Page 1

Technical Bulletin No. RTB-001

SUBJECT: Duplex Jams

- Jogger Home Position Sensor Adjustment

- Jogger Drive Belt Tension Adjustment

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Since we have received field reports concerning the duplex misfeed problems, we have

revised the jogger unit adjustments as a troubleshooting guide.

SYPMTOM:

Paper jams in the duplex unit. K, F, and G jams.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 Type X/Y

DATE: July 15, ’92

PAGE: 1 of 3

CAUSE:

The distance between the jogger fences of the

duplex unit is smaller than the paper width. This

gives excess load to the paper stack in the

jogger unit and causes paper misfeeds.

The followings are possible causes:

1. Paper size is slightly larger than the standard size.

2. Improper jogger home position adjustment.

3. Improper jogger drive belt tension.

ACTION:

If the paper size is not the standard size, the procedure described in the manual would

not give the correct jogger fence positions. Please use the following adjustment procedure

for the jogger home position sensor in the field.

The tension spring for the jogger drive timing belt has not been implemented to any

mass-production units, so please change your manual for the jogger drive belt adjustment

as follows:

Page 2

Technical Bulletin No. RTB-001

SUBJECT: Duplex Jams

- Jogger Home Position Sensor Adjustment

- Jogger Drive Belt Tension Adjustment

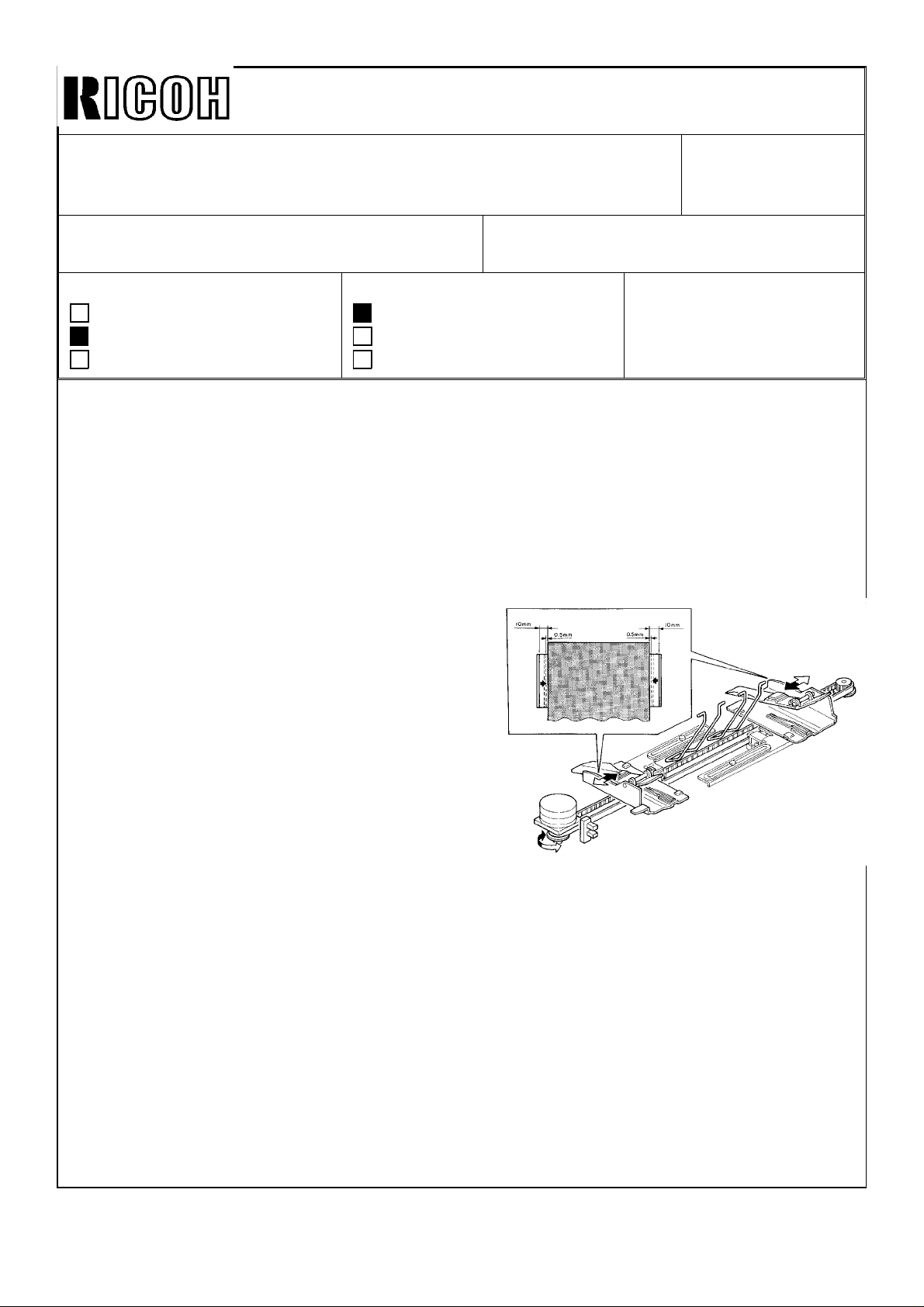

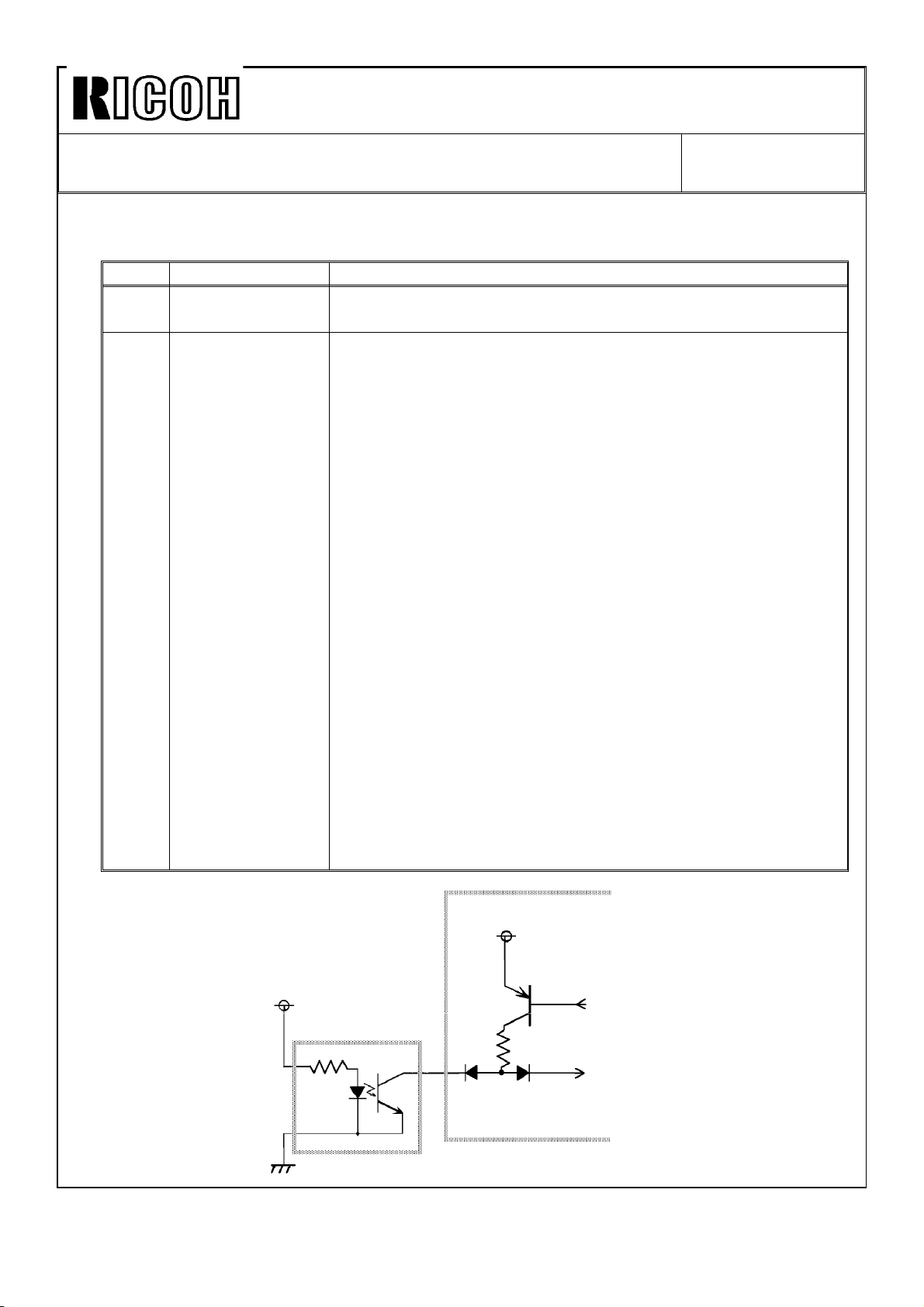

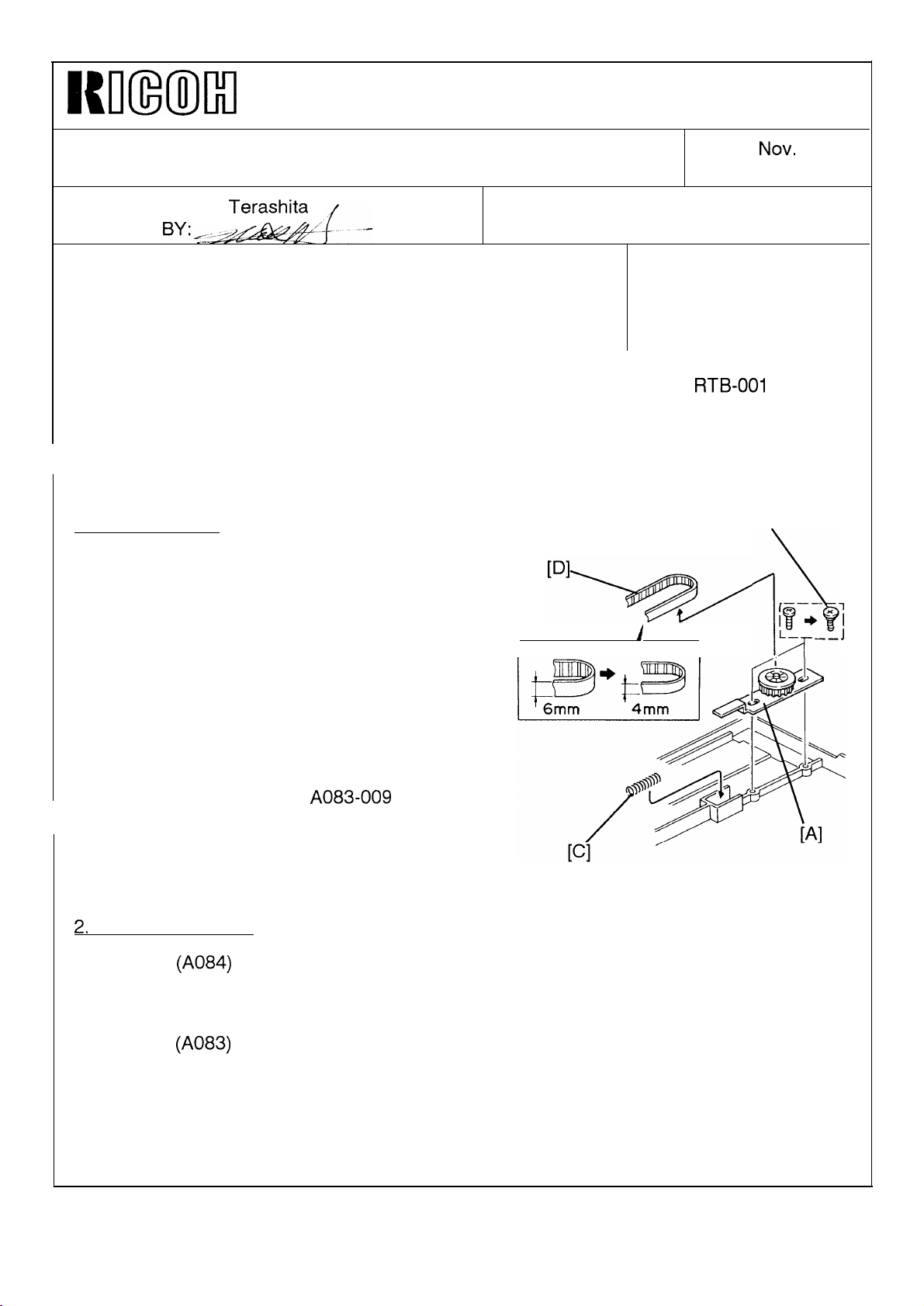

A. Jogger Home Position Sensor Adjustment

Please refer to the service manual page 5-105.

DATE: July 15, ’92

PAGE:2 of 3

[B]

[A]

1. Select a duplex mode and feed a copy paper to the duplex unit.

2. Check the jogger fence position in the duplex unit and measure the gap [B]

between the fence and paper edge.

3. Remove the duplex unit cover (4 screws).

4. If the gap [B] is small and the fences are pressing the paper, shift the jogger home

position sensor bracket [A] to the front (loosen 1 screw).

5. If the gap [B] is wide and skew occurs in duplex mode, shift the sensor bracket to

the rear.

