Page 1

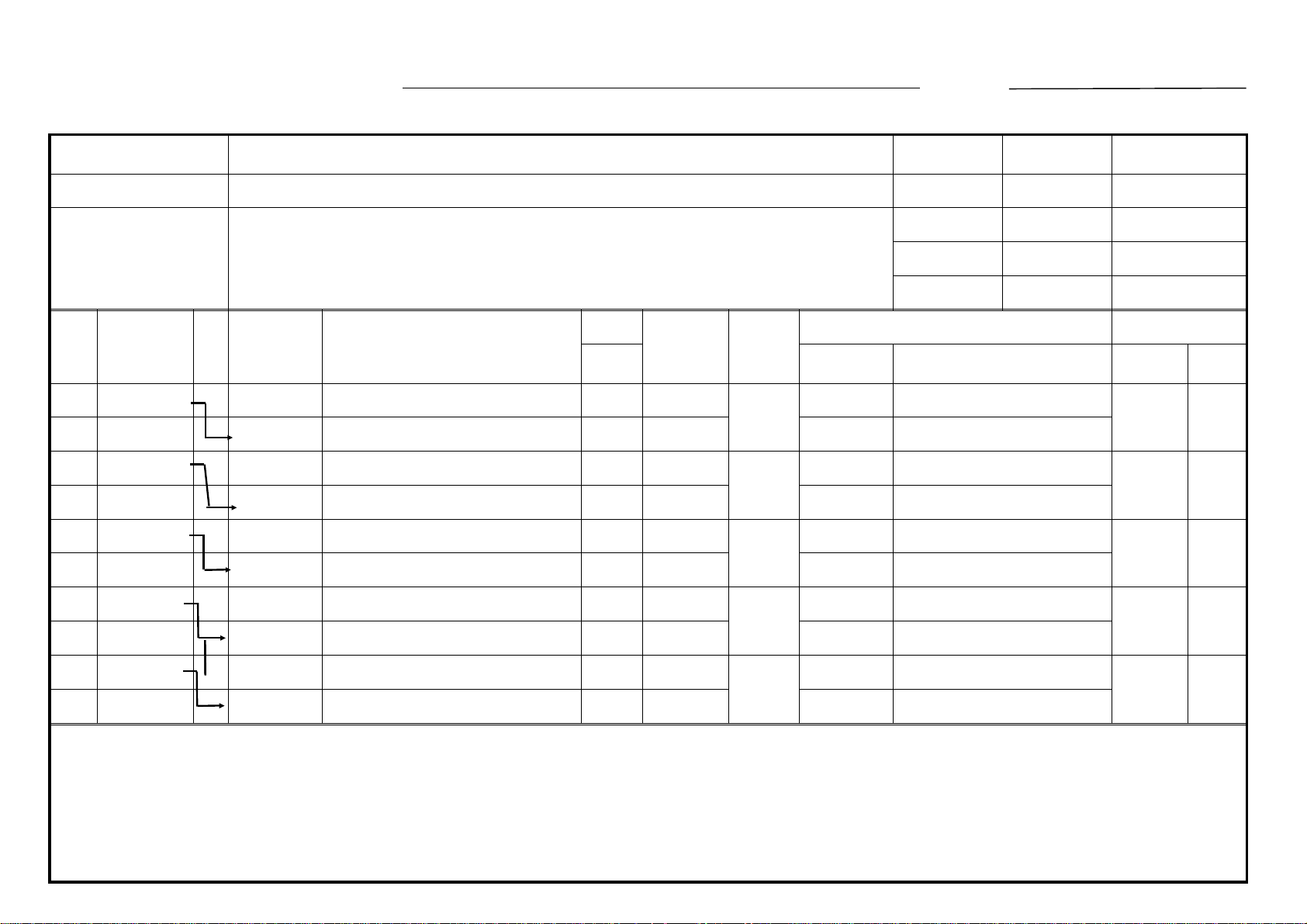

MODIFICATION BULLETIN NO. 9 Page 1 of 2 ISSUED ON: Nov. 15, ’90

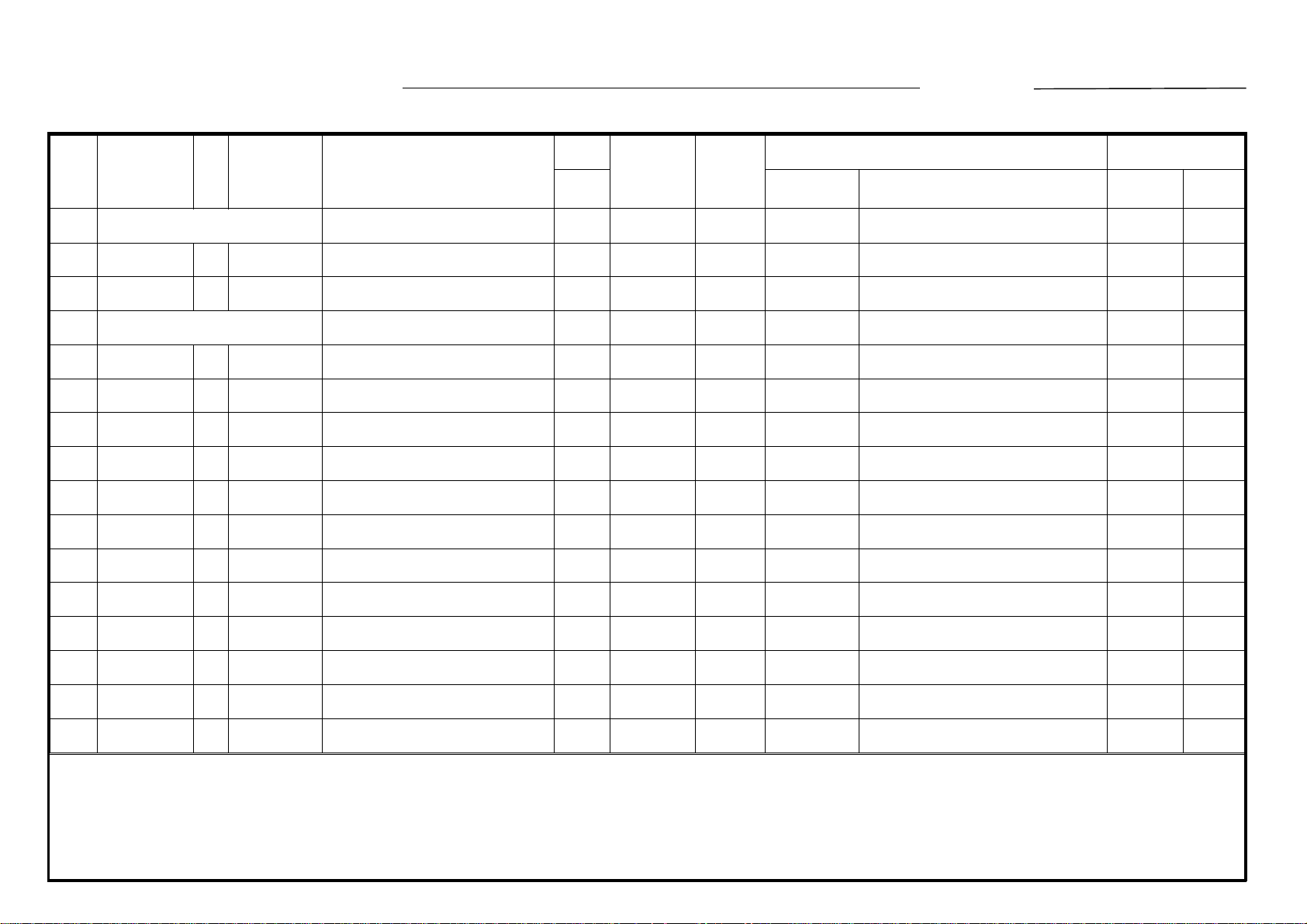

Model NC11 Volt/Hz

Modified Article Cable Guide Plate

Reason for

To ensure the smooth movement of the exposure lamp harness

Modification

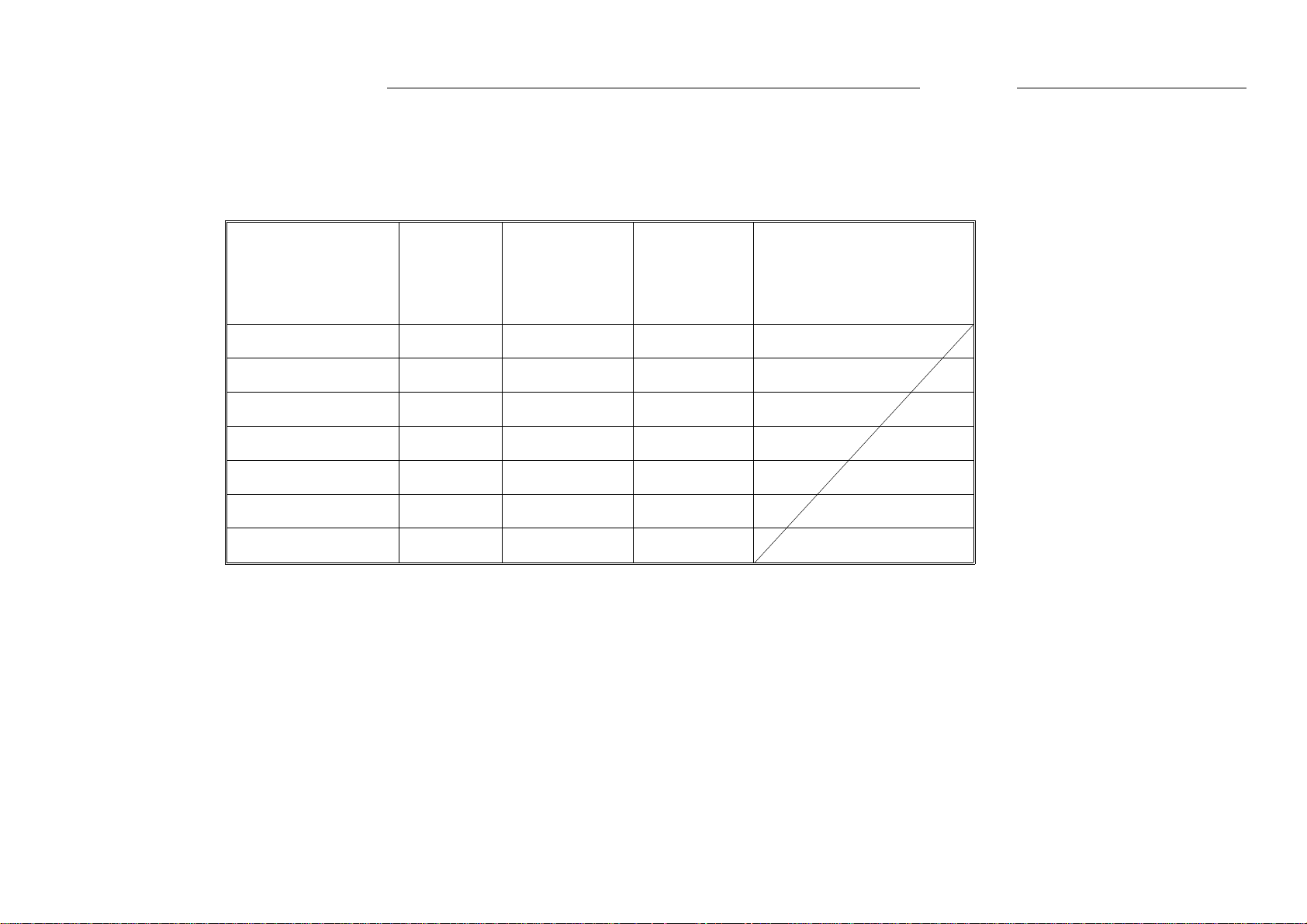

Old Parts No. New Parts No. Description Q’ty used

---- A0301697 Cable Guide Plate 0 ---- 1 #48 (New) 1 - 33

Parts Catalog Index

No.

#33

#24

Page

Date of

Modification

Serial Number

#102

P/C1-53

#104

#48

(New)

