Page 1

Technica l Bulletin No . RTB-00 1

SUBJECT: FT500i Techn ical Info rm atio n DATE: June 30, ’93

PAGE: 1 o f 6

PREPARED BY: Shun Satoh

CHECKED BY: Tony Ito

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The FT500i desig n is b ased on the FT400i. There is n o u niqu e tec hno log y u sed on the

FT500i.

The following are the major different points between the FT400i and t he FT500i.

(1) The co p y sp eed is in cr eased fro m 40 CPM to 50 CPM. To m atc h t he sp eed -up ,

the drum coro na currents and the toner density in the development tank are

changed.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: FT500i

(2) To maintain fusing ability after the speed-up, the pressure between the fusing

ro llers is inc rea sed .

(3) To p reven t th e tem p eratu re ins ide the m ac hine fro m inc r easing , two c oo ling fan s

have been added around the power supply unit. Also, the rear cover material is

changed.

(4) The software (main and optics ROMs) to control the machine operation is modified

to match the new speed of the system.

(5) The C S2090 (Mini so rt er) is n ot used on the FT500i. This is b eca use th is so rter

cann ot be mat ch ed to the FT500i pap er feedin g s peed .

Page 2

Technica l Bulletin No . RTB-00 1

SUBJECT: FT500i Techn ical Info rm ation DATE: June 30, ’93

PAGE: 2 o f 6

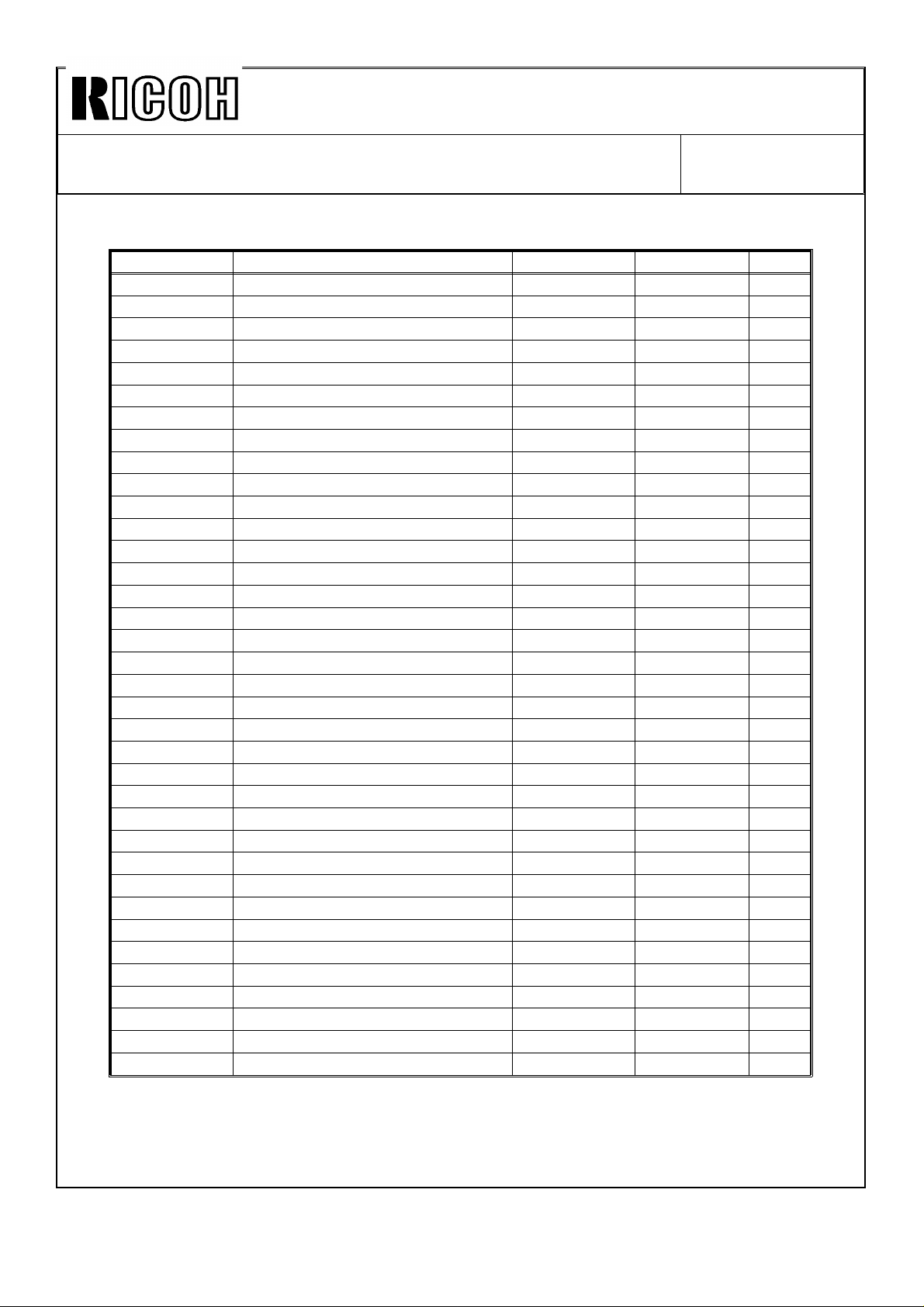

1. U nique pa rts

(1) Parts list

SP50 P/ N Des cr i p t ion SP40 P/ N PC Pa g e Not e

A1081311 Upp er Cover A0891311 7-13 A

A1081276 Rear Cover A0891276 7-17 B

A1085120 Main Bo ard A0895120 7-34 C

A0011897 Fron t Co ver - Terminal A0001897 11-18 D

AX530013 Expo sur e lamp AX530001 11-19 E

