Page 1

Technical Bulletin

No.

RTB-001

SUBJECT: Dirty Background on Color Copies

PREPARED BY: .

CHECKED BY:

CLASSIFICATlON:

■ Action Required

❑ Troubleshooting

Phenomenon ]

[

Cause ]

[

Countermeasure ]

[

Itoh

.

❑ Revision of service manual

❑ Information only

Color copies have a dirty background

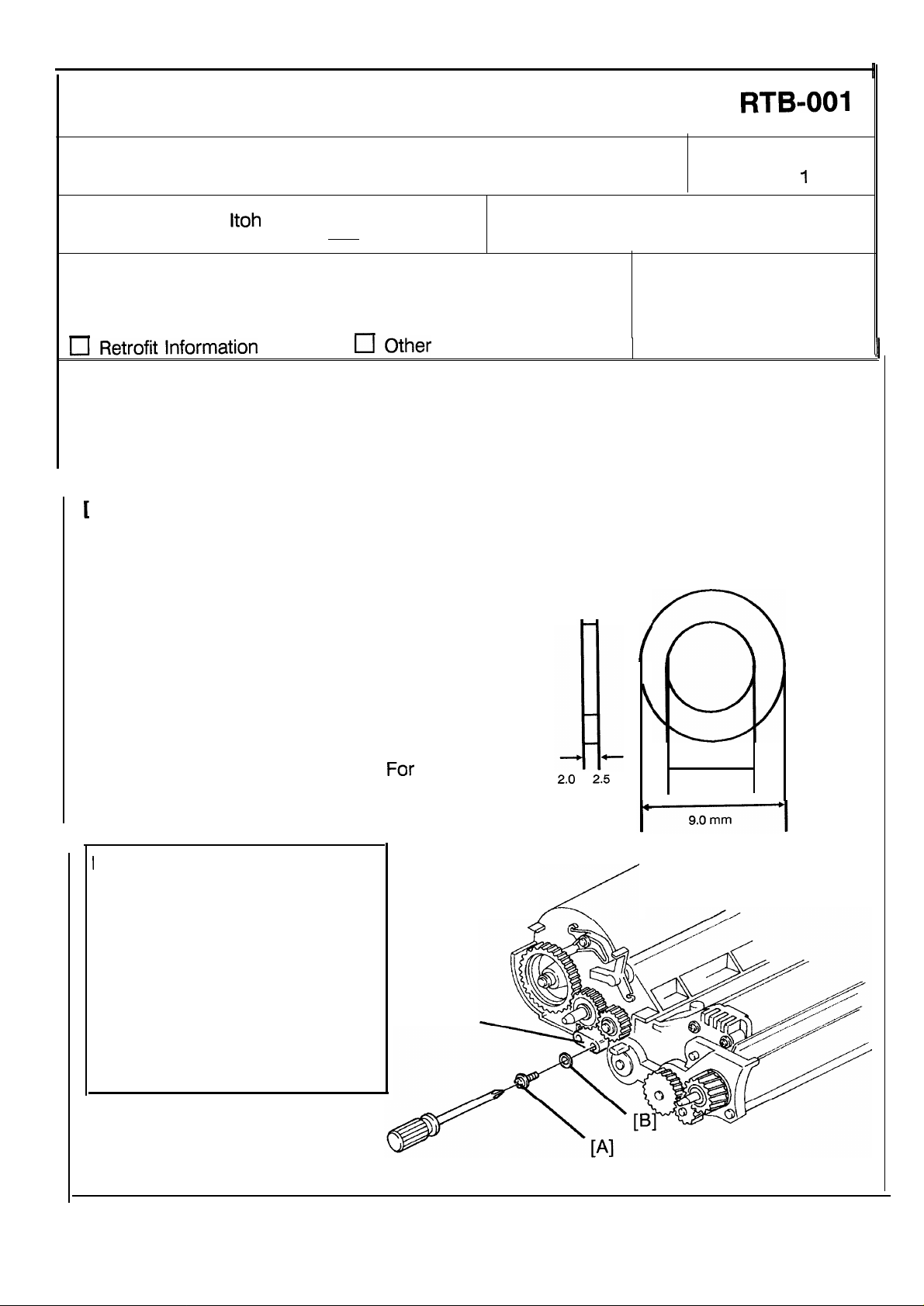

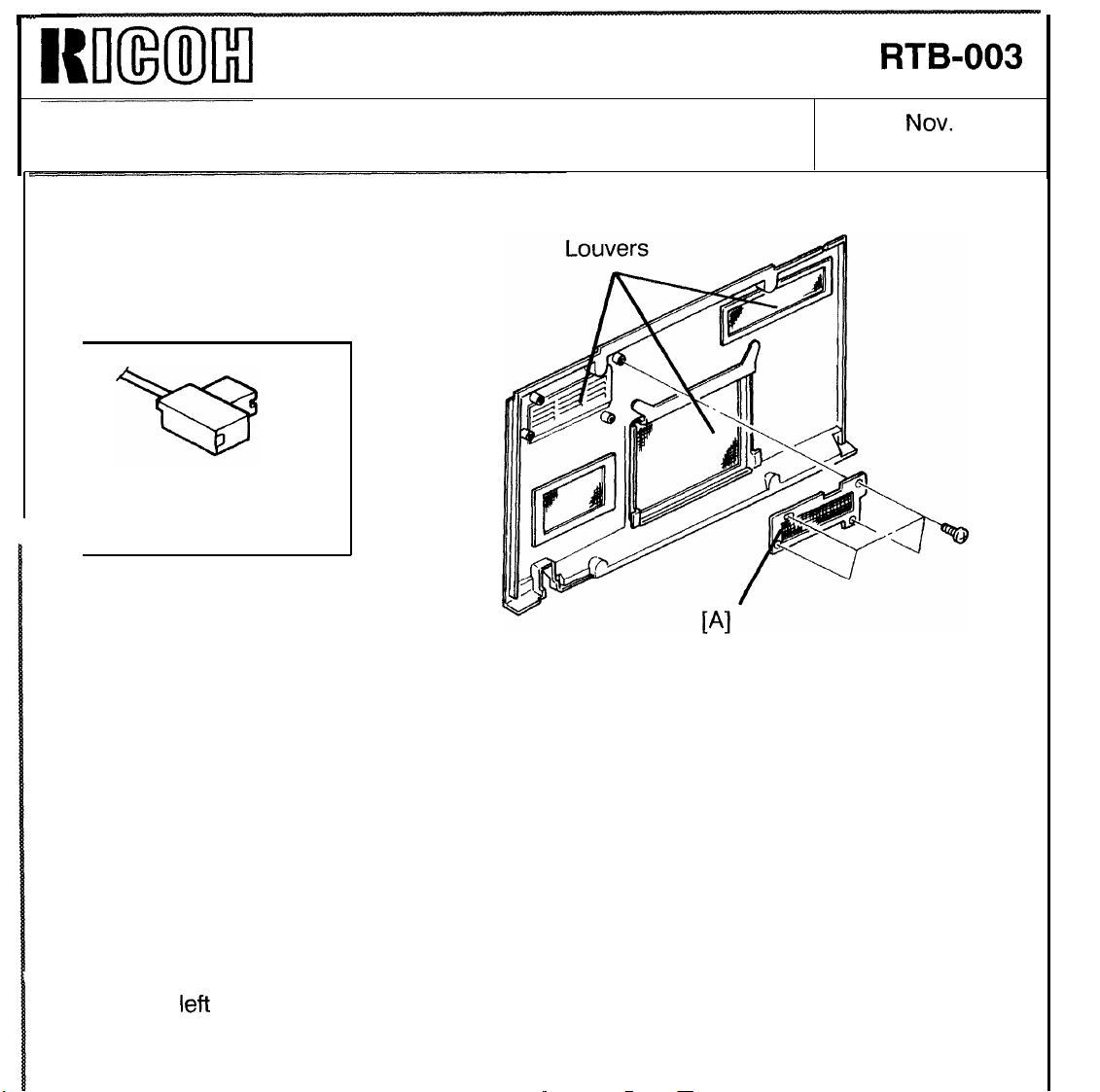

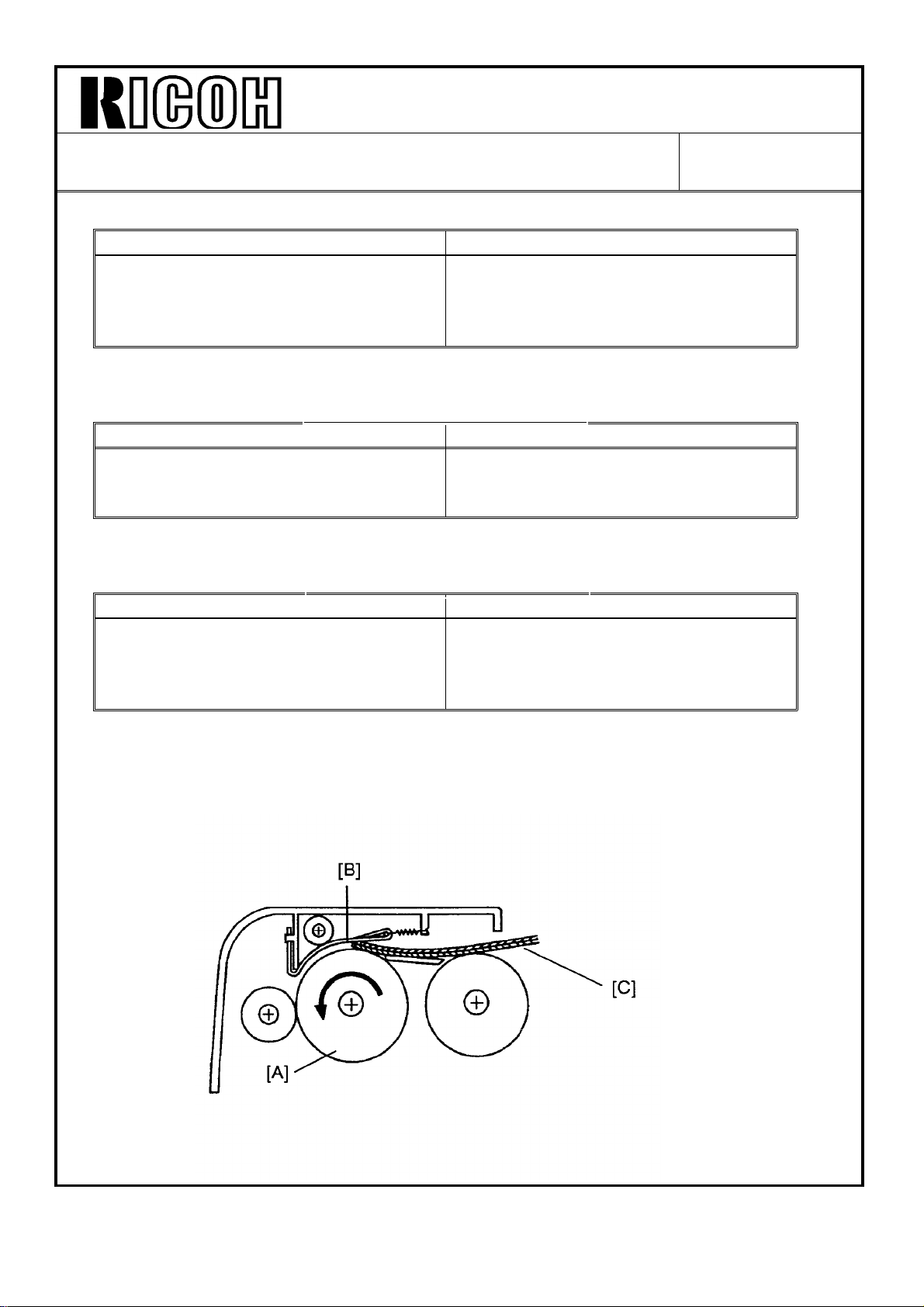

The screw [A] at the rear side of the color development unit does

not extend for enough to push in the color switch. Consequently,

black toner density control is selected and toner density becomes

high. This causes a dirty background.

If the problem occurs or when installing a color development unit,

install a spacer [B] as shown in the following illustration. This

spacer must be 2.0 to 2.5 mm thick and the outside diameter must

be less than 9.0 mm. Then, check whether the color indicator

properlv Iights when the color development unit is installed on the

rnachine.

-

DATE:

PAGE: 1 of

FROM: Copier Technical Support Group

MODEL: N220

.

Oct.

4, ’90

1

!

NOTE1: If a spacer thicker than 2.5 mm is

used, the screw on the

development unit may damage

the color switch.

NOTE2: A 2.0 mm width spacer will be

added as an accessory to the

For

color development unit.

cut-in serial number, please refer

to the modification bulletin that we

will be issuing soon.

the

NOTE:

If you have no spacer that meets

the above specifications, adjust

the position of the screw [A] as

follows:

While inserting a 2.0 mm thickness gauge between the screw

and part [C], tighten the screw

.

[A]

[c]

2,0

to 2.5

4.0 mm

Page 2

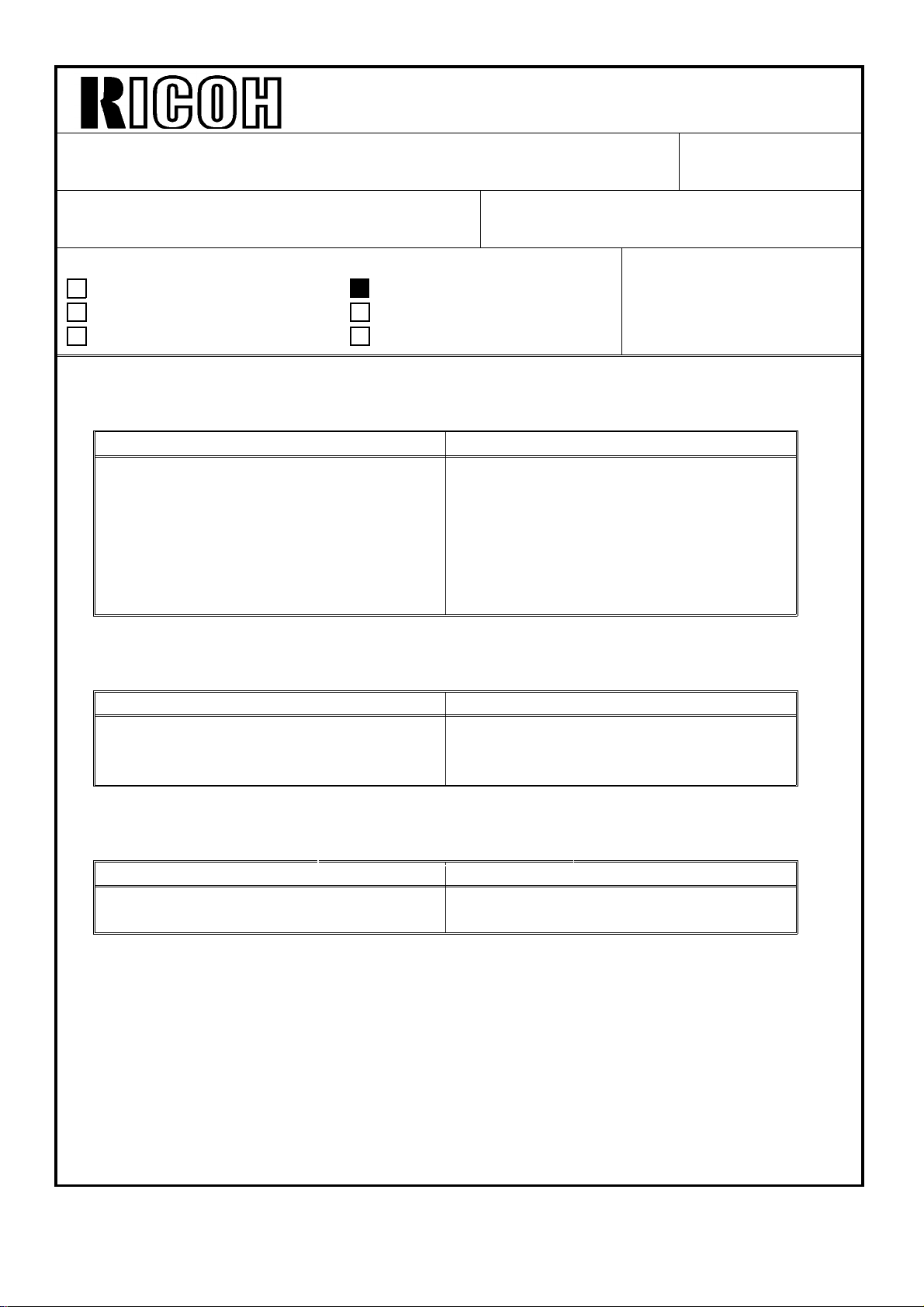

Technical Bulletin

No.