6. Repeat steps 1 thru 4 unitil the gap [B] is between 0 and 1mm.

Page 3

Technical Bulletin No. RTB-001

SUBJECT: Duplex Jams

- Jogger Home Position Sensor Adjustment

- Jogger Drive Belt Tension Adjustment

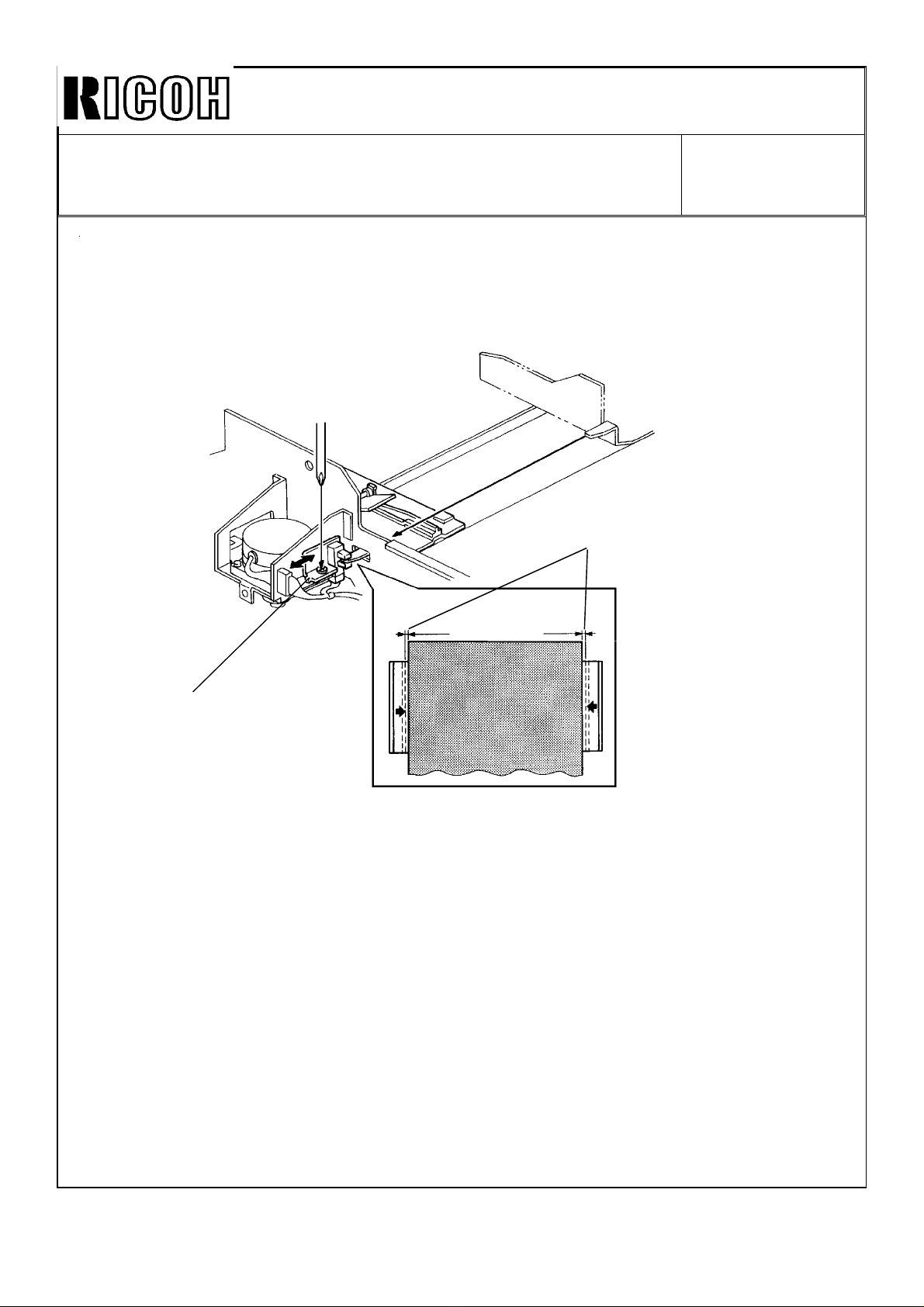

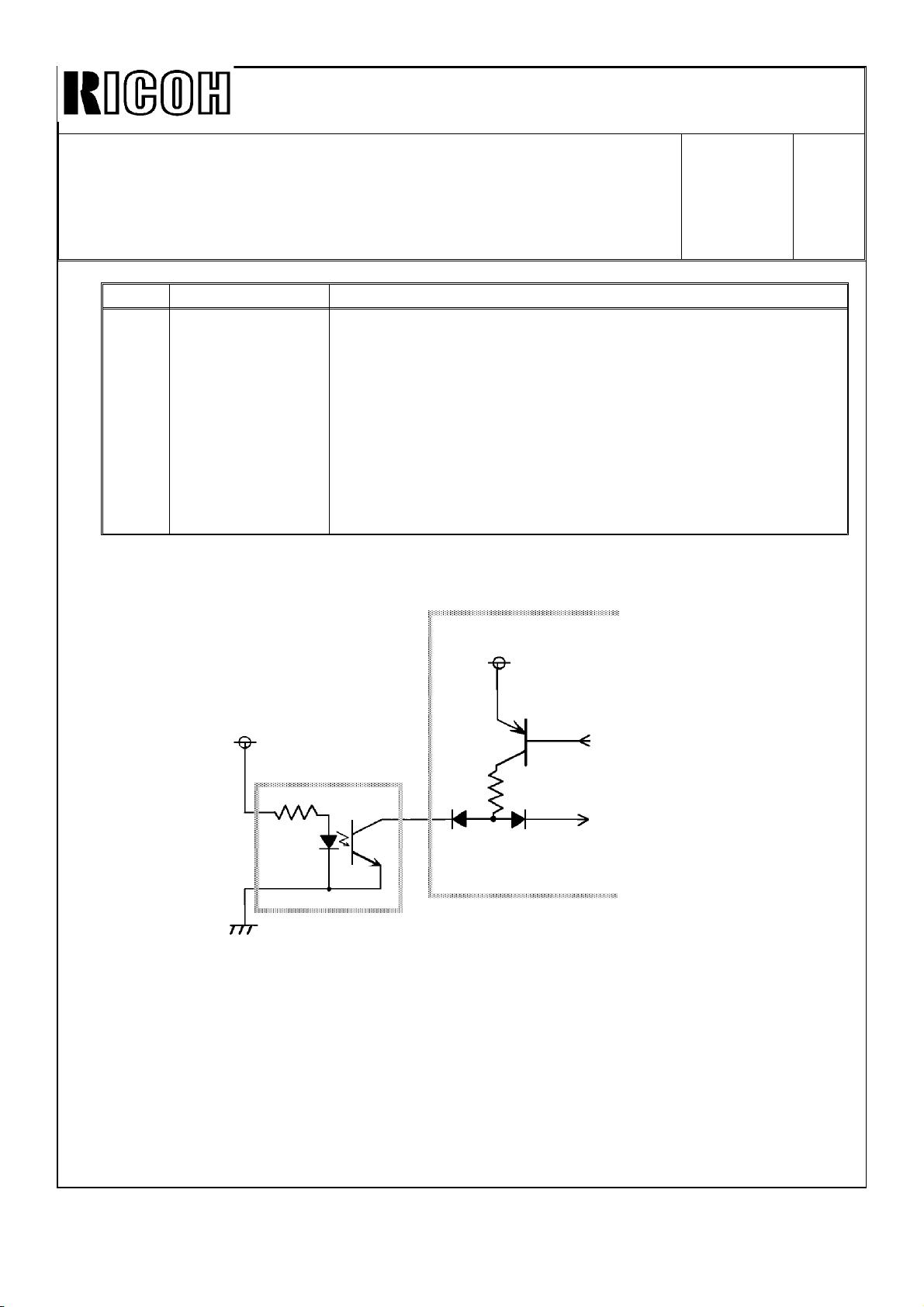

B. Jogger Drive Belt Tension Adjustment

Please refer to the service manual page 5-108.

[B]

DATE: July 15, ’92

PAGE: 3 of 3

[D]

[A]

[C]

1. Remove the duplex unit and the duplex cover (4 screws).

2. Turn over the duplex unit as shown.

3. Unhook the sensor harness [A] clamped on the bottom plate [B].

4. Remove the bottom plate [B] (2 screws and 2 hooks).

5. Move the jogger fences to the most inward positions manually.

6. Loosen two screws [C] for the pulley bracket.

7. Press the pulley shaft [D] using a tension gauge as shown.

8. Tighten the screws [C] when the tension gauge shows between 110 and 140g.

NOTE: If the drive belt tension is higher than the above values, the jogger drive

motor control might step-out due to the excess load.

Page 4

Im!xml

Technical Bulletin

No.

RTB-002

SUBJECT: Inverter Unit Jams (“l” area misfeed)

PREPARED

CHECKED BY:

CLASSIFICATION:

❑ Action Required

■ Troubleshooting

❑ Retrofit Information

SYMPTOM:

“l” area misfeeds occur. Misfed paper is observed in the inverter unit.

This problem occurs especially with thick

CAUSE:

Since the larger feed force is required to feed the thick paper inversion, if the pressure of

the return pinch roller in the inverter unit is Io

BY:

#---

FROM: Copier Technical Support Section

❑ Revision of service manual

❑ Information only

❑ Other

paper

and small

W,

rnisfeeds may

size paper (A5, 51/2 x 81/2).

MODEL: F200 Type X/Y

occur in the inverter section.

DATE:

PAGE: 1 of 2

July 15, ’92

ACTIONS:

Check the return pinch roller pressure according to the following procedure.

1.

2.

3.

Page 5

Technical Bulletin No. RTB-002

SUBJECT: Inverter Unit Jams ("I" area misfeed) DATE: July 15, ’92

PAGE: 2 of 2

5. If the pressure is low, remove the pinch

roller bracket [F] (2 screws) and remove

the cushions [G] for the pinch roller

bracket.

CAUTION:

The pinch roller pressure can be adjusted

by changing the pinch solenoid position,

however, we cannot recommend doing

this for this problem for the following reason.

[J]

[H]

[G]

[F]

[I]

Since the stopper [H] for the inverter unit

lock lever [I] and the solenoid bracket [J]

are one part, if you move the solenoid

bracket position, the lock lever home position would also be changed. This would

make it possible to set the lock lever [I] in

the wrong position (left of the pin [K])

when the inverter unit is closed.

[K]

OK NG

[K]

[K]

Page 6

Rll(mMl

Technical Bulletin

No.

RTB-003

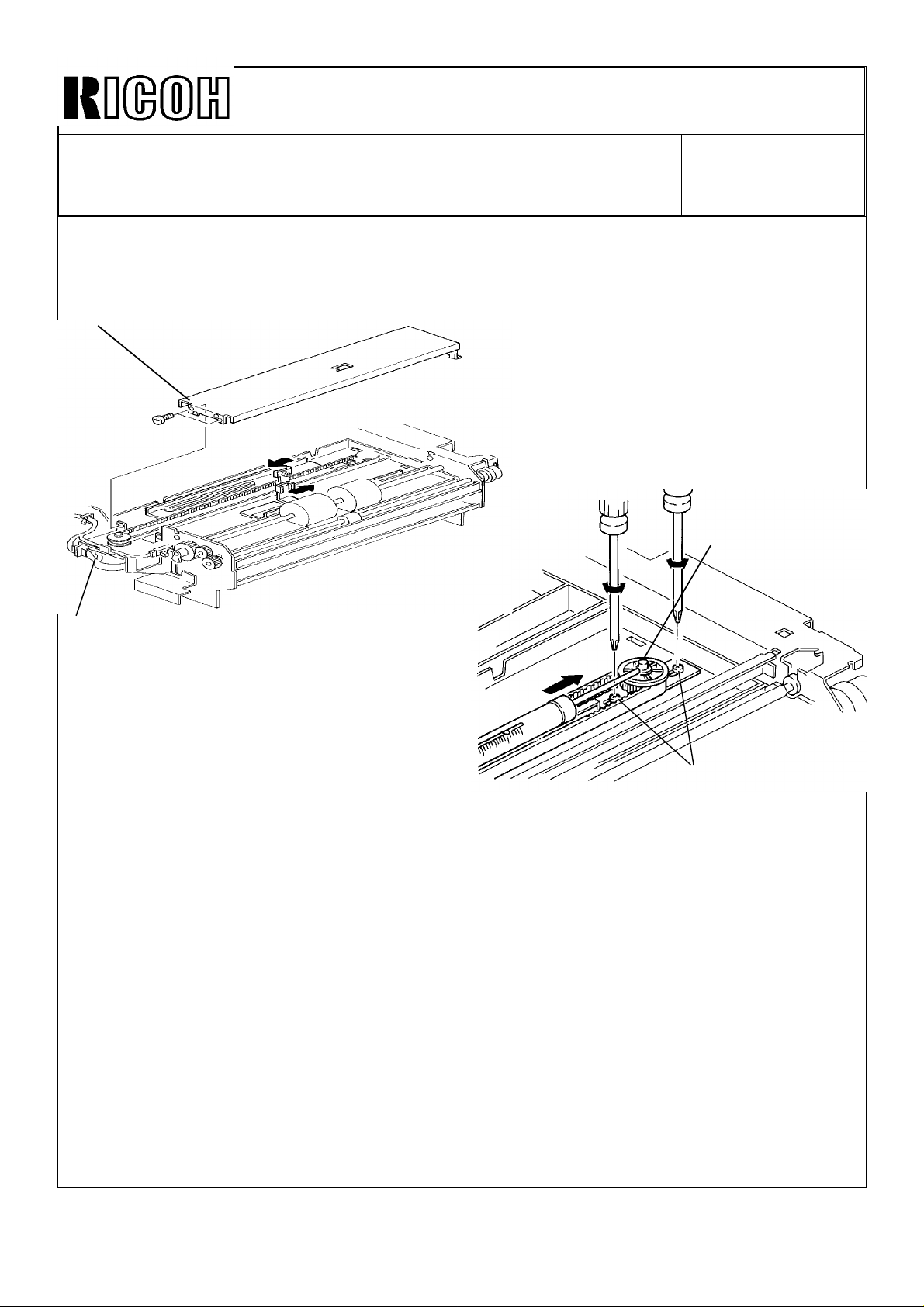

SUBJECT: Duplex Jams (F Area)

PREPARED BY: H.