A1081667 Wire Fixing Plate A0891667 11-22 F

A1081650 First Scann er A0891650 11-25 D

AW110013 Thermo st at AW110003 11-28 G

A1085396 Halog en Lam p Harn ess A0895396 11-29 D

Not us ed Optic s Fan Co ver A0421890 11-54 D

AX020024 Coo ling Blo wer AX620011 11-55 D

A0015465 Interfac e Har ness Not us ed 11-69* D

A1085395 Halog en Lam p Harn ess A0895395 11-58 D

A1081112 Pulley A0891112 21-34 H

AB013799 Gear - 33Z AB013541 21-37 H

AX500045 Erase Lamp AX500041 29-7 E

A1082002 Charg e & Qu ench ing Unit A0892002 29-45 E

AA060531 Spring 52012821 37-24 I

A1084111 Pressure Lever A0894111 37-25 I

AX030005 Main Mo t or AX030004 39-17 J

AB013813 Gear - 25Z AB013646 39-18 K

07413808 B all Bearing - 8x16x5 m m 50530223 39-19 K

A1081136 Drive Arm - Fus ing Exit A0891136 39-26 K

AB013812 Gear 30Z AB013645 39-28 K

A1085302 DC Power Supp ly Un it A0895302 41-13 L

A1085422 Left DC Har ness A0895422 4-14 L

AX640032 Coo ling Fan Q’ ty ch ang e 41-23 L

16061936 C apac ito r-8mF-220V Not used 41-28* M

A1085460 Relay Har ness Not us ed 41-29* M

AX640040 Coo ling Fan Not us ed 41-30* N

A1081175 Coo ling Fan Brac ket No t us ed 41-31* L

AZ320066 Power p ac k AZ320064 43-11 O

A1081885 Right Stay A0421885 45-8 D

A1081154 Shielding Plate - DC Power A0891154 45-28 N

A1085129 IC- AM27C512-155DC A0895134 49-2 P

A1085141 IC- AM27C256-155DC A0895141 49-3 P

Notes: 1. The letters in the Note column refer to the "reasons for changes" which are

explained below.

2. An aster isk in dic ates a new par t ind ex num ber .

Page 3

Technica l Bulletin No . RTB-00 1

SUBJECT: FT500i Techn ical Info rm ation DATE: June 30, ’93

PAGE: 3 o f 6

(2) Reasons for changes

[ A] Model name is changed.