RTB-002

SUBJECT: Service Manual Correction (Water Proof)

PREPARED

CHECKED BY:

CLASSIFICATlON:

❑ Action Required

❑ Troubleshooting

❑ Retrofit Information

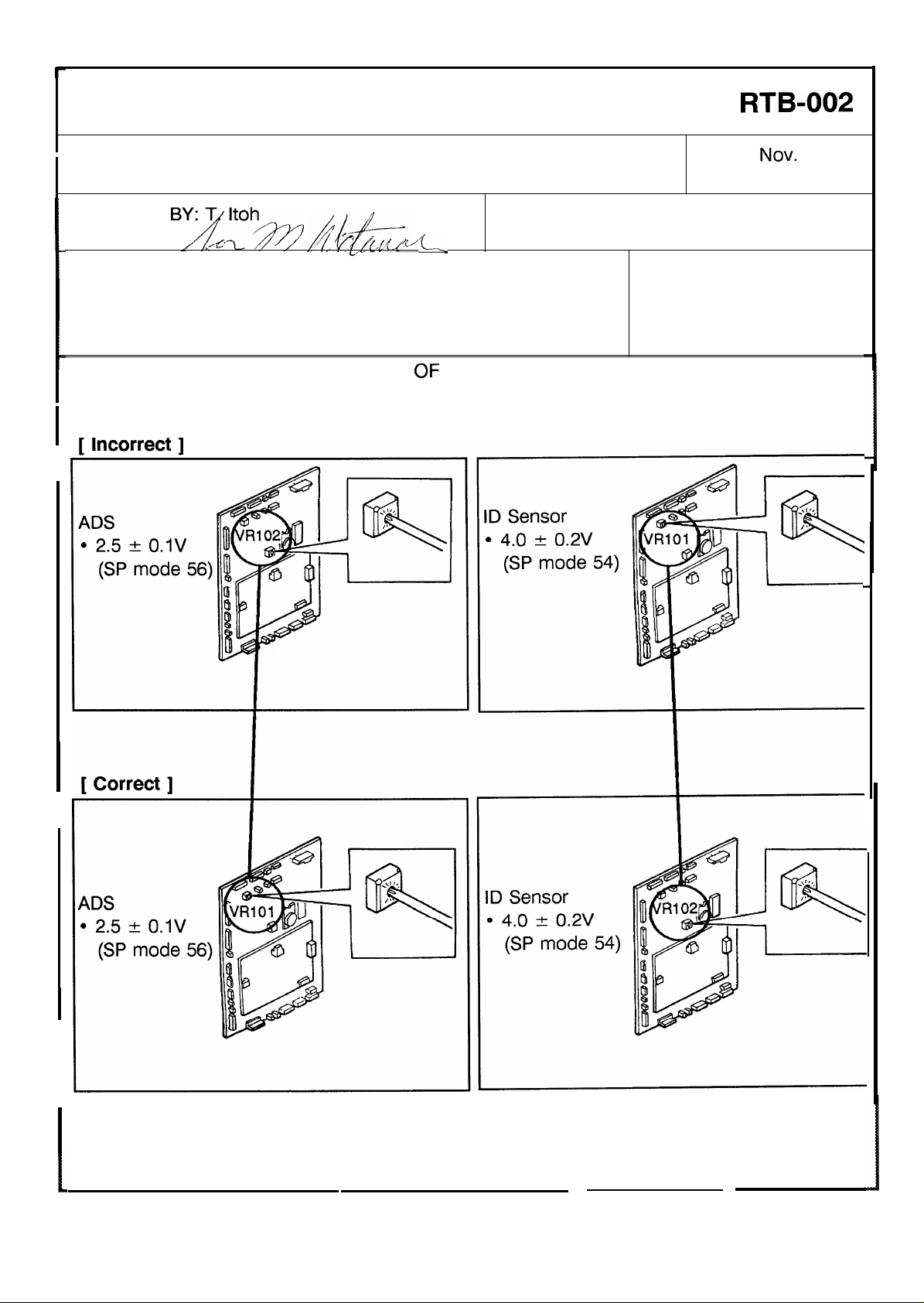

There are some mistakes in the “TABLE

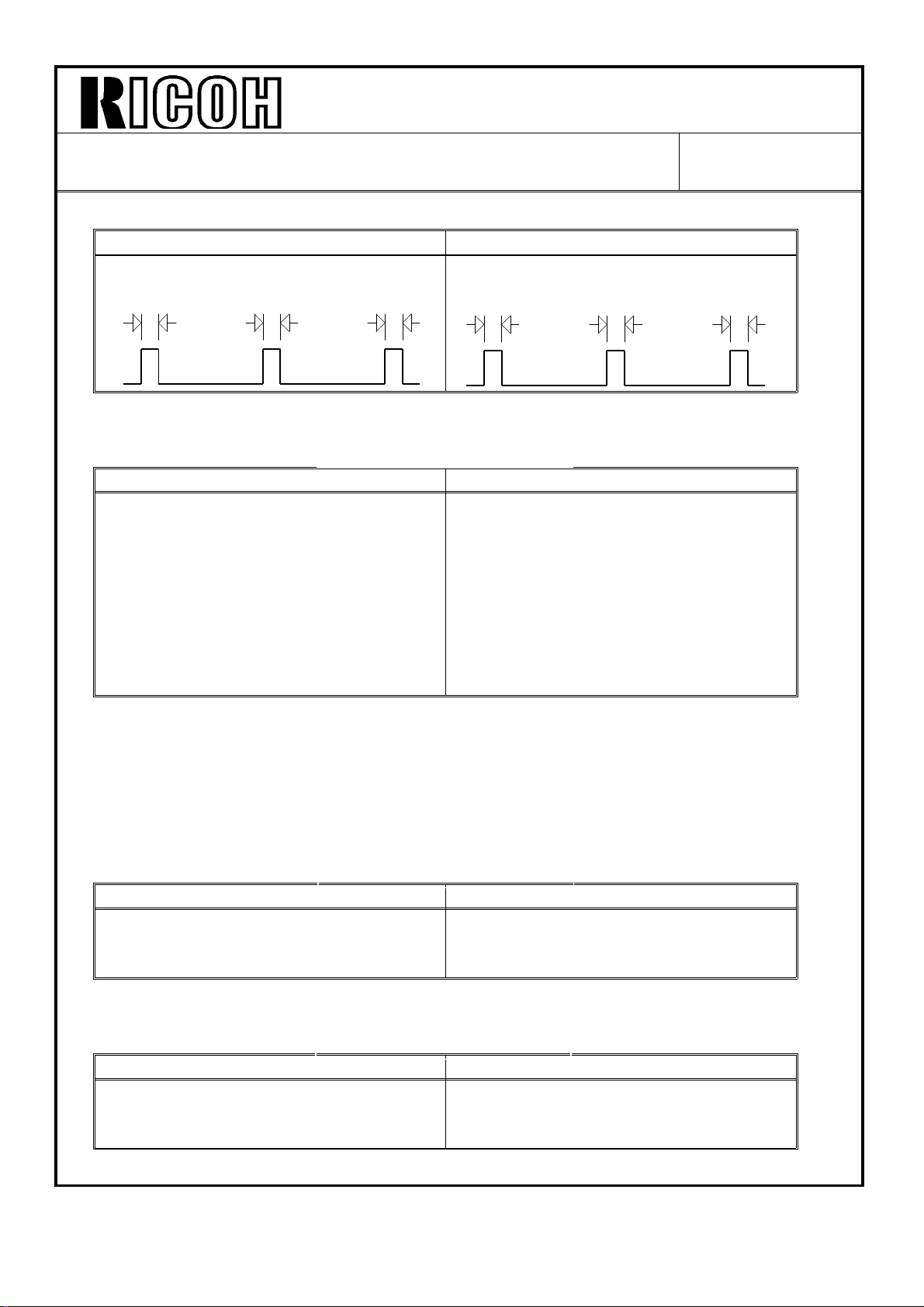

The illustrations for ADS and ID

Please correct your manual as shown below:

l---

■ Revision of service manual

❑ Information only

❑ Other

sensors adjustments are incorrect.

L.

OF

ADJUSTMENTS” section of the waterproof.

DATE:

PAGE: 1 of 1

FROM: Copier Technical Support Sec.

MODEL: N220

NOV. 30, ’90

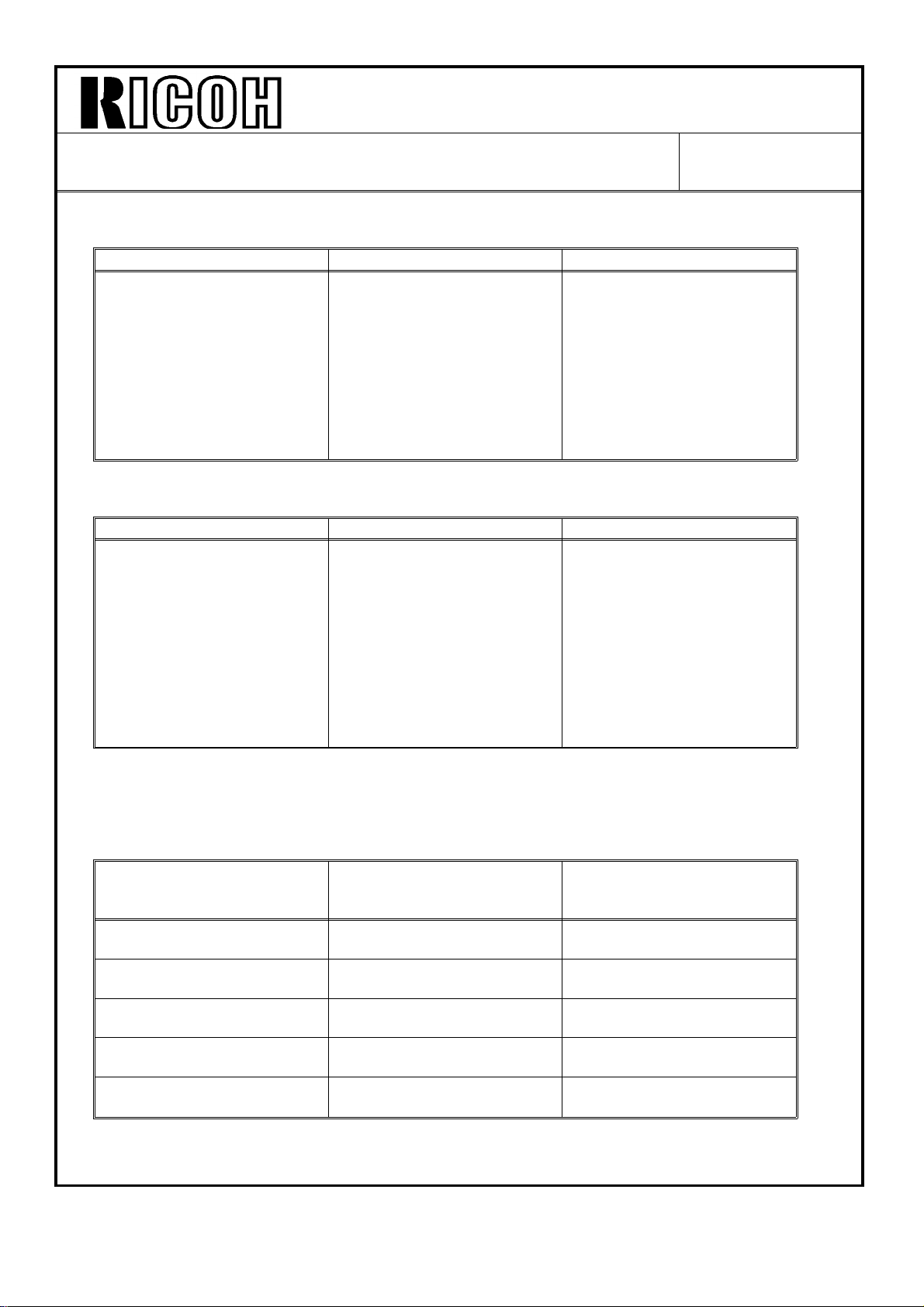

Page 3

Technical Bulletin

No. RTB-003

SUBJECT: C/G/B Power Pack Damage

PREPARED B

CHECKED B

CLASSIFICATI

❑ Action Req

Troubleshooting

❑ Retrofit Information

-—.

[ Phenomenon ]

