mm 0 → 61939

A1081136 Drive Arm - Fusing Exit 0 → 12639

AB013812 Gear 30Z 0 → 22839

A1085302 DC Power Supply Unit 0 → 11341

A1085422 Left DC Harness 0 → 11441

Page 4

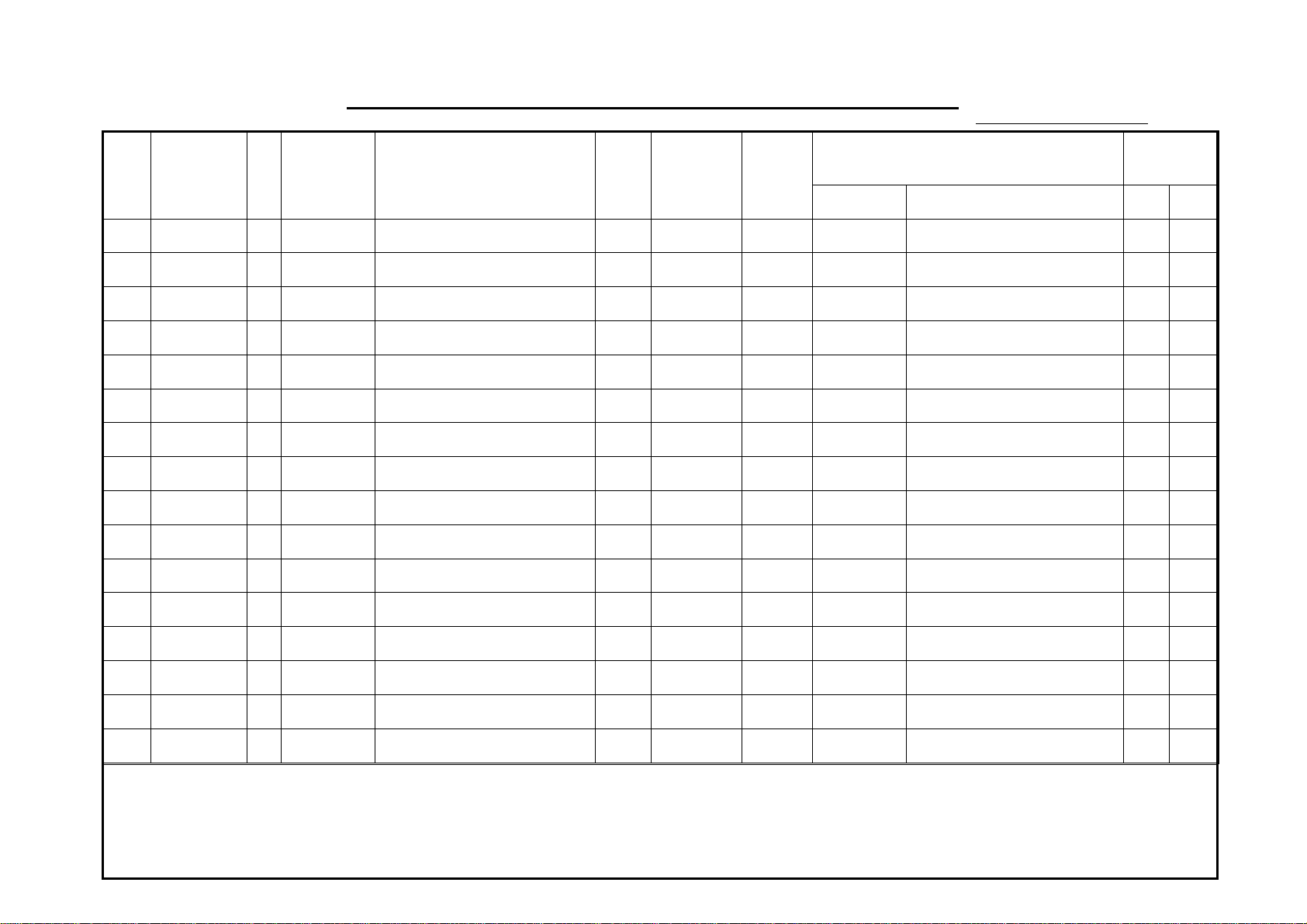

MODIFICATION BULLETIN NO. 2 PAGE 3 OF 4

ISSUED ON: June 30, ’93

Draw

No.

Old Parts

No.

New Parts

No.