CLASSIFICATION:

❑

Action Required

■

Troubleshooting

❑

Retrofit Information

SYMPTOM:

Jams occur in the duplex unit (“F” area Jams).

CAUSE:

Due to static electricity of fed paper, the sheets stick to each other and cause jams in the

duplex tray.

COUNTERMEASURES:

Terash”

❑

Revision of service manual

❑

Information only

❑

Other

FROM: Copier Technical Support Section

MODEL: F200 Type X/Y

DATE:

PAGE: 1 of 2

July

22, ’92

The material of the anti-static brushes in the duplex unit has been changed from stainless

steel to amorphous fiber which has high anti-static characteristic. They are applied from

the following productions:

F200 Type Y (A084) : June 1992 productions onward.

F200 Type X

Modification details will be announced by a later MB.

In the field:

If you have this type of jam, please follow the procedure below:

1. Slide out the duplex unit.

2. Open the duplex fork gate unit as

shown.

3. Remove the old anti-static brush

[A] with the grounding plate [B] (2

screws).

4. Install the new anti-static brush [C]

(P/N AA1 20061 ) with the grounding plate [B] (2 screws),

(A083) : May 1992 productions onward.

[A]

NOTE:

. Make sure the brush holder is

neath the gate

. Make sure the grounding plate po

as shown.

pawls

as shown.

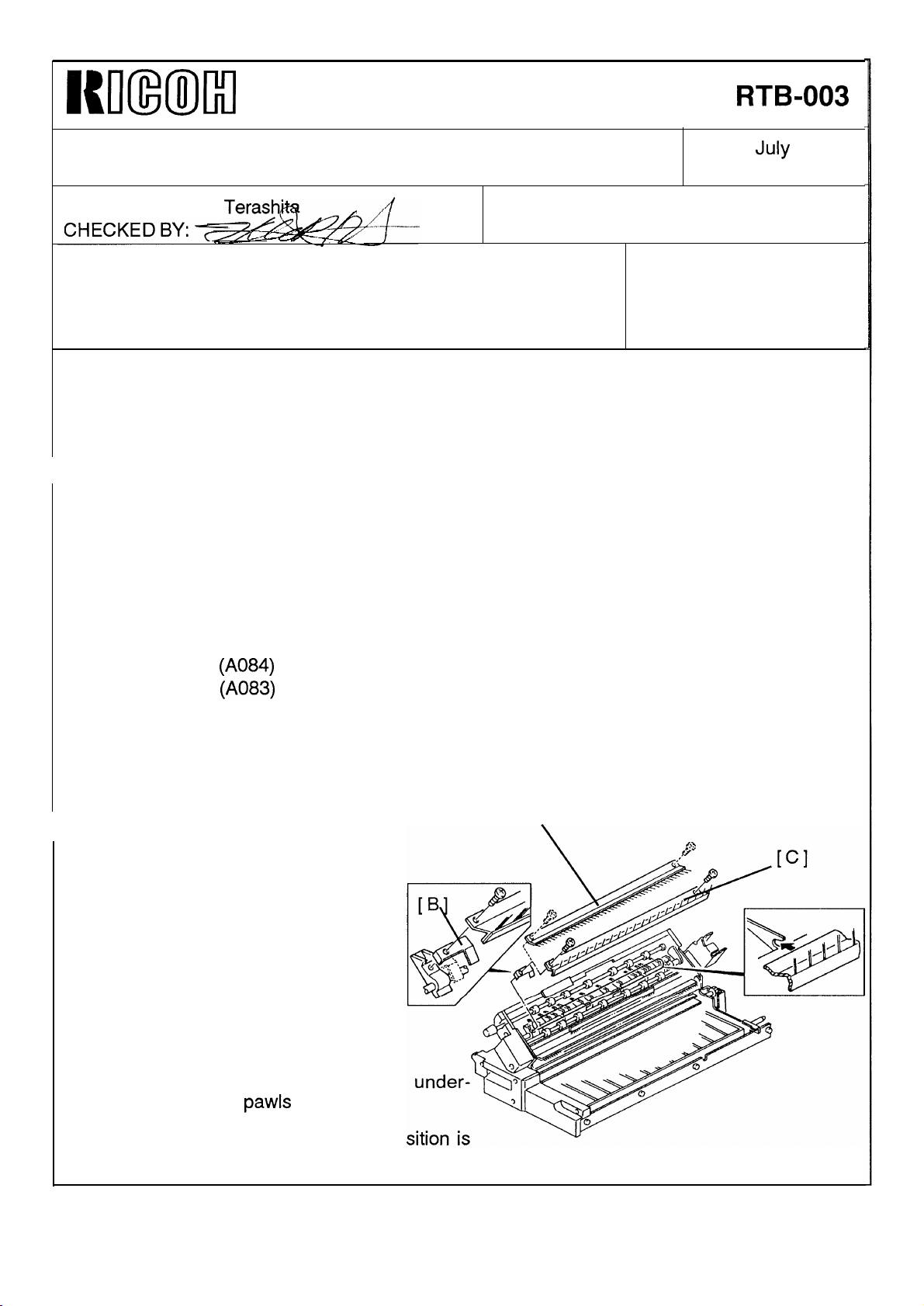

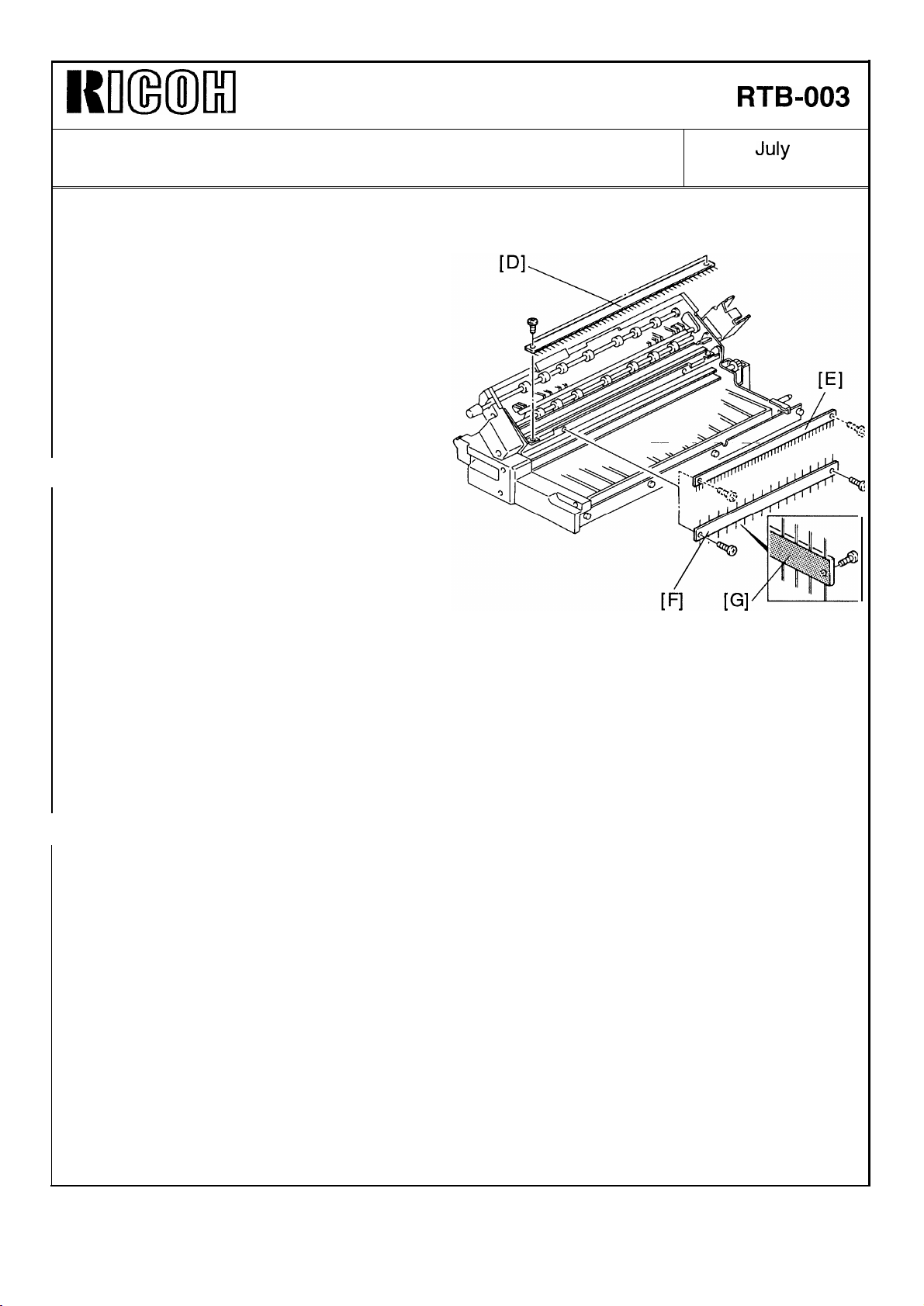

Page 7

I{ouml

Technical Bulletin No.

RTB-003

SUBJECT: Duplex Jams (F Area)

5. Remove the old brushes

[E] (2 screws each).

6. Install the new brush [F]

AA120062) so that the aluminum

seal [G] faces the bracket.

[D] and

(P/N

DATE:

PAGE: 2 of 2

July

31, ’92

Page 8

I{m(mil

Technical Bulletin

No.

RTB-004

SUBJECT: Drum damage by adhered toner on the development

sleeve

PREPARED BY:

CHECKED

CLASSIFICATION:

❑ Action Required

■ Troubleshooting

❑ Retrofit Information

SYMPTOM:

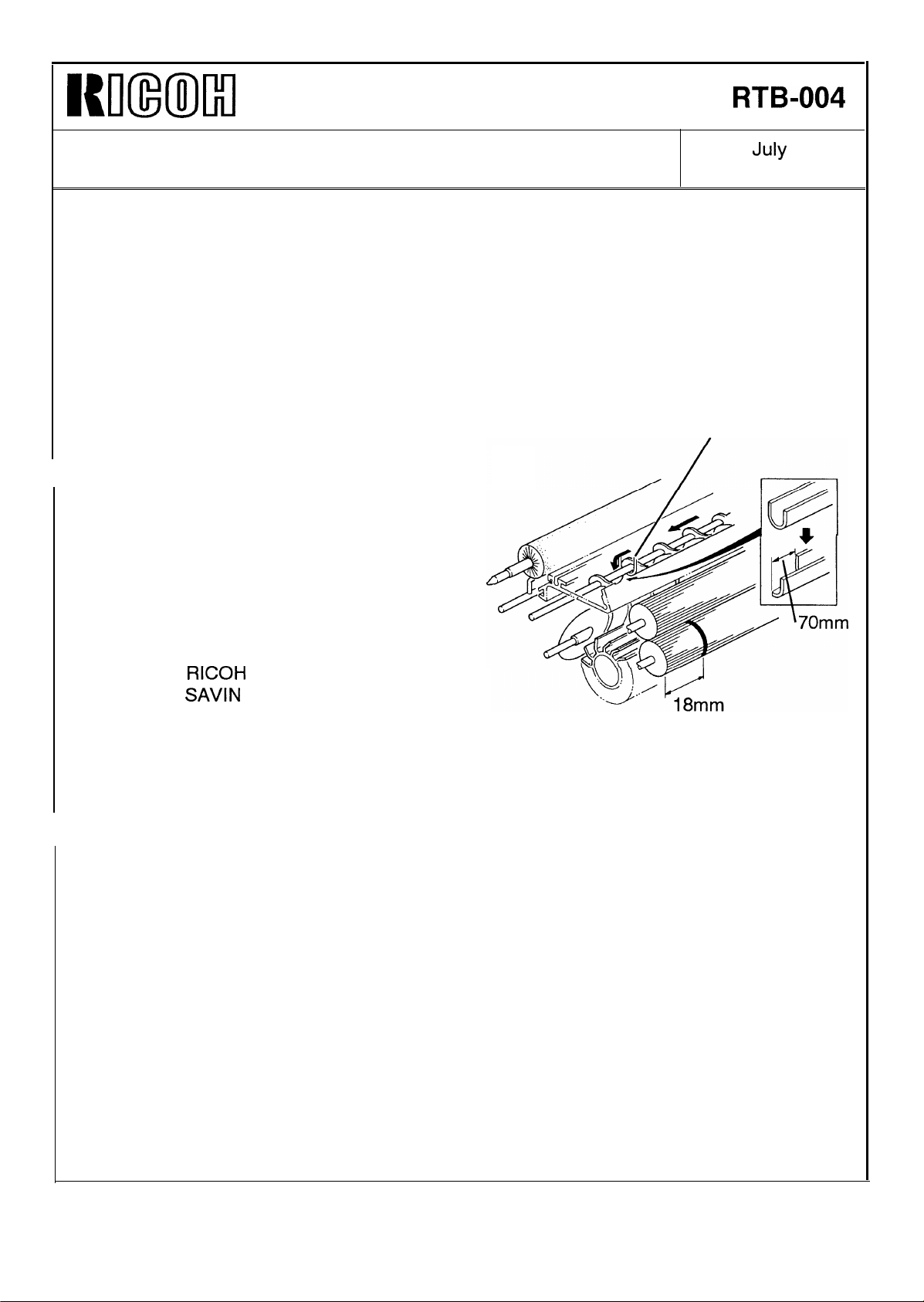

Toner adheres on the surface of the lower development sleeve (about 18mm from the

front end) and it makes scratches on the drum. This shows black lines on the copy image.

