Page 1

Technical Bulletin No. RTB-001

SUBJECT: F-40 SERVICE MANUAL MODIFICATION

PREPARED BY:M. Ninomiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

Page: 01-21 Table location: Paper Feed/FUNCTION

Incorrect: Drives the 1st feed section.

Correct: Drives the feed section.

Page: 01-21 Table location: Feed Relay Clutches/LOCATION

Incorrect: 48,45

Correct: 38,45

Page: 01-27 Location: left side, second box from bottom

Incorrect: Paper Pack

Correct: Power Pack

FROM: COPIER TECHNICAL

SUPPORT SECTION

DATE: Dec.31 1990

PAGE: 1 of 10

MODEL: F40

Page: 02-18 Location: 2nd line in the 2nd paragraph

Incorrect: switch or the lift sensor (ARDF/RDH) is on.)

Correct: switch is on.)

Page: 02-26 Location: 2nd line from the bottom of the page

Incorrect: development roller gear [B] when

Correct: development roller gears [C] when

Page: 02-33 Location: In the 1st illustration

Incorrect: Drum Temp 15°C

Correct: Drum Temp 30°C

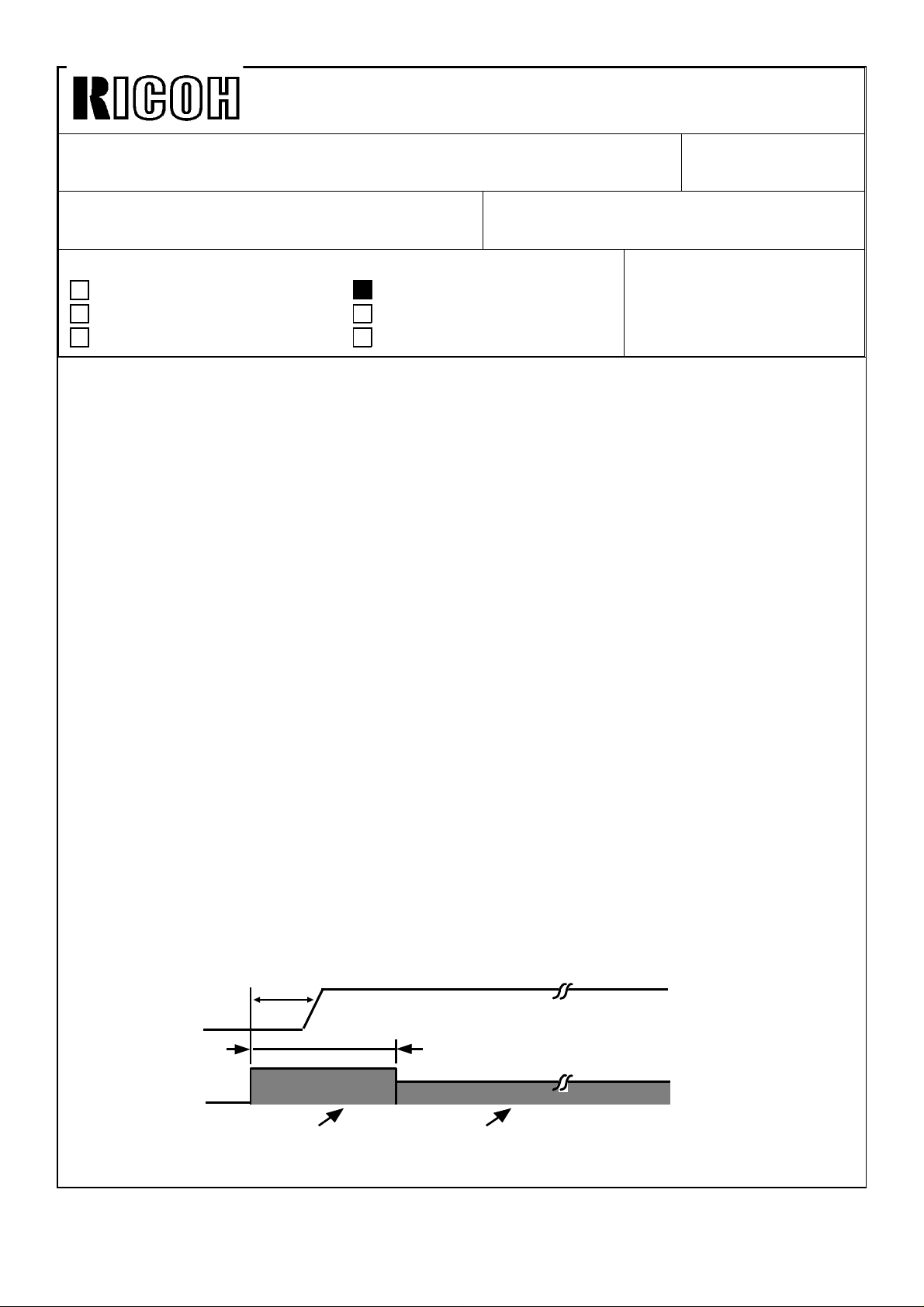

Page: 02-33 Location: 2nd illustration

Modified as below:

40ms

Forward Scan

Scanner On

290ms

Development

Bias

ID Sensor Pattern For Image

(Selected Bias)

Page 2

Technical Bulletin No. RTB-001

SUBJECT: F-40 SERVICE MANUAL MODIFICATION

Page: 02-34 Location: Main PCB box (circuit diagram)

Incorrect: CFL / QC Trigger

Correct: PQC / PTL Trigger

Page: 02-39 Location: End of the 7th line from the bottom of the page

Incorrect: then it stops any further toner supply to the development tank.

Correct: then the CPU changes from detect mode to fixed toner supply mode.

Page: 02-43 Location: The last line in the 3rd paragraph

Incorrect: LOW signal to CN103-7

Correct: LOW signal to CN101-A10

Page: 03-04 Location: item #6 in list

Delete item #6 (Toner Collection Bottle) and renumber the list.

Page: 03-07 Location: 2nd (Right side of the page) and 3rd (Bottom) illustraion

Delete the 2nd illustration and make callouts [D] & [E] to [B] & [C] on the 3rd illustration.

Page: 03-07 Location: Step 6

DATE: Dec.31 1990

PAGE: 2 of 10

Delete step 6 (Slide out the paper feed unit....) and renumber the steps that follow on this

page and the next page

Page: 03-07 Location: Step 7

Incorrect: 7. Remove the left top cover plate [D]and the scanner lock plate[E] (1 screw)

Correct: 6. Remove the left top cover plate [B]and the scanner lock plate[C] (1 screw)

Page: 03-14 Location: step 29

Incorrect: 29. Check the light intensity (SP48).

Correct: 29. Set DIP SW 902-8 to ON, then check the light intensity (SP48).

Page: 04-01 Table location: A. OPTICS section of PM table: Exposure Lamp

Incorrect: I I I I

Correct: I.C I.C I.C I.C

Page: 04-03 Table location: G. OTHERS section of PM table: Drive Chains and Belts

Incorrect: I I I Replace if necessary.

Correct: I.L I.L I.L Replace if necessary.(Lubricate chain if necessary)

Page: 04-03 Table location: G. OTHERS section of PM table: Vacuum Fan Filter

Incorrect: Vacuum Fan Filter

Correct: Transport Fan Filter

Page 4-5 & 6 Location: 2.2 LANGUAGE CODE TABLE and 2.3 DIP SWITCH TABLE

Change LANGUAGE CODE TABLE into section 2.3; change DIP SWITCH TABLE into

section 2.2.

Page 3

Technical Bulletin No. RTB-001

SUBJECT: F-40 SERVICE MANUAL MODIFICATION

Page: 04-05 Location: LANGUAGE CODE TABLE

Incorrect: Nashua South Africa (A4)

SP-12

SP-13

Correct: Nashua South America (A4)

SP-12 (Inch)

SP-13 (Metric)

Page: 04-05 Location: LANGUAGE CODE TABLE

Add "2: Spanish" to the list of languages in the SP-12 column.

Add "5: Spanish" and "5: Dutch" to the list of languages in the SP-13 column.

Note: This list is the same as that in row 2 (0.1.0.)

Page: 04-07 Location: Second DIP SWITCH (101) table from the top

DATE: Dec.31 1990

PAGE: 3 of 10

Delete 2nd table with its above explanation. (* The factor setting of . . . )

Page: 04-11 Location: first paragraph

Correct this paragraph as follows:

If the finisher malfunctions, use Shift Tray Mode and Staple Mode to by-pass the

mainframe data. Then test operate the finisher to determine whether the cause of

the malfunction is in the finisher.

Page: 04-11 Location: step #1 of Shift Tray Mode

Incorrect: SW 101-1,2,and 4 to

Correct: SW 101-1 and 2 to

Page: 04-11 Location: step 3 of Shift Tray Mode

Incorrect: 3. Press SW 100 to start the finisher operation.

Correct: 3. Press SW 100 to put finisher off-line operation on standby.