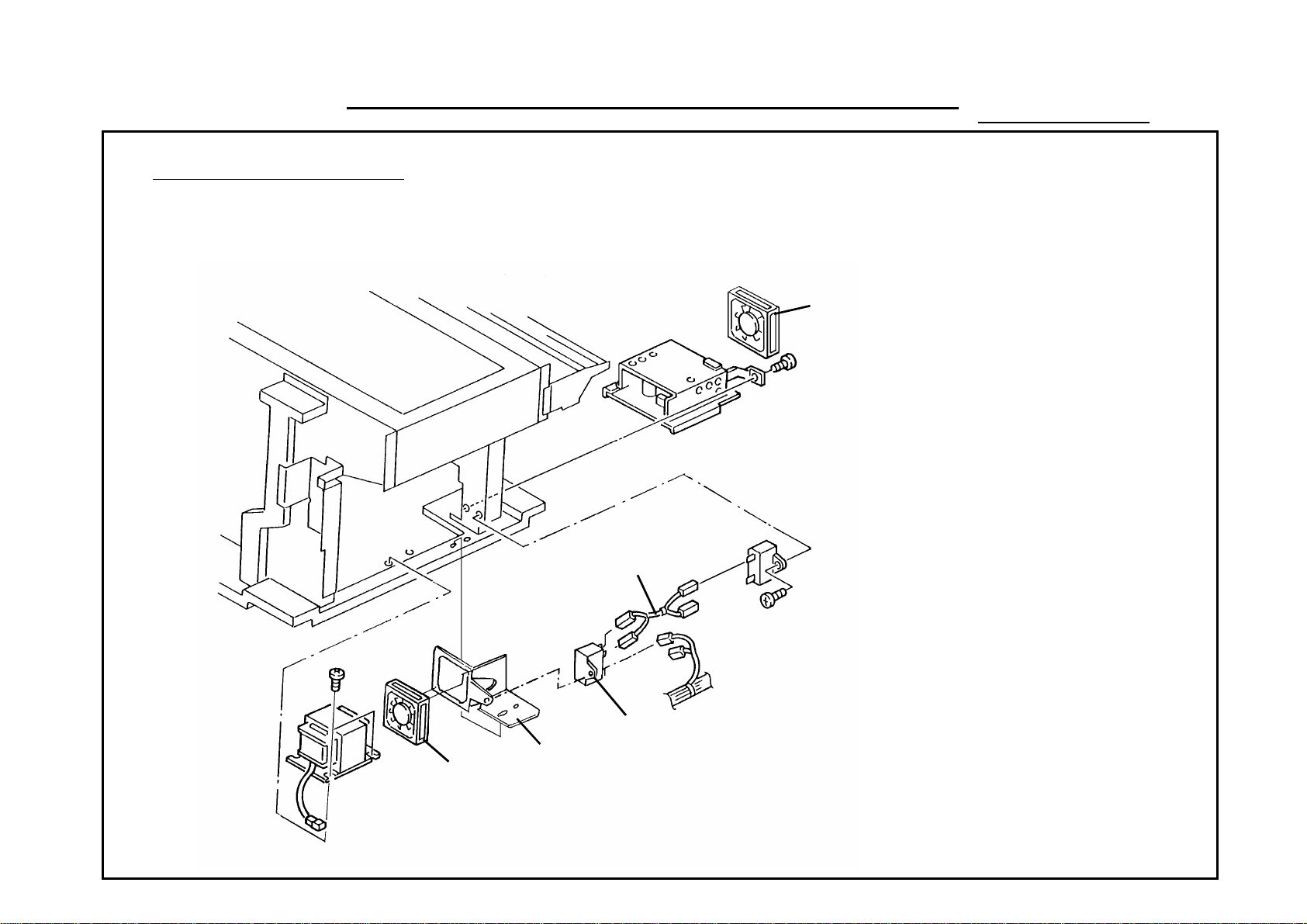

AX640032 Cooling Fan 1 → 22341

16061936 Capacitor - 8mF - 220V 0 → 1 * 28 41

A1085460 Relay Harness 0 → 1 * 29 41

AX640040 Cooling Fan 0 → 1 * 30 41

A1081175 Cooling Fan Bracket 0 → 1 * 31 41

AZ320066 Power Pack 0 → 11143

A1081885 Right Stay 0 → 1845

A1081154 Shielding Plate - DC Power 0 → 12845

A1085129 IC - AM27C512 - 155DC 0 → 1249

A1085141 IC - AM27C256 - 155DC 0 → 1349

Description Rank

Q’ty Used

Old → New

Inter-

change-

ability

Part needed for replacement by new part

Part No. Description No. Page

Parts

Catalog

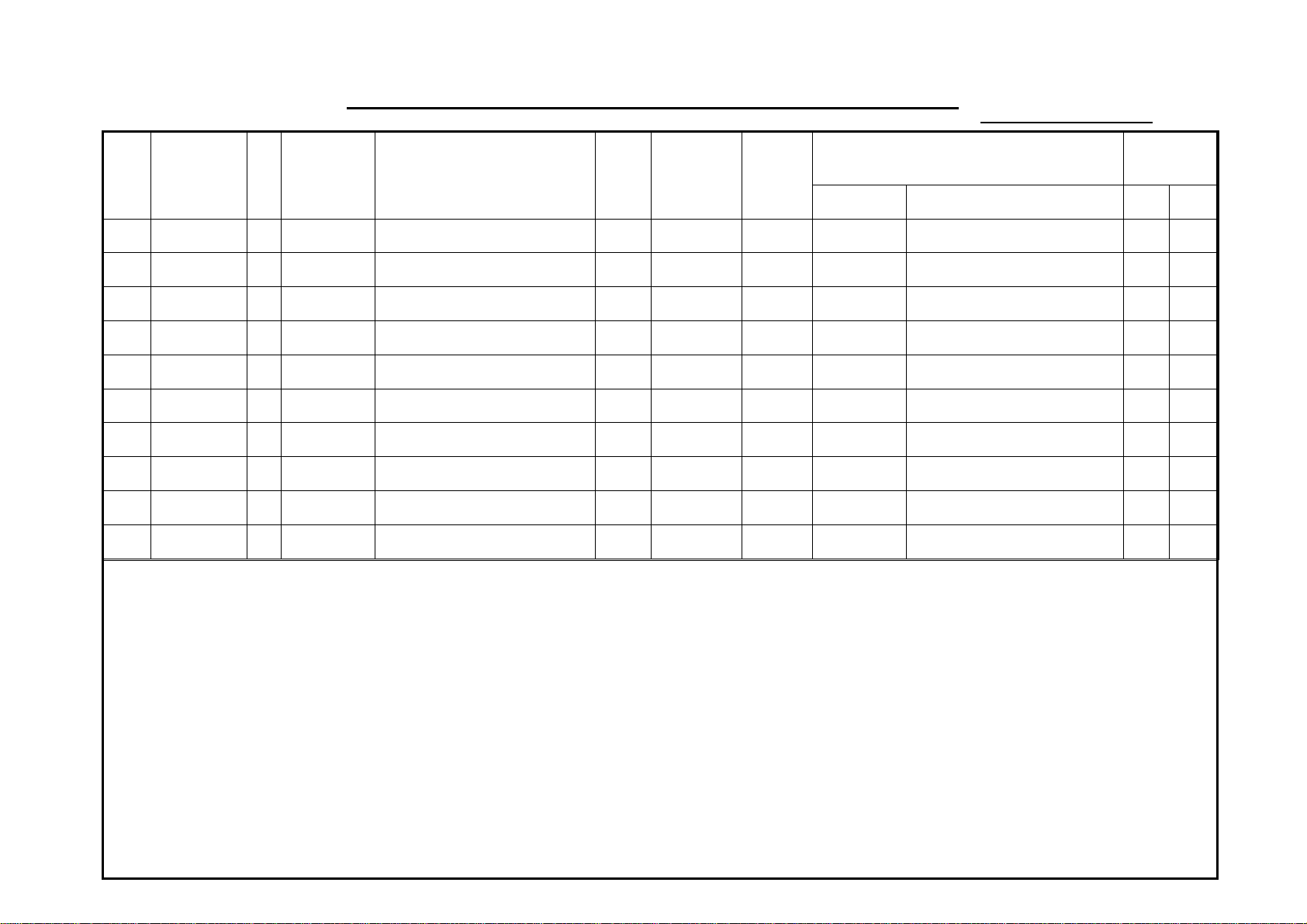

Page 5

MODIFICATION BULLETIN NO. 2 PAGE 4 OF 4

DETAILS OF MODIFICATION

The SP50 design is based on the SP40. Please add these uniq ue parts in the SP40 parts catalog.

The SP50 stand alone parts catalo g is not plan ne d to be published.

Please refer SP40/50 RTB#001 for details.