CAUSE:

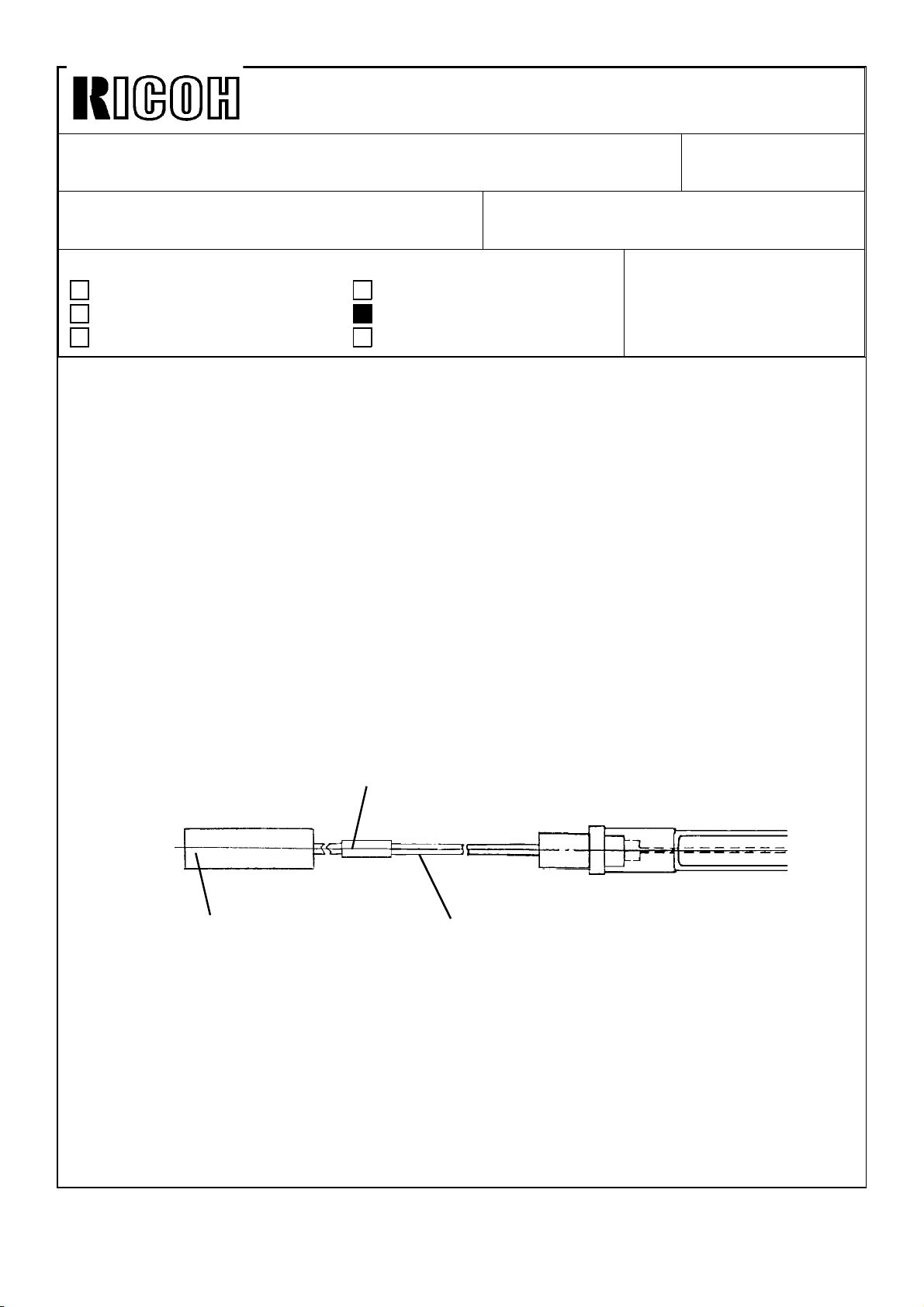

The cross mixing system mixes the

developer in the development unit. The

mixing vane [A] transports developer to the

rear and the auger [B] transports it to the

front.

The development motor turns at slower

speed after image development to remove

the developer on the development sleeves.

This operation reduces developer to the

mixing vane, however, the auger continues

turning and transports developer to the

front side of the development unit. This in-

creases developer amount at the paddle

roller front side area [C].

This uneven developer condition will normally be eliminated by the next copy cycle.

However, if copies are frequently made

one to each original, frequent slow down

operation continues to increase the

developer at the front side. The accumulated developer at the front side is brought

to the lower development sleeve and pack-

ed between the sleeve and the drum. This

large amount of developer makes friction

heat. Then, it melts and adheres toner on

the sleeve. Finally, accumulated adhered

toner on the sleeve damages the drum.

H. Terashita

BY=,~+==

FROM: Copier Technical Support Section

❑ Revision of service manual

❑ Information only

❑ Other

[B]

1

MODEL: F200 Type X/Y

[A]

I

DATE:

PAGE:

July 31, ’92

1

of 2

Page 9

Kmxml

Technical Bulletin

No.

RTB-004

SUBJECT: Drum damage by adhered toner on the development

sleeve

The toner adhesion occurs at about 30mm from the front end of the unit (18mm from the

sleeve end) for the following reasons:

1. The end of the auger guide [D] is located at about 30mm from the unit front end.

2. There is a peak of the magnetic force field of the lower sleeve located at that point.

COUNTERMEASURE:

To disperse the fallen developer from the

auger guide, the guide has been cut as

shown.

This modification has been applied from

July ’92 productions.

The auger guide cannot be replaced in the

field. This is because the guide is fixed on

the doctor blade. The following develop-

ment units are available as service parts,

DATE: July 31, ’92

PAGE: 1 of 2

[D]

A0843010RICOH(-17)

A0843016

A0843012

A0843014 HCS (-26) NRG (-22/25)

NOTE:

When you replace the damaged drum, the cleaning blade, which may be damaged by the

drum, should also be replaced at the same time,

RICOH

SAVIN

(-27)

(-15) NRG (-1 0/16)

Page 10

NKmMl

Technical Bulletin

No.

RTB-005

SUBJECT: EPROM Software History

PREPARED BY: H. Terashita

CHECKED

CLASSIFICATION

BY:~~.&?

:

❑ Action Required

❑ Troubleshooting

❑ Retrofit Information

This bulletin informs the

A084 5111/5112

A084 5131/5132

Suffix

Cut-in production

A

B

c

D

E

Mar. ’92

April ’92

May ’92

June ’92

July ’92

EPROM

(2Mbit

(2Mbit

/

❑ Revision of service manual

■ Information only

❑ Other

history of the main PCB for the model F200 type Y.

: Inch Version)

: Metric Version)

Changed items/Changed reasons

- The 2nd job in the preset mode could not use the stapling

function whenever the first job used stapling.

- The “Add Paper” indication did not disappear even if the

operator selected a different tray. This occurred only in

Cover/Slip sheet mode.

- If a CF had an odd number of pages, in 1 sided original

to 2 sided copy mode, the last copy was not fed out

automatically.

- The auto-staple function was not working in CFF mode.

- The cover sheet mode was not working in CFF mode.

- You could not exit from the SP mode if you stopped the

free run mode by touching the RESET key on the CRT.

- Eliminates SC 514,515,516,790,791, and 792 from the SP

data print out.

- Resets the Auto Drum Current Adjustment Mode and SC

Off Mode automatically whenever exiting from the SP mode.

- The copy quantity limit for sort mode was larger by 1 copy

than it should have been.

- The

function is added.

- Modifications on the RDS functions.

- This suffix EPROM handles data differently in SP mode

(see NOTE on the next page).

- Auto magnification change did not function when the CF

original size is selected in Cover/Slip Sheet mode.

- This EPROM corrects the data handling problem that

arose with the suffix D EPROM.

Savin/HCS

DATE:

PAGE: 1 of 2

FROM: Copier Technical Support Section

MODEL: F200 Type Y

—

serial number code (initial digits) print

July 31, ’92

Page 11

Kmm)ll+l

Technical Bulletin

No. RTB-005

SUBJECT: EPROM Software History

NOTE:

Only suffix D EPROMs have the following SP data handling:

1. Sensor output data (SP #7)

2. Setting of the ADF

SP mode. You have to exit the

A084 5121/5122 (512Kbit)

Suffix

Cut-in production

c

D

E

May ’92

June ’92

July

’92

and CFF

does not change during copy cycle.

registration adjustments can be changed only once in the

SP

mode before the next setting change on the CRT.

Changed items/Change reasons

- Optimizes actual toner supply amount.

- Enables the Clear/Stop key function in

mode.

- Changes the sorter by-pass tray drive timing in the paper

exit mode from the duplex tray.

- Corrects malfunctions in the SC off mode.

—

DATE:

PAGE: 2 of 2

ADF/CFF

July 31, ’92

free run

CAUTION:

When you make any

reading speed of the

Reading speed of the EPROMs must be faster than

2Mbit EPROM :

1

Mbit EPROM :

512Kbit

Most of the EPROM have their reading speed indicated

Example)

EPROM :

copy of the EPROMs of this model, please take care about the

EPROMs as follows:

<150

ns

<150

ns

<120

ns

µ PD27C2001D-15 (Reading Speed =

the values below:

on them.

150 ns)

Page 12

Technical Bulletin No. RTB-006

SUBJECT: Low Temperature Idling Mode (230V version only) DATE: Sept. 15, ’92

PAGE: 1 of 3

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

A capability limitation of the F200 is that, due to the limitation of the power to the copier, it

has a low temperature idling mode.

To minimize the occurrence of the idling time, the following modifications have been

applied.

1. Fusing Lamps

To increase the fusing heat output during the copy cycle, the fusing lamp of 950W, which

is used during the copy cycle, has been changed to 1000W.

The other lamp (720W) was also changed to 670W to keep the total power consumption

the same as before. This is because all the ac components, such as the transformer and

circuit breaker, are designed for a total power of 1670W (1000+670W).

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

(230V version only)

To distinguish the old and new lamps, a white tube has been added to the front lead wire

(black) of the fusing lamp (see figure).

White Tube

Connector

White : 670W

Red : 1000W

The new lamps have been implemented to the production machines as follows:

F200 Type X (A083) : August ’92 productions onward

F200 Type Y (A084) : September ’92 productions onward

Front Lead Wire

(Black)

Page 13

Technical Bulletin No. RTB-006

SUBJECT: Low Temperature Idling Mode (230V version only) DATE: Sept. 15, ’92

PAGE: 2 of 3

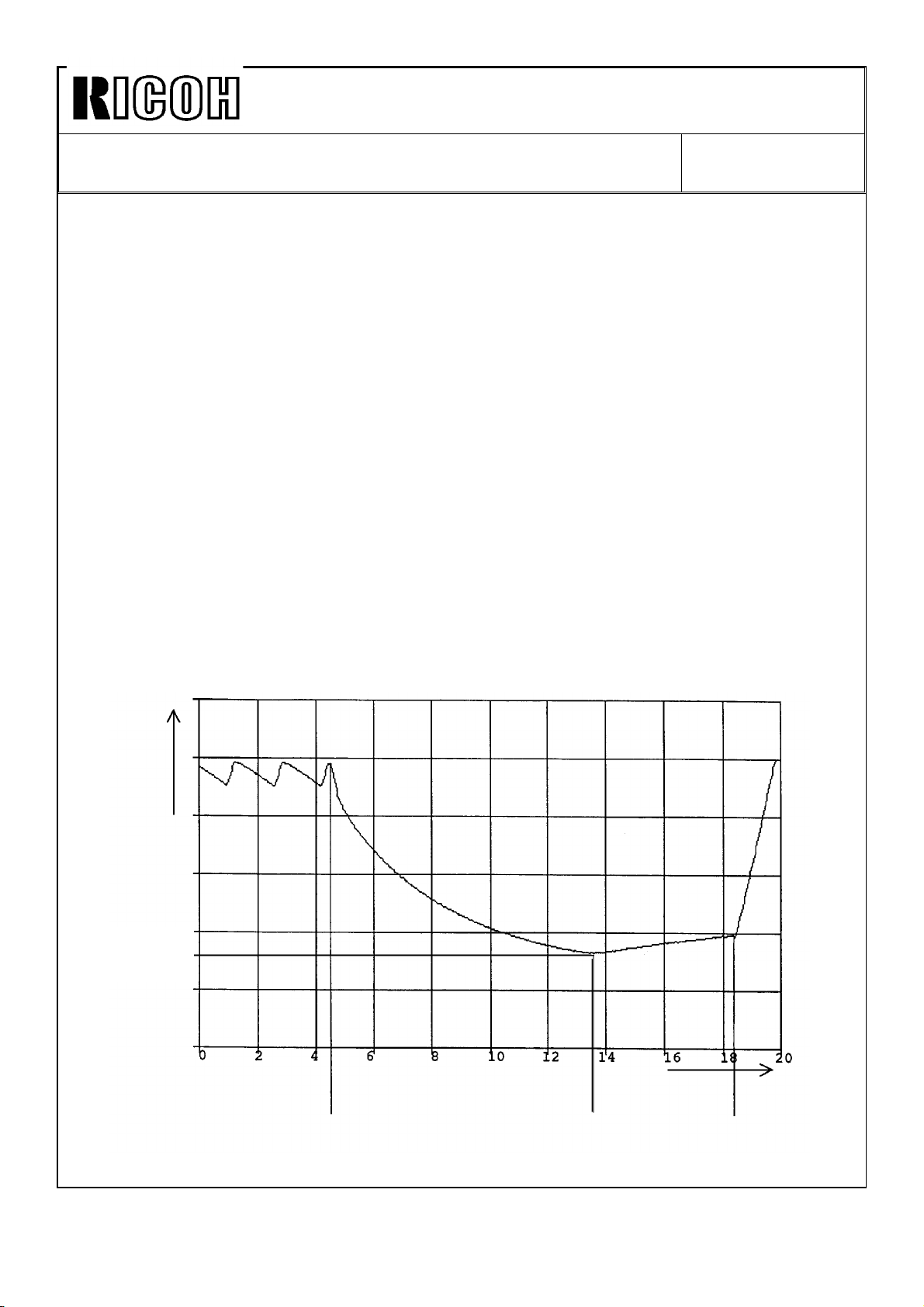

2. Software

To continue the copy run in low fusing temperature conditions as long as possible, the

software has been changed to lower the copy speed when the fusing temperature drops to

a certain temperature.

