Ricoh 4215 4220 f Service Manual

FT4220/4222/4215

FIELD SERVICE

MANUAL

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filter installed.

2. Always replace the ozone filter with the specified one at the specified

interval.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get medical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripheral must be installed and maintained by a

customer service representative who has completed the training course

on those models.

-- CAUTION --

2. The RAM pack has a lithium battery which can explode if handled

incorrectly, replace only with same RAM pack. Do not recharge, or burn

this battery. Used RAM pack must be handled in accordance with local

regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may

ignite suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductors

according to local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

SECTION 1

SPECIFICATIONS

1. SPECIFICATIONS

Configura ti on: Desk top

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum: A3/11" x 17"

Copy Paper Size: Maximum: A3/11" x 17"

Minimum: A6/51/2" x 81/2" (lengthwise)

..... Manual and cassette feeds

A5/11" x 81/2" (sideways)

..... Paper tray feed

(Duplex Copying) A4/11" x 81/2" (sideways)

Copy Paper Weight: Cassette feed: 52 to 157 g/m2 (14 to 42 lb)

Paper tray feed: 64 to 90 g/m2 (17 to 22 lb)

Manual feed: 52 to 157 g/m2 (14 to 42 lb)

Duplex: 58 to 104 g/m2 (16 to 28 lb)

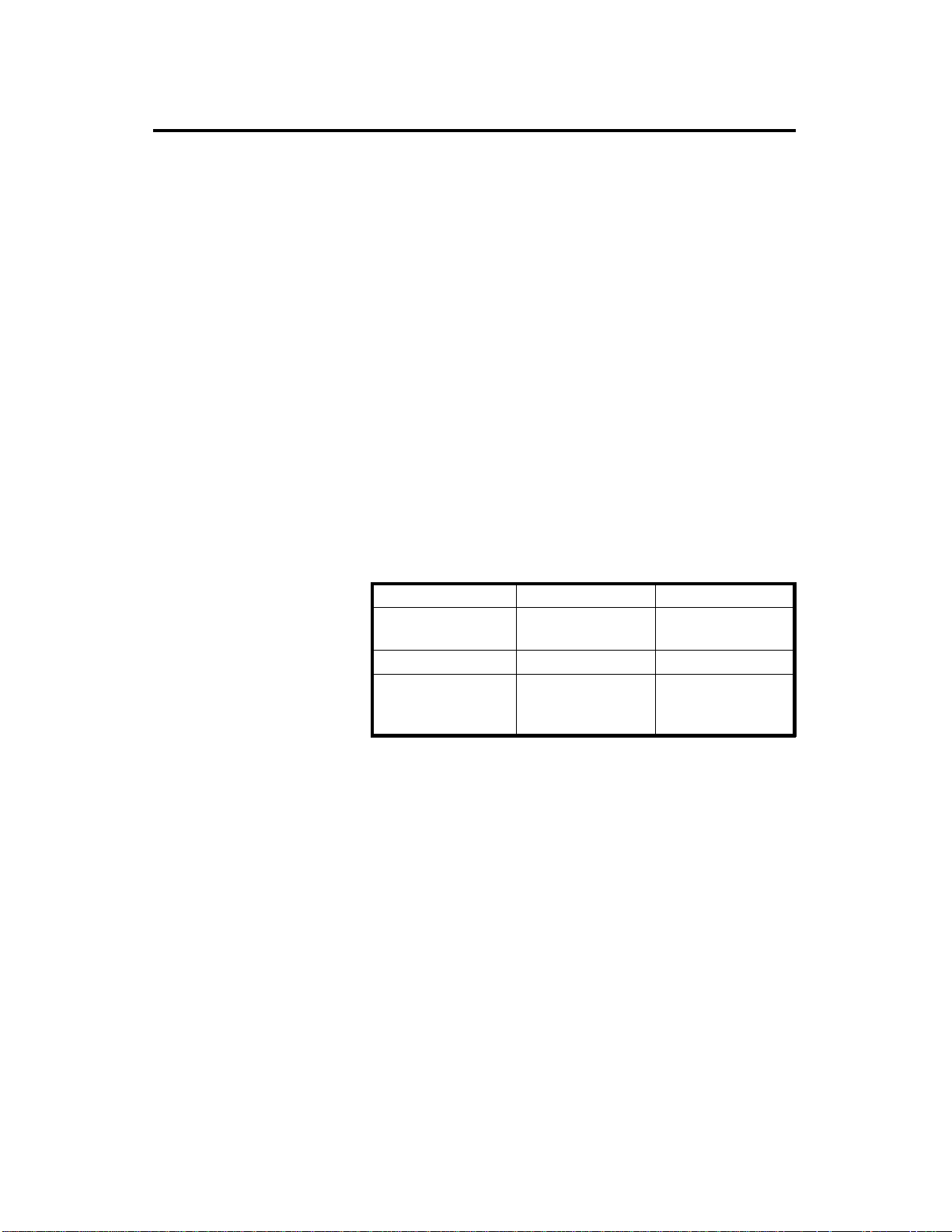

Reproduction Ratio: 2 Enlargement and 3 Reduction

A4/A3 version LT/LDG version

Enlargement 141%

122%

Full size 100% 100%

Reduction 93%

82%

71%

155%

129%

93%

74%

65%

Zoom: From 50% to 200% in 1% steps

Copying Speed: (FT4220 copier)