Page: 04-11 Location: step 5 of Shift Tray Mode

Incorrect: 5. Press SW 101 to stop the finisher operation.

Correct: 5. Press SW 101 to end finisher off-line operation.

Page 4

Technical Bulletin No. RTB-001

SUBJECT: F-40 SERVICE MANUAL MODIFICATION

Page: 04-11 Location: step 2 of Staple Mode

Incorrect: 2. Press SW 100 to start the finisher operation.

Correct: 2. Press SW 100 to put finisher off-line operation on standby.

Page: 04-11 Location: step 4 of Staple Mode

Incorrect: 4. Press SW 101 to stop finisher operation.

Correct: 4. Press SW 101 to end finisher off line operation.

Page: 04-13 Location: bold-text paragraph

Incorrect: 34, 80, 81, 90, 91,

Correct: 34, 80, 81, 91,

Page: 4-16,17 Location: table

Incorrect: 11 Not Used (Japanese Machine Only)

12 Second Paper Feed Clutch

13 Third Paper Feed Clutch

21 Not Used

22 Second Pick-up Solenoid

23 Third Pick-up

DATE: Dec.31 1990

PAGE: 4 of 10

33 First Pick-up Solenoid

Correct: 11 Second Paper Feed Clutch

12 Third Paper Feed Clutch

13 Not Used (Japanese Machine Only)

21 Second Pick-up Solenoid

22 Third Pick-up Solenoid

23 Not Used (Japanese Machine Only)

33 Manual Pick-up Solenoid

Page: 04-18 Table location: Mode No.8/Comments

Incorrect: (Page 4-9)

Correct: (Page 4-15)

Page: 04-18 Table location: Mode No. 9/Comments

Incorrect: (Page 4-10)

Correct: (Page 4-16)

Page: 04-19 Table location: Mode No. 26/Data

Incorrect: 0: NO (50)

Correct: 0: NO

Incorrect: 1: YES (30)

Correct: 1: YES

Page 5

Technical Bulletin No. RTB-001

SUBJECT: F-40 SERVICE MANUAL MODIFICATION

Page: 04-20 Table location: Mode No. 34/Comments

Incorrect: Shifts all bias levels including ID pattern bias.

Correct: Shifts all bias levels except for ID Pattern bias.

Page: 04-21 Table location: Mode No. 48/Comments

Incorrect: (Factory setting = 65)

Correct: (Factory setting = 64, Max. 80V)

Page: 04-22 Table location: Mode No. 60/Function (last line)

Incorrect: less than 0.5V

Correct: less than 0.4V

Page: 04-23 Table location: Mode No. 68/Comments

Delete the following text: No double counts of A3 or 11"x17" copies fed from by-pass

feed table.

Page: 04-24 Table location: Mode No. 83/Comments

Incorrect: is displayed. If "0" is entered, max. is 999. Otherwise, max. is number entered.

Correct: is displayed. Max. is the number entered.

DATE: Dec.31 1990

PAGE: 5 of 10

Page: 04-29 Location: LANGUAGE CODE TBLE

Add "5: Spanish" and "5: Dutch" to the list of languages in the SP13 column.

Note: This list is the same as that in row 2 (010).

Page: 04-30 Location: Items #10,17 and 18

Replace item #10 with item #17 (i.e. delete #10 and change #17 into #10) and

change #18 into #17.

Page: 05-10 Location: Illustration

Make a callout [C] to unmarked side plate cutout. Spring plate callout [C] change to [D]

Page: 05-28 Location: Steps 3 and 4

Incorrect: one-eighth of Vsg.

Correct: one-tenth of Vsg.

Page: 05-32 Location: Steps 9 -- 13

Renumber 9 through 13 to 7 through 11. (Numbers are continuing from previous page.)

Page: 05-46 Location: HOT ROLLER TEMPERATURE ADJUSTMENT, Measure

Incorrect: 10°C/step

Correct: 1°C/step

Page: 05-58 Location: step 5

Incorrect: [A] (2 screws).

Correct: [A] (4 screws).

Page 6

Technical Bulletin No. RTB-001

SUBJECT: F-40 SERVICE MANUAL MODIFICATION

Page: 05-58 Location: step 6

Incorrect: [B] (4 screws).

Correct: [B] (2 screws).

Page: 05-69 Location: 7.5 LIGHT INTENSITY ADJUSTMENT, step 3

Incorrect: ID level and make ten A3/LDG copies to stabilize drum sensitivity.

Correct: ID level and make more than ten A3/LDG copies, then check the light intensity.

Page: 05-69 Location: 7.5 LIGHT INTENSITY ADJUSTMENT, step 5

Renumber #5 to #4.

Page: 05-70 Location: ADS VOLTAGE ADJUSTMENT, Measure

Delete the following text: The ADS output voltage on the main PCB can be changed.

Page: 05-76 Location: illustration

Lower right part of illustration overlaps text. Move it up.

Page: 05-87 Location: step 6

Incorrect: 6 Turn on the D2 switch

Correct: 6 Turn on the D1 switch

DATE: Dec.31 1990

PAGE: 6 of 10

Page: 05-91 Location: section title

Incorrect: 8.13 CHARGE CORONA CURRENT ADJUSTMENT

Correct: 8.13 CHARGE CORONA CURRENT ADJUSTMENT WHEN USING THE DRUM

SHOE

Page: 05-94 Location: step 8

Incorrect: 8. Turn on the SC D2

Correct: 8. Turn on the SC D1

Page: 05-95 Location: Optimum Adjustment Value

Incorrect: (Normal:D18-D2)

Correct: (Normal: D1 and D2)

Page: 05-95 Location: step 10

Delete #10 and renumber the steps that follow.

Page: 05-97 Location: NOTE

Incorrect: After turning on the PCC switch,

Correct: After turning on the PQC switch,

Page: 07-07 Location: Lines 3 -- 5 in 2nd paragraph

Incorrect: feed-in solenoid

Correct: feed-in clutch

Page 7

Technical Bulletin No. RTB-001

SUBJECT: F-40 SERVICE MANUAL MODIFICATION

Page: 07-07 Location: 1st line in the 3rd paragraph

Incorrect: and the paper width

Correct: and the original width

Page: 07-07 Location: The 7th line from the bottom

Incorrect: the original until 140 milliseconds

Correct: the original until 85 milliseconds

Page: 07-33 Location: section title

Incorrect: 13.2 PAPER FEED UNIT REMOVAL

Correct: 13.2 FEED-IN UNIT REMOVAL

Page: 07-36 Location: section title

Incorrect: 13.5 PAPER FEED CLUTCH REPLACEMENT

Correct: 13.5 FEED-IN CLUTCH REPLACEMENT

Page: 07-38 Locaton: section title

Incorrect: 13.7 PAPER FEED MOTOR REPLACEMENT

Correct: 13.7 BELT DRIVE MOTOR REPLACEMENT

DATE: Dec.31 1990

PAGE: 7 of 10

Page: 07-40 Location: section title

Incorrect: 13.9 PAPER FEED ROLLER REPLACEMENT

Correct: 13.9 ORIGINAL FEED ROLLER REPLACEMENT

Page: 07-46 Location: after step 3

Add the following note:

NOTE: When removing the PCB, be careful not to damage any of the components that

protrude from the board.

Page: 08-13 Location: top illustration

Switch callouts [A] and [B].

Page: 09-17 Location: 3rd line in 1st paragraph.

Incorrect: When the DF is lifted

Correct: When the RDH is lifted

Page 09-19 Location: list

Incorrect: 10. Pan head Screw 4 x 6 9

Incorrect: 11. Pan head Screw 1

Incorrect: 12. Pan head Screw 4 x 8 8

Correct: 10. Pan head Screw 4 x 6 11

Correct: 11. Washer 1

Correct: 12. Shoulder Screw 4 x 10 8

Page 8

Technical Bulletin No. RTB-001

SUBJECT: F-40 SERVICE MANUAL MODIFICATION

Page: 09-19 Location: item 9 in list

Delete item #9 and renumber the list.

Page: 09-25 Location: step #18, substep 1)

Incorrect: 1) Remove the RDH rear cover [A] (5 screws), then set the DIP SW 101-2 on to

change timing registaration mode.

Correct: 1) Remove the RDH rear cover [A] (5 screws), then turn on DIP SW 101-2 to

change to timing registration mode.

Page: 09-32 Location: Between step 1 and 1)

Add the following text, then renumber the steps:

1) Remove the RDH rear cover [A] (5 screws), then turn on DIP SW 101-2

to change to timing registration mode.