30

ISSUED ON: June 30, ’93

23

31

Page 40

29

28

T. Ito, Manager

Copier Technical Support

T. Ito, Manager

Copier Technical Support

Page 6

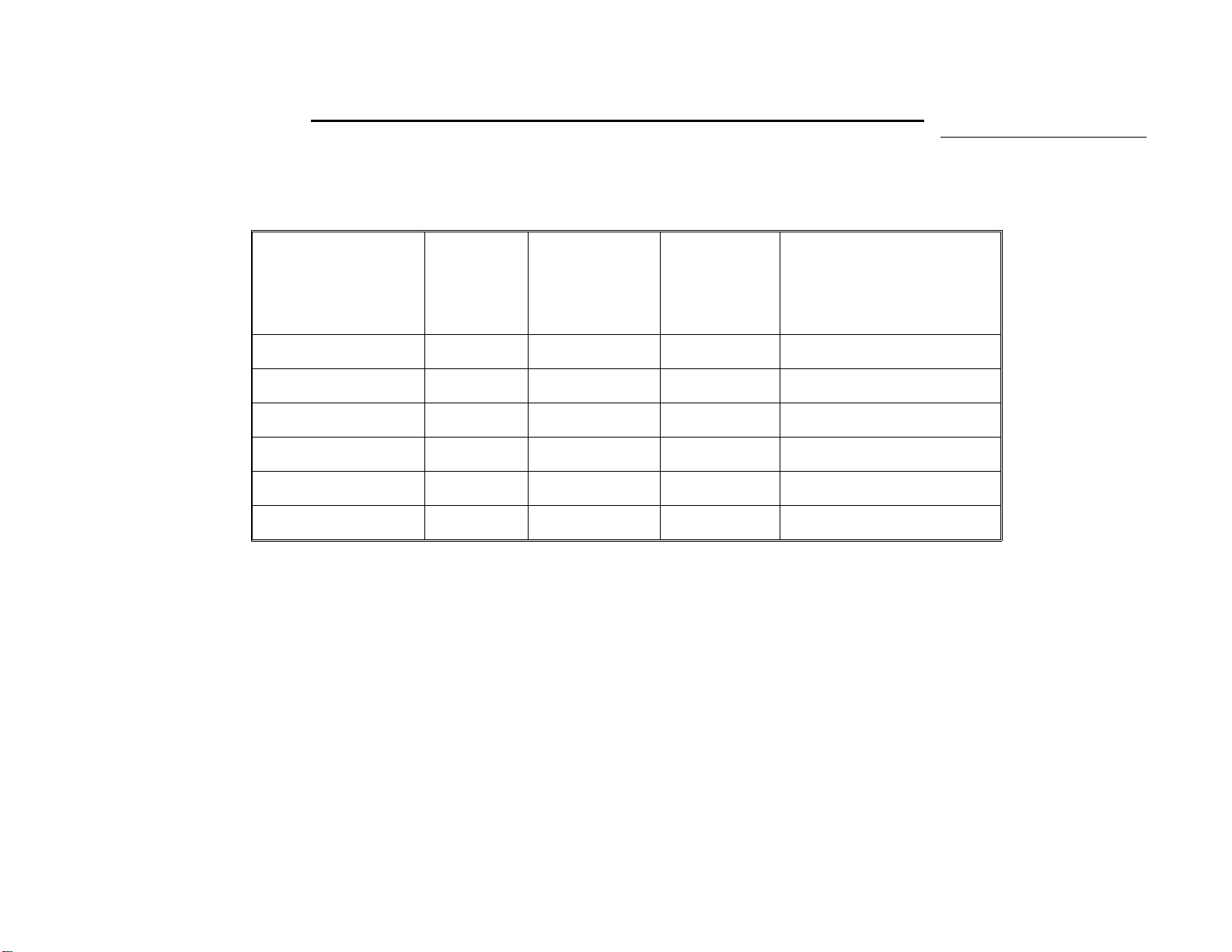

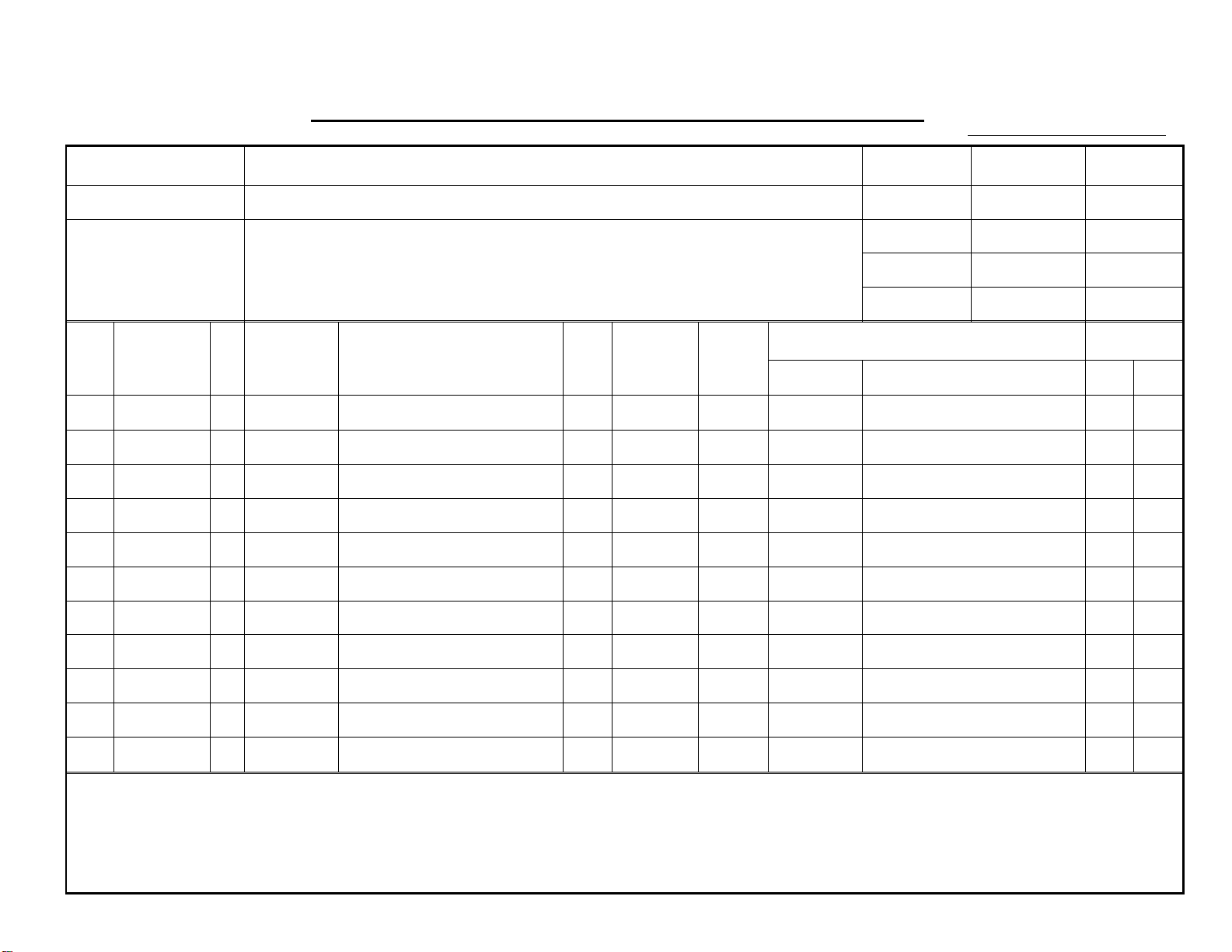

MODIFICATION BULLETIN NO. 3 PAGE 1 OF 1

ISSUED ON: July 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article

Reason for

Parts catalog correction

Modification

Inter-

Incorrect P/N Correct P/N Description Q’ty Used

A0893999 Not used Spacer - 3 x 6 x 0.1 31 29

change-

ability

Parts Catalog

Index No. Page

Date of

Modification

Serial Number

Page 7

T. Ito, Manager

Copier Technical Support

MODIFICATION BULLETIN NO. 4 PAGE 1 OF 1

ISSUED ON: July 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Drum Section / Frame Section

A089-15 3920600043

Reason for

To prevent uneven images in transparency mode

Modification

Date of

Modification

To prevent uneven images in transparency mode, two seals are added to change the air flow from the fusing unit.

This is because the silicon gas from the fu sing unit makes the charge wire dirty.

P/N Description Q’ty Used Page Index

A0892118 Charge Corona Seal 0 → 1 29 * 50

A0892117 Seal - 6 x 7 x 280 0 → 1 45 * 33

* : New Index

Serial Number

Page 8

MODIFICATION BULLETIN NO. 5 PAGE 1 OF 1

ISSUED ON: July 15, ’93

Model SP40 Volt/Hz

Modified Article Frame Section

Reason for

Part Standardization

Modification

Old P/N New P/N Description

A0891860 A1081860 Front Optics Frame 1 → 1 O/O 3 45

A0891153 A1081153 Shielding Plate 1 → 1 O/O 26 45

Q’ty Used

Old → New

Inter-

change-

ability

Parts Catalog

Index No. Page

Date of

Modification

Serial Number

T. Ito, Manager

Copier Technical Support

Page 9

MODIFICATION BULLETIN NO. 6 PAGE 1 OF 2

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Timing Belt Tightener

Reason for

To prevent noise from the drive section

Modification

Inter-

Old P/N New P/N Description Q’ty Used

A0891120 A0891123 Tightener Pulley

1 → 1

change-

ability

X/O 45 37

Index No. Page

Date of

Modification

Parts Catalog

To prevent the possibility t ha t th e tig htener pulley hits the pulse gen era tor, the thickness of the pu lley is re du ced .

Serial Number

S. Hamano, Manager

Technical Support Department

Page 10

MODIFICATION BULLETIN NO. 6 PAGE 2 OF 2

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA, Canada A089-15 3930300001

Ricoh FT400 i 110/60 Taiwan A089-19 A3273030001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273030001

Savin 9050 i 115/60 USA, Canada A089-15 1930300001

Ricoh FT500 i 110/60 Taiwan A089-19 A3333030001

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3333030001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 11