[ Cause

[ Countermeasure

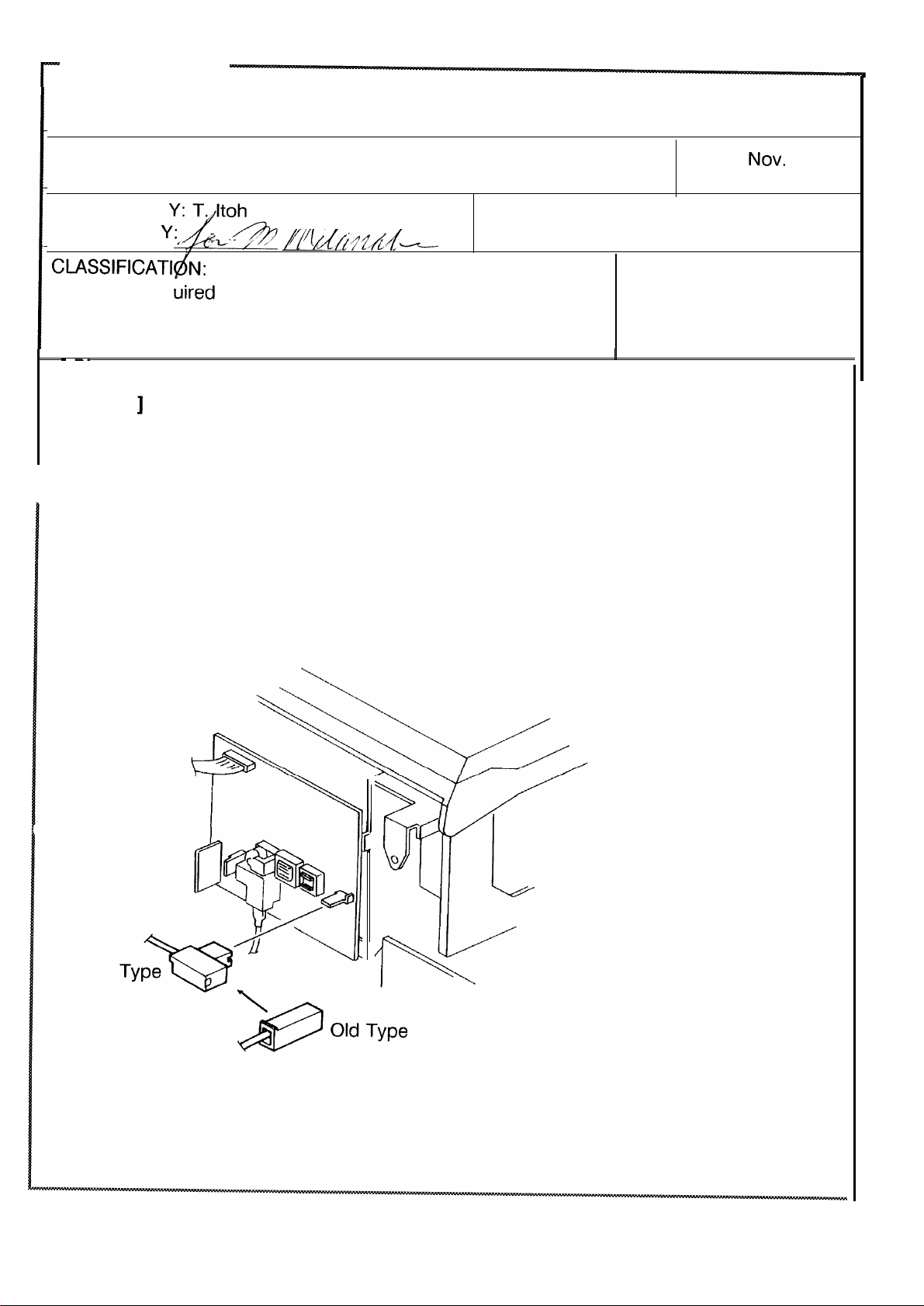

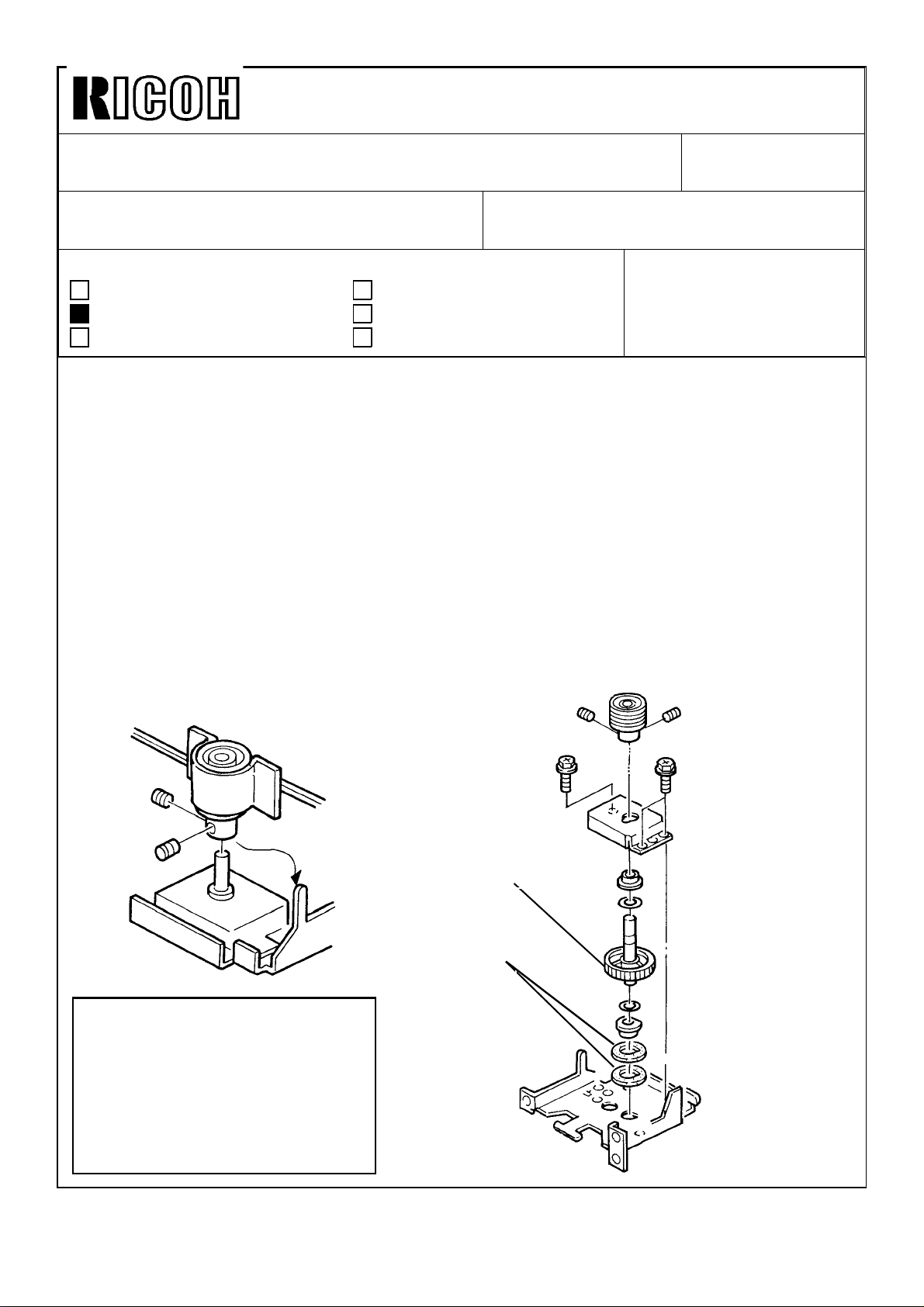

On the production

The clearance between the bias harness connector and the rear cover is increased by

changing the shape of the connector as shown below: This prevents the connector from

being pressed by the rear cover.

]

Dirty background may occur.

The bias connector on the C/G/B power pack may be pressed

against the power pack’s PCB by the rear cover. This damages

the PCB. As a result, incorrect bias voltage is applied to the

development roller and dirty background occurs.

]

line

❑ Revision of service manual

❑ Information only

❑ Other

FROM: Copier Technical Support Sec.

MODEL: N220

I

DATE:

PAGE: 1 of 3

NOV.

30, ‘90

New

This modification has been implemented on the production units from the October

mass-production run.

Page 4

Technical Bulletin

No.

RTB-003

SUBJECT: C/G/B Power Pack Damage

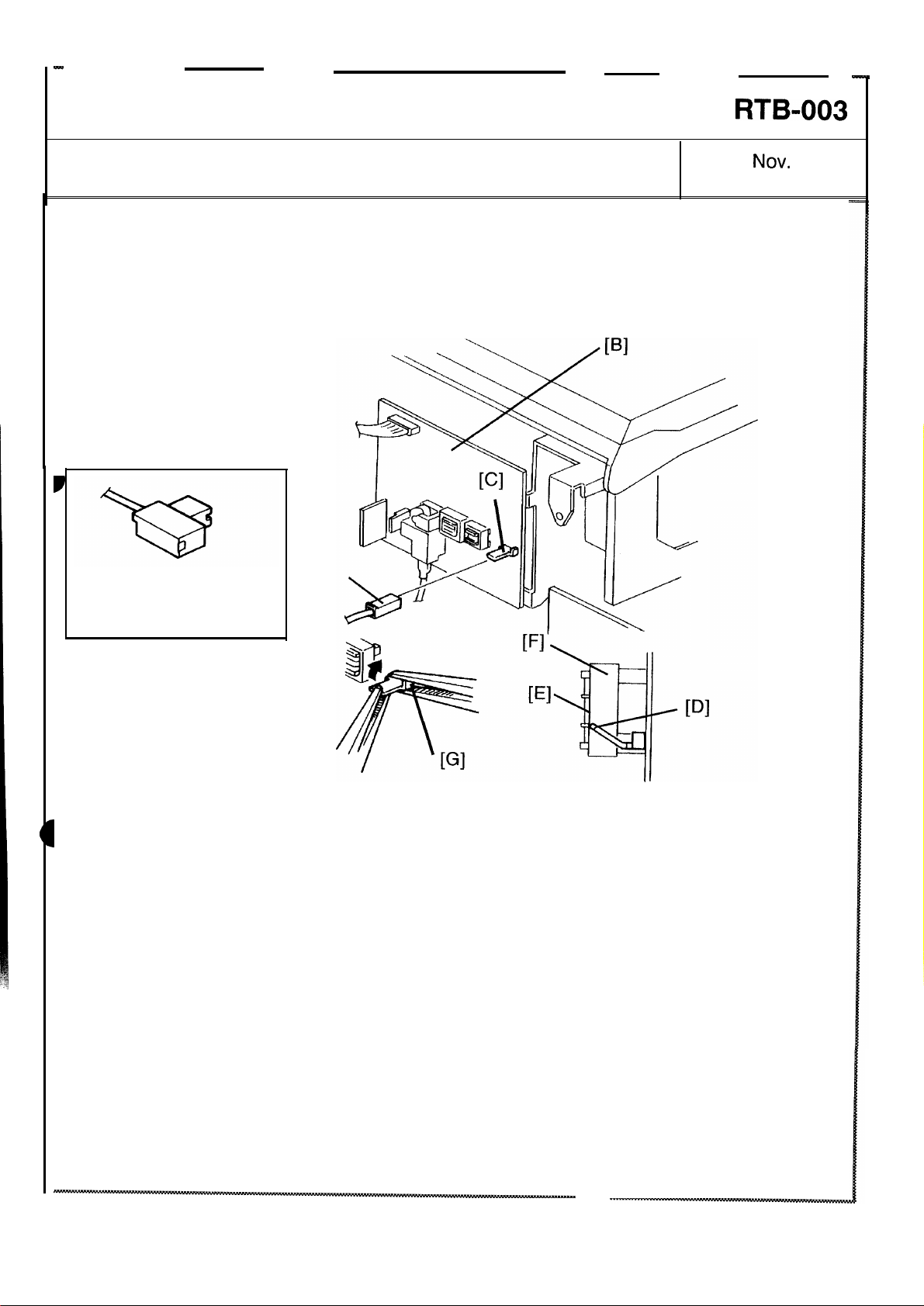

In the field

New Type

Bias Connector

To prevent this from occurring, bend the bias terminal as

explained below to make clearance between the rear cover and

the bias terminal. Do this at installation or during the next

maintenance call.

[A]

DATE:

PAGE: 2 of 3

NOV. 30, ‘90

NOTE: It is not necessary to perform the following procedure on the machine that has a

new type bias connector.

1. Turn off the main switch and unplug the power supply cord.

2. Remove the rear cover (4 screws).

3. Disconnect the bias connector [A] from the C/G/B power pack [B].

4. Bend the bias terminal [C] until the terminal edge [D] is aligned with the line [E] on the

transformer [F] on the power pack while holding the base [G] of the terminal with a pair

of pliers.

NOTE: a. Be careful not to damage the soldered connection between the terminal and the

pattern on the PCB.

b. Do not to far bend the terminal. Otherwise, a poor connection between the

terminal and the connector will result.

5. Reconnect the bias connector and reinstall the rear cover.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

m

Technical Bulletin

SUBJECT: C/G/B Power Pack Damage

New Type

Bias Connector

No.

RTB-003

DATE:

PAGE: 3 of 3

NOV. 30, ’90

NOTE: Some of the May ’90 production machines have the louver plates on the rear

cover as shown in the illustration.

These louver plates have been removed from the rear cover with the modification.

The cut-in serial number was not checked since this modification had an

interchangeability.

If the louver plates are installed on the rear cover, the left upper-side louver plate

[A] contacts the bias connector (new type) when the rear cover is installed. This

may damage the C/G/B power pack.

left

The

new type bias connector (as shown above) and the rear cover having the louver

plates.

upper-side louver plate must be removed on the machines that have the

Page 6

Technical Bulletin No. RTB-004

SUBJECT: The reason why Vsp remains above 0.5 volts DATE: Dec. 31, ’90

PAGE: 1 of 2

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The conditions under which Vsp remains above 0.5 volts are as follows:

The amount of toner supplied to the development unit depends on the ratio of Vsg and

Vsp. (Please refer to the following table for the toner supply levels.)

ID Sensor Data

Vsp/Vsg x 100

(Vsp, if Vsg = 4.0 volts)

0 to 12.5%

(0 to 0.5 volts)

12.5 to 15.0%

(0.5 to 0.6 volts)

15.0 to 17.5%

(0.6 to 0.7 volts)

17.5 to 25.0%

(0.7 to 1.0 volts)

25.0 to 62.5%

(1.0 to 2.5 volts)

(See NOTE below.)

62.5 % to 100% or higher

(2.5 to 5.0 volts)

Revision of service manual

Information only

Other

Toner Supply Level

(Toner Supply Ratio, if SP

#31 = 0)

No toner supply

(0%)

1

(3.75%)

2

(7.5%)

3

(15%)

4

(30%)

Fixed Supply Mode N/A

FROM: Copier Technical Support Sec.

MODEL:

N220

ID Sensor Data

0

15

29

59

118

NOTE:

If this condition is detected two times consecutively, the toner supply ratio rises to 60% (ID

Sensor Data = 236), which is double that at toner supply level 4.

The N220 is designed to vary toner supply according to the type of original and to

continuously supply toner to the development unit as long as the total image area on the

original is 3.75% or higher. Continuous toner supply minimizes variation in the toner

density in the development unit.

Page 7

Technical Bulletin No. RTB-004

SUBJECT: The reason why Vsp remains above 0.5 volts DATE:

PAGE: 2 of 2

Example 1:

If SP mode #31 is set to 0 and Vsp is greater than 0.5 volts but less than 0.6 volts, the

main CPU sets the toner supply level to 3.75%. The toner supply level is set to 3.75% and

toner is supplied at every copy cycle when the total image area on the original is greater

than 3.75 % and less than 7.5%.

Example 2:

When copies are made of the OS-A3 chart (24% total image area), the Vsp remains at

slightly higher than 1.0 volt. The toner supply ratio changes to 30% and toner is supplied

at every copy cycle as shown in the above table.

Therefore, Vsp does not drop below 0.5 volts as long as originals have at least 3.75% total

image area.

Page 8

Technical Bulletin No. RTB-005

SUBJECT: Scanner movement DATE: Dec. 31, ’90

PAGE: 1 of 2

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

[ Phenomenon ]

When the Start key is pressed, the scanner does not start smoothly from the home

position, causing vibration noise.

[ Cause ]

Two sponge spacers [A] are located in the scanner motor assembly as shown in the

illustration. The sponge spacers may interfere with the rotation of the scanner drive gear

[B].

[ Countermeasure ]

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL:

N220

Remove one of the sponge spacers from the scanner motor assembly. (It does not matter

which spacer is removed.)

[B]

[A]

NOTE:

To prevent the scanner wires

come off the pulley when removing the sponge spacer, set the

omega clamp on the pully. Then,

remove the pulley and place it on

the bracket as shown.

Page 9

Technical Bulletin No. RTB-005

SUBJECT: Scanner movement DATE: Dec. 31, ’90

PAGE: 2 of 2

Removal of the sponge spacer is being done on the production line. The machines which

have two sponge spacers are as follows:

Model Code

A048-15 July production units - September production

units

A048-16 & 25 ---A048-17 July production units - 2590100478

A048-19 July production units - September production

units

A048-26 July production units - September production

units

A048-27 July production units - October production units

A048-28 ---A048-29 July production units - October production units

Page 10

Technical Bulletin No. RTB-006

SUBJECT: Service Manual Correction DATE: Feb. 15, ’91

PAGE: 1 of 9

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Some mistakes were found in the manual. Please correct your manual as follows:

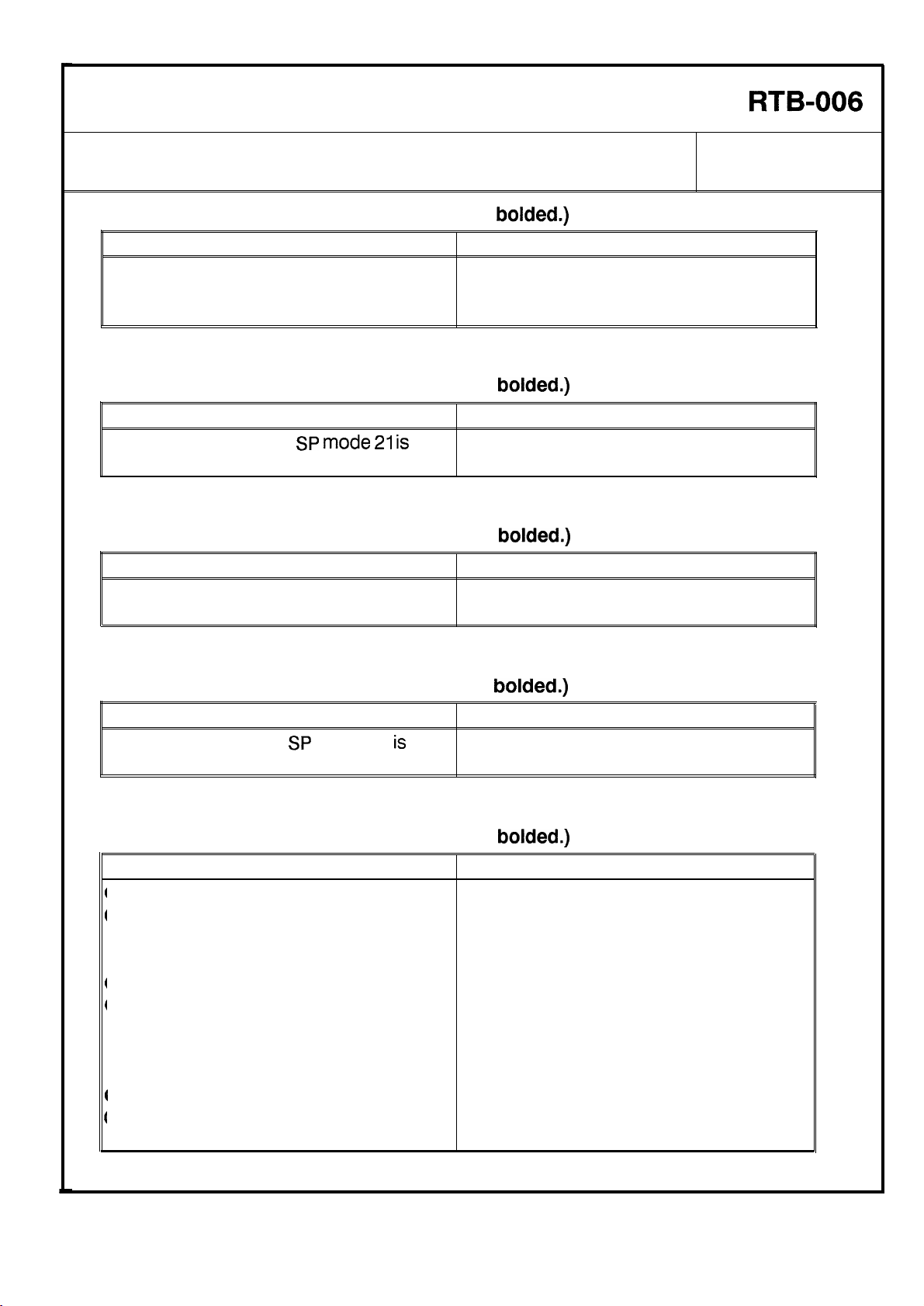

1. Page 1-2

Incorrect Correct

Power Source:

110V/60Hz/15A

115V/60Hz/15A

220V/50Hz/ 8A

220V/60Hz/ 8A

240V/50Hz/ 8A

(The correction is bolded.)