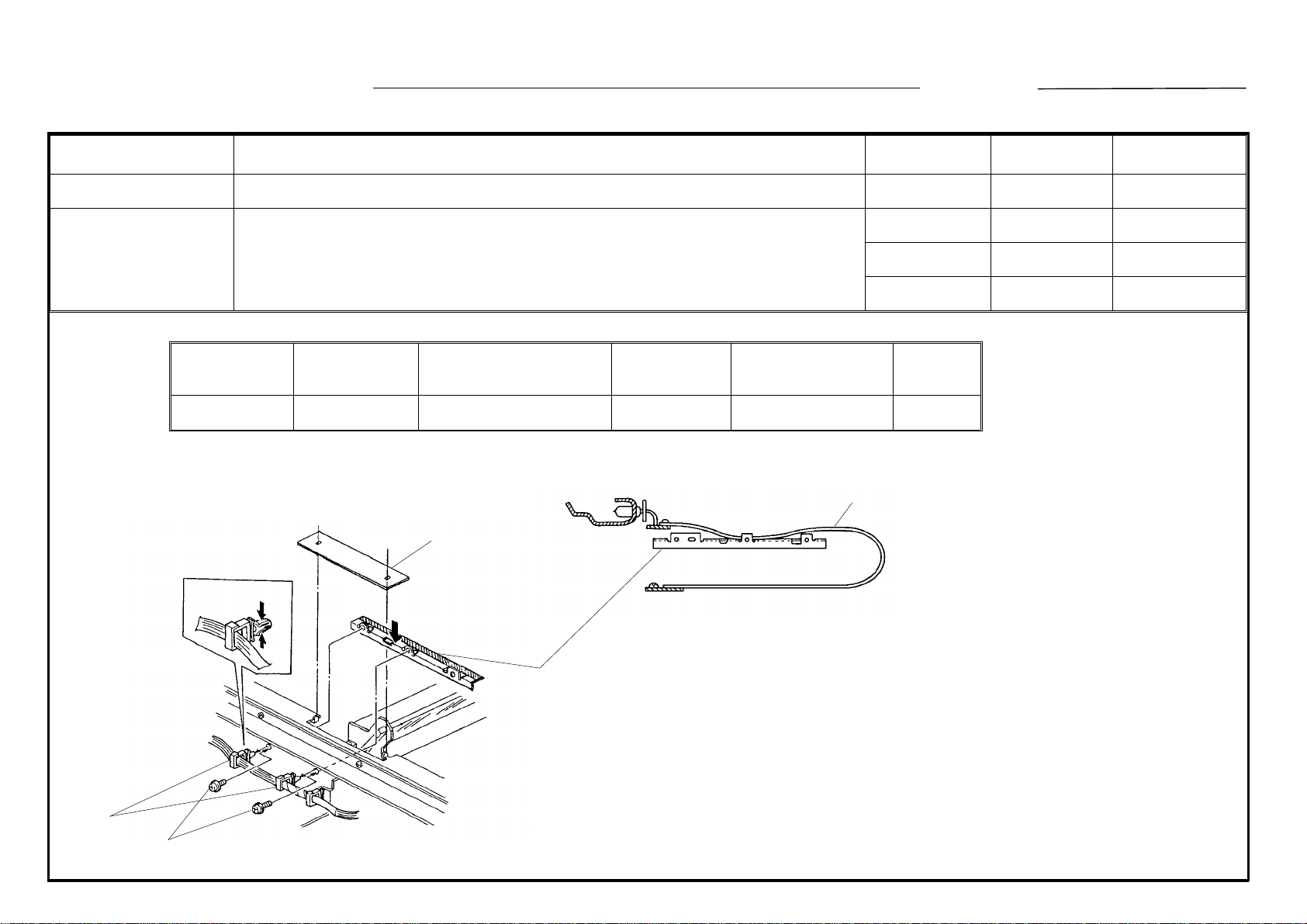

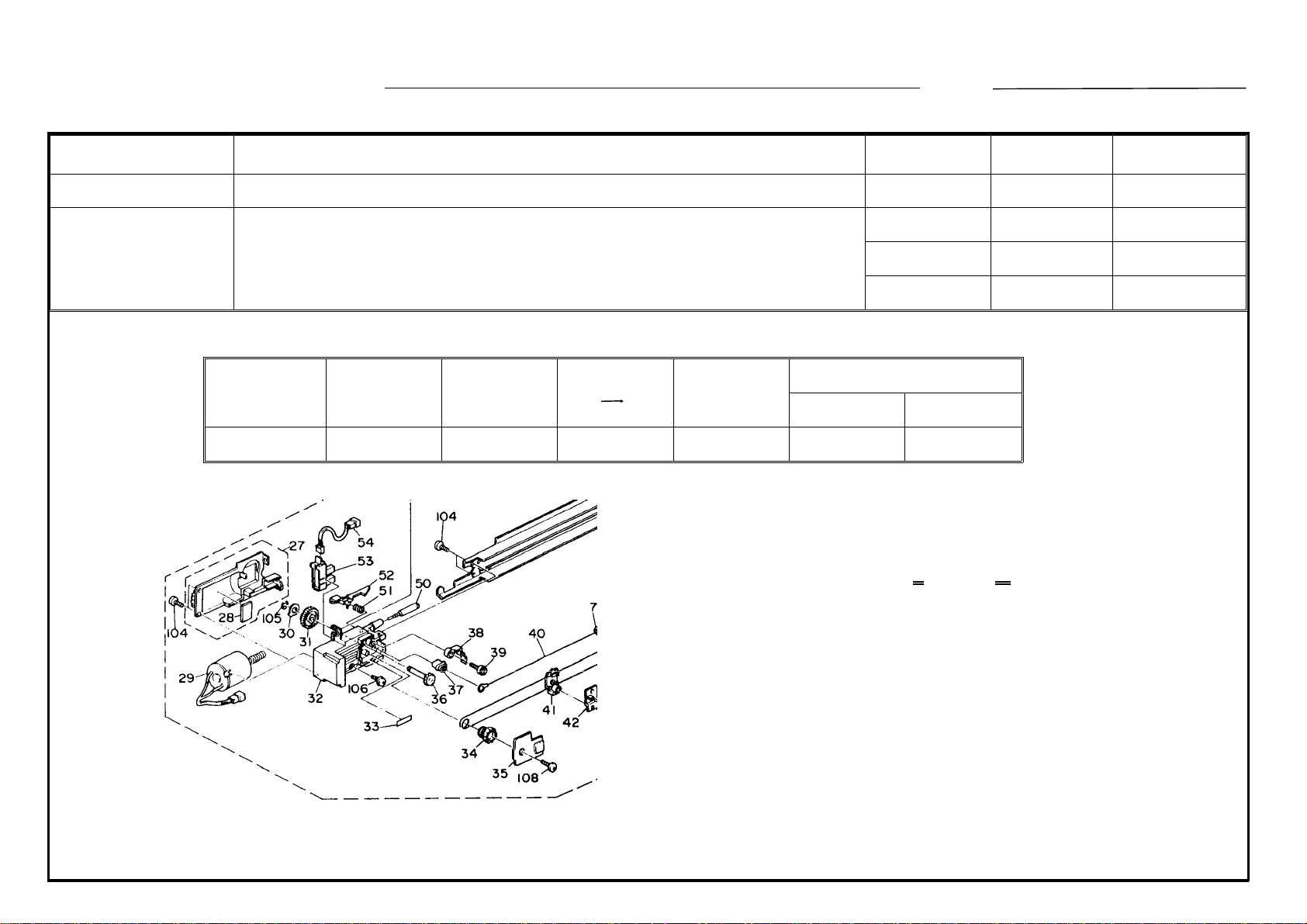

To ensure the smooth movement of the exposure lamp harness (#33), the

cable guide plate (#48, a new index) is newly installed on the front optics

frame as shown.

This plate is located under the lamp harness, and keeps it to be flat while

scanning.

T.Ito, Manager

Copier Technical Support

Page 2

MODIFICATION BULLETIN NO. 9 Page 2 of 2 ISSUED ON: Nov. 15, ’90

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186010XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 2520100001

RICOH NC100 110/60 TAIWAN A030 - 19 2520090144

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 1850090081

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 3910900051

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2520090459

RICOH NC100 220/50 ASIA A030 - 29 2520090478

V/Hz DESTINATION CODE SERIAL NUMBER

Page 3

Reissued on : February 28, ’91

MODIFICATION BULLETIN NO. 10 Page 1 of 3 ISSUED ON: November 30, ’90

Model NC11 Volt/Hz

Modified Article Paddle Roller

Reason for

To increase the duarability

Modification

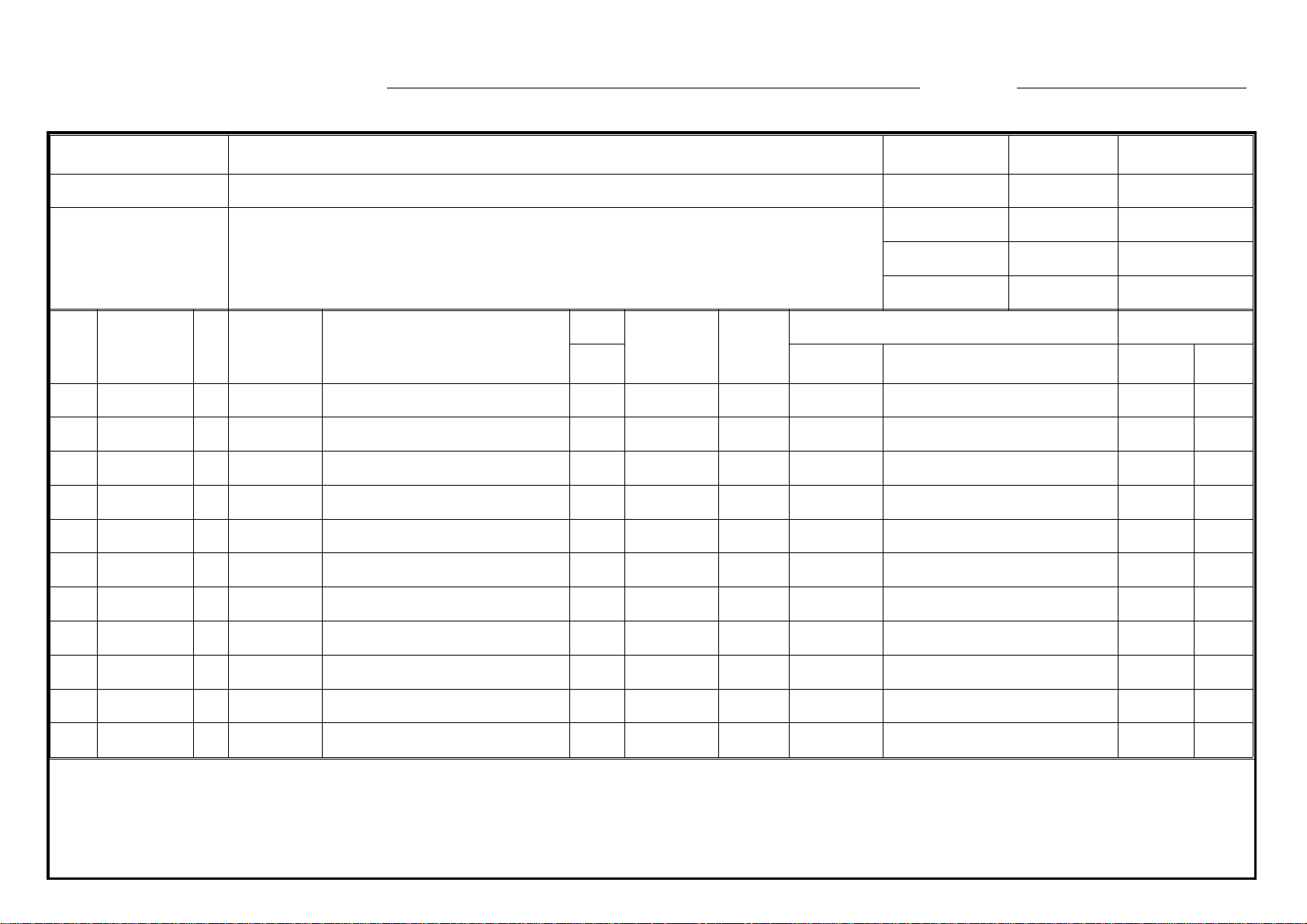

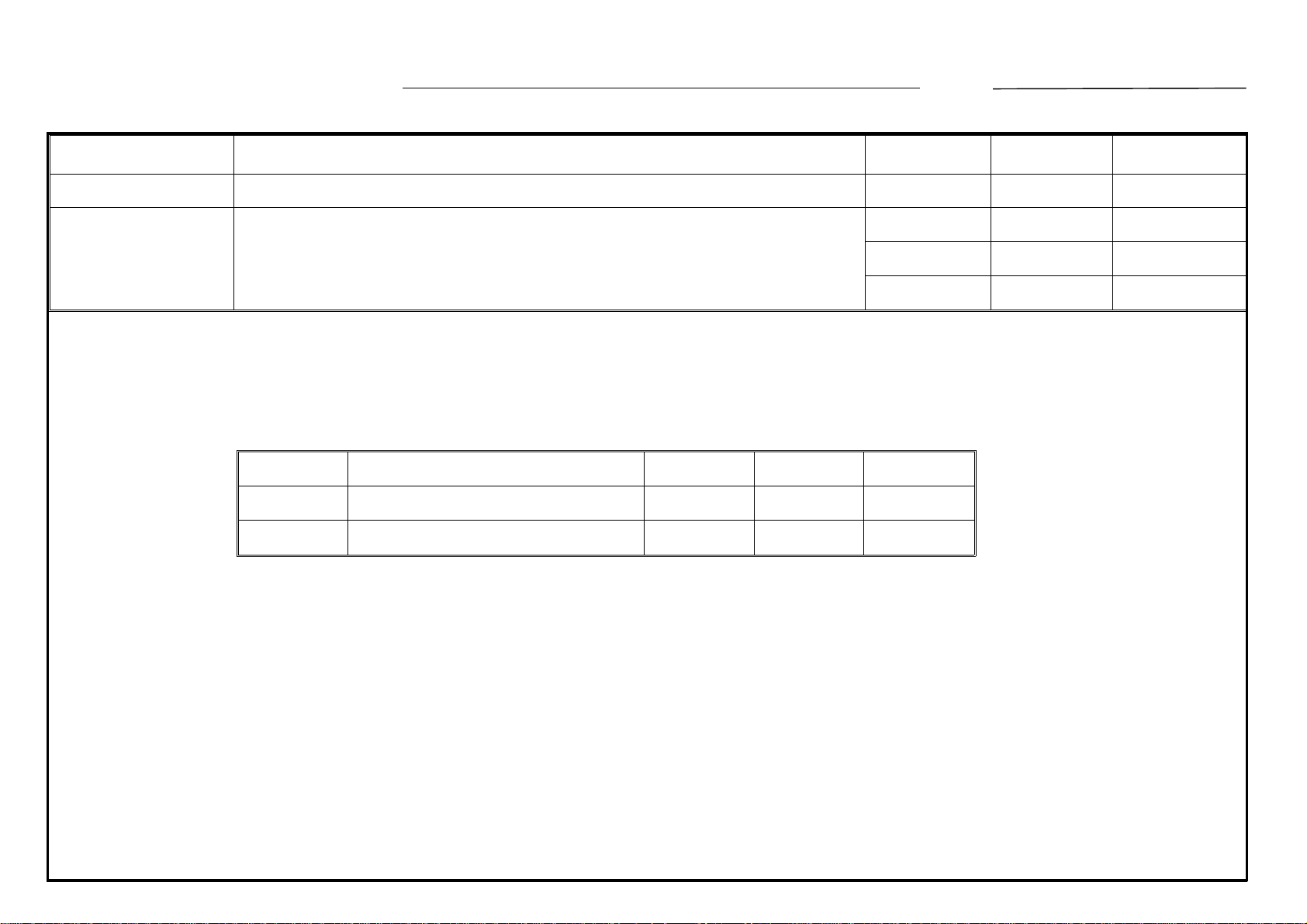

Draw

No.

Old

Parts No.

〈 Black Development Unit 〉

AD038012 AD038029 Paddle Roller 1 ---- 1 X/X 43 1 - 39

A0303065 A0303068 Rear Side Plate - Development 1 ---- 1 X/X 12 1 - 39

AB013253 AB013520 Gear - 44Z 1 ---- 1 X/O 17 1 - 39

New

Parts No.