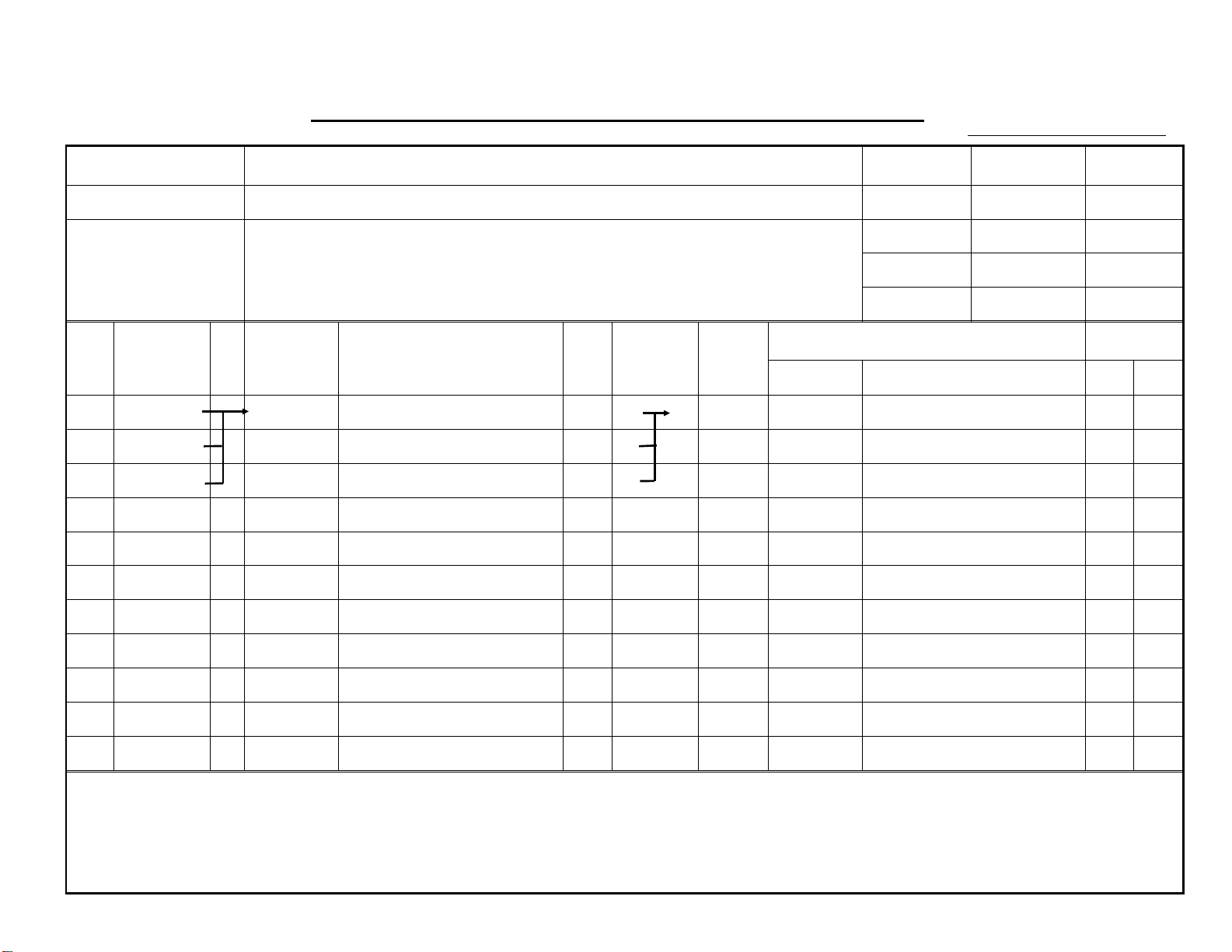

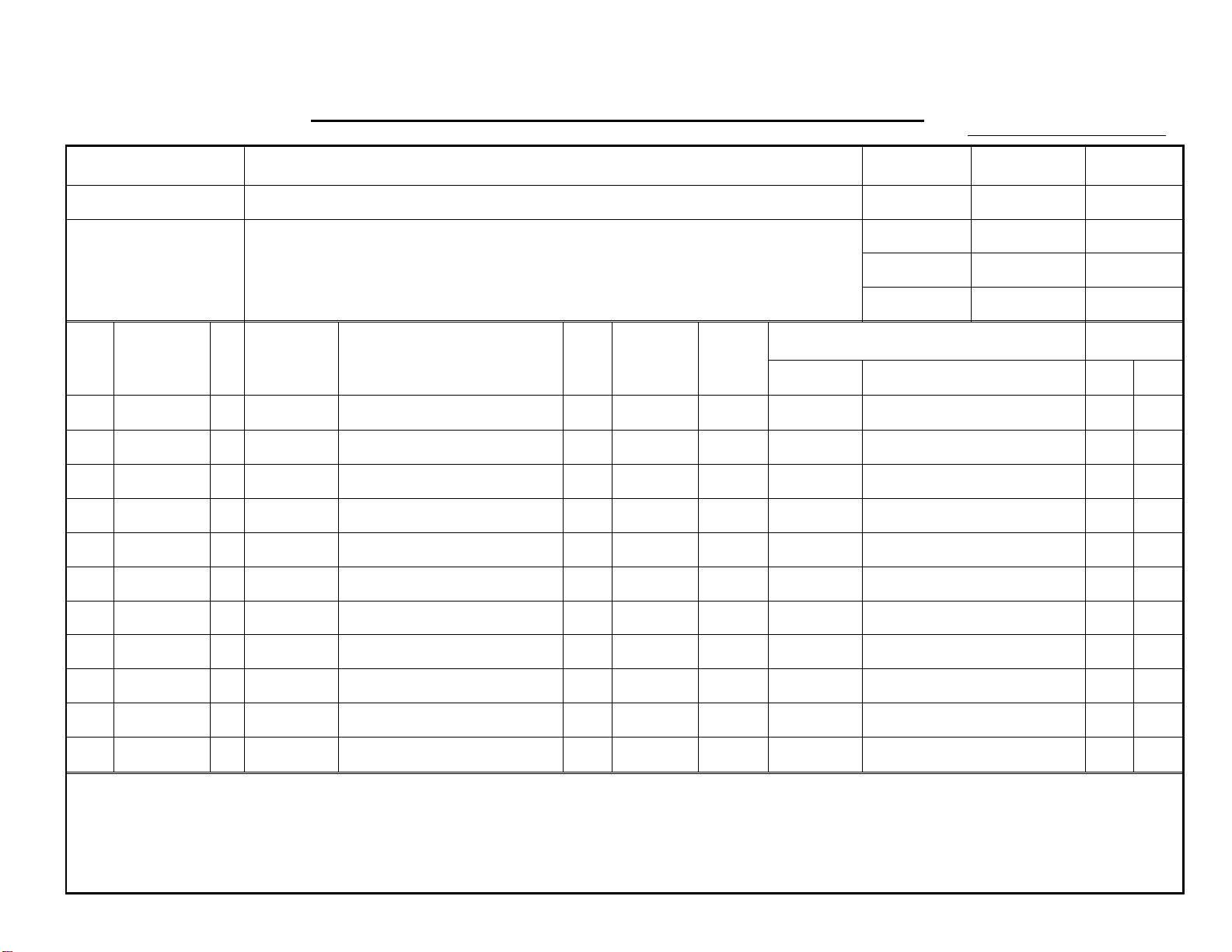

MODIFICATION BULLETIN NO. 7 PAGE 1 OF 3

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Oil Blade

Reason for

Modification

Draw

No.

Old Parts

No.

52154117 A1084017 Oil Blade Ass’y 1 1 X/O 11 37

52154116 1 10 37

09513005W 3 102 37

To extend the hot roller yield

New Parts

No.

Description Rank

Q’ty Used

Old→New

Inter-

change-

ability

Date of

Modification

Parts needed for replacement by new part

Part No. Description No. Page

Serial

Number

Parts

Catalog

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 12

MODIFICATION BULLETIN NO. 7 PAGE 2 OF 3

ISSUED ON: October 15, ’93

DETAILS OF MODIFICATION

The pressure of the oil blade might not be even or equal across the hot roller. Due to uneven

pressure, the roller might be worn out soon er th an expe cted.

The oil blade and the bra cket were assembled at the factory to app ly even pressure to the hot roller.

New Part Number

A1084017

S. Hamano, Manager

Technical Support Department

Page 13

MODIFICATION BULLETIN NO. 7 PAGE 3 OF 3

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15 3930400001

Ricoh FT400 i 110/60 Taiwan A089-19 A3273040001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273040001

Savin 9050 i 115/60 USA Canada A089-15 1930400001

Ricoh FT500 i 110/60 Taiwan A089-19 A3333040001

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3333040001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 14

MODIFICATION BULLETIN NO. 8 PAGE 1 OF 2

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Separator Roller

Reason for

Vendor change

Modification

Inter-

Old P/N New P/N Description Q’ty Used

AF020107 AF021006 Separator Roller

1 → 1

change-

ability

O/O 26 33

Date of

Modification

Parts Catalog

Index No. Page

Serial Number

S. Hamano, Manager

Technical Support Department

Page 15

MODIFICATION BULLETIN NO. 8 PAGE 2 OF 2

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15 3930400001

Ricoh FT400 i 110/60 Taiwan A089-19 A3273040001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273040001

Savin 9050 i 115/60 USA Canada A089-15 1930400001

Ricoh FT500 i 110/60 Taiwan A089-19 A3333040001

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3333040001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 16

MODIFICATION BULLETIN NO. 9 PAGE 1 OF 3

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Main ROM

Reason for

Software change

Modification

Draw

No.

Old Parts

No.

A0895132 A0895129 IC - AM27C512 - 155DC

New Parts

No.

Description Rank

Q’ty Used

Old→New

1 → 1

Date of

Modification

Inter-

change-

ability

X/O 2 49

Parts needed for replacement by new part

Part No. Description No. Page

Serial

Number

Parts

Catalog

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 17

MODIFICATION BULLETIN NO. 9 PAGE 2 OF 3

ISSUED ON: October 15, ’93

DETAILS OF MODIFICATION

Old P/N New P/N Reason for modification

A0895132 A0895133

A0895133 A0895134

A0895134 A0895129

1. Corrects the malfunction of the sorter jam when the sorter adapter and the

MATT 20 are installed.

2. Feeds out all paper inside of the copier if a sorter jam occurs.

1. Selects the APS function automatically whenever originals are inserted in the DF.

2. Enables to select the LCT in the third feed station even if the paper end

condition occurs in the LCT.

3. Enables to rotate the main motor by SP mode.

4. When a user code is input to operate the copier, the operation panel mode

settings become the default settings.

1. The paper lift motor ON/OFF timing is changed to prevent no feeding or

multi-feedings.

2. Corrects the DF jam counter logging data in SP mode.

S. Hamano, Manager

Technical Support Department

Page 18

MODIFICATION BULLETIN NO. 9 PAGE 3 OF 3

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15 3930400001

Ricoh FT400 i 110/60 Taiwan A089-19 A3273040001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273040001

Savin 9050 i 115/60 USA Canada A089-15 1930400001

Ricoh FT500 i 110/60 Taiwan A089-19 A3333040001

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3333040001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 19

MODIFICATION BULLETIN NO. 10 PAGE 1 OF 3

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Turn Belt Pulley Spring

Reason for

To minimize separation jams

Modification

Draw

No.