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: N220

Power Source:

110V/60Hz/15A (for Taiwan)

115V/60Hz/15A (for N.A.)

220V/50Hz/ 8A (for EU.)

220V/60Hz/ 8A (for EU.)

240V/50Hz/ 8A (for EU.)

2. Page 1-3

Incorrect Correct

Section A: See page 7.

Section B: See page 8.

Section C: See page 10.

3. Page 2-23

Incorrect Correct

SE: Side erase margin

2.0 ± 1.0 mm on each side;

4. Page 2-24

Remove the following contents from the manual:

"The side erase margin overlaps the edges of the paper to prevent edge lines from

appearing on the copy."

(The correction is bolded.)

Section A: See page 1-4.

Section B: See page 1-5 or 1-6.

Section C: See page 1-7 or 1-8.

(The correction is bolded.)

SE: Side erase margin

2.0 ± 2.0 mm on each side;

Page 11

Technical Bulletin No. RTB-006

SUBJECT: Service Manual Correction DATE: Feb. 15, ’91

PAGE: 2 of 9

5. Page 2-25

(Incorrect)

Blocks On Paper Size Reproduction Ratio (%)

None

a

a - b

a - c

a - d

a - e

a - f

a - f, g

All

(Correct)

Blocks On Paper Size Reproduction Ratio (%)

None

a

a - b

a - c

a - d

a - e

a - f

a - f, g

All

A3, A4 side ways

11"x17", 11"x8 1/2

B4

8 1/2"x11", 8 1/2"x5 1/2"

A4 lengthwise

B5 lengthwise

A5 lengthwise, 5 1/2"x8 1/2"

A3, A4 side ways

11"x17", 11"x8 1/2

B4

8 1/2"x11", 8 1/2"x5 1/2"

A4 lengthwise

B5 lengthwise

A5 lengthwise, 5 1/2"x8 1/2"

99 - 200

96 - 98

86 - 95

For ID sensor pattern

For Vr Correction

98 - 200

92 - 97

86 - 91

80 - 85

71 - 79

61- 70

50 - 60

For ID sensor pattern

For Vr Correction

6. Page 2-43

(Incorrect)

ID Sensor Data

Vsp/Vsg x 100

(Vsp, if Vsg = 4.0 volts)

0 to 12.5%

(0 to 0.5 volts)

12.5 to 15.0%

(0.5 to 0.6 volts)

15.0 to 17.5%

(0.6 to 0.7 volts)

17.5 to 62.5%

(0.7 to 1.0 volts)

62.5 % to 100% or higher

(2.5 to 5.0 volts)

Toner Supply Level

(Toner Supply Ratio, if SP #31

= 0)

No toner supply 0

1 15

2 29

3 59

Fixed Supply Mode N/A

ID Sensor Data

Page 12

Technical Bulletin No. RTB-006

SUBJECT: Service Manual Correction DATE: Feb. 15, ’91

PAGE: 3 of 9

(Correct)

ID Sensor Data

Vsp/Vsg x 100

(Vsp, if Vsg = 4.0 volts)

0 to 12.5%

(0 to 0.5 volts)

12.5 to 15.0%

(0.5 to 0.6 volts)

15.0 to 17.5%

(0.6 to 0.7 volts)

17.5 to 25.0%

(0.7 to 1.0 volts)

25.0 to 62.5%

(1.0 to 2.5 volts)

(See NOTE below.)

62.5 % to 100% or higher

(2.5 to 5.0 volts)

Toner Supply Level

(Toner Supply Ratio, if SP #31

= 0)

No toner supply

(0%)

1

(3.75%)

2

(7.5%)

3

(15%)

4

(30%)

Fixed Supply Mode N/A

ID Sensor Data

0

15

29

59

118

NOTE: If this condition is detected two times consecutively, the toner supply ratio

rises to 60% (ID Sensor Data = 236), which is double that at toner supply

level 4.

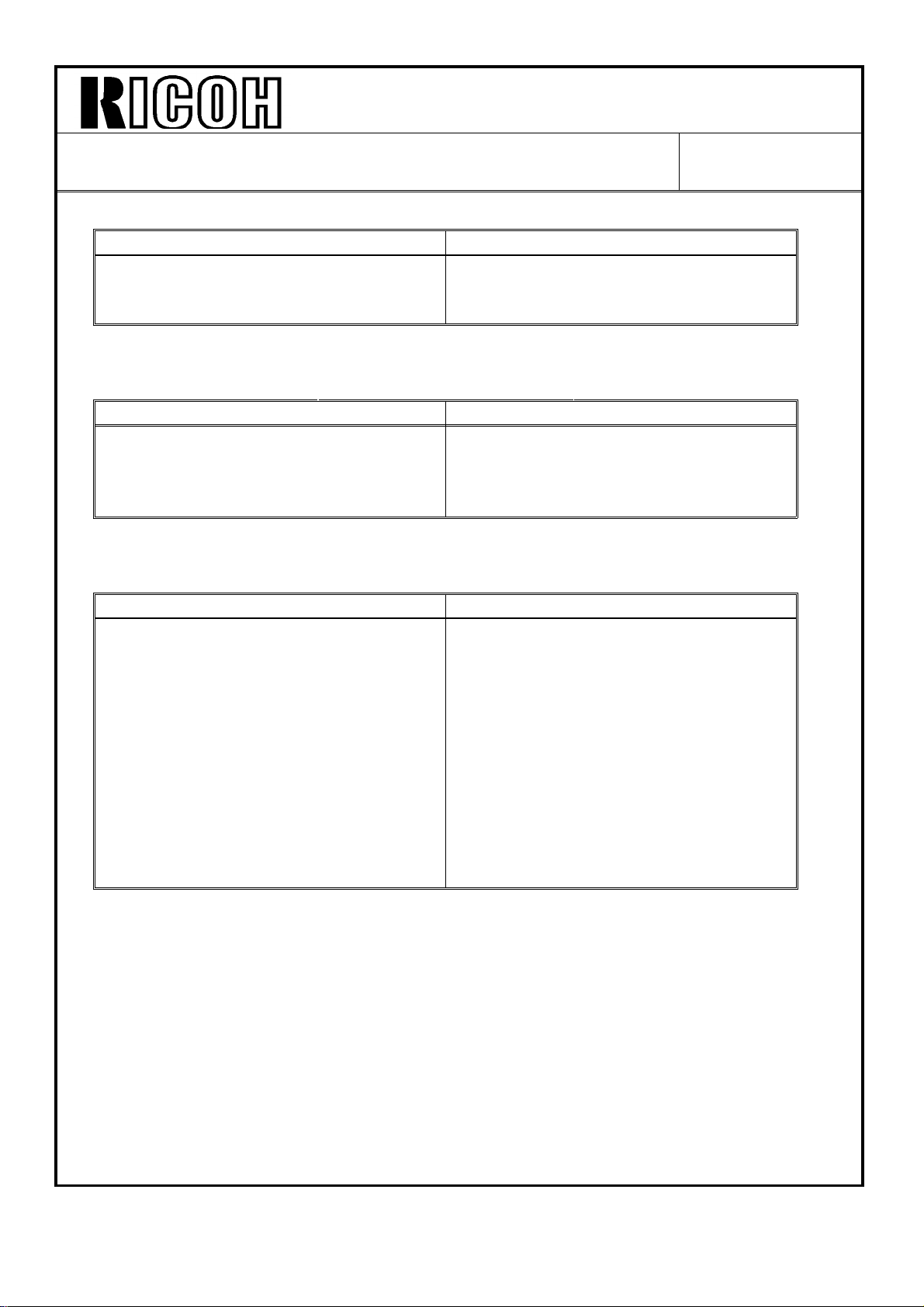

7. Page 2-63

(Incorrect)

(The correction is bolded.)

Paper Size Switch Size Indication

4 5 6 7

11" x 8 1/2" 1 1 1 0 11" x 8 1/2"

(Correct)

Paper Size Switch Size Indication

4 5 6 7

11" x 8 1/2" 1 1 1 0 8 1/2" x 11"

8. Page 2-65

(The correction is bolded.)

Incorrect Correct

The second feed clutch is energized for

150 milliseconds to transfer drive to the

2nd feed roller shaft and turns the 2nd

feed rollers [H].

The second feed clutch is energized for

500 milliseconds to transfer drive to the

2nd feed roller shaft and turns the 2nd

feed rollers [H].

Page 13

Technical Bulletin No. RTB-006

SUBJECT: Service Manual Correction DATE: Feb. 15, ’91

PAGE: 4 of 9

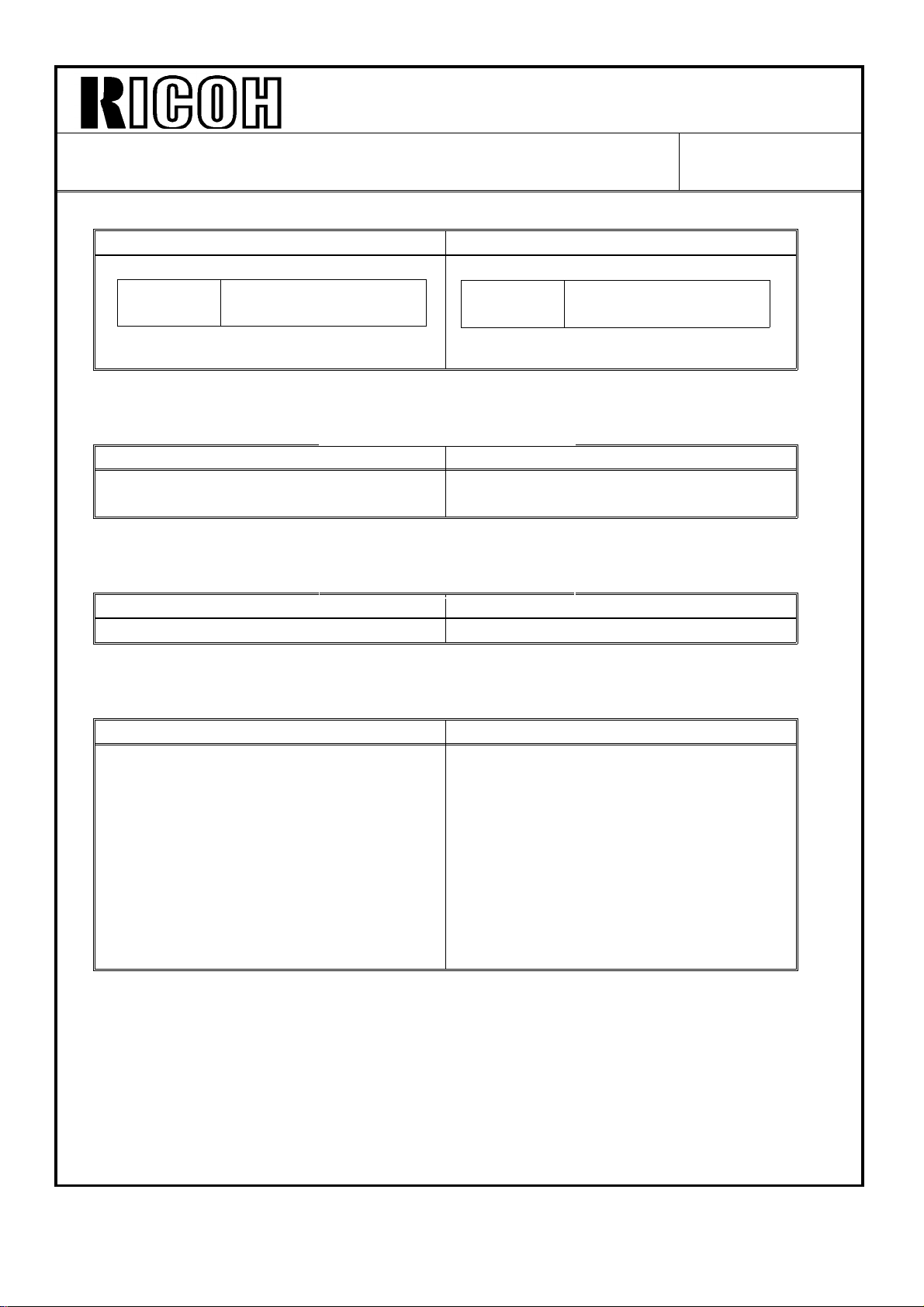

9. Page 2-69

Incorrect Correct

Relay Roller Clutch

150 m sec 150 m sec150 m sec

10. Page 3-3

Incorrect Correct

1. Input Voltage Level:

110V/60Hz/15A:More Than 15A

115V/60Hz/15A:More Than 15A

220V/50Hz/ 8A:More Than 8A

220V/60Hz/ 8A:More Than 8A

240V/50Hz/ 8A:More Than 8A

Relay Roller Clutch

500 m sec 500 m sec500 m sec

(The correction is bolded.)

1. Input Voltage Level:

110V/60Hz/15A:More Than 15A

(for Taiwan)

115V/60Hz/15A:More Than 15A

(for N.A.)

220V/50Hz/ 8A:More Than 8A (for EU.)

220V/60Hz/ 8A:More Than 8A (for EU.)

240V/50Hz/ 8A:More Than 8A (for EU.)

Remove the following contents from the manual:

3. Permissible extension cord : At least 300V, 30A capacity and less than 5 meters

(16.4 ft) long.

11. Page 4-3

Incorrect Correct

When the DF is used with this copier,

DIP switch 101-4 must be turned off to

increase the data transmission speed.

12. Page 4-9

Incorrect Correct

3. Select Service program SP-97 and

press the "1" key on the key pad,

then press the Enter key.

(The correction is bolded.)

When the DF is used with this copier,

DIP switch 101-2 must be turned off to

increase the data transmission speed.

(The correction is bolded.)

3. Select Service program SP-98 and

press the "1" key on the key pad,

then press the Enter key.

Page 14

Technical Bulletin

No.

RTB-006

SUBJECT: Service Manual Correction

13. Page 4-10

Incorrect

SP Modes #5, #6, #11, #37, #42,

#43, #44, #47, #48, #52, #55

#59

14. Page 4-12

Incorrect

The factory setting of SP

in the Service Program Mode Table.

15. Page 4-16

Incorrect

Mode No.

Bias Voltage

*59

Check (Black)

(The correction is

and

j

(The correction is

mode 21 is

(The correction is

“0”

DATE: Feb. 15, ’91

PAGE: 5 of 9

bolded.)

Correct

SP Modes #5, #6, #8, #37,

#42, #43,

#44, #47, #48, #52, #55, and #59

bolded.)