Page: 10-06 Location: 2nd line of 1st paragraph

Incorrect: The motor and

Correct: The belt-drive motor and

Page: 10-20 Location: item 10 of list

DATE: Dec.31 1990

PAGE: 8 of 10

Incorrect: 10. Pan Head Screw with Washer

Correct: 10. Pan head Screw (Long)

Page: 10-20 Location: item 15 of list

Incorrect: 15. Rubber Tightener

Correct: 15. Rubber Washer

Page: 10-20 Location: Between items 18 and 19 of list

Add the following item, then renumber the list:

19. Decal -- Staple Position

Page: 12-09 Location: Code #56, Definition

Incorrect: SC #55 lights

Correct: SC#56 lights

Page: 12-12 Location: Code #86, Definition

Incorrect: the SC #85 counter

Correct: the SC #86 counter

Page: 12-16 Location: Code #B8, Definition

Incorrect: SC #B8 if the does

Correct: SC #B8 if the one-turn sensor does

Page: 12-18 Table location: row 5 in the Name column

Incorrect: 2nd and 3rd Lift

Correct: 1st, 2nd and 3rd Lift

Page 9

Technical Bulletin No. RTB-001

SUBJECT: F-40 SERVICE MANUAL MODIFICATION

Page: 12-18 Table location: row 8 in the Problem column

Incorrect: SC (41:1st, 42:2nd, 43:3rd, 44:4th)

Correct: SC (41:1st, 42:2nd, 43:3rd)

Page: 12-19 Table location: row 11 in the Problem column

Incorrect: SC 29 is indicated 3. . .

Correct: SC 29 is indicated 3.83. . .

Page: 12-19 Table location: row 12 in the Problem column

Incorrect: SC 28 is indicated 3.7. . .

Correct: SC 28 is indicated 3.83. . .

Page: 12-19 Table location: row 13 in the Problem column

Incorrect: SC 2B is indicated 3. . .

Correct: SC 2B is indicated 1.83. . .

Page: 12-19 Table location: row 14 in the Problem column

Incorrect: SC 2A is indicated 0.3. . .

Correct: SC 2A is indicated 1.83. . .

DATE: Dec.31 1990

PAGE: 9 of 10

Page: 12-20 Table location: row 4 in the Problem column

Incorrect: SC 82 is indicated

Correct: SC 81 is indicated.

Page: 12-21 Location: step 2

Incorrect: (2) Repeat step 1 to obtain

Correct: (2) Press SW100 on the RDH board to obtain

Page: 12-22 Table location: row 3 in the Definition column

Incorrect: the feed-in motor

Correct: the feed-out motor

Page: 12-22 Table location: row 5 in the Definition column

Incorrect: two-sides Duplex

Correct: two-side Duplex

Page: 12-22 Table location: row 11 in the Condition column

Incorrect: Feed-out sensor stays on.

Correct: Feed-out sensor stays on. (A4/81/2" x 11"(s) or smaller originals)

Page: 12-22 Table location: row 11 in the Definition column

Incorrect: 850 ms after the feed-out sensor turn on.

Correct: 850 ms after the feed-out motor turns on again to feed out the 1st original.

Page 10

Technical Bulletin No. RTB-001

SUBJECT: F-40 SERVICE MANUAL MODIFICATION

Page: 12-22 Table location: row 12 in the Definition column

Incorrect: not turns off within 850 ms the inverter

Correct: not turn off within 850 ms after the inverter

Page: 12-22 Table location: row 14 in the Condition column

Incorrect: is not turned at correct time.

Correct: is not turned on at correct time.

Page: 12-23 Table location: row 5 in the Definition column

Incorrect: RDH receives the feed-in signal

Correct: RDH receives the feed-out signal

DATE: Dec.31 1990

PAGE: 10 of 10

Page 11

Technical Bulletin No. RTB-002

SUBJECT: Point to Point Diagram Correction DATE: Jan. 15, ’91

PAGE: 1 of 2

PREPARED BY: M. Kitajima

FROM: Copier Technical Support Section

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

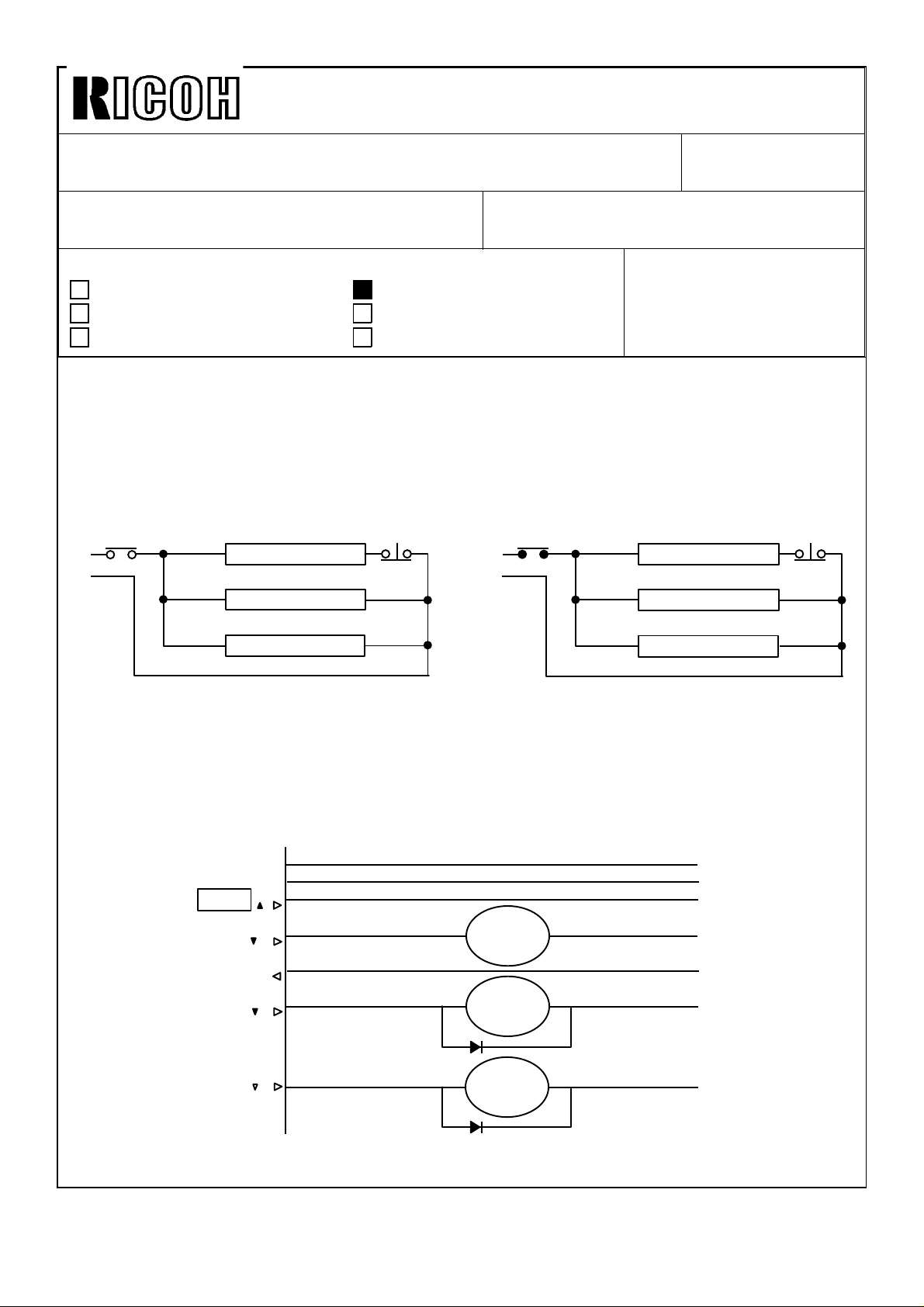

Please correct your point to point diagram as follows:

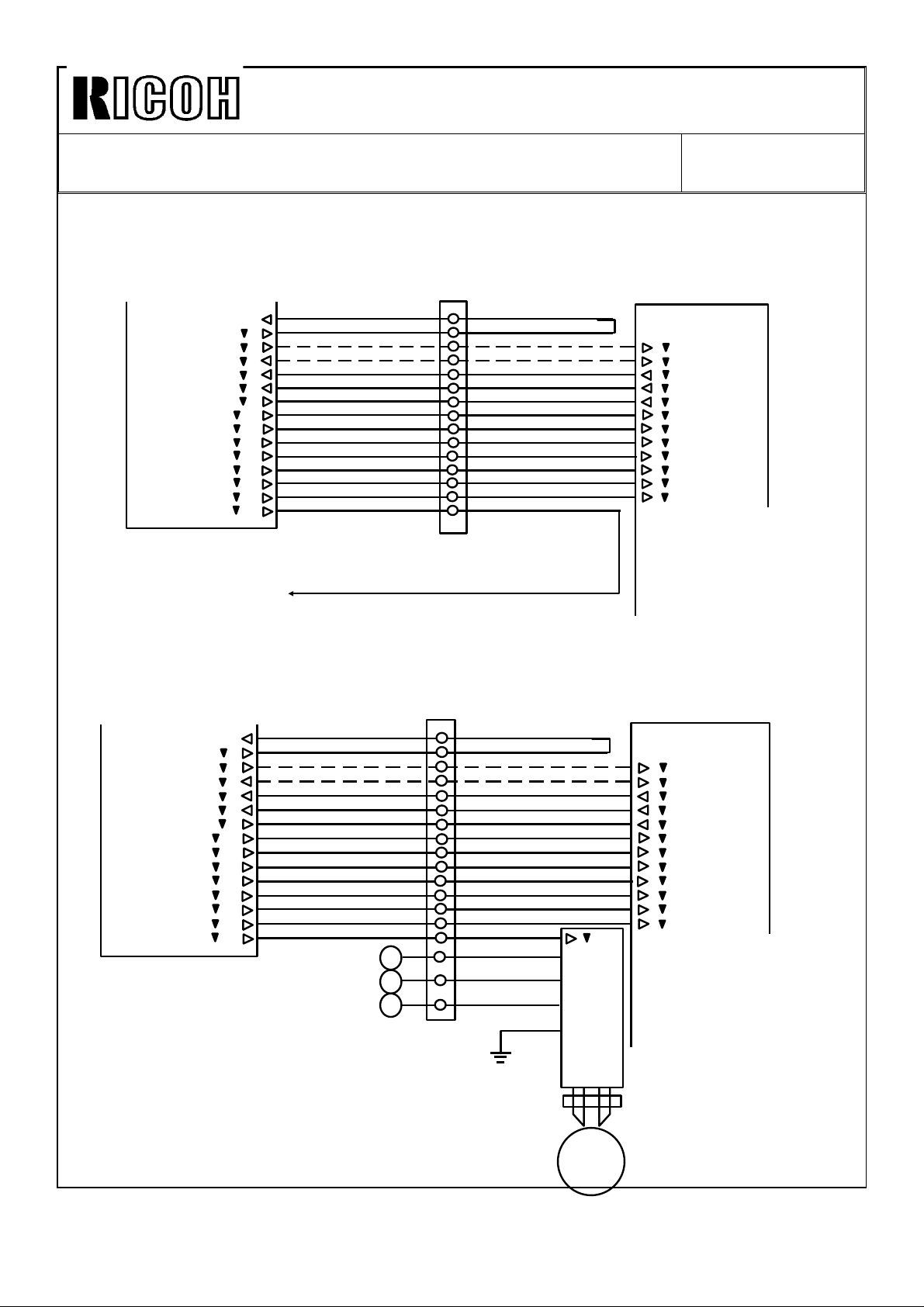

1) Location on Copier P to P: G4

INCORRECT CORRECT

(W) T19

T20

(H) CN701-2

(H) CN672-2

(H) CN609-2

Cleaning Heater

Drum Heater

Anticondensation Heater

CN701-1 (B)

CN672-1 (B)

CN609-1 (B)

(W) T19

RA2

T20

(H) CN701-2

(H) CN672-2

(H) CN609-2

MODEL: F40

Cleaning Heater

Drum Heater

Anticondensation Heater

CN701-1 (B)

CN672-1 (B)

CN609-1 (B)

2) Location on Copier P to P: C5

The signal description is "Fusing Exit Sensor".

VC [5]

C-GND [0]

Fusing

Exit Sensor [ 5]

Fusing Cooling

Fan Motor [ 24]

Fusing

Unit Set [0]

Toner

Supply MC [ 24]

Cleaning SOL [ 24]

CN102-B5 (R)

CN102-B4 (T)

CN101-A20 (H)

CN102-A13 (G)

CN101-B18 (G)

CN101-A18 (C)

CN655-2

CN687-2

CN688-2

NOTE: RA2 is closed.

Fusing

Cooling

Fan M

Toner

Supply

MC

Cleaning

SOL

CN655-2 (W)

CN687-2 (W)

CN688-2 (W)CN101-B7 (C)

Page 12

Technical Bulletin No. RTB-002

SUBJECT: Point to Point Diagram Correction DATE: Jan. 15, ’91

PAGE: 2 of 2

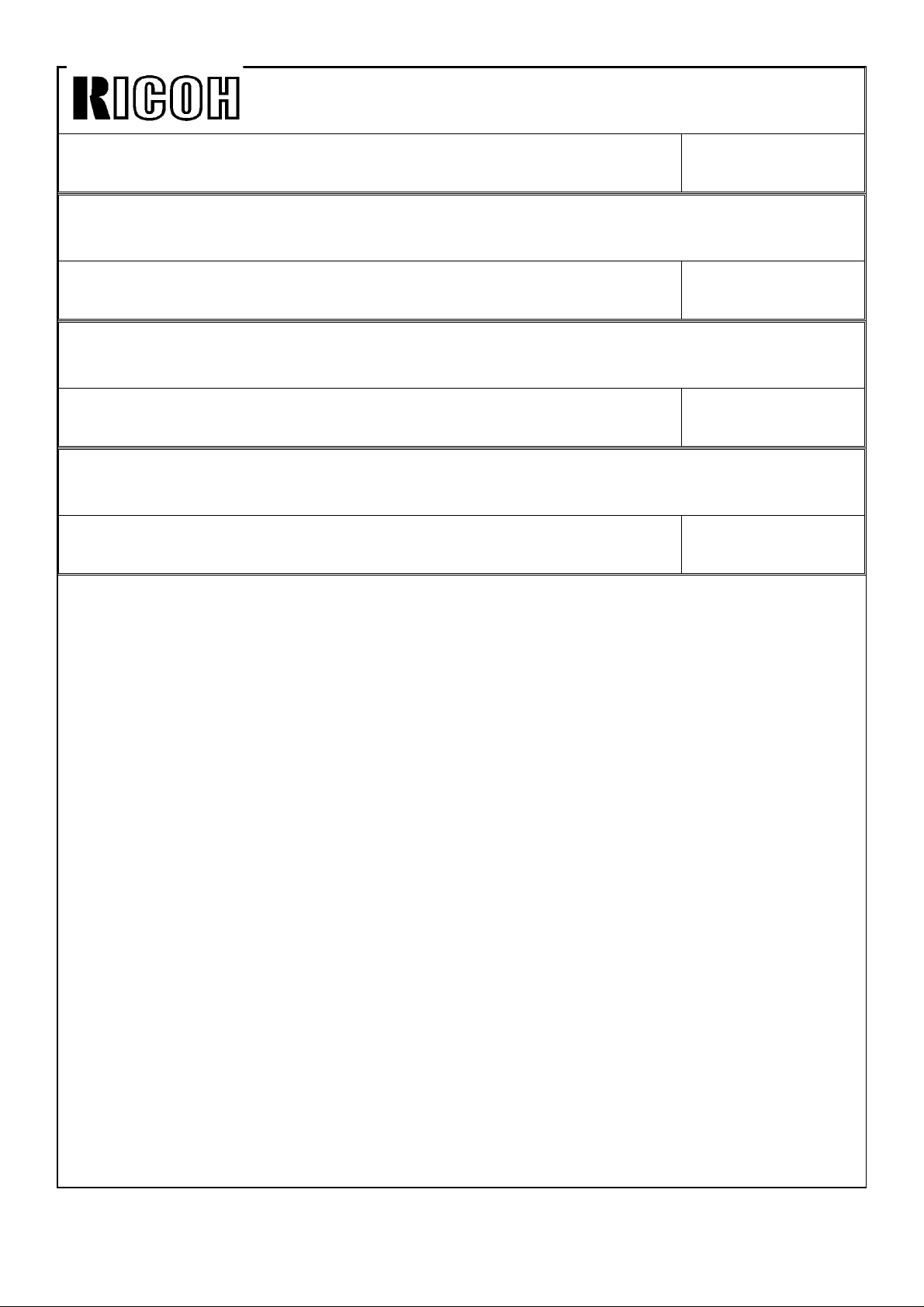

Option (ARDF and RDH) P to P

INCORRECT

Main PCB

GND [0]

Door Safety [ 5]

Scan2 [ 5]

Scan3 [ 5]

2nd Lift [ 5]

3rd Lift [ 5]

2nd Relay [ 5]

2nd Relay MC [ 24]

Lift Motor 2 [ 24]

Lift Motor 3 [ 24]

Feed MC2 [ 24]

Feed MC3 [ 24]

2nd Pick-up [ 24]

3rd Pick-up [ 24]

Bank Drive Motor [ 24]

Paper Feed Motor PCB

CN103-B8

CN103-A8

CN103-B14

CN103-A15

CN103-A4

CN103-B4

CN104-B9

CN104-A9

CN103-B2

CN103-A2

CN104-B5

CN104-A6

CN104-A8

CN104-B8

CN103-A13

(T)

(G)

(Y)

(Y)

(Y)

(Y)

(Y)

(Y)

(C)

(C)

(H)

(M)

(G)

(G)

(G)

CN464

-18

-10

-26

-27

-11

-12

-28

-14

-2

-3

-29

-30

-31

-19

-13

CN1-4 (P)

(Y)

(P)

(Y)

(Z)

(C)

(Y)

(P)

(Y)

(Z)

(C)

(P)

(Y)

(P)

CN453-1

CN453-2

CN453-3

CN453-4

CN453-5

CN453-7

CN453-8

CN453-9

CN453-10

CN453-11

CN453-12

CN453-13

[ 5] Scan2

[ 5] Scan3

[ 5] 2nd Lift

[ 5] 3rd Lift

[ 5] 2nd Relay

[ 24] 2nd Relay MC

[ 24] Lift Motor 2

[ 24] Lift Motor 3

[ 24] Feed MC2

[ 24] Feed MC3

[ 24] 2nd Pick-up

[ 24] 3rd Pick-up

Cassette

Bank

PCB

CORRECT

Please add the cassette bank drive PCB and motor to your P to P.