Old Parts

No.

AA063193 AA063267 Spring

New Parts

No.

Description Rank

Q’ty Used

Old→New

1 → 1

Date of

Modification

Inter-

change-

ability

X/O 8 29

Parts needed for replacement by new part

Part No. Description No. Page

Serial

Number

Parts

Catalog

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 20

MODIFICATION BULLETIN NO. 10 PAGE 2 OF 3

ISSUED ON: October 15, ’93

DETAILS OF MODIFICATION

The lower turn belt pulley is positioned towa rds th e fro nt of the sep ara tion roller resulting in the edge of

the turn belt contacting the roller surface and creating a groove. This might cause separation jams.

The spring that positions th e pu lley ha s bee n cha ng ed to a smalle r one to en sure flat contact of the

turn belt on the separation roller.

S. Hamano, Manager

Technical Support Department

Page 21

MODIFICATION BULLETIN NO. 10 PAGE 3 OF 3

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15 3930400001

Ricoh FT400 i 110/60 Taiwan A089-19 A3273040001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273040001

Savin 9050 i 115/60 USA Canada A089-15 1930400001

Ricoh FT500 i 110/60 Taiwan A089-19 A3333040001

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3333040001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 22

MODIFICATION BULLETIN NO. 11 PAGE 1 OF 2

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Pick-off Pawl Slider

Reason for

To prevent the hot roller damage by pick-off pawls

Modification

Inter-

Old P/N New P/N Description Q’ty Used

A0894461 A0894462 Stopper Bracket

1 → 1

change-

ability

X/O 1 35

Parts Catalog

Index No. Page

Date of

Modification

If a spring for the pick-off pawl is removed accidentally, the to p en d of the pawl migh t da mage the hot roller. To

prevent this, stoppers are added on the pick-off pawl slider. This stopper limits the pawl movement towards the hot

roller even if the spring does come off.

Serial Number

S. Hamano, Manager

Technical Support Department

Page 23

MODIFICATION BULLETIN NO. 11 PAGE 2 OF 2

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA, Canada A089-15 3930400001

Ricoh FT400 i 110/60 Taiwan A089-19 A3273040001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273040001

Savin 9050 i 115/60 USA, Canada A089-15 1930400001

Ricoh FT500 i 110/60 Taiwan A089-19 A3333040001

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3333040001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 24

MODIFICATION BULLETIN NO. 12 PAGE 1 OF 2

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Fusing Thermistor

Reason for

Thermistor damage

Modification

Inter-

Old P/N New P/N Description Q’ty Used

A0895444 A0895445 Thermistor

1 → 1

change-

ability

X/O 30 37

Parts Catalog

Index No. Page

Date of

Modification

To prevent the mylar on the the rmisto r f rom peeling off, apply a special glue between the mylar and th e th ermistor.

Serial Number

S. Hamano, Manager

Technical Support Department

Page 25

MODIFICATION BULLETIN NO. 12 PAGE 2 OF 2

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA, Canada A089-15 3930100001

Ricoh FT400 i 110/60 Taiwan A089-19 A3273010001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273010001

Savin 9050 i 115/60 USA, Canada A089-15 1930100001

Ricoh FT500 i 110/60 Taiwan A089-19 From First Production

Ricoh FT500 i 220/50 Asia, Oceania A089-29 From First Production

V/Hz DESTINATION CODE SERIAL NUMBER

Page 26

MODIFICATION BULLETIN NO. 13 PAGE 1 OF 2

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Separation Guide Plate

Reason for

Vendor change

Modification

Inter-

Old P/N New P/N Description Q’ty Used

A0893909 A0893908 Separation Guide Plate

1 → 1

change-

ability

O/O 27 33

Date of

Modification

Parts Catalog

Index No. Page

Serial Number

S. Hamano, Manager

Technical Support Department

Page 27

MODIFICATION BULLETIN NO. 13 PAGE 2 OF 2

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA, Canada A089-15

Ricoh FT400 i 110/60 Taiwan A089-19

Ricoh FT400 i 220/50 Asia, Oceania A089-29

Savin 9050 i 115/60 USA, Canada A089-15

Ricoh FT500 i 110/60 Taiwan A089-19

Ricoh FT500 i 220/50 Asia, Oceania A089-29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 28

MODIFICATION BULLETIN NO. 14 PAGE 1 OF 2

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article By-pass table magnet

Reason for

To prevent the by-pass table from opening during operation

Modification

Inter-

Old P/N New P/N Description Q’ty Used

A0892785 52052734 Magnet

1 → 1

change-

ability

X/O 20 7

To prevent the by-pass ta ble from opening during opera tio n, a stronger magnet is used.

Date of

Modification

Parts Catalog

Index No. Page

Serial Number

S. Hamano, Manager

Technical Support Department

Page 29

MODIFICATION BULLETIN NO. 14 PAGE 2 OF 2

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA, Canada A089-15 3930700001

Ricoh FT400 i 110/60 Taiwan A089-19 A3273070001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273070001

Savin 9050 i 115/60 USA, Canada A089-15 1930700001

Ricoh FT500 i 110/60 Taiwan A089-19 A3333070001

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3333070001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 30

MODIFICATION BULLETIN NO. 15 PAGE 1 OF 2

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Separation Roller Spring Hook

Reason for

Multiple feeding from the first feed station

Modification

Inter-

Old P/N New P/N Description Q’ty Used

A1082572 Spring Hook Bracket

0 → 1

change-

ability

---- * 68 19

Date of

Modification

Parts Catalog

Index No. Page

Serial Number

* New index no.

The pressure between the feed ro ller and th e separation roller is not enough if rough edge cut pa per is used. This

results in multiple feeding . Add the add itio na l spring hook bracket above the current hook bracket to incre ase tolerance.

52

68

68

52

S. Hamano, Manager

Technical Support Department

Page 31

MODIFICATION BULLETIN NO. 15 PAGE 2 OF 2

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA, Canada A089-15 3930600001

Ricoh FT400 i 110/60 Taiwan A089-19 A3273060001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273060001

Savin 9050 i 115/60 USA, Canada A089-15 1930600001

Ricoh FT500 i 110/60 Taiwan A089-19 A3333060001

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3333060001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 32

MODIFICATION BULLETIN NO. 16 PAGE 1 OF 2

11 ± 1mm

ISSUED ON: October 15, ’93

Model SP40 / 50 Volt/Hz

Modified Article Si Oil Bottle Decal

Reason for

Request from OEM company

Modification

Inter-

Old P/N New P/N Description Q’ty Used

AA000084 AA000087 Decal - Oil Supply

1 → 1

change-

ability

O/O 10 59

Date of

Modification

Parts Catalog

Index No. Page

Serial Number

14 ± 1mm

<New Decal>

S. Hamano, Manager

Technical Support Department

Page 33

MODIFICATION BULLETIN NO. 16 PAGE 2 OF 2

ISSUED ON: October 15, ’93

MODEL NAME

Savin 9040 i 115/60 USA, Canada A089-15

Ricoh FT400 i 110/60 Taiwan A089-19

Ricoh FT400 i 220/50 Asia, Oceania A089-29

Savin 9050 i 115/60 USA, Canada A089-15

Ricoh FT500 i 110/60 Taiwan A089-19

Ricoh FT500 i 220/50 Asia, Oceania A089-29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 34

MODIFICATION BULLETIN NO. 17 PAGE 1 OF 3

ISSUED ON: January 15, ’94

Model SP40 / 50 Volt/Hz

Modified Article Front Cover Stopper

Reason for

To ensure proper oil tank setting

Modification

Draw

No.

Old Parts

No.

A0891252 Door Cover - Lower Stopper

New Parts

No.

A0891249 Front Cover Stopper

Description Rank

Q’ty Used

Old→New

1 → 0

0 → 1

Date of

Modification

Inter-

change-

ability

X/O 41 7

Parts needed for replacement by new part

Part No. Description No. Page

Serial

Number

Parts

Catalog

41 7

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 35

MODIFICATION BULLETIN NO. 17 PAGE 2 OF 3

DETAILS OF MODIFICATION

If the oil tank is not set in the proper posit ion , th e colle cte d silicon e oil does no t ret urn to the tank,

and oil leakage might hap pe n. To preven t this, a bracket [A] has been add ed on th e front cover, so

that the cover cannot be close d if the oil tank is out of position.