Correct

The factory setting of SP mode 21 is “1”

in the Service Program Mode Table.

bolded.)

Correct

Mode No.

*59

Bias Voltage

Check

16. Page 4-18

Incorrect

The factory setting of SP mode

in the Service Program Mode Table.

17. Page 4-23

Incorrect

(

Output No. 2

(

Charge Corona + Standard Grid

[

Output No. 3

(

Charge Corona + ID Sensor Grid

(

Output No. 4

(

Charge Corona + Vrp Grid

(The correction is bolded.)

(The correction is

76 is “0”

Correct

The factory setting of SP mode 76 is “1”

in the Service Program Mode Table.

bolded.)

Correct

Output No. 2

Charge Corona + Standard Grid

(Grid Voltage = -920 volts)

Output No. 3

Charge Corona + ID Sensor Grid

(Grid Voltage =

-660 volts + Vp

Correction Factor)

Output No. 4

Charge Corona + Vrp Grid

(Grid Voltage = -500 volts)

Page 15

Technical Bulletin No. RTB-006

SUBJECT: Service Manual Correction DATE: Feb. 15, ’91

PAGE: 6 of 9

18 Page 4-24

Incorrect Correct

Out Put No. 60 - 67

Applies grid voltage in 60V steps

starting at 640V

19. Page 4-32

Incorrect Correct

a) ADS Voltage (SP NO. 56)

......2.5 + 0.1V

b) Vsg (SP No. 54)

.....4.0 + 0.2V

20. Page 4-35

Incorrect Correct

2. If the RAM on the main board is still

usable, remove it and place it on the

new main board. Then, install the

new main board.

3. After placing a new RAM on the new

main board, clear the RAM memory

using SP mode #99 (Do not clear

RAM memory if you have placed the

old RAM on the new main board.)

Then check and adjust the data of

the following SP modes:

(The correction is bolded.)

(The correction is bolded.)

Out Put No. 60 - 67

Applies grid voltage in 60V steps

starting at 560V

a) ADS Voltage (SP NO. 56)

......2.5 ± 0.1V

b) Vsg (SP No. 54)

.....4.0 ± 0.2V

2. If the RAM on the main board is still

usable, remove and place it on the

new main board. Then, install the

new main board to the copier.

3. After installing the new main board

with the new RAM, clear the RAM

memory using SP mode #99 (Do not

clear RAM memory if you have

placed the old RAM on the new main

board.) Then check and adjust the

data of the following SP modes:

Page 16

Technical Bulletin No. RTB-006

SUBJECT: Service Manual Correction DATE: Feb. 15, ’91

PAGE: 7 of 9

21. Page 4-37

Incorrect Correct

SP Mode

Numbers

22. Page 5-15

3. Put the bead of the silver wire [2] ion

slot [B] on the Allen screw side.

23. Page 5-28

1. Take out the development roller. 1. Take out the development unit.

12, 20-35, 41-44, 47,

48, 54, 56, 70, 71, 74

Incorrect Correct

Incorrect Correct

(The correction is bolded.)

SP Mode

Numbers

(The correction is bolded.)

3. Put the bead of the silver wire [2] in

slot [B] on the Allen screw side.

(The correction is bolded.)

12, 30-35, 41-44, 47,

48, 54, 56, 70, 71, 74

24. Page 5-67

Incorrect Correct

1. Make the gap between the edge of

the bracket [B] and the entrance

guide plate 3.0 mm as shown in the

illustration. Then, tighten both the

front rear screws.

ADJUSTMENT STANDARD:

GAP "X" Front 2.65 ± 0.1 mm

Rear 3.25 ± 0.1 mm

1. Set the Gap "X" between the edge of

the bracket [B] and the entrance

guide plate adjustment standard

using the thickness gauge as shown

in the illustration. Then, tighten both

the front rear screws.

Page 17

Technical Bulletin No. RTB-006

SUBJECT: Service Manual Correction DATE: Feb. 15, ’91

PAGE: 8 of 9

25. Page 5-73

Incorrect Correct

6. Remove the drum knob [A] and the

bearing [B] from the drum, then

install them on the drum shaft [C]

(special tool : P/N #A0069500).

26. Page 6-43

Incorrect Correct

- Possible Causes -

• Thermistor Open

27. Page 8-6

Incorrect Correct

When the Start key is pressed, the

copier CPU moves the scanner 100

mm away from the left scale and

sends the feed-in signal to the DF.

(The correction is bolded.)

(The correction is bolded.)

(The correction is bolded.)

6. Remove the drum knob [A] and the

bearing [B] from the drum, then

install them on the drum shaft [C]

(special tool : P/N #A0069105).

- Possible Causes -

• Thermofuse Open

When the Start key is pressed, the

copier CPU sends the feed-in signal to

the DF.

28. Page 8-11

The illustration on this page is incorrect. The correct illustration is as follows:

Page 18

Technical Bulletin No. RTB-006

SUBJECT: Service Manual Correction DATE: Feb. 15, ’91

PAGE: 9 of 9

28. Page 8-31

The illustration on this page is incorrect. The correct illustration is as follows:

Page 19

Technical Bulletin No. RTB-007

SUBJECT: Warning Description DATE: Mar. 31, ’91

PAGE: 1 of 1

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The following warning description is missing from the service manual. The warning

description must be described in the service manual for Safety Standard.

Please add the following warning description to your service manual (Service Remarks

Section).

WARNING: The RAM board has a lithium battery which can explode if handled

incorrectly, replace only with same RAM board. Do not recharge, disassemble or burn

this battery. Used RAM boards must be handled in accordance with local regulations.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: N220

Page 20

Technical Bulletin No. RTB-008

SUBJECT: SP Modes #45 and #46 (Paper Buckle Adjustment) DATE: Mar. 31, ’91

PAGE: 1 of 3

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The new SP modes (#45 and #46) have been applied to the main ROM (See last page for

cut-in serial numbers.)

SP modes #45 and #46 are to adjust the amount of the paper buckle in the registration

area. The amount of paper buckle can be adjusted by changing OFF timing of the 1st

paper feed clutch or relay roller clutch solenoid.

SP mode #45 is for the 1st feed station and SP mode #46 is for the 2nd feed station.

(Refer to the Table on next page.)

• The reasons for applying these SP modes are as follows:

1. To get the proper amount of paper buckle for various paper, these SP modes were

applied.

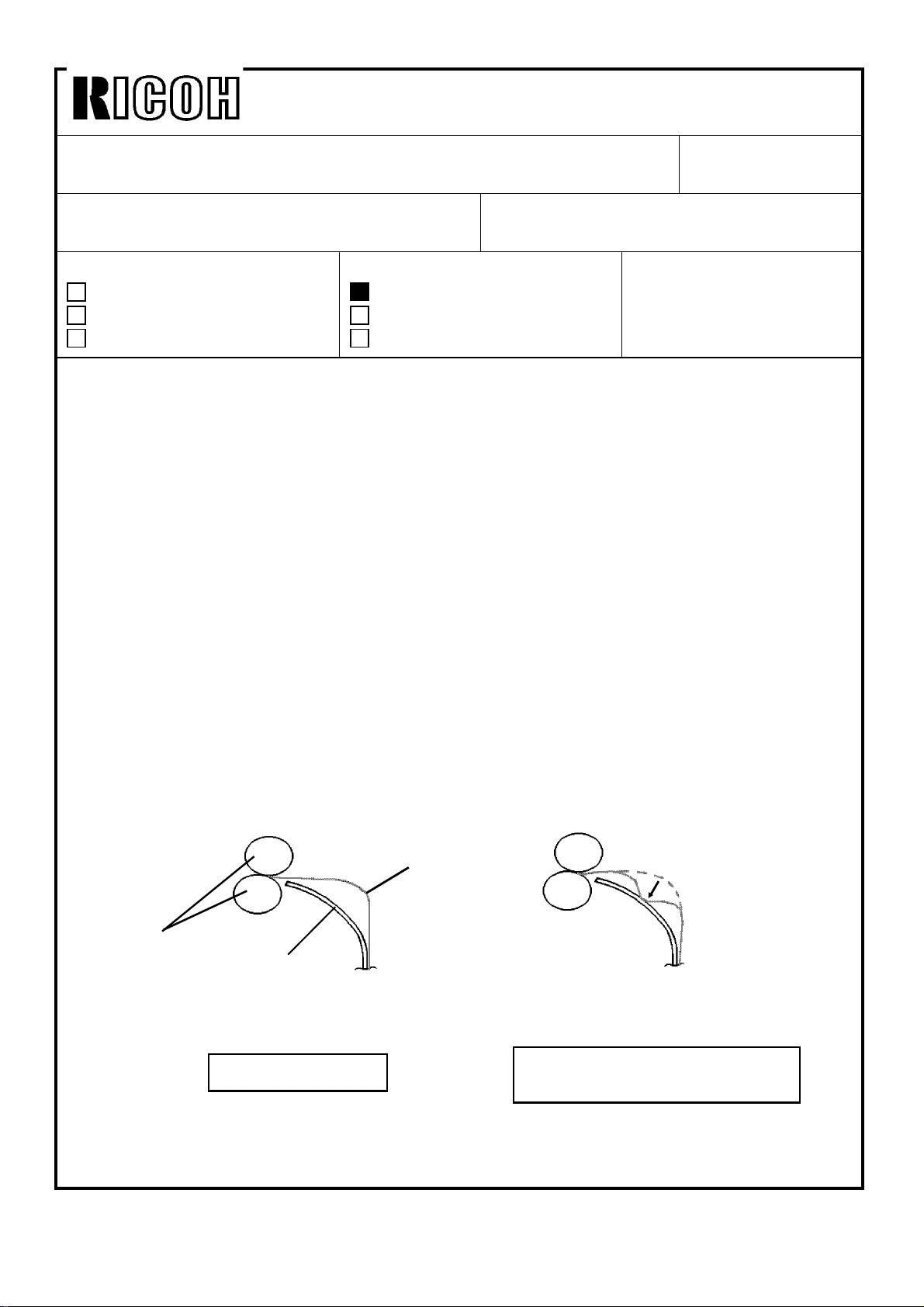

2. When the copy is made using thin paper from the 2nd feed station, noise may occur

due to double buckling. This is caused by the buckled paper hitting the turn guide

plate as shown in the illustrations

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL:

N220

Registration

Rollers

Turn Guide

Plate

Normal Paper Path

Paper

When the paper hits to the turn

guide plate, noise occurs.

Page 21

Technical Bulletin No. RTB-008

SUBJECT: SP Modes #45 and #46 (Paper Buckle Adjustment) DATE: Mar. 31, ’91

PAGE: 2 of 3

Mode No. Function Data

45: Buckle

Adjustment

(1st feed)

46: Buckle

Adjustment

(2nd feed)

[ SP mode #45 ]

The data of SP mode #45 must be "8" for the proper amount of paper buckle.

Do not change this value from "8".

[ SP mode #46 ]

The data of SP mode #46 is normally "8". The data is preset to eliminate double-buckle

on the production line. It is not necessary to readjust the amount of paper buckle in the

field except in the following cases:

• When the main board with the RAM board is replaced

• When the RAM board is replaced

(In these cases, all memory in the RAM board must be cleared using SP mode #99.)

Adjusts the

amount of

paper buckle in

the registration

area.

0 - 15

Factory

Setting

The data must

be "8".

(Default = 8)

2 - 8

(Default = 8)

Remarks

0.5 mm per step

Refer to

NOTE below.

If noise occurs after all memory is cleared using SP mode #99, adjust the amount of

paper buckle according to the following procedure.

- Paper buckle adjustment procedure for the 2nd feed station -

1. Make a copy to check whether or not noise occurs after SP mode #99 is done.

2. If noise occurs, decrease the data of SP mode #46 from "8". (Default value is "8".)

NOTE: 1. If the data is less than 2, paper misfeed may occur. This is because paper may

not reach the registration rollers.

2. If the data is too high, poor solid density may appear on the copy. This is

caused by the paper being creased or bent due to excessive paper buckle.

Page 22

Technical Bulletin No. RTB-008

SUBJECT: SP Modes #45 and #46 (Paper Buckle Adjustment) DATE: Mar. 31, ’91

PAGE: 3 of 3

These SP modes have been applied from the following version main board and ROM:

Main Board : A0485101E

ROM : A0485104D

The cut-in serial numbers of this software change are as follows:

MODEL NAME

Savin 9180 115/60 USA, Canada A048-15 6900700101

Nashua 3018 115/60 Canada,

Ricoh FT4418 115/60 USA, Canada A048-17 2590060001

Ricoh FT4418 110/60 Taiwan A048-19 2590070810

Nashua 3018 220,240/50 Europe. etc. A048-25 From First Production

infotec 9118Z 220,240/50 Europe A048-26 3960600001

Ricoh FT4418 220,240/50 Europe, etc. A048-27 2590060671

Ricoh FT4418 220,240/60 Philippines, etc. A048-28 From First Production

Ricoh FT4418 220,240/50 Asia A048-29 2590061231

V/Hz DESTINATION JAPAN PRODUCTION

CODE SERIAL NUMBER

L. America

A048-16 From First Production

Page 23

Technical Bulletin No. RTB-009

SUBJECT: Service Remarks for RAM Memory Clear DATE: April 30, ’91

PAGE: 1 of 4

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The following problems occur due to RAM memory clear.

• Dirty background

• Paper misfeed

The RAM memory may possibly be cleared.

• Because the connection between the interface board and main board connectors

is poor.

If the DF harness is located on the interface board, a poor connection may occur

because the rear cover presses the DF harness against the interface board. If this

happens, the interface board connector may come out from the main board

connector.

• Because the following PCBs are not grounded properly

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: N220

1. AC Drive Board 2. Main DC Power Supply Board

3. Optional DC Power Supply Board 4. CC/Grid/Bias Power Pack

5. TC/SC Power Pack

Each PCB is grounded by pressing the ground pattern on the PCB to the machine

frame or bracket with the screw. If the PCB is not secured correctly when

reinstalling it, the PCB is not grounded. This may generate electrical noise and this

causes RAM memory clear.

- SERVICE REMARKS -

When servicing the machine:

1. When the DF is installed, make sure that the DF harness is properly wired

and is not located on the interface board. (See page 2 - 3.)

2. Make sure that the screw used for grounding the following PCBs is properly

tightened. (See Page 4.)