20 copies/minute (A4/11" x 81/2" sideways)

10 copies/minute (A3/11" x 17")

(FT4222 copier)

22 copies/minute (A4/11" x 81/2" sideways)

11 copies/minute (A3/11" x 17")

Warm-Up Time: Less than 60 seconds (at 20°C)

First Copy Time: 5.9 seconds (A4/11" x 81/2" sideways for cassette

feed)

Copy Number Input: Ten keys, 1 to 99 (count up)

1-1

Rev. 4/4/94

Manual Image Density

7 steps

Selection:

Automatic Reset: All input modes are reset 1 minute after the copier

is not in use; can also be set to 3 minutes or no

auto reset.

Energy Saver Function: Saving the electricity consumption

(Manual or manual/auto)

Paper Capacity: Cassettes: 500 sheets

Paper tray: 250 sheets

(FT4220 copier ... 1 paper tray)

(FT4222 copier ... 2 paper trays)

Manual feed table: 50 sheets

Toner Replenish ment: Black: Cartri dge e xchange (370g/cartr idge)

YIELD 9500 COPIES

Color (red, blue, & green):

Cartridge e xchan ge (310 g/cartridge)

YIELD 6000 COPIES

Developer

Replenishment: Black (1 Kg/BAG) Yield 60000 copies.

Color (1 Kg/BAG) Yield 30000 copies.

⇒

Copy Tray Capacity: 250 sheets (B4/81/2" x 14" and s maller)

100 sheets (A3/11" x 17")

Power Source: 110 V/ 60 Hz/ 15 A (for Taiwan)

115 V/ 60 Hz/ 15 A (for North America)

220/230/240 V/ 50 Hz/ 8 A (for Europe)

220 V/ 60 Hz/ 8 A (for Middle East)

(Refer to the serial number plate (rating plate) to

determine the power source required by the

machine.)

Power Consumption:

FT4220 (A110) Copier FT4222 (A111) Copier

Copier only Full System Copier only Full system

Maximum 1.2 kVA 1.5 kVA 1.3 kVA 1.5 kVA

Warm-up 800 VA (average) 800 VA (average) 800 VA (average) 800 VA (average)

Copy cycle 900VA (av erage) 800 VA (average) 900VA(av erage) 800 VA (average)

Stand-by

(without

energy saver

function)

180VA (average) 180 VA (average) 180 VA (average) 180 VA (average)