[A]

ISSUED ON: January 15, ’94

[A]

Front Cover Stopper

S. Hamano, Assistant General Man ag er

Technical Support Department

Page 36

MODIFICATION BULLETIN NO. 17 PAGE 3 OF 3

ISSUED ON: January 15, ’94

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15 3931000001

Ricoh FT400 i 110/60 Taiwan A089-19 A327402XXXX

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273090001

Savin 9050 i 115/60 USA Canada A089-15 1931000001

Ricoh FT500 i 110/60 Taiwan A089-19 A333402XXXX

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3333100001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 37

MODIFICATION BULLETIN NO. 18 PAGE 1 OF 3

ISSUED ON: January 15, ’94

Model SP40 / 50 Volt/Hz

Modified Article Oil Supply Tube

Reason for

To ensure proper oil supply

Modification

Draw

No.

Old Parts

No.

AA180038 AA180052 Oil Supply Tube

52154411 Spring Plate

New Parts

No.

A0894218 Guide - Oil End Sensor

A0894217 Guide - Oil Supply

Description Rank

Q’ty Used

Old→New

1 → 1

1 → 0

0 → 1

0 → 1

Date of

Modification

Inter-

change-

ability

X/X X/O as a set 57 35

Parts needed for replacement by new part

Part No. Description No. Page

* New Index

Serial

Number

Parts

Catalog

67 35

*87 35

*88 35

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 38

MODIFICATION BULLETIN NO. 18 PAGE 2 OF 3

[A]

ISSUED ON: January 15, ’94

DETAILS OF MODIFICATION

After a machine has bee n use d fo r a long time , pa pe r powd er an d toner are mixed in the silicone oil, an d sink to the bottom

of the toner tank. If this pre cipitation is pumped up to be supp lied to th e fusing roller, it sticks on the oil sup ply pa d cau sing

insufficient oil supply to the fusin g roller.

To prevent this, the end po sitions of the oil end sensor [A] and the oil supp ly tub e [B ] ha ve be er raise d.

1. The length of the oil supply tube [B] has bee n cha nged from 105mm to 70mm

2. Two guides for the oil end sensor and the oil supply tube have been added.

3. The spring plate (pag e 35 , ind ex 29 ) h as been re move d.

NOTE: Set the two guides as shown [C].

Index 87

[B]

Index 88

[C]

S. Hamano, Assistant General Manager

Technical Support Department

Page 39

MODIFICATION BULLETIN NO. 18 PAGE 3 OF 3

ISSUED ON: January 15, ’94

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15 39402XXXXX

Ricoh FT400 i 110/60 Taiwan A089-19 A327402XXXX

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A327402XXXX

Savin 9050 i 115/60 USA Canada A089-15 1940100001

Ricoh FT500 i 110/60 Taiwan A089-19 A333402XXXX

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A333402XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 40

MODIFICATION BULLETIN NO. 19 PAGE 1 OF 2

ISSUED ON: January 15, ’94

Model SP40 / 50 Volt/Hz

Modified Article Fusing unit gears

Reason for

Modification

To increase durability

Date of

Modification

To increase durability, th e mat erial of the fusing unit gea rs has be en chan ge d. The gea r - 17Z has be en chan ge d to a

gear and bearing combina tio n.

Old P/N New P/N Description Q’ty Used

AB013651 A0894915 Gear - 18Z

AB013648 AB013901 Gear - 17Z

07413506 Ball Bearing - 6 x 12 x 4mm

115

1 → 1

1 → 1

0 → 1

17

Inter-

change-

ability

x/o 33 35

x/o as a set 17 37

Index No. Page

Parts Catalog

115 37

Serial Number

33

S. Hamano, Assistant General Manager

Technical Support Department

Page 41

MODIFICATION BULLETIN NO. 19 PAGE 2 OF 2

ISSUED ON: January 15, ’94

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15 3931200001

Ricoh FT400 i 110/60 Taiwan A089-19 A327402XXXX

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A327402XXXX

Savin 9050 i 115/60 USA Canada A089-15 1940100001

Ricoh FT500 i 110/60 Taiwan A089-19 A333402XXXX

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3334010001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 42

MODIFICATION BULLETIN NO. 20 PAGE 1 OF 3

ISSUED ON: January 15, ’94

Model SP40 / 50 Volt/Hz

Modified Article Oil Blade Ass’y

Reason for

To facilitate servicing

Modification

Draw

No.

Old Parts

No.

A1084017 A0899501 Oil Blade Ass’y

New Parts

No.

A0894110 Clip - Oil Blade

Description Rank

Q’ty Used

Old→New

1 → 1

0 → 2

Date of

Modification

Inter-

change-

ability

O/O 11 37

Parts needed for replacement by new part

Part No. Description No. Page

Serial

Number

Parts

Catalog

42 37

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 43

MODIFICATION BULLETIN NO. 20 PAGE 2 OF 3

ISSUED ON: January 15, ’94

DETAILS OF MODIFICATION

To make it possible to remove the oil blad e with ou t remo ving the oil supply roller, the span of the oil blade ass’y

[A] has been shortened. The oil blade can be removed if it is slid sideways, af te r removing the two newly added

clips [B].

[B]

[A]

S. Hamano, Assistant General Manager

Technical Support Department

Page 44

MODIFICATION BULLETIN NO. 20 PAGE 3 OF 3

ISSUED ON: January 15, ’94

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15 3931100101

Ricoh FT400 i 110/60 Taiwan A089-19 A327402XXXX

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A327402XXXX

Savin 9050 i 115/60 USA Canada A089-15 1940100001

Ricoh FT500 i 110/60 Taiwan A089-19 A333402XXXX

Ricoh FT500 i 220/50 Asia, Oceania A089-29 A3334010001

V/Hz DESTINATION CODE SERIAL NUMBER

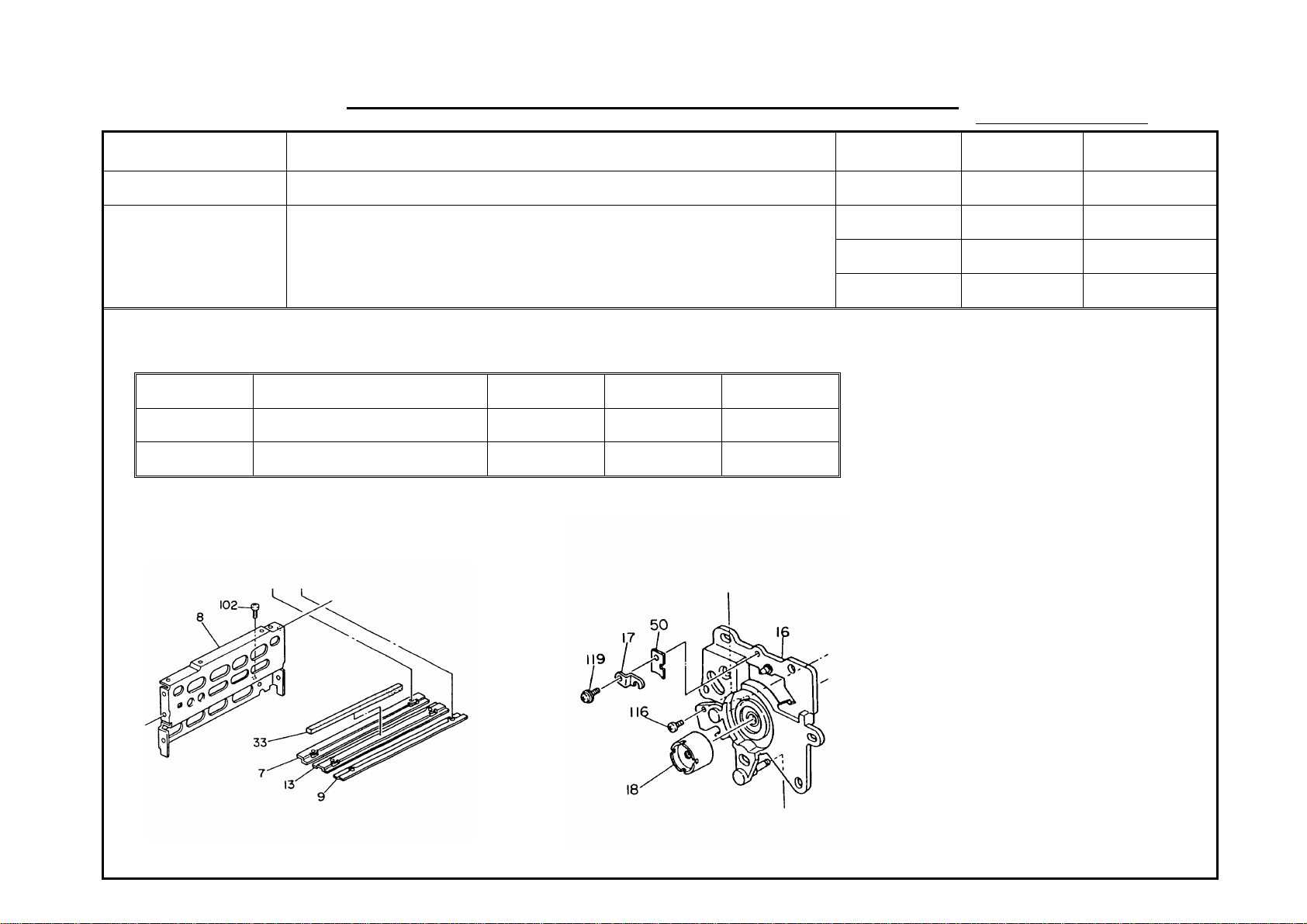

Page 45

MODIFICATION BULLETIN NO. 21 PAGE 1 OF 3

ISSUED ON: January 31, ’94

Model SP40/50 Volt/Hz

Modified Article Paper feed gear

Reason for

To facilitate servicing

Modification

Draw

No.

