Page 1

Technical Bulletin No. RTB-006

SUBJECT: Incomplete Solid Filling DATE: Feb. 28, ’91

PAGE: 1 of 3

PREPARED BY: M. Furusawa

CHECKED BY: T. Ito

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

[ SYMPTOM ]

FROM: Technical Support Department

Copier Technical Support Section

Revision of service manual

Information only

Other

MODEL:

COSMOS

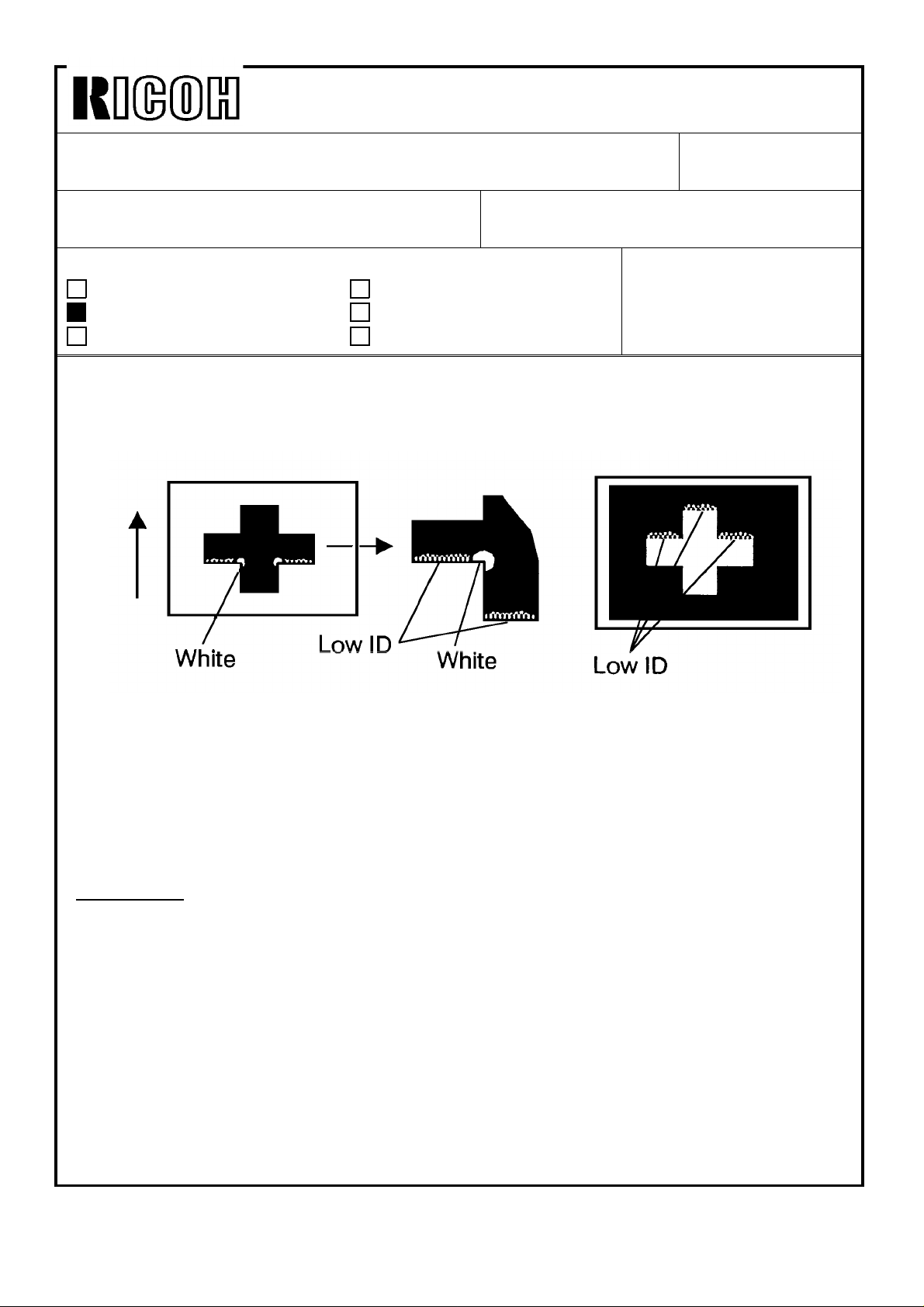

1. The trailing corners of solid cross images become white.

2. The trailing edges of solid areas have low ID.

[ ACTION ]

Procedure 1.