1. AC Drive Board 2. Main DC Power Supply Board

3. Optional DC Power Supply Board 4. CC/Grid/Bias Power Pack

5. TC/SC Power Pack

Page 24

Technical Bulletin No. RTB-009

SUBJECT: Service Remarks for RAM Memory Clear DATE: April 30, ’91

PAGE: 2 of 4

1. DF Harness

Portion "X"

[A]

[A]

[B]

[B]

[C]

[B]

[D]

[E]

[G]

[D]

[F]

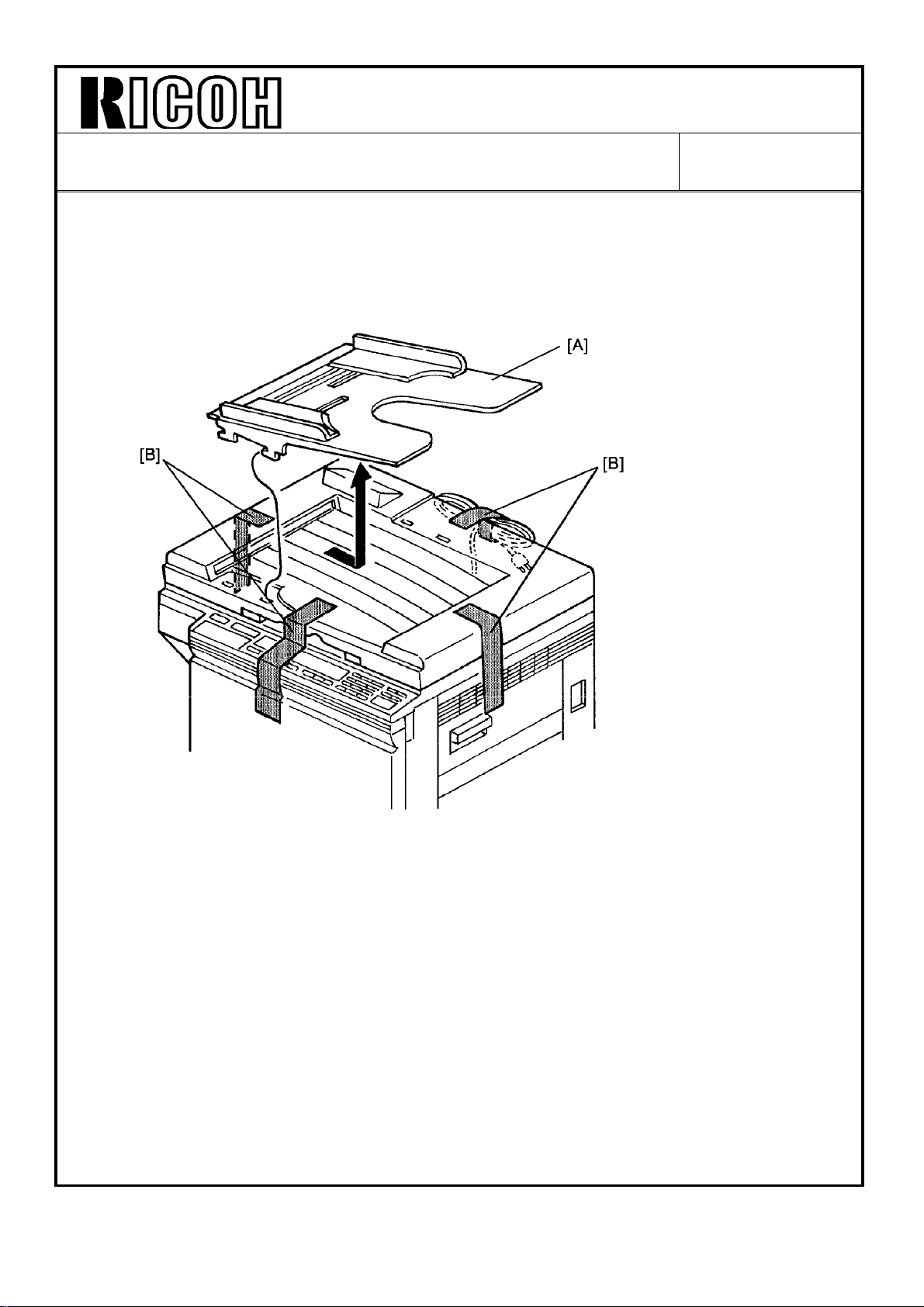

SERVICE REMARKS: When the DF is installed, make sure that the DF harness is

properly wired and is not located on the interface board.

1. Make sure that the main switch is off.

2. Place the bushing [A] at the left side of the binder [B] as shown in the illustration.

3. Place the bushing on the harness bracket [C].

[E]

NOTE: Make sure that the portion "X" of the bushing faces up.

4. Insert the DF harness [D] behind the harness support bracket [E].

5. Position the harness bracket [F] behind the harness support bracket [G] as shown.

Page 25

Technical Bulletin No. RTB-009

SUBJECT: Service Remarks for RAM Memory Clear DATE: April 30, ’91

PAGE: 3 of 4

[A]

[B]

[B]

32 cm

[H]

[C]

[D]

[C]

[I]

[E]

[F]

6. Secure the harness bracket [A] to the harness support bracket [B] (2 screws).

7. Connect the optic cable connector (2P/Black) [C] to CN206 on the interface board.

8. Connect the DC harness connector (4P/White) [D] to the optional harness connector.

9. Secure the ground wire [E] (1 screw and toothed washer).

10. Set the optional harness [F] into the clamp [G] on the main board support bracket.

(This bracket is located on the lower left side of the main board.

11. Make sure that the DF harness [H] does not pass over the interface board [I].

NOTE: Make sure that at least 32 cm of the DF harness extends out of the copier as

shown.

[G]

Page 26

Technical Bulletin

No. RTB-009

SUBJECT: Service Remarks for RAM Memory Clear

2. Grounding Screws

[

DATE: April 30,

PAGE: 4 of 4

’91

[E]

[A] : T&S Power Pack

[C] : AC Drive Board

[E] : Optional DC Power Supply Board

8

] :

The

[

(

1

SERVICE REMARKS:

\

When reinstalling the following PCBS,

i

are properly tightened.

[

screw securing the optional dc power supply board is a Philips pan head

screw. Do not use a tapping screw.

aluminum heat sink. If a tapping screw is used, the threads may be damaged.

1. AC Drive Board

3. Optional DC Power Supply Board

TC/SC Power Pack

5.

[B] : CC/Grid/Bias Power Pack

[D] : Main DC Power Supply Board

This is because

make

sure that the screws circled above [

2. Main DC Power Supply Board

4. CC/Grid/Bias Power Pack

the screw secures to an

f:)

]

Page 27

Technical Bulletin No. RTB-010

SUBJECT: Manual Correction

Belt Drive Motor Speed Adjustment

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The adjustment procedure for the belt drive motor speed on the DF is missing from the

service manual. Please add the "Belt Drive Motor Speed Adjustment" section to your

manual.

NOTE: The belt drive speed adjustment is required under the following cases:

• When the main board is replaced.

• When the following problem occurs:

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: N220

DATE: April 30, ’91

PAGE: 1 of 2

[Phenomenon] The belt drive motor continues to run after the original

turns over for 2nd-side copy when the original is replaced.

[Cause] Two motors are used to feed the originals. One is the belt

drive motor and the other is the feed-out motor. When the

belt drive motor speed increases, the distance between the

original fed-out (1st original) and the original fed-in (2nd

original) decreases. The feed-out sensor cannot detect the

2nd original at the proper time. This causes the belt drive

motor to run continuously.

[Countermeasure] Adjust the belt drive motor speed according to the

adjustment procedure described on next page.

NOTE: The belt drive motor speed is preset at the factory based on the 5 volts supplied

from the copier to the DF. The power supplied from the copier to the DF may vary

depending on the machine. If the power supplied from the copier increases, the

belt drive motor speed also increases. Therefore, the belt drive motor speed

should be readjusted if the above problem occurs during installation.

Page 28

Technical Bulletin No. RTB-010

SUBJECT: Manual Correction

Belt Drive Motor Speed Adjustment

Normal

Setting

[A]

[B]

DATE: April 30, ’91

PAGE: 2 of 2

[C]

1. Turn off the main switch.

2. Check that DIP switch 101 is set for the normal setting as follows:

101-1 101-2 101-3 101-4

ON OFF OFF OFF

3. Turn on the main switch and DIP switch 101-2 and -4.

4. While turning on the lift switch manually, adjust the belt drive motor speed using VR101

[A] so that both the Insert Original indicator [B] and Auto Feed indicator [C] turns off.

NOTE: a) When the Insert Original indicator lights, turn VR101 clockwise to reduce the

motor speed.

b) When the Auto Feed indicator lights, turn VR101 counterclockwise to increase

motor speed.

c) Confirm that both indicators remain off for approximately 5 seconds in order to

stabilize the motor speed.

5. Turn off DIP switch 101-2 and -4.

NOTE: Do not use VR106. This variable register is for adjusting feed-out motor speed.

This is preset by the vendor.

Page 29

Technical Bulletin No. RTB-011

SUBJECT: Software Modification DATE: June 15,’91

PAGE: 1 of 6

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The software was changed (details follow) and the part numbers of the main board and the

ROM have also been changed as follows:

1. Main Board: #A0485105 #A0485121

2. ROM: #A0485104 #A0485124

(For the cut-in serial numbers, please refer to MB #42.)

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: N220

Contents of Software Modification

1. Black copy problem

If a copy is made when all of the following conditions are met, the exposure lamp stays

off and machine produces a black copy.

- Conditions (1) ADF installed on the machine

a. ADF mode

b. Two or more originals set on the DF

c. The ID sensor pattern is developed when making the first copy of the last

original.

(2) Paper fed from the cassette or the manual feed table.

(3) When the original set signal from the DF is off 160 pulses (640 msec) before the

first copy paper of the last original is fed. (Refer to the table on page 4 showing the

lamp off condition.)

The software was modified to prevent black copies when the above conditions were

met.

Page 30

Technical Bulletin No. RTB-011

SUBJECT: Software Modification DATE: June 15,’91

PAGE: 2 of 6

2. AMS mode improvement

Before modification : AMS mode selects one of the fixed magnification ratios.

After modification : AMS mode selects the proper magnification ratio even if it is

not a fixed magnification ratio.

Refer to the table on page 5 or 6 for more information.

3. APS mode (USA version only)

Before modification : Check Paper Size/Direction indicator blinks when the original

size is legal (81/2x14) and the magnification ratio is between

66% and 74%.

After modification : Letter size (length wise) is selected when the original size is

legal (81/2x14) and the magnification ratio is between

66% and 74%..

4. APS mode cancellation

APS mode can be selected only when the DF is used, but in the following cases, the

APS mode is not canceled even when the DF is raised:

a. when the DF is in the SADF mode;

b. when the final original is fed and before the paper is completely out of the exit unit;

c. while scanning in the SADF mode.

The software was modified to cancel the APS mode under the above conditions.

5. Size Magnification mode improvement

A small round off error occurs if both a decimal number and a whole number are input

for the original size and copy size.

Ex.

Original Size Copy Size Magnification Ratio

7 8.5 122%

7.0 8.5 121%

(In this case, 121% should be selected.)

The formula to calculate the round off was changed to yield the proper magnification

ratio.

Page 31

Technical Bulletin No. RTB-011

SUBJECT: Software Modification DATE: June 15,’91

PAGE: 3 of 6

6. Duplex mode (1)

Before modification : The Check Paper Size indicator lights when the wrong paper

size is selected.

After modification : The Check Paper Size indicator lights and the Duplex Unit

indicator blinks when the wrong paper size is selected.

7. Duplex mode (2)

The following software bug was corrected:

If the final copy fed from the duplex unit misfeeds in the sorter section, the misfeed

condition can be reset by opening and closing the sorter after removing the misfed

paper.

However, a misfeed is still detected even if no more paper is in the duplex unit.

8. Paper tray lock condition

The following software bug was corrected:

The paper tray is still locked when the sorter misfeed condition is reset by opening and

closing the sorter.

9. Sorter bin motor free run

The following software bug was corrected:

The sorter bin motor keeps on rotating if the machine goes the following sequence, but

only if the Duplex key or 2 Single Copies key is pressed.

1) Interrupt mode selected while sorter bins are up

2) sorter bins return to their home position

3) interrupt mode canceled

4) the sorter bins return to the position they are in when the interrupt mode

is selected.

5) the sorter bin motor keeps on running when pressing the Duplex key or 2 Single

Copies key while the motor is rotating.

Page 32

Technical Bulletin No. RTB-011

SUBJECT: Software Modification DATE: June 15,’91

PAGE: 4 of 6

Combination Table

The following table shows the combinations of the paper size and original size that cause

the exposure lamp to turn off.

Original

Paper

A4S

11x8.5 OK OK OK OK OK OK

A4L

8.5x11

8.5x14 NG

A3

11x17

A4S

11x8.5 A4L 8.5x11 8.5x14 A3 11x17

NG

(65%)

NG

(77%)

(65%)

NG

(88%)

NG

(88%)

NG

(65%)

NG

(77%)

NG

(65%)

NG

(88%)

NG

(88%)

NG

(65%)

NG

(77%)

NG

(65%)

NG

(88%)

NG

(88%)

NG

(65%)

NG

(77%)

NG

(65%)

NG

(88%)

NG

(88%)

NG

(65%)

NG

(77%)

NG

(65%)

NG

(88%)

NG

(88%)

S : Sideways

L : Lengthwise

NG

(65%)

NG

(77%)

NG

(65%)

NG

(88%)

NG

(88%)

OK : The exposure lamp does not turn off in any of the selected

magnification ratios.

NG (XX%) : The exposure lamp stays off if the magnification ratio is equal to or

less than XX%.

Page 33

Technical Bulletin No. RTB-011

SUBJECT: Software Modification DATE: June 15,’91

PAGE: 5 of 6

Magnification Ration Table In AMS Mode (USA Version)

The following table shows the magnification ratios selected by the combinations of the

paper size and original size in AMS mode (before and after software change).

Paper

Original

11x17 100

11x15 100 100

8.5x14

8.5x11 129 129 100 100 65

5.5x8.5

8.5x5.5

11x8.5

11x17 11x15 8.5x14 8.5x11 5.5x8.5 8.5x5.5 11x.8.5 8.5x13 8x10

85

(*74)

121

(*100)

200

(*155) 155 155 129 100 *65 *100 *129 *100

*129

*100

100 100

*129 *100 *100 *65 100 129 *100 *93

*100

77

(*74) 65

77

(*74) 74

77

(*74)

77

(*74)

*77

(*74)

50

(*65)

50

(*65)

*50

(*65)

*50

(*65)

*50

(*65)

*50

(*65)

*50

(*65)

*50

(*65)

65 100

(*65)

(*65)

(*65)

(*74)

*50

*50

*50

*77

*74

*77

(*74)

*85

(*74)

*100

*77

(*74)

*50

(*65)

*65

*65

*85

(*74)

*65

*129

8.5x13

*129

8x10

* : Combination causing the Check Paper Size/Direction indicator to blink.

( ) : Indicates the magnification ratio selected before modification

*100 *100

*100 *100 *100 *65

85

(*74)

*65 *65 *65 100

*50

(*65)

*85

(*74)

*100 100

(*74)

*77

Page 34

Technical Bulletin No. RTB-011

SUBJECT: Software Modification DATE: June 15,’91

PAGE: 6 of 6

Magnification Ration Table In AMS Mode (Europe Version)

The following table shows the magnification ratios selected by the combinations of the

paper size and original size in AMS mode (before and after software change).

Paper

Original

A3

B4 115

A4L

A5L 200

F4

8.5X13

F

8x13

A4S

A3 B4 A4L A5L

100 82 71

(*100)

100 82

50

(*71)

50

(*71)

F4

8.5x13F8x13

71

82

65

(*71)

75

(*71)

(*71)

(*71)

141 122 100 71 100 93 *71

(*141)

122 100 82

122 100 82

*100 *82 *71

141 141 100 141 122 *100 *71 *82 122

50

(*71)

50

(*71)

*50

(*71)

100 93

100 100

*71

65

(*71)

(*71)

(*71)

A4S A5S B5S B5L B6S B6L

*50

*50

*50

(*71)

*50

(*71)

*50

(*71)

*50

(*71)

*50

(*71)

*50

(*71)

*50

(*71)

71

*82

*50

(*71)

*50

(*71)

*50

(*71)

*50

(*71)

50

(*71)

*50

(*71)

*50

(*71) *82

*50

*50

*50

(*71)

*50

(*71)

*50

(*71)

*50

(*71)

100 71 *82

*75

(*71)

*75

(*71)

50

(*71)

*50

(*71)

*50

(*71)

*50

(*71)

*50

(*71)

*50

(*71)

*50

(*71)

A5S

B5S *115

B5L

B6S

B6L 200

*141 *122 *100 *71 *100 *93 141 100 122 *82 *82

(*100)

*100 *82

*141 141

*141 *141

200

(*!41)

(*141)

115

(*100)

*115

(*!00)

*141

*50

(*71)

82

*82

115

(*100)

*82

*115

(*100)

*115

(*100)

*141 *141

*75

(*71)

115

(*100)

*100 *82

*100 *141

*115

(*100)

82 100 *71 71

*50

(*71)

115

(*100)

*71 100

141 *100 100 *71

*82 *100 141 *71 100

* : Combination causing the Check Paper Size/Direction

indicator to blink.

( ) : Indicates the magnification ratio selected before

modification

*50

(*71)

*50

(*71)

*50

(*71)

71

L : Lengthwise

S : Sideways

Page 35

Technical Bulletin No. RTB-012

SUBJECT: Drum Support Plate Replacement Procedure DATE: June 30, ’91

PAGE: 1 of 3

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The following parts has been modified. (Please refer to MB #23 and #49 for the details.)

Description

Drum Support Plate A0482259 A0482260

Front Drum Side Plate A0482261 A0482263

Drum Support Plate Ass’y A0482254

The position of the following parts has been preset at the factory using the special tools.

1) Drum Support Plate (#A0482260)

2) Front Drum Support Plate (#A0482263)

3) Bias Terminal (#A0487637)

Revision of service manual

Information only

Other

P/N P/N P/N

FROM: Copier Technical Support Sec.

MODEL:

N220

MB #23 MB #49

Please refer to MB #23, for the cut-in serial numbers.