The copy speed is decreased by approximately 25% when the fusing temperature drops

below the lower limit temperature which is determined by the SP and User Tool settings

(see manual page 2- 96). For example, for the default settings, the slow-down copy cycle

will start when the temperature drops below 169°C.

Once the machine shifts to the slow-down copy mode, the mode is kept until the copy job

is finished even if the fusing temperature is recovered during the copy job.

Even if the slow-down mode is applied, the fusing temperature may drop in certain

conditions, such as A3 continuous copy run. A lower limit safety temperature has been

newly added to stop the copy run and to avoid any poor fusing problems when the

temperature drops below it. The lower limit safety temperature is lower than the lower limit

temperature by 5°C (164°C at default settings).

The following chart shows an ideal fusing temperature change in continuous copy run with

this new software.

Fusing Temp. °C

Lower Limit

Temperature

Start

Slow down

Min.

Stop

Page 14

Technical Bulletin No. RTB-006

SUBJECT: Low Temperature Idling Mode (230V version only) DATE: Sept. 15, ’92

PAGE: 3 of 3

The slow-down mode software has been applied to the following EPROMs on the main

PCB:

Type X : From August ’92 productions onward

A083 5131C

A083 5132C

A083 5121C

A083 5122C

Type Y : From August ’92 productions onward

A084 5131F

A084 5132F

A084 5121F

A084 5122F

There is no relationship between the new fusing lamps and the new software. You can use

the new EPROMs on the old machine without changing the fusing lamps and vice versa.

CAUTION:

The fusing lamps must be replaced as a set. If only the high output lamp is replaced to

1000W and old 720W lamp remains unchanged, the total current exceeds the rated values

of the ac components and may, in the worst case, cause damage and fire.

Page 15

Technical Bulletin No. RTB-007

SUBJECT: EPROM Software History DATE: Sept. 15, ’92

PAGE: 1 of 3

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This bulletin describes the EPROM history of the main PCB for the model F200 type X.

1. Operation Unit EPROMs

A083 5251/5252 (1Mbit : Inch Version)

A083 5256/5257 (1Mbit : Metric Version)

Suffix Cut-in production Changed items/Changed reasons

A July ’92 - Spelling mistake corrections

Revision of service manual

Information only

Other

- The "side to side registration adjustment", which is

only for the type Y, has been removed from the SP

mode 9 page 3.

- Inhibit to enter "2" for the paper designate page data

in; Single sided original duplex, Cover sheet, and Paper

designate modes when "Copy onto cover sheet" is set

in the User Tool.

- Enable canceling the Staple mode automatically in

staple inhibit modes, such as single feed and platen

copy modes.

FROM: Copier Technical Support Section

MODEL: F200 Type X

CAUTION:

There are some EPROMs which are not compatible to those used on the F200 even if the

memory size is the same (1Mbit). The following EPROMs are used on the F200.

Mitsubishi M5M27C101K-15

AMD Am27C010-155DC

Intel D27C010-150V10

Page 16

Technical Bulletin No. RTB-007

SUBJECT: EPROM Software History DATE: Sept. 15, ’92

PAGE: 2 of 3

2. Main PCB

A083 5111/5112 (2Mbit : Inch Version)

A083 5131/5132 (2Mbit : Metric Version)

* Suffix A has been applied from the 1st mass-production.

Suffix Cut-in production Changed items/Changed reasons

B July ’92 - The RDH motor remained on when the front door

was opened and closed during the original number

counting mode.

- Start key stayed red when CFF, both cover sheet

and copy onto cover sheet modes were selected.

- A single feed original in interrupt mode was not fed

out when the interrupt mode was canceled.

- P2 jam occurred when;

Original=11x17, Paper=81/2x11, Full size, Stack, and

copy quantity=2

C Aug. ’92 - Optimize the side erase amount.

- RDH fan motor remained on if the SC and Jam, or

SC and door open happened at the same time.

- An incorrect message was displayed when the start

key was pressed in platen or single feed mode with

stapling.

- When originals were set in the RDH and the start key

was pressed after stopping single feed copying, an

RDH jam occurred after the single feed original was

fed out.

- When the single feed mode copy was made with

originals in the RDH, if the start key was pressed just

when the start key turned green, the copying would not

stop until the Stop key was pressed.

- Enable transfering an old user code counter data to a

new one when the user code change function in the

User Tool is used.

- Software change related to the low temperature idling

mode (metric version only).

Page 17

Technical Bulletin No. RTB-007

SUBJECT: EPROM Software History DATE: Sept. 15, ’92

PAGE: 3 of 3

A083 5121/5122 (512Kbit)

Suffix Cut-in production Changed items/Changed reasons

B July ’92 - To adjust the ROM addresses to meet the 2Mbit

ROMs suffix B.

C Aug. ’92 - The junction gate solenoid in the inverter unit stays

on after face down and duplex copying. If the solenoid

check in SP mode is performed at this time, the wrong

error code would be displayed.

To prevent this, the software has been changed to

de-energize the solenoid when the main motor is

stopped.

- The sensor check in the SP mode is performed by

checking the sensor output while the sensor power is

turned on and off. The sensors which are connected to

the interface PCB, the tray upper and lower limit, paper

end, paper exit, and toner cartridge sensors, were

scanned by scan pulse signals from the main PCB.

Since the scan pulse signals are used for both power

and output signal for these sensors, the sensor check

does not work correctly (see figure).

So, the sensor check for these sensors has been

changed to enable only for ON check.

- The paper end sensor check has been changed to

enable only when the paper exists in the tray.

- The condition of the paper tray upper and lower limit

sensor check has been changed so that both are on or

off at the same time. Both sensor numbers will be

indicated under these conditions.

+12V

Sensor

+12V

Scan

Output

Interface PCB

Page 18

Technical Bulletin No. RTB-008

SUBJECT: EPROM Software History DATE: Sept. 15, ’92

PAGE: 1 of 3

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This bulletin describes the EPROM history of the main PCB for the model F200 type Y.

1. Operation Unit EPROMs

A084 5251/5252 (1Mbit : Inch Version)

A084 5256/5257 (1Mbit : Metric Version)

* Suffix A has been used from the 1st mass-productions.

Suffix Cut-in production Changed items/Changed reasons

B May ’92 - Spelling mistake corrections.

C June ’92 - Spelling mistake corrections. (Inch version only)

Revision of service manual

Information only

Other

- Reproduction priority settings have been changed.

77% -> 74%, 85% -> 77% (Inch version only)

FROM: Copier Technical Support Section

MODEL: F200 Type Y

CAUTION:

There are some EPROMs which are not compatible to those used on the F200 even if the

memory size is the same (1Mbit). The following EPROMs are used on the F200.

Mitsubishi M5M27C101K-15

AMD Am27C010-155DC

Intel D27C010-150V10

Page 19

Technical Bulletin No. RTB-008

SUBJECT: EPROM Software History DATE: Sept. 15, ’92

PAGE: 2 of 3

2. Main PCB

A084 5111/5112 (2Mbit : Inch Version)

A084 5131/5132 (2Mbit : Metric Version)

Suffix Cut-in production Changed items/Changed reasons

F Aug. ’92 - Optimize the side erase amount.

- Enable APS and AR/E functions with 11"x147/8"

originals.

- Enable transfering the old user code counter data to

a new one when the user code change function is

used.

- Correct mis-indication of the paper end when the slip

sheet runs out in the slip/paper designate modes.

- Software changes related to the low temperature

idling mode (metric version only).

A084 5121/5122 (512Kbit)

Suffix Cut-in production Changed items/Changed reasons

F Aug. ’92 - The junction gate solenoid in the inverter unit stayed

on after face down and duplex copying. If the solenoid

check in SP mode was performed at this time, the

wrong error code would be displayed.

To prevent this, the software has been changed to

de-energize the solenoid when the main motor is

stopped.

- The sensor check in the SP mode was performed by

checking the sensor output while the sensor power

was turned on and off. The sensors connected to the

interface PCB, the tray upper and lower limit, paper

end, paper exit, and toner cartridge sensors, were

scanned by scan pulse signals from the main PCB.

Since the scan pulse signals were used for both power

and output signal for these sensors, the sensor check

did not work correctly (see the figure on the next

page). So, the sensor check for these sensors has

been changed to enable only for ON check.

- The paper end sensor check has been changed to

enable only when the paper exists in the tray.

(continued)

Page 20

Technical Bulletin No. RTB-008

SUBJECT: EPROM Software History DATE:

Sept. 15,

’92

PAGE: 3

of 3

Suffix Cut-in production Changed items/Changed reasons

F Aug. ’92 - The condition of the paper tray upper and lower limit

sensor check has been changed so that both are on or

off at the same time. Both sensor numbers will be

indicated under these conditions.

- If an SC condition had occurred while the 2nd tray

was lowering, the tray would not move up again after

the SC reset.

- Enable the 7% fixed toner supply function when the

Vsg adjustment in the process control data initialization

fails.

+

+12V

Sensor

+12V

Scan

Output

Interface PCB

Page 21

Icn(mll

Technical Bulletin

No.

RTB-009

SUBJECT: Fusing Temperature Adjustment

PREPARED BY: H.

CLASSIFICATION:

❑ Action Required

❑ Troubleshooting

Terashita

—

■ Revision of service manual

❑ Information only

DATE:

PAGE: 1 of 2

FROM: Copier Technical Support Section

MODEL: F200 X/Y

NOV.

30, ’92

❑ Retrofit Information ❑ Other

The fusing temperature display in SP mode of the F200 is different from that of the

previous models, such as those of the F20 series. This bulletin explains the temperature

display system of the F200 and revises the fusing temperature adjustment procedure.

1. Fusing Temperature Display and the Fusing Temperature Adjustment in SP mode

The displayed figure is calculated using the thermistor resistance and will not be affected

by the setting of the fusing temperature adjustment in SP mode.

The main PCB has a table to convert the thermistor resistance into a temperature figure.

The main PCB, then controls the fusing lamps according to the calculated figure, so that

the lamps are turned on at 195°C and off at 198°C.

The actual hot roller temperature is not the same as the temperature measured with the

machine’s thermistor because of the tolerance of the thermistor. Therefore, the fusing lamp

on/off temperature is compensated machine by the machine. This compensation is done

by changing the setting of the SP mode “Fusing Temperature Adjustment”,

The displayed figure is not the actual temperature, at the time the compensation is applied.

2. Fusing Temperature Adjustment

Please refer to the service manual page 5-94,

Add the following:

Adjustment Target :195 ± 1 °C

NOTE: The fusing temperature adjustment is only necessary when you have

replaced the fusing thermistor.

Page 22

Iul(mlxl

Technical Bulletin

No.

RTB-009

SUBJECT: Fusing Temperature Adjustment

Correct the steps from step 9

9. Using a digital thermometer and probe, measure the temperature at the middle of

the hot roller when the lamp is turned

10. If the measured temperature is out of the adjustment range, change the setting of

the fusing temperature in SP mode (9).

NOTE: Use + to lower the

11. Repeat steps 9 to 10 and

12. Reassemble the parts.

NOTE: When assembling the

connectors are set to

as follows:

on.

temperature.

confirm the lamp on temperature,

safety switch harness connectors, make sure the

the correct position.

DATE: Nov. 30, ’92

PAGE: 2 of 2

Page 23

I{m(ml

Technical Bulletin No. RTB-010

SUBJECT: Duplex Jogger Drive Belt Tension Adjustment

PREPARED BY: H,

CHECKED

CLASSIFICATION:

BY:/~

.-

Terashita

FROM: Copier Technical Support Section

DATE:

PAGE: 1 of 1

MODEL: F200 X/Y

Nov.

30, ’92

❑ Action Required ■ Revision of service manual

❑ Troubleshooting

❑ Retrofit Information

.

The duplex jogger drive belt tension adjustment has been revised by the RTB-001 issued

on July 15, 1992,

The jogger fence drive belt tension mechanism has been reviewed to facilitate assembling

in the factory, and changed to an adjustment free mechanism as shown below,

1. Modified Items

The mounting holes of the timing pulley bracket

[A] has been enlarged and fixed by shoulder

screws [B].

A tension spring [C] has been added.

The width of the timing belt [D] has been

changed from 6mm to 4 mm to decrease the

drive load of the jogger fences.