AA152167 Rubber Bushing 10.5 x 16.5 x 5.5 0 ---- 1 *67 1 - 39

A0303071 Bearing Retainer - Paddle 0 ---- 1 X/O as a set *68 1 - 39

Description

Date of

Modification

A.B.C.

Rank Part No. Description Index No. Page

Q’ty Used

Old → New

Inter-

change-

ability

Part needed for replacement by new part Parts Catalog

Serial Number

07250120E Retaining Ring - M12 6 ---- 7 105 1 - 39

03130060W Philips Head Screw M3 x 6 4 ---- 6 104 1 - 39

〈 Color Development Unit 〉

AD038012 AD038029 Paddle Roller 3 ---- 3 X/X

AB013241 AB013519 Gear 40Z 3 ---- 3 X/O 18 1 - 43

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhall.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for replacement by new part" to

install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether the new part can be used

in the old machine. x = Not interchangeable o = Interchangeable

X/O as a set

* New Index

5 1 - 43

Page 4

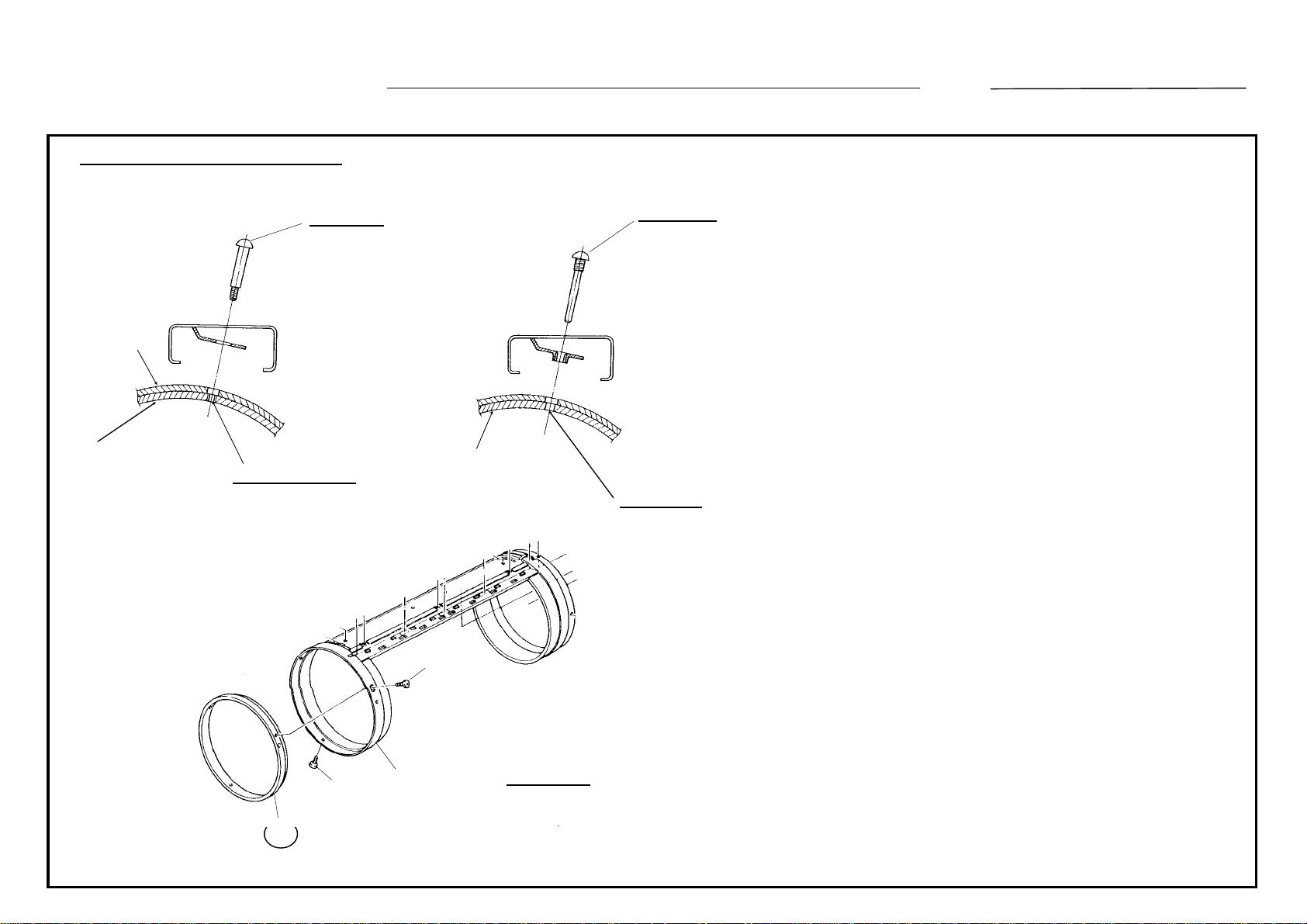

DETAILS OF MODIFICATION

#67 (New)

MODIFICATION BULLETIN NO. 10 Page 2 of 3 ISSUED ON: November 30, ’90

#105 (New)

#12

#104 (New)

#68 (New)

(#117)

(#105)

#17

Reissued on : February 28, ’91

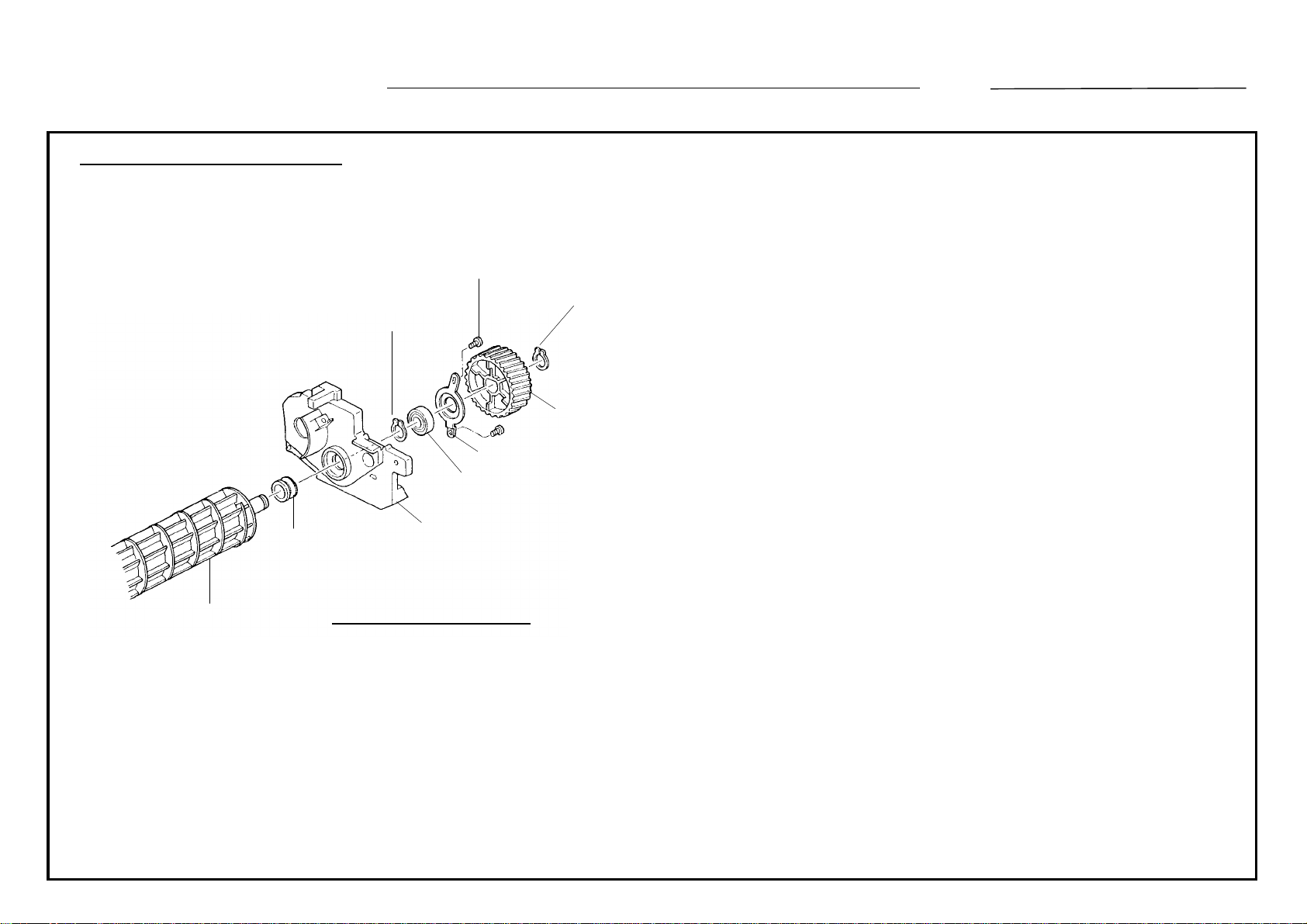

To increase the durability, the material and surface treatment of the front

and rear flanges on the paddle roller [#43] are changed.

[For the black development unit]

At the same time, the rubber bushing [#67] is newly installed on the rear

side to ensure the seal function. Due to these changes, the rear side

plate [#12] is also changed. A retaining ring (C-ring M12) [#105] and the

bearing retainer [#68] are added on the rear frange of the puddle roller.

To get the space for the bearing retainer, the width of the gear - 44Z

(#17) is changed from 15.5mm + 14.5mm.

Note : * The old paddle roller and the old rear side plate are still

available for the machines with the old parts.

* When either the old paddle roller or the old rear side plate in the

black development unit is replaced with a new type replace the

other five parts with new ones as a set.

#43

Black Development Unit

[For the color development unit]

Due to the new puddle roller, the gear - 40Z [#18] is also changed.

Note : When the old paddle roller in the color development unit

is replaced with the new type, replace the gear - 40Z with a new

type, too, as a set.

T. Ito, Manager

Copier Technical Support

Page 5

Reissued on : February 28, ’91

MODIFICATION BULLETIN NO. 10 Page 3 of 3 ISSUED ON: November 30, ’90

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186011XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252011XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 252011XXXX

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 185011XXXX

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 3911100001

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2520110001

RICOH NC100 220/50 ASIA A030 - 29 2520110136

V/Hz DESTINATION CODE SERIAL NUMBER

Page 6

MODIFICATION BULLETIN NO. 11 Page 1 of 3 ISSUED ON: November 30, ’90

Model NC11 Volt/Hz

Modified Article Transfer Drum Ring

Reason for

To accept a new shipping retainer stad

Modification

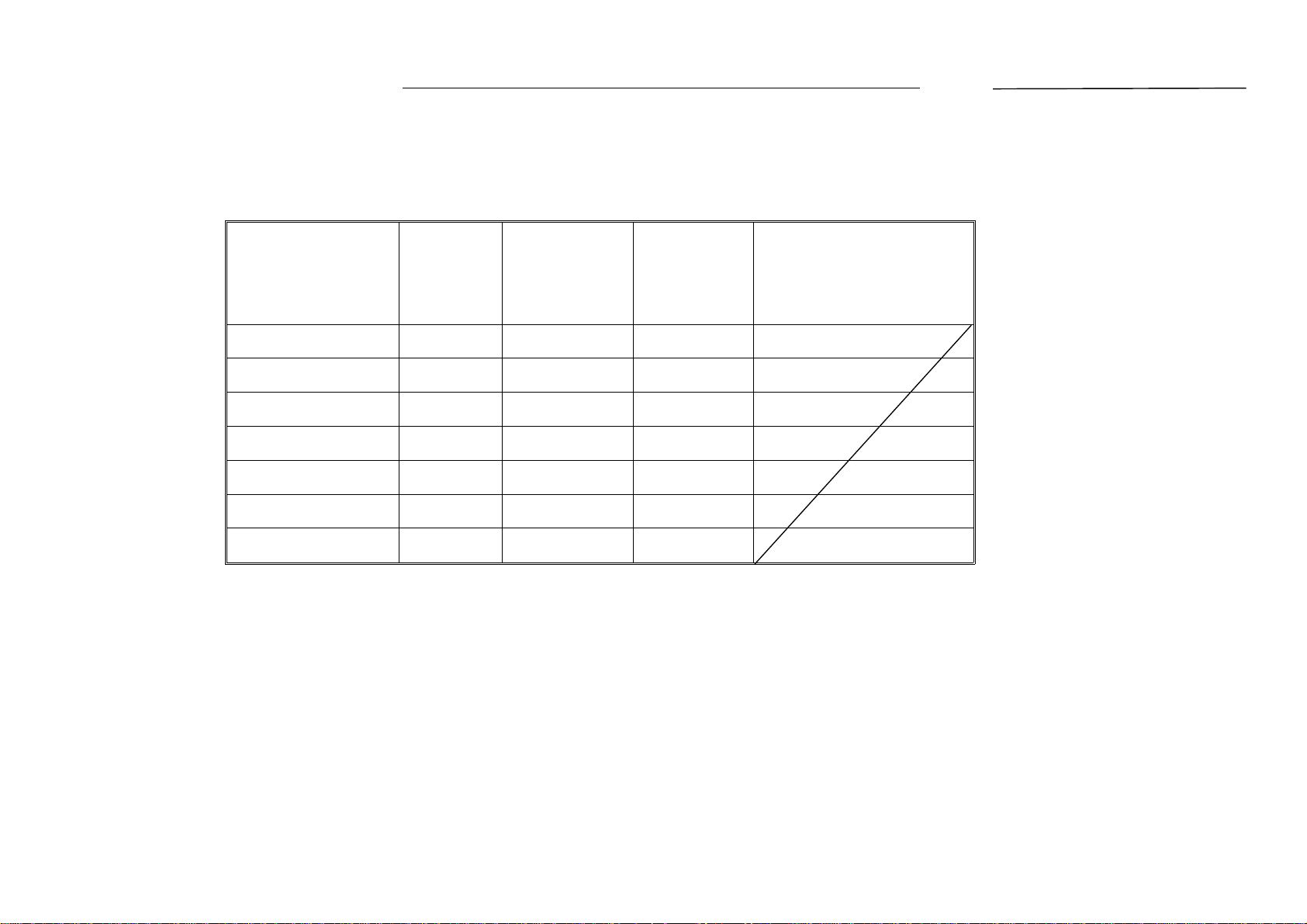

Draw

No.

