Page 1

Technical Bulletin No. RTB-001

SUBJECT: Paper lift and sector gear slipping DATE: Sep. 15, ’91

PAGE: 1 of 1

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

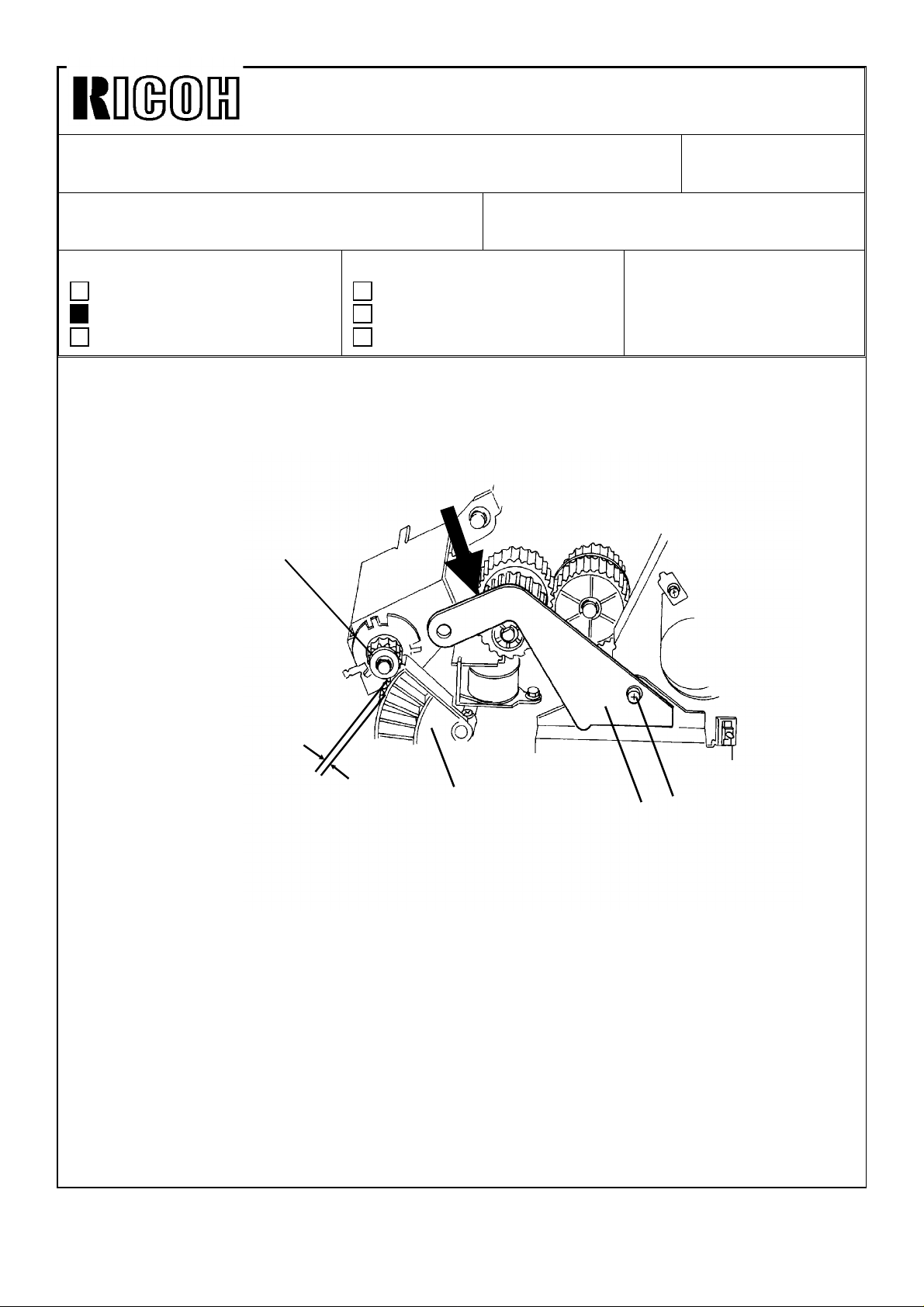

[ Phenomenon ] When the paper stack in the cassette is lifted up, the paper lift

gear [A] and the sector gear [B] slip.

[ Cause ] The mesh between the paper lift gear and the sector gear is too

shallow.

[ Action ]

[A]

Revision of service manual

Information only

Other

Push

TO: Copier Technical Support Section

MODEL: N210

No Gap

1. Turn off the main switch.

2. Make sure that the cassette is installed on the copier and the manual feed table is

closed.