1-2

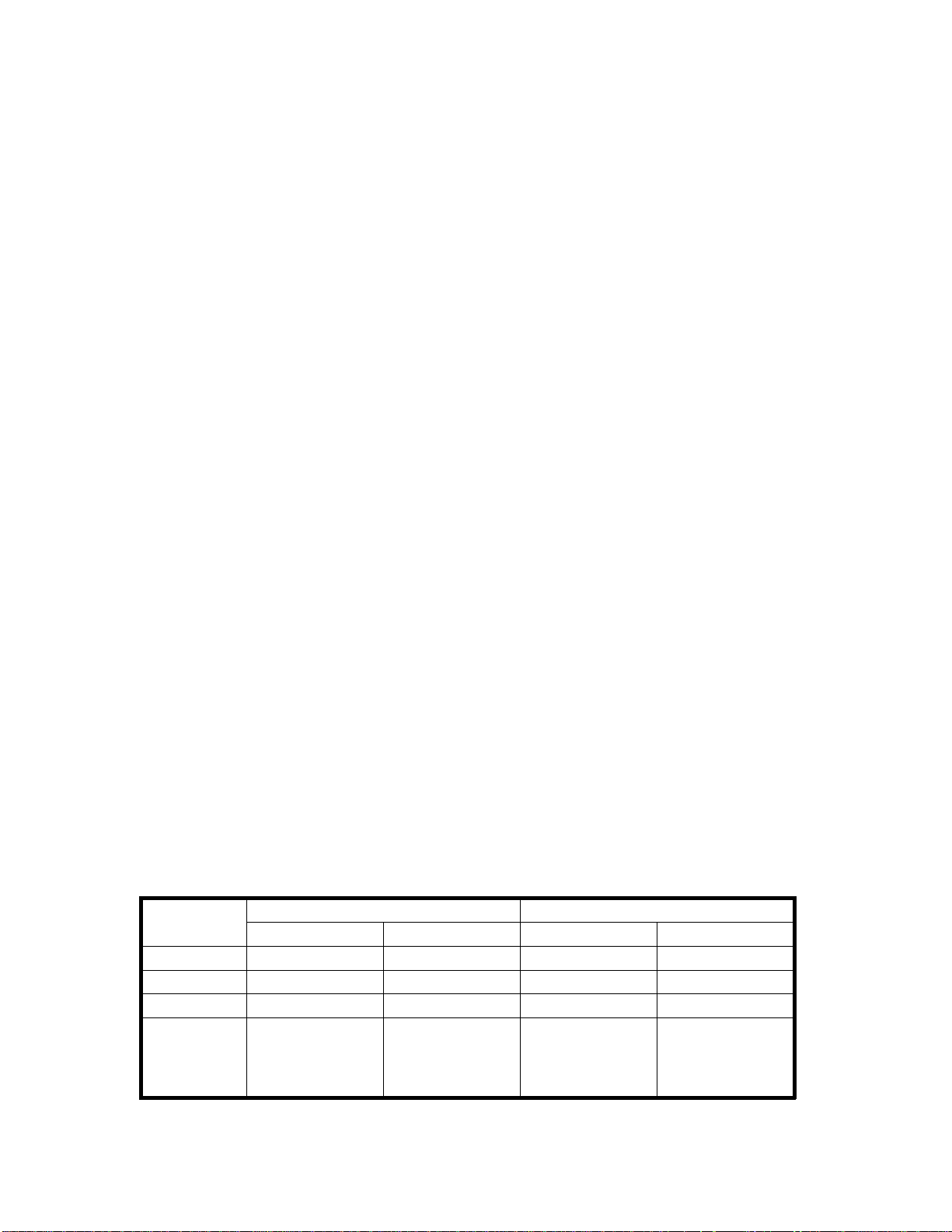

Dimensions:

Width Depth Height

Copier only FT4220

copier

FT4222

copier

Full system FT4220

copier

FT4222

copier

( ): when the cassette and platen cover are installed and the copy tray is extended.

672 mm (1130 mm)

26.5" (44.5")

672 mm (1130 mm)

26.5" (44.5")

1149 mm

45.3"

1149 mm

45.3"

600 mm

23.7"

600 mm

23.7"

600 mm

23.7"

600 mm

23.7"

410 mm (464 mm)

16.1" (18.3")

530 mm (584 mm)

20.9" (23.0")

513 mm

20.2"

633 mm

25.0"

Noise Emissions:

Maximum Copy cycle Stand-by

Copier only less than 58 dB less than 55 dB less than 40 dB

Full system less than 60 dB less than 58 dB less than 40 dB

Weight:

FT4220 copier FT4222 copi er

Copier only 55 kg (121.3 lb) 64 kg (141.1 lb)

Full system 78 kg (172 lb) 83.5 kg (184 lb)

Optional Equipment and Machine Configuration:

( ) Machine Code

Configuratio n Optional dc power supply unit (A525)

Main frame Optional equipment Required Not required

FT4220

copier

(FT4220)

FT4222

copier

(FT4222)

CS110 - 10 bin sorter (A490) O

DF57 - Document feeder (A318) O

AD130 - Duplex unit (A491) O

Color development unit (A313) O

CS110 - 10 bin sorter (A490) O

DF57 - Document feeder (A318) O

AD130 - Duplex unit (A491) O

Color development unit (A313) O

Other Optional Equipment:• Key counter

• Universal cassette

• Optics anti-condensation heater

• Specifications are subject to change without notice.

1-3

SECTION 2

COMPONENT LAYOUT

AND DESCRIPTIONS

1. MECHANICAL COMPONENT LAYOUT

1234 56 789101112 13 14

35

34

33

32

15

16

17

18

19

31

1. Third Mirror

2. Second Mirror

3. First Mirror

4. Exposure Lamp

5. Ozone Filter

6. Cleaning Unit

7. Lens

8. Quenching Lamp (QL)

9. Charge Corona Unit

10. Sixth Mirror

11. Erase Lamp

12. OPC Drum

13. Development Unit

14. Toner Supply Unit

15. Optics Cooling Fans

16. 1st Feed Roller

17. Manual Feed Table

18. Pick-up Roller

222324252627282930

19. Separation Roller

20. 1st Relay Rollers

21. 2nd Relay Rollers (FT4222 copier only)

22. 2nd Feed Rollers (Semi-ci rcul ar)

23. 3rd Feed Rollers (Semi-circ ular )

(FT4222 copier only)

24. Registration Roller s

25. Pre-transfer Lamp (PTL)

26. Transfer and Separation Corona Unit

27. Pick-off P a wls

28. Cleaning Brush

29. Cleaning Blade

30. Pressure Roller

31. Hot Roller

32. Duplex Turn Guide (Optio n)

33. Exit Rollers

34. Hot Roller Stri ppers

35. Exhaust Blowe r

21

20

FSM 2-1 FT4220/4222

2. DRIVE LAYOUT

G23

Cleaning

G11

G5

G6

G7

G9

G8

G10

G4

BP3

G12

BP4

G13

G14

G1: Main Motor Gear

TB2

BP5

G17 BP2 G16 TB1 G19 G18 G22

G3BP1G15G33G32G31

G20: Relay Gear

G24

G26

G27

G28

G29G25G21G20G1G2

G2: Relay Gear G18: Relay Gear

Gear

Drum Fusing and Exit Section

BP1: Timing Bel t Pul le y

TB1: Timing Belt

A

Deve lopment

Section

BP2: Timing Belt Pulley

G16: Development

CL Gear

G17: Toner Supply CL Gear

G21: Cleaning Drive

G22: Relay GearG19: Drum Drive GearG3: Timing Belt Drive

G23: Relay Gear

G24: Relay Gear

G25: Hot Roller Gea r

G26: Relay Gear

G27: Relay Gear

G28: Exit Roller Gea r

G29: Duplex

Transport

Gear (Option)