Old Parts

No.

AB017238 A0891104 Gear - 20Z/32Z

07403808 Bearing - 8 x 19 x 6mm

07403208 Bearing - 8 x 24 x 8mm

New Parts

No.

Description Rank

Q’ty Used

Old→New

1 → 1

1 → 0

1 → 0

Date of

Modification

Inter-

change-

ability

X/O 13 21

Parts needed for replacement by new part

Part No. Description No. Page

Serial

Number

Parts

Catalog

115 21

116 21

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 46

MODIFICATION BULLETIN NO. 21 PAGE 2 OF 3

DETAILS OF MODIFICATION

To facilitate service, the ge ar - 20Z/ 32 Z is to be asse mble d with the two bearings (07403808

and 07403208) to be sup plied as one.

13

116

13

115

ISSUED ON: January 31, ’93

S. Hamano, Assistant General Manager

Technical Support Department

Page 47

MODIFICATION BULLETIN NO. 21 PAGE 3 OF 3

ISSUED ON: January 31, ’93

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15

Ricoh FT400 i 110/60 Taiwan A089-19

Ricoh FT400 i 220/50 Asia, Oceania A089-29

Savin 9050 i 115/60 USA Canada A089-15

Ricoh FT500 i 110/60 Taiwan A089-19

Ricoh FT500 i 220/50 Asia, Oceania A089-29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 48

MODIFICATION BULLETIN NO. 22 PAGE 1 OF 2

ISSUED ON: January 31, ’94

Model SP40 / 50 Volt/Hz

Modified Article Pressure Roller Spring (SP50 only)

Reason for

To facilitate manufacturing

Modification

To make the margin of clearance between the sprin g an d th e pa pe r e xit unit, the

diameter of the spring has been changed from 12.1mm to 9.6mm.

Inter-

Old P/N New P/N Description Q’ty Used

AA060531 AA060564 Spring

1 → 1

change-

ability

O/O 24 37

Parts Catalog

Index No. Page

Date of

Modification

Serial Number

S. Hamano, Assistant General Manager

Technical Support Department

Page 49

MODIFICATION BULLETIN NO. 22 PAGE 2 OF 2

V/Hz DESTINATION CODE SERIAL NUMBER

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15

Ricoh FT400 i 110/60 Taiwan A089-19

Ricoh FT400 i 220/50 Asia, Oceania A089-29

Savin 9050 i 115/60 USA Canada A089-15

Ricoh FT500 i 110/60 Taiwan A089-19

Ricoh FT500 i 220/50 Asia, Oceania A089-29

ISSUED ON: January 31, ’94

Page 50

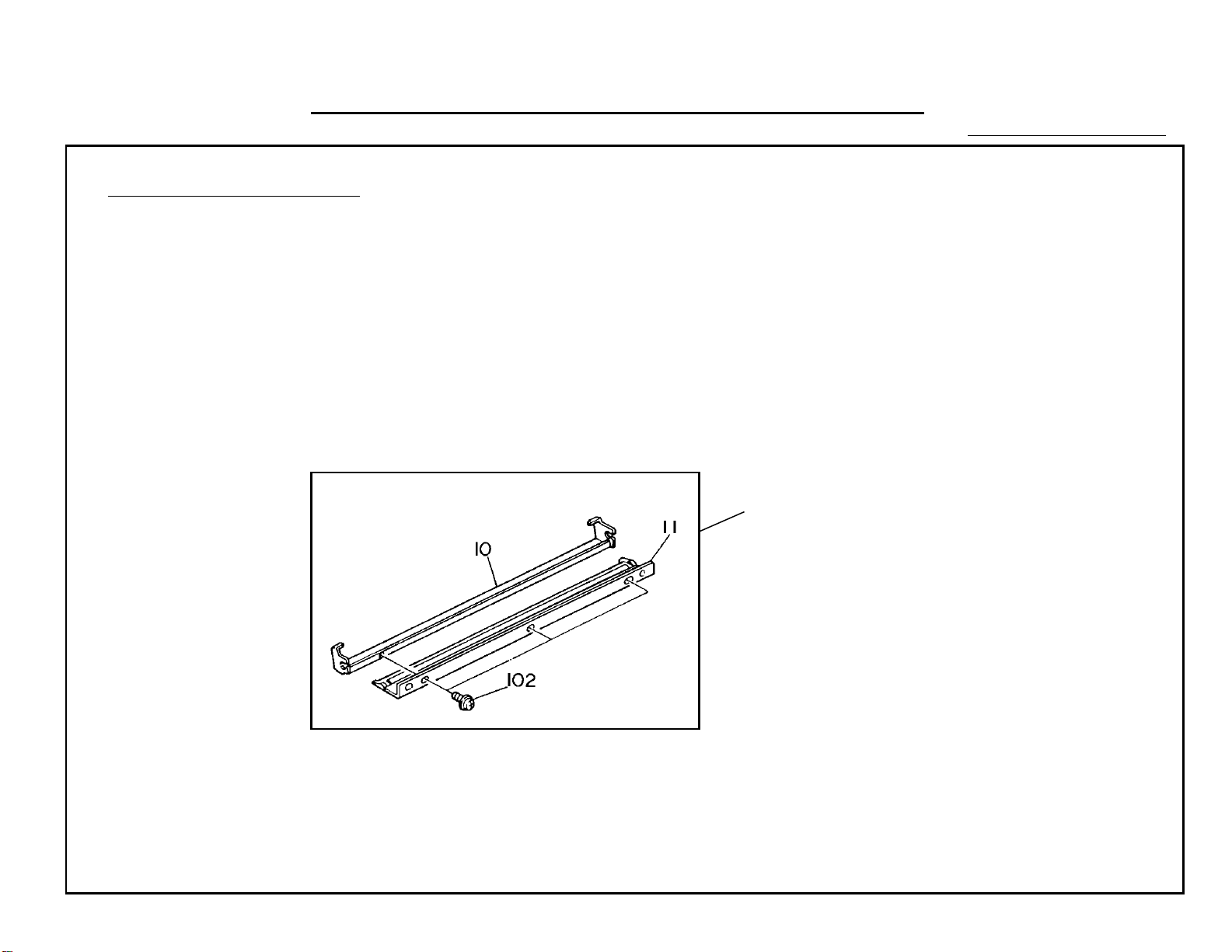

MODIFICATION BULLETIN NO. 24 PAGE 1 OF 2

44

ISSUED ON: July 15, ’94

Model SP40 Volt/Hz

Modified Article Parts Catalog

Reason for

Parts Catalog Correction

Modification

Please collect the illustration of page 34 as shown below.

44 40

39

42

41

Date of

Modification

Serial Number

48

102

S. Hamano, Assistant General Manager

Technical Support Department

Page 51

MODIFICATION BULLETIN NO. 24 PAGE 2 OF 2

ISSUED ON: July 15, ’94

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15

Ricoh FT400 i 110/60 Taiwan A089-19

Ricoh FT400 i 220/50 Asia, Oceania A089-29

Savin 9050 i 115/60 USA Canada A108-15

Ricoh FT500 i 110/60 Taiwan A108-19

Ricoh FT500 i 220/50 Asia, Oceania A108-29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 52

MODIFICATION BULLETIN NO. 25 PAGE 1 OF 2

ISSUED ON: July 31, ’94

Model SP40 / SP50 Volt/Hz

Modified Article Stud

Reason for

Vender Change

Modification

Due to vender chang e, part numbers of the st ud has be en chan ge d.