[ B] One additional cooling fan outlet is added on the rear cover above the power cord

to prevent the temperature inside the machine from rising. Also, the material of the

cover is changed from plastic to metal.

[ C] The ROMs and resistance of the toner density sensor are changed.

[ D] To pr event th e op tic s c avity tem per atur e from risin g, a s tro ng er fan is used

because a higher intensity exposure lamp is used. Due to the bigger cooling fan,

some of the optics parts are changed to prevent the first scanner from hitting the

fan.

[ E] More light intensity is required because the drum speed is higher.

[ F] Due to greater scanner overrun, the wire clamp and the right pulley bracket are

mo d ified t o p reven t c o llisio n s.

[ G] Since a h igh er inten sity exp os ure lam p is u sed, the d etec tion temp eratu re is

changed from 120 °C to 150 °C.

[ H ] To m aint ain th e deve lop men t tan k p um p spee d in spit e o f the fas ter m ain m ot or

speed , t he pu lley and the g ear are c han ged .

[ I] Mo re pressure between rollers is required to maintain fusing ability at the higher

pap er feed speed .

[ J ] To inc reas e th e pr o ces s sp eed fro m 266 mm /s ec t o 333 m m/ sec , the m ain mo t or

is changed.

[ K] To improve durability, bushings are changed to ball bearings. Due to this change,

related g ears an d the d r ive arm ar e c hang ed .

[ L] To cool the transformer and the main motor, a cooling fan is added in between the

main m ot or an d t he DC p o wer su pp ly u nit. This fan is alread y used in t he FT400i

(PC pag e 41, # 23).

Page 4

Technica l Bulletin No . RTB-00 1

SUBJECT: FT500i Techn ical Info rm ation DATE: June 30, ’93

PAGE: 4 o f 6

[ M] A capacitor is added in parallel to the current capacitor to suppress the power on

surge of the bigger main motor.

[ N] To cool the DC power supply unit, a cooling fan is added. Due to this fan, the

shape of the shielding plate and the DC power supply unit are changed.

[ O] To maintain drum currents in spite of the increase in drum speed, the outputs of

the p o wer pac k are in cr eased .

[ P] Software is modified to match the new speed of the system.

#29

#30

#23

#31

#28

Parts Catalog

Pag e 40

Page 5

Technica l Bulletin No . RTB-00 1

SUBJECT: FT500i Techn ical Info rm ation DATE: June 30, ’93

PAGE: 5 o f 6

2. New adjustment specifications for the FT500i

(1) Drum corona current

Charge Corona Transfer

Regular Economy OHP Corona

Drum Sur face Vo ltag e 1,250 V 950 V 475 V 1,000 V

Drum Current 60 ± 2 µA 45 ± 2 µA 25 ± 2 µA 41 ± 2 µA

(2) Toner density in the development tank

Toner den sity is 60 g ram / liter.

The resist ance b etween CN115-3 and CN115-2 fo r the t on er den sity c irc uit o n th e

main board should be 10 ± 0.5 KΩ.

Page 6

Technica l Bulletin No . RTB-00 1

SUBJECT: FT500i Techn ical Info rm ation DATE: June 30, ’93

PAGE: 6 o f 6

3. The ST21 installation

When the ST21 (fixed bin type sorter stapler) is installed, an additional coo ling fan is

required to be installed on the duplex unit to prevent paper jams or wet marks due to

evapo rat ed iso par in t he so r ter stap ler. This fan is us ed in th e FT400i dup lex un it ( P/N

AX650008, P/C Page 17 #13), and it is pr ovid ed as a service p art.

The installation proc edure is as follows:

1. Remove th e fron t [A] and r ear [ B ] c over s of t he du plex u nit. ( 2 and 4 scr ews)

2. Remove the lower cover [ C] . (8 screws)

3. Install the coo ling fan [D] . (2 screws and 1 co nnector)

4. Reassemble t he fro nt an d r ear c over s.

[B]

[A]

[D]

[C]

Loading...

Loading...