Main PCB

Door Safety [ 5]

2nd Relay MC [ 24]

Lift Motor 2 [ 24]

Lift Motor 3 [ 24]

Feed MC2 [ 24]

Feed MC3 [ 24]

2nd Pick-up [ 24]

3rd Pick-up [ 24]

Bank Drive Motor [ 24]

GND [0]

Scan2 [ 5]

Scan3 [ 5]

2nd Lift [ 5]

3rd Lift [ 5]

2nd Relay [ 5]

CN103-B8

CN103-A8

CN103-B14

CN103-A15

CN103-A4

CN103-B4

CN104-B9

CN104-A9

CN103-B2

CN103-A2

CN104-B5

CN104-A6

CN104-A8

CN104-B8

CN103-A13

(T)

(G)

(Y)

(Y)

(Y)

(Y)

(Y)

(Y)

(C)

(C)

(H)

(M)

(G)

(G)

(G)

A

B

C

CN464

-18

-10

-26

-27

-11

-12

-28

-14

-2

-3

-29

-30

-31

-19

-13

(B)

-1

-17

(W)

-4

(W)

(G/Y) CN1-5

CN1-1

CN1-2

CN1-3

(Y)

(P)

(Y)

(Z)

(C)

(Y)

(P)

(Y)

(Z)

(C)

(P)

(Y)

(P)

CN453-1

CN453-2

CN453-3

CN453-4

CN453-5

CN453-7

CN453-8

CN453-9

CN453-10

CN453-11

CN453-12

CN453-13

[ 24]

[24] VM

[0] E-GND

[S] VE

[0] GND

Cassette

Bank Drive

PCB

[ 5] Scan2

[ 5] Scan3

[ 5] 2nd Lift

[ 5] 3rd Lift

[ 5] 2nd Relay

[ 24] 2nd Relay MC

[ 24] Lift Motor 2

[ 24] Lift Motor 3

[ 24] Feed MC2

[ 24] Feed MC3

[ 24] 2nd Pick-up

[ 24] 3rd Pick-up

Cassette

Bank

PCB

Cassette

Bank Drive

M

Page 13

Technical Bulletin No. RTB-000

SUBJECT: DATE:

PAGE: 2 of

Technical Bulletin No. RTB-000

SUBJECT: DATE:

PAGE: 2 of

Technical Bulletin No. RTB-000

SUBJECT: DATE:

PAGE: 2 of

Technical Bulletin No. RTB-000

SUBJECT: DATE:

PAGE: 2 of

Page 14

Technical Bulletin No. RTB-003

REVISED ON MAY 15

SUBJECT: LCT Side to Side Registration Adjustment DATE: Feb. 15, ’91

PAGE: 1 of 2

PREPARED BY: M. Ninomiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

[A]

[B]

2.5 cm

FROM: Copier Technical Support Sec.

MODEL: F-40

Revision of service manual

Information only

Other

[B]

[B]

[B]

Specification

Side registration: 0±2.0 mm

Preparation (Making a test sheet)

1. Fold an A4 (8 1/2 x 11) sheet exactly in half. Then draw a 2.5 cm (1 inch) line [A] on the

crease from an edge of the sheet.

Confirmation

1. Make a copy of the test sheet in platen mode from the LCT.

2. Fold the copy once with the fold running down the middle of the copy, then verify that

the vertical line at the top center of the test chart is on the fold or within 2.0 mm of the

fold.

3. If the side registration of the LCT is not within the specifications, follow the procedure

below:

Page 15

Technical Bulletin No. RTB-003

SUBJECT: LCT Side to Side Registration Adjustment DATE: Feb. 15, ’91

PAGE: 2 of 2

Adjustment procedure

1. Remove the LCT right, front, and rear cover (2, 4 and 5 screws).

* Refer to steps 1 and 2 of LCT Unit Removal on p. 5-3 of the service manual.

2. Loosen 6 screws [B], Then slide the LCT unit to the front or rear to adjust the side

registration, then tighten the 6 screws.

3. Check the side registration again.

Page 16

Technical Bulletin No. RTB-004

REVISED ON MAY 15

SUBJECT: BY PASS PAPER FEED SIDE REGISTRATION

ADJUSTMENT

PREPARED BY: M. Ninomiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

[A]

2.5 cm

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

DATE: Feb. 15, 91

PAGE: 1 of 2

MODEL: F-40

[B]

Specification

Side registration: 0±2.0 mm

Preparation (Making a test sheet)

1. Fold an A4 (8 1/2 x 11) sheet exactly in half. Then draw a 2.5 cm (1 inch) line [A] on the

crease from an edge of the sheet.

Confirmation

1. Make a copy of the test chart in platen mode from the by-pass paper feed table.

2. Fold the copy once with the fold running down the middle of the copy, then verify that

the vertical line at the top center of the test chart is on the fold or within 2.0 mm of the

fold.

3. If the side registration of the by-pass paper feed table is not within the specifications, do

the following procedure.

Page 17

Technical Bulletin No. RTB-004

SUBJECT: BY PASS PAPER FEED SIDE REGISTRATION

ADJUSTMENT

Adjustment procedure

1. Open the by-pass paper feed table.

2. Loosen the Allen screw [B] with an Allen wrench.

3. Slide the table to the front or rear to adjust the side registration.

4. Check the side registration again.

DATE: Feb. 15, 91

PAGE: 2 of 2

Page 18

Technical Bulletin No. RTB-005

REVISED ON DEC. 15, ’91

SUBJECT: Inverter Jam DATE: Feb. 28, ’91

PAGE: 1 of 4

PREPARED BY: M. Ninomiya

CHECKED BY: T. Ito

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

Technical Support Dept.

MODEL: F40

1.SYMPTOM:

An "accordion" paper jam occurs at the inverter unit with the first sheet in duplex mode,

lighting the jam indicator "D" on the display panel.

Exit Relay Roller

Inverter

Pressuure Roller

Inverter return

Roller

The exact position where the leading edge of the paper stops is the third roller from the

front side of the guide plate.

[ Front ]

Inverter Return Roller

Page 19

Technical Bulletin No. RTB-005

SUBJECT: Inverter Jam DATE: Feb. 28, ’91

PAGE: 2 of 4

When this occurs:

After about 100 copies have been made and the inside of the copier has heated up, this

paper jam may occur.

The occurrence ratio differs depending on the temperature, humidity,and paper type.

Paper jamming is most likely to occur under the following conditions:

* at low temperature

* at low humidity

* with certain brands of paper (ex. Sabre-X)

* when sideways A4 copies are made

2. CAUSE:

Open/Shut Guide Plate

Upper Guide Plate

Paper direction

when guide plate is

warped

A. The guide plate warps.

The open/shut guide plate warps and curves downward as shown as the result of heat

from the fusing unit.

Paper direction

when guide plate

is not warped

Open / Shut Guide Plate

(molded plastic)

Page 20

Technical Bulletin No. RTB-005

SUBJECT: Inverter Jam DATE: Feb. 28, ’91

PAGE: 3 of 4

B. The gap between the open/shut guide plate and the lower guide plate narrows.

Open/Shut Guide Plate

Ribs

Lower Guide Plate

The gap narrows in the center.

C. Paper passing through the guide plates has crease marks at the point where the gap

is narrow.

NOTE: This is also done

(intentionally) at the exit rollers to

create stiffness in the paper sheet.

D. This "stiff" paper proceeds strait ahead (due to its stiffness), and hits the inverter return

roller. Jams often occur at this point.

paper

Inverter Return Roller

If the gap between the plates is even, paper jams do not occur.

NOTE: This paper jam occurs only when the first sheet is fed in duplex mode because of

the short interval betweeen pages. The preceding sheet of paper prevents the

following sheet from hitting the inverter return roller.

Preceding paper

Following Paper

Inverter return Roller

Page 21

Technical Bulletin No. RTB-005

SUBJECT: Inverter Jam DATE: Feb. 28, ’91

PAGE: 4 of 4

3. ACTION IN THE FIELD (Temporary Solution)

[ B ]

[ A ]

Install the spacers. Line up the spacers with the arrows as shown.

Spacer : P/N A0458991 (Thickness = 0.5, Size = 10 X 80 mm)

Method of adhesion: Double sided tape

Open/Shut Guide Plate

Place flat spacers [ A ] between the

open/shut guide plate and the magnet.

This will raise the open/shut guide

plate [ B ].

SPACER (A0458991)

NOTE: This temporary solution has already been implemented from the November, ’90

production run. This countermeasure will be applied until a permanent solution is

found.