3. Remove the rear cover and the main board.

4. Loosen the screw [C].

5. Retighten the screw while pushing down the paper lift clutch support bracket [D] so

that there is no gap between the pitch circles of the paper lift gear and the sector gear.

6. Reassemble all parts previously removed.

NOTE: When the paper lift clutch support bracket is removed during servicing, the

bracket must be reinstalled according to the above procedure.

[B]

[D]

[C]

Page 2

Technical Bulletin

No.

RTB-002

SUBJECT: New procedure for the DG (doctor gap) adjustment

PREPARED BY:

CHECKED BY:

CLASSIFIC

FROM: Copier Technical Support Section

MODEL: N210

DATE: Jan. 31, ’92

PAGE: 1 of 4

■ Revision of service manual

❑ Information only

❑ Retrofit Information ❑ Other

This procedure supersedes the doctor gap adjustment procedure in the service manual.

NEW PROCEDURE:

CAUTION: The doctor gap was adjusted at the factory using the special

tool. Therefore, normally this adjustment is not required in the field.

Only when the development unit is disassembled or the development

roller is replaced, this adjustment is required.

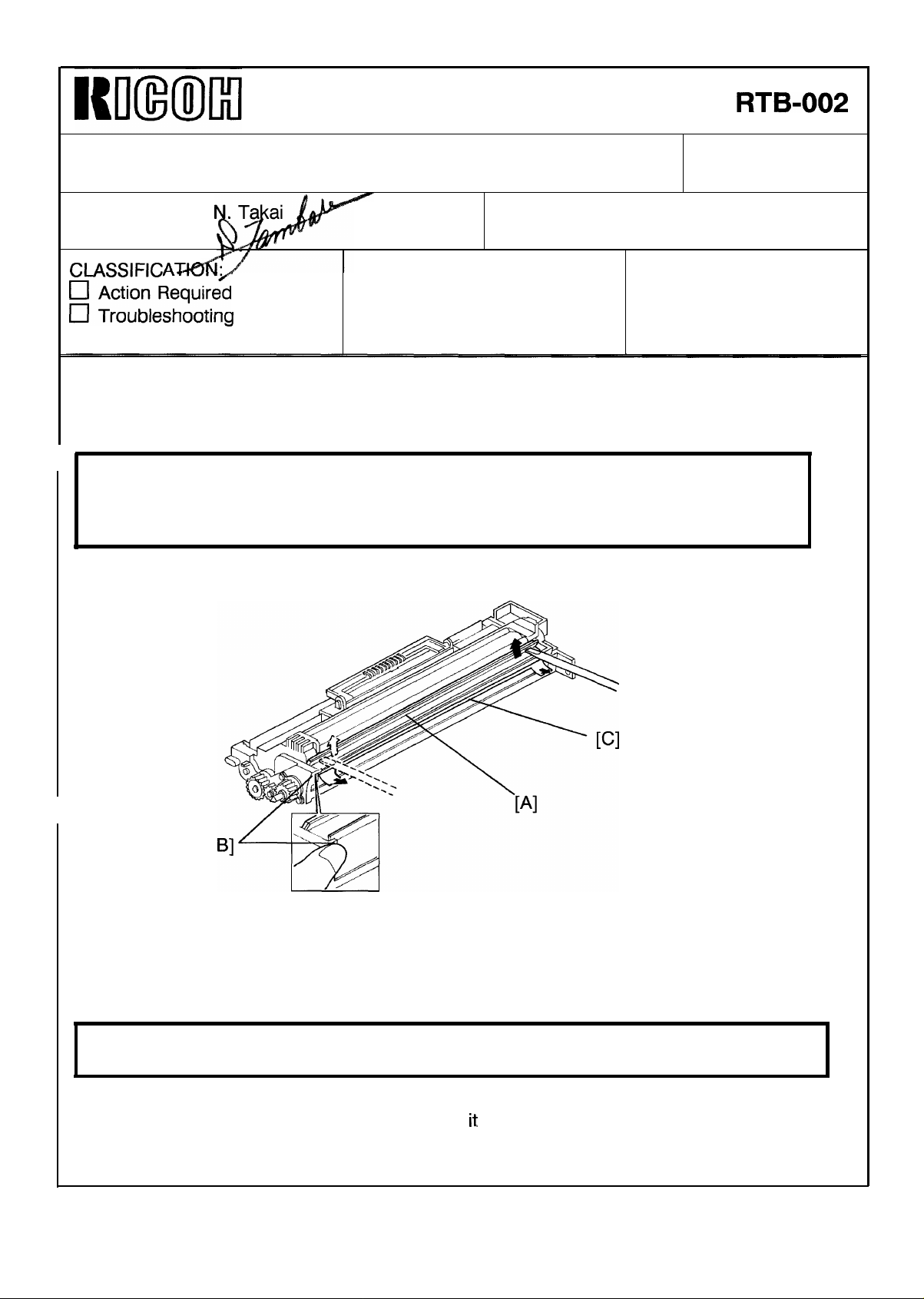

1. Confirmation Procedure

[

1. Take out the development unit.

2. Remove the developer.

3. Remove the inlet seal plate [A] by working a small blade screwdriver along the edge of

the plate while pressing the stoppers [B] with one finger as shown.