Do the following procedure:

NOTE: This is taken from the troubleshooting section of the COSMOS service manual

(page 12-38).

1. Check the charge wire position, and clean the wire and grid plate.

(Make sure the wire cleaner does not push the wire to the left.)

2. Check the doctor gap.

(The gap might be too wide.)

3. Increase the development bias from -600V to -650V by SP33.

Page 2

Technical Bulletin No. RTB-006

SUBJECT: Incomplete Solid Filling DATE: Feb. 28, ’91

PAGE: 2 of 3

Procedure 2.

If the procedure 1 dose not solve the problem with incomplete solid filling to the customer’s

satisfaction, do the following:

1. Change the charge corona receptacle from P/N:AD021054 (Varistor=866V) to

P/N:A0129125 (Varistor=720V).

NOTE: P/N:A0129125 has been newly registered as a service part for this

troubleshooting procedure.

Keep the original charge corona receptacle for future use.

2. Reset SP33 data from "1" to "0" (-650V to -600V).

3. Make sure that there is no dirty background on the copy.

If dirty background is observed, change the SP33 data from "0" to ’2" (-600V to

-550V).

NOTE: The ID on the copy will be slightly lower at this low bias setting.

[ Explanation ]

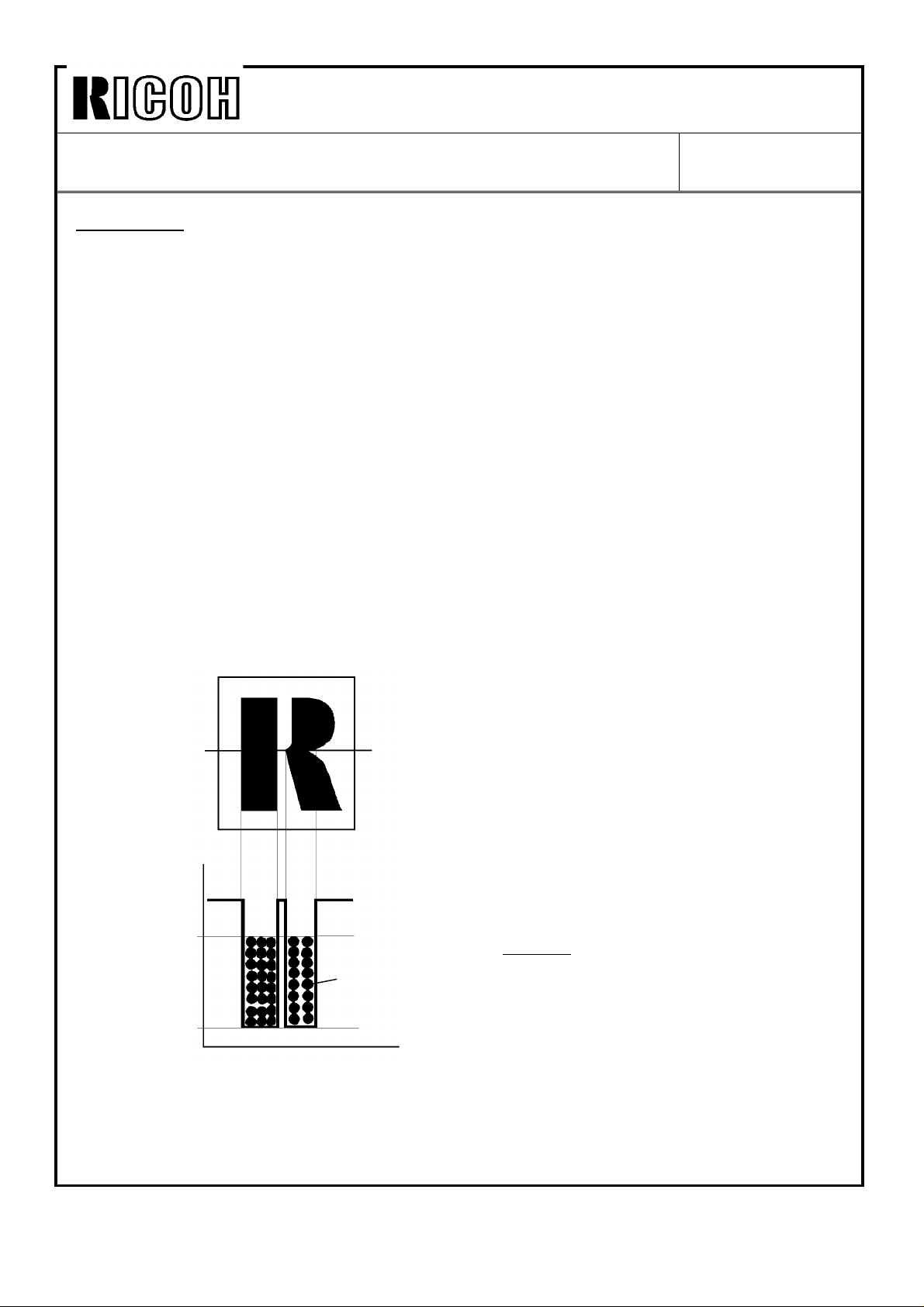

Vd

Vb

Toner

Vr

Vd : Drum potential in white areas

Vr : Drum residual potential in black

areas of original

Vb : Development bias

Vb - Vr : Development potential

Vd - Vb : Dirty background margin

Vb − Vr

Vd − Vb

= A

……………

(1)

Quantity "A" derived in the above equation (1) affects the solid filling.

If "A" is low, the solid filling will be worse.

However, if "A" is high, dirty background will occur as side effect.