Development UnitDevelopment CL Solenoid

Toner Supply CL Toner Supply Unit

FT4220/4222 2-2 FSM

A

Paper Feed Section

BP3: Timing Bel t Pul le y

G11: Registration CL

Gear

Registration CL

Registration Roller

1st Feed Station

1st Paper Feed CL Solenoid

1st Paper Feed Rollers

G4: Relay Gear G12: Relay Roller CL Gea r

G5: Relay Gear

G6: 1st Paper Feed CL Gear

G7: Relay Gear

G8: Paper Lift CL Gear

Paper Lift CL

G9: Paper Lift Gear

G10: Sector Gear

2nd Feed Station Upper Relay Roller

G13: Upper Relay

Roller Gear

Relay Roller C L

3rd Feed Station

(FT4222 copier only)

G14: Relay Gear

G15: 2nd Paper Feed

CL Gear

2nd Paper Feed CL

2nd Paper Feed Roller

FSM 2-3 FT4220/4222

BP4: Timing Bel t Pul le y

TB2: Timing Belt

BP5: Timing Bel t Pul le y

Lower Relay Roller

G31: Lower Relay Roll er Gear

G32: Relay Gear

G33: 3rd Paper Feed CL Gear

3rd Paper Feed CL

3rd Paper Feed Roller

3. ELECTRICAL COMPONENT LAYOUT

567

151617

26

32

31

30

29

28

27

25

34

33

1

2

3

4

8

9

10

11

12

13

14

24

23

22

21

1. Scanner H.P. Sensor

2. Lens H.P. Sensor

3. Scanner Motor

4. Main Motor

5. Development Clutch Solenoid

6. Toner Supply Clutch

7. 4th/5th Mirror H.P. Sensor

8. Color Toner End Sensor

9. 4th/5th Mirror Motor

10. Pick-up Roller Release Solenoid

11. Manual Feed Table Switch

12. Color Switch

13. Paper Lift Clutch

14. 1st Paper Feed Clutch Solenoid

15. Registration Clutch

16. Right Cover Switch

17. Relay Roller Clutchick-up Roller

19. Separation Roller

18

19

20

18. 1st Paper Size Switch

19. 1st Paper End Sensor

20. Relay Sensor (F T4 222 copier o nly)

21. Paper Lift Sensor

22. Registration Sensor

23. Total Counter

24. Pre-transfer Lamp (PTL)

25. ID Sensor Board

26. Erase Lamp

27. Fusing Lamp

28. Quenching Lamp (QL)

29. Auto Image Density Sensor

30. Fusing Thermistor

31. Toner Overflow Sensor

32. Fusing Thermofuse

33. Exit Sensor

34. Lens Motor

FT4220/4222 2-4 FSM

38

39

46

47

35 36

37

62

59

58

57

56

55

60

54

61

53

52

51

50

40

41

42

43

44

45

48

49

35. Platen Cover Closed Swit ch

(FT4222 copier only)

36. Operation Panel Board

37. Original Length Sensor

(FT4222 copier only)

38. Optics Thermoswitch

39. Exposure Lamp

40. Original Width Sensor

(FT4222 copier only)

41. Cover Safety Switch

42. Main Switch

43. Exhaust Bl ower Motor

44. Drum Anti-condensation Heater

45. Main DC Power Supply Board

46. Option DC Power Supply Board

(FT4220 copier only)

47. Option Transformer

(FT4220 copier only)

48. 3rd Paper Size Switches

(FT4222 copier only)

49. Noise Filter Board

(220/230/240 V only)

50. 2nd Paper Size Switches

51. Main Transformer

52. 3rd Paper End Sensor

(FT4222 copier only)

53. AC Drive Board

54. 3rd Paper Feed Clutch

(FT4222 copier only)

55. 2nd Paper End Sensor

56. 2nd Paper Feed Clutch

57. Main Motor Capaci tor

58. Main Board

59. TC/SC Power Pack

60. CC/Grid/Bias Power Pack

61. Platen Cover Posi tion Se nsor

(FT4222 copier only)