Inter-

Old P/N New P/N Description Q’ty Used

AA143045 54032819 Stud

1 → 1

change-

ability

O/O

Date of

Modification

Parts Catalog

Index No. Page

54

16

35

39

Serial Number

S. Hamano, Assistant General Manager

Technical Support Department

Page 53

MODIFICATION BULLETIN NO. 25 PAGE 2 OF 2

ISSUED ON: July 31, ’94

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15

Ricoh FT400 i 110/60 Taiwan A089-19

Ricoh FT400 i 220/50 Asia, Oceania A089-29

Savin 9050 i 115/60 USA Canada A108-15

Ricoh FT500 i 110/60 Taiwan A108-19

Ricoh FT500 i 220/50 Asia, Oceania A108-29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 54

MODIFICATION BULLETIN NO. 26 PAGE 1 OF 2

ISSUED ON: July 31, ’94

Model SP40/50 (SP40 Only) Volt/Hz

Modified Article Main Board ROM

Reason for

To erase white line in the half tone area

Modification

Parts Catalog

Old P/N New P/N Description

Index No. Page

A0895129 A0895128 IC - AM27C512 - 155DC 2 49

Date of

Modification

It was reported that a few thousa nd copies after installation, vertical white lines start to appear on the cop ies. This

especially happens in the half tone are a of the 1st cop y. This problem is caused by toner particles accu mula ting on the

cleaning blade edge during the cop y run. To minimize the vertical white lines on the 1st copy, the transp ort and main

change timings have been changed.

Serial Number

S. Hamano, Assistant General Manager

Technical Support Department

Page 55

MODIFICATION BULLETIN NO. 26 PAGE 2 OF 2

ISSUED ON: July 31, ’94

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15

Ricoh FT400 i 110/60 Taiwan A089-19 A3273040001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A327310001

Savin 9050 i 115/60 USA Canada A108-15

Ricoh FT500 i 110/60 Taiwan A108-19

Ricoh FT500 i 220/50 Asia, Oceania A108-29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 56

MODIFICATION BULLETIN NO. 27 PAGE 1 OF 2

ISSUED ON: July 31, ’94

Model SP40/50 (SP50 Only) Volt/Hz

Modified Article Main Board ROM

Reason for

To minimize paper separation jams

Modification

Parts Catalog

Old P/N New P/N Description

Index No. Page

A1085129 A1085127 IC - AM27C512 - 150DC 2 49

Date of

Modification

It was reported that separa tio n jams (03) are sometimes detected when options (sorter, ADF, duplex unit) are

installed on the SP50. This is becau se sensor on timing in the software is delayed from the actual sensor on time

when an option is installed. If the sen sor on timing in the software is later than the jam det ect ion timing , a pa per ja m

is detected. The occurrence ratio is highe r if more op tio ns are installed.

To counter this, the jam detection timing in the software has been changed.

Serial Number

S. Hamano, Assistant General Manager

Technical Support Department

Page 57

MODIFICATION BULLETIN NO. 27 PAGE 2 OF 2

ISSUED ON: July 31, ’94

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15

Ricoh FT400 i 110/60 Taiwan A089-19

Ricoh FT400 i 220/50 Asia, Oceania A089-29

Savin 9050 i 115/60 USA Canada A108-15 1931100001

Ricoh FT500 i 110/60 Taiwan A108-19 A333401XXXX

Ricoh FT500 i 220/50 Asia, Oceania A108-29 A3333120001

V/Hz DESTINATION CODE SERIAL NUMBER

Page 58

MODIFICATION BULLETIN NO. 28 PAGE 1 OF 3

ISSUED ON: July 31, ’94

Model SP40 / 50 Volt/Hz

Modified Article Decal - Fusing Cover

Reason for

To ensure correct operation by customers

Modification

Draw

No.

Old Parts

No.

AA001239 AA001284 Decal - Fusing Cover

New Parts

No.

Description Rank

Q’ty Used

Old→→New

1 → 1

Date of

Modification

Inter-

change-

ability

X/O 24 35

Parts needed for replacement by new part

Part No. Description No. Page

Serial

Number

Parts

Catalog

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for

replacement by new part" to install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether

the new part can be used in the old machine. x = Not interchangeable o = Interchangeable

Page 59

MODIFICATION BULLETIN NO. 28 PAGE 2 OF 3

ISSUED ON: July 31, ’94

DETAILS OF MODIFICATION

When the fusing unit is pulle d ou t, the Fusing Cover [A] should be handled.

If a customer pulls out the fusing unit by handling th e oil ta nk [B], the tank position would move out of its normal

position causing oil lea kag e.

To ensure correct operatio n, the Decal - Fusing Cover ha s bee n cha nged .

[B]

[A]

S. Hamano, Assistant General Manager

Technical Support Department

Page 60

MODIFICATION BULLETIN NO. 28 PAGE 3 OF 3

ISSUED ON: July 31, ’93

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15 394020001

Ricoh FT400 i 110/60 Taiwan A089-19 A327403XXXX

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A327403XXXX

Savin 9050 i 115/60 USA Canada A108-15 1940200001

Ricoh FT500 i 110/60 Taiwan A108-19 A333403XXXX

Ricoh FT500 i 220/50 Asia, Oceania A108-29 A333403XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 61

MODIFICATION BULLETIN NO. 29 PAGE 1 OF 2

ISSUED ON: January 15, ’95

Model SP40 / SP50 Volt/Hz

Modified Article Fusing Unit Oil Sump

Reason for

To prevent oil leakage

Modification

Date of

Modification

To prevent oil leakage fro m t he oil b lad e an d th e oil sump when paper sludge accumulat es on the oil blad e / oil

sump, guide plates and end fence have been added to the oil sump as sho wn in the illustration. The sup port

bracket has also been changed to mat ch the new style oil sump.

Old P/N New P/N Description Q’ty Used

A0304118 A0894104 Oil Sump

A0894113 A0894114 Oil supply Support Bracket

1 → 1

2 → 2

Inter-

change-

ability

X/O 28 37

X/O 31 37

Parts Catalog

Index No. Page

Support Bracket

Serial Number

Old Style

Guide Plate

Fence

New Style

S. Hamano, Assistant General Manager

Technical Support Departme nt

Page 62

MODIFICATION BULLETIN NO. 29 PAGE 2 OF 2

ISSUED ON: January 15, ’95

MODEL NAME

Savin 9040 i 115/60 USA Canada A089-15 3940800001

Ricoh FT400 i 110/60 Taiwan A089-19 3930900001

Ricoh FT400 i 220/50 Asia, Oceania A089-29 A3273090001

Savin 9050 i 115/60 USA Canada A108-15 194080001

Ricoh FT500 i 110/60 Taiwan A108-19 A333412XXXX

Ricoh FT500 i 220/50 Asia, Oceania A108-29 A3334080008

V/Hz DESTINATION CODE SERIAL NUMBER

Page 63

MODIFICATION BULLETIN NO. 30 PAGE 1 OF 1

ISSUED ON: October 31, ’95

Model SP40 / 50 Volt/Hz

Modified Article Parts Catalog No serial number cut-in information

Reason for

Parts Catalog Correction

Modification

Date of

Modification

Serial Number

Please correct your parts catalog as follows:

Incorrect P/N Correct P/N Incorrect Description Correct Description

Index No. Page

A0894145 A0894140 Fusing Unit Left Rail Entrance Guide Plate 26 37

A0894140 A0894145 Entrance Guide Plate Fusing Unit Left Rail 33 37

Parts Catalog

A0894140

Entrance Guide Plate

A0894145

Fusing Unit Left Rail

M. Iwasa, Manager

Technical Support Department

Page 64

MODIFICATION BULLETIN NO. 30 PAGE 1 OF 1

ISSUED ON: November 15, ’95

Model SP40 / 50 Volt/Hz

Modified Article Power Relay DC 24V No serial number cut-in information

Reason for

Vender change

Modification

Inter-

Old P/N New P/N Description Q’ty Used

12081081 12081394 Power Relay - DC24V

1 → 1

change-

ability

O/O 115 43

Index No. Page

Date of

Modification

Parts Catalog

Serial Number

M. Iwasa, Manager

Technical Support Department

Page 65

MODIFICATION BULLETIN NO. 32 PAGE 1 OF 1

ISSUED ON: December 31, ’95

Model SP40 / 50 Volt/Hz

Modified Article

Reason for

Modification

Old P/N New P/N Description Q’ty Used

1407 2057 IC - 82C55AFP - 5

1407 2058

ICs

Vender change

1407 3336 IC - TMP82C55AM - 10

IC - 82C54FP - 6

1407 3756 TIMER - TMP82C54M - 2

Inter-

change-

ability

1 → 0

O/O 136 49

0 → 1

1 → 0

O/O 137 49

0 → 1

Date of

Modification

No serial number cut-in information

Parts Catalog

Index No. Page

Serial Number

M. Iwasa, Manager

Technical Support Department

Loading...

Loading...