Page 3

Technical Bulletin No. RTB-006

SUBJECT: Incomplete Solid Filling DATE: Feb. 28, ’91

PAGE: 3 of 3

* Vb can be changed by SP33 (-600V, -650V, or -550V). ………………………

1

* Vd can be changed by installing a different charge corona receptacle. ……

CAUTION:

As you may know, the dirty background margin decreases when the 720V varistor is used,

i.e. dirty background becomes more likely. (Refer to the diagram in the previous page.)

Also, Vd decreases over time as the OPC drum is used, and this eventually decreases the

margin.

If you change SP33 data from "0" to "2" in step 3 of the procedure 2 and still do not obtain

satisfactory results with solid filling and dirty background, you must reinstall the original

charge corona receptacle and reset the SP33 data to "1" (Step 3 of procedure 1).

There is nothing more that can be done.

REMEMBER:

For the above-mentioned reasons, the new charge corona receptacle (P/N:A0129125)

should only be installed when complete solid filling is extremely important to a customer.

Procedure

Procedure 2

[ ADDITIONAL INFORMATION]

Incomplete solid filling will become more critical on copies made in Positive/Negative

Reversing mode.

If a customer frequently uses this mode for continuous copy runs, we recommend

changing the following SP modes:

1. SP31: Toner supply amount

Set the next higher amount. [ Ex. "0":30% to "2":45% ]

2. SP33: Development bias

Select data "1". (-650V)

3. SP34: ID check interval

Select data "1". (Every 5 copies)]

4. SP35: Toner near end copy run

Select data "1". (20 copies)

5. SP63: Toner near end detection

Select data "1". (0.15V)

Loading...

Loading...