62. Optics Cooling Fan Motors

FSM 2-5 FT4220/4222

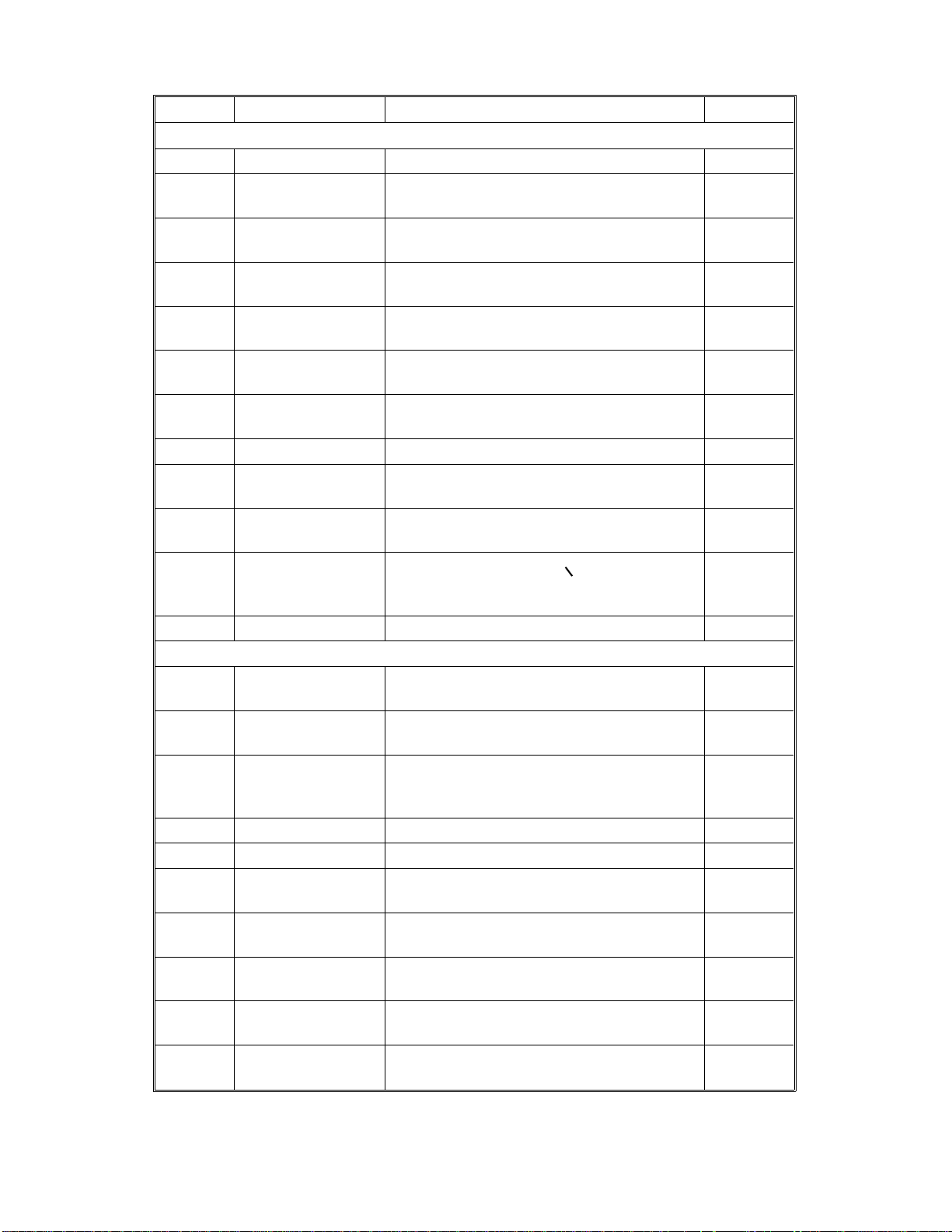

4. ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

Motors

M1 Main Moto r Drives all the main unit com ponents ex c ept

for the optics unit and fan s.

(115/220/230/240 Vac)

M2 Scanner Motor Drives the scanners (1st and 2nd). (dc

stepper)

M3 Lens Motor Moves the lens position according to the

selected magnification. (dc st epper)

M4 4th/5th Mirror Motor Move the 4th/ 5th mi rr or position accordi ng to

the selected magnification. (dc st epper)

M5 Optics Cooling Fan

Motor-1

M6 Optics Cooling Fan

Motor-2

M7 Exhaust Blower

Motor

Preve n ts built up of hot air in the optics

cavity. (24 Vdc)

Preve n ts built up of hot air in the optics

cavity. (24 Vdc)

Removes heat from around the fusing unit

and blower the ozone built up around the

charge section to the ozone filter.

(115/220/230/240 Vac)

4

3

34

9

62

62

43

Magnet ic Clu tch

MC1 Toner Supply Clutch Drive s the toner supply roller. 6

Magnetic Sprin g Clutches

MSC1 2nd Paper Feed

Clutch

MSC2 Paper Lift Clut ch Lifts paper to the appropriate feed station. 13

MSC3 Registration Clutch Drives the registr ation roll ers. 15

MSC4 Relay Roller Clutch Drives the relay rollers f or the 2nd or 3rd

MSC5 3rd Paper Feed

Clutch

Solenoids

SOL1 1st Paper Feed

Clutch Solenoid

SOL2 Pick-up Roller

Release Solenoid

SOL3 Development

Clutch Solenoid

Starts paper feed from the 2nd paper feed

station.

paper feed station.