CAUTION: Be careful not to damage the stoppers [B] when removing the inlet seal

plate.

4. Clean the development roller [C] with a vacuum cleaner until no developer is left on

it

the roller. Turn the roller to make sure that

NOTE: This prevents surface damage to the roller and ensures an accurate adjustment.

is free of developer.

Page 3

Technical Bulletin

No.

RTB-002

SUBJECT: New procedure for the DG (doctor gap) adjustment

20 mm

DATE: Jan. 31, ’92

PAGE: 2 of 4

Position the DG gauge (P/N #A0489507) 20 mm (0.8 inch) from the front end of the

5.

development roller, and insert the gauge into the doctor gap until it stops.

‘

CAUTION: Do not force the DG gauge into the gap and do not press the gauge too

hard on the roller. The roller should not rotate when you insert the

gauge into the gap.

I

Page 4

Technical Bulletin

No.

RTB-002

SUBJECT: New procedure for the DG (doctor gap) adjustment

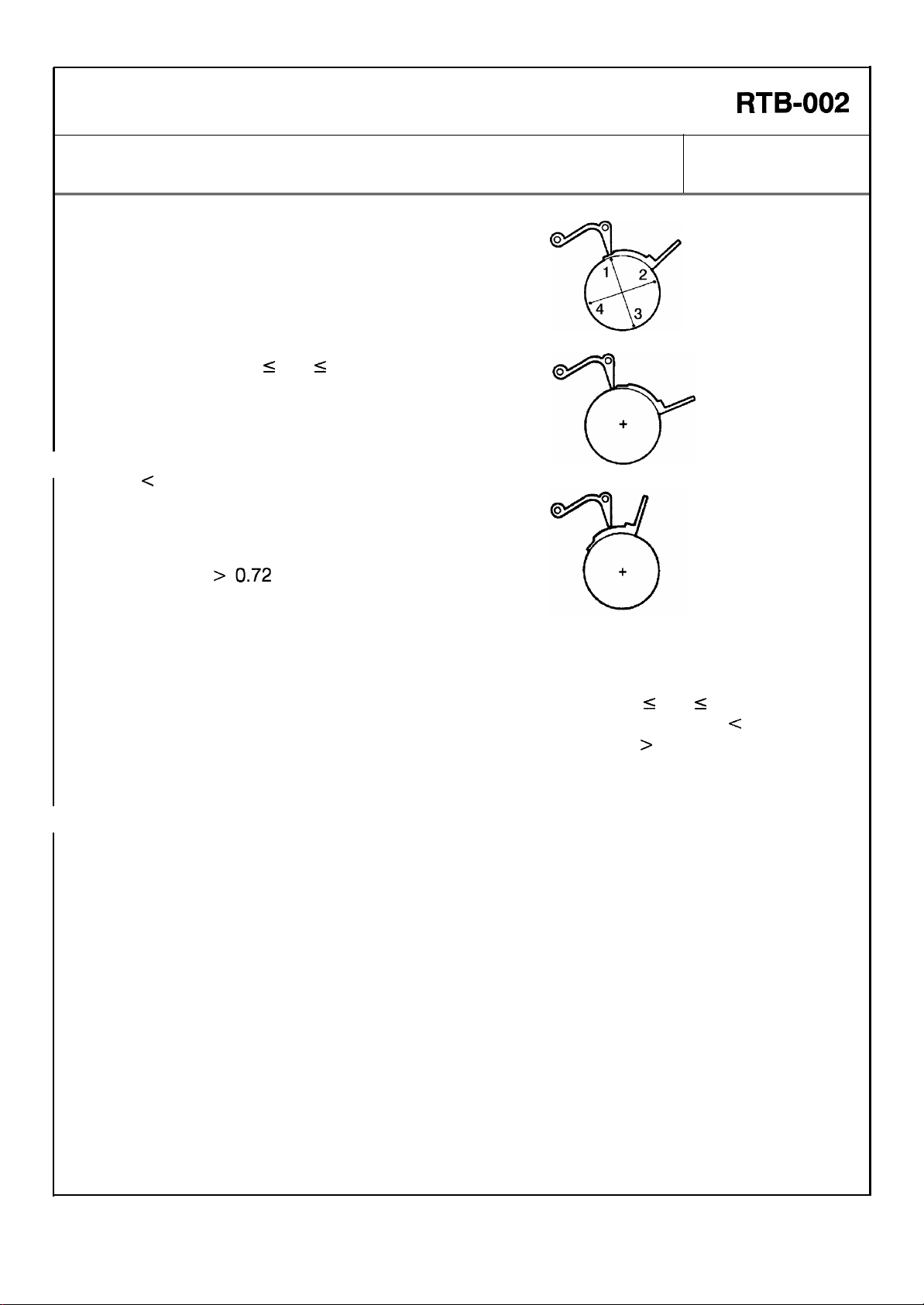

6. Check the doctor gap at four points

turning the development roller 90° each

time.

If the “GO” part of the DG gauge goes

through the doctor gap, and the “NO GO”

part does not go through, the gap at this

s

point is: 0.63 mm

If the “GO” part of the DG gauge does not

go through the doctor gap, the gap at this

point is:

c

0.63 mm

DG

If both “GO” part and “NO GO” part go

through the doctor gap, the gap at this

point is: DG

>0.72

DG s 0.72 mm

mm

DATE: Jan. 31, ’91

PAGE: 3 of 4

Good

Too narrow

Too wide

7. Repeat steps 6 and 7 for the rear side of the development roller.

s

8. If either 3 out of 4 checked points or all 4 points are “0.63 mm

gap is in good condition. If more than 2 out of 4 checked points are “DG

adjust the DG. If more than 2 out of 4 checked points are “DG

DG only when there is any of the following problems:

a. Severe jitter copy

b. Blocking of development drive mechanism

c. Developer leakage

DG s 0.72 mm”, the

> 0.72 mm” adjust the

e

0.63 mm”,

Page 5

Technical Bulletin

No. RTB-002

SUBJECT: New procedure for the DG (doctor gap) adjustment

2.

Adjustment Procedure

Adjustment standard :0.63 <= DG <= 0.72

DATE: Jan. 31, ’92

PAGE: 4 of 4

CAUTION: Before adjusting the doctor gap, the confirmation procedure must be

performed.

1

Go

1. Clean the development roller [A] with a vacuum cleaner until no developer is on the

roller. Turn the roller to make sure that it is free of developer.