Old

Parts No.

A0306066 A0306067 Transfer Drum Ring 1 ---- 1 O/O 9 1 - 23

New

Parts No.

Description

Date of

Modification

A.B.C.

Rank Part No. Description Index No. Page

Q’ty Used

Old → New

Inter-

change-

ability

Part needed for replacement by new part Parts Catalog

Serial Number

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhall.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for replacement by new part" to

install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether the new part can be used

in the old machine. x = Not interchangeable o = Interchangeable

Page 7

DETAILS OF MODIFICATION

MODIFICATION BULLETIN NO. 11 Page 2 of 3 ISSUED ON: November 30, ’90

#8

Old stad

M4 Screw hole

# 9

(New : A0306067)

103

New stad

5mm hole

The shipping retainer stad to prevent the transfer

drum from turning is changed.

For this change, the transfer drum ring (#8) is also

changed;

Old : The ring has a M4 screw hole to be fired with

the old stad.

New : It has a just 5mm hole where the new stad is

inserted.

Since this stad is removed at installation and is no

longer used afterwards, interchangeability of the ring

103

9

8

P/C 1 - 22

T. Ito, Manager

Copier Technical Support

Page 8

MODIFICATION BULLETIN NO. 11 Page 3 of 3 ISSUED ON: November 30, ’90

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186011XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252011XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 252011XXXX

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 185011XXXX

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 3911100001

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2520110001

RICOH NC100 220/50 ASIA A030 - 29 2520110136

V/Hz DESTINATION CODE SERIAL NUMBER

Page 9

MODIFICATION BULLETIN NO. 12 Page 1 of 1 ISSUED ON: November 30, ’90

Model NC11 Volt/Hz

Modified Article Hexagon Bolt

Reason for

Parts catalog correction

Modification

Old

Part No.

05840160B Hexagon Bolt - M4 x 16 (Front) 2 ---- 1 110 1 - 25

New

Part No.

05840180W Hexagon Bolt - M4 x 18 (Rear) 0 ---- 1 #124 1 - 25

Description

Q’ty used

Old New

Index No. Page

# New Index

In NC-11 parts catalog page 1 - 25 #110, two pieces of hexagon bolt - M4 x 16 (P/N 05840160B) are li sted.

The length of this bolt for the rear side is wrong. The correct one is P/N 05840180W (M4 x 18) for the rear side.

Parts Catalog

Date of

Modification

Serial Number

T. ito, Manager

Copier Technical Support

Page 10

MODIFICATION BULLETIN NO. 13 Page 1 of 2 ISSUED ON: November 30, ’90

Model NC11 Volt/Hz

Modified Article Screw for the front transfer corona endblock cover

Reason for

To prevent a crack on the front endblock

Modification

Old

Part No.

03130060W 09523008B Screw M3 x 8 1 ---- 1 X/O 108 1 - 21

New

Part No.

Description

Q’ty used

Old New

Interchange-

ability

Parts Catalog

Index No. Page

To prevent a crack on the front endblock (#32), a screw

(#108) is changed from M3 x 6 to M3 x 8.

Date of

Modification

Serial Number

Page 11

MODIFICATION BULLETIN NO. 13 Page 2 of 2 ISSUED ON: November 30, ’90

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 1860070001

RICOH NC100 115/60 USA, CANADA A030 - 17 2520070001

RICOH NC100 110/60 TAIWAN A030 - 19 2520070261

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 1850070001

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 3910700001

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2520070296

RICOH NC100 220/50 ASIA A030 - 29 252007XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 12

MODIFICATION BULLETIN NO. 14 Page 1 of 3 ISSUED ON: Nov.30, ’90

Model NC11 Volt/Hz

Modified Article Pressure Roller

Reason for

Due to vendor change

Modification

Draw

No.

Old Parts

No.

A0304231 AE020013 Pressure Roller 1 ---- 1 O/O 76 1 - 47

New Parts

No.

Description

Date of

Modification

A.B.C.

Rank Part No. Description Index No. Page

Q’ty Used

Old → New

Inter-

change-

ability

Part needed for replacement by new part Parts Catalog

Serial Number

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhall.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for replacement by new part" to

install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether the new part can be used

in the old machine. x = Not interchangeable o = Interchangeable

Page 13

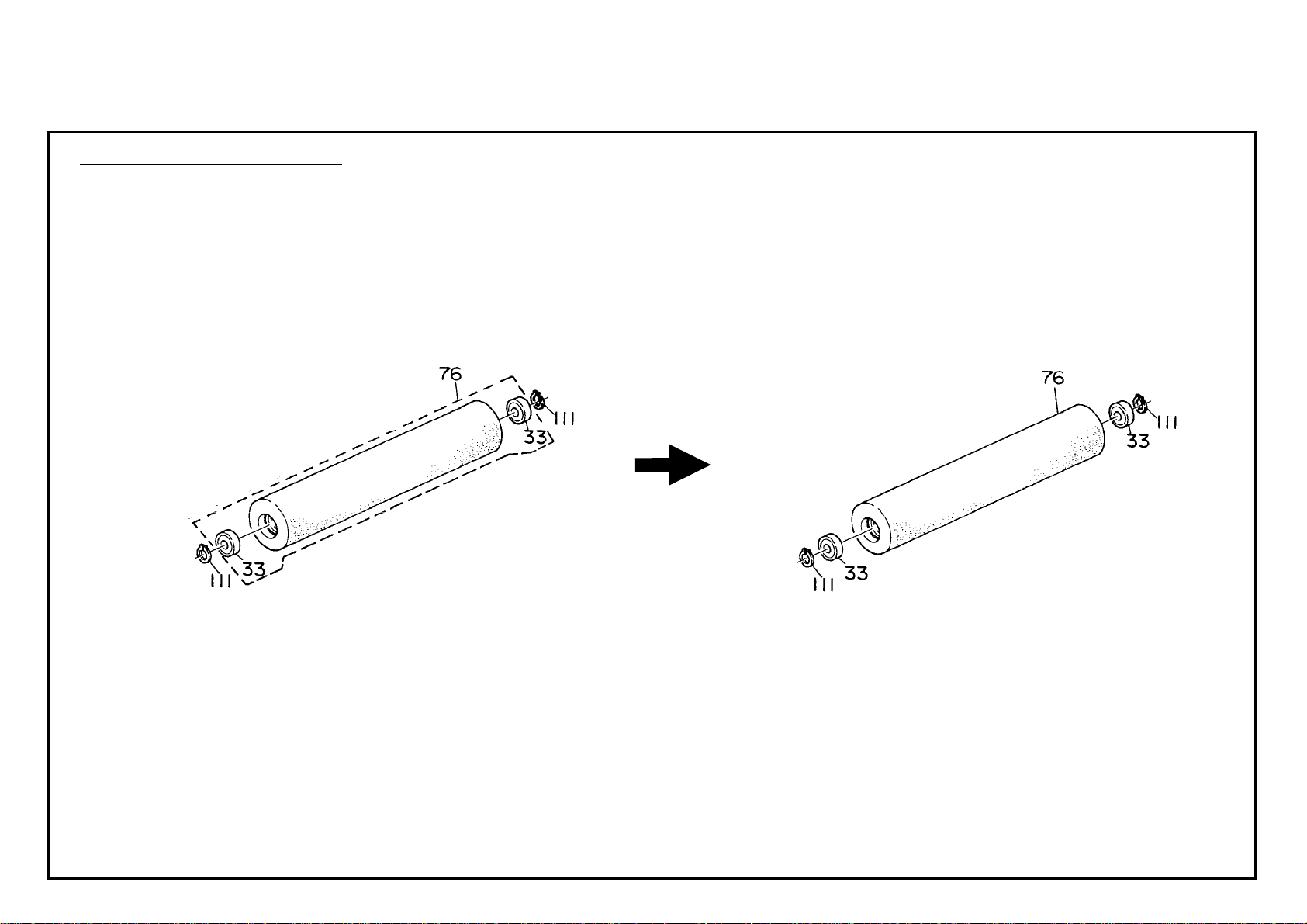

DETAILS OF MODIFICATION

Please correct your parts catalog as follows:

MODIFICATION BULLETIN NO. 14 Page 2 of 3 ISSUED ON: Nov.30, ’90

Incorrect Illustration

In addition, the part number of the pressure roller has been changed due to vendor change.

Correct Illustration

T. Ito, Manager

Copier Technical Support

Page 14

MODIFICATION BULLETIN NO. 14 Page 3 of 3 ISSUED ON: Nov.30, ’90

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 15

MODIFICATION BULLETIN NO. 15 Page 1 of 2 ISSUED ON: December 15, ’90

Model NC11 Volt/Hz

Modified Article Thermofuse

Reason for

As per field’s request

Modification

As per field request, the thermofuse on the exposure lamp unit has been registered as a

service part.

Part No. Description Q’ty Index No. Page

A0305379 Thermofuse - 128°C 1 * 49 1 - 33

09503005M Philips Screw with Lock Washer - M3 x 5 n + 2 * 115 1 - 33

* New Index No.

Date of

Modification

Serial Number

T. Ito, Manager

Copier Technical Support

Page 16

MODIFICATION BULLETIN NO. 15 Page 2 of 2 ISSUED ON: December 15, ’90

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 17

MODIFICATION BULLETIN NO. 16 Page 1 of 3 ISSUED ON: December 15, ’90

Model NC11 Volt/Hz

Modified Article Toner Collection Bottle

Reason for

To provide instructions on the handling of the toner collection bottle

Modification

Draw

No.

Old Parts

No.

A0309505 A0309509 Toner Collection Bottle 1 - 1 X/O 32 1-51

New Parts

No.

AA000059 Caution Decal - English 0 - 1 *48 15

AA000060 Caution Decal - 4 Languages 0 - 1 *48 15

Description

Date of

Modification

A.B.C. Q’ty Used

Old →

Rank Part No. Description Index No. Page

New

Inter-

change-

ability

Part needed for replacement by new part Parts Catalog

* : New Index

Serial Number

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhall.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for replacement by new part" to

install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether the new part can be used

in the old machine. x = Not interchangeable o = Interchangeable

Page 18

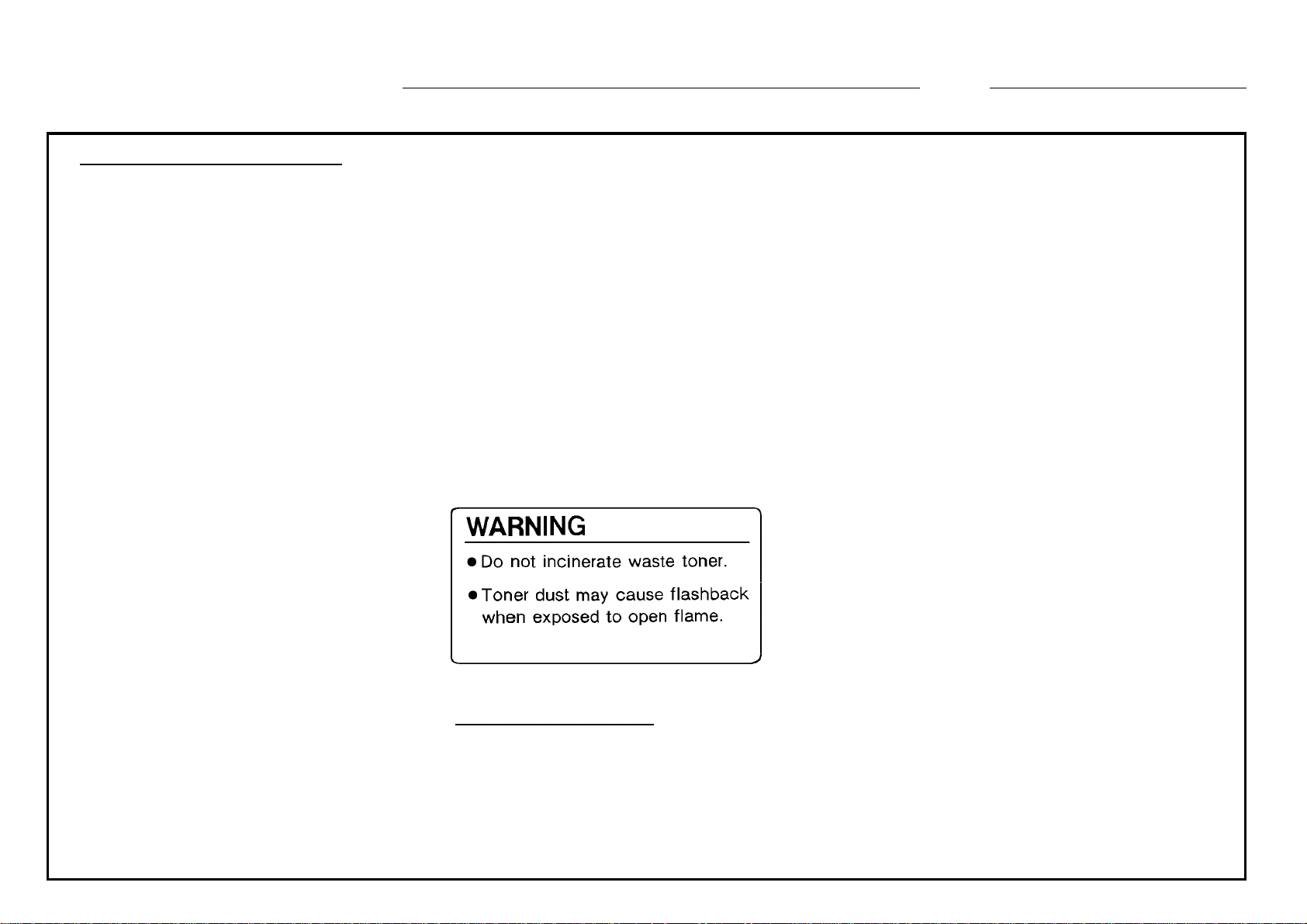

DETAILS OF MODIFICATION

The decal shown below has been applied to the toner collection bottle to instruct customer

engineers on proper handling. Also, a 4 language decal set (German, French, Italian, and

Spanish) have been added to the new part to replace the English decal as occasion calls.