Starts paper feed from the 3rd paper feed

station. (FT4222 co pier on ly)

Starts paper feed from the first paper station. 14

a) After the paper is fed, releases the

pick-up roller from next paper.

b) When the manual feed table is used,

releases the pick-up roller from the tabl e.

Drives the devel opment unit. 5

56

17

54

10

FT4220/4222 2-6 FSM

Symbol Name Function Index No.

Switches

SW1 Main Switch Supplies power to the copier. 42

SW2 Cover Safety Switch Cuts the ac po wer line when the front cover

41

or/and exit cover is open.

SW3 1st Paper Size

Switch

SW4 2nd Paper Size

Switch-1 (Upper)

SW5 2nd Paper Size

Switch-2 (Lower)

SW6 Color Switch Determin e s which color dev elopm e nt unit is

Determin es what size paper is in the

cassette.

Determine s what size paper is in the upper

paper tray.

Determine s what size paper is in the upper

paper tray.

18

50

50

12

installed.

SW7 Manual Feed Table

Detects when the manual feed table is open. 11

Switch

SW8 Ri ght Cover S witch Detects when the right cover is open. 16

SW9 3rd Paper Size

Switch-1 (Upper)

SW10 3rd Paper Size

Switch-2 (Lower)

SW11 Platen Cover

Closed Switch

Determin e s what size paper is in the lower

tray. (FT4222 copier only)

Determin e s what size paper is in the lower

tray. (FT4222 copier only)

Detects when the platen cover or the

document feeder is closed.

48

48

35

(FT4222 copier only)

Sensors

S1 Scanner Home

Position Sensor

S2 Lens Home

Position Sensor

S3 4th/5th Mirror Home

Position Sensor

Informs the CPU when the 1st scanner is at

the home position.

Informs the CPU when the lens is at the

home position (full size position).

Informs the CPU when the 4th/5th mirrors

assembly is at the home p o sition (full size

position).

S4 Registration Sensor Detects misfeeds. 22

S5 Exit Sensor Detects misfeeds. 33

S6 1st Paper End

Sensor

S7 2nd Paper End

Sensor

S8 Color Toner End

Sensor

Informs CPU when the cassette runs out of

paper.

Informs CPU when the upper paper tray

runs out of paper.

Detects when it is time to add toner for the

color development unit.

S9 Paper Lift Se n sor Detects the correct feed height of the

cassette.

S10 Image Density (ID)

Sensor

Detects the density of the image on the

drum to control the t oner density.

1

2

7

19

55

8

21

25

FSM 2-7 FT4220/4222

Symbol Name Function Index No.

S11 Auto Image Densit y

Sensor (ADS)

S12 3rd Paper End

Sensor

Senses the background density of the

original.

Informs CPU when the lower paper tray runs

out of paper. (FT4222 copier only)

29

52

S13 Relay Sensor Detects misfeeds. (FT4222 copier only) 20

S14 Platen Cover

Position Sensor

Detects when the platen cover is po sitioned

about 10 cm (4") above the ex p o sure glass.

61

(FT4222 copier only)

S15 Original Width

Sensor

S16 Original Length

Sensor

S17 Toner Overflow

Detects the original width. (FT4222 copier

40

only)

Detects the original length.

37

(FT4222 copier only)

Detects when the used toner tank is full . 31

Sensor

Printed Circuit Boards

PCB1 Main Board Controls all copier function s both directly

58

and through the other PCBs.

PCB2 AC Drive Board Drive s all ac motors, the exposure lamp,

53

fusing lamp, quenching lamp, ex haust

blower motor.

PCB3 Main DC Po wer

Supply Board

PCB4 Operation Panel

Board

PCB5 Noise Filter Board Removes the electrical noise.

Rectifies 26 (31) Vac and 10 Vac input and

outputs dc voltages.

Informs the CPU of the selected m odes and

displays the situations on the panel.

45

36

49

(220/230/240 V only)

PCB6 Option DC Power

Supply Board

Rectifies 26 and 10 Vac input and outputs

dc voltages . Th is board is required when the

46

document feeder or/and duplex unit is

installed. (FT4220 copi er only)

Lamps

L1 Exposure Lamp Applies high inte n sity light to the original for

39

exposure.

L2 Fusing Lamp Provides heat to the hot roller. 27

L3 Quenching Lamp Neutraliz e s any charge remaining on the

28

drum surface aft er cleaning.

L4 Erase Lamp Discharge the drum outside of the imag e

26

area. Provides leading/trai ling edge, side

and editing erases.

L5 Pre-transfer Lamp Reduces charge on the drum surface before

24

transfer.

FT4220/4222 2-8 FSM

Symbol Name Function Index No.

Power Packs

P1 CC/Grid/ Bias

Power Pack

P2 TC/SC Power Pack Provides high voltage for the transfer and

Heaters

H1 Drum

Anti-condensation

Heater

H2 Optics

Anti-condensation

Heater (Option)

Counters

CO1 Total Counter Keeps track of the total number of copies

CO2 Key Counter

(Option)

Provi des high voltage for th e charge corona,

grid, and the devel opment roller bia s.

separation corona.