4. PERMANENT SOLUTION

The open/shut guide plate has been made thicker by 0.7mm at the place where the

spacers were stuck on.

a + t

NOTE: This permanent solution has been implemented from the September ’91

production run. (Refer to MB No. 24 issued on DEC. 15, ’91)

t = 0.7mm

Page 22

Technical Bulletin No. RTB-006

SUBJECT: Platinum Corona Wire DATE: Apr. 15, ’91

PAGE: 1 of 2

PREPARED BY: H. Kobayashi

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The following platinum corona wires have been registered as service parts. The tungsten

corona wires are currently being installed on the assembly line, but they may be replaced

in the field with the platinum corona wires, if desired.

Platinum

corona P/N

#52199540 Corona Wire (1 pc/set) #52199101

#A0079540 Main Corona Wire (1 pc/set) #A0089001

#A0079541 PQC Corona Wire (1 pc/set) #A0079002

#A0079542 Transfer Corona Wire (1 pc/set) #A0079003

Revision of service manual

Information only

Other

Description Current Tungsten Corona P/N

FROM:Copier Technical Support Section

MODEL: F40

The platinum and the tungsten corona wires are fairly similar in performance and handling;

however, there are the following differences:

Point 1

During the copy cycle, less foreign matter (toner, dust, gas) will build up on the surface of

a platinum corona wire than on a tungsten wire. Consequently, platinum corona wires do

not need to be cleaned as often to maintain copy quality. This is true for both these

platinum corona wires and the third vendor’s platinum corona wires.

Point 2

Negative charges cause portions of the surface of a platinum corona wire to break off,

affecting the copy image and requiring replacement of the wire. A platinum wire cannot be

used as a negative charge corona. (A tungsten wire can be used as a negative charge

corona wire.) This is true for both these platinum corona wires and the third vendor’s

platinum corona wires.

Page 23

Technical Bulletin No. RTB-006

SUBJECT: Platinum Corona Wire DATE: Apr. 15, ’91

PAGE: 2 of 2

--When to install the platinum corona wires-

The platinum corona wires do not have to be cleaned as often as the tungsten wires

(point 1). For this reason, the platinum corona wires are most suitable in cases where a

machine is installed in a relatively inaccessible location (far from a service center) and

service calls are difficult to make.

The platinum wires can be installed in the field on the following models:

Model Main Transfer PQC PCC Separation PTC

F20

F21

F22

F30

F31

F33

F34

F40

#52199540 #52199540 #52199540 Negative

charge.

Do not use.

#A0079540 #A0079542 #A0079541 Negative

charge.

Do not use.

Negative

charge.

Do not use.

Negative

charge.

Do not use.

Negative

charge.

Do not use.

Not used.

Note 1

When installing the platinum corona wires, please take the following actions:

1. Clean the corona casings, end blocks, and new platinum wires with damp cloth.

2. Confirm VSG.

Note 2

#A0079540 can also be used as the F90 main corona wire.

Page 24

Technical Bulletin No. RTB-007

SUBJECT: Improper Stapling DATE: Mar. 31,’91

PAGE: 1 of 3

PREPARED BY: M. Ninomiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

1. Phenomenon

A) Incomplete stapling: The staples are not flush with the paper surface.

2 to 30 sheets of paper

Flat Stapling

(Normal)

B) No stapling: No staples are dispensed from the stapler.

Revision of service manual

Information only

Other

Incomplete stapling

(Loose)

FROM: Copier Technical Support Sec.

MODEL: F40 Finisher

1mm gap

2. Cause

A) If a staple [A] jams inside the staple bending gate [B], the gate cannot close

completely. Staples are not crimped completely, and there is about a 1mm gap

between the staple and the paper surface.

[B]

[A]

Page 25

Technical Bulletin No. RTB-007

SUBJECT: Improper Stapling DATE: Mar 31,1991

PAGE: 2 of 3

B) A bent staple prevents the staple push plate [A] from moving downward or the staple

sheet has not yet reached the stapling position.

[A]

3. Action

A) Remove the jammed staple [B] from the staple bending gate [C].

[C]

[B]

Page 26

Technical Bulletin No. RTB-007

SUBJECT: Improper Stapling DATE: Mar 31,1991

PAGE: 3 of 3

B)

1. Remove the staple cartridge, then check for any staples jammed in the stapling

mechanism [A]. To remove jammed staples, spread apart the side plates [B] and slide

up the front pressure guide plate [C].

NOTE: When installing the staple cartridge, make sure that all the staple sheets are

be in the initial position [D], i.e. the staple sheets have not slid forward into

the staple sheet guide [E].

2. Install the staple cartridge, then make copies in double stapling mode until the staple

sheet reaches the stapling position.

[B]

[A]

[D]

[C]

[E]

Correct Incorrect

Page 27

Technical Bulletin No. RTB-008

REVISED ON JUNE 15

SUBJECT: Bending Finsher Top Cover DATE: Mar. 31,’91

PAGE: 1 of 2

PREPARED BY: M. Ninomiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

1. Phenomenon

The finisher top cover [A] is bent and it makes a noise when it is opened or closed.

Normal

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: F40 Finisher

2. Cause

The rear top cover [B] and/or front top cover [C] of the finisher has not been installed

correctly. It does not fit over part of the finisher frame [D]. As a result, the side(s) of the

finisher’s top cover cannot close completely. The cover also makes a noise as it is being

opened/closed.

[B]

Bent

[D]

[D]

[A]

[C]

[C]

[D]

Page 28

Technical Bulletin No. RTB-008

SUBJECT: Improper Stapling DATE: Mar 31,1991

PAGE: 2 of 2

3. Solution (From April production)

The finisher frame [A] has been redesigned. For the new frame, we eliminated the shaded

area [B], making it easier to reinstall the finisher’s front and rear top covers.

[B]

[A]

3. Action (For before April production)

With a screwdriver, loosen the two screws securing the front and/or rear top cover [C].

Then, use a small flat head screwdriver as shown to pry out the edge of the cover [C] so

that it fits over the edge [D] of the frame. Tighten the screws.

[C]

[C]

[D]

[D]

[C]

[C]

[C]

[C]

Incorrect

[D]

Correct

[D]