❑ Information only

❑ Other

[B]

.—.

r-

A

I

,

j\

1P+ ‘;

L–

/T

__J

As the result, no adjustment is required when

servicing,

Please refer to the MBs,

021, for details,

2,

Modification Cut-in

Type Y

-1 5/1 7/22/25/27

Type X

-1 7/22/25/27

-16

(A084)

(A083)

A083-009

From September ’92 production onward

From September ’92 production onward

From October ’92 production onward

and A084-

Page 24

Imm)lxl

Technical Bulletin

No. RTB-011

SUBJECT: Improper Duplex Jogger Fence Movement

PREPARED BY: H, Terashita

CHECKED BY

CLASSIFICATION:

❑ Action Required

■ Troubleshooting

❑ Revision of service manual

❑ Information only

FROM: Copier Technical Support Section

MODEL: F200 X/Y

❑ Retrofit Information ❑ Other

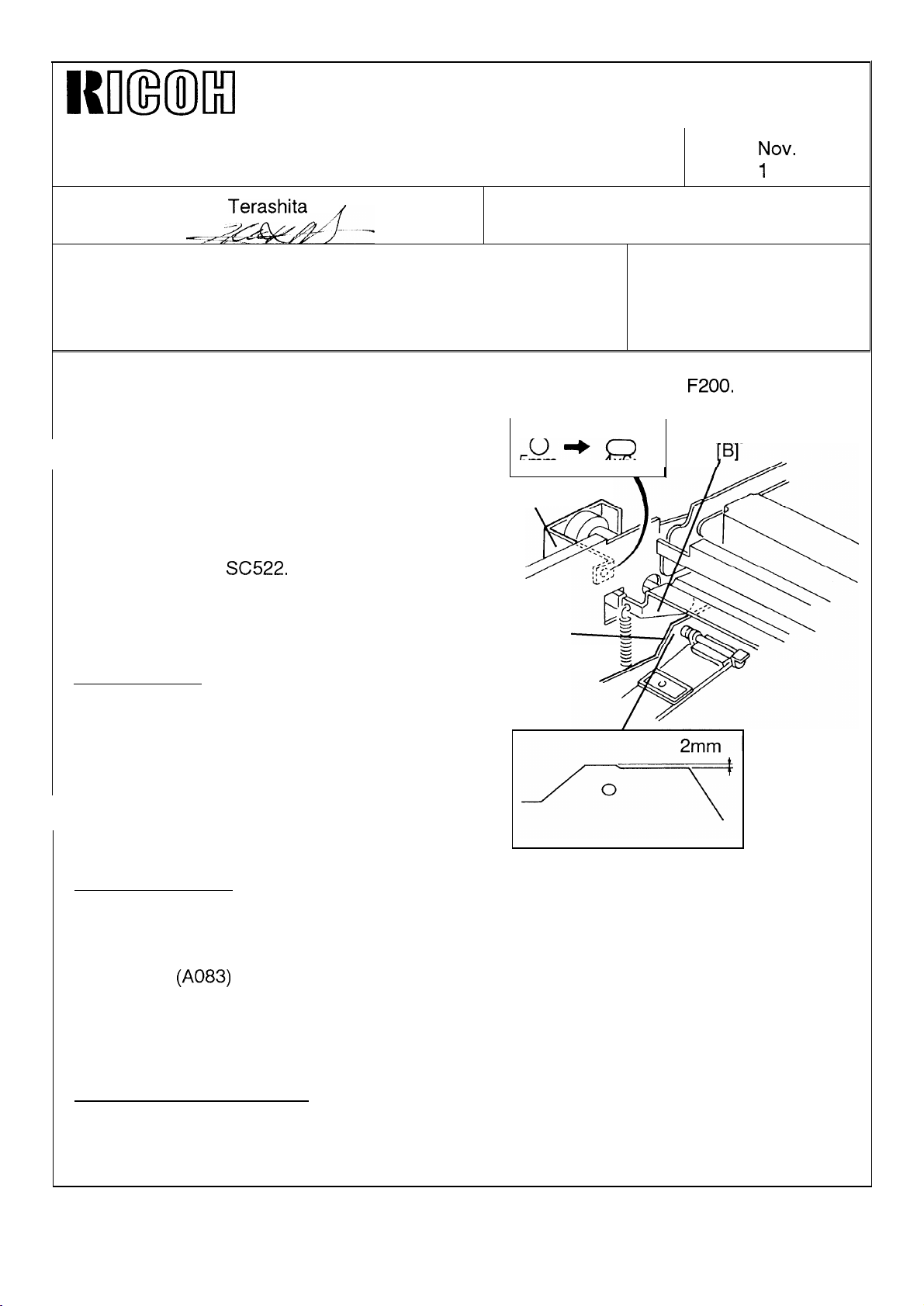

We have found that there is a possibility of the following problem on the

informs you of countermeasures, and gives a tip

for field troubleshooting.

mm

PROBLEM:

The rear jogger fence [A] touches the duplex

positioning roller arm [B]. This affects the jogger

fence movement and may cause duplex paper

feed skew and

SC522.

[c]

x

DATE:

PAGE:

F200.

This bulletin

NOV.

1

of 1

30, ’92

COUNTERMEASURES:

Modified items:

The upper mounting hole of the positioning

roller bracket [C] has been changed from 5mm

to 4x6mm to assure the vertical position of the

bracket.

The rear jogger fence has been cut by 2mm as

shown to widen the gap between the fence and

the arm,

Modification cut-in:

Type Y (A084)

-1 5/1 7/22/25/27

Type X

-1 7/22/25/27

-16

(A083)

From September ’92 production onward

From September ’92 production onward

From October ’92 production onward

[A]

2mm

Troubleshooting in the field:

If the fence is touching the positioning roller arm, remount the positioning roller bracket at the highest position.

Page 25

I{m(ml

Technical Bulletin

No. RTB-012

SUBJECT: Hot Roller and Pressure Roller Replacement DATE:

PAGE: 1 of

PREPARED BY: H. Terashita

.

. .

CLASSIFICATION:

❑ Action Required

■ Revision of service manual

FROM: Copier Technical Support Section

MODEL: F200 X/Y

❑ Troubleshooting

❑ Retrofit Information

Please add the following note in your service manual, page 5-90.

NOTE: Whenever the hot roller and pressure roller are replaced, check the nip

width and adjust fusing pressure

adjustment, manual page 5-95)

The reason for the nip

follows:

width check at

❑ Other

the

if necessary. (See fusing pressure

hot roller

and

pressure roller replacement is as

Nov.

30, ’92

1

The nip band is an important factor for image fusing and must be maintained.

by

The nip band width is determined

conditions. When the rollers are replaced, nip band width may be changed. Especially, the

pressure roller affects the nip band width because of variations of the silicon rubber

hardness.

Therefore, whenever you replace the hot roller and pressure roller, first check the nip band

(8,

width by using SP mode

out of the adjustment range (10 +/- 0.5 mm).

fusing pressure check mode) and then adjust it if the width is

not only the roller pressure but also the roller surface

Page 26

Technica l Bulletin No . RTB-01 3

SUBJ ECT: Low Im ag e De nsity I n M ultip le Co py Ru n DATE: Feb . 15, ’ 9 3

PAGE: 1 o f 1

PREPARED BY: H .Tera shit a

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM :

In multiple copy runs, image density goes down gradually even if small image area

or igin als ar e us ed.

CAUSE:

We have found that the toner supply amount when the Toner Density Selection setting in

the SP mod e (SP#10 p age 3) is at 30% is not enou gh for multip le co p ying of A4/ 81/2"x11"

size.

The toner is supplied by the toner supply roller, which has an A3/11" x 17" width. The

toner amount is correct for 30% area image, however, only toner at the A4/81/2"x11" area

(middle part) is consumed, and this causes low toner concentration at that part.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

COUNTERMEASURES:

Since the actual cause of the low ID problem in multiple copying was not clear, the factory

settin g o f th e ton er d ensity selec tio n was s elected as HIGH o nly o n t he Decem ber 1992

productions as a temporary solution.

From th e Jan uary 1993 p ro d uc tio n, th e fact or y s ettin g of the t on er den sity selec tio n in the

SP mod e has been returned to NORMAL and the toner supply amount has been changed

fro m 30% to 45%.

Please note that we will not modify the software to correct the toner supply amount d ata

for the 30% supply mode. This is because that you must check if the software is new or

old whenever you determine the proper toner supp ly amount setting for each machine.

In case of the low ID problems, the toner density selection in the SP mode is easily set to

HIGH or VHIGH b y field technicians. As for other models, toner scattering problems may

oc cu r if th e high er to ner den sity s electio ns are selec ted , even if to ner co nc entr atio n is

reasonably high in the development unit. There is a possibility of having toner adhering

pr ob lem o n th e d evelop m ent r o ller in an extr emely h igh to n er c on c entr atio n c o nd itio n even

if the machine has the new development unit with the modified auger guide (Refer to the

RTB-004).

To minimize the side effect pro blems, we recommend to return the toner density selection

to NORMAL and use the toner supply amount selection or ID selection in ADS mo de

instead (SP Special Features page 3), if customers need higher image density.

Page 27

Technica l Bulletin No . RTB-01 4

SUBJ ECT: EPROM Software History DATE: Feb . 15, ’ 9 3

PAGE: 1 o f 3

PREPARED BY: H .Tera shit a

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This b ulletin d esc rib es th e EPROM hist or y of t he mo de l F200 type Y.

1. M ain PCB

A084 5111/5112 (2Mbit : Inch Version)

A084 5131/5132 (2Mbit : Metric Version)

Suffix Cut-in produc tion Changed items or reasons

G October ’92 * During the single copy run in the platen mode, if the Start key

is pressed before the main motor operation for the previous

copying job sto ps, the ID sensor pattern control counters are

reset. This results in no ID sensor pattern produc tion if this

operation is repeated.

* During the machine off condition by the weekly timer, the

screen saver function did not work.

*The default (not the factory) setting of the toner density

selection has been changed from HIGH to NORMAL.

* When t he d ifferen t size o rig inals feedin g m o de is s elec ted by

User Tools, large size copy papers hits the jogger bar of the

sorter stapler and causes jams in the ADF, sort, and single

copy modes.

* The staple modes have been inhibited in the different size

or ig inals feed ing m od e is selec t ed .

* To enable the handling of SP/UT printing data by a PC, the

Line Feed (0AH) co mman d h as been ad d ed to th e Carriag e

Return sig nal fo r eac h line p r int d ata. The En d Of File (1AH )

has also been added to the end of the print data.

You have to change the settings of the printer so as not to

perform the line feed by the new command. Otherwise, two

lines will be used for one printed line.

* When th e user c od e is c hec ked by the Us er Too ls, "967295"

was displayed if no user code is registered.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 Type Y

Page 28

Technica l Bulletin No . RTB-01 4

SUBJ ECT: EPROM Software History DATE: Feb . 15, ’ 93

PAGE: 2 o f 3

Suffix Cut-in produc tion Changed items or reasons

H December ’92 * The first three digits of the serial number printout of SP/UT

modes for Gestetner/Nashua versions are corrected as follows:

U.S. versio ns : 490 -> 491

Euro pe ver sion s : 491 -> 490

* Dur ing fu sin g low tem p era tur e id lin g, c o py ing is aut o mat ica lly

resumed even if the ADF is opened or closed.

* The following counters were also double counted in A3/11"x17"

doub le count mode. They were changed to single increment.

Total copy c ounters in copy and original jam counters

PM counter

Daily and Weekly counters

J February ’93 * In the Cover/Slip mode copying, if the Cover/Slip tray runs out

papers, the Tray key cannot be used at all. Even if papers are

sup p lied in t he t ray , t he Tr ay k ey r ema ined in op er ative.

* The counting method o f the following counters in the SP mo de

has been changed.

In Duplex Modes

- Total copies by paper sizes : Double -> Single count

Following counters are changed to count even if in the blank

copy output mode.

- PM cycle counter

- Daily/weekly copy counters

- Total counters in jam/SC counters

All the SP co py counters will be incremented for Cover/Slip

sheets without copy image. The following copy co unters are

no t inc remen ted , as b efor e.

- Total number of copies

- Test mode copy c ounter

- Block copy co unter

- User code counters

A084 5121/5122 (512Kbit : Co mm o n)

Suffix Cut-in produc tion Changed items or reasons

G October ’92 To match the data address with the software of the 2Mbit ROMs.

H December ’92 To match the data address with the software of the 2Mbit ROMs.

J February ’93 To match the data address with the software of the 2Mbit ROMs.

Page 29

Technica l Bulletin No . RTB-01 4

SUBJ ECT: EPROM Software History DATE: Feb . 15, ’ 93

PAGE: 3 o f 3

2. Operation Unit PCB

A084 5251/5152 (1Mbit : Inch Version)

A084 5256/5257 (1Mbit : Metric version)

Suffix Cut-in produc tion Changed items or reasons

Inc h Metr ic

D C January ’93 * The location of the door in the display for the sorter

misfed paper removal is corrected.

* ARDF misfeed message has been changed from "...

inside the covers." to "... on the covers".

* initial digits of the serial number in SP mode has been

co rr ect ed 490 < - > 491 ( Nasu a/ Gestetn er vers ion s) .

* Weekly timer message in User Tool # 7 has been

changed from "To register a time..." to "To register an

access cod e...".

* The CFF size has b een ch ang ed fro m 11"x91/2" t o

12"x141/2" (Metric Version Only).

NOTE:

The English ROM kit (only for Ricoh Metric versions) has different part numbers for each

EPROM . The EPROMs in t he ROM kit are eq uivalent as sh own belo w:

A385 5002 = A084 5256B

A385 5003 = A084 5257B

A385 5006 = A084 5266B

The part numbers in the ROM kit will be standardized with that of the production EPROMs

(A084 ....) from the next productions.

G October ’92 To match the data address with the software of the 2Mbit

ROMs.

H December ’92 To match the data address with the software of the 2Mbit

ROMs.

J February ’93 To match the data address with the software of the 2Mbit

ROMs.

Page 30

Technica l Bulletin No . RTB-01 5

SUBJ ECT: EPROM Software History DATE: Feb . 15, ’ 9 3

PAGE: 1 o f 3

PREPARED BY: H .Tera shit a

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This b ulletin d esc rib es th e EPROM s his tor y o f the mo d el F200 typ e X.