Preve n ts moisture around the drum. 44

Preve n ts mois t ure from formin g o n t he

optics.

made.

Used for control of authorized use. Copier

will not operate until installed.

60

59

N/A

23

N/A

Transformer

TR1 M ain T ransformer Steps down the w all voltage to 26 (31) Vac

and 10 Vac.

TR2 Option Tra nsformer Steps down the wall voltage to 26 Vac and

10 Vac. This transformer is require d when

the document feeder or/and duplex unit is

installed. (FT4220 copi er only)

Others

TH Fusing Thermistor Monitors the fusing temperature. 30

TF Fusing Thermofuse Provides back-up overheat protec tion in the

fusing unit.

TS Optics

Thermoswitch

C Main Motor

Capacitor

Provide s back-up overheat protection

around the exposure lamp.

Start capacitor 57

51

47

32

38

FSM 2-9 FT4220/4222

SECTION 3

INSTALL ATION

1. INSTALLATION REQUIREMENTS

1.1 ENVIRONMENT

1. Temperature Range: 10°C to 30°C (50°F to 86°F)

2. Humidity Range: 15% to 90% RH

3. Ambient Illuminati on: Less than 1,500 lux. (Do not expose to direct

sunlight.)

4. Ventilation: Room of more than 30 m3. Room air should turn over at least

30 m3/hr/person .

5. Ambient Dust: Less than 0.15 mg/m3 (4 x 10-3 oz/yd3)

6. The machine must not be subjected to sudden temperature changes. Do

not install the machine where it will be directly exposed to cool air from an

air conditioner or hot air from a heater.

7. Avo id pla ci ng th e machin e in an area filled with corr osive gas.

8. Do not install at any location over 2,000 meters (6,500 feet) above sea

level.

9. Place the machine on a strong and level base .

10. Avoid any area where the machine may be subjecte d to freque nt, stro ng

vibr ations .

1.2 MACHINE LEVEL

1. Fr ont to back: Withi n 5 mm (0.2") of leve l

2. Right to le ft: Wi thin 5 mm (0.2") of le vel

Make sure that the machine is level using a carpenter’s level.

3-1

1.3 MINIMUM SPACE REQUIREMENTS

70 cm

10 cm

15 cm

30 cm

70 cm

60 cm

30 cm

30 cm

60 cm

1. Front : 70 cm (27.6")

2. Back : 10 cm (3.9")

: 15 cm (6.0")

(when the sorter is insta l led.)

3. Right : 60 cm (31.5")

4. Left : 30 c m (11.8")

NOTE: Make sure there is at least 15 cm (6.0" ) cleara nce b ehind the copie r

so that the sorter will not be damaged when it is opened.

1.4 POW ER REQUIREMENTS

1. Input voltage level:

110 V/60 Hz: More than 15 A (for Taiwan)

115 V/60 Hz: More than 15 A (for North America)

220, 230, 240 V/50 Hz: More than 8 A (for Europe)

2. Permissible voltage fluctuation: ±10%

3. Do not set anything on the power cord.

NOTE: a) Be sure to ground the machine. (Do not connect the groundi ng

wire to a gas pipe.)

b) Make sure the plug is firmly inserted in the outl et.

c) Avoid multiwiring.

3-2

2. INSTALLATION PROCEDURE

2.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box according to

the following list:

1. Receiving Tray.......................... .... .... .... ............ .... .... ............ ..1 pc

2. Cassette - S mall........... .... .... ........................ .... .... .... .... ..........1 pc

3. Paper Size Decal.................. .... ........................ .... .... .... .... ......1 pc

4. Paper Size Actuator.. .... .... .... ........................ .... .... .... .... ..........1 set

5. Outer Decal - Symbol Explanati on................... ......................1 pc

6. Mult i Ling ual Decal (Europ e only)................ .... .... ............ .... ..1 pc

7. 230 V Caution Decal (Europe only).................. .... .... ............ ..1 pc

8. Voltage Conversion Procedur e (A110, Eu rop e only).............1 pc

9. Operating Instructions (Except Europe)............... .... .... ..........1 pc

10. New Equipment Condi tion Report........ .... .... ............ .... .... .... ..1 pc

11. Envelope for NECR (U.S.A. only)...........................................1 pc

12. User Survey Card (U.S.A. only) ... .... .... .... ............ .... .... .... .... ...1 pc

3-3

2.2 COPIER INSTALLATION

[A]

[A]

[D]

[C]

[B]

1. Remove the strips of tape [A] from the copier at the locations shown.

2. Pull out the paper trays [B] and remove the foam block [C], tape, and

silica gel [D].

NOTE: FT4220 copier has one paper tray.

3-4

[D]

[E]

[B]

[D]

[C]

[A]

3. Open the fr ont cover [A], and remove the stri p s of tape [B] as shown.

4. Remove the l ock plate [C] fro m the cle aning blad e release lever.

NOTE: Save the lock plate for future use.