Incorrect

Correct

Page 29

Technical Bulletin No. RTB-009

SUBJECT: Installation Procedure change DATE: May 31,1991

PAGE: 1 of 1

PREPARED BY: F. Noguchi

CHECKED BY: T. Ito

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

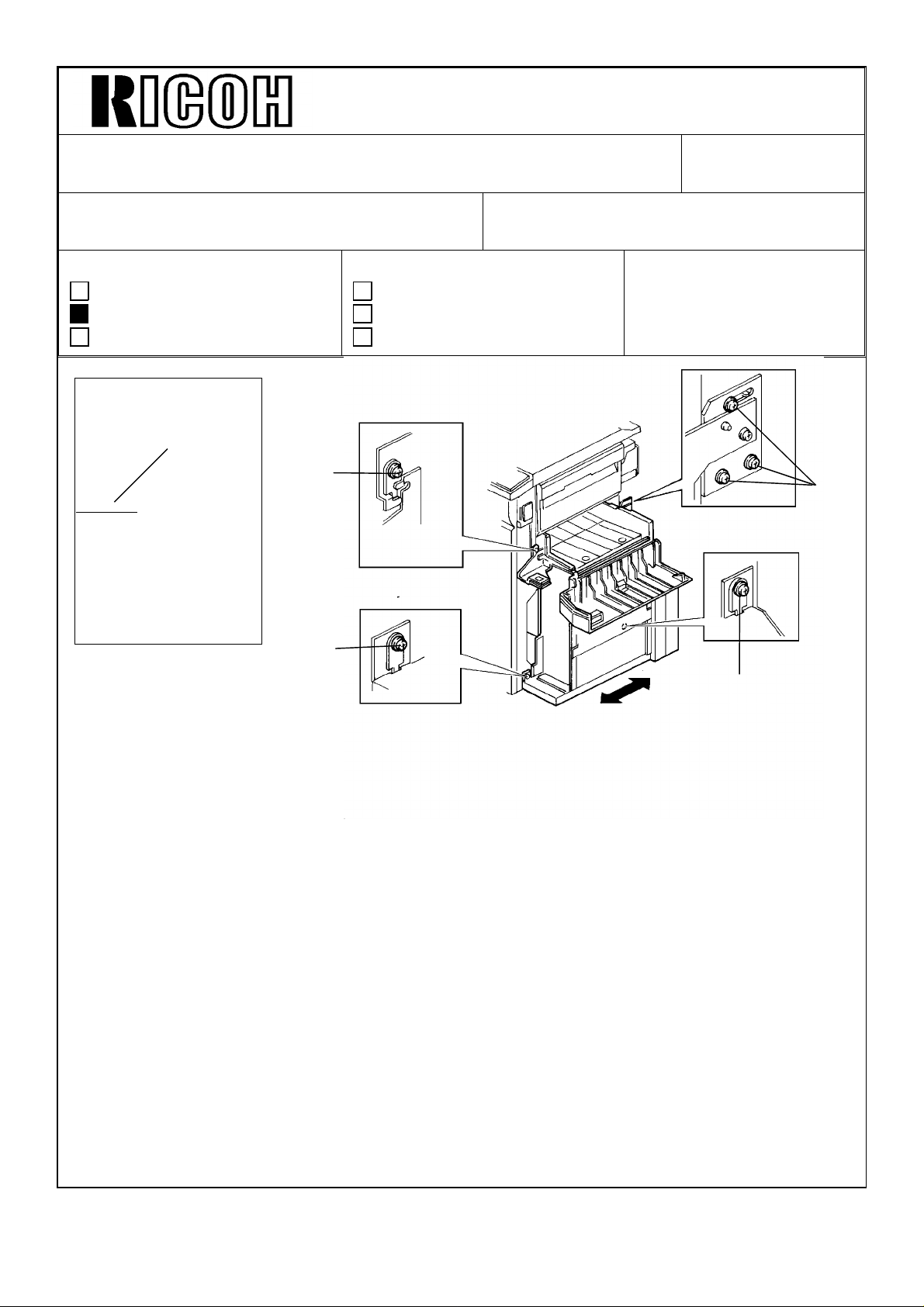

Since the location of shipping tape on the cassette bank section has been changed and a

cushion has been added, the procedure has been changed as follows:

OLD

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F 40

[C]

[B]

6. Slide out the paper feed unit [B], then remove all strips of filament tape [C].

NEW

[C]

[D]

[B]

6. Slide out the paper feed unit [B], then remove all strips of filament tape [C] and the

cushion [D].

This modification is applied from the 1991 May production run.

Page 30

Technical Bulletin No. RTB-010

SUBJECT: Sorter installation procedure correction for the F40. DATE: Jun.15,’91

PAGE: 1 of 2

PREPARED BY: M. Ninomiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

1) Installation procedure correction in the service manual.

Two steps [A] were inserted on page 8-14, between steps 12 and 13 of the current F40

service manual.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: F40

[A]

13. Peel off the cover [C] from the Sort/Staple key panel (left side of the operation

panel).

14. Remove the Staple Position key top [D], and affix the Sort/Stack key cover [E]

(copier accessory) as shown.

Page 31

Technical Bulletin No. RTB-010

SUBJECT: Sorter installation procedure correction for the F40 DATE: Jun. 15, ’91

PAGE: 2 of 2

2) Installation procedure correction for the booklet in the machine container.

Illustration [A] was added, and steps [B] were inserted between installation procedure

steps 8 and 9.

[A]

[B]

9. Peel off the cover [C] from the Sort/Staple key panel (left side of the operation panel).

10. Remove the Staple Position key top [D], and affix the Sort/Stack key cover [E]

(copier accessory) as shown.

11.Set SP71-1 to enable the sorter. (Refer to the copier installation procedure.)

NOTE: Corrected installation procedure will be enclosed from August ’91 production.

Page 32

Technical Bulletin No. RTB-011

SUBJECT: Original side to side registration DATE: 15 Aug. ’91

PAGE: 1 of 5

PREPARED BY: J. Kasamoto

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

1. Replacement of the original table and side fences for machines produced before

June ’91.

Replacement procedure

1. Remove the RDH front [A] and rear [B]

covers (5 and 5 screws).

2. Open the left cover [C] by pushing the

release lever button.

3. Remove the feed-in unit top cover [D] (4

screws).

4. Remove the original stopper solenoid [E]

with the bracket on (1 screw), but do not

let the solenoid hang down by the

harness.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F40 (RDH)

[D]

[C]

[A]

[F]

[E]

[B]

5. Remove the release lever unit [F] (2

screws and 2 springs). The springs may

suddenly release so be careful not to lose

the springs.

6. Remove the original stopper unit this way

(1 screw and 1 stud);

As in figure 2, first remove the front side

screw, then loosen the stopper pin [G].

After loosening the rear stud screw, lift up

the front side of the original stopper unit

[H] and unsecure the stud screw [I].

Remove the tension spring from the

spring anchor.

7. Remove the original entrance guide

assembly [J] (4 screws), and be careful

not to damage the harness and the

mylars.

Fig. 1

[G]

[H]

[J]

[I]

Fig. 2

Page 33

Technical Bulletin No. RTB-011

SUBJECT: Original side to side registration DATE: 15 Aug. ’91

PAGE: 2 of 5

8. Remove the original table with the side

fences (7 screws) as in figure 3.

Make sure that the feed-out unit is placed

at the right end [A].

Be careful not to damage the exit roller

paper guard [B].

9. Remove all the parts from the original

table.

10. Place the side fence in the middle of the

new original table [C], and assemble the

new table unit as shown in figure 4. The

parts marked [*] are new parts. Refer to

Modification Bulletin (F40 - No. 11)

[B]

[A]

11. Reinstall the unit.

NOTE: When reinstalling the unit, make

sure of the following.

• Set the new original table following the

sequence in figure 3, but in reverse.

[*]

Fig. 3

[*]

[*]

[C]

[*]

[*]

Fig. 4

Page 34

Technical Bulletin No. RTB-011

SUBJECT: Original side to side registration DATE: 15 Aug. ’91

PAGE: 3 of 5

• Reinstall the springs for the release lever

unit as in figure 5.

Fig. 5

• When reinstalling the original stopper

solenoid, make sure that the harness is

out of the way [A] and that you place the

bracket in the socket [B] as shown in

figure 6.

[A]

• Check to see if the release lever and the

original stopper unit work properly.

• Make sure the three original stoppers are

parallel and that the stoppers do not

touch the original table unit. The

specifications are shown in figure 7.

• Test run the machine before

reassembling the front and rear covers.

[B]

Fig. 6

Fig. 7

1 ± 0.2 mm

Page 35

Technical Bulletin No. RTB-011

SUBJECT: Original side to side registration DATE: 15 Aug. ’91

PAGE: 4 of 5

2. Adjustment

-- Preparation (making a test sheet) --

1. Fold an A4 (81/2 x 11) sheet exactly in half. Then draw a 2.5 cm (1 inch) line [A] on the

crease from the edge of the sheet.

-- Confirmation --

1. Put the test sheet directly on the exposure glass and make a copy (platen mode).

2. Check to see if the copier side to side registration is adjusted properly.

3. Feed the original in the RDH so that the edge with the line faces away from the original

feed rollers.

4. Compare the copy with the test sheet.

[A]

2.5 cm

Test sheet RDH case 1 RDH case 2 RDH case 3

Case 1: Both are identical. Reassemble the copier. No further steps are

needed.

Cases 2 and 3: The copy image has moved. Follow the procedure below.

5. Open the document feeder.

6. Remove the transport belt unit [B] (4

screws) as in figure 8.

[B]

Fig. 8

Page 36

Technical Bulletin No. RTB-011

SUBJECT: Original Side to Side Registration DATE: 15 Aug. ’91

PAGE: 5 of 5

[B]

[C]

[C]

[A]

Fig. 9

7. Loosen four screws [A] on the original table and adjust the side registration as shown

in figure 9. If case 2, follow procedure a. If case 3, follow procedure b.

a) Case 2: The copy image has moved up. Measure the difference and adjust the

tray’s position by pulling it away from the RDH pedestal [B-direction].

Make sure the adjustment matches the difference.

b) Case 3: The RDH copy image has moved down. Measure the difference and

adjust the tray’s position by pushing it towards the RDH pedestal

[C-direction]. Make sure the adjustment matches the difference.

8. Reassemble the document feeder.

9. Repeat the procedure from step 3. (Until both copies are identical.)

[B]

Page 37

Technical Bulletin No. RTB-012

SUBJECT: 1. Additional steps for scanner wire replacement

2. Troubleshooting for SC21

PREPARED BY: J. Kasamoto

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Additional steps are needed in the service manual’s scanner wire replacement procedure.

Troubleshooting information relating to these steps is explained after.

1. Additional Steps

1-1 First, before reinstalling the wire (service manual P5-14, step 7), make sure of the

following.

• Bring the cushion [A] to the side that has the larger hook.

• The end that has the larger hook and the cushion, will connect to the spring as in

figure 1.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F40

DATE: 15 Aug. ’91

PAGE: 1 of 2

[A]

Fig. 1

1-2 Add these steps to the service manual P5-15, immediately following step 12.

• Loosen the 2 screws on the cushion holder [C]. Pull the holder towards the pulley

as far as it will go ([D]: direction) as in figure 2. Tighten the screws temporarily.

[D]

[B]

Fig. 2

[C]

Page 38

Technical Bulletin No. RTB-012

SUBJECT: 1. Additional steps for scanner wire replacement

2. Troubleshooting for SC21

• Perform a free run for 1 minute (DIP SW 902-1 on). Make sure that the scanners

DATE: 15 Aug. ’91

PAGE: 2 of 2

and wire operate smoothly.