MODIFICATION BULLETIN NO. 16 Page 2 of 3 ISSUED ON: December 15, ’90

Caution Decal - English

T . Ito, Manager

Copier Technical Support

Page 19

MODIFICATION BULLETIN NO. 16 Page 3 of 3 ISSUED ON: December 15, ’90

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186012XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 2520090001

RICOH NC100 110/60 TAIWAN A030 - 19 2520090144

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 1850080001

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 3910900001

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2520090149

RICOH NC100 220/50 ASIA A030 - 29 2520090478

V/Hz DESTINATION CODE SERIAL NUMBER

Page 20

MODIFICATION BULLETIN NO. 17 Page 1 of 4 ISSUED ON: Jan. 31, ’91

Model NC - 11 Volt/Hz

Modified Article Motor PCB, Process PCB, Charge Power Pack etc.

Reason for

Modification

Draw

No.

Old Parts

No.

[--25, --26, and --27]

1 A0305118 A0305613 Motor PCB - Europe 1 → 1 X/O 6 1-55

1 A0305184 A0305617 Process PCB - Europe 1 → 1 X/O 2 1-55

2 A0305897 Shielding Plate 1 → 0 (See NC - 11 M/B No.2) 37 1-55

3 A0305430 A0305425 Motor Control Harness 1 → 1 X/O 13 1-53

3 AZ320028 AZ320054 Charge Power Pack - Europe 1 → 1 X/O 12 1-55

To increase the tolerance for EMI (VDE) standard.

(Only for model codes: --25, --26, and --27)

New Parts

No.

Description

A.B.C. Q’ty Used

Old →

Rank Part No. Description Index No. Page

New

Inter-

change-

ability

Part needed for replacement by new part Parts Catalog

Date of

Modification

Serial Number

[--25 only]

4 A0307474 A0307471 Rear Cover Ass’y - Nashua 1 → 1 O/X 54 1-3

4 A0307475 A0307472 Rear Cover - Nashua 1 → 1 O/X (See NC - 11 M/B No.1, Page 2)) 37 1-3

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhall.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for replacement by new part" to

install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether the new part can be used

in the old machine. x = Not interchangeable o = Interchangeable

Page 21

MODIFICATION BULLETIN NO. 17 Page 2 of 4 ISSUED ON: Jan. 31, ’91

Draw

No.

Old Parts

No.

[--26 only]

4 A0307671 A0307674 Rear Cover Ass’y - Infotec 1 → 1 O/X 54 1-3

4 A0307675 A0307672 Rear Cover - Infotec 1 → 1 O/X (See NC - 11 M/B No.1, Page 2) 37 1-3

[--27 only]

4 A0301303 A0301301 Rear Cover Ass’y - Ricoh 1 → 1 O/X 54 1-3

4 A0301304 A0301306 Rear Cover - Ricoh 1 → 1 O/X (See NC - 11 M/B No.1, Page 2) 37 1-3

New Parts

No.

Description

A.B.C. Q’ty Used

Old →

Rank Part No. Description Index No. Page

New

Inter-

change-

ability

Part needed for replacement by new part Parts Catalog

Page 22

DETAILS OF MODIFICATION

To increase the tolerance of electrolytic intensity for EMI (VDE) standard, the following modificati on has been

applied to European models such as --25, 26, and --27. (There is no change for other models.)

1. Motor PCB and Process PCB

The printed circuit pattern on these PCB’s is changed from single layer to multi-layer.

2. Shielding plate

The shielding plate used in European models is eliminated.

3. Motor control harness and change power pack

A ferrite core is added to:

1) the high voltage cable for PCC on the charge power pack

2) the motor control harness inbetween the main PCB and the 3 servo PCB.

MODIFICATION BULLETIN NO. 17 Page 3 of 4 ISSUED ON: Jan. 31, ’91

4. Rear Cover

The conductive painting layer inside the rear cover is elminated. As a result, the rear cover used in 115V models

is commonly used for European models, too.

T. Ito, Manager

Copier Technical Support

Page 23

MODIFICATION BULLETIN NO. 17 Page 4 of 4 ISSUED ON: Jan. 31, ’91

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 185101XXXX

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 39101XXXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2520120179

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 24

MODIFICATION BULLETIN NO. 18 Page 1 of 1 ISSUED ON: Jan. 31, ’91

Model NC11 Volt/Hz

Modified Article Diode on the DC main harness

Reason for

Discontinuation of the old diode

Modification

Old P/N New P/N Q’ty Used Interchangeability P/C

14020423 (Diode S 5500G) 14021035 (Diode S 5688G) 1 → 1 O/O

Due to discontinuation of an old part, a new part is registered.

Date of

Modification

Page 1 - 69 #184

(See M/B No.1, Page 8)

Serial Number

T. Ito, Manager

Copier Technical Support

Page 25

MODIFICATION BULLETIN NO. 19 Page 1 of 5 ISSUED ON: July 15, ’91

Model NC - 11 Volt/Hz

Modified Article Ozone Filter

Reason for

Modification

Draw

No.

Old Parts

No.

1 AA010037 Ozone Filter - Fusing Exhaust Fan 1 → 0

2 AA010038 Ozone Filter - Transfer Exhaust Fan 1 → 0

3 AA010039 Ozone Filter - Development 2 → 0

1. Thickness change requested by vendor

2. Set parts number registration

New Parts

No.

AA010055 Ozone Filter - Fusing Exhaust Fan 0 → 2

AA010056 Ozone Filter - Transfer Exhaust Fan 0 → 2

AA010057 Ozone Filter - Development 0 → 3

Description

A.B.C.

Rank Part No. Description Index No. Page

Q’ty Used

Old → New

Date of

Modification

Inter-

change-

ability

O/O 38 1 - 3

O/O 33 1 - 3

O/O 11 1 - 57

Part needed for replacement by new part Parts Catalog

Serial Number

4 AA010055 Ozone Filter - Fusing Exhaust Fan 2 → 0

A0309517 Fusing Ozone Filter Set 0 → 1

5 AA010056 Ozone Filter - Transfer Exhaust Fan 2 → 0

A0309518 Transfer Ozone Filter Set 0 → 1

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for replacement by new part" to

install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether the new part can be used

in the old machine. x = Not interchangeable o = Interchangeable

O/O 38 1 - 3

O/O 33 1 - 3

Page 26

MODIFICATION BULLETIN NO. 19 Page 2 of 5 ISSUED ON: July 15, ’91

Draw

No.

Old Parts

No.

6 AA010057 Ozone Filter - Development 3 → 0

New Parts

No.

A0309519 Development Ozone Filter Set 0 → 1

Description

A.B.C.

Rank Part No. Description Index No. Page

Q’ty Used

Old → New

Inter-

change-

ability

O/O 11 1 - 57

Part needed for replacement by new part Parts Catalog

Page 27

DETAILS OF MODIFICATION

MODIFICATION BULLETIN NO. 19 Page 3 of 5 ISSUED ON: July 15, ’91

t = thickness

(Item No. 1 and 4)

Ozone filter for

fusing exhaust fan

(Item No. 2 and 5)

Ozone filter for

transfer exhaust

fan

(Item No. 3 and 6)

Ozone filter for

development

Note Don’t use these numbers for ordering

1. Item No. 1, 2 and 3

Due to the request from these parts vendor, the thickness of each

ozone filter has been changed. So, the necessary number of new

filters per machine has also been changed.

P/N AA010037

t = 30mm

1pce/machine

P/N AA010038

t = 30mm

1 pce/machine

P/N AA010039

t = 25mm

2 pcs/machine

O/O

O/O

O/O

(P/N AA010055)

2 pcs/machine

(P/N AA010056)

2 pcs/machine

(P/N AA010057)

t = 16.7mm

3 pcs/machine

2. Item No. 4, 5 and 6

Due to the parts number change explained at left, the necessary

number of filters per machine is packed and is registered as a set part

number.

P/N A0309517

P/N AA010055 x 2pcs/set

1 set/machine

P/N A0309518

P/N AA010056 x 2pcs/set

1 set/machine

P/N A0309519

P/N AA010057 x 3pcs/set

1 set/machine

t = 15mm

t = 15mm

O/O

O/O

O/O

Page 28

MODIFICATION BULLETIN NO. 19 Page 4 of 5 ISSUED ON: July 15, ’91

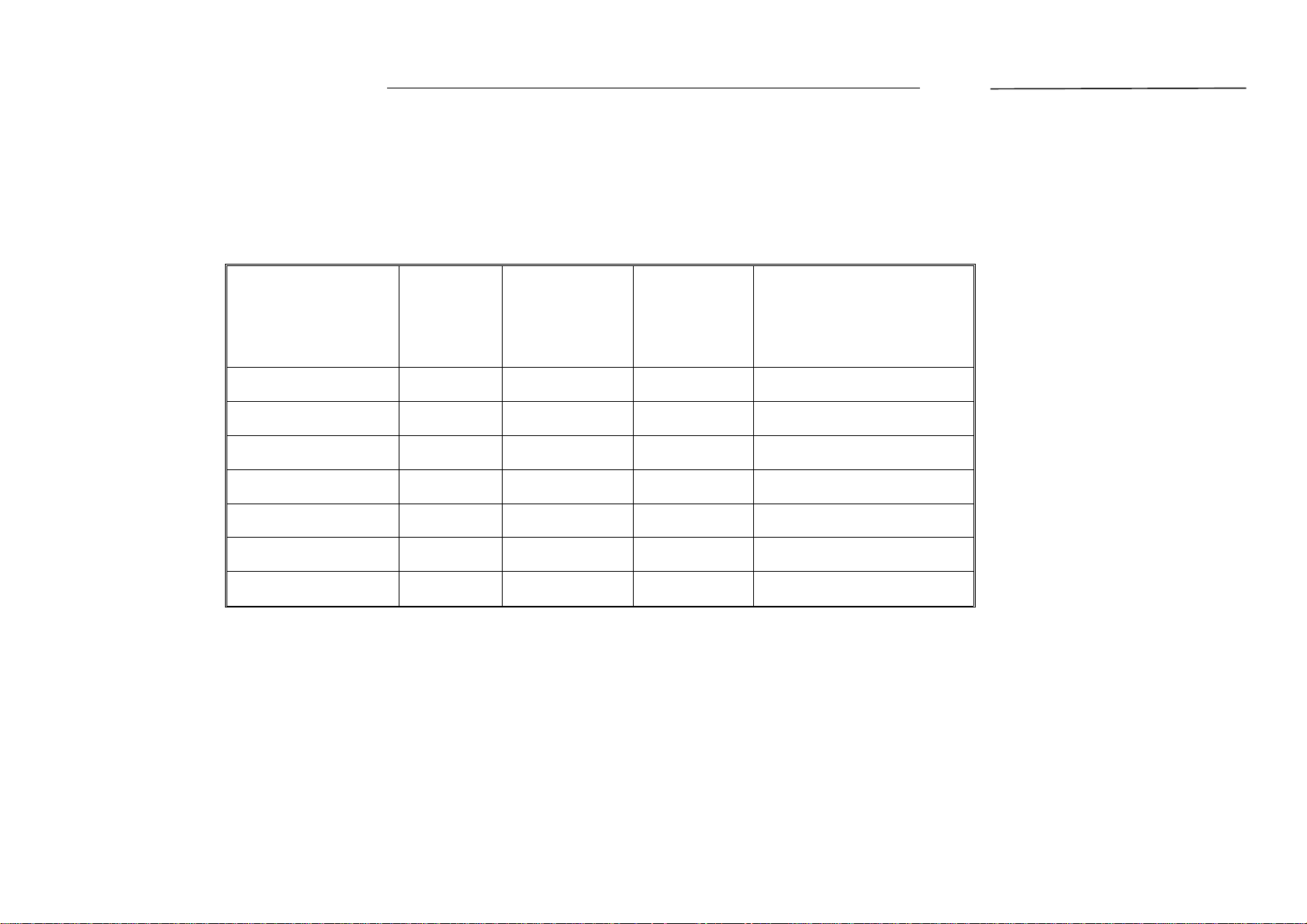

DETAILS OF MODIFICATION

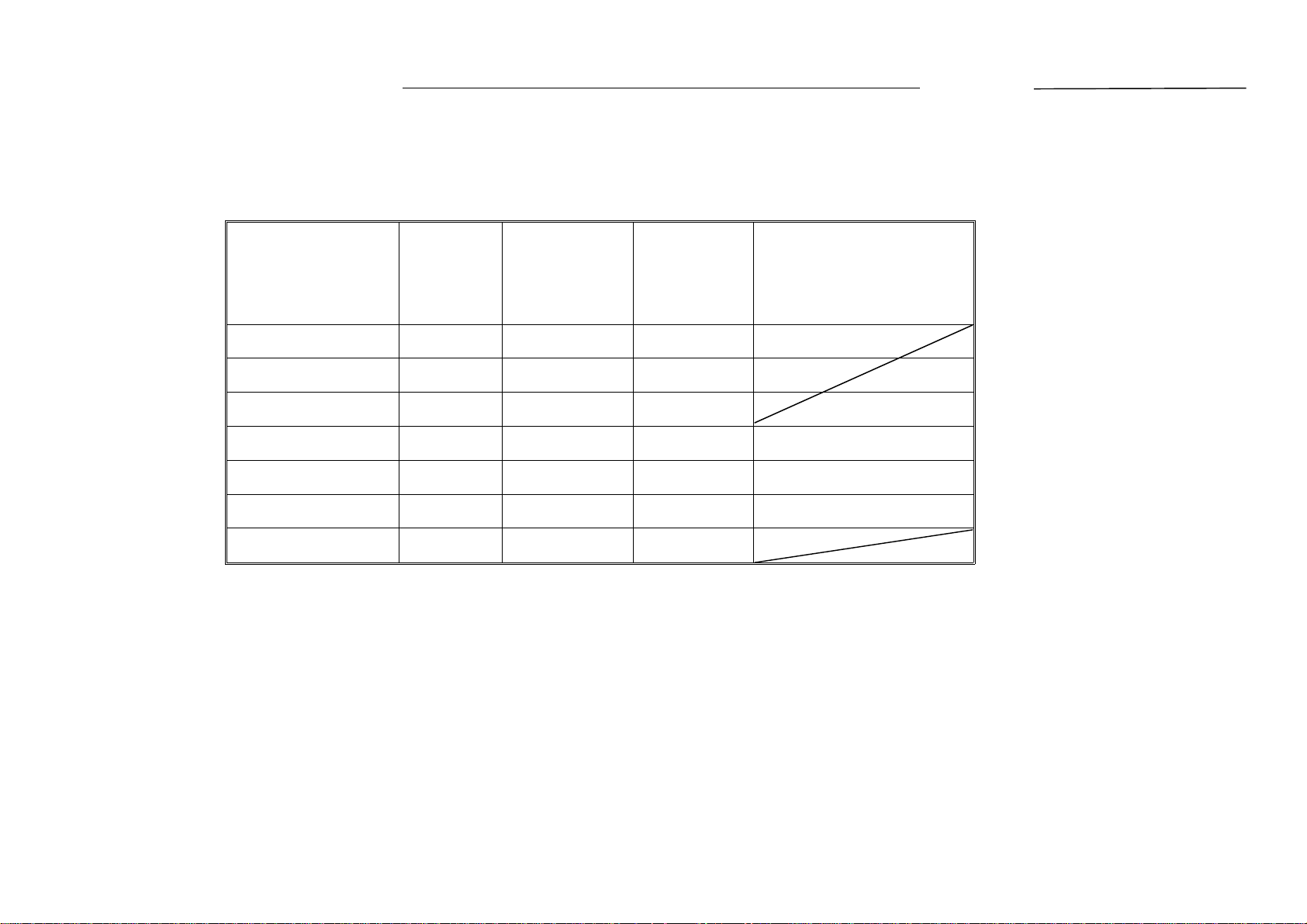

Parts modification history for ozone filters

Ozone filters for NC11 have been changed two or three times. For your reference, the following is t he modification history: For your reference:

Ozone Filter - Fusing

Exhaust Fan

Ozone Filter - Transfer

Exhaust Fan

Ozone Filter - Development

Ozone Filter - Optics

P/N listed in the parts

catalog

P/N AA010029

t = 30mm

1pce/machine

P/N AA010030

t = 30mm

1pce/machine

P/N AA010031

t = 50mm

1 pce/machine

P/N AA010032

1pce/machine

O/O

M/B 1.

O/O

M/B 1.

O/O

M/B 1.

O/O

M/B 1.

M/B 1 : P/C correction

M/B 3 : Vendor change

1 2 (3)

AA010011

t = 30mm

1 pcs/machine

AA010012

t = 30mm

1 pce/machine

AA010016

t = 50mm

1pce/machine

AA010017

1pce/machine

O/O

M/B 3.

O/O

M/B 3.

O/O

M/B 3.

O/O

M/B 3.

AA010037

t = 30mm

1pce/machine

AA010038

t = 30mm

1pce/machine

AA010039 *

t = 25mm

2pcs/machine

AA010040

1pce/machine

O/O

M/B 19.

O/O

M/B 19.

O/O

M/B 19.

* : When using this part, please note that 2pcs are used for one machine.

(AA010055)

t = 15mm

2pcs/machine

(AA010056)

t = 15mm

2pcs/machine

(AA010057)

t = 16.7mm

3pcs/machine

O/O

M/B 19.

O/O

M/B 19.

O/O

M/B 19.

3

(Set Number)

A0309517

t = 15mm x 2pcs/set

1 set/machine

A0309518

t = 15mm x 2pcs/set

a set/machine

A0309519

t = 16.7mm x 3pcs/set

1set/machine

T. Ito, Manager

Copier Technical Support

Page 29

MODIFICATION BULLETIN NO. 19 Page 5 of 5 ISSUED ON: July 15, ’91

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186105XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252105XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 252105XXXX

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 1851040029

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 39105XXXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2521040001

RICOH NC100 220/50 ASIA A030 - 29 252105XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 30

MODIFICATION BULLETIN NO. 20 Page 1 of 4 ISSUED ON: July 15, ’91

Model NC11 Volt/Hz

Modified Article Drum Holder etc.

Reason for

To increase the strength of the rear side plate

Modification

Draw

No.

Old Parts

No.

A0302264 A0302267 Drum Holder 1 - 1 X/O 17 1 - 19

A0302266 A0302268 Rear Drum Bracket 1 - 1 X/X 21 1 - 19

A0303681 A0303683 Duct - Change Fan 1 - 1 X/X 14 1 - 51

New Parts

No.

A0301072 Support Plate 0 - 1 *27 1 - 57

04340080W Tapping Screw - M4x8 n → n+2 101 1 - 57

Description

Date of

Modification

A.B.C.

Rank Part No. Description Index No. Page

Q’ty Used

Old → New

Inter-

change-

ability

Part needed for replacement by new part Parts Catalog

* New Index No.

Serial Number

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for replacement by new part" to

install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether the new part can be used

in the old machine. x = Not interchangeable o = Interchangeable

Page 31

MODIFICATION BULLETIN NO. 20 Page 2 of 4 ISSUED ON: July 15, ’91

DETAILS OF MODIFICATION

To increase the strength of the rear side plate, the support plate [A] with two tapping screw - M4x8 [B] have been added

between the rear side plate [C] and the optics rear side plate [D]. These two rear side plates have been changed, but they are

not the service parts. To ensure correct mounting of the OPC drum motor, the shape of the hook and the screw hole of the rear

drum bracket have been changed. A similar change has been made on the drum holder shown next page.

Rear drum bracket

[D]

[A]

[C]

Front rear side view

[B]

Old

New

Page 32

MODIFICATION BULLETIN NO. 20 Page 3 of 4 ISSUED ON: July 15, ’91

DETAILS OF MODIFICATION

Due to this modification, the shape of the duct-charge fan has been changed as follows:

Duct - charge fan

Old

Old

New

Drum holder

81.72mm

Old

81.59mm

New

T. Ito, Manager

Copier Technical Support

Page 33

MODIFICATION BULLETIN NO. 20 Page 4 of 4 ISSUED ON: July 15, ’91

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186107XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 2521050001

RICOH NC100 110/60 TAIWAN A030 - 19 2521050003

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 1851040001

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 391071XXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2521040001

RICOH NC100 220/50 ASIA A030 - 29 252107XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 34

Reissued on : June 30, ’92

MODIFICATION BULLETIN NO. 21 Page 1 of 3 ISSUED ON: July 15, ’91

Model

Modified Article

Reason for

Modification

Draw

No.

Old Parts

A0305241 A0305246 Erase Lamp 1 - 1 O/O

A0302280 A0302275

No.

NC11

Drum Stay and Erase Lamp

To facilitate servicing

New Parts

No.

A0722101

09524006W

Drum Stay

Erase Lamp Holder

Screw - M4 x 6

Description

Volt/Hz

A.B.C.

Rank Part No. Description Index No. Page

Q’ty Used

Old → New

1 - 1 O/O 1 1-19

0 → 1 58 1-19

n → n+1 119 1-19

Inter-

change-

ability

Part needed for replacement by new part Parts Catalog

* See note

Date of

Modification

Serial Number

38 1-19

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for replacement by new part" to

install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether the new part can be used

in the old machine. x = Not interchangeable o = Interchangeable

Page 35

Reissued on : June 30, ’92

MODIFICATION BULLETIN NO. 21 Page 2 of 3 ISSUED ON: July 15, ’91

DETAILS OF MODIFICATION

To facilitate servicing, the shape of the drum stay and the erase lamp have been changed as shown in the figure below:

The erase lamp holder has been added to the new drum stay. With new drum stay and erase lamp holder it becomes possible to

remove the erase lamp by removing the erase lamp holder (1 screw). (With the old drum stay, it is n ecessary to remove the drum stay (3

screws) before removing the erase lamp.)

Drum Stay

Old

New

Erase Lamp

Old

Erase Lamp Holder

Note : For some combinations of old and new Erase Lamp and Drum Stay there are some notices.

Old Erase Lamp New Erase Lamp

Old Drum Stay No notice No notice

New Drum Stay

Erase Lamp Holder can not be installed due

to shape of erase lamp. Instead of installing

the holder, please be sure to confirm the

Erase Lamp being set securely.

The best way is to install Drum Stay with Erase Lamp

Holder (1 screw). If Erase Lamp Holder is not available

immediately, install only the Drum Stay. In this case, please

be sure to confirm the Erase Lamp being set securely.

New

T. Ito, Manager

Copier Technical Support

Page 36

Reissued on : June 30, ’92

MODIFICATION BULLETIN NO. 21 Page 3 of 3 ISSUED ON: July 15, ’91

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186107XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252107XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 252107XXXX

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 1851060001

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 391071XXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2521050046

RICOH NC100 220/50 ASIA A030 - 29 252107XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 37

Reissued on: December 15, ’91

2nd Reissued on: January 31, ’92

MODIFICATION BULLETIN NO. 22 Page 1 of 2 ISSUED ON: November 15, ’91

Model NC11 (Excluding Ricoh USA and Taiwan versions) Volt/Hz

Modified Article Fusing Cover

Reason for

Due to parts standardization with other model

Modification

Old P/N New P/N Q’ty Used Interchangeability

Index No. Page

A0304055 A0304060 1 → 1 O/O 3 1 - 47

Due to parts standardization with other model, the shape of the fusing cover has been changed as fol lows:

Parts Catalog

Date of

Modification

Serial Number

Old

New

T. Ito, Manager

Copier Technical Support

Page 38

Reissued on: December 15, ’91

2nd Reissued on: January 31, ’92

MODIFICATION BULLETIN NO. 22 Page 2 of 2 ISSUED ON: November 15, ’91

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 39

MODIFICATION BULLETIN NO. 23 Page 1 of 2 ISSUED ON: November 15, ’91

Model NC11 Volt/Hz

Modified Article 3 Service Control Board

Reason for

To increase reliability of 3 servomotor control board

Modification

Old P/N New P/N Q’ty Used Interchangeability

Index No. Page

A0305132 A0305133 1 → 1 O/O 11 1 - 53

To increase reliability (color alignment) of the 3 servomotor control board, the four electronic com ponent parts

(not service part ) on this board have been changed, The interchangeability code is O/O.

Parts Catalog

Date of

Modification

Serial Number

T. Ito, Manager

Copier Technical Support

Page 40

MODIFICATION BULLETIN NO. 23 Page 2 of 2 ISSUED ON: November 15, ’91

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 41

MODIFICATION BULLETIN NO. 24 Page 1 of 3 ISSUED ON: November 30, ’91

Model NC11 Volt/Hz

Modified Article 3 Servomotor Control Board

Reason for

To increase reliability of 3 servomotor control board

Modification

Draw

No.

Old Parts

No.

A0305133 A0305130 3 Servomotor Control Board 1 → 1 O/O 11 1 - 53

A0305136 EP ROM - 3 Servo Motors Board

New Parts

No.

A0305137 IC - TMM27256AD - 15 1 → 1 O/O 4 1 - 53

Description

Date of

Modification

A.B.C.

Rank Part No. Description Index No. Page

Q’ty Used

Old → New

Inter-

change-

ability

Part needed for replacement by new part Parts Catalog

Serial Number

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for replacement by new part" to

install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether the new part can be used

in the old machine. x = Not interchangeable o = Interchangeable

Page 42

DETAILS OF MODIFICATION

When the machine is in the stand by condition, the current is output constantly to the IC on the 3 s ervomotor

control board to keep the home position of the transfer drum, and the IC generates heat. (The funct ion of

this IC is driving the transfer drum.)

To improve IC’s durability, the software program has been changed. In the stand by condition, the c urrent

out put to the IC has been reduced to decrease heat at the IC.

MODIFICATION BULLETIN NO. 24 Page 2 of 3 ISSUED ON: November 30, ’91

T. Ito, Manager

Copier Technical Support

Page 43

MODIFICATION BULLETIN NO. 24 Page 3 of 3 ISSUED ON: November 30, ’91

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186110XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252110XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 2521090001

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 1851080004

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 391101XXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2521070001

RICOH NC100 220/50 ASIA A030 - 29 252110XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 44

MODIFICATION BULLETIN NO. 25 Page 1 of 4 ISSUED ON: January 31, ’92

Model NC11 Volt/Hz

Modified Article See below

Reason for

Due to parts standardization with other model

Modification

Date of

Modification

Due to parts standardization with other model, the following parts has been changed.