5. Raise the development unit lock lever [D], pull out the devel o pment unit

[E], and place it on a clean sheet of paper.

3-5

[C]

[B]

[A]

[D]

6. Remove the toner supply unit [A] from the development unit (3 screws).

7. Pour one pack of devel ope r [B] into the develo p ment unit while turn ing

the development roller knob [C] counterclockwise to distribute the

devel oper.

8. Reinstall the toner supply unit on t he devel opment unit.

NOTE: Make sure that there is no gap [D] between the toner supply unit

and the development unit.

9. Reinsta ll the develo p ment unit as shown.

3-6

[A]

[C]

[B]

10. Remove the seal [A] from the toner supply unit.

11. Shake the toner cartridge [B] well and insert the cartridge while pulling off

the seal [C]. Then, instal l the cart ridge as shown.

12. Close the front cover.

3-7

[A]

[C]

230/240V220V

CN417

[B]

[D]

[E]

13. Plug in the machine and turn on the main switch, the n place a few sheets

of white paper (A3 or 11" x 17") on the expo sure glass and lo wer the

platen cover.

CAUTION: Step 14 must be done only in 230 and 240 volt areas

(FT4220 copi er only). FT4222 copier does not need to have

this step performed.

14. Perfor m the conversion from 220 V to 230 and 240 V as follo ws:

1) Remove the rear cover [A] (4 scre ws).

2) Disconnect the transformer connector [B] (3P/White) on the ac drive

board [C] from CN417 and reconn ect it to CN417 as shown in the

illustration.

3) Reinstall the rear cover.

4) Remove the 220 V caution decal [D] from the rear cover [A].

5) Adhere the 230 V cautio n decal [E] (en closed w ith th e machin e) to t he

rear cover. (This step is requir ed only in 230 volt area s.)

3-8

[B]

[A]

[C]

15. Perform the developer initial setting.

1) To access the SP mode, press the followin g keys in the order given.

1. Energy Saver/Clear Modes key

2. Clear/Stop key

3. Enter key

2) Perform SP65 in the following sequence.

SP Mode Number Procedure

65 Developer Initia l

Setting

Enter "65" using the nu meral keys and

press the Enter key. "20" will be displayed

in the copy counter. Press the Start key for

initial setting.

16. Place the outer decal (symbol explanation) [A] on the upper cover and

install the receiving tray.

NOTE: If the DF is installed on the machine, place the outer decal [A] on

the DF [B] as shown.

17. Load paper into the cassette and/or paper trays according to the

instruction decal.

18. Change the position of paper size block [C] to displa y the correct paper

size.

19. Check the machine opera tion and copy qual ity.

3-9

2.3 CASSETTE MODIFICATION

[B]

[A]

[D]

[E]

[C][F]

1. Take off the cassette cover [A].

2. Remo ve the side fences [B] (1 screw each) and the bo ttom plate [C].

3. Reposition the rear fence [D] in the desi r ed paper size posi ti o n (1 scr e w).

NOTE: Paper size positions are shown on the inside of the cassette.

4. Reinstall the bottom plate.

5. Reinstall the side fences in the desi re d size positions.

6. Attach the proper paper size decals [E] on the cassette at the positions

shown.

7. Insert the actuator plate [F] in the slot on the front of the cassette as

shown.

3-10

2.4 KEY COUNTER HOLDER INSTALLATION (Option)

[B]

[C] [E]

[A]

[D]

[F]

1. Make sure that the main switch is turned off.

2. Open the front cover and the manual feed table.

3. Remove the r ight cover (4 screws).

4. Remo ve the key counter cover [A] (2 screws).

5. Connect the 4P connector [B] of the key counter holder to the key counter

harness [C] through the key counter access hole.

6. Posi tion the fixing plate [D] as shown in the illustration and insert the key

counter holder.

7. Align the holes in the fixing pl ate with the mou nting hole s of the key

counter holder and secure the key counter holder (2 screws).

NOTE: The fixing plate has three differe nt hol e sizes. Use the holes that

match those on the counter that you are installing.

8. Connect the other end of the key counter harness [E] to CN127 on the

main board.

9. Cut off the jumper wire (JP101) [F] with a pair of pliers.

10. Reinstall all covers.

3-11

2.5 OPTICS ANTI-CONDENSATION HEATER INSTALLATION

(Option)

[B]

[C]

[E]

[A]

[D]

1. Make sure that the main switch is turned off.

2. Remove the rear cover.

3. Remove the exposure glass. (See Exposure Glass Removal.)

4. Move the 1st and 2nd scanner unit all the way t o the right.

5. Install the optics heater [A] in the optics cavity as shown (1 screw).

6. Mount the anti-condensation heater harness in the following way.

• Harness clamp [B].

• Rear frame cutout hole [C].

7. Rewire the heater harness [D] as shown in the illustration and conne ct it

to the anti-condensation heater connector [E].

3-12

Loading...

Loading...