• Loosen the 2 screws on the cushion holder. Position the holder so that the cushion

is tightly fit between the holder and the wire hook ([A]: direction) as in figure 3.

[A]

Fig. 3

• Go to the service manual P5-15, step 13.

2. Troubleshooting

[Symptom]

After making about 1 million copies, SC21 lights and the machine stops.

[Cause]

The wire extends and a space appears between the cushion and the holder (figure 4).

This causes the pulley and the wire to slip. When this phenomenon occurs, the scanner

can not go back to its home position.

Fig. 4

[Action in the field]

• Remove the rear cover (2 screws).

• Remove the fusing cooling fan motor [B] as in figure 1 (2 screws, 1 connector).

• Loosen the 2 screws on the cushion holder and slide it towards the spring.

• Secure the screws. Make sure the cushion is tightly positioned between the hook

and the cushion holder. (Figure 3)

NOTE: After making about 2 million copies, SC21 may light on again. If no further

adjustment is possible with the old cushion holder at that time, refer to MB No.

19 and replace with new cushion holder.

Page 39

Technical Bulletin No. RTB-013

SUBJECT: PM Information - Lubrication Points DATE: Aug. 31 ’91

PAGE: 1 of 5

PREPARED BY: J. Kasamoto

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This RTB shows all the lubrication points with the illustrations which should be performed

at Preventive Maintenance.

1. Scanner Guide Rods, Plate, and Guide Rod Felts (Cleaners):

PM Interval = 80 K

Lubricant = Launa oil

Guide Rod Plate

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F40

Guide Rod Felts (Cleaners)

Guide Rods

Page 40

Technical Bulletin No. RTB-013

SUBJECT: PM Information - Lubrication Points DATE: Aug. 31 ’91

PAGE: 2 of 5

2. Separation Roller Slip Clutch:

(1st, 2nd, 3rd Paper Feed Stations, and Duplex Paper Feed Station)

PM Interval = 80 K

Lubricant = Mobil Temp. 78

3. Paper Lift Motor Worm Gear:

(2nd and 3rd Paper Feed Stations)

PM Interval = 160 K

Lubricant = Mobil Temp. 78

(B)

(A)

Remarks:

Oil holes on the inner hub (A) and inside

the spring (B) should be lubricated.

Page 41

Technical Bulletin No. RTB-013

SUBJECT: PM Information - Lubrication Points DATE: Aug. 31 ’91

PAGE: 3 of 5

4. Paper Feed Gears:

PM Interval = 160 K

Lubricant = Mobil Temp. 78

5. Development Unit Drive Gears:

PM Interval = 80 K

Lubricant = Silicon Grease G40M

6. Fusing Roller Drive Gears:

PM Interval = 160 K

Lubricant = Mobil Temp. 78

(A)

Remarks:

Lubricate only the top of the Gear.

Do not lubricate inside the coupling

gear (A).

Page 42

Technical Bulletin No. RTB-013

SUBJECT: PM Information - Lubrication Points DATE: Aug. 31 ’91

PAGE: 4 of 5

7. Registration Roller Gears:

PM Interval = 160 K

Lubricant = Mobil Temp. 78

8. Relay Roller Gears:

(1st, 2nd and 3rd Relay Rollers)

PM Interval = 160 K

Lubricant = Mobil Temp. 78

Page 43

Technical Bulletin No. RTB-013

SUBJECT: PM Information - Lubrication Points DATE: Aug. 31 ’91

PAGE: 5 of 5

9. Exit Rollers Drive Gears:

PM Interval = 160 K

Lubricant = Mobil Temp. 78

Page 44

Technical Bulletin No. RTB-014

SUBJECT: RDH - Original misfeed

(Original stopper solenoid lever breakage)

PREPARED BY: N. Takai

TO: Copier Technical Support Section

DATE: Dec. 31, ’91

PAGE: 1 of 1

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL: F40 RDH

(Phenomenon)

The original misfeed indicator lights because the stack of originals cannot be fed into the

RDH feed-in position, even after the start key is pressed.

As reported from the field (the occurrence ratio is low), it happens about 100 ∼ 200 k

copies after the machine installation. And, the earliest one appeared after about 50 k

copies.

(Cause)

The original stopper solenoid lever which does not have sufficient durability breaks due to

material fatigue. Then, the original stopper gate cannot open.

Original Stopper

Lever

Solenoid

Stress may be concentrated

to this portion

(Action required)

Replace the stopper solenoid lever with a new one.

To increase durability, the material and shape of the solenoid lever was modified as

follows:

(P/N A4991332) (P/N A4991332A)

(old type) (new type)

NOTE: - This modification has been implemented from ’91 November production onward.

- The new part is now available at our parts center.

Page 45

Technical Bulletin No. RTB-015

SUBJECT: Blinking Wrench Mark DATE: Feb. 15, ’92

PAGE: 1 of 2

PREPARED BY: S. Tomoe

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Symptom:

The wrench mark is blinking.

Possible Cause:

1. The following connector pins for the main board have been disconnected.

• CN102--A1 • CN102--B1

• CN102--A8 • CN101--A3

2. The ID sensor board and the connector for the ID sensor are in poor contact because

the position of the connector for the ID sensor does not match the one for the ID

sensor board.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F40

Action Required:

1. Make sure that you reconnect the following connector pins:

• CN102--A1 • CN102--B1

• CN102--A8 • CN101--A3

Blue

e.g.

CN102--B1

Page 46

Technical Bulletin No. RTB-015

SUBJECT: Blinking Wrench Mark DATE: Feb. 15, ’92

PAGE: 2 of 2

2. (1) Remove the ID sensor board.

(2) Clean the connector of the ID sensor board (both faces) using a soft cloth with

alcohol.

(3) Reassemble the ID sensor board.

(4) Remove the upper rear cover.

(5) Loosen the screw of the ID sensor connector bracket [A] then tighten the screw

while pushing down the bracket.

CAUTION: Make sure that you do not turn the bracket when tightening the screw.

[A]

(6) Check the value of Vsg and Vsp using SP55 (the value of Vsg should be around 4.0

V)

Page 47

Technica l Bulletin No . RTB-01 7

SUBJ ECT: Ori gin al m isfe ed . DATE:

Mar. 15, 1993

PAGE: 1 o f 2

PREPARED BY: N . Tak ai

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F40 ARDF

Symptom:

Original misfeed occ urs intermittently.

Possible Ca use:

1. The DF registration sensor is activated by paper dust on the sensor pad, affecting its

color.

2. When t he o rig inal feed ro ller star ts r ot ating , t he DF up pe r g uid e plat e is war ped slig ht ly

downward. The clearance between the DF registration sensor and the sensor pad is

reduced. When this happens, the DF registration sensor (reflective type) can receive the

reflective light from the sensor pad, even though its color is black.

Action Required:

(For cause 1)

1. Op en th e feed -in un it [A] .

2. Clean t he DF regist ratio n s enso r

surface [B] and the sensor pad [C].

NOTE: To remove the paper dust from

the sensor pad, it is better to

use scotch tape.

[B]

[C]

[A]

Page 48

Technica l Bulletin No . RTB-01 7

SUBJ ECT: Ori gin al m isfe ed . DATE:

Mar. 15, 1993

PAGE: 2 o f 2

(For cause 2)

1. Remove the two screws of the pull out

hinge [D].

2. Ins ert 2 pc s eac h of 0. 8 mm sp ac er

(P/No . 07010040) and fix th e sc rew s.

[E].

•

This c an g ive the reg ist ratio n s enso r

enough clearance for the sensor pad.

[E]

[D]

Perma nent Counterme asure :

The shap e of t he pu ll ou t br ack et (P/N o. A4651057) will be mo d ified so that the sen sor

pad is positioned 1.5 mm further from the DF registration sensor.

Soon after the modification is applied to the produc tion, an M/B will be issued.

Page 49

Technical Bulletin No. RTB-018

SUBJECT: No Display DATE: Mar. 15, ’94

PAGE: 1 of 1

PREPARED BY: S.MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

If the transistor "Q7" on the PCC power pack becomes defective due to heating, the

following phenomenon occurs:

The operation panel indicates nothing. This is because the FU3 (fuse for 24V dc line) on

the DC power supply board is blown. This is caused by excessive current due to defective

transistor "Q7" on the PCC power pack.

Under this condition, if the FU3 is replaced without replacing the PCC power pack, the

FU3 may be blown again.

To improve the durability of the PCC power pack, a heat sink has been added to transistor

"Q7" on the PCC power pack.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: F40

This improvement is implemented to the mass-production machines from the following

serial number.

Japan production REI production

A053-19 272 3100 001~ A053 -15 583 4700 001~

A053-22 230 3110 101~ A053 -17 272 3470 204~

A053-25 230 3100 001~

A053-26 3A01130001~

A053-27 272 3100 026~

A053-29 272 3100 076~

The part number of the PCC power pack is the same after the modification. (The suffix of

the improved power pack is "A").

Loading...

Loading...