Old P/N New P/N Q’ty Interchangeability Description

AA140232 AA140419 1 O/O Shaft - Support Roller Bracket 27 41 All

AA145091 AA145160 1 O/O Shaft - Pick-off Lever 25 29 All

AA150187 AA151590 3 O/O Seal - 12 X95 43 17 All

AB013312 AB013523 1 O/O Gear - 32Z 17 8 All

AD031165 AD031218 1 O/O Development Roller - YELLOW 43 23 All

Parts Catalog

Destination

Index No. Page

Serial Number

AW230001 AW230005 1 O/O CYAN Toner Density Sensor 43 8 All

AW230002 AW230005 1 O/O MAGENTA Toner Density Sensor 43 12 All

AW230003 AW230005 1 O/O YELLOW Toner Density Sensor 43 25 All

A0301085 A0721085 1 O/O Bracket - Paper Feed Motor 17 2 All

A0301669 A0721671 1 O/O Scale Mounting Bracket 33 11 All

A0301674 A0721100 1 O/O Platen Cover Bracket - Left 33 25 All

A0301675 A0721837 1 O/O Platen Cover Bracket - Right 33 15 All

A0301831 A0721831 1 O/O Scanner Motor Bracket 33 17 All

A0301900 A0721841 1 O/O 2nd Scanner Slider 33 40 All

Page 45

MODIFICATION BULLETIN NO. 25 Page 2 of 4 ISSUED ON: January 31, ’92

Old P/N New P/N Q’ty Interchangeability Description

A0302630 A0722645 1 O/O

A0302671 A0722671 1 O/O Paper Feed Guide - Middle 17 49 All

A0302687 A0722667 1 O/O Paper Feed Guide - Lower 17 38 All

A0302701 A0722702 1 O/O Paper Relay Guide - Lower 17 53 All

A0302711 A0722611 2 O/O Paper Feed Stay 11 32 All

A0302855 A0722701 2 O/O Pick-up Guide 9 3 All

A0302921 A0722703 1 O/O Front Cassette Holder 9 40 Ricoh version only

A0302925 A0722706 1 O/O Rear Cassette Holder 9 2 Ricoh version only

A0303252 A0723252 1 O/O

A0303260 A0723260 1 O/O

A0303263 A0723263 3 O/O Spacer - Toner Density Sensor 43 7 All

A0303337 A0723337 3 O/O Adjuster - Development Roller 43 44 All

Registration Guide - 3rd Paper

Feed

Front Side Plate - Color

Development

Rear Side Plate - Color

Development

Parts Catalog

Destination

Index No. Page

15 25 All

43 42 All

43 22 All

A0303430 A0723430 1 O/O Connector Bracket - Color Dev. 51 39 All

A0304084 A0724084 1 O/O Entrance Guide Plate - Lower 47 53 All

A0304089 A0724089 1 O/O Right Fusing Rail 47 46 All

A0304090 A0724090 1 O/O Upper Frame 47 9 All

A0305889 A0721120 1 O/O Cooling Fan Bracket 53 20 All

A0306059 A0726059 1 O/O Mylar Seal - Transfer Drum 23 24 All

A0306104 A0726104 1 O/O Front Side Plate 25 60 All

A0306128 A0726128 1 O/O Shaft - Transfer Drum Stripper 25 4 All

Page 46

MODIFICATION BULLETIN NO. 25 Page 3 of 4 ISSUED ON: January 31, ’92

Old P/N New P/N Q’ty Interchangeability Description

A0306220 A0726220 1 O/O Bracket - Lock Release Lever 25 39 All

A0306227 A0726227 1 O/O Release Lever Link 25 79 All

A0304462 A0724462 1 O/O Upper Exit Guide 49 4 All

A0306399 A0726399 1 O/O Base Plate - T/D Cleaning 31 6 All

A0306433 A0726433 1 O/O

A0301694 A0721864 1 O/O Guide - Exposure Lamp Harness 33 36 All

A0306340 A0726340 1 O/O Rail - DC Discharge Unit 17 29 All

A0306345 A0726345 1 O/O Rail - AC Discharge Unit 17 30 All

A0082734 A0602950 1 O/O Large Cassette Cover 5 1 Ricoh version only

A0082737 A0602955 2 O/O Small Cassette Cover 5 1 Ricoh version only

52156436 52156674 2 O/O Small Cassette Cover 5 1 NSA/ Infotec version only

52156445 52156675 1 O/O Large Cassette Cover 5 1 NSA/ Infotec version only

Grounding Plate - Cleaning

Brush

Parts Catalog

Destination

Index No. Page

31 10 All

T. Ito, Manager

Copier Technical Support

Page 47

MODIFICATION BULLETIN NO. 25 Page 4 of 4 ISSUED ON: January 31, ’92

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 48

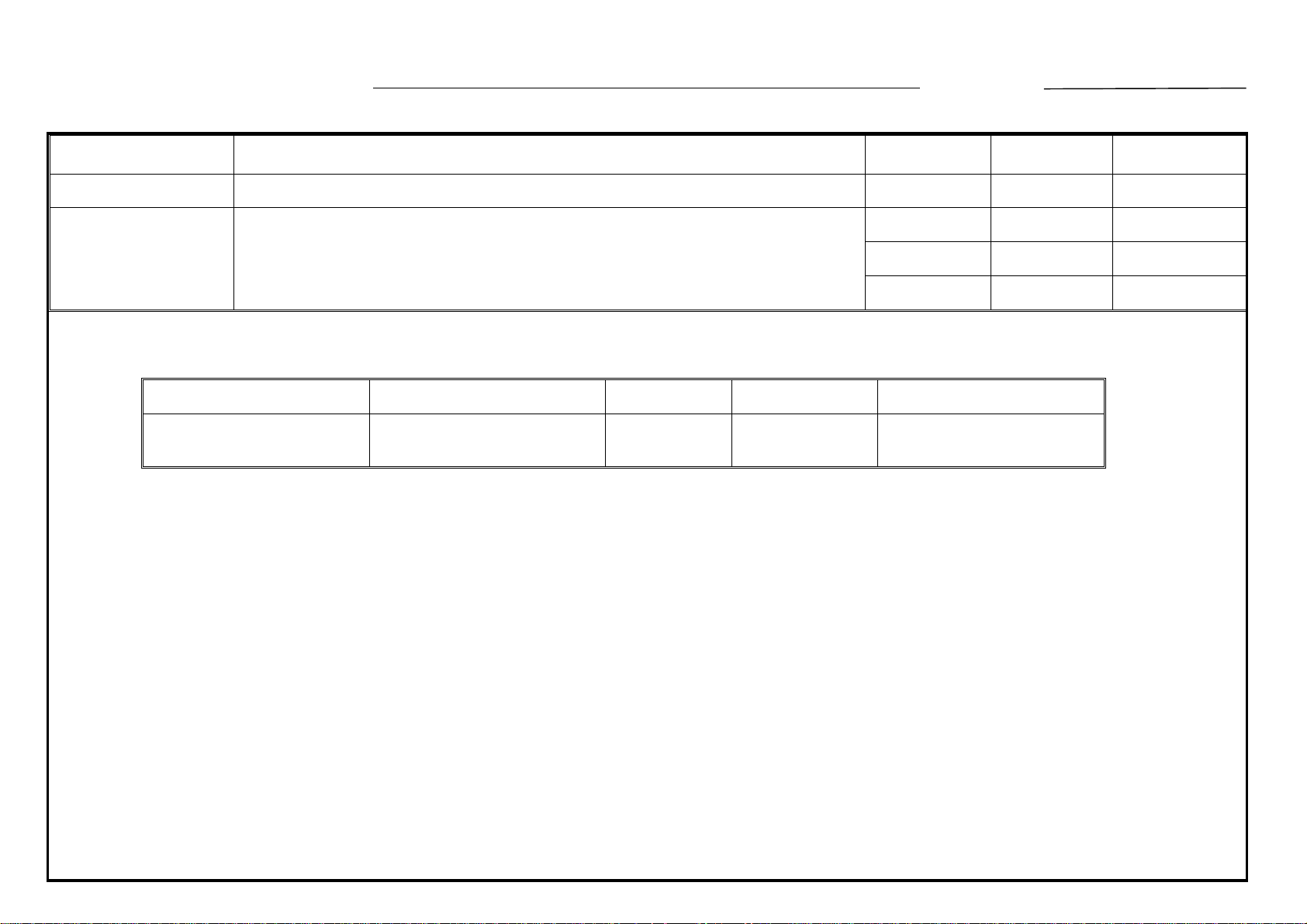

Reissued on: March 15, ’92

MODIFICATION BULLETIN NO. 26 Page 1 of 2 ISSUED ON: February 15, ’92

Model NC11 Volt/Hz

Modified Article See below

Reason for

Modification

Due to parts standardization with other model / To improve the strength of the exposure

glass

Due to parts standardization with other model, Cover-Exposure Lamp Unit has been changed.

To improve the strength of the exposure glass, Exposure Glass has been changed.

Old P/N New P/N Q’ty Interchangeability Description

A0301632 A0301863 1 → 1 X/X Cover - Exposure Lamp Unit 2 1 - 33

A0301862 0 → 1 X/X O/O as a set Lamp Cover Angle * 50 1 - 33

03130050W 0 → 1 X/X Philips Pan Head Screw - M3 X 5 * 116 1 - 33

AC012019 AC012039 1 → 1 X/O Exposure Glass 12 1 - 33

Cover - Exposure

Lamp Unit

Old P/N A0301632

Cover - Exposure

Lamp Unit

New P/N A0301863

Philips Pan Head

Screw - M3 X 5

P/N 03130050W

Parts Catalog

Index No. Page

Exposure Glass

Old P/N AC012019

New P/N AC012039

Date of

Modification

*New Index

Serial Number

Lamp Cover

Angle

P/N A0301862

T. Ito, Manager

Copier Technical Support

Page 49

Reissued on: March 15, ’92

MODIFICATION BULLETIN NO. 26 Page 2 of 2 ISSUED ON: February 15, ’92

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186109XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252109XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 2521090001

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 185108XXXX

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 391091XXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2521070001

RICOH NC100 220/50 ASIA A030 - 29 252109XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 50

Reissued on: April 15, ’92

MODIFICATION BULLETIN NO. 27 Page 1 of 2 ISSUED ON: February 29, ’92

Model NC11 Volt/Hz

Modified Article Paddle Roller

Reason for

To prevent toner from entering the gap between mixing auger and dual mixing paddle.

Modification

Date of

Modification

To prevent toner from entering the gap between mixing auger and dual mixing paddle (at the rear side of the machine),

Paddle Roller has been modified.

Old P/N New P/N Description Q’ty Interchangeability

AD038029 AD038046 Paddle Roller

4 → 4

X/O

Index No. Page

Parts Catalog

43

5

1 - 39

1 - 43

* Toner is carried to rear side by mixing auger. To

Rear Side

dual mixing paddle

reduce toner pressure around the rear inner end of dual

mixing paddle, distance A of mixing auger has been

increased from 42mm to 46mm.

Serial Number

mixing auger

Paddle Roller

Old P/N AD038029 New P/N AD038046

A

T. Ito, Manager

Copier Technical Support

Page 51

Reissued on: April 15, ’92

MODIFICATION BULLETIN NO. 27 Page 2 of 2 ISSUED ON: February 29, ’92

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186109XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252109XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 2521090001

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 1851080001

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 391091XXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2521070001

RICOH NC100 220/50 ASIA A030 - 29 252109XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 52

MODIFICATION BULLETIN NO. 28 Page 1 of 2 ISSUED ON: February 29, ’92

Model NC11 Volt/Hz

Modified Article Cleaning Unit

Reason for

Due to vendor change

Modification

Old P/N New P/N Q’ty Interchangeability

Index No. Page

A0303550 A0303551 1 → 1 O/O * 1 - 45

Due to vendor change, part number of cleaning unit has been changed.

Parts Catalog

Date of

Modification

Serial Number

T. Ito, Manager

Copier Technical Support

Page 53

MODIFICATION BULLETIN NO. 28 Page 2 of 2 ISSUED ON: February 29, ’92

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 54

Reissued on: April 15, ’92

MODIFICATION BULLETIN NO. 29 Page 1 of 2 ISSUED ON: February 15, ’92

Model NC11 Volt/Hz

Modified Article Sleeve - Oil Pump

Reason for

To improve unflamability of the oil pump sleeve

Modification

Parts Catalog

Old P/N New P/N Q’ty Used Interchangeability

Index No. Page

AA180007 AA180035

1 → 1

X/O 67 1 - 47

To improve unflamability of the oil pump sleeve, its material has been changed.

67

60

61

68

59

60

61

62

Sleeve - Oil Pump

Old P/N AA180007

Date of

Modification

105

Serial Number

New P/N AA180035

69

70

T. Ito, Manager

Copier Technical Support

Page 55

Reissued on: April 15, ’92

MODIFICATION BULLETIN NO. 29 Page 2 of 2 ISSUED ON: February 15, ’92

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186111XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252111XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 252111XXXX

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 1851100001

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 391111XXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2521100001

RICOH NC100 220/50 ASIA A030 - 29 252111XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 56

MODIFICATION BULLETIN NO. 30 Page 1 of 3 ISSUED ON: March 15, ’92

Model NC11 Volt/Hz

Modified Article See below

Reason for

Modification

Draw

No.

Old Parts

No.

AA040011 AA040018 Transport Belt 1 → 1 O/O 26 17

A0301360 A0721360 Left Inner Cover - Small 1 → 1 O/O 35 17

A0306350 A0306335 Separation Corona Unit 1 → 1 O/O 1 21

A0303858 A0723852 Transport Guide Plate - Rear 1 → 1 X/X 23 17

A0303853 Fixed Plate - Vacuum Fan 1 → 0 22 17

09524006W Screw M4 x 6 2 → 0 104 17

Due to parts standardization with other model

New Parts

No.

Description

Date of

Modification

A.B.C.

Rank Part No. Description Index No. Page

Q’ty Used

Old → New

Inter-

change-

ability

Part needed for replacement by new part Parts Catalog

Serial Number

A0723889 Right Fan Stopper 0 → 1 X/X O/O as a set * 54 17

A0723890 Left Fan Stopper 0 → 1 X/X * 55 17

A0723870 Fan Bracket 0 → 1 X/X * 56 17

04140082W

Rank: A : Replace with new parts immediately. B : Replace with new parts at time of repair. C : Replace with new parts at time of overhaul.

Interchangeability:

(1) When old and new parts are not mutually interchangeable, use additional parts or an assembly part as indicated in "Parts needed for replacement by new part" to

install the new part.

(2) The mark to the left of the slash indicates whether the old part can be used in the new machine, and the mark to the right indicates whether the new part can be used

in the old machine. x = Not interchangeable o = Interchangeable

Tapping Screw With Flat

Washer - M4

0 → 2 X/X * New Index * 119 17

Page 57

DETAILS OF MODIFICATION

MODIFICATION BULLETIN NO. 30 Page 2 of 3 ISSUED ON: March 15, ’92

P/N A0303858

Transport Guide Plate - Rear

P/N A0303853

Fixed Plate

- Vacuum Fan

P/N 09524006W

Screw M4 x 6

P/N A0723852

Transport Guide Plate - Rear

P/N A0723870

Fan Bracket

P/N A0723890

Left Fan Stopper

P/N A0723889

Right Fan Stopper

P/N 04140082W

Tapping Screw With

Flat Washer - M4

Note: Interchangeability between A0303858 and A0723852 is X/X because the position of the

screw holes receiving the screws (09524006W for A0303858 and 04140082W for

A0723852) have been changed.

T. Ito, Manager

Copier Technical Support

Page 58

MODIFICATION BULLETIN NO. 30 Page 3 of 3 ISSUED ON: March 15, ’92

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186111XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252111XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 252111XXXX

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 1851100001

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 391111XXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 2521100001

RICOH NC100 220/50 ASIA A030 - 29 252111XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 59

MODIFICATION BULLETIN NO. 31 Page 1 of 2 ISSUED ON: March 15, ’92

Model NC11 Volt/Hz

Modified Article Paddle Roller

Reason for

To improve toner sealing at the gap between mixing auger and dual mixing paddle.