2. Loosen the doctor plate [B] (4 screws).

3. Insert the “NO GO” part of the gauge [C] in the doctor gap 20 mm from the front side

of the development roller as shown.

NOTE: The front side should be adjusted first to prevent the doctor gap from being too

narrow.

4. Press down the doctor plate directly above the gauge, and tighten the front doctor

pIate screws [D].

NOTE: Do not press the doctor plate too hard, the doctor gap will become too narrow.

5. Repeat the adjustment procedure at the rear side of the development roller.

6. Confirm that the doctor gap is adequate by following the confirmation procedure.

Page 6

REVISED ON SEPTEMBER 30, ’93

Technical Bulletin No. RTB-003

SUBJECT: Lubrication of the idle gear and the idle gear shaft. DATE:

Feb. 28, 1 993

PAGE: 1 of 2

PREPARED BY: N. Takai

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

A rattling noise comes out from the idle gear engagement or jitter images appear about

100 K to 150 K copies after machine installation. This is because the shaft of the idle

gear-35 Z (P/No. AB013434) is being worn out gradually and the gear engagement

becomes poor.

To prevent this problem, the gear shaft and the gear’s teeth should be lubricated at your

next visit, and the gear teeth at every PM interval afterwards, according to the following

procedure:

- Action required -

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: N210

1. Remove the rear cover (4 screws).

2. Remove the fusing drive release

spring [A].

3. Remove the main motor ass’y [B]

(4 screws and 1 connector)

[A]

[B]

Page 7

Technical Bulletin No. RTB-003

SUBJECT: Lubrication of the idle gear and the gear shaft. DATE:

Feb. 28, 1 993

PAGE: 2 of 2

4. Remove the E-ring [C] and the washer

[D] from the idle gear shaft.

5. Lubricate the gear’s teeth with Grease

G-501 [E] and the gear shaft with the

spindle oil [F].

[D]

6. Reassemble.

[F]

* Confirm that the fusing drive release

spring [A in page 1] is set. If this

spring is not set, drive cannot

transmitted to the fusing section.

NOTES: (1) For the field machines having this problems, we recommend replacing the idle

gear with the modified one (new P/No. AB013841). (Refer to M/B # 15. )

(2) When the modified gear is installed, the two washers (P/No. 52031870 [G] and

08075074 [H]) should be installed together in the order illustrated.