1. M ain PCB

A083 5111/5112 (2Mbit : Inch Version)

A083 5131/5132 (2Mbit : Metric Version)

Suffix Cut-in produc tion Changed items or reasons

D October ’92 * During the single copy run in the platen mode, if the Start key

is pressed before the main motor operation for previous

copying job sto ps, the ID sensor pattern control counters are

reset. This results in no ID sensor pattern produc tion if this

operation is repeated.

* During the machine off condition by the weekly timer, the

screen saver function did not work.

*The default (not the factory) setting of the toner density

selection has been changed from HIGH to NORMAL.

* If larg e size pap er ( A3/11"x17") remain ed in the d up lex tray

and was fed out without copying after a small paper size

(A4/81/2"x11") copying job is finished, the ID sensor pattern is

developed on the large size papers.

* To enable the handling of SP/UT printing data by a PC, the

Line Feed (0AH) co mman d h as been ad d ed to th e Carriag e

Return sig nal fo r eac h line p r int d ata. The En d Of File (1AH )

has also been added to the end of the print data.

You have to change the settings of the printer so as not to

perform the line feed by the new command. Otherwise, two

lines w ill b e us ed for o ne line p rin t.

* When th e user c od e is c hec ked by the Us er Too ls, "967295"

was displayed if no user code is registered.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 Type X

Page 31

Technica l Bulletin No . RTB-01 5

SUBJ ECT: EPROM Software History DATE: Feb . 15, ’ 9 3

PAGE: 2 o f 3

Suffix Cut-in produc tion Changed items or reasons

E December ’92 * The first three digits of the serial number printout of SP/UT

modes for Gestetner/Nashua versions are corrected as follows:

U.S. versio ns : 492 -> 493

Euro pe ver sion s : 493 -> 492

* Dur ing t he fu sing lo w tem per atu re id lin g , c o p ying is

automatically resumed even if the RDH is opened or closed

* The following counters were also double counted in A3/11"x17"

doub le count mode. They were changed to single increment.

Total copy c ounters in copy and original jam counters

PM counter

Daily and Weekly counters

* In Simp lex-Dup lex, Dup lex-Dup lex, an d Imag e Overlay mo d es,

if the originals are set in the RDH, and more than 50 is entered

for the c o p y nu mb er, and th en t he o rig inals ar e rem oved an d

the Start key is pressed, more than 50 copies would be fed

into the duplex tray.

* When the original size is A4 sideways and the copy paper is

A4 lengthwise, if the APS is selected in staple mode copying,

"Check paper size" indication will be displayed and the

mac hin e stay s in "Please wait" c o nd itio n .

F February ’93 * The counting method o f the following counters in the SP mode

has been changed.

In Duplex Modes

- Total copies by paper sizes : Double -> Single count

Following counters are changed to count even if in the blank

copy output mode.

- PM cycle counter

- Daily/weekly copy counters

- Total counters in jam/SC counters

All the SP co py counters will be incremented for Cover/Slip

sheets without copy image. The following copy co unters are

no t inc remen ted , as b efor e:

- Total number of copies

- Test mode copy c ounter

- Block copy co unter

- User code counters

Page 32

Technica l Bulletin No . RTB-01 5

SUBJ ECT: EPROM Software History DATE: Feb . 15, ’ 9 3

PAGE: 3 o f 3

A083 5121/5122 (512Kbit : Co mm o n)

Suffix Cut-in produc tion Changed items

D October ’92 To match the data address with the software of the 2Mbit ROMs.

E December ’92 To match the data address with the software of the 2Mbit ROMs.

F February ’93 To match the data address with the software of the 2Mbit ROMs.

2. Operation Unit PCB

A083 5251/5152 (1Mbit : Inch Version)

A083 5256/5257 (1Mbit : Metric version)

Suffix Cut-in prod uction Changed items or reasons

B January ’93 * "RDH Side Registration Adj." in the SP mode has been

changed to "RDH Registration Adj.".

* Miss pellin g co r rec t ion .

* initial digits of the serial number in SP mode has been

co rr ect ed (492 < -> 493 : Nashua/Gestetner versions).

* Weekly timer message in User Tool # 7 has been changed

from "To register a time..." to "To register an access code...".

* The CFF size has been ch ang ed fro m 11"x91/2" to

12"x141/2" (Metric Version Only).

NOTE:

The English ROM kit (only for Ricoh Metric versions) has different part numbers for each

EPROM . The EPROMs in t he ROM kit are eq uivalent as sh own belo w:

A385 5102 = A083 5256

A385 5103 = A083 5257

A385 5106 = A083 5266

The part numbers in the ROM kit will be standardized with that of the production EPROMs

(A083 ....) from the next productions.

Page 33

Technica l Bulletin No . RTB-01 6

[G]

SUBJ ECT: Origina l Jam s in RDH ( P3 J ams) DATE: March 3, ’93

PAGE: 1 o f 3

PREPARED BY: H .Tera shit a

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM :

Orig inal jams at t he RDH inver ter sec tio n an d P3 in dic at or b link s on th e CRT.

Damage on the original leading edge, skew, dog ear, and accordion jams are observed in

most of the cases.

CAUSE:

The original leading edge hits the inner inverter guide plate [A] [ parts catalog page 176

ind ex 1] .

Revision of service manual

Information only

Other

[A]

FROM: Copier Technical Support Section

MODEL: F200 X/Y

[H]

[G]

COUNTERM EASURES:

In th e field:

You c an ob s erve if t he o r igin al hit s t he in ner inver ter gu id e p late b y o p enin g the invert er

unit guide and remove the antistatic brush b racket [ B] (2 screws) [P/C page 174 ind ex 11

and 12] .

1. Remove the front (6 screws) and rear (8 screws) covers of the RDH.

2. Remove t he m ot or d rive PCB b rac ket [C] (2 sc r ews) [ P/C p age 186 ind ex 11] .

3. Remove t he inver ter mo to r [D] ( 4 sc rew s) [P/C p ag e 180 ind ex 29 and 31].

4. Remove the timing belt tightner [E] (1 screw) [ P/C page 180 in dex 13 an d 27].

[I]

5. Remove th e inverter mo to r b rack et [F] ( 5 scr ews) [ P/C pag e 180 index 26].

Page 34

Technica l Bulletin No . RTB-01 6

SUBJ ECT: Orig inal J am s in RD H (P3 Ja ms) DATE: March 3, ’93

PAGE: 2 o f 3

6. Loosen four screws [G] (two each for the front and rear) fixing the inner inverter guide

plate.

7. Lift th e inner guid e p late and fix it at th e hig hest po sitio n.

In th e facto ry :

To prevent the paper from hitting the guide [H] , additional guides [I] have been added on

the inn er invert er g uid e plate, and the g ap b etw een the g uid e and ro ller has b een m ade

narrower (see figure) from January ’93 production.

B

C

Page 35

Technica l Bulletin No . RTB-01 6

SUBJ ECT: Orig inal J am s in RD H (P3 Ja ms) DATE: March 3, ’93

PAGE: 3 o f 3

[E]

[D]

[F]

Page 36

Technica l Bulletin No . RTB-01 7

SUBJ ECT: Erratic RDH Operation DATE: March 3, ’93

PAGE: 1 o f 3

PREPARED BY: H .Tera shit a

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM :

During or after cop y jobs, the RDH free runs or continuously feeds.

CAUSE:

CPU runs away and cannot contr ol the RDH operation. This is caused by an external

noise.

The vacu um g uid e plat e [ A] is elec tric ally float ed an d m ay ho ld th e electr o-s tatic pr od uc ed

by or igin al feed ing . When the c har ged st atic elect ric ity is dis ch arg ed , th e CPU may r un

away an d k eep th e feed mo to r o r blo wer fan m o to r o n c o ntin uo usly .

COUNTERM EASURES:

In the field s:

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X

1. Remove t he u pp er left tab le [B] (4 sc rew s) [ P/ C p age 162 ind ex 10].

2. Remove th e co atin g [C ] o n th e vacu um g uid e plat e as sho wn .

3. Adh ere a p iec e o f co n du ct ive typ e t ape [D] so th at th e vacu um gu ide p lat e is g ro un ded

to the o rig in al tab le [ E].

In th e facto ry :

A grounding plate [ F] has been added (peened) on the vacuum guide plate [ A] [ P/C page

167 ind ex 7] s o t hat the g uid e p lat e is g ro un ded t o the m ach ine fr ame fr o m J anuar y ’ 93

production.

The new P/N o f th e vacuu m g uide p late is A3521520.

Page 37

Technica l Bulletin No . RTB-01 7

[F]

SUBJECT: Erratic RDH Operation DATE: March 3, ’93

PAGE: 2 o f 3

A

[B]

Page 38

Technica l Bulletin No . RTB-01 7

SUBJECT: Erratic RDH Operation DATE: March 3, ’93

PAGE: 3 o f 3

[D]

[C]

[E]

Page 39

Technica l Bulletin No . RTB-01 8

20gf

SUBJ ECT: Duplex Pick-up Roller M arks DATE: March 3, ’93

PAGE: 1 o f 1

PREPARED BY: H .Tera shit a

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The F200 is usin g the lo wer sid e feed sys tem in th e du p lex unit to keep t he hig h

productivity in duplex copy mode. As this is one of the machine limitation, two duplex

pick-up roller marks may be visible on the copy paper, especially thick papers are used,

due to this feed system.

We cannot eliminate these marks with this feed system, however, following modification

has been applied to the production line to give a possibility to minimize the roller marks.

Regarding the cut-in serial number, please refer to the MB issued in the future.

As shown in the figure, two spring hook holes have been added to the brackets [ A] (P/N

A0794806 → A0794807).

The original hole gives 70gf to the pick-up pressure plate. Two holes give 30gf and 20gf

as shown. The best position must be selected by trial and error by making duplex copies.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

These position could be used in the field, however, you may face the misfeed problems

because of the low pick-up pr essure. This is all depends to the used paper, so that the

factory settings of the spring remains as of highest position (70gf).

When you can accept this low p ressure pick-up, please check the following points too:

1. Make sure the jogger fence stop

position ( refer to RTB 1 )

2. To m inimize t he p ap er feed lo ad, it

is better to set the side fence stop

position wide that the copy paper by

0.5mm each side.

3. This low pressure system could be

work with smaller paper sizes

(< A4/81/2"x11").

4. Check if the duplex unit has excess

static electricity. Use the new type

anti-static brushes ( refer to RTB 3 )

A0794806

A

A0794807

30gf

70gf

Page 40

Technical Bulletin No. RTB-019

SUBJECT: RDH Inverter Belt Tension Adjustment DATE: April 2, ’93

PAGE: 1 of 3

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

1. Noise comes from the RDH inverter drive mechanism.

2. Intermittent SC702 (RDH Inverter Motor Overload).

3. Intermittent inverter jams (P3).

CAUSE:

The inverter drive belt tension is too high.

Since the belt tightener is positioned with an angle to

the timing belt, adjusted tension varies if the tightener

is not guided properly. Therefore, if the timing belt

tension is adjusted too tight, an excess load is applied

to the drive mechanism, especially, to the one way

bearings. This causes the problems listed above.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X

COUNTERMEASURES:

A) Check The Inverter Drive Mechanism

1. Remove the RDH rear cover (7 screws).

2. Remove the blower motor control PCB [A] (2

screws).

3. Remove the inverter drive motor [B] (4

screws).

NOTE:

Mark the motor mounting position before

remove the motor so that you do not need to

readjust the motor drive belt tension.

[A]

[B]

Page 41

Technical Bulletin No. RTB-019

SUBJECT: RDH Inverter Belt Tension Adjustment DATE: April 2, ’93

PAGE: 2 of 3

4. Remove the belt tightener [C] (1 screw)

and the motor bracket [D] (5 screws).

5. Slide out the collars [E] and one-way

bearing pulleys [F].

6. Check if the roller shafts have any

scratches. If there are severe

damages, replace the rollers.

7. If there are no scratches, clean the

shaft with a dry cloth and reassemble

them.

NOTE: 1. Do not apply any grease to

the one-way bearing inside of

the pulleys.

2. Do not lose the collar on the

drive gear [G].

3. The two pulleys [F] are not

interchangeable.

8. Reinstall the motor bracket and adjust the timing belt tightner position according to the

following adjustment procedure.

9. Reinstall the inverter motor to the original position (marked at step 3).

[C]

[D]

[E]

[F]

[G]

10. Reassemble the RDH and perform the motor speed adjustment by SP mode #9 page

4.

11. Confirm that there is no tooth jump on any timing belt by using the RDH free run mode.

B) Timing Belt Tension Adjustment

Do not use the adjustment value mentioned in the manual (manual page 5-11 : 450 ±

50g).

In the field, since we supposed that there is some friction between the bracket and the

tightener, we decided the above tension standard included the friction. However, we have

found that the friction varied much more than our estimation and the adjusted result (belt

tension) tends to be larger than the target.

The factory has changed to use a special tool which guides the tightener and eliminates all

the friction to obtain the accurate tension on the timing belt. They are now using 100 ± 20g

as the new standard with the special tool. However, we cannot supply the special tool due

to its high price.

Since the design target of the timing belt tension is "Weakest without tooth jumping",

adjust the timing belt as weak as possible and confirm that the timing belt tooth do not

make any jumps by performing the RDH free run mode.

Page 42

Technical Bulletin No. RTB-019

SUBJECT: RDH Inverter Belt Tension Adjustment DATE: April 2, ’93

PAGE: 3 of 3

C) Factory Countermeasure

To minimize the variation of the inverter timing belt tension, the tension has been adjusted

more accurately by using a special tool from the March 1993 production.