Modification

Modification

To improve toner sealing at the gap between mixing auger and dual mixing paddle (at the rear side of the machine),

Paddle Roller has been modified.

Old P/N New P/N Description Q’ty Interchangeability

Index No. Page

AD038046 AD038051 Paddle Roller 4 → 4 X/O

Parts Catalog

43

5

1 - 39

1 - 43

* Toner is carried to rear side by mixing auger. To

Rear Side

dual mixing paddle

reduce toner pressure around the rear inner end

of dual mixing paddle, distance A of mixing

auger has been increased from 46mm to 58mm.

Date of

Serial Number

mixing auger

Paddle Roller

Old P/N AD038046 New P/N AD038051

A

T. Ito, Manager

Copier Technical Support

Page 60

MODIFICATION BULLETIN NO. 31 Page 2 of 2 ISSUED ON: March 15, ’92

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186201XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252201XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 252201XXXX

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 185201XXXX

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 391012XXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 252201XXXX

RICOH NC100 220/50 ASIA A030 - 29 252201XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 61

MODIFICATION BULLETIN NO. 32 Page 1 of 4 ISSUED ON: March 15, ’92

Model NC11 Volt/Hz

Modified Article See below

Reason for

Due to parts standardization with other model

Modification

Date of

Modification

Due to parts standardization with other model, the following parts have been modified.

Old P/N New P/N Description Q’ty Interchangeability

AD021044 A0723724

AD021028 A0722005

A0306231 A0726231 Corona Wire Ring 6 → 6 O/O

A0306335 A0306375 Separation Corona Unit 1 → 1 O/O 1 1 - 21

Receptacle Housing PCC

Receptacle Housing Charge Corona

1 → 1 O/O 27 1 - 19

1 → 1 O/O 28 1 - 19

Index No. Page

Parts Catalog

45

7

11

Serial Number

1 - 19

1 - 21

1 - 27

AD022136 AD022241 Cover - Front End Block 3 → 3 O/O 2 1 - 21

AD022138 AD022243 Cover - Rear End Block 2 → 2 O/O 4 1 - 21

AD022188 AD022244 Front End Block 3 → 3 O/O 9 1 - 21

AD022137 AD022242 Rear End Block 2 → 2 O/O 12 1 - 21

A0306355 A0726355

A0306360 A0726360

AD024017 AD024028 Adjusting Screw 1 → 1 O/O 21 1 - 21

DC Discharge Unit Outer

AC Discharge Unit Outer

1 → 1 O/O 14 1 - 21

1 → 1 O/O 18 1 - 21

Page 62

DETAILS OF MODIFICATION

MODIFICATION BULLETIN NO. 32 Page 2 of 4 ISSUED ON: March 15, ’92

Old P/N New P/N Description Q’ty Interchangeability

Index No. Page

AD022148 AD022253 Cover - Rear End Block 1 → 1 O/O 22 1 - 21

AD022147 AD022254 Rear End Block - D. AC Outer 1 → 1 O/O 23 1 - 21

A0306215 A0306237 Cleaner Motor Cover 1 → 1 O/O 27 1 - 21

A0306216 A0726216 Holder - Transfer Corona Wire 1 → 1 O/O 37 1 - 21

A0306218 A0726218 Adjusting Plate 1 → 1 O/O 38 1 - 21

A0306217 A0726217 Adjusting Screw 1 → 1 O/O 39 1 - 21

AD022164 AD022258 Cover - Rear End Block 1 → 1 O/O 47 1 - 21

AD022163 AD022259 Rear End Block - Transfer Corona 1 → 1 O/O 48 1 - 21

AD022132 AD022245 Cover - Front End Block 1 → 1 O/O 2 1 - 27

AD022131 AD022246 Front End Block - Discharge 1 → 1 O/O 6 1 - 27

AD022134 AD022247 Cover - Rear End Block 1 → 1 O/O 10 1 - 27

AD022133 AD022248 Rear End Block 1 → 1 O/O 12 1 - 27

AD022049 AD024029 Adjusting Screw 2 → 2 O/O 13 1 - 27

A0306235 A0726235 AC Discharge Unit - Inner 1 → 1 O/O

Parts Catalog

14

3

1 - 27

1 - 29

AD022151 AD022252 Rear End Block - D. AC Inner 1 → 1 O/O 15 1 - 27

AD022152 AD022251 Cover - Rear End Block 1 → 1 O/O 16 1 - 27

Page 63

DETAILS OF MODIFICATION

MODIFICATION BULLETIN NO. 32 Page 3 of 4 ISSUED ON: March 15, ’92

Old P/N New P/N Description Q’ty Interchangeability

Index No. Page

AD022149 AD022250 Front End Block D. AC Inner 1 → 1 O/O 18 1 - 27

A0306095 A0726099 Receptacle - D. DC 1 → 1 O/O 20 1 - 27

A0306100 A0726106 Receptacle - D. AC 1 → 1 O/O 21 1 - 27

A0306090 A0726091 Receptacle - Transfer Corona 1 → 1 O/O 22 1 - 27

AD022150 AD022249 Cover - Front End Block 1 → 1 O/O 35 1 - 27

AD022123 A0723720 Front End Block - PCC 1 → 1 O/O 22 1 - 45

AD022124 A0723721 Front End Block Cover - PCC 1 → 1 O/O 24 1 - 45

AD022125 A0723722 Rear End Block - PCC 1 → 1 O/O 42 1 - 45

AD022126 A0723723 Rear End Block Cover - PCC 1 → 1 O/O 43 1 - 45

AD021034 A0726110 Receptacle Housing - Discharge 3 → 3 O/O 29 1 - 55

Parts Catalog

T. Ito, Manager

Copier Technical Support

Page 64

MODIFICATION BULLETIN NO. 32 Page 4 of 4 ISSUED ON: March 15, ’92

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 65

MODIFICATION BULLETIN NO. 33 Page 1 of 2 ISSUED ON: May 31, ’92

Model

Modified Article

Reason for

Modification

NC - 11

Cover - Upper Relay Roller

To improve the reliability of the pick-off sensor

Volt/Hz

To improve the reliability of the pick-off sensor, a black mylar is added on the cover-upper relay r oller (A0302658).

Old P/N New P/N Description Q’ty Used

------- A0726344

Shielding Mylar

0 → 1

E

D

C

A

Index No. Page

# 57 (New) 1 - 17

New P/N A0726344

Shielding Mylar

Parts Catalog

* The edge "A" of the mylar is aligned with edge "B" of

cover-upper relay roller.

* * The distance "C" (between the edge "D" of

cover-upper relay roller and the edge "E" of the mylar)

is 96 ± 2mm.

Date of

Modification

Serial Number

B

P/N A0302658

Cover - upper relay roller

T. Ito, Manager

Copier Technical Support

Page 66

MODIFICATION BULLETIN NO. 33 Page 2 of 2 ISSUED ON: May 31, ’92

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 186205XXXX

RICOH NC100 115/60 USA, CANADA A030 - 17 252205XXXX

RICOH NC100 110/60 TAIWAN A030 - 19 252205XXXX

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 185205XXXX

INFOTEC 7125 220, 240/50 EUROPE A030 - 26 391052XXXX

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27 252205XXXX

RICOH NC100 220/50 ASIA A030 - 29 252205XXXX

V/Hz DESTINATION CODE SERIAL NUMBER

Page 67

MODIFICATION BULLETIN NO. 34 Page 1 of 2 ISSUED ON: July 15, ’92

Model

Modified Article

Reason for

Modification

NC11

Parts Catalog

Parts catalog correction

Please correct your parts catalog as follows:

Incorrect P/N Correct P/N Description Q’ty Used

52156674 52156676

Small Cassette Cover

Parts Catalog Note

Index No. Page

1 → 1 1 11

Volt/Hz

Date of

Modification

Nashua Infotec only

Serial Number

T. Ito, Manager

Copier Technical Support

Page 68

MODIFICATION BULLETIN NO. 34 Page 2 of 2 ISSUED ON: July 15, ’92

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 69

ISSUED ON: January 31, ’93

MODIFICATION BULLETIN NO. 36 PAGE 1 OF 2

T. Ito, Manager

Copier Technical Support

Model NC11 Volt/Hz

Modified Article Side Fences

Reason for

Due to parts standardization (OEM only)

Modification

Due to parts srandard izat ion, the rear side fence has be en chan ged.

The interchangeability is O/O .

Old P/N New P/N Description Q’ty Index Page

A0082718 A0082715 Side Fence - Front 1 → 1 2 1 - 5

52152727 A0082727 Side Fence - Rear 1 → 1 3 1 - 5

Date of

Modification

-------- OEM only

-------- OEM only

Serial Number

Page 70

MODIFICATION BULLETIN NO. 36 PAGE 2 OF 2

ISSUED ON: January 31, ’93

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16 Service Parts Only

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19 Service Parts Only

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25 Service Parts Only

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 71

MODIFICATION BULLETIN NO. 37 PAGE 1 OF 2

ISSUED ON:January 15, ’94

Model NC11 Volt/Hz

Modified Article Front Cover Band etc.

Reason for

Parts Standardization

Modification

Due to parts standardization , th e fro nt cover band is modified.

Inter-

Old P/N New P/N Description Q’ty Used

A0301292 A0721292 Front Cover Band

AA151236 — Seal - 3 x 40 x 74mm

2 → 2

3 → 0

change-

ability

O/O 7 3

Date of

Modification

Parts Catalog

Index No. Page

—3643

Serial Number

S. Hamano, Assistant General Manager

Technical Support Department

Page 72

MODIFICATION BULLETIN NO. 37 PAGE 2 OF 2

ISSUED ON:January 15, ’94

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 73

MODIFICATION BULLETIN NO. 38 PAGE 1 OF 2

ISSUED ON:January 15, ’94

Model NC11 Volt/Hz

Modified Article Doctor Blade - Black Development etc.

Reason for

Vendor Change

Modification

Due to vendor change, the part numbe r of fo llowin g part ha ve been chan ged.

Inter-

Old P/N New P/N Description Q’ty Used

A0303140 A0303172 Doctor Blade - Brack Development

A0303256 A0723258 Color Development Unit

1 → 1

1 → 1

change-

ability

O/O 4 39

O/O * 43

Date of

Modification

Parts Catalog

Index No. Page

Serial Number

S. Hamano, Assistant General Manager

Technical Support Department

Page 74

MODIFICATION BULLETIN NO. 38 PAGE 2 OF 2

ISSUED ON: January 15, ’94

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 75

MODIFICATION BULLETIN NO. 39 PAGE 1 OF 2

ISSUED ON:January 15, ’94

Model NC11 Volt/Hz

Modified Article Agitator

Reason for

As per field’s request

Modification

Inter-

Old P/N New P/N Description Q’ty Used

A0303360 Upper Agitator

A0303361 Lower Agitator

0 → 1

0 → 1

change-

ability

—1841

—1941

As per field’s request, the following parts have been regist ered as service parts.

Date of

Modification

Parts Catalog

Index No. Page

Serial Number

Upper Agitator

Lower Agitator

S. Hamano, Assistant General Manager

Technical Support Department

Page 76

MODIFICATION BULLETIN NO. 39 PAGE 2 OF 2

ISSUED ON: January 15, ’94

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 77

MODIFICATION BULLETIN NO. 40 PAGE 1 OF 2

ISSUED ON: February 28, ’94

Model NC11 Volt/Hz

Modified Article LED Sensor Type - T

Reason for

Due to parts standardization

Modification

Date of

Modification

Due to parts standardization with the other models, the followin g parts ha ve be en chan ged. Interchangeability O/O.

Old P/N New P/N Description Q’ty Used

Index No. Page

52055251 LED Sensor Type - T 1 21 49

AW020041 Photointerruptor 1 21 49

Parts Catalog

Serial Number

S. Hamano, Assistant General Manager

Technical Support Department

Page 78

MODIFICATION BULLETIN NO. 40 PAGE 2 OF 2

ISSUED ON: February 28, ’94

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

V/Hz DESTINATION CODE SERIAL NUMBER

Page 79

MODIFICATION BULLETIN NO. 41 PAGE 1 OF 2

ISSUED ON: October 15, ’94

Model NC11 Volt/Hz

Modified Article Transfer Corona Unit

Reason for

Due to parts standardization

Modification

Due to parts standardization with other mo del, th e followin g parts has been cha nged .

Inter-

Old P/N New P/N Description Q’ty Used

A0306210 A0306122 Transfer Corona Unit

1 → 1

change-

ability

O/O 4 1 - 29

Index No. Page

Parts Catalog

Date of

Modification

Serial Number

S. Hamano, Assistant General Manager

Technical Support Department

Page 80

MODIFICATION BULLETIN NO. 41 PAGE 2 OF 2

ISSUED ON: October 15, ’94

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Page 81

MODIFICATION BULLETIN NO. 42 PAGE 1 OF 2

ISSUED ON: November 30, ’94

Model NC11 Volt/Hz

Modified Article Parts Catalog

Reason for

Parts Catalog Correction

Modification

Please correct your parts catalo g as follows:

Old P/N New P/N Description Q’ty Used

09724008 Philips Polycarbonate Screw - M4 x 8

09161112 Bushed Chain - 112P

1 → 0

0 → 1

Date of

Modification

Parts Catalog

Index No. Page

117 1 - 17

117 1 - 17

Serial Number

S. Hamano, Assistant General Manager

Technical Support Department

Page 82

MODIFICATION BULLETIN NO. 42 PAGE 2 OF 2

ISSUED ON: November 30, ’94

MODEL NAME

NASHUA C240 115/60 USA, CANADA A030 - 16

RICOH NC100 115/60 USA, CANADA A030 - 17

RICOH NC100 110/60 TAIWAN A030 - 19

NASHUA C240 220, 240/50 EUROPE, etc. A030 - 25

INFOTEC 7125 220, 240/50 EUROPE A030 - 26

RICOH NC100 220, 240/50 EUROPE, etc. A030 - 27

RICOH NC100 220/50 ASIA A030 - 29

V/Hz DESTINATION CODE SERIAL NUMBER

Loading...

Loading...