* Since the modified gear has ball-bearings inside instead of dry-bearings, this

gear works even if the shaft is worn out.

[C]

[E]

[H]

[G]

Page 8

Technica l Bulletin No . RTB-00 4

[C]

SUBJECT: N o m an ual fee d o p er atio n DATE: Ap r il 30, ’93

PAGE: 1 o f 1

PREPARED BY: N . Tak ai

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

For the machine with the cassette, the manual feed function does not op erate. The manual

feed indicator does not appear on the operation panel, even when the manual feed table

is opened.

This is because the manual feed switch is not activated sufficiently.

- Action required -

1. Remove the copier left cover [A] (4

screws), the key counter cover [B] (2

scr ews) and t he fixing p late [C] .

2. Install the cassette and close the

manual feed table.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: N210

[A]

3. With the screw driver, bend the

manual feed switch bracket [D]

slightly downward (about 1mm) as

shown in the illustration.

This reduces the clearance between

the switch and the release lever.

NOTE: After bending the bracket,

make sure that the switch does not

touch the release lever [E] .

4. Open the manual feed table and

confirm that the manual feed indicator

in the operation panel lights up.

5. Reassemb le th e co p ier.

[B]

[D]

[E]

[D]

Page 9

Technical Bulletin No. RTB-005

4±1mm

SUBJECT:

New procedure for the Cleaning Unit Entrance Seal Replacement

PREPARED BY: J. Kasamoto

FROM: Copier Technical Support Section

DATE: 15 Sep. ’93

PAGE: 1 of 2

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL: N210

The cleaning unit entrance seal has been modified to standardize with the A7 and Pigeon

series. Because of this modification, the entrance seal replacement procedure is changed

as follows:

New PROCEDURE

ENTRANCE SEAL REPLACEMENT

[B]

[A]

4.5±0.5mm

[C]

[F]

[J]

1±1mm

[C]

[G]

[D]

[E]

4±1mm

[H]

[I]

1. Remove the cleaning unit and the following parts:

• Cleaning Blade

• Cleaning Brush

2. Remove the used toner. (See Used Toner Collection.)

3. Clean the cleaning unit with a vacuum cleaner.

[J]

4. Remove the entrance seal [A] together with the strip of 2 sided tape securing it to the

lower casing.

Page 10

Technical Bulletin No. RTB-005

SUBJECT:

New procedure for the Cleaning Unit Entrance Seal Replacement

5. Clean the lower casing [B] with alcohol: make sure that no tape remains on the casing

surface.

6. Place a new strip of 2-sided tape [C] on the lower casing surface as shown in the

illustration. The upper edge [D] of the tape must be flush with the edge [E] of the

projection as shown in the illustration.

7. Place the new entrance seal [F] on the 2-sided tape as shown in the illustration.

NOTE: a) The lower edge [G] of the entrance seal must be aligned with the edge [H] of

the lower casing.

b) Make sure that there are no waves in the upper edge [I] of the entrance seal.

8. Place the new side seals [J] on the entrance seal as shown. Bend and stick the trail

edge of the s eal to the bo ttom casi ng.

DATE: 15 Sep. ’93

PAGE: 2 of 2

Page 11

Technical Bulletin No. RTB-006

SUBJECT: Gear Teeth Damage DATE: 15 Sep. ’93

PAGE: 1 of 1

PREPARED BY: J. Kasamoto

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

– Symptom –

The 2 gears engaged to the gear (P/N AB013201) on the hot roller shaft gets damaged.

– Cause –

The gear on the hot roller shaft is positioned in a way that does not allow it to properly

engage the gears above it.

– Solution –

Perform the following procedure when this symptom occurs or at the next PM cycle:

Remove the gear from the hot roller shaft and reinstall it so that the boss faces out and

the gears engage properly (see illustration).

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: N210

Before After

Page 12

Technical Bulletin No. RTB-007

SUBJECT: Development Unit Idle Gear DATE:July 31, ’95

PAGE: 1 of 1

PREPARED BY: N. Kaiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The 15z gear has been changed from AB013438 to AB013858 as informed by Modification

Bulletin No. 23 dated October 15, 1993. The material of the gear has been changed to a

non-conductive type to prevent leaking of the development bias through this gear.

In some countries, the consumption of the old gear (AB013438) is still high compared to

that of the new gear. (The old gear can still be used with E7 machines produced before

modification of this gear.)

When you need to replace the 15z gear in the field, could you please make sure to use

the new gear , P/N AB0138 58.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

N210

Gear - 15Z

Loading...

Loading...