1. Concerning the drum support plate and front drum side plate:

The screws securing these parts are paint locked. Their position must not be adjusted in

the field. However, it is possible that the parts might have to be replaced in the field. To

reduce the possibility of image problems that such replacement might cause, the service

parts have been changed as follows:

The drum support plate (#A0482260) and the front drum side plate (#A0482263) have

been registered as an assembly service part (drum support plate assembly). (Please

refer to MB #49 for the cut-in serial numbers.)

2. Concerning the bias treminal:

It is difficult to reposition the bias terminal in the field if remove it. Do not loosen or

remove the screw securing the bias terminal in the field.

Please read carefully the following pages about handling the above parts in the field.

Page 36

Technical Bulletin No. RTB-012

SUBJECT: Drum Support Plate Replacement Procedure DATE: June 30, ’91

PAGE: 2 of 3

1. Drum Support Plate/Front Drum Side Plate

[C]

[D]

[E]

[B][A]

[C]

Service Remarks: 1. Do not loosen or remove the screws [D] while servicing the

machine.

2. When replacing the drum support plate [A] or front drum side

plate [B], replace them with a assembly part [C].

NOTE: Two holes [E] are added to the drum support plate so that the drum support plate

assembly [C] can be replaced in the field.

Page 37

Technical Bulletin No. RTB-012

SUBJECT: Drum Support Plate Replacement Procedure DATE: June 30, ’91

PAGE: 3 of 3

2. Bias Terminal

[A]

CAUTION: Do not loosen or remove the screw [A] securing the bias terminal.

Page 38

Technical Bulletin No. RTB-013

SUBJECT: Dust Proof Glass DATE: June 30, ’91

PAGE: 1 of 1

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The dust proof glass has been modified as follows:

Old P/N New P/N

#A0481875 #A0481877

(For the cut-in serial numbers, please refer to MB #48.)

[ Reason for Modification ]

The spectral characteristics of the filter on the dust proof glass was changed to facilitate

servicing. With this modification, the light intensity passing through the filter has been

increased. The new filter can decrease the adjustment value of SP mode #48 (exposure

lamp intensity adjustment) at the factory about by 10 steps.

This increase the adjustment range of SP mode #48 in the filed.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL:

N220

[ Additional Information ]

With this modification, antistatic solution has been applied to the filter surface at the

factory. This is to prevent the filter from attracting the dust in the air.

When cleaning the filter, use a dry cloth.

SERVICE REMARKS: Do not clean the filter with water or any other cleaning solution.

If do so, the antistatic effect will be lost.

Page 39

Technical Bulletin No. RTB-014

SUBJECT: Erase Function Improvement DATE: July 15, ’91

PAGE: 1 of 1

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

To improve the erase function in the reduction zoom mode, the eraser, eraser bracket,

and main board have been modified so that maximum side erase is 6 mm (total of both

sides) with the platen cover (10 mm with the DF).

Please refer to MB #47 for the cut-in serial numbers.

NOTE: The side erase margin when using the DF is greater than that when using the

platen cover. This is because the width of the platen cover sheet is greater than

that of the DF feed belt.

To control the new erase function, the software and ICs on the main board have been

changed, and two IC drivers have been added to the eraser board.

The old and new parts (main board, ROM, eraser, and eraser bracket) are not

interchangeable individually, but they are interchangeable as a set.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL:

N220

[ Additional information ]

To distinguish the new machines from the old ones:

1) the color of the connectors used for the eraser has been changed from "White" to

"Blue".

2) the color of the lettering on the main board has been changed from "White" to

"Yellow".

3) a colored circle (diameter : 30 mm) has been printed on the side of the carton that has

"Made in Japan" printed on it.

Page 40

Technical Bulletin No. RTB-015

SUBJECT: Light or blank copy due to development drive clutch slipping DATE: Sep. 15, ’91

PAGE: 1 of 1

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The development drive clutch has been modified to improve the clutch movement.

(Please refer to MB No. 56 for the cut-in serial numbers.)

If the following problem occurs in the field, the development drive clutch should be

replaced with a modified one.

Description Old P/N New P/N

Development Drive Clutch #AB040007 #AB040011

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: N220

[ Phenomenon ] 1. Light Copy

2. Blank Copy

The above problem may appear after a large number of copies are

made.

[ Cause ] The development roller movement is not smooth due to

development drive clutch slipping.

After making a large number of copies, the hub surface inside of

the spring clutch may be worn out. This causes clutch slipping.

[ Countermeasure ] The hardness of the hub surface has been increased and the inner

diameter of the clutch spring has been made smaller.

[ Troubleshooting ] If a light copy or blank copy appears, check whether or not the

development roller knob rotate smoothly during copy run. If the

development roller knob does not rotate smoothly, replace the

development drive clutch with a modified one.

Page 41

Technical Bulletin No. RTB-016

SUBJECT: Noise or light copy due to toner supply clutch slipping DATE: Sep. 15, ’91

PAGE: 1 of 1

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The toner supply clutch has been modified from a spring type to a magnetic type. (Refer

to MB #41 for the cut-in serial numbers.)

If the following problem occurs, the toner supply clutch should be replaced with a new one.

Old P/N New P/N Description

#A0485263 Toner Supply Clutch

#A0541116 Toner Supply Clutch Assembly

NOTE: The old and new toner supply clutches are not interchangeable. They are

interchangeable as a set. Replace the old clutch with the new clutch assembly.

Refer to MB #41 for the details.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: N220

[ Phenomenon ] 1. Noise

2. Light Copy

The above problem may appear after a large number of copies are

made.

[ Cause ] The toner supply clutch may slip due to the load from the

development unit. If the lubricating grease on the spring is

insufficient, noise may occur. If the toner supply clutch slips, toner

is not supplied to the development unit properly. This causes a

light copy.

[ Countermeasre ] The clutch type has been changed from a spring clutch to a

magnetic clutch.

[ Troubleshooting ] If noise and/or a light copy appears, check whether or not the

toner supply clutch rotates properly. If the toner supply clutch

slips, replace the clutch with a magnetic clutch.

Page 42

Technical Bulletin No. RTB-017

SUBJECT: Paper lift and sector gear slipping DATE: Sep. 15, ’91

PAGE: 1 of 1

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

[ Phenomenon ] When the paper stack in the cassette is lifted up, the paper lift

gear [A] and the sector gear [B] slip.

[ Cause ] The mesh between the paper lift gear and the sector gear is too

shallow.

[ Action ]

[A]

Revision of service manual

Information only

Other

Push

TO: Copier Technical Support Section

MODEL: N220

No Gap

1. Turn off the main switch.

2. Make sure that the cassette is installed on the copier and the manual feed table is

closed.

3. Remove the rear cover and the main board.

4. Loosen the screw [C].

5. Retighten the screw while pushing down the paper lift clutch support bracket [D] so

that there is no gap between the pitch circles of the paper lift gear and the sector gear.

6. Reassemble all parts previously removed.

NOTE: When the paper lift clutch support bracket is removed during servicing, the

bracket must be reinstalled according to the above procedure.

[B]

[D]

[C]

Page 43

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

PREPARED BY: T. Itoh

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This troubleshooting guide is developed to assist your daily service activity for the N220

copier based on the investigation of field machines, the analysis of service calls.

This troubleshooting guide may not pertain to all the cases which you may encounter in

the field, however, it covers typical causes for the following:

SECTION 1 DARK COPY

SECTION 2 RAM DATA CLEAR

Revision of service manual

Information only

Other

TO: Copier Technical Support Section

MODEL: N220

DATE: Oct. 15, ’91

PAGE: 1 of 11

SECTION 3 DIRTY BACKGROUND AND/OR TONER SMUDGE ON THE

LEADING EDGE OF THE COPY (OVER TONING)

Page 44

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

DATE: Oct. 15, ’91

PAGE: 2 of 11

1. DARK COPY

SYMPTOM:

Copies have dirty background prematurely and customer needs to shift manual image

density level to lighter selection.

CAUSE:

An air flow through the 6th mirror area carries and accumulates dust on the surface of the

6th mirror [A] and of the filter on the toner shield glass [B].

Static electricity is produced on the surface of the filter by cleaning it with dry cloth. It will

remain on the surface of the filter and will accelerate accumulation of dust.

[A]

[B]

SOLUTION:

1. Clean all optics parts.

2. Apply the antistatic solution to the filter on the toner shield glass.

3. Install the shield mylar. (See SHIELD MYLAR INSTALLATION PROCEDURE.)

Page 45

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

SHIELD MYLAR INSTALLATION PROCEDURE:

Units Affected:

A shield mylar has been applied to the production units. Refer to MB No. 51 for the cut-in

serial numbers.

Necessary Part:

Part No. Description Q’ty

A0489505 Shield Mylar 1

[B]

[D]

[A]

Ozone

DATE: Oct. 15, ’91

PAGE: 3 of 11

6th Mirror

[C]

Charge Corona Unit

1. Open the front cover and lower the transport unit.

2. Remove the following parts:

a. Cleaning Unit

b. Development Unit

c. Charge Corona Unit

d. Drum Unit (Protect the drum surface with a protective sheet.)

3. Place the cutout [A] face down on the dust shielding mylar [B] and completely insert it

into the gap between the cleaning rail [C] and the upper cleaning stay [D] as shown.

CAUTION: The cutout on the mylar must be inserted face down into the gap. If the

cutout is face up, the ozone stays around the charge corona unit. This may causes

a foggy image, lighter image, or dirty background problem.

Page 46

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

DATE: Oct. 15, ’91

PAGE: 4 of 11

4. Remove the toner shielding glass [E] from the copier.

5. Clean the toner shielding glass and the filter [F] with a dry cloth.

6. Damp a clean and soft cloth with a small amount of antistatic solution.

7. Wipe the filter with the cloth.

[F]

NOTE: You can use any commercially available antistatic solution. If this solution is not

available, wipe the surface of the filter with your finger to remove static electricity

as shown below:

[E]

CAUTION: Do not clean the filter with water or any other cleaning solution after

this. If you do so, the antistatic effect will be lost.

8. Clean the following parts:

• 1st, 2nd, 3rd, 4th, 5th, and 6th Mirrors

• Lens

• Reflectors

• Exposure glass

WARNING: Be careful not to cut your fingers when you clean the 6th mirror. The edges

are sharp.

9. Reassemble the copier.

10. Adjust the lamp intensity by SP mode #48.

11. Adjust the ADS voltage by SP mode #56 and VR101 on the main board.

Page 47

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

DATE: Oct. 15, ’91

PAGE: 5 of 11

2. RAM DATA CLEAR

SYMPTOM:

The following typical symptoms may occur when and after the SP mode data is reset by

electrical noise.

• Dark copies are made suddenly. (The data of SP mode #48 [light intensity adjust-

ment] resets to "126".)

• Paper misfeed (The data of SP mode #45 [1st feed paper buckle adjustment] and

#46 [2nd feed paper buckle adjustment] reset to "0".)

CAUSE:

The following possible causes may generate electrical noise and reset the CPU and the

SP mode data in the RAM board;

• Poor connection between the main board and the interface board

• The following PCBs are not grounded properly;

1. AC Drive Board

2. Main DC Power Supply Board

3. Optional DC Power Supply Board

4. TC/SC Power Pack

5. CC/Grid/Bias Power Pack

NOTE: These PCBs are grounded by pressing the printed pattern on the PCBs to the

machine frame or bracket with screws.

• Current leakage in the separation corona or the transfer corona

Page 48

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

SOLUTION:

1. If the interface board is installed, make sure of the following:

a. The smaller side [A] of the locking supports must be inserted through the main

board [B].

b. The heads of the three locking supports must firmly lock the main board [B] and

interface board [C] together as shown.

[B]

[A]

[A]

DATE: Oct. 15, ’91

PAGE: 6 of 11

[E]

[C]

[A]

[B]

[C]

c. The connector [D] of the interface board must be connected firmly to the main

board connector [E].

d. If the document feeder is installed, make sure that the DF harness is properly wired

and is not located on the interface board. (Refer to RTB-009 for detailed information.)

2. Make sure that the screws used for grounding the following PCBs are properly

tightened. (Refer to RTB-009 for detailed information.)

a. AC Drive Board

b. Main DC Power Supply Board

c. Optional DC Power Supply Board

d. CC/Grid/Bias Power Pack

e. TC/SC Power Pack

[D]

Page 49

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

3. Troubleshoot the current leakage in the separation corona or the transfer corona.

a. Check the transfer and separation corona end block and/or receptacle for current

leaks.

b. If there are leaks, replace the corona end block or the receptacle.

c. To prevent the SP mode data from being reset by current leaks in the future, install

ferrite cores on the high voltage cables for the transfer corona and the separation

corona. (See FERRITE CORE INSTALLATION PROCEDURE.)

4. Reset the following SP mode data to the factory setting.

SP

mode

21 APS Priority 1

41 Leading Edge Erase See NOTE 1

42 Leading Edge Registration See NOTE 1

Function Factory Setting

Data

DATE: Oct. 15, ’91

PAGE: 7 of 11

43 Vertical Magnification See NOTE 1

44 Horizontal Magnification See NOTE 1

45 1st Feed Paper Buckle 8

46 2nd Feed Paper Buckle 8

47 Focus See NOTE 1

62 ID Sensor Grid 7 (See NOTE 2)

71 Sorter Operation 1 (See NOTE 3)

76 Sorter Bin Capacity 1

NOTES: 1. Factory setting data of SP #41, 42, 43, 44, and 47 are recorded on the factory

setting sheet located in the left inner cover.

2. It is necessary to reset the data of SP mode #62 only for the machines which

have the S/N 259005XXXX.

3. This is necessary only for the machines which have the sorter.

5. Perform SP mode #68 (Vr forced detection) and make 5 copies. Making these 5

copies insures the proper Vr correction data based on the current drum condition.

6. Adjust the exposure lamp intensity by SP #48.

7. Adjust the ADS voltage by SP #56 and VR101 on the main board.

Page 50

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

FERRITE CORES INSTALLATION PROCEDURE:

Units Affected:

Ferrite cores have been installed on the production units. Refer to MB No. 53 for the cut-in

serial numbers.