Page 43

Technical Bulletin No. RTB-020

SUBJECT: Second Paper Tray Inoperative DATE: April 2, ’93

PAGE: 1 of 2

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

1. The second tray does not lift.

2. No paper size indication for the second tray.

CAUSE:

1. Paper falls in the second tray rear side.

Since the FRR feed system is used, one or two sheets of paper remain and are caught by

the feed and reverse rollers after paper feed. In case of low stiffness paper, it may

sometimes not be returned to the tray when the second tray is pulled out by an operator.

The paper that could not be returned to the tray may fall in the rear side of the second tray

and get into the tray connectors. This opens the electrical contact between the connectors

and causes the problems listed above.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

2. Incorrect misfed paper removal procedure by the operator.

In case of the U jams (2nd tray misfeed), the misfed paper must be fed to the copier side

by turning the knob "S2" as instructed on the misfed paper removal decal.

Some operators do not follow this procedure and pull the second tray out first. This tears

the misfed paper. The torn paper may get into the tray connectors.

COUNTERMEASURES:

[C]

1. Rear Paper Guide

To increase the paper return force to the

tray when the tray is pulled out, a wing [A]

has been added to the rear paper holder

[B] from the November ’92 production.

The rear paper guide [C] has no paper

size decal [D], so that you need the decal

when you replace the rear paper guide.

The part number of the rear paper guide is

A3551100 (120V version) and A3551300

(230V version). The part number remains

the same as described in the parts

catalog, however, all the service parts

have already been changed to new ones.

[B]

[A]

[D]

Page 44

Technical Bulletin No. RTB-020

SUBJECT: Second Paper Tray Inoperative DATE: April 2, 93

PAGE: 2 of 2

2. Software

To avoid operator error, the software has been changed so as not to lower the second tray

in case of the U jams. This means that the second tray cannot be pulled out until the U

jams are cleared by the correct procedure described on the decal.

This new software is applied on the following EPROMs on the main PCB.

Cut-in serial numbers will be informed by a later RTB.

Type Y Type X

A084 5111L (20DC)

A084 5112L (597F)

A084 5131L (20DD)

A084 5132L (597F )

A084 5121L (8AEE)

A084 5122L (415 A)

A083 5111H ( 419D)

A083 5112H (0DA3)

A083 5131H (419E)

A083 5132H (0D13)

A083 5121H ( 05B6)

A083 5122H (D40D)

For Inch Version (2 Mbit)

"

For Metric Version (2 Mbit)

"

For All Versions (512 Kbit)

"

NOTE:

If the operators are used to handling misfed papers, they will realize that the second tray

does not lower in case of U jams and think that this is caused by a machine failure. This

may cause another service call.

To avoid this, explain the new software to the operators when you replace the EPROMs

on the field machines.

Page 45

Technical Bulletin No. RTB-021

9 mm

SUBJECT: RDH P2/P3 Jams DATE: April 2, ’93

PAGE: 1 of 1

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

1. Intermittent P2 or P3 jams.

2. Original skew in the inverter area.

CAUSE:

The lower inverter entrance roller height is low and its pressure to the inverter middle roller

is not enough. If the height is not even on all eight rollers, original skew may happen.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X

COUNTERMEASURE:

Check the height of the lower inverter

rollers. The design target of the

height of the rollers from the optics

cover metal plate (not from the upper

left cover) is 11 mm.

If they are low, replace the rollers or

reform the spring plates.

The angle of the roller spring plate

has been changed as shown from

the August 1992 production.

11 mm

Page 46

Technical Bulletin No. RTB-022

SUBJECT: Gray Copy / Image Density Problems / SC301 / SC306

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

1. Gray copies (low ID) come out intermittently or continually.

2. Sudden toner density change (overtoning).

3. SC306 (Drum Potential Sensor calibration Error)

4. SC301 (Charge Corona Current Adjustment Error)

CAUSE:

Defective relays (poor contacts) on the drum current detection PCB.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

DATE: April 2, ’93

PAGE: 1 of 1

MODEL: F200 X/Y

The drum current detection PCB has two relays. These relays have the following functions:

1. They g round th e drum sh aft.

2. They apply the bias to the drum shaft for calibration of the potential sensor.

3. They guide the corona current to the measurement circuit.

If the drum shaft grounding is not done properly during the copy cycle, symptom #1 and 2

will happen. If bad operation of the relay happens frequently, the SCs (Symptom #3 and 4)

could be displayed during the process control data initialization.

ACTIONS:

The relay operation itself is not possible to

confirm in the field, however, the drum

grounding can be checked as follows:

1. Open the front doors.

2. Remove the left inner cover.

3. Measure the drum shaft potential

using a multimeter. The voltage

should be almost 0V during a copy

run. If not, replace the drum current

detection PCB.

Page 47

Technical Bulletin No. RTB-023

[A]

4

SUBJECT: SC104 and SC108 DATE: April 2, ’93

PAGE: 1 of 1

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

SC104 (Exposure Lamp Malfunction - Abnormal Off) or SC108 (VL Correction Error) is lit.

The ends of the exposure lamp have turned black.

CAUSE:

Improper connections on the exposure lamp power lines.

If the exposure lamp is used under bad

contact conditions, the life of the exposure

lamp becomes much shorter (50K to 100K).

ACTIONS:

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

Check the connections on the exposure

lamp power as follows:

1. Exposure lamp filaments

The exposure lamp filaments are turned on

with low power during stand-by condition for

pre-heating. For pre-heating, you can see

red colored filaments.

Check if both filaments [A] are turned on

during stand-by by sliding the scanner to

the center as shown.

2. Exposure Lamp Power Harness

Check the power lines on the connector

CN645 [B].

The resistance between the following pins

must be lower than 3 ohms (see figure):

CN645 - 1 and 2

CN645 - 3 and 4

(All four lines are blue)

If not, check the lamp sockets and harness.

[B]

321

Page 48

Technical Bulletin No. RTB-024

SUBJECT: Revised RTB No. - 024 DATE: Sept. 30, ’93

PAGE: 1 of 1

PREPARED BY: H. Kobayashi

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The allowable variation time has been reviewed from 50 msec to 32 msec.

Please note that the figure of the last sentence of RTB No. 024 has been changed

from 50 msec to 32 msec.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

Page 49

Technical Bulletin No. RTB-024

Revised: September 30, ’93

SUBJECT: Paper Feed Clutch Slippage DATE: April 2, ’93

PAGE: 1 of 1

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

Frequent misfeeds from the paper tray and duplex tray.

CAUSE:

The paper feed clutch are slipping due to bad clutch disk surface conditions.

ACTION:

If the machine shows a frequent misfeed record in the SP jam counter on a particular

paper feed area, check the paper feed time (SP #7 page 2) of each paper feed station as

follows:

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

1. Select a particular paper feed station. In case of duplex, feed papers in the

duplex tray first.

2. Enter the SP mode and open the sensor output (#7) page 2.

3. Enter 50 as copy number and press the Start key.

4. Monitor the paper feed time during the copy cycle.

If the displayed time varies more than 32 msec, check the appropriate feed

clutch if the clutch disk surface is dirty.

Page 50

Technical Bulletin No. RTB-025

[C]

SUBJECT: Noise From Cleaning Unit Drive Section DATE: April 2, ’93

PAGE: 1 of 1

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

Noise comes out from the cleaning drive section. At worst, SC440 may be lit.

CAUSE:

The cleaning brush gear [A] is pressed

too strongly to the drive gear [B] due

to wrong bushing bracket [C] position.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

[B]

ACTION:

When reassembling the cleaning unit

after maintenance, fix the bushing

bracket so that the mounting screw is

located in the middle of the long screw

hole [D].

[D]

[A]

Page 51

Technical Bulletin No. RTB-026

SUBJECT: Duplex Jams and Noise DATE: April 2, ’93

PAGE: 1 of 1

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

Frequent duplex misfeeds (K area). Noise

comes from the duplex tray.

CAUSE:

The duplex separation roller [A] turns in

the direction opposite paper feed when the

main motor is rotating to reduce the

separation roller surface wear.

The duplex feed roller [B] is also rotating

together with the separation roller and

turns the pick-up roller gear [C] through

the idle gear [D]. The pick-up drive gear

has a one-way bearing to prevent the

pick-up roller from turning in reverse.

The idle gear has a spring [E] which has

a braking function to prevent the pick-up

roller from turning too much in duplex

paper feed operation.

Since the spring turns together with the

idle gear, if the friction between the spring

end and the frame is too high, the duplex

feed roller does not turn when the

separation roller is turning in reverse. This

gives excess wear on the duplex feed

roller and causes frequent duplex

misfeeds.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

[A]

[B]

[C]

[D]

[E]

ACTION:

Check these rollers rotation using the machine free run mode. If the rotation is not smooth,

check the spring end condition and file the edge of the spring end if necessary.

Page 52

Technical Bulletin No. RTB-027

[B]

[A]

SUBJECT: Duplex Jams (J and K Jams) DATE: April 2, ’93

PAGE: 1 of 2

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

Frequent J or K area jams in the duplex

tray.

CAUSE:

1. Duplex paper stopper is caught by the

duplex feed tray (mainly K jams).

The feed tray [A] sometimes catches the

stopper [B] and hold it down even if the

stopper solenoid [C] is turned off after the

first side copying. This may not happen

every time. Also, it is hard to find it when

you pull out the unit after a jam occurs.

This is because the stopper holding force

is not so high and the stopper is released

by the shock of the unit removal.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

[B]

[A]

[C]

[A]

2. The duplex entrance guide plate is

bent and makes the entrance gap

narrower (mainly J jams).

The duplex entrance guide plate [D] can

be opened by the operator. If the guide

plate has been handled roughly, the

guide plate ends could be bent as shown

in the figure.

[D]

Page 53

Technical Bulletin No. RTB-027

SUBJECT: Duplex Jams (J and K Jams) DATE: April 2, ’93

PAGE: 2 of 2

ACTION:

1. Duplex paper stopper

Check the paper stopper movement by pressing the stopper solenoid manually.

If the stopper is caught by the feed tray, adjust the solenoid position so that the stopper

movement is smooth as shown in the figure.

NOTE: The solenoid is fixed with two screws. One

screw is located at the round hole which does

not allow position adjustment. Remove this

screw and use in the long hole to let you adjust

the position.

2. Duplex entrance guide plate

Check the gap of the duplex entrance guide plates and

reform the guide plate ends if necessary.

Page 54

Technical Bulletin No. RTB-028

[A]

SUBJECT: Noise from Fusing Drive Section DATE: April 2, ’93

PAGE: 1 of 1

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

Noise comes from the fusing drive section.

CAUSE:

Grease on the fusing drive idle gear shaft [A] is

dried up.

ACTION:

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X/Y

The service manual page 4-43 shows the

lubrication points on the fusing drive gears,

however, the idle gear shaft (not only the gear

tooth)needs to be lubricated.

At every EM call, apply grease (Mobil Temp) on the idle gear shaft as shown.

Page 55

Technical Bulletin No. RTB-029

SUBJECT: Erratic RDH Operation (2) DATE: April 2, ’93

PAGE: 1 of 1

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

RTB-017 issued on March 3, 1993 explains the erratic RDH operation. In the RTB, we

recommended using a piece of conductive tape to ground the vacuum guide plate.

Since we have received comments from some distributors that it was not easy to get the

conductive tape in the field, we explain an alternative way which uses a wire instead.

PROCEDURE:

1. Remove the original table [A] (4

screws and 3 connectors).

2. Loosen the Allen screws fixing

the drive shaft joint [B] and slide

it to the front side.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X

[A]

[H]

3. Remove the feed-in belt drive

shaft bearing [C] (1 E-Ring).

4. Slide the drive shaft [D] to the

rear and fix one end of the wire

[E] with the screw [F] fixing the

vacuum guide plate.

5. Fix the other end of the wire [G]

with the screw [H] located underneath the original table.

6. Assemble the unit.

7. Check the conductivity between

the vacuum guide plate and the

unit frame ground.

NOTE:

Use a wire of the proper length to prevent it from touching any movable parts.

[G]

[F]

[C]

[E]

[B]

[D]

Page 56

Technical Bulletin No. RTB-030

SUBJECT: S1 and S2 Jams DATE: April 2, ’93

PAGE: 1 of 1

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

SYMPTOM:

Frequent S1 and S2 jams.

CAUSE:

The relay transport driven

rollers are out of position

due to shocks when it is

lowered by an operator at

jam removal.

FROM: Copier Technical Support Section

Revision of service manual

Information only

Other

[B]

[A]

MODEL: F200 X/Y

[B]

[A]

[C]

The roller bushings [A]

are held by the springs

[B] in the slots on the

relay transport guide. The

bushings may jump out

from the slots if the guide

is lowered forcefully.

COUNTERMEASURES:

The slots will be modified from an open type [C] to a closed type [D] to prevent the

bushing from jumping out.

Modification details, such as the cut-in serial numbers, will be announced by an MB later.

In the field, to minimize the shock of guide lowering, stick a cushion (sponge) [E] as shown

in the figure.

[E]

[D]

Page 57

Technical Bulletin No. RTB-031

SUBJECT: Software Modification DATE: April 2, ’93

PAGE: 1 of 2

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This RTB describes the EPROM software modifications on the main PCB.

1. TYPE Y

A084 5111 /5112 (2Mbit : Inch Version)

A084 5131 /5132 (2Mbit : Metric Version)

A084 5121 /5122 (512Kbit)

Suffix Cut-in Production Changed Items/Reasons

K Not Applied * None

L March ’93 (-17 )

April ’93 (Others)

* The toner supply amount default setting has been

* At the toner end condition in user code mode, if the

* In the ARDF different size original feeding mode, the