Necessary Part:

Part No. Description Q’ty

16070478 Ferrite Core 3

DATE: Oct. 15, ’91

PAGE: 8 of 11

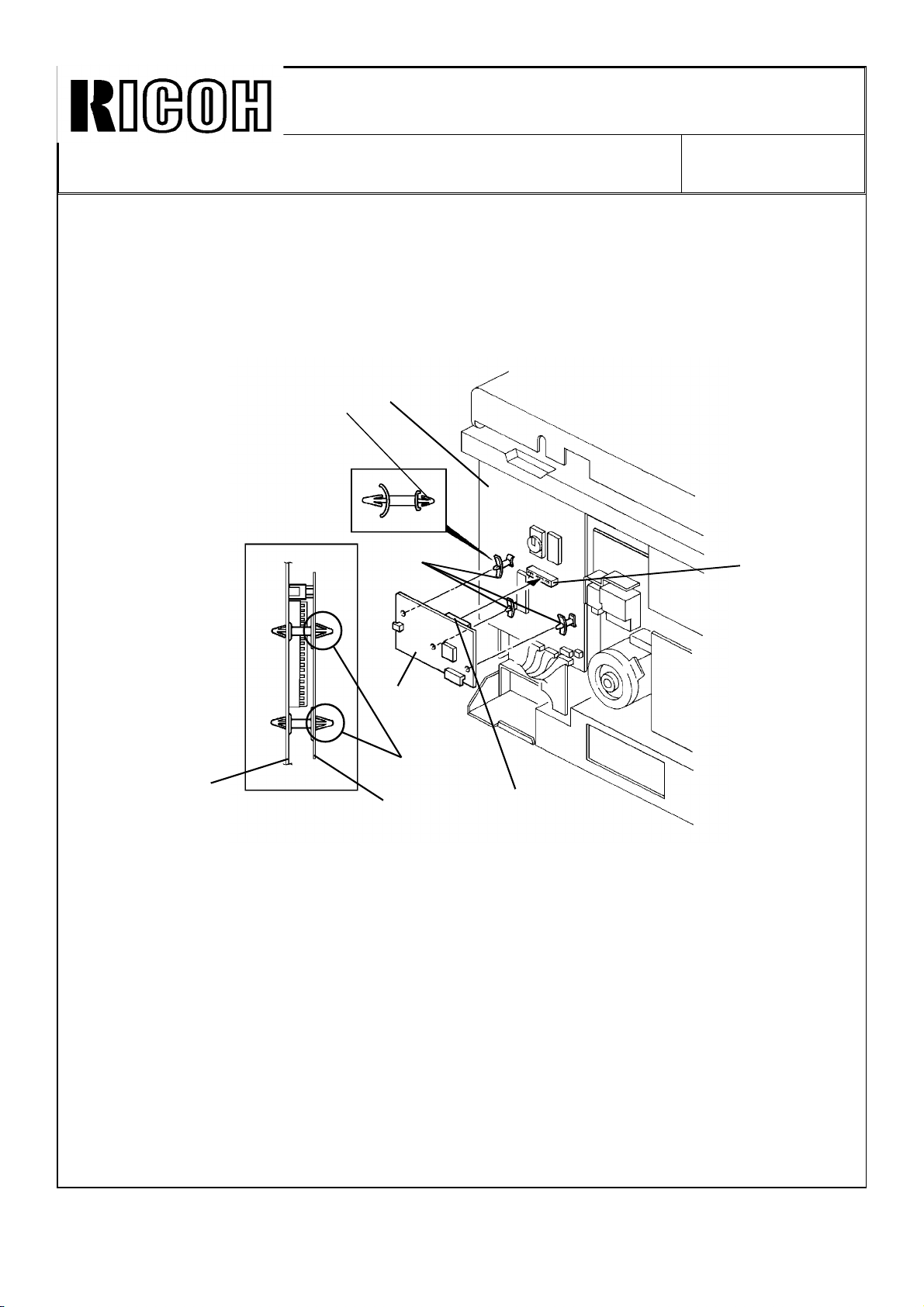

[D]

[B]

[C]

[A]

1. Turn off the main switch and remove the rear cover.

2. Install one ferrite core [A] on the high voltage cable [B] for the transfer corona.

3. Install two ferrite cores [C] on the high voltage cable [D] for the separation corona.

4. Reinstall the rear cover.

Page 51

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

DATE: Oct. 15, ’91

PAGE: 9 of 11

3. DIRTY BACKGROUND AND/OR TONER SMUDGE ON

THE LEADING EDGE OF THE COPY (OVER TONING)

SYMPTOM:

• The background of copies has small speckles (toner particles). This dirty background

remains even when a different image density is selected (Notch 1 through 7).

• The copy leading edge has toner smudges.

CAUSE:

The toner density in the development unit is too high. The following are possible causes:

• The RAM data clear problem has happened before.

• The ID sensor pattern is not developed properly.

SOLUTION:

1. To find out if the RAM data clear problem has happened before, check the data of SP

#45 and 46 (paper buckle adjustment). If they are "0", the RAM data has been cleared

before. (See SECTION 2. RAM DATA CLEAR.)

2. Check whether the ID sensor pattern is developed properly or not. If not, install the ID

sensor pattern patch. (See ID SENSOR PATTERN PATCH INSTALLATION

PROCEDURE.)

3. Replace the developer and perform the developer initial setting (SP #65).

NOTE: Even after performing the above procedures, the toner density may still be too

high. Therefore, replace the old developer with fresh one.

Page 52

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

ID SENSOR PATTERN PATCH INSTALLATION PROCEDURE:

Units Affected:

The ID sensor pattern has been enlarged from the March 1991 production.

1. Confirmation Procedure

OK No Good

DATE: Oct. 15, ’91

PAGE: 10 of 11

ID Sensor Pattern Image

1. Turn off the main switch.

2. Remove the rear cover (4 screws).

3. Turn on the main switch.

4. Connect CN111-1 to TP112 (GND) with a jumper wire so that the registration clutch

stays on.

CAUTION: Do not connect CN111- 2 to TP112 (GND). If you do so, the fuse (FU101)

on the main DC power supply board will be blown.

5. Select the paper tray (the 2nd feed station) by pressing the select paper key.

6. Make 10 copies and then find a copy with the ID sensor pattern copied.

NOTE: The ID sensor pattern is a halftone image.

7. Reassemble the copier.

8. If the ID sensor pattern image is no good, install the ID sensor pattern patch. (See

next page for the procedure.)

Page 53

Technical Bulletin No. RTB-018

SUBJECT: Troubleshooting Guide (1. Dark copy 2. RAM data clear

3. Dirty background (over torning)

2. ID Sensor Pattern Patch Installation Procedure

Necessary Part:

Part No. Description Q’ty

A0489506 ID Sensor Pattern Patch 1

[C]

[E]

[B]

DATE: Oct. 15, ’91

PAGE: 11 of 11

[F]

[H]

[G]

[D]

[A]

1. Turn off the main switch.

2. Remove the left scale (2 screws), and then remove the exposure glass.

3. Move the first scanner so that the ID sensor pattern [A] on the left scale bracket [B] is

reflected by the back side of the 2nd mirror [C] as shown in the illustration.

4. Attach the ID sensor pattern patch [D] to the left scale bracket.

NOTES: 1. Make sure that the side edges of the ID sensor pattern patch are aligned with

those of the ID sensor pattern printed on the left scale bracket.

2. Make sure that the leading edge of the ID sensor pattern patch [E] is aligned

with the edge [F] of the left scale bracket.

3. Make sure the cutout [G] on the ID sensor pattern seal is released from the

screw hole [H] on the left scale bracket.

4. Reassemble the copier.

Page 54

RICOH

Technical Bulletin

No.

RTB-019

SUBJECT: New procedure for the DG (doctor gap) adjustment

PREPARED BY:

CHECKED BY:

“.,.

CLASSIFICATION

-

FROM: Copier Technical Support Section

MODEL: N220

DATE: Jan. 31, ’92

PAGE: 1 of 6

❑ Action Required ■ Revision of service manual

❑ Troubleshooting

❑ Information only

❑ Retrofit Information ❑ Other

The DG adjustment standard in the factory has been changed from 0.53 -- 0.67mm to

0.63 - 0.72mm from the July ’91 production onward. This is to minimize image

overtoning and toner scattering. These problems are due to the DG being too narrowly

adjusted.

When you are forced to adjust the DG in the field, adjust it with the new DG gauge (P/N

A0489507) and refer to the following procedure.

NOTE: If the current development unit has no problem with the DG adjusted to the old

standard, do not re-adjust it to the new standard.

This procedure supersedes the doctor gap adjustment procedure in the service manual.

Page 55

RICOH

SUBJECT: New procedure for the DG (doctor gap) adjustment DATE: Jan. 31, ’92

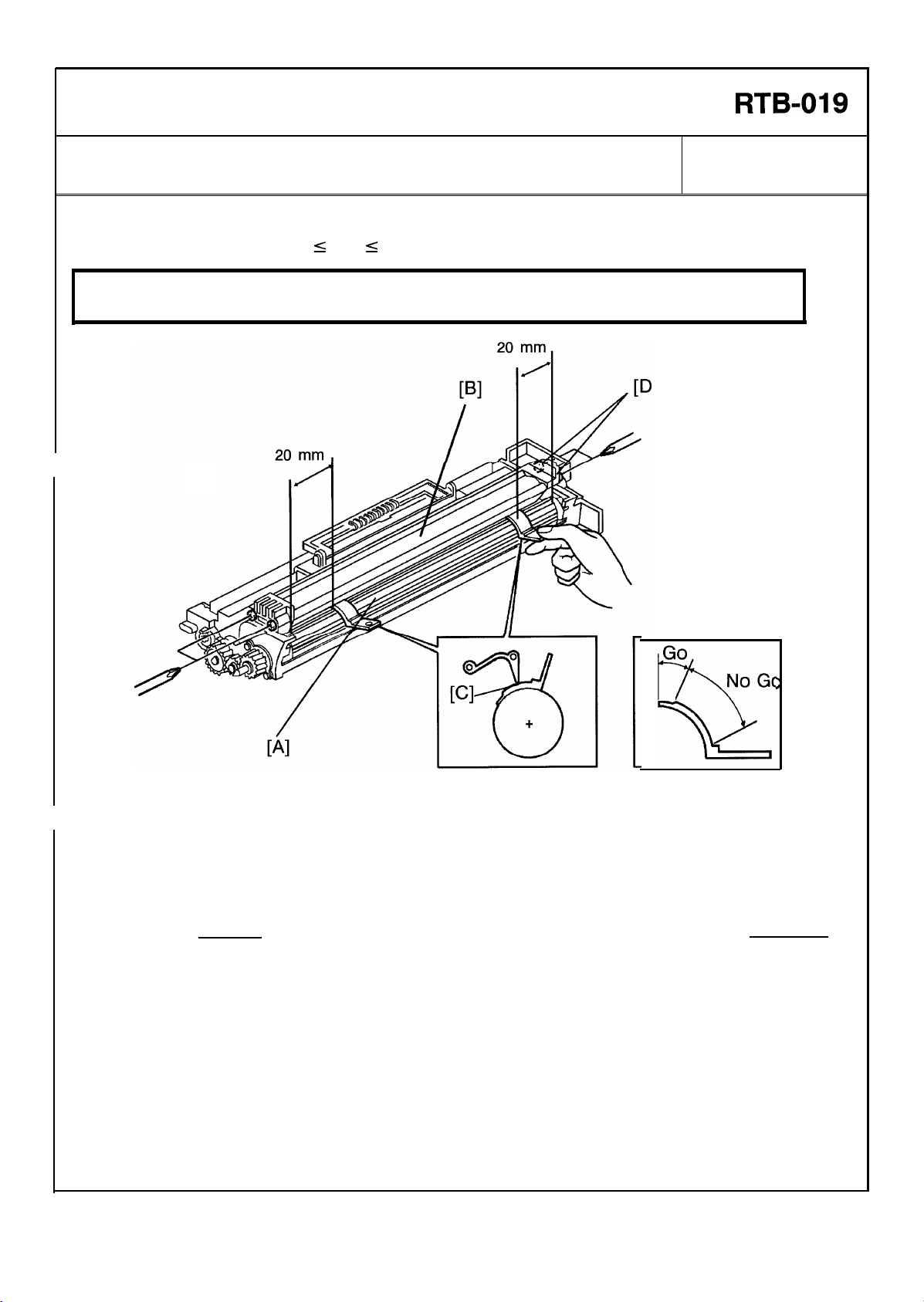

NEW PROCEDURE:

CAUTION: The doctor gap was adjusted at the factory using the special

tool. Therefore, normally this adjustment is not required in the field.

Only when the development unit is disassembled or the development

roller is replaced, this adjustment is required.

1. Confirmation Procedure

Technical Bulletin

No.

RTB-019

PAGE: 2 of 6

1. Take out the development unit.

2. Remove the developer.

3. Remove the inlet seal plate [A] by working a small blade screwdriver along the edge of

the plate while pressing the stoppers [B] with one finger as shown.

CAUTION: Be careful not to damage the stoppers [B] when removing the inlet seal

plate.

4. Clean the development roller [C] with a vacuum cleaner until no developer is left on

the roller. Turn the roller to make sure that it is free of developer.

NOTE: This prevents surface damage to the roller and ensures an accurate adjustment.

Page 56

Technical Bulletin

No. RTB-019

SUBJECT: New procedure for the DG (doctor gap) adjustment

DATE: Jan. 31, ’92

PAGE: 3 of 6

5. Position the DG gauge (P/N #A0489507) 20 mm (0.8 inch) from the front end of the

development roller, and insert the gauge into the doctor gap until it stops.

I

CAUTION:

Do not force the DG gauge into the gap and do not press the gauge too

hard on the roller. The roller should not rotate when you insert the

gauge into the gap.

—

Page 57

RICOH

Technical Bulletin

No.

RTB-019

SUBJECT: New procedure for the DG (doctor gap) adjustment

6. Check the doctor gap at four points

turning the development roller 90° each

time.

If the “GO” part of the DG gauge goes

through the doctor gap, and the “NO GO”

part does not go through, the gap at this

point is: 0.63 mm s DG s 0.72 mm

If the “GO” part of the

go through the doctor gap, the gap at this

point is:

DG

<

0.63 mm

If both “GO” part and “NO GO” part go

through the doctor gap, the gap at this

point is: DG

>0.72

DG gauge does not

mm

DATE: Jan.

PAGE:

Good

Too

Too wide

4

of 6

narrow

31, ’91

7. Repeat steps 6 and 7 for the rear side of the development roller.

8. If either 3 out of 4 checked points or all 4 points are “0.63 mm

gap is in good condition. If more than 2 out of 4 checked points are

adjust the

DG only when there is any of the following problems:

a. Severe jitter copy

b. Blocking of development drive mechanism

c. Developer leakage

DG. If more than 2 out of 4 checked points are “DG > 0.72 mm” adjust the

s

DG s 0.72 mm”, the

“DG <0.63

mm”,

Page 58

RICOH

Technical Bulletin

No.

RTB-019

SUBJECT: New procedure for the DG (doctor gap) adjustment

2.

Adjustment Procedure

Adjustment standard :0.63 s DG s 0.72

CAUTION: Before adjusting the doctor gap, the confirmation procedure must be

performed.

DATE: Jan. 31, ’92

PAGE: 5 of 6

1

7

4

1. Clean the development roller [A] with a vacuum cleaner until no developer is on the

roller. Turn the roller to make sure that it is free of developer.

2. Loosen the doctor plate [B] (4 screws).

3. Insert the “NO GO” part of the gauge [C] in the doctor gap 20 mm from the front side

of the development roller as shown.

NOTE: The front side should be adjusted first to prevent the doctor gap from being too

narrow.

4. Press down the doctor plate directly above the gauge, and tighten the front doctor

plate screws [D].

NOTE: Do not press the doctor plate too hard, the doctor gap will become too narrow.

5. Repeat the adjustment procedure at the rear side of the development roller.

6. Confirm that the doctor gap is adequate by following the confirmation procedure.

Page 59

RICOH

Technical Bulletin

No.

RTB-019

SUBJECT: New procedure for the DG (doctor gap) adjustment

The machine serial numbers cut-in are as follows:

CODE

A048-15

A048-16 Nashua 3018 2111070001

A048-17

A048-19

A048-25 Nashua 3018 2101070001

A048-26

A048-27

A048-28

A048-29

A048-46

A048-47

MODEL NAME

Savin

9180 6910904704

Ricoh

FT4418

Ricoh

FT4418 2591070490

Infotec

Ricoh

Ricoh FT4418 259201XXXX

Ricoh

Infotec

Ricoh FT4418

9118Z

FT4418 2591070560

FT4418 2591070762

9118Z

SERIAL NUMBER

DATE: Jan. 31, ’92

PAGE: 6 of 6

2591070001

3960710001

3966410001

2591640001

Page 60

REVISED ON SEPTEMBER 30, ’93

Technical Bulletin No. RTB-020

SUBJECT: Lubrication of the idle gear and the idle gear shaft. DATE:

Feb. 28, 1 993

PAGE: 1 of 2

PREPARED BY: N. Takai

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

A rattling noise comes out from the idle gear engagement or jitter images appear about

100 K to 150 K copies after machine installation. This is because the shaft of the idle

gear-35 Z (P/No. AB013434) is being worn out gradually and the gear engagement

becomes poor.

To prevent this problem, the gear shaft and the gear’s teeth should be lubricated at your

next visit, and the gear teeth at every PM interval afterwards, according to the following

procedure:

- Action required -

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: N220

1. Remove the rear cover (4 screws).

2. Remove the fusing drive release

spring [A].

3. Remove the main motor ass’y [B]

(4 screws and 1 connector)

[A]

[B]

Page 61

Technical Bulletin No. RTB-020

SUBJECT: Lubrication of the idle gear and the gear shaft. DATE:

Feb. 28, 1 993

PAGE: 2 of 2

4. Remove the E-ring [C] and the washer

[D] from the idle gear shaft.

5. Lubricate the gear’s teeth with Grease

G-501 [E] and the gear shaft with the

spindle oil [F].

[D]

6. Reassemble.

[F]

* Confirm that the fusing drive release

spring [A in page 1] is set. If this

spring is not set, drive cannot

transmitted to the fusing section.

NOTES: (1) For the field machines having this problems, we recommend replacing the idle

gear with the modified one (new P/No. AB013841). (Refer to M/B # 87. )

(2) When the modified gear is installed, the two washers (P/No. 52031870 [G] and